Page 1

HP ProLiant DL760 Generation 2 Server

Maintenance and Service Guide

February 2004 (Third Edition)

Part Number 201262-003

Page 2

© Copyright 2003, 2004 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and

services are set forth in the express warranty statements accompanying such products and services. Nothing herein

should be construed as constituting an additional warranty. HP shall not be liable for technical or editorial errors

or omissions contained herein.

Microsoft, Windows, and Windows NT are U.S. registered trademarks of Microsoft Corporation. Intel, Pentium,

and Itanium are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United States

and other countries. UNIX is a registered trademark of The Open Group. Linux is a U.S. registered trademark of

Linus Torvalds.

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

February 2004 (Third Edition)

Part Number 201262-003

Page 3

Contents

About This Guide

Audience Assumptions............................................................................................................................... vii

Technician Notes........................................................................................................................................ vii

Where to Go for Additional Help.............................................................................................................. viii

Integrated Management Log............................................................................................................... viii

Telephone Numbers............................................................................................................................ viii

Chapter 1

Illustrated Parts Catalog

System Chassis.......................................................................................................................................... 1-2

Media Module ........................................................................................................................................... 1-4

Processor and Memory Module................................................................................................................. 1-6

I/O Module ................................................................................................................................................ 1-8

Miscellaneous.......................................................................................................................................... 1-10

Chapter 2

Service Preparation

Safety Considerations................................................................................................................................ 2-1

Electrostatic Discharge Information ................................................................................................... 2-1

Rack Warnings and Precautions ......................................................................................................... 2-2

Server Warnings and Precautions ....................................................................................................... 2-2

Server Modules.......................................................................................................................................... 2-4

Preparation Procedures.............................................................................................................................. 2-7

System Interconnect LEDs ................................................................................................................. 2-8

Hot-Plug Procedures ........................................................................................................................... 2-8

Non-Hot-Plug Procedures................................................................................................................... 2-8

Power-On Self-Test .......................................................................................................................... 2-11

Re-entering the Server Serial Number .................................................................................................... 2-15

Chapter 3

Chassis Components Removal and Replacement Procedures

I/O Lid....................................................................................................................................................... 3-1

Hot-Plug Power Supply............................................................................................................................. 3-2

System Midplane Assembly...................................................................................................................... 3-5

Cable Management Arm ........................................................................................................................... 3-7

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide iii

Page 4

Contents

Chapter 4

Media Module Removal and Replacement Procedures

Media Module............................................................................................................................................4-2

Media Module Bezel..................................................................................................................................4-4

Integrated Management Display ................................................................................................................4-5

Hot-Plug Hard Drives ................................................................................................................................4-7

Hard Drive Blank ................................................................................................................................4-7

Hot-Plug Hard Drive Replacement Guidelines ...................................................................................4-8

Integrated Diskette Drive and CD-ROM .................................................................................................4-10

Media Module Cable Routing Diagram...................................................................................................4-12

Power On/Standby Switch Assembly................................................................................................4-13

Chapter 5

Processor and Memory Module Removal and Replacement Procedures

Shipping Screws.........................................................................................................................................5-1

Security Screw ...........................................................................................................................................5-2

Processor and Memory Module................................................................................................................. 5-3

Processor Boards and Processors...............................................................................................................5-5

Identifying ...........................................................................................................................................5-5

Removing Processor Boards and Processors.......................................................................................5-6

Memory Cartridge....................................................................................................................................5-10

Identifying .........................................................................................................................................5-10

Removing the Memory Cartridge......................................................................................................5-11

Opening the Memory Cartridge.........................................................................................................5-12

DIMM Overview .....................................................................................................................................5-12

Identifying .........................................................................................................................................5-13

SDRAM Memory Bus Configuration ...............................................................................................5-14

Installing DIMMs into the Cartridge.................................................................................................5-15

Memory Riser Board................................................................................................................................5-17

Chapter 6

I/O Module Removal and Replacement Procedures

I/O Module.................................................................................................................................................6-1

Removing the Cable Management Arm:.............................................................................................6-1

Removing the I/O Module...................................................................................................................6-4

I/O Expansion Boards................................................................................................................................6-6

Locating the I/O Expansion Slots........................................................................................................6-6

I/O Expansion Slot Cover....................................................................................................................6-7

Non-Hot Plug Expansion Boards ........................................................................................................6-8

PCI Hot Plug I/O Expansion Boards.................................................................................................6-10

PCI Hot Plug LED Indicators............................................................................................................6-12

PCI Hot Plug Operating System Support ..........................................................................................6-13

Adding PCI Hot Plug Expansion Boards ..........................................................................................6-14

Removing or Replacing a PCI Hot Plug Expansion Board...............................................................6-16

Hot-Plug Fans ..........................................................................................................................................6-18

Fan Cage Assembly .................................................................................................................................6-20

11-slot Hot-Plug Basket...........................................................................................................................6-22

Internal Battery ........................................................................................................................................6-24

iv HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 5

Chapter 7

Diagnostic Tools

Diagnostic Tools Utility Overview ........................................................................................................... 7-2

For More Information................................................................................................................................ 7-4

Chapter 8

Connectors, Switches, and LED Indicators

Connectors................................................................................................................................................. 8-1

Rear Connectors.................................................................................................................................. 8-1

I/O Board Components ....................................................................................................................... 8-2

Host Board .......................................................................................................................................... 8-3

Switches..................................................................................................................................................... 8-4

LED Indicators .......................................................................................................................................... 8-5

System Power LED Indicator ............................................................................................................. 8-6

Auxiliary Power LED Indicator.......................................................................................................... 8-6

System Interconnect LED Indicators.................................................................................................. 8-7

System Attention LED Indicators....................................................................................................... 8-8

Hot-Plug SCSI Hard Drive LED Indicators........................................................................................ 8-9

Power Supply LED Indicators .......................................................................................................... 8-11

Hot-Plug Fan LED Indicators ........................................................................................................... 8-12

PCI Hot Plug LED Indicators ........................................................................................................... 8-13

Memory Cartridge LED Indicators................................................................................................... 8-15

Contents

Chapter 9

Physical, Operating, and Performance Specifications

Server Specifications................................................................................................................................. 9-2

Power Supply Specifications..................................................................................................................... 9-3

Dual Inline Memory Module (DIMM) Specifications .............................................................................. 9-4

1.44-MB Diskette Drive Specifications .................................................................................................... 9-4

DVD-ROM Drive Specifications .............................................................................................................. 9-5

24X Max IDE CD-ROM Drive Specifications.......................................................................................... 9-7

Hot-Plug U320 SCSI Hard Drives ............................................................................................................ 9-9

Hot-Plug Ultra3 SCSI Hard Drives ......................................................................................................... 9-10

Smart Array 5i Controller Specifications................................................................................................ 9-11

NC7770 PCI-X Gigabit Server Adapter Specifications .......................................................................... 9-12

NC7170 Dual Port PCI-X Gigabit Server Adapter Specifications.......................................................... 9-13

Index

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide v

Page 6

Page 7

This maintenance and service guide can be used for reference when servicing the HP

ProLiant DL760 Generation 2 server.

WARNING: To reduce the risk of personal injury from electric shock and hazardous

energy levels, only authorized service technicians should attempt to repair this

equipment. Improper repairs can create conditions that are hazardous.

Audience Assumptions

This guide is for service technicians. HP assumes you are qualified in the servicing of

computer equipment and trained in recognizing hazard in products with hazardous energy

levels and are familiar with weight and stability precautions for rack installations.

Technician Notes

WARNING: Only authorized technicians trained by HP should attempt to repair this

equipment. All troubleshooting and repair procedures are detailed to allow only

subassembly/module-level repair. Because of the complexity of the individual boards

and subassemblies, no one should attempt to make repairs at the component level or

to make modifications to any printed wiring board. Improper repairs can create a safety

hazard.

WARNING: To reduce the risk of personal injury from electric shock and hazardous

energy levels, do not exceed the level of repairs specified in these procedures.

Because of the complexity of the individual boards and subassemblies, do not attempt

to make repairs at the component level or to make modifications to any printed wiring

board. Improper repairs can create conditions that are hazardous.

WARNING: To reduce the risk of electric shock or damage to the equipment:

• Disconnect power from the system by unplugging all power cords from the power

supplies.

• Do not disable the power cord grounding plug. The grounding plug is an important

safety feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily

accessible at all times.

About This Guide

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide vii

Page 8

About This Guide

CAUTION: To properly ventilate the system, you must provide at least 7.6 cm (3.0 in.) of

clearance at the front and back of the server.

CAUTION: The computer is designed to be electrically grounded (earthed). To ensure proper

operation, plug the AC power cord into a properly grounded AC outlet only.

NOTE: Any indications of component replacement or printed wiring board modifications may void any

warranty.

Where to Go for Additional Help

In addition to this guide, the following information sources are available:

• User documentation

• Service Quick Reference Guide

• Service training guides

• Service advisories and bulletins

• QuickFind information services

• Insight Manager software

Integrated Management Log

The server includes an integrated, nonvolatile management log that contains fault and

management information. The contents of the Integrated Management Log (IML) can be

viewed with Insight Manager.

Telephone Numbers

For the name of the nearest HP authorized reseller:

• In the United States, call 1-800-345-1518.

• In Canada, call 1-800-263-5868.

For HP technical support:

• In the United States and Canada, call 1-800-652-6672.

• Outside the United States and Canada, refer to

www.hp.com

viii HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 9

Illustrated Parts Catalog

This chapter provides the illustrated parts breakdown and a spare parts list for the

HP ProLiant DL760 server. Refer to the table following each illustration for the names of

referenced spare parts.

1

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 1-1

Page 10

Illustrated Parts Catalog

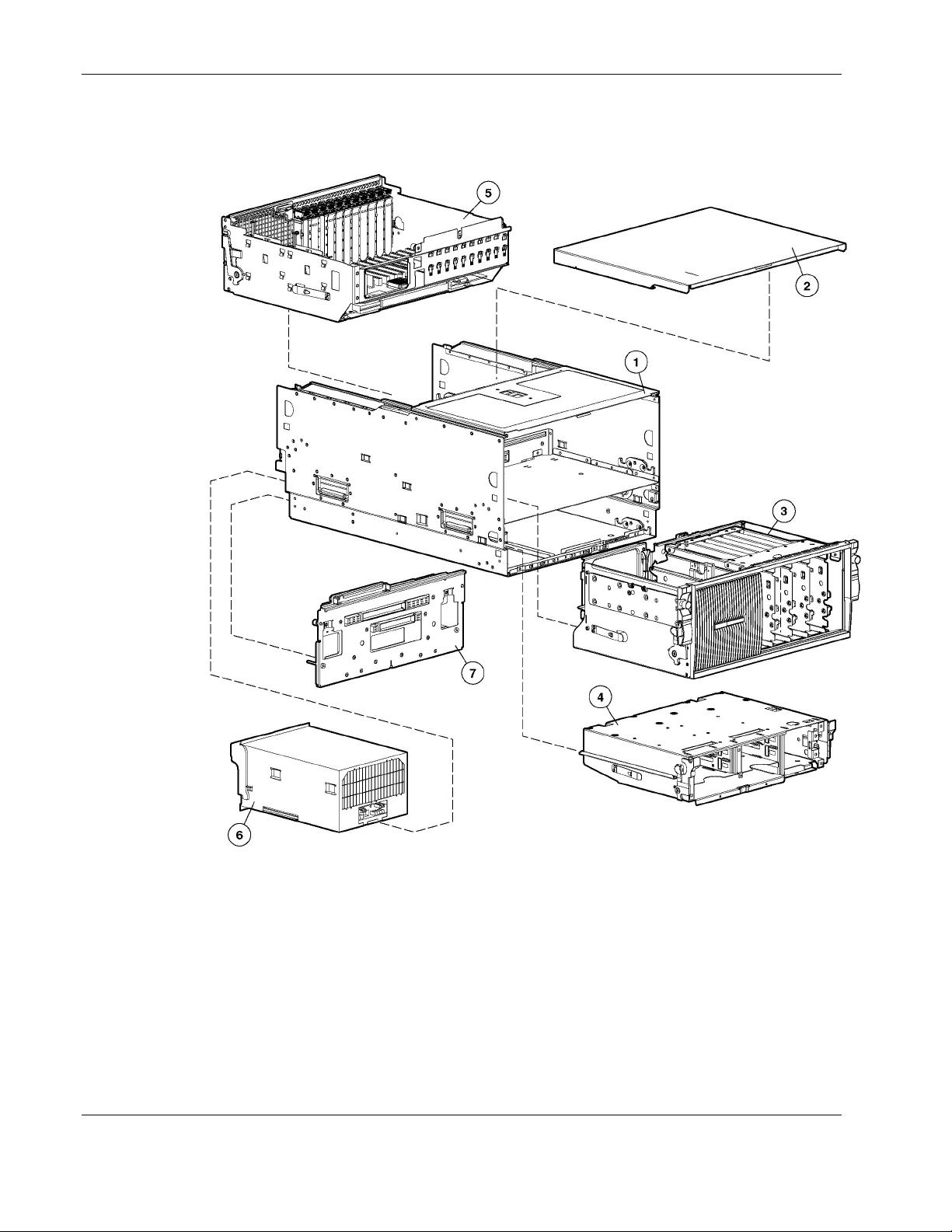

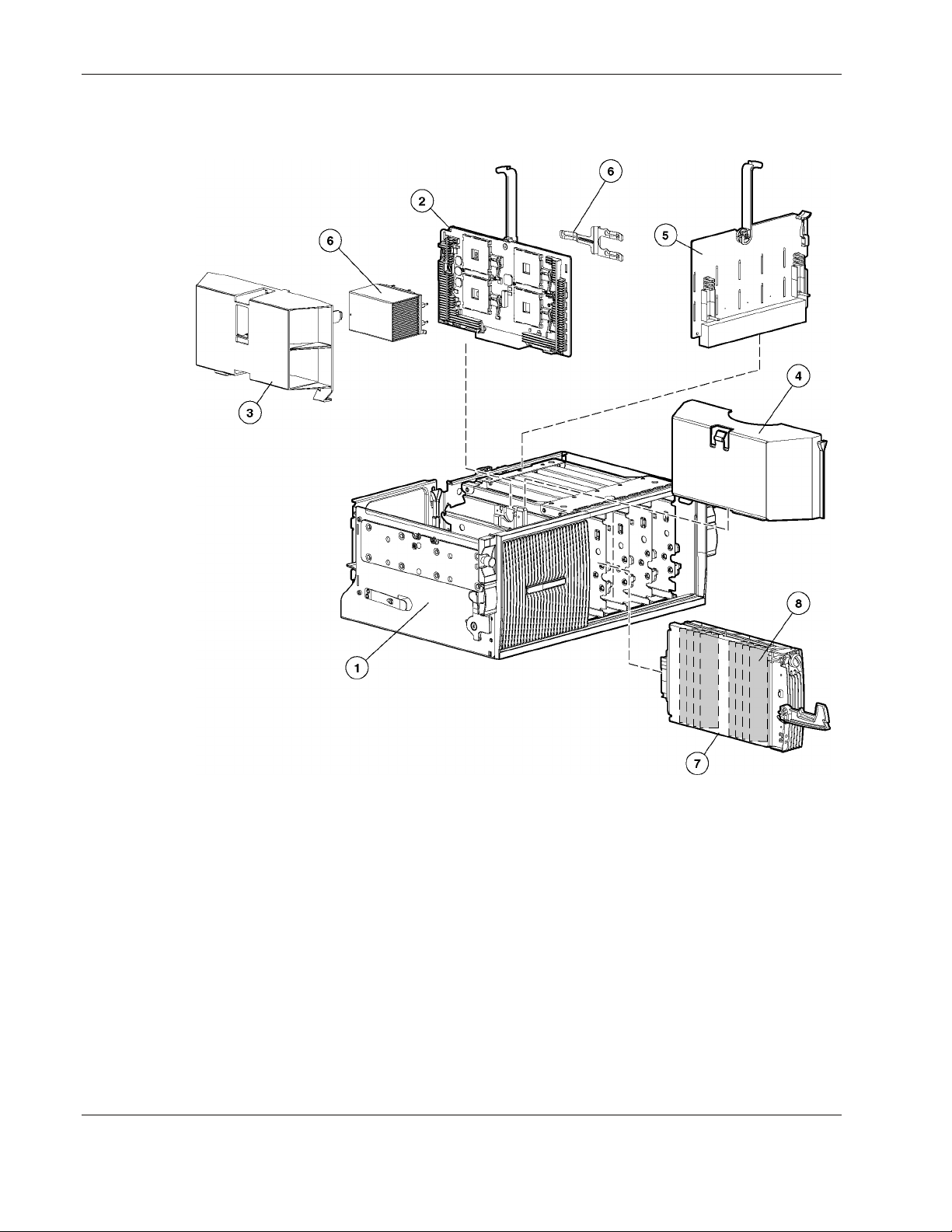

System Chassis

Figure 1-1: System chassis exploded view

1-2 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 11

Illustrated Parts Catalog

Table 1-1: System Chassis Spare Parts List

Item Description Spare Part Number

System Chassis

1 System chassis

2 I/O lid 122214-001

3 Processor and memory module (without processors) 278466-001

4 Media module 319945-001

Heatsink *

Ramp*

Memory module bezel*

5 I/O module with PCI-X I/O board 339661-001

System Components

6 Hot-plug power supply 1150 W 122235-001

7 System midplane assembly 316747-001

*Not shown

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 1-3

Page 12

Illustrated Parts Catalog

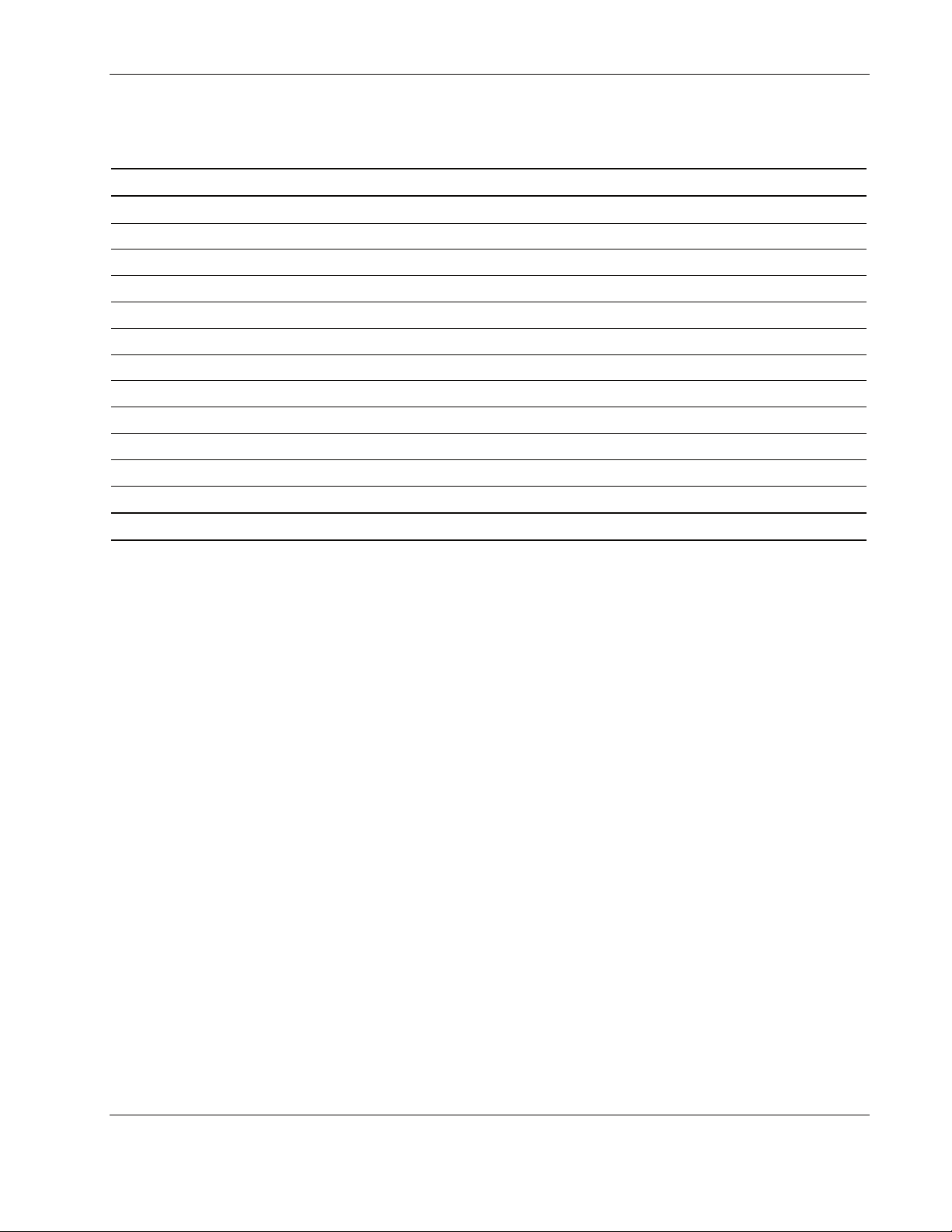

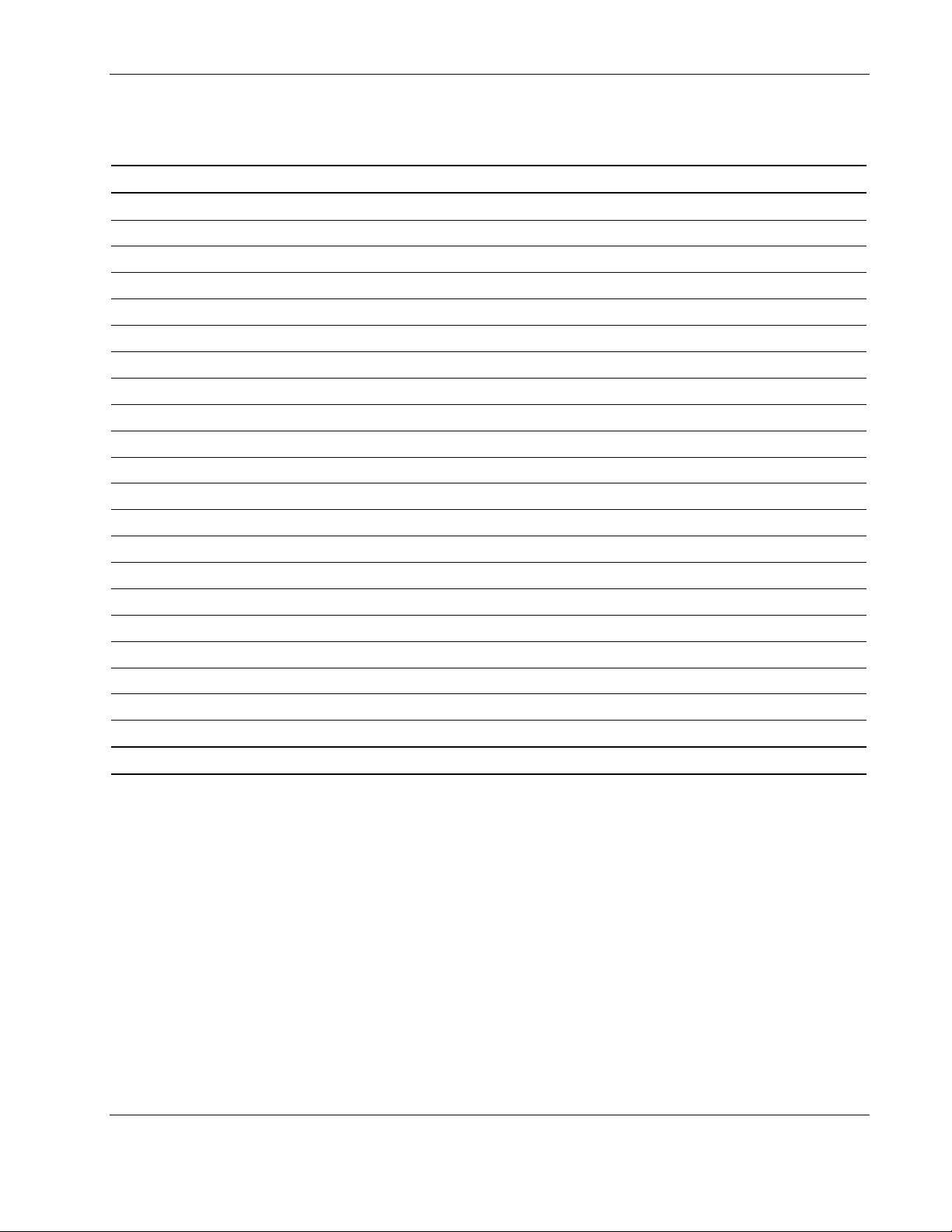

Media Module

Figure 1-2: Media module exploded view

1-4 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 13

Illustrated Parts Catalog

Table 1-2: Media Module Spare Parts List

Item Description Spare Part Number

Media Module Components

1 Media module

a) Drive tray module*

b) Drive cage assembly*

c) Media module bezel

2 IMD with cable, panel, LED 271930-001

3 Power switch assembly with LED 122233-001

Mass Storage

4 Wide Ultra3 hard drive with tray, 18.2-GB, 1-inch, 10000 rpm 152190-001

Wide Ultra3 hard drive with tray, 36.4-GB, 1-inch, 10000 rpm* 177986-001

Wide Ultra3 hard drive with tray, 18.2-GB, 1-inch, 15000 rpm* 189395-001

U320 Universal hard drive with tray, 36.4-GB, 1-inch, 10000 rpm 289041-001

U320 Universal hard drive with tray, 72.8-GB, 1-inch, 10000 rpm 289042-001

U320 Universal hard drive with tray, 146.8-GB, 1-inch, 10000 rpm 289044-001

U320 Universal hard drive with tray, 18.2-GB, 1-inch, 15000 rpm 289240-001

U320 Universal hard drive with tray, 36.4-GB, 1-inch, 15000 rpm 289241-001

U320 Universal hard drive with tray, 72.8-GB, 1-inch, 15000 rpm 289243-001

5 LVDS 1-inch hard drive blank 313046-001

6 1.44-MB diskette drive 233409-001

7 CD-ROM drive 263243-001

319945-001

8 DVD drive*

*Not shown

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 1-5

339811-001

356326-001

Page 14

Illustrated Parts Catalog

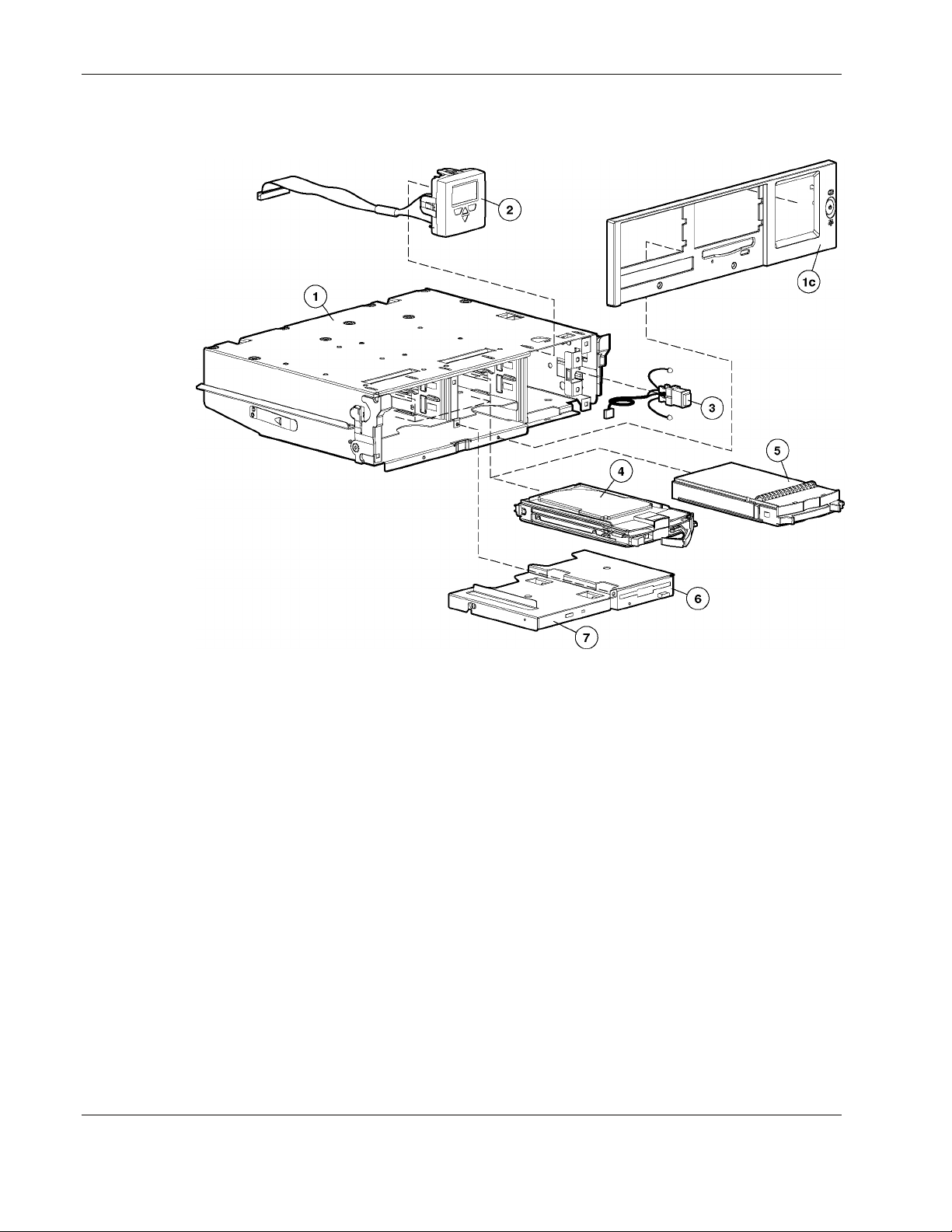

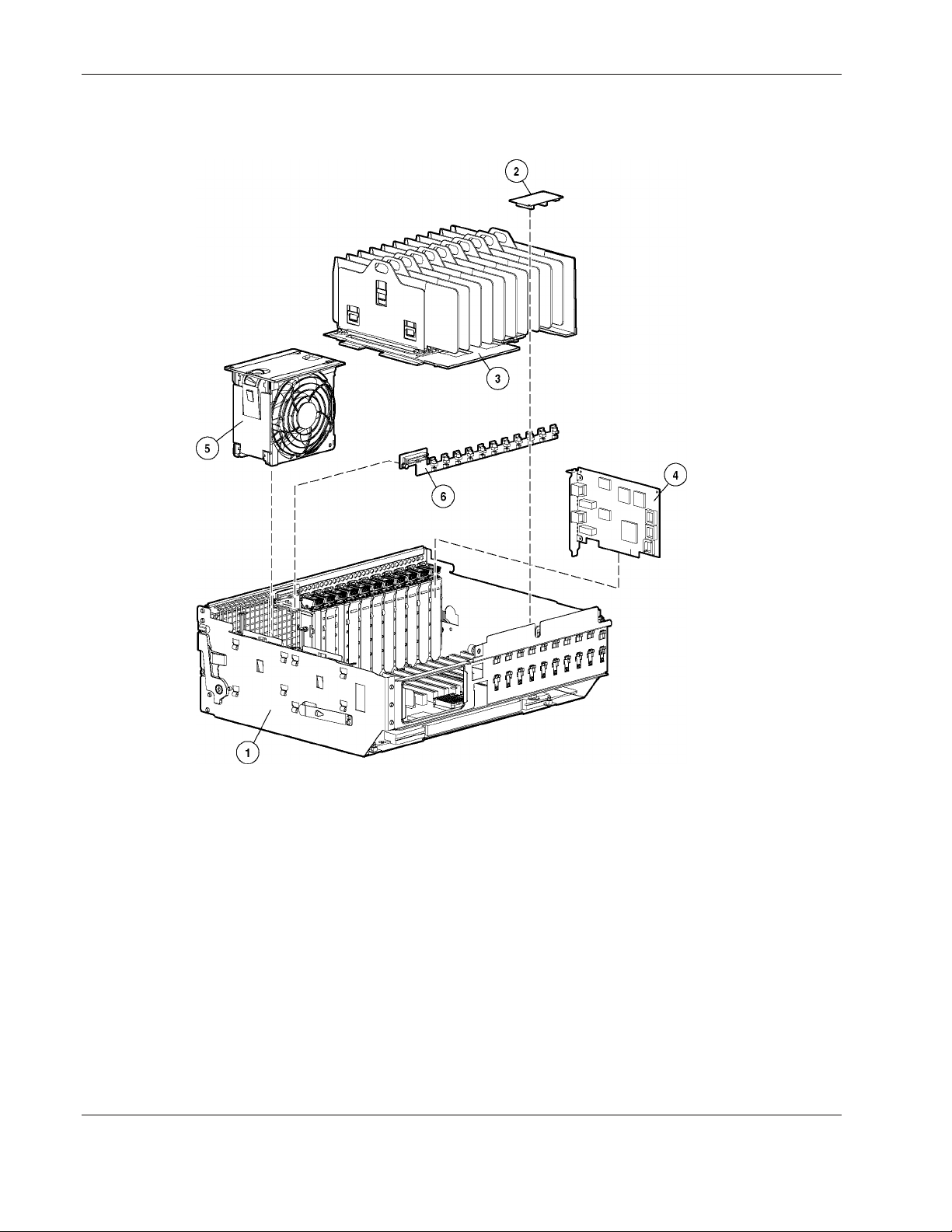

Processor and Memory Module

Figure 1-3: Processor and memory module exploded view

1-6 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 15

Illustrated Parts Catalog

Table 1-3: Processor and Memory Module Spare Parts List

Item Description Spare Part Number

Processor and Memory Module Components

1 Processor and memory module 278466-001

2 Processor board 314379-001

3 Processor cover 320104-001

4 Processor board air baffle and label 323754-001

5 Memory riser board 278467-001

Processors

6 Processor (1.5 GHz with 1-MB cache), clip, and heatsink 319952-001

Processor (2.0 GHz with 1-MB cache), clip, and heatsink* 327839-001

Processor (2.0 GHz with 2-MB cache), clip, and heatsink* 319953-001

Processor (2.2 GHz with 2-MB cache), clip, and heatsink* 352311-001

Processor (2.5 GHz with 1-MB cache), clip, and heatsink* 327840-001

Processor (2.7 GHz with 2-MB cache), clip, and heatsink* 352312-001

Processor (2.8 GHz with 2-MB cache), clip, and heatsink* 327841-001

Processor (3.0 GHz with 4-MB cache), clip, and heatsink* 352313-001

Memory

7 Hot-plug memory cartridge 278470-001

8 Memory module, 256MB, PC133, 128Mb, ECC SDRAM DIMM 159377-001

Memory module, 512MB, PC133, 256Mb, ECC SDRAM DIMM* 177628-001

Memory module, 1GB, PC133, 256Mb, LP, ECC SDRAM DIMM* 321851-001

Memory module, 2GB, PC133, 512Mb, ECC SDRAM DIMM* 321852-001

*Not shown

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 1-7

Page 16

Illustrated Parts Catalog

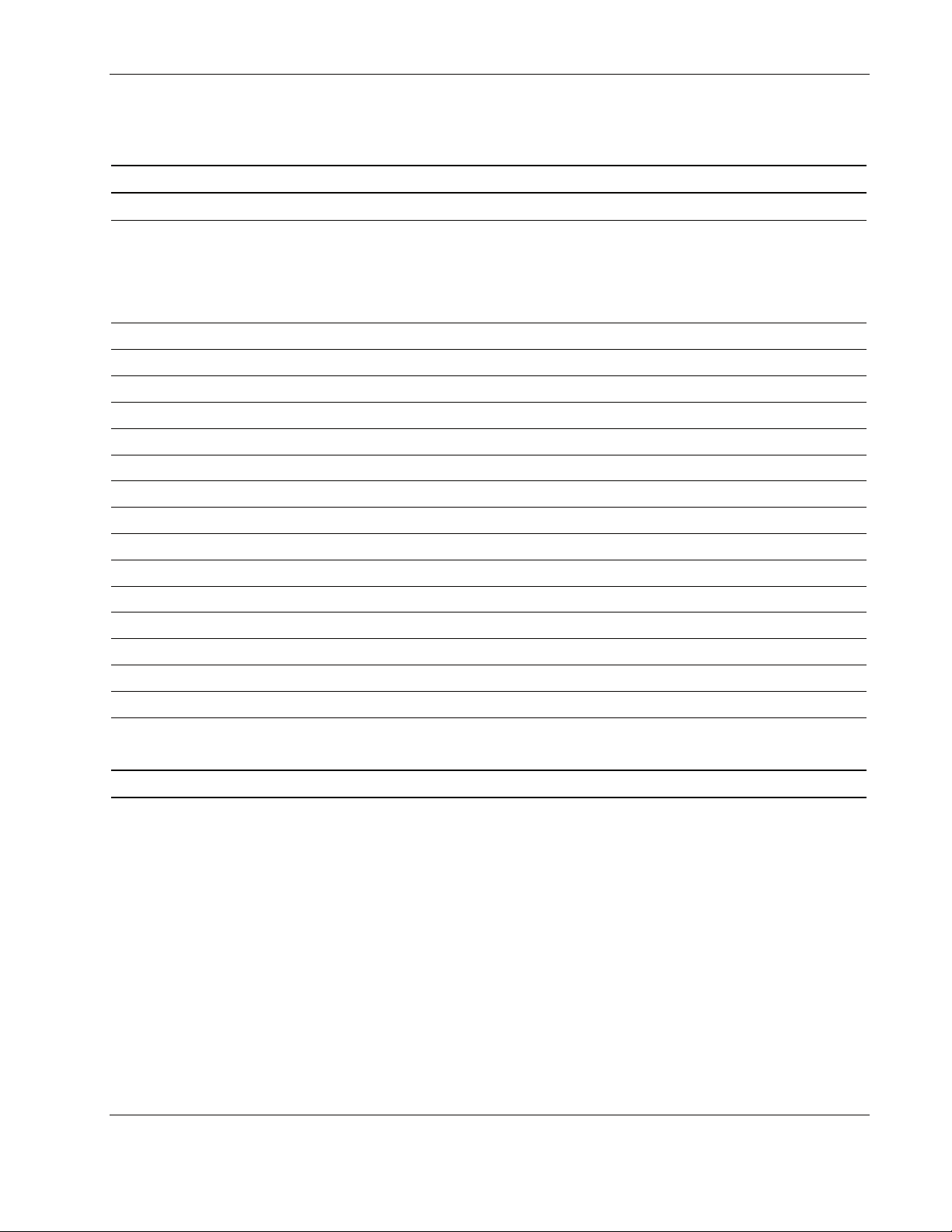

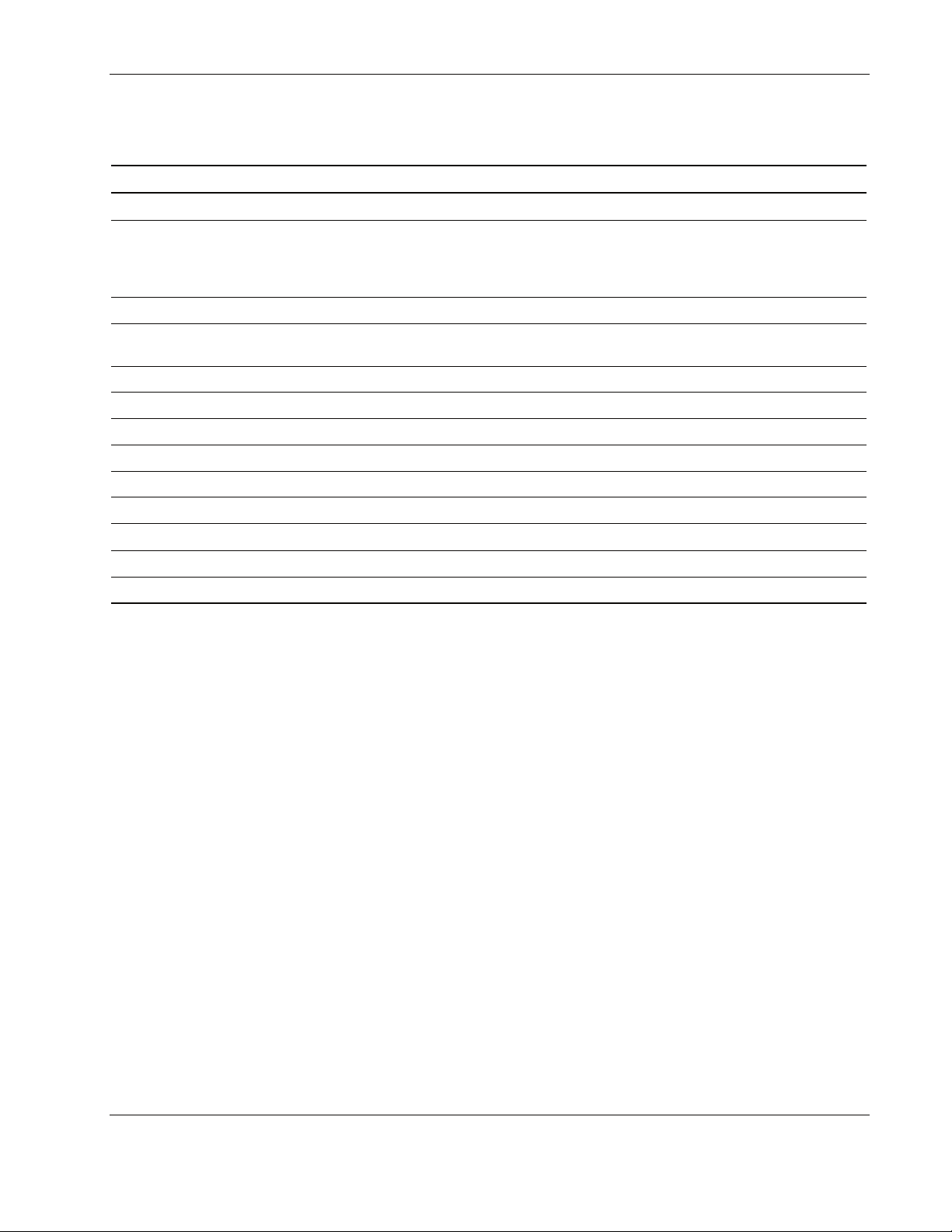

I/O Module

Figure 1-4: I/O module exploded view

1-8 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 17

Illustrated Parts Catalog

Table 1-4: I/O Module Spare Parts List

Item Description Spare Part Number

I/O Module Components

1 I/O module

a) PCI-X I/O board

b) PCI-X Hot Plug switch board cable

2 Array enabler board 122232-001

3 Hot-plug 11-slot basket with dividers (quantity 10) and puller assembly

(quantity 10)

4 NC7770 PCI-X Gigabit Server Adapter 10/100/1000 TX UTP NIC 284848-001

NC7170 Dual Port PCI-X Gigabit Server Adapter* 313586-001

5 Hot-plu g fan 278469-001

6 PCI-X Hot Plug switch board kit 278463-001

7 Remote Insight Lights-Out Edition II (RILOE)* 232386-001

8 SCSI cable board* 146447-003

278457-001

323753-001

Miscellaneous

9 SCSI cable* 278470-001

*Not shown

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 1-9

Page 18

Illustrated Parts Catalog

Miscellaneous

Table 1-5: Miscellaneous Spare Parts List

Item Description Spare Part Number

1 Miscell aneous plastics*

a) Cover, rack rail

b) Retainer, cardguide, double

c) Retain er, cardguide

d) Gear, ejector, processor/memory riser

e) Guide, card, processor

f) Guide, fan, left

g) Guide, fan, right

h) Plenum, fan cage

i) PCA, SW/LED 11-slot hot-plug PCI

j) Cover, cartridge

k) Bezel, top memory cage

l) Hot-plug 11-slot basket with dividers (quantity 10) and puller assemblies

(qua ntity 10)

m) Fiber Optic SISI LED

n) Processor memory ejector kit

o) Air ramp, host PCA

p) Air ramp, F8

q) Light pipe, plate

r) Light pipe, SISI

s) Light pipe, DIMM

278460-001

continued

1-10 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 19

Illustrated Parts Catalog

Table 1-5: Miscellaneous Spare Parts List continued

Item Description Spare Part Number

2 Lever ejector kit, miscellaneous*

Lever, memory cartridge

Latch, memory cartridge

Lever, processor PCA

Spring, processor board / memory riser board and right lever

Latch, processor board / memory riser board

Lever, ejector, memory riser board

Spring, memory cartridge, ZINC

b) Ejector, right, I/O drawer

c) Ejector, left, I/O drawer

Assembly, ejector, drive cage, right, graphite

Assembly, ejector, drive cage, left, graphite

Gear, ejector, processor board / memory riser board

Assembly, PCI, latch and base, CBN, HP (quantity 5)

Ejector, right, processor drawer

Ejector, left, processor drawer

3 Heatsink, F8 chipset* 278472-001

4 Spares, rail kit* 339977-001

5 Return kit* 123189-001

6 Ethernet loopback RJ-45* 317465-001

7 Internal battery* 175115-001

8 Country kit* 152406-001

9 Integrated Management Display 340405-001

278461-001

*Not shown

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 1-11

Page 20

Safety Considerations

Before performing service procedures, review the following safety information.

Electrostatic Discharge Information

A discharge of static electricity can damage static-sensitive devices or microcircuitry. Proper

packaging and grounding techniques are necessary precautions to prevent damage. To

prevent electrostatic damage, observe the following precautions:

• Transport products in static-safe containers, such as conductive tubes, bags, or boxes.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free

stations.

• Cover workstations with approved static-dissipating material. Use a wrist strap connected

to the work surface and properly grounded tools and equipment.

2

Service Preparation

• Keep the work area free of nonconductive materials, such as ordinary plastic assembly

aids and foam packing.

• Make sure you are always properly grounded when touching a static-sensitive component

or assembly.

• Avoid touching pins, leads, or circuitry.

• Always place drives PCB assembly-side down.

• Use conductive field service tools.

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 2-1

Page 21

Service Preparation

Rack Warnings and Precautions

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure

that:

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizers are attached to the rack if it is a single-rack installation.

• The racks are coupled in multiple-rack installations.

• Only one component is extended at a time. A rack may become unstable if more

than one component is extended for any reason.

CAUTION: Always begin by mounting the heaviest item on the bottom of the rack. Continue

to populate the rack from the bottom to the top.

Server Warnings and Precautions

WARNING: The ProLiant DL760 G2 server weighs 73 kilograms (161 pounds) when

fully assembled. To reduce the risk of personal injury or damage to the equipment:

63-73 kg

140-161 lb

• Observe local health and safety requirements and guidelines for manual material

handling.

• Obtain adequate assistance to lift and stabilize the product during installation or

removal.

• Remove all modules and power supplies to reduce the overall weight of the

product.

WARNING: To reduce the risk of personal injury from electric shock and hazardous

energy levels, only authorized service technicians should attempt to repair this

equipment. Improper repairs could create hazardous conditions.

WARNING: To reduce the risk of personal injury from hazardous energy or damage to

the equipment when working on energized servers:

• Remove all watches, rings, and any other loose-fitting jewelry.

• Do not use conductive tools inside the server that could bridge live parts.

WARNING: To reduce the risk of electric shock or damage to the equipment:

• Do not disable the power cord grounding plug. The grounding plug is an important

safety feature.

• Plug the power cord into a grounded electrical outlet that is easily accessible at all

times.

• Install the power supply before connecting the power cord to the power supply.

• Unplug the power cord before removing the power supply from the server.

• If the system has multiple power supplies, disconnect power from the system by

unplugging all power cords from the power supplies.

2-2 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 22

Service Preparation

WARNING: To reduce the risk of personal injury from hot surfaces, allow the internal

system components to cool before touching them.

CAUTION: Because the ProLiant DL760 G2 server does not have safety interlocks, it is

possible for a unit to be operated without the cover and air baffles properly installed. This

could cause thermal damage in the system and could void the warranty. The rack-mountable

ProLiant DL760 G2 server should always be operated with the system unit cover on. Proper

cooling cannot be achieved if the system unit cover is removed for extended periods of time.

CAUTION: Protect the server from power fluctuations and temporary interruptions with a

regulating uninterruptible power supply (UPS). This device protects the hardware from

damage caused by power surges and voltage spikes and keeps the system in operation

during a power failure.

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 2-3

Page 23

Service Preparation

Server Modules

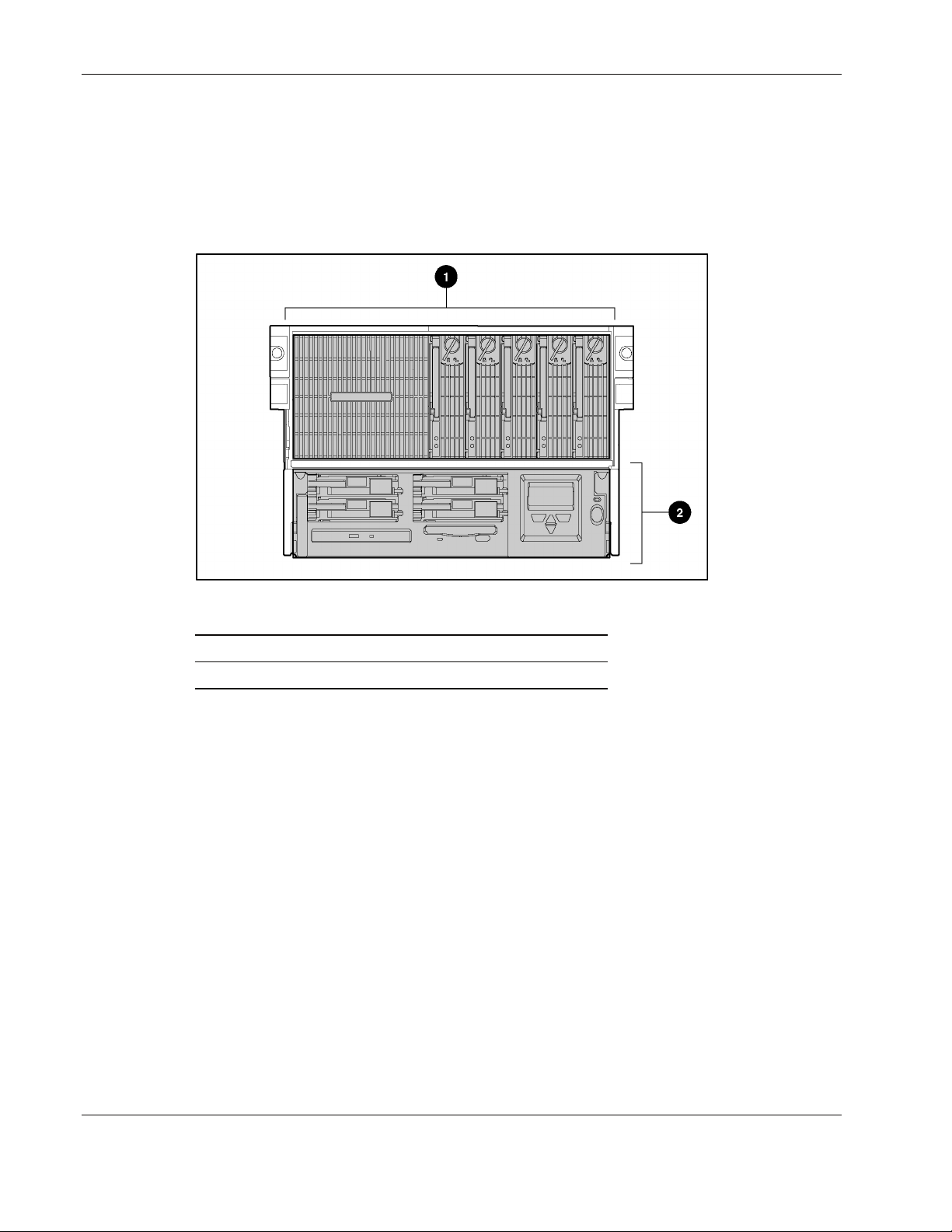

In the ProLiant DL760 G2 server, options and accessories are easily accessed through a

sliding I/O lid and three removable modules: the media module, processor and memory

module, and the I/O module. Refer to Figure 2-1, Figure 2-2, and Figure 2-3 for identification

of these modules and other components.

Figure 2-1: Front modules

Item Description

1 Processor and memory module

2 Media module

2-4 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 24

Service Preparation

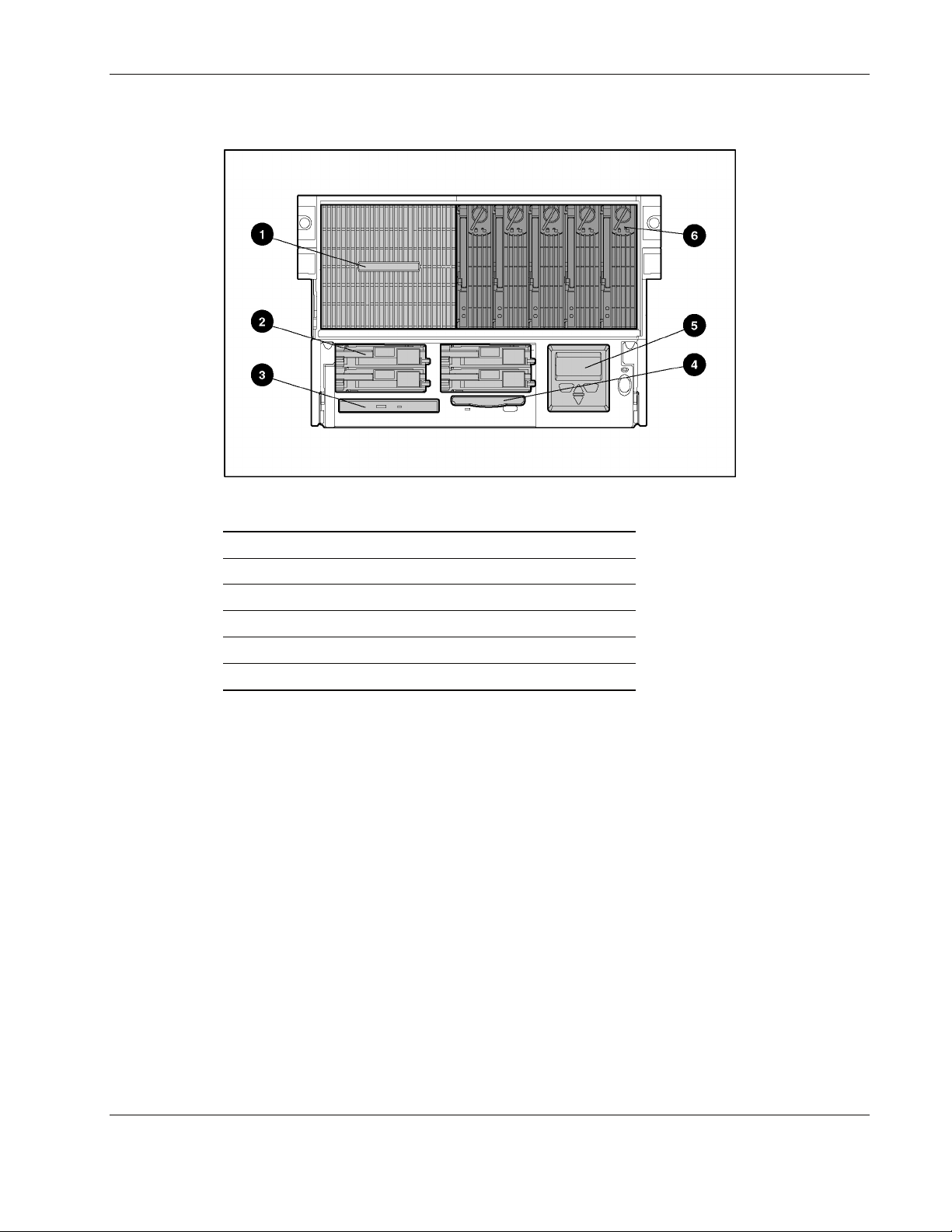

Figure 2-2: Front module components

Item Description

1 Processor area and air intake

2 Hot-plug hard drives

3 IDE CD-ROM drive

4 1.44-MB diskette drive

5 Integrated Management Display (IMD)

6 Hot Plug RAID Memory cartridge

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 2-5

Page 25

Service Preparation

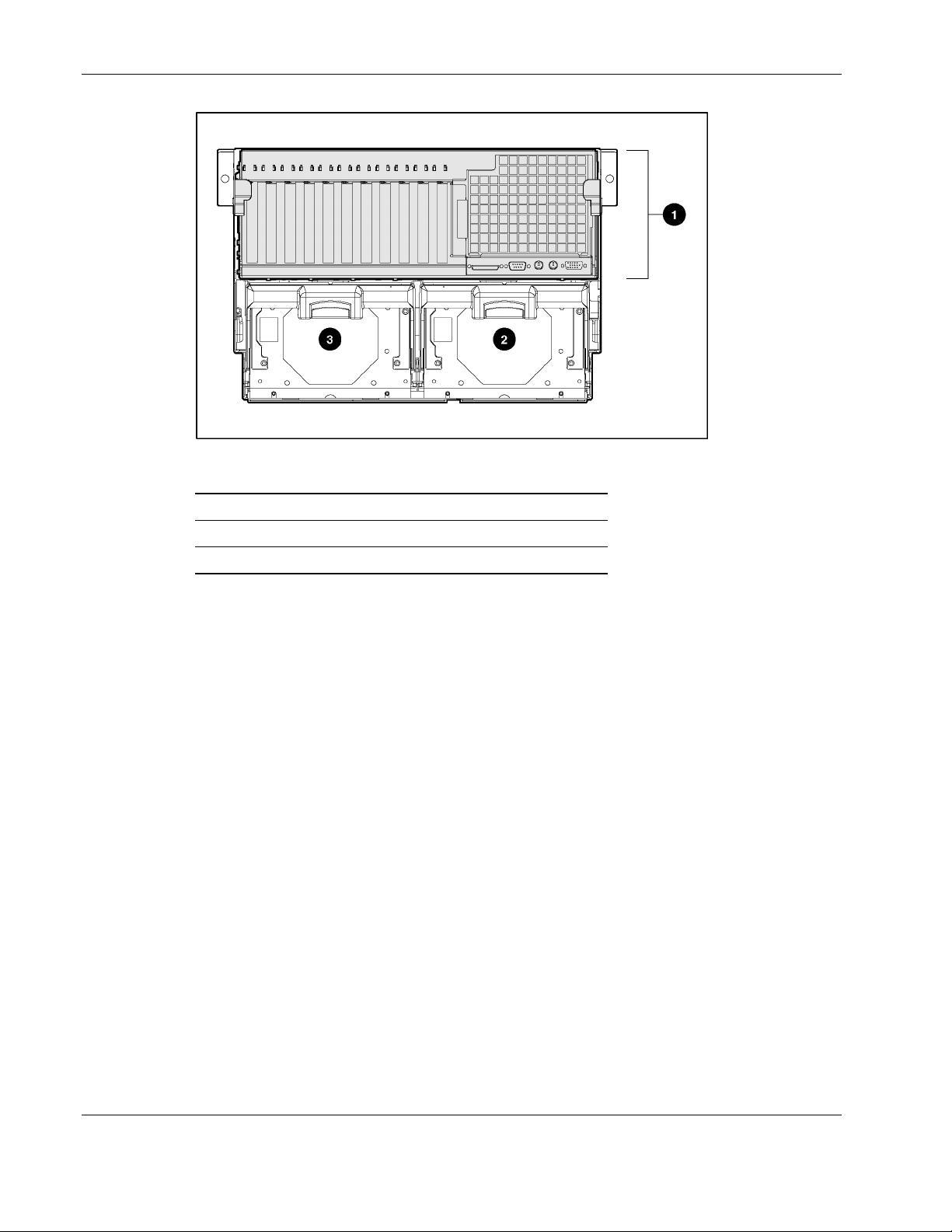

Figure 2-3: Rear components

Item Description

1 I/O module with system fans

2 Hot-plug power supply #1

3 Hot-plug power supply #2

For details on cable connections, refer to Chapter 6, “Cabling the S erver” in the HP ProLiant

DL760 Generation 2 Server User Guide.

2-6 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 26

Service Preparation

Table 2-1: Module and Bay Components and Access describes the contents of the modules

and how to access the components.

Table 2-1: Module and Bay Components and Access

Module Contents Access Method

I/O module with system fans

Processor and memory

module

Media module

Preparation Procedures

To access some components and perform certain service procedures, you must do one or

more of the following:

• Extend the server from the rack.

PCI Hot Plug expansion slots Slide the I/O lid toward the

front of the server.

Configuration switches Slide the I/O lid toward the

front of the server.

Fans 1 and 2 Slide the I/O lid toward the

front of the server.

Processor (CPU) sockets Remove the Processor and

Memory Module and the

processor board.

Memory (DIMMs) Remove the memory cartridge.

CD-ROM/

Diskette/IMD

Hot-plug hard drives Access directly at the front of

Access directly at the front of

the server.

the server.

If you are performing service procedures in an HP rack or third-party rack cabinet, you

can user the locking feature of the rack rails to support the server and gain access to

internal components.

• Power down the server.

If you must remove a server from a rack or a non-hot-plug component from a server,

power down the server.

• Remove the server from the rack.

If the rack environment, cabling configuration, or the server location in the rack creates

awkward conditions, remove the server from the rack.

To service the ProLiant DL760 G2 server, you might need the following:

• Flat-blade screwdriver (4 millimeter)

• Torx T-15 screwdriver

• Phillips screwdriver

• HP SmartStart CD:

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 2-7

Page 27

Service Preparation

— Drive Array Advanced Diagnostics (DAAD) software

— Array Diagnostics Utility (ADU) software

— ROM-Based Inspect

— ROM-Based Diagnostics

System Interconnect LEDs

The system interconnect LEDs on the ProLiant DL760 G2 server provide a closed-loop

checking mechanism for verifying proper component mating and interconnections between

critical server components. LEDs on the I/O lid provide visual assistance in isolating

components to check if the server will not power up due to a component or module that is not

fully installed. If a status indicator light is on, reseat the component represented by the

indicator. Refer to the hood labels for component location. Refer to Chapter 8 for more

information.

Hot-Plug Procedures

You can perform some service procedures without powering down the server. Before

performing hot-plug procedures, observe the following guidelines:

• For hot-plug fan procedures, ensure that the fan zone is fully populated.

• For hot-plug power supply procedures, ensure that a redundant power supply is installed

and connected to a power source.

• For hot-plug drive procedures, determine whether the drive is part of an array. For more

information, refer to the “Hot Plug SCSI Hard Drive Replacement Guidelines” in the HP

Servers Troubleshooting Guide.

• For hot-plug expansion board procedures, ensure that the proper drivers for the PCI Hot

Plug functionality are installed. For more information, refer to the HP ProLiant DL760

Generation 2 Server User Guide.

The access panels can be removed while the server is powered on without causing a system

shutdown. When the server is in standby mode, portions of the power supply, auxiliary power

(+5V), and some internal circuitry remain active.

Non-Hot-Plug Procedures

You must power down the server to perform non-hot-plug procedures.

WARNING: To reduce the risk of electric shock or damage to the equipment,

disconnect power from the server by unplugging all power cords from either the

electrical outlet or the server. In systems with multiple power supplies, you must

disconnect all the power cords to completely remove power from the system.

IMPORTANT: It is necessary to be knowledgeable about electrostatic discharge information before

conducting the preparation procedures. For electrostatic discharge information, refer to “Electrostatic

Discharge Information” in this chapter.

2-8 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 28

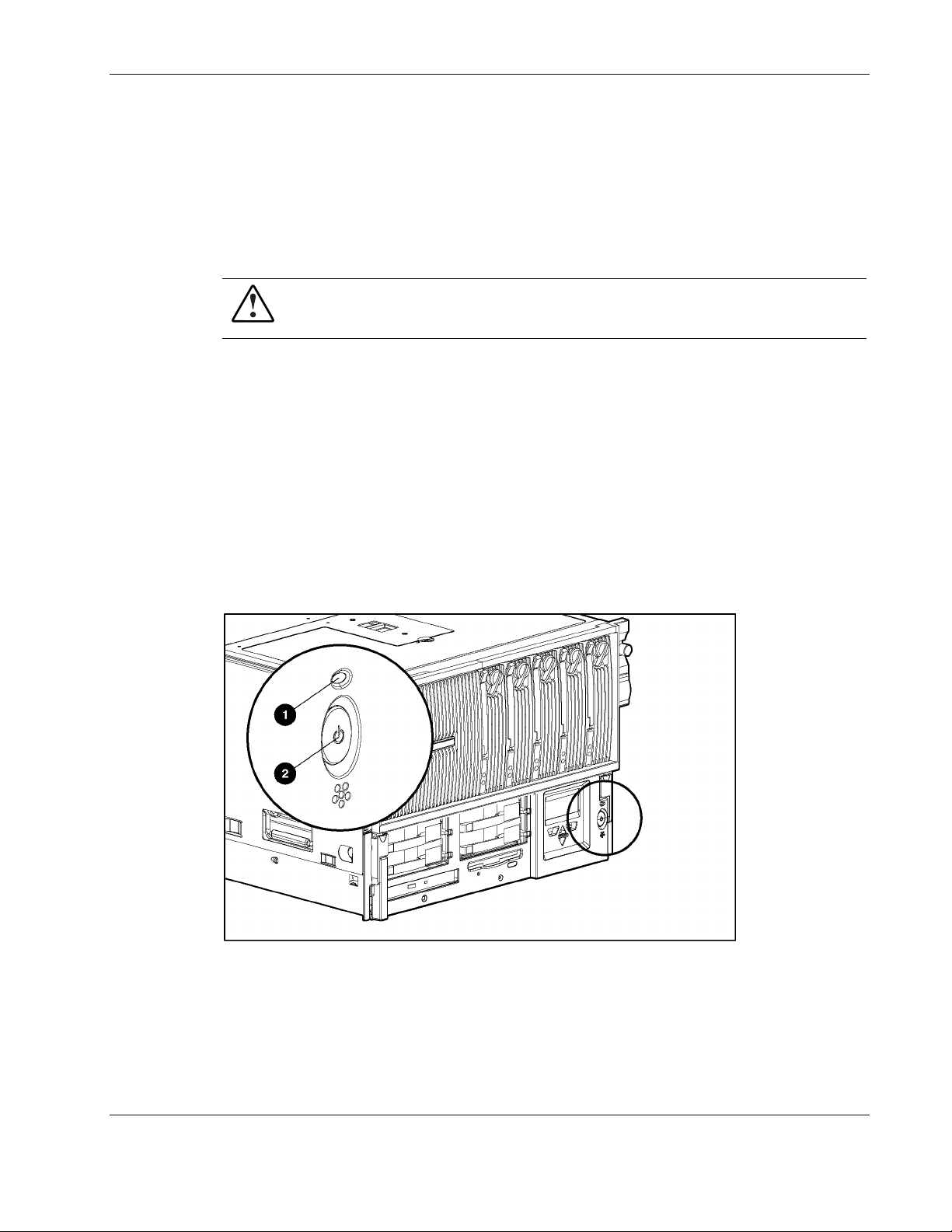

Powering Down the Server

The system power in the ProLiant DL760 G2 server does not shut off completely with the

front panel Power On/Standby switch. The two switch modes are on and standby, rather than

on and off. The Standby position removes power from most of the electronics and the drives,

but portions of the power supply, the IMD, the system interlock circuitry, and some internal

circuitry remain active. To completely remove all power from the system, you must

disconnect all power cords from the server.

WARNING: To reduce the risk of electric shock or damage to the equipment,

disconnect power from the server by unplugging all power cords from either the

electrical outlet or the server.

To power off the server:

1. Back up the server data.

2. Shut down the operating system as directed by the operating system instructions. If the

server is in a rack, press the UID button.

3. Press the Power On/Standby switch (2) to standby. This action places the server in

standby, thereby disabling the main power supply output and providing auxiliary power

(+ 5V) to the server. Standby does not disable main output power.

Service Preparation

4. Be sure that the system power LED (1) on the front panel, near the Power On/Standby

switch, becomes dark and fan noise abates.

5. Disconnect all power cords from the server to disable power to the server.

Figure 2-4: System power LED and Power On/Standby switch

For some removal and replacement procedures, you must remove the server from the rack

and place it on a sturdy table or workbench. Refer to the HP ProLiant DL760 Generation 2

Server User Guide for further instructions.

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 2-9

Page 29

Service Preparation

Powering Up the Server

When you power up the server, it should go through the following sequence. Record any

discrepancies and any error messages that occur. Be sure that the server is safely installed in

an adequate environment before powering up for the first time.

Be sure that power is supplied to each power supply on the back of the server. The IMD is

illuminated if the machine has power.

1. Turn on the machine by pressing the Power On/Standby switch.

2. Check the system power LED:

— The system power LED (1) as shown in Figure 2-4, should blink to indicate that the

system is trying to power up. If the LED does not blink when the power button is

pressed, then either one of the system components is improperly installed, or there is

no main power applied to the system power supplies.

— If the system power LED is amber or if the interconnect check lights are illuminated,

check the system interconnect status indicators (located on the top of the server). For

more information, refer to the “System I nterconnect LEDs” section of this chapter.

— The system power LED will blink every one to two seconds between a power-down

and power-up condition or immediately after applying power to the system. This

action indicates that the Power/On Standby switch has been pressed and that the

system will power up momentarily.

3. Check the power supplies on the back of the server. The following settings indicate that

the power switch is on and the power supply is in a “power-on del ay” mode:

— Top LED begins blinking (green)

— Bottom LED is on (solid green)

If the power supply top LED does not begin blinking (the server will not power up), refer

to the “System Interconnect LEDs” section in this chapter.

When the top LED illuminates solid green, listen for the fans to start.

4. Check the hard drive and CD-ROM drive LEDs on the front of the server. The hard drive

and CD-ROM drive LEDs should blink. If the LEDs do not light, verify that the hard

drives are fully installed in the system and the array bypass is initialized.

5. Check the memory cartridge LEDs. The memory cartridge attention and power LEDs

will illuminate solid and then go out in sequence beginning with memory cartridge 1 and

ending with memory cartridge 5 (left to right cartridge 1, 2, 3, 4, 5).

6. Check the DIMM status LEDs. The DIMM status LEDs for each cartridge will illuminate

solid and then go out in sequence beginning with cartridge 1 and ending with cartridge 5

(left to right cartridge 1, 2, 3, 4, 5).

2-10 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 30

7. Watch for memory system initialization. Memory system initializes as the memory

cartridge power LEDs on all five memory cartridges begin blinking. After the memory

system is initialized, all memory cartridges power LEDs will illuminate solid.

8. The server begins the Power-On Self-Test (POST) sequence. The Integrated Management

Display (IMD) displays each step of the POST sequence.

Power-On Self-Test

As the POST process continues during server power-up:

1. Check for the IMD messages about the following:

a. Server name

b. LCD firmware

c. System initialization

d. PCI auto configuration

e. Video

f. Processors

Service Preparation

2. Check the IMD video initialization message. If there is a monitor connected, refer to the

HP initialization screen.

3. Check the IMD memory test message. The monitor displays the memory initialization,

memory detected, and redundant memory.

4. Check the IMD processors message. The monitor displays the number, speed, and cache

size of the processors.

5. Check for IMD messages about the following:

a. Diskette drive

b. Option ROM

c. SCSI devices

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 2-11

Page 31

Service Preparation

6. Check the monitor for ROM family and date. The system briefly displays the F1 prompt

to open the Memory Configuration Manager.

Figure 2-5: System F1 prompt

2-12 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 32

Service Preparation

7. Press the F1 key to enter the Memory Configuration Manager. This ROM-based tool

(shown in Figure 2-6) is used to examine and upgrade the server memory configuration.

Figure 2-6: Memory Configuration Manager

8. Check the monitor for processor initialization information. Each processor is listed as it

initializes.

9. Check the monitor for controller information. The system briefly displays the F8 prompt

after each controller POSTs to open the Option ROM Configuration for Arrays (ORCA).

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 2-13

Page 33

Service Preparation

10. The system briefly displays the F9 and F10 prompts.

Figure 2-7: System prompts

11. Press the F9 key to start the ROM-Based Setup Utility (RBSU) or the F10 key to open

the System Maintenance Menu (SMM).

12. Be sure that each green PCI Hot Plug LED is illuminated for each PCI/PCI-X I/O

expansion slot (viewable from inside and outside the chassis). To check the inside LEDs,

open the I/O lid. If any LEDs are not on, power down the server and be sure that the

following statements are true:

— Each slot has an expansion board or a slot cover.

— Each slot release lever is closed.

— The expansion boards are properly seated. If necessary, try removing and reseating

the boards.

— The PCI Hot Plug interface board cables are properly connected to the I/O board.

— The PCI Hot Plug interface boards are properly seated on the rear I/O panel of the

chassis.

2-14 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 34

Re-entering the Server Serial Number

After you replace the server I/O module or clear the NVRAM, you must re-enter the server

serial number through RBSU. To re-enter the serial number:

1. During the server startup sequence, press the F9 key to access RBSU.

2. Select the System Options menu.

3. Select Serial Number. The following warning is displayed:

WARNING! WARNING! WARNING! The serial number is loaded into the

system during the manufacturing process and should NOT be

modified. This option should ONLY be used by qualified service

personnel. This value should always match the serial number

sticker located on the chassis.

Press the Enter key to clear the warning.

4. Enter the serial number and press the Enter key.

5. Press the Escape key to close the menu.

6. Press the Escape key to exit RBSU.

7. Press the F10 key to confirm exiting RBSU. The server will automatically reboot.

Service Preparation

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 2-15

Page 35

I/O Lid

3

Chassis Components Removal and Replacement

Procedures

WARNING: To reduce the risk of personal injury from hot surfaces, allow the internal

system components to cool before touching them.

CAUTION: When the server is powered on, the access panel must be installed for proper

system cooling. Otherwise, component stress and permanent equipment damage may result.

Open the I/O lid to access the PCI Hot Plug expansion slots, system fans, and configuration

switches.

To open the I/O lid:

1. Unlock the top latch security screw (1) and then pull the latch forward (2).

2. Slide the I/O lid toward the front of the server (3).

Figure 3-1: Opening the I/O lid

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 3-1

Page 36

Chassis Components Removal and Replacement Procedures

To remove the I/O lid:

1. Remove the processor and memory module. Refer to Chapter 5.

2. Slide the I/O lid out of the front of the server.

Figure 3-2: Removing the I/O lid

NOTE: HP recommends leaving the I/O lid locked during normal use.

Hot-Plug Power Supply

The ProLiant DL760 G2 server ships with two hot-plug power supplies. The system power in

the ProLiant DL760 G2 server does not have to be shut off to replace one of the power

supplies.

WARNING: To reduce the risk of electric shock or damage to the equipment:

• Install the power supply before connecting the power cord to it.

• Unplug the power cord before removing the power supply from the server.

• Disconnect power from the server by unplugging all power cords from either the

electrical outlet or the server.

• Keep the work area free of nonconductive materials, such as ordinary plastic

assembly aids and foam packing.

3-2 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 37

Chassis Components Removal and Replacement Procedures

To estimate the power requirements for a specific server configuration, use the ProLiant

DL760 Generation 2 server Power Calculator located on the HP ActiveAnswers Online

Solutions website:

activeanswers.hp.com

1. Select System Configurator under Tools.

2. Click Select Product Family and select ProLiant Servers.

3. From the list, select ProLiant DL760 G2 Server.

The subsequent Web pages contain information and a link to the ProLiant DL760 Generation

2 server Power Calculator.

To replace a hot-plug power supply with the system power on:

1. Remove the power cord from the power supply to replace and release the power cord

clamp.

Figure 3-3: Removing the power cord

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 3-3

Page 38

Chassis Components Removal and Replacement Procedures

2. Squeeze upward on the release tab in the middle of the power supply handle (1).

3. Rotate the power supply handle down (2) and slide the power supply out of the chassis

(3) as shown in Figure 3-4.

IMPORTANT: Use only the power supply part number for the ProLiant DL760 G2 server. Power

supplies from other servers will not fit.

IMPORTANT: When you remove the power supply, a spring-loaded trap door closes to block the

opening. This door preserves the air path required to cool the internal components of the server.

Figure 3-4: Removing a hot-plug power supply

Reverse steps 1 through 3 to replace the hot-plug power supply.

3-4 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 39

System Midplane Assembly

The system midplane assembly is the board to which the power supply connects.

To remove the system midplane assembly:

1. Power down the server. Refer to “Pow ering Down the Server” in Chapter 2.

2. Open the I/O lid. Refer to “I/O Lid” in this chapter.

3. Remove and disconnect all modules and power supplies. Refer to the sections, “Media

Module” in C hapter 4, “Pro cessor and Memory Module” in Chapter 5, “Removing the

I/O Module” in Chapter 6, “and “Hot-Plug Power Su pply” in t his chapter.

4. Loosen the two thumbscrews securing the system midplane assembly to the chassis (1).

5. Remove the board from the chassis (2).

Chassis Components Removal and Replacement Procedures

Figure 3-5: Removing the system midplane assembly

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 3-5

Page 40

Chassis Components Removal and Replacement Procedures

To install the system midplane assembly:

1. Angle the bottom edge of the midplane assembly into the chassis (1), making sure that

the edge is seated under the chassis midplane retainers.

2. Tilt the midplane assembly vertical (2) unsuring that the tab on the chassis engages the

slot on the assembly. This holds the midplane assembly in place.

3. Secure the midplane assembly with the two thumbscrews (3).

Figure 3-6: Installing the system midplane assembly

3-6 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 41

Cable Management Arm

To remove the cable management arm:

1. Label all cables running through the cable management arm.

2. Disconnect all cables from the rear of the I/O module.

3. Loosen the thumbscrew that secures the cable management arm and bracket to the

I/O module (1).

4. Move the bracket, with cable management arm attached, slightly up and then back from

the server (2) to access the cam levers on the I/O module.

Chassis Components Removal and Replacement Procedures

Figure 3-7: Disconnecting the cable management bracket from the

I/O module

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 3-7

Page 42

Chassis Components Removal and Replacement Procedures

5. Swing the cable management arm to the left and out of the way.

Figure 3-8: Rotating the cable management arm to the left

NOTE: When the cable bundle on the back of the server exceeds 2 inches in diameter,

HP has designed a high-capacity cable management arm. This option is designed for

complex rack installations including a large number of cables. If the system requires a

high-capacity cable management arm, refer to the HP High-Capacity Cable Management

Arm option kit, part number 124711-B21.

3-8 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 43

Media Module Removal and Replacement Procedures

Mass storage in the ProLiant DL760 G2 server is located in the media module. The media

module is capable of configuring a maximum of four 1-inch hot-plug Wide Ultra2 or

Wide Ultra3 SCSI hard drives. The media module supports two non-hot-plug media drive

bays:

• One third-height drive bay occupied by a 1.44-MB diskette drive

• One third-height drive bay occupied by a 24X Max (or higher) IDE CD-ROM drive

CAUTION: Removable media blank bezels and hot-plug drive cage blanking panels must be

installed over unused mass storage and removable media device bays to maintain proper

airflow.

4

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 4-1

Page 44

Media Module Removal and Replacement Procedures

Media Module

To remove the media module from the server:

1. Power down the server. Refer to “Pow ering Down the Server” in Chapter 2.

2. Push in the sides of the cam levers on the media module (1) and rotate the top of the

levers downward (2) and slide the module forward (3).

Figure 4-1: Removing the media module

WARNING: To reduce the risk of personal injury from hot surfaces, allow the internal

em components to cool before touching them.

syst

4-2 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 45

Media Module Removal and Replacement Procedures

3. Pull the media module out of the chassis until it contacts the module stop latch (1).

4. Press in the module stop latches, and then pull the module out of the chassis (2).

Figure 4-2: Media module opened to stops

Reverse steps 2 through 4 to reinstall the module.

IMPORTANT: Check the System Interconnect status LEDs to ensure that the module is properly

seated. Refer to “System Interconnect LED Indicators” in Chapter 8.

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 4-3

Page 46

Media Module Removal and Replacement Procedures

Media Module Bezel

To remove the media module bezel:

1. Power down the server. Refer to “Pow ering Down the Server” in Chapter 2.

2. Remove the media module from the server chassis. Refer to “Media Module” in this

chapter.

3. Remove the four screws securing the bezel to the module.

4. Lift up and pull the bezel away from the chassis.

Figure 4-3: Removing the bezel from the media module

Reverse steps 1 through 4 to replace the media module bezel.

4-4 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 47

Integrated Management Display

To remove the IMD:

1. Power down the server. Refer to “Pow ering Down the Server” in Chapter 2.

2. Remove the media module. Refer to “Media Modul e” in this chapter.

3. Remove the bezel. Refer to “Med ia Module Bezel” in this chapter.

4. Turn the media module over and disconnect the IMD cable from the media backplane

board. Refer to “Media Module Cable R outing Diagram” in this chapter.

Media Module Removal and Replacement Procedures

Figure 4-4: Removing the IMD cable

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 4-5

Page 48

Media Module Removal and Replacement Procedures

5. Press inward on the two locking tabs on the rear of the display panel (1).

6. Pull the IMD from the front of the server (2).

Figure 4-5: Removing the IMD

Reverse steps 1 through 6 to replace the IMD.

4-6 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 49

Hot-Plug Hard Drives

Hard Drive Blank

To remove a hard drive blank from a hard drive bay:

1. Push the side of the retaining clip inward (1).

2. Pull the hard drive blank from the bay (2).

Media Module Removal and Replacement Procedures

Figure 4-6: Removing a hard drive blank

Reverse steps 1 and 2 to replace a hard drive blank.

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 4-7

Page 50

Media Module Removal and Replacement Procedures

Hot-Plug Hard Drive Replacement Guidelines

You should be able to hot-plug a drive during normal activity. Be aware, however, that

replacing a hot-pluggable disk drive will affect system performance and fault tolerance.

NOTE: Depending upon the configuration, both a drive failure and the subsequent rebuild process will

cause storage subsystem performance degradation. For example, the replacement of a single drive on

an array with 50 logical drives will have less impact than if the array has only three logical drives.

Advanced Data Guarding

When a disk drive is hot-plugged, although the system is functionally operational, the disk

subsystem might no longer be fault tolerant. Fault tolerance will be lost until the removed

drive is subsequently replaced and the rebuild operation is completed. This procedure takes

several hours, even if the system is not busy while the rebuild is in progress. If another drive

in the array should incur an error during the period when fault tolerance is unavailable, a fatal

system error could result. If another drive fails during this period, the entire array contents

will be lost.

IMPORTANT: Perform disk drive replacement during low activity periods whenever possible. In

addition, a current valid backup of the logical drives in the array of the drive being replaced should be

available even if the drive replacement is being made during server downtime.

When replacing hot-plug hard drives in a fault-tolerant configuration, you must follow these

guidelines:

• Never remove more than one drive at a time. When a drive is replaced, the controller

uses data from the other drives in the array to reconstruct data on the replacement drive.

If more than one drive is removed, a complete data set is not available to reconstruct data

on the replacement drive.

• Never remove a working drive when another drive has failed. Drives failed by the

controller are indicated by the amber Drive Failure LED on the drive tray. Permanent

data loss will occur if a working drive is removed while a failed drive is being replaced.

• Never remove a drive while another drive is being rebuilt. A drive’s Online LED

flashes green while it is being rebuilt. A replaced drive is restored from data stored on the

other drives.

• Never turn a disk enclosure off while the initiator or controller is powered on or

active. Doing so can cause the initiator or controller to mark the drives as “f ailed.” This

action can result in permanent data loss.

• If a drive is replaced while the system is off, rebuilding the replaced drive might be

necessary. Follow the instructions on the screen or the instructions outlined in the system

reference guide.

CAUTION: During the boot prompt, pressing the F2 key will cause permanent data loss to

the entire logical drive. Press the F2 key only if all of the drives have been replaced or if

complete data loss is required.

4-8 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 51

NOTE: When a drive configured for fault tolerance is replaced, the replacement drive automatically

begins restoring when it is installed. When restoring a drive, the Online LED blinks green. The LED

continues to flash until the drive is completely restored.

Removing a Hot-Plug Hard Drive

To remove a hot-plug hard drive:

1. Push the tab to unlock the drive (1).

2. Rotate the hot-plug drive ejector lever outward (2).

3. Pull the hot-plug drive from the drive bay (3).

Media Module Removal and Replacement Procedures

Figure 4-7: Removing a hot-plug hard drive

Reverse steps 1 through 3 to replace a hot-plug hard drive.

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 4-9

Page 52

Media Module Removal and Replacement Procedures

Integrated Diskette Drive and CD-ROM

The media module has a one third-height drive bay occupied by a 1.44-MB diskette drive and

24X Max (or higher) IDE CD-ROM drive. To remove the integrated diskette drive and

CD-ROM drive:

1. Power down the server. Refer to “Pow ering Down the Server” in Chapter 2.

2. Remove the media module. Refer to “Media Modul e” in this chapter.

3. Remove the media module bezel. Refer to “Media Module Bezel” in this chapter.

4. Turn the media module over and disconnect the CD-ROM drive signal cable (1), the

diskette drive control and data cable (2), and diskette drive power cable (3) from the back

of the drives.

Figure 4-8: Disconnecting the CD-ROM/diskette drive cables

4-10 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 53

Media Module Removal and Replacement Procedures

5. Remove the tray screw located on the front of the media module.

6. Slide out the diskette drive/CD-ROM tray.

Figure 4-9: Removing the integrated diskette drive and CD-ROM

drive

Reverse steps 1 through 4 to replace the integrated diskette drive and CD-ROM drive.

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 4-11

Page 54

Media Module Removal and Replacement Procedures

Media Module Cable Routing Diagram

Figure 4-10: Media module cable routing

Item Description

1 CD-ROM drive signal cable

2 Diskette drive control and data cable

3 Diskette drive power cable

4 IMD cable

5 Power switch/LED/ambient air temperature sensor

cable

4-12 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 55

Power On/Standby Switch Assembly

To remove the Power On/Standby switch assembly:

1. Power down the server. Refer to “Power ing Down the Server ” in Chapter 2.

2. Remove the media module. Refer to “Media Modul e” in this chapter.

3. Remove the media module bezel. Refer to “Media Module Bezel” in this chapter.

4. Turn the media module upside down.

5. Unplug the IMD cable from the media backplane board. Refer to “Media Module Cable

Routing Diagram” in this chapter.

6. Remove the IMD. Refer to “Integrated Management Display” in this chapter.

7. Disconnect the Power On/Standby switch connector from the media backplane board (1).

Refer to “Media Module C able Routing Diagram” in this chapter.

8. Loosen the thumbscrew that secures the power switch plate to the media backplane

board (2).

Media Module Removal and Replacement Procedures

Figure 4-11: Unplugging the power switch cable and loosening the

thumbscrew

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 4-13

Page 56

Media Module Removal and Replacement Procedures

9. Remove the power switch plate from the media module.

Figure 4-12: Removing the power switch plate from the media

module

NOTE: The switch plate has three components visible from the front of the assembled server. Because

the media module is inverted for this procedure, the components are shown reversed.

4-14 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 57

Media Module Removal and Replacement Procedures

10. Referring to Figure 4-13, rotate the Thermistor until you can easily access the flanges on

the side of the grommet (1).

11. Squeeze the grommet around the Thermistor and push it back through the plate (2).

12. Push the Power On/Standby switch LED (3) back through the plate.

Figure 4-13: Removing the Thermistor and Power On/Standby

switch LED

13. Place the plate on its left side and push the Power On/Standby switch down through the

rectangular cutout and clear of the plate.

Figure 4-14: Removing the Power On/Standby switch

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 4-15

Page 58

Media Module Removal and Replacement Procedures

To reinstall the Power On/Standby switch assembly:

1. Place the power switch plate on its left side and push the Power On/Standby switch up

through the rectangular cutout to its original position.

2. Line up the keyhole-shaped cutouts on the power switch plate with the spools in the right

wall of the media module.

3. Slide the plate back into the media module until the hole in the back of the power switch

plate lines up with the thumbscrew.

4. Tighten the thumbscrew.

5. Push the Power On/Standby switch LED through the power switch plate to its original

position.

6. Push the Thermistor through the power switch plate.

7. Rotate the Thermistor to its original position.

8. Reverse steps 1 through 7 of the removal procedure.

4-16 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 59

Processor and Memory Module Removal and

Shipping Screws

To prevent damage to the processor and memory module during shipping, the server ships

with a shipping screw installed on each side of the chassis. These screws must be removed

and the processor and memory module properly seated and secured in the chassis before

powering up the server.

CAUTION: To prevent damage to the processor and memory module during shipping, both

shipping screws must be installed.

1. Remove the left and right shipping screws. The shipping screws may look like (1) or (2)

in the following figure.

5

Replacement Procedures

Figure 5-1: Shipping screws

2. Rotate the module release levers downward.

3. Slide the module into the chassis until the levers begin to rotate.

4. Then push the levers upward until they snap into place.

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 5-1

Page 60

Processor and Memory Module Removal and Replacement Procedures

Security Screw

The server has a top latch security screw as shown in Figure 5-2. The screw prevents access

to the processor and memory module and I/O module. Tighten the security screw to increase

the security of the server in a rack.

1. Open the I/O lid. Refer to “I/O Lid” in Chapter 3.

2. Tighten the security screw.

Figure 5-2: Tightening the security screw

5-2 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 61

Processor and Memory Module Removal and Replacement Procedures

Processor and Memory Module

WARNING: The processor and memory module weighs more than 16 kg (35 lbs). HP

recommends either removing ALL of the memory cartridges before handling the

module or having two people handling the module together.

CAUTION: Do not attempt to remove the processor and memory module while power is

applied to the system. The module is not hot-pluggable. Immediate system shutdown and

data loss will occur.

To remove the processor and memory module:

1. Power down the server. Refer to “Pow ering Down the Server” in Chapter 2.

2. Push in the sides of the cam levers on the processor and memory module (1) and rotate

the top of the levers downward (2), as shown in Figure 5-3.

3. Pull the processor and memory module out of the chassis until the module encounters the

module stop latches (3).

Figure 5-3: Opening the processor and memory module

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 5-3

Page 62

Processor and Memory Module Removal and Replacement Procedures

4. Press the module stop latches in (4) and pull the module out of the chassis (5), as shown

in Figure 5-4.

Figure 5-4: Removing the processor and memory module

WARNING: To reduce the risk of personal injury from hot surfaces, allow the internal

em components to cool before touching them.

syst

NOTE: The I/O lid labels, processor board cover, and memory cartridge covers also provide

instructions about installing processors and DIMMs.

To reassemble the server, slide the module in until the cam levers begin to rotate. Then push

the cam levers shut until they snap into place.

5-4 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 63

Processor and Memory Module Removal and Replacement Procedures

Processor Boards and Processors

Identifying

The ProLiant DL760 G2 server is capable of supporting up to eight Intel® Xeon processors

MP and is shipped with four or eight processors already installed. The ProLiant DL760 G2

server supports two processor boards located in the left side of the processor and memory

module.

Figure 5-5: Processor boards

Table 5-1: Processor Boards

Item Description

1 Processor board in processor board slot 1

2 Processor board in processor board slot 2

The ProLiant DL760 G2 server supports four or eight Intel Xeon processors MP.

• All processors must be the same speed, cache size, and stepping.

• Processor 1 must always be installed to properly terminate the processor bus.

NOTE: Stepping refers to the processor revision.

NOTE: If the server has one processor board (four processors), processor board slot 2 is populated

with a processor board air baffle. This baffle must be removed if you are upgrading to eight processors.

Refer to the HP ProLiant DL760 Generation 2 Server User Guide for upgrade instructions.

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 5-5

Page 64

Processor and Memory Module Removal and Replacement Procedures

Figure 5-6: Processors

Table 5-2: Processors

Item Description

1 Intel Xeon processor MP in socket 1

2 Intel Xeon processor MP in socket 2

3 Intel Xeon processor MP in socket 3

4 Intel Xeon processor MP in socket 4

Removing Processor Boards and Processors

WARNING: The processor and memory module weighs more than 16 kg (35 lbs). HP

recomm

module or having two people handling the module together.

1. Power down the server. Refer to “Pow ering Down the Server” in Chapter 2.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the internal

syst

2. Remove the processor and memory module. Refer to “Processor an d Memory Module” in

this chapter.

ends either removing ALL of the memory cartridges before handling the

em components to cool before touching them.

5-6 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 65

Processor and Memory Module Removal and Replacement Procedures

3. Push the lever latch forward to release the processor board lever (1).

4. Lift the processor board lever up (2), and lift the processor board out of the module (3).

Figure 5-7: Removing the processor board

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 5-7

Page 66

Processor and Memory Module Removal and Replacement Procedures

5. Push in the four tabs on the sides of the processor board cover (1) and then lift the cover

off the processor board (2).

Figure 5-8: Removing the processor board cover

6. Turn over the processor board to access the processor clips.

7. Lift the processor clip to unlock the clip (1) and then slide it forward and up to

remove it from the processor board (2).

Figure 5-9: Removing the processor clip

5-8 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 67

Processor and Memory Module Removal and Replacement Procedures

8. Open the processor release lever (1) and remove the processor (2).

NOTE: The processor locking lever now swings from 15 to 135 degrees. Previous generations of

processor sockets required lever movement of only 0 to 90 degrees.

Figure 5-10: Removing the processor

Reverse steps 1through 8 to install a processor and the processor board.

CAUTION: Fully open the processor locking lever before installing a processor. Open

the processor locking lever completely (until it stops) and ensure the alignment pins are in

place. Though the processor may appear to be seated properly when the lever is partially

open and the processor is placed in the socket, the lever must be fully opened to 150 degrees

for the processor to be inserted properly in the socket. If the processor is improperly seated,

damage can occur to the processor and/or system board.

NOTE: Processor board 2 need not be installed for the server to run.

9. Turn on the server. If the system does not power up, verify that the System Interconnect

LED indicators are normal. Refer to “System Interconnect LED Indicators” in Chapter 8.

10. Verify that the processor was installed correctly. Check the processor frequency, cache

size, and socket location by reviewing the POST messages on the system console or

processor information listed under the System Information Menu of the IMD. For more

information, refer to the HP ProLiant DL760 Generation 2 Server User Guide.

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 5-9

Page 68

Processor and Memory Module Removal and Replacement Procedures

Memory Cartridge

Identifying

The following figure shows the various components of the memory cartridges.

Figure 5-11: Memory cartridge components

Item Component

1 Cartridg e lock

2 Cartridg e latch

3 Cartridg e lever

4 Cartridge power LED

5 Cartridge attention LED

5-10 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 69

Removing the Memory Cartridge

To remove a memory cartridge from the ProLiant DL760 G2 server, complete the following

steps:

1. Unlock the memory cartridge by rotating the cartridge lock counterclockwise (1).

IMPORTANT: If the memory cartridge is not required for continued operation (with at least four other

memory cartridges installed, online, and error free), the memory cartridge power LED will turn off.

IMPORTANT: If the cartridge is required for continued operation, an audible caution alarm will sound

and the memory cartridge attention LED indicator will blink until the cartridge is locked again.

2. Verify that the cartridge power LED is off.

CAUTION: Do not remove a memory cartridge if the cartridge power LED indicator is blinking

or is solid green. The system will halt.

3. Push the lever latch upward to release the memory cartridge lever (2).

4. Pull the memory cartridge lever down (3).

Processor and Memory Module Removal and Replacement Procedures

5. Slide the cartridge out of the processor and memory module (4).

CAUTION: Do not leave a memory cartridge out of its slot for more than two minutes to

ensure proper airflow and cooling.

Figure 5-12: Removing the memory cartridge

CAUTION: Inspect the memory cartridge for bent pins before reinstalling it. Do not “drop” the

cartridge into the cage.

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 5-11

Page 70

Processor and Memory Module Removal and Replacement Procedures

Opening the Memory Cartridge

To gain access to the DIMMs, open the memory cartridge cover:

1. Squeeze the lock tabs together at the end of the cartridge opposite the lock lever (1).

2. Tilt the cartridge cover up until it latches in the up position to access the DIMMs (2).

Figure 5-13: Opening the memory cartridge

DIMM Overview

The ProLiant DL760 G2 server has four memory bank pairs, each consisting of 10 DIMMs

installed across the five memory cartridges. The server supports up to 40 GB of Hot Plug

RAID memory.

5-12 HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide

Page 71

Identifying

Processor and Memory Module Removal and Replacement Procedures

Figure 5-14 and Table 5-3 detail the DIMM socket locations on the memory cartridge.

Figure 5-14: DIMM socket location

Table 5-3: DIMM Socket Location

Item Description Bank

1 DIMM socket 1 DIMM bank 1

2 DIMM socket 2 DIMM bank 2

3 DIMM socket 3 DIMM bank 3

4 DIMM socket 4 DIMM bank 4

5 DIMM socket 5 DIMM bank 5

6 DIMM socket 6 DIMM bank 6

7 DIMM socket 7 DIMM bank 7

8 DIMM socket 8 DIMM bank 8

Bank pair for

interleaving

Bank pair for

interleaving

Bank pair for

interleaving

Bank pair for

interleaving

HP ProLiant DL760 Generation 2 Server Maintenance and Service Guide 5-13

Page 72

Processor and Memory Module Removal and Replacement Procedures

SDRAM Memory Bus Configuration

Figure 5-15 details the SDRAM memory bus configuration. Bank definition ensures that

memory interleaving is always available.