Page 1

Hewlett-Packard Disposable Cartridge

Maintenance Manual

(Applicable to the Following Cartridges: HP51626A, HP51638A,

HP51633M, HPC6117A, HP51640(A,C,M,Y), HP51641A, HPC6105A,

HPC1823A, HPC6116A, HP51645A, HPC6104A, HPC6168A,

HPC6169A, and HPC6170A.)

Rev :X3 11/11/99

Page 2

out for

Wo

rth reading

remember

Watch Out!

Contents

1. INTRODUCTION.......................................................................................................3

1.1. TIJ Background ......................................................................................................... 3

2. PEN CARE.................................................................................................................4

2.1. Set-up....................................................................................................................... 4

2.2. Storage..................................................................................................................... 4

2.3. Disposal.................................................................................................................... 4

3. PRINTHEAD AND INTERCONNECT CARE.......................................................5

3.1. Inserting and Removing the Print Cartidge .................................................................. 5

3.2. Wiping ...................................................................................................................... 5

3.3. Purging the Nozzles………………………………………………………………………………8

4. PEN FAILURE ANALYSIS....................................................................................10

4.1. Troubleshooting Guide .............................................................................................10

5. SUPPLIES ORDERING INFORMATION............................................................11

5.1. Tex Wipes ...............................................................................................................11

5.2. DI Water.................................................................................................................12

Figures

Figure 1. Anatomy of a Printhead .........................................................................................3

Figure 2. Wiping Directions .................................................................................................. 6

Figure 3. Wiping Directions .................................................................................................. 7

Figure 4. Wiping Directions ................................................................................................. 7

Icons:

Stuff to watch

TIP

Shortcut or

Stuff to

Don’t Forget

2

Page 3

1. INTRODUCTION

This document acts as a guide for the maintenance and care of Hewlett-Packard

disposable print cartidge products including the HP51626A, HP51638A,

HP51633M, HPC6117A, HP51640(A,C,M,Y), HP51641A, HPC6105A,

HPC1823A, HPC6116A, HP51645A, HPC6168A, HPC6169A, HPC6170A, and

HPC6104A. Each pen consists of a printhead and a pressurized ink source.

1.1 Background on Thermal Inkjet Technology

The disposable Hewlett-Packard cartridges are used in drop-on-demand thermal

inkjet systems. Inkjet systems fire small drops of ink to form text and images on

various types of medium.

Thermal inkjet uses a firing resistor to vaporize a small amount of ink. The

vaporization process causes a small bubble to form. This bubble formation causes

a small drop of ink to be forced out of the firing chamber through the nozzle.

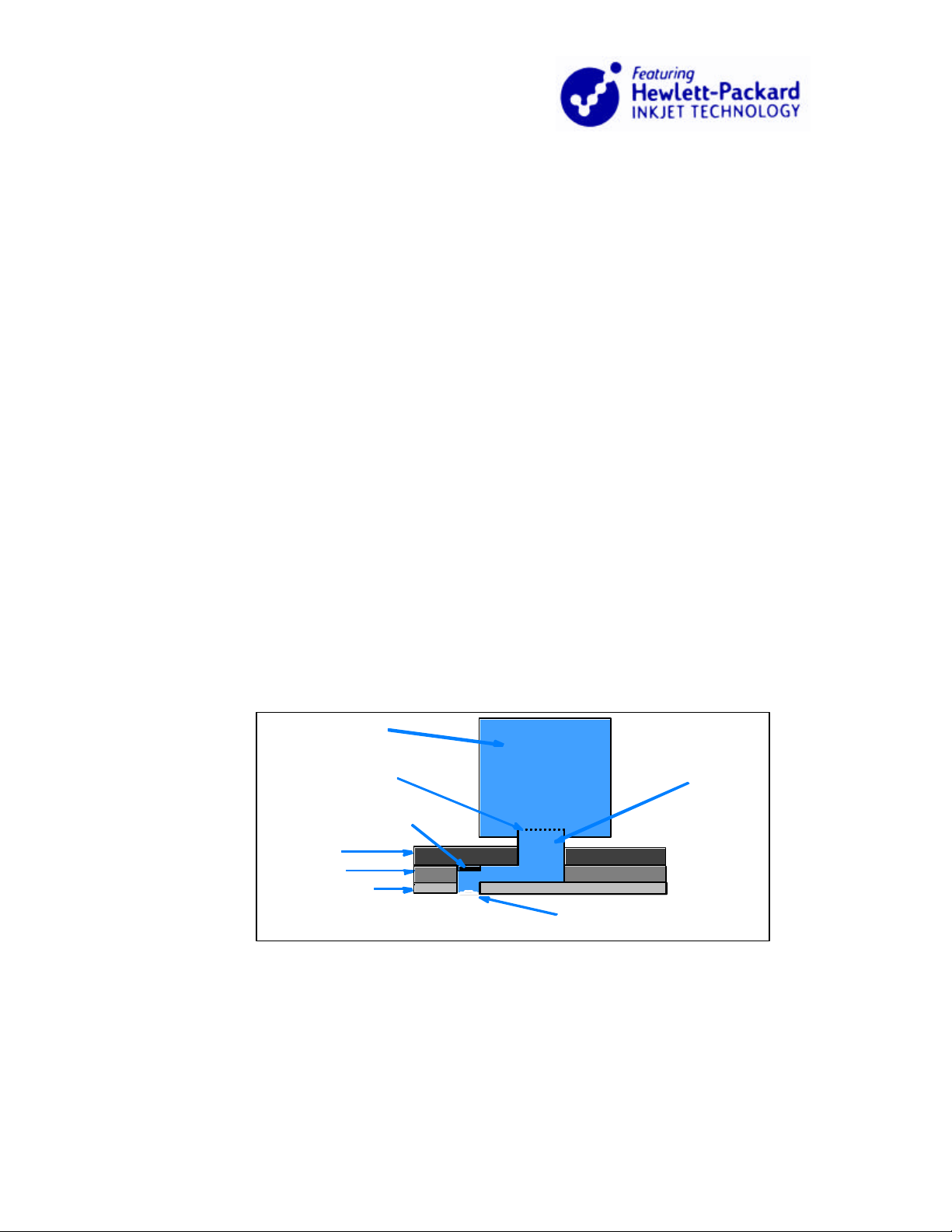

Figure 1 shows the major components of the thermal inkjet system. In the figure,

the entire ink supply is located near the printhead of the print cartridge. This is

the case for all of the Hewlett Packard disposable print cartridges. Back pressure

is controlled in the local ink supply by a spring or foam which prevents the ink

from seeping out of the nozzles. The filter screen keeps any large particles or air

bubbles away from the firing chambers. Bubbles or particles in the firing

chambers will prevent ink from coming out of the nozzle when the resistor heats

up. There is a firing resistor for every nozzle on the printhead.

Ink Supply

(Local or Bulk)

Filter Screen

Firing

Resistor

Substrate

Ink Barrier

Orifice

Surface

Nozzle

Standpipe

Section

of a

Printhead

Figure 1: Anatomy of a Printhead

3

Page 4

relatively free from dust and not too dry.

Don’t Forget

2. PRINT CARTRIDGE CARE

2.1 Set-up

TIP

Once the cartridge is out of the box it can be easily snapped into the carriage. It is

important to remove the tape from the printhead before the cartridge is snapped

into place. The cartridge will not function with the tape still in place.

2.2 Storage

Short-term storage is defined as less than 2 days or less than 1 day in a hot and

dry environment. Long-term storage is defined as more than 2 days or more than

1 day in a hot and dry environment.

Short-term Storage

If the printing system has a capping station:

? Leave the cartridges in the printer

If the printing system does not have a capping station:

? Leave the cartridges in the machine for a short period of time

? The next time that the printer is used, the printhead will have to be

cleaned as instructed in the Printhead Maintenance section

Long-term Storage

If the printing system has a capping station:

? Leave the cartridges in the printer

If the printing system does not have a capping station do the following:

? Keep the printhead in an area that is relatively free of dust and paper

particles and is not too dry

? Place the cartridges in a Tupperware container with a damp sponge or

towel to maintain humidity and prevent the printhead from drying out

? When the cartridges are ready to be used again the printhead will need

to be cleaned as instructed in the Printhead Maintenance section

2.3 Disposal

? The cartridges may be disposed of in normal garbage

? If there should be an ink spill, use soap and water to clean up any

problem areas. Lava brand soap also works well to get the ink off of

hands.

- It is important to take the tape off of the cartridge before it is placed in its holder.

- If the printing system has a capping station, leave cartridge in printer.

- If the printing system does not have a capping station, keep the cartridge in an area that is

4

Page 5

3. PRINTHEAD AND INTERCONNECT CARE

3.1 Inserting and Removing the Print Cartridge

The print cartridge should stay in the carriage at all times except when the

operator is

? Replacing it

? Cleaning it

? Storing it

The print cartridge should never be:

? Shaken

Watch Out!

Shaking the print cartridge does NOT “mix” up the ink and hitting the cartridge

against a hard surface does NOT clear the nozzles. Both of these actions actually

hurt the print quality because they allow bubbles to form near the ink firing

chambers. These bubbles prevent the nozzles from firing causing white streaks in

print and images.

3.2 Wiping

The secret to good print output is the maintenance of the printhead. During

printing, ink can build up on the printhead causing black or colored spray in the

text. Paper fibers and dust can also build up on the printhead degrading the print

quality. Proper printhead maintenance will allow the cartridge to produce good

print quality its whole life. A cotton TexWipe® and de-ionized or distilled water

is one of the best ways to wipe ink and other build-up off of the printhead. A

TexWipe® is a 100% cotton, high-density cloth with no chemical additives.

Contact information to order TexWipes is located at the end of this document.

Something comparable is adequate to wipe the nozzles. A good choice of wipe

would have the following qualities:

A cloth should NOT be:

Watch Out!

? Dropped

? Hit against the palm of one’s hand or any other hard surface (e.g. a

table)

? Soft

? Fiberless

? No chemical additives

? Moist with De-ionized or Distilled Water

? Abrasive

? Dry

? Made of small fibers that can be left behind on the cartridge’s nozzle

plate

5

Page 6

Don’t Forget

Never use the following to wipe the printhead:

? Industrial paper towels (These cloths usually contain a high recycle

content and are abrasive.)

Watch Out!

? Toilet paper (These cloths are usually not fiberless.)

? Sponge (Particles from the sponge can be left behind on the nozzle

plate.)

The cloth must be soft so that it does not scratch the printhead. It should be

fiberless because small fibers from the cloth can be left behind and block the

nozzles of the cartridge. The cloth must also be moist with liquid or it will

scratch the printhead. Scratches on the printhead prevent the ink from coming out

of the nozzle straight. If the ink drops do not come out of the nozzles straight

they will not land on the paper in the proper place causing fuzzy text. Distilled

water is better than tap water because tap water contains an unmonitored amount

of minerals. During wiping the water cleans out the nozzles and the firing

chambers. A small amount of water mixes with the ink in the chambers. Over

time, the minerals in tap water can leave behind deposits in the chambers that

block it completely. A blocked nozzle will show up as a white streak in text or

graphics. The direction and force of the wipe is also important to note. During

wiping, harmful particles on the top of the printhead can be wiped into the nozzles

if one is not careful. Certain cartridges need to be wiped certain ways to obtain

optimal print quality.

It is important to wip e the following cartridges in the direction of the nozzle rows

(see Figure 2) for optimum print quality:

? HP51645A, HPC6104A

? HP51641A, HPC6105A

? HPC1823A, HPC6116A

? HPC6168A, HPC6169A, HPC6170A

6

Page 7

Don’t Forget

Figure 2: Direction of Wiping for the HP51645A, the HPC6104A, the

HP51641A, the HPC6105A, the HPC1823A, the HPC6116A, the

HPC6168A, the HPC6169A, and the HPC6170A.

The direction of the wipe should especially be monitored on the tri-color pens

such as the HP51641A, the HPC6105A, the HPC1823A, and the HPC6116A.

The cartridge can be ruined due to color mixing if the top plate is not wiped in the

direction of the nozzle rows.

The following cartridges should be wiped against the row of nozzles to perform

optimally (see Figure 3 & 4):

? HP51626A, HP51638A

? HP51633M, HPC6117A

Figure 3: Direction of Wiping for the HP51626A, HP51638A, the

HP51633M, and the HPC6117A

? HP51640(A,C,M,Y)

7

Page 8

Figure 4: Direction of Wiping for the HP51640(A,C,M,Y)

In all three wiping configurations the printhead should be pointing down while it

is being wiped. This position will prevent the nozzles from pulling little bubbles

into the firing chambers.

Applying heavy pressure is not necessary to clean the particles off of the

printhead. A large pressure can actually cause particles to scratch the printhead.

Scratches can cause the nozzles to fire in improper directions adversely affecting

print quality. It is very important to always be gentle when cleaning the

printhead.

It is also important to keep the electrica l interconnects of the printhead clean.

The interconnect pads can be cleaned with:

? Moist cotton TexWipe?

? Moist Q-Tip

The interconnects should not be cleaned with:

Watch Out!

? Pencil eraser (A common misconception is that the interconnects can

be cleaned with the eraser of a pencil. The eraser actually damages the

interconnect and will decrease the life of the cartridge.)

It is important to make sure that this section of the cartridge is dry before it is reinserted into the printer to eliminate the chance of an electrical short in the

cartridge or permanent printer damage.

3.3 Purging the Nozzles

If the printhead sits inactive for a period of time, ink may dry in the nozzles.

Printing may not remove these “ink plugs” from the nozzles. White streaks will

then show up in the printed text or graphic. In order to obtain better print quality,

this ink plug needs to be forced out or purged. The printhead should first be

wiped with a wet cloth. Some machines offer purging or servicing functions that

may remove these ink plugs if wiping alone does not cure the problem. If a

machine does not have this capability, most ink plugs can be removed by printing

a few lines of text or graphics in a high resolution. The higher resolutions (600

dots per inch, for example) exe rcise more nozzles and push more ink out. This

purging operation as well as wiping the printhead with a wet cloth should be done

after every extended period of down time in order to prevent unacceptable levels

of print quality.

An example start-up procedure might include:

? Wipe the print cartridge with a moist cloth as described in the wiping

section of this document

? Perform a purge algorithm or print a few lines of text in a higher

resolution (600x600dpi, for example)

? Wipe the print cartridge with a moist cloth again as described in the

wiping section of this document

8

Page 9

- When the cartridge is removed from the carriage, it is important to hold the cartridge by

the black side covers of the cartridge.

TIP

Watch Out!

- The print cartridge should never be shaken, dropped, or hit against a hand or any hard

surface.

- Never use industrial paper towels, toilet paper or sponge to wipe the printhead.

- The interconnects should not be cleaned with a pencil eraser.

9

Page 10

4. PEN FAILURE ANALYSIS

4.1 Trouble Shooting Guide

There are several things that can be done to recover damaged cartridges. The

following list acts to troubleshoot any problems that may appear.

Problem Example Action

Cartridge will not print

“Sheet is blank even after it

has gone underneath

cartridge(s).”

White streaks in text or

graphics

? Check to make sure the

tape is off of the

printhead

? Re-insert the cartridge

into the carriage

? Install a new print

cartridge

? Re-insert the cartridge

into the carriage

? Wet wipe and purge the

cartridge (There are

clogged nozzles.)

? Clean the interconnects

? Insert a new print

cartridge

10

Page 11

Black streaks around

text or streaks the same

? Wet wipe the cartridge

(There is ink buildup.)

color of the ink in the

cartridge

5. SUPPLIES ORDERING INFORMATION

5.1 The following process will work for ordering the suggested TexWipes.

The company TexWipe only sells their products through distributors, but

partners/customers can contact TexWipe directly to obtain information about a

distributor near them. TexWipe can be reached in a variety of different ways. All

of the contact information can be found either below or at

http://www.texwipe.com/corporat/adres.htm

If in the US --

Call the TexWipe North America Customer Service Line at 1-800-TEXWIPE (ext

120). The representative at this number will help determine a local distributor for

the TexWipe products.

Customers can also call the distributor that the Hewlett Packard San Diego site

uses directly. We use VWR Scientific Products. They can be contacted at 1-800932-5000. VWR will sell all items with the exception of syringes and chemical

products to a non-account company via credit card. If partners or end customers

wish to set up accounts for accounting purposes, the process only takes 1-2 days.

11

Page 12

If outside of the US --

Call the TexWipe International Customer Service and Technical Support Line at

1-201-327-9100 (ext 325 or 254). The TexWipe customer service representative

will then determine a local distributor for the TexWipe Products. The

International Customer Service Representatives can also be reached at

intercs@texwipe.com. TexWipe does distribute products all over the world.

TexWipes are all Natural 100% cotton high-density construction cloths. They

have no chemical additives, they are solvent -compatible, heat and acid resistant,

they have strong tensile, absorbency, and antistatic characterist ics, and they are

cleanroom packaged. They come in a variety of quantities and sizes. The

following information can be used to order TexWipes (The pricing information is

from the latest 97/98 VWR catalog and is probably subject to change):

Size (in) TexWipe Number Pack of

3x2.5 TX325 2700/$71.86

4x4 TX304 1200/$64.95

4x4 TX304A 300/$22.40

6x6 TX306 600/$61.50

9x9 TX309 300/$60.10

9x9 TX309A 150/$39.25

12x12 TX312 150/$61.20

17x17 TX318 75/$66.95

The 4x4 size (either TX304 or TX304A) would be perfect. This size would allow

end users plenty of space to wipe the cartridge without wasting a lot of cloth, but

there are a variety of sizes given so the user can find the wipe that best fits their

individual needs.

5.2 The following process will work for ordering the suggested DI Water.

Distilled water is better than tap water because tap water contains an unmonitored

amount of minerals. Over time, the minerals in tap water can leave behind

deposits in the chambers that block it completely. You can obtain distilled water

from most local grocery stores.

12

Loading...

Loading...