Page 1

HP P6300/P6500 EVA Fibre

Channel Controller Enclosure

Replacement Instructions

© Copyright 2011 Hewlett-Packard Development Company, L.P.

First edition: May 2011

The information in this document is subject to change without notice.

About this document

For the latest documentation, go to http://www.hp.com/support/

manuals, and select your product.

The information contained herein is subject to change without notice.

The only warranties for HP products and services are set forth in the

express warranty statements accompanying such products and services.

Nothing herein should be construed as constituting an additional

warranty. HP shall not be liable for technical or editorial errors or

omissions contained herein.

WARRANTY STATEMENT: To obtain a copy of the warranty for this

product, see the warranty information website:

http://www.hp.com/go/storagewarranty

Choosing a storage configuration

The P6300 EVA configuration details are:

• Two HSV340 controllers per controller enclosure

• Four SAS ports

• Four 8 Gb FC ports per controller

• 1/10 (minimum/maximum) controller enclosures

• 8/120 (minimum/maximum) M6612 (LFF) disk drives

• 8/250 (minimum/maximum) M6625 (SFF) disk drives

The P6500 EVA configuration details are:

• Two HSV360 controllers per controller enclosure

• Eight SAS ports

• Four 8 Gb FC ports per controller

• 2/20 (minimum/maximum) controller enclosures

• 8/240 (minimum/maximum) M6612 (LFF) disk drives

• 8/450 (minimum/maximum) M6625 (SFF) disk drives

Printed in Puerto Rico

www.hp.com

*593088-001*

Before you begin

Observe the following precautions when replacing a controller.

CAUTION:

HP recommends that you perform the replacement procedure

within seven minutes from when the controller is removed to

when it is replaced in the enclosure. Ensure all necessary parts

are available so the procedure can be completed without

interruption. Removing a controller module significantly changes

the air flow within the enclosure. Both controllers must be

installed for the enclosure to cool properly. If a controller fails,

leave it in place in the enclosure until a new module is available

to install. The enclosure could shut down due to overheating

unless the controller is replaced within the recommended seven

minutes.

Parts can be damaged by electrostatic discharge. Use proper

anti-static protection. See the documentation that shipped with

your system for additional information.

Page 1

Page 2

NOTE:

• Alloy (gray)-colored latches on components like the controller

means the component is warm-swappable. Halt the I/O of the

failing controller with HP P6000 Command View before removing this component.

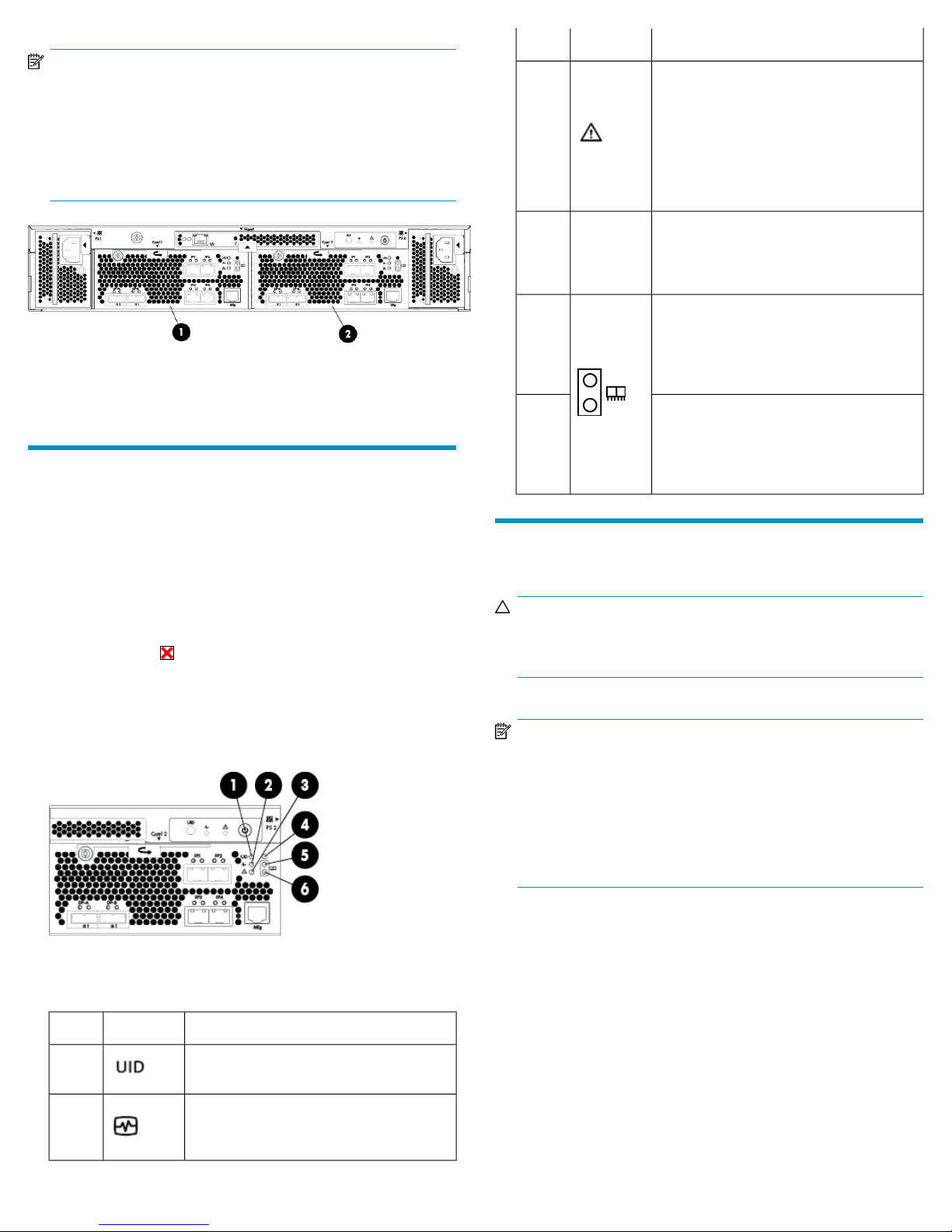

• There are two controllers at the rear of the controller enclosure.

See Figure 1 for the locations.

2. Controller 21. Controller 1

IndicationLEDItem

Flashing amber indicates a controller termination, or the system is inoperative and attention is required. Solid amber indicates

3

that the controller cannot reboot and that

the controller should be replaced. If both

the solid amber and solid blue LEDs are lit,

the controller has completed a warm removal procedures, and can be safely swapped.

Indicator is not used on FC controller. The

MEZZ4

indicator is used on the FC-iSCSI or iSCSI/FCoE controller to indicate iSCSI module

status.

Green LED indicates write-back cache

status. Slow flashing green LED indicates

5

standby power. Solid green LED indicates

cache is good with normal AC power applied.

Figure 1 Controller locations

.

Verifying component failure

Use the following methods to verify component failure:

• Analyze any failure messages received. HP Insight Remote Support

Software provides a recommended fault monitoring solution.

• Check status using HP P6000 Command View:

1. In the navigation pane, select Storage system > Hardware >

Controller Enclosure and then select the controller.

2. The status is displayed in the Condition/State field. An opera-

tional state of (Failed) would indicate a fault that may require

a replacement.

3. To help identify the correct controller, click Locate > Locate On.

This causes the blue UID indicator to light on the controller

module at the rear of the controller enclosure.

• Check the controller status LEDs as shown in Figure 2 and Table 1.

Amber LED indicates DIMM status. The LED

is off when DIMM status is good. Slow

6

flashing amber indicates DIMMs are being

powered by battery (during AC power

loss). Solid amber indicates a DIMM failure.

Removing a controller

CAUTION:

Verify the location of the controller being serviced. Removing

the wrong controller can result in data loss.

NOTE:

• Replacement controllers do not have DIMM modules, therefore

the DIMMs from the controller being removed must be transferred to the replacement controller.

• HP recommends that you replace the controller while the con-

troller enclosure is powered on to ensure the controller software

on the redundant controller is copied to the controller being

installed.

Figure 2 Controller status LEDs

.

Table 1 Controller status LEDs

IndicationLEDItem

1

Blue LED identifies a specific controller

module within the enclosure.

Green LED indicates controller health. LED

2

flashes green during boot and becomes

solid green after boot.

1. Halt I/O to the controller with HP P6000 Command View:

a. In the navigation pane, select Storage System > Hardware >

Controller Enclosure.

b. Select the appropriate controller (Controller 1 or Controller 2)

to halt.

c. Click the Shut down tab.

d. In the Halt Controller section of the Shut Down Controller

window, click Halt. This halts controller processing while the

power remains on.

2. Disconnect the SAS, Fibre Channel, Ethernet, and console cables

from the halted controller. Ensure they are marked to facilitate

reconnecting later.

Page 2

Page 3

3. Remove the controller.

a. Loosen the thumbscrew on the mounting latch and rotate the

latch to the right (1, Figure 3). The controller will slightly eject

from the enclosure.

b. Position one hand under the controller, and with the other hand,

pull the controller out of the enclosure (2).

6. Press the retaining clips outward to unlock each DIMM socket (1,

Figure 6). This action releases the modules, and partially lifts the

modules out of the socket.

Figure 6 Removing a DIMM

.

7. Lift out each DIMM (2).

Figure 3 Removing a controller

.

4. Push the blue button on top of the controller module (1, Figure 4)

and slide off the cover (2). Observe proper anti-static guidelines.

Figure 4 Removing the controller cover

.

5. See Figure 5 for the location of the two DIMMs on the controller.

Installing a controller

1. Press each DIMM from the removed controller into the same DIMM

socket on the replacement controller (1, Figure 7).

Figure 7 Installing a DIMM

.

2. Press the retaining clips inward to lock each DIMM into the socket

(2).

2. Slot 2 (cache memory)1. Slot 1 (policy memory)

Figure 5 Location of controller DIMMs

.

Page 3

Page 4

3. Place the cover on the controller module rails and slide the cover

over the controller until the latch clicks into place.

Figure 8 Installing the controller cover

.

4. Move the small form-factor pluggable (SFP) modules, installed in

the unused FC host ports, from the controller being replaced to the

new controller (if there are unused FC ports).

5. Reinstall the controller.

a. Push the controller halfway into the controller enclosure (1,

Figure 9).

b. Connect the SAS device port cables to the controller device

ports.

Verifying proper operation

After replacing the controller, check the following to verify the component

is operating properly:

NOTE:

Wait approximately 3 minutes for the system to check the

component status.

• Verify the controller health green LED is lit (see Table 1). If not, try

reseating the controller in the enclosure.

• From HP P6000 Command View, navigate to the component as de-

scribed in the Verifying component failure section, and check the

status. It should be (Good).

NOTE:

Inserting a controller without connecting the device

port cables may result in soft diagnostic errors

being reported.

c. Fully insert the controller. Move the mounting latch to the left

until fully engaged and the controller is fully seated in the

enclosure (2). The controller should power up automatically.

Tighten the controller latch thumbscrew.

Figure 9 Installing a controller

.

d. Reinstall the FC host cables and any disconnected Ethernet or

console cables.

Page 4

Loading...

Loading...