Page 1

Contents

HP E1328A Service Manual

Edition 2

Click here to return to HP TS-5400 Systems On-Line Manuals Main Contents

Chapter 1. General Informa tio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DAC Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

DAC Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

DAC Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

DAC Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 2. Ins tallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Preparation for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Shipping Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 3. Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

D/A Converter Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operator’s Chec k . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Self-Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Example: D/A Converter Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 4. Verification Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Test Conditions / Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Verification Test Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Function al Verification Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

DAC Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Voltage Compliance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Test Procedure (Positive Voltage Compliance) . . . . . . . . . . . . . . . . . . . 22

Test Procedure (Negative Voltage Compliance) . . . . . . . . . . . . . . . . . . . . 23

Example: Positive Voltage Compliance . . . . . . . . . . . . . . . . . . . . . . . . 23

Current Compliance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Test Procedure (Positive Current Compliance) . . . . . . . . . . . . . . . . . . . . 26

Test Procedure (Negative Current Compliance) . . . . . . . . . . . . . . . . . . . . 26

Example: Positive Current Compliance . . . . . . . . . . . . . . . . . . . . . . . . 27

Operatio n Verification Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Performance Verification Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Voltage Accuracy Measurements Test . . . . . . . . . . . . . . . . . . . . . . . . . 29

HP E1328A Service Manual Contents 1

Page 2

Counter Accuracy Measurements Test . . . . . . . . . . . . . . . . . . . . . . . . . 31

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 5. Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Voltage Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Adjustment Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Example: Voltage Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Current Ad justments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Adjustment Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Example: Current Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Chapter 6. Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Exchange Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Replaceabl e

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Chapter 7. Manual Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Chapter 8. Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Service Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Troubleshooting Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Identifyi ng the Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Testing the DAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Repair / Maintenance Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Soldering Printed Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Post-Repair Safety Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Appendix A. Calculating D/A Converter Accuracy . . . . . . . . . . . . . . . . . . . . . . 55

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

DAC Accuracy Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

DC Voltage Accuracy Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

DC Current Accuracy Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

HP 3458A Measurement Uncertainty Calculations . . . . . . . . . . . . . . . . . . . . 57

Calculate DCV Measurement Uncertainty . . . . . . . . . . . . . . . . . . . . . . . 57

Calculate DCI Measurement Uncertainty . . . . . . . . . . . . . . . . . . . . . . . 57

Test Accuracy Ratio (T A R) Calculations . . . . . . . . . . . . . . . . . . . . . . . . 58

Appendix B. Verification Tests - C Programs . . . . . . . . . . . . . . . . . . . . . . . . . 61

Function al Verification Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Example: Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Example: Positive Voltage Compliance . . . . . . . . . . . . . . . . . . . . . . . . 62

2 Contents HP E1328A Service Manual

Page 3

Example: Positive Current Compliance . . . . . . . . . . . . . . . . . . . . . . . . 63

Performance Verification Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Example: Voltage Accuracy Measurements . . . . . . . . . . . . . . . . . . . . . . 65

Example: Current Accuracy Measurements . . . . . . . . . . . . . . . . . . . . . . 66

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Example: Voltage Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Example: Current Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

HP E1328A Service Manual Contents 3

Page 4

Notes

4 Contents HP E1328A Service Manual

Page 5

Hewlett-Packard Company certifies that this product met its published specifications at the time of shipment from the factory. Hewlett-P a ck a r d

further certifies that its calibration measurements are traceable to the United States National Institute of Standards and Technology (formerly Na-

tional Bureau of Standards), to the extent allowed by that organization’s calibration facility, and to the calibration facilities of other International

Standards Organization members.

WARRANTY

CERTIFICATION

This Hewlett-Packard product is warrante d against defects in materials and workmanship for a period of three years from date of shipment. Duration and conditions of warranty for this product may be superseded when the product is integrated into (becomes a part of) other HP products.

During the warranty period, Hewlett-Packard Company will, at its option, either repair or replace products which prove to be defective.

For warranty service or repair, this product must be returned to a service facility designated by Hewlett-Packard (HP). Buyer shall prepay shipping charges to HP and HP shall pay shipping charges to return the product to Buyer. However, Buyer shall pay all shipping charges, duties, and

taxes for products returned to HP from another country.

HP warrants that its software and firmware designated by HP for use with a product will execute its programming instruct ions when properly installed on that product. HP does not warrant that the operation of the product, or software, or firmware will be uninterrupted or error free.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance by Buyer, Buyer-supplied products or interfacing, unauthorized modification or misuse, operation outside of the environmental specifications for the product, or improper site preparation or

maintenance.

The design and implementation of any circuit on this product is the sole responsibility of the Buyer. HP does not warrant the Buyer’s circuitry or

malfunctions of HP products that result from the Buyer’s circuitry. In addition, HP does not warrant any damage that occurs as a result of th e

Buyer’s circuit or any defects that result from Buyer-supplied products.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HP SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES. HP SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY

OTHER LEGAL THEORY.

NOTICE

This manual and any examples contained herein are proveded “as is” and are subj ect to change without notice. HEWLETT-PACKARD (HP)

COMPANY MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS MANUAL, INCLUDING, BUT NOT LIMITED TO,

ANY IMPLIED WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Hewlett-Packard Company

shall not be liable for any errors or for incidental or consequential damages in connection with the furnishing, performance or use of this material.

This document contains proprietary information which is protected by copyright. All rights are reserved. No part of this document may be photocopied, reproduced, or translated to another language without the prior written consent of Hewlett-Packard Company. HP assumes no responsibility for the use or reliability of its software on equipment that is not furnished by HP.

Restricted Rights Legend

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subdivision (b)(3)(ii) of the Rights in Technical Data and

Computer Software clause at 52.227-7013. Hewlett-Packard Company; 3000 Hanover Street; Palo Alto, California 94304

Declaration of Conformity

According to ISO/IEC Guide 22 and EN 45014

The Hewlett-Packard Company declares that the HP E1328A conforms to the following Product Specifications.

Safety: IEC 1010-1 (1990) Incl. Amend 1 (1992)/EN61010 (1993)

EMC: CISPR 11:1990/EN 55011 (1991): Group1 Class A

IEC 801-2:1991/EN 50082-1 (1992): 4kVCD, 8kVAD

IEC 801-3:1984/EN 50082-1 (1992): 3 V/m

IEC 801-4:1988/EN 50082-1 (1992): 1kV Power Line

Supplementary Information: The product herewith complies with the requirements of the low voltage Directive 73/23/EEC and the EMC Directive 89/336/EEX.

Tested in a typi ca l co n f i g u r at io n in an H P C-size VXI mainf r ame.

Hewlett-Packard Company

P.O. Box 301

815 14th Street S.W.

Loveland, Colorado 80539 U.S.A.

CSA C22.2 #1010.1 (1992)

UL 1244

Q.A. Manager

June 1996

5

Page 6

The Printing History shown below lists all Editions and Updates of this manual and the printing date(s). The first printing of the manual is Edition 1. The Edition number increments by 1 whenever the manual is revised. Updates, which are issued between Editions, contain replacem en t

pages to correct the current Edition of the manual. Updates are numbered sequentially starting with Update 1. When a new Edition is created, it

contains all the Update information for the previous Edition. Each new Edition or Update also includes a revised copy of this printing history

page. Many product updates or revisions do not require manual changes and, conversely, manual corrections may be done without accompanying

product changes. Therefore, do not expect a one-to-one correspondence between product updates and manual updates.

Edition 1 (Part Number E1328-90010) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . June 1991

Edition 2 (Part Number E1328-90011) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . June 1996

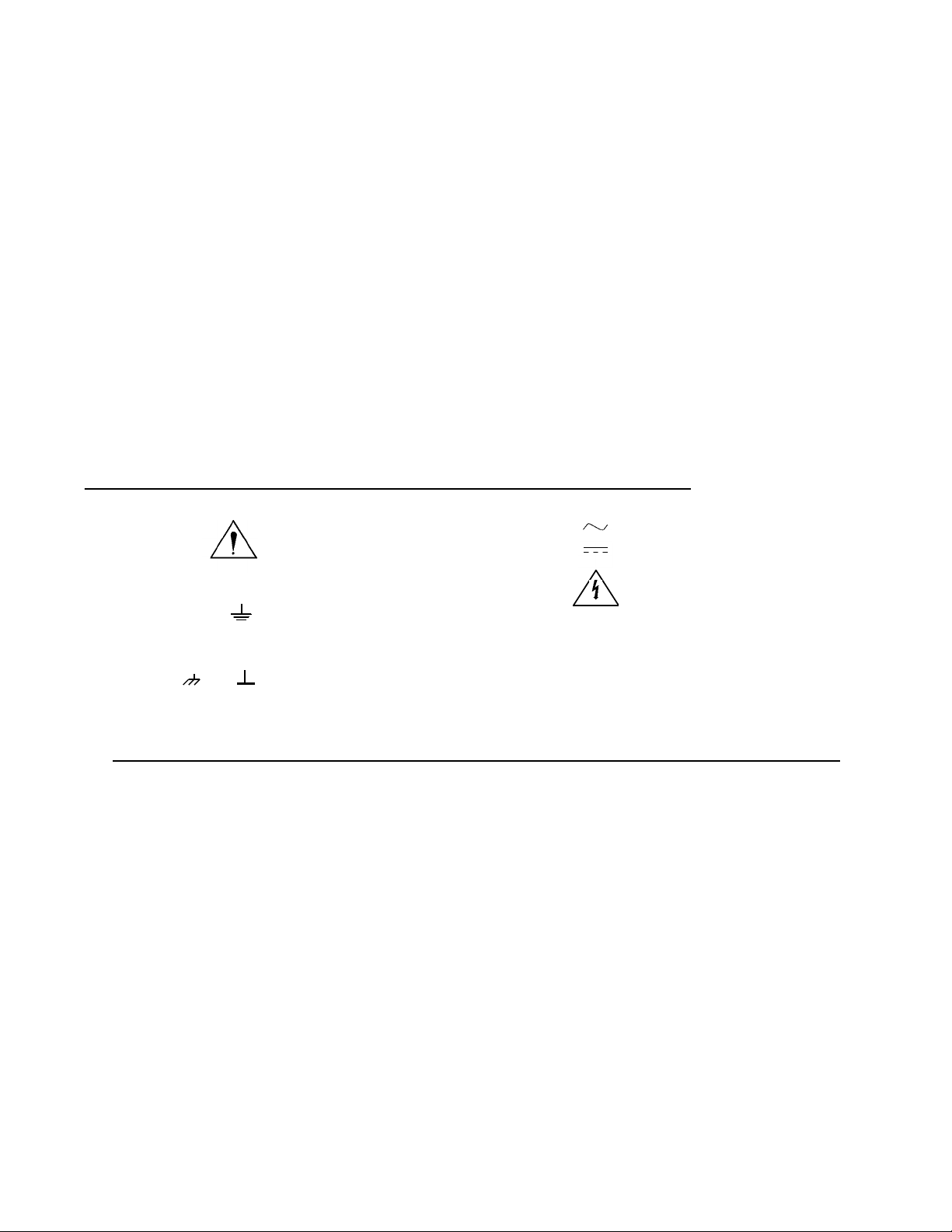

Safety Symbols

Printing History

Instruction

manual symbol

affixed to product. Indicates

Caution information to avoid personal injury or

damage to the

field wiring terminal that must be connected

to earth ground before operating the equip-

ment—protects against elect rical shock in

case of fault.

OR

that the user

must refer to

the manual

for specific

Warning or

product.

Indicates the

Frame or chassis ground tercally connects to

WARNING

CAUTION

Indicates

minal—typi

the equipment’s metal

frame.

Alternating

current (AC).

Direct current

(DC).

hazardous

voltages.

WARNINGS

The following general safety precautions must be observed during all phases of operation, service, and repair of this product. Failure to

comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture, and

intended use of the product. Hewlett-Packard Company assumes no liability for the customer’s failure to comply with these requirements.

Ground the equipment: For Safety Class 1 equipment (equipment having a protective earth terminal), an uninterruptible safety earth ground

must be provided from the mains power source to the product input wiring terminals or supplied power cable.

DO NOT operate the product in an explosive atmosphere or in the presence of flammable gases or fumes.

For continued protection against fire, replace the line fuse(s) only with fuse(s) of the same voltage and current rating and type.

DO NOT use repaired fuses or short-circuited fuse holders.

Keep away from live circuits: Operating personnel must not remove equipment covers or shields. Procedures involving the removal of covers or

shields are for use by service-trained personnel only. Under certain conditions, dangerous voltages may exist even with the equipment switched

off. To avoid dangerous electrical shock, DO NOT perform procedures involving cover or shield removal unless you are qualified to do so.

DO NOT operate damaged equipment: Whenever it is possible that the safety protection features built into this product have been impaired,

either through physical damage, excessive moisture, or any other reason, REMOVE POWER and do not use the product until safe operation can

be verified by service-trained personnel. If necessary, return the product to a Hewlett-Packard Sales and Service Office for service and repair to

ensure that safety features are maintained.

DO NOT service or adjust alone: Do not attempt internal service or adjustment unless another person, capable of rendering first aid and resuscitation, is pr esent.

DO NOT substitute parts or modify equipment: Because of the danger of introducing additional hazards, do not install substitute parts or perform any unauthorized modification to the product. Return the product to a Hewlett-Packard Sales and Service Office for service and repair to ensure that safety features are maintained.

6

Page 7

What’s in this Manual

Manual Overview

This manual shows how to service the HP E1328A 4-Channel D/A Converter. Additional manuals which may

be required for servicing the D/A Converter include the HP E1328A User’s Manual which contains D/A

Converter operation, installation, and configuration information, and the appropriate mainframe user’s

manual(s) for mainframe operation, installation and configuration information.

Manual Content

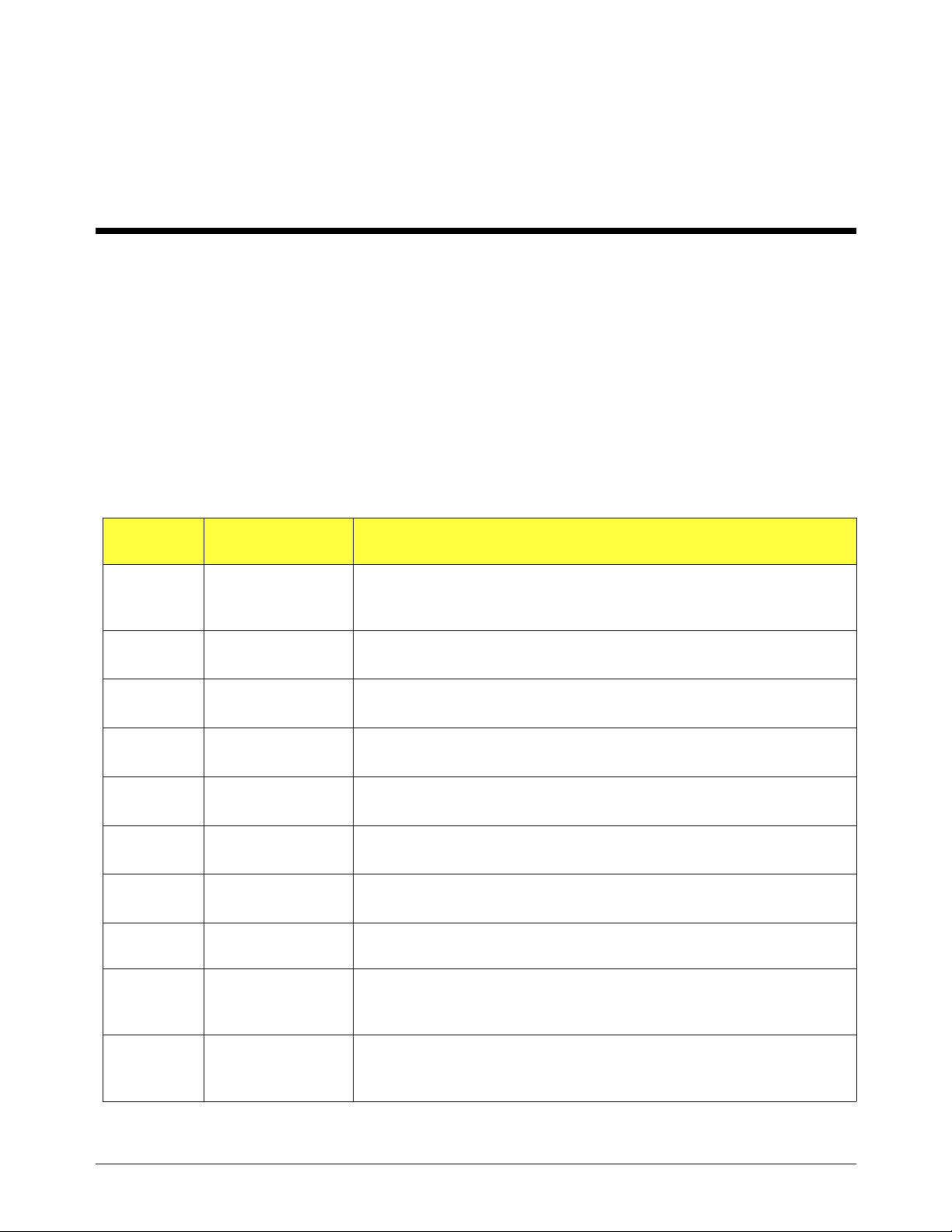

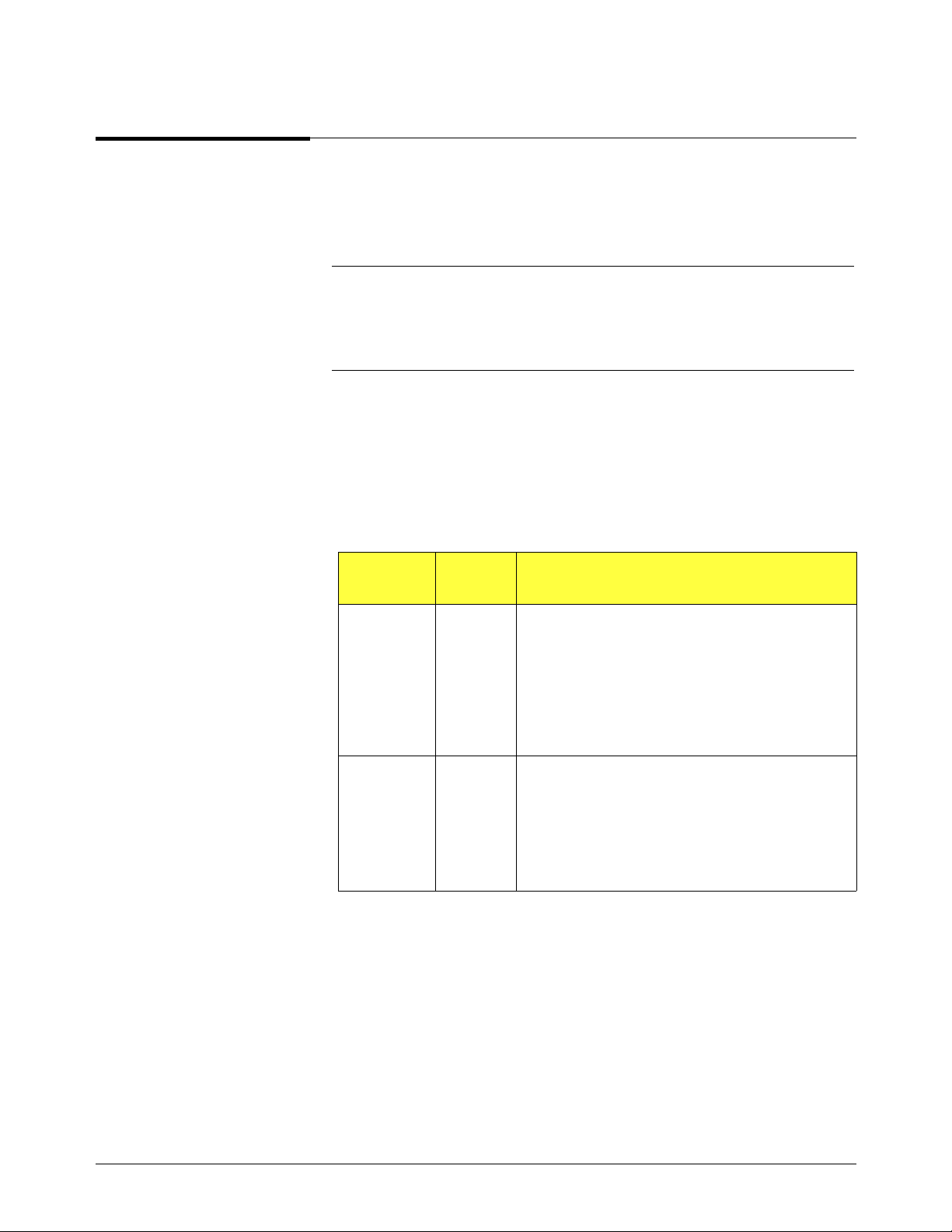

Chapter Title Content

1

2

3

4

5

6

7

8

A

General

Information

Installation Procedures to install the D/A Converter, perform initial inspection,

Operating

Instructions

Verification

Tests

Adjustments Procedures to adjust the D/A Converter to within its rated

Replaceable

Parts

Manual

Changes

Service Procedures to aid in fault isolation and repair of the D/A Converter.

Calculating

D/A Converter

Accuracy

Provides a basic description, and lists available options and

accessories. Also lists the tools and test equipment required for

service.

prepare for use, and store and ship the D/A Converter.

Procedures to operate the D/A Converter and perform operator’s

check.

Functional verification, operation verification, and performance

verification tests to test the D/A Converter.

specifications.

Lists part numbers for user replaceable parts in the D/A Converter.

Provides information on ordering spare parts and module exchange.

Information to adapt this manual to instruments whose serial

numbers are lower than those listed on the title page.

Shows how D/A Converter accuracy, measurement uncertainty,

and test accuracy ratios (TARs) are calculated.

B

Verification

Tests - C

Programs

Gives example C programs to implement the the verification tests

and adjustments.

What’s in this Manual 7

Page 8

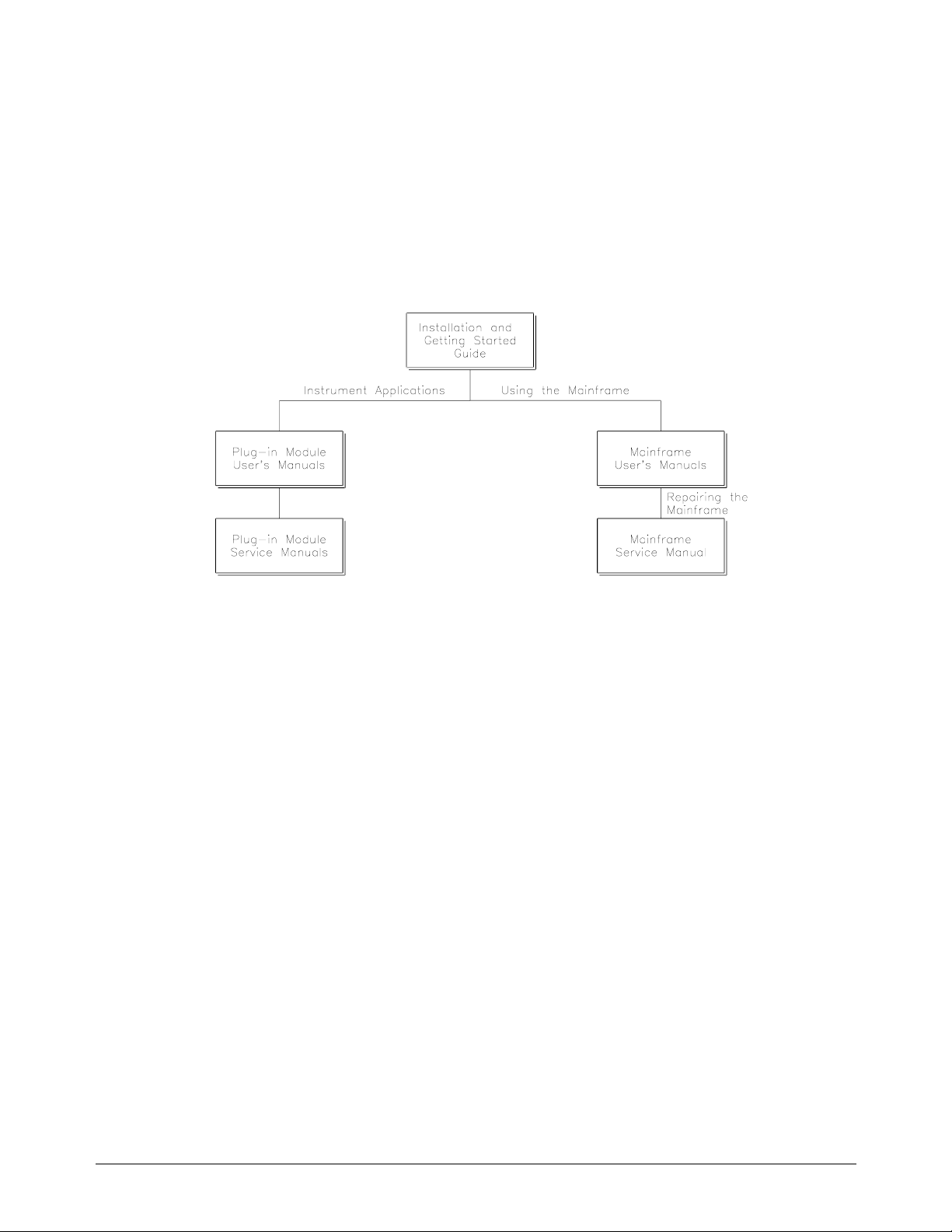

HP 75000 Series B Service Documentation

Suggested Sequence to Use Manuals

Manual Descriptions

Installation and Getting Started Guide. This manual contains step-by-step instructions for all aspects of

plug-in module and mainframe installation. Introductory programming information and examples are also

included.

Mainframe User’s Manual. This manual contains programming information for the mainframe, front panel

operation information ( for the HP E1301A mainframe) , and genera l programming information for instruments

installed in the main frame.

Plug-In Module User’s Manuals. These manuals contain plug-in module programming and configuration

information. Each manual contains examples for the most-used module functions, and a complete SCPI

command re fe re nc e fo r th e pl ug-in module.

Mainframe Service Manual. This manual contains service information for the mainframe. It contains

information for ordering replaceable parts and exchanging assemblies. Information and procedures for

performance verification, adjustment, preventive maintenance, troubleshooting, and repair are also included.

Plug-In Module Service Manuals. These manual s co nt ain pl ug -i n m od ul e se rv ic e in formation. Each m an u a l

contains information for exchanging the module and/or ordering replaceable parts. Depending on the module,

information and procedures for functional verification, operation verification, performance verification,

adjustment, preventive maintenance, troubleshooting, and repair are also provided.

8 HP 75000 Series B Ser vi ce D ocu m en ta ti o n

Page 9

Chapter 1

General Information

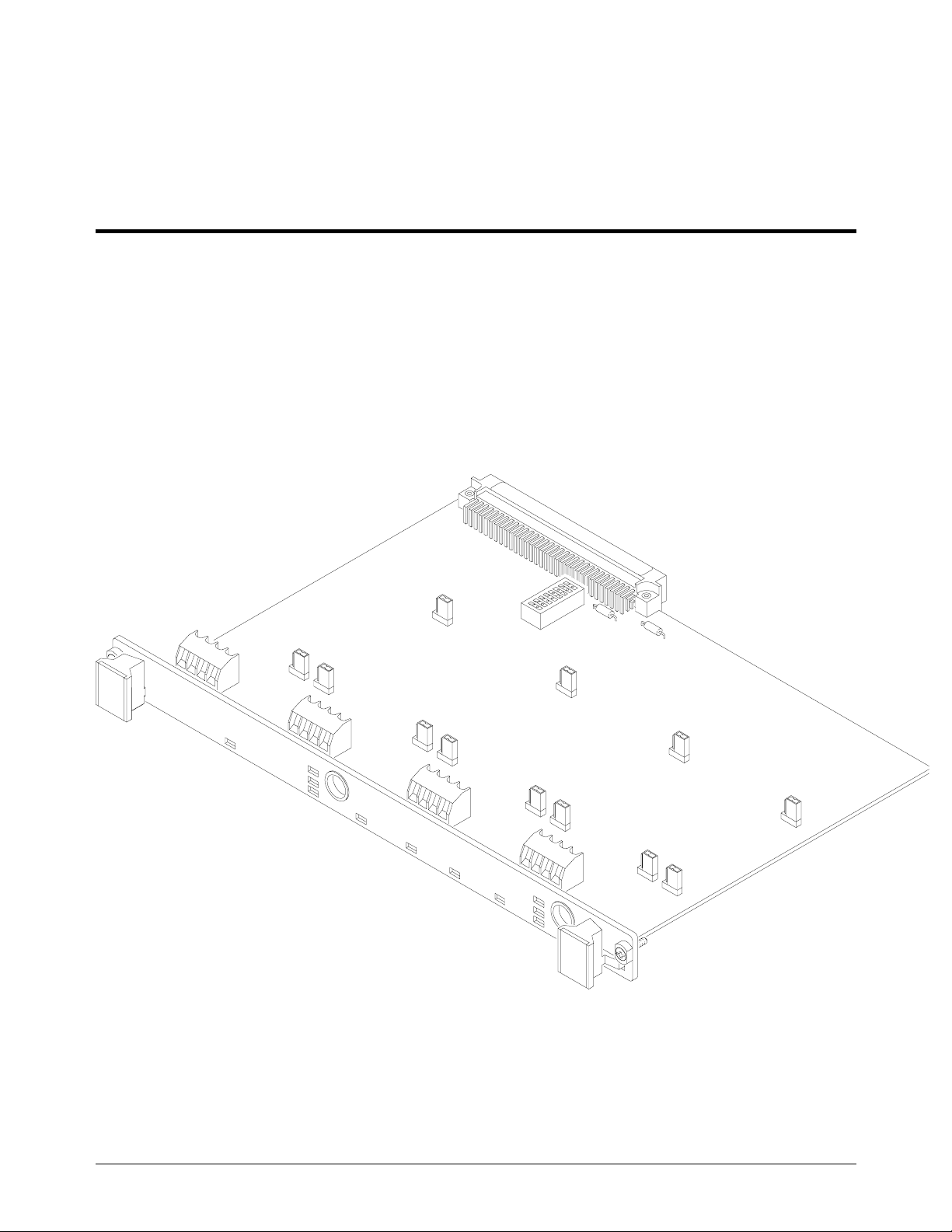

Introduction This HP E1328A Service Manual contains information required to test,

adjust, troubleshoot, and repair the HP E1328A B-Size VXI 4-Channel D/A

Converter (DAC). See the HP E1328A User’s Manual for additional

information on the HP E1328A DAC. Figure 1-1 shows the HP E1328A

DAC.

Figure 1-1. HP E1328A 4-Channel D/A Converter

Chapter 1 General Information 9

Page 10

Safety

Considerations

This product is a Safety Class I instrument that is provided with a protective

earth terminal when installed in the mainframe. The mainframe, DAC, and

all related documentation should be reviewed for familiarization with safety

markings and instructions before operation or service.

Refer to the WARNINGS page (page iii) in this manual for a summary of

safety information. Safety information for preventive maintenance, testing,

adjusting, and service follows and is also found throughout this manual.

Warnings and

Cautions

WARNING

This section contains WARNINGS which must be followed for your

protection and CAUTIONS which must be followed to avoid damage to the

equipment when performing instrument maintenance or repair.

SERVICE-TRAINED PERSONNEL ONLY. The information in

this manual is for service-trained personnel who are familiar

with electronic circuitry and are aware of the hazards involved.

To avoid personal injury or damage to the instrument, do not

perform procedures in this manual or do any servicing unless

you are qualified to do so.

CHECK MAINFRAME POWER SETTINGS. Before applying

power, verify that the mainframe setting matches the line

voltage and the correct fuse is installed. An uninterruptible

safety earth ground must be provided from the main power

source to the mainframe input wiring terminals, power cord, or

supplied power cord set.

GROUNDING REQUIREMENTS. Interruption of the protective

(grounding) conductor (inside or outside the mainframe) or

disconnecting the protective earth terminal will cause a

potential shock hazard that could result in personal injury.

(Grounding one conductor of a two-conductor outlet is not

sufficient protection.)

IMPAIRED PROTECTION. Whenever it is likely that instrument

protection has been impaired, the mainframe must be made

inoperative and be secured against any unintended operation.

REMOVE POWER IF POSSIBLE. Some procedures in this

manual may be performed with power supplied to the

mainframe while protective covers are removed. Energy

available at many points may, if contacted, result in personal

injury. (If maintenance can be performed without power

applied, the power should be removed.)

10 General Information Chapter 1

Page 11

USING AUTOTRANSFORMERS. If the mainframe is to be

energized via an autotransformer (for voltage reduction) make

sure the common terminal is connected to neutral (that is, the

grounded side of the main’s supply).

WARNING

CAUTION

CAPACITOR VOLTAGES. Capacitors inside the mainframe may

remain charged even when the mainframe has been

disconnected from its source of supply.

USE PROPER FUSES. For continued protection against fire

hazard, replace the line fuse(s) only with fuses of the same

current rating and type (such as normal blow, time delay, etc.).

Do not use repaired fuses or short-circuited fuseholders.

MAXIMUM VOLTAGE. Maximum voltage that may be applied

between any two terminals within the same channel is ± 15 Vdc. Do not

apply voltage between any pair of terminals if the D/A Converter is

turned off.

STATIC ELECTRICITY. Static electricity is a major cause of

component failure. To prevent damage to the electrical components in

the DAC, observe anti-static techniques when removing a DAC from

the mainframe or when working on the DAC. Also, when installing a

DAC in a mainframe slot, be sure to tighten the front panel screws.

POWER-UP/DOWN OUTPUTS. At power-up or down, potentials up

to 12V may appear across the channel outputs for up to 10 msec.

Chapter 1 General Information 11

Page 12

DAC

Description

The HP E1328A DAC is an "instrument" in the slots of a VXIbus

mainframe. As su ch, it is assigned an er ro r qu eue, input and ou tput buffers,

status registers, and is allocated a portion of mainframe memory for reading

storage.

NOTE

Instruments are based on the logical addresses of the plug-in modules. See

the HP 75000 Series B Installation and Getting Started Guide to set the

addresses to create an instrument.

There are two E1328A DAC functions (see Table 1-1):

• Isolated Voltage DACs

• Isolated Current DACs

Table 1-1. HP E1328A 4-Channel D/A Converter Functions

Function/

Feature

Voltage

DAC

Chs Description

1,2,3,4

Output DC voltage up to ± 10.92 V independently on

each channel. Can use remote voltage sensing w ith

"no-fault" operation. Connect multiple channels in

series to increase th e ou tp ut to ± 48 Vdc for a si ng le

module. All four channels are independently isolated

and may be floated up to 350 Vdc from ground. Each

channel can be calibrated electronically to 24-hour

specifications.

Current

DAC

1,2,3,4

Output DC current up to ± 21.8 mA independentl y on

each channel. Connect multiple channels in parallel

to increase the outp ut to ± 96 mA for a single module.

All four channels are independently isolated and may

be floated up to 350 Vdc from ground. Each channel

can be calibrat ed electronically to 24-hour

specifications.

DAC Specifications DAC specifications are listed in Appendix A of the HP E1328A Users

Manual. These sp ec ific ai ti on s ar e th e pe rf or mance standards or lim its

against which the instrument may be tested.

12 General Information Chapter 1

Page 13

DAC Serial

Numbers

DACs covered by this manual are identified by a serial number prefix listed

on the title page. Hewlett-Packard uses a two-part serial number in the form

XXXXAYYYYY, where XXXX is the serial prefix, A is the country of

origin (A = USA), and YYYYY is the serial suffix. The serial number

suffix is assigned sequentially to each instrument.

If the serial num b er pre fi x of yo u r in st ru me n t is gre at er th a n th e on e li st ed

on the title page , a M an ua l U pd at e (a s re qu ir ed ) w ill ex pl ain how to adapt

this manual to your instrument. If the serial number prefix is lower than the

one listed on the title page, information contained in Chapte r 7 - M an ua l

Changes explains how to adapt this manual to your instrument.

DAC Options There are no electrical or mechanical options available for the HP E1328A

DAC. However, you can order Option 1BN which provides a

MIL-STD-45662A Calibration Certificate, or Option 1BP which provides

the Calibration Certificate and measurement data. Contact your nearest

Hewlett-Packard Sales and Service Office for information on Options 1BN

and 1BP.

Chapter 1 General Information 13

Page 14

Recommended

Test Equipment

Table 1-2 lists the te st equipment recom m en ded for testing, adj us ti ng , and

servicing the HP E1328A DAC. Essential requirements for each piece of

test equipment are described in the Requirements column.

Table 1-2. Recommended Test Equipme nt

Instrument Requirements Recommended

Model

Controller, HP-IB HP-IB compatibility as def ined by IEEE

Standard 488-1978 and the identical

ANSI Standard MC1.1: SH1, AH1, T2,

TE0, L2, LE0, SR0, RL0, PP0, DC0, DT0,

and C1, 2, 3, 4, 5

Mainframe Compatible with DAC HP E1300A, E1301A,

DC Standard Voltage Range: -20.0 V to +20.0 V Datron 4708 with

Digital Mult im et er

*F = Functional Verification Tests, O = Operation Verification Tests, P = Performance Verification Tests,

A = Adjustments, T = Trou bl es hoooting

Voltage Range: ± 10 VDC

Current Range: ± 20 mA DC

Accuracy: ± (.015% reading + 1 mV)

± (.02% read ing + 1 µA)

HP 9000 Series 300

or

IBM compatib le PC with

HP BASIC

E1302A, or E1401B/T,

E1421A (requires HP

E1306A)

Option 10

HP 3458A multimeter

or

HP E1326B multimeter

Use*

A,F,O,

P,T

A,F,O,

P,T

F,O,P

A,F,O,

P,T

14 General Information Chapter 1

Page 15

Chapter 2

Installation

Introduction This chapter provides information to install the HP E1328A D/A Converter,

including initial inspection, preparation for use, environment, storage and

shipment.

Initial

Inspection

WARNING

Preparation for

Use

Inspect the shipping container for damage. If the shipping container or

cushioning material is damaged, keep the container until the shipment

contents have been checked and the instrument has been checked

mechanically and electrically. See Chapter 1 (Figure 1-1) for shipment

contents. See Chapter 4 for procedures to check electrical performance.

To avoid possible hazardous electrical shock, do not perform

electrical tests if there are signs of shipping damage to any

portion of the outer enclosure (covers, panels, etc.).

If the contents are incomplete, if there is mechanical damage or defect, or if

the instrument does not pass the electrical performance tests, notify your

nearest Hewlett-Packard Sales and Service Office. If the shipping container

is damaged or the cushioning material shows signs of stress, notify the

carrier as well as Hewlett-Packard, and keep the shipping materials for the

carrier’s inspection.

See Chapter 2 of the HP E1328A User’s Manual to prepare the

HP E1328A D/A Converter for use. See the appropriate mainframe user’s

manual(s) to prepare your mainframe. If your mainframe is not

manufactured by Hewlett-Pack a rd , co ns ul t th e m an uf ac tu re r fo r a list of

available manual(s).

Recommended operating environment for the HP E1328A D/A Converter is

o

C to +55oC with humidity <65% re la ti ve (0 oC to +40oC). The instrument

0

should be stored in a clean, dry environment. For storage and shipment, the

temperature range is -40

o

C to +40oC).

(0

Chapter 2 Installation 15

o

C to +75oC with humidity <65% relative humidity

Page 16

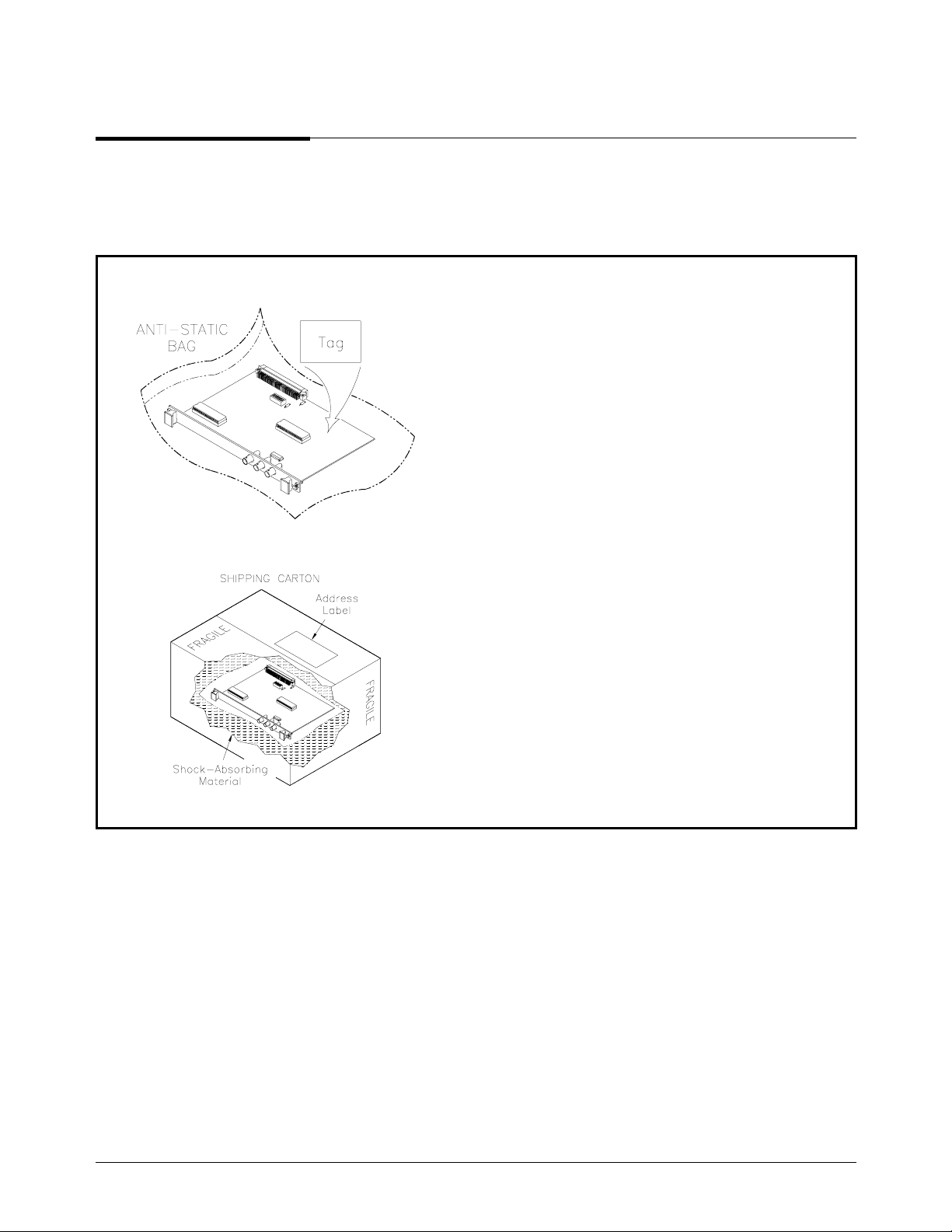

Shipping

Guidelines

Follow the steps in Figure 2-1 to return the HP E1328A D/A Converter to a

Hewlett-Packard Sales and Support Office or Service Center.

1 Prepare the D/A Converter

•

Remove user wiring from the module

•

Attach tag to module/pod that identifies

- Owner

- Model Number/Serial Number

- Service Required

•

Place tagged device in approved anti-static bag

2 Package the D/A Converter

•

Place packaged D/A Converter in shipping carton*

•

Place 75 to 100 mm (3 to 4 inches) of shockabsorbing material around the D/A Converter

•

Seal the shipping carton securely

•

Mark the shipping carton FRAGILE

3 Ship the D/A Converter to Hewlett-Packard

•

Place address label on shipping carton

•

Send carton to Hewlett-Packard

Figure 2-1. Packaging/Shipping Guidelines

* We recommend that you use the same shipping materials as those used in factory packaging (available from Hewlett-Packard). For

other (commercially-available) shipping materials, use a double wall-carton with minimum 2.4 MPa (350 psi) test.

16 Installation Chapter 2

Page 17

Chapter 3

Operating Instructions

Introduction This chapter lists operating information for the HP E1328A D/A Converter,

including:

• D/A Converter operation

• Operator’s check (s elf- te st )

D/A Converter

Operation

Operator’s

Check

CAUTION

See the HP E1328A 4-Channel D/A Converter User’s Manual for D/A

Converter operation, including:

• Getting started

• Configuring the D/A Converter

• Using the D/A Converter

• Understanding the D/A Converter

• D/A Converter command reference

• D/A Converter specifications

• D/A Converter error messages

The Operator’s Check for the HP E1328A D/A Converter consists of

sending the self-test (*TST?) command and checking the return. The

operator’s check can be used at any time to verify the D/A Converter is

connected properly and is responding to the self-test command. See

Chapter 8 - Servic e for a list of D/A Converter self-test errors.

The *TST? command temporarily resets the D/A Converter (to

0 V or 0 A output) on each channel. Make sure any devices

connected to the DAC will not be adversely affected before

using *TST?.

As required, see the mainframe user’s manual for information on address

selection. See the HP E1328A User’s Manual for info rmation on D/A

Converter SCPI commands.

Chapter 3 Operating Instructions 17

Page 18

Self-Test Procedure 1. Verify the D/A Converter is properly installed in the mainframe and

the mainframe has passed its power-on sequence test. See the HP

75000 Series B System Installation and Getting Started Guide for

information on mainframe power-on sequence tests.

2. Execute the D/A Converter self-test using the *TST? command (see

example following).

3. A "0" returned means no self-test failure, while "-330" returned

means a failure was detected. See Chapter 8 - Service for trouble

shooting information (see NOTE following).

NOTE

Example: D/A

Converter Self-Test

Test failures can be caused by improper cabling, improper selection of the

interface select code, primary, and/or secondary address setting. Verify

proper connection and address selection before trouble shooting.

An example follows which uses an HP 9000 Series 300 computer with HP

BASIC and a D/A Converter address of 70909.

10 OUTPUT 70909;"*TST?" Send the self-test command

20 ENTER 70909;A Enter self-test result

30 PRINT A

40 END

18 Operating Instructions Chapter 3

Page 19

Chapter 4

Verification Tests

Introduction The three levels o f te st p ro ce du re s de sc ri be d in this chapter are us ed to

verify that the HP E1328A D/A Converter (DAC):

• is fully functional (Functional Verification)

• meets selected testable specifications (Operation Verification)

• meets all testable specifications (Performance Verification)

WARNING

Test Conditions /

Procedures

Do not perform any of the following verification tests unless

you are a qualified, service-trained person and have read the

WARNINGS and CAUTIONS in Chapter 1.

For valid tests, all test equipment and the HP 3458A multimeter must have a

one-hour warmup, the line voltage must be 115/230 Vac ± 10%, and HP

3458A ACAL must be performed no more than 24 hours before the tests.

See Table 1-2, Recommended Test Equipment for test equipment

requirements.

For best test accuracy, the ambient temperature of the test area should be

between 18°C and 28°C and stable to within ± 1°C. You should perform the

Performance Verification tests at least once a year. For heavy use or severe

operating environments, perform the tests more often.

The verification tests assume the person performing the tests understands

how to operate the mainframe, the DAC and specified test equipment. The

test procedures do not specify equipment settings for test equipment except

in general terms. It is assumed a qualified, service-trained person will select

and connect the cables, adapters, and probes required for the test.

Chapter 4 Verification Tests 19

Page 20

Performance Test

Record

Table 4-2, Performance Test Record for the HP E1328A DAC, at the end of

this chapter, pro v ide s space to enter the res ul ts of ea ch Perf or mance

Verification test and to compare the results with the upper and lower limits

for the test. You can make a copy of this form, if desired.

NOTE

Verification Test

Examples

The upper and lo wer limi ts in th e Per fo rm a nc e Tes t Rec or d as su m e th e te st

equipment used is calibrated and operating at peak performance. If this is

not the case/ problems can occur.

For example, an un ca lib ra ted HP 34 5 8A mul tim eter ma y ca us e wh a t seem s

to be an inaccurate measurement. This condition must be considered when

observed measurements do not agree with the performance test limits.

The value in the "Measurement Uncertainty" column of Table 4-2 is derived

from the specifications for the HP 3458A multimeter used for the test, and

represents the expected accuracy of the HP 3458A. The value in the "Test

Accuracy Ra tio (TA R) " col um n of Tab le 4-2 is th e ra ti o of DAC ac curacy

to HP 3458A measuremen t un cert aint y. If the TAR is ≤ 10:1, the ratio is

rounded to the nearest inte ge r. If the TAR is ≥ 10:1, the TAR is shown as

>10:1.

Each Performance Verification Test includes an example program to

perform the te st. Eac h ex am p le u se s ad dr es s 70 90 9 fo r th e D A C, an d an

HP 9000 Series 200/300 computer running HP BASIC commands. You

may need to change the DAC address and/or command syntax to perform

the examples for your setup.

As required, see the mainframe user’s manual for information on address

selection and cabling guidelines. See the HP E1328A User’s Manual for

information on Standard Commands for Programmable Instruments (SCPI

commands) for the DAC.

20 Verification Tests Chapt er 4

Page 21

Functional

Verification

Tests

DAC Self-Test This test verifies the DAC is communicating with the mainframe, external

The functional verification tests for the HP E1328A DAC can be performed

at any time to verify the DAC is functional and is communicating with the

mainframe , external comp ut er and /or external ter m in al . The fun ct io nal tests

for the HP E1328A DAC are:

• DAC Self-Test

• Voltage Compliance Tests (Optional)

• Current Compliance Tests (Optional)

controller, and/or external terminal by performing a self-test (*TST?

command). See "Operator’s Checks" in Chapter 3 for a description of the

DAC self-test.

Voltage

Compliance Tests

These OPTIONAL tests measure the voltage compliance on each channel of

the DAC.

Positive Voltage Compliance Tests

For positive voltage compliance tests, each channel to be tested is set for

UNCALIBRATED MAX voltage output (+ 12V). A DC source is

connected to V+ and S+ of the channel to be tested. The source is set to

+5V and increased in +0.5V steps until the channel output (as measured

with an HP 3458A multimeter) stops increasing. If the channel maximum

output is ≥ + 15V , th e te st pas se s.

Negative Voltage Compliance Tests

For negative voltage compliance tests, each channel to be tested is set for

UNCALIBRATED MIN voltage output (-12V). A DC source is connected

to V- and S- of the channel to be tested. The source is set to -5V and

increased in -0.5V steps until the channel output (as measured with an HP

3458A multimeter) stops increasing. If the channel minimum output is ≤

-15V, the te st p as se s.

Equipment Setup Connect the DC source (Datron 4708 with Option 10) and HP 3458A

multimeter to Channel 1 as shown in Figure 4-1. (Be sure to set all three

jumpers on the channel to the V position.) Set the DC source output to +5.0

V dc. Set the HP 3458A to DCV function and set NPLC 100.

Chapter 4 Verification Tests 21

Page 22

NOTE

For best measurement accuracy, perform an HP 3458A multimeter ACAL

not more than 24 hours prior to these tests.

Figure4-1. Voltage Compliance Test Connections

Test Procedure

(Positive Voltage

Compliance)

1. Set three jumpers on each channel to the V position

2. Connect DC Source and HP 3458A to Channel 1 (see Figure 4-1 )

3. Set non-cal mode on Channel 1 with CAL1:STAT OFF

4. Set Channel 1 to max voltage output ( + 12V) with VOLT1 MAX

5. Set DC source to + 5V and measure channel output (in V)

6. Increase DC so ur ce out pu t by +0. 5 V an d m ea su re new ch an ne l ou tput

(in V)

7. Repeat step 6 until channel output stops increasing. If the output voltage

is ≥ + 15.0V when the output stops increasing, the test passes.

8. Repeat steps 2 through 7 for Channels 2, 3, and 4 (use CALchan: STAT

OFF and VOLTchan MAX)

9. Remove power and disconnect test equipment

22 Verification Tests Chapt er 4

Page 23

Test Procedure

(Negative Voltage

Compliance)

1. Set three jumpers on each channel to the V position

2. Connect DC Source and HP 3458A to Channel 1 (see Figure 4-1 )

3. Set non-cal mode on Channel 1 with CAL1:STAT OFF

4. Set Channel 1 to min voltage output (-12V) with VOLT1 MIN

5. Set DC source to -5V and measure channel output (in V)

6. Increase DC source output by -0.5V and measure new channel output

(in V)

7. Repeat step 6 until channel output stops increasing. If the output

voltage is ≤ -15.0V when the output stops increasing, the test passes.

8. Repeat steps 2 through 7 for Channels 2, 3, and 4 (use CALchan:

STAT OFF and VOLTchan MIN)

9. Remove power and disconnect test equipment

Example: Positive

Voltage Compliance

NOTE

This program checks the MEASURED voltage output from the DAC

channel being tested. If the measured channel output is ≥ 15.0V when the

output stops increasing, the program generates a "test PASSED" indication.

If the measured channel output is < 15.0V when the output stops increasing,

the program generates a "test FAILED" indication.

To use this program for negative voltage compliance tests, change the

indicated lines as shown:

50 OUTPUT 70909;"VOLT"&VAL$(Chan)&" MIN"

60 Source = -4.5

90 Source = Source-.5

180 IF Value <= -15 THEN Pass$ = "PASSED"

190 IF Value > -15 THEN Pass$ = "FAILED"

Chapter 4 Verification Tests 23

Page 24

10 ! Positive Voltage Compliance Tests

20 !

30 FOR Chan = 1 TO 4

40 OUTPUT 70909;"CAL"&VAL$(Chan)&":STAT OFF"

50 OUTPUT 70909;"VOLT"&VAL$(Chan)&" MAX"

60 Source = 4.5

70 REPEAT

80 PRINT TABXY(1,1),"Voltage Compliance Tests on Channel";Chan

90 Source = Source + .5

100 Old_value = Value

110 PRINT TABXY(4,9),"Set source to ";Source;"Volts DC "

120 PRINT TABXY(4,10),"Measure channel output (in V) "

130 INPUT " Enter channel output (in V) ",Value

140 PRINT TABXY(4,5),"DC Source value = ";Source;"VDC "

150 PRINT TABXY(4,6),"Channel";Chan;"output = ";Value;"VDC "

160 Result = Value-Old _value

170 UNTIL Result = 0

180 IF Value >= 15 THEN Pass$ = "PASSED"

190 IF Value < 15 THEN Pass$ = "FAlLED"

200 CLEAR SCREEN

210 PRINT TABXY(1,8),"Maximum Channel";Chan;"output =

";Value;"Volts"

220 PRINT TABXY(1,9),"Test ";Pass$;" for Channel";Chan

230 DISP " Press Continue for next channel"

240 PAUSE

250 CLEAR SCREEN

260 NEXT Chan

270 END

Current

Compliance

Tests

These tests mea su re the cur ren t com p li an ce on ea ch cha nn el of th e D A C.

Positive Current Compliance Tests

For positive current compliance tests, each channel to be tested is set for

UNCALIBRATED MAX current output (+24 mA). A DC source and

HP 3458A are connected to the channel to be tested. The source is set to

+ 12V and increa se d in + 0.5 V step s unt il the cha nnel output decrea se s to

90% of the maximum current value (decreases to +21.6 mA). If the DC

SOURCE voltag e is ≥ + 13 V wh en the chan n el out pu t de crea se s to 90 % of

maximum cu rr en t th e te st p as se s.

24 Verification Tests Chapt er 4

Page 25

Negative Current Compliance Tests

For negative current compliance tests each channel to be tested is set for

UNCALIBRATED MIN current output (-24 mA). A DC source and

HP 3458A are connected to the channel to be tested. The source is set to

-12V and increased in -0.5V steps until the channel output decreases to 90%

of the maximum current value (decreases to -21.6 mA). If the DC SOURCE

voltage is ≤ -13V when the channel output decreases to 90% of maximum

current, the test passes.

Equipment Setup Connect the DC source (Datron 4708 with Option 10) and HP 3458A

multimeter to Channel 1 as shown in Figure 4-2. (Be sure to set all three

channel jumpers to the I position.) Then, set the DC source output to

+12.0 Vdc. Set the HP 3458A to DCI function and set NPLC 100.

NOTE

For best measurement accuracy, perform an HP 3458A multimeter ACAL

not more than 24 hours prior to these tests.

Figure 4-2. Current Compliance Test Connections

Chapter 4 Verification Tests 25

Page 26

Test Procedure

(Positive Current

Compliance)

1. Set three jum pe rs o n ea ch ch a nn el to the I position

2. Connect source and HP 3458A to Channel 1 (see Figure 4-2)

3. Set non-cal mode on Channel 1 with CAL1:STAT OFF

4. Set Channel 1 max output (+24 mA) with CURR1 MAX

5. Set DC source to + 12.0V and measure channel output (in mA)

6. Increase DC source output by +0.5V and measure channel output (in mA)

7. Repeat step 6 until channel output is 90% of max (21.6 mA). If the

SOURCE voltag e is ≥ 13.0V when the output decreases to 90% of max, the

test passes.

8. Repeat steps 2 through 7 for Channels 2, 3, and 4. (Use CALchan:STAT

OFF and CURRchan MAX.)

Test Procedure

(Negative Current

Compliance)

9. Remove power and disconnect test equipment

1. Set three jum pe rs o n ea ch ch a nn el to the I position

2. Connect source and HP 3458A to Channel 1 (see Figure 4-2)

3. Set non-cal mode on Channel 1 with CAL1:STAT OFF

4. Set Channel 1 min current output (-24 mA) with CURR1 MIN

5. Set DC source to -12.0V and measure channel output (in mA)

6. Increase DC source output by -0.5V and measure channel output (in mA)

7. Repeat step 6 until channel output is 90% of min (-21.6 mA). If the

SOURCE voltag e is ≤ -13.0V when the output decreases to 90% of min, the

test passes.

8. Repeat steps 2 through 7 for Channels 2, 3, and 4 (use CAL chan:STAT

OFF and CURR chan MIN)

26 Verification Tests Chapt er 4

Page 27

9. Remove power and disconnect test equipment

Example: Positive

Current Compliance

NOTE

This program checks the MEASURED current output from the DAC

channel being tested. If the DC SOURCE voltage is ≥ 13.0V when the

output current drops to 90% of maximum current, the program generates a

"test PASSED" indication. If the DC SOURCE voltage is < 13.0V when the

output current drops to 90% of maximum current, the program generates a

"test FAILED" indication.

To use this program for negative current compliance tests, change the

indicated lines as shown:

50 OUTPUT 70909;"CURR"&VAL$(Chan)&" MIN"

60 Source = -11.5

90 Source = Source-.5

180 IF Source <= -13.0 THEN Tst$="PASSED"

190 IF Source > -13.0 THEN Tst$ ="FAILED"

10 ! Current Compliance Tests

20 !

30 FOR Chan = 1 TO 4

40 OUTPUT 70909;"CAL"&VAL$(Chan)&":STAT OFF"

50 OUTPUT 70909;"CURR"&VAL$(Chan)&" MAX"

60 Source = 11.5

70 REPEAT

80 PRINT TABXY(1,1),"Current Compliance Tests on Channel";Chan

90 Source = Source + .5

100 PRINT TABXY(4,10),"Set DC source to ";Source;"Volts DC "

110 PRINT TABXY(4,11),"Measure channel output (in mA)"

120 INPUT " Enter channel output (in mA) ",Value

130 Result = ABS(100*Value/24.0)

140 PRINT TABXY(4,5),"DC Source value = ";Source;"VDC "

150 PRINT TABXY(4,6),"Channel";Chan;"output = ";Value;"mA"

160 PRINT TABXY(4,7),"Output = ";Result;"% of max value "

170 UNTIL Result <= 90.0

180 IF Source >= 13.0 THEN Tst$ = "PASSED"

190 IF Source < 13.0 THEN Tst$ = "FAILED"

200 CLEAR SCREEN

210 PRINT TABXY(4,14),"DC Source value for output 90% of max =

";Source;"VDC"

220 PRINT TABXY(4,15),"Test ";Tst$;" for Channel";Chan

230 NEXT Chan

240 END

Chapter 4 Verification Tests 27

Page 28

Operation

Verification

Tests

Operation verification tests objectives are to instill a high degree of

confidence that the HP E1328A 4-Channel D/A Converter is meeting

selected specifications from those listed in Appendix A - Specifications in

the HP E1328A User’s Manual.

Operation verification tests can be used in applications such as incoming

inspection and af te r HP E132 8A re pa ir. To pe rf or m o pe ratio n verif icat io n

tests, do the parts of the performance verification tests shown in Table 4-1.

See Performance Verification Tests for details on the test procedures.

NOTE

For best results, pe rfor m an ACAL on th e HP 3 45 8A mul tim et er n ot mo re

than 24 hours prior to performing the operation verification tests.

If the operation verification test FAILS on any channel, you may want to

perform the Voltage Adjustment and/or Current Adjustment procedures in

Chapter 5 - Adjustments and then rerun the operation verification tests.

Table 4-1. HP E1328A DAC Operation Verification Tests

For this test: Make these measurements:

Voltage Accuracy -10V, 0V, +10V

Current Accuracy -20 mA, 0 mA, +20 mA

28 Verification Tests Chapt er 4

Page 29

Performance

Verification

Tests

Performance verification tests objectives are to instill a high degree of

confidence that the HP E1328A 4-Channel D/A Converter (DAC) is

meeting the specifications listed in Appendix A - Specifications of the HP

E1328A User’s Manual. Performan ce ver if icat io n te st s ar e re qu ir ed

whenever a calibration is required. The HP E1328A DAC performance

verificatio n te st s ar e:

• Voltage Accuracy Measurements

• Current Accuracy Measurements

NOTE

Voltage Accuracy

Measurements Test

Equipment setup Connect the equipment as shown in Figure 4-3. Be sure the three jumpers in

For best results you should ACAL the HP 3458A multimeter not more than

24 hours prior to the tests. If a DAC channel does not pass the performance

tests, you may want to do the Voltage Adjustment and/or Current

Adjustment (see Chapter 5 - Adjustments) and then rerun the performance

verification tests.

This test checks voltage output accuracy on Channels 1, 2, 3, and 4 of the

DAC. The voltage output levels checked are: -10V, -8V, -5V, -2V, 0V,

+2V, +5V, +8V, and +10V.

each DAC channel are set to the V (voltage) position. Then, set the HP

3458A to DCV function and set NPLC 100.

Figure 4-3. Voltage Accuracy Measurements Connections

Chapter 4 Verification Tests 29

Page 30

NOTE

The value of 1 kΩ in Figure 4-3 is the factory value used for original

measurements. If you previously calibrated your DAC with a different

resistance value, use that resistance value rather than 1 kΩ .

Test Procedure 1. Set three jumpers on each channel to the V position

2. Connect HP 3458A and 1 kΩ resistor to Channel 1 (see Figure 4-3)

3. Set HP E1328A DAC to default with *RST

4. Set Channel 1 to calibrated mode with CAL1:STAT ON

5. Output -10V on Channel 1 with VOLT1 -10.0000

6. Measure Channel 1 output voltage with HP 3458A and compare

with limits in Table 4-2

7. Repeat steps 5 and 6 for -8V, -5V, -2V, 0V, +2V, +5V, +8V, and

+10V

Example: Voltage

Accuracy

Measurements

8. Repeat steps 2 through 7 for Cha nn el s 2, 3, an d 4 (u se

CALchan:STAT ON and VOLTchan value)

9. Remove power and disconnect test equipment

This program checks the MEASURED output voltage on each DAC

channel and compares the result with the 1-year accuracy specifications for

the DAC (see Appendix A - Calculating D/A Converter Accuracy for a

discussion of DAC accuracy).

10 ! Voltage Accuracy Measurements Test

20 !

30 OPTION BASE 1

40 DIM Volts(4,9)

50 DATA -10,-8,-5,-2,0,2,5,8,10

60 DATA -10,-8,-5,-2,0,2,5,8,10

70 DATA -10,-8,-5,-2,0,2,5,8,10

80 DATA -10,-8,-5,-2,0,2,5,8,10

90 READ Volts(*)

100 OUTPUT 70909;"*RST"

110 FOR Chan = 1 TO 4

120 FOR I = 1 TO 9

130 OUTPUT 70909;"VOLT"&VAL$(Chan)&" ";Volts(Chan,I)

140 PRINT TABXY(1,2),"Voltage Accuracy Measurements on Channel

";Chan

30 Verification Tests Chapt er 4

Page 31

150 PRINT TABXY(1,10),"New voltage output on Channel";Chan;" =

":Volts(Chan,I);"V "

160 PRINT

170 INPUT " Enter MEASURED voltage value (in V) ",Meas(Chan,I)

180 GOSUB Accuracy

190 Accuracy: !

200 Acc(Chan,I) = .0035*ABS(Volts(Chan,I)) + .11334

210 Llim(Chan,I) = Volts(Chan,I) - Acc(Chan,I)

220 Ulim(Chan,I) = Volts(Chan,I) + Acc(Chan,I)

230 IF Meas(Chan,I) < Llim(Chan,I) OR Meas(Chan,I) > Ulim(Chan,I)

THEN

240 PRINT TABXY(1,9),"Test FAILED on Channel";Chan;"for

";Volts(Chan,I);"V"

250 ELSE

260 PRINT TABXY(1,9),"Test PASSED on Channel";Chan;"for

";Volts(Chan,I);"V "

270 END IF

280 NEXT I

290 NEXT Chan

300 PRINT TABXY(1,18) ,"Voltage Accuracy Tests Complete"

310 END

Counter Accuracy

Measurements Test

Equipment Setup Connect the equipment as shown in Figure 4-4. Be sure the three jumpers

This test checks current output accuracy on Channels 1, 2, 3, and 4 of the

DAC. The current output levels checked are: -20 mA, -16 mA, -10 mA, -4

mA, 0 mA, 4 mA, 10 mA, 16 mA, and 20 mA.

in each DAC chan ne l ar e se t to the I (cu rr en t) p os itio n. Th en , se t th e

HP 3458A to DCI function and set NPLC 100.

Figure 4-4. Current Measurement Accuracy Connections

Chapter 4 Verification Tests 31

Page 32

NOTE

The value of 500 Ω in Figure 4-4 is the factory value used for original

measurements. If you previously calibrated your DAC with a different

resistance value, use that resistance value rather than 500 Ω .

Test Procedure 1. Set three jumpe rs on ea ch ch a nn el to th e I po si tion

2. Connect HP 3458A and 500 Ω resistor to Channel 1 (see Figure 4-4)

3. Set HP E1328A DAC to default with *RST

4. Set Channel 1 to calibrated mode with CAL1:STAT ON

5. Output -20 mA on Channel 1 with CURR1 -.02000

6. Measure Channel 1 output current with HP 3458A and compare with

limits in Table 4-2

7. Repeat steps 5 and 6 for -16 mA, -10 mA, -4 mA, 0 mA, 4 mA, 10

mA., 16 mA, and 20 mA

Example: Current

Accuracy

Measurements

8. Repeat steps 2 through 7 for Channels 2, 3, and 4 (use CALchan:

STAT ON and CURRchan value)

9. Remove power and disconnect test equipment

This program checks the MEASURED output current on each DAC channel

and compares the result with the 1-year accuracy specifications for the DAC

(See Appendix A - Calculating D/A Converter Accuracy for a discussion of

DAC accura cy ).

10 ! Current Accuracy Measurements Test

20 !

30 OPTION BASE 1

40 DIM Amps(4,9)

50 DATA -.02,-.016,-.01,-.004,0,.004,.01,.016,.02

60 DATA -.02,-.016,-.01,-.004,0,.004,.01,.016,.02

70 DATA -.02,-.016,-.01,-.004,0,.004,.01,.016,.02

80 DATA -.02,-.016,-.01,-.004,0,.004,.01,.016,.02

90 READ Amps(*)

100 OUTPUT 70909;"*RST"

110 FOR Chan = 1 TO 4

120 FOR l=1 TO 9

130 OUTPUT 70909;"CURR"&VAL$(Chan)&" ";Amps(Chan,I)

140 PRINT TABXY(1,2)," Current Accuracy Measurements on Channel

";Chan

32 Verification Tests Chapt er 4

Page 33

150 PRINT TABXY(1,10),"New current output on Channel";Chan;" =

";Amps(Chan,I)*1.E + 3;"mA "

160 INPUT " Enter MEASURED current value (in mA) ",Meas(Chan,I)

170 GOSUB Accuracy

180 Accuracy: !

190 Acc(Chan,I) = .0035*ABS(Amps(Chan,I)) + 2.2665E-4

200 Llim(Chan,I) = Amps(Chan,I) - Acc(Chan,I)

210 Ulim(Chan,I) = Amps(Chan,I) + Acc(Chan,I)

220 IF Meas(Chan,I)*1.E-3 < (Chan,I) OR Meas(Chan,I)*1.E-3 >

Ulim(Chan,I) THEN

230 PRINT TABXY(1,9),"Test FAILED on Channel";Chan;"for

";Amps(Chan,I)*1.E + 3;"mA "

240 ELSE

250 PRINT TABXY(1,9),"Test PASSED on Channel";Chan;"for

";Amps(Chan,I)*1.E + 3;"mA "

260 END IF

270 NEXT I

280 NEXT Chan

290 PRINT TABXY(1,18),"Current Accuracy Tests Complete"

300 END

Performance

Test Record

NOTE

Table 4-2, Performance Test Record for the HP E1328A DAC, can be used

to record the res ul ts of ea ch Op erat io n V er ific at io n an d Per fo rma nc e

Verification test for the HP E1328A DAC (this record can be copied if

desired). The record includes the DAC upper and lower limits, HP 3458A

measurement uncertainty, and the Test Accuracy Ratio (TAR) for the test.

The values for DAC accuracy, HP 3458A measurement uncertainty and

TAR in Table 4-2 assume the following conditions. If your test conditions

differ from thes e co nd it io ns , you will need to compu te the app ro pr ia te

values.

• Calibration ON state (CAL x :STAT O N) fo r ea ch channel

• 1 kΩ load for voltage accuracy measurements

• 500 Ω load for current accuracy measurements

• Test temp ASSUMED to be ± 5° C different than cal temp

• 1-year specifications for DAC accuracy

• 1-year specifications for HP 3458A meas uncertainty

For the conditions listed, all Test Accuracy Ratios (TARs) exceed 4:1

Chapter 4 Verification Tests 33

Page 34

Table 4-2. Performance Test Record for the HP E1328A DAC (Page 1 of 3)

Test Facility:

Name ____________ __ __ ______________ _______

Address ________ __ __ ______________ __ _________

City/State ___________________________________

Phone __________ __ __ __ ______________ __ _____

Special Notes:

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

Report No. __________________________________

Date ______________________ __ ______________ _

Customer ___________________________________

Tested by __________________________________

Test Equipment Record

Model __________ __ __ __ ___________ Report No. ______________ __ ____ Date _________ __ __ __ __ _____

Test Equipment Used:

Description Model No. Trace No. Cal Due Date

1. ____________ ___________________

2. ____________ ___________________

3. ____________ ___________________

4. ____________ ___________________

5. ____________ ___________________

6. ____________ ___________________

7. ____________ ___________________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

______________

34 Verification Tests Chapt er 4

Page 35

Table 4-2. Performance Test Record for the HP E1328A DAC (Page 2 of 3)

Voltage Accuracy Measurements*

Ch Output

Value (V)

1

-10.00000

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

3

3

-8.00000

-5.00000

-2.00000

0.00000

+2.00000

+5.00000

+8.00000

+10.00000

-10.00000

-8.00000

-5.00000

-2.00000

0.00000

+2.00000

+5.00000

+8.00000

+10.00000

-10.00000

-8.00000

-5.00000

-2.00000

0.00000

+2.00000

+5.00000

+8.00000

+10.00000

Low

Limit (V)

-10.14833

-8.14134

-5.13084

-2.12033

-.11334

+1.87967

+4.86916

+7.85867

+9.85167

-10.14833

-8.14134

-5.13084

-2.12033

-.11334

+1.87967

+4.86916

+7.85867

+9.85167

-10.14833

-8.14134

-5.13084

-2.12033

-.11334

+1.87967

+4.86916

+7.85867

+9.85167

Measured Value

(V)

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

High

Limit (V)

-9.85167

-7.85867

-4.86916

-1.87967

+.11334

+2.12033

+5.13084

+8.14134

+10.14833

-9.85167

-7.85867

-4.86916

-1.87967

+.11334

+2.12033

+5.13084

+8.14134

+10.14833

-9.85167

-7.85867

-4.86916

-1.87967

+.11334

+2.12033

+5.13084

+8.14134

+10.14833

Measurement

Uncertainty (

103.60

103.60

103.60

103.60

103.60

103.60

µV)

83.30

52.85

22.40

2.10

22.40

52.85

83.30

83.30

52.85

22.40

2.10

22.40

52.85

83.30

83.30

52.85

22.40

2.10

22.40

52.85

83.30

Test Acc

Ratio (TAR)

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

4

4

4

4

4

4

4

4

4

-10.00000

-8.00000

-5.00000

-2.00000

0.00000

+2.00000

+5.00000

+8.00000

+10.00000

-10.14833

-8.14134

-5.13084

-2.12033

-.11334

+1.87967

+4.86916

+7.85867

+9.85167

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

__________________

-9.85167

-7.85867

-4.86916

-1.87967

+.11334

+2.12033

+5.13084

+8.14134

+10.14833

103.60

83.30

52.85

22.40

2.10

22.40

52.85

83.30

103.60

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

* 1-year DAC and HP 3458A specifications

±5°C temp difference from cal temperature

HP 3458A ACAL within previous 24-hours

Chapter 4 Verification Tests 35

Page 36

Table 4-2. Performance Test Record for the HP E1328A DAC (Page 3 of 3)

Current Accuracy M ea sur eme n ts*

Ch Output

Value (mA)

1

-20.00000

1

-16.00000

1

-10.00000

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

3

3

-4.00000

0.00000

+4.00000

+10.00000

+16.00000

+20.00000

-20.00000

-16.00000

-10.00000

-4.00000

0.00000

+4.00000

+10.00000

+16.00000

+20.00000

-20.00000

-16.00000

-10.00000

-4.00000

0.00000

+4.00000

+10.00000

+16.00000

+20.00000

Low Limit

(mA)

-20.29665

-16.28265

-10.26165

-4.24065

-.22665

+3.75935

+9.73835

+15.71735

+19.70335

-20.29665

-16.28265

-10.26165

-4.24065

-.22665

+3.75935

+9.73835

+15.71735

+19.70335

-20.29665

-16.28265

-10.26165

-4.24065

-.22665

+3.75935

+9.73835

+15.71735

+19.70335

Measured Val u e

(mA)

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

High Limit

(mA)

-19.70335

-15.71735

-9.73835

-3.75935

+.22665

+4.24065

+10.26165

+16.28265

+20.29665

-19.70335

-15.71735

-9.73835

-3.75935

+.22665

+4.24065

+10.26165

+16.28265

+20.29665

-19.70335

-15.71735

-9.73835

-3.75935

+.22665

+4.24065

+10.26165

+16.28265

+20.29665

Meas Uncert

(µA)

1.440

1.272

.330

.168

.060

.168

.330

1.272

1.440

1.440

1.272

.330

.168

.060

.168

.330

1.272

1.440

1.440

1.272

.330

.168

.060

.168

.330

1.272

1.440

Test Acc

Ratio (TAR)

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

4

4

4

4

4

4

4

4

4

-20.00000

-16.00000

-10.00000

-4.00000

0.00000

+4.00000

+10.00000

+16.00000

+20.00000

-20.29665

-16.28265

-10.26165

-4.24065

-.22665

+3.75935

+9.73835

+15.71735

+19.70335

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

____________ ____

-19.70335

-15.71735

-9.73835

-3.75935

+.22665

+4.24065

+10.26165

+16.28265

+20.29665

1.440

1.272

.330

.168

.060

.168

.330

1.272

1.440

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

>10:1

* 1-year DAC and HP 3458A specifications

±5°C temp difference from cal temperature

HP 3458A ACAL within previous 24-hours

36 Verification Tests Chapt er 4

Page 37

Chapter 5

Adjustments

Introduction This chapter contains procedures to adjust the HP E1328A D/A Converter

(DAC), including voltage adjustments and current adjustments.

The DAC should be adjusted after repair to ensure peak performance.

Equipment required for the adjustment procedures is listed in Table 1-2,

Recommended Test Equipment.

Before performing adjustments, the DAC must have a minimum 60-minute

warm up and the line voltage must be 115/230 Vac ± 10%. For best

accuracy, the test area temperature should be between 18°C and 28°C, and

stable to ± 1°C.

WARNING

Voltage

Adjustments

Do not perform any of the following adjustments unless you are

a qualified, service trained person and have read the

WARNINGS and CAUTIONS in Chapter 1.

This adjustment is used to update the stored voltage constants for each DAC

channel, and should be perfomed:

• On initial setup

• Periodically (24 hours or 90 days) to maintain specified output accuracy

(see Appendix A - Specifications of the HP E1328A User’s Manual)

• When temperature has changed more than ± 5°C from last adjustment

temperature

• When the type of load is changed

• Any time accuracy is in d ou bt

Chapter 5 Adjustments 37

Page 38

NOTE

For best measurement accuracy, perform an HP 3458A multimeter ACAL

not more than 24 hours prior to these adjustments. Each DAC channel to

be adjusted MUST be in the non-calibrated mode (CALx:STAT OFF), or

errors in the adjustment constants will occur.

Equipment Setup

NOTE

Connect a 1 kΩ resistor and HP 3458A multimeter to the channel to be

adjusted, as shown in figure 5-1. Be sure to set all three channel jumpers to

the V (voltage) position. Set the HP 3458A to DCV function and set NPLC

100.

The value of 1 kΩ in Figure 5-1 is the factory value used for original

adjustments. If you previously adjusted your DAC with a different

resistance value, use that resistance value rather than 1 kΩ .

Figure 5-5. Voltage Adjustment Connections

38 Adjustments Chapter 5

Page 39

Adjustment

Procedures

1. Set three jumpers on Channel 1 to the V position.

2.

Connect a 1 kΩ resistor and HP 3458A to Channel 1 (see Figure

5-1).

3. Set Channel 1 to non-calibrated mode with CAL1:STAT OFF.

4. Set Channel 1 to minimum output (-12V) with VOLT1 MIN.

Measure and record to 5 1/2 digits the actual output voltage.

5. Set Channel 1 to default output (0V) with VOLT1 DEF. Measure

and record to 5 1/2 digits the actual output voltage.

6. Set Channel 1 to maximum output (+12V) with VOLT1 MAX.

Measure and record to 5 1/2 digits the actual output voltage.

7. Enter recorded minimum, default, and maximum values with

CAL1:VOLT min,def,max. The adjustment constants are

automatica lly up da te d and stored.

8. Repeat steps 1 through 7 for channels 2, 3, and 4 as desired (use

CALchan:STAT OFF, VOLTchan value, and CALchan:VOLT

values).

9. Remove power and disconnect power equipment.

Example: Voltage

Adjustments

This program uses the measured minimum, default, and maximum values

you enter to update the voltage adjustment constants for Channels 1, 2, 3,

and 4.

10 ! Voltage Adjustments

20 !

30 DISP CHR$(129)

40 FOR Chan= 1 TO 4

50 PRINT TABXY(1,1),"Voltage Adjustments on Channel";Chan

60 OUTPUT 70909;"CAL"&VAL$(Chan)&":STAT OFF"

70 OUTPUT 70909;"VOLT"&VAL$(Chan)&" MIN"

80 PRINT TABXY(1,18),"Channel";Chan;"is set to minimum (-12V)"

90 INPUT "Enter measured value (in V to 5.5 digits) ",Min

100 OUTPUT 70909;"VOLT"&VAL$(Chan)&" DEF"

110 PRINT TABXY(1,18),"Channel";Chan;"is set to default (0V) "

120 INPUT "Enter measured value (in V to 5.5 digits) ",Def

130 OUTPUT 70909;"VOLT"&VAL$(Chan)&" MAX"

140 PRINT TABXY(1,18),"Channel";Chan;"is set to maximum (+12V)"

150 INPUT "Enter measured value (in V to 5.5 digits) ",Max

160 OUTPUT 70909;"CAL"&VAL$(Chan)&":VOLT ";Min,Def,Max

170 NEXT Chan

180 CLEAR SCREEN

190 PRINT "Voltage Adjustments Complete"

200 END

Chapter 5 Adjustments 39

Page 40

Current

Adjustments

This adjustment is used to update the stored current constants for each DAC

channel, an d sh ou ld be pe rf or m ed :

• On initial setup

• Periodically (24 hours or 90 days) to maintain specified output accuracy

(see Appendix A - Specifications of the HP E1328A User’s Manual)

• When temperature has changed more than ± 5°C from last adjustment

temperature

• When the type of load is changed

• Any time accuracy is in d ou bt

NOTE

Equipment Setup

For best measurement accuracy, perform an HP 3458A multimeter ACAL

not more than 24 hours prior to these adjustments. Each DAC channel to

be adjusted MUST be in the non-calibrated mode (CALx:STAT OFF), or

errors in the adjustment constants will occur.

Connect the HP 3458A multimeter and a 500 Ω resistor to the channel to be

adjusted, as sh ow n in Fig ur e 5- 2. Be su re to se t al l th re e ch an ne l ju m pe rs to

the I (current) position. Set the HP 3458A to DCI function and set NPLC

100.

Figure 5-6. Current Adjustment Connection s

40 Adjustments Chapter 5

Page 41

NOTE

Adjustment

Procedures

The value of 500 Ω in Figure 5-2 is the factory value used for original

adjustments. If you previously adjusted your DAC with a different

resistance value, use that resistance value rather than 500 Ω .

1. Set three jumpers on C ha n n el 1 to the I position.

2.

Connect a 500 Ω resistor and HP 3458A to Channel 1 (see Figure

5-2).

3. Set Channel 1 to non-calibrated mode with CAL1:STAT OFF.

4. Set Channel 1 to minimum output (-.024 A) with CURR1 MIN.

Measure and record to 5 1/2 digits the actual output current (in

Amps).

5. Set Channel 1 to default output (0 A) with CURR1 DEF. Measure

and record to 5 1/2 digits the actual output current (in Amps).

6. Set Channel 1 to maximum output (+.024 A) with CURR1 MAX.

Measure and record to 5 1/2 digits the actual output current (in

Amps).

7. Enter recorded minimum, default, and maximum values with

CAL1:CURR min,def,max. The adjustment constants are

automatica lly up da te d and stored.

8. Repeat steps 1 through 7 for channels 2, 3, and 4 as desired (use

CALchan:STAT OFF, CURRchan value, and CALchan:CURR

values).

9. Remove power and disconnect power equipment.

Example: Current

Adjustments

This program uses the measured minimum, default, and maximum values

you enter to update the current adjustment constants for Channels 1, 2, 3,

and 4.