Page 1

HP BladeSystem c7000 Enclosure

Quick Setup Instructions

Part Number 411762-005

July 2008 (Fifth Edition)

Page 2

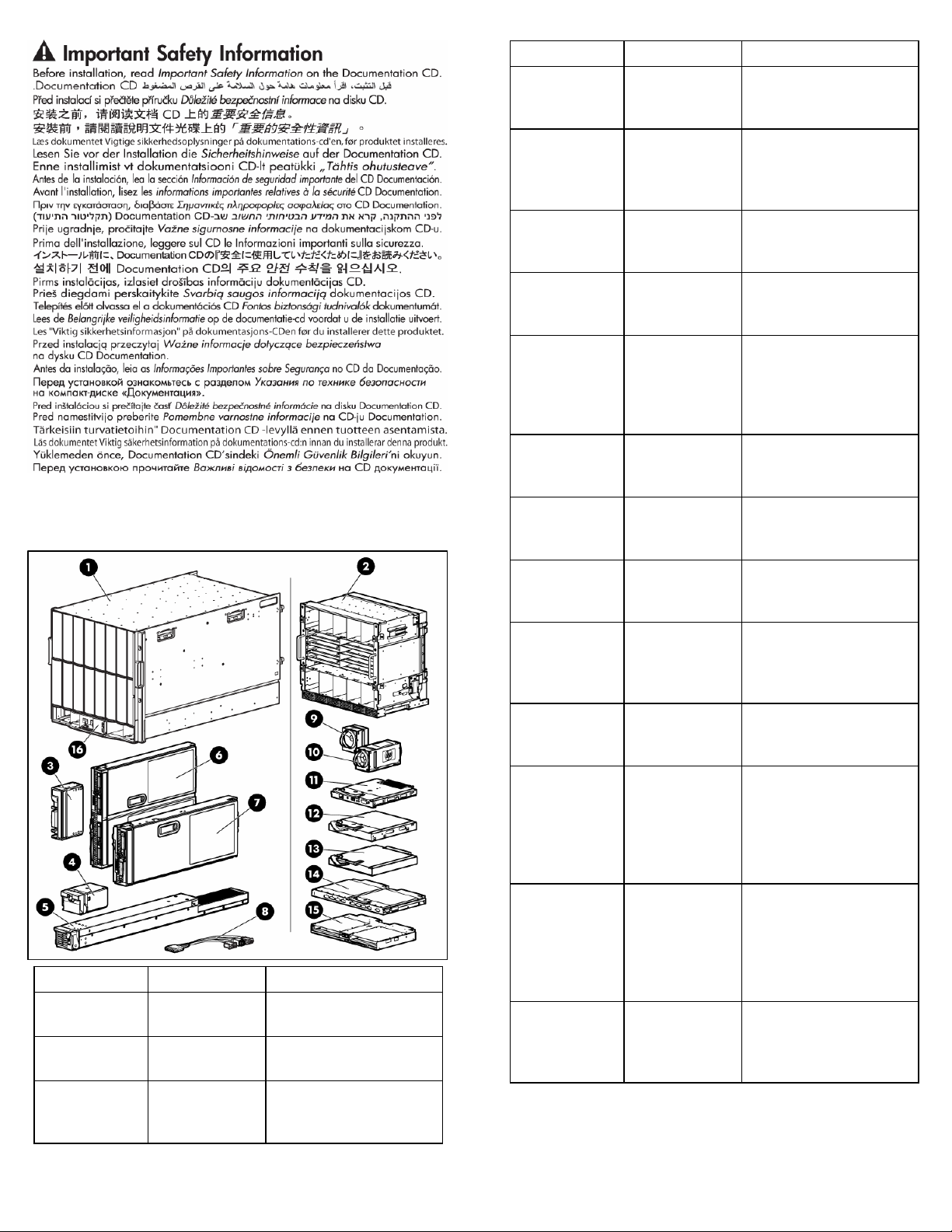

Verifying the pallet contents

Item Name Description

1 HP BladeSystem

c7000 Enclosure

2 Rear cage The rear section of the

3 Device bay blank A mandatory insert

The HP BladeSystem

enclosure

enclosure

installed in any unused

device bay

Item Name Description

4 Power supply

blank

A mandatory insert

installed in any unused

power supply bay

5 Enclosure hot-

plug power

The power supply for the

enclosure

supply (quantity

as ordered)

6 Full-height device

(quantity as

The full-height server or

storage blade

ordered)

7 Half-height

device (quantity

The half-height server or

storage blade

as ordered)

8 Local I/O cable A cable with serial, USB,

and video connectors that

connects to the I/O

connector on the front of a

blade

9 Fan blank A mandatory insert

installed in any unused fan

bay

10 HP Active Cool

Fan (quantity as

ordered)

11 Onboard

Administrator

module

12 Onboard

Administrator

blank

A fan used to cool the

components installed in the

enclosure

An optional module used to

manage the components

installed in the enclosure

A mandatory cover

installed in any unused

Onboard Administrator

bay

13 Interconnect

blank

A mandatory insert

installed in any unused

interconnect bay

14 Interconnect

module (quantity

and type as

ordered)

Any of several

components, such as pass-

throughs or switches that

enable communication

between the blade and the

enclosure

15 Onboard

Administrator tray

A tray that contains the

entire management

subsystem of the enclosure

(this tray should be

removed only by a

qualified technician)

16 HP BladeSystem

Insight Display

A display that provides

information about the

health and operation of the

enclosure

Page 3

Item Name Description

17* Power retention

ties (single-phase

enclosures only;

in the bag, taped

Tie straps that help prevent

single-phase power cables

from disconnecting from

the power connectors

to the top of the

enclosure)

18* Documentation

CD

The CD containing detailed

documentation on using the

enclosure

19* SmartStart CD A CD containing

SmartStart software, a

collection of software that

optimizes single-server

setup

20* Hard copy

installation

The printed installation

instructions

instructions for

blades, options

and interconnects

21* Installation

checklist

A checklist to guide you

through installation of the

enclosure and its

components

* Not shown

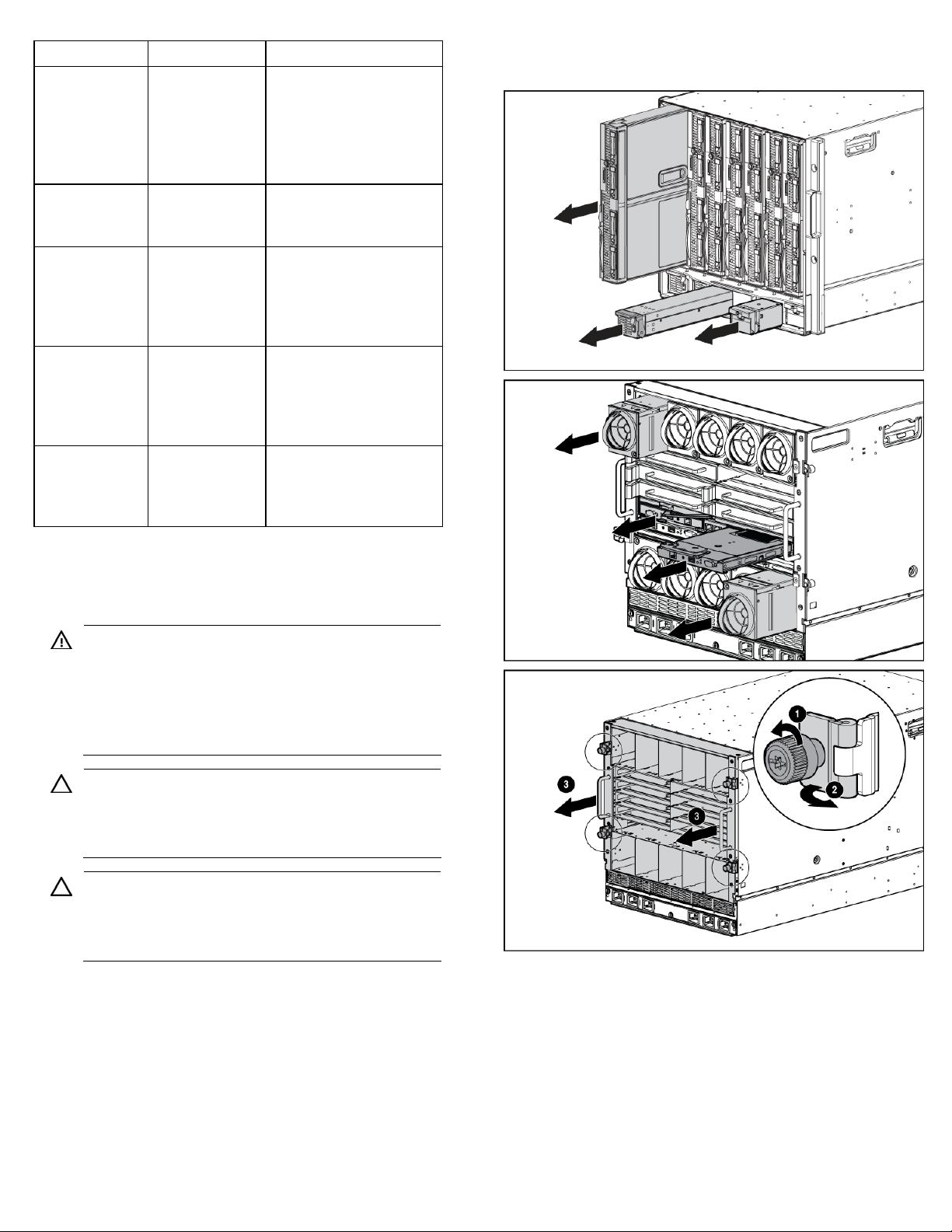

2. Remove all components from the front and rear of the

enclosure, and then remove the rear cage.

Installing the enclosure

WARNING: Because the fully-populated enclosure

can weigh up to 217.7 kg (480 lb), remove all

components and the rear cage from the enclosure

before removing the enclosure from the pallet to

reduce the risk of personal injury when moving the

enclosure.

CAUTION: When removing the rear cage and

midplane assembly, the connectors on the midplane

assembly are susceptible to damage. Use caution to

avoid damage to the pins and connectors.

CAUTION: Be sure the hinges are completely open

before installing the rear cage into the enclosure.

Failure to do so can cause damage to pins and

connectors.

1. The enclosure can be installed in a rack or rack-free

environment. Select the proper location based on

requirements detailed in the HP BladeSystem c7000

Enclosure Setup and Installation Guide.

Page 4

3. (Optional) Install the enclosure into a rack. See the HP

BladeSystem c7000 Enclosure Rack Template. For rack-

free installations, omit this step.

4. Install the rear cage into the enclosure, close the hinges,

and tighten the thumbscrews.

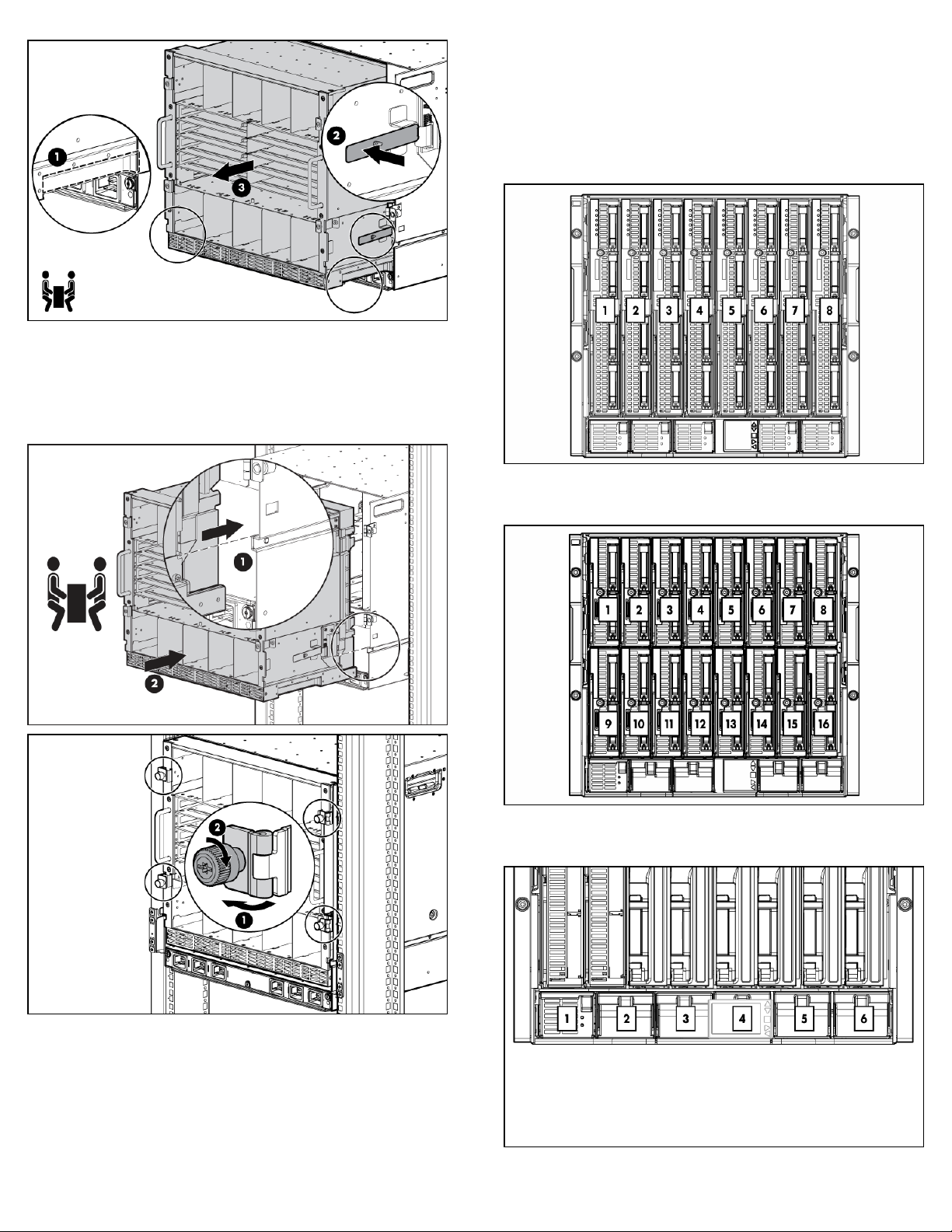

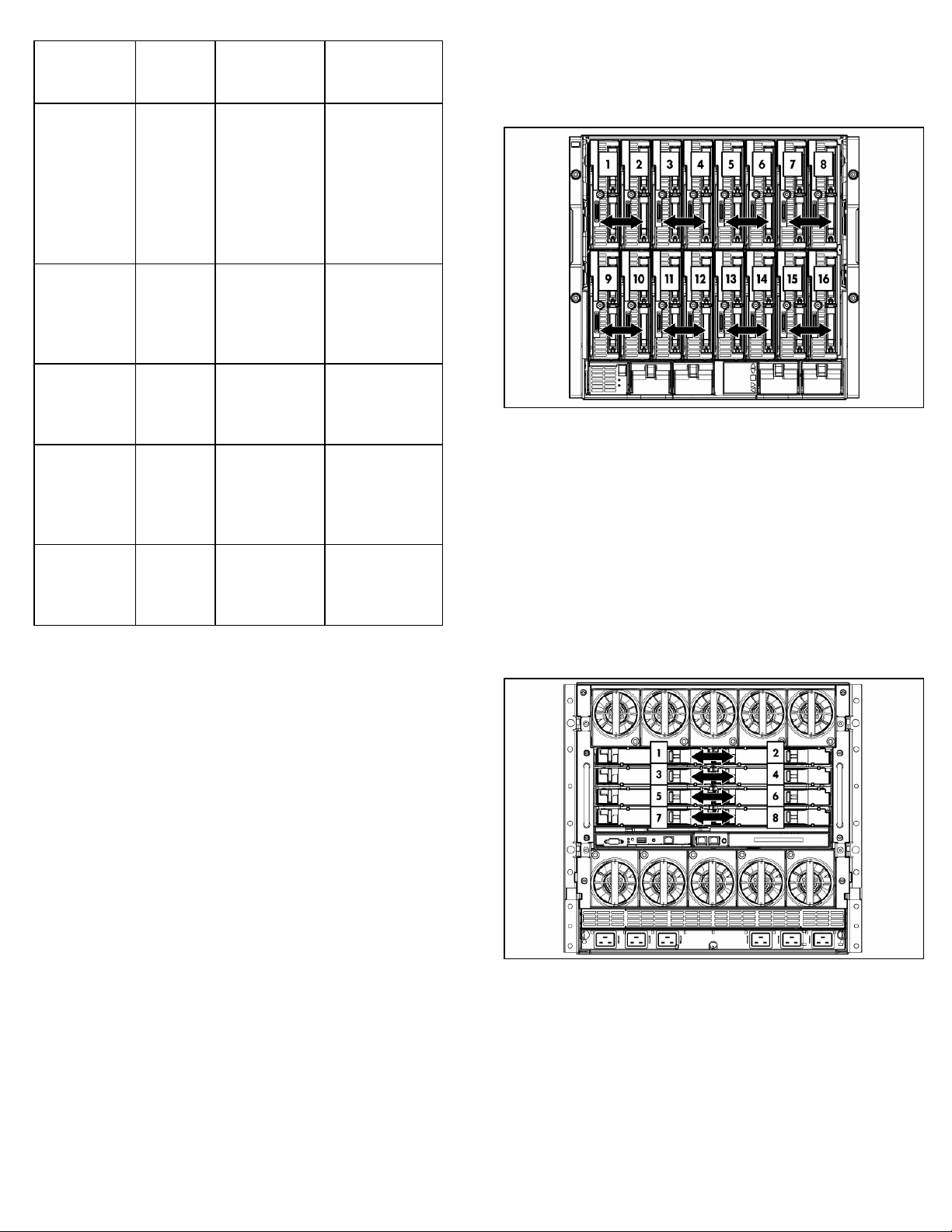

Enclosure bay identification

Before installing front or rear components into the enclosure,

review enclosure bay numbering for each component.

Full-height device bay numbering

Half-height device bay numbering

Power supply bay numbering

Page 5

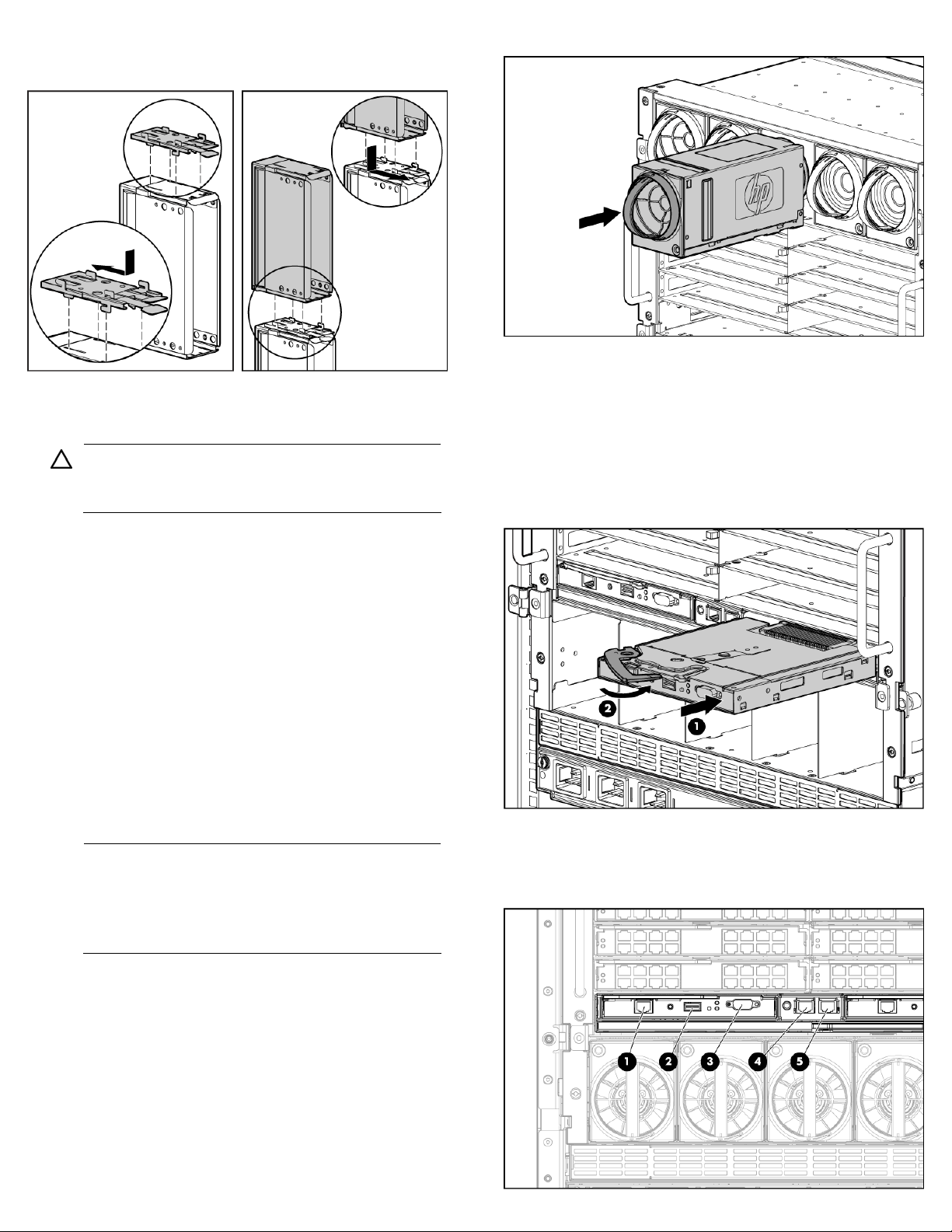

Fan bay numbering

g

1. Add any ordered options to each server blade:

o Additional processor

Installing the front components

CAUTION: To prevent improper coolin

damage, do not operate the enclosure unless all

bays are populated with a component or a blank.

1. Install the power supplies based on the total number of

supplies needed:

o Two power supplies: Bays 1 and 4

o Three power supplies: Bays 1, 2, and 4

o Four power supplies: Bays 1, 2, 4, and 5

o Five power supplies: Bays 1, 2, 3, 4, and 5

o Six power supplies: One in each bay

Install power supply blanks in any unused power supply

bays.

Power supplies are installed in this manner to provide

maximum flexibility for redundancy and three-phase

configuration options. To calculate how many power

supplies are needed, see the HP power calculator

(http://www.hp.com/go/bladesystem/powercalculator

NOTE: This document discusses installation of AC

power supplies only. For information on configuring

DC power supplies or HP Carrier Grade Solutions,

see the documentation that came with your power

supply.

NOTE: Slide the HP BladeSystem Insight Display to

the right or left to gain access to all power supply

bays.

and thermal

o Additional memory

o Mezzanine option cards

2. (Optional) If you are installing a full-height device,

remove the half-height device bay shelf. If you are

installing a half-height device, omit this step.

).

3. Remove the connector covers.

4. Install the server or storage blades.

5. Install device bay blanks into any unused device bays.

Page 6

g

g

If the empty bays are configured for a full-height device,

join two device bay blanks to create a full-height blank.

Installing the rear components

CAUTION: To prevent improper coolin

damage, do not operate the enclosure unless all

bays are populated with a component or a blank.

and thermal

2. Install fan blanks in any unused fan bays.

3. Install the Onboard Administrator modules into the

Onboard Administrator tray based on the total number

ordered:

o One Onboard Administrator module: Bay 1

o Two Onboard Administrator modules: Bays 1 and 2

Install an Onboard Administrator blank into any unused

Onboard Administrator bay.

1. Install fans in even-numbered groups, based on the total

number of blades installed in the enclosure:

o Four fan configuration—Fan bays 4, 5, 9, and 10

are used to support a maximum of two devices

located in device bays 1, 2, 9, or 10. Only two

device bays can be used with four fans.

o Six fan configuration—Fan bays 3, 4, 5, 8, 9, and

10 are used to support devices in device bays 1, 2,

3, 4, 9, 10, 11, or 12.

o Eight fan configuration—Fan bays 1, 2, 4, 5, 6, 7,

9, and 10 are used to support devices in all device

bays.

o Ten fan configuration—All fan bays are used to

support devices in all device bays.

NOTE: When installing a fan in the top row of fan

bays, orient the fan so that the LED is in the lower

ht corner. When installing a fan in the bottom row

ri

of fan bays, orient the fan so the LED is in the upper

left corner.

Connecting the cables

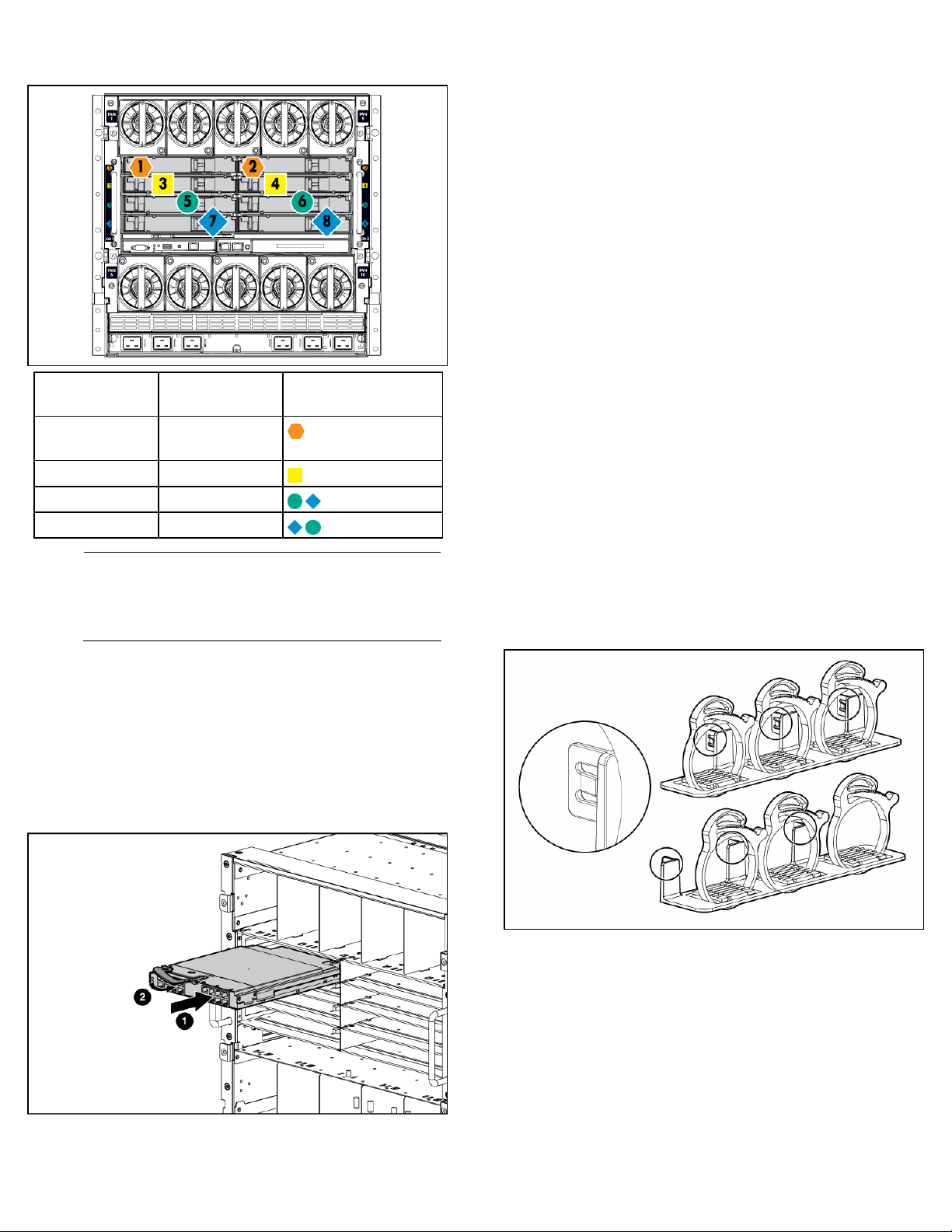

1. Identify all connectors.

Page 7

Item Connector Description

1 OA/iLO Onboard Administrator Ethernet connection.

Use a CAT5 patch cable to connect to the

management network. This is the connector for

the IP address of the Onboard Administrator

and for the iLO ports on each server blade.

2 USB For future USB connections. Not currently

supported.

3 Serial

connector

Used for command line interface (CLI). Connects

to a laptop or computer with a null-modem

serial cable (RS232).

4 Enclosure

link-down

Connects to the enclosure link-up port on the

enclosure below with a CAT5 patch cable.

port

5 Enclosure

link-up

port and

service

port

Connects to the enclosure link-down port on the

enclosure above with a CAT5 patch cable. On

a stand-alone enclosure or the top enclosure in

a series of linked enclosures, the top enclosure

link-up port functions as a service port.

2. Connect a standard CAT5 patch cable to the OA/iLO

port of each installed Onboard Administrator module to

connect to the management network.

Mapping to interconnect ports

Several port types are referenced in the following tables.

• Examples of 1x ports are 1-Gb Ethernet (1 GbE) switch

modules and Fibre Channel interconnect modules.

• An example of a 2x port is a Serial Attached SCSI (SAS)

interconnect module. (Reserved for future use.)

• Examples of 4x ports are 10-Gb Ethernet (10 GbE)

interconnect modules.

NOTE: 1x and 2x port mezzanine cards interface

with single-wide interconnect modules. 4x port

mezzanine cards interface with double-wide

interconnect modules.

The term "1x/2x" refers to the number of interconnect lanes

per port provided by the controller. The more lanes provided

per port, the higher the data transmission rate coming from

that port.

Mapping half-height blades

3. If more than one enclosure is installed in the rack, use a

CAT5 patch cable to connect the enclosure link-down

port on the upper enclosure to the enclosure link-up port

on the lower enclosure.

NOTE: The enclosure link ports are designed only to

support c-Class enclosures in the same rack. The

enclosure link-up port on the top enclosure is the

service port, and the enclosure link-down port on the

bottom linked enclosure is unused.

NOTE: The HP BladeSystem c-Class enclosure link

ports are not compatible with the HP BladeSystem

p-Class enclosure link ports.

Page 8

The following table lists the available configurations for halfheight devices installed in device bay N (1–16).

Connection Port number Connects to

interconnect

bay/port

Embedded

NIC

Mezzanine

slot 1—1x or

2x cards

Mezzanine

NIC 1

NIC 2

1x/2x port 1

1x/2x port 2

1/Port N

2/Port N

3/Port N

4/Port N

4x port 1 3/Port N • One doubleslot 1—4x

cards

Mezzanine

slot 2—1x or

2x cards

Mezzanine

slot 2—4x

cards

1x/2x port 1

1x/2x port 2

1x/2x port 3

1x/2x port 4

4x port 1

4x port 2

5 / port N

6 / port N

7 / port N

8 / port N

5/Port N

7/Port N

* Connectivity to interconnect bays 7 and 8 is only available with

four-port mezzanine cards or port 2 of 4x card in Mezzanine slot 2.

Comments

One or two

single-wide

Ethernet

interconnect

modules

• One single-

wide

interconnect

module

• Four port

cards will

only connect

the first two

ports.

wide

interconnect

module

• Only port 1

of a two port

card will be

connected.

One or two

single-wide

interconnect

modules

One or two

double-wide

interconnect

modules

Mapping full-height blades

The following table lists the available configurations for fullheight devices installed in device bay N (1–8).

Connection Port

number

Connects to

interconnect

bay/port

NIC NIC 1

NIC 2

NIC 3

NIC 4

Mezzanine

slot 1—1x or

2x cards

1x/2x port

1

1x/2x port

2

1x/2x port

1/Port N+8

2/Port N+8

1/Port N

2/Port N

3/Port N

4/Port N

3/Port N+8

4/Port N+8

3

1x/2x port

4

Comments

One or two

single-wide

Ethernet

interconnect

modules

One or two

single-wide

interconnect

modules

Page 9

Connection Port

number

Mezzanine

slot 1—4x

cards

Mezzanine

slot 2—1x or

2x cards

Mezzanine

slot 2—4x

cards

Mezzanine

slot 3—1x or

2x cards

Mezzanine

slot 3—4x

cards

* Connectivity to interconnect bays 7 and 8 is only available with

four-port mezzanine cards or port 2 of 4x card in Mezzanine slot 2.

4x port 1 3/Port N • One double-

1x/2x port 1

1x/2x port 2

1x/2x port 3

1x/2x port 4

4x port 1

4x port 2

1x/2x port 1

1x/2x port 2

1x/2x port 3

1x/2x port 4

4x port 1

4x port 2

Connects to

interconnect

bay/port

5/Port N

6/Port N

7/Port N+8

8/Port N+8

5/Port N

7/Port N

7/Port N

8/Port N

5/Port N+8

6/Port N+8

5/Port N

7/Port N

Comments

wide

interconnect

module

• Only port 1

of a two port

card will be

connected

Up to four singlewide interconnect

modules

One or two

double-wide

interconnect

modules

Up to four singlewide interconnect

modules

One or two

double-wide

interconnect

modules

Device bay crosslinks

Device bay crosslinks are wired between adjacent horizontal

device bay pairs.

For half-height blades, these signals connect a four-lane PCIe

module to a partner blade such as a tape blade or a PCI

expansion blade. For full-height blades, these signals are used

to connect a PCIe module to a partner blade in the lower

adjacent bay and require a PCIe pass-thru mezzanine card

installed in mezzanine connector 3. The Onboard

Administrator disables the device bay crosslinks when they

cannot be used, such as when two server blades reside in

adjacent device bays.

Interconnect bay crosslinks

Interconnect bay crosslinks are wired between adjacent

interconnect bay pairs.

Bay-to-bay crosslinks

Four trace SerDes signals between adjacent bays are

provided in the enclosure midplane to permit bay-to-bay

communications. Interconnect modules can only connect

horizontally.

You can enable these signals to provide module-to-module

connections, such as Ethernet crosslink ports between

matching switches, or Virtual Connect modules as stacking

links. Onboard Administrator disables the interconnect bay

crosslinks when they cannot be used, such as when two

different modules reside in adjacent horizontal interconnect

bays.

Page 10

Installing interconnect modules

Server blade

signal

NICs 1, 2, 3, and

4 (embedded)

Mezzanine 1 3, 4

Mezzanine 2 5, 6 and then 7, 8

Mezzanine 3 7, 8 and then 5, 6

NOTE: For information on the location of LEDs and

ports on individual interconnect modules, see the

documentation that ships with the interconnect

module.

Interconnect bay

number

1, 2

Interconnect bay label

3. Connect each installed interconnect module to the

external connections with the appropriate cable.

Powering up the enclosure

Single-phase power configuration

For a single phase power configuration:

1. Connect the AC power cables to the power connectors

on the rear of the enclosure corresponding to the power

supply that was populated on the front of the enclosure.

2. Be sure each power cable is securely attached to the

power connectors.

3. Connect the AC power cables to the AC power source

or to an installed power distribution unit (PDU).

4. Turn on the AC circuit breakers that power the power

cables installed in the enclosure.

5. Locate the power retention bracket that came with the

enclosure.

6. Verify that the power cord retention tabs are on the

correct side.

o On the left side: To install the power cord retention

bracket on the left side of the enclosure, ensure the

power cord retention tabs are located to the right of

the snap clamps.

o On the right side: To install the power cord retention

bracket on the right side of the enclosure, ensure the

power cord retention tabs are located on the left side

of the snap clamps.

1. Install the interconnect modules based on the number

ordered and the number of fabrics in the configuration.

The enclosure ships with interconnect bay dividers

installed. The interconnect bay dividers must be removed

before installing double-wide interconnect modules. To

remove an interconnect bay divider, press the release

tab, and pull the interconnect bay divider out of the

enclosure.

2. Install interconnect blanks in any unused interconnect

bays.

7. Place the power cord retention bracket under the power

cords, and then align the power cords with the snap

clamps.

8. Open the snap clamps, and then insert each power cord

inside each clamp.

9. Slide the power cord retention bracket until the bracket

touches the enclosure.

Page 11

Insert the power cord retention tabs into the slots on the

10.

enclosure until they snap into place.

11. Slide each snap clamp over the end of each power cord

overmold, and then squeeze each snap clamp closed.

To set up an enclosure with network connectivity to the

Onboard Administrator:

1. On the Enclosure Settings screen, confirm the default

settings.

o Use the navigation arrows to navigate to a particular

setting, and press OK.

o Navigate to the "?" box next to a setting and press

OK to get help on that setting.

2. Confirm the Redundancy mode, which is typically AC

Redundant, for the power supplies.

3. Set the Limit AC Input VA if the facility must limit AC

power to the enclosure below what the power supplies

can draw.

4. Enable Dynamic Power Savings to provide the highest

power efficiency without affecting server performance.

5. Write down the OA1 and OA2 (if present) IP address.

This information is needed when deploying the

management software.

o If the OA1 or OA2 IP address is 0.0.0.0., set the

address. Navigate to the address and press OK. Use

the up and down arrows to select Static IP address.

Use the up and down arrows on each field to set the

IP, netmask and gateway one octet at a time. Press

OK when done, and then press OK again on Accept

to confirm the new IP address settings.

Three-phase power configuration

For a three-phase power configuration, the AC power cables

are already attached to the enclosure. To cable the enclosure

using a three-phase AC configuration:

1. Connect the AC power cables to the AC power source.

2. Turn on the AC circuit breakers that power the power

cables installed in the enclosure.

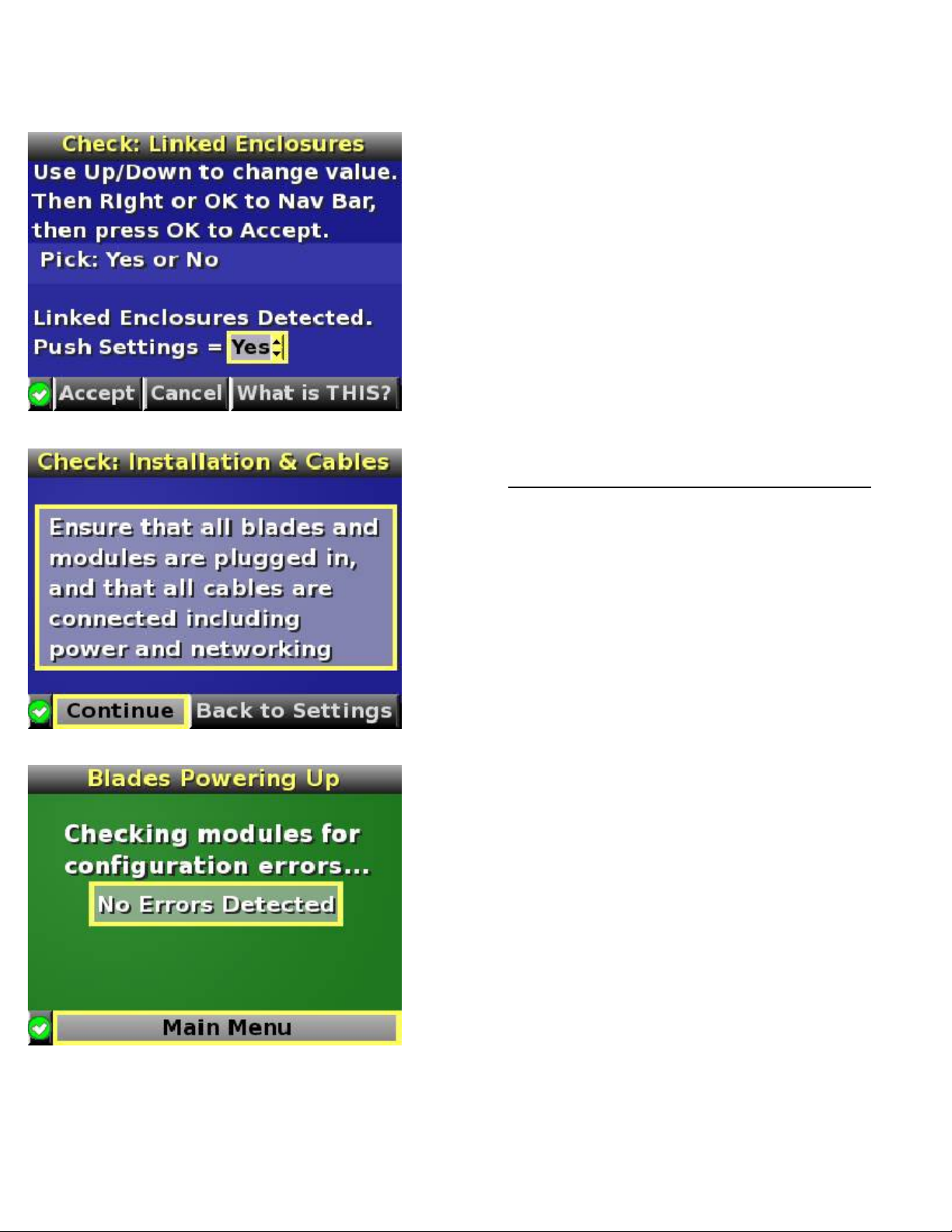

Setting up the HP BladeSystem Insight Display

When the enclosure is powered up for the first time, the

Insight Display launches an installation wizard to guide you

through the configuration process. After configuring the

enclosure, the Insight Display verifies that there are no

installation or configuration errors.

o If the address is not 0.0.0.0., record the displayed

address to use for remote login to the Onboard

Administrator over the management network.

6. (Optional) Edit the Enclosure Name. The default value is

the Onboard Administrator serial number.

7. (Optional) Edit the Rack Name. The default value is

UnnamedRack.

8. Set the Insight Display PIN to prevent other users of the

LCD from changing the settings.

9. Navigate to Accept at the bottom of the Enclosure

Settings, and press OK to Accept all the settings to

continue. If you are setting up a single enclosure,

proceed to step 11.

To identify the enclosure, the rear enclosure UID light and the

background of the Insight Display are illuminated blue when

the enclosure is powered on initially.

Page 12

J

Navigate to Accept, and press OK to apply the

10.

Enclosure Settings (Redundancy Mode, Limit AC, Power

Savings, Rack Name, and Insight Display PIN) to other

linked enclosures.

11. Follow the instructions on the next screen.

13. Open a browser and connect to the active Onboard

Administrator module using the Onboard Administrator

IP address that was configured during the Insight Display

installation wizard process.

14. Enter the user name and password from the tag supplied

with the Onboard Administrator module to access the

remote Onboard Administrator web interface and

complete the Onboard Administrator first time installation

wizard.

To set up the enclosure without network connectivity to the

Onboard Administrator, see the HP BladeSystem Onboard

Administrator User Guide.

The installation is complete.

For more information

For more detailed setup and configuration information, see

the HP BladeSystem c-Class Solution Overview and the HP

BladeSystem c7000 Enclosure Setup and Installation Guide.

You can also find information on the HP website

(http://www.hp.com/go/bladesystem/documentation

).

12. Follow the instructions on the next screen.

© Copyright 2006, 2008 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only

warranties for HP products and services are set forth in the express warranty

statements accompanying such products and services. Nothing herein should

be construed as constituting an additional warranty. HP shall not be liable for

technical or editorial errors or omissions contained herein.

Part Number 411762-005

uly 2008 (Fifth Edition)

Loading...

Loading...