HP HBCS-1100 Datasheet

High Resolution Optical

Reflective Sensor

Technical Data

H

HBCS-1100

Features

• Focused Emitter and

Detector in a Single Package

• High Resolution–0.190 mm

Spot Size

• 700 nm Visible Emitter

• Lens Filtered to Reject

Ambient Light

• TO-5 Miniature Sealed

Package

• Photodiode and Transistor

Output

• Solid State Reliability

Description

The HBCS-1100 is a fully integrated module designed for

optical reflective sensing. The

module contains a 0.178 mm

(0.007 in.) diameter 700 nm

visible LED emitter and a

Package Dimensions

MAXIMUM

SIGNAL POINT

C

L

REFERENCE

5.08

(0.200)

PLANE

(0.168 ± 0.010)

4.27 ± 0.25

matched I.C. photodetector. A

bifurcated aspheric lens is used

to image the active areas of the

emitter and the detector to a

single spot 4.27 mm (0.168 in.)

in front of the package. The

reflected signal can be sensed

directly from the photodiode or

through an internal transistor

that can be configured as a high

gain amplifier.

Applications

Applications include pattern

recognition and verification,

object sizing, optical limit

switching, tachometry, textile

thread counting and defect

detection, dimensional monitoring, line locating, mark, and bar

code scanning, and paper edge

detection.

9.40 (0.370)

8.51 (0.335)

0.86 (0.034)

0.73 (0.029)

4.11

(0.162)

1.14 (0.045)

0.73 (0.029)

5.08

(0.200)

Mechanical Considerations

The HBCS-1100 is packaged in a

high profile 8 pin TO-5 metal can

with a glass window. The emitter

and photodetector chips are

mounted on the header at the

base of the package. Positioned

above these active elements is a

bifurcated aspheric acrylic lens

that focuses them to the same

point.

R.P.

8.33 (0.328)

7.79 (0.307)

11.50 (0.453)

11.22 (0.442)

15.24 (0.600)

12.70 (0.500)

S.P.

12.0

(0.473)

5965-5944E

NOTES:

1. ALL DIMENSIONS IN MILLIMETERS AND (INCHES).

2. ALL UNTOLERANCED DIMENSIONS ARE FOR REFERENCE ONLY.

3. THE REFERENCE PLANE IS THE TOP SURFACE OF THE PACKAGE.

4. NICKEL CAN AND GOLD PLATED LEADS.

5. S.P. SEATING PLANE.

6. THE LEAD DIAMETER IS 0.45 mm (0.018 IN.) TYP.

4-15

The sensor can be rigidly secured

by commercially available two

piece TO-5 style heat sinks, such

as Thermalloy 2205, or Aavid

Engineering 3215. These fixtures

provide a stable reference platform and their tapped mounting

holes allow for ease of affixing

this assembly to the circuit board.

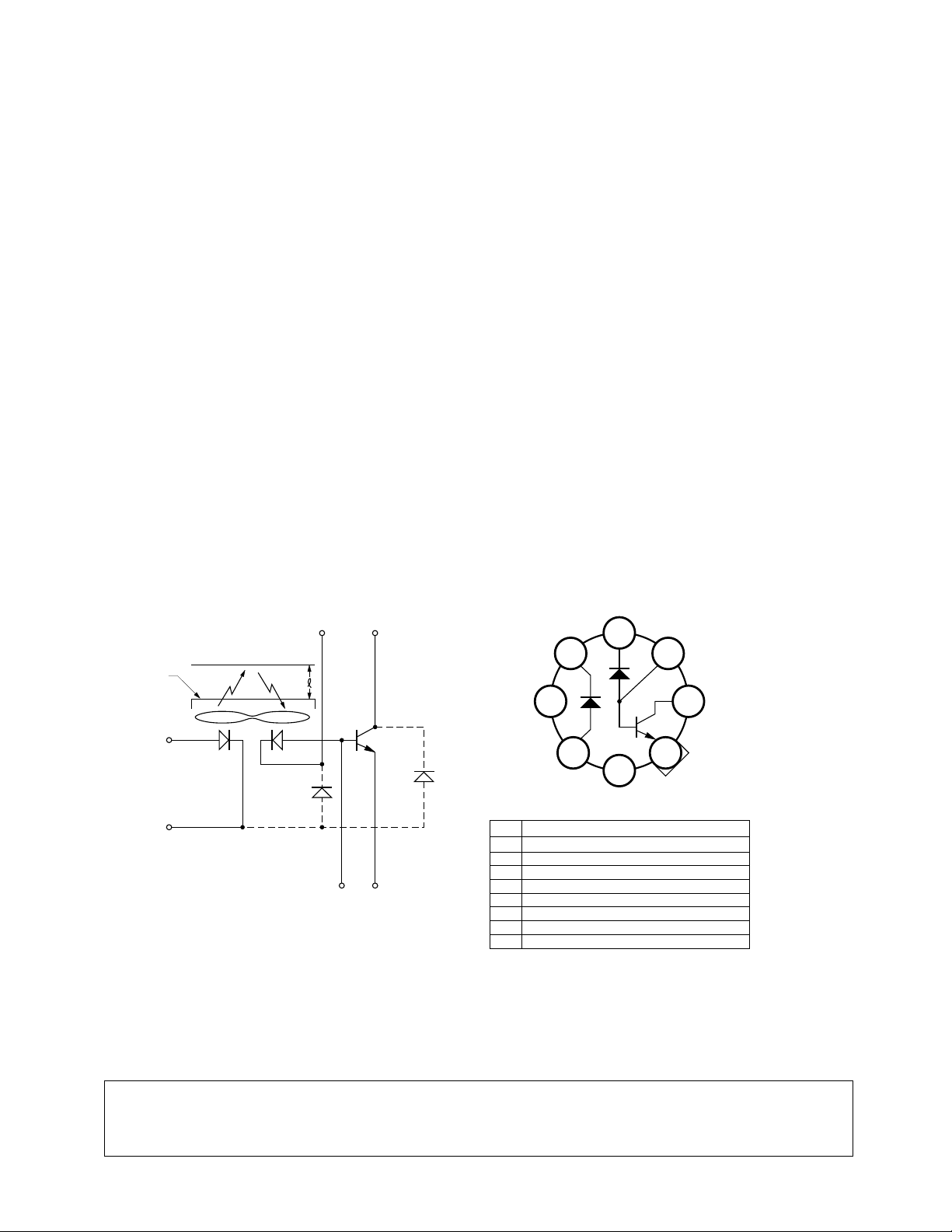

Electrical Operation

The detector section of the

sensor can be connected as a

single photodiode or as a

photodiode transistor amplifier.

When photodiode operation is

desired, it is recommended that

the substrate diodes be defeated

by connecting the collector of the

transistor to the positive potential

of the power supply and shorting

the base-emitter junction of the

transistor. Figure 15 shows

photocurrent being supplied from

the anode of the photodiode to an

inverting input of the operational

amplifier. The circuit is recommended to improve the reflected

photocurrent to stray photocurrent ratio by keeping the

substrate diodes from acting as

photodiodes.

The cathode of the 700 nm

emitter is physically and

electrically connected to the casesubstrate of the device. Applications that require modulation or

switching of the LED should be

designed to have the cathode

connected to the electrical

ground of the system. This

insures minimum capacitive

coupling of the switching

transients through the substrate

diodes to the detector amplifier

section.

The HBCS-1100 detector also

includes an NPN transistor which

can be used to increase the

output current of the sensor. A

current feedback amplifier as

shown in Figure 6 provides

moderate current gain and bias

point stability.

Schematic Diagram

REFLECTOR

REFERENCE

PLANE

ANODE

6

V

F

CATHODE

SUBSTRATE, CASE

– SUBSTRATE DIODES

D

S

4

V

D

S

V

D

31

C

28

V

V

B

E

D

S

Connection Diagram

3

42

51

68

7

PIN FUNCTION

TRANSISTOR COLLECTOR

1

TRANSISTOR BASE, PHOTODIODE ANODE

2

PHOTODIODE CATHODE

3

LED CATHODE, SUBSTRATE, CASE

4

NC

5

LED ANODE

6

NC

7

TRANSISTOR EMITTER

8

TOP VIEW

CAUTION: The small junction sizes inherent to the design of this bipolar component increase the component's

susceptibility to damage from electrostatic discharge (ESD). It is advised that normal static precautions be

taken in handling and assembly of this component to prevent damage and/or degradation which may be

introduced by ESD.

4-16

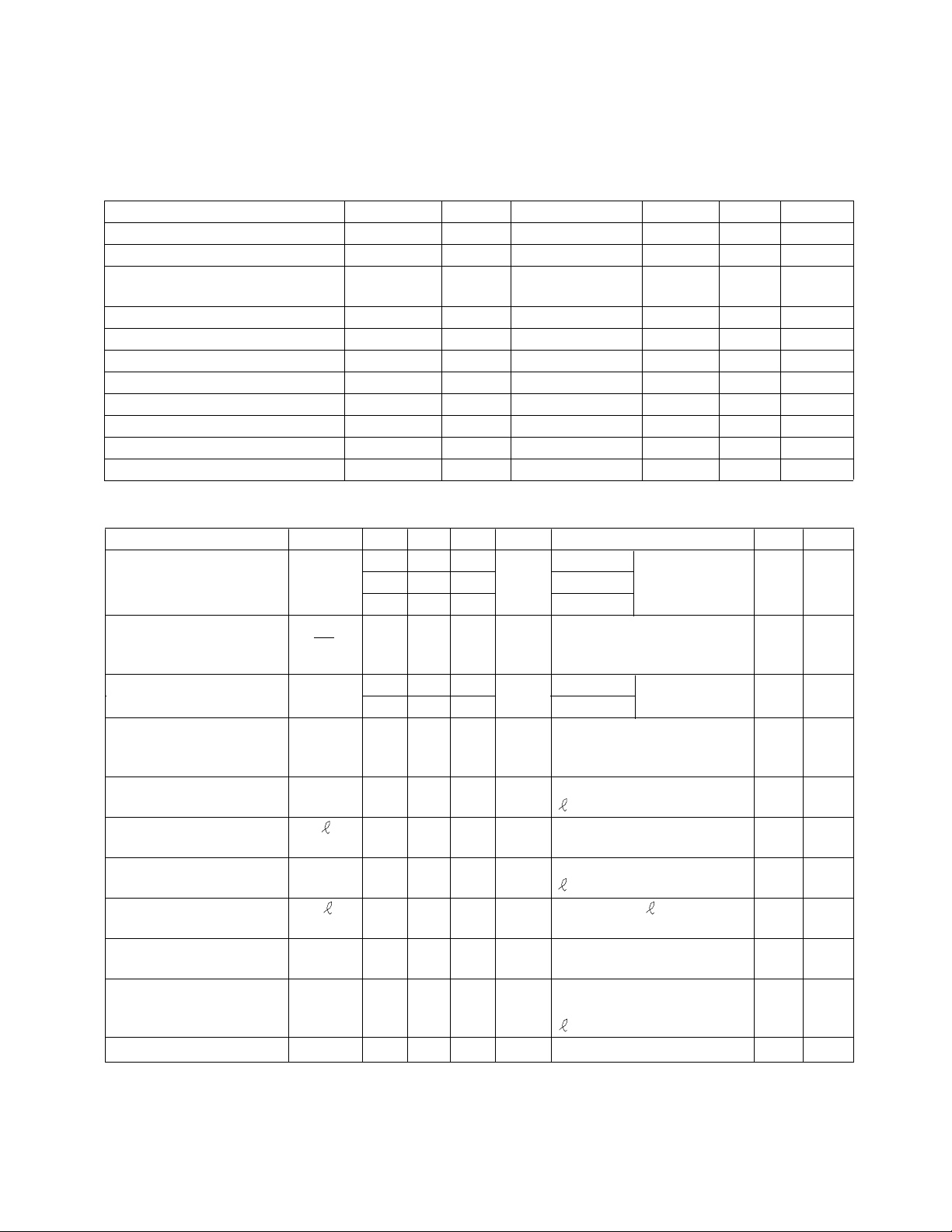

Absolute Maximum Ratings at T

= 25°C

A

Parameter Symbol Min. Max. Units Fig. Notes

Storage Temperature T

Operating Temperature T

S

A

-40 +75 °C

-20 +70 °C

Lead Soldering Temperature 260 for 10 sec. °C11

1.6 mm from Seating Plane

Average LED Forward Current I

Peak LED Forward Current I

Reverse LED Input Voltage V

Package Power Dissipation P

Collector Output Current I

F

FPK

R

P

O

Supply and Output Voltage VD, VC, V

Transistor Base Current I

Transistor Emitter Base Voltage V

B

EB

-0.5 20 V 10

E

50 mA 2

75 mA 1 1

5V

120 mW 3

8mA

5mA

0.5 V

System Electrical/Optical Characteristics at T

= 25°C

A

Parameter Symbol Min. Typ. Max. Units Conditions Fig. Note

Total Photocurrent I

(IPR + IPS)

P

150 250 375 TA = 25°C

575 nA TA = 20°CIF = 35 mA, 2, 3 4

VD = VC = 5 V

15

80 TA = 70°C

Reflected Photocurrent I

(IPR) to Internal Stray I

PR

PS

4 8.5 IF = 35 mA, 3

VC = VD = 5 V

Photocurrent (IPS)

Transistor DC Static h

FE

Slew Rate 0.08 V/µsRL = 100 K, I

50 TA = 20° CVCE = 5 V, 4, 5

100 200 TA = 25°C

IC = 10 µACurrent Transfer Ratio

= 50 mA, 6

PK

RF = 10 M, tON = 100 µs,

Rate = 1 kHz

Image Diameter d 0.17 mm IF = 35 mA, 8, 10 8, 9

= 4.27 mm (0.168 in.)

Maximum Signal Point 4.01 4.27 4.52 mm Measured from Reference 9

Plane

50% Modulation MTF 2.5 I

npr/mmIF

= 35 mA, 10, 5, 7

Transfer Function =4.27 mm 11

Depth of Focus ∆ 1.2 mm 50% of IP at = 4.27 mm 9 5

FWHM

Effective Numerical N.A. 0.3

Aperture

Image Location D 0.51 mm Diameter Reference to 6

Centerline

= 4.27 mm

Thermal Resistance Θ

JC

85 °C/W

4-17

Loading...

Loading...