Page 1

HP D300 Digital Dispenser

Operating Manual

Page 2

HP D300 Digital Dispenser 2

Legal notices

Copyright 2008-2012 Hewlett-Packard Company, L.P.

The HP D300 Digital Dispenser, software and documentation manufactured by the Hewlett-Packard Company, 1000

Circle Boulevard, Corvallis, Oregon 97330. All products made in the U.S.A.

The information contained herein is subject to change without notice.

The only warranties for HP products and services are set forth in the express warranty statements accompanying such

products and services. Nothing herein should be construed as constituting an additional warranty. HP shall not be liable

for technical or editorial errors or omissions contained herein.

Page 3

HP D300 Digital Dispenser

3

Contents

1 Product description

1-1 System requirements ..................................................................................................................................... 6

1-1-1 Hardware ............................................................................................................................................... 6

1-1-2 Software ................................................................................................................................................ 6

1-1-3 Environmental operating conditions ...................................................................................................... 6

1-1-4 Shipping and storage conditions ........................................................................................................... 6

2 Safety

2-1 General safety rules ....................................................................................................................................... 7

2-2 Personal protective equipment ....................................................................................................................... 7

2-3 Possible inhalation hazard ............................................................................................................................. 7

2-4 Pinch hazard .................................................................................................................................................. 7

2-5 Laser safety .................................................................................................................................................... 8

2-6 Electrical safety .............................................................................................................................................. 8

2-7 Electrical emissions safety ................................ ............................................................................................. 8

2-8 Decontamination prior to servicing ................................................................................................................. 9

2-9 Safe disposal of Dispensehead Cassettes and pipette tips ........................................................................... 9

2-10 Ergonomic safety ......................................................................................................................................... 9

2-11 Additional assistance ................................................................................................................................... 9

3 Clean the dispenser

4 Get started

4-1 Start up the dispenser .................................................................................................................................. 11

4-2 Get familiar with the software ....................................................................................................................... 12

4-3 Load an existing plate configuration ............................................................................................................. 14

4-4 Get to know the Options dialog box ............................................................................................................. 16

4-4-1 Options: General ................................................................................................................................. 17

4-4-2 Options: Edit: Units .............................................................................................................................. 17

4-4-3 Options: Edit: Fluid Defaults ................................................................................................................ 18

4-4-4 Options: Edit: Assay Defaults .............................................................................................................. 19

4-4-5 Options: Plate Jitter ............................................................................................................................. 19

4-4-6 Options: Report ................................................................................................................................... 20

4-5 Plate dispense procedure ............................................................................................................................ 21

4-5-1 Initiate plate dispense .......................................................................................................................... 21

4-5-2 Scan and load the well plates .............................................................................................................. 22

4-5-3 Load a Dispensehead Cassette .......................................................................................................... 22

4-5-4 Load fluid into the Dispensehead ........................................................................................................ 23

4-6 View the report ............................................................................................................................................. 27

4-7 Turn off the HP D300 Digital Dispenser ....................................................................................................... 30

5 Create plate configurations

5-1 Create the fluids table .................................................................................................................................. 31

5-2 Edit the Fluids List ........................................................................................................................................ 32

5-3 Edit the well plate ......................................................................................................................................... 33

5-4 Set concentrations or volumes in wells ........................................................................................................ 35

5-5 Use the Paste Special dialog box ................................................................................................................ 38

5-6 Normalize ..................................................................................................................................................... 39

5-7 Randomize ................................................................................................................................................... 41

5-8 Save the plate configuration ......................................................................................................................... 42

5-9 Plate Layout Wizard basics .......................................................................................................................... 43

5-9-1 Create single zone titration1layouts .................................................................................................... 43

5-9-2 Position NoDispense controls .............................................................................................................. 47

5-10 Plate Layout Wizard advanced functions ................................................................................................... 49

Page 4

HP D300 Digital Dispenser

4

5-10-1 Create multizone titration1 layouts .................................................................................................... 49

5-10-2 Create modified range titration1 layouts ............................................................................................ 52

5-10-3 Create titration2 layouts: two fluids per well ...................................................................................... 55

6 Troubleshooting and error messages

6-1 Troubleshooting ........................................................................................................................................... 58

6-1-1 Problems with software ....................................................................................................................... 58

6-1-2 Computer issues .................................................................................................................................. 58

6-1-3 Unable to home stage ......................................................................................................................... 59

6-1-4 Check the A1 location .......................................................................................................................... 59

6-1-5 A1 alignment procedure ...................................................................................................................... 59

6-1-6 Check the fuses and replace if necessary ........................................................................................... 61

6-2 Error messages ............................................................................................................................................ 64

Appendix A

HP D300 Digital Dispenser software basics ....................................................................................................... 70

Appendix B

Glossary ............................................................................................................................................................. 71

Appendix C

Quick Start Guide ............................................................................................................................................... 72

Appendix D

Revision History ................................................................................................................................................. 74

Page 5

HP D300 Digital Dispenser 5

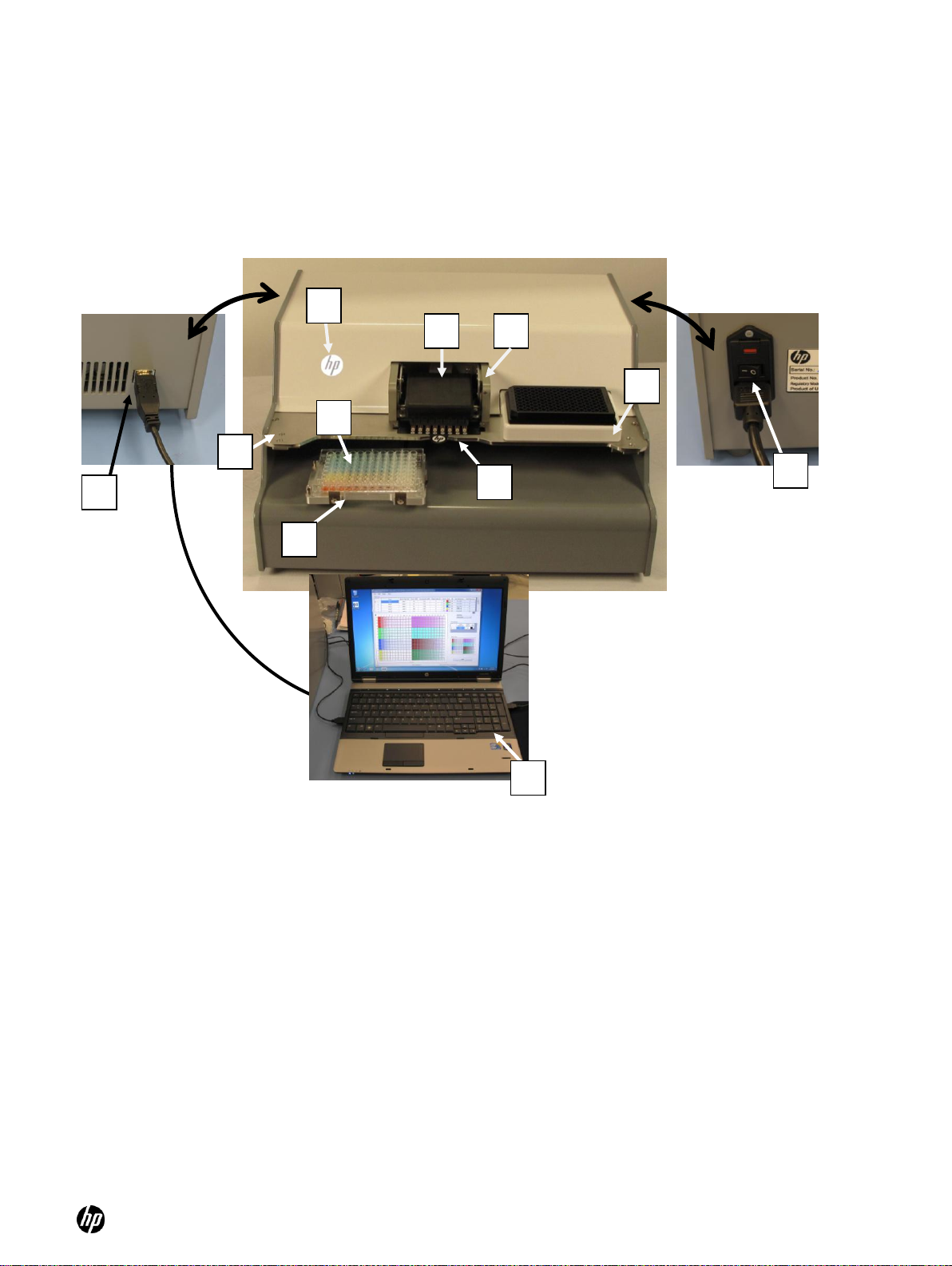

1

Dispensehead Cassette

2

Pogo mechanism

3

Pogo block

4

Source plate holder

5

Motorized stage and destination plate holder

6

Destination plate

7

Deck

8

Power indicator light (HP logo)

9

Dispenser USB connection

10

Power switch

11

PC with D300 software

(Rear view)

(Rear view)

7 9 11

10 4 3

8

1

5

6

2

1 Product description

The HP D300 Digital Dispenser dispenses precise amounts of dilute small molecule compounds in

DMSO into standard 96- and 384-well plates. The dispenser is intended to be used in the lab

environment for drug discovery purposes with small molecules in DMSO.

Page 6

HP D300 Digital Dispenser 6

1-1 System requirements

1-1-1 Hardware

Dimensions of Dispenser (W x D x H): 47cm x 44cm x 24cm

Grounded electrical outlet (2 required, one for dispenser, 1 for PC):

○ 120 V (US) or 230 V (Europe) AC power

1 GHz or faster 32 bit (x86) or 64 bit processor

1 GB (32-bit) or 2 GB (64 bit) RAM

16 GB (32-bit) or 20 GB (64-bit) available disk space

Display: 1024 x 768, 256 colors minimum

USB ports

1-1-2 Software

Microsoft Windows 7, Vista or XP

Microsoft .NET Framework 3.5

○ .NET 3.5 is included with Windows 7

○ .NET 3.5 is available for Windows XP and Vista (www.microsoft.com)

Microsoft Excel 2003 or later

Adobe Acrobat Reader (www.adobe.com/downloads)

Do not adjust text size in Windows – use 100% only

1-1-3 Environmental operating conditions

Temperature: 20C - 30C laboratory conditions (68 - 86F)

Humidity: 30% - 80% RH

1-1-4 Shipping and storage conditions

Temperature: 10C - 32C (50F – 90F)

Humidity: 20% - 80% RH

Page 7

HP D300 Digital Dispenser 7

NOTE: If this unit requires servicing, or you are unsure about any aspect of operation or safety,

contact your Tecan Service Help Desk. The phone number can be found at

http://www.tecan.com/customersupport.

CAUTION: Do not remove any of the dispenser covers. Contact your Tecan Service Help Desk if

the dispenser is not working properly. Do not attempt to repair the dispenser yourself.

CAUTION: Do not place fingers under or on top of the pogo block at any time.

2 Safety

The HP D300 Digital Dispenser is intended to be used in the lab environment for drug discovery

purposes with small molecules in DMSO only. Other uses of the dispenser are not recommended at

this time because they may introduce safety or performance issues.

Under no circumstances should the dispenser be used to dispense bacteria, viruses, cells, biofluids, biologicals, pathogens, contagions, infectious agents, potent toxins, oncogenes, radioactive

materials or other potentially hazardous substances. The dispenser should not be exposed to Bio

Safety Level 3 (BSL3) or greater conditions, contaminants or locations.

The dispenser should be used in accordance with all applicable safety rules that are in effect in the

lab in which it is installed. Usage of the dispenser should also follow common sense safety

guidelines for chemical, mechanical, and electrical safety.

2-1 General safety rules

Place the dispenser on a work surface that supports all four feet securely.

Plug the dispenser into a standard, grounded, electrical outlet. Note the power requirement

(120V in North America or 230V in Europe) listed on the back label of the dispenser.

Avoid the moving parts of the dispenser during operation.

2-2 Personal protective equipment

The HP D300 Digital Dispenser dispenses chemicals normally used by your company. The same

safety precautions and personal protective equipment (PPE) specified by your employer for fluid

transfer operations, such as pipetting into bio-assay well plates, should be used when operating the

dispenser and handling these materials.

2-3 Possible inhalation hazard

The dispenser was designed with chemical safety in mind; however, it does dispense picoliter

droplets of fluid and generates a small amount, less than 1% by volume, of very small aerosol

droplets that might not be trapped within the well plate that you are dispensing into. If the fluids are

known or suspected to be an inhalation hazard or contact hazard, consider using the dispenser in

an exhausted enclosure such as a lab fume hood.

2-4 Pinch hazard

The dispenser was designed with mechanical safety in mind; however, there are potential pinch

points between the pogo block and either the Dispensehead Cassette, the Dispenser deck or the

top cover. This pinch hazard is labeled on the pogo block.

Page 8

HP D300 Digital Dispenser 8

WARNING: Do not look at the laser beam directly. Similarly, do not continue to look at laser light

reflected on a highly reflective substance for a long duration.

2-5 Laser safety

A Class 1 laser is used in the dispenser to determine the height of the destination plate. This Class

1 Laser follows the requirements of Laser Notice No. 50 of the FDA (CDRH), Accession No.

0520365-02. This product complies with 21 CFR Part 1040.10 for laser products. See Figure 2-1.

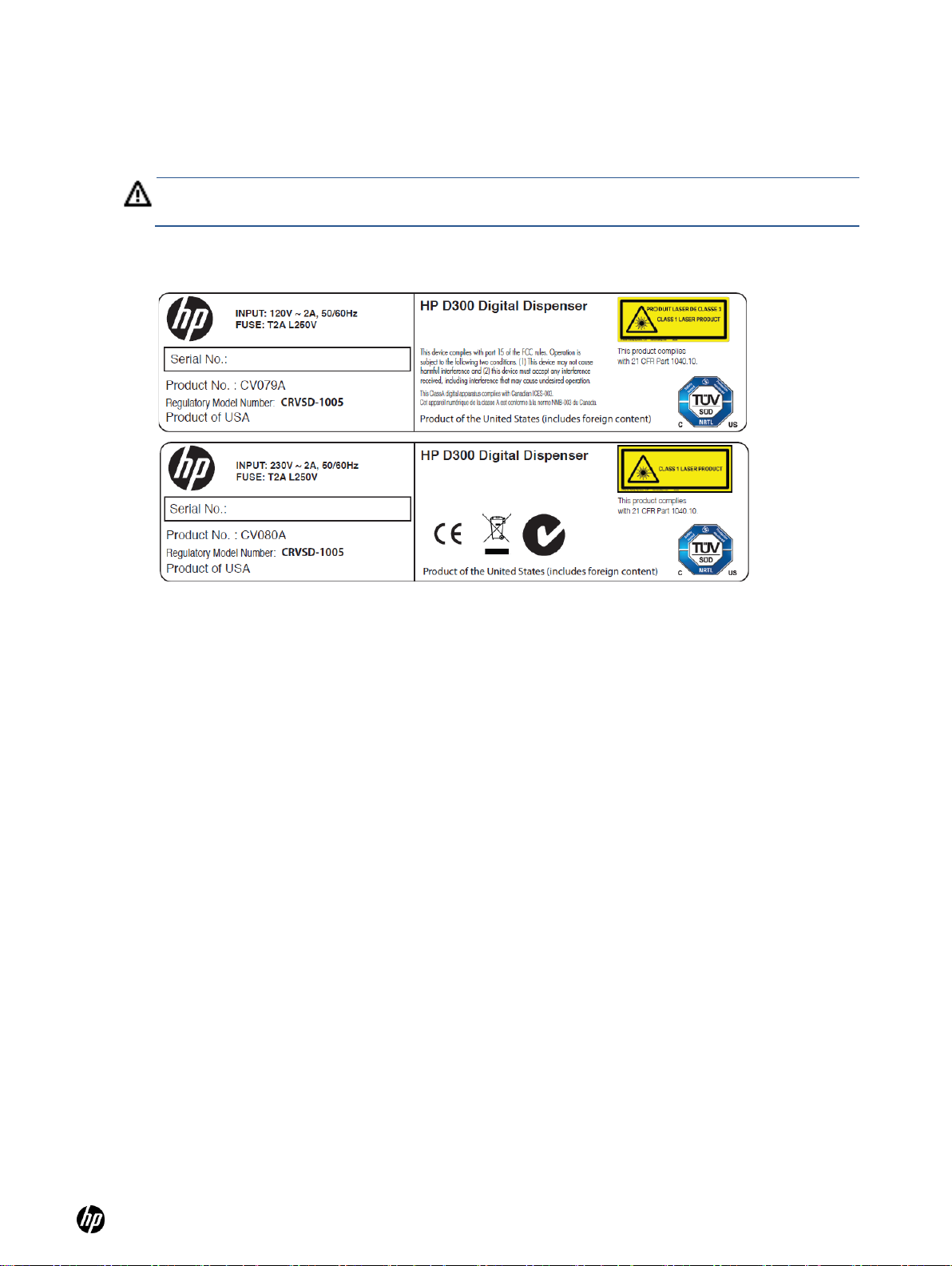

Figure 2-1 D300 Digital Dispenser rear placards indicating safety certifications for North America

(top) and Europe (bottom)

2-6 Electrical safety

The HP D300 Digital Dispenser has passed a TUV certification for a CUE marking signifying

compliance with applicable electrical regulations in the EU and North America. As shown in Figure

2-1, a placard is attached to the rear of the dispenser, noting this certification and the electrical

specifications of the dispenser: voltage 120V or 230V AC, 1 phase/3 wire, 50/60 Hertz, 2A full load

amperage, and short circuit interrupt rating 5000A. The dispenser includes two user-replaceable

T2A L250V (time lag, low breaking capacity 2A, 250V) fuses contained in the power inlet module at

the rear of the dispenser.

2-7 Electrical emissions safety

The HP D300 Digital Dispenser has passed an FCC/EMC test for electrical emissions safety. This

device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation. Any changes or

modifications to this equipment not expressly approved by the Hewlett-Packard Company may

cause harmful interference, and void your warranty.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at their own expense. Also, this Class A digital

apparatus complies with Canadian ICES -003.

Page 9

HP D300 Digital Dispenser 9

2-8 Decontamination prior to servicing

You may be required by Tecan service personnel to certify that appropriate cleaning,

decontamination, and other abatement of potential threats to Tecan service personnel have been

performed prior to shipping the dispenser for servicing. Recommended cleaning and

decontamination procedures are described in the ―Clean the dispenser‖ section of this manual.

2-9 Safe disposal of Dispensehead Cassettes

and pipette tips

Disposal of used pipette tips and HP Dispensehead Cassettes (DHCs) should be performed in

accordance with your company’s chemical waste procedures. The DHCs do not require any special

disposal procedures except for those required for the chemicals which have been placed in them by

your laboratory.

2-10 Ergonomic safety

The HP D300 Digital Dispenser typically requires a single manual pipetting operation for each

dispensed compound. In most situations, using the HP dispenser in the intended manner decreases

the frequency of shoulder, arm, and wrist motions and so decreases the stress on these joints.

As with any work task, ergonomics are heavily influenced by workstation setup. To minimize

ergonomic risks associated with the use of the dispenser, consider the following work area design

ideas:

Place the dispenser on a work bench at a height that allows for proper visual and physical

access for operators. Having the dispenser too high can lead to greater shoulder elevation

when pipetting into the Dispensehead and having the dispenser too low can lead to increased

neck and back flexion.

If an operator is too short to comfortably access the dispenser, consider moving the dispenser

to a lower bench height. Alternatively, use a footstool or high lab stool that adjusts to the proper

work height.

Place the dispenser close to the front of the work surface to minimize the distance the operator

must reach to pipette into the Dispensehead.

Place the pipette tip disposal receptacle close to the dispenser.

Place the computer keyboard close to the dispenser to minimize reach distance.

Adjust the computer monitor height and screen angle for good physical and visual access

during dispenser operation.

Use a separate mouse rather than the laptop’s touchpad whenever possible.

Perform data analysis at a separate ergonomically designed workstation whenever possible

rather than at the dispenser computer.

2-11 Additional assistance

Contact your local Tecan Service Help Desk for additional assistance. The phone number can be

found at http://www.tecan.com/customersupport.

Page 10

/Clean the dispenser

HP D300 Digital Dispenser

10

WARNING: Observe the following cautions when cleaning the dispenser:

Do not spray cleaning fluid directly onto the Dispenser when a Dispensehead

Cassette is installed. Always avoid exposing unused Dispenseheads to cleaning

fluids.

Do not spray or wipe the ionizer bar that is mounted under the deck between the

plate opening and the Dispenseheads.

Do not spray or wipe the sensors under the Dispenser deck. Doing so could cause

the sensors to become misaligned.

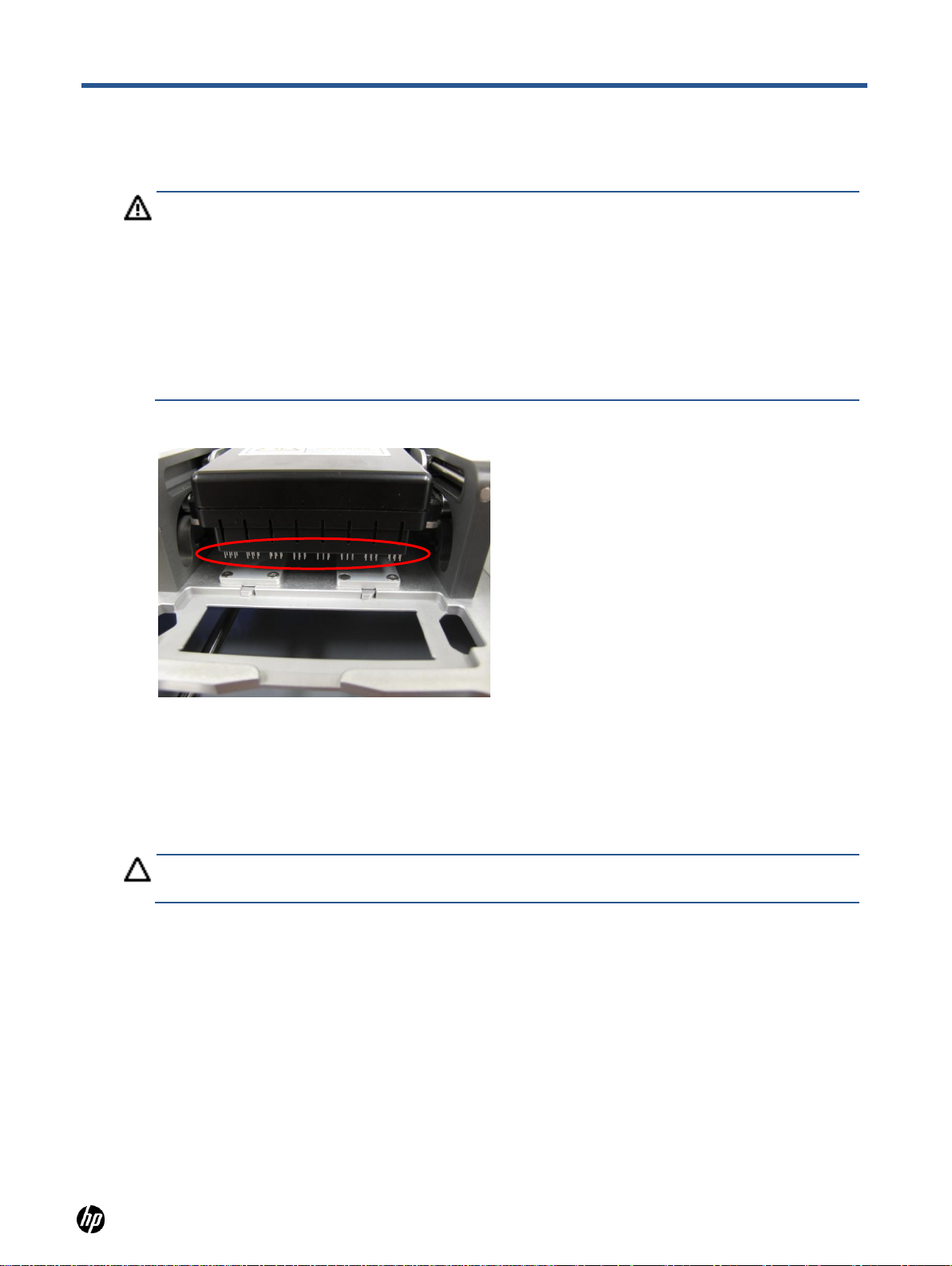

Do not wipe the pogo pins. See Figure 3-2.

CAUTION: Exposing unused Dispensehead Cassettes to cleaning fluids may compromise their

performance.

3 Clean the dispenser

Figure 3-2 Pogo pin region of pogo block which should not be sprayed or wiped with cleaning fluid

As with any lab instrument, it is a best practice to routinely clean areas of the Dispenser that come

into contact with chemicals.

1. Turn off the dispenser as instructed in the ―Turn off the HP D300 Digital Dispenser‖ section

of this document.

2. Remove any unused Dispensehead Cassettes from the Dispenser.

3. Spray a cleaning solution, such as a bleach or a 70% ethanol solution, onto a fabric Texwipe or

other cloth that does not generate particles.

4. Wipe down all accessible Dispenser surfaces, including the following (See the ―Product

description― section for the location of described areas):

○ The top and bottom surfaces of the dispenser deck, avoiding the ionizer bar in the cutout

on the right side of the bottom of the deck and the sensors at the front corners of the deck

○ The pogo mechanism housing, excluding the pogo pin area as described above

○ The destination plate holder

○ The source plate holder

○ All of the outside surfaces of the dispenser

Page 11

HP D300 Digital Dispenser

11

WARNING: Be sure the dispenser matches your outlet voltage. The voltage requirement is shown

on the label on the rear of the dispenser. Do NOT plug the dispenser in to the incorrect voltage.

If the labeled voltage on your dispenser does not match your standard outlet, contact your Tecan

Service Help Desk. The phone number can be found at http://www.tecan.com/customersupport.

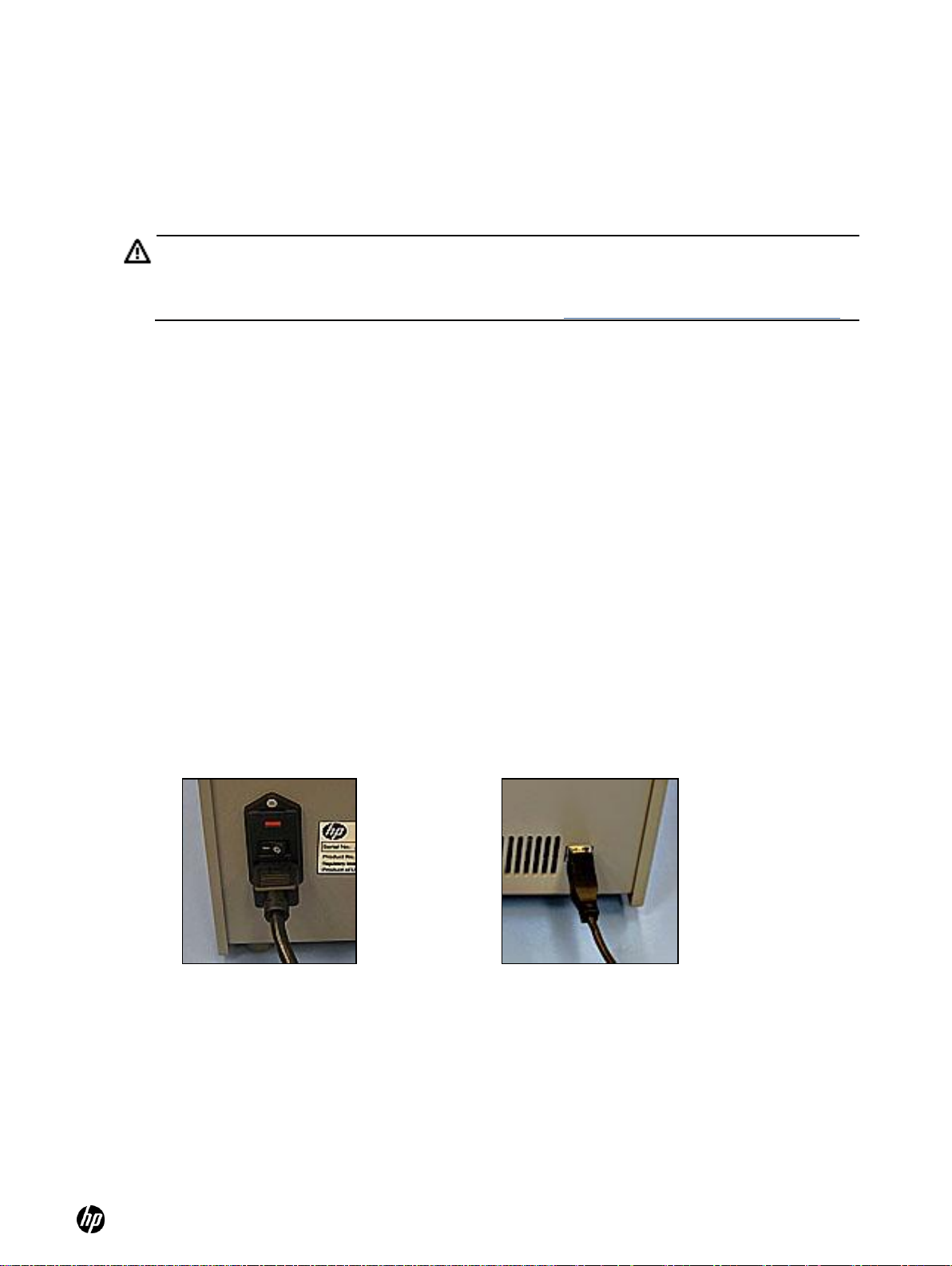

Figure 4-3 On/off switch on rear of

dispenser. Depress ―1‖ to turn on.

Figure 4-4 USB port on rear of

dispenser

4 Get started

The HP D300 Digital Dispenser runs on standard AC power, either 120V or 230V, depending on the

Dispenser version. HP Product Number CV079A runs on 120V and CV080A runs on 230V. The

Product Number and the voltage requirement is shown on the label on the rear of the Dispenser.

Two electrical outlets are required, one for the dispenser and another for the computer. A dedicated

circuit is not required as the dispenser draws less than two amps.

The dispenser requires a level bench space which is 50 cm (19 inches) wide, 46 cm (18 inches)

deep, and 26 cm (10 inches) high. This does not include space for the required computer.

4-1 Start up the dispenser

1. Unpackage the dispenser and remove the four pieces of the shipping bracket.

2. Connect the separately packaged power cord to the rear of the dispenser. See Figure 4-3.

3. Plug the other end of the power cord into the appropriate power outlet. See ―Get started.‖

4. Turn the dispenser on using the main power switch adjacent to the power cord connection on

the rear of the Dispenser. Press the ―l‖ on the switch to turn the dispenser on. See Figure 4-3.

5. The HP logo on the front of the dispenser will illuminate and the pogo block LEDs will flash,

indicating the beginning of the Dispenser initialization routine.

6. Use the USB cable that came with the dispenser to connect the computer to the dispenser.

The USB port is on the rear of the dispenser. See Figure 4-4.

7. The first time the Dispenser is connected to the computer, Device Manager will ask you for a

device driver.

8. Insert the CD that was enclosed with the Dispenser into your computer’s disk drive.

9. If your computer does not autorun the installer, use Windows Explorer to locate the setup.exe

file on the CD disk drive.

10. Run setup.exe and follow the on-screen instructions to install both the device driver and the

HP D300 Digital Dispenser software.

Page 12

HP D300 Digital Dispenser

12

11. Check to see if an update is available for your software. Look for the latest version available

and run the *.exe file for it on the Tecan FTP site: ftp.tecan.com

Username: HP-D300

Password: HP+Tecan

12. Click on the HP D300 Digital Dispenser Software program icon on the computer desktop to

start up the HP D300 Digital Dispenser software. See Figure 4-5.

13. Wait for the Dispenser to go through the software startup routine. The stage will move to the

home position every time the HP D300 Digital Dispenser software is started.

Figure 4-5 Laptop computer showing the HP D300 Digital Dispenser software logo

4-2 Get familiar with the software

Every time the software starts, if the computer is connected to a Dispenser, the computer checks

the Dispenser USB communication, verifies that the dispenser components are operational, and

moves the stage and the pogo mechanism to their home positions. If the computer is not connected

to the Dispenser, the software is fully functional but the GO operation works in a demonstration

mode.

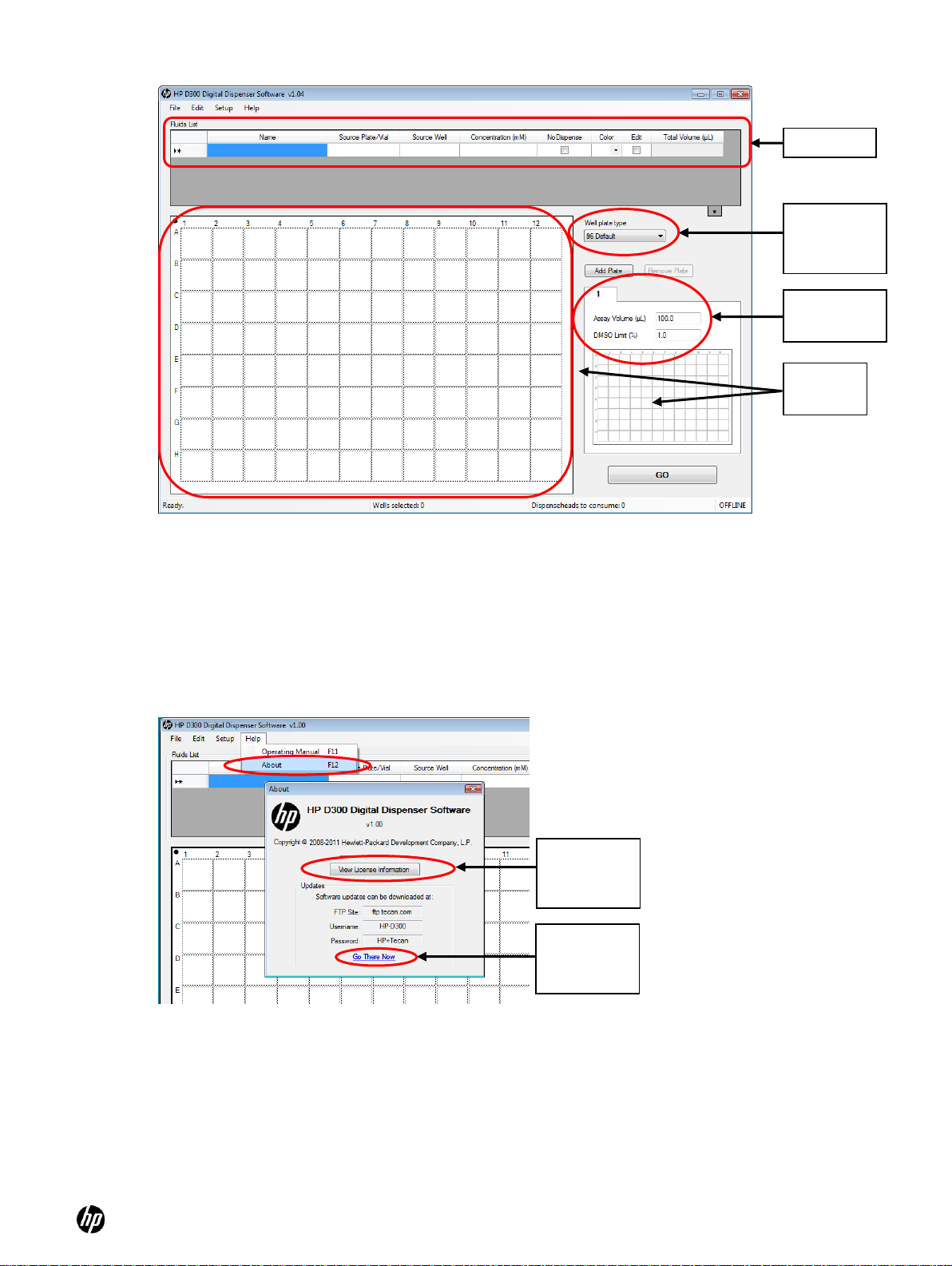

Once the startup routine is complete, the HP D300 Digital Dispenser main operating window

appears, showing an empty Fluids List and an image of an empty well plate. See Figure 4-6.

Page 13

HP D300 Digital Dispenser

13

Software

license

information

Look for

software

updates

Fluids List

Well plate

drop-down

list box

Well plate

images

Plate 1

information

Figure 4-6 HP D300 Digital Dispenser main operating window

The application has a standard MS Windows® look and feel. Once you get started, you can work in

different areas of the main operating window by clicking in them, you can select cells by left-clicking,

control-clicking or shift-click combined with dragging, you can right-click to perform context sensitive

operations, or see information about wells that contain fluids by hovering over them in the well plate.

1. Note that this Operating Manual is accessible two different ways, either by opening the pdf file

in the C:\Program Files\HP-D300 directory, or by clicking on Help/Operating Manual from the

main operating window as shown in Figure 4-7.

Figure 4-7 Help menu and Help/About Window

2. Note that the About window also provides access to the License information and to the Tecan

FTP site that always contains the latest version of the software. Click on Go There Now to

directly access the FTP site from the D300 Digital Dispenser software.

3. Select either 96 or 384 from the Well Plate drop-down list box.

Page 14

HP D300 Digital Dispenser

14

NOTE: Either Set Volume or Set Concentration is available on the well plate options list

depending on whether Volume or Concentration mode was selected in the Options: Edit:

Units. See ―Options: Edit: Units‖ for how to set Volume or Concentration mode.

TIP: If the Set Volume or Set Concentration option is grayed out, the fluids table is empty, so

follow step 4 above to add a fluid to the fluid table.

NOTE: Two different drop volumes are used in the dispenser. For dispense volumes less than

3.5nL, the dispenser uses the closest number of either 13pL or 20pL drops to dispense as close

as possible to the requested volume. For volumes greater than 3.5nL, the dispenser uses the

closest number of 400pL bursts (20 drops simultaneously dispensed from 20 nozzles which are

each 20pL) in order to dispense very close to the requested volume very rapidly.

NOTE: To build a new plate configuration, see ―Create plate configurations‖.

4. Put at least one fluid in the Fluids List, by entering any characters in the Name cell, or by

copying and pasting a list of compounds from an Excel file. The order of the fluids in the Fluids

List is the order in which the fluids will be dispensed.

5. Learn how to select and deselect wells in the plate design:

○ Select any number of wells by clicking and dragging in the well plate image. Any well

which is partially selected becomes one of the selected wells. Give it a try!

○ Select nonadjacent wells by holding down the CTRL key while selecting wells.

○ Deselect wells by clicking on them again while holding down the CTRL key.

○ Deselect all selected wells by clicking on other wells or clicking on the edge of the well

plate (outside the wells) while not holding down the CTRL key.

6. Just for fun, select some wells, then right-click on them to open the Edit Well Plate menu. Click

on Set Volume or Set Concentration, enter the number 1 in the volume or concentration box

and click OK. The wells you selected will turn red because they now contain fluid 1 in your

plate design.

In general, this is a great way to learn to use the software—try things out, right- or left-click

when you are unsure, and move the mouse over areas to check them out.

Don’t worry, you won’t break anything!

7. Now that you have set up some wells, place the cursor over a colored well and observe the

information that appears in the well pop-ups.

Note that the first three values (assay volume, total volume, and DMSO content) regard the

entire contents of the well. Below these values, information is given separately for each fluid in

that well. With the exception of assay volume, there are two values for each well pop-up entry:

the first value and then a second value enclosed by square brackets, for example [0.960 nl].

The first value is the volume or concentration that was requested, and the second bracketed

value is what will actually be dispensed since only an integer number of drops can be

dispensed. This is where the name Digital Dispenser comes from, an integer number of

ultrasmall droplets.

4-3 Load an existing plate configuration

Page 15

HP D300 Digital Dispenser

15

NOTE: These identifiers may be typed into the Fluids List individually, or they may be entered by

scanning a barcode, or pasted in from an Excel or other tab-separated file that has a compatible

layout. To copy and paste information from another file, the information must be arranged in

columns as the Fluids List is, but it is not necessary that the originating table contain all of the

columns that the Fluids List contains. Once you have pasted information into the Fluids List, if

certain cells (such as those in the Concentration column) do not contain the proper numerical

data, then default values will be used for those cells.

TIP: Paste information from another file into the Fluids List just as you would in any other

Windows program: click in the upper left-most cell that you want to paste into, then right-click and

select Paste.

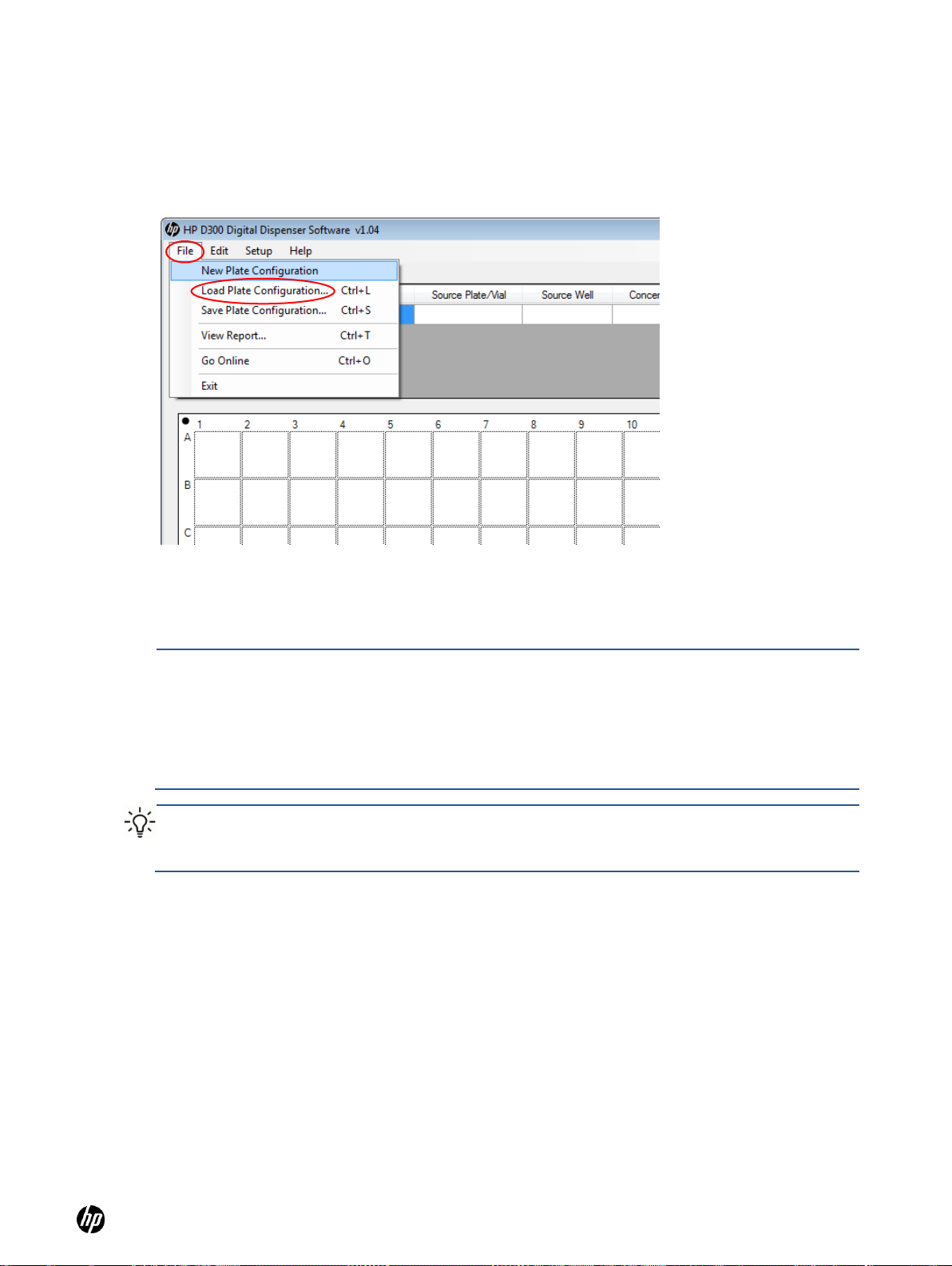

8. On the HP D300 Digital Dispenser main operating window, click File and then Load Plate

Configuration, then locate and select a plate configuration (.xls) that has been previously

saved on your computer. Example configurations are in C:\Program Files\HP-D300\Configs.

Many of the settings, including the Fluids List, assay volume, DMSO limit, plate layout and the

plate jitter option, will change to reflect the configuration you select. See Figure 4-8. Up to

five plates can be included in a Plate Configuration for multiplate configurations.

Figure 4-8 Click File and then Load Plate Configuration

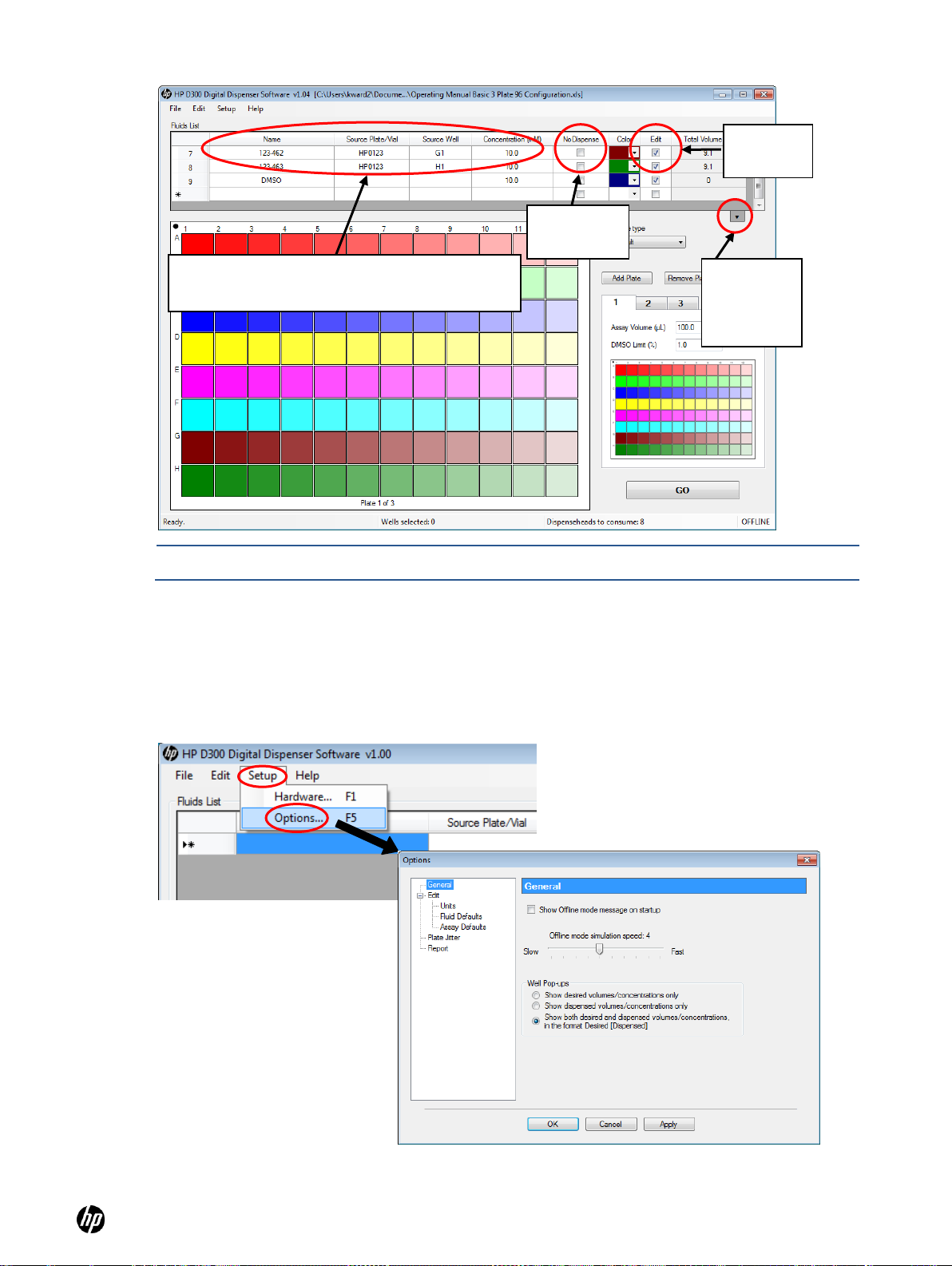

9. If the Fluids List needs to be modified, enter the new fluid name, source plate, source well and

concentration in the Source Plate/Vial, Source Well and Concentration columns in the Fluids

List. Only the fluid name and concentration are required. See Figure 4-9.

○ If the NoDispense check box is selected, you can program that fluid just like the other

fluids, but it will not be dispensed. This may be useful when you want to maintain

information in the output report file about wells that have not been dispensed into. See

Figure 4-9.

○ If the Edit check box is deselected, that fluid cannot be added to the configuration and will

not be displayed in the plate layout. This fluid will still be displayed in the Global View

layout if it was added to any wells prior to deselecting the Edit check box, and it will still be

dispensed. Deselecting the Edit check box may be useful when you have added multiple

fluids to individual wells and want to view or manipulate one or more fluids in the well, but

not all the fluids in the well.

10. Click on the arrow at the lower-right corner of the Fluids List to display the entire Fluids List.

See Figure 4-9.

Page 16

HP D300 Digital Dispenser

16

NOTE: The Fluids List can also be managed by clicking Edit and then Fluids List.

Click here

to view the

entire fluids

list

If necessary, enter the new fluid name, source

plate, source well and concentration here

NoDispense

check-box

Edit

check-box

Figure 4-9 Main operating window showing Fluid Table options.

4-4 Get to know the Options dialog box

At the HP D300 Digital Dispenser main operating window, click Setup and then Options to open

the Options dialog box.

Figure 4-10 Click Setup and then Options to open the Options dialog box

Page 17

HP D300 Digital Dispenser

17

4-4-1 Options: General

From the main operating window, click Setup, then Options , then General to open the General

pane of the Options dialog box. See Figure 4-10. In the General pane, you can choose whether to

show the Offline mode message when you use the software when not connected to an HP D300

Digital Dispenser. When in Offline mode, you can choose how rapidly to ―pseudo-dispense‖ upon

using the Go button using the Offline mode simulation speed. You can also choose whether to

show the requested volume or the dispensed volume, or both, in the Well Pop-ups, as described

below. For small volumes, the dispensed volume may be slightly different than the requested

volume due to the integer number of drops resolution of the Digital Dispenser.

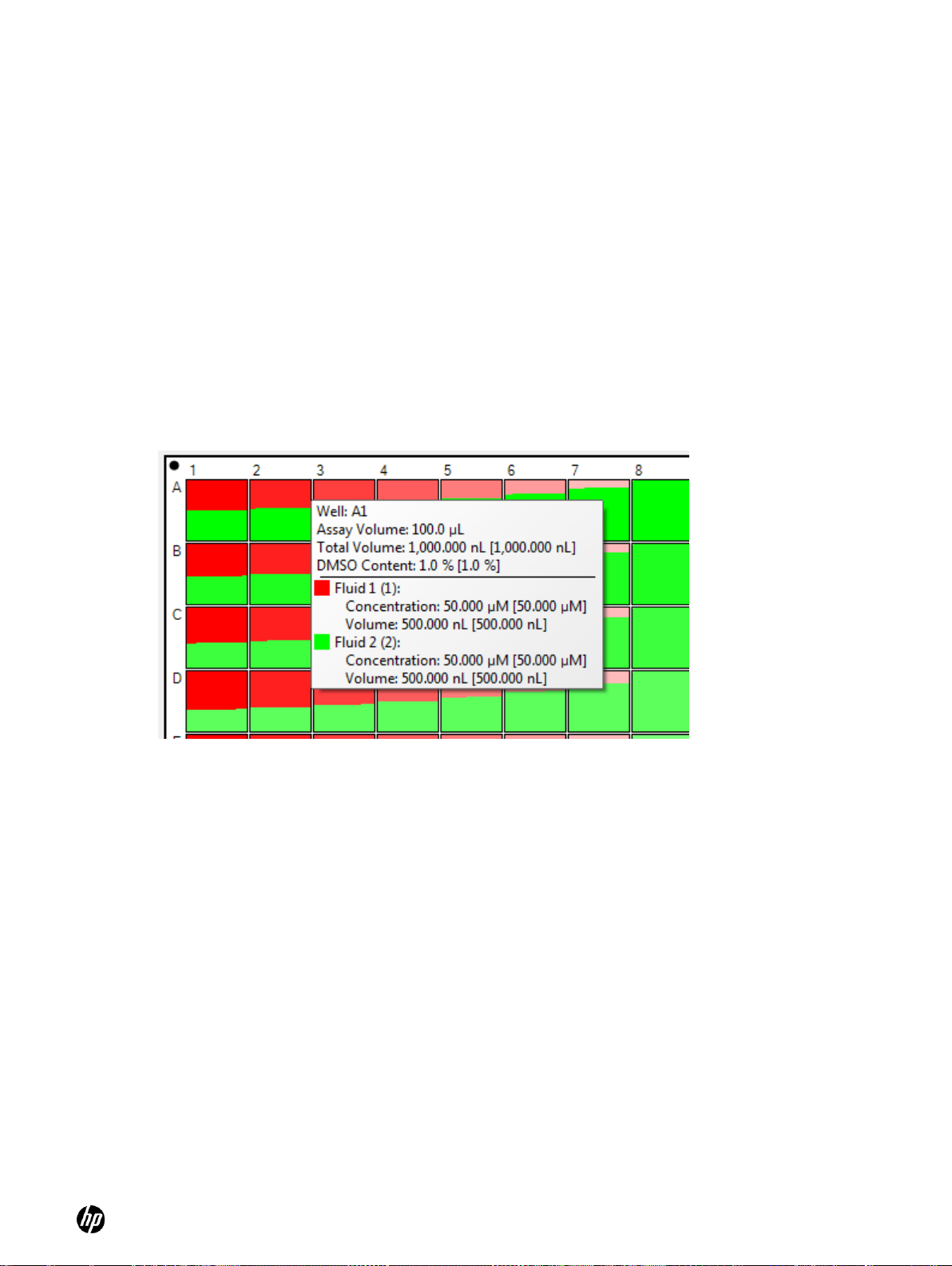

Well pop-ups are the information about the contents of a well that is displayed when you move the

mouse over the well plate image on the main operating window. Note that when ―Show both

requested volume and dispensed volumes/concentrations‖ is selected, the format of the pop-up is

Requested [Dispensed], , as shown in Figure 4-11, such that the requested volumes and

concentrations are shown first and the dispensed volumes and concentrations are shown next,

enclosed in brackets.

Figure 4-11 Example of a well pop-up that displays both requested and [dispensed] volumes and

concentrations

4-4-2 Options: Edit: Units

In the Options dialog box, click Edit and then Units to open the Edit: Units pane of the Options

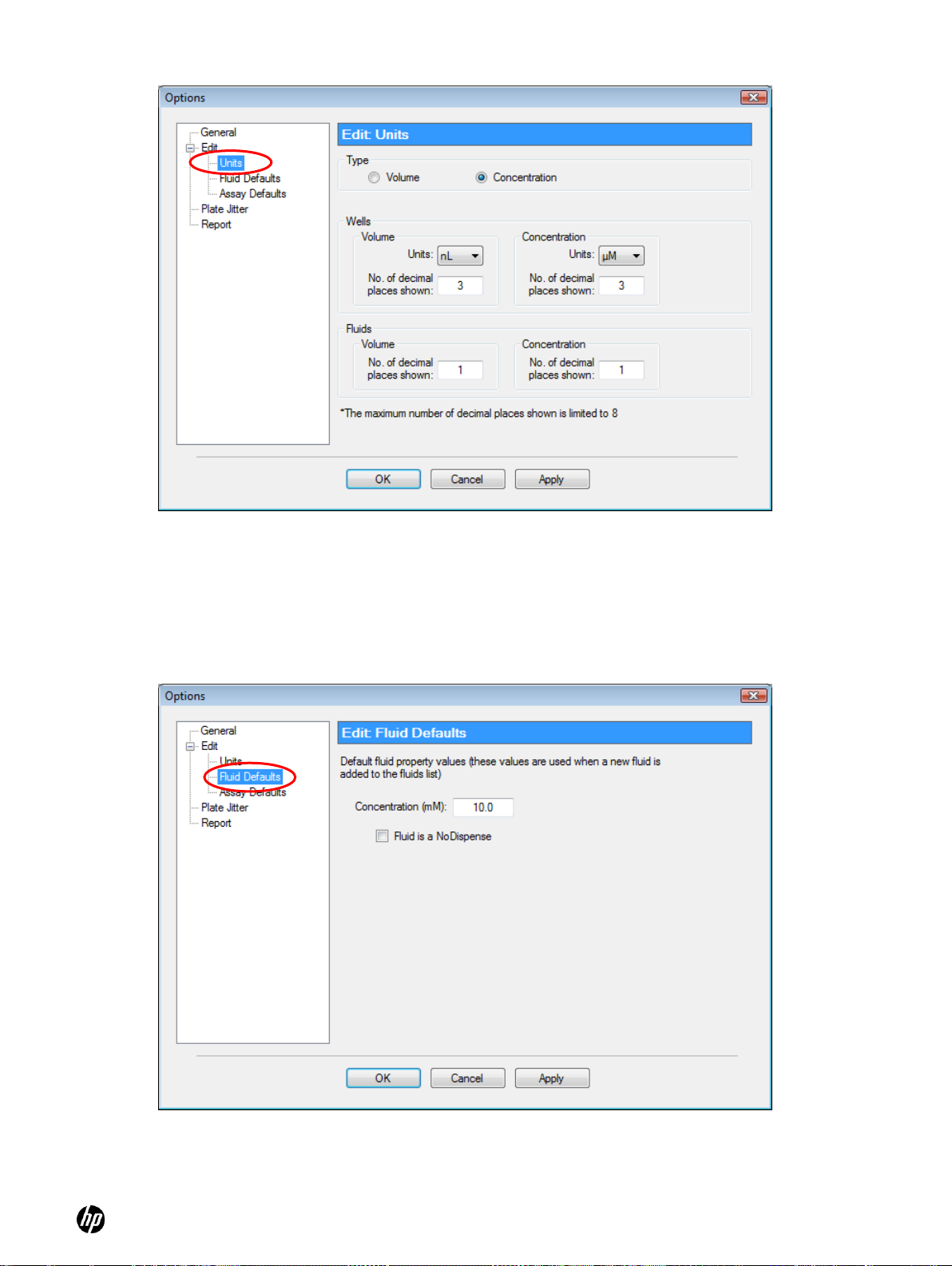

dialog box. See Figure 4-12.

The Type area of the dialog box allows you to determine whether the setup mode for titrations

is specified using concentration or volume.

The Wells area allows you to specify the unit type for volume and concentration and to specify

the number of decimal places used in plate setup.

The Fluids area allows you to specify the number of decimal places used in the Fluids List.

Page 18

HP D300 Digital Dispenser

18

Figure 4-12 Edit: Units pane of the Options dialog box

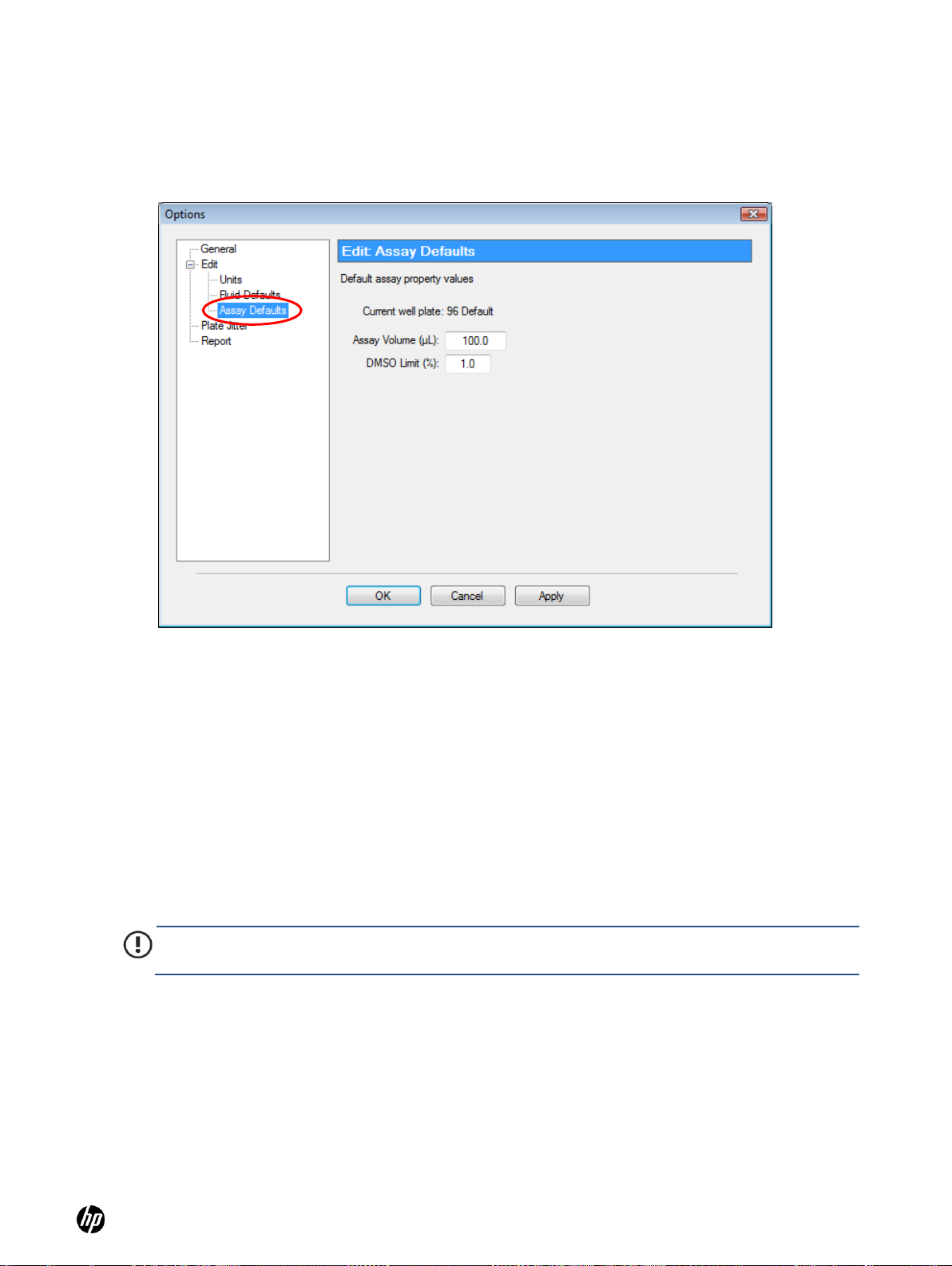

4-4-3 Options: Edit: Fluid Defaults

In the Options dialog box, click Edit and then Fluid Defaults to open the Edit: Fluid Defaults pane

of the Options dialog box. Set the default concentration for new fluids and specify whether default

fluids will be dispensed. See Figure 4-13.

Figure 4-13 Edit: Fluid Defaults pane of the Options dialog box

Page 19

HP D300 Digital Dispenser

19

IMPORTANT: Plate Jitter while dispensing is highly recommended when dispensing directly into

plates containing live cells to reduce the deleterious effect of a DMSO bolus on the cells.

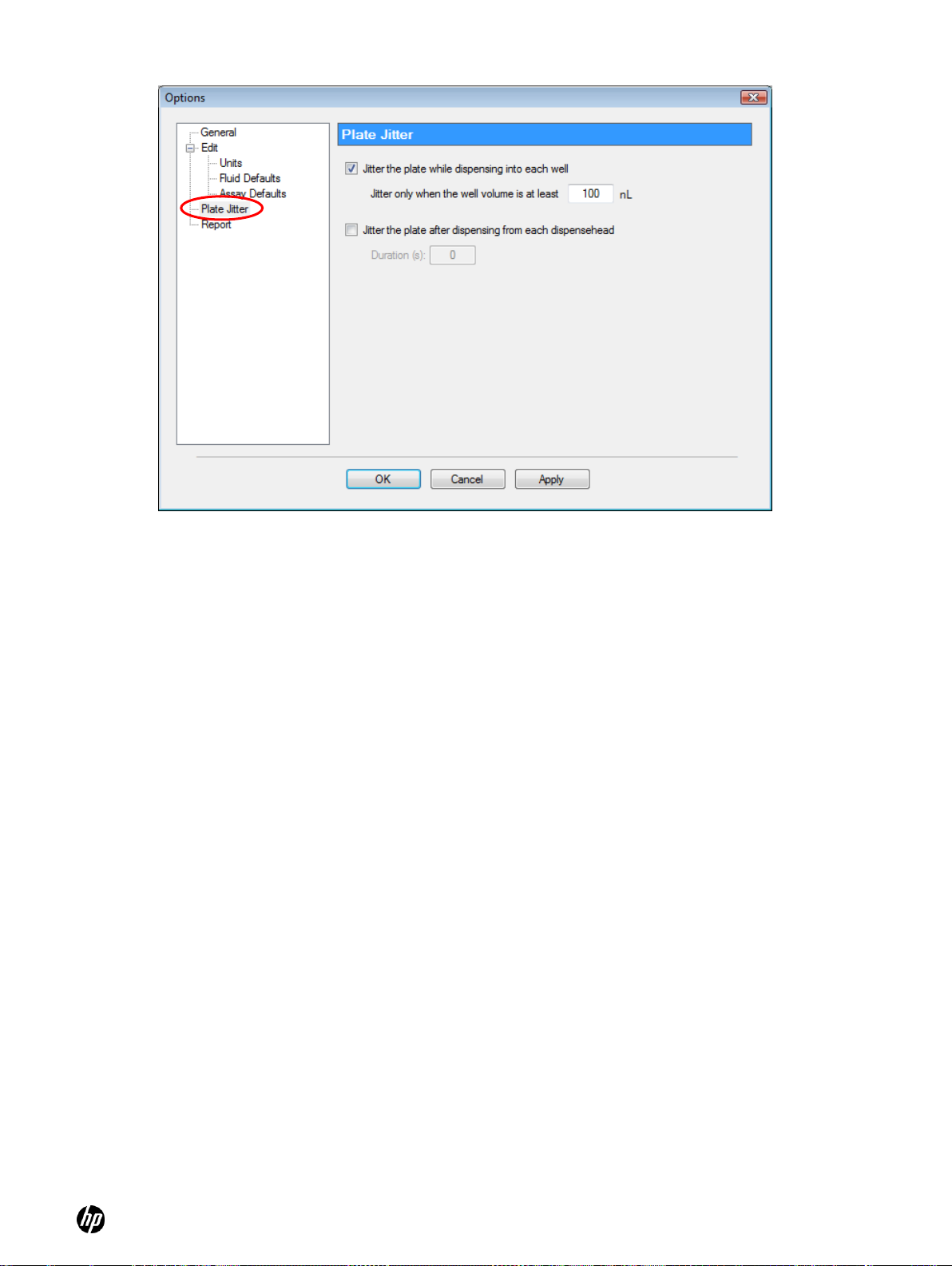

4-4-4 Options: Edit: Assay Defaults

In the Options dialog box, click Edit and then Assay Defaults to open the Edit: Assay Defaults

pane of the Options dialog box. Set the default assay volume and the default DMSO limit here.

See Figure 4-14.

Figure 4-14 Edit: Assay Defaults pane of the Options dialog box

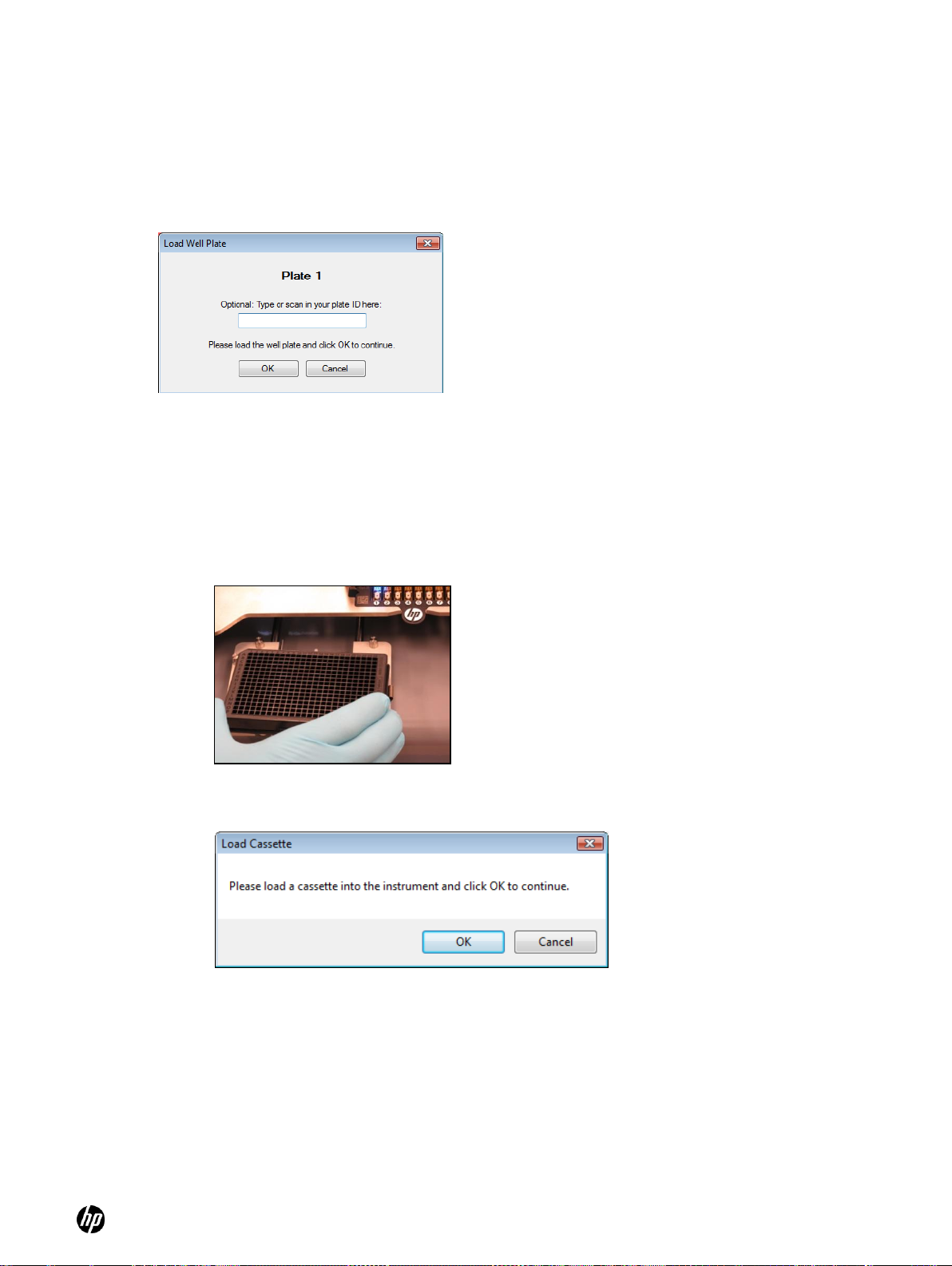

4-4-5 Options: Plate Jitter

In the Options dialog box, click Plate Jitter to open the Plate Jitter pane of the Options dialog box.

See Figure 4-15. Use plate jitter if shaking the destination plate is desired either during and/or after

dispense, for example if you are dispensing into wells containing cells.

Select Jitter the plate while dispensing into each well to shake the destination plate during the

dispense. When this option is chosen, shaking only above a specified volume may be entered.

Typically, only dispense volumes greater than 100nL have a deleterious effect on plated cells.

Additionally, Jitter the plate after dispensing from each Dispensehead may be selected to shake

the destination plate post-dispense. If this option is utilized, enter the number of seconds to shake

after each Dispensehead has completed dispensing.

Page 20

HP D300 Digital Dispenser

20

Figure 4-15 Plate Jitter pane of the Options dialog box

4-4-6 Options: Report

In the Options dialog box, click Report to open the Report pane of the Options dialog box as shown

in Figure 4-16. Use the Report pane to alter options related to the output report that the HP D300

Digital Dispenser software automatically generates after every dispense run (plate). In the Report

pane, you can choose to Display the report after every run, alternatively you would choose

File/View Report or use Excel to view the report after the run. Select Automatically save the

report after every run to save Report files, and Only save if the run was successful to omit

reports for aborted runs. You may also choose to use the default report naming convention by

selecting Use “HP-D300_configurationame_date_time” as the file name and enter the Report

File Path where these reports should be saved, or if this option is not selected, Report File Path will

change to Report File Name where you enter your own report file location and naming convention.

When this option selected, you can choose to rename each new report with automatic incrementing,

overwrite existing reports or to prompt you for a new file name at the completion of each run.

Page 21

HP D300 Digital Dispenser

21

Figure 4-16 Report pane of the Options dialog box

4-5 Plate dispense procedure

4-5-1 Initiate plate dispense

After selecting the desired plate configuration and verifying the options, click the GO button in the

lower-right corner of the main operating window. See Figure 4-17.

Figure 4-17 Main operating window

Page 22

HP D300 Digital Dispenser

22

4-5-2 Scan and load the well plates

1. Optional. If the destination well plate has an identification code you would like to track, scan

the bar code on the well plate using a USB bar code reader attached to your computer, or

enter its identification number manually into the box on the Load Well Plate dialog box. See

Figure 4-18.

Figure 4-18 Load Well Plate dialog box. Be very careful to load the plate that is requested.

2. Place the well plate on the destination plate holder. See Figure 4-19. Engage the top left

corner of the well plate on the pillars first, then snap the well plate fully into the spring clips.

○ Make sure the plate is completely level and down on the destination plate holder.

○ Ensure that the A1 well position is at the top-left corner of the destination plate holder.

3. Click OK. The Load Cassette dialog box appears. See Figure 4-20.

Figure 4-19 Destination plate holder on the dispenser

Figure 4-20 Load Cassette dialog box

4-5-3 Load a Dispensehead Cassette

1. If a Dispensehead Cassette is already in place with unused Dispenseheads, click OK in the

Load Cassette dialog box to continue (see Figure 4-20). If you are unsure whether there are

any unused Dispenseheads on the Cassette, click OK and the dispenser will test the

Dispenseheads to find which ones are unused.

2. Load a new Dispensehead Cassette if necessary as shown in Figure 4-21:

a. If a Cassette is already loaded in the dispenser, lift the tab with the HP logo and pull the

Cassette out of the deck.

Page 23

HP D300 Digital Dispenser

23

CAUTION: Using a multichannel pipette enables the loading of multiple Dispenseheads

simultaneously. Make sure that you fill the Dispenseheads with the LARGEST load volume of the

set of Dispenseheads you are loading. It is indicated in the upper right of the dialog box (―Max.

Load Volume‖) as shown in Figure 4-22.

b. Lift a new Cassette out of the clamshell container and place it white logo side up into the

cutout on the Dispenser deck.

c. Make sure it is fully inserted so the top surface of the Cassette is the same height as the

top of the deck all the way around the cassette.

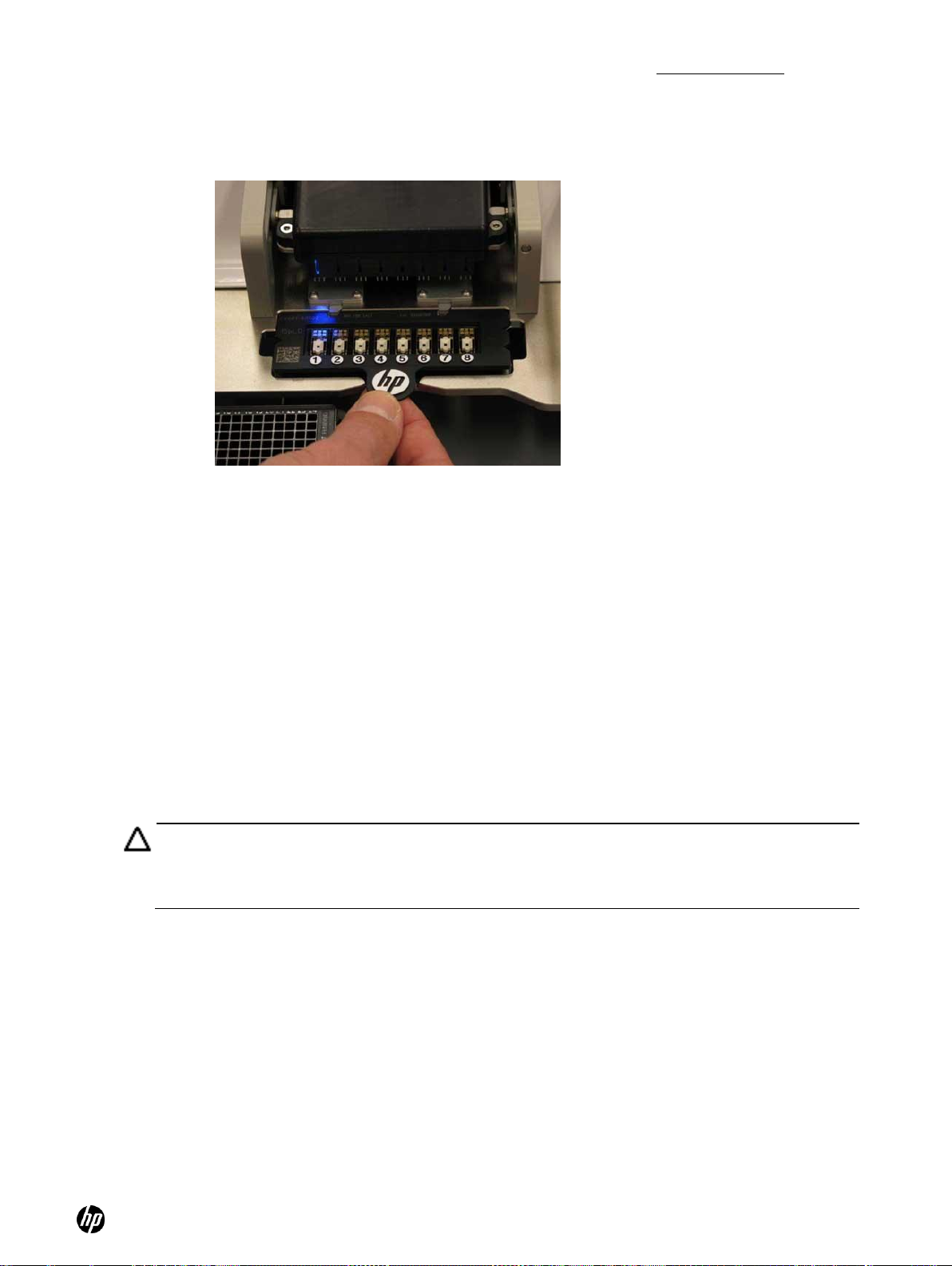

Figure 4-21 Loading a new Dispensehead Cassette

3. Once the Cassette is fully inserted, click OK in the Load Cassette dialog box (see Figure 4-

20). The pogo mechanism will engage and the Dispenseheads will be electrically tested to

ensure quality. Then the Load Fluid dialog box appears. See Figure 4-22.

4-5-4 Load fluid into the Dispensehead

When the Load Fluid dialog box opens, the OK and Skip buttons flash above the first Dispensehead

that will be loaded (see Figure 4-22), and a blue LED illuminates the first Dispensehead on the front

of the pogo mechanism.

1. Fill a low volume pipette with at least the amount of fluid that is indicated in the Load Fluid

dialog box, or fill a multipipetter with the appropriate number of fluids in the proper order as

shown in the Load Fluids dialog box. If a multipipetter is used, use the Max. Load Volume for

all Dispenseheads as shown on the right side of the dialog, as circled in Figure 4-22. The

source plate and source well location of the fluid to load will also be identified in the Load Fluid

dialog box if that information was entered in the Fluids List. Be sure to load the proper

compound into the proper Dispensehead.

Page 24

HP D300 Digital Dispenser

24

NOTE: The amount displayed in the Load Volume column in the Load Fluid dialog box

(Figure 4-22) will always be greater than the amount of fluid that was requested to be

dispensed. The volume to be dispensed for each fluid is labelled as the ―Total Volume‖ in

the right hand column of Fluids Table on the main operating window. The difference

between the dispense volume and the load volume is to account for fluid which is retained

in the Dispensehead after dispense, also known as the dead volume. The dead volume is

dependent upon the amount of fluid loaded into the Dispensehead, with greater dispense

volumes leading to greater dead volumes.

NOTE: The maximum amount of fluid that can be dispensed from a Dispensehead is 10μL.

If the total dispense volume of a fluid exceeds 10μL, the volume will be split between two or

more Dispenseheads. The split will be identified in the Load Fluid dialog box and in the

report file (as ―1 of 1‖ or ―1 of 2,‖ for instance). See Figure 4-23 for an example of using two

Dispenseheads per fluid.

Maximum

volume of the

fluids to load on

this cassette

Figure 4-22 Load Fluid dialog box

Page 25

HP D300 Digital Dispenser

25

WARNING: Make sure to load the fluid into the opening on top of the Dispensehead.

Do NOT depress the pipette plunger to the second ―blow out‖ stop as this could introduce

air into the Dispensehead.

Figure 4-24 A blue LED illuminates the

Dispensehead on the Dispensehead Cassette

Figure 4-25 Examples of a good load and a bad load

Good load

Bad load

Figure 4-23 Load fluids dialog box with two Dispenseheads per fluid

2. If you determine that the Dispensehead in the load position is not good, or if you mistakenly

load the Dispensehead incorrectly or with the wrong fluid, press Skip instead of OK. This will

cause the blue LED indicator to move to the next good position, and you will be prompted to

load the fluid that was skipped into that next Dispensehead.

3. Load fluid into the Dispensehead position indicated in the Load Fluid dialog box when

prompted. This Dispensehead will be indicated on the dispenser by an illuminated blue LED.

See Figure 4-24.

Page 26

HP D300 Digital Dispenser

26

WARNING: For multiplate configurations, the D300 software first minimizes the use of

dispenseheads, so that fluids which are used on multiple plates are dispensed into all of

those plates as long as the total dispense volume for that fluid does not exceed 10uL. This

dispensehead conservation can result in a non-intuitive plate loading order. Be careful to

load the correct well plate as prompted by the software! Minimizing the number of

dispenseheads used may sometimes result in more plate swaps than expected.

4. Click OK. All dispensing for the current fluid will occur. In the main operating window, only the

wells for the current fluid are shown, and each well is covered with an X while it is being

dispensed and then turns black when the dispensing for that well is complete.

5. Repeat steps 1 through 4 to load and dispense each fluid in the plate configuration. Fluid

loading can occur during the dispense operation; you do not have to wait until the current

Dispensehead has finished. Just remember to click on OK as each fluid is loaded in its

Dispensehead, or to click on OK All when all Dispenseheads of the current Cassette are

loaded, as shown in Figure 4-26.

6. If loading all Dispenseheads simultaneously with a multichannel pipette or individually prior to

starting the dispense, then after all Dispenseheads of the current Cassette are loaded, click on

OK All as shown in Figure 4-26.

Figure 4-26 Load fluid dialog box showing OK All button

7. After the fluids in the currently loaded cassette are dispensed into plate 1, then depending

upon the configuration, you will be asked to either load a new cassette or a new plate. Read

the prompt dialog box carefully to determine the next step.

8. If you are prompted to load the next plate in the configuration, you will see a prompt similar to

Figure 4-18, where you can enter or scan a name for the plate. If the plate has been loaded

previously, you will be prompted with the plate name you previously entered or scanned in for

the plate, along with the plate number.

Page 27

HP D300 Digital Dispenser

27

9. After the current set of fluids is dispensed into all appropriate plates, if needed the software will

prompt you to load a new cassette using the message shown in Figure 4-20. After a fully used

T8 cassette is removed from the D300 dispenser it may be disposed, as it will not be reused.

10. You will then be shown which fluids to place in each dispensehead of the new cassette as

shown in Figure 4-22, and steps 7 - 9 above will continue until the configuration is complete.

4-6 View the report

Depending on the options selected in the Report pane, a report may be automatically generated and

saved on your computer after the plate dispense operation is completed. To change these report

settings, click Setup, then Options, and then Report (see ―Options: Report‖).

If you have chosen not to display the report after each run, you can still view data from the most

recently completed run by clicking File and then View Report. See Figure 4-27.

Figure 4-27 Open the Report dialog box by clicking File and then View Report

If you are not sure if a report was automatically saved, look at the title bar of the Report dialog box

(see Figure 4-28). If a file name is displayed in the title bar, then the report was automatically

saved. Even if you did not choose to automatically save the report, you can still save the current

report by clicking the Save button in the lower-right corner of the Report dialog box.

Page 28

HP D300 Digital Dispenser

28

Figure 4-28 Report dialog box

When the Report dialog box opens, the Event Log pane is initially displayed, but information about

the fluids and assay volumes can be examined by clicking Fluids or Options in the menu on the left

pane. To view more information about the dispense operation, click the menu options to section of

the report you want to view as shown in Figure 4-29 and Figure 4-30.

Figure 4-29 Report Fluids sheet

Page 29

HP D300 Digital Dispenser

29

Figure 4-30 Report Options sheet

While most data is displayed in rectangular plate format, the Tabulated Results pane displays

concentration data in long skinny columns in order to sort randomized plates. See Figure 4-31.

To derandomize your data in order to create IC50 or EC50 plots, use this report file saved in Excel

format, and add a column of your plate reader data also in this long skinny format. Next, sort the

data by fluid name and concentration in order to process or plot the data by compound and

concentration.

Figure 4-31 Tabulated Results pane

Any previously saved report must be viewed in Excel. If you have trouble finding the reports, the

folder that the last report was saved in is listed in the Report pane of the Options dialog box (click

Setup, then Options…, and then Report).

Page 30

HP D300 Digital Dispenser

30

4-7 Turn off the HP D300 Digital Dispenser

If you are finished using the dispenser and will not use it again for an extended period of time, turn it

off as follows:

1. Close the HP D300 Digital Dispenser software, either by clicking the red X in the upper right

corner of the main operating window, or by clicking on File/Exit.

2. Turn the Dispenser off using the main power switch on the rear of the dispenser. (Press down

the ―O‖ of the rocker switch to turn the dispenser off.)

Figure 4-32 On/off switch in the ON position

3. Remove any unused Dispensehead Cassettes from the dispenser to avoid contamination from

cleaning solutions or the laboratory environment and place them back in the Cassette tray.

4. Clean the dispenser according to the cleaning procedures described in the ―Clean the

dispenser‖ section of this document.

Page 31

HP D300 Digital Dispenser

31

TIP: If desired, information can be entered into the Name, Source Plate/Vial columns by

scanning a bar code, using a USB bar code reader attached to your computer.

TIP: The Fluids List can also be created by copying and pasting information from an Excel

spreadsheet that contains some or all of the fluid data (see ―Get familiar with the

software‖). Fluid information in the Excel file must have columns in the same order as the

Fluids Table.

Plate selection

tabs

Name, Source

Plate/Vial &

Source Well

columns

NoDispense

check box

Concentration

column

Edit check

box

Assay Properties

for current plate

Well Plate dropdown list box

Total Volume

column

5 Create plate configurations

5-1 Create the fluids table

1. On the right side of the main operating window, select the type of well plate you will use from

the Well Plate drop-down list box, either 96 or 384. Up to five plates can be part of a single

configuration, but all of them must be of the same type, 96 or 384. The same fluids, or different

fluids, can used in all the plates in a configuration.

Figure 5-1 The HP D300 Digital Dispenser main operating window

2. Enter one or more fluids (compounds to dispense in this set of plates):

a. Click in a cell in the Name column of the Fluids List and type the name.

b. Optional: click in a cell in the Source Plate/Vial column and type the source plate name.

c. Optional: click in a cell in the Source Well column and type the source well location.

d. Enter the source fluid concentration in the Concentration column.

e. Select a color for each of the fluids in the Color column if you do not want to use the default

colors.

f. Repeat steps a through e for all of the fluids that will be dispensed into this set of well

plates. Up to five plates to be run together can be saved in a single configuration file.

Page 32

HP D300 Digital Dispenser

32

NOTE: If no value is entered into the Concentration column, the default values set in the

Edit: Fluid Defaults pane of the Options dialog box will be used for those cells.

NOTE: If the fluids to be dispensed into a well exceed the DMSO limit, a warning will be

generated and the well pop-up data displayed for that well will appear in red; however, the

Dispenser will dispense whatever concentration/volume you have specified after you have

been warned.

NOTE: These options are also available by right-clicking on selected fluids in the Fluids List.

3. Type the plate assay volume and the DMSO limit for the first plate into the Assay Properties

box. If more than one plate is in a configuration, they may each have different assay volumes

and DMSO limits.

4. In order to program a fluid into wells, the Edit check box in the Fluids List for that fluid must be

selected. When the Edit check box is selected, that fluid can be added or removed from wells,

and is visible in the well plate image. Fluids with the Edit box not checked cannot be added or

removed from wells, and if that fluid was previously programmed into wells, it will remain in the

well plate layout and will be dispensed during the Go process, but will not be shown in the well

plate image. Clear the Edit check box if you want to simplify the view or copy and paste only

some fluids in wells where multiple fluids are being dispensed. The effect of unchecking an

Edit check box is shown in Figure 5-4.

5. To set a fluid or fluids to be non-dispensed, select the NoDispense check box in the Fluids

List. This may be useful when you want to maintain information about nondispensed fluids in

the output report such as for manually or robotically pipetted controls, or for blanks.

6. To program more than one well plate to be run with the same fluids list, select Add Plate. To

remove the current plate from the current configuration, select Remove Plate.

The Total Volume column values cannot be changed. The total volume is the sum of the volume of

a fluid in all of the wells of the plate, also known as the dispense volume of the fluid. This total

volume is less than the volume you will be asked to load in the DispenseHead Cassette due to the

amount of fluid retained in the DispenseHead after dispense, also known as the dead volume.

5-2 Edit the Fluids List

In addition to typing directly into the Fluids List table as described in ―Create the fluids table‖, the

Fluids List can also be edited by clicking Edit and then Fluids List.

1. Select one or more fluids you would like to edit by clicking on the row number (in the left-most

column in the Fluids List). To select multiple fluids, hold down the CTRL key while clicking on

the row number.

2. Click Edit and then Fluids List.

○ Select Enable All for Editing or Disable All for Editing to change all fluids to be shown or

not shown in the well plate image, and able to be added or not to the plate layout.

○ Select Move to Top, Move Up, Move Down, or Move to Bottom to change the order in

which fluids are dispensed into the well plate.

○ Select Delete Fluid to remove the selected fluid from the table.

○ Select Copy, Paste, or Insert Fluid to copy, paste, or insert a fluid into the table.

○ Select Clear Fluids List to remove all fluids from the Fluids List.

Page 33

HP D300 Digital Dispenser

33

TIP: This menu can also be accessed by clicking Edit and then Well Plate after selecting a

well or wells in the well plate image.

Figure 5-2 Edit the Fluids List (or right click within the Fluids Table)

5-3 Edit the well plate

Once the fluid table is set up with at least one compound, Edit Well Plate operations such as adding

fluids to the wells may begin. To see the Edit Well Plate menu options, click on Edit/Well Plate or

select some wells in the well plate image and right-click. As shown in Figure 5-3, the following

options are available:

○ Select or Deselect All Wells

○ Set Titration (see ―Set concentrations or volumes in wells‖, step 3 )

○ Set Concentration or Set Volume (see ―Set concentrations or volumes in wells‖, Step 1)

○ Normalize (see ―Normalize‖)

○ Randomize (see ―Randomize‖)

○ Remove a single fluid and remove all fluids

○ Cut, Copy, Paste, and Paste Special (see ―Use the Paste Special dialog box‖)

○ Clear Well Plate

○ Plate Layout Wizard (see ―Plate Layout Wizard basics‖)

Page 34

HP D300 Digital Dispenser

34

TIP: All of the fluids are shown in the Global View, whereas only the fluids marked for

editing (by selecting the Edit check box in the Fluids List) are shown in the well plate

image. See Figure 5-4.

TIP: If a well does not contain any fluid, it has a dotted outline. The dotted outline is also

used to denote a well that exceeds a dispense condition, such as containing more fluids

than the DMSO limit, or having a requested volume of less than one 13pL drop.

Figure 5-3 Edit Well Plate menu

Each well in the well plate can contain multiple fluids. For example, two fluids of interest in a drugdrug interaction experiment can each be added to the desired wells in the desired sequence of

concentrations or volumes, then a third fluid can be added to the same wells to normalize the wells

to a constant DMSO level. Each fluid is added to the selected wells in a separate programmatic

step.

Page 35

HP D300 Digital Dispenser

35

NOTE: The lowest possible concentration or volume is determined by the single drop

volume, the fluid concentration, and the assay volume. The maximum concentration or

volume is determined by the DMSO limit and the fluid concentration.

Valid concentration range

(from one small drop to the DMSO limit)

Edit check box

Global View

Well plate image

Figure 5-4 The difference between Global View and the well plate image

5-4 Set concentrations or volumes in wells

1. Click and drag in the well plate image to select the wells where a fluid will be dispensed.

2. To add the same single concentration or volume of fluid to the selected wells, right-click

anywhere in the well plate image and then click Set Concentration or Set Volume. The Set

Concentration or Set Volume dialog box appears. See Figure 5-5. Whether Set Concentration

or Set Volume is displayed is determined by the setting chosen in the Edit: Units pane of the

Options dialog box as described in ―Options: Edit: Units‖.

○ Select a fluid from the Fluid drop-down list box and then type in a concentration or volume

that is within the valid range that is stated in the dialog box. See Figure 5-5, shown for

concentration mode.

Figure 5-5 Set Concentration dialog box

Page 36

HP D300 Digital Dispenser

36

3. To generate a sequence of concentrations or volumes in the selected wells (a titration series,

with different concentrations and volumes in each well), right-click anywhere in the well plate

image and click Set Titration. The Set Titration dialog box opens (see Figure 5-6). Whether

concentration or volume is used in this dialog depends on the setting chosen in the Edit: Units

pane of the Options dialog box (see Figure 4-12).

a. Select Zig-Zag, Snake or Random:

○ Zig-Zag builds the titration one row or column at a time (depending on whether

Horizontal is selected in the Direction area), then starts the next row or column in a well

adjacent to the first well.

○ Snake builds the titration continuously, so that every well of the titration is adjacent to

the wells closest in concentration or volume.

○ Random takes the set of concentrations or volumes and distributes them randomly

among the selected wells. Randomization of the entire plate can also be accomplished

later, using the Randomize function as described in the ―Randomize‖ section.

b. Select the direction that the titration will be built. These choices are not available for

random titrations. Note that the arrows and shadings of the graphic in this window change

as you make different selections to help you understand the options.

○ Horizontal: This option creates doses from left to right. If this box is not checked, the

default is a vertical dose order (top to bottom).

○ Reverse: This option reverses the concentration or volume order from high-to-low to low-

to-high. If this box is not checked, the default is a high-to-low titration.

○ Mirror: This option flips the titration either horizontally or vertically depending on whether

the Horizontal check box is selected. The easiest way to understand this is to select the

Mirror check box and observe what happens to the displayed graphic.

c. Select the fluid to be programmed in the Fluid drop-down list box.

d. Select the type of concentration or volume titration in the General Type area of the dialog

box. Select either Linear or Logarithmic.

○ Linear: The titration steps are evenly spaced in concentration or volume units

○ Logarithmic: The titration steps are evenly spaced in log concentration or log volume

units

Page 37

HP D300 Digital Dispenser

37

NOTE: The lowest possible well concentration is determined by the minimum drop volume, the

fluid concentration, and the assay volume. The maximum well concentration is determined by the

DMSO limit and the fluid concentration.

Direction

area

Fluid drop-down

list box

General Type area

Figure 5-6 Set Titration dialog box

e. Select the type of titration to use in the Titration Options area of the dialog box. Choose

from the following options:

○ General titration: you set both lowest and highest concentrations or volumes and let the

middle concentrations or volumes fall along either a linear or log scale (as selected)

○ Specific titration: you set the highest or lowest concentrations or volumes and select one

of the following specific types of concentration or volume spacing:

○ 1/2 log

○ 1/3 log

○ 1/4 log

○ 1:1 (50% dilution)

○ 1:2 (33% dilution)

○ 1:3 (25% dilution)

f. Type in the highest and/or lowest well concentration or volume within the valid

concentration range shown in the lower-left portion of the Set Titration dialog box.

g. Type the number of replicates at each well concentration or volume level in the Titration

Definition area of the dialog box, for example type ―3‖ for a triplicate titration.

4. Additional fluids can be added to the same wells using the same steps as above. If multiple

fluids are in a single well, the well will have two or more colors in relative proportion to

represent all the fluids that will be dispensed into the well as shown in Figure 5-7.

Page 38

HP D300 Digital Dispenser

38

Figure 5-7 Array of wells with two fluids per well

5. To easily replicate a plate design, you can select all the wells in a plate you have designed,

then right click and select Copy, then click on Add Plate. Select the A1 well of the new plate,

then right click and select either Paste or Paste Special depending on whether you want to

have the same fluids in both plates. For more information about Paste Special, see ―Use the

Paste Special dialog box‖ below.

5-5 Use the Paste Special dialog box

Instead of defining titrations separately for each fluid as described above, titrations can be copied

and pasted with new fluids once a starting titration is created. If you would like your plate to contain

the same titration for many different fluids, you can use ―Plate Layout Wizard basics” or you can

use Paste Special. For Paste Special, follow these steps:

1. Program the initial titration, then ensure the wells you want to copy are selected, then right-

click in the well plate image and then click Copy.

2. Click in a new well to select the new starting well for the Paste Special, then right-click, and do

one of the following:

○ To paste the same fluid into new wells, click Paste.

○ To paste a different fluid into new wells, click Paste Special. This opens the Paste Special

dialog box where you can accept the suggested fluid to paste or use the drop-down list box

to select a different new fluid to paste. See Figure 5-8.

In the example shown below, wells A1 to B12 were copied, and fluid 1 will be mapped to fluid

3 and fluid 2 mapped to fluid 4. The result of this Paste Special operation is shown in Figure

5-9.

Figure 5-8 Paste Special dialog box

Page 39

HP D300 Digital Dispenser

39

Figure 5-9 Result of Paste Special operation shown in Figure 5-8

3. Repeat steps 1 and 2 for each fluid until all desired wells on the plate are designed.

5-6 Normalize

Once the plate has been fully configured with the fluids that will be dispensed, a DMSO

normalization can be programmed.

1. Ensure that the Fluids List contains the normalization fluid, for example a fluid named DMSO.

2. Click and drag in the well plate image to select wells to normalize (using the control key if you

need to select more than one region because some areas of the well plate do not need

normalization), then right-click to open the Edit Well Plate menu, and then click Normalize.

The DMSO Normalize dialog box appears (see Figure 5-11).

Figure 5-10 Select Normalize in the Edit Well Plate menu

Page 40

HP D300 Digital Dispenser

40

TIP: You may enter a normalization percentage that is less than the valid normalization range,

however all wells will not be normalized to the same DMSO percentage. For example, entering

0.1% DMSO normalization will only add DMSO to wells which are less than 0.1% DMSO, and any

wells which are greater than 0.1% DMSO will have no additional DMSO added to them.

TIP: To ensure proper DMSO normalization volumes, perform the DMSO normalization function

after configuring the wells with all fluids. To add another fluid to wells which already had the

normalization operation applied to them, delete the DMSO normalization fluid from those wells by

selecting the appropriate wells, right click and select Remove Fluid, then pick the DMSO from the

fluid drop down. After removing normalization, add the new fluid in the appropriate wells before

repeating the DMSO normalization step.

3. In the Fluid drop-down list box, select a fluid to use for normalization.

Figure 5-11 DMSO Normalize dialog box

4. Type a value in the box following ―DMSO normalize to‖, or you can choose to normalize up to

the highest % DMSO already programmed into any of the selected wells, by selecting the

Backfill only up to the highest-filled well option.

The maximum normalization range is determined by the DMSO Limit % entered for the

selected fluid in the Fluids List. The minimum normalization range is determined by maximum

amount of DMSO already present in the selected wells. You can enter a normalization

percentage below the minimum valid range; see the note below.

Page 41

HP D300 Digital Dispenser

41

TIP: To return to the non-randomized, ordered plate, click Edit and select Undo.

NOTE: When DMSO is added to the Fluids List, the default concentration is often left at 10mM.

Since this is not the concentration of neat DMSO, this means that the well pop-up concentrations

(as shown in Figure 4-11) for DMSO in normalized wells will be incorrect. For DMSO, enter the

source fluid concentration as 14100 mM , or ignore the concentration part of the well pop-up.

Either way, the percentages and volumes for DMSO shown in the well pop-ups are correct.

Figure 5-12 Result of using fluid 3 for DMSO Normalization

5-7 Randomize

Once the plate has been fully configured, the wells can be reordered randomly on the plate. This is

a useful way to minimize the impact of systematic plate edge effects on the output data.

1. In the well plate image, select the wells that you want to randomize. To omit areas of the plate

from randomization, use the CTRL key to select multiple noncontiguous regions. To deselect

single wells, hold down the CTRL key while clicking on the well.

2. Right-click to open the Edit Well Plate menu and select Randomize. See Figure 5-13.

3. Only the selected wells are randomized.

Page 42

HP D300 Digital Dispenser

42

Figure 5-13 Right-click and select Randomize

Figure 5-14 Example of a randomized well plate

5-8 Save the plate configuration

1. On the HP D300 Digital Dispenser software main operating window, click File and then Save

Plate Configuration. All plates will be saved in a single file.

2. Name the new plate configuration. The plate configurations are saved as Excel files. They

can be edited or even created in Excel, but be extremely careful because the format must

exactly match what is expected by the HP D300 Digital Dispenser software.

Figure 5-15 To save the plate configuration, click File and Save Plate Configuration

Page 43

HP D300 Digital Dispenser

43

Select desired

well plate type

here first

5-9 Plate Layout Wizard basics

The Plate Layout Wizard may be used for several purposes, both simple and complex. Complex examples

are described in ―Plate Layout Wizard advanced functions‖. In the simple case, you can replicate a single

titration (a set of different concentrations or volumes) for many or all of a set of fluids. For example if you

would like each row of a 384 plate to be an 8 point triplicate, and use those concentrations for all 16 rows of

the plate for 16 different compounds, the Wizard can create this configuration much more quickly than a

series of copy and paste special commands. This simple case is described here in section 5-9-1, it is a

―single zone titration 1‖ because all the concentrations in the titration are evenly spaced in linear or log scale

(known as a ―single zone‖) and because each well only contains a single compound (known as a ―titration 2‖).

5-9-1 Create single zone titration1layouts

Ensure that the desired well plate type, either 96 or 384, is selected using the Well Plate drop down

menu prior to starting the Plate Layout Wizard.

1. In the HP D300 Digital Dispenser main operating window, click Edit and then Plate Layout

Wizard. The Plate Layout Wizard: Initialization dialog box appears. See Figure 5-16.

The Plate Layout Wizard can also be accessed by right-clicking on any well in the well plate

image and then selecting the Wizard option in the Well Plate menu.

Figure 5-16 Click Edit and then Plate Layout Wizard

2. If there were existing entries in the Fluids List or fluids in any wells in the well plate, the

following statement appears in the dialog box:

―Some fluid and/or well data already exists. How would you like to proceed?‖

a. Select one of the three options:

○ To use the wizard to add fluid to empty wells remaining in the current plate configuration

only, select Leave all existing data alone.

○ To retain the fluids from the Fluids List and design a new plate configuration, select

Clear the well plate only; leave the fluids alone.

Page 44

HP D300 Digital Dispenser

44

IMPORTANT: Once titrations and positioning are initiated, changes cannot be made to the

fluids table because changes could disrupt the design. To make changes to the fluids table,

click Cancel, then make changes to the fluids table before launching the Plate Layout

Wizard again.

Select one of these

three options

Answer these

questions unless

you chose to leave

all existing data

Change concentration

here if desired

Type fluid

information

in this area

if desired

Select at least one

NoDispense to

allow placement of

controls

○ To start from a new Fluids List to design a new plate configuration, select Clear all data

Figure 5-17 Plate Layout Wizard: Initialization dialog box

and start from scratch (no fluids, empty well plate).

b. If you selected the first option, the next two questions involving assay volume and the

DMSO limit will be unavailable because the previous values are used. If you selected the

second or third option, type the assay volume and DMSO limit for the new plate design into

the boxes and press the ENTER key on the keyboard.

c. The next question involving the number of fluids you are using also changes depending on

which option was selected above. Read the question carefully, type an answer into the box,

and press the ENTER key.

d. Click in the first column of the table to edit the names of the additional fluids, if desired, and

then type the source plate/vial, source well, and concentration information into the following

columns.

e. Select the NoDispense check box if the fluid should be a no dispense fluid (fluids are

which are non-HP dispensed fluids). There needs to be at least one fluid with NoDispense

checked in order to reserve rows or columns for controls which are not dispensed by the

HP dispenser.

f. To apply a concentration other than the default, type the appropriate value in the box at the

bottom of the Initialization dialog box and click the Use this concentration for all fluids

button to apply the new value to all of the new fluids.

g. Click Continue to move to the next step. The Plate Layout Wizard: Titrations and

Positioning dialog box appears. See Figure 5-18.

Page 45

HP D300 Digital Dispenser

45

3. Notice the left pane of the Plate Layout Wizard: Titrations and Positioning dialog box.

Recall that a titration is simply a set of concentrations or volumes that form a titration. Two

types of titrations can be programmed:

○ Titration1 is denoted as Titration1 in the menu in the left pane, and is used for titration

series with one fluid per well.

○ Titration2 is denoted as Titration2 and is used for titration series with two fluids per well.

Plate designs can have zero or many titration1s and/or titration2s on a plate. Each titration1

can use from one to all of the fluids in the fluids table. If all fluids in the plate will have the

same set of concentrations or volumes, only one titration1 is required. Additional titration1s

are only needed in order to use a different set of concentrations or volumes for one or more

fluids.

a. By default, designs start with the definition of any titration1 fluids. If the desired plate

design involves only titration2 fluids, click Titration2: <none> in the left pane, or click the

Next button to move down the list to the next item. Click the Back and Next buttons to go

up or down the list as desired.

Figure 5-18 Plate Layout Wizard Titration1 fluid selection pane

b. Select the Use check box next to each fluid that will use this titration to create a titration1