Page 1

HP Performance Optimized Datacenter 40c G2

Part Number: 695161-001

Maintenance and Service Guide

Abstract

This guide provides maintenance and service guidance for the HP Performance Optimized Datacenter 40c (HP POD 40c G2).

August 2012

Edition: 1

Page 2

© Copyright 2012 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

Page 3

Contents

Illustrated parts catalog ................................................................................................................. 6

Structural component identification .............................................................................................................. 6

Parts and part number identification ................................................................................................... 6

Life safety component identification ............................................................................................................. 7

Power feeders ........................................................................................................................................... 9

Electrical panels ...................................................................................................................................... 10

Cooling system component identification .................................................................................................... 11

HP POD 40c G2 racks ............................................................................................................................. 11

Replaceable spare parts ........................................................................................................................... 12

Removal and replacement procedures ........................................................................................... 15

Safety considerations ............................................................................................................................... 15

Operator safety ............................................................................................................................. 15

Fire detection and suppression .................................................................................................................. 15

Air filter ................................................................................................................................................. 16

Removing the air filter .................................................................................................................... 16

Replacing the air filter .................................................................................................................... 17

Busway drop box .................................................................................................................................... 18

Removing the busway drop box ...................................................................................................... 18

Replacing the busway drop box ...................................................................................................... 19

Differential pressure sensor ....................................................................................................................... 20

Removing the differential pressure sensor .......................................................................................... 21

Replacing the differential pressure sensor ......................................................................................... 21

Door position contact ............................................................................................................................... 22

Removing the door position contact ................................................................................................. 22

Replacing the door position contact ................................................................................................. 22

Drain pan sensor ..................................................................................................................................... 23

Removing the drain pan sensor ....................................................................................................... 23

Replacing the drain pan sensor ....................................................................................................... 24

ECS touchscreen ..................................................................................................................................... 26

Removing the ECS touchscreen ........................................................................................................ 26

Replacing the ECS touchscreen ....................................................................................................... 27

EPO button ............................................................................................................................................. 27

Removing the EPO button ............................................................................................................... 28

Replacing the EPO button ............................................................................................................... 29

EPO LED indicators .................................................................................................................................. 30

Removing the EPO LED indicator ..................................................................................................... 30

Replacing the EPO LED indicator ..................................................................................................... 31

EPO thermister ........................................................................................................................................ 32

Removing the EPO thermister .......................................................................................................... 32

Replacing the EPO thermister .......................................................................................................... 32

External chilled water flow actuator ........................................................................................................... 33

Removing the external chilled water flow actuator .............................................................................. 33

Replacing the external chilled water flow actuator ............................................................................. 35

External chilled water flow valve ............................................................................................................... 35

Removing the external chilled water flow valve .................................................................................. 36

Replacing the external chilled water flow valve .................................................................................. 36

Contents 3

Page 4

External pressure gauge isolation valve ...................................................................................................... 37

Removing the external pressure gauge isolation valve ........................................................................ 37

Replacing the external pressure gauge isolation valve ........................................................................ 37

Fan ....................................................................................................................................................... 38

Removing the fan ........................................................................................................................... 38

Replacing the fan .......................................................................................................................... 39

Fan bank ................................................................................................................................................ 40

Removing the fan bank ................................................................................................................... 40

Replacing the fan bank .................................................................................................................. 41

Fire strobe light ....................................................................................................................................... 42

Removing the fire strobe light .......................................................................................................... 42

Replacing the fire strobe light .......................................................................................................... 43

Humidifier .............................................................................................................................................. 43

Removing the humidifier ................................................................................................................. 44

Replacing the humidifier ................................................................................................................. 46

Humidistat .............................................................................................................................................. 47

Removing the humidistat ................................................................................................................. 47

Replacing the humidistat ................................................................................................................. 48

Humidity sensor ...................................................................................................................................... 50

Removing the humidity sensor ......................................................................................................... 50

Replacing the humidity sensor ......................................................................................................... 52

LED light ................................................................................................................................................. 53

Removing the LED light ................................................................................................................... 53

Replacing the LED light ................................................................................................................... 54

Temperature sensor (cold aisle) ................................................................................................................. 55

Removing the cold aisle temperature sensor ...................................................................................... 55

Replacing the cold aisle temperature sensor ...................................................................................... 56

Temperature sensor (hot aisle) ................................................................................................................... 57

Removing the hot aisle temperature sensor ........................................................................................ 58

Replacing the hot aisle temperature sensor ........................................................................................ 59

VESDA filter ............................................................................................................................................ 60

Removing the VESDA filter .............................................................................................................. 61

Replacing the VESDA filter .............................................................................................................. 61

Periodic maintenance .................................................................................................................. 63

Periodic maintenance overview ................................................................................................................. 63

Cooling system maintenance schedule ....................................................................................................... 63

Leak detection maintenance ............................................................................................................ 64

Drains .................................................................................................................................................... 65

ECS ....................................................................................................................................................... 65

Electrical ................................................................................................................................................ 65

Fire alarm and suppression system ............................................................................................................ 67

Generator (if applicable) .......................................................................................................................... 67

HP POD 40c G2 structure ........................................................................................................................ 68

Life safety ............................................................................................................................................... 68

Security .................................................................................................................................................. 68

Switchgear ............................................................................................................................................. 69

Third-party components ............................................................................................................................ 69

UPS ....................................................................................................................................................... 69

Specifications ............................................................................................................................. 70

General HP POD 40c G2 specifications ..................................................................................................... 70

Electrical specifications ............................................................................................................................ 70

Water specifications ................................................................................................................................ 71

Contents 4

Page 5

Rack specifications .................................................................................................................................. 71

Thermal and air flow performance ............................................................................................................. 71

Environmental specifications ..................................................................................................................... 71

Optional features specifications................................................................................................................. 72

Contacting HP ............................................................................................................................ 73

Before you contact HP .............................................................................................................................. 73

HP contact information ................................................................................................................... 73

Regulatory compliance notices ..................................................................................................... 74

HP POD 40c G2 regulatory compliance ..................................................................................................... 74

Safety and NEC compliance ........................................................................................................... 74

Regulatory compliance identification numbers ............................................................................................. 75

Federal Communications Commission notice ............................................................................................... 75

Modifications .......................................................................................................................................... 75

Cables ................................................................................................................................................... 75

Canadian notice (Avis Canadien) .............................................................................................................. 75

Regulatory requirements for EXIT signs ....................................................................................................... 76

Glossary .................................................................................................................................... 77

Documentation feedback ............................................................................................................. 79

Index ......................................................................................................................................... 80

Contents 5

Page 6

Illustrated parts catalog

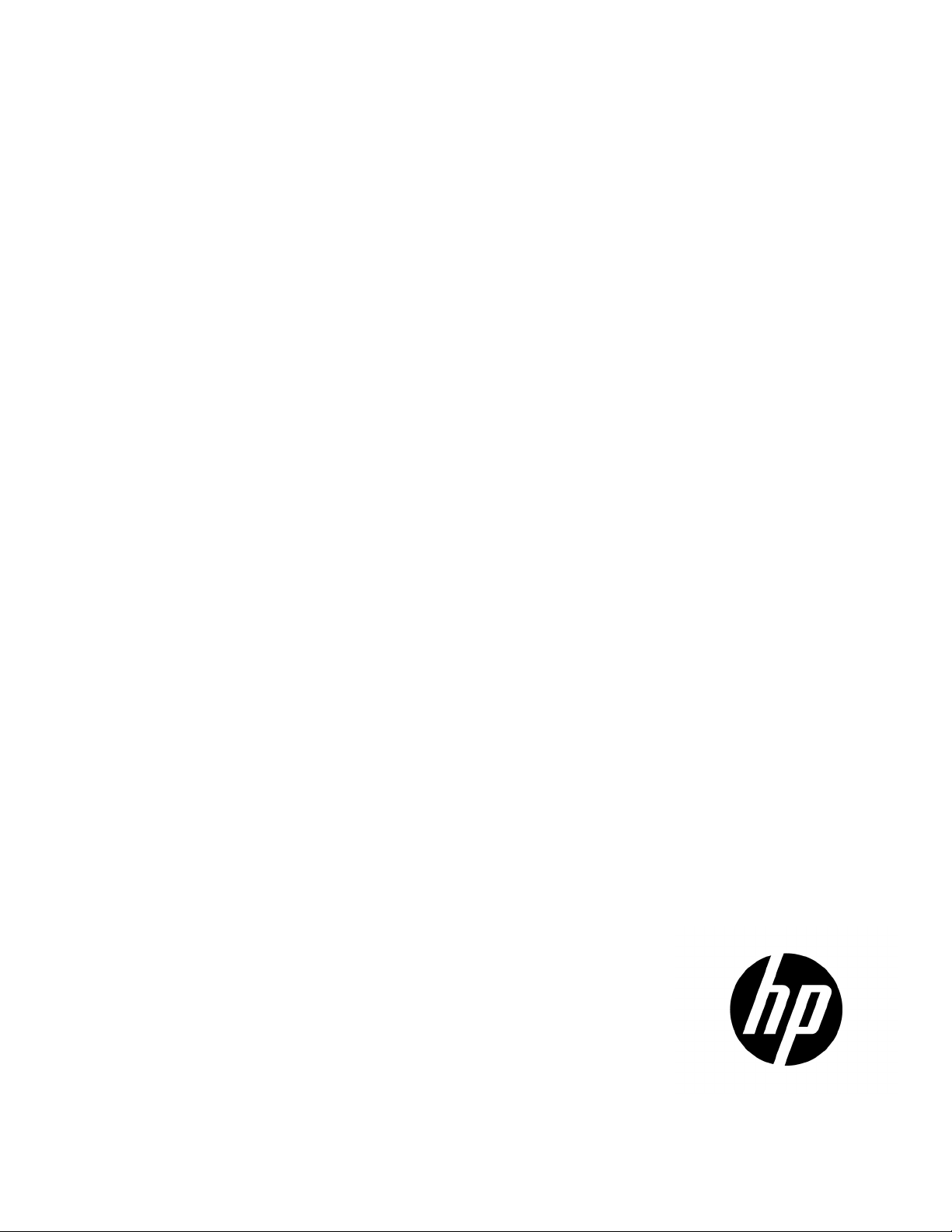

Structural component identification

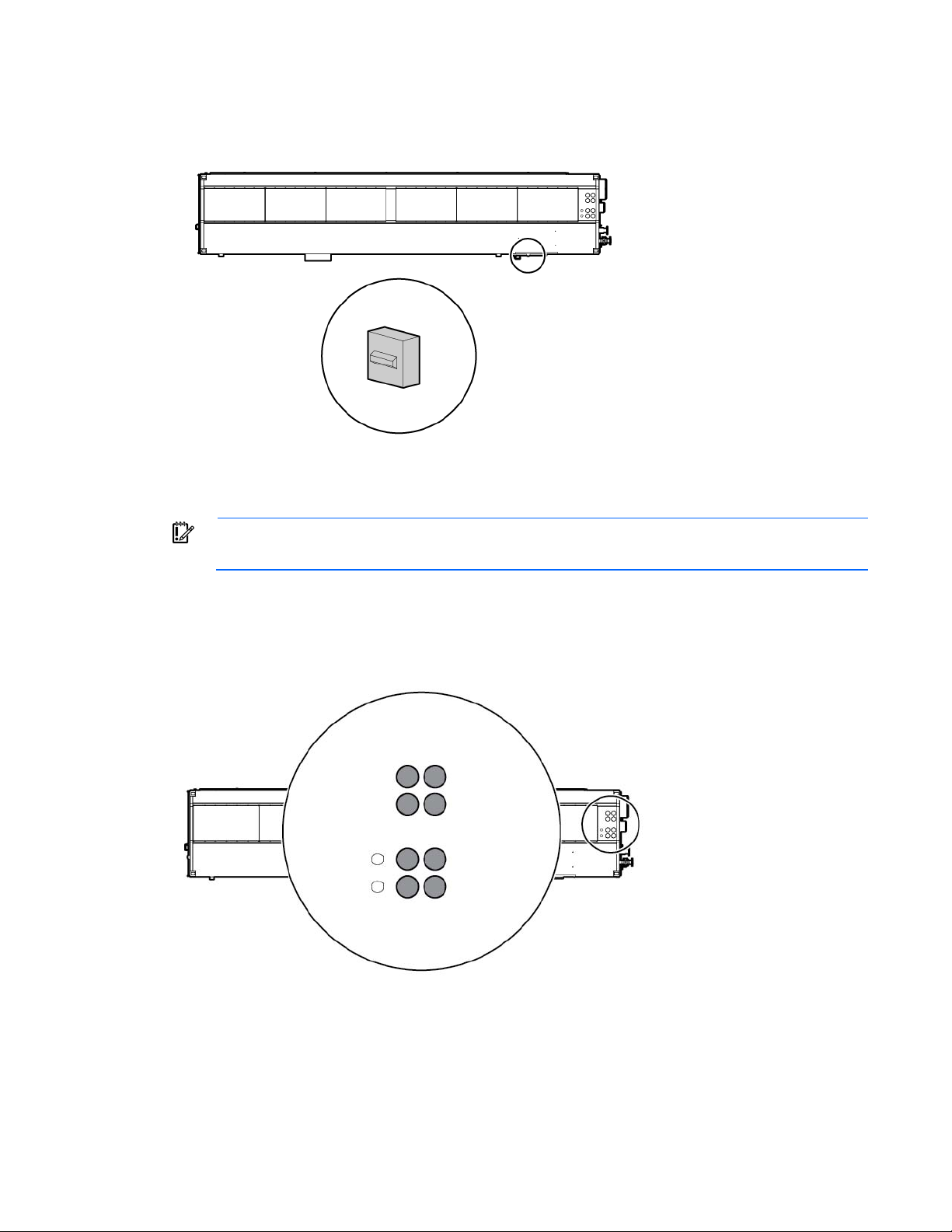

The HP POD 40c G2 documentation frequently refers to the specific components of the HP POD 40c G2 as

shown in the following figure and described in the following table.

Item Component Description

Heat exchanger access hatches Provides access to the overhead heat exchangers

1

Personnel access doors Provides access to the POD

2

Facility chilled water return Facilitates the return of chilled water to the POD

3

Facility chilled water supply Facilitates the supply of chilled water to the POD

4

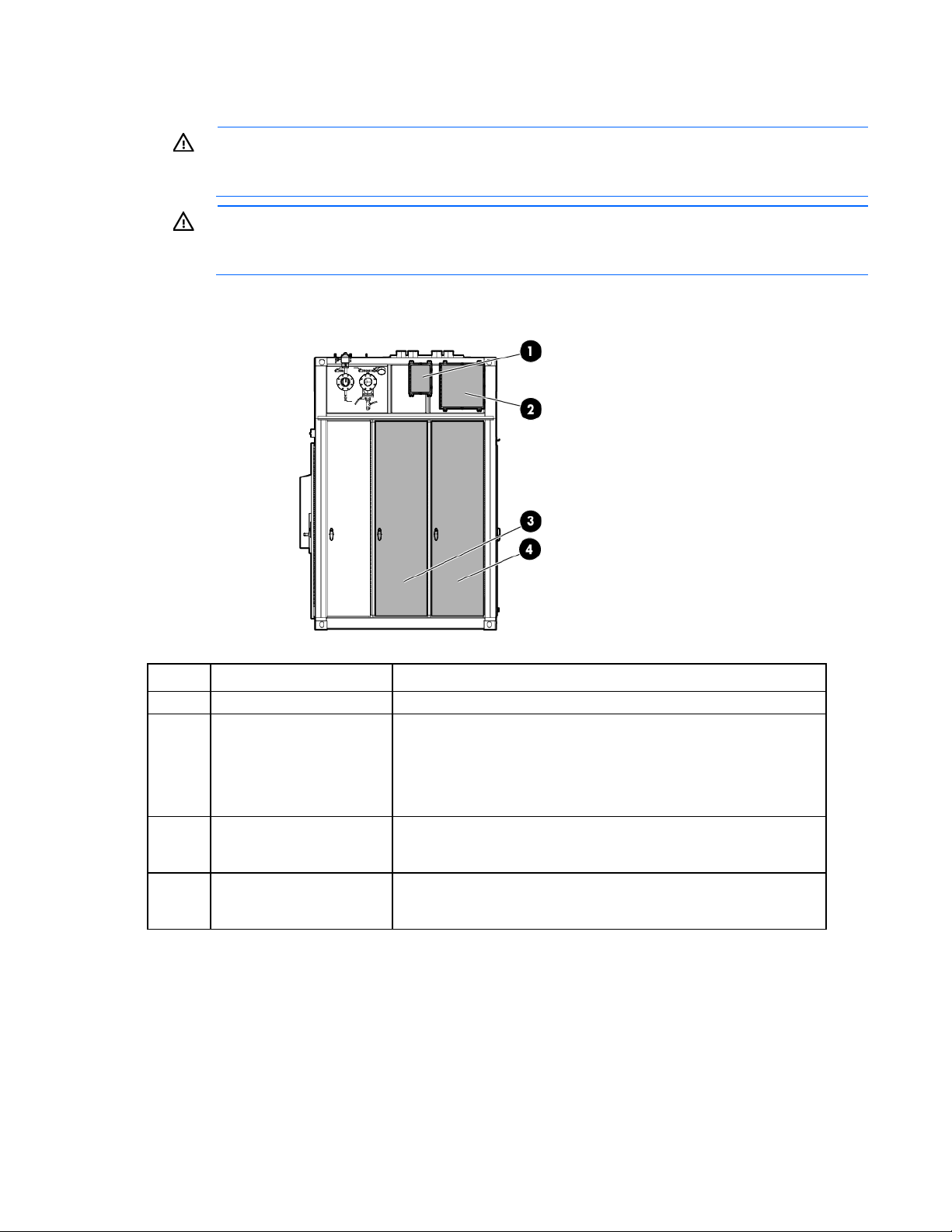

Parts and part number identification

Review the contents of the HP POD 40c G2 to identify the following for each component:

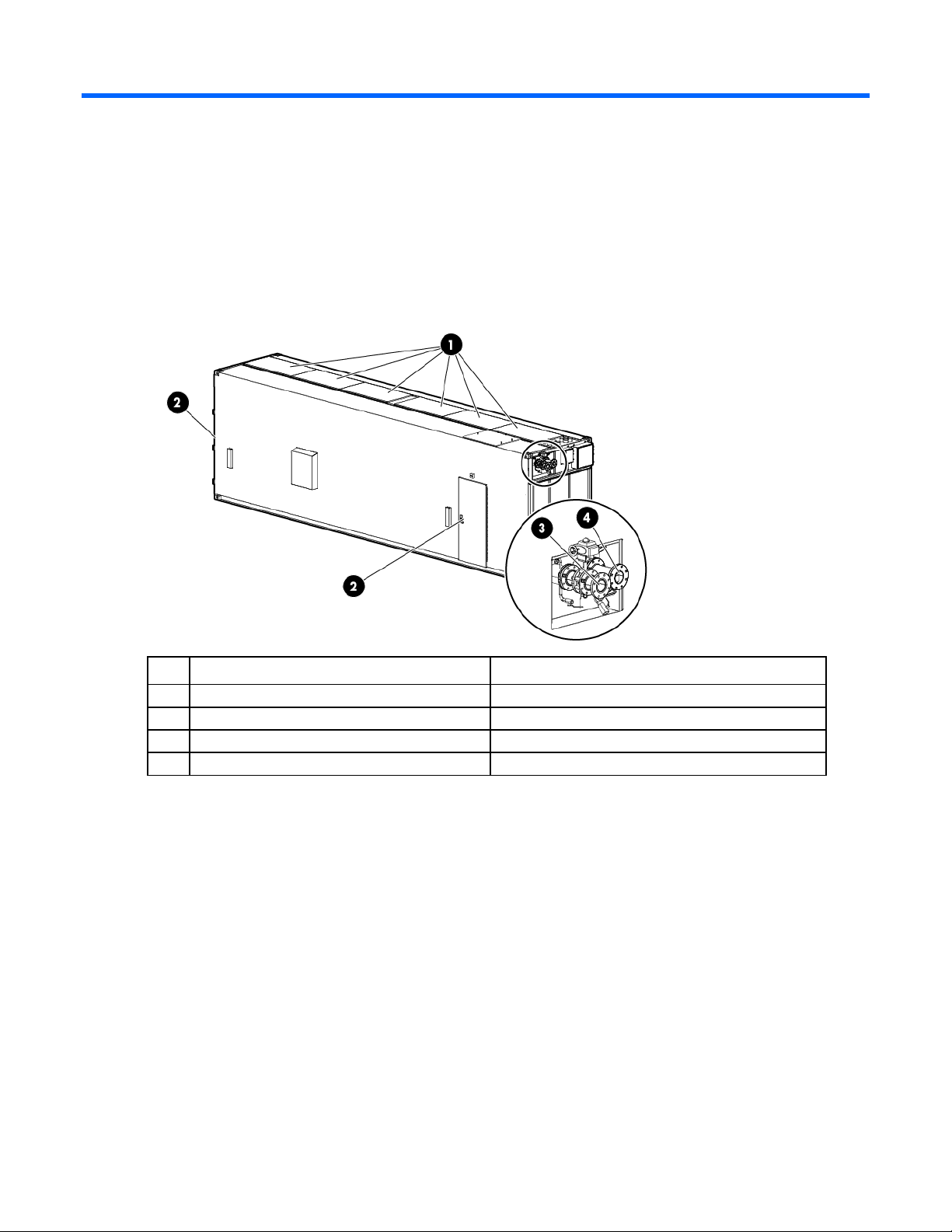

• Model number—The model number is located on the door to the control panel inside the cold aisle of

the HP POD 40c G2, as shown in the following figure.

Illustrated parts catalog 6

Page 7

• Regulatory compliance identification number—This product has been assigned a unique regulatory

model number and is located on the door to the control panel inside the cold aisle of the HP POD 40c

G2, as shown in the following figure.

• CSC Safety Approval placard—Each HP POD 40c G2 has a CSC Safety Approval placard that includes

the model number, serial number, and proof load. The CSC Safety Approval placard is located on the

cargo end of the HP POD 40c G2, as shown in the following figure.

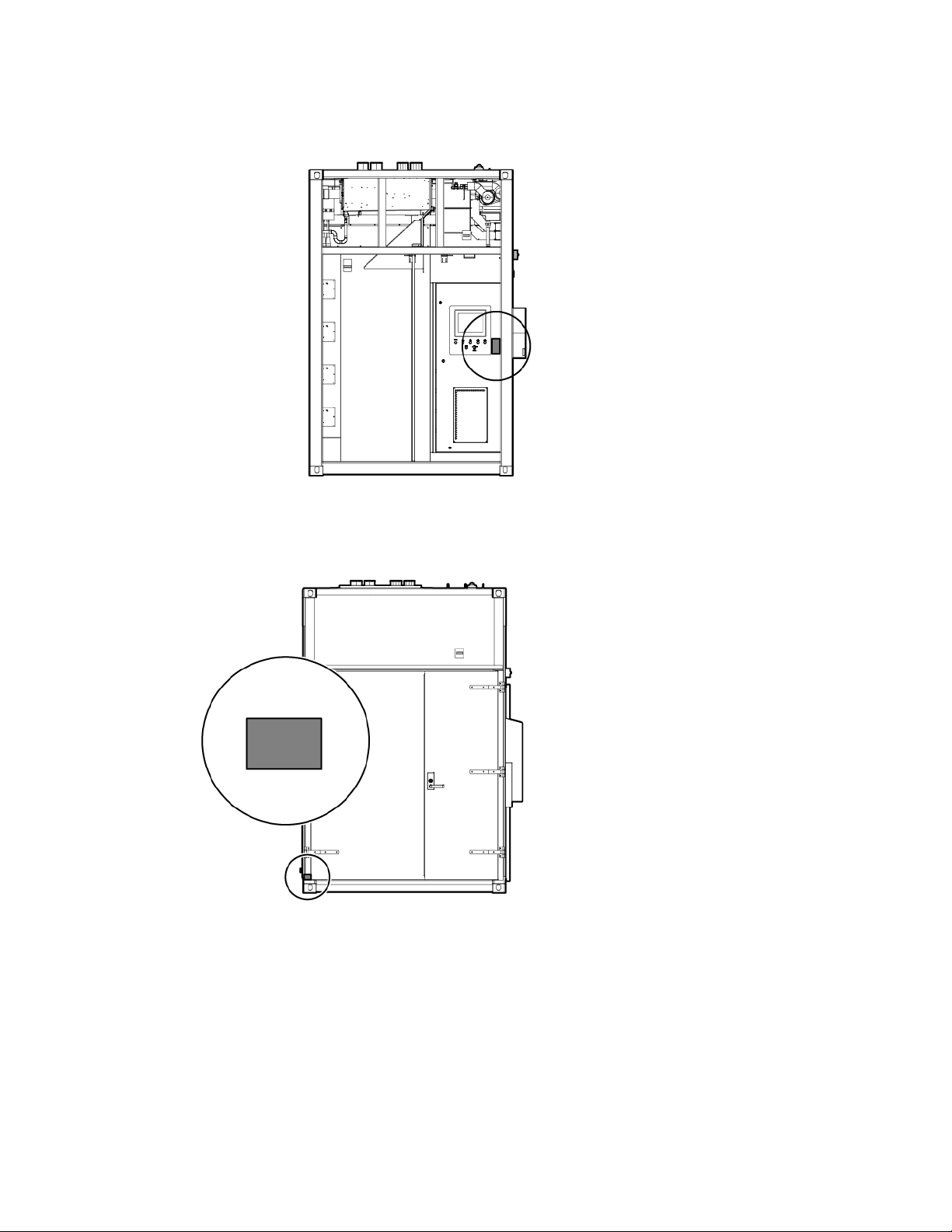

Life safety component identification

Internal life safety components

Illustrated parts catalog 7

Page 8

Top view shown

Item Component Description

1

2

3

4

5

*This is an optional component that might not be included.

Exit sign locations Indicates the location of an exit

Fire strobe light Indicates a fire alarm condition within the HP POD 40c G2

EPO button Disconnects the HP POD 40c G2 from main power feeds

Fire alarm manual pull* Enables manual initiation of the fire system, which includes

activating the interior and exterior fire strobe lights and the

optional fire suppression system

Fire suppression abort button* Aborts the fire suppression system. A fire suppression abort

button is located next to each personnel door.

Exit sign locations

The exit signs within the HP POD 40c G2 contain tritium. For information about the regulatory requirements

regarding the handling, transfer, and disposal of the signs, see "Regulatory requirements for EXIT signs (on

page 76)."

Top view shown

External emergency status indicators

The HP POD 40c G2 has one external fire strobe light that indicates a fire alarm condition.

Illustrated parts catalog 8

Page 9

Top view shown

A licensed electrician must connect the power according to all local and national

Power feeders

IMPORTANT:

The HP POD 40c G2 has eight power feeder couplings that provide the entrance for power to the POD. The

power feeders route into the top of each electrical panel on the end of the HP POD 40c G2.

Top view shown

electrical codes, and must comply with manufacturer specifications.

The top of each electrical panel has four 10.16 cm (4 in) welded couplings where the power feeders are

connected.

Power feeders are sized in accordance with NEC and IEC regulations.

Illustrated parts catalog 9

Page 10

requirements when opening or working inside areas of the HP POD 40c G2 that are marked as

•

•

•

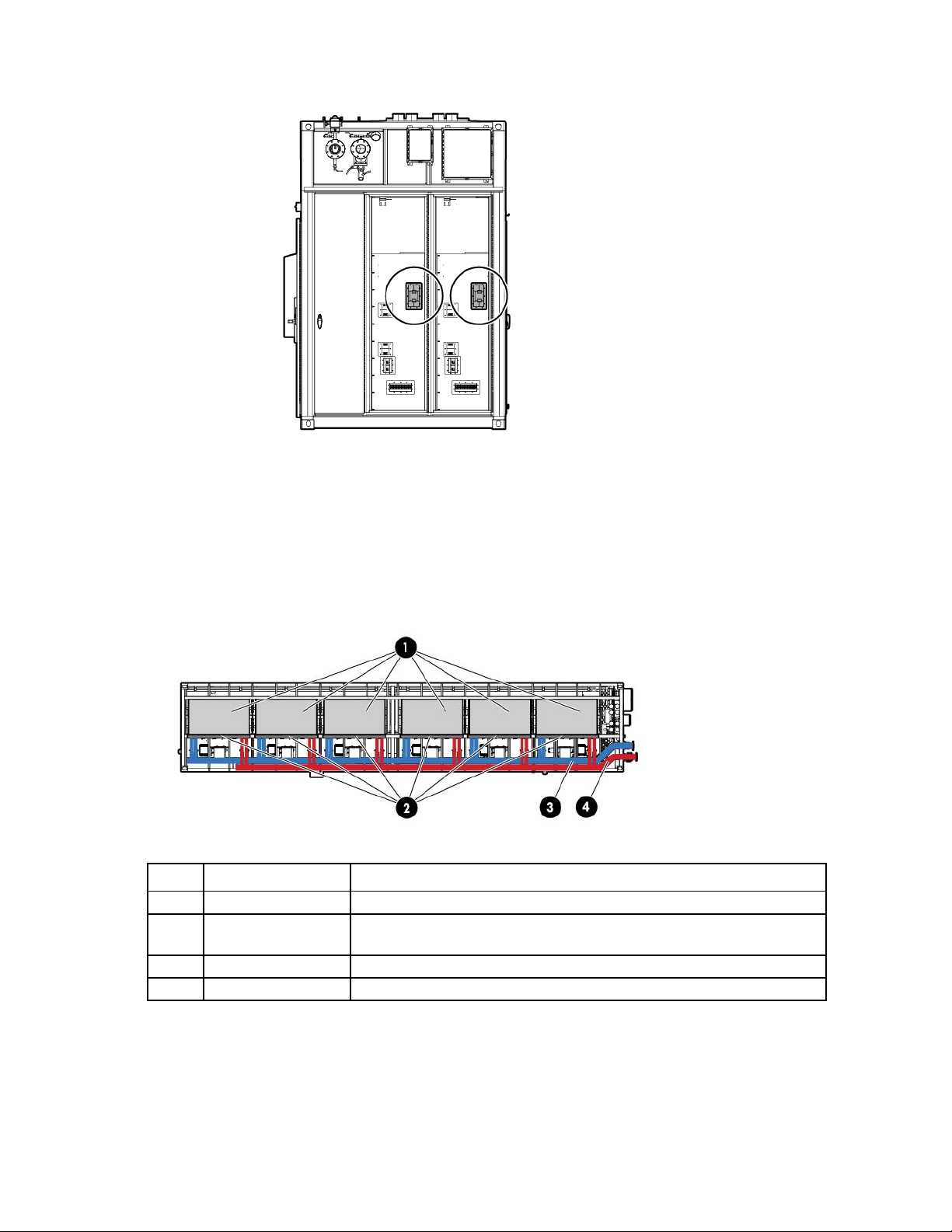

Electrical panels

WARNING: To avoid the risk of personal injury or loss of life, all personnel must comply with PPE

End view shown

hazardous voltage, per NFPA 70E in accordance with NEC (NA) and IEC (EMEA and APJ).

WARNING: To avoid the risk of personal injury or loss of life, all personnel must comply with

electrical warning labels when operating and maintaining the electrical panels and systems of the

HP POD 40c G2.

Item Component Description

1

2

Fire box* Connection location for fire emergency and VESDAnet signals

Demarcation box* Customer communication connection point for the following

components:

ECS

Security

Phone

3

415 Y/240 V 3-phase,

4-wire, 800 A electrical

panel

4

415 Y/240 V 3-phase,

4-wire, 800 A electrical

panel

*The demarcation box and the fire box are communication data points that are provided on the POD by HP. Connecting

these data points is the responsibility of the customer, unless an approved Statement of Work is initiated.

Feed A power for critical IT loads (electrical busways) and house power

Feed B power for critical IT loads (electrical busways) and house power

Main breaker locations

Illustrated parts catalog 10

Page 11

End view shown

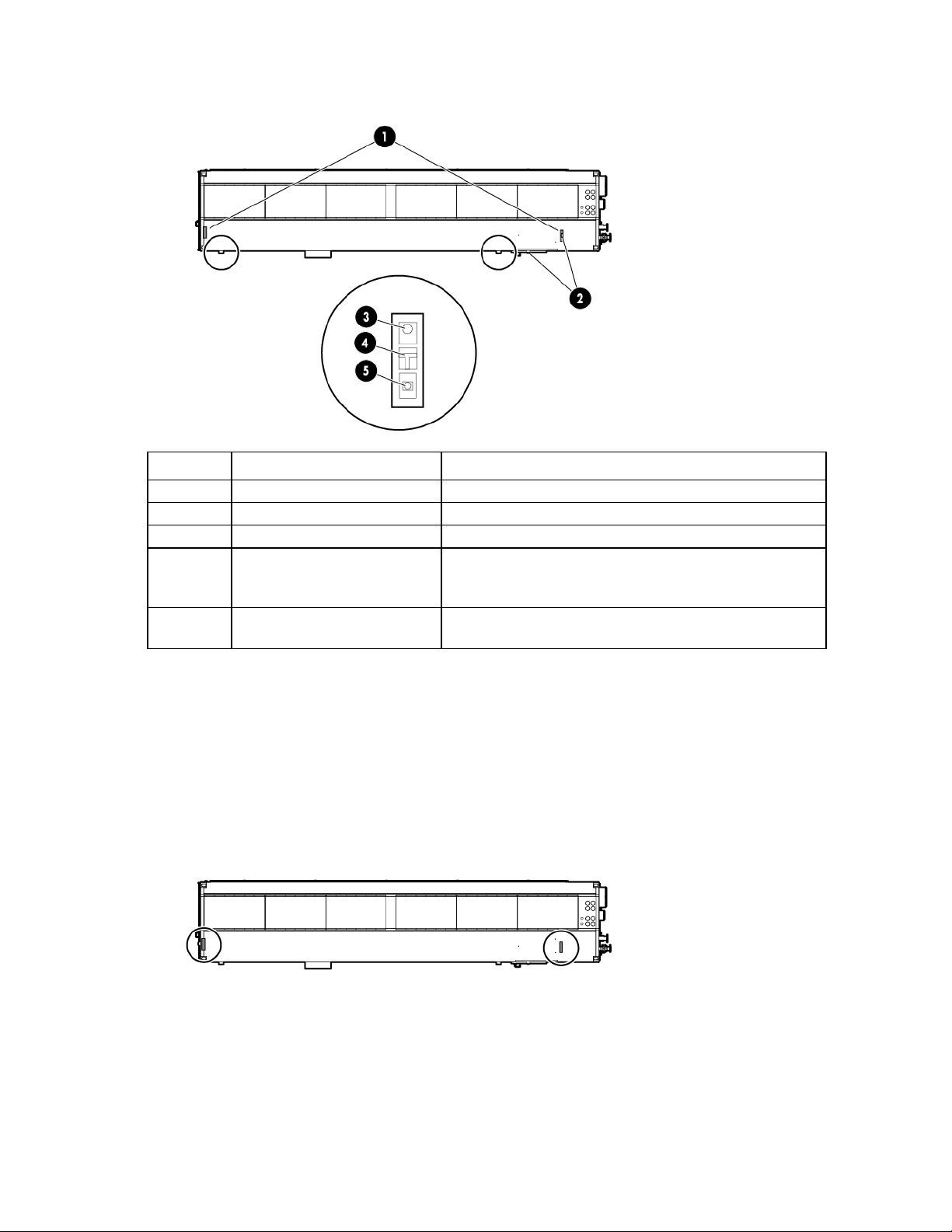

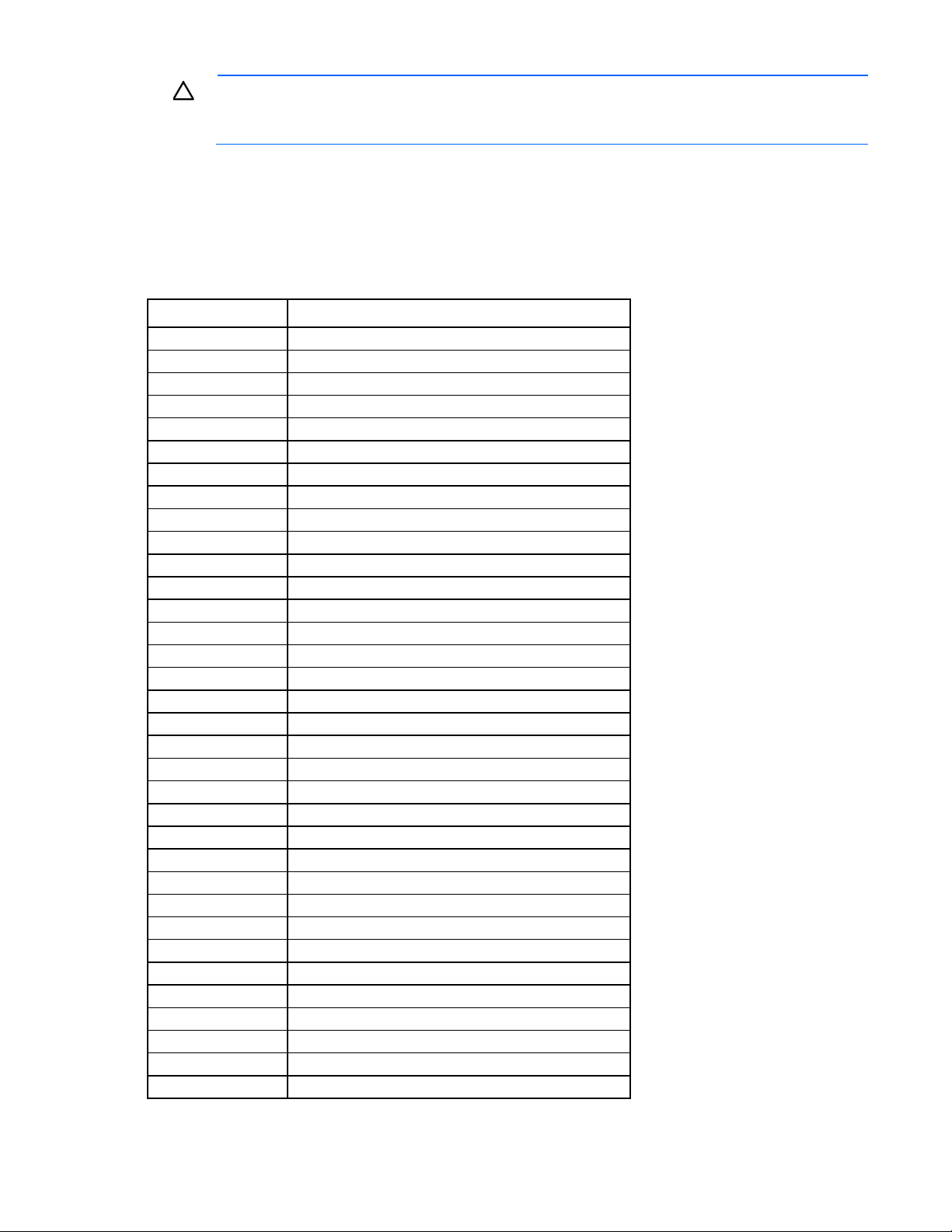

Cooling system component identification

The heat exchanger access hatches are located on top of the POD. The hatches are coated with a durable

finish to prevent corrosion.

Side view shown

Item Component Description

1

2

3

4

Heat exchangers Use facility chilled water to cool the air in the HP POD 40c G2

Heat exchanger fan

banks

Chilled water supply Supplies facility chilled water to cool the HP POD 40c G2

Chilled water return Returns heated chilled water to the facility

Operate at variable speeds to maintain the preprogrammed differential

pressure setpoint and the hot aisle temperature setpoint

HP POD 40c G2 racks

The HP POD 40c G2 contains a total of 20 IT racks.

Illustrated parts catalog 11

Page 12

CAUTION: If any racks contain empty RU space, use the HP POD 40c G2 filler panels to

SPS-TERMINAL SER INTFC RS4222 RS485

maintain the efficiency of the HP POD 40c G2 thermal system. Filler panels are available from HP

in 10-pack quantities (part number AQ682A) and 100-pack quantities (part number AS993A).

For more information about racks and network cabling, see the HP Performance Optimized Datacenter

Networking Guide.

Replaceable spare parts

The spare parts in the following table can be replaced by qualified facilities personnel.

Spare part number Description

660063-001

660064-001

637086-001

637087-001

637088-001

637089-001

637090-001

637091-001

637092-001

637093-001

637094-001

637095-001

637096-001

637097-001

637098-001

637099-001

637100-001

637101-001

637102-001

637103-001

637104-001

637118-001

637119-001

637120-001

637121-001

637122-001

637123-001

637124-001

637129-001

637131-001

637134-001

637135-001

637136-001

637137-001

3-phase, 20A busway drop box; NA POD

3-phase, 60A busway drop box; NA POD

SPS-FUSE BLOCK 600V 3P

SPS-FUSE BLOCK 600V 1P

SPS-CPU TOUCH SCREEN

8 port ETHERNET SWITCH

SPS-TERMINAL DIGITAL OUTPUT 4CH

SPS-TERMINAL END BUS EXT

SPS-TERMINAL BUS TERM ETHERCAT

SPS-TERMINAL COUPLER ETHERCAT

SPS-ANALOG INPUT 4 20mA 4CH

SPS-TERMINAL ANALOG OUTPUT 0-10V 2CH

SPS-TERMINAL BUS END

SPS-TERMINAL PRESSURE DIFF 1CH

SPS-TERMINAL DIGITAL INPUT 4CH

SPS-TERMINAL 100PT INPUT 4CH

SPS-SIREN 24V DC

White LED light

Yellow LED light

Red LED light

SPS-RELAY 4POLE 2NC 240VAC

SPS-SOCKET RELAY LOGIC 4POLE

SPS-SENSOR TEMP POD

SPS-FUSE ATDR TIME DELAY 600VAC 1A

SPS-FUSE ATDR TIME DELAY 600VAC 4A

SPS-FUSE ATDR TIME DELAY 600VAC 10A

SPS-RELAY 4POLE 24V DC 10A

SPS-TSAT 60

SPS-MAGNETIC FLOW METER

NETWORK INTERFACE CARD

SPS-SENSOR TEMP INSERTION

SPS-SENSOR PRESSURE ABS 10 BAR

SPS-SENSOR TEMP ROOM

Illustrated parts catalog 12

Page 13

Spare part number Description

SPS-SENSOR TEMP RH NEMA 4 4 20mA OUT

A licensed electrician must connect the power according to all local and national

SPS-PWR SPLY SNGL ZONE 220VAC VESDA

637138-001

637139-001

637140-001

637141-001

637371-001

637372-001

637373-001

664744-001

664868-001

671748-001

671749-001

671756-001

VS-005 (Mfg PN)

EPO switch cover w/ horn

EPO BUTTON

ELECTRIC VALVE ACTUATOR

BUTTERFLY VALVE

SPS-FAN 235 CFM

Temperature sensor duct

SPS-SENSOR LEAKAGE

SPS-INDICATOR LED 6 24VDC GREEN

SPS-SENSOR PRESSURE GAUGE 160 PSI

SPS-SENSOR FLOW METER GEMU

SPS-HUMIDISTAT GEN M3

Filter, replacement, VESDA, Laser Series

The spare parts in the following table are electrical components that must be replaced by a certified

electrician.

IMPORTANT:

electrical codes, and must comply with manufacturer specifications.

Spare part number Description

637117-001

637126-001

637128-001

637130-001

637132-001

637142-001

637143-001

637144-001

637145-001

637146-001

637496-001

664738-001

664748-001

671746-001

671750-001

671751-001

671752-001

671755-001

671757-001

671759-001

671760-001

671761-001

671762-001

671763-001

SPS-CKT BKR T2 100AF 40AT

SPS-CKT BKR T4 200A 600V 3POLE

SPS-POWER METER PAC 3200

SPS-TRANSFORMER CT PANEL MT

SPS-TVSS

SPS-SHUNT TRIP 800A CKT BRKR

SPS-CKT BREAKER SMD 3P 800A

24V UPS power supply

SPS-PWR SUPPLY REDUNDANT MOD

SPS-PWR SUPPLY 24V 7ah ACCUMULATOR

230V power supply

SPS-TRANSFORMER 2000VA 240x480 120x240

SPS-TRANSFORMER CT 3 PHASE

SPS-HOUSING LED LIGHT FXTR

SPS-LED LIGHT FXTR ASSY

SPS-FUSE TIME DELAY

SPS-CONTACT MAG DOOR

SPS-HUMIDIFIER 230VAC

SPS-CKT BRKR SNGL POLE 15A

SPS-CKT BRKR MINI 5A

SPS-CKT BRKR MINI 20A

SPS-CKT BRKR BRANCH SNGL POLE 10A

SPS-CKT BRKR 3P MAIN LUG 150A

Illustrated parts catalog 13

Page 14

The spare parts in the following table must be replaced by a licensed fire safety contractor.

These parts must be replaced by a licensed fire safety contractor according to all

IMPORTANT:

local and regional fire codes, and in compliance with manufacturer specifications.

Spare part number Description

637133-001

Smoke detector

Illustrated parts catalog 14

Page 15

Removal and replacement procedures

requirements when opening or working inside areas of the HP POD 40c G2 that are marked as

Safety considerations

The HP POD 40c G2 is listed to the UL 69050 standard as an Information Technology Product and Classified

according to the NEC, NFPA-70, 2008.

The HP POD 40c G2 is not suitable for long term personnel occupancy.

The safety information is specific to the people operating and maintaining the components of the HP POD

40c G2.

IMPORTANT: All plumbing to and from the HP POD 40c G2 must be completed by a licensed

plumber.

IMPORTANT: All wiring in and around the HP POD 40c G2 must be completed by a licensed

electrician.

Operator safety

The HP POD 40c G2 provides service access areas for periodic maintenance and service and is only to be

used by owner-authorized personnel specifically trained in the maintenance and service of the HP POD 40c

G2.

The HP POD 40c G2 is not a habitable structure suitable for long term personnel occupancy.

WARNING: To avoid the risk of personal injury or loss of life, all personnel must comply with PPE

The customer is responsible for completing any Environmental Health and Safety (EHS) evaluation of the HP

POD 40c G2 or any attached structural component purchased through HP. The customer must complete an

arc flash assessment of the HP POD 40c G2 and the associated electrical supply system for operation,

maintenance, and so on.

hazardous voltage, per NFPA 70E in accordance with NEC (NA) and IEC (EMEA and APJ).

WARNING: To avoid the risk of personal injury, hearing protection must be worn at all times

when working inside the HP POD 40c G2.

WARNING: To avoid the risk of personal injury or damage to the equipment, do not insert

anything inside the electrical busways except the approved HP busway drop boxes.

Fire detection and suppression

The fire suppression system, supplied as an optional component of the HP POD 40c G2, is a "Manufacturer

Designed" system specifically for this HP product, in compliance with national standards.

Removal and replacement procedures 15

Page 16

The HP standard suppression system includes a Novec 1230 clean agent system. However, if the customer

or local AHJ requires specific modifications or a replacement, HP can assist in these actions at the expense

of the customer.

HP does not certify that the fire suppression system installed in the HP POD 40c G2 meets all local and

jurisdictional requirements. The customer is responsible for the following actions as related to the fire

suppression system:

• Verifying that the POD suppression system meets local codes, including specific local requirements for

initial and periodic inspections.

• Arranging for and receiving all required local permits, including initial commissioning as well as

standard and repair maintenance.

• Arranging for the connection of the agent tanks, refilling of tanks, and all system testing, including

pressure tests. All general maintenance of the suppression system must be completed by an authorized

technician.

Additional local requirements are not covered as part of the option price or basic installation and

deployment services, unless specifically included in an executed Statement of Work.

Air filter

There are 2 air filters per cooling zone, for a total of 12 filters.

Tools are not required for installation.

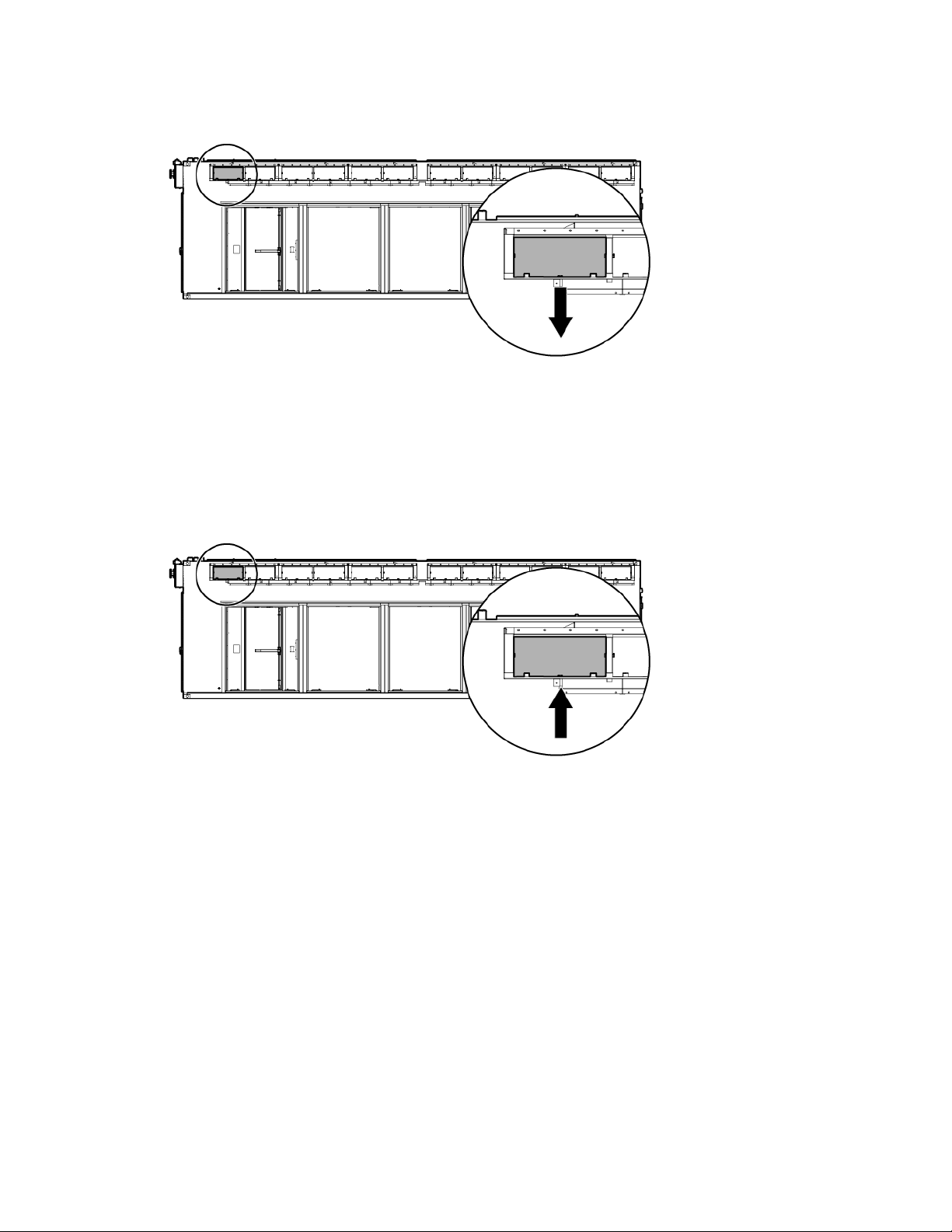

Removing the air filter

1. Pull the locking tabs away from the air filter to release the filter.

Removal and replacement procedures 16

Page 17

2.

Pull the filter down through the frame channels to remove the filter.

Replacing the air filter

1. Angle the filter to position the top corners in the frame channels, and then push the filter up to the top of

the frame.

2. Press in the bottom corners of the filter until the locking tabs engage and the filter clicks into place.

Removal and replacement procedures 17

Page 18

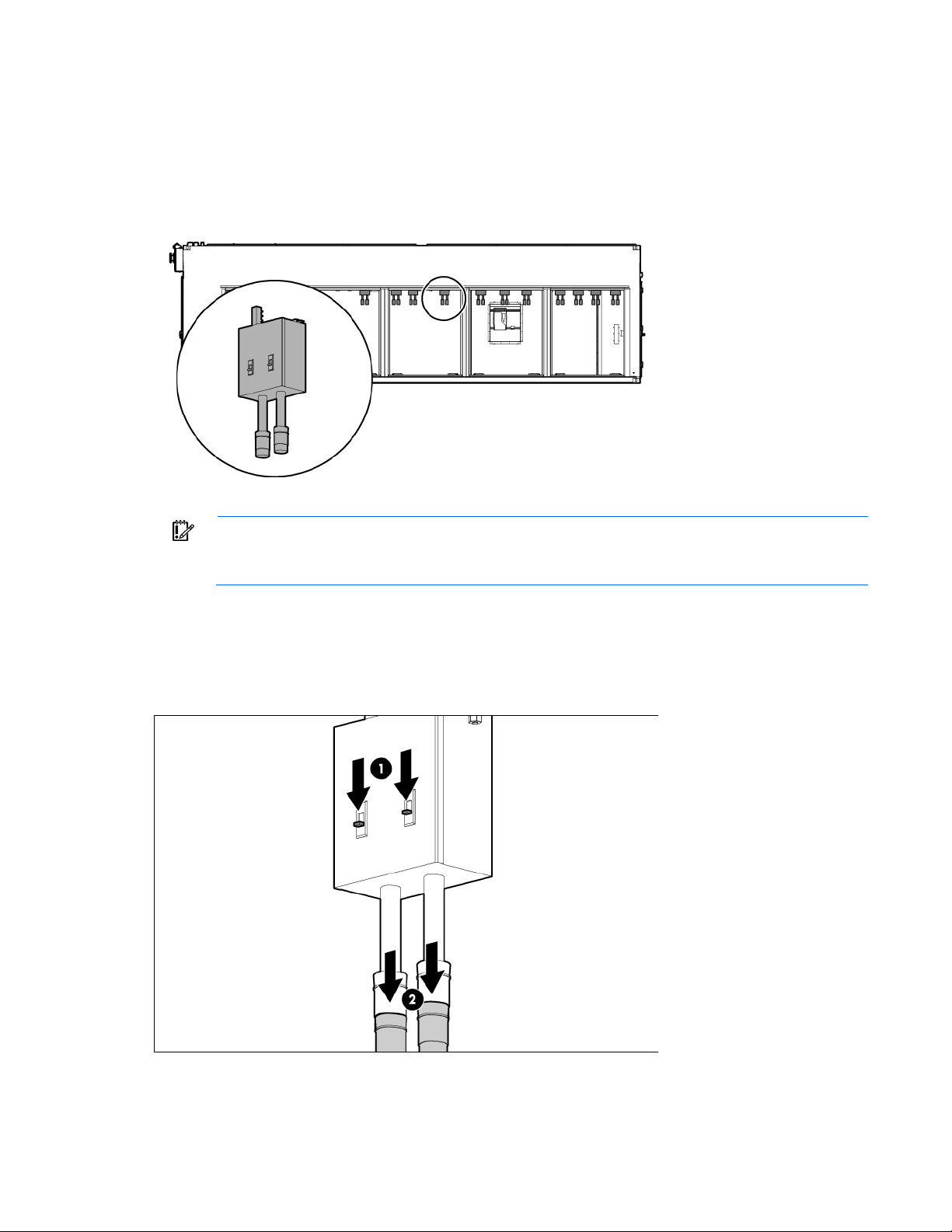

Busway drop box

The internal electrical busways provide a location to connect each of the drop boxes, which then power the

PDUs. Stagger the drop boxes on the electrical busways by connecting one drop box to busway #1 and

connecting the next drop box to busway #2. A staggered configuration enables load balancing with the rack

equipment and is necessary to ensure redundancy.

You need a socket wrench for installation.

IMPORTANT: HP recommends that you shut down the associated IT equipment and de-energize

the appropriate section of the power busway before attempting to remove or replace a busway

drop box. The corresponding branch circuit breaker is labeled on the busway.

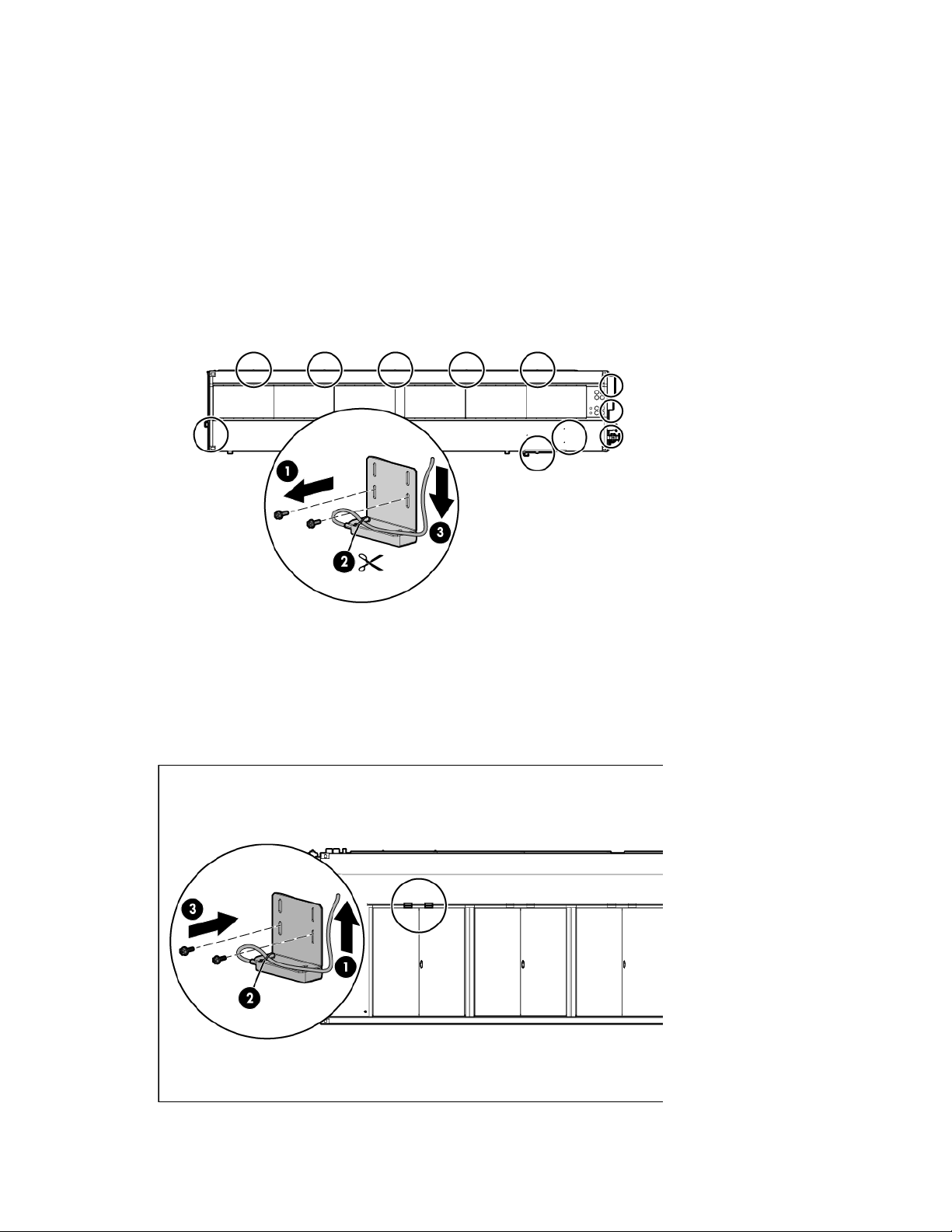

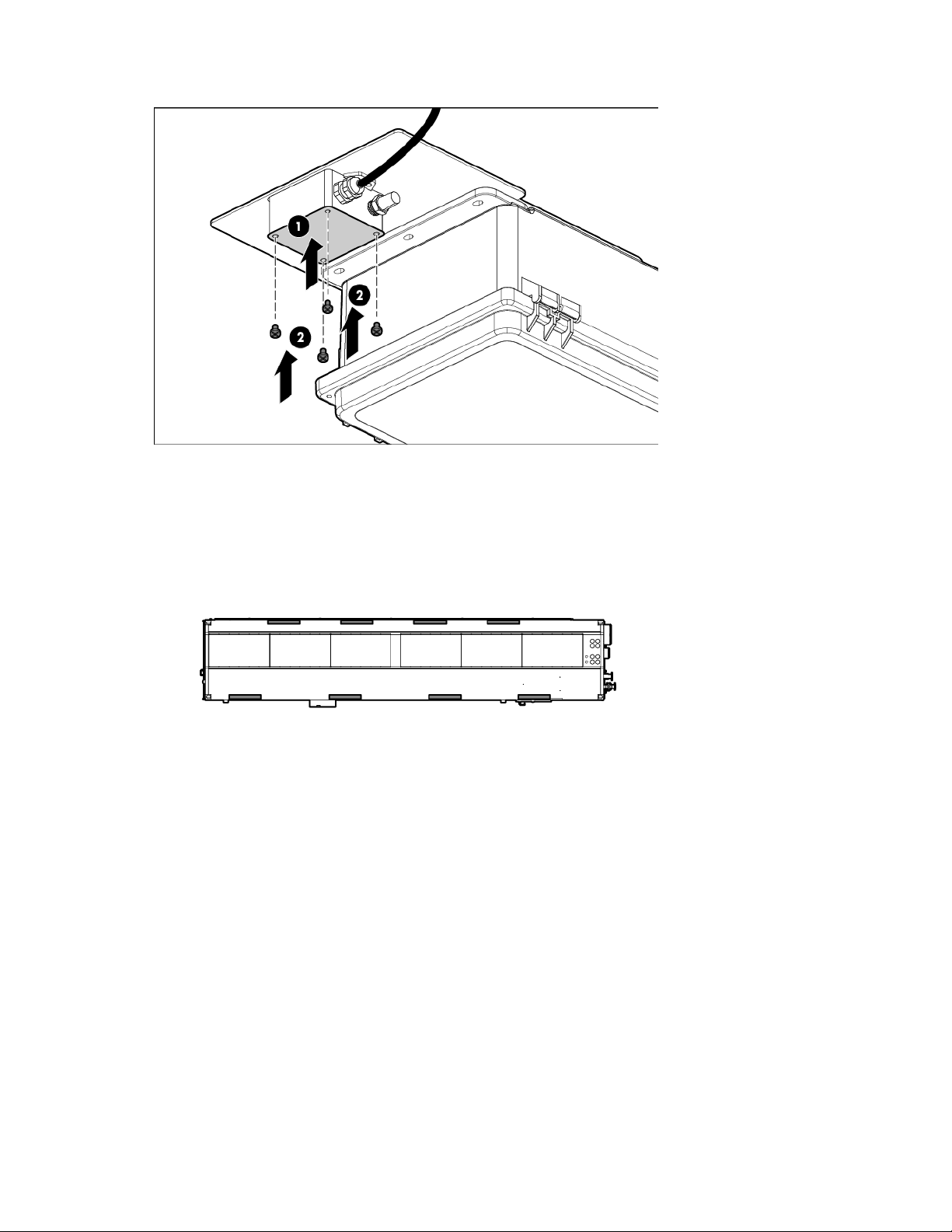

Removing the busway drop box

1. Turn the power off by opening both breakers on the busway drop box (1).

2. Disconnect the PDUs that are connected to the busway drop box (2).

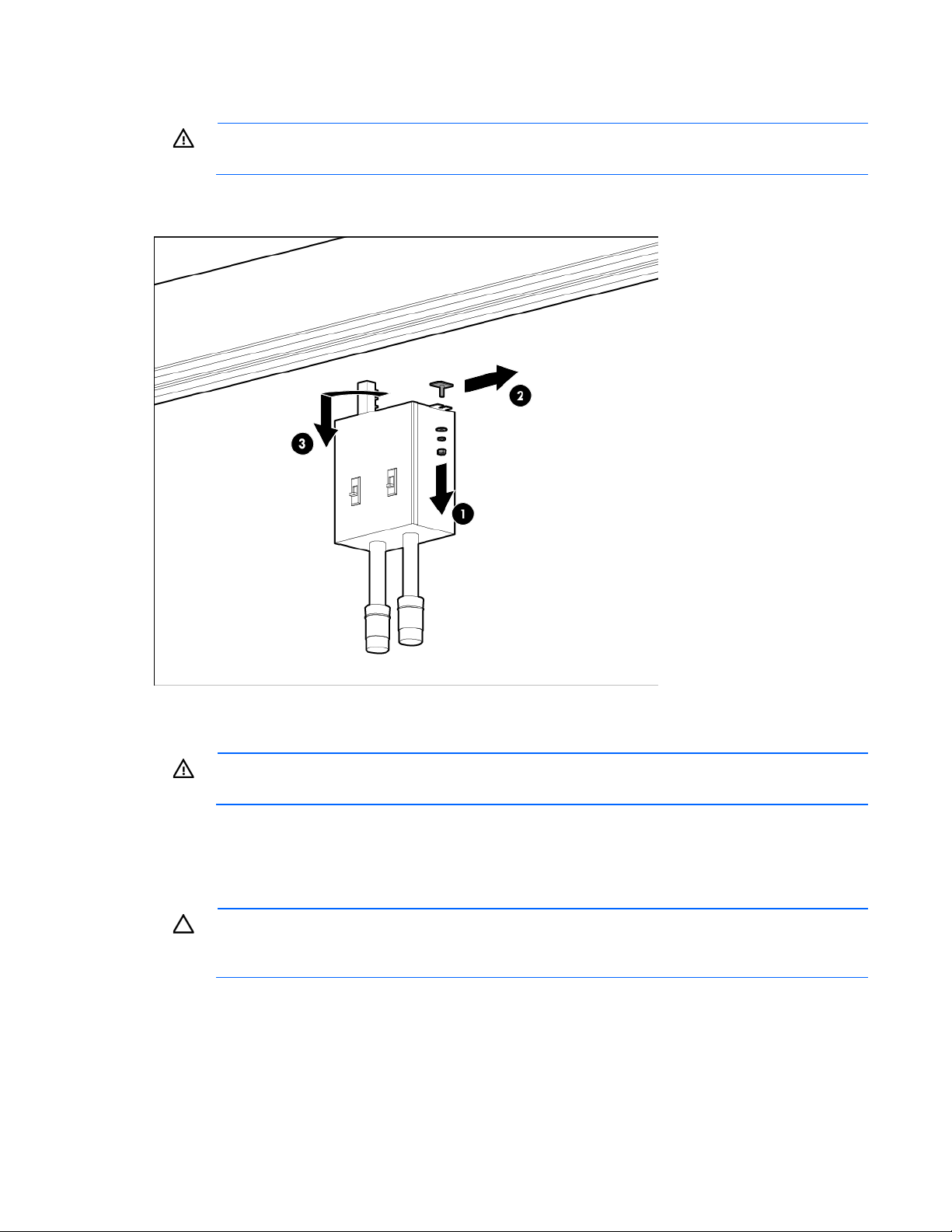

3. Use a socket wrench to loosen and remove the bolt securing the busway drop box to the retaining

hardware bracket (1).

Removal and replacement procedures 18

Page 19

4.

Slide the hardware bracket to the right along the busway, completely disconnecting it from the busway

drop box (2).

WARNING: Use caution when removing and replacing the busway drop box. The drop box

weighs approximately 9 kg (20 lb).

5. Rotate the busway drop box 90° so that it is perpendicular to the electrical busway, and then remove

the drop box from the electrical busway (3).

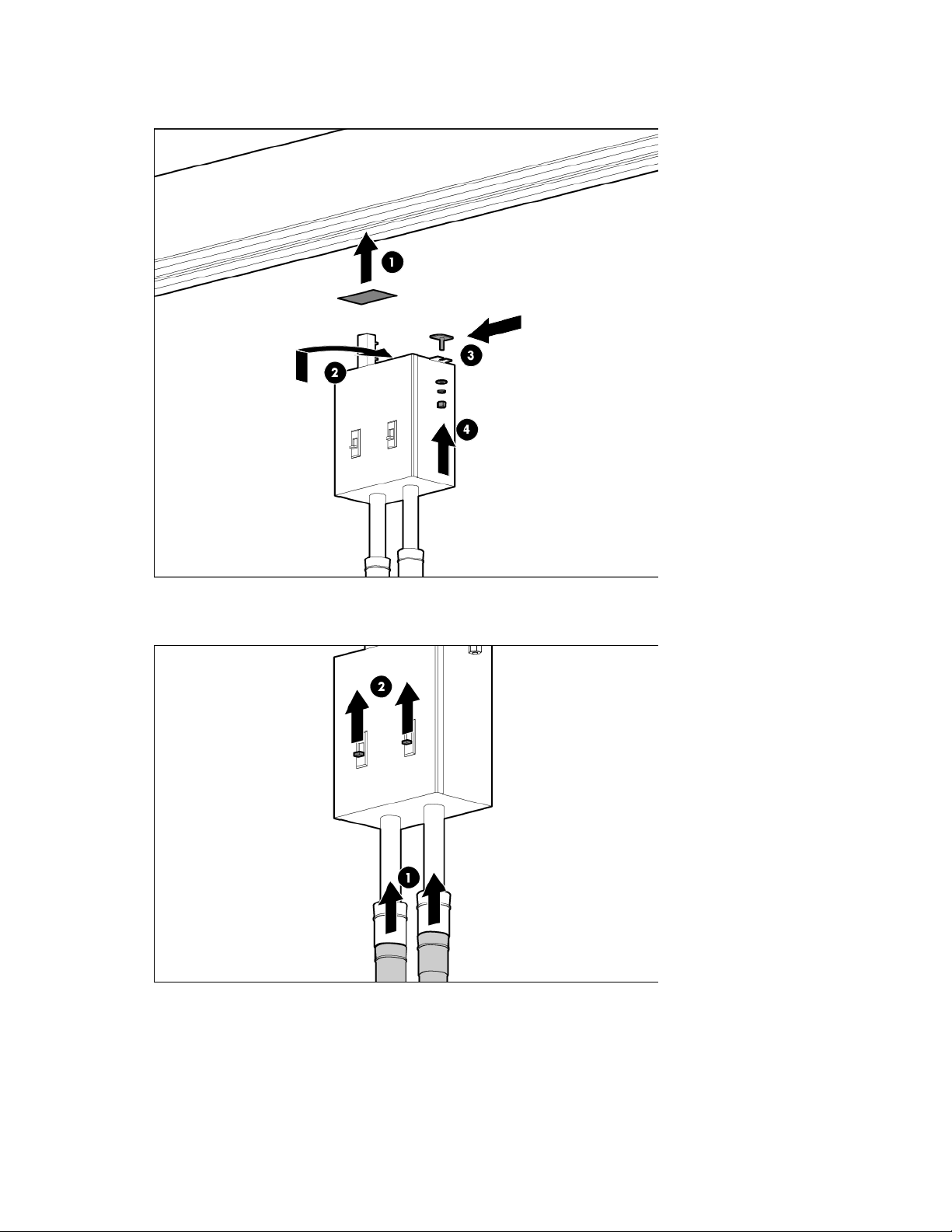

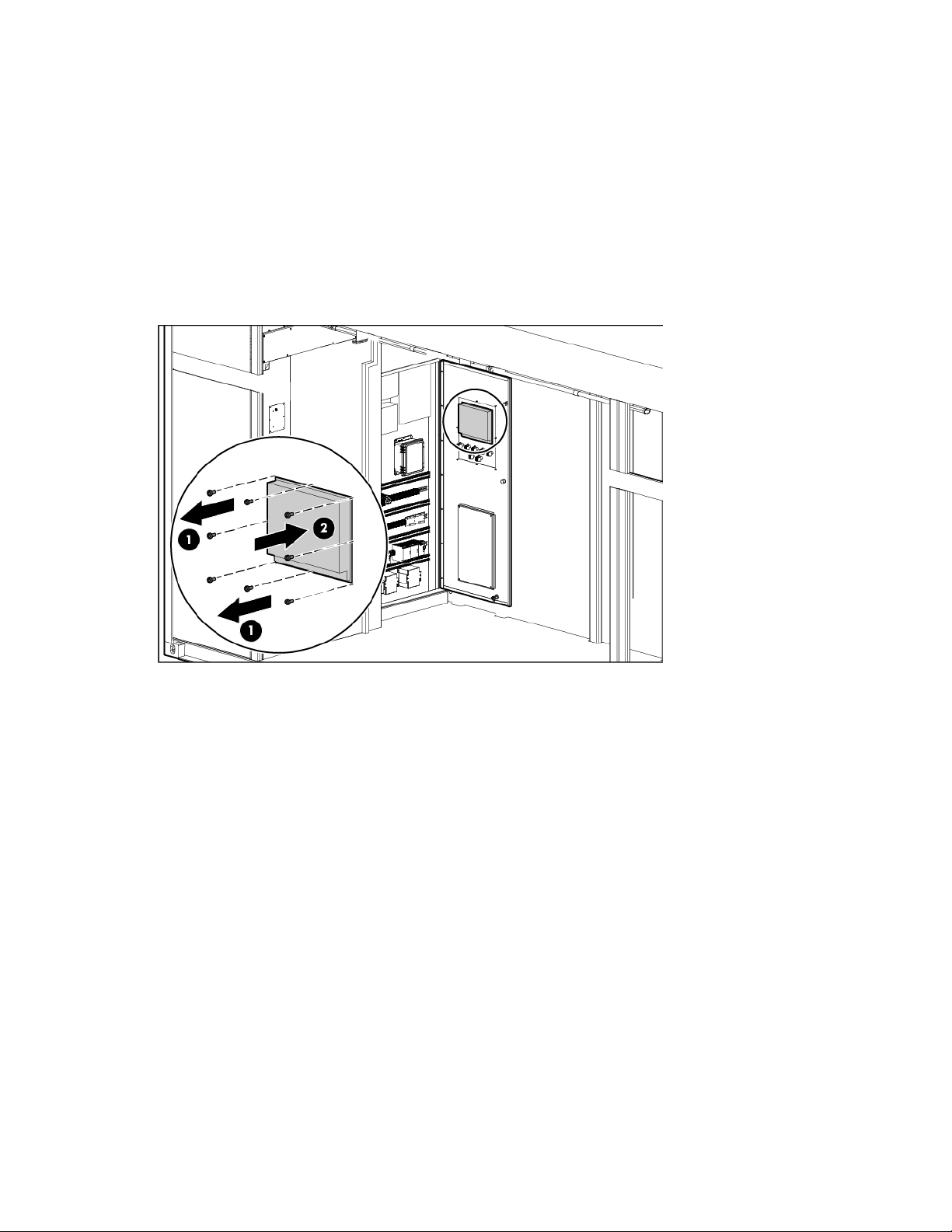

Replacing the busway drop box

WARNING: Use caution when removing and replacing the busway drop box. The drop box

1. Place the silver drop box bracket onto the electrical busway where you want to replace the busway

2. Note the required rotation indicated on the drop box, insert the drop box into the drop box bracket on

3. Slide the hardware bracket to the left along the busway until it connects to the drop box (3).

weighs approximately 9 kg (20 lb).

drop box (1).

the electrical busway, and then rotate the drop box 90° until it locks into place (2).

CAUTION: To prevent damage to the drop box and ensure that the drop box engages properly,

be sure that the drop box is completely flush to the busway. If a drop box is damaged during

installation, do not attempt to re-engage or repair the drop box.

Removal and replacement procedures 19

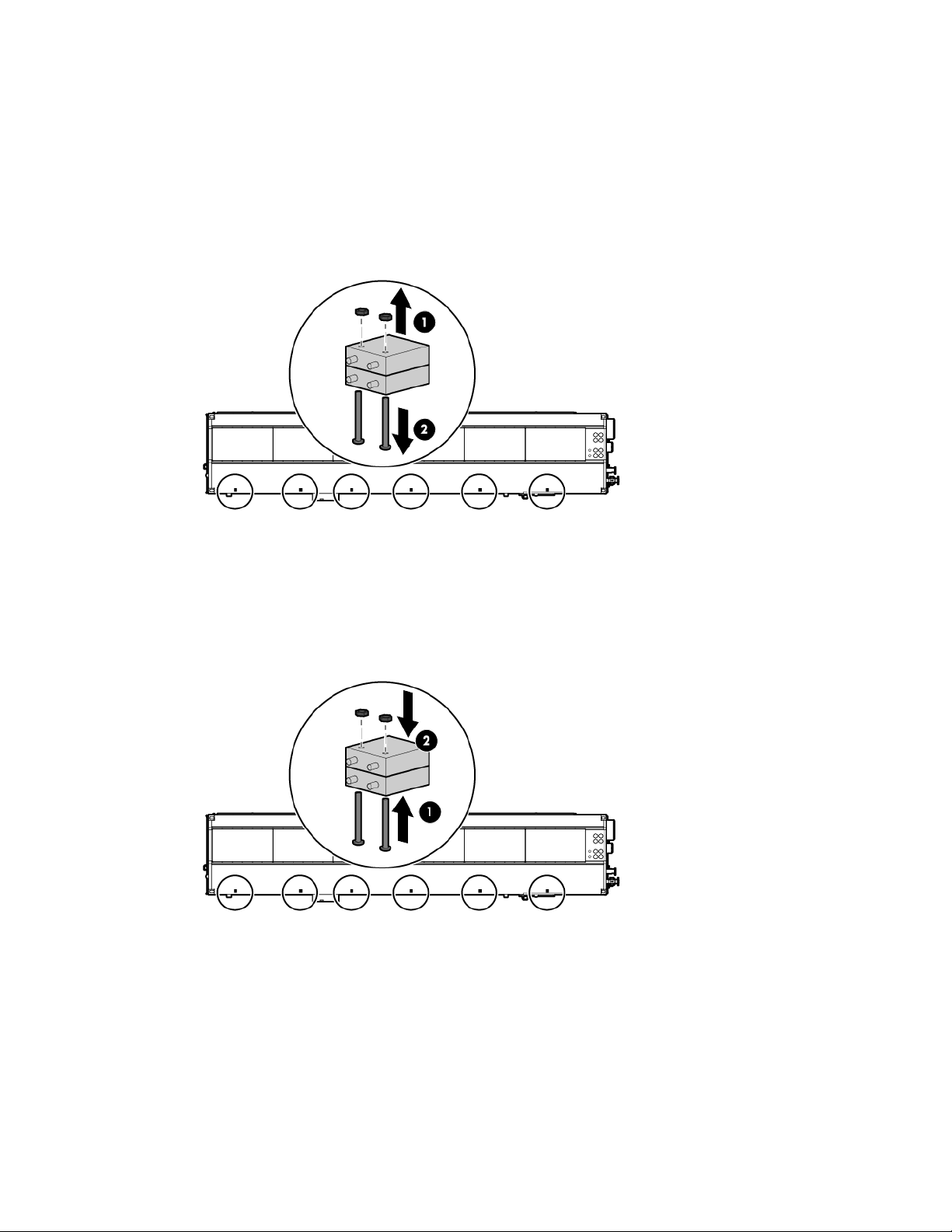

Page 20

4.

Secure the busway drop box to the retaining hardware bracket by using a socket wrench to insert and

tighten a bolt (4).

5. Connect the PDUs to the busway drop box (1).

6. Turn the power on by closing both breakers on the busway drop box (2).

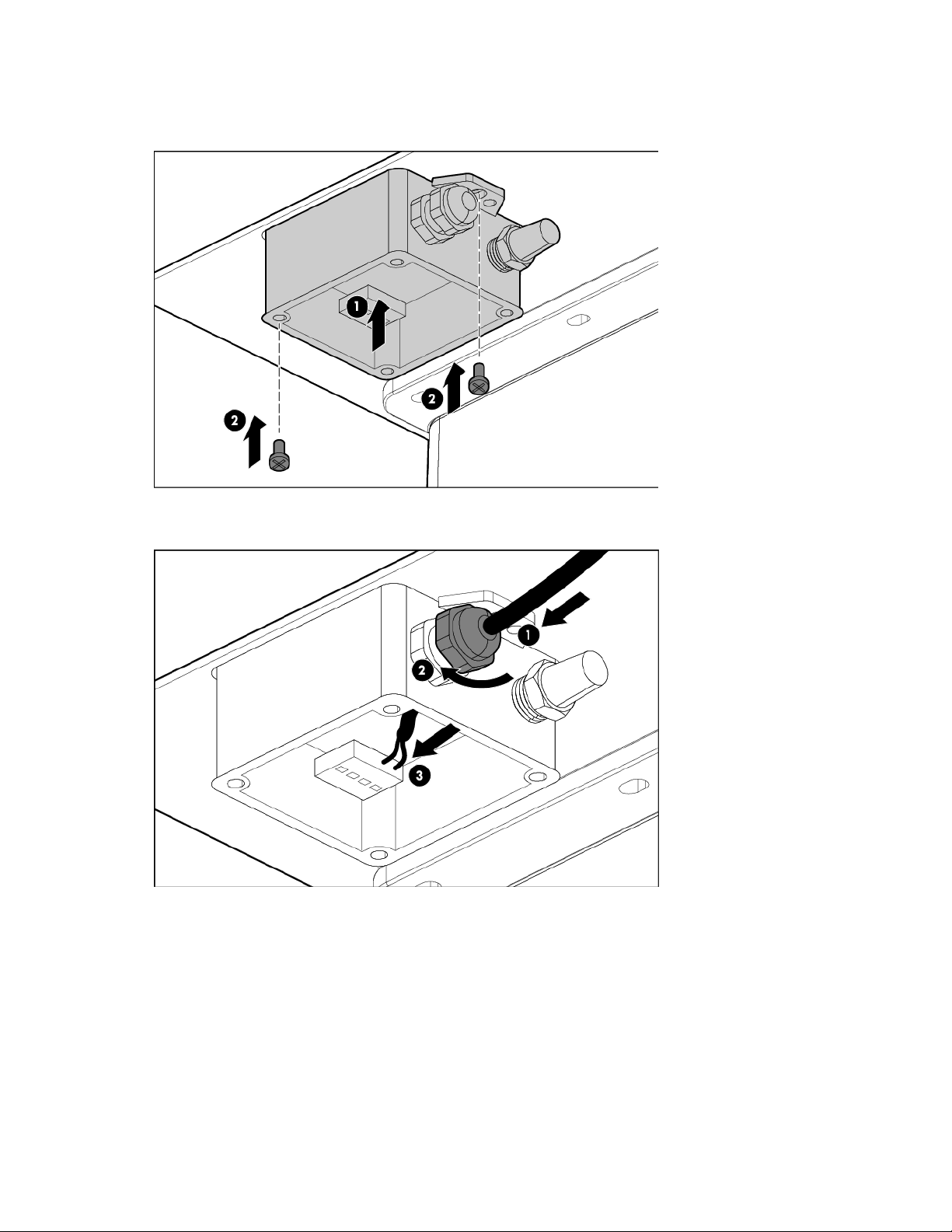

Differential pressure sensor

The differential pressure sensors are located in the cold aisle.

You need a Phillips-head screwdriver for installation.

Removal and replacement procedures 20

Page 21

Removing the differential pressure sensor

1. Label the pressure sensor tube connection locations, and then remove the tubes from the differential

pressure sensor.

2. Label the sensor wire connection locations, loosen the screws securing the sensor wires, and then

remove the sensor wires.

3. Remove the two nuts (1) and two bolts (2) securing the differential pressure sensor, and then remove the

differential pressure sensor.

Replacing the differential pressure sensor

1. Replace the differential pressure sensor, and then secure the differential pressure sensor with two bolts

(1) and two nuts (2).

2. Insert the pressure sensor tubes into the differential pressure sensor according to the connection

locations you labeled during the removal procedure.

3. Replace the sensor wires according to the connection locations you labeled during the removal

procedure, and then secure the sensor wires by tightening the screws.

Removal and replacement procedures 21

Page 22

Door position contact

Door position contacts are located on all doors and cabinets.

You need a Phillips-head screwdriver and scissors for installation.

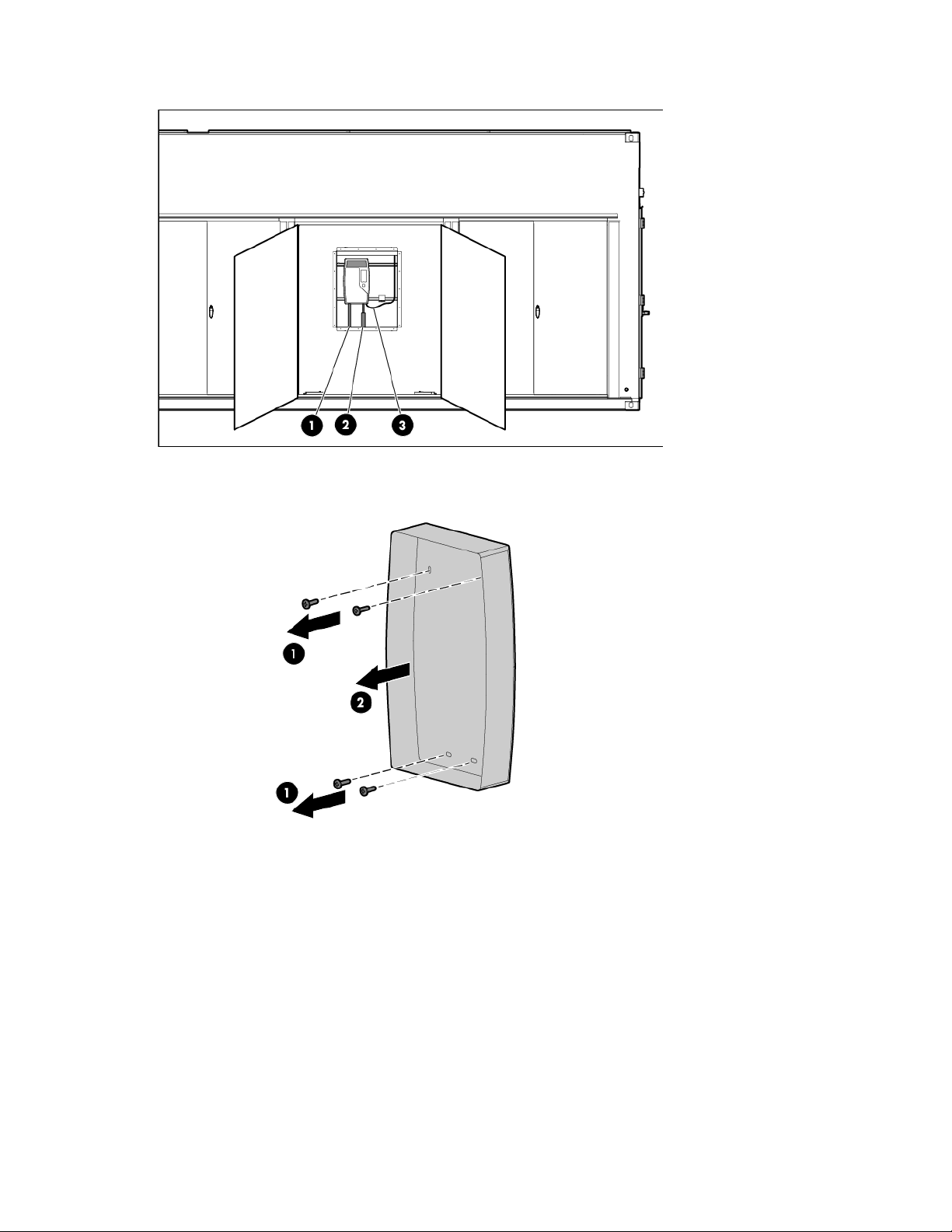

Removing the door position contact

1. Remove the two screws securing the upper magnet (1).

2. Cut the tie wrap (2) and loosen the nut on the HP POD 40c G2 structure that secures the wire.

3. Pull the wire all the way through to the point of entry or ECS panel (3).

Replacing the door position contact

1. Feed the wire all the way through from the point of entry or ECS panel (1).

2. Tighten the nut on the HP POD 40c G2 structure that secures the wire, and then replace the tie wrap (2).

3. Secure the magnet to the bracket using two screws (3).

Removal and replacement procedures 22

Page 23

Drain pan sensor

The HP POD 40c G2 includes six heat exchanger condensate drains. One drain pan sensor is located in the

drain tray below each set of heat exchangers.

Two sensors are also located in the header drain pans, one in cooling zone 2 and one in cooling zone 5.

The normally-open circuit is closed when the probes of the drain pan sensor become wet, which allows 24

VDC to travel back to the ECS panel and trigger the alarm.

You need a Phillips-head screwdriver and a small flathead screwdriver for installation.

Removing the drain pan sensor

1. If you are removing a heat exchanger drain pan sensor, do the following:

a. Inspect the area by removing the center, bottom fan from the center fan bank in the associated zone.

For more information, see "Removing the fan (on page 38)."

b. To gain additional working space, you might need to remove a fan bank in the associated zone. For

more information, see "Removing the fan bank (on page 40)."

2. Follow the sensor wire to the associated satellite box. Disconnect the wire from the satellite box terminal

and note the wire location.

Heat exchanger drain pan sensor

-orHeader drain pan sensor

Removal and replacement procedures 23

Page 24

3.

Pull the wire through from the satellite box to the sensor location, and then remove the sensor.

Heat exchanger drain pan sensor

-orHeader drain pan sensor

Replacing the drain pan sensor

1. Position the sensor in the drain pan.

Heat exchanger drain pan sensor

-or-

Removal and replacement procedures 24

Page 25

Header drain pan sensor

2. Route the wire through the flex tubing to the associated zone satellite box.

3. Connect the sensor wire to the appropriate port on the satellite box terminal.

Heat exchanger drain pan sensor

-orHeader drain pan sensor

4. If you are replacing a heat exchanger drain pan sensor, do the following:

a. Replace the fan bank you removed, if applicable. For more information, see "Replacing the fan

bank (on page 41)."

b. Replace the fan you removed, if applicable. For more information, see "Replacing the fan (on page

39)."

Removal and replacement procedures 25

Page 26

ECS touchscreen

The ECS touchscreen is located on the door to the control panel inside the cold aisle of the HP POD 40c G2.

You need a Phillips-head screwdriver for installation.

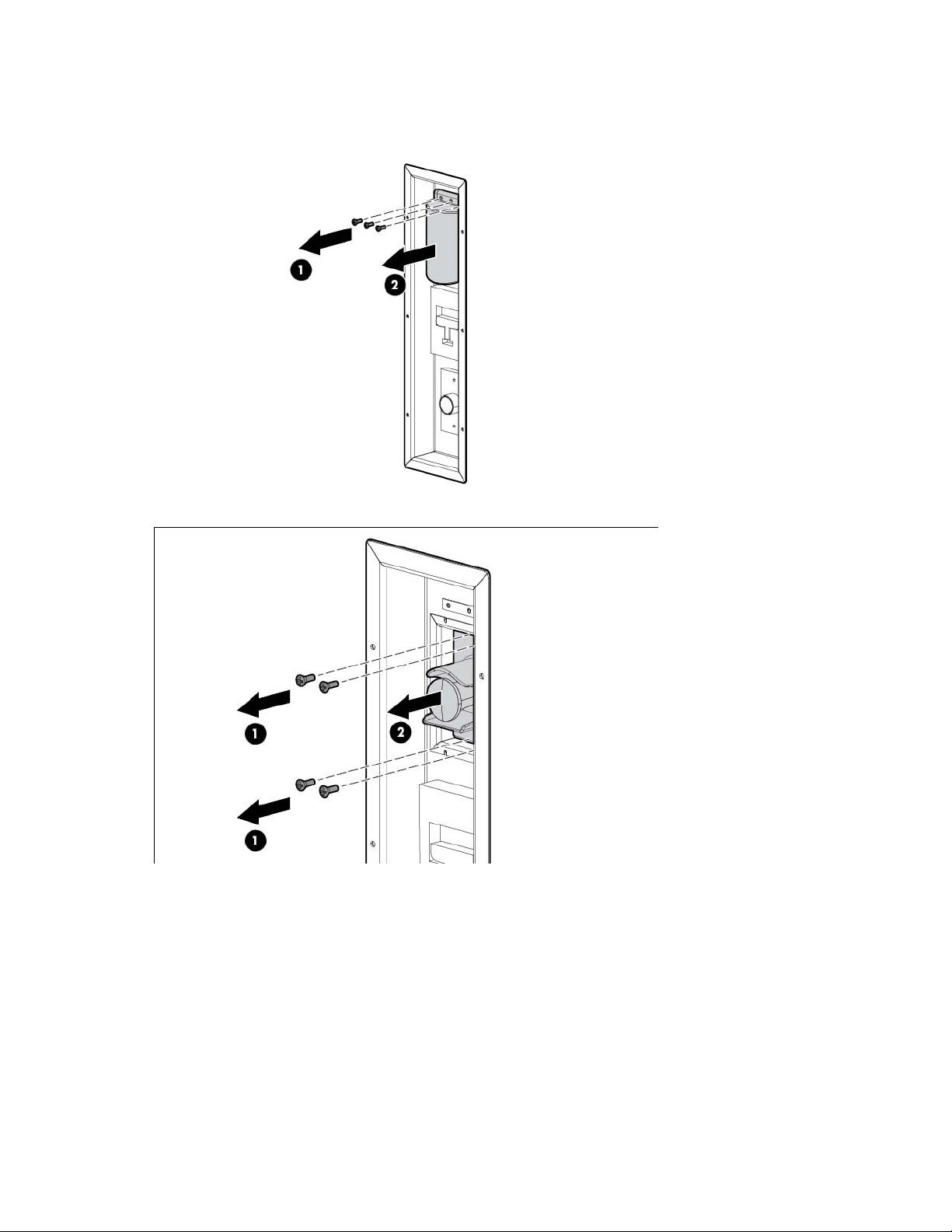

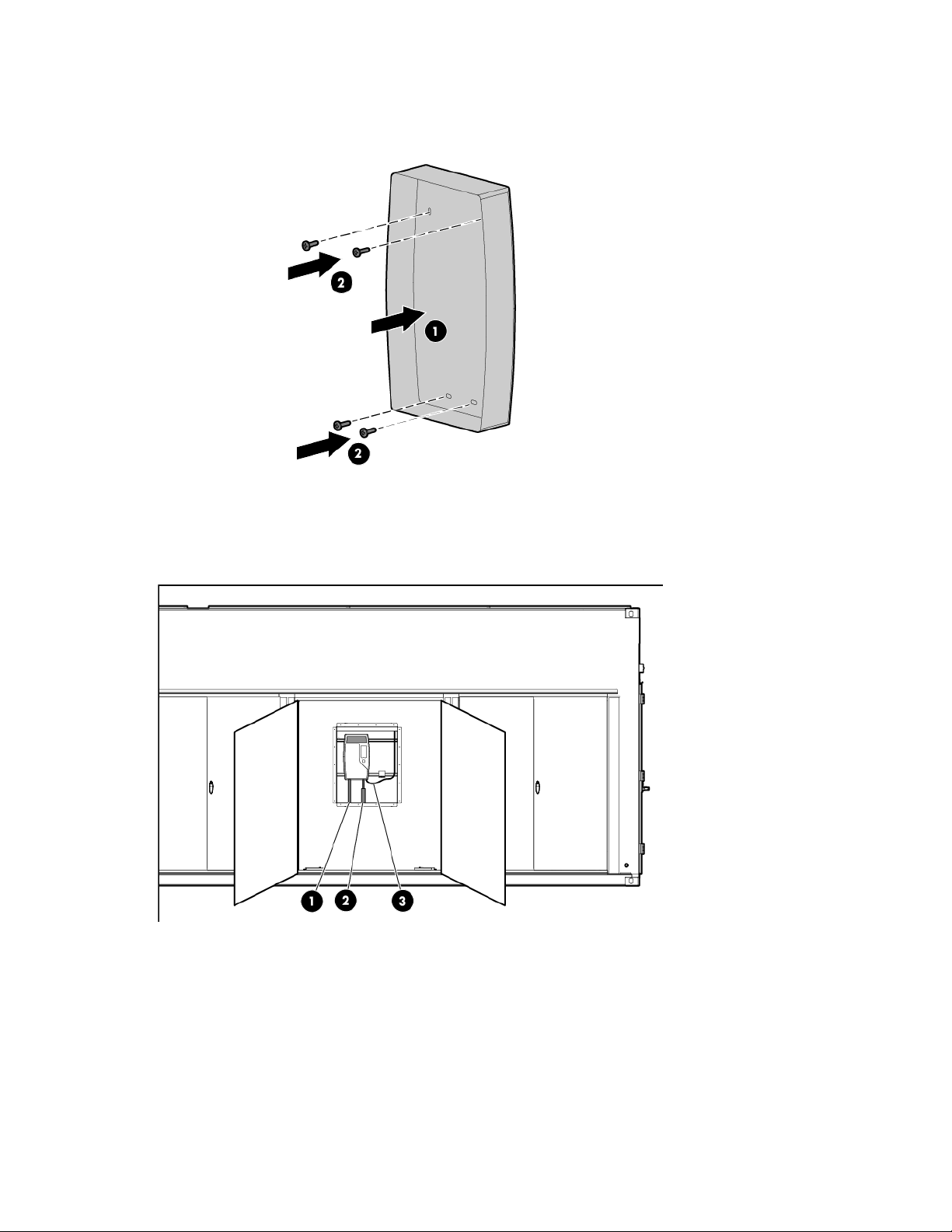

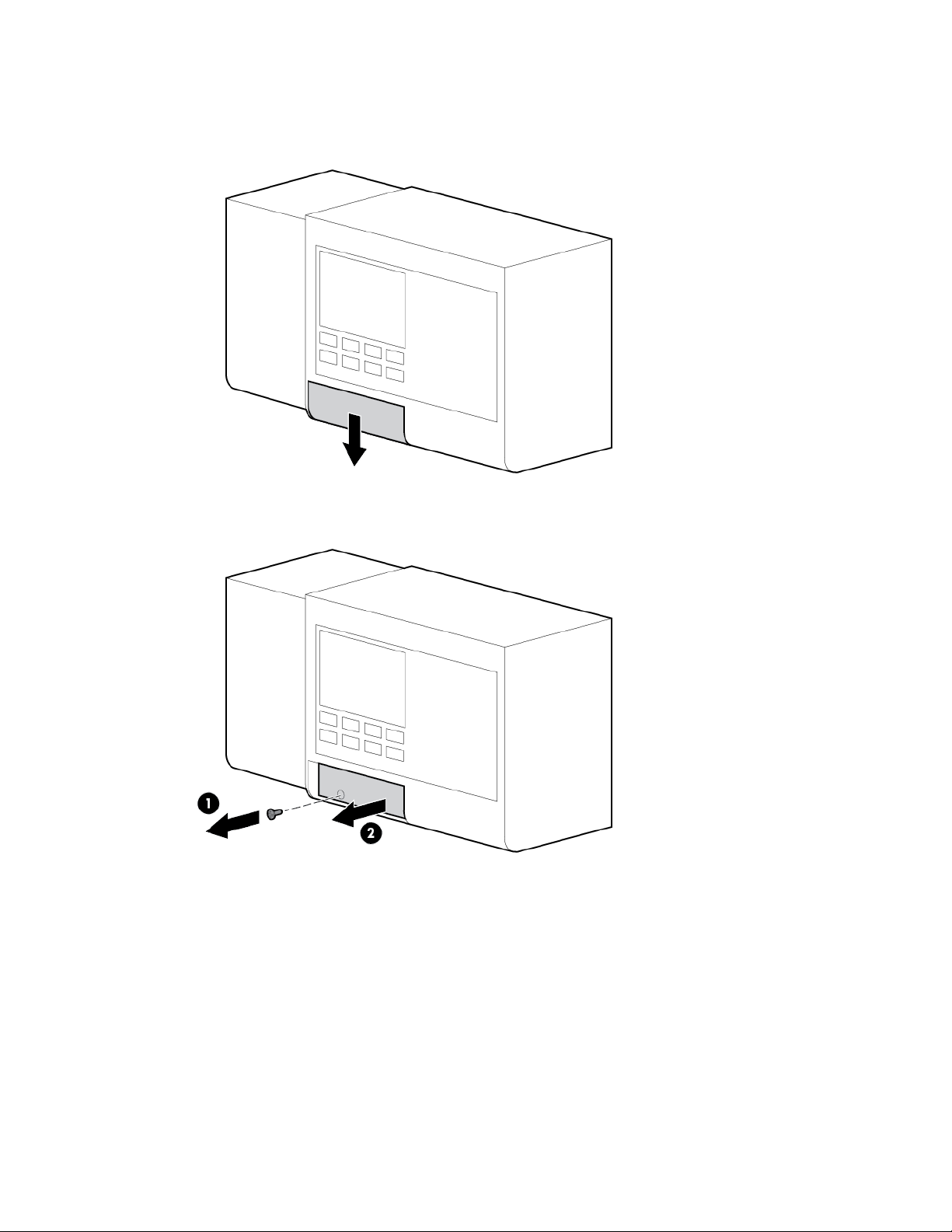

Removing the ECS touchscreen

1. Disconnect the cables attached to the back of the ECS touchscreen.

2. Remove the eight screws on the back of the door that secure the ECS touchscreen (1), and then push the

ESC touchscreen through the front of the door to remove the ECS touchscreen (2).

Removal and replacement procedures 26

Page 27

Replacing the ECS touchscreen

1. Replace the ESC touchscreen through the front of the door (1), and then secure the ECS touchscreen to

the back of the door with eight screws (2).

2. Connect the cables to the back of the ECS touchscreen.

EPO button

There are two EPO buttons, one by each personnel access door in the HP POD 40c G2.

You need a Phillips-head screwdriver for installation.

Removal and replacement procedures 27

Page 28

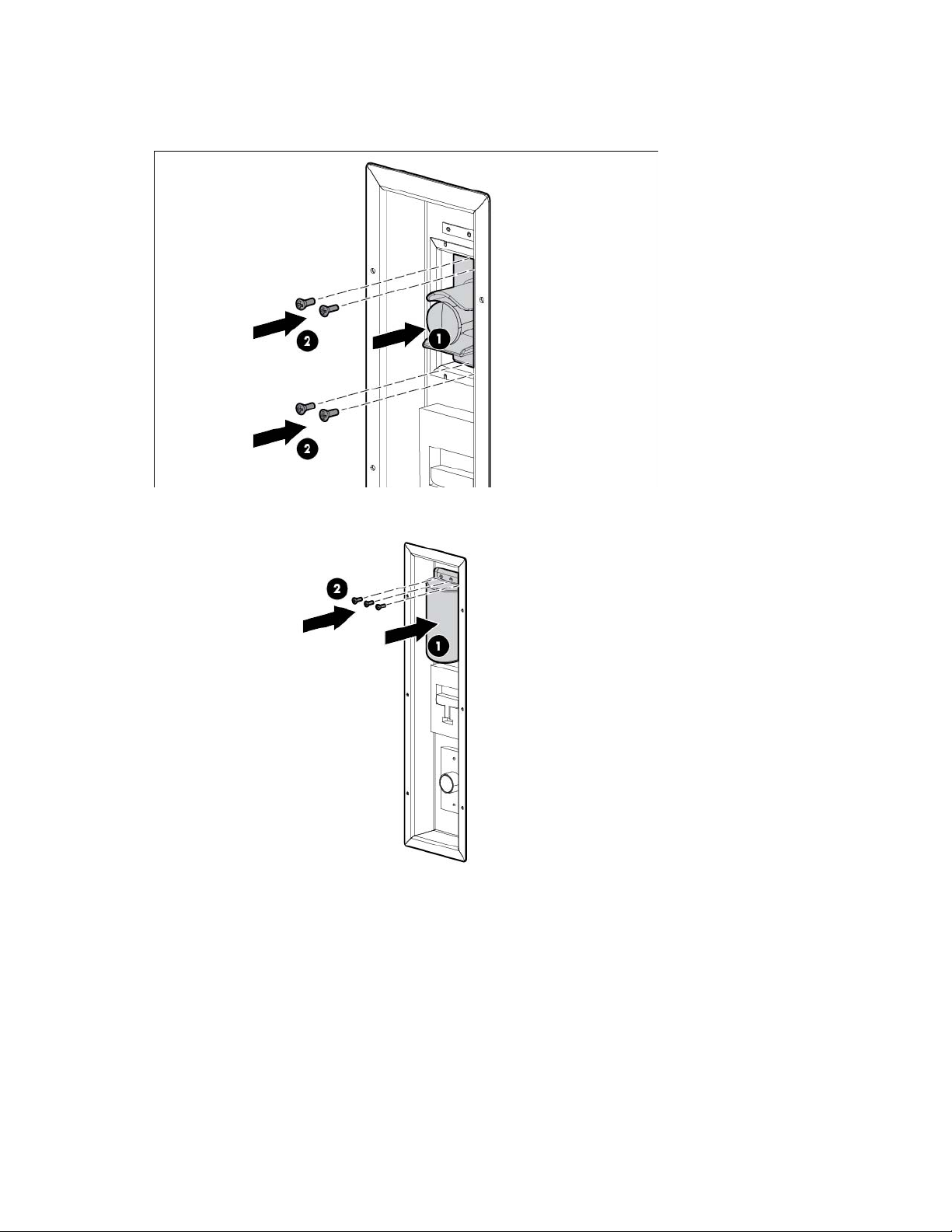

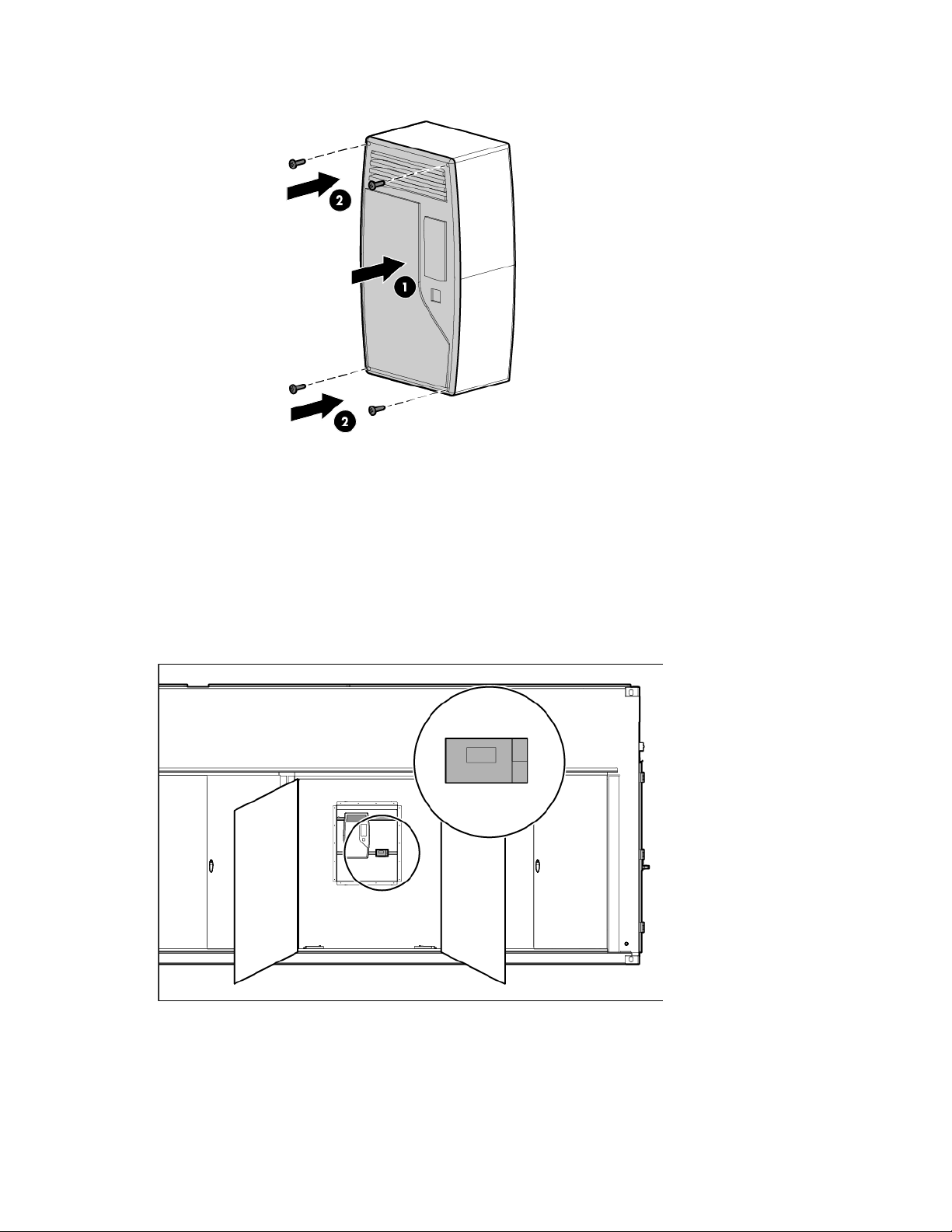

Removing the EPO button

1. Remove the two screws securing the tamper cover (1), and then remove the tamper cover (2).

2. Remove the four screws securing the EPO button (1), and then remove the EPO button (2).

Removal and replacement procedures 28

Page 29

Replacing the EPO button

1. Replace the EPO button (1), and then replace the four screws that secure the EPO button (2).

2. Replace the tamper cover (1), and then replace the two screws that secure the tamper cover (2).

Removal and replacement procedures 29

Page 30

EPO LED indicators

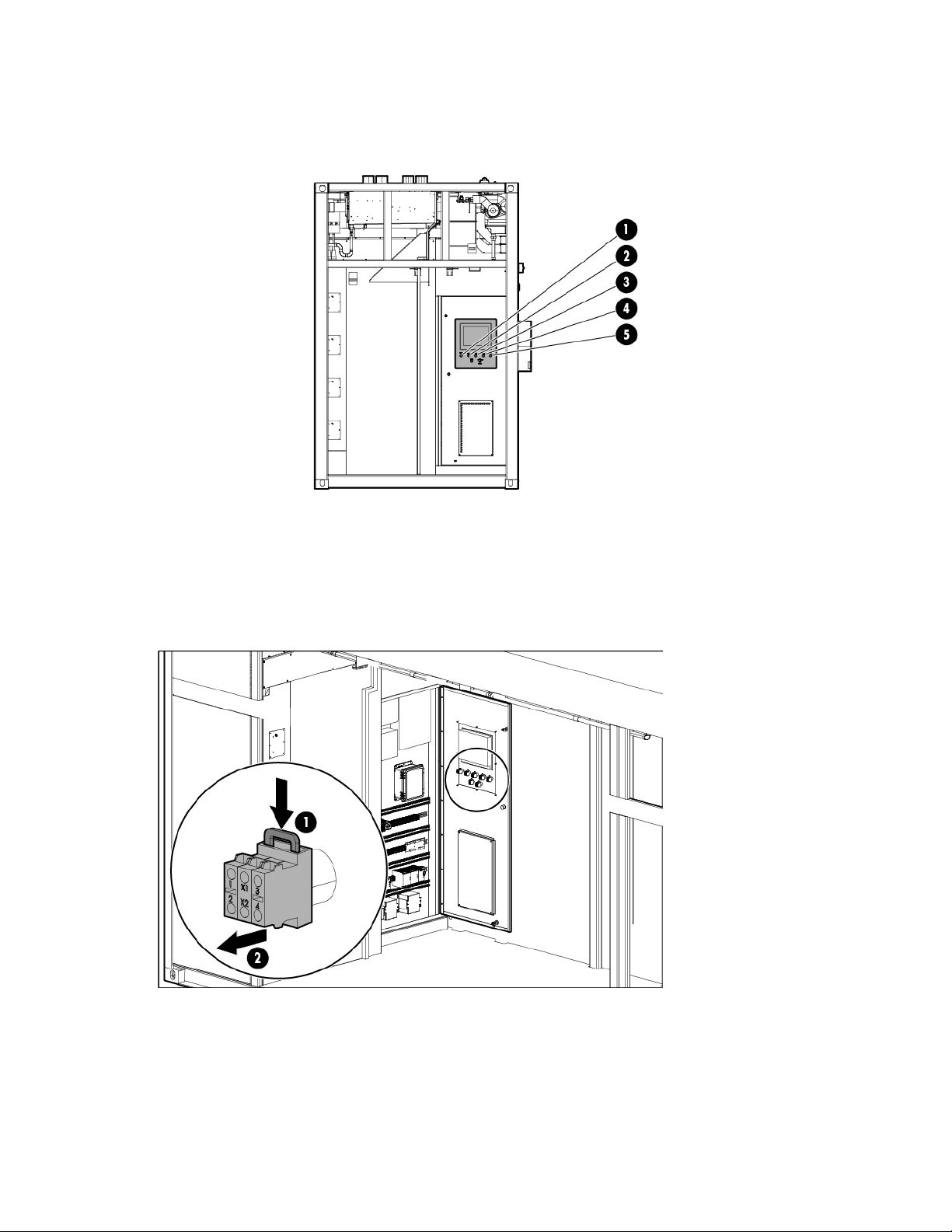

The ECS cabinet contains white (1, 3), red (2), yellow (4), and green (5) EPO LED indicators.

Tools are not required for installation.

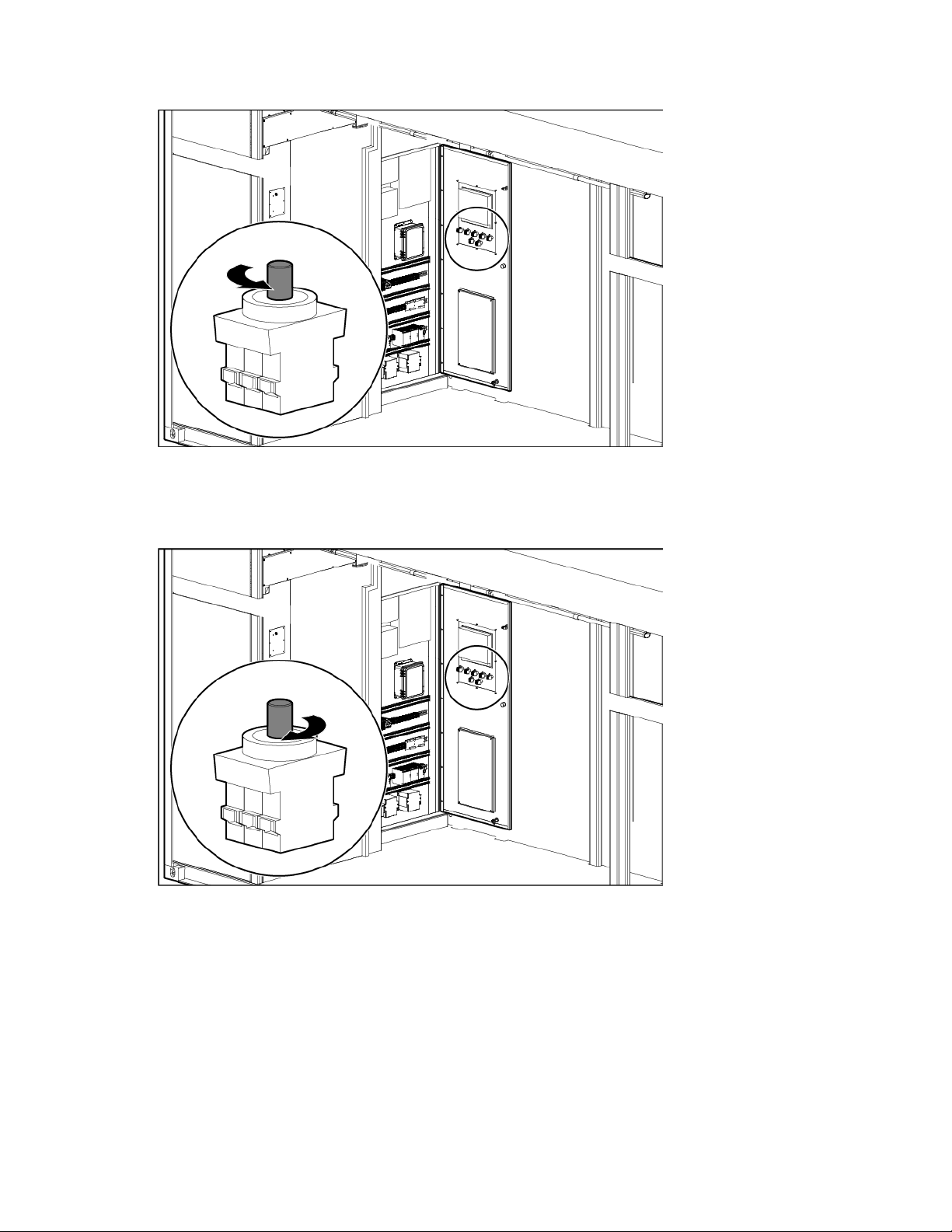

Removing the EPO LED indicator

1. On the back of the ECS cabinet door, push the gray tab on the EPO LED indicator module down to

release the module (1), and then pull the module out of the door (2).

Removal and replacement procedures 30

Page 31

2.

Unscrew the EPO LED indicator bulb.

Replacing the EPO LED indicator

1. Screw the new EPO LED indicator bulb into the module.

Removal and replacement procedures 31

Page 32

2.

Push the module into the slot on the back of the ECS cabinet door until it clicks into place.

EPO thermister

Two EPO thermisters are located in the hot aisle, one in cooling zone 2 and one in cooling zone 5.

While the thermisters are not technically at-temperature monitoring devices, when the hot aisle temperature

reaches 60ºC (140ºF), the thermister switch closes. When both thermister switches are closed, the EPO

system initiates an emergency shutdown.

Removing the EPO thermister

You need scissors for installation.

1. Cut the tie wraps securing the thermister (1).

2. Pull the thermister down to remove the thermister (2).

Replacing the EPO thermister

1. Insert the replacement thermister (1).

Removal and replacement procedures 32

Page 33

2.

Secure the thermister with tie wraps (2).

External chilled water flow actuator

The external chilled water flow actuator is located on top of the HP POD 40c G2.

You need a wrench for installation.

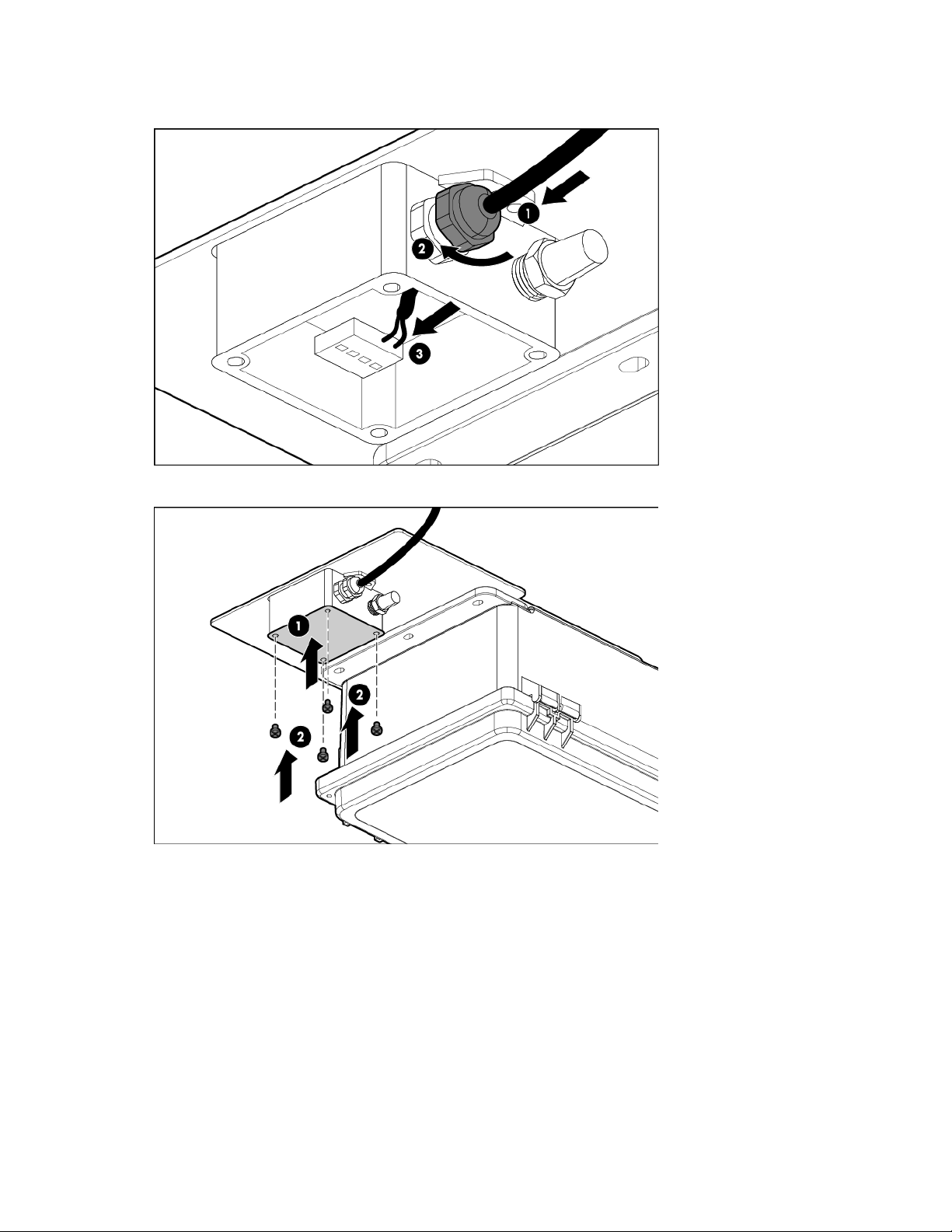

Removing the external chilled water flow actuator

1. Open and danger tag the associated circuit breaker in the ECS cabinet. The circuit breakers are

identified on the panel schedule.

Removal and replacement procedures 33

Page 34

2.

Remove the four bolts securing the face plate (1), and then remove the face plate (2).

3. Disconnect the power to the actuator.

4. Remove the four bolts securing the actuator (1), and then remove the actuator (2).

Removal and replacement procedures 34

Page 35

Replacing the external chilled water flow actuator

1. Replace the actuator (1), and then secure the actuator using four bolts (2).

2. Connect the power to the actuator.

3. Replace the actuator face plate (1), and then secure the face plate with four bolts (2).

4. Close the associated circuit breaker in the ECS cabinet.

External chilled water flow valve

The external chilled water flow valve is the butterfly valve located on top of the HP POD 40c G2.

You need a wrench for installation.

Removal and replacement procedures 35

Page 36

Removing the external chilled water flow valve

1. Remove the external chilled water flow actuator. For detailed instructions, see "Removing the external

chilled water flow actuator (on page 33)."

2. Remove the eight bolts surrounding the valve (1), and then remove the valve (2).

Replacing the external chilled water flow valve

1. Replace the valve (1), and then secure the valve with eight bolts (2).

2. Replace the external chilled water flow actuator. For detailed instructions, see "Replacing the external

chilled water flow actuator (on page 35)."

Removal and replacement procedures 36

Page 37

External pressure gauge isolation valve

The external pressure gauge isolation valve is located on top of the HP POD 40c G2.

You need an adjustable wrench or an appropriately sized box wrench for installation.

Removing the external pressure gauge isolation valve

Loosen the connection securing the valve (1), and then remove the valve (2).

Replacing the external pressure gauge isolation valve

Insert the new valve (1), and then tighten the connection (2).

Removal and replacement procedures 37

Page 38

Fan

Power must be removed from the fan power assembly before removing or replacing

There are 18 fans per cooling zone.

CAUTION:

a fan or fan bank.

You need a Phillips-head screwdriver for installation.

Removing the fan

1. Disconnect both power supplies from the fan power assembly.

Removal and replacement procedures 38

Page 39

2.

Remove the three screws that secure the fan in the assembly (1), and then partially remove the fan by

pulling it straight out (2).

3. Disconnect the wire.

4. Remove the fan from the assembly.

Replacing the fan

1. Connect the wire.

2. Insert the fan into the assembly and push until the fan is fully seated (1).

3. Secure the fan with three screws (2).

4. Connect the power supplies to the fan power assembly.

Removal and replacement procedures 39

Page 40

Fan bank

Power must be removed from the fan power assembly before removing or replacing

There are three fan banks per cooling zone.

You need a Phillips-head screwdriver for installation.

CAUTION:

a fan or fan bank.

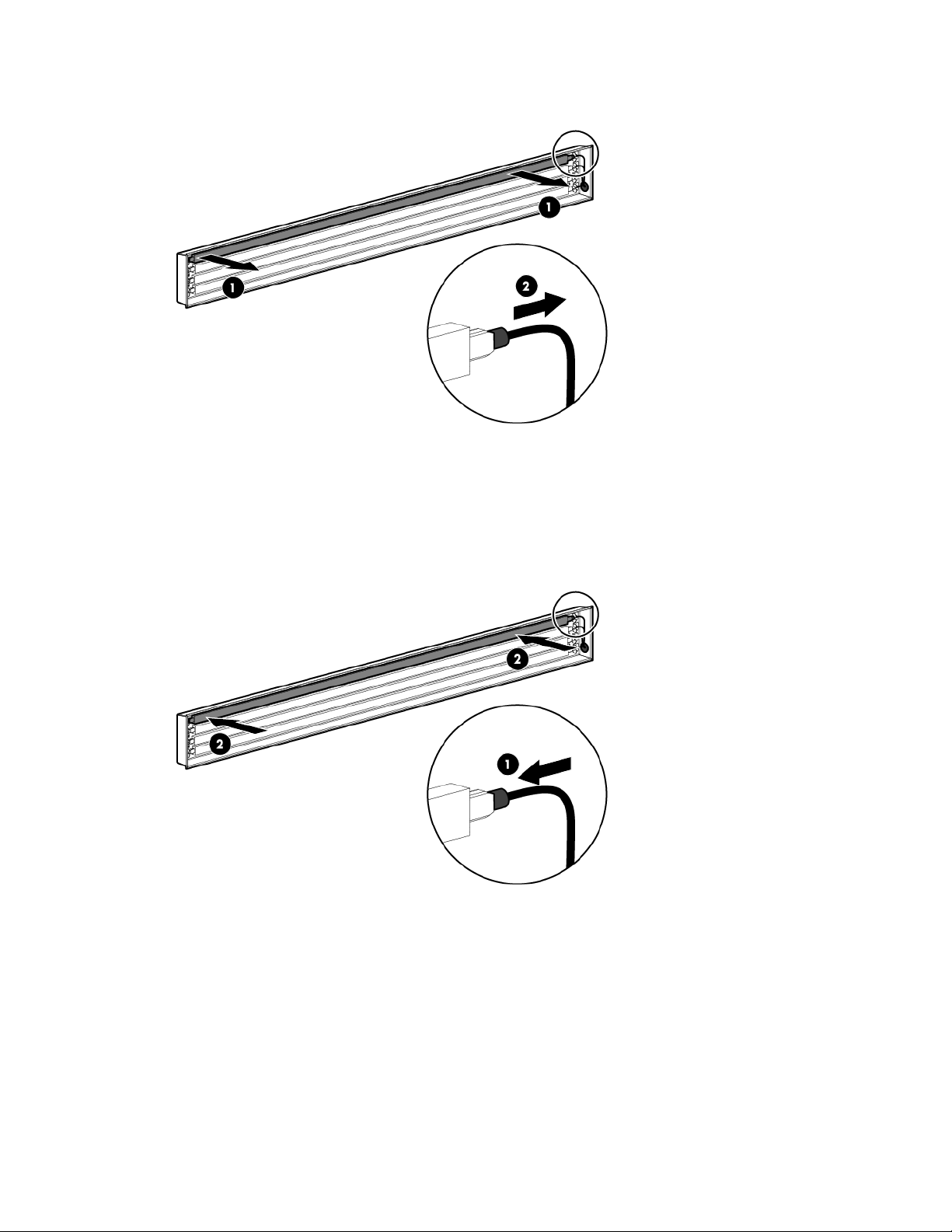

Removing the fan bank

1. Disconnect both power supplies from the fan power assembly.

2. Remove the fan bank wire harness (1).

3. Remove the six screws that secure the fan bank (2).

Removal and replacement procedures 40

Page 41

4.

Remove the fan bank by pulling it straight out (3).

Replacing the fan bank

1. Insert the fan bank (1).

2. Secure the fan bank with six screws (2).

3. Replace the fan bank wire harness (3).

4. Connect the power supplies to the fan power assembly.

Removal and replacement procedures 41

Page 42

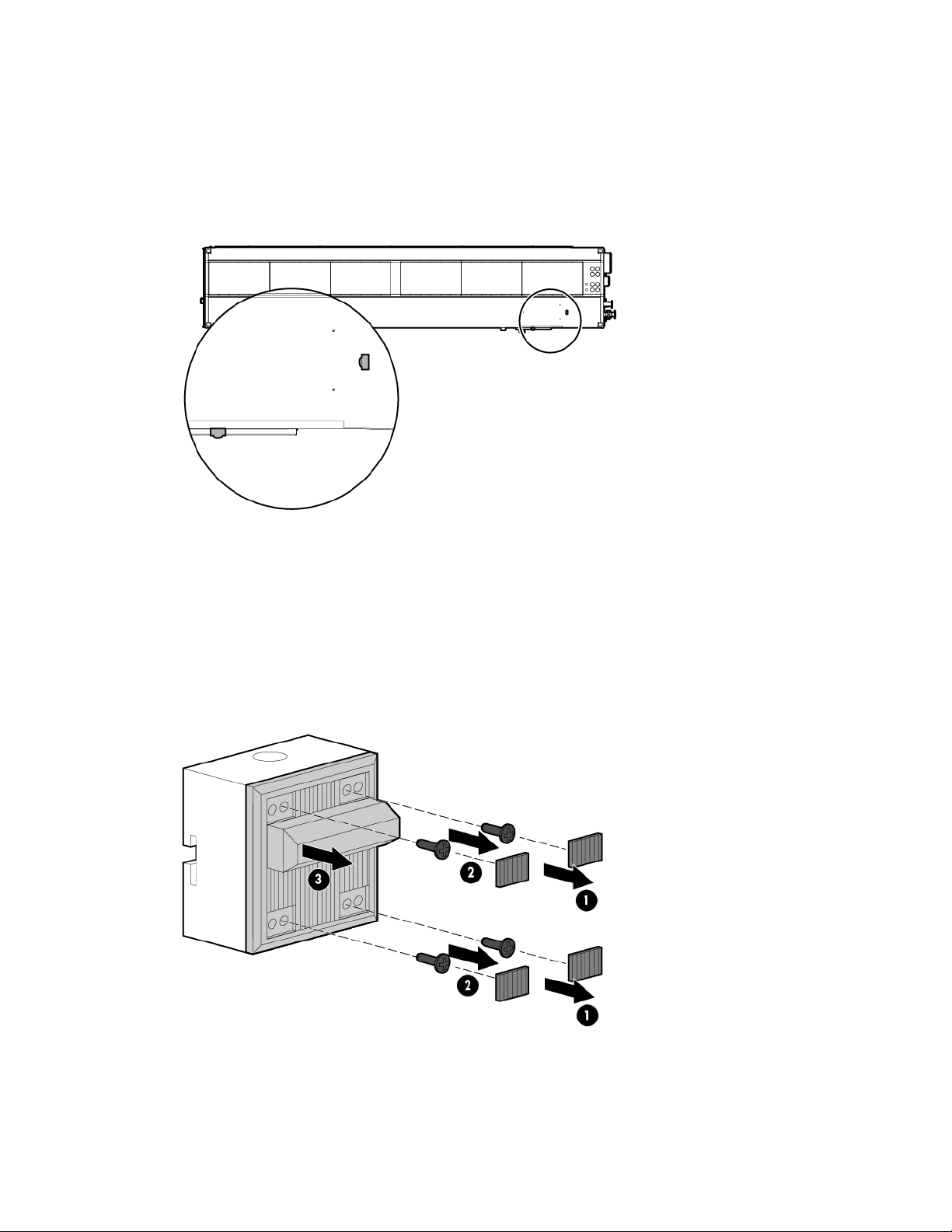

Fire strobe light

The HP POD 40c G2 contains an internal fire alarm strobe light in the cold aisle and an external fire alarm

strobe light at the standard personnel entry door.

You need a Phillips-head screwdriver for installation.

Removing the fire strobe light

1. Remove the four screw cover plates (1).

2. Remove the four screws securing the components (2), and then disconnect the wiring.

3. Remove the electric sounder with strobe, the semi-flush plate, and the standard back box (3).

Removal and replacement procedures 42

Page 43

Replacing the fire strobe light

1. Assemble the standard back box, the semi-flush plate, and the electric sounder with strobe (1), and then

attach the wiring.

2. Secure the components with four screws (2).

3. Attach the four screw cover plates (3).

Humidifier

The humidifier is located in the cold aisle humidifier bump out.

You need a Phillips-head screwdriver for installation.

Removal and replacement procedures 43

Page 44

Removing the humidifier

1. Hold the drain button on the humidifier exterior until the humidifier cylinder drains completely.

2. Press the power button on the outside of the humidifier to power down the humidifier.

3. Close the water supply isolation valve on the HP POD 40c G2 exterior.

4. Disconnect the water supply line to the humidifier on the HP POD 40c G2 exterior to relieve the water

pressure.

5. Open and danger tag the associated circuit breaker in the ECS cabinet. The circuit breakers are

identified on the panel schedule.

6. Remove the four screws on the corners of the humidifier cover (1), and then remove the cover (2).

7. Locate the power board and disconnect the two internal electrical wires.

8. Disconnect the drain (1).

9. Disconnect the humidifier from the water supply line (2).

Removal and replacement procedures 44

Page 45

10.

Disconnect and remove the external electrical wiring from the housing (3).

11. Remove the four screws that secure the humidifier body to the wall (1), and then remove the humidifier

(2).

Removal and replacement procedures 45

Page 46

Replacing the humidifier

1. Replace the humidifier (1), and then secure the humidifier to the wall with four screws (2).

2. Connect the drain (1).

3. Connect the humidifier to the water supply line (2).

4. Route and connect the external electrical wiring to the housing (3).

5. Locate the power board and connect the two internal electrical wires.

Removal and replacement procedures 46

Page 47

6.

Replace the humidifier cover (1), and then secure the cover with four screws (2).

7. Open the water supply isolation valve on the HP POD 40c G2 exterior.

8. Connect the water supply line to the humidifier on the HP POD 40c G2 exterior.

9. Close the associated circuit breaker in the ECS cabinet.

10. Press the power button on the outside of the humidifier to power up the humidifier.

Humidistat

The humidistat is located in the cold aisle humidifier bump out.

You need a Phillips-head screwdriver and a flathead screwdriver for installation.

Removing the humidistat

1. Press the power button on the outside of the humidifier to power down the humidifier.

Removal and replacement procedures 47

Page 48

2.

Open and danger tag the associated circuit breaker in the ECS cabinet. The circuit breakers are

identified on the panel schedule.

3. Detach the front panel of the humidistat from the mounting base:

a. Remove the screw securing the tab in the opening (1), and then slide the tab to the open position (2).

b. Use a flathead screwdriver to the press the release button (1), and then pull the front panel from the

bottom to detach the panel (2). The two parts remain connected by a flat cable.

4. Squeeze the two terminal cover fins to remove the cables from the terminal block.

5. Remove the screws securing the mounting base to the wall.

Replacing the humidistat

1. Detach the front panel of the replacement humidistat from the mounting base.

Removal and replacement procedures 48

Page 49

a.

Remove the screw securing the tab in the opening (1), and then slide the tab to the open position (2).

b. Use a flathead screwdriver to the press the release button (1), and then pull the front panel from the

bottom to detach the panel (2). The two parts remain connected by a flat cable.

2. Secure the mounting base to the wall using the screws provided.

3. Squeeze the two terminal cover fins to remove the terminal covers.

4. Make the required connections by running the connection cables through the center hole in the bottom

of the mounting base and connecting the cables to the terminal block.

5. Separate the connection and control cables from the relay cables.

6. Attach the front panel.

7. Close the associated circuit breaker in the ECS cabinet.

8. Press the power button on the outside of the humidifier to power up the humidifier.

Removal and replacement procedures 49

Page 50

Humidity sensor

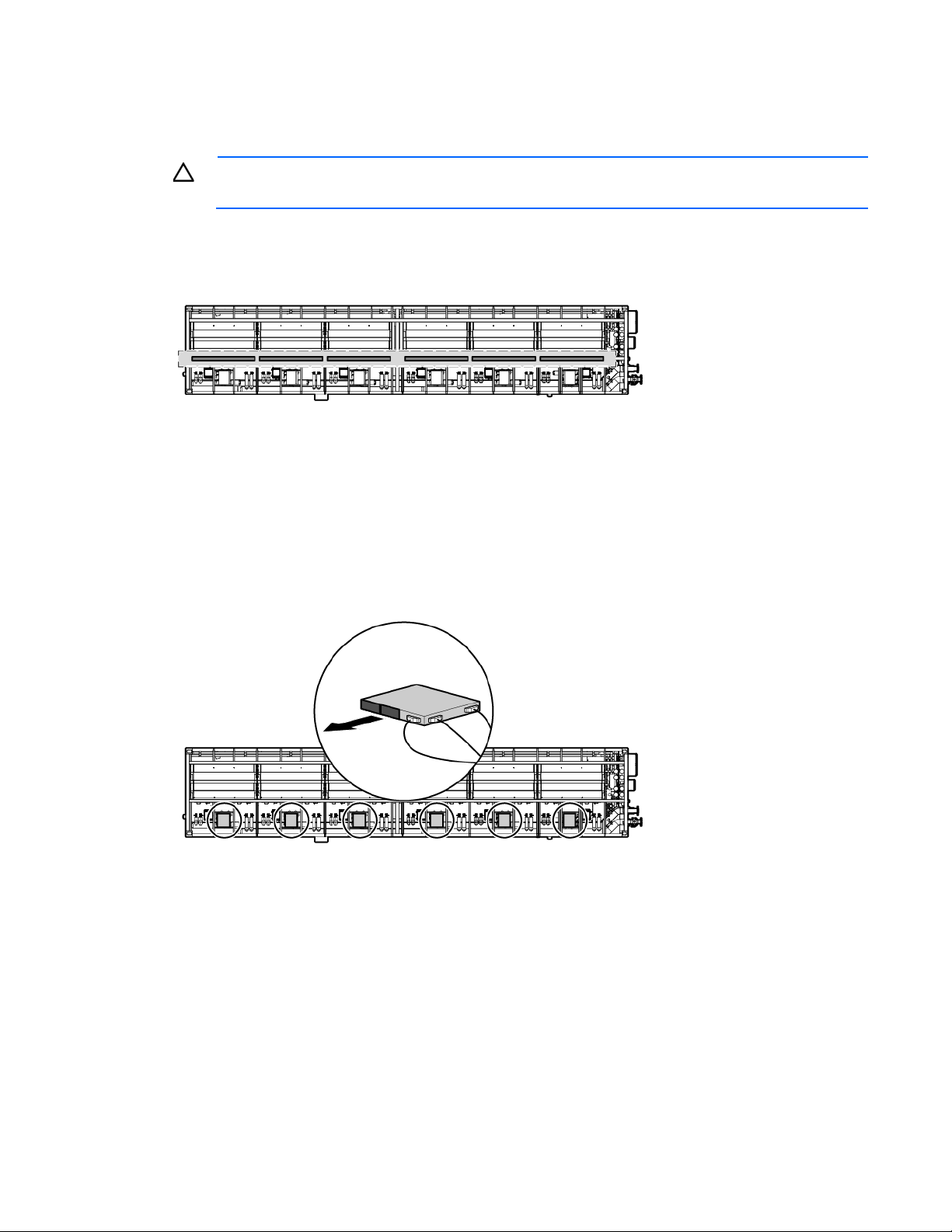

The HP POD 40c G2 contains two humidity sensors, one in cooling zone 2 and one in cooling zone 5.

Removing the humidity sensor

You need a Phillips-head screwdriver for installation.

1. Remove the four screws that secure the sensor cover (1), and then remove the cover (2).

Removal and replacement procedures 50

Page 51

2.

Loosen the sensor wires by turning the nut counter clockwise (1), remove the sensor wires from the

terminal block, and then remove the sensor wires (3).

3. Remove the two screws that secure the sensor (1), and then remove the sensor (2).

Removal and replacement procedures 51

Page 52

Replacing the humidity sensor

1. Replace the sensor (1), and then secure the sensor with two screws (2).

2. Insert the sensor wire into the nut (1), secure the wire by turning the nut clockwise (2), and then insert the

wire into the terminal block (3).

Removal and replacement procedures 52

Page 53

3.

Replace the sensor cover (1), and then secure the cover with four screws (2).

LED light

Each POD contains eight LED lights.

Removing the LED light

You need adhesive tape for installation.

1. Pull the LED light panel out (1).

Removal and replacement procedures 53

Page 54

2.

Disconnect the LED light panel (2).

Replacing the LED light

1. Connect the new LED light panel to the LED fixture (1).

2. Replace the LED light panel by pressing it into the LED fixture (2).

Removal and replacement procedures 54

Page 55

Temperature sensor (cold aisle)

The HP POD 40c G2 contains six temperature sensors in the cold aisle.

Removing the cold aisle temperature sensor

You need a Phillips-head screwdriver and scissors for installation.

1. Remove the two screws that secure the sensor cover (1), and then remove the cover (2).

2. Cut the two red wires inside the sensor box.

Removal and replacement procedures 55

Page 56

3.

For each of the five clamps securing the sensor tube to the HP POD 40c G2 structure, remove the screw

that secures the clamp (1), rotate the clamp (2), and then pull the clamp out to remove the clamp (3).

4. Remove the sensor tube.

Replacing the cold aisle temperature sensor

1. Replace the sensor tube, and then secure the tube with five clamps. For each clamp, replace the clamp

(1), and then secure the clamp with a screw (2).

2. Splice the two sensor tube wires with the red wires inside the sensor box.

Removal and replacement procedures 56

Page 57

3.

Replace the sensor cover (1), and then secure the cover with two screws (2).

Temperature sensor (hot aisle)

The HP POD 40c G2 contains six temperature sensors in the hot aisle.

You need a Phillips-head screwdriver for installation.

Removal and replacement procedures 57

Page 58

Removing the hot aisle temperature sensor

1. Remove the four screws that secure the sensor cover (1), and then remove the cover (2).

2. Loosen the sensor wires by turning the nut counter clockwise (1), remove the sensor wires from the

terminal block, and then remove the sensor wires (3).

Removal and replacement procedures 58

Page 59

3.

Remove the two screws that secure the sensor (1), and then remove the sensor (2).

Replacing the hot aisle temperature sensor

1. Replace the sensor (1), and then secure the sensor with two screws (2).

Removal and replacement procedures 59

Page 60

2.

Insert the sensor wire into the nut (1), secure the wire by turning the nut clockwise (2), and then insert the

wire into the terminal block (3).

3. Replace the sensor cover (1), and then secure the cover with four screws (2).

VESDA filter

The VESDA filter sensor notifies you through the ECS when a filter must be changed. HP recommends

periodically inspecting and changing each VESDA filter. A VESDA filter can be replaced during normal HP

POD 40c G2 operation.

You need a Phillips-head screwdriver for installation.

Removal and replacement procedures 60

Page 61

Removing the VESDA filter

1. Remove the filter cover on the front of the VESDA unit.

2. Remove the 10mm screw that secures the VESDA filter (1), and then remove the filter (2).

Replacing the VESDA filter

1. Insert the new VESDA filter (1), and then replace the 10mm screw that secures the filter (2).

Removal and replacement procedures 61

Page 62

2. Replace the VESDA filter cover.

Removal and replacement procedures 62

Page 63

Periodic maintenance

Inspect and replace as necessary

As needed

HP and certified

•

•

•

•

•

•

Periodic maintenance overview

Perform periodic inspections on the components in this section to ensure that the HP POD 40c G2 continues

to perform within the designed parameters.

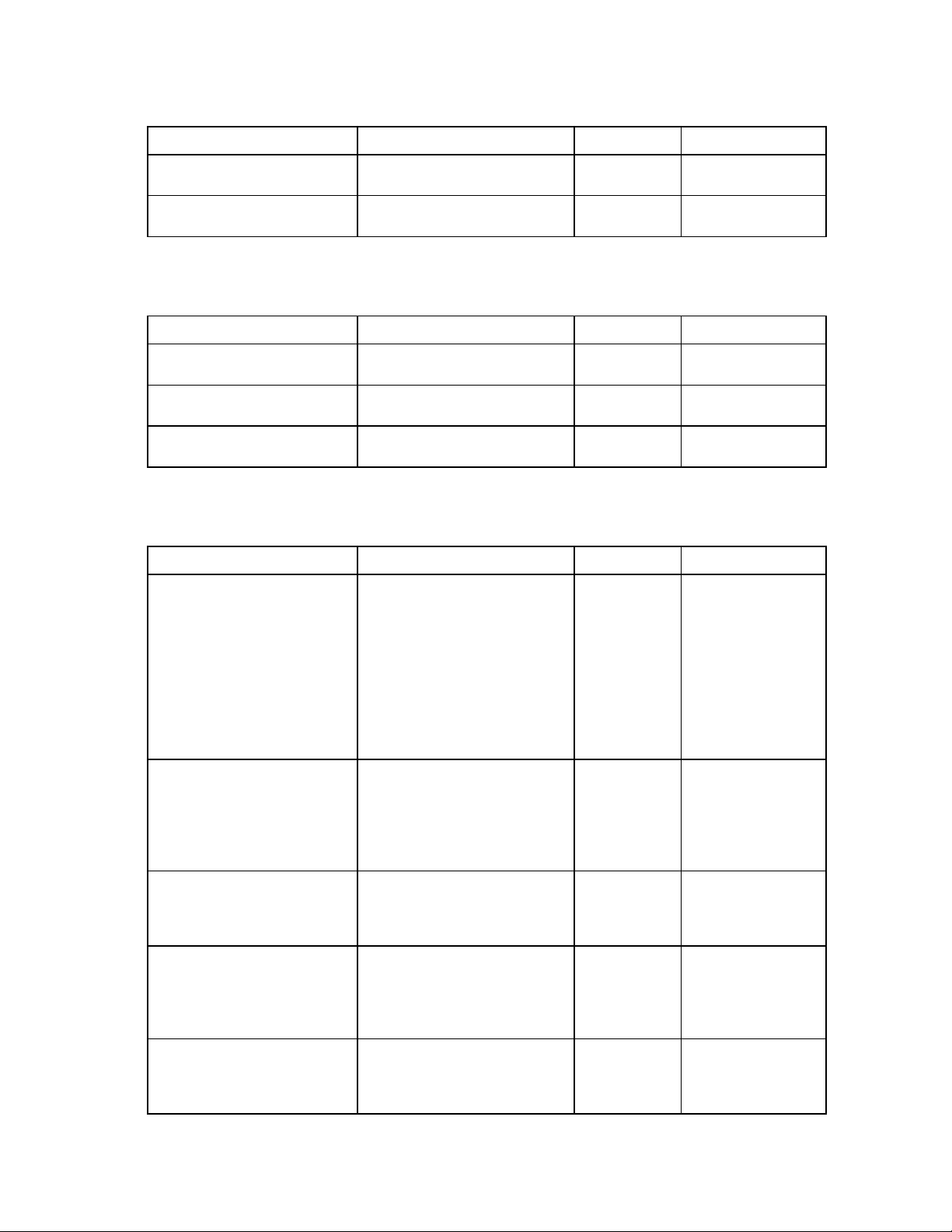

Cooling system maintenance schedule

Component to be inspected Task Frequency Capable Party

Air filters

Air filter differential pressure

switch

Condensate drain lines and

p-trap

Condensate drain pans

Inspect and test, replace as

necessary

Inspect and clean or blowout

p-trap and lines as necessary

Inspect pans:

Annually HP and certified

Quarterly HP and certified

Quarterly HP and certified

Free of debris

No leaks

Leakage detectors are in

proper position

Drain line is open

Water can pass through freely

Condensate traps are filled

with water

Clean pans as necessary

Drain pan sensors

Conduct visual inspection for

leakage during the air filter

checks

Heat exchanger fans

Humidifier (if installed)

—

Inspect and test, replace as

necessary

If a leak is detected, see "Leak

detection maintenance (on page

64)."

Inspect and clean as necessary Quarterly HP and certified

Inspect wiring and verify that

electrical components are secure

and fan power supplies are locked

into position

Inspect for water leaks, verify that

no sparks form between the

electrodes during operation, and

inspect the general operation of

the cylinder.

Put the humidifier in system flush

mode and inspect drain flow and

water supply flow. Inspect, clean,

and/or replace as necessary.

Quarterly HP and certified

Quarterly HP and certified

Bi-weekly HP and certified

Quarterly HP and certified

facilities personnel

facilities personnel

facilities personnel

facilities personnel

facilities personnel

facilities personnel

facilities personnel

facilities personnel

facilities personnel

Periodic maintenance 63

Page 64

Component to be inspected Task Frequency Capable Party

—

Inspect for any water leaks and

replace the cylinder if necessary.

Inspect for blackened areas on the

cylinder and, if present, check the

condition of the electrodes. If

necessary, replace the cylinder.

—

Replace the cylinder. Annually HP and certified

Quarterly HP and certified

facilities personnel

facilities personnel

Leak detection maintenance

WARNING: To reduce the risk of electric shock or damage to the equipment, use extreme

caution when removing and replacing components that involve water around the electrical

Non-isolable leak detection

A non-isolable leak is a leak from the main supply line or the return header.

To repair a non-isolable leak:

1. Power down all IT equipment.

2. Re-direct the leaking water away from the IT equipment.

3. Repair the leak or contact HP if you are still within your service contract.

Isolable leak detection

equipment. There is great risk of electrical shock when water is used near electricity.

CAUTION: If a serious leak develops, shut down the POD immediately and isolate the chilled

water cooling system from the site. Contact HP immediately to initiate a field service call. Do not

attempt to repair the chilled water cooling system. Attempting to self-repair the chilled water

cooling system during the warranty or service contract period shifts all liability to you.

IMPORTANT: HP recommends shutting down the POD after a leak is detected. For more

information, see "Power down procedure" in the user guide.

An isolable leak is any type of leak that does not occur from the main supply line or the return header.

To repair an isolable leak:

1. Inspect the zone indicated on the ECS Status Overview screen. You might need to inspect each zone

condensate drain pan to determine the exact location of the leak.

2. Power down the IT equipment in the zone where the leak is located.

3. Determine the affected heat exchanger.

4. Close and danger tag the supply and return valves to the affected heat exchanger.

If the heat affected exchanger cannot be identified, close all the heat exchanger supply and return

valves in the affected zone and open one supply valve at a time to determine the location of the leak.

5. Repair the leak or contact HP if you are still within your service contract.

Periodic maintenance 64

Page 65

Check and clear alarm log

Quarterly

Certified facilities

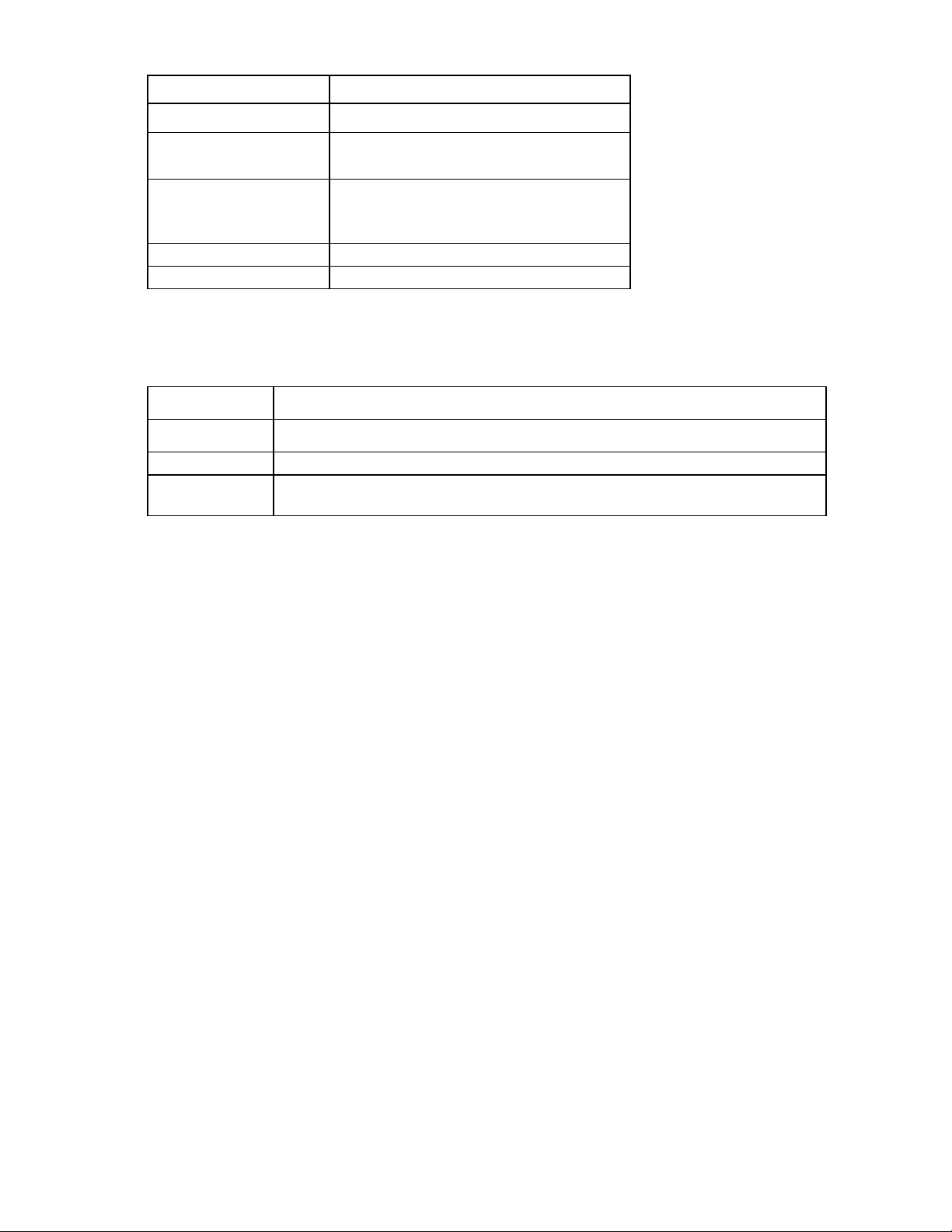

Drains

Component to be inspected Task Frequency Capable Party

Drains

—

ECS

Component to be inspected Task Frequency Capable Party

Full system functional check

—

—

Electrical

Component to be inspected Task Frequency Capable Party

Electrical connections (might

require a scheduled shutdown)

—

—

—

—

Visually check drains for blockage Monthly Certified facilities

personnel

Functionally test drains Quarterly Certified facilities

personnel

Operational check of all system

components

Inspect and test ECS battery

backup system

Infrared inspections of all power

connections under normal

customer load including

transformer, switchboard, and

electrical panels (Periodic thermal

scans of all electrical connections

can reduce issues caused by

connections becoming loose due

to operational vibrations over

time.)

Busway drop box visual inspection

and torque test of connections.

Retighten as necessary and verify

adequate distance between

connection lugs and drop box

grounded steel.

Busway visual inspection of

busway section and connector

interconnects. Retighten as

necessary.

Busway drop box connections and

locking bolt. Visual inspection and

torque test of locking bolt. Visually

inspect drop box load cable and

cord-cap.

Visually inspect drop box breaker

and torque test breaker lug

connections. Mechanically

exercise drop box breaker.

Quarterly Certified facilities

personnel

personnel

Bi-annually Certified facilities

personnel

Annually Licensed electrician

Annually Licensed electrician

Annually Licensed electrician

Annually Licensed electrician

Annually Licensed electrician

Periodic maintenance 65

Page 66

Component to be inspected Task Frequency Capable Party

—

Electrical panel, breaker,

disconnect, and transformer visual

inspection for condensation or

other degradation of buses and

connections

—

Electrical panel, breaker,

disconnect, and transformer bolt

torque testing. Retighten as

necessary.

—

—

Grounding system resistance test Bi-annually Licensed electrician

Ground and grounding

connection/lug located internal of

each electrical panel torque test.

Clean and retighten as necessary.

—

Grounding connection/lug

located external on the POD

torque test. Clean and retighten as

necessary.

—

Service entrance ground

connection/lug located at external

transformer and switchboard

torque test. Clean and retighten as

necessary.

—

Service entrance grounding

ground-rod/ground well

connecting/lug located at

locations external to POD torque

test. Clean and retighten as

necessary.

—

Grounding system bonding

jumpers connecting racks to POD

structure and rack to rack torque

test. Clean and retighten as

necessary.

—

Panel breaker operational test

(Simulate a breaker response to a

load greater than the breaker

rating.)

—

Visual inspection of breakers,

disconnects, motor starters, and

fuse holders

—

Calibrate all temperature,

pressure, and humidity sensors.

—

Visual inspection of lighting

fixtures and lamps. Measure foot

candles and replace as necessary.

Annually Licensed electrician

Annually Licensed electrician

Bi-annually Licensed electrician

Bi-annually Licensed electrician

Bi-annually Licensed electrician

Bi-annually Licensed electrician

Bi-annually Licensed electrician

Annually Licensed electrician

Bi-annually Licensed

electrician/Certified

facilities personnel

Annually Certified facilities

personnel

Bi-annually Licensed

electrician/Certified

facilities personnel

Periodic maintenance 66

Page 67

Fire alarm and suppression system

Component to be inspected Task Frequency Capable Party

Full system functional check

Inspect and perform a functional

check of the system.

—

Inspect and test fire panel

battery backup system.

—

Inspect and test VESDA power

supply.

—

Inspect the VESDA pipe

network.

—

—

Inspect the VESDA filter. Annually Certified facilities

Conduct a VESDA pipe integrity

smoke test.

—

—

Check the VESDA pipe flow. Annually Licensed fire safety

Clean the VESDA sampling

points.

—

—

Flush the VESDA pipe network. Every 2 years Licensed fire safety

VESDA system air

sampling/smoke test

—

—

Suppression system test As required by

Fire-pull visual and operational

inspection

—

Fire strobe and horn visual and

operational inspection

As required by

local code

Bi-annually Licensed fire safety

Quarterly Licensed fire safety

Bi-annually Licensed fire safety

Annually Licensed fire safety

Every 2 years Licensed fire safety

As required by

local code

local code

As required by

local code

As required by

local code

Licensed fire safety

contractor

contractor

contractor

contractor

personnel

contractor

contractor

contractor

contractor

Licensed fire safety

contractor

Licensed fire safety

contractor

Licensed fire safety

contractor

Licensed fire safety

contractor

Generator (if applicable)

Component to be inspected Task Frequency* Capable Party

Generator

—

—

—

—

—

*These are typical frequencies. See the documentation for the installed component for the recommended schedule.

Visual inspection of the generator Quarterly HP and certified

Oil change Annually HP

Oil filter change Annually HP

Oil analysis Annually HP

Fuel filter change Annually HP

Coolant freeze point and

inhibition check each time the

generator is viewed

facilities personnel

— HP

Periodic maintenance 67

Page 68

Personnel door emergency egress

Bi-annually

Certified facilities

HP POD 40c G2 structure

Component to be inspected Task Frequency Capable Party

Complete structure

—

—

Visually inspect the structural

integrity.

Inspect the door operation and

inspect the door gaskets for water

and air leaks.

Visually inspect the paint. Perform

prep and touch-up as necessary.

Life safety

Component to be inspected Task Frequency Capable Party

EPO system

—

—

—

—

—

—

—

EPO functional test with manual

and automatic shutdown. (Verify

all shunt-trips on all panels trip.)

EPO alarms Annually Licensed EPO safety

EPO bypass keyed switch

(functional test)

EPO bypass switch located at

each personnel door. (Functional

test. Verify system time-out reset

when switch is activated.)

EPO status light. (Verify operation

in different modes. Replace lamps

as necessary.)

Exit lights. (Verify exit lights are

visible when all lighting is off and

POD doors are closed.)

Tritium exit signs (Visual

inspection)

panic bars. (Visual and

operational inspection.)

Annually Certified facilities

personnel

Annually Certified facilities

personnel

Annually Certified facilities

personnel

Annually Licensed EPO safety

contractor

contractor

Annually Licensed EPO safety

contractor

Annually Licensed EPO safety

contractor

Annually Licensed EPO safety

contractor

Bi-annually Certified facilities

personnel

Bi-annually Certified facilities

personnel

personnel

Security

Component to be inspected Task Frequency Capable Party

System functional test

—

Visual inspection and operational

test of door access contact

switches

Visual inspection and operational

test of door access card readers,

electric strikes, and door release

switches at each personnel door

and/or in each personnel door

panic bar

Annually Certified facilities

personnel

Annually Certified facilities

personnel

Periodic maintenance 68

Page 69

Telemetry review

Annually

HP

Component to be inspected Task Frequency Capable Party

—

Exterior water proofing check for

ingress using water hose

Annually Certified facilities

personnel

Switchgear

Component to be inspected Task Frequency Capable Party

Switchgear

—

—

—

Infrared inspection of all electrical

power connections while under

normal load

Grounding and electrical systems Annually HP and certified

Panel operational testing Annually HP and certified

Breakers/disconnects Annually HP and certified

Third-party components

See the Operations and Maintenance Manual for the HP Performance Optimized Datacenter 40c for other

required maintenance items.

UPS

Component to be inspected Task Frequency Capable Party

UPS

—

—

—

—

Vacuum Pump oil change Annually HP

Log file review Annually HP

Calibration verification Annually HP

Replace bearings Every 2.5 to 3

Annually HP and certified

facilities personnel

facilities personnel

facilities personnel

facilities personnel

HP

years

Periodic maintenance 69

Page 70

Specifications

•

•

•

30 kW

General HP POD 40c G2 specifications

Features Specifications

Overall dimensions

Weight1

Maximum power2

Power input voltage

Power distribution3

Maximum rack quantity

Rack Units (RU) per rack

Rack Units (RU) total

Average capacity per rack (kW)

Peak rack capacity

Voltage to rack

Minimum quantity of PDUs per HP POD 40c G2

Maximum quantity of PDUs per HP POD 40c G2

Maximum power per PDU

Network supported

1

The Empty weight includes the HP POD 40c G2 structure, empty racks, PDUs, and drop boxes. It does not include IT

equipment.

2

The maximum power depends on the exact installation and power configuration in your POD. The HP POD 40c G2 is

electrically limited to 600 kW.

3

The HP POD 40c G2 can be configured for redundancy or non-redundancy.

Height—3.66 m (12 ft)

Length—12.19 m (40 ft)

Width—2.43 m (7.97 ft)

Empty—16,783 kg (37,000 lb)

Maximum fully loaded—46,266 kg (102,000 lb)

600 kW HP POD 40c G2

380 VAC to 415 VAC

8 x 200 A electrical busways

20 racks

50 RU

1000 RU

69 kW

200 VAC to 240 VAC

20 (one per rack)

40 (two per rack)

30A = 17 kW; 60A = 34 kW

Bulk cable pass-through-fiber

Bulk cable pass-through-copper

(Optional) External rated DEMARC box

Electrical specifications

Electrical busway system information

Feature Specification

Number of busways

Frequency

Amps (per busway)

Voltage (per busway)

Grounding

Busway configuration

8

60 Hz

200 A

380 to 415 V

Copper

3-phase + neutral + equipment ground

Specifications 70

Page 71

Fire alarm panel connections

•

•

The electrical layout of the fire alarm system is as described in the schematic drawing supplied with the HP

POD 40c G2.

Water specifications

The following table describes the chilled water system specifications for the HP POD 40c G2.

Feature Specification

Facility input temperature to the HP POD

40c G2

Working pressure

HP POD 40c G2 pressure drop

HP POD 40c G2 water flow rate

Chilled water supply and return

connections

Rack specifications

Standard HP POD 40c G2 racks (AT978A)

Feature Specification

U height

Width

Depth

Maximum load weight

*This specification indicates the maximum clearance for the cold aisle. Equipment cannot exceed this measurement.

50U

54.6 cm (21.5 in)

99 cm (39 in)*

1,360.7 kg (3,000 lb)

12ºC to 24ºC (55ºF to 75ºF)

1,034 kPa (150 psi)

172.4 kPa (25 psi)

908.5 lpm (240 gpm)

North America—Two 10.16 cm (4 in) ASME B16.5 class #150

flanges

International—Two DIN PN16 DN100 flanges

Thermal and air flow performance

Maximum thermal and air flow

HP POD 40c G2 specification

performance parameters

Air temperature—Inlet to rack-mounted

components)

Chilled water temperature

Total rack-mounted component air flow

Heat rejection capacity

Dependent on IT configuration and chilled water inlet temperature

12°C to 24°C (55°F to 75°F)

Variable as required to maintain the hot aisle setpoint temperature

and dependent on IT configuration

600 kW

Environmental specifications

Feature Specification

Operating temperature

-28ºC to 54ºC (-18ºF to 130ºF)

Specifications 71

Page 72

Feature Specification

•

•

•

•

Non-operating temperature*

-29ºC to 54ºC (-20ºF to 130ºF)

Operating humidity

0% to 100% external

10% to 90% non-condensing internal

Non-operating humidity*

5% to 95% relative non-condensing

39ºC (102ºF) maximum wet bulb

temperature

Operating altitude

Non-operating altitude

*For non-operating specifications, consider the temperature of computer and IT equipment inside the HP POD 40c G2.

-76.2 m to 3,048 m (-250 ft to 10,000 ft)

-76.2 m to 9,144 m (-250 ft to 30,000 ft)

Optional features specifications

Feature Specification

Fire suppression

Card reader

Humidifier

3M Novec 1230 fire extinguishing system provided in two canisters (main and reserve)

12-key pad with 125 KHz proximity and 13.56 MHz contactless smart card

Provides 2-8 lb/hr of water vapor into cold aisle to maintain POD environment within 20%

to 80% relative humidity

Specifications 72

Page 73

Contacting HP

Before you contact HP

Be sure to have the following information available before you call HP:

• Active Health System log

Download and have available an Active Health System log for 3 days before the failure was detected.

For more information, see the HP iLO 4 User Guide or HP Intelligent Provisioning User Guide on the HP

website (http://www.hp.com/go/ilo/docs).

• Onboard Administrator SHOW ALL report (for HP BladeSystem products only)

For more information on obtaining the Onboard Administrator SHOW ALL report, see the HP website

(http://h20000.www2.hp.com/bizsupport/TechSupport/Document.jsp?lang=en&cc=us&objectID=c

02843807).

• Technical support registration number (if applicable)

• Product serial number

• Product model name and number

• Product identification number

• Applicable error messages

• Add-on boards or hardware