Page 1

User Guide

rp5400 Family of Servers

First Edition

Manufacturing Part Number : A5191-96018

November 2002

USA

© Copyright 2002

Page 2

Legal Notices

The information in this document is subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to this manual, including, but not limited to, the

implied warranties of merchantability and fitness for a particular purpose. Hewlett-Packard shall not be held

liable for errors contained herein or direct, indirect, special, incidental or consequential damages in

connection with the furnishing, performance, or use of this material.

Restricted Rights Legend. Use, duplication or disclosure by the U.S. Government is subject to restrictions

as set forth in subparagraph (c) (1) (ii) of the Rights in Technical Data and Computer Software clause at

DFARS 252.227-7013 for DOD agencies, and subparagraphs (c) (1) and (c) (2) of the Commercial Computer

Software Restricted Rights clause at FAR 52.227-19 for other agencies.

HEWLETT-PACKARD COMPANY 3000 Hanover Street Palo Alto, California 94304 U.S.A.

Copyright Notices. ©copyright 1983-2002 Hewlett-Packard Company, all rights reserved.

Windows“, Windows NT“, Windows 95“, Windows 2000“, and Windows XP“ are registered trademarks of

Microsoft in the U.S. and other countries.

Reproduction, adaptation, or translation of this document without prior written permission is prohibited,

except as allowed under the copyright laws.

ii

Page 3

1. Server Overview

2. Server Unpacking and Installation

Factory Integrated rp54xx Cabinet Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Receive and Unpack A Non-Integrated Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Unpacking the server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Install Deskside Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Install Stand-Alone Server in a Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Stationary L-Bracket Rail Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Identifying Approved Non-E-Series HP Cabinets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Identifying E-Series HP Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Identifying Static Rail Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installing Stationary Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3. Installing Additional Components

Additional Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installing Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Memory Configuration Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Installing Peripheral Component Interconnect (PCI) Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

rp5400/rp5450 PCI Card Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

rp5470 PCI Card Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

PCI I/O Card Installation Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

PCI I/O Card Installation Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Installing a PCI Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Online Addition/Replacement (OLA/R) of PCI I/O cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Installing Graphics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Graphics Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Installing Disk Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Contents

4. Cable Connections

Core I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Revision A GSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Revision B GSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Guardian Service Processor (GSP) Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

GSP LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

GSP RS-232. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

GSP Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Revision A GSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Revision B GSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Configure System Consoles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

GSP Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Configure RS-232 Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Configure Remote Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Configure the LAN Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Configure the Web Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Secure Web Console Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

iii

Page 4

Contents

GSP Configurable Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Adding Users. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Removing Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Return the GSP to Default Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

rp54xx Server Boot Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Initial Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5. Utilities

Configuring the Rev A Guardian Service Processor (GSP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Configuring the GSP LAN Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Adding Users. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Removing Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Changing the Default GSP Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Configuring the Rev B Guardian Service Processor (GSP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Configuring the GSP LAN Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Adding Users. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Removing Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Changing the Default GSP Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6. Troubleshooting

Determine Current System State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Troubleshooting and FRU identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Problem Symptoms and Repair Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Chassis Code to FRU Decode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Cross-Referencing Chassis Log Errors to rp54xx FRUs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Interpreting System Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Interpreting Service Processor Error Chassis Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Interpreting Chassis Logs Using the chassis_code.codes File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

rp5400 and rp5450 System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

rp5400 and rp5450 I/O Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

rp5430 and rp5470 System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

rp5430 and rp5470 I/O Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Run/Attention/Fault LED States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

PCI I/O LED States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Expansion I/O LED States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

GSP LED States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

LAN/SCSI LED States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Fan, Power Supply, and Disk LED States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

7. Removing and Replacing Components

List of Changeable Parts with Remove and Replace Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Cardcage Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Core I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

HotSwap Chassis Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Display Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

iv

Page 5

Contents

Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Memory DIMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

PCI I/O Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

HotSwap Power Converter Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Platform Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Processor Support Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Individual Component Remove/Replace Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Extend the Server out the Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Insert the Server from the Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Stand-alone Server Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Stand-alone Server Cover Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Top Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Top Cover Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Side Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Side Cover Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Front Bezel Removal (Single Piece) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Front Bezel Replacement (Single Piece) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Front Bezel Removal (Two Piece) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Front Bezel Replacement (Two Piece) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Core I/O Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Core I/O Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

PCI Card Separator/Extractor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

PCI Card Separator/Extractor Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

HotPlug Disk Drive Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

HotPlug Disk Drive Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

HotSwap Chassis Fan Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

HotSwap Chassis Fan Cover Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

HotSwap Chassis Fan Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

HotSwap Chassis Fan Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

HotSwap Card Cage Fan Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

HotSwap Card Cage Fan Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

HotSwap Power Supply Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

HotSwap Power Supply Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

HotSwap Power Converter Fan Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

HotSwap Power Converter Fan Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Processor Support Module Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Processor Support Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Memory DIMM Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Memory DIMM Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Display Board Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Display Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Platform Monitor Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Platform Monitor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

PCI I/O Card Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

PCI I/O Card Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

v

Page 6

Contents

A. Parts and Accessories

CRU Physical Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Customer Replaceable Unit Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

B. System Specifications

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Uncrating Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Computer Room Physical Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Computer Room Unpacking Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Office High Availability Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Power Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Modular PDUs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

System Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

LAN and Telephone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Acoustic Safety Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Altitude Operation Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Effects of Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Temperature and Humidity Operating Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Thermal Protection Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

C. General Site Preparation Guidelines

Electrical Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Computer Room Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Electrical Load Requirements (Circuit Breaker Sizing). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Power Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Distribution Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Grounding Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

System Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Environmental Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Computer Room Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Cooling Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Humidity Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Dust and Pollution Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Metallic Particulate Contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Electrostatic Discharge (ESD) Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Facility Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Floor Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Space Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Delivery Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Operational Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Floor Plan Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

vi

Page 7

Contents

Typical Installation Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Site Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Delivery Survey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

vii

Page 8

Contents

viii

Page 9

Tab les

Table 6-1. Problem Symptoms and Repair Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Table 6-2. Chassis Log Error to FRU Decoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Table A-1. Exchange CRUs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Table A-2. Non-Exchange CRUs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Table B-1. Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Table C-1. Effect of Humidity on ESD Charge Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Table C-2. Floor Loading Term Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Table C-3. Typical Raised Floor Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Table C-4. Customer and Hewlett-Packard Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Table C-5. Site Inspection Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

ix

Page 10

Table s

x

Page 11

Figures

Figure A-1. Server Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Figure A-2. Side Service Bay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Figure A-3. System Board (Access via Top Service Bay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Figure A-4. Server Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Figure C-1. Raised Floor Metal Strip Ground System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Figure C-2. Delivery Survey (Part 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Figure C-3. Delivery Survey (Part 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

xi

Page 12

Figures

xii

Page 13

Preface

Printing History

The Printing History below identifies the edition dates of this manual. Updates are made to this publication

on an unscheduled, as needed, basis. The updates will consist of a complete replacement manual and

pertinent on-line or CD-ROM documentation.

First Edition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . November 2002

What’s New?

The, Upgrade Guide, rp5400 Family of Servers, is new and was developed to provide customers with system

maintenance information for those components called customer replaceable units (CRUs). Maintenance of

CRUs does not require HP customer engineering services, except when specifically cautioned. The cautions

are shown primarily to protect customer product warrantees.

xiii

Page 14

xiv

Page 15

1 Server Overview

The rp5400 family of servers are 1-way to 4-way servers based on the PA-RISC processor architecture. The

rp5400 family of servers accommodate up to 16GB of memory and internal peripherals including disks and

DVD ROM/Tape. High availability features include HotSwap fans and power supplies, and HotPlug internal

disk drives. The supported operating system is HP-UX.

Chapter 1

1

Page 16

Server Overview

2

Chapter 1

Page 17

2 Server Unpacking and Installation

Chapter 2

3

Page 18

Server Unpacking and Installation

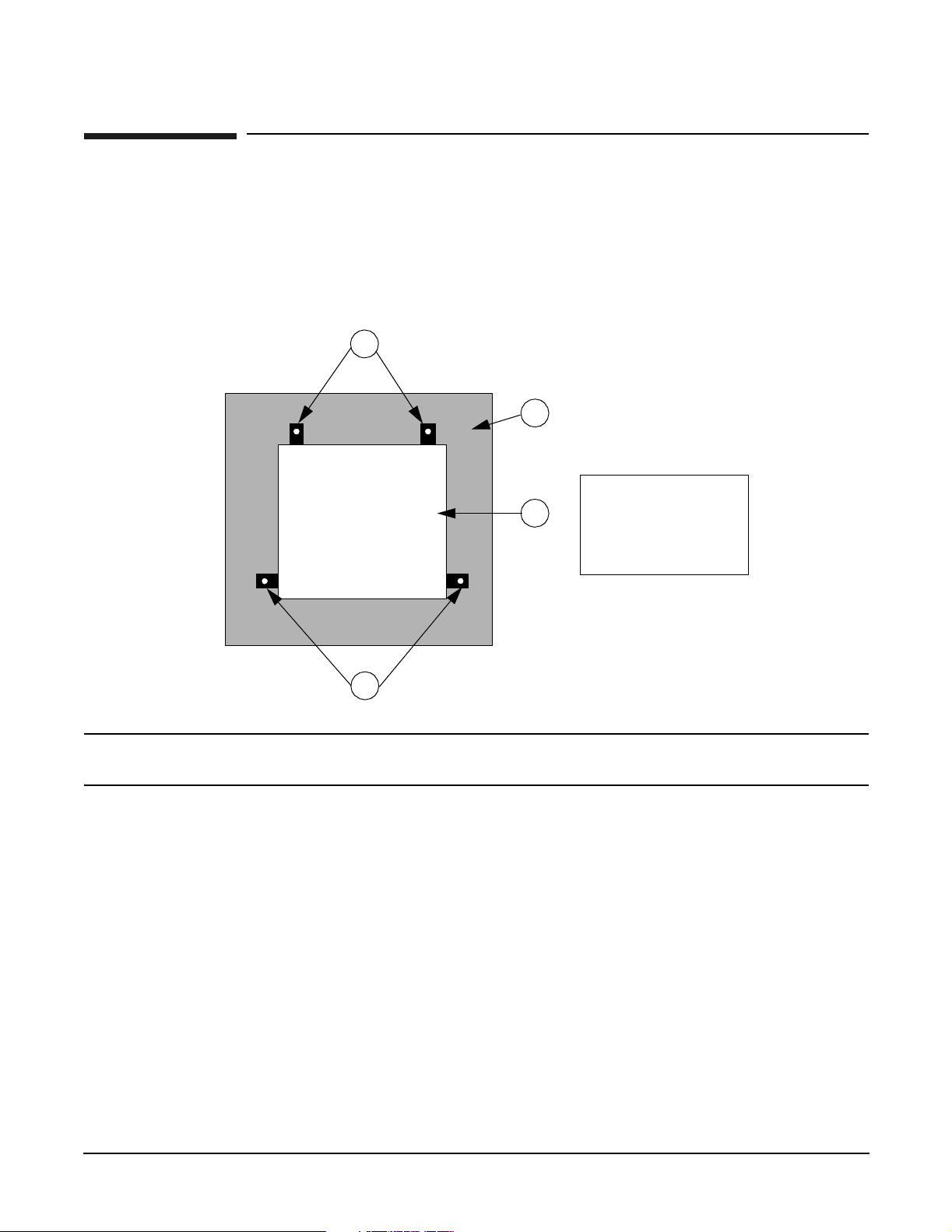

Factory Integrated rp54xx Cabinet Installation

Factory Integrated rp54xx Cabinet Installation

A factory integrated server is one in which the rp54xx server and associated components are pre-assembled

and shipped from the factory already installed in a Hewlett-Packard E-Series cabinet. Factory integrated

systems reduce the amount of time required to set-up and begin server operation.

1. Carefully remove the carton and anti-static bag from the pallet.

2. Remove the front two (2) L-brackets. Retain the 1/2-inch bolts for later use.

1

Rear

2

3

Front

1

NOTE As viewed from the front, one bracket is located on each side at the base of the cabinet near

the front.

1. Shipping L-Bracket

2. Shipping Pallet

3. Cabinet (Top View)

4

Chapter 2

Page 19

Server Unpacking and Installation

Factory Integrated rp54xx Cabinet Installation

3. At the rear of the cabinet:

a. Open the door.

b. Remove the anti-tip foot by removing and retaining the two (2) 1/2-inch bolts.

For Shipping:

L-brackets are

mounted behind

anti-tip foot.

Same bolts

secure both.

Bolts

c. Remove the two (2) L-brackets (revealed by removing the anti-tip foot).

4. Remove the two ramps from the pallet and carefully place them into the slots at the front of the pallet.

WARNING Use extreme care when rolling the racked system down the ramps. A rack

containing one rp54xx can weigh up to 418 lbs. Do not stand in front of the ramps

when rolling the cabinet off the pallet or injury may occur. All but the smallest

configurations require two persons to safely remove the rack from the pallet.

If anti-tip feet or ballast are not installed or are improperly installed the cabinet

can tip. Failure to follow this precaution can cause injury to personnel or damage

to equipment.

Chapter 2

5

Page 20

Server Unpacking and Installation

Factory Integrated rp54xx Cabinet Installation

5. Straighten the rollers on the cabinet base, if needed, and carefully roll it down the ramps.

WARNING After removing the server from the pallet, Do not move the cabinet unless the

anti-tip feet are installed! The cabinet can tip if care is not used. Due to their low

ground clearance the feet may catch on irregularities on the floor, thresholds, or

ramps.

Do not move the cabinet without first installing the anti-tip feet. The cabinet may

tip if moved without the anti-tip feet or ballast installed.

Do not move the cabinet after installing the anti-tip feet unless they are in the

fully-raised position. Once installed, the anti-tip feet must be fully raised to allow

ground clearance.

Because of their low ground clearance, the fully-raised anti-tip feet may need to

be removed temporarily to clear some obstacles such as door jambs, ramps, and

other large irregularities or obstructions on the floor.

If you must temporarily remove the anti-tip feet to clear an obstacle, use extreme

caution when moving the cabinet. Always reinstall the anti-tip feet as soon as the

obstacle has been cleared.

Lower and secure both the anti-tip feet and the cabinet leveling/stabilizer feet

once the cabinet is in place.

Failure to follow these precautions can result in equipment damage or personal

injury.

6. Install the front and rear anti-tip feet using the 1/2 inch bolts provided. Ensure that the anti-tip feet are

installed in the fully up position in the mounting slots. This will provide maximum ground clearance

while moving the cabinet to its final position.

7. Carefully move the cabinet to its installation location.

8. Lower the anti-tip feet to the fully down position and adjust the cabinet leveling feet for best cabinet

stability.

6

Chapter 2

Page 21

Server Unpacking and Installation

Receive and Unpack A Non-Integrated Server

Receive and Unpack A Non-Integrated Server

WARNING The typical rp54xx system can weigh up to 68kg (150lbs). HP recommends using an

an approved lifting device. Lift and move the server in accordance with all local

safety regulations. Failure to follow this precaution can cause injury to personnel or

damage to equipment.

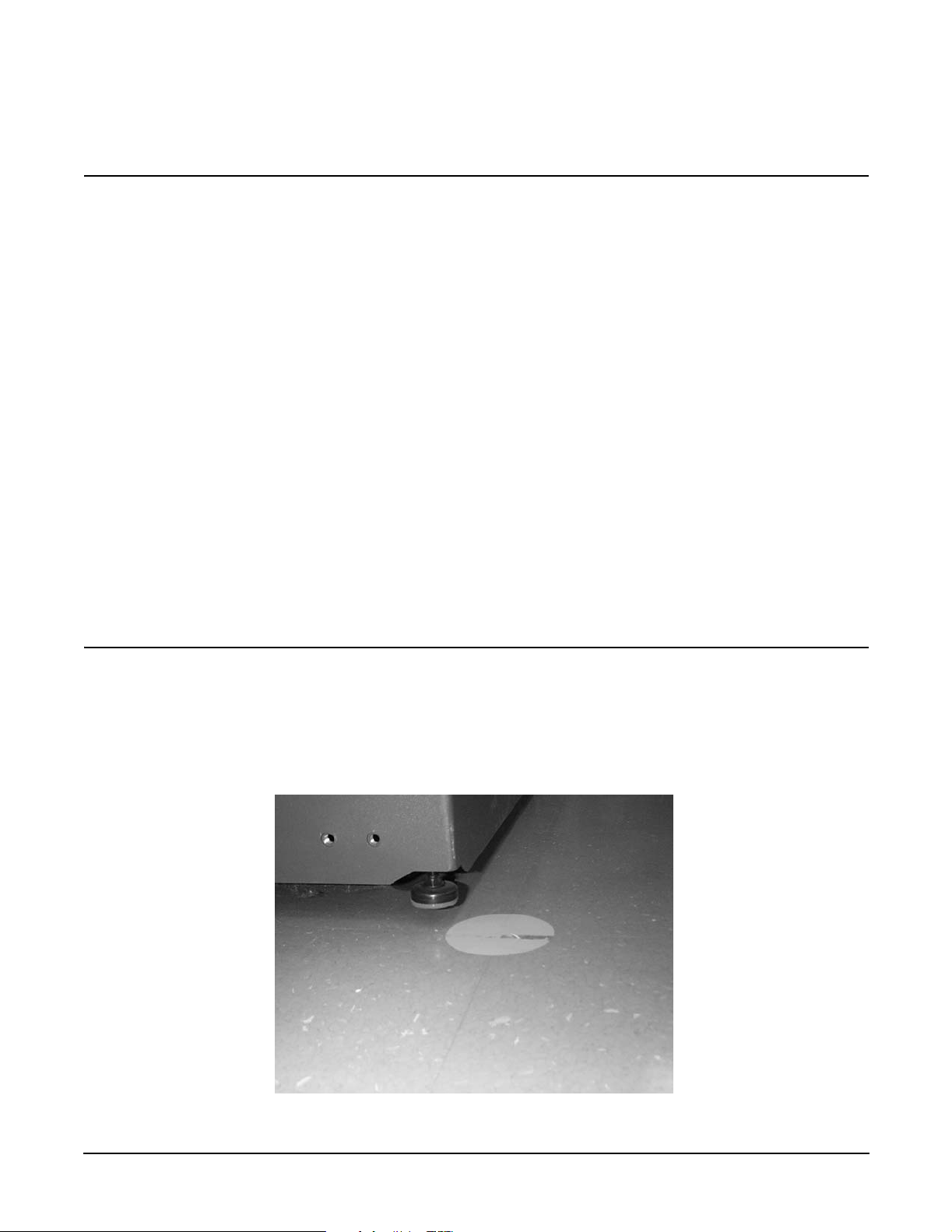

Unpacking the server

The following procedure describes the steps involved in unpacking the server, whether to function as a

stand-alone Deskside unit, or to be integrated into a cabinet.

Step 1. Remove the shipping carton and anti-static bag from the server as depicted below.

Chapter 2

7

Page 22

Server Unpacking and Installation

Receive and Unpack A Non-Integrated Server

NOTE The packaging for rp74xx and rp54xx servers is the same, rp74xx is shown.

Step 2. If you are moving the server manually, use three people to lift the server from the packing material

and pallet. Carefully move the server to the selected location.

Step 3. If you are moving the server by an approved lifting device (such as Genie Lift ), remove the tear

flap from the front lip of the carton bottom to allow access to the server, as illustrated below.

Removal of the tear flap will reveal a slot between the bottom of the server and the inside bottom of

the cardboard box.

8

Chapter 2

Page 23

Server Unpacking and Installation

Receive and Unpack A Non-Integrated Server

Step 4. Carefully raise the lift’s platform so that it will slide into the slot located under the center of the

server, but over the top of the pallet.

Lifting Device

Platform.

NOTE The server’s center of gravity will vary with the hardware configuration, but it is

generally located slightly behind the middle of the server.

Step 5. Raise the lifting device platform enough for the server to clear the pallet and packing materials, as

show below.

Chapter 2

9

Page 24

Server Unpacking and Installation

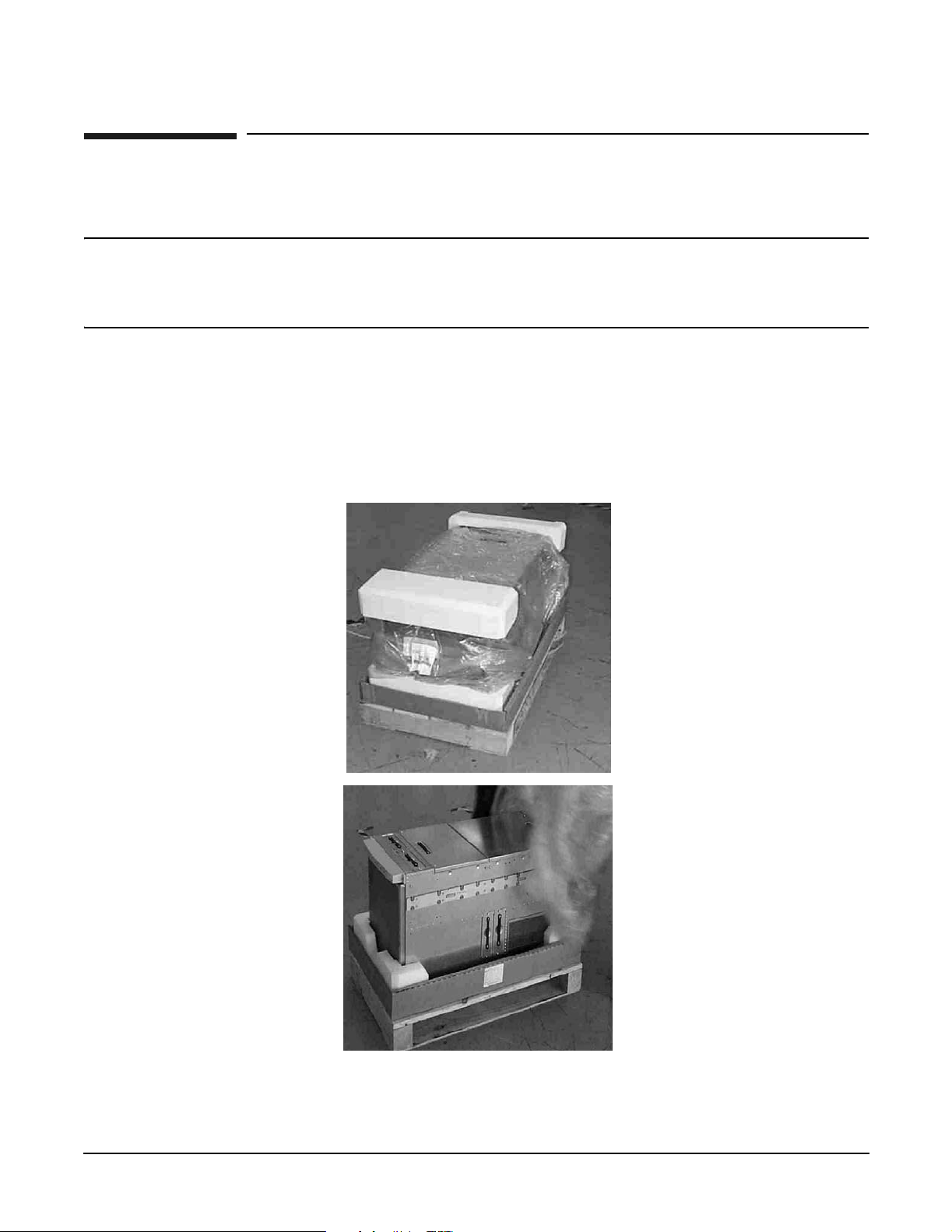

Install Deskside Server

Install Deskside Server

The following section describes the installation of a server into a Deskside enclosure for installation in an

office environment.

WARNING The typical rp54xx system can weigh up to 68kg (150lbs). HP recommends using an

approved lifting device.

• Lift and move the server in accordance with all local safety regulations.

• Do not attempt to lift the server by the plastic handles on the top and side covers.

Failure to follow these precautions can cause injury to personnel or damage to

equipment.

Step 1. Unpack the server.

Step 2. Unpack the deskside enclosure.

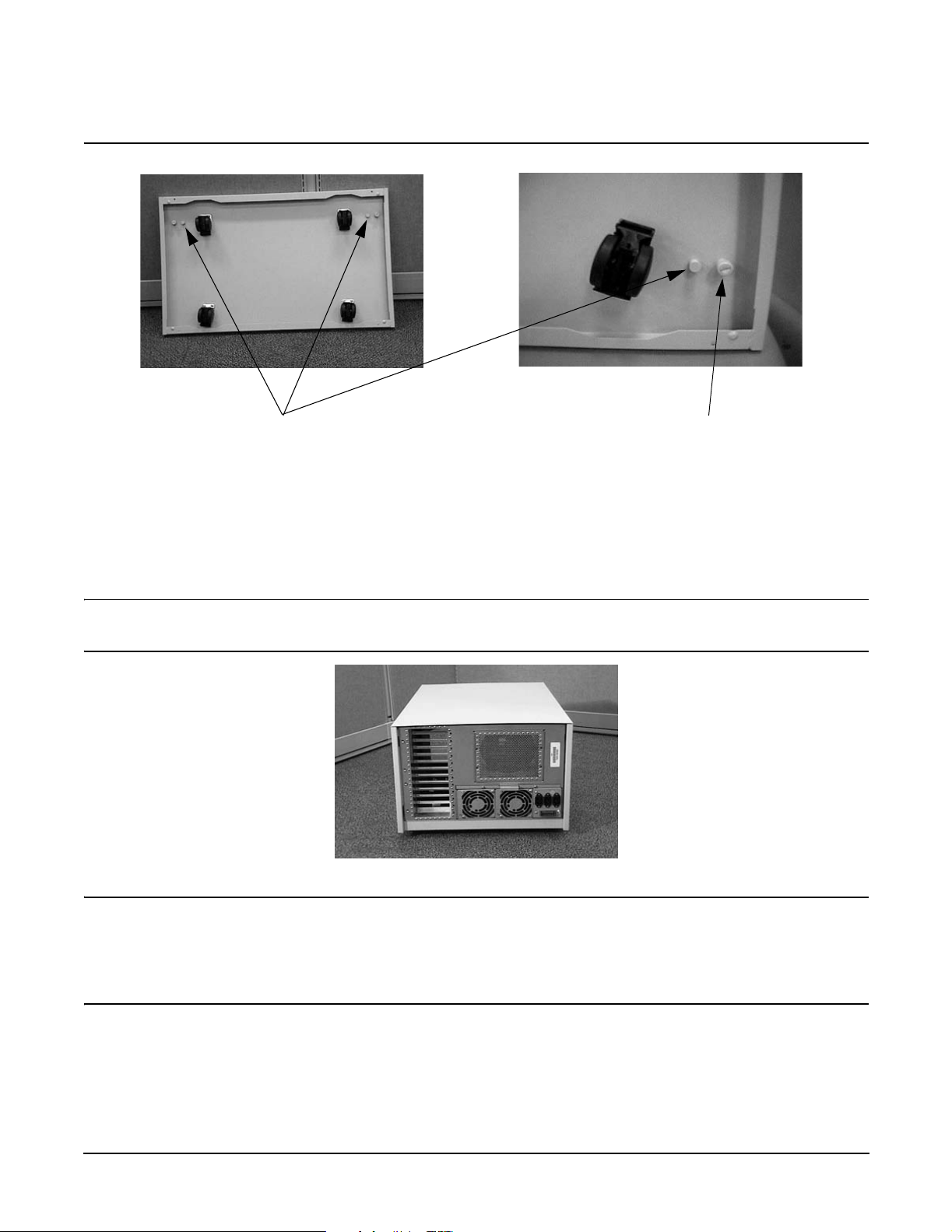

Server

Enclosure

Outside

Cover

(Skin)

NOTE Ensure that the positioning spring pins in the enclosure base align with the

alignment holes in the bottom of the server.

Wheeled

Enclosure

Base

10

Chapter 2

Page 25

Server Unpacking and Installation

Install Deskside Server

Alignment Spring Pins

Captive Fastener

Step 3. Position the server on the wheeled enclosure base.

Step 4. Tighten the two captive screws in the enclosure base to secure the server to the base.

Step 5. Position the enclosure cover (outside skin) over the server and install and tighten the screws to

secure it to the base.

NOTE The perforations and the lip of the outside skin should be toward the rear of the

server.

WARNING Stacking rp54xx servers in deskside enclosures is not supported.

Stacking rp54xx servers in deskside enclosures can damage equipment,

may cause injury to personnel, and may void your warranty or service

contract.

Step 6. Install the Front Bezel.

Step 7. Locate the two pull-tabs. One pull-tab is longer than the other. The shorter pull-tab is blank on both

sides. The back of the shorter pull-tab provides a writable surface for Customer use.

Chapter 2

11

Page 26

Server Unpacking and Installation

Install Deskside Server

Step 8. Locate the plastic bag containing the label sheet (taped to the server).

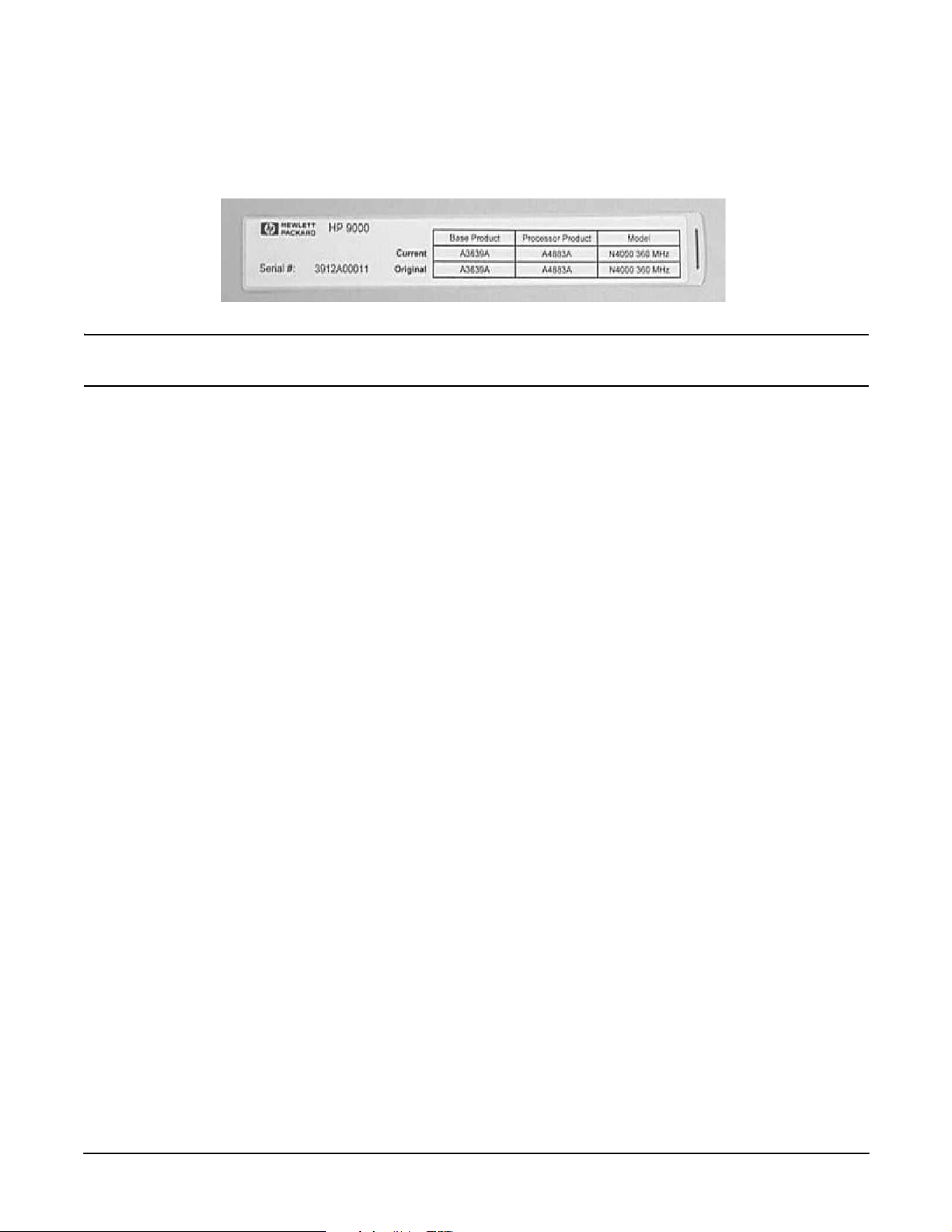

Step 9. Remove the label containing serial number, base product, processor product, and model information

from the label sheet and apply to the back of the longer pull-tab.

NOTE Pull-tab and label shown above is for an rp74xx server. rp54xx uses the same style

label and similar pull-tab.

Step 10. Insert the pull-tabs into the front bezel. Install the longer pull-tab in the left side plastic window in

such a way that the rp54xx logo is visible. Install the shorter pull-tab in the right side plastic

window with either surface visible. Refer to the diagram above for pull-tab locations.

12

Chapter 2

Page 27

Server Unpacking and Installation

Install Stand-Alone Server in a Cabinet

Install Stand-Alone Server in a Cabinet

The following describes how to install the A5556A slide-tray assembly into an approved HP cabinet in

preparation for installing an rp54xx server.

This slide-tray assembly can be installed in an HP E-Series cabinet or other HP cabinets approved for rp54xx

system installation. To install the A5556A slide-tray assembly in an approved HP equipment cabinet, proceed

as follows:

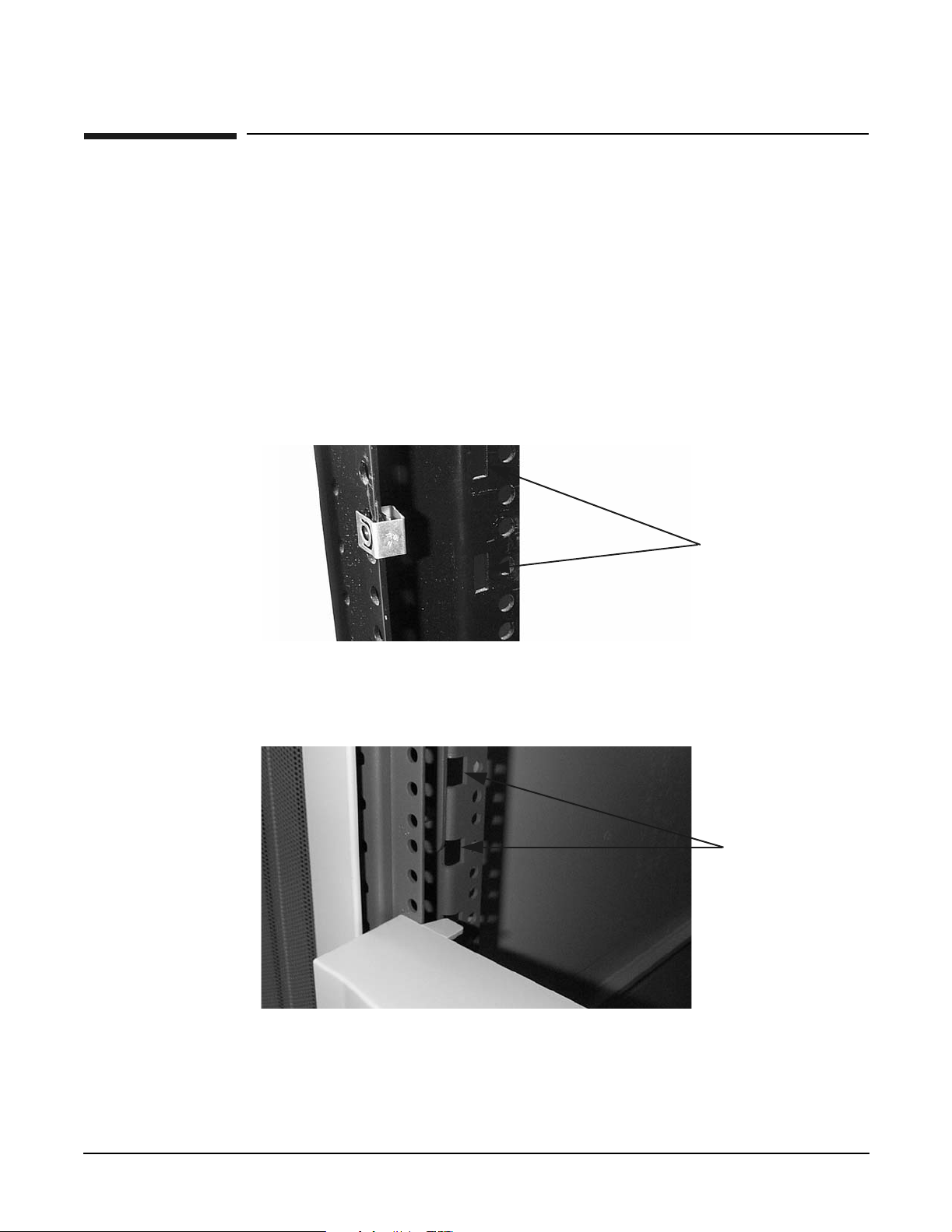

Step 1. Determine what type of cabinet you are installing the slide-tray assembly into.

a. E-Series cabinets have:

• Parchment white, plastic, sectional, side panels

• Black painted vertical frame posts with a partial return flange.

b. Approved, non-E-Series, cabinets have:

• Single piece metal side panels

• Gray painted verticle frame posts with full return flanges.

Vert ica l ,

Rectangular,

Mounting Slots

Vertica l,

Rectangular,

Mounting Slots

Step 2. Note the vertical, rectangular, slots in the return flanges on the vertical mounting posts. Determine

into which of these vertical slots the slide/tray kit will be installed. This is done by counting down

eight rectangular slots from the top of the cabinet or the bottom of the equipment above.

Chapter 2

13

Page 28

Server Unpacking and Installation

Install Stand-Alone Server in a Cabinet

Step 3. On the front vertical mounting posts only, slide M5 sheet metal nuts onto the posts over the holes

immediately adjacent to the vertical slots determined in the previous step. Also place M5 sheet

metal nuts on the holes directly above these. Orient the sheet metal nuts so that the threaded

portion faces towards the outside of the cabinet. There should now be a total of four (4) sheet metal

nuts installed.

Step 4. If the cabinet is a non-E-Series cabinet, discard the left hand and right hand aluminum spacers and

two of the M5 x 16 screws with cress-cup washers and proceed to step 12.

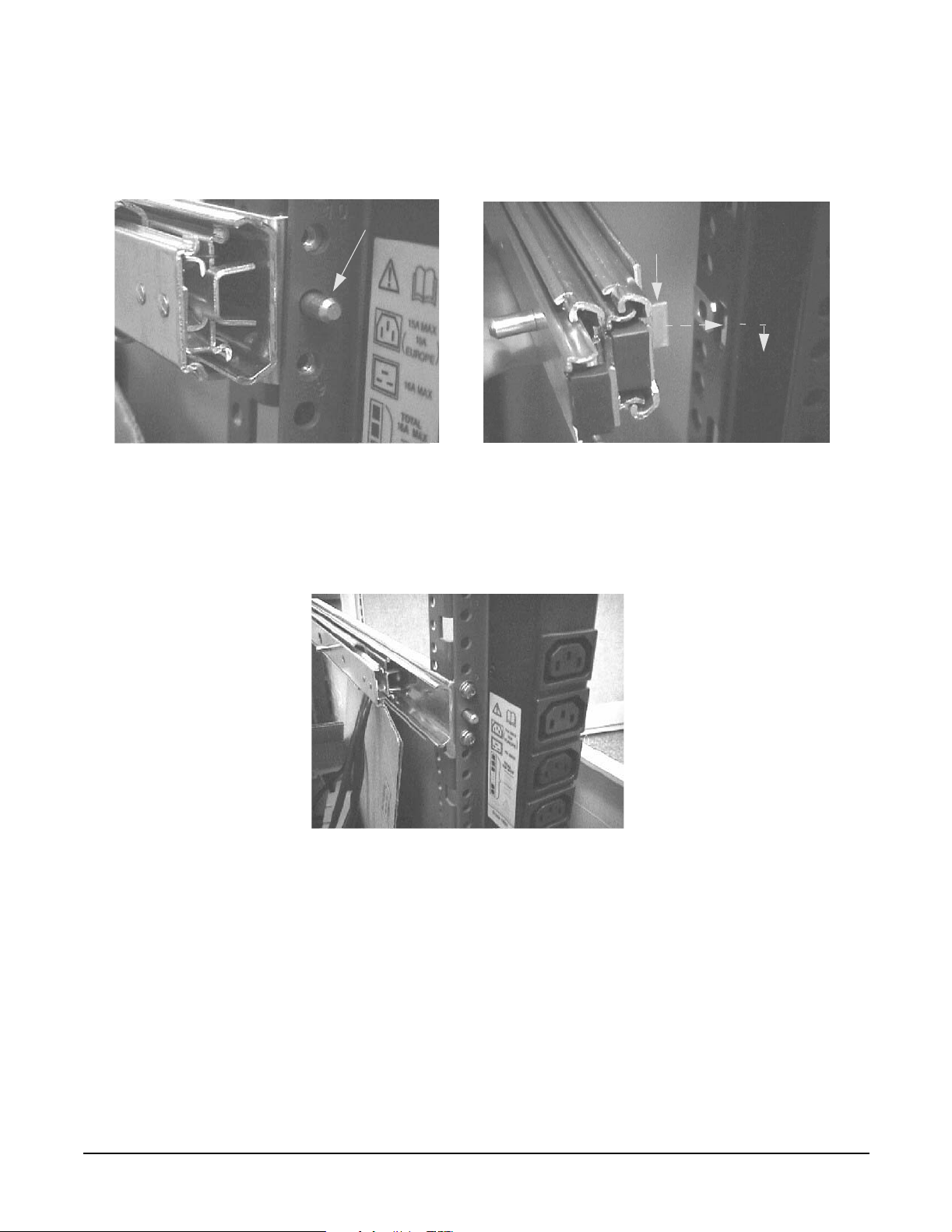

Step 5. If the cabinet is an E-Series cabinet, place the hook of the aluminum spacer marked “L” (5183-1864)

into the appropriate vertical, rectangular slot on the front, left hand mounting post. The hook

points downward. Similarly, place the spacer marked “R” (5183-1863) into the appropriate slot on

the right hand mounting post.

Step 6. Use one M5 x 16 screw with cress-cup washer to attach each spacer to its vertical post. Do this by

inserting the screw through the top hole in the spacer, through the mounting rail and tightening it

into the sheet metal nut located at that position.

Step 7. Take the left hand slide/bracket assembly (marked 337079-1L) and install it into the left hand

vertical mounting posts. This is done by inserting the pin at the rear of the slide's mounting bracket

into the 23rd hole in the rear vertical mounting post and inserting the hook at the front of the

14

Chapter 2

Page 29

Server Unpacking and Installation

Install Stand-Alone Server in a Cabinet

bracket into the vertical, rectangular slot in the aluminum spacer. The slide should be positioned in

the cabinet so that it is horizontal and level.

Guide Pin

Hook

Step 8. Securely fasten the rear of the slide's mounting bracket to the rear vertical mounting post by

installing and tightening two of the M5 x 16 screws with cress-cup washers thorough the mounting

post, through the slides mounting bracket and into the threaded nuts attached to the mounting

bracket.

Chapter 2

15

Page 30

Server Unpacking and Installation

Install Stand-Alone Server in a Cabinet

Step 9. Fully extend the slide so that it is locked in the fully open position.

Step 10. Use an M5 x 30 screw with a cress cup washer to attach the front of the slide to the vertical

mounting post. Insert the screw through the slide, through the center hole of the aluminum spacer,

through the vertical mounting post, and tighten into the sheet metal nut located at that position.

Step 11. Use a procedure similar to steps 7 through 10 to install the right hand slide/bracket assembly

(marked 337079-1R) and then proceed to step 12.

16

Chapter 2

Page 31

Server Unpacking and Installation

Install Stand-Alone Server in a Cabinet

Step 12. Take the tray and place it onto the pins that extend from the slides' inner members. The slots with

wide lead-in guides on the side of the tray fit down onto the slides' pins. The flat part of the tray will

be on top, and the mounting holes in the top of the tray will be located to the right of the center of

the tray. Slide the tray all the way down on both sides so that the pins reach the top of the slots in

the side of the tray.

Pins in Slots

Step 13. Use six, M5 x 12 screws (without washers) to attach the tray to the slides. Three screws are used to

attach each slide. Insert the screws through the slides, through the tray and tighten into the

threaded nuts located on the inside of the sides of the tray.

3 Pan Head

M5x12 T25 screws

on each side

Step 14. From the bottom of the tray pull the plunger pin down and give it a 1/4 turn to hold it in place.

Chapter 2

17

Page 32

Server Unpacking and Installation

Install Stand-Alone Server in a Cabinet

Step 15. Position the server on the tray aligning the plunger pins with the alignment holes in the chassis.

Step 16. Release the plunger pins to secure the server.

18

Chapter 2

Page 33

Server Unpacking and Installation

Stationary L-Bracket Rail Assembly

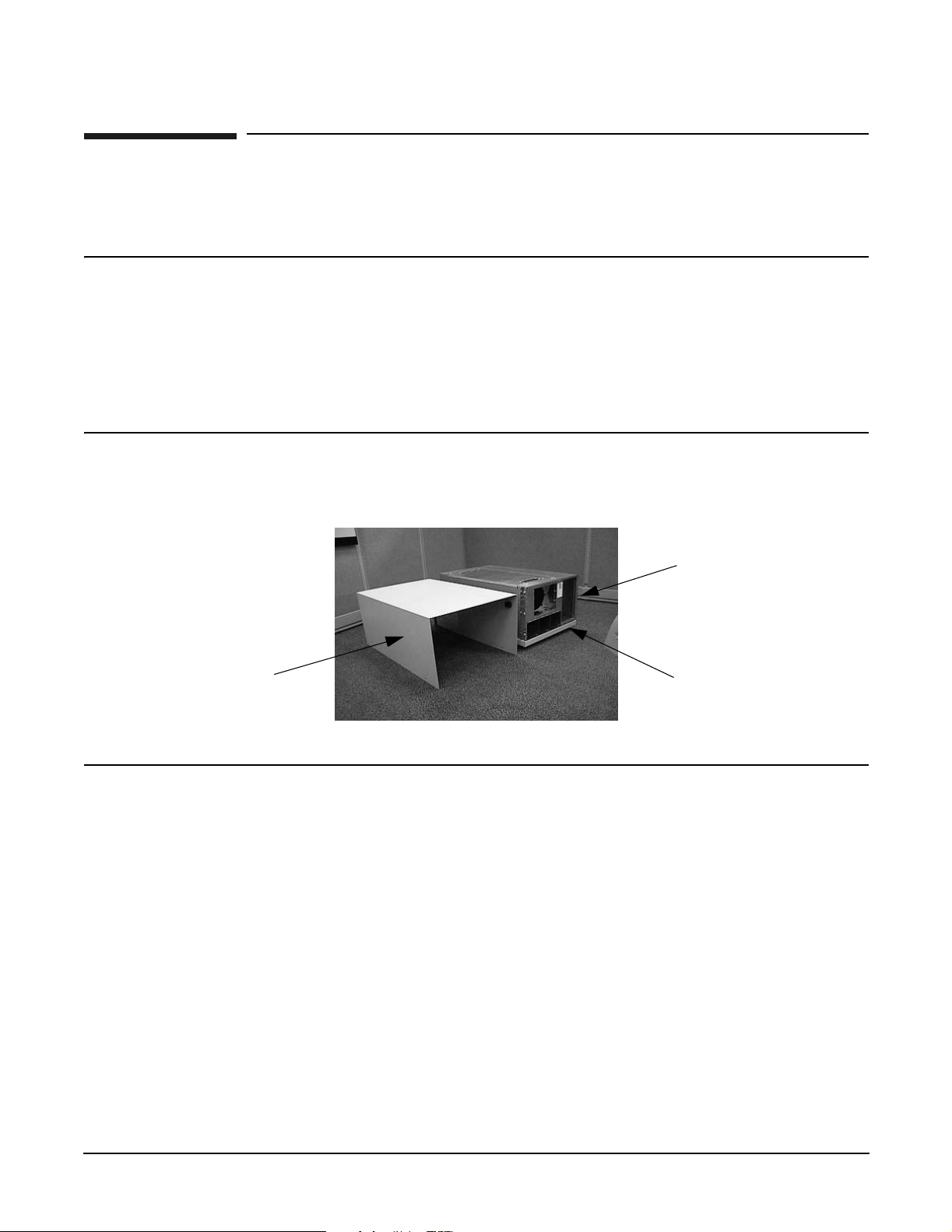

Stationary L-Bracket Rail Assembly

rp54xx servers may be installed into E-Series and approved Non- E-Series cabinets using stationary

L-bracket rail assembly kits listed below.

NOTE rp54xx servers are supported in Hewlett-Packard E-series and approved Non- E-series

Hewlett-Packard cabinets, and approved rail kits.

For information on additional qualified 3rd party cabinets and rail kits, contact the nearest

Hewlett-Packard Response Center.

Cabinet Type Rail Kit Product Number

E-Series HP Cabinet A5575A

Other Approved HP Cabinet A5562A

Identifying Approved Non-E-Series HP Cabinets

Approved Non- E-Series cabinets have black frames, one piece outside sheet metal skins, a partial return

flange, and requires the installation of the aluminum spacer blocks, supplied with the rail kits.

Approved Non- E-Series cabinets include the following product numbers: A1883A, A1884A, A1896A, A1897A,

C1897A, C2785A, C2786A, and C2787A.

Chapter 2

19

Page 34

Server Unpacking and Installation

Stationary L-Bracket Rail Assembly

Identifying E-Series HP Cabinets

E-Series cabinets have light gray frames, sectioned, plastic outside “skins”, a full return flange, and does not

require the installation of the aluminum spacer block supplied, with the rail kits.

E-Series cabinets include the following product numbers: A5134A, A5136A, A5136A, A4900A, A4901A,

A4902A, J1500A, J1502A, and J1502A.

Identifying Static Rail Kit

Hewlett-Packard has currently approved two static rail kits for use in cabinet mounting the rp54xx server.

They are illustrated below.

20

A5575A Kit RailA5562A Kit Rail

Chapter 2

Page 35

Server Unpacking and Installation

Stationary L-Bracket Rail Assembly

Installing Stationary Rails

The installation of stationary rails is similar for most cabinet and rail combinations.

The key considerations to are:

• Ensure that all safety precautions are read, understood, and observed

• Follow all installation instructions provided with the cabinet and rail kits, and

• Ensure that the rails extend out from the cabinet posts sufficiently to properly and safely support the

equipment being installed.

To install an rp54xx server on stationary rails in an approved cabinet proceed as follows:

Step 1. Locate the rail mounting height in the cabinet. Allow for the following space requirements:

• For each rp54xx server, allow 31.8cm (12.5 inches) vertically (7 EIAs or Rack Units (RUs).

• If installing the A5575A rail kit, allow an additional vertical 4.45cm (1.75 inches (1 EIA) each

set of rails.

31.8 cm

(12.5

inches

4.45 cm

(1.75

Inches

Step 2. Install sheet metal nut(s) in the vertical cabinet posts at the required height for the kit being

installed:

• Install the first nut either:

rp54xx

Server

Rail

rp54xx

Server

Rail

31.8 cm

(14.25

inches

A5575A Rail Kit

in approved

Non- E-Series

cabinet shown

— 4.45 cm (1.75 Inches) above the top, or

— 31.8 cm (12.5 inches) below the bottom of the last server.

• If installing a A5562A rail kit, install the second nut in the next frame hole below the first.

Step 3. Hold the rail in place and insert and tighten the screws.

Chapter 2

21

Page 36

Server Unpacking and Installation

Stationary L-Bracket Rail Assembly

For installation of other qualified cabinet and rail combinations refer to the safety precautions and

instructions accompanying them.

22

Chapter 2

Page 37

3 Installing Additional Components

Chapter 3

23

Page 38

Installing Additional Components

Additional Components

Additional Components

Some internal components are too delicate to be installed in the server prior to shipping. These internal

components are shipped with the server, but are packed separately. They can be installed after the cabinet

has been unpacked and positioned.

Some of the internal components that are packed separately are not user-installable. To maintain warranty

validation, these items must be installed by a Hewlett-Packard Customer Engineer.

If you received either (or both) of the components listed below, contact your Hewlett-Packard provider to

arrange for installation.

• Central Processing Units (CPUs)

• Power Distribution Units (PDUs)

24

Chapter 3

Page 39

Installing Additional Components

Installing Memory

Installing Memory

Memory Configuration Rules

rp54xx servers have 16 slots (8 DIMM pairs) for memory DIMMs. These slots are numbered 0a/b, 1a/b,... 7a/b.

8 of these slots (4a/b - 7a/b) are disabled on rp5400 servers. rp5450 servers can access all slots. rp5400 and

rp5450 servers have DIMM slots located on the System Board.

rp5470 servers install DIMMs using Memory Carriers. The Memory Carriers fit into slots on the System

Board.

The following rules govern the installation of memory DIMMs for rp5400, rp5450, and rp5470 servers:

• Memory must be installed in DIMM pairs.

• The capacity of DIMMs within a pair must be the same.

• Install DIMMs with the greatest capacity in the lowest slot numbers.

• Install DIMMs the following slot order: 0a/b, 1a/b, 2a/b, 3a/b, and so on.

Installing rp5400 and/or rp5450 DIMMs

Step 1. Power down and unplug the rp54xx server.

CAUTION DC voltages are present when the server is connected to AC power. Do not install or

service rp54xx internal components while DC voltage is present. Failure to observe

this precaution can result in damage to the server.

Step 2. Loosen the captive T-15 screws that hold the top cover in place, then grasp the strap handle, raise

the cover slightly, and pull the cover toward the front of the server to free the cover tabs from the

slots in the chassis. The air baffle will be exposed.

Step 3. Make the top of the server accessible for service.

Chapter 3

25

Page 40

Installing Additional Components

Installing Memory

Step 4. Loosen the captive T-15 screws on the air baffle. Grasp the two handles on the baffle, and lift the

baffle remove it.

CAUTION Observe all ElectroStatic Discharge (ESD) precautions Do not touch internal

components. Failure to observe ESD precautions can cause damage to components.

Step 5. Observe Electrostatic Discharge (ESD) precautions.

Step 6. Refer to the following graphic for memory slot locations.

26

Chapter 3

Page 41

Installing Additional Components

Installing Memory

Locate the correct DIMM pair slots. Insert the DIMM connectors into the guides until the card

snaps firmly in place. It may be necessary to apply downward force using the palm of your hand on

the DIMM. Observe the top of the DIMM to make sure one side is not higher than the other.

NOTE It may be necessary to remove PSM 1 when installing a DIMM in slot 0a and PSM 0

when installing a DIMM in slot 1b. If either PSM is removed to install memory,

ensure it is re-installed.

Step 7. Replace the air baffle. Tighten the four captive screws to secure the air baffle in place.

Step 8. Replace the top cover. Tighten the four captive screws to secure the top cover in place.

Step 9. For rack configurations, insert the rp54xx server back into the rack.

Step 10. For deskside enclosure configurations, replace the deskside enclosure cover.

Step 11. Power the rp54xx server on.

Step 12. Use the BCH command in me to verify the system recognizes the memory that you have just

added.

Chapter 3

27

Page 42

Installing Additional Components

Installing Memory

Installing rp5470 DIMMs

DIMMs for the rp5470 system are installed in memory carriers instead of the system board, as are the other

rp54xx systems. However, rp5470 memory carriers are also located on the system board, so the method for

opening and closing the system is the same. Procedures for removing and replacing the server top and baffle

are listed below, without the pictures shown in the section titled, “Installing rp5400 and/or rp5450 DIMMs.”

If you wish to reveiw the pictures, please refer to the aforementioned section.

Step 1. Power down and unplug the rp54xx server.

NOTE DC voltages are present when the server is connected to AC power. Do not attempt to

install or service: CPUs, Memory, PSMs, the Platform Monitor or PCI I/O cards

installed in non-Turbo slots (1-6) while DC voltage is present. Failure to observe this

warning may result in damage to the server.

Step 2. Make the top of the server accessible for service.

Step 3. Loosen the captive T-15 screws that hold the top cover in place, then grasp the strap handle, raise

the cover slightly, and pull the cover toward the front of the server to free the cover tabs from the

slots in the chassis. The air baffle will be exposed.

Step 4. Loosen the four (4) captive T-15 screws on the air baffle. Grasp the two handles on the baffle, and

lift and remove the baffle.

Step 5. Observe Electrostatic Discharge (ESD) precautions.

Step 6. Refer to the following graphic for Memory Carrier locations.

MemoryCarrier Assemblies

28

Chapter 3

Page 43

Installing Additional Components

Installing Memory

a. Locate the Memory Carrier and pull up on the extractor levers on each end of the Memory

Carrier to unseat the Memory Carrier from its socket.

b. When the Memory Carrier unseats from the socket, pull it away from the System Board.

c. Loosen the captive screws that secure the DIMM Clip and remove the DIMM Clip from the

Memory Carrier.

d. Seat the memory DIMM into its socket on the Memory Carrier.

e. Press the extractor levers on each end of the memory DIMM slot inward until the levers snap

into place.

f. Attach the Memory Clip to the Memory Carrier with the DIMM slot markings on the top of the

Memory Clip aligned with the DIMM slot markings on the Memory Carrier.

g. Secure the Memory Clip using the captive screws.

h. Seat the Memory Carrier into the appropriate slot on the System Board.

i. Push down on the extractor levers and snap them into place.

Step 7. Replace the air baffle. Tighten the four captive screws to secure the air baffle in place.

Step 8. Replace the top cover. Slide the cover tabs into the slots in the chassis and close the cover. Tighten

the two captive screws to secure the top cover in place.

Step 9. For rack configurations, insert the rp54xx server back into the rack.

Step 10. For deskside enclosure configurations, replace the deskside enclosure cover.

Step 11. Power the rp54xx server on.

Step 12. Use the BCH command in me to verify the system recognizes the memory that you have just

added.

Chapter 3

29

Page 44

Installing Additional Components

Installing Peripheral Component Interconnect (PCI) Cards

Installing Peripheral Component Interconnect (PCI) Cards

rp54xx servers have a total of 12 PCI I/O slots. Slots 1 and 2 are reserved for the LAN/SCSI and GSP Core I/O

cards, leaving 10 PCI I/O slots available for Customer use.

rp5400/rp5450 PCI Card Slots

For rp5400 and rp5450 models, 10 PCI I/O slots consist of Turbo and non-Turbo slots. Server PCI slots are

shown below.

rp5400/rp5450 PCI Card Slots

• Slots 1 and 2 are reserved for the rp54xx LAN/SCSI and GSP (Guardian Service Processor) Core I/O

cards, respectively. Slots 1 and 2 are non-Turbo slots. Non-Turbo slots share a single 250MB/s PCI bus

and are incapable of HotPlug functionality. The server must be turned off prior to removing or installing

the LAN/SCSI or GSP cards in these slots.

• Slots 3 - 6 are non-Turbo slots. These four Non-Turbo slots share a single 250MB/s PCI bus, run at 33MHz

and support 32 and 64-bit PCI cards. Non-Turbo slots are incapable of HotPlug functionality. The server

must be turned off prior to removing or installing PCI cards in these slots.

• Slots 7 - 12 are Turbo slots. Each Turbo slot has a dedicated 250MB/s PCI bus, run at 66MHz and support

32 and 64-bit PCI cards. Turbo slots are HotPlug capable. Below each Turbo slot is a plastic PCI card

separator. The PCI card separator has two LEDs and a pull tab on the outer edge. The LED’s provide

power and status for the slot. The pull tab allows the PCI card to be easily removed.

rp5400 servers have access to slots 1, 2 and 8-12 while rp5450 servers have access to all (1-12) slots.

NOTE Slot 3 will become enabled on rp5400 servers with server firmware versions later than 40.48.

A slot 3 enabled label (A5576-84009) is available for rp5400 systems.

30

Chapter 3

Page 45

Installing Additional Components

Installing Peripheral Component Interconnect (PCI) Cards

rp5470 PCI Card Slots

For rp5470 models, the 10 PCI I/O slots consist of Twin Turbo, Turbo, and non-Turbo slots. The following

illustration shows the PCI card slot layout.

rp5470 PCI Slots

• Slots 1 and 2 are reserved for the rp54xx LAN/SCSI and GSP (Guardian Service Processor) Core I/O

cards, respectively. Slots 1 and 2 are non-Turbo slots. Non-Turbo slots share a single 250MB/s PCI bus

and are incapable of HotPlug functionality. The server must be turned off prior to removing or installing

the LAN/SCSI or GSP cards in these slots.

• Slots 3 and 4 are non-Turbo slots. These two Non-Turbo slots share a single 250MB/s PCI bus, run at

33MHz and support 32 and 64-bit PCI cards. Non-Turbo slots are incapable of HotPlug functionality. The

server must be turned off prior to removing or installing PCI cards in these slots.

• Slots 5 - 10 are Turbo slots. Each Turbo slot has a dedicated 250MB/s PCI bus, run at 66MHz and support

32 and 64-bit PCI cards. Turbo slots are HotPlug capable. Below each Turbo slot is a plastic PCI card

separator. The PCI card separator has two LEDs and a pull tab on the outer edge. The LED’s provide

power and status for the slot. The pull tab allows the PCI card to be easily removed.

• Slots 11 and 12 are Twin Turbo slots. Each Twin Turbo slot has a dedicated 500MB/S PCI bus, runs at 66

MHz, and supports 32- and 64-bit PCI cards. Twin Turbo slots are HotPlug capable. Below each Twin

Turbo slot is a plastic PCI card separator. The PCI card separator has two LEDs and a pull tab on the

outer edge. The LED’s provide power and status for the slot and the pull tab allows the PCI card to be

easily removed.

rp5470 servers have access to all (1-12) slots.

Chapter 3

31

Page 46

Installing Additional Components

Installing Peripheral Component Interconnect (PCI) Cards

PCI I/O Card Installation Restrictions

Restrictions apply regarding the installation of PCI I/O cards which contain a PCI-to-PCI bridge:

• HP-UX boot is currently not supported for cards that contain a PCI-to-PCI bridge.

• HP-UX patches are required when more than one card containing a PCI-to-PCI bridge is installed in

non-Turbo slots.

PCI I/O Card Installation Order

The following table shows a standard factory PCI card installation that begins with slot 12. Use this table as

a guideline for installing PCI I/O cards in the field.

NOTE A system shipped from the factory may have a different configuration than the same system

built in the field. For example: The factory will install the graphics card in slot 12 and add

other cards below. In the field, slot 12 may already be occupied by another PCI card. It is

acceptable for the graphics card to be installed in any available Turbo slot.

Product

Number

A6150A Graphics, Graphics Card 1 No 1 A4982-66501 3,8

A5838A Combo No 3 A5838-60001 9

A5483A ATM 622Mbps MMF Adapter 10 No 4 A5483-60001 10

A4926A 1000Base SX PCI LAN Adapter 10 No 5 A4926-60001

A4926A 1000Base TX PCI LAN Adapter 10 No 6 A4926-60001

A6092A HYPERFabric No 7 A6092-60001 11

A5158A FC Taclite Y 8 A5846-60001

A5486A Praesidium Speed Card 10 No 9 A5486-60001

A5506A 4 Port 100Base TX LAN Adapter 7/10 No 10 A5506-60101 1,2,6

A5506B 4 Port 100Base TX LAN Adapter 7/10 No 10 A5506-60102

A5150A Dual Port Ultra 2 SCSI adapter 10 Yes 11 A5150-60001 4

A5149A Single Port Ultra 2 SCSI HBA 10 Yes 12 A5149-60001

J3526A High Perf 4 Ports Synchronous Adapter 10 No 13 5063-1322 7,5

Description (all are PCI cards) Max Boot

Load

Order

*

Part

Number

Notes

A4800A FWD SCSI-2 adapter 10 Yes 14 A4800-67002

A5230A 100Base-T LAN Adapter 10 No 15 B5509-66001

A3738A 10/100Base-T LAN Adapter 10 No 16 A3738-60001

A3739A Dual FDDI LAN Adapter 10 No 17 A3739-60001

A5783A Token Ring 4/16/100 Hardware Adapter 10 No 18 A5783-60101

32

Chapter 3

Page 47

Installing Additional Components

Installing Peripheral Component Interconnect (PCI) Cards

Product

Number

Description (all are PCI cards) Max Boot

Load

Order

*

Part

Number

Notes

J3525A Dual Port Synchronous Adapter 10 No 19 J3525-60001

J3593A 64 port Serial MUX system card 10 No 20 J3593-60001

J3592A 8 Port PCI Serial MUX card 4 No 21 J3592-60101

A6150A Graphics, USB Card 1 No 22 A6150-60001

A6150BX Pinnacle 2 Graphics 1 No 1 A6150-60003 12,13

A6386A Hyper Fabric 2 Interconnect 10 No 6 A3686-60001

A5506A Quad Port 10/100B-TX LAN 10 No 10 A5506-60102 14

A6749A 3.3v 64 Port Terminal MUX 10 No 24 A6749-60001

A6748A 3.3v 8 Port Terminal MUX 10 No 25 A6748-60001

*In top down order.

Notes:

1. Card contains a PCI-to-PCI bridge.

2. Requires PHKL_20123, PHKL_20629 and PHNE_19826 or their superseded equivalents.

3. Not supported in non-Turbo slots. Install in Turbo slots only.

4. Requires server firmware revision 39.46 or later.

5. Requires HP-UX 11.1

6. Maximum is 7 for HP-UX versions prior to 11.0. Maximum is 10 for HP-UX version 11.1 and later.

7. Requires PHKL_19543 and PHKL_19544 or their superseded equivalents.

8. Requires HP-UX 11.0 Support Plus (IPR) 0006, June 2000 or later. This product to be released 6/00.

9. Not supported in a shared slot (slots 3-4 for rp5470, slots 3-6 for rp5450, not applicable for rp5400).

10. If you are installing ATM 622 cards in an rp5470 configuration, do not install them in slots 3 and 4

(shared slots).

11. Requires 768 MB for first card and 512 MB for each additional card.

12. Not supported in shared slots.

13. Max of 1. Needs USB card for keyboard and mouse.

14. Contains PCI bridge.

Chapter 3

33

Page 48

Installing Additional Components

Installing Peripheral Component Interconnect (PCI) Cards

Installing a PCI Card

Follow these procedures to install a PCI card.

Step 1. Power down and unplug the rp54xx server.

NOTE DC voltages are present when the server is connected to AC power. Do not attempt to

install or service: CPUs, Memory, PSMs, the Platform Monitor or PCI I/O cards

installed in non-Turbo slots (1-6) while DC voltage is present. Failure to observe this

warning may result in damage to the server.

Step 2. Make the right side of the server accessible for service.

Step 3. Using a Torx 15 screwdriver, loosen the captive screws on the right side panel. This panel has a

label which shows which PCI I/O slots are available and the corresponding paths. The PCI I/O slot

paths for rp5400, rp5450, and rp5470 are shown below.

rp5400 rp5450 rp5430/rp5470

Slot

Slot Type Path Slot/Type Path Slot Type Path

12 Turbo 0/4/0 Turbo 0/4/0 Twin Turbo 0/10/0

11 Turbo 0/7/0 Turbo 0/7/0 Twin Turbo 0/12/0

10 Turbo 0/3/0 Turbo 0/3/0 Turbo 0/8/0

9 Turbo 0/6/0 Turbo 0/6/0 Turbo 0/9/0

8 Turbo 0/2/0 Turbo 0/2/0 Turbo 0/3/0

7 Not Available Turbo 0/5/0

6 Not Available Shared 0/1/0

5 Not Available Shared 0/1/1

4 Not Available Shared 0/1/2

3Not

Available

b

Shared 0/1/3 Shared 0/4/2

Turbo

Turbo

Turbo

Shared

a

a

a

a

0/1/0

0/5/0

0/2/0

0/4/0

2GSP GSP GSP

1 LAN/SCSI LAN/SCSI LAN/SCSI

a. Slot is NOT AVAILABLE for rp5430.

b. Slot 3 becomes available with server firmware versions later than 40.48.

Step 4. Remove the PCI slot cover from the slot that will receive the PCI card. To remove the PCI slot cover,

slide the PCI slot cover away from the server.

34

Chapter 3

Page 49

Installing Additional Components

Installing Peripheral Component Interconnect (PCI) Cards

Step 5. Slide the PCI card connectors into the slot, snapping firmly in place. For full length (cards that

extend to the left side card guides) PCI cards, use the UPPER card guide.

Step 6. At the rear of the chassis, connect the I/O cable to the card just installed.

Step 7. Replace the right side panel and tighten the captive screws.

Step 8. For rack configurations, insert the rp54xx server back into the rack.

Chapter 3

35

Page 50

Installing Additional Components

Installing Peripheral Component Interconnect (PCI) Cards

Step 9. For deskside enclosure configurations, replace the deskside enclosure cover.

Step 10. Power the server on.

Step 11. Use the server firmware in io command to verify the PCI cards are recognized by the server. If

AUTOBOOT is ON, it will be necessary to interrupt the boot process to get to the server firmware

Main Menu: Enter command or menu > prompt.

Step 12. Boot HP-UX and run the ioscan utility to verify the system recognizes the new PCI card.

Online Addition/Replacement (OLA/R) of PCI I/O cards

Beginning with HP-UX 11i (11.11) rp54xx servers support the on-line addition and replacement of PCI I/O

cards. In order for this high availability feature to be fully implemented, the following server requirements

must be met:

• rp5400A/rp5450A firmware must be later than 40.26 (rp5400B/rp5450B/rp5470A firmware will support

OLA/R upon its release).

• HP-UX operating system must be 11i (11.11) or later.

There is a bit that the HP-UX operating system examines to determine if the server hardware and firmware

is capable of OLA/R. This bit is controlled by server firmware. If the bit is ON, OLA/R is possible (when

requirements have been met). The bit was mistakenly set to ON for all rp5400 and rp5450 revision A

(rp5400A and rp5450A) servers. As a result, HP-UX may incorrectly identify these models as being OLA/R

capable. In order to avoid this confusion, verify that the correct level of server firmware is installed.

36

Chapter 3

Page 51

Installing Additional Components

Installing Graphics

Installing Graphics

This section explains how to install rp54xx 2D graphics hardware. For a complete graphics solution, three

products are required. The products listed below are the only products supported on rp54xx servers.

• A6150A rp54xx Graphics Package

— Includes PCI graphics card

— Includes PCI USB (Universal Serial Bus) card

• A4983B Keyboard and Mouse Kit

— Includes mouse with 114” cable

— Includes keyboard with 109” cable

• D8910W (19”) or D2847W (21)” Monitor

— Includes localized power cord and 75” 15-pin video cable

NOTE rp54xx graphics requires HP-UX 11.0 Support Plus (IPR) 0006, June 2000 or later.

The photo below includes the A6150A, A4983B and D8910W products. The video cable for the monitor is not

shown. Black ESD mat not included.

Chapter 3

37

Page 52

Installing Additional Components

Installing Graphics

rp54xx servers have a total of 12 PCI I/O slots. Slots 1 and 2 are reserved for the LAN/SCSI and GSP Core I/O

cards, leaving 10 PCI I/O slots available for Customer use. These 10 PCI I/O slots consist of Turbo and

non-Turbo slots.

rp54xx PCI Slots

• Slots 1 and 2 are reserved for the rp54xx LAN/SCSI and GSP (Guardian Service Processor) Core I/O

cards, respectively. Slots 1 and 2 are non-Turbo slots. Non-Turbo slots share a single 250MB/s PCI bus.

Non-Turbo slots are incapable of HotPlug functionality. The server must be turned off prior to removing

or installing the LAN/SCSI or GSP cards in these slots.

• Slots 3 - 6 are non-Turbo slots. These four Non-Turbo slots share a single 250MB/s PCI bus, run at 33MHz

and support 32 and 64-bit PCI cards. Non-Turbo slots are incapable of HotPlug functionality. The server

must be turned off prior to removing or installing PCI cards in these slots.

• Slots 7 - 12 are Turbo slots. Each Turbo slot has a dedicated 250MB/s PCI bus, run at 66MHz and support

32 and 64-bit PCI cards. Turbo slots are HotPlug capable. Below each Turbo slot is a plastic PCI card

separator. The PCI card separator has two LEDs and a pull tab on the outer edge. The LED’s provide

power and status for the slot. The pull tab allows the PCI card to be easily removed.

rp5400 servers can access PCI slots 1,2 and 8-12. rp5450/3000 servers can access all PCI slots.

Follow these procedures to install graphics cards.

Step 1. Install HP-UX 11.0 Support Plus (IPR) 0006, June 2000 or later. This step ensures the appropriate

HP-UX drivers are installed.

Step 2. Power down and unplug the rp54xx server.

38

Chapter 3

Page 53

Installing Additional Components

Installing Graphics

NOTE DC voltages are present when the server is connected to AC power. Do not attempt to

install or service: CPUs, Memory, PSMs, the Platform Monitor or PCI I/O cards

installed in non-Turbo slots (1-6) while DC voltage is present. Failure to observe this

warning may result in damage to the server.

Step 3. Make the right side of the server accessible for service.

Step 4. Using a Torx 15 screwdriver, loosen the captive screws on the right side panel. This panel has a

label which shows which PCI I/O slots are available and the corresponding paths. The label shown

below is for an rp5400.

Chapter 3

39

Page 54

Installing Additional Components

Installing Graphics

Step 5. Grasp the handle on the right rear panel and remove the panel from the side of the chassis. The 12

PCI slots, numbered 1-12 from bottom to top, will be in view.

Step 6. Remove the PCI slot cover from the slot that will receive the PCI card. To remove the PCI slot cover,

slide the PCI slot cover away from the server.

Step 7. Center the graphics card within the space created by removing the PCI I/O slot cover. Slide the card

toward the edge connectors. Ensure the edge connectors on the card are in alignment with the

connectors of the slot. Apply pressure to the card until it snaps firmly in place. Repeat process for

USB card.

NOTE The graphics card must be installed in any Turbo slot while the USB will work in any

slot. To reserve Turbo slots for high performance I/O cards, install the USB card in a

non-Turbo slot

40

Chapter 3

Page 55

Installing Additional Components

Installing Graphics

Step 8. At the rear of the chassis, connect the keyboard and mouse cables to the USB card. It does not

matter which connector is used for the keyboard or mouse.

Chapter 3

41

Page 56

Installing Additional Components

Installing Graphics

Step 9. Connect one end of the 15-pin video cable connector on the graphics card. This connector is labeled

“Graphics Display” and “Video Out”. Connect the other end of this cable to the graphics monitor.

Step 10. Replace the right side panel and tighten the captive screws.

Step 11. For rack configurations, insert the rp54xx server back into the rack.

Step 12. For deskside enclosure configurations, repalce the deskside enclosure cover.

Step 13. Power the server on.

42

Chapter 3

Page 57

Installing Additional Components

Installing Graphics

Step 14. Use the server firmware in io command to verify the graphics cards are recognized by the server.

If AUTOBOOT is ON, it will be necessary to interrupt the boot process to get to the server firmware

Main Menu: Enter command or menu > prompt.

Step 15. Boot HP-UX and run the ioscan utility to verify the system recognizes the new PCI card.

Step 16. Logon as root and install X/CDE/Motif if not already installed.

Graphics Troubleshooting

This section describes how to troubleshoot common problems encountered during installation or attempted

use of graphics. The following system utilities can be used to display or set the graphics configuration:

• /opt/graphics/common/bin/graphinfo allows you to display the current graphics configuration and the

graphics drivers that are being used.

• /opt/graphics/common/bin/setmon allows you to reconfigure the monitor type.

•The display menu of the HP-UX System Administration Manager (SAM) utility allows you to configure

the X-Server and set the monitor type.

• On-line diagnostics provide information, verify and diagnose coverage for the graphics and USB

cards.Off-line diagnostics do not exist for either the graphics or USB card.

•The HP-UX ioscan utility can be used to verify the HP-UX operating system recognized the hardware.

Symptom: CDE will not come up.

Step 1. Ensure /dev/crt was created. If not created, use insf -e to create.

Step 2. Ensure the system is at run level 3. Use who -r to determine run level. Use init 3 to change to

run level 3.

Step 3. Ensure dt is enabled. Use /usr/dt/bin/dtconfig -e to enable dt.

Step 4. Ensure /etc/dt/config/Xservers exists. If not, use /usr/dt/config/dtrc.d/20_graph_conf to

create.

Step 5. Ensure the line: * Local local@console /usr/bin/X11/X :0 is not commented out of the

/etc/dt/config/Xservers file.

Step 6. Reboot HP-UX.

Symptom: HP-UX does not recognize the graphics cards. unknown appears in the ioscan output for these

cards

.

Step 1. Examine the output of the swlist command to ensure the correct version of HP-UX is installed.

Step 2. Update HP-UX as necessary

Chapter 3

43

Page 58

Installing Additional Components

Installing Disk Drives

Installing Disk Drives

rp54xx servers support up to four optional internal hard drives. These drives must be installed in the

following sequence:

It is not necessary to shutdown the HP-UX operating system or power off the server to install a new disk.

Follow this procedure to add internal hard disk drives to your rp54xx server.

Step 1. If a front bezel is installed on the face of the server, open the right-hand panel to gain access to the

disk slots.

Step 2. Remove the disk drive slot cover.

Step 3. Insert the new disk drive into the slot until the rear connectors snap into place in the card guide. As

shown in the following graphic, the notches at the top of the disk drives must snap over the small

brackets in the disk bay to ensure a firm connection.

44

Chapter 3

Page 59

Installing Additional Components

Installing Disk Drives

Step 4. Secure the connection by pushing the blue release lever closed.

Step 5. Refer to HP-UX documentation to configure the new disk.

Chapter 3

45

Page 60

Installing Additional Components

Installing Disk Drives

46

Chapter 3

Page 61

4 Cable Connections

Chapter 4

47

Page 62

Cable Connections

Core I/O Connections

Core I/O Connections

The following paragraphs describe the indicators and connections of the rp54xx Core I/O. Core I/O consists of