Optical Reflective Sensors

Technical Data

hH

HBCC-1570

HBCC-1580

HBCC-1590

Features

• Focused Emitter and

Detector in a Single

Package

• TO-5 Miniature Sealed

Package

• Photodiode Output

• Choice of Resolutions

(0.13 mm, 0.178 mm, 0.33 mm)

• Two Wavelengths

Available; 655 nm, 820 nm

(see selection guide)

Description

The HBCC-15XX series sensors

are fully integrated modules

designed for applications requiring optical reflective sensing. The

modules contain a 655 nm (or 820

nm) LED emitter and a photodiode. A bifurcated aspheric lens

is used to image the active areas

of the emitter and detector to a

single spot 4.27 mm (0.168 in.) in

front of the package. The output

signal is a current generated by

the photodiode.

Applications

The HBCC-15XX sensors are

intended for use with the HewlettPackard HBCC-0500 and HBCC0600 low current digitizer ICs, or

Selection Guide

Sensor Part Number HBCC-1570 HBCC-1580 HBCC-1590

LED Resolution 0.33 mm (0.013 in.) 0.185 mm (0.007 in.) 0.13 mm (0.005 in.)

LED Wavelength 655 nm 655 nm 820 nm

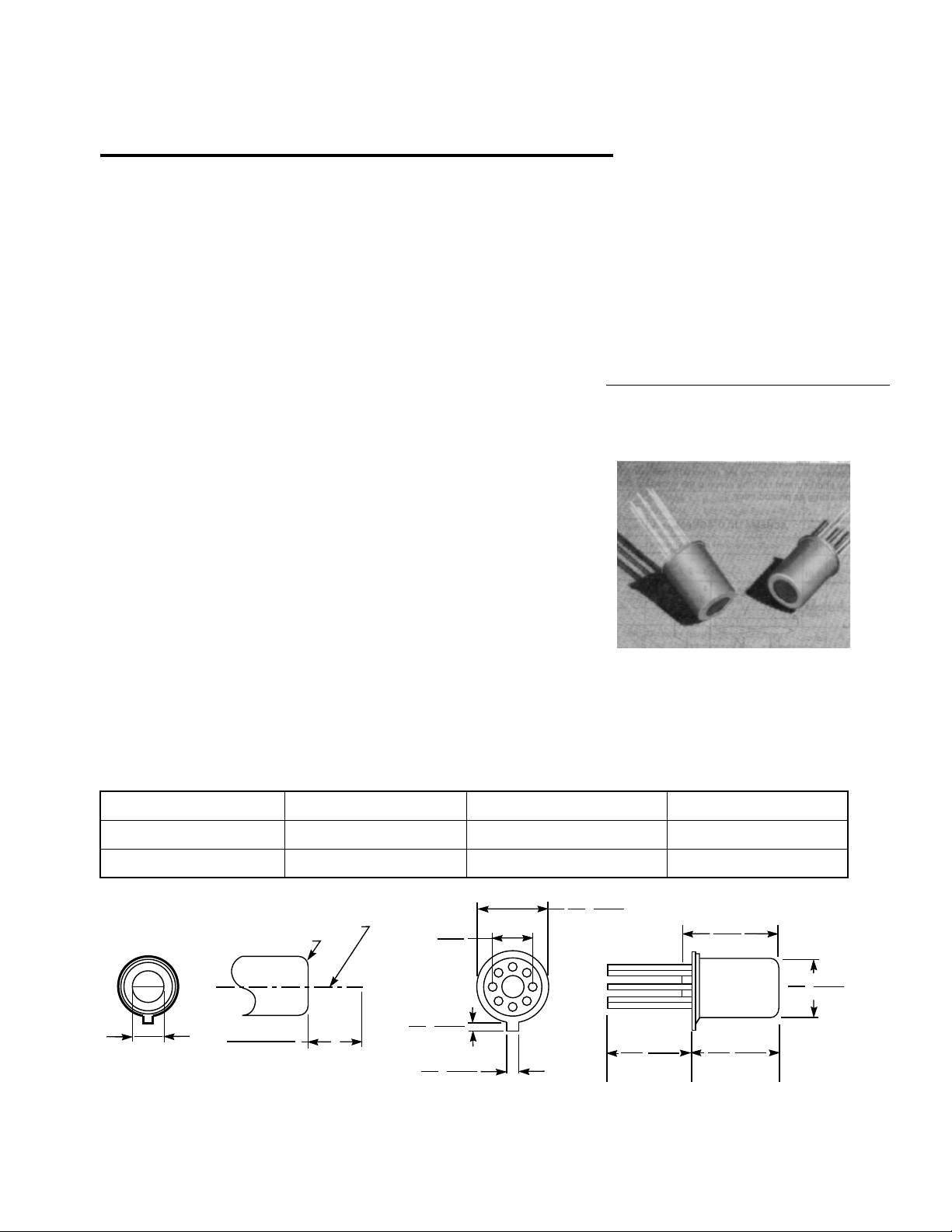

Package Dimensions

MAXIMUM SIGNAL POINT – MSP

REFERENCE PLANE

5.08

(0.200)

9.40

8.51

(0.370)

(0.335)

S.P.

12.0

(0.473)

R.P.

O.D.

C

L

5.08

(0.200)

NOTES:

A. ALL DIMENSIONS IN MILLIMETERS AND (INCHES).

B. ALL UNTOLERANCED DIMENSIONS ARE FOR REFERENCE ONLY.

C. THE REFERENCE PLANE (R.P.) IS THE TOP SURFACE OF THE PACKAGE.

D. NICKEL CAN AND GOLD PLATED LEADS.

(0.168) ± (0.010)

4.27

0.25

±

Z

5965-5942E

1.14

0.73

0.86

0.73

(0.045)

(0.029)

(0.034)

(0.029)

E. S.P. = SEATING PLANE.

F. THE LEAD DIAMETER IS 0.45 mm (0.018 in.) TYP.

G. O.D. = OUTSIDE DIAMETER OF CAN MEASURED IN REGION ABOVE

WELD FLANGE TO MIDWAY OF CAN LENGTH.

15.24

12.70

(0.600)

(0.500)

11.50

11.22

(0.453)

(0.442)

8.33

8.12

(0.328)

(0.320)

4-7

with suitable PCB assemblies

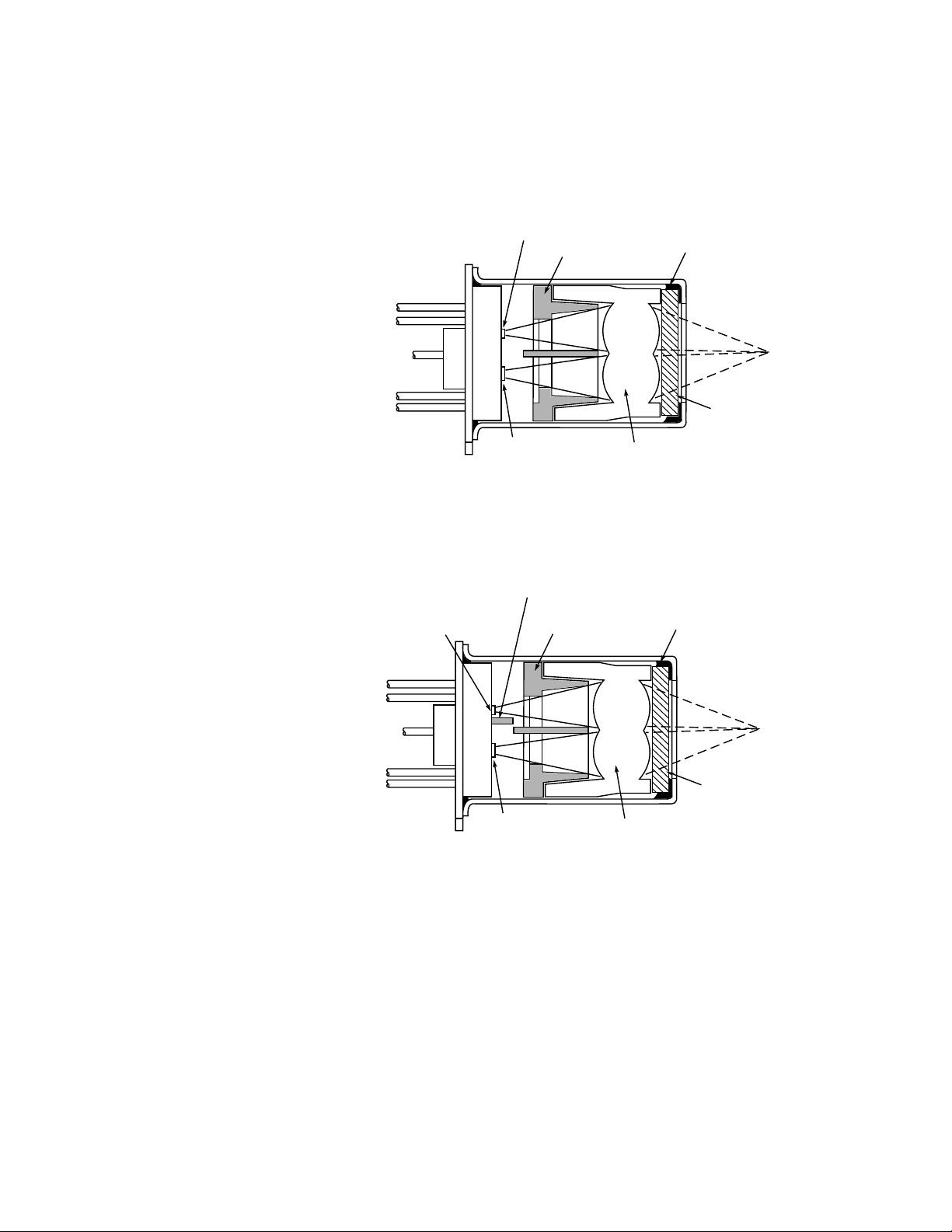

EMITTER

BAFFLE

EPOXY SEAL

SENSING

AREA

GLASS

LENS

DETECTOR

provided by HP for use with these

sensors. The HBCC-15XX sensors

have been characterized for use

only with Hewlett-Packard’s

digitizer IC technology. Use of

these sensors in designs or applications other than those stated is

at the customer’s risk.

Mechanical Considerations

The HBCC-15XX series are

packaged in a high profile 8 pin

TO-5 metal can with a glass

window. The LED and photodiode

are mounted on a header at the

base of the package. Positioned

above these active elements is a

bifurcated aspheric acrylic lens

that focuses them to the same

point.

The sensor can be rigidly secured

by commercially available TO-5

style heat sinks or 8 pin 0.200 inch

diameter pin circle sockets. These

fixtures provide a stable reference

platform for affixing the HBCC15XX sensors to a circuit board.

HBCC-1570, 1580 Optical System

HBCC-1590 Optical System

SILICON

BAFFLE

EMITTER

0.089 mm DIA. JUNCTION

OPTICAL

APERTURE

BAFFLE

EPOXY SEAL

SENSING

AREA

In applications requiring contact

scanning (such as bar code

reading), protective focusing tips

are available. Focusing tips are

available in either metal or polycarbonate packages using a

sapphire ball as the contact

surface. The Hewlett-Packard part

numbers are HBCS-2999, HBCS4999, HBCS-A998, and

HBCS-A999.

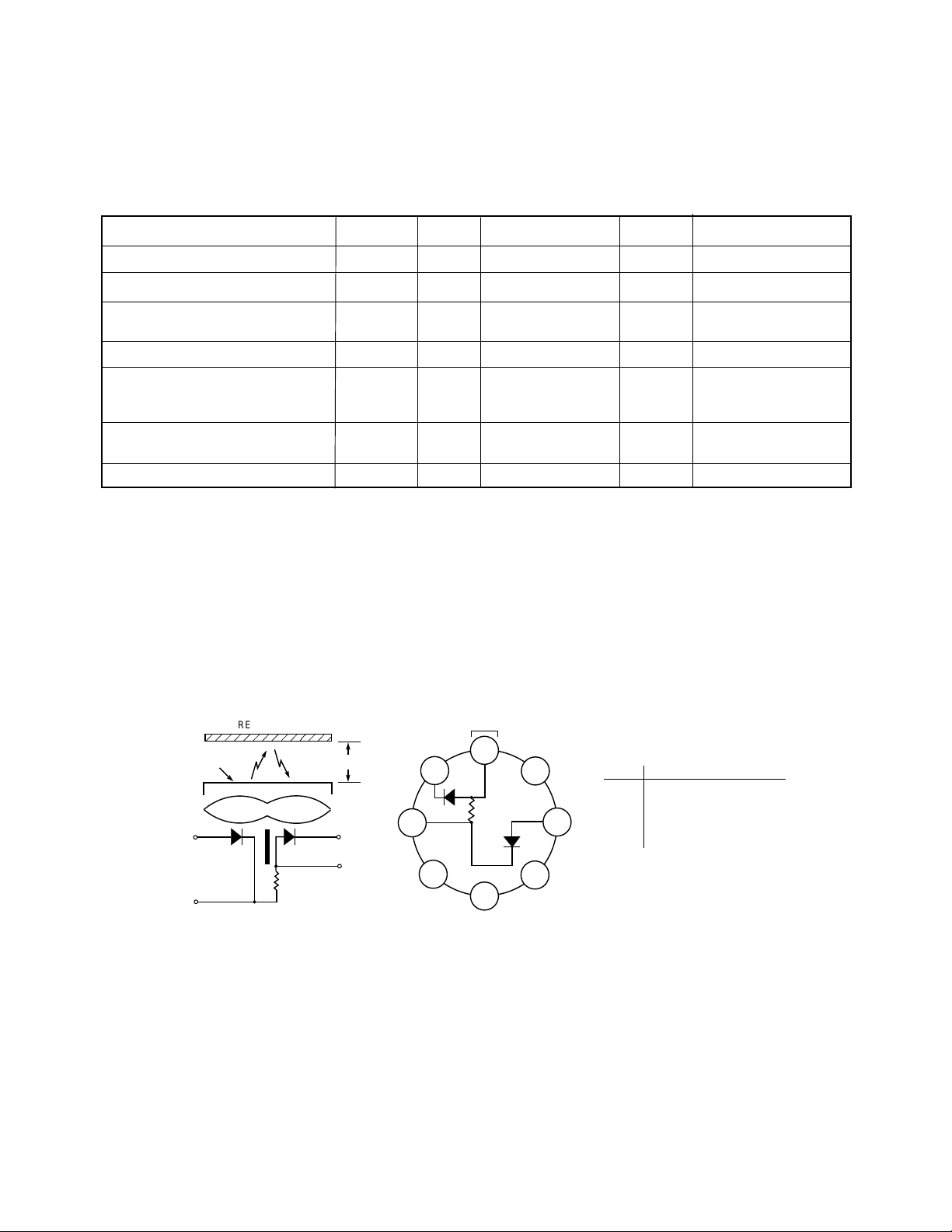

Electrical Operation

The sensor detector is a pn

photodiode. The LED cathode is

physically and electrically connected to the case-substrate of the

sensor.

4-8

DETECTOR

0.406 mm SQUARE

The HBCC-15XX sensors are

characterized for use with HewlettPackard’s low current digitizer

ICs. The digitizer IC part numbers

are HBCC-0500 and HBCC-0600.

Data Sheets including circuit

diagrams are available.

GLASS

LENS

Absolute Maximum Ratings

TA = 25°C unless specified otherwise (unless specified separately, data applies to all sensors)

Parameter Symbol Min. Max. Units Notes

Storage Temperature T

Operating Temperature T

S

A

Lead Soldering Temperature 260 °C1

(1.6 mm from Seating Plane) (for 10 seconds)

Average LED Forward Current I

Peak LED Forward Current I

Reverse LED Input Voltage V

Photodiode Bias V

Notes:

1. CAUTION: The thermal constraints of the acrylic lens will not permit conventional wave soldering procedures. The typical

preheat and post-soldering cleaning procedures and dwell times can subject lens to thermal stresses beyond the absolute

maximum ratings and can cause it to defocus.

2. These sensors are specified for use with the drive conditions provided by the HBCC-0500 and HBCC-0600 Digitizer IC ONLY.

3. When used with HBCC-0500 or HBCC-0600 digitizer ICs.

4. At all combinations of pulse width and duty cycle.

5. Voltage differential between Pin 1 and Pin 8 with Pin 8 taken as reference. Exceeding maximum conditions may cause permanent

damage to photodiode or to chip metallization.

f

fp

r

d

-40 +75 °C

-20 +75 °C

2

125 mA 3 (HBCC-1570)

100 mA 3 (HBCC-1580)

40 mA 4 (HBCC-1590)

5.0 V

2.5 V HBCC-1590 Only

-0.3 6.0 V 5

REFERENCE

PLANE

6

2

REFLECTOR

Z

LED

CASE, SUBSTRATE

SCHEMATIC DIAGRAM CONNECTION DIAGRAM

D

ps

R

s

Rs = CHARACTERISTIC NOT DEFINED

1

8

1

2

3

8

D

ps

R

s

+

4

TOP VIEW

7

LED

5

PIN#

1

6

2

6

8

FUNCTION

PHOTODIODE CATHODE

HEADER GROUND

LED ANODE

PHOTODIODE ANODE

4-9

Loading...

Loading...