Page 1

October 1998 Edition

HP Color LaserJet Family

Quick Reference Service Guide

Page 2

Page 3

HP Color LaserJet Family

Quick Reference

Service Guide

October 1998 Edition

Page 4

© Copyright Hewlett-Packard

Company 1998

All Rights Reserved. Reproduction,

adaptation, or translation without prior

written permission is prohibited, except

as allowed under the copyright laws.

Publication number

5040-9071

First edition, October 1998

Warranty

The information contained in this

document is subject to change without

notice.

Hewlett-Packard makes no warranty

of any kind with respect to this

information. HEWLETT-PACKARD

SPECIFICALLY DISCLAIMS THE

IMPLIED WARRANTY OF

MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

Hewlett-Packard shall not be liable for

any direct, indirect, incidental,

consequential, or other damage

alleged in connection with the

furnishing or use of this information.

Trademark credits

Adobe™ and PostScript

™

are

registered trademarks of Adobe

Systems, Inc., which may be

registered in certain jurisdictions.

®

Microsoft

is a U.S. registered

trademark of Microsoft Corporation.

®

MS-DOS

is a U.S. registered

trademark of Microsoft Corporation.

®

UNIX

is a registered trademark in the

United States and other countries,

licensed exclusively through X/Open

Company Limited.

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714 U.S.A.

Page 5

Contents

1 Troubleshooting control panel messages. . . . . . . . . . . . . 1

2 Service tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4 Input/Output (I/O) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5 Media specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6 Toner cartridge information . . . . . . . . . . . . . . . . . . . . . . 83

7 Printer options and consumables. . . . . . . . . . . . . . . . . . 95

8 Printer parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

9 Image quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

10 Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

11 Services and support resources . . . . . . . . . . . . . . . . . 157

A Acronyms and abbreviations . . . . . . . . . . . . . . . . . . . . 169

Index

EN

iii

Page 6

Ordering other manuals

This

HP Color LaserJet Family Quick Reference Service Guide

been created to help the HP LaserJet service engineer quickly

troubleshoot common printer problems. While this reference is intended

to provide information the service engineer will need f or on-site r epair of

HP LaserJet color products, it is not intended to replace the service

manual for any HP LaserJet color product. For detailed information

about the HP LaserJet color products described in this guide, see the

user guide or service manual for that product.

Service manuals for HP LaserJet products are available from

Hewlett-Packard. The phone number for the Service Parts Order

Desk is:

(800) 227-8164 (U.S. only)

If you are located outside of the U.S., contact your local HP Sales and

Service Office. See “Services and support resources” on page 157.

has

Supported products

Name used in

this guide

HP Color LaserJet

4500/4500 N/

4500 DN

Note

This guide will be updated as the service needs change, as new

products are introduced, or as information becomes available.

Model

number

C4084A/C4089A/

C4094A

Maximum

pages per

month

35 K C4084-90958

Service

manual part

number

iv

EN

Page 7

Troubleshooting

1

control panel

messages

Overview

This chapter provides a list of control panel messages for the HP Color

LaserJet printers. Alphabetical messages are listed first, followed by

numerical messages. Control panel messages that are self-explanatory

are not included. See the service manual for more detailed information.

Following the control panel messages are suggestions for

troubleshooting paper path problems.

EN

Overview

1

Page 8

Pre-troubleshooting checklist

WARNING!

Always unplug the printer before servicing. Current is present in the

DC power supply whenever the printer is plugged in.

Note

The customer is responsible for ensuring that the maintenance units

are in good condition.

Before troubleshooting any specific printer problem, check the following:

• Has the printer been maintained on a regular basis?

• Are all of the maintenance units within their rated life?

• Is the customer using media as specified in Chapter 5, “Media

specifications” and the

Guide

?

• Is the media stored correctly and within environmental limits?

• Is the printer installed on a solid, level surface?

• Has the line voltage been chec ked to ma ke sure that it does not v ary

more than 20% from the nominal rated v alue specifi ed on the po w errating label?

– Large motors used near the printer can cause temporary voltage

changes.

• Is the operating environment within the parameters listed in the

printer service manual?

• Is the printer protected from substances such as office cleaning

materials and the ammonia gas that is produced by diazo copiers?

• Is the printer protected from direct sunlight?

HP LaserJet Family Paper Specification

2 Chapter 1 Troubleshooting control panel messages

EN

Page 9

CAUTION

Using non-HP components, such as toner, may cause permanent

damage to the printer.

• Have all non-HP components (toner, typeface DIMMs, memory

boards, and MIO cards) been removed from the printer?

• Has the printer hardware or software configuration changed?

Or could the problem be associated with any specific software?

– Contact the Customer Care Center for software-related problems

(see Chapter 11, “Services and support resources”).

• Could the problem be related to network configuration changes?

– Remove the printer from the network and make sure that the

failure is associated with the printer before beginning

troubleshooting.

1

EN

Pre-troubleshooting checklist

3

Page 10

Control panel messages

Alphabetical messages

Access denied, menus locked

This message is displayed for approximately 5 seconds when a user

has attempted to select a menu value while the printer control panel

locking is enabled.

• See the system administrator for access to the printer control panel.

Bad duplexer connection

The duplex-printing accessory is not correctly installed.

1 Check the duplex-printing accessory power cord.

2 Turn the printer off, and then turn the printer on.

3 If the error continues, verify that the duplex-printing accessory is

correctly installed.

4 If the error persists, replace the duplexer.

Calibration executing

The printer is executing an internal color calibration. This process

should take approximately 90 seconds.

• No action is required.

4 Chapter 1 Troubleshooting control panel messages

EN

Page 11

Canceling job

The printer is canceling the current print job. Incoming data for the

current job will be discarded.

• No action is required.

1

Cannot duplex check rear bin

alternates with

Cannot duplex check paper

The printer cannot duplex because the rear output bin is open or the

media is not supported by the duplex-printing accessory.

Close the rear output bin.

1

Verify that the media is supported by the duplex-printing accessory.

2

Checking printer

The printer is performing an internal test. This process should take

approximately 30 seconds. The message is displayed during the

initiation of the engine test. When finished, the printer goes online.

• No action is required

Clearing paper from printer

The printer has jammed or was turned on and media was detected in

the paper path. The printer is attempting to clear these pages.

• No action is required.

EN

Control panel messages

5

Page 12

Close middle front drawer

The drawer that holds the intermediate transfer belt (ITB) is open.

Switch SW1 indicates the drawer is open. When the drawer is closed, a

plastic protrusion on the lower left corner of the drawer pivots an arm

allowing SW1 to toggle to the open position.

1 Close the middle front drawer.

2 If the message persists, remove the printer’s left-side cover and

inspect the mechanical linkage that closes SW1.

3 Refer to the wiring diagram to verify the wiring; the two-wire

connector should be firmly seated to SW1 and the wiring harness

should be firmly seated to connector J1003 of the DC controller

PCB.

4 If the message persists, use an ohmmeter to verify the functionality

of SW1.

6 Chapter 1 Troubleshooting control panel messages

EN

Page 13

Close upper rear door

Switch SW5 monitors the closing of the printer’s upper rear door (this

door allows you to access the fusing assembly). When the fusing door

is closed, a tab on the rear door pushes a door switch actuator that runs

along the left side of the printer and closes SW5.

WARNING!

High voltages occur during operation. Closing the rear door and the

upper and middle front draw ers closes SW4 and SW5, enabling +24B

Vdc. When either drawer or the rear door is open +24B Vdc is

disabled. This safety f eature protects the operator from high v oltages.

Close the upper rear door.

1

If the message persists, remove the printer’s left-side cover and

2

inspect the mechanical linkage of SW5 and the lever.

Refer to the wiring diagram and verify that all connections (J103 of

3

the DC controller PCB and SW5) are firmly seated.

Verify that both the front upper and middle drawers are firmly closed;

4

closing these drawers also closes SW4.

Close top cover

SW2 indicates if the printer’s toner cartr i dge access door is closed.

When the toner cartridge door is closed a lever is pushed down. This in

turn rotates a pivot forward, opening the top cover switch (SW2).

Close the top cover.

1

If the message persists, remove the printer’s top cover and verify all

2

mechanical linkages associated with SW2.

Verify that the connector on J1003 of the DC controller PCB is firmly

3

seated.

1

EN

Control panel messages

7

Page 14

Close upper front drawer

The drawer that holds the imagi ng drum is open. Swi tch SW3 i ndicates

that the drawer is open. When the drawer is closed a plastic protrusion

on the lower left corner of the drawer pivots an arm that allows SW3 to

toggle to the open position.

Note

Closing the drawer also closes SW4 (the front dr a wer s witch). Whe n

SW4 is open +24B Vdc is disabled. This safety feature protects the

operator from any high voltages when the upper or middle front

drawers are open.

1 Open the drawer and firmly push the drawer closed using one hand

in the middle of the drawer.

2 If the message persists, remove the printer’s left-side cover and

inspect the mechanical linkage that closes SW3.

3 Refer to the wiring diagram (chapter 10) and verify the wiring; the

two-wire connector should be firmly seated to SW3 and the wiring

harness should be firmly seated to connector J1003 of the DC

controller PCB.

4 If message persists, use an ohmmeter to verify the functionality of

SW3.

Cold reset

The cold reset power-up sequence has been entered.

• Most printer variables will reset to their factory default values.

8 Chapter 1 Troubleshooting control panel messages

EN

Page 15

Continuous page, press cancel job

The printer configuration page is being printed continuously.

• Press

C

ANCEL JOB

printing and return the printer to the

to terminate continuous configuration page

state.

READY

1

Density sensor out of range

alternates with

Clean density sensor

A density sensor out of range error was detected during a color

calibration.

• The density sensor may be dirty. Inspect and clean the sensor. See

“Cleaning the toner density sensor” in the service manual.

Data received

The printer has received and processed data and is waiting for a form

feed.

• Load the appropriate media to continue the print job.

Diagnostics mode

The extended diagnostics power-up key sequence has been entered.

Refer to the diagnostics procedures provided in the service manual.

• No action is required.

Drum error replace drum kit

An error has been detected with a component of the print drum kit.

• Replace the print drum kit.

EN

Control panel messages

9

Page 16

Drum life low replace drum kit

Approximately 80% of the drum’s life has been consumed.

• Drum replacement will be required in the near future.

Drum life out replace drum kit

The imaging drum has reached the end of its expected life.

• Replace the print drum kit.

Duplexer error check duplexer

An error has occurred in the duplex-printing accessory.

• Verify that the duplex-printing accessory is correctly installed and

plugged in.

EIO x initializing yyy

alternates with

Do not power off

The EIO device in slot “x” is initializing. The yyy value will increment

every 10 seconds during this process.

• No action is required.

EIO x not functional

The EIO slot specified does not have a card installed or is not

functional.

• No action is required.

10 Chapter 1 Troubleshooting control panel messages

EN

Page 17

Event log empty

SHOW EVENT LOG

event log has no entries.

• No action is required.

was selected from the Information menu, but the

Fuser life low replace kit

Approximately 95% of the fuser’s life has been consumed.

• Fuser replacement will be required in the near future. Continue

printing, or replace the fuser kit.

Fuser life out replace kit

The fuser has reached the end of its expected life.

• Replace the fuser kit.

Install drum kit

The drum kit is not installed or is incorrectly installed.

• Verify that the drum kit is correctly installed.

Install Tray 2

The printer cannot print until media is loaded into Tray 2. The paper

path for Tray 3 passes through Tray 2.

• Insert T ray 2 into the printer so that printing from Tray 3 can begin or

continue.

1

EN

Control panel messages

11

Page 18

Memory full stored data lost

The printer has no available memory. The current job may not print

correctly. Some downloaded fonts may have been deleted.

• Try printing simplified pages. If this does not resolve the problem,

add printer memory.

Memory settings changed

The I/O buffering settings w ere ch anged by the printer because there is

not enough memory available to use the previous settings.

• No action is required. However, adding printer memory can prevent

this from occurring.

Memory shortage job cleared

The available memory was not enough to continue printing. The

remainder of the job was canceled.

• Adding printer memory can prevent this from occurring.

Memory shortage page simplified

The printer’s adaptive data compression had to resort to lossy

compression to fit raster graphics in the available memory. This has

caused a data loss in the raster output.

• Reduce the complexity of the page to improve the print quality.

Note

Adding memory will not correct this problem.

12 Chapter 1 Troubleshooting control panel messages

EN

Page 19

No job to cancel

C

ANCEL JOB

cancel. The printer automatically returns to the

• No action is required.

was pressed but there is no active job or buffered data to

READY

state.

1

Page cannot print now

alternates with

Retry when printing stops

An internal page has been requested while the printer is printing an

incoming job. Interrupting the job to print the internal page would

corrupt the job’s environment and potentially cause the job to finish

printing incorrectly after the internal page is completed. Consequently,

internal pages are not permitted to interrupt jobs and can only be

printed when the printer is idle.

• Retry print job after printer has completed current job.

Page simplified

The printer’s adaptive data compression had to resort to lossy

compression to fit raster graphics in the available memory. This has

caused a data loss in the raster output.

• Reduce the complexity of the page to improve the print quality.

Note

Adding memory will not correct this problem.

EN

Control panel messages

13

Page 20

Page too complex to print

alternates with

Press Go to continue

The page could not be printed.

Note

Reducing the complexity of the page could allow it to print

successfully. Adding memory will not correct this problem.

• Press GO to continue printing the current page (with noticeably poor

results on this page).

• Press C

ANCEL JOB

to terminate the entire job.

Press Go to print

alternates with

Press Select to change toner

The top cover was opened and closed when the printer was not in the

toner cartridge replacement mode.

• Press G

replacement menu.

to resume printing or press S

O

to enter the toner

ELECT

Printer language not available

The printer received a request for a new language (personality) that

does not exist in the printer.

• No action is required.

14 Chapter 1 Troubleshooting control panel messages

EN

Page 21

Reinstall transfer belt

This message occurs if you do not have the intermediate transfer belt

installed in the printer or if the home positions (marks on the ITB) are

not detected by sensor PS5.

Note

The intermediate transfer belt must be rotating before PS5 is able to

detect the “home position” marks on the ITB. Both the ITB and the

imaging drum are driven by the drum motor (M4).

Check SW1 for correct operation and make sure the cables are

1

connected.

Verify that the ITB is installed in the printer.

2

If the ITB is installed and seated properly, verify that PS5 is not

3

damaged. PS5 is located on the ITB assembly. If the sensor

appears damaged, replace the entire ITB assembly.

Clean PS5.

4

Verify all wiring within the ITB drawer. Note the connection on the

5

ITB assembly (located on the front, lower, left-hand corner of the

assembly). When the drawer is closed the connector “mates” with a

receptacle connector on the drawer. V erify that the connector and al l

wiring are in good condition.

Verify that the drum motor (M4) is rotating both the imaging drum

6

and the ITB. If necessary use a light felt marker and identify a spot

(outside the imaging area) on the edge of the imagin g drum. Turn on

the printer, then open the drawer to see if the mark has moved.

If the imaging drum is not rotating, verify that the imaging drum

7

connector is firmly seated into the J204 connector of the developing

PCB.

1

EN

Control panel messages

15

Page 22

Remove paper top output bin

The top output bin holds 200 sheets of paper . Sensor PS9 along with its

sensor flag detects the height of the output paper stack.

1 Verify that PS9 moves freely and its movement is not blocked.

2 Verify that PS9 is free of dust and debris (the printer’s top cover

must be removed to access the sensor).

3 Verify that all connectors are firmly seated. Refer to the wiring

diagram in chapter 10.

Note

For more information, see the service manual for the printer.

Resetting memory

The printer is executing a memory reset. The printer returns to the

READY

state upon completion of this process.

• No action is required.

Resetting values finished

The color calibration density values have been reset to their default

values.

• No action is required.

Select language

The language selection power-up k e y sequence h as been entere d. The

printer will prompt the user to select a new control panel display

language once it has completed its initialization process.

• Select a new language when prompted.

16 Chapter 1 Troubleshooting control panel messages

EN

Page 23

Service mode

The service mode powerup key sequence has been entered. The

printer will remain in service mode until

• Press

to exit the service mode.

G

O

is pressed.

G

O

Toner CMYK low

The toner cartridge specified is low on toner.

• Printing will continue until a

change the toner cartridge now, press

TONER OUT

message appears. To

.

S

ELECT

1

Toner CMYK low

alternates with

Press Select to change toner

The toner cartridge specified is low on toner and must be replaced.

• Press

Toner CMYK out

to enter the toner replacement menu.

S

ELECT

alternates with

Press Select to change toner

The toner cartridge specified is out of toner.

• If the

TONER OUT

OVERRIDE

• Press

EN

S

ELECT

resume printing without changing the cartridge.

setting in the Configuration menu is set to

, press

to resume printing.

G

O

to enter the toner replacement menu. Press

Control panel messages

G

O

to

17

Page 24

Toner position [color] = [state]

Indicates the current state of a particular toner cartridge. This message

is displayed when S

is displayed.

• If necessary, replace the specified toner cartridge.

is pressed while a

ELECT

TONER LOW/OUT

message

Transfer kit low replace kit

The transfer kit is near the end of its expected life.

• Although printing can continue, the transfer kit should be replaced

for optimum printer operation.

Transfer kit out replace kit

The transfer kit has reached the end of its expected life.

• Replace the transfer kit.

Tray x empty [type] [size]

The specified tray is empty b ut the cu rrent job doe s not requ ire this tr ay

to complete the job.

• No action is required. However, to avoid this message in the future,

load the proper media type and size into the tray.

Tray x load [type] [size]

The specified media type and size need to be loa ded into the requested

tray.

• Load the specified media type and size into the requested tray.

Press G

on different media.

18 Chapter 1 Troubleshooting control panel messages

to override this request and cause the page to be printed

O

EN

Page 25

Tray x size [size]

Media has been loaded into Tray 1. The most recently configured size

will be displayed with an asterisk next to it.

• Use

V

• Press

and

+

ALUE

for the currently displayed size. Press

S

ELECT

to view all possible sizes.

V

-

ALUE

to clear the

G

O

message.

Tray x type [type]

Media has been loaded into Tray 1. The most recently configured type

will be displayed with an asterisk next to it.

• Use

V

• Press

and

+

ALUE

for the currently displayed type. Press

S

ELECT

to view all possible sizes.

V

-

ALUE

to clear the

G

O

message.

Waste toner full replace drum kit

Waste toner full sensor PS13 detects a waste toner full condition. Light

receiver and light pipe arrangement along with a window in the drum

assembly look for a waste fill condition. Verify that the sensors and light

pipes are not blocked.

Replace the drum kit.

1

Check the sensor, and if it is defective, replace it.

2

1

EN

Control panel messages

19

Page 26

Numerical messages

13.xx Paper jam

xx = Description:

0 = Jam in input feed area

1 = Jam in fusing area

2 = Jam in fusing area

3 = Jam in duplex reversing unit

4 = Jam in duplex feed unit

5 = Jam in duplex paper feed area

6 = Jam in duplex paper feed area

7 = Jam in paper feed area

8 = Door open jam

9 = Irregular paper jam in paper path

10 = Paper in the paper path is too short

11 = Paper in the paper path is too long

13.xx Paper jam

alternates with

Check all rear door

Media is jammed in the rear paper path or rear duplexing area.

1 Open the rear duplex cover (if installed) and remove any jammed

media.

2 Open the upper rear door and remove any jammed media.

13.xx Paper jam

alternates with

Check middle front doors

Media is jammed in the transfer belt area or media is not picking.

• Open the middle front drawer and remove any jammed media.

• Watch the pick roller to ensure it is turning.

20 Chapter 1 Troubleshooting control panel messages

EN

Page 27

13.xx Paper jam

alternates with

Check front duplex drawer

Media is jammed in the front duplexing area.

• Open the front duplex drawer and remove any jammed media.

1

13.1 Paper jam

alternates with

Check in rear of drawer

A jam has occurred inside the middle front drawer area.

• Open the middle front drawer and carefully inspect for and remove

any jammed media.

13.1 Paper jam open middle front drawer

with

Check in rear of drawer

A jam has occurred inside the middle front drawer area. The jam may

be located in the fuser area or between the transfer area and the fuser.

Open the middle front drawer and carefully inspect for any media.

1

Be sure to inspect the fusing area. You may need to access the

2

fusing area through the rear door.

Remove any jammed media.

3

20 Insufficient memory

alternates with

alternates

Press Go to continue

More data has been received from the computer than fits in the printer’s

internal memory.

To continue printing, press

1

the printer’s internal memory is printed.

To cancel the job, press

2

Add more memory to resolve the problem.

3

. Only the amount of data that fits in

G

O

C

ANCEL JOB

.

EN

Control panel messages

21

Page 28

22 EIO x buffer overflow

alternates with

Press Go to continue

The EIO buffer for the EIO card in slot “x” has overflowed du ring a b usy

state.

• The current data in the print buffer will be lost.

• Press GO to resume printing and then resend the job.

22 Parallel IO buffer overflow

alternates with

Press Go to continue

This message indicates that the parallel buffer has overflowed.

• The current data in the print buffer will be lost.

• Press G

40 EIO x data error

to resume printing and then resend the job.

O

alternates with

Press Go to continue

A connection with the card in the specified slot has been broken.

1 Check that all cables are connected to the EIO ports and that the

EIO board is seated properly.

2 If possible, print to another network printer to verify that the network

is working properly.

Note

All data in the print buffer will be lost.

41.3 Unexpected paper size

alternates with

Check paper in Tray x

A tray is configured for a specific paper size, but the sheet loaded is a

different size. This error often occurs when the printer is multifeeding.

• Load the tray with the requested size media.

22 Chapter 1 Troubleshooting control panel messages

EN

Page 29

41.5 Unexpected paper type

alternates with

Check paper in Tray x

A tray is configured for a specific media type, but the printer detects that

a different media type is loaded. The most common cause for this error

is a paper jam at the registration plate (under the ITB) where the

customer does not remove the paper. The engine tries to check the

OHT sensor and receives an error.

Verify that the correct media is loaded in the input tray and that the

1

printer control panel is configured correctly.

Clean the detection windows of OHT sensors 1 and 2.

2

49 Error xxxx cycle power

This message indicates that a critical firmware error has occurred. An

invalid command or data was sent to the formatter causing the

processor to stop. This is the last action taken by the processor. The

most likely cause of this error is invalid data or a bad command sent to

the printer. A poor quality parallel cable, connection, or homegrown

application has been known to cause this error.

Verify that all cables are connected.

1

Turn the printer off and on to reset the printer.

2

Cancel all print jobs then resend. Try to isolate any offending print

3

job.

If the formatter pan assembly or DC controller was removed, make

4

sure the ribbon cable between the DC controller and the

interconnect PCB is connected.

1

EN

Control panel messages

23

Page 30

50.x Fuser error

The fusing assembly contains two heating bulbs, two thermo-switches,

and two thermistors. AC power is provided to the fusing assembly via

the DC power supply, which is controlled by the DC controller PCB. The

thermistors monitor the temperature of the fusing assembly and provide

feedback to the DC controller PCB to regulate the fusing temperature.

The two thermo-switches are wired in series with the fusing b ulbs . The y

“open” if the temperature exceeds 240° C (464° F).

x = Description:

1 = Low temperature error

2 = Fuser warm-up service

3 = High fuser temperature

4 = Faulty fuser

5 = Fuser voltage mismatch (verify that you have NOT installed a

110V fuser in a 220V printer or vice-versa)

6 = Fuser heater cutoff

7 = Fuser motor malfunction (see recommended action for 50.7

Fuser error).

Note

A visual check to determine if the fusing assembly is functional can

be made by defeating the rear door interlock switch. To do so, press

in on the white plastic button abo ve the left-rear corner of the fan while

turning the printer on. If the fusing bulbs and thermoswitches are

good, you should observe light from the lower fusing bulb as the

printer warms up.

1 Turn the printer off and on to reset the printer. If the error persists,

try re-installing the fusing assembly. If the error continues to persist,

proceed to step 2.

24 Chapter 1 Troubleshooting control panel messages

EN

Page 31

Turn the power off and remove the fusing assembly. Measure the

2

resistance between pin 3 and pin 4. The resistance should be

between 6+/-2 ohms. If there is no contin uity between pin s, it ma y be

assumed that either a heating bulb and/or a th ermo-switch is “open.”

Replace the fusing assembly. If resistance limits were acceptable,

proceed to step 3.

Measure the resistance for both the upper and lower thermistors.

3

The resistance should be between 430K ohms and 310K ohms at

room temperature (25° C or 77° F). If the resistance exceeds limits,

replace the fusing assembly. If resistance is within limits proceed to

step 4.

V erify, that the connectors at J1011 of the DC controller PCB and J1

4

of the low-voltage power supply assembly are firmly seated.

Replace the power supply assembly.

5

1

EN

Control panel messages

25

Page 32

50.7 Fuser error

The fusing motor (M1) provides drive for the fusing assembly, the “web”

paper transfer belt, transfer belt/drum contact clutch, secondary transfer

roller, roller clutch, face-down output delivery, and the stacker rollers. A

50.7 fuser error is displayed when no motion is detected. Photosensor

PS6 (the fusing unit pressure switch) provides feedback regarding

fusing unit motion.

1 Power cycle the printer to try to clear the message.

2 Remov e the left-side co v er of the printer . Verify that the fusing motor

(M1) connector is seated firmly into J102 of the feed PCB.

3 Ensure connector at J110 of the feed PCB is firmly seated (this

connector contains the wiring for PS6 which provides fuser motion

feedback).

Note

Closely inspect the gears along the gear drive path. Mak e sure there

is no binding. Binding of the gears may prevent M1 from rotating.

4 If the error persists, observe the drive shaft of M1. If this shaft DOES

NOT rotate, the failure is related to the motor drive circuitry.

Referring to the printer’s wiring diagram, verify that connectors J102

and J106 of the feed PCB are firmly seated. If there still is an error,

replace the fusing motor and then feed PCB in sequence.

5 If the shaft rotates (both forward and reverse), and the 50.7 fuser

error is displayed, the cause of the error is related to the motion

feedback circuitry. Remove the fusing assembly and verify that the

sensor flag is in good condition and functional. Verify that the

connector at sensor PS6 is firmly seated; clean the sensor of dust

and debris. If the error persists, replace sensor PS6.

26 Chapter 1 Troubleshooting control panel messages

EN

Page 33

51 Laser error

This message indicates that a laser malfunction has occurred due to a

beam detect error or laser failure.

Turn the printer off and on to reset the printer.

1

Reconnect laser driver PCB connector J1102 and the DC controller

2

PCB connector J1008 correctly.

Replace the laser scanner unit.

3

Reconnect BD PCB connector J551 and the DC controller PCB

4

connector J1006 correctly.

52 Scanner error

This message indicates that a scanner error has occurred.

Turn the printer off and on to reset the printer.

1

Reconnect the BD PCB connector J551, the scanner motor

2

connector J1103, and the DC controller PCB connector J1006

correctly.

Replace the laser scanner unit.

3

1

EN

Control panel messages

27

Page 34

53.xy.zz Printer error

This message indicates a memory error. If a DIMM caused the error,

the DIMM will not be recognized (configured).

x = Memory Type

0 = ROM

1 = RAM

y = Device Location

0 = Onboard

1 = DIMM slot 1

2 = DIMM slot 2

3 = DIMM slot 3

zz = Error Number

0 = Unsupported memory

1 = Unrecognized memory

3 = Failed RAM test

1 Verify that the DIMM board is installed correctly and the DIMMs are

configured correctly. DIMMs must be installed in synchronous pairs

in adjacent slots, with the same size and speed in both slots.

2 Turn the printer off and on to reset the printer.

3 Remove and replace the DIMM that caused the error.

54.1 Printer error control panel messages

This message indicates that an internal power failure has occurred.

1 Turn the printer off, and then turn the printer on.

2 Replace the high-voltage power supply

28 Chapter 1 Troubleshooting control panel messages

EN

Page 35

54.2 Printer error control panel messages

Drive motor (M3) drives the toner cartridge carousel. If motion is not

detected, a 54.2 error is displayed. M3 is a 6-phase stepping motor and

receives its drive signal from J203 o f the De v elopi ng PCB . Photosensor

PS10 monitors “movement” (and the position) of the toner cartridge

carousel. Different width tabs (four tabs, one for each cartridge) on the

left end of the carousel-housing pass through PS10 to provide

positioning information. The black toner cartridge tab is the “home”

position.

Turn the printer off and then on to reset the printer.

1

Note

The printer CANNOT operate with the top co v er re mov e d unless the

carousel brake has been released or removed!

Open the color toner door and look for an obstruction. If necessary,

2

remove the toner cartridges individually by manually releasing the

carousel brake and rotating the carousel to each cartridge position

to remove the cartridges. Turn the printer off and on to reset the

printer.

Verify that the carousel drive motor wiring harness is firmly seated

3

into connector J203 of the developing PCB.

Verify that PS10 is not e xcessively dirty (clean if necessary) and that

4

the wiring harness is firmly seated into both the sensor assembly,

and into connector J206 of the developing PCB.

Verify that all connectors to the developing PCB and the DC

5

controller PCB are firmly seated.

1

EN

Control panel messages

29

Page 36

54.3 Printer error

The printer is NOT receiving data back from the density sensor (PS14).

PS14 is located in the bottom of the imaging drum drawer. During

calibration routines, a series of images are written on the imaging drum

and the densitometer measures the density of the image (i.e. the

amount of toner that is placed into the drum). These measurements

provide the feedback to ensure image quality is consistent throughout

the life of the consumable.

1 Verify that the densitometer is clean; perform the toner density

sensor cleaning procedure provided in the online user guide that

came with the printer.

2 Inspect the density sensor wiring harness for damage. The harness

runs from the density sensor through the left-side upper control arm

of the imaging drum drawer to J1010 of the DC controller PCB.

Verify that the cable is firmly seated into the J1010 of the DC

controller PCB.

3 If the error persists, replace the density sensor assembly.

54.4 Printer error

Optional equipment is not recognized.

• Turn the printer off and on to reset the printer.

30 Chapter 1 Troubleshooting control panel messages

EN

Page 37

54.5 Printer error

This message indicates a waste toner sensor malfunction.

Turn the printer off and on to reset the printer.

1

Remove the drum cartridge and clean the waste toner detection

2

window with a dry cloth.

Clean the waste toner sensor unit at the printer side with a dry cloth.

3

Re-set the light guide, or replace it if scarred or damaged.

4

Reconnect the waste toner sensor unit connector and the DC

5

controller PCB connector (J1009) correctly.

Replace the waste toner sensor (PS13).

6

54.6 Printer error

The print OHT sensor has malfunctioned.

Remove stray paper from sensor.

1

Check the connection.

2

Replace the sensor.

3

55 DC controller error

The print engine is not communicating with the formatter.

• Turn the printer off and on to reset the printer.

1

EN

Control panel messages

31

Page 38

57.1 Fan failure

The printer detected that the fan (an exhaust fan located in the upper,

left-rear corner of the printer) was not rotating. This fan operates off

+24 Vdc and is enabled by the DC controller PCB’s microprocessor.

1 Turn the printer off and on to reset the printer. Visually check to see

if the fan is rotating. (If you cann ot see any ro tation, place y ou r hand

over the outlet vents to see if exhaust air is moving).

2 Remove the printer’s left-side cover. Check to see if anything is

preventing the fan from rotating freely.

3 Verify that the fan’s connector is firmly seated into connector J208 of

the developing PCB.

4 If the error persists, replace the fan.

57.2 Fan failure

The printer detected that the fan (an exhaust fan located in the upper,

right rear corner of the printer) was not rotating. This fan operates off

+24 Vdc and is enabled by the DC controller PCB’s microprocessor.

1 Turn the printer off and on to reset the printer. Visually check to see

if the fan is rotating (if you cannot see any rotation, place your hand

over the outlet vents to see if exhaust air is moving).

2 Remove the printer’s left-side cover. Check to see if anything is

preventing the fan from rotating freely.

3 Verify that the fan’s connector is firmly seated into connector J209 of

the developing PCB.

4 If the error persists, replace the fan.

32 Chapter 1 Troubleshooting control panel messages

EN

Page 39

57.3 Fan error

alternates with

Close upper front drawer

The intake fan is located in the front center of the upper-front drawer.

Fan rotation stops when the drawer is opened. A fan error is displayed

when fan motion is

if the drawer is closed and the printer is not in PowerSave mode.

Turn the printer off and on to reset the printer. Due to the difficulty of

1

observation, listen to hear if the fan is rotating.

Verify that the fan connector is firmly seated into connector J1022 of

2

the DC controller PCB.

If the error persists, replace the fan.

3

detected by the DC controllers microprocessor

NOT

62 No system

This message indicates that there is a printer firmware problem.

Turn the printer off and on to reset the printer.

1

Reseat the firmware DIMM.

2

62.x Printer error

This message indicates that a problem exists with the internal memory.

x = Description

0 = Internal memory

1-3 = DIMM slots 1-3.

Turn the printer off and on to reset the printer.

1

Reseat and then replace the DIMM.

2

Replace the formatter board.

3

Do a NVRAM initialization. See “NVRAM initialization instructions”

4

on page 57.

1

EN

Control panel messages

33

Page 40

62.m Bad MPTR

The firmware ran out of memory trying to build the static entity directory.

1 Check the printer settings to determine which values have been

changed.

2 Clear the message by pressing G

.

O

68 NVRAM error check settings

One or more settings saved in the non-volatile storage device are

invalid. Some settings may have been reset to factory defaults.

1 Check the printer settings to determine which values have been

changed.

2 Clear the message by pressing G

.

O

68 NVRAM full check settings

This message indicates that a non-volatile storage device is full. Some

settings may have been reset to factory defaults.

1 Check the printer settings to determine which values have been

changed.

2 Clear the message by pressing G

.

O

34 Chapter 1 Troubleshooting control panel messages

EN

Page 41

79 Service (xxxx) printer error

A hardware error has occurred.

x = Description

01xx = IO ASIC register error

02xx = video ASIC register error

03xx = IDE ASIC register error

Reseat the formatter.

1

Reseat the firmware DIMM.

2

Run formatter diagnostics.

3

Replace the firmware DIMM.

4

Replace the formatter.

5

Do a NVRAM initialization. See “NVRAM initialization instructions”

6

on page 57.

80 Service (xxxx) EIO error

A critical EIO failure has occurred. X indicates the slot number of the

device and xxxx indicates the error type.

Turn the printer off and on to reset the printer.

1

Reseat the EIO card.

2

Replace the EIO card.

3

1

EN

Control panel messages

35

Page 42

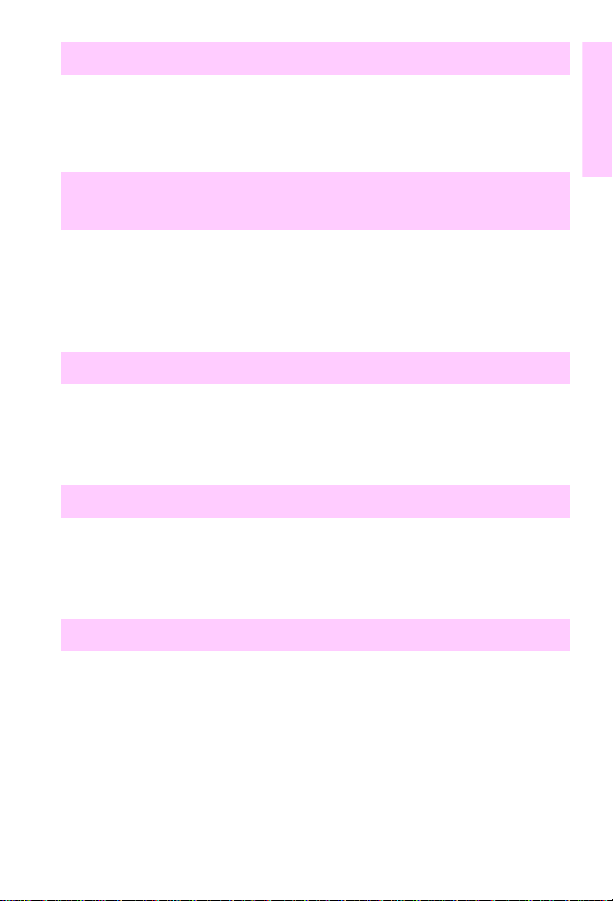

Troubleshooting paper path problems

Paper jams

Paper jams are posted if paper fails to arrive at or clear the paper path

sensors in the allowed time. Dedicated paper sensors (PS2, PS7,

PS3101, PS3103, and PS3104) detect whether paper is present in the

sensor and if the paper is fed normally (see the figure be low). When th e

control board detects a paper jam, it immediately stops the printing

process and displays the appropriate paper jam message for the sensor

that detects the paper jam.

5

1

4

2

3

Paper jam sensors (shown with the optional 500-sheet paper feeder

and duplex-printing accessory installed)

Registration paper sensor (PS2)

1

Duplex paper-pick sensor (PS3104)

2

Reversed unit pape r se nsor (PS3103)5Delivery paper sensor (PS7)

3

36 Chapter 1 Troubleshooting control panel messages

Reversed paper sensor

4

(PS3101)

EN

Page 43

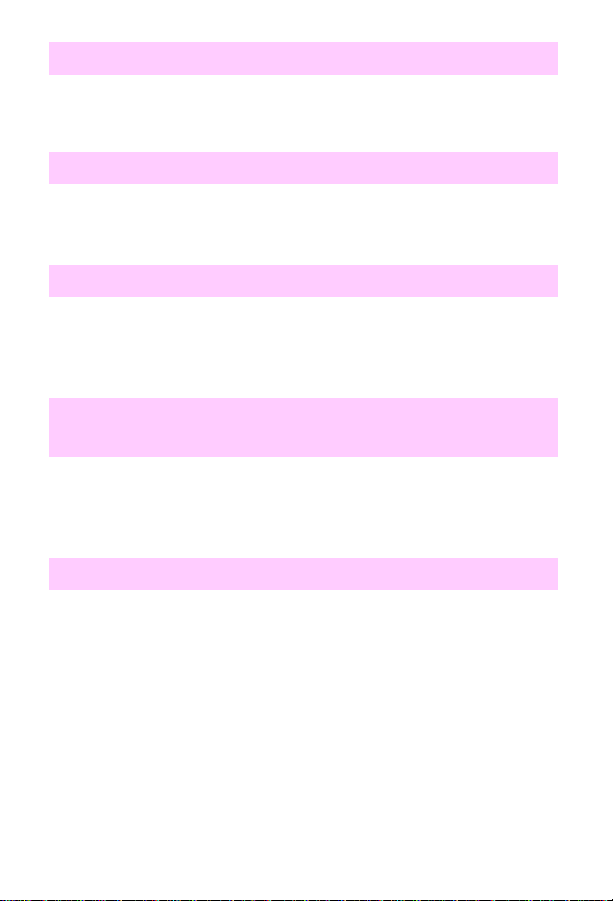

Paper jam locations

Use the figure below to troubleshoot paper jams in the printer. For

instructions on clearing paper jams, see the sections later in this

chapter.

8

1

1

7

6

Paper jam locations

and duplex-printing accessory installed)

Input tray 1 area

1

Transfer belt area

2

Input tray 2 area

3

Front duplex drawer area

4

EN

(shown with the optional 500-sheet paper feeder

5

6

7

8

Troubleshooting paper path problems

2

3

4

5

Tray 3 (500-sheet paper feeder) area

Rear duplex cover area

Fuser area

Rear paper path area

37

Page 44

General paper path checklist

• Verify that media is correctly loaded in the input trays and that all

length and width guides are set correctly.

• Clean the printer. Toner and paper dust in the paper path inhibits

free movement of media through the printer and blocks the sensors.

• Vary the input and output selecti ons of the printer to determine if the

problem is associated with a particular area of the printer.

• Worn separation pads on the multi-purpose tray cause multifeeds.

Check the condition of the pickup rollers and customer replaceable

feed roller. Bent separation tabs cause misfeeds and multifeeds.

Replace the tray if necessary.

• Defective paper tray switches can cause paper jams by indicating

the wrong size paper to the formatter.

• Scraps of paper left in the paper path can cause intermittent paper

jams. Always check that the paper path is clear when cleaning the

printer and when clearing paper jams. Also, remove the fuser and

carefully check it for jammed paper.

• Scraps of paper may be difficult to find in the following areas.

• The ITB drawer connector on the engine side.

• The OHT sensor under the registration plate.

• The fuser. Remove the fuser and check it carefully.

• The web transport. Paper scrapes are sometimes found in the

center of the web transport before the fuser.

38 Chapter 1 Troubleshooting control panel messages

EN

Page 45

Print media checklist

Many print problems are caused by printing on media that does not

meet specifications. See “Supported media weights and sizes” on

page 72 and th e

for detailed information about media specifications. In addition, the

following list helps to quickly check common media-related printing

problems.

• Rough paper causes poor transfer and smeared print problems.

Check that the paper meets specifications for smoothness.

• The printer handles only 60 to 159g/m

media, and 0.13 mm (5-mil) thick transparencies.

• Paper that has absorbed moisture causes paper feed problems. If

the printer is used in a humid area, suspect damp paper as a cause

of recurring paper feed and print quality problems.

• Damaged paper, paper with ragged edges, or paper whose edges

stick together cause paper jams.

• Using paper that has already been through a laser printer or a

copier causes paper jams.

CAUTION

Using media that does not conform to the specifications listed here

or in the

problems that require service. This service is not covered by the

Hewlett-Packard warranty or service agreements.

HP LaserJet Printer Family P aper Specifications Guide

2

(16 to 42-pound) bond

HP LaserJet Family Paper Specification Guide

can cause

1

EN

Troubleshooting paper path problems

39

Page 46

40 Chapter 1 Troubleshooting control panel messages

EN

Page 47

2

Service tools

Overview

This chapter provides information on service tools that service

personnel can use to verify and manipulate i nternal printer settings and

diagnostics.

Note

Only authorized service personnel should use the service mode.

EN

Overview

41

Page 48

Cold Reset

Cold reset clears all data from the print buffer and returns the printing

menu and the configuration menu to the factory default settings.

To perform a cold reset

RESTORE FACTORY DEFAULTS

Select

from the Reset menu.

Service mode

Service mode allows for the modification of page counts and certain

registration values for the printer. When the configuration page is

printed while in service mode, all event log messages are printed as

well. If both the formatter and DC controller are replaced at the same

time, service mode will need to be utilized to execute the color plane

registration sequence to ensure optimum print quality.

To access service mode

1 Hold down the C

printer on until the display is blank and the 3 LEDs are on.

2 Press the right side of the M

Service mode will be displayed on the front panel briefly followed b y

two rows of asterisks. The printer will go through its normal start up

cycle then display

3 Press the M

42 Chapter 2 Service tools

ANCEL JOB

SERVICE MODE

key to access the Service menu.

ENU

key and S

key, and then press the S

ENU

on the front panel.

key while turning the

ELECT

ELECT

key.

EN

Page 49

Service menu

Serial number=

Transfer maint

count=

Fuser maint

count=

Color page

count=

Total page

count=

Cold reset

paper=

Clear event

log

Cyan

registration=

Magenta

registration=

Yellow

registration=

Top margin=

Tray 1

left margin=

Trays 2 and 3

left margin=*

Print registr’tn

page tray=

g

2

et

Service mode menu map

EN

Service mode

43

Page 50

Service menu items

The Service menu provides the options listed below. Press the

key to scroll through the Service menu.

I

TEM

• Serial number

• Transfer maintenance count

• Fuser maintenance count

• Color page count

• Total page count

• Clear event log (see page 70)

• Registration page (see page 45)

• Diagnostics mode (see page 49)

• Paper path test (see page 50)

• Developer test (see page 51)

• Drum test (see page 52)

• Door sensor test (see page 54)

• Formatter diagnostics (see page 55)

• Engine test (see page 56)

See the page number referenced opposite the item for more details.

44 Chapter 2 Service tools

EN

Page 51

Registration page

Note

The setting of the registration values must be done if both the

formatter and DC controller are replaced at the same time. If only one

is replaced, the registration values are copied from the other.

Printing a registration page

Scroll through the Service menu until

1

displayed.

Select the paper tray to pull paper from (only when setting left side

2

margins will the tray actually matter).

3

Press

to print the registration page.

S

ELECT

PRINT REGISTR

’

TN PAGE

is

2

EN

Service mode

45

Page 52

Registration page

46 Chapter 2 Service tools

EN

Page 53

Setting registration numbers

On each of the color bars in the process section are bolded numbers

that indicate the current number set on the control pa nel. These bol ded

numbers will always be in the middle of the bars. To set the correct

value for each of the colors, look at the lines within the bar and find the

grouping that has the color line directly on top of the black line (it will

have more white space). Print at least five registration pages to see if

the new settings are correct.

Note

Using a magnifying glass to look at the lines will help in selecting the

best number.

Setting the registration number:

1

Use the

key to select the appropriate color (Cyan, Magenta, or

I

TEM

Yellow) to view or change its registration number.

Press the

2

V

key to change the registration number to the

+/-

ALUE

one identified.

Press the

3

key to enter the value.

S

ELECT

Setting margin numbers

The top margin number is not tray dependent like the left side margin.

You can print the registration page from whichever tray has paper.

Using a ruler, measure from the top edge of the paper to the series of

lines. Find the line that is 13 mm (0.5 in) away from the edge of the

paper.

Setting the top margin registration value:

Press the

1

margin is displayed.

Press the

2

Press the

3

Print another registration page and the number just entered will align

with the arrow and be bolded.

key to scroll through the Service menu until top

I

TEM

M

S

key until the number to be entered is displayed.

+/-

ENU

key to enter the number.

ELECT

2

EN

Service mode

47

Page 54

The left-side margin setting is tray dependent. Tray 1 has its own

number while Trays 2 and 3 are combined. The procedure is the same

as the top margin with one exception. The page must be printed from

the tray that will be adjusted.

Printing from Tray 1:

1 Press the I

TEM

key until

PRINT REGISTR’TN PAGE TRAY = 1

(default) is displayed.

2 Press the S

ELECT

key.

3 Measure from the left side of the paper to the lines and find the line

that is 13 mm (0.5 in) from the edge of the paper.

If the number for the line is different then the current number:

1 Press the I

2 Press the V

3 Press the S

TEM

ALUE

ELECT

key until

TRAY 1 LEFT MARGIN = #

is displayed.

key to change the number to the number required.

key.

Printing from Tray 2 and 3:

1 Press the I

TEM

key until

PRINT REGISTR’TN PAGE TRAY = 2

or 3 is

displayed.

2 Press the S

ELECT

key.

3 Measure from the left side of the paper to the lines and find the line

that is 13 mm (0.5 in) from the edge of the paper.

If the number for the line is different then the current number:

1 Press the I

TEM

key until

TRAY 2 AND 3 LEFT MARGIN = #

is

displayed.

2 Press the V

3 Press the S

key to change the number to the number required.

ALUE

key.

ELECT

48 Chapter 2 Service tools

EN

Page 55

Diagnostics mode

This section provides an overview of the diagnostic tools incorporated

into the HP Color LaserJet 4500/4500 N/4500 DN printer.

CAUTION

When performing printer diagnostics, caution must be taken to avoid

risk of injury. Only trained service personnel should access the

diagnostic mode with the skins removed.

There are two diagnostic sections built into the firmware, one for the

formatter and the other for the engine. Each section contains different

tests that allow the service technician to verify printer functionality.

While in diagnostic mode there are no error messages associated with

these tests. Therefore, determination of the problem will rely on the

technicians skill. To exit diagnostic mode, turn the printer off.

Accessing diagnostics

• T o access the diagnostics mode, hold do wn the

the printer.

Engine diagnostics

A good understanding of how the printer operates is required to use the

engine diagnostics successfully.

To have a better vie w of th e areas be ing exercised, remove the left-si de

cover and the lower front drawer (ITB drawer). Defeat the two ITB

drawer switches located on the left side of the drawer cavity.

key and turn on

I

TEM

2

EN

Diagnostics mode

49

Page 56

Listed below are the diagnostics available and a brief description of

what the diagnostic will do.

Engine diagnostics

Menu item Selectable value Description

Continuous N (default) Selected test runs once.

Y Selected test runs in a

continuous loop.

Paper path test Turns on the motors that

control the paper path

section of the printer.

Developer test Rotates the carousel and

the developers.

Drum test Turns on the drum drive

motor that drives the drum

and ITB.

Path sensors Displays the state for each

of the paper path sensors

and switches.

Door sensors Displays the state for each

of the door and drawer

switches.

Paper path test

Note

If an error occurs during the paper path test, the message

PATH_1PAPER PATH TEST FAILED

1 Press the I

2 Press the S

key until you see

TEM

key to activate the test. While the test is running

ELECT

ENGINE DIAGS E1:PAPERPATH

The test takes approximately 15 seconds to run.

50 Chapter 2 Service tools

displays.

ENGINE DIAGS PAPER PATH TEST

displays in the front panel.

.

EN

Page 57

Components exercised by the paper path test include the fusing motor

(M1), paper path motor (M2), and associated gears and assemblies.

The paper pick roller for tray 2 can be activated by manually activating

the paper pick solenoid (SL2). This test will not pick paper and move it

through the paper path. To test this function, run a configuration page.

For multiple pages, select

control panel.

The paper path test allows the service technician to verify the ope ration

of components within the paper path. When the test is initiated, both M1

and M2 are activated. You will see the ITB lift cams rotate once and the

ITB drive gear turn briefly. The remaining portion of the test allows both

M1and M2 to run, thus exercising the associated gears and rollers.

CONTINUOUS CONFIGURATION PAGE

in the

Developer test

The developer te st rotates the carousel stoppin g at each toner cartridge

and rotating the dev eloper slee v e . F or the best vie w of the caro usel and

the toner cartridge sleeves, remove the drum cartridge. The top front

drawer (drum drawer) must be closed before the test can run.

Press the

1

displayed.

Press the

2

ENGINE DIAGS E2:DEVELOPER

carousel and make sure that the toner cartridge developer sleeve

rotates. The sequence is black followed by a pause, then magenta,

cyan, and finally yellow.

The test takes approximately 35 seconds. While the developer test is

running you will see the drum turn if it is installed, as well as the drive

gear for the ITB.

I

TEM

S

ELECT

key until

ENGINE DIAGS DEVELOPER TEST

key to run the test. The front panel displays

while the test is running. Watch the

is

2

EN

Diagnostics mode

51

Page 58

Drum test

The drum test exercises the drum drive mechanism. In addition, the

fuser motor is turned on to allow the lift cams for the ITB to be rotated

into the ITB up position.

1 Press the I

2 Press the S

TEM

ELECT

key until

ENGINE DIAGS E3:DRUM

Watch to see if the ITB lift cams turn and if both the drum drive gear and

the ITB drive gear is rotating

ENGINE DIAGS DRUM TEST

key to run the test. The front panel displays

while the test is running.

displays.

Path sensors

The path sensors test allows the paper path sen sors and s witches to be

tested for correct operation. The table below shows the correlation

between the identifier on the front panel and the sensor or switch it

represents.

Paper path sensors and switches

Identifier Name Description

A PS8 Tray 2 paper detect sensor

B PS3 Tray 1 last piece of media pulled sensor

C PS4 Tray 1 paper detect sensor

D SW801 Tray 2 paper size switch 2

E SW802 Tray 2 paper size switch 1

F SW803 Tray 2 paper size switch 0

G PS3001 Optional Tray 3 paper detect sensor

H SW3001 Optional Tray 3 paper size switch 2

I SW3002 Optional Tray 3 paper size switch 1

J SW3003 Optional Tray 3 paper size switch 0

K PS10 Carousel position sensor

52 Chapter 2 Service tools

EN

Page 59

Paper path sensors and switches (continued)

Identifier Name Description

L PS11 N/A

M N/A 500-sheet feeder: 1=installed, 0=uninstalled

N PS9 Top output tray full sensor

Press the

1

on the front panel.

Press the

2

A through N with a binary value below it.

When running this test, make sure the ITB drawer is installed with Tray

2 and Tray 3 (if installed) removed. In this state, the default value on the

front panel should be: 0X111111110010, where the x ca n be either 0 or

. If there is any other value, then there is a possible problem. Identify

1

the sensor or switch in the table above and test to see if the value

changes. Cassette paper-size settings f or each tra y are described in the

table below.

I

TEM

S

ELECT

key until

ENGINE DIAGS PATH SENSORS

key to activate the test. The front panel will displa y

is displayed

Paper-size settings

Paper Size Tray 2 switches (DEF) Tray 3 switches (HIJ)

A4 000 000

B5 001 001

Custom (A5) 010 011*

Custom (B5 ISO) 011 011*

Letter 100 100

Executive 101 101

Legal 110 110

No tray installed 111 111

2

* These values are the same for tray 3.

EN

Diagnostics mode

53

Page 60

Door sensor test

The door sensor test allows service personnel to open and close doors

on the printer while watching the sensor status on the front panel.

Switches 4 and 5 are in series with each other, which causes the value

to toggle under identifier A.

Once the door sensor test is initiated, the front panel displays the status

for each sensor listed in the table below. As a door is opened and

closed, the state of the sensor changes the indicator v alues on the fr ont

panel.

Sensor status

Identifier Name Description

A SW4 and

SW5

B SW1 * ITB drawer switch

C SW2 * Toner cartridge door *

D SW3 * Drum drawer switch *

E Drum detect Detect if a drum cartridge is installed

F Fuser Detects if fuser is installed. Changes the

* Activates (A) when opened.

1 Press the I

TEM

on the front panel.

2 Press the S

ELECT

The front panel displays A through F with a binary value below it. All the

doors and drawers should be closed. In this state, the display will show

all 0’s. Open the doors and drawers one at a time to verify correct

functionality. If operating correctly, the 0 will change to a 1. If a 1 is

displayed with all doors and drawers closed; there is a bad switch or

connection.

Front and rear door switches

state of the sensor if not detected or removed

when rear door is opened and closed.

key until

ENGINE DIAGS DOOR SENSORS

key to activate the test.

is displayed

54 Chapter 2 Service tools

EN

Page 61

Formatter diagnostics

Formatter diagnostics are designed to be used b y qualified service

personnel. This set of tests are designed to thoroughly test the

functionality of the formatter. If all the tests pass, the formatter is

working correctly and it is likely that the problem resides elsewhere.

Listed below are descriptions of the formatter tests available.

CAUTION

NVRAM can be lost if the printer is turned off during testing.

Formatter diagnostics

Test Description

REPEAT If set to yes, the tests will run continuously until

interrupted

ON FAULT The following will occur for each setting:

BREAK – the test will stop when a failure occurs

PAUSE – stops the test for a short period of time

then resume with the remaining tests

CONT – continues to execute the tests ev en when

a failure occurs

ROM CRC Tests the firmware ROM for correct functionality

DRAM Tests the on-board RAM and the DIMMs

SRAM 1 Tests the SRAM inside the ASIC

SRAM 2 Tests the SRAM physically mounted on the

formatter

NVRAM Tests the formatter NVRAM. This test takes 15

minutes to run and should only be used when

NVRAM values are being lost. In almost all cases,

this test should never be run

EXECUTE TESTS Runs the selected tests

2

EN

Diagnostics mode

55

Page 62

Engine test

The printer has one test pattern (vertical lines). When an image defect

appears, a test print can be made to identify the problem. The test print

can be made by pressing the test print switch located on the right side

of the printer (see figure below). A test pattern can be printed by

pressing the test print switch once after the photosensitive drum has

stopped and the printer has entered the standby mode. If the switch is

held down, the test pattern is printed continuously. The switch can be

used when paper is loaded in any tray other than Tray 1.

The engine test does the following:

• Verifies that the print engine is functioning correctly (the fo rmatter

PCB is completely bypassed during an engine test).

• Isolates printer problems.

• Checks and adjusts registration.

• Prints from Tray 2 or 3 only, not from Tray 1.

• Can be activated with the formatter PCB removed.

Note

For the printer to perform an engine test, Tray 2 or Tray 3 must be

installed and loaded with paper, and the toner cartridges must be

installed in the printer.

Engine test button

Location of the engine test button

56 Chapter 2 Service tools

EN

Page 63

NVRAM initialization

NVRAM initialization should always be executed after replacing

firmware or the formatter board.

NVRAM initialization instructions

Before replacing the firmware, formatter board, or performing an

NVRAM initialization be sure to gather and write down the information

listed below.

• serial number

• total page count and color page count

– Print a configuration page to obtain both page counts and the

serial number.

• percentage of life remaining for both the transfer kit and the fuser kit

From

1

2

3

4

SERVICE MODE

Go to

SERVICE MENU

Use the

V

COUNT=XXXXXXX

Go to

FUSER MAINT COUNT=XXXXXXX

numbers shown.

keys to go to

+/-

ALUE

and write down the exact numbers shown.

NVRAM initialization

Hold down both the

1

lights are on, then release the keys.

Press

2

3

Press

C

ANCEL JOB

S

ELECT

.

C

ANCEL JOB

.

on the printer display panel, press

and press

I

TEM

.

TRANSFER MAINT

and write down the exact

and

keys until all the LED

S

ELECT

.

M

ENU

2

NVRAM initialization results

• Loss of color page count (defaults to 0).

• Loss of transfer kit percentage of life remaining (defaults to 100%).

• Loss of fuser kit percentage of life remaining (defaults to 100%).

• Loss of printer serial number.

EN

NVRAM initialization

57

Page 64

Firmware replacement results

Note

NVRAM initialization should always be executed after replacing

firmware. See “NVRAM initialization instructions” on page 57.

• Loss of color page count (defaults to 0).

• Loss of transfer kit percentage of life remaining (defaults to 100%).

• Loss of fuser kit percentage of life remaining (defaults to 100%).

• Loss of printer serial number.

• If a NVRAM initialization is not executed when firmware is replaced,

incorrect printer functionality may result.

• An NVRAM initialization aligns the firmware with the formatter.

Formatter replacement results

Note

NVRAM initialization should always be executed the first time the

printer is turned on after replacing the formatter. See “NVRAM

initialization instructions” on page 57.

• Loss of both color and total page counts. If not done correctly the

default is reset to 0.

– NVRAM initialization results in a correct total page count.

– If an NVRAM initial ization is not done the total page co unt on the

new formatter board (usually 0) is written to the engine. This

results in an incorrect page count.

• Loss of transfer kit percentage of life remaining (defaults to 100%).

• Loss of fuser kit percentage of life remaining (defaults to 100%).

• Loss of printer serial number.

• If a NVRAM initialization is not executed when formatter is replaced,

incorrect printer functionality may result.

• An NVRAM initialization aligns the firmware with the formatter.

58 Chapter 2 Service tools

EN

Page 65

3

Overview

Three power supplies are used to po we r v arious sections o f the printer:

AC, DC, and a high-voltage power supply. This chapter details the

distribution of these power supplies.

Power supply

EN

Overview

59

Page 66

AC/DC power supply

The low-voltage power supply circuit supplies +24 Vdc and +5 Vdc

required for the printer and 3.3 and 5 Vdc required for the video

controller.

+24 Vdc

• The paper pickup motor, scanner motor, and high-voltage power

supply PCB use +24 Vdc.

• The front door switch or the rear door switch is deactivated by

opening the drum cartridge drawer, ITB unit drawer, toner cartridge

door, or delivery door. These switches are in series and disable the

24 Vdc when open.

+5 Vdc

• The sensors and the ICs on the DC controller PCB use +5 Vdc.

• The low-voltage power supply circuit monitors the 5 VS (volt signal)

fed back from the connector PCB to e nsure the 5 V power supply to

the formatter.

+3.3 Vdc

• Formatter PCA

• DIMM

• EIO PCA

60 Chapter 3 Power supply

EN

Page 67

Overcurrent overvoltage protection

Each DC power supply circuit has an overcurrent protective function

and overvoltage protective function. This prevents a power supply

circuit failure by automatically interrupting the output voltage when

anomalies such as a short develop on the loads that result in

overcurrent flow or abnormal voltage.

Note

Protective functions remain active for 2 minutes after activation. Wait

for at least 2 minutes to turn the power back on again.

If this function is activated and no DC voltage is output from the

low-voltage power supply circuit:

Turn off the power switch (SW6).

1

Unplug the power cord.

2

Resolve the anomaly on the load.

3

Turn the power switch (SW6) on again.

4

3

EN

Overcurrent overvoltage protection

61

Page 68

High-voltage power supply

The printer contains two high-voltage PCBs mounted in one assembly.

Together these PCBs generate the voltage supplied to the following:

• primary charging roller

• developing sleeve

• primary transfer roller

• secondary transfer roller

• ITB cleaning roller

• upper fusing roller

DC voltage or a superimposed AC voltage and DC voltage is applied to

the primary charging roller, developing sleeve, and ITB cleaning roller.

Positive or negative DC voltage is applied to the primary transfer roller

and secondary transfer roller. Negative DC voltage is applied to the

upper fusing roller.

Protection systems

Problems on the load side, such as short-circuits, can cause an

excessive flow of current from the DC power supplies or can generate

abnormal voltage. When this happens, the excess-current and

excess-voltage protection systems automatically shut off output voltage

to protect the power supplies.

If the protection systems are activated and the power supply circuit

does not output DC voltage, turn the printer off, correct the problem in

the faulty load, and then turn the printer on again.

62 Chapter 3 Power supply

EN

Page 69

4

Overview

This chapter provides information on cabling and the printer interface.

Input/Output (I/O)

EN

Overview

63

Page 70

Enhanced I/O (EIO) configuration

The 4500 series printers come equipped with two enhanced input/

output (EIO) slots. These slots hold compatible external devices such

as the HP JetDirect 600N Print Server. Plugging EIO cards into the

slots increases the number of network interfaces available to the printer.

EIO cards can maximize printer performance when you are printing

from a network. In addition, they provide the ability to place the printer

anywhere on a network. This eliminates the need to attach the printer

directly to a server or a workstation and enables y ou to p lace the printer

closer to your network users.

The printer control panel will have an additional menu (EIO Menu) if the

printer is configured with EIO cards. (See the chapter on using the

printer control panel in the online user guide.)

Note

Installation of cards and network configuration should be performed

by a network administrator.

HP JetDirect print servers

HP JetDirect print serv ers (network cards) can be installed in one of the

printer EIO slots. These cards support multiple network protocols and

operating systems. HP JetDirect print servers facilitate network

management by allowing you to connect a printer directly to your

network at any location. HP JetDirect print servers also support the

Simple Network Management Protocol (SNMP), which provides