Industrial Digital Bar Code Slot

Reader

Technical Data

H

HBCS-7100 Series

Features

• Multi Resolution

Compatible with virtually all bar

code resolutions

• Large Slot Width

Allows reading thickly

laminated cards

• Sealed Metal Case (IP 66/67)

Can be installed outdoors or in

wet environments

• Tamper Proof Design

Ideal for security applications

• Minimal First Bar Distortion

• 880 nm Light

• Wide Operating Temperature

Range

-40°C to +70°C

• Wide Scan Speed Range

• Black Textured Epoxy Finish

• Digital Output

Open collector output compatible with TTL and CMOS logic

• Single +5 Volt Supply

Description

Hewlett-Packard’s Industrial

Digital Slot Reader is designed to

provide excellent scanning

performance on a wide variety of

bar coded cards and badges. It

contains a unique optical/

electrical system that integrates

over a large vertical area of the

bar/space pattern, providing a

greatly improved first read rate

even on poorly printed bar codes.

The HBCS-7100 Series uses an

infrared (880 nm) light with 0.19

mm (0.0075 in.) resolution.

The extra large depth of field

allows the slot reader to have a

slot width of 3.2 mm (0.125 in.),

thus making it possible to read

even thickly laminated cards and

badges. When used as a stand

alone optics module, the

maximum depth of field is

dependent upon resolution.

The optics and electronics are

housed in a rugged metal case.

The case is fully gasketed and

sealed, making it suitable for use

in outdoor or wet environments.

The black epoxy coating adds a

durable, finished look to the

Digital Slot Reader. When

installed using the rear screw

holes, the units become tamper

proof, making an excellent choice

for security access control.

The optical system is centered in

the slot track, allowing the user to

easily scan from either direction.

The wide slot width makes it easy

to insert and slide the cards. The

optical system is covered with a

recessed window to prevent

contamination and reduce the

wear on the cards.

The standard slot reader comes

with the optics module mounted

on a base plate with an opposite

rail and 122 cm (48 in.) straight

cord. Two standard connectors

are available: a male 5 pin, 240°,

locking DIN (HBCS-7100); or a

female, 9 pin D-sub squeeze to

release, (HBCS-7108).

The optics module (HBCS-7150)

is available which can be

integrated into other equipment

or used as a stand alone sensor

assembly.

Applications

The digital bar code slot reader is

a highly effective alternative to

5965-3007E

4-75

keyboard data entry. Bar code

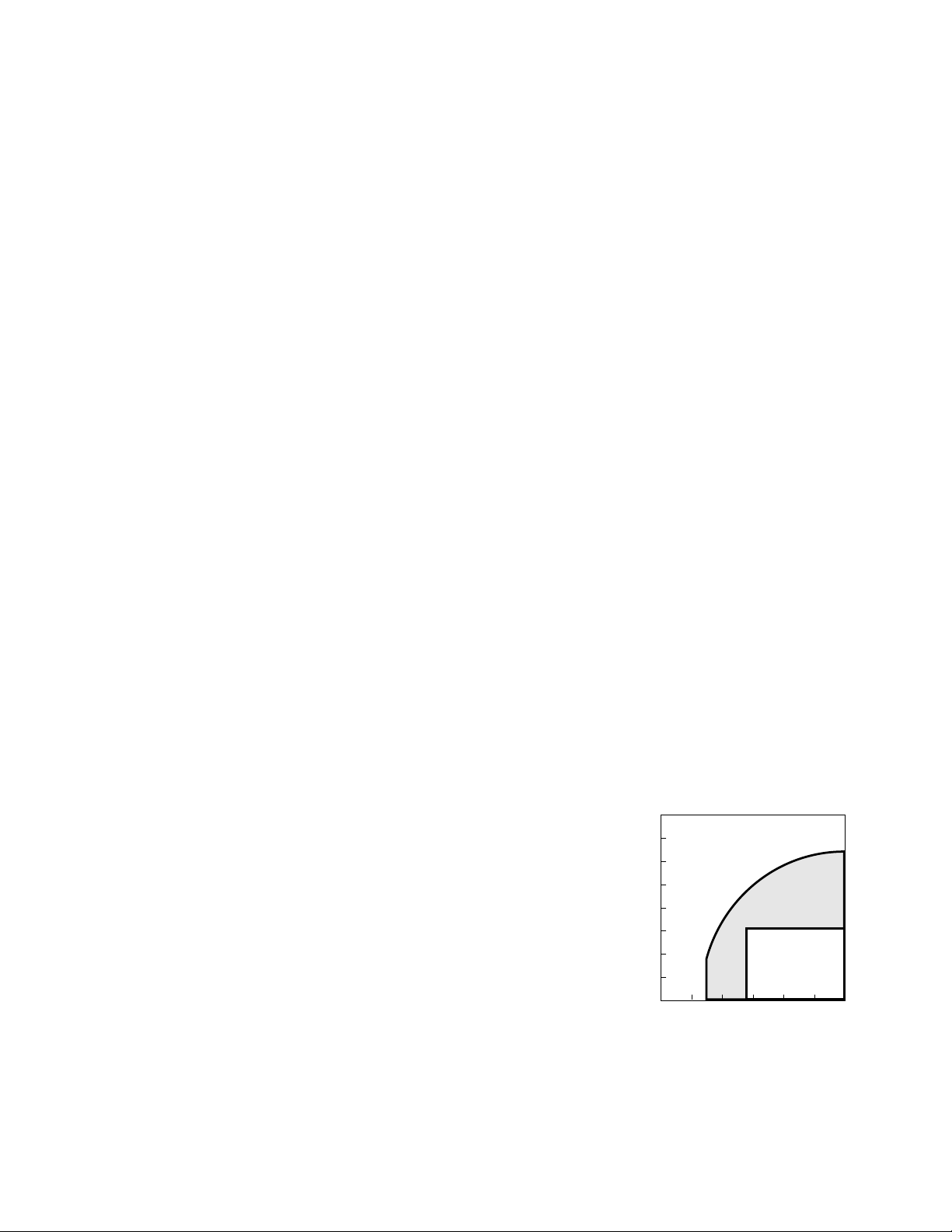

OPERATING DISTANCE – mm (INCHES)

0.05

(0.002)

8.0

(0.32)

MINIMUM SYMBOL RESOLUTION – mm (INCHES)

0.35

(0.014)

7.0

(0.23)

6.0

(0.24)

4.0

(0.16)

1.0

(0.04)

0.15

(0.006)

0.25

(0.010)

2.0

(0.08)

5.0

(0.20)

3.0

(0.12)

0.10

(0.004)

0.20

(0.008)

0.30

(0.012)

GUARANTEED

OPERATING

REGION

OPERATING

TYPICAL

REGION

scanning is faster and more

accurate than key entry and

provides far greater throughput.

In addition, bar code scanning

typically has a higher first read

rate and greater data accuracy

than optical character recognition. When compared to magnetic

stripe encoding, bar code offers

significant advantages in flexibility of media, symbol placement

and immunity to electromagnetic

fields.

Hewlett-Packard’s Industrial

Digital Slot Reader is designed for

applications where high first read

rate and durability are important

factors. The epoxy coated metal

case with its tamper proof

mounting system, makes these

slot readers ideal choices for

security access control, time and

attendance recording and other

bar coded badge and card reading

applications.

Electrical Operation

The HBCS-71XX family of digital

slot readers consists of a precision optical system, an analog

amplifier, a digitizing circuit, and

an output transistor. These

elements provide a TTL compatible output from a single 4.5 V to

5.5 V DC power supply. The open

collector transistor requires a

pull-up resistor for proper

operation.

A non-reflecting black bar results

in a logic high (1) level output,

while a reflecting white space will

cause a logic low (0) level output.

After power up, the slot reader

will be fully operational after

approximately 6 seconds. During

operation, the slot reader will

4-76

assume a logic low state after a

short period (typically 1 second)

if no bar code is scanned. This

feature allows multiple scanners

(slot readers and wands) to be

connected together with a simple

OR gate.

The slot reader connector provides a shield which is connected

to signal ground. The shield is

connected either to the metal

housing of the 5 pin DIN

connector, or to pin 8 of the 9 pin

D-sub connector. A good

connection to earth ground is

recommended.

The maximum recommended

cable length is 7.6 m (25 ft.).

WARNING:

OBSERVING THE INFRARED

LIGHT SOURCE IN THE HBCS7150 AT CLOSE DISTANCES

FOR PROLONGED PERIODS OF

TIME MAY CAUSE INJURY TO

THE EYE. When mounted with

the rail in place, the infrared

output flux is radiologically safe.

With the rail removed, precautions should be taken to avoid

prolonged visual observation.

Mounting Considerations

Slot Reader

The slot reader (HBCS-7100/

7108) is designed to be virtually

tamper proof when mounted

using the two rear mounting

holes. In this case, the cable must

be routed from the rear of the slot

reader through the mounting

surface (wall, door, etc.).

When mounting the slot reader,

the cable may be routed through

the mounting surface (see above),

or it may be routed along grooves

in the base and exit the side of the

slot reader at any of four points.

This allows flexibility in the

mounting orientation.

Optics Module

The optics/electronics module

(HBCS-7150) is designed for

applications which require a

different slot width, integration

into a larger housing, or a fixed

beam stationary scanner. When

using the optics module, the

operating distance from the front

surface of the module to the

symbol will vary depending on the

symbol resolution. Figure 1 shows

the relationship between operating range and minimum symbol

resolution for a typical optics

module.

This relationship was applied in

the design of the slot reader,

where a slot width of 3.2 mm

(0.125 in.) insures excellent

performance reading bar code

symbols which have a nominal

resolution of 0.19 mm (0.0075

in.) and include normal printing

errors.

Figure 1.

Loading...

Loading...