hp 9085mfp

System

administrator

guide

Copyright and License

© 2003 Copyright Hewlett-Packard Development Company, L.P.

Reproduction, adaptation, or translation without prior written permission

is prohibited, except as allowed under the copyright laws.

The information contained herein is subject to change without notice.

The only warranties for HP products and services are set forth in the

express warranty statements accompanying such products and services.

Nothing herein should be construed as constituting an additional

warranty. HP shall not be liable for technical or editorial errors or

omissions contained herein.

Part number: Q3218-90901

Edition 1: 10/ 2003

FCC Regulations

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC rules. These limits

are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses,

and can radiate radio frequency energy. If this equipment is not installed

and used in accordance with the instructions, it may cause harmful

interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or

more of the following measures:

Reorient or relocate the receiving antenna. Increase separation between

equipment and receiver.

Connect equipment to an outlet on a circuit different from that to which

the receiver is located.

Consult your dealer or an experienced radio/TV technician.

Any changes or modifications to the printer that are not expressly

approved by HP could void the user's authority to operate this

equipment. Use of a shielded interface cable is required to comply with

the Class A limits of Part 15 of FCC rules. For more regulatory

information, see the hp 9085mfp user's guide. Hewlett-Packard shall not

be liable for any direct, indirect, incidental, consequential, or other

damage alleged in connection with the furnishing or use of this

information.

Trademark Credits

PostScript® is a trademark of Adobe Systems Incorporated.

Windows® is a U.S. registered trademark of Microsoft Corporation.

Thank you very much for your purchase of the hp 9085mfp.

This Manual deals with making copies, correct handling of the machine, and

precautions for safety. Please read before copying.

In order to maintain a satisfactory copying performance, please keep this

Manual readily available for reference in the rear pocket of the machine.

ENERGY STAR

The ENERGY STAR Program has been established

to encourage the widespread and voluntary use of

energy-efficient technologies that reduce energy

consumption and prevent pollution. As an ENERGY

®

Program

STA R Partner, Hewlett-Packard Corporation, Inc. has

determined that this product meets the

ENERGY

STA R guidelines for energy efficiency grounding it on

the following features.

Auto Low Power

This function conserves energy by lowering the set temperature of the fixing

unit. In the standard setting, Auto Low Power operates automatically when 15

minutes have elapsed after completion of the last copy, with the mfp remaining

in the ready to copy state during that time.

The time period for the Auto Low Power function can be set for 5 minutes, 10

minutes, 15 minutes, 30 minutes, 60 minutes, 90 minutes, 120 minutes, or 240

minutes. See p. 2-20 for details.

Automatic Shut-Off

This function achieves further energy conservation by partially turning OFF the

power supply, thereby reducing energy consumption to 20W or less. In the

standard setting, Automatic Shut-Off follows Auto Low Power, operating

automatically when 90 minutes have elapsed after completion of the last copy,

with the mfp remaining in the ready to copy state during that time.

The time period for the Automatic Shut-Off function can be set for 30 minutes,

60 minutes, 90 minutes, 120 minutes or 240 minutes. See p. 2-20 for details.

Automatic Duplex Copying

To reduce paper consumption, use this function to make double-sided (duplex)

copies, automatically.

We recommend that you utilize the Auto Low Power function, the Automatic

Shut-Off function, and the Automatic Duplex Copying function.

blank page

Contents

Contents

Features of the hp 9085mfp.

Basic

1

Safety

Section 1: Safety Information

Information

Caution Labels and Indicators ............................................................................1-2

Requirements for Safe Use.................................................................................1-6

Power Source ..........................................................................................................1-6

Environment.............................................................................................................1-7

Precautions for Routine Handling ..........................................................................1-10

2

Machine

Section 2: Machine Information

Information

Machine Configuration ........................................................................................ 2-2

External Machine Items ...........................................................................................2-2

Internal Machine Items.............................................................................................2-4

Standard/Optional Equipment..................................................................................2-5

Q3219A/Q3220A Finishers.......................................................................................2-6

Q3221A Post Insertion Unit......................................................................................2-

Q3637A/Q3638A Tray 4 /HCI...................................................................................2-9

Q3224A Trimmer Unit ............................................................................................2-10

Q3222A/Q5684A Hole Punching Unit ....................................................................2-12

Q322·3A/Q5685A Hole Punching/Z-Folding Unit....................................................2-13

Basic Screen..........................................................................................................2-14

Control Panel Layout .............................................................................................2-16

Turning On the Power Switch ........................................................................... 2-17

To Turn On the Power............................................................................................2-17

To Turn Off the Power ............................................................................................2-19

Reducing the Power in Standby Mode (Auto Low Power) .....................................2-20

Shutting Off Automatically (Auto Shut-Off) ............................................................2-20

Shutting Off / Reducing the Power Manually .........................................................2-21

Entering an ECM Password (ECM)........................................................................2-22

Loading Paper...................................................................................................2-23

Loading Paper in Tray 1, 2, and 3..........................................................................2-23

Loading Paper in HCI (Q3637A/Q3638A)...............................................................2-25

Loading Paper in Multi-Sheet Bypass Tray............................................................2-27

Loading Tabbed Sheets in Tray 1, 2, or 3 ..............................................................2-28

Loading Tabbed Sheets in HCI (Q3637A/Q3638A)................................................2-29

Loading Tabbed Sheets in Multi-Sheet Bypass Tray .............................................2-30

8

1

Safety

Information

2

Machine

Information

3

Copying

Operations

4

Job Memory

&Help Mode

5

Trouble-

shooting

6

Machine

Specifications

7

Advanced

Information

8

Special

Original

9

Applications

10

Image Store

Function

11

Paper &

Original Info

12

Maintenance

13

Key Operator

i

& Supplies

Mode

Contents (continued)

3

Copying

Section 3: Copying Operations

Operations

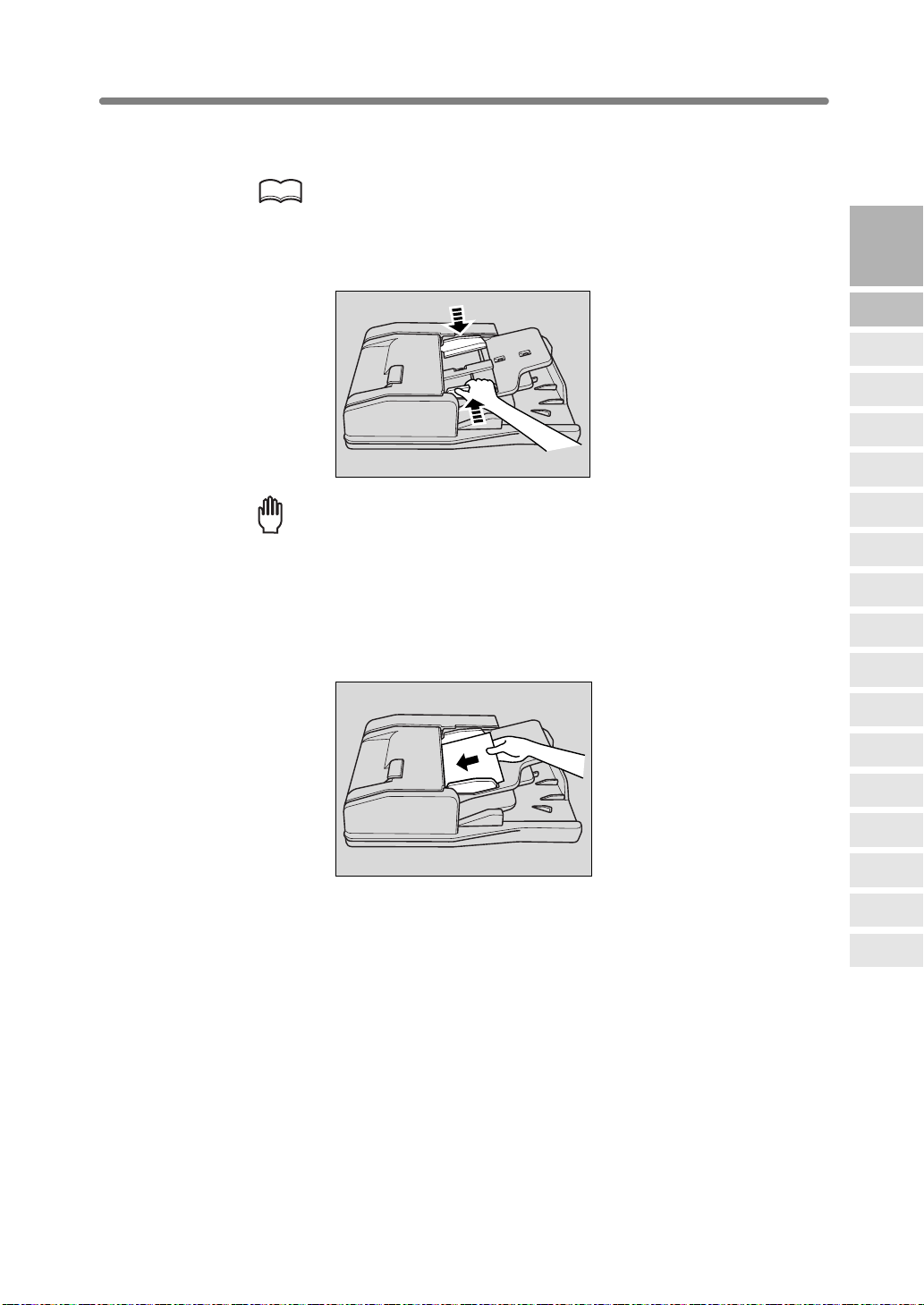

Positioning Originals ........................................................................................... 3-2

Positioning Originals in RADF..................................................................................3-2

Positioning Original on Platen Glass........................................................................3-6

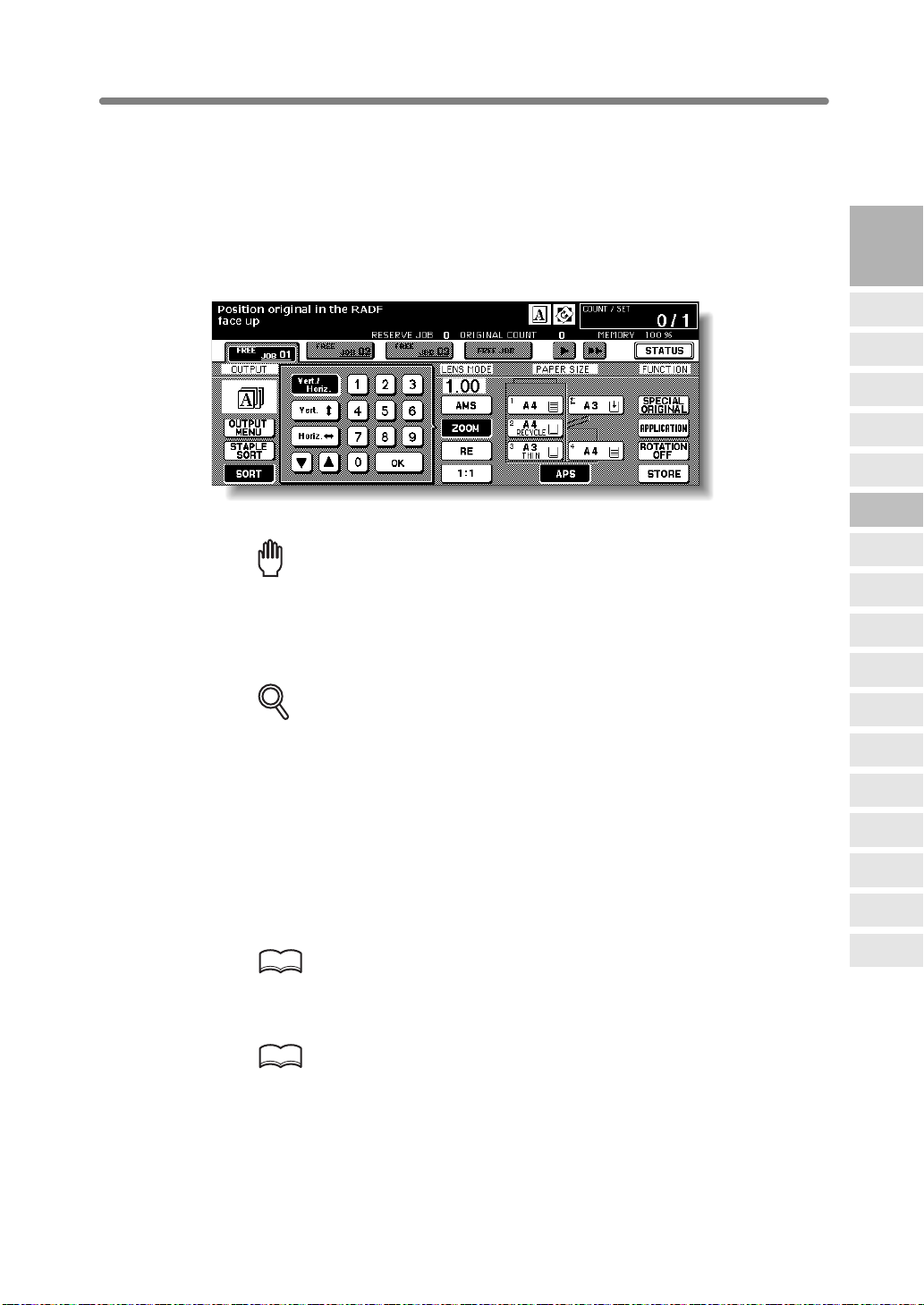

Setting Print Quantity .......................................................................................... 3-7

To Set Print Quantity ................................................................................................3-7

To Change Print Quantity.........................................................................................3-7

Setting Job During Warm-up...............................................................................3-8

To Stop Scanning/Printing.................................................................................3-10

Selecting Paper Size.........................................................................................3-11

To Select Paper Size Automatically (APS).............................................................3-11

To Specify Desired Paper Size (AMS) ...................................................................3-13

Selecting Magnification Ratio (Lens Mode) ......................................................3-15

To Copy in 1.00 Magnification Mode ......................................................................3-15

To Copy in Fixed Magnification Mode (RE)............................................................3-16

To Copy in Zoom Mode..........................................................................................3-17

Selecting Density Level.....................................................................................3-18

To Select Copy Density..........................................................................................3-18

Density Shift...........................................................................................................3-20

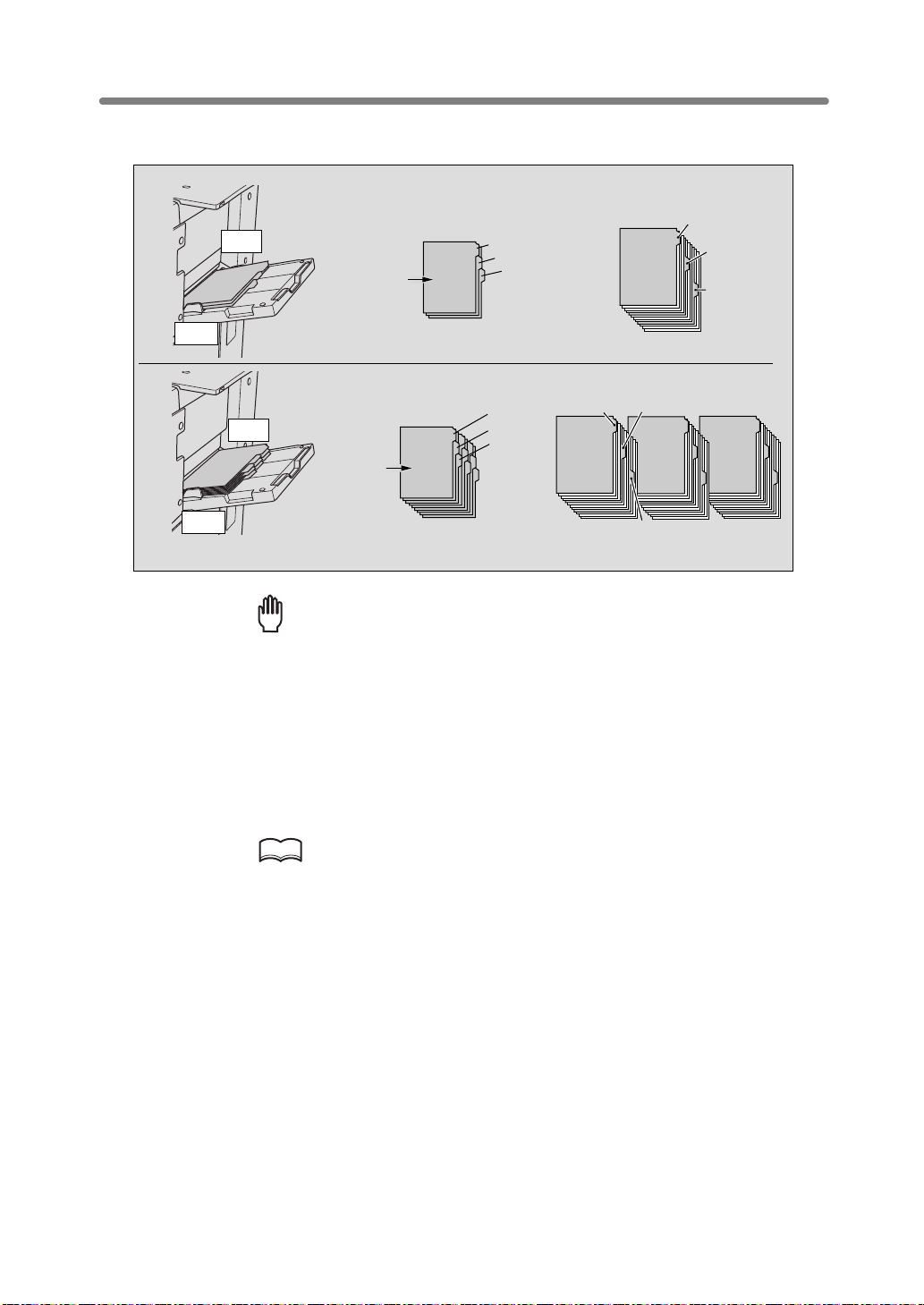

Making Double-Sided Copies (1u2, 2u2) ........................................................ 3-21

Using RADF ...........................................................................................................3-21

Using Platen Glass ................................................................................................3-24

Making Single-Sided Copies from Double-Sided Originals (2u1) .................... 3-27

Copying Using Special Paper (Multi-Sheet Bypass Tray).................................3-29

Copying Using Memory..................................................................................... 3-32

To Scan Originals into Memory (Store Mode)........................................................3-32

To Set Next Copying Job (Reserve).......................................................................3-34

To Check/Control Jobs in Progress (Job Status Screen).......................................3-37

Output Mode for Machine without Finisher ....................................................... 3-40

Output Mode for Machine with Finisher ............................................................ 3-43

Selecting Binding Mode .................................................................................... 3-48

Recalling Previous Job Settings ....................................................................... 3-49

Checking Feature Selections and Proof Copying .............................................3-50

Interrupt Copying ..............................................................................................3-53

4

Job Memory

Section 4: Job Memory & Help Mode

&Help Mode

Storing Job Conditions (Job Memory: Job Store) ...............................................4-2

Recalling Stored Job Settings (Job Memory: Job Recall)...................................4-5

Displaying Screen for Operation Guide (Help Mode)..........................................4-6

To Display Help Screen from Basic Screen .............................................................4-6

To Display Help Screen from Other Screens ...........................................................4-8

ii

Contents (continued)

1

Safety

Information

5

Trouble-

shooting

Section 5: Troubleshooting

When “Call for Service” Message Is Displayed...................................................5-2

Limited Use of the mfp in Trouble ...........................................................................5-3

Preventive Maintenance .....................................................................................5-4

To Check the PM Counter........................................................................................5-4

Clearing Mishandled Paper.................................................................................5-6

When “JAM” Appears on Folder Key (Or Arrow Key Flashes)............................5-8

When “ADD PAPER” Appears on Folder Key (Or Arrow Key Flashes) ............5-10

When “Memory Full” Message Is Displayed (Memory Overflow)....................... 5-11

Memory Overflow in Current Job ............................................................................5-11

Memory Overflow in Reserve Job..........................................................................5-12

When Power OFF/ON Screen Is Displayed......................................................5-13

Troubleshooting Tips.........................................................................................5-14

6

Machine

Section 6: Machine Specifications

Specifications

Engine Specifications.......................................................................................... 6-2

Engine......................................................................................................................6-2

Option Specifications .......................................................................................... 6-3

RADF (Q5682A)...................................................................................................... 6-3

Q3219A/Q3220A In-Bin Stapler Finisher .................................................................6-3

Q3221A Cover Sheet Feeder ...................................................................................6-3

Q3224A Trimmer Unit ..............................................................................................6-3

Q3222A/Q5684A Punching Unit ..............................................................................6-4

Q3223A/Q5685A Punching/Z-Folding Unit...............................................................6-4

Q3637A Tray 4 /HCI.................................................................................................6-4

Q3638A Tray 4 /HCI.................................................................................................6-4

Memory Unit.............................................................................................................6-5

Others ......................................................................................................................6-5

2

Machine

Information

3

Copying

Operations

4

Job Memory

&Help Mode

5

Trouble-

shooting

6

Machine

Specifications

7

Advanced

Information

8

Special

Original

9

Applications

iii

10

Image Store

Function

11

Paper &

Original Info

12

Maintenance

& Supplies

13

Key Operator

Mode

Contents (continued)

Advanced

7

Advanced

Section 7: Advanced Information

Information

Programmed Shut-Off (Weekly Timer)................................................................ 7-2

Rotation...............................................................................................................7-4

Vertical/Horizontal Zoom Mode........................................................................... 7-5

Making Folded Booklet (Fold / Stitch&Fold)........................................................7-8

Punching File Holes in Copies (Punch) ............................................................ 7-11

Output Z-Folded Copies (Z-Fold)......................................................................7-14

Making Trimmed Booklet (Trimming) ................................................................ 7-16

Cover Sheet Feeding........................................................................................7-19

Using Finisher Manually....................................................................................7-22

Using Two mfps in Tandem ...............................................................................7-25

To Stop Scanning/Printing......................................................................................7-28

Troubleshooting .....................................................................................................7-29

8

Special

Section 8: Special Original

Original

Specifying Original Direction...............................................................................8-2

Making Copy Quality Closer to Originals (Text/Photo Enhance).........................8-4

Copying Mixed Size Originals (Mixed Original)................................................... 8-6

Copying Z-Folded Originals (Z-Folded Original) .................................................8-8

Feeding Single Original from RADF (SDF).......................................................8-10

Copying Non-Standard Size Originals (Original Form) .....................................8-12

9

Applications

Section 9: Applications

To Display Application Selection Screen.............................................................9-2

Inserting Sheets and Covers (Sheet/Cover Insertion) ........................................9-3

Locating Title Pages on the Right Side (Chapter)...............................................9-7

Lay Out Several Pages onto One Sheet (Combination) ...................................9-10

Making a Multiple Page Signature Booklet (Booklet)........................................9-13

Copying onto Transparent Films (OHP Interleave) ...........................................9-16

Inserting Images into Printed Sets (Image Insert).............................................9-18

Dividing an Image into Right and Left Pages (Dual Page)................................9-21

Programming Different Settings for an Output Job (Program Job) ...................9-25

Erasing Outside of the Original (Non-Image Area Erase).................................9-27

Reversing Colour in Black and White Image (Reverse Image).........................9-29

Repeating Selected Image Area (Repeat: Vert./Horiz. Mode) ..........................9-31

Repeating Automatically or Selecting Repeating Times

(Repeat: AUTO/ Repeat Mode)...............9-34

iv

Section 9: Applications (continued)

Contents (continued)

1

Safety

Information

Eliminating Black Copy Marks Along Borders (Frame/Fold Erasure) ...............9-37

Copying Image in the Centre of Copy Paper (AUTO Layout)...........................9-40

Printing Images Fully to the Edges (Full-Image Area)......................................9-42

Adjusting Position of Copy Image (Image Shift) ...............................................9-44

Reducing Images to Create Binding Margin (Reduce&Shift)............................9-47

Printing Stamp, Page, Date/Time onto Copies (Stamp)....................................9-50

Printing Watermark onto Copies (Stamp) .........................................................9-56

Overlaying an Image onto Each Page Copied in the Job (Overlay) .................9-59

Storing an Overlay Image in HDD /

Overlaying Image Stored in HDD (Overlay Memory) ..........9-61

10

Image Store

Section 10: Image Store Function

Function

To Use Server Functions...................................................................................10-2

Storing/Deleting Image Data in HDD (Image Store/Delete)..............................10-4

To Store Image Data in HDD .................................................................................10-4

To Delete Image Data from HDD ...........................................................................10-8

Storing Image Data While Copying (Image Store & Output)...........................10-11

Recalling Image Data from HDD (Image Recall) ............................................10-14

2

Machine

Information

3

Copying

Operations

4

Job Memory

&Help Mode

5

Trouble-

shooting

6

Machine

Specifications

7

Advanced

Information

11

Paper &

Section 11: Paper and Original Information

Original Info

Paper Information .............................................................................................11-2

Paper Weight ......................................................................................................... 11-2

Tray/ Exit Tray Capacity.........................................................................................11-3

Paper Size ............................................................................................................. 11-5

Special Paper in Multi-Sheet Bypass Tray.............................................................11-7

To Store Copy Paper..............................................................................................11-7

Original Information........................................................................................... 11-8

Platen Glass Originals ...........................................................................................11-8

RADF Originals ......................................................................................................11-9

8

Special

Original

9

Applications

10

Image Store

Function

11

Paper &

Original Info

12

Maintenance

& Supplies

13

Key Operator

Mode

v

Contents (continued)

12

Maintenance

Section 12: Maintenance & Supplies

& Supplies

Adding Toner.....................................................................................................12-2

Inserting a New Staple Cartridge into Q3219A/Q3220A Finisher .....................12-5

Empty Waste Basket of Q3222A/Q5684A/Q3223A/Q5685A

Hole Punching Z - Folding Unit .................................................................12-9

Empty Waste Basket of Q3224A Trimmer Unit ...............................................12-11

Cleaning Image Scanning Section.................................................................. 12-13

Cleaning the Document Glass .............................................................................12-13

Cleaning the Left Partition Glass .........................................................................12-13

Cleaning the RADF Platen Guide Cover..............................................................12-14

Checking Copy Count ..................................................................................... 12-15

To Display the Counter List Screen......................................................................12-15

To Print the Counter List ......................................................................................12-16

13

Key Operator

Section 13: Key Operator Mode

Mode

How to Access the Key Operator Mode ............................................................13-2

To Display the Key Operator Mode Screen............................................................13-2

[1] System Initial Setting ...................................................................................13-4

[1] Date & Time Setting ..........................................................................................13-4

[2] Language Select Setting...................................................................................13-6

[3] IP Address Setting ............................................................................................13-7

[4] E-Mail Transmission Setting .............................................................................13-7

[2] mfp Initial Setting.........................................................................................13-8

[3] User Setting Mode .....................................................................................13-10

[1] User Density Level 1 Setting...........................................................................13-10

[2] User Density Level 2 Setting...........................................................................13-11

[3] User Lens Mode Ratio Setting........................................................................13-12

[4] E.C.M. (Electronic Key Counter) Function Setting .................................... 13-13

How to Access the ECM Setting Mode................................................................13-14

[1] E.C.M. Data Edit .............................................................................................13-15

[2] E.C.M. All Count Reset...................................................................................13-18

[3] E.C.M. Function Setting..................................................................................13-19

[5] Lock/Delete Job Memory ........................................................................... 13-20

[6] Paper Type / Special Size Set ...................................................................13-21

[7] Panel Contrast / Key Sound Adjustment....................................................13-23

[8] Key Operator Data Setting .........................................................................13-24

[9] Weekly Timer .............................................................................................13-25

How to Access the Weekly Timer Setting Mode ..................................................13-26

[1] Weekly Timer On/Off Setting ..........................................................................13-27

[2] Timer Setting...................................................................................................13-28

[3] Timer Action On/Off Setting ............................................................................13-30

[4] Lunch Hour Off Setting ...................................................................................13-32

[5] Timer Interrupt Password Setting ...................................................................13-33

[10] Control Panel Adjustment ........................................................................13-34

[11] Tray Auto Select Setting........................................................................... 13-35

[12] Power Save Setting .................................................................................13-36

[13] Memory Switch Setting ............................................................................ 13-37

vi

Section 13: Key Operator Mode (continued)

Contents (continued)

1

Safety

Information

[14] Machine Management List Print ..............................................................13-43

[15] Call Remote Centre .................................................................................13-44

[16] Side 2 Lens Adjustment...........................................................................13-45

[17] Finisher Adjustment ................................................................................. 13-46

[18] HDD Management Setting.......................................................................13-48

[19] Scan Transmission Setting ...................................................................... 13-50

[20] Non-Image Area Erase Setting ................................................................ 13-52

[21] Timing Adjustment ................................................................................... 13-53

[22] Centering Adjustment ..............................................................................13-55

Index

2

Machine

Information

3

Copying

Operations

4

Job Memory

&Help Mode

5

Trouble-

shooting

6

Machine

Specifications

7

Advanced

Information

8

Special

Original

9

Applications

10

Image Store

Function

11

Paper &

Original Info

12

Maintenance

& Supplies

13

Key Operator

Mode

vii

Features of the hp 9085mfp

• AE - Automatic Exposure

Automatically adjusts exposure to compensate for quality of the original.

• AMS - Automatic Magnification Selection

Automatically selects an appropriate magnification ratio when Paper Size is selected

manually. Automatically selected when the AMS key is touched.

• APS - Automatic Paper Selection

Automatically selects copy paper size to match the original documents.

• ATS - Automatic Tray Switching

Automatically switches tray to allow copying to continue without interruption if the

selected tray empties while copying is in progress.

• Auto Layout

The original image on the platen glass or in the document feeder is copied and centred

on a sheet.

• Auto Low Power

Automatically lowers the power after a specified period of mfp inactivity.

• Auto Reset

Automatically resets to auto mode defaults after a specified period of mfp inactivity.

• Auto Shut-Off

Automatically shuts off the main power after a specified period of mfp inactivity.

• Booklet

Creates a multiple page signature booklet copied on both sides of paper in 1u2 or 2u2

copy mode.

• Chapter

Starts chapter pages on the right side (front pages) of the finished document. Only

duplex mode (1u2) is compatible with this feature.

• Combination

Copies a fixed number (2, 4, or 8) of pages onto one sheet of copy paper to create a

draft copy of a multi-page report at the same time as saving paper.

• Copy Density

Manually selects up to 9 density levels.

• Copy Mode

Selects the desired simplex mode (1u1 or 2u1); or duplex mode (1u2 or 2u2).

• Counter List

Displays on the screen and prints the following data: total counter of the machine,

mfp counter, print counter and the date when the counter started.

• Density Shift

Shifts each of nine density levels in four density modes (Auto, Text, Photo, Increase

Contrast) to three levels lighter or three levels darker.

viii

Features of the hp 9085mfp (continued)

• Dual Page

Copies both pages of an open book or A3/B4 size sheet separately onto two A4/B5 size

sheets in 1u1 mode or separately onto each side of one A4/B5 size sheet in 1u2

mode. You can use the Dual Page mode with the Front or Front/Back cover mode. The

cover page(s) will be scanned and copied normally before image division is performed

on the other pages.

• Frame/Fold Erasure

Erases border and/or fold image area using Frame (1 - 300mm), Fold (1 - 99mm), or

Frame & Fold.

• Full-Image Area

Makes copies printed completely to the edges of the paper to avoid image loss.

• Image Insert

Stores pages in memory from the platen glass, and inserts the pages into a document

copied from the document feeder.

• Image Shift

Creates or removes a binding margin at the top, bottom, right and left edges (shift

amount from 0 ~ 250mm, in 1mm increments); reduces image to prevent image loss

(reduce & shift amount from 0 ~ 250mm, in 1mm increments).

• Interrupt Copying

Interrupts copying-in-progress to perform an urgent copy, using any of the mfp

features for the interrupt job.

• Job Memory

Programs up to 30 jobs and recalls each job by job number, as needed. All compatible

platen glass functions can be programmed into Job Memory directly after they are

selected.

• Job Status

Displays the Job Status Screen to view the current machine status, changes the operation order of reserve jobs, deletes the unused reserve job, or displays the previous job

list.

• Lens Mode (RE, Zoom)

Selects fixed ratios, four reduction, four enlargement, and three user-set ratios.

Zoom ratios can be selected from 25% ~ 400% in 1% increments.

• Machine Status Confirmation

Displays the current machine status on LCD for confirmation.

• Manual Shut-off

Shuts off the machine’s power when pressing [SLEEP ON/OFF] on the control

panel.

• Mixed Original

Copies mixed size originals from the document feeder in APS or AMS mode. APS

automatically selects the paper size of each original. AMS mode allows you to select

one paper size for all originals.

ix

Features of the hp 9085mfp (continued)

•

Image Store Function

Store the scanned image data to the HDD.

• Non-Image Area Erase

When copying from the platen glass when the document cover is open, copies only the

image area and not the exposed area of glass, which would otherwise copy as black.

• Non STD Size for Multi-Sheet Bypass Tray

Enters the special paper size to be loaded on the Multi-sheet bypass tray using the

touch screen keypad in order to avoid paper misfeed.

• Non STD Size for Original

Identifies the special original size which the hp 9085mfp cannot detect, in order to

select theoptimal paper size for copying or printing.

• OHP Interleave

Copies onto transparent film and interleave blank or copied paper for each original

copied.

•

Output Mode for Machine with Q3219A/Q3220A Finisher Installed:

Non-Sort, Sort, Staple-Sort, and Group modes using the primary (main) tray

Non-Sort Face Down exit, Non-Sort Face Up exit, Group Face Down exit, and Group

Face Up exit modes using the secondary (sub) tray

Fold and Stitch & Fold modes using the booklet tray (Q3220A only)

Selects an output tray and output mode on the Output Mode popup menu.

• Output for Machine with no Finisher Installed:

Non-sort, Rotation sort, Group, and Rotation group modes are available in combination with Face down or Face up exit.

Selects an output mode on the Output Mode popup menu.

•

Output for Q3219A/Q3220A Finisher with Q3221A Cover Sheet Feeder Installed:

Cover Sheet mode

Manual Finishing mode

For details, see Section 7: Advanced Information.

• Overlay

Scans an original image and overlays it on the pages of another document. For

example, you may want to incorporate a page heading, graphic design or logo into the

pages of your document.

• Overlay Memory

Same as for “Overlay” except the overlay image is stored in memory.

x

Features of the hp 9085mfp (continued)

•

Paper Capacity

Total 2,150 sheets, including two 500-sheet trays, a 1,000 sheet tray, and a 150-sheet

Multi-sheet bypass tray. By adding an optional HCI, the system total capacity increases

to 6,150 sheets.

• Platen Memory

Scans documents into memory from the platen glass and/or the document feeder and

inserts the pages into another document copied from the document feeder. If an

incompatible function is selected in this mode, the latter function will not be selected,

and an Error message will be displayed.

•

Sleep

Automatically turns off all but nominal power supply after a specified period of mfp

inactivity, for optimal efficiency. Power is returned after a brief warm up period by

pressing [SLEEP ON/OFF] on the control panel.

• Program Job

Scans documents into memory while designating different copy conditions for each

original, then prints all the documents collectively.

• Proof Copy

To ensure correct output before running multiple copies, run a proof copy by pressing

[PROOF COPY] on the control panel or touching PROOF COPY on the Check Screen.

•

Punch Mode for Q3219A/Q3220A Finisher with Q3222A/Q5684A Punching

Unit (Q3223A/Q5685A Punching/Z-Folding Unit) Installed:

Punches four holes in output copies.

• Repeat

Selects the horizontal image area across the page, and repeats it down the page as

many times as the repeat width setting (10 ~ 150mm) permits in manual or auto.

• Reserve

Scans in subsequent copy jobs while the hp 9085mfp is busy printing or

copying.

• Reverse Image

Reverses the image from black-on-white to white-on-black or vice versa.

•Rotation

Rotates the image before copying when the portrait/landscape orientation of the original is different from the orientation of the copy paper.

• Rotation Exit (Rotation Sort / Rotation Group)

When no Finisher is installed, Rotation Exit alternately switches the horizontal and

vertical orientation of each sorted set as it outputs to the exit tray. Be sure to load both

A4 and A4R in separate trays (including the Multi-sheet bypass tray) before selecting

this feature.

• Server Function (option)

Stores image data in the HDD for future printing.

xi

Features of the hp 9085mfp (continued)

• Sheet/Cover Insertion

Insert up to 30 blank or copied sheets from any tray including the Multi-sheet bypass

tray, or inserts blank or copied front and back covers from any tray including the Multisheet bypass tray to enhance the presentation of multi-page documents.

•Stamp

Prints watermark, regular stamp, date/time, page number, and numbering onto the

output copies to enhance the presentation and usefulness of the copies.

•Staple

Selects the stapling position and number of staples.

• STD Size (Special)

Detects the standard paper sizes which cannot normally be detected when loaded in a

engine tray or Multi-sheet bypass tray.

•Tab Paper

Copies onto tabbed sheets from tabbed originals, allowing the image on the tab part of

the original to be printed on the same part of the tabbed copy paper.

•

Tandem Mode for Two mfps

Works in tandem to distribute a large copying job in half the time of non-tandem mode.

• Text/Photo Enhance

Enhances photo image in Photo mode, regular image in Text/Photo mode, text image in

Text mode, lighter image in Increase Contrast mode.

•

Trimming Mode for Q3220A Finisher with Q3224A Trimmer Unit Installed:

Trim the end of folded or stapled&folded booklets.

• Userset Density (USERSET 1, USERSET 2)

Outputs up to 16 density samples on a total of 4 pages that display 4 samples per page,

then programs the desired density under USERSET 1 and/or USERSET 2.

• Weekly Timer

Can be set according to the needs of each work environment. Turns engine power

Off/On daily or weekly, during lunch time, on holidays, and also enables the Timer

Interrupt mode, which allows temporary use of the machine even when the machine is

in the daily, weekly, or holiday Off mode.

•Wide Size Paper

Copies onto paper slightly larger than the specified regular size.

• Z-Folded Original

This feature sets the RADF to accept Z-folded originals.

•

Z-Fold Mode for Q3219A/Q3220A Finisher with Q3223A/Q5685A Hole

Punching / Z-Folding Unit Installed:

Z-folds (A3) or double-folds (B4) output copies.

xii

1

Safety

Information

2

Machine

Basic

Information

3

Copying

Operations

4

Job Memory

&Help Mode

5

Trouble-

shooting

6

Machine

Specifications

blank page

Safety Information

1

Safety

Information

1

Caution Labels and Indicators ................................................................ 1-2

Requirements for Safe Use ................................................................ 1-6

Precautions for Installation and Use

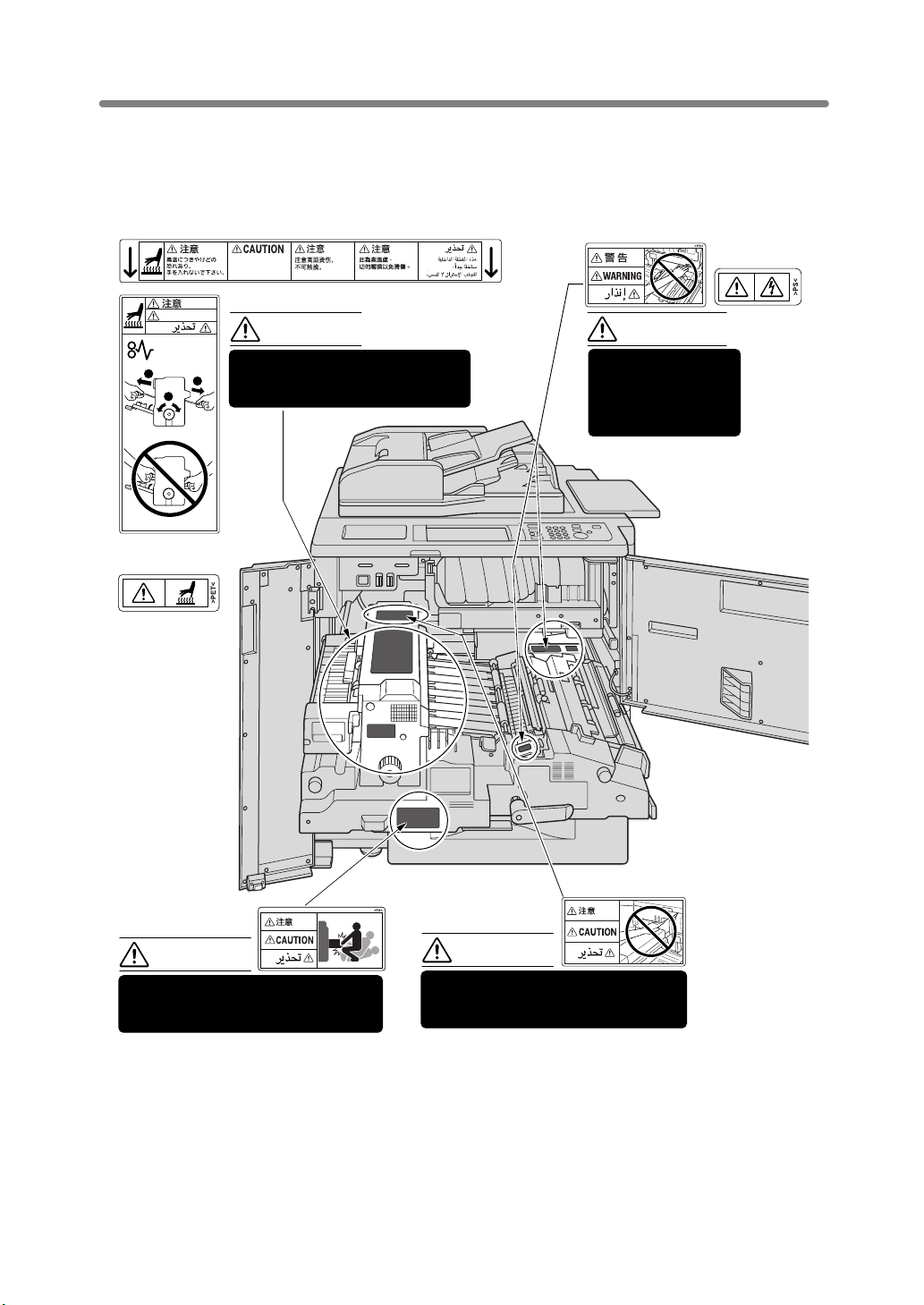

Caution Labels and Indicators

The caution labels and indicators are attached to the machine areas, as shown

below, where you are advised to pay special attention to avoid any dangerous

situations or serious injury.

This internal area is very

hot. To avoid getting

burned, DO NOT TOUCH.

(Both sides of the fixing unit)

CAUTION

2

2

1

(Top surface of

the fixing unit)

CAUTION

The fixing unit is very hot.

To avoid getting burned DO NOT

TOUCH.

WARNING

This area generates

high voltage. If

touched, electrical

shock may occur. DO

NOT TOUCH!

(Front side

and Inside of

the fixing unit)

CAUTION

The fixing conveyance unit is heavy.

Use care and draw it out gently;

otherwise you may be injured.

CAUTION

DO NOT put your hand between the

engine and fixing conveyance

unit; otherwise you may be injured.

1-2

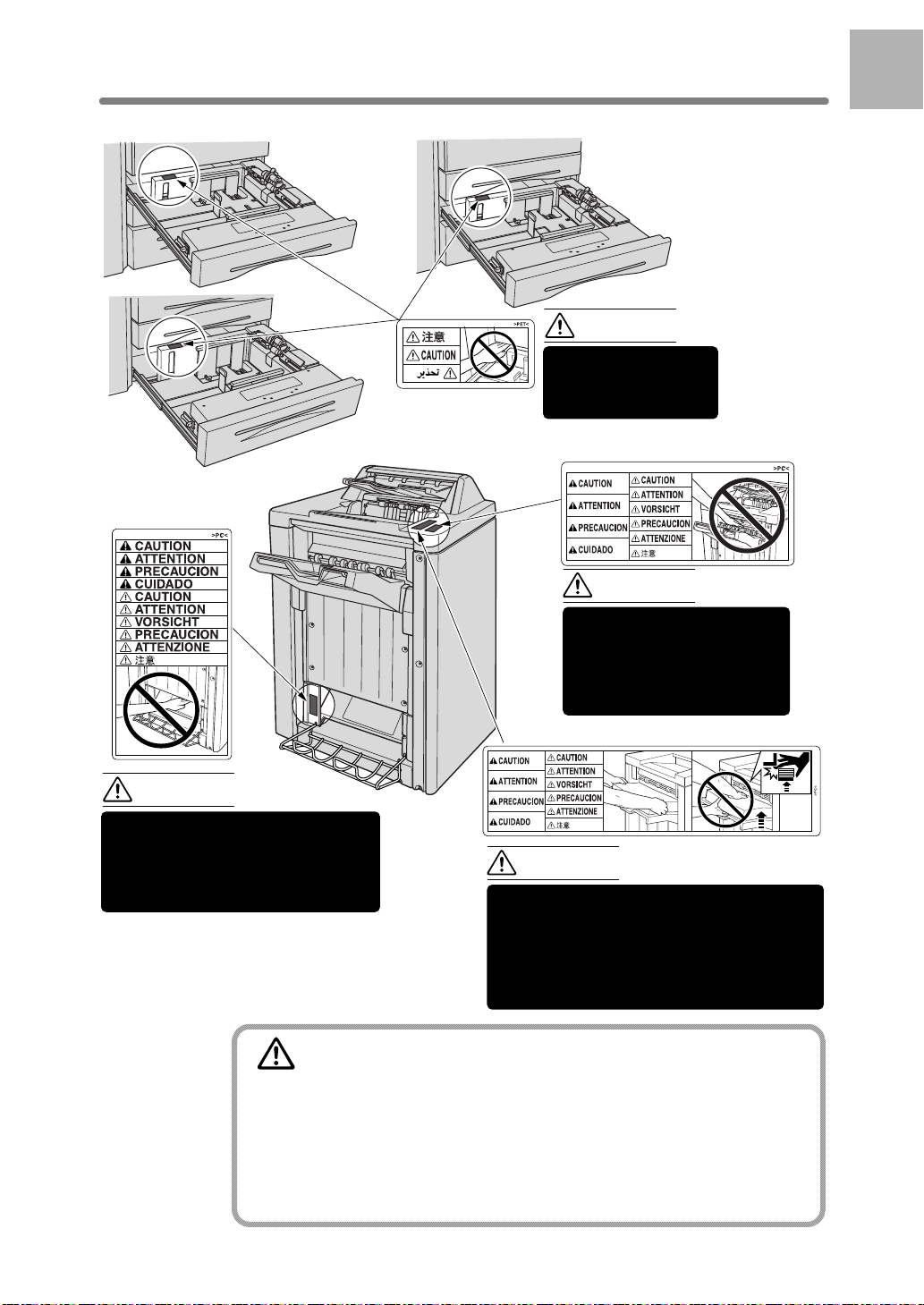

Caution Labels and Indicators (continued)

Tray 1

Tray 2

CAUTION

DO NOT put your hand

between the engine

and tray; otherwise you

may be injured.

1

Safety

Information

Tray 3

(Q3220A only)

CAUTION

Inside the lower paper exit outlet

is the roller drive unit.

DO NOT put your hands into the

paper exit outlet as you may be

injured.

Q3220A Finisher

To avoid injury, DO NOT put your hand on

the top of the printed sheets. Be sure to hold

both sides of the printed sheets when

removing them, and DO NOT leave your

hand on the printed sheets while the primary

(main) tray goes up.

(Q3219A/Q3220A)

CAUTION

Use care after opening the

paper exit outlet. DO NOT

put your hands into the

paper exit outlet as you

may be injured.

(Q3219A/Q3220A)

CAUTION

CAUTION

Burns or injury may occur from touching the areas detailed in

the caution labels and caution indicators. Do not remove

caution labels or indicators. If any caution label or caution

indicator is soiled, please clean to make legible. If you cannot

make them legible, or if the caution label or indicator is

damaged, please contact your service representative for

replacement labels.

1-3

Caution Labels and Indicators (continued)

The following indicators are used on the caution labels or in this manual to categorize

the level of safety cautions.

DANGER:

Action highly liable to cause death or serious injury.

WARNING:

Action liable to cause death or serious injury.

CAUTION:

Action liable to cause minor injury, machine trouble or physical damage.

If you find any of these indicators when removing jammed paper, adding toner, or

reading the manual, be sure to follow the information.

Reminder!

If the safety cautions in the manual become illegible due to soilage, etc.,

please procure a new copy from your service representative.

1-4

Regulations

FCC Regulations

Warning: The hp 9085mfp generates, uses, and can radiate radio frequency energy. If it is

not installed and used in accordance with the instruction manual, interference with radio

communications may result. This equipment has been tested and found to comply with the

limits for a Class A computing device, pursuant to Subpart B, Part 15, of FCC rules, which

are designed to provide reasonable protection against interference from such equipment

when it is operating in a commercial environment.

Users operating this equipment in a residential area are likely to cause interference, in

which case they may be required to correct the interference at their own expense.

Canadian Department of Communications Regulations

Le présent appareil n’émet pas de bruits radioélectriques dépassant les limites

applicables aux de Classe A prescrites dans le règlement sur la brouitlage radioélectrique

édicté par Le Ministère des Communications du Canada.

This equipment does not exceed the Class A limits for radio noise emissions as set out in

the radio interference regulations of the Canadian Department of Communications.

1

Safety

Information

FDA Regulations

This Copier is certified as a “Class 1” laser product under the U.S.Department of Health

and Human Service (DHHS) Radiation Performance Standard according to the Radiation

Control for Health and Safety Act of 1968. Since radiation emitted inside this printer is

completely confined within protective housings and external covers, the laser beam cannot

escape during any phase of normal user operation.

1-5

Requirements for Safe Use

To ensure your safe use of the machine, the following describes the precautions you

are required to observe without fail for the power source of the machine and during

installation and routine handling. Be sure to read and observe them.

Power Source

CAUTION: Plug Socket

• A plug socket is limited in capacity. Use only a power source with the correct rating

for the machine; otherwise, hazardous situations such as smoking or overheating

may occur. See the following list to match the power supply and power

consumption:

a) 230V / 50Hz: More than 15A

b) 230V / 60Hz: More than 15A

• Avoid multiple connections in the same outlet. Do not use multiple outlet adaptors.

CAUTION: Power Plug and Cord

• Be sure to insert the power plug firmly into the power socket. Otherwise an

accident may occur as a result of smoking or overheating. If the inserted power

plug is loose in the socket, even after it has been positively inserted, disconnect the

plug and contact your electrical contractor.

• For plug cable equipment, the socket-outlet shall be installed near the equipment

and shall be easily accessible.

• Do not bend or crush the power cord. If your mfp power cord is bent or damaged

in any way, contact your service representative immediately. Do not attempt to

repair it yourself, and do not continue to operate the mfp. A damaged power cord

may result in overheating, a short circuit, or fire.

• Do not bundle or coil the power cord of the mfp. Otherwise an accident may

occur as a result of overheating or fire.

CAUTION:

Never connect multiple loads to one socket outlet using a multi-outlet extension cord or

branched socket. Otherwise an accident may occur as a result of overheating or fire.

Connecting Multiple Loads to One Socket Outlet Prohibited

CAUTION: Extension Cord

An extension cord must never be used with this machine.

1-6

Requirements for Safe Use (continued)

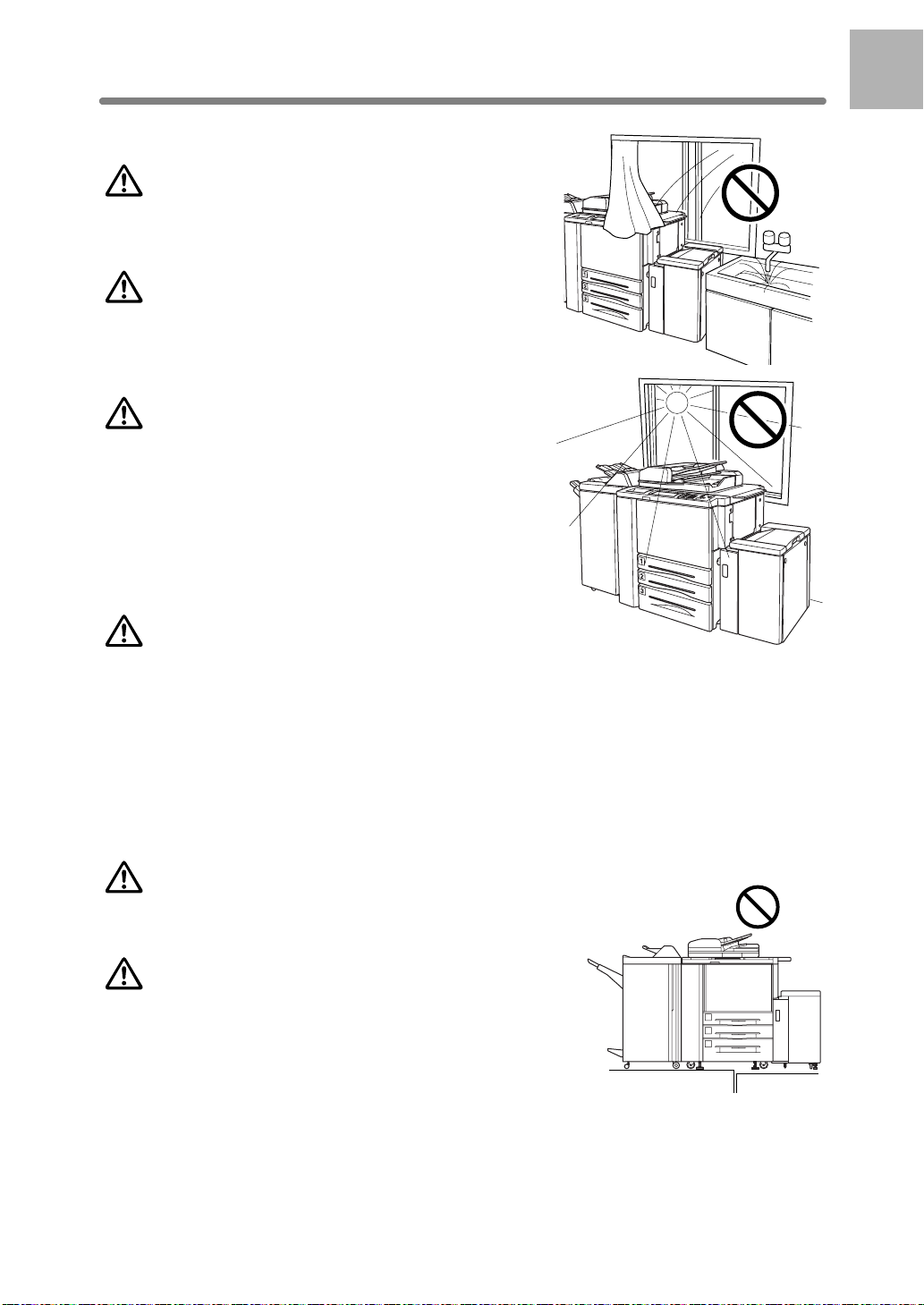

Environment

CAUTION: Prevention of Fire

Do not install near flammable materials, curtains and

volatile combustibles, that can catch or cause fire.

CAUTION: Prevention of Short Circuit

Do not install the mfp where it could be splashed

with rain water or water from a tap, to avoid a short

circuit.

CAUTION: Temperature and Humidity

• Keep away from direct sunlight, heat sources

such as stoves, cool air from an air conditioner

and hot air from a heater.

• Avoid any environment that is outside the range

shown below:

10 to 30°C in temperature

10 to 80% in humidity

1

Safety

Information

CAUTION: Ventilation

• Maintain the installation place well-ventilated.

• Keep away from dust or corrosive gases. These materials may cause poor image

quality.

• During the use of machine, the machine generates ozone in an insufficient amount

to cause any hazard to the human body.

However, if the machine is used in a poorly ventilated room and many copies are

made or more than one mfp is used at the same time, an odor may be detected.

Ensure adequate ventilation for a comfortable working environment.

CAUTION: Vibration

Do not install on a floor which is subject to vibration or

is not level.

CAUTION: Transportation

Be sure to contact your service representative when

moving or transporting the machine. If you move the

machine with the Hard disk drive or Memory unit

installed, trouble may be caused by vibration.

1-7

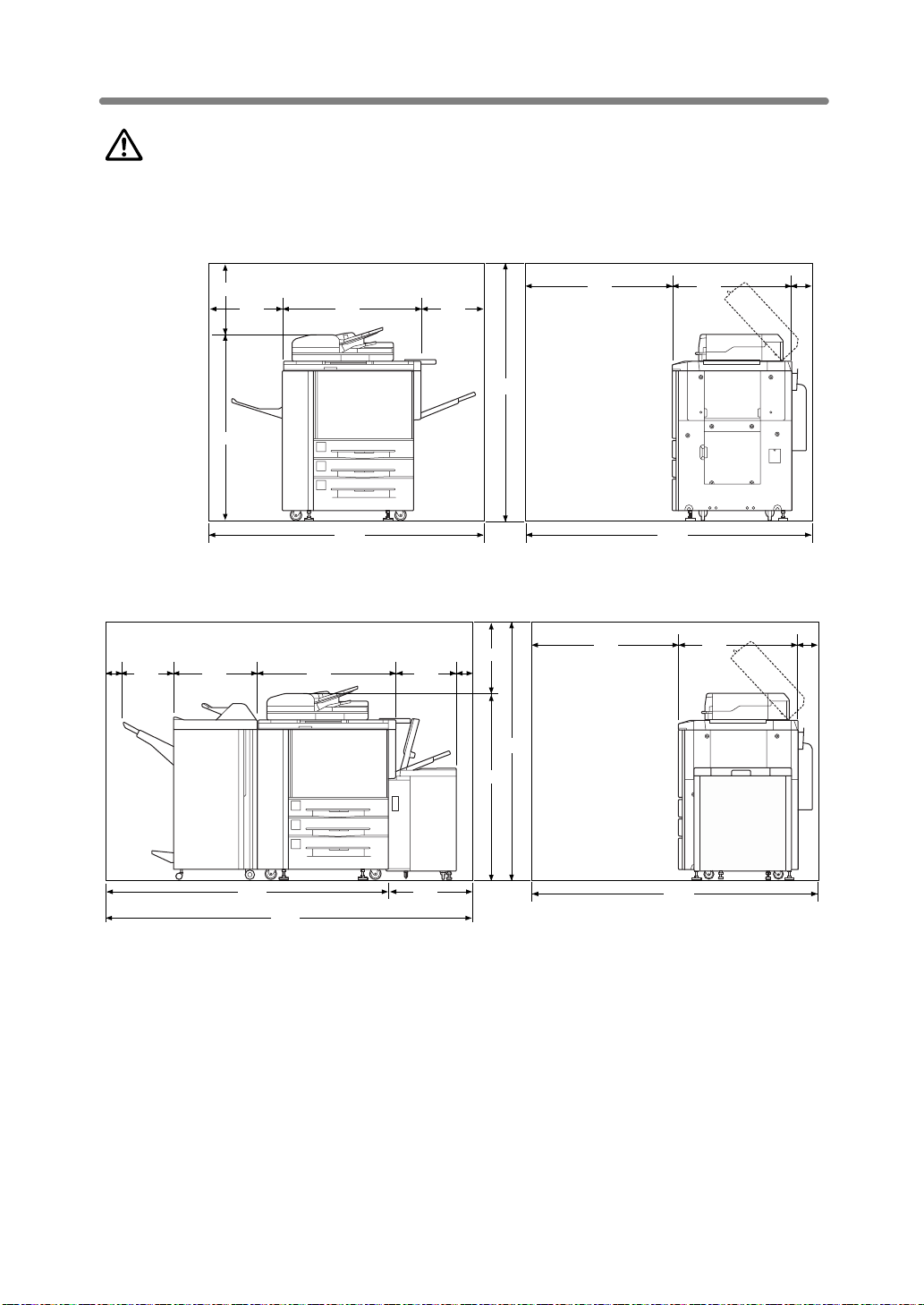

Requirements for Safe Use (continued)

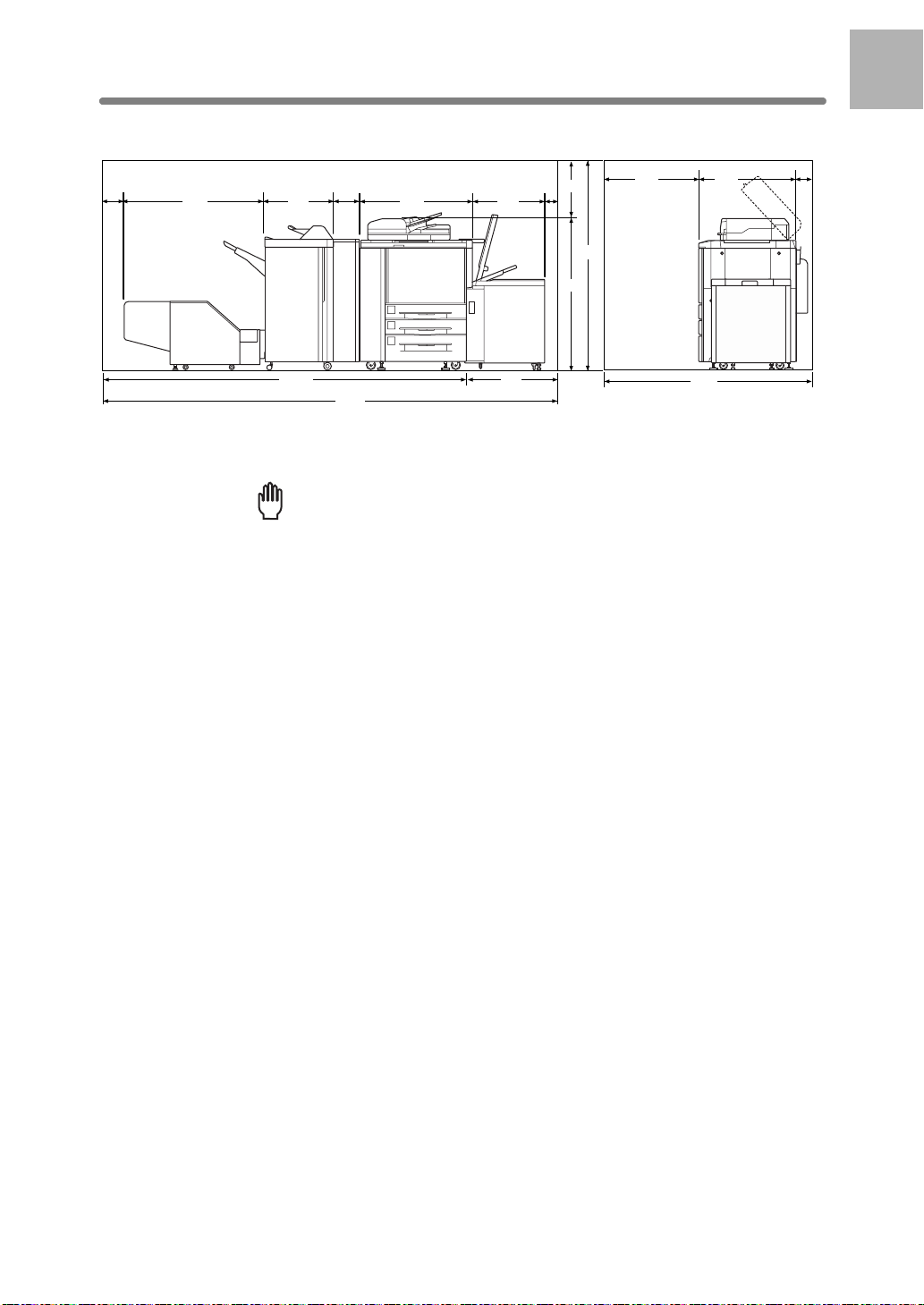

CAUTION: Installation Space

Allow sufficient space for facilitating copy operation, changing parts, and periodic

inspection. Leave an adequate space behind the machine to let hot air out from the

rear fan.

(Unit: mm)

400

1160

475

887

400

1560

950

775

120

1762

100 100

546321

1807

2337

887

386

530

hp 9085mfp + Finisher + High Capacity Input

hp 9085mfp

400

1560

1160

950

1845

1845

775

(Unit: mm)

120

1-8

150

1118

546

Requirements for Safe Use (continued)

(Unit: mm)

174

887

626

400

100

1560

1160

950

775

120

1

Safety

Information

2831

3601

770

1845

hp 9085mfp + Multifuntion Finisher + Trimmer unit + Hole Punch Unit + High Capacity Input

Reminder!

Finisher primary (main) tray of Q3219A/Q3220A Finisher gradually goes

down while printed materials output. DO NOT allow any object to interfere

with the operation of the tray on the left side of the finisher, as any

interference may cause damage to the finisher.

1-9

Requirements for Safe Use (continued)

Precautions for Routine Handling

WARNING: High Voltage

DO NOT TOUCH the high voltage parts indicated with WARNING label or described

in the manual.

CAUTION: Actions in Response to Troubles

• If the Service Call screen is displayed and mfp operations cannot be continued

anymore, stop the operation to prevent any unexpected accident. Write down the

report code as stated on the 2nd line of the message, then switch off the mfp and

disconnect from the power socket. Contact your service representative and inform

them of the report code.

• Do not touch the high temperature parts indicated with CAUTION labels or

described in the manual.

• Do not touch the inside of the machine for any other purpose than removing

jammed paper or adding toner.

• If machine repair is necessary, be sure to contact your service representative.

Never attempt to repair it by yourself.

• If any abnormal sound, smell or smoke comes from the machine, immediately stop

using it, turn off the power switch, disconnect the power plug and contact your service representative.

• If the breaker trips or the fuse blows, turn off the power switch, reset the breaker or

the fuse, and turn on the machine. If the same situation occurs again, contact your

service representative.

• Ensure the replacement fuse conforms with the rating of the power source. Never

use a fuse with an incorrect rating.

CAUTION: Prevention of Fire

Do not use volatile combustibles, such as thinner or alcohol, near the machine.

CAUTION: Prohibition of Machine Modification

Do not modify or remove any parts by yourself.

1-10

Requirements for Safe Use (continued)

CAUTION: Prevention of Machine Troubles

• Do not drop small metallic objects, such as paper clips

or staples, inside the machine.

• Do not place any heavy or hard objects such as a vase,

books or ornaments on the machine.

CAUTION: Recommendation of Periodic Check

Be sure to periodically check the following points:

(1) The main cord or the power plug does not generate abnormal heat.

(2) The power plug is not inserted loosely or the cord is not cut or scratched.

(3) The grounding wire is correctly connected.

(4) The power plug or the power outlet is not covered with dust.

If you find anything abnormal in the above items, stop using the machine and contact

your service representative.

CAUTION: Toner

• Keep the toner cartridge away from children. The toner is nontoxic; however if you

inhale or it makes contact with eyes by accident, flush with water and seek medical

advice.

• Do not throw the empty toner cartridge into a fire. If it is thrown into a fire the toner

may ignite and cause a dangerous situation.

1

Safety

Information

CAUTION: Paper

Check paper to be sure it conforms to the specifications outlined in Section 11.

• Do not use paper with staples or paper that conducts electricity (silver, carbon,

etc.), otherwise an accident may occur as a result of fire.

• To avoid machine trouble, do not use heat-sensitive paper, paper that conducts

electricity (silver, carbon, etc.), or colored OHP film.

CAUTION: Sleep and Weekly Timer

• In Sleep mode the mfp is still connected to the main power supply and

power is still applied to certain areas of the machine. To avoid any unexpected

troubles turn the power OFF when not using the mfp for long periods of time.

• When the Weekly Timer function is operating, turning power OFF will disable the

function.

CAUTION: Inside the Booklet Mode Outlet

Inside the Booklet mode outlet is the roller drive unit. DO NOT put your hand into it,

when removing the folded or stapled & folded sheet; otherwise you may be injured.

1-11

Requirements for Safe Use (continued)

CAUTION: Finisher Paper Exit Outlet

To avoid injury when stapling large size copies, DO NOT put your hand into the open

Paper Exit Outlet.

CAUTION: Fixing Unit

The internal fixing unit is very hot. To avoid getting burned, DO NOT TOUCH. Be

careful when withdrawing the fixing unit.

WARNING: Drum Unit

The internal drum unit generates a high voltage.

To avoid an electrical shock, DO NOT TOUCH.

CAUTION: Disposal of mfp

Do not dispose of this mfp yourself. Contact your service representative, who can

arrange for its safe disposal.

If you change the place of installation, please contact your service representative.

CAUTION: Paper Capacity for the Exit Tray

The exit tray capacity is max. 150 sheets. If a copy run of more than 150 is required,

be sure to remove the copies from the exit tray before the maximum capacity is

reached. Failure to do so will cause the mfp to jam.

CAUTION: Q3219A/Q3220A Finisher Paper Capacity

The Q3219A Finisher is equipped with two exit trays, and Q3220A Finisher is equipped

with three exit trays.

Select an exit tray and output mode on the Output Mode popup menu.

To prevent paper misfeed, do not exceed the paper capacity of the Finisher.

When the total number of copies in the copy run exceeds the capacity stated in Section 11, be sure to unload the exit tray while the mfp is still copying. Failure to do so

will cause the mfp to jam.

CAUTION: Q3219A/Q3220A Finisher Primary (Main) Tray

When printed materials are removed from the primary (main) tray of the Finisher, the

tray goes up automatically. To avoid injury, DO NOT put your hand on top of the

printed sheets. Be sure to hold both sides of the printed sheets when removing them,

and DO NOT leave your hand on the printed sheets while the primary tray goes up.

1-12

Machine Information

2

Machine

Information

Machine

Configuration

Turn On/Off

the Power

Loading

Paper

2

Machine Configuration............................................................................ 2-2

Turning On the Power Switch ........................................................... 2-17

Loading Paper ...................................................................................... 2-23

Machine Configuration, Turning On the Power

and Loading Paper

Machine Configuration

External Machine Items

15 Power switch

Q3219A/Q3220A

12

Finisher (option)

10 Front door

9 Left door

14 Cover sheet feeder

Q3221A (option)

17 Control panel

16 LCD touch screen

8 Tray 1

7 Tray 2

6 Tray 3

5 Right side door

(not shown)

1 RADF

4 Tray 4: tray 4 /HCI

Q3637A (option)

2 Work table

3

Multi-sheet

bypass tray

13 Q3224A Trimmer unit (option)

11

Q3222A/Q5684A Punching unit

or Q3223A/Q5685A Punching /

Z-Folding unit (option)

2-2

4 Tray 4: tray 4 /HCI

Q3638A (option)

Machine Configuration (continued)

RADF (Reversing Automatic Document Feeder) automatically feeds multiple

1

originals one at a time to the platen glass for copying.

2 Work table provides a convenient workspace for documents both before and after

copying.

3 Multi-sheet bypass tray used for small quantity copying onto plain paper or

special paper.

HCI ( Tray 4 /HCI Q3637A/Q3638A) (option) holds 4,000 sheets.

4

5 Right side door opens to allow removal of mishandled paper.

6 Tray 3 (universal tray) is user-adjustable and holds 1,000 sheets.

Tray 2 (universal tray) is user-adjustable and holds 500 sheets.

7

8 Tray 1 (universal tray) is user-adjustable and holds 500 sheets.

Left side door opens together with the front door to allow removal of mishandled

9

paper, and have access to optional EFI print controller.

10 Front door opens to allow removal of mishandled paper.

Q3222A/Q5684A Hole Punching unit (option) punches file holes in the output

11

copies.

Q3223A/Q5685A Hole Punching / Z-Folding unit (option) punches file holes

and/or Z-folds the output copies.

12 Q3219A/Q3220A Finisher (option) sorts, staple-sorts, and groups copies

into finished sets.

Q3220A also folds or staples & folds copies into booklet-styled sets.

13 Q3224A Trimmer unit (option) trims the end of booklet.

14 Q3221A Cover sheet feeder (option) loads cover sheet paper and feeds the

sheetas cover.

15 Power switch turns mfp power On/Off when pressed.

16 LCD Touch screen displays interactive operation screens.

17 Control panel controls mfp operations and displays messages as required.

2

Machine

Information

Machine

Configuration

Turn On/Off

the Power

Loading

Paper

2-3

Internal Machine Items

Machine Configuration (continued)

1 Toner cartridge

7 Reset switch

6 Fixing unit

5 Drum unit

2 Toner unit

3 Conveyance fixing

unit

4 Lever A

1 Toner cartridge holds toner and is to be replaced when supplying toner.

2 Toner unit holds the toner supply.

3 Conveyance fixing unit passes the paper through the drum unit, and fuses the

toner onto the copy paper, and is to be withdrawn for removal of mishandled

paper.

4 Lever A can be moved to withdraw the conveyance fixing unit for removal of

mishandled paper.

5 Drum unit forms the copy image.

6 Fixing unit fuses the toner onto the copy paper.

7 Reset switch used only by service representative turns machine power on/off

when pressed.

2-4

Standard/Optional Equipment

Q3221A Cover sheet feeder

Q3219A Finisher

Machine Configuration (continued)

Video interface

Memory unit

2

Machine

Information

Machine

Configuration

Turn On/Off

the Power

Loading

Paper

Q3220A Finisher

Q3224A Trimmer unit

hp 9085mfp engine

EFI Print controller

Q3222A/Q5684A Hole Punching unit or

Q3223A/Q5685A Hole Punching / Z-Folding unit

Q3637A tray 4 /HCI

Q3638A tray 4 /HCI

2-5

Q3219A/Q3220A Finisher

5 Secondary

(Sub) tray

1 Finisher door

Machine Configuration (continued)

6 Secondary (Sub) tray cover6 Secondary (Sub) tray cover

5 Secondary

(Sub) tray

1 Finisher door

4 Primary

(Main) tray

1

Finisher door

Q3219A Finisher

opens to the internal Finisher to allow clearing mishandled paper

4 Primary

(Main) tray

2 Booklet mode outlet

3 Booklet tray

Q3220A Finisher

and replenishing staples.

2

Booklet mode outlet (Q3220A Finisher only) outputs finished copied sets

when selecting Fold mode or Stitch & Fold mode.

Booklet tray (Q3220A Finisher only) holds sets output in Fold mode or Stitch

3

& Fold mode.

4 Primary (Main) tray holds sets output in Non-sort mode, Sort mode (offset),

Staple-sort mode, or Group mode (offset).

5 Secondary (Sub) tray holds sets output in Non-sort mode or Group mode with

face down/up mode.

6 Secondary (Sub) tray cover opens to allow clearing mishandled paper.

2-6

Machine Configuration (continued)

Q3219A Finisher

1 Upper lever

2 Upper knob

6 Stacker unit handle

9 Cartridge housing

3 Right lever

4 Left lever

5 Stacker unit

6 Stacker unit

handle

1 Upper lever

9 Cartridge housing

Q3220A Finisher

2 Upper knob

3 Right lever

4 Left lever

5 Stacker unit

6 Stacker unit

handle

7 Lower lever

8 Knob

6 Stacker unit handle

2

Machine

Information

Machine

Configuration

Turn On/Off

the Power

Loading

Paper

1 Upper lever opens upward to remove mishandled paper.

2 Upper knob can be turned to ease removal of mishandled paper.

3 Right lever opens to remove mishandled paper.

4 Left lever opens to remove mishandled paper.

5

Stacker unit holds stapler, and also holds the device to provide Fold and Stitch &

Fold mode in Q3220A.

6 Stacker unit handle withdraws unit to allow removal of mishandled paper and

replacement of staple cartridge.

7 Lower lever opens to remove mishandled paper.

8 Knob can be turned to ease removal of mishandled paper.

9 Cartridge housing holds staple cartridge and is to be replaced when supplying

staples.

2-7

Machine Configuration (continued)

Q3221A Cover Sheet Feeder

2 Cover sheet feeder

1 Manual finishing

operation panel

3 Cover sheet feeder

guide plates

1 Manual finishing operation panel controls cover sheet feeder operations.

2 Cover sheet feeder holds cover sheets for use in cover sheet output mode.

3 Cover sheet feeder guide plates hold cover sheets to fix the position.

2-8

Q3637A/Q3638A Tray 4 /HCI

1

2

HCI left

side door

HCI lever

4

HCI paper guides

HCI top door

6

HCI bottom plate

Machine Configuration (continued)

1

2

HCI left

side door

33

HCI lever

4

HCI paper guides

HCI top door

6

HCI bottom plate

2

Machine

Information

Machine

Configuration

Turn On/Off

the Power

Loading

Paper

5 Paper loading

button

7 Rear stopper

5 Paper loading

button

1

HCI top door opens to allow paper loading.

2

HCI left side door opens to allow removal of mishandled paper.

3

HCI lever can be moved downward to ease removal of mishandled paper.

4

HCI paper guides hold copy paper to fix the position.

Q3637A tray 4 /HCI

Q3638A tray 4 /HCI

7 Rear stopper

5 Paper loading button is pressed to lower the bottom plate to allow loading paper.

6

HCI bottom plate goes up automatically when paper supply becomes low, and

goes down when the paper loading button is pressed.

7 Rear stopper fixes the rear end of copy paper.

2-9

Q3224A Trimmer Unit

5 Trimmer stacker cover

4 Trimmer unit tray

Machine Configuration (continued)

Q3220A Finisher

1 Front-right cover

2 Front door

3 Trimmer stacker

1 Front-right cover opens to allow removal of mishandled paper.

2 Front door opens to allow removal of mishandled paper or waste paper.

3 Trimmer stacker holds sets output in Trimming mode.

4 Trimmer unit tray slides to the left side each time a trimmed booklet is delivered.

5 Trimmer stacker cover opens to allow you to take out the finished sets.

Reminder!

DO NOT place heavy objects on the trimmer stacker or apply any weight

on it, and DO NOT use it for storage.

Excessive weight applied to the inside or outside of the trimmer stacker

will damage the equipment.

2-10

Machine Configuration (continued)

1 Trimmer unit knob

2

Machine

Information

Machine

Configuration

Turn On/Off

the Power

Loading

Paper

3 Trimmer pressure

release lever

2 Waste basket

1 Trimmer unit knob can be turned to ease removal of mishandled paper.

2 Waste basket holds waste paper cut off from the booklets.

3 Trimmer pressure release lever opens to allow removal of mishandled paper.

2-11

Machine Configuration (continued)

Q3222A/Q5684A Hole Punching Unit

3 Upper lever

4 Knob

5 Left lever

1 Punching unit

front door

1

Hole Punching unit front door opens to allow removal of mishandled paper or

6 Waste basket

2 Right lever

wastepaper.

2 Right lever opens to allow removal of mishandled paper.

3 Upper lever opens to allow removal of mishandled paper.

4 Knob can be turned to ease removal of mishandled paper.

5 Left lever opens to allow removal of mishandled paper.

6 Waste basket holds waste paper punched out.

2-12

Machine Configuration (continued)

Q3223A/Q5685A Hole Punching / Z-Folding Unit

4 Handle

5 Left lever

1

Hole Punching / Z-Folding

unit front door

6 Waste basket

3 Knob

2 Right lever

2

Machine

Information

Machine

Configuration

Turn On/Off

the Power

Loading

Paper

1

Hole Punching / Z-Folding unit front door opens to allow removal of

mishandledpaper or waste paper.

2 Right lever opens to allow removal of mishandled paper.

3 Knob can be turned to ease removal of mishandled paper.

4 Handle can be withdrawn to allow removal of mishandled paper.

5 Left lever opens to allow removal of mishandled paper.

6 Waste basket holds waste paper punched out.

2-13

Machine Configuration (continued)

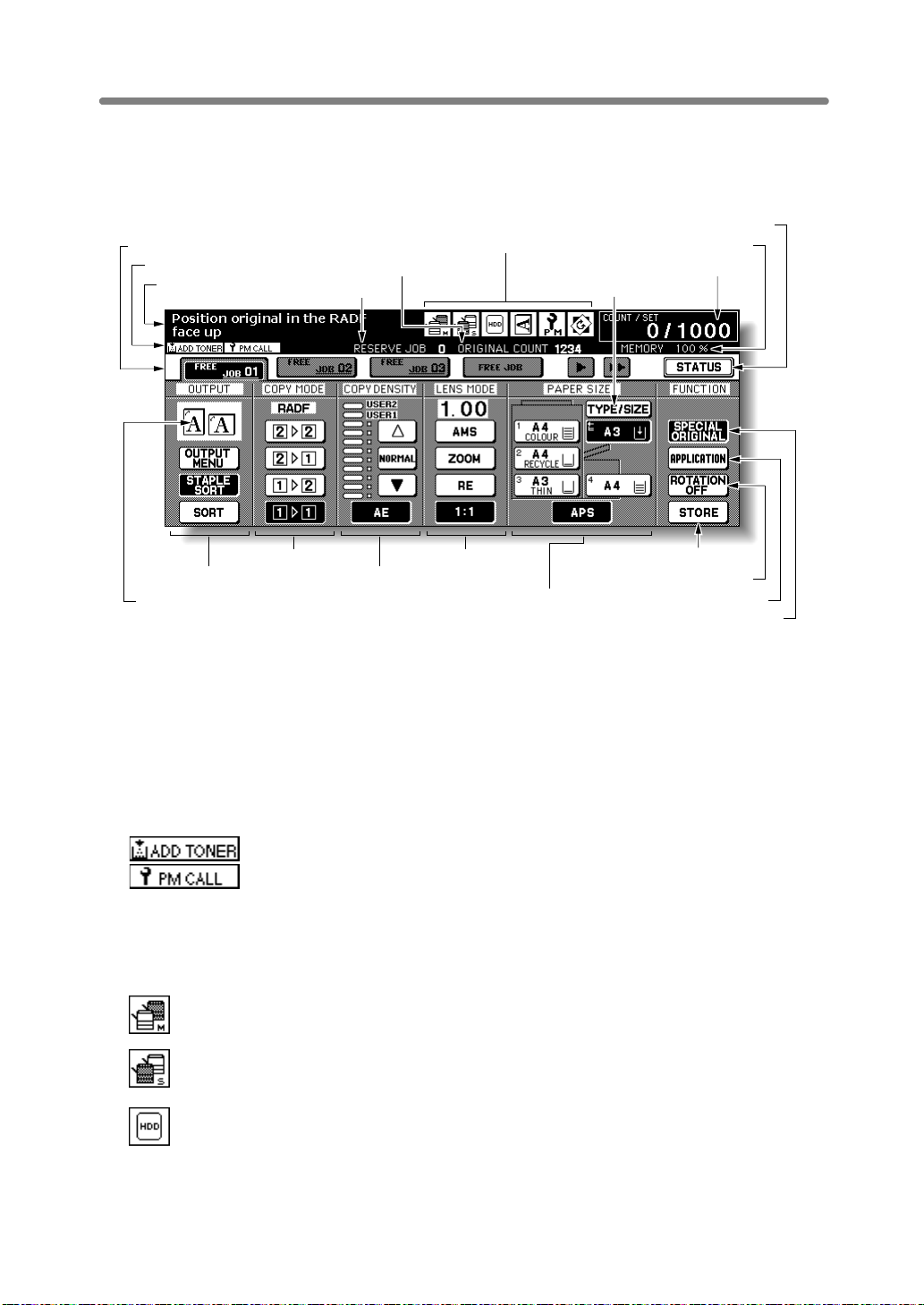

Basic Screen

The Basic Screen displays when copying operation becomes available after warmup.

6 Master/ Sub/ HDD/ Original

1 Folder keys 9 Memory indicator

2 Notice icons

3 Message area

20 Output icon area

5 Original count

4 Reserve job

17 Copy density area19 Output mode keys

direction/ PM/ Rotation icons

8 Count/Set indicator

7 TYPE/SIZE key

16 Lens mode area18 Copy mode area

13 ROTATION OFF key

15 Paper size area

11 SPECIAL ORIGINAL key

10 STATUS key

14 STORE key

12 APPLICATION key

1 Folder keys

FREE JOB is selected to specify a copy job conditions.

When scanning starts, FREE JOB changes to SCAN JOB, then changes to

PRINT JOB when the machine starts printing.

FREE JOB at the right side of SCAN JOB or PRINT JOB can be touched to

specify a reserve job conditions. Up to 10 reserve jobs can be set. The arrow keys

at the right side of folder keys are used to scroll.

2 Notice icons

: ADD TONER icon is displayed when toner supply becomes low.

: PM CALL icon is displayed when preventive maintenance is due.

3 Message area displays the machine status and procedure required at that time.

4 Reserve job counts the reserve jobs already specified.

5 Original count counts the original pages placed in the document feeder as they

are scanned.

6 : Master icon is displayed when the TANDEM key is selected on the Output

Mode popup menu.

: Sub icon is displayed when the mfp operates in tandem with the primary

(master) mfp.

: HDD icon is displayed when using Image Store & Output mode of Server

function.

2-14

Machine Configuration (continued)

: Original direction icon indicates the original direction

specified on the Special Original popup menu.

: PM icon is displayed when preventive maintenance is due.

: Rotation icon is displayed when Rotation automatically functions.

7 TYPE/SIZE key is touched to specify the type and size of the paper loaded in the

Multi-sheet bypass tray.

8 Count/Set indicator indicates the print quantity entered from the control panel

keypad, and also indicates the print count on the left of the set count while

printing.

9 Memory indicator indicates the remaining memory available for the next

operation.

10 STATUS key is touched to view the current job status, to change the printing

order of reserve jobs, or to cancel printing a reserve job.

11 SPECIAL ORIGINAL key is touched to specify the condition of originals to be

scanned.

12 APPLICATION key is touched to select various application functions.

13 ROTATION OFF key is touched to release the Rotation function.

14 STORE key is touched to store scanned images into memory.

15 Paper size area is used to select the desired paper size or APS.

16 Lens mode area is used to select the desired magnification ratio.

17 Copy density area is used to specify the desired exposure level.

18 Copy mode area is used to select the copy mode (11, 12, 21, or 22).

19 Output mode keys are used to specify the desired output mode.

20 Output icon area displays the appropriate output icon according to the selected

output mode.

2

Machine

Information

Machine

Configuration

Turn On/Off

the Power

Loading

Paper

2-15

Control Panel Layout

Machine Configuration (continued)

1245678

CHECK

JOB MEMORY

COPY

SCAN

PRINT

AUTO RESET

HELP

3

STOP

TIMER

SLEEP

ON / OFF

910

COUNTER

CLEAR QTY.

1112131415

INTERRUPT

PROOF COPY

START

1 LCD TOUCH SCREEN displays machine and copying status, help information,

interactive screens, and touch keys for selecting all functions.

2CHECK displays a screen showing all settings that are selected for the current job.

3MODE switches the machine operation mode to copy, scan/server, and print.

4 KEYPAD enters numeric values.

5 PROOF COPY outputs a single set of copies to confirm whether the current settings are

selected properly.

6 INTERRUPT stops copying in progress to allow copying from the platen glass.

7STOP stops the copying sequence; deletes the stored memory.

8TIMER lights when the timer function is set.

9

SLEEP ON/OFF

activates power-saving mode for times when the mfp is

inactive, or activates Timer Interrupt mode when Weekly Timer function is active.

10 START activates copying or scanning.

11 [C] (CLEAR QTY.) allows resetting of print quantity.

12 [P] (COUNTER) displays the Counter Screen or accesses programming modes for

setting special functions.

13 HELP displays a screen with help for the currently selected function, or to access the

Key Operator Mode Screen.

14

AUTO RESET restores mfp to automatic mode settings or to Key Operator settings.

15 JOB MEMORY displays screens for selecting job store/job recall functions.

2-16

Turning On the Power Switch

To Turn On the Power

1. Turn ON the power switch.

The power switch is located on the left side of the engine.

HINT

If the mfp can not be turned on by the power switch, open the left door

of the engine, then check that the internal reset switch of the mfp is

ON. (See p. 2-4.)

Be sure not to use the reset switch in normal operation.

2. The Wake-up Screen and Warm-up Screens will be displayed.

2

Machine

Information

Machine

Configuration

Turn On/Off

the Power

Loading

Paper

A few seconds after the Wake-up Screen appears in the LCD touch screen, seven

types of Warm-up Screens will be displayed in succession for approx. 6.0 minutes.

HINT

You can set reserve jobs while the machine is warming up. Touch the LCD

screen to change the Warm-up Screen to the Basic Screen, then check

that the message “Ready to copy reserve” is displayed on the Basic

Screen. See p. 3-8 to p. 3-9.

2-17

Turning On the Power Switch (continued)

3. The Basic Screen will be displayed.

The message on the Basic Screen will inform you that copying job is now available.

DETAILS

• When the initial settings are changed by the Key Operator, the modified

conditions will be displayed on the Basic Screen.

When “Enter E.C.M. password” is displayed, enter your password to

•

use the machine.

2-18

Turning On the Power Switch (continued)

To Turn Off the Power

1. Turn OFF the power switch.

The power switch is located on the left side of the engine.

The touch screen and all the LEDs on the control panel will go out.

Reminder!

Be sure not to use the reset switch in normal operation.

DETAILS

When the machine is under control of the Weekly Timer function, turning

off the power switch will deactivate the function.

2

Machine

Information

Machine

Configuration

Turn On/Off

the Power

Loading

Paper

2-19

Turning On the Power Switch (continued)

Reducing the Power in Standby Mode (Auto Low Power)

This function automatically lowers the power after a specified period (initially 15

minutes) of mfp inactivity. The LCD screen becomes dark with the message “Low

Power Mode / Press any key to cancel” displayed.

HINT

The Auto Low Power function can be set to 5 minutes/ 10 minutes/ 15

minutes/ 30 minutes/ 60 minutes/ 90 minutes/ 120 minutes/ 240 minutes

in the Key Operator mode. For the Key Operator setting, see p. 13-38.

To start a copying job, press any key on the control panel.

The Auto low power will be released and the LCD screen recovers usual brightness.

DETAILS

• If the Auto Shut-Off function activates at the same time, the power will

be turned off without the LCD screen becoming dark.

• The LCD screen will not be come dark during a duplex copying job or

when the Jam Position Screen is displayed.

Shutting Off Automatically (Auto Shut-Off)

This function automatically shuts off the power after a specified period (initially 90

minutes) of mfp inactivity.

To start a copying job, press [SLEEP ON/OFF].

The copying operation will become available.

HINTS