Page 1

HP 8935 CDMA Cellular/PCS Bas e St ati o n

Main Menu

Test Set

Reference Guide

Firmware Version: A.01.00 and above

HP Part N u mber E6380- 90019

Revision A

Printed in U.S.A.

November 1997

© Copyright 1997 Hewlett-Packard Company

Page 2

Notice

Main Menu

Information contained in this document is subject to change without

notice.

All Rights Reserved. Reproduction, adaptation, or translation without

prior written permission is prohibited, except as allowed under the

copyright laws.

This material may be reproduced by or for the U.S. Government

pursuant to the Copyright License under the clause at DFARS

52.227-7013 (APR 1988).

2

Page 3

Contents

Main Menu

Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

In This Book. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Conventions Used in this Book. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1. Getting Started

Before Connecting a Radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Changing the Test Set’s Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Changing the Measurement Screen . . . . . . . . . . . . . . . . . . . . . . . . . 25

Changing the Control Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

How do I Verify that the Test Set is Operating Properly? . . . . . . . . . 31

Instrument Quick Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2. Operating Overview

Displaying CDMA Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Channel Power, Rho, EVM, Average Power. . . . . . . . . . . . . . . . . . . 34

Code Domain Measurements (Power, Timing, Phase). . . . . . . . . . . 35

Displaying Analog Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

RF Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Displaying AF Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Displaying Analog Measurement Results on a Meter Scale . . . . . . 39

Using Channel Numbers to Set Analyzer and Generator Frequencies40

Calibrating the Channel Power Measurement . . . . . . . . . . . . . . . . . . 41

Changing the Increment or Decrement Setting. . . . . . . . . . . . . . . . . . 42

Specifying An Increment Value for the Arrow Keys or Knob . . . . . 42

Using the Factor of 10 Increment/Decrement Keys . . . . . . . . . . . . . 42

Using Measurement Limit Indicators . . . . . . . . . . . . . . . . . . . . . . . . . 43

Setting A Measurement Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Averaging Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

How the Test Set Averages Measurements . . . . . . . . . . . . . . . . . . . 46

Setting an RF Generator/Analyzer Offset . . . . . . . . . . . . . . . . . . . . . . 47

Saving and Recalling Instrument Se tups. . . . . . . . . . . . . . . . . . . . . . . 48

Register Names. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Memory Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Instrument Hardware Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Using USER Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Using Pre-Defined USER Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Assigning and Releasing USER Keys . . . . . . . . . . . . . . . . . . . . . . . . 52

Replacing Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3. Overview of the Test Set’s

Built-In Tools

Using RF Tools Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Swept Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Discrete Freq Insertion Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Swept Insertion Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Swept Return Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Cable Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Replot Data Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3

Page 4

Contents

Main Menu

Transfer Stored Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

SA (spectrum analyzer) Self Calibration ON/OFF. . . . . . . . . . . . . . 65

Catalog PC (Memory) Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Set Up Printer/Data Collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Using the Code Domain Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Selecting the Code Domain Analyzer’s Controls Menus . . . . . . . . . 67

Using the Spectrum Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Automatic Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Setting Resolution Bandwidth and Sweep Rate. . . . . . . . . . . . . . . . 68

Selecting the Spectrum Analyzer’s Controls Menus. . . . . . . . . . . . . 69

Using the Voltmeter and Audio Frequency Counter. . . . . . . . . . . . . . 70

Using the Oscilloscope (Scope) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Selecting the Oscillo sc op e’s Inp u t . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Selecting the Oscillo sc op e’s F ilte rs . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Triggering the Osc illo sc ope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Using the Oscilloscop e ’ s Mark er . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Using IB_UTIL Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

COPY_PL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

FILE_XFER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

RAM_USAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Securing a Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Clearing RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Using the LISTOPTS (list options) Program. . . . . . . . . . . . . . . . . . . . 77

Using the DEMO Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Using the ST_PLT (store or plot) Program . . . . . . . . . . . . . . . . . . . . . 79

4. CDMA Measurements - Screens

and Contr ol Fields

CDMA Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Average Power Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Channel Power Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Rho Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Error Vector Magnitude (EVM) Measurements . . . . . . . . . . . . . . . . 88

Code Domain Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Control Fields for CDMA Measurements. . . . . . . . . . . . . . . . . . . . . . . 93

ADCfs or ADC FS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Analyzer (CDMA analyzer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Analyzer (code domain analyzer). . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Anl Dir. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Anl Special . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Auto Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Car FT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Chn Pwr Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

CW RF Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Data Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Data Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Even Sec In. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

4

Page 5

Contents

Main Menu

Freq Err. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Gain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Gen Dir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Gen Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Gen Special . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Input Atten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Input Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Lvl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Meas Intvl. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Num Avgs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Ofs Trnsfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Output Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

PN Offset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Pwr Gain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Pwr Intvl. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Pwr Scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Pwr Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Qual Event . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

RF Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

RF Gen Freq . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

RF In/Ant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Time Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

TmOfs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Trig Event. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Tune Freq . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Walsh Chan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

5. Analog Measurements - Screens

and Contr ol Fields

Analog Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

AC Level Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

AM Depth Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

AF Freq Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

DC Level Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Distn (Distortion) Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

FM Deviation Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Frequency Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Frequency Error Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

TX Power Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

FM Deviation Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

AF Freq (Audio Frequency) Measurement . . . . . . . . . . . . . . . . . . . 121

SINAD Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

SNR Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Control Fields for Analog Measurements. . . . . . . . . . . . . . . . . . . . . . 123

AF Anl In. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

AF Cnt Gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

AFGen1 Freq. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

5

Page 6

Contents

Main Menu

AFGen1 To . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

AFGen2 Freq. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

AFGen2 To . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Atten Hold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Audio In Lo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Audio Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Auto/Norm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Auto Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Center Freq. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Cont/Single . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

De-Emp Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

De-Emphasis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Detector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Ext Load R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Filter 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Filter 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

FM Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Freq (marker) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Gain Cntl. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

IF Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Input Atten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Input Gain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Input Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Internal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Level (div) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Lvl (marker) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Marker To Peak+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Marker To Peak- . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Marker To (spectrum analyzer). . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Mod In To . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

No Pk/Avg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Normalize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Notch Freq . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Notch Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Offset Freq . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Output Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Pk Det To . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Port/Sweep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Ref Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

RF Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

RF Cnt Gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

RF Gen Freq . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

RF In/Ant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Scope To . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Sensitivity (RF analyzer). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

6

Page 7

Contents

Main Menu

Sensitivity (spectrum analyzer). . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Settling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Span. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Speaker ALC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Speaker Vol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Squelch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Time/div . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Track/Fixed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Trig-Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Tune Freq . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

TX Pwr Meas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

TX Pwr Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Vert/div . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Vert Offset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

6. Configuration - Screens and Control Fields

Configuring the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Setting the Date and Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Changing the Beeper’s Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Turning Off User Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Configuring for Printing A Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Printing a Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Control Fields on the Configuration Screens. . . . . . . . . . . . . . . . . . . 162

Abort Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Antenna In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Base Freq (User Defined) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Beeper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Chan Space (User Defined) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Data Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Date. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Display User Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Duplex Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Ext Ref In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

FF at End:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

FF at Start:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Frame Clock Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

(Gen)-(Anl) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

(Gen)-(Anl) (User Defined). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

HP-IB Adrs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

IBASIC Echo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Inst Echo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Lines/Page: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Model: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Notch Coupl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Opt CDMA TB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

7

Page 8

Contents

Main Menu

Parity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Printer Port: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Print Title:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Range Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Ref Select. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

RF Chan Std. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

RF Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

RF Gen Volts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

RF In/Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

RF Level Offset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

RF Offset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Save/Recall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Serial Baud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Serial_9 In. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Serial No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Stop Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Total RAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

7. Connectors

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

10 MHz REF OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

16 × CHIP CLOCK 19.6608 MHz OUT. . . . . . . . . . . . . . . . . . . . . . 184

ANALOG MODULATION IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

ANT IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

AUDIO IN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

AUDIO OUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

BASEBAND OUT (I and Q). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Chassis Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

CHIP CLOCK 1.2288 MHz OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

DATA IN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

DUPLEX OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

EVEN SECOND SYNC IN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

EXT REF IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

EXT SCOPE TRIG IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

FRAME CLOCK OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

HP-IB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

MEMORY CARD Slot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

PARALLEL PORT 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

PARALLEL PORT 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

RF IN/OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

SCOPE MONITOR OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

SERIAL PORTs 9, 10, and 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

TRIGGER QUALIFIER IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

VIDEO OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

8. Accessories, Manuals, Support

Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

8

Page 9

Contents

Main Menu

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

External Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Manuals (English and non-English) . . . . . . . . . . . . . . . . . . . . . . . . 197

Test Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

HP Support for Your Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Customer Training. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

9. Error Me ss a ges

General Information About Error Messages . . . . . . . . . . . . . . . . . . . 204

Positive Numbered Error Messages . . . . . . . . . . . . . . . . . . . . . . . . 204

Negative Numbered Error Messages. . . . . . . . . . . . . . . . . . . . . . . . 205

IBASIC Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

HP-IB Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Text Only Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

The Message Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Non-Recoverable Firmware Error. . . . . . . . . . . . . . . . . . . . . . . . . . 207

Text Only Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

9

Page 10

Contents

Main Menu

10

Page 11

Product In formation

Main Menu

11

Page 12

Manufacturer’s

Main Menu

Declaration

This statement is provided to comply with the requirements of the

German Sound Emission Directive, from 18 January 1991.

This product has a sound pressure emission (at the operator position)

< 70 dB( A).

• Sound Pressure Lp < 70 dB(A).

• At Operator Position.

• Normal Operation.

• According to ISO 7779:1988/EN 27779:1991 (Type Test).

Herstellerbescheinigung

Diese Information steht im Zusammenhang mit den Anf orderungen der

Maschinenlärminformationsverordnung vom 18 Januar 1991.

• Schalldruckpegel Lp < 70 dB(A).

• Am Arbeitsplatz.

• Normaler Betrieb.

• N ach I SO 7779:198 8/ E N 27779:19 91 (Typprüfu n g) .

12

Page 13

Safety

!

Main Menu

Considerations

GENERAL

This product and related documentation must be reviewed for

familiarization with safety markings and instructions before operation.

This product has been designed and tested in accordance with IEC

Publication 1010, "Safety Requirements for Electronic Measuring

Apparatus," and has been supplied in a safe condition. This instruction

documentation contains information and warnings which must be

followed by the user to ensure safe operation and to maintain the

product in a safe condition.

SAFETY EARTH GROUND

A uninterruptible safety earth ground must be provided from the main

power source to the product input wiring terminals, power cord, or

supplied power cord set.

CHASSIS GROUND TERMINAL

To prevent a potential shock hazard, always connect the chassis ground

terminal to earth ground when operating this instrument from a dc

power source.

SAFETY S Y M BOLS

Indicates instrument damage c an occur if indica ted operating l imits are

exceeded. Refer to the instructions in this guide.

Indicates hazardous voltages.

Indicates earth (ground) terminal

WARNING A WARNING note denotes a hazard. It calls attention to a

procedure, practice, or the like, which, if not correctly

performed or adhered to, could result in personal injury. Do n ot

proceed beyond a WARNING sign until the indicated conditions

are fully understood and met.

CAUTION A CAUTION note denotes a hazard. It calls attention to an operation

procedure, practice, or the like, which, if not correctly performed or

adhered to, could result in damage to or destruction of part or all of the

product. Do not proceed beyond an CAUTION note until the indicated

conditions are fully understood and met.

13

Page 14

Safety Considerations for this Instrument

Main Menu

WARNING This product is a Safety Class I instrument (provided with a

!

protective earthing ground incorporated in the power cord).

The mains plug shall only be inserted in a socket outlet

provided with a protective earth contact. Any interruption of

the protective conductor inside or outside of the product is

likely to make the product dang erous. Intentional interruption

is prohibited.

Do not expose to or operate this instrument in outdoor

!

atmospheric conditions such a s direct rain, hail, sleet, snow,

icing, sunshine or wind. Op erate th is i nstrument onl y within its

specified temperature humidity conditions.

This instrument is equipped with internal gr ound fault circuit

!

interrupter class A.

• This device does not protect against electrical shock due to

contact with both circuit conductors or a fault in supply

wiring to product.

• Do not use extension cord to connect this product to power

receptacle. At tention-ne pas utiliser de ra llonge pour

raccorder le detecteur-disjoncteur a la prise de courant.

• Replace cordset only with HP 8120 series. Attention Remplacer uniquement par un cordon amovible numero

8120.

• Do not use in wet location. Ne pas utilise r dans un

emplacement mouille.

WARNING Whenever it is likely tha t the protection has been im paired, the

instrument must be made inoperative and be secured against

any unintended operation.

If this instrument is to be energized via an autotransformer (for

voltage reduction), make sure the common terminal is

connected to the earth termina l of the power source.

If this product is not used as specified, the protection provided

by t he equipm en t c o ul d b e i mpa i re d. Th is pr o d uc t m u s t b e u se d

in a normal condition (in which all means for protection are

intact) only.

No operator servi ceable parts in t his product. Refer servicing to

qualified personnel. To prevent electrical shock, do not remove

covers.

14

Page 15

Servicing inst ructions are for use by qualified personnel only.

Main Menu

To avoid electrical shock, do not perform any servicing unless

you are qualified to do so.

The opening of covers or removal of parts is likely to expose

dangerous voltages. Disconnect the product from all voltage

sources while it is being opened.

Adjustments described in the manual are performed with

power supplied to the instrument while protective covers are

removed. Energy available at many points may, if contacted,

result in personal injury.

The power cord is connected to internal capacitors that my

remain live for 5 seconds after disconnecting the plug from its

power supply.

For Continued protection against fire hazard, replace the line

fuse(s) only with 250 V fuse(s) or the same current rating and

type (for example, normal blow or time delay). Do not use

repaired fuses or short circuited fuseholders. FUSE: T 5.0A

CAUTION Always use the three-prong ac power cord supplied with this product.

Failure to ensure adequate earth grounding by not using this cord may

cause personal injury and/or product damage.

This product is designed for use in Installation Category II and

Pollution Degree 2 per IEC 1010 and IEC 664 respectively. For indoor

use only.

This product has autoranging line voltage input, be sure the supply

voltage is within the specified range.

Ventilation Requirements: When installing the product in a cabinet,

the convection into and out of the product must not be restricted. The

ambient temperature (outside the cabinet) must be less than the

maximum operating temperature of the product by 4° C for every 100

watts dissipated in the cabinet. If the total power dissipated in the

cabinet is greater than 800 watts, then forced convection must be used.

To prevent electrical shock, disconnect instrument from mains (line)

before cleaning. Use a dry cloth or one sl ightly d ampened with water to

clean the external case parts. Do not attempt to clean internally.

Product Markings CE - the CE mark is a registered trademark of the European

Community. A CE mark accompanied by a year indicated the year the

desi gn was pro ven.

CSA - the CSA mark is a registered trademark of the Canadian

Standards Associatio n .

15

Page 16

CERTIFICATION Hewlett-Packard Company certifi es that this p r oduct met its published

Main Menu

specifications at the time of shipment from the factory.

Hewlett-Packard further certifies that its calibration measurements

are traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institute’s calibration facility,

and to the calibration facilities of other International Standards

Organization members.

WARRANTY This Hewlett-Packard instrume nt produc t i s warr anted a gainst d ef ec ts

in material and workmanship for a period of one year from date of

shipment. During the warranty period, Hewlett- Packard Company will

at its option, either repair or replace products which prove to be

defective.

For warranty service or repair, this product must be returned to a

service facility designated by HP. Buyer shall prepay shipping charges

to HP and HP shall pay s hipping cha rges, duti es, and taxes for product s

returned to HP from another country.

HP warrants that its software and firmware designated by HP for use

with an instrument will execute its programming instructions when

properly installed on that instrument. HP does not warrant that the

operation of the instrument, or software, or firmware will be

uninterrupted or error free.

LIMITATION OF

WARRANTY

EXCLUSIVE

REMEDIES

ASSISTANCE Product maintenance agreements and other customer assistance

The foreg o in g warranty shall not apply t o de fe ct s re su lting from

improper or inadequate maintenance by Buyer, Buyer-supplied

software or inte rfa cing, una uthor ized modification or misuse, operation

outside of the enviro nmental sp ec ifications for the pro duct, or im proper

site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HP

SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND

EXCLUSIVE REMEDIES. HP SHALL NOT BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASE ON CONTRACT,

TORT, OR ANY OTHER LEGAL THEORY.

agreements are available for Hewlett-Packard products. For any

assistance, contact your nearest Hewlett-Packard Sales and Service

Office.

16

Page 17

Table 1 Regional Sales and Service Offices

Main Menu

Eastern USA

Sales Office

Hewlett-Packard Company

2101 Gather Rd.

Rockville, MD 20850

Tel: (301) 258-2000

Southern USA

Sales an d S ervice

Hewlett-Packard Company

1995 North Park Place

Atlanta, GA 30339

Sales

Tel: (404) 955-1500

Fax: (404) 980-7292

Service

Tel: (404) 850-2544

Fax: (404) 980-7292

Western USA

Sales an d S ervice

Hewlett-Packard Company

24 Inverness Place East

Englewood, CO 80112

Sales

Tel: (303) 649-5000

Fax: (303) 649-5787

Service

Tel: (303) 649-5512

Fax: (303) 649-5787

Eastern USA

Sales Office

Hewlett-Packard Company

2101 Gather Rd.

Rockville, MD 20850

Tel: (301) 258-2000

Southern USA

Service Center

Hewlett-Packard Company

930 E. Campbell Road

Richardson, TX 75081

Tel: (214) 699-4331

Western USA

Sales and Service

Hewlett-Packard Company

1421 South Manhattan Avenue

Fullerton, CA 92631

Sales

Tel: (714) 999-6700

Fax: (714) 778-3033

Service

Tel: (714) 758-5490

Fax: (714) 778-3033

Midwestern USA

Sales and Service

Hewlett-Packard Company

5201 Tollview Drive

Rolling Meadows, IL 60008

Tel: (708) 342-2000

Western USA

Service Center

Hewlett-Packard Company

301 E. Evelyn Avenue

Mountain View, CA 94041

Tel: (415) 694-2000

Fax: (415) 694-0601

United States of America

Customer Information Center

Hewlett-Packard Company

Tel: (800) 752-0900

6:00 am to 5:00 pm Pacific Time

Parts Direct: 1-800-227-8164

South Eastern Europe

Sales an d S ervice

Hewlett-Packard Ges. m.b.h.

Liebigasse 1

P.O. Box 72

A-1222 Vienna, Austria

Telephone: 43 222 2500 0

Telex: 13 4425

European Multicountry Region

Sales and Service

Hewlett-Packard S.A.

P.O. Box 95

150, Route dv Nant_dl_AVRIL

CH-1217 Meyrin 2

Geneva , Switzerland

Telephone: (41/ 22) 780-8111

Fax: (41/22) 780-8542

Northern Euro pe

Sales and Service

Hewlet t-Packard Nederland B.V .

Startbaan 16

1187 XR

Amstelveen, The Ne therlands

P.O. Box 667

Telephone: 31/20 5476911 X 6631

Fax: 31-20-6471825NL

17

Page 18

Asia

Main Menu

Sales and Service

Hewlett-Packard Asia Ltd.

22-30/F Peregrine Tower

Lippo Center

89 Queensway, Central

Hong Kong

G.P.O. Box 863 Hong Kong

Telephone: 852-848-7777

Fax: 852-868-4997

Japan

Sales an d S ervice

Yokogawa-Hewlett-Packard Ltd.

3-29-21, Takaido-Higashi

Suginami-Ku, Tokyo 168

Telephone: 81 3 3331-6111

Fax: 81 3 3331-6631

International Sale s Bra nch

Headquarters

Sales and Service

Hewlett-Packard S.A.

39 Rue Veyrot

P.O. Box 365

1217 Meyrin 1

Geneva , Sw i t z e rl a n d

Telephone: 41-22-780-4111

Fax: 41-22-780-4770

Australia, New Zealand

Sales and Service

Hewlett-Packard Ltd.

P.O. Box 221

31-41 Joseph Street

Blackburn, Victoria 3130

Telephone: (61/ 3) 895-2895

Fax: (61/3) 898-9257

Canada

Service Center

Hewlett-Packard Ltd.

11120 178 Street

Edmonton, Alberta T5S 1P2

Canada

Telephone: (403) 486-6666

Fax: (403) 489-8764

Canada

Sales an d S ervice

Hewlett-Packard (Canada) Ltd.

5150 Spectrum Way

Missi ssaug a , Ontari o L4W 5G1

Canada

Telephone: (416) 206-4725

Fax: (416) 206-4739

Latin America

Hewlett-Packard Company

LAHQ Mexico City

Col. Lomas de Virreyes

11000 Mexico D.F.

Mexico

Telephone: (52/5 ) 326-4000

Fax: (52/5) 202 7718

Canada

Service Center

Hewlett-Packard Company

17500 Transcanada Highway

S. Serv Road

Kirkland, Quebec H9J 2X8

Canada

Telephone: (416) 206-3295

United Kingdom

Sales and Service

Hewlett-Packard Ltd.

Cain Road

Amen Corner

Bracknell, Berkshire

RG12 1HN

United Kingdom

Telephone: 44 344 360000

18

Page 19

Product Description

Main Menu

The HP 8935 CDMA Cellular/PCS Base Station Test Set offers full

signal gene ration and an alysis capab il ity and support for c el lular

frequency bands and international PCS frequency bands.

You can perform the following CDMA measurements using the

Test Set:

• Signal Quality Measurements

• Rho (ρ)

• Time Offset

• Frequency Error

• Carrier Feedthrough

• Code Domain Measurements

• Code Domain Power

• Code Domain Timing

• Code Domain Phase

• Average Power

• Channel Power

• Error Vector Magnitude

The Test Set’s CDMA generator also has the following capabilities:

• Reverse Channel Source with Data Buffer

• AWGN (built-in calibrated E

The Test Set also supports CDMA reference clocks and triggers.

In addition to its CDMA measurements and capabilities, the Test Set

also provides the following analog measurements:

• AC Level

• A M De pth

• AF Frequency

•DC Level

• Distortion

• Frequency and Frequency Error

• Transmitter Power

• F M Deviatio n

• Audio Frequency

•SINAD

•SNR

b/No

levels)

19

Page 20

In This Book

Main Menu

• Chapter 1, “Getting Started,” on page 23 familiarizes you with the

front panel controls. It introduces the differ ent types of control fields

that are used to make measurements

• Chapter 2, “Operating Overview,” on page 33 provides general

information about how to change measurement screens and change

control field settings. This chapter also provides some utility

procedures: calibrating channel power, setting a reference, setting

measurement limits, setting a generator/analyzer offset, averaging

measurements, saving and recalling setups, and using USER keys.

• Chapter 3, “Overview of the Test Set’s Built-In Tools,” on page 55

introduces the RFTOOLS program. This program automates some

measurements: cable fault location, swept return loss, swept and

discrete insertion loss, spectrum analyzer self-calibration. The

program also includes utilities for printing and data collection.

Basic operation of the built-in signal strength meter, spectrum

analyzer, oscilloscope, and code domain analyzer is also included in

this chapter.

• Chapter 4, “CDMA Measurements - Screens and Control Fields,” on

page 81 explains the measurements that can be made from these

screens and the fields that control the measurement’s parameters.

CDMA measurements include average power measurements,

channel power measurements, rho measurements (including

frequency error, time offset, and carrier feedthrough), EVM

measurements (including phase error and magnitude error), and

code domain measurements (including timing, phase, and power).

• Chapter 5, “Analog Measurements - Screens and Control Fields,” on

page 115 explains the measurements that can be made from these

screens and the fields that control the measurement’s parameters.

Analog measurements include ac/dc level, AM depth, AF frequency,

distortion, frequency and frequency error, transmitter power, FM

deviation, SINAD, and SNR.

• Chapter 6, “Configuration - Screens and Control Fields,” on page

159 explains the configuration controls for the Test Set.

• Chapter 7, “Connectors,” on page 183 describes the function and

physical attributes of each connector on the Test Set.

• Chapter 8, “Accessories, Manuals, Support,” on page 195 describes

any available upgrades, accessories, training and support for the

Test Set.

• Chapter 9, “Error Messages,” on page 203 provides any available

information about error recovery when messages are displayed.

20

Page 21

Conventions Used in this Book

Main Menu

Screen names are shown as follows: CODE DOM.

Keys are shown in the following typeface:

CDMA Gen. Shifted functions

(labeled in blue above the keys) are accessed by pressing and releasing

the blue Shift key, and then the key below the blue label.

Fields and messages displayed on the CRT are shown in the following

typeface: Input Atten.

The term “Test Set” is used to refer to the HP 8935.

The screens shown in this manual may not exactly match the screens

displayed on the Test Set’ s CRT. Some di fferences may b e due to cont rol

field settings, while other differences may be due to instrument

revisions.

Which Document is

Required?

Table 2 Document Navigation

Document Part Number Usage

CDMA Application Guide E6380-90016 Use this manual for basic CDMA measure ments and

AMPS Application Guide E6380-90017 Use this manual for making AMPS base station

The following documents are part of the HP 8935 document set. Use the

table to help you decide which document you need.

for get ti n g sta rted with th e Te s t Se t.

measurements.

Reference Guide E6380-90019 Use this manual for screen and field descriptions and

general operation information about the Test Set.

Programmer’ s Guide E6380-90018 Use this manual to learn HP-IB syntax and for learning

how to program the Test Set.

Assembly Level Repair

Guide

E6380-90015 Use this manual to perform calibration on the Test Set

and for general service information.

21

Page 22

22

Main Menu

Page 23

1 Getting St arted

Main Menu

• “Before Connecting a Radio” on page 24

• “Changing the Measurement Screen” on page 25

• “Changing the Control Fields” on page 26

• “Instrument Quick Check” on page 31

23

Page 24

Getting Started

Main Menu

Before Connecting a Radio

Before Connecting a Radio

NOTE The RF IN/OUT port should be used for all transmitter

tests when the radio is connected directly to the Test Set.

(All UUT transmitter power measurements are made

through this port). Off - the- air measur ement s can be made

using the ANT IN port.

CAUTION Overpower Damage — Refer to the Test Set’s side panel

for maximum input power level at the RF IN/OUT,

DUPLEX OUT, and ANT IN connectors. Exceeding these

levels can cause permanent instrument damage.

24 Chapter 1

Page 25

Changing the Test Set’s Display

Main Menu

Changing the Measurement Sc reen

The measurement screen is changed using the titlebar at the top of the

screen and the cursor-control knob, using the

GENERATOR/ANALYZER keys, or by using the UTILS keys. Rotate

the knob to move the cursor from field to field or to change settings.

Press the knob to make selecti ons (s ee “Changing the Control F ields” on

page 26 for more information about fields).

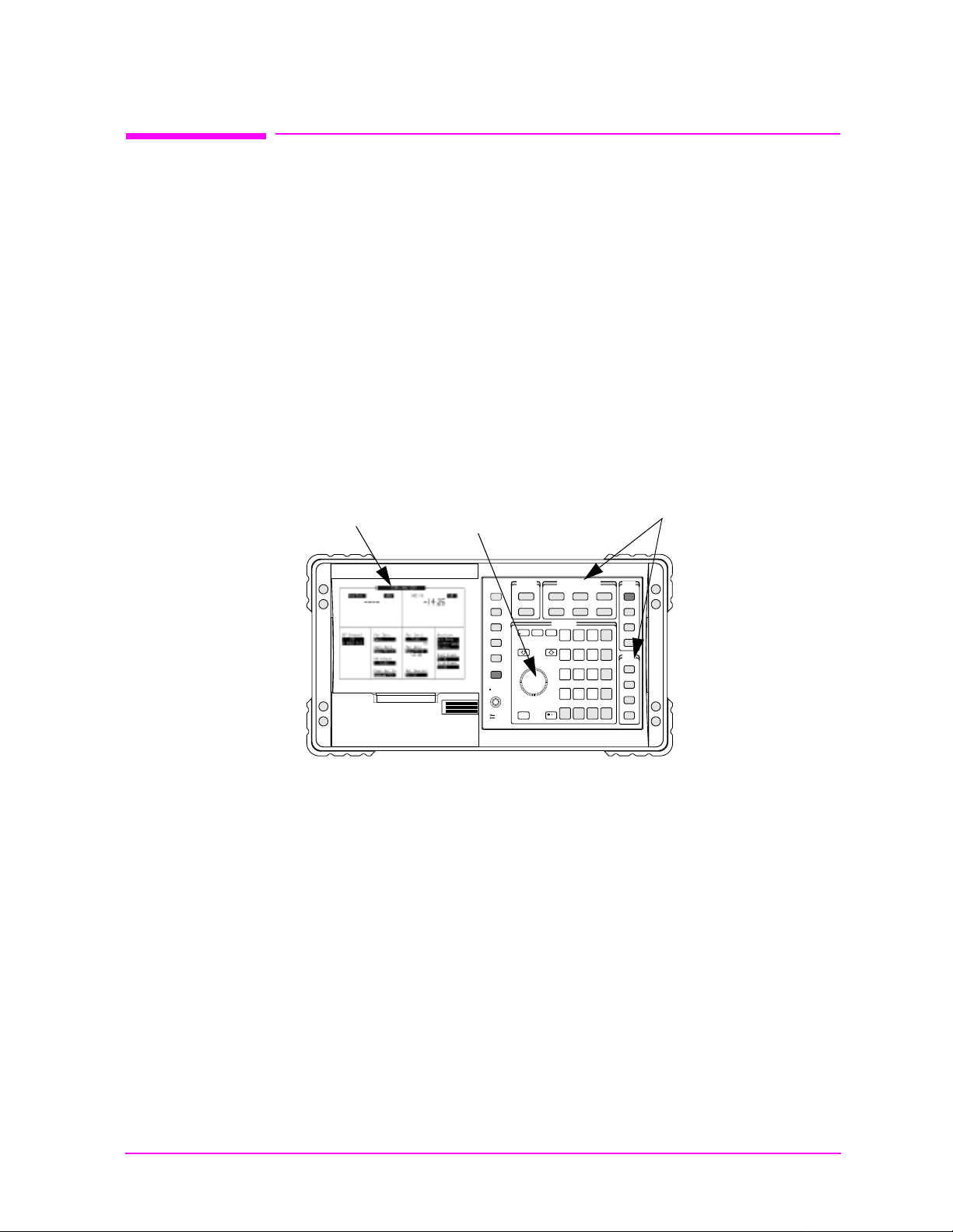

Figure 1-1 Using the cursor-control Knob or Screen Keys

Getting Started

Changing the Test Set’s Display

Titlebar

Push the knob to

make a selection.

Rota te the k n ob

to move the

cursor , or change

settings.

USER

k1’

Menu

k1

k2’

Pause/

k2

Continue

k3’

k3

Ref Set

Incr

10

k4’

k4

Lo Limit

Release

k5

Push to Select

Shift

Out of Lock

Cancel

Volume

Squelch

Meter

Incr

Set

Press one of the

GENERATOR/ANALYZER or

UTILS keys for a shortcut to

the measurement or

configuration screens.

CDMA

Gen

RF

Gen

Avg

Incr

x 10

Hi limit

GENERATOR/ ANALYZERSOFTWARE

DATA ENTRY

7

E

4

B

1

A EEX

0

Yes

On/Off

CDMA

Anl

AF Anl ScopeReset

RF

Anl

8

F

5

C

2

.

No

ppm

W

STATE

Code

Preset

Dom

Meas

Reset

Spec

Hold

Anl

Save

Recall

Enter

9

ADRS

Local

dB

GHz

dBm

6

UTILS

D

%

Prev

MHz

V

3

Printer

Config

Print

s

kHz

mV

I/O

+/-

Config

Inst

Config

mW

ms

Error

Hz

%D

Message

V

dBV

Help

To change the measurement screen

Step 1. Select the titlebar at the top of the screen (placement of the

titlebar may vary slightly on some screens).

Chapter 1 25

Step 2. Select the measurement screen from the list of choices.

OR

Step 1. Press a screen key:

Spec Anl, AF Anl, Scope, Prev, Inst Config, Help, Pr i nter Config, I/O Config,

Error Message.

CDMA Gen, CDMA Anl, Code Dom, RF Gen, RF Anl,

AF Anl, Scope, Printer Config, I/O Config, and Error Message

are shifted functions (labeled in blue above a key). You must

press and release the blue

Shift key then the key below the blue

label to access the screen (or other function) labeled in blue.

Pressing the

Prev key displays the previous screen.

Page 26

Getting Started

Main Menu

Changing the Test Set’s Display

Changing the Control Fie lds

There are several types of control fields in the Test Set. This section

describes some of the different types of fields.

Unit-of -M easure Fi eld

Unit-of-measure can be changed to display measurements in different

values or magnitudes. The unit-of-measure field can also be used to

turn a measurement on or off (use the On/Off Yes key).

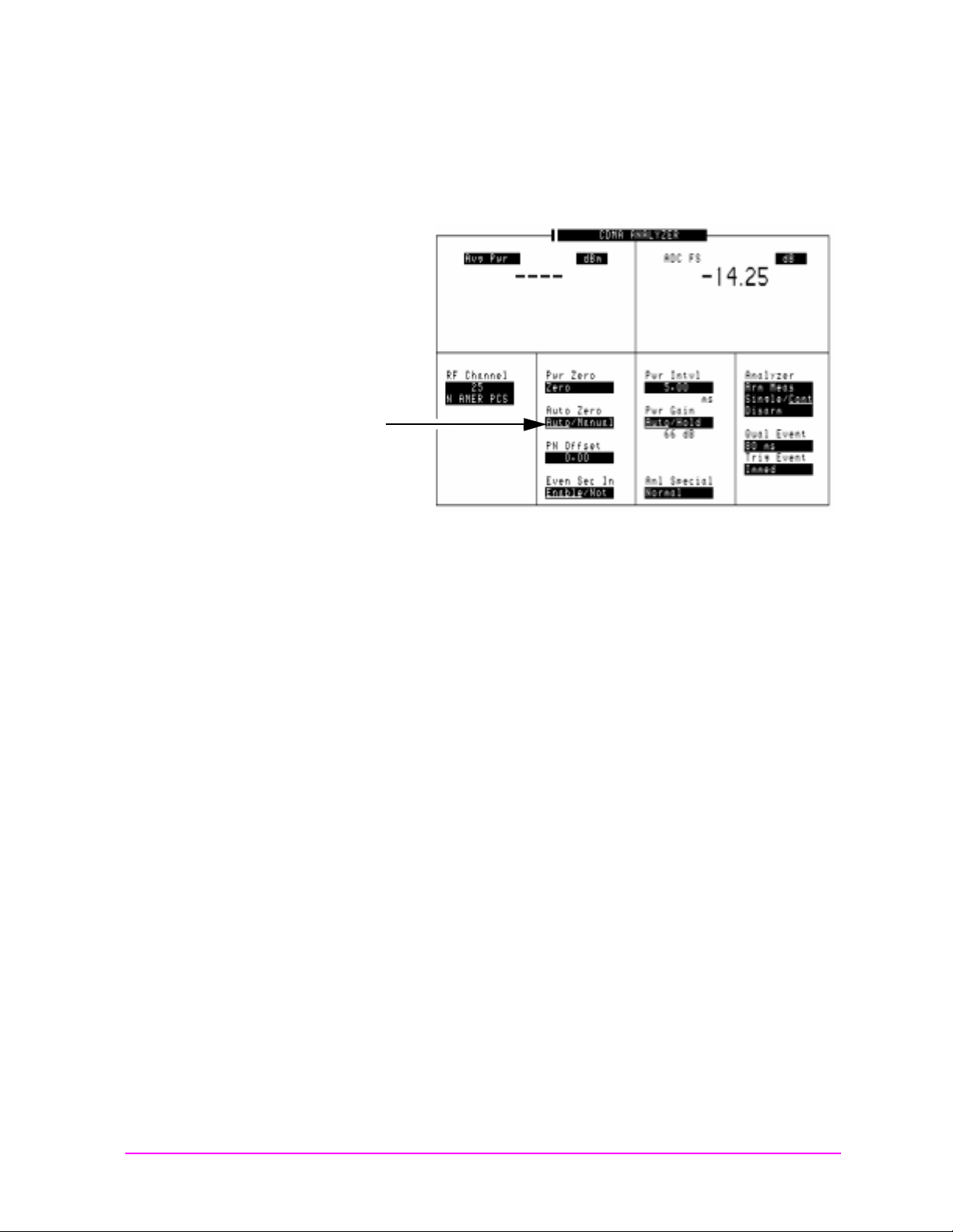

Figure 1-2 Unit-of-Measure Field

Unit-of-Measure

26 Chapter 1

To change a unit-of-measure field

Step 1. Position the cursor at the unit field on the display.

Step 2. Press a key labeled with a different unit-of-measure

(such as W) .

If the new units are valid, the measurement value is d isplayed

in the unit.

If the new units are not valid, the message Invalid

keystroke. is displayed and the units are not changed.

Page 27

Getting Started

Main Menu

Changing the Test Set’s Display

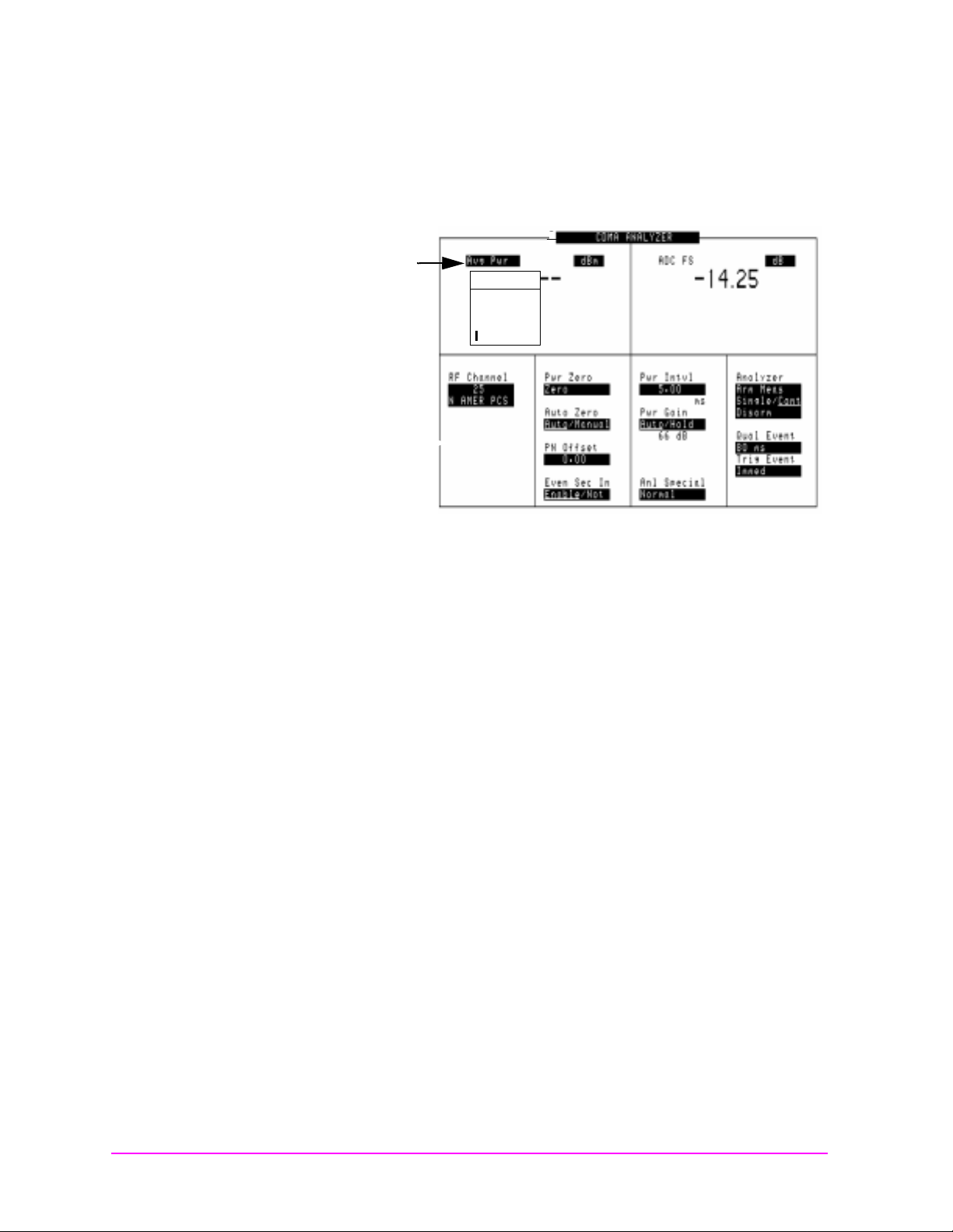

Underlined Entry Field

Underlined entry fields provide a choice of two settings (toggle).

Figur e 1- 3 Und erline d E n tr y F i el d

Underlined

Entry Field

To Change an underlined entry

Step 1. Position the cursor at the field.

Step 2. Push the cursor-control knob or the

underline under the desired choice.

The underlined setting is immediately activated when

selected.

Enter key to move the

Chapter 1 27

Page 28

Getting Started

Main Menu

Changing the Test Set’s Display

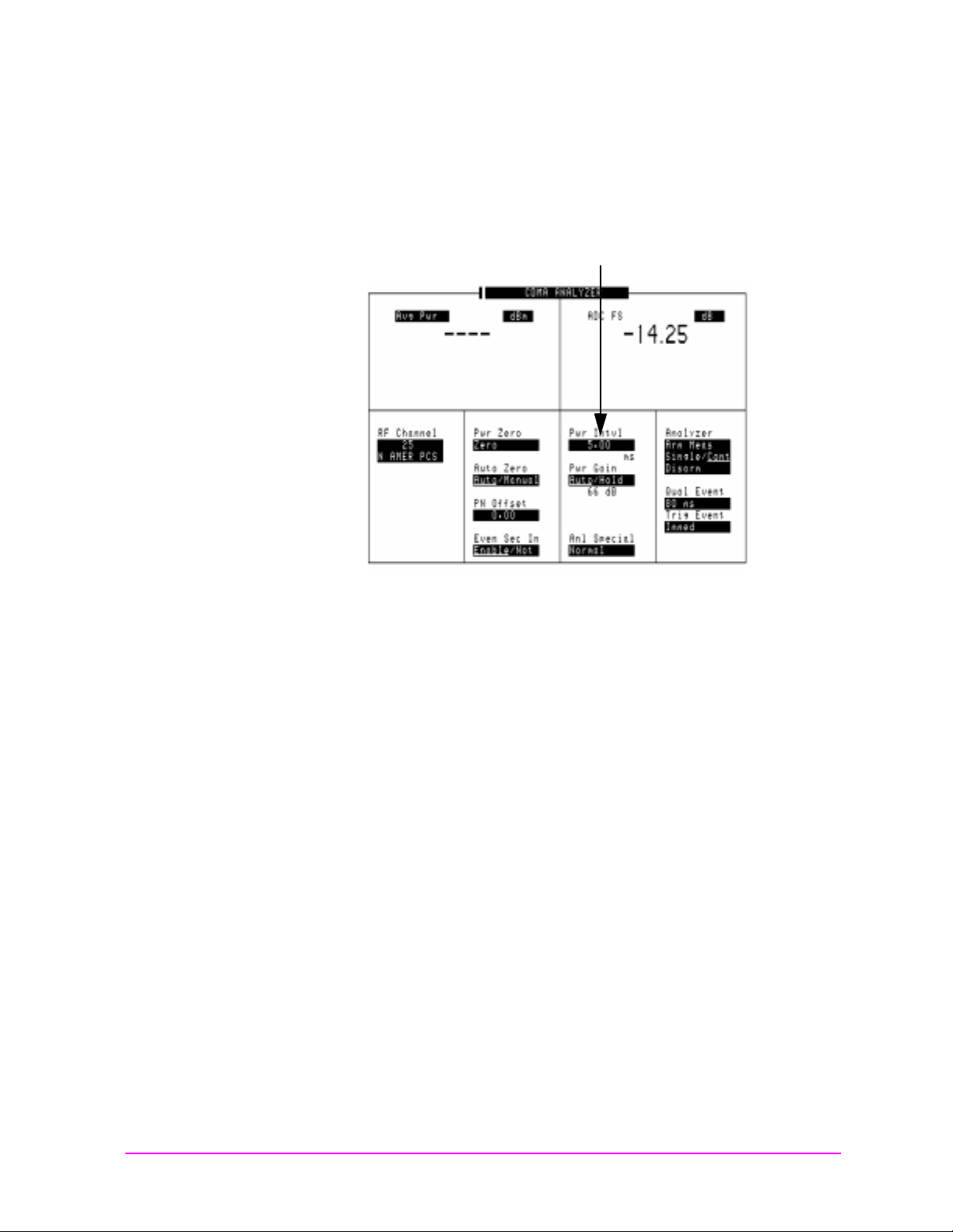

One-of-Many Field

One-of-many fields display a list of choices when selected.

Figure 1-4 One-of-Many Field

One-of-Many

Field

Choices:

Chan Pwr

Rho

EVM

Avg Pwr

To make a one-of-many choice

Step 1. Position the cursor at the field.

Step 2. Push the cursor-control knob or the

Enter key to display the

choices.

Step 3. Move the cursor through the choices by turning the knob.

Step 4. Push the cursor-control knob or the

Enter key to make the

choice.

The choice is immediately activated when selected.

28 Chapter 1

Page 29

Getting Started

Main Menu

Changing the Test Set’s Display

Numeric-Entry Fields

Values for numeric entry fields can be entered and changed using

various methods, depending on your testing needs.

Figure 1-5 Nume ri c -Entr y Fi e l d

Numer ic E ntry Field

To change a value

Step 1. Position the cursor at the field.

Step 2. Key in the desired number using the DATA ENTRY keys.

Step 3. Press

Enter to select the choice.

OR

Step 1. Position the cursor at the field.

Step 2. Push the cursor-control knob (the flashing >> cursor appears) .

Step 3. Turn the knob to increment or decrement the value. (The

current increment value may not be appropriate for your

operation. See See “Changing the Increment or Decrement

Setting” on page 42.)

Step 4. Push the cursor-control knob or the

Enter key to select the

choice.

OR

Step 1. Position the cursor at the field.

Step 2. Push the cursor-control knob to highlight the desired choice.

Chapter 1 29

Step 3. Use the up-arrow or down-arrow keys to increment or

decrement the value.

Page 30

Getting Started

Main Menu

Changing the Test Set’s Display

Decimal Valu e s

Decimal values are used for most numeric entry fields. The acceptable

entries for decimal values are 0 through 9,, +/-, and EEX.

The

+/- key is used for entering negative numbers.

EEX key is used to enter values in exponential notation. For

The

example to enter 10-9 you would enter 1, 0, EEX (Shift, +/-), +/-, 9.

Hexadecimal Values

Hexadecimal (Hex) values are used for entering some signaling

parameters. The acceptable entries values are 0 through 9 and A

through F. No unit-of-measure is associated with these values.

Hexadecimal values are either entered from the keypad (A through F

are shifted functions) or for some fields, values are selected from a list

of choices.

30 Chapter 1

Page 31

How do I Verify that the Test Set is Operating Properly?

Main Menu

How do I Verify that the Test Set is Operating

Properly?

If your Test Set powers-up and dis pla ys the CDMA ANALYZER screen,

but you suspect an instrument problem, use the Instrument Quick

Check to verify operation of the basic instrument functions.

If no failure is indicated by this test, but you still suspect a problem,

refer to the “Performance Tests” information in the Assembl y L ev el

Repair Manual.

Instrument Quick Check

Step 1. Set up the quick check:

a. Remove any connected cables ( excep t for AC or DC power).

b. Turn instrument power on (if it is not already on).

Getting Started

c. Press

d. Press

e. Press

Preset.

Inst Config and set the RF Display field to Freq.

CDMA Anl and select the Avg Pwr field, then select Rho

from the Choices: menu.

f. Set the Tune Freq field to 800 MHz.

g. Set the Anl Dir field to Rev

h. Press

CDMA Gen and set the Output Port field to RF Out.

i. Set the RF Gen Freq field to 800 MHz.

j. Set the Amplitude field to −40 dBm

k. Set the Gen Dir. field to Fwd

displayed.)

Step 2. Check the following reading:

a. Rho should be greater than 0.96.

Step 3. Press

Spec Anl to access the SPEC ANL screen.

You should see the characteristic CDMA spectrum.

.

. (The EQ In/Out field is

Chapter 1 31

Page 32

Getting Started

Main Menu

How do I Verify that the Test Set is Operating Properly?

Figure 1-6 CDMA Spectrum

32 Chapter 1

Page 33

2Operating Overview

Main Menu

• "Displaying CDMA Measurements" on page 34

• "Displaying Analog Measurements" on page 36

• "Using Channel Numbers to Set Analyzer and Generator

Frequencies" on page 40

• "Calibrating the Channel Power Measurement" on page 41

• "Changing the Increment or Decrement Setting" on page 42

• "Using Measurement Limit Indicators" on page 43

• "Setting A Measurement Reference" on page 45

• "Averaging Measurements" on page 46

• "Setting an RF Generator/Analyzer Offset" on page 47

• "Saving and Recalling Instrument Setups" on page 48

• "Using USER Keys" on page 51

• "Replacing Batteries" on page 53

33

Page 34

Ope rati ng Overvi ew

Main Menu

Displaying CDMA Measurements

Displayi ng CDMA Measure me nts

Channel Power, Rho, EVM, Average Power

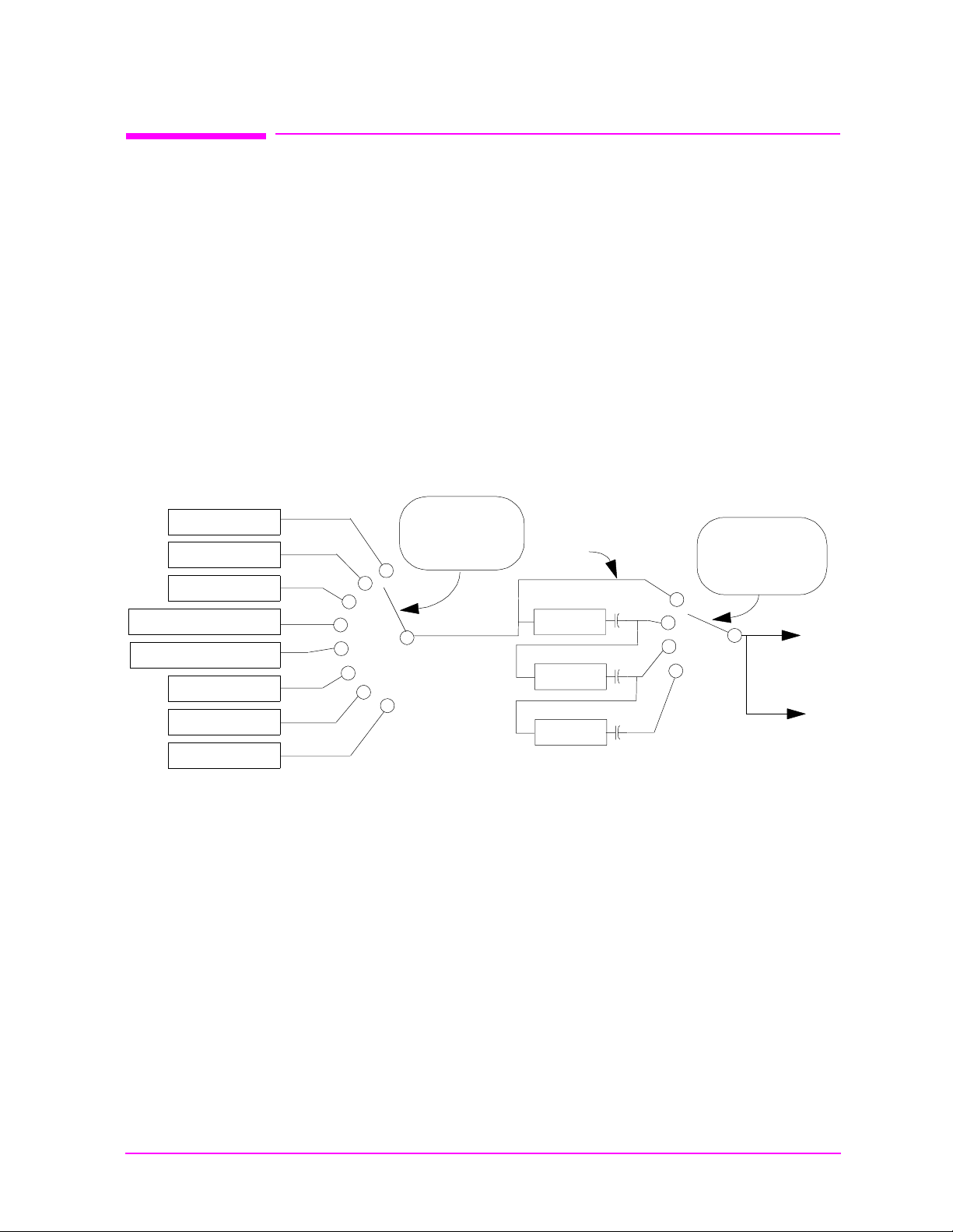

You can select channel power, rho, EVM, or average power on the

CDMA ANALYZER or CDMA GENERATOR screen as shown in

Figure 2-1.

For more information about these measurements see "CDMA

Measurements" on page 82.

Figure 2-1 Displaying Channel Po wer, Rho, EVM, or Average

Power

Choices:

Chan Pwr

Rho

EVM

Avg Pwr

Time Offset, Frequen cy Erro r, Ca rrier Feedthrough

When you select Rho, the Time Offset, Frequency Error, and

Carrier Feedthru measurements are displayed. Time offset and

carrier feedthrough are also displayed on the CODE DOM screen along

with frequency offset.

Frequency Offset

Frequency offset is displayed on the CODE DOM screen.

Magnitude Error, Phase Error

When you select EVM, the Magnit ud e Err or and Ph as e Er ro r

measurements are displayed.

34 Chapter 2

Page 35

Operating Ov erview

Main Menu

Displaying CDMA Measurements

Code Domain Measurements (Power, Timing, Phase)

Code domain measurements are displayed on the CODE DOM screen.

To select a code domain measurement, go to the CODE DOM screen

and select a measurement from the Measurement field in the Main

controls menu.

For more information about code domain measurements see "Code

Domain Measurements" on page 89.

Figure 2-2 Selecting Code Domain Measurements

Choices:

Power

Fast Pwr

Timing

Phase

Chapter 2 35

Page 36

Ope rati ng Overvi ew

Main Menu

Displaying Analog Measurements

Displayi ng An al og Meas ur e ments

RF Measurements

Frequency Error, Frequency

RF Frequency Error and RF Frequency are displayed on the RF

ANALYZER, RF GENERATOR, and AF ANALYZER screens.

Figure 2-3 Displaying RF Frequency Error or RF Frequency,

and TX Power

Choices:

Freq Error

Frequency

TX

Power

Transmitter (TX)Power

TX Power is only measured and displayed here when the Input Po rt

on the RF ANALYZER screen is set to RF In. If Ant (antenna) is

selected, the measurement is replaced by four dashes (- - - -).

You can measure low power levels on the ANT IN port using the

spectrum an a lyzer.

Refer to the "TX Power Measurement" field on page 120 and the "TX

Pwr Zero" field on page 157 for more information on measuring

transmitter po wer.

CAUTION Connecting a signal of >60 mW to the ANT IN (antenna)

port can cause instrument damage (although internal

protection circuits can typically withstand a

short-duration signal of 1 or 2 Watts). If the overpower

circuit is triggered, remove the signal from the ANT IN

port and turn the Test Set off and on to reset it.

36 Chapter 2

Page 37

Displaying AF Measurements

Main Menu

FM Deviation, AM Depth, AC Level

The AF Anl In setting determines the AF analyzer’s input and the

measurement displayed in the top-right corner of the measurement

area (see figure 2-4). These measurements are displayed on the RF

GENERATOR, RF ANALYZER, and AF ANALYZER screens.

Table 2-1 lists the measurement displayed for each AF Anl In setting.

Figure 2-4 Displaying FM Deviation, AM Depth, or AC Level

Choices:

FM Demod

AM Demod

SSB Demod

Audio In

Ext Mod

FM Mod

AM Mod

Operating Ov erview

Displaying Analog Measurements

Table 2-1 Measurements Selected with the AF Anl In field

Measurement AF Anl In Setting

FM Deviation FM Demod, FM Mod

AM Depth AM Demod, AM Mod

AC Level SSB Demod, Audio In, Ext Mod, Audio Out

Chapter 2 37

Page 38

Ope rati ng Overvi ew

Main Menu

Displaying Analog Measurements

SINAD, Distortion, SNR, AF Frequency, DC Level,

These measurements are available on the RF GENERATOR,

RF ANAL YZER, and AF ANALYZER screens. See figure 2 -5 .

Figure 2-5 Displaying SINAD, Distortion, SNR, DC Level, or

AF Frequency

Choices:

SINAD

Distn

SNR

AF Freq

DC Level

The Distortion measurement is only for a 1 kHz tone.

Selecting SNR (Signal/Noise Ratio) turns off any other audio

measurement. For more information on making this measurement, see

the RF Gen Freq field description, on page 148.

38 Chapter 2

Page 39

Operating Ov erview

Main Menu

Displaying Analog Measurements

Displaying Analog Measurement Results on a Meter Scale

Figure 2-6 Displaying the Meter Scale

Unit-o f -Measure

Fields

Meters:

On/Off

Lo End

Hi End

Intervals

Measurement results can be displayed on a meter scale. The digital

numeric value is still displayed (but smaller) under the meter scale.

To display the meter scale

Step 1. Move the cursor to the unit-of-measure field for the

measurement you want displayed on the meter.

Step 2. Press and release the blue Shift key, then the Incr Set key to

access the meter function.

Step 3. Select On/Off from the Meters: menu (or press the

On/Off key ).

To set the meter’s end points and scale intervals

Step 1. Use the knob to select the unit-of-measure field for the

measurement you want displayed on the meter.

Step 2. Press and release the blue

Shift key, then the Incr Set key to

access the meter function.

Step 3. Select Hi End, Lo End, or Interval from the Meters: menu

and enter the value for your selection, then press the

Enter key.

Step 4. Repeat steps 2 and 3 until you have set the desired

parameters for the meter’s scale.

Chapter 2 39

Page 40

Ope rati ng Overvi ew

Main Menu

Using Cha nn el Num bers to Set Analyzer and Generat o r Frequencies

Using Chann el Numbers t o Set Analyz er and Gene rator

Frequencies

RF analyzer and RF generator frequencies can be entered by channel

number (the default setting) or by discrete frequencies (in MHz). The

RF Disp la y fie ld on the INSTRUMENT CONFIGURE screen controls

which way frequencies are entered. This screen is accessed by pressing

the

Inst Config key.

If the RF Disp lay field is set to Chan

to set the RF Chan Std field to indicate the standard for your base

station (such as North American PCS). This automatically sets the

correct frequency of f set needed to ge nerate r ev erse c ha nnel si gna ls a nd

analyze forward channel signals for base stations.

If you do not know the channel number of your base station, but know

the transmit and r eceive frequenc ies, s et the RF Display field to Freq

You can then enter these frequencies directly for the RF generator and

RF analyzer during tests.

Figure 2-7 Con figuration to Use Channel Numbers for RF

Set the RF Display field to Chan

to turn on channel tuning.

Select the RF Chan Std field to

display a list of system types.....

for channel tuning, you also need

.

Generator and Analyzer Settings

..and then sel ec t the channel standard

for testing your base stations.

40 Chapter 2

Page 41

Operating Ov erview

Main Menu

Calibrating the Channel Power Measuremen t

Calibrati ng th e Cha nne l Power Meas ure me nt

To calibrate a channel power measurement at the RF IN/OUT port

using the internal CDMA generator

Step 1. Go to the CDMA ANALYZER s creen and choos e the Chan Pwr

measurement.

Step 2. Set the Tune Freq field (or RF Channel field) to the center

frequency of your CDMA signal.

Step 3. Select the C hn Pw r Ca l field and wait until the calibration is

complete.

Chapter 2 41

Page 42

Ope rati ng Overvi ew

Main Menu

Changing the Increment or Decrement Setting

Changing the Increment or D ecrement Setting

Specifying An Increment Value for the Arrow Keys or Knob

The Incr Set key is used to assign a specific increment value. The

increment value may use different units than the field you are

incrementing/decrementing. For instance; if the RF generator’s

Amplitude setti n g is disp layed in dB µV, you could increment in units

of dB or mV.

To change the increm en t/decrem ent value

Step 1. Move the cursor to the numeric entry field to be changed.

Step 2. Press

unit-of-measure using the DATA ENTRY keys.

Step 3. Use the down-ar ro w an d up-arrow ke ys or cursor

control knob to increment the field’s value. The field’s value

changes by the value you set for each key press or knob click.

Incr Set, and enter the desired incremental value and

Using the Factor of 1 0 Inc rement/Decrement Keys

The Incr × 10 and Incr ÷ 10 keys change the increment/decrement value by a

factor of 10.

For example, if you set the increment for Tune Freq to 10 MHz for

every click of the knob or push of the down-arrow or up-arrow keys,

pushing

Incr ×10 changes the increment value to 100 MHz.

42 Chapter 2

Page 43

Using Measurement Li m it In di c at or s

Main Menu

Using Measurement Limit Indicators

The Lo Limi t and Hi Limit functions are used to define a measurement

“window.” You can set a high limit, a low limit, or both. When limits are

assigned, Lo, Hi or both are indicated on the screen.

A measurement that goes above or below the defined limits causes

three things to happen:

1. A message appears at the top of the screen indicating a limit was

exceeded.

2. The Lo or Hi indicator flashes.

3. The beeper beeps (if it is has been enabled in the INSTRUMENT

CONFIGURE screen).

Limits are helpful when you can’t watch the Test Set’s display while

you are making an adjustment on the equipment you are testing or

repairing. They are also a convenient way of alerting you to long-term

measurement drift.

Operating Ov erview

To set high and low limits

Step 1. Position the cursor in front of the unit-of-measure for the

measurement for which you are setting limits.

Step 2. Press and release the

Shift key, then the down-arrow key to

access the Lo Limit function, and enter the measurement’s

low-limit value and its unit-of-measure.

1

Step 3. Press and release the Shift key, then the up-arrow key to access

the

Hi Limit function, and enter the measurement’s high-limit

value and its unit-of-measure.

2

Chapter 2 43

1. The fundamental unit for the limits does not have to be the same as the mea-

surement’s units. For instance; when measuring AC Level in Volts, you can set

high and low limits in units of dBm.

Page 44

Ope rati ng Overvi ew

Main Menu

Using Measurement Limit Indicators

To reset or remove limits

To reset a limit that has been exceeded

Step 1. Position the cursor in front of the measurement’s

unit-of-measure.

Step 2. Press and release the

Shift key, then the down-arrow (or

up-arrow key) to access the Lo Limit (or Hi Limit) function.

Step 3. Press

Enter or Shift then Hold to access the Meas Reset function.

To remove a limit

Step 1. Position the cursor in front of the unit-of-measure for the

assigned limit.

Step 2. Press and release the

Shift key, then the down-arrow (or

up-arrow key) to access the Lo Limit (or Hi Limit) function, then

press the On/Off key.

44 Chapter 2

Page 45

Setting A Measurement Reference

Main Menu

The reference set (Ref Set) function establishes a measurement

reference point. This allows you to make a direct comparison between

two measurement results, or between a measurement standard and the

actual measurement results.

Depending on the type of measurement, referenced measurements are

displayed in one of two ways:

1. Displayed val u e = Measurement − Reference. The difference between

the measured value and the reference value is displayed.

or

2. Displayed value = Measurement ÷ Reference. A ratio of the measured

value to the reference value is displayed. This ratio is expressed in

dB.

To set a reference

Operating Ov erview

Setting A Measurement Reference

Step 1. Position the cursor in front of the unit-of-measure for the

measurement you want to set the reference for.

Step 2. Press and release the

Shift key, then the Incr ÷10 key to access

the Ref Set function.

Step 3. Enter a reference value, then press

Enter. (To use the currently

measured value as a reference, just press Enter.)

Step 4. The Reference indicator shows that an internal reference has

been set.

Step 5. To turn the reference off press and release the

Shift key, then

the Incr ÷10 key to access the Re f Set functi on, and then press the

On/Off key .

Chapter 2 45

Page 46

Ope rati ng Overvi ew

Main Menu

Averaging Measuremen ts

Averaging Measurements

The Avg (average) function allows you to display the average value of a

number of measurements. You enter the number of measurement

samples used to calculate and display the measurement average. This

dampens the effects of rapidly changing measurements, providing a

more usable measurement display.

To use measurement averaging

Step 1. Position the cursor in front of the measurement’s

unit-of-measure.

Step 2. Press and release the

Shift key, then the Incr ×10 key to access

the Avg function.

Step 3. Enter the d esir ed number of meas ure ment samples to be used

for calculating the average, then press the knob or the

key.

or

Press

On/Off to use the currently-displayed number of samples.

Step 4. To turn averaging off, position the cursor in front of the

unit-of-measure and press and release the

Incr ×10 key to access the Avg function, then press the On/Off key.

How the Test Set Averages Measurements

When the averaging function is first enabled, a numeric average is

calculated and displayed each time a measurement is made. This

continues until the specified number of samples is reached. From that

point on, the averaging function performs an exponential filtering

operation that mimics an RC filter.

Because of the exponential response, any large measurement changes

result in a displayed value that ramps up or down to the actual

measured value.

Enter

Shift key, then the

46 Chapter 2

A measurement reset clears the measurement history for all

measurements and starts the averaging process over. (Press and

release the

Shift key then the Hold key (Meas Reset) to reset the

measurement.)

Page 47

Setting an RF Generator/Analyzer Offset

Main Menu

Setting an R F Gener at or/ An aly ze r Offs et

You can set a fixed frequency offset between the RF generator and the

RF analyzer. This feature is convenient for testing radios with a fixed

transmit/receive frequency offset.

To set an R F Offset

Step 1. Go to the INSTRUMENT CONFIGURE screen.

Operating Ov erview

Step 2. Set the RF Display field to Freq

Step 3. Set the RF Offset field to On.

Step 4. Select the (Gen)-(Anl) field and enter the frequency offset

value.

Step 5. Go to the RF GENERATOR screen.

Step 6. Select the RF Gen Freq field, and rotate the cursor control

knob to vary the RF generator’s frequency.

Step 7. Go to the RF ANALYZER screen. Notice that the Tune Freq

value changes to maintain the offset between the generator

and the analyzer. (You can use the

the generator and analyzer screens.)

.

Prev key to switch between

Chapter 2 47

Page 48

Ope rati ng Overvi ew

Main Menu

Saving and Recalling Instrument Setups

Saving and Re cal li ng In st ru ment Se t up s

The save and recall functions allow you to store different instrument

setups and retrieve them later, eliminating the task of re-configuring

the Test Set.

The number of available save registers depends on how many changes