Page 1

INSTALLATION & SERVICE

INDUSTRIAL PUMPS

Models: D-04, G-04

WANNER ENGINEERING, INC.

1204 Chestnut Avenue, Minneapolis, MN 55403

TEL: (612) 332-5681 FAX: (612) 332-6937

TOLL-FREE FAX [US only]: (800) 332-6812

www.hydra-cell.com

email: sales@wannereng.com

Page 2

D/G-04 Contents

Page

Specifications......................................................................... 2

Dimensions ............................................................................ 4

Installation.............................................................................. 5

Maintenance .......................................................................... 9

Service (Fluid End) .............................................................. 10

Service (Hydraulic End)....................................................... 14

Troubleshooting ................................................................... 17

D/G-04 Specifications

Max Pressure 2,500 psi (170 bar)

Capacity @ Max Pressure

rpm gpm I/min

D/G-04-X 1750 2.9 11.0

D/G-04-E 1750 2.1 7.8

D/G-04-S 1750 1.6 6.1

Delivery @ Rated Pressure

revs/gal

500 psi 1500 psi 2500 psi

D/G-04-X 565 583 603

D/G-04-E 761 795 833

D/G-04-S 921 972 1,093

revs/liter

35 bar 100 bar 170 bar

D/G-04-X 149 154 159

D/G-04-E 201 211 224

D/G-04-S 244 257 287

Max Inlet Pressure 500 psi (35 bar)

Max Temperature 250°F (121°C) – consult factory for

temperatures above 160°F (71°C)

Inlet Port D-04: 1/2 inch NPT

G-04: 1/2 inch BSPT

Discharge Port D-04: 1/2 inch NPT

G-04: 1/2 inch BSPT

Shaft Diameter 7/8 inch (22.22 mm)

Shaft Rotation Bi-directional

Bearings Ball bearings

Oil Capacity 1.1 US quarts (1.05 liters)

Weight 37 lbs (16.8 kg)

Calculating Required

Horsepower (kW)*

6 x rpm

63,000

6 x rpm

84,428

* rpm equals pump shaft rpm. HP/kW is required application

power. Use caution when sizing motors with variable speed

drives.

+

+

gpm x psi

1,460 –

gpm x bar

511 –

psi – 500

(

bar – 35

(

4

20

=

electric motor HP*

)

=

electric motor kW*

)

2 D04-991-2400 5/1/04

Page 3

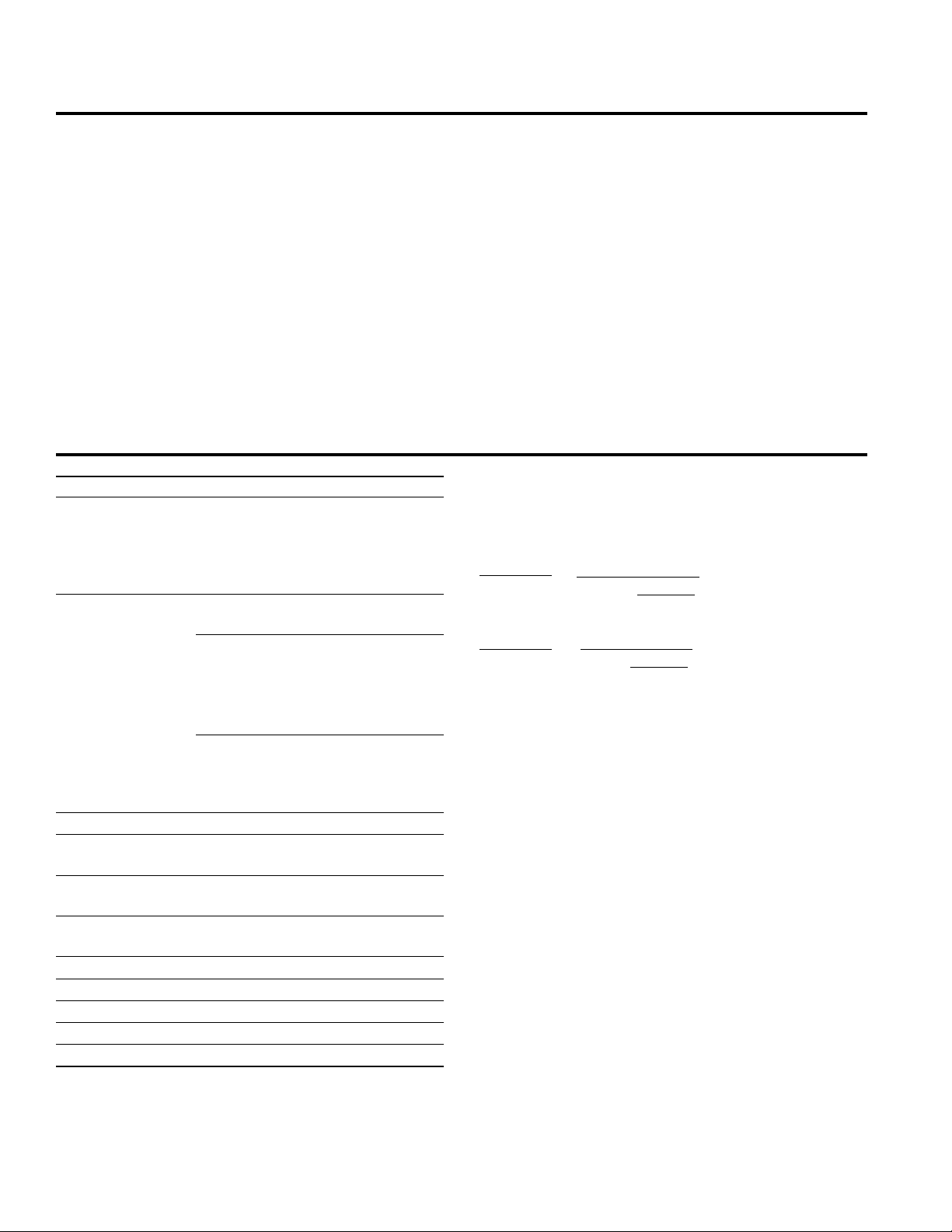

D/G-04 Specifications

Performance Net Positive Suction Head –

0 200 400 600 800 1000 1200 1400 1600 1800

3.33

3.00

2.66

500 PSI (35 bar)

1500 PSI (100 bar)

2500 PSI (170 bar)

2.33

RPM

D/G-04-X

12.5

1750

11.25

10

8.75

NPSHr

12

11

10

9

8

7

6

D/G-04-X

D/G-04-E

D/G-04-S

3.5

1750

3.0

2.5

2.0

2.00

1.66

Gallons per Minute

1.33

1.00

0.66

0.33

D/G-04-E

D/G-04-S

7.5

6.25

Liters per Minute

5.0

3.75

2.5

1.25

0

0

5

NPSHr (feet of water)

4

3

2

1

0

0 200 400 600 800 1000 1200 1400 1600 1800

RPM

Dry Lift

8.0

7.0

6.0

5.0

4.0

3.0

Lift (feet of water)

2.0

1.0

0

0

D/G-04-X

D/G-04-E

D/G-04-S

200 400 600 800 10001200 14001600 1800

RPM

240

1750

220

200

180

160

140

120

100

1.5

NPSHr (meters of water)

1.0

0 .5

Lift (cm of water)

80

60

40

20

3 D04-991-2400 5/1/04

Page 4

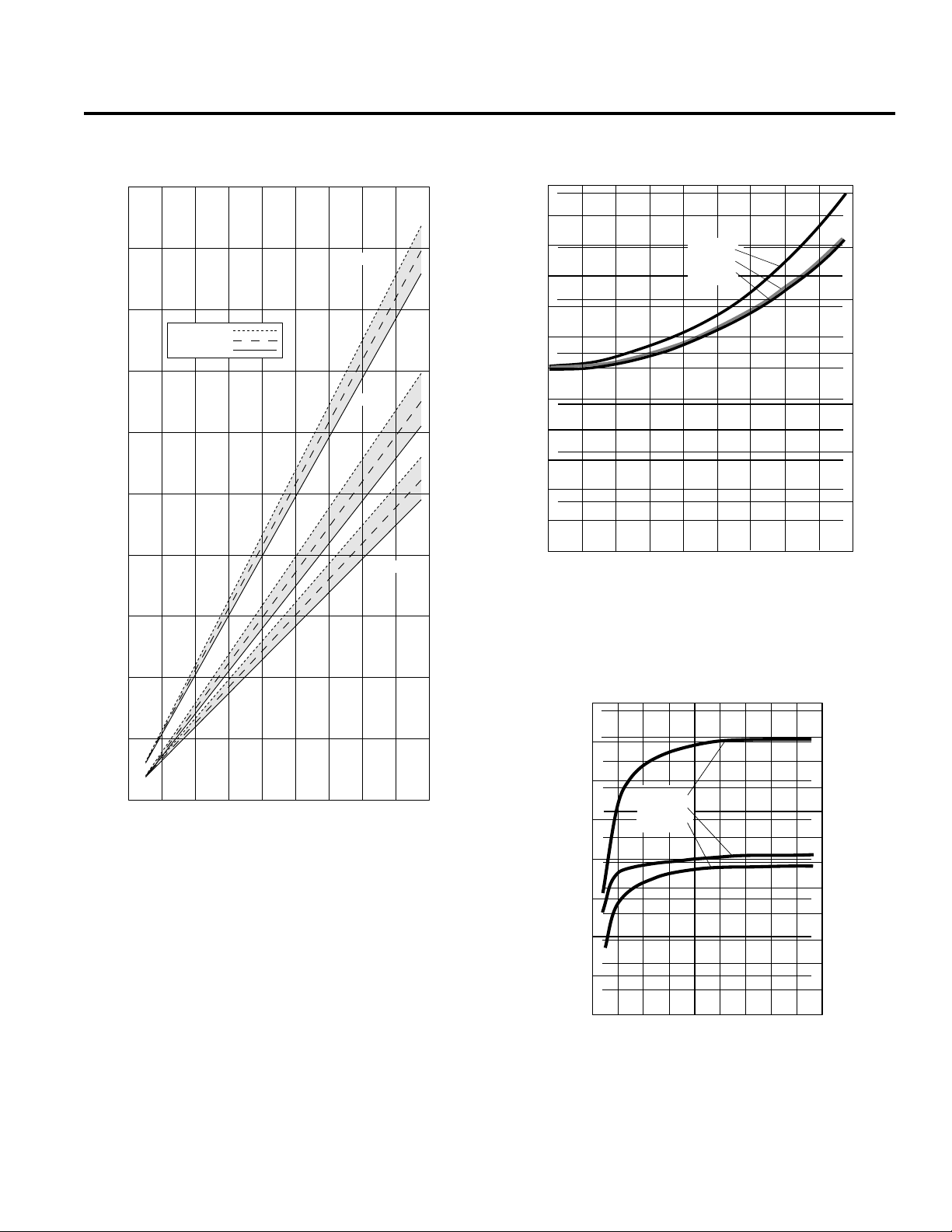

D/G-04 Dimensions

D/G-04 Models with Metallic Pumping Head

Brass

304 Stainless Steel

316 Stainless Steel

8.71

(221.2)

4.25

(108)

0.75

(19.1)

10.38

(263.7)

(57.2)

2.75

(69.9)

2.25

2.75

(69.9)

3.35

(85.1)

7.01

(178)

0.75

(19.1)

0.189

(4.8)

4.250

(107.9)

2.25

(57.2)

1.73

(43.9)

Good Key

0.875

(22.23)

1.71

(43.4)

9.93

(252.2)

Outlet

5.00

(127)

Inlet

D-04: 1/2" NPT

G-04: 1/2" BSPT

D-04: 1/2" NPT

G-04: 1/2" BSPT

6.55

(166)

3.52

(89.4)

4.97

(126)

4 D04-991-2400 5/1/04

Page 5

D/G-04 Installation

NOTE: The numbers in parentheses are the Reference

Numbers on the illustrations in the Parts Manual.

Location

Locate the pump as close to the supply source as possible.

Install it in a lighted clean space where it will be easy to inspect

and maintain. Allow room for checking the oil level, changing

the oil, and removing the pump head (manifold, valve plate and

related items).

Mounting

The pump shaft can rotate in either direction.To prevent

vibration, securely attach the pump to a rigid base.

On a belt-drive system, align the sheaves accurately; poor

alignment wastes horsepower and shortens the belt and bearing

life. Make sure the belts are properly tightened, as specified by

the belt manufacturer.

On a direct-drive system, align the shafts accurately. Unless

otherwise specified by the coupling manufacturer, maximum

parallel misalignment should not exceed .015” and angular

misalignment should be held to 1 degree maximum. Careful

alignment extends life of the coupling, pump, shafts, and support

bearings. Consult coupling manufacturer for exact alignment

tolerances.

On a close-coupled system, coat the motor shaft liberally with

anti-seize.

Important Precautions

Adequate Fluid Supply. To avoid cavitation and

premature pump failure, be sure that the pump will have

an adequate fluid supply and that the inlet line will not be

obstructed. See “Inlet Piping”.

Positive Displacement. This is a positive-displacement

pump. To avoid severe system damage if the discharge

line ever becomes blocked, install a relief valve

downstream from the pump. See “Discharge Piping”.

Safety Guards. Install adequate safety guards over all

pulleys, belts, and couplings. Follow all codes and

regulations regarding installation and operation of the

pumping system.

Shut-Off Valves. Never install shut-off valves between

the pump and discharge pressure regulator, or in the

regulator bypass line.

Freezing Conditions. Protect the pump from freezing.

See also the Maintenance Section.

Consult the Factory for the following situations:

• Extreme temperature applications above 160° F (71°C)

or below 40° F (4°C)

• Pressure feeding of pumps

• Viscous or abrasive fluid applications

• Chemical compatibility problems

• Hot ambient temperatures above 110° F(43°C)

• Conditions where pump oil may exceed 200° F (93°C)

because of a combination of hot ambient temperatures,

hot fluid temperature, and full horsepower load — an

oil cooler may be required

5 D04-991-2400 5/1/04

Page 6

D/G-04 Installation

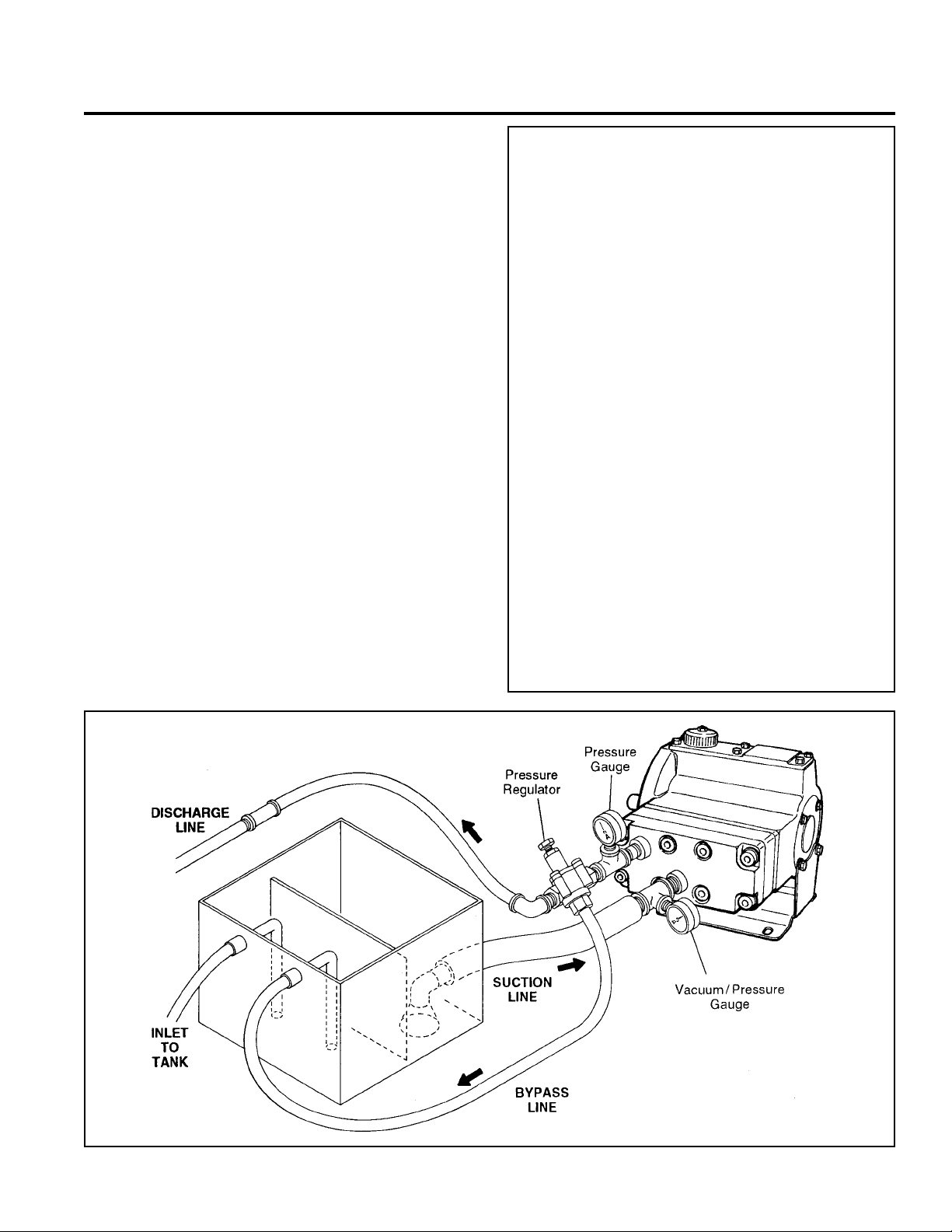

Inlet Piping (Suction Feed)

CAUTION: When pumping at temperatures above 160° F

(71

° C), use a pressure-feed system.

Install draincocks at any low points of the suction line, to permit

draining in freezing conditions.

Provide for permanent or temporary installation of a vacuum

gauge to monitor the inlet suction. To maintain maximum flow,

vacuum at the pump inlet should not exceed 7 in. Hg at 3 gpm

and 70° F (180 mm Hg at 11.4 liters/min and 21° C). Do not

supply more than one pump from the same inlet line.

Supply Tank

Use a supply tank that is large enough to provide time for any

trapped air in the fluid to escape. The tank size should be at

least twice the maximum pump flow rate.

Isolate the pump and motor stand from the supply tank, and

support them separately.

Install a separate inlet line from the supply tank to each pump.

Install the inlet and bypass lines so they empty into the supply

tank below the lowest water level, on the opposite side of the

baffle from the pump suction line.

If a line strainer is used in the system install it in the inlet line to

the supply tank.

To reduce aeration and turbulence, install a completely

submerged baffle plate to separate the incoming and outgoing

liquids.

Install a vortex breaker in the supply tank, over the outlet port

to the pump.

Place a cover over the supply tank, to prevent foreign objects

from falling into it.

Inlet Piping (Pressure Feed)

Provide for permanent or temporary installation of a vacuum/

pressure gauge to monitor the inlet vacuum or pressure.

Pressure at the pump inlet should not exceed 500 psi (34 bar);

if it could get higher, install an inlet pressure regulator.

Do not supply more than one pump from the same inlet line.

Inlet Calculations

Acceleration Head

Calculating the Acceleration Head

Use the following formula to calculate acceleration head losses.

Subtract this figure from the NPSHa, and compare the result to

the NPSHr of the Hydra-Cell pump.

Ha = (L x V x N x C) ÷ (K x G)

where:

Ha = Acceleration head (ft of liquid)

L= Actual length of suction line (ft) — not equivalent length

V= Velocity of liquid in suction line (ft/sec) [V = GPM x (0.408 ÷

N=RPM of crank shaft

C=Constant determined by type of pump — use 0.066 for the

K= Constant to compensate for compressibility of the fluid —

G=Gravitational constant (32.2 ft/sec2)

2

pipe ID

D-04 and G-04 Hydra-Cell pumps

use: 1.4 for de-aerated or hot water; 1.5 for most liquids;

2.5 for hydrocarbons with high compressibility

)]

Hose Size and Routing

Use the shortest, most-direct route from the supply tank to the

pump. If elbows are needed, 45° are recommended. Any

restrictions in the inlet piping may cause pump output to drop.

Do not install any 90

• Use flexible noncollapsible hose between the pump and rigid

piping or supply tank. This will absorb vibration, and allow

for expansion or contraction.

• Use the largest practical hose. The smallest permissible size

is 5/8 in. (16 mm) I.D.

• All valves, fittings, and unions must also have 5/8-in. (16

mm) minimum I.D. Do not exceed 5 feet of hose and piping

between and supply tank and the pump inlet.

• Support the pump and piping independently.

• Make sure all joints are sealed and tight, to prevent the pump

from drawing air into the inlet.

• Do not use a line strainer or filter in the suction line unless

regular maintenance is assured. If used, it should have a

free-flow area of at least three times the free-flow area of

the inlet.

Loctite is a registered trademark of Loctite Corporation.

Teflon is a registered trademark of E. I. DuPont de Nemours & Co. Inc.

° elbows in the pump inlet.

6 D04-991-2400 5/1/04

Page 7

D/G-04 Installation

Friction Losses

Calculating Friction Losses in Suction Piping

When following the above recommendations (under “inlet

Piping”) for minimum hose/pipe I.D. and maximum length,

frictional losses in the suction piping are negligible (i.e., Hf = 0)

if you are pumping a water-like fluid.

When pumping more-viscous fluids such as lubricating oils,

sealants, adhesives, syrups, varnishes, etc., frictional losses

in the suction piping may become significant. As Hf increases,

the available NPSH (NPSHa) will decrease, and cavitation will

occur.

In general, frictional losses increase with increasing viscosity,

increasing suction-line length, increasing pump flowrate, and

decreasing suction-line diameter. Changes in suction-line

diameter have the greatest impact on frictional losses: a 25%

increase in suction-line diameter cuts losses by more than two

times, and a 50% increase cuts losses by a factor of five times.

Consult the factory before pumping viscous fluids.

Minimizing Acceleration Head and Frictional Losses

To minimize the acceleration head and frictional losses:

• Keep inlet lines less than 3 ft (1 m) long

• Use at least 5/8 in. (16 mm) I.D. inlet hose

• Use soft hose (low-pressure hose, noncollapsing) for the

inlet lines

• Minimize fittings (elbows, valves, tees, etc.)

• Use a suction stabilizer on the inlet.

Net Positive Suction Head

NPSHa must be equal to or greater than NPSHr. If not, the

pressure in the pump inlet will be lower than the vapor pressure

of the fluid— and cavitation will occur.

Calculating the NPSHa

Use the following formula to calculate the NPSHa:

NPSHa = Pt + Hz - Hf - Ha - Pvp

where:

Pt = Atmospheric pressure

Hz = Vertical distance from surface liquid to pump centerline (if

liquid is below pump centerline, the Hz is negative)

Hf = Friction losses in suction piping

Ha = Acceleration head at pump suction

Pvp = Absolute vapor pressure of liquid at pumping temperature

NOTES:

• In good practice, NPSHa should be 2 ft greater than NPSHr

• All values must be expressed in feet of liquid

Atmospheric Pressure at Various Altitudes

Altitude Pressure Altitude Pressure

(ft) (ft of H

0 33.9 1500 32.1

500 33.3 2000 31.5

1000 32.8 5000 28.2

O) (ft) (ft of H2O)

2

Discharge Piping

NOTE: Consult the Factory before manifolding two or more

pumps together.

NOTE: Single-acting pumps create a pulsing flow. Using

pulsation dampening devices in the discharge line can

reduce or eliminate this.

Hose and Routing

Use the shortest, most-direct route for the discharge line.

Select pipe or hose with a working pressure rating of at least

1.5 times the maximum system pressure. EXAMPLE: Select a

3000-psi W.P.-rated hose for systems to be operated at 2000psi-gauge pressure.

Use about 6 ft (1.8 m) of flexible hose between the pump and

rigid piping.

Support the pump and piping independently.

Pressure Regulation

IInstall a pressure regulator or unloader in the discharge

line. Bypass pressure must not exceed the pressure limit of

the pump.

Size the regulator so that, when fully open, it will be large enough

to relieve the full capacity of the pump without overpressurizing

the system.

Locate the valve as close to the pump as possible and ahead

of any other valves.

Adjust the pressure regulating valve to no more than 10% over

the maximum working pressure of the system. Do not exceed

the manufacturer’s pressure rating for the pump or regulator.

Route the bypass line to the supply tank, or to the suction line

as far as possible from the pump (to reduce the chance of

turbulence and cavitation).

If the pump may be run for a long time with the discharge closed

and fluid bypassing, install a thermal protector in the bypass

line (to prevent severe temperature buildup in the bypassed

fluid).

CAUTION: Never install shutoff valves in the bypass line

or between the pump and pressure regulator or relief valve.

Provide for permanent or temporary installation of a pressure

gauge to monitor the discharge pressure at the pump.

For additional system protection, install a “pop-off” safety relief

valve in the discharge line, downstream from the pressure

regulator.

7 D04-991-2400 5/1/04

Page 8

D/G-04 Installation

Before Initial Start-Up

Before you start the pump, be sure that:

• All shutoff valves are open, and the pump has an adequate

supply of fluid.

• All connections are tight.

• The oil level is 1/4 inch (6 mm) above the cast surface in

the upper oil reservoir.

• The relief valve on the pump outlet is adjusted so the pump

starts under minimum pressure.

• All pulleys and belts are properly aligned, and belts are

tensioned according to specification.

• All pulleys and belts have adequate safety guards.

Initial Start-Up Procedure

1. Turn on power to the pump motor.

2. Check the inlet pressure or vacuum. To maintain maximum

flow, inlet vacuum must not exceed 7 in. Hg at 70° F (180

mm Hg at 21° C). Inlet pressure must not exceed 500 psi

(34 bar).

3. Listen for any erratic noise, and look for unsteady flow. If

the pump does not clear, refer to the Trouble-shooting

Section.

4. If the system has an air lock and the pump fails to prime:

a. Turn off the power.

b. Remove the pressure gauge or plug from the tee fitting

at the pump outlet (refer to the illustration on page 3).

NOTE: Fluid may come out of this port when the plug

is removed. Provide an adequate catch basin for fluid

spillage, if required. Fluid will come out of this port when

the pump is started, so we recommend that you attach

adequate plumbing from this port so fluid will not be

sprayed or lost. Use high-pressure-rated hose and

fittings from this port. Take all safety precautions to

assure safe handling of the fluid being pumped.

c. Jog the system on and off until the fluid coming from

this port is air-free.

d. Turn off the power.

e. Remove the plumbing that was temporarily installed,

and reinstall the pressure gauge or plug.

5. Adjust the discharge pressure regulator to the desired

operating and bypass pressures. Do not exceed the

maximum pressure rating of the pump.

6. After the pressure regulator is adjusted, set the “pop-off”

safety relief valve at 100 psi (7 bar) higher than the desired

operating pressure. To verify this setting, adjust the

discharge pressure regulator upward until the relief valve

opens. Follow the recommendations in the above NOTE

(step 4b) for handling the fluid that will come from the relief

valve.

7. Reset the discharge pressure regulator to the desired system

pressure.

8. Provide a return line from the relief valve to the supply tank,

similar to the bypass line from the pressure regulator.

8 D04-991-2400 5/1/04

Page 9

D/G-04 Maintenance

NOTE: The numbers in parentheses are the Ref. Nos. on

the illustrations in the Parts Manual.

Daily

Check the oil level and the condition of the oil. The oil level

should be 1/4 in. (6 mm) above the cast surface in the upper oil

reservoir.

Use the appropriate Hydra-Oil for the application (contact

Wanner Engineering if in doubt).

CAUTION: If you are losing oil but don’t see any external

leakage, or if the oil becomes discolored and contaminated,

one of the diaphragms (17) may be damaged. Refer to the

Fluid-End Service Section. Do not operate the pump with a

damaged diaphragm.

CAUTION: Do not leave contaminated oil in the pump

housing or leave the housing empty. Remove contaminated

oil as soon as discovered, and replace it with clean oil.

Periodically

Change the oil after the first 100 hours of operation, then change

according to the quidelines below. When changing, remove the

drain plug (60) at the bottom of the pump so all oil and

accumulated sediment will drain out.

Hours Between Oil Changes @ Various

Process Fluid Temperatures

<90°F <139°F<180°F

Pressure RPM (32°C) (60°C) (82°C)

<1500 psi (100 bar) <1200 6,000 4,000 2,000

<1800 3,000 2,000 1,500

<2500 psi (170 bar) <1200 3,000 2,000 1,500

<1800 1,500 — 1,000

Shutdown Procedure During

Freezing Temperatures

Take all safety precautions to assure safe handling of the

fluid being pumped. Provide adequate catch basins for fluid

drainage and use appropriate plumbing from drain ports,

etc., when flushing the pump and system with a compatible

antifreeze.

1. Adjust the discharge pressure regulating valve so the pump

runs under minimum pressure. Stop the pump.

2. Drain supply tank; open any draincocks in system piping

and collect drainage. Drain as much fluid from the pump

manifold and plumbing attached directly to the pump

manifold by loosening fittings or removing plugs or gauges.

3. Close draincocks in system piping and tighten or replace

any fittings, gauges or plugs.

4. Fill supply tank with enough antifreeze to fill system piping

and pump.

NOTE: Disconnect the system return line from the

supply tank and connect it to a separate reservoir.

5. Start the pump and allow it to run until the system is filled

with antifreeze. NOTE: If the system has an airlock and

the pump fails to prime, follow step 4 of the Initial Startup Procedure to clear the air.

6. When mostly antifreeze is flowing from the system return

line, stop the pump. Connect the system return line back to

the supply tank and circulate the antifreeze for a short period.

7. It is also good practice to change the oil in the hydraulic end

before storage for an extended period. This will remove any

accumulated condensation and sediment from the oil

reservoir. Drain and refill the hydraulic end with the

appropriate Hydra-Oil and operate the pump for a short

period to assure smooth performance.

NOTE: Minimum oil viscosity for proper hydraulic end

lubrication is 16-20 cST (80-100 SSU).

NOTE: Use of an oil cooler is recommended when process

fluid and/or hydraulic end oil exceeds 180

CAUTION: Do not turn the drive shaft while the oil reservoir

is empty.

Check the inlet pressure or vacuum periodically with a gauge.

If vacuum at the pump inlet exceeds 7 in. Hg (180 mm Hg),

check the inlet piping system for blockages. If the pump inlet is

located above the supply tank, check the fluid supply level and

replenish if too low.

CAUTION: Protect the pump from freezing. Refer also to

the “Shutdown Procedure”.

°F (82°C).

9 D04-991-2400 5/1/04

Page 10

D/G-04 Service (Fluid End)

Bolt Torque Specifications

Ref. No. D-04 G-04

1 50 ft-lbs 70 Nm

17 10 in-lbs 110 Ncm

10 D04-991-2400 5/1/04

Page 11

D/G-04 Service (Fluid End)

NOTE: The number in parentheses are the Reference

numbers on the illustration at right and in the Parts Manual.

This section explains how to disassemble and inspect all easily

serviceable parts of the pump. Repair procedures for the

hydraulic end (oil reservoir) of the pump are included in a later

section of the manual.

CAUTION: Do not disassemble the hydraulic end unless you

are a skilled mechanic. For assistance, contact Wanner

Engineering (TEL 612-332-5681 or FAX 612-332-6937) or the

distributor in your area.

CAUTION: The two capscrews (16) that screw through the

diaphragm plate in the pump housing hold the diaphragm plate

over the hydraulic end of the pump. Do not remove them except

when repairing the hydraulic end.

Tools and Supplies

• Straightedge (at least 6 in. long)

• Grease or petroleum jelly

• Torque wrench, rated to at least 50 ft-lbs (70 N-m)

• Emery cloth

• 1/2-in. drive socket wrench

• 5/16-in. (8-mm) open-end wrench

• 5-mm hex Allen wrench

• 8-mm hex bit socket (1/2 inch drive)

• Wanner D-04/G-04 Tool Kit, which includes the following:

• Seat puller

• Plunger holder

• Plunger guide lifter

• Shaft rotator

2. Inspect Valves (5-11)

The three inlet and three outlet valve assemblies are identical

(but face in opposite directions). Inspect each valve as

follows:

a. Check the spring retainer (10), and replace if worn.

b. Check the valve spring (8). If shorter than a new spring,

replace it (do not stretch a used spring).

c. Check the valve (7). If worn excessively, replace it.

d. Remove the valve seat (6), O-ring (5), and dampening

washer (11) (See note below). A seat puller is included

in the Wanner Tool Kit. Inspect all parts for wear. In all

instances, O-ring (5) should be replaced. Replace the

valve seat and/or dampening washer if necessary.

NOTE: On newer pump models, the dampening

washer (11) is not used because the valve seat (6) is

thicker. When replacing the valve seat on an older

pump model which has dampening washers, do

reinstall the dampening washers as the new valve

seat is thicker than the original.

e. Reinstall the valve assemblies:

• Clean the valve ports and shoulders with emery cloth,

and lubricate them with lubricating gel or petroleum jelly.

• Install the O-ring (5) on the valve seat (6).

• Inlet (3 lower valves in the illustration below). Insert

the spring retainer (10) into the valve plate, then insert

the spring, valve, Tetra seal, valve seat, and dampening

washer (8,7,9,6,11). A flat O-ring (Tetra seal, 9) goes

between the retainer and seat.

• Outlet (3 upper valves in the illustration below).

Insert the dampening washer, valve seat, Tetra seal,

valve, and spring, then the retainer. Install the flat O-ring

(Tetra seal, 9) between the retainer and seat.

not

Service Procedures

1. Remove Manifold (3) and Valve

Plate (12)

a. Remove all eight capscrews (1) around the manifold.

Use an 8-mm hex Allen wrench.

b. Remove the manifold (3).

c. Inspect the manifold for warping or wear around the inlet

and outlet ports. If wear is excessive, replace the

manifold.

To check if the manifold is warped, place a straightedge

across it. A warped manifold should be replaced.

d. Remove the two socket-head capscrews (14) that hold

the valve plate to the pump housing. Use a 5-mm hex

Allen wrench.

e. Inspect the valve plate in the same manner as the

manifold, for excessive wear and/or warping. Replace if

necessary.

11 D04-991-2400 5/1/04

Page 12

D/G-04 Service (Fluid End)

3. Inspect and Replace

Diaphragms (17)

a. Lift a diaphragm by one edge, and turn the pump shaft

until the diaphragm moves up to “top dead center”. This

will expose machined cross-holes in the plunger shaft

behind the diaphragm.

b. Insert the plunger holder tool through one of the

machined cross-holes, to hold the diaphragm up. (Don’t

remove the tool until the new diaphragm is installed in

step “f” below.)

c. Unscrew the diaphragm. Use a 5/16-in. (8-mm) open-

end wrench, and turn counterclockwise.

d. Inspect the diaphragm carefully. A damaged diaphragm

generally indicates a pumping system problem and

replacing only the diaphragm will not solve the larger

problem. Inspect the diaphragm for the following:

• Small puncture. Usually caused by a sharp foreign

object in the fluid, or by an ice particle.

• Diaphragm pulled away from the metal insert. Usually

caused by excessive inlet vacuum, or by

overpressurization of the pump inlet.

• Outer diaphragm bead extruded. Usually caused by

overpressurization of the pump.

• Diaphragm becoming stiff and losing flexibility.

Usually caused by pumping a fluid that is incompatible

with the diaphragm material.

• Cut diaphragm convolute. Usually caused by

excessive inlet vacuum.

CAUTION: If a diaphragm has ruptured and foreign

material or water has entered the oil reservoir, do

not operate the pump. Check all diaphragms, then

flush the reservoir completely (as outlined below)

and refill it with fresh oil. Never let the pump stand

with foreign material or water in the reservoir, or with

the reservoir empty.

e. Clean away any spilled oil.

f. Install a good or new diaphragm and tighten to 10 in.-lbs

(110 N-cm).

g. Repeat the above inspection procedure (and

replacement, if necessary) with the other two

diaphragms.

4. Flush Contaminant from

Hydraulic End

(only if a diaphragm has ruptured)

a. With the valve plate and manifold still removed (see

above), remove the oil drain cap (60) allow all oil and

contaminant to drain out.

b. Fill the reservoir with kerosene or solvent, manually turn

the pump shaft to circulate the kerosene, and drain.

Dispose of this contaminated fluid properly.

c. Repeat the flushing procedure (step “b” above).

d. Fill the reservoir with fresh oil, manually turn the pump

shaft to circulate the oil, and drain again.

e. Refill the reservoir. If the oil appears milky, there is still

contaminant in the reservoir. Repeat the flushing

procedure until the oil appears clean.

5. Prime the Hydraulic Cells

a. With the pump horizontal, fill the reservoir with the

appropriate Hydra-oil for the application.

b. All air in the oil within the hydraulic cell (behind the

diaphragms) must be forced out by turning the shaft —

and thus pumping the piston. Use a glove when turning

the shaft by hand.

Turn the shaft until a bubble-free flow of oil comes from

behind all the diaphragms. Watch the oil level in the

reservoir: if it gets too low during priming, air will be drawn

into the piston (inside the hydraulic end). This will cause

the pump to run rough, and you will have to start over

again with priming the hydraulic cells.

c. After the Hydra-Cells are fully primed, ensure that the

oil level is 1/4 in. (6 mm) above the cast surface in the

upper oil reservoir.

d. Wipe excess oil from the diaphragm plate and

diaphragms.

12 D04-991-2400 5/1/04

Page 13

D/G-04 Service (Fluid End)

6. Reinstall Valve Plate (12) and

Manifold (3)

a. Reinstall the valve plate (12), with the valve assemblies

installed as outlined above, onto the diaphragm plate

(18) and alignment pins (29).

Tighten the two socket-head capscrews evenly and

snugly to compress the outer diaphragm beads and hold

the valve plate in place.

b. Reinstall the O-rings (4) on the front side of the valve

plate. Use petroleum jelly or lubricating gel to hold them

in place.

c. Reinstall the manifold onto the valve plate.

d. Insert all capscrews (1), with washers (2), around the

edge of the manifold, and alternately tighten opposite

bolts until all are secure. Torque to 50 ft-lbs (70 N-m).

e. Recheck all bolts for tightness and proper torque.

13 D04-991-2400 5/1/04

Page 14

D/G-04 Service (Hydraulic End)

14 D04-991-2400 5/1/04

Page 15

D/G-04 Service (Hydraulic End)

NOTE: The numbers in parentheses are the Ref. Nos. on

the illustrations in the Parts Manual.

This section explains how to disassemble and inspect the

hydraulic end (oil reservoir) of the pump.

CAUTION: Do not disassemble the hydraulic end unless

you are a skilled mechanic. For assistance, contact Wanner

Engineering (TEL 612-332-5681 or F AX 612-332-6937) or the

distributor in your area.

Depending on the repair you are attempting, you may or may

not have to remove the motor from a direct-drive pump/motor

unit.

Internal piston components (21-27) can be serviced without

removing the motor or crankshaft. The motor and crankshaft

must be removed to service the connecting rod (59), piston

housing (20), crankshaft (57), front bearing (68), back bearing

(56), or seal (54).

Tools and Supplies

• Tools required for hydraulic end only:

• Snap-ring pliers

• Small hook

• 8-mm socket wrench

T o Service Pistons Without

Removing Motor or Crankshaft

1. Disassemble Pistons

With the manifold, valve plate, diaphragm plate, and

diaphragms removed, and the oil drained from the pump

(see the Fluid-End Service Section):

a. Remove the snap ring (27) from one of the pistons, using

a standard snap-ring pliers.

b. Pull out the valve plunger (24). This also removes the

washer (26) and spring (25).

c. Insert a small hook through the center hole of the valve

cylinder (22), and pull the cylinder out of the piston. Be

careful not to damage the piston.

d. Inspect all parts, and replace the O-ring and any other

parts that are worn or may be damaged.

e. Repeat steps “a” through “d” for the remaining pistons.

2. Reassemble Pistons

a. Tip the pump so the pistons are vertical.

b. Drop a ball (21) into the opening in the bottom of the

piston.

c. Insert the valve plunger (24) into a valve cylinder (22).

Slide a spring (25) over the plunger, inside the valve

cylinder.

d. Slide the assembled valve cylinder, plunger, and spring

(22-25) into the piston (20).

e. Insert the washer (26) over the plunger.

f. Using the snap-ring pliers, insert a snap ring (27) into

the piston.

g. Repeat the above procedure for the other two pistons.

To Service Remainder of

Hydraulic End

1. Remove Pump Housing

a. Remove the manifold, valve plate, diaphragm plate, and

diaphragms, as outlined in the Fluid-End Service Section.

b. Drain the oil from the pump housing by removing the

drain plug (60).

c. Stand the pump on end, with the drive shaft up.

d. Remove the bolts (50) that secure the back cover (52)

to the housing (78). Use an 8-mm socket wrench. Save

the O-rings (51).

e. Remove the cover and the cover O-ring (53).

f. Remove the crankshaft (57) by pulling it through the

connecting rods (59).

2. Remove and Replace Pistons

To remove the pistons (20), first remove the connecting rod

(59) and pin (58) by pressing the pin through the connecting

rod.

Reverse the process to reinstall the piston.

Refer to Steps 5 and 6 below to replace the diaphragm and

reassemble the pump.

15 D04-991-2400 5/1/04

Page 16

D/G-04 Service (Hydraulic End)

3. Replace Shaft Seal

NOTE: Inspect the shaft seal (54) before continuing. If

it looks damaged in any way, replace it.

a. Press the back bearing (55) and seal (54) out of the cover

(52). Discard the seal.

b. Apply a coating of Loctite High-Performance Pipe Sealant

with Teflon

surface of a new seal and the inside surface of the

opening in the back cover (52) where the seal will rest.

c. Press the new seal into the back cover.

d. Inspect the bearing (55). If pitted or damaged, replace

it.

e. Apply a coating of Loctite Rc/609 Retaining Compound

or comparable product to the outer surface of the bearing.

Press the bearing into the back cover until it rests on the

shoulder. The shield on the bearing must face away from

the back cover.

©

, or a comparable product, to the outer

4. Reassemble Housing and

Back Cover

a. Stand the pump on end.

b. With the pistons and connecting rods in place, reinstall

the crankshaft by threading it through the connecting

rods.

c. Reinstall the back cover, cover O-ring, and bolts (with

their O-rings).

5. Reinstall Diaphragms

a. Screw the plunger guide lifter (from the Wanner T ool Kit

or Repair Kit) into the valve plunger (24). Pull out to

expose the cross holes in the plunger. Rotate the shaft

until the piston is at top dead center.

b. Insert the plunger holder tool (from the Wanner T ool Kit),

through the plunger hole — to hold the plunger away

from the diaphragm plate (18), and to keep the plunger

from turning when the diaphragm is being installed.

c. Engage the diaphragm insert threads to the plunger

threads, and turn the diaphragm by hand until the insert

hits the shoulder of the valve plunger (24).

d. Hold the plunger holder tool to secure the valve plunger,

and torque the diaphragm insert to 10 in.-lbs (110 N-cm)

using a 5/16-in. (8-mm) open-end wrench.

e. Repeat the above procedure for the plungers and

diaphragms of the other two cylinders.

f. Fill the reservoir with fresh oil and prime the pump, as

outlined in the Fluid-End Service Section.

6. Reassemble Pump

Reassemble the pump as outlined in the Fluid-End Service

Section.

16 D04-991-2400 5/1/04

Page 17

D/G-04 Troubleshooting

Cavitation

• Inadequate fluid supply because:

— Inlet line collapsed or clogged

— Clogged line strainer

— Inlet line too small or too long

— Air leak in inlet line

— Worn or damaged inlet hose

— Suction line too long

— Too many valves and elbows in inlet line

• Fluid too hot for inlet suction piping system.

• Air entrained in fluid piping system.

• Aeration and turbulence in supply tank.

• Inlet vacuum too high (refer to “Inlet Calculations”, page 3).

Symptoms of Cavitation

• Excessive pump valve noise

• Premature failure of spring or retainer

• Volume or pressure drop

• Rough-running pump

• Premature failure of diaphragms

Pump Runs Rough

• Worn pump valves

• Airlock in outlet system

• Oil level low

• Wrong weight of oil for cold operating temperatures (change

to lighter weight)

• Cavitation

• Air in suction line

• Restriction in inlet/suction line

• Hydraulic cells not primed after changing diaphragm

• Foreign material in inlet or outlet valve

• Damaged diaphragm

• Fatigued or broken valve spring

Premature Failure of Diaphragm

• Frozen pump

• Puncture by a foreign object

• Elastomer incompatible with fluid being pumped

• Pump running too fast

• Excess pressure

• Cavitation

Drop in Volume or Pressure

A drop in volume or pressure can be caused by one or more of

the following:

• Air leak in suction piping

• Clogged suction line or suction strainer

• Suction line inlet above fluid level in tank

• Inadequate fluid supply

• Pump not operating at proper RPM

• Relief valve bypassing fluid

• Worn pump valve parts

• Foreign material in inlet or outlet valves

• Loss of oil prime in cells because of low oil level

• Ruptured diaphragm

• Cavitation

• Warped manifold from overpressurized system

• O-rings forced out of their grooves from overpressurization

• Air leak in suction line strainer or gasket

• Cracked suction hose.

• Empty supply tank

• Excessive aeration and turbulence in supply tank

• Cavitation

• Abrasives in the fluid

• Valve incompatible with corrosives in the fluid

• Pump running too fast

• Worn and slipping drive belt(s)

• Worn spray nozzle(s)

Water (or Process Fluid) in Oil

Reservoir

• Condensation

• Ruptured diaphragm

• Hydraulic cell not properly primed after diaphragm

replacement

• Frozen pump

Strong Water (or Process Fluid)

Pulsations

NOTE: Small pulsations are normal in single-acting pumps

with multiple pumping chambers.

• Foreign object lodged in pump valve

• Loss of prime in hydraulic cell because of low oil level

• Air in suction line

• Valve spring (8) broken

• Cavitation

• Aeration or turbulence in supply tank

17 D04-991-2400 5/1/04

Page 18

D/G-04 Troubleshooting

Valve Wear

• Normal wear from high-speed operation

• Cavitation

• Abrasives in the fluid

• Valve incompatible with corrosives in the fluid

• Pump running too fast

Loss of Oil

• External seepage

• Rupture of diaphragm

• Frozen pump

• Worn shaft seal

• Oil drain piping or fill cap loose.

• Valve plate and manifold bolts loose

• Pump housing porosity

Premature Failure of V alve

Spring or Retainer

• Cavitation

• Foreign object in the pump

• Pump running too fast

• Spring/retainer material incompatible with fluid being

pumped

• Excessive inlet pressure.

18 D04-991-2400 5/1/04

Page 19

Limited Warranty

Wanner Engineering, Inc. extends to the original purchaser

of equipment manufacturerd by it and bearing its name, a

limited one-year warranty from the date of purchase against

defects in material or workmanship, provided that the

equipment is installed and operated in accordance with

the recommendations and instructions of Wanner

Engineering, Inc. Wanner Engineering, Inc. will repair or

replace, at its option, defective parts without charge if such

parts are returned with transportation charges prepaid to

Wanner Engineering, Inc., 1204 Chestnut Avenue,

Minneapolis, Minnesota 55403.

This warranty does not cover:

1. The electric motors (if any), which are covered by the

separate warranties of the manufacturers of these

components.

2. Normal wear and/or damage caused by or related to

abrasion, corrosion, abuse, negligence, accident, faulty

installation or tampering in a manner which impairs normal

operation.

3. Transportation costs.

This limited warranty is exclusive, and is in lieu of any other

warranties (express or implied) including warranty of

merchantability or warranty of fitness for a particular

purpose and of any noncontractual liabilities including

product liabilities based on negligence or strict liability.

Every form of liability for direct, special, incidental or

consequential damages or loss is expressly excluded and

denied.

19 D04-991-2400 5/1/04

Page 20

WANNER ENGINEERING, INC.

1204 Chestnut Avenue, Minneapolis, MN 55403

TEL: (612) 332-5681 FAX: (612) 332-6937

TOLL-FREE FAX [US only]: (800) 332-6812

www.hydra-cell.com

email: sales@wannereng.com

©2004 Wanner Engineering, Inc. Printed in USA

20 D04-991-2400 5/1/04

Loading...

Loading...