Page 1

HP® cc3300 Carrier Grade Server

Product Guide

Document Release Date: March 2003

Page 2

Disclaimer

The server may contain design defects or errors known as errata which may cause the product to deviate from published

specifications. Current characterized errata are available on request.

Information in this document is provided in connection with HP products. No license, express or implied, by estoppel or

otherwise, to any intellectual property rights is granted by this document. Except as provided in HP's Terms and Conditions

of Sale for such products, HP assumes no liability whatsoever, and HP disclaims any express or implied warranty, relating to

sale and/or use of HP products including liability or warranties relating to fitness for a particular purpose, merchantability, or

infringement of any patent, copyright or other intellectual property right. HP

authorized for use in any medical, life saving, or life sustaining applications or for any other application in which the failure of

the HP product could create a situation where personal injury or death may occur. HP may make changes to specifications

and product descriptions at any time, without notice.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

†

Other names and brands may be claimed as the property of others.

Copyright © 2002 HP Corporation. All rights reserved. No part of this document may be copied, or reproduced in any form,

or by any means without prior written consent of HP.

®

products are not designed, intended or

ii Server System Product Guide

Page 3

Contents

Part I: User’s Guide............................................................................................. 9

1 Chassis Description..................................................................................... 13

Environmental Specifications................................................................................................14

Chassis Feature Location .....................................................................................................16

Front Panel...................................................................................................................16

Back Panel...................................................................................................................19

Internal Chassis Features.....................................................................................................20

PCI I/O Riser Cards......................................................................................................29

Power Supplies ............................................................................................................30

DC Power Subsystem..................................................................................................31

AC Power Subsystem ..................................................................................................33

Peripheral Bay..............................................................................................................34

Hard Drive Tray............................................................................................................34

Cooling Subsystem ......................................................................................................35

Server Management Summary.............................................................................................36

Server Board Management Controller..........................................................................36

2 Regulatory Specifications and Disclaimers .............................................. 37

Declaration of the Manufacturer or Importer.........................................................................37

Safety Compliance.......................................................................................................37

Electromagnetic Compatibility (EMC)...........................................................................37

FCC Electromagnetic Compatibility Notice (USA)........................................................38

Electromagnetic Compatibility Notices (International)...........................................................40

Europe (CE Declaration of Conformity)........................................................................40

Japan EMC Compatibility.............................................................................................40

ICES-003 (Canada)......................................................................................................40

BSMI (Taiwan)..............................................................................................................40

3 Configuration Software and Utilities.......................................................... 42

Using BIOS Setup.................................................................................................................43

Recording Your Setup Settings....................................................................................43

If You Cannot Access Setup ........................................................................................43

Starting Setup ..............................................................................................................43

Setup Menus................................................................................................................44

Main Menu ...................................................................................................................45

Advanced Menu ...........................................................................................................46

Security Menu ..............................................................................................................48

Server Menu.................................................................................................................49

Boot Menu....................................................................................................................51

Exit Menu .....................................................................................................................52

Upgrading the BIOS..............................................................................................................53

Using the System Setup Utility..............................................................................................54

What You Need to Do ..................................................................................................54

Running the SSU from the CD.....................................................................................54

Starting the SSU...........................................................................................................54

Part 1: Users Guide iii

Page 4

HP cc3300 Carrier Grade Server Product Guide

Launching a Task.........................................................................................................55

SEL Manager Add-in....................................................................................................55

SDR Manager Add-in...................................................................................................56

FRU Manager Add-in ...................................................................................................56

Exiting the SSU............................................................................................................57

FRUSDR Load Utility ............................................................................................................57

When to Run the FRUSDR Load Utility........................................................................57

What You Need to Do ..................................................................................................57

How You Use the FRUSDR Load Utility.......................................................................58

Using the Adaptec SCSI Utility..............................................................................................62

Running the SCSI Utility...............................................................................................62

Part II: Technical User’s Guide ....................................................................... 63

Equipment Rack Precautions................................................................................................64

4 Upgrading the Hardware.............................................................................. 65

Tools and Supplies Needed..................................................................................................65

Cautions................................................................................................................................65

Replacing Power Supply Modules ........................................................................................66

Replacing Hard Disk Drives..................................................................................................67

Replacement Disks...............................................................................................................68

Installing a Second Disk Drive in the Server Chassis...........................................................68

Disk Types ............................................................................................................................69

Working Inside the System ...................................................................................................70

Safety: Before You Remove Server Covers................................................................70

Warnings and Cautions................................................................................................70

Removing and Installing the Top Cover.......................................................................72

Internal Chassis Layout................................................................................................73

Removing and Installing Memory.................................................................................74

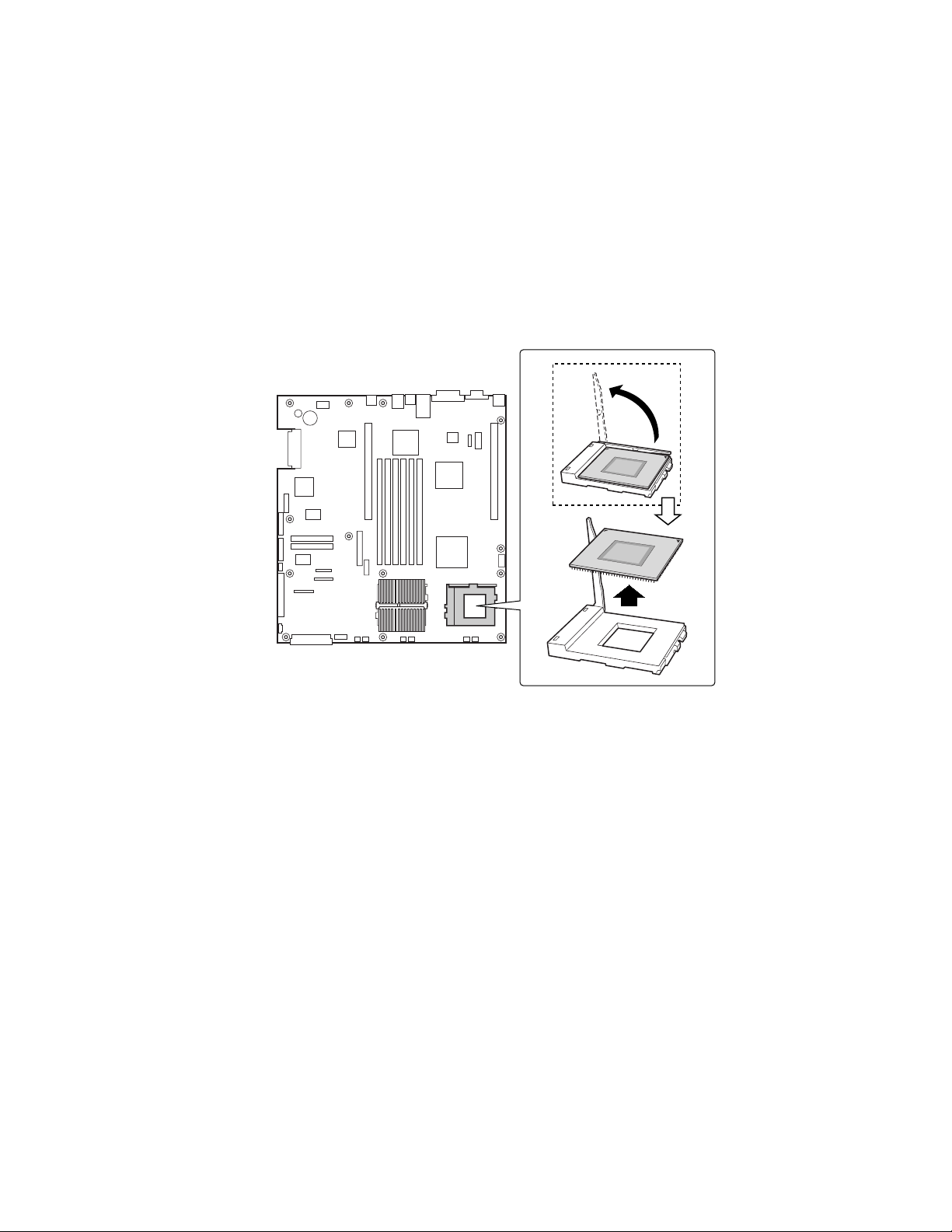

Removing and Installing Processors............................................................................75

Replacing 3.3 Volt and 5 Volt PCI Add-in Cards..........................................................81

Replacing the Back Up Battery ....................................................................................83

5 Upgrading the Chassis................................................................................ 85

Replacing the Server Board.........................................................................................85

Replacing the CD-ROM and Floppy Assembly............................................................86

Replacing the Front Panel Board.................................................................................87

Replacing Fans ............................................................................................................88

Removing the Power Supply Cage ..............................................................................90

Replacement Parts................................................................................................................91

6 Technical Reference .................................................................................... 93

Connector Pinouts.................................................................................................................93

Alarms .......................................................................................................................93

DC Power Input for DC-Input Power Supply Cage.......................................................94

Serial Port ....................................................................................................................95

Configuration Jumpers..........................................................................................................96

System Recovery and Update Jumpers (J1E1)...........................................................96

DSR/DCD Configuration Jumper (J6A2)......................................................................97

iv Contents

Page 5

HP cc3300 Carrier Grade Server Product Guide

A POST Error Codes and Messages.............................................................. 99

POST Codes and Error Messages.............................................................................103

B Equipment Log and Configuration Worksheet........................................ 109

Equipment Log....................................................................................................................109

C Warnings..................................................................................................... 111

WARNING: English (US)....................................................................................................112

AVERTISSEMENTS : Français..........................................................................................114

WARNUNG: Deutsch.........................................................................................................116

AVVERTENZA: Italiano......................................................................................................118

ADVERTENCIA: Español...................................................................................................120

D Solving Problems....................................................................................... 123

Resetting the System..........................................................................................................123

Initial System Startup..........................................................................................................123

Initial System Startup Checklist..................................................................................123

Running New Application Software.....................................................................................123

Running New Application Software Checklist ............................................................124

After the System Has Been Running Correctly...................................................................124

After the System Has Been Running Correctly Checklist...........................................124

More Problem Solving Procedures .....................................................................................124

Preparing the System for Diagnostic Testing.............................................................125

Monitoring POST........................................................................................................125

Verifying Proper Operation of Key System Lights......................................................125

Confirming Loading of the Operating System ............................................................125

Specific Problems and Corrective Actions..........................................................................125

Power Light Does Not Light........................................................................................126

No Characters Appear on Screen..............................................................................126

Characters Are Distorted or Incorrect.........................................................................126

System Cooling Fans Do Not Rotate Properly...........................................................127

Diskette Drive Activity Light Does Not Light...............................................................127

Hard Disk Drive Activity Light Does Not Light............................................................127

CD-ROM Drive Activity Light Does Not Light.............................................................127

Cannot Connect to a Server.......................................................................................128

Problems with Network...............................................................................................128

PCI Installation Tips ...................................................................................................128

Problems with Application Software....................................................................................129

Bootable CD-ROM Is Not Detected ....................................................................................129

Index................................................................................................................. 130

Contents v

Page 6

HP cc3300 Carrier Grade Server Product Guide

Figures

Figure 1. cc3300 Carrier Grade Server Chassis........................................................................................13

Figure 2. Front Panel..................................................................................................................................16

Figure 3. Front View with Bezel Removed ...............................................................................................18

Figure 4. Back Panel DC Version, AC Version Shown at Right...............................................................19

Figure 5. Server Board Connector and Component Locations..................................................................20

Figure 6. 5 Volt Riser Card........................................................................................................................29

Figure 7. 3.3 Volt Riser Card.....................................................................................................................29

Figure 8. Non-redundant AC-Power Supply Subsystem (Filler Module shown at Left)...........................31

Figure 9. Fan Array with Four System Fans Installed...............................................................................35

Figure 10. Tools and Supplies Needed ......................................................................................................65

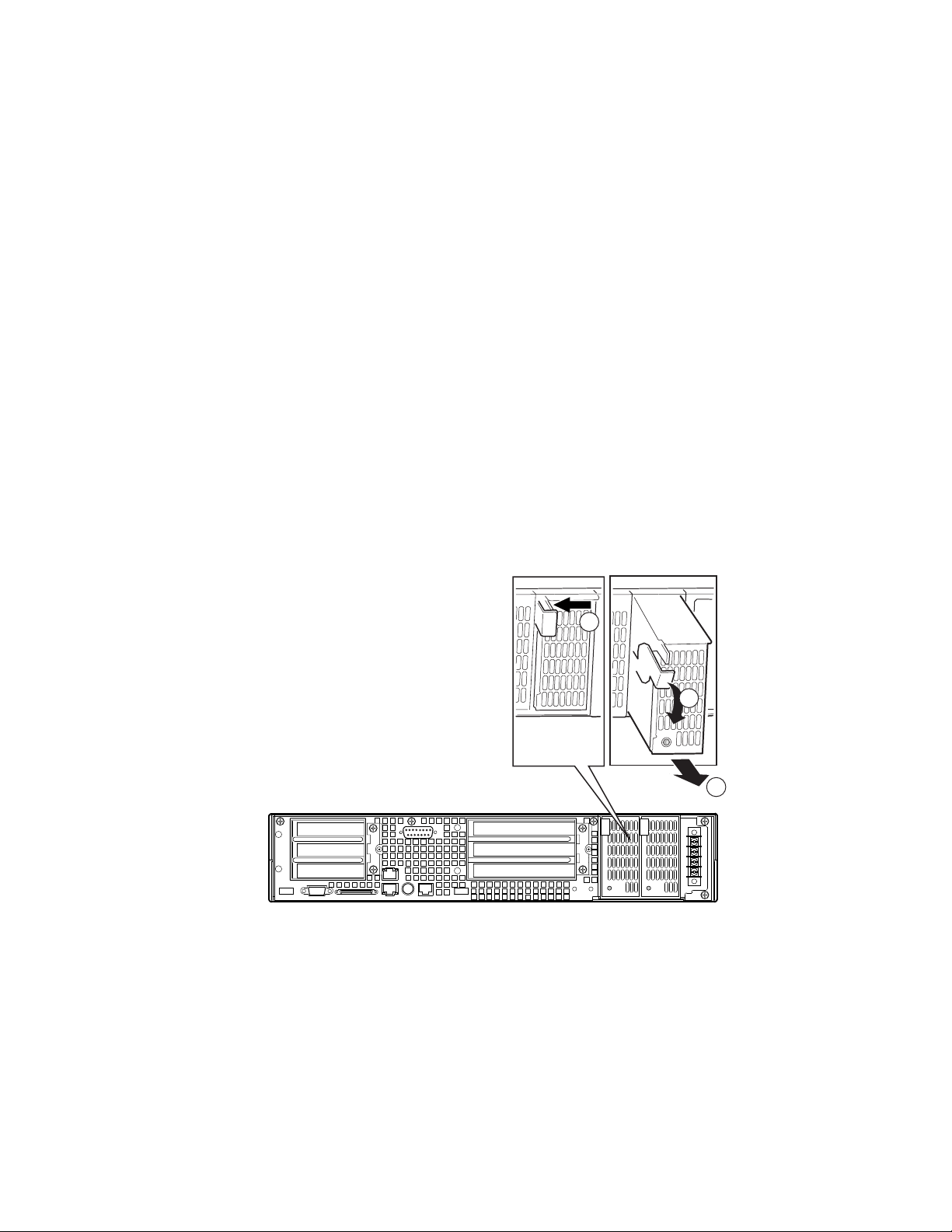

Figure 11. Unlocking and Removing the Power Supply Modules.............................................................66

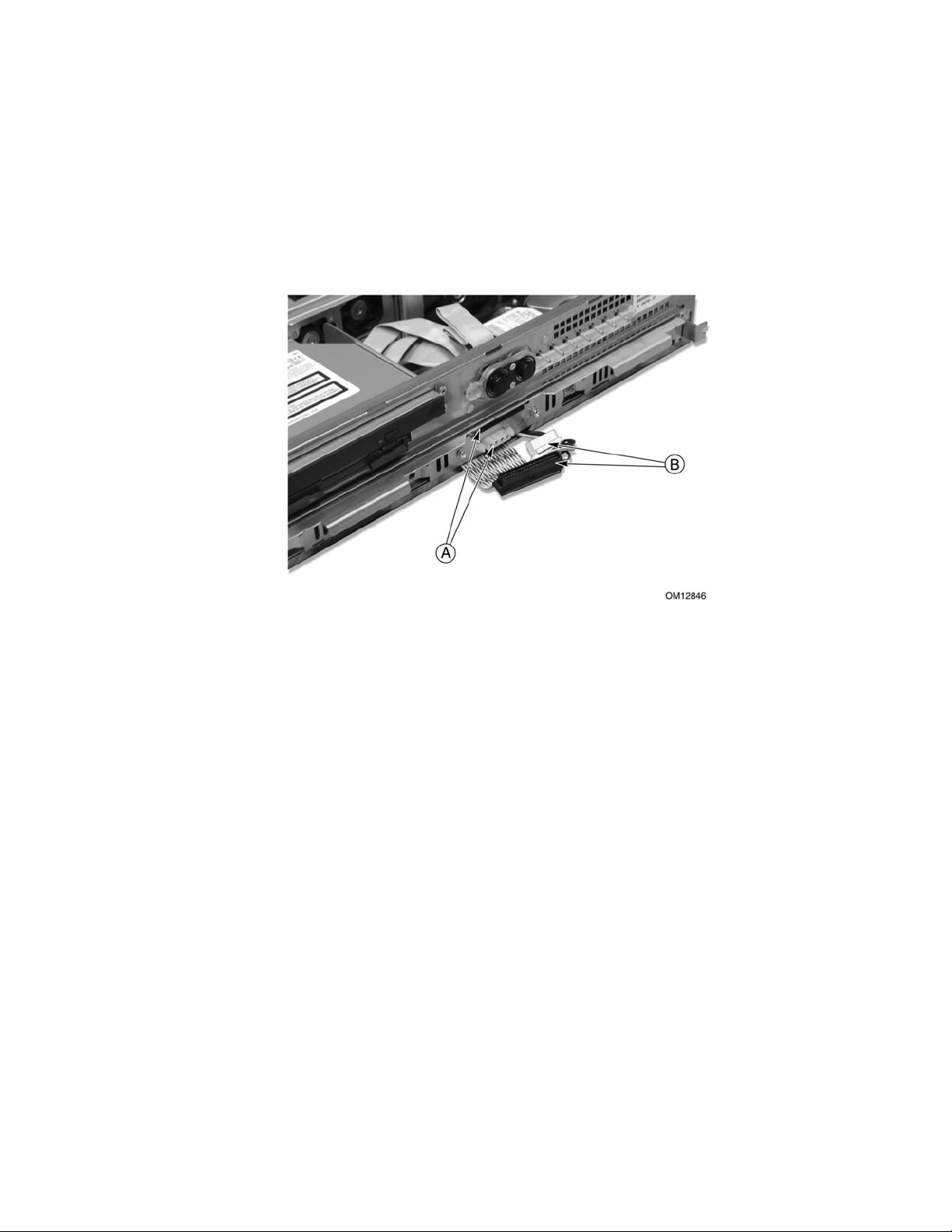

Figure 12. Disconnecting the Hard Disk Drive Bay Cables ......................................................................67

Figure 13. Removing a Hard Disk Drive...................................................................................................68

Figure 14. Removing the Top Cover .........................................................................................................72

Figure 15. Internal Chassis Layout............................................................................................................73

Figure 16. Installing DIMMs.....................................................................................................................74

Figure 17. Raising the Locking Bar and Removing the Terminator..........................................................76

Figure 18. Inserting the Processor and Lowering the Locking Bar ...........................................................77

Figure 19. Aligning the Heatsink and Installing the Heatsink Retaining Clip...........................................78

Figure 20. Unlatching the Heatsink Retaining Clip...................................................................................79

Figure 21. Raising the Locking Bar on the Processor Socket....................................................................79

Figure 22. Installing a Terminator .............................................................................................................80

Figure 23. Replacing 3.3 Volt or 5 Volt PCI Add-in Cards.......................................................................81

Figure 24. PCI Adapter Cable Installation.................................................................................................82

Figure 25. Replacing the Backup Battery..................................................................................................84

Figure 26. Removing the Peripheral Bay from the Chassis.......................................................................86

Figure 27. Front Panel Removal................................................................................................................87

Figure 28. Replacing 80 mm Fans.............................................................................................................88

Figure 29. Replacing 40 mm Fans.............................................................................................................89

Figure 30. Removing the Power Supply Cage...........................................................................................90

Figure 31. 15-pin Alarms Connector .........................................................................................................93

vi Contents

Page 7

HP cc3300 Carrier Grade Server Product Guide

Figure 32. DC Power Input Connector ......................................................................................................94

Figure 33. DC Power Terminal Lug ..........................................................................................................94

Figure 34. DC Power Terminal Connectors...............................................................................................94

Figure 35. Serial Port Connector................................................................................................................95

Figure 36. Jumper Locations (J1E1 and J6A2)..........................................................................................96

Figure 37. J6A2 Jumper Block Configured for DCD Signal.....................................................................97

Figure 38. J6A2 Jumper Block Configured for DSR Signal (Default)......................................................97

Contents vii

Page 8

HP cc3300 Carrier Grade Server Product Guide

Tables

Table 1. Server Physical Specifications.....................................................................................................13

Table 2. Environmental Specifications Summary......................................................................................14

Table 3. Front Panel Features ....................................................................................................................17

Table 4. Back Panel Features.....................................................................................................................19

Table 5. Rear COM2 Port Adapter Pin-out................................................................................................24

Table 6. Software Security Features..........................................................................................................27

Table 7. HP cc3300 Carrier Grade Server PCI I/O Riser Card Details ......................................................30

Table 8. LED Indicators.............................................................................................................................32

Table 9. DC Input Rating...........................................................................................................................32

Table 10. 350W Load Ratings ...................................................................................................................33

Table 11. LED Indicators...........................................................................................................................33

Table 12. AC Input Rating.........................................................................................................................34

Table 13. 350W Load Ratings ...................................................................................................................34

Table 14. Configuration Utilities...............................................................................................................42

Table 15. Alarms Connector Pinout...........................................................................................................93

Table 16. Serial Port Connector Pinout .....................................................................................................95

Table 17. System Recovery and Update Jumper Options..........................................................................96

Table 18. Port-80h Code Definition...........................................................................................................99

Table 19. Boot Block POST Codes ...........................................................................................................99

Table 20. POST Code - Port 80h Codes ..................................................................................................100

Table 21. POST Codes and Error Messages............................................................................................103

viii Contents

Page 9

Part I: User’s Guide

1 Chassis Description

2 Regulatory Specifications and Disclaimers

3 Configuration Software and Utilities

Detailed server management tool information and supported operating system information is

contained in the Intel Server Control (ISC) Installation Guide For the cc2300 & cc3300 Carrier

Grade Server. ISC is a server management tool that provides real time monitoring and alerting for

server hardware, emergency remote management and remote server setup.

This document provides an overview of the HP Carrier Grade cc3300 Server. This manual

consists of two parts:

• User’s Guide, beginning on page 9 describes procedures that DO NOT REQUIRE removing

and replacing boards.

• Technical User’s Guide, beginning on page 63 describes procedures that REQUIRE removing

and replacing boards.

• Reference URLs:

• http:www.software.hp.com keyword search: cc3300

Contains firmware update utility information.

• http:www.doc.hp.com

Contains HP Carrier Grade Server cc3300 Manual set.

WARNING

Before removing the covers, see “Safety: Before You Remove Server

Covers” on page 70 and “Warnings and Cautions” on page 70.

WARNING

If AC power supplies are installed:

Mains AC power disconnect: The AC power cord(s) is considered the

mains disconnect for the server and must be readily accessible when

installed. If the individual server power cord(s) will not be readily

accessible for disconnection then you are responsible for installing an

AC power disconnect for the entire rack unit. This main disconnect

must be readily accessible, and it must be labeled as controlling power to

the entire rack, not just to the server(s). To remove all power, two

AC cords must be removed.

User’s Guide 9

Page 10

HP cc3300 Carrier Grade Server Product Guide

Grounding the rack installation: To avoid the potential for an electrical

shock hazard, you must include a third wire safety ground conductor

with the rack installation. If the server power cord is plugged into an

AC outlet that is part of the rack, then you must provide proper

grounding for the rack itself. If the server power cord is plugged into a

wall AC outlet, the safety ground conductor in the power cord provides

proper grounding only for the server. You must provide additional,

proper grounding for the rack and other devices installed in it.

Overcurrent protection: The server is designed for an AC line voltage

source with up to 20 amperes of overcurrent protection per cord feed. If

the power system for the equipment rack is installed on a branch circuit

with more than 20 amperes of protection, you must provide

supplemental protection for the server. The overall current rating of a

server configured with two power supplies is less than 4 amperes.

If DC power supplies are installed:

The DC source must be electrically isolated by double or reinforced

insulation from any hazardous AC or DC source. The DC source must

be capable of providing up to 300 W of continuous power per feed pair.

Connection with a DC source should only be performed by qualified

personnel.

Main DC power disconnect: You are responsible for installing a

DC power disconnect for the entire rack unit. This mains disconnect

must be readily accessible, and it must be labeled as controlling power to

the entire unit, not just to the servers(s).

Grounding the rack installation: To avoid the potential for an electrical

shock hazard, you must include a third wire safety ground conductor

with the rack installation. The safety grounding conductor must be a

minimum 14AWG connected to the chassis on the rear of the server.

The safety ground provides proper grounding only for the server. You

must provide additional, proper grounding for the rack and other

devices installed in it.

Overcurrent protection: Overcurrent protection circuit breakers must

be provided as part of each host equipment rack and must be installed

between the DC source and the server. The server is designed for a

DC line voltage power source with up to 10 amperes of overcurrent

protection per feed pair. If the DC power system for the equipment rack

is installed with more than 10 amperes of protection, you must provide

supplemental protection for the server. The overall current rating of a

server configured with two power supplies is less than 7 amperes.

10 User’s Guide

Page 11

WARNING

Do not attempt to modify or use an AC power cord that is not the exact

type required. You must use a power cord that meets the following

criteria:

1. Rating: For U.S./Canada cords must be UL Listed/CSA Certified

type SJT, 18-3 AWG. For outside U.S./Canada cords must be

flexible harmonized (<HAR>) or VDE certified cord with

3 x 0.75mm conductors rated 250 VAC.

2. Connector, wall outlet end: Cords must be terminated in

grounding-type male plug designed for use in your region. The

connector must have certification marks showing certification by an

agency acceptable in your region and for U.S. must be rated

125% of overall current rating of the server.

3. Connector, server end: The connectors that plug into the

AC receptacle on the server must be an IEC 320, sheet C13, type

female connector.

HP cc3300 Carrier Grade Server Product Guide

4. Cord length and flexibility: Cords must be less than 4.5 meters

(14.76 feet) long.

CAUTION

Temperature: The temperature, in which the server operates when installed

in an equipment rack, must be maintained between 5 °C (41 °F) and 40 °C

(104 °F). Extreme fluctuations in temperature can cause a variety of

problems in your server.

Ventilation: The equipment rack must provide sufficient airflow to the front

of the server to maintain proper cooling. The rack must also include

ventilation sufficient to exhaust a maximum of 1023 BTU's per hour for each

installed server. The rack selected and the ventilation provided must be

suitable to the environment in which the server will be used.

User’s Guide 11

Page 12

Page 13

1 Chassis Description

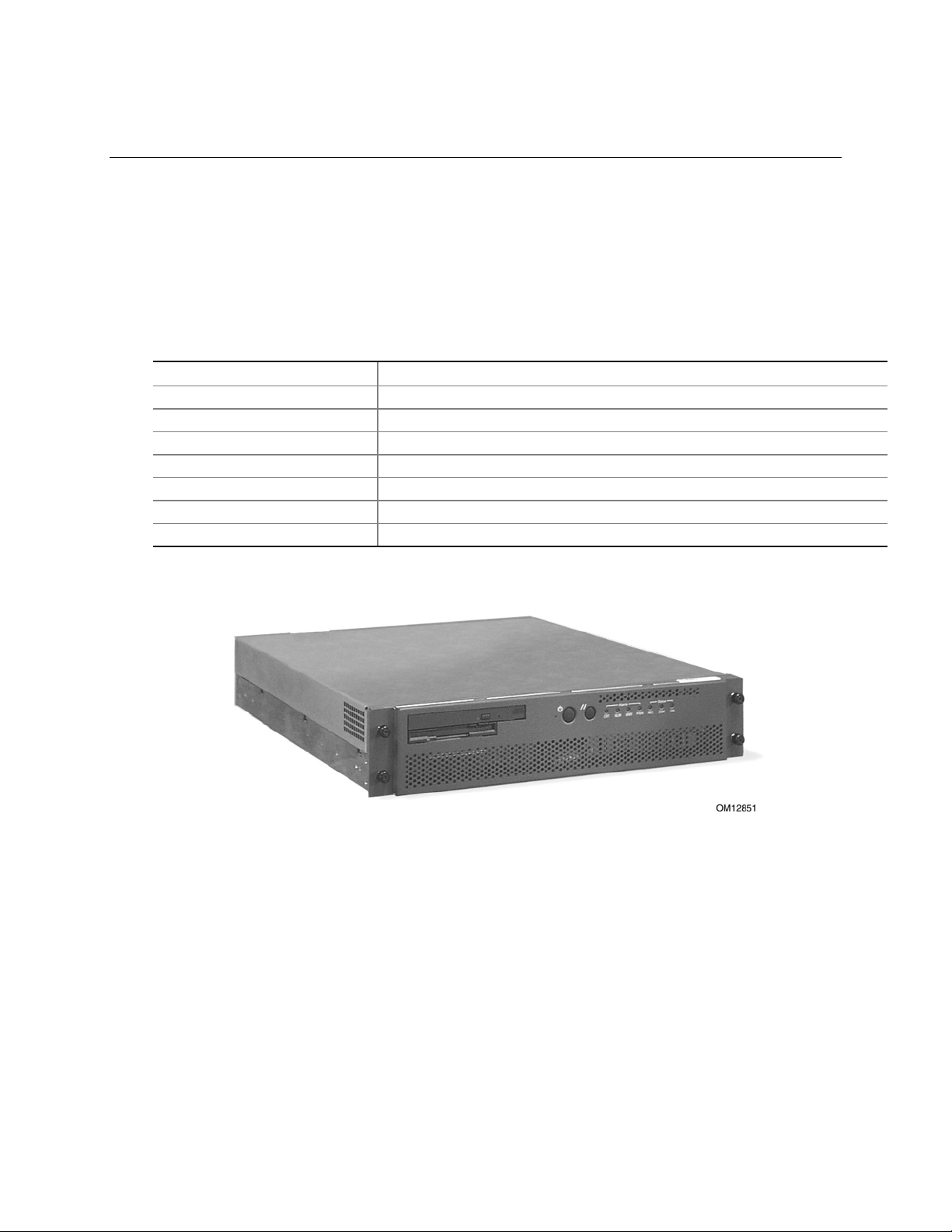

The cc3300 Carrier Grade Server is a rack-mounted server that supports one to two Intel® Pentium®

III processors and up to 6 Gbytes of SDRAM memory. The server supports high availability

features such as hot-swap and redundant power supply modules. The scalable architecture of the

server supports symmetric multiprocessing (SMP).

Physical Specifications

Table 1. Server Physical Specifications

Specification Value

Weight 35 lbs

Height 3.5 inches (89 mm)

Width 17.5 inches (445 mm)

Depth 20 inches (508 mm)

Front clearance 2 inches (76 mm)

Side clearance 1 inches (25 mm)

Rear clearance 3.6 inches (92 mm)

Figure 1. cc3300 Carrier Grade Server Chassis

Chassis Description 13

Page 14

HP cc3300 Carrier Grade Server Product Guide

Environmental Specifications

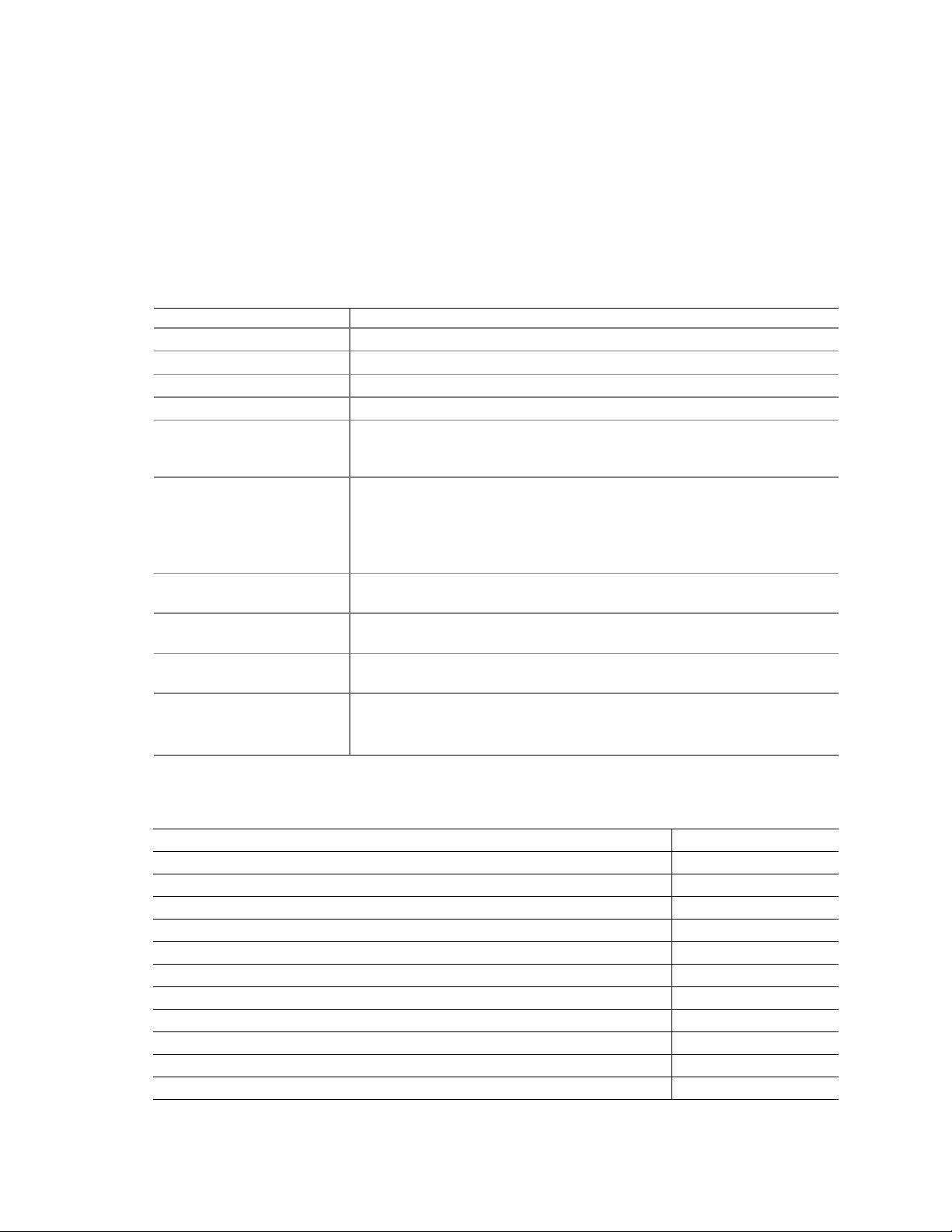

The cc3300 Carrier Grade Server has been tested to the environmental specifications as indicated in

Table 2. All testing has been performed per procedures defined in Bellcore GR-63-CORE NEBS

Physical Protection, Bellcore GR-3580 NEBS Criteria Levels, Bellcore GR-1089-CORE EMC and

Electrical Safety – Generic Criteria for Network Telecommunications Equipment. .

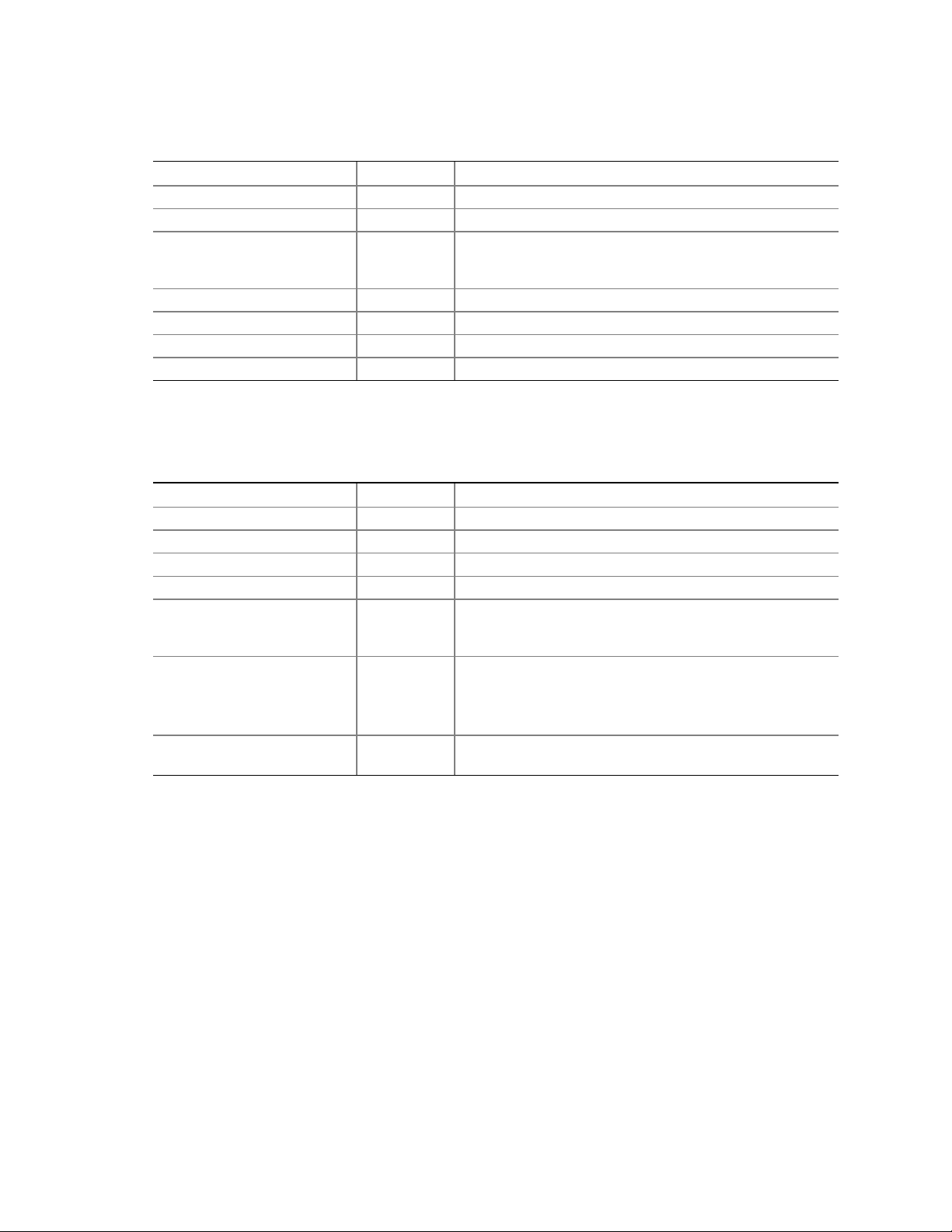

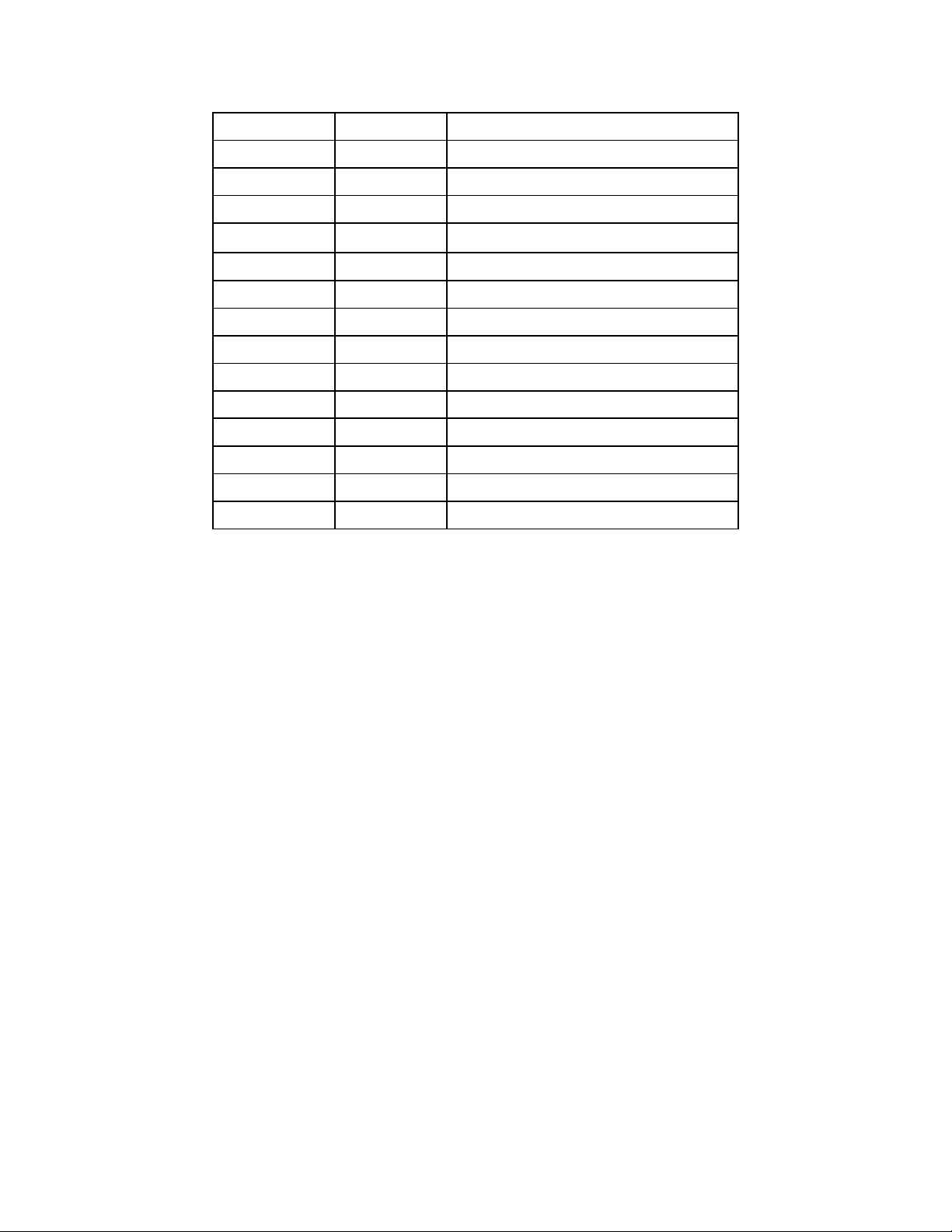

Table 2. Environmental Specifications Summary

Environment Specification

Temperature operating

Temperature non-operating

Altitude 0 to 1,800 m (0 to 5,905 ft)

Humidity non-operating

Vibration operating Swept sine survey at an acceleration amplitude of 0.1 g from 5 to 100 Hz

Vibration non-operating Swept sine survey at an acceleration amplitude of 0.5 g from 5 to 50 Hz at a

Shock operating Half-sine 2 G, 11 ms pulse, 100 pulses in each direction, on each of the

Shock non-operating Trapezoidal, 25 G, 170-inch/sec delta V, three drops in each direction, on

Electrostatic discharge

(ESD)

Acoustic

10 °C to 35 °C (50° F to 95° F)

-40 °C to 70 °C (-104° F to 158° F)

95%, non-condensing at temperatures of 23° C (73° F) to 40° C (104° F)

and back to 5 Hz at a rate of 0.1 octave/minute, 90 minutes per axis on all

three axes as per Bellcore GR-63-CORE standards.

rate of 0.1 octaves/minute, and an acceleration amplitude of 3.0g from 50 to

500 Hz at a rate of 0.25 octaves/minute, on all three axes as per Bellcore

GR-63-CORE standard.

2.2 Grms, 10 minutes per axis on all three axes.

three axes.

each of the three axes.

Tested to ESD levels up to 15 kilovolts (kV) air discharge and up to

8 kV contact discharge without physical damage.

Sound pressure: < 55 dBA at ambient temperatures < 28°C measured at

bystander positions in operating mode.

Sound power: < 6.5 BA at ambient temperatures < 28°C in operating mode.

Power

Maximum current at 100 VAC 1.8 Amps

Maximum current at 120 VAC 1.5 Amps

Maximum current at 230 VAC 0.8 Amps

Does the input current differ at 50 to 60Hz (if yes, input the highest value) No

Maximum peak inrush current 17.7 Amps

Time to decay to 25% of maximum peak 0.3 Seconds

Time duration to return to nominal 6 Seconds

Total harmonic distortion (voltage) 0.12%

Power factor 0.87

KVA rating 0.19 KVA

Heat dissipation 190 Watts

BTU’s per hour 649 BTU/hr

14 Chassis Description

Page 15

HP cc3300 Carrier Grade Server Product Guide

Kcal per hour 45 Cal/sec

Nominal rated voltages 100 – 240 V

Maximum operating voltage 264 V

Minimum operating voltage 87 V

Rated (marked) line current(s) 4 / 2 Amps

Line voltage power-fail threshold 73 V

Dropout carry-through time at minimum line voltage 20 mSec

Mating AC input receptacle type C-13 C13, etc

Branch circuit breaker size at 100 VAC 15/20 Amps

Branch circuit breaker size at 120 VAC 15/20 Amps

Frequency range non-strappable 47 - 66 Hz

DC input (if applicable) 48 Volts nominal

DC input (if applicable) 4.6 Amps

EMC

Radiated filed immunity – what frequencies are sensitive below 10 v/m None

ESD immunity – Maximum kV with no loss of function 4/8 kV

ESD immunity – Maximum kV with no component damage 4/8 kV

Sound power level (LWA) 6.8 B

Sound pressure level (LPA) at operator position 50.3 dB

Transient spike immunity amplitude 2 Kv

Transient spike immunity duration 50 Micro Sec.

Transient spike immunity rise time 1.2 Micro Sec.

Chassis Description 15

Page 16

HP cc3300 Carrier Grade Server Product Guide

Chassis Feature Location

Front Panel

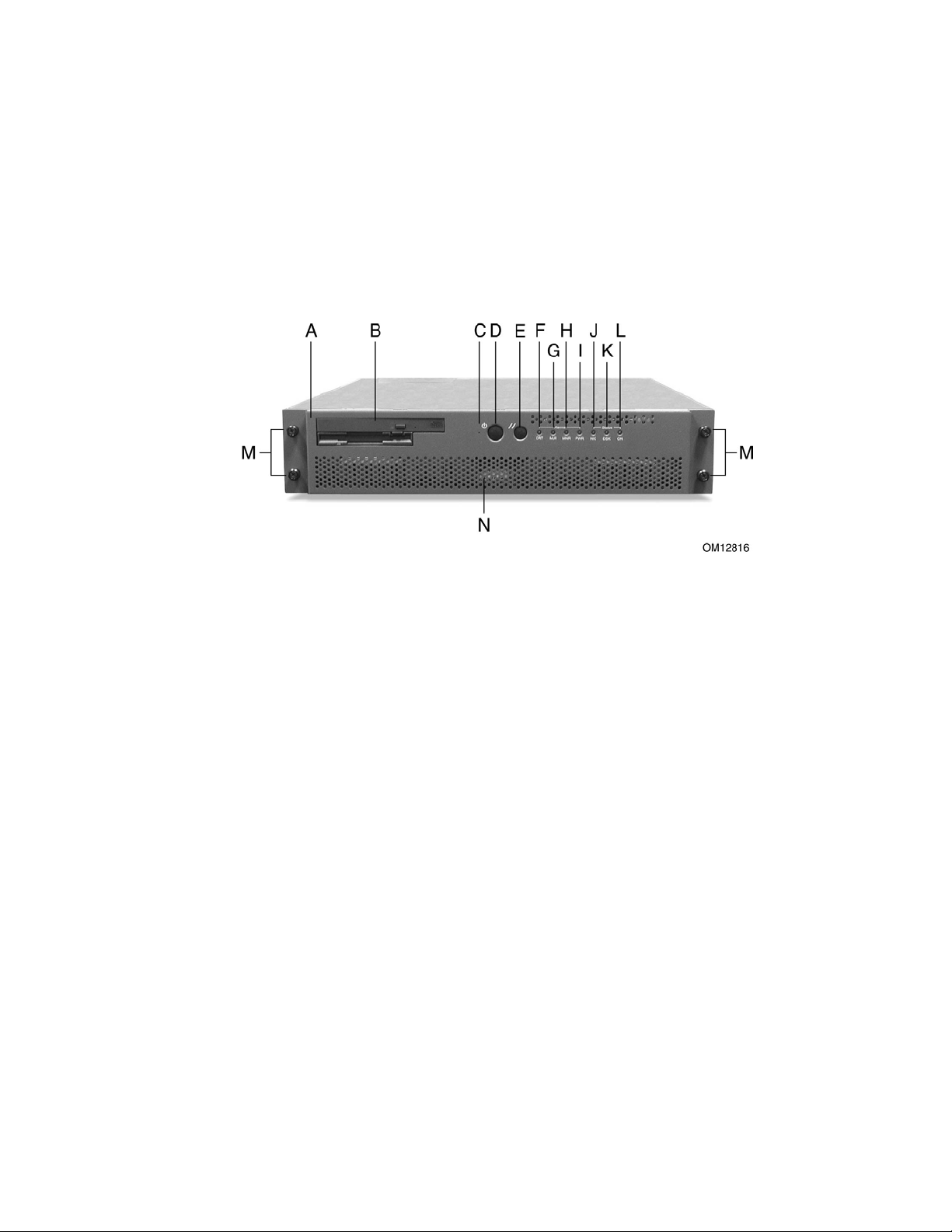

Figure 2 shows the front view of the system including the front panel. The front panel contains

system control switches, alarm indicators and relays, and status indicators. Front panel controls and

LEDs are summarized in Table 3.

A Bezel H Alarm: MNR

B Peripheral Bay I Alarm: PWR

C NMI Switch J Status: NIC

D Power Switch K Status: DSK

E Reset Switch L Status: ON

F Alarm: CRT M Bezel Removal Thumbscrews

G Alarm: MJR N Hard Drive Tray

Figure 2. Front Panel

16 Chassis Description

Page 17

Table 3. Front Panel Features

Item Feature Description

Front Panel Switches

C NMI switch A momentary switch used to instruct the processor to copy system memory to

D Power switch Toggles the system power on/off.

E Reset switch Reboots and initializes the system.

Front Panel Alarm LEDs and Relays

F Critical (amber) When continuously lit, indicates the presence of a Critical System Fault. A

G Major (amber) When continuously lit, indicates the presence of a Major System Fault. A major

H Minor (amber) When conti nuously lit, indicates the presence of a Minor System Fault. A minor

I Power (amber) When continuously lit, indicates the presence of a Power System Fault.

Front Panel Status LEDs

J NIC activity LED

(green)

K HDD activity

LED (green)

L Main power

LED (green)

HP cc3300 Carrier Grade Server Product Guide

the hard drive. Pressing the recessed button with a paper clip or pin puts the

server in a halt state for diagnostic purposes and allows you to issue a

non•maskable interrupt. After issuing the interrupt, a memory dump can be

performed to determine the cause of the problem.

critical system fault is an error or event that is detected by the system with a

fatal impact to the system. In this case, the system cannot continue to operate.

An example could be the loss of a large section of memory. . Additionally, the

front panel critical alarm relay will engage.

system fault is an error or event that is detected by the system that has

discernable impact to system operation. In this case, the system can continue

to operate but in a “degraded” fashion (reduced performance or loss of nonfatal feature reduction). An example could be the loss of one of two mirrored

disks. Additionally, the front panel major alarm relay will engage.

system fault is an error or event that is detected by the system but has little

impact to actual system operation. An example would be a correctable

ECC error. Additionally, the front panel minor alarm relay will engage.

Additionally, the front panel power alarm relay will engage.

Indicates NIC activity.

Indicates any system SCSI hard drive activity.

When continuously lit, indicates the presence of DC power in the server. The

LED goes out when the power is turned off or the power source is disrupted.

When it is blinking green, it indicates that the system is in ACPI sleep mode.

Chassis Description 17

Page 18

HP cc3300 Carrier Grade Server Product Guide

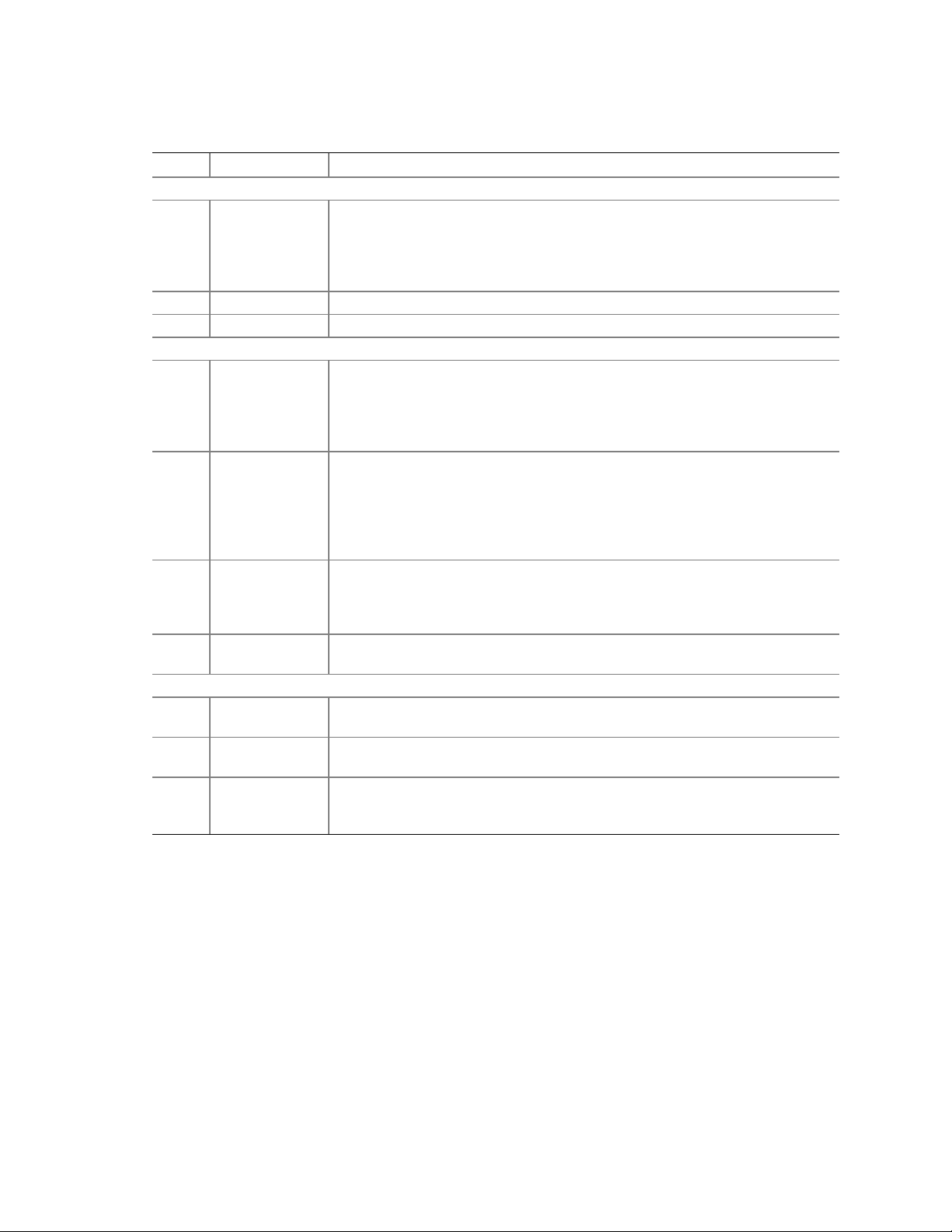

Figure 3 shows the front view of the system with the bezel removed.

A B C

H EFG

A Floppy Drive E Left SCSI Drive Bay

B CD-ROM Drive F Hard Drive Tray Ribbon Cable Connector

C Front Panel Switches and LEDs G Hard Drive Tray Power Connector

D Hard Drive Tray H Right SCSI Drive Bay

Figure 3. Front View with Bezel Removed

OM12817

D

18 Chassis Description

Page 19

Back Panel

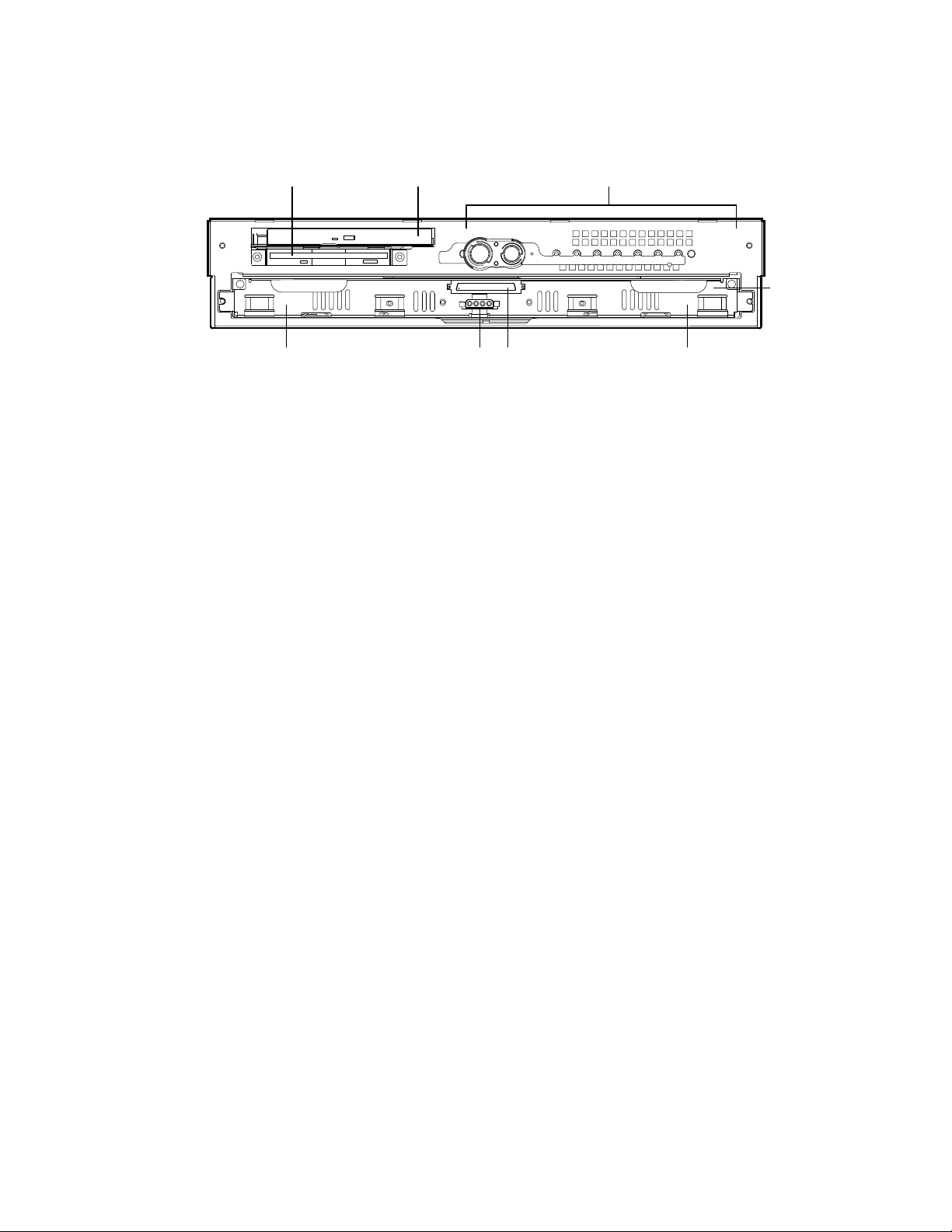

Figure 4 shows the back panel view of the system.

HP cc3300 Carrier Grade Server Product Guide

A C EB D

N

+

-

+

-

F G H I J K L

Figure 4. Back Panel DC Version, AC Version Shown at Right

Table 4. Back Panel Features

Item Description

A Three low profile, half-length 64-bit, 66 MHz PCI add-in board slots (3.3V riser board)

B DB-15 male connector for front panel alarm relay contacts

C Three full height, full length 64-bit, 33 MHz PCI add-in board slots (5 V riser board), or,

Three full height, full length 64-bit, 66 MHz PCI add-in board slots (3.3 V riser board)

D Redundant, hot-plug power supplies (AC and DC power supplies require different power supply

cages)

E Four-terminal DC input power connector for DC input power supply cage

F USB port 1

G Video connector

H External wide SCSI Ultra† 160 68-pin connector

I Dual NIC 10/100 E/N RJ45 connectors NIC 1 (lower) and NIC 2 (upper)

J PS/2†-compatible keyboard port

K Serial port (COM2), 8-pin RJ45 connector

L USB port 0

M Two grounding lugs for attachment of grounding wire to chassis. Use only when configured with

DC input power supply

N and O AC input power connectors for AC input power supply cage (shown in inset)

M

OM12818

O

Chassis Description 19

Page 20

HP cc3300 Carrier Grade Server Product Guide

Internal Chassis Features

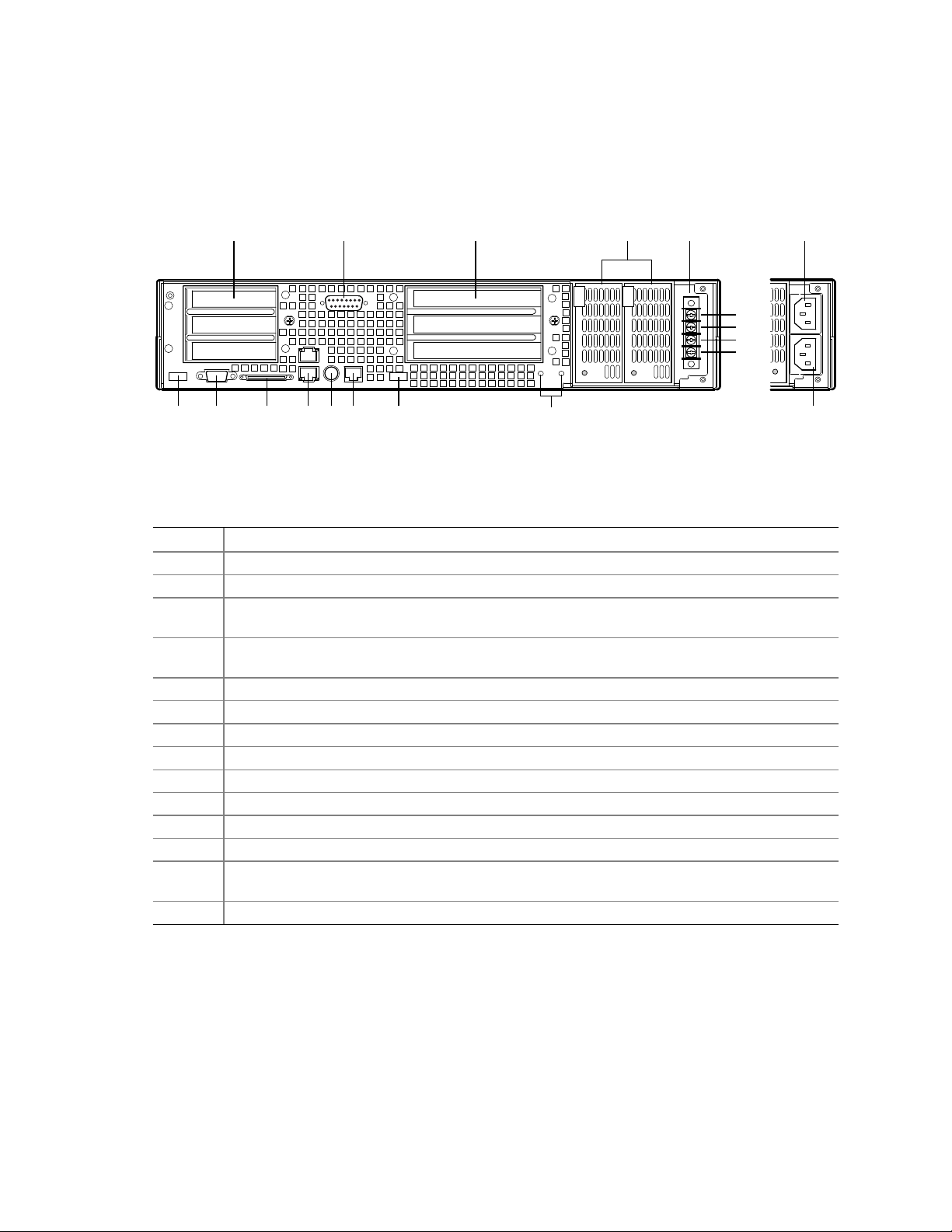

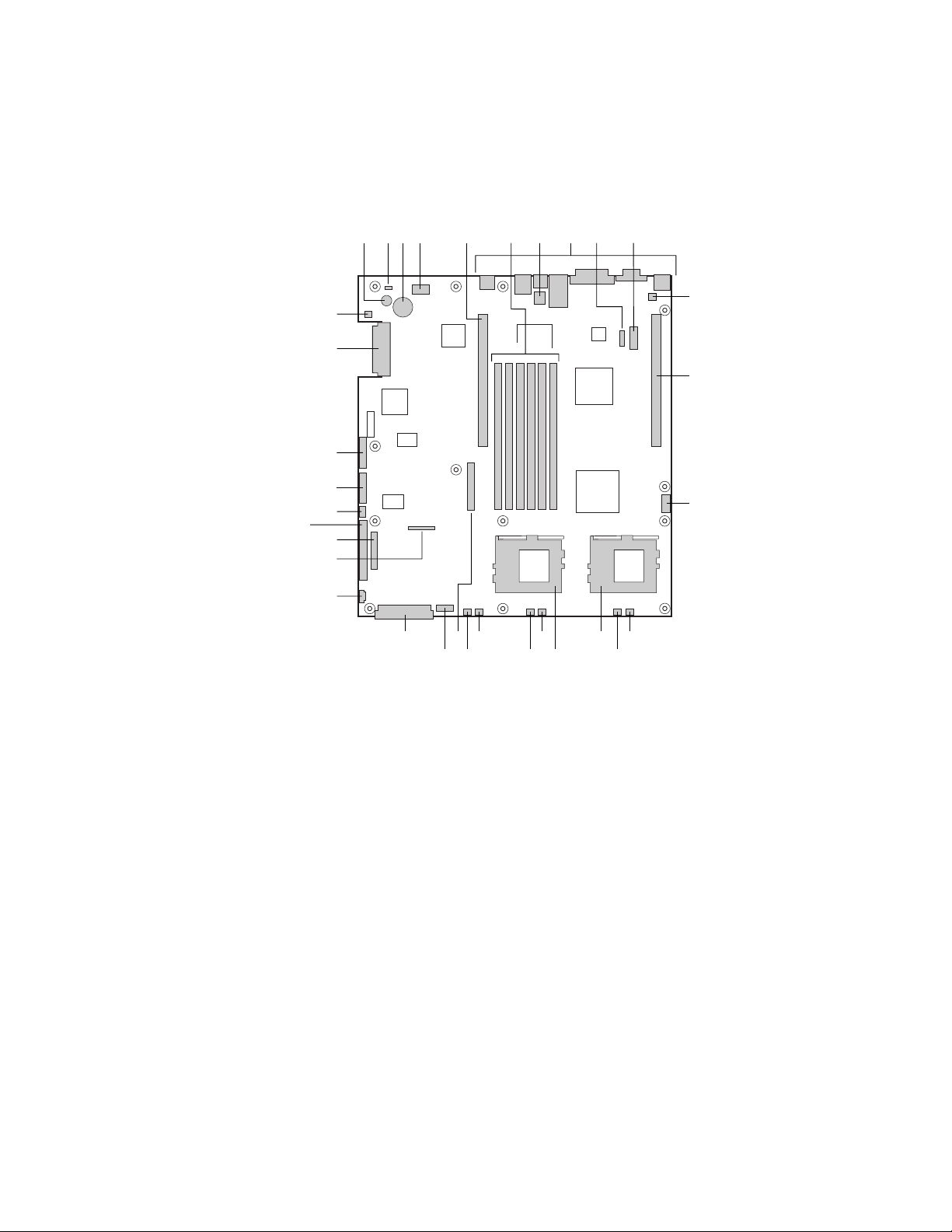

Figure 5 shows the location of the server board’s connectors and other components.

A C D E

B

GG

FF

EE

DD

CC

BB

AA

Z

Y

TV

UW

A

Speaker R Sys fan 2 connector

B

ID LED S CPU 1 fan connector

C

Battery T Sys fan 1 connector

D

Diagnostic LEDs (POST code) U Aux fan connector

E

66 MHz/64-bit PCI riser slot (full height) V Floppy drive connector

F

DIMM slots W Fan module connector

G

DCD/DSR jumper block X Main power connector

H

I/O ports Y Auxiliary signal connector

I

ICMB connector Z Floppy/FP/IDE connector

J

COM 1 serial header AA Alternate front panel connector

K

Chassis intrusion connector BB ATA/IDE connector

L

66 MHz/64-bit PCI riser slot (low profile) CC IPMB connector

M

USB 3 & 4 header DD SSI front panel connector

N

Sys fan 3 connector EE Configuration jumper block

O

CPU 2 fan connector FF SCSI connector (SCSI version only)

P

Secondary processor socket GG Hard Disk Drive LED header

Q

Primary processor socket

H

G

R

S

JF I

K

L

M

PX N

OQ

OM12815

Figure 5. Server Board Connector and Component Locations

20 Chassis Description

Page 21

HP cc3300 Carrier Grade Server Product Guide

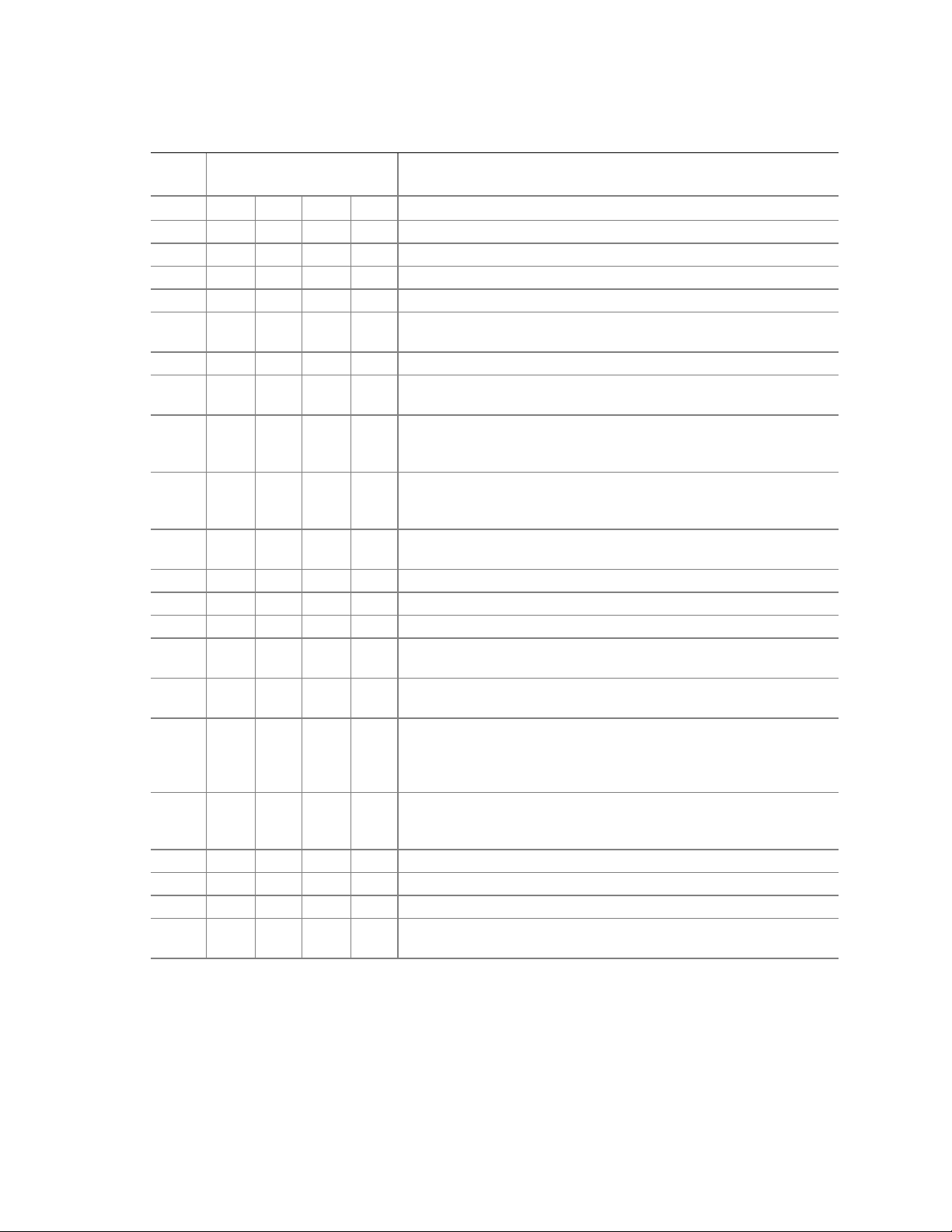

Processor

The server board accommodates one or two Intel Pentium III processors up to 1-26 GHz with

512k cache.

Memory

The system board contains six 168-pin DIMM slots each supporting 72-bit ECC (64-bit main

memory plus ECC) registered SDRAM DIMMs (PC-133 compatible). You may install a minimum

of 256 MB (128MB x 2) and as much as 6 GB.

NOTE

DIMMs supplied with the server have been tested for compatibility with the

cc3300 server. It is recommended that HP tested memory is used when

adding memory capacity to the server.

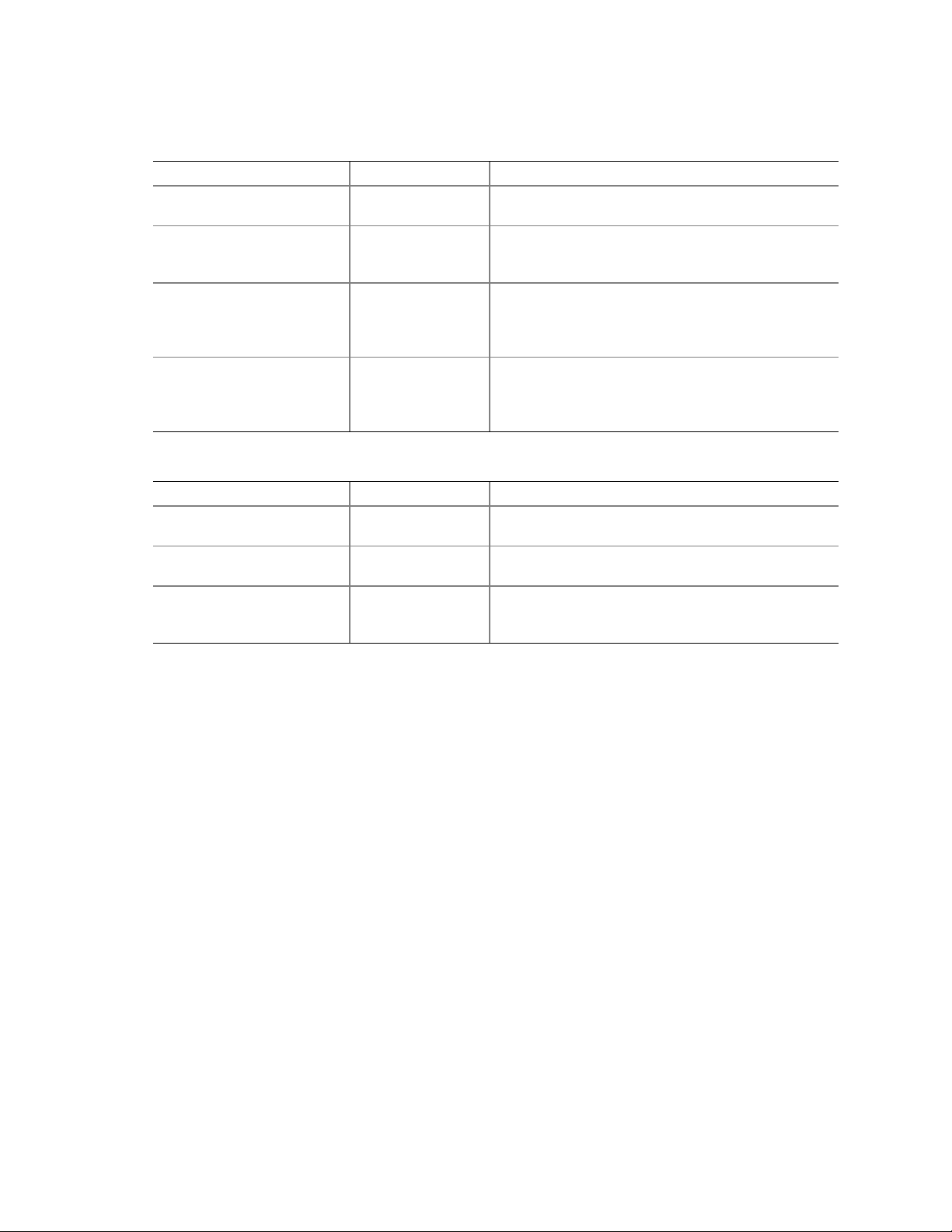

HP cc3300 Carrier Grade Server Memory Products

Product Number ECC SyncDRAM in module DIMM cards in module Height of DIMMs Server Used With

A6950A 256 MB Two cards (128 MB each) 43.2 mm (1.7") hp carrier grade server cc3300

A6909A 512 MB Two cards (256 MB each) 43.2 mm (1.7") hp carrier grade server cc3300

A6910A 1,024 MB Two cards (512 MB each) 43.2 mm (1.7") hp carrier grade server cc3300

A6916A 2,048 MB Two cards (1,024 MB each) 43.2 mm (1.7") hp carrier grade server cc3300

PCI Riser Slots

The server board has two PCI riser slots, each capable of supporting 64-bit/66-MHz PCI riser cards.

PCI features:

• Bus speed up to 66 MHz

• 32 bit memory addressing

• 5 V/3.3 V signaling environment

• Burst transfers of up to 512 Mbps

• 8, 16, 32, or 64-bit data transfers

• Plug and Play ready

• Parity enabled

Video

The server board uses an ATI RAGE XL PCI graphics accelerator with 8 MB of video SDRAM

that supports all standard IBM

• Pixel resolutions up to 1600 x 1200 under 2D and 1024 x 768 under 3D

• CRT and LCD monitors up to 100 Hz vertical refresh rate

The server board supports disabling of the onboard video through the BIOS setup menu or when a

plug in video card is installed in any of the PCI slots.

†

VGA modes. The embedded SVGA video subsystem supports:

SCSI Controller

The server board includes an embedded Adaptec† AIC-7899W SCSI controller providing dual

Ultra160 Low Voltage Differential (LVD) SCSI channels.

Chassis Description 21

Page 22

HP cc3300 Carrier Grade Server Product Guide

The SCSI bus is terminated on the server board with active terminators that cannot be disabled.

The onboard device must always be at one end of the bus. The device at the other end of the cable

is terminated with the active terminator on the SCSI cable installed in the system.

Network Controller

NOTE

To ensure EMC product regulation compliance for intra-building lighting

surges, the system must only be used with shielded LAN cables that are

grounded at both ends.

®

The server board uses two Intel

10Base-T/100Base-TX network subsystems.

On the server board, NIC 1 can be used as both a network interface and server management

interface.

NIC Connector and Status LEDs

The 82550 controller drives LEDs on the network interface connector that indicate link/activity on

the LAN and 10- or 100-Mbps operation. The green LED indicates network connection when on

and TX/RX activity when blinking. The yellow LED indicates 100-Mbps operation when lit.

82550PM Fast Ethernet Controllers and supports two

Network Teaming Features

NOTE

Using both on-board NICs in a team does not allow the use of NIC 1 for

server management access. To support both network teaming features and

server management features, a third NIC must be added and teamed to NIC 2.

The network controller provides several options for increasing throughput and fault tolerance when

†

running Linux

• Adapter Fault Tolerance (AFT) - provides automatic redundancy for your adapter. If the

primary adapter fails, the secondary takes over. AFT works with any hub or switch.

• Adaptive Load Balancing (ALB) - creates a team of 2 - 6 adapters to increase transmission

throughput. Also includes AFT. Works with any 10Base-TX or 100Base-TX switch.

• Fast EtherChannel

increase transmission and reception throughput. Also includes AFT. Requires a FEC-enabled

switch.

To set up an option, read the instructions in the Linux readme files.

Adapter Fault Tolerance

Adapter Fault Tolerance (AFT) is a simple, effective, and fail-safe approach to increase the

reliability of server connections. AFT gives you the ability to set up link recovery to the server

adapter in case of a cable, port, or network interface card failure. By assigning two server adapters

as a team, AFT enables you to maintain uninterrupted network performance.

:

†

(FEC) or Intel® Link Aggregation - creates a team of up to 6 adapters to

AFT is implemented with two server adapters: a primary adapter and a backup, or secondary,

adapter. During normal operation, the backup will have transmit disabled. If the link to the

primary adapter fails, the link to the backup adapter automatically takes over.

22 Chassis Description

Page 23

HP cc3300 Carrier Grade Server Product Guide

Preferred Primary Adapter

With multiple adapters installed, you can specify one as the Preferred Primary adapter. For

example if you have a server with a Gigabit LAN as the primary adapter and a 10/100 Base TX

LAN adapter as the secondary, you could configure the Gigabit LAN server adapter to be the

preferred primary. In this scenario, if the Gigabit LAN server adapter fails, the 10/100 Base TX

will take over. Then when the Gigabit LAN server adapter is replaced, it will automatically revert

to being the primary adapter in the team.

If a Preferred Primary is not selected, PROSet will attempt to select the best adapter, based on

adapter model and speed.

Mixed Adapter Teaming

AFT supports up to six server adapters per team, in any mix.

Adaptive Load Balancing

Adaptive Load Balancing (ALB) is a simple and efficient way to increase your server's transmit

throughput. With ALB you group server adapters in teams to provide an increased transmit rate

(up to 8 Gbps) using a maximum of eight adapters. The ALB software continuously analyzes

transmit loading on each adapter and balances the rate across the adapters as needed. Adapter

teams configured for ALB also provide the benefits of AFT. Receive rates remain at 100 Mbps or

1 Gbps depending on the primary adapter’s capability.

To use ALB, you must have 2-6 server adapters installed in your server or workstation and linked

to the same network switch.

Keyboard and Mouse

The keyboard controller is PS/2-compatible. If specified through the System Setup Utility (SSU),

the server may be locked automatically if there is no keyboard or mouse activity for a predefined

length of time. Once the inactivity (lockout) timer has expired, the keyboard and mouse do not

respond until the previously stored password is entered.

Chassis Description 23

Page 24

HP cc3300 Carrier Grade Server Product Guide

RJ-45 Serial Port

The rear RJ-45 serial port is a fully functional COM port that supports any standard serial device

and provides support for serial concentrators, which typically support RJ45 serial connectors. For

server applications that use a serial concentrator to access the server management features of the

baseboard, a standard 8-pin CAT-5 cable from the serial concentrator is plugged directly into the

rear RJ45 serial port. The 8 pins of the RJ45 connector can be configured to match either of two

pin-out standards used by serial port concentrators. To accommodate either standard, the

J6A2 jumper block located directly behind the rear RJ45 serial port must be jumpered appropriately

according to which standard is desired.

NOTE

The RJ45 serial port’s default configuration is DSR. For serial concentrators

requiring a DCD signal, configure the jumper block as shown in Figure 37.

For those server applications requiring a DB9 serial connector, use an 8-pin RJ45-to-DB9 adapter

(A6900-6303). Table 5 defines the pin-out required for the adapter to provide RS232 support.

Table 5. Rear COM2 Port Adapter Pin-out

RJ45 Signal Abbreviation DB9

1 Request to Send RTS 7

2 Data Terminal Ready DTR 4

3 Transmitted Data TD 3

4 Signal Ground SGND 5

5 Ring Indicator RI 9

6 Received Data RD 2

7 DCD or DSR DCD/DSR 1 or 6

8 Clear To Send CTS 8

NOTE

The RJ45-to-DB9 adapter should match the configuration of the serial device

used. One of two pin-out configurations are used depending on whether the

serial device requires a DSR or DCD signal. The final adapter configuration

should also match the desired pin-out of the RJ45 connector, as it can also be

configured to support either DSR or DCD.

24 Chassis Description

Page 25

HP cc3300 Carrier Grade Server Product Guide

ACPI

The SERVER BOARD supports the Advanced Configuration and Power Interface (ACPI) as

defined by the ACPI 1.0 and PC97 specifications. An ACPI aware operating system can put the

system into a state where the hard drives spin down, the system fans stop, and all processing is

halted. However, the power supply will still be on and the processors will still be dissipating some

power, so the power supply fans will still run.

The SERVER BOARD supports sleep states s0, s1, s4, and s5:

• s0: Normal running state.

• s1: Processor sleep state. No context will be lost in this state and the processor caches will

maintain coherency.

• s4: Hibernate or Save to Disk: The memory and machine state are saved to disk. Pressing the

power button or other wakeup event will restore the system state from the disk and resume

normal operation. This assumes that no hardware changes have been made to the system while

it was off.

• s5: Soft off: Only the RTC section of the CSB and the BMC are running in this state. No

context is saved by the OS or hardware.

CAUTION

The system is off only when the AC power cord is disconnected.

Security

Software Locks

The BIOS Setup and the System Setup Utility (SSU) provide a number of security features to

prevent unauthorized or accidental access to the system. Once the security measures are enabled,

you can access the system only after you enter the correct password(s). For example:

• Enable the keyboard lockout timer so that the server requires a password to reactivate the

keyboard and mouse after a specified time out period1 to 120 minutes.

• Set and enable a supervisor password.

• Set and enable a user password.

• Set secure mode to prevent keyboard or mouse input and to prevent use of the front panel reset

and power switches.

• Activate a hot key combination to enter secure mode quickly.

• Disable writing to the diskette drive when secure mode is set.

• Disable access to the boot sector of the operating system hard disk drive.

Using Passwords

You can set the user password, the supervisor password, or both passwords.

If only the user password is set, you:

• Must enter the user password to enter BIOS Setup or the SSU.

• Must enter the user password to boot the server if Password on Boot is enabled in either the

BIOS Setup or SSU.

• Must enter the user password to exit secure mode. If only the supervisor password is set, you:

• Must enter the supervisor password to enter BIOS Setup or the SSU.

Chassis Description 25

Page 26

HP cc3300 Carrier Grade Server Product Guide

• Must enter the supervisor password to boot the server if Password on Boot is enabled in

either the BIOS Setup or SSU.

• Must enter the supervisor password to exit secure mode.

If both passwords are set, you:

• May enter the user password to enter BIOS Setup or the SSU. However, you will not be able to

change many of the options.

• Must enter the supervisor password if you want to enter BIOS Setup or the SSU and have

access to all of the options.

• May enter either password to boot the server if Password on Boot is enabled in either the BIOS

Setup or SSU.

• May enter either password to exit secure mode.

Secure Mode

Configure and enable the secure boot mode by using the SSU. When secure mode is in effect:

• You can boot the server and the operating system will run, but you must enter the user

password to use the keyboard or mouse.

• You cannot turn off system power or reset the server from the front panel switches.

• Secure mode has no effect on functions enabled via remote server management or power

control via the watchdog timer.

Taking the server out of secure mode does not change the state of system power. That is, if you

press and release the power switch while secure mode is in effect, the system will not be powered

off when secure mode is later removed. However, if the front panel power switch remains

depressed when secure mode is removed, the server will be powered off.

26 Chassis Description

Page 27

HP cc3300 Carrier Grade Server Product Guide

Summary of Software Security Features

Table 6 lists the software security features and describes what protection each offers. In general, to

enable or set the features listed here, you must run the SSU and go to the Security Subsystem

Group, menu. The table also refers to other SSU menus and to the Setup utility.

Table 6. Software Security Features

Feature Description

Secure mode How to enter secure mode:

Setting and enabling passwords automatically places the system in secure mode.

If you set a hot-key combination (through Setup), you can secure the system

simply by pressing the key combination. This means you do not have to wait for

the inactivity time-out period.

When the system is in secure mode:

The server can boot and run the operating system, but mouse and keyboard input

is not accepted until the user password is entered.

At boot time, if a CD is detected in the CD-ROM drive or a diskette in drive A, the

system prompts for a password. When the password is entered, the server boots

from CD or diskette and disables the secure mode.

If there is no CD in the CD-ROM drive or diskette in drive A, the server boots from

drive C and automatically goes into secure mode. All enabled secure mode

features go into effect at boot time.

To leave secure mode: Enter the correct password(s).

Disable writing to

diskette

In secure mode, the server will not boot from or write to a diskette unless a

password is entered.

To write protect access to diskette whether the server is in secure mode or not, use

the Setup main menu, Floppy Options, and specify Floppy Access as read only.

Continued

Chassis Description 27

Page 28

HP cc3300 Carrier Grade Server Product Guide

Table 6. Software Security Features (continued)

Feature Description

Set a time out period

so that keyboard and

mouse input are not

accepted

Also, screen can be

blanked, and writes to

diskette can be

inhibited

Control access to

using the SSU: set

supervisor password

Control access to the

system other than

SSU: set user

password

Boot without

keyboard

Specify the boot

sequence

Specify and enable an inactivity time out period of from 1 to 120 minutes.

If no keyboard or mouse action occurs for the specified period, attempted keyboard

and mouse input will not be accepted.

The monitor display will go blank, and the diskette drive will be write protected

(if these security features are enabled through Setup).

To resume activity: Enter the correct password(s).

To control access to setting or changing the system configuration, set a supervisor

password and enable it through Setup.

If both the supervisor and user passwords are enabled, either can be used to boot

the server or enable the keyboard and/or mouse, but only the supervisor password

will allow Setup to be changed.

To disable a password, change it to a blank entry or press CTRL-D in the Change

Password menu of the Supervisor Password Option menu found in the Security

Subsystem Group.

To clear the password if you cannot access Setup, change the Clear Password

jumper (see Chapter 5).

To control access to using the system, set a user password and enable it through

Setup.

To disable a password, change it to a blank entry or press CTRL-D in the Change

Password menu of the User Password Option menu found in the Security

Subsystem Group.

To clear the password if you cannot access Setup, change the Clear Password

jumper (see Chapter 5).

The system can boot with or without a keyboard. During POST, before the system

completes the boot sequence, the BIOS automatically detects and tests the

keyboard if it is present and displays a message.

The sequence that you specify in setup will determine the boot order. If secure

mode is enabled (a user password is set), then you will be prompted for a

password before the server fully boots. If secure mode is enabled and the “Secure

Boot Mode” option is also enabled, the server will fully boot but will require a

password before accepting any keyboard or mouse input.

28 Chassis Description

Page 29

HP cc3300 Carrier Grade Server Product Guide

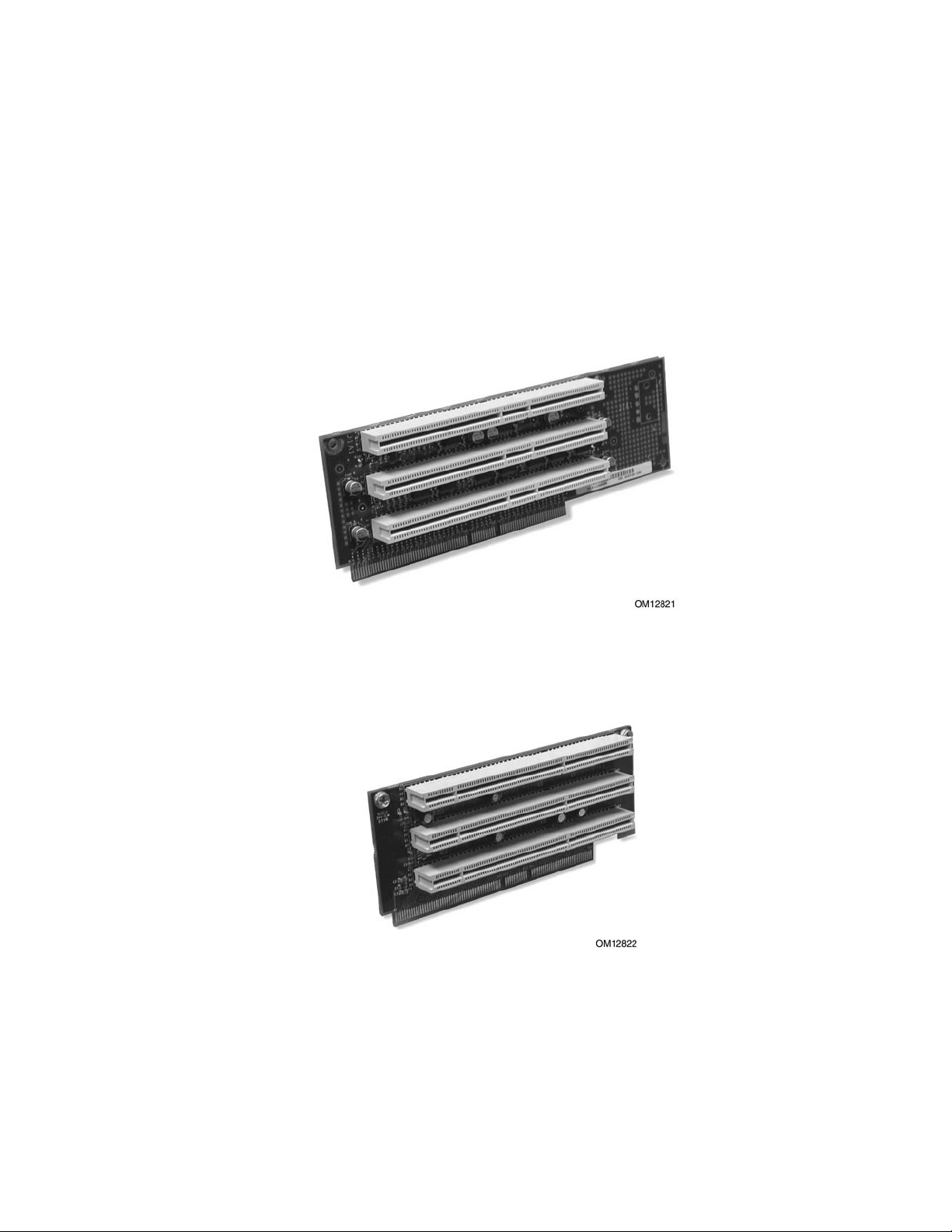

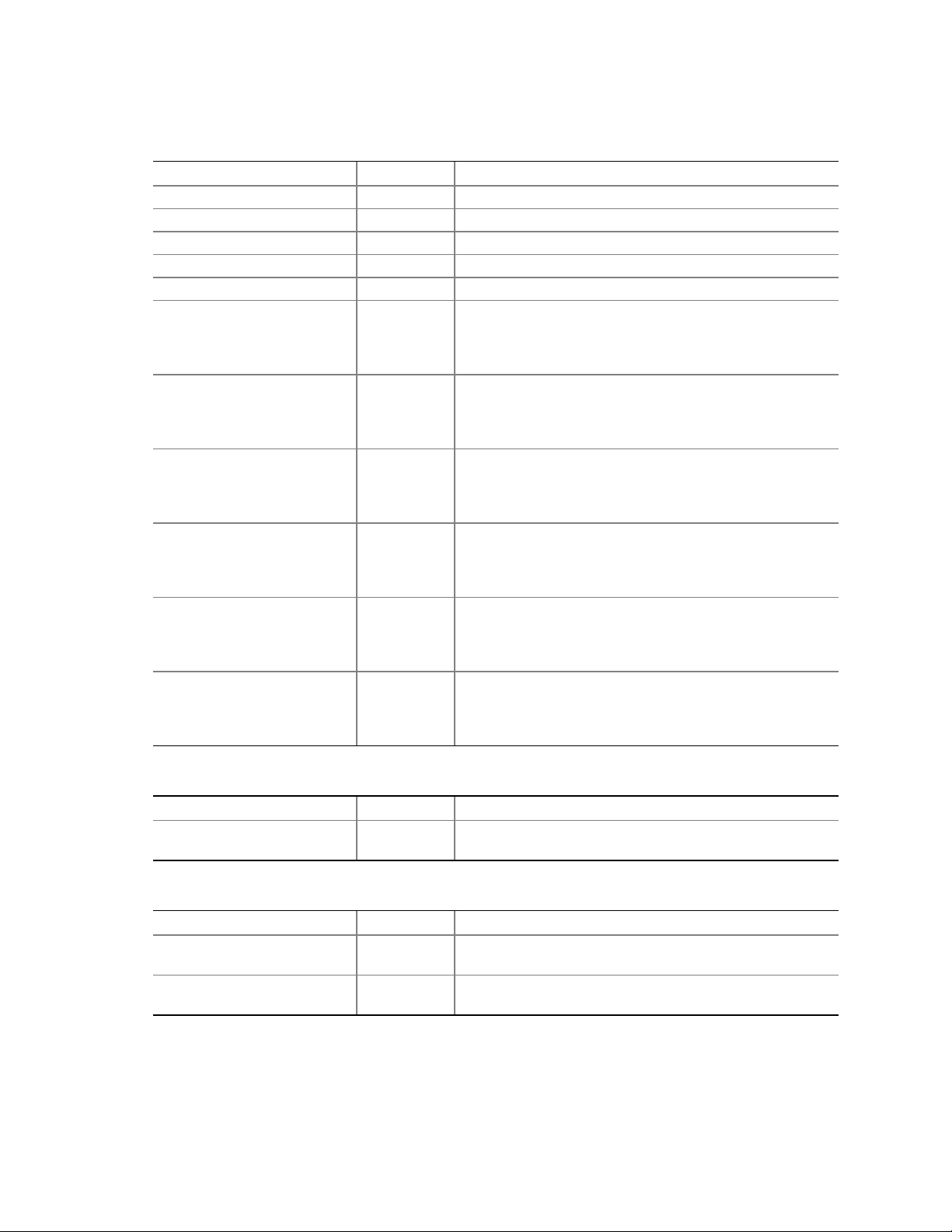

PCI I/O Riser Cards

The server can support two riser cards, a 5 Volt full height riser card, and a 3.3 Volt half-height

riser card or two 3.3 volt half-height riser cards. Features of the 5 Volt riser card include:

• Support for three 33 MHz 5 Volt 64-bit PCI add-in cards

• Provides 5 Volt to 3.3 Volt signal level translation

The 5 Volt riser card contains voltage level translation, converting the 5 Volt PCI add-in card

signals to conform to the server board, which has 3.3 Volt signaling levels. The card supports up to

50 W total with a limit of 25 Watts per slot. Figure 6 illustrates the 5 Volt riser card.

Figure 6. 5 Volt Riser Card

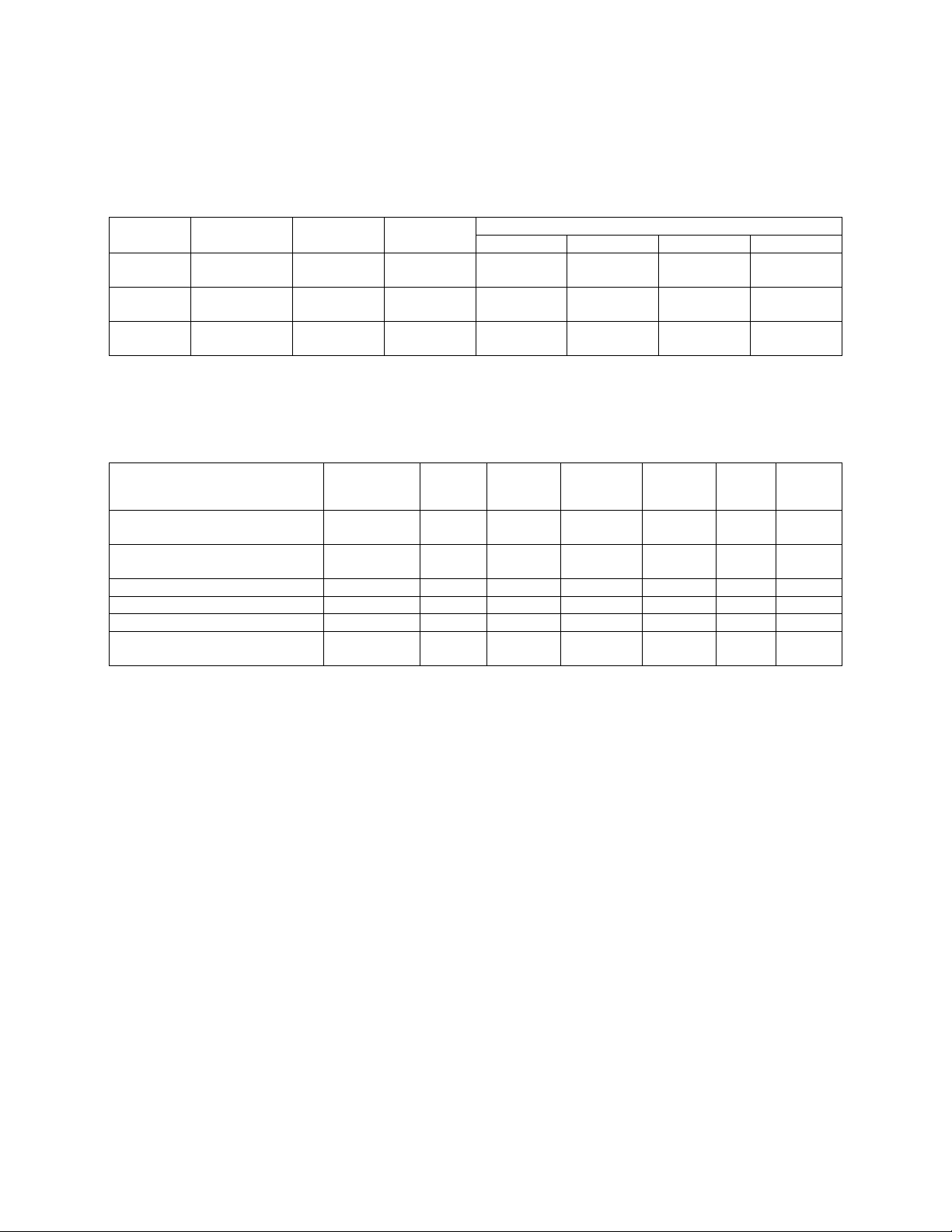

The 3.3 Volt riser card supports three 3.3 Volt 64-bit slots at 66 MHz. The card supports up to 30

W total power consumption. Figure 7 illustrates the 3.3 Volt riser card.

Figure 7. 3.3 Volt Riser Card

Chassis Description 29

Page 30

HP cc3300 Carrier Grade Server Product Guide

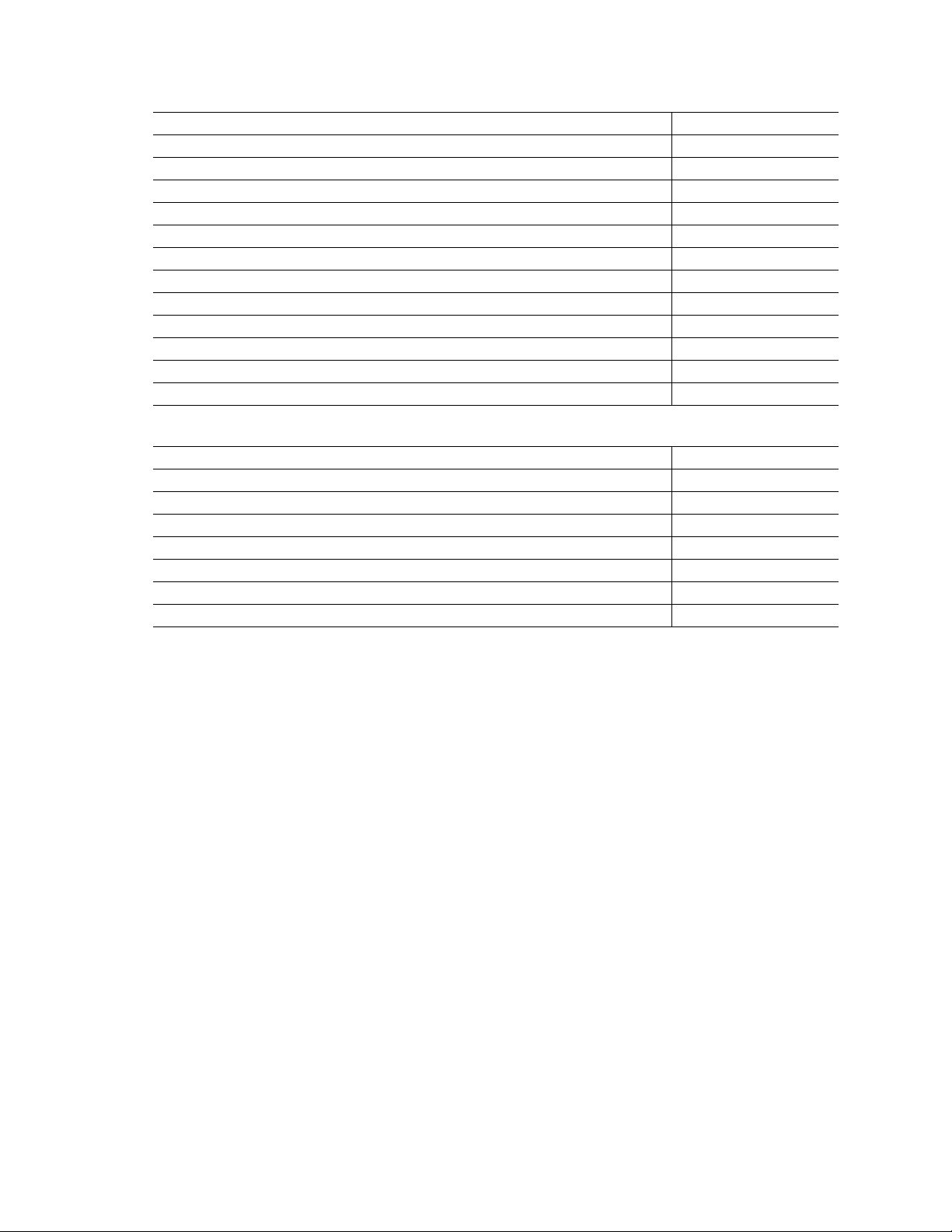

A 3.3v PCI riser card is installed in the server as a part of the standard configuration. Optional PCI

riser cards are also available. Refer to the following table for riser card details.

Table 7. HP cc3300 Carrier Grade Server PCI I/O Riser Card Details

Supported Card Dimensions Product

Number

standard

configuration

A6928A (3.3

volt Riser Card)

A6929A (5 volt

Riser Card

Number of PCI I/O

Slots

3 3.3 volt 64/66, 64/33,

3 3.3 volt 64/66, 64/33,

3 5.0 volt 64/33, 32/33 Yes Yes No Yes

Voltage Operation

(bits / MHz)

32/66, 32/33

32/66, 32/33

Full Length Half Length Low Profile Full Height

No Yes Yes No

Yes Yes No Yes

PCI I/O Cards

The following PCI cards are available for the cc3300 Carrier Grade Server.

I/O Card

Ultra 160 SCSI interface, low profile A6919A Universal Half length Low profile VHDCI

Ultra 160 SCSI interface, full height A6919A opt.001 Universal Half length Full height VHDCI

10/100BaseTX LAN Adapter, low profile A6920A Universal Half length Low profile RJ45 Yes 2

10/100BaseTX LAN Adapter, full height A6920A opt.001 Universal Half length Full height RJ45 Yes 2

Gigabit LAN Adapter over copper A6921A Universal Half Length Low Profile RJ45 Yes 2

Gigabit LAN Adapter over copper, full

height

Product

Number

A6921A opt 001 Universal Half length Full Heighte RJ45 Yes 2

3.3 volt,

5.0 volt, or

Universal

Full or Half

Length

Low Profile or

Full Height

Connector

Types

(VHDTS68)

(VHDTS68)

Factory

Integrate

Max Cards

Per hp

cc3300

Yes 2

Yes 2

Power Supplies

The power supply cage shown in Figure 8 is accessed from the rear of the chassis. The power

supply cage supports up to two hot-swap 350 W power supplies (either AC input or DC input) in a

(1 + 1) redundant configuration. A power supply filler module (shown at left in Figure 8) for the

empty power supply site is supplied for systems without redundancy.

Only the DC input version is NEBS certified.

30 Chassis Description

Page 31

HP cc3300 Carrier Grade Server Product Guide

OM13104

Figure 8. Non-redundant AC-Power Supply Subsystem (Filler Module shown at Left)

DC Power Subsystem

This section defines the features of the DC input switching power subsystem.

Features

• 350 W output capability in full DC input voltage range

• “Power Good” indication LEDs

• Predictive failure warning

• Internal cooling fans with multi-speed capability

• Remote sense of 3.3 Volt, 5 Volt, and 12 Volt DC outputs

• “DC_OK” circuitry for brown out protection and recovery

• Built-in load sharing capability

• Built-in overloading protection capability

• Onboard field replaceable unit (FRU) information

2

• I

C interface for server management functions

• Integral handle for insertion/extraction

Introduction

The DC version of the cc3300 Carrier Grade Server uses a -48 to -60 VDC input switching power

subsystem, which provides up to 350 Watts with -48 to -60 VDC input and with current and remote

sense regulation. The power subsystem consists of one or two 350-Watt power supply modules. A

system with two modules forms a redundant, hot-swappable (1+1) power subsystem.

Interface Requirements

DC Input

The DC power source may produce hazardous voltage levels exceeding -60 VDC and high energy

levels above 240VA that may cause electric shock or burns. All DC input connections should be

Chassis Description 31

Page 32

HP cc3300 Carrier Grade Server Product Guide

made only by a qualified service person only to prevent injury. All wiring terminals connected to

the DC input terminal block must be fully insulated with no exposed bare metal.

DC Output Connectors

The power subsystem DC power and control signals are interfaced to the server system via wire

harnesses when the power supply modules are inserted into the power subsystem enclosure. The

safety ground pin of the power supply module is the first pin to connect and the last to disconnect

when the module is being inserted or removed from the power subsystem housing. In addition to

the 5 V Standby, -12 V, +3.3 V, +5 V and +12 V DC outputs, the following signals and output pins

are included:

• +3.3 VDC remote sense

• +5 VDC remote sense

• +12 VDC remote sense

• Remote sense return

• Power Subsystem On (DC PWR enable)

• Power Good

2

• I

C*

*

PS Failure, PS Presence, PS Predictive Fail, +12 V Mon, +5 V Mon, and the 5 V Standby rails

failure are being monitored via an I

2

C interface chip.

Power Supply Module LED Indicators

There is a single bi-color LED to indicate power supply status visible on the back of the system.

Table 8 shows the conditions confirmed by the LED indicators.

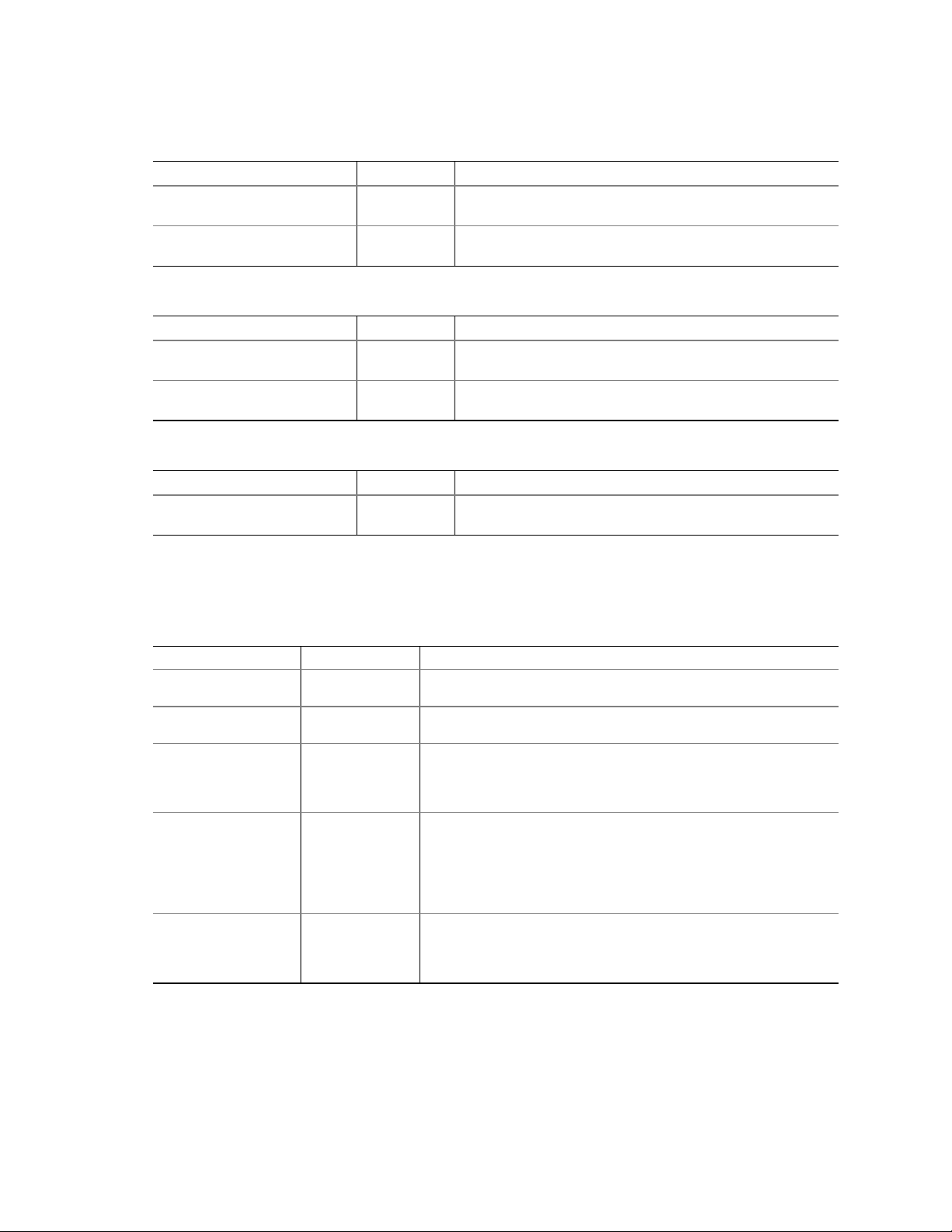

Table 8. LED Indicators

Power Supply Condition Power Supply LED

No DC power to all PSU OFF

No DC power to this PSU only AMBER

DC present / Only Standby Outputs On BLINK GREEN

Power supply DC outputs ON and OK GREEN

Power Supply in Alert Condition BLINK AMBER

Power supply failure (OTP, OCP, OVP, UV) AMBER

DC Input Voltage Specification

The power supply will operate within all specified limits over the following input voltage range.

The power supply will power-off if the DC input is less than -34 VDC.

Table 9. DC Input Rating

Parameter

Voltage -38VDC -48 to -60VDC -75VDC 13.5 Amps

1

Maximum input current is measured at the lowest input voltage that the power supply continues to operate. This is not to

be used for determining agency input current markings.

Minimum

Tolerance

Nominal

Rating

Maximum

Tolerance

1

Maximum Input

Current

32 Chassis Description

Page 33

HP cc3300 Carrier Grade Server Product Guide

DC Output Current Specifications

The combined output power of all outputs will not exceed 350 W. Each output has a maximum and

minimum current rating shown in Table 10. The power supply meets both static and dynamic

voltage regulation requirements for the minimum dynamic loading conditions. The power supply

meets only the static load voltage regulation requirements for the minimum static load conditions.

Table 10. 350W Load Ratings

+3.3V +5V +12V -12V 5VSB

PEAK (10sec) 30A

MAX 20A 20A 25A 0.5A 1.5A

MIN DYNAMIC 2.0A 2.0A 1.5A 0A 0A

MIN STATIC 1A 1A 0A 0A 0A

Note: The maximum combined power of the 3.3 V and 5 V outputs is 150 W.

AC Power Subsystem

This section defines the AC-input switching power subsystem.

Features

• 350 W output capability in full DC input voltage range

• “Power Good” indication LEDs

• Predictive failure warning

• Internal cooling fans with multi-speed capability

• Remote sense of 3.3 V, 5 V, and 12 VDC outputs

• AC_OK circuitry for brown out protection and recovery

• Built-in load sharing capability

• Built-in overloading protection capability

• Onboard field replaceable unit (FRU) information

2

• I

C interface for server management functions

• Integral handle for insertion/extraction

Introduction

The AC version of the cc3300 Carrier Grade server uses a -48 to -60 VDC input switching power

subsystem, which provides up to 350 Watts with -48 to -60 VDC input and with current and remote

sense regulation. The power subsystem consists of one or two 350-Watt power supply modules. A

system with two modules forms a redundant, hot-swappable (1+1) power subsystem. There is a

single bi-color LED to indicate power supply status. Refer to Table 11 for conditions of the power

supply LEDs.

Table 11. LED Indicators

Power Supply Condition Power Supply LED

No AC power to all PSU OFF

No AC power to this PSU only AMBER

DC present / Only Standby Outputs On BLINK GREEN

Power supply DC outputs ON and OK GREEN

Chassis Description 33

Page 34

HP cc3300 Carrier Grade Server Product Guide

Power Supply in Alert Condition BLINK AMBER

Power supply failure (OTP, OCP, OVP, UV) AMBER

AC Input Voltage Specification

The power supply operates within all specified limits over the following input voltage ranges.

Harmonic distortion of up to 10% THD will not cause the power supply to exceed specified limits.

Table 12. AC Input Rating

Parameter MIN RATED MAX Max Input Current (350W Version)

Voltage (110) 90 V

Voltage (220) 180 V

Frequency 47 Hz 63 Hz

100-127 V

rms

200-240 V

rms

140 V

rms

264 V

rms

6.7 A

rms

rms

rms

DC Output Current Specifications

The combined output power of all outputs should not exceed 350 W. Each output has a maximum

and minimum current rating shown in Table 13. The power supply meets both static and dynamic

voltage regulation requirements for the minimum dynamic loading conditions. The power supply

meets only the static load voltage regulation requirements for the minimum static load conditions.

Table 13. 350W Load Ratings

+3.3V +5V +12V -12V 5VSB

PEAK (10sec) 30A

MAX 20A 20A 25A 0.5A 1.5A

MIN DYNAMIC 2.0A 2.0A 1.5A 0

MIN STATIC 1A 1A 0A 0A 0A

A

0A

NOTE

The maximum combined power of the 3.3 V and 5 V outputs is 150 W.

Peripheral Bay

The peripheral bay consists of the following two removable media devices. Both devices are

replaced as one assembly.

• ½” Floppy drive

• ½” CD-ROM drive

Hard Drive Tray

The HP cc3300 Carrier Grade Server supports up to two internal disk drives. These disks may be of

different capacities and rotational speeds. An Ultra 160 SCSI controller contained on the system board as

part of core I/O provides the disk drives with an independent SCSI channel. This Ultra 160 SCSI controller

channel is independent of the Ultra 160 SCSI controller channel in core I/O that provides the external Ultra

160 SCSI port.

34 Chassis Description

Page 35

HP cc3300 Carrier Grade Server Product Guide

Cc3300 Internal Disk Drive Product Numbers

Product Number Disk Capacity Rotational speed Disk Replacement Part Number

A6917A 18 GB 10,000 RPM A6917-69001

A6942A 18 GB 15,000 RPM A6942-69001

A6918A 36GB 10,000 RPM A6918-69001

A6943A 36 GB 15,000 RPM A6943-69001

Cooling Subsystem

The cooling subsystem contains a fan array consisting of two 80 x 38 mm fans and two 40 x 28 mm

fans to cool the server board and other components as shown in Figure 9. A fan failure is indicated

by one of the fault LEDs located on the front panel.

OM12820

Figure 9. Fan Array with Four System Fans Installed

Air flows through the bezel, over the peripheral bay and the hard drive tray, passes through the

fans, over the server board, and exhausts through the rear of the chassis.

Each fan provides a tachometer signal output to the server board to indicate a fan failure.

Ambient Temperature Control

The server board contains a pulse-width-modulation (PWM) circuit, that cycles the 12 VDC fan

voltage to provide quiet operation when system baseboard temperature is low, and there are no fan

failures. Under normal baseboard temperature conditions (less than 45 °C), the fan power circuit

supplies an effective fan voltage of 7.0 VDC. When the baseboard temperature exceeds 45 °C, the

fan control circuit ceases cycling and delivers 12 VDC. Following a baseboard temperature

excursion above 45 °C the fan voltage does not reenter PWM mode until the baseboard temperature

drops below 45 °C and all fans are operational.

The cooling subsystem’ design meets acoustic and thermal requirements at the lower fan speed

settings. At the higher fan speed settings, thermal requirements are met for the maximum ambient

temperatures but acoustic requirements may be exceeded.

Chassis Description 35

Page 36

HP cc3300 Carrier Grade Server Product Guide

Server Management Summary

The server board’s server management architecture features a board management controller (BMC),

which autonomously monitors server status and provides the interface to server management

control functions. The BMC is responsible for controlling system power, resets, monitoring

voltages, temperatures, fans, and communicating with secondary controllers on its Intelligent

Platform Management Bus (IPMB).

Detailed server management tool information and supported operating system information is

contained in the Intel Server Control Installation (ISC) Guide For the cc2300 & cc3300 Carrier

Grade Server. ISC is a server management tool that provides real time monitoring and alerting for

server hardware, emergency remote management and remote server setup.

The functions of each controller are summarized in the following sections.

Server Board Management Controller

The BMC on the server board provides server management monitoring capabilities. Associated

with the BMC is a flash memory that holds the operational code, sensor data records (SDR), and

system event log (SEL). A serial EEPROM holds the BMC configuration defaults and field

replaceable unit (FRU) information. The BMC supports the following:

• Server board voltage monitoring

• Fan failure detection

• Fan speed control

• Processor voltage monitoring

• Processor presence detection

• Processor internal error (IERR) monitoring

• Fault resilient booting (FRB)

• Processor disable control

• Watchdog timer

• Periodic system management interrupt (SMI) timer

2

• I

C master controller for the Intelligent Platform Management Bus (IPMB)

• Three private I

• Server management software (SMS) and server management mode (SMM) IPMB message

receiver

• Event message receiver

• System event log (SEL) management and access

• Sensor data record (SDR) repository management and access

• Processor nonmaskable interrupt (NMI) monitoring

• Processor SMI monitoring

• Time-stamp clock

• Secure mode, video blank, and floppy write protect

• Software front panel NMI generation

2

C management bus interfaces

36 Chassis Description

Page 37

2 Regulatory Specifications and Disclaimers

Declaration of the Manufacturer or Importer

We hereby certify that this product is in compliance with European Union EMC Directive

89/336/EEC, using standards EN55022 (Class A) and EN55024 and Low Voltage Directive

73/23/EEC, Standard EN60950.

Safety Compliance

USA: UL 1950 – 3rd Edition/CSA 22.2. No. 950-M93

Canada: UL Certified – 3rd Edition/CSA 22.2. No. 950-M93 for Canada (product bears

the single UL mark for U.S. and Canada)

Europe: Low Voltage Directive, 73/23/EECTUV/GS to EN60950 2nd Edition with