HP BladeSystem bc2800, BladeSystem bc2200, BladeSystem PC Blade Enclosure G2 Reference Manual

Page 1

Service Reference Guide

HP BladeSystem PC Blade Enclosure G2

Assemblies

Page 2

© Copyright 2009 Hewlett-Packard

Development Company, L.P. The

information contained herein is subject to

change without notice.

Microsoft and Windows are trademarks of

Microsoft Corporation in the U.S. and other

countries.

The only warranties for HP products and

services are set forth in the express

warranty statements accompanying such

products and services. Nothing herein

should be construed as constituting an

additional warranty. HP shall not be liable

for technical or editorial errors or omissions

contained herein.

This document contains proprietary

information that is protected by copyright.

No part of this document may be

photocopied, reproduced, or translated to

another language without the prior written

consent of Hewlett-Packard Company.

Service Reference Guide

Business PCs

First Edition (February 2009)

Document Part Number: 536464-001

Page 3

Table of contents

1 About this Guide ............................................................................................................................................. 1

Audience Assumptions ......................................................................................................................... 1

Technician Notes .................................................................................................................................. 1

Where to Go or Additional Help ............................................................................................................ 2

2 Illustrated Parts Catalog ................................................................................................................................. 3

HP BladeSystem PC Blade Enclosure Components (Exploded View) ................................................ 3

3 Removal and Replacement Procedures ....................................................................................................... 5

Safety Considerations .......................................................................................................................... 5

Electrostatic Discharge ........................................................................................................ 5

Symbols on Equipment ........................................................................................................ 5

Rack Warnings and Cautions .............................................................................................. 6

Enclosure and HP Blade PC Warnings and Cautions ......................................................... 7

Hot-Plug Procedures ............................................................................................................................ 7

Hot-Plug Power Supplies ..................................................................................................... 8

Hot-Plug Fans ...................................................................................................................... 9

Preparing for Non-Hot-Plug Procedures ............................................................................................ 10

Powering Down the Enclosure ........................................................................................... 10

Performing a Graceful Shutdown ...................................................................... 10

Using the Integrated Administrator ................................................... 10

Pressing the Enclosure Power Button .............................................. 10

Performing an Emergency Shutdown ............................................................... 11

Using the Integrated Administrator ................................................... 11

Pressing and Holding the Enclosure Power Button .......................... 11

Completely Removing AC Power ...................................................................... 11

Powering Down a Blade PC .............................................................................................. 12

Removing a Blade PC ....................................................................................................... 13

Removing an HP Blade PC Blank Bezel ........................................................................... 14

Removing the Interconnect Tray ........................................................................................ 15

Removing the HP PC Blade Enclosure from the Rack ...................................................... 16

Opening the Access Door .................................................................................................. 17

Non-Hot-Plug Procedures .................................................................................................................. 18

Fan Cage ........................................................................................................................... 18

iii

Page 4

Fan Backplane Assembly .................................................................................................. 19

Integrated Administrator Module ........................................................................................ 20

Enclosure Status Assembly ............................................................................................... 21

Midplane Assembly ............................................................................................................ 23

Swapping the Interconnect Tray ........................................................................................ 24

4 Diagnostic Tools ........................................................................................................................................... 26

Diagnostic Software and Firmware Tools ........................................................................................... 26

Hardware Diagnostic Tools ................................................................................................................ 27

Diagnostic Adapter ............................................................................................................ 27

Null-Modem Cable Pin-Out ................................................................................................ 29

5 Connectors, Switches, and LEDs ................................................................................................................ 30

Connectors ......................................................................................................................................... 30

Enclosure Connectors ....................................................................................................... 30

Interconnect Switch Connectors ....................................................................... 30

RJ-45 Patch Panel Connectors ......................................................................... 31

Fan Cable Connector ........................................................................................ 32

Enclosure Status Cable Connector ................................................................... 32

HP Blade PC Connectors .................................................................................................. 33

Diagnostic Adapter Connectors (USB 1.1 and USB 2.0) ................................................... 33

Switches ............................................................................................................................................. 35

Front Panel Switches ......................................................................................................... 35

Rear Panel Switches ......................................................................................................... 36

CMOS ................................................................................................................................ 36

LEDs ................................................................................................................................................... 37

Enclosure Front Panel LEDs ............................................................................................. 37

Enclosure Rear Panel LEDs .............................................................................................. 38

Rear panel LEDs with HP PC Blade Switch ...................................................... 38

Rear Panel LEDs with RJ-45 Patch Panel Interconnect Tray ........................... 40

Fan Health LEDs ............................................................................................................... 41

HP Blade PC and Diagnostic Adapter LEDs ..................................................................... 42

6 POST Error Messages .................................................................................................................................. 44

7 Troubleshooting ............................................................................................................................................ 49

When the enclosure does not start ..................................................................................................... 50

Enclosure diagnostic steps ................................................................................................................. 51

When the Blade PC Does Not Start ................................................................................................... 57

Blade PC Diagnostic Steps ................................................................................................................ 58

Problems After Initial Boot .................................................................................................................. 63

Remote Troubleshooting .................................................................................................................... 64

Opening a Remote Console Session to a Blade PC ......................................................... 64

iv

Page 5

Web-Based Interface ........................................................................................ 64

Command Line Interface ................................................................................... 64

Accessing the Computer Setup (F10) Utility for a Blade PC ............................................. 64

Web-Based Interface ........................................................................................ 64

Command Line Interface ................................................................................... 65

Reviewing Activity of a Blade PC ....................................................................................... 66

Web-Based Interface ........................................................................................ 66

Command Line Interface ................................................................................... 66

Powering Off the Blade PC ................................................................................................ 66

Web-Based Interface ........................................................................................ 66

Command Line Interface ................................................................................... 67

Reviewing the Integrated Administrator System Log ......................................................... 67

Web-Based Interface ........................................................................................ 67

Command Line Interface ................................................................................... 67

8 Specifications ................................................................................................................................................ 68

Blade Enclosure ................................................................................................................................. 68

Blade PC ............................................................................................................................................ 69

Hot-Plug Power Supply ...................................................................................................................... 70

Index ................................................................................................................................................................... 72

v

Page 6

vi

Page 7

1 About this Guide

Use this service reference guide when servicing HP BladeSystem PC Blade Enclosure G2

assemblies.

WARNING! To reduce the risk of personal injury from electric shock and hazardous energy levels,

only authorized service technicians should attempt to repair this equipment. Improper repairs can

create conditions that are hazardous.

Audience Assumptions

This guide is for service technicians. HP assumes you are qualified in the servicing of computer

equipment and trained in recognizing hazard in products with hazardous energy levels and are

familiar with weight and stability precautions for rack installations.

Before installing this product, read the Important Safety Information document provided.

Technician Notes

WARNING! Only authorized technicians trained by HP should attempt to repair this equipment. All

troubleshooting and repair procedures are detailed to allow only subassembly/module-level repair.

Because of the complexity of the individual boards and subassemblies, no one should attempt to

make repairs at the component level or to make modifications to any printed wiring board. Improper

repairs can create a safety hazard.

WARNING! To reduce the risk of personal injury from electric shock and hazardous energy levels,

do not exceed the level of repairs specified in these procedures. Because of the complexity of the

individual boards and subassemblies, do not attempt to make repairs at the component level or to

make modifications to any printed wiring board. Improper repairs can create conditions that are

hazardous.

WARNING! To reduce the risk of electric shock or damage to the equipment:

– Disconnect power from the system by unplugging all power cords from the power supplies.

– Do not disable the power cord grounding plug. The grounding plug is an important safety feature.

– Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all times.

CAUTION: To properly ventilate the system, you must provide at least 7.6 cm (3.0 in) of clearance

at the front and back of the server.

CAUTION: The computer is designed to be electrically grounded (earthed). To ensure proper

operation, plug the AC power cord into a properly grounded AC outlet only.

Audience Assumptions 1

Page 8

NOTE: Any indications of component replacement or printed wiring board modifications may void

any warranty.

Where to Go or Additional Help

In addition to this guide, the following information sources are available:

●

User documentation

●

Service training guides

●

Service advisories and bulletins

●

QuickFind information services

●

HP Systems Insight Manager

●

Integrated Administrator user guide

●

Quickspecs

●

HP BladeSystem bc2000/bc2500 Blade PC and HP BladeSystem bc2200/bc2800 Blade PC

Service Reference Guide

For HP technical support

●

In the United States and Canada, call 1-800-652-6672.

●

Outside the United States and Canada, refer to

http://welcome.hp.com/country/us/en/

contact_us.html

2 Chapter 1 About this Guide

Page 9

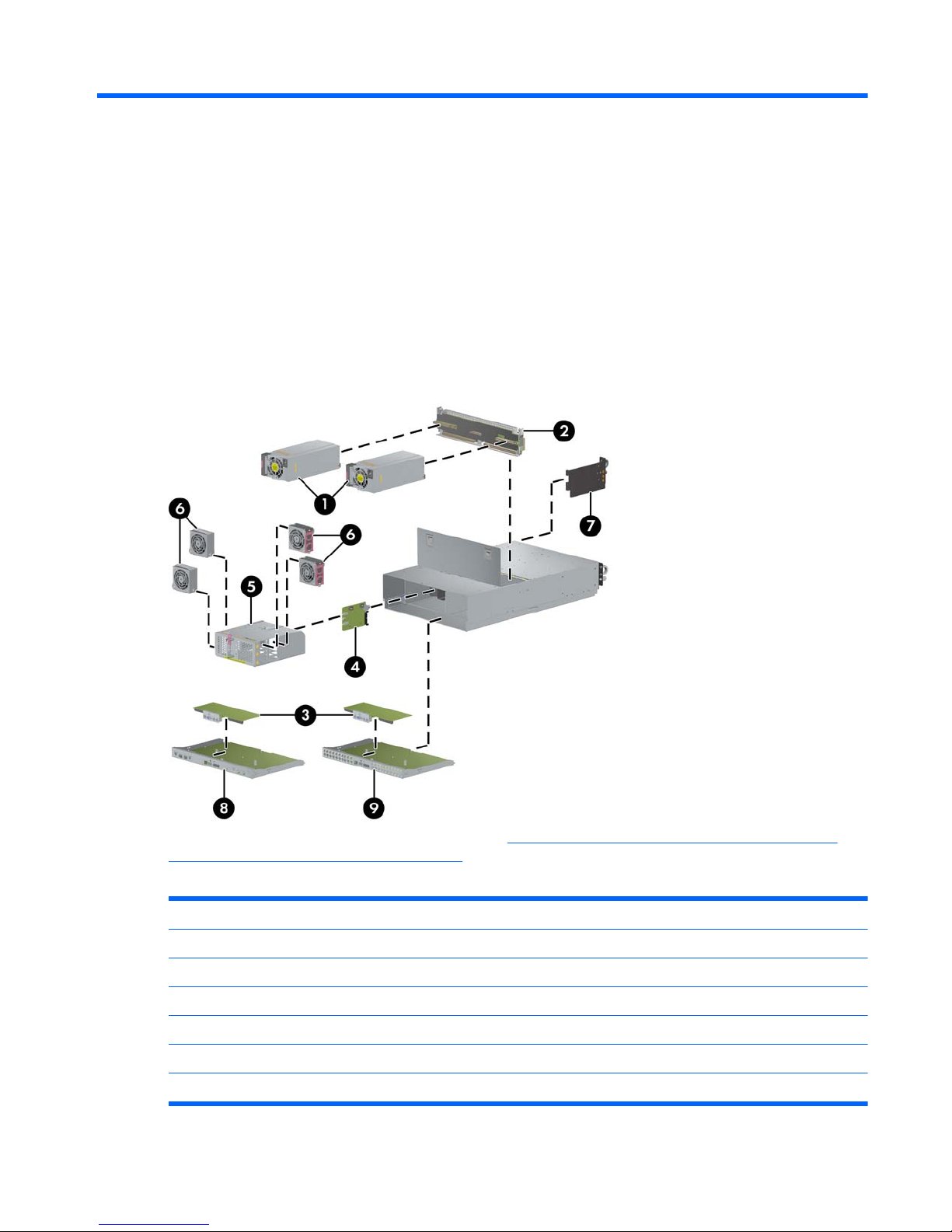

2 Illustrated Parts Catalog

HP BladeSystem PC Blade Enclosure Components

(Exploded View)

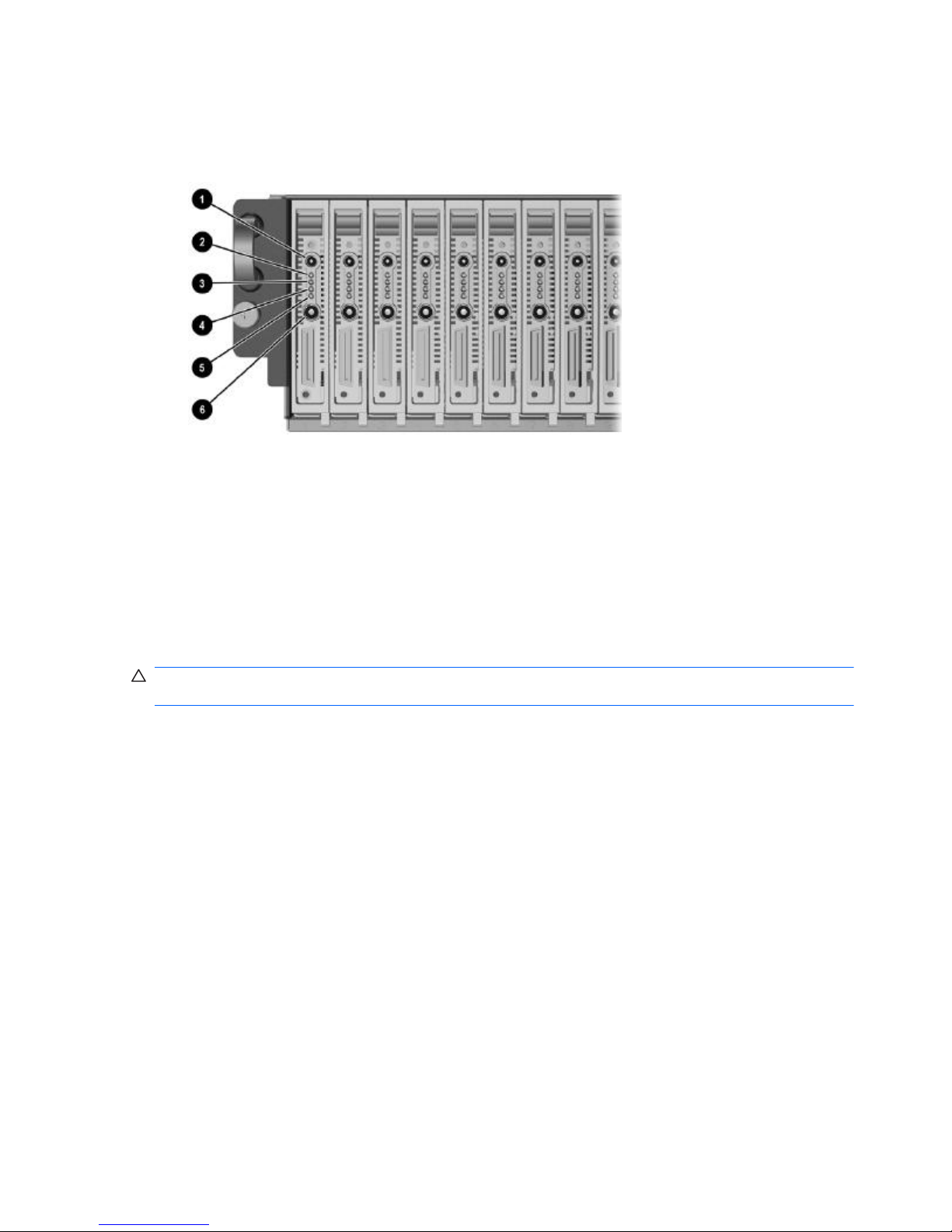

Figure 2-1 Enclosure components

For detailed information about the blade PC, see http://bizsupport.austin.hp.com/bc/docs/support/

SupportManual/c01091959/c01091959.pdf.

Table 2-1 Spare Parts List

Item Description Spare Part Number

1 Hot plug power supply 493969-001

2 Center wall assembly with bracket — Enclosure/switch 493967-001

2 Center wall assembly with bracket — Enclosure patch panel 493968-001

* Midplane signal PCA assembly with bracket 510453-001

* Midplane power PCA assembly with bracket 510454-001

3 Integrated Administrator (IA) module n/a

HP BladeSystem PC Blade Enclosure Components (Exploded View) 3

Page 10

4 Fan backplane assembly with cable 510553-001

5 Fan cage n/a

6 Hot-plug fan, 80 mm 417425-001

7 Enclosure status assembly n/a

8 HP PC Blade Switch assembly (with IA board) n/a

9 HP PC Blade RJ-45 Patch Panel assembly (with IA board) n/a

*Not shown

Table 2-1 Spare Parts List (continued)

4 Chapter 2 Illustrated Parts Catalog

Page 11

3 Removal and Replacement Procedures

This chapter provides information about the subassembly/module-level removal and replacement

procedures for HP PC Blade Enclosures with reference to HP Blade PCs.

Safety Considerations

Before performing service procedures, review the following safety information.

Electrostatic Discharge

A discharge of static electricity can damage static-sensitive devices or microcircuitry. Proper

packaging and grounding techniques are necessary to prevent damage. To prevent electrostatic

damage, observe the following precautions:

●

Transport products in static-safe containers such as conductive tubes, bags, or boxes.

● Keep electrostatic-sensitive parts in their containers until they arrive at static-free stations.

● Cover workstations with approved static-dissipating material. Use a wrist strap connected to the

work surface and properly grounded tools and equipment.

● Keep the work area free of non-conductive materials such as ordinary plastic assembly aids and

foam packing.

●

Always be properly grounded when touching a static-sensitive component or assembly.

● Avoid touching pins, leads, or circuitry.

● Use conductive field service tools.

Symbols on Equipment

These symbols may be located on equipment in areas where hazardous conditions may exist.

This symbol in conjunction with any of the following symbols indicates the presence of a potential

hazard. The potential for injury exists if warnings are not observed. Consult the documentation for

specific details.

This symbol indicates the presence of hazardous energy circuits or electric shock hazards. Refer all

servicing to qualified personnel.

WARNING! To reduce the risk of injury from electric shock hazards, do not open this enclosure.

Refer all maintenance, upgrades, and servicing to qualified personnel.

Safety Considerations 5

Page 12

This symbol indicates the presence of electric shock hazards. The area contains no user or field

serviceable parts. Do not open for any reason.

WARNING! To reduce the risk of injury from electric shock hazards, do not open this enclosure.

This symbol on an RJ-45 receptacle indicates a Network Interface Connection.

WARNING! To reduce the risk of electric shock, fire, or damage to the equipment, do not plug

telephone or telecommunications connectors into this receptacle.

This symbol indicates the presence of a hot surface or hot component. If this surface is contacted, the

potential for injury exists.

WARNING! To reduce the risk of injury from a hot component, allow the surface to cool before

touching.

These symbols on power supplies or systems indicate the equipment is supplied by multiple sources of

power.

WARNING! To reduce the risk of injury from electric shock, remove all power cords to completely

disconnect power from the system.

Weight kg

Weight lb

This symbol indicates that the component exceeds the recommended weight for one individual to

handle safely.

WARNING! To reduce the risk of personal injury or damage to the equipment, observe local

occupational health and safety requirements and guidelines for manual material handling.

Rack Warnings and Cautions

WARNING! To reduce the risk of personal injury or damage to the equipment, adequately stabilize

the rack before extending a component outside the rack. Extend only one component at a time. A

rack may become unstable if more than one component is extended.

WARNING! To reduce the risk of personal injury or damage to the equipment:

– Extend the leveling jacks to the floor.

– Rest the full weight of the rack on the leveling jacks.

– Attach the stabilizers to the rack if it is a single rack installation.

– Couple the racks together in multiple rack installations.

WARNING! When installing the HP PC Blade Enclosure in a Telco rack, adequately secure the rack

frame to the building structure at the top and bottom.

6 Chapter 3 Removal and Replacement Procedures

Page 13

WARNING! To reduce the risk of personal injury or damage to the equipment, use two or more

people to safely unload the rack from the pallet. An empty 42U rack weighs 115 kg (253 lb), is over

2.1 m (7 ft) tall, and may become unstable when moved on its casters. Handle the rack from both

sides as it rolls down the ramp from the pallet. Do not stand in front of the rack.

CAUTION: Always begin by mounting the heaviest item on the bottom of the rack. Continue to

populate the rack from the bottom to the top.

Enclosure and HP Blade PC Warnings and Cautions

WARNING! The DPS-1200KB power supply must be used in the HP PC Blade Enclosure G2. No

other power supply may be used. Attempting to use a different power supply in the HP PC blade

Enclosure G2, or attempting to use the DPS-1200KB power supply in a different enclosure, may

result in damage to your equipment. The DPS-1200KB power supply ships with a bright yellow label

attached for easy identification.

WARNING! To reduce the risk of personal injury from hot surfaces, allow the drives and the internal

system components to cool before touching.

WARNING! To reduce the risk of electric shock or damage to the equipment:

– Plug the power cords into a grounded (earthed) electrical outlet that is easily accessible at all times.

– Unplug the power cord from each power supply to disconnect power to the enclosure.

WARNING! Because the rack enables you to stack enclosure components in a vertical rather than a

horizontal plane, you must take precautions to provide for rack stability and safety to protect both

personnel and property. Heed all cautions and warnings throughout the installation instructions that

came with the enclosure.

WARNING! There is a risk of injury or damage to the equipment from hazardous energy. The

access door provides access to hazardous energy currents. The door should remain locked during

normal operation, or the HP PC Blade Enclosure should be installed in a controlled access location

where only qualified personnel have access to the system.

CAUTION: Protect the HP PC Blade Enclosure from power fluctuations and temporary interruptions

with a regulating uninterruptible power supply (UPS). This device protects the hardware from damage

caused by power surges and voltage spikes and keeps the system in operation during a power

failure.

Hot-Plug Procedures

You do not need to power down the enclosure to remove or replace hot-plug components. Hot-plug

components in the HP BladeSystem PC Blade Enclosure include:

●

Hot-plug power supplies

●

Hot-plug fans

Hot-Plug Procedures 7

Page 14

Hot-Plug Power Supplies

WARNING! The DPS-1200KB power supply must be used in the HP PC Blade Enclosure G2. No

other power supply may be used. Attempting to use a different power supply in the HP PC blade

Enclosure G2, or attempting to use the DPS-1200KB power supply in a different enclosure, may

result in damage to your equipment. The DPS-1200KB power supply ships with a bright yellow label

attached for easy identification.

CAUTION: To avoid a thermal event, do not remove a failed power supply until a replacement

power supply is available.

NOTE: You can use the Integrated Administrator to identify a failed power supply. Refer to the HP

Integrated Administrator User Guide for details.

To remove a redundant hot-plug power supply:

1. Disconnect the power cord from the AC power source.

2. Disconnect the power cord from the hot-plug power supply.

3. Press the port-colored release button and open the hot-plug power supply handle (1).

4. Pull the hot-plug power supply out of the enclosure (2).

Figure 3-1 Removing a hot-plug power supply

Reverse the previous steps to replace the hot-plug power supply.

8 Chapter 3 Removal and Replacement Procedures

Page 15

Hot-Plug Fans

NOTE: You can use the Integrated Administrator to identify a failed hot-plug fan. Refer to the HP

Integrated Administrator User Guide for details.

To remove a hot-plug fan:

1. Press the release latch on the fan cage (1).

2. Pull the fan cage out of the enclosure until it locks in the open position (2).

Figure 3-2 Extending the fan cage

3. Identify the failed hot-plug fan by observing the fan status LED on each hot-plug fan. An amber

LED indicates a failed hot-plug fan.

4. Remove the hot-plug fan from the fan cage.

Figure 3-3 Removing a hot-plug fan

Reverse the previous steps to replace a hot-plug fan.

Hot-Plug Procedures 9

Page 16

Preparing for Non-Hot-Plug Procedures

Replacement of non-hot-plug components may require some or all of the following procedures:

1. Powering down an HP Blade PC (

Powering Down a Blade PC on page 12).

2. Powering down the HP PC Blade Enclosure (

Powering Down the Enclosure on page 10).

3. Removing an HP Blade PC (

Removing a Blade PC on page 13).

4. Removing an HP Blade PC blank bezel (

Removing an HP Blade PC Blank Bezel on page 14).

5. Removing the interconnect tray (

Removing the Interconnect Tray on page 15).

6. Removing the HP PC Blade Enclosure from the rack (

Removing the HP PC Blade Enclosure

from the Rack on page 16).

7. Opening the access door (

Opening the Access Door on page 17).

Powering Down the Enclosure

Two different methods are available for powering down an HP BladeSystem PC Blade Enclosure:

● Graceful shutdown

●

Emergency shutdown

Performing a Graceful Shutdown

Two methods are available for performing a graceful shutdown on an HP BladeSystem PC Blade

Enclosure:

●

Using the Integrated Administrator

●

Pressing the HP PC Blade Enclosure power button

Using the Integrated Administrator

You can perform a graceful shutdown of an HP BladeSystem PC Blade Enclosure by using the

POWEROFF ENCLOSURE command in the Integrated Administrator. To power down the enclosure

using the Integrated Administrator, refer to the HP Integrated Administrator User Guide.

CAUTION: If the Integrated Administrator cannot perform a graceful shutdown of the enclosure and

all HP Blade PCs, after five minutes, the Integrated Administrator will perform an emergency

shutdown of the enclosure and all HP Blade PCs. Performing an emergency shutdown on the

enclosure may result in the loss of user connectivity and the loss of any unsaved data on all HP Blade

PCs in that enclosure.

Pressing the Enclosure Power Button

You can also perform a graceful shutdown of an HP BladeSystem PC Blade Enclosure and all the HP

Blade PCs by pressing the enclosure power button on the rear of the enclosure. If the HP Blade PC

operating system is Microsoft Windows XP or Vista, the enclosure automatically performs a graceful

shutdown of all HP Blade PCs, and then removes power from the enclosure. If the operating system

is RedHat Linux, you must have ACPI enabled for the HP Blade PCs to shut down gracefully.

10 Chapter 3 Removal and Replacement Procedures

Page 17

Performing an Emergency Shutdown

Two methods are available for performing an emergency shutdown on the enclosure and all HP

Blade PCs:

●

Using the Integrated Administrator

●

Pressing and holding the enclosure power button

Using the Integrated Administrator

The Integrated Administrator performs an emergency shutdown of the enclosure and all HP Blade

PCs only after trying for five minutes to perform a graceful shutdown. For more information, see the

Performing a Graceful Shutdown on page 10. If, after five minutes, the Integrated Administrator

cannot perform a graceful shutdown on the enclosure and all HP Blade PCs, the Integrated

Administrator performs an automatic emergency shutdown. To power down the enclosure using the

Integrated Administrator, refer to the HP Integrated Administrator User Guide for detailed instructions.

Pressing and Holding the Enclosure Power Button

You can also perform an emergency shutdown of an HP BladeSystem PC Blade Enclosure and all

HP Blade PCs by pressing and holding the power button on the rear of the enclosure for four

seconds.

CAUTION: Performing an emergency shutdown on an HP Blade PC may result in the loss of any

unsaved data on all HP Blade PCs in that enclosure.

Briefly press the button again to power up the HP BladeSystem PC Blade Enclosure.

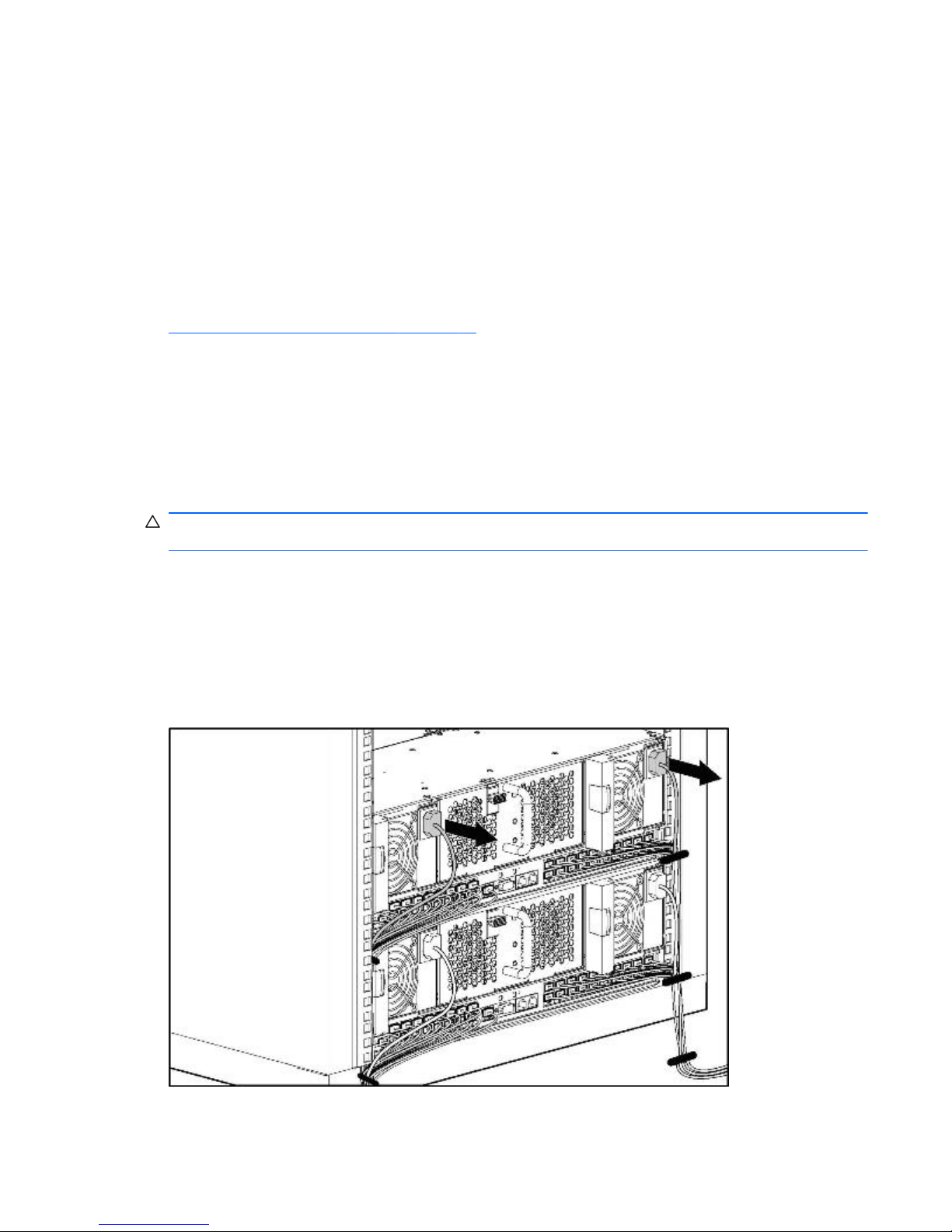

Completely Removing AC Power

To completely remove power from the enclosure and all HP Blade PCs, after powering down the

enclosure, disconnect both of the power cords from the AC power source, then disconnect both of the

power cords from the rear panel of the enclosure.

Figure 3-4 Disconnecting the power cords from the rear panel

Reverse these steps to power up the enclosure.

Preparing for Non-Hot-Plug Procedures 11

Page 18

Powering Down a Blade PC

1. Ensure the blade PC is not active by verifying that the Health LED (Item 2) is off.

Figure 3-5 Blade PC LEDs

2. If the blade is active, notify the users and stop applications as necessary.

3. Shut down the operating system. This may shut off the blade PC power.

4. If the blade PC still has power, power down the blade PC by either:

●

Using the Integrated Administrator, or

●

Pressing the power button (6) on the front of the blade PC above.

To perform an emergency shut down of the blade PC, press and hold the blade power button for four

seconds.

CAUTION: Performing an emergency shutdown on a blade PC may result in the loss of any

unsaved data.

12 Chapter 3 Removal and Replacement Procedures

Page 19

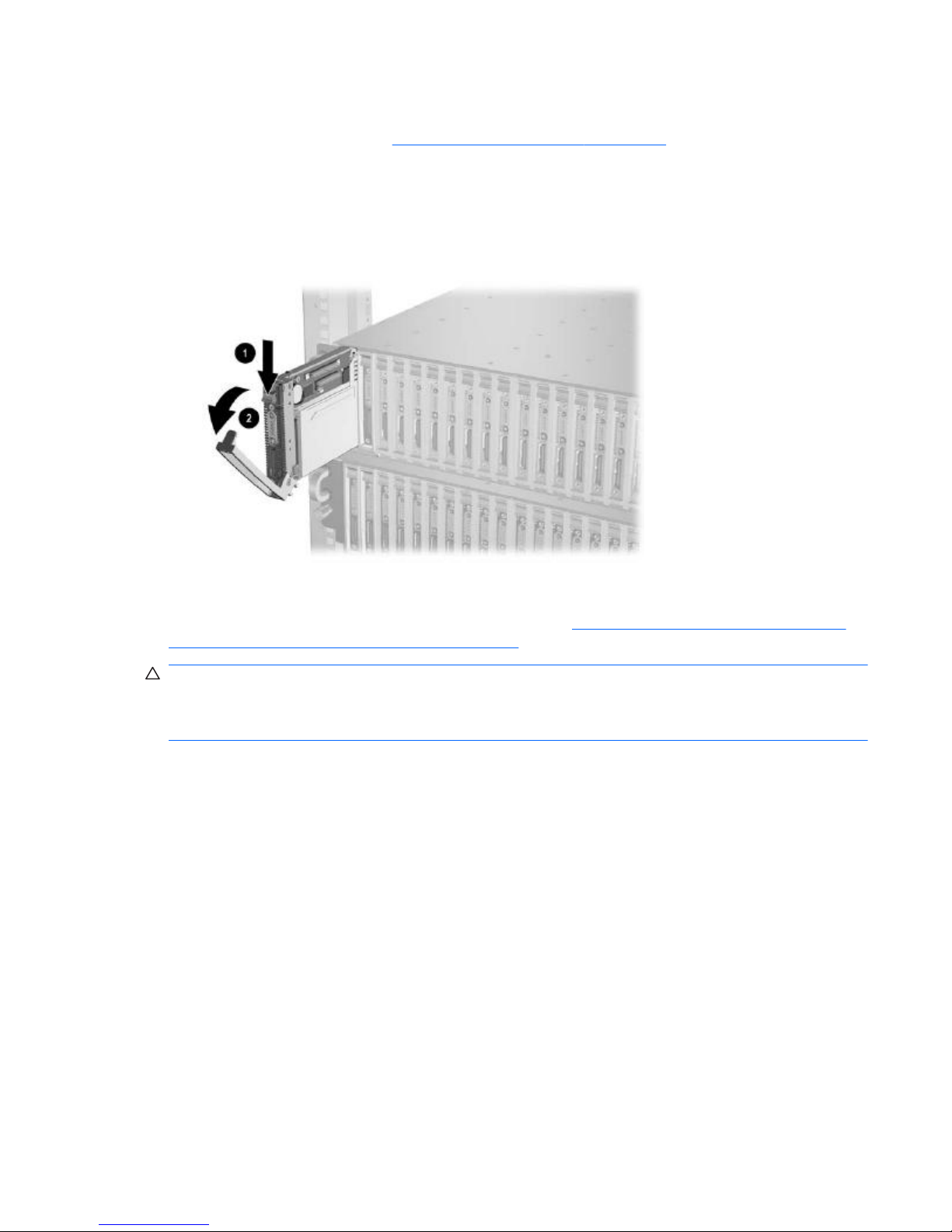

Removing a Blade PC

1. Power down the blade PC (Powering Down a Blade PC on page 12).

2. Press the release latch (1).

3. Pull down the ejector lever (2).

4. Remove the blade PC from the enclosure.

Figure 3-6 Removing a blade PC

To install a new blade PC, reverse the removal procedures.

For more information, see the Service Reference Guide at

http://bizsupport.austin.hp.com/bc/docs/

support/SupportManual/c01091959/c01091959.pdf.

CAUTION: Integrated Administrator security settings are assigned to HP Blade PC bays, not to HP

Blade PCs. If HP Blade PCs change locations within the enclosure, Integrated Administrator settings

must also be adjusted to ensure accurate security. Refer to the HP Integrated Administrator User

Guide for more information on security settings.

Preparing for Non-Hot-Plug Procedures 13

Page 20

Removing an HP Blade PC Blank Bezel

CAUTION: To avoid thermal events, be sure that each HP Blade PC bay contains an HP Blade PC

or HP Blade PC blank bezel while the enclosure is powered up.

To remove the HP Blade PC blank bezel:

1. Press the ejector tabs on the HP Blade PC blank bezel (1).

2. Remove the HP Blade PC blank bezel from the enclosure (2).

Figure 3-7 Removing a one-bay HP Blade PC blank bezel

Figure 3-8 Removing a five-bay HP Blade PC blank bezel

Reverse the previous steps to replace the HP Blade PC blank bezel.

14 Chapter 3 Removal and Replacement Procedures

Page 21

Removing the Interconnect Tray

To remove the interconnect tray:

1. Power down each HP Blade PC (

Powering Down a Blade PC on page 12).

2. Power down the enclosure (

Powering Down the Enclosure on page 10).

3. Disconnect all cables and power cords from the AC power source.

4. Disconnect all cables and power cords from the enclosure rear panel.

5. Remove both hot-plug power supplies (

Hot-Plug Power Supplies on page 8).

6. Push the locking latches toward the front of the enclosure to expose the release latches securing

the interconnect tray in the enclosure (1).

7. Pull the release latches toward the rear of the enclosure (2).

8. Remove the interconnect tray from the enclosure (3).

Figure 3-9 Removing the interconnect tray from the enclosure

NOTE: Perform step 6 simultaneously in both power supply bays.

Reverse the previous steps to replace the interconnect tray.

NOTE: When installing the interconnect tray, be sure that the release latches are in the open

position. When closing the release latches on the interconnect tray, be sure that the locking latches

click audibly into place.

Preparing for Non-Hot-Plug Procedures 15

Page 22

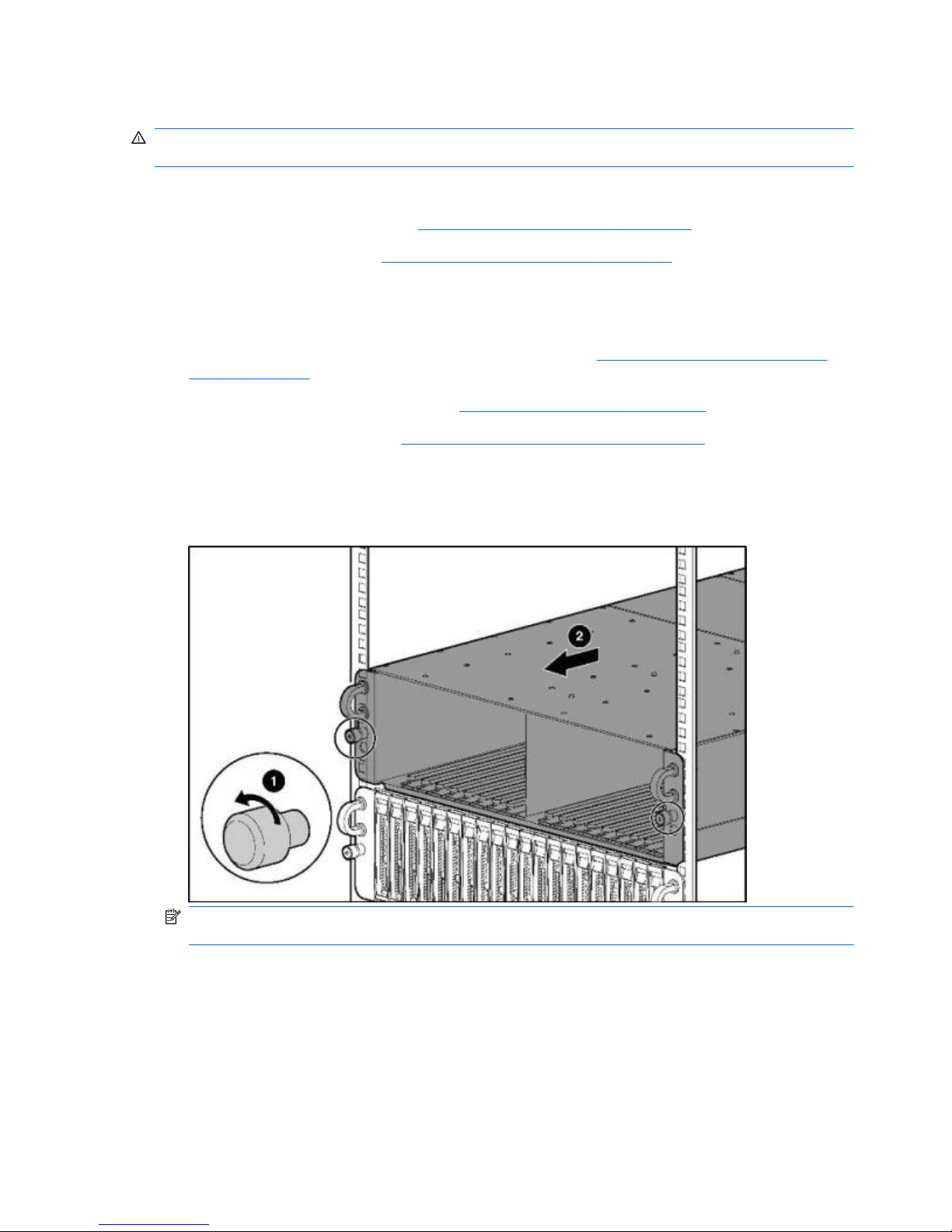

Removing the HP PC Blade Enclosure from the Rack

WARNING! Rack rails do not have safety latches. Be sure that at least two persons are available to

prevent the enclosure from falling and causing bodily harm when removing it from the rack.

To remove the HP PC Blade Enclosure from the rack:

1. Power down each HP Blade PC (

Powering Down a Blade PC on page 12).

2. Power down the enclosure (

Powering Down the Enclosure on page 10).

3. Disconnect all cables and power cords from the AC power source.

4. Disconnect all cables and power cords from the enclosure rear panel.

5. Remove all HP Blade PCs and HP Blade PC blank bezels (

Removing an HP Blade PC Blank

Bezel on page 14).

6. Remove both hot-plug power supplies (

Hot-Plug Power Supplies on page 8).

7. Remove the interconnect tray (

Removing the Interconnect Tray on page 15).

8. Loosen the thumbscrews on the front of the enclosure (1).

9. Remove the enclosure from the rack (2).

Figure 3-10 Removing the enclosure from the rack

NOTE: Pull the enclosure out using the handles. Pulling the enclosure by the thumbscrews

damages the thumbscrews.

Reverse the previous steps to install the enclosure into the rack.

16 Chapter 3 Removal and Replacement Procedures

Page 23

Opening the Access Door

To open the access door:

1. Power down each HP Blade PC (

Powering Down a Blade PC on page 12).

2. Power down the enclosure (

Powering Down the Enclosure on page 10).

3. Disconnect all cables and power cords from the AC power source.

4. Disconnect all cables and power cords from the enclosure rear panel.

5. Remove all HP Blade PCs and HP Blade PC blank bezels (

Removing a Blade PC on page 13

and

Removing an HP Blade PC Blank Bezel on page 14).

CAUTION: Integrated Administrator security settings are assigned to HP PC Blade Enclosure

bays, not to HP Blade PCs. If HP Blade PCs change locations within the enclosure, Integrated

Administrator settings must also be adjusted to ensure accurate security. Refer to the HP

Integrated Administrator User Guide for more information on security settings.

6. Remove the enclosure from the rack (Removing the HP PC Blade Enclosure from the Rack

on page 16).

7. Place the enclosure on a level, non-conductive surface.

8. Release the latches on the access door (1).

9. Open the access door (2).

Figure 3-11 Opening the access door

Preparing for Non-Hot-Plug Procedures 17

Page 24

Non-Hot-Plug Procedures

Before removing or replacing non-hot-plug components, you must power down the HP PC Blade

Enclosure completely. Non-hot-plug components in the HP BladeSystem PC Blade Enclosure system

include:

●

Fan cage

●

Fan backplane assembly

●

Interconnect tray

●

Integrated Administrator module

●

Enclosure status assembly

●

Midplane assembly

Fan Cage

To remove the fan cage:

1. Power down each HP Blade PC (

Powering Down a Blade PC on page 12).

2. Power down the enclosure. For more information see the

Powering Down the Enclosure

on page 10.

3. Disconnect all cables and power cords from the AC power source.

4. Disconnect all cables and power cords from the enclosure rear panel.

5. Remove all HP Blade PCs (

Removing a Blade PC on page 13).

CAUTION: Integrated Administrator security settings are assigned to HP PC Blade Enclosure

bays, not to HP Blade PCs. If HP Blade PCs change locations within the enclosure, Integrated

Administrator settings must also be adjusted to ensure accurate security. Refer to the HP

Integrated Administrator User Guide for more information on security settings.

6. Remove both hot-plug power supplies (Hot-Plug Power Supplies on page 8).

7. Remove the interconnect tray (

Removing the Interconnect Tray on page 15).

8. Remove the enclosure from the rack (

Removing the HP PC Blade Enclosure from the Rack

on page 16).

9. Place the enclosure on a level, non-conductive surface.

10. Open the access door (1) (

Opening the Access Door on page 17).

11. Press the fan cage release latch (2).

12. Pull the fan cage out of the enclosure until it locks in the open position (3).

13. Open the latches on the cable connector (4).

14. Disconnect the fan cable from the midplane (power board) (5).

15. Press the fan cage removal latch on top of the fan cage (6).

18 Chapter 3 Removal and Replacement Procedures

Page 25

16. Remove the fan cage from the enclosure (7).

Figure 3-12 Removing the fan cage from the enclosure

Reverse the previous steps to replace the fan cage.

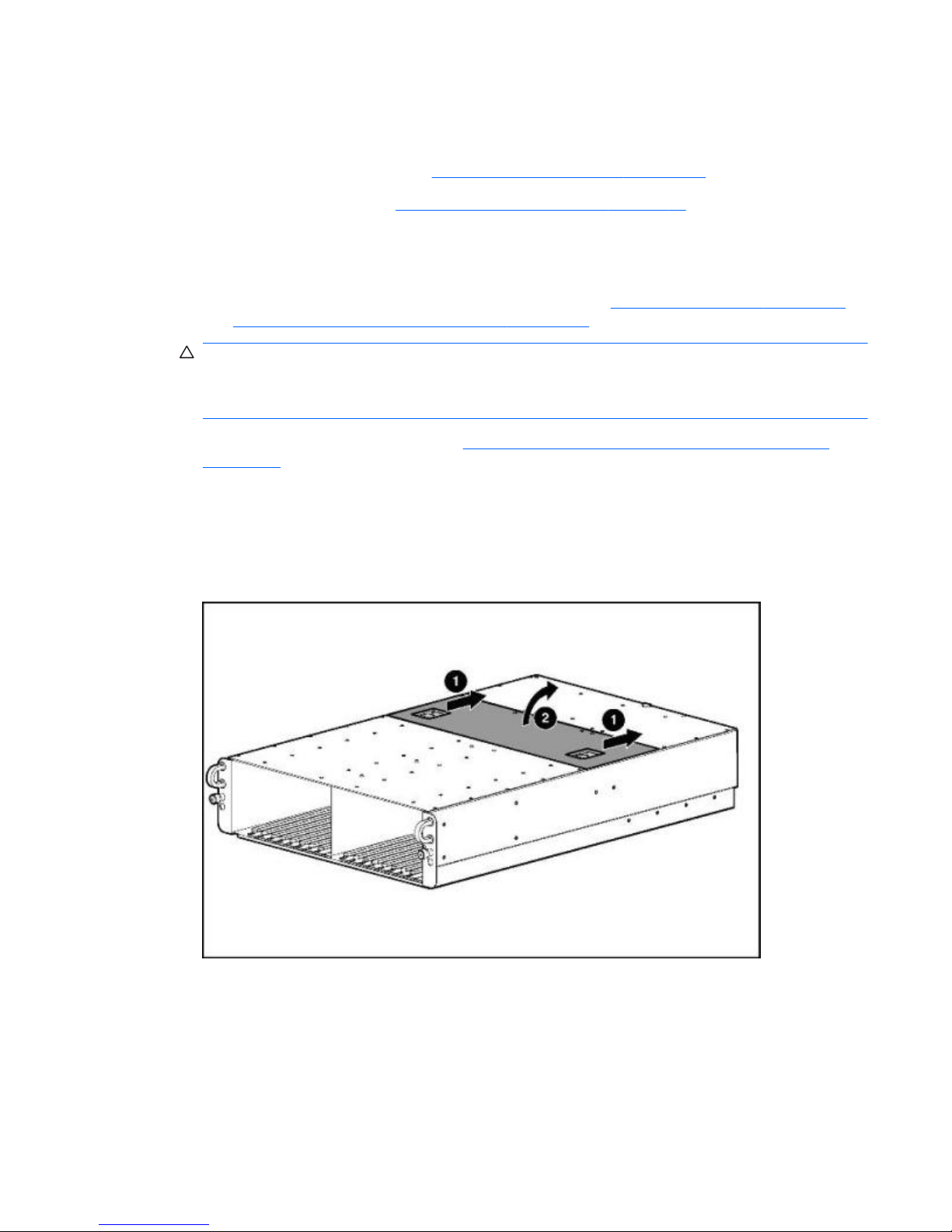

Fan Backplane Assembly

To remove the fan backplane assembly:

1. Power down each HP Blade PC (

Powering Down a Blade PC on page 12).

2. Power down the enclosure (

Powering Down the Enclosure on page 10).

3. Disconnect all cables and power cords from the AC power source.

4. Disconnect all cables and power cords from the enclosure rear panel.

5. Remove all HP Blade PCs (Removing a Blade PC on page 13).

CAUTION: Integrated Administrator security settings are assigned to HP PC Blade Enclosure

bays, not to HP Blade PCs. If HP Blade PCs change locations within the enclosure, Integrated

Administrator settings must also be adjusted to ensure accurate security. Refer to the HP

Integrated Administrator User Guide for more information on security settings.

6. Remove both hot-plug power supplies (Hot-Plug Power Supplies on page 8).

7. Remove the interconnect tray (

Removing the Interconnect Tray on page 15).

8. Remove the enclosure from the rack (

Removing the HP PC Blade Enclosure from the Rack

on page 16).

9. Place the enclosure on a level, non-conductive surface.

10. Open the access door (

Opening the Access Door on page 17).

11. Disconnect the fan cable from the power backplane.

12. Remove the fan cage (

Fan Cage on page 18).

Non-Hot-Plug Procedures 19

Page 26

13. Remove the hot-plug fans (Hot-Plug Fans on page 9).

14. Loosen the thumbscrew at the back of the fan cage (1).

15. Remove the fan backplane assembly from the fan cage (2).

Figure 3-13 Removing the fan backplane assembly

Reverse the previous steps to replace the fan backplane assembly.

Integrated Administrator Module

The Integrated Administrator module removal procedure is the same for both types of interconnect

trays.

To remove the Integrated Administrator module:

1. Power down each HP Blade PC (

Powering Down a Blade PC on page 12).

2. Power down the enclosure (

Powering Down the Enclosure on page 10).

3. Disconnect all cables and power cords from the AC power source.

4. Disconnect all cables and power cords from the enclosure rear panel.

5. Remove both hot-plug power supplies (

Hot-Plug Power Supplies on page 8).

6. Remove the interconnect tray from the enclosure (

Removing the Interconnect Tray on page 15).

7. Rotate the three quarter-turn posts on the Integrated Administrator module 90 degrees (1).

8. Remove the two screw locks with a 5-mm Torques driver (2).

9. Loosen the two screws (3) that secure the hold down clamps for the IA and rotate one half turn

(90 degrees) from the edges of the IA board.

20 Chapter 3 Removal and Replacement Procedures

Page 27

10. Lift the Integrated Administrator module off the anchor pins, and then remove the Integrated

Administrator module from the interconnect tray (4).

Figure 3-14 Removing the Integrated Administrator module from the interconnect tray

Reverse the previous steps to replace the Integrated Administrator module.

Enclosure Status Assembly

To remove the enclosure status assembly:

1. Power down each HP Blade PC (

Powering Down a Blade PC on page 12).

2. Power down the enclosure (

Powering Down the Enclosure on page 10).

3. Disconnect all cables and power cords from the AC power source.

4. Disconnect all cables and power cords from the enclosure rear panel.

5. Remove all HP Blade PCs and HP Blade PC blank bezels (

Removing a Blade PC on page 13

and

Removing an HP Blade PC Blank Bezel on page 14).

CAUTION: Integrated Administrator security settings are assigned to HP PC Blade Enclosure

bays, not to HP Blade PCs. If HP Blade PCs change locations within the enclosure, Integrated

Administrator settings must also be adjusted to ensure accurate security. Refer to the HP

Integrated Administrator User Guide for more information about security settings.

6. Remove both hot-plug power supplies (Hot-Plug Power Supplies on page 8).

7. Remove the interconnect tray from the enclosure (

Removing the Interconnect Tray on page 15).

8. Remove the enclosure from the rack (

Removing the HP PC Blade Enclosure from the Rack

on page 16).

Non-Hot-Plug Procedures 21

Page 28

9. Place the enclosure on a level, non-conductive surface.

10. Open the access door (

Opening the Access Door on page 17).

11. Disconnect the enclosure status cable from the midplane (signal board).

Figure 3-15 Disconnecting the enclosure status cable from the midplane signal board

12. Remove the screws securing the enclosure status assembly in the enclosure (1).

13. Remove the enclosure status assembly from the enclosure (2).

Figure 3-16 Removing the enclosure status assembly from the enclosure

Reverse the previous steps to replace the enclosure status assembly.

22 Chapter 3 Removal and Replacement Procedures

Page 29

Midplane Assembly

To remove the midplane assembly:

1. Power down each HP Blade PC (

Powering Down a Blade PC on page 12).

2. Power down the enclosure (

Powering Down the Enclosure on page 10).

3. Disconnect all cables and power cords from the AC power source.

4. Disconnect all cables and power cords from the enclosure rear panel.

5. Remove all HP Blade PCs (

Removing a Blade PC on page 13).

CAUTION: Integrated Administrator security settings are assigned to HP PC Blade Enclosure

bays, not to HP Blade PCs. If HP Blade PCs change locations within the enclosure, Integrated

Administrator settings must also be adjusted to ensure accurate security. Refer to the HP

Integrated Administrator User Guide for more information on security settings.

6. Remove both hot-plug power supplies (Hot-Plug Power Supplies on page 8).

7. Remove the interconnect tray from the enclosure (

Removing the Interconnect Tray on page 15).

8. Remove the enclosure from the rack (

Removing the HP PC Blade Enclosure from the Rack

on page 16).

9. Place the enclosure on a level, non-conductive surface.

10. Open the access door (

Opening the Access Door on page 17).

11. Disconnect the fan cable from the midplane (power board) (

Fan Backplane Assembly

on page 19).

12. Disconnect the enclosure status cable from the midplane (signal board) (

Enclosure Status

Assembly on page 21).

13. Loosen the thumbscrews on the midplane assembly (1).

Non-Hot-Plug Procedures 23

Page 30

14. Remove the midplane assembly from the enclosure (2).

Figure 3-17 Removing the midplane assembly from the enclosure

Reverse the previous steps to replace the midplane assembly.

Swapping the Interconnect Tray

To swap the existing interconnect tray with a replacement interconnect tray:

1. Remove the interconnect tray from the enclosure (

Removing the Interconnect Tray on page 15).

2. Remove the Integrated Administrator module from the interconnect tray (

Integrated

Administrator Module on page 20).

3. Place the replacement interconnect tray on a level, non-conductive surface.

4. Position the Integrated Administrator module so that its holes are aligned with the anchor pins of

the replacement interconnect tray (1).

5. Rotate the three anchor pins 90 degrees to lock the Integrated Administrator module into

position (2).

6. Replace the two screw locks (3).

24 Chapter 3 Removal and Replacement Procedures

Page 31

7. Secure the two hold down clamps to the opposite edges of the Integrated Administrator board,

and then tighten the two screws (4).

NOTE: The Integrated Administrator board is spared as part of the interconnect tray assembly

within the standard warranty period.

Figure 3-18 Installing the Integrated Administrator module onto the interconnect tray

Replace the interconnect tray. For more information, see Removing the Interconnect Tray

on page 15.

Non-Hot-Plug Procedures 25

Page 32

4 Diagnostic Tools

This chapter is an overview of hardware, software, and firmware diagnostic tools that are available for

configuring, monitoring, and managing HP BladeSystem PC Blade systems.

Diagnostic Software and Firmware Tools

The HP Integrated Administrator is a standard component of the HP BladeSystem PC Blade

Enclosure system. The Integrated Administrator provides enclosure health, HP Blade PC health, and

remote server manageability. Integrated Administrator features are accessed from any network-based

client using a supported Web browser. In addition to other features, Integrated Administrator provides

keyboard and mouse capability for an HP Blade PC, regardless of the state of the host operating

system or host HP Blade PC.

Use the following tools to diagnose problems, test hardware, and monitor and manage HP

BladeSystem PC Blade system operations.

Table 4-1 Diagnostic tools

Tool Description How to run the tool

HP Integrated

Administrator (IA)

The HP Integrated Administrator is a centralized

management and monitoring system for the HP

BladeSystem PC Blade enclosure and HP Blade

PCs. The Integrated Administrator acts as a

combination web/console server and remote

power controller, enabling in-band or out-ofband, secure, serial console connections to all

HP Blade PCs in the enclosure.

Refer to the HP Integrated Administrated User

Guide for complete details.

The Integrated Administrator keeps a system

log resident and records and health diagnostic

information provided by the blade PC.

Additionally, the IA can receive additional status

information from blade PCs equipped with a

blade management controller (BMC) including

network (PXE) boot status, diagnostic adaptor

present, POST boot completion, front IO

blanking mode, and ASR mode status (requires

at least IA version 4.30 and BMC version 25h).

Automatic Server

Recovery-2 (ASR-2)

ASR-2 automatically restarts a HP Blade PC

after a catastrophic operating system failure.

With ASR-2, you have multiple recovery options:

●

Available Recovery provides software error

recovery and environmental recovery.

●

Unattended Recovery logs the error

information to the IA system log (IA version

4.2), resets the HP Blade PC, and tries to

restart the operating system.

Run the ROM-Based Setup Utility and set

ASR-2 to enable this tool.

26 Chapter 4 Diagnostic Tools

Page 33

HP Systems Insight

Manager (SIM)

Systems Insight Manager is a client/server

application used to remotely manage HP

hardware in a network environment. SIM reports

HP Blade PC and HP Blade PC Enclosure

hardware fault conditions (both failure and prefailure) and collects data for reporting and

graphing.

For more information on viewing and printing the

event list, refer to the Management CD or the

SIM User Guide.

ROM-Based Setup

Utility (RBSU)

RBSU configures the hardware installed in or

connected to the HP Blade PC. Specifically, it

can:

● Store configuration information in

nonvolatile memory.

●

Manage memory installation, processor

upgrades, network interface cards, and

mass storage devices.

●

Assist in installing an operating system.

● Configure connectors and IRQs, if

required.

Attach a keyboard to the HP Blade PC using the

diagnostic adapter.

Run RBSU by pressing the F10 key during

POST.

BMCFlash Utility Update utility for the Blade Management

Controller (BMC) firmware..

Flash the BMC on BC2x00 blades only.

Hardware Diagnostic Tools

The HP BladeSystem PC Blade system offers the following HP Blade PC and HP PC Blade

Enclosure hardware diagnostic tools.

Diagnostic Adapter

Use the diagnostic adapter(s) to attach peripheral devices to any individual HP Blade PC for local HP

Blade PC diagnosis and management. See

Connectors, Switches, and LEDs on page 30 for the

location of diagnostic adapter connectors.

NOTE: You can hot-add peripheral devices using the diagnostic adapter if the devices support hot-

plug capability.

1. Power down the HP Blade PC (Powering Down a Blade PC on page 12).

2. Plug the diagnostic adapter into the diagnostic connector on the HP Blade PC (1).

Table 4-1 Diagnostic tools (continued)

Hardware Diagnostic Tools 27

Page 34

3. Tighten the thumbscrews securing the diagnostic adapter in place (2).

Figure 4-1 Installing a diagnostic adapter USB 1.1 version pictured (obsolete)

4. Power up the HP Blade PC.

NOTE: Because PS/2 devices do not support hot-plug technology, restart the HP Blade PC after

attaching the diagnostic adapter. USB devices are hot-plug supported and do not require restarting

the HP Blade PC after attachment.

Table 4-2 Cable Pin Out for a Null Modem Cable

Signal name EM PIN DB 9 PIN DB 25 PIN

TxD 3 2 3

RxD 2 3 2

RTS 7 8 5

CTS 8 7 4

GND 5 5 7

DSR 6 4 20

CD 1 4 20

28 Chapter 4 Diagnostic Tools

Page 35

Figure 4-2 Installing a diagnostic adapter USB 2.0 version

Table 4-3 Cable Pin Out for a Null Modem Cable

Signal name EM PIN DB 9 PIN DB 25 PIN

TxD 3 2 3

RxD 2 3 2

RTS 7 8 5

CTS 8 7 4

GND 5 5 7

DSR 6 4 20

CD 1 4 20

Null-Modem Cable Pin-Out

Use the above table(s) to determine the specifications of the cable(s). If you are cabling a serial

device (such as a laptop computer) to the console connector on the Integrated Administrator, be sure

that you use a null-modem cable and not a straight-through cable.

Hardware Diagnostic Tools 29

Page 36

5 Connectors, Switches, and LEDs

This chapter explains the location and function of system connectors, system switches, and internal

and external LEDs.

Connectors

The figures and tables on the following pages show connector locations on the HP BladeSystem

Blade PCs and HP BladeSystem PC Blade Enclosures.

Enclosure Connectors

This section explains the location and function of rear panel connectors associated with the HP PC

Blade Switch and RJ-45 patch panel interconnect tray.

Interconnect Switch Connectors

Figure 5-1 HP PC Blade Switch connectors

NOTE: bc2800 shown.

Item Description Location

(1) Gigabit Ethernet jack for port 43 Interconnect switch

(2) Socket for optional GBIC SFP module for port 43 Interconnect switch

(3) Socket for optional GBIC SFP module for port 44 Interconnect switch

(4) Gigabit Ethernet jack for port 44 Interconnect switch

30 Chapter 5 Connectors, Switches, and LEDs

Page 37

(5) 10/100 Ethernet jack for Integrated Administrator management port 42 Integrated Administrator module

(6) Integrated Administrator console connector (serial) Integrated Administrator module

(7) Gigabit Ethernet jack for port 45 Interconnect switch

(8) Socket for optional GBIC SFP module for port 45 Interconnect switch

(9) Socket for optional GBIC SFP module for port 46 Interconnect switch

(10) Gigabit Ethernet jack for port 46 Interconnect switch

CAUTION: See QuickSpecs for supported uses of the enclosure link (RJ-45) connectors on the

Integrated Administrator module. Connecting an unsupported external device to the enclosure link

(RJ-45) connectors may damage the external device.

RJ-45 Patch Panel Connectors

This section identifies the RJ-45 patch panel connectors.

Figure 5-2 RJ-45 patch panel connectors

Item Description Location

1 RJ-45 connector for HP PC Blade Enclosure bay 20 NIC B (2) RJ-45 patch panel

2 RJ-45 connector for HP PC Blade Enclosure bay 20 NIC A (1) RJ-45 patch panel

3 Integrated Administrator management connector (10/100

Ethernet)*

Integrated Administrator module

4 Integrated Administrator console connector (serial)* Integrated Administrator module

5 RJ-45 connector for HP PC Blade Enclosure bay 1 NIC A (1) RJ-45 patch panel

6 RJ-45 connector for HP PC Blade Enclosure bay 1 NIC B (2) RJ-45 patch panel

*These items denote connectors for the Integrated Administrator module.

CAUTION: See QuickSpecs for supported uses of the enclosure link (RJ-45) connectors on the

Integrated Administrator module. Connecting an unsupported external device to the enclosure link

(RJ-45) connectors may damage the external device.

Connectors 31

Page 38

Fan Cable Connector

This section identifies the connector on the midplane assembly for the fan cable.

Figure 5-3 Fan cable connector on the midplane assembly

Enclosure Status Cable Connector

This section identifies the connector on the HP PC Blade Enclosure midplane for the enclosure status

cable.

Figure 5-4 Enclosure status cable connector on the midplane assembly

32 Chapter 5 Connectors, Switches, and LEDs

Page 39

HP Blade PC Connectors

This section identifies the connectors on each HP Blade PC.

Figure 5-5 Identifying the HP Blade PC connectors

Item Description

1 Midplane assembly connectors

2 Diagnostic connector

Diagnostic Adapter Connectors (USB 1.1 and USB 2.0)

This section identifies the connectors on the diagnostic adapter version USB 1.1.

Figure 5-6 Diagnostic adapter connectors USB 1.1 version – (obsolete)

Item Description Item Description

1 Mouse connector (PS/2) 4 Serial connector

2 Keyboard connector (PS/2) 5 USB connector (1.1)

3 USB connector (1.1) 6 Video connector

Connectors 33

Page 40

This section identifies the connectors on the diagnostic adapter version USB 2.0

Figure 5-7 Diagnostic adapter connectors USB 2.0 version

Item Description

1 Keyboard connector (PS/2)

2 Mouse connector (PS/2)

3 Serial connector

4 Video connector

5 USB 2.0 connector #1

6 USB 2.0 connector #2

34 Chapter 5 Connectors, Switches, and LEDs

Page 41

Switches

With system switches, you can enable or disable certain settings or perform advanced diagnostic

procedures.

Front Panel Switches

This section identifies the location and function of the switches on the front panel of the enclosure

and HP Blade PC.

Figure 5-8 HP Blade PC and enclosure front panel buttons

Item Description Function

1 HP Blade PC unit identification button Activates the unit identification LED for easy HP Blade PC

identification

2 Enclosure unit identification button Activates the unit identification LED for easy enclosure

identification

3 HP Blade PC power button Powers up or down an HP Blade PC. (Hold down for 4

seconds to perform an emergency shutdown.)

Switches 35

Page 42

Rear Panel Switches

This section identifies the location and function of the buttons on the rear panel of the enclosure.

Figure 5-9 Enclosure rear panel buttons

NOTE: bc2800 shown.

Item Description On/Off Function

1 Enclosure unit identification button Activates the unit identification LED for easy enclosure

identification

2 Enclosure power button Powers the enclosure and all HP Blade PCs up or down

3 Integrated Administrator reset button Restarts the Integrated Administrator

CAUTION: Pressing and holding the enclosure power button for 4 seconds causes an emergency

shutdown on the enclosure and all HP Blade PCs, and may result in the loss of any unsaved data on

all HP Blade PCs.

CMOS

Press the CMOS button (labeled SW50) on the blade PC’s system board for 2 seconds to clear

CMOS.

36 Chapter 5 Connectors, Switches, and LEDs

Page 43

LEDs

The figures and tables on the following pages show the location and function of LEDs associated with

the HP BladeSystem PC Blade system.

Enclosure Front Panel LEDs

Figure 5-10 Enclosure front panel LEDs

Table 5-1 Enclosure Front Panel LEDs

Item LED Status Description

1 Enclosure unit ID (unit identification) Off Off

Blue Identification of unit

2 Enclosure health Off Enclosure off and health good

Green Enclosure on and health good

Amber Enclosure degraded: A redundant component has

failed or other fault condition – check IA for

additional information.

Red Enclosure critical: Immediate attention required,

enclosure at risk of down time

LEDs 37

Page 44

Enclosure Rear Panel LEDs

The enclosure rear panel LEDs differ according to which interconnect tray configuration you have

installed.

Rear panel LEDs with HP PC Blade Switch

Figure 5-11 Rear panel LEDs with the HP PC Blade Switch

NOTE: bc2800 shown.

This section identifies the LEDs on the enclosure rear panel with an HP PC Blade Switch .

Table 5-2 Rear panel LEDs with the HP PC Blade Switch

Item LED Status Description

1 Power supply power Off No power to the system

Blinking green Standby, AC present

Green System power turned on

2 Power supply fault Off Power supply OK

Amber No AC power or over-voltage or over-

temperature

Blinking amber Current limit

3 Enclosure power Off No power to enclosure

Amber Enclosure shutdown; power available; hibernate

Green Enclosure power on

4 Fan health Off Enclosure off, fan health good

Green Enclosure on, fan health good

Amber Fan subsystem degraded

Red Fan subsystem critical

5 Enclosure unit identification Off Unit not identified

Blue Identification of unit

38 Chapter 5 Connectors, Switches, and LEDs

Page 45

6 Integrated Administrator health Off Enclosure off, Integrated Administrator health

good

Green Enclosure on, Integrated Administrator health

good

Amber Integrated Administrator critical

7 Interconnect switch health Green Interconnect switch health good

Yellow Interconnect switch health degraded

Red Interconnect switch health critical

Off Switch booting/No power

8 Stacking Status Green Master of the stack

Yellow The one of the member in stack

Off Not in the stack

9 Link/activity Green Network link

Flashing green Network activity

Yellow Port disabled

Off No network link

10 Connector speed Yellow 1000 Mbps

Green 100 Mbps

Off 10 Mbps

Table 5-2 Rear panel LEDs with the HP PC Blade Switch (continued)

LEDs 39

Page 46

Rear Panel LEDs with RJ-45 Patch Panel Interconnect Tray

Figure 5-12 Rear panel LEDs with RJ-45 patch panel interconnect tray

Item LED Status Description

1 Power supply power Off No power to the system

Blinking green Standby, AC present

Green System power turned on

2 Power supply fault Off Power supply OK

Amber No AC power or over-voltage or over-temperature

Blinking amber Current limit

3 Enclosure power Off No power to enclosure

Amber Enclosure shutdown; power available; hibernate

Green Enclosure power on

4 Fan health Off Enclosure off, fan health unknown

Green Enclosure on, fan health good

Amber Fan subsystem degraded

Red Fan subsystem critical

5 Enclosure unit identification Off Unit not identified

Blue Identification of unit

6 RJ-45 link/activity On Network link

Off No network link

Flashing Network activity

7 Integrated Administrator health Off Enclosure off, Integrated Admin health unknown

Green Enclosure on, Integrated Administrator health good

Amber Integrated Administrator critical

40 Chapter 5 Connectors, Switches, and LEDs

Page 47

Fan Health LEDs

This section identifies the LEDs on the hot-plug fans.

Figure 5-13 Hot-plug fan health LEDs

NOTE: bc2800 shown.

Table 5-3 Hot-Plug Fan Health LEDs

Item LED

1 Fan 1

2 Fan 2

3 Fan 3

4 Fan 4

Green = Normal

Amber = Failed

LEDs 41

Page 48

HP Blade PC and Diagnostic Adapter LEDs

This section identifies the LEDs on the HP Blade PCs and diagnostic adapters. LEDs on the HP

Blade PC and the USB 1.1 version diagnostic adapter are identical in function and location. There are

no LEDs on the USB 2.0 version diagnostic adapter.

Figure 5-14 HP Blade PC LEDs

Figure 5-15 Diagnostic adapter LEDs for USB 1.1 version (obsolete)

Table 5-4 HP Blade PC and Diagnostic Adapter LEDs

Item LED Status Description

1 Unit Identification Off Unit not identified

Blue Identification of HP Blade PC

2 Health Off HP Blade PC off and health last good

Green HP Blade PC on and health good

Amber HP Blade PC degraded, or power-up prohibited by

the Integrated Administrator

Red HP Blade PC critical

3 NIC 1 Off No connection

Green Linked to network

42 Chapter 5 Connectors, Switches, and LEDs

Page 49

Blinking green Linked and activity on the network

4 NIC 2 Off No connection

Green Linked to network

Blinking green Linked and activity on the network

5 Drive activity Off No drive activity

Blinking green Drive activity

6 Power Off No AC power to HP Blade PC

Amber Enclosure on and health good

Green HP Blade PC power turned on

Blinking green HP Blade PC in standby *

NOTE: Does not apply to the ProLiant BL10e G2 server blade.

NOTE: The USB 2.0 Diagnostic Adapter does not have LEDs.

Table 5-4 HP Blade PC and Diagnostic Adapter LEDs (continued)

LEDs 43

Page 50

6 POST Error Messages

NOTE: Refer to the Service Reference Guide: HP BladeSystem PC bc2200/bc2800 for other error

messages such as BMC blink codes.

Use POST error messages to assist in troubleshooting and performing basic diagnostic functions.

POST error messages represent what the BIOS reports. The following table lists the numeric codes

and text messages specific to blade PCs.

For information about troubleshooting, see

Troubleshooting on page 49.

NOTE: Attempt the recommended actions in the order in which they are listed. If the first does not

resolve the issue, try the next on the list.

POST Error Messages

Code/Message Health LED Possible Cause Recommended Action

101-Option ROM Checksum

Error

Red Blade system board

has failed.

● Clear CMOS.

●

Flash the system ROM.

●

Replace the blade PC.

102/103-System Board Failure Red Blade PC system

board has failed.

● Clear CMOS

●

Replace the blade PC.

162-System Options Not Set Amber CMOS was cleared or

the blade PC’s battery

has failed.

● Reset the system time and date in

Computer Setup (F10).

● Replace the blade PC’s RTC battery.

163-Time & Date Not Set Amber CMOS was cleared Reset the system time and date in Computer

Setup (F10).

164-Memory Size Error Amber Memory configuration

is incorrect.

●

Ensure the SODIMM(s) are properly

installed.

● Verify that the proper type of SODIMM is

installed.

● Reseat the SODIMM(s).

●

Replace the SODIMM(s).

●

Replace the blade PC.

44 Chapter 6 POST Error Messages

Page 51

POST Error Messages

Code/Message Health LED Possible Cause Recommended Action

201-Memory Error Red An SODIMM may not

be seated correctly or

is bad.

●

Ensure the SODIMM(s) are properly

installed.

● Verify that the proper type of SODIMM is

installed.

● Reseat the SODIMM(s).

●

Replace the SODIMM(s).

●

Replace the blade PC.

301-Keyboard Error Amber Keyboard controller

has failed.

● Reconnect the keyboard with the blade PC

turned off.

● Use a different keyboard that is known to

work properly.

●

Replace the blade PC.

303-Keyboard Controller Error Amber Keyboard controller

has failed.

● Reconnect the keyboard with the blade PC

turned off.

● Use a different keyboard that is known to

work properly.

●

Replace the blade PC.

304-Keyboard or System Unit

Error

Amber Keyboard has failed. ● Reconnect the keyboard with the blade PC

turned off.

● Use a different keyboard that is known to

work properly.

●

Replace the blade PC.

1720-SMART Hard Drive

detects imminent failure

Amber Hard drive is about to

fail.

● Run Drive Protection System if applicable.

●

Apply firmware patch (

http://www.hp.com/

support).

●

Back up contents and replace the hard

drive.

1780-Disk 0 Failure Amber Hard drive has failed. ● Run IDE Self-Test from Computer Setup

(F10).

● Replace the hard drive.

1782-Disk Controller Error Red Hard drive circuitry

error has occurred.

●

Run IDE Self-Test from Computer Setup

(F10).

● Replace the hard drive.

●

Replace the blade PC.

1790-Disk 0 Error Amber Hard drive has failed. ● Run IDE Self-Test from Computer Setup

(F10).

● Replace the hard drive.

●

Replace the blade PC.

45

Page 52

POST Error Messages

Code/Message Health LED Possible Cause Recommended Action

1800-Temperature Alert Amber Internal temperature

exceeds specification.

●

Ensure that the system fans are functioning

properly and that the enclosure has

adequate ventilation.

●

Check the processor heatsink.

● Replace the blade PC.

1998-Master Boot Record

Backup has been lost. Press

any key to enter Setup to

update the MBR Backup.

Amber The previously saved

copy of the MBR has

been corrupted.

Run Computer Setup to update the MBR

backup.

Invalid Electronic Serial

Number

Amber Electronic serial

number has been lost.

● Run Computer Setup. If data is loaded/will

not allow changes, download SP5572.EXE

(SNZERO.EXE) from http://www.hp.com.

● Run Computer Setup, enter serial number

under Security, System ID, then save

changes.

6817-System was rebooted

due to a potential lock-up

Amber System image or

software issue.

●

Check event logs in the operating system

to ensure you do not have a software

lockup.

●

Disable Automated System Recovery in

F10 Setup.

● Follow standard operating system

debugging procedure.

● Reinstall the system image.

6901-System was gracefully

shut down due to CPU

overheating.

Green Internal temperature

exceeds specification.

●

Ensure that the system fans are functioning

properly and that the enclosure has

adequate ventilation.

●

Check the processor heatsink.

● Replace the blade PC.

6904–System experienced an

unexpected shutdown on

previous boot.

Green Forced enclosure

shutdown or improper

diagnostic adaptor

insertion

If the problem persists, replace the blade PC.

6906–Embedded Network

Controller B Hardware Failure

Detected

Red NIC B has failed. ● Clear CMOS.

●

Replace the blade PC.

6907-Embedded Network

Controller A Hardware Failure

Detected

Red NIC A has failed.

●

Clear CMOS.

● Replace the blade PC.

6908-System Board Hardware

Failure Detected

Red System Board has

failed.

● Clear CMOS.

●

Replace the blade PC.

6909-System Board Graphics

Subsystem Failure Detected

Red System board

graphics have failed.

● Clear CMOS

●

Replace the blade PC.

46 Chapter 6 POST Error Messages

Page 53

POST Error Messages

Code/Message Health LED Possible Cause Recommended Action

6911-System Board CPU

Subsystem Failure Detected

Red Processor has failed.

●

Clear CMOS.

● Replace the blade PC.

6912-System Board Voltage

Regulator Failure Detected

Red Potential enclosure or

blade PC issue.

●

Swap the blade PC to a different bay in the

enclosure and retest.

● Put the blade PC into a different enclosure.

If the blade PC works in a different

enclosure, troubleshoot the original

enclosure. For troubleshooting information,

see

Troubleshooting on page 49.

●

Replace the blade.

6913-System Board Main

Voltage Failure Detected

Red Potential enclosure or

blade PC issue.

●

Swap the blade PC to a different bay in the

enclosure and retest.

● Put the blade PC into a different enclosure.

If the blade PC works in a different

enclosure, troubleshoot the original

enclosure. For troubleshooting information,

see

Troubleshooting on page 49.

●

Replace the blade.

6914-Forced System

Shutdown from an over-temp

fault condition on previous boot

Green Internal temperature

exceeds specification.

●

Ensure that the system fans are functioning

properly and that the enclosure has

adequate ventilation.

●

Check the processor heatsink.

● Replace the blade PC.

6915-CPU not detected on

previous attempt to boot.

Green The CPU was not

detected on previous

boot attempt.

Informational message only.

6916-CPU Heatsink not

properly attached

Amber The heatsink is loose. ● Remove the blade PC and check if

heatsink is loose or not present. Tighten

CPU heatsink screws to 8 inch-lbs of

tension.

●

Replace the blade PC if the messages

persist.

6918-System Real Time Clock

Oscillator not running within

tolerance.

Amber System Real Time

Clock Oscillator not

running within

tolerance.

● Replace CMOS battery.

●

If the problem persists, replace the blade

PC.

6919-Temperature and Power

Monitoring Hardware failure

Red Blade PC failure. Replace the blade PC.

47

Page 54

POST Error Messages

Code/Message Health LED Possible Cause Recommended Action

6920-Processor in ForceThrottle Mode

Amber Enclosure or

environmental issue.

●

Ensure the enclosure health LED is green

and health status is OK. If LED not green,

troubleshoot the enclosure. For

troubleshooting information, see

Troubleshooting on page 49.

●

If the enclosure health LED is green, check

heatsink installation and operating ambient.

Make sure every enclosure slot is filled with

a blank or a blade PC.

6921-Blade System

Management Controller

firmware update failed

Amber The flashing process

was interrupted.

Re-flash the BMC firmware image.

6922-Blade temperature

detected to be below 0 degrees

Celsius

Amber The blade PC is

operating in

temperatures below

specification.

Check operating ambient. Operate the blade PC

within environmental specifications.

6923-CPU Temperature

Monitoring Hardware failure

Red CPU temperature

monitoring hardware

has failed.

Replace the blade PC.

6924-Graphics Temperature

Monitoring Hardware failure

Red System graphics

temperature

monitoring hardware

has failed.

Replace the blade PC.

6925-Blade/Enclosure

Communication error

Amber Potential enclosure or

blade PC issue.

● Swap the blade PC to a different bay in the

enclosure and retest.

●

Put the blade PC into a different enclosure.

If the blade PC works in a different

enclosure, troubleshoot the original

enclosure. For troubleshooting information,

see

Troubleshooting on page 49.

●

Replace the blade.

6927-Previous POST under

Recovery BIOS.

Green Previous POST under

Recovery BIOS.

Informational message only.

6928-POST under Recovery

BIOS image.

Amber POST under Recovery

BIOS image.

● Re-flash the BIOS.

●

If the problem persists, replace the blade

PC.

6929- Blade performance is

reduced due to insufficient

enclosure power and/or

cooling.

Amber Blade was a bc2800

and inserted into an

enclosure that cannot

support full processor

performance.

Power off blade and remove blade, or update

enclosure Integrated Administrator firmware to

version 4.30 or greater, or update enclosure to

HP BladeSystem PC Blade Enclosure G2.

6931-BIOS unable to update

BMC Primary Firmware

Red Three consecutive

attempts to update the

BMC firmware failed

during POST.

BIOS 3.xx introduces BIOS BMC Firmware

Updating. This feature links the BIOS version to

the BMC firmware version. The BMC firmware is

updated during BIOS POST. BIOS will attempt

to update the BMC firmware 3 times before

booting to an OS without successfully updating

the BMC firmware.

48 Chapter 6 POST Error Messages

Page 55

7 Troubleshooting

This appendix provides specific troubleshooting information for HP BladeSystem PC Blade

technology. Use it to find details about the enclosure and blade PC startup and operation errors.

For information on LEDs and switches specific to the blade PCs and enclosure, see the LED and

Switch appendix.

WARNING! A risk of injury or damage to the equipment from hazardous energy is present. The

access door provides access to hazardous energy circuits. The door should remain locked during

normal operation or troubleshooting, or the system should be installed in a controlled access location

where only qualified personnel have access to the system.

This appendix includes the following topics:

●