Page 1

User's Manual

HP 9000 Model A-180

Manufacturing Part Number : Z4045-90002

February 2000

Page 2

Notice

Hewlett-Packard makes no warranty of any kind with regard to this material, including but not

limited to, the implied warranties of merchantability and fitness for a particular purpose.

Hewlett-Packard shall not be liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this material.

Hewlett-Packard assumes no responsibility for the use or reliability of its software on equipment that is not

furnished by Hewlett-Packard.

All rights are reserved. No part of this document may be photographed, reproduced, or translated to another

language without prior written consent of Hewlett-Packard Company.

The information contained in this document is subject to change without notice.

Revision History

First Edition Initial Release.

2

Page 3

3

Page 4

4

Page 5

1. A-Class System Overview and Reference

A-Class Server - System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

System Hardware Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

System Software Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

A-Class Server Service Reference Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

A-Class Server System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

A-Class Server System Regulatory Compliance Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Battery Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2. A-Class Server Installation

A-Class Server System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

A-Class Server Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Input Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Cooling Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Stand-Alone A-Class Server Unpack and Install Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Open and Unload the Carton . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Unpack the Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Open the Accessory Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Open the Installation Instructions and Regulatory Information Packet . . . . . . . . . . . . . . . . . . . . . . 28

Installing a Stand-alone System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Cabinet-Mounted A-Class Server System Unpack and Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installing a Factory-integrated Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installing a Stand-alone System in an HP-supported Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

External Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Installing Internal Add-On Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Installing Memory (RAM) Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Installing Cache Memory SIMMs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Installing Embedded Disk Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Installing Input/Output (I/O) Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

A-Class Server Power Up and Boot Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Power Up Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Configuring the integrated A-Class Web Console. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Operating System Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Boot Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Contents

5

Page 6

Contents

A-Class Server System Software Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

3. A-Class System Service

A-Class System Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

A-Class Server Fault Condition Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Review Front Panel Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Review Console Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

A-Class Server Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

A-Class Server Selftest Failures/Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Troubleshooting with Light-Emitting Diode (LED) Interpretation . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Firmware Warning Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Chassis Code Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Troubleshooting the ASCII Console. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Troubleshooting the Secure Web Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Troubleshooting Embedded Disks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Troubleshooting LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

A-Class Server Corrective Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Ordering Repair Parts for the A-Class Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

A-Class Server RAM Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Electrostatic Discharge Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Before You Do Anything... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

RAM Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

RAM Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

RAM Removal and Replacement Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

A-Class Server Cache Memory Removal and Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Electrostatic Discharge Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Before You Do Anything... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Cache Memory Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Cache Memory Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Cache Memory Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

A-Class Server Disk Drive Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Electrostatic Discharge Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Before You Do Anything... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Disk Drive and Bracket Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Remove the Bracket Containing the Disk Drive(s). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Remove the Disk Drive(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Disk Drive Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6

Page 7

Contents

A-Class Server I/O Card Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Electrostatic Discharge Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Before You Do Anything... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Card Load Order Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

I/O Card Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

I/O Card Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Replacing an A-Class Server Exchange Base Unit (EBU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Electrostatic Discharge Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Before You Do Anything... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Removable Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Move the Components to the EBU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Reinstall the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Restart the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

7

Page 8

Contents

8

Page 9

A-Class System Overview and Reference

1 A-Class System Overview and

Reference

Chapter 1

9

Page 10

A-Class System Overview and Reference

A-Class Server - System Overview

A-Class Server - System Overview

The A-Class server is a compact addition to the HP9000 server family, targeted at the

ISP server market. The A-Class server design allows the use of existing qualified

peripherals and I/O add-in options. It is a PCXL-2 (PA-7300 RISC Processor) based

platform designed to support the UNIX Internet Service Provider (ISP) market.

System Hardware Overview

A-Class server hardware has the following characteristics:

• It has a two rack unit height that makes it suitable for racked (up to 20 per rack) or

stand-alone installations.

• It comes configured with one (1-way) 180 MHz. PA-7300 RISC Processor. An

additional (optional) 1Mb of 2nd-level cache is available.

• It has eight RAM memory slots that can use 128, 256 or 512MB memory modules.

• There are two I/O slots each capable of handling either PCI or HSC add-in cards.

One slot is Access Port (AP) card capable.

• The embedded disk bay is capable of supporting 2 single-ended type-1 SCSI drives.

• The server supports the following core I/O functions:

One 10/100 Base-T port supports connection to the primary LAN.

One 10 Base-T Port supports connection to the integrated web-based console.

One 9-Pin RS-232 port supports connection to an ASCII console.

The internal SCSI bus is available externally to connect additional single-ended

Type-1 SCSI devices.

System Software Overview

A-Class servers require the HP-UX 10.20 or 11.0 operating system with an Independent

Peripheral Release (IPR) date of October 1998 (9810) or later.

NOTE HP-UX is the only supported operating system for A-Class servers.

10

Chapter 1

Page 11

A-Class System Overview and Reference

A-Class Server Service Reference Information

A-Class Server Service Reference Information

Overview

Service reference data consists of the following:

• 11”x14” maintenance label

• A A-Class Server System Block Diagram for maintenance personnel and operators.

• The A-Class Server System Regulatory Compliance Statements required by the U. S.

government and required by some countries that import HP products.

Chapter 1

11

Page 12

A-Class System Overview and Reference

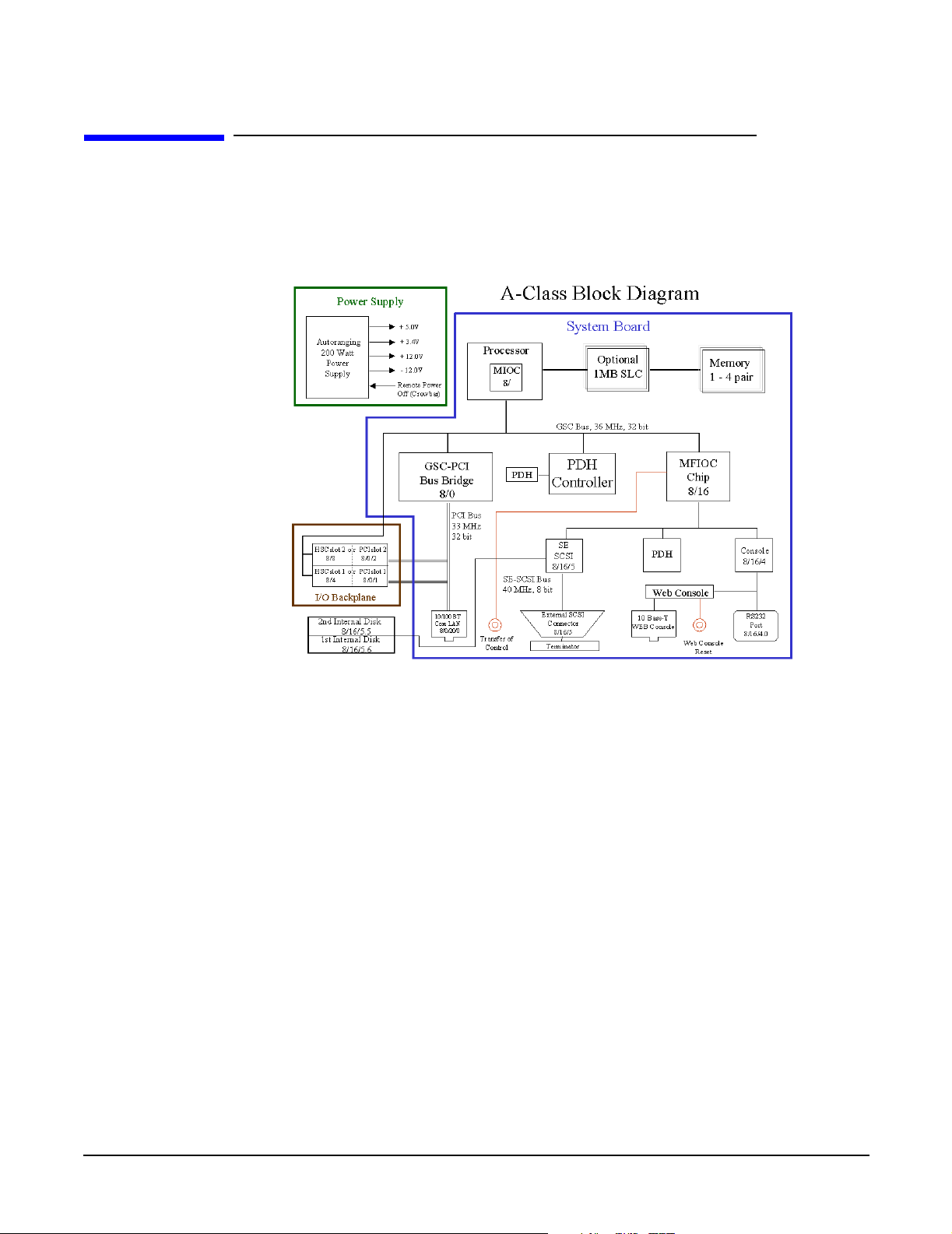

A-Class Server System Block Diagram

A-Class Server System Block Diagram

Overview

The A-Class server block diagram is included for information.

12

Chapter 1

Page 13

A-Class System Overview and Reference

A-Class Server System Regulatory Compliance Statements

A-Class Server System Regulatory Compliance

Statements

Overview

Regulatory Compliance statements are required by some countries for international

importation of A-Class servers. The following information is provided:

• Regulatory Information

• Safety

•Declaration of Conformity

• FCC STATEMENT (USA Only)

• FCC Regulations for Telephone Line Interconnection

• Canada RFI Statement

• European Union RFI Statement

• Japan RFI Statement

• Korean RFI Statement

• Taiwan RFI Statement

•Japan-Only JATE Mark

• Japan Harmonic Statement

• Acoustics (Germany)

• UK General Approval (United Kingdom only)

• Internal Modem and HP A2991-600xx Line Access Module (LAM)

• Terminal DOC (Canada only)

• National Post and Telecom Agency Statement (Sweden only)

• AUSTEL Telecom Statement (Australia only)

• New Zealand and Telecom Statement (New Zealand only)

Chapter 1

13

Page 14

A-Class System Overview and Reference

A-Class Server System Regulatory Compliance Statements

Regulatory Information

For your protection, this product has been tested for conformance to various national and

international regulations and standards. The scope of this regulatory testing includes

electrical and mechanical safety, electromagnetic emissions, immunity, acoustics and

hazardous materials.

When required, approvals are obtained from third party test agencies. Approval marks

appear on the product label. In addition, various regulatory bodies require some

information under the headings listed in this section.

Safety

This product has not been evaluated for connection to an “IT” power system (ac

distribution system having no direct connection to earth according to IEC 950).

Locate the AC outlet near the computer! The ac power cord is this product's main ac

disconnect device and must be easily accessible at all times.

Battery Notice

This product contains a Lithium battery.

This battery is not to be removed or replaced by the user. If the battery needs to be

replaced, contact your Hewlett-Packard authorized service personnel.

CAUTION Lithium batteries may explode if mistreated. Do not recharge, disassemble, or dispose of

in a fire.

Please properly recycle all used batteries.

14

Chapter 1

Page 15

A-Class System Overview and Reference

A-Class Server System Regulatory Compliance Statements

Declaration of Conformity

FCC STATEMENT (USA Only)

The United States Federal Communications Commission has specified that the following

notice be brought to the attention of users of this product:

NOTE This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

Hewlett-Packard's system verification tests were conducted with HP-supported

peripheral devices and HP shielded cables, such as those you receive with your computer.

Changes or modifications not expressly approved by Hewlett-Packard could void the

user's authority to operate the equipment. Cables used with this device must be properly

shielded to comply with the requirements of the FCC.

FCC Regulations for Telephone Line Interconnection

• This equipment complies with Part 68 of the FCC rules. On the outside surface of

this equipment is a label that contains, among other information, the FCC

registration, the FCC registration number and ringer equivalence number (REN). If

requested, this information must be provided to the telephone company.

• This equipment uses the following Universal Service Code (USOC) jacks: RJ11C or

RJ11W (single line).

• The REN is used to determine the quality of devices which may be connected to the

telephone line. Excessive RENs on the telephone line may result in the devices not

ringing in response to an incoming call. In most, but not all areas, the sum of the

RENs should not exceed five (5.0). To be certain of the number of devices that may be

connected to the line, as determined by total RENs, contact the telephone company

to determine the maximum REN for the calling area.

• If this equipment causes harm to the telephone network, the telephone company

will, where practicable, notify you in advance that temporary discontinuance of

service may be required. If advance notice isn’t practical, the telephone company will

notify the customer as soon as possible. Also, you will be advised of your right to file

a complaint with the FCC if you believe it is necessary.

• The telephone company may make changes in its facilities, equipment, operations, or

procedures that could affect the operation of the equipment. If this happens, the

telephone company will provide advance notice in order for you to make the

necessary modifications in order to maintain uninterrupted service.

Chapter 1

• If trouble is experienced with this equipment, please contact: Hewlett-Packard

Company, Response Center, 20 Perimeter Summit Boulevard, Atlanta, GA 30319

U.S.A. 1 (800) 633-3600 (Toll Free - North America Only) or 1 (404) 648-0000 (Main

Number)

15

Page 16

A-Class System Overview and Reference

A-Class Server System Regulatory Compliance Statements

for repair and/or warranty information. If the trouble is causing harm to the

telephone network, the telephone company may request that you remove the

equipment from the network until the problem is resolved.

• No repairs are to be made by you. Repairs are to be made only by Hewlett-Packard or

its licensees. Unauthorized repairs void registration and warranty.

• This equipment cannot be used on telephone company-provided coin service.

Connection to Party Line Service is subject to state tariffs. (Contact the state public

utility commission, public service commission, or corporation commission for

information).

• If so required, this equipment is hearing-aid compatible.

Canada RFI Statement

• This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

• Cet appareil numÅrique de la classe A respecte toutes les exigences du RÉglement

sur le matÅriel brouilleur du Canada.

European Union RFI Statement

This is a Class A product. In a domestic environment, this product may cause radio

interference in which case the user may be required to take adequate measures.

16

Chapter 1

Page 17

Japan RFI Statement

Korean RFI Statement

A-Class System Overview and Reference

A-Class Server System Regulatory Compliance Statements

Taiwan RFI Statement

Japan-Only JATE Mark

Japan Harmonic Statement

Chapter 1

17

Page 18

A-Class System Overview and Reference

A-Class Server System Regulatory Compliance Statements

Acoustics (Germany)

Acoustic noise level per ISO 9296 (25° C):

LpA

<57dB (operators position)

m

GerÌuschemission nach ISO 9296 (25° C):

LpA

<57dB (Arbeitsplatte)

m

UK General Approval (United Kingdom only)

Pursuant to Section 22 of Telecommunications Act of 1984, this product is approved for

indirect connection to Public Telecommunications systems within the United Kingdom

under the General Approval number NS/G/1234/J/100003.

Internal Modem and HP A2991-600xx Line Access Module (LAM)

The following warnings apply to the use of the HP 2991-60001 internal modem and HP

A2991-600xx LAM that may be provided with the computer.

Terminal DOC (Canada only)

NOTE The Canadian Department of Communications label identifies certified equipment. This

certification means that the equipment meets certain telecommunication network

protective operational and safety requirements. The Department does not guarantee the

equipment will operate to the user's satisfaction.

Before installing this equipment, users should ensure that it is permissible to be

connected to the facilities of the local telecommunications company. The equipment must

also be installed using an acceptable method of connection. In some cases, the company's

inside wiring associated with a single line individual service may be extended by means

of a certified assembly (telephone extension cord). The customer should be aware that

compliance with the above conditions may not prevent degradation of service in some

situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance

facility designated by the supplier. Any repairs or alterations made by the user to this

equipment, or equipment malfunctions, may give the telecommunications company

cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of

the power utility, telephone lines and internal metallic water pipe system, if present, are

connected together. This precaution may be particularly important in rural areas.

The Load Number (LN) assigned to each terminal device denotes the percentage of total

load to be connected to a telephone loop which is used by the device to prevent

overloading. The termination on a loop may consist of any combination of devices subject

only to the requirement that the total of the Load Numbers of all devices does not exceed

100. The load number for this product is 33.

18

Chapter 1

Page 19

A-Class System Overview and Reference

A-Class Server System Regulatory Compliance Statements

CAUTION Users should not attempt to make such connections themselves, but should contact the

appropriate electric inspection authority, or electrician, as appropriate.

National Post and Telecom Agency Statement (Sweden only)

The LAM Interface shall be connected to SELV (max.42.4 V peak, or 60 V DC) according

to EN 60950. (The internal modem complies with this requirement.)

AUSTEL Telecom Statement (Australia only)

When setting the number of automatic redials for the modem, ensure the following:

The number of automatic redials that the modem performs should be limited to a

maximum of 9 redials plus the original call. If the above retries are unsuccessful, no

further attempts should be made to the same number for a minimum period of 5

minutes.

CAUTION Failure to set the modem, and any communication software used with the modem to the

values contained in the listing will result in the modem being operated in a

non-compliant manner. Consequently, there would be no permit in force for this

equipment, and the Telecommunications Act 1991 prescribes a penalty of A$12,000 for

the connection of non-permitted equipment.

Australian C-Tick Label

New Zealand and Telecom Statement (New Zealand only)

When using an application software that allows the setting of automatic redialing, the

following guidelines should be followed:

• Not more than five call attempts to the same number within a one hour period.

• A minimum of 60 seconds between each attempt.

• Not more than a total of 10 call attempts to the same number.

Any setting that violates the above guidelines will cause the equipment to go out of

compliance, and thus no Telepermit will be in force for this equipment which will make it

subject to penalties.

Chapter 1

19

Page 20

A-Class System Overview and Reference

A-Class Server System Regulatory Compliance Statements

The operation of this equipment on the same line as telephones or other equipment with

audible warning devices or automatic ring detectors will give rise to bell tinkle or noise

and may cause false tripping of the ring detector. Should such problems occur, the user is

not to contact Telecom Faults Service.

20

Chapter 1

Page 21

2 A-Class Server Installation

A-Class Server Installation

Chapter 2

21

Page 22

A-Class Server Installation

A-Class Server System Installation

A-Class Server System Installation

Overview

The sections listed below describe the procedures you will use to prepare for, install, and

begin operation of, your A-Class server:

A-Class Server Site Preparation. Contains environmental requirements for

preparing the area where your server is to be located.

Stand-Alone A-Class Server Unpack and Install Instructions. Details what you will

find when you open the carton containing your A-Class server and how to set it up

for stand-alone operation.

Cabinet-Mounted A-Class Server System Unpack and Install. Tells you how to

install and connect the server to external devices and power, either as a stand-alone

unit or in an HP-supported cabinet. Unpacking, set up, and connection information

is also included for those who ordered a cabinet from the factory with one or more

servers installed,

A-Class Server System Software Configuration. Tells you how to install memory

(RAM), cache memory, embedded disk and I/O card add-on components.

A-Class Server Power Up and Boot Procedures. Leads you through the process for

powering up external devices and the server, gives the software commands for

customizing the A-Class Secure Web Console IP address, and lists the steps required

for booting the server to an operating state.

A-Class Server System Software Configuration. Directs you to the software

commands necessary for preparing both the A-Class server and the A-Class Secure

Web Server for operation.

22

Chapter 2

Page 23

A-Class Server Installation

A-Class Server Site Preparation

A-Class Server Site Preparation

Overview

This section contains the following environmental requirements for preparing a site for

the A-Class Server:

Space Requirements. Space requirements for both stand-alone and cabinet-mounted

A-Class servers.

Input Power Requirements. Nominal input voltage, nominal frequency, and typical

current requirements.

Cooling Requirements. Operating and non-operating temperature extremes and

relative humidity parameters.

Space Requirements

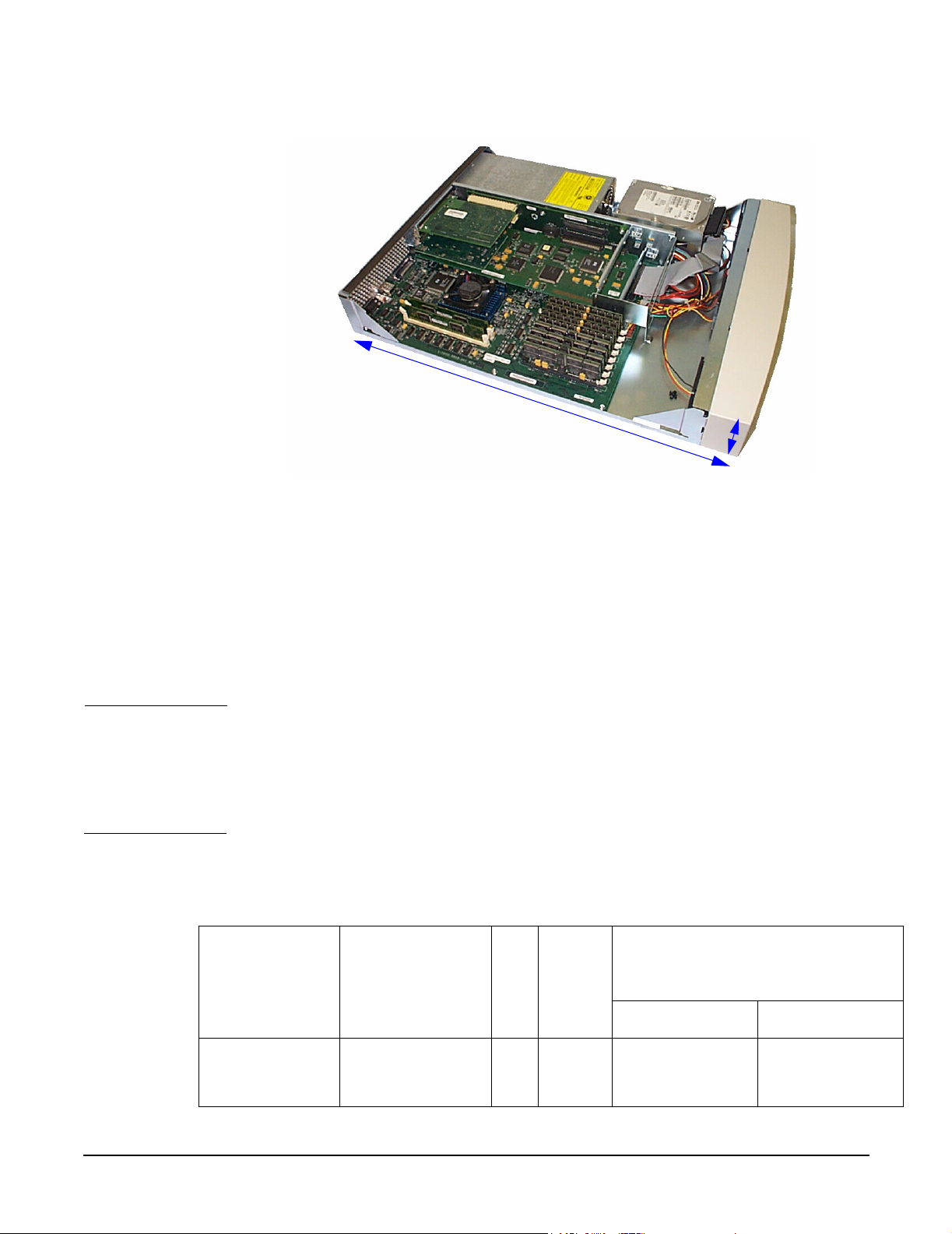

Stand-Alone Server Dimensions

The physical characteristics of the A-Class server are listed as follows:

Dimension

Height 8.89 cm (3.5 in.)

Width 43.18

cm

Depth 58.42

cm

Weight 9.98kg (22 lbs)

(17 in.)

(23 in.)

Chapter 2

23

Page 24

A-Class Server Installation

A-Class Server Site Preparation

Stand-Alone Server Minimum Service Access Requirements

23” (58.42cm)

Access

Location

Rear 15 cm (6 in.)

Sides 7.5 cm (3 in.)

Front 7.5 cm (3 in.)

CAUTION Stacking A-Class servers in any manner and mounting in any cabinet other than a

Hewlett-Packard approved cabinet, is not supported.

While they are constructed to be strong, A-Class servers have not been tested for

stacking load carrying capacity. Failure to follow this precaution may result in major

damage to the server.

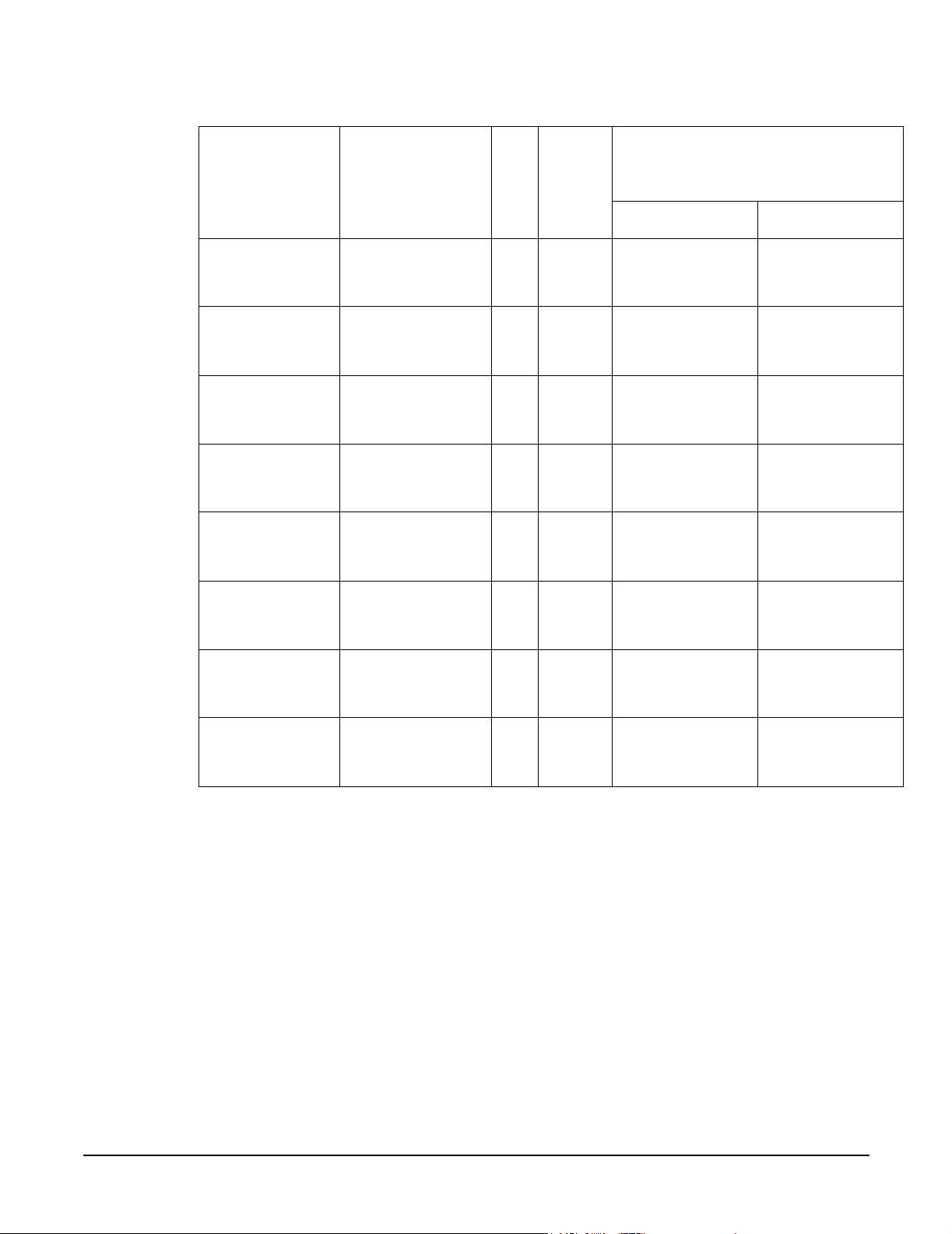

Cabinet Dimensions

A-Class servers can be installed in any of the following cabinets:

Max.

Cabinet

Product

Number

Description

EI

A

A-Clas

s

Server

s

External Dimensions (width x

depth x height)

Centimeters Inches

24

A4900A Factory

Integrated 1.25m

x 19” Cabinet

25 12 59.7 x 100.3 x

125.7

23.5 x 39.5 x 49.5

Chapter 2

Page 25

Cabinet

Product

Number

Description

EI

A

Max.

A-Clas

s

Server

s

A-Class Server Installation

A-Class Server Site Preparation

External Dimensions (width x

depth x height)

Centimeters Inches

A4901A Factory

Integrated 1.6m x

19” Cabinet

A4902A Factory

Integrated 2.0m x

19” Cabinet

J1502A Field Integrated

1.25m x 19”

Cabinet

J1501A Field Integrated

1.6m x 19”

Cabinet

J1500A Field Integrated

2.0m x 19”

Cabinet

C2785A Field Integrated

1.1m x 19”

Cabinet

C2786A Field Integrated

1.6m x 19”

Cabinet

33 16 59.7 x 100.3 x

161.3

41 20 59.7 x 100.3 x

196.9

25 12 59.7 x 100.3 x

125.7

33 16 59.7 x 100.3 x

161.3

41 20 59.7 x 100.3 x

196.9

21 10 61 x 91.4 x 111.8 24 x 36 x 44

32 16 61 x 91.4 x 162.6 24 x 36 x 64

23.5 x 39.5 x 63.5

23.5 x 39.5 x 77.5

23.5 x 39.5 x 49.5

23.5 x 39.5 x 63.5

23.5 x 39.5 x 77.5

Chapter 2

C2787A Field Integrated

2.0m x 19”

Cabinet

Cabinet Minimum Service Access Requirements

Access

Location

Rear 61 cm (24 in.)

Sides NA (NA)

Front 100.3 (39.5

41 20 61 x 91.4 x 203.2 24 x 36 x 80

in.)

Input Power Requirements

Input power requirements for the A-Class server are listed as follows:

• Nominal Input Voltage (VAC): 100 - 240

25

Page 26

A-Class Server Installation

A-Class Server Site Preparation

• Nominal Frequency: 50 or 60 Hz

• Typical current requirements:

If an Uninterruptible Power Supply (UPS) is to be used, ensure that it is properly

connected to the server. Refer to the, External Connections section for UPS information.

Power cord plugs for stand-alone servers are configured to meet unique power

configurations used all over the world.

Cabinet-mounted servers have the same power requirements as stand-alone servers.

However, the power cords for cabinets are dependent on the type of Power Distribution

Unit (PDU) operation.

PDU power cords with one end stripped are also available for attaching country-specific

power plugs. Refer to the cabinet documentation for more electrical power information.

Cooling Requirements

1.0A at 100V

0.43A at 240V.

Temperature Parameters

The operating and non-operating temperatures shown below are the extremes at which

server parameters have been established.

Operating Non-Operati

ng

+5°-+35°C

(41° - 95°F)

Relative Humidity

Operating and non-operating relative humidity parameters are shown below:

Operating Relative

Humidity

15% to 80%,

non-condensing

-40° - +65°C

(-40° - 149°F)

Non-Operating Relative

Humidity

5% to 90%, non-condensing

26

Chapter 2

Page 27

A-Class Server Installation

Stand-Alone A-Class Server Unpack and Install Instructions

Stand-Alone A-Class Server Unpack and Install

Instructions

Overview

Unpacking the A-Class server consists of opening and unloading the carton. Inside the

carton you will find, in addition to the server, an accessory kit and a packet containing

installation instructions and regulatory information.

• Open and Unload the Carton

•Unpack the Server

• Open the Accessory Kit

• Open the Installation Instructions and Regulatory Information Packet

NOTE The following instructions do not apply to A-Class servers that are received pre-installed

in a cabinet. These procedures pertain to individual servers, only.

Open and Unload the Carton

Step 1. Place the sealed carton on a work surface with the correct side up as indicated by the

“This Side Up” symbol (below).

CAUTION Use sharp instruments carefully when unpacking electronics equipment. Failure to

follow this precaution may result in personal injury or damage to components.

Step 2. Carefully open the carton, remove the contents, and set them on the work surface. Each

carton will contain:

• The server.

• An accessory kit.

• A packet containing installation instructions and regulatory information.

NOTE Report any missing items to your local Hewlett-Packard office immediately. If there is

obvious freight damage, contact your shipper immediately.

Chapter 2

We recommend that you retain all packing materials in case any of the items received

require return to Hewlett-Packard.

27

Page 28

A-Class Server Installation

Stand-Alone A-Class Server Unpack and Install Instructions

Unpack the Server

CAUTION Do not set the server on its side, or in any position other than upright on its rubber

“feet,” for operation. Failure to observe this precaution may result in component damage

or loss of system reliability.

Carefully unwrap the server and set it upright on the work surface.

Open the Accessory Kit

Open the Accessory Kit and verify that the contents agree with the packing list.

NOTE Plastic Front Anchor Bracket end caps are included in each kit. Do not discard them.

They will be needed if the server is installed in a cabinet.

Open the Installation Instructions and Regulatory Information Packet

The Installation Instructions/Regulatory Information Packet contains the following

information:

• Installation Instruction Sheet (A5182-96002), which includes:

Basic cable connection information necessary to power on and boot the server to

the Firmware Main Menu screen.

The Universal Resource Locator (URL) for the A-Class Server home page on the

World Wide Web.

• Regulatory Information. Contains consumer safety and regulatory statements for

the United States and for those countries that require publishing and dissemination

of their own consumer safety and regulatory data.

Installing a Stand-alone System

A-Class servers are compact in design and can be installed on table or desk tops in the

same manner as any standard Personal Computer (PC).

Heating and cooling conditions must be met for the system to function at peak efficiency.

Attention must be paid to system access. There must be room for external connections on

the rear of the server and there must be ready access to an electrical outlet with the

correct electrical output. These environmental requirements are found in the section

titled, A-Class Server Site Preparation.

28

When you have installed the server and are ready to connect external devices, refer to

the,External Connections section.

To power up and boot the server, refer to the section titled, A-Class Server Power Up and

Boot Procedures.

Chapter 2

Page 29

A-Class Server Installation

Cabinet-Mounted A-Class Server System Unpack and Install

Cabinet-Mounted A-Class Server System Unpack and

Install

Overview

A-Class servers can be procured in two modes: stand-alone or pre-installed in a cabinet

at the factory. Stand-alone servers can be configured for installation in an existing

HP-supported cabinet. The following subsections provide system installation

information:

• Information Sheet

• Installing a Factory-integrated Cabinet

• Installing a Stand-alone System in an HP-supported Cabinet

• External Connections

Information Sheet

Each system is packed with an Information Sheet that contains basic installation

instructions. Review the Information Sheet thoroughly and follow the steps listed to

perform the installation. The information sheet may refer you to the LED Interpretation

and Removal & Replacement Procedures label located inside the cover, adhered to the

top. This label provides instructions for interpreting LED combinations and information

about system components.

Installing a Factory-integrated Cabinet

Unpacking the Cabinet

NOTE It is the customer's responsibility to inspect the shipping package for damage.

It is the Hewlett-Packard Customer Engineer’s responsibility to remove the cabinet

assembly from the shipping pallet.

WAR NING A fully configured 2.0 meter cabinet can weigh up to 362.8 kg (800 lbs). Be

careful not to tip the cabinet while unpacking. Failure to heed this warning

can result in serious injury or equipment destruction.

Chapter 2

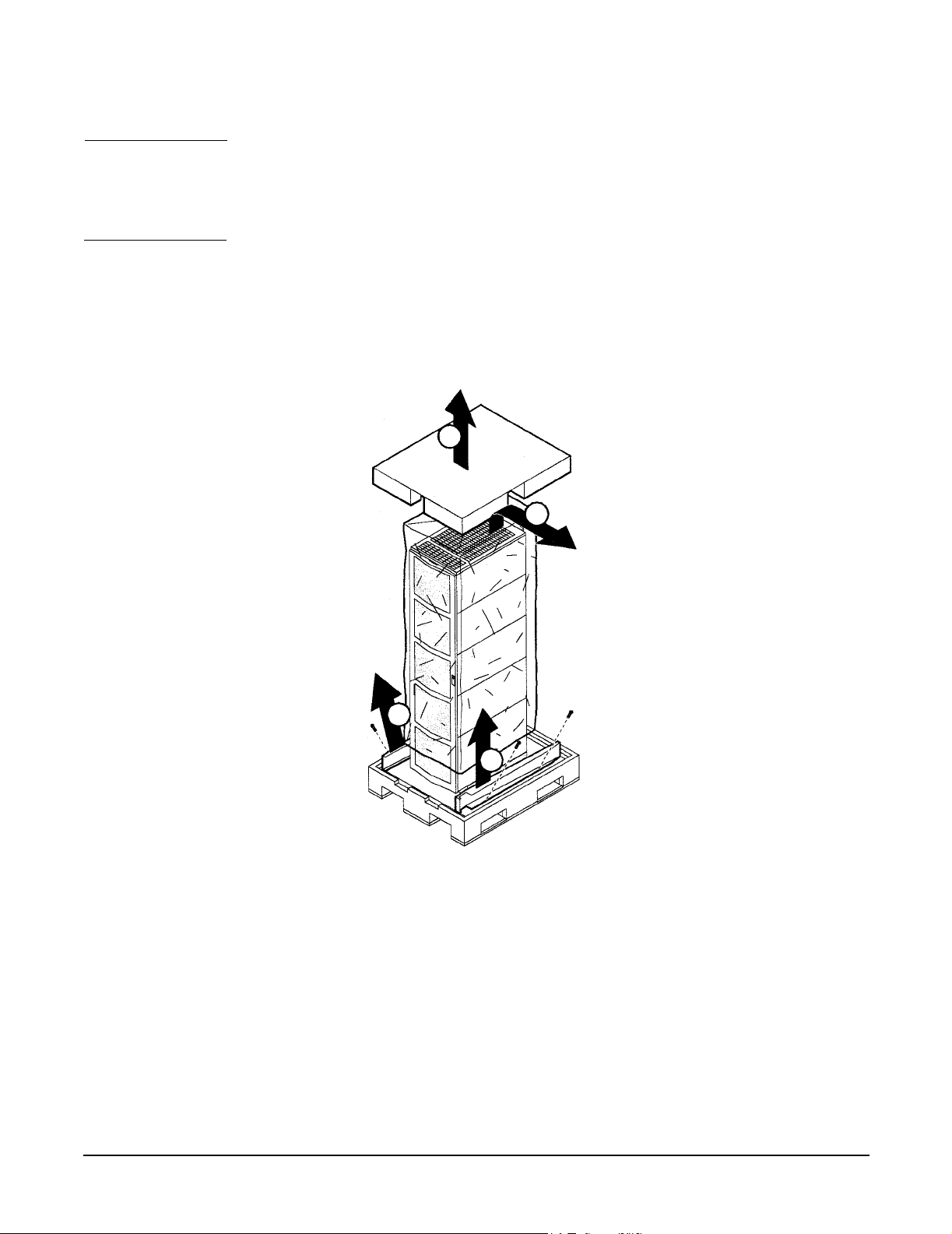

To unpack the cabinet, perform the following steps:

29

Page 30

A-Class Server Installation

Cabinet-Mounted A-Class Server System Unpack and Install

WAR NING Wear protective glasses while cutting the plastic bands around the shipping

container. These bands are under tension. Failure to heed this warning can

result in serious eye injury if the bands snap back and hit you in the face when

cut.

Step 1. Cut the plastic polystrap bands around the shipping container.

Step 2. Lift the cardboard top cap off of the shipping box (callout 1) and remove the packing

material underneath (callout 2). Remove the screws that secure the ramps in place and

lift the ramps out (callout 3).

1

2

3

3

3

30

Chapter 2

Page 31

Cabinet-Mounted A-Class Server System Unpack and Install

Step 3. Remove the brackets securing the cabinet to the pallet (callout 4).

4

4

4

A-Class Server Installation

Step 4. Insert the ramps in the notches provided on the pallet (callout 5). Remove the side

panels from the cabinet and set them aside (callout 6).

6

6

5

5

5

Chapter 2

31

Page 32

A-Class Server Installation

Cabinet-Mounted A-Class Server System Unpack and Install

WAR NING

A fully configured 2.0 meter cabinet can weigh up to 362.8 kg (800 lbs). Always

use at least two people to roll the cabinet off of the pallet. Failure to heed this

warning can result in serious injury or equipment destruction.

Step 5. Use at least two people to roll the cabinet off of the pallet and down the ramp (callout 7).

7

Cabinet Inspection

Once the cabinet is off the shipping pallet, but before moving it to the installation site,

inspect the internal and external condition of the cabinet.

Cabinet Exterior Checklist:

Check the cabinet exterior for signs of shipping damage:

• Look at the top and sides for dents, warpage, or scratches.

32

• Check the front bezels for alignment, scratches, and that they open and close

normally.

• Check any filler panels on the front of the cabinet, for proper fit.

• Check the forehead assembly for any signs of damage.

Chapter 2

Page 33

A-Class Server Installation

Cabinet-Mounted A-Class Server System Unpack and Install

• Check the rear door for dents, scratches, proper fit when its closed, and operation.

Cabinet Interior Checklist: Open the rear door and inspect the inside of the cabinet:

• Inspect all cables, make sure they are secure.

• Inspect all rails for signs of damage.

• Check all mounting screws for tightness.

• Check all components for signs of shifting during shipment or any signs of damage.

NOTE If the shipment is incomplete, or if the equipment is damaged or fails to meet

specifications, notify the nearest Hewlett-Packard Sales and Support Office. If damage

occurred in transit, notify the carrier as well. Hewlett-Packard will arrange for

replacement or repair without waiting for settlement of claims against the carrier. If the

shipment was damaged in transit, keep the shipping containers and packaging material

for inspection.

If extensive damage is found, it may be necessary to return the entire cabinet to HP.

Refer to the Repacking instructions.

Cabinet Installation

Installation of a factory-loaded cabinet consists of the following steps:

Step 1. Move the cabinet to installation site.

Step 2. Lower the leveling feet. (This will prevent excessive wear on the casters.)

CAUTION Extend the cabinet stabilizers, located at the bottom of the front of the cabinet, as an

additional safeguard against overturning the cabinet during installation. Failure to

observe this precaution could result in personal injury or equipment damage.

Step 3. Connect the console and system peripherals to the server.

For information about connecting external devices, refer to External Connections at the

end of this section.

NOTE Attaching cables while the rails are extended fully forward will ensure that sufficient

slack is available for later maintenance.

Step 4. Connect the cabinet power cord to the appropriate wall outlet.

NOTE If the cabinet being installed contains a PowerTrust Uninterruptible Power Supply

(UPS), perform the steps shown under the PowerTrust UPS OptionOption subsection.

Step 5. Be sure all peripherals outside the cabinet are connected to wall outlets.

Chapter 2

33

Page 34

A-Class Server Installation

Cabinet-Mounted A-Class Server System Unpack and Install

The cabinet/server system assembly is now ready for the power up process. Refer to the

section titled, A-Class Server Power Up and Boot Procedures.

PowerTrust UPS Option

Unpack the PowerTrust UPS and read all the installation information in the PowerTrust

System Guide, part number 5961-8383. Once all the procedures listed in the UPS guide

are complete, perform the following steps to complete the UPS installation with the

cabinet.

1. Position the UPS next to the cabinet on the floor.

2. Remove the jumper cord from the SPU to the PDU inside the cabinet.

3. Install one of the convenience cords (output cord) that came with the UPS into the

AC receptacle in the back of the SPU.

4. Place the other end of that cord into one of the Output outlets in the back of the UPS.

5. The other convenience cord is connected between the UPS and the system console.

6. Locate the appropriate input line cord for the UPS in the supplemental package

shipped with the UPS.

7. Plug the UPS into the appropriate wall outlet.

WAR NING

8. The system should now be ready for power up. Refer to the section titled, A-Class

Server Power Up and Boot Procedures.

Repackaging the Cabinet for Shipment

Use the original packing material to repackage the cabinet for shipment. If the packing

material is not available, contact your local Hewlett-Packard Sales and Support Office

regarding shipment.

Before shipment, place a tag on the container (or equipment) to identify the owner and

the service to be performed. Include the equipment model number and the full serial

number, if applicable. The label showing the model number and the full serial number is

located on the outside of the rear door.

Due to the weight of a fully loaded cabinet, it will require two people to push the cabinet

up the ramp onto the pallet.

34

Repackaging a loaded cabinet may be hazardous because a fully configured 2.0

meter cabinet can weigh up to 362.8 kg (800 lbs). Always use two people when

moving the cabinet and when positioning the cabinet on the pallet. Check the

condition of the loading/unloading ramp before use. If the ramp appears

damaged, DO NOT attempt to push a loaded cabinet up the ramp onto the

Chapter 2

Page 35

A-Class Server Installation

Cabinet-Mounted A-Class Server System Unpack and Install

pallet. Contact your local Hewlett-Packard Sales and Support Office regarding

shipment. Failure to heed this warning can result in serious injury or

equipment destruction.

To repackage the cabinet, follow the repacking checklist and refer to the unpacking

instructions for detail.

Repacking Checklist:

• Assemble the HP packing materials that came with the cabinet.

• Connect the loading ramp to the pallet.

• Raise the cabinet levelers before moving the cabinet.

• Push the cabinet up the ramp onto the pallet. Be sure to position the cabinet so that

the front goes up the ramp first.

• Secure the cabinet to the pallet with the shipping clamps, shipping block, and rear

door support.

• Place the anti-static bag over the cabinet.

• Place bezel support packing on the front corners of the cabinet. Secure it with a

wrap.

• Place the top cap packing material and loading/unloading ramp on top of the cabinet.

• Wrap the clam shell box around the cabinet.

• Put the box top on the box and secure the assembly to the pallet.

Be sure to follow the tagging and labeling instructions mentioned earlier. The cabinet is

now ready for shipment.

Installing a Stand-alone System in an HP-supported Cabinet

Cabinet Identification

The following cabinets can hold multiple A-Class servers:

Cabinet

Product

Number

A4900A Factory 1.25m x 19” 12 A5180A

A4901A Factory 1.6m x 19” 16 A5180A

A4902A Factory 2.0m x 19” 20 A5180A

J1502A Field 1.25m x 19” 12 A5214A

Assembl

ed by:

Size

(Height x

Width)

Maximum

Servers

Adapter

Kit

Number

Chapter 2

J1501A Field 1.6m x 19” 16 A5214A

J1500A Field 2.0m x 19” 20 A5214A

C2785A Field 1.1m x 19” 10 A5214A

C2786A Field 1.6m x 19” 16 A5214A

35

Page 36

A-Class Server Installation

Cabinet-Mounted A-Class Server System Unpack and Install

Cabinet

Product

Number

C2787A Field 2.0m x 19” 20 A5214A

Cabinet Loading Requirements

A-Class servers require two EIA of cabinet space (each two EIA of space is equivalent to

the height of a server without the server’s “feet”). Ensure that the cabinet has this

amount of space available.

NOTE Replace the rubberized feet on the server with plugs provided in the cabinet mounting

adapter kit.

Fill empty cabinets from the top down, with A-Class servers on top. If you are mounting

one or more servers into an empty cabinet, start at the inside top of the cabinet and

count down four of the holes in the columns at each corner to determine the position of

the rails for the first server. When the first rails are installed, continue to use the four

hole requirement as your guide for installing additional A-Class servers.

Refer to the Rail Kit Installation Sheet (A5214-96001) for instructions necessary to

install rails in the HP computer cabinet.

Assembl

ed by:

Size

(Height x

Width)

Maximum

Servers

Adapter

Kit

Number

Mounting the Server To mount the server in the cabinet, follow the procedure listed

below:

Step 1. From the front of the cabinet, slide the server onto the rails. Push the server into the

cabinet until approximately three inches of the server remains protruding from the

front.

Step 2. Install sheet metal nuts on the left and right front columns and align with front anchor

bracket slots.

Step 3. Install the left and right front anchor brackets on each side of the server as follows:

36

• Insert each hooked tab into its slot on the bottom of the front corner of the server.

Chapter 2

Page 37

A-Class Server Installation

Cabinet-Mounted A-Class Server System Unpack and Install

• Hold the tabs upright and slide the server all the way into cabinet until the tabs butt

up against the columns on each side.

Step 4. Fasten the both front anchor brackets securely to both front cabinet columns with the

prepositioned sheet metal nuts.

Step 5. Attach a plastic end cap to each anchor bracket.

Step 6. At the rear of the cabinet, position the rear rail mounting clamps on each rail at the back

of the server. Tilt each clamp forward slightly and slide the angled tab completely into

the available slot in the server so that each clamp sits flat on the rail.

Step 7. Fasten each rear mounting clamp to its rail with the screws provided.

When you are ready to connect external devices, refer to External Connections for

further information.

Chapter 2

37

Page 38

A-Class Server Installation

Cabinet-Mounted A-Class Server System Unpack and Install

External Connections

External devices are interfaced with the A-Class server by means of specific connectors

located in the rear of the server. Exterior connections to the server include ports for:

• Small Computer System Interface (SCSI) devices

•System Consoles

• Local Area Networks (LANs)

• Power Cords.

38

Connect External Small Computer System Interface (SCSI) Devices

Connect external SCSI devices to the Single Ended SCSI bus (labeled SCSI

(Single-Ended) 8/16/5) on the system card or to additional SCSI interface cards. If

external devices will not be connected to the SCSI bus, make sure the terminator

(1252-3932) is in place.

Make sure all devices on the SCSI bus have a unique address and the last device is

terminated. Refer to the documentation accompanying each device to learn how to set

addresses and where to place terminators.

Chapter 2

Page 39

A-Class Server Installation

Cabinet-Mounted A-Class Server System Unpack and Install

Connect external DDS (Digital Data Storage) tape and DVD/ CDROM drives to A-Class

servers as shown in the diagram below. Connecting these devices in this manner reduces

the likelihood of excessive parity errors and unexpected interrupts from occurring on the

SCSI bus.

Connect a System Console

• Using the ASCII Terminal as a System Console. If an ASCII terminal is to be used as

a system console, connect it to the back of the server with a 24542G cable by

attaching it to the 9- pin male connector labeled, Console 8/16/4.0.

Make sure the keyboard is connected and a power cable is available.

NOTE When the web console is used, the RS232 Console Port (8/16/4.0) is disabled

• Using the Web Console as a System Console. If the Web Console is to be used as a

system console, connect an RJ45 LAN cable to the RJ45 connector labeled, LAN Web

Console, on the back of the server.

NOTE The Web Console has a default Internet Protocol (IP) address of 192.0.0.192. Make

sure that no other device, including other A-Class servers, has this address before

connecting the A-Class server to your LAN.

Connect the Core Local Area Network (LAN)

Connect the 100baseT Core LAN on the system board to your LAN by using an RJ45

LAN cable. Connect the RJ45 LAN cable to the server by attaching it to the RJ45

connector labeled, 10/100 Base-T 8/0/20/0.

Chapter 2

39

Page 40

A-Class Server Installation

Cabinet-Mounted A-Class Server System Unpack and Install

Connect Power Cords

CAUTION Do not press and hold the Web Console Reset button (located on the rear of the server

between the LAN Web Console receptacle and the ASCII terminal receptacle) while

connecting the server power cord. Failure to observe this precaution will cause erasure of

all settings in the Web Console that is connected to the server.

Connect the power cord that is provided with the system to the server. For stand-alone

servers, the power cord will be localized to each country’s power application. If an HP

Uninterruptible Power Supply (UPS) is the power source, use the power cord provided

with the UPS. If an HSC Remote Management card is installed in the server, use the

cable provided with the HP UPS to connect the RS232 serial port to the port labeled

“UPS” on the HSC Remote Management card.

Connect power cords to all external devices at this time with the localized power cord,

cabinet power cord, or the UPS power cord.

For cabinet mounted servers, the server power cord connects to the C13 connector of the

Power Distribution Unit in the cabinet.

40

Chapter 2

Page 41

A-Class Server Installation

Installing Internal Add-On Components

Installing Internal Add-On Components

This section explains how to install internal add-on components into A-Class servers.

Internal add-on components include memory, cache memory, embedded disks and I/O

cards. For cabinet mounted servers, it is necessary to remove the server from the cabinet

to install internal add-on components.

Refer to the appropriate section for internal add-on component installation information:

• Installing Memory (RAM) Modules.

• Installing Cache Memory SIMMs.

• Installing Embedded Disk Drives.

• Installing Input/Output (I/O) Cards.

Installing Memory (RAM) Modules.

This section describes how to install memory (RAM) into A-Class servers. Computer

memory is commonly referred to as Random Access Memory (RAM). The terms RAM and

memory are used interchangeably in this documentation. Abbreviated Memory SIMM

installation instructions also appear on the 11” x 14” maintenance label adhered to the

bottom of the top cover.

A-Class memory is sold as a module. A module is defined as two SIMMs. A-Class servers

support three memory module sizes: 128MB, 256MB and 512MB. The 128MB memory

module consists of two 64MB SIMMS. The 256MB memory module consists of two

128MB SIMMs and the 512MB memory module consists of two 256MB SIMMs. A

memory module occupies two slots. The size (or capacity) of a memory SIMM is printed

along the top edge of the SIMM.

NOTE SIMM is an acronym for Single Inline Memory Module. A SIMM has components on one

side of the card, only.DIMM is an acronym for Dual Inline Memory Module. A DIMM has

components on both sides of the card.The acronym SIMM will be used throughout this

section to refer to either SIMM or DIMM.

A-Class servers provide 8 slots for memory. These slots are labeled in pairs and are

numbered 0a, 0b, 1a, 1b, 2a, 2b, 3a and 3b. The nomenclature for a pair of SIMM slots is

0a/b, 1a/b, 2a/b and 3a/b. The following rules govern the installation memory in A-Class

Servers.

• Memory must be installed in SIMM pairs.

• The capacity of SIMMs must be the same.

• Install SIMMs with the greatest capacity in the lowest slot numbers.

Chapter 2

Follow the steps below to install memory in A-Class servers.

41

Page 42

A-Class Server Installation

Installing Internal Add-On Components

Electrostatic Discharge Precautions.

The procedures in this section require opening the server and exposing the system to

electrostatic discharge. Always observe all electrostatic precautions when working with

components inside or out of the server. Failure to follow these precautions may result in

component damage or loss of system reliability.

• Use a grounding mat and an anti-static wrist strap.

• Wear the anti-static wrist strap to ensure that any accumulated electrostatic charge

is discharged from your body to ground.

Before You Do Anything...

• Power down the system.

• Unplug the server.

NOTE Cabinet-mounted servers must be removed from the cabinet before proceeding.

• Remove the top of the server by unscrewing the knurled captive screws on each side

of the rear of the server. Slide the top back, lift it off, and set it aside.

Step 1. Document which size SIMMs are already installed and in which slots.

Step 2. Determine the size of the memory SIMMs to be installed.

Step 3. If the capacity of the memory SIMMs to be installed is less than or equal to existing

memory, install the new SIMMs in the next available slots.

Step 4. If the capacity of the memory SIMMs to be installed is greater than existing memory,

remove all existing memory RAM Removal, install RAM Replacement, the largest

capacity SIMMs first beginning with slot 0a/b. Continue to add SIMMs in this manner.

Step 5. Proceed to A-Class Server Power Up and Boot Procedures.

Installing Cache Memory SIMMs.

This section describes how to install Cache Memory SIMMs into A-Class servers.

Abbreviated Cache Memory SIMM installation instructions also appear on the 11” x 14”

maintenance label adhered to the bottom of the top cover.

A-Class Cache Memory is sold as a module. A module is defined as two SIMMs. A-Class

servers support a single 1MB Cache Memory module. The 1MB Cache Memory module

consists of two 512MB SIMMs. A Cache Memory module occupies two slots. The size (or

capacity) of the Cache Memory SIMM is printed along the top edge of the SIMM.

NOTE SIMM is an acronym for Single Inline Memory Module. A SIMM has components on one

side of the card, only.DIMM is an acronym for Dual Inline Memory Module. A DIMM has

components on both sides of the card.The acronym SIMM will be used throughout this

section to refer to either SIMM or DIMM.

42

Chapter 2

Page 43

A-Class Server Installation

Installing Internal Add-On Components

A-Class servers provide 2 slots for Cache Memory. The following rules govern the

installation memory in A-Class Servers.

• Cache Memory must be installed in SIMM pairs.

• The capacity of SIMMs must be the same.

Follow the steps below to install Cache Memory in A-Class servers.

Electrostatic Discharge Precautions.

The procedures in this section require opening the server and exposing the system to

electrostatic discharge. Always observe all electrostatic precautions when working with

components inside or out of the server. Failure to follow these precautions may result in

component damage or loss of system reliability.

• Use a grounding mat and an anti-static wrist strap.

• Wear the anti-static wrist strap to ensure that any accumulated electrostatic charge

is discharged from your body to ground.

Before You Do Anything...

• Power down the system.

• Unplug the server.

NOTE Cabinet-mounted servers must be removed from the cabinet before proceeding.

• Remove the top of the server by unscrewing the knurled captive screws on each side

of the rear of the server. Slide the top back, lift it off, and set it aside.

Step 1. Install the first 512MB Cache Memory SIMM in either unoccupied slot.

Step 2. Install the second 512MB Cache Memory SIMM in the remaining unoccupied slot.

Step 3. Proceed to A-Class Server Power Up and Boot Procedures.

Installing Embedded Disk Drives.

This section describes how to install embedded disk drives into A-Class servers.

Abbreviated embedded disk drive installation instructions also appear on the 11” x 14”

maintenance label adhered to the bottom of the top cover.

A-Class servers support up to two embedded disk drives. As of April 2000, disk capacities

of 4GB, 9GB and 18GB are supported.

Follow the steps below to install embedded disk drives in A-Class servers.

Chapter 2

Electrostatic Discharge Precautions.

The procedures in this section require opening the server and exposing the system to

electrostatic discharge. Always observe all electrostatic precautions when working with

components inside or out of the server. Failure to follow these precautions may result in

component damage or loss of system reliability.

43

Page 44

A-Class Server Installation

Installing Internal Add-On Components

• Use a grounding mat and an anti-static wrist strap.

• Wear the anti-static wrist strap to ensure that any accumulated electrostatic charge

is discharged from your body to ground.

Before You Do Anything...

• Power down the system.

• Unplug the server.

NOTE Cabinet-mounted servers must be removed from the cabinet before proceeding.

• Remove the top of the server by unscrewing the knurled captive screws on each side

of the rear of the server. Slide the top back, lift it off, and set it aside.

Step 1. Remove the disk carrier by removing the slotted T15 TORX screw and slide the disk

carrier upward and toward the power supply.

Step 2. If an embedded disk is already installed, disconnect the power and data cables from that

disk. Place the disk carrier on a ESD safe mat.

Step 3. Set address and configuration jumpers on the disk to be installed. The lower disk is

usually the boot disk and the recommended address is 6. The upper disk is recommended

to be address 5. DO NOT use address 7 as this address is reserved for the SCSI

controller internal to the server. The SCSI controller address of 7 can not be modified.

Step 4. Check configuration jumpers existing disks. Make sure the TERMINATION ENABLED

jumper is removed.

NOTE The TERMINATION ENABLED jumper must be REMOVED on all

embedded disk drives. Failure to remove this jumper will prevent

the SCSI bus from operating properly. Symptoms include failing to

boot from the embedded disk drives when external devices are

connected to the “SCSI (Single Ended) 8/16/5 path”.

44

Chapter 2

Page 45

A-Class Server Installation

Installing Internal Add-On Components

Chapter 2

Set the upper drive to ID to 5

Set the lower drive to ID to 6

Step 5. Install the first embedded disk drive in the lower slot and the second embedded disk in

the upper slot of the disk carrier. Orient the disk drive and the carrier such that the

power and data connectors on the disk drive are on the same side as the sheetmetal tabs.

Slide the disk drive into the carrier and secure the disk drive to the disk carrier with the

four slotted T15 TORX screws that came with the disk drive.

Step 6. Attach power and data cables to the embedded disk drives.

45

Page 46

A-Class Server Installation

Installing Internal Add-On Components

Step 7. Install the disk carrier by inserting the two sheetmetal tabs on the disk carrier into the

cut-outs in the server chassis. Secure the disk carrier using the slotted T15 TORX screw

removed in step 1.

Step 8. Proceed to A-Class Server Power Up and Boot Procedures.

Installing Input/Output (I/O) Cards.

This section describes how to install I/O cards into A-Class servers. Abbreviated

embedded PCI I/O card installation instructions also appear on the 11” x 14”

maintenance label adhered to the bottom of the top cover.

A-Class servers provide two slots for I/O cards. The cards which plug into these slots can

be Peripheral Component Interconnect (PCI), High Speed Connect (HSC) I/O cards or

both (see photo).

The following rules govern the installation of I/O cards:

• When present, the A3342A HSC Remote Management I/O card must be installed in

the bottom slot.

• For one HSC and one PCI card configurations, the HSC card must be installed in the

bottom slot.

• For two HSC or two PCI cards, the load order does not matter.

NOTE When the A3342A HSC Remote Management card is installed, the console path changes

from 8/16/4 to 8/4/0. This may prevent HP-UX from booting.

During selftest, server firmware detects the presence or absence of the A3342A HSC

Remote Management card and will automatically direct server firmware output to the

appropriate path (8/4/0.0 when the A3342A is present, 8/16/4.0 when the A3342A is

absent). These path changes are transparent to the physical console which should be

connected to the server via the connector labeled “Console 8/16/4.0”. These path changes

are also transparent to the server firmware ‘CONSOLE PATH’ value. Server firmware

will not change the ‘CONSOLE PATH’ value. It is not necessary to manually change the

‘CONSOLE PATH’ value when installing or removing the A3342A. You may do so if you

chose.

46

Chapter 2

Page 47

A-Class Server Installation

Installing Internal Add-On Components

Example: A3342A is not installed. ‘CONSOLE PATH’ value is 8/16/4. Server firmware

directs output to 8/16/4.0. Install A3342A. The ‘CONSOLE PATH’ value is still 8/16/4 but

server firmware directs output to 8/4/0.0. Where the console is connected never changes.

NOTE When the A3342A HSC Remote Management card is installed, do not move the console

cable from the server connector labeled “Console 8/16/4.0” to the 9-pin connector on the

A3342A HSC Remote Management card. This connector is for UPS use only.

While server firmware can automatically respond to presence or absence of the A3342A

HSC Remote Management card, HP-UX can not. If HP-UX was installed without a

A3342A HSC Remote Management card installed, the HP-UX path for the console will

be 8/16/4.0. If an A3342A HSC Remote Management card is installed, the path changes

to 8/4/0.0. The driver for this path is mux2. If mux2 is not configured to be ‘in’, HP-UX

will no longer communicate with the console. The symptom is that the server boots from

the root disk, displays the following message then hangs;

Trying Primary Boot Path

------------------------

Booting

Boot IO Dependent Code (IODC) revision 144

HARD Booted.

ISL Revision A.00.38 OCT26, 1994

ISL booting hpux

Boot

:disk (8/16/5.6.0.0.0.0.0;0)/stand/vmunix

3605260 + 327680 + 408736 start 0x16b2e8

To correct this condition, remove the A3342A Remote Management card, boot HP-UX,

run SAM and configure the mux2 driver to be ‘in’. If necessary, refer to the web-based

information at http://docs.hp.com

A3342A Remote Management card can be installed after the mux2 driver has been

verified to be ‘in’.

Follow the steps below to install I/O cards in A-Class servers.

for instructions on how to perform this task. The

Chapter 2

Electrostatic Discharge Precautions.

The procedures in this section require opening the server and exposing the system to

electrostatic discharge. Always observe all electrostatic precautions when working with

components inside or out of the server. Failure to follow these precautions may result in

component damage or loss of system reliability.

47

Page 48

A-Class Server Installation

Installing Internal Add-On Components

• Use a grounding mat and an anti-static wrist strap.

• Wear the anti-static wrist strap to ensure that any accumulated electrostatic charge

is discharged from your body to ground.

Before You Do Anything...

• Power down the system.

• Unplug the server.

NOTE Cabinet-mounted servers must be removed from the cabinet before proceeding.

• Remove the top of the server by unscrewing the knurled captive screws on each side

of the rear of the server. Slide the top back, lift it off, and set it aside.

Step 1. If necessary, remove I/O card brackets. Refer to A-Class Server I/O Card Removal and

Replacement.

Step 2. Carefully insert the I/O card into the backplane connector. The tab on the bulkhead will

slide into its slot in the chassis.

Step 3. Attach the card support guide to the front edge of the I/O card, hook the tab into its slot,

and secure the support guide with the mounting screw.

Step 4. Slide the bulkhead slotted tab up into position between the captive screw and chassis,

and tighten the captive screw.

48

Chapter 2

Page 49

A-Class Server Installation

A-Class Server Power Up and Boot Procedures

A-Class Server Power Up and Boot Procedures

Overview

This Section discusses the following power up and boot procedures:

• Power Up All External Devices

• Power Up the Server

• Configuring the integrated A-Class Web Console. This procedure includes:

— Configuring The Web Browser Host

— Configure the Web Browser

— Configure The integrated A-Class Web Console Software

— Accessing the Secure Web Console

Optional procedures for identifying external devices and mapping diagnostics:

• Boot to Initial System Loader (ISL) (Optional)

• Run Online Diagnostic Environment (ODE) Mapper (Optional)

The command to Boot HP-UX after running either of the preceding options is also

included.

Power Up Procedures

Power Up All External Devices

Apply power to all external devices, such as additional disk drives, Universal Power

Supply, and Digital Data Storage. Observe that each device passes its own selftest and is

ready for operation. Refer to the device-specific documentation as necessary.

Power Up the Server

Apply power to the A-Class server by toggling the rocker power switch on the rear of the

server from the 0 position to the 1 position. All of the front panel LEDs will illuminate

for a moment, then turn off. Only the green power LED will remain illuminated until

power is switched off. If the LEDs do not illuminate or the server does not appear to

power on, refer to Chapter 3, “A-Class System Service,” on page 61.

The server will automatically conduct a selftest and, upon completion, the firmware

Main Menu screen will be displayed at the system console. Only the power LED should

be illuminated at this point.

Chapter 2

If AUTOBOOT is enabled, the system will automatically try to boot HP-UX from the

PRIMARY PATH. If you want to interrupt the boot process, press any key on the

keyboard within 10 seconds after the message, Hit any key to interrupt the boot

sequence is displayed.

49

Page 50

A-Class Server Installation

A-Class Server Power Up and Boot Procedures

Configuring the integrated A-Class Web Console

CAUTION The integrated A-Class Web Console is preconfigured with IP address 192.0.0.192.