Page 1

HP Performance Optimized Datacenter 40c G2

Part Number: 695164-002

User Guide

Abstract

This guide is intended for the person who operates and maintains the HP Performance Optimized Datacenter 40c G2 (HP POD 40c G2).

August 2012

Edition: 2

Page 2

© Copyright 2012 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

Confidential computer software. Valid license from HP required for possession, use or copying. Consistent with FAR 12.211 and 12.212,

Commercial Computer Software, Computer Software Documentation, and Technical Data for Commercial Items are licensed to the U.S. Government

under vendor’s standard commercial license.

Microsoft® and Windows® are U.S. registered trademarks of Microsoft Corporation.

Intel® Core™ is a trademark of Intel Corporation in the U.S. and other countries.

Page 3

Contents

Overview ..................................................................................................................................... 6

Before you begin ....................................................................................................................................... 6

Operator safety ......................................................................................................................................... 6

Component safety ..................................................................................................................................... 6

Fire detection and suppression .................................................................................................................... 7

Environmental considerations ...................................................................................................................... 7

Component identification ............................................................................................................... 8

Structural component identification .............................................................................................................. 8

Parts and part number identification ................................................................................................... 8

Life safety component identification ............................................................................................................. 9

Electrical power component identification ................................................................................................... 11

Control cabinet component identification .................................................................................................... 14

HP POD 40c G2 racks ............................................................................................................................. 14

Life safety systems ....................................................................................................................... 16

Life safety overview ................................................................................................................................. 16

EPO system ............................................................................................................................................ 16

ECS touchscreen and EPO indicators ............................................................................................... 17

EPO modes ................................................................................................................................... 18

EPO accidental activation ............................................................................................................... 18

Battery backup during an EPO event ................................................................................................ 18

Fire protection system .............................................................................................................................. 18

Manual fire pulls ........................................................................................................................... 19

Fire alarm indicators ...................................................................................................................... 19

VESDA air sampling smoke detection system ..................................................................................... 19

(Optional) Fire suppression system ................................................................................................... 20

Emergency egress ................................................................................................................................... 21

Power, electrical, and controls ...................................................................................................... 22

Site electrical system ................................................................................................................................ 22

Power safety ........................................................................................................................................... 22

Grounding .................................................................................................................................... 22

Capacities .............................................................................................................................................. 24

HP POD 40c G2 capacity limitations ............................................................................................... 24

Electrical and mechanical cooling capacities .............................................................................................. 24

Power feeders ......................................................................................................................................... 24

Electrical panels ...................................................................................................................................... 25

Arc flash safety ............................................................................................................................. 26

Power distribution: Electrical busway system ..................................................................................... 26

Panel schedules ............................................................................................................................. 27

Wire color code ............................................................................................................................ 27

Control cabinet power components ............................................................................................................ 28

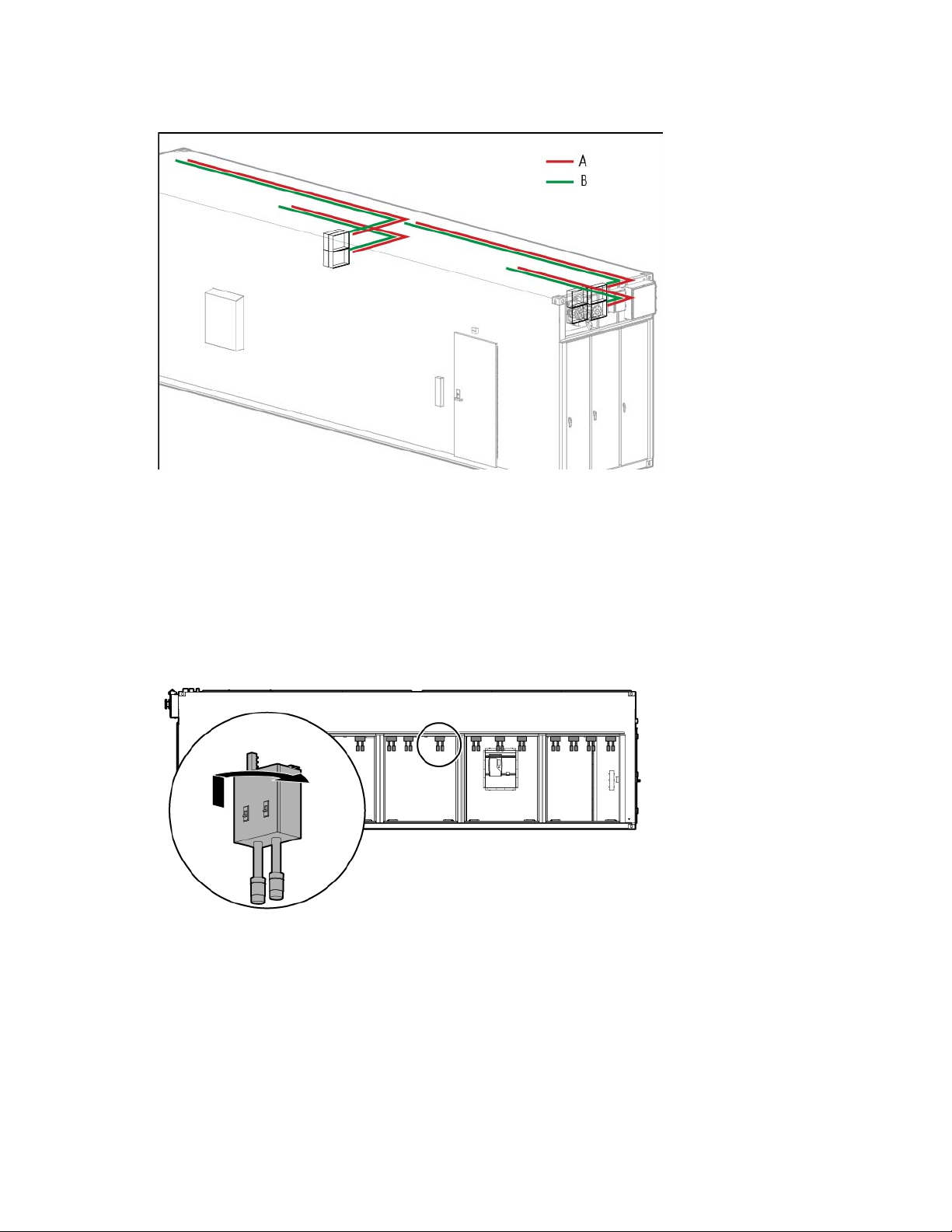

Electrical busways ................................................................................................................................... 28

Drop boxes ............................................................................................................................................ 30

Power configurations ............................................................................................................................... 31

Rack power ............................................................................................................................................ 31

Contents 3

Page 4

HP POD 40c G2 lighting .......................................................................................................................... 31

Environmental control system ........................................................................................................ 33

Environmental control system overview ....................................................................................................... 33

Using the ECS ......................................................................................................................................... 33

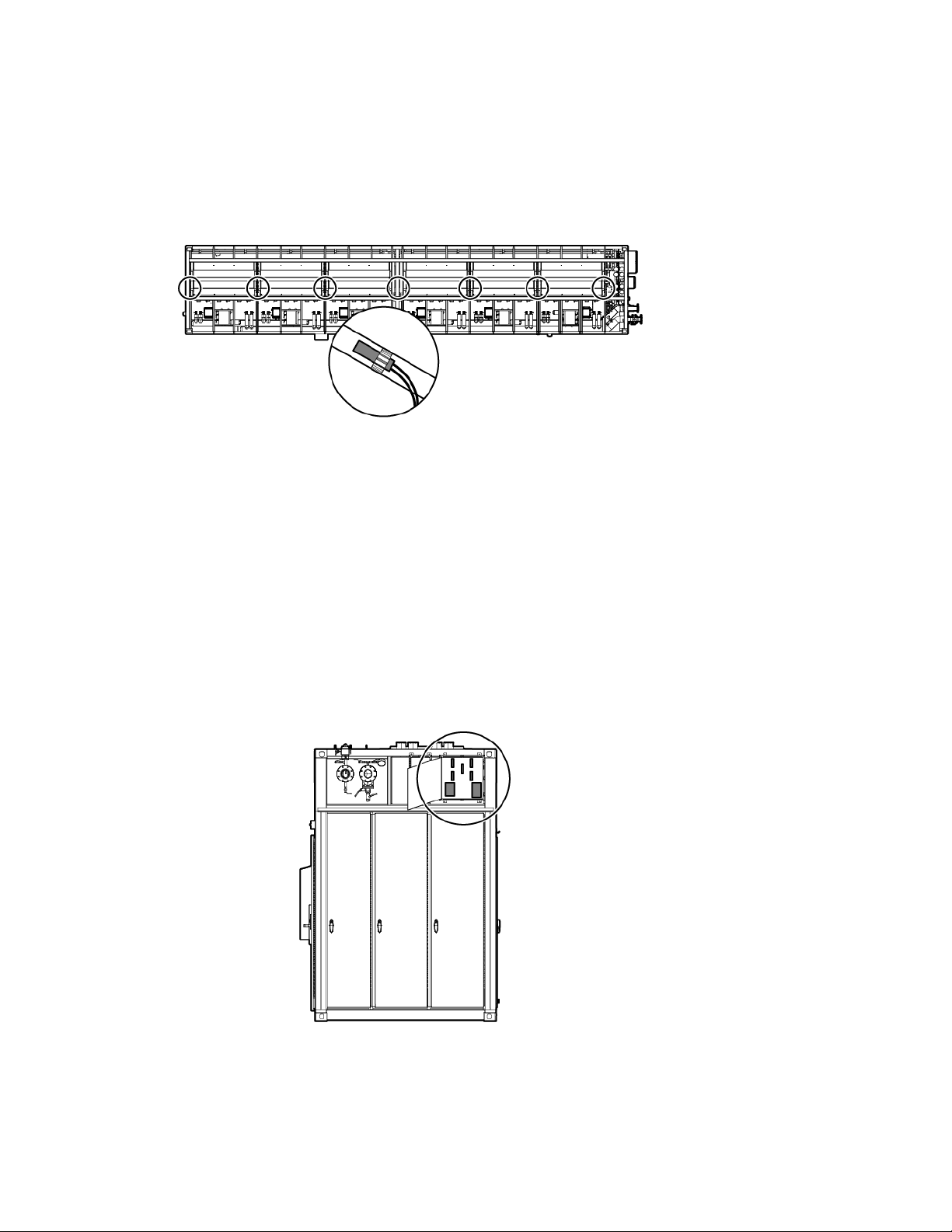

Satellite control boxes .................................................................................................................... 34

Sensors ........................................................................................................................................ 34

Facility connections to ECS ....................................................................................................................... 36

Connecting to the ECS ................................................................................................................... 36

Managing the ECS from the HP POD 40c G2 ............................................................................................. 37

Configuring the ECS ...................................................................................................................... 37

Logging in remotely to the ECS ........................................................................................................ 39

Password protection ....................................................................................................................... 41

Navigating the ECS interface .......................................................................................................... 41

ECS alarms ............................................................................................................................................ 54

Safety and security alarms .............................................................................................................. 55

Cooling system ........................................................................................................................... 56

HP POD 40c G2 cooling system theory of operation .................................................................................... 56

Water supply temperature .............................................................................................................. 56

Water quality requirements and specifications .................................................................................. 57

Cooling system components ...................................................................................................................... 58

Fans ............................................................................................................................................ 59

Condensation management ...................................................................................................................... 60

Drains .......................................................................................................................................... 60

Leak detection ............................................................................................................................... 61

IT networking and communications ............................................................................................... 62

Networking ............................................................................................................................................ 62

Connection portals .................................................................................................................................. 62

Demarcation box .................................................................................................................................... 63

Fire box ................................................................................................................................................. 63

Optional components .................................................................................................................. 65

Fire protection system .............................................................................................................................. 65

Humidifier .............................................................................................................................................. 65

Controlled access .................................................................................................................................... 65

Power up procedure .................................................................................................................... 66

Standard HP POD 40c G2 power up procedure ......................................................................................... 66

Standard power up checklist ........................................................................................................... 66

Standard power up procedure ........................................................................................................ 66

Cold weather HP POD 40c G2 power up procedure ................................................................................... 67

Cold weather power up checklist ..................................................................................................... 68

Cold weather power up procedure .................................................................................................. 68

Power down procedure ............................................................................................................................ 70

Specifications ............................................................................................................................. 71

General HP POD 40c G2 specifications ..................................................................................................... 71

Electrical specifications .................................................................................................................. 71

Water specifications ...................................................................................................................... 72

Rack specifications .................................................................................................................................. 72

Thermal and air flow performance ............................................................................................................. 72

Environmental specifications ..................................................................................................................... 72

Maintenance .............................................................................................................................. 74

Contents 4

Page 5

Periodic maintenance .............................................................................................................................. 74

Sample HP POD 40c G2 maintenance schedule.......................................................................................... 74

Contacting HP ............................................................................................................................ 75

Before you contact HP .............................................................................................................................. 75

HP contact information ................................................................................................................... 75

Regulatory compliance notices ..................................................................................................... 76

HP POD 40c G2 regulatory compliance ..................................................................................................... 76

Safety and NEC compliance ........................................................................................................... 76

Regulatory compliance identification numbers ............................................................................................. 77

Federal Communications Commission notice ............................................................................................... 77

Modifications .......................................................................................................................................... 77

Cables ................................................................................................................................................... 77

Canadian notice (Avis Canadien) .............................................................................................................. 77

Regulatory requirements for EXIT signs ....................................................................................................... 78

Glossary .................................................................................................................................... 79

Documentation feedback ............................................................................................................. 82

Index ......................................................................................................................................... 83

Contents 5

Page 6

Overview

opening or working inside areas of the HP POD 40c G2 that are marked as

If the HP POD 40c G2 is shut down for an extended period of time, such as during

Before you begin

For more information on site requirements, specifications, power requirements, management requirements,

and supported facility connections, see the HP Performance Optimized Datacenter 40c G2 Site Preparation

and Requirements Guide.

The actual location of various components or included subsystems in your HP POD 40c G2 might vary from

what is described in this document. For information specific to your HP POD 40c G2, see the drawings

included in the Operations and Maintenance Manual for the HP Performance Optimized Datacenter 40c

Operator safety

G2.

The HP POD 40c G2 provides service access areas for periodic maintenance and service and is only to be

used by owner-authorized personnel specifically trained in the maintenance and service of the HP POD 40c

G2.

The HP POD 40c G2 is not a habitable structure suitable for long term personnel occupancy.

WARNING: To avoid the risk of personal injury or loss of life, all personnel must comply with PPE

requirements when

hazardous voltage, per NFPA 70E in accordance with NEC (NA) and IEC (EMEA and APJ).

WARNING: To avoid the risk of personal injury, hearing protection must be worn at all times

when working inside the HP POD 40c G2.

WARNING: To avoid the risk of personal injury or damage to the equipment, do not insert

anything inside the electrical busways except the approved HP busway drop boxes.

The customer is responsible for completing any Environmental Health and Safety (EHS) evaluation of the HP

POD 40c G2 or any attached structural component purchased through HP. The customer must complete an

arc flash assessment of the HP POD 40c G2 and the associated electrical supply system for operation,

maintenance, and so on.

Component safety

CAUTION:

routine maintenance, use desiccant units or materials to eliminate condensation within the HP

POD 40c G2. Condensation causes damage to IT equipment and HP POD 40c G2 controls.

CAUTION: Electrostatic discharge might damage electronic components. Be sure that you are

properly grounded (earthed) by wearing approved grounding straps before beginning any

installation procedure or repair.

Overview 6

Page 7

CAUTION: If any racks contain empty RU space, use the HP POD 40c G2 filler panels to

maintain the efficiency of the HP POD 40c G2 thermal system. Filler panels are available from HP

in 10-pack quantities (part number AQ682A) and 100-pack quantities (part number AS993A).

Fire detection and suppression

The fire suppression system, supplied as an optional component of the HP POD 40c G2, is a "Manufacturer

Designed" system specifically for this HP product, in compliance with national standards.

The HP standard suppression system includes a Novec 1230 clean agent system. However, if the customer

or local AHJ requires specific modifications or a replacement, HP can assist in these actions at the expense

of the customer.

HP does not certify that the fire suppression system installed in the HP POD 40c G2 meets all local and

jurisdictional requirements. The customer is responsible for the following actions as related to the fire

suppression system:

• Verifying that the POD suppression system meets local codes, including specific local requirements for

initial and periodic inspections.

• Arranging for and receiving all required local permits, including initial commissioning as well as

standard and repair maintenance.

• Arranging for the connection of the agent tanks, refilling of tanks, and all system testing, including

pressure tests. All general maintenance of the suppression system must be completed by an authorized

technician.

Additional local requirements are not covered as part of the option price or basic installation and

deployment services, unless specifically included in an executed Statement of Work.

Environmental considerations

CAUTION: To maintain accurate environmental conditions and minimize condensation inside

the HP POD 40c G2, do not leave the HP POD 40c G2 doors open during operation.

Overview 7

Page 8

Component identification

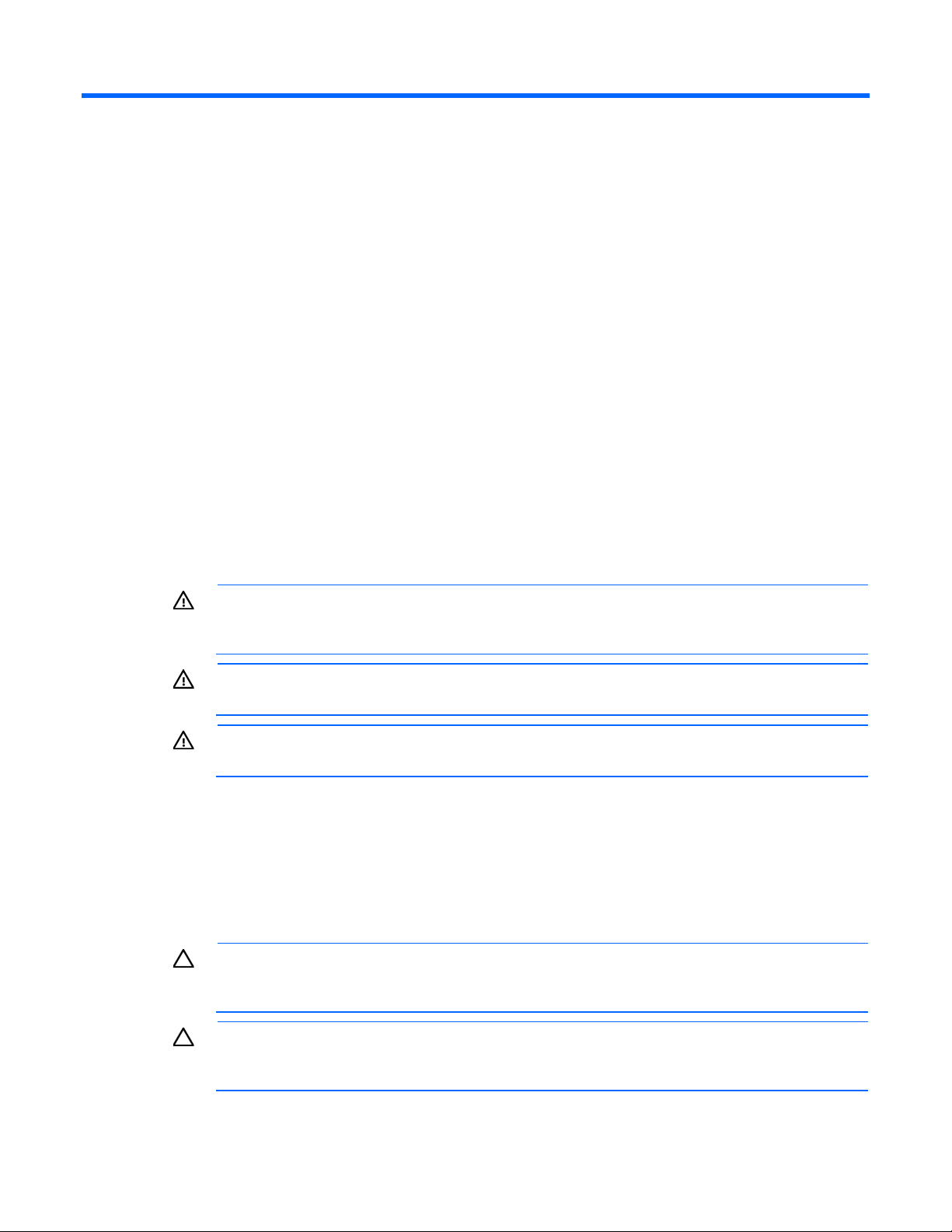

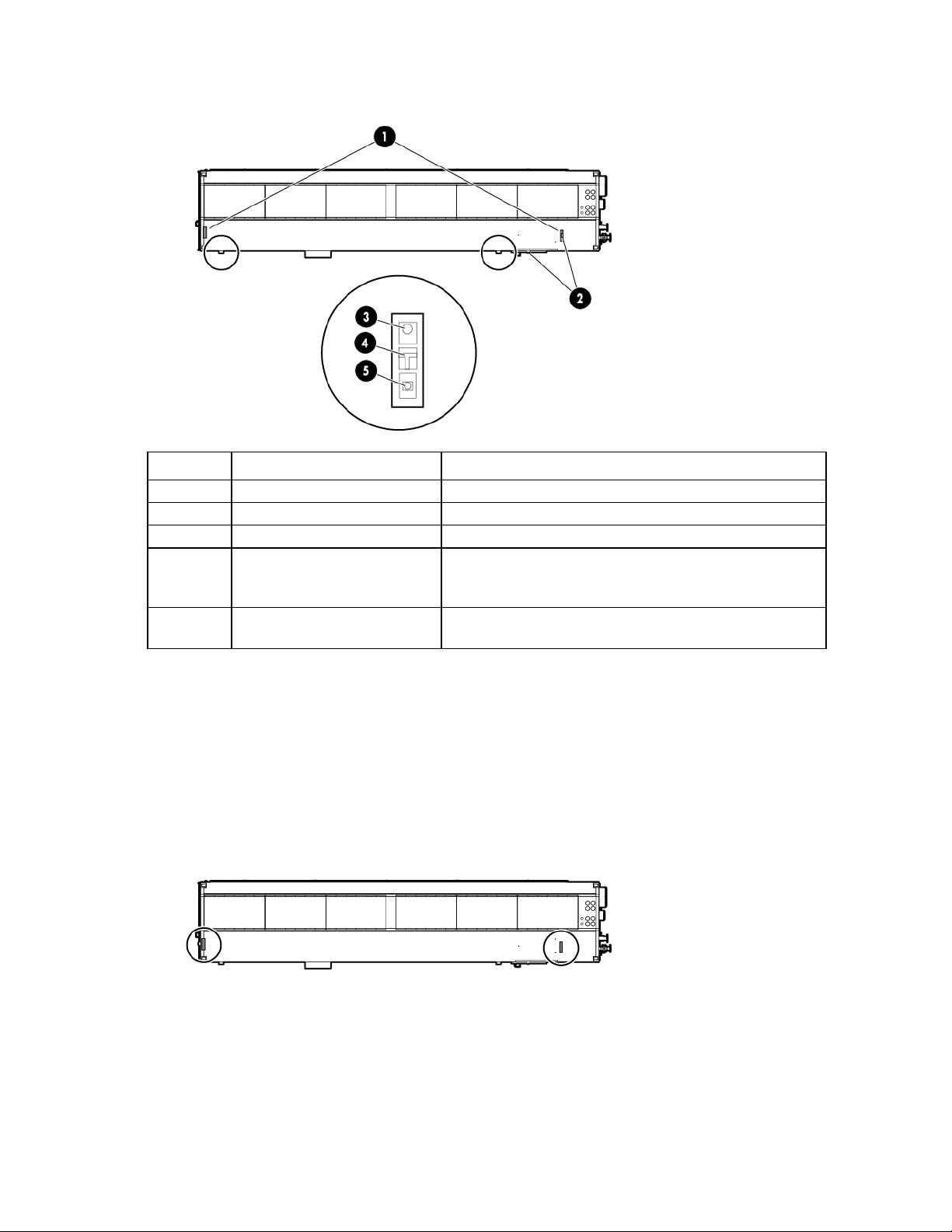

Structural component identification

The HP POD 40c G2 documentation frequently refers to the specific components of the HP POD 40c G2 as

shown in the following figure and described in the following table.

Item Component Description

Heat exchanger access hatches Provides access to the overhead heat exchangers

1

Personnel access doors Provides access to the POD

2

Facility chilled water return Facilitates the return of chilled water to the POD

3

Facility chilled water supply Facilitates the supply of chilled water to the POD

4

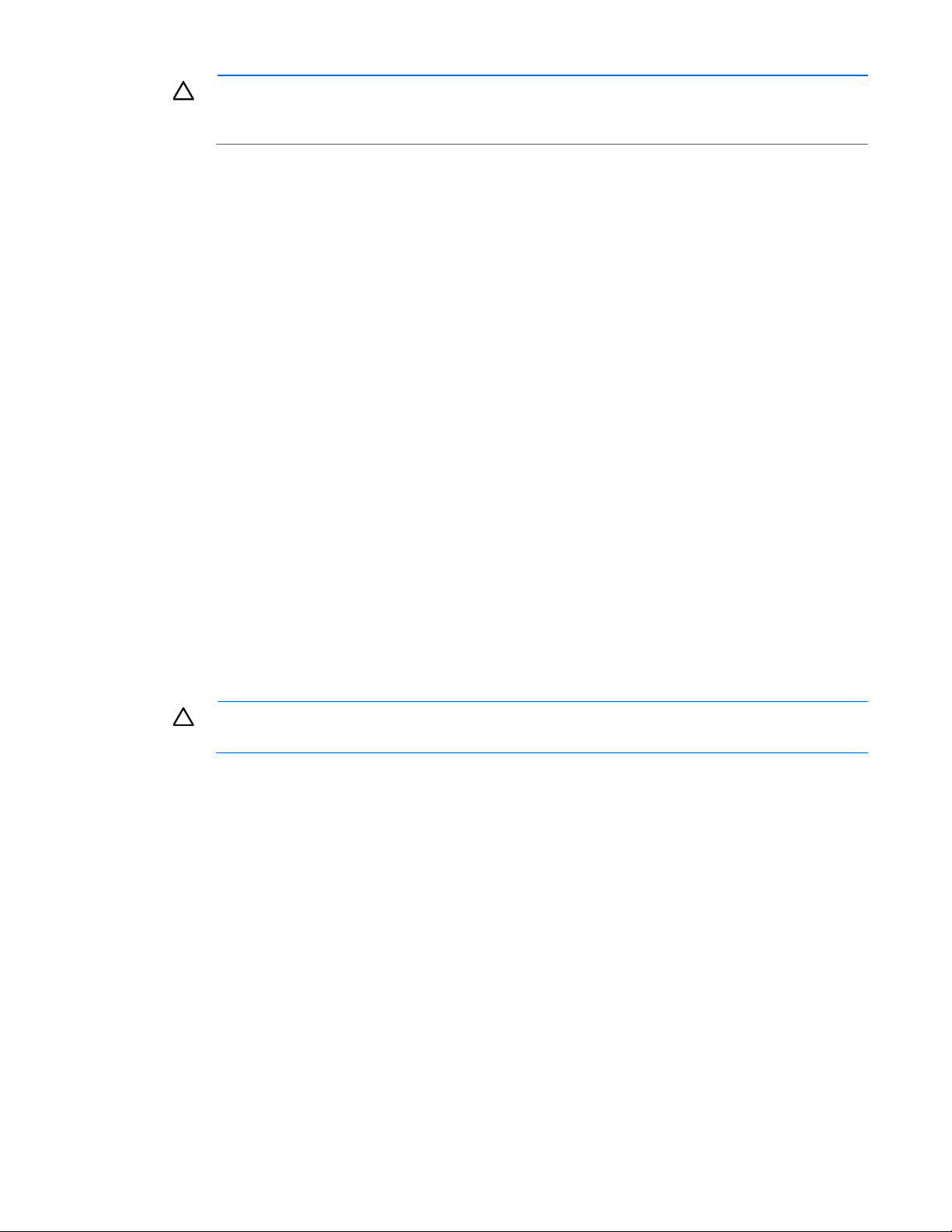

Parts and part number identification

Review the contents of the HP POD 40c G2 to identify the following for each component:

• Model number—The model number is located on the door to the control panel inside the cold aisle of

the HP POD 40c G2, as shown in the following figure.

Component identification 8

Page 9

• Regulatory compliance identification number—This product has been assigned a unique regulatory

model number and is located on the door to the control panel inside the cold aisle of the HP POD 40c

G2, as shown in the following figure.

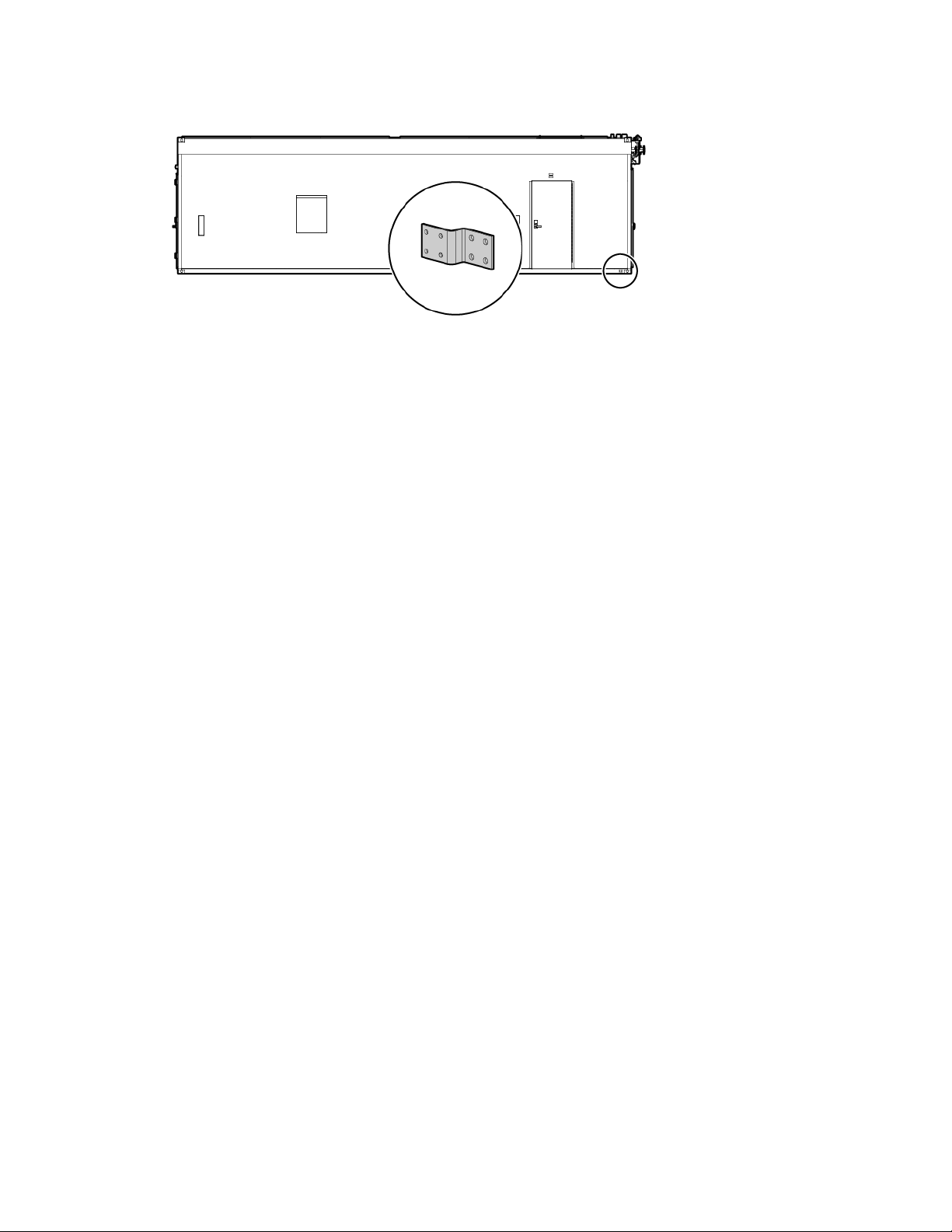

• CSC Safety Approval placard—Each HP POD 40c G2 has a CSC Safety Approval placard that includes

the model number, serial number, and proof load. The CSC Safety Approval placard is located on the

cargo end of the HP POD 40c G2, as shown in the following figure.

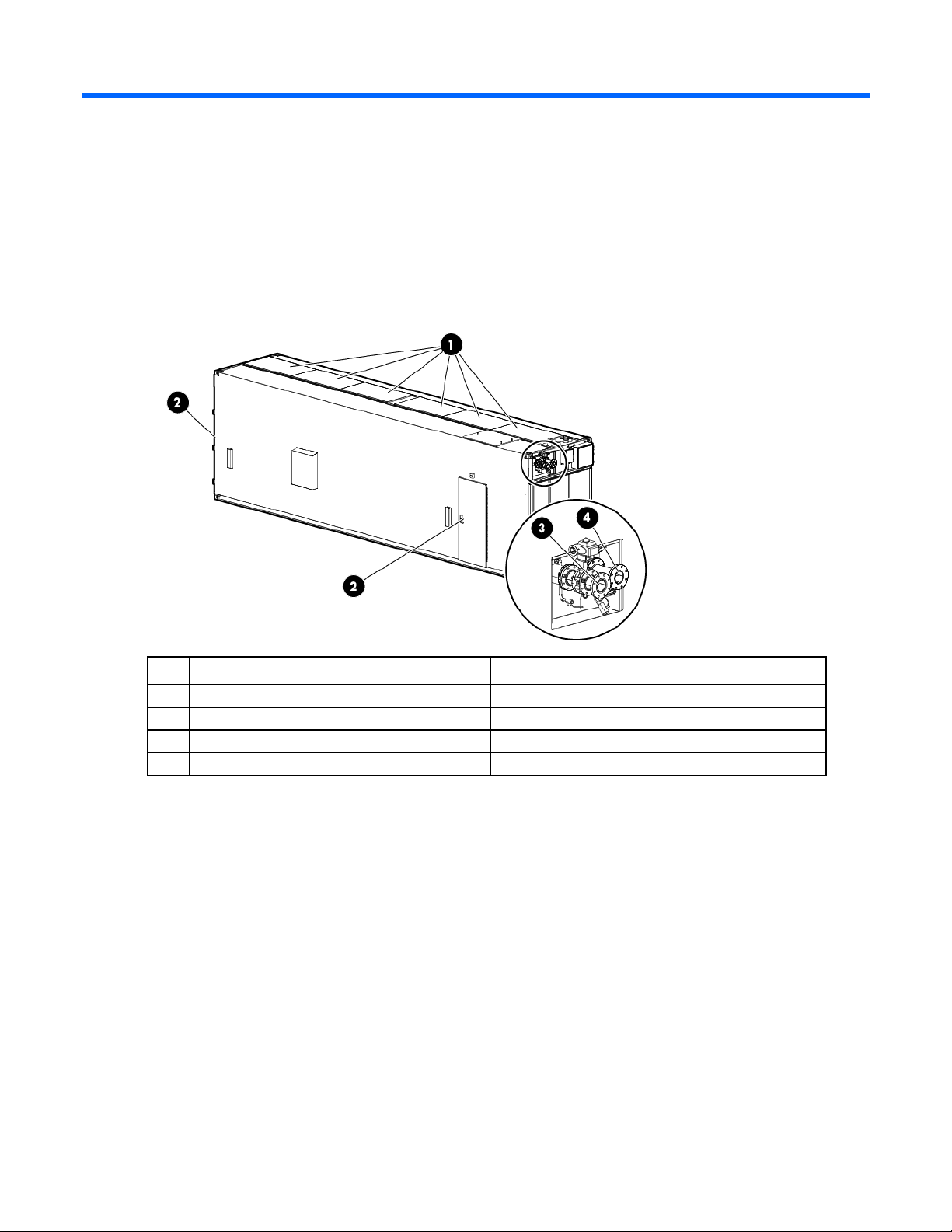

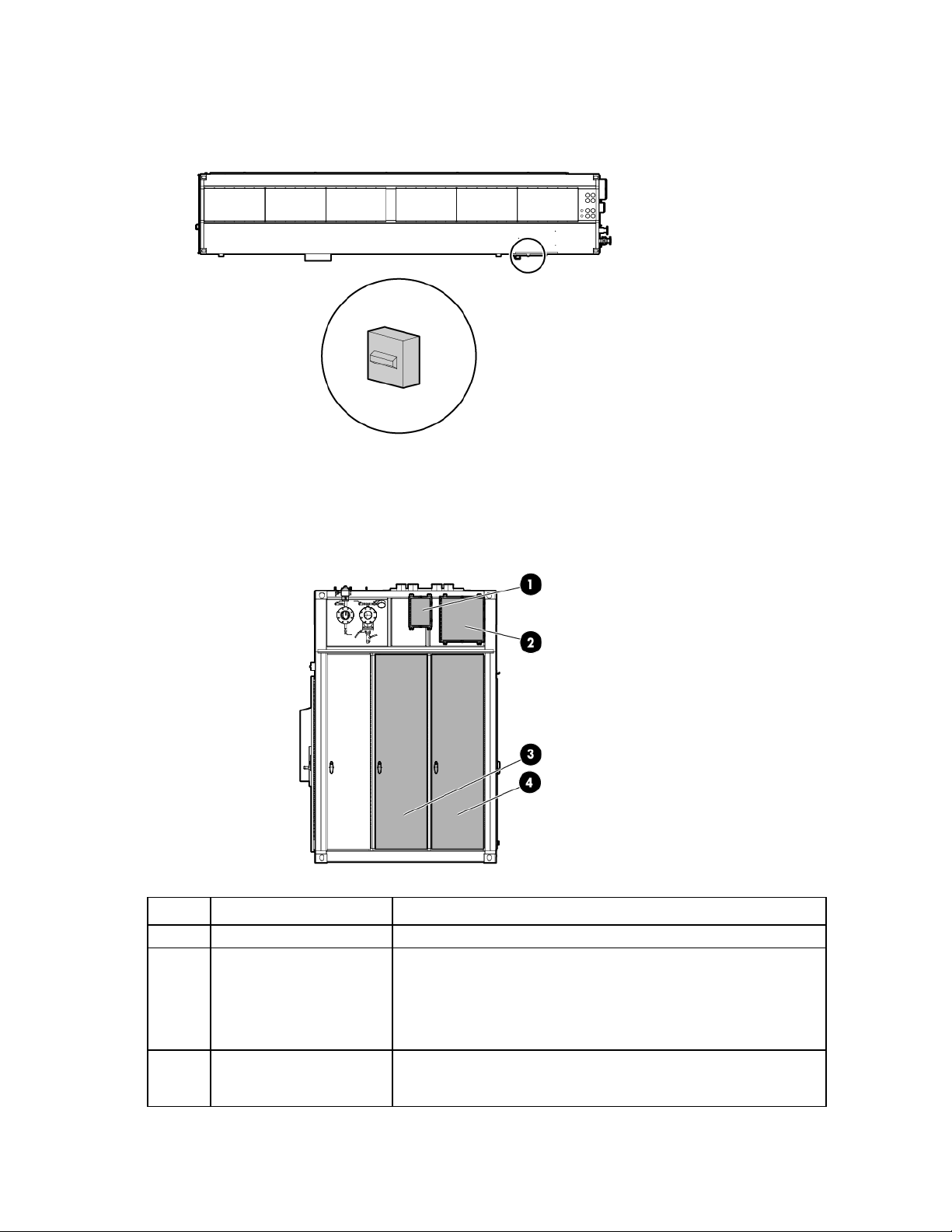

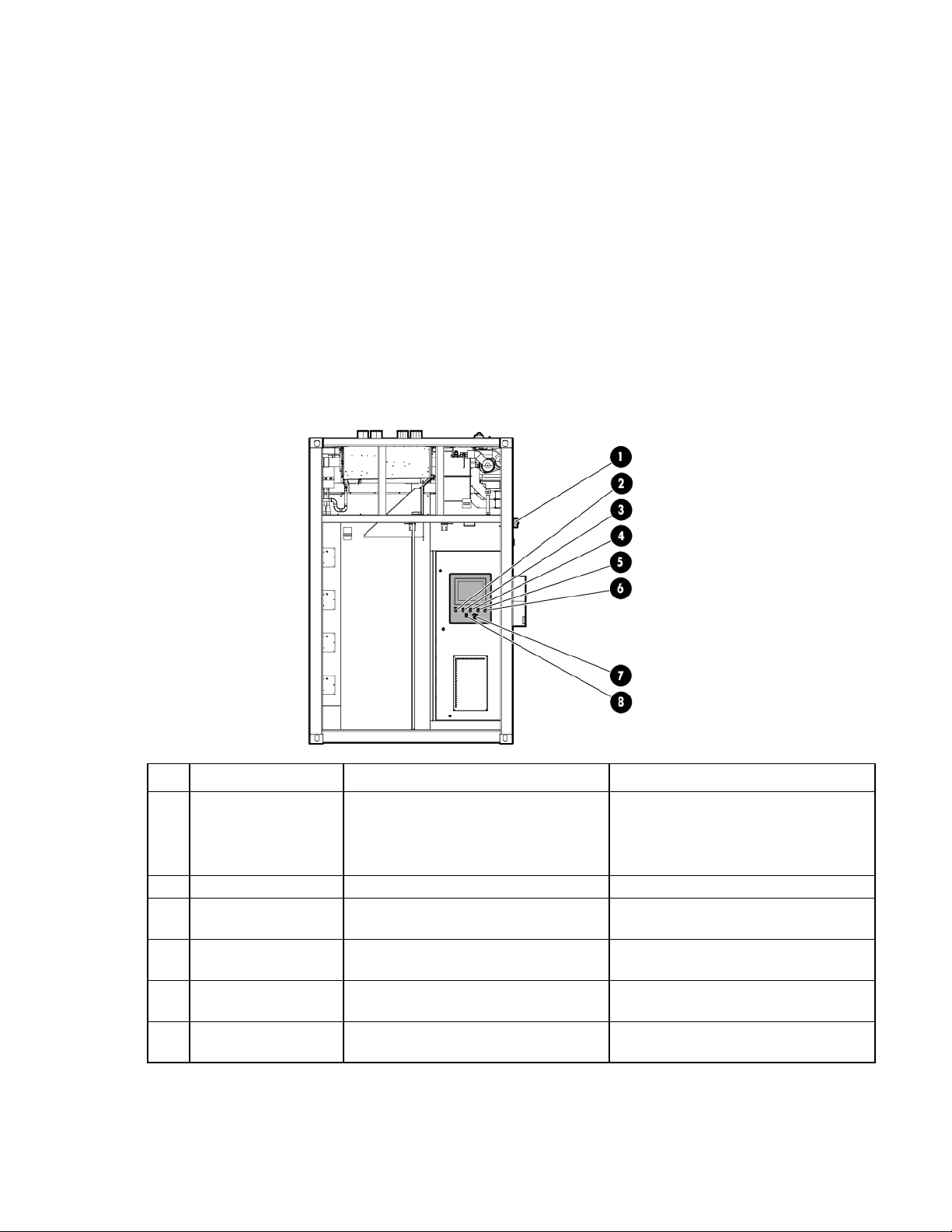

Life safety component identification

Internal life safety components

Component identification 9

Page 10

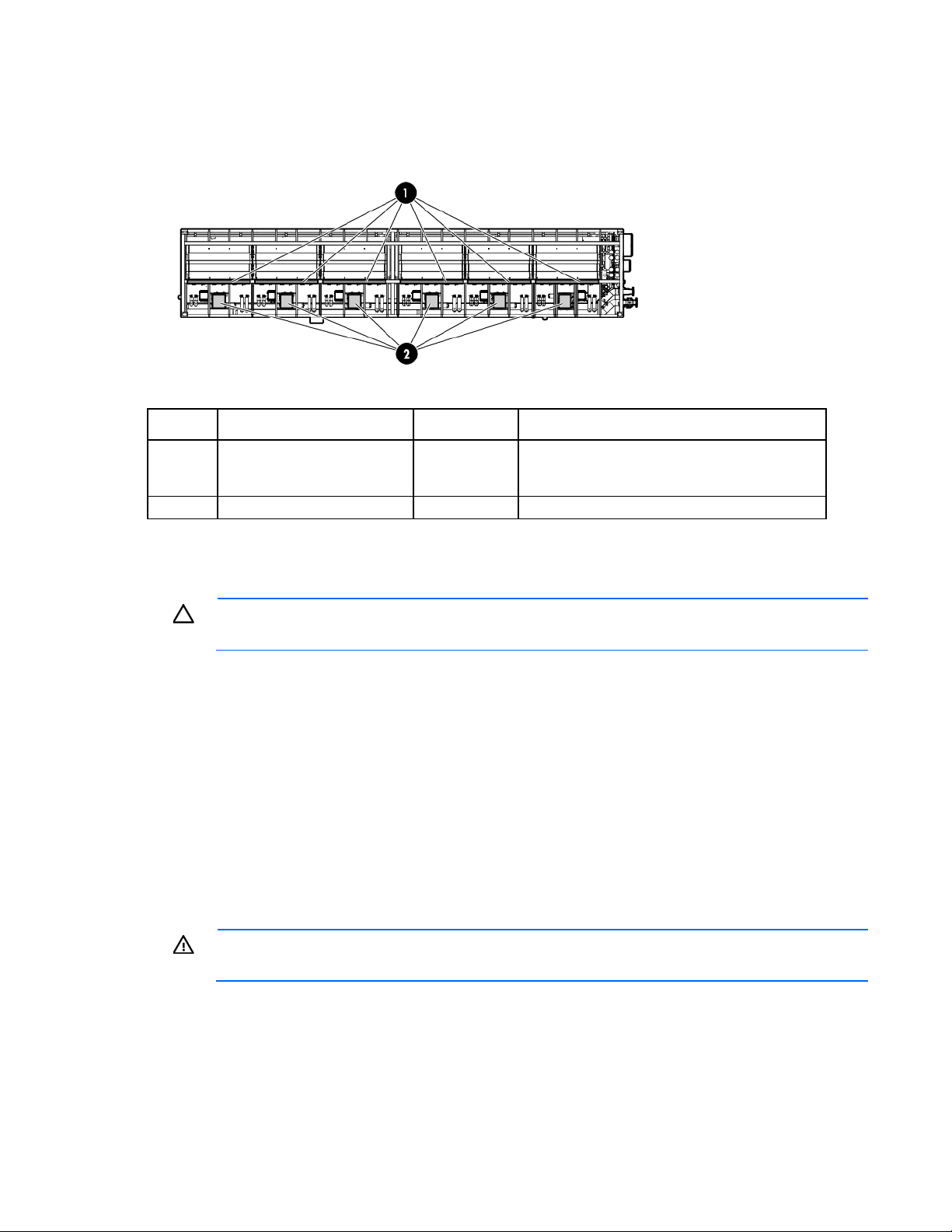

Top view shown

Item Component Description

1

2

3

4

5

*This is an optional component that might not be included.

Exit sign locations Indicates the location of an exit

Fire strobe light Indicates a fire alarm condition within the HP POD 40c G2

EPO button Disconnects the HP POD 40c G2 from main power feeds

Fire alarm manual pull* Enables manual initiation of the fire system, which includes

activating the interior and exterior fire strobe lights and the

optional fire suppression system

Fire suppression abort button* Aborts the fire suppression system. A fire suppression abort

button is located next to each personnel door.

Exit sign locations

The exit signs within the HP POD 40c G2 contain tritium. For information about the regulatory requirements

regarding the handling, transfer, and disposal of the signs, see "Regulatory requirements for EXIT signs (on

page 78)."

Top view shown

External emergency status indicators

The HP POD 40c G2 has one external fire strobe light that indicates a fire alarm condition.

Component identification 10

Page 11

Top view shown

•

•

•

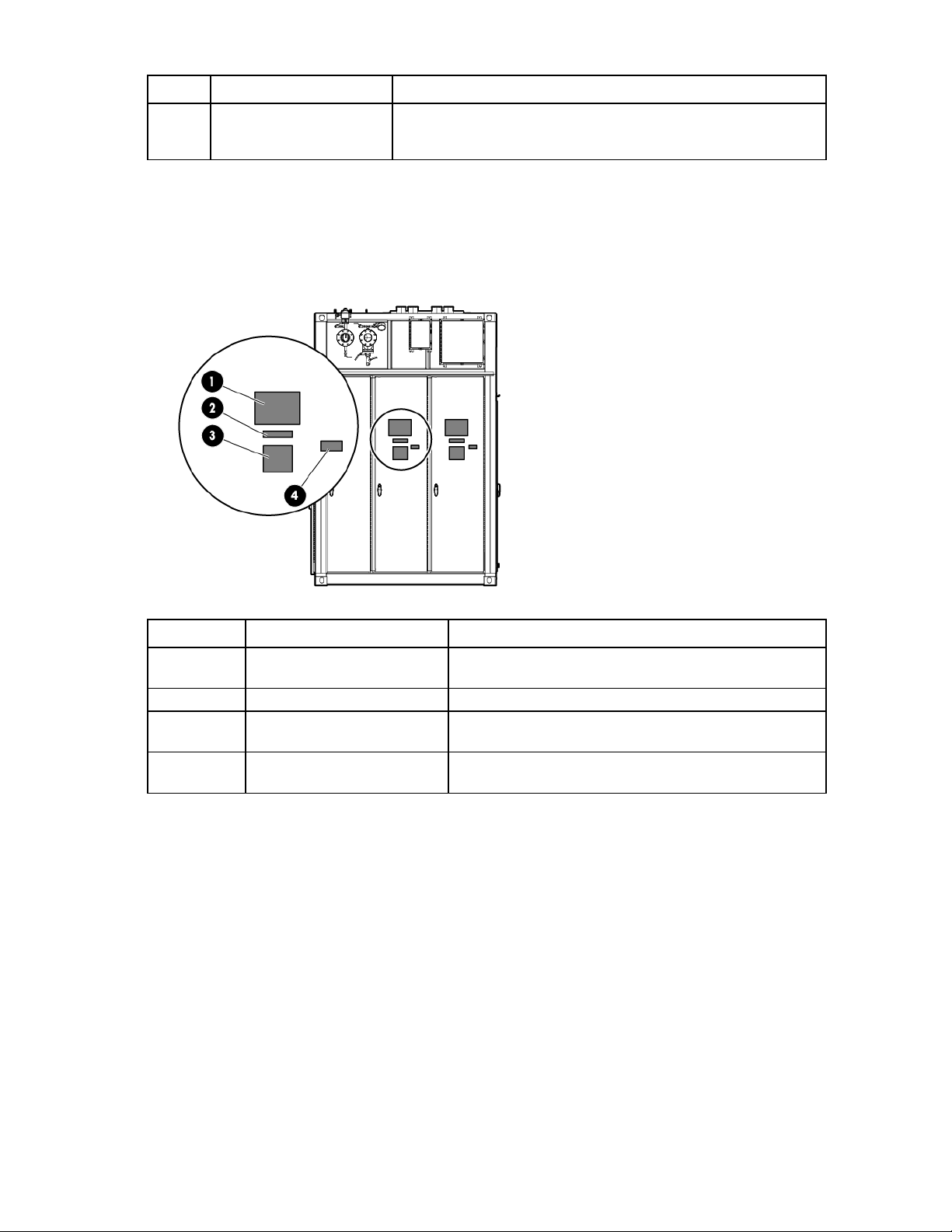

Electrical power component identification

Front view shown

Item Component Description

1

2

Fire box* Connection location for fire emergency and VESDAnet signals

Demarcation box* Customer communication connection point for the following

components:

ECS

Security

Phone

3

415 Y/240 V 3-phase,

4-wire, 800 A electrical

panel

Feed A power for critical IT loads (electrical busways) and house power

Component identification 11

Page 12

Item Component Description

4

415 Y/240 V 3-phase,

4-wire, 800 A electrical

panel

*The demarcation box and the fire box are communication data points that are provided on the POD by HP. Connecting

these data points is the responsibility of the customer, unless an approved Statement of Work is initiated.

Feed B power for critical IT loads (electrical busways) and house power

External panel labels

Front view shown

Callout Electrical safety label Description

1

2

3

4

Danger sign Provides a reminder to users that the electrical panels must be

accessed only by authorized personnel

Disconnect label Provides the order for disconnecting all of the electrical panels

Caution Cautions users about isolating power from the HP POD 40c

G2

Arc flash warning Provides a reminder to users of the danger of arc flash and

required PPE

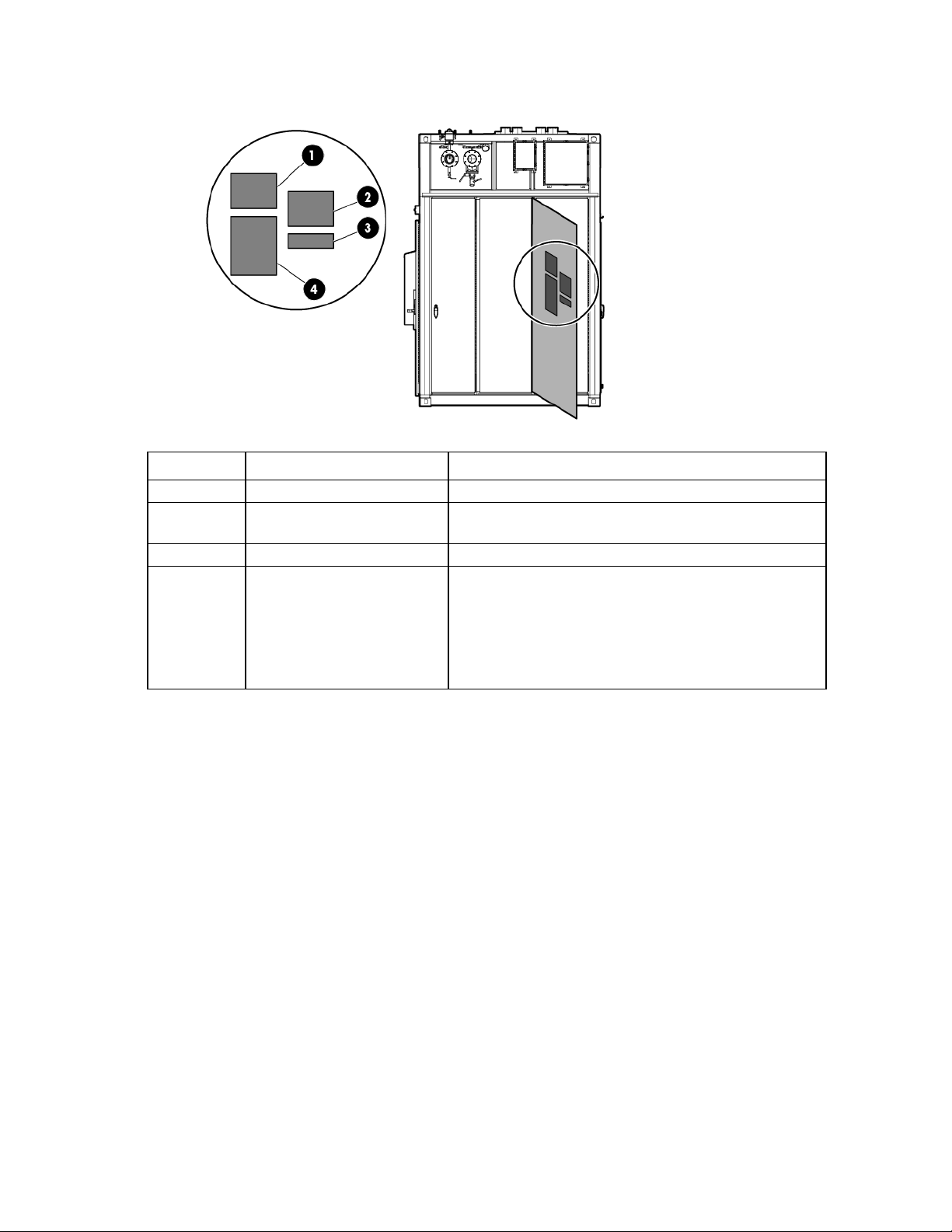

Internal panel labels

Component identification 12

Page 13

Front view shown

•

•

•

•

•

Item Electrical safety label Description

1

2

3

4

Input power Lists the input power information

Panel schedule/circuit breaker

table

Fuse type table Lists all fuse type and sizes

Wire color code (on page 27) 415Y/240V color codes

Lists the layout and designation for all circuit breakers on the

panel

Purple/Brown—Phase A/L1

Purple/Orange—Phase B/L2

Purple/Yellow—Phase 3/L3

Purple/White—Neutral

Green and yellow—Equipment ground

Component identification 13

Page 14

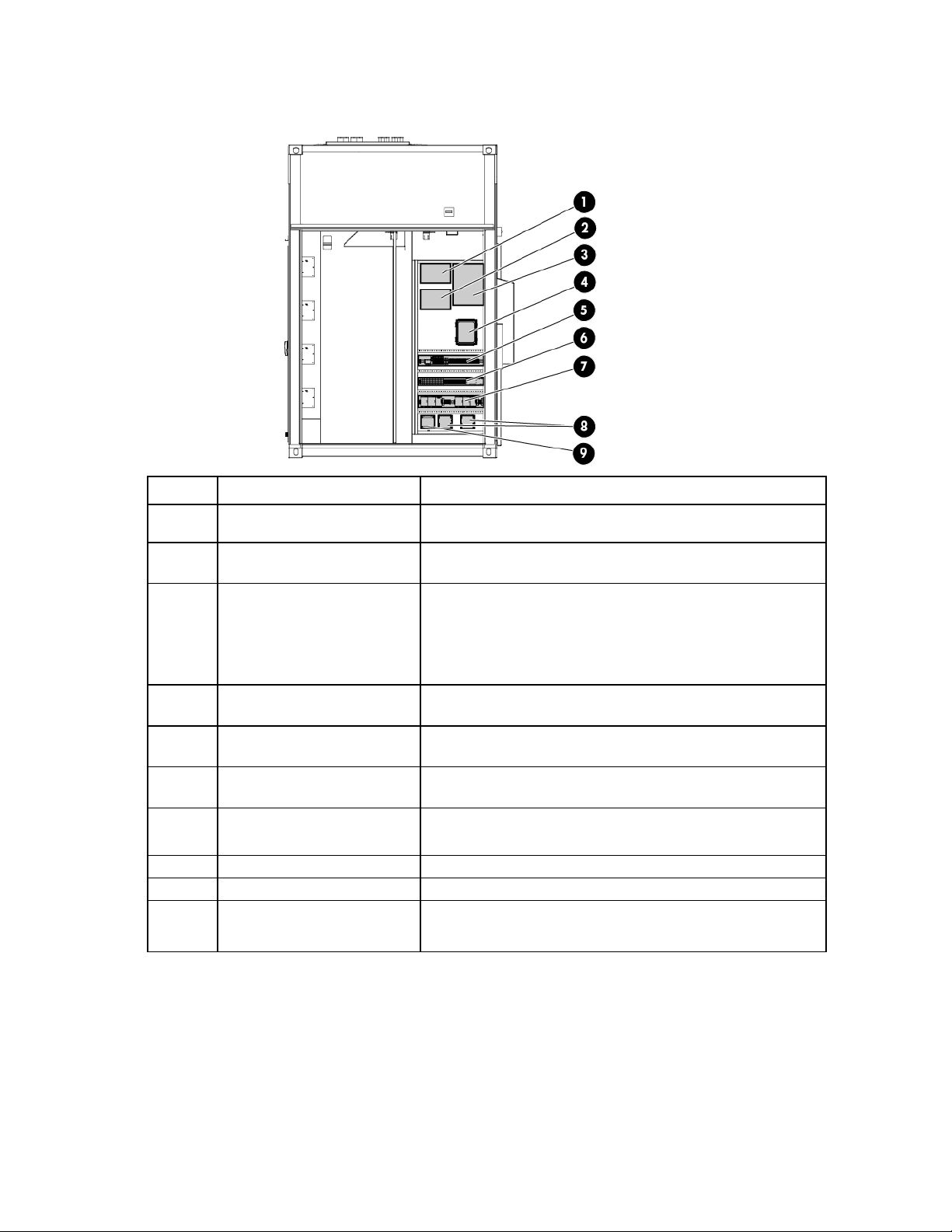

Control cabinet component identification

•

•

Includes a battery backup system that provides backup power

Item Component Description

1

2

3

VESDA air sampling smoke

detection unit

VESDA power supply with

battery backup

Fire alarm and suppression

release control panel

An early warning laser scan smoke detection unit

Provides power to the VESDA and backup power to the VESDA

during a utility power loss

Controls all fire systems within the HP POD 40c G2, including

the smoke detection system, fire suppression system, fire pulls,

and so on

to the fire system during a utility power loss

4

5

6

7

8

9

—

Customer connection box Controls and organizes information monitored by the HP POD 40c

G2 security components

ECS relays and ECS modules Relays for the ECS control, ECS communications, I/O connections,

and terminal block connections

EPO controller board and house

panel fuses

Dual power supplies with

battery backup

Battery backup power supply Provides 24 V DC power to the PLC and ECS system

240/120 V transformer Provides house power to the convenience outlets

PLC The computer that controls the ECS system (located on the inside

Connections for the EPO system and fuses for other house panel

components

Provides 24 V DC power to the PLC, LED lighting, and ECS systems

door of the control cabinet)

HP POD 40c G2 racks

The HP POD 40c G2 contains a total of 20 IT racks.

Component identification 14

Page 15

CAUTION: If any racks contain empty RU space, use the HP POD 40c G2 filler panels to

maintain the efficiency of the HP POD 40c G2 thermal system. Filler panels are available from HP

in 10-pack quantities (part number AQ682A) and 100-pack quantities (part number AS993A).

For more information about racks and network cabling, see the HP Performance Optimized Datacenter

Networking Guide.

Component identification 15

Page 16

Life safety systems

Life safety overview

The HP POD 40c G2 has multiple life safety systems that all work together to protect the HP POD 40c G2

equipment and personnel. The following life safety systems are available on the HP POD 40c G2:

• EPO system (on page 16)

• VESDA air sampling smoke detection system (on page 19)

• (Optional) fire suppression system (on page 20)

• Emergency egress (on page 21)

• ECS connection to customer emergency systems

EPO system

If the HP POD 40c G2 must be shut down during an emergency, the EPO system automatically shuts off all

power to the HP POD 40c G2 and activates the EPO indicator on the ECS panel door.

To ensure that all rack-mounted UPS devices are shut down during an EPO event, be sure that each

rack-mounted UPS device is connected to the HP POD 40c G2 EPO system.

The EPO system can be activated two ways:

• Excessive high temperature in the hot aisle—The HP POD 40c G2 includes two thermisters. If both

thermisters reach 60ºC (140ºF), an EPO shutdown is triggered automatically. One thermister is located

in zone 2 and one thermister is located in zone 5.

• Manual initiation—To manually trigger an EPO shutdown, press at least one of the EPO buttons. Both

EPO buttons are located on the POD interior. One button is located near the main exit and the second

button is located near the emergency exit on the cargo end.

For the location of EPO buttons, see "Life safety component identification (on page 9)."

Life safety systems 16

Page 17

The EPO system must be reset before you can power up and restart the HP POD 40c G2. To reset the EPO

•

•

•

system:

1. Verify that the key control for the EPO mode is in the Armed position.

2. Press the white EPO Reset button.

If you triggered the EPO system manually, you must reset the EPO button that you pressed to the Active

position.

ECS touchscreen and EPO indicators

The ECS touchscreen and EPO indicators are located on the door to the control panel.

The touchscreen enables you to easily configure the environmental parameters, access data, and monitor

environmental, life safety, and security conditions within the HP POD 40c G2.

The EPO indicators provide EPO status. The EPO key control and EPO reset button enable you to adjust the

EPO system mode.

Item Component Indicator color Description

External EPO status

1

indicator

White—Normal operating mode

Yellow—EPO cover open alarm or

EPO system operating in test mode

Indicates the operating status of the HP

POD 40c G2

Red—EPO shutdown

Power on White Indicates the EPO power status

2

EPO shutdown Red Indicates an EPO shutdown or alarm

3

EPO armed White Indicates that the EPO system is armed and

4

EPO test mode Yellow Indicates that the EPO system is operating

5

EPO bypassed Green Indicates that the EPO functionality and

6

situation

operational

in test mode or that an EPO cover is open

shutdown is bypassed

Life safety systems 17

Page 18

Item Component Indicator color Description

•

•

•

EPO mode Key control Enables you to select the EPO mode:

7

EPO reset White button Resets the EPO system when pressed

8

EPO modes

The EPO system has three operating modes:

• Armed—The EPO system is armed and operational.

• Test—The EPO system is in test mode and does not initiate during events that normally trigger an EPO.

• Bypass—The EPO system is non-operational and does not initiate during events that normally trigger an

EPO.

Armed

Test

Bypass

For more information, see "EPO modes (on

page 18)."

EPO accidental activation

To help prevent accidentally pressing the EPO button and activating the EPO system, each EPO button is

covered with a clear Lexan cover.

Battery backup during an EPO event

The following components are equipped with a UPS to ensure that service is not interrupted during a loss of

power to the HP POD 40c G2:

• ECS system

• VESDA air sampling smoke detection system

• Optional fire suppression system

• Emergency lighting in the HP POD 40c G2

Fire protection system

Each HP POD 40c G2 is equipped with a fire alarm panel that is integrated with the fire detection system and

the optional fire suppression system.

The fire system is designed as a stand-alone system, but can also interface with customer site fire alarm

systems. Customer site connections are the responsibility of the customer. Consult with HP for connection

locations.

The fire protection system includes:

• Manual fire pulls (on page 19)

• Fire alarm indicators (on page 19)

• VESDA air sampling smoke detection system (on page 19)

• (Optional) Fire suppression system (on page 20)

Life safety systems 18

Page 19

The fire suppression abort button will not delay the release of the fire suppression

Manual fire pulls

The HP POD 40c G2 includes two fire pulls. One fire pull is located next to the personnel access door and

the second fire pull is located next to the emergency exit.

Manually activating a fire pull does the following:

• Activates the POD fire alarm system horn and strobe lights

• Triggers a fire alarm signal to the BMS in the fire box (on page 63) and activates a 30-second delay

before releasing the fire suppression agent

IMPORTANT:

agent if a manual fire pull is initiated. All personnel should evacuate immediately.

Fire alarm indicators

Upon activation of a fire alarm within the HP POD 40c G2, the following alarms alert personnel:

• Strobe lights

o Internal—The HP POD 40c G2 includes one fire strobe light located in the cold aisle.

o External—The HP POD 40c G2 includes one fire strobe light located at the standard personnel entry

door.

o Optional—There is an additional fire strobe light located in the cold aisle that can be connected to

the site fire alarm system at the expense of the customer.

• Audible horn—The HP POD 40c G2 includes two integrated horns. One horn is located on the internal

strobe light and the second horn is located on the optional strobe light.

• Alarm within the ECS—The ECS system notifies you of a fire alarm condition with an alarm alert on the

ECS screen.

VESDA air sampling smoke detection system

CAUTION: Excess dust within the HP POD 40c G2 can cause the VESDA smoke detector to

The VESDA system features a single zone laser scan early warning smoke detector to provide the earliest

warning of a potential fire.

The orange VESDA conduits that run throughout the HP POD 40c G2 include inlets for smoke sampling. The

VESDA uses a high-efficiency aspirator to continuously draw in air from the HP POD 40c G2 and circulate

the air through a dual-stage filter:

• Stage 1—Dust and dirt are removed from the air sample.

trigger a fire alarm.

• Stage 2—Remaining contaminants in the air sample are removed with an ultra-fine filter.

After the air passes through the dual-stage filter, it enters a calibrated detection chamber where a laser scans

the air sample for the presence of smoke. When the smoke concentration reaches the first setpoint, the

VESDA system will send an alarm signal indicating that a fire might exist. When the smoke concentration

reaches the second setpoint, the VESDA system indicates that a fire does exist in the HP POD 40c G2 and

sends an activation signal to the fire suppression system.

Life safety systems 19

Page 20

suppression system meets all local jurisdiction requirements. Compliance with local codes is your

Any additional local requirements are not covered as part of the option price or basic installation

IMPORTANT: The VESDA filter must be changed regularly to ensure accurate smoke detection

readings. For more information about changing the VESDA filters, see the HP Performance

Optimized Datacenter 40c G2 Maintenance and Service Guide.

(Optional) Fire suppression system

CAUTION: The POD fire suppression system is manufacturer designed, engineered, and

installed to comply with national standards. However, HP does not certify that the installed fire

responsibility, and includes specific local requirements for initial and periodic inspections,

certifications, and maintenance.

The fire suppression system contains conventional fire alarm control circuits and includes features required

for single or dual-hazard suppression release applications, including a low-toxicity agent. In the event of fire

suppression release, the suppression tanks must be refilled by a certified technician.

and deployment services, unless specifically included in an executed Statement of Work.

WARNING: Fire suppression agents include a pre-discharge warning and evacuating system. In

the event of a fire, all protected space must be evacuated as soon as possible.

IMPORTANT: The fire suppression abort buttons that are located next to each personnel door

can be pressed to interrupt the 30-second fire suppression agent release delay for an additional

30 seconds. This button interrupts the countdown, but does not reset the 30-second fire

suppression agent release delay. The fire suppression agent release countdown will continue

when the abort button is released until the time is exhausted and the fire suppression agent is

released.

Fire system operator panel

The panel is configured by the manufacturer in accordance with the local fire marshal and fire code

requirements.

The operator panel includes the following:

• Alarm status LED

• Trouble status LED

• Input status LED

• Output status LED

• Acknowledge button

• Alarm Silence button

• System Reset button

The fire system and panel are tested by the local certified fire system supplier and witnessed and certified by

the local AHJ or fire marshal.

The fire system operator panel requires regular maintenance and service. For more information on the fire

system operator panel component, see the Operation and Maintenance Manual for the HP Performance

Optimized Datacenter 40c G2.

Life safety systems 20

Page 21

Fire suppression sequence of operations

After the fire suppression system is activated by a VESDA signal or a manual fire pull, a 30-second

countdown begins before the fire suppression agent is released to the HP POD 40c G2 interior through the

fire system piping.

VESDA initiation

Press the fire suppression abort button to interrupt the fire suppression release countdown for 30 seconds. The

abort button can be pressed multiple times to interrupt fire suppression release agent countdown for an

additional 30 seconds until the 30-second fire suppression release countdown has been exhausted.

Press and hold the abort button to stop the immediate activation of the fire suppression system until the button

is released. When the button is released, the 30-second delay will begin. The remaining fire suppression

release agent countdown will continue after the 30-second delay until the time is exhausted.

Manual initiation

The fire suppression abort button will not delay the release of the fire suppression agent if a manual fire pull

was activated. All personnel should immediately evacuate.

Emergency egress

The HP POD 40c G2 includes the following features for life safety egress on all access doors:

• Panic bar

• Door strikes

o Standard hardware—Door strikes

o Optional hardware—Electric door strikes

Each personnel door includes a standard panic bar to ensure safe exit. The optional egress hardware

included in the HP POD 40c G2 (including electric panic bars, electric strikes, and magnetic locks) are tied

to the fire alarm to enable uninhibited egress in the event of an emergency.

Life safety systems 21

Page 22

Power, electrical, and controls

requirements when opening or working inside areas of the HP POD 40c G2 that are marked as

Site electrical system

To ensure a complete and safe integration of the HP POD solution with your facility, HP requires that you

complete the following actions for the installed electrical system prior to the installation of the HP POD

solution:

• Short circuit analysis

• Arc flash study

• Circuit breaker coordination study

These actions must be performed for all associated parts of the electrical power train. The majority of the

details and factors required to complete these studies are associated with the existing installed facility

infrastructure.

CAUTION: Failure to complete these studies can cause serious issues with the electrical

integration of the POD into your electrical system.

Power safety

WARNING: To avoid the risk of personal injury or loss of life, all personnel must comply with PPE

Grounding

The HP POD 40c G2 must be properly grounded to the earth to ensure a common return path for electric

current, limit the build-up of static electricity, and absorb an unlimited amount of current without changing its

potential. To properly ground the HP POD 40c G2 to the earth, you must connect the POD to building steel,

a ground rod, or a properly installed ground well that is connected to a building’s grounding system. The

grounding electrode conductor connection point is located on the cold aisle side adjacent to the power

cabinet.

hazardous voltage, per NFPA 70E in accordance with NEC (NA) and IEC (EMEA and APJ).

WARNING: To avoid the risk of personal injury or electric shock, the HP POD 40c G2 must be

properly grounded per NFPA 70 in accordance with NEC (NA) and IEC (EMEA and APJ).

Power, electrical, and controls 22

Page 23

A certified electrician must test and verify that the HP POD 40c G2 is properly grounded.

Lightning protection

The HP POD 40c G2 structure and internal components are all bonded together. A common Grounding

Electrode Conductor Connection point is provided. Proper bonding and grounding of the HP POD 40c G2

minimizes the effects of a lightning strike. A surge protection device is provided on the HP POD 40c G2 input

connection to protect the HP POD 40c G2 electrical system from voltage transients. If your site is in an area

that is subject to frequent lightning strikes, the HP POD 40c G2 must be protected in accordance with NFPA

70 (NA) and IEC (EMEA and APJ). HP recommends that you contact a certified lightning protection

consultant.

Power, electrical, and controls 23

Page 24

Capacities

•

•

A licensed electrician must connect the power according to all local and national

HP POD 40c G2 capacity limitations

The capacity limitations for the HP POD 40c G2 are separated into two categories: electrical power and

mechanical cooling capacities. Both of these categories are interdependent and must be considered in

conjunction with the overall customer requirements.

Electrical and mechanical cooling capacities

Feature Specification

Critical IT electrical

connections

Critical IT power

capacity

Mechanical cooling

electrical connections

Mechanical cooling

capacity

2 x 800A feeders at 415Y/240 V, 3-phase, 4-wire,

with equipment ground conductors

10.2 x 10.2 cm (4 x 4 in) conduit fittings per feeder

provided

2N Redundant—576 kW

Not applicable

Power for the cooling system fans comes from house

power.

N+1 Redundant—400 kW

Non-redundant—600 kW

Power feeders

IMPORTANT:

The HP POD 40c G2 has eight power feeder couplings that provide the entrance for power to the POD. The

power feeders route into the top of each electrical panel on the end of the HP POD 40c G2.

electrical codes, and must comply with manufacturer specifications.

Power, electrical, and controls 24

Page 25

Top view shown

requirements when opening or working inside areas of the HP POD 40c G2 that are marked as

The top of each electrical panel has four 10.16 cm (4 in) welded couplings where the power feeders are

connected.

Power feeders are sized in accordance with NEC and IEC regulations.

Electrical panels

WARNING: To avoid the risk of personal injury or loss of life, all personnel must comply with PPE

For the external electrical power component locations, see "Electrical power component identification (on

page 11)."

Main breaker locations

hazardous voltage, per NFPA 70E in accordance with NEC (NA) and IEC (EMEA and APJ).

WARNING: To avoid the risk of personal injury or loss of life, all personnel must comply with

electrical warning labels when operating and maintaining the electrical panels and systems of the

HP POD 40c G2.

Power, electrical, and controls 25

Page 26

Front view shown

Arc flash safety

The customer must complete an arc flash assessment of the HP POD 40c G2 and the associated electrical

supply system for operation, maintenance, and so on.

Power distribution: Electrical busway system

The rack power distribution system for the HP POD 40c G2 is protected by electrical circuit breakers located

on the end of the HP POD 40c G2.

End view shown

Feature Specification

Number of busways

8

Power, electrical, and controls 26

Page 27

Feature Specification

•

•

•

•

•

•

Frequency

Amps (per busway)

Voltage (per busway)

Grounding

Busway conductors

Panel schedules

The panel schedule for each electrical panel is permanently affixed to the inside cabinet door of each

electrical panel.

60 Hz

200 A

415 V

Copper

3-phase + neutral + equipment ground

Wire color code

IMPORTANT: UL-approved colored tape over another color of wire is only acceptable on wire

120 V wiring system—Power required for the transformer in the control cabinets

Wire color Description

Black

White

Green or green and

yellow

415 V wiring system—Power required for the electrical busway feeders

Wire color Description

Brown and violet

Orange and violet

Yellow and violet

White and violet

Green or green and

yellow

sizes #2 and larger.

Single-phase current carrying conductor

Neutral

Equipment grounding conductor

Bonding conductor

Earth ground

A Phase/L1

B Phase/L2

C Phase/L3

Neutral

Equipment grounding conductor

Bonding conductor

Earth ground

Power, electrical, and controls 27

Page 28

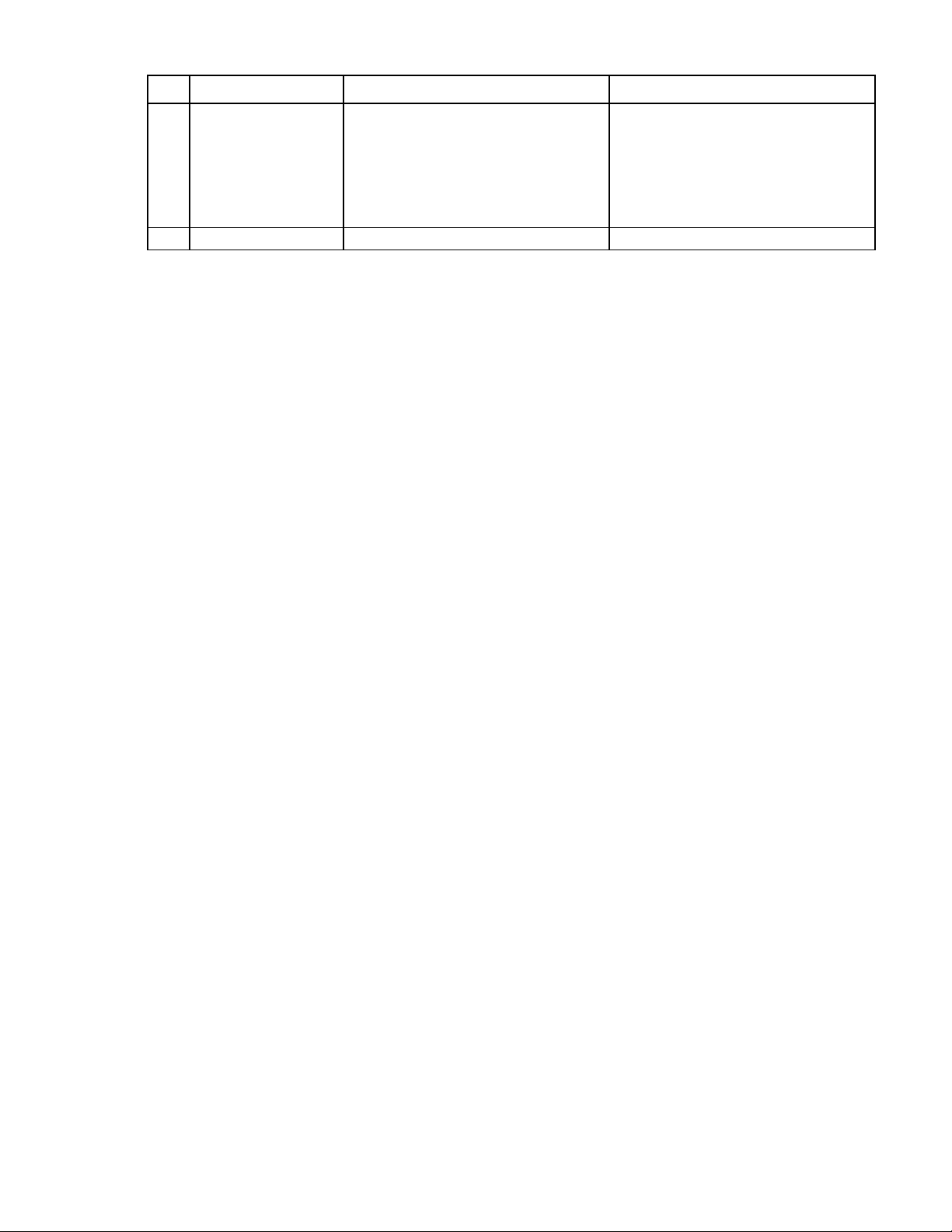

Control cabinet power components

Item Component Description

1

2

3

4

5

6

VESDA power supply and battery

backup

Customer connection box Controls and organizes information monitored by the HP POD

ECS modules and relays Relays for the ECS control, ECS communications, I/O

EPO controller board and house

panel fuses

Dual power supplies with battery

backup

Battery backup power supply Provides 24 V DC power to the PLC and ECS systems

Electrical busways

The electrical busway is a modular, overhead electrical distribution system that supplies power to the HP POD

40c G2 IT loads. The HP POD 40c G2 includes eight busways, and each busway can support 200 A.

Provides power to the VESDA as well as backup power during a

power failure

40c G2 security components

connections and terminal block connections

Connections for the EPO system and fuses for other house panel

components

Provides 24 V DC power to the PLC and ECS systems

Power, electrical, and controls 28

Page 29

Top view shown

The HP POD 40c G2 electrical busways can be configured for non-redundant power or redundant power.

The HP POD 40c G2 can be installed as a single source 1N load by providing all required feeders from one

common power source and from common switchboards and transformers. A 2N redundancy installation is

configured by feeding the parallel power paths from independent power sources, switchboards, and

transformers.

• Non-redundant power installation (1N load)—All eight busways are powered from the same power

feed.

Power, electrical, and controls 29

Page 30

• Redundant power installation (2N load)—Four busways are powered from one power feed, and the

remaining four busways are powered from a different power feed.

Drop boxes

The internal electrical busways provide a location to connect each of the drop boxes, which then power the

PDUs. Stagger the drop boxes on the electrical busways by connecting one drop box to busway #1 and

connecting the next drop box to busway #2. A staggered configuration enables load balancing with the rack

equipment and is necessary to ensure redundancy.

Side view shown

Disabling power

• To disable power to a single PDU, open the drop box breaker that powers the PDU, and then disconnect

the PDU from the drop box.

• To disable power to a single rack, open the drop box breakers that power each of the PDUs installed

in that rack.

• To disable power to a single busway, open the appropriate breaker for that busway on the

corresponding electrical busway panel on the HP POD 40c G2 exterior.

Power, electrical, and controls 30

Page 31

• To disable power to all racks, open the breaker for each busway on the corresponding electrical panel

on the HP POD 40c G2 exterior.

Power configurations

IMPORTANT: Different PDUs can alter the average power capacity per rack.

Configuration Number of 3-phase

PDUs per HP POD

40c G2

Non-redundant

Redundant

*The HP POD 40c G2 is mechanically cooling limited to N=600 kW / N+1=400 kW

40 24 30 600 kW*

40 24 20 400 kW*

Rack power

Power is provided to each rack by PDUs and drop boxes. The PDUs are powered by the drop boxes attached

to each electrical busway. For more information about electrical busway drop boxes, see the HP

Performance Optimized Datacenter 40c G2 Maintenance and Service Guide.

Feature Specification

Rack type

Max number of racks

Max U space per rack

Max U space per HP POD 40c G2

Server capacity

Average capacity per rack

Peak capacity per rack

Voltage to rack

Rack configuration

Total number of PDUs

Max power per PDU

Max load (chilled POD cooling mode)*

Airflow per rack (chilled POD cooling

mode)

*

Dependent on configuration

Number of drop

boxes per HP POD

Average power

capacity per rack

40c G2

HP POD 40c G2 rack

20

50U

1,000U

600 kW power capacity

30 kW

69 kW

240 V

Redundant/non-redundant

capabilities

40 (two per rack)

30 A = 17 kW; 60 A = 34 kW

600 kW

2,000 CFM average

Total HP POD 40c

G2 power capacity

HP POD 40c G2 lighting

The HP POD 40c G2 includes eight LED lights. Four lights are located in the cold aisle and four lights are

located in the hot aisle.

A light switch is located at every personnel door. For more information on light switch locations, see "Life

safety component identification (on page 9)."

Power, electrical, and controls 31

Page 32

All emergency lights are tied to the battery backup power, keeping the interior of the HP POD 40c G2

illuminated during a power outage or emergency.

For more information about the LED lights, see the HP Performance Optimized Datacenter 40c G2

Maintenance and Service Guide.

Power, electrical, and controls 32

Page 33

Environmental control system

Environmental control system overview

The ECS developed for the HP water-cooled POD is a stand-alone control system that requires no external

connections with an external site system, BMS, public or private Internet sites, cloud, or wireless system to

properly control the POD operation.

The ECS includes Modbus TCP/IP connections through which a variety of data can be retrieved. These

capabilities enable you to connect, at your expense, with the stand-alone ECS system to monitor the

operating parameters of the POD. It is your responsibility (or your representative's or agent's responsibility)

to integrate this communication capability into any existing BMS or monitoring system.

CAUTION: To ensure that alarm conditions can be identified and resolved, HP recommends that

you remotely monitor all alarm conditions. Failure to monitor the alarm conditions can cause

delays in appropriate action during an alarm condition.

Using the ECS

HP recommends connecting the HP POD 40c G2 to your facility BMS and establishing communication

through the Ethernet cable connected to the external communications box. For more information, see

"Configuring the ECS (on page 37)."

The HP POD 40c G2 ECS is a Windows-based system with the following features:

• Intel Core Duo processor

• 15-inch touchscreen

• 512 MB RAM

• 80 GB hard drive

• 24 V DC power supply

• One serial port

• Four USB ports

• 1x10/100 BASE-T and 1x10/100/1000 BASE-T Ethernet connectors

The standard ECS protocol, Modbus TCP/IP, is a data communication protocol for building automation and

control networks. Connecting across different protocols might require additional engineering labor and

coordination between your in-house control manufacturer and HP. It is your responsibility to make the

connection between the HP POD 40c G2 and a BMS system.

The ECS provides the following:

• A supported communication interface that can monitor and control certain HP POD 40c G2

components remotely

• Immediate notification of all supported alarm messages

Environmental control system 33

Page 34

By connecting your HP POD 40c G2 to a BMS system, you can monitor the various parameters and alarms.

For more information, see "Navigating the ECS interface (on page 41)." The complete list of parameters and

alarms that can be monitored will be discussed with your facilities personnel.

IMPORTANT: If your site does not have a BMS, HP POD 40c G2 ECS data can be sent to and

viewed from a set IP address. Communication occurs through an Ethernet cable that is connected

to the demarcation box (on page 63).

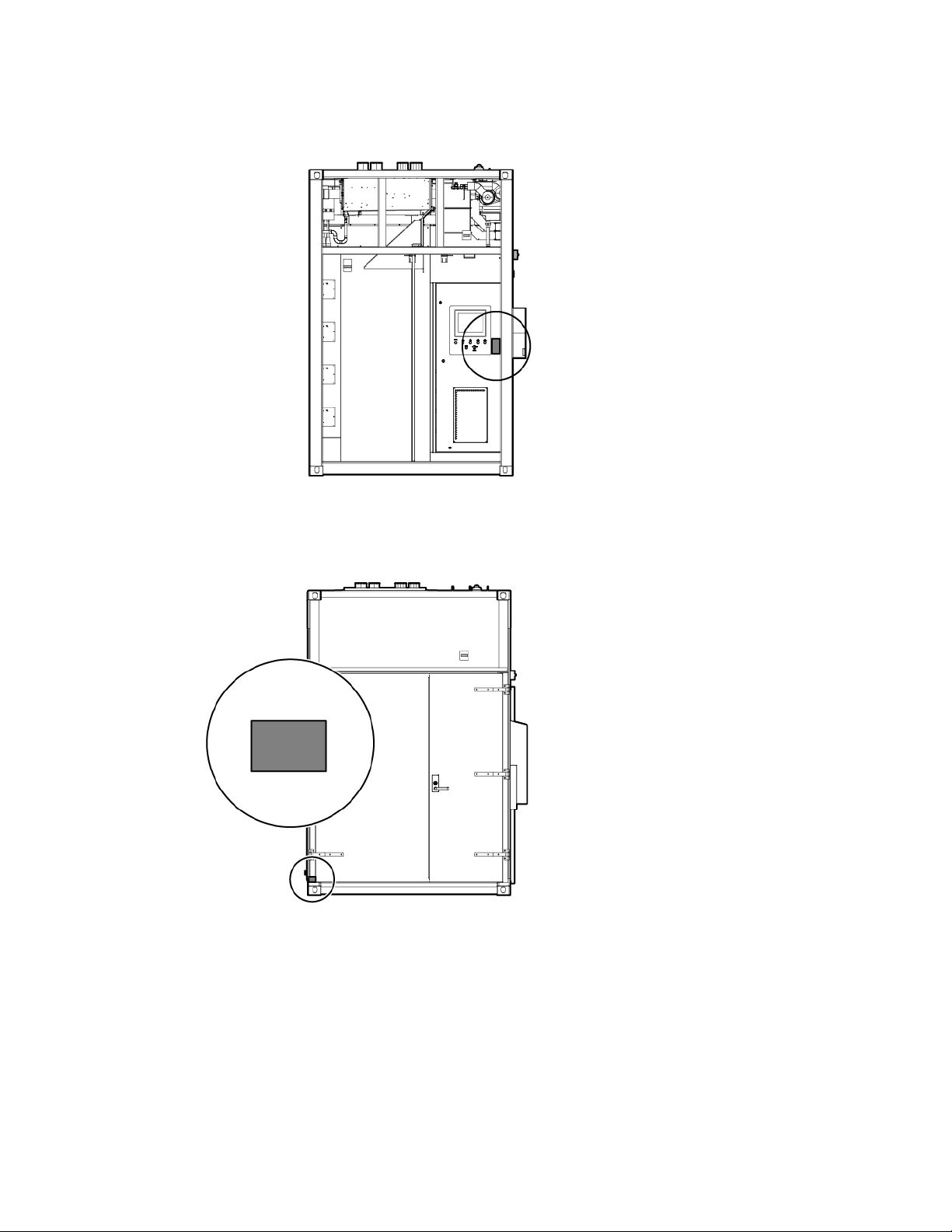

Satellite control boxes

The satellite control boxes facilitate communication from the ECS to the cooling system fans. Each satellite

control box controls the fans in the zone that corresponds with its location.

The HP POD 40c G2 has six satellite control boxes, one box per cooling zone.

Top view shown

Sensors

The HP POD 40c G2 has several temperature and pressure sensors that monitor the environmental factors

and communicate data back to the ECS.

• The values from the temperature sensors are calculated together to determine an average temperature

• The pressure sensors measure the differential pressure between the hot aisle and the cold aisle.

Cold aisle sensors

for each aisle of the HP POD 40c G2.

Environmental control system 34

Page 35

Top view shown

•

•

•

•

•

•

•

•

Item Sensor Quantity Description

1

Differential pressure sensor

probes

12

Monitors the hot and cold aisle differential

pressure and the air filter differential pressure

in various locations throughout the HP POD

40c G2

Reports data to the ECS

2

Temperature sensors 6

Monitor the temperature in various locations

throughout the cold aisle of the HP POD 40c

G2

Reports data to the ECS

3

Humidity sensors 2

Monitors humidity for the cold aisle

Reports data to the ECS

4

Humidistat 1

Monitors humidity for the cold aisle

Reports data to the humidifier control

For more information, see "Humidifier (on page

65)."

Hot aisle sensors

Six temperature sensor probes are located in the hot aisle of the HP POD 40c G2. These temperature sensors

monitor the temperature in various locations throughout the hot aisle and report data to the ECS.

Top view shown

Environmental control system 35

Page 36

Heat exchanger temperature sensors

There are two contact temperature sensors per heat exchanger. One temperature sensor is located on the

inlet supply piping and one temperature sensor is located on the outlet return piping. These sensors measure

water temperature and report data to the ECS.

Top view shown

Facility connections to ECS

You can connect your facility to the ECS using the RJ45 located in the demarcation box (on page 63) or

cables that are hard-wired through the two 5.08 cm (2 in) portals on the roof of the utility end of the HP POD

Connecting to the ECS

40c G2. The system uses Modbus TCP/IP for communication.

To connect the network to the ECS control panel, route an Ethernet cable to the appropriate RJ45 connector

inside the HP POD 40c G2 demarcation box (on page 63).

End view shown

Environmental control system 36

Page 37

Managing the ECS from the HP POD 40c G2

The ECS interface is viewed directly from the ECS screen on the control cabinet door in the cold aisle. For

more information, see "ECS touchscreen and EPO indicators (on page 17)."

To access the ECS using a host computer, connect an Ethernet cable between the host computer and the

designated ECS jack on the back of the door inside of the control cabinet.

Configuring the ECS

1. Connect a host computer to the ECS. For more information, see "Managing the ECS from the HP POD

40c G2 (on page 37)."

2. Configure your computer network groups:

a. Select Start>Control Panel>Network Connections.

Environmental control system 37

Page 38

b.

Double-click Local Area Connection.

c. Select Internet Protocol (TCP/IP).

d. Click Properties.

e. Select Use the following IP address.

f. Enter the new IP address. Be sure to specify an IP address in the same network group as the ECS

controller. By default, the ECS controller uses 192.168.20.1. The IP address for your computer can

include any number in the group from 2 to 254.

Environmental control system 38

Page 39

g.

Click OK.

3. Click OK to save changes and close the TCP/IP Properties screen.

4. Click OK to close the Local Area Connections Properties screen.

Logging in remotely to the ECS

Before you can log in remotely, you must do the following:

• Add the PLC to a network

• Obtain a username and password

• Obtain the static IP address of the PLC. For more information, see "Locating the ECS IP addresses (on

page 40)."

Use the remote desktop application to log in to the ECS remotely:

1. On the remote computer, select Start> All Programs> Accessories> Remote Desktop Connection.

The Remote Desktop window appears.

2. In the Computer field, enter the IP address for the PLC.

3. In the User name field, enter the user name.

IMPORTANT: When logging in to the Remote Desktop, the default user name is

Administrator and the default password is 1.

Environmental control system 39

Page 40

4.

Click Connect.

Locating the ECS IP addresses

IMPORTANT: The ECS has three NIC addresses: 10.10.10.1, 10.10.10.2, and an IP address

that is set up by the customer for external communication.

The PLC must be connected to locate the IP address for each NIC. For more information, see "Managing the

ECS from the HP POD 40c G2 (on page 37)."

To locate the ECS IP address:

1. Select Start>Run.

2. Enter ipconfig.

The IP address appears.

-or-

1. Select Start>Network and Sharing Center.

2. Right-click Local Area Network.

3. Click the Support tab.

The IP address appears.

Environmental control system 40

Page 41

Password protection

The ECS has two levels of security:

• Customer

• Service

The following screens are available using the customer-level password:

• Overview screen (on page 43)

• Status overview screen (on page 45)

• Basic System Configuration screen (on page 45)

The following screens require the service-level password:

CAUTION: Making changes to the ECS in the service-level area can cause the cooling system

components to fail. Only allow authorized, qualified, and trained personnel to change

• Advanced System Configuration screen (on page 49)

configuration settings in the service-level area of the ECS.

• Controller Settings screen (on page 53)

Navigating the ECS interface

The ECS interface provides information for several environmental and security conditions that can be

monitored and configured from the ECS touchscreen.

To navigate to specific screens from the Overview screen (on page 43), select the button for the appropriate

screen.

IMPORTANT: Depending on the ECS configuration, the ECS numbers and screens might vary.

Environmental control system 41

Page 42

•

•

Item Icon name Description

1

2

3

Zone (#) power

supply status

Fan Bank Output

Enter Password

Navigates directly to the Power Details screen for

the specified Zone (#)

Navigates directly to the Fan Control Detail screen

for the specified Zone (#)

Customer-level password—Navigates directly

to the Basic System Configuration screen

Service-level password—Navigates directly to

the Advanced Configuration screen

("Advanced System Configuration screen" on

page 49) or Control Settings screen

("Controller Settings screen" on page 53)

4

5

Reset Alarms Resets existing alarm conditions for the POD

System Status Navigates directly to the Status Overview screen

(on page 45)

Environmental control system 42

Page 43

Overview screen

•

•

Indicates the differential pressure values from

The Overview screen appears upon activation of and displays an overview of the ECS components and the

status of each component.

The Overview screen displays the following information.

Information Description

EPO system status

Indicates the status of the EPO system:

Green—The EPO system is armed and

operational.

Red—The EPO system is activated.

Average voltage, current,

and power drawn on the A

and B busways

Relative humidity

Differential pressure values

Door access indicators

Fan speed

Hot aisle temperature

Indicates electrical usage

Indicates the relative humidity percentages from

each of the humidity sensors

each of the differential pressure zones between

the hot aisle and the cold aisle

Indicates whether an access door is open or

closed

Indicates the fan bank speed percentage

Indicates the average temperature in the hot aisle

Environmental control system 43

Page 44

Information Description

•

•

Average cooling system

performance data

System status

Indicates cooling system sensor averages

Indicates the status of the ECS system:

Green—All components within the ECS

system are operating within normal

parameters and no active ECS alarms exist.

Red—One or more of the ECS components is

indicating an alarm condition.

Manual mode indicators for

fans and dampers

Fire and Manual override

indicators

Indicates that the fans and dampers are running

in manual mode

Indicates whether the fire system is running in

manual or override mode

The ECS component icon colors indicate the component status:

• Green—No alarm conditions exist and the component is operating within normal parameters.

• Red—An alarm condition for that component exists.

• Bold numbering on a yellow background—Indicates that an instrument reading is outside of alarm

limits.

For more information about alarm conditions, see "ECS alarms (on page 54)."

To navigate to another screen, select one of the buttons at the bottom of the screen. Additional buttons

appear when working under the service-level password. The following figure shows the buttons for the

service-level password. For more information, see "Navigating the ECS interface (on page 41)."

Environmental control system 44

Page 45

Status Overview screen

The Status Overview screen displays the status of all system component alarms. For more information about

the alarms, see "ECS alarms (on page 54)."

The ECS component icon colors indicate the component status:

• Green—No alarm conditions exist and the component is operating within normal parameters.

Basic System Configuration screen

• Red—An alarm condition for that component exists.

IMPORTANT: The ECS parameters must be set by qualified service personnel only.

Environmental control system 45

Page 46

The Basic System Configuration screen enables you to configure the basic alarm parameters and the

definition of units. The configured parameters are used to trigger an ECS alarm only and do not configure the

cooling system.

You can select and configure the following parameters:

• Cold aisle temperature alarm parameters

• Hot aisle temperature alarm parameters

• Humidity alarm parameters

• Differential pressure alarm parameters

• Chilled water supply pressure parameters

• Chilled water supply temperature parameters

• Chilled water return temperature parameters

• Type of units displayed

You must select Save to store the parameter changes in the system configuration file. If you do not save your

changes, the old parameters stored in the configuration file reload when the system starts.

Configuring the cold aisle temperature alarm parameters

The current temperature parameters appear on the related buttons.

Environmental control system 46

Page 47

To configure the cold aisle low temperature alarm parameters:

1. Select Cold Aisle Low Alarm Temperature.

A keypad appears.

2. Enter a temperature alarm parameter.

3. Select Save to store the new parameters in the system configuration file.

To configure the cold aisle high temperature alarm parameters:

1. Select Cold Aisle High Alarm Temperature.

A keypad appears.

2. Enter a temperature alarm parameter.

3. Select Save to store the new parameters in the system configuration file.

Configuring the hot aisle temperature alarm parameters

The current temperature parameters appear on the related buttons.

To configure the hot aisle low temperature alarm parameters:

1. Select Hot Aisle Low Alarm Temperature.

A keypad appears.

2. Enter a temperature alarm parameter.

3. Select Save to store the new parameters in the system configuration file.

To configure the hot aisle high temperature alarm parameters:

1. Select Hot Aisle High Alarm Temperature.

A keypad appears.

2. Enter a temperature alarm parameter.

3. Select Save to store the new parameters in the system configuration file.

Configuring the humidity alarm parameters

The current relative humidity parameters appear on the related buttons.

To configure the low humidity parameters:

1. Select the Humidity Low Alarm.

A keypad appears.

2. Enter a humidity alarm parameter.

3. Select Save to store the new parameters in the system configuration file.

To configure the high humidity parameters:

1. Select the Humidity High Alarm.

A keypad appears.

2. Enter a humidity alarm parameter.

3. Select Save to store the new parameters in the system configuration file.

Configuring the differential pressure alarm parameters

The current differential pressure parameters appear on the related buttons.

Environmental control system 47

Page 48

To configure the low differential pressure parameters:

1. Select Difference Pressure Low Alarm.

A keypad appears.

2. Enter a differential pressure alarm parameter.

3. Select Save to store the new parameters in the system configuration file.

To configure the high differential pressure parameters:

1. Select Difference Pressure High Alarm.

A keypad appears.

2. Enter a differential pressure alarm parameter.

3. Select Save to store the new parameters in the system configuration file.

Configuring the chilled water supply pressure alarm parameters

The current differential pressure parameters appear on the related buttons.

To configure the chilled water supply pressure low alarm parameters:

1. Select Chilled Water Supply Pressure Low Alarm.

A keypad appears.

2. Enter a differential pressure alarm parameter.

3. Select Save to store the new parameters in the system configuration file.

To configure the chilled water supply pressure high alarm parameters:

1. Select Chilled Water Supply Pressure High Alarm.

A keypad appears.

2. Enter a differential pressure alarm parameter.

3. Select Save to store the new parameters in the system configuration file.

Configuring the chilled water supply pressure alarm parameters

The current chilled water return pressure alarm parameters appear on the related buttons.

To configure the chilled water return pressure low alarm parameters:

1. Select Chilled Water Return Pressure Low Alarm.

A keypad appears.

2. Enter a chilled water return pressure alarm parameter.

3. Select Save to store the new parameters in the system configuration file.

To configure the chilled water return pressure high alarm parameters:

1. Select Chilled Water Return Pressure High Alarm.

A keypad appears.

2. Enter a chilled water return pressure alarm parameter.

3. Select Save to store the new parameters in the system configuration file.

Configuring the chilled water supply temperature alarm parameters

The current temperature parameters appear on the related buttons.

Environmental control system 48

Page 49

To configure the chilled water supply low temperature alarm parameters:

1. Select Chilled Water Supply Low Alarm Temperature.

A keypad appears.

2. Enter a temperature alarm parameter.

3. Select Save to store the new parameters in the system configuration file.

To configure the chilled water supply high temperature alarm parameters:

1. Select Chilled Water Supply High Alarm Temperature.

A keypad appears.

2. Enter a temperature alarm parameter.

3. Select Save to store the new parameters in the system configuration file.

Configuring the chilled water return temperature alarm parameters

The current temperature parameters appear on the related buttons.

To configure the chilled water return low temperature alarm parameters:

1. Select the Chilled Water Return Low Alarm Temperature.

A keypad appears.

2. Enter a temperature alarm parameter.

3. Select Save to store the new parameters in the system configuration file.

To configure the chilled water return high temperature alarm parameters:

1. Select the Chilled Water Return High Alarm Temperature.

A keypad appears.

2. Enter a temperature alarm parameter.

3. Select Save to store the new parameters in the system configuration file.

Setting the dimensions of the ECS

To set the dimensions of the ECS:

1. Select Dimensions.

2. Select the dimensions (metric or imperial) to be displayed throughout the ECS interface.

3. Select Save.

Advanced System Configuration screen

You can only access this screen after you have entered a service-level password.

Environmental control system 49

Page 50

The Advanced System Configuration screen displays the static IP address for each power meter, fan controls,

and other details about the HP POD 40c G2.

Perform the following tasks on this screen:

• Configure the IP address for each power meter

• Control the fans in each zone

• Control the valve

• Configure the HP POD 40c G2 serial number

• Configure the switchboard serial number

• Calibrate the flowmeter

• Calibrate the chilled water and differential pressure sensors

• Enable or disable power measurement

You must select Save to store the parameter changes in the system configuration file. If you do not save your

changes, the old parameters stored in the configuration file reload when the system starts.

CAUTION: Making changes to the ECS in the service-level area can cause the cooling system

components to fail. Only allow authorized, qualified, and trained personnel to change

configuration settings in the service-level area of the ECS.

Environmental control system 50

Page 51

Calibrating the flowmeter

This option enables flow rate calibration based on the value of a calibrated flow meter.

To calibrate the flowmeter:

1. Power down the HP POD 40c G2. For more information, see "Power down procedure (on page 70)."

2. Select Flowmeter Calibration Factor.

A keypad appears

3. Enter the calibration factor.

4. Select OK.

5. Select Save to store the new parameters in the system configuration file.

Calibrating the chilled water pressure sensors

This option is available only when the flow rate is zero and the chilled water pressure on the chilled water

supply and return lines is less than 12.75 psi. (1.5 bar).

To calibrate the chilled water pressure sensors:

1. Power down the POD. For more information, see "Power down procedure (on page 70)."

2. Vent the exterior chilled water vent valves to relieve pressure.

3. Verify that the ECS Overview screen (on page 43) indicates a flow rate of 0.0 lpm (0.0 gpm).

4. Select Calibrate Chilled Water Pressure Sensors.

5. Note the current calibration factor.

6. Enter 0.1 as the new calibration factor.

7. Select OK.

8. Select Calibrate Chilled Water Pressure Sensor when the button reads Available.

9. Enter the original calibration factor that you noted down in step 5.

10. Select Save to exit.

Calibrating the differential pressure sensors

This option is available only when all fans and the IT load are powered off and there is no air flowing inside

the HP POD 40c G2.

To calibrate the chilled water pressure sensors:

1. Power down the POD. For more information, see "Power down procedure (on page 70)."

2. Set the fan speed for each fan control zone to Manual mode and 0% fan speed. For more information,

see "Setting the fan controls for each fan control zone (on page 52)."

3. Open the doors for 5 minutes to equalize the pressure between the hot and cold aisles.

4. Select Calibrate Differential Pressure Sensors.

5. Select Save.

6. Set the fan speeds to Auto mode.

Environmental control system 51

Page 52

Enable/disable power management

The current power management setting appears on the Enable/disable Power Management button. To

enable or disable power management in the ECS:

1. Select Enable/disable Power Management.

2. Select Save to store the new parameters in the system configuration file.

Setting the IP address for each power meter

The current, preset static IP address appears above the Change IP address button. Change the IP address of

a power meter to network multiple meters together or to resolve an IP address conflict.

To configure a power meter IP address: