Page 1

LASERJET ENTERPRISE 600 M601, M602, AND

M603 SERIES PRINTER

Service Manual

Page 2

Page 3

HP LaserJet Enterprise 600 M601,

M602, and M603 Series Printer

Service Manual

Page 4

Copyright and License

Trademark Credits

© 2011 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is

prohibited, except as allowed under the

copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Part number: CE988-90945

Edition 1, 11/2011

ENERGY STAR and the ENERGY STAR mark

are registered U.S. marks.

Page 5

Conventions used in this guide

TIP: Tips provide helpful hints or shortcuts.

NOTE: Notes provide important information to explain a concept or to complete a task.

CAUTION: Cautions indicate procedures that you should follow to avoid losing data or damaging

the product.

WARNING! Warnings alert you to specific procedures that you should follow to avoid personal

injury, catastrophic loss of data, or extensive damage to the product.

ENWW iii

Page 6

iv Conventions used in this guide ENWW

Page 7

Table of contents

1 Theory of operation .......................................................................................................... 1

Basic operation ........................................................................................................................ 2

Major print systems ................................................................................................... 2

Internal components .................................................................................................. 3

Operating sequence .................................................................................................. 7

Formatter system ...................................................................................................................... 8

Sleep mode .............................................................................................................. 8

Input/output ............................................................................................................. 8

USB .......................................................................................................... 8

Embedded print server ................................................................................ 9

Hard-disk .................................................................................................. 9

CPU ......................................................................................................... 9

Memory ................................................................................................................... 9

Random-access memory .............................................................................. 9

Nonvolatile memory ................................................................................... 9

DIMM slot ................................................................................................................ 9

PJL overview ........................................................................................................... 10

PML ....................................................................................................................... 10

Control panel ......................................................................................................... 10

Engine-control system .............................................................................................................. 11

DC controller PCA ................................................................................................... 12

Sensors, solenoids, and switches ............................................................................... 13

Motors and fans ...................................................................................................... 14

Failure detection ...................................................................................... 14

Motor failure ............................................................................ 14

Fan motor failure ....................................................................... 14

Engine power supply ................................................................................ 15

Fuser-control circuit .................................................................... 15

Low-voltage power supply .......................................................... 17

High-voltage power supply ......................................................... 18

Overcurrent/overvoltage protection ............................................. 19

Image-formation system ........................................................................................................... 20

ENWW v

Page 8

Image-formation process .......................................................................................... 21

Block 1: Latent image formation ................................................................. 23

Step 1: Primary charging ........................................................... 23

Step 2: Laser-beam exposure ...................................................... 23

Block 2: Developing ................................................................................. 24

Step 3: Developing .................................................................... 24

Block 3: Transfer ...................................................................................... 25

Step 4: Transfer ........................................................................ 25

Step 5: Separation .................................................................... 25

Block 4: Fusing ........................................................................................ 26

Step 6: Fusing ........................................................................... 26

Block 5: Drum cleaning ............................................................................. 27

Step 7: Drum cleaning ............................................................... 27

Step 8: Drum charge elimination ................................................. 27

Laser/scanner system ............................................................................................................. 28

Laser failure detection .............................................................................................. 30

Pickup, feed, and delivery system ............................................................................................. 31

Pickup-and-feed block .............................................................................................. 32

Fuser/delivery block ................................................................................................ 33

Pressure roller pressure release control ....................................................................... 33

Paper trays ............................................................................................................. 34

Printing from Tray 1 .................................................................................. 34

Printing from Tray 2 .................................................................................. 34

Cassette media size detection and cassette presence detection ...................... 34

Jam detection ......................................................................................................... 36

1x500-sheet paper feeder ....................................................................................................... 40

Pickup-and-feed operation (PF) .................................................................................. 41

Cassette lift operation (PF) ........................................................................................ 43

Cassette media size detection and cassette presence detection (PF) ............................... 43

Cassette multiple-feed prevention (PF) ........................................................................ 43

Jam detection (PF) ................................................................................................... 43

1x1500-sheet paper deck ....................................................................................................... 44

Pickup-and-feed operation (PD) ................................................................................. 45

Cassette lift operation (PD) ....................................................................................... 47

Media size detection (PD) ........................................................................................ 48

Multiple-feed prevention (PD) .................................................................................... 48

Jam detection (PF) ................................................................................................... 48

Envelope feeder ..................................................................................................................... 49

Pickup-and-feed operation (EF) .................................................................................. 50

Multiple-feed prevention (EF) ..................................................................................... 50

Multiple-feed detection (EF) ....................................................................................... 51

vi ENWW

Page 9

Jam detection (EF) ................................................................................................... 51

Duplexer ............................................................................................................................... 53

Motor and fan control (DP) ....................................................................................... 54

Failure detection (DP) ................................................................................ 55

Reverse-and-re-pickup operation (DP) ......................................................................... 55

Side registration adjustment operation (DP) ................................................................ 56

Jam detection (DP) ................................................................................................... 58

2 Removal and replacement .............................................................................................. 59

Introduction ........................................................................................................................... 60

Removal and replacement strategy ........................................................................................... 60

Electrostatic discharge ............................................................................................................ 60

Required tools ........................................................................................................................ 61

Types of screws ..................................................................................................................... 62

Service approach ................................................................................................................... 63

Before performing service ........................................................................................ 63

After performing service ........................................................................................... 63

Post-service test ....................................................................................................... 63

Print-quality test ........................................................................................ 63

Customer replaceable units (CRUs) ........................................................................................... 64

Print cartridge ......................................................................................................... 64

Tray 2 ................................................................................................................... 65

Tray 2 separation, pickup, and feed rollers ................................................................ 66

Transfer roller ........................................................................................................ 69

Fuser ..................................................................................................................... 70

Remove the fuser ...................................................................................... 70

Formatter cover and formatter cage ........................................................................... 71

Installing a new formatter .......................................................................... 73

Hard drive ............................................................................................................. 74

Remove the SSM ...................................................................................... 74

Remove the encrypted HHD ....................................................................... 76

Installing a replacement hard drive ............................................................. 78

SSM firmware upgrade .............................................................. 78

HDD firmware upgrade .............................................................. 79

Memory DIMM ....................................................................................................... 80

Remove the memory DIMM ....................................................................... 80

Install the memory DIMM ........................................................................... 81

Tray 1 pickup and feed rollers .................................................................................. 82

Tray 1 separation roller ........................................................................................... 85

Rear output bin ....................................................................................................... 87

Covers .................................................................................................................................. 88

ENWW vii

Page 10

Top-accessory cover ................................................................................................ 88

Envelope feed accessory covers ................................................................................ 89

Duplex accessory or cover ....................................................................................... 90

Tray 2 extension door .............................................................................................. 91

Remove the Tray 2 extension door .............................................................. 91

Top cover ............................................................................................................... 92

Remove the top cover ............................................................................... 92

Right-side cover ....................................................................................................... 95

Remove the right-side cover ....................................................................... 95

Reinstall the right cover ............................................................................. 97

Left-side cover ......................................................................................................... 98

Remove the left-side cover ......................................................................... 98

Right-front cover .................................................................................................... 100

Remove the right-front cover ..................................................................... 100

Rear-upper cover ................................................................................................... 103

Remove the rear-upper cover ................................................................... 103

Front cover ........................................................................................................... 105

Remove the front cover ............................................................................ 105

Main assemblies .................................................................................................................. 107

Registration assembly ............................................................................................ 107

Control-panel assembly .......................................................................................... 109

Remove the control-panel assembly ........................................................... 109

Walk-up USB port and cable .................................................................................. 111

Remove the walk-up USB port and cable ................................................... 111

Inner connecting PCA ............................................................................................ 114

Remove the inner connecting PCA ............................................................ 114

Reinstall the inner connecting PCA ........................................................... 116

Fan FN102 .......................................................................................................... 117

Remove fan FN102 ................................................................................ 117

Fan FN103 .......................................................................................................... 119

Remove fan FN103 ................................................................................ 119

Pickup-motor assembly (M101) ............................................................................... 121

Remove the pickup-motor assembly ........................................................... 121

Drum-motor assembly (M102) ................................................................................. 123

Remove the drum motor .......................................................................... 123

Lifter-motor assembly (M103) .................................................................................. 125

Remove the lifter motor ........................................................................... 125

DC controller PCA ................................................................................................. 128

Remove the DC controller PCA ................................................................. 128

Reinstallation tip ..................................................................................... 129

Installing a new formatter and a new DC controller .................................... 129

viii ENWW

Page 11

Pickup-drive assembly ............................................................................................ 131

Remove the pickup-drive assembly ............................................................ 131

Reinstall the pickup-drive assembly ........................................................... 136

Fuser-motor assembly (M299) ................................................................................. 137

Remove the fuser-motor assembly ............................................................. 137

Drum-drive assembly .............................................................................................. 139

Remove the drum-drive assembly .............................................................. 139

Reinstall the drum-drive assembly ............................................................. 141

Fan FN101 .......................................................................................................... 142

Remove fan FN101 ................................................................................ 142

Fan FN301 .......................................................................................................... 144

Remove fan FN301 ................................................................................ 144

Environmental sensor (TH3) .................................................................................... 146

Remove the environmental sensor (TH3) .................................................... 146

High voltage power supply .................................................................................... 148

Remove the high-voltage power-supply assembly ........................................ 148

Feed-guide assembly ............................................................................................. 152

Remove the feed-guide assembly .............................................................. 152

Reinstall the feed-guide assembly ............................................................. 154

Tray 1 paper-pickup assembly ................................................................................ 155

Remove the Tray 1 pickup assembly ......................................................... 155

Feed-roller assembly .............................................................................................. 157

Remove the feed-roller assembly ............................................................... 157

Laser/scanner assembly ......................................................................................... 158

Remove the laser/scanner assembly ......................................................... 158

Paper-delivery assembly ........................................................................................ 161

Remove the paper-delivery assembly ......................................................... 161

Reinstall the paper-delivery assembly ........................................................ 164

1,500-sheet paper deck (PD) ................................................................................................. 165

Separation roller (PD) ............................................................................................ 165

Rear cover (PD) ..................................................................................................... 167

Right-side cover (PD) .............................................................................................. 168

1,500-sheet paper deck left-side cover ..................................................................... 169

Remove the left-side cover ....................................................................... 169

Door (PD) ............................................................................................................. 172

Motor (PD) ........................................................................................................... 174

Remove the Motor (PD) ........................................................................... 174

Driver PCA (PD) .................................................................................................... 176

Remove the Driver PCA (PD) .................................................................... 176

Lift-drive assembly (PD) ........................................................................................... 178

Remove the Lift-drive assembly (PD) ........................................................... 178

ENWW ix

Page 12

3 Solve problems ............................................................................................................. 181

Solve problems checklist ....................................................................................................... 182

Menu map .......................................................................................................................... 184

Preboot menu options ........................................................................................................... 185

Current settings pages .......................................................................................................... 192

Troubleshooting process ........................................................................................................ 193

Determine the problem source ................................................................................. 193

Pre-troubleshooting checklist .................................................................... 193

Troubleshooting flowchart ....................................................................... 194

Power subsystem ................................................................................................... 196

Power-on checks .................................................................................... 196

Overview ............................................................................... 196

Tools for troubleshooting ....................................................................................................... 199

Component diagnostics .......................................................................................... 199

LED diagnostics ...................................................................................... 199

Understand lights on the formatter ............................................. 199

Engine diagnostics ................................................................................. 204

Engine test button .................................................................... 204

Formatter test .......................................................................... 204

Print/Stop test ......................................................................... 205

Drum rotation test .................................................................... 205

Paper-path test (and automatic sensor test) ................................................. 206

Paper path sensors test (automatic) ............................................ 206

Manual sensor test ................................................................................. 208

Top of page sensor (PS103) ..................................................... 210

Pre-feed sensor (PS102) ........................................................... 211

Fuser delivery sensor (PS700) ................................................... 212

Duplex sensor (PS1502) ........................................................... 213

Media width sensors 1/2 (PS106/108) ..................................... 214

Output bin full sensor (PS104) .................................................. 215

Tray 1 paper present sensor (PS105) ......................................... 216

Tray 2 paper present sensor (PS101) ......................................... 217

Tray 2 top of stack sensor (PS107) ............................................ 218

Tray 2 paper size switches (SW102) ......................................... 219

Tray/Bin manual sensor test .................................................................... 220

Print/stop test ........................................................................................ 220

Component tests ..................................................................................... 221

Diagrams ............................................................................................................. 223

Block diagrams ...................................................................................... 223

Main assemblies ..................................................................... 223

Main parts ............................................................................. 224

x ENWW

Page 13

Motors and fans ...................................................................... 225

PCAs ..................................................................................... 226

500-sheet feeder ..................................................................... 226

1,500-sheet feeder .................................................................. 227

Connectors ............................................................................................ 229

DC controller PCA connectors ................................................... 229

Product base connectors ........................................................... 231

500-sheet paper tray connectors ............................................... 232

1,500-sheet paper tray connectors ............................................ 232

Duplexer connectors ................................................................ 233

Envelope feeder connectors ...................................................... 233

General timing chart ............................................................................... 234

Circuit diagrams .................................................................................... 235

Internal print-quality test pages ................................................................................ 241

Print-quality-troubleshooting pages ............................................................ 241

Clean the paper path ............................................................................. 242

Set up an auto cleaning page ................................................... 242

Print configuration page .......................................................................... 243

Configuration page ................................................................. 243

HP embedded Jetdirect page .................................................... 245

Print quality troubleshooting tools ............................................................................ 246

Repetitive image defect ruler .................................................................... 246

Control-panel menus .............................................................................................. 247

Retrieve Job from USB menu .................................................................... 247

Retrieve Job from Device Memory menu .................................................... 247

Supplies menu ....................................................................................... 248

Trays menu ............................................................................................ 249

Administration menu ............................................................................... 250

Reports menu .......................................................................... 250

General Settings menu ............................................................. 250

Retrieve From USB Settings menu .............................................. 253

General Print Settings menu ...................................................... 253

Default Print Options menu ....................................................... 255

Display Settings menu .............................................................. 255

Manage Supplies menu ........................................................... 256

Manage Trays menu ................................................................ 257

Stapler/Stacker Settings menu .................................................. 258

Multi-Bin Mailbox Settings menu ................................................ 258

Network Settings menu ............................................................ 259

Troubleshooting menu .............................................................. 263

Device Maintenance menu ...................................................................... 264

ENWW xi

Page 14

Backup/Restore menu .............................................................. 264

Calibrate/Cleaning menu ........................................................ 264

USB Firmware Upgrade menu ................................................... 265

Service menu .......................................................................... 265

Interpret control-panel messages, status-alert messages, and event code errors .............. 266

10.00.33 .............................................................................................. 266

10.00.35 .............................................................................................. 266

10.00.60 .............................................................................................. 266

10.00.69 .............................................................................................. 267

10.00.91 .............................................................................................. 267

10.0X.Y0 Supply memory error ............................................................... 267

10.23.35 .............................................................................................. 268

10.23.50 .............................................................................................. 268

10.23.51 .............................................................................................. 268

10.23.52 .............................................................................................. 268

10.23.60 .............................................................................................. 268

10.23.70 Printing Past Very Low .............................................................. 269

10.26.15 .............................................................................................. 269

10.26.50 .............................................................................................. 269

10.26.60 .............................................................................................. 270

10.XX.34 Used Supply In Use .................................................................. 270

10.XX.40 Genuine HP Supplies Installed ................................................... 270

10.XX.41 Unsupported Supply In Use ....................................................... 271

10.XX.70 Printing past very low ............................................................... 271

10.YY.15 Install <supply> ....................................................................... 271

10.YY.35 Incompatible <supply> ............................................................. 272

11.00.YY Internal clock error .................................................................. 272

13.00.00 .............................................................................................. 272

13.00.EE .............................................................................................. 273

13.A3.FF .............................................................................................. 273

13.D3.DZ ............................................................................................. 273

13.E5.FF ............................................................................................... 273

13.EA.EE .............................................................................................. 274

13.EE.FF ............................................................................................... 274

13.FF.EE ............................................................................................... 274

13.FF.FF ............................................................................................... 274

13.WX.EE ............................................................................................. 274

13.WX.FF ............................................................................................. 275

13.WX.YZ Fuser Area Jam ...................................................................... 275

13.WX.YZ Fuser wrap jam ...................................................................... 275

13.WX.YZ Jam below control panel ......................................................... 275

xii ENWW

Page 15

13.WX.YZ Jam in Tray 1 ........................................................................ 275

13.WX.YZ Jam in Tray <X> ..................................................................... 276

13.WX.YZ Jam inside envelope feeder ..................................................... 276

13.WX.YZ Jam inside top cover ............................................................... 276

14.00.XX .............................................................................................. 276

20.00.00 Insufficient memory: <Device> To continue, touch “OK” ............... 277

21.00.00 Page Too Complex .................................................................. 277

32.08.AX .............................................................................................. 277

32.1C.XX .............................................................................................. 278

32.21.00 .............................................................................................. 284

33.01.XX .............................................................................................. 285

33.XX.YY Used board/disk ..................................................................... 285

40.00.01 USB I/O buffer overflow To continue, touch “OK” ....................... 285

40.00.02 Embedded I/O buffer overflow To continue, touch “OK” .............. 285

40.00.05 Embedded I/O bad transmission To continue, touch “OK” ........... 286

41.02.00 Error ...................................................................................... 286

41.03.YZ Unexpected size in envelope feeder To use another tray, touch

"Options" .............................................................................................. 286

41.03.YZ Unexpected size in tray <X> ..................................................... 287

41.05.YZ Unexpected type in tray <X> .................................................... 288

41.XX.YZ Error To continue, touch “OK” ................................................... 290

42.XX.YY .............................................................................................. 291

47.00.XX .............................................................................................. 291

47.01.XX .............................................................................................. 291

47.02.XX .............................................................................................. 292

47.03.XX .............................................................................................. 292

47.04.XX .............................................................................................. 292

47.05.00 .............................................................................................. 292

47.06.XX .............................................................................................. 292

47.WX.YZ Printer Calibration Failed To continue, touch “OK” ..................... 293

49.XX.YY To continue turn off then on ....................................................... 294

50.WX.YZ Fuser error To continue turn off then on ..................................... 294

51.00.YY Error ...................................................................................... 296

52.XX.00 Error To continue turn off then on ............................................... 296

54.XX.YY Error ...................................................................................... 297

55.00.YY DC controller error To continue turn off then on ........................... 298

55.0X.YY DC controller error To continue turn off then on ........................... 298

56.00.YY Error To continue turn off then on ............................................... 298

57.00.0Y Error To continue turn off then on .............................................. 299

58.00.0Y Error To continue turn off then on .............................................. 300

59.00.YY error To continue turn off then on ............................................... 300

ENWW xiii

Page 16

59.A2.0x Error ...................................................................................... 301

60.00.0Y Tray <Y> lifting error ............................................................... 302

62.00.00 No system To continue turn off then on ....................................... 302

65.X0.A1 Output accessory disconnected ................................................. 303

66.80.YY Stapler/Stacker failure ............................................................. 303

69.11.YY Error To continue turn off then on ............................................... 305

70.00.00 Error To continue turn off then on .............................................. 305

79.XX.YY Error To continue turn off then on ............................................... 306

80.0X.YY Embedded JetDirect error ......................................................... 306

81.YY.ZZ EIO-1 Card Failure .................................................................. 308

82.73.46 OR 82.73.47 ......................................................................... 309

98.00.01 Corrupt data in firmware volume ............................................... 310

98.00.02 Corrupt data in solutions volume ............................................... 310

98.00.03 Corrupt data in configuration volume ......................................... 310

98.00.04 Corrupt data in job data volume ............................................... 310

99.00.01 Upgrade not performed file is corrupt ........................................ 311

99.00.02 Upgrade not performed timeout during receive ........................... 311

99.00.03 Upgrade not performed error writing to disk ............................... 311

99.00.04 Upgrade not performed timeout during receive ........................... 311

99.00.05 Upgrade not performed timeout during receive ........................... 312

99.00.06 Upgrade not performed error reading upgrade ........................... 312

99.00.07 Upgrade not performed error reading upgrade ........................... 312

99.00.08 Upgrade not performed error reading upgrade ........................... 312

99.00.09 Upgrade canceled by user ....................................................... 313

99.00.10 Upgrade canceled by user ....................................................... 313

99.00.11 Upgrade canceled by user ....................................................... 313

99.00.12 Upgrade not performed the file is invalid ................................... 313

99.00.13 Upgrade not performed the file is invalid ................................... 314

99.00.14 Upgrade not performed the file is invalid ................................... 314

99.00.2X .............................................................................................. 314

99.09.60 Unsupported disk .................................................................... 315

99.09.61 Unsupported disk .................................................................... 315

99.09.62 Unknown disk ......................................................................... 315

99.09.63 Incorrect disk .......................................................................... 316

99.09.64 Disk malfunction ...................................................................... 316

99.09.65 Disk data error ........................................................................ 316

99.09.66 No disk installed ..................................................................... 316

99.09.67 Disk is not bootable please download firmware .......................... 316

99.XX.YY .............................................................................................. 317

<binname> full Remove all paper from bin ................................................ 317

<Supply> low OR Supplies low ................................................................ 317

xiv ENWW

Page 17

<Supply> very low OR Supplies very low .................................................. 318

[File System] device failure To clear press “OK” ......................................... 318

[File System] file operation failure To clear press “OK” ............................... 318

[File System] file system is full To clear press “OK” ..................................... 318

[File System] is not initialized ................................................................... 319

[File System] is write protected ................................................................. 319

Accept bad signature ............................................................................. 319

Bad optional tray connection ................................................................... 319

Canceling ............................................................................................. 320

Canceling... <jobname> ......................................................................... 320

Cartridge Low ........................................................................................ 320

Cartridge Memory Abnormal ................................................................... 320

Cartridge Out ........................................................................................ 320

Checking engine .................................................................................... 321

Checking paper path .............................................................................. 321

Chosen personality not available To continue, touch “OK” .......................... 321

Cleaning do not grab paper .................................................................... 321

Cleaning... ............................................................................................ 322

Clearing event log .................................................................................. 322

Clearing paper path ............................................................................... 322

Close stapler/stacker multi bin mailbox door ............................................. 322

Close top cover ...................................................................................... 322

Cooling device ...................................................................................... 323

Creating cleaning page... ....................................................................... 323

Data received To print last page press “OK” ............................................. 323

Event log is empty .................................................................................. 323

Expected drive missing ........................................................................... 324

External device initializing ....................................................................... 324

Face Down Tray Full ............................................................................... 324

FIM Load Error Send full FIM on <X> port ................................................. 324

Fuser Kit low .......................................................................................... 324

Fuser Kit very low To continue, touch “OK” ............................................... 325

Genuine HP cartridge installed ................................................................ 325

Genuine HP supply installed .................................................................... 325

HP Secure hard drive disabled ................................................................. 325

Incompatible <supply> ............................................................................ 326

Incompatible supplies ............................................................................. 326

Initializing... .......................................................................................... 326

Install fuser unit ...................................................................................... 326

Install supplies ....................................................................................... 327

Install supply .......................................................................................... 327

ENWW xv

Page 18

Internal disk device failure To clear press “OK” .......................................... 327

Internal disk file operation failed .............................................................. 327

Internal disk file system is full ................................................................... 328

Internal disk is write protected .................................................................. 328

Internal disk not found ............................................................................ 328

Internal disk not functional ....................................................................... 328

Internal disk not initialized ....................................................................... 328

Internal disk spinning up ......................................................................... 329

Job not stapled due to mixed sizes ........................................................... 329

Load Tray <X>: [Type], [Size] .................................................................. 329

Load Tray <X>: [Type], [Size] To use another tray, press “OK” .................... 330

Loading program <XX> ........................................................................... 330

Manually feed output stack Then touch "OK" to print second side ................ 330

Manually feed: <Type><Size> ................................................................. 330

Manually feed: <Type><Size> To use another tray, press “OK” ................... 331

Moving solenoid .................................................................................... 331

Moving solenoid and motor ..................................................................... 331

No job to cancel .................................................................................... 331

NON HP SUPPLY INSTALLED ................................................................... 332

Output Bin Full ....................................................................................... 332

Paused… .............................................................................................. 332

Performing Paper Path Test… ................................................................... 332

Please Wait... ........................................................................................ 332

Printing Configuration... .......................................................................... 333

Printing Event Log... ................................................................................ 333

Printing File Directory... ........................................................................... 333

Printing Font List... .................................................................................. 333

Printing Fuser Test Page... ....................................................................... 333

Printing Help Page... .............................................................................. 334

Printing Menu Map... ............................................................................. 334

Printing Registration Page… .................................................................... 334

Printing stopped ..................................................................................... 334

Printing Supplies Status Page... ................................................................ 334

Printing Usage Page... ............................................................................ 334

Printing…engine test ............................................................................... 335

Processing duplex job Do not grab paper until job completes ...................... 335

Processing job from tray <X>... Do not grab paper until job completes ......... 335

Processing... .......................................................................................... 335

Processing... copy <X> of <Y> ................................................................ 335

RAM disk device failure To clear press “OK” ............................................. 336

RAM disk file operation failed To clear press “OK” .................................... 336

xvi ENWW

Page 19

RAM disk file system is full To clear press “OK” ......................................... 336

RAM disk is write protected To clear press “OK” ........................................ 336

RAM disk not initialized .......................................................................... 336

Ready ................................................................................................... 337

Ready <IP Address> ............................................................................... 337

Receiving Upgrade ................................................................................. 337

Remove one print cartridge ..................................................................... 337

Remove USB accessory ........................................................................... 337

Replace <supply> .................................................................................. 338

Replace supplies .................................................................................... 338

Resend external accessory firmware ......................................................... 339

Resend Upgrade .................................................................................... 339

Restore Factory Settings .......................................................................... 339

ROM disk device failed To clear press “OK” ............................................. 339

ROM disk file operation failed To clear press “OK” .................................... 339

ROM disk file system is full To clear press “OK” ......................................... 340

ROM disk is write protected To clear press “OK” ....................................... 340

ROM disk not initialized To clear press “OK” ............................................ 340

Rotating Motor ....................................................................................... 340

Size Mis-Match ...................................................................................... 340

Size mismatch in Tray <X> ...................................................................... 341

Sleep mode on ...................................................................................... 341

Staple Cartridge low .............................................................................. 341

Staple Cartridge very low ....................................................................... 341

Stapler/Stacker staple jam ...................................................................... 342

Supplies low .......................................................................................... 342

SUPPLY MEMORY WARNING ................................................................. 342

The unit has corrupt data ......................................................................... 342

Tray <X> empty: [Type], [Size] ................................................................ 343

Tray <X> lifting ...................................................................................... 344

Tray <X> open ....................................................................................... 344

Tray <X> overfilled ................................................................................. 345

Type mismatch Tray ................................................................................ 345

Unsupported drive installed To continue, touch “OK” .................................. 345

Unsupported supply in use OR Unsupported supply installed To continue,

touch “OK” ........................................................................................... 346

Unsupported tray configuration ................................................................ 346

Unsupported USB accessory detected Remove USB accessory ...................... 346

Upgrade Error ....................................................................................... 346

USB accessory not functional ................................................................... 347

USB hubs are not fully supported Some operations may not work properly .... 347

ENWW xvii

Page 20

USB is write protected To clear press “OK” ............................................... 347

USB needs too much power ..................................................................... 347

USB needs too much power Remove USB and Then Turn Off then On ........... 347

USB not initialized .................................................................................. 348

USB storage accessory removed Clearing any associated data .................... 348

USB storage device failure To clear press “OK” ......................................... 348

USB storage file operation failed To clear press “OK” ................................ 348

USB storage file system is full To clear press “OK” ...................................... 348

Used supply installed To continue, touch “OK” OR Used supply in use .......... 349

Waiting for tray <X> to lift ...................................................................... 349

Windows Login Required to Use this Feature ............................................. 349

Event-log messages ............................................................................................... 350

Print an event log ................................................................................... 351

View an event log .................................................................................. 352

Clear an event log .................................................................................. 352

Clear jams .......................................................................................................................... 353

Jam locations ........................................................................................................ 354

Common causes of jams ........................................................................................ 355

Clear jams from the input trays ............................................................................... 356

Clear jams from Tray 1 ........................................................................... 356

Clear jams from Tray 2 or an optional 500-sheet tray ................................. 356

Clear jams from the optional 1,500-sheet tray ........................................... 357

Clear jams from the optional duplexer ..................................................................... 359

Clear jams from the optional envelope feeder ........................................................... 361

Clear jams from the output areas ............................................................................ 363

Clear jams from the rear output bin .......................................................... 363

Clear jams from the optional stacker or stapler/stacker ............................... 364

Clear paper jams from the optional stacker or stapler/stacker ...... 364

Clear staple jams from the optional stapler/stacker ..................... 365

Clear jams from the optional 5-bin mailbox ............................................... 367

Clear jams from the fuser ....................................................................................... 369

Clear jams from the print-cartridge (top cover) .......................................................... 373

Change jam recovery ............................................................................................ 375

Paper does not feed automatically .......................................................................................... 376

The product does not pick up paper ........................................................................ 376

The product picks up multiple sheets of paper ........................................................... 376

Prevent paper jams ................................................................................................ 376

Use manual print modes ....................................................................................................... 378

Solve image-quality problems ................................................................................................ 380

Print-quality examples ............................................................................................ 380

Clean the product ................................................................................................................ 388

xviii ENWW

Page 21

Clean the paper path ............................................................................................ 388

Set up an auto cleaning page .................................................................. 388

Solve performance problems ................................................................................................. 389

Solve connectivity problems ................................................................................................... 390

Solve direct-connect problems ................................................................................. 390

Solve network problems ......................................................................................... 390

Service mode functions ......................................................................................................... 391

Service menu ........................................................................................................ 391

Product resets ....................................................................................................... 392

Restore factory-set defaults ....................................................................... 392

Clean Disk and Partial Clean functions .................................................................... 393

Active and repository firmware locations ................................................... 393

Partial Clean ......................................................................................... 394

Execute a Partial Clean ............................................................ 394

Clean Disk ............................................................................................ 395

Execute a Clean Disk ............................................................... 395

Product updates ................................................................................................................... 397

Determine the installed revision of firmware .............................................................. 397

Perform a firmware upgrade ................................................................................... 397

Embedded Web Server ........................................................................... 397

USB storage device (Preboot menu) .......................................................... 398

USB storage device (control-panel menu) ................................................... 399

4 Parts and diagrams ...................................................................................................... 401

Order parts by authorized service providers ............................................................................ 402

Order parts, accessories, and supplies .................................................................... 402

Supplies part numbers ........................................................................................... 402

Customer-self repair parts ....................................................................................... 402

Accessories part numbers ....................................................................................... 404

Related documentation and software ....................................................................... 405

How to use the parts lists and diagrams .................................................................................. 406

Assembly locations ............................................................................................................... 407

Base product (no optional trays or accessories) ......................................................... 407

Covers ................................................................................................................................ 410

Product base ........................................................................................................ 410

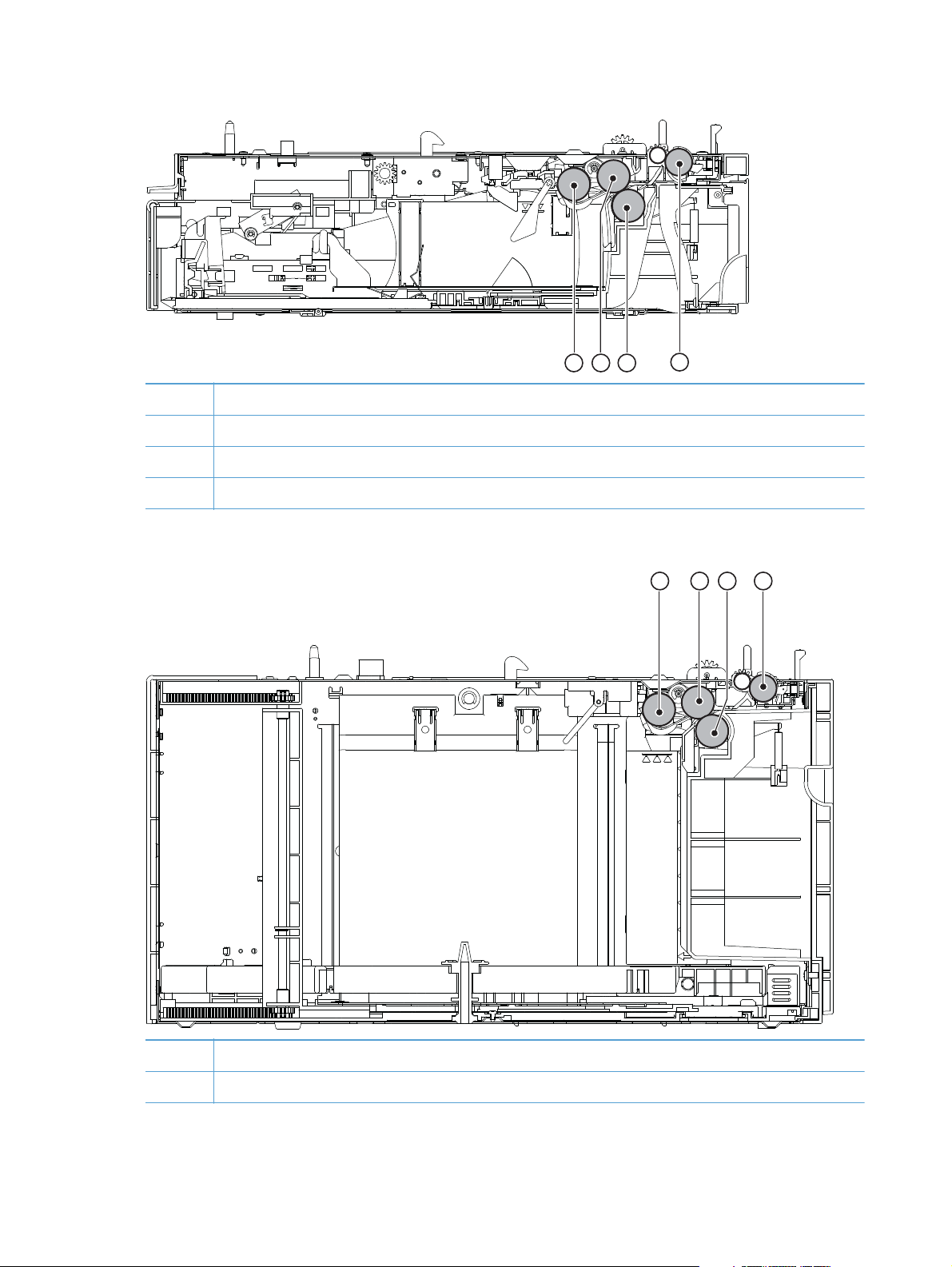

Internal components ............................................................................................................. 412

Internal components (1 of 3) ................................................................................... 412

Internal components (2 of 3) ................................................................................... 414

Internal components (3 of 3) ................................................................................... 416

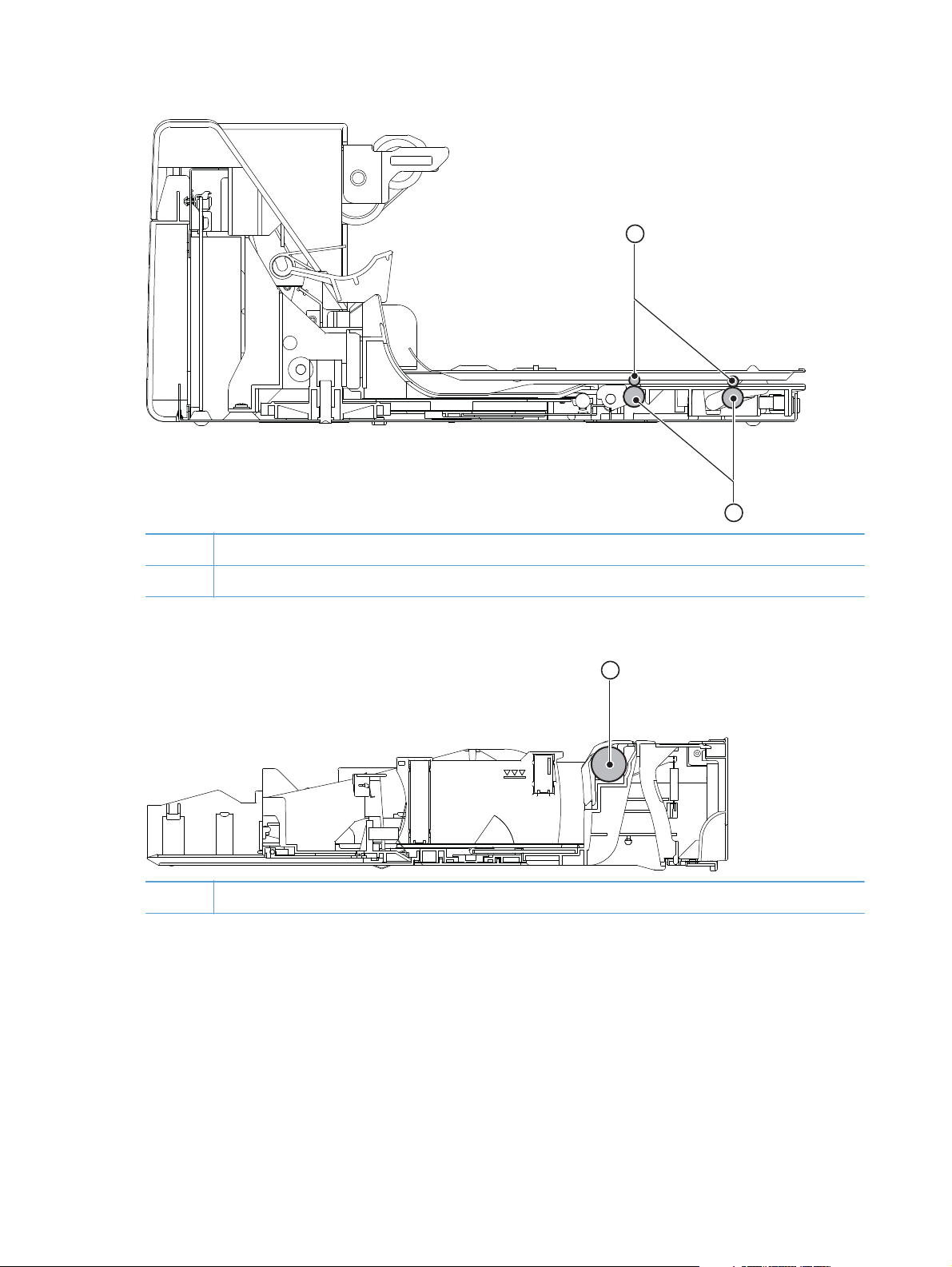

High-voltage power supply ..................................................................................... 418

Cassette (Tray 2) ................................................................................................... 420

ENWW xix

Page 22

Cassette (custom media) ......................................................................................... 422

Paper feed roller assembly ..................................................................................... 424

Registration assembly ............................................................................................ 426

Tray 1 (MP) pickup assembly .................................................................................. 428

Paper delivery assembly ........................................................................................ 430

Fuser assembly ..................................................................................................... 432

PCAs (product base) .............................................................................................. 434

Input devices ....................................................................................................................... 436

1x500-sheet feeder ............................................................................................... 436

Covers (1x500) ..................................................................................... 436

Main body (1x500) ................................................................................ 438

Cassette (1x500) ................................................................................... 440

PCA (1x500) ......................................................................................... 442

1x1500-sheet paper deck ...................................................................................... 444

Covers (1x1500) ................................................................................... 444

Front door assembly (1x1500) ................................................................. 446

Main body (1x500; 1 of 2) ..................................................................... 448

Main body (1x500; 2 of 2) ..................................................................... 450

Paper pickup assembly (1x500) ............................................................... 452

PCA (1x1500) ....................................................................................... 454

Duplexer ............................................................................................................................. 456

Main body (duplexer) ............................................................................................ 456

PCA (duplexer) ..................................................................................................... 458

Envelope feeder ................................................................................................................... 460

Covers (envelope feeder) ....................................................................................... 460

Main body (1 of 2; envelope feeder) ....................................................................... 462

Main body (2 of 2; envelope feeder) ....................................................................... 464

PCA (envelope feeder) ........................................................................................... 466

Output devices .................................................................................................................... 468

Stapler/stacker multi-bin mailbox (MBM) .................................................................. 468

Covers (MBM) ....................................................................................... 468

Main body (MBM) .................................................................................. 470

Main body (MBM; 1 of 2) ........................................................ 470

Main body (MBM; 2 of 2) ........................................................ 472

PCA (MBM) ........................................................................................... 474

Stacker and Stapler/Stacker (S and S/S) ................................................................. 476

Covers (S and S/S) ................................................................................ 476

Main body (SS) ...................................................................................... 478

Main body (S) ....................................................................................... 480

Middle assemblies (S and S/S) ................................................................ 482

Stapler/Stacker middle assembly (1 of 2; S/S) ........................... 482

xx ENWW

Page 23

Stapler/Stacker middle assembly (2 of 2; S/S) ........................... 484

Stacker middle assembly (1 of 2; S) ........................................... 486

Stacker middle assembly (2 of 2; S) ........................................... 488

PCA (S and S/S) .................................................................................... 490

Alphabetical parts list ........................................................................................................... 492

Numerical parts list .............................................................................................................. 501

Appendix A Service and support ..................................................................................... 511

Hewlett-Packard limited warranty statement ............................................................................. 512

HP's Premium Protection Warranty: LaserJet print cartridge limited warranty statement .................. 514

Data stored on the print cartridge ........................................................................................... 515

End User License Agreement .................................................................................................. 516

Customer self-repair warranty service ..................................................................................... 519

Customer support ................................................................................................................. 520

Repack the product .............................................................................................................. 521

Appendix B Product specifications ................................................................................... 523

Physical specifications .......................................................................................................... 524

Power consumption, electrical specifications, and acoustic emissions .......................................... 524

Operating environment ......................................................................................................... 525

Appendix C Regulatory information ................................................................................. 527

FCC regulations ................................................................................................................... 528

Environmental product stewardship program ........................................................................... 529

Protecting the environment ...................................................................................... 529

Ozone production ................................................................................................. 529

Power consumption ............................................................................................... 529

Toner consumption ................................................................................................ 529

Paper use ............................................................................................................. 529

Plastics ................................................................................................................. 529

HP LaserJet print supplies ....................................................................................... 530

Return and recycling instructions ............................................................................. 530

United States and Puerto Rico .................................................................. 530

Multiple returns (more than one cartridge) .................................. 530

Single returns .......................................................................... 530

Shipping ................................................................................ 530

Non-U.S. returns .................................................................................... 531

Paper .................................................................................................................. 531

Material restrictions ............................................................................................... 531

Disposal of waste equipment by users in private households in the European Union ...... 532

ENWW xxi

Page 24

Chemical substances ............................................................................................. 532

Material Safety Data Sheet (MSDS) ......................................................................... 532

For more information ............................................................................................. 532

Declaration of Conformity ..................................................................................................... 534

Certificate of Volatility .......................................................................................................... 536

Types of memory ................................................................................................... 536

Volatile memory ..................................................................................... 536

Non-volatile memory .............................................................................. 536

Hard-disk-drive memory .......................................................................... 536

Safety statements ................................................................................................................. 537