Page 1

User’s Guide

HP EPM E4419A

EPM-442A Power Meter

HP Part no. E4419-90000

April 23, 1997

Page 2

© Copyright Hewlett-Packard Company

All rights reserved. Reproduction, adaptation, or translation without prior

written permission is prohibited, except as allowed under the copyright

laws.

Printed in the UK.

ii HP EPM-442A User’s Guide

Page 3

Legal Information

Legal Information

Notice

Information contained in this document is subject to change without

notice. Hewlett-Packard makes no warranty of any kind with regard to

this material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Hewlett-Packard

shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishings, performance,

or use of this material. No part of this document may be photocopied,

reproduced, or translated to another language without the prior written

consent of HP.

Certification

Hewlett-Packard Company certifies that this product met its published

specifications at the time of shipment from the factory. Hewlett-Packard

further certifies that its calibration measurements are traceable to the

United States National Institute of Standards and Technology, to the

extent allowed by the Institute’s calibration facility, and to the calibration

facilities of other International Standards Organization members.

Warranty

This Hewlett-Packard instrument product is warranted against defects in

material and workmanship for a period of one year from date of shipment.

During the warranty period, Hewlett-Packard Company will at its option,

either repair or replace products which prove to be defective. F or warranty

service or repair, this product must be returned to a service facility

designated by HP. Buyer shall prepay shipping charges to HP and HP

shall pay shipping charges, duties, and taxes for products returned to HP

from another country. HP warrants that its software and firmware

designated by HP for use with an instrument will execute its

programming instructions when properly installed on that instrument.

HP does not warrant that the operation of the instrument, or firmware

will be uninterrupted or error free.

HP EPM-442A User’s Guide iii

Page 4

Legal Information

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper

or inadequate maintenance by Buyer, Buyer-supplied software or

interfacing, unauthorized modification or misuse, operation outside of the

environmental specifications for the product, or improper site preparation

or maintenance. NO OTHER WARRANTY IS EXPRESSED OR IMPLIED .

HP SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND

EXCLUSIVE REMEDIES. HP SHALL NOT BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY

OTHER LEGAL THEORY.

iv HP EPM-442A User’s Guide

Page 5

Equipment Operation

Equipment Operation

Warnings and Cautions

This guide uses warnings and cautions to denote hazards.

WARNING A warning calls attention to a procedure, practice or the

like, which, if not correctly performed or adhered to, could

result in injury or the loss of life. Do not proceed beyond a

warning until the indicated conditions are fully

understood and met.

Caution A caution calls attention to a procedure, practice or the like which,

if not correctly performed or adhered to, could result in damage to

or the destruction of part or all of the equipment. Do not proceed

beyond a caution until the indicated conditions are fully

understood and met.

Personal Safety Considerations

WARNING This is a Safety Class I product (provided with a protective

earthing ground incorporated in the power cord). The

mains plug shall only be inserted in a socket outlet

provided with a protective earth contact. Any interruption

of the protective conductor, inside or outside the

instrument, is likely to make the instrument dangerous.

Intentional interruption is prohibited.

If this instrument is not used as specified, the protection

provided by the equipment could be impaired. This

instrument must be used in a normal condition (in which

all means of protection are intact) only.

No operator serviceable parts inside. Refer servicing to

qualified personnel. To prevent electrical shock, do not

remove covers.

For continued protection against fire hazard, replace the

line fuse(s) only with fuses of the same type and rating (for

example, normal blow, time delay, etc.). The use of other

fuses or material is prohibited.

HP EPM-442A User’s Guide v

Page 6

General Safety Considerations

General Safety Considerations

WARNING Before this instrument is switched on, make sure it has

been properly grounded through the protective conductor

of the ac power cable to a socket outlet provided with

protective earth contact.

Any interruption of the protective (grounding) conductor,

inside or outside the instrument, or disconnection of the

protective earth terminal can result in personal injury.

Caution Any adjustments or service procedures that require operation of

the instrument with protective covers removed should be

performed only by trained service personnel.

Markings

The CE mark shows that the product complies with

all the relevant European legal Directives (if

accompanied by a year, it signifies when the design

was proven.

GROUP 1

ISM

vi HP EPM-442A User’s Guide

CLASS A

This is the symbol of an Industrial Scientific and

Medical Group 1 Class A product.

The CSA mark is a registered trademark of the

Canadian Standards Association.

External Protective Earth Terminal.

While this is a Class I product, provided with a

protective earthing conductor in a power cord, an

external protective earthing terminal has also been

provided. This terminal is for use where the earthing

cannot be assured. At least an 18AWG earthing

conductor should be used in such an instance, to

ground the instrument to an assured earth terminal.

Page 7

General Safety Considerations

IEC 1010-1 Compliance

This instrument has been designed and tested in accordance with IEC

Publication 1010-1 +A1:1992 Safety Requirements for Electrical

Equipment for Measurement, Control and Laboratory Use and has been

supplied in a safe condition. The instruction documentation contains

information and warnings which must be followed by the user to ensure

safe operation and to maintain the instrument in a safe condition.

HP EPM-442A User’s Guide vii

Page 8

Regulatory Information

Regulatory Information

Sound Emission

Herstellerbescheinigung

Diese Information steht im Zusammenhang mit den Anforderungen der

Maschinenlarminformationsverordnung vom 18 Januar 1991.

• Sound Pressure LpA < 70 dB.

• Am Arbeitsplatz.

• Normaler Betrieb.

• Nach DIN 45635 T. 19 (Typprufung).

Manufacturers Declaration

This statement is provided to comply with the requirements of the

German Sound DIN 45635 T. 19 (Typprufung).

• Sound Pressure LpA < 70 dB.

• At operator position.

• Normal operation.

• According to ISO 7779 (Type Test).

Australian EMC Regulations

The C-Tick mark is a registered trademark of the Spectrum Management

Agency of Australia. This signifies compliance with the Australian EMC

Framework Regulations under the terms of the Radiocommunications Act

of 1992.

viii HP EPM-442A User’s Guide

Page 9

Declaration of Conformity

Declaration of Conformity

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN45014

Manufacturer’s Name: Hewlett-Packard Limited.

Manufacturer’s Address: Queensferry Microwave Division

South Queensferry,

West Lothian, EH30 9TG.

Scotland, United Kingdom.

Declares that the product:

Product Name: Power Meter

Model Number(s): HP EPM-441A and HP EPM-442A

Product Option(s): All

Conforms to the following Product Specifications:

Safety : EN61010-1:1993/IEC 1010-1:1990+A1/CSA C22.2

No. 1010-1:1993

EN60825-1:1994/IEC 825-1:1993 Class 1

EMC : EN 55011:1991/CISPR11:1990, Group 1-Class A

EN 50082-1:1992

Supplementary Information:

The product herewith complies with the requirements of the Low Voltage Directive 72/23/EEC and

the EMC Directive 89/336/EEC and carries the CE-marking accordingly.

South Queensferry, Scotland December 1 1996

Location Date R.M. Evans/Quality Manager

European Contact:

Your local Hewlett-Packard Sales and Service Office or Hewlett-Packard GmbH, Department ZQ / Standards

Europe, Herrenberger Strasse 130, D-7030 Boeblingen, Germany (FAX +49-7031-143143)

HP EPM-442A User’s Guide ix

Page 10

List of Related Publications

List of Related Publications

The HP EPM-442A User’s Guide is also available in the following

languages:

• English Language User’s Guide - Standard

• German Language User’s Guide - Option ABD

• Spanish Language User’s Guide - Option ABE

• French Language User’s Guide - Option ABF

• Italian Language User’s Guide - Option ABZ

• Japanese Language User’s Guide - Option ABJ

HP EPM-441A/442A Programming Guide is shipped as standard.

HP EPM-441A/442A Service Guide is available by ordering Option 915.

HP EPM-441A/442A CLIPs (Component Location and Information Pack)

is available by ordering E4418-90007.

Useful information on SCPI (Standard Commands for Programmable

Instruments) can be found in:

• A Beginner’s Guide to SCPI, which is available by ordering

HP Part Number 5010-7166.

• The SCPI reference manuals which are available from:

SCPI Consortium,

8380 Hercules Drive, Suite P3,

La Mesa, CA 91942, USA.

Telephone: 619-697-4301

Fax: 619-697-5955

x HP EPM-442A User’s Guide

Page 11

HP EPM-442A Options

HP EPM-442A Options

The HP EPM-442A power meters have the following options available:

• Option 002, supplies parallel rear panel sensor input(s). The

power reference oscillator output is on the front panel.

• Option 003, supplies parallel rear panel sensor input(s). The

power reference oscillator output is also on the rear panel.

• Option 004, deletes the HP 11730A sensor cable(s) provided.

• Option 0BO, deletes manual set.

• Option 908, provides rackmount kit for one instrument.

• Option 909, provides rackmount kit for two instruments.

• Option 915, provides the HP EPM-441A/442A Service Guide.

• Option 916, provides an additional HP EPM-442A User’s Guide

and HP EPM-441A/442A Programming Guide.

• Option 1BN, provides MIL-STD 45662A, ANSI/NCSL Z540-1-1994

Certificate of Calibration.

• Option 1BP, provides MIL-STD-45662A, ANSI/NCSL Z540-1-1994

Certificate of Calibration and data.

Available Accessories

• HP 34161A Accessory Pouch

• The following HP power sensor cables are available:

■ HP 11730A 1.5 m (7.5 ft)

■ HP 11730B 3 m (10 ft)

■ HP 11730C 6.1 m (20 ft)

■ HP 11730D 15.2 m (50 ft)

■ HP 11730E 30.5 m (100 ft)

■ HP 11730F 61 m (200 ft)

HP EPM-442A User’s Guide xi

Page 12

About this Guide

About this Guide

Chapter 1: Getting Started

This chapter prepares the power meter for use and helps you to get

familiar with a few of the front panel features.

Chapter 2: Power Meter Operation

This chapter gives a detailed description of the capabilities and operation

of the power meter. You will find this chapter useful when you are

operating the power meter from the front panel.

Chapter 3: Menu Map Reference

This chapter details diagrammatically the menu maps for the power

meter. It also gives a description of all the power meter’s keys.

Chapter 4: Error Messages

This chapter lists the error messages that may appear as you are working

with the power meter. Each description contains information to help you

diagnose and solve the problem.

Chapter 5: Specifications

This chapter lists the power meter’s specifications and describes how to

interpret these specifications.

xii HP EPM-442A User’s Guide

Page 13

Table of Contents

Page

Legal Information ........................................................................iii

Equipment Operation................................................................... v

Personal Safety Considerations............................................. v

General Safety Considerations.................................................... vi

Markings................................................................................ vi

IEC 1010-1 Compliance........................................................ vii

Regulatory Information.............................................................viii

Sound Emission...................................................................viii

Australian EMC Regulations..............................................viii

Declaration of Conformity........................................................... ix

List of Related Publications ......................................................... x

HP EPM-442A Options................................................................ xi

Available Accessories ............................................................xi

About this Guide.........................................................................xii

Getting Started.................................................................................... 1-1

Introduction................................................................................... 1-2

Turning On the Power Meter....................................................... 1-3

The Front Panel at a Glance ........................................................ 1-4

The Display Layout....................................................................... 1-7

Selecting Your Display Layout.............................................. 1-9

Display Tutorial...................................................................... 1-10

Window Symbols........................................................................... 1-12

Warning Symbol..................................................................... 1-12

Confirmation Window ............................................................ 1-12

Wait Symbol............................................................................ 1-12

1 of N Entry Window.............................................................. 1-13

Numeric or Alphanumeric Entry Window............................ 1-13

The Rear Panel at a Glance................................................... 1-14

Adjusting the Carrying Handle............................................. 1-16

Rack Mounting the Power Meter........................................... 1-17

HP EPM-442A User’s Guide Contents-1

Page 14

Power Meter Operation..................................................................... 2-1

Introduction................................................................................... 2-2

Zeroing the Power Meter.............................................................. 2-3

Calibrating the Power Meter........................................................ 2-4

Calibration Procedure Using HP E-Series

Power Sensors......................................................................... 2-5

Calibration Procedure using HP 8480 Series

Power Sensors......................................................................... 2-5

Making Measurements with the HP E-Series

Power Sensors............................................................................... 2-8

Procedure................................................................................ 2-8

Making Measurements with the HP 8480 Series

Power Sensors............................................................................... 2-10

Procedure................................................................................ 2-10

Making Measurements using Sensor Calibration Tables........... 2-13

Selecting a Sensor Calibration Table.................................... 2-13

Making the Measurement...................................................... 2-14

Editing Sensor Calibration Tables........................................ 2-15

Setting the Units of Measurement............................................... 2-22

Selecting Units of Measurement from the Softkeys ................... 2-23

Making Relative Measurements.................................................. 2-24

Procedure................................................................................ 2-24

Setting the Resolution.................................................................. 2-25

Setting Offsets............................................................................... 2-26

Setting Channel Offsets......................................................... 2-26

Setting Display Offsets .......................................................... 2-26

Setting Averaging......................................................................... 2-28

Measuring Pulsed Signals............................................................ 2-30

Setting Measurement Limits ....................................................... 2-32

Checking for Limit Failures................................................... 2-33

Channel Measurements................................................................ 2-35

Making Difference Measurements............................................... 2-36

Making Ratio Measurements....................................................... 2-37

Selecting a Digital or Analog Display.......................................... 2-38

Setting the Range ......................................................................... 2-41

Configuring the Remote Interface................................................ 2-42

HP-IB Address........................................................................ 2-42

Recorder Output............................................................................ 2-43

Leveling a Source Output ...................................................... 2-44

Saving and Recalling Power Meter Configurations.................... 2-45

How Measurements are Calculated............................................. 2-47

Presetting the Power Meter ......................................................... 2-48

Preset Conditions ................................................................... 2-48

Contents-2 HP EPM-442A User’s Guide

Page 15

Self Test......................................................................................... 2-50

Power On Self Test................................................................. 2-50

Front Panel Selection of Self Tests........................................ 2-51

HP-IB Testing......................................................................... 2-53

Test Descriptions.................................................................... 2-54

Operator Maintenance.................................................................. 2-56

Replacing the Power Line Fuse............................................. 2-56

Contacting Hewlett-Packard........................................................ 2-57

Before calling Hewlett-Packard............................................. 2-57

Check the Basics..................................................................... 2-58

Instrument serial numbers.................................................... 2-58

Sales and Service Offices ....................................................... 2-60

Returning Your Power Meter for Service.............................. 2-63

Menu Reference................................................................................... 3-1

Introduction................................................................................... 3-2

The Front Panel Menu Maps ....................................................... 3-3

dBm/W Menu..........................................................................3-3

Frequency/Cal Fac Menu....................................................... 3-4

Meas Setup Menu................................................................... 3-5

Rel/Offset Menu...................................................................... 3-6

Save/Recall Menu................................................................... 3-6

System Inputs Menu.............................................................. 3-7

System Inputs Menu Continued............................................ 3-8

Zero/Cal Menu ........................................................................ 3-9

Front Panel Menu Reference........................................................ 3-10

Diagrammatical Hardkeys..................................................... 3-27

Error Messages .................................................................................... 4-1

Introduction................................................................................... 4-2

Error Messages ............................................................................. 4-4

Specifications....................................................................................... 5-1

Introduction................................................................................... 5-2

Power Meter Specifications.......................................................... 5-3

Meter.......................................................................................5-3

Accuracy.................................................................................. 5-4

Power Reference ..................................................................... 5-5

Power Meter Supplemental Characteristics................................ 5-6

Power Reference ..................................................................... 5-6

Measurement Speed............................................................... 5-6

Zero Drift of Sensors............................................................... 5-7

Measurement Noise................................................................ 5-7

Settling Time.......................................................................... 5-9

HP EPM-442A User’s Guide Contents-3

Page 16

Power Sensor Specifications .................................................. 5-12

General Characteristics................................................................ 5-13

Rear Panel Connectors........................................................... 5-13

Environmental Characteristics.................................................... 5-14

General Conditions................................................................. 5-14

Operating Environment......................................................... 5-14

Storage Conditions................................................................. 5-14

General.......................................................................................... 5-15

Dimensions ............................................................................. 5-15

Weight..................................................................................... 5-15

Safety ...................................................................................... 5-15

Remote Programming ............................................................ 5-15

Non-Volatile Memory............................................................. 5-15

Contents-4 HP EPM-442A User’s Guide

Page 17

List of Figures

Page

2-1 “Sensor Tbls” Screen.................................................................. 2-14

2-2 “Edit Cal” Screen ....................................................................... 2-16

2-3 Effect of Offsets on a Channel Measurement........................... 2-27

2-4 Effect of Offsets on a Maths Measurement..............................2-27

2-5 Averaged Readings.................................................................... 2-29

2-6 Pulsed Signal ............................................................................. 2-30

2-7 Limits Checking Application..................................................... 2-32

2-8 Limits Checking Results ........................................................... 2-33

2-9 Pass/Fail Limit Indicators......................................................... 2-34

2-10 Digital Display........................................................................... 2-38

2-11 Analog Display........................................................................... 2-38

2-12 Digital and Analog Display....................................................... 2-38

2-13 Test Setup for Recording Swept Measurements...................... 2-43

2-14 “Save/Recall” Screen.................................................................. 2-46

2-15 How Measurements are Calculated.......................................... 2-47

2-16 Replacing the Fuse .................................................................... 2-56

4-1 Error Annunciator Position....................................................... 4-2

HP EPM-442A User’s Guide Contents-5

Page 18

Contents-6 HP EPM-442A User’s Guide

Page 19

List of Tables

Page

2-1 Connecting the HP 8480 Series Power Sensors During

Calibration ................................................................................. 2-7

2-2 Measurement Units................................................................... 2-22

3-1 .................................................................................................... 3-11

5-1 Zero Set Specifications .............................................................. 5-4

5-2 Noise Multiplier......................................................................... 5-7

5-3 Power Sensor Specifications...................................................... 5-8

5-4 Settling Time ............................................................................. 5-9

5-5 Settling Time ............................................................................. 5-10

HP EPM-442A User’s Guide Contents-7

Page 20

Contents-8 HP EPM-442A User’s Guide

Page 21

1

Getting Started

Page 22

Getting Started

Introduction

Introduction

One of the first things you will want to do with your power meter is to

switch it on and become acquainted with its front panel. The sections in

this chapter prepare the power meter for use and help you get familiar

with some of the front panel operations.

The front panel consists of both hardkeys and softkeys which allow you to

select various functions and operations. When some hardkeys are selected

the corresponding softkey labels are displayed on the power meter display.

If you are using the power meter remotely refer to the

HP EPM-441A/442A Programming Guide for remote operating details.

1-2 HP EPM-442A User’s Guide

Page 23

Getting Started

Turning On the Power Meter

Turning On the Power Meter

The following steps show you how to turn on the power meter and verify

that it is operating correctly.

1. Connect the power cord and turn on the power meter.

The front panel display and the green power LED light up when

the power meter is switched on. The power meter performs it’s

power on self test. If the self test is not successful the error

annunciator turns on. If this occurs contact your Hewlett-Packard

Sales and Service office for instructions on returning the power

meter to Hewlett-Packard for service.

Caution This instrument is designed for use in Installation Category II and

Pollution Degree 2 per IEC 1010 and 664 respectively.

Caution This instrument has an autoranging line voltage input, be sure

the supply voltage is within the range of 85 to 264 Vac.

Note If the power meter has been stored at extremely low temperatures

outwith the operating range of the power meter, the display may

take a few minutes to operate.

2. Set the display contrast if required.

The display contrast is adjusted by pressing and . If

these softkeys are not displayed press repeatedly until they

Prev

appear.

3. Connect the power sensors.

Connect one end of each of the sensor cables to the power meter’s

channel inputs and the other ends to the power sensors.

4. Making a measurement.

A minimum warm up time of 30 minutes is recommended before

accurate measurements can be made.

Prior to making your first measurement you must zero and

calibrate the sensor and meter combination. Refer to Chapter 2 for

further information if you are not familiar with zeroing,

calibrating or making measurements with a power meter.

HP EPM-442A User’s Guide 1-3

Page 24

Getting Started

The Front Panel at a Glance

The Front Panel at a Glance

101112

1

2

3

9

8

1.

4

Preset

Local

5

6

7

This hardkey allows you to preset the power meter if you are

currently working in local mode (that is, front panel operation). In

local mode a confirmation pop up window is displayed prior to a

preset being carried out. However, if you are in remote mode (that

is, HP-IB operation), then pressing this hardkey places the power

meter in local mode provided local lock out (LLO) is not enabled.

2. Hardkeys relating to the display layout.

This hardkey allows you to select the upper or lower

measurement window on the power meter’s display. The window

which is selected is highlighted by a shadowed box. Any

measurement setup you create is implemented in the selected

window.

This hardkey allows you to choose either a one or a two

window display.

1-4 HP EPM-442A User’s Guide

Page 25

Getting Started

The Front Panel at a Glance

3.

This hardkey switches the power meter between on and standby.

When the power meter is switched to standby (that is, when this

hardkey has not been selected but the line power is connected to

the instrument) the red LED is lit. When the power meter is

switched on the green LED is lit.

4. “System/Inputs” hardkey with softkey menu.

System

The hardkey allows access to softkey menus which affect

Inputs

the general power meter system setup, (for example the HP-IB

address) and also to softkey menus which effect the setup of the

channel inputs. Refer to Chapter 3 for further information about

this hardkey and it’s softkey menu.

Save

5.

Recall

This hardkey is the only one that is completely dedicated to the

control of the power meter as a system. The only other hardkey

which affects system parameters is the hardkey. Refer to

System

Inputs

Chapter 3 for further information about this hardkey and it’s

softkey menu.

6. Dedicated “Window” hardkeys with softkey menus.

Meas

Setup

Rel

,,

Offset

dBm/W

These hardkeys allow access to softkey menus which affect the

setup of the measurement windows. Refer to Chapter 3 for further

information about these hardkeys and their softkey menus.

7. Dedicated “Channel” hardkeys with softkey menus.

Frequency

Cal Fac

Zero

,

Cal

These hardkeys allow access to softkey menus which affect the

measurement channel. Refer to Chapter 3 for further information

about these hardkeys and their softkey menus.

8. Channel Inputs.

The HP EPM-442A has two sensor inputs. Power meters

configured with options 002 or 003 have the sensor inputs on the

rear panel and the front panel.

HP EPM-442A User’s Guide 1-5

Page 26

Getting Started

The Front Panel at a Glance

9. POWER REF Output.

The power reference output is a 50 Ω type N connector . The output

signal of 1 mW at 50 MHz is used for calibrating the sensor and

meter combination. Power meters configured with option 003 have

the power reference on the rear panel.

10. Arrow hardkeys.

, , and hardkeys allow you to move the

position of the cursor, select fields for editing, and edit

alphanumeric characters. Refer to Chapter 3 for further

information.

11. Menu related hardkeys.

More

This hardkey allows you to move through all pages of a

menu. The bottom right of the power meter display indicates the

number of pages in the menu. For example, if “1 of 2” is

displayed, pressing moves you to “2 of 2”. Pressing

again moves you back to “1 of 2”.

Prev

This hardkey allows you to move back one level in the

softkey menu. Repeatedly pressing accesses a menu which

allows you to increase and decrease the display contrast.

More More

Prev

12. Softkeys.

These four keys are used to make a selection from the menus.

1-6 HP EPM-442A User’s Guide

Page 27

Getting Started

The Display Layout

The Display Layout

The following figure details the display layout when two measurement

windows are displayed, one analog and one digital. However it is possible

using the key to display just one measurement window.

15

1

2

3

4

5

6

1. The status reporting line displays five fields, three associated with

the HP-IB status and two associated with error and warning

conditions. The first field displays either “RMT” (remote, HP-IB

operation) or “LCL” (local, front panel operation). The second field

displays “TLK” if the power meter is addressed to talk or “LSN” if it

is addressed to listen. The third field indicates an “SRQ” (service

request). The fourth field indicates “ERR” for any error conditions.

The last field is used to report error and warning messages.

2. This field displays the channel setup being measured, either A, B,

A/B, B/A, A-B or B-A.

3. The measurement data is displayed in either one or two

rectangular windows depending on the setting of . Pressing

allows you to toggle between a one or two window display.

When two windows are displayed and this hardkey is pressed the

single window then displayed is the one which was previously

highlighted with the shadowed box. On the two window display

the measurement setup menus work on the window which is

shadowed.

4. This is the measurement result field.

1011121314

9

7

8

HP EPM-442A User’s Guide 1-7

Page 28

Getting Started

The Display Layout

5. This field displays the units of measurement, either dBm, dB,

Watts or %.

6. This window is configured to show an analog meter which displays

the measurement result and the meter scaling.

7. This field displays the number of pages in the current softkey

menu. For example , “1 of 2” indicates that there are two pages of

softkeys and you are on the first page. Pressing moves you

More

to page “2 of 2”.

8. Any softkeys available are displayed in these four fields.

9. This field displays the title of the menu. For example, when the

power meter is initially switched on the “Contrast” menu is

displayed, and, if you press “Zero/Cal” is displayed.

Zero

Cal

10. This field indicates if the measurement result is outwith the upper

or lower limits set. If the measurement is within the limits this

field is empty. If the measurement result is less than the minimum

limit set, “Undr Lmt” is displayed. If the measurement result is

more than the maximum limit set, “Over Lmt” is displayed. Refer

to “Setting Measurement Limits”, on page 2-32 for further

information.

11. This field displays “Rel” if relative mode is on. Refer to “Making

Relative Measurements”, on page 2-24 for further information.

12. This field displays “Ofs” if an offset is set. Refer to “Setting

Offsets”, on page 2-26 for further information.

13. This field displays “Rng Hld” if a range is selected. Refer to

“Setting the Range”, on page 2-41 for further information.

14. This field displays “Dty Cyc” if a duty cycle is set. This allows you

to measure the power of a pulsed signal. Refer to “Measuring

Pulsed Signals”, on page 2-30 for further information.

15. This field displays the currently selected frequency or calibration

factor.

1-8 HP EPM-442A User’s Guide

Page 29

Getting Started

The Display Layout

Selecting Your Display Layout

Your power meter display is extremely flexible. It can be used to display a

variety of different measurements and windows depending on your needs.

The following diagram details the various options available to you.

Display

Select using

One Window

Measurement Type

A, B, A/B, B/A,

A-B, B-A

Digital

Display

Select using

Meas

, Input Select

Setup

Select using

Meas

, Display Format

Setup

Analog

Display

Upper

Window

Measurement Type

A, B, A/B, B/A,

A-B, B-A

Meas

Setup

Digital

Display

Analog

Display

Two Windows

Select using

Select using

Meas

, Input Select

Setup

Select using

, Display Format

Lower

Window

Measurement Type

A, B, A/B, B/A,

A-B, B-A

Digital

Display

Analog

Display

HP EPM-442A User’s Guide 1-9

Page 30

Getting Started

The Display Layout

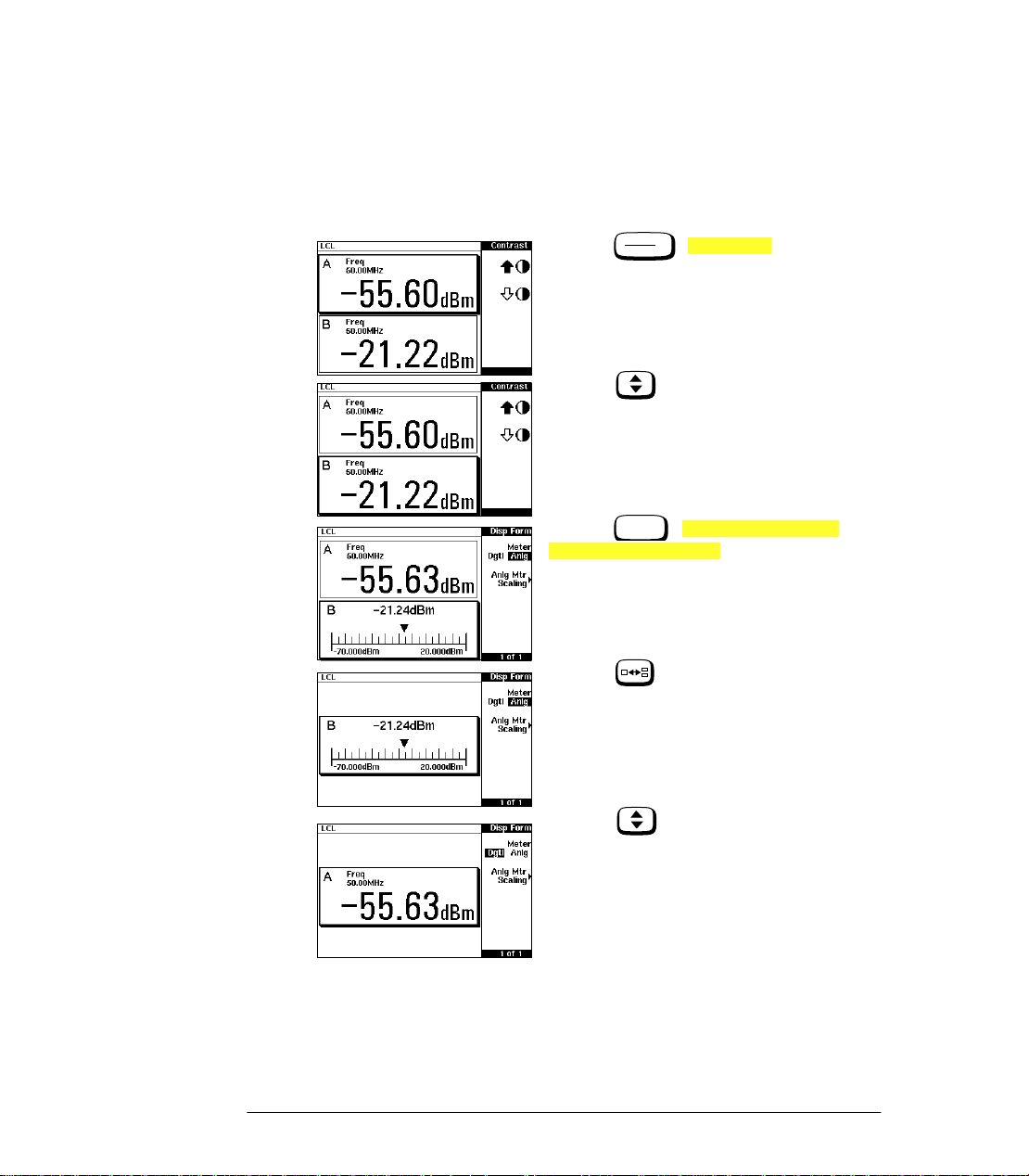

Display Tutorial

If you wish to experiment with the display layout before you move on to

make measurements, the following procedure guides you through a few of

the display setups you can choose.

1.Press , .

Preset

Local

Notice that the upper window is the

one which is highlighted by the dark

box.

2.Press . The display remains the

same apart from the fact that it is now

the lower window that is highlighted

by the shadowed box.

Confirm

3.Press , ,

Meas

Setup

Meter Dgtl Anlg

Display Format

(Anlg should be

highlighted). The display now shows

one analog and one digital window.

4.Press . The display now only

shows one window. This is the analog

window which was selected in the

previous step.

5.Press . The display now shows

only the digital window.

1-10 HP EPM-442A User’s Guide

Page 31

6. Press . The display now shows

both an analog and digital window.

Getting Started

The Display Layout

7. Press , , .

Meas

Setup

Input Select B/A

Notice that the upper window is now

set up to make a channel B over

channel A ratio measurement.

8. Press to select the lower window.

A/B

Press . Notice that the lower

window is now set up to make a

channel A over channel B ratio

measurement.

HP EPM-442A User’s Guide 1-11

Page 32

Getting Started

Window Symbols

Window Symbols

There are a number of different graphic symbols and pop up windows that

can occur on the power meter display. These can occur for a variety of

reasons such as when:

• an error or warning occurs.

• a confirmation is required.

• you are required to wait while the power meter carries out a

procedure.

• you are required to select an entry from a list.

• you are required to enter an alphanumeric value.

Warning Symbol

The warning symbol is displayed either directly in the

measurement window or in a pop up window when such

an event occurs. A pop up window is displayed for

approximately two seconds. The text in the pop up

window gives details of the warning type. This symbol

may also appear on a measurement window, for example,

to indicate that a power sensor is not connected.

Confirmation Window

This pop up window is displayed when

you are required to press to

verify your previous selection. For

example, prior to a preset being

carried out.

Confirm

Wait Symbol

The wait symbol is displayed when the power meter is carrying

out a procedure but no action is required from you. The symbol

may appear directly in the measurement window or in a pop up

window. It may appear, for example, during, zeroing or

calibration.

1-12 HP EPM-442A User’s Guide

Page 33

1 of N Entry Window

This pop up window is displayed when

you are required to select an entry using

and from the list.

Numeric or Alphanumeric Entry

Window

This pop up window is displayed when

you are required to modify numeric or

alphanumeric data. The and

keys move the position of the cursor.

The and keys increment and

decrement the alphanumeric digit on

which the cursor is currently

positioned.

Getting Started

Window Symbols

HP EPM-442A User’s Guide 1-13

Page 34

Getting Started

The Rear Panel at a Glance

The Rear Panel at a Glance

1345

1. Channel A (Option 002 or 003 only)

2. Channel B (Option 002 or 003 only)

3. Power Ref (Option 003 only)

The power reference output is a 50 Ω type N connector . The output

signal is used for calibrating the sensor meter combination.

4. Recorder Output

This output produces a dc voltage that corresponds to the power

level of the selected channel input. Refer to “Recorder Output”, on

page 2-43 for further information.

2

678

5. Power socket

This power meter has an auto configuring power supply. This

allows it to operate over a range of voltages without manually

being set to a certain voltage.

6. Fuse

An F3.15AH fuse is installed for all voltage supplies.

7. HP-IB

The Hewlett-Packard Interface Bus allows the power meter to be

controlled remotely.

1-14 HP EPM-442A User’s Guide

Page 35

Getting Started

The Rear Panel at a Glance

8. Serial Label

Each power meter has it’s own individual identification number.

Refer to “Instrument serial numbers”, on page 2-58 for further

information.

HP EPM-442A User’s Guide 1-15

Page 36

Getting Started

Adjusting the Carrying Handle

Adjusting the Carrying Handle

To adjust the position, grasp the handle by the sides and pull outward.

Rotate the handle to the desired position.

Bench top viewing positions Carrying position

1-16 HP EPM-442A User’s Guide

Page 37

Getting Started

Rack Mounting the Power Meter

Rack Mounting the Power Meter

You can mount the power meter in a standard 19 inch rack cabinet using

one of three optional kits. Instructions and mounting hardware are

included with each rack mounting kit. Any HP System II instrument can

be rack mounted beside the HP EPM-442A power meter.

To rack mount the power meter:

1. Remove the handle by rotating it to the vertical position and

pulling the ends outward

2. Remove the rubber bumper by stretching a corner and sliding it

off.

Front

HP EPM-442A User’s Guide 1-17

Rear (bottom view)

Page 38

Getting Started

Rack Mounting the Power Meter

To rack mount a single instrument, order option 908, or adapter kit

5063-9239.

To rack mount two instruments side by side , order option 909, or loc k-link

kit 5061-9694 and flange kit 5063-9212.

To install one or two instruments in a sliding support shelf, order shelf

5063-9255, and slide kit 1494-0015 (for a single instrument, also order

filler panel 5002-3999).

1-18 HP EPM-442A User’s Guide

Page 39

2

Power Meter Operation

Page 40

Power Meter Operation

Introduction

Introduction

This chapter describes the parameters which configure the power meter to

make measurements and help you determine settings to optimize

performance. This chapter contains the following sections:

• “Zeroing the Power Meter”, on page 2-3.

• “Calibrating the Power Meter”, on page 2-4.

• “Making Measurements with the HP E-Series Power Sensors”, on

page 2-8.

• “Making Measurements with the HP 8480 Series Power Sensors”,

on page 2-10.

• “Making Measurements using Sensor Calibration Tables”, on

page 2-13.

• “Setting the Units of Measurement”, on page 2-22.

• “Selecting Units of Measurement from the Softkeys”, on page 2-23.

• “Making Relative Measurements”, on page 2-24.

• “Setting the Resolution”, on page 2-25.

• “Setting Offsets”, on page 2-26.

• “Setting Averaging”, on page 2-28.

• “Measuring Pulsed Signals”, on page 2-30.

• “Setting Measurement Limits”, on page 2-32.

• “Channel Measurements”, on page 2-35.

• “Making Difference Measurements”, on page 2-36.

• “Making Ratio Measurements”, on page 2-37.

• “Selecting a Digital or Analog Display”, on page 2-38.

• “Setting the Range”, on page 2-41.

• “Configuring the Remote Interface”, on page 2-42.

• “Recorder Output”, on page 2-43.

• “Saving and Recalling Power Meter Configurations”, on page 2-45.

• “How Measurements are Calculated”, on page 2-47

• “Presetting the Power Meter”, on page 2-48.

• “Self Test”, on page 2-50.

• “Operator Maintenance”, on page 2-56.

• “Contacting Hewlett-Packard”, on page 2-57.

2-2 HP EPM-442A User’s Guide

Page 41

Power Meter Operation

Zeroing the Power Meter

Zeroing the Power Meter

This section describes how to zero the power meter.

Zeroing adjusts the power meter for a zero power reading with no power

applied to the power sensor. During zeroing, which takes approximately

10 seconds, the wait symbol is displayed.

To zero the power meter:

1. Press .

2. To zero channel A or channel B use or

respectively. Alternatively, to zero both channel A and channel B

sequentially, use . During zeroing the wait symbol is

displayed.

When to Zero?

Zeroing of the power meter is recommended:

• when a 50C change in temperature occurs.

• when you change the power sensor.

• every 24 hours.

• prior to measuring low level signals. F or example , 10 dB above the

lowest specified power for your power sensor.

Zero

Cal

Zero A Zero B

Zero Both

HP EPM-442A User’s Guide 2-3

Page 42

Power Meter Operation

Calibrating the Power Meter

Calibrating the Power Meter

This section describes how to calibrate the power meter. You should

always zero the power meter prior to calibrating it.

Calibration sets the gain of the power meter using a 50 MHz 1 mW

calibrator as a traceable power reference. The power meter’s POWER REF

output or a suitable external reference is used as the signal source for

calibration. An essential part of calibrating is setting the correct reference

calibration factor for the power sensor you are using. The HP 8480 series

power sensors require you to set the reference calibration factor. The

HP E-series power sensors set the reference calibration factor

automatically. During calibration the wait symbol is displayed. Offset,

relative and duty cycle settings are ignored during calibration.

Note During calibration the power meter automatically switches the

power reference calibrator on (if it is not already on), then after

calibration it switches it to the state it was in prior to the

calibration.

2-4 HP EPM-442A User’s Guide

Page 43

Power Meter Operation

Calibrating the Power Meter

Calibration Procedure Using HP E-Series Power Sensors

The following procedure describes how you calibrate the power meter with

an HP E-series power sensor. Since the power meter automatically

downloads the HP E-series power sensor’s calibration table there is no

requirement to enter the reference calibration factor. The power meter

identifies that an HP E-series power sensor is connected and will not

allow you to select certain softkeys. The text on these softkeys appears

grayed out.

Note The following procedure details the calibration for channel A. To

calibrate channel B use the same procedure using the equivalent

channel B softkeys.

1. Press .

Zero

Cal

2. Connect the power sensor to the POWER REF output.

3. Press , to calibrate the power meter. During

Cal Cal A

calibration the wait symbol is displayed. (The power meter

automatically turns on the POWER REF output.)

Example

To calibrate both channels of the power meter with HP E-series power

sensors connected to both channels.

Zero

• Press , .

Cal

Cal

• Connect the channel A power sensor to the POWER REF output.

• Press then wait till the calibration is completed.

Cal A

• Remove the channel A power sensor from the POWER REF

output.

• Connect the channel B power sensor to the POWER REF output.

• Press then wait till the calibration is completed.

Cal B

Calibration Procedure using HP 8480 Series Power Sensors

The following procedure describes how you calibrate the power meter with

the HP 8480 series power sensors.

There are a variety of different methods to connect the power sensors to

the power meter depending on the model of power sensor you are using.

Refer to Table 2-1 on page 2-7 for details on connecting different power

sensor models.

HP EPM-442A User’s Guide 2-5

Page 44

Power Meter Operation

Calibrating the Power Meter

Note The following procedure details the calibration for channel A. To

calibrate channel B use the same procedure using the equivalent

channel B softkeys. To calibrate both c hannels sequentially follow

this procedure for channel A then repeat step “2” through to step

“5” using the equivalent channel B softkeys.

Zero

1. Press , .

Cal

Cal

2. Verify the reference calibration factor of your power sensor with

that displayed under . The value shown is obtained

A Ref CF

from the sensor calibration table if one is selected, otherwise it is

the last value set or the default of 100%. If the value is not correct

A Ref CF

press . The power meter displays the reference

calibration factor in a pop up window. Modify this reference

calibration factor (see below) as desired.

■ Use or to modify the digit on which the cursor is

currently positioned.

■ Use or to move to other digits.

3. To confirm your choice press .

%

4. Connect the power sensor to the POWER REF output.

5. Press to calibrate the power meter. During calibration the

Cal A

wait symbol is displayed. (The power meter automatically turns

on the POWER REF output.)

Example

To calibrate both channels of the power meter. The reference calibration

factors for the power sensors being 98.8% and 99.4% for channel A and

channel B respectively:

Zero

• Press , .

• Press . Use the , , and hardkeys to

enter 98.8. Press .

• Press . Use the , , and hardkeys to

enter 99.4. Press .

Cal

Cal

A Ref CF

B Ref CF

%

%

• Connect the channel A power sensor to the POWER REF output.

• Press .

Cal A

• Remove the channel A power sensor from the POWER REF

output.

• Connect the channel B power sensor to the POWER REF output.

• Press .

Cal B

2-6 HP EPM-442A User’s Guide

Page 45

Power Meter Operation

Calibrating the Power Meter

Table 2-1: Connecting the HP 8480 Series Power Sensors During Calibration

Sensor

Model

HP 8481A

HP 8481H

HP 8482A

HP 8482H

HP 8481D

HP 8484A

HP 8483A This power sensor requires a 75Ω (f) to 50 Ω (m) N-Type adapter

HP R8486A

HP Q8486A

HP R8486D

HP Q8486D

HP W8486D

HP 8481B

HP 8482B

HP 8485A This power sensor requires an APC 3.5 (f) to 50Ω (m) N-Type

HP 8485D Prior to the power meter being zeroed and calibrated an

HP 8487A This power sensor requires an APC 2.4 (f) to 50Ω (m) N-Type

HP 8487D Prior to the power meter being zeroed and calibrated an

These power sensors connect directly to the reference calibrator.

Prior to the power meter being calibrated an HP 11708A 30 dB

reference attenuator should be connected between the power

sensor and the reference calibrator. This attenuator must be

removed from the power sensor input prior to making

measurements.

(1250-0597) to connect to the reference calibrator. This adapter

must be removed from the power sensor input prior to making

measurements.

The waveguide power sensors have two connectors. The N-Type

connector is the one which is used to calibrate the power meter.

These power senors are configured with an attenuator. Prior to

the power meter being calibrated, this attenuator must be

removed. The attenuator must be reconnected prior to making

measurements.

adapter (08485-60005) to connect to the reference calibrator.

HP 11708A 30 dB reference attenuator and an APC 3.5 (f) to

50 Ω (m) N-Type adapter (08485-60005) should be connected

between the power sensor and the reference calibrator. This

attenuator must be removed from the power sensor input prior to

making measurements.

adapter (08487-60001) to connect to the power meter.

HP 11708A 30 dB reference attenuator and an APC 2.4 (f) to

50 Ω (m) N-Type adapter (08487-60001) should be connected

between the power sensor and the reference calibrator. This

attenuator must be removed from the power sensor input prior to

making measurements.

Connection Requirements

HP EPM-442A User’s Guide 2-7

Page 46

Power Meter Operation

Making Measurements with the HP E-Series Power Sensors

Making Measurements with the HP E-Series Power

Sensors

This section describes how to make continuous wave measurements using

the HP E-series power sensors. The HP E-series power sensors have their

sensor calibration tables stored in EEPROM. This allows the frequency

and calibration data to be downloaded to the power meter automatically.

To make measurements, perform the following steps:

1. Zero and calibrate the power meter.

2. Set the frequency for the signal you want to measure.

3. Take a reading.

Procedure

The following procedure details how to make a measurement on channel A

of the power meter. To make a measurement on channel B use the same

procedure using the equivalent channel B softkeys.

1. Ensure that no power is applied to the power sensor.

2. Press .

3. Press . During zeroing, which takes approximately 10

Zero

Cal

Zero A

seconds, the wait symbol is displayed.

4. Connect the power sensor to the POWER REF output.

5. Press , to calibrate the power meter. During

Cal Cal A

calibration the wait symbol is displayed. (The power meter

automatically turns on the POWER REF output.)

6. Press . The current setting of the frequency is displa yed

under the softkey.

7. To change this setting press . The power meter displays

Frequency

Cal Fac

A Freq

A Freq

the frequency in a pop up window. Modify this frequency (see

below) as desired.

■ Use or to modify the digit on which the cursor is

currently positioned.

■ Use or to move to other digits.

8. To confirm your choice press the appropriate frequency units.

9. Connect the power sensor to the signal to be measured.

10. You must set the display to the type of measurement you require.

This can either be a direct channel measurement, a ratio

2-8 HP EPM-442A User’s Guide

Page 47

Power Meter Operation

Making Measurements with the HP E-Series Power Sensors

measurement of both channels, or a difference measurement

between both channels. Use the following key presses:

Press , . Select the appropriate softkey for

the measurement you require, either , , , , or ,

then , or .

Meas

Setup

Input Select

A-B B-A

A B A/B B/A

More

11. The measurement result is now displayed.

Example

To make a measurement on channel A using an HP E-series power sensor.

The frequency of the signal to be measured is 100 MHz.

• Disconnect the power sensor from any source.

• Press .

• Press .

Zero

Cal

Zero A

• Connect the power sensor to the POWER REF output.

• Press , .

• Press , . Use the , , and

Cal Cal A

Frequency

Cal Fac

hardkeys to enter 100. Press .

A Freq

MHz

• Connect the power sensor to the signal to be measured.

• The measurement result is now displayed.

HP EPM-442A User’s Guide 2-9

Page 48

Power Meter Operation

Making Measurements with the HP 8480 Series Power Sensors

Making Measurements with the HP 8480 Series

Power Sensors

This section applies to all HP 8480 series power sensors. It does not apply

to the HP E-series power sensors.

For the HP 8480 series power sensors there are two methods of providing

correction data to the power meter:

A inputting the individual calibration factor for a frequency prior to

making the measurement, or

B using sensor calibration tables.

This section describes how to make measurements without using sensor

calibration tables, that is, inputting the individual calibration factor for a

frequency prior to making the measurement. This method is

advantageous if you are only measuring at one frequency, as entering all

the calibration data in this instance is not required.

To make measurements without sensor calibration tables perform the

following steps:

1. Zero and calibrate the power meter. Before carrying out the

calibration you must set the reference calibration factor of the

power sensor.

2. Set the calibration factor value for the frequency of the signal you

want to measure.

3. Take a reading.

Procedure

The following procedure details how to make a measurement on

channel A. To make a measurement on channel B use the same procedure

using the equivalent channel B softkeys.

1. Ensure that no power is applied to the power sensor.

2. Press .

3. Press . During zeroing, which takes approximately 10

seconds, the wait symbol is displayed.

4. Press .

5. Connect the power sensor to the POWER REF output.

2-10 HP EPM-442A User’s Guide

Zero

Cal

Zero A

Cal

Page 49

Power Meter Operation

Making Measurements with the HP 8480 Series Power Sensors

6. The current setting of the reference calibration factor is displayed

under the softkey. To change this setting press

A Ref CF

A Ref CF

. The power meter displays the reference calibration

factor in a pop up window. Modify this reference calibration factor

(see below) as desired.

■ Use or to modify the digit on which the cursor is

currently positioned.

■ Use or to move to other digits.

7. To confirm your choice press .

8. Press , to calibrate the power meter. During

Cal Cal A

%

calibration the wait symbol is displayed. (The power meter

automatically turns on the POWER REF output.)

9. Press . The current setting of the calibration factor is

displayed under the softkey. To change this setting

press . The power meter displays the calibration

Frequency

Cal Fac

A Cal Fac

A Cal Fac

factor in a pop up window. Modify this calibration factor (see

below) as desired.

■ Use or to modify the digit on which the cursor is

currently positioned.

■ Use or to move to other digits.

10. To confirm your choice press .

%

11. Connect the power sensor to the signal to be measured.

12. You must set the display to the type of measurement you require.

This can either be a direct channel measurement, a ratio

measurement of both channels, or a difference measurement

between both channels. Use the following key presses:

Press , . Select the appropriate softkey for

the measurement you require, either , , , , or ,

then , or .

Meas

Setup

Input Select

A-B B-A

A B A/B B/A

More

13. The measurement result is now displayed.

Example

To make a measurement on channel A with a power sensor which has a

reference calibration factor of 99.8% and a calibration factor of 97.8% at

the measurement frequency.

• Disconnect the power sensor from any source.

• Press .

• Press .

• Press .

Zero

Cal

Zero A

Cal

HP EPM-442A User’s Guide 2-11

Page 50

Power Meter Operation

Making Measurements with the HP 8480 Series Power Sensors

• Press . Use the , , and hardkeys to

A Ref CF

enter 99.8. Press .

%

• Connect the power sensor to the POWER REF output.

• Press .

• Press , . Use the,, and

Cal A

Frequency

Cal Fac

hardkeys to enter 97.8. Press .

A Cal Fac

%

• Connect the power sensor to the signal to be measured.

• The measurement result is now displayed.

2-12 HP EPM-442A User’s Guide

Page 51

Power Meter Operation

Making Measurements using Sensor Calibration Tables

Making Measurements using Sensor Calibration

Tables

This section applies to all HP 8480 series power sensors. It does not apply

to the HP E-series power sensors.

For the HP 8480 series power sensors there are two methods of providing

correction data to the power meter:

A inputting the individual calibration factor for a frequency prior to

making the measurement, or

B using sensor calibration tables.

This section describes how to use sensor calibration tables. Sensor

calibration tables are used to store the measurement calibration factors,

supplied with each power sensor, in the power meter. These calibration

factors are used to correct measurement results.

Using sensor calibration tables provides you with a quick and convenient

method for making power measurements over a range of frequencies using

one or more power sensors. The power meter is capable of storing 20

sensor calibration tables of 80 frequency points each.

To use sensor calibration tables you:

1. Select the table to work on a channel. Refer to “Selecting a Sensor

Calibration Table”, on page 2-13 for further information. If you

require to edit the table refer to “Editing Sensor Calibration

Tables”, on page 2-15 for further information.

2. Zero and calibrate the power meter. The reference calibration

factor used during the calibration is automatically set by the

power meter from the sensor calibration table.

3. Specify the frequency of the signal you want to measure. The

calibration factor is automatically set by the power meter from the

sensor calibration table. Refer to “Making the Measurement”, on

page 2-14 for further information.

4. Make the measurement.

Selecting a Sensor Calibration Table

You can select a sensor calibration table for use by pressing ,

Sensor Cal Tables A Table Off On B Table Off On

HP EPM-442A User’s Guide 2-13

, or . The

System

Inputs

Page 52

Power Meter Operation

Making Measurements using Sensor Calibration Tables

“State” field indicates if any sensor calibration tables are currently

selected. The “Sensor Tbls” screen is displayed as shown in Figure 2-1.

Figure 2-1: “Sensor Tbls” Screen

Making the Measurement

To make the power measurement, you zero and calibrate the power meter,

then set it for the frequency of the signal you want to measure. The power

meter automatically selects the calibration factor from the sensor

calibration table.

Note The following procedure details the calibration for channel A. To

calibrate channel B use the same procedure using the equivalent

channel B softkeys. To calibrate both channels, zero the power

meter using in step “2”, then follow this procedure for

Zero Both

channel A then repeat step “3” through to step “9” using the

equivalent channel B softkeys.

1. Press .

2. Press . During zeroing, which takes approximately 10

Zero

Cal

Zero A

seconds, the wait symbol is displayed.

3. Press . The setting of the reference calibration factor is

Cal

obtained from the sensor calibration table and displayed under the

A Ref CF

softkey.

4. Connect the power sensor to the POWER REF output.

5. Press to calibrate the power meter. During calibration the

Cal A

wait symbol is displayed. (The power meter automatically turns

on the POWER REF output.)

2-14 HP EPM-442A User’s Guide

Page 53

Power Meter Operation

Making Measurements using Sensor Calibration Tables

6. Press . The current setting of the frequency is displa yed

under the softkey.

7. To change this setting press . The power meter displays

Frequency

Cal Fac

A Freq

A Freq

the frequency in a pop up window. Modify this frequency (see

below) as desired.

■ Use or to modify the digit on which the cursor is

currently positioned.

■ Use or to move to other digits.

8. To confirm your choice press the appropriate frequency unit.

9. Connect the power sensor to the signal to be measured.

10. You must set the display to the type of measurement you require.

This can either be a direct channel measurement, a ratio

measurement of both channels, or a difference measurement

between both channels. Use the following key presses:

Press , . Select the appropriate softkey for

the measurement you require, either , , , , or ,

then , or .

Meas

Setup

Input Select

A-B B-A

A B A/B B/A

11. The measurement result is now displayed.

Note If the measurement frequency does not correspond directly to a

frequency in the sensor calibration table, the power meter

calculates the calibration factor using linear interpolation.

More

If you enter a frequency outside the frequency range defined in the

sensor calibration table, the power meter uses the highest or

lowest frequency point in the sensor calibration table to set the

calibration factor.

The value of the calibration factors being used by the power meter

to make a measurement is displayed under the or

B Cal Fac

softkeys.

A Cal Fac

Editing Sensor Calibration Tables

You can edit sensor calibration tables using the “Edit Cal” menu as shown

in Figure 2-2.

To view the sensor calibration tables currently stored in the power meter,

press , . The “Sensr Tabs” screen is

displayed as shown in Figure 2-1.

HP EPM-442A User’s Guide 2-15

System

Inputs

Sensor Cal Tables

Page 54

Power Meter Operation

Making Measurements using Sensor Calibration Tables

Figure 2-2: “Edit Cal” Screen

2-16 HP EPM-442A User’s Guide

Page 55

Power Meter Operation

Making Measurements using Sensor Calibration Tables

The power meter is shipped with a set of predefined sensor calibration

tables. The data in these tables is based on statistical averages for a range

of Hewlett-Packard power sensors.

These power sensors are:

• DEFAULT

1

• HP 8481A

• HP 8482A

2

• HP 8483A

• HP 8481D

• HP 8485A

• R8486A

• Q8486A

• R8486D

• HP 8487A

There are also ten sensor calibration tables named CUSTOM_0 through

CUSTOM_9 which do not contain any data when the power meter is

shipped from the factory.

You cannot delete any of the 20 sensor calibration tables. Each sensor

calibration table can contain a maximum of 80 frequency points each. If

you want a new sensor calibration table you must edit an existing one.

To edit a table:

1. Select one using the and hardkeys to scroll through the

displayed tables. When the table you want to edit is highlighted

Edit Cal Table

press . The “Edit Cal” screen is displayed as

shown in Figure 2-2 on page 2-16. In this screen you can modify,

add and remove frequency and calibration factors and also edit the

table name. Use the , , and hardkeys to move

between the table name and its frequency and calibration factors.

A frequency in the range of 0.1 MHz to 999.999 GHz can be

entered.

1. DEFAULT is a sensor calibration table in which the reference calibration

factor and calibration factors are 100%. This sensor calibration table can be

used during the performance testing of the power meter.

2. The HP 8482B and HP 8482H power sensors use the same data as the

HP 8482A.

HP EPM-442A User’s Guide 2-17

Page 56

Power Meter Operation

Making Measurements using Sensor Calibration Tables

A calibration factor in the range of 1% to 150% can be entered.

The following rules apply to naming sensor calibration tables:

■ The name must consist of no more than 12 characters.

■ All characters must be upper or lower case alphabetic

characters, or numeric (0-9), or an underscore (_).

■ No other characters are allowed.

■ No spaces are allowed in the name.

2. To edit the parameter you currently have selected press .

The power meter displays the data in a pop up window. Modify

this data (see below) as desired.

■ Use or to modify the character on which the cursor

is currently positioned.

■ Use or to move to other characters.

3. To confirm your choice press the appropriate softkey.

4. To add a new sensor calibration table entry press . Y ou are

Insert

prompted for the frequency and calibration factor. The entry is

sorted by frequency.

5. To remove a sensor calibration table entry use the , ,

and hardkeys to select the entry, press . If you

Delete

delete the frequency the equivalent calibration factor is also

removed and vice versa.

Change

Note You can only edit the table name you cannot delete it.

6. When you have completed editing the sensor calibration table

Done

press to return to the “Sensor Tables” screen.

Note Ensure that the frequency points you use cover the frequency

range of the signals you want to measure. If you measure a signal

with a frequency outside the frequency range defined in the sensor

calibration table, the power meter uses the highest or lowest

frequency point in the sensor calibration table to calculate the

calibration factor.

2-18 HP EPM-442A User’s Guide

Page 57

Power Meter Operation

Making Measurements using Sensor Calibration Tables

The following lists detail the contents of the predefined sensor calibration

tables.

DEFAULT HP 8482A

RCF 100 RCF 98

0.1 MHz 100 0.1 MHz 98

110 GHz 100 0.3 MHz 99.5

HP 8481A 1 MHz 99.3

RCF 100 3 MHz 98.5

50 MHz 100 10 MHz 98.5

100 MHz 99.8 30 MHz 98.1

2 GHz 99 100 MHz 97.6

3 GHz 98.6 300 MHz 97.5

4 GHz 98 1 GHz 97

5 GHz 97.7 2 GHz 95

6 GHz 97.4 3 GHz 93

7 GHz 97.1 4.2 GHz 91

8 GHz 96.6 HP 8483A

9 GHz 96.2 RCF 94.6

10 GHz 95.4 0.1 MHz 94

11 GHz 94.9 0.3 MHz 97.9

12.4 GHz 94.3 1MHz 98.4

13 GHz 94.3 3MHz 98.4

14 GHz 93.2 10 MHz 99.3

15 GHz 93 30 MHz 98.7

16 GHz 93 100 MHz 97.8

17 GHz 92.7 300 MHz 97.5

18 GHz 91.8 1 GHz 97.2

2 GHz 96.4

HP EPM-442A User’s Guide 2-19

Page 58

Power Meter Operation

Making Measurements using Sensor Calibration Tables

HP 8481D HP 8485A

RCF 99 RCF 100

50 MHz 99 50 MHz 100

500 MHz 99.5 2 GHz 99.5

1 GHz 99.4 4 GHz 98.9

2 GHz 99.5 6 GHz 98.5

3 GHz 98.6 8 GHz 98.3

4 GHz 98.6 10 GHz 98.1

5 GHz 98.5 11 GHz 97.8

6 GHz 98.5 12 GHz 97.6

7 GHz 98.6 12.4 GHz 97.6

8 GHz 98.7 14 GHz 97.4

9 GHz 99.5 16 GHz 97

10 GHz 98.6 17 GHz 96.7

11 GHz 98.7 18 GHz 96.6

12 GHz 99 19 GHz 96

12.4 GHz 99.1 20 GHz 96.1

13 GHz 98.9 21 GHz 96.2

14 GHz 99.4 22 GHz 95.3

15 GHz 98.9 23 GHz 94.9

16 GHz 99.1 24 GHz 94.3

17 GHz 98.4 25 GHz 92.4

18 GHz 100.1 26 GHz 92.2

R8486A 26.5 GHz 92.1

RCF 100 R8486D

50 MHz 100 RCF 97.6

26.5 GHz 94.9 50 MHz 97.6

27 GHz 94.9 26.5 GHz 97.1

28 GHz 95.4 27 GHz 95.3

29 GHz 94.3 28 GHz 94.2

30 GHz 94.1 29 GHz 94.5

31 GHz 93.5 30 GHz 96.6

32 GHz 93.7 31 GHz 97.6

33 GHz 93.7 32 GHz 98

34 GHz 94.9 33 GHz 98.9

34.5 GHz 94.5 34 GHz 99.5

35 GHz 94.4 34.5 GHz 99

36 GHz 93.7 35 GHz 97.6

37 GHz 94.9 36 GHz 99

38 GHz 93.5 37 GHz 98.2

39 GHz 93.9 38 GHz 97.4

40 GHz 92.3 39 GHz 97.6

40 GHz 100

2-20 HP EPM-442A User’s Guide

Page 59

Power Meter Operation

Making Measurements using Sensor Calibration Tables

HP 8487A HP 8487A continued

RCF 100 37 GHz 92.4

50 MHz 100 38 GHz 90.9

100 MHz 99.9 39 GHz 91.3

500 MHz 98.6 40 GHz 91.4

1 GHz 99.8 41 GHz 90.6

2 GHz 99.5 42 GHz 89.9

3 GHz 98.9 43 GHz 89.1

4 GHz 98.8 44 GHz 88.1

5 GHz 98.6 45 GHz 86.9

6 GHz 98.5 46 GHz 85.8

7 GHz 98.4 47 GHz 85.4

8 GHz 98.3 48 GHz 83.2

9 GHz 98.3 49 GHz 81.6

10 GHz 98.3 50 GHz 80.2

11 GHz 98.1 Q8486A

12 GHz 97.9 RCF 100

13 GHz 98 50 MHz 100

14 GHz 98.2 33.5 GHz 91.3

15 GHz 97.7 34.5 GHz 92

16 GHz 96.8 35 GHz 91.7

17 GHz 97 36 GHz 91.5

18 GHz 96.3 37 GHz 92.1

19 GHz 95.9 38 GHz 91.7

20 GHz

21 GHz 95.6 40 GHz 90.7

22 GHz 95.5 41 GHz 90.3

23 GHz 95.4 42 GHz 89.5

24 GHz 95 43 GHz 88.5

25 GHz 95.4 44 GHz 88.7

26 GHz 95.2 45 GHz 88.2

27 GHz 95.1 46 GHz 87

28 GHz 95 47 GHz 86.4

29 GHz 94.4 48 GHz 85.3

30 GHz 94 49 GHz 84.7

31 GHz 93.7 50 GHz 82.9

32 GHz 93.8

33 GHz 93

34 GHz 93.2

34.5 GHz 93.5

35 GHz 93.1

36 GHz 92

95.2

39 GHz 91

HP EPM-442A User’s Guide 2-21

Page 60

Power Meter Operation

Setting the Units of Measurement

Setting the Units of Measurement

The “dBm/W” menu is used to select the measurement units on the

currently selected window. These can either be logarithmic (dBm or dB) or

linear (Watt or %) units. sets the measurement units to dBm

(logarithmic units). Table 2-2 shows which units are applicable to the

individual measurement modes.

Press , then select the unit of measurement from , , or

%

dBm/W

. Softkeys which cannot be selected in your particular mode of operation

appear with their text grayed out.

Note When the unit of measurement is set to Watt, it is possible that