Page 1

HP 3,000-sheet Stapler/Stacker (C4788A)

HP 3,000-sheet Stacker (C4779A)

Service Manual Supplement

for Paper-Handling Accessories

Page 2

HP 3,000-Sheet Stapler/Stacker

(C4788A)

HP 3,000-Sheet Stacker (C4779A)

Service Manual

Page 3

Copyright Information

© 1999 Hewlett-Packard

Company

All Rights Reserved.

Reproduction, adaptation, or

translation without prior written

permission is prohibited except

as allowed under copyright

laws.

Part Number: C4788-90904

First Edition, January 1999

Warranty

The information contained in

this document is subject to

change without notice.

Hewlett-Packard makes no

warranty of any kind with

respect to this information.

HEWLETT-PACKARD

SPECIFICALLY DISCLAIMS

THE IMPLIED WARRANTY OF

MERCHANTABILITY AND

FITNESS FOR A PARTICULAR

PURPOSE

Hewlett-Packard shall not be

liable for any dire ct, indirect,

incidental, consequential, or

other damage alleged in

connection with the furnishing or

use of this information.

NOTICE TO U.S.

GOVERNMENT USERS:

RESTRICTED RIGHTS

COMMERCIAL COMPUTER

SOFTWARE: “Use, duplication,

or disclosure by the

Government is subject to

restrictions as set forth in

subparagraph (c)(1)(ii) of the

Rights in Technical Data Clause

at DFARS 52.227-7013.”

Trademark Credits

E

NERGY STAR is a U.S.

registered service mark of the

United States Environmental

Protection Agency.

All other products mentioned

herein may be trademarks of

their respective companies.

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714 U.S.A.

Page 4

Contents

1 Product informa tion

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Product features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Product specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Media specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Theory of operation

Basic functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

C-link communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Device configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Paper path sensors and jam detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Paper path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 Removal and replacement

Removal and replacement strategy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Required tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Bins and covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Face-up bin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Stapler bin/Stacker bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Back cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Foot cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Stapler door assembly with label/stacker door assembly. . . . . . . . . . . . . . . . . 24

Controller PCA cover (with label) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Internal assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Flipper assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Carriage assembly (Stapler/Stacker only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Accumulator assembly (Stapler/Stacker only) . . . . . . . . . . . . . . . . . . . . . . . . . 29

Offset module (Stacker only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Stapler (Stapler/Stacker only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Controller PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

LED PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Interlock switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Safety switch assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Attachment assembly (rod, bracket, cables). . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Flipper ribbon cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Stationary caster. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

EN

3

Page 5

Adjustable caster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4 Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Basic troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Verifying power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Printing the configuration page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Evaluating the configuration page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Printing the event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Evaluating the event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Calibrating the staple position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Troubleshooting tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Paper path test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Standalone diagnostic tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Service LED flashing patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

User LED status interpretation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Printer messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Control panel messages and errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

HP 3,000-Sheet Stapler/Stacker error messages. . . . . . . . . . . . . . . . . . . . . . . 60

HP 3,000-Sheet Stacker error messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5 Parts and diagrams

How to use the parts lists and diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Ordering parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Refilling the stapler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Ordering staples cartridges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Bins and covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Internal assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4 Contents

EN

Page 6

1

Left side

Front

Right side

Back

Face-up bin

Stapler bin/Stacker bin

Product information

Introduction

The 3,000-Sheet Stapler/Stacker and the 3,000-Sheet Stacker from

Hewlett-Packard are powerful enhancements to the capablilties of

your high-capacity laser printer.

The HP 3,000-Sheet Stapler/Stacker is an optional multi-speed

output device designed to handle different printer speeds. It staples

up to 50 sheets of plain paper at a time and can hold a total of 3,125

sheets—3,000 sheets in the stapler bin and 125 sheets, not stapled,

in the face-up bin.

The HP 3,000-Sheet Stacker is another optional multi-speed output

device designed to handle different printer speeds. The Stacker

stacks up to 3,000 sheets of plain paper in the stacker bin, has job

offset capabilities for easy handling, and has job separation (first

page offset) for shared environments. The Stacker includes a face-up

bin that holds another 125 sheets.

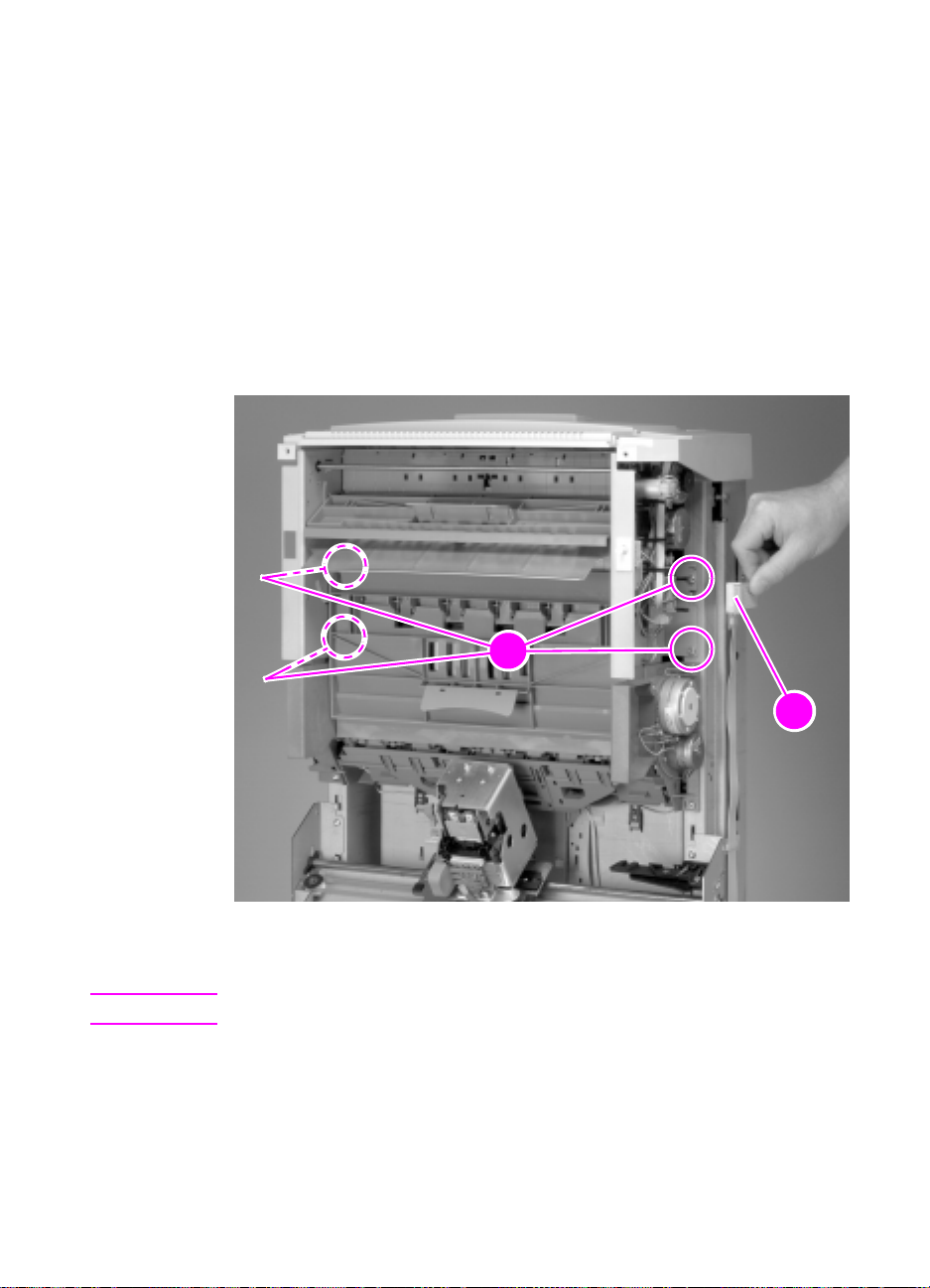

Figure 1. Stapler/Stacker

EN

Introduction

5

Page 7

P roduct feature s

Table 1. Output capacity (unstaple d)

Letter- or A4-sized paper

Ledger- or A3-sized paper Up to 1,500 sheets of 20 lb or lighter paper in the stapler bin or

Up to 3,000 sheets of 20 lb [75 g/m

lighter paper in the stapler bin or stacker bin

Up to 125 sheets of 20 lb or lighter paper in the face-up bin

stacker bin

Up to 125 sheet of 20 lb or lighter paper in the face-up bin

2

(grams per square meter)] or

Table 2. Stapling (Stapler/Stacker only)

Two to 50 sheets of 20 lb bond or equivalent stack height—approximately 5 millimeters (mm)

Multiple staple positions:

●

One angled

●

One, two, three, or six staples

●

Custom stapling with up to seven staples

Table 3. Stacking (Stacker only)

Job offset Whole print jobs or mopies are offset from each other.

Job separation Only the first page of print job or mopy is offset.

6 1 Product information

EN

Page 8

P roduct specifications

Table 4. Physical dimensions

Weig h t 65 pounds [29.5 kg (kilograms)]

Packaging weight 16.9 pounds (7.7 kg)

Height 39.84 inches (1012 mm) includes face-up bin

38 inches (965 mm) without face-up bin

Depth 19.45 inches (494 mm)

Width

(front cover-to-back cover)

21.14 inches (537 mm)

Table 5. Electrical specifications

External power supply Input: automatic 100/240 Vac (volts alternating current)

Power consumption 60.0 watts (Stapler/Stacker)

38.8 watts (Stacker)

Rated power 1.2 amps (110 volts)

0.5 amps (220 volts)

Sleep mode Less than 2.0 watts

Off mode Less than 2.0 watts

EN

Product specifications

7

Page 9

Table 6. Environme ntal specifications

Temperature (operating) 0 to 45 degrees C (Celsius)

Temperature (storage) -40 to 70 degrees C

Humidity (operating) 20 to 80% RH (relative humidity)

Humidity (storage) 15 to 80% RH

Electrostatic discharge

(ESD)

15 to 25 kV (kilovolts)

Table 7. Acoustic emissions

Operating 5.0 bels or less

Idle 4.0 bels or less

Stacking 50 dB (decibels)

8 1 Product information

EN

Page 10

M edia specifica t ions

The following table lists supported paper sizes and output bin

capacities for the HP 3,000-Sheet Stapler/Stacker and the HP 3,000Sheet Stacker.

Table 8. Bin specifica tions

Bin Capacity Paper size Weight

Stacker Bin

(Optional Bin 1)

Face-up Bin Up to 125 sheets of

Up to 3,000 sheets of

letter- or A4-sized, 20

lb (80 g/m

Note: The stacker bin

capacity varies

depending on the

paper size and

weight. For example,

the bin capacity is

reduced to 1,500

sheets if you use

11x17-inch, 20 lb

bond.

20 lb (80 g/m

2

) bond.

2

) bond

Letter

A4

Legal

Ledger (11x17 inch)

A3

JIS B4

JIS B5

A5

Executive

JIS Executive

8K

16K

Custom sizes:

Minimum—190 mm length x

148 mm width

Maximum—460 mm length x

297 mm width

Note:

Envelopes, labels, and

transparencies are NOT

supported in the stacker bin.

The face-up bin supports any paper sizes and

weights that the printer supports. See the printer user

guide for information about supported sizes and

weights.

16 to 28 lb bond (60

to 110 g/m

2

)

EN

Media specifications

9

Page 11

The following table lists supported paper sizes and capacities for the

stapler in the HP 3,000-Sheet Stapler/Stacker.

Table 9. Stapler Specifications

Capacity Paper Weight

Maximum 5 mm

stack height. For

example, 50 sheets

of 20 lb bond.

Note:

The stapling

capacity varies

depending on the

paper's thickness.

Letter

A4

Legal

Ledger (11 by 17 in)

A3

JIS B4

JIS B5

A5

Executive

JIS Executive

8K

16K

Note:

Envelopes, labels, and

transparancies are NOT

supported in the stapler.

16 to 28 lb bond (60

to 110 g/m

2

)

10 1 Product information

EN

Page 12

2

Theory of operation

Ba sic functions

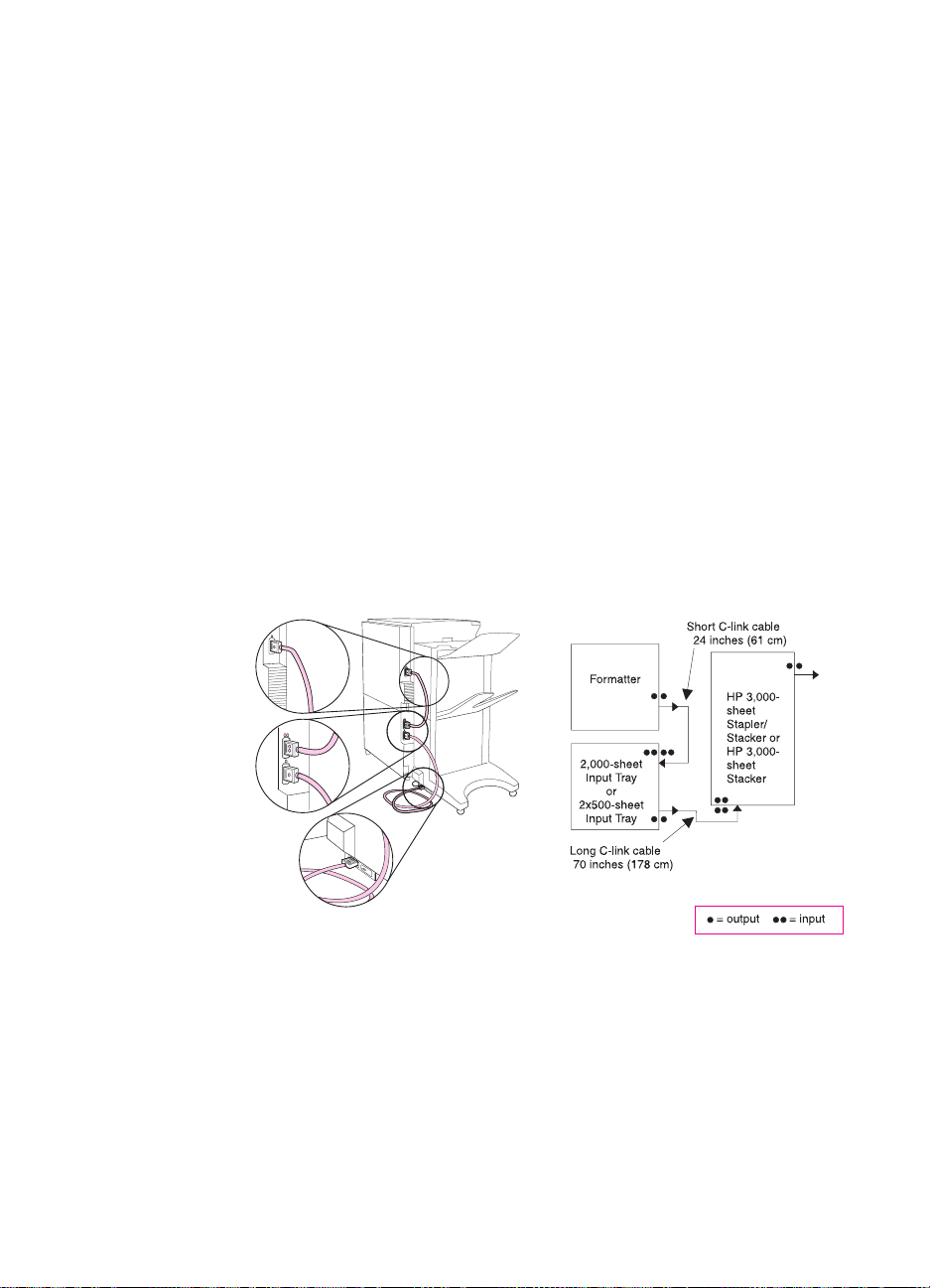

C -link communication

Communication and control of the C-link devices is accomplished

through the paper-handling controller embedded on the formatter

PCA (printed circuit assembly) in the printer. The C-link devices have

their own power supplies and controller boards that receive signals

and commands from the paper-handling controller.

Figure 2. C-link cab ling

EN

Basic functions

11

Page 13

D evice configur ation

The HP 3,000-Sheet Stapler/Stacker and the HP 3,000-Sheet Stack er

attach to printers’ left sides.

3,000-Sheet Stapler/Stacker

Set the default offset action and default stapler action at the printer

control panel under Configuration of Stkr.

The options for default offset action are:

●

No Print jobs or mopies are stacked without separation

(although stapling options override this setting).

●

Yes Print jobs or mopies are offset from each other.

The options for default stapler action are:

●

No Staple Print jobs of mopies are delivered to the stapler bin

without being stapled.

●

One Angled

Staple

Print jobs or mopies are stapled with one staple at a

40° angle.

●

(#) Staples Print jobs or mopies are stapled with the configured

●

Custom Staples Print jobs or mopies are stapled with the configured

3,000-Sheet Stacker

Set the default offset action at the printer control panel under

Configuration of Stkr. The options for default offset action are:

●

No Print jobs or mopies are stacked without separation.

●

Yes Print jobs or mopies are offset from each other.

●

Job Separator Print jobs or mopies are separated by offsetting the

12 2 Theory of operation

number (1, 2, 3, or 6) of staples.

number of staples as defined by the network

administrator.

first page.

EN

Page 14

Pow er supply

A universal power supply is activ ated when the printer’s power s witch

is turned on. The printer’s paper handling controller sends a power-on

signal to the power supply through the controller PCA.

The power supply provides +26 V (volts) for motors and +5 V for

sensors and controller electronics. The power supply is also acitva ted

when the controller PCA is set to service mode.

Pow er- on seque nce

During the power-on sequence, an internal self-test is performed. All

motors, electronics, and main assemblies are tested.

After successful power-on sequence, the user LED (light-emitting

diode) is lit green.

If the power-on sequence is NOT successful, a jam condition or a

hardware malfunction is indicated through the printer control panel

and the user LED is lit amber.

EN

Basic functions

13

Page 15

Paper pa th sensors and ja m detection

The paper path sensors detect paper jams as follows:

●

Flipper entry sensor 1 (FLEntry1) and flipper entry sensor

(FLEntry):

• paper in the flipper at power on or after clearing a paper jam

(when either sensor is activated at power on or after clearing a

jam)

• paper jammed before entering the flipper (when the printer

sends a message that pages are being sent to the Stapler/

Stacker or Stacker, but FLEntry1 is never activated)

• paper jammed in the flipper (when FLEntry1 is activated, but

FLEntry is not, or when FLEntry1 is never deactivated, or

when FLEntry is never deactivated)

●

Flipper exit sensor (FLExit)

• paper in the flipper at power on or after clearing a paper jam

(when FLExit is activated at power on or after clearing a jam)

• paper jammed in the last part of flipping (FLExit never

activated)

• paper jammed entering the accumulator (FLExit never

deactivated)

●

Gear wheel sensor (GWSens)—Stapler/Stacker only

• paper jammed in the accumulator (GWSens never activated)

●

Accumulator exit sensor (ACExit)—Stapler/Stacker only

• paper in the accumulator at power on or after clearing a paper

jam (when ACExit is activated at power on or after clearing a

jam)

• paper jammed in the accumulator (when ACExit is not

deactivated after eject)

●

Exit (Exit)—Stacker only

• paper jammed in the offset module (Exit never activated)

14 2 Theory of operation

EN

Page 16

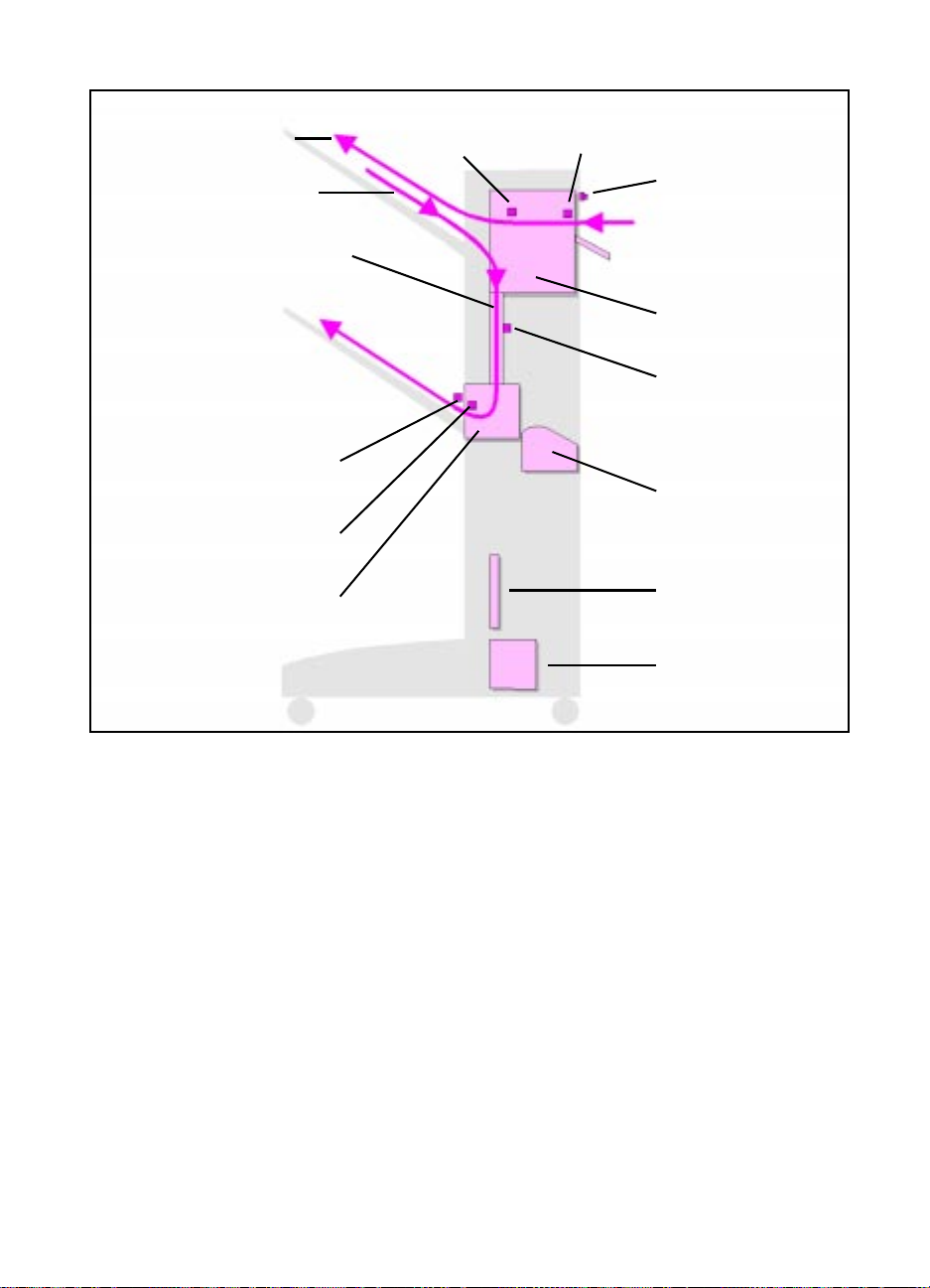

Paper pa th

Pape r input

The device receives paper from the printer at different speeds—106,

117, or 147 mm/second—depending on the printer in use.

Flipper

Paper arrival is sensed by FLEntry1, which activates the flipper

motors. For face-up printing, the flipper simply delivers paper sensed

by FLEntry to the face-up bin. Otherwise, the flipper changes page

orientation from face-up to face-down and delivers paper sensed by

FLExit to the accumulator assembly (Stapler/Stacker) or offset

module (Stacker).

Accumula tor asse mb ly (S taple r/S tacke r ON LY )

The accumulator assembly collects and registers print jobs/mopies

from the flipper (sensed by GWSens), sends them to the carriage

assembly for stapling, and deliv ers them to the stapler bin (sensed b y

ACExit).

O ffset module (S tacker O NLY)

EN

The offset module collects and registers print jobs/mopies from the

flipper (sensed by FLExit), offsets them (if selected), and delivers

them to the stacker bin (sensed by Exit).

Basic functions

15

Page 17

Face-up paper path

Flipper entry sensor

(FLEntry)

Flipper entry sensor 1 (FLEntry1)

Face-down paper path

Path through accumulator

Accumulator exit sensor

(ACExit)

Gear wheel sensor

(GWSens)

Accumulator

Interlock switch

Paper input from

the printer

Flipper

Flipper exit sensor

(FLExit)

Stapler/Carriage

Controller PCA

Power supply

Figure 3. Stapler/S tacker pape r path and sensors

16 2 Theory of operation

EN

Page 18

Face-up paper path

Flipper entry sensor

(FLEntry)

Flipper entry sensor 1 (FLEntry1)

Face-down paper path

Path through offset

module

Exit sensor (Exit)

Offset module

Interlock switch

Paper input from

the printer

Flipper

Flipper exit sensor

(FLExit)

Controller PCA

Power supply

Figure 4. Stacke r paper path a nd sensors

EN

Basic functions

17

Page 19

18 2 Theory of operation

EN

Page 20

Removal and

3

replacement

R emoval and replace ment str ate gy

This chapter documents removal and replacement of field

replaceable units (FRUs) only.

Replacement is generally the rev erse of remo val. Occasionally, notes

are included to provide direction for difficult or critical replacement

procedures.

Removal of some FRUs does not require that all covers and bins be

removed first from the Stacker or Stapler/Stacker. The disassembly

procedure described here details initial removal of all bins and cov ers

for unobstructed views of internal components.

EN

Removal and replacement strategy

19

Page 21

WARNING! Unplug the power cord from the power outlet before attempting to

service the HP 3,000-Sheet Stacker or HP 3,000-Sheet Stapler/

Stacker . Otherwise, se vere injury can result. Certain functional checks

must be performed during troubleshooting with power supplied to the

product. However, the power supply should be disconnected during

disassembly.

CAUTION The HP 3,000-Sheet Stapler/Stacker and the HP 3,000-Sheet Stack er

contain parts that are electrostatic discharge (ESD) sensitive.

Note Disconnecting the attachment assembly from the bottom of the printer

and moving the product away from the printer can make removal of

FRUs easier.

R equired tools

Torx TX-10 and TX-20 screwdrivers and a small flatblade screwdriver

are the only tools you need to disassemble the Stacker and the

Stapler/Stacker.

20 3 Removal and replacement

EN

Page 22

Bins a nd covers

2

3

2

1

2

2

2

4

Face -up bin

Lift slightly the end of the bin (callout 1).

1

Pull the bin away from the product (callout 2).

2

CAUTION

When replacing the bin, make sure you position it under the bin-full flag

(callout 3). Placing it over the bin-full flag and then attempting to f orce

the bin into its slots can damage the flag.

S taple r bin/Sta c ker bin

Unhook the plastic tabs underneath the bin (callout 4).

1

Carefully lift the bin straight up until it is released from the frame.

2

Figure 5. Bins remo val

EN

Bins and covers

21

Page 23

Front co ve r

2

2

2

1

2

3

1 Use the TX-20 screwdriver to remove three screws (callout 1).

2 Lift the cover straight up until it is released from the product.

Ba ck co ver

1 Use the TX-20 screwdriver to remove three screws (callout 2).

2 Press and hold in the interlock switch (callout 3) while lifting the

cover straight up until the cover is released from the product.

Figure 6. Front a nd back cove rs remova l

22 3 Removal and replacement

EN

Page 24

F oot cover

Remove the front and back covers.

1

Grasp the foot cov er on one side , rotate it out slightly, and then lift

2

it up to clear the locating pin. Repeat this step for the opposite

side of the foot cover.

Lift up the cover and pull it away from the product.

3

Figure 7. Foot co ver removal

To r eins tall

The cover can be difficult to replace correctly. Make sure you line up

the ridges on the bottom of the cover with the grooves on the product.

EN

Bins and covers

23

Page 25

S taple r door assembly with la bel/sta ck er door

2

1

2

2

assembly

1 Open the door assembly and, on a Stapler/Stacker, center the

stapler unit.

2 Use the TX-20 screwdriver to remove two screws (callout 1) from

inside the door, one at the front and one at the bac k of the device.

Note The screws remain attached to the plastic screwholders.

3 Rotate the door down until the flat sides of the hinges are parallel

to the floor and pull the door straight away from the product.

C ontroller P CA cover ( with label)

1 Use the TX-20 screwdriver to remov e the upper and lower scre ws

(callout 2) from the cover.

2 Rotate the cover to clear the tabs at the back of the product and

lift the cover away from the product.

Figure 8. Staple r door assembly/Stacke r door asse mbly and controller

PCA cove r remova l

24 3 Removal and replacement

EN

Page 26

I nterna l assemblies

2

2

1

2

F lipper a ssembly

Remove the front and back covers.

1

At the back of the product, disconnect the flipper ribbon cable

2

(callout 1) by pressing the black tabs on the connector to release

the cable.

Use the TX-20 screwdriver to remov e four screws (callout 2), two

3

on each side of the assembly.

Figure 9. Flipper assembly re moval ( 1 of 2)

Note

EN

Sheet metal edges may be sharp.

Internal assemblies

25

Page 27

4 Use both hands to grasp the assembly on each side and, with a

2

1

firm tug, lift the assembly straight up to clear the tabs (callout 1;

one of the two tabs is shown) on each side of the assembly.

5 Pull the assembly straight away from the product, being careful of

the bin-full flag.

Figure 10. F lipper assembly re moval (2 of 2 )

26 3 Removal and replacement

EN

Page 28

C arr iage asse mb ly ( Staple r/Sta cker only)

2

1

Remove the front cover, the back cover, and the controller PCA

1

cover.

Disconnect the ribbon cable (callout 1) from the controller PCA by

2

pressing the black tabs to release the cable.

Figure 11. Carriage assembly removal (1 of 2)

Push the ribbon cable up through the hole.

3

EN

Internal assemblies

27

Page 29

4 Use the TX-20 screwdriver to remove two screws (callout 1), one

2

1

on each side of the assembly.

5 Lift the assembly to clear the tabs on each side of the assembly

and pull the assembly straight away from the frame.

Figure 12. Carriage assembly removal (2 of 2)

28 3 Removal and replacement

EN

Page 30

Accumulator a ssembly (S tapler/ Stacker only)

2

1

Remove the front cov er, the back cover, the controller PCA co v er,

1

the flipper assembly, and the carriage assembly.

Note

While it is possible to remove the accumulator assembly without first

removing the carriage assembly, HP strongly recommends that the

carriage assembly be removed before removing the accumulator

assembly. Otherwise, you might find it very difficult to reposition the

accumulator assembly with the carriage assembly in the way.

Disconnect the ribbon cable (callout 1) from the controller PCA by

2

pressing the black tabs to release the cable.

Figure 13. Accumula tor asse mbly remova l (1 of 2)

Push the ribbon cable up through the hole.

3

EN

Internal assemblies

29

Page 31

4 Use the TX-20 screwdriver to remov e four screws (callout 1), two

2

1

on each side of the assembly.

Figure 14. Accumula tor asse mbly remova l (2 of 2)

5 Lift the accumulator assembly up to clear the tabs at each side

and rotate the top of the assembly down while pulling it aw ay from

the product.

30 3 Removal and replacement

EN

Page 32

O ffset module (Sta cker only)

2

2

1

2

Remove the front cov er, the back cover, the controller PCA co v er,

1

and the flipper assembly.

Disconnect the ribbon cable (callout 1) from the controller PCA by

2

pressing the black tabs to release the cable.

Push the ribbon cable up through the hole.

3

Use the TX-20 screwdriver to remov e four screws (callout 2), two

4

on each side of the module.

Figure 15. O ffset module remova l

Lift the offset module to clear the tabs at each side and rotate the

5

top of the module away from the product while pulling it away

from the product.

EN

Internal assemblies

31

Page 33

S taple r (Sta pler/ Stacke r only)

1 Remove the carriage assembly from the 3,000-Sheet Stapler/

Stacker and place it on a work surface.

2 Remove the staples cartridge from the stapler.

3 Disconnect the cable from its connector and unthread the cable

from the cable guides.

Figure 16. Stapler removal (1 of 3)

32 3 Removal and replacement

EN

Page 34

Use the TX-10 screwdriver to remove the grounding screw

2

2

2

1

4

(callout 1) and release the grounding cable.

Use the TX-20 screwdriver to remove two screws and their

5

washers (callout 2) from the stapler.

Note

Keep the washers with the screws to make sure they are reinstalled.

Figure 17. Stapler removal (2 of 3)

The stapler is affixed tightly to the carriage assembly. Once the two

screws have been remo ved, the stapler is held in place by the two metal

tabs located on the side of the stapler opposite the screws.

Use firm pressure to slide the stapler toward the tab side of the

6

stapler, clearing the tabs.

Note

EN

Internal assemblies

33

Page 35

7 Lift the stapler away from the carriage.

2

2

1

2

Note In the figure below, the stapler has been removed from the carriage

assembly and is rotated to show the tabs (callout 1) and tab slots

(callout 2).

Figure 18. Stapler removal (3 of 3)

To r eins tall

Place the tabs in the tab holes and use firm pressure to slide the

stapler toward the screws side of the stapler, lining up the screw

holes. Do not attempt to replace the screws until the screw holes are

lined up.

34 3 Removal and replacement

EN

Page 36

C ontroller P CA

2

1

2

2

2

2

2

3

Remove the controller PCA cover.

1

Release the seven cables, including the C-link cable, from their

2

connectors (callout 1) on the stapler/stacker controller PCA (or

six from the stacker controller PCA).

Use the TX-20 screwdriver to remove three screws (callout 2).

3

Figure 19. S taple r/Stacker controller PCA or Stacker controller PCA removal

Note

Note

CAUTION

EN

You might have to squeeze the three locating pins to allow the holes

on the controller PCA to clear the pins.

Pull the controller PCA from the product.

4

See Chapter 4—Troubleshooting—for information about the service

LEDs (callout 3).

Placing the controller PCA on a metal surface can damage the

controller. Place the controller PCA on an ESD mat.

Internal assemblies

35

Page 37

LE D P CA

2

2

1

2

1 Remove the front cover.

2 Use the TX-10 screwdriver to remove one screw (callout 1) from

the LED PCA.

3 Disconnect the cable (callout 2) to release the LED PCA.

Figure 20. LED PCA removal

36 3 Removal and replacement

EN

Page 38

Pow er supply

2

2

2

2

1

3

Remove the controller PCA cover.

1

Unplug the power cable (callout 1) from the power supply.

2

Disconnect the cable from the controller PCA (callout 2).

3

Use the TX-20 screwdriver to remove one screw (callout 3) from

4

the bracket that holds the power supply in place.

Figure 21. Pow er supply removal

Lift the bracket and the power supply out and away from the

5

product.

EN

Internal assemblies

37

Page 39

I nter lock switch

2

1

2

2

2

3

1 Remove the back cover.

2 Disconnect two cables (callout 1) from the interlock switch.

3 Squeeze the interlock switch on the top and bottom (callout 2),

and slide the interlock through the hole (callout 3).

Figure 22. I nterlock switch remova l

38 3 Removal and replacement

EN

Page 40

S afe ty switch assembly

2

2

2

1

2

3

Remove the front cover, the back cover, and the carriage

1

assembly.

Press the two tabs on the sides of the safety switch assembly

2

cover (callout 1) to release it from the frame and lift the cover

away from the assembly.

Disconnect two cables (callout 2) from the safety switch

3

assembly.

Press the tabs on the bottom of the safety switch assembly (one

4

tab on each side—callout 3) to release it from the frame and lift

the assembly away from the product.

Figure 23. S afety switch assemb ly removal

EN

Internal assemblies

39

Page 41

Atta chment a ssembly (rod, bracket, cables)

2

1

1 Unplug the attachment assembly’ s C-link cable from the controller

PCA and power cable from the power supply.

2 Use the TX-20 screwdriver to remov e f our scre ws (callout 1) from

the attachment assembly.

3 Guide both cables through the hole and pull the assembly away

from the product.

Figure 24. Atta chment assembly remo val

40 3 Removal and replacement

EN

Page 42

F lipper r ibbon cable

2

2

2

1

Remove the back cover and the controller PCA cover.

1

Disconnect the cable (callout 1) at both ends by pressing the

2

black tabs on the connectors.

Open the three cable clips (callout 2; two of the three cable clips

3

are shown) to release the cable.

Figure 25. F lipper ribbon cable remova l

EN

Internal assemblies

41

Page 43

S tationa ry caste r

2

1

1 Remove front or back co v er, depending upon the caster you want

to replace.

2 Lay the Stapler/Stack er on its front or back side so that the caster

being replaced is off the floor.

3 Use the TX-20 screwdriver to remove one screw (callout 1) from

the inside of the frame.

4 Rotate the caster 90° to clear the tabs and pull the caster away

from the product.

Figure 26. S tationary ca ster remo val

42 3 Removal and replacement

EN

Page 44

Adjusta ble ca ster

2

1

Remove the front cover, the back cover, and the foot cover.

1

Lay the Stapler/Stack er on its front or back side so that the caster

2

being replaced is off the floor.

Use a flatblade screwdriver to snap the e-clip off of the adjusting

3

knob (callout 1).

Figure 27. Adjusta ble caster re moval

Slide the caster out of its position.

4

EN

Internal assemblies

43

Page 45

44 3 Removal and replacement

EN

Page 46

4

Troubleshooting

Introduction

This section provides a systematic approach to identifying the causes

of malfunctions and errors on the output paper handling devices—the

HP 3,000-Sheet Stapler/Stacker and the HP 3,000-Sheet Stacker—

that attach to the printer. The troubleshooting process addresses the

major problems, allowing you to identify malfunctions and errors in the

devices.

Note

This chapter provides troubleshooting information, the standalone

diagnostics tool, control panel messages, and the event log error

messages for the HP 3,000-Sheet Stapler/Stacker and the HP 3000Sheet Stacker. For troubleshooting information about the printer, see

the printer’s service manual.

EN

Introduction

45

Page 47

Ba sic troubleshooting

Ve r ifying po wer

Confirm that the printer is turned on and that a message appears on

the control panel display. The message should indicate Ready,

Offline, or Powersave On for a normal operating condition. The user

LED on the Stapler/Stacker or Stack er should be lit g reen when there

is a ready message on the control panel display.

P r inting the configuration page

Use the configuration page to verify proper installation of the paperhandling devices, firmware versions, and important printer

information.

To print a configur ation pa ge

1 Press M

display.

2 Press I

3 Press S

until Information Menu appears on the control panel

ENU

until Print Configuration appears.

TEM

to print the configuration page.

ELECT

E valua ting the configuration page

After printing the configuration page, make sure it shows that the

Stapler/Stacker or Stacker is installed.

If the product does not appear on the configuration, check the cable

connections. Make sure that the C-link cables and power cables are

correctly installed and are functional and that the power cables supply

power to the paper-handling devices.

46 4 Troubleshooting

EN

Page 48

P r inting the eve nt log

If the control panel display does not indicate a normal operating

condition, an error message will be displayed and logged in the event

log. You can access the event log through the printer’s Test Menu to

display more specific information about the current error message.

The printer's internal event log stores the most recent error messages

and can be printed or displayed at any time . If the printer cannot print

or move any paper, follow the steps below to display the event log.

Otherwise, print the event log.

To display the event log

1

Press M

ENU

until

Information Menu

appears on the control panel

display.

Press I

2

Press

3

Press – V

4

Write down the error messages.

5

until

TEM

Select

ALUE

Show Event Log

to show the event log.

+ to scroll through the event log.

appears.

To print the eve nt log

1

2

3

Press M

display.

Press I

Press S

ENU

TEM

ELECT

until

Information Menu

until

Print Event Log

to print the event log.

appears on the control panel

appears.

E valua ting the eve nt log

The event log can point to specific problems in the product.

Check the event log for specific error trends in the last 10,000

●

printed pages.

Ask the customer for any observed error trends.

●

Record any specific error trends.

●

See the alphabetical and numerical event log tables.

●

See the section about error messages later in this chapter for

●

recommended courses of action.

EN

Basic troubleshooting

47

Page 49

C alibrating the staple position

Note Recalibrate the staple position only if the accumulator assembly, the

carriage assembly , or the controller PCA is replaced. Non-volatile RAM

(NVRAM) located in the controller PCA keeps in memory the

configured compensation values for the staple position. When the

device is in service mode, you can access the fle xible calibration menu.

To calibrate the staple position

1 Turn the printer off.

2 Enter service mode (see “To set the device in service mode” later

in this chapter). As the device powers on, the NVRAM receives

the calibration values.

3 After successful power on, exit service mode (see “To exit service

mode” later in this chapter).

4 Turn the printer on and wait until Ready appears on the control

panel display. The user LED, located at the top of the front cover,

should blink green.

until Configuration of Stkr appears on the control

5 Press M

panel display.

ENU

6 Press I

7 Press – V

8 Press S

9 Press M

10 Press I

until Default of Staples appears.

TEM

+ until One Staple appears.

ALUE

.

ELECT

until Information Menu appears.

ENU

until Print Paper Path Test appears.

TEM

11 Print a ten-page job to the stapler bin (optional bin 1).

12 Check the staple position of the 10-page print job against the

staple position in Figure 28—Staple position.

• If the positons are not comparable, then the device should be

recalibrated; continue with step 13 below.

• If the positions match or are close to a match, the device does

not require recalibration; proceed to step 18.

13 Press M

14 Press I

15 Press – V

16 Press S

until Configuration of Stkr appears.

ENU

until X Compensation/Y Compensation appears.

TEM

+ to set the correct compensation (in millimeters).

ALUE

.

ELECT

48 4 Troubleshooting

EN

Page 50

Repeat steps 9 through 16 until you are comfortable with the

X-axis

Y-axis

–+

–+

Staple position

17

staple position.

Press M

18

Press I

19

Press – V

20

Press S

21

Press GO.

22

ENU

TEM

ALUE

ELECT

until

Configuration of Stkr

until

Calibra Values

+ until

appears.

Set

.

appears.

appears.

If you set compensation values, the printer should return to Ready

automatically and the user LED should return to the solid green

status.

Because you set calibration values, the printer should not allow

access to the compensation values in service mode.

If you did not set compensation values, repeat steps 1 through 4 and

steps steps 18 through 22.

Figure 28. S taple position

EN

Basic troubleshooting

49

Page 51

Troubleshooting tools

Paper pa th test

Using the information from the event log, you can verify a specific

printer paper path with the paper path test. The paper path test menu

allows you to select the paper source and the output destination.

Note See Chapter 2—Theory of operation—for graphic representations of

the paper path.

To perfor m a pa per path test

1 Press M

until Information Menu appears on the control panel

ENU

display.

2 Press I

S

ELECT

3 Press – V

S

ELECT

4 Press – V

S

ELECT

5 Press – V

press S

6 Press – V

S

ELECT

until Print Paper Path Test appears and then press

TEM

.

+ to choose the correct input tray and then press

ALUE

.

+ to choose the correct destination and then press

ALUE

.

+ to choose the correct duplex mode and then

ALUE

.

ELECT

+ to choose the number of copies and then press

ALUE

.

To stop the paper path test, press C

ANCEL JOB

on the control panel.

50 4 Troubleshooting

EN

Page 52

Timing

Figure 29 shows timeouts related to jam declarations. The number in

parentheses is the jam’s error log code.

Note

Figure 29. D evice timing

Jam codes used in the drawing and in the explanation are in

hexadecimal representation.

The time is the maximum time allowed between two events. The

figure shows the flow of a normal sheet, from entry to the

accumulator/offset module.

EN

The printer sends a delivery notice for each sheet. When the device

detects the signal, a timeout of three seconds begins.

F LEntry 1 se nsor and F LEntr y sensor

If the sheet does not arrive to the FLEntry 1 sensor within three

seconds, the device declares a jam 02.

When the sheet arrives at the FLEntry 1 sensor, which means that the

sheet is being pushed by the printer and pulled by the device, the

timer is reset to timeout in one second. If the sheet does not arrive at

FLEntry sensor in one second, the device declares a jam 03.

Next, the FLEntry 1 sensor is deactivated. Since this event depends

on the paper length and the printer speed, it is independent of time.

The device counts steps in the receiving stepper motor. With the

proper relation of steps to length, the device knows when the sheet

Troubleshooting tools

51

Page 53

leaves the printer rollers. At that time, the device switches to high

speed and begins a timeout of one second. If the sheet fails to leave

the FLEntry 1 sensor in one second, the device declares a jam 04.

Once FLEntry 1 is deactivated, a timeout of .75 seconds begins to the

next event—deactivation of the FLEntry sensor. If the FLEntry sensor

is not deactivated, the device declares a jam 05. If the FLEntry sensor

is deactivated, a timeout of 1.5 seconds begins for activation of the

FLExit sensor.

F LExit se nsor

If the FLExit sensor is not activated within the timeout, the device

declares a jam 0A.

FLExit sensor deactivatation depends on the internal paper path

speed and the paper length. The device declares a jam when internal

step counter exceeds 133% of number of steps that represent the

paper length.

If the FLExit sensor is not deactivated, which can occur when sheet

stops in the paper path because of an obstruction or slipping, the

device declares a jam 0B.

When the FLExit sensor is deactivated correctly, a timeout of 1.5

seconds begins for activation of the registration wheel's sensor.

G WS ens se nsor/E xit sensor

If the GWSens sensor (in the Stapler/Stacker) or the Exit sensor (on

the Stacker) is not activated within the timeout, the device declares a

jam 12.

52 4 Troubleshooting

EN

Page 54

S tanda lone diagnostic tool

The standalone diagnostic routines differ between the 3,000-Sheet

Stapler/Stacker and the 3,000-Sheet Stacker.

The standalone diagnostic tool tests the device's motors and

functionality without the C-link commands from the printer.

The device has a “user LED” and a set of “service LEDs.”

User LED—the single LED located at the top of the front cover

●

provides information about the power-on status and attachment/

alignment to the printer.

Service LEDs (see Figure 19, callout 3)—three LEDs (green,

●

yellow, and red) located near the bottom of the controller PCA,

toward the back of the device, provide additional technical

information about the device.

Note

Note

To interpret the LED patterns, see the tables later in this chapter.

When service mode is entered, the Stapler/Stacker performs a

power-up sequence. While in service mode, the stapler test/stacker

test, stacker bin test, face-up bin full sensor test, and stacker bin full

test can be performed.

To set the device in ser vice mode

Make sure the printer is turned off before performing this test. If the

printer is on when service mode is enabled, some C-link signals might

affect the test performance.

Unplug the C-link cable that connects the device to the printer.

1

Unplug the power cable that connects the device to the printer

2

and plug the power cable directly into a grounded power source.

Remove the controller PCA cover (see Chapter 3—Removal and

3

Replacement—for removal and replacement procedures).

Slide the service mode switch on the controller PCA to the “ON”

4

position (toward you).

Press and hold in the interlock switch.

5

EN

To exit service mode

Release the interlock switch and slide the service mode switch on

1

the controller PCA back to the normal position.

Reinstall the controller PCA cover and C-link and power cables.

2

Troubleshooting tools

53

Page 55

Note The user LED blinks green when the printer is turned on after setting

and exiting service mode. Perform steps 18 through 22 under

“Calibrating the staple position” earlier in this chapter to return to

normal operation.

S tapler test/ stacker te st

For the stapler test/stacker test, use letter- or A4-sized paper. Feed

the paper straight, centered, and slowly to av oid skews and jams. If a

jam occurs, release the interlock switch and depress it again to reset

the device.

Note Any stapler settings or offset settings configured at the printer control

panel are ignored during the stapler test/stacker test.

1 Feed two sheets of paper into the paper input area. The sheets

are sent to the face-up bin.

2 Feed two sheets at a time into the paper input area.

• In the 3,000-Sheet Stapler/Stacker, the sheets are stapled

as shown below and sent to the stacker bin:

next two sheets: no staples

next two sheets: 1 staple

• In the 3,000-Sheet Stacker, the sheets are routed as follows:

54 4 Troubleshooting

next two sheets: 2 staples

next two sheets: 3 staples

next two sheets: 6 staples

next two sheets: 1 staple, angled at 40°

next two sheets restart the cycle: to the face-up bin

next two sheets: to the stacker bin, offset in

one direction

next two sheets: to the face-up bin

next two sheets: to the stacker bin, offset in

the opposite direction

next two sheets restart the cycle: to the face-up bin

EN

Page 56

S tacke r bin test

Block the upper optical sensor and observe the movement of the

stacker bin.

Face -up bin full se nsor test

Lift and hold up the bin-full flag until the user LED blinks amber. The

user LED should blink amber within a few seconds.

S tacke r Bin Full S ensor Test

Block the upper optical sensor until the stacker bin reaches the

bottom of its motion, triggering the stacker bin full sensor; the user

LED should blink amber.

EN

Troubleshooting tools

55

Page 57

S er vice LED flashing pa tterns

The blinking of the service LEDs will be 0.5 seconds on and 0.5

seconds off, during the coding sequence. After a two-second delay

the sequence will be repeated.

Table 10. S ervice LE D flashing patterns

LED blinking

pattern (number

LED Meaning

Solid green Device OK

Blinking green Device detached from the printer 1

Blinking yellow Staple jam 1

Jam in flipper 2

Jam in paper path 3

Jam in accumulator 4

Jam in carriage 5

Blinking red Stapler malfunction 1

Flipper malfunction 2

Malfunction in paper path 3

of blinks)

Accumulator/offset module malfunction 4

Carriage malfunction 5

Controller PCA malfunction 6

U ser LE D status inte rpreta tion

The blinking of the user LED is continuous.

Table 11. User LED status interpretation

Color Solid/blinking Meaning

Off N/A Printer in powersave mode or de vice not

receiving power

Green Solid Device is on and ready

Green Blinking Device is in service mode

Amber Solid Device has a hardware malfunction

Amber Blinking Device is not correctly attached to

printer, one or more bins are full, or

device has a paper jam or a staple jam

56 4 Troubleshooting

EN

Page 58

P rinte r messages

C ontrol pane l message s and e rrors

Be sure to read the exact text of the control panel message , including

the error message number and the text, in order to locate the error

message in the tables.

The printer has enhanced information in the control panel.

Printer messages displayed on the control panel display provide five

categories of information. Each message category is assigned a

priority. If more than one condition occurs at the same time, the

highest priority message is displayed. When it has been cleared, the

next priority message will be displayed, and so on. The displayed

messages and their priorities are:

Printer status

●

Warning messages

●

Error messages

●

Critical error messages

●

External paper-handling device messages

●

Co ntrol panel and e vent log me ssage forma t

The format of control panel messages is:

13.xy—paper jam in input/output device

●

Input/output device condition—xy.zz

●

66.xy.zz—input/output device failure

●

The format of event log messages is:

13.xy zz—input/output device paper jam

●

65.xy.zz—input/output device condition

●

66.xy.zz—input/output device hardware malfunction

●

EN

Printer messages

57

Page 59

For both the control panel and event log messages:

●

x is the C-link device number in the daisy chain:

0 Paper handling controller

1 First C-link device

2 Second C-link device

3 Third C-link device

4 Fourth C-link device

5 Fifth C-link device

●

y is the C-link device type:

0 Paper handling controller

1 Input device

2 Output device

3 Finishing device

4 Other supported device (not in use)

5 Other supported device (not in use)

●

zz is the error code. See the error message tables later in this

chapter for more information.

Shown below are examples of control panel messages with their

corresponding event log messages and meanings. Recommended

actions are not shown; see the error message tables later in this

chapter for recommended actions.

Control panel message Event log Meaning

13.11 Paper Jam in Input

Device

66.22.09 Output Device

Failure

13.11.1B A paper jam occurred in the first C-link device

configured. It is an input device (2,000-Sheet

Input Tray or 2 x 500-Sheet Input Tray) with an

error code 1B. This is normally a timeout at an

entry or exit sensor.

66.22.09 A hardware malfunction occurred in t he second

C-link device configured. It is an output device

(Mailbox) with an error code 09. This is an

external memory error.

58 4 Troubleshooting

EN

Page 60

Note

Print a configuration page to properly identify the input or output device

configured. Notice that the error format only identifies the C-link device

number and the device type; it does not identify which input or output

device is used in the system.

Figure 30. E rror for m at for paper handling

EN

Printer messages

59

Page 61

HP 3,000-Sheet Stapler/Stacker error messages

Operating errors

Table 12. Operating errors in the Stapler/Stacker

Event

Control pane l

messages

●

Output bin

full

●

Clear

paper from

face up

●

Output bin

full

●

Clear

paper from

optional

bin 1

log erro r

message

N/A Blinking

N/A Blinking

User

LED

amber

(print job

or mopy in

progress)

amber

(print job

or mopy in

progress)

Service

LED Description

N/A Face up bin is full;

125 sheets have

been collected in

the face-up bin.

N/A Stapler bin is full;

3,000 sheets have

been collected in

the stapler bin.

-OrMore than 1,500

sheets of A3- or 11by-17-inch-sized

paper have been

collected in the

stapler bin.

Recommended

action

Remove paper from

the face-up bin.

Remove paper from

the stapler bin.

Stapler low

N/A N/A N/A There are only 20

on staples

●

Check

stapler

device

●

Clear

jammed

staple

Stapler out

N/A Blinking

of staples

Too many

N/A Blinking

pages in job

to staple

60 4 Troubleshooting

Blinking

amber

Blinking

yellow

(one blink)

yellow

(one blink)

yellow

(one blink)

to 50 staples left.

A staple is jammed

in the stapler.

The cartridge is out

of staples.

The maximum

height of stack to

be stapled has

been exceeded.

Print job is

completed, but not

stapled.

Refill the stapler.

Clear the jammed

staple.

Refill the stapler.

Do not configure

the equipment to

staple stacks that

are thicker than the

maximum height

allowed; follow the

guidelines listed in

the user’s guide.

EN

Page 62

Open Doors

Table 13. O pen doors in the Stapler/ Stacker

Event

Control pane l

messages

log erro r

message

User

LED

Service

LED Description

Recommended

action

Stkr: Attach

to printer

Stkr: Close

stapler door

N/A Blinking

amber

N/A Blinking

amber

Blinking

green

Blinking

green

The device is

detached from the

printer.

The stapler door is

open.

Attach the device to

the printer and

verify the user LED

is green.

Close the stapler

door.

EN

Printer messages

61

Page 63

Pape r jams

Table 14. Paper jams in the Stapler/Stacker

Event

Control pane l

messages

Stkr: Detach

and Clear Jam

log erro r

message

13.13 01

or

13.23 01

13.13 02

or

13.23 02

13.13 03

or

13.23 03

User

LED

Blinking

amber

Blinking

amber

Blinking

amber

Service

LED Description

Blinking

yellow

(two

blinks)

Blinking

yellow

(two

blinks)

Blinking

yellow

(two

blinks)

When powering on

or after clearing a

jam, a paper jam is

present at the

flipper entry area.

Paper never

reached the flipper

entry sensors.

Paper jammed at

flipper entry sensor.

Recommended

action

●

Clear the paper

jam.

●

Pow er cycle the

the printer and

the computer, if

neccesary.

●

If the problem

persists,

replace the

flipper

assembly.

●

Clear the paper

jam.

●

Pow er cycle the

printer and the

computer, if

neccesary.

●

If the problem

persists,

replace the

flipper

assembly.

●

Clear the paper

jam.

●

Pow er cycle the

printer and the

computer, if

neccesary.

●

If the problem

persists,

replace the

flipper

assembly.

62 4 Troubleshooting

EN

Page 64

Table 14. Paper jams in the Stapler/Stacker

Event

Control pane l

messages

Stkr: Detach

and Clear Jam

(continued)

log erro r

message

13.13 04

or

13.23 04

13.13 05

or

13.23 05

13.13 06

or

13.23 06

13.13 09

or

13.23 09

User

LED

Blinking

amber

Blinking

amber

Blinking

amber

Blinking

amber

Service

LED Description

Blinking

yellow

(two

blinks)

Blinking

yellow

(two

blinks)

Blinking

yellow

(two

blinks)

Blinking

yellow

(three

blinks)

Paper jammed in

the flipper area.

Paper jammed on

the flipper area.

Self-adjustment

routine incomplete.

When powering on

or after clearing a

jam, a paper jam is

present in the

paper path.

Recommended

action

●

Clear the paper

jam.

●

Pow er cycle the

printer and the

computer, if

neccesary.

●

If the problem

persists,

replace the

flipper

assembly.

●

Clear the paper

jam.

●

Pow er cycle the

printer and the

computer, if

neccesary.

●

If the problem

persists,

replace the

flipper

assembly.

●

Check for

mechanical

interferences in

the flipper's

rollers area.

●

If the problem

persists,

replace the

flipper

assembly.

●

Clear the paper

jam.

●

Pow er cycle the

printer and

computer, if

neccesary.

●

If the problem

persists,

replace the

flipper

assembly.

EN

Printer messages

63

Page 65

Table 14. Paper jams in the Stapler/Stacker

Event

Control pane l

messages

Stkr: Detach

and Clear Jam

(continued)

log erro r

message

13.13 0A

or

13.23 0A

13.13 0B

or

13.23 0B

13.13 11

or

13.23 11

13.13 12

or

13.23 12

User

LED

Blinking

amber

Blinking

amber

Blinking

amber

Blinking

amber

Service

LED Description

Blinking

yellow

(three

blinks)

Blinking

yellow

(three

blinks)

Blinking

yellow

(four

blinks)

Blinking

yellow

(four

blinks)

Paper jammed

when flipping and

not reaching the

exit sensor.

Paper jammed

when entering the

accumulator.

When powering on

or after clearing a

jam, a paper jam is

present in the

accumulator

assembly.

Paper jammed in

the paper path

between the flipper

and the

accumulator.

Recommended

action

●

Clear the paper

jam.

●

Pow er cycle the

printer and the

computer, if

neccesary.

●

If the problem

persists,

replace the

flipper

assembly.

●

Clear the paper

jam. Make sure

you remove all

shreds of paper

from the path.

●

Pow er cycle the

printer and the

computer, if

neccesary.

●

If the problem

persists,

replace the

flipper

assembly.

●

Clear the paper

jam.

●

Pow er cycle the

printer and the

computer, if

neccesary.

●

Replace the

accumulator

assembly.

●

Clear the paper

jam.

●

Pow er cycle the

printer and the

computer, if

neccesary.

●

Replace the

accumulator

assembly.

64 4 Troubleshooting

EN

Page 66

Table 14. Paper jams in the Stapler/Stacker

Event

Control pane l

messages

Stkr: Detach

and Clear Jam

(continued)

Stkr: Detach

and clear

staple jam

log erro r

message

13.13 13

or

13.23 13

13.13 19

or

13.23 19

User

LED

Blinking

amber

Blinking

amber

Service

LED Description

Blinking

yellow

(four

blinks)

Blinking

yellow

(five

blinks)

A paper jam

occurred when

trying to eject a

print job or mopy.

Paper jammed

between the

carriage and the

stack of paper to be

stapled.

Recommended

action

●

Clear the paper

jam.

●

Pow er cycle the

printer and the

computer, if

neccesary.

●

Replace the

accumulator

assembly.

●

Clear the paper

jam.

●

Pow er cycle the

printer and the

computer.

●

Verify unit

calibration (Y

compensation).

●

Replace the

stapler

assembly.

H ardwa re ma lfunctions

Table 15. Hardware malfunctions in the Stapler/Stacker

Event

Control pane l

messages

●

Stkr: Call

Service

●

Stkr:

Error 04

●

66.13.17

or

66.23.17

Output

device

failure

EN

log erro r

message

66.13.17

or

66.23.17

User

LED

Solid

amber

Service

LED Description

Blinking

red

(four

blinks)

The accumulator

assembly

malfunctioned.

-Or-

The DC motor

retainer or sensor is

damaged.

Recommended

action

●

Replace the

accumulator

assembly.

●

If the problem

perisists,

replace the

controller PCA.

Printer messages

65

Page 67

Table 15. Hardware malfunctions in the Stapler/Stacker

Event

Control pane l

messages

●

Stkr: Call

Service

●

Stkr:

Error 04

●

66.13.18

log erro r

message

66.13.18

or

66.23.18

User

LED

Solid

amber

Service

LED Description

Blinking

red

(four

blinks)

The accumulator

assembly

malfunctioned.

-Or-

or

66.23.18

Output

device

failure

●

Stkr: Call

Service

●

Stkr:

Error 05

●

66.13.25

66.13.25

or

66.23.25

Solid

amber

Blinking

red

(five

blinks)

The bearing

bracket or gear

wheel sensor is

damaged.

The stapler is

damaged.

or

66.23.25

Output

device

failure

●

Stkr: Call

Service

●

Stkr:

Error 06

●

66.13.33

or

66.23.33

66.13.33

or

66.23.33

Solid

amber

Blinking

red

(six blinks)

The controller PCA

is damaged.

-Or-

There is a RAM

error.

Output

device

failure

●

Stkr: Call

Service

●

Stkr:

Error 06

●

66.13.34

or

66.23.34

66.13.34

or

66.23.34

Solid

amber

Blinking

red

(six blinks)

The controller PCA

is damaged.

-Or-

There is an

EEPROM error.

Output

device

failure

Recommended

action

●

Replace the

accumulator

assembly.

●

If the problem

persists,

replace the

controller PCA.

●

Replace the

stapler.

●

Replace the

controller PCA.

●

Pow er cycle the

printer and the

computer.

●

If the problem

persists,

replace the

controller PCA.

●

Pow er cycle the

printer and the

computer.

●

If the problem

persists,

replace the

controller PCA.

66 4 Troubleshooting

EN

Page 68

Table 15. Hardware malfunctions in the Stapler/Stacker

Event

Control pane l

messages

●

Stkr: Call

Service

●

Stkr:

Error 06

●

66.13.35

or

66.23.35

log erro r

message

66.13.35

or

66.23.35

User

LED

Solid

amber

Service

LED Description

Blinking

red

(six blinks)

The controller PCA

is damaged.

-Or-

ROM has been

corrupted.

Output

device

failure

●

Stkr: Call

Service

●

Stkr:

Error 06

●

66.13.36

or

66.23.36

66.13.36

or

66.23.36

Solid

amber

Blinking

red

(six blinks)

The controller PCA

is damaged.

-Or-

The C-link register

is damaged.

Output

device

failure

●

Stkr: Call

Service

●

Stkr:

Error 06

●

66.13.37

or

66.23.37

Output

66.13.37

or

66.23.37

Solid

amber

Blinking

red

(six blinks)

The controller PCA

is damaged.

-Or-

The DAC (digit al-toanalog converter) is

damaged.

device

failure

Recommended

action

●

Pow er cycle the

printer and the

computer.

●

If the problem

persists,

replace the

controller PCA.

●

Pow er cycle the

printer and the

computer.

●

If the problem

persists,

replace the

controller PCA.

●

Pow er cycle the

printer and the

computer.

●

Replace the

controller PCA.

●

Replace the

flipper

assembly.

EN

Printer messages

67

Page 69

HP 3,000-Sheet Stacker error messages

Operating errors

Table 16. Operating errors in the Stacker

Event

Control pane l

messages

●

Output bin

full

●

Clear

paper from

face up

●

Output bin

full

●

Clear

paper from

optional

bin 1

log erro r

message

N/A Blinking

N/A Blinking

User

LED

amber

(print job

or mopy in

progress)

amber

(print job

or mopy in

progress)

Service

LED Description

N/A Face up bin is full;

N/A Stacker bin is full;

125 sheets have

been collected in

the face-up bin.

3,000 sheets have

been collected in

the stacker bin.

-OrMore than 1,500

sheets of A3- or 11by-17-inch-sized

paper have been

collected in the

stacker bin.

Recommended

action

Remove paper from

the face-up bin.

Remove paper from

the stacker bin.

O pen doors

Table 17. O pen doors in the Stac ker

Event

Control pane l

messages

Stkr: Attach

to printer

68 4 Troubleshooting

log erro r

message

N/A Blinking

User

LED

amber

Service

LED Description

Blinking

green

The device is

detached from the

printer.

Recommended

action

Attach the device to

the printer and

verify the user LED

is green.

EN

Page 70

Pape r jams

Table 18. Paper jams in the Stacker

Event

Control pane l

messages

Stkr: Detach

and Clear Jam

log erro r

message

13.12 01

or

13.22 01

13.12 02

or

13.22 02

13.12 03

or

13.22 03

User

LED

Blinking

amber

Blinking

amber

Blinking

amber

Service

LED Description

Blinking

yellow

(two

blinks)

Blinking

yellow

(two

blinks)

Blinking

yellow

(two

blinks)

When powering on

or after clearing a

jam, a paper jam is

still present at the

flipper entry area.

Paper never

reached the flipper

entry sensors.

Paper jammed at

flipper entry sensor.

Recommended

action

●

Clear the paper

jam.

●

Pow er cycle the

the printer and

the computer, if

neccesary.

●

If the problem

persists,

replace the

flipper

assembly.

●

Clear the paper

jam.

●

Pow er cycle the

printer and the

computer, if

neccesary.

●

If the problem

persists,

replace the

flipper

assembly.

●

Clear the paper

jam.

●

Pow er cycle the

printer and the

computer, if

neccesary.

●

If the problem

persists,

replace the

flipper

assembly.

EN

Printer messages

69

Page 71

Table 18. Paper jams in the Stacker

Event

Control pane l

messages

Stkr: Detach

and Clear Jam

(continued)

log erro r

message

13.12 04

or

13.22 04

13.12 05

or

13.22 05

13.12 06

or

13.22 06

13.12 09

or

13.22 09

User

LED

Blinking

amber

Blinking

amber

Blinking

amber

Blinking

amber

Service

LED Description

Blinking

yellow

(two

blinks)

Blinking

yellow

(two

blinks)

Blinking

yellow

(two

blinks)

Blinking

yellow

(three

blinks)

Paper jammed in

the flipper area.

Paper jammed in

the flipper area.

Self-adjustment

routine incomplete.

When powering on

or after clearing a

jam, a paper jam is

present in the

paper path.

Recommended

action

●

Clear the paper

jam.

●

Pow er cycle the

printer and the

computer, if

neccesary.

●

If the problem

persists,

replace the

flipper

assembly.

●

Clear the paper

jam.

●

Pow er cycle the

printer and the

computer, if

neccesary.

●

If the problem

persists,

replace the

flipper

assembly.

●

Check for

mechanical

interferences in

the flipper's

rollers area.

●

If the problem

persists,

replace the

flipper

assembly.

●

Clear the paper

jam.

●

Pow er cycle the

printer and

computer, if

neccesary.

●

If the problem

persists,

replace the

flipper

assembly.

70 4 Troubleshooting

EN

Page 72

Table 18. Paper jams in the Stacker

Event

Control pane l

messages

Stkr: Detach

and Clear Jam

(continued)

log erro r

message

13.12 0A

or

13.22 0A

13.12 0B

or

13.22 0B

13.12 21

or

13.22 21

13.12 22

or

13.22 22

User

LED

Blinking

amber

Blinking

amber

Blinking

amber

Blinking

amber

Service

LED Description

Blinking

yellow

(three

blinks)

Blinking

yellow

(three

blinks)

Blinking

yellow

(four

blinks)

Blinking

yellow

(four

blinks)

Paper jammed

when flipping and

not reaching the

exit sensor.

Paper jammed

when entering the

offset module.

When powering on

or after clearing a

jam, a paper jam is

present in the offset

module.

Paper jammed

between the path

and the offset

module.

Recommended

action

●

Clear the paper

jam.

●

Pow er cycle the

printer and the

computer, if

neccesary.

●

If the problem

persists,

replace the

flipper

assembly.

●

Clear the paper

jam.

●

Pow er cycle the

printer and the

computer, if

neccesary.

●