Page 1

HP Performance-Optimized Datacenter User Guide

Part Number 510055-001

March 2009 (First Edition)

Page 2

© Copyright 2009 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP

shall not be liable for technical or editorial errors or omissions contained herein.

Confidential computer software. Valid license from HP required for possession, use or copying. Consistent with FAR 12.211 and 12.212,

Commercial Computer Software, Computer Software Documentation, and Technical Data for Commercial Items are licensed to the U.S.

Government under vendor’s standard commercial license.

Microsoft, Windows, and Windows Server are U.S. registered trademarks of Microsoft Corporation. Intel, Pentium, and Itanium are trademarks

or registered trademarks of Intel Corporation or its subsidiaries in the United States and other countries. UNIX is a registered trademark of The

Open Group.

Intended audience

This document is for the person who installs, administers, and troubleshoots servers and storage systems. HP assumes you are qualified in the

servicing of computer equipment and trained in recognizing hazards in products with hazardous energy levels.

Page 3

Contents

Site requirements .......................................................................................................................... 6

Optimum environment................................................................................................................................6

Location considerations ....................................................................................................................6

Moving the HP POD ........................................................................................................................ 6

System utilities.................................................................................................................................6

Transformer, switchboard, and water distribution kit locations ............................................................... 7

Work space requirements.................................................................................................................8

Environmental considerations...................................................................................................................... 8

Temperature considerations ..............................................................................................................8

Leveling requirements.......................................................................................................................9

Grounding requirements...................................................................................................................9

Lightning protection .........................................................................................................................9

Component documentation......................................................................................................................... 9

Safety considerations .................................................................................................................. 10

Safety information ...................................................................................................................................10

Operator safety.............................................................................................................................10

Component health .........................................................................................................................10

Component identification............................................................................................................. 12

HP POD components ............................................................................................................................... 12

HP POD emergency components ...............................................................................................................13

HP POD panel locations........................................................................................................................... 14

Transformer and switchboard components (optional)....................................................................................15

Water distribution kit components (optional) ............................................................................................... 16

Installation ................................................................................................................................. 17

HP POD contents.....................................................................................................................................17

Preinstallation checklist.............................................................................................................................18

Required tools............................................................................................................................... 18

Installing the HP POD using the optional components ................................................................................... 19

Connecting the water..................................................................................................................... 19

Connecting the power....................................................................................................................23

Commissioning the HP POD...................................................................................................................... 25

Cooling system........................................................................................................................... 27

HP POD cooling system............................................................................................................................ 27

Water supply temperature .............................................................................................................. 27

Controlling the fan speed .........................................................................................................................27

Condensation management ......................................................................................................................28

HP POD drains ....................................................................................................................................... 28

Leak detection......................................................................................................................................... 29

Water quality requirements.......................................................................................................... 30

Water quality requirements and specifications ............................................................................................30

Acceptable water quality specifications ............................................................................................30

Frost damage................................................................................................................................ 31

Plumbing materials to avoid............................................................................................................ 31

Contents 3

Page 4

Water precautions.........................................................................................................................31

Water temperature ........................................................................................................................ 31

Power management .................................................................................................................... 32

Electrical busway ....................................................................................................................................32

Power distribution.................................................................................................................................... 33

Rack power............................................................................................................................................ 34

Panels....................................................................................................................................................35

ASSD panel.................................................................................................................................. 36

BMS panel ................................................................................................................................... 36

Electrical busway enclosed circuit breaker ........................................................................................36

EPO Panel .................................................................................................................................... 36

EPMS panel.................................................................................................................................. 38

Fan control panel ..........................................................................................................................38

Fire alarm control panel .................................................................................................................38

House panel .................................................................................................................................38

Security panel location................................................................................................................... 39

Building management system ....................................................................................................... 40

Using a building management system (BMS)............................................................................................... 40

Connecting the HP POD to the BMS...........................................................................................................40

Managing BMS settings from the HP POD ..................................................................................................41

BMS alarms............................................................................................................................................41

Safety and security alarms........................................................................................................................42

Fire alarm sequence of operations ...................................................................................................42

Optional components.................................................................................................................. 44

Additional insulation................................................................................................................................ 44

Air filter sensor........................................................................................................................................ 44

Humidifier (optional)................................................................................................................................ 44

Fire protection system .............................................................................................................................. 44

HP POD security...................................................................................................................................... 44

Transformers and switchboards................................................................................................................. 45

Water distribution kit ...............................................................................................................................45

Water distribution kit power requirements......................................................................................... 46

Frequently asked questions .......................................................................................................... 47

HP POD frequently asked questions ........................................................................................................... 47

Troubleshooting.......................................................................................................................... 49

HP POD troubleshooting........................................................................................................................... 49

Specifications............................................................................................................................. 50

HP POD specifications .............................................................................................................................50

Electrical specifications ............................................................................................................................50

Water specifications................................................................................................................................ 51

Rack specifications ..................................................................................................................................52

Thermal and air flow performance.............................................................................................................52

Environmental specifications .....................................................................................................................53

Water distribution kit specifications ...........................................................................................................53

Maintenance.............................................................................................................................. 54

Periodic maintenance .............................................................................................................................. 54

Electrical busway maintenance.................................................................................................................. 54

Water system maintenance.......................................................................................................................54

Air filter replacement ...............................................................................................................................54

Contents 4

Page 5

Air and water heat exchanger maintenance................................................................................................ 54

Before you contact HP.............................................................................................................................. 55

HP contact information................................................................................................................... 55

Regulatory compliance notices ..................................................................................................... 56

Regulatory compliance identification numbers............................................................................................. 56

Federal Communications Commission notice............................................................................................... 56

Modifications.......................................................................................................................................... 56

Cables................................................................................................................................................... 56

Canadian notice .....................................................................................................................................56

European Union regulatory notice .............................................................................................................56

Disposal of waste equipment by users in private households in the European Union......................................... 57

BSMI notice............................................................................................................................................ 57

Chinese notice ........................................................................................................................................ 58

Korean class A notice ..............................................................................................................................58

Japanese class A notice ...........................................................................................................................58

Acronyms and abbreviations........................................................................................................ 59

Index......................................................................................................................................... 61

Contents 5

Page 6

Site requirements

Optimum environment

Specific environmental requirements must be met to provide optimum performance with minimum

maintenance for your unit.

HP provides the HP Performance-Optimized Datacenter Site Requirements Information document to learn

about these requirements and plan your configuration more efficiently. The latest version of the guide is

Location considerations

available on the HP website (http://www.hp.com/go/pod

The HP POD can be located either inside or outside your facility.

).

If you decide to remove the HP POD from the trailer, it must be installed on a flat, level surface capable of

supporting up to 110,000 lb.

Consider the proximity to existing facility utilities (power and water) when choosing the final location.

A site map with the final location of the HP POD, final location of the connection kit, final location of the

water distribution kit, facility connection points, and any obstructions must be provided to HP prior to

scheduling your delivery and installation.

For more specific power, water, and electrical considerations, see the HP Performance-Optimized

Datacenter Site Requirements Information document on the HP website (http://www.hp.com/go/pod

POD exterior dimensions and weight

The HP POD is approximately 12.2 m (40 ft) long, 2.4 m (8 ft) wide, and 2.0 m (9.5 ft) tall.

The HP POD weighs approximately 11,340 kg (25,000 lb) when it is empty and can weigh up to

49,895 kg (110,000 lb) fully loaded.

Before the arrival of your HP POD, verify that the location you have chosen can adequately support the

size and weight of the HP POD.

Moving the HP POD

IMPORTANT: If you move the HP POD on your own, it will void your warranty.

).

If you choose to move the HP POD to a new location, contact HP before attempting to move the HP POD.

HP can provide detailed instructions and/or services for shutting down and moving the HP POD.

System utilities

Your site location must accommodate the following utilities:

Site requirements 6

Page 7

• Cooling water

• Power

• Drain (optional)

Available to connect to central facility infrastructure

• BMS via BacNet protocol

• Security system

• Convenience outlet power

• Site networking connection

• Domestic water for humidifier (optional)

Transformer, switchboard, and water distribution kit locations

If you choose to purchase the kits, consider:

• Distance from the facility utilities

• Distance from the HP POD

The transformer and switchboard can be installed within 3 m (10 ft) of the HP POD during normal

installation. The transformer and switchboard can be installed over 3 m (10 ft) from the HP POD, but this

requires additional planning and costs. HP recommends installing the transformer and switchboard no

more than 30 m (98 ft) from the HP POD.

The water distribution kit can be installed within 3 m (10 ft) of the HP POD during normal installation. The

water distribution kit can be installed over 3 m (10 ft) from the HP POD, but this requires additional

planning and costs. HP recommends installing the water distribution kit no more than 30 m (98 ft) from

the HP POD.

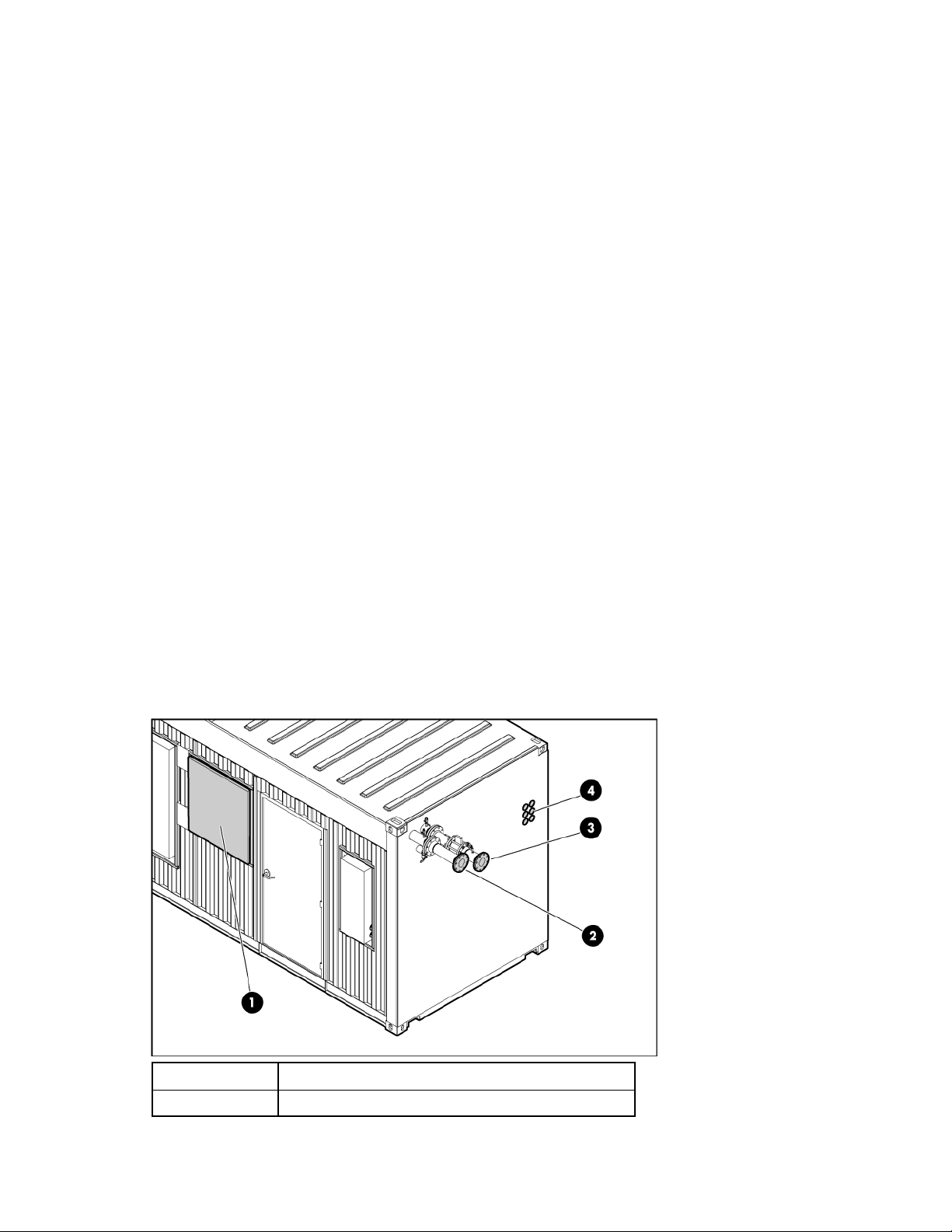

HP POD connection locations

Callout Connection

1 Main input power junction box

Site requirements 7

Page 8

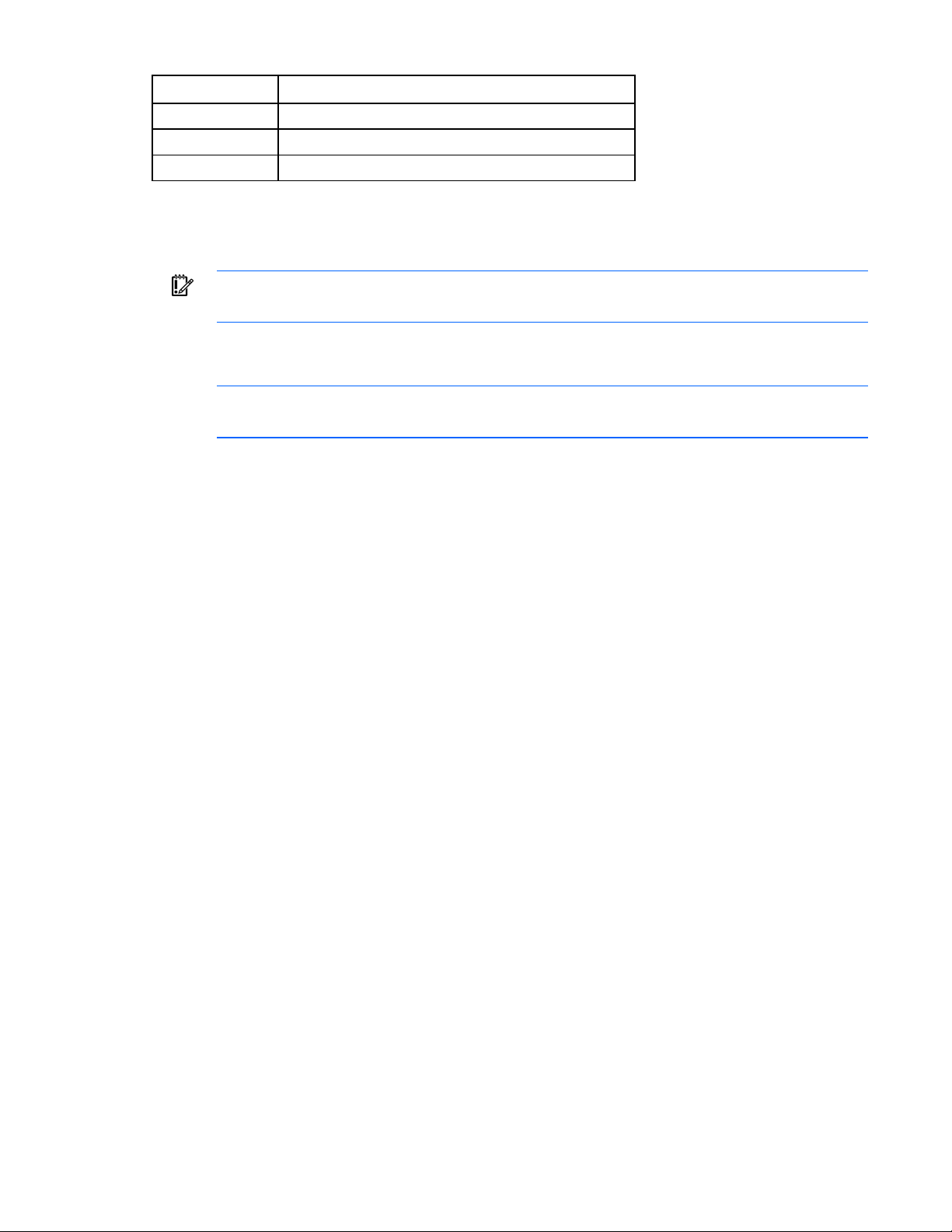

Callout Connection

2 Chilled water return connection

3 Chilled water supply connection

4 IT cable portals∗

∗There are identical IT cable portals on the left side of the HP POD.

Work space requirements

IMPORTANT: Failure to comply with the work space requirements can result in failed

Work platform requirements

The area outside of the HP POD directly in front of the panels must have a work platform. The

specifications of the work platform are:

• The work platform must be a minimum of 1 m (3 ft) wide for standard platforms, and 1.1 m (3.5 ft)

• The work platform surface must be <2.0 m (6.6 ft) from the center of any circuit breaker actuator

Work space lighting

Make sure that the HP POD, transformer, switchboard, and water distribution kit are installed in a well lit

area that complies with local work space lighting requirements, per code regulations.

authorization to power your HP POD by local electrical inspectors.

NOTE: The base of the work platform should be level with the base of the HP POD. If you

choose to leave the HP POD on a trailer, a work platform is required.

wide if the work platform is constructed of grounded metal.

handle.

Environmental considerations

• Install a properly engineered awning to enable access to the building in adverse weather conditions.

• Install lightning protection for the HP POD.

• Make sure that the HP POD is properly grounded.

• Avoid placing the HP POD directly along a drainage path or in an area prone to flooding.

• Raise the HP POD slightly off the ground, or set it on a higher point of elevation. In low elevated

areas, HP recommends setting the HP POD on a concrete housekeeping pad.

• Avoid placing the HP POD directly in the path of external heat loads such as a diesel generator or

Temperature considerations

an air cooled chiller.

The standard operating temperature for the HP POD is from -17.8°C to 54.4°C (0°F to 130°F).

If you choose to purchase the additional insulating paint ("Additional insulation" on page 44), the

operating temperature of the HP POD is from -28.9°C to 54.4°C (-20°F to 130°F).

Site requirements 8

Page 9

Leveling requirements

The site location for the HP POD must be level +/- 0.5 degree tolerance.

Grounding requirements

IMPORTANT: Before installing the HP POD, consult your local AHJ for applicable codes and to

review site-specific location guidelines.

The HP POD must be grounded in accordance to local electric code. HP recommends grounding the HP

POD, the transformer and switchboard, and the water distribution kit to your ground grid system for full

protection.

Lightning protection

If the HP POD is installed in an outdoor environment, HP recommends hiring a lightning protection

consultant to evaluate potential lightning risks and assess possible HP POD lightning protection schemes.

Component documentation

The Operations and Maintenance Manual, that includes all contractor-installed component documentation

and all server and IT equipment documentation is delivered with your HP POD.

Site requirements 9

Page 10

Safety considerations

Safety information

The HP POD has been listed to the UL 69050 as an Information Technology Product and Classified

according to the National Electric Code, NFPA-70, 2008.

The HP POD is not suitable for long term human occupancy.

The HP POD has service access areas for periodic maintenance and service, only to be used by owner

authorized personnel specifically trained in the maintenance and service of the HP POD IT components.

The safety information is specific to the people operating and maintaining the components of the HP POD.

IMPORTANT: All plumbing to and from the HP POD must be completed by a licensed plumber.

IMPORTANT: All wiring in and around the HP POD must be completed by a licensed

electrician.

Operator safety

WARNING: Hearing protection must be worn at all times when working in or around the HP

POD.

WARNING: Any water that drains around the HP POD causes a potential slip hazard. Use

caution where slip hazards are present.

Component health

CAUTION: If the cooling water stops flowing into the HP POD:

• Turn off all IT equipment

• Open the HP POD doors, if weather permits

• View the BMS alarm conditions

CAUTION: Do not put anything inside any of the electrical busways, except the approved

connections to the HP busway dropboxes.

CAUTION: During operation of the HP POD, the overhead fan doors must remain closed.

Safety considerations 10

Page 11

CAUTION: All customer supplied water fittings must be composed of carbon steel, stainless

steel, or copper. Do not use cast iron, aluminum, or PVC fittings.

CAUTION: During operation, avoid leaving the HP POD doors open, to minimize

condensation conditions.

Safety considerations 11

Page 12

Component identification

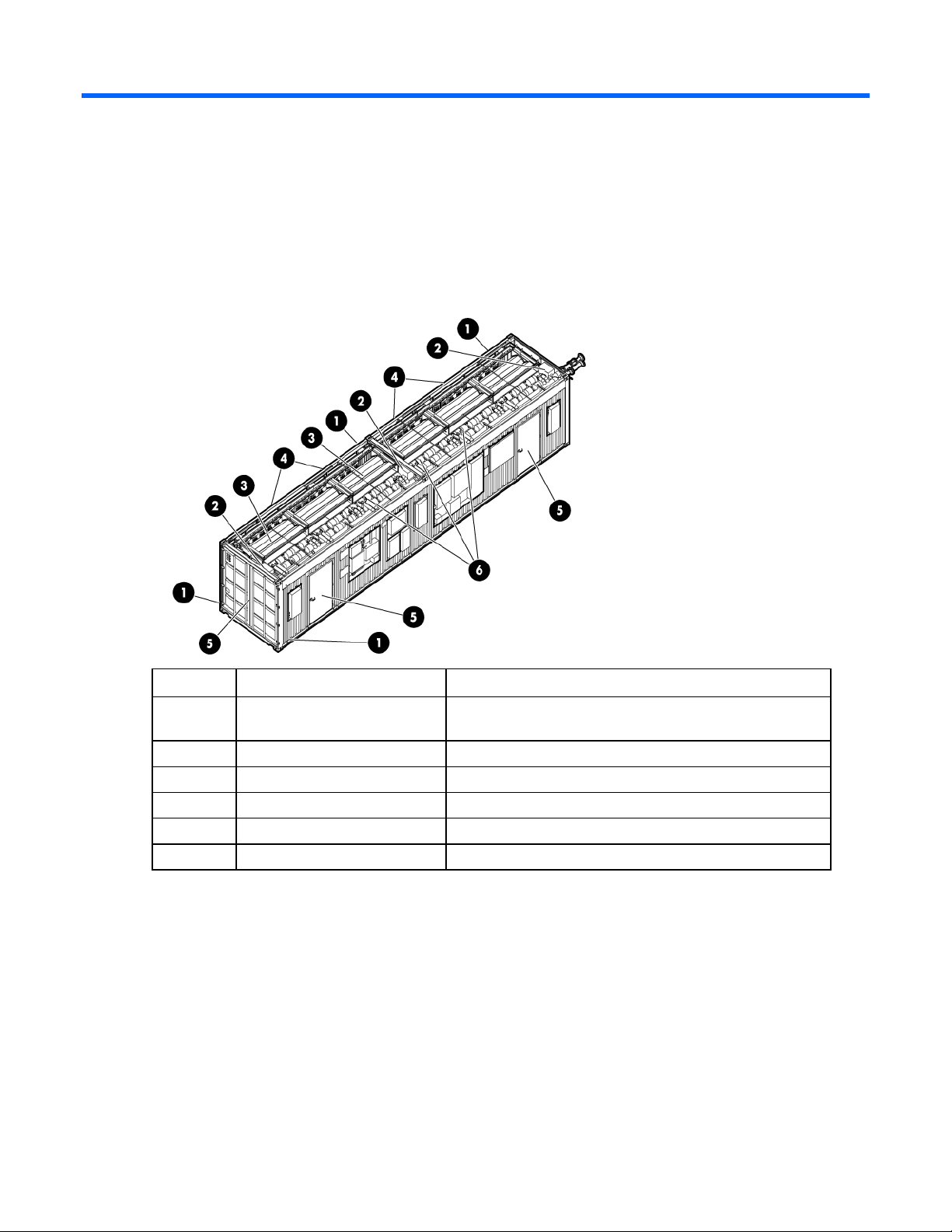

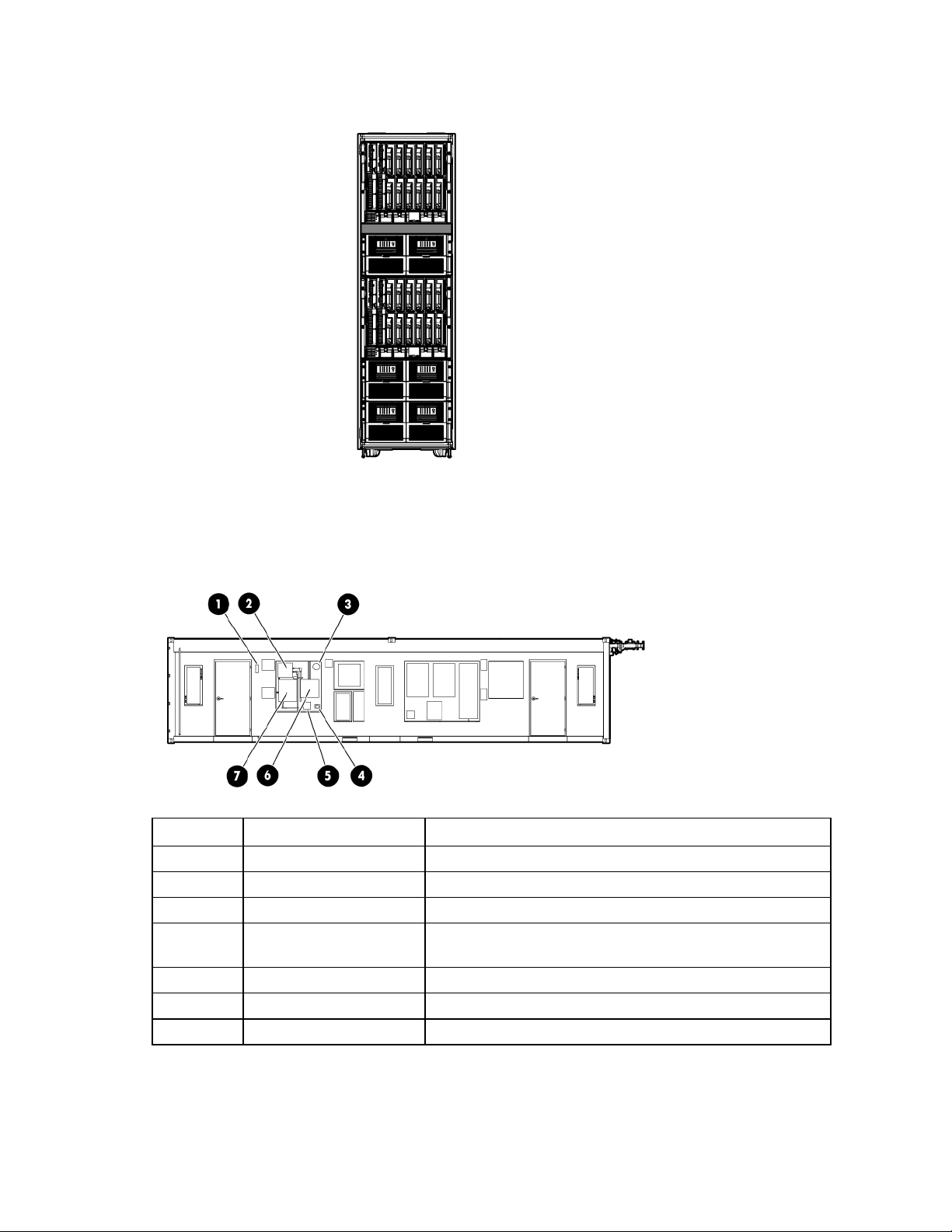

HP POD components

HP POD components

Item Component Description

1 Drain lines Collect water from the drain pans and removes it from the HP

POD

2 Electrical busways Main source of distributing power throughout the HP POD

3 Heat exchangers Use cooling water to cool the air

4 Rear service doors Enable access to the rear of the rack-mounted components

5 Entrance doors Enable access to the front of the rack-mounted components

6 Fan units Circulate the cool air throughout the HP POD

Rack components

There are 22 configured racks inside the HP POD. The following diagram is an example of a fully-loaded

and configured rack. Your rack might include different servers and components.

Component identification 12

Page 13

If any of the racks within the HP POD contain empty U space, you must use a heavy duty filler panel to

avoid compromising the integrity of the hot and cold aisle temperatures.

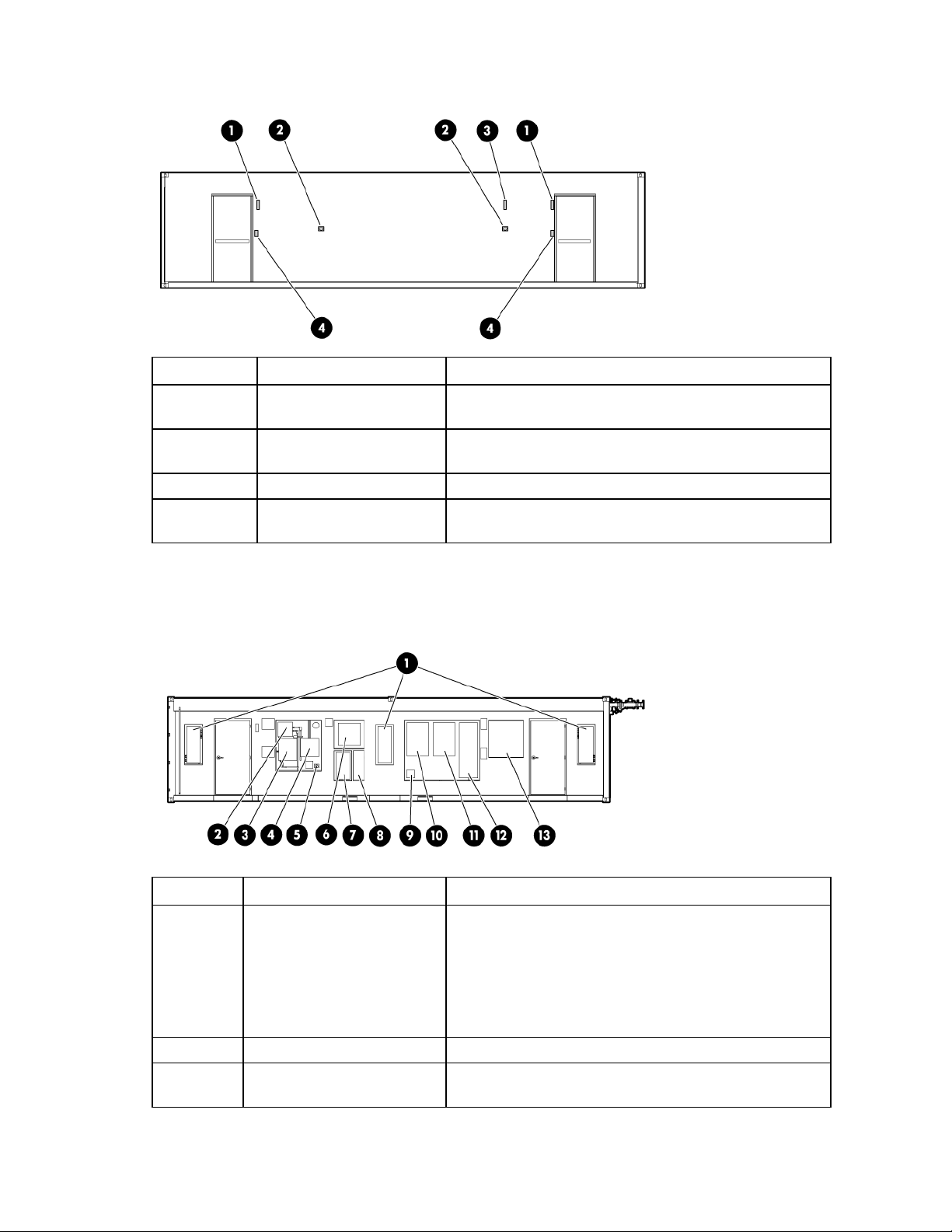

HP POD emergency components

External emergency components

Item Component Description

1 Fire strobe and horn Indication of a fire alarm condition within the HP POD.

2 EPO panel Contains controls and status indicators for the EPO system.

3 EPO alarm lamp (red) Activated when an EPO alarm button is pressed.

4 EPO button Pressing this button cuts off all power to the HP POD and

activates the EPO alarm lamp.

5 Fire alarm XFMR* Fire alarm transformer

6 ASSD panel Samples the air in the HP POD, monitoring smoke

7 Fire alarm control panel Contains controls and status indicators for the fire alarm system.

*Optional component

Component identification 13

Page 14

Internal emergency components

Item Component Description

1 Internal fire strobe and horn

(x2)

2 EPO button (x2) Pressing one of these buttons cuts off all power to the HP POD

3 EPO strobe Activated when an EPO button is pressed.

4 Fire alarm pull switch (x2) Pulling one of these switches activates the fire strobes and

HP POD panel locations

Indication of a fire alarm condition within the HP POD.

and activates the EPO strobe.

horns.

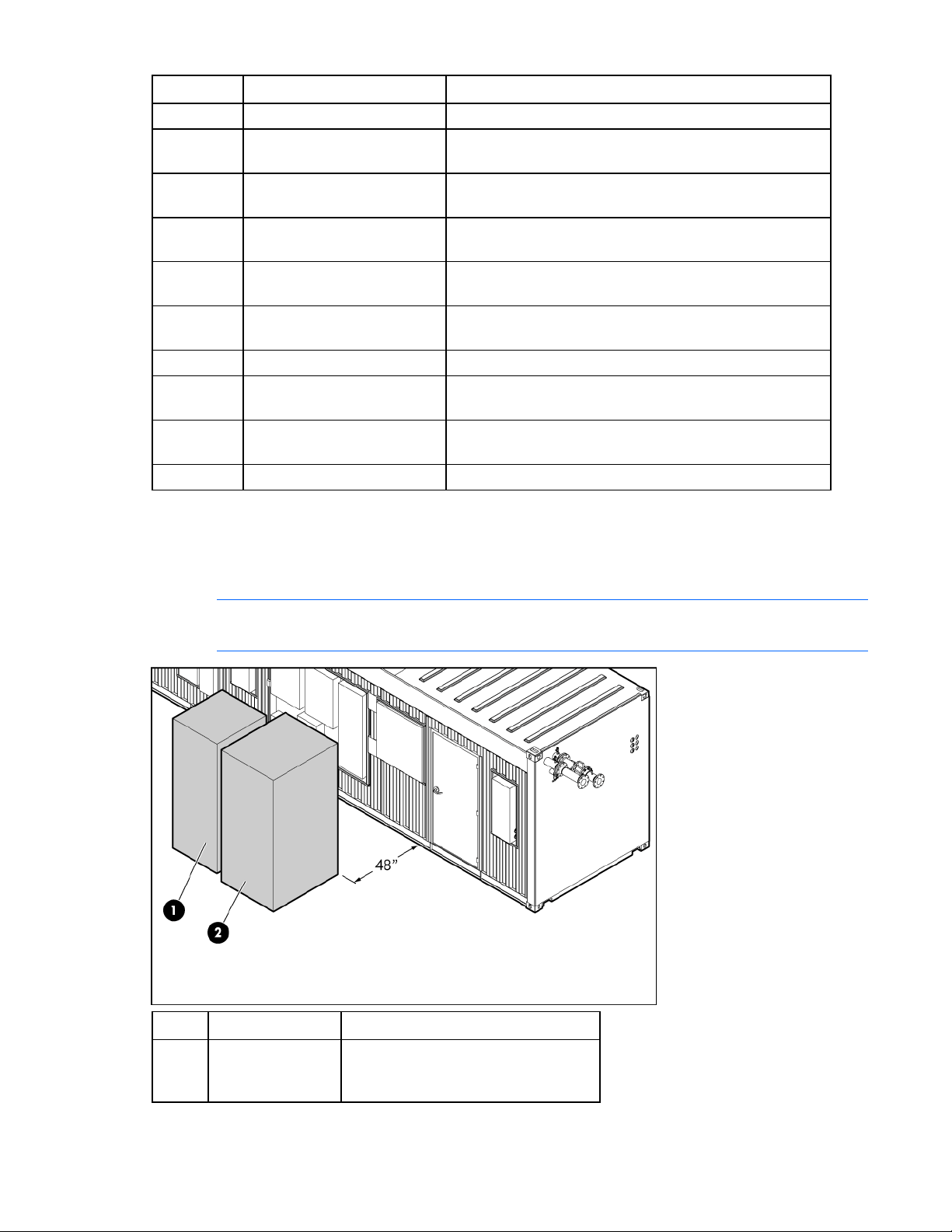

Item Component Description

1 Electrical busway enclosed

circuit breaker (on page 36)

400A enclosed circuit breakers that powers the electrical

busways:

• Two electrical busway panels are activated in the

standard HP POD.

• Three electrical busway panels are activated in the high

density HP POD.

2 EPO panel (on page 36) Contains controls and status indicators for the EPO system

3 Fire alarm panel ("Fire alarm

control panel" on page 38)

Contains controls and status indicators for the fire alarm

system

Component identification 14

Page 15

Item Component Description

4 ASSD panel (on page 36) Air sampling smoke detection system

5 EPO button Cuts off all power to the POD and activates the EPO alarm

lamp.

6 Security panel ("Security panel

location" on page 39)

7 EPMS panel∗ ("EPMS panel"

on page 38)

8 Humidifier ("Humidifier

(optional)" on page 44)*

9 Auxiliary Land power* Provides auxiliary power for the BMS or convenience outlets.

10 BMS panel (on page 36) Building Management System

11 Fan control (FC) panel ("Fan

control panel" on page 38)

12 House panel (on page 38) 120A electrical panel board providing auxiliary HP POD

13 Junction Box Main input box for incoming electrical feeder cables

Reserved for installing interface and power requirements for

any optional security devices installed.

Electrical power monitoring system

Maintains the humidity inside the HP POD within a set range

to minimize static electricity.

120V owner-provided power.

Circuit breakers that control the fan units

electrical requirements

∗Optional component

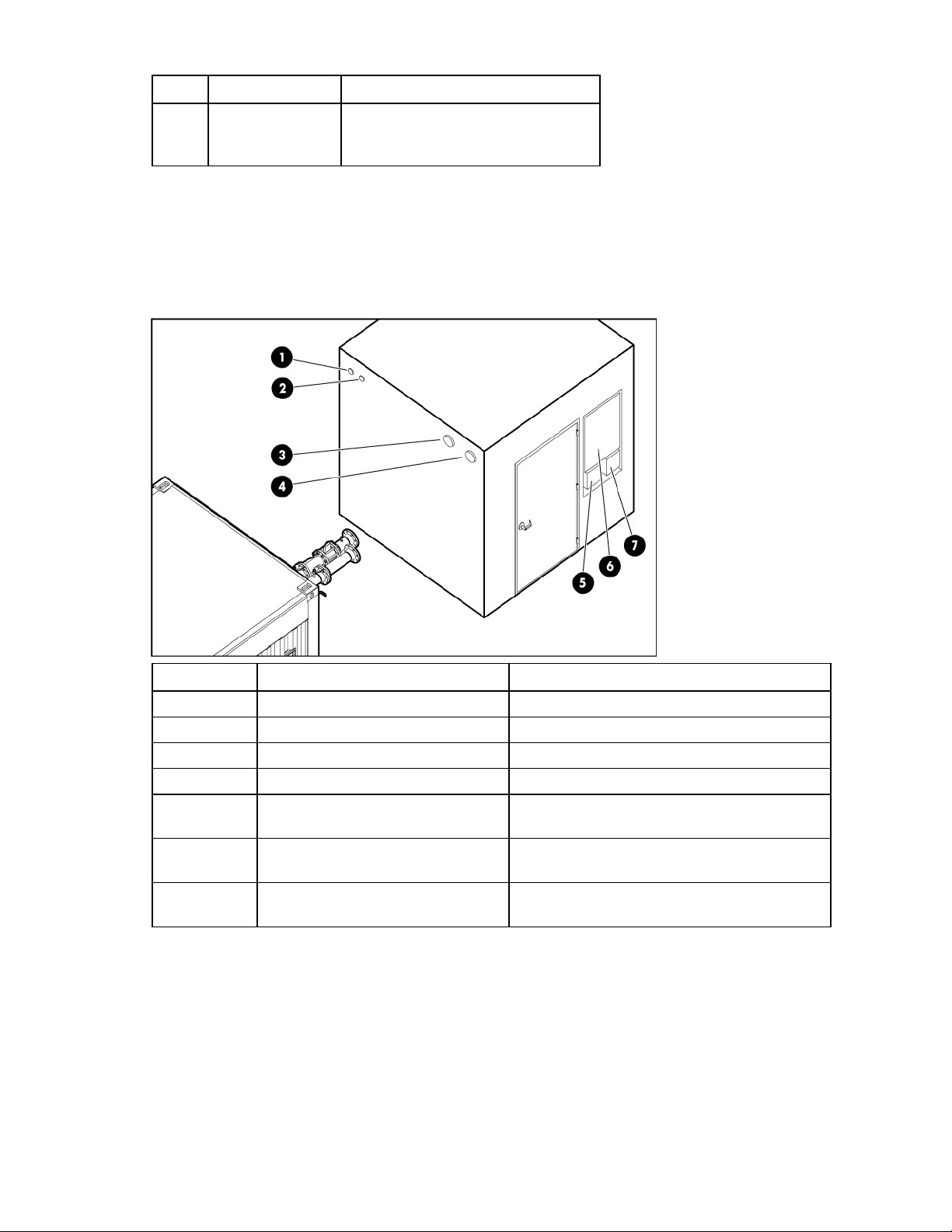

Transformer and switchboard components (optional)

NOTE: The transformer and switchboard must be a minimum of 1.2 m (48 in) away from the

HP POD.

Item Component Description

1 Switchboard Distributes power to each of the

electrical busways breakers and the

House panel

Component identification 15

Page 16

Item Component Description

2 Transformer Transforms power from 480V at your

facility to the 415V needed for the HP

POD

Water distribution kit components (optional)

The water distribution kit is an optional component that is composed of two closed-loop systems: one for

the facility water and one for the HP POD water. The water for the HP POD is supplied through the fill

tank and chemically treated prior to entering the HP POD to ensure adequate water quality.

Item Component Description

1 Facility supply connection Connection to the facility supply line

2 Facility return connection Connection to the facility return line

3 HP POD supply line Connection to the HP POD supply line

4 HP POD return line Connection to the HP POD return line

5 Panel disconnect Power disconnect for water distribution kit

components

6 400A controller board 400A electrical panel board providing auxiliary

electrical requirements

7 Panel disconnect Power disconnect for water distribution kit

components

Component identification 16

Page 17

Installation

HP POD contents

The following items are shipped with the HP POD, and are delivered at the time of your HP POD delivery

and installation.

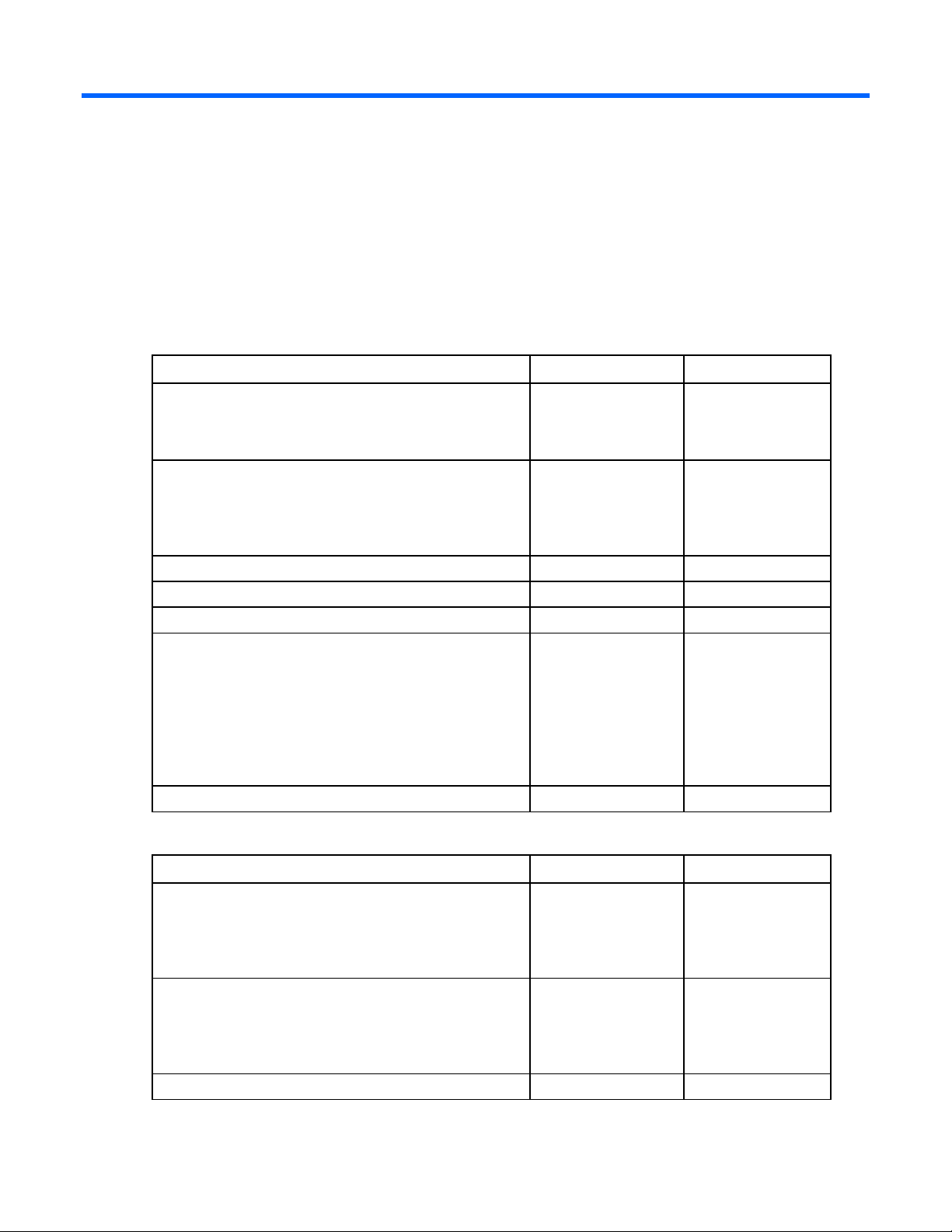

Standard 40-ft HP POD

Component Quantity Part number

Either of the following:

• HP Transformer and HP Switchboard

• Engineer your own site power for a minimum of 1200A

Either of the following:

• HP Water distribution kit

• Engineer your own site water for a minimum of 240

gal/min

HP 50U rack 22 AN982A

Side panel 50U kit 1 AN991A

50U rack bracket kit 21 AP014A

Either of the following busway dropbox and PDU kits:

• Single phase HP POD busway dropbox kit

• Single phase HP POD PDU bracket kit

-or-

• Three phase HP POD busway dropbox kit

• Three phase HP POD PDU bracket kit

Rack interface seal kit 21 AP013A

Not applicable Not applicable

1

15

44

15

44

AH988A

AP912A

AQ684A

AS613A

AQ683A

High density 40-ft HP POD

Component Quantity Part number

Either of the following:

Not applicable Not applicable

• HP Transformer and HP Switchboard

• Engineer your own site power for a minimum of 1600A

Either of the following:

• HP Water distribution kit

1

AH988A

• Engineer your own site water for a minimum of 240

gal/min

HP 50U rack 22 AN982A

Installation 17

Page 18

Component Quantity Part number

Side panel 50U kit 1 AN991A

50U rack bracket kit 21 AP014A

Either of the following busway dropbox and PDU kits:

• Single phase HP POD busway dropbox kit

• Single phase <sci)short_name> PDU bracket kit

-or-

• Three phase HP POD busway dropbox kit

• Three phase HP POD PDU bracket kit

Rack interface seal kit 21 AP013A

30

88

30

88

AP912A

AQ684A

AS613A

AQ683A

The HP POD is delivered with heavy duty filler panels installed in every empty U space of the racks.

However, HP recommends purchasing additional heavy duty filler panels (AF073A) to prevent

compromising the integrity of the cold aisle set point temperature when IT equipment is removed for

upgrades or maintenance.

The quantity and model of PDUs included with your HP POD are dependent on the IT equipment load they

are supporting.

Preinstallation checklist

CAUTION: Tighten the electrical busway connections after the HP POD is in its final location

Before you begin the installation of your HP POD, verify the following action items have been completed:

• All components are delivered to your facility.

• The HP POD, transformer, switchboard, and water distribution kit are in their final locations.

• You must have facility power at your final location. You can provide the connection cables from the

• You must have facility water at your final location. You can provide the connection hoses from the

• The HP POD has been properly grounded.

Required tools

• 10-ft ladder (2)

• 6-ft ladder (2)

and before you begin the installation process.

facility to the transformer and switchboard or purchase connection cables from HP at additional

costs.

facility to the water distribution kit or purchase connection hoses from HP at additional costs.

• Tongue-and-groove pliers with 4.25-in capacity jaws

• Screwdriver set

• Ratchet set

• Diagonal cutters

• Heavy-duty tie wraps

Installation 18

Page 19

• Pipe wrench

Installing the HP POD using the optional components

The following steps are an overview of the installation procedure for installing a HP POD, using the

transformer, switchboard, and the water distribution kit.

You must obtain service professionals to connect your power and water.

IMPORTANT: All wiring in and around the HP POD must be completed by a licensed

Connecting the water

1. Before you connect your facility water to the water distribution kit, flush the cooling water pipes.

electrician.

IMPORTANT: All plumbing to and from the HP POD must be completed by a licensed plumber.

CAUTION: All customer supplied water fittings must be composed of carbon steel, stainless

steel, or copper. Do not use cast iron, aluminum, or PVC fittings.

a. Connect water directly to the HP POD.

b. Allow the water to run until it is clean, flushing any contaminates that might have entered the

cooling pipes during shipping or delivery.

• NOTE: For quick reference, the water hoses are labeled with green tape and white arrows

pointing in the direction of the water flow.

2. Connect the 4-in return and supply lines from the water distribution kit to the HP POD.

Installation 19

Page 20

3.

Pump domestic or industrial water into the water distribution kit closed-loop system fill tank,

according to the water quality requirements (on page 30).

NOTE: The HP POD pipe design is rated for a maximum pressure rating of 150 psi.

4. Verify that your facility water pressure is within the acceptable range (20-25 psi).

5. Initiate the system pumps on the water distribution kit:

o Manually initiate the system pumps with the main power switch located on the pumps.

- or -

o Connect the water distribution kit to the BMS system, and initiate the system pumps through the

BMS.

Installation 20

Page 21

6.

Open the bleeder valve on the HP POD return line.

7. When the tank is full and there is no more air coming out of the bleeder valve, close the bleeder

valve on the HP POD return line.

8. Verify that your facility water pressure is within the acceptable range (20-25 psi).

• NOTE: For quick reference, the water hoses are labeled with green tape and white arrows

pointing in the direction of the water flow.

Installation 21

Page 22

9.

Connect the facility supply and return lines to the water distribution kit.

10. Connect the water distribution kit to your facility power source.

IMPORTANT: The water supply to the humidifier must be heat-traced to prevent freezing.

Installation 22

Page 23

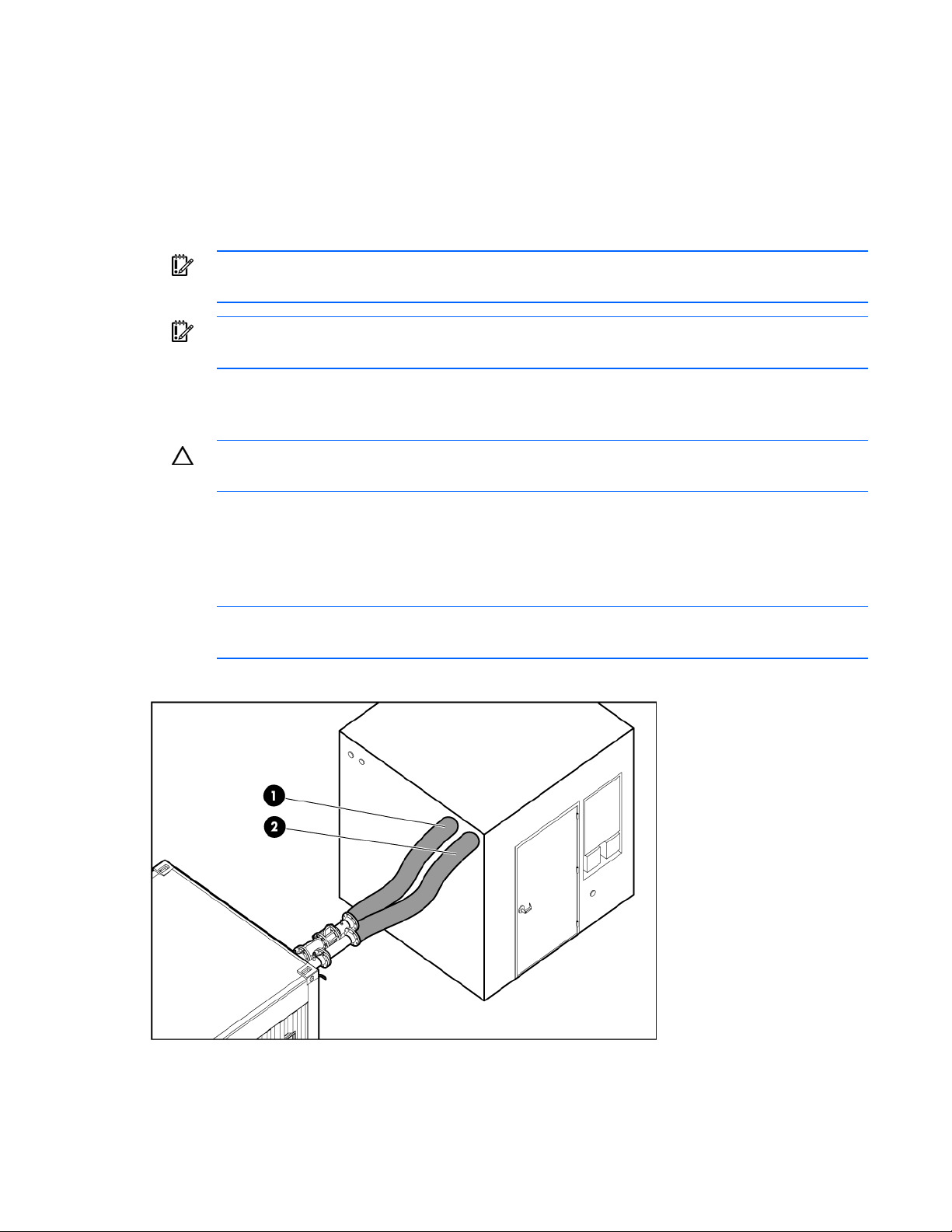

11.

(Optional) Connect the HP POD humidifier to the domestic or industrial water drain (1) and supply

(2) lines. For more information about the humidifier, see the product documentation.

12. Perform one of the following:

o If your HP POD is located inside, HP recommends connecting each of the drains to the local

drain line.

o If your HP POD is located outside, you can choose to connect to the local drain line, or allow the

water to drain off freely in your location. For more information, see Drain locations ("HP POD

drains" on page 28).

Connecting the power

IMPORTANT: A licensed electrician must connect the power according the local electric code,

1. Verify that the HP POD, transformer, and switchboard are in their final locations.

2. Make all connections:

consistent with supplier and consulting engineer drawings.

o Connect the main power leads from your facility to the transformer (1 to 2).

Each connection is labeled with colored tape, according to local standard requirements.

o Connect the transformer to the switchboard (2 to 3).

o Connect the three 3-in flexible conduits from the switchboard to the junction box on the HP POD

(3 to 4).

Installation 23

Page 24

Each connection is labeled. Two of the conduits power the electrical busway breakers and one

powers the house panel.

3. Turn on facility power.

4. Close the three main breakers on the switchboard.

Installation 24

Page 25

5.

Close the main breaker in the House panel on the exterior of the HP POD.

6. Close the remaining breakers in the House panel one by one, following the panel schedule on the

inside of the House panel.

NOTE: If you are installing a high density HP POD, you must also close the main breaker in

the electrical busway 3 panel.

7. Close the main breakers in the electrical busway 1 and electrical busway 2 panels.

8. Inside the HP POD, close the breaker on each drop box that is connected to a rack of IT

components.

9. Power up your remaining racks and IT components following your standard IT startup procedure.

Commissioning the HP POD

Commissioning your HP POD is an optional service and is customized based on your facility. A typical

commissioning process includes the following tests:

• Tighten the electrical busway connections

• Verify accurate electrical installation

• Verify accurate mechanical installation

• Test the operation of the BMS and Cooling controls

• Test the operation of the smoke detection system

• Test the operation of EPO system

Installation 25

Page 26

• Test the operation of the analog and digital phone system

• Verify initial IT start-up

• Conduct an infrared scan of all electrical connections under the start-up IT load

• Verify accurate cooling under start-up IT load

• Provide the HP POD operation owner training

Installation 26

Page 27

Cooling system

HP POD cooling system

CAUTION: Contaminated supply water might cause decreased cooling capacity or disruption

in service. The supply water must meet the guidelines states in the HP Performance-Optimized

Datacenter Site Requirements Information document. Damage caused by contaminated supply

The HP POD has 12 heat exchangers that maintain temperature and cool the equipment installed in the

HP POD. The HP POD heat exchangers receive chilled water from either the water distribution kit or your

facility, cycles the water through the heat exchangers to cool the air, and then the fan units circulate the

cool air throughout the HP POD.

To control the fan speed, you must set a cold aisle temperature through the BMS. A predetermined

differential pressure setpoint between the hot aisle temperature and cold aisle temperature is factory set,

and cannot be altered. The fan units regulate speeds to maintain the cold aisle temperature and

differential pressure between the hot and cold aisle. For more information, see Controlling the fan speed

(on page 27).

Water supply temperature

If you are using a water distribution kit, water is supplied to the HP POD between 13°C and 24°C (55°F

and 75°F). HP recommends that you supply water to the water distribution kit between 4°c and 10°C

(40°F and 50°F).

water is not covered by the warranty.

If you are not using a water distribution kit, HP recommends supplying water to the HP POD between

13°C and 24°C (55°F and 75°F).

Controlling the fan speed

The HP POD fans operate at variable speeds to maintain a predetermined differential pressure setpoint

between the hot aisle and the cold aisle. You set your desired cold aisle temperature through your BMS,

and the fan speed adjusts to maintain the differential pressure setpoint between the hot and cold aisle

temperatures.

You cannot manually adjust the fan speed.

To access the fan units:

1. Unlock the latch for that fan overhead.

Cooling system 27

Page 28

2.

Pull the overhead down.

Condensation management

CAUTION: During operation, avoid leaving the HP POD doors open, to minimize

Supply cooling water that is above the dewpoint inside the HP POD to reduce condensation forming on

the heat exchangers, and also cold enough to maintain the cold aisle temperature setpoint. If both

conditions cannot be met during the HP POD startup, adjust either the cooling water or the cold aisle

temperature setpoint above the dewpoint by one degree every fifteen minutes. During this process, the

coils act as a dehumidifier and establish conditions inside the HP POD for sustained operation. Significant

amounts of condensation might drain from the HP POD during the startup process, if the conditions inside

the HP POD are very warm with high humidity.

During normal operation, some condensation might form on the heat exchangers, and it will be collected

in the heat exchanger drip tray. The drip trays then collect and drain through the condensate drains out of

the HP POD.

HP recommends connecting condensate drains on the HP POD to a facility drain to prevent the collection

of water near the HP POD.

There are three 1.9 cm (¾ inch) condensate drain outlets across the rear of the HP POD directly

connected to the heat exchanger drip trays. The water main external drain is located at the front, left

corner of the HP POD. A fifth drain is located on the (optional) humidifier. For specific drain locations, see

Drain locations ("HP POD drains" on page 28).

condensation conditions.

To avoid excessive buildup of condensate and to conserve energy, consider raising the cooling water

temperature above the dewpoint to manage condensation while maintaining the necessary cooling

capacity.

HP POD drains

Cooling system 28

Page 29

WARNING: Any water that drains around the HP POD causes a potential slip hazard. Use

caution where slip hazards are present.

Water from natural condensation might form. Condensation from the heat exchangers flow to the three

condensate drains across the rear of the HP POD (1). The water main drain catches any water from a

water main leak (2). The humidifier drain removes excess moisture from the air (3).

Item Component

1 Heat exchanger condensate drains

2 Water main supply/return drain

3 Humidifier drain

IMPORTANT: You might have to pipe directly to your local storm or sanitary drain, depending

on local jurisdiction.

If your HP POD is located indoors, you can connect to an external drain line. If your HP POD is located

outdoors, the drained water will simply drip from the HP POD drains out the back of the HP POD.

HP recommends connecting the condensate drains on the HP POD to a facility drain to prevent collection

of water near the HP POD.

Leak detection

If too much water accumulates in a drain tray, an alarm is triggered and sent through the BMS, indicating

that there might be a leak. For more information about alarms, see BMS alarms (on page 41).

Cooling system 29

Page 30

Water quality requirements

Water quality requirements and specifications

• Closed-loop water must not contain any lime scale deposits or loose debris.

• The water must have a low level of hardness, particularly a low level of carbon hardness.

Additionally, the water must not be so soft that it attacks the materials with which it comes into

contact.

• The chilled water temperature to be supplied to the HP POD is 12º to 24ºC (55º to 75ºF). Freezing

water might cause a blockage and damage to the unit. In outside locations subject to freezing

temperatures, an additive such as glycol might be necessary to lower the freezing point. However,

the heat transfer potential of the water is lower, so the equipment must be derated properly.

Acceptable water quality specifications

Water must be maintained per the following acceptable water quality standards.

Parameter Range

pH 8.0–10

Specific conductance at 25ºC

(77ºF)

Alkalinity ("M" as CaCO3) 150–1000 ppm

Sulfur (SO4) 0–150 ppm

Chloride (Cl) 0–100 ppm

Hardness (CaCO3) 0–350 ppm

Calcium hardness (CaCO3) 0–200 ppm

Magnesium hardness (CaCO3) 0–150 ppm

Copper (Cu) < 0.20 ppm

Iron (Fe) < 3.0 ppm

Aluminum (Al) < 0.50 ppm

Sodium (Na) 0–1000 ppm

Silica (SiO2) 0–150 ppm

Zinc (Zn) < 1.0 ppm

Manganese (Mn) < 0.1 ppm

Phosphate Ortho- (PO4) < 3 ppm

Bacteria < 1000 CFU/ml

Suspended solids < 10 ppm

0–2500 µmhos/cm

If your water is out of range, consult a water quality expert.

Water quality requirements 30

Page 31

Frost damage

To avoid frost damage, the water temperature must not be allowed to fall below the minimum permissible

temperature of +4 ºC (+39.2 ºF) at any point in the water cycle.

The water cycle must be drained completely using compressed air before storage or transportation at

freezing temperatures or below.

Plumbing materials to avoid

Do not use the following materials in a closed water system:

• Oxidizing biocides

• Aluminum components

• Brass components with high levels of zinc

• Non-stainless steel Iron components

Water precautions

Take the following precautions before installation of the HP POD:

• Verify that all foreign matter and particulates are flushed from the system.

• Evaluate the short-term and long-term system requirements against the available water capacity.

• Ensure that the chilled water loop is properly designed for liquid cooling systems and is separate

from the sanitary water systems in your building (bathroom, sink, drinking water).

• Ensure facility managers understand the additional load being added to the chilled water supply of

the building. Be aware that the added heat load might affect other components being cooled by the

chilled water plant.

Water temperature

Without a water distribution kit, the temperature of the water supplied to the HP POD must be 12º to 24ºC

(55º to 75ºF). Freezing water might cause a blockage and damage to the unit.

Water quality requirements 31

Page 32

Power management

Electrical busway

The electrical busway is a modular, overhead electrical distribution system that supplies power to the HP

POD IT loads. There are two electrical busways in the standard HP POD (1 and 3) and three electrical

busways in the high density HP POD (1, 2, and 3).

Each PDU is powered by the dropboxes attached to each of the electrical busways.

Disabling power

Power management 32

Page 33

• To disable power to a single PDU, turn off the main switch on that PDU.

• To disable power to a single rack, open the main breaker on the dropbox connected to the electrical

busway.

• To disable power to a single electrical busway, open the appropriate main breaker for that busway

on the corresponding electrical busway panel outside of the HP POD.

Power distribution

The standard HP POD is powered by two electrical busways on the ends of the unit.

Standard HP POD

Feature Specification

Number of busways 2

Frequency 60Hz

Amps (per busway) 400A

Neutral Ampacity (per breaker) 480A

Amps derated percentage 20%

Max usable amps (per busway) 320A

Voltage (per busway) 415V

Grounding Aluminum casing

Phases 3

Power management 33

Page 34

The high density HP POD includes an additional electrical busway in the center of the unit.

High density HP POD

Feature Specification

Number of busways 3

Frequency 60Hz

Amps (per breaker) 400A

Neutral Ampacity (per breaker) 480A

Amps derated percentage 20%

Max usable amps (per busway) 320A

Voltage (per busway) 415V

Grounding Aluminum casing

Phases 3

Rack power

Power is provided to each of the rack by PDUs. The PDUs can be moved around the HP POD to support

component power requirements. The PDUs are powered by the drop boxes attached to each electrical

busway.

For more information regarding power shortages to the PDUs or electrical busway drop boxes, see

Troubleshooting (on page 49).

Power management 34

Page 35

Panels

The following panels are on the exterior of the HP POD.

Item Component Description

1 Electrical busway enclosed

circuit breaker (on page 36)

400A enclosed circuit breakers that powers the electrical

busways:

• Two electrical busway panels are activated in the

standard HP POD.

• Three electrical busway panels are activated in the high

density HP POD.

2 EPO panel (on page 36) Contains controls and status indicators for the EPO system

3 Fire alarm panel ("Fire alarm

control panel" on page 38)

4 ASSD panel (on page 36) Air sampling smoke detection system

5 EPO button Cuts off all power to the POD and activates the EPO alarm

6 Security panel ("Security panel

location" on page 39)

7 EPMS panel∗ ("EPMS panel"

on page 38)

8 Humidifier ("Humidifier

(optional)" on page 44)*

9 Auxiliary Land power* Provides auxiliary power for the BMS or convenience outlets.

10 BMS panel (on page 36) Building Management System

11 Fan control (FC) panel ("Fan

control panel" on page 38)

12 House panel (on page 38) 120A electrical panel board providing auxiliary HP POD

13 Junction Box Main input box for incoming electrical feeder cables

∗Optional component

Contains controls and status indicators for the fire alarm

system

lamp.

Reserved for installing interface and power requirements for

any optional security devices installed.

Electrical power monitoring system

Maintains the humidity inside the HP POD within a set range

to minimize static electricity.

120V owner-provided power.

Circuit breakers that control the fan units

electrical requirements

Power management 35

Page 36

ASSD panel

The ASSD panel draws air from the piping network inside the HP POD and monitors the smoke levels in

the air. If smoke is detected, the ASSD panel automatically sends an alarm to the prewired Fire Alarm

Control Panel.

No user interface settings are required. Interface is established through the Fire Alarm Control Panel.

For more information, see the product documentation included in the Operations & Maintenance Manual

("Component documentation" on page 9).

BMS panel

The BMS panel enables you to connect the HP POD to your building management system. You must bring

an Ethernet cable through the internal passway to connect to the BMS panel.

There is no external user access to the HP POD BMS panel, and all interface settings are controlled

through your facility BMS.

For more information, see Connecting the HP POD to the BMS (on page 40).

Electrical busway enclosed circuit breaker

The electrical busway panels are enclosed circuit breakers that provide power to each of the electrical

busways. For more information, see Electrical busway (on page 32).

EPO Panel

IMPORTANT: If the remote powered 120V branch circuits are operational, they are not turned

The EPO panel contains controls and status lamps for the EPO system, which enables all power in the HP

POD to be turned off except for emergency lighting. Power to the EPO panel is single-phase 240V AC,

provided by the house panel.

Two EPO alarm buttons for directly shutting off non-emergency HP POD power are located inside the HP

POD, and one EPO alarm button is located on the outside of the HP POD.

To check that the EPO alarm buttons and alarms are functional, switch to Test mode and then press an

EPO alarm button. This procedure activates the EPO alarms without cutting off power to the HP POD.

off during an EPO shutdown.

Power management 36

Page 37

To enable remote access to the EPO system, switch to Bypass mode.

Callout Component Description

1 Power On LED Indicates the EPO is functional, and

operating in Test mode, Armed mode,

or Bypass mode.

2 EPO Armed mode LED Indicates the EPO is operating in

Armed mode.

3 Reset button Resets the EPO system after an EPO

alarm has been triggered.

4 Three way key-operated

switch

5 System alarm/ EPO

shutdown

(red)

6 System Test mode LED

(amber)

7 EPO Bypass mode LED

Sets the EPO operating mode (Test,

Armed, or Bypass).

Indicates an EPO alarm has been

triggered and non-emergency HP POD

power has been shut off.

Indicates the EPO is undergoing a

system test.

Indicates the EPO is in Bypass mode.

(green)

After an EPO alarm, reset the EPO system:

1. Use the button key release mechanism to restore the EPO alarm buttons to their normal state.

2. Reset the main breaker in the House panel.

3. Reset the electrical busway breakers.

4. Press the Reset button on the EPO panel.

EPO modes

The EPO panel operates in three modes: Armed, Test, and Bypass. The operating mode is determined by

the status of a key-operated selector switch on the EPO panel. The switch status can be reported to a

monitoring system that is external to the POD.

Power management 37

Page 38

Armed mode—Pressing a red EPO button on the POD causes the following events:

• The red System Alarm/EPO Shutdown light on the EPO panel illuminates to indicate that an EPO

switch has been activated. (This light remains illuminated until all EPO buttons are restored to their

normal state by means of a key release mechanism, and the Reset button on the EPO panel is

pressed.)

• The EPO activated relay is energized and sends a signal to the EPO panel to energize the

associated control relays.

• The control relays within the EPO panel shut down the affected circuit breakers in the POD.

Test mode—All associated EPO functions are disabled, and the amber System Test Mode light on the EPO

panel is illuminated. This mode enables the EPO buttons to be tested without removing power to the POD.

When an EPO button is pressed, the EPO Activated relay is energized, and it energizes the associated

control relays in the EPO panel. Although the EPO functions are disabled, the horn and strobe alarm are

activated. To silence the alarm, press the Reset button on the EPO panel.

Bypass mode—All EPO functions and test functions are disabled. When the EPO panel is operating in this

mode, the green EPO Bypass light on the EPO panel is illuminated.

EPMS panel

The electric power managing system (EPMS) is composed of 120V, Nema 515R rated auxiliary power.

The panel optionally provides additional power for auxiliary components, mainly the BMS.

• If you connect land power to this panel, the BMS is powered by external land power.

• If you do not connect land power to this panel, the BMS is powered by the House panel.

Fan control panel

The Fan Control panel houses the relay system that controls the fan speeds within the HP POD, based on

maintaining the cold aisle temperature set through the BMS.

You do not have to access to the Fan Control panel, and no interface setting is required.

Fire alarm control panel

If you connect your central fire alarm system to the fire alarm control panel, any emergency alarm can be

sent directly over your facility alarm system.

For more information about the fire alarm control panel, see the product documentation included in the

Operations & Maintenance Guide.

House panel

The House panel is a 120A panel board that provides power and electrical requirements to all auxiliary

HP POD components.

If a breaker is tripped open, you can access to the outside of the House panel and reset the breakers. You

can also reset the HP POD components after an EPO alarm. If one or more breakers continually trip,

contact HP ("HP contact information" on page 55).

The standard panel schedule resides inside the panel breaker box and can be referenced when

necessary.

Power management 38

Page 39

Security panel location

If you decide you want to install a security panel, the HP POD has a predesignated location for a security

panel.

Power management 39

Page 40

Building management system

Using a building management system (BMS)

NOTE: If your site does not have a BMS, then BMS data can be sent and viewed to a set IP

address, communicating via Ethernet cable connected to the internal passway of the BMS

HP recommends connecting the HP POD to your facility building management system (BMS),

communicating through Ethernet cable connected to the internal passway of the BMS Panel. For more

information, see Connecting the HP POD to the BMS (on page 40).

The standard BMS protocol, BACnet, is a data communication protocol for building automation and

control networks.

A BMS offers:

• A supported communication interface that can monitor and control HP POD components remotely

• Immediate notification of all alarm messages

• Ability to manage and configure utility devices

By connecting your HP POD to a BMS system, you can monitor:

• Cold and hot aisle temperatures

• Supply and return water temperatures

• Cooling water flow rate entering the HP POD

Panel.

• Cooling tonnage

• Smoke alarms

• EPO alarms

For additional points that can be monitored, see the I/O (Input/Output) Controls Points List in the

Operations and Maintenance Manual ("Component documentation" on page 9).

Connecting the HP POD to the BMS

1. Install and configure the operating system (Microsoft® Windows® or Linux) on a designated

management server.

2. Install the management software on the management server.

3. Connect the management servers to the building network.

4. Insert your BMS Ethernet cable through the IT portals on the left end of the HP POD.

5. Plug the Ethernet cable into the designated BMS jack on the interior of the HP POD.

Building management system 40

Page 41

For more information, see the junction control system documentation included in the Operations &

Maintenance Manual ("Component documentation" on page 9).

Managing BMS settings from the HP POD

The BMS controls can be accessed from a laptop if necessary. To access the BMS using a laptop at the

HP POD, connect an Ethernet cable between a laptop and the designated BMS jack on the interior of the

HP POD.

BMS alarms

The alarms pertaining to the health of the HP POD and its components are relayed through the BMS.

Building management system 41

Page 42

Alarm Meaning Solution

Fan failure One of the fans is not working. If you are still within your service

contract, contact HP service.

Sensor failure One of the sensors is not working. If you are still within your service

contract, contact HP service.

Leak detection The drain tray senses water. Turn off the water flowing into your HP

POD at the facility line. Turn off all IT

components, so that the components do

not overheat. If you are still within your

service contract, contact HP service.

Change filter* The return air filters are full. Replace the return air filters.

High temperature The cold aisle temperature has

surpassed the set point temperature.

Low temperature The cold aisle temperature is too low. Check you HP POD components to

EPO Someone has activated the EPO

system and shut down the HP POD.

*The change filter alarm is only relayed to your BMS if you have the optional filter replacement sensor installed.

Check to make sure that you have

water flowing into your HP POD and

that the fans are blowing. If you are still

within your service contract, contact HP

service.

make sure all components are

operating as normal. If you are still

within your service contract, contact HP

service.

Follow emergency procedures.

After the emergency is cleared, reset

the EPO and other HP POD systems.

Safety and security alarms

Alarms pertaining to the safety of the HP POD are (optionally) relayed through your building fire and

security dispatch.

Alarm Meaning Solution

Fire alarm* A fire has been detected in the HP

POD.

Security alarm

(optional)

EPO Someone has activated the EPO

*The fire alarm is only relayed to your building fire and security dispatch if you have connected your facility to the

fire alarm panel.

Fire alarm sequence of operations

If a fire alarm or manual pull station is activated, the HP POD follows this sequence of operations.

1. The HP POD sends an alarm signal to the building fire and security dispatch.

2. The AC unit shuts down.

3. The HP POD security lights flash and the horns sound the 30-second evacuation alarm.

There has been a security breach. Follow emergency procedures for your facility.

system and shut down the HP POD.

Activate the EPO. Follow emergency

procedures for your facility.

Follow emergency procedures for your facility.

Building management system 42

Page 43

4.

After a 30-second delay, the HP POD releases the suppressant gas, if the optional fire suppressant

system is installed.

Building management system 43

Page 44

Optional components

Additional insulation

You can choose to have additional insulated paint added to your HP POD prior to shipment. The

Air filter sensor

additional insulation will enable the HP POD to function properly in temperatures as low as -29°C (-20°F).

The air filter sensor is an optional component that, if installed, alerts you to change your air filters. The

sensors are located near each of the 12 air filters. If the air filters are full and should be replaced, an alert

will be sent via your BMS.

Humidifier (optional)

If you choose to connect to the humidifier, it maintains the humidity within the HP POD within a set range,

according to ASHRAE standards.

Maintaining the humidity helps to minimize static electricity within the HP POD.

For more information about the humidifier, see the product documentation included in the Operations &

Maintenance Manual ("Component documentation" on page 9).

Fire protection system

The fire protection system is a HP POD self-contained system, with no connection to your BMS. The fire

protection system consists of 12/30 pre-em novac, a clean agent fire suppressant, eliminating the need

for additional water to be connected to the HP POD in case of a fire emergency.

HP POD security

Routing raceways for the following security options are provided by HP and can be installed as a custom

service option. You are responsible for providing additional hardware, cabling, and controllers to support

these options.

Security options:

• Key lock hardware—Standard security provided

• Card reader security—Junction boxes provided at every entrance to upgrade security, if desired.

• Magnetic or electronic locks—Prewiring provided at every entrance to upgrade security, if desired.

Magnetic or electronic locks are not provided.

• Internal/external cameras—Camera mounting locations are provided along with empty conduit and

pull drag lines.

Optional components 44

Page 45

Each external panel is secured through key lock hardware.

The following locations have been prewired for your own security upgrades.

Callout Description

1 Prewired junction box locations

2 Card reader locations

3 Internal camera locations

4 External camera locations

Transformers and switchboards

HP offers several transformers and switchboards to supply your power needs.

On-site connections include:

• From your main facility power to the primary side of the transformer

• From the transformer to the switchboard

• From the feeder breaker lugs within the switchboard assembly to the HP POD

The standard cables should allow for placing the transformer and switchboard approximately 3.0 m (10

ft) away from the HP POD. Installation costs assume that connections are within the 3.0 m (10 ft)

recommendation. If you place the transformer and switchboard more than 3.0 m (10 ft) away from the HP

POD, additional planning and costs are involved.

Water distribution kit

HP recommends using the optional water distribution kit to provide water to your HP POD. For more

information about the kit, see Water distribution kit components ("Water distribution kit components

(optional)" on page 16).

NOTE: The water distribution kit pipes are flushed prior to shipment.

The water distribution kit is enclosed within a 10 ft ISO container that includes internal lighting and

heating. The heater comes equipped with a programmable thermostat that you can set to run as needed

to ensure the water temperature inside does not drop below freezing.

Optional components 45

Page 46

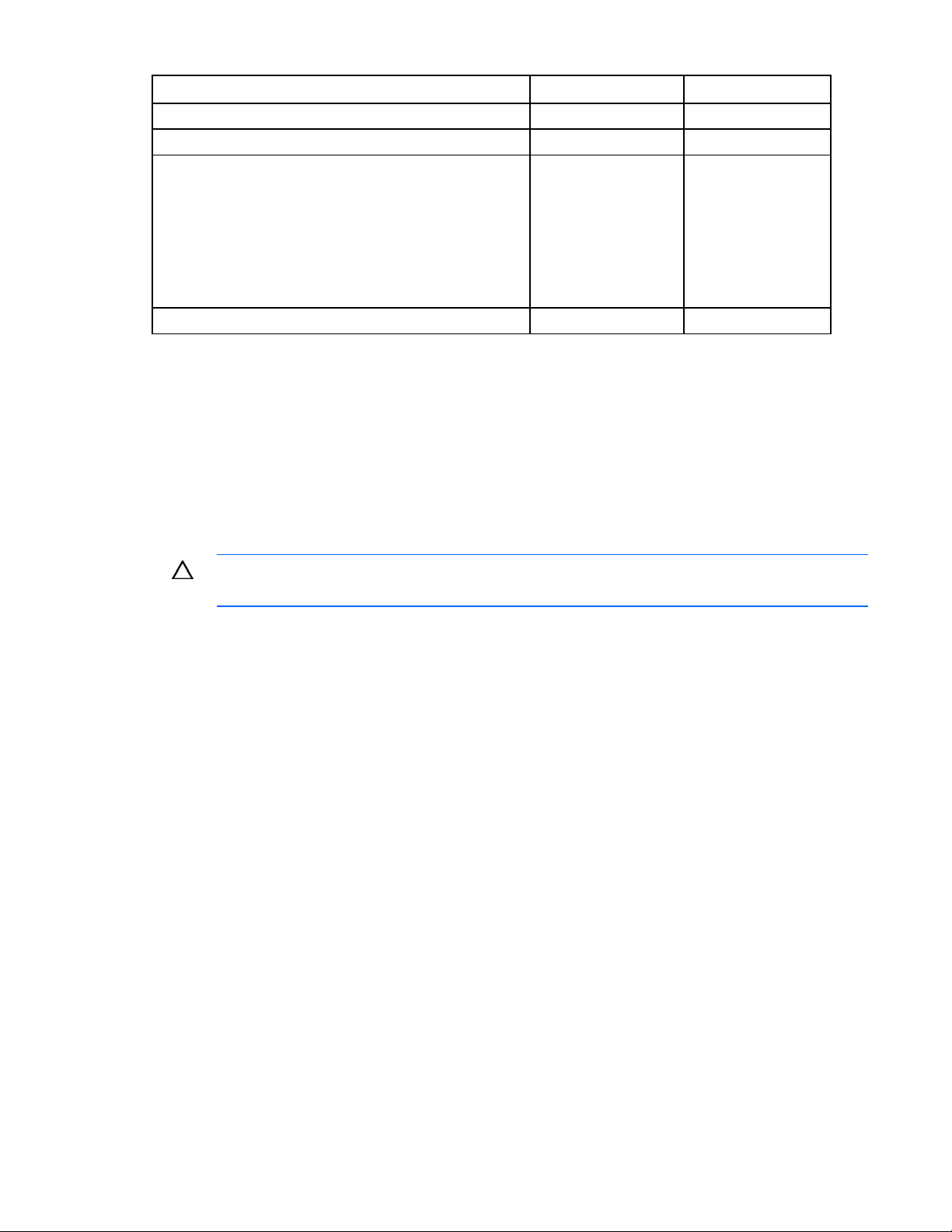

Water distribution kit power requirements

Callout Specification

1 30 AT, 30 AF, 3P

2 Within facility 480V, 3 phase power distribution equipment

3 (3)#10, (1)#10G, 1"C. Feeder sized on a maximum run of

100 ft

4 Motor controller at skid

5 30 AT, 30 AF, 3P

6 20 AT, 3P

7 15 AT, 3P

8 (3)#12, (1)#12G ¾"C

9 P–1

10 P–2

11 UH–1

Optional components 46

Page 47

Frequently asked questions

HP POD frequently asked questions

Question Answer

Can I keep the HP POD on the trailer? Yes, if you choose to lease the trailer from HP or if your

purchase your own trailer and have the HP POD installed on

your trailer prior to shipment. You must also:

• Ensure that the site is stable and has been prepared

correctly for the additional weight of the trailer.

• Provide a work platform to access exterior panels.

What cooling capacity ranges are available

in the HP POD?

What electrical power capacity ranges are

available in the HP POD?

Can the level of heat removal be regulated

in proportion to the waste heat generated?

How is water connected to the HP POD? There are two options to connect water:

Does the HP POD require maintenance? Yes, general maintenance is outlined in this document. Contact

Does condensation form? During normal operation some condensation might form, but the

How does the HP POD control humidity? The relative humidity is maintained between 30–70%.

Does the air flow within the HP POD

produce static electricity?

The HP POD is capable of cooling rack-mounted components

consuming up to 605 kW of electrical power.

The low density HP POD is capable of powering components up

to 450 kW of electrical power.

The high density HP POD is capable of powering components

up to 605 kW of electrical power.

Yes, the control system automatically adjusts the air flow to

remove heat generated in the HP POD.

• You directly connect your facility water to the HP POD,

making sure the water meets the water requirements

("Water quality requirements" on page 30) for quality,

temperature, and flow rate.

• You connect your facility water to the water distribution kit,

which is then connected to the HP POD through two 4-in

150-psi hoses.

HP service for additional information.

condensation does not reach any rack-mounted components or

cause any damage. Excess condensation from the heat

exchangers is collected and drained via three condensate

drains ("HP POD drains" on page 28) across the rear of the HP

POD. In most cases, the condensation evaporates prior to

reaching the condensate drains.

If additional humidity is required, connect your facility water to

the humidifier supply on the front of the HP POD.

The humidity of the HP POD is maintained between 30–70% to

ensure that dangerous levels of static electricity cannot build.

Frequently asked questions 47

Page 48

Question Answer

Is the HP POD weather resistant? If there is an external leak, the HP POD is weatherproof and

has sufficient protection against the encroachment of water

inside the HP POD.

What happens if there is an internal leak? If there is an internal leak, the water collects in the condensation

drain pans or the water main drain pan. The additional water

present in the condensation drain pan triggers a Leak Detection

alarm, sent over the BMS.

What will happen if water stops flowing to

the HP POD?

The building BMS receives a High Temperature alarm. An EPO

will occur automatically if the hot aisle temperature exceeds

66°C (150ºF).

HP recommends shutting down all IT components or pressing

any EPO button to manually power down the servers, to

maintain server health, until the root problem can be solved.

At what smoke level will an alarm be

issued?

You can set the four different ranges at which the ASSD panel

smoke detector issues an alarm. For more information, see the

smoke detector manual supplied with the HP POD.

Can I switch out my servers and other rackmounted components?

The HP POD supports any IT equipment that uses front to rear

air flow cooling to maintain thermal integrity.

If you must remove a server or other rack-mounted component

for any prolonged period, you must replace it with a similar

component or a heavy-duty blanking panel so that the HP POD

interior can maintain thermal integrity.

How will I be notified if there is an

emergency in the HP POD?

The smoke alarm automatically detects incipient fires and

activates several different types of fire alarms:

• Visible—Internal and external HP POD strobes

• Audible—Horn

• Remote notification through the building fire alarm control

panel (optional)

Water emergencies are detected through the fire alarm control

panel and drain trays, an alarm is initiated, and the building

BMS is notified.

If the fans are not functioning correctly, an alarm is initiated

and the building BMS is notified.

Frequently asked questions 48

Page 49

Troubleshooting

HP POD troubleshooting

Issue Resolution

The water is not flowing, or flowing too

slowly.

The HP POD is overheating. If the fan is not functioning, check the integrity of the electrical

The strobe lights are flashing. Either the EPO or the fire alarm system has been activated. Get

There is a leak inside the HP POD. Locate and note the source of the leak. Prevent the leaking

There is no power to one rack. 1 Verify that the racks on either side of the rack have power.

There is no power to multiple racks. 1 Verify that the HP POD is receiving power.

There is no power to the HP POD. Check the status of the connection transformer and switchboard.

Verify that all applicable valves are open. Inspect the water

lines for blockage, unblock, or replace them as necessary.

connection to the fan. If the electrical connection seems OK,

replace the fan.

If the fan is functioning, check for a kink or blockage in the

water line to the heat exchanger.

Contact HP service.

out of the HP POD immediately and follow standard emergency

procedures for your facility.

water from contacting any electrical equipment. Repair the leak

as soon as possible.

2 Check the status of the busway dropbox for that rack.

• If a breaker has tripped, reset the breaker box and verify

• If none of the busway dropbox breakers has tripped, check

• If none of the breakers on the busway dropbox or PDUs

2 Check the status of each of the electrical busway panels. If

3 Check the status of the connection transformer and

If one of the breakers has tripped, reset the breaker and verify

that power has been restored to the HP POD.

that power has been restored to the rack.

the status of the PDUs for the rack. If the input or output

breakers have tripped, reset the PDU and verify that power

has been restored to the rack.

have tripped, replace the busway dropbox.

one of the breakers has tripped, reset the breaker and verify

that power has been restored to the racks.

switchboard. If one of the breakers has tripped, reset the

breaker and verify that power has been restored to the

racks.

Troubleshooting 49

Page 50

Specifications

HP POD specifications

Features Specifications

Dimensions 40 ft x 8 ft x 9.5 ft

Maximum weight 30,000 lb (empty)- 101,000 lb (fully-loaded)

Maximum power/ cooling

Maximum rack quantity 22 racks

Rack Units (RU) per rack 50 RU

Rack Units (RU) maximum 1100 RU

Nominal power/ cooling per rack 25 kW

Maximum power/ cooling per rack 35 kW

Power input voltage 415 VAC, 3 Phase, 50/60 Hz, with neutral

Power distributed internally Through 2 400A electrical busways

Customer access Double-door on one end

Network supported Bulk cable pass-through-fiber

• 450 kW (Standard POD)

• 605 kW (High density POD)

240/415 VAC, 50/60 Hz

Two 3 ft x 7 ft doors to the cold aisle (customer access)

Four 6 ft x 7 ft doors to the hot aisle (rear component access)

Bulk cable pass-through-copper

(Optional) External rated DEMARC box

Electrical specifications

Panel information

Feature Electrical busway panel House panel

Number of panels

Amps (per panel) 400A 225A

Poles (per panel) 1 30–42

Phases 3 3

Circuit breaker information (Input)

• 2 (Standard HP POD)

• 3 (High density HP POD)

1

Specifications 50

Page 51

Feature Specification

Number of input circuit breakers 2: 1 per panel

Protection percentage 80%

Amps (per breaker) 400A

Fire alarm panel connections

The electrical layout of the fire alarm system is as described in the schematic drawing supplied with the

HP POD.

Water specifications