Page 1

Contents

HP E1330A Digital I/O Module Service Manual

Edition 3

Click here to return to HP TS-5400 Systems On-Line Manuals Main Contents

Chapter 1. Gener a l Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Digital I/O Descripti o n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

HP E1330A/B Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Digital I/O Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Digital I/O Module Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Digital I/O Module Seri al Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Digital I/O Module Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Recommended Test Equip m ent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Inspection / Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Shipping Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 2. Verification Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Test Conditions / Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Verification Test Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Function al Verification Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operatio n Verification Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Performance Verification Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Test Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Test 2-1: Digital Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Test Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Measurement Uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Test Accuracy Ratio (TAR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 3. Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Replaceable Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Mechanical Parts Locator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

HP E1330A Digital I/O Module Service Manual Contents 1

Page 2

Chapter 4. Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Service Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Digital I/O Module Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Repair Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Troubleshooting Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Identifyi ng the Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Making Visual Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Testing the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Repair and Maintenance Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Soldering Printed Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Post-Repair Safety Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Appendix A. Verification Tests - C Programs . . . . . . . . . . . . . . . . . . . . . . . . . 37

Function al Verification Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Performance Verification Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Example: Digital Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2 Content s HP E1330A Digital I/O Module Service Manual

Page 3

Hewlett-Packard Company certifies that this product met its published specifications at the time of shipment from the factory. Hewlett-Pack ard

further certifies that its calibration measurements are traceable to the United States National Institute of Standards and Technology (formerly Na-

tional Bureau of Standards), to the extent allowed by that organization’s calibration facility, and to the calibration facilities of other International

Standards Organization members.

WARRANTY

CERTIFICATION

This Hewlett-Packard product is warrante d against defects in materials and workmanship for a period of three years from date of shipment. Duration and conditions of warranty for this product may be superseded when the product is integrated into (becomes a part of) other HP products.

During the warranty period, Hewlett-Packard Company will, at its option, either repair or replace products which prove to be defective.

For warranty service or repair, this product must be returned to a service facility designated by Hewlett-Packard (HP). Buyer shall prepay shipping charges to HP and HP shall pay shipping charges to return the product to Buyer. However, Buyer shall pay all shipping charges, duties, and

taxes for products returned to HP from another country.

HP warrants that its software and firmware designated by HP for use with a product will execute its programming instruct ions when properly installed on that product. HP does not warrant that the operation of the product, or software, or firmware will be uninterrupted or error free.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance by Buyer, Buyer-supplied products or interfacing, unauthorized modification or misuse, operation outside of the environmental specifications for the product, or improper site preparation or

maintenance.

The design and implementation of any circuit on this product is the sole responsibility of the Buyer. HP does not warrant the Buyer’s circuitry or

malfunctions of HP products that result from the Buyer’s circuitry. In addition, HP does not warrant any damage that occurs as a result of the

Buyer’s circuit or any defects that result from Buyer-supplied products.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HP SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES. HP SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY

OTHER LEGAL THEORY.

NOTICE

The information contained in this document is subject to change without notice. HEWLETT-PACKARD (HP) MAKES NO WARRANTY OF

ANY KIND WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. HP shall not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing, performance or use of this material. This document contains proprietary information which

is protected by copyright. All rights are reserved. No part of this document may be photocopied, reproduced, or translated to another language

without the prior written consent of Hewlett-Packard Company. HP assumes no responsibility for the use or reliability of its softwa re on equipment that is not furnished by HP.

Restricted Rights Legend

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subdivision (b)(3)(ii) of the Rights in Technical Data and

Computer Software clause at 52.227-7013. Hewlett-Packard Company; 3000 Hanover Street; Palo Alto, California 94304

Declaration of Conformity

According to ISO/IEC Guide 22 and EN 45014

The Hewlett-Packard Company declares that the HP E1330A/E1330B conforms to the following Product Specifications.

Safety: IEC 1010-1 (1990) Incl. Amend 1 (1992)/EN61010 (1993)

EMC: CISPR 11:1990/EN 55011 (1991): Group1 Class A

IEC 801-2:1991/EN 50082-1 (1992): 4kVCD, 8kVAD

IEC 801-3:1984/EN 50082-1 (1992): 3 V/m

IEC 801-4:1988/EN 50082-1 (1992): 1kV Power Line

Supplementary Information: The product herewith complies with the requirements of the low voltage Directive 73/23/EEC and the EMC Directive 89/336/EEX.

Tested in a typi ca l co n f i g u r at io n in an H P B-size VXI main fr ame.

Hewlett-Packard Company

P.O. Box 301

815 14th Street S.W.

Loveland, Colorado 80539 U.S.A.

CSA C22.2 #1010.1 (1992)

UL 1244

Q.A. Manager

November 1994

3

Page 4

The Printing History shown below lists all Editions and Updates of this manual and the printing date(s). The first printing of the manual is Edition 1. The Edition number increments by 1 whenever the manual is revised. Updates, which are issued between Editions, contain replacement

pages to correct the current Edition of the manual. Updates are numbered sequentially starting with Update 1. When a new Edition is created, it

contains all the Update information for the previous Edition. Each new Edition or Update also includes a revised copy of this printing history

page. Many product updates or revisions do not require manual changes and, conversely, manual corrections may be done without accompanying

product changes. Therefore, do not expect a one-to-one correspondence between product updates and manual updates.

Edition 1 (Part Number E1330-90010) . . . . . . . . . . . . . . . . . . . . . . . . . . . . December 1992

Edition 2 (Part Number E1330-90011) . . . . . . . . . . . . . . . . . . . . . . . . . . . November 1994

Edition 3 (Part Number E1330-90012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . April 1996

Safety Symbols

Printing History

Instruction

manual symbol

affixed to product. Indicates

Caution information to avoid personal injury or

damage to the

field wiring terminal that must be connected

to earth ground before operating the equip-

ment—protects against elect rical shock in

case of fault.

OR

that the user

must refer to

the manual

for specific

Warning or

product.

Indicates the

Frame or chassis ground tercally connects to

WARNING

CAUTION

Indicates

minal—typi

the equipment’s metal

frame.

Alternating

current (AC).

Direct current

(DC).

hazardous

voltages.

WARNINGS

The following general safety precautions must be observed during all phases of operation, service, and repair of this product. Failure t o

comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture, and

intended use of the product. Hewlett-Packard Company assumes no liability for the customer’s failure to comply with these requirements.

Ground the equipment: For Safety Class 1 equipment (equipment having a protective earth terminal), an uninterruptible safety earth ground

must be provided from the mains power source to the product input wiring terminals or supplied power cable.

DO NOT operate the product in an explosive atmosphere or in the presence of flammable gases or fumes.

For continued protection against fire, replace the line fuse(s) only with fuse(s) of the same voltage and current rating and type.

DO NOT use repaired fuses or short-circuited fuse holders.

Keep away from live circuits: Operating personnel must not remove equipment covers or shields. Procedures involving the removal of covers or

shields are for use by service-trained personnel only. Under certain conditions, dangerous voltages may exist even with the equipment switched

off. To avoid dangerous electrical shock, DO NOT perform procedures involving cover or shield removal unless you are qualified to do so.

DO NOT operate damaged equipment: Whenever it is possible that the safety protection features built into this product have been impaired,

either through physical damage, excessive moisture, or any other reason, REMOVE POWER and do not use the product until safe operation can

be verified by service-trained personnel. If necessary, return the product to a Hewlett-Packard Sales and Service Office for service and repair to

ensure that safety features are maintained.

DO NOT service or adjust alone: Do not attempt internal service or adjustment unless another person, capable of rendering first aid and resuscitation, is pr esent.

DO NOT substitute parts or modify equipment: Because of the danger of introducing additional hazards, do not install substitute parts or perform any unauthorized modification to the product. Return the product to a Hewlett-Packard Sales and Service Office for service and repair to ensure that safety features are maintained.

4

Page 5

MANUAL COMMENT SHEET

HP E1330A/B Digital I/O Service Manual

Manual Part Number E1330-90011

Edition 2 (November 1994)

You can help us improve our manuals by sharing your comments and suggestions. Please complete this

questionnaire after becoming familiar with the manual and then return it to us. In appreciation of your time, we

will enter your name in a quarterly drawing for a Hewlett-Packard Palmtop PC.

Please describe the system controller, operating system, and programming language you are using to program

this product.

Please pencil-in one circle for each statement below as it applies to this documentation:

Disagree Agree

•

The manual is well organized. OOOOO

•

Instructions are easy to understand. OOOOO

•

The manual is clearly written. OOOOO

•

Examples are clear and useful. OOOOO

•

The manual contains enough examples. OOOOO

•

Illustrations are clear and helpful. OOOOO

•

The manual meets my overall expectations. OOOOO

Please write any comments and/or suggestions in the space provided below. Use additional pages if you wish. The

more specific your comments, the more useful they are to us.

Your Name:

Address:

City/State:

Company:

Job Title:

Telephone:

Zip/Postal Code:

Country:

Today’s Date:

Please fold and tape for mailing.

Page 6

Page 7

What’s in this Manual

Manual Overview

This manual shows how to service the HP E1330A/B Quad 8-Bit Digital I/O Module. Consult the HP E1330A/B

User’s Manual for additional information on installing, configuring, and operating the HP E1330A/B. Consult

the appropriate mainframe user’s manual for information on configuring and operating the mainframe.

Manual Content

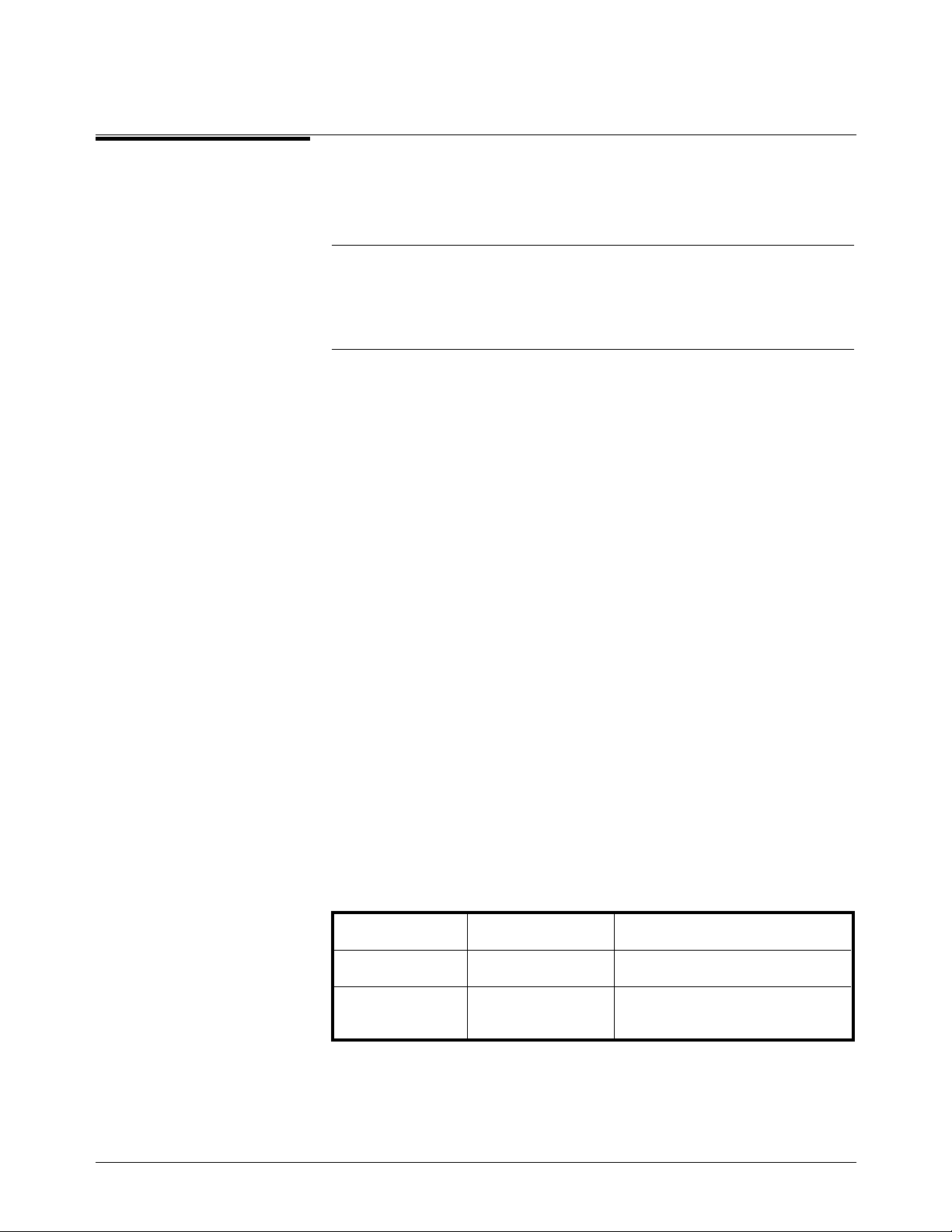

Chapter Title Content

1 General

Information

2 Verification

Tests

3 Replaceable

Parts

4 Service Procedures to aid in fault isolation and repair of the module.

Provides a basic description and lists the test equipment required for service.

Functional verification, operation verification, and performance verification tests.

Lists replaceable parts for the module.

What’s in this Manual 7

Page 8

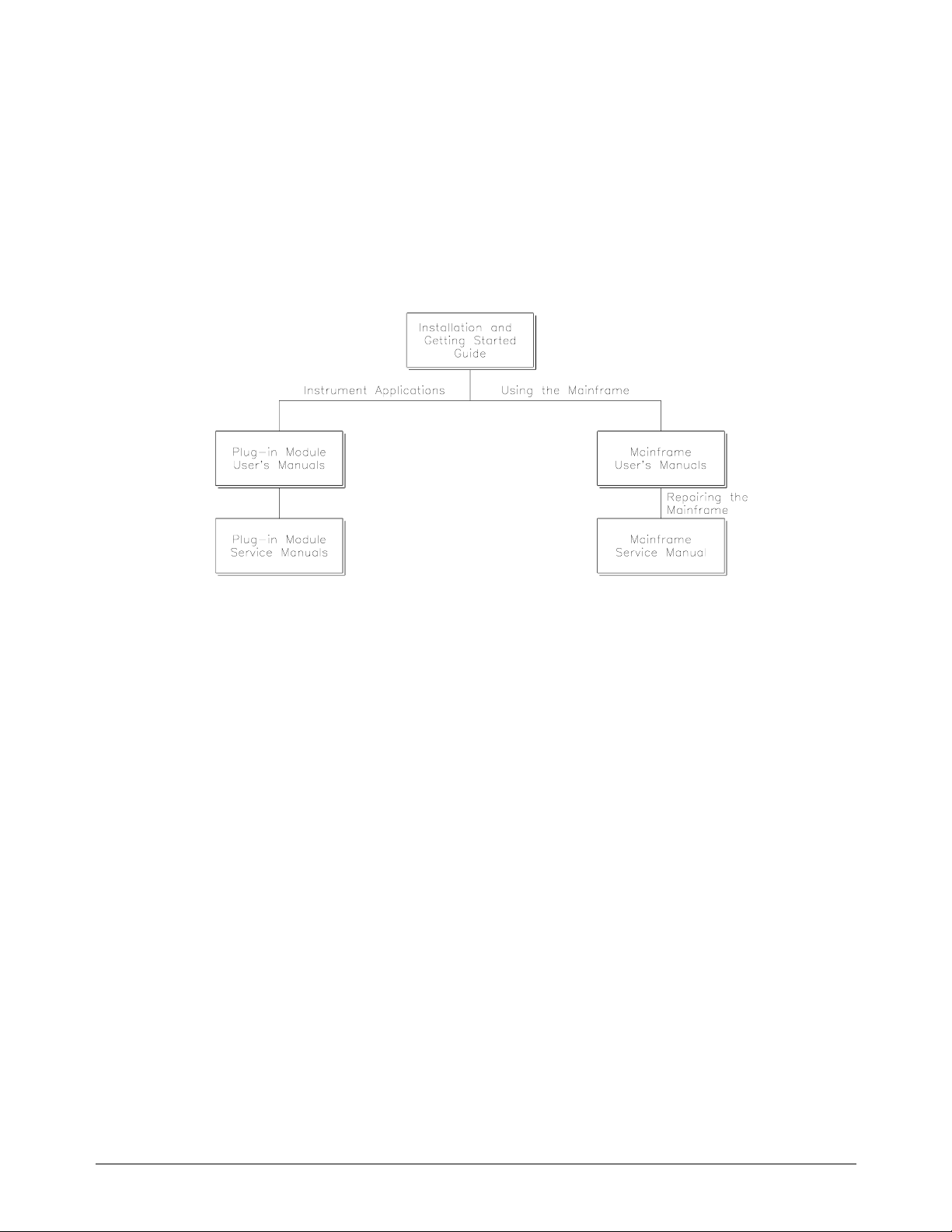

HP 75000 Series B Service Documentation

Suggested Sequence to Use Manuals

Manual Descriptions

Installation and Getting Started Guide. This manual contains step-by-step instructions for all aspects of

plug-in module and mainframe installation. Introductory programming information and examples are also

included.

Mainframe User’s Manual. This manual contains programming information for the mainframe, front panel

operation information (for the HP E1301A mainframe), and general programming information for instruments

installed in the mainframe.

Plug-In Module User’s Manuals. These manuals contain plug-in module programming and configuration

information. Each manual contains examples for the most-used module functions, and a complete SCPI

command re fe re nc e fo r th e pl ug-in module.

Mainframe Service Manual. This manual contains service information for the mainframe. It contains

information for ordering replaceable parts and exchanging assemblies. Information and procedures for

performance verification, adjustment, preventive maintenance, troubleshooting, and repair are also included.

Plug-In Module Service Manuals. These manual s co nt ai n plug -i n m od ul e se rv ic e information. Eac h manual

contains information for exchanging the module and/or ordering replaceable parts. Depending on the module,

information and procedures for functional verification, operation verification, performance verification,

adjustment, preventive maintenance, troubleshooting, and repair are also provided.

HP 75000 Series B Ser vi ce D ocu m en ta ti o n 8

Page 9

Chapter 1

General Information

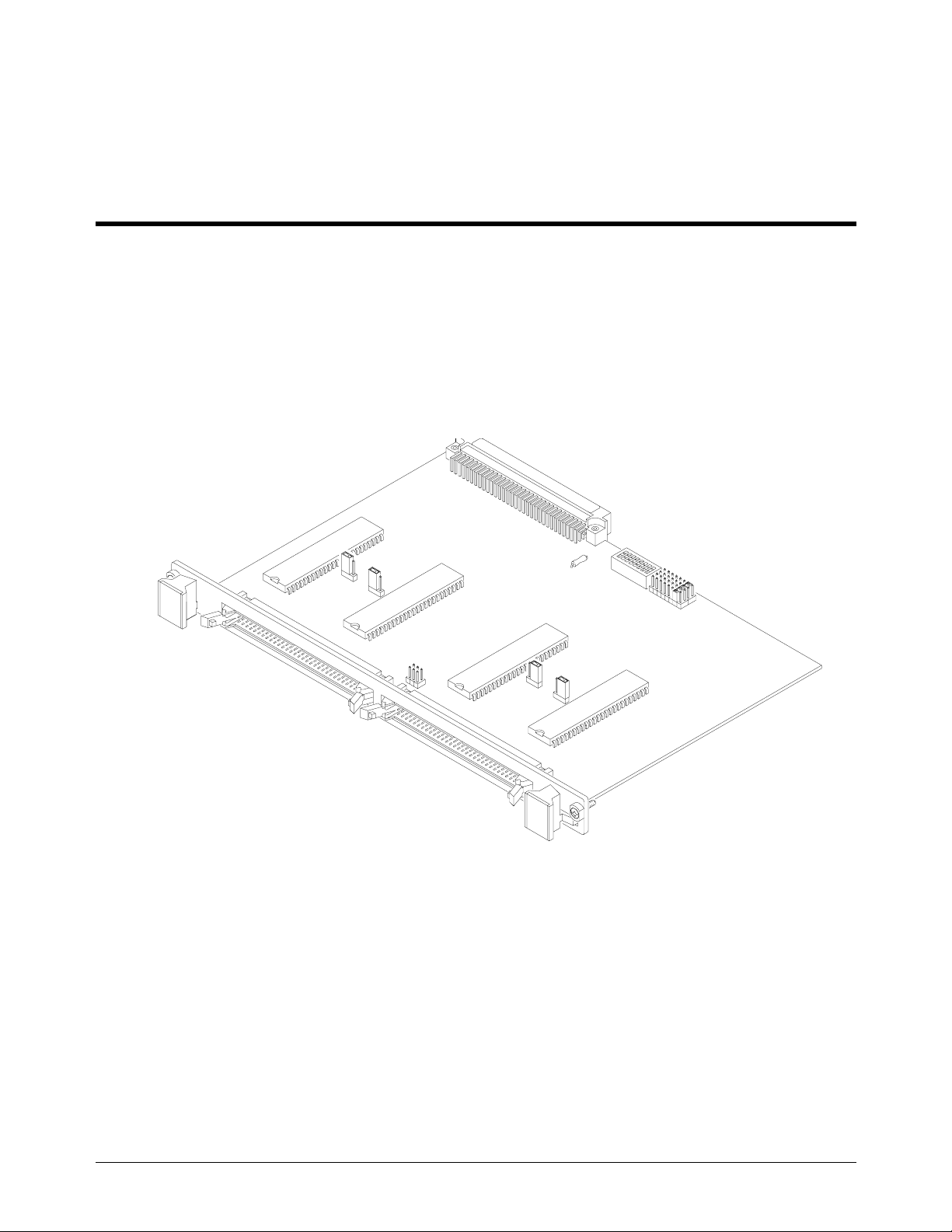

Introduction This manual contains information required to test, troubleshoot, and repair

the HP E1330A/B Quad 8-Bit Digital I/O Module. See the HP E1330A/B

User’s Manual for additional information on the HP E1330A/B. Figure 1-1

shows the HP E1330A/B Quad 8-Bit Digital I/O Module.

Figure 1-1. HP E1330A/B Digital I/O Module

Chapter 1 General Information 9

Page 10

Safety

Considerations

Warnings This section contains WARNINGS which must be followed for your

This product is a Safety Class I instrument that is provided with a protective

earth terminal when installed in the mainframe. Check the mainframe,

Digital I/O Module, and all related documentation for safety markings and

instructions before operation or service.

Refer to the WARNINGS page (page iii) in this manual for a summary of

safety information. Safety information for preventive maintenance, testing,

and service follows and is also found throughout this manual.

protection when pe rfor m in g eq uipm e nt main te na nc e or repai r.

WARNING

SERVICE-TRAINED PERSONNEL ONLY. The information in this

manual is for service-trained personnel who are familiar with

electronic circuitry and are aware of the hazards involved. To

avoid personal injury or damage to the instrument, do not

perform procedures in this manual or do any servicing unless

you are qualified to do so.

CHECK MAINFRAME POWER SETTINGS. Before applying

power, verify that the mainframe setting matches the line

voltage and that the correct fuse is installed. An uninterruptible

safety earth ground must be provided from the main power

source to the supplied power cord set.

GROUNDING REQUIREMENTS. Interruption of the protective

(grounding) conductor (inside or outside the mainframe) or

disconnecting the protective earth terminal will cause a

potential shock hazard that could result in personal injury.

(Grounding one conductor of a two-conductor outlet is not

sufficient protection.)

IMPAIRED PROTECTION. Whenever it is likely that instrument

protection has been impaired, the mainframe must be made

inoperative and be secured against any unintended operation.

REMOVE POWER IF POSSIBLE. Some procedures in this

manual may be performed with power supplied to the

mainframe while protective covers are removed. Energy

available at many points may, if contacted, result in personal

injury. (If maintenance can be performed without power applied,

the power should be removed.)

10 General Information Chapter 1

Page 11

WARNING

USING AUTOTRANSFORMERS. If the mainframe is to be

energized via an autotransformer (for voltage reduction) make

sure the common terminal is connected to neutral (that is, the

grounded side of the main’s supply).

CAPACITOR VOLTAGES. Capacitors inside the mainframe may

remain charged even when the mainframe has been

disconnected from its source of supply.

USE PROPER FUSES. For continued protection against fire

hazard, replace the line fuses only with fuses of the same

current rating and type (such as normal blow, time delay, etc.).

Do not use repaired fuses or short-circuited fuseholders.

Cautions This section contains CAUTIONS which must be followed to avoid damage

to the equipment when performing instrument maintenance or repair.

CAUTION

MAXIMUM VOLTAGE/CURRENT. The maximum voltage that may

be applied between any connector pin and any other point, shield, or

chassis is 5 VPeak.

STATIC ELECTRICITY. Static electricity is a major cause of

component failure. To prevent damage to the electrical components in

the Digital I/O module, observe anti-static techniques whenever

working on a Digital I/O module.

Chapter 1 General Information 11

Page 12

Digital I/O

Description

The HP E1330A/B Digital I/O Module is an "instrument" in a VXIbus

mainframe. As such, each Digital I/O module is assigned an error queue,

input and output buffers, and a status register.

NOTE

HP E1330A/B

Description

Instruments are based on the logical addresses of the plug-in modules. See

the HP 75000 Series B Installation and Getting Started Guide to set the

addresses to create an instrument.

The HP E1330A/B provides four independent 8-bit digital I/O ports

compatible with TTL logic levels. Each port can be software config ured for

operation as input or output with either positive or negative true logic. The

ports can be combined to provide 16 bit (WORD) or 32 bit (LWORD)

operations. In addition to the eight digital data lines, six handshake lines are

included per port. The handshake lines can also be combined (via jumpers

on the component assembly) to provide proper handshaking for combined

ports. The data lines of each port are provided with a jumpered pull-up for

dry contact closure sensing. User connections to the Digital I/O module are

made through two 60-pin connectors on the rear panel.

The HP E1330B added SCPI command capabilities related to LWORD and

Block operations. The procedures in this manual work equally well with

either an HP E1330A or HP E1330B.

Digital I/O Module

Specifications

Digital I/O Module

Environment

See Appendix A of the HP E1330A/B User’s Manual for HP E1330A/B

specifications. These specifications are the performance standards or limits

against which the instrument may be tested.

The recommended operating environment for the HP E1330A/B Digital I/O

module is:

Environment Temperature Humidity

Operating 0

Storage and

Shipment

o

C to +55oC <65% relative (0oC to +40oC)

o

C to +75oC <65% relativ e (0oC to +40oC)

-40

12 General Information Chapter 1

Page 13

Digital I/O Module

Serial Numbers

Digital I/O modules covered by this manual are identified by a serial

number prefix listed on the title page. Hewlett-Packard uses a two-part

serial number in the form XXXXAYYYYY, where XXXX is the serial

prefix, A is the country of origin (A=USA), and YYYYY is the serial

suffix. The serial number prefix identifies a series of identical instruments.

The serial number suffix is assigned sequentially to each instrument.

The serial number plate is located on the backplane connector. If the serial

number prefix of your instrument is greater than the one listed on the title

page, a Manual Update (as required) will explain how to adapt this manual

to your instrument.

Digital I/O Module

Options

There are no electrical or mechanical options available for the HP

E1330A/B Digital I/O Modules.

Chapter 1 General Information 13

Page 14

Recommended

Test Equipment

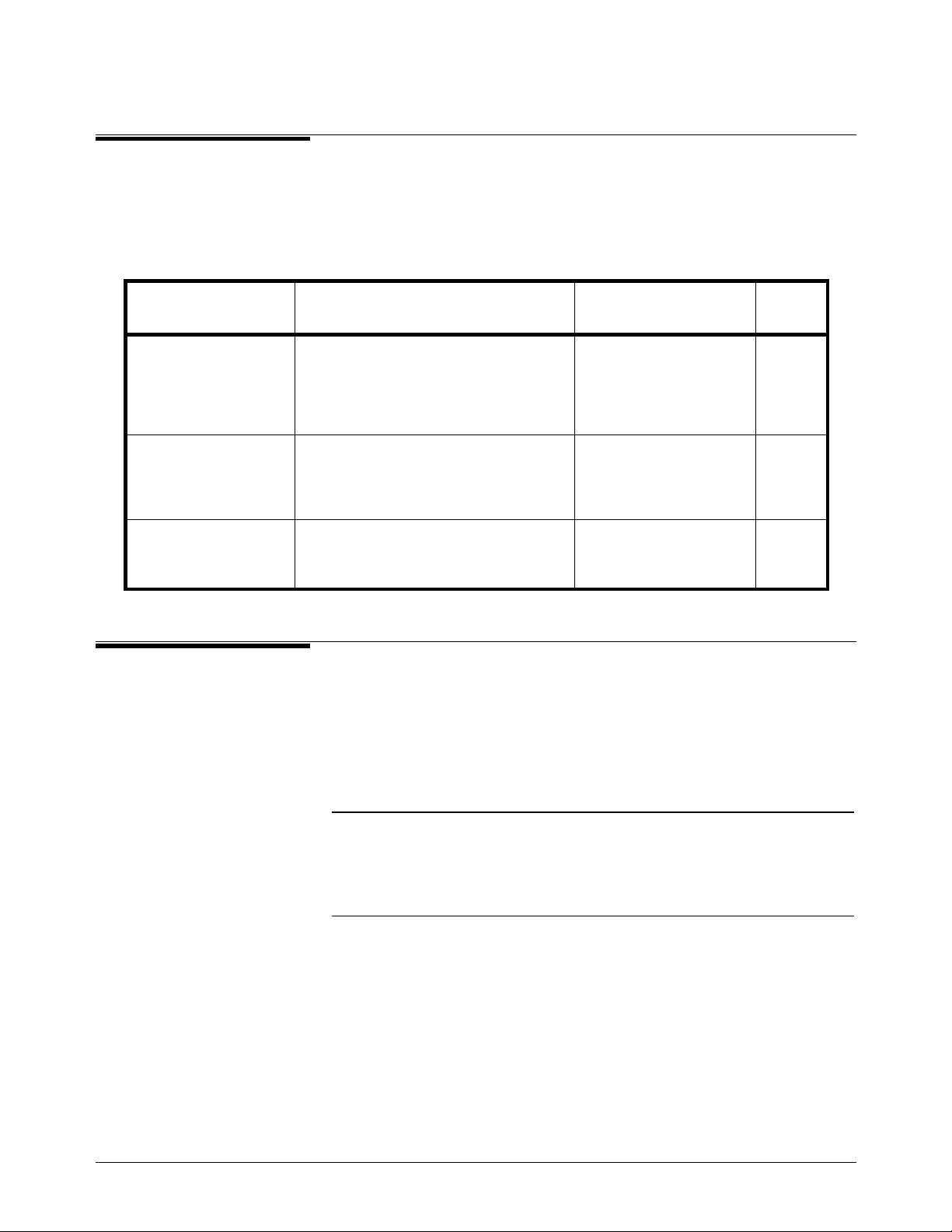

Table 1-1 lists the te st equipment reco mm en d e d fo r te st in g, adjusting, an d

servicing the Digital I/O modules. Essential requirements for each piece of

test equipment are described in the Requirements column.

Table 1-1. Recommended Test Equipment

Instrument Requirements Recommended

Model

Controller, HP-IB HP-IB compatibility as def ined by IEEE

Standard 488-1987 and the identical

ANSI Standard MC1.1: SH1, AH1, T2,

TE0, L2, LE0, SR0, RL0, PP0, DC0,

DT0, and C1, 2, 3, 4, 5.

Mainframe Compatible with Dig it al I/O Mo du le HP E1300A, E1301A,

Test Cable Connects handshake and data lines

from Port 0 to Port 2 and from Port 1 to

Port 3.

HP 9000 Series 300

or

IBM compatible PC with

HP BASIC

E13002A or E1401B/T,

E1421A (req uires

E1405A/B)

HP E1330-61603 O,P

Use*

F,O,

P,T

F,O,

P,T

* F = Functional Verification Tests, O = Operation Verification Tests, P = Performance Verification Tests, T = Troubleshooting

Inspection /

Shipping

This section co n ta in s in it ia l (i nc om i ng ) in spection and shi pp in g gu id el in es

for the Digital I/O module.

Initial Inspection Use the steps in Figure 1-2 as guidelines to perform initial inspection of a

Digital I/O module. Performance Verification tests are optional.

WARNING

14 General Information Chapter 1

To avoid possible hazardous electrical shock, do not perform

electrical tests if there are signs of shipping damage to the

shipping container or to the instrument.

Page 15

Figure 1-2. Initial (Incoming) Inspection Guidelines

Chapter 1 General Information 15

Page 16

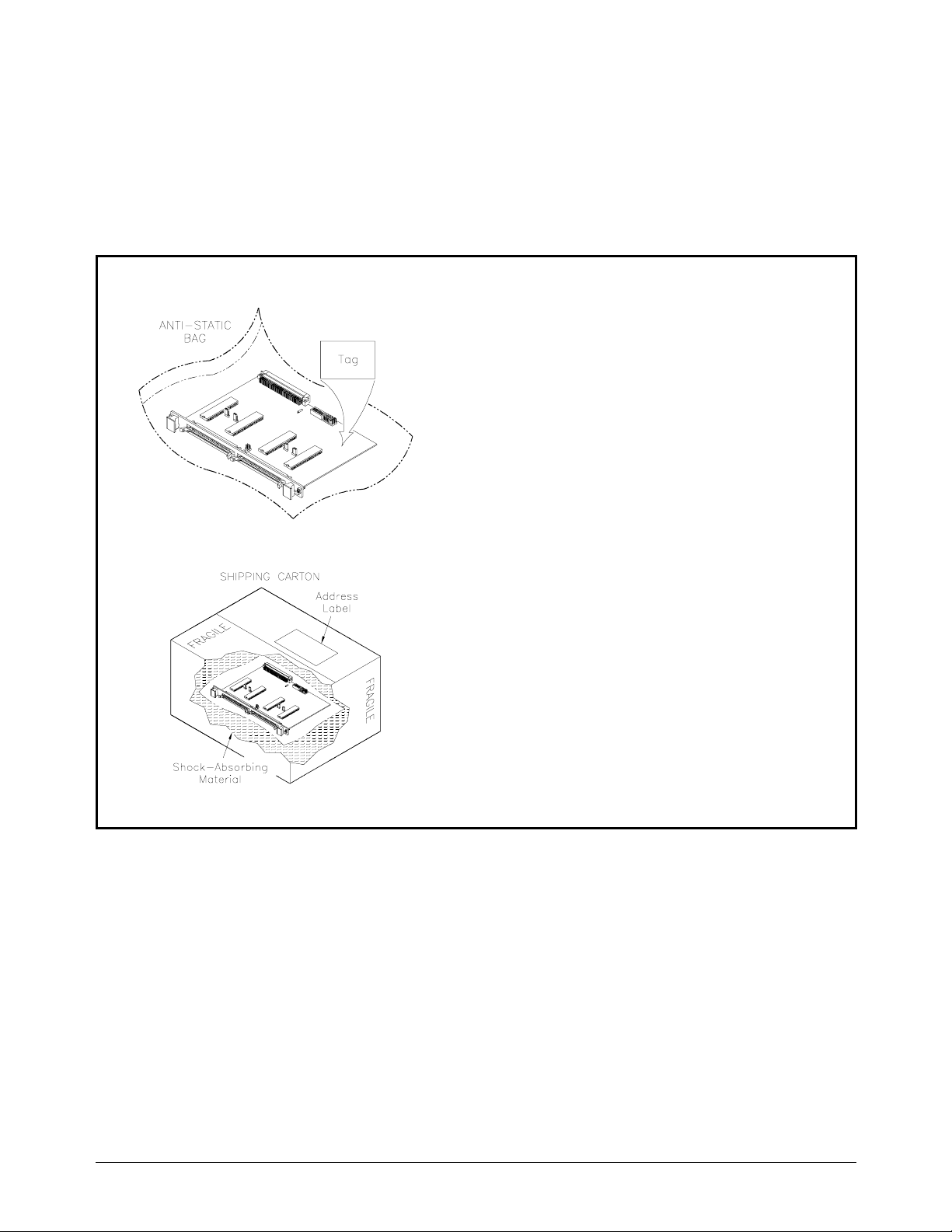

Shipping Guidelines Follow the steps in Figure 1-3 to return a Digital I/O module to a

Hewlett-Packard Sales and Support Office or Service Center.

1 Prepare the Digital I/O module

•

Remove user wiring from the module

•

Attach tag to module/pod that identifies

- Owner

- Model Number/Serial Number

- Service Required

•

Place tagged device in approved anti-static bag

2 Package the Digital I/O module

•

Place packaged Digital I/O module in shipping

carton*

•

Place 75 to 100 mm (3 to 4 inches) of shockabsorbing material around the Digital I/O module

•

Seal the shipping carton securely

•

Mark the shipping carton FRAGILE

3 Ship the Digital I/O module to Hewlett-Packard

•

Place address label on shipping carton

•

Send carton to Hewlett-Packard

* We recommend that you use the same shipping materials as those

used in factory packaging (available from Hewlett-Packard). For other

Figure 1-3. Packaging/Shipping Guidelines

(commercially-available) shipping materials, use a double wall-carton with minimum 2.4 MPa (350 psi) test.

16 General Information Chapter 1

Page 17

Chapter 2

Verification Tests

Introduction This chapter describes the verification tests for the HP E1330A/B modules.

The three levels o f test pro ce dures described in thi s ch ap te r ar e us ed to

verify that the HP E1330A/B:

• is functional (Functional Verification Test)

• meets selected testable specifications (Operation Verification)

• meets all testable specifications (Performance Verification)

Test Conditions /

Procedures

Performance Test

Record

Verification Test

Examples

See Table 1-1 for test equipment requirements. You should complete the

Performance Verification tests at least once a year. For heavy use or severe

operating environments, perform the tests more often. The verification tests

assume that the person performing the tests understands how to operate the

mainframe, the module, and the specified test equipment. The test

procedures do not specify equipment settings for test equipment except in

general terms. It is assumed that a qualified, service-trained technician will

select and connect the cables, adapters, and probes required for the test.

The results of each Performance Verification test may be recorded in Table

2-1, Performance Test Record, at the end of this chapter. You can make a

copy of this form, if desired.

Each verification test procedure includes an example program that performs

the test. All example programs assume the following configuration:

• HP 9000 Series 200/300 co mpu te r

• HP BASIC programming language

• Module address 70918

Chapter 2 Verification Tests 17

Page 18

Functional

Verification

Test

Procedure 1. Verify that the module is properly installed in mainframe

The Functional Verific atio n Tes t fo r th e HP E133 0A/ B mo du le s co ns is ts of

sending the *IDN? command and checking the response. This test can be

used to verify that the module is connected properly and is responding to a

basic command.

2. Verify that the mainframe has passed its power-on test.

3. Send *IDN? to the module (see example following)

4. The return should be as follows (revision number may vary):

HEWLETT-PACKARD,E1330A,0,A.06.00

NOTES

Example An example follows which uses an HP 9000 Series 300 computer with HP

Operation

Verification

Test

If the primary add re ss set ting, secondary ad dr es s se tt in g, or the interfac e

select code is set incorrectly, the module will not respond. Verify proper

address selection before troubleshooting.

Both the HP E1330A and HP E1330B return the string shown in Step 4. The

HP E1330B will return "E1330A" in response to the *IDN? query.

BASIC and a module address of 70918.

10 DIM A$[100]

20 OUTPUT 70918;"*IDN?" Send the ID command

30 ENTER 70918;A$ Get response

40 PRINT A$

50 END

The procedures in this section are used to provide a high level of confidence

that the module is meeting published specifications. The Operation

Verification test is a subset of the Performance Verification tests and is

suitable for checkout after performing repairs.

The Operation Verification Test is performed by completing the Digital

Test (Test 2-1) as described in the Performance Verification test procedures.

This test is usually sufficient to verify that the module is meeting its

specifications.

18 Verification Tests Chapter 2

Page 19

Performance

Verification

Tests

Test Cable A test cable is required to ru n th e Per fo rm a nc e Ver if ic atio n te st . Thi s te st

The procedure in thi s se ct io n is use d to tes t th e m od ul e’ s elec tr ic al

performance using the specifications in Appendix A — Specifications of the

HP E1330A/B Modules User’s Manual as the performance standard.

The Performanc e Ver if icat io n te st is a te st of ea ch Di gi ta l I/O lin e on eac h

port and a test of th e th re e m ai n ha nd sh ak e li ne s fo r ea ch p or t. This test is

sufficient to determine that the module is operating within specifications.

This test is suitable for incoming inspection, troubleshooting, and

preventive maintenance.

cable is available from Hewlett-Packard (Part Number E1330-61603).

Test 2-1: Digital

This test verifi es tha t al l po rt s m ee t th e sp ec if ic at io n for the modul e.

Test

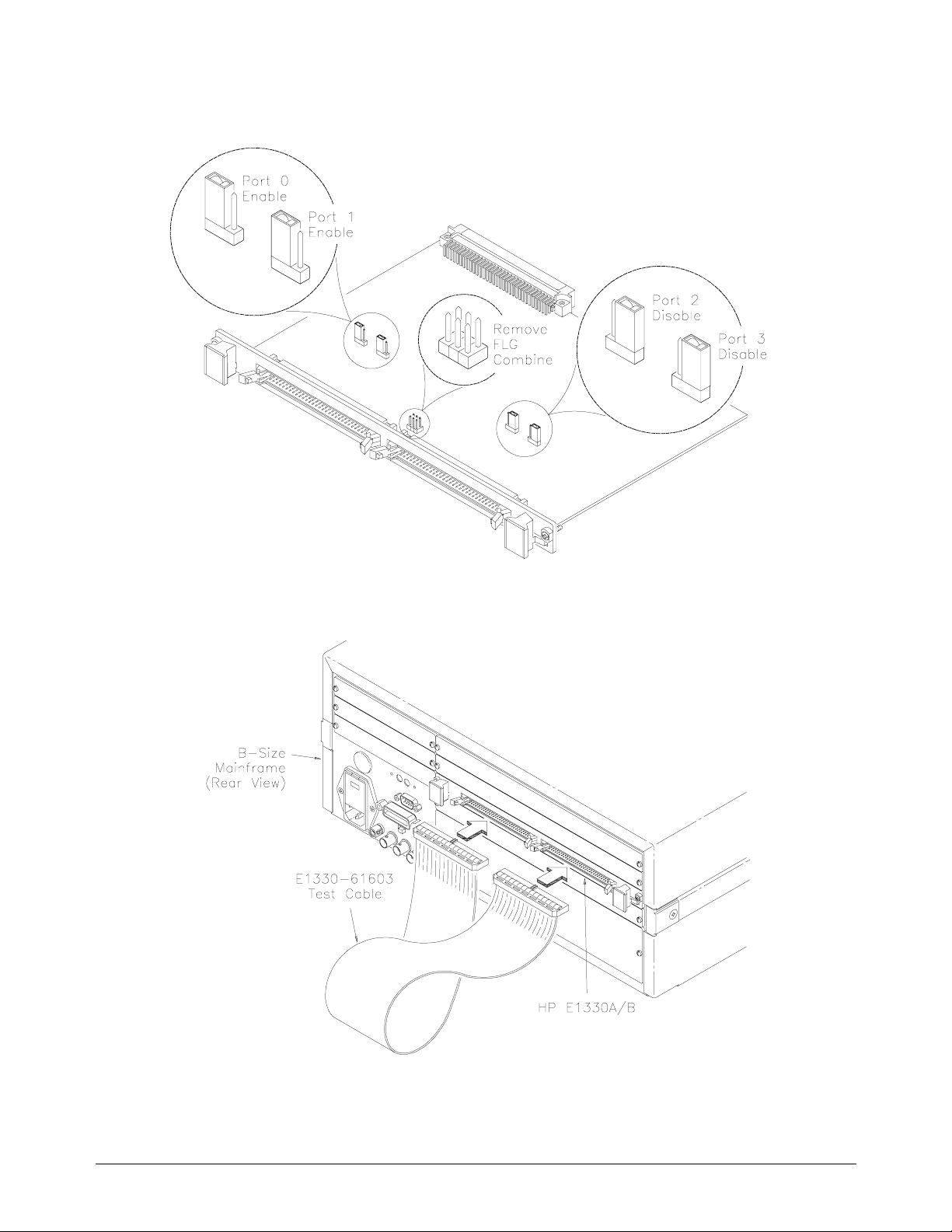

Data Line Test 1. Setup and Install the Digital I/O module

• Remove power from the mainframe. Remove HP E1330A/B

from the mainframe (as required).

• Record the locations of the Pull-up Enable and any FLG

Combine jumpers on the HP E1330A/B.

• Set Port 0 and Port 1 Pull-up Enable jumpers to the Enable

position as shown in Figure 2-1.

• Set Port 2 and Port 3 Pull-up Enable jumpers to the Disable

position as shown in Figure 2-1.

• Remove any FLG Combine jumpers installed.

• Install the HP E1330A/B in the mainframe.

• Install the Test Cable as shown in Figure 2-2.

• Turn the mainframe power ON.

2. Check Port 0 Write and Port 2 Read

• Send *RST to the module.

• Send SOUR:DIG:DATA0 #B00000001 to the module.

• Send MEAS:DIG:DATA2? to the module.

• Enter the response and compare to the binary data sent.

• Repeat this step using the following binary data strings:

"00000010", 00000100", "00001000",

"00010000","00100000","01000000",and "10000000". Use the

command SOUR:DIG:DATA0 #Bssssssss where ssssssss = the

binary data string.

• Enter a Pass or Fail in Table 2-1.

Chapter 2 Verification Tests 19

Page 20

Figure 2-1. Jumper Settings

Figure 2-2. Test Cable Installation

20 Verification Tests Chapter 2

Page 21

3. Repeat for Ports 1 through 3

• Repeat step 2 for ports 1, 2, and 3.

• Use SOUR:DIG:DATAn #Bssssssss and MEAS:DIG:DATAn?

where n = port number and ssssssss = the binary string.

• For Port 1 Write, use Port 3 Read. For Port 2 Write, use Port 0

Read. For Port 3 Write, use Port 1 Read.

4. Check Port 0 CTL and Port 2 FLG handshake lines

• Send *RST to the module.

• Send SOUR:DIG:CONT0 1 to the module.

• Send MEAS:DIG:FLAG2? to the module.

• Enter the response. The response should be 1.

• Enter a Pass or Fail in Table 2-1.

• Send SOUR:DIG:CONT0 0 to the module.

• Send MEAS:DIG:FLAG2? to the module.

• Enter the response. The response should be 0.

• Enter a Pass or Fail in Table 2-1.

5. Repeat for Ports 1, 2, and 3

• Repeat step 4 for ports 1, 2, and 3.

• Send SOUR:DIG:CONTn f to the module where n = port

number and f = is a binary toggle (0 and 1).

• Send MEAS:DIG:FLAGn to the module where n = port

number.

• For Port 1 CTL, use Port 3 FLG. For Port 2 CTL, use Port 0

FLG. For Port 3 CTL, use Port 1 FLG.

6. Reset the module jumpers

• Turn mainframe power OFF.

• Remove the Test Cable from the module.

• Remove the module from the mainframe.

• Reset the module jumpers to the positions recorded in Step 1.

Example: Digital Test This example performs a bit walk test of all bits on all ports and checks the

module’s ability to set and reset the handshake lines on each port.

10! RE-SAVE "DIO_TEST"

20 DISP CHR$(129)

30 ASSIGN @Dio TO 70918

40 OUTPUT @Dio;"*CLS"

50 Fail = 0

60 DIM A$[255],B$[32],Bit_walk$(7)[8]

70 DATA "00000001","00000010","00000100","00001000",

"00010000","00100000","01000000","10000000"

80 READ Bit_walk$(*)

Chapter 2 Verification Tests 21

Page 22

90 CLEAR SCREEN

100 PRINT "Install Component Assembly and Test Cable"

110 PRINT

120 PRINT " 1. Turn mainframe power OFF"

130 PRINT " 2. Install HP E1330A/B component assembly into

mainframe "

140 PRINT " 3. Attach test cable to component assembly"

150 PRINT " 4. Turn mainframe power ON "

160 PRINT " 5. Press Continue when ready to begin testing "

170 PAUSE

180 CLEAR SCREEN

190 OUTPUT @Dio;"*IDN?"

200 ENTER @Dio;A$

210 IF A$[17,21]<>"E1330" THEN

220 PRINT "Incorrect Card Type detected"

230 STOP

240 END IF

250 PRINT "Bit walk test of all ports for read and write (no handshake)"

260 FOR I=0 TO 7

270 FOR J=0 TO 3

280 OUTPUT @Dio;"SOUR:DIG:DATA"&VAL$(J)&"

#B"&Bit_walk$(I)

290 IF J<2 THEN

300 OUTPUT @Dio;"MEAS:DIG:DATA"&VAL$(J+2)&"?"

310 ELSE

320 OUTPUT @Dio;"MEAS:DIG:DATA"&VAL$(J-2)&"?"

330 END IF

340 ENTER @Dio;A$

350 Number=VAL(A$)

360 B$=DVAL$(Number,2)

370 IF B$[25,32]<>Bit_walk$(I) THEN

380 Fail = 1

390 PRINT "Failure of bit walk"

400 PRINT "WRITE at port ";J

410 IF J<2 THEN

420 PRINT "READ at port ";J+2

430 ELSE

440 PRINT "READ at port ";J-2

450 END IF

460 END IF

470 NEXT J

480 NEXT I

490 PRINT "End of bit walk test"

22 Verification Tests Chapter 2

Page 23

500 PRINT

510 PRINT "Handshake line test"

520 FOR T=1 TO 0 STEP -1

530 FOR I =0 TO 3

540 OUTPUT @Dio;"SOUR:DIG:CONT"&VAL$(I)&" "&VAL$(T)

550 IF I <2 THEN

560 OUTPUT @Dio;"MEAS:DIG:FLAG"&VAL$(I+2)&"?"

570 ELSE

580 OUTPUT @Dio;"MEAS:DIG:FLAG"&VAL$(I-2)&"?"

590 END IF

600 ENTER @DIO;A$

610 IF VAL(A$)<>T THEN

620 Fail = 1

630 PRINT "Failure of handshake lines"

640 IF I<2 THEN

650 PRINT "CTL line on port ";I;" to FLG line on port ";I+2

660 ELSE

670 PRINT "CTL line on port ";I;" to FLG line on port ";I-2

680 END IF

690 END IF

700 NEXT I

710 NEXT T

720 PRINT "End of handshake line test"

730 PRINT

740 IF Fail=0 THEN

750 PRINT "Digital I/O PASSED all tests"

760 ELSE

770 PRINT "Digital I/O failed tests"

780 END IF

790 END

Typical Result

Bit walk test of all ports for read and write (no handshake)

End of bit walk test

Handshake line tes t

End of handshak e line test

Digital I/O PASSED all tests

Chapter 2 Verification Tests 23

Page 24

Performance

Test Record

Test Limits The HP E1330A/B test is a pass/fail test and has no test limits. Minimum

Table 2-1, Performance Test Record, is a form you can copy and use to

record performance verification test results for the Module.

and Maximum values are marked NA (Not Applicable) in Table 2-1.

Measurement

Uncertainty

Test Accuracy

Ratio (TAR)

The HP E1330A/B test is a pass/fail test and has no measurement

uncertainty. The measurement uncertainty column is marked NA(Not

Applicable) in Table 2-1.

Test Accuracy Ratios (TAR) are not defined for pass/fail measurements, so

all measurements show NA (Not Applicable) in the TAR column.

24 Verification Tests Chapter 2

Page 25

Table 2-1. Performance Test Record (Page 1 of 2)

Model __________________________ Report No._________________ Date __________________

General Information

Test Facility:

Name _____________________________________

Address ________ __ __ ______________ ___________

City/State ___________________________________

Phone _____________________________________

Special Notes:

_____________________________________________________________________________________________

_____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

Report No. _________________________________

Date ________________________ _____________

Customer ___________________________________

Tested by __________________________________

Test Equipment Record

Test Equipment Used:

Description

1. _______________________________

Model No. Trace No. Cal Due Date

_______________

_______________

_______________

2. _______________________________

3. _______________________________

_______________

______________

_______________

______________

_______________

______________

Chapter 2 Verification Tests 25

Page 26

Table 2-1. Performance Test Record (Page 2 of 2)

Model __________________________ Report No._________________ Date __________________

Performance Test Record

Test No/Description

Test 2-1: Digital Test

Read/Write Test

Port 0 Write/Port 2 Read NA Pass Fail NA NA NA

Port 1 Write/Port 3 Read NA Pass Fail NA NA NA

Port 2 Write/Port 0 Read NA Pass Fail NA NA NA

Port 3 Write/Port 1 Read NA Pass Fail NA NA NA

Handshake Test

Port 0 CTL/Port 2 FLG NA Pass Fail NA NA NA

Port 1 CTL/Port 3 FLG NA Pass Fail NA NA NA

Minimum

Value

Measured Value Maximum

Value

Meas

Uncert

Test Acc

Ratio (TAR)

Port 2 CTL/Port 0 FLG NA Pass Fail NA NA NA

Port 3 CTL/Port 1 FLG NA Pass Fail NA NA NA

26 Verification Tests Chapter 2

Page 27

Chapter 3

Replaceable Parts

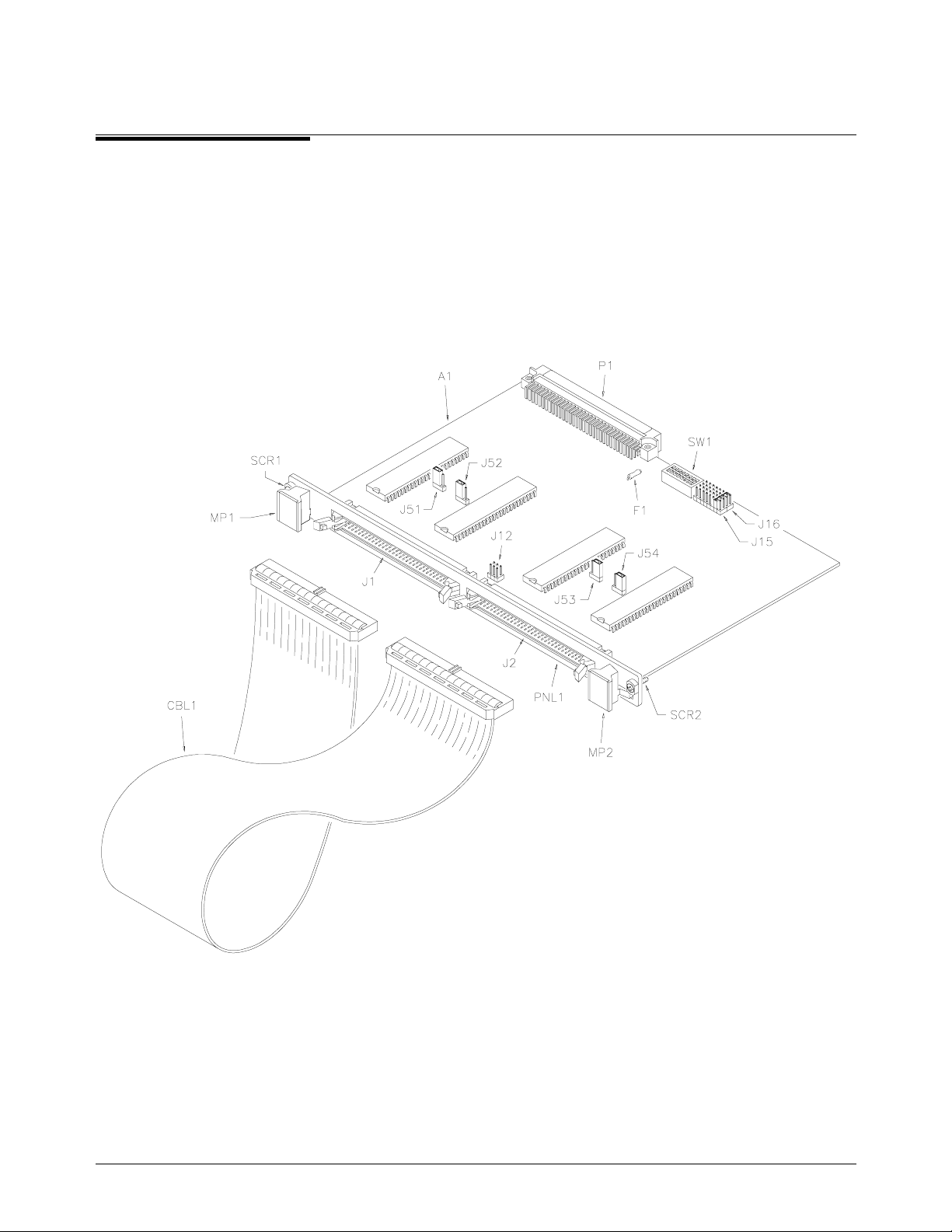

Introduction This chapter co n ta in s in formation to or de r re pl ac ea bl e pa rt s fo r th e H P

E1330A Quad 8-Bit Digital I/O Modules with serial number prefixes 2934A

and HP E1330B with serial number prefixes 3221A. Table 3-1 lists

replaceable parts for the HP E1330A Module and Table 3-2 lists replaceable

parts for the HP E1330B Module. Table 3-3 shows reference designators for

parts in Tables 3-1 and 3-2. Table 3-4 shows the manufacturer code list for

these parts.

To order a part listed in Table 3-1 or 3-2, specify the Hewlett-Packard part

number and the quantity required. Send the order to your nearest

Hewlett-Packard Sales and Support Office.

Replaceable

Parts List

Table 3-1 lists mechanical replaceable parts for the HP E1330A Quad 8-Bit

Digital I/O Module with serial number prefix 2934A. Table 3-2 lists

mechanical replaceable parts for the HP E1330B Quad 8-Bit Digital I/O

Module with serial number prefix 3221A. See Figure 3-1 for locations of

mechanical parts.

Chapter 3 Replaceable Parts 27

Page 28

Table 3-1. HP E1330A Replaceable Parts

Reference

Designator

A1 E1330-66501 1 PC Assembly - Digital I/O 32-Channel 28480 E1330-66501

CBL1 E1330-61603 1 Test Cable (issued with Service Kit) 28480 E1330-61603

CBL2-CBL3 E1330-61601 2 Ribbon Cable (not illustrated) 28480 E1330-61601

MP1 E1300-45101† 1 HNDL-KIT TOP, HP† 28480 E1300-45101†

MP2 E1300-45102† 1 HNDL-KIT BTM, VXI† 28480 E1300-45102†

F1 2110-0712

J1-J2 1252-1044 2 Connector-post type .100-pin-spcg 60-contact 76381 3372-5302

J12 1251-6515 1 Connector-post type .100-pin-spcg 6-contact 18873 67996-606

J15-J16 1251-4927 2 Connector-post type .100-pin-spcg 16-contact 76381 2416-6182TB

J51-J54 1251-4682 4 Connector-post type .100-pin-spcg 3-contact 27264 22-10-2031

P1 1252-1596 1 Connector-post type 2.54-pin-spcg 96-contact 00779 536010-5

P15 1258-0247 1 Four-position Jumper 22526 69146-204

P51-P57 1258-0141 7 Removable Jumper 00779 530153-2

PNL1 E1330-00212†

SCR1-SCR2 0515-2140 2 SCR-THD-RLG M2.5 X0.45 14mm 28480 0515-2140

SCR3-SCR4 0515-1968 2 Screw M2.5 X 0.45 11mm-long pan-head 28480 0515-1968

SCR5-SCR6 0515-2743 2 SCR-FH M2.5 X 8 THREAD ROLLING 28480 0515-2743

SW1 3101-3066 1 Switch-dip Rocker 8-1A 0.15A 30 VDC 81073 76YY22968S

HP Part

Number Qty Part Description

ASSEMBLIES and CABLES

(See Figure 3-1)

E1330-66201 1 REPLACEMENT ASSEMBLY 28480 E1330-66201

Fuse-subminiature 4A 125V NTD AX

1

PNL-RR 4 CH DAC†

1

Mfr.

Code

75915

28480

Mfr. Part

Number

R251004T1

E1330-00212†

† These parts are not compatible with older version fixed handles or their corresponding front panels. To replace one or more of these

old parts, you must order all three new parts (Top and Bottom Handle Kits AND Front Panel).

28 Replaceable Parts Chapter 3

Page 29

Table 3-2. HP E1330B Replaceable Parts

Reference

Designator

A1 E1330-66521 1 PC Assembly - Digital I/O 32-Channel 28480 E1330-66521

CBL1 E1330-61603

CBL2-CBL3 E1330-61601 2 Ribbon Cable (not illustrated) 28480 E1330-61601

MP1 E1300-45101† 1 HNDL-KIT TOP, HP† 28480 E1300-45101†

MP2 E1300-45102† 1 HNDL-KIT BTM, VXI† 28480 E1300-45102†

F1 2110-0712 1 Fuse-subminiature 4A 125V NTD AX 75915 R251004T1

J1-J2 1252-1044 2 Connector-post type .100-pin-spcg 60-contact 76381 3372-5302

J12 1251-6515 1 Connector-post type .100-pin-spcg 6-contact 18873 67996-606

J15-J16 1251-4927 2 Connector-post type .100-pin-spcg 16-contact 76381 2416-6182TB

J51-J54 1251-4682

P1 1252-1596 1 Connector-post type 2.54-pin-spcg 96-contact 00779 536010-5

P15 1258-0247 1 Four-position Jumper 22526 69146-204

P51-P57 1258-0141 7 Removable Jumper 00779 530153-2

PNL1 E1330-00212† 1 PNL-RR 4 CH DAC† 28480 E1330-00212†

SCR1-SCR2 0515-2140 2 SCR-THD-RLG M2.5 X0.45 14mm 28480 0515-2140

SCR3-SCR4 0515-1968 2 Screw M2.5 X 0.45 11mm-long pan-head 28480 0515-1968

SCR5-SCR6 0515-2743 2 SCR-FH M2.5 X 8 THREAD ROLLING 28480 0515-2743

SW1 3101-3066

HP Part

Number Qty Part Description

ASSEMBLIES and CABLES

(See Figure 3-1)

E1330-66202 1 REPLACEMENT ASSEMBLY 28480 E1330-66202

Test Cable (issued with Service Kit)

1

Connector-post type .100-pin-spcg 3-contact

4

Switch-dip Rocker 8-1A 0.15A 30 VDC

1

Mfr.

Code

28480

27264

81073

Mfr. Part

Number

E1330-61603

22-10-2031

76YY22968S

† These parts are not compatible with older version fixed handles or their corresponding front panels. To replace one or more of these

old parts, you must order all three new parts (Top and Bottom Handle Kits AND Front Panel).

NOTE

If the 4 IC’s placed in the sockets are square in shape rather than

rectangular, the PC assembly (A1 reference designator) is the most recent

HP E1330B release, as listed above. If the 4 IC’s are rectangular (see

Figure 3-1), the PC assembly is an earlier E1330B release and must be

replaced with a new Replacement Assembly (Part Number E1330-66202).

Chapter 3 Replaceable Parts 29

Page 30

Table 3-3. HP E1330A/B Reference Designators

HP E1330A/B Reference Designators

A................................................... assembly MP. ..................................... mechanical part

F ............................................................fuse P......................... electrical connector (plug)

J.......................... electrical connector (jack) PNL .....................................................panel

JM......................................................jumper SCR.................................................... screw

SW .....................................................switch

Table 3-4. HP E1330A/B Code List of Manufacturers

Mfr.

Code

00779 AMP Inc. Harrisburg PA US 17111

18873 Dupont E I De Nemours & CO Wilmington DE US 19801

22526 Berg Electronics Inc. Ettersill PA US 17319

27264 Molex Inc. Lisle IL US 60532

28480

75915 Littelfuse Inc. Des Plaines IL US 60016

76381 3M CO St Paul MN US 55144

81073 Grayhill Inc. La Grange IL US 60525

Hewlett-Packard Company - Corporate Palo Alto CA US

Manufacturer’s

Name

Manufacturer’s

Address

Zip

Code

94304

30 Replaceable Parts Chapter 3

Page 31

Mechanical

Parts Locator

Figure 3-1 shows the location of selected mechanical parts for the HP

E1330A/B Quad 8-Bit Digital I/O Module.

Figure 3-1. Mechanical Parts

Chapter 3 Replaceable Parts 31

Page 32

32 Replaceable Parts Chapter 3

Page 33

Chapter 4

Service

Introduction This chapter contains service information for the HP E1330A/B Quad 8-Bit

Digital I/O Modules. Also included are trouble shooting, repair, and

maintenanc e guidelines.

WARNING

Equipment

Required

Service Aids See Chapter 3 — Replaceable Parts for descriptions and locations of HP

Digital I/O Module

Description

Do not perform any of the service procedures shown unless

you are a qualified, service-trained technician and have read

the WARNINGS and CAUTIONS in Chapter 1.

Equipment required for module troubleshooting and repair is listed in Table

1-1, Recommended Test Equipment. Any equipment that satisfies the

requirements given in the table may be substituted. To avoid damage to the

screw head slots, use a T8 Torx driver to remove the front panel handles.

E1330A/B replaceable parts. Service notes, manual updates, and service

literature for the modules may be available through Hewlett-Packard. For

information, contact your ne ar es t Hew l ett- Pac ka rd Sale s and Service Office .

The HP E1330A/B provides four independent 8-bit digital I/O ports

compatible with TTL logic levels. Each port can be software config ured for

operation as either input or output with either positive or negative true logic.

The ports can be combined to provide 16 bit (WORD) or 32 bit (LWORD)

operations.

In addition to the eight digital data lines, six handshake lines are included

per port. The handshake lines can also be combined (via jumpers on the

component assembly) to provide proper handshaking for combined ports.

The data lines of each port are provided with a jumpered pull-up resistors

for dry contact closure sensing. User connections to the Digital I/O module

are made through two 60-pin connectors on the rear panel.

Chapter 4 Service 33

Page 34

Repair Strategy Hewlett-Packard recommends replacement of the entire assembly in the

event of a failure. Procedures in this chapter describe troubleshooting

techniques.

Troubleshooting

Techniques

Identifying the

Problem

To troubleshoot an HP E1330A/B module problem you must first identify

the problem and then isolate the cause of the problem to a replaceable

assembly. See Chapter 3 — Replaceable Parts for descriptions and

locations of HP E1330A/B replaceable parts.

Table 4-1 lists some common problems for the HP E1330A/B modules,

along with symptoms and possible solutions. If the problem cannot be

identified using these steps, replace the assembly.

Table 4-1. HP E1330A/B Typical Problems

Symptom Possible Solutions

Non-zero error code in

response to SYST:ERR?

Module not responding to

commands.

Module fails Digital Test

(Test 2-1).

See Appendix A of the HP E1330A/B

Quad 8-Bit Digital I/O Module User’s

Manual.

See “Making Visual Checks” in thi s

chapter.

See “Testing the Module” in this

chapter.

Making Visual

Checks

NOTE

Visual checks for the HP E1330A/B modules include the following. See

Table 4-2 for typi ca l ch ec ks .

• Check switches/jumpers

• Check for heat damage

• Check connector contacts

See the HP E1330A/B Quad 8-Bit Digital I/O Module User’s Manual for

information on logical address and IRQ settings. If there are no apparent

problems following the visual checks, run the Performance Verification

Tests in Chap te r 2 to see if th e m odule is defecti ve .

34 Service Chapter 4

Page 35

Table 4-2. HP E1330A/B Visual Tests/Checks

Test/Check Reference

Designator

Heat Damage - - - - -

- - - - -

- - - - -

Switch/Jumper

Settings

Component

Assembly

J15, J16

SW1

J51,J52,J53,J54

J12

F1

J1-J2

P1

Discolored PC boards

Damaged insulation

Evidence of arcing

IRQ Level sett in g

Logical address setting

Pull-up Enable

FLG Combine

Fuse continuity

Dirty or bent connector pi ns

Dirty or bent connector pi ns

Check Action/Notes

If there is damage, do not

operate the module until you

have corrected the problem.

Factory set at 1

Factory set at 144

Factory set to Enable

Factory set to no jumpers

Check fuse with ohmmeter

Straighten/clean pins

Straighten/clean pins

Testing the Module You can use the tests and checks in Chapter 2 — Verification Tests, to

identify a problem with the assembly. See Chapter 3 — Replaceable Parts

for locations of mechanical parts.

Chapter 4 Service 35

Page 36

Repair and

Maintenance

This section p ro vi de s guidelines for rep a iri ng and mainta in in g th e H P

E1330A/B Quad 8-Bit Digital I/O Module including:

Guidelines

• ESD precautions

• Soldering printed circuit boards

• Post-repair safety checks

ESD Precautions Electrostatic discharge (ESD) may damage static sensitive devices in the

module. This damage can range from slight parameter degradation to

catastrophic failure. When handling the module observe the following

guidelines:

• Always use a static-free work st ation with a pad of conductive rubber o r

similar material when handling module components.

• If a device requires soldering, be sure the assembly is placed on a pad of

conductive material. Also , be sure that you, the pad, and the soldering

iron tip are grounded to the assembly.

Soldering Printed

Circuit Boards

Post-Repair Safety

Checks

The etched circuit board of this module has plated-through holes that

provide a solder path to both sides of the insulating material. Soldering can

be done from either side of the board with equally good results. When

soldering to any circuit board, keep in mind the following guidelines:

• Avoid unnecessary component unsoldering and soldering. Excessive

replacement can result in damage to the circuit board, adjacent

components, or both.

• Do not use a high power soldering iron on etched circuit boards, as

excessive heat may lift a conductor or damage the board.

• Use a suction device or wooden toothpick to remove solder from

component mounting holes. When using a suction device, be sure that

the equipment is properly grounded.

After makin g re pa ir s to the module, inspect the module for any signs of

abnormal internally generated heat, such as discolored printed circuit boards

or components, damaged insulation, or evidence of arcing. Determine and

correct the cause of the condition. Then perform Test 2-1 as described in

Chapter 2 — Verification Tests to verify that the module is functional.

36 Service Chapter 4

Page 37

Appendix A

Verification Tests - C Programs

Functional

Verification

Test

Example This example sends a *IDN? command to the Digital I/O Module. This test

This program is designed to do the Functional Verification Test found in

Chapter 2 - Verification Tests.

can be used to verify that the module is connected properly and is

responding to a basic command.

#include <stdio.h>

#include <sicl.h>

#define ADDR "hpib7,9,18" /* Address of Device */

void main ()

{

INST id; /* Define id as an instrument */

char a[256] = {0}; /* Result variable */

id = iopen (ADDR); /* Open instrument session */

ipromptf (id, "*IDN?\n", "%t", a); /* ID command */

printf ("\n %s", a); /* Print result */

getchar (); /* Pause */

iclose (id); /* Close instrument session */

}

Appendix A Verification Tests - C Programs 37

Page 38

Performance

Verification

Test

This program is designed to do the Performance Verification Test found in

Chapter 2 - Verification Tests.

Example: Digital

Test

This example performs a bit walk test of all bits on all ports and checks the

module’s ability to set and reset the handshake lines on each port.

/* Digital I/O Test E1330A */

#include <stdio.h>

#include <stdlib.h>

#include <sicl.h>

#define ADDR "hpib7,9,18" /* Address of device */

void main (void)

{

INST id; /* Define id as an instrument */

char a[255], b[32];

char *bit_walk[] = {"00000001", "00000010", "00000100", "00001000",

"00010000", "00100000", "01000000", "10000000"};

int bit_val[] = {1, 2, 4, 8, 16, 32, 64, 128};

int fail, i, j, number;

int atoi (const char *a);

#if defined(__BORLANDC__) && !defined(__WIN32__)

_InitEasyWin();

#endif

ionerror(I_ERROR_EXIT);

id = iopen (ADDR); /* Open instrument session */

iprintf (id, "*CLS\n");

fail = 0;

printf("\nInstall component assembly and test cable");

printf("\n\n 1. Turn mainframe power off");

printf("\n 2. Install HP E1330A/B component assemby into

mainframe");

printf("\n 3. Attach test cable to component assembly");

printf("\n 4. Turn mainframe power on");

printf("\n 5. Press ENTER when ready to begin testing");

gets (a);

/*-----------------------------------Bit walk test-------------------------------------*/

38 Verification Tests - C Programs Appendix A

Page 39

printf("\n\nBit walk test of all ports for read and write (no handshake)");

for (i = 0; i <= 7; i++)

{

for (j = 0; j <= 3; j++)

{

iprintf (id, "SOUR:DIG:DATA%u #B%s\n", j, bit_walk[i]);

if (j < 2)

iprintf (id, "MEAS:DIG:DATA%u?\n", j+2);

else

iprintf (id, "MEAS:DIG:DATA%u?\n", j-2);

iscanf(id, "%t", a);

number = atoi(a);

if (number != bit_val[i])

{

fail = 1;

printf("\nFailure of bit walk");

printf("\n WRITE at port %u", j);

if (j < 2)

printf("\n READ at port %u", j+2);

else

printf("\n READ at port %u", j-2);

}

}

}

printf("\nEnd of bit walk test");

/*---------------------------------Handshake line test-----------------------------*/

printf("\n\nHandshake line test");

(j = 1; j >= 0; j = j - 1)

{

for (i = 0; i <= 3; i++)

{

iprintf(id, "SOUR:DIG:CONT%u %u\n", i, j);

if (i < 2)

iprintf(id, "MEAS:DIG:FLAG%u?\n", i+2);

else

iprintf(id, "MEAS:DIG:FLAG%u?\n", i-2);

iscanf(id, "%1t", a);

if (atoi(a) != j)

{

fail = 1;

printf("\nFailure of handshake lines");

if (i < 2)

printf("\n CTL line on port %u to FLG line on port %u", i, i+2);

else

printf("\n CTL line on port %u to FLG line on port %u", i, i-2);

Appendix A Verification Tests - C Programs 39

Page 40

}

}

}

printf("\nEnd of handshake line test\n");

/*------------------------------------Results----------------------------------------------*/

if (fail == 0)

printf("\nDigital I/O PASSED all tests");

else

printf("\nDigital I/O failed tests");

iclose (id); /* Close instrument session */

}

40 Verification Tests - C Programs Appendix A

Loading...

Loading...