Power Bipolar Transistor

Base Drive Optocoupler

Technical Data

H

HCPL-3000

Features

• High Output Current

IO2 (2.0 A Peak, 0.6 A

Continuous)

IO1 (1.0 A Peak, 0.5 A

Continuous)

• 1.5 kV/µs Minimum Common

Mode Rejection (CMR) at

VCM = 600 V

• Wide VCC Range (5.4 to 13

Volts)

• 2 µs Typical Propagation

Delay

• Recognized under UL 1577

for Dielectric Withstand

Proof Test Voltage of 5000

Vac, 1 Minute

Applications

• Isolated Bipolar Transistor

Base Drive

• AC and DC Motor Drives

• General Purpose Industrial

Inverters

• Uninterruptable Power

Supply

Description

The HCPL-3000 consists of a

Silicon-doped GaAs LED optically

coupled to an integrated circuit

with a power output stage. This

optocoupler is suited for driving

power bipolar transistors and

power Darlington devices used in

motor control inverter applications. The high peak and steady

state current capabilities of the

output stage allow for direct

interfacing to the power device

without the need for an intermediate amplifier stage. With a CMR

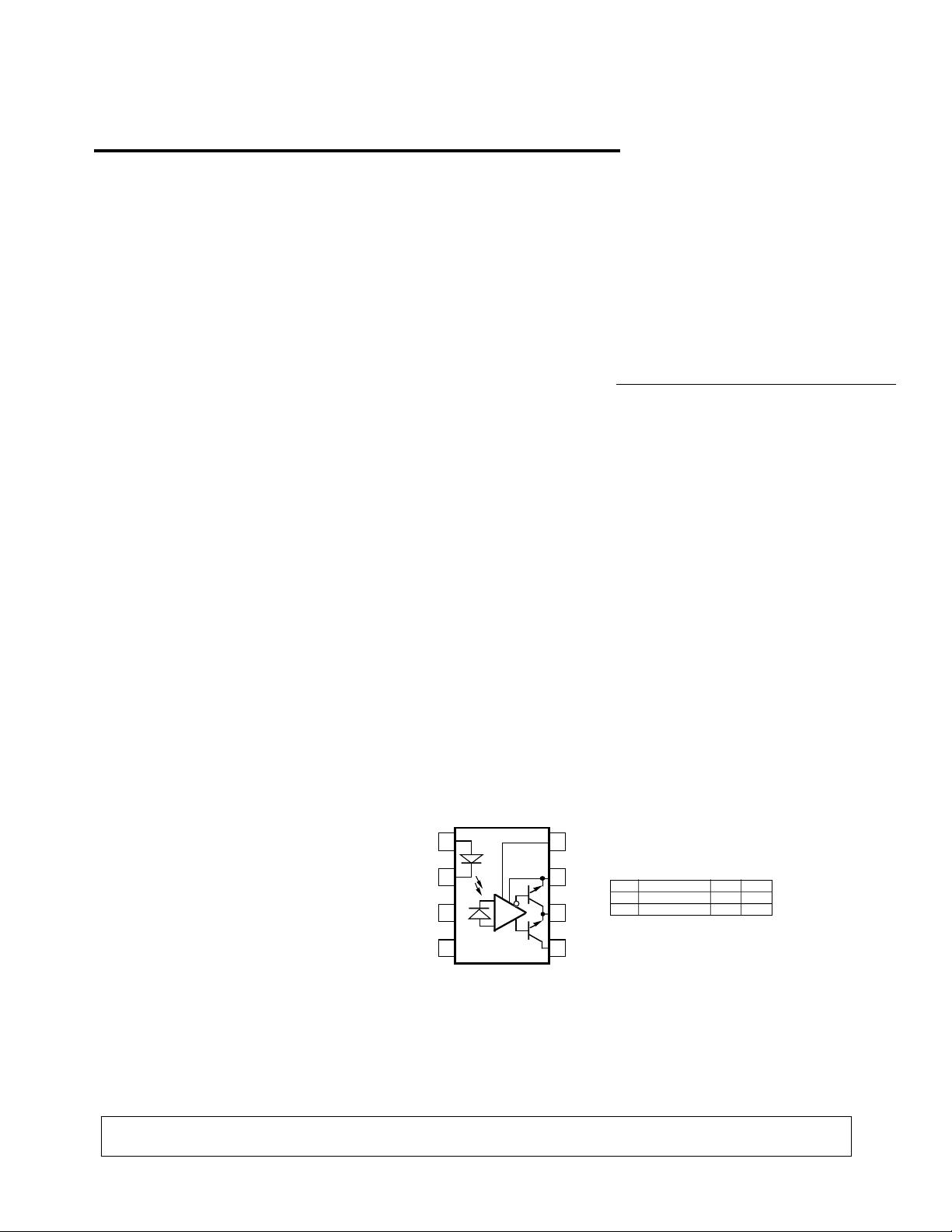

Functional Diagram

HCPL-3000

V

ANODE

CATHODE

1

2

3

4

8

7

GND

Q2

6

V

Q1

5

V

rating of 1.5 kV/µs this optocoupler readily rejects transients found

in inverter applications.

The LED controls the state of the

output stage. Transistor Q2 in the

output stage is on with the LED

off, allowing the base of the

power device to be held low.

Turning on the LED turns off

transistor Q2 and switches on

transistor Q1 in the output stage

which provides current to drive

the base of a power bipolar

device.

CC

TRUTH TABLE

LED

OUTPUT

ON

HIGH LEVEL

OFF

O2

O1

LOW LEVEL

Q1

ON

OFF

Q2

OFF

ON

THE USE OF A 0.1µF BYPASS CAPACITOR CONNECTED BETWEEN PINS 8 AND 7 IS RECOMMENDED. ALSO, CURRENT LIMITING

RESISTORS ARE RECOMMENDED (SEE FIGURE 1, NOTE 2, AND NOTE 7).

CAUTION: It is advised that normal static precautions be taken in handling and assembly of this component to

prevent damage and/or degradation which may be induced by ESD.

5965-3584E

1-329

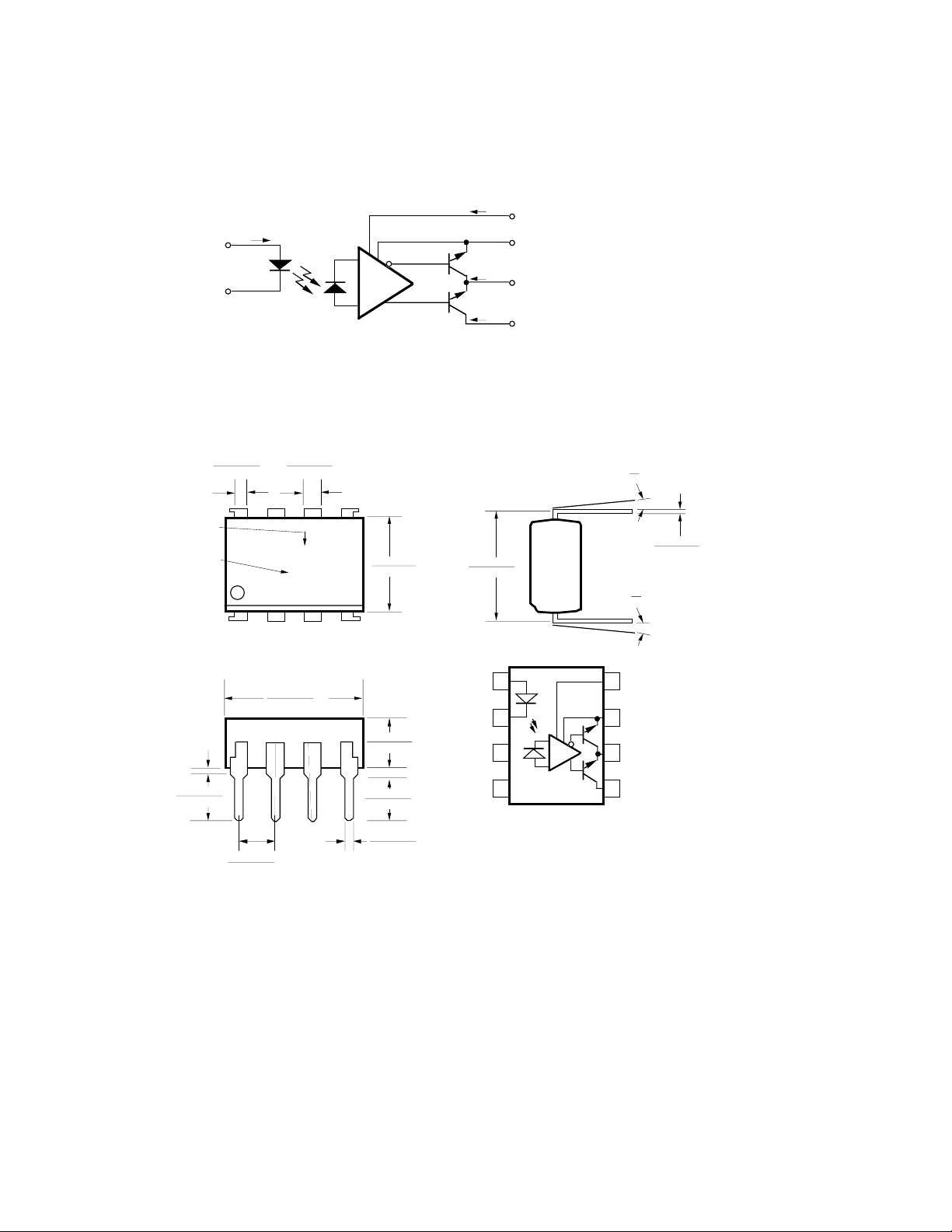

Schematic

1

ANODE

CATHODE

I

+

-

2

Outline Drawing

I

CC

V

CC

8

F

Q2

Q1

GND

7

I

O2

V

O2

6

I

O1

V

O1

5

TYPE

NUMBER

DATE

CODE

0.50

(0.020)

TYP

2.90 (0.114)

3.90 (0.154)

0.65 (0.026)

1.05 (0.041)

87 65

12 34

2.29 (0.090)

2.79 (0.110)

0.90 (0.035)

1.50 (0.059)

HP XXXX

YYWW

9.16 (0.361)

10.16 (0.400)

6.00 (0.236)

7.00 (0.276)

3.00 (0.118)

4.00 (0.157)

2.55 (0.100)

3.55 (0.140)

0.40 (0.016)

0.60 (0.024)

7.32 (0.288)

7.92 (0.312)

ANODE

CATHODE

1

2

3

4

HCPL-3000

0°

13°

0.16 (0.006)

0.36 (0.014)

0°

13°

V

8

CC

7

GND

Q2

6

V

O2

Q1

5

V

O1

Regulatory Information

The HCPL-3000 has been

approved by the following

organizations:

Demonstrated ESD Performance

Human Body Model: MIL-STD-

883 Method 3015.7: Class 2

Machine Model: EIAJ IC-121-

UL

Recognized under UL 1577,

Component Recognition Program,

1988 (1988.3.28 Version 2),

Test Method 20, Condition C:

1200 V

File E55361.

1-330

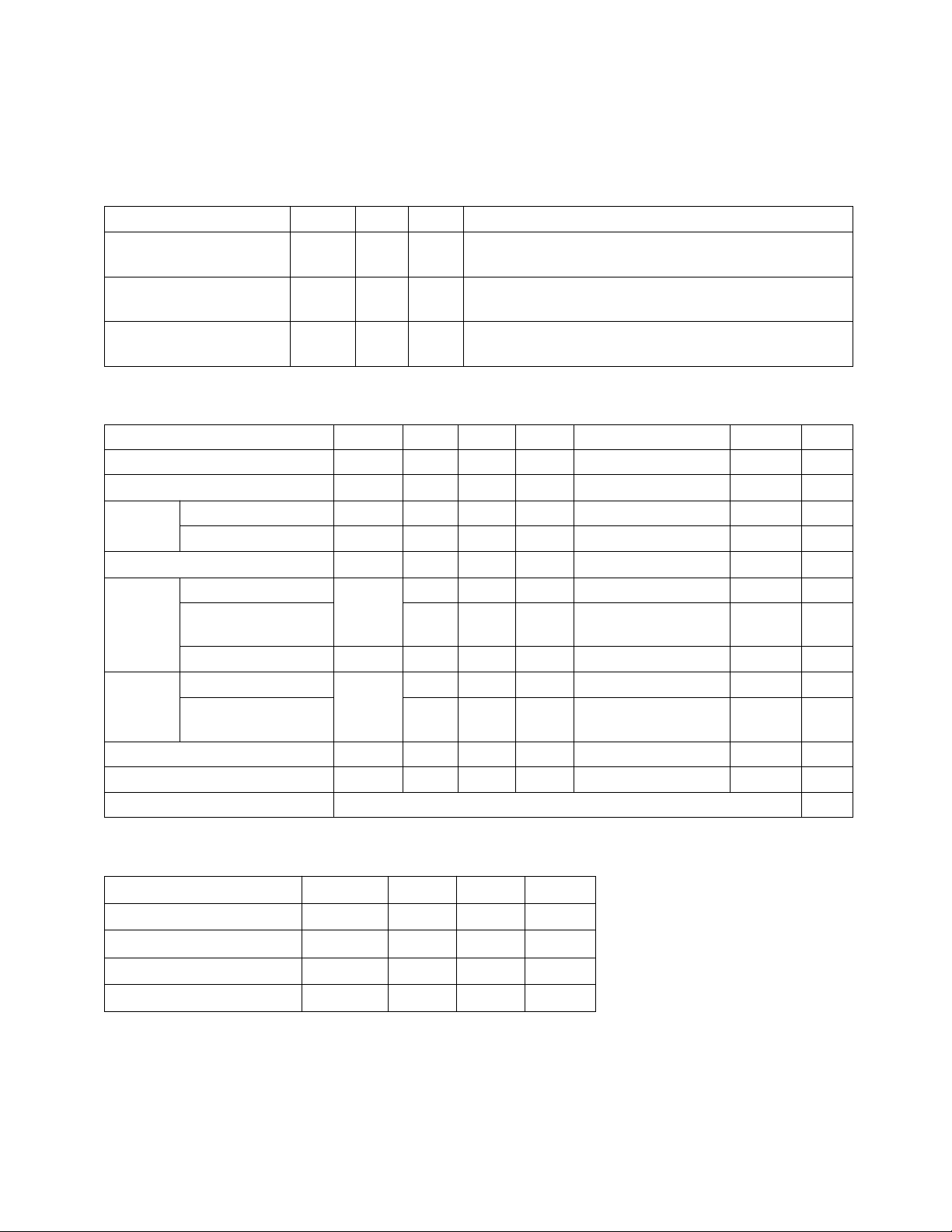

Insulation and Safety Related Specifications

Parameter Symbol Value Units Conditions

Min. External Air Gap L(IO1) 6.0 mm Shortest distance measured through air, between

(External Clearance) two conductive leads, input to output

Min. External Tracking L(IO2) 6.0 mm Shortest distance path measured along outside surface

Path (External Creepage) of optocoupler body between the input and output leads

Min. Internal Plastic 0.15 mm Through insulation distance conductor to conductor

Gap (Internal Clearance) inside the optocoupler cavity

Absolute Maximum Ratings

Parameter Symbol Min. Max. Unit Conditions Fig. Note

Storage Temperature T

Operating Temperature T

Input Continuous Current I

Reverse Voltage V

Supply Voltage V

Output 1 Continuous Current I

S

A

F

R

CC

O1

Peak Current 1.0 A Pulse Width < 5 µs, 1

Voltage V

Output 2 Continuous Current I

O1

O2

Peak Current 2.0 A Pulse Width < 5 µs, 12 1

Output Power Dissipation P

Total Power Dissipation P

O

T

Lead Solder Temperature 260° C for 10 s, 1.0 mm below seating plane

-55 125 °C

-20 80 °C

25 mA 9 1

6VT

18 V

0.5 A 10,11 1

18 V

0.6 A 10,11,12 1

500 mW 10 1

550 mW 11 1

= 25°C

A

Duty cycle = 1%

Duty cycle = 1%

Recommended Operating Conditions

Parameter Symbol Min. Max. Units

Power Supply Voltage V

Input Current (ON) I

Input Current (OFF) I

Operating Temperature T

*The initial switching threshold is 5 mA or less.

CC

F(ON)

F(OFF)

A

Recommended Protection for Output Transistors

During switching transitions, the

output transistors Q1 and Q2 of

the HCPL-3000 can conduct large

amounts of current. Figure 1

describes a recommended circuit

design showing current limiting

resistors R1 and R2 which are

necessary in order to prevent

5.4 13 V

8* 20 mA

- 0.2 mA

-20 80 °C

damage to the output transistors

Q1 and Q2 (see Note 7). A bypass

capacitor C1 is also recommended

to reduce power supply noise.

1-331

+5 V

CONTROL

INPUT

TTL

OR

LSTTL

1

240 Ω

TOTEM

POLE

OUTPUT

GATE

1

2

R1 = 5 - 250 Ω

R

= 1 - 2 Ω

2

BYPASS CAPACITOR C

HCPL-3000

= 0.1 µF

1

8

C

1

Q2

Q1

7

6

R

2

5

R

1

I

O1

V (+ 5.4 V + 13 V)

CC

POWER TRANSISTOR

MODULE

+ HVDC

3-PHASE

AC

- HVDC

Figure 1. Recommended Output Transistor Protection and Typical Application Circuit.

Electrical Specifications

Over recommended temperature (TA = -20°C to +80°C) unless otherwise specified.

Parameter Sym. Min. Typ. Max. Units Test Conditions Fig. Note

Input Forward Voltage V

Input Reverse Current I

Input Capacitance C

Output 1 Low Level V

F

R

IN

O1L

Voltage RL2 = 10 Ω, IF = 5 mA 17

Leakage I

O1L

Current IF = 0 mA

Output 2 High Level V

O2H

Voltage IF = 5 mA, VO1 = 6 V 19

Low Level V

O2L

Voltage IF = 0 mA 21

Leakage I

O2L

Current VO2 = 13 V

Supply High Level I

CCH

Current

Low Level I

Low to High I

CCL

FLH

Threshold Input 6, 14, 3

Current 0.2 - 5.0 mA VCC = 6 V, RL1 = 5 Ω,15

- 1.1 1.4 V IF = 5 mA, TA = 25°C13

0.6 0.9 - V IF = 0.2 mA, TA = 25°C

--10µAVR = 3 V, TA = 25°C

- 30 250 pF VF = 0 V, f = 1 kHz,

TA = 25°C

- 0.2 0.4 V VCC = 6 V, IO1 = 0.4 A, 2, 16, 2

- - 200 µAVCC = VO1 = 13 V, VO2 = 0 V, 4

4.5 5.0 - V VCC = 6 V, IO2 = -0.4 A 3, 18, 2

- 0.2 0.4 V VCC = 6 V, IO2 = 0.5 A, 20,

- - 200 µAVCC = 13 V, IF = 5 mA, 5

-913mAT

--17 V

-1115mAT

--20 V

= 25°C222

A

= 6 V, IF = 5 mA

CC

= 25°C23

A

= 6 V, IF = 0 mA

CC

0.3 1.5 3.0 mA TA = 25°C

R

= 10 Ω

L2

1-332

Switching Specifications (T

= 25°C)

A

Parameter Sym. Min. Typ. Max. Units Test Conditions Fig. Note

Propagation Delay t

PLH

-25µsVCC = 6 V, IF = 5 mA, 7, 2, 6

Time to High Output RL1 = 5 Ω, RL2 = 10 Ω 24,

Level 25

Propagation Delay Time t

PHL

-25

to Low Output Level

Rise Time t

Fall Time t

r

f

- 0.2 1

- 0.1 1

Output High Level |CMH| 1500 - - V/µsVCM = 600 V Peak,82

Common Mode IF = 5mA, RL1 = 470 Ω,

Transient Immunity RL2 = 1 kΩ, ∆V

02H

= 0.5 V

Output Low Level |CML| 1500 - - V/µsVCM = 600 V Peak,

Common Mode IF = 0 mA, RL1 = 470 Ω,

Transient Immunity RL2 = 1 kΩ, ∆V

= 0.5 V

02L

Package Characteristics

Parameter Sym. Min. Typ. Max. Units Test Conditions Fig. Note

Input-Output Momentary V

Withstand Voltage* t = 1 min., TA = 25°C

Resistance R

(Input-Output) RH = 40% to 60%

Capacitance C

(Input-Output)

*The Input-Output Momentary Withstand Voltage is a dielectric voltage rating that should not be interpreted as an input-output

continuous voltage rating. For the continuous voltage rating refer to the VDE 0884 Insulation Characteristics Table (if applicable), your

equipment level safety specification, or HP Application Note 1074, “Optocoupler Input-Output Endurance Voltage.”

5000 V rms RH = 40% to 60%, 4, 5

ISO

I-O

I-O

5x101010

– 1.2 – pF f = 1 MHz 4

11

– Ω V

= 500 V, TA = 25°C, 4

I-O

Notes:

1. Derate absolute maximum ratings with ambient temperatures as shown in Figures 9, 10, and 11.

2. A bypass capacitor of 0.01 µF or more is needed near the device between VCC and GND when measuring output and transfer

characteristics.

3. I

represents the forward current when the output goes from low to high.

FLH

4. Device considered a two terminal device; pins 1-4 are shorted together and pin 5-8 are shorted together.

5. For devices with minimum V

insulation test voltage ≥ 6000 V rms for one second (leakage current detection limit, I

6. The t

7. R1 sets the base current (I

and t

PLH

is turning off. For more applications and circuit design information see Application Note “Power Transistor Gate/Base Drive

Optocouplers.”

propagation delays are measured from the 50% level of the input pulse to the 50% level of the output pulse.

PHL

specified at 5000 V rms, in accordance with UL1577, each optocoupler is proof-tested by applying an

ISO

in Figure 1) supplied to the power bipolar device. R2 limits the peak current seen by Q2 when the device

O1

≤ 200 µA).

I-O

1-333

HCPL-3000

V

CC

GND

8

+

V

CC

-

I

F

7

R

Q2

Q1

L2

6

V

O2

5

V

O1

–

V

O1L

+

I

O1

1

I

F

2

3

4

HCPL-3000

V

CC

GND

8

+

V

CC

7

Q2

6

V

O2

Q1

-

–

V

O2H

I

+

O2

5

V

O1

1

2

3

4

Figure 2. Test Circuit for Low Level Output Voltage V

I

F

I

F

SWEEP

HCPL-3000

1

2

3

4

HCPL-3000

1

2

3

4

V

GND

V

GND

CC

8

+

V

CC

-

7

Q2

6

V

O2

Q1

V

CC

Q2

V

Q1

V

I

5

O1

O1L

O1L

.

8

+

V

CC

7

6

O2

5

O1

-

R

–

V

L2

O2

+

R

L1

Figure 6. Test Circuit for Threshold Input Current I

FLH

O1L

Figure 3. Test Circuit for High Level Output Voltage V

.

O2H

.

HCPL-3000

V

CC

GND

8

+

V

CC

-

7

Q2

V

Q1

I

6

O2

O2L

5

V

O1

.Figure 4. Test Circuit for Leakage Current I

O2L

1

I

F

2

3

4

Figure 5. Test Circuit for Leakage Current I

HCPL-3000

V

IN

I

F

t = t = 0.01µs

rf

Z = 50 Ω

o

47 Ω

1

2

3

4

V

GND

CC

8

7

Q2

6

V

O2

Q1

5

V

O1

+

V

CC

-

R

R

–

V

L2

O2

+

L1

50%

V WAVE FORM

IN

t

PLH

.

t

PHL

90%

50%

V WAVE FORM

02

10%

1-334

Figure 7. Test Circuit for t

, tr and tf.

PHL

t

f

t

r

, t

PLH

I

F

SW

AB

V

CM

CM , V

HO2

SW AT A, I = 5 mA

F

CM , V

LO2

SW AT B, I = 0 mA

F

HCPL-3000

1

2

3

4

∆ V

V

V

GND

CM

O2L

CC

8

V

V

CC

–

O2

+

V

GND

V

V

GND

CM

O2L

O2H

+

-

30

25

F

20

15

10

5

LED FORWARD CURRENT I (mA)

0

-20 0 25 50 75

AMBIENT TEMPERATURE T (°C)

100

80

A

R

L1

7

Q2

Q1

–+

R

L2

6

V

O2

5

V

O1

∆ V

O2H

Figure 9. LED Forward Current vs. Ambient Temperature.Figure 8. Test Circuit for CMH and CML.

600

(mW)

o

500

400

300

200

100

IC OUTPUT POWER DISSIPATION P

0

-20 0 25 50 75

AMBIENT TEMPERATURE TA (°C)

100

80

Figure 10. Maximum IC Output Power

Dissipation vs. Ambient Temperature.

600

550

500

(mW)

tot

400

300

(LED AND IC)

200

100

TOTAL POWER DISSIPATION P

0

-20 0 25 50 75

AMBIENT TEMPERATURE T

80

(°C)

A

Figure 11. Maximum Total Power

Dissipation vs. Ambient Temperature.

10.0

5.0

02P

I MAX (PULSE)

02

2.0

1.0

I MAX (CONTINUOUS)

02

0.5

0.2

PEAK OUTPUT 2 CURRENT I (A)

0.1

100

0.2 0.5 1.0 2.0 5.0 10.0 20.0

DC (T = 80°C)

100 ms•

10 ms• 1 ms•

A

V (MAX)

CC

OUTPUT 2 VOLTAGE V (V)

Figure 12. Typical Peak Output 2

Current vs. Output 2 Voltage (Safe

Operating Area Q2).

• SINGLE OSC.

PULSE

T = 25°C

A

I •

S

DC

02

1-335

500

TA = 75°C

200

50°C

25°C

100

(mA)

F

0°C

50

-20°C

20

10

5

FORWARD CURRENT I

2

1

0 0.5 1.0 1.5 2.0 2.5 3.0

FORWARD VOLTAGE V

1.2

1.1

1.0

0.9

0.8

NORMALIZED THRESHOLD INPUT CURRENT

3.5

(V)

F

0.7

4

6 8 10 12 14

SUPPLY VOLTAGE V (V)

T = 25°C

A

CC

1.6

VCC = 6 V

1.4

1.2

1.0

0.8

NORMALIZED THRESHOLD INPUT CURRENT

0.6

-25 0 25 50 75 100

AMBIENT TEMPERATURE TA (°C)

Figure 13. Typical Forward Current

vs. Forward Voltage.

0.4

(V)

01L

LOW LEVEL OUTPUT 1 VOLTAGE V

V = 6 V

CC

R = 10 Ω

L2

0.2

T = 25°C

A

I = 5 mA

0.1

F

0.05

0.02

0.01

0.005

0.01 0.02 0.05 0.1 0.2 0.5 1.0

OUTPUT 1 CURRENT I

(A)

01

Figure 16. Typical Low Level Output 1

Voltage vs. Output 1 Current.

Figure 14. Normalized Low to High

Threshold Input Current vs. Supply

Voltage.

0.5

01L

0.4

0.3

I = 0.5 A

01

0.4 A

0.2

0.1

0.1 A

LOW LEVEL OUTPUT 1 VOLTAGE V (V)

0

-25 0 25 50 75 100

AMBIENT TEMPERATURE T (°C)

V = 6 V

CC

R = 10 Ω

L2

I = 5 mA

F

A

Figure 17. Typical Low Level Output 1

Voltage vs. Ambient Temperature.

Figure 15. Normalized Low to High

Threshold Input Current vs. Ambient

Temperature.

5.4

02L

5.3

5.2

5.1

5.0

4.9

HIGH LEVEL OUTPUT 2 VOLTAGE V (V)

4.8

0 -0.1 -0.2 -0.3 -0.4 -0.5 -0.6

OUTPUT 2 CURRENT I (A)

V = 6 V

CC

T = 25°C

A

I = 5 mA

F

02

Figure 18. Typical High Level Output 2

Voltage vs. Output 2 Current.

5.4

(V)

02H

5.3

I = -0.1 A

5.2

5.1

5.0

4.9

HIGH LEVEL OUTPUT 2 VOLTAGE V

4.8

-25 0 25 50 75 100

O2

-0.4 A

-0.5 A

AMBIENT TEMPERATURE TA (°C)

V = 6 V

CC

I = 5 mA

F

Figure 19. Typical High Level Output 2

Voltage vs. Ambient Temperature.

1-336

0.4

V = 6 V

CC

T = 25°C

A

02L

0.2

I = 0 mA

F

0.1

0.05

0.02

0.01

0.005

LOW LEVEL OUTPUT 2 VOLTAGE V (V)

0.01 0.02 0.05 0.1 0.2 0.5 1.0

OUTPUT 2 CURRENT I (A)

02

Figure 20. Typical Low Level Output 2

Voltage vs. Output 2 Current.

0.5

02L

0.4

0.3

0.2

0.1

LOW LEVEL OUTPUT 2 VOLTAGE V (V)

0

-25 0 25 50 75 100

I = 0.6 A

O2

0.5 A

0.1 A

AMBIENT TEMPERATURE TA (°C)

V = 6 V

CC

I = 0 mA

F

Figure 21. Typical Low Level Output 2

Voltage vs. Ambient Temperature.

14

I = 5 mA

F

12

CCH

10

8

6

HIGH LEVEL SUPPLY CURRENT I (mA)

4

4 6 8 101214

SUPPLY VOLTAGE V (V)

T = -20°C

A

25°C

80°C

CC

16

I = 0 mA

F

14

CCL

12

10

8

LOW LEVEL SUPPLY CURRENT I (mA)

6

4 6 8 101214

SUPPLY VOLTAGE V (V)

T = -20°C

A

25°C

80°C

CC

6

5

PHL PLH

4

3

2

1

T = 80°C

PROPAGATION DELAY TIME t , t (µs)

0

0 5 10 15 20 25

A

FORWARD CURRENT I (mA)

V = 6 V

CC

R = 5 Ω

L1

R = 10 Ω

L2

I = 5 mA

F

t

PLH

25°C

T = 80°C

F

t

PHL

A

25°C

-20°C

-20°C

Figure 22. Typical High Level Supply

Current vs. Supply Voltage.

5

4

PHL PLH

3

2

1

PROPAGATION DELAY TIME t , t (µs)

0

-25 0 25 50 75 100

AMBIENT TEMPERATURE TA (°C)

V = 6 V

CC

R = 5 Ω

L1

R = 10 Ω

L2

I = 5 mA

F

t

PLH

t

PHL

Figure 25. Typical Propagation Delay

Time vs. Ambient Temperature.

Figure 23. Typical Low Level Supply

Current vs. Supply Voltage.

Figure 24. Typical Propagation Delay

Time vs. Forward Current.

1-337

Loading...

Loading...