Page 1

User Guide

rp5400 Family of Servers

HP Part Number: A5191-96018_ed2

Published: August 2010

Edition: 2

Page 2

© Copyright 2002, 2010

Legal Notices

The information in this document is subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to this manual, including, but not limited to, the implied warranties of merchantability and fitness

for a particular purpose. Hewlett-Packard shall not be held liable for errors containedherein ordirect, indirect,special, incidentalor consequential

damages in connection with the furnishing, performance, or use of this material.

Restricted Rights Legend. Use, duplication or disclosure by theU.S. Government is subject to restrictions as set forth insubparagraph (c) (1) (ii)

of the Rights in Technical Data and Computer Software clause at DFARS 252.227-7013 for DOD agencies, and subparagraphs (c) (1) and (c) (2)

of the Commercial Computer Software Restricted Rights clause at FAR 52.227-19 for other agencies.

HEWLETT-PACKARD COMPANY 3000 Hanover Street Palo Alto, California 94304 U.S.A.

Copyright Notices. ©copyright 1983-2002, 2010 Hewlett-Packard Company, all rights reserved.

Windows", WindowsNT",Windows 95", Windows2000", and Windows XP"are registeredtrademarks ofMicrosoft in the U.S. andother countries.

Reproduction, adaptation, ortranslation of this documentwithout prior written permissionis prohibited, except as allowed under thecopyright

laws.

Page 3

Table of Contents

Preface..............................................................................................................................11

Printing History....................................................................................................................................11

What's New?.........................................................................................................................................11

1 Server Overview...........................................................................................................13

2 Server Unpacking and Installation.............................................................................15

Factory Integrated rp54xx Cabinet Installation....................................................................................15

Receive and Unpack A Non-Integrated Server....................................................................................17

Unpacking the server.......................................................................................................................17

Install Deskside Server..........................................................................................................................19

Install Stand-Alone Server in a Cabinet................................................................................................20

Stationary L-Bracket Rail Assembly.....................................................................................................25

Identifying Approved Non-E-Series HP Cabinets..........................................................................25

Identifying E-Series HP Cabinets....................................................................................................25

Identifying Static Rail Kit................................................................................................................26

Installing Stationary Rails................................................................................................................26

3 Installing Additional Components..............................................................................29

Additional Components.......................................................................................................................29

Installing Memory.................................................................................................................................29

Memory Configuration Rules..........................................................................................................29

Installing rp5400 and/or rp5450 DIMMs....................................................................................29

Installing rp5470 DIMMs...........................................................................................................31

Installing Peripheral Component Interconnect (PCI) Cards................................................................32

rp5400/rp5450 PCI Card Slots..........................................................................................................32

rp5470 PCI Card Slots......................................................................................................................33

PCI I/O Card Installation Restrictions.............................................................................................34

PCI I/O Card Installation Order......................................................................................................34

Installing a PCI Card.......................................................................................................................36

Online Addition/Replacement (OLA/R) of PCI I/O cards...............................................................38

Installing Graphics................................................................................................................................38

Graphics Troubleshooting...............................................................................................................42

Installing Disk Drives...........................................................................................................................43

4 Cable Connections......................................................................................................45

Core I/O Connections............................................................................................................................45

Revision A GSP................................................................................................................................45

Revision B GSP................................................................................................................................46

Guardian Service Processor (GSP) Overview.......................................................................................47

GSP LAN.........................................................................................................................................48

GSP RS-232......................................................................................................................................48

GSP Features....................................................................................................................................48

Revision A GSP................................................................................................................................48

Revision B GSP................................................................................................................................49

Configure System Consoles..................................................................................................................49

GSP Cables.......................................................................................................................................50

Configure RS-232 Console...............................................................................................................50

Table of Contents 3

Page 4

HP 700 Series System Console Configuration...........................................................................51

HP700 VT-100 Mode Configuration.....................................................................................51

Configure the Asynchronous Values of the GSP.......................................................................52

Configure Remote Console..............................................................................................................53

Configure the LAN Console............................................................................................................53

Configuring the GSP LAN Port via an ASCII console...............................................................54

Configuring the GSP LAN Port via LAN...................................................................................54

Configure the Web Console.............................................................................................................55

Secure Web Console Installation...........................................................................................................58

GSP Configurable Parameters..............................................................................................................60

Adding Users...................................................................................................................................60

Removing Users...............................................................................................................................61

Return the GSP to Default Configurations......................................................................................62

rp54xx Server Boot Process...................................................................................................................62

Initial Power-up...............................................................................................................................64

5 Utilities...........................................................................................................................67

Configuring the Rev A Guardian Service Processor (GSP)..................................................................67

Configuring the GSP LAN Port.......................................................................................................67

Adding Users...................................................................................................................................67

Removing Users...............................................................................................................................68

Changing the Default GSP Configuration.......................................................................................69

Configuring the Rev B Guardian Service Processor (GSP)...................................................................69

Configuring the GSP LAN Port.......................................................................................................69

Adding Users...................................................................................................................................69

Removing Users...............................................................................................................................70

Changing the Default GSP Configuration.......................................................................................71

6 Troubleshooting............................................................................................................73

Determine Current System State..........................................................................................................73

Troubleshooting and FRU identification..............................................................................................73

Problem Symptoms and Repair Actions.........................................................................................73

Chassis Code to FRU Decode...............................................................................................................75

Cross-Referencing Chassis Log Errors to rp54xx FRUs..................................................................76

Power Supply Failure Example..................................................................................................77

Processor Failure Example.........................................................................................................77

Interpreting System Alerts..............................................................................................................78

Interpreting System Alerts.........................................................................................................78

Sample System Alert..................................................................................................................79

Key FRU Identification Fields for System Alerts.......................................................................79

Interpreting Service Processor Error Chassis Logs.........................................................................79

Accessing Error Chassis Logs....................................................................................................80

Example of Accessing Error Logs..............................................................................................80

Key FRU Identification Fields for Error Chassis Logs...............................................................81

Interpreting Chassis Logs Using the chassis_code.codes File.........................................................81

Run/Attention/Fault LED States...........................................................................................................82

PCI I/O LED States................................................................................................................................89

Expansion I/O LED States.....................................................................................................................91

GSP LED States.....................................................................................................................................93

LAN/SCSI LED States...........................................................................................................................95

Fan, Power Supply, and Disk LED States.............................................................................................96

4 Table of Contents

Page 5

7 Removing and Replacing Components......................................................................97

List of Changeable Parts with Remove and Replace Components ......................................................97

Cardcage Fan...................................................................................................................................97

Core I/O...........................................................................................................................................97

HotSwap Chassis Fan......................................................................................................................97

Disk Drive........................................................................................................................................97

Display Board..................................................................................................................................98

Front Bezel.......................................................................................................................................98

Memory DIMM................................................................................................................................98

PCI I/O Card....................................................................................................................................98

Power Supply...................................................................................................................................99

HotSwap Power Converter Fan.......................................................................................................99

Platform Monitor.............................................................................................................................99

Processor Support Module..............................................................................................................99

Individual Component Remove/Replace Instructions.........................................................................99

Extend the Server out the Front.....................................................................................................100

Insert the Server from the Front ....................................................................................................100

Stand-alone Server Cover Removal...............................................................................................100

Stand-alone Server Cover Replacement........................................................................................101

Top Cover Removal.......................................................................................................................102

Top Cover Replacement.................................................................................................................103

Side Cover Removal.......................................................................................................................104

Side Cover Replacement................................................................................................................104

Front Bezel Removal (Single Piece)...............................................................................................105

Front Bezel Replacement (Single Piece).........................................................................................105

Front Bezel Removal (Two Piece)..................................................................................................106

Front Bezel Replacement (Two Piece)............................................................................................107

Core I/O Removal .........................................................................................................................108

Core I/O Replacement....................................................................................................................108

PCI Card Separator/Extractor Removal.........................................................................................110

PCI Card Separator/Extractor Replacement..................................................................................110

HotPlug Disk Drive Removal........................................................................................................110

HotSwap Software Procedure..................................................................................................111

HotPlug Hardware Procedure.................................................................................................113

HotPlug Disk Drive Replacement.................................................................................................114

Hardware HotPlug Procedure.................................................................................................114

Hot Swap Software Procedure for Attached Physical Volumes..............................................115

Hot Swap Procedure for Unattached Physical Volumes..........................................................116

HotSwap Chassis Fan Cover Removal..........................................................................................117

HotSwap Chassis Fan Cover Replacement ...................................................................................118

HotSwap Chassis Fan Removal.....................................................................................................118

HotSwap Chassis Fan Replacement..............................................................................................118

HotSwap Card Cage Fan Removal................................................................................................119

HotSwap Card Cage Fan Replacement ........................................................................................120

HotSwap Power Supply Removal.................................................................................................120

HotSwap Power Supply Replacement...........................................................................................121

HotSwap Power Converter Fan Removal .....................................................................................121

HotSwap Power Converter Fan Replacement...............................................................................122

Processor Support Module Removal.............................................................................................122

Processor Support Module Replacement......................................................................................123

Memory DIMM Removal..............................................................................................................123

Removing rp5400 Memory DIMMs.........................................................................................123

Removing rp5470 Memory DIMMs.........................................................................................124

Memory DIMM Replacement........................................................................................................124

Table of Contents 5

Page 6

Replacing rp5400 and/or rp5450 Memory DIMMs..................................................................124

Replacing rp5470 Memory DIMMs..........................................................................................125

Display Board Removal.................................................................................................................125

Display Board Replacement..........................................................................................................126

Platform Monitor Removal............................................................................................................127

Removing rp5400 and/or rp5450 Model Platform Monitors....................................................127

Removing The rp5470 Model Platform Monitor......................................................................127

Platform Monitor Replacement.....................................................................................................128

Replacing rp5400 and/or rp5450 Platform Monitors................................................................128

Replacing rp5470 Platform Monitor.........................................................................................129

PCI I/O Card Removal...................................................................................................................129

PCI I/O Card Replacement............................................................................................................130

A Parts and Accessories...............................................................................................133

CRU Physical Location........................................................................................................................133

Customer Replaceable Unit Part Numbers.........................................................................................134

B System Specifications.................................................................................................137

Dimensions..........................................................................................................................................137

Uncrating Space.............................................................................................................................137

Space Requirements.......................................................................................................................137

Computer Room Physical Space Requirements............................................................................137

Server........................................................................................................................................137

Aisle Space................................................................................................................................138

Computer Room Unpacking Space...............................................................................................138

Specify Uncrating Space...........................................................................................................138

Electrical..............................................................................................................................................138

Office High Availability Requirements.........................................................................................139

Server-level Enhanced Power Availability...............................................................................139

Power Protection............................................................................................................................139

Modular PDUs ..............................................................................................................................139

System Power Requirements.........................................................................................................140

LAN and Telephone............................................................................................................................140

Acoustic Safety Standards...................................................................................................................140

Altitude Operation Standards.............................................................................................................141

Effects of Altitude..........................................................................................................................141

Temperature and Humidity Operating Standards.............................................................................141

Thermal Protection Features..........................................................................................................141

C General Site Preparation Guidelines......................................................................143

Electrical Factors.................................................................................................................................143

Computer Room Safety.................................................................................................................143

Fire Protection..........................................................................................................................143

Lighting Requirements for Equipment Servicing....................................................................143

Power Consumption......................................................................................................................144

Electrical Load Requirements (Circuit Breaker Sizing).................................................................144

Power Quality................................................................................................................................144

Sources of Voltage Fluctuations...............................................................................................144

Power System Protection..........................................................................................................144

Distribution Hardware..................................................................................................................145

Wire Selection...........................................................................................................................145

Raceway Systems (electrical conduits) [LAHJ]........................................................................145

Building Distribution...............................................................................................................145

6 Table of Contents

Page 7

Grounding Systems.......................................................................................................................145

Power Distribution Safety Grounding [LAHJ].........................................................................145

Main Building Electrical Ground........................................................................................145

Electrical Conduit Ground..................................................................................................145

Power Panel Ground...........................................................................................................145

Computer Safety Ground....................................................................................................146

Cabinet Performance Grounding (High Frequency Ground)..................................................146

Raised Floor "High Frequency Noise" Grounding...................................................................146

Equipment Grounding Implementation Details......................................................................147

System Installation Guidelines......................................................................................................147

Wiring Connections..................................................................................................................147

Data Communications Cables..................................................................................................148

Environmental Elements ....................................................................................................................148

Computer Room Preparation........................................................................................................148

Cooling Requirements...................................................................................................................148

Basic Air Conditioning Equipment Requirements...................................................................149

Air Conditioning System Guidelines.......................................................................................149

Air Conditioning System Types...............................................................................................149

Basic Air Distribution Systems.................................................................................................149

Air Conditioning System Installation......................................................................................150

Air Conditioning Ducts............................................................................................................150

Humidity Level..............................................................................................................................150

Dust and Pollution Control............................................................................................................150

Metallic Particulate Contamination...............................................................................................151

Electrostatic Discharge (ESD) Prevention......................................................................................152

Static Protection Measures.......................................................................................................152

Acoustics........................................................................................................................................152

Facility Characteristics........................................................................................................................152

Floor Loading.................................................................................................................................152

Raised Floor Loading...............................................................................................................153

Floor Loading Terms................................................................................................................153

Average Floor Loading.............................................................................................................153

Typical Raised Floor Site..........................................................................................................153

Windows........................................................................................................................................154

Space Requirements............................................................................................................................154

Delivery Space Requirements........................................................................................................154

Operational Space Requirements..................................................................................................154

Floor Plan Grid..............................................................................................................................155

Typical Installation Schedule..............................................................................................................155

Site Inspection.....................................................................................................................................155

Delivery Survey...................................................................................................................................157

Index...............................................................................................................................161

Table of Contents 7

Page 8

List of Figures

A-1 Server Rear View.........................................................................................................................133

A-2 Side Service Bay...........................................................................................................................133

A-3 System Board (Access via Top Service Bay)................................................................................134

A-4 Server Front.................................................................................................................................134

C-1 Raised Floor Metal Strip Ground System....................................................................................147

C-2 Delivery Survey (Part 1)..............................................................................................................158

C-3 Delivery Survey (Part 2)..............................................................................................................159

8 List of Figures

Page 9

List of Tables

6-1 Problem Symptoms and Repair Actions.......................................................................................74

6-2 Chassis Log Error to FRU Decoder...............................................................................................76

A-1 Exchange CRUs...........................................................................................................................134

A-2 Non-Exchange CRUs...................................................................................................................135

B-1 Power Requirements....................................................................................................................140

C-1 Effect of Humidity on ESD Charge Levels..................................................................................152

C-2 Floor Loading Term Definitions..................................................................................................153

C-3 Typical Raised Floor Specifications.............................................................................................154

C-4 Customer and Hewlett-Packard Information..............................................................................155

C-5 Site Inspection Checklist..............................................................................................................156

9

Page 10

List of Examples

4-1 CA command.................................................................................................................................52

4-2 LC command.................................................................................................................................54

4-3 LAN Configuration from a PC......................................................................................................55

4-4 GSP Browser Window...................................................................................................................57

4-5 GSP Web Browser Help Screen.....................................................................................................57

4-6 Combined GSP Browser Window.................................................................................................58

6-1 Chassis Log: Reporting Entity Type = System Firmware..............................................................82

10 List of Examples

Page 11

Preface

Printing History

The Printing History below identifies the edition dates of this manual. Updates are made to this

publication onan unscheduled, as needed, basis.The updates will consist of acomplete replacement

manual and pertinent on-line or CD-ROM documentation.

What's New?

The, Upgrade Guide, rp5400 Family of Servers, is new and was developed to provide customers

with system maintenance information for those components called customer replaceable units

(CRUs). Maintenance of CRUs does not require HP customer engineering services, except when

specifically cautioned.The cautions are shown primarily to protect customerproduct warrantees.

November 2002. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .First Edition

August 2010. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Second Edition

Printing History 11

Page 12

12

Page 13

1 Server Overview

The rp5400 family of servers are 1-way to 4-way servers based on the PA-RISC processor

architecture. The rp5400 family of servers accommodate up to 16GB of memory and internal

peripherals including disks and DVD ROM/Tape. High availability features include HotSwap

fans and power supplies, and HotPlug internal disk drives. The supported operating system is

HP-UX.

13

Page 14

14

Page 15

2 Server Unpacking and Installation

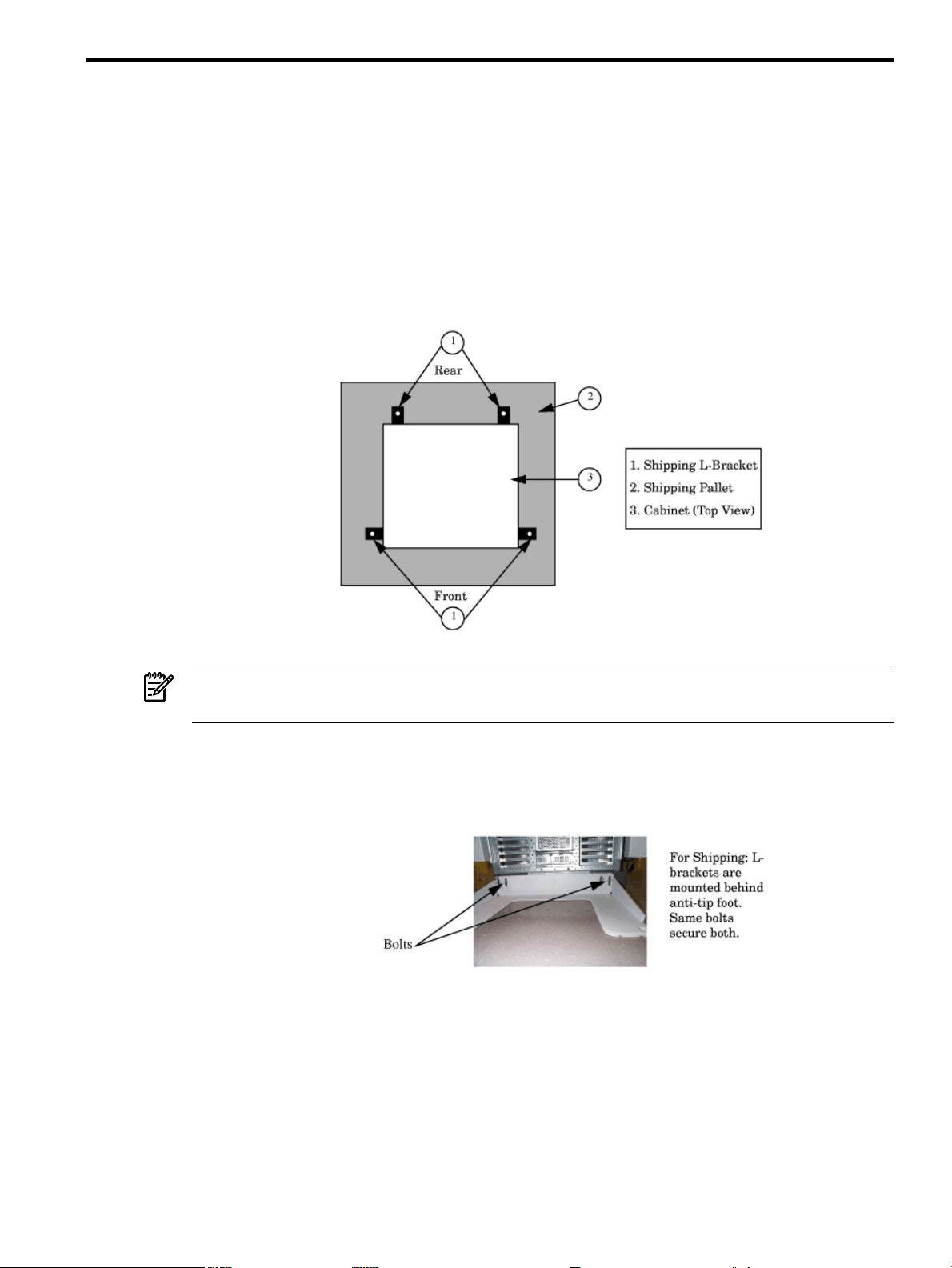

Factory Integrated rp54xx Cabinet Installation

A factory integrated server is one in which the rp54xx server and associated components are

pre-assembled and shipped from the factory already installed in a Hewlett-Packard E-Series

cabinet. Factory integrated systems reduce the amount of time required to set-up and begin

server operation.

1. Carefully remove the carton and anti-static bag from the pallet.

2. Remove the front two (2) L-brackets. Retain the 1/2-inch bolts for later use.

NOTE: As viewed from the front, one bracket is located on each side at the base of the

cabinet near the front.

3. At the rear of the cabinet:

a. Open the door.

b. Remove the anti-tip foot by removing and retaining the two (2) 1/2-inch bolts.

c. Remove the two (2) L-brackets (revealed by removing the anti-tip foot).

Factory Integrated rp54xx Cabinet Installation 15

Page 16

4. Remove the two ramps from the pallet and carefully place them into the slots at the front

of the pallet.

WARNING! Use extreme care when rolling the racked system down the ramps. A rack

containing one rp54xx can weigh up to 418 lbs. Do not stand in front of the ramps when

rolling the cabinet off the pallet or injury may occur. All but the smallest configurations

require two persons to safely remove the rack from the pallet.

If anti-tip feet or ballast are not installed or are improperly installed the cabinet can tip.

Failure to follow this precaution can cause injury to personnel or damage to equipment.

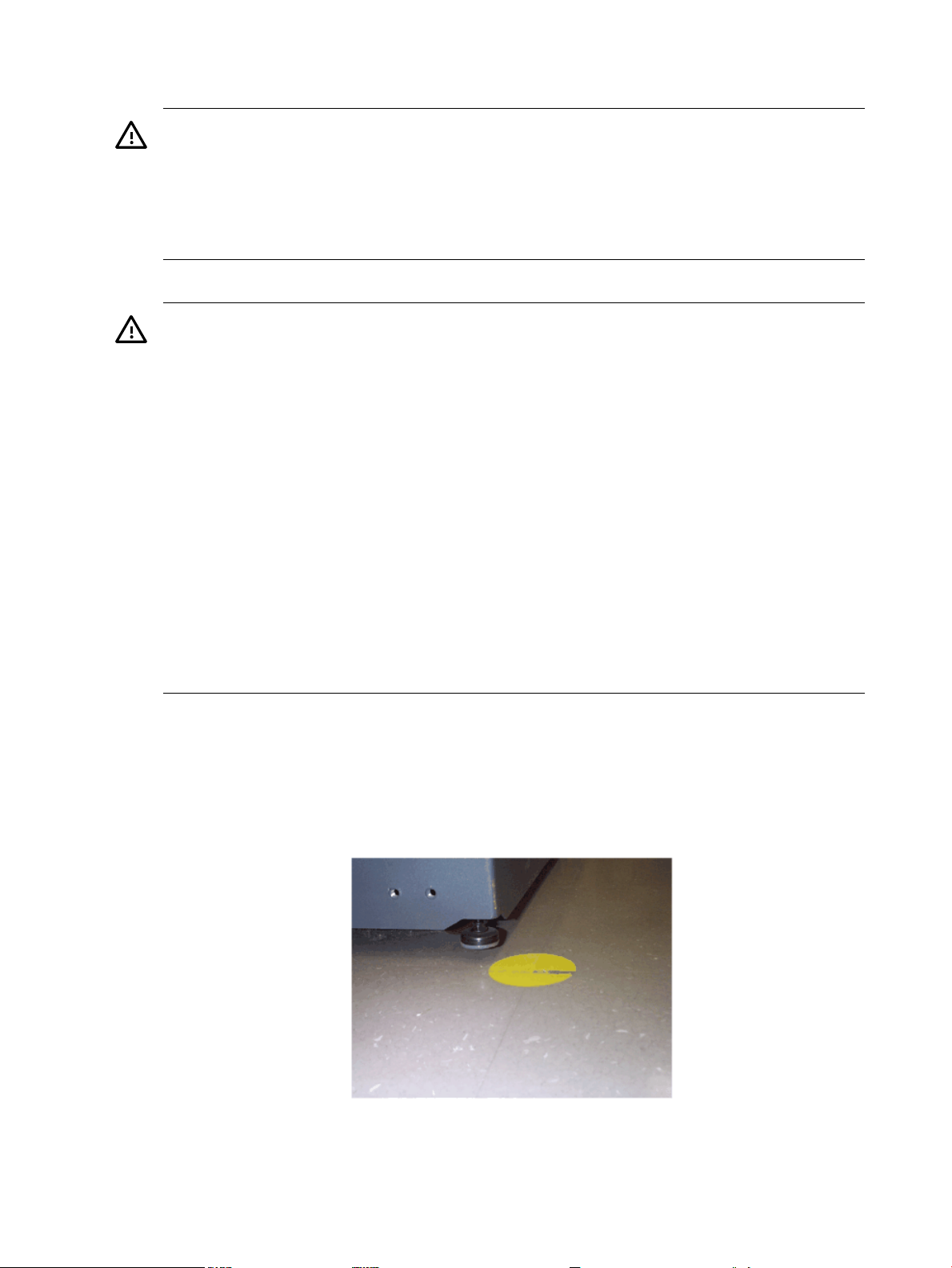

5. Straighten the rollers on the cabinet base, if needed, and carefully roll it down the ramps.

WARNING! After removing the server from the pallet, Do not move the cabinet unless the anti-tip

feet are installed! The cabinet can tip if care is not used. Due to their low ground clearance

the feet may catch on irregularities on the floor, thresholds, or ramps.

Do not move the cabinet without first installing the anti-tip feet. The cabinet may tip if moved

without the anti-tip feet or ballast installed.

Do not move the cabinet after installing the anti-tip feet unless they are in the fully-raised position.

Once installed, the anti-tip feet must be fully raised to allow ground clearance.

Because oftheir lowground clearance,the fully-raised anti-tip feet may need to be removed

temporarily to clear some obstacles such as door jambs, ramps, and other large irregularities

or obstructions on the floor.

If you must temporarily remove the anti-tip feet to clear an obstacle, use extreme caution

when moving the cabinet. Always reinstall the anti-tip feet as soon as the obstacle has been

cleared.

Lower and secure both the anti-tip feet and the cabinet leveling/stabilizer feet once the

cabinet is in place.

Failure to follow these precautions can result in equipment damage or personal injury.

6. Install the front and rear anti-tip feet using the 1/2 inch bolts provided. Ensure that the

anti-tip feet are installed in the fully up position in the mounting slots. This will provide

maximum ground clearance while moving the cabinet to its final position.

7. Carefully move the cabinet to its installation location.

8. Lower the anti-tip feet to the fully down position and adjust the cabinet leveling feetfor best

cabinet stability.

16 Server Unpacking and Installation

Page 17

Receive and Unpack A Non-Integrated Server

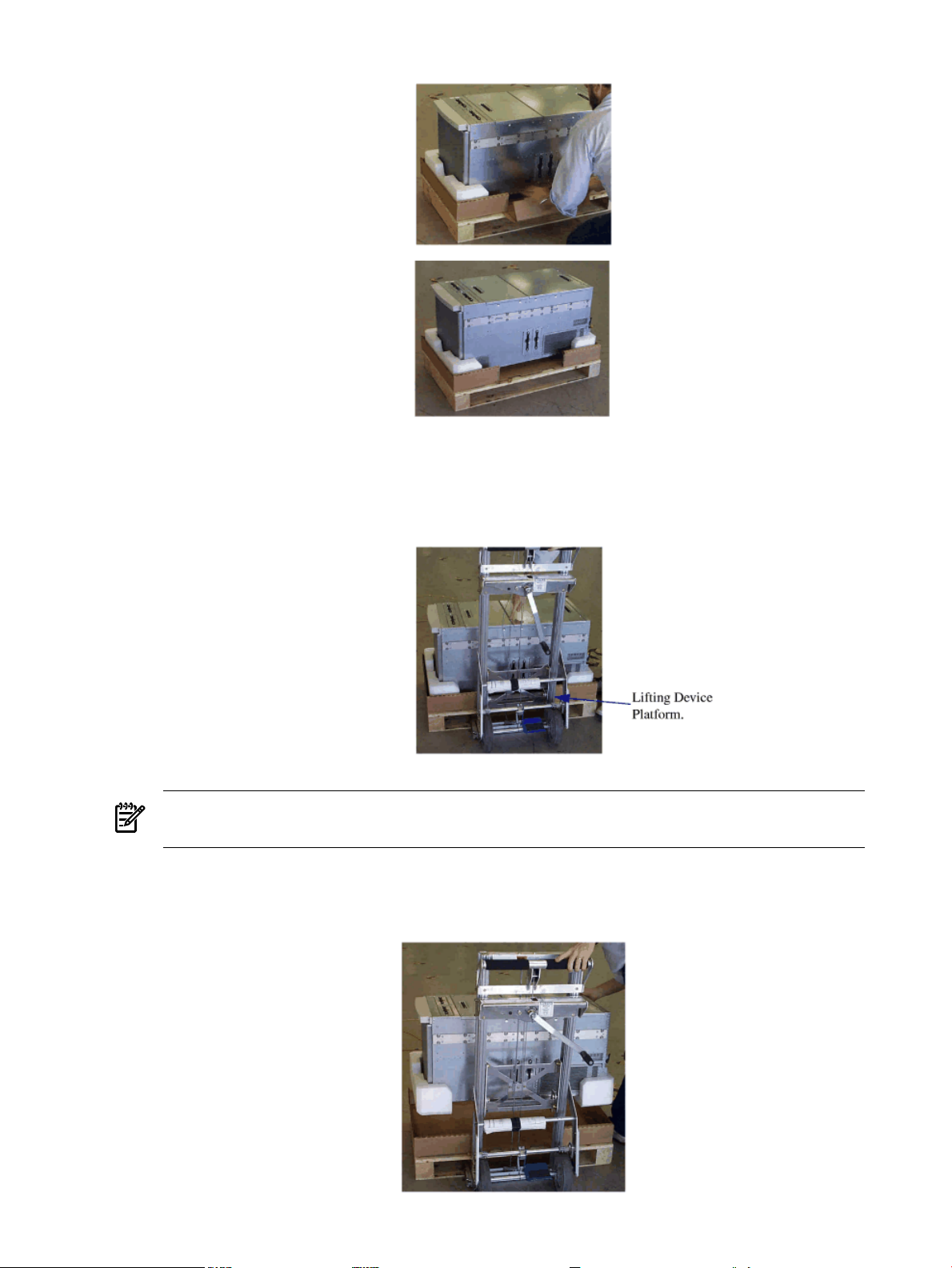

WARNING! The typical rp54xx system can weigh up to 68kg (150lbs). HP recommends using an

an approved lifting device. Lift and move the server in accordance with all local safety regulations.

Failure to follow this precaution can cause injury to personnel or damage to equipment.

Unpacking the server

The followingprocedure describes the steps involved in unpackingthe server,whether tofunction

as a stand-alone Deskside unit, or to be integrated into a cabinet.

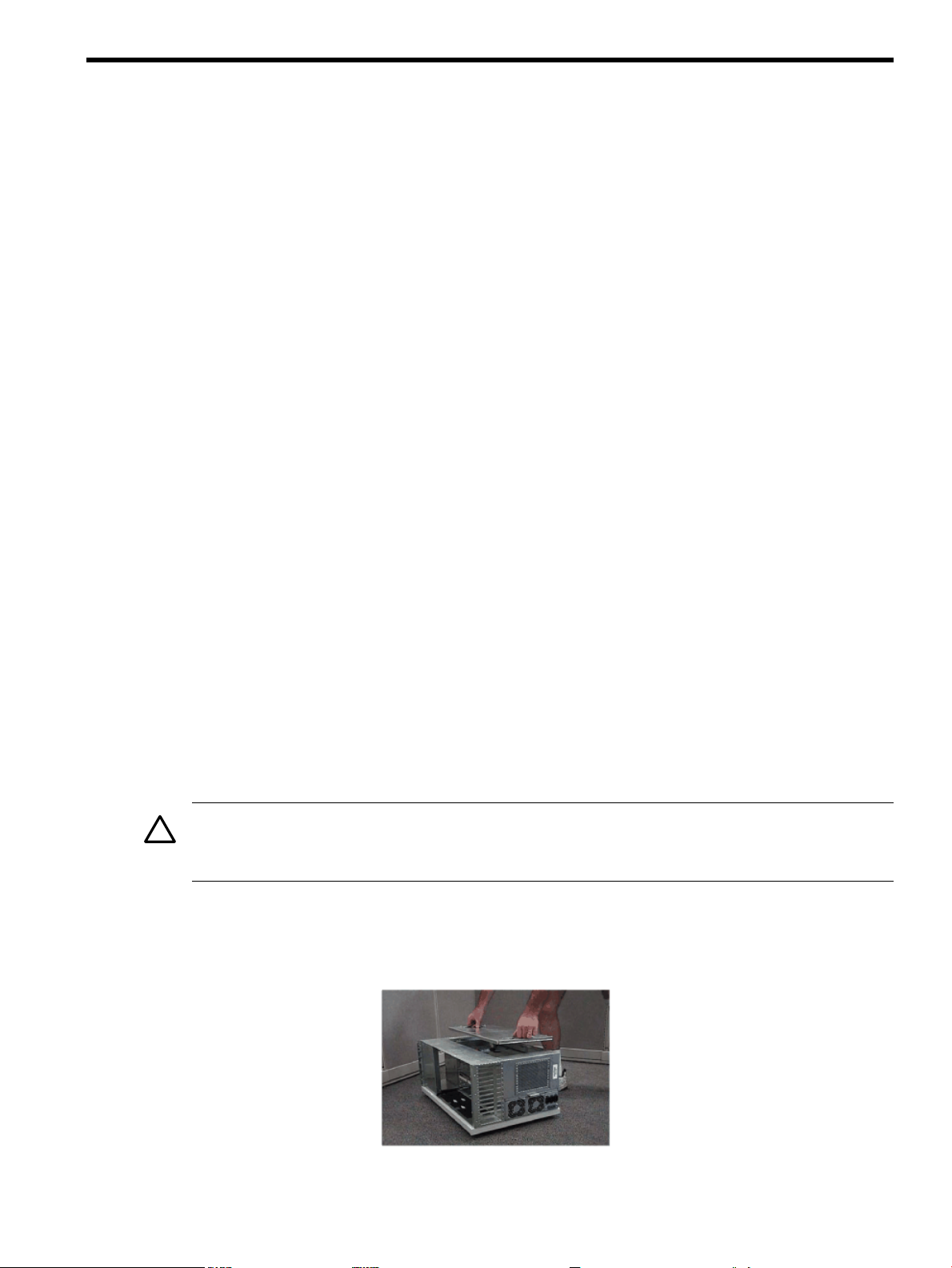

1. Remove the shipping carton and anti-static bag from the server as depicted below.

NOTE: The packaging for rp74xx and rp54xx servers is the same, rp74xx is shown.

2. If you are moving the server manually, use three people to lift the server from the packing

material and pallet. Carefully move the server to the selected location.

3. If you are moving the server by an approved lifting device (such as Genie Lift ™), remove

the tearflap fromthe frontlip ofthe cartonbottom toallow accessto the server, as illustrated

below. Removal of the tear flap will reveal a slot between the bottom of the server and the

inside bottom of the cardboard box.

Receive and Unpack A Non-Integrated Server 17

Page 18

4. Carefully raise the lift's platform so that it will slide into the slot located under the center

of the server, but over the top of the pallet.

NOTE: The server's center of gravity will vary with the hardware configuration, but it is

generally located slightly behind the middle of the server.

5. Raise the lifting device platform enough for the server to clear the pallet and packing

materials, as show below.

18 Server Unpacking and Installation

Page 19

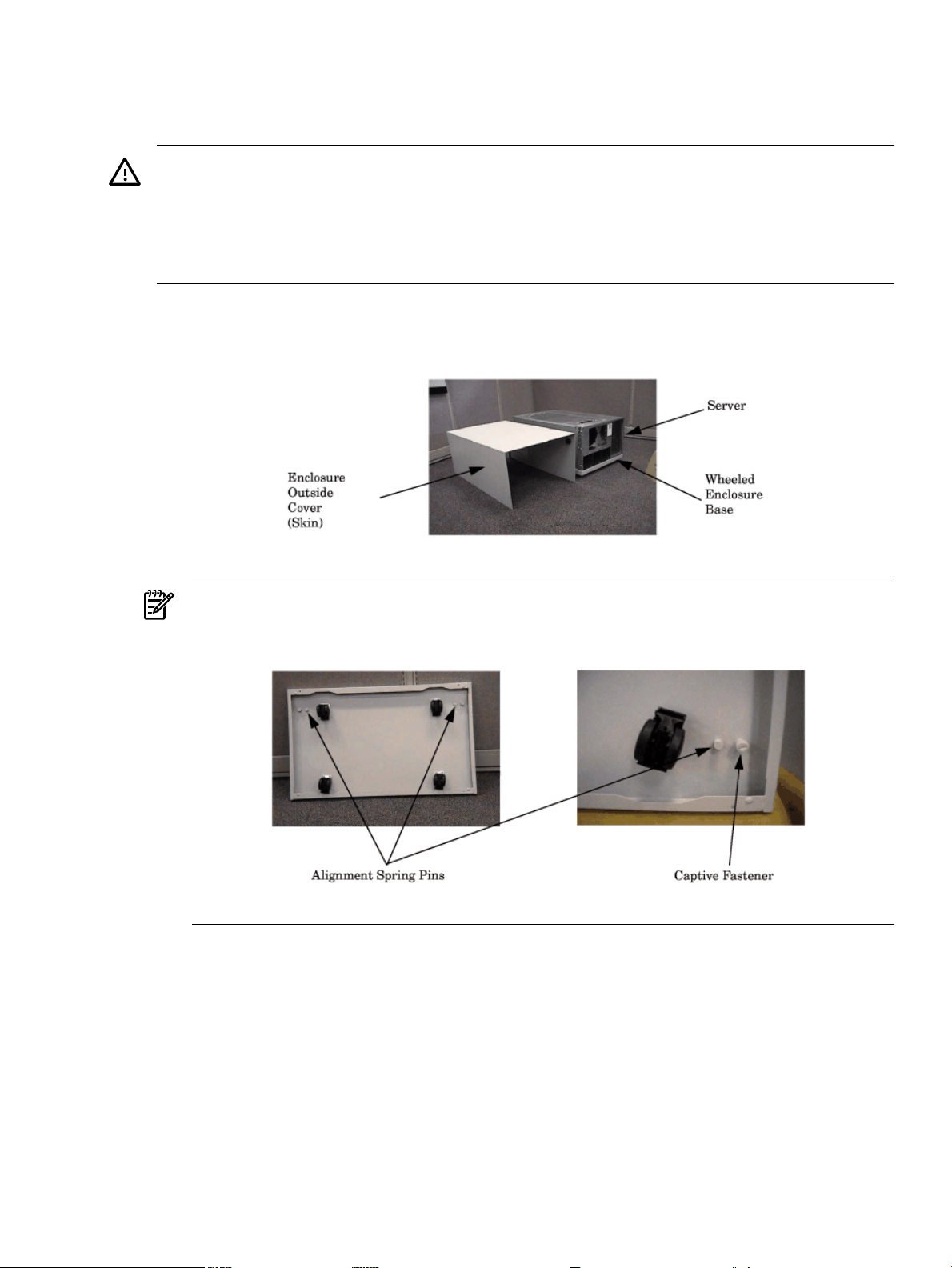

Install Deskside Server

The followingsection describes theinstallation of aserver into a Deskside enclosure forinstallation

in an office environment.

WARNING! The typical rp54xx system can weigh up to 68kg (150lbs). HP recommends using an

approved lifting device.

• Lift and move the server in accordance with all local safety regulations.

• Do not attempt to lift the server by the plastic handles on the top and side covers.

Failure to follow these precautions can cause injury to personnel or damage to equipment.

1. Unpack the server.

2. Unpack the deskside enclosure.

NOTE: Ensure that the positioning spring pins in the enclosure base align with the

alignment holes in the bottom of the server.

3. Position the server on the wheeled enclosure base.

4. Tighten the two captive screws in the enclosure base to secure the server to the base.

5. Position the enclosure cover (outsideskin) over theserver and install andtighten the screws

to secure it to the base.

Install Deskside Server 19

Page 20

NOTE: The perforations and the lip of the outside skin should be toward the rear of the

server.

WARNING! Stacking rp54xx servers in deskside enclosures is not supported.

Stacking rp54xx servers in deskside enclosures can damage equipment, may cause injury

to personnel, and may void your warranty or service contract.

6. Install the Front Bezel.

7. Locate the two pull-tabs. One pull-tab is longer than the other. The shorter pull-tab is blank

on bothsides. The back of the shorter pull-tab provides a writable surface for Customer use.

8. Locate the plastic bag containing the label sheet (taped to the server).

9. Remove the label containing serial number, base product, processor product, and model

information from the label sheet and apply to the back of the longer pull-tab.

NOTE: Pull-tab and label shown above is for an rp74xx server. rp54xx uses the same style

label and similar pull-tab.

10. Insert the pull-tabs into the front bezel. Install the longer pull-tab in the left side plastic

window in such a way that the rp54xx logo is visible. Install the shorter pull-tab in the right

side plastic window with either surface visible. Refer to the diagram above for pull-tab

locations.

Install Stand-Alone Server in a Cabinet

The following describes how to install the A5556A slide-tray assembly into an approved HP

cabinet in preparation for installing an rp54xx server.

This slide-trayassembly can beinstalled in anHP E-Series cabinetor other HPcabinets approved

for rp54xx system installation. To install the A5556A slide-tray assembly in an approved HP

equipment cabinet, proceed as follows:

20 Server Unpacking and Installation

Page 21

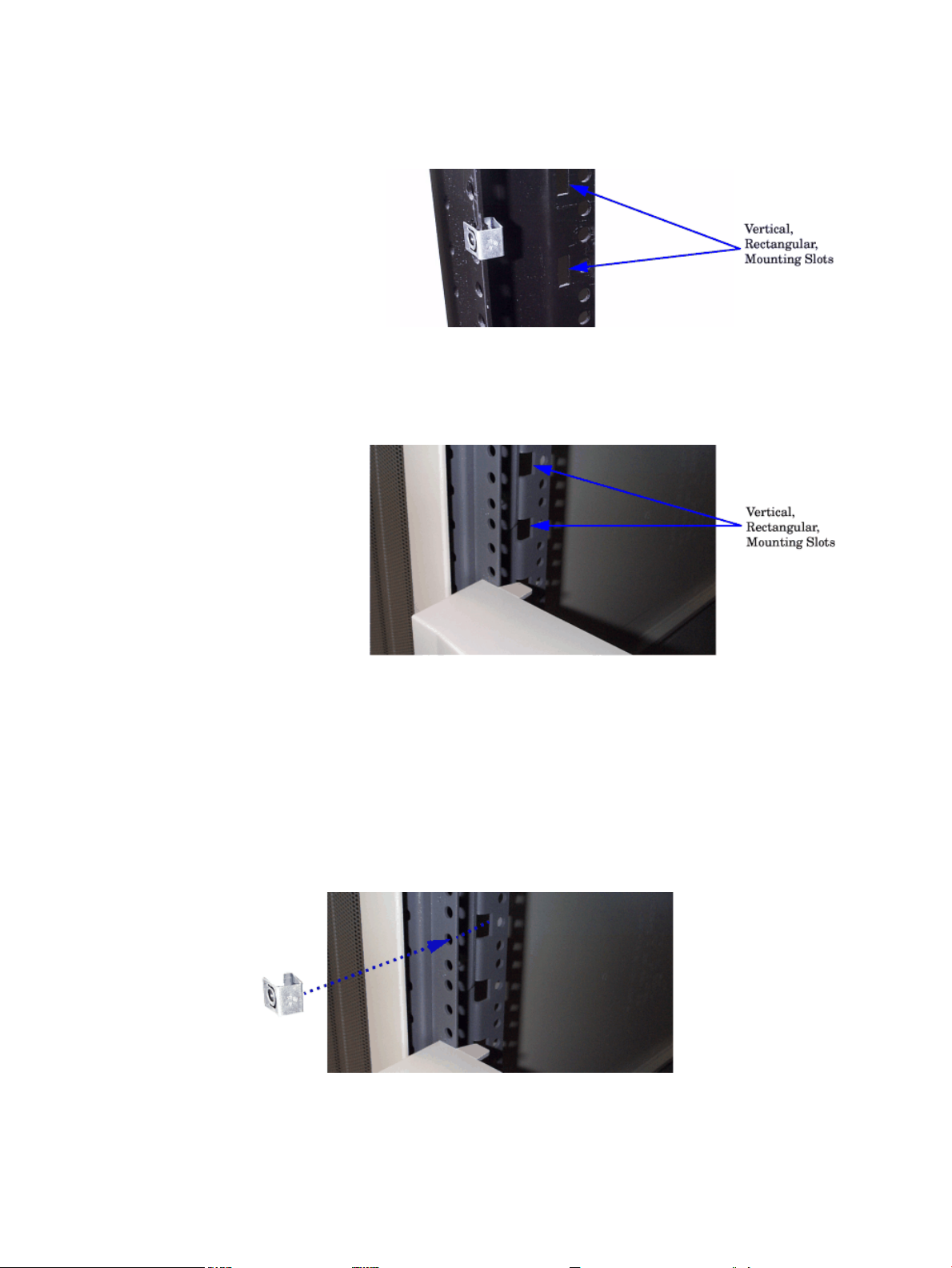

1. Determine what type of cabinet you are installing the slide-tray assembly into.

a. E-Series cabinets have:

• Parchment white, plastic, sectional, side panels

• Black painted vertical frame posts with a partial return flange.

b. Approved, non-E-Series, cabinets have:

• Single piece metal side panels

• Gray painted verticle frame posts with full return flanges.

2. Note the vertical, rectangular, slots in the return flanges on the vertical mounting posts.

Determine into which of these vertical slots the slide/tray kit will be installed. This is done

by counting down eight rectangular slots from the top of the cabinet or the bottom of the

equipment above.

3. On the front vertical mounting posts only, slide M5 sheet metal nuts onto the posts over the

holes immediately adjacent to the vertical slots determined in the previous step. Also place

M5 sheet metal nuts on the holes directly above these. Orient the sheet metal nuts so that

the threaded portion faces towards the outside of the cabinet. There should now be a total

of four (4) sheet metal nuts installed.

4. If the cabinet is a non-E-Series cabinet, discard the left hand and right hand aluminum

spacers and two of the M5 x 16 screws with cress-cup washers and proceed to step 12.

5. If the cabinet is an E-Series cabinet, place the hook of the aluminum spacer marked "L"

(5183-1864) into the appropriate vertical, rectangular slot on the front, left hand mounting

Install Stand-Alone Server in a Cabinet 21

Page 22

post. The hook points downward. Similarly, place the spacer marked "R" (5183-1863) into

the appropriate slot on the right hand mounting post.

6. Use one M5 x 16 screw with cress-cup washer to attach each spacer to its vertical post. Do

this by inserting the screw through the top hole in the spacer, through the mounting rail

and tightening it into the sheet metal nut located at that position.

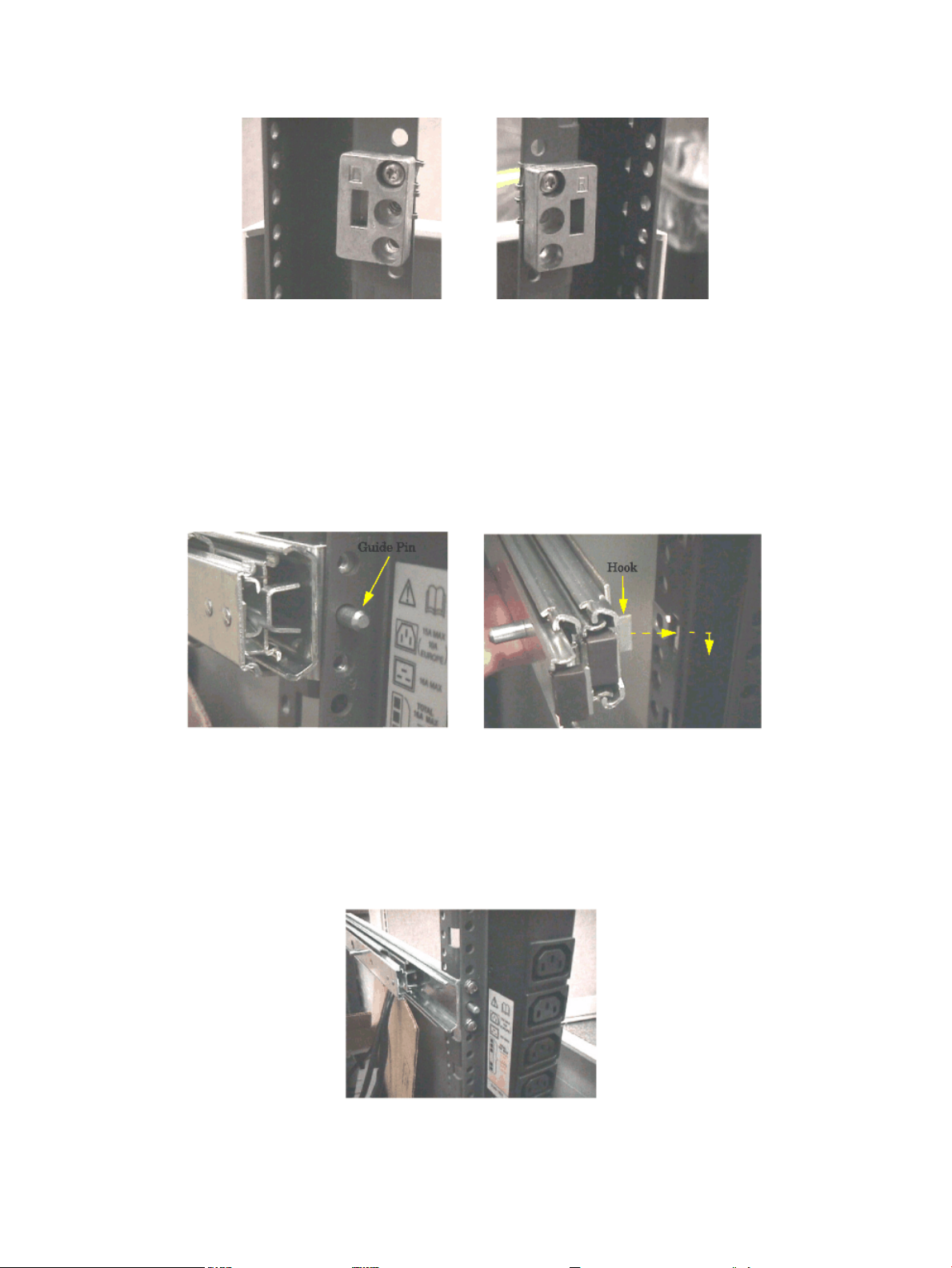

7. Take the lefthand slide/bracket assembly (marked337079-1L) and install it intothe left hand

vertical mounting posts. This is done by inserting the pin at the rear of the slide's mounting

bracket into the 23rd hole in the rear vertical mounting post and inserting the hook at the

front of the bracket into the vertical, rectangular slot in the aluminum spacer. The slide

should be positioned in the cabinet so that it is horizontal and level.

8. Securely fasten the rear of the slide's mounting bracket to the rear vertical mounting post

by installing and tightening two of the M5 x16 screws with cress-cup washers thorough the

mounting post, through the slides mounting bracket and into the threaded nuts attached to

the mounting bracket.

9. Fully extend the slide so that it is locked in the fully open position.

22 Server Unpacking and Installation

Page 23

10. Use an M5 x 30 screw with a cress cup washer to attach the front of the slide to the vertical

mounting post. Insert the screw through the slide, through the center hole of the aluminum

spacer, through the vertical mounting post, and tighten into the sheet metal nut located at

that position.

11. Usea procedure similarto steps 7 through 10 to install theright handslide/bracket assembly

(marked 337079-1R) and then proceed to step 12.

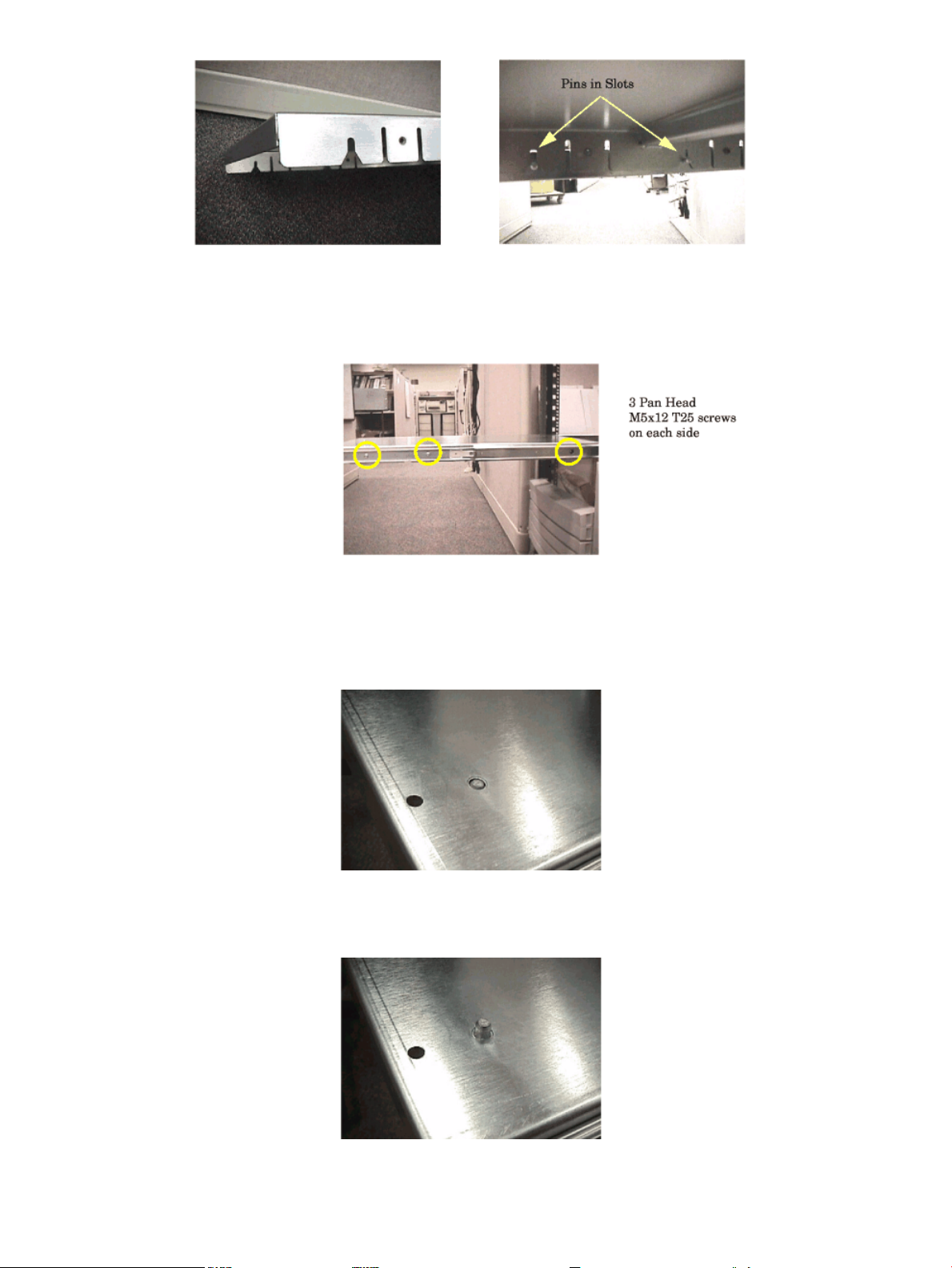

12. Take the trayand place it onto the pins that extend from the slides' inner members. The slots

with wide lead-in guides on the side of the tray fit down onto the slides' pins. The flat part

of the tray will be on top, and the mounting holes in the top of the tray will be located to

the right of the center of the tray. Slide the tray all the way down on both sides so that the

pins reach the top of the slots in the side of the tray.

Install Stand-Alone Server in a Cabinet 23

Page 24

13. Use six, M5 x 12 screws (without washers) to attach the tray to the slides. Three screws are

used to attach each slide. Insert the screws through the slides, through the tray and tighten

into the threaded nuts located on the inside of the sides of the tray.

14. From the bottom of the tray pull the plunger pin down and give it a 1/4 turn to hold it in

place.

15. Position the server on the tray aligning the plunger pins with the alignment holes in the

chassis.

16. Release the plunger pins to secure the server.

24 Server Unpacking and Installation

Page 25

Stationary L-Bracket Rail Assembly

rp54xx servers may be installed intoE-Series andapproved Non- E-Series cabinetsusing stationary

L-bracket rail assembly kits listed below.

NOTE: rp54xx servers are supported in Hewlett-Packard E-series and approved Non- E-series

Hewlett-Packard cabinets, and approved rail kits.

For information on additional qualified 3rd party cabinets and rail kits, contact the nearest

Hewlett-Packard Response Center.

Rail Kit Product NumberCabinet Type

A5575AE-Series HP Cabinet

A5562AOther Approved HP Cabinet

Identifying Approved Non-E-Series HP Cabinets

Approved Non- E-Series cabinets haveblack frames, onepiece outside sheet metal skins, a partial

return flange, and requires the installation of the aluminum spacer blocks, supplied with the rail

kits.

Approved Non- E-Series cabinets include the following product numbers: A1883A, A1884A,

A1896A, A1897A, C1897A, C2785A, C2786A, and C2787A.

Identifying E-Series HP Cabinets

E-Series cabinets have light gray frames, sectioned, plastic outside "skins", a full return flange,

and does not require the installation of the aluminum spacer block supplied, with the rail kits.

Stationary L-Bracket Rail Assembly 25

Page 26

E-Series cabinets include the following product numbers: A5134A, A5136A, A5136A, A4900A,

A4901A, A4902A, J1500A, J1502A, and J1502A.

Identifying Static Rail Kit

Hewlett-Packard has currently approved two static rail kits for use in cabinet mounting the

rp54xx server. They are illustrated below.

Installing Stationary Rails

The installation of stationary rails is similar for most cabinet and rail combinations.

The key considerations to are:

• Ensure that all safety precautions are read, understood, and observed

• Follow all installation instructions provided with the cabinet and rail kits, and

• Ensure that the rails extend out from the cabinet posts sufficiently to properly and safely

support the equipment being installed.

To install an rp54xx server on stationary rails in an approved cabinet proceed as follows:

26 Server Unpacking and Installation

Page 27

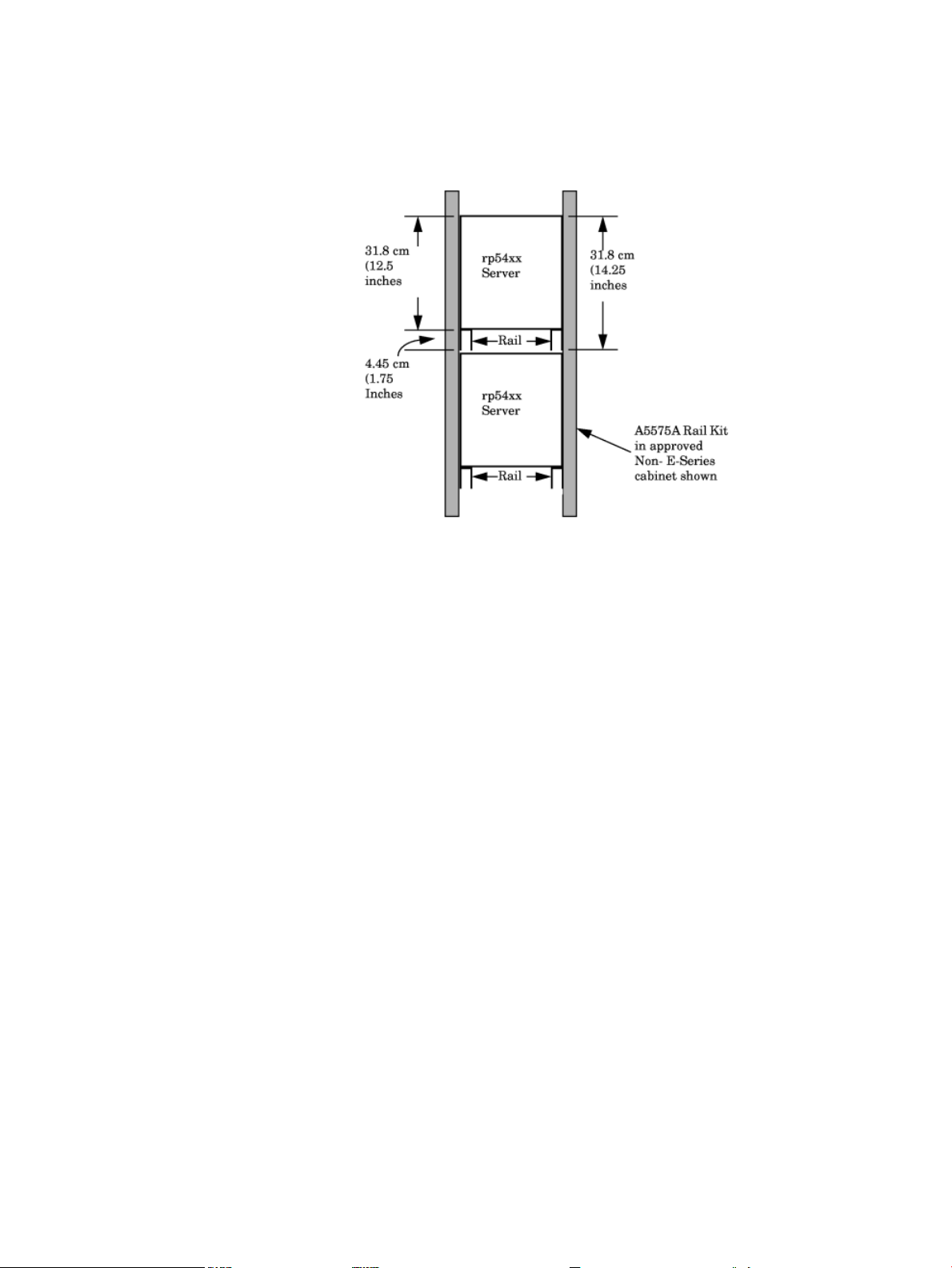

1. Locate the rail mounting height in the cabinet. Allow for the following space requirements:

• For each rp54xx server, allow 31.8cm (12.5 inches)vertically (7 EIAs or Rack Units (RUs).

• If installing the A5575A rail kit, allow an additional vertical 4.45cm (1.75 inches (1 EIA)

each set of rails.

2. Install sheet metal nut(s) in the vertical cabinet posts at the required height for the kit being

installed:

• Install the first nut either:

— 4.45 cm (1.75 Inches) above the top, or

— 31.8 cm (12.5 inches) below the bottom of the last server.

• If installing a A5562A rail kit, install the second nut in the next frame hole below the

first.

3. Hold the rail in place and insert and tighten the screws.

For installation of other qualified cabinet and rail combinations refer to the safety precautions

and instructions accompanying them.

Stationary L-Bracket Rail Assembly 27

Page 28

28

Page 29

3 Installing Additional Components

Additional Components

Some internal components are too delicate to be installed in the server prior to shipping. These

internal componentsare shipped withthe server, butare packed separately. They can be installed

after the cabinet has been unpacked and positioned.

Some ofthe internal components that are packed separately are not user-installable. To maintain

warranty validation, these items must be installed by a Hewlett-Packard Customer Engineer.

If you received either (or both) of the components listed below, contact your Hewlett-Packard

provider to arrange for installation.

• Central Processing Units (CPUs)

• Power Distribution Units (PDUs)

Installing Memory

Memory Configuration Rules

rp54xx servers have 16slots (8DIMM pairs) for memory DIMMs. These slots arenumbered 0a/b,

1a/b,... 7a/b. 8 of these slots (4a/b - 7a/b) are disabledon rp5400 servers. rp5450 servers canaccess

all slots. rp5400 and rp5450 servers have DIMM slots located on the System Board.

rp5470 servers install DIMMs using Memory Carriers. The Memory Carriers fit into slots on the

System Board.

The following rules govern the installation of memory DIMMs for rp5400, rp5450, and rp5470

servers:

• Memory must be installed in DIMM pairs.

• The capacity of DIMMs within a pair must be the same.

• Install DIMMs with the greatest capacity in the lowest slot numbers.

• Install DIMMs the following slot order: 0a/b, 1a/b, 2a/b, 3a/b, and so on.

Installing rp5400 and/or rp5450 DIMMs

1. Power down and unplug the rp54xx server.

CAUTION: DC voltages are present when the server is connected to AC power. Do not

install or service rp54xx internalcomponents while DC voltage is present. Failure toobserve

this precaution can result in damage to the server.

2. Loosen the captive T-15 screws that holdthe top cover in place, then grasp the strap handle,

raise the cover slightly, and pull the cover toward the front of the server to free the cover

tabs from the slots in the chassis. The air baffle will be exposed.

Additional Components 29

Page 30

3. Make the top of the server accessible for service.

4. Loosen the captive T-15 screws on the air baffle. Grasp the two handles on the baffle, and

lift the baffle remove it.

CAUTION: Observe all ElectroStatic Discharge (ESD) precautions Do not touch internal

components. Failure to observe ESD precautions can cause damage to components.

5. Observe Electrostatic Discharge (ESD) precautions.

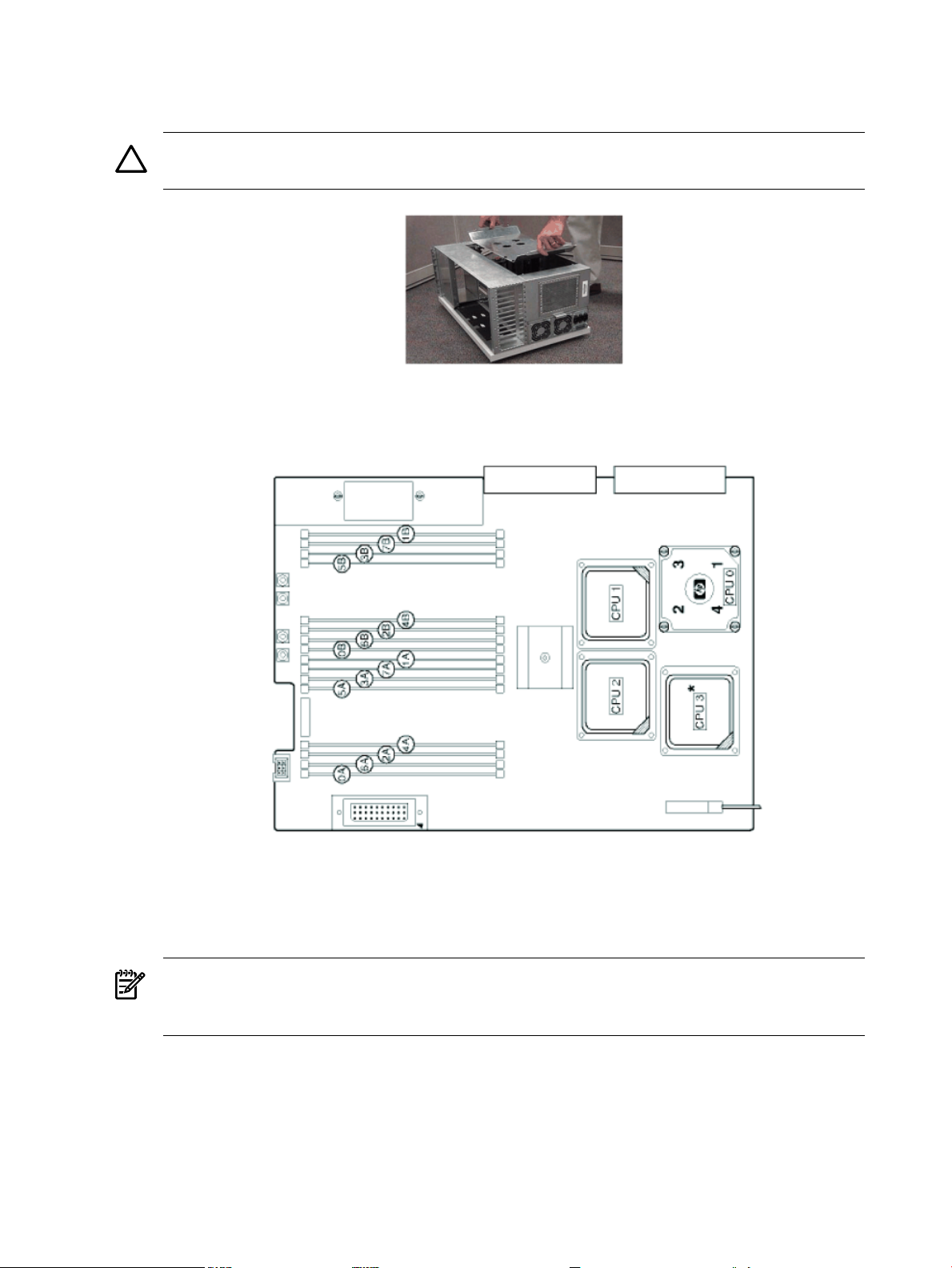

6. Refer to the following graphic for memory slot locations.

Locate the correct DIMM pair slots. Insert the DIMM connectors into the guides until the

card snaps firmly in place. It may be necessary to apply downward force using the palm of

your hand on the DIMM. Observe the top of the DIMM to make sure one side is not higher

than the other.

NOTE: It may be necessary to remove PSM 1 when installing a DIMM in slot 0a and PSM

0 when installing a DIMM in slot 1b. If either PSM is removed to install memory, ensure it

is re-installed.

7. Replace the air baffle. Tighten the four captive screws to secure the air baffle in place.

30 Installing Additional Components

Page 31

8. Replace the top cover. Tighten the four captive screws to secure the top cover in place.

9. For rack configurations, insert the rp54xx server back into the rack.

10. For deskside enclosure configurations, replace the deskside enclosure cover.

11. Power the rp54xx server on.

12. Use the BCH command in meto verify the system recognizes the memory that you have

just added.

Installing rp5470 DIMMs

DIMMs for the rp5470 system are installed in memory carriers instead of the system board, as

are the other rp54xx systems. However, rp5470 memory carriers are also located on the system

board, so the method for opening and closing the system is the same. Procedures for removing

and replacing theserver top andbaffle are listed below,without the pictures shownin thesection

titled, "Installing rp5400 and/or rp5450 DIMMs." If you wish to reveiw the pictures, please refer

to the aforementioned section.

1. Power down and unplug the rp54xx server.

NOTE: DC voltages are present when the server isconnected toAC power. Do not attempt

to install or service: CPUs, Memory, PSMs, the Platform Monitor or PCI I/O cards installed

in non-Turbo slots (1-6) while DC voltage is present. Failure to observe this warning may

result in damage to the server.

2. Make the top of the server accessible for service.

3. Loosen the captive T-15 screws that holdthe top cover in place, then grasp the strap handle,

raise the cover slightly, and pull the cover toward the front of the server to free the cover

tabs from the slots in the chassis. The air baffle will be exposed.

4. Loosen the four (4) captiveT-15 screws on the air baffle. Grasp thetwo handles on the baffle,

and lift and remove the baffle.

5. Observe Electrostatic Discharge (ESD) precautions.

6. Refer to the following graphic for Memory Carrier locations.

Installing Memory 31

Page 32

a. Locate the Memory Carrier and pull up on the extractor levers on each end of the

Memory Carrier to unseat the Memory Carrier from its socket.

b. When the Memory Carrier unseatsfrom the socket, pullit awayfrom the System Board.

c. Loosen the captivescrews that secure the DIMM Clip and remove the DIMM Clip from

the Memory Carrier.

d. Seat the memory DIMM into its socket on the Memory Carrier.

e. Press theextractor levers on each end of the memory DIMM slot inward until the levers

snap into place.

f. Attach the Memory Clip to the Memory Carrier with the DIMM slot markings on the

top of the Memory Clip aligned with the DIMM slot markings on the Memory Carrier.

g. Secure the Memory Clip using the captive screws.

h. Seat the Memory Carrier into the appropriate slot on the System Board.

i. Push down on the extractor levers and snap them into place.

7. Replace the air baffle. Tighten the four captive screws to secure the air baffle in place.

8. Replace the top cover. Slide the cover tabs into the slots in the chassis and close the cover.

Tighten the two captive screws to secure the top cover in place.

9. For rack configurations, insert the rp54xx server back into the rack.

10. For deskside enclosure configurations, replace the deskside enclosure cover.

11. Power the rp54xx server on.

12. Use the BCH command in meto verify the system recognizes the memory that you have

just added.

Installing Peripheral Component Interconnect (PCI) Cards

rp54xx servers have a total of 12 PCI I/O slots. Slots 1 and 2 are reserved for the LAN/SCSI and

GSP Core I/O cards, leaving 10 PCI I/O slots available for Customer use.

rp5400/rp5450 PCI Card Slots

For rp5400 and rp5450 models, 10 PCI I/O slots consist of Turbo and non-Turbo slots. Server PCI

slots are shown below.

32 Installing Additional Components

Page 33

• Slots 1 and 2 are reserved for the rp54xx LAN/SCSI and GSP (Guardian Service Processor)

Core I/O cards, respectively. Slots 1 and 2 are non-Turbo slots. Non-Turbo slots share a

single 250MB/s PCI bus and are incapable of HotPlug functionality. The server must be

turned off prior to removing or installing the LAN/SCSI or GSP cards in these slots.

• Slots 3 - 6 are non-Turbo slots. These four Non-Turbo slots share a single 250MB/s PCI bus,

run at33MHz and support 32 and 64-bit PCI cards.Non-Turbo slots are incapable ofHotPlug

functionality. The server must be turned off prior to removing or installing PCI cards in

these slots.

• Slots 7 - 12 are Turbo slots. Each Turbo slot has a dedicated 250MB/s PCI bus, run at 66MHz

and support 32 and 64-bit PCI cards. Turbo slots are HotPlug capable. Below each Turbo

slot is a plastic PCI card separator. The PCI card separator has two LEDs and a pull tab on

the outer edge. The LED's provide power and status for the slot. The pull tab allows the PCI

card to be easily removed.

rp5400 servers have access to slots 1, 2 and 8-12 while rp5450 servers have access to all (1-12)

slots.

NOTE: Slot 3 will become enabled on rp5400 servers with server firmware versions later than

40.48.

A slot 3 enabled label (A5576-84009) is available for rp5400 systems.

rp5470 PCI Card Slots

For rp5470 models, the 10 PCI I/O slots consist of Twin Turbo, Turbo, and non-Turbo slots. The

following illustration shows the PCI card slot layout.

Installing Peripheral Component Interconnect (PCI) Cards 33

Page 34

• Slots 1 and 2 are reserved for the rp54xx LAN/SCSI and GSP (Guardian Service Processor)

Core I/O cards, respectively. Slots 1 and 2 are non-Turbo slots. Non-Turbo slots share a

single 250MB/s PCI bus and are incapable of HotPlug functionality. The server must be

turned off prior to removing or installing the LAN/SCSI or GSP cards in these slots.

• Slots 3 and 4 are non-Turbo slots. These two Non-Turbo slots share a single 250MB/s PCI

bus, run at 33MHz and support 32 and 64-bit PCI cards. Non-Turbo slots are incapable of

HotPlug functionality. The server must be turned off prior to removing or installing PCI

cards in these slots.

• Slots 5 - 10 are Turbo slots. Each Turbo slot has a dedicated 250MB/s PCI bus, run at 66MHz

and support 32 and 64-bit PCI cards. Turbo slots are HotPlug capable. Below each Turbo

slot is a plastic PCI card separator. The PCI card separator has two LEDs and a pull tab on

the outer edge. The LED's provide power and status for the slot. The pull tab allows the PCI

card to be easily removed.

• Slots 11 and 12 are Twin Turbo slots. Each Twin Turbo slot has a dedicated 500MB/S PCI

bus, runs at 66 MHz, and supports 32- and 64-bit PCI cards. Twin Turbo slots are HotPlug

capable. Below each Twin Turbo slot is a plastic PCI card separator. The PCI card separator

has two LEDs and a pull tab on the outer edge. The LED's provide power and status for the

slot and the pull tab allows the PCI card to be easily removed.

rp5470 servers have access to all (1-12) slots.

PCI I/O Card Installation Restrictions

Restrictions applyregarding the installation of PCI I/O cards which containa PCI-to-PCI bridge:

• HP-UX boot is currently not supported for cards that contain a PCI-to-PCI bridge.

• HP-UX patches are required when more than one card containing a PCI-to-PCI bridge is

installed in non-Turbo slots.

PCI I/O Card Installation Order

The following table shows a standard factory PCI card installation that begins with slot 12. Use

this table as a guideline for installing PCI I/O cards in the field.

34 Installing Additional Components

Page 35

NOTE: A system shipped from the factory may have a different configuration than the same

system built in the field. For example: The factory will install the graphics card in slot 12 and

add other cards below. In the field, slot 12 may already be occupied by another PCI card. It is

acceptable for the graphics card to be installed in any available Turbo slot.

Number

BootMaxDescription (all are PCI cards)Product

Order*

A4926-600015No101000Base SX PCI LAN AdapterA4926A

A4926-600016No101000Base TX PCI LAN AdapterA4926A

A5846-600018YFC TacliteA5158A

A5486-600019No10Praesidium Speed CardA5486A

A5506-6010210No7/104 Port 100Base TX LAN AdapterA5506B

A5149-6000112Yes10Single Port Ultra 2 SCSI HBAA5149A

A4800-6700214Yes10FWD SCSI-2 adapterA4800A

NotesPart NumberLoad

3,8A4982-665011No1Graphics, Graphics CardA6150A

9A5838-600013NoComboA5838A

10A5483-600014No10ATM 622Mbps MMF AdapterA5483A

11A6092-600017NoHYPERFabricA6092A

1,2,6A5506-6010110No7/104 Port 100Base TX LAN AdapterA5506A

4A5150-6000111Yes10Dual Port Ultra 2 SCSI adapterA5150A

7,55063-132213No10High Perf 4 Ports Synchronous AdapterJ3526A

B5509-6600115No10100Base-T LAN AdapterA5230A

A3738-6000116No1010/100Base-T LAN AdapterA3738A

A3739-6000117No10Dual FDDI LAN AdapterA3739A

A5783-6010118No10Token Ring 4/16/100 Hardware AdapterA5783A

J3525-6000119No10Dual Port Synchronous AdapterJ3525A

J3593-6000120No1064 port Serial MUX system cardJ3593A

J3592-6010121No48 Port PCI Serial MUX cardJ3592A

A6150-6000122No1Graphics, USB CardA6150A

12,13A6150-600031No1Pinnacle 2 GraphicsA6150BX

A3686-600016No10Hyper Fabric 2 InterconnectA6386A

14A5506-6010210No10Quad Port 10/100B-TX LANA5506A

A6749-6000124No103.3v 64 Port Terminal MUXA6749A

A6748-6000125No103.3v 8 Port Terminal MUXA6748A

*In top down order.

Notes:

1. Card contains a PCI-to-PCI bridge.

2. Requires PHKL_20123, PHKL_20629 and PHNE_19826 or their superseded equivalents.

3. Not supported in non-Turbo slots. Install in Turbo slots only.

Installing Peripheral Component Interconnect (PCI) Cards 35

Page 36

4. Requires server firmware revision 39.46 or later.

5. Requires HP-UX 11.1

6. Maximum is 7 for HP-UX versions prior to 11.0. Maximum is 10 forHP-UX version11.1 and

later.

7. Requires PHKL_19543 and PHKL_19544 or their superseded equivalents.

8. Requires HP-UX11.0 Support Plus (IPR) 0006, June 2000 orlater.This product to be released

6/00.

9. Not supported in a shared slot (slots 3-4 for rp5470, slots 3-6 for rp5450, not applicable for

rp5400).

10. If you are installing ATM 622 cards in an rp5470 configuration, do not install them in slots

3 and 4 (shared slots).

11. Requires 768 MB for first card and 512 MB for each additional card.

12. Not supported in shared slots.

13. Max of 1. Needs USB card for keyboard and mouse.

14. Contains PCI bridge.

Installing a PCI Card

Follow these procedures to install a PCI card.

1. Power down and unplug the rp54xx server.

NOTE: DC voltages are present when the server isconnected toAC power. Do not attempt

to install or service: CPUs, Memory, PSMs, the Platform Monitor or PCI I/O cards installed

in non-Turbo slots (1-6) while DC voltage is present. Failure to observe this warning may

result in damage to the server.

2. Make the right side of the server accessible for service.

3. Using a Torx 15 screwdriver, loosen the captive screws on the right side panel. This panel

has a label which shows which PCI I/O slots are available and the corresponding paths. The

PCI I/O slot paths for rp5400, rp5450, and rp5470 are shown below.

rp5430/rp5470rp5450rp5400

Slot PathSlot TypePathSlot/TypePathSlot Type

0/10/0Twin Turbo0/4/0Turbo0/4/0Turbo12

0/12/0Twin Turbo0/7/0Turbo0/7/0Turbo11

0/8/0Turbo0/3/0Turbo0/3/0Turbo10

0/9/0Turbo0/6/0Turbo0/6/0Turbo9

0/3/0Turbo0/2/0Turbo0/2/0Turbo8

0/5/0TurboNot Available7

0/1/0SharedNot Available6

0/1/1SharedNot Available5

0/1/2SharedNot Available4

3

2

1

1

1

1

0/1/0Turbo

0/5/0Turbo

0/2/0Turbo

0/4/0Shared

0/4/2Shared0/1/3SharedNot Available

1 Slot is NOT AVAILABLE for rp5430.

2 Slot 3 becomes available with server firmware versions later than 40.48.

36 Installing Additional Components

GSPGSPGSP2

LAN/SCSILAN/SCSILAN/SCSI1

Page 37

4. Remove the PCI slot cover from the slot that will receive the PCI card. To remove the PCI

slot cover, slide the PCI slot cover away from the server.

5. Slide the PCI card connectors into the slot, snapping firmly in place. For full length (cards

that extend to the left side card guides) PCI cards, use the UPPER card guide.

6. At the rear of the chassis, connect the I/O cable to the card just installed.

7. Replace the right side panel and tighten the captive screws.

8. For rack configurations, insert the rp54xx server back into the rack.

9. For deskside enclosure configurations, replace the deskside enclosure cover.

10. Power the server on.

11. Use the server firmware in io command to verify the PCI cards are recognized by the

server. If AUTOBOOT is ON, it will be necessary to interrupt the boot process to get to the

server firmware Main Menu: Enter command or menu > prompt.

12. Boot HP-UX and run the ioscan utility to verify the system recognizes the new PCI card.

Installing Peripheral Component Interconnect (PCI) Cards 37

Page 38

Online Addition/Replacement (OLA/R) of PCI I/O cards

Beginning with HP-UX 11i (11.11) rp54xx servers support the on-line addition and replacement

of PCII/O cards. In order for this high availabilityfeature to be fully implemented, the following

server requirements must be met:

• rp5400A/rp5450A firmware must be later than 40.26 (rp5400B/rp5450B/rp5470A firmware

will support OLA/R upon its release).

• HP-UX operating system must be 11i (11.11) or later.

There is a bit that the HP-UX operating system examines to determine if the server hardware

and firmware is capable of OLA/R. This bit is controlled by server firmware. If the bit is ON,

OLA/R is possible (when requirements have been met). The bit was mistakenly set to ON for all

rp5400 andrp5450 revision A (rp5400A and rp5450A) servers. As a result, HP-UXmay incorrectly

identify these models as being OLA/R capable. In order to avoid this confusion, verify that the

correct level of server firmware is installed.

Installing Graphics

This section explains how to install rp54xx 2D graphics hardware. For a complete graphics

solution, three productsare required.The products listed beloware the only productssupported

on rp54xx servers.

• A6150A rp54xx Graphics Package

— Includes PCI graphics card

— Includes PCI USB (Universal Serial Bus) card

• A4983B Keyboard and Mouse Kit

— Includes mouse with 114" cable

— Includes keyboard with 109" cable

• D8910W (19") or D2847W (21)" Monitor

— Includes localized power cord and 75" 15-pin video cable

NOTE: rp54xx graphics requires HP-UX 11.0 Support Plus (IPR) 0006, June 2000 or later.

The photo below includes the A6150A, A4983B and D8910W products. The video cable for the

monitor is not shown. Black ESD mat not included.

rp54xx servers have a total of 12 PCI I/O slots. Slots 1 and 2 are reserved for the LAN/SCSI and

GSP Core I/O cards, leaving 10 PCI I/O slots available for Customer use. These 10 PCI I/O slots

consist of Turbo and non-Turbo slots.

38 Installing Additional Components

Page 39

• Slots 1 and 2 are reserved for the rp54xx LAN/SCSI and GSP (Guardian Service Processor)

Core I/O cards, respectively. Slots 1 and 2 are non-Turbo slots. Non-Turbo slots share a

single 250MB/s PCI bus. Non-Turbo slots are incapable of HotPlug functionality. The server

must be turned off prior to removing or installing the LAN/SCSI or GSP cards in these slots.

• Slots 3 - 6 are non-Turbo slots. These four Non-Turbo slots share a single 250MB/s PCI bus,

run at33MHz and support 32 and 64-bit PCI cards.Non-Turbo slots are incapable ofHotPlug

functionality. The server must be turned off prior to removing or installing PCI cards in

these slots.

• Slots 7 - 12 are Turbo slots. Each Turbo slot has a dedicated 250MB/s PCI bus, run at 66MHz

and support 32 and 64-bit PCI cards. Turbo slots are HotPlug capable. Below each Turbo

slot is a plastic PCI card separator. The PCI card separator has two LEDs and a pull tab on

the outer edge. The LED's provide power and status for the slot. The pull tab allows the PCI

card to be easily removed.

rp5400 servers can access PCI slots 1,2 and 8-12. rp5450/3000 servers can access all PCI slots.

Follow these procedures to install graphics cards.

1. Install HP-UX 11.0 Support Plus (IPR) 0006, June 2000 or later. This step ensures the

appropriate HP-UX drivers are installed.

2. Power down and unplug the rp54xx server.

NOTE: DC voltages are present when the server isconnected toAC power. Do not attempt

to install or service: CPUs, Memory, PSMs, the Platform Monitor or PCI I/O cards installed

in non-Turbo slots (1-6) while DC voltage is present. Failure to observe this warning may

result in damage to the server.

3. Make the right side of the server accessible for service.

4. Using a Torx 15 screwdriver, loosen the captive screws on the right side panel. This panel

has a label which shows which PCI I/O slots are available and the corresponding paths. The

label shown below is for an rp5400.

Installing Graphics 39

Page 40

5. Grasp the handle on the right rear panel and remove the panel from the side of the chassis.

The 12 PCI slots, numbered 1-12 from bottom to top, will be in view.

6. Remove the PCI slot cover from the slot that will receive the PCI card. To remove the PCI

slot cover, slide the PCI slot cover away from the server.

7. Center the graphics card within the space created by removing the PCI I/O slot cover. Slide

the cardtoward the edge connectors.Ensure the edgeconnectors on the card are in alignment

with the connectors of the slot. Apply pressure to the card until it snaps firmly in place.

Repeat process for USB card.

40 Installing Additional Components

Page 41

NOTE: The graphics card must be installed in any Turbo slot while the USB will work in

any slot. To reserve Turbo slots for high performance I/O cards, install the USB card in a

non-Turbo slot

8. At the rear of the chassis, connect the keyboard and mouse cables to the USB card. It does

not matter which connector is used for the keyboard or mouse.

9. Connect one end of the 15-pin video cable connector on the graphics card. This connector

is labeled "Graphics Display" and "Video Out". Connect the other end of this cable to the

graphics monitor.

Installing Graphics 41

Page 42

10. Replace the right side panel and tighten the captive screws.

11. For rack configurations, insert the rp54xx server back into the rack.

12. For deskside enclosure configurations, repalce the deskside enclosure cover.

13. Power the server on.

14. Use the server firmware in io command to verify the graphics cards are recognized by

the server. If AUTOBOOT is ON, it will be necessary to interrupt the boot process to get to

the server firmware Main Menu: Enter command or menu > prompt.