Page 1

HPE D3600/3700 Disk Enclosure Maintenance and Service Guide

Abstract

This guide is intended for users who maintain the HPE D3600/3700 Disk Enclosures. Some of the actions described are more

appropriate to Hewlett Packard Enterprise service specialists and require an Support login.

Part Number: 734754-001R

Published: November 2015

Edition: 2

Page 2

© Copyright 2014, 2015 Hewlett Packard Enterprise Development LP

The information contained herein is subject to change without notice. The only warranties for Hewlett Packard Enterprise products and services

are set forth in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting

an additional warranty. Hewlett Packard Enterprise shall not be liable for technical or editorial errors or omissions contained herein.

Confidential computer software. Valid license from Hewlett Packard Enterprise required for possession, use, or copying. Consistent with FAR

12.211 and 12.212, Commercial Computer Software, Computer Software Documentation, and Technical Data for Commercial Items are licensed

to the U.S. Government under vendor's standard commercial license.

Page 3

Contents

1 Introduction..........................................................................................................5

Hardware components..........................................................................................................................5

2 Removal and replacement procedures...............................................................6

Required tools.......................................................................................................................................6

Required items......................................................................................................................................6

Safety precautions................................................................................................................................6

General precautions........................................................................................................................6

Preventing electrostatic discharge..................................................................................................7

Symbols on equipment....................................................................................................................7

Warning and caution messages......................................................................................................9

Precautions for maintaining and servicing products......................................................................10

Power cords...................................................................................................................................11

Power supplies..............................................................................................................................11

Powering off disk enclosures..............................................................................................................11

Powering on........................................................................................................................................12

Before powering on.......................................................................................................................12

Power on procedures....................................................................................................................12

Verifying the operating status of the disk enclosures....................................................................13

Front panel LEDs.....................................................................................................................13

Fan module..............................................................................................................................13

I/O module LEDs......................................................................................................................14

Power supply module ..............................................................................................................14

Verifying the status of the disk drives............................................................................................14

Hard drive blanks................................................................................................................................15

Hard drive...........................................................................................................................................15

Disk drive guidelines......................................................................................................................16

Removing a drive...........................................................................................................................16

Replacing a drive...........................................................................................................................16

Removing and replacing I/O Cables...................................................................................................17

Removing and replacing the I/O module............................................................................................18

Removing and replacing a power supply............................................................................................18

Removing and replacing the fan module............................................................................................19

Removing and replacing the fan control card................................................................................21

Removing and replacing the enclosure..............................................................................................22

Removing and replacing the Power Distribution Board......................................................................23

Removing and replacing the UID-health module................................................................................24

Removing and replacing the enclosure backplane.............................................................................25

Installing the rail kit.............................................................................................................................27

Rack installation best practices.....................................................................................................27

Procedures....................................................................................................................................28

3 Troubleshooting.................................................................................................30

If the enclosure does not initialize.......................................................................................................30

Diagnostic steps.................................................................................................................................30

Is the enclosure front fault LED amber?........................................................................................30

Is the enclosure rear fault LED amber?.........................................................................................31

Is the System Health LED amber?................................................................................................31

Is the power supply LED green?...................................................................................................31

Is the I/O module fault LED amber?..............................................................................................31

Is the fan LED amber?...................................................................................................................32

Recognizing disk drive failure.............................................................................................................33

Effects of a disk drive failure..........................................................................................................33

Contents 3

Page 4

Compromised fault tolerance.........................................................................................................33

Factors to consider before replacing disk drives...........................................................................33

Automatic data recovery (rebuild).................................................................................................34

Time required for a rebuild.......................................................................................................34

Failure of another drive during rebuild.....................................................................................35

Handling disk drive failures......................................................................................................35

I/O module error codes.......................................................................................................................36

4 Component identification...................................................................................40

5 Technical specifications.....................................................................................42

Physical specifications........................................................................................................................42

Power and environmental specifications............................................................................................42

Acoustic noise levels..........................................................................................................................42

6 Support and other resources.............................................................................44

Accessing Hewlett Packard Enterprise Support.................................................................................44

Accessing updates..............................................................................................................................44

Websites.............................................................................................................................................44

Customer self repair...........................................................................................................................45

Remote support..................................................................................................................................45

Documentation feedback....................................................................................................................45

A Warranty and regulatory information.................................................................46

Warranty information...........................................................................................................................46

Regulatory information........................................................................................................................46

Belarus Kazakhstan Russia marking.............................................................................................46

Turkey RoHS material content declaration....................................................................................47

Ukraine RoHS material content declaration..................................................................................47

4 Contents

Page 5

1 Introduction

This is the Service and Maintenance Guide for the D3600/3700 disk enclosures.

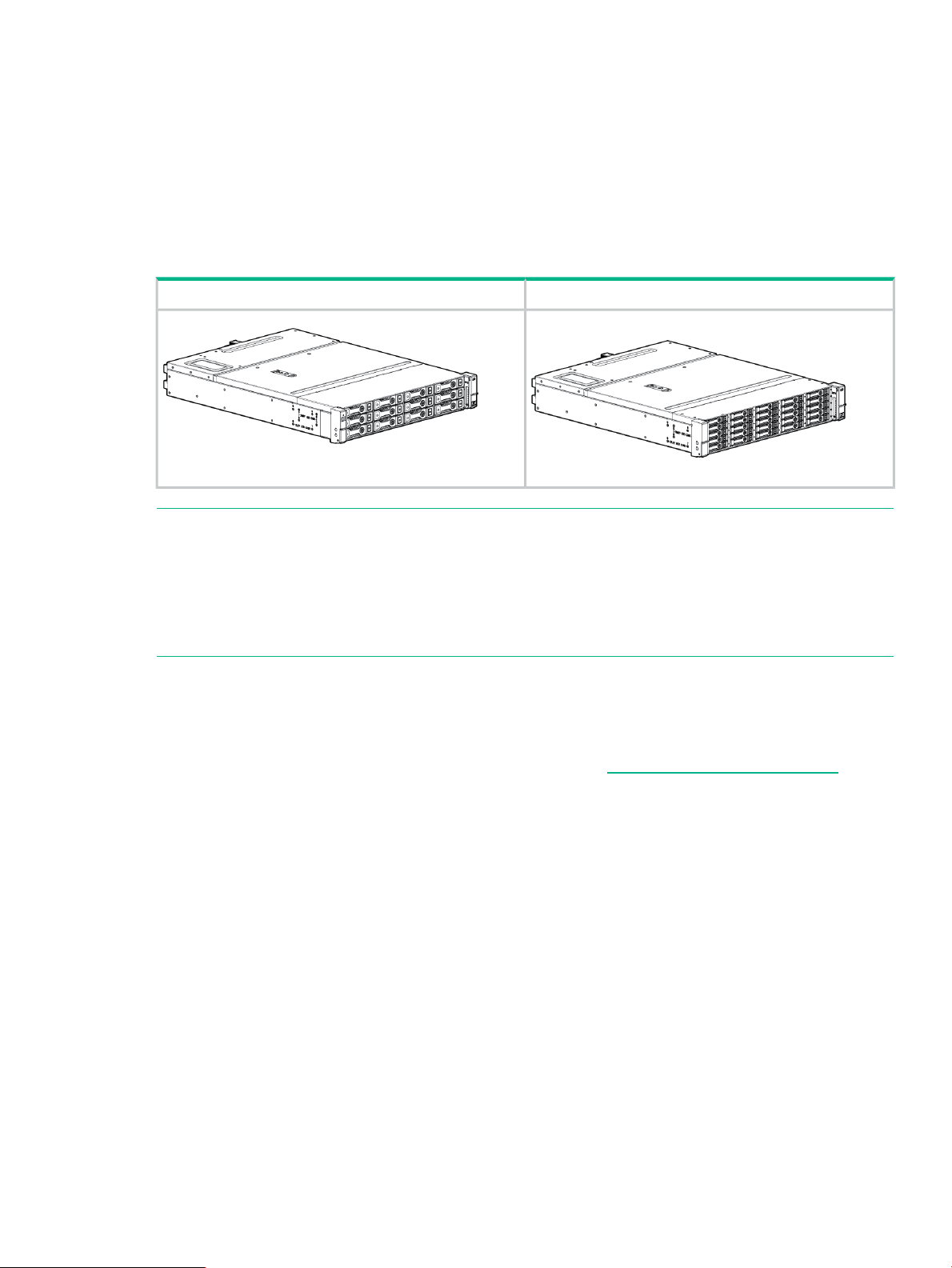

The HPE 12Gb SAS disk enclosures are available in two models:

• D3600: supports up to 12 Large Form Factor (LFF) SAS drives for a maximum capacity of

7.2 TB with 600GB SAS drives or 48 TB with 4 TB SAS MDL or 4TB SATA MDL drives.

• D3700: supports up to 25 Small Form Factor (SFF) SAS drives for a maximum capacity of

30 TB with 1.2 TB SAS drives or 25 TB with 1 TB SAS MDL or 1 TB SATA MDL drives.

NOTE: Each enclosure is shipped with an optional Digital Rain bezel which customers can

install as needed. The graphics in this guide are portrayed without the bezel for clarity.

D3700 SFF EnclosureD3600 LFF Enclosure

NOTE: Depending on your disk enclosure model and controller installation environment, one

or more disk enclosures can be cascaded from the disk enclosure that is connected to the

controller. For more information, see the QuickSpecs for the disk enclosure, available on the

D3000 website.

Hardware components

For a parts diagram, see “Component identification” (page 40)

To order a replacement part, contact an Hewlett Packard Enterprise-authorized service provider

or see the Hewlett Packard Enterprise Parts Store online: http://www.hpe.com/buy/parts

Hardware components 5

Page 6

2 Removal and replacement procedures

Required tools

The following items are required for some procedures:

• T-8 Torx screwdriver

• T-10 Torx screwdriver

• T-15 Torx screwdriver

• Phillips screwdriver

Required items

Items required for installation include the following, some of which ship with the disk enclosure:

• Rack mounting kit

• Disk enclosure

• Disk drives and drive blanks

• SAS controller or controller enclosure

• SAS cables

• MiniSAS HD cables

NOTE: The included MiniSAS HD cables can be used with the 12Gb JBOD. In order to

connect the 12Gb JBOD to either a 6Gb Smart Array or to 6Gb HBAs, customers must

purchase the MiniSAS HD to MiniSAS cable.

• Power cables

• Access to a workstation on the server

• Access to the Internet

Safety precautions

Retain and follow all product safety and operating instructions. Always refer to the documentation

(printed or electronic) supplied with your product. If there is a conflict between this document and

the product documentation, the product documentation takes precedence. Observe all warnings

on the product and in the operating instructions to reduce the risk of bodily injury, electric shock,

fire, and damage to the equipment.

General precautions

CAUTION: The installation and maintenance of products must be carried out by qualified

personnel.

If the product sustains damage requiring service, disconnect the product from the AC electrical

outlet and refer servicing to an Hewlett Packard Enterprise authorized service provider. Examples

of damage requiring service include:

• The power cord, extension cord, or plug has been damaged.

• Liquid has been spilled on the product or an object has fallen into the product.

• The product has been exposed to rain or water.

6 Removal and replacement procedures

Page 7

• The product has been dropped or damaged.

• The product does not operate normally when you follow the operating instructions.

To reduce the risk of personal injury or damage to the product:

• Place the product away from radiators, heat registers, stoves, amplifiers, or other products

that produce heat.

• Never use the product in a wet location.

• Avoid inserting foreign objects through openings in the product.

• Move products with casters carefully. Avoid quick stops and uneven surfaces.

Preventing electrostatic discharge

To prevent damaging the system, be aware of the precautions you need to follow when setting

up the system or handling parts. A discharge of static electricity from a finger or other conductor

may damage system boards or other static-sensitive devices. This type of damage may reduce

the life expectancy of the device.

To prevent electrostatic damage:

• Avoid hand contact by transporting and storing products in static-safe containers.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free workstations.

• Place parts on a grounded surface before removing them from their containers.

• Avoid touching pins, leads, or circuitry.

• Always be properly grounded when touching a static-sensitive component or assembly.

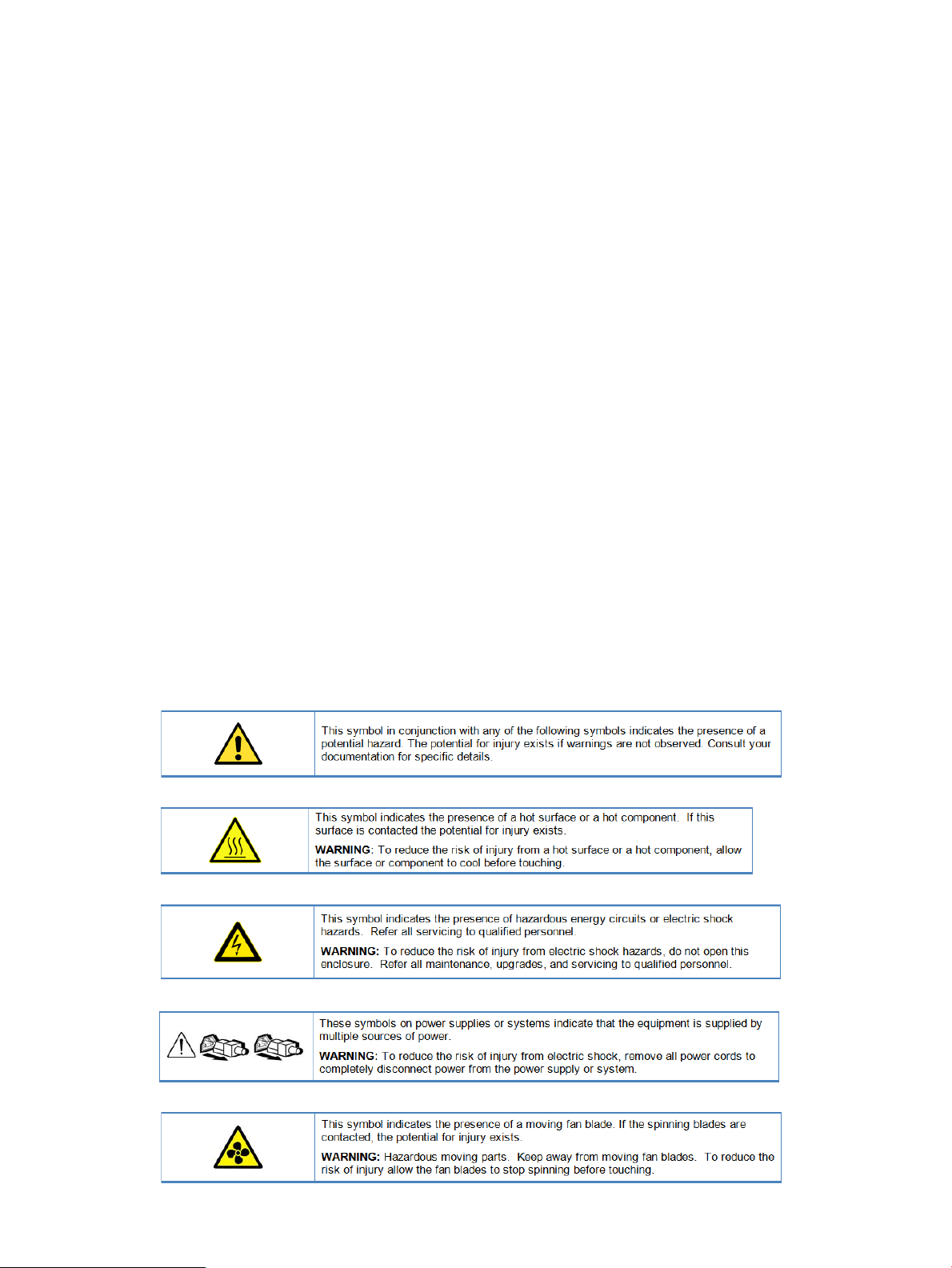

Symbols on equipment

The following symbols may be placed on equipment to indicate the presence of potentially

hazardous conditions:

Safety precautions 7

Page 8

8 Removal and replacement procedures

Page 9

Warning and caution messages

WARNING! To reduce the risk of personal injury or damage to equipment, heed all warnings

and cautions throughout the installation instructions.

WARNING! To reduce the risk of personal injury or damage to the equipment, be sure that:

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become unstable if more than one

component is extended for any reason.

WARNING! To reduce the risk of personal injury or equipment damage when unloading a rack:

• At least two people are needed to safely unload the rack from the pallet. An empty 42U rack

can weigh as much as 115 kg (253 lb), can stand more than 2.1 m (7 ft) tall, and might

become unstable when being moved on its casters.

• Never stand in front of the rack when it is rolling down the ramp from the pallet. Always

handle the rack from both sides.

WARNING! The enclosure is very heavy. To reduce the risk of personal injury or damage to

the equipment:

• Observe local occupational health and safety requirements and guidelines for manual material

handling.

• Remove all hard drives before installing or moving the enclosures.

• Use caution and get help to lift and stabilize enclosures during installation or removal,

especially when the enclosure is not fastened to the rack.

• Never stack an enclosure on top of another enclosure.

• Never place equipment on top of an enclosure.

• Never place an enclosure on a surface that cannot support up to 163.3 kg (360.0 lb).

WARNING! To reduce the risk of personal injury or damage to the equipment, you must

adequately support enclosures during installation and removal.

WARNING! Always use at least two people to lift an enclosure into the rack. If the enclosure

is being loaded into the rack above chest level, a third person must assist with aligning the

enclosure with the rails while the other two people support the weight of the enclosure.

WARNING! Be sure to install enclosures starting from the bottom of the rack and work your

way up the rack.

WARNING! To reduce the risk of personal injury from hot surfaces, allow the drives and the

internal system components to cool before touching them.

WARNING! To reduce the risk of electric shock or damage to the equipment:

• Never reach inside the chassis while the system is connected to a power source.

• Perform service on system components only as instructed in the user documentation.

WARNING! A risk of electric shock from high leakage current exists. Before connecting the

AC supply to the power enclosures, be sure that the electrical outlets are properly grounded

(earthed).

Safety precautions 9

Page 10

CAUTION: Always be sure that equipment is properly grounded and that you follow proper

grounding procedures before beginning any installation procedure. Improper grounding can result

in ESD damage to electronic components. For more information, see “Preventing electrostatic

discharge” (page 7)

CAUTION: When performing non-hot-plug operations, you must power down the server blade

and/or the system. Use caution when performing other operations, such as hot-plug installations

or troubleshooting.

CAUTION: Protect the equipment from AC power fluctuations and temporary interruptions with

a regulating facility UPS device. This device protects the hardware from damage caused by

power surges and voltage spikes and keeps the system in operation during a power failure.

Precautions for maintaining and servicing products

To reduce the risk of electric shock or damage to the equipment when installing, maintaining, or

servicing products, observe the following precautions:

• Some products contain power supplies that are capable of producing hazardous energy

levels. Refer to the documentation included with your product to determine whether it contains

these power supplies. The installation of internal options and routine maintenance and

service of this product should be performed by individuals who are knowledgeable about

the procedures, precautions, and hazards associated with equipment containing hazardous

energy levels.

• Allow the product to cool before removing covers and touching internal components.

• Do not use conductive tools that could bridge live parts.

• Remove all watches, rings, or loose jewelry when working in hot-plug areas of an energized

server and storage products.

• Do not attempt to defeat safety interlocks (where provided).

• Some products have covers or doors to access hot-plug components and may allow access

to hazardous energy circuits or moving fans.

◦ The doors should remain locked during normal operation.

OR

• The product should be installed in a controlled access location where only qualified personnel

have access to the product.

• Power down the equipment and disconnect all AC power cords before removing any access

covers for non-hot-plug areas.

• Do not replace non-hot-plug components while power is applied to the product. First, shut

down the product and disconnect all AC power cords.

• Do not exceed the level of repair specified in the procedures in the product documentation.

All troubleshooting and repair procedures are detailed to allow only subassembly or

module-level repair. Because of the complexity of the individual boards and subassemblies,

do not attempt to make repairs at the component level or to make modifications to any printed

wiring board. Improper repairs can create a safety hazard.

• Verify that the AC power supply branch circuit that provides power to the rack is not

overloaded. This will reduce the risk of personal injury, fire, or damage to the equipment.

The total rack load should not exceed 80 percent of the branch circuit rating. Consult the

electrical authority having jurisdiction over your facility wiring and installation requirements.

10 Removal and replacement procedures

Page 11

Power cords

To reduce the risk of electric shock or damage to the equipment:

• Use an approved power cord. If you have questions about the type of power cord to use,

contact your Hewlett Packard Enterprise authorized service provider.

• If you have not been provided with a power cord for your product or for any AC-powered

option intended for your product, purchase a power cord that is approved for use in your

country.

• You must use a power cord rated for your product and for the voltage and current marked

on the electrical ratings label of the product. The voltage and current rating of the cord must

be greater than the voltage and current rating marked on the product.

• Do not place objects on AC power cords or cables. Arrange them so that no one may

accidentally step on or trip over them.

• Do not pull on a cord or cable. When unplugging from the electrical outlet, grasp the cord

by the plug.

• Make sure that the total ampere rating of all products plugged into an extension cord or

power strip does not exceed 80 percent of the ampere ratings limit for the extension cord or

power strip.

• Do not disable the power cord grounding plug. The grounding plug is an important safety

feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at

all times.

Power supplies

Hot-plug power supplies are not designed to be removed or installed with AC power connected

to the power supply. To reduce the risk of electric shock or damage to the equipment when

handling hot-plug power supplies:

• Install the power supply before connecting the power cord to the power supply.

• Unplug the power cord before removing the power supply from the product.

• If the system has multiple sources of power, you must unplug all AC power cords from the

power supplies to completely disconnect power from the system.

Verify that the external power source connected to your product matches the type of power source

indicated on the electrical ratings label. If you are not sure of the type of power source required,

consult your authorized service provider or local power company.

Powering off disk enclosures

IMPORTANT: Always power off disk enclosures after controller enclosures and servers.

IMPORTANT: When installing a hot-pluggable component, such as a disk drive, it is not

necessary to power down the enclosure.

To power off a disk enclosure:

1. Power off any attached servers. For more information, see the server documentation.

2. Power off the controller enclosure (if included in the configuration.) For more information,

see the controller enclosure documentation.

3. Disconnect power cords.

The system is now without power.

Powering off disk enclosures 11

Page 12

Powering on

After disk enclosures are physically installed and cabled, power up all devices and verify that

they are operating properly.

Before powering on

Observe the following best practices before powering on the enclosure for the first time:

• Complete the server, controller, or controller enclosure installation. For more information,

see the server, controller, or controller enclosure user documents.

• Install the disk enclosures.

• Install disk drives in the disk enclosures so that the connected host controller can identify

and configure them at power on.

• Connect the SAS cables and power cords to the enclosure.

Power on procedures

1. Connect the enclosure to a live power source.

NOTE: There is no power on/standby button. Power flows to the enclosure immediately

upon connecting to a live power source.

2. Once power is applied to the power supplies, the enclosure starts running.

The power on LED turns solid green.

3. Wait a few minutes for the disk enclosures to complete their startup routines.

CAUTION: If power is applied to the server before the disk enclosures complete their

startup routine, the server might not properly discover the storage.

4. Apply power to the controller enclosure (if included in the configuration).

5. Power on (or restart) the server with access to the disk enclosures, start the operating system,

and log on as administrator.

CAUTION: When you power on the server, the monitor might display a “New Hardware

Found” message. Cancel out of this window to prevent the installation of unsupported

software.

6. Verify that each component is operating properly.

12 Removal and replacement procedures

Page 13

Verifying the operating status of the disk enclosures

To verify that the disk enclosures and disk drives are operating properly, view the enclosure and

disk drive LEDs and compare them with the patterns described in the following table. If LED

patterns are not as expected, check cable connections between the devices, check the availability

of your power source, review the installation procedures, and remove and reinsert the module.

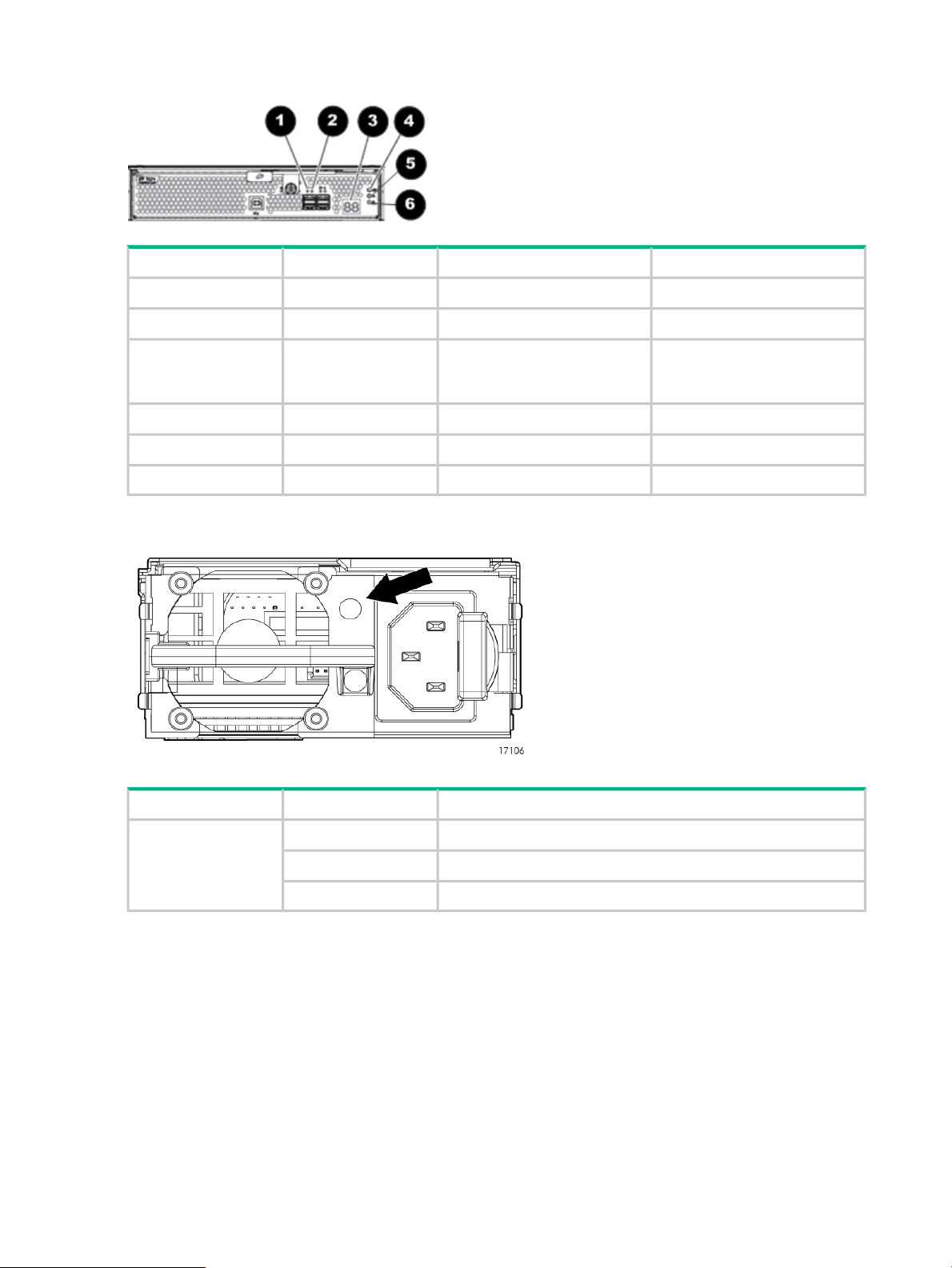

Front panel LEDs

Operating

conditionStartup conditionIndicator

Fault conditions

Fan module

N/A1. HDD

Solid greenSolid green2. Bi-color System Health LED

The UID is a locator LED activated by pressing the rear or the front UID buttons.3. Blue UID LED

• Flashing amber:

non-critical error

• Solid amber:

critical failure

Fault conditionsOperating conditionStartup conditionIndicator

OffOffBlue1. Blue Fan UID LED

LED

Solid amberSolid greenSolid green2. Bi-color Health/Status

OffOffBlue3. Blue System UID

Powering on 13

Page 14

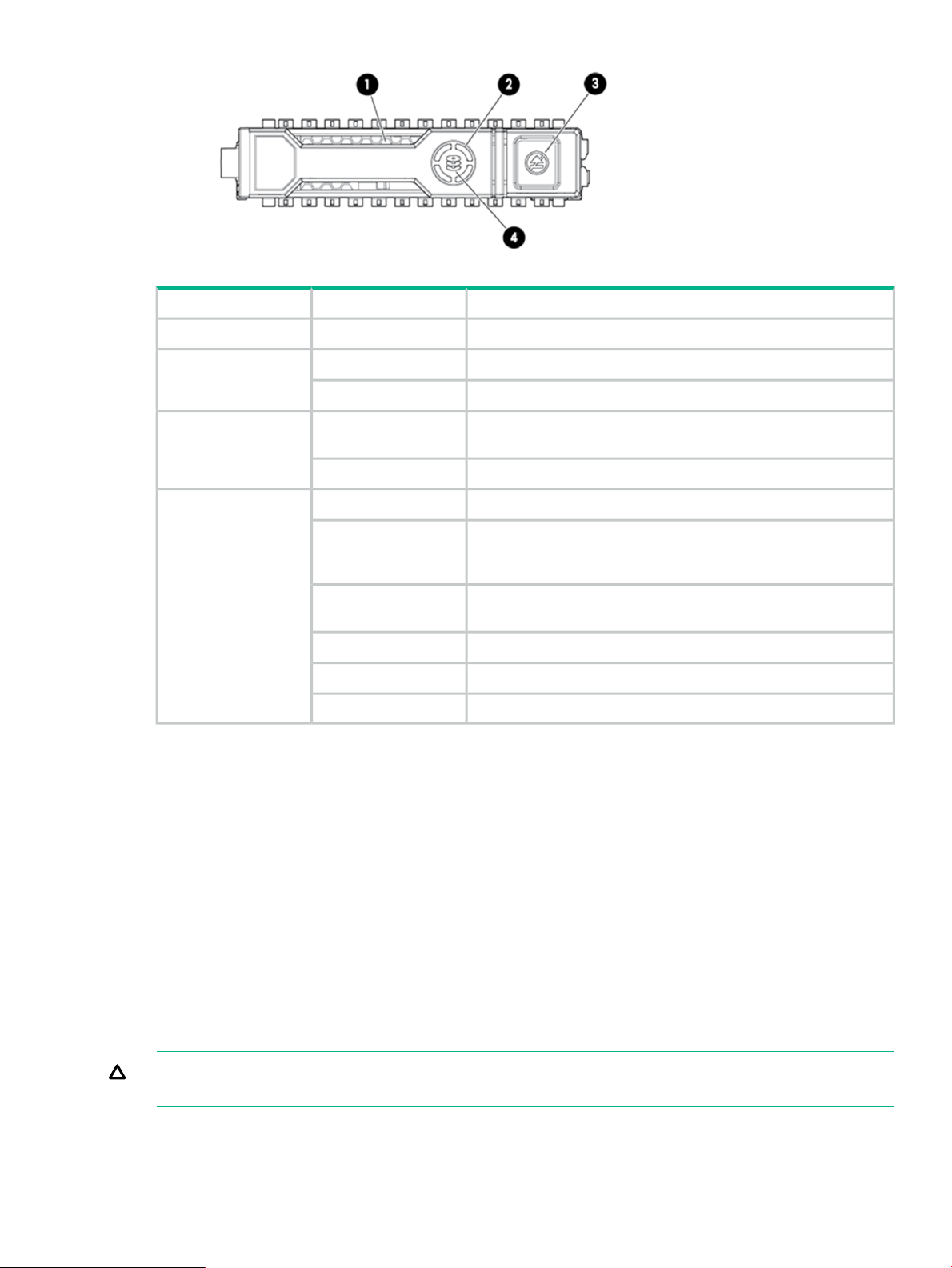

I/O module LEDs

Fault conditionsOperating conditionStartup conditionIndicator

OffBlinking or solid green1. Port Link

Solid amberOff2. Port Error

3. 7–segment display

Power supply module

OffA number, representing the box

number, or an error/warning

code.

OffOffBlue4. UID

OffSolid greenBlinking green5. Health

Blinking or solid amberOff6. Fault

DefinitionStatusIndicator

Verifying the status of the disk drives

Both the HPE G8 LFF and SFF drive carrier system uses I2C communication for drive

authentication, failure and configuration info, activity animation and enhanced LEDs.

14 Removal and replacement procedures

Powering upFlashing greenStatus LED

Normal operationSolid green

No power or faultUnlit

Page 15

DefinitionStatusIndicator

The drive is being identified by a host application.Solid blue1 Locate

Drive activity.Rotating green2. Activity ring

No drive activity.Off

Hard drive blanks

To maintain the proper enclosure air flow, a disk drive or a disk drive blank must be installed in

each drive bay. The disk drive blank maintains proper airflow within the disk enclosure.

Hard drive

Depending on the types of hard disk drives (HDDs) you are using, the following numbers of drives

can be installed in a single enclosure:

Solid white3. Do not remove

Flashing green

Flashing amber/green

Do not remove the drive. Removing the drive causes one or more

of the logical drives to fail.

Drive is safe to remove. Will not cause a logical drive to fail.Off

The drive is a member of one or more logical drives.Solid green4. Drive status

The drive is rebuilding or performing a RAID migration, stripe size

migration, capacity expansion, or logical drive extension, or is

erasing.

The drive is a member of one or more logical drives and predicts

the drive will fail.

The drive is not configured and predicts the drive will fail.Flashing amber

The drive has failed.Solid amber

The drive is not configured by a RAID controller.Off

• Large form factor (LFF): 12 HDDs

• Small form factor (SFF): 25 HDDs

A variety of disk drive models are supported for use, including dual-ported and single-ported

models. For more information about supported disk drives, see the QuickSpecs for the disk

enclosure, available on the D3000 website.

CAUTION: To prevent improper cooling and thermal damage, operate the enclosure only when

all bays are populated with either a component or a blank.

Hard drive blanks 15

Page 16

Disk drive guidelines

CAUTION:

• Follow industry-standard practices when handling disk drives. Internal storage media can

be damaged when drives are shaken, dropped, or roughly placed on a work surface.

• When installing a disk drive, press firmly to make sure the drive is fully seated in the drive

bay and then close the latch handle.

• When removing a disk drive, press the release button and pull the drive only slightly out of

the enclosure. Then, to allow time for the internal disk to stop rotating, wait approximately

10 seconds before completely removing the drive from the enclosure.

• Always populate hard drive bays starting with the lowest bay number. If only one hard drive

is used, install it in the bay with the lowest device number.

• Disk drives are hot-pluggable.

• SAS and SATA disk drives may be installed in the same enclosure, but cannot be included

in the same RAID logical volume.

Removing a drive

CAUTION: To prevent improper cooling and thermal damage, operate the enclosure only when

all bays are populated with either a component or a blank.

1. Press the release button to open the latch handle.

2. Swing out the latch handle on the drive (1). Then, pull the drive from the bay (2).

Replacing a drive

CAUTION: To prevent improper cooling and thermal damage, operate the enclosure only when

all bays are populated with either a component or a blank.

1. Do one of the following:

• If you are installing the disk drive into an empty bay, remove the drive blank.

16 Removal and replacement procedures

Page 17

• If you are replacing a disk drive, refer to “Removing a drive” (page 16)

2. Unlatch and swing out the latch handle on the drive. Then, slide the drive into the bay (1),

pressing firmly on the drive to seat it. Close the latch handle (2), pressing firmly until it locks

in place.

IMPORTANT: When a drive is inserted in an operational enclosure, the drive LEDs flash

to indicate that the drive is seated properly and receiving power.

3. If you are replacing a drive, confirm that the replacement drive matches the drive that is

being replaced.

4. Determine the status of the hard drive.

IMPORTANT: For proper airflow and cooling, a drive blank must remain installed in all unused

drive bays.

Removing and replacing I/O Cables

NOTE: If the cable is malfunctioning, check the LED displays on the I/O module back panel.

See “I/O module LEDs” (page 14)

1. Confirm the correct port(s) for the cable to be replaced.

2. Disconnect the I/O cable(s) to be replaced.

Removing and replacing I/O Cables 17

Page 18

3. Replace the cable(s).

4. Confirm basic communication using LEDs See “Verifying the operating status of the disk

enclosures” (page 13).

Removing and replacing the I/O module

1. Unplug the two cables from the back panel of the I/O module. See “Removing and replacing

I/O Cables” (page 17)

2. Loosen the captive retaining thumbscrew (1), and swing out the hood latch (2).

3. Slide out the I/O module (3) and set aside.

4. Then, slide the replacement I/O module into the correct bay and swing in the hood latch until

it closes.

5. Re-tighten the captive retainer thumbscrew.

6. Replace the two I/O cables.

7. Read the LEDs to confirm the unit is operating. See “I/O module LEDs” (page 14)

Removing and replacing a power supply

1. Remove the power cable from the power supply to be replaced.

18 Removal and replacement procedures

Page 19

2. Press the latch (1) and slide module out (2).

3. Slide new power supply into the enclosure bay until it clicks into place.

4. Replace the power cable.

5. Confirm that the system is in normal state. See “Verifying the operating status of the disk

enclosures” (page 13).

Removing and replacing the fan module

1. Pinch the release buttons and slide the module out.

2. Slide in new fan module until it clicks into place

Removing and replacing the fan module 19

Page 20

3. Confirm that the system is in normal state. See “Verifying the operating status of the disk

enclosures” (page 13).

20 Removal and replacement procedures

Page 21

Removing and replacing the fan control card

This operation is performed after Hewlett Packard Enterprise Support determines that the

enclosure is the source of the issue and requests the fan control card to be replaced

WARNING! Check to make sure data on the drives is backed up Back up data if required.

1. Unplug the power cables.

2. Remove I/O cables. See “Removing and replacing I/O Cables” (page 17)

3. Remove the fan modules. See “Removing and replacing the fan module” (page 19)

4. Remove the rear CTO hold down bracket.

5. Remove the enclosure from the rack. See “Removing and replacing the enclosure” (page 22)

6. Pull hood latch up and back (1 and 2), and lift enclosure cover up and remove (3).

7. Remove fan control card cable (1).

8. Loosen the T-15 captive thumbscrew (2).

9. Slide the fan control card sideways to free it from the retaining pins and lift out (3).

10. Insert the new fan control card and slide sideways to engage it with the retaining pins.

11. Re-tighten the captive T-15 thumbscrew.

12. Attach the fan control card cable.

13. Replace the enclosure cover and press the hood latch down to latch.

14. Replace the enclosure in rack. See “Removing and replacing the enclosure” (page 22)

15. Tighten the front retaining screws.

CAUTION: The front CTO retaining screws must be attached at all times when the

enclosure is racked.

Removing and replacing the fan module 21

Page 22

16. Replace the fan modules. See “Removing and replacing the fan module” (page 19)

17. Replace the I/O module cables. See “Removing and replacing the I/O module” (page 18)

18. Replace the power cables.

19. Apply power to the enclosure and confirm the system is powered on. See “Verifying the

operating status of the disk enclosures” (page 13)

20. Confirm that the system is operating normally. See “Verifying the operating status of the disk

enclosures” (page 13)

Removing and replacing the enclosure

The operation is performed after Support determines that the enclosure is the source of the issue

and requests the enclosure be replaced

WARNING! Check to make sure data on the drives is backed up. Back up the data if required.

1. Unplug the power cables.

2. Remove I/O cables. See “Removing and replacing I/O Cables” (page 17)

3. Label drives for removal.

4. Remove the drives. See “Removing a drive” (page 16)

5. Remove power supplies See “Removing and replacing a power supply” (page 18)

6. Remove the I/O modules. See “Removing and replacing the I/O module” (page 18)

7. Remove both fan modules. See “Removing and replacing the fan module” (page 19)

8. Loosen the captive CTO screws behind the latch on the front left and right bezel ears of the

chassis (1)

9. Loosen the rear CTO hold-down bracket.

10. Slide the enclosure out of the rails (2) and set it on a secure surface.

WARNING! Always use at least two people to lift an enclosure into the rack. If the enclosure

is being loaded into the rack above chest level, a third person must assist with aligning the

enclosure with the rails while the other two people support the weight of the enclosure.

11. Slide in the new enclosure and tighten the retaining screws.

12. Re-attach the rear CTO hold-down bracket.

13. Replace the I/O modules. See “Removing and replacing the I/O module” (page 18)

14. Replace the power supplies. See “Removing and replacing a power supply” (page 18)

15. Replace the fan modules. See “Removing and replacing the fan module” (page 19)

16. Replace the hard drives and/or SSDs. See “Replacing a drive” (page 16)

17. Replace I/O module cables. See “Removing and replacing the I/O module” (page 18)

22 Removal and replacement procedures

Page 23

18. Replace power cables and connect the cables to a live power source.

19. Confirm system is powered on and that it is operating normally. See “Verifying the operating

status of the disk enclosures” (page 13)

Removing and replacing the Power Distribution Board

This operation is performed after Support determines that the enclosure is the source of the issue

and recommends that the Power Distribution Board be replaced.

WARNING! Check to make sure data on the drives is backed up. Back up data if required.

1. Unplug the power cables.

2. Remove the I/O cables. See “Removing and replacing I/O Cables” (page 17)

3. Remove power supplies See “Removing and replacing a power supply” (page 18)

4. Remove the enclosure. See “Removing and replacing the enclosure” (page 22)

5. Pull up hood latch and remove enclosure cover.

6. Remove the power supply cables.

7. Loosen the captive T-15 thumbscrew (1) on the air guide.

8. Lift up the air guide and then pull toward front of enclosure to remove (2).

9. Loosen the T-15 captive thumbscrew on the Power Distribution Board.

10. Slide the Power Distribution Board toward the front of the enclosure and lift out of the

enclosure.

11. Replace Power Distribution Board in the enclosure and slide toward the back of the enclosure.

12. Tighten the captive T-15 screw to secure the Power Distribution Board.

13. Attach power cables to the backplane.

14. Replace air guide making sure cables are routed through the air guide opening.

15. Tighten the captive T-15 screw to secure the air guide in the enclosure.

16. Replace enclosure cover and press lever down to latch.

17. Replace enclosure in rack. See “Removing and replacing the enclosure” (page 22)

18. Replace the power supplies. See “Removing and replacing a power supply” (page 18).

19. Replace the I/O module cables. See “Removing and replacing the I/O module” (page 18).

20. Replace power cables and connect the cables to a live power source.

21. Confirm system is powered on and that it is operating normally. See “Verifying the operating

status of the disk enclosures” (page 13)

Removing and replacing the Power Distribution Board 23

Page 24

Removing and replacing the UID-health module

This operation is performed after Support determines that the UID-health module is the source

of the issue and requests the module be replaced

WARNING! Check to make sure data on the drives is backed up. Back up data if required

1. Unplug the power cables.

2. Remove the I/O cables. See “Removing and replacing I/O Cables” (page 17)

3. Remove the fan module(s) with the failed control card. See “Removing and replacing the

fan module” (page 19)

4. Remove enclosure from rack. See “Removing and replacing the enclosure” (page 22)

5. Pull up hood latch and remove enclosure cover.

6. Disconnect the rear UID-Health module cable from the backplane.

7. Remove the UID-Health module retaining screw (1).

8. Slide out the UID-Health module (2) while guiding the cable through the enclosure.

WARNING! The UID cable is adhered to the chassis. Care should be taken to remove it.

The cable could become unusable.

9. Replace the UID-Health module by sliding the cable through the slot in the enclosure.

10. Reconnect the UID-Health module cable to the backplane.

11. Fasten the UID-Health module using the retaining screw.

12. Replace enclosure cover and press hood latch down to latch.

13. Replace the enclosure in the rack. See “Removing and replacing the enclosure” (page 22)

24 Removal and replacement procedures

Page 25

14. Tighten the retaining screws. See “Removing and replacing the enclosure” (page 22)

15. Replace the fan modules. See “Removing and replacing the fan module” (page 19).

16. Replace the I/O module cables. See “Removing and replacing the I/O module” (page 18)

17. Replace power cables and connect the cables to a live power source.

18. Confirm system is powered on and that it is operating normally. See “Verifying the operating

status of the disk enclosures” (page 13)

Removing and replacing the enclosure backplane

This operation is performed after Support determines that the backplane is the source of the

issue and requests the backplane be replaced

WARNING! Check to make sure data on the drives is backed up. Back up data if required.

1. Unplug the power cables.

2. Remove I/O cables. See “Removing and replacing I/O Cables” (page 17)

3. Label drives for removal.

4. Remove the drives. See “Removing a drive” (page 16)

5. Remove power supplies See “Removing and replacing a power supply” (page 18)

6. Remove I/O modules. See “Removing and replacing the I/O module” (page 18)

7. Remove fan modules. See “Removing and replacing the fan module” (page 19)

8. Remove enclosure. See “Removing and replacing the enclosure” (page 22)

9. Pull up hood latch and remove enclosure cover.

10. Disconnect the following cables from the backplane:

CableNumber

Front UID health module1

Fan control card2

Fan control card3

Rear UID health module4

Power distribution unit5

Rear UID health module6

Power supply7

Power supply8

11. Remove the eight T-10 drive cage retaining screws. There are four to a side.

Removing and replacing the enclosure backplane 25

Page 26

NOTE: Depending on whether the drive cage is for LFF or SFF drives, the screws are in

slightly different locations.

12. Slide the drive cage toward the front of the enclosure and lift free of the enclosure.

13. Remove the two T-15 screws attaching the back plane to the drive cage.

14. Slide the back plane toward the top of the drive cage and lift the back plane off the drive

cage.

15. Place the new back plane on the drive cage and slide toward the bottom of the drive cage

on to the retaining hooks.

16. Replace the two T-15 back plane screws.

17. Place the drive cage in the enclosure and slide toward the back of the enclosure making

sure the locating pins in the bottom of the enclosure are all correctly located in the drive

cage.

NOTE: Depending on the specific unit, there are 6 or 8 locating pins.

18. Replace the eight T-10 drive cage retaining screws.

19. Connect the two UID/Health module cables.

20. Connect the power cables.

21. Connect the fan control card cables.

22. Replace the cover and press lever down to secure.

23. Replace the enclosure in the rack. See “Removing and replacing the enclosure” (page 22)

24. Replace the I/O modules. See “Removing and replacing the I/O module” (page 18)

25. Replace the power supplies. See “Removing and replacing a power supply” (page 18)

26. Replace the fan modules. See “Removing and replacing the fan module” (page 19)

27. Replace the hard drives and/or SSDs. See “Replacing a drive” (page 16)

28. Replace I/O module cables. See “Removing and replacing the I/O module” (page 18)

29. Replace power cables and connect the cables to a live power source.

30. Confirm system is powered on and that it is operating normally. See “Verifying the operating

status of the disk enclosures” (page 13)

26 Removal and replacement procedures

Page 27

Installing the rail kit

The disk enclosure can be installed into most standard server racks. To verify that your rack is

supported for use with the disk enclosure, see the QuickSpecs for the disk enclosure at the

website: http://www.hpe.com/products/quickspecs.

CAUTION: Install disk drives in the enclosures only after mounting the enclosures in the rack.

• A disk enclosure populated with disk drives is too heavy to lift safely by a single person.

• Movement of a disk enclosure during installation might damage the internal storage media

of installed disk drives.

Rack installation best practices

In addition to industry-standard recommendations, consider the following:

• Locate the heaviest items, such as uninterruptible power supplies (UPS) and additional disk

enclosures near the bottom of the rack.

• To make cabling easy, install the disk enclosures below the server.

• Install similar components next to each other in the rack. Because disk enclosures, switches,

and servers are of differing depths, if you have more than one of a device, mount those

devices adjacent to one another to accommodate working behind the rack.

WARNING! To reduce the risk of personal injury or damage to the equipment, be sure that:

• At least two people lift the storage system during removal or installation if the weight exceeds

22.7 kg (50 lb). If the system is being loaded into the rack above chest level, a third person

MUST assist with aligning the system with the rails while the other two people support the

weight of the system.

• The leveling jacks on the rack are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component in a rack is extended at a time. A rack might become unstable if more

than one component is extended.

• To prevent damage and to ease insertion of the device into the rack, support the weight of

the device and keep it level when sliding it into the rack.

Installing the rail kit 27

Page 28

Procedures

1. Position left and right rack rails at the desired 'U' position in the rack, adjusting the rails to

2. Use guide pins to align the shelf mount kit to the RETMA column holes.

3. To engage the rear, push the rail toward the back of the rack until the spring hook (1) snaps

fit the rack, as needed.

Front and Rear bottom edge of rails must align with the bottom of EIA boundary in the

lowermost 'U'

NOTE: Rails are marked L and R with an arrow indicating the direction in which the rail

should be installed.

into place.

4. To engage the front, pull the rail towards the front of the rack to engage the spring hook with

the RETMA column in the same manner as the rear spring hook.

NOTE: Make sure that the respective guide pins for the square or round hole rack align

properly into RETMA column hole spacing.

5. Secure rear of rack rail to the RETMA column with either the round- or square-hole shoulder

screws provided in the package.

6. Secure front of rail to the front RETMA column using the provided flat securing screw/guide

pin in the bottom screw position of the rail.

7. Slide the enclosure into position on the rails (1). Secure the chassis into the rack by tightening

the captive CTO screw behind the latch on the front left and right bezel ears of the chassis

(2).

CAUTION: The front CTO screw must be attached at all times when racked.

28 Removal and replacement procedures

Page 29

8. Attach rear hold down brackets by sliding the tab with the arrow pointed forward (1) into the

corresponding slot on the left and right side of the rear of the chassis. Use the black headed

thumb screw to secure tightly to the rail (2).

Installing the rail kit 29

Page 30

3 Troubleshooting

If the enclosure does not initialize

IMPORTANT: After a power failure, the system automatically returns to the On state when

A/C power is restored, except in the following cases:

• If both power supplies are damaged.

• If there is a single power supply in the system, and it is damaged.

1. Ensure that power has been applied to the enclosure.

2. Verify that the power LED is green.

3. Verify that the power source is working:

a. Verify that the power supplies are working by viewing the power supply LEDs. If

necessary, remove and reinstall the power supplies to verify that they are seated properly.

b. Remove and inspect AC power cords from both power supplies and reconnect them.

Diagnostic steps

Is the enclosure front fault LED amber?

ActionsPossible ReasonsAnswer

Yes

• Front Status and UID module

might not be inserted properly,

might have a damaged connector,

or might have failed.

No action required.System functioning properly.No

• Be sure that the Front Status and

UID module is undamaged and is

fully seated.

• Check rear fault LEDs to isolate

failed component.• Possible error condition exists.

• Contact an authorized service

provider for assistance.

30 Troubleshooting

Page 31

Is the enclosure rear fault LED amber?

ActionsPossible ReasonsAnswers

No action requiredFunctioning properly.No

Yes

Rear power and UID module might

not be inserted properly, might have

a damaged connector, or might have

failed.

Is the System Health LED amber?

Yes

• The system might have

• The system midplane might need

Is the power supply LED green?

No

• Power cords not connected or AC

• Power supply not functioning

• Be sure that the rear power and UID

module is undamaged and is fully

seated.

• Contact an authorized service

provider for assistance.

Possible SolutionsPossible ReasonsAnswer

No action required.System functioning properly.No

• Be sure that all components are

experienced a short. Controller

firmware might be corrupted.

replacement.

power is unavailable.

properly. • Replace with a known-good power

fully seated.

• Update controller firmware.

• Contact an authorized service

provider for assistance.

ActionsPossible ReasonsAnswers

• Remove and inspect the AC power

cords from both power supplies and

reconnect them.

supply.

Yes

normally.

Is the I/O module fault LED amber?

Yes

• The I/O module is locked.

• The I/O module has failed.

• Other fault condition exists.

No action required.The component is functioning

Possible SolutionsPossible ReasonsAnswer

No action required.Functioning properly.No

• Make sure that the I/O module is

seated properly by pressing the I/O

module firmly into its bay after the

handle has clicked in place.

CAUTION: Never remove an I/O

module from the chassis while the

status LED is green. Removing an

active I/O module can result in data

loss.

• Contact an authorized service

provider for assistance.

Diagnostic steps 31

Page 32

Is the fan LED amber?

ActionsPossible ReasonsAnswers

No action requiredFunctioning properly.No

Yes

Fan might not be inserted properly,

might have a damaged connector, or

might have failed.

• Be sure that the fan is undamaged

and is fully seated.

• Contact an authorized service

provider for assistance.

32 Troubleshooting

Page 33

Recognizing disk drive failure

In an Hewlett Packard Enterprise enclosure, a steadily glowing fault LED indicates that a disk

drive has failed. Other indications of failed disk drives are as follows:

• ACU represents failed drives with a distinctive icon.

• HPE SIM can detect failed drives remotely across a network. (For more information about

SIM, see the documentation on the Management CD.)

• ADU lists all failed drives.

• Operating System log files

For additional information about diagnosing disk drive problems, see the HPE ProLiant servers

troubleshooting guide.

Effects of a disk drive failure

When a disk drive fails, all logical drives that are in the same array are affected. Each logical

drive in an array might be using a different fault-tolerance method, so each logical drive can be

affected differently.

• RAID0 configurations cannot tolerate drive failure. If any physical drive in the array fails, all

non-fault-tolerant (RAID0) logical drives in the same array also fail.

• RAID1+0 configurations can tolerate multiple drive failures as long as no failed drives are

mirrored to one another (with no spares assigned).

• RAID5 configurations can tolerate one drive failure (with no spares assigned).

• RAID6 with ADG configurations can tolerate simultaneous failure of two drives (with no

spares assigned).

Compromised fault tolerance

If more disk drives fail than the fault-tolerance method allows, fault tolerance is compromised,

and the logical drive fails.

Factors to consider before replacing disk drives

Before replacing a degraded drive:

• Open SIM and inspect the Error Counter window for each physical drive in the same array

to confirm that no other drives have any errors. For details, see the SIM documentation on

the management cd.

• Be sure that the array has a current, valid backup.

• Use replacement drives that have a capacity at least as great as that of the smallest drive

in the array. The controller immediately fails drives that have insufficient capacity.

Recognizing disk drive failure 33

Page 34

To minimize the likelihood of fatal system errors, take these precautions when removing failed

drives:

• Do not remove a degraded drive if any other drive in the array is offline (the online LED is

off). In this situation, no other drive in the array can be removed without data loss.

• Exceptions:

When RAID1+0 is used, drives are mirrored in pairs. Several drives can be in a failed

◦

condition simultaneously (and they can all be replaced simultaneously) without data

loss, as long as no two failed drives belong to the same mirrored pair.

◦ When RAID6 with ADG is used, two drives can fail simultaneously (and be replaced

simultaneously) without data loss.

◦ If the offline drive is a spare, the degraded drive can be replaced.

• Do not remove a second drive from an array until the first failed or missing drive has been

replaced and the rebuild process is complete. The rebuild is complete when the Online LED

on the front of the drive stops blinking.

Exceptions:

◦ In RAID6 with ADG configurations, any two drives in the array can be replaced

simultaneously.

◦ In RAID1+0 configurations, any drives that are not mirrored to other removed or failed

drives can be simultaneously replaced offline without data loss.

Automatic data recovery (rebuild)

When you replace a disk drive in an array, the controller uses the fault-tolerance information on

the remaining drives in the array to reconstruct the missing data (the data that was originally on

the replaced drive) and write it to the replacement drive. This process is called automatic data

recovery, or rebuild. If fault tolerance is compromised, this data cannot be reconstructed and is

likely to be permanently lost.

Time required for a rebuild

The time required for a rebuild varies considerably, depending on several factors:

• The priority that the rebuild is given over normal I/O operations (you can change the priority

setting by using ACU).

• The amount of I/O activity during the rebuild operation.

• The rotational speed of the disk drives.

• The availability of drive cache.

• The model and age of the drives.

• The amount of unused capacity on the drives.

• The number of drives in the array (for RAID5 and RAID6 with ADG).

Allow approximately five minutes per gigabyte without any I/O activity during the rebuild process.

This figure is conservative, and newer drive models usually require less time to rebuild.

34 Troubleshooting

Page 35

System performance is affected during the rebuild, and the system is unprotected against further

drive failure until the rebuild has finished. Therefore, replace drives during periods of low activity

when possible.

CAUTION: If the Online LED of the replacement drive stops blinking and the amber fault LED

glows, or if other drive LEDs in the array go out, the replacement drive has failed and is producing

unrecoverable disk errors. Remove and replace the failed replacement drive.

When automatic data recovery has finished, the online LED of the replacement drive stops

blinking and begins to glow steadily.

Failure of another drive during rebuild

If a non-correctable read error occurs on another physical drive in the array during the rebuild

process, the Online LED of the replacement drive stops blinking and the rebuild abnormally

terminates. If this situation occurs, restart the server. The system might temporarily become

operational long enough to allow recovery of unsaved data. In any case, locate the faulty drive,

replace it, and restore data from backup.

Handling disk drive failures

If the controller was configured with hardware fault tolerance, complete the following steps after

a disk drive failure:

1. Determine which physical drive failed. On hot-plug drives, an amber drive failure LED

illuminates.

2. If the unit containing the failed drive does not support hot-plug drives, perform a normal

shutdown.

3. Remove the failed drive and replace it with a drive that is of the same capacity. For hot-plug

drives, after you secure the drive in the bay, the LEDs on the drive each flash once in an

alternating pattern to indicate a successful connection. The online LED flashes, indicating

that the controller recognized the drive replacement and began the recovery process.

4. Power on the server, if applicable.

5. The controller reconstructs the information on the new drive, based on information from the

remaining physical drives in the logical drive. While reconstructing the data on hot-plug

drives, the online LED flashes. When the drive rebuild is complete, the online LED is

illuminated.

Recognizing disk drive failure 35

Page 36

I/O module error codes

This table describes the possible error codes appearing in the 7–segment display on the back

panel of the I/O module. For information on the location of the 7–segment display, see “I/O module

LEDs” (page 14)

Recommended ActionError DetailError CodeError Type

Error

A2

A3

A4

A6

A8

A9

AE

ESP generic errorA0I/O Module

ESP watchdog is firedA1

ESP Conflict in SAS

domain (domain A/B)

Error in Expander

communication

Missing information in

IO Module

manufacturing NVRAM

I2C arbitration errorA5

Error in inter ESP

communication

Error in GPIO Expander

I2C bus

Permanent error in ESP

NVRAM I2C bus

Error in ESP event logAD

Permanent error in

Backplane I2C bus

1. Remove the module, wait 10 seconds, reinsert the

module.

2. If the error persists, then check for new firmware

releases and upgrade the enclosure firmware. New

firmware versions, containing new features and

defect fixes, are released periodically.

3. If the error persists, contact an Hewlett Packard

Enterprise representative. An I/O module

replacement may be necessary.

Firmware Error

AF

B1

B2

B3

B5

BD

BF

A7I/O Module

Error in Backplane

NVRAM access

Expander generic errorB0

Expander watchdog is

fired

Expander conflict in

SAS domain (side A/B)

Expander using default

SAS address

I2C arbitration errorB4

Error in inter Expander

communication

System event log errorB7

Error in ESP

communication

System identification

value is not available

ESP firmware version

mismatch with ESP

firmware version in

partner I/O module

1. Update the firmware of the I/O module that displays

the error and wait until it restarts.

2. Then update the firmware of the other I/O module

and wait until it restarts.

36 Troubleshooting

Page 37

Recommended ActionError DetailError CodeError Type

Error

Error

B6

B8

BE

B9SAS Cable

BA

Expander firmware

version mismatch with

Expander firmware

version in partner I/O

module

Expander firmware

image error

Expander firmware

version mismatch with

ESP firmware version in

own I/O module

SAS cable hardware

error

Hewlett Packard

Enterprise unsupported

SAS cable

Error in disk driveBBDisk Drive

1. Verify the SAS cable status indicators. For the cables

with an amber LED (error), check if the cables are

properly connected in both sides.

2. If the cables are properly connected and the error

persists, replace the cables.

3. If replacing the cables does not resolve the issue,

then check for new firmware releases. A firmware

upgrade might fix the issue

4. If there is no new firmware available, or upgrading

the firmware is not possible, contact an Hewlett

Packard Enterprise representative. An I/O module

replacement may be necessary.

Check your storage administration software for more

information about the problem detected and how to

properly fix it.

Control Error

Shutdown

Alarms

BC

C0Thermal

C1

C2

C3Thermal

C4

C5

Not authentic drive in

the enclosure

Generic temperature

error

Permanent error in

temperature sensor I2C

bus

Error reading data from

temperature sensor

Warning temperature

reached in temperature

sensor

Critical temperature

reached in temperature

sensor

Minimum temperature

reached in temperature

sensor

There is at least one non-authentic HPE disk drive on

the system. Non-authentic disks may not work properly

on this system.

Check your storage administration software for more

information about the problem detected and how to

properly fix it.

1. Remove the module, wait 10 seconds, reinsert the

module.

2. If the error persists, then check for new firmware

releases and upgrade the enclosure firmware. New

firmware versions, containing new features and

defect fixes, are released periodically.

3. If the error persists, contact an Hewlett Packard

Enterprise representative. An I/O module

replacement may be necessary.

Check for thermal issues, such as extremely hot drives,

air blockages, missing or failed fans, or high ambient

temperature.

C6

Fans commanded to

maximum speed

I/O module error codes 37

Page 38

Recommended ActionError DetailError CodeError Type

Module Error

C7

D0Power Supply

D1

D2

D3

DA

DB

System shutdown

because of over

temperature

Generic error in Power

Supply module 1

Generic error in Power

Supply module 2

Absence of the Power

Supply module 1

Absence of the Power

Supply module 2

Error in system voltageD9

Input power loss in

Power Supply module 1

Input power loss in

Power Supply module 2

If a power supply module does not have a green LED

illuminated, verify that it is correctly cabled to a power

source.

NOTE: This warning can also be caused by a failed

power supply.

1. If cabling was not the root cause, troubleshoot by

reinserting each power supply in turn.

2. If the error persists, then check for new firmware

releases and upgrade the enclosure firmware. New

firmware versions, containing new features and

defect fixes, are released periodically.

3. If the error persists, contact an Hewlett Packard

Enterprise representative. A power supply

replacement may be necessary.

• Verify that the power supply is tightly inserted in the

slot.

• If a power supply is missing, then insert a module in

the empty slot and connect it to a power source.

If a power supply module does not have a green LED

illuminated, verify that it is correctly cabled to a power

source.

NOTE: This warning can also be caused by a failed

power supply.

1. If cabling was not the root cause, troubleshoot by

reinserting each power supply in turn.

2. If the error persists, then check for new firmware

releases and upgrade the enclosure firmware. New

firmware versions, containing new features and

defect fixes, are released periodically.

3. If the error persists, contact an Hewlett Packard

Enterprise representative. A power supply

replacement may be necessary.

Module

Communication

Error

Error

38 Troubleshooting

D4Power Supply

D5

D6

E0Fan Module

E1

Permanent error in

Power Supply modules

I2C bus

Communication error

with Power Supply

module 1

Communication error

with Power Supply

module 2

Generic error in Fan

module 1

Generic error in Fan

module 2

1. Remove and reinsert each power supply in turn.

2. If the error persists, then check for new firmware

releases and upgrade the enclosure firmware. New

firmware versions, containing new features and

defect fixes, are released periodically.

3. If the error persists, contact an Hewlett Packard

Enterprise representative. A power supply

replacement may be necessary.

1. If a fan module has an amber LED indication, try

removing and reinserting it. If none of the fans have

an amber LED, replace one fan module and wait 30

seconds.

2. If the error persists, then check for new firmware

releases and upgrade the enclosure firmware. New

firmware versions, containing new features and

defect fixes, are released periodically.

3. If the error persists, contact an Hewlett Packard

Enterprise representative, a fan module replacement

may be necessary.

Page 39

Recommended ActionError DetailError CodeError Type

Communication

Error

E2

E3

E9 1. If a fan module has an amber LED indication, try

EA

E4Fan Module

E5

E6

Absence of the Fan

module 1

Absence of the Fan

module 2

Failure in one or more

rotors of Fan module 1

Failure in one or more

rotors of Fan module 2

Permanent error in Fan

modules I2C bus

Communication error

with Fan module 1

Communication error

with Fan module 2

• Verify that the fan module is tightly inserted in the

slot.

• If a fan module is missing, then insert a module in

the empty slot.

reinserting it.

2. If none of the fans have an amber LED, replace one

fan module and wait 30 seconds.

3. If the error persists, then check for new firmware

releases and upgrade the enclosure firmware. New

firmware versions, containing new features and

defect fixes, are released periodically.

4. If the error persists, contact an representative, a fan

module replacement may be necessary.

1. Remove and reinsert each fan module in turn.

2. If this does not resolve the issue, then remove and

reinsert the I/O module that shows the status code.

3. If the error persists, then check for new firmware

releases and upgrade the enclosure firmware. New

firmware versions, containing new features and

defect fixes, are released periodically.

4. If the error persists, contact an representative, a fan

module replacement may be necessary.

I/O module error codes 39

Page 40

4 Component identification

40 Component identification

Page 41

CSR statusDescription

1. Chassis Bezel Ear

2. Chassis Bezel Ear

Not a CSR part (part of

drive cage)

Not a CSR part (part of

drive cage)

Not a CSR part3. Drive Cage

Mandatory4. Backplane

Mandatory5. Fan module interconnect board

Mandatory6. Air guard

Mandatory7. Voltage Regulator Module (VRM) or power module

Mandatory8. Power supply

Not a CSR part9. Enclosure

Mandatory10. I/O module

Mandatory11. Fan module

Mandatory12. Rear Unit ID

Mandatory13. Disk drive

41

Page 42

5 Technical specifications

Physical specifications

HPE D3600 LFF: 3.44 x 17.64 x 23.54 in (8.7 x 44.8 x 59.8 cm)Height/Width/Depth

HPE D3700 SFF: 3.44 x 17.64 x 21.48 in (8.7 x 44.8 x 54.6 cm)

No disk drives: 38 lb (17.2 kg)Weight

D3700 SFF fully populated with SFF disk drives: 54.90 lb (24.9 kg)

D3600 fully populated with LFF disk drives: 60 lb (27.2 kg)

Power and environmental specifications

shown are for sea level. An altitude rating of

1°C per 300 m (1.8°F per 1,000 ft) to 3048 m

(10,000 ft) is applicable. The upper limit might

be limited by the type and number of options

installed.)

humidity of 95% is based on a temperature of

45°C (113°F). Altitude maximum for storage

corresponds to a pressure minimum of 70

KPa.)

Shipping

50° to 104° F (10° to 40° C)OperatingTemperature range (Temperature ratings

-22° to 149° F (-30° to 65° C)

NOTE: Rated 1°C per 1000 feet of elevation

to 10,000 ft.

10% to 90% relative humidity (Rh)OperatingRelative humidity (Non-operating maximum

0% to 95% relative humidity (Rh)Non-operating

Maximum wet bulb temperature

rate is 457 m/min (1500 ft/min))

specifications are maximum values and apply

to worst-case conditions at full rated power

supply load. The power/heat dissipation for

your installation will vary depending on the

equipment configuration.)

Acoustic noise levels

Listed are the declared A-Weighted sound power levels (LWAd) and declared average bystander

position A-Weighted sound pressure levels (LpAm) when the product is operating in a 23°C

ambient environment. Noise emissions were measured in accordance with ISO 7779 (ECMA 74)

and declared in accordance with ISO 9296 (ECMA 109). The listed sound levels apply to standard

shipping configurations. Additional options may result in increased sound levels.

(operating)

storage

(non-operating)

OperatingAltitude (Maximum allowable altitude change

current

82.4° F (28° C)Long-term storage

101.6° F (38.7° C)Short-term

3048 m (10,000 ft) This value might be limited

by the type and number of options installed.

9144 m (30,000 ft)Non-operating

100 to 240 VAC (Common- slot Power Supply)Input voltageInput power (Input Power and Heat Dissipation

50 to 60 Hz (Common-slot Power Supply)Input frequency

120V power source: 6ARated input

240V power source: 3A

526WInput power (max)

42 Technical specifications

LWAd= 7.0 BIdle Acoustic Noise (sound power)

LpAm - 53 dBAIdle Acoustic Noise (sound pressure)

Page 43

LWAd= 7.0 BOperating Acoustic Noise (sound power)

LpAm - 53 dBAOperating Acoustic Noise (sound pressure)

Acoustic noise levels 43

Page 44

6 Support and other resources

Accessing Hewlett Packard Enterprise Support

• For live assistance, go to the Contact Hewlett Packard Enterprise Worldwide website:

www.hpe.com/assistance

• To access documentation and support services, go to the Hewlett Packard Enterprise Support

Center website:

www.hpe.com/support/hpesc

Information to collect

• Technical support registration number (if applicable)

• Product name, model or version, and serial number

• Operating system name and version

• Firmware version

• Error messages

• Product-specific reports and logs

• Add-on products or components

• Third-party products or components

Accessing updates

• Some software products provide a mechanism for accessing software updates through the

product interface. Review your product documentation to identify the recommended software

update method.

• To download product updates, go to either of the following:

Hewlett Packard Enterprise Support Center Get connected with updates page:

◦

www.hpe.com/support/e-updates

◦ Software Depot website:

www.hpe.com/support/softwaredepot

• To view and update your entitlements, and to link your contracts and warranties with your

profile, go to the Hewlett Packard Enterprise Support Center More Information on Access

to Support Materials page:

www.hpe.com/support/AccessToSupportMaterials

IMPORTANT: Access to some updates might require product entitlement when accessed

through the Hewlett Packard Enterprise Support Center. You must have an HP Passport

set up with relevant entitlements.

Websites

44 Support and other resources

LinkWebsite

www.hpe.com/info/enterprise/docsHewlett Packard Enterprise Information Library

www.hpe.com/support/hpescHewlett Packard Enterprise Support Center

Page 45

LinkWebsite

www.hpe.com/assistanceContact Hewlett Packard Enterprise Worldwide

www.hpe.com/support/e-updatesSubscription Service/Support Alerts

www.hpe.com/support/softwaredepotSoftware Depot

www.hpe.com/support/selfrepairCustomer Self Repair

www.hpe.com/info/insightremotesupport/docsInsight Remote Support

www.hpe.com/info/hpux-serviceguard-docsServiceguard Solutions for HP-UX

nl

Storage compatibility matrix