Page 1

HP StorageWorks

Tape Blade

User Guide

Part number: 509508–001

Third edition: October 2008

Page 2

Legal and notice information

© Copyright 2008 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth

in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting

an

additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Linear Tape-Open, LTO, LTO Logo, Ultrium and Ultrium Logo are trademarks of Certance, HP and IBM in the US, other countries

or both.

Patented under one or more of U.S. Patents Nos. 5,003,307; 5,016,009; 5,463,390; 5 ,506,580; held by Hi/fn, Inc.

Microsoft, Windows, Windows XP, and Windows NT are U.S. registered trademarks of Microsoft Corporation.

UNIX is a registered trademark of The Open Group.

Page 3

Contents

Aboutthisguide .......................... 9

Intendedaudience...................................... 9

Relateddocumentation.................................... 9

Documentconventionsandsymbols .............................. 9

HPtechnicalsupport.................................... 10

Productwarranties..................................... 10

Subscriptionservice .................................... 10

HPwebsites........................................ 10

Documentationfeedback .................................. 11

1Beforeyoustart......................... 13

SupportedTapeBlades................................... 13

Installationguidelines ................................... 13

Partnerserverblade .................................. 14

OnboardAdministrator................................... 14

Power specifications .................................... 14

YourHPStorageWorksTapeBlade.............................. 14

UsingtheHPStorageWorksTapeCD-ROM .......................... 15

2Driversandbackupsoftware ................... 17

Installdrivers ....................................... 17

SAScontrollerdriver.................................. 17

HPUltriumTapedriver ................................. 17

InstallingonWindows ............................... 17

InstallingonUNIX................................. 18

InstallingonIA64 ................................. 18

Upgradebackupsoftware.................................. 18

Enablingencryption .................................. 18

3InstallinganHPStorageWorksTapeBlade ............. 19

Beforeyoustart ...................................... 19

Installationwithahalf-heightpartnerserverblade ....................... 20

Installationwithafull-heightpartnerserverblade........................ 24

Poweringthetapebladeonandoff ............................. 28

Powerup....................................... 28

Powerdown ..................................... 28

4 Verify installation ........................ 29

5 Understanding LEDs ....................... 31

TapeBladeChassisLEDs.................................. 31

TroubleshootingwithTapeBladeLEDs .......................... 31

TapeDriveLEDs...................................... 32

TroubleshootingwithTapeDriveLEDs........................... 32

6 Loading and unloading cartridges and removing tape blade . . . . . . 35

Insertingcartridges .................................... 35

Tape Blade

3

Page 4

Removingcartridges.................................... 35

Removingthetapeblade.................................. 36

7Usethecorrectmedia . ..................... 39

Cartridges ........................................ 39

Datacartridges .................................... 39

Cleaningcartridges .................................. 40

HPUltriumWORMdatacartridges............................ 40

HPStorageWorksSB1760cTapeBladesandencryption................... 40

WhenshouldIuseencryption? ........................... 40

HowdoIenableencryption? ............................ 41

WhenwillIbeaskedtoenterthekey? ........................ 41

WhathappensifIdon’trememberthekey? ...................... 41

Doesencryptionaffecttapedriveperformance? .................... 41

DoesthetapedriveencryptmediainanearlierUltriumformat?.............. 41

WherecanIgetmoreinformation?.......................... 41

Cleaningthetapedrive................................... 42

Writeprotectingcartridges ................................. 42

Handlingcartridges .................................... 43

Operatingandstorageenvironment ............................. 43

8UsingHPOBDR......................... 45

Compatibility....................................... 45

WhatdoesHPOBDRdo? ................................. 45

Remotedisasterrecovery(ProLiantserversonly) ........................ 45

Testingforcompatibility .................................. 46

RunningHPOBDR..................................... 46

9Troubleshooting . . ....................... 49

Whenthetapebladedoesnotpowerup ........................... 49

ManagementandDiagnostictools.............................. 49

OnboardAdministrator................................. 50

HPLibrary&TapeTools ................................ 50

TroubleshootingwithLibrary&TapeTools....................... 50

Optimizingperformance ................................ 50

Problemswithcartridges .................................. 51

Thecartridgeisjammed ................................ 51

Emergencyreset.................................. 52

Thedrivewillnotacceptthecartridge(orejectsitimmediately)................ 52

10Replacingatapebladechassisortapedrive............ 53

Beforeyoureplaceapart.................................. 53

Replacingthetapedrive .................................. 53

Removethetapedrive ................................. 53

Installthenewtapedrive ................................ 55

Replacingthetapebladechassis............................... 57

Removethetapeblade................................. 57

Remove the coupler plate, full-height partner servers in a c7000 enclosure only . . . . . . . . . 58

Removethetapedrive ................................. 59

Installthereplacementchassis.............................. 60

Returningthefaultypart .................................. 63

Index .............................. 65

4

Page 5

Figures

1

2

3

4

5

FrontviewofHPStorageWorksTapeBlade..................... 15

Half-heightdevicebaynumberinginac7000enclosure ............... 20

Half-heightdevicebaynumberinginac3000enclosure ............... 20

Paired locations in a c7000 enclosure with a half-height par tner server blade . . . . . . 21

Paired locations in a c3000 enclosure with a half-height partner server blade . . . . . . 22

6

Removing the

7

Removingtheconnectorcover .......................... 23

8

Installing the tape blade, partnered with a half-height server blade . . . . . . . . . . . 23

9

Paired locations in a c7000 enclosure with a full-height partner server blade . . . . . . 25

10

Paired locations in a c3000 enclosure with a full-height par tner server blade . . . . . . 25

11

Removingtheblank............................... 26

12

Installin

13

Removingtheconnectorcover .......................... 27

14

Installing the tape blade, partnered with a full-height server blade . . . . . . . . . . . 27

15

SystemhealthLED ............................... 28

16

TapeBladechassisLEDs............................. 31

17

TapedriveLEDs ................................ 32

18

Insertingacartridge .............................. 35

19

Ejectingacartridge............................... 36

20

Removingthetapeblade ............................ 37

21

Writeprotectingacartridge ........................... 43

blank............................... 22

gthecouplerplate............................ 26

22

InsertingcartridgeforOBDR........................... 46

23

Keepingejectbuttonpresseddown,poweroninOBDRmode............. 46

24

Releasingthetapedrive............................. 54

25

DisconnectingthepowerandSAScables ..................... 54

26

Removingtheclip-onmountingrailsonafaultytapedrive .............. 55

27

Replacingtheclip-onmountingrailsonanewtapedrive............... 55

28

ReconnectingthepowerandSAScablestothetapedrive .............. 56

29

Installingthetapedrive ............................. 56

30

emovingthetapeblade ............................ 58

R

31

Disconnectingthecouplerplate.......................... 58

32

Releasingthetapedrive............................. 59

33

DisconnectingthepowerandSAScables ..................... 59

Tape Blade

5

Page 6

34

Removingthetapebladecover.......................... 60

35

Removingtheconnectorcover .......................... 60

36

Reconnecting t

37

Installingthetapedrive ............................. 61

38

Cablinginthereplacementchassis ........................ 62

39

Replacingthetapebladecover.......................... 62

40

Installingthecouplerplate............................ 62

41

Installingthereplacementchassis......................... 63

hepowerandSAScablestothetapedrive .............. 61

6

Page 7

Tables

1

2

3

4

5

6

Documentconventions............................... 9

Power specifications............................... 14

TapedriveLEDsequences ............................ 33

Datacartridgecompatibility ........................... 39

Cleaningcartridgecompatibility ......................... 40

Troubleshootingtapebladeoperation ....................... 49

Tape Blade

7

Page 8

8

Page 9

About this guide

This guide provides information about:

• Installing the HP StorageWorks Tape Blade

• Using the HP StorageWorks Tape Blade

• Troubleshooting the HP StorageWorks Tape Blade

Intended audi

This guide is intended for users who install, operate and maintain the HP StorageWorks Tape Blade.

ence

Related documentation

The following documents provide related information:

• ‘Start here’poster foranoverviewofthe installation informationinthisguide (available in

English, French, German and Japanese)

You can find this document from the Manuals page of the HP Business Support Center website:

ttp://www.hp.com/support/manuals

h

In the Storage section, click Tape Storage and M e dia and then select your product.

Document conventions and symbols

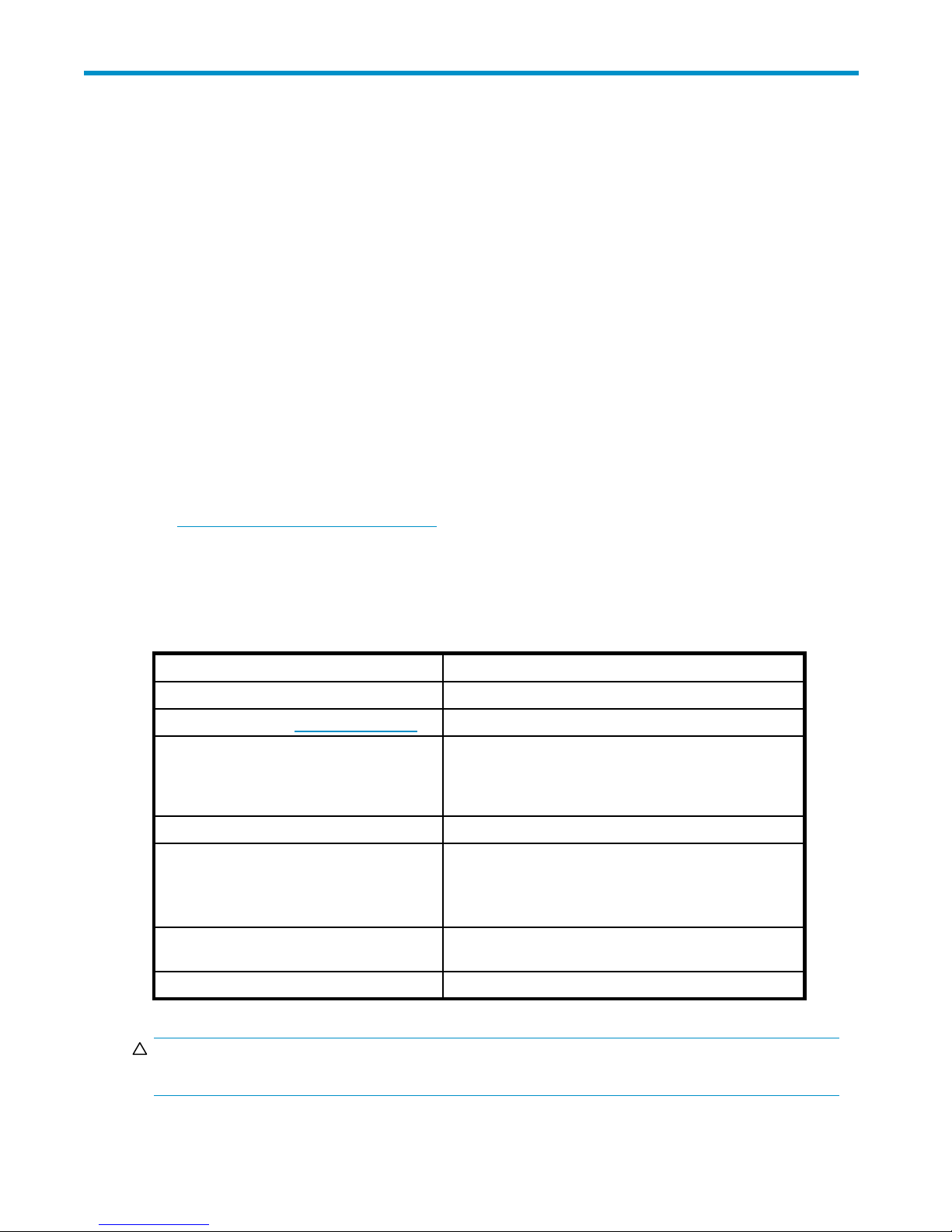

Table 1 Document conventions

Convention

Blue text: Table 1

Blue, underlined text: http://www.hp.com website addresses

Bold text

Element

Cross-reference links and e-mail addresses

• Keys that are pressed

Text typed into a GUI element, such as a box

•

GUI elements that are clicked or selected, such as

•

menu

and list items, buttons, tabs, and check boxes

Italic text Text emphasis

Monospace text

Monospace, italic text

Monospace, bold text

CAUTION:

Indicates that failure to follow directions cou ld result in damage to equipment or data.

• File and directory names

System output

•

Code

•

Commands, their arguments, and argument values

•

• Code variables

Command variables

•

Emphasized monospace text

Tape Blade

9

Page 10

IMPORTANT:

Provides clarifying information or specific instructions.

NOTE:

Provides additional information.

HP technical support

For worldwide technical support information, see the HP support website:

ttp://www.hp.com/support

h

Before contacting HP, collect the following information:

• Product model names a nd numbers

• Technical support registration number (if applicable)

• Product serial numbers

• Error messages

• Operating system type and revision level

• Detailed questions

Product warr

For information about HP StorageWorks product warranties, see the warranty information website:

ttp://www.hp.com/go/storagewarranty

h

anties

Subscription service

HP recommends that you register your product at the Subscriber’s Choice for Business website:

ttp://www.hp.com/go/e-updates

h

After registering, you will receive e-mail notification of product enhancements, n ew driver versions,

firmware updates, and other product resources.

After signing up, you can quickly locate your products by selecting Business support and then Storage

under Product Category.

HP websites

information, see the following HP websites:

For additi

• h

• http://www.hp.com/go/bladesystem/documentation

• http://ww

• http://www.hp.com/go/connect/

• http://www.hp.com/service_locator

• http://w

• http://www.hp.com/support/downloads

onal

ttp://www.hp.com

w.hp.com/go/bladesystemupdates/

ww.hp.com/support/manuals

10

About this guide

Page 11

Documentation feedback

HP welcomes your

To make comments and suggestions about product documentation, please send a message to

storagedocs.feedback@hp.com. All submissions become the property of HP.

feedback.

Tape Blade

11

Page 12

12

About this guide

Page 13

1 Before you start

In this chapter:

•

“Supported Tape Blades” on page 1 3

•

“Installation guidelines” on page 1 3

• “Onboard Administrator”onpage14

• “Power specifications” on page 14

• “Your HP StorageWorks Tape Blade” on page 14

• “Using the HP StorageWorks Tape CD-ROM” on page 15

Supported Tape Blades

This guide describes how to install and operate the following Tape Blades:

• the H P Stora

blade

• the HP StorageWo rks SB920c Tape Blade, which is an Ultrium 920 tape drive within a tape blade

assembly.

• the HP StorageWorks Ultrium 448c Tape Blade, which is an Ultrium 448 tape drive within a tape

blade assembly

These tape

be

running the correct firmware for it to support the tape blade. Firmware version 1.3 or later is required

when installing in a c7000 enclosure. In a c3000 enclosure all versions of the firmware support the

HP

StorageWorks Tape Blade. For the best reliability, performance and new features update to the

most recent version of the firmware.

For the most up-to-date information about supported operating systems and configurations, refer to

h

ttp://www.hp.com/go/bladesystem/documentation.

geWorks SB1760c Tape Blade, which is an Ultrium 1760 tape d rive within a tape

assembly

assemblies may only be installed in an HP BladeSystem c-Class enclosure, which must

blade

Before performing any procedures specific to the HP StorageWorks Tape Blade, install and configure an

HP BladeSystem c-Class enclosure. The m ost current d o cumentation for HP BladeSystem components is

ble at the HP BladeSystem website (h

availa

Docume

• Documentation CD that ships with the enclosure

• HP BladeSystem Technical Resources website (h

• HP Business Support Center website (h

• HP Technical Documentation website (h

ntation is also available in the following locations:

entation)

docum

Installation guidelines

Observe the following guidelines when installing the HP StorageWorks Ultrium Tape Blade:

• An HP StorageWorks Tape Blade supports one partner server blade, and a partner server blade

supports one HP StorageWorks Tape Blade.

• The server blade and the HP StorageWorks Tape Blade must be adjacent to each other in the

HP BladeSystem enclosure.

• Install the partner server blade first and ensure that it is powered down before installing the

HP

StorageWorks Tape Blade.

ttp://www.hp.com/go/bladesystem).

ttp://www.hp.com/go/bladesystem/

ttp://www.hp.com/support)

ttp://www.hp.com/support/manuals)

Tape Blade

13

Page 14

Partnerserverb

The partner server b la de may be half-height or full-height. When partnering the tape blade with a

full-height server blade, a n HP PCI Express Mezzanine Pass-Thru Card is required (option kit par t number:

431643-B21). This must be installed prior to operation with the tape blade.

When installin

• the tape blade may be installed in the upper or lower bay adjacent to the server blade. See

“Installation with a half-height par tner server blade”onpage20.

When installing the HP StorageWorks Ultrium Tape Blade with a full-height server blade:

• In a c7000 encl

blade.

• In a c3000 enclosure, the tape blade must be installed immediately above the partner server

blade in devi

to the

HP

• Before insta

require ins

enclosures require installation of a m ini divider (supplied with the enclosure). See

“Installation with a full-height partner ser ver blade ” on page 24.

lade

the HP StorageWorks Tape Blade with a half-height server blade:

g

osure , the tape blade must be installed in the lower bay adjacent to the server

bay 8. A half-height server blade can be installed in the empty bay next

ce

HP StorageWorks Tape Blade, but this server blade cannot be partnered with the

StorageWorks Tape Blade.

lling a

tallation of a coupler plate (supplied with the Tape Blade), and c3000

server blade in the empty bay above the tape blade, c 7000 enclosures

Onboard Administrator

Theblade enclosure must berunning thecorrect firmware for it to support the Tape Blade. Onboard

Administrator is used to power the partner server blade on and off, update firmware for the enclosure

and configure it to function with the Tape Blade. Onboard Administrator version 1.3 or later is

required when installing in a c7000 enclosure. In a c3000 enclosure all OA versions support the HP

StorageWorks Tape Blade. For the best reliability, performance and new features update to the most

recent version of the firmware.

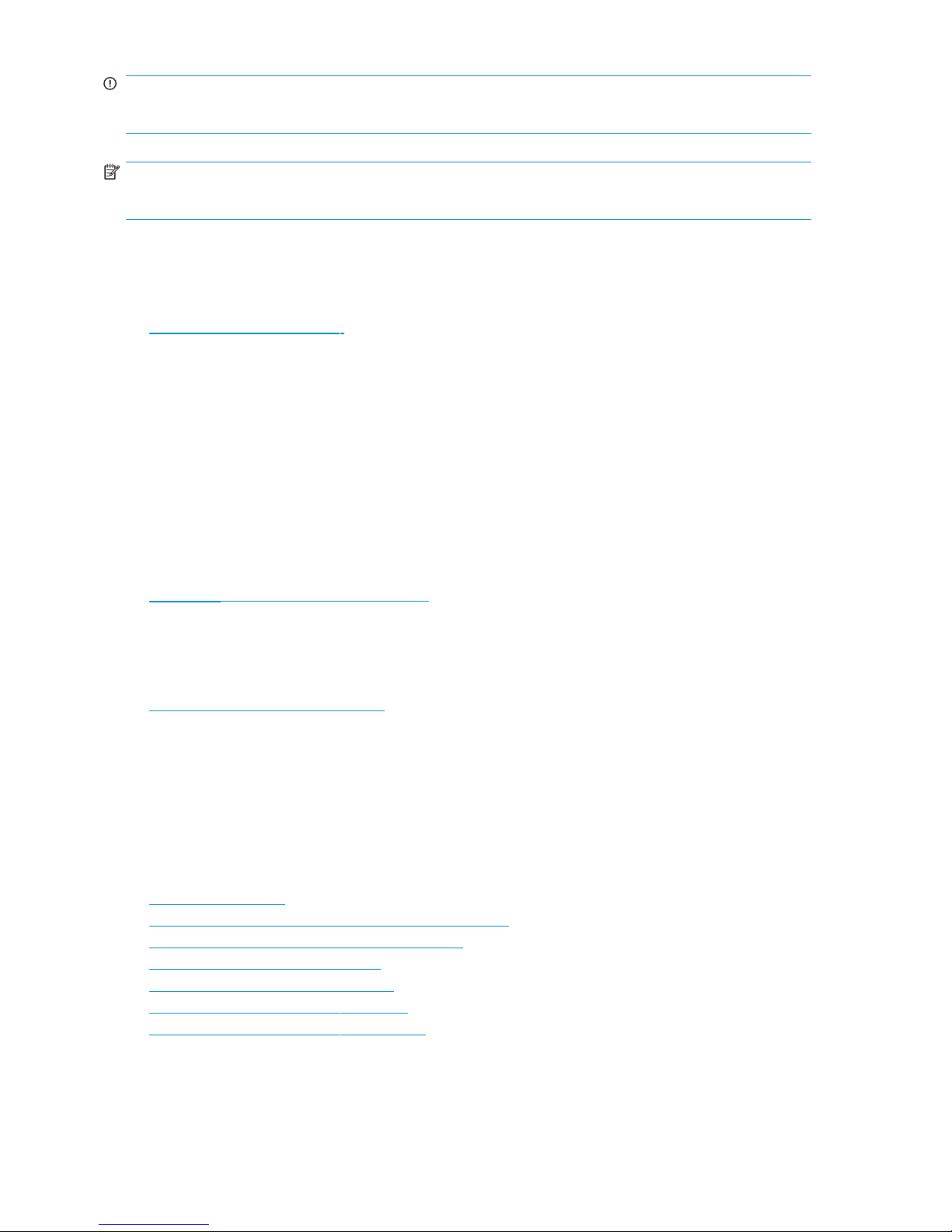

Power specifications

Maximum power consumption for the Tape Blade is approximately 45 Watts.

Table 2 Power specifications

Tape Drive SC44Ge

13 Watts idle

Power consumption

Power re quirements

20 Watts typical

33 Watts maximum

+5V @ 2.5A typical

+5V @ 2.5A maximum

+12V @ 0.7A typical

+12V @ 2.1A maximum

6.8 Watts maximum 5.2 Watts maximum

+12V @ 0.56A maximum +12V @ 0.43A maximum

Your HP StorageWorks Tape Blade

For a detailed product specification, please refer to our website (http://www.hp.com/go/bladesystem/

documentation).

Main Logic Board

14

Before you start

Page 15

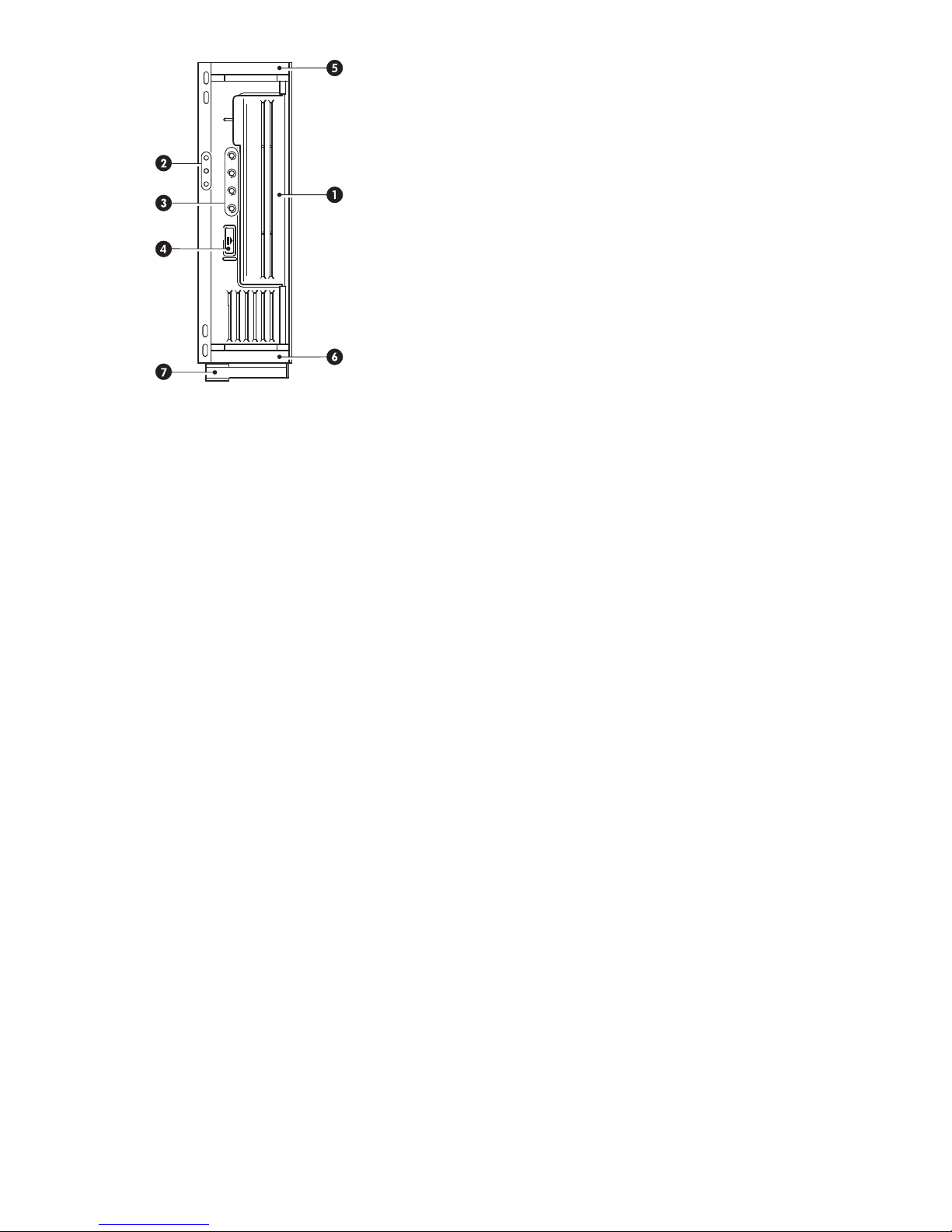

1. Cassette door 4. Cartridge eject button

2. Tape blade LEDs 5 and 6. Mounting rails

3. Tape drive LEDs 7. Release latch

Figure 1 Front view of HP StorageWorks Tape Blade

Using the HP StorageWorks Tape CD-ROM

The HP StorageWorks Tape CD-ROM is a central source of information about your tape blade with utilities

for g etting the best performance from your tape blade.

Use the H P StorageWorks Tape CD-ROM to check installation, as described in this guide, and to verify

and

troubleshoot performance after installation. It helps you to:

• Install your product, which includes access to drivers, and performance information a nd tools

• Learn about your product

• Register your product

• Buy media online

• Troubleshoot with HP Library & Tape Tools.

Tape Blade

15

Page 16

16

Before you start

Page 17

2Drivers andbackupsoftware

In this chapter:

• “Install drivers ” on page 17

•

“Upgrade backup software” on page 18

Install driv

Two drivers are required:

• An SC44Ge SAS controller driver for the tape blade assembly

• An HP Ultrium

IMPORTANT:

The SC44Ge SAS controller driver must be installed first.

Drivers may be downloaded from the web at the following location:

nl

http://h18004.www1.hp.com/products/blades/components/c-class-storageworks.html.

To download drivers:

1. Select Tape Blades and click the product link (for example HP StorageWorks SB920c Tape Blade).

2. Click Support — > Technical Doc uments.

3. Click Download Drivers and Soft ware.

ers

SAS controller driver

The SC44Ge SAS controller driver is only available from the HP website. It can be installed from the link

on the

HP StorageWorks Tape CD-ROM or directly from the HP StorageWorks BladeSystem website,

ttp://h18004.w ww1.hp.com/products/blades/components/c-class-storageworks.html.

h

The SC44Ge SAS controller driver must be installed before the HP Ultrium Tape driver.

Tape driver for the tape drive

HP Ultrium Tape driver

Please refer to http://h18004.www1.hp.com/products/blades/components/c-class-storageworks.html

for the latest information about supported operating systems.

NOTE:

Certain backup applications require you to use their own Tape driver instead of the HP Ultrium Tape

driver.

Installing on Windows

The CD-ROM contains a Tape driver install package for supported Microsoft Windows operating systems.

If you prefer to use Windows Device Manager to install the tape drivers manually, you will find them in

the

drivers directory on the CD-ROM.

Updates to the drivers will be provided on the HP StorageWorks BladeSystem website

(h

ttp://h18004.w ww1.hp.com/products/blades/components/c-class-storageworks.html).

Tape Blade

17

Page 18

Installing on UN

The recommended backup applications use the operating system’s standard, built-in device drivers. To

upgrade drivers we recommend that you patch to the latest version of the operating system.

IX

Installing on IA64

If you are installing on an IA64 system, such as an HP Integrity server, check http://

h18004.www1. hp.com/products/blades/components/c-class-storageworks.html for the latest

information on the availability of backup application upgrades and drivers.

Upgrade back

software

up

to check h

It is importa

c-class-storageworks.html for software compatibility and install any recommended upgrades.

For optimum performance it is important to use a backup application that is appropriate for your

system’s configuration. HP, Symantec, Legato, Yosemite and Computer Associates all provide suitable

products. Further details about these and other products that may be appropriate can be found on

the

HP conne

1. Go to h

and select Tape Blades.

2. Select you

3. Click on the Tape Blade tab and select your combination of operating system and tape drive model

in

Alist ofsu

is

drives and tape blades support HP OBDR. However, you can only use this feature if your system

configuration and backup application also s upport it. See “Compatibility” on page 45.)

4. Make sure

downloa

nt

ctivity website.

ttp://h18004.www1.hp.com/products/blades/components/c-class-storageworks.html

model of tape blade and select Support -> Compatibility & Tools.

r

the table.

pported backup applications is displayed. This will also tell you whether your configuration

compatible with HP One-Button Disaster Recovery, HP OBDR. (All HP StorageWorks tape

you have a backup application that supports HP StorageWorks Ultrium tape drives and

any upgrades or patches, if required.

d

Enabling encryption

Your HP StorageWorks Tape Blade includes hardware capable of performing data encryption while

writing and data decryption while reading, both at full speed. This is only possible with Ultrium 1.6 TB

media. See also “HP StorageWorks SB1760c Tape Blades and encryption” on page 40.

ttp://h18004.w ww1.hp.com/products/blades/components/

If you wish to make use of the encryption capability, you must enable this feature via the backup

software application. Refer to h

c-class-storageworks.html to find out which applications support this advanced data protection capability.

18

Drivers and backup software

ttp://h18004.w ww1.hp.com/products/blades/components/

Page 19

3 Installing an HP StorageWorks

Tape Blade

In this chapter:

•

“Before you start”onpage19

•

“Installation with a half-height par tner server blade” o n page 20

• “Installation with a full-height partner server blade” on page 24

•

“Powering the tape blade on and off”onpage28

Before you s

These installation instructions assume you have already:

1. Installed and configured an HP BladeSystem c-Class enclosure. It must be running the correct

firmware for it to support the tape blade. Firmware version 1.3 or later is required when installing in

a

c7000 enclosure. In a c3000 enclosure all versions of the firmware support the HP StorageWorks

Tape Blade. For the best reliability, performance and new features update to the most recent version

of

the firm

2. Installed the partner ser ver blade. It must be powered off before you install the tape blade. We

recommend that you use the Shutdown command on the partner server blade to do this.

3. Install

enclosure.

NOTE:

The most current documentation for HP BladeSystem components is available at the HP website

/www.hp.com/go/bladesystem/documentation).

ttp:/

(h

You need one half-height device bay in which to install the HP StorageWorks Ultrium Tape Blade. The

tape blade may be used with a half-height or a full-height server blade and must be installed next

to the partner server blade.

tart

ware.

ed any device bay dividers as recommended in the documentation provided with the c-Class

Tape Blade

19

Page 20

Figure 2 H alf-height device bay numbering in a c7000 enc l osure

NOTE:

In c3000enclosuresdevices areseatedhorizontallybut thesameinstallationrules apply. Thetape

in the adjacent device bay below or above the pa rtner server blade. Slot combinations

resi

des

blade

are1&2,3&4,5&6,7&8.

Figure 3 H alf-height device bay numbering in a c3000 en c losure

Installation with a half-height partner server blade

If you are installing with a full-height partner server blade, refer to

“Installation with a full-height partner server blade” on page 24.

NOTE:

The partner server blade and any device bay dividers must be installed and powered down before you

install the tape blade. See the documentation that ships with the server blade.

20

Installing an HP StorageWorks Tape Blade

Page 21

CAUTION:

To prevent improper cooling and thermal damage, do not operate the server blade or the enclosure

unless all device bays are populated with either a component or a blank.

1. Identify the partner server blade to be installed with the HP StorageWorks Tape Blade. The two

blades

always occupy a pair of device bays.

• c7000 enclosures: Slotcombinationsare: 1&2,3&4,5&6,7&8,9&10,11&

12, 13 & 14, 15 & 16.

Partnerserverblade in

bay:

Tape Blade in bay: even-numbered bay to the right

HP

odd-numbered bay even-numbered bay

odd-numbered bay to the left

Figure 4 Paired locations in a c7000 enclosure with a half-heig ht partner server

blade

• c3000 enclosures: Slotcombinationsare: 1&2,3&4,5&6,7&8.

Partnerserverblade in bay:

HP Tape Blade in bay:

1

2

2 3

1

4

4

3 6

5

6

5

7

8

8

7

Tape Blade

21

Page 22

Figure 5 Paired locations in a c3000 enclosure with a half-height partner server

blade

2. Use the Shutdown command on the partner server blade to power down the partner server blade.

3. Remove the bla nk from the device bay. Squeeze in the release tabs (1) and pull the blank away

from the assembly (2), as illustrated in Figure 6.

In the following figure the partner server blade is installed in device bay 2. So, the blank has

been

removed from device bay 1.

e6Removing theblank

Figur

4. Remo

ve the connector cover on the rear of the tape blade assembly. Release the back of the cover

(1) and pull it away from the tape blade (2) , as illustrated in Figure 7.

22

Installing an HP StorageWorks Tape Blade

Page 23

Figure 7 Rem

oving the connector cover

CAUTION:

To prevent d

blade assem

amage to the backplane connector, take special care when handling the tape

bly. If the tape blade is installed with a damaged connector, the enclosure

backplane may also be damaged.

5. Install the tape blade, ensuring that it is in the correct orientation: in a c7000 enclosure the latch is

at the

bottom of the blade assembly, as illustrated; in a horizontal orientation in a c3000 enclosure it

is to the

the

right of the tape blade. Carefully push the tape blade into the device bay (1) and push

latch in (2) to secure the blade in position.

CAUTION:

Take care as you p ush the blade into position. Do not press directly on the cassette door,

because this may damage it.

Figure 8 Installing the tape blade, partnered with a half-height server blade

6.

Now go to “Powering the tape blade on and off” on page 28.

Tape Blade

23

Page 24

Installation wi

If you are insta

“Installation

When partnerin

Card is required (option kit part number: 431643-B21). The Mezzanine Card must be installed in

mezzanine 3 connector in the ser ver blade. The exact location of this connector varies according to the

model of server blade. Please refer to the schematic on the server blade’s panel or the server blade

documentatio

NOTE:

The partner server blade must be installed and powered down b efore you install the tape blade. See the

documentation that ships with the server blade.

CAUTION:

To prevent improper cooling and thermal damage, do not operate the server blade or the enclosure

unless all device bays are populated with either a component or a blank.

1. Identify the partner server blade to be installed with the HP StorageWorks Tape Blade. The two

blades

• c7000 enclosures: The tape blade is always located on the lower row of the enclosure

always occupy a pair of device bays.

(bays 9 to 16).

th a

with a half-height partner server blade” on page 20.

for detailed instructions on installing the Mezzanine Card.

n

full-height partner server blade

with a half-height partner server blade, refer to

lling

the tape blade with a full-height server blade, an HP PCI Express Mezzanine Pass-Thru

g

Partnerserverblade in bays:

HP Tape Blade in bay:

1/9 2/103/114/125/136/147/158/16

10 9 12

11

14

13 16

15

24

Installing an HP StorageWorks Tape Blade

Page 25

Figure 9 Pa

ired locations in a c7000 enclosure with a full-height partner server

blade

• c3000 enclosures:The tape blade is always located in bay 8.

Partnerserverblade in bays: 3and 7

HP Tape Blade in bay:

8

Figure 10 Paired locations in a c3000 enclosure with a full-height partner server

blade

2. Use the Shutdown command on the par tner server blade to power down the partner server blade.

Tape Blade

25

Page 26

If not already installed, install a HP PCI Express Mezzanine Pass-Thru Card in mezzanine 3 connector

in the

server blade. See the documentation that ships with the mezzanine card and the server blade

documentation for more information.

3. Remove the bla nk from the device bay. Squeeze in the release tabs (1) and pull the blank away

from the assembly (2).

Figure 11 Removing the blank

4. c7000 enclosures only: lnstall the supplied coupler plate. (This allows you to install a separate

upper bay above the tape blade, if required.) Align the slots, as illustrated, and slide

device in t

forward to

he

lock into place.

Figure 12 Installing t he coupler plate

NOTE:

If you need to return the tape blade for service, you must first remove the coupler plate. See

“Remove the coupler plate”onpage58for furtherdetails.

NOTE:

c3000 enclosures require a mini divider. This is supplied with the enclosure. Refer to the

documentation provided with the enclosure for installation instructions.

26

Installing an HP StorageWorks Tape Blade

Page 27

5. Remove the connector cover on the rear of the tape blade assembly. Release the back of the cover

(1) and pull the cover away from the tape blade (2).

Figure 13 Removing the connector cover

CAUTION:

To prevent damage to the backplane connector, take special care when handling the tape

blade assembly. If the tape blade is installed with a damaged connector, the enclosure

backplane may also be damaged.

6. Install the tape blade, ensuring that it is in the correct orientation: in a c7000

enclosure the latch is at the bottom of the blade assembly, as illustrated; in a

horizontal orientation in a c3000 enclosure it is to the right of the tape blade. In

“Installing the tape blade, partnered with a full-height server blade” on page 27 the partner server

blade is installed in device bay 9. So, the tape blade must be installed in device bay 10. Carefully

push the tape blade into the device bay (1) and push the latch in to secure the blade in position (2).

Figure 14 Installing the ta pe blade, partnered with a full-height server bla de

7.

Now go to “Powering the tape blade on and off” on page 28.

When installing the HP StorageWorks Tape Blade with a full-height server blade, a half-height server

blade can

be installed in the empty bay next to the tape blade. (In a c7000 enclosure this is the

bay above the tape blade. In a c3000 enclosure this will be bay 4.) This server blade cannot be

partnered with the HP StorageWorks Tape B lade.

If the bay is left empt y, a b lank must be fitted to maintain proper airflow for cooling.

Tape Blade

27

Page 28

P owering the tap

Power up

1. Install the tape blad e, as described in the previous sections. The system health LED (item 1 in

Figure 15 on page 28) flashes red while the connection is established. (If it continues to flash red

for more than 2 minutes, there is a fault. M ake sure that the partner server blade is powered off

and

re-install the tape blade.)

2.

When the tape blade is recognized, the system health LED (item 1 in Figure 15 on page 28)

illuminates solid green.

3. Power up the partner server blade. See the server blade documentation for more information. This

powers up the tape blade and the tape drive performs its hardware self-test.

blade on and off

e

Power d

Figure 15 System health LED

own

Use the On board Administrator or the Shutdown command on the partner server blade to power down

the

partner server blade and tape blade. See the server blade and onboard administrator documentation

information.

for mor

e

28

Installing an HP StorageWorks Tape Blade

Page 29

4 Verify installation

Once you have installed the tape blade assembly, check that drivers have been installed correctly and

you have the correct version of backup software, and verify that the tape blade is functioning properly

before you store your valuable data.

NOTE:

Check h

latest information on the availability of backup application upgrades and drivers.

1. Use the Onboard Administrator to power up the partner server blade, see

2. The system health LED flashes red while the connection is established. When the tape blade is

3. The tape drive will run its hardware self-test, which takes about 5 seconds. If self-test p asses, the

4. Make sure that the drivers are installed; two are required.

ttp://h18004.www1.hp.com/products/blades/components/c-class-storageworks.html for the

“Powering the tape blade on and off”onpage28. This also powers on thetapeblade.

recognized, the system health LED (1) illu minates solid green.

NOTE:

If the System Health LED continues to flash red for more than 2 minutes, there is a fault. Make sure that

thepartner server bladeispowered offand re-install thetapeblade.

green Ready LED flashes and then shows steady green. If the test fails, the Drive Error and Tape

Error LEDs flash, while the Ready and Clean L EDs are off. This continues until the drive is reset. See

LEDs” on page 32 for more information about front panel lights.

“Tape Dri

• SC44Ge SAS co n troller driver

• HP Ultr

ve

SAS controller driver must be installed first. It is only available

The SC44G

from the HP web site. It can be installed from the link on the HP StorageWorks

Tape CD-ROM or directly from the HP BladeSystem Technical Resources website,

ttp://h18004.w ww1.hp.com/products/blades/components/c-class-storageworks.html.

h

The CD-ROM contains a Tape driver install package for Microsoft Windows operating

systems. If you prefer to use Windows Device Manager to install the tape drivers manually,

you will find them in the drivers directory on the CD-ROM or on the HP BladeSystem

Technical Resources website, h

ss-storageworks.html.

c-cla

For other operating systems, the recommended backup applications use the operating

system’s standard, built-in device drivers. To upgrade drivers we recommend that you patch

to the latest version of the operating system.

e

Tape driver

ium

ttp://h18004.www1.hp.com/products/blades/components/

NOTE:

Certain backup applications require you to use their own Tape driver instead of the HP Ultrium

river.

Tape d

Tape Blade

29

Page 30

5. Verify that the tape drive installation was successful.

HP StorageWorks Library & Tape Tools (L&TT) is the recommended diagnostic and support tool for

your HP tape drive. Useittoverifyinstallation andconfirm that your tape drive is functioning

correctly before you use it for backup. It is available free at h

ttp://www.hp.com/support/tapetools.

NOTE:

L&TT tests tape drive operation only; use the Onboard Administrator to diagnose the

tape blade.

6. For all operating systems ensure that you have downloaded any upgrades necessary for your backup

application. Check for software compatibility and install any recommended upgrades.

7. Perform a backup and restore test to check that the drive can write data to tape. Use a blank

cartridge.

Windows Backup or Unix native backup applications can be used to check basic tape drive

operation, but they will not support all the advanced features of your tape drive. We recommend

that

you upgrade your software application before running this test.

30

Verify installation

Page 31

5 Understanding LEDs

There are t wo sets of LEDs; one for the tape blade chassis and one for the Ultrium tape d rive.

In this

chapter:

•

“Tape Blade Chassis LEDs”onpage31

•

“Tape Drive LEDs” on page 32

Tape Blade Chassis LEDs

Figure 16 Tape Blad e chassis LEDs

1 UID LED

2

3

System health LED

Reserved Not used

Blue = Identified

Off = Not identified

Green = Normal operation

Flashing amber = Degraded condition

Flashing red = Critical condition

Troubleshooting with Tape Blade LEDs

The UID LED helps you identify the location of a specific tape blade, if several are installed in an

enclosure. It can be toggled on and off.

The system health LED flashes red whenever the tape blade connection is established with the enclosure;

either immediately after installation or when the tape b lade is removed and reinserted. If it continues to

flash for more than 2 minutes, there is a fault. Make sure that the partner server was powered down

before the tape blade was installed.

If the fault condition persists, other causes are:

Tape Blade

31

Page 32

• c7000 enclosures only: The enclosure firmware is earlier than version 1.30. (In a c3000 enclosure

all versions of the firmware support the HP StorageWorks Tape Blade.) For the best reliability,

performance and new features update to the most recent version of the firmware.

• The adjacent blade is not a server blade

• The tape blade is adjacent to a full-height partner server blade but a mezzanine card has not been

installed, see “Installation with a full-height partner server blade”onpage24.

See the HP BladeSystem Technical Resources website h

components/c-class-storageworks.html for more comprehensive troubleshooting information.

Tape Drive LEDs

ttp://h18004.w ww1.hp.com/products/blades/

Figure 1

1

2

3

4

7Tapedrive LEDs

Clean LED

Tape LED

Drive LED

Ready LED

Off: the drive does not require cleaning

Amber: cleaning cartridge in use

Flashing: the drive needs cleaning

Off: no f

Flashin

or

unsup

Off: no fault has been detected

Flashing amber: the drive mechanism has detected a hardware error

Green: the drive is ready for use

Off: the drive power is off or there was a failure during self-test

Flashing: the drive is busy

Troubleshooting with Tape Drive LEDs

The meaning of different patterns of tape drive LEDs is as follows. See the HP BladeSystem

Technical Resources website h

c-class-storageworks.html for more comprehensive troubleshooting information.

ttp://h18004.www1.hp.com/products/blades/components/

ault has

g

amber: the cartridge currently in the drive is faulty (damaged

ported). Discard the cartridge.

been detected

32

Understanding LEDs

Page 33

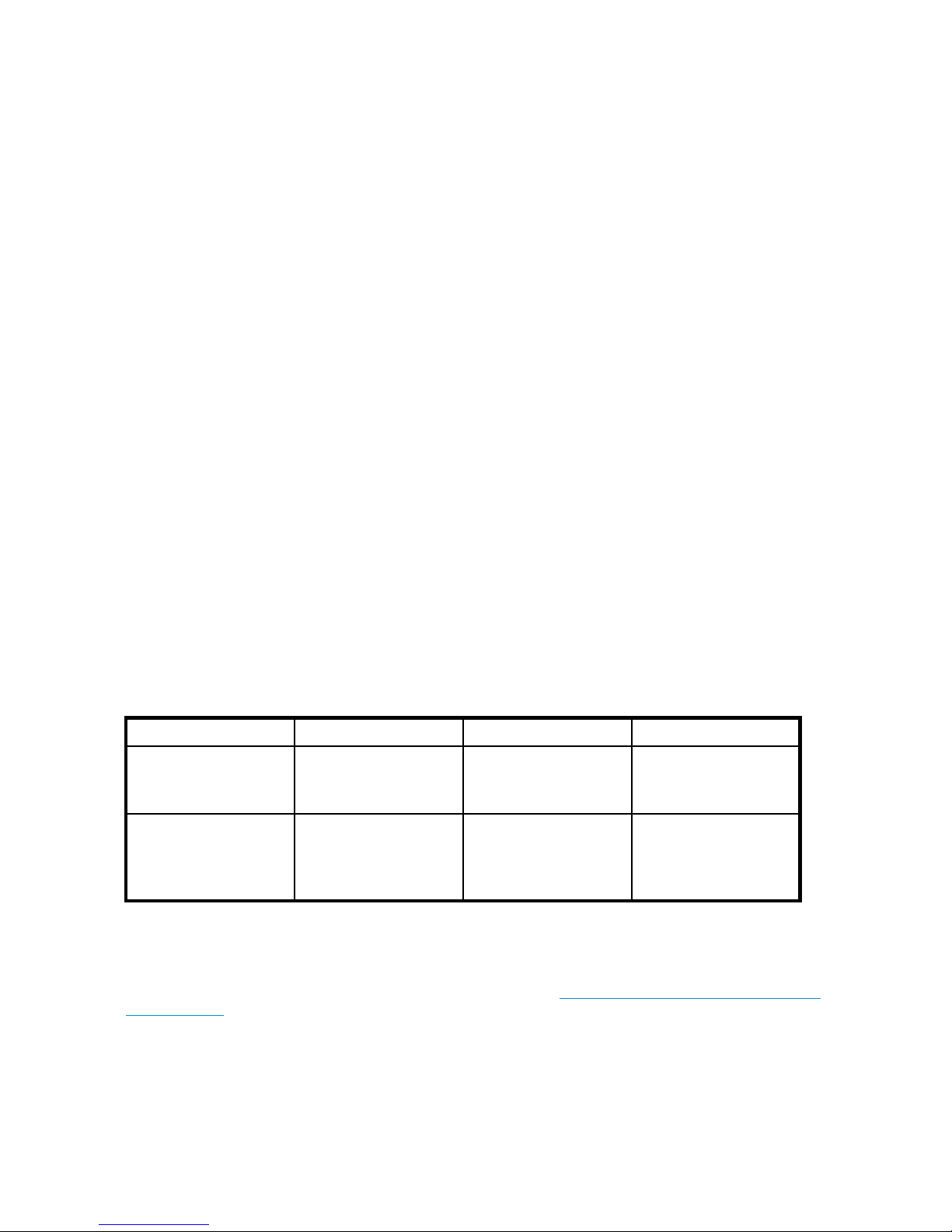

Table 3 Tape drive LED sequences

LED Sequence Cause

Drive may not have power,

All LEDs OFF.

Ready and Clean OFF. Drive

and

Tape FLASH.

Ready is ON.

Ready FLASHES.

Ready sequence FLASHESON- FLASHES.

Ready FLASHES fast.

Ready isOFF,othersare ON.

maybefaultyormay have

been power cycled or reset

during a firmware upgrade.

The drive has failed to execute

power-on self test (POST).

The drive is ready for

operation.

The drive is carrying out a

normal activity (read, write).

The drive is in OBDR mode.

The drive is downloading

firmware.

Firmware is being

reprogrammed.

Action required

Check that the t

correctly.

Check the Syst

Use the Onboar

the

status of t

If thetapedri

service.

Power the server blade off and on again.

If the

error condition reappears, call for

service.

None. This is normal.

None.

drive is upgrading firmware, do not

If the

reset or power cycle it.

See “Running HP OBDR”onpage46for

further details.

None.

Do not reset or power cycle the drive.

None.

rese

Do not

ape blade is installed

em

Health LED is green.

d

Administrator to check

he

tape blade.

ve LEDs are still off, call for

torpower cyclethe drive.

Clean FLASHES. The drive requires cleaning.

Ready FLASHES and Clean is

ON.

Tape FL ASHES.

The tape is ejected immediately

and

Tape FLASHES, or Drive

FLASHES on unloading tape.

Cleaning is in progress.

Thedrive believes thecurrent

tape or the tape just ejected

is

faulty.

The tape cartridge memory

(CM) may be faulty.

Load the Ultrium cleaning cartridge. See

“Cleaning the tape drive” on page 42

for supported cartridges and instructions.

If the

Clean LED is still flashing when

you load a new or known good data

cartridge after cleaning, call for service.

None. The cleaning cartridge will eject

on

completion.

The cleaning cycle can take up to 5

minutes to complete.

the

Unload

that you are using the correct format

cartridge; an Ultrium data cartridge or

Ultrium universal cleaning cartridge. (See

“Use the correct media”onpage39.)

Reloa

flashes or starts flashing during the

still

next backup, load a new or known good

cartridge.

he

If

t

spect’ tape cartridge. If it is still on,

’su

call for service.

Write-protect the car tridge by sliding the

switch on the tape cartridge, see “Write

protecting cartridges” on page 42. The

tape can be loaded and the data read.

Once the

must be discarded.

tape cartridge. Make sure

dthe cartridge. If theTapeLED

Tape LED is now off, discard the

data is recovered, the cartridge

Tape Blade

33

Page 34

LED Sequence Cause

Action required

Drive FLASHES.

Drive, Tape and Ready FLASH.

Drive and Ready ON with Tape

and Clean OFF. Alternates

repeatedly.

The drive mechanism has

detected an error.

There is a firmware download

problem.

The drive has a firmware

error.

Loadanew cartri

persists, powe

Drive LED

If the

dge. If the error

rcycle or resetthe drive.

remains on, call for

service.

Insert a cartridge to clear the LED

sequence. If the condition persists, call

for service.

Power cycle or reset the drive.

Upgrade the firmware. If the condition

persists, call for service.

34

Understanding LEDs

Page 35

6 Loading and unloading cartri dges

and removing tape bla de

In this chapter:

•

“Inserting cartridges”onpage35

•

“Removing cartridges” on page 35

•

“Removing the tape blade” on page 36

Inserting ca

1. Arrow indicates leading direction 3. Label area

2. Cartridge door

Figure 1

1. Lift th

facing

2. Apply gentle pressure until the drive takes the cartridge and loads it.

rtridges

Inserting a cartridge

8

cartridge door and inser t the cartridge into the slot with the white arrow uppermost and

e

cartridge door.

the

3. The Ready light flashes green while the drive performs its load sequence. When the cartridge is

loaded, the Ready light shows steady green.

Removing cartridges

CAUTION:

Never try to remove a cartridge before it is fully ejected.

Tape Blade

35

Page 36

1. Press the Eject button on the front panel.

1. Eject button

Figure 19 Ej

2. The drive will complete its current task, rewind the tape to the beginning, and eject the car tridge.

Therewindprocess maytakeupto10 minutes. The Readylight will flash to indicate that the

unload is

ecting a car trid ge

still in p rogress.

Removing the tape blade

The tape blade is powered down from the partner server blade, see

“Powering the tape blade on and off” on page 28. To ensure reliable operation, do not power

down the partner server blade and remove power from the drive during read, write, fast-search,

load and

Before removing the tape blade:

•

• Make sure the partner server blade is powered down. This powers down the tape blade. (The

To remove the tape blade from the enclosure:

1. Grasp the metal latch, located at the bottom of the tape blade in a c7000 enclosure and to the

2. Carefully slide the tape blade assembly out from the enclosure.

unload activities.

Unload the cartridge as described in “Removing cartridges” on page 35.

tape blade is not a hot-plug device and should always be powered down before removal.)

right of the tape blade in a c3000 enclosure, and pull the latch forward as far as it will go to

release the locking m echanism.

36

Loading and unloading cartridges and removing tape blade

Page 37

Figure 20 Removing the tape blade

CAUTION:

Do not pull on the tape drive bezel when removing the tape blade.

Tape Blade

37

Page 38

38

Loading and unloading cartridges and removing tape blade

Page 39

7Use thecorrect media

For best per formance we recommend HP branded media. Order online at: http://www.hp.com/

go/storagemedia.

In this chapter:

•

“Cartridges” on page 39

• “Cleaning the tape drive” on page 42

• “Write protecting cartridges” on page 42

•

“Handling cartridges”onpage43

•

“Operating and storage environment” on page 43

Cartridges

Data cartridges

HP StorageWorks Tape Blades use Ultrium tape cartridges. These are single-reel cartridges that match

your drive’s format and are optimized for high capacity, throughput and reliability. Compatible media can

be

recognized by the U ltrium logo, which is the same as the logo on the front of your drive. Do not use

other

format cartridges in your tape drive and do not use Ultrium cartridges in other format tape drives.

For optimum performance always use a cartridge that matches the specification of your tape drive, see

Table 4 on page 39. A lower specification will have a lower transfer rate and may not s uppor t write

activities; a higher specification will not support read or write activities. Use:

• Ultrium 1.6 TB

• Ultrium 800 GB

• Ultrium 400 G B

1

1,

RW and Ultrium 1.6 TB1 WORM cartridges with Ultrium SB1760c Tape Blades

1,

RW and Ultrium 800 GB1 WORM car tridges with Ultrium SB920c Tape Blades

1

cartridges with Ultrium 448c Tape Blades

Table 4 Data cartridge compatibility

Ultrium 200 GB

nl nl nl nl

data

cartridge

SB1760c Tape

Blade

SB920c Tape

Blade

448c Tape Blade

1

Capacity assumes 2:1 compression.

not supported read only

read only

read/write

Ultrium 400 G B

data cartridge

read/write

read/write

(C7972A)

nl

recom

mended

Ultrium 800 GB

data

cartridge

Ultrium 1.6 TB

data

cartridge

read/write

read/write

nl

write once/read

many

(C7974A)

nl

write once/read

many (C7974W)

nl

recommended

read/write

(C7973A)

nl

write once/read

many (C7973W)

nl

not supported

recommended

not supported not supported

Tape Blade

39

Page 40

Cleaning cartri

You must use Ultrium cleaning cartridges with HP StorageWorks Tape Blades, as other cleaning cartridges

will not load and run. HP recommends the HP Ultrium universal cleaning car tridge (see Table 5). Unlike

some earlier Ul

designed to work with any Ultrium drive.

Table 5 Cleaning cartridge compatibility

dges

trium cleaning cartridges, the orange-colored HP Ultrium universal cleaning cartridge is

Type of car trid

Cleaning

ge

Recommended cartridge Other options

HP Ultrium universal cleaning

cartridge C7978A (Orange)

HP Ultrium WORM data cartridges

The HP StorageWorks SB1760c and SB920c Tape Blade include support for both re-writable and

Write-Once, Read-Many, WORM, data ca r tridges. WORM cartridges provide for an enhanced level

of

data security against accidental or m a licious alteration of data on the tape cartridge. The WORM

data cartridge can be appended to maximize the full capacity of the tape cartridge, but the user will

be unable to erase or overwrite data on the cartridge. Any attempt to modify a WORM cartridge to

enable

should still be readable in a WORM drive, depending upon the severity of the tampering, but no further

appended

WORM da ta cartridges are clearly identified by their distinctive, two-tone cartridge color. They do not

have a write-protect slider and can only be used with Ultrium tape drives that support the WORM feature.

To check whether your backup or archive software application supports WORM cartridges,

refer to the following web site: h

c-class-storageworks.html.

writing over existing data will result in the media bec om ing permanently write protected. It

backups will be possible.

ttp://h18004.www1.hp.com/products/blades/components/

HP Ultrium cleaning cartridge

C7979A (Blue) . Do not use

early, non-universal Ultrium

cleaning cartridges from other

manufacturers.

HP Stor

ageWorks SB1760c Tape Blades and encryption

The HP S

full s

Encry

prote

stro

To ma

• A b ackup application that supports hardware encryption

• Ultrium 1.6 TB media (C7974A or C7974W); no encryption will be performed when writing earlier

torageWorks SB1760c Tape Blade includes hardware capable of performing data encryption at

peed while writing data, and decrypting when reading.

ption is the process of changing data into a form that cannot be read until it is deciphered,

cting the data from unauthorized access and use. HP StorageWorks SB1760c Tape Blades use the

ngest version of the industry-standard AES encrypting algorithm to protect your data.

ke use of this feature you need:

generations of tape

When should I use encryption?

Your company policy will determine when you need to use encryption. For example, it may be mandatory

for company confidential and financial data, but not for personal data. Company policy will a lso define

how encryption keys should be generated and m anaged. Backup applications that support encryption

will generate a key for you or a llow you to enter a key manually.

40

Use the correct media

Page 41

NOTE:

Encryption with keys that are generated directly from passwords or passphrases may be less secure than

encryption using truly random keys. Your application should explain the options and methods that are

available. Please refer to your application’s user documentation for more information.

How do I enable encryption?

Hardware encryption is turned off by default and is switched on by settings in your backup application,

where you also generate and supply the encryption key. Your backup application must support hardware

encryption for this feature to work. The software supplied with the tape drive provides this support.

See

ttp://h18004.w ww1.hp.com/products/blades/components/c-class-storageworks.html for an

h

up-to-date list of other suitable backup software.

When will I be asked to enter the key?

Encryption is primarily designed to protect the m edia once it is offline and to prevent it being accessed

from another machine. You will be able to read and append the encrypted media without being

prompted for a key as long as it is being accessed by the machine and application that first encrypted it.

There are two main instances when you will need to know the key:

• If you try to import the media to another ma chine or another instance of the backup application

• If you are recovering your system after a disaster

What happens if I don’t remember the key?

CAUTION:

You should keep a record or backup of your encryption keys and store them in a secure place separate

from the computer running the backup software. If you are unable to supply the key when requested to

do

so, neither you nor HP Support will be able to access the encrypted data.

This guarantees the security of your data, but also means that you must be careful in the management

of the encryption key used to generate the tape.

Does enc

ryption affect tape drive performance?

Hardware encryption can be used with o r without compression and without spee d or capacity penalties.

Does the tape drive encrypt media in an earlier Ultrium format?

No. Encryption is supported only on Ultrium 1.6 TB media (C7974A or C7974W ).

Ultrium 1.6 TB tapes encrypted on an HP StorageWorks SB1760c Tape Blade can be read on any

compatible HP StorageWorks SB1760c Tape B lade (or Ultrium 1760 or Ultrium 1840 tape drive) that

supports hardware encryption.

HP StorageWorks SB1760c Tape Blades can read Ultrium 800 GB and Ultrium 400 GB media and write

Ultrium 800 GB media, but hardware encryption is not supported on these formats.

Where can I get more information?

For more information about AES encryption, encryption keys, and using hardware encryption with your

HPStorageWorks SB1760c Tape Blade, see h

lto4Encryp/index.html or refer to the White Papers on http://h18006.www1.hp.com/storage/

hitepapers.html.

tapew

ttp://h18006.www1.hp.com/products/storageworks/

Tape Blade

41

Page 42

For detailed instructions about enabling encryption please refer to the documentation supplied with

your backup application. This will also highlight any default states, for example when copying tapes,

that may need changing if using encrypted tapes.

Cleaning the t

HP StorageWorks Tape Blade tape drives do not require regular cleaning. An Ultrium universal cleaning

cartridge should only be used when the orange Clean LED is flashing.

1. Insert the Ultrium universal cleaning cartridge.

2. The drive wil

to 5 minutes). During the cleaning cycle the orange Clean LED will be on solidly and the green

Ready LED will flash.

Each HP Ultrium universal cleaning cartridge (C7978A) can be used up to 50 times with Ultrium tape

drives. (Th

tape drive.

ape

e

)

drive

carry out its cleaning cycle and eject the cartridge on completion (which can take up

l

blue HP Ultrium cleaning cartridges, C7979A, can only be used up to 15 times with any

If the cleaning cartridge is ejected immediately with the Tape LED on, it has expired.

Write protecting cartridges

If you want to protect the data on a car tridge from being altered or overwritten, you can write protect the

cartridge.

IMPORTANT:

Always remove thecartridge from thetapedrive before youchangethe write protection.

• To write protect a ca rtridge, push the switch to the right to prevent any data recording on the

cartridge. Note the padlock on the tab that indicates that the cartridge is protected.

• To write enable a cartridge, push the switch to the left to allow data recording on the cartridge.

Figure 21 illustrates the location of the write-protect tab.

NOTE:

Write-protection will not protect your cartridges against magnets. Write-protection will not prevent a

cartridge being erased by bulk-erasure or degaussing. Do not bulk erase Ultrium format cartridges. This

will destroy pre-recorded servo information and make the cartridge unusable.

42

Use the correct media

Page 43

1. Write-protect tab

Figure 21 Write protecting a cartridge

Handling cartridges

• Do not touch the tape media.

• Do not attempt to clean the tape path or tape guides inside the cartridge.

• Do not leave cartridges in the d rive. The tape loses tension in the p ower-off state, which can lead

to problems, par ticularly if the drive has been moved.

• Store cartridges in a vertical orientation.

• Do not leave cartridges in excessively dry or humid conditions.

• Do not leave cartridges in direct sunlight or in places where magnetic fields a re present (for

example, under telephones, next to monitors or near transformers).

• Do not drop cartridges or handle them roughly.

• Attach labels to the label area only.

• Do not bulk erase (or degauss) Ultrium format cartridges because this will render them unusable.

Operating and storage environment

To prevent condensation and for long life, the cartridge sho uld only be operated o r stored as follows:

• Operation: 10°Cto 45°C(50° Fto113°F)

• Day-

• Non-condensing relative humidity: 10% to 80% (operating), 20% to 60% (non-operating)

• Wet bulb temperature should not exceed 26° C (79° F)

• Sto

to-day storage (in plastic container): 16° C to 32º C (60° F to 90° F)

re cartridges in a vertical orientation

es intended for long-term storage should be stored in the plastic containers, at temperatures between

Tap

5° C

and 23° C (41° F and 73° F) and 20% to 60% relative humidity.

Tape Blade

43

Page 44

44

the correct media

Use

Page 45

8Using HP OBDR

In this chapter:

•

“Compatibility” on page 45

•

“What does HP OBDR do?” on page 45

•

“Remote disaster recovery (ProLiant servers only)” on page 45

•

“Testing for compatibility” on page 46

•

“Running HP OBDR”onpage46

Compatibi

HP One-But

Blades. H

HP

To check whether your system (server blade, operating system and backup software) is OBDR-compatible,

please refer to our World Wide Web site h

For more specific information concerning the benefits of OBDR and the latest new features please refer to

our

If your system does not support HP One-Button Disaster Recovery, you can still use your tape blade

normally to back up and restore data. H owever, you must remember to create a separate set of

emergen

lity

ton Disaster Recovery, HP O B DR, is a standard feature on all H P StorageWorks Ultrium Tape

owever, it can only be used with specificconfigurations. To use HP OBDR with the

StorageWorks Ultrium Tape Blade, it must be partnered with a ProLiant server blade.

World Wide Web site h

cy recovery disks for your op erating system whenever you change your system configuration.

ttp://www.hp.com/go/obdr.

What does HP OBDR do?

Using just the tape blade and the most recent backup car tridge HP OBDR allows you to recover from

the

following types of system disasters:

• Hardware failures where the server blade is replaced by an identical component

• File corruption because of an operating system error

• File corruption because of an application software error

• Viruses that prevent you from booting your system correctly

• User errors that stop you from booting your system correctly

When you run HP One-Button Disaster Recovery, your tape blade goes through the following sequence:

ttp://www.hp.com/go/connect.

1. It goes into a special disaster recovery mode that enables it to restore your operating system and

reboot. It acts like a bootable CD-ROM. (Your system’s ability to boot from CD-ROM is normally

enabled by default. If you have changed this set ting, you will need to enable it again. Refer to

your system BIOS manual for further details.)

2. It returns to normal tape blade mo d e and restores the data.

Remote disaster recovery (ProLiant servers only)

HP Remote Insight Lights-Out Edition (RILOE) on ProLiant servers gives the IT Administrator the abilit y

The

completely recover a failed server at a remote location without physically traveling to where the

to

server resides. The on-site non-technical person need only insert the bootable cartridge into the tape

drive when asked to do so by the administrator.

fer to the HP OBDR web site at h

Re

is feature and comp atibility.

th

ttp://www.hp.com/go/obdr for more information about using

Tape Blade

45

Page 46

Testing for compatibility

We recommend that you perform a full backup and test disaster recovery as soon as possible after

possible, onto a blank hard disk. If you do not have a blank hard disk and do not want

installation—

to

overwrite your system, you can safely cancel the disaster recovery process at step 3 in the “Running

HP OBDR” procedure. Refer to our connectivity web site (h

information about suitable backup applications.

if

Running HP OBDR

HP OBDR can only be used with backup applications that support one-button disaster recovery and

methods

Web site (http://www.hp.com/go/ obdr) for the latest information about software compatibility, firmware

upgrades and troubleshooting before you use HP OBDR.

1. Insert the latest bootable cartridge in the tape drive. Every full backup with overwrite creates a

of o perating OBDR will vary between different software companies. Check our World Wide

bootable tape.

ttp://www.hp.com/go/connect) for more

Figure 22 Inserting cartridge for OBDR

2. Power on the blade server for approximately 3 seconds then power off. This will reset the tape blade.

Immediately hold down the eject button on the tape drive to invoke OBDR. Release the button as

soon as the Ready LED on the front panel flashes in the OBDR sequence. This is a repeated flashing

pattern. Once the tape blade is in OBDR mode, power on the blade server again.

Figure 23 Keeping eject button pressed down, power on in OBD R mode

Keyboard shortcut for HP ProLiant servers

There is no need to press the Eject button. Just power on your server and press the [F8] function key

during the Power On Self Test (POST). This invokes OBDR to restore your system. For more information

and

specific instructions please refer to our World Wide Web site at h

NOTE:

The firmware for the embedded SC44Ge HBA may need to be upgraded to the latest version in order to

take advantage of this feature.

ttp://www.hp.com/go/obdr.

Using

46

HP OBDR

Page 47

3. Follow the on-screen instructions to restore your system. Once the operating system has been restored

and

rebooted, you may remove the backup cartridge.

Tape Blade

47

Page 48

Using HP OBDR

48

Page 49

9 Troub l eshooting

Read this chapter for information about:

•

When the tape blade does not power up ,page49

•

Management and Diagnostic tools ,page49

• Problems with cartridges, page 51

NOTE:

For information about troubleshooting using tape blade and tape drive LEDs, see

“Understanding LEDs”onpage31.

When the tape blade does not power up

If the tape blade does not start, use the following table to help resolve the problem:

Table 6 Troubleshooting tape blade operation

Possible reasons Possible solutions

• The tape bla de is not installed in the

correct location for the partner server

blade.

• The partner server blade was not

restarted after the tape blade was

installed.

Verify that the tape blade is installed adjacent to the partner

server blade. See “Installing an HP StorageWorks Tape

Blade”on page 19.

Restart the server blade and verify that the tape blade front panel

system health LED changes from flashing red to solid green.

1. Power down the partner server b lade.

Reseat thetapeblade in the devicebay.

• The tape blade is not properly seated

in thedevicebay.

• No mezzanine pass-thru card

installed

• The c-Class enclosure firmware is at

the

• There is insufficient power or cooling

with a full-height server

wrong version

2.

Restart the server blade and verify that the tape blade front

3.

panel

system health LED changes from flashing red to solid

green.

Purchase and install the required card, option kit part number:

431643-B21.

Firmware version 1.3 or later is required when installing in

a

c7000 enclosure. In a c3000 enclosure all versions of the

firmware support the HP StorageWorks Tape Blade. For the best

reliability, performance and new features update to the most

recent version of the firmware .

Use the Onboard Administrator to verify that sufficient power

and

cooling are available.

Management and Diagnostic tools

HP BladeSystem Onboard Administrator is the management and diagnostic tool for the tape blade

assembly. HP Library & Tapetools provides diagnostic and troubleshooting tools for the tape drive.

Tape Blade

49

Page 50

Onboard Adminis

HP BladeSystem Onboard Administrator is the enclosure managem ent processor, subsystem, and

firmware base used to support the HP BladeSystem c–Class enclosure and all the managed devices

contained within the enclosure.

Onboard Admini

blades, tape blades or switches within the enclosure. Utilizing this hardwired knowledge, Onboard

Administrator performs initial configuration steps for the enclosure, allows for run-time management and

configuration of the enclosure components, and informs you of problems within the enclosure through

email, SNMP, or the Insight Display.

Please read the HP BladeSystem Onboard Administrator User Guide for more information.

trator

strator provides a single point from which to perform basic management tasks on server

HP Library & Tape Tools

HP StorageWorks Library & Tape Tools is the recommended diagnostic and s upport tool for your HP tape

drive product. It is available from a link on the CD shippe d with your product or as a free download from

the

HP web site. It is supported on nearly all major operating systems.

HP recommends installation of Library & Tape Tools, so that it can be quickly accessed at any time. HP

Support will also request that you use Library & Tape Tools should you need to contact them in the

future, so it is a good idea to have it installed.

ttp://www.hp.com/support/tapetools for compatibility information, updates and the latest version

See h

of the tool.

Troublesh

ooting with Library & Tape Tools

1. When Library & Tape Tools is first run, it will scan for HP tape drives a n d libraries on your system

and

ask you to select the one to work with. At this time you can see the HBA configuration of your

how your devices are connected.

server an

2. Once you have selected your device you have a number of choices for troubleshooting.

•Device identification: shows part number, serial number and information about any cartridge

• Firmware upgrade: allows you to locate and upgrade to the latest firmware. To check for

•Run tes

• G enerate a support ticket: this is a full dump of the drive logs along with interpretation and

•Run t

d

loaded.

anddownloadthe latest firmware from the HP web site, the server on which Library and

Tape Tools is running must have an internet connection.

ts: allows you to run proactive tests on your drive, such as the drive assessment test,

which will verify the functionality of your drive in around 20 minutes. HP recommends

running this test before ca lling HP Support. You will need to provide a ‘trusted’ cartridge that

can

is used by HP Support to learn about the condition of your drive. Most useful is the device

analysis section which is the output from approximately 20 rules forming a comprehensive

analysis of thehealthofyourdrive. Theserules maygiveadvicesuchascleaning the head

or

for further analysis.

drive and the data generation rates of your disk subsystem are also integrated into Library &

Tape Tools. Use these tests to find the per formance bottleneck in your system.

ritten to during this test.

be w

trying a different tape if issues are found. The suppor t ticket can be sent to HP Support

performance tests: the tests to measure the write/read performance of your tape

he

Optimizing performance

• The HP StorageWorks SB1760c Tape Blade can write uncompressed data at up to 80 MB/s (288

GB/hour).

• The HP StorageWorks SB920c Tape Blade can write uncompressed data at up to 60 MB/s (216

GB/hour).

50

Troubleshooting

Page 51

• The HP StorageWorks Ultrium 448c Tape Blade c an write uncompressed data at up to 24 MB/s

(86 GB/hour).

If your tape blade is not performing as well as expected—for example, if backup windows are longer

than

expected—please try the tools and consider the following points b efore c ontacting HP Support at

ttp://www.hp.com/support.

h

Typical areas where bottlenecks can occur are:

• Disk subsystem

A

single spindle disk will not be able to deliver good data throughput at poor compression

ratios. Bestpracticeto ensuregood throughputistoutilize multiple disk spindles in a RAID

configuration or use multiple data sources.

• System architecture

Be

aware of the architecture of your data protection environment.

The aggregation of multiple client sources over a network provides a good way of delivering

good performance, but anything less than Gigabit Ethernet will limit performance.

Some enterprise class backup applications ca n be made to interleave data from multiple sources,

such as clients or disks, to keep the tape drive working at optimum performance. The drawback

of interleaving is that it will increase the time needed to restore data.

• Tape me dia type

The data cartridge should match the specification of the tape drive. A lower specification will

have a lower transfer speed (see “Data cartridges” on page 39). Use

• Ultrium 1.6 TB cartridges with the HP StorageWorks SB1760c Tape Blade

• Ultrium 800 GB cartridges with the HP StorageWorks SB920c Tape Blade

• Ultrium 400 GB cartridges with the HP StorageWorks Ultrium 448c Tape Blade.

• Data and file types

The type of data being backed up or restored can affect performance. Typically, small files incur

greater overhead in processing and access than large files. Equally, data that is not compressible

will always limit the speed at which the drive can write/read data. You will achieve no more

than

native rates with unc ompressible data.

Examples of files that compress well are plain text files, spreadsheets; those that compress poorly

are those that are either compressed as part of their format (such as, JPEG photographic files) or

stored as compressed (such as, .ZIP files or .gz/.Z files on Unix platforms).

Problems with cartridges

If you experience any problems using HP branded cartridges, check:

• You are using an Ultrium cartridge. Compatible media can be recognized by the Ultrium logo,

which is the same as the logo on the front of your drive.

• You are

use with HP StorageWorks SB1760c Tape Blades; Ultrium 800 GB* tape cartridges (C7973A or

C7973W) for use with HP StorageWorks SB920c Tape Blades; Ultrium 400 GB* tape cartridges

(C7972A) for use with HP StorageWorks Ultrium 4 48c Tape Blades.

• If you are using C7974W or C7973W tape cartridges with the HP StorageWorks SB1760c or

SB920

• The cartridge case is intact and that it contains no splits, cracks or damage.

• The cartridge has been stored at the correct temperature and humidity. This p revents

condensation. See the insert included with the tape cartridge for storage conditions.

• The

• The World Wide Web site for more detailed troubleshooting i nformation:

h

ttp://h18004.w ww1.hp.com/products/blades/components/c-class-storageworks.html.

The cartridge is jammed

If the cartridge is jammed or the backup application is unable to eject it, you can force eject the