Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

Contents

HP E1418A 8/16-Ch D/A Converter User Manual

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Reader Comment Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 1. Module Setup and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Module Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ordering Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Field Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Terminal Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Functional D escription . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Front Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Setting the Logical Address Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installation in a Mainframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Terminal Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Scre w-T ype Terminal M odu le (Standard) . . . . . . . . . . . . . . . . . . . . . . 22

Wiring the Terminal Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Attaching the Terminal Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Removing the Ter minal Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Terminal Module Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Option A3E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Option A3H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Option 135 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Terminal Module Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Configuring the Term inal Modul e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

P/J Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

V/I Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Termina l Module Conne ctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Voltage and Current Output Connecti ons . . . . . . . . . . . . . . . . . . . . . . 33

Combining Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Conne cting an Exter nal Trigger Source . . . . . . . . . . . . . . . . . . . . . . . 35

Using the CAL Output Ter m inal s . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Initial Opera ti on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Device Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Module Iden tification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Chapter 2. Programming E xamples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Program Exam ples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Querying M odule Identification and Configuration . . . . . . . . . . . . . . . . . . . . 40

HP E1418A 8/16-Ch D/A Converter User Manual Contents 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

Configuration Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

APPLy Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Error Che cking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

I/O Error Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

SCPI Error Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

SOURce Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Setting the Output M ode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Controlling the Output Rel ay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Triggerin g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Using *OPC? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Combining Output Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Chapter 3. HP E1418A SCPI Command Refer ence . . . . . . . . . . . . . . . . . . . . . . 59

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Command Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Common Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

SCPI Command F ormat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Linking Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

SCPI Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

ABORt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

APPLy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

APPLyn:C URRent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

APPLyn:VOLTage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

CALibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

CALibration:CONDit ion ? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

CALibration:CONFig ure:RESi sta nce? . . . . . . . . . . . . . . . . . . . . . . . . 68

CALibration:RE Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

CALibration:STORe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

CALibration:TEST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

CALibration:VALue:RESistance . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

CALibrationn:CONFigure: CURRent? . . . . . . . . . . . . . . . . . . . . . . . . 71

CALibrationn:CONFigure:VOLTage? . . . . . . . . . . . . . . . . . . . . . . . . 72

CALibrationn:VALue:CURRent? . . . . . . . . . . . . . . . . . . . . . . . . . . 73

CALibrationn:VALue:VOLTage? . . . . . . . . . . . . . . . . . . . . . . . . . . 74

DIAGnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

DIAGnostic:CALibr a tion: OUTPut[:MODE] . . . . . . . . . . . . . . . . . . . . 76

DIAGnostic:CALibr a tion: OUTPut[:MODE]? . . . . . . . . . . . . . . . . . . . . 77

DIAGnostic:CONFigure? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

DIAGnostic:OUTPut:ALL[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . 78

DIAGnostic:S O URc en:F UNCtion: MODE . . . . . . . . . . . . . . . . . . . . . . 78

DIAGnostic:T RIGger ed? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

INITiate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

INITiate[:I M M ediate] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

OUTPut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

OUTPut:TTLTrgn[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

OUTPut:T TLTrgn[:STAT e]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

OUTPutn[:STATe] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

OUTPutn[:STATe]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

SOURce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

2 HP E1418A 8/16-Ch D/A Con verter User Manual Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

SOURcen:CURRent[:LEVel][:IMMediate][: AMPLitude] . . . . . . . . . . . . . 85

SOURcen:CURRent[:LEVel][:IMMediate][: AMPLitude]? . . . . . . . . . . . . . 86

SOURcen:CURRent [:LEVel]:TRIGgered[:AMPLitude] . . . . . . . . . . . . . . 87

SOURcen:CURRent[:LEVel]:TRIGgered[ :AMPLitude]? . . . . . . . . . . . . . . 88

SOURcen:FUNCtion:MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

SOURcen:FUNCtion:MODE? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

SOURcen:VOLTage[:LEVel][:IMMediate][: AMPLit ude] . . . . . . . . . . . . . 91

SOURcen:VOLTage[:LEVel][:IMMediate][:AMPLitude]? . . . . . . . . . . . . . 92

SOURcen:VOLTage[:LEVel]:TRIGgered[ :AMPLitude] . . . . . . . . . . . . . . 93

SOURcen:VOLTage[:LEVel]:TRIGgered[ :AMPLitude]? . . . . . . . . . . . . . . 94

STATus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

STATus:OPE Ra tion:CONDition? . . . . . . . . . . . . . . . . . . . . . . . . . . 96

STATus:OPE Ra tion:ENABle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

STATus:OPE Ra tion:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

STATus:OPE Ra tion[:EVENt]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

STATus:PRESet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

STATus:QUEStionable:CONDition? . . . . . . . . . . . . . . . . . . . . . . . . 98

STATus:QUEStionable:ENABle . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

STATus:QUEStionable:ENABle? . . . . . . . . . . . . . . . . . . . . . . . . . . 99

STATus:QUEStionable[:EVENt]? . . . . . . . . . . . . . . . . . . . . . . . . . . 99

SYSTem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

SYSTem:ER Ror? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

SYSTem:VERSion? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

TEST:NUMBer? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

TEST:TST[:RE Sults]? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

*TST? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

TRIGger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

TRIGger[:IMMediate] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

TRIGger:SOURce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

TRIGger:SOURce? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

IEEE-488. 2 Common Command Qu ick Reference . . . . . . . . . . . . . . . . . . . . 106

HP E1418A Comma nd Quick Reference . . . . . . . . . . . . . . . . . . . . . . . . . 107

Appendix A. HP E1418A Speci fications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

DC Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

DC Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

General Cha ra cteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Cooling Requiremen ts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Appendix B. HP E1418A Register-Based Programming . . . . . . . . . . . . . . . . . . . 113

Address ing the Reg isters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

A16 Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

A24 Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

The Base Addres s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Register Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

HP E1418A 8/16-Ch D/A Converter User Manual Contents 3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

Reset and Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Register Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

A16/A24 REGIST ERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

A24 REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Register Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Manufacturer ID Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Logical Address Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Device T ype Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

VXI Status/Control Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

VXI Offset Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Calibration Control Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Card Configuration Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Software T ri gger Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Trigger Control Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Interrupt Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Isolation Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Channel Pr ogram Jumper Re gister . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Channel Tr igger Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Channel M ode Regist er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Channel Relay Control Register . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Card Contr ol Reg ister . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Main_DAC Im mediate Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Main_DAC Tr iggered Regist ers . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Offset_DAC Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Gain_DAC Regist er s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Undefined Regi sters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Channel Voltage Offset Cali bra tion Register s . . . . . . . . . . . . . . . . . . . . 140

Channel Voltage Gain Calibra tion Registers . . . . . . . . . . . . . . . . . . . . . 141

Channel Cur rent Offset Cal ibration Regi sters . . . . . . . . . . . . . . . . . . . . 142

Channel Curr en t Gain Calibration Registers . . . . . . . . . . . . . . . . . . . . . 143

Calibrati on R esistor Value Register s . . . . . . . . . . . . . . . . . . . . . . . . . 144

Voltage Ca libration Status Regi ster . . . . . . . . . . . . . . . . . . . . . . . . . 144

Current Calibration Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Calibration Isolation Status Register . . . . . . . . . . . . . . . . . . . . . . . . . 146

Calibration Car d Configuration Register . . . . . . . . . . . . . . . . . . . . . . . 147

Calibration Checksum Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Module S erial Number Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Register Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Appendix C. HP E1418A Error M e ssages . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Error Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Error Message s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Appendix D. Voltage/Current Out p ut Adjus t ment . . . . . . . . . . . . . . . . . . . . . . 154

Using This Appen dix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Calibrati on Constants and Non-Volatile Memory . . . . . . . . . . . . . . . . . . . . . 155

Equipment Require d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

4 HP E1418A 8/16-Ch D/A Con verter User Manual Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

Making Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Voltage Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Current Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Storing the Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Return the Module t o Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Example Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Appendix E. Configuration and Disasse mbly . . . . . . . . . . . . . . . . . . . . . . . . . 166

Using This Appen dix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Checking Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Changing Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Adding 8 Channe l s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Installing Isol ate d/Non-Isolated Plug-on Modul es . . . . . . . . . . . . . . . . . . 171

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Isolating an Assembly (Self-Test) . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Assembly Exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

To Exchange an Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

HP E1418A 8/16-Ch D/A Converter User Manual Contents 5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 7

Notes

6 HP E1418A 8/16-Ch D/A Con verter User Manual Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

Certification

Hewlett-Packard C ompa n y certifi es that this produ ct met its publi sh ed speci fica tions a t the time of shipme nt from the factor y. HewlettPackard furth er cert ifi es that its cali brat ion mea sureme nt s are tracea bl e to the Unit ed Sta tes Na tion al Inst itute of Stan dards and Technology (formerly National Bureau of Standards), to the extent allowed by that organization’s calibration facility, and to the calibration

facilities of other International Standards Organization members.

Warranty

This Hewlet t-Pa ck ar d product is warr ante d agai nst de fect s in mate rials and w orkmansh ip for a period of three yea rs from date of shipment. Duration and conditions of warranty for this product may be superseded when the product i s i nt egrated into (be com es a part of)

other HP products. During the warranty period, Hewlett-Packard Company will, at its option, either repai r or re pl ace pr oducts which

prove to be defective.

For warrant y se r vice or repair, this product must be returned to a service facility de si gnated by Hewlett -Packard (HP). Buyer shall prepay shippin g charges to HP and HP sh al l pay shipping charges t o re tu rn t he p r oduct to Buyer. Howe ver, Buyer shall pay all shipping

charges, dutie s, an d taxe s for products ret urned to HP from an other cou ntry.

HP warrants tha t its softwar e and fir mwar e designa t ed b y HP for use with a product will exe cu te its pr ogrammin g instru cti ons wh en

properly installe d on that product . HP does not warrant that t he operat ion of the product, or software, or firmware wi ll be uninterrupted

or er ro r f r ee.

Limitation Of Warranty

The foreg oin g warranty shall not appl y t o defects resulting from i mproper or inadequate maintenance by Bu yer, Buyer-supplied products or interfacing, unauthori ze d m odificati on or misus e, opera tion outside of the environmental specificat ions for the product, or improper site prep arat i on or maint ena nce.

The design an d imp le mentation of any circuit on this product is the sole responsibility of th e Buyer. HP does not warrant th e Buyer’s

circuitr y or malfunction s of HP products that result from the Bu yer’s circuit r y. In addition, HP does not warrant an y damage tha t occurs as a result o f the Buyer’s circuit or any defects th at re sult fr om Buyer-supplied products.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HP SPECIFICALLY DISCLAIMS THE IMPLIED WARR ANTIES OF

MERCHANTABILITY AND FITNESS FOR A PAR TICULAR PURPOSE.

Exclusive Remedie s

THE REMED IES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES. HP SHALL NOT BE LIABLE

FOR ANY DIRECT, INDIRECT, SPECIAL, IN C IDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Notice

The information contained in this document is subject to change without notice. HEWLETT-PACKARD (HP) MAKES NO WARRANTY OF ANY KIND W ITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMP LIED WARRANTIES OF MERCHANTABILIT Y AND FITNESS FOR A PARTICULAR PURPOSE. HP shall not be liable for errors contained

herein or for incidental or consequentia l damages in connection wit h the furnishing, performance or use of this material. This document c ontai ns proprietary information which is prote ct ed by copyright. A ll ri ghts are reserved. No part of thi s document may be photocopied, reproduced, or tran slate d to anothe r langua ge wit h out the prior written c onsent of Hewlett -P ackar d Company. HP assumes no

responsibility for the use or reliability of its software on equipment that is not furnished by HP.

U.S. Government Restricted Rights

The Software and Do cumentat ion ha ve bee n develope d entir ely at privat e expe nse . The y are delivered and lice nsed as "c omme rcia l

computer software" as defin ed in DF ARS 252.227-701 3 (October 1988 ), DF ARS 252.211.701 5 (May 1991) or DFARS 252.227-7014

(June 1995), as a "comme rcia l item" as defined in F AR 2.101(a ), or as "Restrict e d comp uter software " as define d in FAR 52.227-19

(June 1987) (or any equival en t agen cy re gula tion or c ontract cla use ), whi ch ever is appl ica bl e. You have only those right s provided for

such Software and D ocum ent at ion by the applicable FAR or DFARS clause or the H P st andar d software agreement for t he pr oduct invol ved.

HP E1418A User’s Manual

Copyright © 1996 He wle tt-Pa cka rd Company. All Right s Reser ve d.

Edition 2

HP E1418A User’s Man ual 7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

Documentatio n History

All Editions and Updates of this manual and their creation date are listed below. The first Edition of the manual is Edition 1. The Edition number increment s by 1 whenever the manua l is revised . Updates , which are issued betw een Edi ti ons, c ontain repla ce ment pa ges

to correct or add additional information to the current Edi tion of the manua l. Whene ver a new Edition is creat ed, it will c ontain all of

the Update information for the pre vious Edit ion. Each new Ed ition or Update also include s a revised c op y of this documentation hi story page.

Edition 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . October 1995

Edition 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . October 1996

Safety Symbols

Instruction manual symbol affixed to product. Indicat es that the user must refe r t o the

manual for specific WARNING or CAUTION information to avoid personal injury

or damage to the product.

Indicates the field wiring terminal that must

be connected to earth ground before operating the equipment—protects against electrical shock in case of fault.

Frame or chassis ground termi nal — t ypi-

or

cally connects to the equipment’s metal

frame.

WARNING

CAUTION

Alternating current (AC).

Direct curren t (DC).

Indicate s ha za rdous voltage s.

Calls at te nt i on t o a pr ocedure, practi ce, or

condition that could cause bodily injury or

death.

Calls at te nt i on t o a pr ocedure, practi ce, or condition that could possibly cause damage to

equipme nt or perma nen t los s of data.

WARNINGS

The following ge ner al safet y prec aut ions mu s t be observed du ri ng al l phas es of oper ation, service, and re pai r of this pr oduct .

Failure to comply with these prec aut ions or with specific war nings elsewhe re in this manual violates safety stand ard s of design ,

manufacture, and intended use of the product. H ewl ett-Packard Company assumes no liability for the customer’s failu re to

comply with these requirements.

Ground the equipment: For Safety Cl as s 1 equipmen t (equ ipment ha vin g a protective ea rth ter mi nal) , an unint erru ptib le sa fety earth

ground must be provide d from the ma in s power sour ce to the produ ct input wi rin g termi nals or suppli ed power cable .

DO NOT operate the produc t in an explosive at mospher e or in the presen ce of flammable gases or fumes.

For continued protect ion a gainst fire, repl ace the li ne fuse(s) only with fuse(s) of the same voltage and current rating and type .

DO NOT use repaired fuses or short-circui ted fuse holders.

Keep away from live circuits: Operatin g personnel must not remove equipment covers or shields. Procedures involving the removal

of covers or shields are for use by service-trained personn el onl y. Under certain conditions , dangerous voltages m ay exist even with the

equipment switched off. To avoid dangerous ele ctrical shock , DO NOT perf orm procedures involving cover or shield removal unless

you are qualified to do so.

DO NOT operate damaged equipment: Whenever it is possible that the safety protection features built into this pr oduct have been impaired, either t hr ough physical dama ge, excessive moisture, or an y ot her re as on, REMOVE POWER and do not use the product until

safe operation can be verified by service-trained personnel. If necessar y, return the produ ct to a Hewlett -Packar d Sa les and Se rvice O ffice for service and repair to ensure that safety features are maintained.

DO NOT service or adjust alon e: Do not attempt internal service or adjustment unless another person, capable of rendering first aid

and resuscitation, is present.

DO NOT substitute par ts or modify equipme nt: Because of the danger of introducing additional hazards, do not install substitute

parts or perform any unauth orized modifica tion to the product. Ret urn the produ ct to a Hewlett -Packar d Sa les and Ser vice O ffice for

service and repair to ensure that safety features a re ma i nt ai ned.

8 HP E1418A User’s Manual

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

Declaration of Conformity

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name: Hewlett-Pa ckar d C ompany

Loveland Manufacturing Center

Manufact ure r’s Addre s s: 815 14th Street S.W.

Loveland, Colorado 80537

declares, that the product:

Product Name: 8/16-Ch an nel D/A Con ver ter Modul e

Model Number : HP E1 418A

Produc t Opt ion s: All

conforms to the following Pr od uct Spe cifi cati ons :

Safety: IEC 1010-1 (1990) Incl . Amend 1 (1992) /E N610 10-1 (1993)

CSA C22.2 #1010.1 (1 992)

UL 3111

EMC: CISPR 11:1990/EN55011 (1991): Group 1 Class A

IEC 801-2:1991/ E N5008 2-1 (1 992) : 4 kVCD, 8 kVAD

IEC 801-3:1984/ E N5008 2-1 (1 992) : 3 V/m

IEC 801-4:1988/ E N5008 2-1 (1 992) : 1 kV Power Line

.5 kV Signal Lin es

Supplementary Information: The product herewith c omplies wit h th e requirements of the Low Voltage

Directive 73/23/EEC and the EMC Directive 89/336/ EEC (inclu sive 93/68/E EC) and carr ies the "CE" mark ing

accordingly.

Tested in a typical HP C-Si ze VXI Ma infr ame configuration .

November 6, 1995 Jim White, QA Manager

European c ontact : Your loca l He wlett-Pa cka rd Sa les and Ser vi ce O ffic e or Hewlett- Packa rd GmbH,

Department HQ- TRE, Herrenberg er Stra ße 130, D-71034 Böblingen, German y (FAX +4 9-7031-14-3143).

HP E1418A User’s Man ual 9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

Notes

10 HP E1418A User’s Manual

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

Please fold and tape for mailing

Reader Comment Sheet

HP E1418A User’s Manual

Editio n 2

You can help us improve our manual s b y sharing your commen ts and sug gesti ons. In apprec iat i on of your time, we will

enter yo u in a quarterly drawing for a Hewle tt -Pac kar d Palmt op Per s onal C omputer (U.S. government employees

cannot par ticipate in the drawing).

Your Name

C ompany N a me

Job Title

Address

Please list the s ystem c ontroller, opera ting system, programmi ng lan gua ge, and plug-in modules you are using.

City, State/Province

Country

Zip/Postal C ode

Telephone Number with Area Code

fold here

BUSINESS REPLY MAIL

FIRST CLASS PERMIT NO. 37 LOVELAND,CO

HEWLETT-PACKARD COMPANY

cut along this line

Measurement Systems Division

Learning Products Department

P.O. Box 301

Loveland, CO 80539-9984

NO POSTAGE

NECESSARY

IF MAILED

IN THE

UNITED STATES

fold here

Please pencil- in on e circle for each statement below: Disagree Agree

• The documentation is well organized. OOOOO

• Instructions are easy to understand. OOOOO

• The documentation is clearly written. OOOOO

• Examples are clear and useful. OOOOO

• Illustrations are clear and helpful. OOOOO

• The documentation meets my overall expectations. OOOOO

Please write any comments or suggestions below--be specific.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

12 HP E1418A User’s Manual

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

Using This Chapter

This chapter provides general module information and tasks you must

perform to install a nd pr e pa re your module. A procedur e to verify your

installation is also given. The chapter is divided into the followin g s ections:

Chapter 1

Module Setup and In stalla tion

• Module Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 13

• Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 16

• Fron t Pan el C onne ctors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 18

• Setting the Logical Address Switch. . . . . . . . . . . . . . . . . . . . Page 19

• Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 20

• Terminal Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 22

• Wiring the Terminal Modu le. . . . . . . . . . . . . . . . . . . . . . . . . Page 23

• Atta ching t he Ter minal Module. . . . . . . . . . . . . . . . . . . . . . . Page 2 5

• Removin g the Terminal Mo dule . . . . . . . . . . . . . . . . . . . . . . Page 26

• Terminal Module Options . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 27

• Terminal Modul e Connect ors . . . . . . . . . . . . . . . . . . . . . . . . Page 30

• Configuring the Terminal Module. . . . . . . . . . . . . . . . . . . . . Page 31

• Terminal Modul e Connect ions . . . . . . . . . . . . . . . . . . . . . . . Page 33

• Initial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 37

Module Description

The HP E1418A is an 8 or 16 channel digital- t o-ana log converter module

for use in a VXIbus C-s ize mainframe. The modu le is a regis ter-based

device. The module can be programmed via direct register access or, with

the appropriat e driver , by high level commands. This manual de scribes

programming the module using SCPI (Standard Commands for

Programmable Instruments) a nd the SCPI driver.

Each HP E1418A module is a unique instrument having its own output

buffer and error queu e. Multiple modules cannot be combined into a single

instrument.

Each channel can be configured to eith er voltage or current output mo de.

When configu r ed f or voltage output, voltages in the range of -16.0 to

+16.0 Volts can be set. When configured f or current output, current in the

range of -0.02 to + 0.02 Amps can b e s et. The c hannel output mode can be

programmatically set, or, can be forced to either voltage or current by

mechanical jumpers on the terminal module.

Chapter 1 Module Setup and Insta ll ation 13

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 15

Each output channel is individually configurable to be either an isolated

output or a non-isolated output. Cha nne l configuration to is olated or

non-isolat ed is made by individual plu g- on modules for each channel.

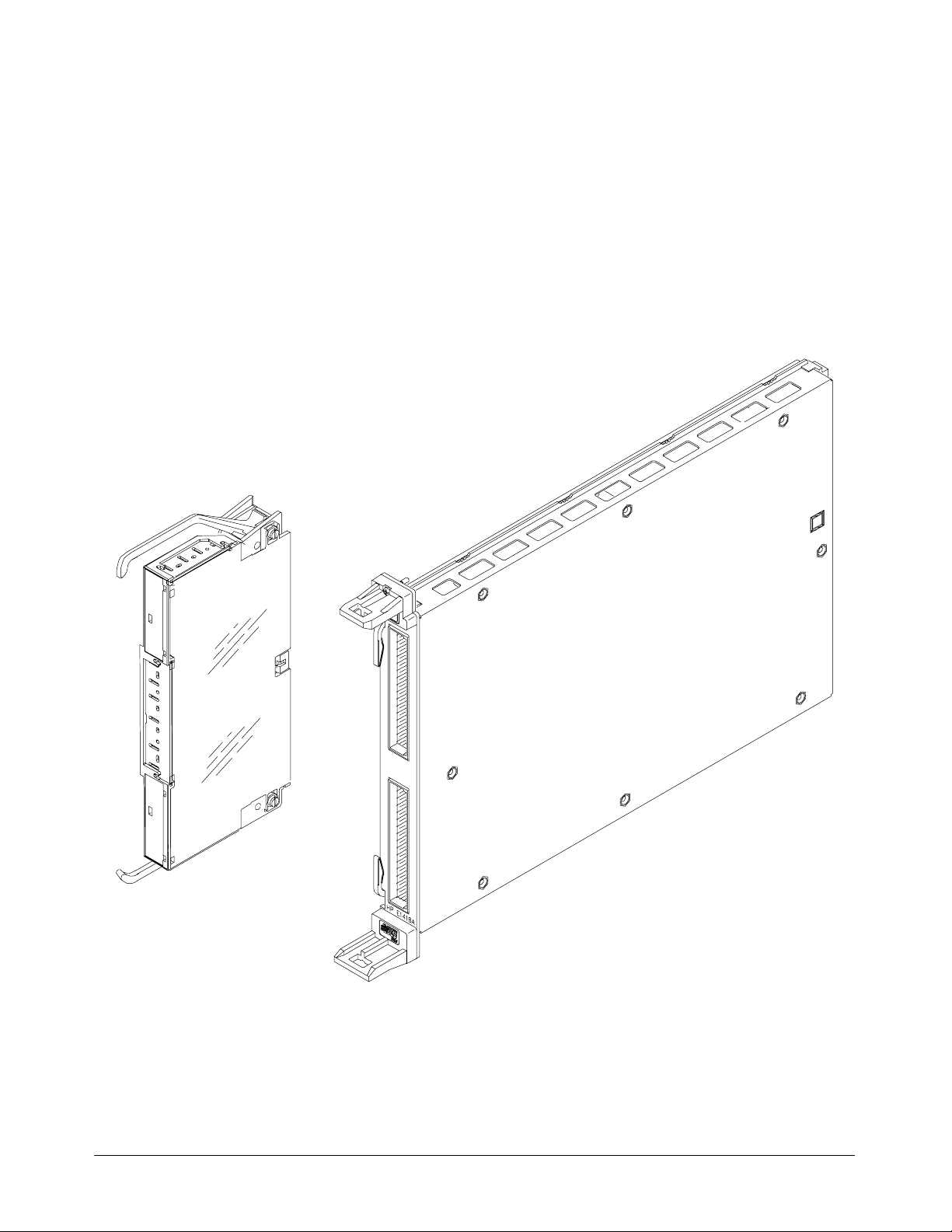

Figure 1-1 shows the module.

Figure 1-1. T h e HP E1418A 8/16-Channel D/A Converter

with Terminal Module

14 Module Setup and Instal lation Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

Ordering Opti ons The HP E1418A may be ordered from Hewlett-Pa c kard in a va r iety of

configurations. As ordered, the module has t he following options:

Description

HP E1418A 8-Channel D/A Converter with Non-Isolated Outpu ts

HP E1418A Option 001 16-Channel D/A Converter with Non-Isolated Outp uts

HP E1418A Option 002 8-Channel D/A Converter with Isolated Outpu ts

HP E1418A Option 003 16-Channel D/A Converter with Isolated Output s

Field Kits The module can also be us er configured as described beginning on page 166

of this manual. The following field expansion and configuration kits are

available:

Description Use

HP E1523A Single Channel Isolated

plug-on modul e

HP E1524A Expansion kit, 8-Channel

Non-Isolated Out put s

HP E1525A Expansion kit, 8-Channel

Isolated Out pu t s

To change a single channel from

non-isolated to isolated ou tput.

To add 8 additional non-isolated

channels to an existing 8- cha n nel

module .

To add 8 addit io nal isol at e d cha n n els to

an existing 8-cha n n el modul e.

Terminal Modules The standard HP E1418A Terminal Module provides screw terminals for

connections. Two other terminal options are available with the HP E1418A:

– Crimp an d Ins er t ( O ptio n A3E )

– Ribbon Cable (Option A3H)

– Terminal Module Housing wit hout a terminal module PC board or

connectors included (Option 135)

Chapter 1 Module Setup and Insta ll ation 15

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 17

Functional Description

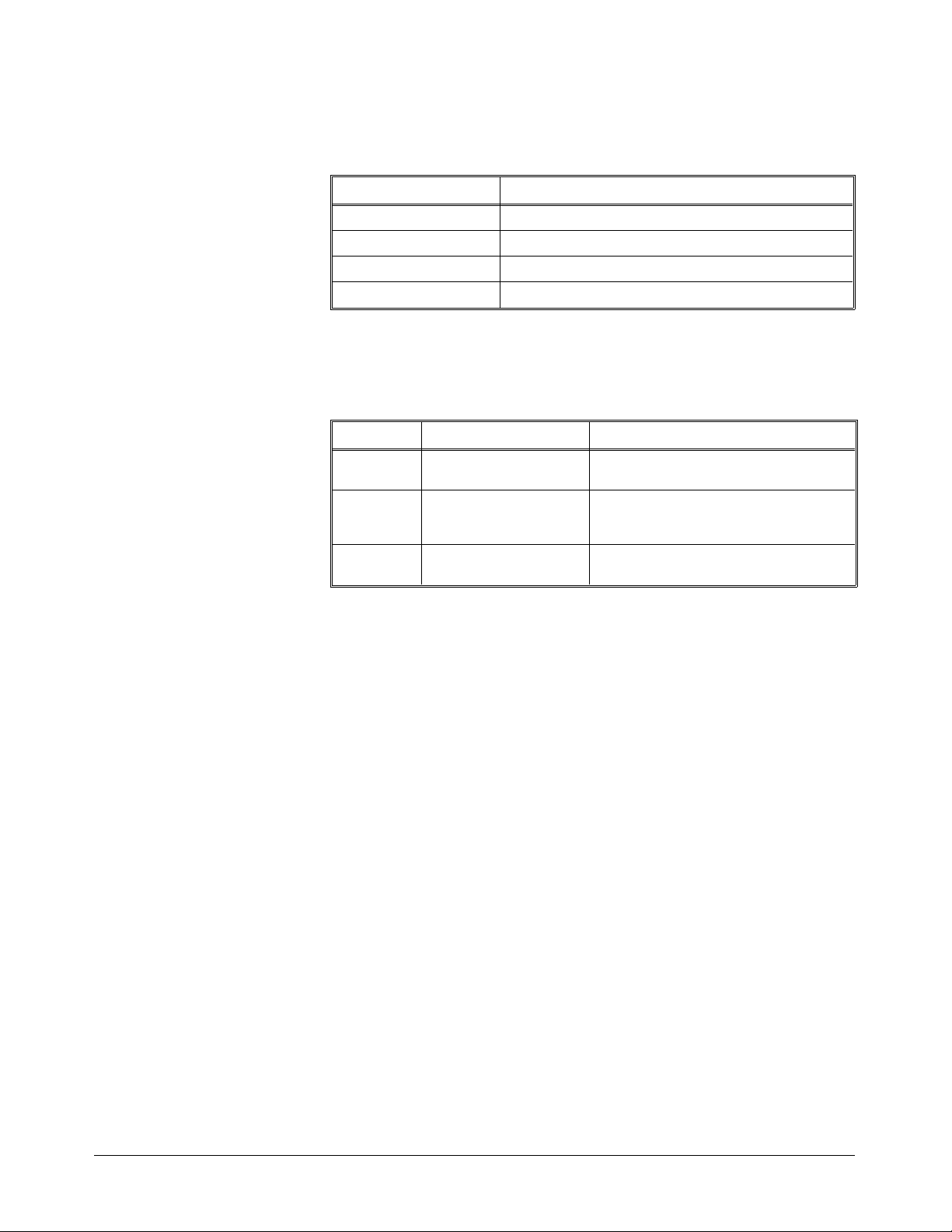

The HP E1418A provides great flexibility in configuration. This functional

description will help you become famil iar with the various configurations

and how th e module is structured. A functio nal bloc k diagra m is shown in

Figure 1-2.

Figure 1-2. A Function al Blo ck Diag ra m

Each channel MUST have either an isolated or non-isolated plug-on module installed. Channels may be configured

*

using any combination of Isola ted and Non -Isol ated plug-on modules.

16 Module Setup and Instal lation Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

As shown, there are four major assemblies that m a k e up an HP E1418A:

– Channels 1 through 8 main board and VXIbus backplane circuitry.

– Channels 9 through 16 expansion board.

– Isolated or Non- isola ted plug-on modules.

– Terminal Module.

Cha nnels 1–8 m ain board and VXIbus backplane circuitry.

This assembly contains all the VXIbus interface and decoding circuitry.

Isolated and Non-Isolated plug-on modules f or channels 1–8 connect to this

assembly. The panel connectors for the terminal module are also mounte d

on this assemb ly.

The optional C hannels 9–16 expansion board is electrically connected and

mechanically mounted to the main board. I s olated and Non-Isolated

plug-on modules for channels 9–16 connect to this assembly.

Isolated or Non-isolated plug-on modules are required for every channel.

Eight plug-on modules mount to the main board and 8 plug-on modules

mount to the expansion board. Any c omb inati on of is olated or non-isolated

plug-on modules may be used, but every channel must ha ve a plug-on

module ins ta lle d.

The Terminal Module shown i n Figure 1-2 is the standard screw-type

terminal module. This module provides screw connections for each channel

output, the calibration connections, and the external trigger in connections.

This module also contains two jumpers for each channel; one, called the P/J

Jumper, to enable or disable VXIbu s programming of the channel mode

(either voltage or current) and one, called the V/I Jumper, to set the channel

mode when the P/J Jumper is in the Jumper position.

Chapter 1 Module Setup and Insta ll ation 17

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 19

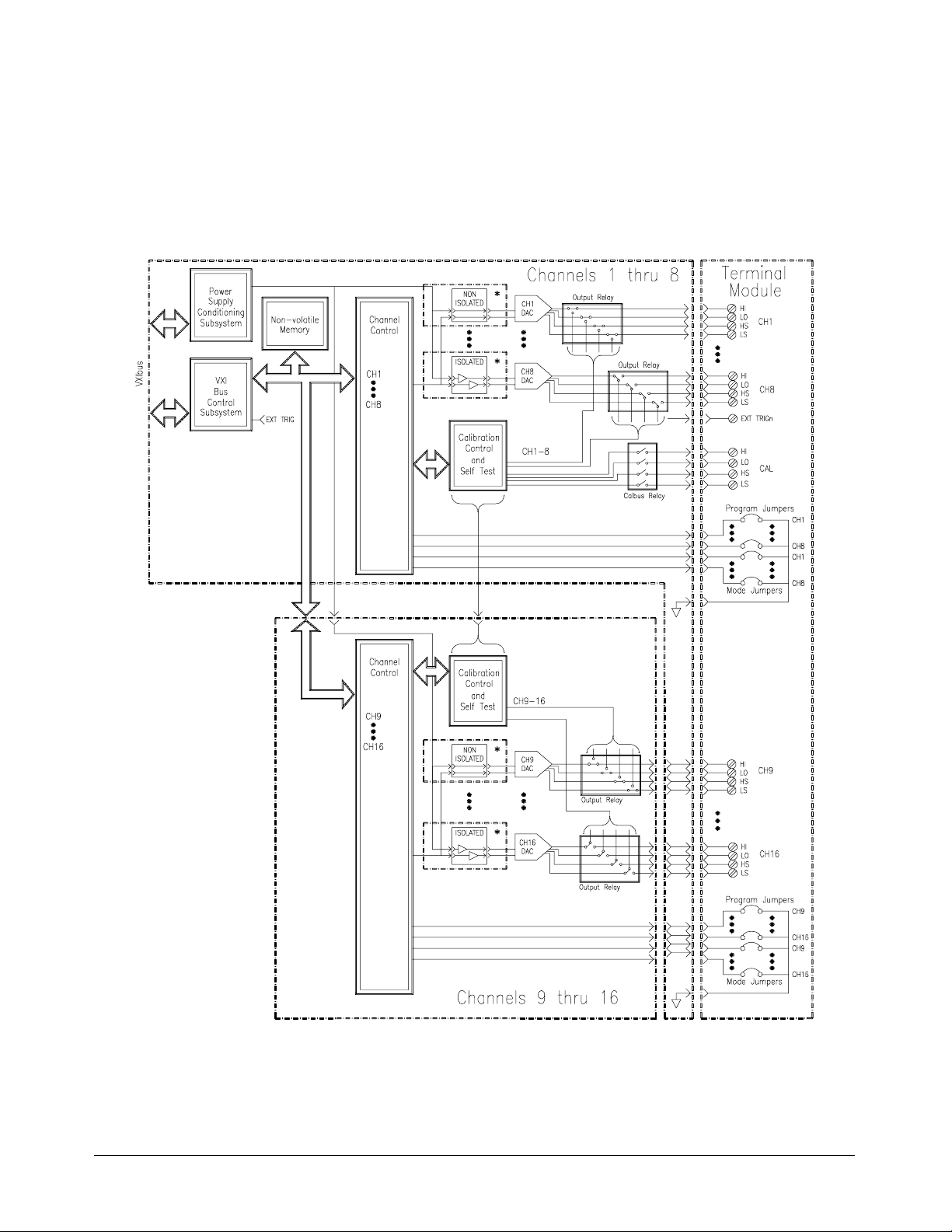

Front Panel Connectors

Figure 1-3 shows the connections at the front panel connectors of the main

module.

Figure 1-3. HP E1418A Front Panel Connector Pinout

18 Module Setup and Instal lation Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

Setting the Logical Address Switch

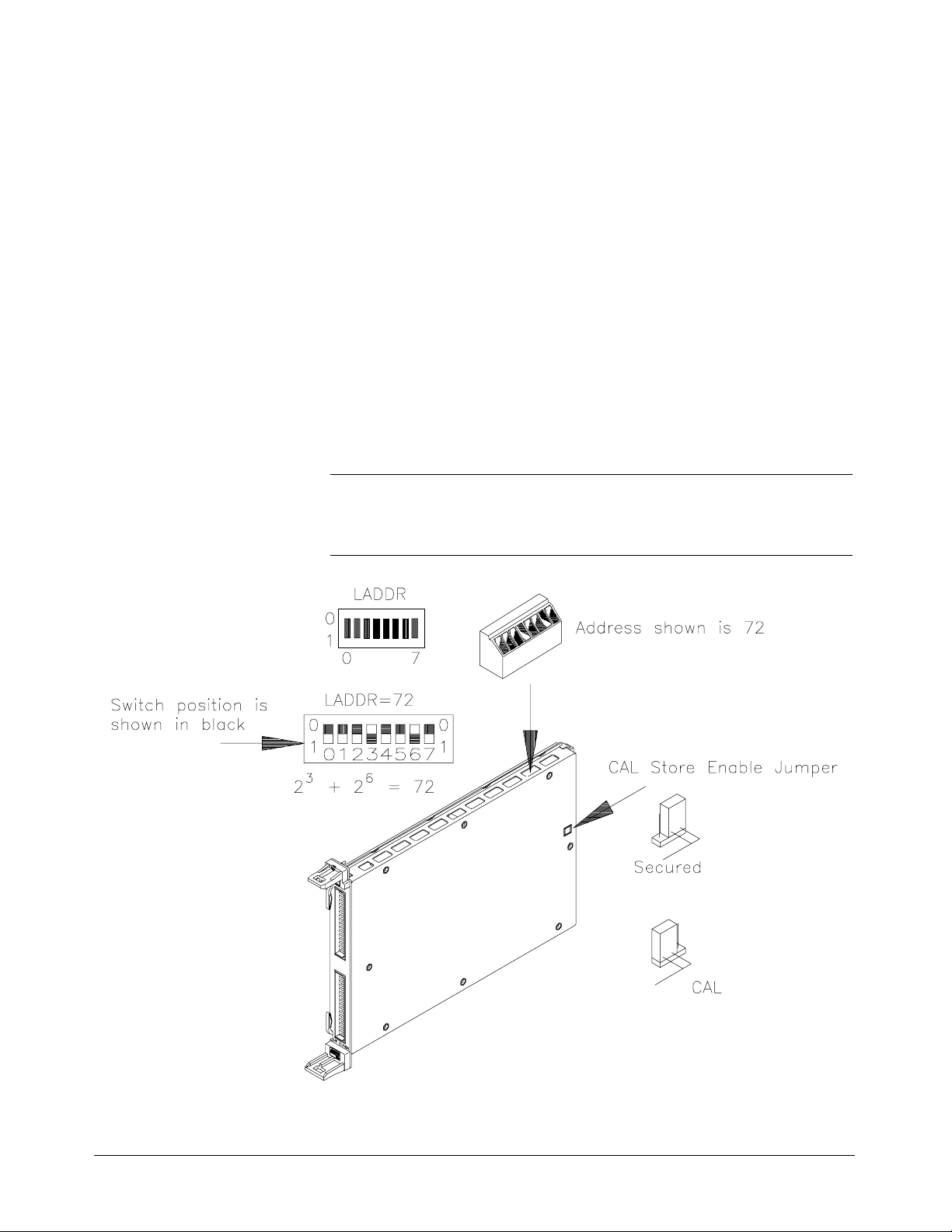

Figure 1-4 shows the logical address switch location and setting. The logical

address switch factory setting is 72. Valid addresses range from 1 to 255.

When used with an HP Command Module the fac t ory set address of

decimal 72 results in a module address of 9 (72 divided by 8). The module

address is used as a secondary address when using HP-IB and a Command

Module. For ex ample, the module address may be 7 09 09, wher e 7 is the

HP-IB interfac e address, 09 is the command module addr ess, and 09 is the

HP E1418A addre ss.

The HP E1418A supports dynamic address configuratio n. When you set the

logical address to 255, the res o ur ce manager s ets the logical address

programmatically.

Note When using an HP C-size mainframe with the HP E1405/E1406 Command

Modules, the logical address setting must be a multipl e of 8.

Figure 1-4. Setting the Logical Address

Chapter 1 Module Setup and Insta ll ation 19

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 21

Module Installation

To install t he module:

1. Verify the position of the CAL Store Enable Jumper for your

application. The Jumper, as shipped, is in the CAL position. In this

position, a calibration may be performed and the results stored in

non-volatil e memory. In the Secured positio n, a calibration may be

performed , but may NOT be stored in no n- volat ile memory. This

jumper is described in more detail on page 156.

2. Verify or set the logical address switch as shown in Figure 1-4.

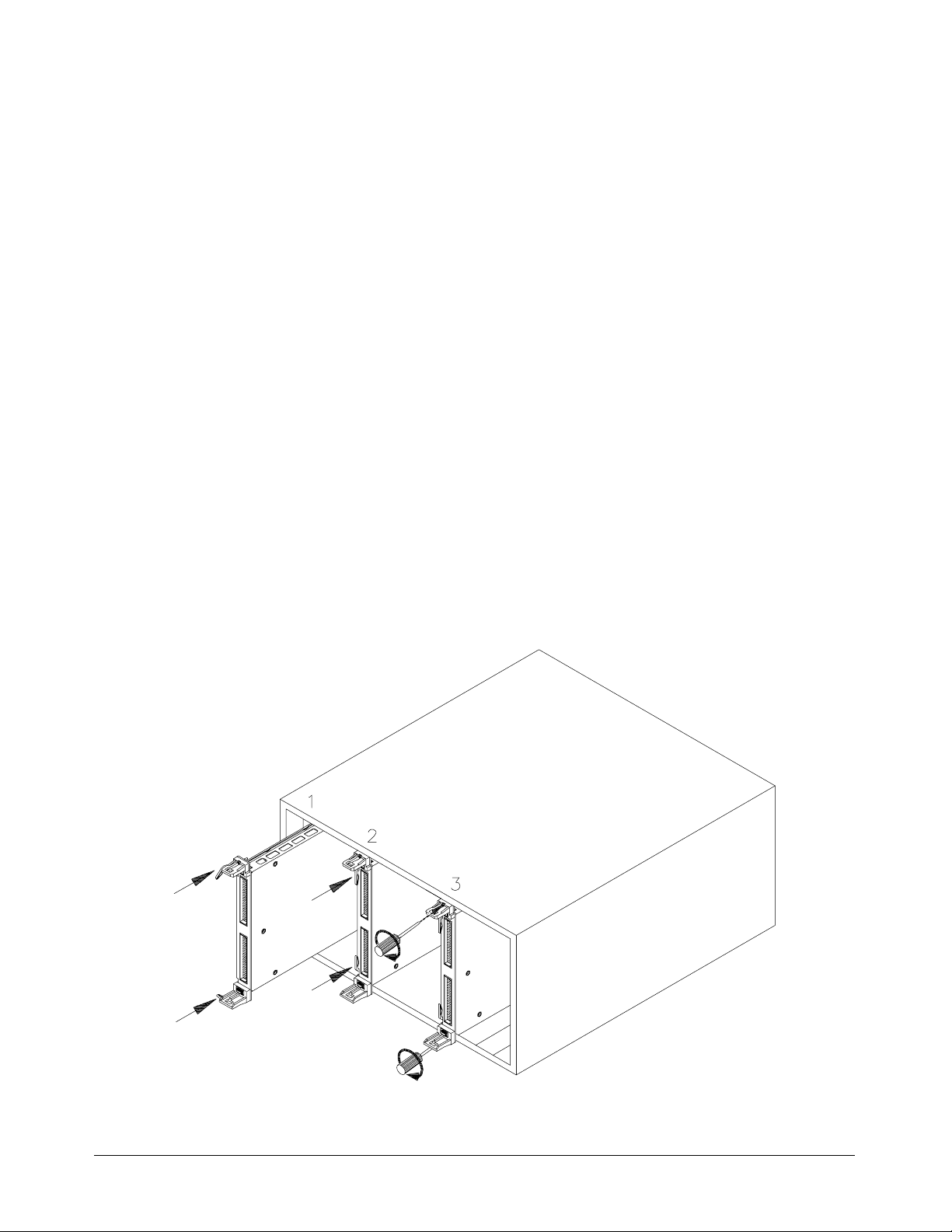

3. Install the module in a mainframe as shown in Figure 1-5.

Installation in a

Mainframe

The HP E1418A may be installed in any slot (except slot 0) in a C-size

VXIbus mainframe. To install in a mainframe:

1. Set the extraction levers out. Slide t he module into an y s lot ( ex cept

slot 0) until the backplane connectors touch.

2. Seat the mo dule by moving the levers toward each other.

3. Tighten the top and bottom screws to secure the modu le in the

mainframe.

Figure 1-5. Installing the HP E1418A in a VXIbus Mainframe

20 Module Setup and Instal lation Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

To Remove a Module: To remove a module from a mainframe:

1. Remove any terminal modules.

2. Loosen the top and bottom screws securing the module in the

mainframe.

3. Move the extraction levers away from each other. As the levers are

moved, the module will detach from t he ba ck plane connectors.

4. Slide the module out.

Note The extraction levers will not seat and unseat the backplane connectors on

older HP VXIbus mainframes and n on-HP ma inframes . You must

manually seat the connectors by pushing the module into the mainframe

until the front panel is flush with the front of the mainframe. The extraction

levers may be used to guide or remove the module.

Chapter 1 Module Setup and Insta ll ation 21

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 23

Terminal Modules

Four terminal modules are available for the HP E1418A; a screw- type, a

crimp-and-insert type, a ribbon cable type, and an empty terminal housing

(without a PC board or connectors).

Screw-Type

Terminal Module

(Standard)

The standard terminal module uses screw-type terminals to make

connectio ns. Figure 1-6 may be photocop ied a nd used for wiring layout .

Figure 1-6. Screw-Type Termin al Modu le Layou t

22 Module Setup and Instal lation Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

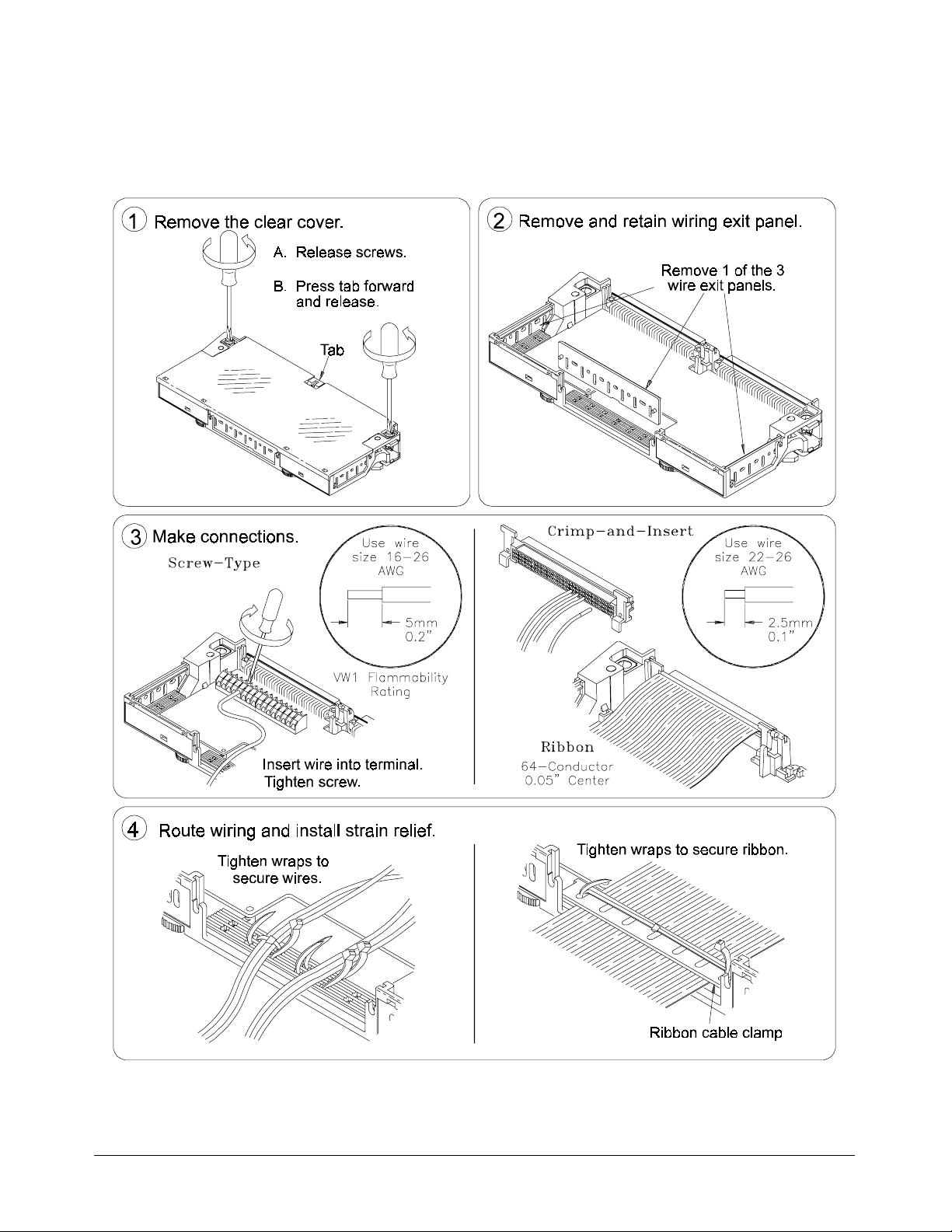

Wiring the Terminal Module

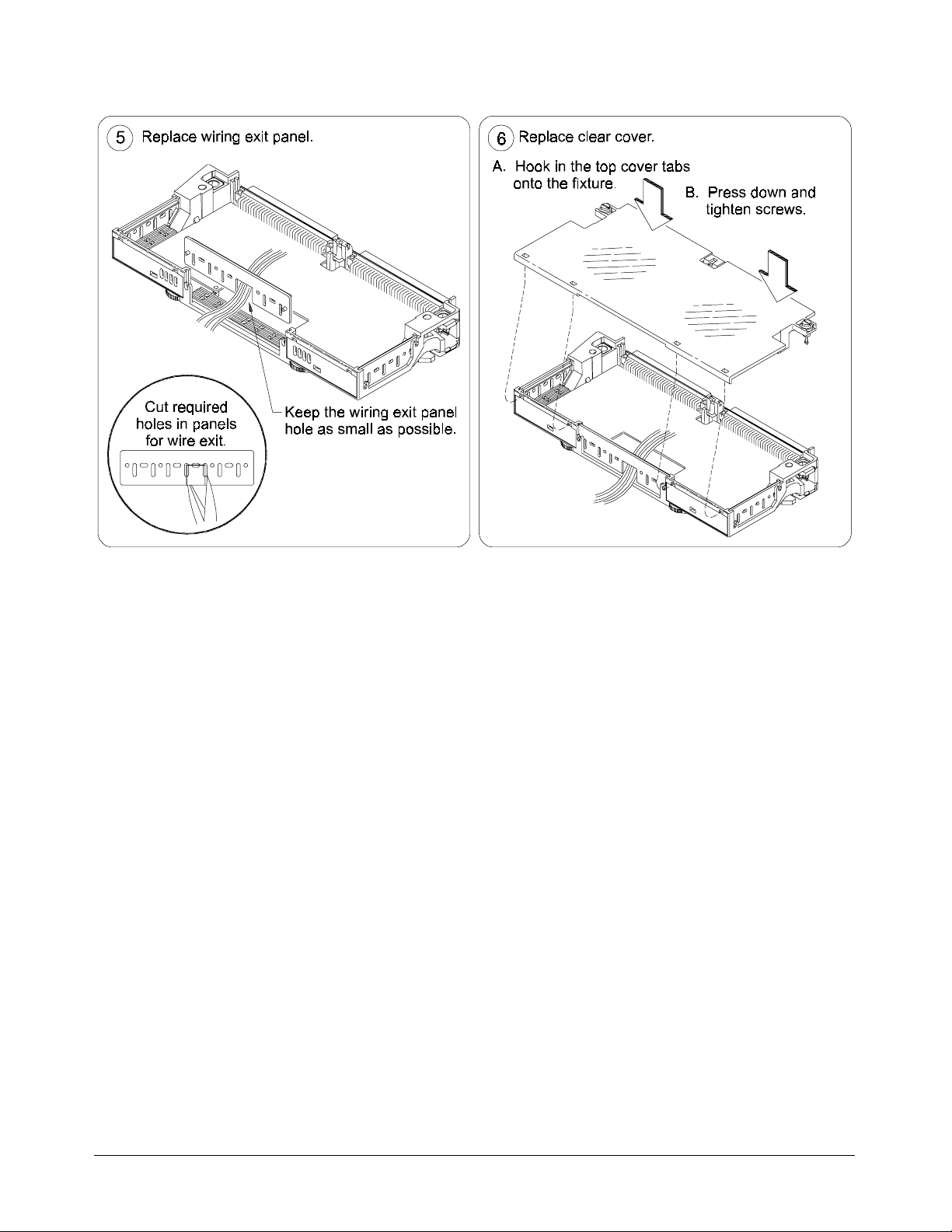

Figure 1-7 shows how to open and wire the HP E1418A terminal module.

Figure 1-7. Wiring the HP E1418A Terminal Module

(

continued on next page)

Chapter 1 Module Setup and Insta ll ation 23

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 25

Figure 1-7. Wiring the HP E1418A Terminal Module

(

continued from previous page)

24 Module Setup and Instal lation Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

Attaching the Terminal Module

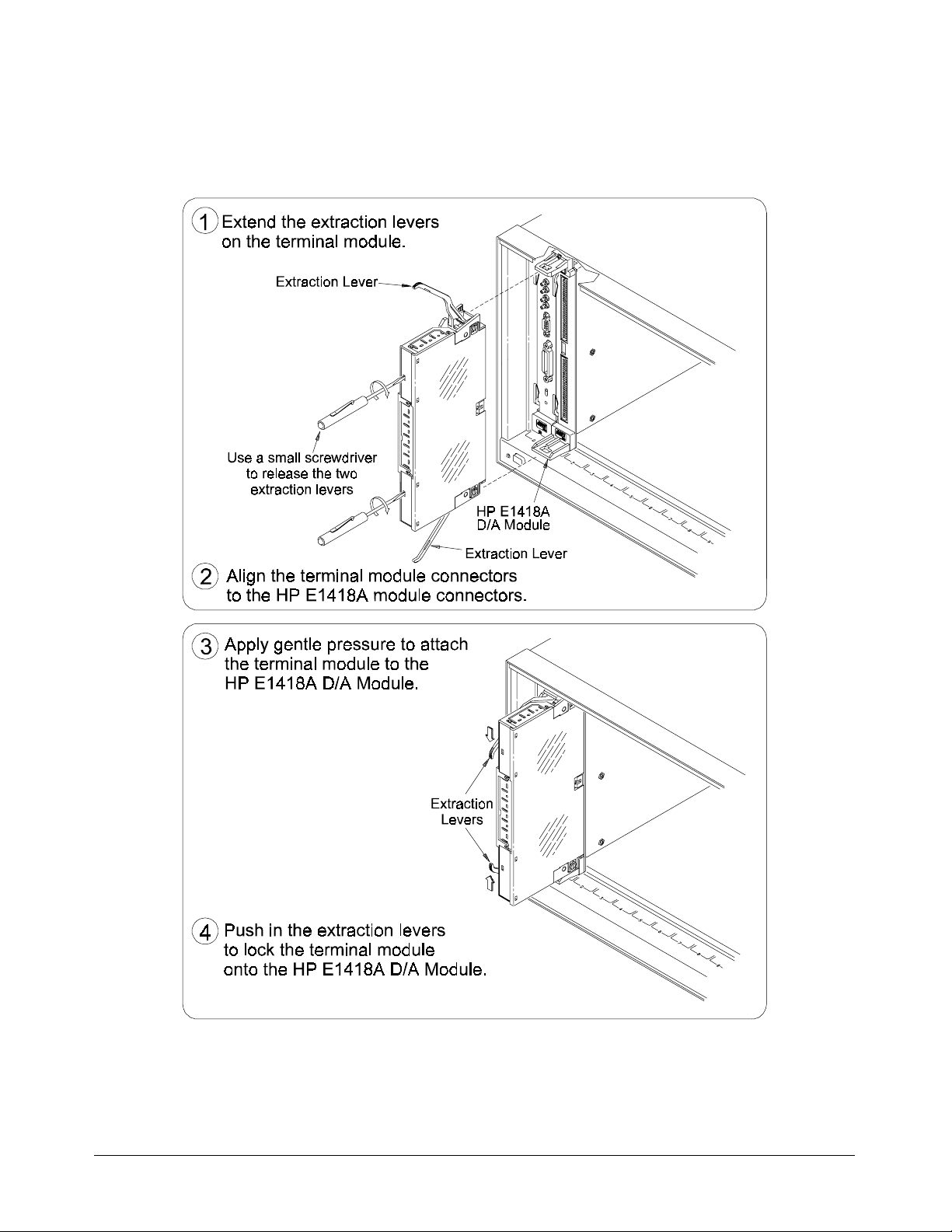

Figure 1-8 shows how to attach the HP E1418A terminal module.

Figure 1-8. Attaching the HP E1418A Terminal Module

Chapter 1 Module Setup and Insta ll ation 25

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 27

Removing the Terminal Module

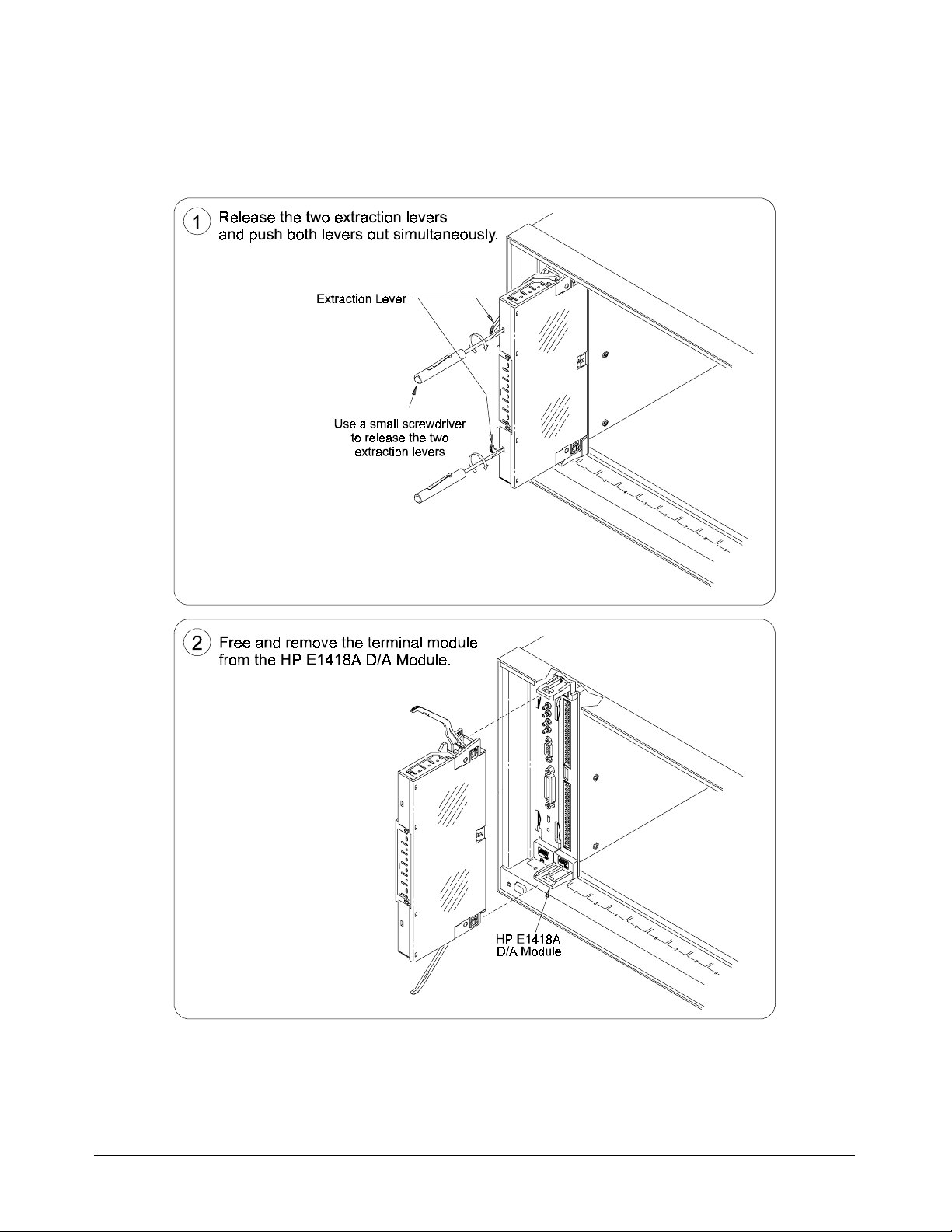

Figure 1-9 shows ho w to remove the HP E1418A terminal module.

Figure 1-9. Removing the HP E1418A Termi nal Module

26 Module Setup and Instal lation Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

Terminal Module Options

Besides the standard screw-type terminal module, the HP E1418A can be

ordered with the following two optio ns. One option (A3E) provides

crimp-and-insert connectors and terminal housing. The other option (A3H)

provides a ribbon cable con nector and termina l hous ing.

Option A3E HP E1418A Option A3E can be ordered if a crimp-an d -insert terminal

module is desired. This allows you to crimp connectors onto wires which

are then inserted directly into the HP E1418A faceplate connector. Ref er to

the pin-out diagram on page 30 to make the connections. The

crimp-and-insert connector is shown in Figure 1-10.

Note The pin numbering on th e crimp-and-insert conn ector may not agree with the

pin nu mberi ng on the HP E1418’s fa ceplate connector. Use the pin

numbering on the faceplate connector to wire the crimp-and-insert connector.

Figure 1-10. Option A3E Crimp- and-I nsert Con necto r

Chapter 1 Module Setup and Insta ll ation 27

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

Crimp-and-Insert

Terminal Module

Accessories

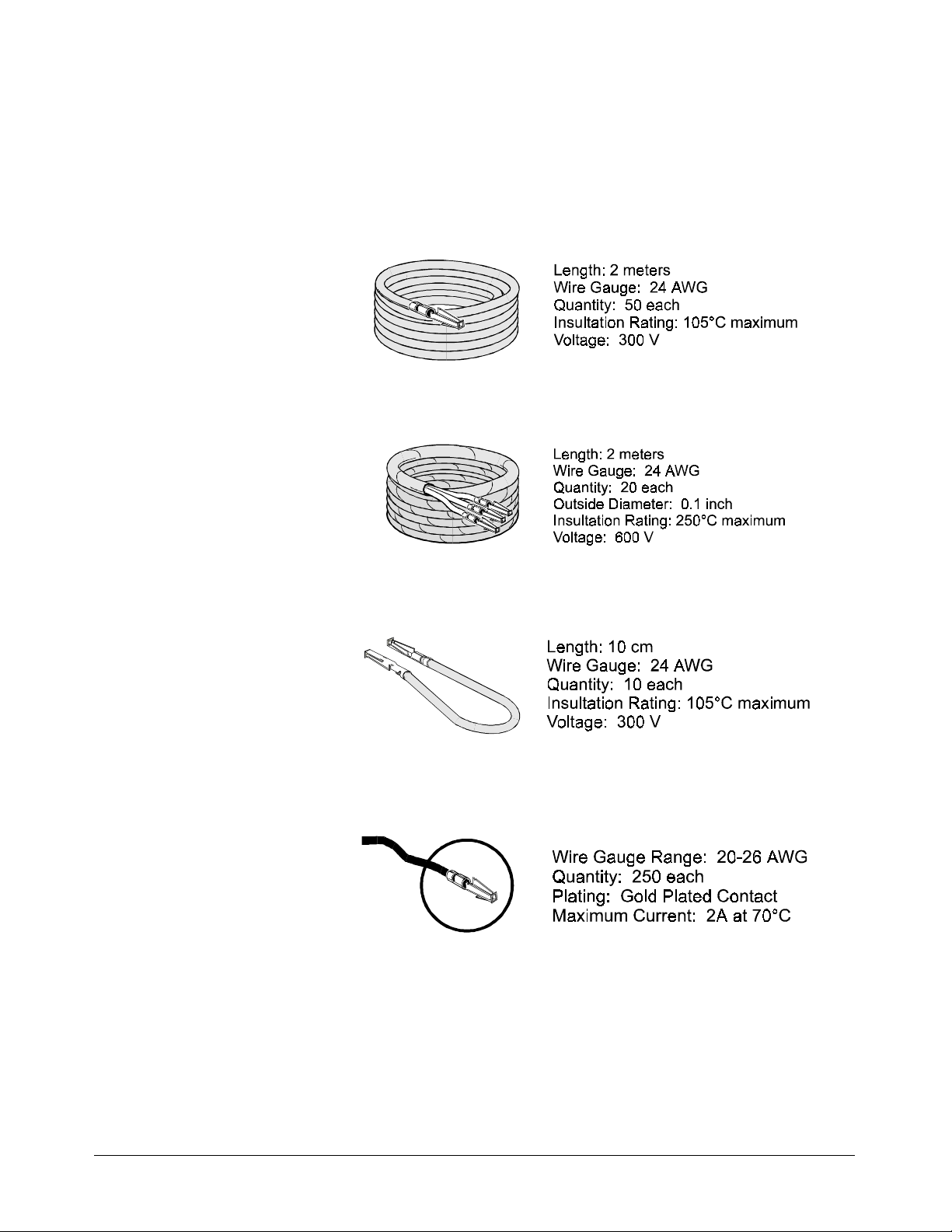

The following accessories are necessary f or use with crimp-and-insert

Option A3E:

Single-Conductor and

Contact

Shielded-Twisted-Pair and

Contacts

A crimp-and-insert contact is crimped onto o ne end of a wire. The other

end is not t erminated. Order HP 91510A.

A crimp-and-insert contact is cr im ped onto each conductor at one e nd of a

shi elded- t wist ed -pair cable. The other end is not terminated. Order

HP 91511A.

Jumper Wire and Contacts A crimp-and-insert contact is crimped onto each end of a single-conductor

ju mper wire. This jump er is typica l ly used to tie t wo p i n s togethe r in a

single crimp-and-insert connector. Order HP 91512A.

Crimp-and-Insert Co ntacts These co ntacts ma y be crimped onto a conductor and then ins erted into a

crimp-and-insert connector. The crimp too l kit is required to crimp the

contacts ont o a conductor and remove the contact from the connector.

Order HP 91515A.

Crimp-and-Insert Tools The hand crimp tool (part number HP 91518A) is used for crimping

contacts ont o a conductor. The pin extractor to ol (pa rt number HP 91519A)

is required f or removing contacts from the crimp-a nd-insert connector.

These products are not included with Option A3E or with the terminal

option accessories listed earlier.

28 Module Setup and Instal lation Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

Extra Crimp-and-Insert

Connectors

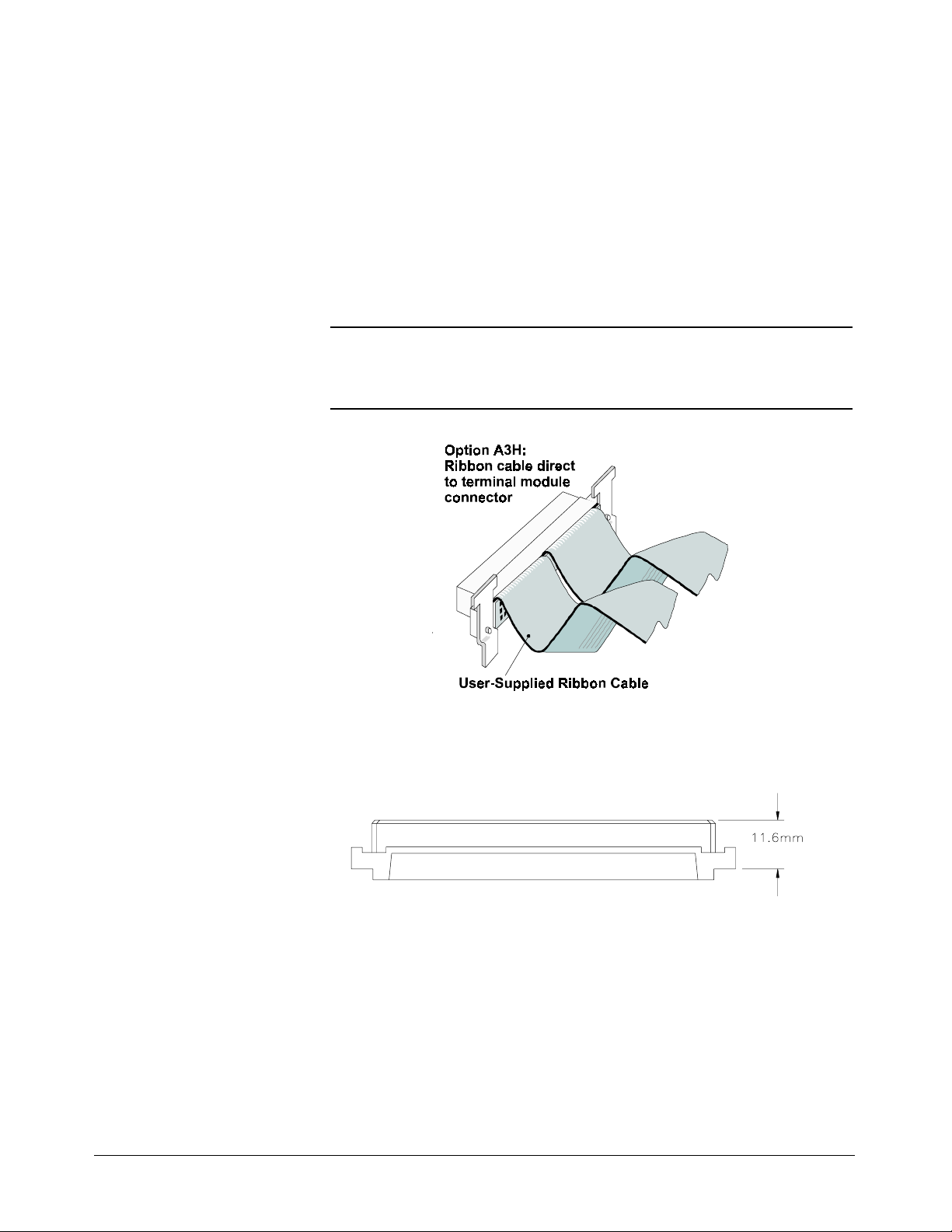

Option A3H The Ribb on Cable Connector Terminal Option provides a terminal housing

Note In Figure 1-12, t he center row of each connector is not u s ed in t he ribbon

The crimp-and-insert connector is normally supplied with Option A3E.

Contact H ewl ett-Pa c kard if addit ional connectors are need ed.

Order HP 91484B.

and ribbon cabl e connectors. The connectors ar e designed to be used with

64-pin 0.05 inch center ribbon cables (not provided). Us e Figure 1-12 to

make the connections.

cable. The center row of both connectors is module ground (GND).

Figure 1-11. Option A3H Ribbon Cable Con nect or

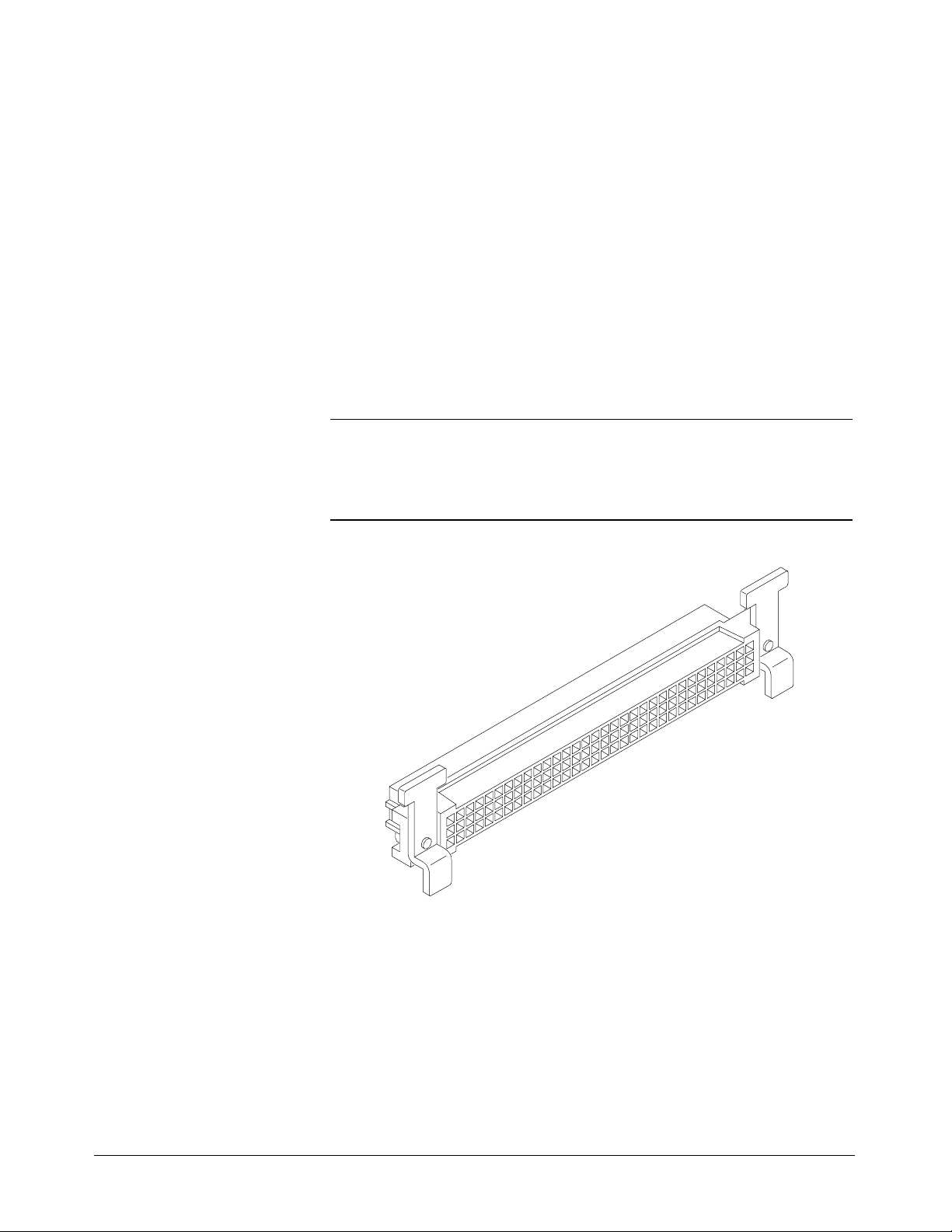

Option 135 The Terminal Module H ousing Option provides a termina l housing with no

connectors of any type.

The user-supplied connector must be a DIN 41612 type C female,

11.6 mm dime ns ion as shown above.

Chapter 1 Module Setup and Insta ll ation 29

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 31

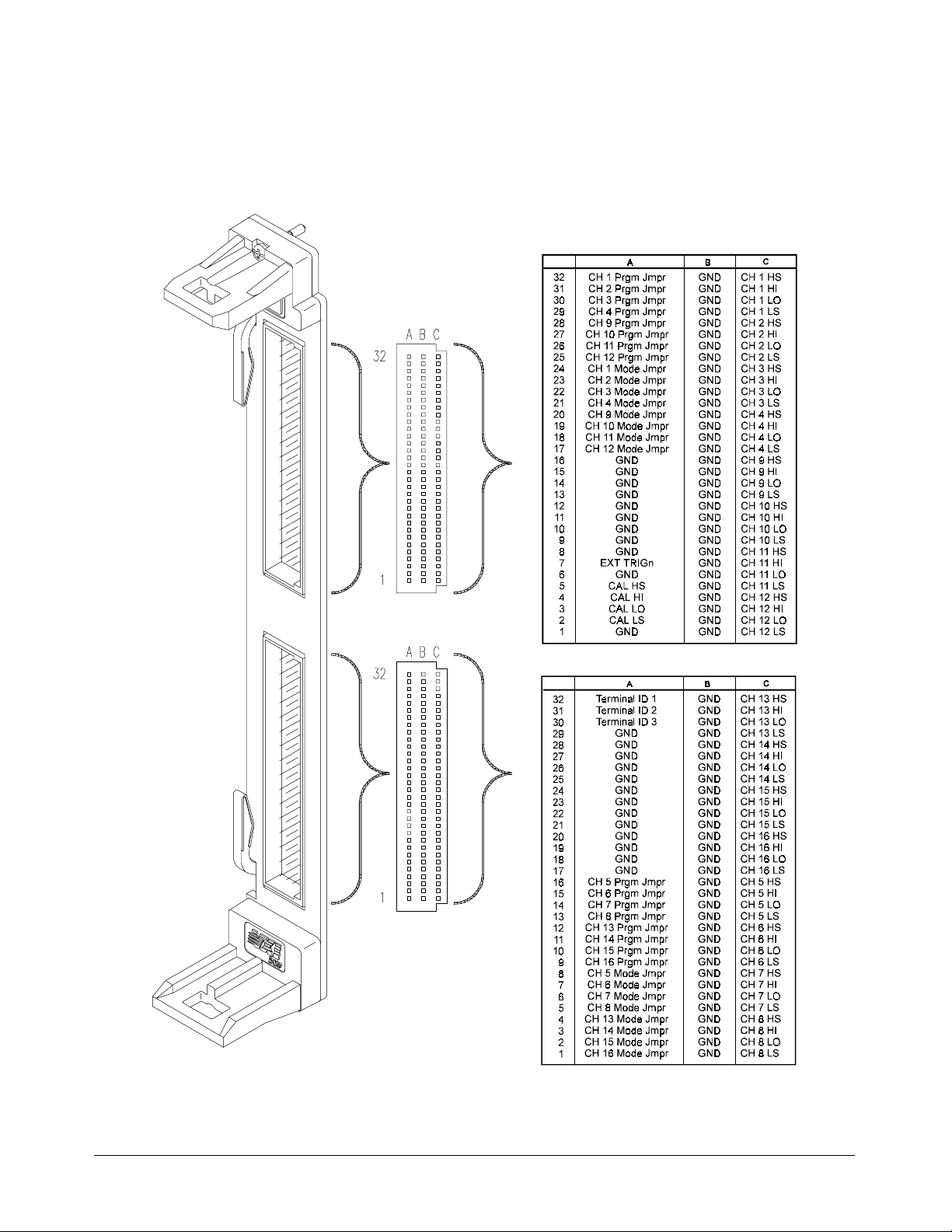

Terminal Module Connectors

Figure 1-12 s hows the connections at the terminal module connectors.

Figure 1-12. HP E1418A Terminal Module Connector Pinout

30 Module Setup and Instal lation Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

Configuring the Terminal Module

The screw-type terminal mod u le contains jumpers that control how the

HP E1418A operates. The jumpers are shipped in a separate bag with the

terminal module. The HP E1418A will operate without any jumpers

installed. You can, however, store the jumpers on the terminal module for

later reconfiguration. Figure 1-13 shows the jumper locations and example

settings.

There are two j u mpers for each channel; a P/J jumper and a V/I jumper.

The two j umpers work together.

Figure 1-13. P/J and V/I Jumpers

P/J Jumper The P/J jumper s ets the channel output mode to b e either Progra m

Selectable or Jumper Sel ectable. When the jumper is in the program

selectable position, the channel output mode can be s et via progra m ming

commands. In the jumper selectable position, the channel output mode is

set via the V/I jumper.

V/I Jumper The V/I jumper sets the channel output mode to either voltage or cur r ent

when the P/J jumper is set to the Jumper Sel ectable position. When the P/J

ju mper is set t o Pr o g r am Selectab l e , this j umper has no effect.

Notes With no jumpers installed, the module will be in the Program S electa b le

output mo de.

When the P/J Jumper is set to the Jumper Selectab le position, the output

mode cannot be changed with SCPI co mman ds. The output mode follo wing

*RST common command will be the mode s et by t he V/I jumper.

a

Chapter 1 Module Setup and Insta ll ation 31

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 33

Options A3E and A3H

Terminals

The P/J jumper connectio n for each channel is named CH X PRGM JMPR

in the conn ection diagram on page 30. W ith no connection to this pin, the

module will operate in the Program Selectable mode. Shorting this pin to

GND will set the Jumper Selectable mode for channel X.

When CH X PRGM JMPR is short ed to GND, th e CH X MODE JMPR pin

(corresponding to the V/I Jumper) sets the output mode f or channel X. If

the pin is op en, volt age output mode is s elec ted. If the pin is shorted to

GND, current output m ode is selec t ed for channel X.

32 Module Setup and Instal lation Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 34

Terminal Module Connections

Each channel has four output l ines; HI, LO, HS (Hi Sense), and LS (Low

Sense). Wh en using a c hannel in the voltage output mo de, you can use t he

sense lines to increase accuracy or to compensate f or long lead lengths. The

sense leads ar e not used in the current output mode.

Voltage and

Current Output

Connections

Note The sense leads are internally disconnected for current output. External

Figure 1-14 shows connections for three types of output. Channel 1 is

connected in t he 2-wire voltage output mode, the sense leads are not used

(and the sense connections need not be made). Channel 2 is connected in

the 4-wire v oltage output mode. Us e this connection for the hig hest volta ge

accuracy and to compensat e for long lead lengths. Channel 3 is connected

for current output m ode (sen s e is not used for current output).

wiring may be left connected to th e sense outputs on the terminal module

with no effect.

Figure 1-14. Typical Output Connecti o ns

Options A3E and A3H

HI, HS, LO, a nd LS connections are shown on the diagram on pa ge 30.

Terminals

Chapter 1 Module Setup and Insta ll ation 33

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 35

Combining

Channels

You can combine channels in s eries t o obt a in higher output vo ltage s or in

parallel to obtain higher output cur r ents.

Channels in Series • All channels conn ected in series MUS T be configured as isolated

channels ( with isolated plug-on modules installed).

• Up to 3 c hannels may be c ombined, but the output volta g e MUST

NOT exceed 42 Vdc/42 Vpeak.

Channels in Parallel • Channels may be either Isolated or Non-Isolated.

• Up to 16 channels may be combined.

Figure 1-15 s hows h ow to c ombine volt age channels (in series) and current

channels (in para llel).

CAUTIONS All SERIES CONNECTED o utp ut channels MUST be configure d as

ISOLATED O U T PUTS.

When combin i ng output v olt ag e chan nels, be s ure not to exc e ed the

maximum module isolation rating of 42 Vdc or 42 Vpeak.

Figure 1-15. Combined Chann els Outpu t Connecti ons

34 Module Setup and Instal lation Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 36

Connecting an

External Trigger

Source

An external trigger input is provided on the terminal module. Use the

external trigger to externally synchronize multiple outputs or multiple

instruments. The External Trigger us es TTL levels. The trigger occurs

when the EXT TRIGn connection is pulled low for at least 1 µS. T ypical

connections to th e external trigger is shown in Figure 1-16.

Options A3E and A3H

Terminals

Figure 1-16. External Trigger Con necti ons

The external tri gger l ine is loca ted on the upper conn ector and is lab eled

EXT TRIGn in the diagram on page 30.

Chapter 1 Module Setup and Insta ll ation 35

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 37

Usi ng the CAL

Output Terminals

The CAL Output Terminals provide one set of connections that can be used

to calibrate the output on all 16 channels. Calibration and adjustment

procedures are described in Appendix D beginning on pa g e 154.

The CAL out put terminals ar e ava ila ble on the terminal module. There ar e

four lines; HI, LO, HS (Hi Sense), an d LS (Low Sense). Typical CAL

output t erminal connections are shown in Figure 1-17.

Options A3E and A3H

Terminals

Figure 1-17. Calbus Connect ions

The CAL Output Terminals are located on the upper connector and are labeled

CAL HI, CAL HS, CAL LO, and CAL LS in the diagram on page 30.

36 Module Setup and Instal lation Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 38

Initial Operation

Note This discussion applies to SCPI programming using the driv er provided

Device Driver The HP E1418A module is shipped a driver CD. This CD contains the SCPI

This section provides a programming example to help verify correct module

installation and operation. Additional programming exa mpl es and procedures

are given in the next chapter.

The examples shown here use HP BASIC and SCPI (Standard Commands for

Programmable Instruments). The example assumes a f ac tory set logical

address of 72 for the HP E1418A module and uses an HP Command Modul e

for co mmand interpretation. Examples in A NSI C are given in the next chapter.

with the module. The SCPI commands are described in Chapter 3 of this

manual. Appendix B of this manual describes direct register access.

instrument driver, VXIplug&play drivers, example programs, and HP VIC

(VXI Installation Consultant). Follow the instructions contai ned on the CD to

properly install the device driver.

The following example shows how to query the command module and

verify that the correct device driver is installed:

10 DIM A$[256]

20 OUTPUT 70900;"DIAG:DRIV:LIST?"

30 ENTER 70900;A$

40 PRINT A$

50 END

In this exam ple, the co mmand modu le is loca ted on H P- IB ( inter face a ddr es s 7)

and uses a primary address of 09. Responses to this example vary depending

upon the drivers loaded on your system. A typical response might look like:

E1418,E1418,A.01.00,RAM;SWITCH,SWITCHBOX,A.08.00,RAM;

SYSTEM,E1405A,A.08.00,ROM;IBASIC,IBASIC,A.04.02,ROM;

VOLTMTR,E1326A,A.05.00,ROM;SWITCH,SWITCHBOX,A.07.00,

ROM;COUNTER,E1332A,A.04.02,ROM;COUNTER,E1333A,A.04.02,

ROM;DIG_I/O,E1330A,A.04.03,ROM;D/A,E1328A,A.04.02,ROM

Verify that the string “E1418,E1418,A.01.00,” is loca ted somewhere

within the returned string.

Chapter 1 Module Setup and Insta ll ation 37

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 39

Module

Identification

This example can be used to verify that the logical addr e ss ha s been

correctly set, that the module is corr e c t ly installe d, and that the module is

communicat ing with the command module . The terminal module do es not

need to be instal led for t h is example to work. This example qu eries t he

module for the identific ation st ring.

10 DIM A$[256]

20 OUTPUT 70909;"*IDN?"

30 ENTER 70909;A$

40 PRINT A$

50 END

The response should be similar to one of the fo llowing:

HEWLETT-PACKARD,E1418A_8CH,xxxxAxxxx,A.01.00

or

HEWLETT-PACKARD,E1418A_16CH,xxxxAxxxx,A.01.00

The xxxxAxxxx port ion of the response string is the module serial number.

38 Module Setup and Instal lation Chapter 1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 40

Using This Chapter

This chapter provides examples and descriptions of the mo st c ommon

operations using the HP E1418A. Use this chapter to gain an overview of how

to program the module, and to obtain programming hints. The examples

shown in this chapter are in ANSI C and use SCPI commands to control the

module. The SCPI commands are described in detail in Chapter 3 of this

manual. SCPI usag e conventions and synta x r ules are described beginning on

page 60.

This chapter is divided into the following sections:

Chapter 2

Programming Examples

• Querying Module Identification and Configuration. . . . . . . . . Page 40

• APPLy Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pa ge 45

• Error Check ing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 47

• SOURce Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 50

• Setting the Output M ode . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 52

• Controlling th e Output R elay. . . . . . . . . . . . . . . . . . . . . . . . . Page 53

• Trig geri ng. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pa ge 54

• Using *OP C? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 56

• Combining Output Cha nne ls . . . . . . . . . . . . . . . . . . . . . . . . . Page 57

Program Examples Example programs in ANSI C format are included on the driver CD

supplied with the HP E1418A. Most examp les in this chapter are included.

The examples are ASCII files wit h the *.c extension.

Note The int data type is system dependent. Thes e exa mples were developed on

a system where int is a 16-bit integer. Other systems may define int to be a

different width.

In the examples, t he HP VI S A Trans ition L ib rary is used for I/O operations

with the VXIbus. An HP command module (HP E1405/ E1406) is used and

controlled via HP-IB.

To use the HP VISA Transition Library (ab br eviated as VTL), include th e

visa.h header fil e.

#include visa.h

Chapter 2 Programming Examples 39

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 41

Hewlett-Packard V T L function calls and data types typically begin with the

lower cas e let ters vi. Output and enter are performed with functions na med

viPrintf and viScanf. Both these functions require a s ession (a VTL

defined I/O funct ion ) to uniquely identify the d evice being controlled. In

the examples, the session has b een name d dac.

Querying Module Identification and Configuration

This examp le will query the modu le for the identificati on string and

determine the module configuration.

The module identification is obtained using the IEEE-488 Command

!Send query to the module.

*IDN?

!Enter a string.

The string retur ne d should be similar to one of the f ollowing:

HEWLETT-PACKARD,E1418A_8CH,xxxxAxxxxx,A.01.00

or

HEWLETT-PACKARD,E1418A_16CH,xxxxAxxxxx,A.01.00

The xxxxAxxxxx portion of t he respon se string is the module seria l

number.

The module co nfiguration is obtained using the

query.

!Send query to the module.

DIAG:CONF?

DIAGnostic:CONFiguration ?

*IDN?.

!Enter six inte gers and decod e the integ ers.

40 Programming Examples Chapter 2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 42

The DIAG:CONF? query returns six integers. The six integers returned

contain the module configuration and have the following meaning.

Integer

Returned Meaning

1st Expansion Board ID in the form : 0 = present, 7 = none

(expansion board contains channels 9 through 16)

2nd Terminal Modul e ID in the form

0 = screw type, 7 = none or other

3rd Isolated/Non-isolated Channel status

A bit set to 0 indicates an isolated channel

A bit set to 1 indic ates a non-isolated channel or no plug-on

module installed (DO NOT operate the module without a plug-on

module)

Bits 0 – 15 correspond to channels 1 – 16, respectively*

4th Channel Mode

A bit set to 0 indi c ates a current out put channel

A bit set to 1 indic ates a voltage output channel

Bits 0 – 15 correspond to channels 1 – 16, respectively*

5th Channel Output State

A bit set to 0 indicates the channel output relay is closed

A bit set to 1 indicates the channel output relay is open

Bits 0 – 15 correspond to channels 1 – 16, respectively*

6th Channel Mode Programmable State (P/J Jumper)

A bit set to 0 indi c ates a channel is not mode programmabl e

A bit set to 1 indi c ates a channel is mode programmable

Bits 0 – 15 correspond to channels 1 – 16, respectively*

* For 8-channe l configurations, the upper 8 bits of integers 3, 4, 5, and 6 are set to 1’s.

For example, if the f ollo wing six integers ar e returned, the module has the

configurat i on indicated.

Decimal

Integer

1st 7 No expansion board installed

2nd 7 No Terminal Module installed or

3rd -1 All channels are non-isolated.

4th -1 All channels are voltage output channels.

5th -1 All channel outputs are disabled

6th -1 All channels are output mode

Value Configuration

(Only channels 1 through 8).

unknown terminal module installed.

(all output relays are open).

programmable.

Chapter 2 Programming Examples 41

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 43

Configuration

Example

The following program segment demo nstrat es how to rea d the module

identification string and the configurat ion. The configuration integers are

bit manipulated using the C operator for bit shifting result = result <<1

(a one bit shift to the left).

•

•

•

/** FUNCTION PROTOTYPE S **/

void main (void);

void err_handler(ViS ession vi, ViStat u s x); /* VTL error routine */

void sys_err(ViS e ssion re source); /* Checks for SCPI programming error s */

/** GLOBAL **/

ViStatus err;

ViSession defaultRM, cmd, dac;

•

•

•

void main (void)

{

int i,num_chan,result = {0},config [6]={0};

char buf[256] = { 0 };

/*** Check the module identification ***/

err=viPrintf(dac, “*IDN?\n”); /* request id from the module */

err=viScanf(dac, “%t”, &buf ) ; /* enter string returned */

printf (“Module is identified as a %s\n”, buf); /* print the result */

/*** Get the module conf i gurati on ***/

err=viPrintf(dac, “DIAG:CONF?\n”); /* request m odul e configurat ion */

err=viScanf (dac, “%,6d”, &config); /* ret urns six integers */

/* Decode the first integer */

result=conf ig[0] ; /* Expansion board */

if (result < 7)

{

printf (“Module is a 16 channel dev ic e\n”);

num_chan = 16;

}

else

{

printf (“Module is an 8 channel device\n”);

num_chan=8;

}

42 Programming Examples Chapter 2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 44

/* Decode the second integer */

result = config [1]; /* Term inal Modul e */

if (result > 0)

{

printf (“Module does NOT have a terminal module installed\n” );

}

else

{

printf (“Module has a screw-type terminal module installed\n”);

}

/* Decode the third integer */

result=conf ig[2] ; /* Isolated or non-isol ated output s */

if (num_chan < 9) result = re sult << 8; /* strip upper 8 bits */

for (i=num_chan;i>0;i – –)

{

if (result >= 0x8000)

{

printf (“Channel %d is configured for non-isolated output\n”,i);

}

else

{

printf(“Channel %d is configured for isol ated output\ n”,i);

}

result = result < < 1;

}

/* Decode the fourth integer */

result=conf ig[3] ; /* Output Mode Volt age or Current */

if (num_chan < 9) result = re sult << 8; /* strip upper 8 bits */

for (i=num_chan;i>0;i – –)

{

if (result >= 0x8000)

{

printf (“Channel %d is set to v ol tage out put mode\n”,i);

}

else

{

printf(“Channel %d is set to current output mode\n”,i);

}

result = result < < 1;

}

Chapter 2 Programming Examples 43

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 45

/* Decode the fifth integer */

result=conf ig[4] ; /* Channel relay open or closed */

if (num_chan < 9) result = re sult << 8; /* strip upper 8 bits */

for (i=num_chan;i>0;i – –)

{

if (result >= 0x8000)

{

printf (“Channel %d output is disabled\n”,i);

}

else

{

printf(“Channel %d output is enabled\n”,i);

}

result = result < < 1;

}

/* Decode the sixth integer */

result=conf ig[5] ; /* P/J Jumper p osition */

if (num_chan < 9) result = re sult << 8; /* strip upper 8 bits */

for (i=num_chan;i>0;i – –)

{

if (result >= 0x8000)

{

printf (“Channel %d output mode is programmable\n”,i);

}

else

{

printf(“Channel %d output mode is fixed and jumper selected\n”,i);

}

result = result < < 1;

}

•

•

•

}

44 Programming Examples Chapter 2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 46

APPLy Output

The APPLyn subsystem commands provide th e easiest method to output

voltages or currents.

/* Set channel 1 for 5.0 Volt output */

APPLy1:VOLTage 5.000

/* Channel is se t to volta ge outp ut and 5. 000 V appl ie d */

/* Set channel 8 for 10 mA output */

APPLy8:CURRent 0.0100

/* Channel is set to curre nt output and 10 mA applie d */

The APPLyn subsyst em outpu ts t he volta ge or cur r ent s pecified on the

channel specified immediately. The output relay for that channel is closed.

Other channel outputs and output states are not disturb ed.

APPLyn subsystem command performs several actions with a single

An

command. Each

– Sets the channel output mode ( voltage or current).

– Sets the output value (volts or amps).

APPLyn c omma nd a ffects a single channel and:

– Enables th e outputs (closes the output relay).

The output c hannel rem a ins e na b led, a nd outputs the last progra mm ed

voltage or current valu e, unless you take explic it action to turn off the

output. For exa mple, if you send two

APPLyn commands to the same

channel, t he first command sets an outp ut va lue and closes th e output relay.

The second c omma nd changes only the outp ut va lue (since the relay is

already closed).

/* Set cha n ne l 1 f o r 5. 0 Volt output */

APPLy1:VOLTage 5.000

/* Channel 1 is se t to vol ta ge output an d 5. 000 V appl ie d */

/* No w set channel 1 for 6.0 Vol t out put */

APPLy1:VOLTage 6.000

/* Channel 1 is se t to vol ta ge output an d 6. 000 V appl ie d */

The comman ds ab ove will s et a 5.000 Volt output on Channe l 1, a nd then

set a 6.000 Volt outpu t on channel 1. The output rela y is not affected by the

second command.

Chapter 2 Programming Examples 45

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 47

The output can also be disabled before changing the mode or output value.

Use the

OUTPutn commands to disab le t he output.

/* Set channel 1 for 5.0 Volt output */

APPLy1:VOLTage 5.000

/* Disable the output */

OUTPut1 OFF

/* Channel 1 output rel ay is ope ne d */

/* No w, enabl e t he outp ut */

OUTPut1 ON

/* Channel 1 is se t to vol ta ge output an d 5. 000 V appl ie d */

/* Disable the output */

OUTPut1 OFF

/* Now set channel 1 for 20 mA curre nt outpu t */

APPLy1:CURRent .0200

/* Channel 1 is set to current out put and 20 mA appl ie d */

The OUTPut subs ys tem commands only affect the output relay. The

programmed mode and output value for a given channel is not changed.

Once the mode is set and the desired output value programmed, the output

can be turned on or off as needed with the

OUTPutn[:STATe] command.

It is also possible, with the

APPLyn commands, to change the channel

output mode from volt age to current.

/* Set channel 1 for 5.0 Volt output */

APPLy1:VOLTage 5.000

/* Channel 1 is se t to vol ta ge output an d 5. 000 V appl ie d */

/* Now set channel 1 for 20 mA curre nt outpu t */

APPLy1:CURRent .0200

/* Channel 1 is set to current out put and 20 mA appl ie d */

During the c hange from voltage t o current (or current to voltage), the

channel out put r e la y is opened. Sendi ng a c omma n d sequenc e similar to the

one above performs the following actions:

– Programs channel 1 to th e voltage mode and 5.000 Volts output.

– Closes th e channel 1 output relay.

– Opens the channel 1 output relay.

– Programs channel 1 to current mode and 20 mA outp ut.

– Closes th e channel 1 output relay.

46 Programming Examples Chapter 2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 48

Error Checking

To develop pro gra ms you wi ll need t o creat e one or more error checking

routines. For example, you will need routines to check for errors in the

fol lo wi ng operations:

– I/O operations to t he VXIb us, a n d

– SCPI commands to the module.

I/O Error Checking I/O error checking is specific to th e type of I/O library you are using to

communicate with the VXIbus. In this manual and on the CD, the

HP VISA Transition Library is used.

Function calls to the HP VISA Transition Library (VTL) typically begin

with a lower case vi. For example, viPrintf is a VTL output function call.

The HP VTL I/O function calls return a var iable that can be tested for errors

against the VTL variable VI_SUCCESS. In the examp les, the variable err

is used to trap the VTL errors and is declared as a gl obal variab le of the

ViStatus type (defined in visa.h).

I/O error checking is illustrated in the f ollowing program example. The

VTL error chec king function is named error_handler. Errors found are

report ed to the standard output device.

SCPI Error

Checking

You must also c hec k for errors r eported by t he SCPI drive r. The SCPI

driver reports errors in response to the

/* Repeat … */

SYST:ERR?

/* …until no errors found */

The query returns two values: an int eger error code and an error description

string. The integer value returns +0 and the string returns “No Error” if

no errors are fou nd.

SCPI error s are reported in an error q ueue. The error queue is a first in, f irst

out queue. Each response to the

from the queue. Multiple SCPI errors may be generated by a single

incorrect command and the error queue should be read until it reports +0,

"No Error".

SYSTem:ERRor ? query.

SYSTem:ERRor? query removes one error

Chapter 2 Programming Examples 47

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 49

SCPI error checking is illustrated in the following program example. The

SCPI error routine is named sys_error. Errors found are reported to the

standard output device.

•

•

•

/** FUNCTION PROTOTYPE S **/

void main (void);

void err_handler(ViS e ssion vi, ViStat u s x); /* VTL error routine */

void sys_err(ViS ession resource); /* SCPI error routine */

•

•

•

/** GLOBAL **/

ViStatus err;

ViSession defaultRM, cmd, dac;

•

•

•

void main (void)

{

/*** Open the resource manager, command module, and dac sessions ***/

viOpenDefaultRM (&defaultRM);

viOpen (default RM, CMD_ADDRESS, VI_NULL, VI_NULL, &cmd);

viOpen(defaul tRM , DAC_ADDRESS, VI_NULL, VI_NULL, &dac);

/*** Set the timeout for the dac ***/

viSetAttribute(dac , VI_ATTR_T MO_VA LUE, 10000); /* 10 second timeout */

err=viPrintf(dac, “*RST\n”); /* reset the dac */

if(err < VI_SUCCESS) err_handler(dac, err) ; /* VTL error check */

sys_err (dac); /* SCPI error check */

•

•

•

}

/***VTL Error handling function ***/

void err_handler (ViSe ssion dac, ViStatus err)

{

char buf[1024]={0};

viStatusDesc(dac,err,buf);

printf(“VTL ERROR = %s\n”, buf);

return;

}

/***End of VTL error handler ***/

48 Programming Examples Chapter 2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 50

•

•

•

/*** SCPI Error check ***/

void sys_err(ViSession resource)

{

char buf [1024] = {0};

int err_no;