Page 1

service

Page 2

Page 3

output finishing devices:

hp LaserJet multifunction finisher, 3,000-sheet

stapler/stacker, 3,000-sheet stacker,

and 8-bin mailbox

service supplement__________

Page 4

Copyright and License

© 2004 Copyright HewlettPackard De v elopment Compan y,

LP

Reproduction, adaptation or

translation without prior written

permission is prohibited, except

as allowed under the copyright

laws.

Part number: Q5693-90002

Edition 1, 9/2004

The information contained herein

is subject to change without

notice.

The only warranties for HP

products and services are set

forth in the express warranty

statements accompanying such

products and services. Nothing

herein should be construed as

constituting an additional

warranty. HP shall not be liable

for technical or editorial errors or

omissions contained herein.

Trademark Credits

Adobe

®

and PostScript® are

trademarks of Adobe Systems

Incorporated.

MS-DOS

®

is a U.S. registered

trademark of Microsoft

Corporation.

E

NERGY STAR

®

is a U.S.

registered service mark of the

United States Environmental

Protection Agency.

Page 5

Contents 3

Contents

1 Product information

Product features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Multifunction finisher (C8088A/C8088B). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3,000-sheet stapler/stacker (C8085A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3,000-sheet stacker (C8084A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8-bin mailbox (Q5693A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3,000-sheet stapler/stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3,000-sheet stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8-bin mailbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3,000-sheet stapler/stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3,000-sheet stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8-bin mailbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3,000-sheet stapler/stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3,000-sheet stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8-bin mailbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Regulatory information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Declaration of Conformity—multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Declaration of Conformity—3,000-sheet stapler/stacker . . . . . . . . . . . . . . . . . . . . . . . . 33

Declaration of Conformity—3,000-sheet stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Declaration of Conformity—8-bin mailbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Service approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Parts and supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Exchange program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2 Installation

Environmental requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Physical requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3,000-sheet stapler/stacker and 3,000-sheet stacker . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8-bin mailbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3 Operation

Supported media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3,000-sheet stapler/stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3,000-sheet stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8-bin mailbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Using media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3,000-sheet stapler/stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Page 6

4 Contents ENWW

4 Maintenance

Cleaning the outside of the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Cleaning inside the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5 Theory of operation

Power-on sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3,000-sheet stapler/stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3,000-sheet stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8-bin mailbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Basic operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Offset specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3,000-sheet stapler/stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Offset specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3,000-sheet stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Offset specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8-bin mailbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Electric circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3,000-sheet stapler/stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3,000-sheet stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

8-bin mailbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Motors, solenoids, and clutches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8-bin mailbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3,000-sheet stapler/stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3,000-sheet stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8-bin mailbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6 Removal and replacement

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Removal and replacement strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Electrostatic discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Required tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Before performing service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Multifunction finisher external doors and covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Stapler door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Product-release handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Folding knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Handle-mounting gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Back cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Upper panel assembly (top door) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Internal-path cover (dispose subcover) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Foot cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Multifunction finisher assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Paper-guide wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Product-attachment latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Stapling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Aligner racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Booklet bin-full sensor flag (main lever weight assembly) . . . . . . . . . . . . . . . . . . . . . . 106

Paper deflector (deflector weight) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Anti-static brush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Page 7

ENWW Contents 5

Stacker bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Booklet bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Stapling-door switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Interlock switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Flipper assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

Folding mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

User LED PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Controller PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

Service LED PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Jet-Link cable (interface cable) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Adjustable casters (left side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Stationary extended caster (back right) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Stationary caster (front right) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

3,000-sheet stapler/stacker and 3,000-sheet stacker external doors and covers. . . . . . .129

Face-up bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Stapler/stacker bin (stapler/stacker only) or stacker bin (stacker only) . . . . . . . . . . . . .129

Back inner cover and front inner cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

Front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

Back cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

Foot cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

Controller PCA cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Door assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

3,000-sheet stapler/stacker and 3,000-sheet stacker assemblies. . . . . . . . . . . . . . . . . . .137

Flipper assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Paper-path assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Accumulator wings (stapler/stacker only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

Paper-stop clips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

Accumulator assembly (stapler/stacker only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

Carriage assembly (stapler/stacker only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .144

Offset module (stacker only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Stapler (stapler/stacker only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

Controller PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

LED PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

Interlock switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

Safety-switch assembly (stapler/stacker only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Optical sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

Cable assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

8-bin mailbox external doors and covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

Bubbled cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

Front cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .161

Back cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

Top cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

Cable channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

Paper bins and blind cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .167

8-bin mailbox assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

Flipper assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

Delivery head motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

Transport belt motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Input paper guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

Face-up full lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

Rollers kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

Magnets assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

Metal tape and housing assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

Controller PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

Anticurl strings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

Page 8

6 Contents ENWW

Delivery head assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Interlock switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Diagnostic LED PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

User status LED PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Adjustable, fixed, and extended fixed casters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Attachment assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

7 Troubleshooting

Understanding the troubleshooting process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Preliminary operating checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Troubleshooting flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Troubleshooting by using the event log and the control panel messages . . . . . . . . . . . . 199

Event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Event log messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Device error conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Control panel messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Multifunction finisher control panel and event log messages . . . . . . . . . . . . . . . . . . . . 203

3,000-sheet stapler/stacker control panel and event log messages. . . . . . . . . . . . . . . 211

3,000-sheet stacker control panel and event log messages . . . . . . . . . . . . . . . . . . . . . 218

8-bin mailbox control panel and event log messages . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Troubleshooting jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Clearing jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Troubleshooting media problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Determine the problem source: print media or output device . . . . . . . . . . . . . . . . . . . . 231

Isolate a paper path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Isolate a media brand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Isolate a media type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Using the service-level diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Service mode—printer or MFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Service mode—multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Service mode—3,000-sheet stapler/stacker and 3,000-sheet stacker . . . . . . . . . . . . 239

Service mode—8-bin mailbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Performing calibration and adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

3,000-sheet stapler/stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Using troubleshooting tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Information pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Paper-path test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

User LED light patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

8 Parts and diagrams

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Ordering parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Consumables and documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Common hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Illustrations and parts lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Multifunction finisher system assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Mounting hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

External panels and covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Internal components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Dispose assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Paper feeder assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Reverse assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Fold assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

PCB assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Alphabetical parts list (multifunction finisher) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Page 9

ENWW Contents 7

Numerical parts list (multifunction finisher) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .265

Illustrations and parts lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .266

3,000-sheet stapler/stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .266

3,000-sheet stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .270

Alphabetical parts list (3,000-sheet stapler/stacker and 3,000-sheet stacker) . . . . . . . . .273

Numerical parts list (3,000-sheet stapler/stacker and 3,000-sheet stacker) . . . . . . . . . . .275

Illustrations and parts lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .277

8-bin mailbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .277

Alphabetical parts list (8-bin mailbox) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .283

Numerical parts list (8-bin mailbox). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .284

Index

Page 10

8 Contents ENWW

Page 11

Contents 9

List of tables

Table 1. Physical specifications—multifunction finisher. . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 2. Electrical specifications—multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 3. Environmental specifications—multifunction finisher . . . . . . . . . . . . . . . . . . . . . 28

Table 4. Acoustic emissions specifications—multifunction finisher . . . . . . . . . . . . . . . . . . 28

Table 5. Physical specifications—3,000-sheet stapler/stacker . . . . . . . . . . . . . . . . . . . . . 29

Table 6. Electrical specifications—3,000-sheet stapler/stacker. . . . . . . . . . . . . . . . . . . . . 29

Table 7. Environmental specifications—3,000-sheet stapler/stacker . . . . . . . . . . . . . . . . 29

Table 8. Acoustic emissions specifications—3,000-sheet stapler/stacker. . . . . . . . . . . . . 29

Table 9. Physical specifications—3,000-sheet stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 10. Electrical specifications—3,000-sheet stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 11. Environmental specifications—3,000-sheet stacker . . . . . . . . . . . . . . . . . . . . . . 30

Table 12. Acoustic emissions specifications—3,000-sheet stacker. . . . . . . . . . . . . . . . . . . 30

Table 13. Physical specifications—8-bin mailbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 14. Power requirements and circuit capacity—8-bin mailbox . . . . . . . . . . . . . . . . . . 31

Table 15. Power consumption—8-bin mailbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 16. Operating and storage environment—8-bin mailbox . . . . . . . . . . . . . . . . . . . . . 31

Table 17. Approximate number of sheets that can be stapled, listed by media weight. . . . 48

Table 18. Number of sheets that can be st apled and folded, listed by media weight . . . . . 48

Table 19. Number of sheets that can be stapled and folded, listed by booklet size . . . . . . 48

Table 20. Skew specifications—multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 21. Approximate number of sheets that can be stapled, listed by media weight. . . . 50

Table 22. Offset specifications for the multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 23. Offset specifications for the 3,000-sheet stapler/stacker . . . . . . . . . . . . . . . . . . . 65

Table 24. Offset specifications for the 3,000-sheet stacker. . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 25. Motors, solenoids, and clutches for feeding and aligning media . . . . . . . . . . . . . 76

Table 26. Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 27. Control panel and event log messages—multifunction finisher . . . . . . . . . . . . . 203

Table 28. Control panel and event log messages—3,000-sheet stapler/stacker. . . . . . . . 211

Table 29. Control panel and event log messages—3,000-sheet stacker . . . . . . . . . . . . . 218

Table 30. Control panel and event log messages—8-bin mailbox. . . . . . . . . . . . . . . . . . . 223

Table 31. Consumables and documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Table 32. Common hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Table 33. HP recommended torque values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Table 34. Multifunction finisher system assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Table 35. Mounting hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Table 36. External panels and covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Table 37. Internal components (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Table 38. Internal components (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Table 39. Dispose assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Table 40. Paper feeder assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Table 41. Reverse assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Table 42. Fold assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Table 43. PCB assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Table 44. Alphabetical parts list (multifunction finisher). . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Table 45. Numerical parts list (multifunction finisher) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Table 46. 3,000-sheet stapler/stacker (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Table 47. 3,000-sheet stapler/stacker (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Table 48. 3,000-sheet stacker (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Table 49. 3,000-sheet stacker (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Table 50. Alphabetical parts list (3,000-sheet stapler/stacker and 3,000-sheet stacker). . 273

Table 51. Numerical parts list (3,000-sheet stapler/stacker and 3,000-sheet stacker) . . . 275

Table 52. 8-bin mailbox (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Page 12

10 List of tables ENWW

Table 53. 8-bin mailbox (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Table 54. 8-bin mailbox (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Table 55. Alphabetical parts list (8-bin mailbox). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Table 56. Numerical parts list (8-bin mailbox) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Page 13

Contents 11

List of figures

Figure 1. Sample identification label—multifunction finisher (C8088A). . . . . . . . . . . . . . . 19

Figure 2. Sample identification label—multifunction finisher (C8088B). . . . . . . . . . . . . . . 19

Figure 3. Sample identification label—3,000-sheet stapler/stacker. . . . . . . . . . . . . . . . . . 20

Figure 4. Sample identification label—3,000-sheet stacker . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 5. Sample identification label—8-bin mailbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 6. External assembly locations—multifunction finisher (front view) . . . . . . . . . . . . 23

Figure 7. External assembly locations—multifunction finisher (back view) . . . . . . . . . . . 23

Figure 8. Cross-section—multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 9. External assembly locations—3,000-sheet stapler/stacker (front view). . . . . . . 25

Figure 10. External assembly locations—3,000-sheet stapler/stacker (back view). . . . . . . 25

Figure 11. Cross-section—3,000-sheet stapler/stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 12. Cross-section—3,000-sheet stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 13. External assembly locations—8-bin mailbox (left side view) . . . . . . . . . . . . . . . 27

Figure 14. External assembly locations—8-bin mailbox (right side view) . . . . . . . . . . . . . . 27

Figure 15. Multifunction finisher (side view and top view) . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 16. 3,000-sheet stapler/stacker (side view and top view). . . . . . . . . . . . . . . . . . . . . 40

Figure 17. 8-bin mailbox (top view and side view). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 18. Basic operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 19. Simple stacking (face-down delivery). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 20. Simple stacking (face-up delivery) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 21. Job offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 22. Staple positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 23. Stapling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 24. Booklet making (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 25. Booklet making (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 26. Booklet making (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 27. Stapler/stacker main modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 28. Stapler/stacker jam detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 29. Stapler-bin-full condition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 30. 3,000-sheet stacker main modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 31. Stacker jam detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 32. Stacker-bin-full-condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 33. 8-bin mailbox main modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 34. 8-bin mailbox paper path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 35. Signal flow between the output device and the video controller. . . . . . . . . . . . . 73

Figure 36. Multifunction finisher power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 37. Motors, solenoids, and clutches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 38. Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 39. Sensors—multifunction finisher (1 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 40. Sensors—multifunction finisher (2 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 41. Sensors—multifunction finisher (3 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 42. Sensors—multifunction finisher (4 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Figure 43. Sensors—multifunction finisher (5 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 44. Sensors—3,000-sheet stapler/stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 45. Sensors—3,000-sheet stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 46. Sensors—8-bin mailbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 47. Stapler door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 48. Product-release handle (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 49. Product-release handle (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 50. Folding knob. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 51. Handle-mounting gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Figure 52. Front cover (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Page 14

12 List of figures ENWW

Figure 53. Front cover (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 54. Back cover (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Figure 55. Back cover (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Figure 56. Upper panel assembly (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Figure 57. Upper panel assembly (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Figure 58. Internal-path cover (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Figure 59. Internal-path cover (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Figure 60. Foot cover (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Figure 61. Foot cover (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Figure 62. Paper-guide wire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Figure 63. Product-attachment latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Figure 64. Stapling unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 65. Booklet bin-full sensor flag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Figure 66. Paper deflector (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Figure 67. Paper deflector (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Figure 68. Anti-static brush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Figure 69. Booklet bin (1 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Figure 70. Booklet bin (2 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Figure 71. Booklet bin (3 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Figure 72. Booklet bin (4 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Figure 73. Stapling-door switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Figure 74. Interlock switch (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Figure 75. Interlock switch (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Figure 76. Flipper assembly (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Figure 77. Flipper assembly (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Figure 78. Flipper assembly (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Figure 79. Folding mechanism (1 of 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Figure 80. Folding mechanism (2 of 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Figure 81. Folding mechanism (3 of 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Figure 82. Folding mechanism (4 of 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Figure 83. Folding mechanism (5 of 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Figure 84. Folding mechanism (6 of 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Figure 85. User LED PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Figure 86. Controller PCA (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Figure 87. Controller PCA (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Figure 88. Controller PCA (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Figure 89. Service LED PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Figure 90. Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Figure 91. Jet-Link cable (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Figure 92. Jet-Link cable (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Figure 93. Adjustable casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Figure 94. Stationary extended caster. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Figure 95. Stationary caster. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Figure 96. Face-up bin and stapler/stacker bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Figure 97. Back inner cover and front inner cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Figure 98. Front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Figure 99. Back cover (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Figure 100. Back cover (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Figure 101. Foot cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Figure 102. Controller PCA cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Figure 103. Door assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Figure 104. Flipper assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Figure 105. Paper-path assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Figure 106. Accumulator wings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Figure 107. Paper-stop clips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Figure 108. Accumulator assembly (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Figure 109. Accumulator assembly (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Figure 110. Accumulator assembly (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Figure 111. Carriage assembly (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Page 15

ENWW List of figures 13

Figure 112. Carriage assembly (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Figure 113. Offset module (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Figure 114. Offset module (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

Figure 115. Stapler (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

Figure 116. Stapler (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .149

Figure 117. Stapler/stacker controller PCA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

Figure 118. Stacker controller PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Figure 119. Stapler/stacker power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

Figure 120. Stacker power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

Figure 121. LED PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

Figure 122. Interlock switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

Figure 123. Safety-switch assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Figure 124. Optical sensors (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

Figure 125. Optical sensors (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

Figure 126. Optical sensors (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

Figure 127. Cable assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

Figure 128. Stationary caster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

Figure 129. Adjustable caster. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

Figure 130. Bubbled cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

Figure 131. Front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .161

Figure 132. Back cover (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

Figure 133. Back cover (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .162

Figure 134. Back cover (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163

Figure 135. Top cover (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

Figure 136. Top cover (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

Figure 137. Top cover (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165

Figure 138. Cable channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

Figure 139. Paper bins and blind cover (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .167

Figure 140. Paper bins and blind cover (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .167

Figure 141. Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

Figure 142. Flipper assembly (1 of 7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

Figure 143. Flipper assembly (2 of 7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

Figure 144. Flipper assembly (3 of 7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

Figure 145. Flipper assembly (4 of 7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

Figure 146. Flipper assembly (5 of 7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .172

Figure 147. Flipper assembly (6 of 7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .172

Figure 148. Flipper assembly (7 of 7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

Figure 149. Delivery head motor (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

Figure 150. Delivery head motor (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

Figure 151. Transport belt motor (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Figure 152. Transport belt motor (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Figure 153. Transport belt motor (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .176

Figure 154. Input paper guide (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

Figure 155. Input paper guide (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

Figure 156. Face-up full lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

Figure 157. Rollers kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

Figure 158. Magnets assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

Figure 159. Metal tape and housing assembly (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

Figure 160. Metal tape and housing assembly (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

Figure 161. Controller PCA (1 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

Figure 162. Controller PCA (2 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

Figure 163. Controller PCA (3 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

Figure 164. Controller PCA (4 of 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

Figure 165. Anticurl strings (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

Figure 166. Anticurl strings (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

Figure 167. Delivery head assembly (1 of 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

Figure 168. Delivery head assembly (2 of 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

Figure 169. Delivery head assembly (3 of 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

Figure 170. Delivery head assembly (4 of 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

Page 16

14 List of figures ENWW

Figure 171. Delivery head assembly (5 of 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Figure 172. Delivery head assembly (6 of 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Figure 173. Interlock switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Figure 174. Diagnostic LED PCA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Figure 175. User status LED PCA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Figure 176. Adjustable and fixed casters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Figure 177. Attachment assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Figure 178. Troubleshooting flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Figure 179. Service-mode configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Figure 180. Service-diagnostics label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Figure 181. DIP switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Figure 182. Power-supply switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Figure 183. 3,000-sheet stapler/stacker and 3,000-sheet stacker diagnostics labe l. . . . . . 239

Figure 184. Booklet adjustment—multifunction finisher. . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Figure 185. Sample event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Figure 186. Sample configuration page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Figure 187. Multifunction finisher system assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Figure 188. Mounting hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Figure 189. External panels and covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Figure 190. Internal components (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Figure 191. Internal components (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Figure 192. Dispose assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Figure 193. Paper feeder assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Figure 194. Reverse assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Figure 195. Fold assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Figure 196. PCB assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Figure 197. 3,000-sheet stapler/stacker (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Figure 198. 3,000-sheet stapler/stacker (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Figure 199. 3,000-sheet stacker (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Figure 200. 3,000-sheet stacker (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Figure 201. 8-bin mailbox (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Figure 202. 8-bin mailbox (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Figure 203. 8-bin mailbox (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Page 17

ENWW Chapter 1 Product information 15

1 Product information

Chapter contents

Product features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Multifunction finisher (C8088A/C8088B). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3,000-sheet stapler/stacker (C8085A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3,000-sheet stacker (C8084A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8-bin mailbox (Q5693A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3,000-sheet stapler/stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3,000-sheet stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8-bin mailbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3,000-sheet stapler/stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3,000-sheet stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8-bin mailbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Multifunction finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3,000-sheet stapler/stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3,000-sheet stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8-bin mailbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Regulatory information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Service approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Parts and supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Page 18

16 Product information ENWW

Product features

Multifunction finisher (C8088A/C8088B)

This section lists the major product features of the HP LaserJet

multifunction finisher.

¹See table 17 on page 48 for a description of how many sheets can be stapled, list ed by

media weight.

²The number of stapled and folded sheets will be reduced if the paper is heavier than

75 g/m

2

(20 lb). See tables 17 and 18 on page 48.

³See table 18 on page 48 for a description of how many sheets can be stapled for

booklets, listed by media weight.

Speed

● Up to 50 pages per minute (ppm) when used with an HP LaserJet 9000 printer,

an HP LaserJet 9000mfp, an HP Laser Jet 9050 series printer, or an

HP LaserJet 9050mfp

● Up to 40 ppm when used with an HP LaserJet 9040mfp

● Up to 24 ppm when used with an HP LaserJet 9500 printer or an HP LaserJet

9500mfp

Consumables ● HP 5,000-staple cartri dge (C8092A)

Throughput ● Staples up to 25 sheets of A3-size or ledger-size paper per document¹

● Staples up to 50 sheets of A4-size or letter-size paper per document¹

● Saddle-stitches and folds up to 10 sheets of 75 g/m² (20-lb) paper²

● Provides high-capacity stacking for up to 1,000 sheets of A4- and letter-size

paper or up to 500 sheets of A3-size and ledger-size paper (75 g/m2, 20 lb)

● Provides stacking for transparencies, envelopes, labels, and prepunched and

cut-sheet paper

● Stacks up to 40 booklets that are composed of up to 5 sheets (20 finished

pages) of A3- and ledger-size paper (75 g/m2, 20 lb)³

Note: Capacity might vary depending on the stiffness of the media.

● Accepts cardstock up to 216 g/m

2

(58 lb) in weight

Functions ● Stacking

● Job offset

● Stapling

● Booklet-making (saddle-stitching and folding)

● Single-page folding

Page 19

ENWW Chapter 1 Product information 17

3,000-sheet stapler/stacker (C8085A)

This section lists the major product features of the HP 3,000-sheet

stapler/stacker.

¹See table 21 on page 50 for a description of how many sheets can be stapled, listed by

media weight.

3,000-sheet stacker (C8084A)

This section lists the major product features of the HP 3,000-sheet stacker.

Speed ● Up to 50 ppm when used with an HP LaserJet 9000 printer, an HP LaserJet

9000mfp (letter-size or A4-size, unstapled), an HP LaserJet 9050 series

printer, or an HP LaserJet 9050mfp

● Up to 40 pages ppm when used with an HP Laserjet 9040mfp

● Up to 24 ppm when used with an HP LaserJet 9500 printer or HP LaserJet

9500mfp

Consumables ● HP 5,000-staple cartridge (C8091A)

Throughput

● Stacks up to 3,000 sheets of A4-size or letter-size paper

● Stacks up to 1,500 sheets of A3-size or ledger-size paper

● Staples up to 50 sheets of A3-size and ledger-size paper per document¹

● Staples up to 50 sheets of A4-size and letter-size paper per document¹

● Bin 1 (face-up bin) holds up to 125 sheets of paper

● Bin 2 (face-down bin) holds up to 3,000 sheets of paper

● Accepts cardstock up to 216 g/m

2

(58 lb) in weight

Speed

● Up to 50 ppm when used with an HP LaserJet 9000 printer, an HP LaserJet

9000mfp (letter-size or A4-size, unstapled), an HP LaserJet 9050 series

printer, or an HP LaserJet 9050mfp

● Up to 40 pages ppm when used with an HP Laserjet 9040mfp

● Up to 24 ppm when used with an HP LaserJet 9500 printer or HP LaserJet

9500mfp

Throughput ● Stacks up to 3,000 sheets of A4-size or letter-size paper

● Stacks up to 1,500 sheets of A3-size or ledger-size paper

● Bin 1 (face-up bin) holds up to 125 sheets of paper

● Bin 2 (face-down bin) holds up to 3,000 sheets of paper

● Accepts cardstock up to 216 g/m

2

(58 lb) in weight

Page 20

18 Product information ENWW

8-bin mailbox (Q5693A)

This section lists the major product features of the HP 8-bin mailbox.

Note The 8-bin mailbox is not compatible with the HP LaserJet 9000 series printer or the HP LaserJet

9000mfp.

Speed ● Up to 50 ppm when used with an HP LaserJet 9050 series printer or an

HP LaserJet 9050mfp

● Up to 40 ppm when used with an HP Laserjet 9040mfp

● Up to 24 ppm when used with an HP LaserJet 9500mfp

Throughput ● Provides high-capacity stacking for up to 2,125 sheets of 75 g/m² (20-lb bond)

media

● Face-up bin (upper-left bin) holds up to 125 sheets of 75 g/m² (20-lb bond)

media, and jobs are stacked in reverse order

● Face-down bins hold up to 250 sheets 75 g/m² (20-lb bond) media each, and

jobs are stacke d i n ord e r

● Face-up bin supports cardstock, envelopes, labels, and transparencies, and

supports media up to 216 g/m² (58-lb bond )

Note

Capacity might vary depending on the media weight.

Functions Provides stacking in four operation modes:

● Mailbox. The eight face-down bins can be assigned to a user or a group of

users. All jobs that a user or group of users sends are delivered to the assigned

bin (default operation mode).

● Stacker. The eight face-down bins can stack up to 2,000 sheets of 75 g/m² (20-

lb bond) media. Jobs are sent to the lowest available (empty) bin, and large

jobs might stack into the next bin up.

● Job separator. Jobs are delivered to the first available (empty) bin, beginning

with the top bin. A job can include the original copy and the copies.

● Sorter/Collator. Copies of a single job are delivered to consecutive bins.

Page 21

ENWW Chapter 1 Product information 19

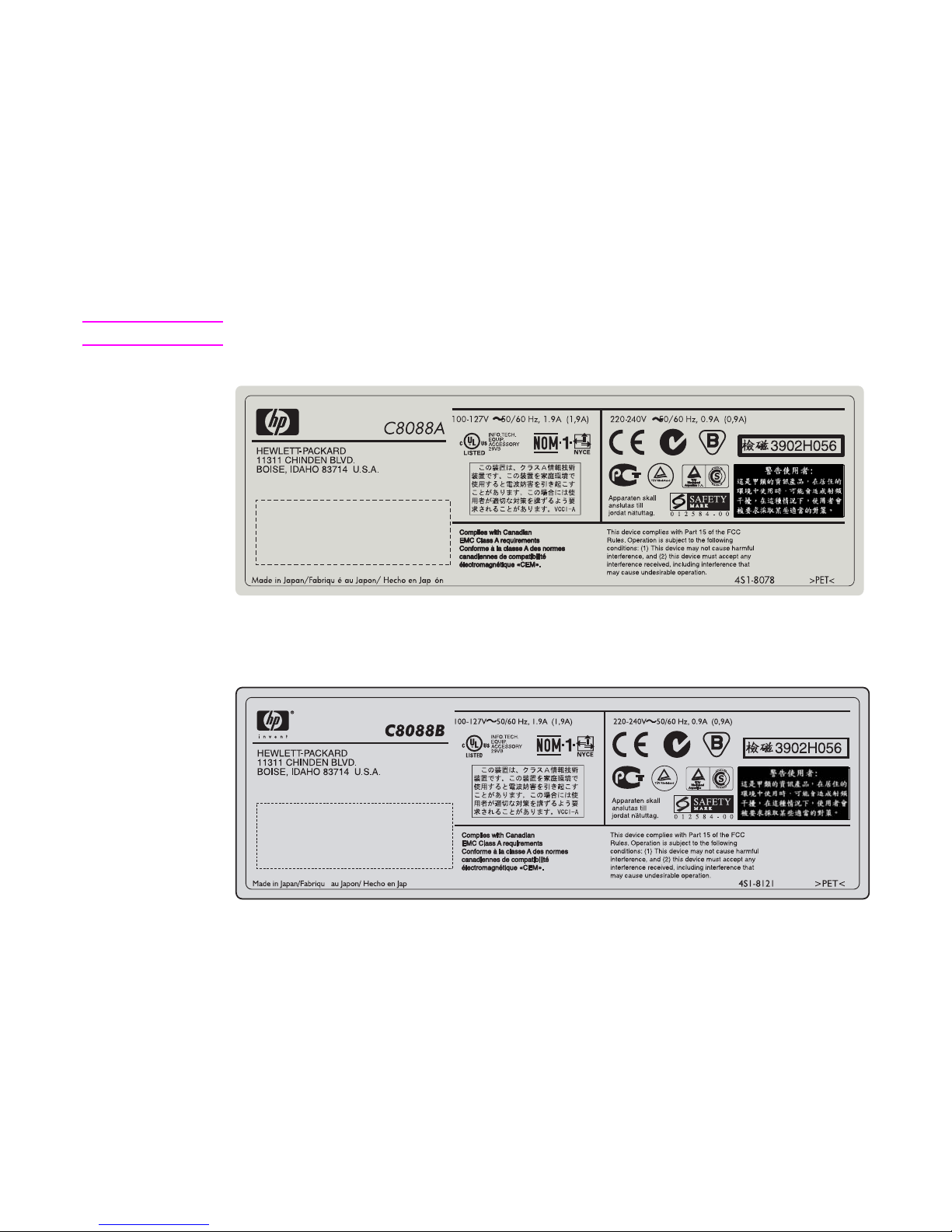

Identification

Multifunction finisher

The model number and serial number are listed on an identification label that is located on the

right side of the output device.

The serial number contains information about the country/region of origin, revision level,

production site, and manufacturing line, and the production number of the output device. An

example of a serial number is JPBGA12345.

The identification label also contains electrical information and regulat ory information. See

figure 1 or figure 2.

Note The electrical information and regulatory information vary by country/region.

Figure 1. Sample identification label—multifunction finisher (C8088A)

Figure 2. Sample identification label—multifunction finisher (C8088B)

é ón

Page 22

20 Product information ENWW

3,000-sheet stapler/stacker

The model number and serial number are listed on an identifi cation label that is located on the

back of the stapler/stacker.

The serial number contains information about the country/region of origin, revision level,

production site, and manufacturing line, and the production number of the output device. An

example of a serial number is MX04C04388.

The identification label also contains electrical information and regulatory information. See

figure 3.

Note The electrical information and regulatory information vary by country/region.

Figure 3. Sample identification labe l—3,000-sheet stapler/stacker

Page 23

ENWW Chapter 1 Product information 21

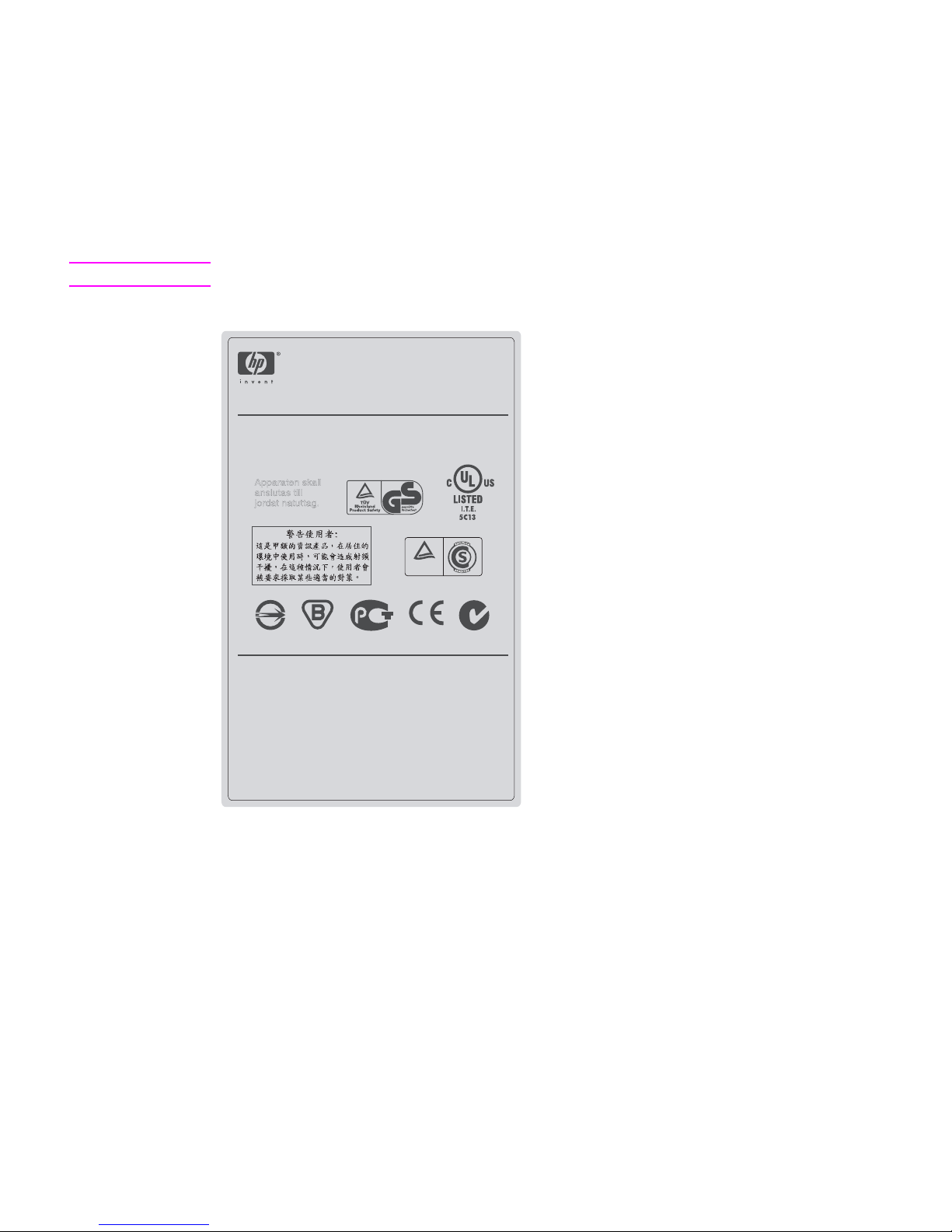

3,000-sheet stacker

The model number and serial number are listed on an identification label that is located on the

back of the stacker.

The serial number contains information about the country/region of origin, revision level,

production site, and manufacturing line, and the production number of the output device. An

example of a serial number is MX04G04388.

The identification label also contains electrical information and regulat ory information. See

figure 4.

Note The electrical information and regulatory information vary by country/region.

Figure 4. Sample identification label—3,000-sheet stacker

Page 24

22 Product information ENWW

8-bin mailbox

The model number and serial number are listed on an identification label that is located on the

back of the 8-bin mailbox.

The serial number contains information about the country/region of origin, revision level,

production site, and manufacturing line, and the production number of the output device. An

example of a serial number is JPBGA12345.

The identification label also contains electrical information and regulatory information. See

figure 5.

Note The electrical information and regulatory information vary by country/region.

Figure 5. Sample identification label—8-bin mailbox

Hewlett-Packard Company

11311 CHINDEN BLVD.

BOISE, IDAHO 83714 U.S.A.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesirable operation.

Complies with Canadian EMC Class A requirements Conforme

a la classe A des normes canadiennes de compatibilite

electromagnetique <<CEM>>

Apparaten skall

anslutas till

jordat natuttag.

D33001

Model Number:

Q5693A

Regulatory Model Number:

GUADA-0401-00

T.U.V

Rheinland

Ar gentina S.A

Product of Germany/Produit d'Allemagne

Page 25

ENWW Chapter 1 Product information 23

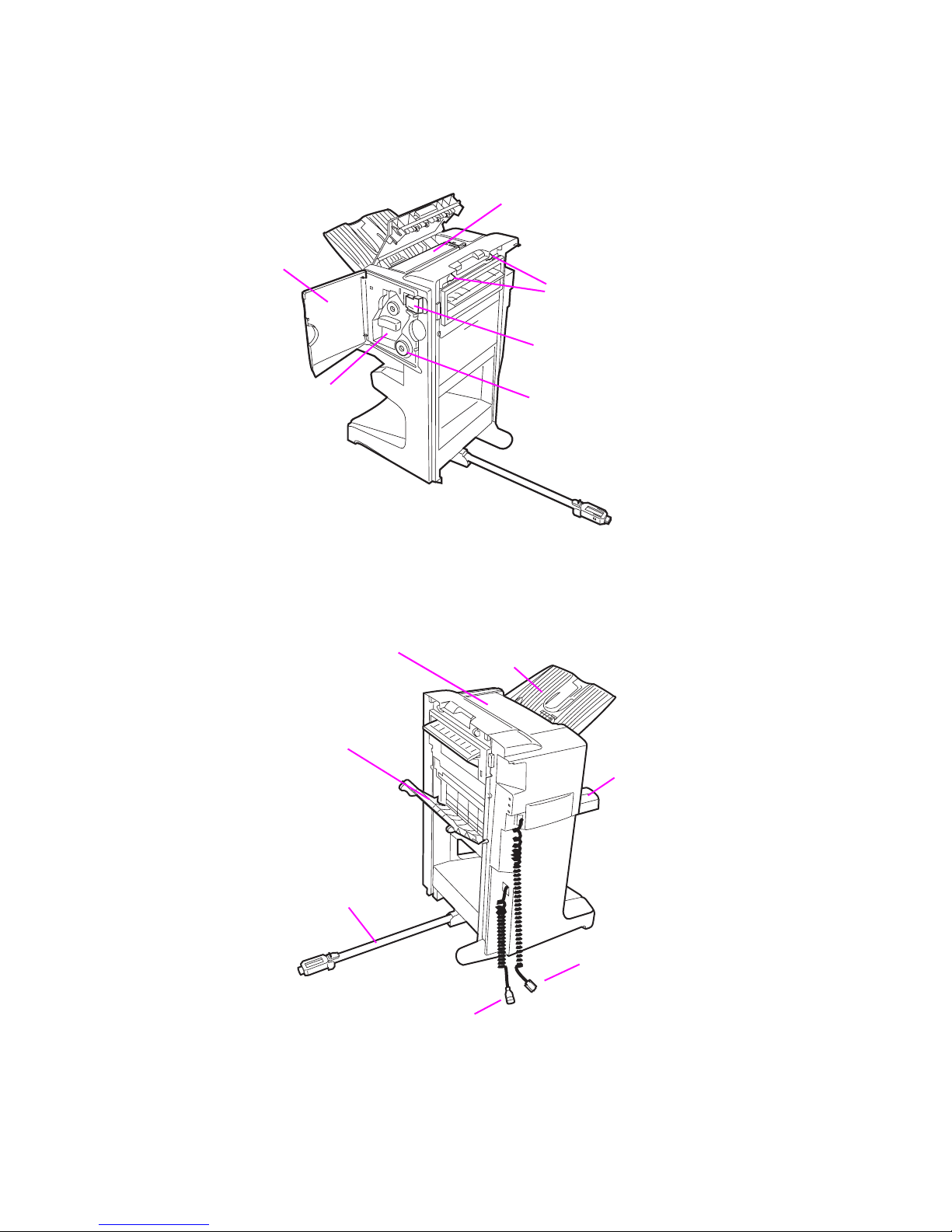

Product overview

Multifunction finisher

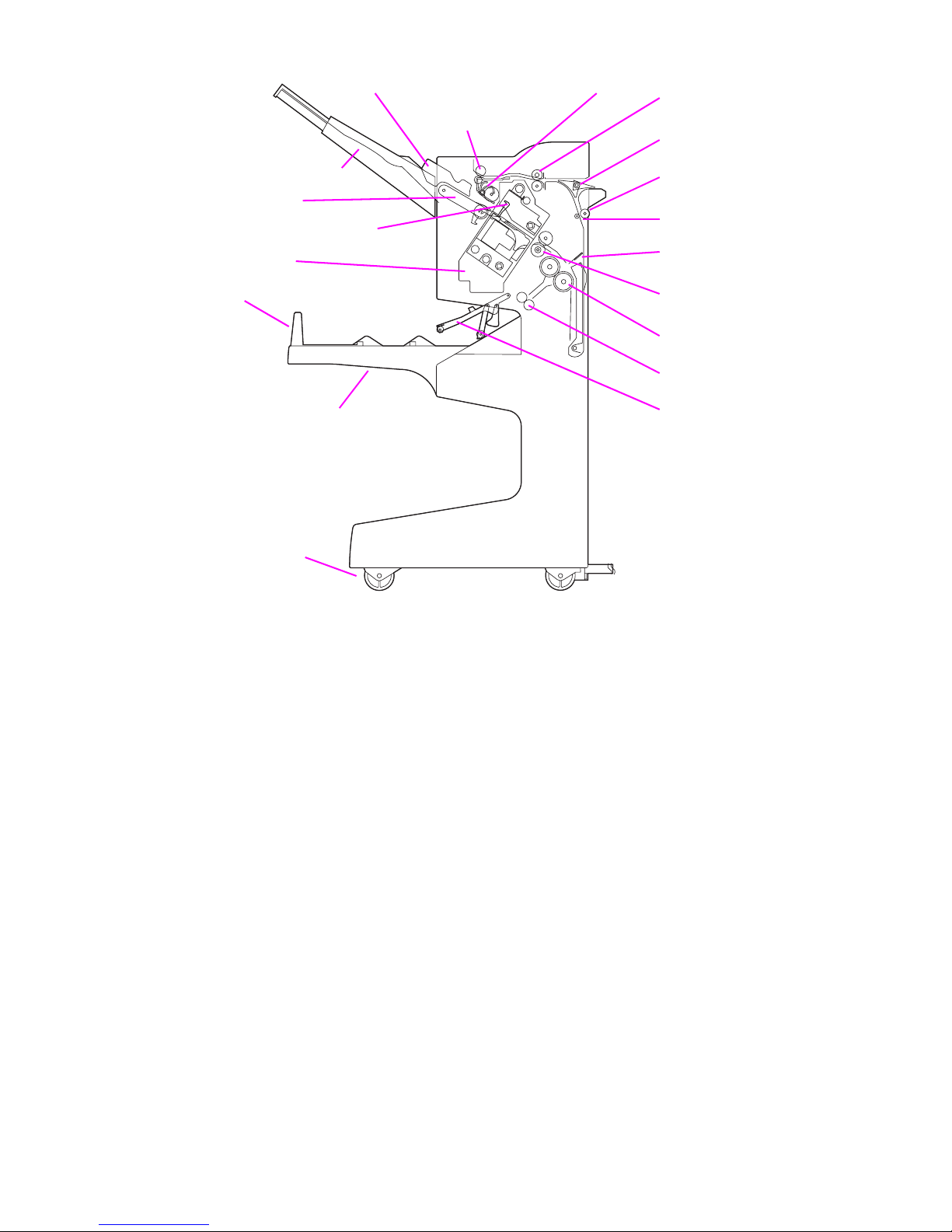

Figure 6. External assembly locations—multifunction finisher (front view)

Figure 7. External assembly locations—multifunction finisher (back view)

Processing-tray

Product-attachment

Product-release

upper cover

Jam-removal dial

Stapling unit

Stapler door

latch

handle

Booklet bin

(bin 2)

Stacker bin

(bin 1)

Jet-Link cable

Attachment-rod

Jam-removal cover

Top cover

assembly

Power cord

Page 26

24 Product information ENWW

Figure 8. Cross-section—multifunction finisher

Processing tray stopper

Booklet bin stopper

Delivery roller

Stapling unit

Aligning plate (front and back)

Booklet bin (bin 2)

Stacker bin (bin 1)

Reversing flapper

Reversing roller

Paper-fold roller

Feed roller

Reversing nip roller

Paddle

Stack feed roller

Booklet-delivery roller

Paper-pushing plate

Delivery belt

Adjustable casters

Booklet-bin-full actuator

Page 27

ENWW Chapter 1 Product information 25

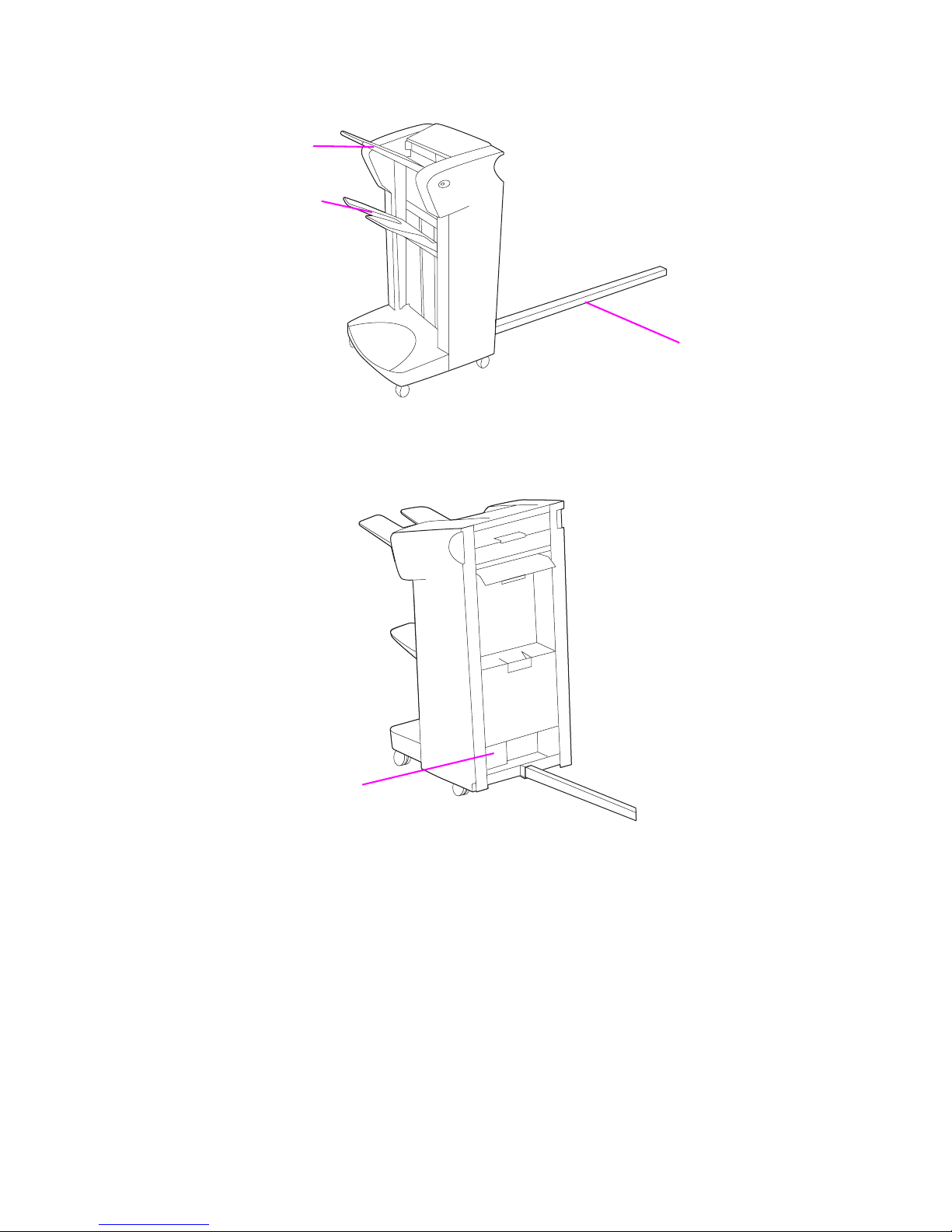

3,000-sheet stapler/stacker

Figure 9. External assembly locations—3,000-sheet stapler/stacker (front view)

Figure 10. External assembly locati ons—3,000-sheet stapler/stacker (back view)

Face-down or

Face-up bin

Attachment rod

stacker bin

Identification label

Page 28

26 Product information ENWW

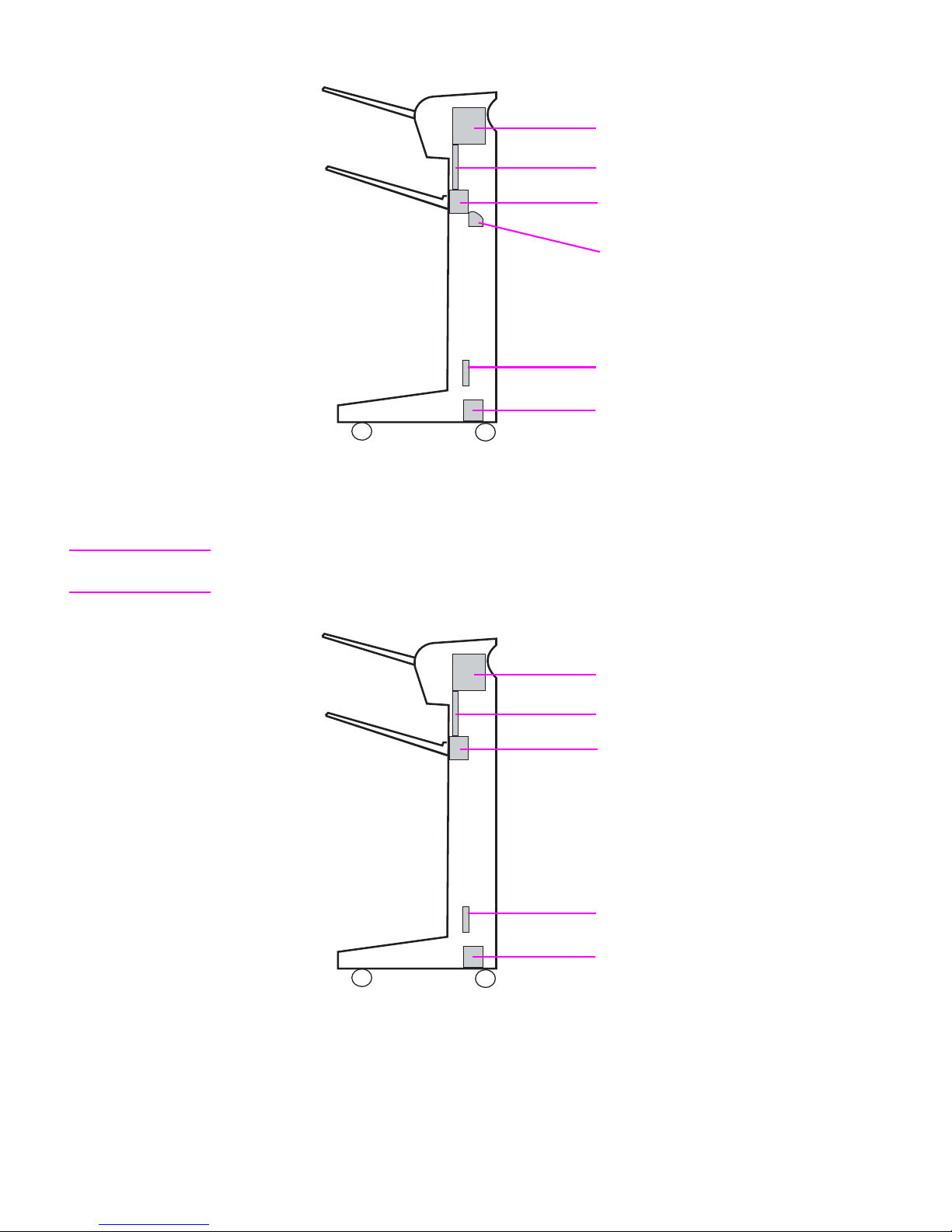

Figure 11. Cross-section—3,000-sheet stapler/stacker

3,000-sheet stacker

Note The external assembly locations on the 3, 000-sheet stacker is t he same as that of the 3,000-sheet

stapler/stacker.

Figure 12. Cross-section—3,000-sheet stacker

Flipper

Paper path

Accumulator

Stapler cartridge

Controller PCA

Power supply

Flipper

Paper path

Offset module

Controller PCA

Power supply

Page 29

ENWW Chapter 1 Product information 27

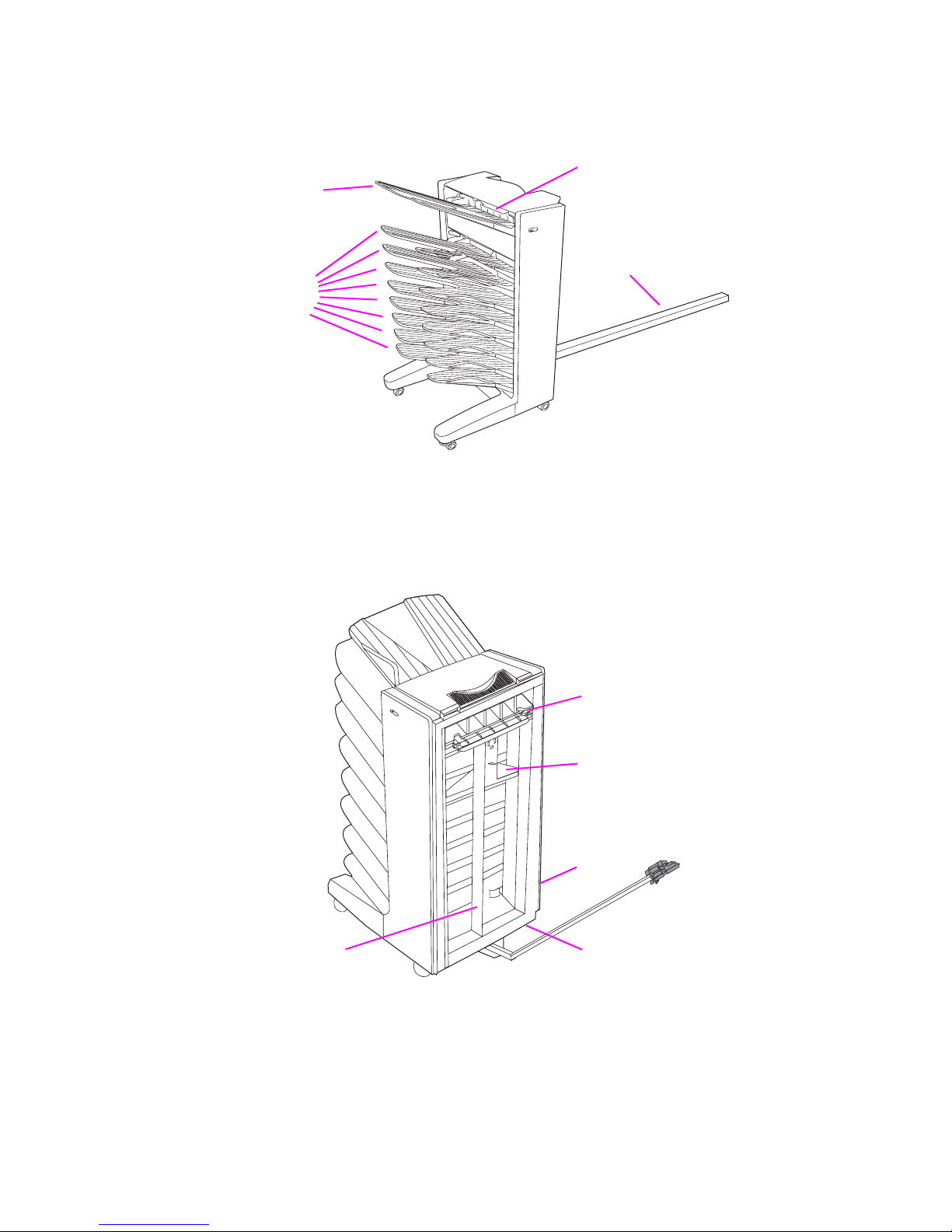

8-bin mailbox

Figure 13. External assembly locations—8-bin mailbox (left side view)

Figure 14. External assembly locations—8-bin mailbox (right side view)

Face-up bin

Face-down

bins

Attachment rod

Flipper

Input paper guide

Delivery head

Belt

Power

PCA

supply

Page 30

28 Product information ENWW

Specifications

Multifunction finisher

CAUTION Power requirements are based on the country/region where the output device is sold. Do not

convert operating v oltages. This can damage the output device and void the product warranty.

Note Testing per International Standards Organization (ISO) 9296.

Table 1. Physical specifications—multifunction finisher

Specification Multifunction finisher

Measurements Height: 985 mm (38.8 inches)

Width: 690 mm (27.2 inches)

Depth: 60 mm (23.6 inches)

Weight 44.4 kg (98 lb)

Table 2. Electrical specifications—multifu nction finisher

Volts Frequency

Amperes

(amps) Watts (W) (typical)

Thermal units per hour

(Btu/hr)

100-127 Vac

±10%

50/60 Hz

±2 Hz

Minimum

recommended

current capacity

= 13.0 amp

Printing = 1,075 W

Standby = 440 W

PowerSave 1 = 70 W

Low power = 230 W

Off = 0.5 W

ADF printing = 1,130 W

Printing = 3,670 Btu/hr

Standby = 1,500 Btu/hr

PowerSave 1 = 240 Btu/hr

Low power = 785 Btu/ hr

Off = 1.7 Btu/hr

ADF printing = 3,860 Btu/hr

220-240 Vac

±10%

50/60 Hz

±2 Hz

Minimum

recommended

current capacity

= 6.5 amp

Printing = 1,075 W

Standby = 440 W

PowerSave 1 = 70 W

Low power = 230 W

Off = 1.3 W

ADF printing = 1,130 W

Printing = 3,650 Btu/hr

Standby = 1,420 Btu/hr

PowerSave 1 = 240 Btu/hr

Low power= 785 Btu/hr

Off = 4.5 Btu/hr

ADF printing = 3,670 Btu/hr

Table 3. Environmental specifications—multifunction finisher