HP LaserJet P1000 Series

Service Manual

HP LaserJet P1000 Series

Service Manual

Copyright and license

Trademark credits

© 2006 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products

and services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Edition 1, 6/2007

Part numberCB410-99010

Microsoft® and Windows® are U.S.

registered trademarks of Microsoft

Corporation.

Linux is a U.S. registered trademark of Linus

Torvalds.

PostScript® is a trademarks of Adobe

Systems Incorporated.

UNIX® is a registered trademark of The

Open Group.

Energy Star® and the Energy Star® logo are

U.S. registered marks of the United States

Environmental Protection Agency.

Table of contents

1 Product information

Product configuration ........................................................................................................................... 2

Product features ................................................................................................................................... 3

Identify product parts ............................................................................................................................ 4

2 Managing and maintenance

Replace the print cartridge ................................................................................................................... 8

Printer information pages ................................................................................................................... 10

Demo page ........................................................................................................................ 11

Configuration page ............................................................................................................ 12

Clean the device ................................................................................................................................. 13

Clean the print-cartridge area ............................................................................................ 13

Clean the device paper path .............................................................................................. 15

Change the pickup roller .................................................................................................................... 17

Clean the pickup roller ........................................................................................................................ 20

Change the printer separation pad ..................................................................................................... 21

EconoMode ........................................................................................................................................ 24

3 Theory of operation

Introduction ......................................................................................................................................... 26

Internal components ........................................................................................................................... 27

Timing ................................................................................................................................................. 28

Engine control system ........................................................................................................................ 29

Laser/scanner system ........................................................................................................................ 31

Pickup/feed/delivery system ............................................................................................................... 32

Image-formation system ..................................................................................................................... 33

Step 1: Primary charging ................................................................................................... 33

Step 2: Laser beam exposure ............................................................................................ 34

Step 3: Developing ............................................................................................................ 34

Step 4: Transfer ................................................................................................................. 35

Step 5: Separation ............................................................................................................. 35

Step 6: Fusing .................................................................................................................... 36

Step 7: Drum cleaning ....................................................................................................... 36

4 Removal and replacement

Introduction ......................................................................................................................................... 38

Removal and replacement strategy ................................................................................... 38

Electrostatic discharge ....................................................................................................... 38

ENWW iii

Before performing service .................................................................................................................. 39

Covers ................................................................................................................................................ 40

Formatter ............................................................................................................................................ 46

Fuser .................................................................................................................................................. 47

Laser/scanner ..................................................................................................................................... 51

DC controller ...................................................................................................................................... 54

Transfer roller ..................................................................................................................................... 56

Motor drive belt ................................................................................................................................... 57

Rear paper-feed roller ........................................................................................................................ 59

Main motor ......................................................................................................................................... 61

5 Problem solving

Problem-solving checklist ................................................................................................................... 68

Contact HP support ............................................................................................................................ 70

Status-light patterns ........................................................................................................................... 71

Clearing jams ..................................................................................................................................... 73

Improve print quality ........................................................................................................................... 76

Media problem-solving ....................................................................................................................... 80

Printed page is different from what appeared on screen .................................................................... 81

Required tools .................................................................................................................... 38

Pre-service procedures ...................................................................................................... 39

Parts removal order ........................................................................................................... 39

Front Cover ........................................................................................................................ 40

Control panel ..................................................................................................................... 40

Side Covers ....................................................................................................................... 41

Back Cover ........................................................................................................................ 43

Top Cover .......................................................................................................................... 44

Step 1: Is the device set up correctly? ............................................................................... 68

Step 2: Is the Ready light on? ............................................................................................ 68

Step 3: Can you print an engine test page? ...................................................................... 68

Step 4: Is the device communicating with the computer? .................................................. 69

Step 5: Does the printed page look like you expected? ..................................................... 69

Typical media jam locations ............................................................................................... 73

Removing a jammed page ................................................................................................. 73

Light print or faded ............................................................................................................. 76

Toner specks ..................................................................................................................... 76

Dropouts ............................................................................................................................ 76

Vertical lines ...................................................................................................................... 77

Gray background ............................................................................................................... 77

Toner smear ...................................................................................................................... 77

Loose toner ........................................................................................................................ 78

Vertical repetitive defects ................................................................................................... 78

Misformed characters ........................................................................................................ 78

Page skew ......................................................................................................................... 78

Curl or wave ....................................................................................................................... 79

Wrinkles or creases ........................................................................................................... 79

Toner-scatter outline .......................................................................................................... 79

Garbled, incorrect, or incomplete text ................................................................................ 81

Missing graphics or text, or blank pages ........................................................................... 81

Page format is different than on another HP LaserJet printer ........................................... 81

iv ENWW

Graphics quality ................................................................................................................. 82

Printer software problems .................................................................................................................. 83

Common Macintosh problems ............................................................................................................ 84

Network-setup problem-solving .......................................................................................................... 86

6 Parts and diagrams

Assembly locations ............................................................................................................................. 88

Covers ................................................................................................................................................ 90

Internal assemblies ............................................................................................................................ 96

Alphabetical parts list ....................................................................................................................... 102

Numerical parts list ........................................................................................................................... 107

Appendix A Service and support

Hewlett-Packard limited warranty statement .................................................................................... 114

Customer self repair warranty service .............................................................................................. 115

Hewlett-Packard software license agreement .................................................................................. 116

Limited warranty for print cartridges and image drums .................................................................... 117

Appendix B Device specifications

Appendix C Regulatory information

FCC compliance ............................................................................................................................... 122

Declaration of Conformity statements for HP LaserJet P1000 Series .............................................. 123

Regulatory statements ..................................................................................................................... 124

Laser safety statement .................................................................................................... 124

Canadian DOC regulations .............................................................................................. 124

Korean EMI statement ..................................................................................................... 124

Laser statement for Finland ............................................................................................. 125

Substances Table (China) ............................................................................................... 126

Environmental product stewardship program ................................................................................... 127

Protecting the environment .............................................................................................. 127

Ozone production ............................................................................................................ 127

Power consumption ......................................................................................................... 127

Toner consumption .......................................................................................................... 127

Paper use ........................................................................................................................ 127

Plastics ............................................................................................................................ 127

HP LaserJet print supplies ............................................................................................... 127

Return and recycling instructions ..................................................................................... 128

United States and Puerto Rico ........................................................................ 128

Non-US returns ............................................................................................... 128

Paper ............................................................................................................................... 128

Material restrictions .......................................................................................................... 128

Disposal of waste equipment by users in private households in the European Union .... 129

Material Safety Data Sheet (MSDS) ................................................................................ 129

For more information ....................................................................................................... 129

Multiple returns (two to eight cartridges) ........................................ 128

Single returns ................................................................................. 128

Shipping .......................................................................................... 128

ENWW v

Index ................................................................................................................................................................. 131

vi ENWW

List of tables

Table 3-1 Sequence of operation ..................................................................................................................... 28

Table 5-1 Status-light legend ........................................................................................................................... 71

Table 5-2 Control-panel light messages ........................................................................................................... 71

Table 5-3 Printer software problems ................................................................................................................ 83

Table 5-4 Problems with Mac OS X ................................................................................................................. 84

Table 6-1 Assembly locations (1 of 1) .............................................................................................................. 89

Table 6-2 HP LaserJet P1006/P1008 covers ................................................................................................... 91

Table 6-3 HP LaserJet P1005 covers .............................................................................................................. 93

Table 6-4 HP LaserJet P1007 covers .............................................................................................................. 95

Table 6-5 Internal components (1 of 3) ............................................................................................................ 97

Table 6-6 Internal components (2 of 3) ............................................................................................................ 99

Table 6-7 Internal components (3 of 3) .......................................................................................................... 101

Table 6-8 Alphabetical parts list ..................................................................................................................... 102

Table 6-9 Numerical parts list ......................................................................................................................... 107

Table B-1 Physical specifications ................................................................................................................... 119

Table B-2 Electrical specifications .................................................................................................................. 119

Table B-3 Power consumption (average, in Watts) ........................................................................................ 119

Table B-4 Acoustic emissions ........................................................................................................................ 120

Table B-5 Environmental specifications ......................................................................................................... 120

Table C-1

有毒有害物 表 ............................................................................................................................. 126

ENWW vii

viii ENWW

List of figures

Figure 1-1 HP LaserJet P1000 Series ................................................................................................................ 2

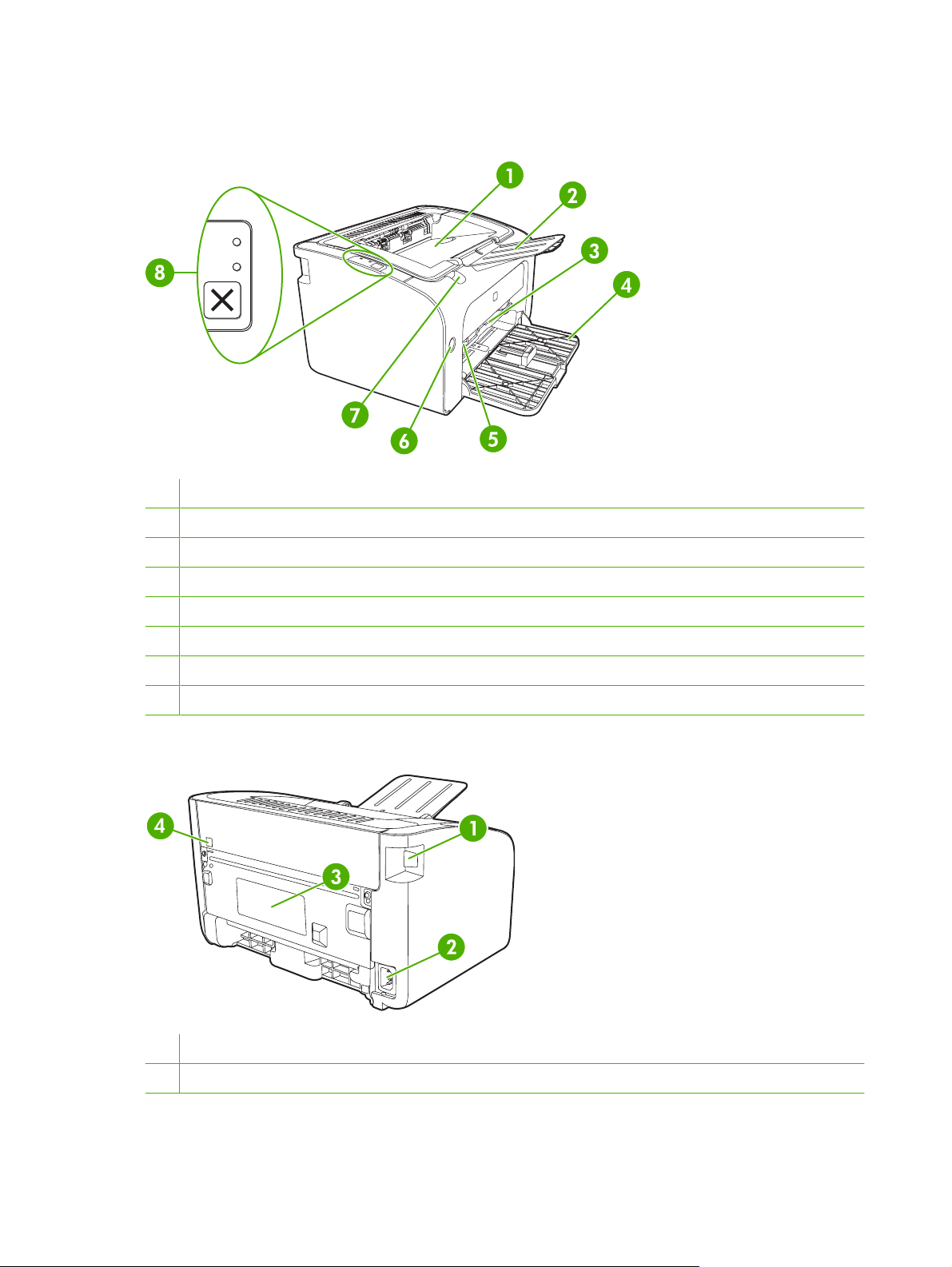

Figure 1-2 HP LaserJet P1000 Series, front view (HP LaserJet P1006/P1008 shown) ..................................... 4

Figure 1-3 HP LaserJet P1000 Series, back view (HP LaserJet P1006/P1008 shown) .................................... 4

Figure 3-1 Block diagram ................................................................................................................................. 26

Figure 3-2 Cross-section of printer ................................................................................................................... 27

Figure 3-3 Engine control system ..................................................................................................................... 29

Figure 3-4 Engine control system circuit diagram ............................................................................................ 30

Figure 3-5 Laser/scanner system ..................................................................................................................... 31

Figure 3-6 Pickup/feed/delivery system ........................................................................................................... 32

Figure 3-7 Image-formation system ................................................................................................................. 33

Figure 3-8 Primary charging ............................................................................................................................. 33

Figure 3-9 Laser beam exposure ..................................................................................................................... 34

Figure 3-10 Developing .................................................................................................................................... 34

Figure 3-11 Transfer ......................................................................................................................................... 35

Figure 3-12 Separation ..................................................................................................................................... 35

Figure 3-13 Fusing ........................................................................................................................................... 36

Figure 3-14 Drum cleaning ............................................................................................................................... 36

Figure 4-1 Remove front cover (1 of 1) ............................................................................................................ 40

Figure 4-2 Remove control panel (1 of 1) ......................................................................................................... 41

Figure 4-3 Remove side covers (1 of 4) ........................................................................................................... 41

Figure 4-4 Remove side covers (2 of 4) ........................................................................................................... 42

Figure 4-5 Remove side covers (3 of 4) ........................................................................................................... 43

Figure 4-6 Remove side covers (4 of 4) ........................................................................................................... 43

Figure 4-7 Remove back cover (1 of 2) ............................................................................................................ 44

Figure 4-8 Remove back cover (2 of 2) ............................................................................................................ 44

Figure 4-9 Remove top cover (1 of 1) .............................................................................................................. 45

Figure 4-10 Remove formatter (1 of 2) ............................................................................................................. 46

Figure 4-11 Remove formatter (2 of 2) ............................................................................................................. 46

Figure 4-12 Remove fuser (1 of 6) ................................................................................................................... 47

Figure 4-13 Remove fuser (2 of 6) ................................................................................................................... 48

Figure 4-14 Remove fuser (3 of 6) ................................................................................................................... 48

Figure 4-15 Remove fuser (4 of 6) ................................................................................................................... 49

Figure 4-16 Remove fuser (5 of 6) ................................................................................................................... 49

Figure 4-17 Remove fuser (6 of 6) ................................................................................................................... 50

Figure 4-18 Remove laser/scanner (1 of 4) ...................................................................................................... 51

Figure 4-19 Remove laser/scanner (2 of 4) ...................................................................................................... 52

Figure 4-20 Remove laser/scanner (3 of 4) ...................................................................................................... 52

Figure 4-21 Remove laser/scanner (4 of 4) ...................................................................................................... 53

Figure 4-22 Remove DC controller (1 of 4) ...................................................................................................... 54

ENWW ix

Figure 4-23 Remove DC controller (2 of 4) ...................................................................................................... 54

Figure 4-24 Remove DC controller (3 of 4) ...................................................................................................... 55

Figure 4-25 Remove DC controller (4 of 4) ...................................................................................................... 55

Figure 4-26 Remove transfer roller (1 of 1) ...................................................................................................... 56

Figure 4-27 Remove motor drive belt (1 of 4) .................................................................................................. 57

Figure 4-28 Remove motor drive belt (2 of 4) .................................................................................................. 57

Figure 4-29 Remove motor drive belt (3 of 4) .................................................................................................. 58

Figure 4-30 Remove motor drive belt (4 of 4) .................................................................................................. 58

Figure 4-31 Remove rear paper feed roller (1 of 3) ......................................................................................... 59

Figure 4-32 Remove rear paper feed roller (2 of 3) ......................................................................................... 60

Figure 4-33 Remove rear paper feed roller (3 of 3) ......................................................................................... 60

Figure 4-34 Remove main motor (1 of 5) ......................................................................................................... 61

Figure 4-35 Remove main motor (2 of 5) ......................................................................................................... 62

Figure 4-36 Remove main motor (3 of 5) ......................................................................................................... 63

Figure 4-37 Remove main motor (4 of 5) ......................................................................................................... 64

Figure 4-38 Remove main motor (5 of 5) ......................................................................................................... 65

Figure 6-1 Assembly locations (1 of 1) ............................................................................................................. 88

Figure 6-2 HP LaserJet P1006/P1008 covers .................................................................................................. 90

Figure 6-3 HP LaserJet P1005 covers ............................................................................................................. 92

Figure 6-4 HP LaserJet P1007 covers ............................................................................................................. 94

Figure 6-5 Internal components (1 of 3) ........................................................................................................... 96

Figure 6-6 Internal components (2 of 3) ........................................................................................................... 98

Figure 6-7 Internal components (3 of 3) ......................................................................................................... 100

x ENWW

1 Product information

Product configuration

●

Product features

●

Identify product parts

●

ENWW 1

Product configuration

Figure 1-1 HP LaserJet P1000 Series

First Page Out: < 8 seconds

●

Speed: 14 A4 pages per minute (ppm), 15 Letter-size ppm.

●

Tray: 150 sheet universal tray.

●

Connectivity: Hi-Speed USB 2.0 port.

●

HP LaserJet P1006/P1008 only

First Page Out: < 8 seconds

●

Speed: 22 A4 pages per minute (ppm), 17 Letter-size ppm.

●

Tray: 10 sheet priority feed slot and a 150 sheet universal tray.

●

Connectivity: Hi-Speed USB 2.0 port.

●

2 Chapter 1 Product information ENWW

Product features

Benefit Supporting features

Excellent print quality

Ease of use

Flexible paper handling

Interface connections

Energy savings

Economical printing

HP print cartridges.

●

True 600 by 600 dots per inch (dpi) text and graphics.

●

Adjustable settings to optimize print quality.

●

The print cartridge is easy to install.

●

Convenient access to the print cartridge and to the paper path

●

through the cartridge door.

Adjust paper tray with one hand.

●

Main tray for letterhead, envelopes, labels, transparencies,

●

custom-sized media, postcards, and heavy paper.

Priority feed slot for letterhead, envelopes, labels,

●

transparencies, custom-sized media, postcards, and heavy

paper.

A 125-sheet top output bin.

●

Print on Both Sides (manually).

●

Hi-Speed 2.0 USB port.

●

The device automatically conserves electricity by

●

substantially reducing power consumption when it is not

printing.

N-up printing (printing more than one page on a sheet) and

●

Printing on Both Sides features save paper.

Archive printing

Supplies

Accessibility

Security

When printing pages that are to be stored long-term, this

●

option sets the device to a mode that reduces toner smearing

and dusting.

Select Archive as the paper type.

●

A Supplies Status page with print cartridge gauges that

●

estimate remaining supply level. Not available for non-HP

supplies.

No-shake cartridge design.

●

Authentication for original HP print cartridges.

●

Easy ordering for replacement supplies.

●

Online user guide compatible with text screen-readers.

●

All doors and covers can be opened with one hand.

●

Kensington lock receptacle on back of device.

●

ENWW Product features 3

Identify product parts

Figure 1-2 HP LaserJet P1000 Series, front view (HP LaserJet P1006/P1008 shown)

1 Output bin

2 Foldable Output Tray Extension

3 Priority feed slot (HP LaserJet P1006/P1008 only)

4 Foldable Main Input tray

5 Short Media Extender (HP LaserJet P1005/P1007 only)

6 Power button

7 Cartridge door lift-tab (access to print cartridge)

8 Control panel (HP LaserJet P1006/P1008 control panel shown)

Figure 1-3 HP LaserJet P1000 Series, back view (HP LaserJet P1006/P1008 shown)

1 USB Port (2.0)

2 Power receptacle

4 Chapter 1 Product information ENWW

3 Serial number

4 Kensington lock receptacle

ENWW Identify product parts 5

6 Chapter 1 Product information ENWW

2 Managing and maintenance

Replace the print cartridge

●

Printer information pages

●

Clean the device

●

Change the pickup roller

●

Clean the pickup roller

●

Change the printer separation pad

●

EconoMode

●

ENWW 7

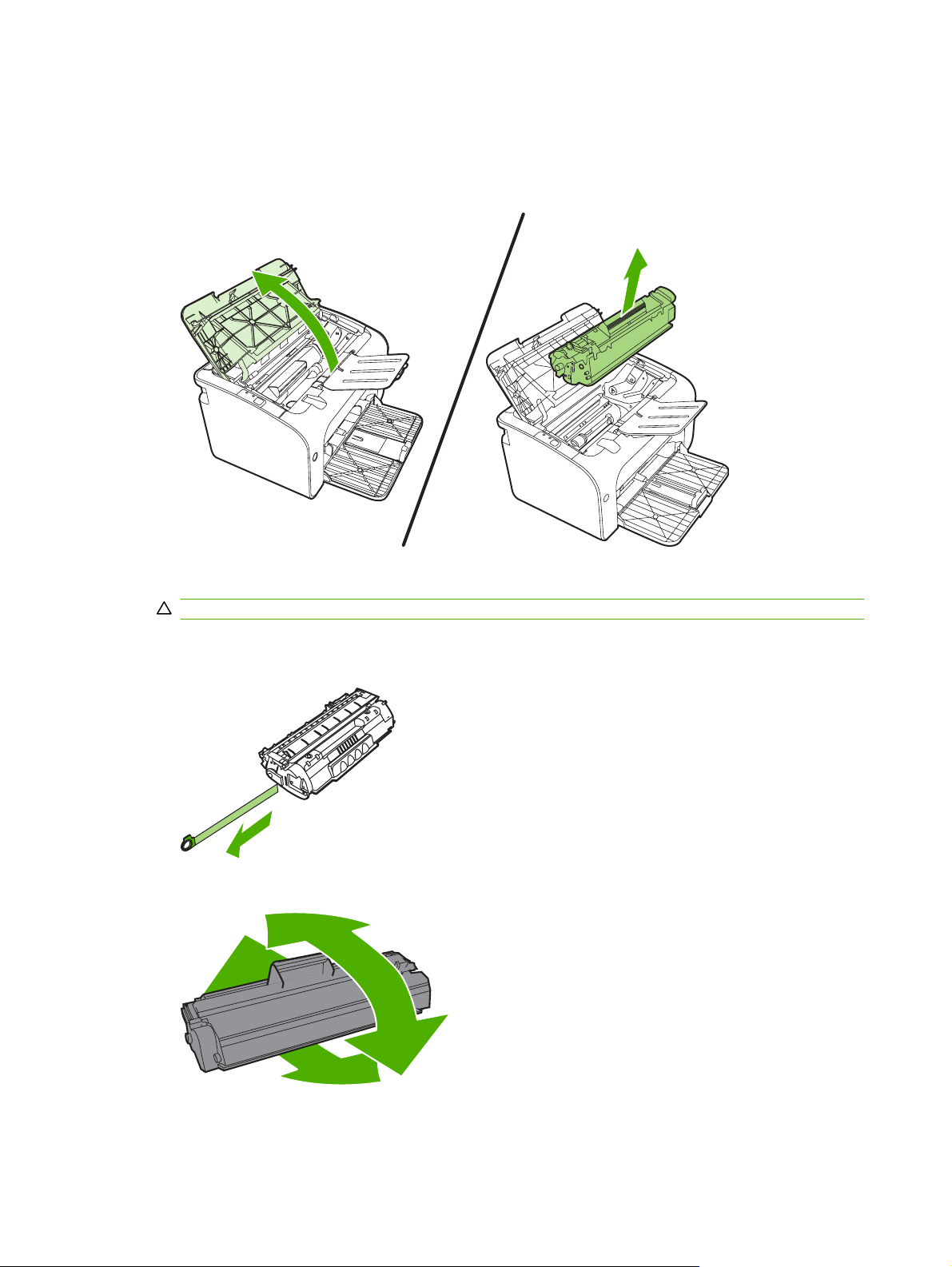

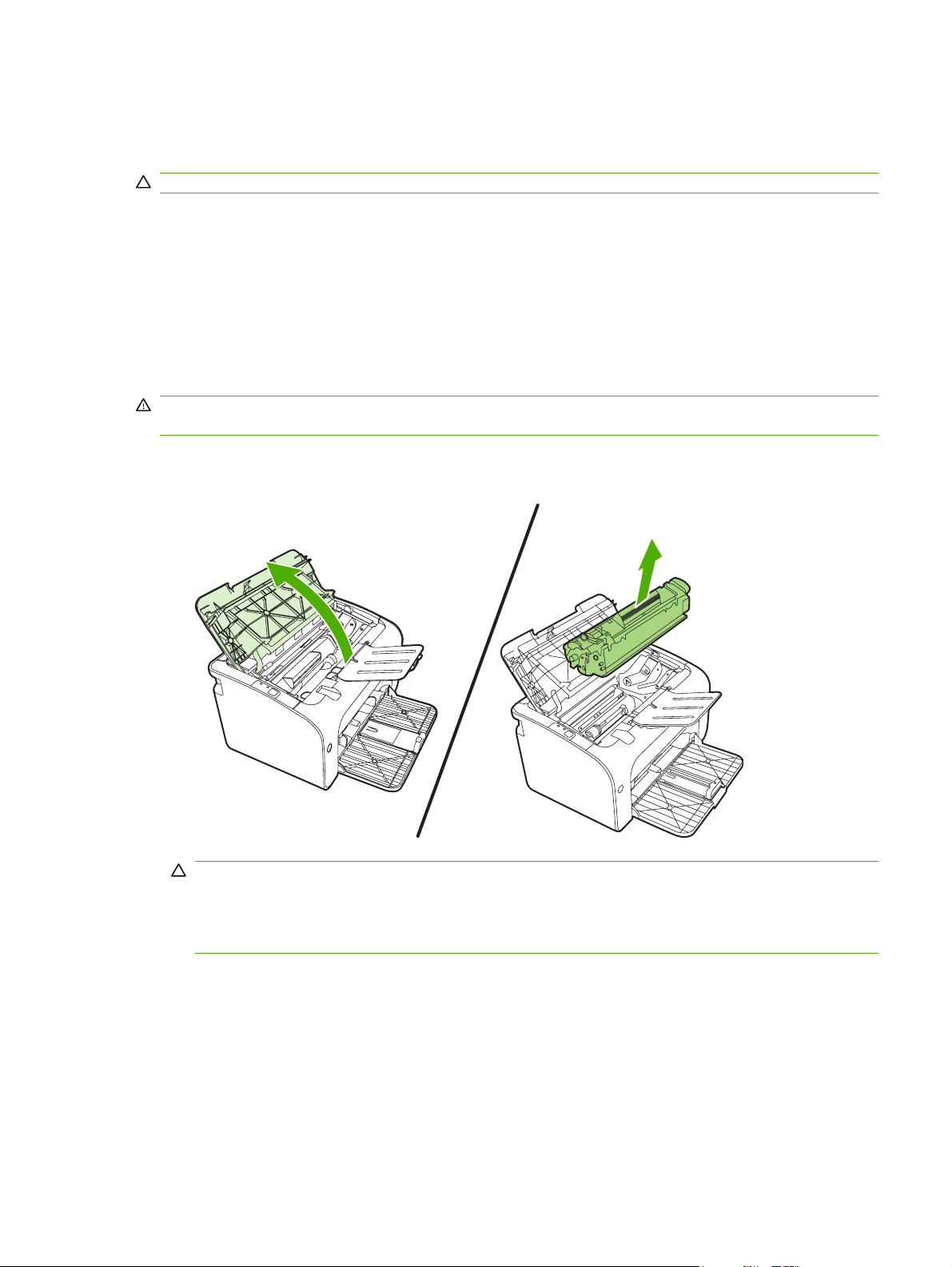

Replace the print cartridge

1. Open the print-cartridge door, and remove the old print cartridge. See the recycling information

inside the print-cartridge box. To prevent damage to the print cartridge, minimize its exposure to

direct light by covering it with a sheet of paper.

2. Remove the new print cartridge from the packaging.

CAUTION: To prevent damage to the print cartridge, hold the print cartridge at each end.

3. Pull the tab until all the tape is removed from the cartridge. Put the tab in the print-cartridge box to

return for recycling.

4. Gently rock the toner cartridge from front to back to distribute the toner evenly inside the cartridge.

8 Chapter 2 Managing and maintenance ENWW

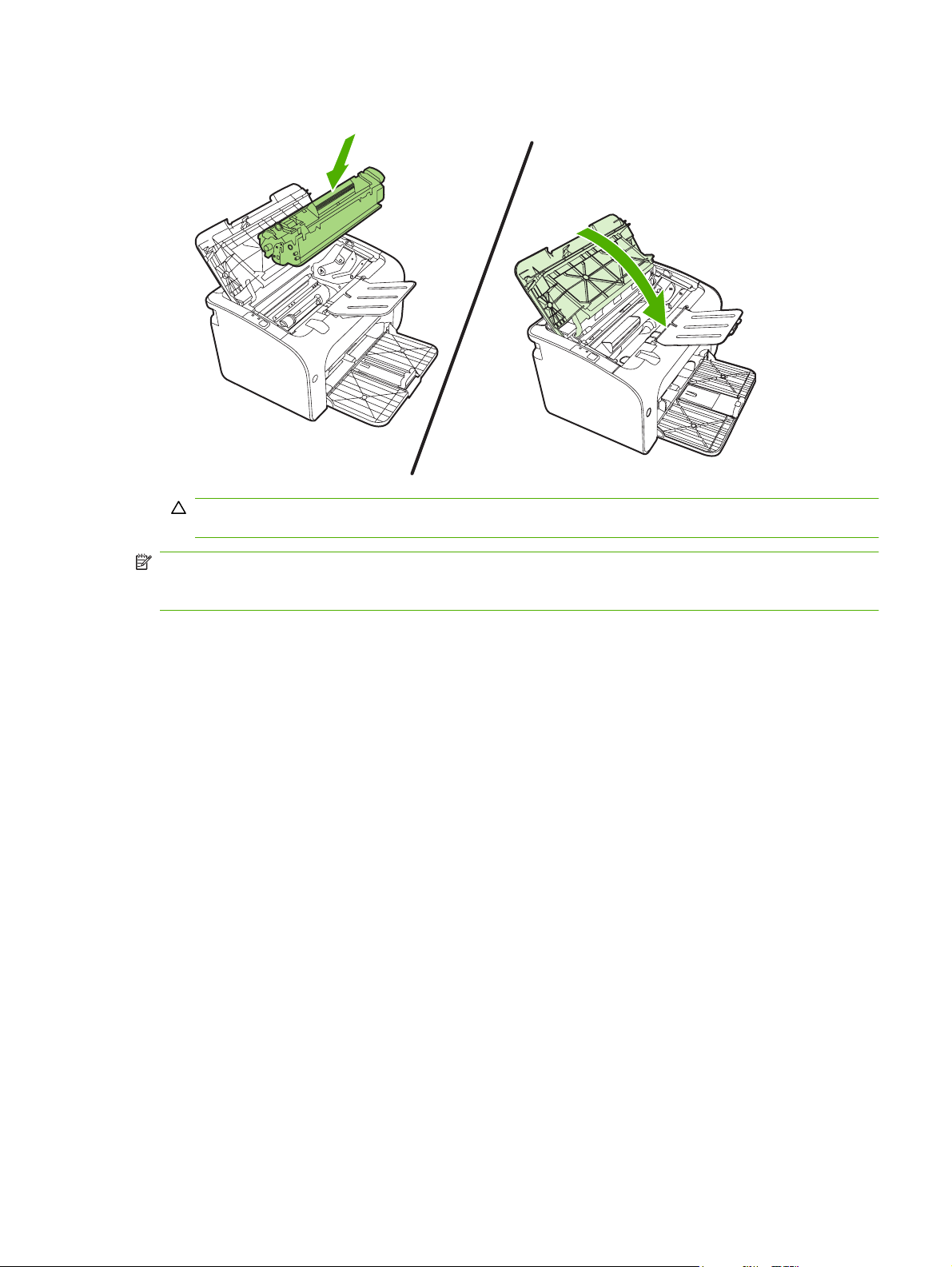

5. Insert the print cartridge in the device and close the print-cartridge door.

CAUTION: If toner gets on your clothing, wipe it off with a dry cloth and wash the clothing in cold

water. Hot water sets toner into the fabric.

NOTE: When toner is low, faded or light areas appear on the printed page. You might be able to

temporarily improve print quality by redistributing the toner. To redistribute the toner, remove the

cartridge from the device and gently rock it from front to back.

ENWW Replace the print cartridge 9

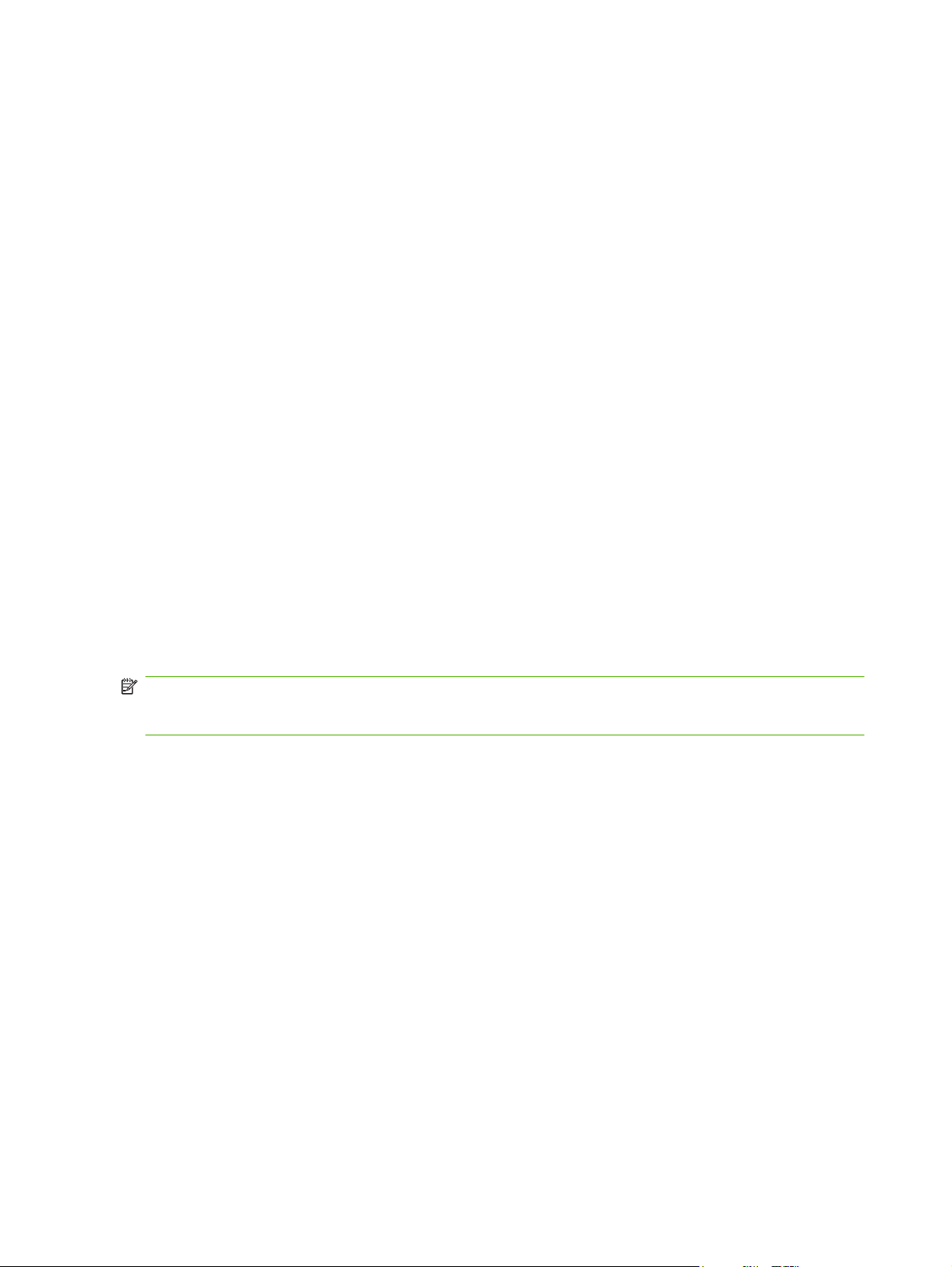

Printer information pages

You can print the following information pages. To print an information page, select it from the Print

Information Pages drop-down list on the Services tab in Printer Preferences.

10 Chapter 2 Managing and maintenance ENWW

Demo page

The Demo page contains examples of text and graphics.

ENWW Printer information pages 11

Configuration page

The Configuration page lists current settings and properties of the printer. It also contains a status log

report.

12 Chapter 2 Managing and maintenance ENWW

Clean the device

Clean the outside of the device with a clean, damp cloth when necessary.

CAUTION: Do not use ammonia-based cleaners on or around the device.

During the printing process, paper, toner, and dust particles can accumulate inside the device. Over

time, this buildup can cause print quality problems, such as toner specks or smearing, and paper jams.

To correct and prevent these types of problems, clean the print cartridge area and the device media

path.

Clean the print-cartridge area

You do not need to clean the print-cartridge area often. However, cleaning this area can improve the

quality of the printed sheets.

WARNING! Before cleaning the device, turn the device off by unplugging the power cord, and wait for

the device to cool.

1. Unplug the power cord from the device. Open the print-cartridge door, and remove the print

cartridge.

CAUTION: Do not touch the black-sponge transfer roller inside the device. Doing so can damage

the device.

CAUTION: To prevent damage, do not expose the print cartridge to light. Cover it with a piece

of paper.

ENWW Clean the device 13

2. With a dry, lint-free cloth, wipe any residue from the paper-path area and the print-cartridge cavity.

3. Replace the print cartridge, and close the print-cartridge door.

14 Chapter 2 Managing and maintenance ENWW

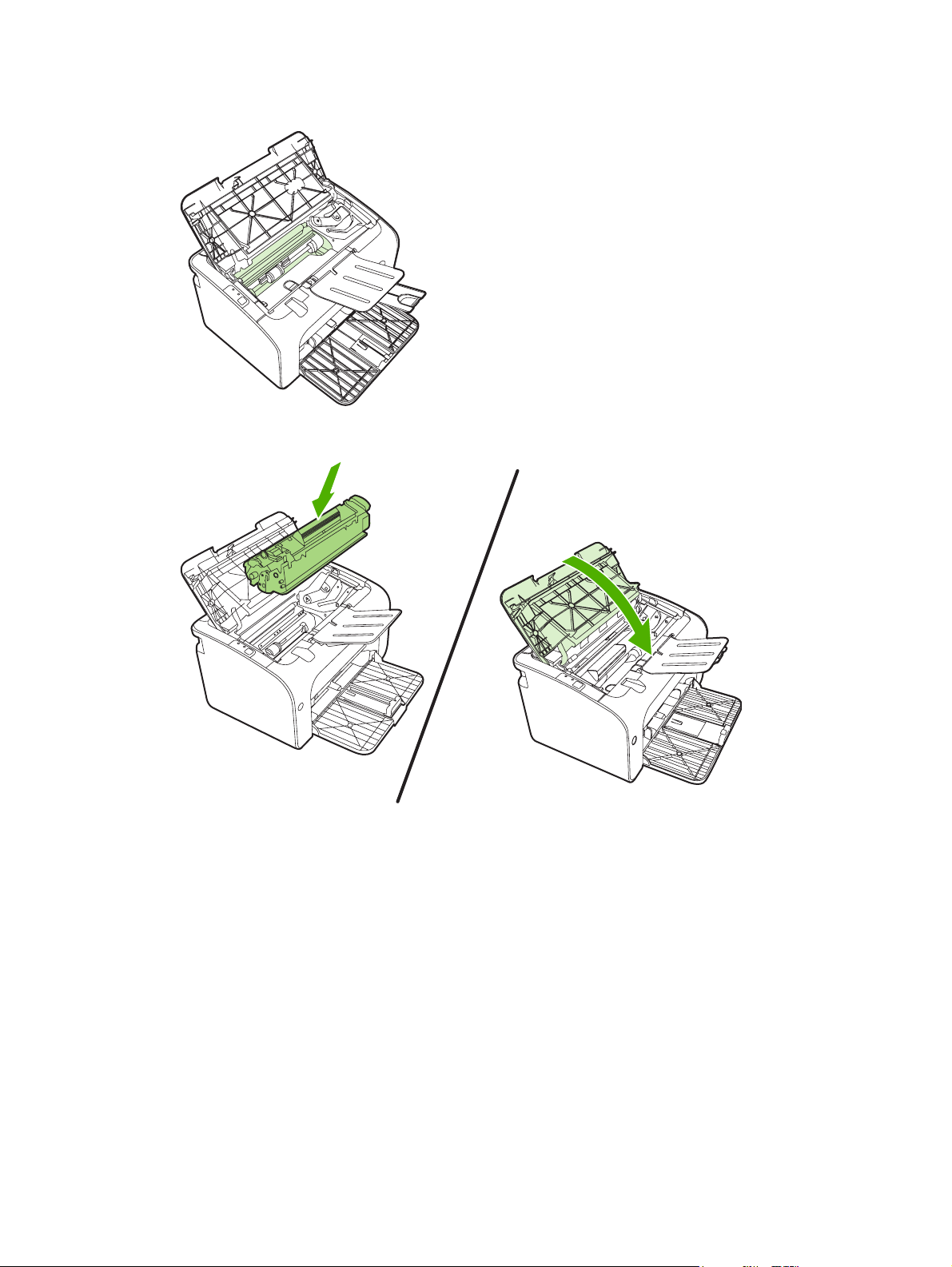

4. Plug the power cord into the device.

Clean the device paper path

If you are experiencing toner specks or dots on the printouts, clean the paper path. This process uses

a transparency to remove dust and toner from the paper path. Do not use bond or rough paper.

NOTE: For best results use a sheet of transparency. If you do not have any transparencies, you can

use copier-grade media (70 to 90 g/m

1. Make sure that the device is idle and the Ready light is on.

2. Load the media in the input tray.

ENWW Clean the device 15

2

(18 to 24 lb.)) that has a smooth surface.

3. Print a cleaning page. Access the printer Properties (or Printing Preferences in Windows 2000

and XP) then click on the Device Settings tab.

NOTE: The cleaning process takes approximately 2 minutes. The cleaning page will stop periodically

during the cleaning process. Do not turn the device off until the cleaning process has finished. You might

need to repeat the cleaning process several times to thoroughly clean the device.

16 Chapter 2 Managing and maintenance ENWW

Change the pickup roller

Normal use with good media causes wear. The use of poor media might require more frequent

replacement of the pickup roller.

If the device regularly mispicks (no media feeds through), you might need to change or clean the pickup

roller. See

CAUTION: Failure to complete this procedure might damage the device.

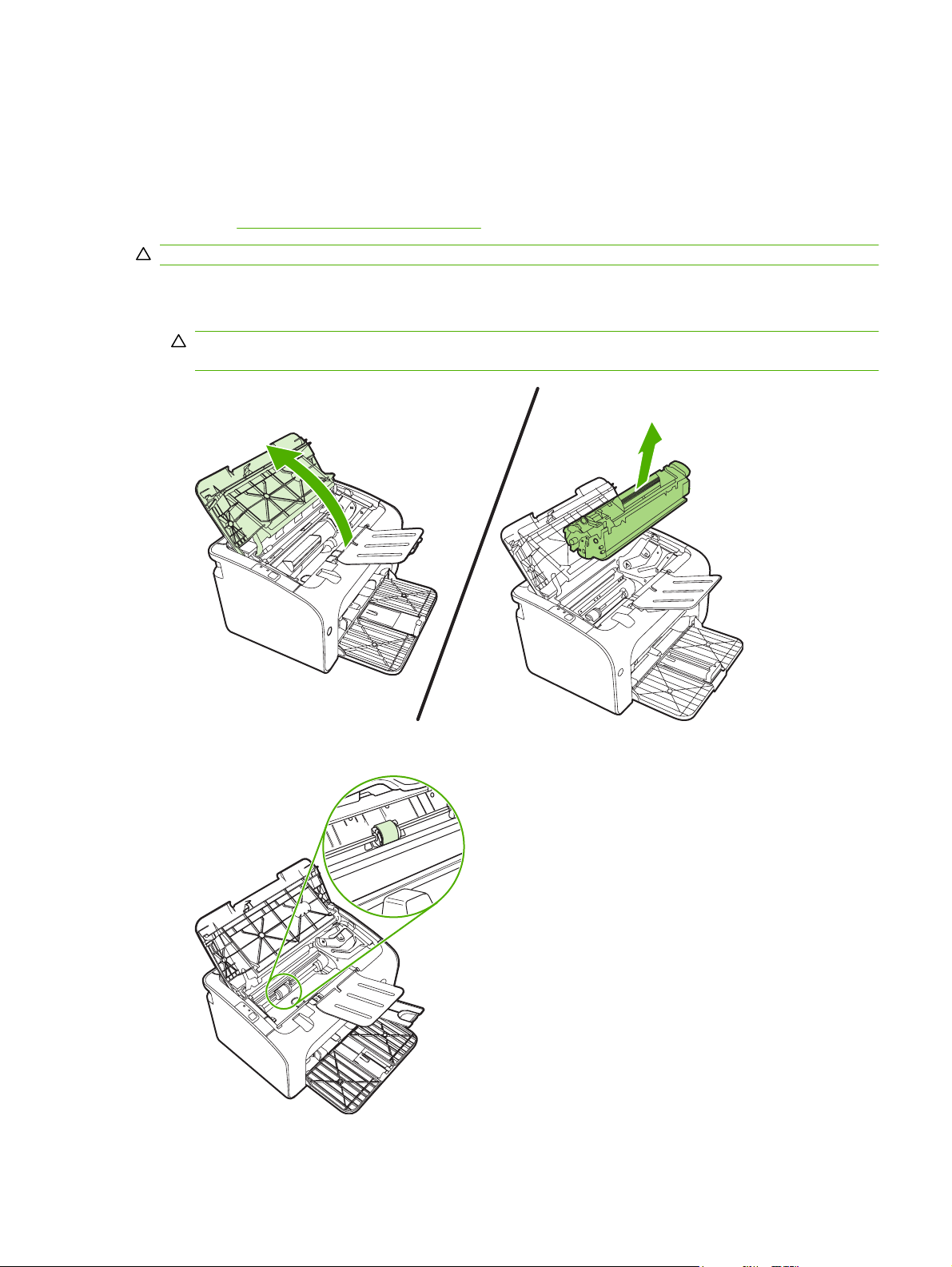

1. Open the print-cartridge door, and remove the old print cartridge. See the recycling information

Clean the pickup roller on page 20 to order a new pickup roller.

inside the print-cartridge box.

CAUTION: To prevent damage to the print cartridge, minimize its exposure to direct light. Cover

the print cartridge with a sheet of paper.

2. Find the pickup roller.

ENWW Change the pickup roller 17

3. Release the small tabs on each side of the pickup roller, and rotate the pickup roller toward the

front.

4. Gently pull the pickup roller up and out.

5. Position the new pickup roller in the slot. The circular and rectangular slots on each side prevents

you from installing the roller incorrectly.

6. Rotate the top of the new pickup roller away from you until both sides snap into place.

18 Chapter 2 Managing and maintenance ENWW

7. Insert the print cartridge in the device and close the print-cartridge door.

ENWW Change the pickup roller 19

Clean the pickup roller

If you want to clean the pickup roller before deciding to replace it, follow these instructions:

1. Unplug the power cord from the device and remove the pickup roller as described in steps 1

through 5 of

2. Dab a lint-free cloth in isopropyl alcohol, and scrub the roller.

WARNING! Alcohol is flammable. Keep the alcohol and cloth away from an open flame. Before

you close the device and plug in the power cord, allow the alcohol to dry completely.

3. Using a dry, lint-free cloth, wipe the pickup roller to remove loosened dirt.

Change the pickup roller on page 17

4. Allow the pickup roller to dry completely before you reinstall it in the device.

5. Plug the power cord into the device.

20 Chapter 2 Managing and maintenance ENWW

Change the printer separation pad

Normal use with good media causes wear. The use of poor media might require more frequent

replacement of the separation pad.

If the device regularly pulls multiple sheets of media at a time, you might need to change the separation

pad.

NOTE: Before you change the separation pad, clean the pickup roller. See Clean the pickup roller

on page 20.

WARNING! Before changing the printer separation pad, turn the device off by unplugging the power

cord, and wait for the device to cool.

1. Unplug the device from the wall outlet.

2. Remove paper and close main input tray. Set device on its front.

3. At the bottom of the device, unscrew the two screws holding the separation pad in place.

ENWW Change the printer separation pad 21

4. Remove the separation pad.

5. Insert the new separation pad, and screw it into place.

22 Chapter 2 Managing and maintenance ENWW

6. Plug the device into the wall outlet, and turn on the device.

ENWW Change the printer separation pad 23

EconoMode

With EconoMode, the device uses less toner per page. Selecting this option can extend the life of the

print cartridge and reduce your cost per page. However, it also reduces print quality. The printed image

is lighter, but it is adequate for printing drafts or proofs.

HP does not recommend the full-time use of EconoMode. If EconoMode is used full-time, the toner

supply might outlast the mechanical parts in the print cartridge. If print quality begins to degrade under

these circumstances, you must install a new print cartridge even if toner remains in the cartridge.

1. To use EconoMode, open the printer Properties (or Printing Preferences in Windows 2000

and XP).

2. On the Paper/Quality tab or the Finishing tab (the Paper Type/Quality tab for some Mac drivers),

select the EconoMode check box.

NOTE: Not all printer features are available in all drivers or operating systems. See the printer

Properties (driver) online Help for information about availability of features for that driver.

24 Chapter 2 Managing and maintenance ENWW

3 Theory of operation

Introduction

●

Internal components

●

Timing

●

Engine control system

●

Laser/scanner system

●

Pickup/feed/delivery system

●

Image-formation system

●

ENWW 25

Introduction

This chapter presents an overview of the relationships between major components in the printer, and

includes a detailed discussion of the image-formation system. The following systems are discussed:

Engine control system

●

Laser/scanner system

●

Pickup/feed/delivery system

●

Image-formation system

●

Figure 3-1 Block diagram on page 26 illustrates the relationships among the four systems.

Figure 3-1 Block diagram

LASER/SCANNER SYSTEM

ENGINE CONTROL

SYSTEM

IMAGE-FORMATION SYSTEM

PICKUP-AND-FEED SYSTEM

26 Chapter 3 Theory of operation ENWW

Internal components

Figure 3-2 Cross-section of printer on page 27 highlights the major internal components.

Figure 3-2 Cross-section of printer

1 2 3 4 5

6

1 Fusing unit

2 Pressure roller

3 Delivery roller

4 Fusing film

5 Laser/scanner unit

6 Single-sheet-feed slot (HP LaserJet P1006/P1008 only)

7 Multi-purpose tray

8 Photosensitive drum

9 Pickup roller

10 Separation pad

11 Feed roller

12 Transfer roller

789101112

ENWW Internal components 27

Timing

Sequence of operation

Operation sequences are controlled by the microprocessor on the DC controller.

Table 3-1 Sequence

of operation on page 28 describes engine operations for each period of a print operation.

Table 3-1 Sequence of operation

Name Timing Purpose

WAIT From power-on until the end of the main motor initial

drive

STBY (standby) From the end of the WAIT or LSTR period until either

a print command is sent from the formatter or the

power is turned off.

INTR (initial

rotation)

PRINT From the end of the INTR period until the last page

LSTR (last

rotation)

From the time of the print command until the pickup

solenoid is turned on.

completes the fusing operation.

From the end of the PRINT period until the main

motor stops rotating.

Detects presence of a print cartridge. Clears potential

from the drum surface and cleans the transfer roller.

Prepares the printer to receive print commands

Prepares the photosensitive drum for printing.

Forms the image on the photosensitive drum and

transfers the toner image to the media.

Delivers the last page of a print job.

After LSTR, the printer either returns to STBY or, if

another print command was sent from the formatter,

enters INTR.

28 Chapter 3 Theory of operation ENWW

Engine control system

The engine control system coordinates all printer functions, according to commands sent from the

formatter. It drives the laser/scanner system, the image-formation system, and the pickup/feed/delivery

system.

The engine control system contains the following components:

DC controller

●

Low-voltage power supply

●

High-voltage power supply

●

Fusing control

●

Figure 3-3 Engine control system

ENGINE CONTROL SYSTEM

DC controller

LASER/SCANNER SYSTEM

Formatter

Low-voltage power supply

IMAGE-FORMATION SYSTEM

High-voltage power supply

PICKUP-AND-FEED SYSTEM

Fixing control

ENWW Engine control system 29

Figure 3-4 Engine control system circuit diagram

Engine controller

Fixing unit

AC input

Transfer roller

Cartridge

Formatter

Fixing control

Low-voltage

power supply

High-voltage

power supply

DC controller

M

Laser/scanner

Motor

Solenoid

Sensor

Switch

unit

30 Chapter 3 Theory of operation ENWW

Laser/scanner system

The laser/scanner system receives video signals from the dc controller and the formatter and converts

the signals into latent images on the photosensitive drum.

Figure 3-5 Laser/scanner system

BD sensor

Laser unit

Photosensitive drum

Four-faced mirror

BD INPUT signal

LASER CONTROL signal

VIDEO signal

Scanner motor unit

SCANNER MOTOR SPEED

CONTROL signal

Engine controller

Formatter

ENWW Laser/scanner system 31

Pickup/feed/delivery system

The pickup/feed/delivery system consists of several types of feed rollers and sensors. The dc controller

uses two motors and two solenoids to drive the rollers. Three media-detection sensors detect media as

it passes through the printer. If media does not reach or pass each sensor within a specified time period,

the dc controller determines that a jam has occurred and alerts the formatter.

The following components are identified in

M1, main motor

●

SL1, pickup solenoid

●

PS701, fuser delivery sensor

●

PS702, media-width sensor

●

PS751, top-of-page sensor

●

Figure 3-6 Pickup/feed/delivery system

Pressure roller

PS702

Feed roller

PS701

Fixing sleeve

Photosensitive drum

Figure 3-6 Pickup/feed/delivery system on page 32:

Transfer roller

PS751

SL1

Separation pad

Pickup roller

M1

Single-sheet-feed tray

Multi-purpose tray

32 Chapter 3 Theory of operation ENWW

Image-formation system

Laser printing requires the interaction of several different technologies, including electronics, optics, and

electrophotographics, to provide a printed page. Each process functions independently and must be

coordinated with the other printer processes. Image formation consists of the following five

processes:

electrostatic latent-image formation

●

developing

●

transfer

●

fusing

●

drum cleaning

●

The five processes contain eight steps.

Figure 3-7 Image-formation system

Step 1: Primary charging

The DC bias is applied to the primary charging roller, which transfers a uniform negative potential to the

photosensitive drum.

Figure 3-8 Primary charging

Primary charging roller

DC bias

Photosensitive drum

ENWW Image-formation system 33

Step 2: Laser beam exposure

The laser beam scans the photosensitive drum to neutralize negative charges on parts of the drum. An

electrostatic latent image is formed on the drum where negative charges were neutralized.

Figure 3-9 Laser beam exposure

Unexposed area Exposed area

Step 3: Developing

The toner acquires a negative charge from the friction that occurs when the developing cylinder rotates

against the developing blade. When the negatively charged toner comes in contact with the drum, it

adheres to the electrostatic latent image because the drum surface has a higher potential. The image

on the drum becomes visible because of the toner. The AC bias that is superimposed over the develping

negative DC bias is applied to the developing cylinder.

Laser beam

Figure 3-10 Developing

Blade

Exposed area

Unexposed area

Developing cylinder

Photosensitive drum

Unexposed area

Exposed area

AC bias

DC bias

34 Chapter 3 Theory of operation ENWW

Step 4: Transfer

The positive DC bias is applied to the transfer roller. As the media passes between the transfer roller

and the photosensitive drum, the transfer roller applies a positive DC bias to the media. The positively

charged media attracts the negatively charged toner from the drum surface.

Figure 3-11 Transfer

Transfer roller

Step 5: Separation

The elasticity of the print media causes its separation from the photosensitive drum. A static charge

eliminator aids separation by weakening any electrostatic adhesion.

Photosensitive

drum

Media

DC bias

Figure 3-12 Separation

Static charge eliminator

Photosensitive

drum

Media

Transfer roller

ENWW Image-formation system 35

Step 6: Fusing

The printer uses the on-demand fusing method to permanently fuse the toner image to the media using

heat and pressure.

Figure 3-13 Fusing

Fixing heater

Step 7: Drum cleaning

The cleaning blade scrapes the residual toner off the photosensitive drum and deposits it into the waste

toner case.

Figure 3-14 Drum cleaning

Cleaning blade

Fixing film

Toner

Media

Pressure roller

Waste toner container

Photosensitive

drum

36 Chapter 3 Theory of operation ENWW

4 Removal and replacement

Introduction

●

Before performing service

●

Covers

●

Formatter

●

Fuser

●

Laser/scanner

●

DC controller

●

Transfer roller

●

Motor drive belt

●

Rear paper-feed roller

●

Main motor

●

ENWW 37

Introduction

This chapter documents removal and replacement of field replaceable units (FRUs) only.

Removal and replacement strategy

Replace parts in the reverse order of their removal. Directions for difficult or critical replacement

procedures are included.

WARNING! The sheet-metal edges of the product can be sharp. Use caution when working on the

product.

NOTE: Note the length, diameter, color, type, and location of each screw. Be sure to return each screw

to its original location during reassembly.

Incorrectly routed or loose wire harnesses can interfere with other internal components and can become

damaged or broken. Frayed or pinched harness wires can be difficult to locate. When replacing wire

harnesses, always use the provided wire loops, lance points, or wire-harness guides.

Electrostatic discharge

CAUTION: The product contains parts that are sensitive to electrostatic discharge (ESD). Always

service the product at an ESD-protected workstation, or use an ESD mat.

Watch for the ESD symbol to identify the parts that are sensitive to ESD. Protect these parts by using

an ESD wrist strap and by placing ESD-sensitive parts into protective ESD pouches.

Required tools

The following tools are needed to service this product:

#2 Phillips screwdriver with magnetic tip

●

Small flat-blade screwdriver

●

Small needle-nose pliers

●

ESD mat

●

Penlight

●

CAUTION: A pozidrive screwdriver can damage the screw heads on the product. Use a #2 Phillips

screwdriver.

If you use a multispeed screwdriver, use a torque limiter.

38 Chapter 4 Removal and replacement ENWW

Before performing service

Follow the pre-service procedures before you perform service.

Pre-service procedures

1. Remove all media from the product.

2. Place the product on an ESD mat. If an ESD mat or an ESD-protected workstation is not available,

discharge body static and ground the product chassis before servicing the product.

3. Remove the print cartridge.

4. Unplug the power cord and the interface cable.

Parts removal order

Use the following diagram to determine which parts must be removed before removing other parts.

ENWW Before performing service 39

Covers

Front Cover

1. Turn the device over so that it is resting on its back.

2. Using a flat-blade screwdriver, lift the plastic edges of the front cover out of their sockets (callout

1) and rotate the cover back.

Figure 4-1 Remove front cover (1 of 1)

Control panel

1. Remove the front cover. See Front Cover on page 40.

2. Remove control panel cover by prying up the leading edge, then sliding it towards the front of the

printer and lifting it out.

40 Chapter 4 Removal and replacement ENWW

3. Remove light-pipe (callout 1) and button (callout 2).

NOTE: The button (callout 2) is only present on the HP LaserJet P1006/P1008 and does not

need to be removed from the HP LaserJet P1005/P1007.

Figure 4-2 Remove control panel (1 of 1)

Side Covers

1. Remove the front cover. See Front Cover on page 40.

2. Remove the control panel. See

3. Remove two screws (callout 1).

Figure 4-3 Remove side covers (1 of 4)

Control panel on page 40.

ENWW Covers 41

4. Turn the device on its left side. Remove the right side cover by using a small flat blade screwdriver

to lift it out of the socket. A small arrow in the plastic indicates where the leverage should be applied.

Rotate the cover towards the front of the device and remove it.

Figure 4-4 Remove side covers (2 of 4)

42 Chapter 4 Removal and replacement ENWW

5. Turn the device on its right side. There are three catches that must be released. Use a small flat

blade screwdriver to release the catch on the back of the printer (callout 1) and the bottom of the

printer (callout 2). Then open the top of the printer and release the catch on the inside (callout 3).

Once all three catches are released, rotate the cover towards the front of the device and remove

it.

Figure 4-5 Remove side covers (3 of 4)

Figure 4-6 Remove side covers (4 of 4)

Back Cover

1. Remove the front cover. See Front Cover on page 40.

2. Remove the control panel. See

3. Remove both side covers. See

ENWW Covers 43

Control panel on page 40.

Side Covers on page 41.

4. Remove one grounding screw (callout 1).

Figure 4-7 Remove back cover (1 of 2)

5. Lift plate in three of the four corners (callout 2) to pop the plate off. Use a small flat blade screwdriver

to get leverage on each of the corners.

Top Cover

1. Remove the front cover. See Front Cover on page 40.

Figure 4-8 Remove back cover (2 of 2)

2. Remove the control panel. See

3. Remove both side covers. See

4. Remove the back cover. See

44 Chapter 4 Removal and replacement ENWW

Control panel on page 40.

Side Covers on page 41.

Back Cover on page 43.

5. Separate the tabs (callout 1) and lift the top cover off of the device.

Figure 4-9 Remove top cover (1 of 1)

NOTE: There are two link arms that slide through slots in the top cover. They are disengaged

when the cover is removed. Be sure to feed the link arms back through the slots when reinstalling

the top cover.

ENWW Covers 45

Formatter

1. Remove the front cover. See Front Cover on page 40.

2. Remove the control panel. See

3. Remove the left side cover. See

4. Remove four screws (callout 1) and unplug the cable (callout 2).

Figure 4-10 Remove formatter (1 of 2)

Control panel on page 40.

Side Covers on page 41.

5. Remove the formatter board.

Figure 4-11 Remove formatter (2 of 2)

NOTE: When reinstalling the formatter board, place the board on the support bracket first and

align holes before attaching it with the screws.

46 Chapter 4 Removal and replacement ENWW

Fuser

1. Remove the front cover. See Front Cover on page 40.

2. Remove the control panel. See

3. Remove both side covers. See

4. Remove the back cover. See

5. Remove the top cover. See

6. Unplug and unthread the red wire from the retaining clips (callout 1).

Figure 4-12 Remove fuser (1 of 6)

Control panel on page 40.

Side Covers on page 41.

Back Cover on page 43.

Top Cover on page 44.

ENWW Fuser 47

7. Unplug the power connector (callout 2). Unplug the remaining three connectors (callout 3).

Figure 4-13 Remove fuser (2 of 6)

NOTE: When removing the thin two-wire connector on the left, use a small flat-blade screwdriver

to flex out the left side of the cable socket so that the cable comes free without damaging the cable

or the socket.

8. Unthread the wires from the retaining clips in the rear of the device.

Figure 4-14 Remove fuser (3 of 6)

48 Chapter 4 Removal and replacement ENWW

9. Remove the black plastic cable guide from the rear of the device (callout 4). Use a tool to push on

the tab from the left as indicated.

Figure 4-15 Remove fuser (4 of 6)

10. Remove three screws from top of device (callout 5).

Figure 4-16 Remove fuser (5 of 6)

ENWW Fuser 49

11. Remove the fuser assembly.

Figure 4-17 Remove fuser (6 of 6)

NOTE: To reinstall the fuser, the notches on either side of the fuser must slide into the groves on

the inside of the cartridge bay.

50 Chapter 4 Removal and replacement ENWW

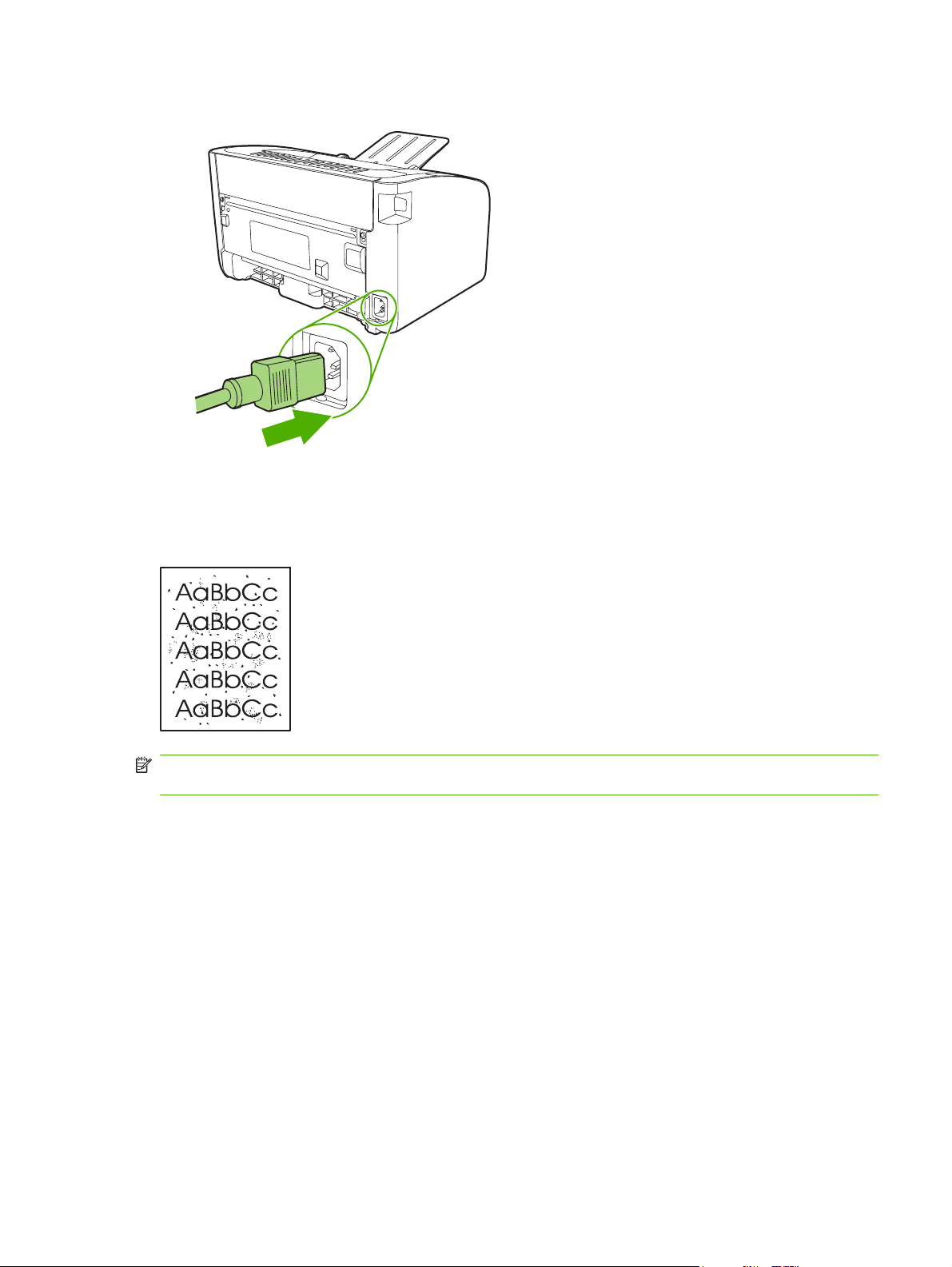

Laser/scanner

1. Remove the front cover. See Front Cover on page 40.

2. Remove the control panel. See

3. Remove both side covers. See

4. Remove the top cover. See

5. Remove four screws (callout 1).

Figure 4-18 Remove laser/scanner (1 of 4)

Control panel on page 40.

Side Covers on page 41.

Top Cover on page 44.

ENWW Laser/scanner 51

6. Remove the scanner cover from the device.

Figure 4-19 Remove laser/scanner (2 of 4)

NOTE: When reinstalling the cover, feed the lever through the plastic slot in the top of the cover.

7. Unplug two cables (callout 2) and remove four screws (callout 3).

Figure 4-20 Remove laser/scanner (3 of 4)

52 Chapter 4 Removal and replacement ENWW

8. Remove the laser/scanner

Figure 4-21 Remove laser/scanner (4 of 4)

ENWW Laser/scanner 53

DC controller

1. Remove the front cover. See Front Cover on page 40.

2. Remove the control panel. See

3. Remove the left side cover. See

4. Remove the fuser. See

5. Remove three screws from the metal plate (callout 1). Remove the metal plate.

Figure 4-22 Remove DC controller (1 of 4)

Fuser on page 47.

Control panel on page 40.

Side Covers on page 41.

6. Remove the black plastic crossmember (callout 2) by lifting up on the left tab.

Figure 4-23 Remove DC controller (2 of 4)

54 Chapter 4 Removal and replacement ENWW

7. Unplug three cables (callout 3).

Figure 4-24 Remove DC controller (3 of 4)

8. Remove two screws from the rear of the device (callout 4) and remove three screws from the DC

controller board (callout 5).

Figure 4-25 Remove DC controller (4 of 4)

9. Remove the DC Controller board.

ENWW DC controller 55

Transfer roller

1. Open the top cover and remove the print cartridge.

2. Pinch the white plastic clip on the right side of the transfer roller to release the roller (callout 1).

Slide the roller to the right and remove it.

NOTE: Do not touch the pad on the transfer roller.

Figure 4-26 Remove transfer roller (1 of 1)

56 Chapter 4 Removal and replacement ENWW

Motor drive belt

1. Remove the front cover. See Front Cover on page 40.

2. Remove the right side cover. See

3. Turn the device up on its left side and remove four screws (callout 1).

Figure 4-27 Remove motor drive belt (1 of 4)

Side Covers on page 41.

4. Remove the gear cover plate.

Figure 4-28 Remove motor drive belt (2 of 4)

ENWW Motor drive belt 57

5. Remove three loose gears (callout 2).

Figure 4-29 Remove motor drive belt (3 of 4)

6. Pinch the drive belt and carefully slide it off the drive gear.

2

Figure 4-30 Remove motor drive belt (4 of 4)

58 Chapter 4 Removal and replacement ENWW

Rear paper-feed roller

1. Remove the front cover. See Front Cover on page 40.

2. Remove the control panel. See

3. Remove both side covers. See

4. Remove the back cover. See

NOTE: While it is possible to remove the rear paper feed roller without removing the gear plate

on the right side of the printer, the process is easier if the plate has been removed. Follow steps 1

through 4 for removing the motor drive belt to remove the gear plate. See

on page 57.

5. Remove black cartridge sensor rod by detaching the right side of the rod from the clip and sliding

it to the right (callout 1). Be careful not to lose attached spring

Figure 4-31 Remove rear paper feed roller (1 of 3)

Control panel on page 40.

Side Covers on page 41.

Back Cover on page 43.

Motor drive belt

NOTE: When reinserting the sensor rod, make sure the left tab feeds into the slot in the rear of

the device. Wind the spring an extra revolution before attaching to ensure proper tension.

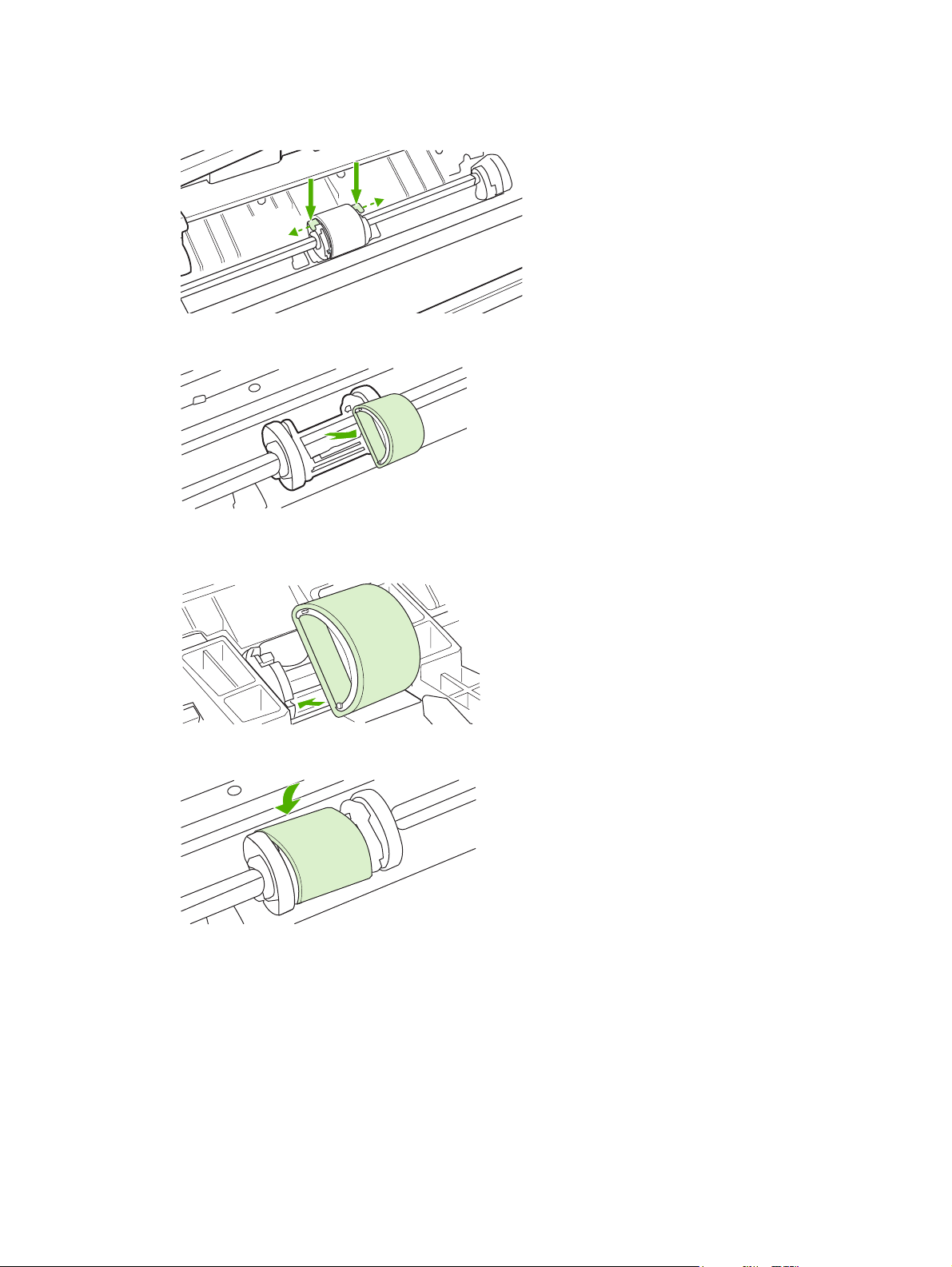

6. There are two roller catches on either side of the roller pads that are locked in place with tabs. Lift

up the inside tabs of the two roller catches and slide them away from the roller pads. Remove them

from the device.

ENWW Rear paper-feed roller 59

7. Release the gear at the left end of the roller by pinching the tab inside the gear housing. Slide the

gear away from the roller.

Figure 4-32 Remove rear paper feed roller (2 of 3)

8. Slide the roller away from the drive gear and out of the back of the device.

Figure 4-33 Remove rear paper feed roller (3 of 3)

60 Chapter 4 Removal and replacement ENWW

Main motor

1. Remove the front cover. See Front Cover on page 40.

2. Remove the control panel. See

3. Remove both side covers. See

4. Remove the back cover. See

5. Remove the top cover. See

6. Remove the laser/scanner. See

NOTE: You only need to follow the steps in the Laser/scanner section until the scanner cover is

removed (step six). It is not necessary to remove the entire laser/scanner assembly in order to

access the main motor.

7. Unplug two cables (callout 1).

Figure 4-34 Remove main motor (1 of 5)

Control panel on page 40.

Side Covers on page 41.

Back Cover on page 43.

Top Cover on page 44.

Laser/scanner on page 51.

1

ENWW Main motor 61

8. Pinch and remove motor-control card (it will hang by a soldered ribbon cable). Unthread the wire

from the plastic bracket and remove one screw (callout 2).

Figure 4-35 Remove main motor (2 of 5)

62 Chapter 4 Removal and replacement ENWW

9. Remove the plastic bracket.

Figure 4-36 Remove main motor (3 of 5)

ENWW Main motor 63

10. Remove two screws (callout 3).

Figure 4-37 Remove main motor (4 of 5)

64 Chapter 4 Removal and replacement ENWW

11. Remove the main motor.

Figure 4-38 Remove main motor (5 of 5)

ENWW Main motor 65

66 Chapter 4 Removal and replacement ENWW

5 Problem solving

Problem-solving checklist

●

Contact HP support

●

Status-light patterns

●

Clearing jams

●

Improve print quality

●

Media problem-solving

●

Printed page is different from what appeared on screen

●

Printer software problems

●

Common Macintosh problems

●

Network-setup problem-solving

●

ENWW 67

Problem-solving checklist

Step 1: Is the device set up correctly?

Is the device plugged into a power outlet that is known to work?

●

Is the on/off switch in the on position?

●

Is the print cartridge properly installed? See

●

Is paper properly loaded in the input tray?

●

Yes If you answered yes to the questions above, go to Step 2: Is

No If the device will not turn on, Contact HP support

Step 2: Is the Ready light on?

Verify that the Ready light (1) is illuminated on the control panel.

Yes Go to Step 3: Can you print an engine test page?

Replace the print cartridge on page 8.

the Ready light on? on page 68

on page 70.

on page 68

No If the control panel lights do not look like the picture above, see

Status-light patterns on page 71.

If you are unable to resolve the problem,

on page 70.

Contact HP support

Step 3: Can you print an engine test page?

To print an engine test page, open and close the cartridge door five times while the printer is in ready

mode. The printer should print one page with multiple horizontal lines.

Yes If the engine test page printed, go to Step 4: Is the device

communicating with the computer? on page 69

No If no paper came out, see Media problem-solving

on page 80.

If you are unable to resolve the problem,

on page 70.

68 Chapter 5 Problem solving ENWW

Contact HP support

Step 4: Is the device communicating with the computer?

Try printing a document from a software application.

Yes If the document prints, go to Step 5: Does the printed page look

like you expected? on page 69

No If the document does not print, see Printer software problems

on page 83.

If you are using a Macintosh computer, see

Macintosh problems on page 84.

If you are unable to resolve the problem,

on page 70.

Step 5: Does the printed page look like you expected?

Yes The problem should be resolved. If it is not resolved, Printed

page is different from what appeared on screen

on page 81.

No If the print quality is poor, see Improve print quality

on page 76.

Verify that the print settings are correct for the media you are

using.

If you are unable to resolve the problem,

on page 70.

Common

Contact HP support

Contact HP support

ENWW Problem-solving checklist 69

Contact HP support

In the United States, see

●

In other locations, see

●

http://www.hp.com/support/ljp1000 for the HP LaserJet P1000 Series

http://www.hp.com/.

70 Chapter 5 Problem solving ENWW

Status-light patterns

Table 5-1 Status-light legend

Symbol for "light off"

Symbol for "light on"

Symbol for "light blinking"

Table 5-2 Control-panel light messages

HP LaserJet P1000 Series light status State of the device Action

Initialization/Startup

HP LaserJet P1000 Series: During

Startup, the Go and Ready lights cycle (at

the rate of 500 ms) one after another.

HP LaserJet P1500 Series: While in the

Startup state, the Go, Ready, and

Attention lights cycle (at the rate of

500 ms) one after another.

Reconfiguration Initialization: During

the device start up, you can request

special initialization sequences that

reconfigure the device. The lights then

cycle as in the Initialization Startup state.

Job Cancel

After the cancellation process is

complete, the device returns to the Ready

state.

During the Initialization and Job Cancel

processes, pressing buttons has no

effect.

ENWW Status-light patterns 71

Table 5-2 Control-panel light messages (continued)

HP LaserJet P1000 Series light status State of the device Action

Ready

The device is ready with no job activity.

Processing Data

The device is processing or receiving

data.

Manual Feed or Continuable Error

This state occurs in the following

circumstances:

Manual feed

●

General continuable error

●

To print a Configuration page, press and

release the Go button (HP LaserJet

P1500 network models only).

To cancel the current job, press the

Cancel button (HP LaserJet P1006/

P1008/P1500 Series only).

To recover from the error and print the

available data, press the Go button

(HP LaserJet P1500 Series only).

If the recovery is successful, the device

continues to the Processing Data state

and completes the job.

If the recovery is unsuccessful, the

device continues to the Continuable

Error state. Try removing any media from

the media path and cycling the device

power.

Attention

Print-cartridge door is open

●

Paper jam

●

No cartridge installed

●

Paper out

●

Fatal Error

The device has encountered a nonrecoverable error.

Close the print-cartridge door, remove

the paper jam, install the cartridge, or

add paper.

Turn off the device, wait 10

●

seconds, and turn on the device.

If you cannot resolve the problem,

●

see

Contact HP support

on page 70.

72 Chapter 5 Problem solving ENWW

Clearing jams

Occasionally, media becomes jammed during a print job. You are notified through the control panel

lights.

The following are some of the causes of jams:

The input trays are loaded incorrectly or are too full.

●

NOTE: When you add new media, always remove all of the media from the input tray and

straighten the entire stack. This helps prevent multiple feeds and reduces media jams.

The media does not meet HP specifications.

●

The device might need to be cleaned to remove paper dust and other particles from the paper path.

●

Loose toner might remain in the device after a media jam. This toner clears up after a few sheets print.

CAUTION: If you get any toner on your clothes, wash them in cold water. Hot water will permanently

set the toner into the fabric.

Typical media jam locations

Print cartridge area: See

●

Input tray areas: If the page is still sticking out of the input tray, gently try to remove it from the

●

input tray without tearing the page. If you feel resistance, see

on page 73.

Output path: If the page is sticking out of the output bin, see

●

on page 73.

NOTE: Loose toner might remain in the device after a media jam. This toner clears up after a few

sheets are printed.

Removing a jammed page

CAUTION: Media jams might result in loose toner on the page. If you get any toner on your clothes,

wash them in cold water. Hot water will permanently set the toner into the fabric.

Removing a jammed page on page 73.

Removing a jammed page

Removing a jammed page

ENWW Clearing jams 73

To clear a jam in the print-cartridge area

CAUTION: Do not use sharp objects, such as tweezers or needle-nose pliers, to remove jams.

Damage they cause is not covered by the warranty.

1. Open the print-cartridge door, and then remove the print cartridge from the device.

CAUTION: To prevent damage to the print cartridge, minimize its exposure to direct light.

2. With both hands, grasp the side of the media that is most visible (this includes the middle), and

carefully pull it free from the device.

74 Chapter 5 Problem solving ENWW

3. Replace the print cartridge, and close the print-cartridge door.

NOTE: When you add new media, remove all the media from the input tray and straighten the

entire stack.

ENWW Clearing jams 75

Improve print quality

This section provides information about identifying and correcting print defects.

NOTE: If these steps do not correct the problem, contact an HP-authorized dealer or service

representative.

Light print or faded

Toner specks

The print cartridge is nearing end of life.

●

The media might not meet Hewlett-Packard's media

●

specifications (for example, the media is too moist or too

rough).

If the whole page is light, the print density adjustment is

●

too light or EconoMode might be turned on. Adjust the

print density, and disable EconoMode in the printer

Properties.

The media might not meet Hewlett-Packard's media

●

specifications (for example, the media is too moist or too

rough).

Dropouts

The device might need to be cleaned. See

●

device on page 13

A single sheet of media might be defective. Try reprinting

●

the job.

The media moisture content is uneven or the media has

●

moist spots on its surface. Try printing with new media.

The media lot is bad. The manufacturing processes can

●

cause some areas to reject toner. Try a different type or

brand of media.

The print cartridge might be defective.

●

Clean the

76 Chapter 5 Problem solving ENWW

Vertical lines

Gray background

The photosensitive drum inside the print cartridge has probably

been scratched. Install a new HP print cartridge. See

the print cartridge on page 8.

Make sure that tray 1 is in place.

●

Decrease the print density setting through the embedded

●

Web server. This decreases the amount of background

shading.

Change the media to a lighter basis weight.

●

Check the device environment. Very dry (low humidity)

●

conditions can increase the amount of background

shading.

Replace

Toner smear

Install a new HP print cartridge. See

●

cartridge on page 8.

If toner smears appear on the leading edge of the media,

●

the media guides might be dirty. Wipe the media guides

with a dry, lint-free cloth

Check the media type and quality.

●

Try installing a new HP print cartridge. See

●

print cartridge on page 8.

The fuser temperature might be too low. In your printer

●

driver, make sure the appropriate media type is selected.

Replace the print

Replace the

ENWW Improve print quality 77

Loose toner

Vertical repetitive defects

Clean the inside of the device. See

●

on page 13.

Check the media type and quality.

●

Try installing a new HP print cartridge. See

●

print cartridge on page 8].

In your printer driver, make sure the appropriate media

●

type is selected.

Plug the device directly into an AC outlet instead of into

●

a power strip or surge protector.

The print cartridge might be damaged. If a repetitive mark

●

occurs at the same spot on the page, install a new

HP print cartridge. See

on page 8.

The internal parts might have toner on them. If the defects

●

occur on the back of the page, the problem will probably