Page 1

SCITEX Dual Roll Kit

User’s guide

Page 2

© 2011 Hewlett-Packard Development

Company, L.P.

First edition

Legal notices

The information contained herein is subject

to change without notice.

The only warranties for HP Products and

services are set forth in the express warranty

statement accompanying such products and

services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Page 3

Table of contents

1 Introduction ...................................................................................................................... 1

Purpose .................................................................................................................................. 1

Main components .................................................................................................................... 1

Requirements ........................................................................................................................... 1

2 Use of the dual-roll spindle ............................................................................................... 2

Load rolls onto the spindle ......................................................................................................... 2

Load rolls into the printer ........................................................................................................... 5

3 Troubleshooting .............................................................................................................. 10

4 Specifications .................................................................................................................. 11

ENWW iii

Page 4

iv ENWW

Page 5

1 Introduction

Purpose

The purpose of this document is to describe how to install, use and troubleshoot the Dual Roll used in

the following Printers:

HP Scitex LX800 Printer (126-in)

●

HP Scitex LX820 Printer (126-in)

●

HP Scitex LX850 Printer (126-in)

●

HP Scitex LX600 Printer (104-in)

●

HP Designjet L65500 Printer (104-in)

●

Introduction

For information about using these printers, refer to the corresponding User Guide or Maintenance and

Troubleshooting Guide.

Main components

The Dual Roll Kit includes the following components.

Two dual-roll spindles, each including one differential hub

●

One pair of substrate edge holders

●

One Allen key

●

Requirements

Before using the Dual Roll Kit with an HP LX Designjet printer, you must check that the printer's firmware

and HP Internal Print Server software are up to date.

Go to

http://www.hp.com/ and click Support & Drivers > Download drivers and software

(and firmware), enter the product name, click the name of your operating system, and download the

latest firmware and the latest Internal Print Server, if you do not already have them.

ENWW

Purpose

1

Page 6

2 Use of the dual-roll spindle

Dual-roll spindle

Load rolls onto the spindle

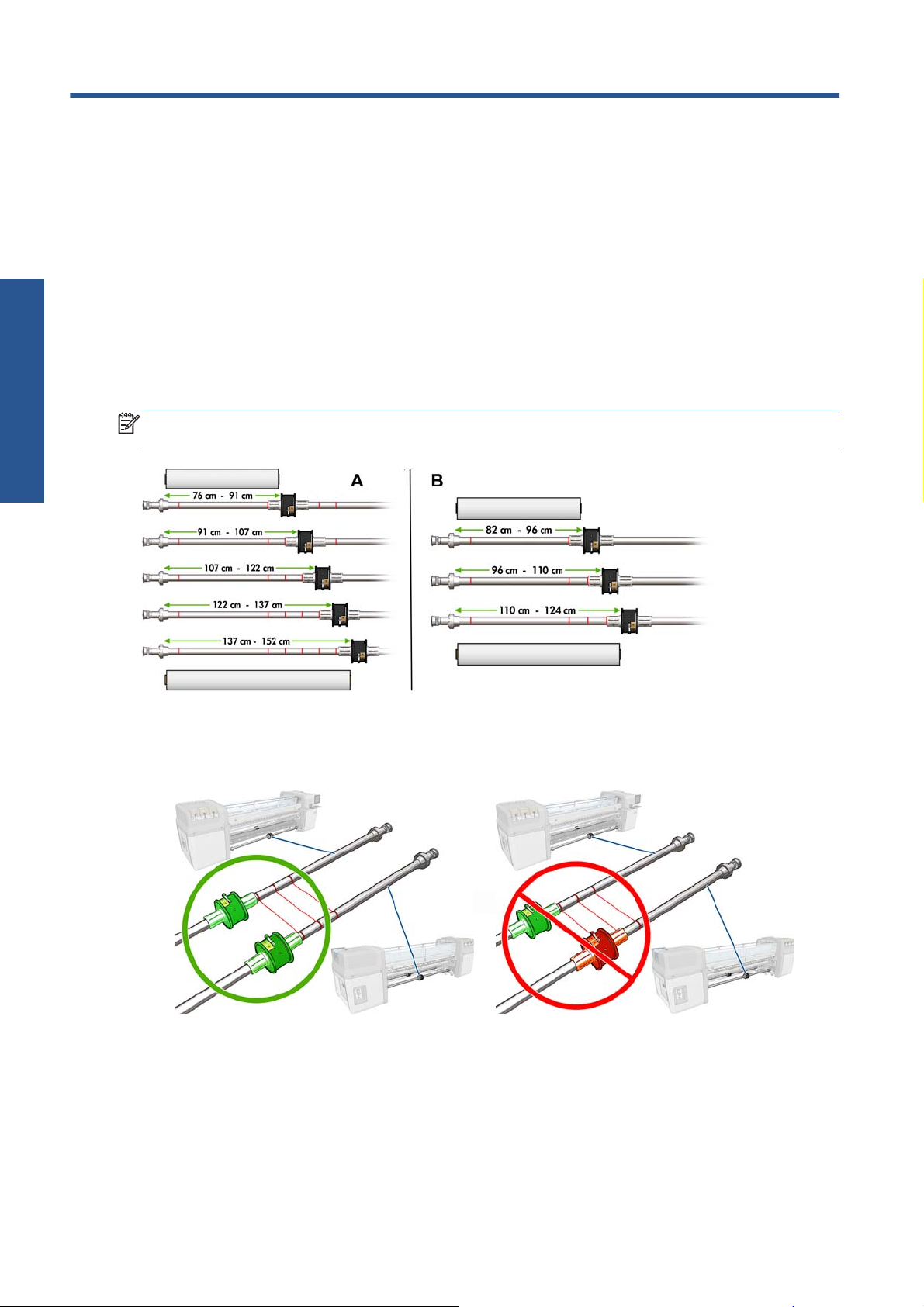

The dual-roll spindle is marked to assist you in positioning the differential hub.

NOTE: The spindle marked A is for the dimensions of the 126-in spindle. The spindle marked B is for

the dimensions of the 104-in spindle.

Loading the dual-roll spindles

1. Ensure that the differential hubs on the input and output spindles are aligned with each other.

2 Chapter 2 Use of the dual-roll spindle ENWW

Page 7

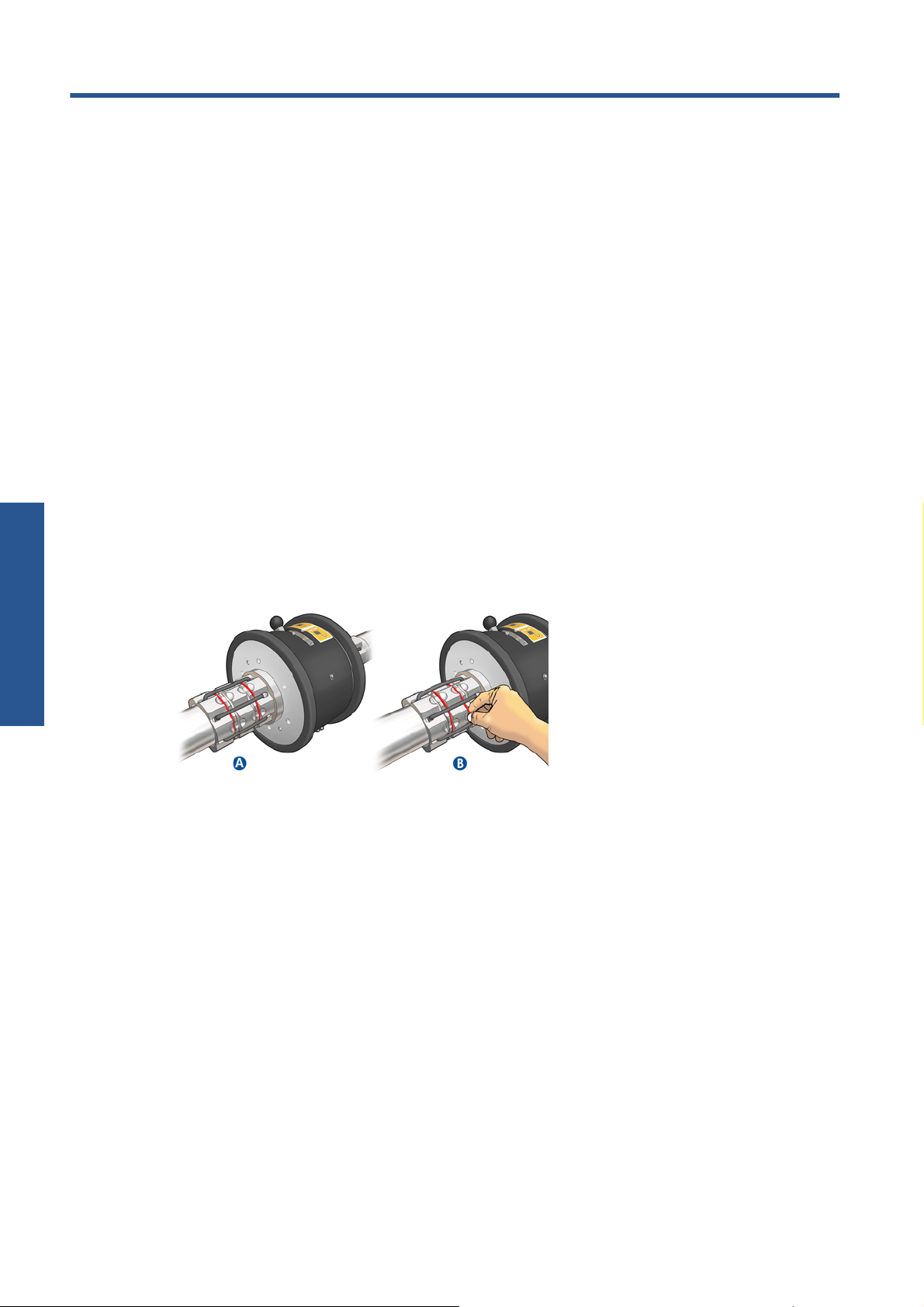

2. When both differential hubs are correctly positioned, use the Allen key to tighten the screws and

secure them in place. If a differential hub is loose, the substrate could become skewed during

printing.

TIP: You should tighten the screw until the washer touches the bolt. If you can still see the yellow

spring, tighten the screw further.

3. At each end of the spindle, unscrew and remove the outer parts of the hub, using the Allen key.

4. Unscrew and remove the inner part of each hub.

Dual-roll spindle

ENWW

Load rolls onto the spindle

3

Page 8

Dual-roll spindle

5. Insert the first roll on the spindle.

6. Replace the hub, and secure it with the Allen key.

7. Insert the second roll on the spindle.

8. Replace the hub, and secure it with the Allen key.

9. Ensure that the end of the right-hand roll is located within the maximum allowed distance from the

right-hand end of the spindle: it should be between the gear and the dashed line.

10. Ensure that the roll core fits tightly on the hub.

4 Chapter 2 Use of the dual-roll spindle ENWW

Page 9

11. Ensure that the roll core fits tightly on the differential hub.

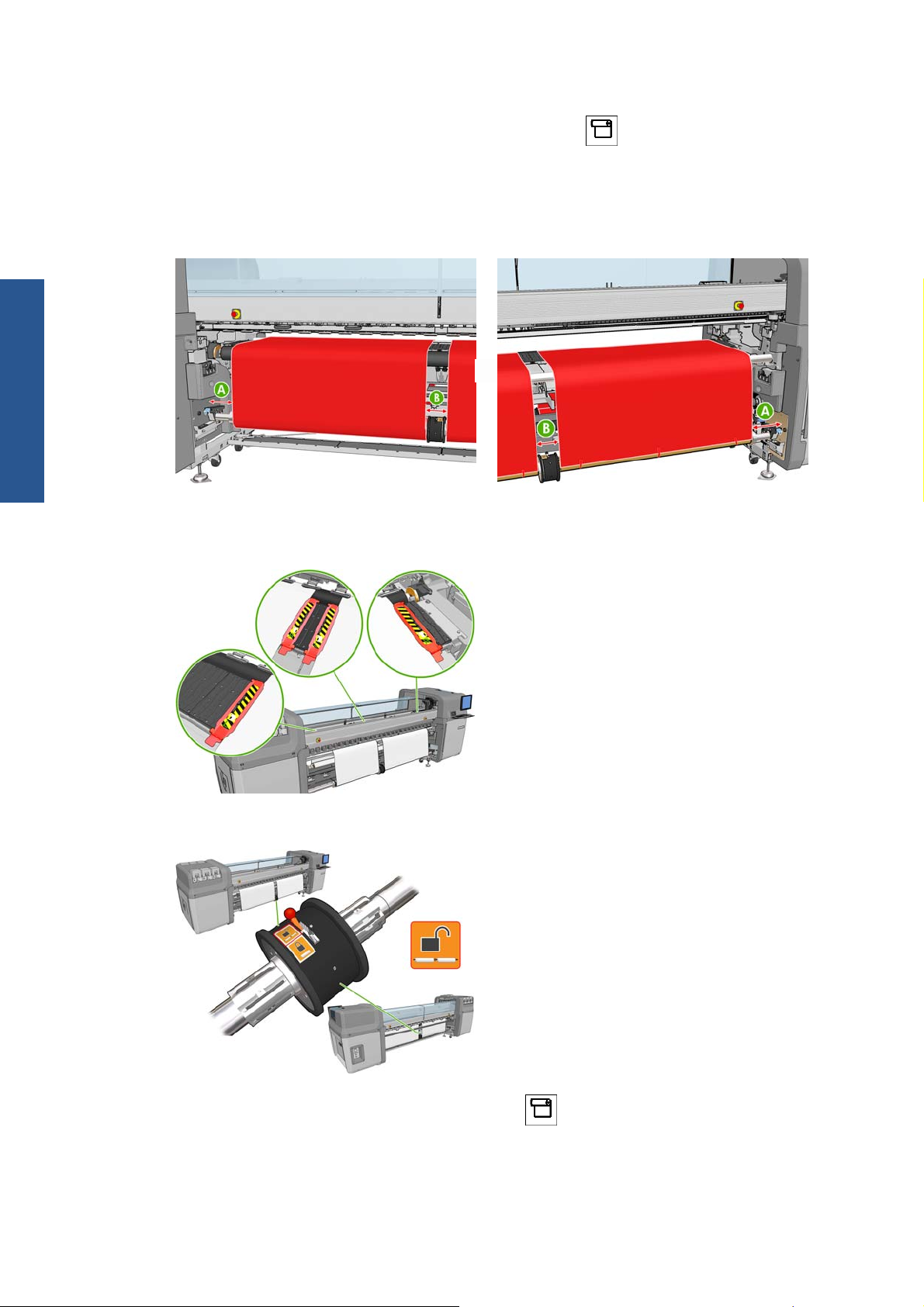

12. Load the spindle at the rear of the printer, and secure the spindle latches.

13. Use the same process to load the output spindle at the front of the printer, but load the spindle with

two empty cores to receive the printed substrate.

Load rolls into the printer

The two substrate rolls are mounted on the rear dual-roll spindle and will be collected on the front dualroll spindle. The substrate goes from the rear spindle over the main roller, over the platen, over the front

roller and then to the front spindle.

NOTE: You can load substrate with the printed face inwards or outwards on the spindle, in which

case the spindle will turn in the opposite direction. The printer asks you for the winding direction if it

cannot detect it automatically.

Before loading two rolls into the printer, you must have both rolls loaded on the rear dual-roll spindle

and two empty cores loaded on the front dual-roll spindle. See

Dual-roll spindle

Load rolls onto the spindle on page 2.

ENWW

1. Tell the printer that you are going to begin loading for dual-roll printing.

2. Remove the substrate edge holders in the print platen, or move them aside, so that they do not get

in the way while loading the substrate.

CAUTION: Loading the substrate on top of the edge holders could severely damage the

printheads and carriage.

3. Lift the substrate pressure handles at the rear of the printer.

Load rolls into the printer

5

Page 10

4.

If you need to raise the carriage beam, go to the front panel and select the Substrate menu

then Substrate management, and press OK. Select Carriage beam position > Move to

highest position. This process takes about 2 minutes to complete.

,

Dual-roll spindle

The printer raises the carriage beam, making it easy to insert the substrate. This process takes

about 2 minutes to complete. During this period, you can load the input and output rolls.

NOTE: While the carriage beam is rising, you can stop it by pressing the Cancel key.

5. You may find it helpful to lock the differentials on the input and output spindles while loading.

6. Bring the new rolls on their spindle to the rear of the printer, with the geared end of the spindle on

the left.

7. If the two rolls are of unequal lengths, the longer roll should be on the right as seen from the front

of the printer; on the left as seen from the rear.

NOTE: When the shorter roll comes to an end, you should lock the differential hub if you intend

to continue printing on the longer roll.

8. Rest the ends of the spindle on the platforms provided at the rear of the printer; plastic pads are

provided to absorb the impacts.

6 Chapter 2 Use of the dual-roll spindle ENWW

Page 11

9. Open the latches at both ends of the spindle (if they were closed) and push the roll on its spindle

into the printer.

10. Close the latches to secure the spindle in place.

TIP: If you cannot close the gear side latch, try sliding the spindle towards the side plate to make

sure the end flange is not sitting on the bearings.

Dual-roll spindle

11. In the same way, load the spindle with the empty cores into the front of the printer. In this case, the

geared end of the spindle should be on the right.

12. Check that the printer has finished raising the carriage beam.

13. Pass the leading edges of both rolls through the printer to the output spindle.

TIP: LX850/LX820 only: Use the Media Loading Tool to load both rolls through the media

path at the same time.

ENWW

Load rolls into the printer

7

Page 12

14. Once in front of the printer, if you find that you haven't unrolled enough substrate, select Start

Dual-roll spindle

main roller motion from the front panel's Substrate menu

substrate unrolls only when you pull it.

15. Before taping the leading edges of the two substrate rolls to the empty cores on the output spindle,

check by measurement that they are in the same positions on the output spindle as on the input

spindle.

16. Tape the leading edges of both rolls to the empty cores on the output spindle.

17. Ensure that the four edge holders are correctly positioned, leaving the substrate free to move.

to unroll some more. The

18. Unlock the differentials on the input and output spindles.

19.

Go to the front panel and select the Substrate menu

press OK. Select Carriage beam position > Move to printing (normal) to lower the

carriage beam into its normal position, close to the substrate. This process takes about 2 minutes

to complete.

8 Chapter 2 Use of the dual-roll spindle ENWW

, then Substrate management, and

Page 13

NOTE: The Move to printing (custom) position allows you to set the printhead-to-substrate

distance for thick substrates or substrates that may wrinkle in the print zone, to avoid ink smearing.

Be aware that raising the printhead from the substrate may give poorer print quality.

WARNING! Do not insert your hands or anything else into the printer while the carriage beam

is descending.

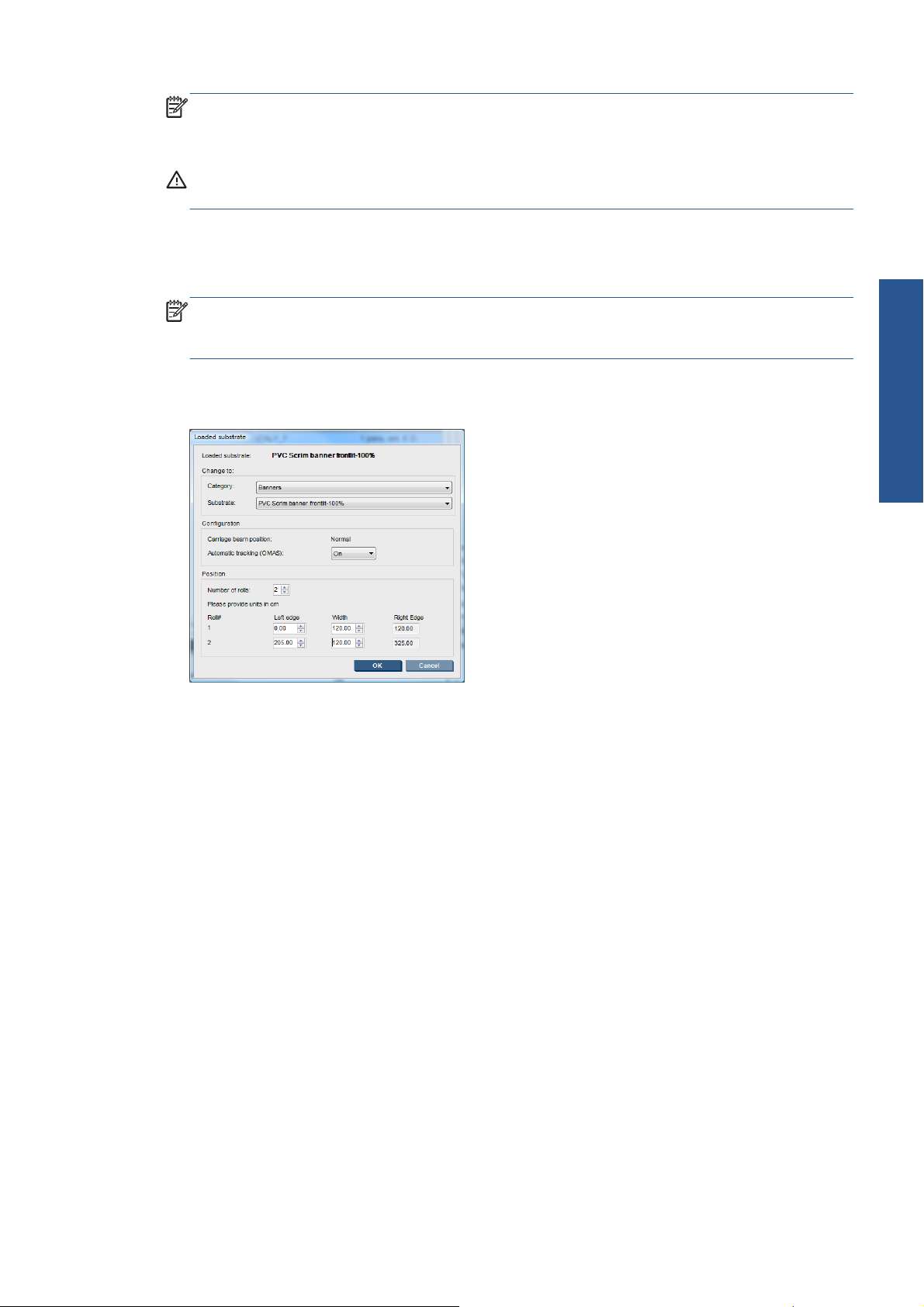

20. Tell the printer to check the loaded substrate. The printer rotates the rolls to check their diameters,

and it also checks the width of the roll, the winding direction, the vacuum and the substrate

advance calibration (this takes 3–4 min).

NOTE: Some substrates (such as transparent substrates) cannot be measured by the printer in

this way. In such cases, you will be asked to enter the required information manually. Use the

scale on the curing module to see the value for the right-hand edge that must be entered manually.

21. In the HP Internal Print Server, choose from the list of substrate types the type that you have

loaded.

Dual-roll spindle

The contents of the Loaded Substrate window are determined automatically when the substrate is

loaded and checked. However, if the printer is unable to detect the edges of the substrate (for

instance, in the case of a transparent substrate), you will have to measure the distance of the left

edge from the printer's side plate, and complete the Left Edge and Width fields yourself.

An alert regarding substrate advance tracking may appear at this point. For more information, see

your printer's documentation.

The printer is now ready to print.

ENWW

Load rolls into the printer

9

Page 14

Troubleshooting

3 Troubleshooting

If you see an error message numbered 78.2:01, it means that the substrate may have become

detached from the rear spindle, or the core is slipping on the dual roll. This could mean that you have

reached the end of the roll, or the roll is a non-standard size and is too big in diameter, or the dual-roll

differential hub is locked. The substrate is automatically unloaded when this error occurs.

You should respond to this error in the following ways.

Check whether you have reached the end of a roll.

●

For dual-roll printing, check that the differential hub is unlocked.

●

Check that the hubs are tightly secured to the spindle.

●

Check that the diameter of each substrate core is not too large for the spindle, if it is, move the

●

rubber ring of the Dual Roll to a larger diameter so that it grips the core tighter.

To check to see if the core is slipping on the dual roll, make a mark on the core and the on the

differential of the dual roll at the same level, and check if the marks separate as the substrate

advances. This type of issue will not trigger an error message, but there will be poor advance

accuracy, which will look like banding.

Check that each substrate core is tightly connected to the hubs on each side of it.

●

If the roll cannot be inserted on to the differential, ensure that the rubber ring is in the smallest

●

diameter slot.

If the substrate is skewed, check that the hubs are tightly connected to the spindle and to the substrate

core.

If you experience banding or lack of tension in the substrate, check that the differential hub is unlocked

and tightly connected to the spindle. Lack of tension can also occur when successive layers of substrate

stick to each other on the roll.

If you experience ink smears on the substrate after a period of dual-roll printing, try removing the

central edge holders.

10 Chapter 3 Troubleshooting ENWW

Page 15

4 Specifications

Printer length 126-in Printer 104-in Printer

Minimum roll width 914 mm (36 in) 914 mm (36 in)

Maximum roll width 2 × 1.52 m (2 × 60 in) 2 × 1.24 m (2 × 49 in)

Minimum gap between

rolls

Maximum roll diameter 250 mm (9.84 in) 250 mm (9.84 in)

Maximum total weight

of both rolls

152 mm (6 in) 152 mm (6 in)

2 × 60 kg (2 × 132 lb) 2 × 50 kg (2 × 110 lb)

ENWW 11

Specifications

Loading...

Loading...