Page 1

HP Indigo Labels and Packaging Color Kit

powered by EskoArtwork

User Guide

Page 2

HP Indigo Labels and Packaging

powered by EskoArtwork

Color Kit

User Guide

Page 3

Introduction

Copyright

© 2008 Copyright Hewlett-Packard Development Company,

L.P.

Reproduction, adaptation, or translation without prior written

permission is prohibited, except as allowed under the copyright laws.

The information contained herein is subject to change

without notice.

The only warranties for HP products and services are set

forth in the express warranty statements accompanying

such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall not

be liable for technical or editorial errors or omissions contained herein.

HP, HP Indigo Press, HP Indigo Press RIP, and

HP ElectroInk are trademarks or registered trademarks of

HP.

All other products or name brands are trademarks of their

respective holders.

Copyright 2007 Esko nv, Gent, Belgium

All rights reserved. Esko nv. does not warrant, guarantee or

make any representations regarding the use, or the results of

the use of the software or the information contained herein.

Esko nv shall not be liable for any direct, indirect, consequential or incidental damages arising out of the use or inability to

use the software or the information contained herein.

PANTONE Colors displayed here may not match

PANTONE-identified standards. Consult current PANTONE

Color Publications for accurate color. PANTONE and other

Pantone, Inc. trademarks are the property of Pantone, Inc.

Pantone, Inc., 2000. Pantone, Inc. is the copyright owner of

color data and/or software which are licensed to Esko nv to

distribute for use only in combination with LW-Brix and CT-Brix

based applications. PANTONE Color Data and/or Software

shall not be copied onto another disk or into memory unless as

part of the execution of the LWBrix and CTBrix based applications.This software is based in part on the work of the Independent JPEG Group.

This product includes software developed by the Apache

Software Foundation (http://www.apache.org/)

Adobe, the Adobe logo, Acrobat, the Acrobat logo, Adobe

Creative Suite, Illustrator, InDesign, PDF, Photoshop, PostScript, XMP and the Powered by XMP logo are either registered trademarks or trademarks of Adobe Systems Incorporated in the United States and/or other countries.

Microsoft and the Microsoft logo are registered trademarks of

Microsoft Corporation in the United States and other countries.

"SolidWorks is a registered trademark of SolidWorks Corporation."

Portions of this software are owned by Spatial Corp. 1986

2003. All Rights Reserved.

JDF and the JDF logo are trademarks of the CIP4 Organisation. Copyright 2001 The International Cooperation for the

Integration of Processes in Prepress,

Press and Postpress (CIP4). All rights

reserved.

The Esko software contains the "RSA

Data Security, Inc. MD5 Message-Digest

Algorithm".

Java and all Java-based trademarks and

logos are trademarks or registered

trademarks of Sun Microsystems in the

U.S. and other countries.

Confidentiality notice

This guide and any information contained herein is confidential and should

not be disclosed to any third party outside of HP Indigo. Do not copy and/or

disseminate any information contained

in this guide. This guide should be

maintained in a manner which shall

ensure compliance with the confidentiality requirements set forth herein.

This document contains valuable trade

secrets and confidential information of

Hewlett-Packard Company. Nothing

herein may be copied, reproduced or

distributed in any form or medium, or

disclosed to any third party in any

manner, without prior written authorization of Hewlett-Packard Company. The

copyright notice, which appears in this

document, is purely precautionary and

shall not be deemed to constitute publication or intent to publish, in whole or

in part.

Part Number:

CA294-05750

First Edition:

February 2008

2

Page 4

Contents

Introduction.......................................................................................................................... 4

About this manual ............................................................................................................................ 4

What is Color Kit? ............................................................................................................................ 4

Solution for special colors ................................................................................................................ 5

Multi-color profiles ............................................................................................................................ 5

System solution for color management............................................................................................5

Prerequisites........................................................................................................................ 6

Spectrophotometer .............................................................................................................. 7

Supported spectrophotometers........................................................................................................ 7

Connecting a spectrophotometer..................................................................................................... 7

Calibration of the spectrophotometer............................................................................................. 13

Working with filters ......................................................................................................................... 15

Using the profiles ........................................................................................................................... 29

Color Strategies ............................................................................................................................. 29

ICC profiles........................................................................................................................ 44

Definition of ICC profiles ................................................................................................................ 44

Notes on importing an ICC profile.................................................................................................. 44

Exporting to ICC profiles ................................................................................................................ 45

Notes on exporting to an ICC profile.............................................................................................. 46

Importing ICC profiles .................................................................................................................... 47

Viewing ICC profiles....................................................................................................................... 47

Dealing with Special colors................................................................................................ 48

How to create your own inks?........................................................................................................ 48

Info on inks..................................................................................................................................... 50

Export an ink book ......................................................................................................................... 50

Import an ink book.......................................................................................................................... 51

Proof an ink book ........................................................................................................................... 51

Tools.................................................................................................................................. 54

Links............................................................................................................................................... 54

Gamut View.................................................................................................................................... 56

Compare Inks................................................................................................................................. 58

Gamut Check ................................................................................................................................. 59

Average Profiles............................................................................................................................. 60

Preferences.................................................................................................................................... 62

Example of a workflow....................................................................................................... 65

Appendix, a closer look at the standard Color Strategies.................................................. 76

Page 5

Introduction

Introduction

HP Indigo Labels and Packaging Color Kit powered by Esko includes:

• software to measure color charts.

• software to generate profiles (both native and ICC).

• a ‘Color management Module’.

• a database with charts, profiles and inks.

About this manual

This manual explains all the tools in Color Kit. It explains all features in detail You may want to proceed straightaway to how-to section in section 9, which guides you through a step-by-step calibration.

Therefore some illustrations might appear in both the reference section as in the step-by-step section.

What is Color Kit?

HP Indigo Labels and Packaging Color Kit powered by Esko is a complete color system. It offers

profiling tools to profile presses and proofing devices and offers all required features to create, modify

and execute profiles.

In addition, Color Kit uses a central color database which digitizes all color knowledge. This database

can be used for output to any devices using FlexRip. For the HP Indigo press the color database

provides full color conversion automation and eliminates the need for operator intervention to prepare

conventionally printed jobs for digital reruns. It is the ideal platform to optimize press uptime and

number of jobs run on the HP Indigo digital press.

Color Kit goes well beyond ICC capabilities when special colors (Pantone and brand colors) are

concerned. Color Kit profiles are 100% spectral profiles providing, in addition to LAB values, much

more information about color behavior and characteristics than ICC profiles and ICC based color

management systems.

To profile devices (proofing devices, conventional and digital presses) Esko's Color Kit uses special

measuring charts for up to 7 color processes. This can be used to create a profile of the HP Indigo

digital press using Indichrome or Indichrome + green. This profile is stored in the Color Kit database.

Measure color charts

Color Kit comes with its own layouts to measure CMYK and multi-color profiles but you can also

measure IT8 or ECI2002 charts. Interfaces with the most common spectrophotometers are available.

Generate profiles

From measured charts, both native Color Kit profiles and ICC profiles can be generated.

Note: The Color Kit module is not an actual CMM that can be used

on a MAC.

A database

Color Kit keeps track of all the proofer, press or ink profiles in a database. Thanks to this database, it

is possible to tell when the profile was made, which chart (and how many patches) was used to make

4

Page 6

Introduction

the profile and what kind of profile it is: a proofer, press, monitor or scanner profile. It will also tell you

if the profile is referenced in a device link profile. Additionally, when using 'Color Strategies' the

database keeps track of conversion tables. It will tell you what kind of colormatch was used. In other

words, the CMS database provides an enormous amount of quality control. A database is built over

time. Over time, you will create a database of colours for every substrate/press condition

combinations that will help you to maximize production on the press.

So far, apart from the database, Color Kit looks like a traditional color management package.

Solution for special colors

A traditional color management system relies on colorimetric modeling only. The goal is to obtain a

color match between input, monitor, proof and printed output. But what about special colors? The

problem of special colors becomes dramatically complex when dealing with overprints between

specials, often used in packaging.

Multi-color profiles

Color Kit enables you to create multi-color profiles. These profiles can either be output profiles (for

proofing devices or digital presses that run more than 4 colors, e.g. HP Indigo) or press profiles.

Multi-color Press Profiles can be very handy when dealing with a standardized set of 6 or 7 inks. The

profile will help to convert legacy jobs into the press colorspace with InkWizard and will help to make

an accurate simulation of the press on the digital proofing system.

System solution for color management

Color Kit offers a solution for every step in the color workflow:

• Measuring profile charts: whether you choose to use IT8 charts or Esko charts for press or proofer

or you advance to the ink profiles, Color Kit will measure them for you.

• Generating profiles: Color Kit can deliver an Esko profile or an ICC profile.

• CMS: Color Kit also provides the CMS kernel which converts from one color space to another

(comparable to a CMM in an ICC environment), which is built into all Esko products mentioned

above.

5

Page 7

Prerequisites

Before Esko Color Kit can be of any use to you, the following prerequisites need to be fulfilled:

• A spectrophotometer is essential. (See: Supported spectrophotometers (page 7). To measure

multi-color profiles, a high-speed measuring device (e.g I1IO or DTP70) is recommended.

• You need a stable press. You need to understand perfectly how the press can be calibrated.

Consistent colour output can only be obtained through optimal calibration of the Indigo press. A

good communication between the pre-press department and press operator is essential, especially

where it concerns usage of LUT tables on the press. Here’s why: Profiles reflect every aspect of

paper, ink an press conditions. One should not change press conditions without communicating

with the pre-press department and vice versa.

• You need the correct licenses on your system.

• You can find all the Esko and IT8 color charts on your system after the software has been installed.

• In order to have a reliable optical comparison between colors from your proofing device and from

your press, a viewing booth with D50 illumination is required.

6

Page 8

Spectrophotometer

Supported spectrophotometers

The following spectrophotometers are supported for USB:

• Gretag SpectroEye

• Gretag Eye-One

• Gretag ICColor

• Xrite DTP70

• Gretag Eye-One IO

Connecting a spectrophotometer

Please hook up your spectrophotometer to a serial port of your system. Esko Color Kit will detect the

meter automatically.

Connecting a spectrophotometer to a USB port

The following meters can be connected to a USB port:

• Gretag Eye-One

• Gretag Eye-One IO

• DTP70, ICColor

Note: No USB drivers for Windows NT are available.

Connect the meter to a USB port on your PC (not via the keyboard).

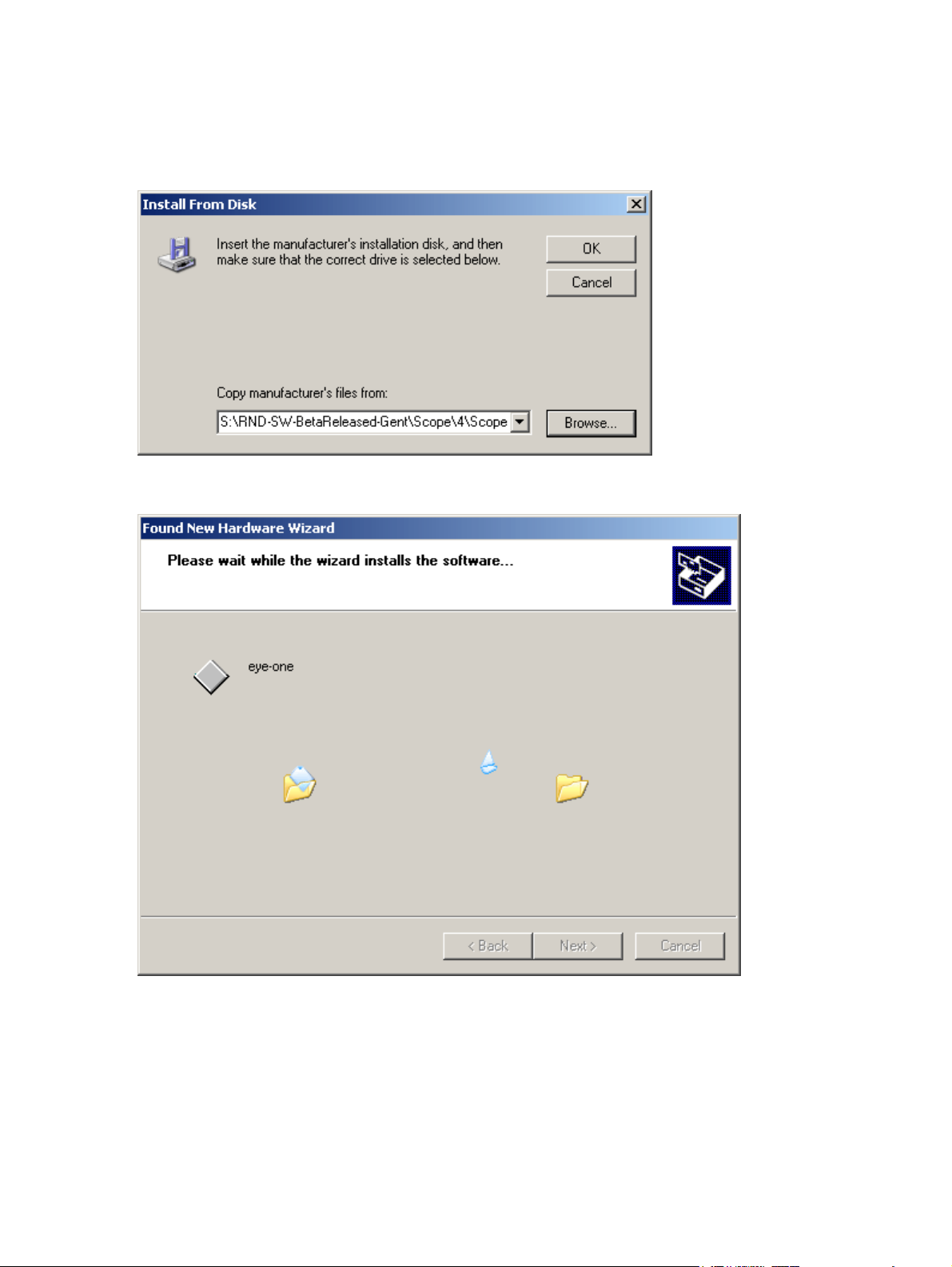

The system detects new hardware and will prompt you to install the drivers. Proceed as follows:

1. Choose to install the drivers from a specific location

7

Page 9

Spectrophotometer

8

Page 10

Spectrophotometer

2. Choose to install the driver yourself.

3. Select Eye-One and click 'Have Disk'.

9

Page 11

Spectrophotometer

4. Click 'Browse'.

5. Browse to the Documentation DVD under Extra - Spectrophotometer drivers, select the

corresponding driver and click 'Open'.

10

Page 12

Spectrophotometer

11

Page 13

Spectrophotometer

6. Click 'OK'.

7.

12

Page 14

Spectrophotometer

8.

9. The Eye-One is now ready to be used in Color Kit

Calibration of the spectrophotometer

1. Your spectrophotometer can be calibrated by double-clicking the spectrophotometer icon

First, Color Kit will automatically detect the type of spectrophotometer that is connected.

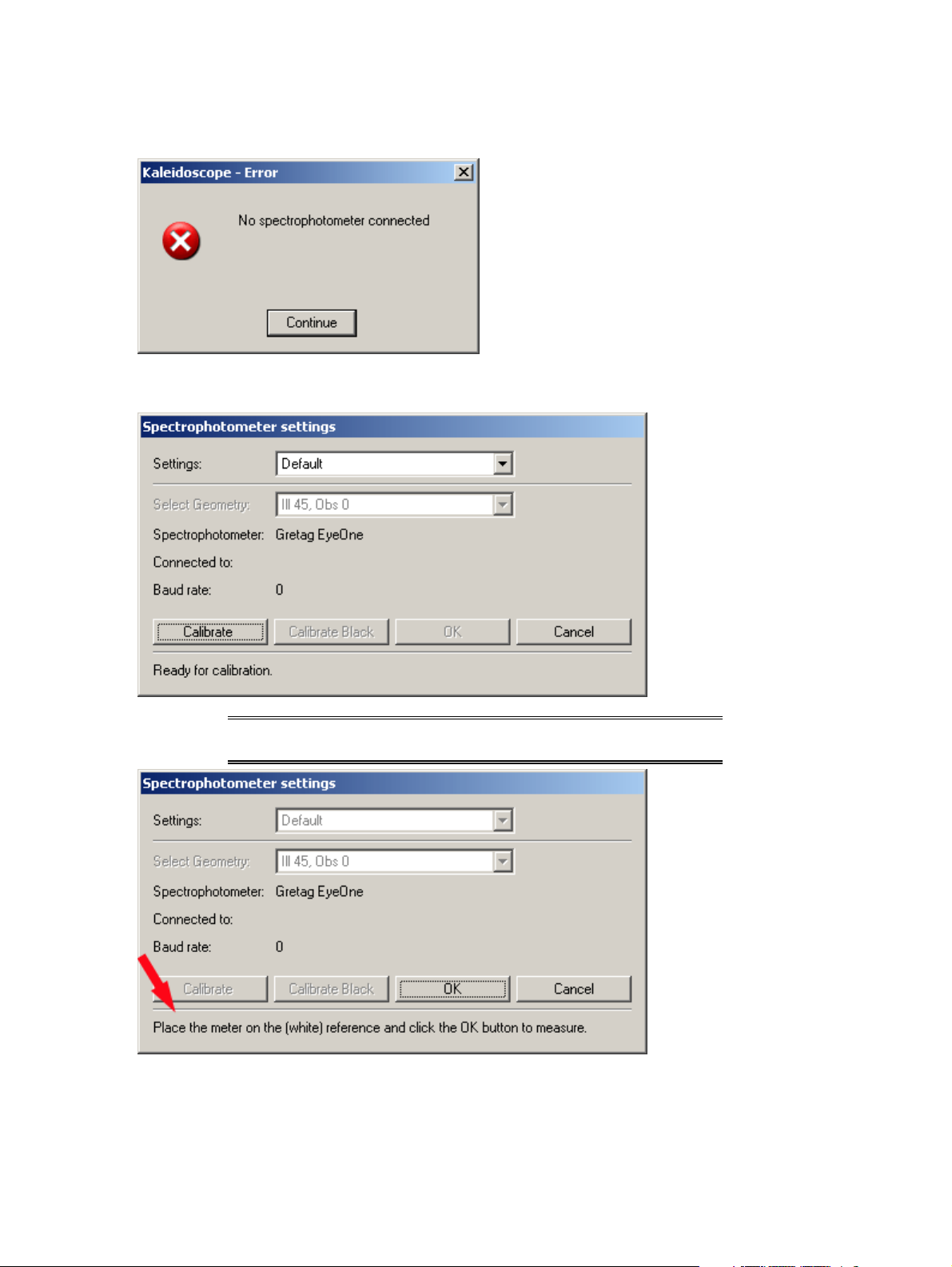

Warning

If no spectrophotometer is connected to your system the following error will come up.

13

Page 15

Spectrophotometer

2. Click 'Calibrate'.

Note: For hand-held spectrophotometers, you will be asked to put the

meter on the absolute white reference first.

14

Page 16

Spectrophotometer

3. If the calibration was successful, the following message will appear:

4. Click 'OK' to close the spectrophotometers settings window.

Note: With the ICColor, there is no need to perform a calibration

since the device calibrates itself.

Working with filters

Different filters can be used on a spectrophotometer:

• a Polarization filter, which can be used to take away the disturbing effect of measuring on a glossy

substrate.

• a D65 filter, which has to be used if D65 is used as reference light temperature.

• a UV filter, which can be used to take away UV light from the spectrophotometer light source. This

can be helpful if you are measuring on substrates with optical brighteners.

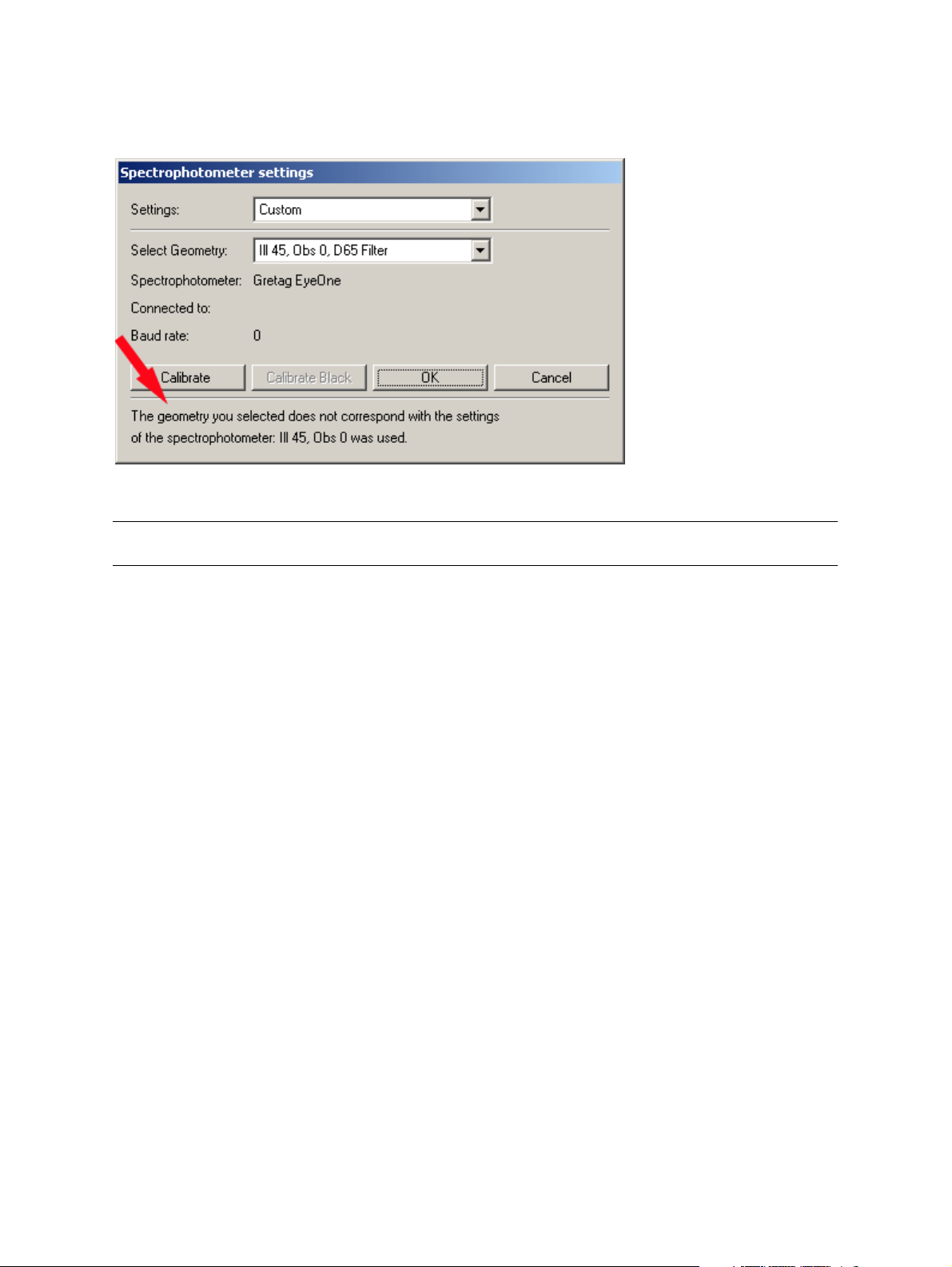

The default setting in Color Kit is NO filter. If you want to work with a filter please proceed as follows:

1. Make sure your spectrophotometer is connected to your workstation.

2. Put on the right filter.

3. Double-click the Spectrophotometer button (or go to the 'File' menu and choose 'Settings').

4. Change the Settings to Custom.

5. Select the right Geometry (D65 or Pol).

6. Click 'Calibrate'.

7. Click 'OK' and you come back to the same window.

8. Click 'OK' again.

If the following window comes up, the filter that you used does not correspond with the settings in

Color Kit. Please change either the filter or the settings and recalibrate.

15

Page 17

Spectrophotometer

Caution! If you have decided to use a filter, please use this filter to measure all profiles. Mixing

profiles measured with and without profiles might cause unwanted effects.

16

Page 18

Deciding on a testchart

First of all you have to decide which test chart to use. A couple of parameters will decide which

parameters will decide which chart is best for you:

• The type of spectrophotometer you will be using to measure the testchart.

• The number of patches you want to measure (normal or high quality). The choice between normal

or high quality is not available for all spectrophotometers.

• Whether you want to make a multi-color press profile or just CMYK.

For profiling CMYK only, we recommend charts that include black overprints. This means that not

only overprints of C,M,Y will be measured, but also overprints of K. Try to use the highest possible

quality. Some spectrophotometers have normal and high-resolution charts

The following overview chart will help you decide for CMYK charts.

All these testcharts can be found on Esko\bg_data_cms_v010\r\tim

If you are making a press profile please pick one from the chart underneath.

17

Page 19

Digital Proofing: Step by step

As you can see from the overview, different charts will be used for press profiles covering different

color regions. The naming convention for the color regions is as follows:

CMYK = CMYK

Orange, Red area = R

Green = G

Blue, Violet area = B

So if you are profiling a press with CMYK, Orange, and Violet, please pick the CMYKRB chart that

corresponds with your spectrophotometer.

Note! The list above explains all the possible combinations. In practice, the

choice of a chart will be practically intuitive. The list of charts is limited through

the choice of the output inks and the connected spectrophotometer. In the

step-by step workflow in section 9 this will become clear!

Making a new profile and printing the test chart on the press

Outputting charts on your press is needed to make a profile. A profile will describe overprints of

CMYK, CMYKOV or CMYKOVG in the CieLab colorspace.

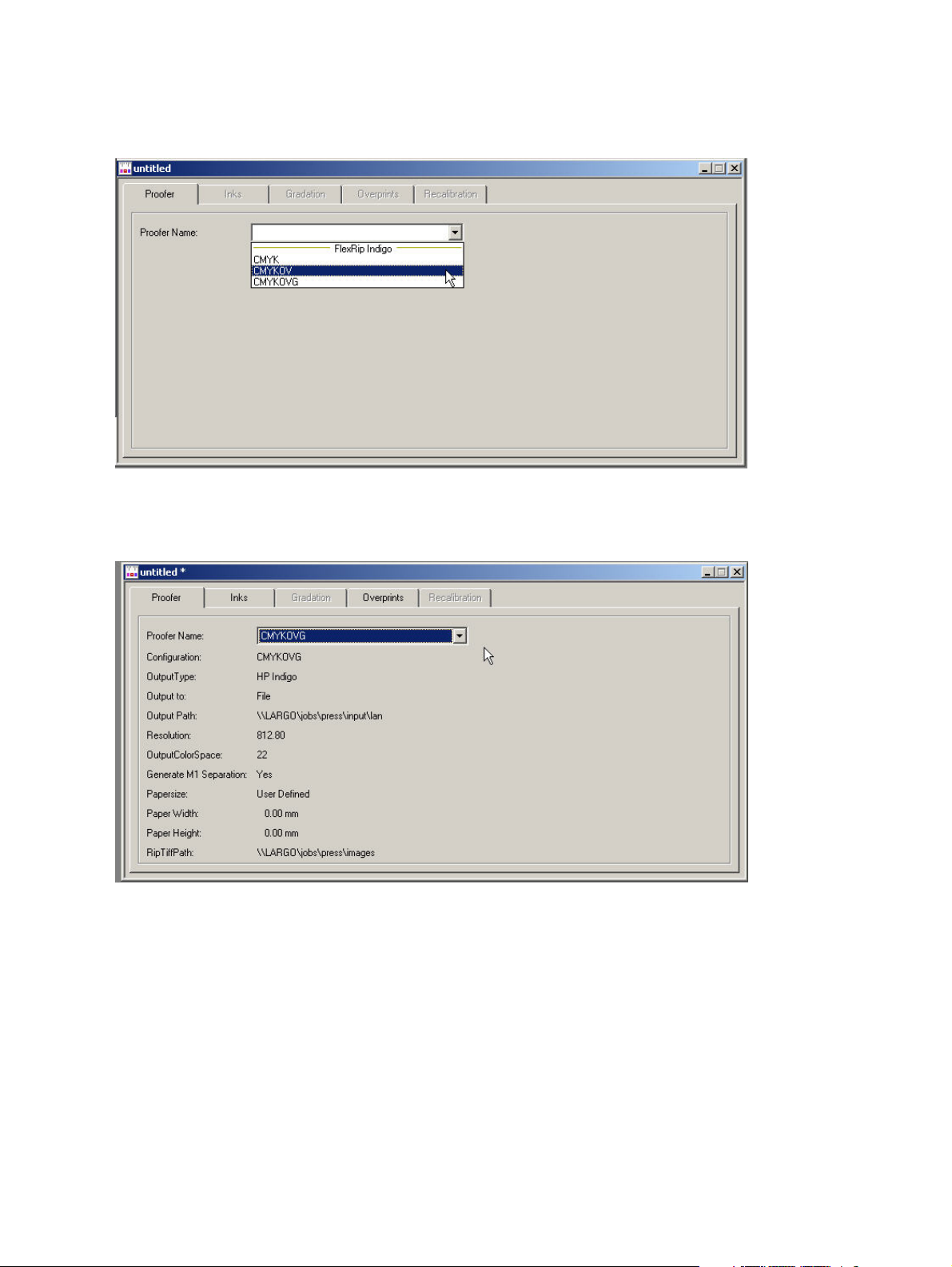

Start by defining a new proof process. In Color Kit, right-click on ‘Esko profiles, Proofer’ and choose

‘new’, or alternatively go to the File menu and choose ‘New’.

18

Page 20

Digital Proofing: Step by step

Choose your FlexRip configuration in the ‘proofer’ window. This can be CMYK, CMYKOV or

CMYKOGV. Remember that you can make configurations with the FlexRip Coinfigurator. The configurations mentioned above are pre-installed though, for your convenience. In the example below, we

decide to measure a profile for CMYKOV.

19

Page 21

Digital Proofing: Step by step

You will see some extra information displayed about the configuration.

Now you need to save the file, with ‘File’, ‘Save as”. Make sure the configuration and the substrate is

reflected in the name that you give. We also suggest to include press parameters, when you work with

different LUTs

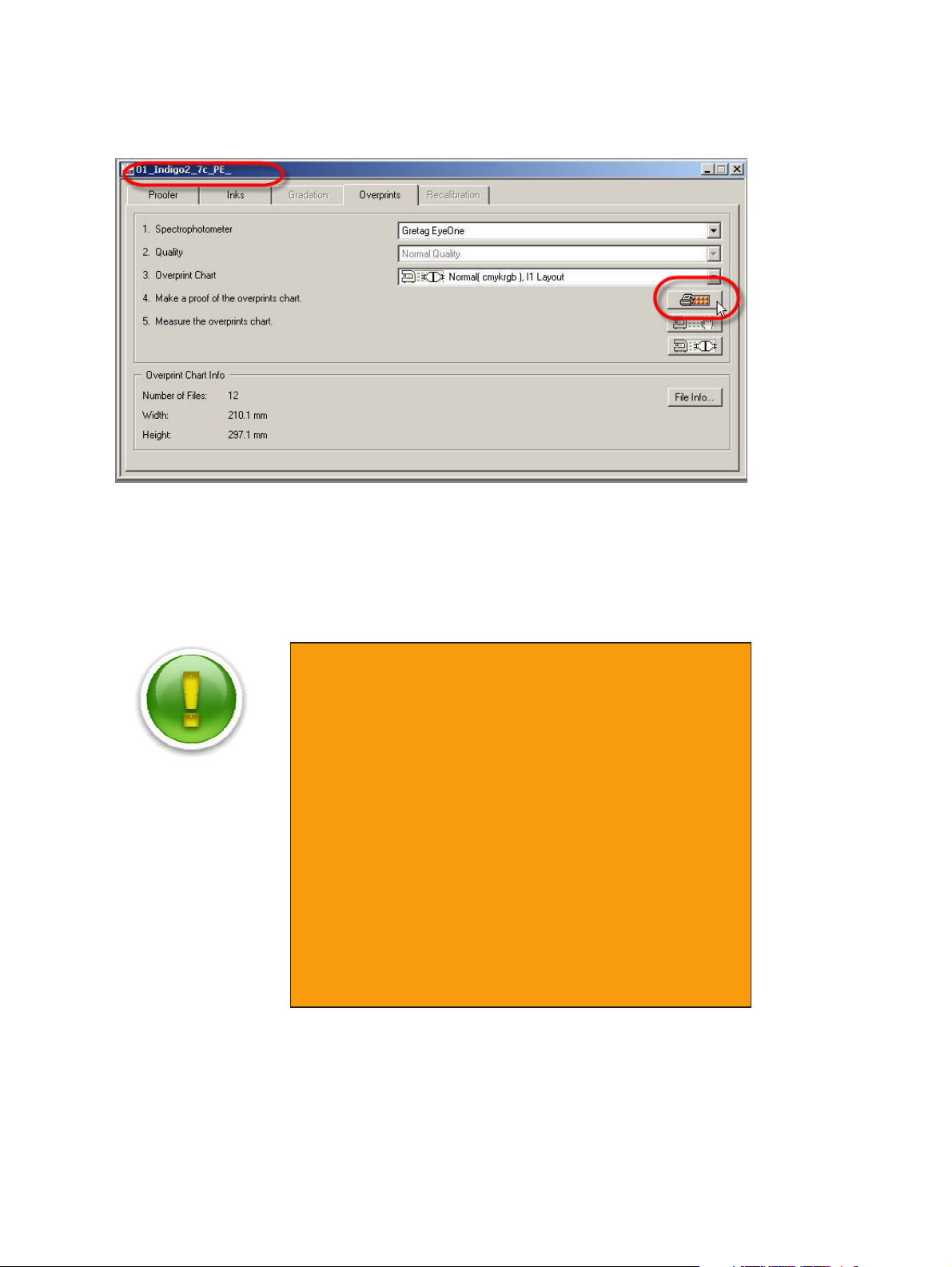

Proceed to the ‘Overprints’ tab. Mind that the icons on the right will stay grayed-out when you have not

saved the file!

20

Page 22

Digital Proofing: Step by step

You see the name that you have given in the upper-left corner. All you need to do to get the files

printed on the press is to click the proof button. You will see a progress bar at the bottom of your

screen. The charts can now be printed on the press. The screenshot above shows you an example of

a 7 color profile, with an i1 spectrophotometer attached.

IMPORTANT REMARK: It is when you actually print

the charts on the press, that all the parameters are

applied. Therefore we strongly advise to observe a

clear naming convention when you save profiles.

Please choose an accurate name that includes

substrate, output ink set and LUT.

When the charts to make this profile have been printed

with LUT05, you should later only apply it in your

production workflow duringon jobs to be printed with

THE CORRESPONDING LUT. Ripping jobs with a profile

made for one kind of LUT, and outputting it on the

press with a totally different LUT wo uld ha ve a s eri ous

effect on the output of colours.

Measuring the testchart

To start measuring the test-chart, make sure the spectrophotometer is hooked up to your system. See

Connecting a Spectorophotometer (page 7).

21

Page 23

Digital Proofing: Step by step

Go to the 'Overprints' tab.

Color Kit will now check which spectrophotometer is connected to your system. Only the layouts

available for this meter will be shown.

If the meter is not connected the following message will appear:

Please connect the meter, restart Color Kit and start again.

Click the measurement icon that corresponds with your meter.

• Gretag Eye One (strip reading) (page 22)

• Gretag Eye One (manual mode) (page 23)

• Gretag SpectroScan (page 23)

• Hand-held spectrophotometer (page 23)

• Xrite DTP41 (page 23)

• Gretag ICColor (page 24)

• Xrite DTP70 (page 25)

• Gretag Eye-One IO (page 25)

Note:

For automatic meters, click

For hand-held meters click

Automatic meters are: Gretag Spectroscan, Xrite Spectrofiler, Xrite DTp70, Gretag ICColor and

Gretag Eye One IO. All other meters are considered hand-held.

The Gretag Eye-One has 2 modes: it can be used as a strip reader using the ruler. In this case it is

considered an automatic meter. It can also be used to measure individual patches; then it is

considered manual.

If you are working with an ICColor, please refer to the chapter on the Gretag ICColor If you are

working with a DTP70 please refer to the chapter on the DTP70 .

Gretag Eye One (strip reading)

1. Take the first chart and put the ruler along the strip.

2. Click the manual measurement button (this starts a measurement session).

3. Press the button on the Eye-One.

4. Wait for the beep (while keeping the button on the Eye One pressed).

22

Page 24

Digital Proofing: Step by step

5. Slide the meter along the ruler at a constant pace (still holding the button pressed).

6. Release the button.

7. Wait until all measurements have been transferred.

8. Repeat this action until all strips have been measured and click 'OK' to finish the measurement.

Note: Only when there is a measurement error (e.g. bad reading),

you will have to click the measurement button again (to restart

the session).

Gretag Eye One (manual mode)

1. Take the first chart and place the meter holder on the first patch (100%C 100%M 100%Y).

2. Click the manual measurement button.

3. Repeat this action until all patches have been measured and click 'OK' to finish the measurement.

Gretag SpectroScan

You are prompted to put the overprints chart on the measuring table.

1. Place the (first) overprints chart on the measuring table.

2. Click 'OK'. Paper hold will now be activated.

3. Align the crosshair of the meter on the top left crosshair on the paper and press 'OK' to continue.

4. Align the crosshair of the meter on the top right crosshair on the paper and press 'OK' to continue.

5. Align the crosshair of the meter on the bottom left crosshair on the paper and press 'OK' to

continue. The SpectroScan will now measure the (first) chart.

If you are measuring a chart that contains more than one page, you will be asked to put the next

page on the measuring table. Click 'OK' when the next chart is placed on the table and repeat the

alignment procedure to measure the next page. Repeat this procedure for every page (e.g.

sp16x16_1234 has 4 pages, spscan_nonuni_cmyk has 2 pages).

6. When all pages are measured, click 'OK' to finish the measurement.

Xrite DTP41

1. Have the first chart ready.

2. Click the manual measurement button. With every click one row will be measured.

3. Feed the first row through the DTP41. The row number is printed on the chart.

23

Page 25

Digital Proofing: Step by step

4. Wait until all the measurements have been passed to Color Kit.

; Note

The CMYK combination shown in Color Kit corresponds with the next row that needs to be

measured. If a row was not measured correctly, it should be measured again.

5. Continue to feed all other rows through the meter.

6. When all rows have been fed through, click 'OK' to finish the measurement.

Gretag ICColor

1. Have the first page ready (the page number is mentioned on the chart).

2. Click the automatic measurement button.

3. Feed the first page through the ICColor.

4. Feed all other page through the meter.

5. When all pages have been measured, click 'OK' to finish.

24

Page 26

Digital Proofing: Step by step

Note: The chart can be inserted both ways: arrow first or arrow last.

Xrite DTP70

1. Have the first page ready (the page number is mentioned on the chart).

2. Click the automatic measurement button.

3. Feed the first page through the DTP70.

4. Feed all other page through the meter.

5. When all pages have been measured, click 'OK' to finish.

Gretag Eye-One IO

1. Adjust the height of the meter if necessary. Slide the substrate under the white reference to test the

height. The substrate should not get stuck and should not slide through too easily.

2. Click the automatic measurement button.

3. Follow the instuctions to place the page and align.

4. Place the first page on the scanning table (page number is mentioned on the chart).

5. Activate the electro-magnetic filed by pressing the button a the top-right of the meter.

6. Align the meter to the 3 crosshair and click OK (there is no need to click the Eye-One button)

7. Measure all pages and press 'OK' when finished'.

Verifying a profile

To avoid using a profile with measurement mistakes (due to the meter, the operator or the software),

the profile should be verified. Color Kit features a tool to visualize a native profile as an image.

Proceed as follows:

1. Go to the 'File' menu > 'Open' to open the proofer profile.

2. Go to the 'File' menu and click 'Show measurements'.

A new window opens in which all measurements are shown in an image.

A CMYK chart that includes black will look like this:

25

Page 27

Digital Proofing: Step by step

Visualizing the measurements of a multi-color profile looks like this: (mind the device coordinates

window, where you see the ink precentages when moving the cursor)

Check for white, black or double patches. When the profile is OK, it is ready to be used. If there are

mistakes in the profile, you can correct them by re-measuring. Color Kit can re-measure only the

patches that are wrong. Just go to the wrong patch with your mouse in the the "Show measurements"

tool and it will indicate the CMYK combination that you have to remeasure.

This CMYK value can be entered in when you re-measure.

26

Page 28

Digital Proofing: Step by step

To find the bad patch on the chart, select the patch by clicking it, and then select the Chart View tab.

The patches will now be shown as they are arranged on the chart, and the bad patch will be selected.

For the Eye-One and the X-Rite DTP41 spectrophotometers, row numbers will be indicated. This way

you will know where to place the meter when remeasuring.

Note: For some profiles, the name of the used chart is not stored in

the profile. In this case, the Chart Info group will contain

dropdown lists for selecting the Spectrophotometer and Chart.

On making a selection, the Chart View tab will become

available.

27

Page 29

Digital Proofing: Step by step

Recover a profile

If you have found mistakes in the measurement (see Verifying a profile (page 25)), you can correct the

mistakes by re-measuring the patches that were wrong. Please make sure the flaws are not in the

chart itself. When you have a fast spectrophotometer, sometimes remeasuring the complete charts(s)

is the easiest solution)

1. Open the printer/proofer process that you want to correct.

2. Go to the 'Overprints' tab.

3. Color Kit will now check which spectrophotometer is connected to your system. Only the layouts

available for this meter will be shown.

If the meter is not connected the following message will appear.

Please connect the meter and start again.

4. Select the type of chart you used to measure the profile.

5. Click the measurement button that corresponds with your meter.

6. Fill in the combination of C,M,Y and K where you want to start recovering.

Warning! If one of the numbers in the combination of CMYK

is 0, please fill in 0, do not leave the field blank!

7. Click 'Initialize'.

8. Click the measurement button.

28

Page 30

Digital Proofing: Step by step

Note: If you have to re-measure several non-subsequent patches,

you do not have to re-measure all the patches in-between.

Once you have re-measured the patches that were wrong you

can stop the measurements by clicking the measurement

button.

Export a profile

You can export a reference profile so it can be used at a remote site.

1. Open the profile.

2. Go to 'File' > 'Export'.

3. Browse to the directory in which you want to save the exported profile.

4. Click 'OK'.

This will result in an .FP file, which can be sent to the remote site.

Note: Ink books, process links and color strategies can also be

exported and will also result in an .FP file. It is good practice to

mention the type of element you exported in the name because

Color Kit does not distinguish between different types of .FP

files when importing. e.g my_press.fp or designer_inkbook.fp

or this_is_a_process_link.fp.

Import a profile

An exported profile can be imported at a remote site.

1. Go to 'Measured profiles'.

2. Select 'Proofer'.

3. Go to 'File' ⇒ 'Import'.

4. Browse to the directory where the .FP file is located.

5. Select the .FP file and click 'OK'.

6. Save the imported profile with 'Save as'.

Note: If you do not know what document type the .FP file is, you can

drag it on to the Color Kit shortcut on your desktop. Color Kit

will then open the file, automatically determine the document

type, and import it.

Using the profiles

We recommend that you make color strategies from your profiles.

Color Strategies

Color Strategies are a bundle of Color management settings. By bundling these options, it becomes

very easy for users to select the right 'strategy'. Trained Color Kit users will generate these strategies

29

Page 31

Digital Proofing: Step by step

and other operators just pick one. This makes life easier for operators and makes a color workflow

less error prone. Color Strategies are only used in FlexProof and can be selected in BackStage, in

the Dispatcher and in the Image Downloader (task). Color strategies may contain:

• Input and output color space

• Settings for a CMYK color conversion (typically a device link)

• Settings to overrule a substrate color

• Settings to determine the ink order

• Settings for conversion of special inks

Input and output color space

A color strategy should contain an input (reference profile) and an output (proofer or destination) color

profile.

Click on strategy and right-click on ‘New’. You just made your new strategy.

Note

Output profile can be set to 'Automatic', in which case the input profile will also serve as output profile.

Ink Mapping

Ink mapping allows you to map a job ink to another ink.

This is particularly interesting in an ink profiler workflow.

Dot gain simulation

Dot gain simulation is a dot gain compensation curve or a group of dot gain curves that can be

specified when making digital proofs. You can also specify a different curve per ink in your job.

Note

Specific sets of dot gain simulation curves can be saved under a 'Quick Set'.

Dot gain simulation allows you to:

• Specify a reverse DGC curve when making digital proofs (for Flexo) (page 31).

• Specify a "bump up" curve for highlight correction when making digital proofs (page 31).

• Measure once, simulate many processes on your digital proof (page Error! Bookmark not

defined.).

30

Page 32

Digital Proofing: Step by step

• Simulate a different dot gain for special colors and process colors (page Error! Bookmark not

defined.).

Convert special inks

Here you can decide how special inks are converted. The general rule how inks should be converted,

is set under 'conversion values’:

Depending on the number of output inks (3,4, 6 or 7) the list of conversion methods will change.

For CMYK output there are several ways to convert Pantone colors:

1. Use destination profile: with this option, Pantone inks will be converted to CMYK using the Use

destination profile. It takes into account the proofer CMYK color space. This option is the most

accurate if you have measured a profile of your proofer.

2. Pantone CMYK: With this option Pantones will be converted to CMYK according to the Pantone

table (SWOP and EURO).

3. HP Indigo CMYK 1.0: with this option Pantones will be converted to CMYK according to the HP

Indigo CMYK 1.0 table. Remember that using this option causes the Pantone

be converted anymore with the profile, but a fixed table is used. Investing work in the creation of a

profile and then choosing this option is contradictory. This option is used for the standard color

strategy HPI-CMYKW106use of custom2

For 6 color output (HP IndiChrome. Or with any 6 color Esko profile), there are two ways to convert

Spot colors to 6 output colors:

• Use destination profile: with this option, Pantone inks will be converted to CMYKOG or CMYKOV

using the destination profile . It takes into account the output color space. This option is the most

accurate if you have measured a profile of your proofer.

• Pantone HexaChrome: (only if a HexaChrome profile is selected) with this option Pantones will be

converted to CMYKOG according to the Pantone table. We do not recommend to use this

®

or spot inks not to

31

Page 33

Digital Proofing: Step by step

conversion method in an HP Indigo workflow, as the ink characteristics of the Indigo press are

®

different than the characteristics of the Pantone

HexaChrome inks.

• HP IndiChrome: (only if an IndiChrome profile is selected) with this option Pantones will be

converted to CMYKOV according to the HP IndiChrome table. Remember that using this option

causes the Pantone

®

or spot inks not to be converted anymore with the profile, but a fixed table is

used. Investing work in the creation of a profile and then choosing this option is contradictory. This

option is used for the standard color strategy HPI-CMYKOVW

Note

If you are working with an Esko multi-color profile as destination, you can decide whether you want to

use the full color gamut (5, 6 or 7 colors) or limit the output inks to CMYK.

‘Generate no CMYK’ means you will use the full color gamut. Spot colors will be simulated using 3

colors (2 neighboring colors + black).

‘Generate only CMYK’ means that, even though you are specifying a multi-color profile, you would

like spot colors to be simulated with CMYK only.

This option makes spot color simulation cheaper (in case of Kodak Approval less donors will be used;

in case of Indigo less impressions) but also makes spot color simulation less accurate.

‘Generate preferably CMYK’ means you would like to simulate spot colors using CMYK if the color

deviation is not bigger than a certain tolerance. Only if the deviation is bigger than the entered Delta E,

it will use all available output colors.

For 7 color output (HP Indigo CMYK OGV), there is only 1 option: Use Destination Profile.

Exceptions to these rules can be specified in the window 'Exceptions (page 32)'.

Exceptions

Exceptions to these rules can be specified in the window 'Exceptions'. To make an exception to the

rule, proceed as follows:

32

Page 34

Digital Proofing: Step by step

1. Open an ink book by double-clicking an empty patch or by clicking the ink book symbol in the ink

toolbar.

2. Drag and drop the ink(s) that you want to assign exceptions to choose the kind of exception.

; Note

You can skip step 1 and 2 by simply clicking the name field of an empty row and entering the name

or abbreviation of an ink .

When you press 'Enter', the ink is searched first in Pantone and then in Designer book and the row

is completed if the ink is found in any of these books.

If you are not happy with the ink you can start by entering the ink book name and afterwards the

ink name.

3. If you click the ‘Use’ column, you will see that there are 5 options:

• Destination profile: with this option, Pantone inks will be converted to CMYK using the output

profile.

• Keep in output: with this option, FlexProof will generate an extra separation. This is where you

should specify the white ink that should appear as a separate separation on the Indigo press.

• Do not proof: with option the ink will not be proofed.

• Use Custom Values: you can define your own output values. This option allows you to finetune

spot colors. When you select 'Use Custom Values', the fields become editable and you can

change the numbers. In the example below the profile gives us 1.1% of Cyan for Pantone

106. We reduce this to 0%

®

33

Page 35

Digital Proofing: Step by step

Choose the conversion method ‘Custom values’ for the ink PANTONE

®

106.

You now manually adapt the percentage. In this example we replace the 1.1.% by 0.

• Smallest CIELAB Delta E: This option will further refine the values obtained through the

Destination profile in order get a lower CIELAB DeltaE between target and proof.

4. Depending on the type of ink that you put in the exceptions list and the amount of inks in the

output profile, there may be different conversion tables in the list of options. At this moment there

are only conversion tables for Pantone inks:

• Pantone CMYK Swop (Has been overruled by Color Bridge but we still provide it for

compatibility with the past)

34

Page 36

Digital Proofing: Step by step

• Pantone CMYK Euro (Has been overruled by Color Bridge but we still provide it for compatibility

with the past)

• Pantone Color Bridge Swop (As released in June 2006 by Pantone)

• Pantone Color Bridge Swop

• Pantone Hexachrome

• HP Indigo CMYK 1.0

• HP IndiChrome

• HP IndiChrome Plus 1.0

In the example below, all Pantone inks are converted to CMYK using the proofer profile, except for all

Cool Grey inks. When you use Pantone conversion for Cool Gray inks, they will be converted to K

only, which is much less prone to color casts.

Refine tool

When reproducing spot colors on a proofer, a profile gives you the best first shot possible. However,

fine tuning spot color simulation is common practice and extra tools will make fine-tuning easier. The

Color Refine Tool is accessible from the convert special inks dialog for Color Strategies. Users are

able to refine inks using either custom values or destination profile values. Click the refine icon in the

inks toolbar to open the Refine Tool.

The Color Refine Tool offers the following functionality:

• Fine-tuned colors are visualized on the monitor.

• For colors using customized values, the user can manually adjust the proofer coordinates,

comparing the new color to both the current color and the input color, both visually and through

Lab / ∆E.

• For colors using customized values, a grid chart can be proofed, allowing the user to manually

select the right patch from the proofed output.

• For colors using destination profile values, the user can re-measure the simulated spot color

(iteration). Multiple iterations are possible.

35

Page 37

Digital Proofing: Step by step

Refining the values obtained through the destination profile

When opening the refine tool for an ink that is using Destination Profile, the dialog will look like to this:

There are only three buttons: the OK button, which is disabled in the beginning, the cancel button, and

the measure button. If you click the measure button, a single measurement will be made. This

measurement is compared to the Proofed Color and from that a Refined Color is calculated, matching

the predicted Lab values for the Destination Profile. Once a refined color is obtained, the OK button is

enabled. Clicking it will reopen the convert special inks dialog, where now, instead of Destination

36

Page 38

Digital Proofing: Step by step

Profile, the option Refined Destination Profile is selected for the refined ink, while the selected values

will be the new refined values.

Remark that in the example above, we provoked distinctively different values, just to show you how

the interface behaves.

Some explanation may be needed here about the difference between Destination Profile and Proofed

Color. This is best illustrated by a description of a possible workflow. Typically, a user creating a color

strategy will have all his special inks converted using the destination profile, which is the best possible

first guess. Then, after making a proof containing a number of spot colors he will decide that some

spot colors may need refinement. The user will then add these inks to the special inks exception list,

select the Destination Profile option and start the Refinement Tool. When the user has proofed using

the destination profile values, the values in the Destination Profile and Proofed Color columns will be

the same. The Lab values shown in the Destination Profile column are those values that CMS expects

to be measured.

37

Page 39

Digital Proofing: Step by step

When making a measurement, the measured Lab values will appear in the Proofed Color column.

Comparing those to the Lab values in the Destination Profile column, CMS will estimate how ‘wrong’

the profile is (due to drift of the proofer, or inaccuracy due to limited resolution), and shift the profile a

little bit to match the measurement , just for this ink. With this ‘shifted profile’ a new match will be

calculated.

After the user has accepted the refined values, new proofs will be made. At this point the user can

decide to do another refinement, because the refined color still is not accurate enough. The option in

the special inks list for the ink to be refined will now be Refined Destination Profile, showing the

refined values. When opening the Color Refinement Tool, the user will see that Destination Profile and

Proofed Color have different values: Proofed Color shows the values obtained in the previous

refinement, while Destination Profile is still the same. Make sure that the patch you are about to

measure was proofed using the refined values.

Why is this important? To make any prediction, CMS must know what ink values were used to

produce the measured color. There is no point in telling CMS that the measured color is very different

from the target color when it was made with totally unrelated ink values. Without this, there would be

no point in multiple measurements.

Why take multiple measurements? CMS may be able to make an accurate prediction for smaller color

differences, but as the difference becomes larger, the prediction is likely to become inaccurate.

Making a first refinement will bring you closer, while a second or even third refinement may correct for

the over- or undershoot of the first refinement.

Note that this workflow assumes that the predicted Lab values for the destination profile conversion

are assumed to be the best match. For out-of-gamut colors, depending on the opinion of the user, this

may not be the case. For this reason, the ‘Custom Values’-based workflow is advised for out-of-gamut

colors.

Refining Custom Values

Refining custom values works somewhat different compared to refining destination profile values.

Here the user manually adjusts the ink values, judging the result either visually or through one of the

supplied ∆E formulas. Values can be edited by clicking the ink percentage you want to modify (inside the black

rectangle). It is also possible to proof grid charts, which are discussed in the next section.

Several precautions should be taken into account when interpreting the result. First of all, even when the monitor

has been calibrated, the colors are not absolute, so only color differences should be judged visually, never absolute

colors. Also, colors outside monitor gamut may seem the same while in reality they are considerably different.

For this reason, an option is available to desaturate the colors so they are all inside monitor gamut. The accuracy of

this desaturation is however limited.

Proofing a Grid Chart

For inks/colors using customized values, a grid chart can be proofed, allowing the user to manually select the right

patch from the proofed output. These grid charts contain patches with different ink combinations that vary around

a central value. The user can specify up to 3 varying inks, and for each ink several parameters can be set:

38

Page 40

Digital Proofing: Step by step

• The central value: by default the new custom value selected in the Refine Custom Values dialog

box.

• The difference in ink percentage for each variation.

• The number of upward and downward variations.

A preview function is also available.

Custom Values and double strike

The HP indigo press can print more then 100% of an ink, e.g.. For these proofers Color Kit allows to

specify custom values higher then 100% in the color strategy.

When the color strategy above is used in FlexProof, two magenta separations will be generated if the

job contains Pantone Purple. The first separation will contain 100% Magenta , the second will contain

50% Magenta.

If for an exception ink one of the custom values is higher then 100%, a warning sign will appear in the

Delta E column. This is because we can no longer calculate nor guarantee the color accuracy.

Match solids / Match Inks

Choose match solids to maximize the simulation of spot color solids (100% spot color).

39

Page 41

Digital Proofing: Step by step

We recommend that you use this option in your color strategies for HP Indigo.

Note

Match inks is the default behavior and is compatible with previous versions of Color Kit/FlexRip

Gamut Mapping

Out of gamut colors can be rendered in different ways. Closest color (classic) will map the

out-of-gamut color to the closest color within the color gamut. This might introduce a hue shift.

Example

When trying to reproduce PMS Purple on an HP Indigo press, the closest color gamut mapping

technique causes the PMS Purple to shift to a blue-ish color.

To avoid PMS Purple from shifting to a blue-ish color in the example above, the ‘constant hue gamut

mapping technique can be used. This technique tries to maintain the hue of the color. The result in the

example above would be that PMS Purple would be reproduced as a much less saturated purple.

Tuning curve

With tuning curves, the final output can be finetuned. We do not recommend to use this feature for

color strategies for HP Indigo.

Example

Proofs turn out to have a red cast. With 'tuning curves' you can pull down the yellow and the magenta

to compensate.

40

Page 42

Digital Proofing: Step by step

Extra Output inks

'Extra output inks' allows you to specify extra output inks for printers that have more than CMYK inks.

If you proof to this device with a strategy that contains extra output inks, these separations will not be

color managed but passed on directly to a separate output file.

To add extra output inks, proceed as follows:

1. Open the 'Extra output inks' window by double-clicking on 'Extra Output inks'.

2. Open an ink book by double-clicking the ink book icon.

3. Drag and drop the inks from the Pantone ink book or the designer ink book to the extra output inks

window.

For HP Indigo, "White" will typically be defined as an extra output ink. You can set an ink ONLY in the

‘Extra Output Inks’.

Also in the ‘Convert Special Inks’ menu, inks specified as extra output inks appear in the exception

list, but one cannot SET it there. The extra output inks are greyed-out and are shown as ‘Keep in

Output’.

41

Page 43

Digital Proofing: Step by step

Also, when mixing custom inks for HP Indigo, they will need to be defined as extra output ink.

Export a color strategy

Color strategies can be exported to one single file to be used on a remote site. All elements (inks,

profiles, process links, dot gain simulation curves) will be included in one File Packer (.FP) file.

1. Open the color strategy.

2. Go to 'File' > 'Export'.

3. Browse to the directory where you want to store the exported file and click 'OK'.

Note

Ink books, profiles and device links can also be exported separately and will also result into an .FP

file. It is good practice to mention the type of element you exported in the name because Color Kit

does not distinguish between different types of .FP files when importing. e.g.

this_is_a_color_strategy.fp

Import a color strategy

An exported color strategy can be imported on a remote site.

1. Go to 'Color Strategies'.

2. Go to 'File' ⇒ 'Import'.

3. Browse to the directory where the .FP file is located.

4. Select the .FP file and click 'OK'.

5. Save the imported profile with 'Save as'.

Note

If the imported color strategy contains elements that already are in your database, the original files will

not be overwritten. The following message will pop up:

42

Page 44

Digital Proofing: Step by step

Note

If you are trying to import an .FP file that is not a color strategy, the following error will pop up:

43

Page 45

ICC profiles

• Definition of ICC profiles (page 44)

• Notes on importing an ICC profile (page 44)

• Exporting to ICC profiles (page 45)

• Notes on exporting to an ICC profile (page 46)

• Importing ICC profiles (page 47)

• Viewing ICC profiles (page 47)

Definition of ICC profiles

An ICC Profile is a piece of data that defines the color and reproduction characteristics of a device.

ICC Profiles are written in a standard data format that is OS independent.

Everybody can read and write ICC profiles if they know the data format.

; Note

Esko only supports V2 ICC profiles, not V4 (2001 specification)

In order to represent a color on a device, we need to know the color's coordinates for that device. This

is done by the Color Management System. The CMS is capable of translating colors specified in a

device dependent coordinate into the coordinates for another device, thus matching colors between

an original image, scanner, monitor, printer... ColorSync is the built-in CMS for Apple computers and

is also used by some third party vendors. Colorsync 'links together' ICC-profiles to get a translation

from one device to another. This can be compared to processlinks in Color Kit. Another important

CMS is Image Color Matching (ICM) for a Windows platform.

An ICC Profile can be compared to an Esko profile since it is also a piece of data that defines the

colors of a specific device.

However, there are some important differences.

Notes on importing an ICC profile

When importing ICC profiles into Color Kit, bear in mind that the quality of the profile strongly depends

on:

• The precision of the spectrophotometer with which the profiles are made. Not all

spectrophotometers are high-end and produce accurate data. Esko has carefully selected the

accurate spectrophotometers (See: supported spectrophotometers (page 7).)

44

Page 46

ICC profiles

• Stability of the devices. If you downloaded a profile of a particular monitor, it does not necessarily

mean that your monitor produces the same colors, even though it concerns exactly the same

model. Every device can be different and should be profiled separately for optimal results.

• Stability in time of the device. The colors of the device might have drifted since the profile was

made.

Also bear in mind that ICC has standardized the dataformat of the profiles, not the characterization of

devices, for colormatching. ICC allows for private tags which makes that a profile can contain

information that cannot be read by everyone.

In other words, if you have a proofer profile which produced good results with a particular RIP, it does

not mean that it will yield the same results with FlexProof because of the private tags.

Exporting to ICC profiles

All types of Esko profiles (except special color and multi color profiles) can be converted to ICC

profiles. Proceed as follows:

1. Go the ICC profiles dialog box.

2. Choose which kind of ICC profile you want to generate (monitor, printer).

; Note

There are no 'native' scanner profiles to be exported by Color Kit.

3. Go to the 'File' menu and choose 'New'.

4. Choose the Esko profile you want to export.

5. Choose a quality and a Gamut Mapping Technique.

6. Go to the 'File' menu and choose 'Save as'.

7. Enter a name and click 'OK'.

The ICC profile will now be calculated.

; Note

Depending on the quality chosen and the speed of your computer, calculation time may vary.

45

Page 47

ICC profiles

; Note

It is not possible to influence the settings for black generation at this moment. The ICC profiles that

Color Kit generates, alwayswill use minimal black.

• Using Dot gain simulation curves (page 46)

• Using Refinement curves (page 46)

• Using Black Generation (page 46)

Using Dot gain simulation curves

When exporting to an ICC profile, it is possible to use 'dot gain simulation' curves. These curves will

only have an effect if the profile is used as a reference profile.

This type of dot gain simulation can be compared to the dot gain simulation used in Color Strategies.

Using Refinement curves

When exporting to an ICC profile, it is also possible to use 'refinement' curves. These curves will have

an effect only if the profile is used as an output profile.

Refinement curves can be used to fine-tune the output colors.

Example

If the reds on your calibrated proofer are too strong, dgc curves can be used to cut back the magenta

and yellow. This information will be stored in the ICC profile.

Using Black Generation

When exporting a CMYK profile, the Separation tab will be enabled. This is where you can specify a

black generation preset, as described in the chapter Black Generation in ICC Profiles.

Notes on exporting to an ICC profile

When exporting to ICC, bear in mind that different CMS vendors will make different colormatches,

even if the same profiles were used. These differences can be caused by the fact that:

• ICC profiles do not contain measured data points. The relation between data points in the profile

and the measured data points is profile vendor specific.

• The accuracy of the algorithms and the techniques that are used in the CMM and by the different

answers to the following questions:

• What to do with out-of-gamut colors?

• How to interpolate between the measured points in the Profiles?

46

Page 48

ICC profiles

Importing ICC profiles

• Import an ICC profile (page 47)

• Use the ICC profile in any Esko application (page 47)

• Build process links and color strategies with ICC profiles (page 47)

Import an ICC profile

To import an ICC profile (.ICC or .ICM file) into the Color Kit database, proceed as follows:

1. Go to 'Icc Profiles'.

2. Go to the 'File' menu and choose 'Register'.

3. Browse to the directory in which the profile is located, select the profile(s) and click 'OK'.

; Note

ICC profiles are not converted to Esko profiles.

Build process links and color strategies with ICC profiles

ICC profiles can also be used to build device links and color strategies. Note that using device links

and color strategies will generate a more accurate result than just using the profiles.

Viewing ICC profiles

You can use Color Kit to view the conversion tables stored inside an ICC profile’s, by opening an ICC

profile and then selecting 'Show Measurements' from the File menu. This function is very similar to

verifying a measured Esko profile, except that for an Esko profile you can see the actual

measurements, while for an ICC profile the conversion table generated from the measurement data is

shown.

Imported as well as Esko-generated ICC profiles can be viewed. Both the A2B and B2A Absolute

Colorimetric tags can be viewed, for profiles with up to 7 inks. For the B2A tag, you can view both the

input Lab and the Lab after gamut mapping.

47

Page 49

Dealing with Special colors

Color Kit features tools that enable you to characterize inks.

The standard library of Pantone inks was also characterized in this way (Cromalin based).

With Color Kit, you can also create your inks (and ink database).

We strongly advise to use the Designer Ink Book for Profiled inks since only 3 books are recognized

throughout the system: Process, Pantone Colors Coated and Designer. In all your jobs, you should

ONLY use inks that are in those three inkbooks.

However, if you would measure your own Pantone

incoming inks (used in your job) to that special inkbook.

How to create your own inks?

®

book, you must use inkmapping to map

• Copying from an existing ink book (page 48)

• Measuring an ink with a spectrophotometer (page 48)

• Creating an ink by entering an LAB value (page Error! Bookmark not defined.)

Copying from an existing ink book

This can be useful if you want to use the spectral information and accuracy of a Pantone ink but you

want to give the ink another name.

1. Open the ink book you want to copy an ink from (e.g. the Pantone Color Coated book).

2. Open the ink book you want to copy the ink to (e.g. the Designer inkbook).

3. Drag and drop the ink into the ink book (or use Copy/Paste).

Measuring an ink with a spectrophotometer

For outputting to your HP Indigo digital Press, we recommend to introduce special colours into the

designer book by measuring the 100% patch. Click

Measuring the 100% patch

You can 'profile' an ink with only one measurement. This can be very useful if you want to simulate a

special flat tint and the thing you have is an original. In this case you can measure this single color

with your spectrophotometer. Proceed as follows:

1. Open the ink book you want to add the ink to.

2. Select an empty color patch.

3. Put the head of your spectrophotometer on the color that you want to measure.

48

Page 50

Dealing with Special colors

; Note

If you are working with a Gretag SpectroScan, you will have to align the crosshair on the patch that

you want to measure.

4. Click the 'one measurement' button:

5. Give an appropriate name to the ink.

6. Go to the 'File' menu and click 'Save' to save the changes you made to the ink book.

Creating an ink by entering an LAB value

A third way to add an ink to the database is by entering an LAB value:

1. Open the ink book you want to add the ink to.

2. Select an empty color patch.

3. Click the Lab icon

4. The 'Add Lab color...' window appears:

5. Enter a LAB value or use the sliders to determine the color.

; Note

'L' determines the Lightness, 'a' is the Green-Red axis and 'b' is the Yellow-Blue axis.

49

Page 51

Dealing with Special colors

Info on inks

Inks from the standard Esko ink books:

Inks based on an LAB value:

Export an ink book

1. Open the ink book you want to export.

2. Go to the 'File' menu > 'Export'.

3. Browse to a location, enter an appropriate file name and click 'OK'.

This will result in a .FP (File Packer) file, which can be sent to a remote site.

; Note

Profiles, device links and color strategies can also be exported and will also result into an .FP file. It is

good practice to mention the type of element you exported in the name because Color Kit does not

distinguish between different types of .FP files when importing. e.g. my_press.fp or

designer_inkbook.fp or this_is_a_process_link.fp

50

Page 52

Dealing with Special colors

Import an ink book

1. Go to 'Ink books' in the main dialog box.

2. Go to the 'File' menu > 'Import'.

3. Browse to the location where the packed ink book (an .FP file) is located and click 'OK'.

4. Go to the 'File' menu and save the ink book with an appropriate name.

; Note

Only 3 books are recognized throughout the system: Process, Pantone Colors Coated and Designer.

Proof an ink book

You can make a proof of an ink book by opening the ink book and clicking the Proof button in the

toolbar on the right:

A dialog box will pop up in which you can specify print settings. In the Color tab you can select the

proofer configuration and color conversion settings. Two modes are available: to a profile, and through

a color strategy. This is similar to the Gamut Check tool (page 59).

In the Layout tab you can select the layout style for the ink book. You can make the book look like the

standard PANTONE book, or make a smaller book or print patches only if you want to use less ink

51

Page 53

Dealing with Special colors

and substrate. You can also limit the page dimensions (by default, the full page width will always be

used) and specify a page range.

; Note

For the PANTONE book, the page numbers of the ink book in the database do not match those on the

official printed books, because additional pages with numbers like e.g. 10.5 are inserted. So when

specifying a page range, make sure that you specify numbers from the book in the CMS database.

In the Advanced tab, you can specify whether or not to keep the ink book’s layout as it is shown in

Color Kit, or to put all patches next to each other and skip empty patches. You can also specify to print

various information about the inks next to the patches.

52

Page 54

Dealing with Special colors

; Note

Pages and columns that are completely empty will be skipped automatically.

53

Page 55

Tools

• Links (page 54)

• Gamut View (page 56)

• Compare Inks (page 58)

• Gamut Check (page 59)

• Average Profiles (page 60)

• Preferences (page 62)

Links

'Links' allows you to quickly find out if a certain element (an ink, a profile, …) is referenced somewhere

else in the CMS database.

Example

To find out if a profile is used in a device link, you can use Links. The main objective is not only to find

out but also to delete elements from the database. Since elements cannot be deleted when they are

still referenced, it is important to know what element needs to be deleted first.

Example

I would like to delete a profile from the database because I do not use it anymore. Color Kit does not

allow me to delete it because there is a device link that uses this process.

• How to use 'Links'? (page 54)

• How to use 'Links' to delete elements (page 55)

How to use 'Links'?

Links can be used on inks, measured profiles, ICC profiles, device links and Color strategies.

The basic procedure is:

1. Open the element of which you want to check the links.

2. Go to the 'File' menu and click 'Links…'

Example

To check Links of a particular print process, proceed as follows:

1. Open the print process.

2. Go to the 'File' menu and click Links…

54

Page 56

Tools

The red arrows tells you that the selected profile 'proofer_8x8_black' is referenced 5 times in device

links and as many color strategies.

; Note

Other Links can be found from the first window. Just double-click an element or select an element and

click 'Links for Selected'.

The links for the selected profile 'HP5000', are shown in a new window. In this example, the profile is

not linked anywhere and could be deleted.

How to use 'Links' to delete elements

As soon as the links for a certain element have been found, 'Links' can be used to delete the elements

selected in RED.

To delete all red elements at once, click 'Delete' in the 'Links' window and confirm.

; Note

Only elements selected in red can be deleted.

; Note

Green arrows indicate what the selected elements are made of.

55

Page 57

Tools

; Note

Read-only elements cannot be deleted from “Links”.

Gamut View

With gamut view, you can evaluate the color gamut of a device and compare different color gamuts

with each other. The color gamut(s) can be viewed along the L axis or along the a-b axis. A 2-D

section will be shown.

Example

You can see the differnce between the gamut of press output on a glossy paper with press output on

matte paper.

1. Go to the 'Tools' menu and choose 'Gamut View'.

2. In Plane selection, click 'L' to see the gamut from on top, click 'Hue' to see the gamut from the side.

The sliders determine the place where the section will be taken.

Example

With L set to 50, the gamut section will be taken at L=50.

3. Double-click the white field under 'Profile' and select a profile from the list.

4. Click 'Show Plane' to view the profile's color gamut.

56

Page 58

Tools

To delete a profile from the list, press the 'Delete' button on your keyboard or select the icon from the

toolbar next to ‘Profiles:’

You can change the color of the visualization by first selecting a profile and then select the refine icon

in the toolbar next to ‘Profiles:’

An RGB slider pops up, which allows you to change the color. Click 'Show plane again' to work with

the new color.

To compare two or more profiles with each other, add more profiles to the list, give them different

colors to be able to see the difference, make sure the profile is checked and click 'Show Plane'.

57

Page 59

Tools

In the example above, a press profile (blue) and a proofer profile (red) are compared. You can see

that the press profile is virtually completely covered by the proofer profile.

Compare Inks

This tool allows you to compare colors. Colors can be dragged and dropped from an inkbook (e.g

Pantone book) and compared with a sample color that is measured or also dragged from an ink book.

Both the LAB of the individual color and the Delta E between the 2 colors are displayed.

You can also add colors by measuring a single patch, or specifying either CMYK, RGB or Lab values.

58

Page 60

Tools

A list of comparions can be made and exported to a text file by clicking the 'Save As...' button in the

bottom-right corner.

Gamut Check

A Gamut check allows you to verify if colors are in or outside gamut of a given profile (which can be

3,4,5,6,7 color profiles).

The example above shows how Pantone colors will be simulated on an Indigo using 7 colours.

59

Page 61

Tools

For every Pantone, the Gamut check window tells you:

• How it will be separated.

• If it is inside gamut or not (a tick means it is inside).

• The last column tells something about how far the color is out of gamut.

• The last column also indicates the accuracy of the profile. If the tick is on and the Delta E is high, it

means the profile is not accurate in this area (typically with ICC profiles).

• At the bottom of the window an overview is given with a total amount of inks inside gamut.

• Double-click an ink to view Lab values of the target ink, and Lab values of the match, and to see

the difference visually. This way you can see exactly how the colors differ. Based on this you may

decide to change a color strategy’s rendering intent, or to use custom values for this ink.

• For Color Strategies, you will find an extra option ‘Source Process Inks’ at the bottom of the ink

book list in the ink book dropdown list. This option allows you to do a quick check on your process

ink solids, to see if they are in gamut.

Average Profiles

The Average Profiles tool allows you to create an averaged profile from a number of measured

profiles. The profile is averaged out sample by sample, and therefore, all profiles need to be based on

the same chart.

60

Page 62

Tools

You will find the Average Profiles tool in the Tools menu. First, you will need to select your base

profile. This profile will determine what chart type you are going to use. This profile will also be the first

in the list of profiles to use for averaging.

; Note

To use a profile for averaging, it must be completely measured. ICC profiles and calculated press

profiles cannot be used.

After selecting the base profile, you can add more profiles by clicking the 'add' button:

A list of profiles that are compatible with the base profile will be generated. If you have a large number

of profiles in the database, this may take a while.

; Note

To be compatible, only the profile’s chart type needs to be the same. The same chart type is often

available for different spectrophotometers. This means that you can measure the same chart on

different instruments and average out, compensating for differences between spectrophotometer

types.

You can give some profiles a greater or smaller weight, which makes a profilel have more or less

influence on the averaged profile. By default, all profiles are attributed the same weight.

61

Page 63

Tools

To generate and save the new profile, click 'Save Averaged Profile…'.

Preferences

You can specify a number of preferences in Esko Color Kit so that these settings are kept between

different Color Kit sessions. Go to the 'File' menu and click 'Preferences'.

• Modules (page 62)

• Spectrophotometer (page 63)

• Color Settings (page 63)

• Chart Settings (page 64)

Modules

In the modules tab you can choose which icons you want to see in the icon bar. Modules like inkswitch

or BlackSmith are not used in an HP Indigo workflow. We recommend to switch off InkSwitch and

62

Page 64

Tools

Spectrophotometer

By default, Color Kit automatically detects the connected spectrophotometer. If you always connect

your spectrophotometer to the same port, you could specify the port name in the spectrophotometer

tab of the preferences dialog box in order to speed up the automatic detection.

Color Settings

Color Kit offers a number of dialog boxes where you can specify the illuminant under which the color

match is done, e.g. the Compare tool, Gamut View, device links and color strategies. If the illuminant

under which you are matching colors is different from D50, e.g. D65, you can specify this in the Color

Settings tab and all dialog boxes will come up with this selection as default. You can only match under

an illuminant different from ‘CIE Illuminant D50’ if you use profiles with spectral data. This is not the

case for ICC profiles.

In a number of dialog boxes the quality of a color match is indicated with a number. In the past this

number was calculated with the classical CIELab DeltaE formula also known as Delta E 76. Now you

can select between 5 different formulas: CIELab DeltaE (classical), Delta E 94, Delta E 2000, CMC

63

Page 65

Tools

(1:1) and CMC (2:1). The selection that you make in the Color Settings tab will be used as default in

the dialog boxes of the Compare Tool, Gamut Check, and Color Strategies.

Chart Settings

A number of dialog boxes shows the dimensions of charts. The Chart Settings option allows you to

specify in which units the dimensions need to be expressed.

64

Page 66

Example of a workflow

We explain how to proceed if you want to output jobs on your HPIndigo.

1. Make sure your press is in perfect condition. (We advise to do a LUT generation before

outputting the color charts). You need to be aware for which substrate you are going to make

a profile, which LUT you are going to use to output it, which substrate settings you are going

to apply on the press etc. Connect your spectrophotometer to your system and switch it on if

applicable. (the drivers should already be installed)