Page 1

HP Color LaserJet 8500,

8500 N, 8500 DN Printer

Service Manual

Page 2

Copyright Information

© 1998 Hewlett-Packard

Company

All Rights Reserved.

Reproduction, adaptations, or

translation without prior written

permission is prohibited except

as allowed under copyright

laws.

Part number C3983-90954

First edition, October 1998

Printed in USA

Warranty

The information contained in

this document is subject to

change without notice.

Hewlett-Packard makes no

warranty of any kind with

respect to this information.

HEWLETT-PACKARD

SPECIFICALLY DISCLAIMS

THE IMPLIED WARRANTY OF

MERCHANTABILITY AND

FITNESS FOR A

PARTICULAR PURPOSE.

Hewlett-Packard shall not be

liable for any direct, indirect,

incidental, consequential, or

other damage alleged in

connection with the furnishing or

use of this information.

NOTICE TO U.S.

GOVERNMENT USERS:

RESTRICTED RIGHTS

COMMERCIAL COMPUTER

SOFTWARE: “Use, duplication,

or disclosure by the

Government is subject to

restrictions as set forth in

subparagraph (c) (1)(ii) of the

Rights in Technical Data Clause

at DFARS 52.227-7013.

Trademark Credits

CompuServe™ is a U.S.

trademark of CompuServe, Inc.

®

MS-DOS

trademark of Microsoft

Corporation.

Photoshop™ and PostScript

are registered trademarks of

Adobe Systems Incorporated.

TrueType™ is a U.S. trademark

of Apple Computer, Inc.

UNIX® is a registered trademark

in the United States and other

countries, licensed exclusively

through X/Open Company

Limited.

is a U.S. registered

®

Safety Information

WARNING

Electrical Shock Hazard

To avoid electrical shock, use

only supplied power cords and

connect only to properly

grounded (3-hole) wall outlets.

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714 USA

Page 3

Contents

List of figures

List of tables

1 Product information

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Printer features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Site requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Media requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Identification (model and serial numbers) . . . . . . . . . . . . . . . . . . .34

Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

2 Service approach

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Parts and supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Technical assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

EN

3 Operational overview

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Verifying package contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Verifying the cables are installed. . . . . . . . . . . . . . . . . . . . . . . . . .60

Connecting the printer to the network . . . . . . . . . . . . . . . . . . . . . .62

Changing the printer control panel overlay . . . . . . . . . . . . . . . . . .65

Printer control panel layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Menu maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Selecting the display language . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Installing the consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Configuring input trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Verifying the printer is installed correctly. . . . . . . . . . . . . . . . . . . .92

Verifying DIMM installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Paper handling accessory status LEDs. . . . . . . . . . . . . . . . . . . . .94

Contents

3

Page 4

4 Printer maintenance

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Cleaning procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Printer consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Installing consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

5 Theory of operation

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Color theory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Image formation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Consumable detection mechanisms . . . . . . . . . . . . . . . . . . . . . .142

Electrical systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

Mechanical systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

Paper path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

EPH controller board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

2,000-sheet input unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

Multi-bin mailbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

Duplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .192

Printer timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .192

6 Removal and replacement

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

Maintenance units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

Doors and covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

Top assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .223

Front assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .227

Left assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

Right assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .237

Rear assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .246

2,000-sheet input unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .271

Multi-bin mailbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .286

4 Contents

EN

Page 5

7 Troubleshooting

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .311

Pre-troubleshooting checklist . . . . . . . . . . . . . . . . . . . . . . . . . . .315

Printer message troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . .316

Aids to troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .361

Paper path troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . .378

Image formation troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . .383

Image defects troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . .386

Color balance adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .414

Repetitive defects troubleshooting . . . . . . . . . . . . . . . . . . . . . . .419

2,000-sheet input unit troubleshooting . . . . . . . . . . . . . . . . . . . .426

Multi-bin mailbox troubleshooting . . . . . . . . . . . . . . . . . . . . . . . .434

Communications troubleshooting . . . . . . . . . . . . . . . . . . . . . . . .439

Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .440

8 Parts and diagrams

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .443

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .445

Ordering parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .445

Illustrations and parts lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .449

Numerical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .502

Alphabetical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .513

Index

EN

Contents

5

Page 6

6 Contents

EN

Page 7

List of figures

Figure 1. Space requirements . . . . . . . . . . . . . . . . . . . . . . . .25

Figure 2. Example of printer model number and serial

number label (110 V and 220 V) . . . . . . . . . . . . . . . 34

Figure 3. Front view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Figure 4. Rear view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 5. Formatter assemblies . . . . . . . . . . . . . . . . . . . . . . .37

Figure 6. Paper handling accessories and options . . . . . . . . .38

Figure 7. Contents of printer box . . . . . . . . . . . . . . . . . . . . . .59

Figure 8. Power cord connection . . . . . . . . . . . . . . . . . . . . . .60

Figure 9. C-link and power cables connections . . . . . . . . . . .61

Figure 10. Network connections . . . . . . . . . . . . . . . . . . . . . . . .62

Figure 11. Parallel cable connection . . . . . . . . . . . . . . . . . . . . . 64

Figure 12. Changing the printer control panel overlay . . . . . . .65

Figure 13. Location of printer control panel features . . . . . . . .66

Figure 14. Consumable installation order . . . . . . . . . . . . . . . . .85

Figure 15. DIMM slot configuration . . . . . . . . . . . . . . . . . . . . . .93

Figure 16. Paper handling accessory status LEDs . . . . . . . . . .94

Figure 17. Cleaning the post charger unit . . . . . . . . . . . . . . . . . 99

Figure 18. Cleaning the density sensor . . . . . . . . . . . . . . . . .100

Figure 19. Cleaning the transfer charger . . . . . . . . . . . . . . . .101

Figure 20. Removing the waste toner tray cover . . . . . . . . . .102

Figure 21. Cleaning the waste toner tray . . . . . . . . . . . . . . . .103

Figure 22. Location of consumables in printer . . . . . . . . . . . .104

Figure 23. Contents of transfer kit . . . . . . . . . . . . . . . . . . . . .106

Figure 24. Contents of drum kit . . . . . . . . . . . . . . . . . . . . . . .110

Figure 25. Contents of fuser kit . . . . . . . . . . . . . . . . . . . . . . . . 113

Figure 26. Cross-section view of internal components . . . . . .124

Figure 27. Image formation . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Figure 28. Electrostatic latent image formation block . . . . . . .130

Figure 29. Preconditioning exposure . . . . . . . . . . . . . . . . . . .131

Figure 30. Primary charging of imaging drum . . . . . . . . . . . . . 132

Figure 31. Black toner cartridge (left) and color toner cartridge

(right) development . . . . . . . . . . . . . . . . . . . . . . . . 133

Figure 32. Primary transfer . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Figure 33. Post charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Figure 34. Secondary transfer . . . . . . . . . . . . . . . . . . . . . . . .136

Figure 35. Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Figure 36. Cleaning roller charging . . . . . . . . . . . . . . . . . . . . . 138

EN

List of figures

7

Page 8

Figure 37. Transfer drum cleaning . . . . . . . . . . . . . . . . . . . . . 139

Figure 38. Imaging drum cleaning block . . . . . . . . . . . . . . . . .140

Figure 39. Fusing the toner . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Figure 40. Waste toner level detection . . . . . . . . . . . . . . . . . .143

Figure 41. Color toner level detections . . . . . . . . . . . . . . . . . .145

Figure 42. Color toner lever detection . . . . . . . . . . . . . . . . . .146

Figure 43. Density sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

Figure 44. Transfer belt control . . . . . . . . . . . . . . . . . . . . . . . . 149

Figure 45. Cleaning roller control . . . . . . . . . . . . . . . . . . . . . . 150

Figure 46. Carousel control . . . . . . . . . . . . . . . . . . . . . . . . . .151

Figure 47. Power distribution circuit diagram . . . . . . . . . . . . . 152

Figure 48. Power Save circuit diagram . . . . . . . . . . . . . . . . . .153

Figure 49. High-voltage power supply circuit . . . . . . . . . . . . .156

Figure 50. Laser/scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

Figure 51. Printer motors and heaters . . . . . . . . . . . . . . . . . .159

Figure 52. Carousel motor (M1) . . . . . . . . . . . . . . . . . . . . . . . 160

Figure 53. Drum motor (M2) . . . . . . . . . . . . . . . . . . . . . . . . . .161

Figure 54. Cartridge motor (M3) . . . . . . . . . . . . . . . . . . . . . . .162

Figure 55. Main motor (M4) . . . . . . . . . . . . . . . . . . . . . . . . . .163

Figure 56. Pick-up motor (M5) . . . . . . . . . . . . . . . . . . . . . . . .164

Figure 57. Paper path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

Figure 58. Tray 2 and 3 pick-up . . . . . . . . . . . . . . . . . . . . . . .169

Figure 59. Tray 1 pick-up . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

Figure 60. Printer sensors . . . . . . . . . . . . . . . . . . . . . . . . . . .172

Figure 61. Printer switches . . . . . . . . . . . . . . . . . . . . . . . . . . .174

Figure 62. Printer clutches and solenoids . . . . . . . . . . . . . . . . 177

Figure 63. Fusing and delivery unit . . . . . . . . . . . . . . . . . . . . . 179

Figure 64. 2,000-sheet input unit sensors, switches, clutches,

and motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Figure 65. 2,000-sheet input unit paper path . . . . . . . . . . . . .185

Figure 66. Multi-bin mailbox cabling . . . . . . . . . . . . . . . . . . . .188

Figure 67. Multi-bin mailbox sensors . . . . . . . . . . . . . . . . . . .189

Figure 68. Multi-bin mailbox paper path . . . . . . . . . . . . . . . . .191

Figure 69. Timing chart for WAIT period (1 of 2) . . . . . . . . . .193

Figure 70. Timing chart for WAIT period (2 of 2) . . . . . . . . . .194

Figure 71. Timing chart for printing full color letter-sized

page (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

Figure 72. Timing chart for printing full color letter-sized

page (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .196

Figure 73. Timing chart for printing full color 11-by-17-inch sized

page (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .197

Figure 74. Timing chart for printing full color 11-by-17 inch sized

page (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .198

8 List of figures

EN

Page 9

Figure 75. Orientation of printer and accessories: top, front,

and right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Figure 76. Orientation of printer and accessories: rear

and left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

Figure 77. Removing the front cover . . . . . . . . . . . . . . . . . . .208

Figure 78. Front right cover . . . . . . . . . . . . . . . . . . . . . . . . . .209

Figure 79. Inside left panel . . . . . . . . . . . . . . . . . . . . . . . . . . .210

Figure 80. Screws behind left door . . . . . . . . . . . . . . . . . . . . .211

Figure 81. Screws behind right door . . . . . . . . . . . . . . . . . . . .212

Figure 82. Connector on top cover . . . . . . . . . . . . . . . . . . . . .212

Figure 83. Left door and strap . . . . . . . . . . . . . . . . . . . . . . . .213

Figure 84. Screws on left rear cover . . . . . . . . . . . . . . . . . . . .214

Figure 85. Screws on upper left door . . . . . . . . . . . . . . . . . . . 215

Figure 86. Stopper hinges on lower left cover . . . . . . . . . . . .216

Figure 87. Connectors on the right upper door . . . . . . . . . . . .217

Figure 88. E-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .218

Figure 89. Spring on right cover subassembly . . . . . . . . . . . .219

Figure 90. Right rear cover . . . . . . . . . . . . . . . . . . . . . . . . . . .220

Figure 91. Screws on the right lower cover . . . . . . . . . . . . . .221

Figure 92. Rear cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .222

Figure 93. Bottom of the control panel . . . . . . . . . . . . . . . . . . 223

Figure 94. Scanner unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . .224

Figure 95. Upper airflow vent . . . . . . . . . . . . . . . . . . . . . . . . . 225

Figure 96. Face-down exit sensor rail . . . . . . . . . . . . . . . . . . . 225

Figure 97. Face-down output assembly . . . . . . . . . . . . . . . . . 226

Figure 98. Toner lock sensor and color cartridge sensor . . . .227

Figure 99. Subrelay PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . .228

Figure 100. Formatter board . . . . . . . . . . . . . . . . . . . . . . . . . . .230

Figure 101. Connector on formatter board . . . . . . . . . . . . . . . .232

Figure 102. Back side of formatter board . . . . . . . . . . . . . . . . .232

Figure 103. Feeder assembly . . . . . . . . . . . . . . . . . . . . . . . . . .233

Figure 104. Face-up solenoid . . . . . . . . . . . . . . . . . . . . . . . . . .234

Figure 105. Face-up solenoid . . . . . . . . . . . . . . . . . . . . . . . . . .235

Figure 106. Screws on the face-up exit assembly . . . . . . . . . .236

Figure 107. Tray 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .237

Figure 108. Pick-up roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Figure 109. Registration roller assembly (front) . . . . . . . . . . . . 239

Figure 110. Registration roller assembly (back) . . . . . . . . . . . .240

Figure 111. Connectors on registration roller assembly . . . . . .241

Figure 112. Density sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . .242

Figure 113. Paper pick-up assembly . . . . . . . . . . . . . . . . . . . .243

Figure 114. Paper pick-up assembly . . . . . . . . . . . . . . . . . . . .244

Figure 115. Paper pick-up assembly . . . . . . . . . . . . . . . . . . . .245

EN

List of figures

9

Page 10

Figure 116. Rear of printer with cover removed . . . . . . . . . . . .246

Figure 117. Rear of printer with formatter pan removed . . . . . .247

Figure 118. Formatter pan . . . . . . . . . . . . . . . . . . . . . . . . . . . .248

Figure 119. Formatter pan (left side) . . . . . . . . . . . . . . . . . . . .249

Figure 120. Fan 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250

Figure 121. Fan 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .251

Figure 122. Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . .252

Figure 123. Controller board . . . . . . . . . . . . . . . . . . . . . . . . . . .253

Figure 124. Cartridge motor . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Figure 125. Main motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Figure 126. Carousel motor PCA . . . . . . . . . . . . . . . . . . . . . . . 256

Figure 127. Fans 1 and 2 housing assemblies . . . . . . . . . . . . .257

Figure 128. Carousel motor . . . . . . . . . . . . . . . . . . . . . . . . . . .258

Figure 129. Lower air duct . . . . . . . . . . . . . . . . . . . . . . . . . . . .259

Figure 130. Screws on the delivery drive assembly . . . . . . . . .260

Figure 131. Access to main gear assembly . . . . . . . . . . . . . . .261

Figure 132. High-voltage converter 1 PCA . . . . . . . . . . . . . . . .262

Figure 133. High-voltage converter 1 . . . . . . . . . . . . . . . . . . . .263

Figure 134. High-voltage converter 2 PCA . . . . . . . . . . . . . . . .264

Figure 135. High-voltage converter 2 . . . . . . . . . . . . . . . . . . . .265

Figure 136. High-voltage converter 2 . . . . . . . . . . . . . . . . . . . .266

Figure 137. Drum/cartridge drive assembly . . . . . . . . . . . . . . .267

Figure 138. Separation discharge high-voltage converter . . . .268

Figure 139. Plate over media size sensing PCAs . . . . . . . . . . . 269

Figure 140. Media size sensing PCAs . . . . . . . . . . . . . . . . . . .270

Figure 141. Front cover of the 2,000-sheet input unit . . . . . . . .272

Figure 142. Back cover removal . . . . . . . . . . . . . . . . . . . . . . . .273

Figure 143. Left cover removal . . . . . . . . . . . . . . . . . . . . . . . . .274

Figure 144. Vertical transfer unit (VTU) . . . . . . . . . . . . . . . . . .275

Figure 145. Right cover with VTU removed . . . . . . . . . . . . . . .276

Figure 146. Tray 4 removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Figure 147. Paper pick-up assembly . . . . . . . . . . . . . . . . . . . .278

Figure 148. Controller PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Figure 149. Screw on front LED PCA assembly . . . . . . . . . . . .280

Figure 150. Front LED PCA . . . . . . . . . . . . . . . . . . . . . . . . . . .281

Figure 151. Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . .281

Figure 152. Main drive assembly . . . . . . . . . . . . . . . . . . . . . . .282

Figure 153. Paper quantity switch assembly . . . . . . . . . . . . . .283

Figure 154. Paper size switch assembly . . . . . . . . . . . . . . . . .284

Figure 155. Tension springs . . . . . . . . . . . . . . . . . . . . . . . . . . .285

Figure 156. Front and back covers . . . . . . . . . . . . . . . . . . . . . .287

Figure 157. Top cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Figure 158. Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . .289

Figure 159. Paper bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .290

10 List of figures

EN

Page 11

Figure 160. Flipper assembly (1 of 3) . . . . . . . . . . . . . . . . . . . .291

Figure 161. Flipper assembly (2 of 3) . . . . . . . . . . . . . . . . . . . .292

Figure 162. Flipper assembly (3 of 3) . . . . . . . . . . . . . . . . . . . .292

Figure 163. Delivery head motor . . . . . . . . . . . . . . . . . . . . . . .293

Figure 164. Transport belt motor . . . . . . . . . . . . . . . . . . . . . . .294

Figure 165. Input paper guide (1 of 2) . . . . . . . . . . . . . . . . . . .295

Figure 166. Input paper guide (2 of 2) . . . . . . . . . . . . . . . . . . .296

Figure 167. Metallic tape and housing assembly (1 of 2) . . . . .297

Figure 168. Metallic tape and housing assembly (2 of 2) . . . . .298

Figure 169. Controller PCA (1 of 2) . . . . . . . . . . . . . . . . . . . . .299

Figure 170. Controller PCA (2 of 2) . . . . . . . . . . . . . . . . . . . . .300

Figure 171. Anti-curl strings (1 of 2) . . . . . . . . . . . . . . . . . . . . .301

Figure 172. Anti-curl strings (2 of 2) . . . . . . . . . . . . . . . . . . . . .302

Figure 173. Delivery head assembly (1 of 4) . . . . . . . . . . . . . .303

Figure 174. Delivery head assembly (2 of 4) . . . . . . . . . . . . . .304

Figure 175. Delivery head assembly (3 of 4) . . . . . . . . . . . . . .304

Figure 176. Delivery head assembly (4 of 4) . . . . . . . . . . . . . .305

Figure 177. Interlock switch . . . . . . . . . . . . . . . . . . . . . . . . . . .306

Figure 178. Diagnostic LED PCA . . . . . . . . . . . . . . . . . . . . . . .307

Figure 179. User status LED PCA . . . . . . . . . . . . . . . . . . . . . .308

Figure 180. Attachment assembly . . . . . . . . . . . . . . . . . . . . . .309

Figure 181. Example of a configuration page . . . . . . . . . . . . . .362

Figure 182. Right upper cover detection interlock . . . . . . . . . .370

Figure 183. Drum cartridge detection interlock . . . . . . . . . . . . .370

Figure 184. Black toner cartridge detection interlock . . . . . . . . 371

Figure 185. Toner carousel door detection interlock . . . . . . . .371

Figure 186. Front cover/delivery cover detection interlocks . . .372

Figure 187. Laser shutters . . . . . . . . . . . . . . . . . . . . . . . . . . . .373

Figure 188. Left upper cover detection . . . . . . . . . . . . . . . . . . .374

Figure 189. Right lower cover detection . . . . . . . . . . . . . . . . . .374

Figure 190. Printer paper path . . . . . . . . . . . . . . . . . . . . . . . . .380

Figure 191. Image orientation and direction of travel . . . . . . . .386

Figure 192. Incorrect registration (late and early print) . . . . . . .388

Figure 193. Image skew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .389

Figure 194. Blank or partially blank page . . . . . . . . . . . . . . . . .390

Figure 195. Horizontal lines (in one color) . . . . . . . . . . . . . . . .391

Figure 196. Horizontal lines (in all colors, CMYK) . . . . . . . . . .392

Figure 197. Rain or speckled print . . . . . . . . . . . . . . . . . . . . . .393

Figure 198. Black, brown, or orange bands . . . . . . . . . . . . . . .394

Figure 199. Background toner scatter . . . . . . . . . . . . . . . . . . .395

Figure 200. Mottled process colors or poor transfer . . . . . . . . .396

Figure 201. Stray toner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .397

Figure 202. Dark yellow or contaminated print . . . . . . . . . . . . .398

Figure 203. Color adjust page . . . . . . . . . . . . . . . . . . . . . . . . .415

EN

List of figures

11

Page 12

Figure 204. Repetitive defect ruler . . . . . . . . . . . . . . . . . . . . . . 420

Figure 205. Cleaning the transfer drum . . . . . . . . . . . . . . . . . .423

Figure 206. Rear view of 2,000-sheet input unit . . . . . . . . . . . .428

Figure 207. Location of sensors in the 2,000-sheet input unit .432

Figure 208. Multi-bin mailbox power supply test mode switch . 434

Figure 209. Connectors on the controller board . . . . . . . . . . . .440

Figure 210. General printer circuit diagram (1 of 2) . . . . . . . . .441

Figure 211. General printer circuit diagram (2 of 2) . . . . . . . . .442

Figure 212. Major assembly locations (1 of 2) . . . . . . . . . . . . .450

Figure 213. Major assembly locations (2 of 2) . . . . . . . . . . . . .451

Figure 214. Printer covers and doors (1 of 3) . . . . . . . . . . . . . .452

Figure 215. Printer covers and doors (2 of 3) . . . . . . . . . . . . . .454

Figure 216. Printer covers and doors (3 of 3) . . . . . . . . . . . . . .456

Figure 217. Internal cover assembly . . . . . . . . . . . . . . . . . . . . . 458

Figure 218. Internal components (1 of 6) . . . . . . . . . . . . . . . . . 460

Figure 219. Internal components (2 of 6) . . . . . . . . . . . . . . . . . 462

Figure 220. Internal components (3 of 6) . . . . . . . . . . . . . . . . . 464

Figure 221. Internal components (4 of 6) . . . . . . . . . . . . . . . . . 466

Figure 222. Internal components (5 of 6) . . . . . . . . . . . . . . . . . 468

Figure 223. Internal components (6 of 6) . . . . . . . . . . . . . . . . . 470

Figure 224. Drum/cartridge drive assembly . . . . . . . . . . . . . . .472

Figure 225. Delivery drive assembly . . . . . . . . . . . . . . . . . . . . . 473

Figure 226. Tray 3 assembly . . . . . . . . . . . . . . . . . . . . . . . . . .474

Figure 227. Tray 2 assembly . . . . . . . . . . . . . . . . . . . . . . . . . .475

Figure 228. Paper pick-up assembly (1 of 3) . . . . . . . . . . . . . .476

Figure 229. Paper pick-up assembly (2 of 3) . . . . . . . . . . . . . .477

Figure 230. Paper pick-up assembly (3 of 3) . . . . . . . . . . . . . .478

Figure 231. Registration frame assembly . . . . . . . . . . . . . . . . .480

Figure 232. Registration roller assembly . . . . . . . . . . . . . . . . .481

Figure 233. Feeder assembly . . . . . . . . . . . . . . . . . . . . . . . . . .482

Figure 234. Tray 1 pick-up assembly . . . . . . . . . . . . . . . . . . . . 483

Figure 235. Tray 1 assembly . . . . . . . . . . . . . . . . . . . . . . . . . .484

Figure 236. Delivery assembly . . . . . . . . . . . . . . . . . . . . . . . . .485

Figure 237. Delivery cover assembly . . . . . . . . . . . . . . . . . . . . 486

Figure 238. Transfer belt assembly . . . . . . . . . . . . . . . . . . . . .487

Figure 239. Fuser assembly (1 of 2) . . . . . . . . . . . . . . . . . . . . .488

Figure 240. Fuser assembly (2 of 2) . . . . . . . . . . . . . . . . . . . . .489

Figure 241. PCA assembly location diagram . . . . . . . . . . . . . . 491

Figure 242. 2,000-sheet input unit covers and doors . . . . . . . .492

Figure 243. 2,000-sheet input unit internal components . . . . . . 494

Figure 244. Multi-bin mailbox components (1 of 3) . . . . . . . . . . 496

Figure 245. Multi-bin mailbox components (2 of 3) . . . . . . . . . . 498

Figure 246. Multi-bin mailbox components (3 of 3) . . . . . . . . . . 500

12 List of figures

EN

Page 13

List of tables

Table 1. Features and optional accessories by printer model. . 19

Table 2. Printer performance . . . . . . . . . . . . . . . . . . . . . . . . . .20

Table 3. Electrical specifications. . . . . . . . . . . . . . . . . . . . . . . .21

Table 4. Operating environment specifications. . . . . . . . . . . . .21

Table 5. Acoustic emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 6. Printer dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Table 7. Consumable storage specifications . . . . . . . . . . . . . .23

Table 8. Media capacity and sizes for input trays . . . . . . . . . . .28

Table 9. Media capacity and sizes for the multi-bin mailbox. . .30

Table 10. Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . .49

Table 11. Technical support websites. . . . . . . . . . . . . . . . . . . . .50

Table 12. Printer control panel menu map overview. . . . . . . . . .69

Table 13. Information Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Table 14. Proof and Print Menu . . . . . . . . . . . . . . . . . . . . . . . . .72

Table 15. Paper Handling Menu . . . . . . . . . . . . . . . . . . . . . . . . .72

Table 16. Configuration Menu. . . . . . . . . . . . . . . . . . . . . . . . . . .75

Table 17. Printing Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Table 18. I/O Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Table 19. Resets Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Table 20. Color Adjust Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Table 21. Service Mode Menu . . . . . . . . . . . . . . . . . . . . . . . . . .80

Table 22. Paper handling accessory status LEDs . . . . . . . . . . .95

Table 23. Replacement frequencies for printer consumables. .105

Table 24. Subtractive color absorption . . . . . . . . . . . . . . . . . . . 126

Table 25. Subtractive color mixing . . . . . . . . . . . . . . . . . . . . . .127

Table 26. Additive color mixing. . . . . . . . . . . . . . . . . . . . . . . . .128

Table 27. Fusing temperatures . . . . . . . . . . . . . . . . . . . . . . . . .154

Table 28. Printer motor and heater names and descriptions . .159

Table 29. Fan operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165

Table 30. Feed speeds based on media type. . . . . . . . . . . . . .167

Table 31. Printer sensor names and descriptions. . . . . . . . . . .173

Table 32. Printer switch names and descriptions . . . . . . . . . . . 175

Table 33. Tray 2 and Tray 3 paper size detection. . . . . . . . . . . 176

Table 34. Printer clutch and solenoid names and descriptions.177

Table 35. 2,000-sheet input unit sensors, switches, clutches,

and motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

Table 36. Paper quantity detection switches. . . . . . . . . . . . . . . 183

Table 37. Paper size detection switches. . . . . . . . . . . . . . . . . .183

EN

List of tables

13

Page 14

Table 38. Multi-bin mailbox sensors, switches, motors, and

controller board PCA. . . . . . . . . . . . . . . . . . . . . . . . .190

Table 39. Numbered printer messages. . . . . . . . . . . . . . . . . . .316

Table 40. Unnumbered printer messages. . . . . . . . . . . . . . . . .334

Table 41. Sensor monitor test. . . . . . . . . . . . . . . . . . . . . . . . . .369

Table 42. Media jam detection . . . . . . . . . . . . . . . . . . . . . . . . .381

Table 43. Streaking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .401

Table 44. Neutral axis adjustments. . . . . . . . . . . . . . . . . . . . . .418

Table 45. Status LED on the 2,000-sheet input unit . . . . . . . . .427

Table 46. Patterns of LED flashing (2-second pause between

each pattern). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .429

Table 47. DIP switch settings for troubleshooting test

procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .430

Table 48. Status LEDs on the multi-bin mailbox . . . . . . . . . . . .436

Table 49. Options, accessories, and consumables. . . . . . . . . . 446

Table 50. Miscellaneous parts . . . . . . . . . . . . . . . . . . . . . . . . .448

Table 51. Printer doors and covers (1 of 3). . . . . . . . . . . . . . . . 453

Table 52. Printer doors and covers (2 of 3). . . . . . . . . . . . . . . . 455

Table 53. Printer covers and doors parts . . . . . . . . . . . . . . . . .457

Table 54. Internal cover assembly parts. . . . . . . . . . . . . . . . . .459

Table 55. Internal components parts (1 of 6) . . . . . . . . . . . . . .461

Table 56. Internal components parts (2 of 6) . . . . . . . . . . . . . .463

Table 57. Internal components parts (3 of 6) . . . . . . . . . . . . . .465

Table 58. Internal components parts (4 of 6) . . . . . . . . . . . . . .467

Table 59. Internal components parts (5 of 6) . . . . . . . . . . . . . .469

Table 60. Internal components parts (6 of 6) . . . . . . . . . . . . . .471

Table 61. Drum/cartridge drive assembly parts . . . . . . . . . . . .472

Table 62. Delivery drive assembly parts. . . . . . . . . . . . . . . . . .473

Table 63. Tray 3 assembly parts. . . . . . . . . . . . . . . . . . . . . . . .474

Table 64. Tray 2 assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .475

Table 65. Paper pick-up assembly parts. . . . . . . . . . . . . . . . . .479

Table 66. Registration frame assembly parts . . . . . . . . . . . . . . 480

Table 67. Registration roller assembly parts. . . . . . . . . . . . . . .481

Table 68. Feeder assembly parts . . . . . . . . . . . . . . . . . . . . . . . 482

Table 69. Tray 1 pick-up assembly parts . . . . . . . . . . . . . . . . .483

Table 70. Tray 1 assembly parts. . . . . . . . . . . . . . . . . . . . . . . .484

Table 71. Delivery assembly parts . . . . . . . . . . . . . . . . . . . . . .485

Table 72. Delivery cover assembly parts . . . . . . . . . . . . . . . . .486

Table 73. Transfer belt assembly parts. . . . . . . . . . . . . . . . . . .487

Table 74. Fuser assembly parts . . . . . . . . . . . . . . . . . . . . . . . .490

Table 75. PCA assembly parts . . . . . . . . . . . . . . . . . . . . . . . . . 491

Table 76. 2,000-sheet input unit cover and door parts . . . . . . . 493

Table 77. 2,000-sheet input unit internal component parts. . . .495

Table 78. Multi-bin mailbox component parts (1 of 3). . . . . . . .497

14 List of tables

EN

Page 15

Table 79. Multi-bin mailbox component parts (2 of 3). . . . . . . .499

Table 80. Multi-bin mailbox component parts (3 of 3). . . . . . . .501

Table 81. Numerical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . 502

Table 82. Alphabetical parts list . . . . . . . . . . . . . . . . . . . . . . . .513

EN

List of tables

15

Page 16

16 List of tables

EN

Page 17

1

Product information

Chapter contents

Printer features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . 21

Operating environment specifications . . . . . . . . . . . . . 21

Acoustic emission specifications . . . . . . . . . . . . . . . . . 22

Printer dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Consumable storage specifications. . . . . . . . . . . . . . . 23

Site requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

General guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Media requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Selecting media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Storing media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Media capacity and sizes for input trays . . . . . . . . . . . 28

Media capacity and sizes for the multi-bin mailbox . . . 30

Media weights and sizes for duplexer . . . . . . . . . . . . . 31

Envelopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Transparencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Glossy media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Heavy paper stock. . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Colored media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Media to avoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

EN

Chapter contents

17

Page 18

Identification (model and serial numbers) . . . . . . . . . . . . . . . 34

Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

External views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Formatter assemblies . . . . . . . . . . . . . . . . . . . . . . . . . 37

Paper handling accessories and options. . . . . . . . . . . 38

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

FCC regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Canadian DOC regulations . . . . . . . . . . . . . . . . . . . . . 39

Declarations of conformity. . . . . . . . . . . . . . . . . . . . . . 40

VCCI statement (Japan) . . . . . . . . . . . . . . . . . . . . . . . 43

EMI statement (Korea). . . . . . . . . . . . . . . . . . . . . . . . . 43

Laser safety statement . . . . . . . . . . . . . . . . . . . . . . . . 43

Laser statement for Finland. . . . . . . . . . . . . . . . . . . . . 44

Product information sheet . . . . . . . . . . . . . . . . . . . . . . 45

Toner safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Material Safety Data Sheet . . . . . . . . . . . . . . . . . . . . . 45

Ozone safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

18 Chapter 1 - Product information

EN

Page 19

Printer features

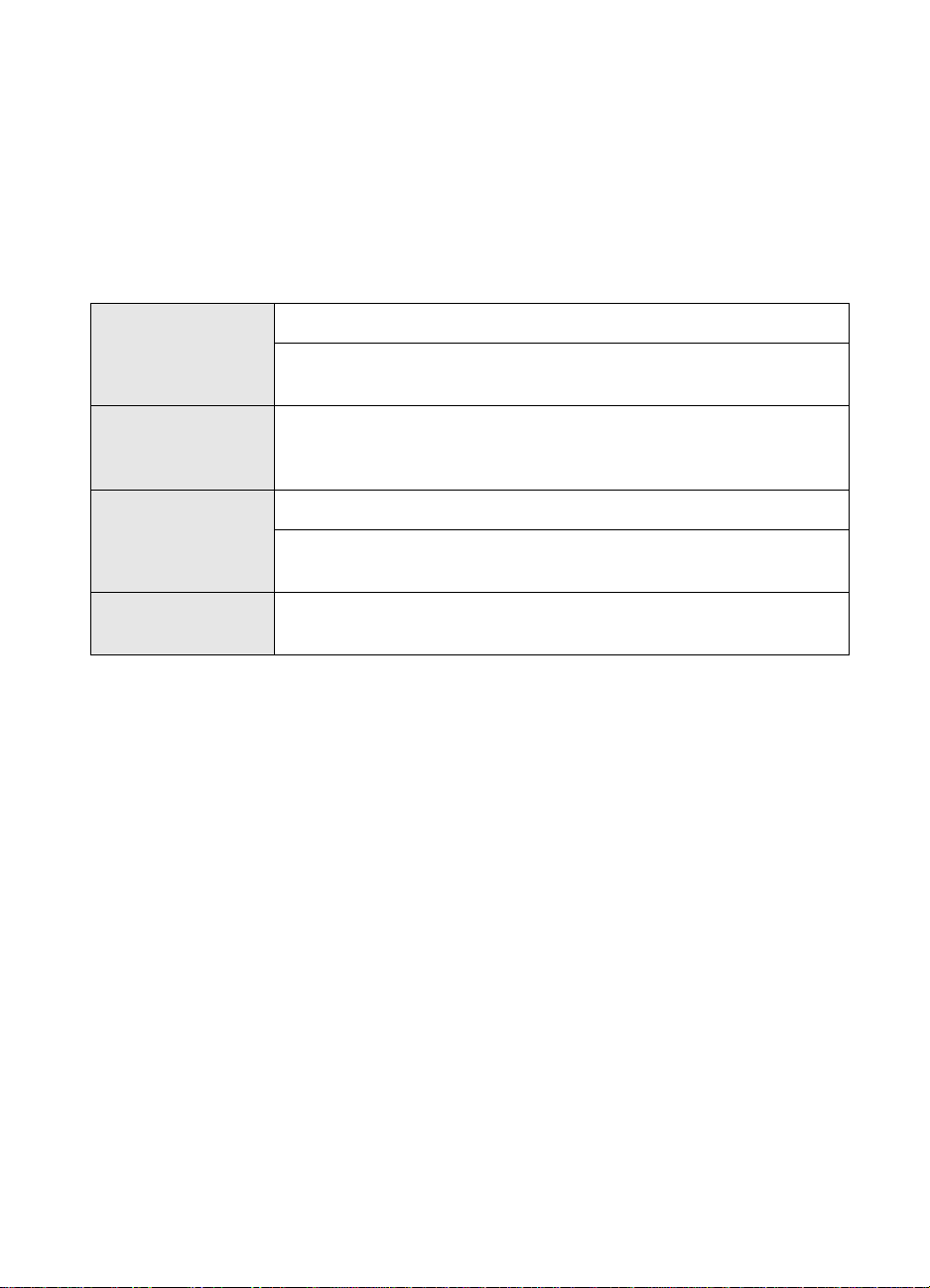

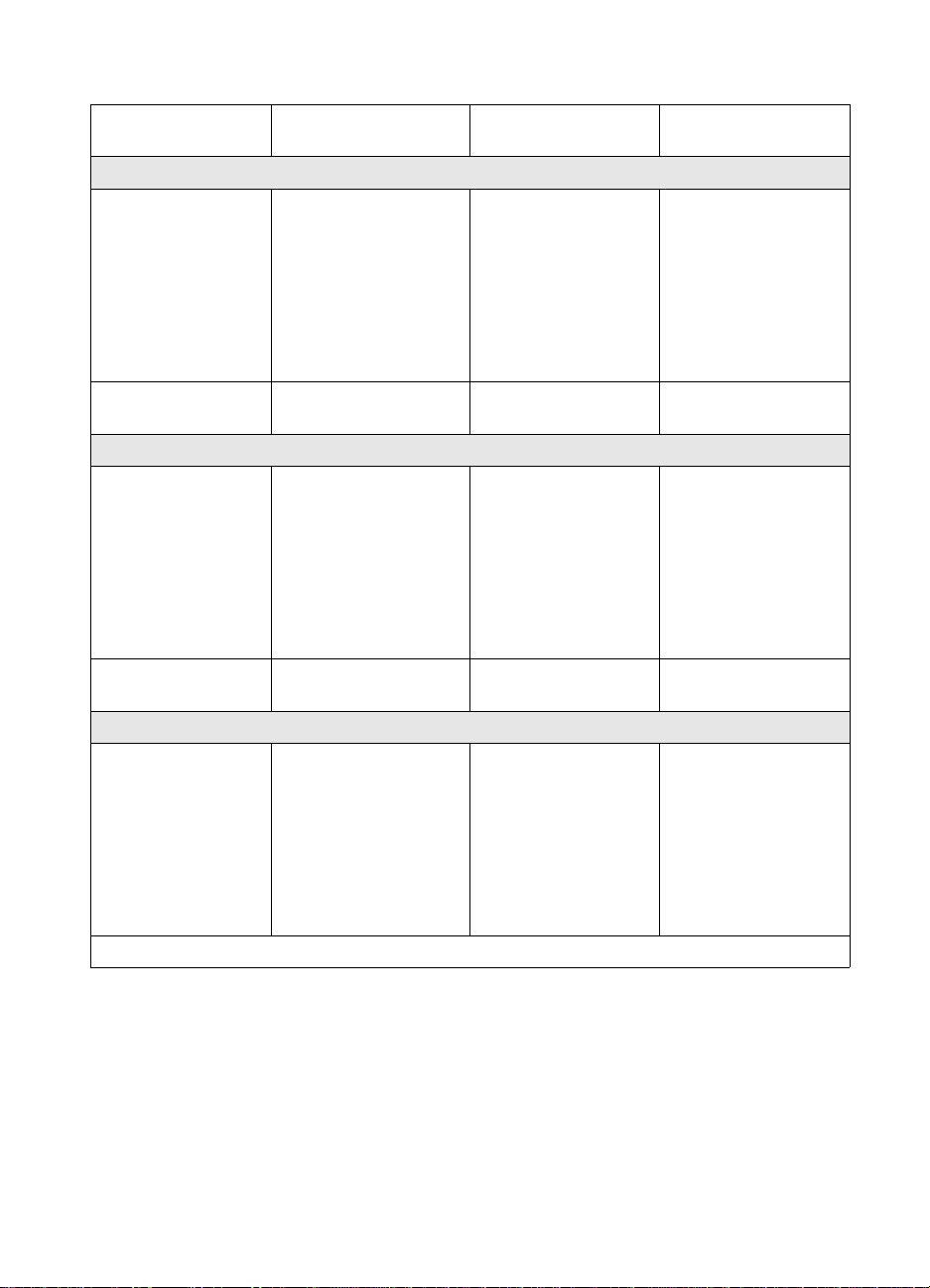

Table 1. Features and optional accessories by printer model

8500 8500 N 8500 DN

Features

Standard DIMM memory 32 MB 32 MB 64 MB

Expandable to 512 MB of DIMM

Internal printer hard disk X

2,000-sheet input unit X

Duplexer X

HP JetDirect 600N internal

print server X X

Optional accessories

1

memory X X X

External (EIO-compatible) printer

hard disk

ROM, or synchronous DRAM DIMMs X X X

Duplexer X X

HP JetDirect 600N internal

print server X

Multi-bin mailbox X

1

To expand the DIMM memory to 512 MB, install 64-MB DIMMs in all eight DIMM slots.

XX

EN

Printer features

19

Page 20

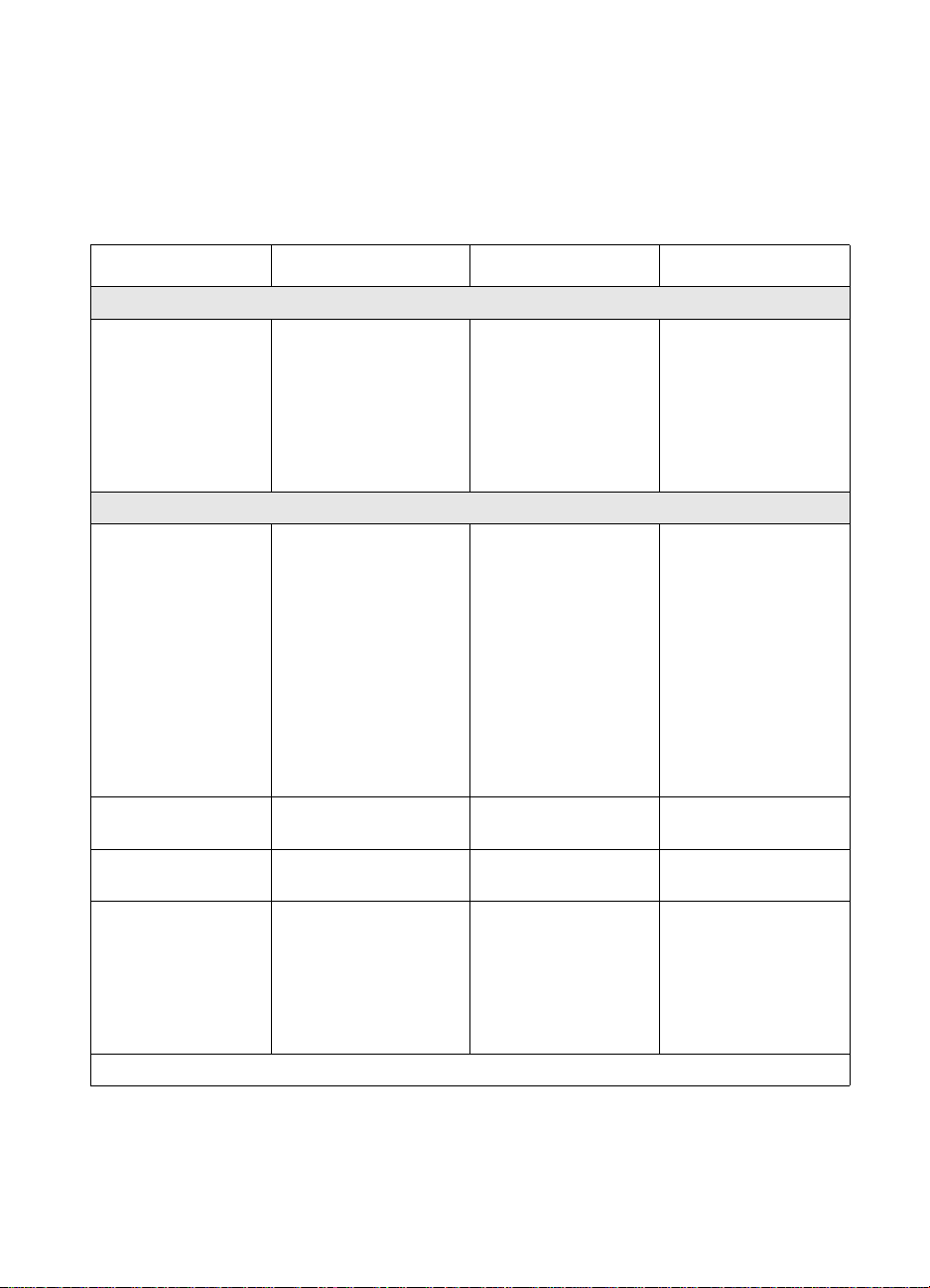

Table 2. Printer performance

Print speeds

●

●

Text and graphics

resolution

●

Approximate print

speeds

Letter, A4-size

●

Legal, Executive,

11-by-17 inch size

Heavy paper

Transparencies

Fonts

Printer personality

support

User interface and EIO

1

Not available at initial product introduction.

●

●

●

●

●

●

●

●

●

●

24 pages per minute (ppm) black and white (b/w)

6 ppm color

600 dpi resolution

24 ppm b/w; 6 ppm color

12 ppm b/w; 3 ppm color

3.2 ppm b/w; 2.2 ppm color

2.6 ppm b/w; 2.0 ppm color

HP LaserJet 45 TrueType™ font set

PostScript® fonts

Automatic personality switching

PCL1 and PostScript support

Standard ECP or bidirectional parallel cable interface

(IEEE-1284 compliant)

2 enhanced input/output (EIO) slots

Automatic I/O switching

The approximate print speeds offered by this printer might vary from

those listed above because the following factors affect processing

time:

●

complexity and size of graphics

●

I/O configuration

●

computer configuration

●

amount of printer memory

●

network operating system

●

network configuration

●

printer color calibration

20 Chapter 1 - Product information

EN

Page 21

Specifications

Electrical specifications

Table 3. Electrical specifications

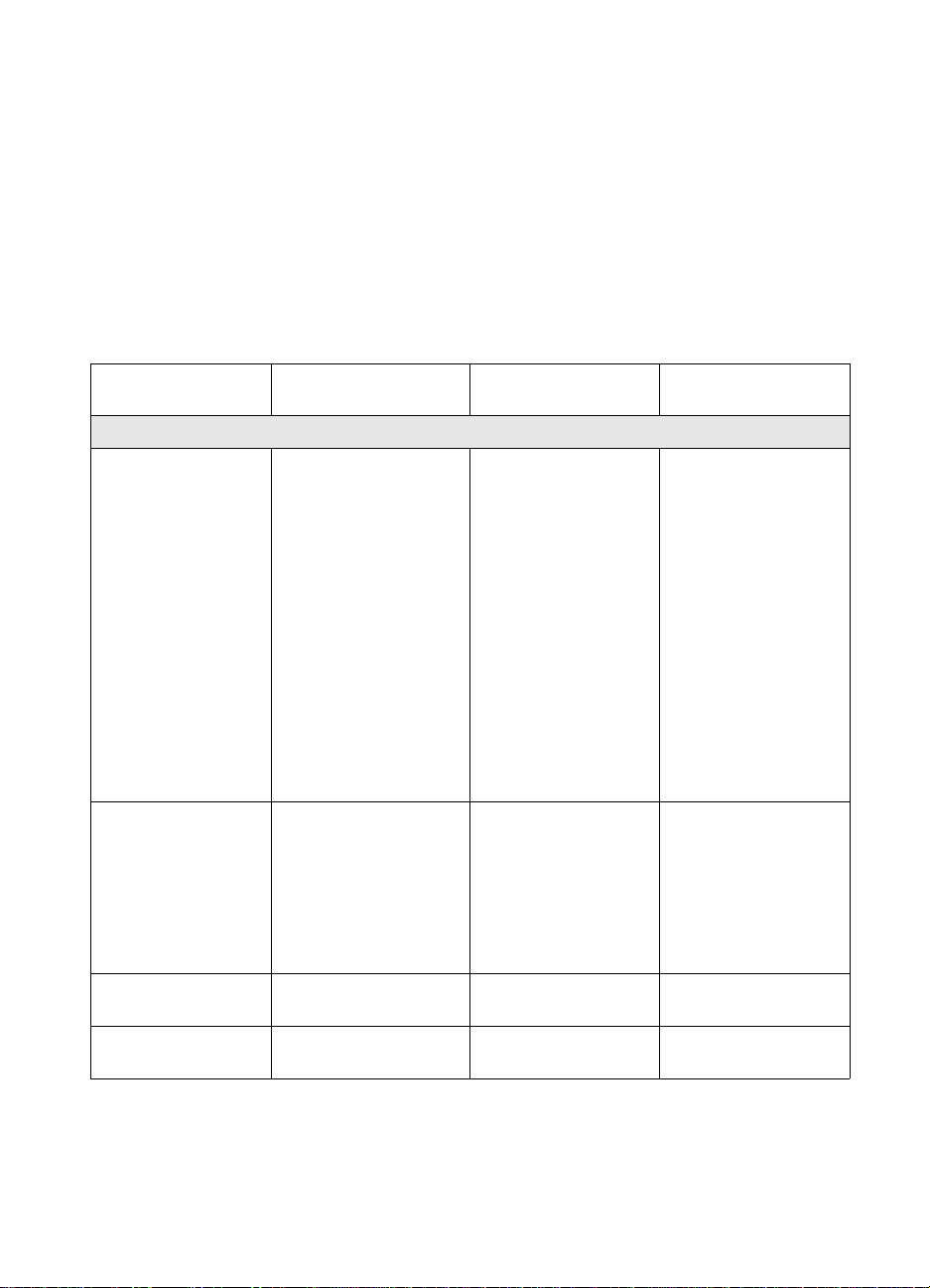

Item 110-volt models 220-volt models

Power requirements 100 to 127 V (+/- 10%)

50/60 Hz (+/- 2 Hz)

Power consumption (typical)

During printing (black and

white)

During printing (color)

During standby

During Power Save mode

During Off mode

Minimum recommended circuit

capacity for typical product

750 W (average)

375 W (average)

190 W (average)

< 45 W

< 2 W

12.0 A at 120 V 6.0 A at 220 V

Operating environment specifications

Table 4. Operating environment specifications

Item Operating Storage

Temperature

Recommended

Allowed

20 to 26° C (68 to 79° F)

15 to 30° C (59 to 86° F)

220 to 240 V (+/- 10%)

50/60 Hz (+/- 2 Hz)

750 W (average)

375 W (average)

190 W (average)

< 45 W

< 2 W

0 to 35° C (32 to 95° F)

-20 to 60° C (-4 to 140° F)

Humidity

Recommended

Allowed

Altitude

Allowed 0 to 3,048 m (0 to 10,000 ft) 0 to 3,048 m (0 to 10,000 ft)

EN

20 to 50% RH

10 to 80% RH

35 to 85% RH

10 to 95% RH

Specifications

21

Page 22

Acoustic emission specifications

Table 5. Acoustic emissions

Operation position (per ISO 9296, DIN 45635, T.19)

Printing LpA 54 dB(A)

Standby L

A 49 dB(A)

p

Bystander 1 meter (per ISO 7779, DIN 45635, T.19)

Printing LpA 50 dB(A)

Standby L

A 45 dB(A)

p

Sound power (per ISO 9296)

Printing 6.7 B (A)

Standby 6.1 B (A)

Printer dimensions

Table 6. Printer dimensions

Printer Printer with stand

Height

Width

750 mm

30 in

566 mm

22 in

1111 mm

44 in

566 mm

22 in

Printer with 2,000-

sheet input unit and

multi-bin mailbox

1230 mm

48 in

1056 mm

42 in

625 mm

Depth

Weight (with

consumables)

25 in

87 kg

192 lb

22 Chapter 1 - Product information

625 mm

25 in

100 kg

220 lb

625 mm

25 in

118 kg

260 lb

EN

Page 23

Consumable storage specifications

The life of consumables is greatly affected by their storage

environment. Use the following table to determine shelf life of stored

consumables.

For consumable replacement specifications , see page 105.

Table 7. Consumable storage specifications

Normal (maximum of 2.5 years) 0 to 35° C (32 to 95° F)

Temperature

Severe (maximum of 18 days) High 35 to 40° C (95 to 104° F)

Low 0 to -20° C (32 to -4° F)

Maximum

temperature

change rate

Humidity

Atmospheric

pressure

40 to 15° C (104 to 59° F) within 3 minutes

-20 to 25° C (-4 to 77° F) within 3 minutes

Normal (maximum of 2.5 years) 35 to 85% RH

Severe (maximum of 18 days) High 85 to 95% RH

Low 10 to 35% RH

460 to 760 mm Hg

EN

Specifications

23

Page 24

Site requirements

General guidelines

Locating and placing the printer correctly are important in maintaining

the performance level that has been set at the factory. In particular,

be sure to adhere to the environmental specifications listed in this

chapter. The following are recommendations for locating and placing

the printer:

●

Install in a well-ventilated, dust-free area.

●

Install on a hard, level surface.

●

Install where the temperature and humidity do not change

abruptly. Do not install near water sources, humidifiers, air

conditioners, refrigerators, or other major appliances.

●

Do not expose the printer to direct sunlight, dust, open flames, or

ammonia fumes.

●

Install the printer away from w alls or other objects. There m ust be

enough space around the printer for proper access and

ventilation (see figure 1 on page 25).

●

Install the printer away from the direct flow of exhaust from air

ventilation systems.

24 Chapter 1 - Product information

EN

Page 25

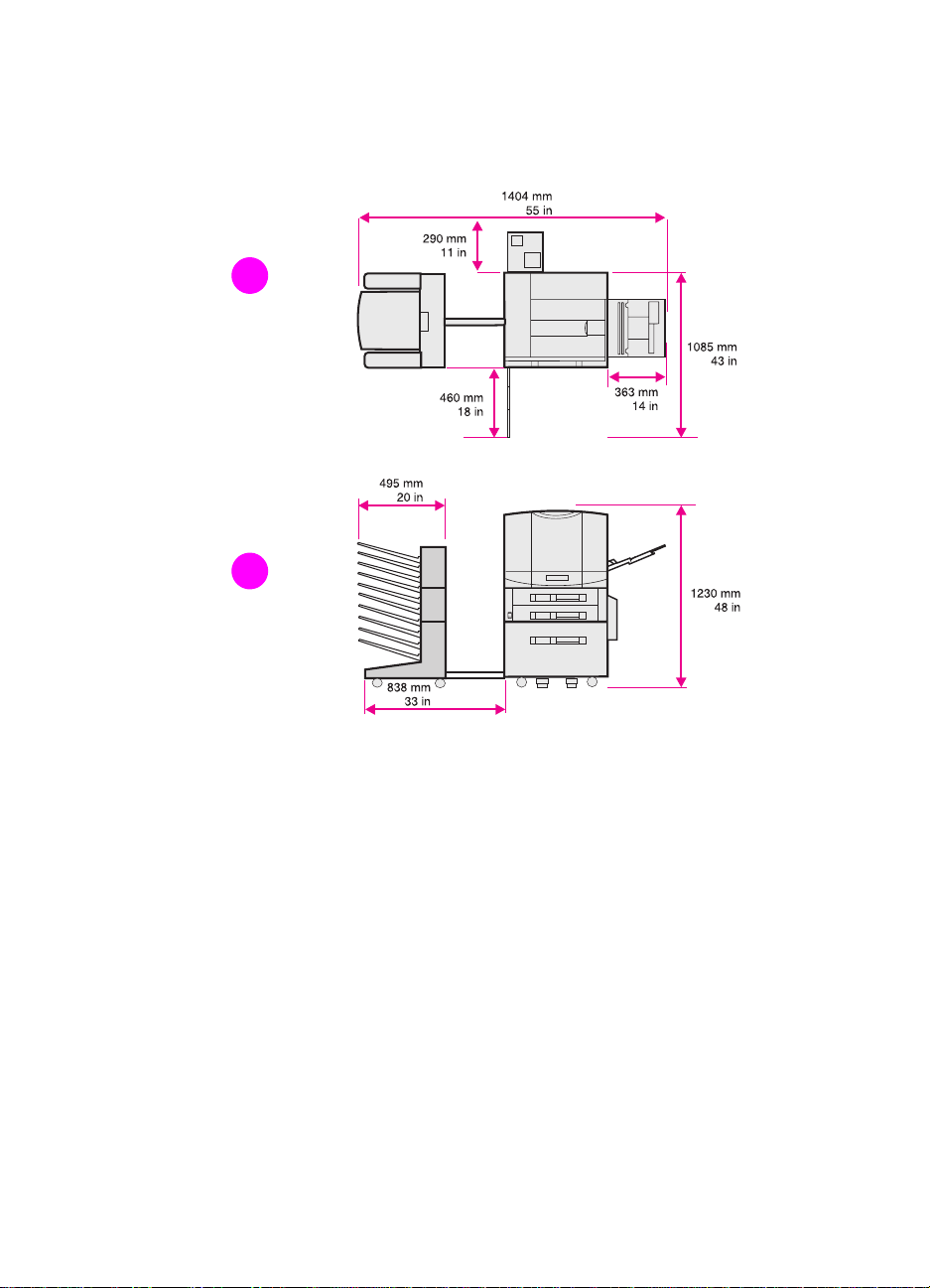

Space requirements

1

2

Figure 1. Space requirements

Top view (with optional multi-bin mailbox and 2,000-sheet input

1

unit)

Front view (with optional multi-bin mailbox and 2,000-sheet input

2

unit)

EN

Site requirements

25

Page 26

Media requirements

Selecting media

Many types of paper and other print media can be used with the

printer, within certain specifications. Using media that does not meet

the specifications outlined in this chapter can increase the incidence

of media jams, contribute to repair and maintenance costs, and cause

premature wear, print quality problems, and problems requiring

service. This service might not be covered by the HP warranty or

service agreements.

Before purchasing media or specialized f orms, test a small quantity in

the printer. Make sure your media supplier obtains and understands

the media specifications in the

Specification Guide

. For ordering information, see page 445.

Note It is possible that media could meet all of the specifications in this

chapter and still not print satisfactorily. This might be caused by

abnormal characteristics of the printing environment, such as extremes

in temperature and humidity.

●

For complete media specifications, see the

Family Paper Specification Guide

●

Use only print media that meet the specifications outlined in this

chapter.

●

Do not try to print unsupported sizes or weights of media or other

unsupported media.

●

Always handle transparencies and glossy media b y their edges to

avoid fingerprints in the image area.

●

Adhesives on any type of media must be compatible with the

printer’s fusing temperatures (approximately 190° C or 374° F).

●

Do not use media that have already passed through the printer or

through a copy machine, even if there is no printing on the page.

●

Recycled media can be used with this printer. Recycled media

must meet the specifications described in this chapter.

HP LaserJet Printer Family Paper

HP LaserJet Printer

.

26 Chapter 1 - Product information

EN

Page 27

Storing media

Follow these guidelines when stacking and storing media:

Store paper in its ream wrapper until you are ready to use it.

●

Rewrap partially used packages of media before storing.

●

Stack each carton upright and squarely on top of each other.

●

Store envelopes in a protective box to avoid damaging the

●

envelope edges.

Keep stored media away from temperature and humidity

●

extremes.

●

●

●

●

●

store cartons or reams directly on the floor where they will

Do not

absorb humidity. Instead, place cartons on a pallet or on shelves.

store individual reams in any manner that causes them to

Do not

curl or warp along the edges.

stack more than six cartons on top of each other.

Do not

place anything on top of media, regardless of whether the

Do not

media is packaged or unpackaged.

store printed documents in vinyl folders or expose the

Do not

documents to petroleum-based solvents.

EN

Media requirements

27

Page 28

Media capacity and sizes for input trays

The following table lists the types and sizes of media supported by

each input tray. For best results, use HP LaserJet paper or

conventional white copier paper. The media should be of good quality

and free of cuts, nicks, tears, spots, loose particles, dust, wrinkles,

voids, perforations, and curled or bent edges. For a complete list of

media specifications, see the

Specification Guide

.

Table 8. Media capacity and sizes for input trays

Media size and

Media type

Tray 1

Pape r

Plain

Preprinted

Letterhead

Prepunched

Bond

Recycled

Color

Card stock

Heavy (more

than 28 lb,

2

105 g/m

Glossy

Envelopes B5 (portrait)

Labels A4 (landscape)

Transparencies A4 (landscape)

)

orientation Media weight Maximum capacity

11 by 17 in (portrait)

JIS B4 (portrait)

A3 (portrait)

A4 (portrait)

A5 (portrait)

Custom min. (99 by

190 mm, 3.90 by 7.49 in)

(portrait)

Custom max. (304 by

469 mm, 11.98 by 18.48

in) (portrait)

Executive (portrait)

ISO B5 (portrait)

JIS B4 (portrait)

JIS B5 (portrait)

Letter (landscape)

Legal (landscape)

C5 (portrait)

Commercial #10 (Com10)

(portrait)

DL (portrait)

Double Post Card

(JPOSTD)

Monarch (portrait)

Letter (landscape)

Letter (landscape)

HP LaserJet Printer Family Paper

16 to 58 lb

(60 to 216 g/m

Maximum 24 lb (90 g/m

bond

— Limit to media-fill mark on

4 to 5 mils (0.10 to 0.13

mm) thick*

2

) bond

100 sheets of

20 lb (75 g/m2) bond

Limit to media-fill mark on

the media width guides

2

)

Approximately 10

Limit to media-fill mark on

the media width guides

the media width guides

Limit to media-fill mark on

the media width guides

28 Chapter 1 - Product information

EN

Page 29

Table 8. Media capacity and sizes for input trays (continued)

Media size and

Media type

Tray 2

Pape r

Plain

Preprinted

Letterhead

Prepunched

Bond

Recycled

Color

Glossy

Transparency A4 (portrait)

Tray 3

Pape r

Plain

Preprinted

Letterhead

Prepunched

Bond

Recycled

Color

Glossy

Transparency A4 (portrait)

2,000-sheet input unit (only available on 8500 DN model)

Paper

Plain

Preprinted

Letterhead

Prepunched

Bond

Recycled

Color

Glossy

* HP recommends using transparencies that are 5 mil (0.13 mm) thick with this printer.

orientation Media weight Maximum capacity

A4 (landscape)

JIS B4 (portrait)

Letter (landscape)

Legal (portrait)

Letter (portrait)

11 by 17 in (portrait)

A3 (portrait)

A4 (landscape)

JIS B4 (portrait)

Legal (portrait)

Letter (landscape)

Letter (portrait)

11 by 17 in (portrait)

A4 (landscape)

JIS B4 (portrait)

Legal (portrait)

Letter (landscape)

16 to 28 lb

(60 to 105 g/m

4 to 5 mils (0.10 to 0.13

mm) thick*

16 to 28 lb

(60 to 105 g/m

4 to 5 mils (0.10 to 0.13

mm) thick*

16 to 28 lb

(60 to 105 g/m

2

) bond

2

) bond

2

) bond

500 sheets of

20 lb (75 g/m2) bond

Limit to media-fill mark on

the media width guides

Limit to media-fill mark on

the media width guides

500 sheets of

20 lb (75 g/m2) bond

Limit to media-fill mark on

the media width guides

Limit to media-fill mark on

the media width guides

2,000 sheets of

20 lb (75 g/m2) bond

Limit to media-fill mark on

the media width guides

EN

Media requirements

29

Page 30

Media capacity and sizes for the multi-bin

mailbox

The following table lists the types and sizes of media supported by

multi-bin mailbox output bins.

Table 9. Media capacity and sizes for the multi-bin mailbox

Media type Media size Media weight Maximum capacity

Mailboxes

Paper

Plain

Preprinted

Letterhead

Prepunched

Bond

Recycled

Color

Left (face-up) output bin

Paper

Plain

Preprinted

Letterhead

Prepunched

Bond

Recycled

Color

Card Stock

Heavy (more

than 28 lb,

2

105 g/m

Glossy

Labels A4

Transparency A4

Envelopes B5

* HP recommends using transparencies that are 5 mils (0.13 mm) thick with this printer.

)

11 by 17 in

3

A4

JIS B4

Legal

Letter

11 by 17 in

A3

A4

A5

Custom min. (99 by 190

mm, 3.90 by 7.49 in)

Custom max. (304 by 469

mm, 11.98 by 18.48 in)

Executive

JIS B4

JIS B5

Legal

Letter

Letter

Letter

C5

Commercial #10 (Com10)

DL

Double Post Card

(JPOSTD)

Monarch

16 to 28 lb (60 to

2

105 g/m

16 to 58 lb (60 to

216 g/m

——

4 to 5 mils (0.10 to 0.13

mm) thick*

Maximum 24 lb (90 g/m

bond

) bond

2

) bond

250 sheets of 20 lb

(75 g/m2) bond

125 sheets of 20 lb

(75 g/m2) bond

—

2

)

30 Monarch-sized

envelopes

30 Chapter 1 - Product information

EN

Page 31

Media weights and sizes for duplexer

The duplexer accepts media up to 28 lb (105 g/m2) bond and as large

as A3 size.

Envelopes

CAUTION

CAUTION

The

●

Envelope

media type setting in the printer driver has been

optimized for the best print adhesion for most envelopes.

The

●

Heavy Paper

mode might also work well for some

envelopes, especially if the printing environment humidity is low.

Output envelopes to the left (face-up) output bin to reduce curl.

●

To prevent sev ere printer damage, en v elopes with a peel-off adhesive

strip or with more than one flap must use adhesives compatible with

the printer’s fusing temperatures (approximately 190° C or 374° F).

Extra flaps or strips can result in wrinkling or creasing, and can cause

jamming.

Transparencies

The printer’s internal color settings are optimized for the best

●

color quality if

T ransparenc y

printer driver. Using other media type settings will result in less

accurate colors.

Use only transparencies supported for use in this printer. Using

transparencies that do not meet the specifications for this printer can

cause poor print quality , media jams , and printer damage not cov ered

under warranty.

is selected as the media type in the

WARNING!

EN

Although this printer supports transparencies between 4 and 5

●

mils (0.10 to 0.13 mm) thick, HP recommends using

transparencies that are 5 mil (0.13 mm) thick.

To prevent damage to the printer, transparencies must be able to

●

withstand the printer’s fusing temperature (approximately 190° C

or 374° F).

Handle transparencies by the edges. Oil from y our fingers can be

●

deposited on the transparencies, causing print quality problems.

Also, allow transparencies to cool before handling to prevent

curling.

Allow transparencies to cool before handling to prevent burns.

Media requirements

31

Page 32

Glossy media

If you want the effect of glossy media, use only HP LaserJet glossy

media in this printer. For ordering information, see page 445.

Heavy paper stock

Heavy paper stock is any paper heavier than 28 lb up to 58 lb (105 to

216 g/m2) bond. Always print heavy paper stock from tray 1. In the

printer driver, select Heavy Paper or Cardstock as the paper type on

the paper tab to ensure the correct finish on the media. Also, use the

left (face-up) output bin to prevent media jams. For more information

on changing the printer driver settings, see the online help.

not

use extremely heavy paper stock (greater than 58 lb, or

Do

216 g/m2 bond). Misfeeds, mis-stacking, media jams, poor toner

fusing, poor print quality, and excessive mechanical wear can result.

Colored media

Colored media should be of the same high quality as white

xerographic paper. Pigments used must be able to withstand the

printer’s fusing temperature (approximately 190° C or 374° F). Do not

use media with a colored coating that was added after the media was

produced.

The printer cannot detect the color of media you are using. Varying

the shade or color of the media can change the shades of the printed

colors.

32 Chapter 1 - Product information

EN

Page 33

Media to avoid

To avoid poor print quality or damage to the printer, do not use any of

the following:

media that is coated or embossed

●

media with cutouts or perforations (except prepunched paper)

●

multi-part forms

●

media with irregularities, such as tabs or staples

●

preprinted media that contains thermography or inks that melt,

●

vaporize, or release hazardous emissions when subjected to the

fusing temperature (approximately 190° C or 374° F)

media that produces hazardous emissions, melts, offsets, or

●

discolors when heated to the printer’s fusing temperature

(approximately 190° C or 374° F)

media that has already been through a photocopier or laser

●

printer, even if there is no printing on the page

media with a watermark if solid fill areas are to be printed

●

transparencies designed for ink jet printers

●

EN

Media requirements

33

Page 34

Identification (model and serial numbers)

To identify the model number and serial number, find the label

located on the rear of the printer similar to the one shown in figure 2.

Figure 2. Example of printer model number and serial number label

(110 V and 220 V)

34 Chapter 1 - Product information

EN

Page 35

Product overview

External views

1

7

8

2

3

4

5

6

Figure 3. Front view

Printer control panel (see

1

page 66)

Left (face-up) output bin

2

Front door

3

Input tray 2

4

Power button

5

Input tray 3

6

9

10

11

12

Top (face-down) output bin

7

Flip-up media stop

8

Right upper cover

9

Input tray 1

10

Right lower cover

11

Printer stand

12

EN

Product overview

35

Page 36

1

2

Figure 4. Rear view

1 Air filter door

2 Formatter board

3

4

5

3 Left upper cover

4 Left lower cover

5 Power connector

36 Chapter 1 - Product information

EN

Page 37

Formatter assemblies

3

2

4

Figure 5. Formatter assemblies

Formatter board

1

DIMM slots

2

Printer hard disk location (factory installed)

3

EIO slot 2 (shown with HP JetDirect internal print server)

4

Parallel IEEE-1284 interface port (C-size)

5

EIO slot 1

6

C-link connector

7

1

5

6

7

7

Note

EN

Either EIO slot can have a hard disk installed if there is not a factory

installed internal hard drive mounted on the formatter board.

Product overview

37

Page 38

Paper handling accessories and options

1

2

3

Figure 6. Paper handling accessories and options

1 Multi-bin mailbox

2 Duplexer (internal)

3 2,000-sheet input unit (only available on 8500 DN model)

38 Chapter 1 - Product information

EN

Page 39

Safety information

FCC regulations

This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy, and if not

installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or

more of the following measures:

Reorient or relocate the receiving antenna.

●

Increase separation between equipment and receiver.

●

Connect equipment to an outlet on a circuit different from that on

●

which the receiver is located.

Consult your dealer or an experienced radio/television technician.

●

Note

EN

Any changes or modifications to the printer not expressly approv ed by

HP could void the user’s authority to operate this equipment.

Use of a shielded interface cable is required to comply within the Class

B limits in Part 15 of FCC rules.

Canadian DOC regulations

Complies with Canadian EMC Class B requirements.

«Conforme á la classe B des normes canadiennes de compatibilité

électromagnétiques. «CEM».»

Safety information

39

Page 40

Declarations of conformity

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name:

Manufacturer’s Address:

declares, that the product

Product Name:

Model Number:

Product Options:

conforms to the following Product Specifications:

Safety: IEC 950:1991+A1+A2+A3+A4 / EN 60950:1992+A1+A2+A3+A4

IEC 825-1:1993 / EN 60825-1:1994 Class 1 (Laser/LED)

EMC: CISPR 22:1993+A1 / EN 55022:1994 Class B

CISPR 22:1993+A1 / EN 55022:1994 Class A*

EN 5081-1:1992

EN 50082-1:1992

IEC 801-2:1991 / prEN 55024-2:1992 -4 kV CD, 8 kV AD

IEC 801-3:1984 / prEN 55024-3:1991 -3 V/m

IEC 801-4:1988 / prEN 55024-4:1992 -0.5 kV Signal Lines

1.0 kV Power Lines

FCC Title 47 CFR, Part 15 Class B

AS / NZS 3548:1992 / CISPR 22:1993 Class

Supplementary Information:

The product herewith complies with the requirements of the following Directives and carries the CEmarking accordingly:

- the EMC directive 89/336/EEC

- the Low Voltage Directive 73/23/EEC

1

The product was tested in a typical configuration with Hewlett-Packard Personal Computer Systems.

2

This Device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714-1021, USA

HP Color LaserJet 8500, 8500 N, 8500 DN

C3983A, C3984A, C3985A

ALL

1

2

/ICES-003, Issue 2/VCCI-2

1

1

* This printer contains Local Area Network (LAN) options. When the inte rface cable is attached to either of

the IEEE 802.3 connectors, the printer meets the requirements of EN55022 Class A.

February 12, 1997

For Compliance Information ONLY, contact:

Australia Contact: Product Regulations Manager, Hewlett-Packard Australia Ltd., 31-41 Joseph

Street, Blackburn, Victoria 3130, Australia

Europe Contact: A Local Hewlett-Packard Sales and Service Office or Hewlett-Packard GmbH,

Department HQ-TRE / Standards Europe, Herrenberger Strasse 130, D-71034

Böblingen (Fax: +49-7031-14-3143)

USA Contact: Product Regulations Manager, Hewlett-Packard Company, P.O. Box 15 Mail Stop

160, Boise, ID 83707-0015 (Phone: 208-396-6000)

40 Chapter 1 - Product information

EN

Page 41

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name:

Manufacturer’s Address:

Hewlett-Packard Company

Montemorelos 299

Guadalajara Jalisco, 45060

México

declares, that the product

Product Name:

Model Number:

Product Options:

conforms to the following Product Specifications:

EMC: CISPR 22:1993+A1 / EN 55022:1994 Class B

Duplexer

C4782A

N/A

1

CISPR 22:1993+A1 / EN 55022:1994

EN 50081-1:1992

EN 50082-1:1992

IEC 801-2:1991 / prEN 55024-2:1992 -4 kV CD, 8 kV AD

IEC 801-3:1984 / prEN 55024-3:1991 -3 V/m

IEC 801-4:1988 / prEN 55024-4:1992 -0.5 kV Signal Lines

FCC Title 47 CFR, Part 15 Class B

2

/ICES-003, Issue 2/VCCI-2

AS / NZS 3548:1992 / CISPR 22:1993 Class B

1

1.0 kV Power Lines

1

Supplementary Information:

The product herewith complies with the requirements of the following Directives and carries the CEmarking accordingly:

- the EMC directive 89/336/EEC

- the Low Voltage Directive 73/23/EEC

1

The product was tested in a typical configuration with Hewlett-Packard Personal Computer Systems.

2

This Device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

July 16, 1997

For Compliance Information ONLY, contact:

Australia Contact: Product Regulations Manager, Hewlett-Packard Australia Ltd., 31-41 Joseph

Street, Blackburn, Victoria 3130, Australia

Europe Contact: A Local Hewlett-Packard Sales and Service Office or Hewlett-Packard GmbH,

Department HQ-TRE / Standards Europe, Herrenberger Strasse 130, D-71034

Böblingen (Fax: +49-7031-14-3143)

USA Contact: Product Regulations Manager, Hewlett-Packard Company, P.O. Box 15 Mail

Stop 160, Boise, ID 83707-0015 (Phone: 208-396-6000)

EN

Safety information

41

Page 42

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name:

Manufacturer’s Address:

Hewlett-Packard Company

Montemorelos 299

Guadalajara Jalisco, 45060

México

declares, that the product

Product Name:

Model Number:

Product Options:

2,000-Sheet Input Tray

C4781A

N/A

conforms to the following Product Specifications:

Safety: IEC 950:1991+A1+A2+A3+A4 / EN 60950:1992+A1+A2+A3+A4

IEC 825-1:1993 / EN 60825-1:1994 Class 1 (Laser/LED)

EMC: CISPR 22:1993+A1 / EN 55022:1994 Class B

1

CISPR 22:1993+A1 / EN 55022:1994

EN 50081-1:1992

EN 50082-1:1992

IEC 801-2:1991 / prEN 55024-2:1992 -4 kV CD, 8 kV AD

IEC 801-3:1984 / prEN 55024-3:1991 -3 V/m

IEC 801-4:1988 / prEN 55024-4:1992 -0.5 kV Signal Lines

1.0 kV Power Lines

FCC Title 47 CFR, Part 15 Class B

AS / NZS 3548:1992 / CISPR 22:1993 Class B

2

/ICES-003, Issue 2/VCCI-2

1

1

Supplementary Information:

The product herewith complies with the requirements of the following Directives and carries the CEmarking accordingly:

- the EMC directive 89/336/EEC

- the Low Voltage Directive 73/23/EEC

1

The product was tested in a typical configuration with Hewlett-Packard Personal Computer Systems.

2

This Device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

July 16, 1997

For Compliance Information ONLY, contact:

Australia Contact: Product Regulations Manager, Hewlett-Packard Australia Ltd., 31-41 Joseph

Street, Blackburn, Victoria 3130, Australia

Europe Contact: A Local Hewlett-Packard Sales and Service Office or Hewlett-Packard GmbH,

Department HQ-TRE / Standards Europe, Herrenberger Strasse 130, D-71034

Böblingen (Fax: +49-7031-14-3143)

USA Contact: Product Regulations Manager, Hewlett-Packard Company, P.O. Box 15 Mail

Stop 160, Boise, ID 83707-0015 (Phone: 208-396 -6000)

42 Chapter 1 - Product information

EN

Page 43

VCCI statement (Japan)

EMI statement (Korea)

Laser safety statement

The Center for Devices and Radiological Health (CDRH) of the U.S.

Food and Drug Administration has implemented regulations for laser

products manufactured since August 1, 1976. Compliance is

mandatory for products marketed in the United States. This printer is

certified as a “Class 1” laser product under the U.S. Department of

Health and Human Services (DHHS) Radiation Performance

Standard according to the Radiation Control for Health and Safety Act

of 1968. Since radiation emitted inside this printer is completely

confined within protective housings and external covers, the laser

beam cannot escape during any phase of normal user operation.

EN

Safety information

43

Page 44

Laser statement for Finland

Luokan 1 laserlaite

Klass 1 Laser Apparat

HP LaserJet 8500, 8500 N, 8500 DN laserkirjoitin on käyttäjän kannalta turvallinen

luokan 1 laserlaite. Normaalissa käytössä kirjoittimen suojak otelointi estä ä lasersäteen

pääsyn laitteen ulkopuolelle. Laitteen turvallisuusluokka on määritetty standardin EN

60825-1 (1994) mukaisesti.

Varoitus!

Laitteen käyttäminen muulla kuin käyttöohjeessa mainitulla tavalla saattaa altistaa

käyttäjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

Varning!

Om apparaten används på annat sätt än i bruksanvisning specificerats, kan

användaren utsättas för osynlig laserstrålning, som överskrider gränsen för laserklass

1.

HUOLTO

HP LaserJet 8500, 8500 N, 8500 DN -kirjoittimen sisällä ei ole käyttäjän huollettavissa

olevia kohteita. Laitteen saa avata ja huoltaa ainoastaan sen huoltamiseen koulutettu

henkilö. Tällaiseksi huoltotoimenpiteeksi ei katsota väriainekasetin vaihtamista,

paperiradan puhdistusta tai muita käyttäjän käsikirjassa lueteltuja, käyttäjän tehtäväksi

tarkoitettuja ylläpitotoimia, jotka voidaan suorittaa ilman erikoistyökaluja.

Varo!

Mikäli kirjoittimen suojakotelo avataan, olet alttiina näkymättömälle lasersäteilylle

laitteen ollessa toiminnassa. Älä katso säteeseen.

Varning!

Om laserprinterns skyddshölje öppnas då apparaten är i funktion, utsättas användaren

för osynlig laserstrålning. Betrakta ej strålen.

Tiedot laitteessa käytettävän laserdiodin säteilyominaisuuksista:

Aallonpituus 775-795 nm

Teho 5 mW

Luokan 3B laser

44 Chapter 1 - Product information

EN

Page 45

Product information sheet

The Toner Product Information Sheet can be obtained by calling U.S.

HP FIRST (Fax Information Retrieval Support Technology) at (1)

(800) 231-9300. International customers should see page 52 for

appropriate phone numbers and information.

Toner safety

Toner is composed of plastic and a small amount of pigment. Avoid

breathing toner particles; toner might be harmful to your health. T oner

can also stain clothing. Skin and clothing are best cleaned by

removing as much toner as possible with a dry tissue, then washing

with cold water . Hot water causes toner to melt and permanently fuse

into clothing.

Material Safety Data Sheet

The Toner Cartridge/Drum MSDS can be obtained by calling U.S.

HP FIRST (Fax Information Retrieval Support Technology) at (1)

(800) 231-9300. Use Index number 7 for a listing of the Toner

Cartridge/Drum Material/Chemical Safety Data Sheets. International

customers should see page 52 for appropriate phone numbers and

information.

EN

Safety information

45

Page 46

Ozone safety

Ozone emission

The corona assemblies found in laser printers and photocopiers

generate ozone gas (O3) as a by-product of the electrophotographic

process. Ozone is generated only while the printer is printing (while

the coronas are energized).

This HP LaserJet printer contains an charcoal filter to protect office

air quality. See page 105 for suggested replacement intervals.

Ozone standards

Standards for exposure to ozone have been established by the

Department of Labor - Occupational Safety and Health Administration

(DOL-OSHA) and the American Conference of Governmental

Industrial Hygienists (ACGIH). These standards are 0.1 parts per

million as a time-weighted aver age and a ceiling limit respectively. All

HP LaserJet family printers meet these standards when shipped from

the factory.

Recommendations for minimizing ozone exposure

Some people are extremely sensitive to ozone. In such cases, it is

advisable to position the printer away from the sensitive user . Also, a

more frequent filter replacement might be necessary.

Almost all ozone concerns arise from abnormal site or operating

conditions. The following conditions might generate an ozone

complaint:

●

installation of multiple laser printers in a confined area

●

extremely low relative humidity

●

poor room ventilation

●

the exhaust port of the printer is directed towards the face of

personnel

●

the existing ozone filter is in poor condition

●