Page 1

HP Performance Optimized Datacenter 40c G2

Part Number: 695162-002

Site Preparation and Requirements Guide

Abstract

This document provides site preparation guidance for the HP Performance Optimized Datacenter 40c G2 (HP POD 40c G2).

August 2012

Edition: 2

Page 2

© Copyright 2012 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

Page 3

Contents

Overview ..................................................................................................................................... 5

About this document .................................................................................................................................. 5

Safety and NEC compliance ....................................................................................................................... 5

Site assessment ......................................................................................................................................... 6

Site preparation ........................................................................................................................................ 6

Site safety and security .............................................................................................................................. 6

Fire detection and suppression .................................................................................................................... 6

HP POD 40c G2 capacities ........................................................................................................... 7

HP POD 40c G2 capacity limitations ........................................................................................................... 7

Electrical power capacities (critical IT power) ...................................................................................... 7

Mechanical cooling capacities .......................................................................................................... 7

Overall system capacities ........................................................................................................................... 7

Site requirements .......................................................................................................................... 8

Site pad ................................................................................................................................................... 8

HP POD 40c G2 weight ............................................................................................................................. 8

Dimensions and clearances ........................................................................................................................ 8

Safety and clearance area .............................................................................................................. 10

Future expansions .......................................................................................................................... 11

Grounding requirements ........................................................................................................................... 11

Utilities ................................................................................................................................................... 12

Humidifier water supply ................................................................................................................. 12

Drainage ...................................................................................................................................... 13

Chilled water supply ...................................................................................................................... 13

Piping materials ............................................................................................................................ 15

Power infrastructure installation ................................................................................................................. 15

Site electrical system ...................................................................................................................... 15

Electrical power system configuration ............................................................................................... 15

Transformers and switchboards ....................................................................................................... 16

Supported facility connections ...................................................................................................... 17

Environmental control system .................................................................................................................... 17

Additional POD connections ..................................................................................................................... 17

Connection portals .................................................................................................................................. 17

Demarcation box .................................................................................................................................... 18

Fire box ................................................................................................................................................. 19

Humidifier .............................................................................................................................................. 20

HP POD 40c G2 security ......................................................................................................................... 20

Fire, safety, and security notifications ......................................................................................................... 20

Environmental considerations ....................................................................................................... 22

Environmental risks .................................................................................................................................. 22

Cold weather .......................................................................................................................................... 22

Areas prone to lightning or power surges ................................................................................................... 22

Seismic activity ....................................................................................................................................... 22

Site plan requirements and actions ............................................................................................... 23

Contents 3

Page 4

Completing a site assessment .................................................................................................................... 23

HP Site Preparation Drawing Package ....................................................................................................... 23

Zoning and permit requirements ................................................................................................................ 23

Project coordination ................................................................................................................................. 23

Site planning .......................................................................................................................................... 24

HP POD 40c G2 installation ........................................................................................................... 24

Appendix A: HP site assessment ................................................................................................... 27

HP POD 40c G2 site assessment checklist .................................................................................................. 27

Appendix B: Preparing for delivery ............................................................................................... 31

Pre-delivery tasks ..................................................................................................................................... 31

Installation prerequisites ................................................................................................................. 31

HP POD 40c G2 site readiness checklist .................................................................................................... 31

Appendix C: Regulatory compliance notices .................................................................................. 35

HP POD 40c G2 regulatory compliance ..................................................................................................... 35

Regulatory compliance identification numbers ................................................................................... 35

Federal Communications Commission notice ..................................................................................... 35

Modifications ................................................................................................................................ 35

Cables ......................................................................................................................................... 36

Canadian notice (Avis Canadien) .................................................................................................... 36

Glossary .................................................................................................................................... 37

Documentation feedback ............................................................................................................. 39

Index ......................................................................................................................................... 40

Contents 4

Page 5

Overview

About this document

This document outlines the site preparation requirements for an HP Performance Optimized Datacenter 40c

G2. The customer must provide a qualified architectural or consulting engineering team to generate

site-specific documents for each HP POD 40c G2 installation, including final site drawings. The customer's

site installation design must comply with all local and national regulations, ordinances, codes, and the

Safety and NEC compliance

specifications listed in this document.

The HP POD 40c G2 is certified to UL 69050-1/IEC 60950-22 as a Modular Data Center Information

Technology Product and classified according to the National Electric Code NFPA 70 in accordance with

NEC (NA) and IEC (EMEA and APJ). Relevant parts of UL1995 are applied to the air handling features of the

product. For more information, see "HP POD 40c G2 regulatory compliance (on page 35)."

The HP POD 40c G2 is not suitable for long-term human occupancy. The HP POD 40c G2 has service access

areas for periodic maintenance and service. These areas must be used only by owner-authorized personnel

who are trained in the maintenance and service of the HP POD 40c G2 components.

IMPORTANT: Before installing the HP POD 40c G2, consult your local AHJ for applicable codes

and to review site-specific location guidelines. If needed, obtain any necessary permits.

Additional considerations for safety and NEC compliance are as follows:

• The HP POD 40c G2 is listed as an Information Technology Equipment Product to UL 60950.

• The HP POD 40c G2 is evaluated as a "non-inhabitable product" that provides "service access" areas

for customer-authorized, qualified, and trained service personnel.

• The electrical connections of the HP POD 40c G2 are evaluated as feeder connections for connection

to an existing facility, and are not suitable as "service entrance" for connection to the utility.

• The HP POD 40c G2 is designed for stationary installation outdoors in a Pollution Degree 3

environment, in restricted access locations, with field wiring terminals provided for permanent supply

connections.

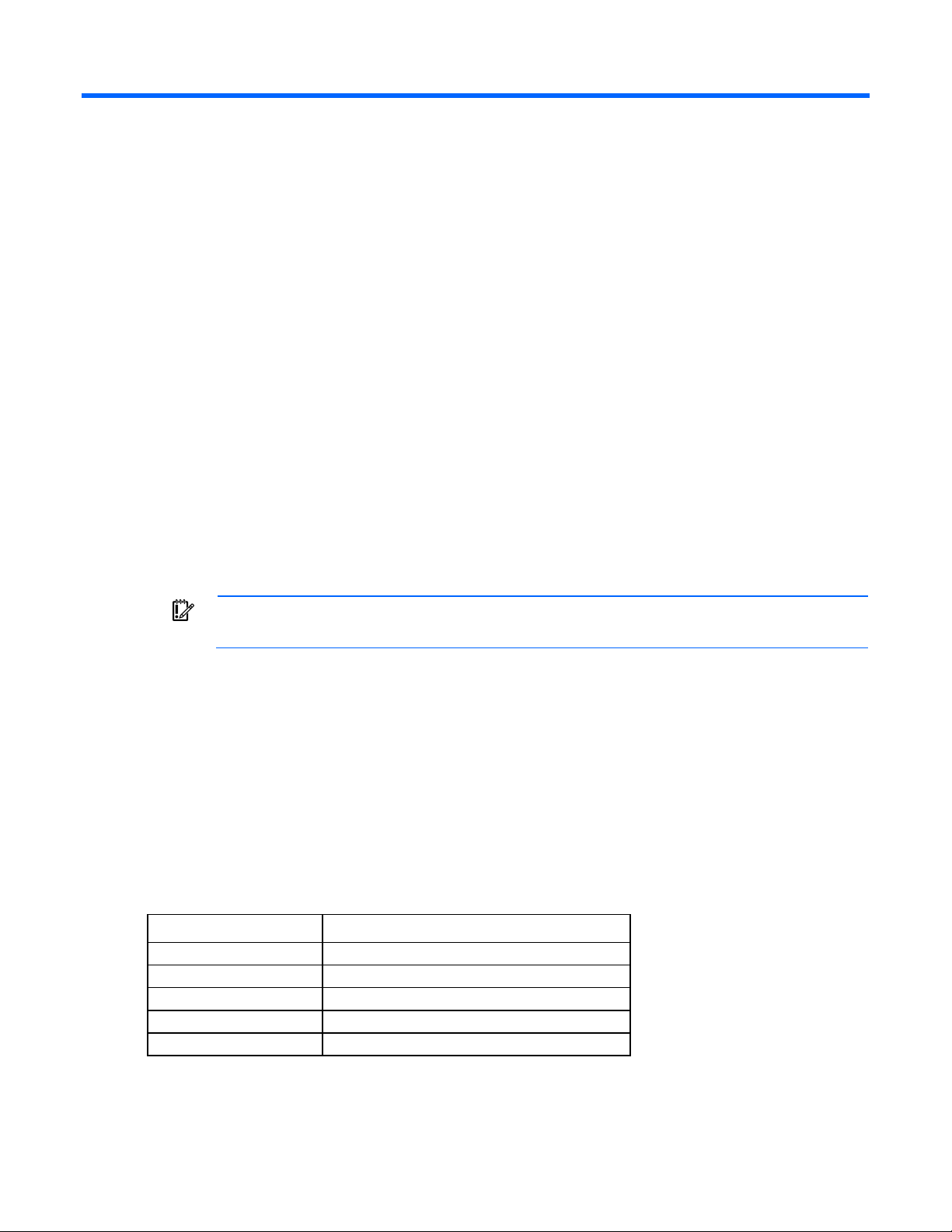

• The HP POD 40c G2 meets the following ratings:

Feature Specification

Category

Protection

Class

Ambient temperature

Relative humidity

Rated Overvoltage Category III

Surge protection device

Class1

2°C to 54°C (35.6°F to 129.2°F)

0% to 100% humidity

• As part of the overall certification, relevant sections of the International Building Code have been

applied as part of the design and evaluation. The current design supports wind loads up to 90 mph.

Overview 5

Page 6

Site assessment

HP requires a detailed site assessment prior to planning and preparing the customer site location for the HP

POD 40c G2. Consult with HP to schedule a site assessment.

Site preparation

Site preparation must be complete prior to the POD delivery to ensure a timely installation and

commissioning. The site must meet all pad, power, and chilled water requirements.

Site safety and security

Each customer site must have its own standard safety and security requirements. The HP Program Managers

work with the customer to ensure adherence to the appropriate precautions. HP is not responsible for

determining or enforcing safety or security requirements. The customer must conduct all health and safety

evaluations of the HP POD 40c G2, only using HP as a support mechanism.

Fire detection and suppression

The fire suppression system, supplied as an optional component of the HP POD 40c G2, is a "Manufacturer

Designed" system specifically for this HP product, in compliance with national standards.

The HP standard suppression system includes a Novec 1230 clean agent system. However, if the customer

or local AHJ requires specific modifications or a replacement, HP can assist in these actions at the expense

of the customer.

HP does not certify that the fire suppression system installed in the HP POD 40c G2 meets all local and

jurisdictional requirements. The customer is responsible for the following actions as related to the fire

suppression system:

• Verifying that the POD suppression system meets local codes, including specific local requirements for

initial and periodic inspections.

• Arranging for and receiving all required local permits, including initial commissioning as well as

standard and repair maintenance.

• Arranging for the connection of the agent tanks, refilling of tanks, and all system testing, including

pressure tests. All general maintenance of the suppression system must be completed by an authorized

technician.

Additional local requirements are not covered as part of the option price or basic installation and

deployment services, unless specifically included in an executed Statement of Work.

Overview 6

Page 7

HP POD 40c G2 capacities

HP POD 40c G2 capacity limitations

The capacity limitations for the HP POD 40c G2 are separated into two categories: electrical power and

mechanical cooling capacities. Both of these categories are interdependent and must be considered in

Electrical power capacities (critical IT power)

Mechanical cooling capacities

conjunction with the overall customer requirements.

The electrical system of the HP POD 40c G2 has two main feeds, A and B, each rated at 800 A 415 VAC

Wye 3-Phase.

The HP POD 40c G2 cooling system consists of 6 zones. Each zone includes 2 heat exchangers and 18 fans.

Cooling capacities are based on:

• Chilled water inlet temperature of 15.6ºC (60ºF)

• Heat exchanger fluid delta temperature of 5.5ºC (10ºF)

• Pure water cooling

• Chilled water flow rate of 908 lpm (240 gpm)

• Average air flow of 2000 cfm per rack

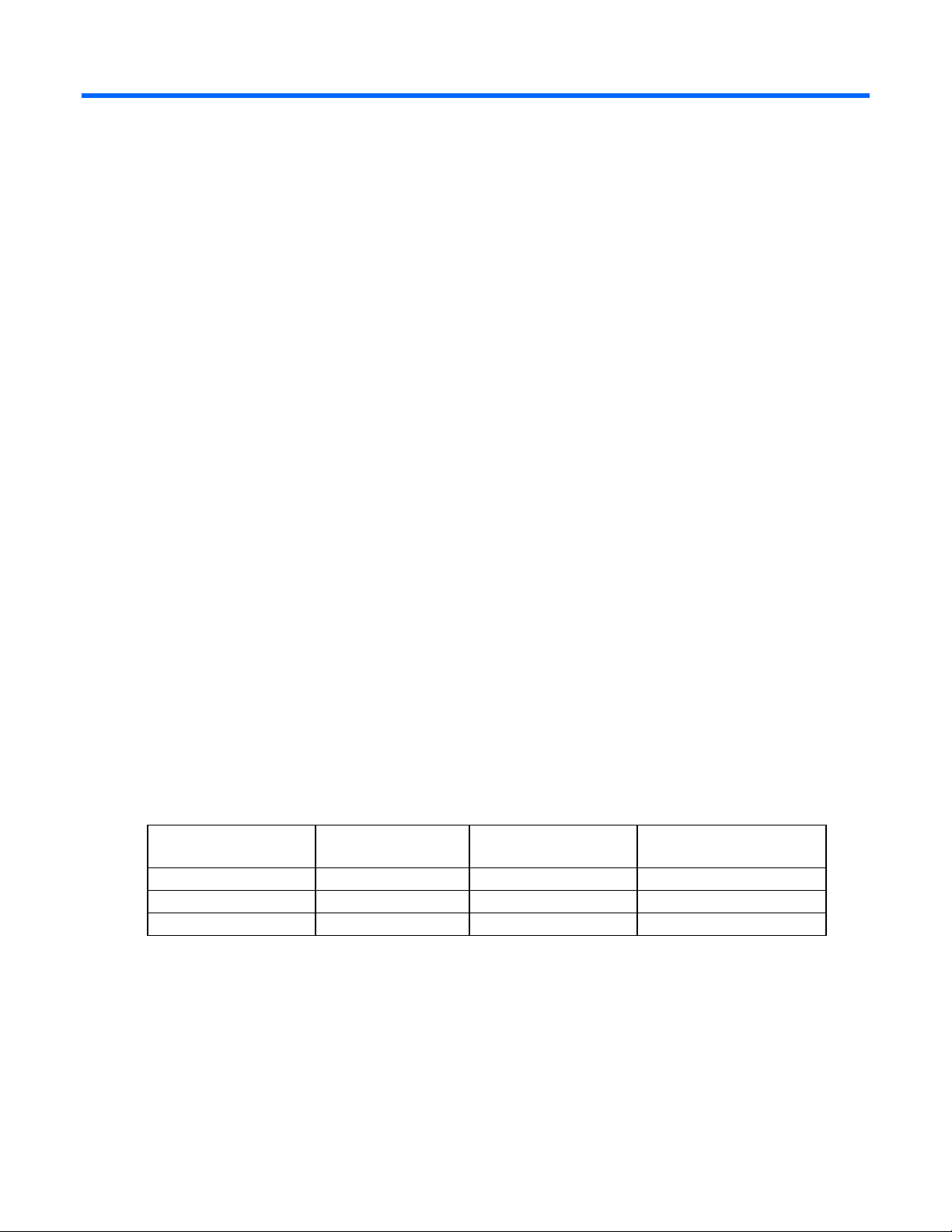

Overall system capacities

The HP POD 40c G2 overall system capacities are provided in the following table. It is the customer's

responsibility to understand the level of redundancy required for their particular application and its

associated limiting factor.

Redundancy level Electrical (kW) Thermal (kW) Limiting factor

N

N+1

2N

*The thermal limitation factors are described in "Mechanical cooling capacities (on page 7)."

— 600 Thermal*

— 400 Thermal*

576 300 Thermal*

HP POD 40c G2 capacities 7

Page 8

Site requirements

total weight of the HP POD 40c G2 differs based on the IT equipment and optional components

Site pad

The structural design of the HP POD 40c G2 site pad must be based on the specific weight load of the

complete POD solution with IT installed, as well as any additional equipment. During design calculations, HP

recommends that you provide structural support along the entire perimeter of the POD and use the maximum

allowable POD weight.

Upon installation, the POD structure must be leveled to ≤ 0.5º. Shimming is allowed around the perimeter of

the POD to ensure that the POD remains level.

IMPORTANT: The HP POD 40c G2 is designed for ground level installation. If you install the HP

POD 40c G2 on an elevated surface, verify that the minimum height requirements for circuit

breaker actuators are considered per local and national requirements and electrical codes. The

area in front of the outside panels must include a work platform.

HP POD 40c G2 weight

IMPORTANT: The weight provided is a minimum and an absolute maximum rated weight. The

purchased and installed.

The overall weight might significantly vary depending on the final customer-chosen solution for the HP POD

40c G2. Each site pad must meet the weight requirements of the equipment that is expected to be installed.

The HP POD 40c G2 must be installed on a surface capable of supporting the following weights:

• HP POD 40c G2 without IT equipment installed—Approximately 16,783 kg (37,000 lb)

• HP POD 40c G2 with IT equipment installed—Maximum 46,266 kg (102,000 lb)

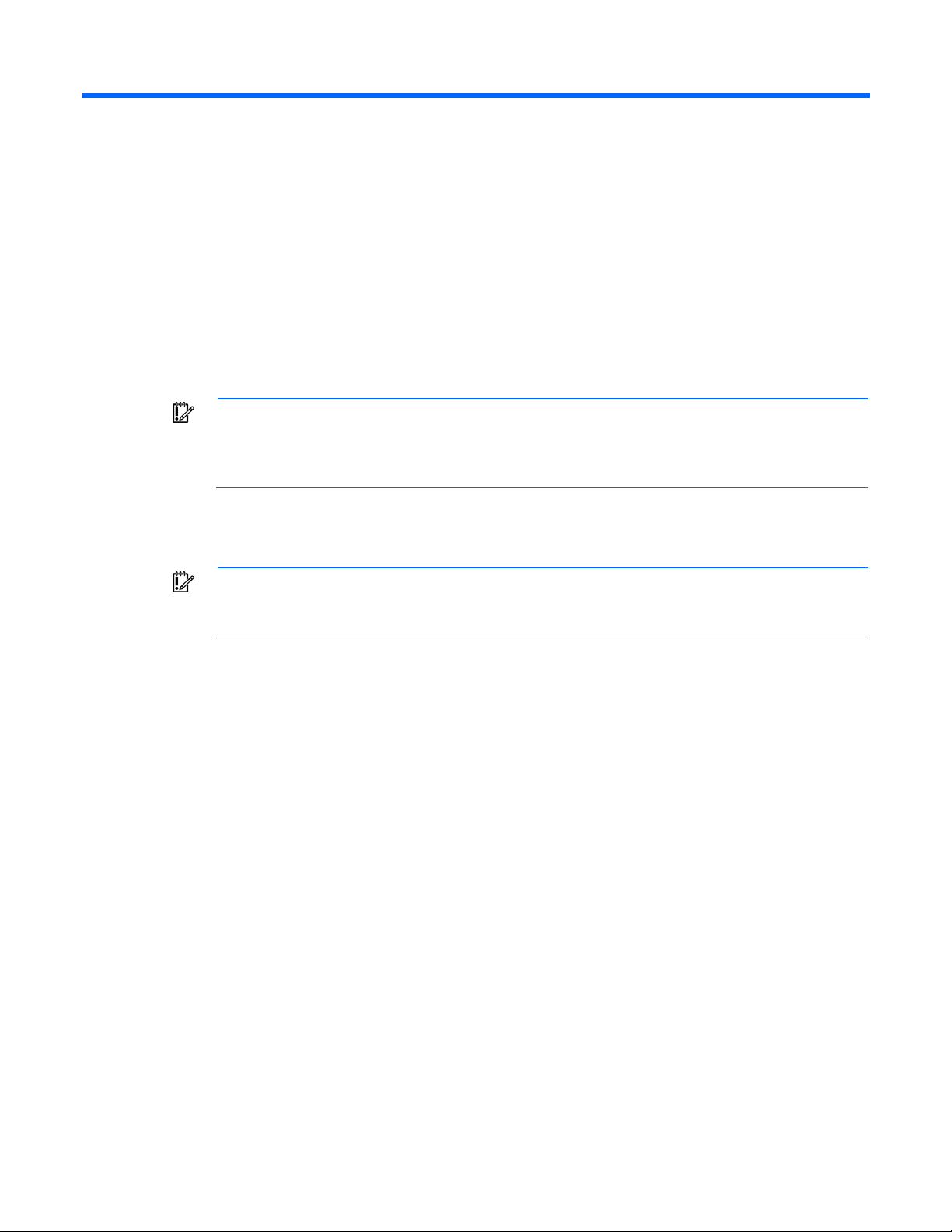

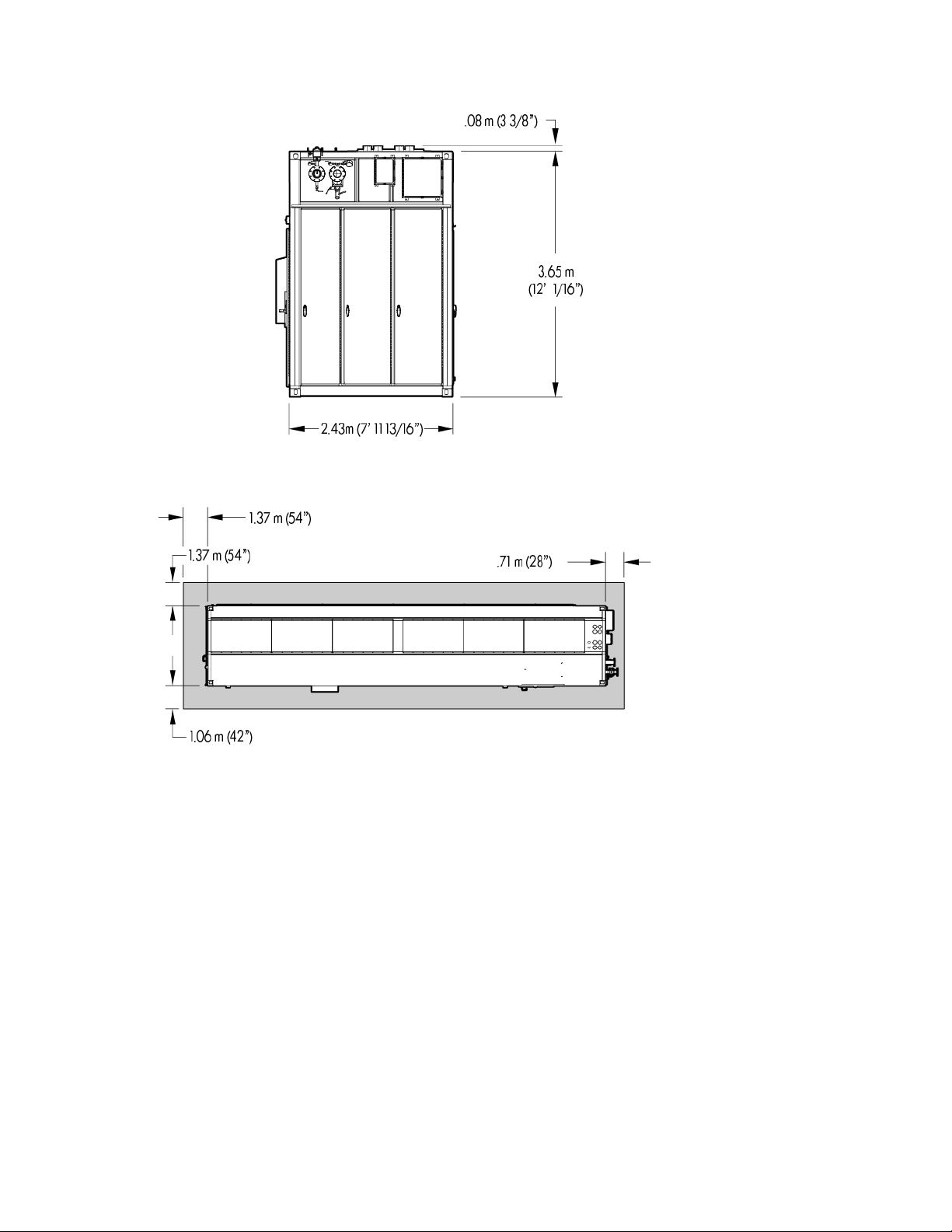

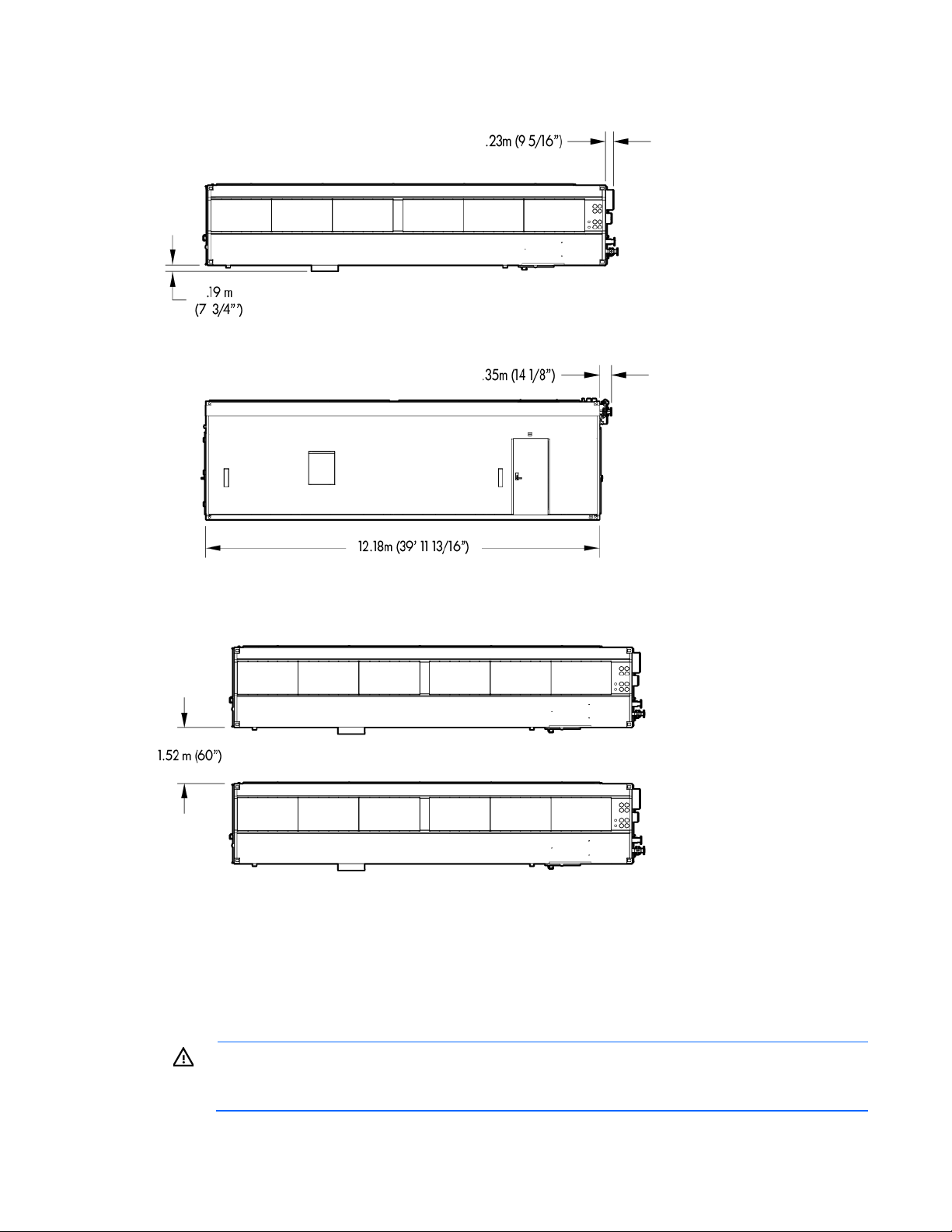

Dimensions and clearances

The selected site for the HP POD 40c G2 must be large enough to install, service, maintain, and have space

for potential growth or expansion with additional PODs.

Site requirements 8

Page 9

End 1 view clearances shown

Top view keep-out clearances shown (shaded areas indicate required clearances)

Site requirements 9

Page 10

Top view clearances shown

Side view clearances shown

Adequate space around the HP POD 40c G2 is necessary for airflow and cooling purposes.

These minimum clearances provide room for door opening only. Consider additional space as necessary for

your site.

Safety and clearance area

WARNING: Check for electrical distribution and transmission lines in, over, and under the

construction site and maintain a safe working clearance from energized electrical lines. Consult

your local utility company or AHJ for required clearances.

Site requirements 10

Page 11

Verify the following clearances prior to delivery:

• Working distance clearance—Maintain a safe working clearance according to the local utility

company or AHJ for each of the following items:

o Buildings

o Fences

o Gate headers

o Underground and overhead utilities

• Infrastructure clearance

o Underground power conduits, excluding power, water, and drainage lines connected to the HP

POD 40c G2

o Underground water lines, excluding power, water, and drainage lines connected to the HP POD

40c G2

o Underground sewage lines, excluding power, water, and drainage lines connected to the HP POD

40c G2

• Traffic clearance

For more information, see the local and national requirements, and site safety requirements.

Future expansions

When selecting a site location, consider future space and accessibility requirements. Adequate space

around the HP POD 40c G2 is necessary for locating additional equipment within close proximity, such as

generators and UPS devices. When installing additional equipment within close proximity to the HP POD

40c G2, consult with HP for site locations.

For specific space requirements, see "Dimensions and clearances (on page 8)."

Grounding requirements

The HP POD 40c G2 structure and internal components are all bonded together. A common grounding

electrode conductor connection point is provided on the utility-end cold aisle.

WARNING: To avoid the risk of personal injury or electric shock, the HP POD 40c G2 must be

The following is a list of component requirements for grounding and bonding:

• Grounding of the HP POD 40c G2 must comply with the requirements of Article 250 of the NEC, NFPA

properly grounded (earthed) in accordance with local and national requirements.

70-2011 (NA/JPN) and with local and regional regulations (IEC for EMEA and AP).

• Bonding of the piping systems and any exposed structural steel, installed to support the HP POD 40c

G2, must be in accordance with NEC (NA) and with local and regional regulations (IEC for EMEA and

APJ).

Site requirements 11

Page 12

•

•

•

•

Between 20 and 110 psi, 0.1 and 0.8 MPa

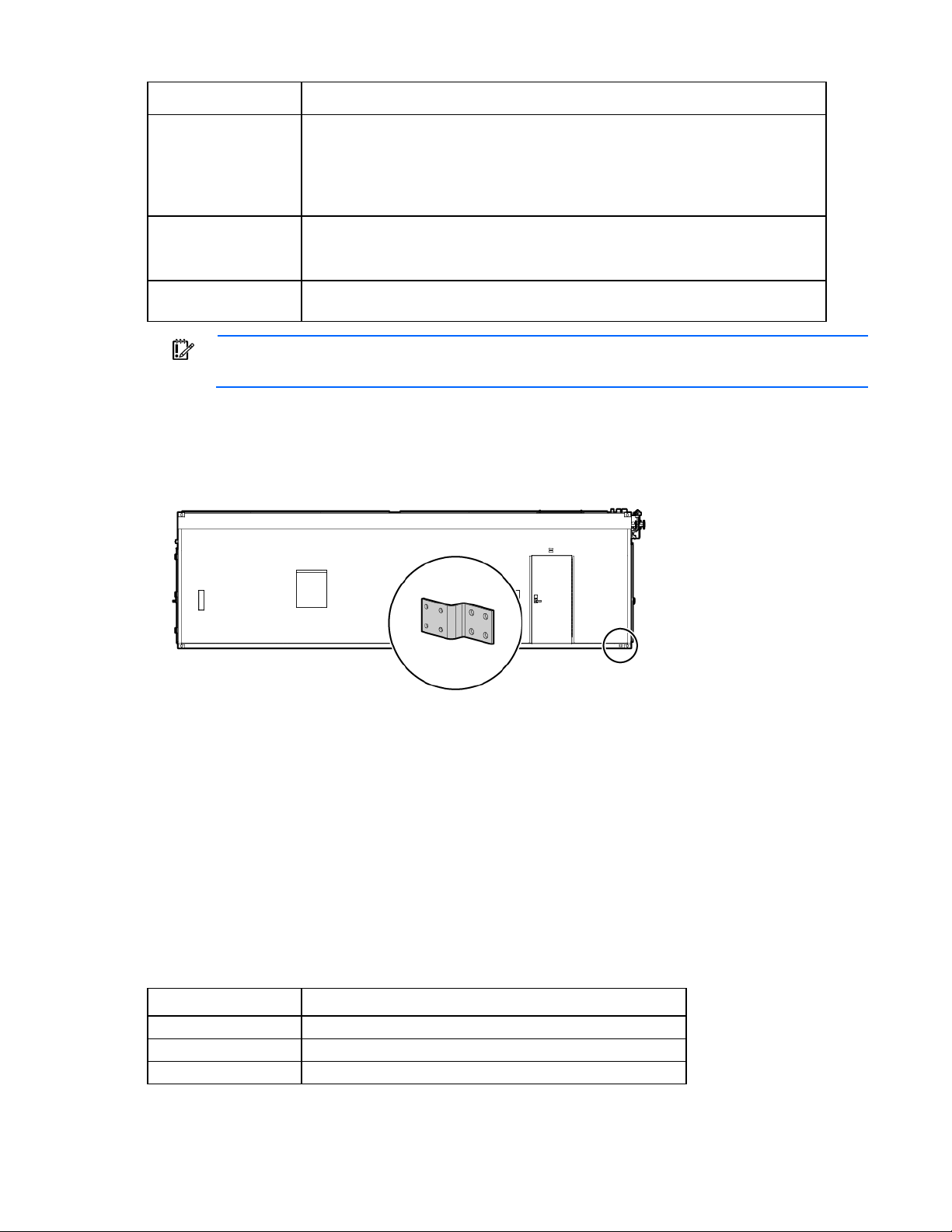

Grounding feature Specification

Grounding electrode

conductor pad

The grounding electrode conductor connection bus pad is located on the outside of

the HP POD 40c G2 on the cold aisle adjacent to the power cabinet.

The grounding pad must be connected to the grounding electrode system or

building steel in accordance with Article 250 of the NEC or equivalent regional

regulation.

Grounding lugs

Grounding lugs cannot be attached to any painted surface.

Grounding lugs must be compression-type 2-hole lugs and UL listed specifically for

grounding.

Ground rod system or

ground well

IMPORTANT: Before installing the HP POD 40c G2, consult your local AHJ for applicable codes

The customer must provide an effective grounding system with a ground rod or a

ground well.

and to review site-specific location guidelines. If needed, obtain any necessary permits.

The following figure shows the grounding electrode conductor connection that is located on the cold aisle of

the HP POD 40c G2.

Side view shown

Utilities

Consider the proximity to required utilities, such as power, water, and network connections. While the

required utilities can be brought to nearly any selected site, there is the potential for increased costs and

decreased efficiency when the HP POD 40c G2 is located farther from the utility sources.

Humidifier water supply

For utility clearance information, see "Dimensions and clearances (on page 8)."

The HP POD 40c G2 requires supply water for the humidifier. The supply water must meet the following

requirements.

Requirement Specification

Pressure

Temperature

Minimum flow rate

Between 1º and 40°C (33º and 104°F)

1.45 lpm (0.12 gpm)

Site requirements 12

Page 13

Requirement Specification

Connection

Hardness

Conductivity

Organic compounds

Type of water

Instant water fill flow

rate

Humidifier

IMPORTANT: If your water is out of range, consult a water quality expert.

IMPORTANT: You must provide a humidification water supply isolation valve that is external to

1.9 cm (.75 in) G

Adapter to 1.9 cm (.75 in) FPS

No greater than 40°fH (equal to 400 ppm of CaCO

)

3

100 to 1250 μS/cm

None

Drinking water. Do not use de-mineralized or softened water.

0.6 lpm (0.16 gpm)

For the exact requirements, see the humidifier documentation.

the HP POD 40c G2.

In addition to the previous requirements, observe the following requirements and recommendations:

• Do not treat the water with softeners. Softeners can produce foam, which affects the operation of the

unit.

• Do not use well water, industrial water, water from cooling circuits, or water contaminated by any

chemicals or bacteria.

• Do not add potential irritants to the water, such as disinfectants or anti-corrosive compounds.

• The manufacturer recommends installing an in-line filter for the water supply. It is your responsibility to

determine if a filter should be installed, and if so, its location. The filter cannot be installed inside the HP

POD 40c G2 and must be compatible with the type of humidifier that is installed.

For more information, see the HP Performance Optimized Datacenter 40c G2 Maintenance and Service

Guide.

Drainage

Requirement Location Specification

Condensate drains

Humidifier drains

Hot aisle side (2) 3.18 cm (1.25 in) drain line and 26.5 lpm (7 gpm) max

Cold aisle side (1) 3.18 cm (1.25 in) drain line and 26.5 lpm (7 gpm) max

Chilled water supply

The following are the water quality requirements and specifications:

• Closed-loop water must not contain any lime scale deposits or loose debris.

• The temperature of the chilled water supplied to the HP POD 40c G2 must be 12ºC to 24ºC (55ºF to

75ºF).

CAUTION: Freezing water can cause a blockage and damage to the unit. In outside locations

that are subject to freezing temperatures, an additive such as glycol might be necessary to lower

the freezing point. However, since the heat transfer potential of water with glycol is lower, the HP

POD 40c G2 must be de-rated accordingly.

Site requirements 13

Page 14

IMPORTANT: The chilled water system piping and heat exchangers must be drained completely,

•

•

and then purged using compressed air when storing or transporting at or below freezing

temperatures.

IMPORTANT: Operating the chilled water system at the higher end of the acceptable range

decreases the overall thermal capacity of the POD.

Acceptable water quality specifications

Water must be maintained per the following acceptable water quality standards.

Parameter Range

pH

Specific conductance at 25ºC (77ºF)

Alkalinity ("M" as CaCO3)

Sulfur (SO4)

Chloride (Cl)

Hardness (CaCO3)

Calcium hardness (CaCO3)

Magnesium hardness (CaCO3)

Copper (Cu)

Iron (Fe)

Aluminum (Al)

Sodium (Na)

Silica (SiO2)

Zinc (Zn)

Manganese (Mn)

Phosphate Ortho- (PO4)

Bacteria

Suspended solids

8.0–10

10–2500 µmhos

150–1000 ppm

0–150 ppm

0–100 ppm

0–350 ppm

0–200 ppm

0–150 ppm

< 0.20 ppm

< 3.0 ppm

< 0.50 ppm

0–1000 ppm

0–150 ppm

< 1.0 ppm

< 0.1 ppm

< 3 ppm

< 1000 CFU/ml

< 10 ppm

If your water is out of range, consult a water quality expert.

The following table describes the chilled water system specifications for the HP POD 40c G2.

Feature Specification

Facility input temperature to the HP POD

40c G2

Working pressure

HP POD 40c G2 pressure drop

HP POD 40c G2 water flow rate

Chilled water supply and return

connections

12ºC to 24ºC (55ºF to 75ºF)

1,034 kPa (150 psi)

172.4 kPa (25 psi)

908.5 lpm (240 gpm)

North America—Two 10.16 cm (4 in) ASME B16.5 class #150

flanges

International—Two DIN PN16 DN100 flanges

Site requirements 14

Page 15

Piping materials

Do not use the following interconnecting piping materials in a closed water system:

• Oxidizing biocides

• Aluminum components

• Brass components with high levels of zinc

• Non-stainless steel iron components

• PVC

IMPORTANT: Even though some PVC grade piping materials are designed to handle the

expected water pressure, the use of PVC materials should be reviewed and approved by the

customer site engineers.

Power infrastructure installation

When determining the final location of the power connections, consider the following:

• Distance between the facility utilities and the location of the transformer and switchboard

• Distance between the transformer and switchboard and the HP POD 40c G2

• Distance between the UPS/Generator locations and the HP POD 40c G2 switchboard

• Requirements for routing electrical feeders (underground or overhead)

The facility power connection must be installed in compliance with local electrical codes and regulations. HP

reference electrical installation design is based on a maximum distance of 15.2 m (50 ft) or line of sight

between the switchboard and the HP POD 40c G2.

Site electrical system

To ensure a complete and safe integration of the HP POD solution with your facility, HP requires that you

complete the following actions for the installed electrical system prior to the installation of the HP POD

solution:

• Short circuit analysis

• Arc flash study

• Circuit breaker coordination study

These actions must be performed for all associated parts of the electrical power train. The majority of the

details and factors required to complete these studies are associated with the existing installed facility

infrastructure.

CAUTION: Failure to complete these studies can cause serious issues with the electrical

integration of the POD into your electrical system.

Electrical power system configuration

A preliminary meeting with the HP POD Electrical Engineering team is necessary to discuss your decision

concerning capacity limitations and the impacts of this decision on the electrical design.

Site requirements 15

Page 16

A 1N electrical configuration can be achieved by providing all required electrical feeders from a common

power source and from common switchboards, and transformers.

A 2N electrical configuration can be achieved by feeding parallel power paths from independent power

sources, switchboards, and transformers.

IMPORTANT: The required neutral must be provided as part of the 800 A 415VAC Y direct

connection to the HP POD 40c G2.

IMPORTANT: All 3-Phase Wye feeders for the HP POD 40c G2 require that the neutrals and the

equipment grounding conductors remain isolated. Bonding of the two conductors is allowed at

the power source only.

Transformers and switchboards

The input power for the critical IT loads requires a source of 380-415V, 3-Phase Wye power. To achieve this

input power, a custom transformer might be required if it does not already exist at the source. In addition to

the overall loading and KVA size, you must consider the Harmonic Content of the installation when

specifying the K-Factor of the transformer. Alternatively, you can use Harmonic Mitigating Transformers to

passively cancel the harmonics generated by the IT Equipment.

HP offers several power solutions that include automatic transfer switching, UPS backup, transformers and

output distribution switchboards to supply your power needs.

On-site connections might include:

• Main facility power to the primary side of the transformer

• Transformer to the switchboard

For connection information, see the HP Site Preparation Drawing Package (on page 23).

Site requirements 16

Page 17

Supported facility connections

Environmental control system

The ECS developed for the HP water-cooled POD is a stand-alone control system that requires no external

connections with an external site system, BMS, public or private Internet sites, cloud, or wireless system to

properly control the POD operation.

The ECS includes Modbus TCP/IP connections through which a variety of data can be retrieved. These

capabilities enable you to connect, at your expense, with the stand-alone ECS system to monitor the

operating parameters of the POD. It is your responsibility (or your representative's or agent's responsibility)

to integrate this communication capability into any existing BMS or monitoring system.

CAUTION: To ensure that alarm conditions can be identified and resolved, HP recommends that

you remotely monitor all alarm conditions. Failure to monitor the alarm conditions can cause

delays in appropriate action during an alarm condition.

Additional POD connections

The HP POD 40c G2 provides various connection points to your facility. It is your responsibility to facilitate

these connections. HP can make these connections when specifically contracted to deliver these services and

a Scope of Work has been drafted, reviewed, and signed for delivery services. Available POD connections

include the following:

• Life safety systems

o EPO

o Fire detection

o Fire suppression

• Site communication

o Phone

o Security

• Networking—IT connections

Connection portals

There are networking and connection portals located on the top of the utility-end of the HP POD 40c G2.

These portals are provided to allow the customer to make connections to the HP POD 40c G2.

Each HP POD 40c G2 has 10 portals, which are shown in the following figure and described in the following

table. The connection portal location and configuration might vary, depending on the HP POD 40c G2

model.

Supported facility connections 17

Page 18

Top view shown

•

•

•

•

Connection portal

Connection point Quantity

diameter

10.16 cm (4 in) portal

5.08 cm (2 in) portal

Main electrical power

feeds

Communication connection

for all communication

ECS

EPO

Fire alarm

Telephone

Demarcation box

The following communication connections between the customer facility and the HP POD 40c G2 are made

through the demarcation box:

• ECS communication

• Security communication

• Telephone

8

2

Supported facility connections 18

Page 19

End view shown

You must make the connections between the facility and the HP POD 40c G2. For configuration and

installation instructions, consult with HP.

Fire box

The communication connections between the fire system and the HP POD 40c G2 are made through the fire

box.

End view shown

You must make the connections between the facility and the HP POD 40c G2. For configuration and

installation instructions, consult with HP.

Supported facility connections 19

Page 20

Humidifier

A dedicated water supply and approved drainage is required for the humidifier. For more information about

the humidifier, see the HP Performance Optimized Datacenter 40c G2 Operation and Maintenance Manual

provided with the HP POD 40c G2.

The following image shows the location of the humidifier drain and water supply.

End view shown

IMPORTANT: Confirm with the AHJ that condensate water and rain water can be mixed in the

same drainage.

HP POD 40c G2 security

The HP POD 40c G2 is equipped with standard key lock hardware for each personnel entry door and

external electrical cabinet. Each personnel entry door includes a door access contact that can be connected

to the customer facility security system.

Additional options for controlled access security include the following:

• Electronic card reader

• 12-digit security code keypad

• Magnetic lock on each personnel entry door and dynamic hot aisle door

Fire, safety, and security notifications

Dry contacts are provided to enable the connection between the HP POD 40c G2 fire alarm system and the

customer facility fire system. If the HP POD 40c G2 is connected to the customer facility systems, then the

alarms initiated by the HP POD 40c G2 notify the facility systems.

Supported facility connections 20

Page 21

It is your responsibility to facilitate these connections. HP can make these connections when specifically

contracted to deliver these services and a Scope of Work has been drafted, reviewed, and signed for

delivery services.

The customer must provide an independent connection for each system listed in the following table.

Alarm Description

Fire prevention alarm

Fire suppression

system (optional)

Security

EPO

Smoke is detected in the HP POD 40c G2.

The suppression system alarm is activated and gas is

dispersed to suppress a fire.

A security breach occurred.

The EPO system is activated by manually pressing the

EPO button or by a thermal event, and the HP POD 40c

G2 is shut down.

The electrical layout of the fire alarm system is described in the schematic drawing that is supplied with the

HP Performance Optimized Datacenter 40c G2 Site Drawing Package.

Supported facility connections 21

Page 22

Environmental considerations

Environmental risks

• Avoid placing the HP POD 40c G2 directly along a drainage path or in an area prone to flooding.

• Verify that the HP POD 40c G2 is properly grounded in accordance with NFPA 70 and local and

Cold weather

regional regulations (IEC for EMEA and APJ).

The HP POD 40c G2 requires a site chilled water supply and return, humidifier supply and drain, and

condensate drains. Extreme cold weather can cause damage to the supply and drain lines. Evaluate the

following for additional cold weather protection:

• Regional location of the HP POD 40c G2

• Exposure of the supply and drain lines to extreme cold temperatures

Extreme cold weather can affect crane and lifting operations. When temperatures drop below -12.2°C

(10°F), appropriate consideration must be made with respect to shock loading, crane hydraulics, and

possible de-rating of the crane.

Areas prone to lightning or power surges

The HP POD 40c G2 structure and internal components are all bonded together. A common Grounding

Electrode Conductor Connection point is provided. Proper bonding and grounding of the HP POD 40c G2

minimizes the effects of a lightning strike. A surge protection device is provided on the HP POD 40c G2 input

connection to protect the HP POD 40c G2 electrical system from voltage transients. If your site is in an area

that is subject to frequent lightning strikes, the HP POD 40c G2 must be protected in accordance with NFPA

70 (NA) and IEC (EMEA and APJ). HP recommends that you contact a certified lightning protection

consultant.

Seismic activity

If your site is in an area that has frequent seismic activity, HP recommends that you contact a seismic activity

consultant. If your site is in an area that has high vibration level, HP recommends that you contact a vibration

isolation consultant. You must specify the method of anchoring the HP POD 40c G2, if necessary.

Environmental considerations 22

Page 23

Site plan requirements and actions

Completing a site assessment

HP requires a detailed site assessment prior to planning and preparing the customer site location for the HP

POD 40c G2. Consult with HP to schedule a site assessment.

A standard site assessment visit includes the following tasks:

• Selecting an appropriate site for the HP POD 40c G2

• Assessing the proposed site for:

o Measurements for clearances

o Infrastructure for the final solution

o Access to utilities

o Site pad

o Installation considerations, including locations for delivery trucks, large installation equipment (such

as cranes), and storage

o Electrical infrastructure

o Chilled water infrastructure

o Facility network and security systems

• Developing an engagement plan and verifying customer contacts

• Discussing future development and growth plans

For a complete site assessment checklist, see "Appendix A: HP site assessment (on page 27)."

HP Site Preparation Drawing Package

After receiving a signed purchase agreement, HP provides detailed engineering drawings. These drawings

contain information to assist you and your MEP team to prepare the site for POD installation. If there are

areas of special interest, HP can work directly with your MEP team to provide additional assistance.

Zoning and permit requirements

You are responsible for compliance of the overall installation in accordance with all local and national

regulations, ordinances, codes, and the product specifications.

Project coordination

Your Project Manager must perform the following tasks:

• Coordinate with all trades prior to installation to ensure that trade conflicts are resolved.

• Coordinate the installation and integration of all systems.

Site plan requirements and actions 23

Page 24

• Ensure that the site safety and security programs are properly administered.

• Interface directly with the HP installation project manager to ensure clear lines of communication during

the installation and commissioning processes.

Site planning

A comprehensive site plan assists with the site design (MEP) and ensures the best possible HP POD 40c G2

installation process. When creating a site plan, consider the following information:

• HP POD 40c G2 site requirements detailed in this document

• HP POD 40c G2 site preparation drawing package

• HP POD 40c G2 readiness checklist ("HP POD 40c G2 site readiness checklist" on page 31)

• HP POD 40c G2 installation (on page 24)

The HP team can assist you by answering questions and help to guiding you throughout the process.

HP POD 40c G2 installation

HP POD 40c G2 installation includes the following:

• Installation equipment staging (on page 24)

• HP POD 40c G2 lifting layout (on page 24)

• HP POD 40c G2 storage requirements (on page 25)

Installation equipment staging

HP POD 40c G2 lifting layout

• Additional structures (on page 25)

Staging for the following items must be identified and considered:

• Truck and component staging

• Installation equipment staging

• Site traffic

• Regulatory or local permits

When preparing a site plan, identify where to place the HP POD 40c G2 and the equipment used for

assembly. The figure below shows the following locations on an HP POD 40c G2 assembly site:

• HP POD 40c G2 location

• Crane location

Site plan requirements and actions 24

Page 25

• Assembly equipment locations

HP POD 40c G2 lifting requirements

WARNING: The only approved method for lifting the HP POD 40c G2 is the use of a spreader

bar harness. Lifting an HP POD 40c G2 in any other manner can cause damage to the HP POD

40c G2 and void your warranty.

HP POD 40c G2 storage requirements

If the site is not ready for assembly and operation, determine a location for storage when creating the site

plan.

CAUTION: The HP POD 40c G2 must maintain 20% relative humidity to minimize condensation

and oxidation within the HP POD 40c G2.

CAUTION: While being stored, the HP POD 40c G2 must be kept in a level position even if

stored on a trailer.

Changes in ambient temperatures can cause condensation in a non-operational HP POD 40c G2. If the HP

POD 40c G2 is placed in storage or is in non-operating mode for over 72 hours, HP recommends using one

of the following methods to minimize condensation and oxidation within the HP POD 40c G2:

• Desiccant unit

• Desiccant material

• Heater with a fan

• Air conditioner with a heater strip

Consult with HP Services to determine the most effective method.

Additional structures

If a customer-provided vestibule or other structure is installed and connected to the HP POD 40c G2, the

following specifications must be maintained:

• To protect the HP POD 40c G2 and ensure a waterproof barrier, flashing must be installed to the

exterior of the HP POD 40c G2 in the location where the other structure is attached.

Site plan requirements and actions 25

Page 26

• Access landings might be required to maintain the required access to the HP POD 40c G2 electrical

panels.

Site plan requirements and actions 26

Page 27

Appendix A: HP site assessment

•

•

•

•

HP POD 40c G2 site assessment checklist

During a survey of the readiness of a proposed customer site for the HP POD 40c G2, the site is inspected for

the following:

• Accessibility of machinery for the transportation and installation of the HP POD 40c G2

• Assessment of the suitability of the site infrastructure for installing the HP POD 40c G2 and for

supporting infrastructure preparation and serviceability requirements

HP responsibilities

Item Description Sign-off

1. Engagement plan

2. Site visits

3. Test equipment

4. Installation site

review

5. Indoor/outdoor

installation

6. Site pad

Develop an engagement plan with specific

requirements relating to the proposed installation site.

Schedule site visits on mutually acceptable dates,

during normal HP business hours.

Document any test equipment used in the customer

report.

Review and discuss the proposed installation site with

the customer. This initial review includes physical

examination of the proposed installation site and, at

the sole discretion of HP, can include physical

measurements of the area size and clearances.

Identify whether the HP POD 40c G2 installation is

indoors or outdoors as this can affect the degree and

type of infrastructure required and the mounting needs.

Inspect the proposed installation site to assess

compliance with the HP POD 40c G2 mounting

specifications. Ensure that the customer is fully aware

of the following requirements:

Proper support capabilities must exist. If the

customer intends to edge or point load on the utility

and cargo ends, there must be support in the center

to prevent deflection.

Upon installation, the POD structure must be

leveled to ≤ 0.5º, which can be checked at that

time with a surveyor’s transit.

Shimming is allowed around the perimeter of the

POD.

Place shims in increments across the length of the

HP POD 40c G2 to ensure that the HP POD 40c

7. Materials and

construction

inspection

G2 is level.

Visually inspect the materials and construction at the

proposed installation site to identify issues that can

impact the HP POD 40c G2 installation. Verify that the

area is adequate for truck delivery, staging, and crane

location.

Appendix A: HP site assessment 27

Page 28

Item Description Sign-off

8. Clearances

9. Support

infrastructure

location

10. Support

infrastructure for

access requirements

11. Site engineering

interviews

12. Capacity of

electrical

infrastructure

Inspect the proposed installation site to confirm

clearance requirements for installation and

serviceability as per the HP POD 40c G2

specifications. Necessary clearances are determined,

in part, based on the specific installation plans and

infrastructure design. Location, orientation, and

planned utilization can affect the necessary

clearances. Consider future planning for the space

around the installation site.

Evaluate the HP POD 40c G2 installation site in

relation to the planned support infrastructure location.

Conduit lengths and the utility pathway design must be

taken into consideration in the planning stages. The

proposed support infrastructure design and the

location of required utilities are discussed with the

customer's site engineering personnel to identify

elements that can impact the HP POD 40c G2

installation site decisions.

Evaluate the proposed installation site for the HP POD

40c G2 and the support infrastructure for access

requirements. The evaluation is based on the

information provided by the customer at the time of the

site visit. In the absence of installation-specific

information, general requirements are used as the

basis for the evaluation. The delivery path is visually

examined and discussed with the customer's site

engineering personnel to identify obstacles to

installation.

Conduct interviews with the customer's site

engineering personnel and site facilities personnel to

gather information related to the origin of the power

source and network services proposed for use with the

HP POD 40c G2. HP must visually inspect the

proposed power protection equipment. Means of

delivery, connections, and pathways are documented.

Based on the review of customer-provided site

documentation (such as single-line and as-built

drawings), examine equipment panels and monitoring

system data, as available. HP must determine whether

adequate capacity exists in the current electrical

infrastructure to be used or if additional study is

required. Determine if the level of redundancy required

as stated by the site engineering personnel can be

provided by using the existing infrastructure. This takes

into consideration the proposed installation site of the

HP POD 40c G2, the potential HP POD 40c G2

payload, and the customer stated redundancy

requirement. Components can include generators,

UPSs, and switch gear.

Appendix A: HP site assessment 28

Page 29

Item Description Sign-off

13. Chilled water

infrastructure

Determine the overall chilled water capacity, available

flow rates, and supply/return temperature restrictions.

Determine if there are any site specific requirements

that mandate additional chilled water equipment, such

as heat exchangers or mixing apparatus. Locate any

existing or planned supply/return headers.

14. Security

Conduct interviews with the customer site engineering

personnel to determine the level of security required for

the HP POD 40c G2 and its infrastructure. The

proposed installation site is assessed for suitability in

relation to the customer requirements.

15.

Recommendations

Following the HP installation site visit, analyze the data

collected and prepare a report of findings. HP must

identify potential obstacles to installation and

recommendations for any additional testing or

Customer responsibilities

changes to the installation plan.

Item Description Sign-off

1. Point of contact

information

2. Service listing

information

3. Timely

response

4. Access to

subject areas and

support areas

5. Badge access

6. Site

engineering

personnel

7. Documentation

8. Network

infrastructure

information

Provide HP with the name and telephone number of the

designated point of contact for the purposes of this

service.

Provide all information required under this service listing

or reasonably determined by HP to be necessary to

deliver the service, including but without limitation, any

documentation (internal or external) regarding prior

plans or investigations used to identify the proposed

installation site.

Provide a timely response (such as, in a time period that

does not adversely affect the HP scheduled performance

of the service) to all requests for information by HP.

Provide HP access to all subject areas and support areas,

including the proposed installation site and the

mechanical or electrical infrastructure provided to

support the HP POD 40c G2.

Provide HP badge access or an escort for the duration of

the site visit to facilitate required access to all necessary

areas.

Customer site engineering personnel familiar with the

proposed installation site and personnel responsible for

the maintenance and support of the existing infrastructure

must be available to answer questions.

Provide HP copies of all available mechanical and

electrical system design documentation, including as-built

drawings and electrical single-line drawings. As

appropriate to the specific location, provide HP with

campus maps, building drawings, floor plans, and other

relevant prints to assist in the documentation and

evaluation of the proposed installation site.

Provide HP information regarding the planned network

infrastructure connection points and pathways.

Appendix A: HP site assessment 29

Page 30

Item Description Sign-off

9. Permission for

Photographs

10. Project

logistics

11. Business visas

Grant HP permission to take photographs for report

illustration purposes.

Arrange site-specific project logistics at the time of

scheduling. Failure to provide necessary authorizations

can limit the effectiveness of the service and can, at the

discretion of HP, impact scheduling or result in the

postponement of the service.

Provide assistance in instances where a temporary

business visa is required for HP personnel to visit the site.

This assistance typically takes the form of preparing a

letter of invitation. In some cases, a formal request must

be made by the local company for which the work is

taking place.

Appendix A: HP site assessment 30

Page 31

Appendix B: Preparing for delivery

Pre-delivery tasks

Allow adequate time for planning, scheduling, obtaining permits, design approval, inspections, and so on.

Installation prerequisites

Before installing the HP POD 40c G2, verify that the following prerequisites are met:

• All components are delivered to the facility.

• The HP POD 40c G2 and power distribution components are in the final location.

• Facility power, water, and drainage are at the final location.

• Provisions for properly grounding the HP POD 40c G2 are made.

• Required clearances exist, including overhead.

• All trade personnel required for assembly are coordinated.

HP POD 40c G2 site readiness checklist

Before installing the HP POD 40c G2, follow all steps listed in this guide, the site plan, and the following

checklists.

Architectural/environmental considerations

Item Description Sign-off

1

2

3

4

5

6

Verify that the site location supplies sufficient locations for

support. Ensure that upon installation the POD can be leveled to

≤ 0.5º. If edge or point loading is used, ensure a center

support can be accomplished using shims and so on, to ensure

that the POD can be properly leveled. Shimming is allowed

around the perimeter in increments. A surveyor’s transit should

be used upon installation to check the POD leveling

requirements.

Verify that the pad can support the total weight of the HP POD

40c G2 solution by verifying that load calculations have been

performed by your engineering team.

Verify that the site has provisions for grounding.

Verify the HP POD 40c G2 is not in the direct path of any

external heat loads, such as generators.

Determine the average local temperatures and ensure that

adequate environmental protection is provided, such as cold

weather protection, if required.

Verify that the site altitude is less than 3,048 m (10,000 ft).

Appendix B: Preparing for delivery 31

Page 32

Item Description Sign-off

Verify the planning for required egress routes for all HP POD

Verify that the local AHJ is contacted, all applicable codes and

Verify that the safety equipment is planned for and in place in

Verify that a temporary or permanent load bank is available, if

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

When installing on an elevated surface, verify that the

maximum height requirements for the circuit breaker actuator

meet the local and national requirements. Verify that proper

landings and the catwalk are planned for electrical cabinet

access.

40c G2 personnel doors, cargo doors, and service area doors,

including landings, the catwalk, and stairs.

site-specific location guidelines are reviewed, and all required

permits are obtained.

Verify that the site location has clearances for the HP POD 40c

G2 installation, including any permanent structures, such as

fences, walls, vestibules, and buildings.

Verify that all utilities, overhead and underground, are

identified to maintain required clearance.

Verify that there is adequate clearance around the HP POD 40c

G2 for door operation, installation, and maintenance

equipment.

Verify that the site location and site pads are marked for any

transformer, external switchboard, generators, and

powerhouses.

Verify that the site has provisions for proper grounding and that

the site location includes a grounding electrode system.

Verify that the site location has adequate lighting for the HP

POD 40c G2 installation.

Verify that a truck and equipment staging areas are identified.

Verify the location for the fuel tanks for generators,

powerhouses, and other equipment, if applicable.

Verify the locations for cranes off-loading and operation during

HP POD 40c G2 installation.

Verify site access and clearances for equipment, including the

crane and forklifts. A clear path to the site must be maintained

with clearance for all gates, headers, utility lines, and so on.

Verify that the locations for storage and trash disposal are

identified.

accordance with the customer’s site safety program.

Verify the site interfaces and locations to connect the fire alarm,

security system, and communication system to the HP POD 40c

G2. This ensures that the POD can be properly connected to the

site BMS.

Verify that proper disposal methods are used for existing or

potentially contaminated and/or hazardous materials.

Verify the availability of security systems or equipment,

including site fences, required after construction.

Verify the availability of temporary facilities associated with the

relocation of existing services and operations.

Verify that all work relating to soil testing, removal, and that site

remediation is complete.

applicable.

Appendix B: Preparing for delivery 32

Page 33

Item Description Sign-off

Verify the chilled water supply and return headers are

28

Verify the location of the EPO system external to the

powerhouses, if applicable.

29

30

Verify the location of the remote electronic monitoring system.

Verify that tie-downs and other AHJ-required facilities for the HP

POD 40c G2 and power containers are complete at least one

General water supply

week prior to arrival of HP-provided equipment.

Item Description Sign-off

1

Verify that the site drainage is complete, and the HP POD 40c

G2 is not in a drainage path or flood prone area. HP

recommends placing the HP POD 40c G2 on a raised site pad

to prevent water from entering the HP POD 40c G2.

2

Verify that the humidification water quality meets or exceeds

these standards, which are essentially drinking water

standards.

3

Chilled water system

Verify the humidification water supply isolation valve is

installed for each POD.

Item Description Sign-off

1

2

3

4

accessible, in the appropriate location, and 100 cm (4 in) in

diameter.

Verify that the chilled water supply temperature meets the

minimum POD chilled water supply temperature of 10°C

(50°F).

Verify that a sufficient chilled water flow rate is available.

If necessary, verify that the customer-required chilled water

return temperatures can be attained.

Power requirements

Item Description Sign-off

1

2

3

General

Verify that the short circuit analysis, arc flash, and circuit

breaker coordination studies are complete. Verify power work

is completed according to the approved conduit routing

drawings that show the exact routes, plan view, sections, and

elevations.

Verify that temporary site power for installation and

construction is planned and available, if applicable.

Verify that adequate site power exists per the HP POD 40c G2

requirements.

Item Description Sign-off

1

2

Verify the utility connection to the HP POD 40c G2 and any

required metering equipment.

Verify the third-party commissioning services that might be

required by the owner.

Appendix B: Preparing for delivery 33

Page 34

Item Description Sign-off

3

Verify that the HP Project Team coordinates with other site

construction activities.

Appendix B: Preparing for delivery 34

Page 35

Appendix C: Regulatory compliance notices

•

•

HP POD 40c G2 regulatory compliance

The HP POD 40c G2 complies with the following regulatory standards.

Standard Certification level Standard title

UL 60950

NFPA 70

NFPA 72

NFPA 2001

IBC 2009

ETL "Listed"

UL 60950—Standard for Safety Information Technology

Equipment, Part 1: General Requirements, Issue: 2007/03/27,

Edition: 2

UL 60950—Standard for Safety Information Technology

Equipment, Part 22: Equipment to be Installed Outdoors, Issue:

2007/04/23, Edition: 1

ETL "Classified" NFPA 70—National Electric Code, 2008 Edition, © 2008 National

Fire Protection Association

Designed to Comply

With

Designed to Comply

With

Designed to Comply

With

National Fire Alarm code, 2007 Edition, © 2006 National Fire

Protection Association

NFPA 2001, Standard on Clean Agent Fire Extinguishing Systems,

2008 Edition, © 2008 National Fire Protection Association

2009 International Building Code, © 2010 International Code

Council, Inc.

Regulatory compliance identification numbers

For the purpose of regulatory compliance certifications and identification, this product has been assigned a

unique regulatory model number. The regulatory model number can be found on the product nameplate

label, along with all required approval markings and information. When requesting compliance information

for this product, always refer to this regulatory model number. The regulatory model number is not the

marketing name or model number of the product.

Federal Communications Commission notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. Operation of this equipment in a residential area

is likely to cause harmful interference, in which case the user will be required to correct the interference at

personal expense.

Modifications

The FCC requires the user to be notified that any changes or modifications made to this device that are not

expressly approved by Hewlett-Packard Company may void the user’s authority to operate the equipment.

Appendix C: Regulatory compliance notices 35

Page 36

Cables

Connections to this device must be made with shielded cables with metallic RFI/EMI connector hoods in

order to maintain compliance with FCC Rules and Regulations.

Canadian notice (Avis Canadien)

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur

du Canada.

Appendix C: Regulatory compliance notices 36

Page 37

Glossary

AHJ

authority having jurisdiction

APJ

Asia Pacific Japan

BMS

building management system

door

A hinged portion of an enclosure that covers an opening.

DX

direct expansion

ECS

environmental control system

EMEA

Europe, Middle East, and Africa

EPO

emergency power off

equipment

A general term, including fittings, devices, appliances, luminaires, apparatus, machinery, and the like used

as a part of, or in connection with, a modular data center. (Source: NEC.)

IEC

International Electrotechnical Commission

ISO

International Organization for Standardization

Glossary 37

Page 38

labeled

Equipment or materials to which has been attached a label, symbol, or other identifying mark of an

organization that is acceptable to the authority having jurisdiction and concerned with product evaluation,

that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling

the manufacturer indicates compliance with appropriate standards or performance in a specified manner.

listed

Equipment, materials, or services included in a list published by an organization that is acceptable to the

authority having jurisdiction and concerned with evaluation of products or services, that maintains periodic

inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing

states that either the equipment, material, or service meets appropriate designated standards potential of not

more than 42.4 V (DC or peak) supplied by a primary battery or by an isolated secondary circuit, and where

the current capacity is limited by an overcurrent device, such as a fuse, or by the inherent capacity of the

secondary transformer or power supply, or a combination of a secondary winding and an impedance. A

circuit derived from a line-voltage circuit by connecting a resistance in series with the supply circuit to limit the

voltage and current is not identified as a low-voltage limited energy circuit. or has been tested and found

suitable for a specified purpose.

The means for identifying listed equipment might vary for each organization concerned with product

evaluation, some of which do not recognize equipment as listed unless it is also labeled. Use of the system

employed by the listing organization allows the authority having jurisdiction to identify a listed product.

NA

North American

overcurrent protection

A device designed to open a circuit when the current through it exceeds a predetermined value. The ampere

rating of the device is selected for a circuit to terminate a condition where the current exceeds the rating of

conductors and equipment due to overloads, short circuits and faults to ground.

structure

Enclosure of sufficient size to enable entry of personnel.

UL

Underwriters Laboratory

UPS

uninterruptible power system

VESDA

very early smoke detection apparatus

Glossary 38

Page 39

Documentation feedback

HP is committed to providing documentation that meets your needs. To help us improve the documentation,

send any errors, suggestions, or comments to Documentation Feedback (mailto:docsfeedback@hp.com).

Include the document title and part number, version number, or the URL when submitting your feedback.

Documentation feedback 39

Loading...

Loading...