Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

HP

75000

SERIES

C

21

MHz

Synthesized

Generator

HP

E1440A

User's

Manual

SERIAL NUMBERS

This manual applies to

all

instruments.

Fa

HEWLETT

PACKARD

HP Part No.

E1440-90011;

Microfiche Part

Number:

E1440-95011

Printed

in

the Federal Republic of Germany, April

1992

Second Edition

E0492

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

Notices

Subject Matter

Restricted Rights

Legend

Front Cover Photograph

The information contained in this document is subject to change

without notice. HEWLETT-PACKARD

(HP)

MAKES

NO

WARRANTY OF ANY KIND WITH REGARD TO THIS

MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. HP shall not be

liable for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance or use of this

material.

Hewlett-Packard Company assumes no responsibility for the use or

reliability of its software on equipment that is not furnished by HP.

Use, duplication, or disclosure by the Government is subject to

restrictions as set forth in subdivision

(b)(3)(ii) of the Rights in

Technical Data and Computer Software clause at 52.227-7013.

Hewlett-Packard Company; 3000 Hanover Street; Palo Alto,

California 94304

--.-

The instrument photograph on the front cover shows the HP E1440A

This document contains proprietary information which is protected

by copyright. All rights are reserved.

No part of this document may be photocopied, reproduced, or

translated to another language without the prior written consent of

Hewlett Packard GmbH.

@

Copyright 1992 by Hewlett-PaLkard GmbH

Herrenberger Str. 130, D-7030 Boeblingen

Federal Republic of Germany

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

-

Printing History

The Printing History shown below lists

of this manual and the printing date(s). The first printing of the

manual is Edition

The Edition number increments by 1 whenever the manual is revised.

Updates, which are issued between Editions, contain replacement

pages to correct the current Edition of the manual. Updates are

numbered sequentially starting with Update

is created, it contains

Edition. Each new Edition or Update also includes a revised copy of

this printing history page. Many product updates or revisions do

not require manual changes and, conversely, manual corrections may

be done without accompanying product changes. Therefore, do not

expect a one-to-one correspondence between product updates and

manual updates.

Control Serial Number: Edition

1.

all

the Update information for the previous

Printing History

Edition Date

Edition

Edition

1

May

2

April 1992 E1440-90011 E0492

2

1990 E1440-90011 E0590

all

Editions and Updates

1.

When a new Edition

applies directly to all instruments.

Part

Number

CODE

Operational Safety

This product has been designed and tested according to International

Safety Requirements. To ensure safe operation, and to keep the

product safe, heed the symbols, warnings and cautions contained in

this section.

The following general safety precautions must be observed during

all

phases of operation, service, and repair of this product. Failure

to comply with these precautions or with specific warnings elsewhere

in this manual violates safety standards of design, manufacture, and

intended use of the product. Hewlett-Packard Company assumes no

liability for the customer's failure to comply with these requirements.

DO NOT operate the product in an explosive atmosphere or in the

presence of flammable gases or fumes.

Keep away from live circuits: Operating personnel must not remove

equipment covers or shields. Procedures involving the removal of

covers or shields are for use by service-trained personnel only. Under

certain conditions, dangerous voltages may exist even with the

equipment switched off.

To avoid dangerous electrical shock, DO NOT perform procedures

involving cover or shield

removal unless you are qualified to do so.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

DO

NOT

operate damaged equipment: Whenever it is possible

that the safety protection features built into this product have been

impaired, either through physical damage, excessive moisture, or

any other reason, REMOVE POWER and do not use the product

until safe operation can be verified by service-trained personnel.

If

necessary, return the product to a Hewlett-Packard Sales and

Service Office for service and repair to ensure that safety features are

maintained.

DO NOT service or adjust alone: Do not attempt internal service or

adjustment unless another person, capable of rendering first aid and

resuscitation, is present.

DO NOT substitute parts or modify equipment: Because of the

danger of introducing additional hazards, do not install substitute

parts or perform any unauthorized modification to the product.

Return the product to a Hewlett-Packard Sales and Service Office for

service and repair to ensure that safety features are maintained.

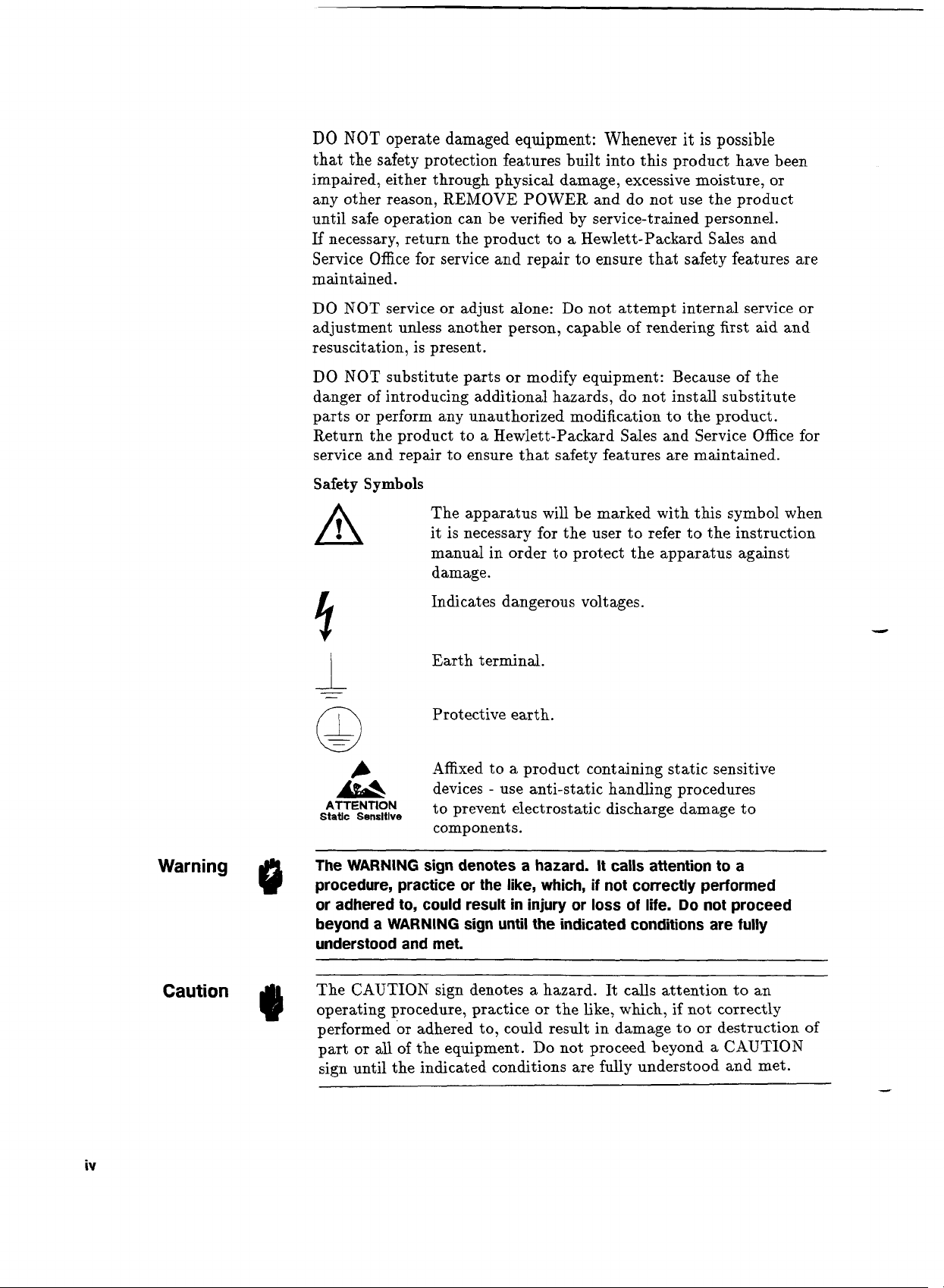

Warning

@

Safety

A

I

The WARNING sign denotes a hazard. It calls attention to a

procedure, practice or the like, which, if not correctly performed

or adhered to, could result in injury or loss of life. Do not proceed

beyond a WARNING sign until the indicated conditions are fully

understood and met.

Symbols

I

-

-

A

ATTENTION

Static Sensltlve

The apparatus will be marked with this symbol when

it is necessary for the user to refer to the instruction

manual in order to protect the apparatus against

damage.

Indicates dangerous voltages.

Earth terminal.

Protective earth.

Affixed to a product containing static sensitive

-

devices

to prevent electrostatic discharge damage to

components.

use anti-static handling procedures

The CAUTION sign denotes a hazard. It calls attention to an

Caution

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1)

operating procedure, practice or the Like, which, if not correctly

performed or adhered to, could result in damage to or destruction

part or

sign until the indicated conditions are fully understood and met.

all

of the equipment. Do not proceed beyond a CAUTION

of

Page 6

Warranty

This Hewlett-Packard product is warranted against defects in

materials and workmanship for a period of three years from date of

shipment. Duration and conditions of warranty for this product may

be superseded when the product is integrated into (becomes a part

of) other HP products. During the warranty period, Hewlett-Packard

Company will, at its option, either repair or replace products which

prove to be defective.

For warranty service or repair, this product must be returned to a

service facility designated by Hewlett-Packard (HP). Buyer shall

prepay shipping charges to

return the product to Buyer. However, Buyer shall pay all shipping

charges, duties, and taxes for products returned to HP from another

country.

HP warrants that its software and firmware designated by HP

for use with a product will execute its programming instructions

when properly installed on that product. HP does not warrant

that the operation of the product, or software, or firmware will be

uninterrupted or error free.

HP

and

HP

shall pay shipping charges to

Limitation

of

Warranty

Exclusive Remedies

The foregoing warranty shall not apply to defects resulting from

improper or inadequate maintenance by Buyer, Buyer-supplied

products or interfacing, unauthorized modification or misuse,

operation outside of the environmental specifications for the product,

or improper site preparation or maintenance.

The design and implementation of any circuit on this product is the

sole responsibility of the Buyer. HP does not warrant the Buyer's

circuitry or malfunctions of HP products that result from the Buyer's

circuitry. In addition, HP does not warrant any damage that occurs

as a result of the Buyer's circuit or any defects that result from

Buyer-supplied products.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HP

SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES

MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

The remedies provided herein are Buyer's sole and exclusive

remedies. Hewlett Packard shall not be liable for any direct, indirect,

special, incidental, or consequential damages whether based on

contract, tort, or any other legal theory.

OF

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 7

Assistance

Product maintenance agreements and other customer assistance

agreements are available for Hewlett-Packard products. For any

assistance contact your nearest Hewlett-Packard Sales and Service

Office. Addresses are provided at the back of this manual.

Radio Frequency

Interference Statement

Deutsche Bundespost

Manufacturer's

Declaration

(Federal Republic of Germany only)

Herste]lerbescheinigUng

Hiermit wird bescheinigt, dass dieses Geraet/System

C

betrieben im HP 75000 Series

den Bestimmungen von Postverfuegung 1046 184 funkentstoert ist

Der Deutschen Bundespost wurde das Inverkehrbringen dieses

Geraetes/Systems angezeigt und die Berechtigung zur Ueberpruefung

der Serie auf Einhalt ung der Bestimmungen eingeraeumt

Zusatzinformation fuer Mess- und Testgeraete:

Werden Mess- und Testgeraete mit ungeschirmten Kabeln

und/oder in offenen Messaufbauten verwendet, so ist vom Betreiber

sicherzustellen, dass die Funk-Ent st oerbestimmungen unt er

Betriebsbedingungen an seiner Grundstuecksgrenze eingehalten

werden.

This is to certify that the equipment HP E1440A meets the radio

frequency interference requirements of Directive FTZ 1046184, when

used in the

been notified that this equipment was put into circulation and has

been granted the right to check the product type for compliance with

these requirements.

HP

75000 Series C System. The German Bundespost has

System in Uebereinstimmung mit

HP

E1440A,

.

.

&

Certification

Additional Information for Test and Measurement Equipment:

If

test and measurement equipment is operated with unscreened

cables and/or used for measurements on open set-ups, the user has to

assure that under operating conditions the Radio Interference Limits

are still met at the border of the user's premises.

Hewlett-Packard Company certifies that this product met its

published specifications at the time of shipment from the factory.

Hewlett-Packard further certifies that its calibration measurements

are traceable to the United States National Institute of Standards

and Technology (formerly National Bureau of Standards), to the

extent allowed by that organization's calibration facility, and to the

calibration facilities of other International Standards Organization

members.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

--

Introduction

This manual is arranged into five categories:

General Information

General descriptions of the equipment and preparation for use

instructions

-

Chapters 1 and

2

Operating Information

Setting up and sample programs, programming techniques

-

Chapters 3 and

4

Programming Informat ion

Explanation of each software command applicable to the

HP

E1440A

-

Chapter

5,

Appendix B and Appendix

D

Specifications

Appendix

A

Customer Assistance

Sales and Service information: Appendix

F.

vii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

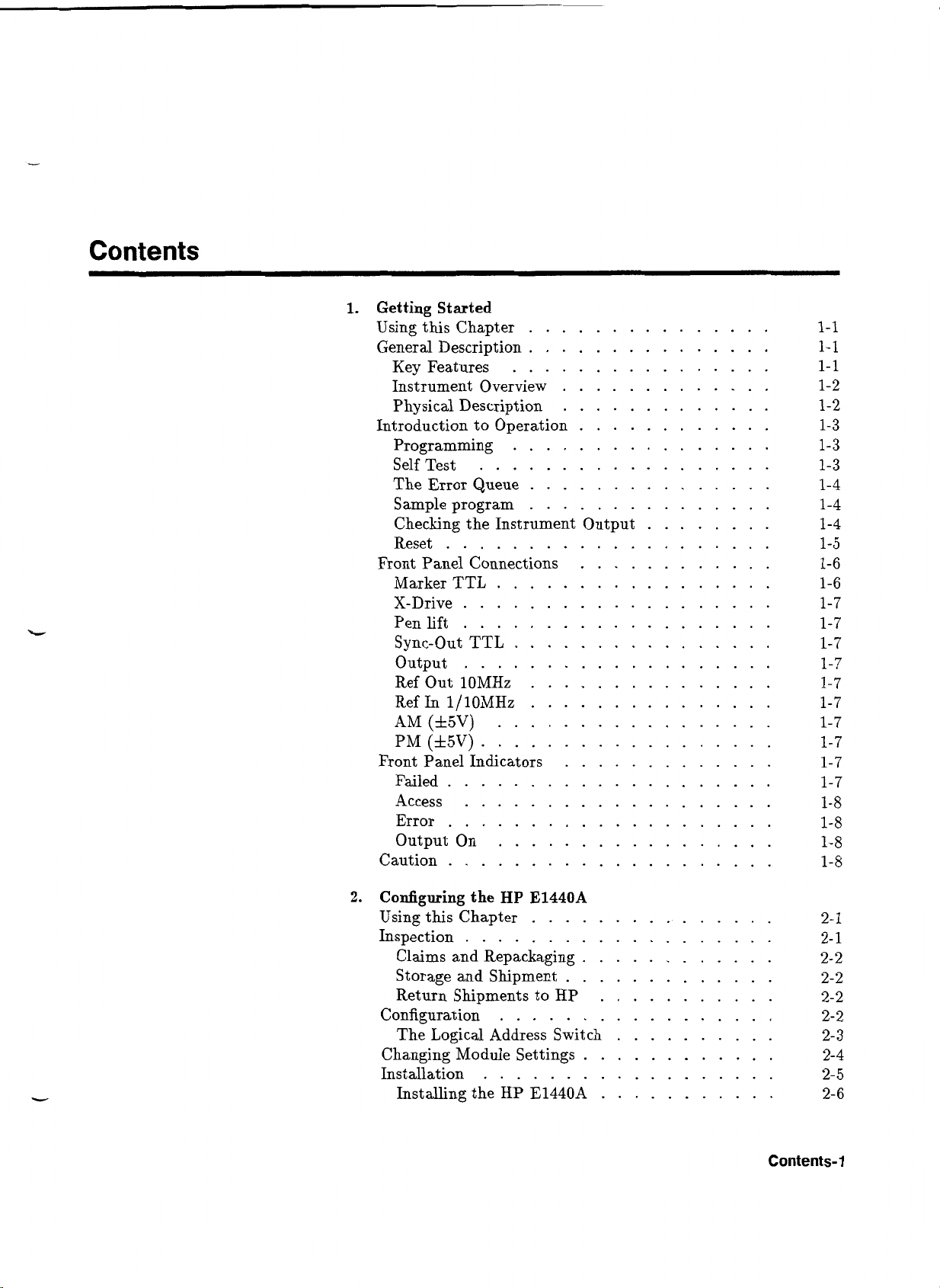

Contents

1

.

Getting Started

...............

Using this Chapter

...............

General Description

................

Key Features

.............

Instrument Overview

.............

Physical Description

............

Introduction to Operation

................

Programming

Self Test

..................

...............

The Error Queue

...............

Sample program

........

Checking the Instrument Output

....................

Reset

............

Front Panel Connections

Marker TTL

.................

X-Drive

...................

...................

Pen lift

Sync-Out TTL

................

Output

...................

...............

Ref Out lOMHz

Ref

In

1/1OMHz

...............

.................

AM

(f

5V)

..................

PM

(f

5V)

Front Panel Indicators

.............

Failed

....................

...................

Access

Error

....................

Output On

.................

....................

Caution

2

.

Coniiguring the

HP

E1440A

Using this Chapter

...............

...................

Inspection

Claims and Repackaging

............

.............

Storage and Shipment

Return Shipments to HP

...........

.................

Configuration

..........

The Logical Address Switch

............

Changing Module Settings

Installation

..................

...........

Installing the HP E1440A

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

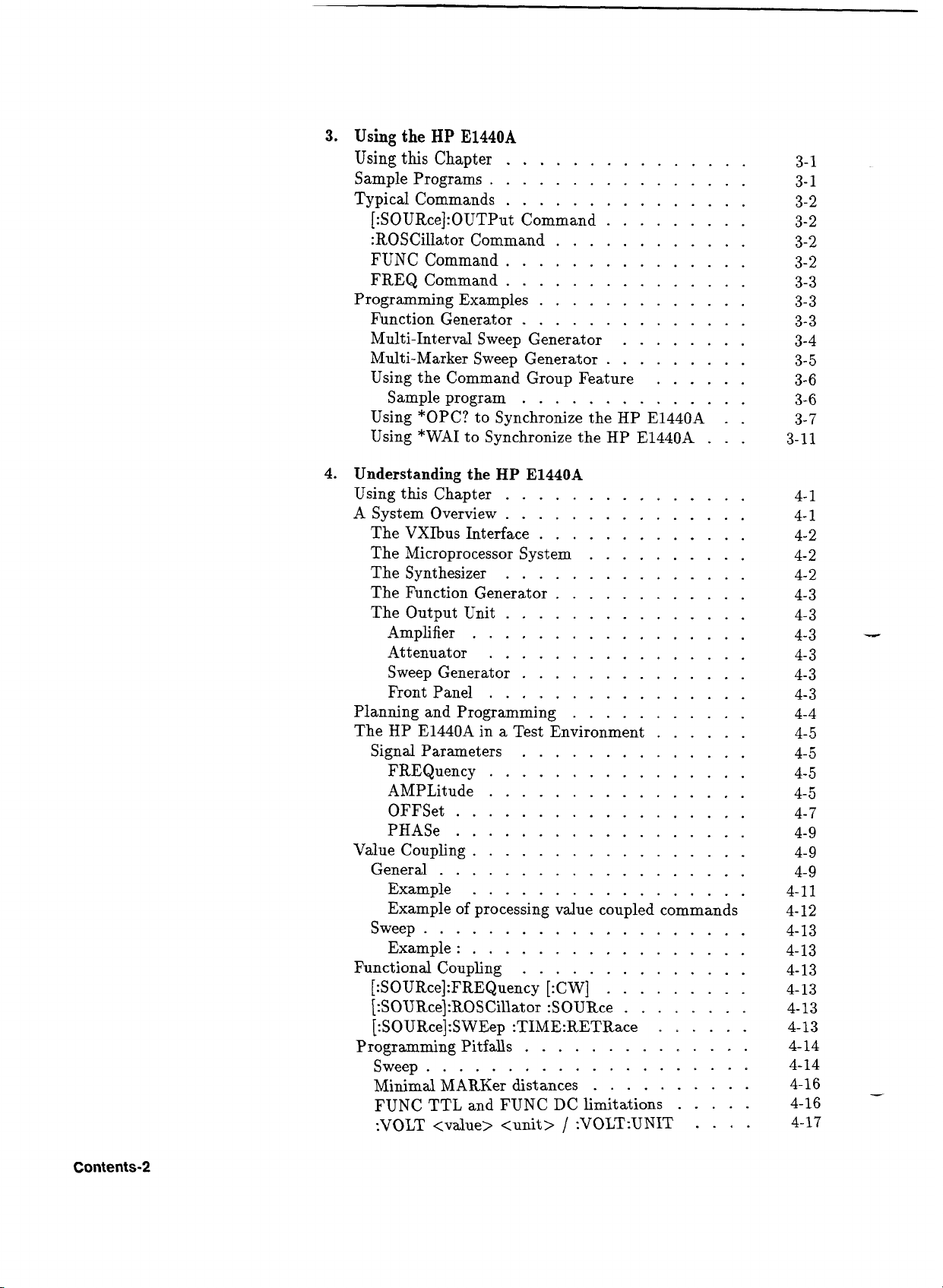

3

.

Using

the

HP

E1440A

Using

this Chapter

...............

3-1

Sample Programs

................

3-1

...............

Typical Commands 3-2

.........

[:S 0URceI:OUTPut Command 3-2

:ROSCillator Command

............

3-2

...............

FUNC Command 3-2

...............

FREQ Command 3-3

Programming Examples

.............

3-3

Function Generator

..............

3-3

Multi-Interval Sweep Generator

........

3-4

Multi-Marker Sweep Generator

.........

3-5

Using the Command Group Feature

......

3-6

..............

Sample program 3-6

Using *OPC? to Synchronize the HP E1440A

. .

3-

7

Using *WAI to Synchronize the HP E1440A

...

3-11

4

.

Understanding the HP

E1440A

Using this Chapter

...............

...............

A System Overview

The VXIbus Interface

.............

The Microprocessor System

..........

The Synthesizer

...............

The Function Generator

............

The Output Unit

...............

Amplifier

.................

Attenuator

................

Sweep Generator

..............

Front Panel

................

Planning and Programming

...........

The HP E1440Ain a Test Environment

......

..............

Signal Parameters

FREQuency

................

AMPLitude

................

OFFSet

..................

PHASe

..................

.................

Value Coupling

General

...................

.................

Example

Example of processing value coupled commands

Sweep

....................

Example

:

.................

Functional Coupling

..............

[:SOURce]:FREQuency [:CW]

.........

........

[:SOURce]:ROSCillator :SOURce

......

[:SOURce]:SWEep :TIME:RETRace

..............

Programming Pitfalls

Sweep

....................

Minimal MARKer distances

..........

FUNC TTL and FUNC DC limitations

.....

:VOLT <due> <unit> / :VOLT:UNIT

....

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

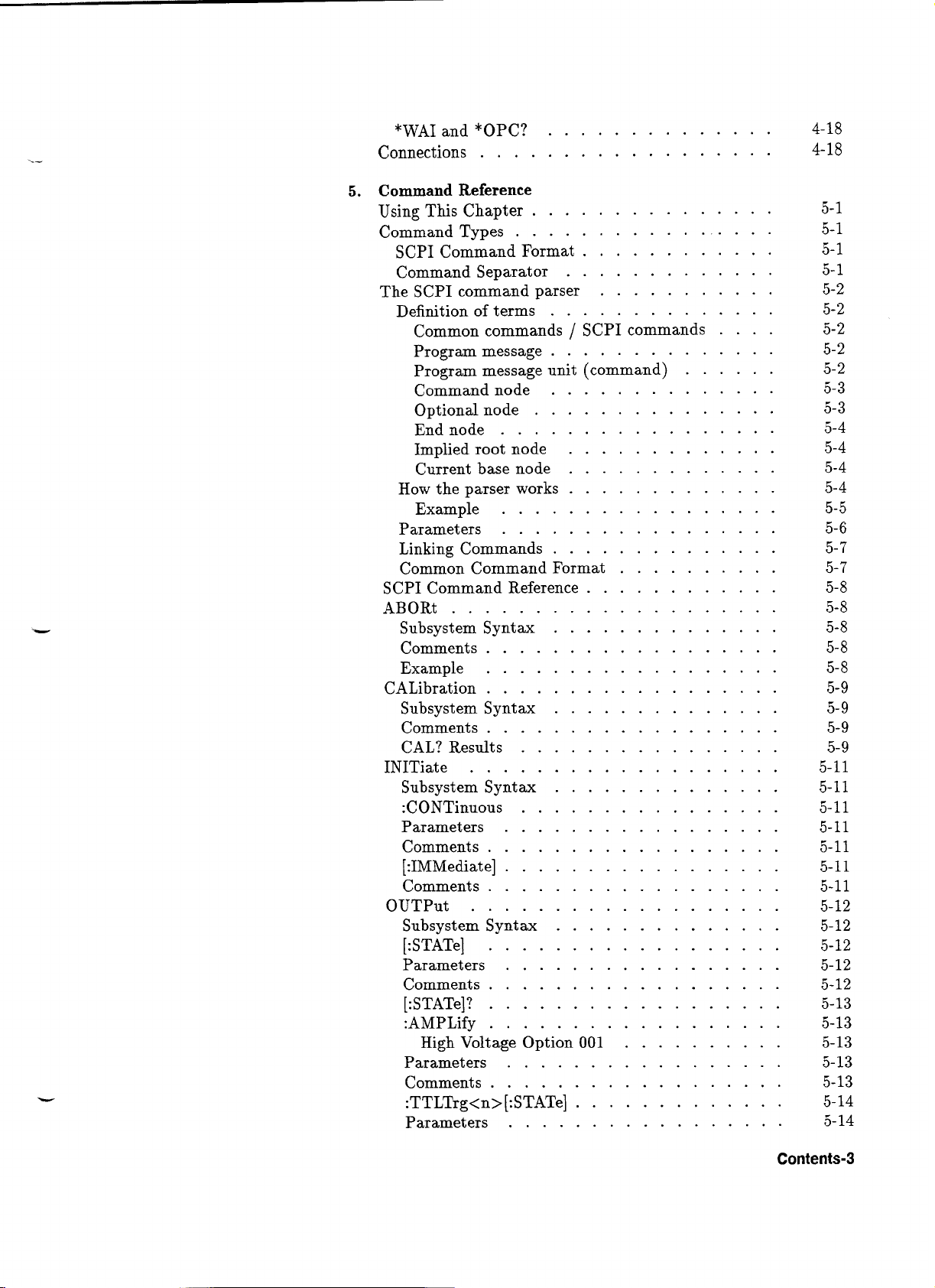

Page 11

"WAI and *OPC?

..............

4-18

Connections

..................

4-18

5

.

Command

Reference

Using This Chapter

...............

5-1

Command Types

................

5-1

SCPI Command Format

............

5-1

Command Separator

.............

5-1

The SCPI command parser

...........

5-2

Definition of terms

..............

5-2

Common commands

/

SCPI commands

....

5-2

Program message

..............

5-2

Program message unit (command)

......

5-2

Command node

..............

5-3

Optional node

...............

5-3

End node

.................

5-4

Implied root node

.............

5-4

Current base node

.............

5-4

How the parser works

.............

5-4

Example

.................

5-5

Parameters

.................

5-6

Linking Commands

..............

5-7

Common Command Format

..........

5-7

SCPI Command Reference

............

5-8

....................

ABORt 5-8

Subsystem Syntax

..............

5-8

Comments

..................

5-8

..................

Example 5-8

CALibration

..................

5-9

Subsystem Syntax

..............

5-9

..................

Comments 5-9

CAL? Results

................

5-9

...................

INITiate 5-11

Subsystem Syntax

..............

5-11

................

:CONTinuous 5-11

Parameters

.................

5-11

Comments

..................

5-11

[:IMMediate]

.................

5-11

Comments

..................

5-11

...................

OUTPut 5-12

Subsystem Syntax

..............

5-12

..................

[:STATe] 5-12

Parameters

.................

5-12

Comments

..................

5-12

..................

[:STATe]? 5-13

:AMPLify

..................

5-13

High Voltage Option 001

..........

5-13

Parameters

.................

5-13

Comments

..................

5-13

:TTLTrg<n> [:STATe]

.............

5-14

Parameters

.................

5-14

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

..................

Comments

:TTLTrg<n>:SOURce

............

.................

Parameters

:TTLTrg<n>:AOFF

.............

[:SOURce]

...................

Subsystem Syntax

..............

..................

Comments

.................

[:SOURce]:AM

Subsystem Syntax

..............

.................

Parameters

Comments

..................

.............

[:

SOURce] :FREQuency

Subsystem Syntax

..............

:FREQuency[:CW I :FIXed]

..........

:FREQuency:MODE

.............

:FREQuency :STARt :STOP

..........

:FREQuency:CENTer

.............

:FREQuency:SPAN

..............

..............

[:SOURce]:FUNCtion

..............

Subsystem Syntax

..................

Comments

................

[:SOURce]:LIST

Subsystem Syntax

..............

:LIST:FREQuency

..............

................

:LIST:DWELl

...............

:LIST:SEQuence

[:SOURce] :MARKer[<n>]

...........

..............

Subsystem Syntax

..................

Comments

[:SOURce]:PHASe

...............

Subsystem Syntax

..............

..................

Comments

Example:

..................

.................

[:SOURce]:PM

Subsystem Syntax

..............

Parameters

.................

..................

Comments

.............

[:SOURce] :ROSCillator

Subsystem Syntax

..............

..................

Comments

...............

[:SOURce]:SWEep

Subsystem Syntax

..............

:SWEep:TIME

................

:S WEep:TIME:RETRace

...........

.................

Comments

.STATUS

....................

.............

:STATus:OPERation

Subsystem Syntax

..............

comments

..................

:STATus:QUEStionable

............

:STATus:QUEStionable :FREQUENCY

.....

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

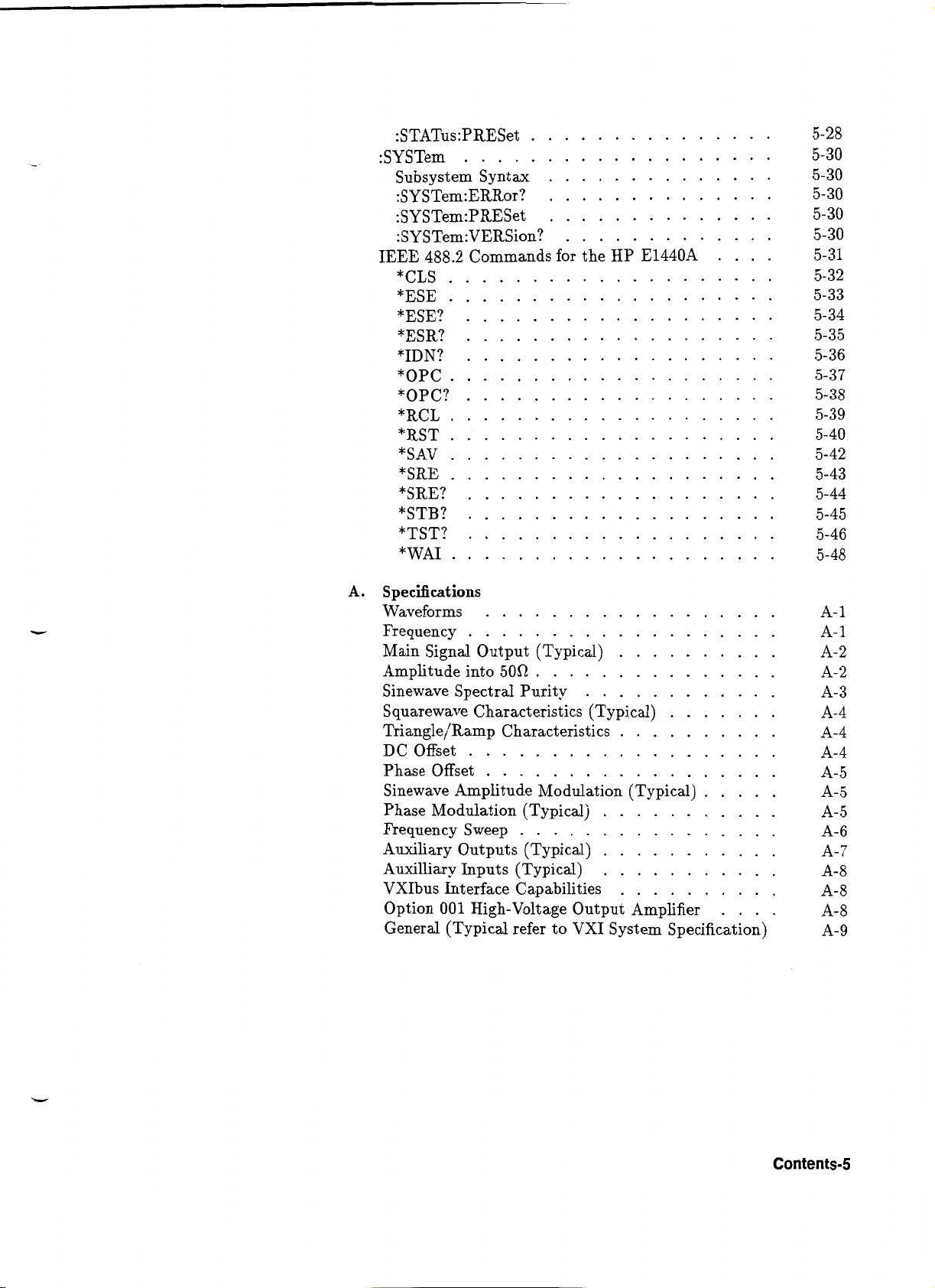

...............

:STATus:PRESet

...................

:SYSTem

..............

Subsystem Syntax

..............

:SYSTem:ERRor?

..............

:SYSTem:PRESet

.............

:SYSTem:VERSion?

....

IEEE 488.2 Commands for the HP E1440A

....................

*CLS

....................

*ESE

...................

*ESE?

...................

*ESR?

...................

*IDN?

....................

*OPC

...................

*OPC?

....................

*RCL

....................

*RST

....................

*SAV

....................

*SRE

...................

*SRE?

*STB?

...................

...................

*TST?

....................

*WAI

A

.

Specifications

..................

Waveforms

Frequency

...................

..........

Main Signal Output (Typical)

...............

Amplitude into 50fl

............

Sinewave Spectral Purity

.......

Squarewave Characteristics (Typical)

..........

Triangle/Ramp Characteristics

...................

DC Offset

Phase Offset

..................

Sinewave Amplitude Modulation (Typical)

.....

...........

Phase Modulation (Typical)

................

Frequency Sweep

...........

Auxiliary Outputs (Typical)

...........

Auxilliary Inputs (Typical)

VXIbus Interface Capabilities

..........

Option

001

High-Voltage Output Amplifier

....

General (Typical refer to VXI System Specification)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

B

.

Register Programming

Registers

...................

...............

Status Reporting

.................

Error Queue

Status Registers

................

Using the Registers

...............

...............

Sample Program

.................

Program

Performance tests

Introduction

.................*

Test Record

..................

Recommended Test Equipment

..........

Functional Verification Tests

...........

Performing a Self-test

.............

Starting the test

..............

Reading the Error Queue

..........

Example program

.............

Checking the Instrument Output

........

Operational Verification Tests

..........

Without a Controller

.............

With a Controller

..............

Performance Verification Tests

..........

.................

Introduction

Harmonic Distortion

.............

Specifications

...............

............

Equipment Required

Procedure

.................

High-Voltage Output (Option 001)

......

Spurious Signal

...............

...............

Specifications

Equipment Required

............

Mixer Spurious Procedure

..........

Close-in Spurious (Fractional N Spurs) Procedure

Integrated Phase Noise

............

...............

Specifications

............

Equipment Required

Procedure

.................

Frequency Accuracy

.............

...............

Specifications

............

Equipment Required

Procedure

.................

Phase Increment Accuracy

...........

Specifications

...............

............

Equipment Required

.................

Procedure

.............

Amplitude Accuracy

Specifications

...............

Equipment Required

............

Amplitude Accuracy at Frequencies upto 100

kHz

Procedure

...............

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 15

......

High-Voltage Output (Option 001)

Amplitude Accuracy (Frequencies

>

100

kHz)

.

......

High-Voltage Output (Option 001)

.........

DC Offset Accuracy (DC only)

...............

Specifications

............

Equipment Required

.................

Procedure

.............

Attenuator Test

......

High-Voltage Output (Option 001)

.....

DC Offset Accuracy with AC Functions

...............

Specifications

............

Equipment Required

.................

Procedure

..............

Triangle Linearity

...............

Specifications

............

Equipment Required

.................

Procedure

.................

Test Facility

:

................

Test Conditions

:

..............

Installed Options

:

............

Ambient Temperature

:

..............

Relative Humidity

:

Line Frequency

:

...............

Special Notes

:

.................

Test Equipment Used

:

.............

Harmonic Distortion

..............

Spurious Signals

................

Integrated Phase Noise

.............

Frequency Accuracy

..............

Phase Increment Accuracy

............

Amplitude Accuracy

..............

DC Offset Accuracy (DC only)

..........

DC Offset Accuracy with AC Function

......

Triangle Linearity

...............

D

.

Command Quick Reference

..................

Introduction

E

.

Error Messages

..................

Introduction

..................

Message List

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

F

.

Sales

and

Service Offices

Information

..................

F-

1

Asia

....................

F-

1

Canada

...................

F-1

Eastern Europe

...............

F-

1

Northern Europe ...............

F-

1

South East Europe ..............

F-

1

Middle East and Central Africa

........

F-

2

United Kingdom

...............

F-2

United States of America

...........

F-2

Eastern USA .................

F-2

Midwestern USA

...............

F-2

Southern USA

................

F-2

Western USA

................

F-2

Other International Areas

............

F-3

Index

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 17

Figures

1.1

.

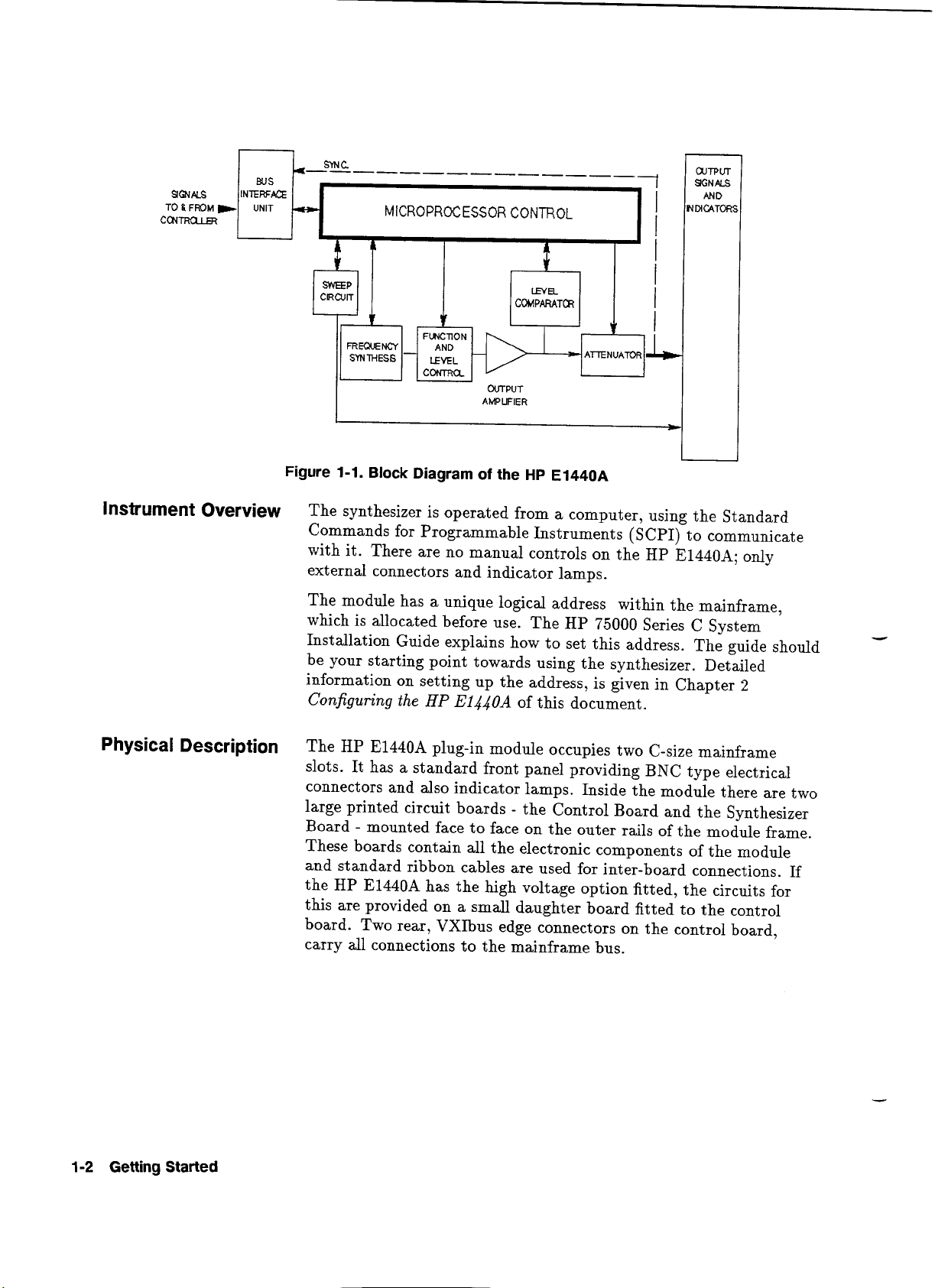

Block Diagram of the HP E1440A

.......

1-2

1.2

.

HP E1440A Front panel

............

1-6

2.1

.

Address Switch and Jumper Location

......

2-3

2.2 . Address Switch Settings

............

2-4

2.3

.

Jumper JlOl Links Settings

..........

2-5

4.1

.

Simplified Block Diagram

...........

4-1

4.2

.

Synthesizer Block Diagram

..........

4-2

4.3

.

Handling of Value Coupled Commands

.....

4-12

B.1

.

Status Register Subset

............

B-2

C.1

.

Service Switch

................

C- 7

C.2

.

Example Service Switch Setting

........

C-7

C.3

.

Harmonic Distortion Verification Test Set-Up

(High-Voltage Output)

...........

C-12

C.4

.

Mixer Spurious Test Set-Up

..........

C-14

C.5

.

Integrated Phase Noise Test Set-Up

.......

C-17

C.6

.

Phase Increment Accuracy Test Set-Up

.....

C-20

C.7

.

Function Amplitude Accuracy Test Set-Up

...

C-23

C.8

.

High voltage sinewave accuracy test set.up

....

C-26

C.9

.

Function Amplitude Accuracy Test Set-Up

(High-Voltage Output)

...........

C-27

C.10

.

Test set-up for Amplitude Accuracy Adjustment

(Frequency

>

100 kHz)

...........

C-28

C.11

.

500 0 300 pF loadlvoltage divider

.......

C-30

C.12

.

DC Offset Test Set-Up

............

C-34

.........

C.13 . Triangle Linearity Test Set-Up

C-36

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

Tables

1.1

. Instrument Reset State

............

3.1

. Values for FUNC Command

..........

3.2 . Frequency Controls

..............

4-

1

. Frequency Ranges

..............

4.2 . Amplitude Limits of AC Functions

.......

4.3 . High-Voltage Output Amplitudes

........

4.4 . Maximum DC Offset with any AC Function

...

4.5 . El440 Command Group Assignment

......

4.6 . Illegal El440 Commands in FREQ:MODE LIST

/

.................

SWEEP

5.1

. Operation Status Register

...........

5.2 . Questionable Status Register

..........

5.3 . Questionable Frequency Register

........

5.4 . Common Command Summary

.........

5.5 . Reset State (Standard Setting)

.........

C.1 . Recommended Test Equipment for Tests

....

.

..............

C.2 Self-test result bits

C.3

. Service Switch Parameter Settings

.......

.......................

C.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 19

Getting Started

Using this Chapter

This chapter introduces you to the VXIbus, HP E1440A Synthesized

FunctionJSweep Generator. The main sections of the chapter are:

..............................................

rn

General Description

1-1

Introduction to Operation

....................................

1-3

Front Panel

........................................................

1-6

General Description

The HP E1440A Synthesized FunctionJSweep Generator is a

multi-task signal generator, built as a C-size (double slot) plug-in

module, for use with other similar modules in a VXI mainframe. It

can be used as:

a reference source

Produces a sine wave of a specified frequency, amplitude, DC offset

and phase.

a function generator

Produces various waveforms at a specified frequency, amplitude,

DC offset and phase.

a sweep generator

Produces logarithmic and linear frequency sweeps.

Key

Features

Key features of the HP E1440A are as follows:

5

different waveforms can be output

Variable offsets and amplitudes

rn

Can be used as a DC source

rn

Multi-interval or multi-marker sweep capabilities

rn

Sweep sequencing

rn

Combined linear and logarithmic sweeps

rn

Phase-continuous sweep

Message based module (responds to

high

level ASCII SCPI

commands)

rn

Save/recall instrument settings

rn

Compatible with VXIbus mainframe unit and associated modules

Getting

Started

1-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 21

-

Introduction to

Operation

This section contains information on checking communication

between the synthesizer, mainframe and the computer. It includes

information on returning the synthesizer to a known operating state

if

(reset), should programming errors occur or

a restart is necessary.

Note

Programming

Before the

adjustments may need to be made to the module and then it has

to be installed in the mainframe. Details of these tasks are given in

Chapter 2

The HP El4408 has been designed so that it can be controlled by

an external computer. Its operations are therefore performed by a

series of programmable commands using SCPI. There are no manual

controls.

This section gives only brief general information on how to control

the HP

the commands specific to the HP E1440A, see Appendix

Quick

Programming information in this chapter is restricted to HP

E1440A specifics, and assumes that you are familiar with VXIbus or

VMEbus intrinsics.If you are not familiar with these, then refer to

industry standard publications about the VMEbus and the following

publications:

rn

The "VXIbus System Specification7' published by The VXIbus

Consortium, Inc.

HP

E1440A can be used, some system configuration

Configuring the

E1440A using a controller module. For a short form list of

Reference.

HP

E1440A.

D

Command

Self

Note

Test

)46

rn

ANSIIIEEE-488.2-1987, "Digital Interface for Programmable

Instrumentation" published by the Institute of Electrical and

Electronic Engineers

A complete syntax list of the HP E1440A programming commands

can be found in Chapter

Once the mainframe and module have been powered up (see Chapter

2 for instructions on how to check and set the module address),

the synthesizer is ready for use. During power-up, the HP

automatically executes an internal check and makes sure it is able to

communicate with the back plane of the VXI mainframe.

The HP E1440A has a "Failed" indicator that remains on if the

synthesizer is not able to communicate with the controller.

This self test routine can also be executed on command and therefore

sending the self test command is an easy way to check that you

are correctly addressing the synthesizer. Self test is also useful in

locating intermittent problems which might occur during operation.

5

Command Syntax Reference.

E1440A

Getting

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Started

1-3

Page 22

The command used to execute self test is:

On execution of this command, the synthesizer performs a self test

routine which is built into the module firmware. The result of the self

test is placed in the error queue, which is subsequently interrogated

by the controller.

*TST?

The

Error

Queue

Sample program

When an error occurs during operation, a suitable error code and

message are stored in the synthesizer error queue. These errors can

be read out using the

(zero) means there are no more errors. The error queue can store up

to 30 codes and messages on a 'first in first out'

messages are described in Appendix

The following BASIC program executes self test; this program

assumes the mainframe is at a primary interface address

the synthesizer is at a secondary address of

assumes that an

!Send the self-test command to the synthesizer

I

'SYS:ERR?'command. A returned value of 0

(FIFO)

E

Error

Messages

11.

The program also

HP

9000 Series 200/300 computer is used.

basis. Error

of

09 and

OUTPUT 7091 1 ; ll*TST?l'

I

!Enter

I

and

display the self test code

ENTER70911;A

PRINT

!

A

!Reset the synthesizer

I

OUTPUT 709 11 ; *RSTI1

END

Note

Checking the

Instrument Output

1-4

Getting

Started

3

Last line of program

After testing, always reset the synthesizer to a known state.

After using the above program to reset the

test with an oscilloscope will check that the module is functional.

Connect an oscilloscope to the output BNC and then send the

following short program:

!

10

20

30

Set frequency value

!

OUTPUT 7091

!

!

Set function to sinewave

OUTPUT 70911

!

!

Set output level to

!

1

;

"FREQ

;

"FUNC

lE3

SIN"

"

1

V

HP

E1440A, a simple

OUTPUT 70911 ; "VOLT 1"

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 23

110

!

120

Switch

!

130

140 OUTPUT

END

150

on

the

70911

output

;

"OUTP ON"

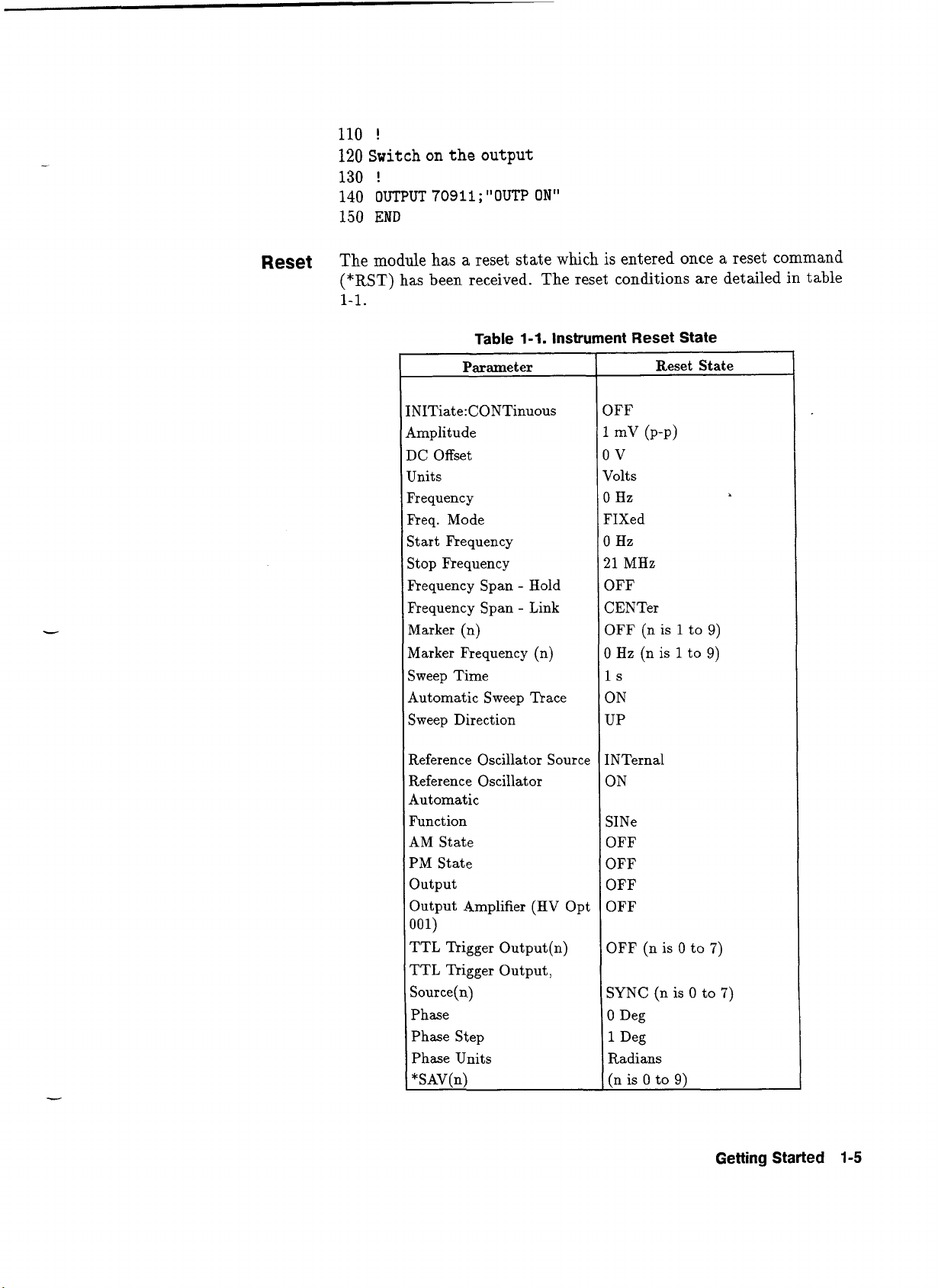

Reset

The module has a reset state which is entered once a reset command

(*RST)

has been received. The reset conditions are detailed in table

-

N1Tiate:CONTinuous

lmplitude

IC Offset

Tnits

?requenc y

?req. Mode

Start Frequency

stop Frequency

Frequency Span

Frequency Span

Marker (n)

Marker Frequency (n)

Sweep Time

Automatic Sweep Trace

Sweep Direction

Table 1-1. Instrument Reset State

Parameter

-

-

Hold

Link

IFF

:

1

dolts

1

FIXed

3

21

3FF

SENTer

3FF (n

I Hz

I

3N

UP

Reset State

mV

(P-P)

V

Hz

Hz

MHz

(n is 1 to 9)

s

is

1

to 9)

Reference Oscillator Source

Reference Oscillator

Automatic

Function

AM State

PM

State

Output

(HV

Output Amplifier

001)

TTL

Trigger Output(n)

TTL Trigger Output,

Source(n)

Phase

Phase Step

Phase Units

*

SAV(n)

Opt

SINe

OFF

OFF

OFF

OFF

OFF (n is

SYNC (n is 0 to

0 Deg

1

Deg

Radians

(n is

0 to

0

9)

to

7)

7)

Getting Started

1-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

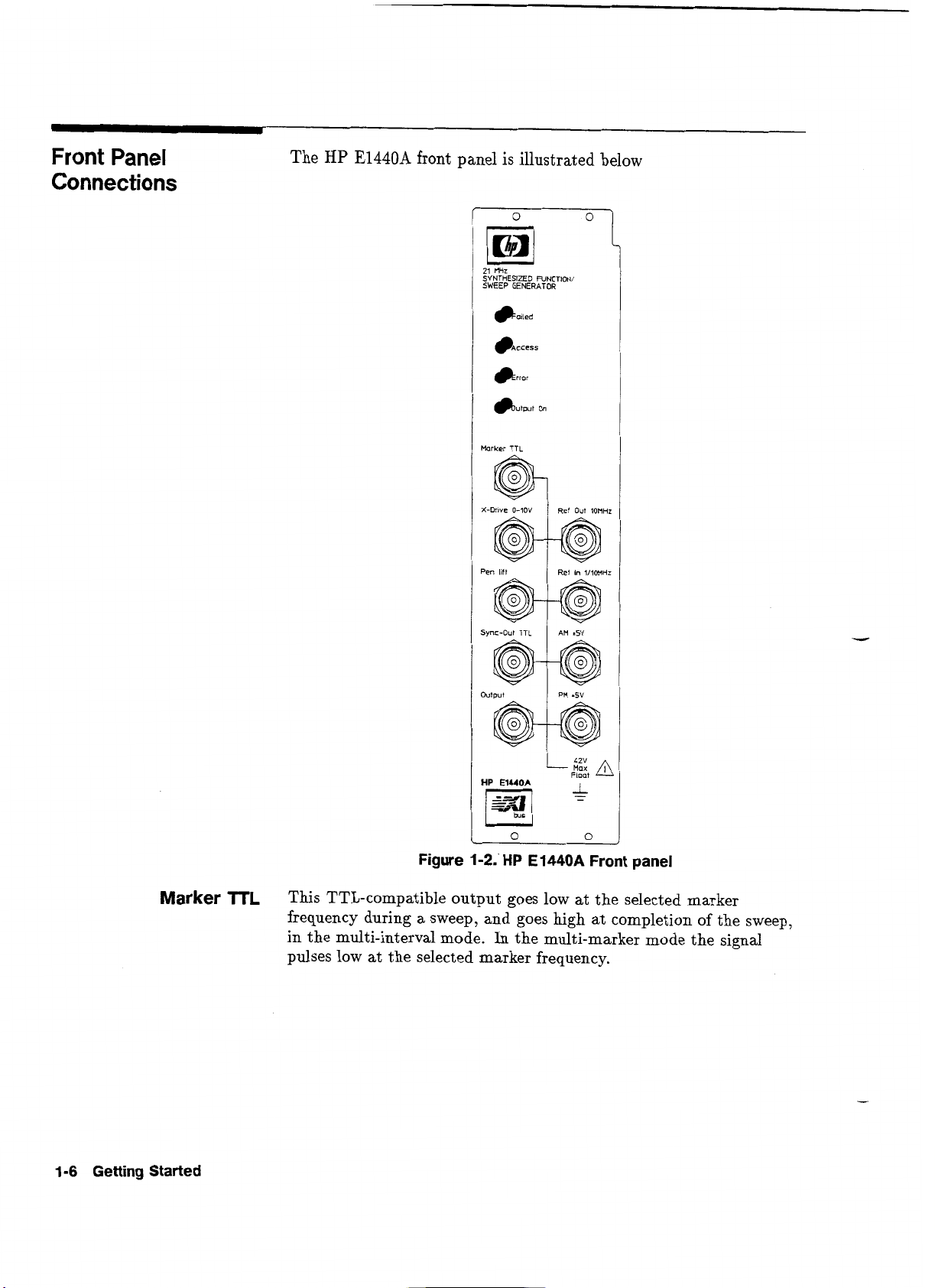

Front

Panel

Connections

The

HP

E1440A

front panel is illustrated below

Faled

Access

Error

~utput

On

0

21 MHz

SYNTHESIZED PJNCTIONI

SWEEP GENERATOR

Wrker

TTL

@

(-Dnve

0-10V

@

'en

lift

wc-Out

TTL

@

utput

@

IP

E1440A

W]

,-.

Ref

Out lotiHz

@

Ref

In

11lOMHr

@

@

@

-

6%

Float

i

-

Figure

1-2.'HP

E1440A

Front panel

Marker

TTL

This TTL-compatible output goes low at the selected marker

frequency during a sweep, and goes high at completion of the sweep,

in the multi-interval mode.

In

the multi-marker mode the signal

pulses low at the selected marker frequency.

1-6

Getting Started

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 25

X-Drive

This output ramps from 0 V to 10 V during a sweep.

Pen

lift

This output provides a pen lift signal for a plotter at the end of a

signal.

Sync-Out

TTL

A

TTL

compatible square wave synchronized output signal, is

available at this connector. The signal is synchronized with the

output signal crossover point (zero volts or

DC

offset voltage). The

connector functions for frequencies up to 60 MHz.

Output

Standard output impedance is 50R. High-voltage option (001) output

impedance is nominally

<

3Q

at

DC,

and < 10R at 1 MHz.

Ref

Out

10MHz

A 10 MHz signal from the

HP

E1440A reference circuits is available

here.

Ref

In

1/1OMHz

This external frequency reference may be used to phase-lock the

internal 30 MHz oscillator.

AM

(f

5V)

An Amplitude Modulation input reference can be connected here for

input to the synthesizer circuit. Range is

*5

volts in all modes, i.e.

sine, square, triangle, ramps.

PM

(f

5V)

A Phase Modulation input reference can be connected here for input

to the synthesizer circuit. Range is

f

5

volts in all modes, i.e. sine,

square, triangle, ramps.

Front Panel

Indicators

Failed

This red lamp illuminates as soon as power is applied to the module.

The module then checks out it's connections to the VXIbus i.e. it

checks that it is able to communicate with the mainframe. When

that check is verified, the module extinguished the Failed lamp.

Note

Absence of the

Failed

lamp does not necessarily mean that the

module is suit able for use.

Getting

Started

1-7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

Access

This green lamp flickers when the

communication between the module and mainframe is taking place.

HP

E1440A

is in use, showing

that

Caution

Error

Output

On

This red lamp illuminates to indicate there are error codes queued in

the

store, ready for collection

This green lamp illuminates when there is a signal available at the

output connector.

The outputs and externally applied voltages may be

floating at upto

exist

The

input/output connectors should not be subjected

to overload. Carefully note the max. applicable

voltage for each connector as specified in Appendix A

to this manual.

by

the controller.

42

V.

Risk of electric shock may

1-8

Getting

Started

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 27

Configuring

the

HP

E1440A

Using this Chapter

This chapter provides instructions on preparation for use and how

to install the HP

E1440A

module. It also includes information

about initial inspection and damage claims, packaging, storage and

shipment.

Before operation, the instrument and manual, including the red

safety page, should be reviewed for safety markings and instructions.

These must then be observed to ensure safe operation and to

maintain the instrument in safe condition.

............................................................

Inspection

2-1

........................................................

Configuration

2-2

Changing Module Settings

...................................

2-4

Installation

..........................................................

2-5

-

l

nspection

Warning

Inspect the shipping container for damage. If the container or

cushioning is damaged, it should be kept until the contents of the

shipment have been checked for completeness and the instrument has

been verified both mechanically and electrically.

Procedures for checking the operation of the instrument are given

in Chapter

1

Getting

Started.

If the contents are incomplete,

mechanical damage or defect is apparent, or if an instrument does

not pass the operator's checks, notify the nearest Hewlett-Packard

office. Keep the shipping materials for carrier's inspection. The

HP office will arrange for repair or replacement without awaiting

settlement.

To avoid hazardous electrical shock, do not perform electrical tests

0

when there are signs of shipping damage to any portion of the outer

enclosure (covers, panels, etc.).

Configuring the

HP

E1440A

2-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

Claims and

Repackaging

If physical damage is evident or if the instrument does not meet

specification when received, notify the carrier and the nearest

Hewlett-Packard Service Office. The Sales/Service Office will arrange

for repair or replacement of the unit without waiting for settlement of

a claim against the carrier.

Storage and Shipment

Return Shipments to

HP

The instrument can be stored or shipped at temperatures between

-40°C

and

f75"C.

The instrument should be protected from

temperature extremes which may cause condensation within it.

If the instrument is to be shipped to a Hewlett-Packard Sales/Service

F),

Office (see Appendix

attach a tag showing owner, return address,

model number and full serial number and the type of service

required.

The original shipping carton and packing material may be re-usable,

but the Hewlett-Packard Sales/Service Office will also provide

information and recommendations on

materials to be used if

the original packing is no longer available or reusable. General

instructions for repacking are as follows:

1.

Wrap instrument in heavy paper or plastic.

2.

Use strong shipping container. A double wall carton is adequate.

3.

Use enough shock-absorbing material

all

sides of the instrument to provide a firm cushion and prevent

(3

to 4 inch layer) around

movement inside container.

4.

Seal shipping container securely.

5.

Mark shipping container

FRAGILE

to encourage careful handling.

I

Configuration

2-2

Configuring

the

HP

E1440A

6.

In any correspondence, refer to instrument by model number and

serial number.

As detailed in the VXIbus Mainframe System Installation Guide,

each plug-in module has a row of switches which are used to set the

logical address of the module. The mainframe operating system uses

these unique addresses, to combine different modules into virtual

is

instruments within the mainframe slots. The module

addressed by

the computer program, using the logical address to distinguish it

from other modules in the system.

4

ATTENTION

Static Sensltlve

ATTENTION STATIC SENSITIVE Handle the

module, only at 'Static Safe' work stations

!

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

The

Logical

Address

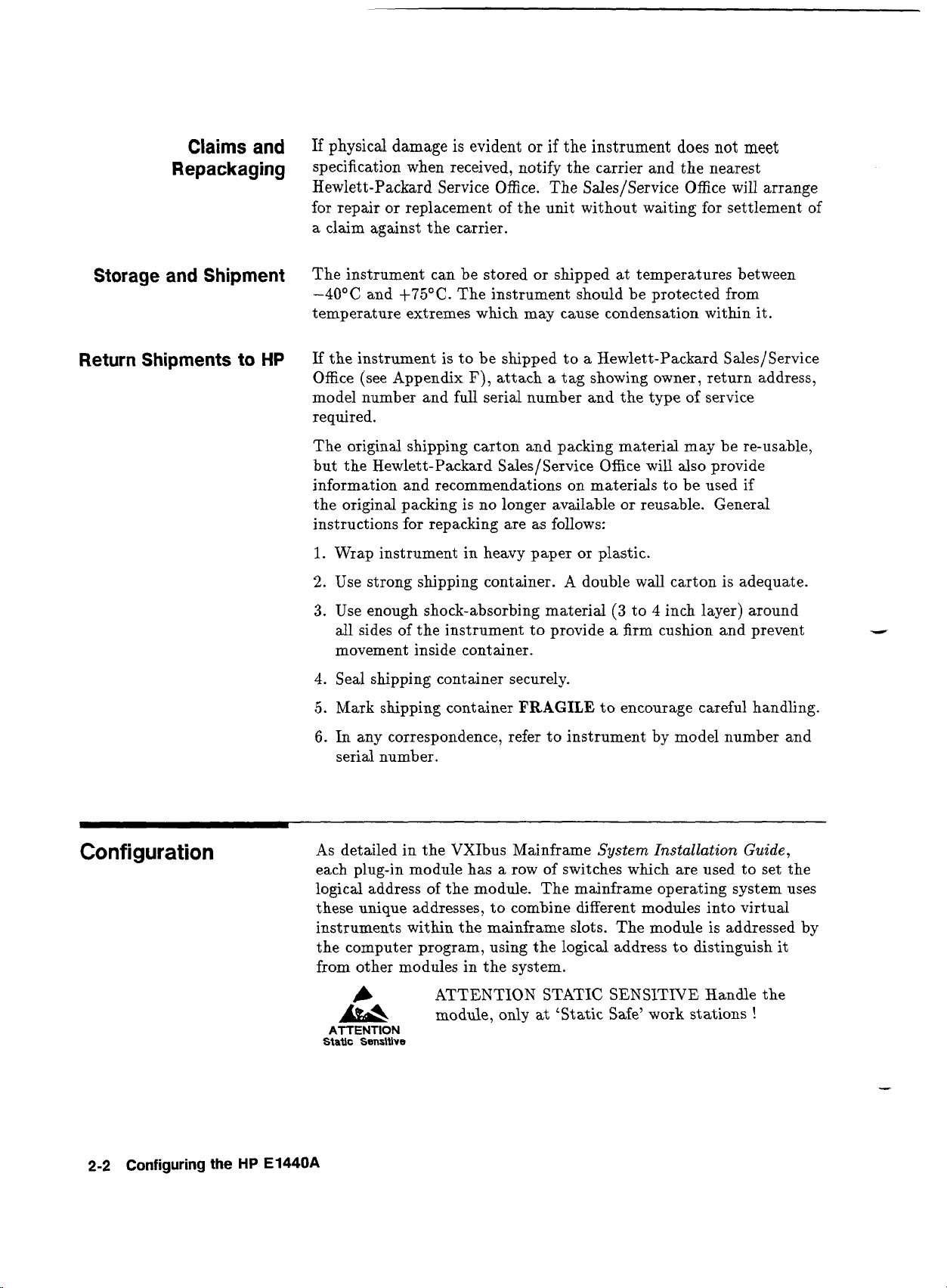

Figure 2-1 shows the location of the

HP

E1440A

logical address

Switch

switch. Access to alter the switch settings may be gained through a

cutout in the module cover.

Logical

Address

Switch

\

/

Cutaway

view

J101

to

J106

(on

rear)

Figure

2-1.

Address Switch and Jumper Location

The Logical Address switch has a factory setting of 88 which is

equivalent to a secondary address of

11.

Figure

2-2

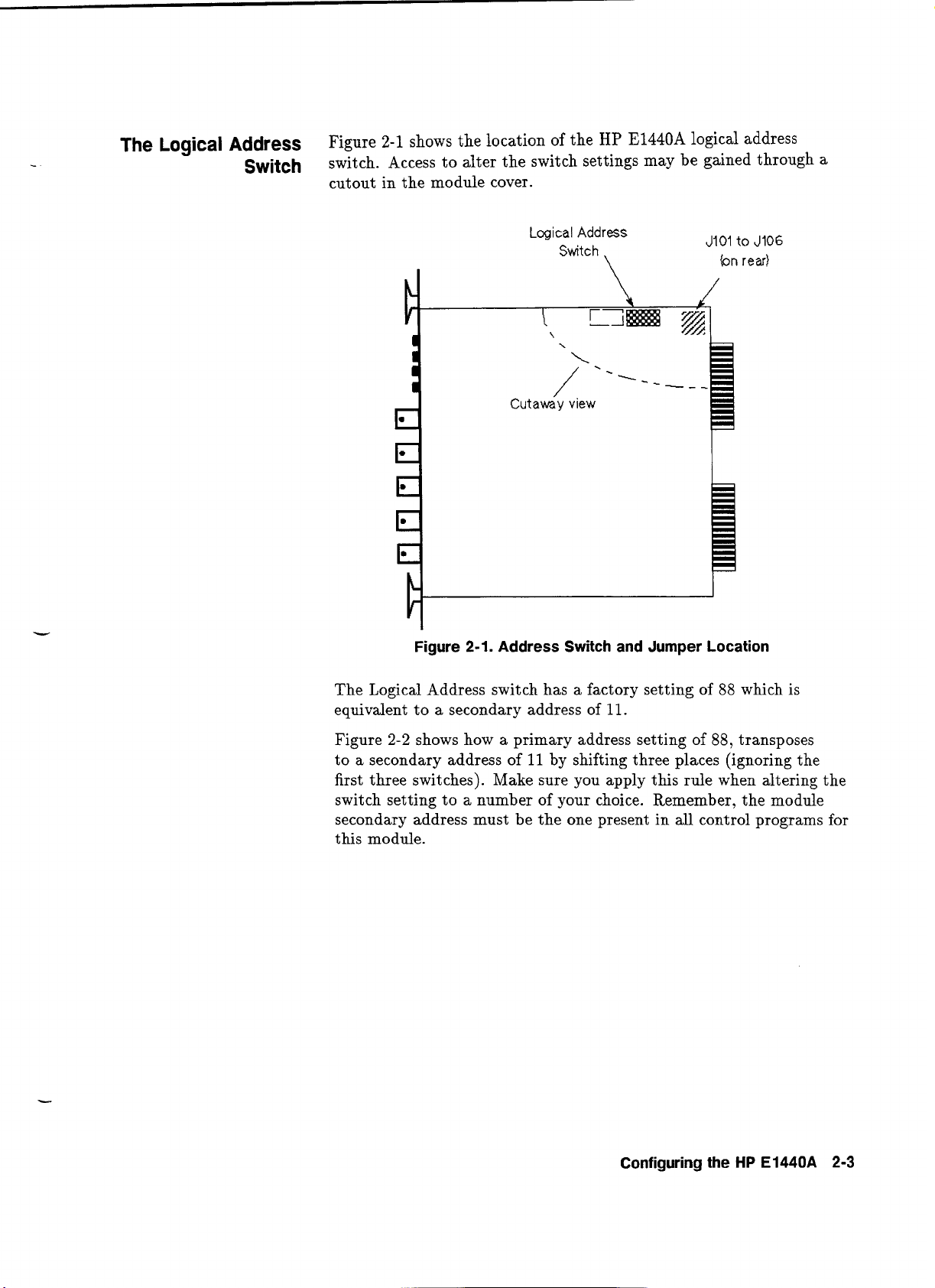

shows how a primary address setting of 88, transposes

to a secondary address of

11

by shifting three places (ignoring the

first three switches). Make sure you apply this rule when altering the

switch setting to a number of your choice. Remember, the module

secondary address must be the one present in

all

control programs for

this module.

Configuring the

HP

E1440A

2-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

,

Service

Switch - DO

NOT

ALTER

,

Logical

Address

128

switch

MSB LSB

MSB LSB

Figure

2-2.

Address

Switch

Settings

This view of the switch settings is the one you will see when looking

directly into the top of the module. The switch positions are shown

from the same viewpoint.

Note

If

there is no other identical

HP

E1440A module in the mainframe

with this address, and this factory set address does not conflict with

one of the other modules, then the factory setting may be left as it is

set.

A

The service switch beside the logical address switch

-

is factory set as shown and is for use by service

personnel only. It must not be altered!

Changing

Settings

Module

On the left hand side, close to the VXIbus connectors, mounted on

the circuit land side of the control printed circuit board, there are

several connecting links which you can change to alter the module

configuration for control interrupt priority. The link locations are

shown on Figures 2-1,

2-2

and configurations are shown on Figure

2-3. Access is gained through

a

cutout in the cover.

Jumpers JlOl to J106 can be used to alter the interrupt priority

setting of the HP E1440A module.

In

most cases this would not

need to be altered from the factory setting of

BG/BR3.

However, if

the

HP

E1440A is being used in a mainframe with other non-HP

instruments, or in a specialized. test equipment set-up, there may be a

requirement to alter the controller interrupt priority of the module.

Proceed as follows:

When altering the

BG/BR

level you will touch electronic

components.

ESD

precautions

such as a wristlet connector to module

cover, must be used. Do not use

BNC

outer shields they are not

ground!

2-4

Configuring

the

HP

E1440A

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 31

1.

Place module on a bench with the jumper access cutout

uppermost

2.

Refer to figure

2-3

and remove the single jumper from the column

where you want the full column jumpered according to the

BG/BR

level you require

3.

Move the three jumpers that are together, across to the column

you have just emptied

4.

Place the single jumper in the vacated column in line with the

other two single jumpers

5.

Check that the final jumper positions are correct for the

BG/BR

level you require and that

all

jumpers are secure on their pins

3210 3210 3210 3210

BGiBRO BGIBR1 BGiBR2

BGiBR3

(Factory setting)

Figure 2-3. Jumper 5101 Links Settings

A

The Jumper positions are factory set as shown. Do

LA

not alter unless absolutely necessary.

l

nstallation

In

addition to C-Size modules, the mainframe also accepts A- and

B-Size modules. If you intend using the

HP

E1440A with these

smaller size modules, it is better to install them first. Refer to the

mainframe manual for details.

SHOCK HAZARD. Remove all sources of power from the mainframe

Warning

@

before removing or installing the HP E1440A module.

A

ATTENTION STATIC SENSITIVE Handle the

module, only at 'Static Safe' work stations

!

ATTENTION

Static

Sensitive

Configuring the HP E1440A

2-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

Installing the

E

IUOA

HP

Choose the mainframe location for the module and place the module

card edges into the front mainframe guides (top and bottom). Fit the

module as follows:

a

Slide the module towards the rear of the mainframe until the

connectors approach the backplane

I

Check that the module connectors align with the backplane

receptacles

Caution

#I

There are

receptacles, which could be damaged or altered, if the module

connectors are pushed against them

Carefully push the module home so that the connectors mate

solidly with the back plane receptacles, the screening fingers rest

comfortably against the adjacent module, and the front panel is

flush against the front bar of the mainframe

rn

Secure the module using the captive screws in the front panel to

lock the module into the mainframe

Power can now be restored to the mainframe.

DIL

switches on the backplane beside the connector

2-6

Configuring the

HP

E1440A

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 33

Using

the

HP

E1440A

Using

this

Chapter

The purpose of this chapter is to provide example programs that

show you how to operate the synthesizer. With minor modifications,

these programs can also be used for many of your applications. The

examples in this chapter include:

Function Generator

....................................................

3-3

Multi-Interval Sweep Generator

.................................

3-4

Command Group Feature

..........................................

3-5

Synchronizing the

E1440A

.........................................

3-

7

Sample Programs

This chapter provides only basic programming information for the

HP

E1440A.

More advanced examples may be found in Chapter

4

Understanding

the

HP

Eld40A

After power-on of the VXI mainframe, check that the

Failed

lamp

on the HP

E1440A

front panel, has extinguished. This means that

the microprocessor within the unit, has checked that it is connected

properly to the VXIbus and can operate with the rest of the system.

To check if the controller and the HP

E1440A

are talking with each

other, send a query and look at the response from the

HP

E1440A.

For example:

Program

Result

10

DIM

A$[2551

Dimensions

A$.

20

OUTPUT

70911;

Queries the type of output waveform the

"

:

FUNC?"

HP

E1440A

is set to.

30

ENTER

70911;A$

The HP

E1440A

waveform type is received by

the

controller.

40

PRINT

A$

The type is displayed.

50

END

Program end.

The display should read SIN (Sine wave) because after a reset, that is

what the HP

E1440A

is set to.

Note

Whilst messages (Command strings and responses) are being

exchanged between the

HP

E1440A

and the controller, the

Access

lamp will flash intermittently on the front panel.

Using

the

HP

E1440A

3-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 34

If

the function is not shown, the first thing to check is that the

HP

address set on the

E1440A is the same as the one you are using

(in this case 11). Details of address set up are given in Chapter

Configuring

the

HP

EI&OA.

2

Typical

Commands

[:SOURce]:OUTPut

Command

:ROSCiliator Command

FUNC

Command

Any commands shown here in square

([

I)

brackets, are optional.

They are included to help your understanding of the command logic.

The

[:SOUR]:OUTP ON/OFF command is used to switch a relay

that applies the instrument output signal to the output connector, or

isolates the connector. The command switches the output signal.

The

HP

E1440A may use alternative reference oscillators as follows:

Source Keyword Description

:ROSC:SOUR

An internal 30 MHz crystal

INTernal

A

:ROSC:SOUR

EXTernal

:ROSC:SOUR

CLK

10

reference input to the front panel connector in

the range

A

10

(available to

1

MHz to 10 MHz

MHz signal taken from the VXIbus

all

mainframe modules)'

The function, FUNC[:SHAPe], command allows you to set the shape

and frequency of your waveform.

Table

3-1.

Values

for

FUNC

Command

3-2

Using

the

HP

E1440A

Function

DC

SINusoid

SQUare

TRIangle

RUP

(Pos. slope ramp)

RDOWn

TTL

(Neg.

slope ramp)

1

pHz

1

pHz

1

pHz

1

pHz

1

pHz

1

pHz

Range

DC

to

to

to

to

to

to

level

21

11

11

11

11

60

MHz

MHz

kHz

kHz

kHz

MHz

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 35

FREQ

Command

The frequency sweep controls are as follows:

Table

3-2.

Frequency

Controls

Range

CW,

FIXed,

SWEep or

LIST

numeric value sets start frequency

numeric value sets stop frequency

numeric value sets center frequency

numeric value sets frequency span

Note

3

Changing the span alters the start and stop frequencies but not

center

Programming

The following sections give programming examples for the

Examples

HP E1440A. The examples are divided into three different sections,

a simple function generator, a multi-interval sweep generator and

a multi-marker sweep generator.

All

of the programs assume the

following:

rn

an HP 9000, Series 200 or 300 Computer as controller

rn

that BASIC is the programming language

rn

that the HP E1440A is preset to HP-IB address

11

rn

that the slot 0 commander (E1405) is set to primary HP-IB

address 9

Function Generator

The following program shows an example of how to program the

HP

E1440A as a function generator. The program shows how to:

1.

Clear all devices (resets E1440A)

2.

Set the waveform as a square wave

3. Set the frequency to 10

kHz

4. Set the amplitude to 1 V(p-p)

5.

Set the DC offset to 4.5 V

6.

Set the phase to

45'

7.

Switch the output on

Using

the

HP

E1440A

3-3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 36

Program

10

OUTPUT 70911; "*RST;*CLS"

20

OUTPUT 70911; ":SOUR:WC

sqult

30

OUTPUT 70911; ":FREQ 10000"

40

OUTPUT 70911; ":VOLT

1"

50

OUTPUT 70911; ":VOLT:OFFS

4.5"

60

OUTPUT 70911; ":PHAS 45 DEG"

70

OUTPUT 709 11 ; I' : OUTP ON"

Result

Clears all status registers.

selects square wave

sets frequency to 10 kHz

sets amplitude to

1

volt

sets offset to 4.5 volts

sets phase to

45'

switches output signal to the front

panel

BNC

connector

Program end.

Note

Lines

20

to 70 could have been sent as one composite instruction

$

OUlPUT70911;":SOUR:FIMCSQU;:FREQ10000;:VOLT1;:VOLT:OFFS

4.5

;

:

PHAS

45

DEG"

Multi-Interval Sweep

Generator

The following program shows

an

example of how to program the

HP

E1440A as a multi-interval sweep generator. The program

assumes that the amplitude, waveform,

DC

offset and phase, are the

same as set in the previous example, retrace time is set to

5

seconds

and the sweep is to run continuously. The program then shows how

to set five sweep intervals with the following parameters:

Interval

1:

start frequency

1

kHz

stop frequency 3 kHz

marker frequency

2

kHz

sweep time

1

sec.

sweep mode linear

Interval

2

start frequency 500 Hz

stop frequency 10 kHz

sweep time

1

sec.

sweep mode logarithmic

Interval 3 start frequency

2

kHz

stop frequency

4

kHz

marker frequency

3

kHz

sweep time

1

sec.

sweep mode linear

Interval

4

start frequency 900 Hz

stop frequency 10 kHz

sweep time

1

sec.

sweep mode logarithmic

Interval

5:

start frequency 3 kHz

stop frequency 5 kHz

marker frequency

4

kHz

sweep time

1

sec.

sweep

mode

linear

3-4

Using

the

HP

E1440A

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 37

10

OUTPUT 70911; ":LIST:FREQ:STAR 1000,500,2000,900,3000"

20

OUTPUT 70911; ":LIST:FREQ:STOP 3000,10000,4000,10000,5000"

30

OUTPUT 70911; ":LIST:FREQ:MARK 2000,200,3000,500,4000"

40

OUTPUT 70911; I1:LIST:FREQ:MARK:STAT ON,OFF,ON,OFF,ON"

50

OUTPUT 70911; ":LIST:FREQ:SPAC LIN,LOG,LIN,LOG,LIN"

60

OUTPUT 70911; ":LIST:DWELL 1"

70

OUTPUT 70911; ":SWE:RTIM 5"

80

OUTPUT 70911; ":LIST:SEQ (1:5)"

90

OUTPUT 70911; ":FREQ:MODE LIST"

100

OUTPUT 70911; ":INIT:CONT ON"

110

END

Multi-Marker Sweep

The following program shows an example of how to program the

Generator

HP

E1440A

as a multi-marker sweep generator. The program sets up

the following continuous sweep:

Interval Start Frequency 1.0 kHz

Interval

Stop

Frequency 5.0 kHz

Interval Sweep Time 1.0

s

with the following markers:

Marker 1 1.5 kHz

Marker 2 2.0 kHz

Marker 3 2.5 kHz

Marker 4 3.0 kHz

Marker 5 3.5 kHz

Marker

6

4.0 kHz

Marker 7 4.5 kHz

1

OUTPUT 70911

;

It

:

FREQ : STAR 1E3"

2

OUTPUT 709 11

;

It

:

FREQ : STOP 5E3"

3

OUTPUT 70911;":MARKl:FREQ l.SE3;:MARK2:FREQ 2E3"

4

OUTPUT 70911;":MARK3:FREQ 2.5E3;:MARK4:FREQ 3E3"

5

OUTPUT 7091l;":MARKS:FREQ 3.5E3;:MARKG:FREQ 4E3"

6

OUTPUT 70911;":MARK7:FREQ 4.5E3"

7

OUTPUT 70911;":MARKl:STAT ON;:MARK2:STAT

ON"

8

OUTPUT 70911;":MARK3:STAT ON;:MARK4:STAT

ON"

9

OUTPUT 70911;":MARK5:STAT 0N;:MARKG:STAT

ON"

10

OUTPUT 709 11

;

"

:

MARK7 : STAT ON"

11

OUTPUT 70911;":SWE:TIME 1"

12

OUTPUT 7091 1

;

"

:

FREQ :MODE SWE"

13

OUTPUT 70911

;

"

:

INIT : CONT ON"

14

END

Using

the

HP

E1440A

3-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 38

Using

the

Command

Group

Feature

This

example program in RMBASIC (Rocky Mountain

demonstrates the benefits of the 'Command Group Feature'

implemented in the El440 See Chapter

HP

E1440A.

The :VOLT and :VOLT:OFFSet commands are used as an example

and the measurement task is

Base setup:

Frequency

Function

First measurement:

Voltage

Voltage offset

:

:

:

:

11

MHz

SIN

0.1

V

0.2 V

:

4

Understanding

BASIC),

the

Second

Volt age

Voltage offset

Third

Voltage

Voltage offset

The problem here is that, if parameters are programmed in separate

output statements, you would enter temporarily incompatible states.

Referring to the example above, if you always program in the order

:VOLT and then :VOLT:OFFS, you will get an error at the beginning

of the third measurement because an offset of 0.1

with an amplitude of 2 V (leftover from second measurement).

Reverting the order of programming (first offset then amplitude) will

just move the problem, not eliminate it. In this case you will get an

error at the first

incompatible with an amplitude of 0.001 (value after "RST).

There are three ways out of the dilemma

1.

2. Keep track of the current value and select programming sequence

3.

measurement:

:

:

measurement:

:

:

:VOLT:OFFS command because an offset of 0.1

Every time you want to program amplitude and offset set them to

save values first. This doubles the programming effort.

(amplitude/offset or offset/amplitude) accordingly. Very time

consuming.

Send amplitude and offset in one string. The most efficient

method.

2.0

V

3.0

V

0.1 V (again

0.2 V (again)

V

is incompatible

V

:

-

is

3-6

10

20

3

0

40

Using

Sample program

!

REAL

El440

!

the

HP

E1440A

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

for the instrument HP-IB address.

!

Note that

!

a HP-IB address with secondary addressing.

an

INTEGER is too small to hold

Page 39

E1440=70911

!

assumed slot 0 commander

is

connected to

!

HP-IB interface with select code

7,

!

primary

HP-IB

address of slot 0 commander

is

9

!

and logical address of

El440

is

11

(secondary

!

HP-IB address

is

logical add. shifted left 3 bits)

!

!

At

the start we put instrument into a known state.

CLEAR El440

OUTPUT El440

;

I1*RST

;

:

STATUS : PRESET ; *CLS1'

!

!

Base setting

I

OUTPUT E1440;I1:FUNC SIN; :FREQ 11

MHz;

:OUTP ON"

!

!

Setup

1

!

OUTPUT El440

;

"

:VOLT :AWL 0.1

V;

OFFSET 0.2 V"

!

!

Do measurement

1

I

OUTPUT El440

;

I'

:VOLT :AWL

2.0

V

;

OFFSET 3.0 V"

!

!

Do measurement

2

!

OUTPUT El440;":VOLT:AMPL 0.1

V;

OFFSET 0.2 V"

!

!

Do measurement

3

!

END

Using

*OPC?

to

This example program demonstrates the use of the "OPC? to

Synchronize the

HP

synchronize the controller with the

E1440.

It also shows how one

~1440~

can deal with the

LIST

subsystem which can sometimes be slightly

unwieldy.

The requirement is to set up a list sweep comprising:

rn

one lin interval 1 MHz to 13 MHz

,

1

second

one equi interval 13 MHz to 13 MHz

,

2

seconds

rn

one lin interval 13 MHz to 1 MHz

,

1

second

one log interval 1 MHz to

13

MHz , 3 seconds

Output function is

SIN,

amplitude is

5

V.

When the sweep stops we will print the message

List

sweep finished

on the computer screen

Using

the

HP

E1440A

3-7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 40

Note

I

We will not program markers because we do not need

them.

r

After

*RST

the

L1ST:FREQ:MARK:STAT

list contains one entry

with the value

OFF.

This entry can be thought of as being replicated

as many times as imposed by the other non-singular lists. We will

store the parameters

in

data lines.

The

first data line is the sweep sequence as a string and the number

of intervals is defined by the succeeding data lines.

10 List-data:

!

20

!

30 DATA "(1:4)",4

40

!

50

!

The following 4 data lines contain

:

60

!

start

,

stop , "spacing" , time

70 DATA lE6

,

13E6

,

"LIN"

,

1

80 DATA 13E6 , 13E6

,

"LIN"

,

2

90 DATA 13E6

,

1E6

,

"LIN"

,

1

100 DATA 1E6 , 13E6 , "LOG"

,

3

110

!

120

!

some variables

130

!

140

!

first the arrays for the

list

parameters

150

!

160 REAL

Lstart

(1

:

10)

!

start

frequencies

170 REAL Lstop(1: 10)

!

stop frequencies

180 REAL Ltime (1

:

10)

!

dwell times

190

DIM

Lspac$ (1 : 10) C51

!

spacing modes

200

DIM

Lseq$[801

!

sequence

210

DIM

Opc-resp$ C31

!

for entering the *OPC? response

220

!

230 INTEGER

I

!

the famous all purpose

I

240 INTEGER No-of-int

!

number of intervals

250

!

260 REAL El440

!

for the instruments HP-IB address.

270

!

Notice that

an

INTEGER

is

too small to hold

280

!

a HP-IB address with secondary addressing.

290

!

300 E1440=70911

!

assumed slot 0 commander

is

connected to

310

!

HP-IB interface with select code 7,

320

!

primary

HP-IB

address of slot 0 commander

is

9

330

!

and logical address of El440

is

11

(secondary

340

!

HP-IB address

is

logical add shifted left 3 bits)

350

!

360

!

lets fill the parameter arrays first

370

!

380 RESTORE List-data

!

not necessary in a program as short as this

3-8

Using

the

HP

E1440A

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 41

!

but always good style.

READ

Lseq$,No-of-int

!

FOR 1=1 TO No-of-int

READ Lstart(1) ,Lstop(I) ,Lspac$(I) ,Ltime(I)

NEXT I

!

!

To start with, we put instrument into known state.

CLEAR El440

OUTPUT El440

;

"

*RST

;

:

STATUS :PRESET ; *CLStl

!

!

Setup the list

!

OUTPUT El440 ; I' :LIST : FREQ : START I'

;

!

mind the

';'!

it suppresses

!

the <CR/LF> at the end of

!

the output statement.

!

also watch the space

' '

!

after START

!

now output the parameters in a loop

FOR 1=1 TO No-of-int

OUTPUT

E1440;Lstart (I)

;

IF I<No-of-int THEN OUTPUT E1440;","; ! insert

'

,'

if not last param.

NEXT I

OUTPUT

El440

;

I'

;

"

!

output

'

;