Page 1

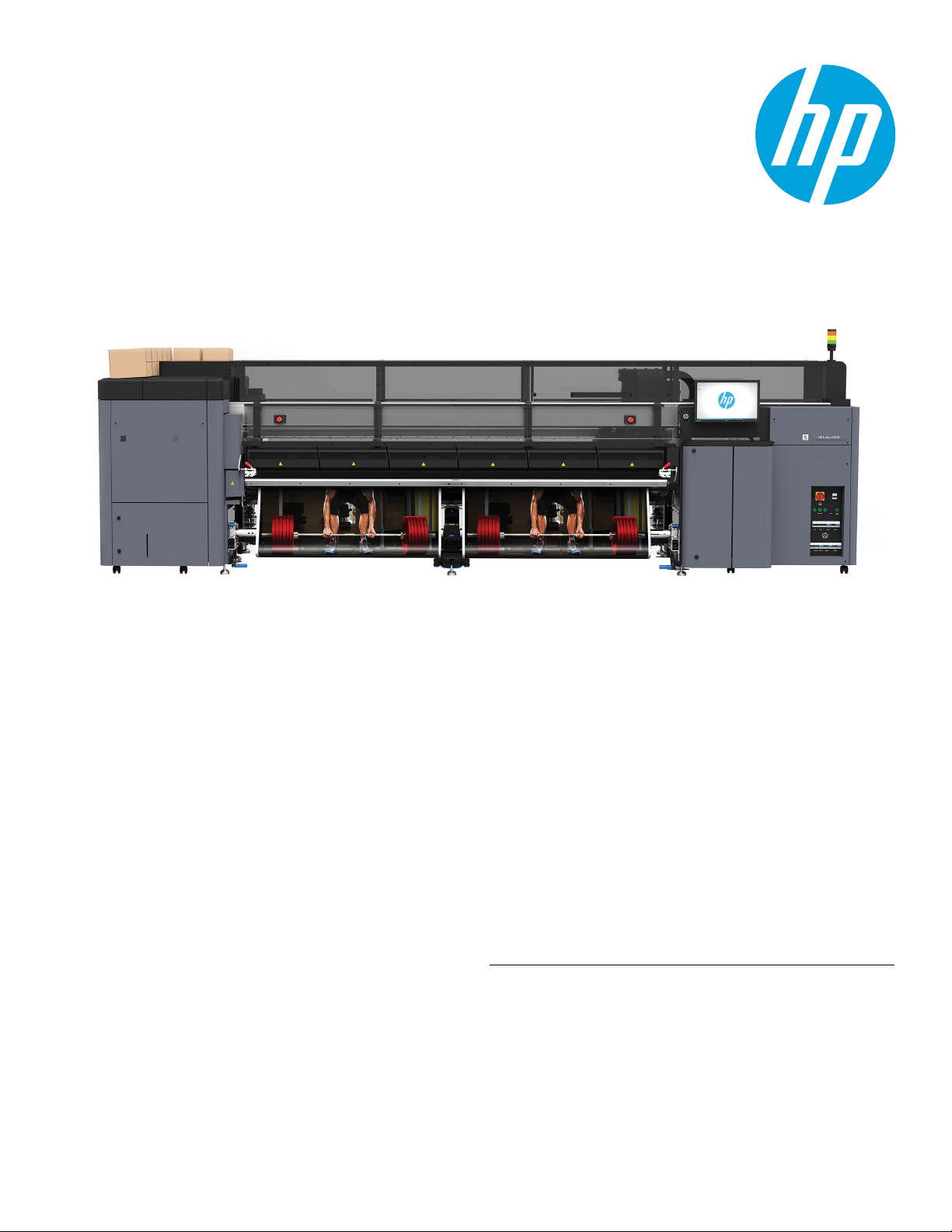

HP Latex 3500 Printer

Eicient high-volume production for standardized workows

up to 3.2 m (126 in)

High quality at speed

• Versatile HP Latex Technology and HP Latex Optimizer deliver high image

quality at speed

• Suppress banding even at high speeds with HP Dynamic Swath Alignment

and OMAS technology—3 pass 120 m²/hr (1290 ft²/hr)

• Superb qualit y for signage and decoration— wide color gamut, shar p,

repeatable quality, 6 colors, 1200 dpi

• Retain media value—HP Latex Inks conform to the media surface,

preserving gloss and texture, unlike UV

1

1

2

Drive a new level of highly eicient

production

• Increase production capacity with heavy-duty rolls and 10-liter ink supplies,

ideal for overnight printing

• Achieve quicker turnaround times—HP Latex In-line Slitters reduce

bottlenecks in nishing

• Proof while printing with the LED Proong Lights for on-printer visual

assessment and proong

• Highly unattended operation—Printer Status Beacon, HP Latex Mobile app3

work together for remote monitoring

Help drive down costs

• Reduce material costs—economies of scale help reduce the cost per square

meter

• Reduce waste—fewer roll changes help cut media waste

• Single operator roll change with dual-roll split spindles

• JDF enabled for integrating production data—for more accurate data

analysis, accounting, and cost control

For more information, please visit

hp.com/go/Latex3500

Join the community, nd tools, and talk to experts.

Visit the HP Latex Knowledge Center at

hp.com/communities/LKC

1

The HP L atex 3500 Printer is based on HP Ther mal Inkjet technology—seven

printhead s providing over 70,000 nozzles w ith 12 picoliter drops, nozzle redun dancy,

and automatic maintenance features —enabling hig h image qual ity at high sp eed over

long runs compared to piezo-based technology.

2

Printed in Outdoor m ode (3-pass 6-color 80%).

3

HP Late x Mobile is compatible with Android™ 4.1.2 or later and iOS 7 or later, and

requi res the printer and t he smart phone or tablet to b e connected to the Internet.

Page 2

HP Late x 3500 Printe r

Eicient high-volume production

The HP Latex 3500 Printer delivers a profound new level of productivity and operational eiciency for the most demanding sectors of industry,

bringing new material handling and technological innovation designed for high-volume standardized workows, making it ideal for dedicated

application production.

Heavy-duty roll handling for printing oversized rolls responds to increasing industry trends for standardizing workows, overnight printing, and

the need for greater unattendedness around the printer to make the most of labor resources.

Single-roll handling of 1 x 300 kg (660 lbs), 40-cm (16-inches) diameter and dual-roll handling of 2 x 200 kg (440 lbs), 40-cm (16-inches)

diameter makes it possible to print up to 8, 10—even 12 hours—of continuous uninterrupted printing.

HP Latex prints are completely cured inside the printer, forming a durable print that’s ready for instant nishing, lamination, shipment, or display.

HP 3M 891 10-liter Latex Inks

Take advantage of the wide color

gamut and versatile performance

of HP Latex Inks, plus:

• Complement the oversized

roll handling capabilities and

productivity of the HP Latex 3500

Printer with 10-liter ink supplies—

extending the production capacity

of the printer

• Ideal for overnight printing, long

runs, and dedicated application

production

HP Latex 3500 Dual-roll Split

Spindles

For quick, safe, single-operator

roll change, especially when

working with oversized rolls:

• Optional accessories of extra

spindles for pre-loading media, to

push eiciency even fur ther

• Reducing roll changeover times

HP Latex In-line Slitters

Achieve quicker turnaround times:

• Reduce bottlenecks in nishing

with the HP Latex In-line Slitters

• Signicantly increased productivity

compared to manual cutting,

especially on very large, full-width

3.2-m prints where a

3.2-m cutting device is not

available

• Tool-free setup saves time

• Cutting accuracy +/- 2 mm over

4

50 m

Consistent image quality

Benet from industry-leading

innovation designed to maintain

consistent image quality:

• Embedded spectrophotometer for

closed-loop color calibration

• Automatic nozzle-out detection

and replacement

• Automatic printhead cleaning

• HP Dynamic Swath Alignment and

OMAS sensor suppress banding,

even at high speeds

4

+/- 2 mm o ver 50 m, ave rage devi ation acr oss dier ent media t ypes dur ing HP inter nal testi ng. Slit ter accura cy is inue nced by the a ccurac y of the media l oading po sition, a nd how consi stent the m edia has bee n

wound on the roll by the manufacturer.

2

Page 3

PRODUCT CERTIFIED

HP Late x 3500 Printe r

PRODUCT CERTIFIED

FOR REDUCED

ENVIRONMENTAL

IMPACT. VIEW SPECIFIC

ATTRIBUTES

EVALUATED:

UL.COM/GG UL 2801

FOR LOW CHEMICAL

EMISSIONS.

VIEW SPECIFIC

ATTRIBUTES

EVALUATED:

UL.COM/GG UL 2818

LED Proong Lights

Proof while printing, saving time

and reducing waste:

• LED Proong Lights for on-the-y

visual inspection and proong

• Front light, and a backlight for

back light applications

• No need to stop the printer, saving

time, media, and ink

Build a healthier environment, inside and out

5

Water-based HP Latex Inks enable a healthier approach to signage printing with advantages from the work

zone to the point-of-display of nished prints:

• Healthier printing with HP Latex—no special ventilation, no hazard warning label s or HAPs

• UL ECOLOGO® Certied HP Latex Inks meet a range of stringent human health criteria

• A safer workplace—HP Latex Inks are non-ammable, non-combustible and nickel free

5

6

7

• UL GREENGUARD GOLD Certied HP Latex Inks;8 produce odorless prints ideal for indoor display

®

HP Latex Mobile application

Improve operational eiciency

with condence during

unattended operation:

• The HP Latex Mobile app and

the Printer Status Beacon work

together to provide remote

visibility of production

• Intuitive signaling systems

• Enables one operator to manage

multiple printers and nishing

equipment much more eectively

• Monitor job status

• Push-message notications for

warnings

• No need to be at the printer

9

JDF enabled

Integrate the HP Latex 3500

Printer production data directly

into an MIS system or the RIP via

JDF:

• JDF—the industry-standard

communication language/

protocol between devices

• Helps improve production

planning

• More accurate costing and

estimating

• Helps improve competitive pricing

HP Latex 3000 Ink Collector Kit

(optional)

Print unlined mesh banner and

porous textiles:

• Simply install and remove the ink

collector as needed

• Disposable foams absorb excess

ink and are easy to replace when

full

• Easy post-printing clean up and

disposal with the advantages of

HP Latex Inks, unlike printing mesh

and textiles with UV inks

and protability

• Data for LEAN initiatives and OEE

analysis

• Helps reduce labor costs through

automation

5

Base d on a comparis on of HP Latex In k technolo gy to compet itors with le ading mar ket share as of De cember, 2013 and ana lysis of publ ished MSDS /SDSs and/o r internal e valuatio n. Perfor mance of spe cic attr ibutes

may var y by competi tor and ink tec hnolog y/formul ation. Spe cial venti lation eq uipment (ai r ltratio n) is not requi red to meet U.S . OSH A require ments. Spe cial venti lation eq uipment in stallat ion is at the disc retion of th e

custo mer—see t he Site Pre paratio n Guide fo r detail s. Custom ers shou ld consult s tate and lo cal requi rements a nd regul ations. C ontains n o Hazard ous Air Pol lutant s accordi ng to EPA Meth od 311.

6

UL ECOL OGO® Cert icatio n to UL 2801 dem onstrate s that an ink m eets a ran ge of multi- attrib ute, lifec ycle base d criteri a related to hu man healt h and envi ronmenta l conside rations (s ee ul.com/EL).

7

Water-b ased HP Lat ex Inks ar e not classi ed as am mable or com bustibl e liquids u nder the US DOT or inter nationa l transpo rtation r egulatio ns. Testing p er the Pens ky-Mar tens Clos ed Cup meth od demons trated

ash p oint great er than 110° C. Nic kel free dem onstrate d accordi ng to testin g conduct ed for HP Late x Inks to ac hieve UL ECO LOGO® Cer ticati on. UL ECOLO GO® Cert icatio n to UL 2801 dem onstrate s that an ink

meets a range of multi-attribute, lifecycle based criteria related to human health and environmental considerations (see ul.com/EL).

8

UL GRE ENGUAR D GOLD Cert icatio n to UL 2818 demon strates th at produc ts are cer tied to UL’s GRE ENGUARD s tandard s for low chem ical emis sions into i ndoor air d uring pr oduct usa ge. For mor e informat ion,

visi t ul.com/gg or greenguard.org.

9

HP Lat ex Mobile i s compatib le with And roid™ 4.1.2 or lat er and iOS 7 or l ater, and req uires the p rinter and t he smart p hone or tab let to be conn ected to th e Internet .

3

Page 4

HP Late x 3500 Printe r

®

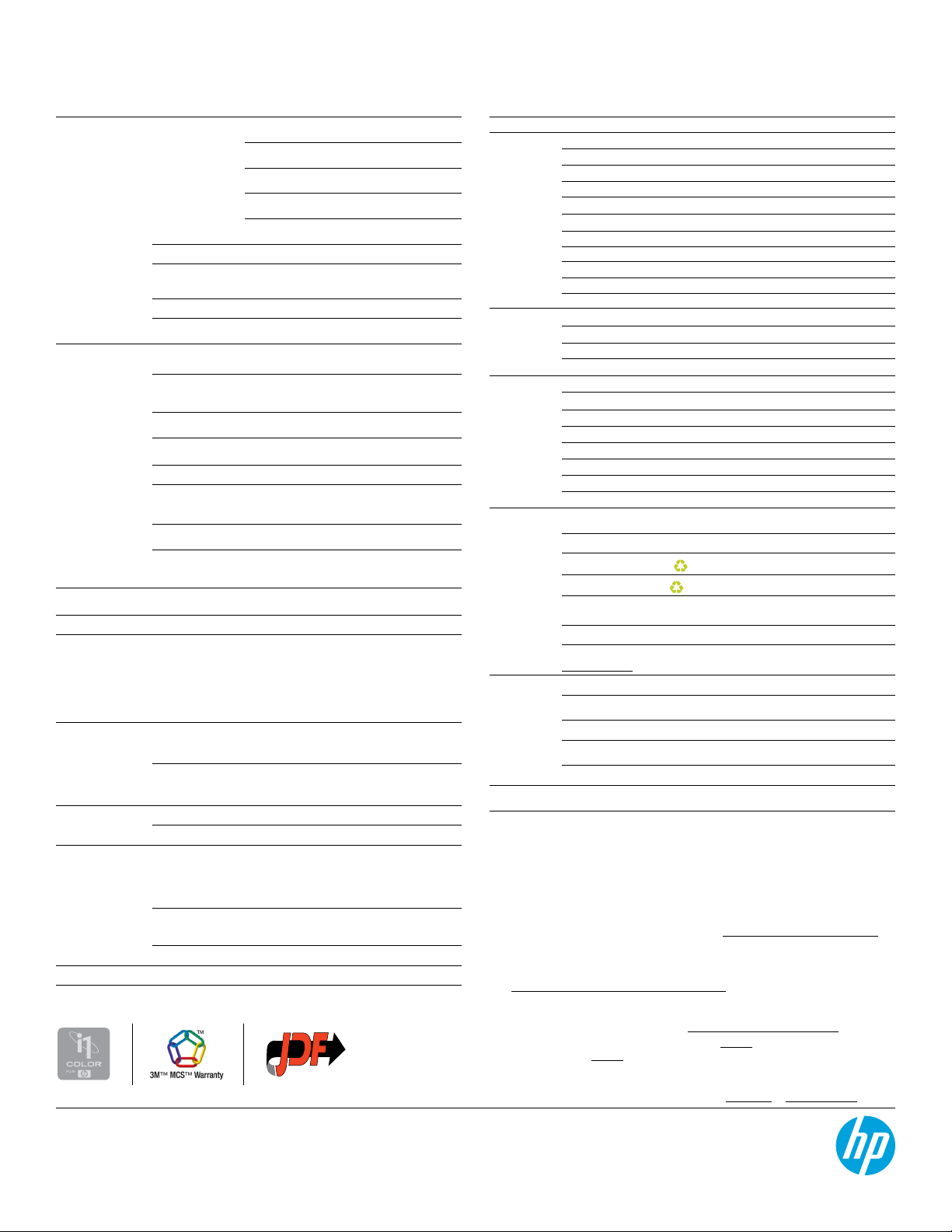

Technical specications Ordering information

Printing Printing modes 27 m²/hr ( 290 ft²/hr) - H igh Satur ation Bac klits

(18-pas s 6c 230%)

44 m²/h r (470 ft²/hr) - Texti les and Ca nvas (10-pa ss

6c 170%)

77 m²/h r (830 ft²/hr) - I ndoor Hig h Qualit y (6-pass

6c 100%)

120 m²/hr (1290 ft ²/hr) - Outdoo r

(3-p ass 6c 80%)

180 m²/hr (1950 ft²/hr) - Billboard

(2-pas s 4c 70%)

Print resolution Up to 1200 x 1200 dpi

Ink cartridges Black, cyan, light cyan, light magenta, magenta,

yello w, HP Latex Optimizer

Cartridge size 10 l iter

Color consistency Maxi mum color dieren ce (95% of colors)

<= 2 dE2000

10

Media Handling Roll-to-roll, roll-to-free fall, roll-to-collector,

dual-roll, double-sided blockout

Media types B anners, s elf-adhesive vinyls , lms, pap ers,

wallc overings , canvas; mesh and porou s textiles

with optional ink collector

Roll si ze Single rol l up to 3.2 m (126 in )

Dual roll up to 2 x 1.55 m (2 x 61 i n)

Roll weight Single roll u p to 300 kg (660 lb)

Dual roll up to 2 x 200 kg (2 x 440 lb)

Roll diameter U p to 40 cm (15.75 in)

Thickness Up to 0.4 mm (0.015 in), by de fault

Up to 2.0 mm (0.08 in), with c ustom carr iage

height setting

Dimensions

(w x d x h)

Double-sided

blockout

Doublesided backlit

(optional)

Printer: 598 x 172 x 187 cm (235 x 68 x 74 in)

Shipping: 586 x 193 x 216 cm (231 x 76 x 85 in)

Regis tration acc uracy 5 mm/m (0.06 in/ft ),

intended for double-sided PVC blockout banners

Regis tration acc uracy of 2 mm (0.08 in),

11

intended for double-sided backlit outdoor

advertising applications

Weight Printer: 1870 kg (4120 lb); Sh ipping: 2630 kg (580 0 lb)

What ’s in the box HP Latex 3500 Pri nter, HP 881 Latex Printheads, HP 881 Latex

Cleaning Ro ll, 126-in spi ndles (x2), H P Latex 3500 Du al Roll Split

Spindles (x4); HP Latex 3500 d ual roll center supp ort and doc king

plate, HP Inte rnal Print S erver, HP webcam, d ocumentation so ftware,

user manual, med ia edge holders (x4), i n-line sl itters (x4), O riginal

HP sam ple media, c leaning su pplies, sp indle supp orts (x2), p neumatic

gun

Environmental

ranges

Standard operating conditions:

Temperature: 15 to 30°C (59 to 86° F)

Humidity: 20 to 70% RH (non-condensing)

Optimal IQ operating conditions:

Temperature: 20 to 25°C (68 to 77°F )

Humidity: 30 to 60% RH (non-condensing)

Power consumption 9 kW (typical) - high-quality indoor mode (6-pass)

11 kW (typical) - o utdoor mod e (3-pass)

Certication Safety IEC 6095 0-1+A1 compli ant; United States a nd

Cana da (CSA listed); EU (LVD and MD compliant,

EN60950-1, EN12100-1, EN60204-1, and

EN1010); Russia, Belaru s and Kazakhstan (EAC );

Australia, New Ze aland (RCM)

Electromagnetic Compliant with Class A requirements, including

USA (FCC rules), Canada (IC ES), EU (EMC

Directiv e), Australia (AC MA), New Zealand (RSM)

Environmental WEEE, EU RoHS, China RoHS, REACH

Warranty One-year limited hardware warranty

Product K4G10A HP Late x 3500 Printer

Accessories L5 E74A HP Sci tex Caldera Gran d RIP v10 Softwa re

D9Z 41A HP Sci tex Onyx Thrive 211 RIP S oftware

M2J33A HP Late x In-line Slit ters

J8 J14A HP Late x 3000 Doub le-sided D ay Night Kit

Z3R55 A HP Latex 3000 D ay Night Edge H older Kit

Z3R56A H P Latex 300 0 Day Night Protector Media

CZ065A H P Latex 3000 I nk Collect or Kit

F1V49 A HP Late x 3000 Ink Collector Foa ms Kit

F0 D27A HP Lat ex 3000 Edge H older Kit

CZ059A HP La tex 126- in Carbon F iber Spind le

L2E28A HP Latex 3500 Du al Roll Spli t Spindles

Orig inal HP

printheads

CR 327A HP 881 Yel low/Magent a Latex Prin thead

CR328 A HP 881 Cyan/Black Latex Printhead

CR329A H P 881 Light Ma genta/Li ght Cyan Latex P rinthead

CR330 A HP 881 Latex Optimizer Printhead

Original

HP ink

cartridges and

maintenance

supplies

G0Y72A HP & 3M™ 891 10-liter Cyan L atex Ink Cartridge

G0Y73A HP & 3M™ 891 10- liter Mage nta Latex Ink Cartridge

G0 Y74A HP & 3M ™ 891 10-liter Yel low Latex Ink Cartridge

G0Y75A HP & 3M™ 891 10-liter Bla ck Latex Ink C artridg e

G0Y 76A HP & 3M ™ 891 10-liter L ight Cyan Late x Ink Cartr idge

G0 Y77A HP & 3M™ 891 10-lit er Light Mag enta Latex Ink Car tridge

G0Y78 A HP & 3M™ 891 10- liter Late x Optimizer I nk Cartri dge

CR339 B HP 881 Latex Cleaning Roll

Orig inal HP

large format

printing

materials

HP pri nting mater ials are designed together wi th HP Latex In ks and HP

Latex p rinters to provid e optimal im age qualit y, consisten cy, and relia bility.

HP Per manent Glo ss Adhesiv e Vinyl RE ACH

HP Premium Poster Paper

HP Bac klit Polye ster Film

HP PVC-free D urable Smo oth Wall Pap er REACH,12 FSC® c ertied ,

UL GRE ENGUARD G OLD Certi ed

HP Premium Satin Canvas

13

FSC® c ertied

,

13

12

14

15

14

For the entire HP Lar ge Format Printing Material s portfol io, please se e

HPLFMedia.com.

Serv ice kits D4J02A HP Late x 3000 Series Stan dard Uptime k it D4J02A

M7J 62 A/

HP Late x 3000 Seri es Extend ed Uptime Ki t

K4G10- 67076

K4G10- 67077 HP Late x 3500 Exten ded Delta Ki t

M7J 49A /

HP Late x 3100/3500 Pri nter Maint. Kit

K4G10- 67078

CZ056-67494 HP Latex 300 0 Series Service Main tenance Kit

Service

contracts

10

The color variation i nside a printed job has been measured to be within this limit:

H K7 07A CK4G10A

HP Par ts and Remote Hardw are Suppor t Contrac t

maximum color dierence (95% of colors) <= 2 dE2000. Reec tive measurements on

a 943 color target under CIE standard illu minant D50, and according to the standard

CIEDE200 0 as per CIE Draft Standard DS 014-6/E :2012. 5% of colors may experience

variations above 2 dE2000. Ba cklit substrates measured in t ransmission mod e may

yield d ierent results.

11

Printing double-sided backlit applications requires the optional HP Latex 3000 Double-

sided D ay Night Kit . Front-to-ba ck image registration accuracy of 2 mm or better when

using certi ed PVC banner and paper m edia, see hp.com/go/mediasolutionslocator.

12

This produc t does not contain substances listed as S VHC (155) per A nnex XIV of th e EU

REACH dire ctive publishe d as of June 16, 2014 in concentrations exceed ing 0.1%. To

determine the status of SVHC in HP p roducts, see the HP REACH Declaration published

at HP Printing Products and Consumable Supplies.

13

HP Large Format Media take-back program availability varies. Some re cyclable

HP papers can be rec ycled throu gh commonly a vailable recycling programs. Re cycling

progr ams may not exist in yo ur area. See HPLFMedia.com/hp/ecosolutions for details.

14

BMG trademark lice nse code FSC®-C115319, see fsc.org. HP trademark licen se code

FSC®-C017543, see fsc.org. Not all FSC®- certied produ cts are available in all regions.

15

UL GREENGUARD GOLD Cer tication to UL 2818 demonstr ates that product s are

certied to U L’s GREENGUARD standards for low ch emical emission s into indoor a ir

during product usage. For more infor mation, visit ul.com/gg or greenguard.org.

© Copyr ight 2015, 2016 HP Development Compa ny, L.P. The inform ation contained herein is subje ct to change without noti ce. The only warranties

for HP produc ts and services a re set forth in the ex press warranty statem ents accompanying such products a nd services. Not hing herein should be

construed as const ituting an additional warranty. HP shall not be liable fo r technical or editorial errors or omissio ns contained herein.

4AA5-7703ENW, November 2016, Rev. 3

Loading...

Loading...