Page 1

Setup and Installation Guide

HP Blade PC bc1000 in an HP

Consolidated Client Infrastructure Solution

Document Part Number: 355079-002

July 2004

This guide provides step-by-step instructions for installation, and

reference information for operation, troubleshooting, and future

upgrades for the HP Consolidated Client Infrastructure (CCI)

solution.

Page 2

Å

Ä

© Copyright 2004 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice.

Microsoft and Windows are U.S. registered trademarks of Microsoft

Corporation.

The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein

should be construed as constituting an additional warranty . HP shall not be liable

for technical or editorial errors or omissions contained herein.

This document contains proprietary information that is protected by copyright.

No part of this document may be photocopied, reproduced, or translated to

another language without the prior written consent of Hewlett-Packard

Company.

WARNING: Text set off in this manner indicates that failure to follow

directions could result in bodily harm or loss of life.

CAUTION: Text set off in this manner indicates that failure to follow

directions could result in damage to equipment or loss of information.

Setup and Installation Guide

HP Blade PC bc1000 in an HP Consolidated Client Infrastructure

Solution

Second Edition (July 2004)

First Edition (February 2004)

Document Part Number: 355079-002

Page 3

Contents

1 About This Guide

Audience Assumptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Symbols on Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Rack Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Symbols in Text. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Technical Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

HP Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

2 HP CCI Solution Technology

Hardware Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

ProLiant BL e-Class Blade Enclosure Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Blade PC Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

Software Deployment and Management Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

Diagnostic Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–10

3 Planning the Installation

Optimum Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Rack Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

ProLiant BL e-Class Blade Enclosure Warnings and Cautions . . . . . . . . . . . . . . . . . . 3–3

Preparing for Software Deployment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Rapid Deployment Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Alternate Deployment Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Shipping Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Blade Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Rack-Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

Blade PCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

Setup and Installation Guide www.hp.com iii

Page 4

Contents

Interconnect Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

Optional RJ-45 Patch Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

Optional Installation Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

4 Installing and Cabling the HP CCI Solution

Installing the Interconnect Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Measuring with the Rack Template. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

Installing the Rack Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–7

Installing the Enclosure into the Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–10

Cabling the HP CCI Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–12

ProLiant BL e-Class C-GbE Interconnect Switch Connectors. . . . . . . . . . . . . . . 4–13

Optional RJ-45 Patch Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–14

Cabling the Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–15

Installing a Blade PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–18

Powering Up the HP CCI Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–22

Powering Down the HP CCI Solution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–22

Powering Down a Blade PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–22

Powering Down the Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–23

Removing a Blade PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–24

Installing Additional Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–24

Attaching the Graphics Diagnostic Card and Diagnostic Adapter . . . . . . . . . . . . . . . 4–28

5 Deployment and Management

Blade PC Deployment Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Automated Deployment Using Rapid Deployment Pack . . . . . . . . . . . . . . . . . . . . 5–2

Alternate Deployment Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Diagnostic Adapter and Optional Graphics Diagnostic Card. . . . . . . . . . . . . . . . . 5–3

Blade PC Features and Supported Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

Supported Operating Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

Computer Setup (F10) Utility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

Flashing the Blade PC ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–14

ProLiant BL e-Class Integrated Administrator. . . . . . . . . . . . . . . . . . . . . . . . . . . 5–15

Blade PC Event Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–18

HP Systems Insight Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–19

ProLiant BL e-Class C-GbE Interconnect Switch Management Tools and Utilities . . .

5–20

iv www.hp.com Setup and Installation Guide

Page 5

A Regulatory Compliance Notices

Regulatory Compliance Identification Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

Federal Communications Commission Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

Class A Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–2

Class B Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–2

Declaration of Conformity for Products Marked with the FCC Logo, United States

Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–3

Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–3

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–3

Canadian Notice (Avis Canadien). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–4

Class A Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–4

Class B Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–4

Mouse Compliance Statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–4

European Union Notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–4

Japanese Notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–5

Korean Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–5

Class A Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–5

Class B Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–5

Taiwanese Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–6

Laser Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–6

Laser Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–6

Compliance with CDRH Regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–6

Compliance with International Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–7

Laser Product Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–7

Laser Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–7

Battery Replacement Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–8

Contents

B Electrostatic Discharge

Preventing Electrostatic Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–1

Grounding Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–1

C POST Error Messages

D Troubleshooting

When the Enclosure Does Not Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–3

Enclosure Diagnostic Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–5

Setup and Installation Guide www.hp.com v

Page 6

Contents

When the Blade PC Does Not Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–14

Blade PC Diagnostic Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–16

Problems After Initial Boot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–21

E LEDs and Switches

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E–1

Enclosure Front Panel LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E–1

Enclosure Rear Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E–2

Enclosure Rear Panel LEDs with RJ-45 Patch Panel . . . . . . . . . . . . . . . . . . . . . . . E–5

Fan Health LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E–7

Blade PC and Diagnostic Adapter LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E–8

Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E–10

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E–10

Rear Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E–11

CMOS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E–11

F Specifications

Blade Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F–2

Blade PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F–3

Hot-Plug Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F–4

G Blade PC Battery

Blade PC Battery Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G–1

Index

vi www.hp.com Setup and Installation Guide

Page 7

About This Guide

This guide provides step-by-step instructions for installation, and

reference information for operation, troubleshooting, and future

upgrades for the HP Consolidated Client Infrastructure (CCI)

solution.

1

✎

The cross-references in this guide are linked to the referenced section.

Click on a cross-reference to go directly to that section.

Audience Assumptions

This guide is for the person who installs, administers, and

troubleshoots HP CCI solutions. HP assumes you are qualified in the

servicing of computer equipment and trained in recognizing hazards

in products with hazardous energy levels.

Important Safety Information

WARNING: Before installing this product, read the Important Safety

Å

Information document included with the system.

Symbols on Equipment

The following symbols may be placed on equipment to indicate the

presence of potentially hazardous conditions:

Setup and Installation Guide www.hp.com 1-1

WARNING: This symbol, in conjunction with any of the

following symbols, indicates the presence of a potential hazard.

The potential for injury exists if warnings are not observed.

Consult your documentation for specific details.

Page 8

About This Guide

This symbol indicates the presence of hazardous energy circuits or

electric shock hazards. Refer all servicing to qualified personnel.

WARNING: To reduce the risk of injury from electric shock

hazards, do not open this enclosure. Refer all maintenance,

upgrades, and servicing to qualified personnel.

This symbol indicates the presence of electric shock hazards. The

area contains no user or field serviceable parts. Do not open for

any reason.

WARNING: To reduce the risk of injury from electric shock

hazards, do not open this enclosure.

This symbol on an RJ-45 receptacle indicates a network interface

connection.

WARNING: To reduce the risk of electric shock, fire, or damage

to the equipment, do not plug telephone or telecommunications

connectors into this receptacle.

This symbol indicates the presence of a hot surface or hot

component. If this surface is contacted, the potential for injury

exists.

WARNING: To reduce the risk of injury from a hot component,

allow the surface to cool before touching.

These symbols, on power supplies or systems,

indicate that the equipment is supplied by multiple

sources of power.

WARNING: To reduce the risk of injury from electric

shock, remove all power cords to completely

disconnect power from the system.

1-2 www.hp.com Setup and Installation Guide

Page 9

Rack Stability

Weight in kg

Weight in lb

About This Guide

This symbol indicates that the component exceeds the

recommended weight for one individual to handle safely.

WARNING: To reduce the risk of personal injury or

damage to the equipment, observe local occupational health

and safety requirements and guidelines for manual material

handling.

WARNING: To reduce the risk of personal injury or damage to

the equipment, be sure that:

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizing feet are attached to the rack if it is a

single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may

become unstable if more than one component is extended for

any reason.

Symbols in Text

These symbols may be found in the text of this guide. They have the

following meanings.

WARNING: Text set off in this manner indicates that failure to follow

Å

Ä

Setup and Installation Guide www.hp.com 1-3

directions in the warning could result in bodily harm or loss of life.

CAUTION: Text set off in this manner indicates that failure to follow

directions could result in damage to equipment or loss of information.

IMPORTANT: Text set off in this manner presents essential information to

explain a concept or complete a task.

Page 10

About This Guide

✎

Text set off in this manner presents additional information to

emphasize or supplement important points of the main text.

Related Documents

For additional information on the topics covered in this guide, refer to

the following documents:

■ HP ProLiant BL e-Class Integrated Administrator User Guide

■ ProLiant Integration Module for Altiris User Guide

■ Servers Troubleshooting Guide

■ Product Service Card

■ HP ProLiant BL e-Class C-GbE Interconnect Switch User Guide

■ White paper: HP ProLiant BL e-Class System Overview and

Planning

■ QuickSpecs

Getting Help

If you have a problem and have exhausted the information in this

guide, you can get further information and other help in the following

locations.

Technical Support

For technical support, call the HP T echnical Support Phone Center for

your region. Telephone numbers are listed in the WorldWide

Telephone Numbers guide included on the Documentation CD that

ships with Blade PCs. Telephone numbers for worldwide Technical

Support Centers are also listed on the HP website,

HP Website

The HP website has information on this product as well as the latest

drivers and flash ROM images. You can access the HP website at

www.hp.com.

1-4 www.hp.com Setup and Installation Guide

www.hp.com.

Page 11

HP CCI Solution Technology

Hardware Features

The HP CCI solution is comprised of a rack-mount blade enclosure

that contains advanced electronics for managing up to 20

single-processor Blade PCs.

2

ProLiant BL e-Class blade enclosure with Blade PCs (20)

The enclosure and Blade PC features described in the following

sections are standard on HP CCI solutions, unless otherwise

specified.

Setup and Installation Guide www.hp.com 2-1

Page 12

HP CCI Solution Technology

ProLiant BL e-Class Blade Enclosure Features

Blade enclosure features include:

■ 3U height and standard 48 cm (19 inch) width

■ Support for up to 20 Blade PCs

■ Interconnect Tray options for each server blade enclosure:

❏ Interconnect switch with four RJ-45 Gigabit Ethernet uplink

connectors

❏ Optional patch panel with forty RJ-45 connectors

■ ProLiant BL e-Class Integrated Administrator for local and

remote management and monitoring

■ Redundant power

■ Redundant cooling

■ System health LEDs

ProLiant BL e-Class C-GbE Interconnect Switch (Optional)

The ProLiant BL e-Class C-GbE Interconnect Switch features

include:

■ Significant cable reduction (40 Blade PC NIC connections to four

RJ-45 Gigabit Ethernet uplink connectors)

■ Interconnect tray form factor that fits into blade enclosure

■ Low wattage for maximum power efficiency

■ Compatibility with common core switches

■ Network fault tolerance: Two integrated switch modules, switch

A and switch B, provide redundant paths to the network ports on

the blade PCs

2-2 www.hp.com Setup and Installation Guide

Page 13

RJ-45 Patch Panel (Optional)

The RJ-45 Patch Panel features:

■ 40 port 10/100 RJ-45 connectors

■ 1 to 1 mapping between each NIC on the blade PCs to one of the

40 RJ-45 ports on the back of this tray-mounted patch panel

■ Separate Link and Activity LEDs, for each 10/100 port

■ Network fault tolerance: Two integrated switch modules, switch

A and switch B, provide redundant paths to the network ports on

the blade PCs

ProLiant BL e-Class Integrated Administrator

ProLiant BL e-Class Integrated Administrator features include:

■ Local and remote access to enclosure and Blade PC information

■ Secure Shell, T elnet, and Secure Sockets Layer (SSL) Web access

HP CCI Solution Technology

■ Virtual power and Unit Identification (UID) buttons

■ Access to any Blade PC’s remote console

■ Access to any Blade PC’s Computer Setup (F10) Utility

■ Support for command line scripting

Setup and Installation Guide www.hp.com 2-3

Page 14

HP CCI Solution Technology

Redundant Power

The ProLiant BL e-Class blade enclosure includes two 600-W

redundant hot-plug power supplies

■ 1 + 1 redundancy

■ Integrated hot-plug capability

■ Autosensing input voltage range from 100 to 127 VA C and 200 to

■ Load-sharing across all Blade PCs

Redundant Cooling

The ProLiant BL e-Class blade enclosure ships with four redundant

hot-plug fans. These fans offer:

■ 2 + 2 redundancy

■ Hot-swapping among all fan positions

240 VAC

■ Variable-speed fans

■ Individual fan status LEDs

System Health LEDs

System health information is displayed locally through a full set of

system LEDs, including:

■ Internal fan health LEDs

■ External health LEDs

❏ Fan health LED

❏ Enclosure health LED

❏ Blade PC LEDs

❏ Power supply LEDs

❏ Integrated Administrator health LED

2-4 www.hp.com Setup and Installation Guide

Page 15

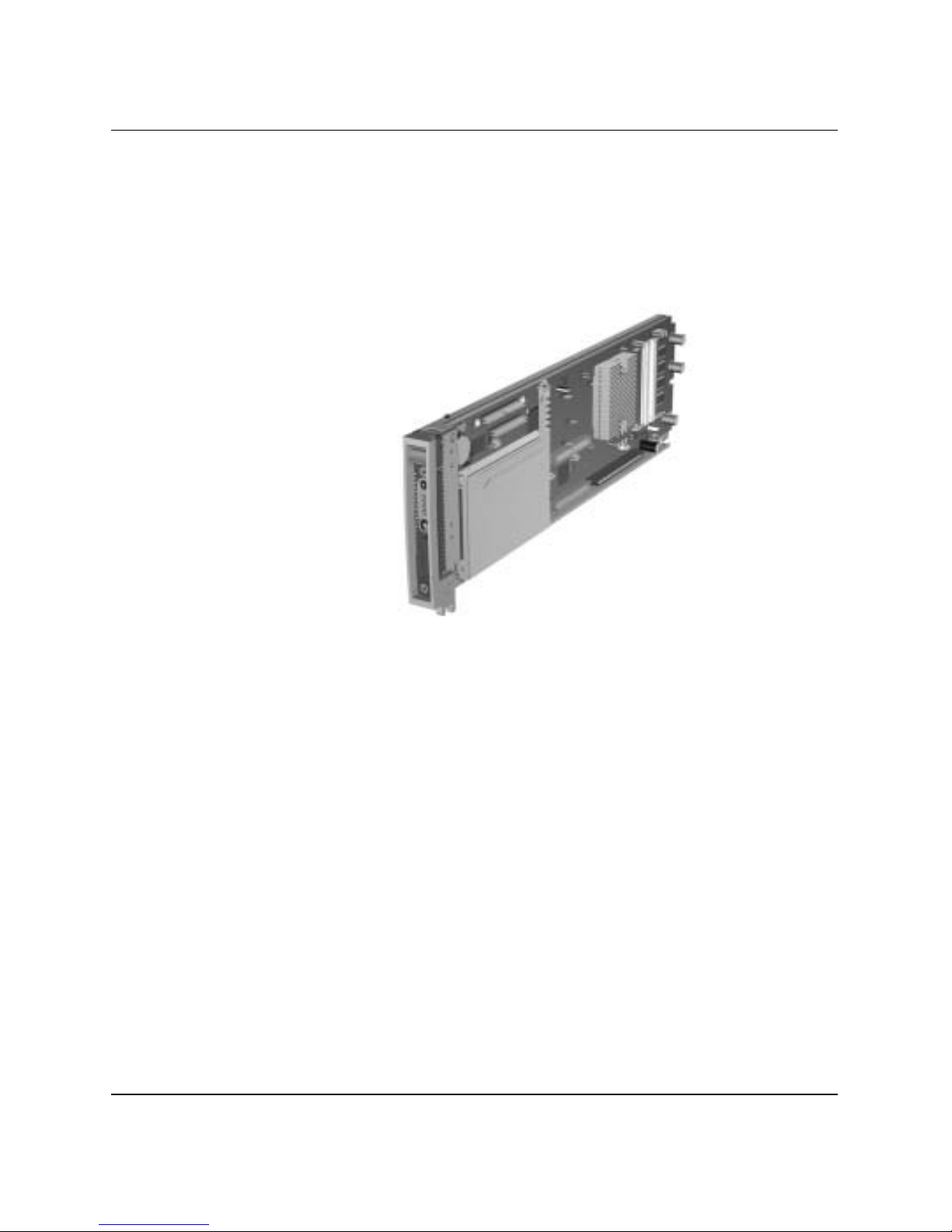

Blade PC Features

The Blade PC is simple to install, deploy, and service. A Blade PC

that requires out-of-the-rack upgrades, service, or maintenance can be

easily replaced by another Blade PC. The following figure shows a

Blade PC.

HP CCI Solution Technology

Blade PC

A Blade PC supports processor and system architecture technology,

including the following:

■ Processor

■ Memory

■ Mass storage

■ Blade PC status and monitoring

■ Diagnostic adapter (requires optional graphics diagnostic card)

■ Video (connector for a graphics diagnostic card; optional

graphics diagnostic card part number is 346204-001)

■ ROM

■ 2 LOM (LAN on mother board)

■ Health and power control

Setup and Installation Guide www.hp.com 2-5

Page 16

HP CCI Solution Technology

Processor

Ä

Memory

Each Blade PC ships with an integrated Transmeta Ef f iceon processor

with 1MB cache.

CAUTION: The processor heatsink assembly is integrated into the system

board and cannot be removed.

The Blade PC supports the following memory features:

■ DDR 333 (2 SODIMM connectors)

For more information, refer to QuickSpecs located on the HP

website:

■

512MB system memory expandable to 1GB (32MB of system

www.hp.com

memory is reserved for processor usage)

Mass Storage

The Blade PC ships with one ATA hard drive attached with screws.

Blade PC Status and Monitoring

A Blade PC provides the following status and monitoring features:

■ Blade PC Unit Identification (UID) button/LED

■ Blade PC health LED

■ Blade PC network activity LEDs

■ Hard drive activity LED

■ Power button/LED

■ Diagnostic support through the Computer Setup (F10) Utility , the

Integrated Management Log (IML), and HP Systems Insight

Manager

2-6 www.hp.com Setup and Installation Guide

Page 17

Diagnostic Adapter and Graphics Diagnostic Card

Each Blade PC has a diagnostic connector. Using the diagnostic

adapter and the graphics diagnostic card (available together as an

after-market option), the following capabilities are available:

■ USB connectivity for two USB devices including diskette drive,

CD-ROM drive, keyboard, and mouse

■ PS/2 connectivity for keyboard and mouse

■ Video connectivity through a standard 15-pin VGA connector

(optional graphics diagnostic card required for video)

■ Serial connectivity for facilitating software maintenance

Video (optional)

The Blade PC supports video through the diagnostic adapter and the

graphics diagnostic card (available together as an after-market

option). Video features include:

HP CCI Solution Technology

ROM

■ Support for SVGA, VGA, and EGA graphics resolution

■ Video is obtained by attaching an optional graphics diagnostic

card to the Blade PC (the optional graphics diagnostic card

supports a resolution of up to 1024 x 768 @ 24 bit color depth)

■ 4MB SDRAM video memory

Blade PC ROM features include:

■ 2MB ROM to support system, video, and CPU BIOS

requirements

■ ROMPaq utility used to upgrade the system ROM

■ Hardware boot block protection

■ Remote ROM flash support

■ Bootable USB diskette drive support

■ Bootable USB CD-ROM drive (limited support)

Setup and Installation Guide www.hp.com 2-7

Page 18

HP CCI Solution Technology

NICs

The two embedded NICs on the Blade PC have the following

features:

■ Embedded 10/100-Mbps Broadcom 5705F Fast Ethernet NICs

■ Preboot eXecution Environment (PXE) support (first NIC only)

■ Auto-negotiation of 10/100-Mbps link speeds

■ Full-duplex Ethernet support

■ Teaming for network fault tolerance or load balancing (also

known as port bonding or trunking)

Software Deployment and Management Features

HP offers an extensive set of features and optional tools to support

effective software deployment and management. See Chapter 5,

“Deployment and Management, ” for more detailed descriptions of the

following:

■ ProLiant BL e-Class Integrated Administrator

The ProLiant BL e-Class Integrated Administrator is a

centralized management and monitoring system for the ProLiant

BL e-Class enclosure and Blade PCs. The Integrated

Administrator acts as a combination terminal server and remote

power controller, enabling out-of-band, secure, serial console

connections to all Blade PCs in the enclosure.

■ Computer Setup (F10) Utility

Computer Setup performs a wide range of configuration activities

and provides access to numerous settings, including those for

system devices, security, storage, and boot order.

■ Rapid Deployment Pack

Rapid Deployment Pack features include:

❏ A graphical deployment console which provides intuitive

drag-and-drop events, such as scripts and images, to deploy

the operating systems and applications on any combination of

Blade PCs installed in the enclosures

❏ Simultaneous deployment of multiple Blade PCs

2-8 www.hp.com Setup and Installation Guide

Page 19

HP CCI Solution Technology

❏ Advanced features that can detect and display Blade PCs

based on their physical rack, enclosure, and bay locations

❏ The ability to set the deployment console to automatically

install pre-defined configurations on newly-installed Blade

PCs

For more information about Rapid Deployment Pack, refer to

your authorized reseller, the Rapid Deployment CD that ships

with the enclosure, or visit the HP website:

■

HP Systems Insight Manager

www.hp.com

HP Systems Insight Manager provides in-depth fault, inventory,

and configuration management of HP server platforms (including

hundreds of Blade PCs) from a single console.

■ Diagnostics Utility

The Diagnostics Utility displays information about a Blade PC's

hardware and tests the system to ensure it is operating properly.

■ Automatic System Recovery-2 (ASR-2)

ASR-2 is a diagnostic/recovery feature that automatically restarts

the Blade PC in the event of a critical operating system failure.

■ Enclosure Self Recovery (ESR)

ESR, similar to ASR-2, is a self-monitoring reliability feature of

the Integrated Administrator . If the Inte grated Administrator does

not boot or hangs during operation, ESR automatically resets the

Integrated Administrator for an attempted self-recovery. The

Blade PCs and interconnect tray are not affected by ESR.

■ Integrated Management Log (IML)

The IML provides a detailed log of key system events. This log,

which also monitors the health log, is accessible by utilities,

including HP Systems Insight Manager.

■ ROMPaq

ROMPaq enables you to upgrade the firmware (BIOS) with

system or option ROMPaq utilities.

Setup and Installation Guide www.hp.com 2-9

Page 20

HP CCI Solution Technology

■ Online ROM Flash

Using the Smart Components for Remote ROM Flash with the

Remote Deployment Utility (RDU) console application, Remote

ROM Flash enables you to upgrade the firmware (BIOS) from a

remote location.

■ ProLiant BL e-Class C-GbE Interconnect Switch

The interconnect switch concentrates the forty 10/100 Ethernet

Blade PC network connections into four RJ-45 Gigabit Ethernet

uplink connectors. Each uplink can communicate with all 40

network connections; thus, only one to all four of these

connectors may be used providing up to a 40-to-1 reduction in the

number of network cables connected to the enclosure. The

interconnect switch is compatible with industry standards and is

fully pre-configured for immediate use.

For more information about these tools and utilities, see Chapter 5,

“Deployment and Management.”

Diagnostic Features

The hardware, software, and firmware diagnostic tools that are

available include:

■ ProLiant BL e-Class Integrated Administrator

■ Diagnostic adapter for local Blade PC access (requires optional

graphics diagnostic card)

■ Optional graphics diagnostic card

■ HP Systems Insight Manager

■ Power-On Self Test (POST)

■ Diagnostics Utility

■ ROMPaq

■ Health monitoring LEDs

2-10 www.hp.com Setup and Installation Guide

Page 21

Planning the Installation

Optimum Environment

For maximum performance and availability from your HP CCI

solution, be sure that your operating environment meets the required

specifications for the following:

■ Floor strength

■ Space

■ Power

■ Electrical grounding

■ Temperature

■ Airflow

3

For detailed information on these requirements, refer to the HP

ProLiant BL e-Class System Overview and Planning white paper on

the Documentation CD and at the HP website:

www.hp.com

Rack Warnings and Cautions

Before installing your rack, observe the following warnings and

cautions:

WARNING: To reduce the risk of personal injury or equipment damage,

Å

Setup and Installation Guide www.hp.com 3-1

be sure that:

• The rack is adequately stabilized before installing or removing a

component.

• Only one component is extended at a time.

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizers are attached to the rack for single-rack installation.

Page 22

Planning the Installation

Å

Å

Ä

WARNING: To reduce the risk of personal injury or equipment damage,

AT LEAST two people are needed to safely unload the rack from the pallet.

An empty 42U rack can weigh as much as 115 kg (253 lb), can stand

more than 2.1 m (7 ft) tall, and may become unstable when being moved

on its casters.

Never stand in front of the rack when it is rolling down the ramp from the

pallet; always handle the rack from both sides.

WARNING: When installing the enclosure in a Telco rack, be sure that

the rack frame is adequately secured to the top and bottom of the building

structure.

CAUTION: When using a Compaq branded 7000 Series rack, you must

install the high airflow rack door insert [P/N 327281-B21 (for 42U rack)

and P/N 157847-B21 (for 22U rack)] to provide proper front-to-back

airflow and cooling and to prevent damage to the equipment.

Ä

Ä

CAUTION: If an HP or third-party rack is used, observe the following

additional requirements to ensure adequate airflow and to prevent

damage to the equipment:

• Front and rear doors: If the 42U rack includes closing front and rear doors,

you must allow 5,350 sq cm (830 square inches) of holes evenly

distributed from top to bottom to permit adequate airflow (equivalent to the

required 64 percent open area for ventilation).

• Side: The clearance between the installed rack component and the side

panels of the rack must be a minimum of 7 cm (2.75 inches).

CAUTION: Always use blanking panels to fill all remaining empty front

panel U-spaces in the rack. This arrangement ensures proper airflow.

Using a rack without blanking panels results in improper cooling that can

lead to thermal damage.

3-2 www.hp.com Setup and Installation Guide

Page 23

Planning the Installation

ProLiant BL e-Class Blade Enclosure Warnings

and Cautions

Before installing the ProLiant BL e-Class blade enclosure, carefully

review the following warnings and cautions:

WARNING: To reduce the risk of personal injury or damage to

Å

Å

equipment, heed all warnings and cautions throughout the installation

instructions.

WARNING: A risk of injury or damage to the equipment from

hazardous energy is present. The access door provides access to

hazardous energy circuits. The door should remain locked during normal

operation or troubleshooting, or the system should be installed in a

controlled access location where only qualified personnel have access to

the system.

Å

Å

WARNING: To reduce the risk of electrical shock or damage to the

equipment:

• Only enter or perform service on specific parts of the HP CCI solution as

instructed in the user documentation.

• Do not disable the power cord grounding plugs. The grounding plugs are

an important safety feature.

• Plug both power cords into a grounded (earthed) electrical outlet that is

easily accessible at all times.

• Unplug the power cords from the power supplies to disconnect power to

the enclosure.

WARNING: To reduce the risk of personal injury from hot surfaces,

allow the internal system components to cool before touching them.

Setup and Installation Guide www.hp.com 3-3

Page 24

Planning the Installation

Å

Å

Ä

WARNING: The ProLiant BL e-Class blade enclosure is very heavy. To

reduce the risk of personal injury or damage to the equipment:

• Observe local occupational health and safety requirements and guidelines

for manual material handling.

• Remove Blade PCs and power supplies from the enclosures before

installing or removing the enclosures.

• Use caution and get help to lift and stabilize an enclosure during

installation or removal, especially when the enclosure is not fastened to the

rack. If the enclosure is being loaded into the rack above chest level, a

third person MUST assist with aligning the enclosure with the rails while the

other two people support the weight of the enclosure.

WARNING: The ProLiant BL e-Class blade enclosure has two power

cords for redundant AC power sources. If it is necessary to remove power

for servicing, disconnect all power by removing both power supply cords

from either the wall or the AC connectors on the rear of the enclosure.

CAUTION: When servicing non-hot-plug components, you must power

down the Blade PCs and/or the enclosure and Blade PCs. However, it

may be necessary to leave the Blade PCs powered up when performing

other operations, such as hot-plug replacement or troubleshooting.

CAUTION: Protect your equipment from power fluctuations and

Ä

Ä

Ä

3-4 www.hp.com Setup and Installation Guide

temporary interruptions with a regulating UPS device. This device protects

the hardware from damage caused by power surges and voltage spikes

and keeps the system in operation during a power failure.

CAUTION: Always be sure that equipment is properly grounded before

beginning any installation procedure. Electrostatic discharge resulting

from improper grounding can damage electronic components. For more

information, see Appendix B, “Electrostatic Discharge.”

CAUTION: Do not remove a power supply without a replacement ready

to install. A failed power supply must remain in the system for proper

airflow to prevent overheating while the system is operating.

Page 25

Preparing for Software Deployment

To prepare for software deployment, you must first set up Rapid

Deployment Pack or another deployment method. These deployment

methods are discussed in Chapter 5, “Deployment and Management.”

Rapid Deployment Pack

T o deploy your Blade PCs using Rapid Deplo yment Pack, be sure that

you have a DHCP server for IP address assignment, a deployment

server (can be the same system as the DHCP server), and the Rapid

Deployment CD included with your enclosure.

Alternate Deployment Method

If you are not using Rapid Deployment Pack, use your preferred

deployment infrastructure. Blade PCs have a PXE-enabled NIC (the

first NIC only) and support bootable USB CD-ROM and USB

diskette drives (attached via the diagnostic adapter).

Planning the Installation

Shipping Contents

IMPORTANT: All of the rack-mounting hardware necessary for installing

the ProLiant BL e-Class blade enclosure into an HP, Compaq branded, or

third-party rack is included with your enclosure. For Telco racks, a

separate option kit with Telco rack-mounting hardware is available.

For detailed information on deployment options and infrastructure,

refer to the HP ProLiant BL e-Class System Installation and Planning

white paper on the Documentation CD.

Setup and Installation Guide www.hp.com 3-5

Page 26

Planning the Installation

Blade Enclosure

The ProLiant BL e-Class blade enclosure ships with the following:

■ Two redundant hot-plug power supplies and power cords

■ Four redundant hot-plug fans

■ Blade PC blanks

■ ProLiant Essentials Foundation Pack for ProLiant BL Servers

■ Rack-mounting hardware for HP, Compaq branded, and

■ Null-modem cable

CAUTION: Always install either a Blade PC or a Blade PC blank in each

Ä

Blade PC bay to maintain proper airflow and cooling. Improper airflow

can lead to thermal damage.

third-party racks

CAUTION: Do not remove a power supply without a replacement ready

Ä

to install. A failed power supply must remain in the system for proper

airflow to prevent overheating while the system is operating.

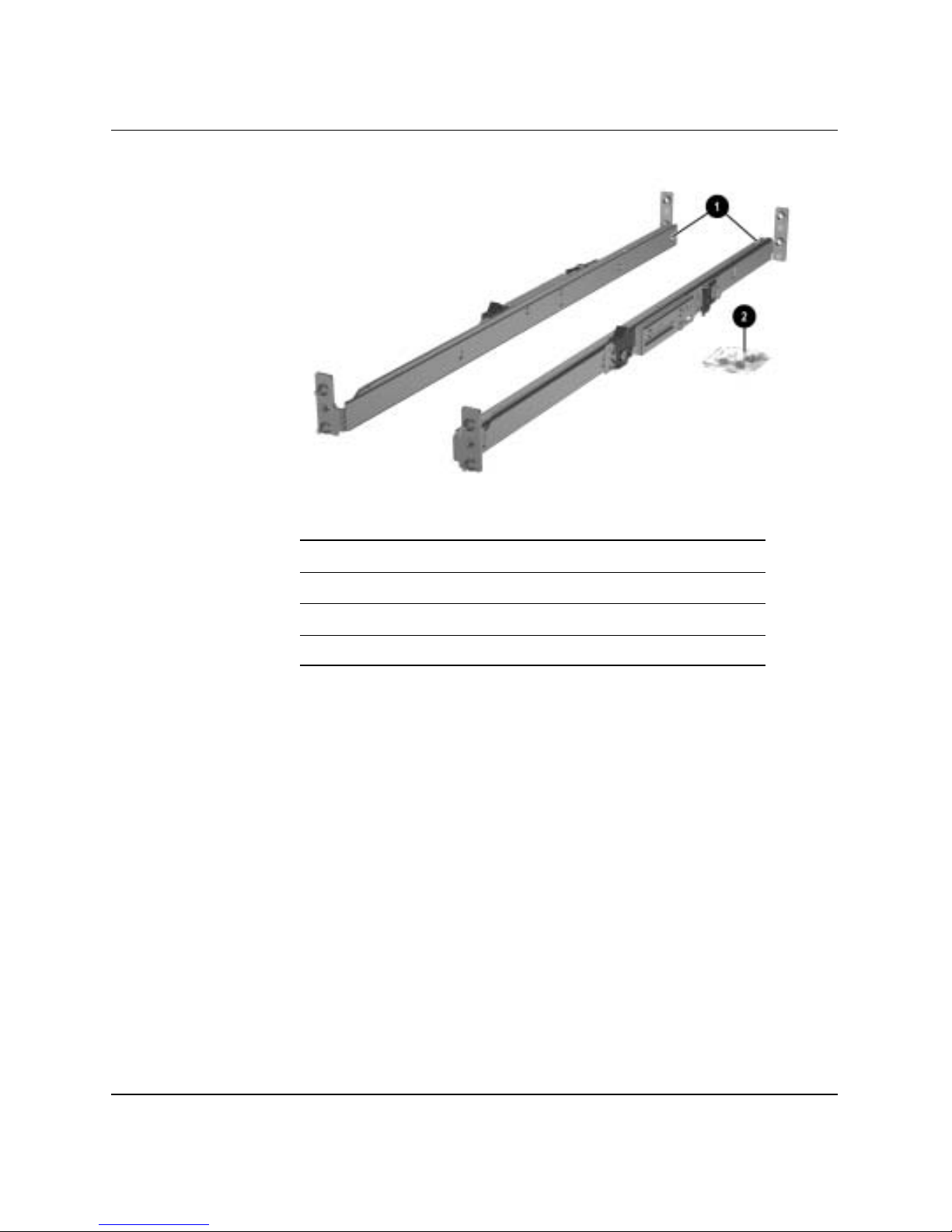

Rack-Mounting Hardware

The following figure and table show the standard rack-mounting

hardware (for HP, Compaq branded, and third-party racks) that ships

with the ProLiant BL e-Class blade enclosure.

CAUTION: Do not ship the blade PCs and enclosure while inside the

Ä

rack without first installing the e-Class Enclosure Shipping Bracket (part

number PH555A). Failure to use the shipping bracket may cause damage

to the blade PC and/or enclosure, thereby voiding the warranty. Refer to

the documentation in the option kit for more information.

IMPORTANT: All of the rack-mounting hardware necessary for installing

the ProLiant BL e-Class blade enclosure into an HP, Compaq branded, or

third-party rack is included with your enclosure. For Telco racks, a

separate option kit with Telco rack-mounting hardware is available.

3-6 www.hp.com Setup and Installation Guide

Page 27

Standard rack-mounting hardware

Item Description

Planning the Installation

Blade PCs

1

2

Not shown Enclosure rack template

Rack rails (2, left and right)

Bag of screws

Rack rails have the following features:

■ Adjustable depth of 61 cm to 91 cm (24 inches to 36 inches)

■ Depth indicator, visible in the middle of the rail

■ "L" and "R" markings to identify left and right rack rails (from

the front of the rack)

Blade PCs ship in packages of one or ten Blade PCs.

Setup and Installation Guide www.hp.com 3-7

Page 28

Planning the Installation

Interconnect Switch

The HP CCI solution supports an interconnect switch that slides into

the back of the enclosure as shown below.

Rear of enclosure with Interconnect switch installed

Optional RJ-45 Patch Panel

Rear of enclosure with RJ-45 patch panel installed

Optional Installation Service

You may choose to have HP install your HP CCI solution. This

method helps ensure top performance from the start and is especially

valuable for business-critical environments. Contact your HP account

representative to obtain more detailed information and pricing.

3-8 www.hp.com Setup and Installation Guide

Page 29

4

Installing and Cabling the HP CCI

Solution

This chapter contains the following procedures:

■ Installing the interconnect tray in the enclosure

■ Measuring with the rack template

■ Installing the rack rails

■ Installing the enclosure into the rack

■ Cabling the HP CCI solution

❏ Identifying interconnect tray connectors

❏ Cabling the enclosure

■ Powering up the HP CCI solution

■ Powering down the HP CCI solution

❏ Powering down a Blade PC

❏ Powering down the enclosure

■ Installing a Blade PC

■ Removing a Blade PC

■ Installing additional memory

■ Attaching the diagnostic adapter and optional graphics diagnostic

card

Setup and Installation Guide www.hp.com 4-1

Page 30

Installing and Cabling the HP CCI Solution

Installing the Interconnect Tray

Before installing the interconnect tray into the enclosure, you must

first purchase one as an option. The Integrated Administrator module

is included with the interconnect tray.

✎

✎

The procedure is the same for any interconnect tray.

To install the interconnect tray:

1. Press the purple-colored latch to release one hot-plug power

supply 1.

Purple color indicates hot-plug components.

2. Open the handle 2.

3. Slide the hot-plug power supply out of the enclosure 3.

Removing a hot-plug power supply

4. Repeat steps 1 through 3 to remove the other hot-plug power

4-2 www.hp.com Setup and Installation Guide

supply.

Page 31

Installing and Cabling the HP CCI Solution

5. Press the interconnect tray release buttons 1.

6. Pull the blue ejector levers toward the rear of the enclosure 2.

✎

Blue indicates internal touch point components.

Pulling the interconnect tray ejector levers

7. Insert the interconnect tray into the enclosure 1.

8. Rotate the interconnect tray levers to the locked position 2.

Inserting the interconnect tray and engaging the interconnect tray

levers (interconnect switch shown)

Setup and Installation Guide www.hp.com 4-3

Page 32

Installing and Cabling the HP CCI Solution

9. Install the hot-plug power supplies 1.

10. Close the power supply handles 2.

Installing a hot-plug power supply

4-4 www.hp.com Setup and Installation Guide

Page 33

Installing and Cabling the HP CCI Solution

Measuring with the Rack Template

Using the rack template, identify the proper holes for inserting the

tabs on the vertical rack supports. Use a pencil to mark the top and

bottom edges for the rack supports on the rack template, which

identify the position for the rails supporting the enclosure.

To use the rack template to identify the required space and location

for the enclosure:

1. Stand at the front of the rack and identify the front side of the rack

template.

2. Starting at the top of the last item installed, secure the rack

template against the front of the rack by sliding the two push tabs

into the holes in the rack supports.

WARNING: Racks must be adequately stabilized before and after

Å

product installation. If you are installing an enclosure into an empty rack,

you must install the enclosure at the bottom of the rack and work your

way up with additional enclosures as needed.

IMPORTANT: Match the hole pattern on the rack template with the

holes in the rack supports.

Measuring with the rack template

Setup and Installation Guide www.hp.com 4-5

Page 34

Installing and Cabling the HP CCI Solution

3. Align the rack template so that its sides are square with the sides

of the rack.

IMPORTANT: Tick marks on the rack supports help you to maintain

proper alignment of the rack template.

4. Use a pencil to mark an “M” at the locations on the rack where

the rack rails are to be inserted 1.

5. On the rack, mark the top and bottom edges of the rack template

to help align the rack template for the next enclosure 2.

Marking the rack for enclosure installation

6. Remove the rack template from the front of the rack and move to

the back of the rack.

7. Identify the back side of the rack template.

8. Repeat steps 2 through 5 for the back of the rack.

Store the rack template for future use.

✎

4-6 www.hp.com Setup and Installation Guide

Page 35

Installing the Rack Rails

1. Measure the depth of your rack.

2. Be sure that the rail locking gear is in the unlocked position 1.

3. Press the rail locking tab to unlock the rack rail 2.

4. Adjust the rack rail to the depth of the rack using the numbers on

the rack rail as a guide 3. The depth of a Compaq branded rack

(29 inches) is clearly indicated on the rack rails.

Installing and Cabling the HP CCI Solution

Unlocking and adjusting a rack rail

IMPORTANT: Numbers on the rack rail provide a gross adjustment of

the depth of the rack. The rack rail may need to be tightened to ensure

proper fit.

Setup and Installation Guide www.hp.com 4-7

Page 36

Installing and Cabling the HP CCI Solution

5. Insert the rear of the right rack rail into the rack at the marks you

made when measuring with the template.

✎

The rack rails feature “L” and “R” markings to identify the left and

right rack rails (from the front of the rack).

Inserting the rear of the rack rail

4-8 www.hp.com Setup and Installation Guide

Page 37

Installing and Cabling the HP CCI Solution

6. Compress the spring-loaded rack rail toward the rear of the

rack 1.

7. Using the marks you made when measuring with the template,

align the front of the right rail with the holes and release the rail,

allowing it to lock into position 2.

8. Engage the locking gear 3.

Inserting the front of the rack rail and engaging the locking gear

CAUTION: Rack rails must be installed as tightly as possible. Failure to

Ä

Setup and Installation Guide www.hp.com 4-9

obtain a correct fit may result in damage to equipment.

Once the right rack rail is properly installed, install the left rack rail

using the same procedure.

Page 38

Installing and Cabling the HP CCI Solution

Installing the Enclosure into the Rack

The enclosure ships with two different sizes of thumbscrews:

■ Size 10-32 thumbscrews with white hexagonal washers, which

are compatible with Compaq-branded racks and some HP and

third-party racks

■ Size M6 thumbscrews with black hexagonal washers, which are

compatible with some third-party racks that require metric sizes

To replace a thumbscrew:

1. Pull the thumbscrew outward 1.

2. Unscrew the thumbscrew 2 while holding on to the hexagonal

washer.

3. Remove the thumbscrew and hexagonal washer 3.

Removing a thumbscrew and hexagonal washer

4-10 www.hp.com Setup and Installation Guide

Page 39

Installing and Cabling the HP CCI Solution

4. Place the hexagonal washer at the back of the hole in the

enclosure 1.

5. Insert the screw through the hole in the enclosure.

6. Press the head of the screw inward so that the spring is

completely compressed 2.

7. Screw the hexagonal washer onto the shaft of the screw until it

passes all the threads and is secure within the thumbscrew

housing 3.

Replacing a thumbscrew, spring, and hexagonal washer

8. Repeat steps 1 through 7 for the other thumbscrew.

WARNING: Remove the two hot-plug power supplies before installing

Å

Å

Ä

Setup and Installation Guide www.hp.com 4-11

the enclosure into the rack to reduce weight.

WARNING: At least two people must lift the enclosure into the rack

together. If the enclosure is loaded into the rack above chest level, a third

person must assist with aligning the enclosure with the rails while the

other two people support the weight of the enclosure.

CAUTION: Do not remove the enclosure from the rack by the

thumbscrews. Use the handles located above the thumbscrews.

Page 40

Installing and Cabling the HP CCI Solution

To load the enclosure into the rack:

1. Install the interconnect tray. See the “Installing the Interconnect

Tray” section in this chapter.

2. Stand at the front of the rack.

3. Align the bottom of the enclosure with the top of the rack rails.

4. Slide the enclosure fully into the rack 1.

5. Tighten the thumbscrews to secure the enclosure in the rack 2.

Installing the enclosure into the rack

Cabling the HP CCI Solution

An HP CCI solution requires no internal cabling. External cabling is

achieved through the interconnect switch installed in your solution.

The procedure for cabling an enclosure consists of the following

steps:

■ Identifying the interconnect switch connectors

■ Cabling the blade enclosure

4-12 www.hp.com Setup and Installation Guide

Page 41

Installing and Cabling the HP CCI Solution

ProLiant BL e-Class C-GbE Interconnect Switch Connectors

The interconnect switch reduces forty 10/100 Ethernet networking

connections coming from the Blade PCs to four Gigabit Ethernet

uplink RJ-45 connectors.

✎

Item Description Location

Gigabit Ethernet port 26 connector on switch B Interconnect switch

1

Gigabit Ethernet port 25 connector on switch B Interconnect switch

2

Integrated Administrator management connector

3

(10/100 Ethernet)*

switch.

Interconnect switch connectors

Integrated Administrator module

An Integrated Administrator module is included with the interconnect

Integrated Administrator console connector (serial)* Integrated Administrator module

4

Enclosure link (RJ-45) connector—Reserved* Integrated Administrator module

5

Enclosure link (RJ-45) connector—Reserved* Integrated Administrator module

6

Gigabit Ethernet port 26 connector on switch A Interconnect switch

7

Gigabit Ethernet port 25 connector on switch A Interconnect switch

8

*These items denote connectors for the Integrated Administrator module.

✎

Setup and Installation Guide www.hp.com 4-13

Page 42

Installing and Cabling the HP CCI Solution

Optional RJ-45 Patch Panel

The RJ-45 patch panel functions as a fault tolerant Ethernet

pass-through for a 1 to 1 mapping between each NIC on each Blade

PC to one of the 40 RJ-45 ports on the back of this tray-mounted

patch panel.

Rear of enclosure with RJ-45 patch panel installed

Item Description Location

1 RJ-45 connector for Blade PC bay 20 NIC 1 RJ-45 patch panel

2 RJ-45 connector for Blade PC bay 20 NIC 2 RJ-45 patch panel

3 Integrated Administrator management connector (10/100

Ethernet)*

4 Integrated Administrator console connector (serial)* Integrated Administrator module

5 Enclosure link (RJ-45) connector (reserved)* Integrated Administrator module

6 Enclosure link (RJ-45) connector (reserved)* Integrated Administrator module

7 RJ-45 connector for Blade PC bay 1 NIC 1 RJ-45 patch panel

8 RJ-45 connector for Blade PC bay 1 NIC 2 RJ-45 patch panel

*These items denote connectors for the Integrated Administrator module.

✎

Integrated Administrator module

4-14 www.hp.com Setup and Installation Guide

Page 43

Cabling the Enclosure

CAUTION: Do not connect external devices to the enclosure link (RJ-45)

Ä

connectors unless the device is listed as a supported device on the

Quickspecs. Connecting an unsupported external device to the enclosure

link (RJ-45) connectors may damage your external device.

To cable a ProLiant BL e-Class blade enclosure already installed in a

rack:

1. For accessing and configuring the Integrated Administrator

locally, connect a client device (running VT-100 terminal

emulation software) to the Integrated Administrator console

connector using a null-modem cable (provided with your

enclosure). For accessing and configuring the Integrated

Administrator over your network, connect the Integrated

Administrator to your management network via the management

connector.

Installing and Cabling the HP CCI Solution

Ä

2. Connect the Blade PC network connectors to your network

❏ For the interconnect switch, be sure that at least one of the

uplink connectors is cabled. Any Blade PC NIC can be routed

to any of the uplink connectors. However, because only

NIC 1 is PXE-enabled by default on each Blade PC, it is

recommended that either port 25 or 26 of switch A be used

for PXE functions.

❏ For the RJ-45 patch panel, be sure that cables are connected

for each Blade PC you intend to install in the enclosure. Only

the NIC 1 RJ-45 connector for each blade PC provides

PXE-enabled connectivity by default.

3. Connect an AC power cord to each hot-plug power supply.

CAUTION: The enclosure will power up as soon as an AC power cord is

connected to a power source and a power supply.

Setup and Installation Guide www.hp.com 4-15

Page 44

Installing and Cabling the HP CCI Solution

4. Bundle network and power cables together and route them to the

outer edge of the rack.

Cabling the solution with the interconnect switch

Cabling the solution with the RJ-45 patch panel

IMPORTANT: Be sure to route the cables for your enclosure in a manner

that provides rapid, easy access to the console connector for a local

client device, such as a laptop computer.

4-16 www.hp.com Setup and Installation Guide

Page 45

Null-Modem Cable

If you are cabling a serial device such as a laptop computer to the

console connector on the Integrated Administrator, be sure that you

use the null-modem cable provided with the enclosure and not a

straight-through cable. Use the following table to determine the

specifications of this cable.

Cable Pinout for a Null-Modem Cable

Installing and Cabling the HP CCI Solution

5. Repeat steps 1 through 4 for each Blade PC enclosure you have

installed.

Signal Name EM PIN DB-9 PIN DB-25 PIN

TxD323

RxD232

RTS785

CTS874

GND557

DSR 6 4 20

CD 1 4 20

DTR 4 1 & 6 6 & 8

TxD323

Setup and Installation Guide www.hp.com 4-17

Page 46

Installing and Cabling the HP CCI Solution

Installing a Blade PC

CAUTION: Electrostatic discharge can damage electronic components.

Ä

Ä

Properly ground yourself before beginning any installation procedure.

See Appendix B, “Electrostatic Discharge,” for more information.

To install a Blade PC:

1. Determine your hardware configuration and deployment process.

See Chapter 5, “Deployment and Management.”

2. Install or upgrade memory before installing Blade PCs into an

enclosure. See the “Installing Additional Memory” section in this

chapter.

CAUTION: Always populate the Blade PC bays with either a Blade PC

or Blade PC blank. Proper airflow can only be maintained when the bays

are populated. Unpopulated bays can lead to improper cooling and

thermal damage.

3. Remove the Blade PC blank:

a. Press the ejector tabs on the Blade PC blank 1.

b. Slide the Blade PC blank out of the bay 2.

Removing a single-bay Blade PC blank

4-18 www.hp.com Setup and Installation Guide

Page 47

Installing and Cabling the HP CCI Solution

Removing a five-bay Blade PC blank

✎

Store the Blade PC blank for future use.

IMPORTANT: Before installing Blade PCs for the first time, define your

hardware configuration and deployment process. See Chapter 5,

“Deployment and Management.”

Setup and Installation Guide www.hp.com 4-19

Page 48

Installing and Cabling the HP CCI Solution

4. Install the Blade PC:

a. Align the Blade PC with the Blade PC bay on the enclosure

and slide the blade partially into the enclosure.

b. Press the release latch 1 on the blade.

c. Pull down the ejector lever 2.

Opening the blade eject lever

4-20 www.hp.com Setup and Installation Guide

Page 49

Ä

Installing and Cabling the HP CCI Solution

CAUTION: The Blade PC is keyed to fit only one way in the bay. If the

Blade PC does not slide easily into the bay, be sure that the Blade PC is

oriented properly.

d. Slide the Blade PC inward until the ejector lever engages the

enclosure 1.

e. Close the ejector lever until you hear an audible click that

indicates the Blade PC is properly seated 2.

Installing a Blade PC

IMPORTANT: Install a Blade PC for each of the blanks you have

removed.

5. Repeat steps 2 to 4 for each Blade PC you wish to install.

Setup and Installation Guide www.hp.com 4-21

Page 50

Installing and Cabling the HP CCI Solution

Powering Up the HP CCI Solution

As soon as you connect an AC po wer cord to a hot-plug po wer supply

on the rear panel, the enclosure powers up. All PC Blades installed in

the enclosure also power up one at a time in approximately

one-second intervals. Plug in the second power supply for

redundancy.

As soon as you remove a Blade PC blank and install a Blade PC into

the front panel of the enclosure, the Blade PC powers up.

Powering Down the HP CCI Solution

You can power down one or more Blade PCs or the entire enclosure.

Powering Down a Blade PC

To power down a Blade PC:

1. Be sure that the Blade PC is not active.

For specific information about Blade PC LEDs, see Appendix E,

“LEDs and Switches.”

2. If the Blade PC is active, notify users and stop applications as

necessary.

3. Shut down the operating system. This may shut off the Blade PC

power.

4. If the Blade PC still has power, power down the Blade PC by

either:

❏ Using the Integrated Administrator

or

❏ Pressing the power button on the front of the Blade PC

IMPORTANT: Refer to the HP ProLiant BL e-Class Integrated

Administrator User Guide to power down the Blade PC using the

Integrated Administrator.

4-22 www.hp.com Setup and Installation Guide

Page 51

Installing and Cabling the HP CCI Solution

Powering down the Blade PC

To perform an emergency shut down of a Blade PC, press and hold

the blade power button for four seconds.

CAUTION: Performing an emergency shutdown on a Blade PC may

Ä

result in the loss of any unsaved data.

Powering Down the Enclosure

To perform a graceful shutdown of the enclosure and all the Blade

PCs, press the enclosure power button. If your operating system is

Microsoft Windows XP, the enclosure automatically performs a

graceful shutdown of all Blade PCs, and then removes power from

the enclosure.

To perform an emergency shut down of the enclosure and all Blade

PCs at the same time, press and hold the enclosure power button for

four seconds.

CAUTION: Performing an emergency shutdown on the enclosure may

Ä

result in the loss of any unsaved data on all Blade PCs.

Setup and Installation Guide www.hp.com 4-23

Page 52

Installing and Cabling the HP CCI Solution

Removing a Blade PC

To remove a Blade PC:

1. Press the release latch 1.

2. Pull down the ejector lever 2.

3. Remove the Blade PC from the enclosure 3.

Removing a Blade PC

Installing Additional Memory

The Blade PCs support the following memory features:

■ Unregistered SODIMM DDR 333 memory

For more information, refer to QuickSpecs located on the HP

website:

■

512MB system memory expandable to 1GB (32MB of system

memory is reserved for processor usage)

■ Two SODIMM slots

4-24 www.hp.com Setup and Installation Guide

www.hp.com

Page 53

Installing and Cabling the HP CCI Solution

To install SODIMMs on a Blade PC:

1. Power down the Blade PC. See the “Po wering Do wn a Blade PC”

section in this chapter.

2. Remove the Blade PC from the enclosure. See the “Removing a

Blade PC” section in this chapter.

3. Place the Blade PC on a level, nonconductive surface.

4. Locate the SODIMM socket keys on the Blade PC:

❏ SODIMM socket 1 keys 1

❏ SODIMM socket 2 keys 2

IMPORTANT: SODIMMs are installed inverted from one another. If the

labels on SODIMM 1 are face-up, the labels on SODIMM 2 are probably

face-down.

SODIMM socket keys

Setup and Installation Guide www.hp.com 4-25

Page 54

Installing and Cabling the HP CCI Solution

IMPORTANT: Step 5 applies only when you wish to upgrade

SODIMMs.

5. Remove the existing SODIMM:

a. Release the latches on each side of the SODIMM slot 1 1.

b. Remove the SODIMM from the Blade PC 2.

Removing an SODIMM

4-26 www.hp.com Setup and Installation Guide

Page 55

Installing and Cabling the HP CCI Solution

6. Install SODIMM 1:

a. Match the notch on the SODIMM with the tab on the

SODIMM socket and insert the SODIMM into the socket at a

slight angle 1.

b. Press the SODIMM down towards the board, ensuring that it

is fully seated and the latches snap into place 2.

Installing an SODIMM

7. Repeat step 6 to install a second SODIMM into SODIMM slot 2.

Setup and Installation Guide www.hp.com 4-27

Page 56

Installing and Cabling the HP CCI Solution

Attaching the Graphics Diagnostic Card and

Diagnostic Adapter

Install the optional graphics diagnostic card on the Blade PC system

board to enable video.

Attach the diagnostic adapter to the diagnostic connector on the front

of the Blade PC in order to attach peripherals such as a keyboard,

video, mouse, USB diskette drive, or USB CD-ROM drive.

IMPORTANT: You can hot-add peripheral devices using the diagnostic

adapter if the devices support hot-plug capability. Because PS/2 devices

do not support hot-plug technology, restart the Blade PC after attaching

the diagnostic adapter. USB devices support hot-plug capability and do

not require restarting the Blade PC after attachment.

To install the graphics diagnostic card and diagnostic adapter:

1. Power down the Blade PC. See the “Po wering Do wn a Blade PC”

section in this chapter.

2. Remove the Blade PC. See the “Removing a Blade PC” section in

this chapter.

3. Lay the Blade PC down on a flat surface and install the optional

graphics diagnostic card into the sockets.

Installing the optional graphics diagnostic card

4-28 www.hp.com Setup and Installation Guide

Page 57

Installing and Cabling the HP CCI Solution

4. Install the blade in the enclosure. See the “Installing a Blade PC”

section in this chapter.

5. Insert the diagnostic adapter into the diagnostic connector on the

Blade PC 1.

6. Tighten the thumbscrews securing the diagnostic adapter in

place 2.

Attaching the diagnostic adapter

Setup and Installation Guide www.hp.com 4-29

Page 58

Installing and Cabling the HP CCI Solution

Use the following figure and table to identify connectors on the

diagnostic adapter .

Connectors on the diagnostic adapter

Item Description

1

2

3

4

5

6

PS/2 Mouse connector

USB 1.1 #2

Serial connector

PS/2 Keyboard connector

USB 1.1 #1

Video connector

4-30 www.hp.com Setup and Installation Guide

Page 59

5

Deployment and Management

This chapter provides the following information:

■ An overview of available methods for deploying software on

Blade PCs

❏ Automated deployment using Rapid Deployment Pack

❏ Alternate deployment methods

❏ Diagnostic adapter and optional graphics diagnostic card

■ A description of the configuration software and utilities

supported by the HP CCI solution

❏ Supported operating systems

❏ Computer Setup (F10) Utility

❏ ROMPaq Utility

❏ Remote ROM Flash

❏ ProLiant BL e-Class Integrated Administrator

❏ HP Systems Insight Manager

❏ ProLiant BL e-Class C-GbE Interconnect Switch

management tools and utilities

Setup and Installation Guide www.hp.com 5-1

Page 60

Deployment and Management

Blade PC Deployment Options

The Blade PCs are designed for rapid deployment and are ideally

suited for headless (unattended), network-based software installation

and configuration. Rapid Deployment Pack is the optimum choice for

Blade PCs and facilitates the configuration of a few or hundreds of

blades from an easy-to-use, remote-based graphical deployment

console. The PXE-enabled NIC (only the first NIC) and support for

bootable USB diskette and USB CD-ROM drives on the Blade PC

also facilitate the use of other deployment methods.

Automated Deployment Using Rapid Deployment Pack

Rapid Deployment Pack (RDP) integrates two powerful products:

Altiris Deployment Solution and the ProLiant Integration Module.

The RDP console’s graphical interface provides intuitive

drag-and-drop events, such as scripts and images, for deploying

operating systems and applications to multiple Blade PCs

simultaneously. Rapid Deployment Pack also has advanced features

that can detect and display Blade PCs based on their physical rack,

enclosure, and bay locations. You can set the deployment console to

automatically install pre-defined configurations on newly installed

Blade PCs.

For more information about Rapid Deployment Pack, refer to your

authorized reseller, the Rapid Deployment CD that ships with your

enclosure, or visit the following website:

www.hp.com/servers/rdp

Alternate Deployment Methods

Blade PCs have a PXE-enabled NIC (the first NIC only) and support

bootable USB diskette and CD-ROM drives, as well as a keyboard,

video, and a mouse attached via the diagnostic adapter. These

features enable you to use your own network-based or local, attended

deployment methods for booting and installing software onto Blade

PCs.

5-2 www.hp.com Setup and Installation Guide

Page 61

Deployment and Management

Diagnostic Adapter and Optional Graphics Diagnostic

Card

The diagnostic adapter and the optional graphics diagnostic card

enable local health monitoring and management by enabling you to

attach peripheral devices directly to a Blade PC. Using the diagnostic

adapter and optional graphics diagnostic card, you can:

■ View Blade PC event messages (See the “Blade PC Event

Messages” section in this chapter.)

■ Flash the Blade PC ROM (See the “Flashing the Blade PC R O M”

section in this chapter.)

■ View software information during deployment

For instructions on how to attach the diagnostic adapter and optional

graphics diagnostic card, see Chapter 4, “Installing and Cabling the

HP CCI Solution.”

IMPORTANT: You can hot-add peripheral devices using the diagnostic

adapter if the devices support hot-plug capability.

Setup and Installation Guide www.hp.com 5-3

Page 62

Deployment and Management

Blade PC Features and Supported Software

Configuring your Blade PC includes installing an operating system,

applications, and optimized drivers.

Rapid Deployment Pack enables you to auto-detect and configure

your hardware and to install optimized drivers.

Supported Operating Systems

Blade PCs support Microsoft Windows XP Professional SP1a or

later.

Computer Setup (F10) Utility

The Computer Setup (F10) Utility performs configuration activities

and enables you to view Blade PC configuration information. The

Blade PC comes pre-configured and does not require interaction with

Computer Setup, unless you would like to change the default settings.

The following table contains the Computer Setup menu options.

✎

To access the Computer Setup (F10) Utility, install the optional

graphics diagnostic card and the diagnostic adapter along with a

keyboard and monitor on the blade you want to access and press the

F10 key during boot.

For remote console users, you can access the Computer Setup (F10)

Utility through the Integrated Administrator. Reboot the blade

through the Integrated Administrator and press the

0 (zero) key. Refer to the HP ProLiant BL e-Class Integrated

the

Administrator User Guide for details.

The function keys in remote console are accessed by pressing Esc

then the numbers

by pressing Esc then ! and F12 is accessed by pressing Esc then @.

Blade PC configuration information can also be managed remotely

using System Software Manager (SSM). For more information, refer

to the following website:

1 through 0 for F1 through F10. F11 is accessed

www.hp.com/go/ssm

Esc key than press

5-4 www.hp.com Setup and Installation Guide

Page 63

Computer Setup (F10) Utility

Heading Option Description

File System Information Lists:

•Product name

• Processor type/speed/stepping

• Cache size (L1/L2)

• Installed memory size/speed

• Integrated MAC address for embedded,

enabled NIC 1

• Integrated MAC address for embedded,

enabled NIC 2

• System ROM (includes family name

and version)

• Chassis serial number

Deployment and Management

• Asset tracking number

• CMS (Transmeta Code Morphing

Software) revision

•Rack name

•Enclosure name

• Enclosure model

About Displays copyright notice.

Set Time and Date Allows you to set system time and date.

Save to Diskette Saves system configuration, including CMOS,

in file named CPQsetup.txt to a formatted

1.44-MB diskette or a USB Drive Key.

Restore from Diskette Restores system configuration from a diskette

or USB Drive Key.

Support for specific Computer Setup options may vary depending on the hardware

✎

configuration.

Setup and Installation Guide www.hp.com 5-5

Page 64

Deployment and Management

Computer Setup (F10) Utility (Continued)

Heading Option Description

File (continued) Set Defaults and Exit Restores factory default settings, which

includes clearing any established passwords.

Ignore Changes

and Exit

Save Changes and Exit Saves changes to system configuration and

Storage Device Configuration Lists all installed BIOS-controlled storage

Exits Computer Setup without applying or

saving any changes.

exits Computer Setup.

devices.

When a device is selected, detailed

information and options are displayed.

Transfer Mode (IDE devices only)

Specifies the active data transfer mode.

Options (subject to device capabilities)

are PIO 0, Max PIO, Enhanced DMA, Ultra

DMA 0, and Max UDMA.

Translation Mode (IDE disks only)

Lets you select the translation mode to be

used for the device. This enables the BIOS to

access disks partitioned and formatted on

other systems and may be necessary for

users of older versions of UNIX (e.g., SCO

UNIX version 3.2). Options are Bit-Shift,

LBA Assisted, User, and None.

Support for specific Computer Setup options may vary depending on the hardware

✎

configuration.

5-6 www.hp.com Setup and Installation Guide

CAUTION: Ordinarily, the translation

Ä

mode selected automatically by the BIOS

should not be changed. If the selected

translation mode is not compatible with

the translation mode that was active when

the disk was partitioned and formatted,

the data on the disk will be inaccessible.

Page 65

Computer Setup (F10) Utility (Continued)

Heading Option Description

Deployment and Management

Storage

(continued)

Device Configuration

(continued)

Storage Options Removable Media Boot

Translation Parameters (IDE disks only)

Allows you to specify the parameters (logical

cylinders, heads, and sectors per track) used

by the BIOS to translate disk I/O requests

(from the operating system or an application)

into terms the hard drive can accept. Logical

cylinders may not exceed 1024. The number

of heads may not exceed 256. The number of

sectors per track may not exceed 63. These

fields are only visible and changeable when

the drive translation mode is set to User.

Multisector Transfers (IDE disks only)

Specifies how many sectors are transferred

per multi-sector PIO operation. Options

(subject to device capabilities) are Disabled,

8, and 16.

Enables/disables ability to boot the system

from removable media.

Primary IDE Controller

Allows you to enable or disable the primary

IDE controller. This feature is supported on

select models only.