Page 1

HP Performance Optimized Datacenter (POD)

240a

Site Requirements Guide

Part Number: 663155-001

October 2011

Edition: 1

Page 2

© Copyright 2011 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

Page 3

Contents

Overview ..................................................................................................................................... 5

About this document .................................................................................................................................. 5

Site assessment ......................................................................................................................................... 5

Site requirements .......................................................................................................................... 6

HP Site Preparation Drawing Package ......................................................................................................... 6

Site preparation ........................................................................................................................................ 6

Early infrastructure requirements .................................................................................................................. 6

Site pad ......................................................................................................................................... 7

Other structures ............................................................................................................................... 7

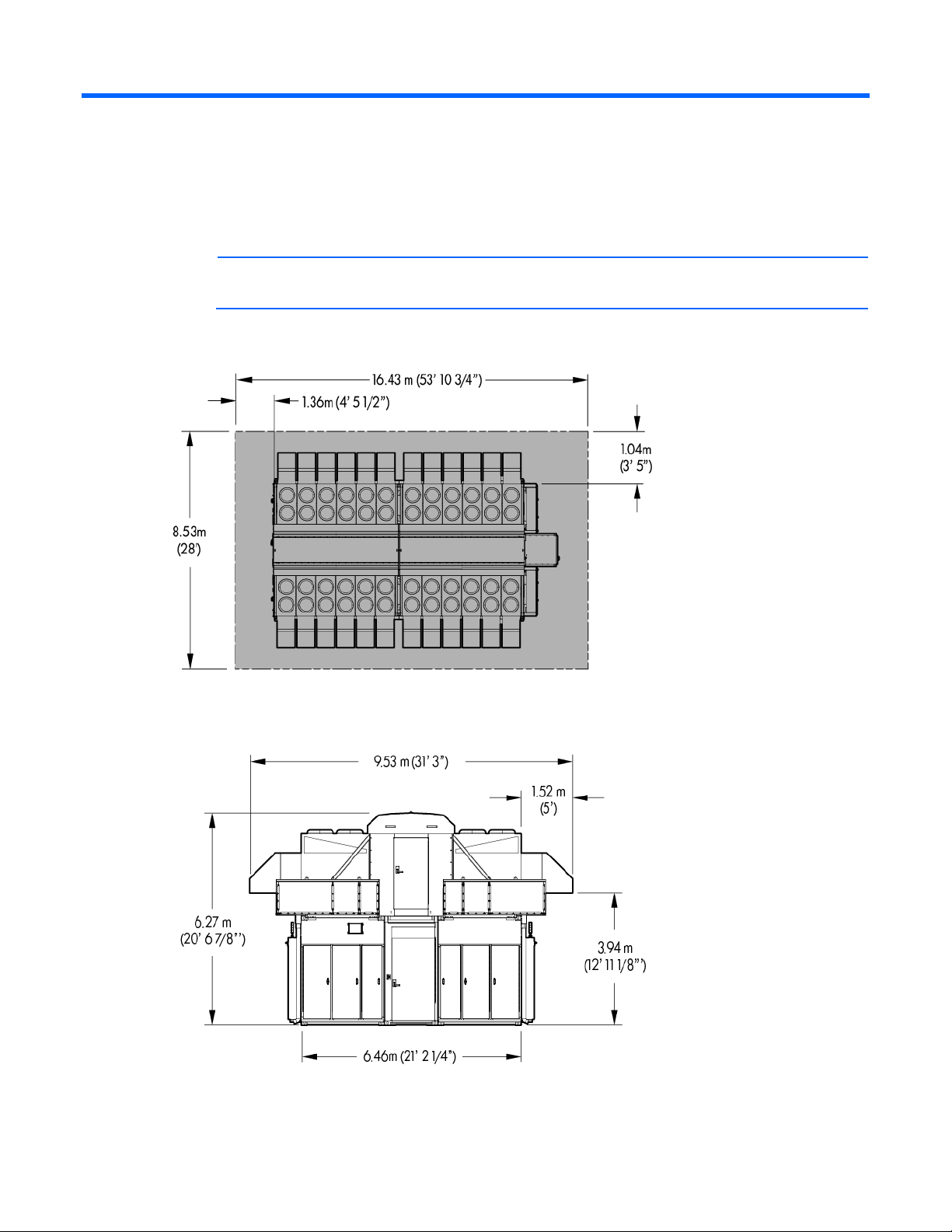

Space requirements and clearances ................................................................................................ 8

HP POD 240a dimensions and required clearances ....................................................................................... 8

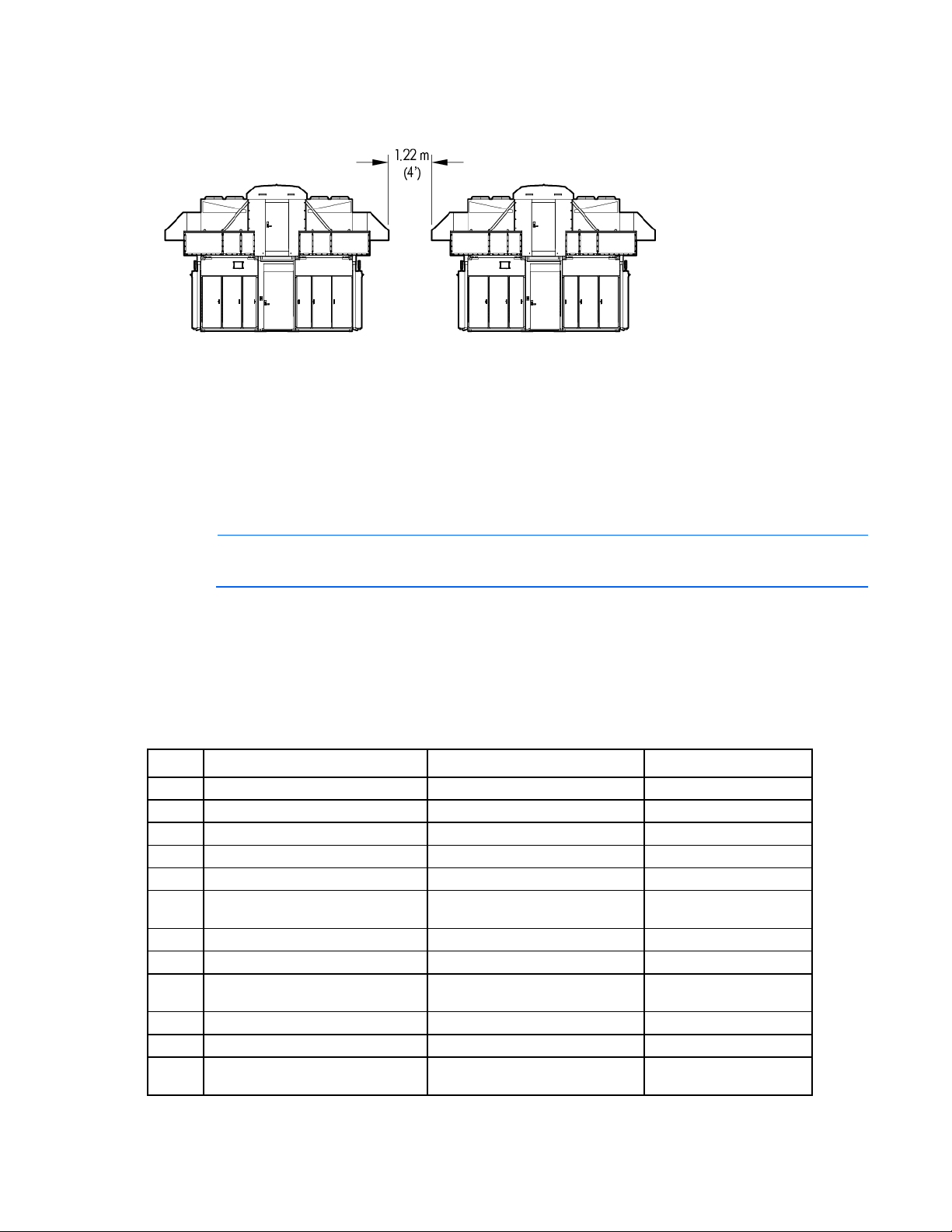

HP POD 240a weight .............................................................................................................................. 10

HP POD 240a and support equipment sample offload plan ................................................................ 10

Site space and clearance requirements ...................................................................................................... 11

Additional equipment space requirements .................................................................................................. 11

Future expansions .................................................................................................................................... 11

Preparing for delivery and assembly ............................................................................................. 12

Shipping considerations ........................................................................................................................... 12

Suggested assembly installation equipment ................................................................................................. 12

Safety for assembly ........................................................................................................................ 12

Temporary lighting and power .................................................................................................................. 13

Storage requirements ............................................................................................................................... 13

Assembly prerequisites ............................................................................................................................. 13

Environmental considerations ....................................................................................................... 14

Environmental considerations .................................................................................................................... 14

Cold weather .......................................................................................................................................... 14

Areas prone to lightning or power surges ................................................................................................... 14

Seismic activity ....................................................................................................................................... 14

Utilities ...................................................................................................................................... 15

Proximity to utilities and drains .................................................................................................................. 15

System utilities......................................................................................................................................... 15

Water supply ................................................................................................................................ 15

Drainage ...................................................................................................................................... 16

Power .......................................................................................................................................... 17

Required facility connections ........................................................................................................ 19

Connections to central facility infrastructure ................................................................................................ 19

Network connections ............................................................................................................................... 19

Connection portals ........................................................................................................................ 19

Grounding requirements ........................................................................................................................... 20

Supported facility connections ...................................................................................................... 23

Humidifier .............................................................................................................................................. 23

HP POD 240a security ............................................................................................................................. 24

Contents 3

Page 4

Fire, safety, and security notifications ......................................................................................................... 24

Glossary .................................................................................................................................... 25

Contents 4

Page 5

Overview

About this document

This document outlines the site requirements for an HP Performance Optimized Datacenter (POD) 240a. The

customer must provide a qualified architectural or consulting engineering team to generate site-specific

documents for each HP POD 240a installation, including final site drawings. The customer's site installation

design must comply with all local and national regulations, ordinances, codes, and the specifications listed

Site assessment

in this document.

HP requires a detailed site assessment prior to planning and preparing the customer site location for the HP

POD 240a. Consult with HP to schedule a site assessment.

For more information, see the Site Assessment Checklist in the HP Performance Optimized Datacenter (POD)

240a Site Preparation Guide.

Overview 5

Page 6

Site requirements

HP Site Preparation Drawing Package

HP provides detailed schematic engineer drawings of the HP POD 240a in the HP Site Preparation Drawing

Package, included on the documentation CD.

Site preparation

NOTE: The weight provided is an estimate. The total weight of the HP POD 240a will differ

The structural design of the HP POD 240a site pad design is based on specific weight load locations,

accounting for the HP POD 240a structural footing and supported IT infrastructure.

The HP POD 240a must be installed on a surface capable of supporting the following weights:

HP POD 240a with 24 HVAC/DX units—117,526 kg (259,100 lb)

HP POD 240a with 24 HVAC/DX units and IT equipment installed—Approximately 183,750 kg

The site pad must be level with less than +/-0.5 degrees differential from extreme to extreme. Shimming is

allowed when shims are used directly under the HP POD 240a load pads, and are placed in increments

across the length of the HP POD 240a, ensuring the HP POD 240a is level.

The customer is responsible for adequately protecting the surrounding environment during excavation.

For HP POD 240a load specifications and load distribution, see the HP Site Preparation Drawing Package

(on page 6):

based on the IT equipment installed.

(405,100 lb)

IMPORTANT: The HP POD 240a is designed for ground level installation. If you install the HP

POD 240a on an elevated surface, make sure the minimum height requirements for circuit

breaker actuators are considered per local and national electric code requirements. The area in

front of the outside panels must include a work platform.

External top view—Load distribution within IT sections

External bottom view—Load bearing footprint

External bottom view—Load bearing footprint, weights

External bottom view—Load distribution pads (site dependant)

Early infrastructure requirements

The following work is expected to be complete on-site prior to the HP POD 240a assembly:

Customer power equipment and feeders

Underground construction requirements

Site requirements 6

Page 7

Operational clearance around the HP POD 240a

Power (on page 17)

Water supply (on page 15)

Drainage (on page 16)

Site pad (on page 7)

Other structures (on page 7)

Site pad

The structural design of the HP POD 240a site pad design is based on specific weight load locations,

accounting for the HP POD 240a structural footing and supported IT infrastructure.

Other structures

If a customer-provided vestibule or other structure will be installed at the HP POD 240a site, the following

specifications must be maintained:

Flashing must be installed to the exterior of the HP POD 240a in the location where the other structure

will be attached to protect the HP POD 240a and ensure a waterproof barrier.

Access catwalks and/or landings might be required to maintain the required egress from the HP POD

240a HVAC/DX service area.

Access catwalks and/or landings might be required to maintain the required access to the HP POD

240a electrical panels.

Site requirements 7

Page 8

Space requirements and clearances

HP POD 240a dimensions and required clearances

NOTE: Shaded areas indicate required clearances.

Top view clearances shown

End 1 view clearances shown

Space requirements and clearances 8

Page 9

End 2 view clearances shown

Side view clearances shown

Space requirements and clearances 9

Page 10

End 1 view clearances shown

k

HP POD 240a weight

For information on the trucks, deliverables, and the approximate weight of the contents, see the HP POD

240a and support equipment sample offload plan (on page 10). The exact number of required trucks and the

components included on each truck might be different depending on the power redundancy in configuration.

NOTE: Allow additional space required to accommodate any additional equipment that is to be

HP POD 240a and support equipment sample offload plan

This is a sample of trucks and weights for the HP POD 240a structure and equipment that is delivered to the

customer site. Each offload plan will vary based on the components purchased, the configuration of the HP

POD 240a (redundant and non-redundant). The exact number of required trucks and components included

on each truck may differ based on the specific customer POD solution.

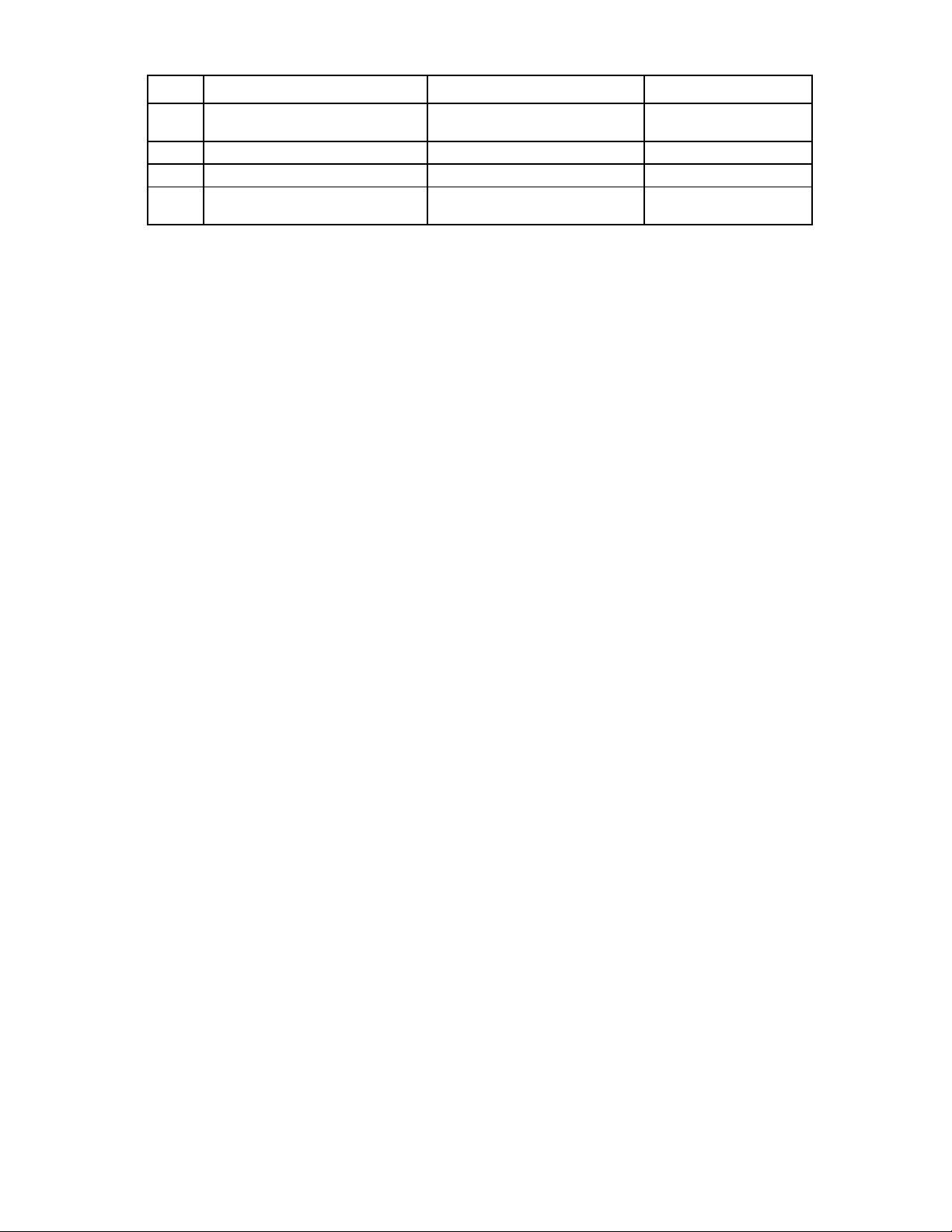

Truck* Contents Comments Truck weight (lbs)

1

2

3

4

5

6a

6b

7

8a

8b

9

10

installed, such as a generator or UPS.

Generator enclosure P1 Optional

Fuel tank for Generator-P1 —

Generator enclosure P2 Optional

Fuel tank for Generator-P2 —

UPS enclosure A1 Optional

IT section A without IT installed

IT section A with IT installed —

Hot aisle Includes fans and catwal

IT section B without IT installed

IT section B with IT installed —

UPS enclosure B1 Optional

HVAC/DX cradles 1 and 2 Each with 12 HVAC/DX and a

Includes racks, PDUs, and

dropboxes, but has no IT installed.

Includes racks, PDUs, and

dropboxes, but has no IT installed.

catwalk

57,935

29,455

57,935

29,455

62,895

50,000

93,000

23,000

50,000

93,000

62,895

18,000 per cradle

Space requirements and clearances 10

Page 11

Truck* Contents Comments Truck weight (lbs)

11

12

13

14

HVAC/DX cradles 3 and 4 Each with 12 HVAC/DX and a

catwalk

Canopy and end walls Creates the service area

HP POD 240a electrical pull boxes For electrical service entry

Misc. parts and pieces Gutter assembly, condensation,

piping, and hardware

18,000 per cradle

8,100

875

1,000

*The truck number does not reflect the actual order of the trucks arrival.

Site space and clearance requirements

The selected site for the HP POD 240a must be large enough to install, service, maintain, and potentially

upgrade the unit and its payload.

Here are two examples for site clearances:

If the HP POD 240a is to be installed in a warehouse, ensure that the warehouse doors are large

enough to accommodate it.

If the HP POD 240a is to be installed outdoors, ensure there is adequate clearance for all buildings,

utility lines, or other site structures, such as gates and headers.

Every site must have sufficient clearance for assembly, maintenance, and service, such as handling devices

such as a forklift, scissor lift, boom lift, or crane.

Adequate space around the HP POD 240a is necessary for airflow and cooling purposes. For specific space

requirements, see HP POD 240a dimensions and required clearances (on page 8).

Additional equipment space requirements

Allow additional space required to accommodate any additional equipment that is to be installed, such as a

generator or UPS.

Future expansions

When selecting a site location, consider future space and accessibility requirements. Adequate space

around the HP POD 240a is necessary for airflow and cooling purposes. When locating additional

equipment in close proximity of the HP POD 240a, for example, additional HVAC/DX, generators, and UPS

devices, consult with HP for site locations.

For specific space requirements, see the HP POD 240a dimensions and required clearances (on page 8).

Space requirements and clearances 11

Page 12

Preparing for delivery and assembly

Shipping considerations

The HP POD 240a is packaged for shipping such that exposure to weather does not result in damage

to the components.

The HP POD 240a is shipped on air-ride trailers to avoid vibrations during shipment.

The HP POD 240a components are shipped based on the assembly plan and available space at the

customer site.

Depending on the site location, additional restrictions and permits might be required, which can effect

Suggested assembly installation equipment

the delivery time line.

Crane (2)

Forklift (1)

Scissor lift (2)

Boom lift (1)

Temporary flood light towers (2)

Fuel spill containment kit

Portable generator

Safety for assembly

National, state, regional, and local safety regulations must be enforced at all times to prevent work-related

injuries. Before installation, HP recommends reviewing the following OSHA safety sections:

Equipment safety—Crane, forklift, scissor-lift, boom-lift, and tools

Traffic safety

Assembly and personnel safety

Electrical safety

Fuel spill containment safety

PPE and head protection

All contractors must adhere to OSHA requirements for the use of PPE to reduce employee exposure to

hazards. The construction area around the HP POD 240a construction site is a required hard-hat area, and

all personnel who enters the construction site must wear a hard hat, safety vest, and any additional OSHA,

HP, and customer required PPE.

Preparing for delivery and assembly 12

Page 13

Temporary lighting and power

Proper temporary lighting and power must be installed and maintained in all construction work areas.

When using temporary lighting:

Label panels and breakers that are used for temporary lighting and power.

The location of panels must be shown on the construction site plan and posted at the entrance to work

area.

Lamps for general illumination must be protected from breakage, and metal shell sockets must be

grounded.

Temporary lights must not be suspended by cords, unless they are so designed.

Storage requirements

CAUTION: The HP POD 240a must maintain 20% relative humidity to minimize condensation

Changes in ambient temperatures cause cond ensat ion in a HP POD 240a t hat is n ot oper ating. If the HP POD

240a is placed in storage or is non-operating mode for over 72 hours, HP recommends using one of the

following methods to minimize condensation and oxidation within the HP POD 240a:

and oxidation within the HP POD 240a.

Dessicant unit

Dessicant material

Heater with a fan

Air conditioner with heater strip

Consult with HP Services to determine the most effective method.

Assembly prerequisites

Before installing the HP POD 240a, verify that the following prerequisites have been met:

All components have been delivered to the facility.

The HP POD 240a and power distribution components are in final location.

Facility power, water, and drainage are at the final location.

Provisions for properly grounding the HP POD 240a have been made.

There are required clearances, including overhead

Coordination of all trade personnel required for assembly

Completed Job Safety Analysis

Required PPE and head protection (on page 12) for all personnel is available

Preparing for delivery and assembly 13

Page 14

Environmental considerations

Environmental considerations

Avoid placing the HP POD 240a directly along a drainage path or in an area prone to flooding.

Verify that the HP POD 240a is properly grounded in accordance with NFPA 70 in accordance with

Cold weather

NEC (NA) and IEC (EMEA and APJ).

The HP POD 240a requires a water supply and several water drains. Extreme cold weather might cause

damage to the supply and drain lines. Evaluate the following for additional cold weather protection:

Regional location of HP POD 240a

Exposure of supply and drain lines to extreme cold temperature

Extreme cold weather can affect crane and lifting operations. When temperatures drop below 10°F,

appropriate consideration must be made with respect to shock loading, crane hydraulics, and possible

derating of the crane.

Areas prone to lightning or power surges

The HP POD 240a structure and internal components are all bonded together. A common Grounding

Electrode Conductor Connection point is provided. Properly bonding and grounding of the HP POD 240a

minimizes the effects of a lightning strike. A TVSS device is provided on the HP POD 240a input connection

to protect the HP POD 240a electrical system from voltage transients. If your site is in an area that is subject

to frequent lightning strikes, the HP POD 240a must be protected in accordance with NFPA 780/NEC (NA)

and IEC (EMEA and APJ). HP recommends that you contact a certified lightning protection consultant.

Seismic activity

If your site is in an area that has frequent seismic activity, HP recommends that you contact a seismic activity

consultant. If your site is in an area that has high vibration level, HP recommends that you contact a vibration

isolation consultant. There are no provisions for anchoring the HP POD 240a.

Environmental considerations 14

Page 15

Utilities

Proximity to utilities and drains

Consider proximity to required utilities, such as power, water, and network connections. While required

utilities can be brought to nearly any selected site, there is a potential for increased costs and decreased

efficiency when the HP POD 240a is located further from the utility source.

For utility clearance information, see HP POD 240a dimensions and required clearances (on page 8).

System utilities

The site location must accommodate the following utilities:

Water supply (on page 15)

Drainage (on page 16)

Water supply

Power (on page 17)

The HP POD 240a requires supply water for the humidifier. The supply water must meet the following

requirements:

Requirement Specification

Pressure

Temperature

Instant flow-rate

Connection

Hardness

Conductivity

Organic compounds

Do not treat the water with softeners, because softeners might produce foam, which affects the

operation of the unit.

between 0.1 and 0.8 MPa (1 and

8 bars)

between 1 and 40 °C

no lower than the rated flow of the

fill solenoid valve

G3/4M

no greater than 40°fH (equal to

400 ppm of CaCO3)

125 to 1250 μS/cm

None

Do not use well water, industrial water, water from cooling circuits, or water contaminated by any

chemicals or bacteria.

Do not add disinfectants or anti-corrosive compounds to the water, which are potential irritants.

For additional dimensions, see the HP Site Preparation Drawing Package (on page 6).

Utilities 15

Page 16

Water quality

Water must be maintained per the following acceptable water quality standards.

Requirement Specification

Type of water introduced

Instant water fill flow-rate

Drinking water

Do not use demin or softened water.

0.6 l/min 0.16 gpm

If your water is out of range, consult a water quality expert.

Drainage

The following figure illustrates the drain locations on the HP POD 240a.

Side view shown

Callout Component Description Quantity per

side

Total quantity

per HP POD

240a

1

Condensate drain Removes condensation and water

2

from the HP POD 240a exterior.

2

Humidifier drain Removes excess water pulled from the

1

interior of the HP POD 240a by the

humidifier.

3

Rain water drain Removes rain water from the HP POD

2

240a

4

2

4

Utilities 16

Page 17

Power

IMPORTANT: To provide power to the HP POD 240a, external transformers and switchboards

may be required. This equipment must be designed and installed to adhere with local, state, and

national codes, and installed by contractors with licensing required by the local jurisdiction;

For all site preparation drawings, see the HP Site Preparation Drawing Package (on page 6) included on the

documentation CD.

Power requirements

The HP POD 240a can be installed as a single source 1N load by providing all required feeders from one

common power sources and from common switchboards and transformers, if required. A fully redundant 2N

installation can be achieved by feeding the parallel power paths from independent power sources,

switchboards and transformers if required.

Power feeder requirements:

Feature Specification

Enclosure rating

Mechanical power for

cooling system

components

Critical power for IT

equipment

city, township, and state.

IMPORTANT: All 3-phase WYE feeders for the HP POD 240a require that the neutrals and the

equipment grounding conductors remain isolated. Bonding of the two conductors is allowed at

the power source only.

NEMA 3R

4 x 300A feeders at 480VΔ, 3-phase, 3-wire, with

equipment ground conductor

2 x 3" conduit fittings per feeder provided

4 x 1000A feeders at 415Y/240V, 3-phase, 4-wire,

with equipment ground conductors

4 x 4" conduit fittings per feeder provided

Total critical power

required for HP POD

240a full capacity

External power source

When determining the final location of the power connections, consider the following:

Distance between the facility utilities and the location of the transformer and switchboard

Distance between the transformer and switchboard and the HP POD 240a

Distance between the UPS/Generator locations and the HP POD 240a switchboard

Requirements for routing electrical feeders (underground or overhead)

The facility power connection must be installed in compliance with local electrical codes and regulations. HP

reference electrical installation design is based on a maximum distance of 15.2 m (50 ft) or line of sight

between the switchboard and the HP POD 240a.

2N Redundant—1.2 MVA

Non-redundant—2.4 MVA

Utilities 17

Page 18

Transformers and switchboards

The input power for the Critical IT Loads requires a source of 380-415V, 3phase Wye power. This may

require custom transformer(s) be provided to derive this power if it does not already exist at the source. In

addition to the overall loading and KVA size, considerations should be given to the Harmonic Content of the

installation when specifying the K-Factor of the transformer(s). Alternatively, Harmonic Mitigating

Transformers might be used to passively cancel the harmonics generated by the IT Equipment.

HP offers several powerhouse solutions that include automatic transfer switching, UPS backup, transformers

and output distribution switchboards to supply your power needs.

On-site connections may include:

Main facility power to the primary side of the transformer

Transformer to the switchboard

Switchboard assembly to the HP POD 240a

For connection information, see the HP Site Preparation Drawing Package (on page 6).

Preparing the site for power

The customer must provide and submit the following fully coordinated drawings showing the exact

routing, plan view, sections, and elevations, for approval before beginning site preparation:

o Coordinated underground conduit routing drawings

o Site pad drawings

The HP POD 240a requires an external transformer and switchboard. If the customer provides their own

transformer and switchboard, they must also provide HP with the engineering drawings.

IMPORTANT: To provide power to the HP POD 240a, external transformers and switchboards

may be required. This equipment must be designed and installed to adhere with local, state, and

national codes, and installed by contractors with licensing required by the local jurisdiction;

city, township, and state.

Utilities 18

Page 19

Required facility connections

Connections to central facility infrastructure

The HP POD 240a is designed to function standalone but may be connected to existing facility systems with

additional engineering and costs.

HP POD 240a Environmental Control System

o Operational status

o Power consumption

o Environmental status

Life safety systems

o EPO

o Fire detection

o Fire suppression

Site communication

o Phone

o Security

Networking

o IT connections

Network connections

Connection portals

For information on the network connections, see the HP POD 240a Networking Guide.

The networking and connection portals are located on the cargo-end of the HP POD 240a. There are eight

portals per IT section, and each of the different sized portals are used for different connections.

Required facility connections 19

Page 20

End view shown

4

Connection portal

Connection point Quantity per IT

diameter

3-inch portal

1.5-inch portal

Networking connection for all IT

Communication connection for all

communication

ECS

EPO

Fire alarm

Phone

1.5-inch portal

(Optional) vestibule communication

connections

NOTE: The connection portal location and configuration might look different, depending on the

HP POD 240a model.

Grounding requirements

The HP POD 240a structure and internal components are all bonded together. A common Grounding

Electrode Conductor Connection point is provided.

WARNING: To avoid the risk of personal injury or electric shock, the HP POD 240a must be

properly grounded, and each of the individual sections must be bonded together in accordance

Grounding and bonding of the HP POD 240a must comply with Article 250 of the NFPA 70 in

with NFPA 70 in accordance with NEC (NA) and IEC (EMEA and APJ).

CAUTION: You must remove any painted surface from all grounding surfaces. Failure to do so

results in an ineffective ground.

accordance with NEC (NA) and IEC (EMEA and APJ).

section

2

2

Total quantity per

HP POD 240a

8

4

4

Required facility connections 20

Page 21

The HP POD 240a structural sections, metal raceways, wireways, conduit, boxes, and other external

intersystem components must be bonded with grounding conductors per NFPA 70 in accordance with

NEC (NA) and IEC (EMEA and APJ).

Bonding of Piping Systems and Exposed Structural Steel must comply with NF PA 70 in accordance with

NEC (NA) and IEC (EMEA and APJ).

Feature Specification

Grounding pad

A grounding pad is located on the underside of the HP POD 240a at the outside

corner of each IT section, under the electrical panel.

Grounding pads are located inside the HP POD 240a at ceiling level to bond the

sections together and bond the IT racks.

Grounding lugs

Grounding lugs cannot be attached to any painted surface.

Grounding lugs must be compression-type 2-hole lug

Ground rod system or

ground well

IMPORTANT: Before installing the HP POD 240a, consult your local AHJ for applicable codes

Customer must provide an effective grounding system with ground rod or ground well.

and to review site-specific location guidelines. If needed, obtain any necessary permits.

The grounding electrode conductor connections are located on IT sections A and B of the HP POD 240a.The

following figure shows the location for one of the IT sections.

Side view shown

Required facility connections 21

Page 22

End view shown

Item Component

1

Grounding electrode conductor connection

Required facility connections 22

Page 23

Supported facility connections

Humidifier

A dedicated water supply and approved drainage is required for the humidifier. For more information about

the humidifier, see the HP Performance Optimized Datacenter (POD) 240a Operation and Maintenance

Manual provided with the HP POD 240a.

End view shown

Item Component

1

2

Humidifier drain and water supply on IT section A

Humidifier drain and water supply on IT section B

NOTE: Confirm with AHJ that condensate water and rain water can be mixed in the same

drainage.

Supported facility connections 23

Page 24

HP POD 240a security

A

The HP POD 240a is equipped with standard key lock hardware at each personnel entry door and six

external electrical cabinets. Each personnel entry door includes a door access contact that can be connected

to the customer facility security system. Conduit and junction boxes are provided for customer installed

controlled access systems.

Additional options for controlled access security includes:

Electronic card reader

12-digit security code keypad

Magnetic lock on each entry door

Fire, safety, and security notifications

Dry contacts are provided to enable the connection between the HP POD 240a fire alarm system and the

customer facility fire system. If the HP POD 240a is connected to the customer facility systems, then the HP

POD 240a-initiated alarms, notify the facility systems.

The customer must provide an independent connection for each system listed in the following table.

Alarm Meaning

Fire prevention alarm

Fire suppression

system (optional)

Security

EPO

The electrical layout of the fire alarm system is as described in the schematic drawing that is supplied with the

HP Performance Optimized Datacenter (POD) 240a Operations and Maintenance Manual.

Smoke has been detected in the HP POD 240a.

The suppression system alarm has been activated, and

gas will be dispersed to suppress a fire.

security breach has occurred.

The EPO system has been activated by an EPO button

or thermal event, and shut down the HP POD 240a.

Supported facility connections 24

Page 25

Glossary

AHJ

Authority Having Jurisdiction

door

A hinged portion of an enclosure that covers an opening.

DX

direct expansion

ECS

environmental control system

EPO

emergency power off

equipment

A general term, including fittings, devices, appliances, luminaires, apparatus, machinery, and the like used

as a part of, or in connection with, a modular data center. (Source: NEC.)

HVAC

Heating, Ventilation, and Air Conditioning

IEC

International Electrotechnical Commission

ISO

International Organization for Standardization

labeled

Equipment or materials to which has been attached a label, symbol, or other identifying mark of an

organization that is acceptable to the authority having jurisdiction and concerned with product evaluation,

that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling

the manufacturer indicates compliance with appropriate standards or performance in a specified manner.

(Source: NEC.)

Glossary 25

Page 26

listed

Equipment, materials, or services included in a list published by an organization that is acceptable to the

authority having jurisdiction and concerned with evaluation of products or services, that maintains periodic

inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing

states that either the equipment, material, or service meets appropriate designated standards potential of not

more than 42.4 V (DC or peak) supplied by a primary battery or by an isolated secondary circuit, and where

the current capacity is limited by an overcurrent device, such as a fuse, or by the inherent capacity of the

secondary transformer or power supply, or a combination of a secondary winding and an impedance. A

circuit derived from a line-voltage circuit by connecting a resistance in series with the supply circuit to limit the

voltage and current is not identified as a low-voltage limited energy circuit. or has been tested and found

suitable for a specified purpose. (Source: NEC.)

The means for identifying listed equipment might vary for each organization concerned with product

evaluation, some of which do not recognize equipment as listed unless it is also labeled. Use of the system

employed by the listing organization allows the authority having jurisdiction to identify a listed product.

NA

North American

NEC

National Electrical Code

NFPA

National Fire Protection Association

overcurrent protection

A device designed to open a circuit when the current through it exceeds a predetermined value. The ampere

rating of the device is selected for a circuit to terminate a condition where the current exceeds the rating of

conductors and equipment due to overloads, short circuits and faults to ground.

PPE

personal protective equipment

structure

Enclosure of sufficient size to allow entry of personnel.

UL

Underwriters Laboratory

UPS

uninterruptible power system

VESDA

Very Early Smoke Detection Apparatus

Glossary 26

Loading...

Loading...