Page 1

..

,

.':tis:.

.**e..

:

.

:

.

Agilent Technologies. Inc

24001

E

Mission

Liberty

take, WA

99019

.

Ag

i I en

t

Technologies

Innovating

June

Dear Customer,

As

semiconductor products, health care solutions, and chemical analysis became a new company,

Agilent Technologies. Now, many of your Hewlett-Packard products and services are in the care

Agilent Technologies.

the

8,2000

of

November

HP

Way

1,1999,

four of Hewlett-Packard's businesses, test and measurement,

www

agilent

corn

of

At Agilent Technologies, we are working diligently to make this transition as smooth as possible for

you. However, as a result of this transition, the products and related documentation contained in this

shipment may be labeled with either the Hewlett-Packard name and logo, the Agilent Technologies

of

name and logo, or a combination

(HP), but applies to your Agilent Technologies product. Hewlett-Packard and Agiient branded

products with the same model number are interchangeable.

Whatever logo you see, the information, products, and services come from the same reliable source.

If

you have questions about Agilent Technologies products and services, please visit our website at

http://www. anilent.com.

both. Information in this package may refer to Hewlett-Packard

Sincerely,

Rebranding

Team

Page 2

HP

8903B

2450A

AUDIO

(Including Option

ANALYZER

001)

Operation and Calibration Manual

SERIAL

This

manual applies directly to instruments with

serial numbers prefixed

to

2922A

For

numbers, refer

THIS

and all

additional important information about serial

MANUAL’’

Mqior

to

“INSTRUMENTS COVERED

in Section

NUMBERS

changes that apply

rev.ZOJUN91

1.

Fourth Edition

to

your

instrument.

BY

This

material may be reproduced by

Government pursuant

der the clause at

Copyright

EAST 24001

Operation and Calibration Manual HP Part 08903-90079

Other Documents Available:

Service Manual (Volume

Microfiche Operation and Service Manual HP Part 08903-90080

MISSION

1,

2)

HP Part 08903-90062

GHEWLETT-PACKARD COMPANY 1985

AVENUE, TAF C-34, SPOKANE, WASHINGTON, U.S.A. 99220

to

DFARS

the Copyright License

52.227-7013

or

for the

(AF’R

US.

un-

1988).

Printed in U.S.A. : November 1989

HEW

PACKARD

LETT@

Page 3

1

Regulatory Information

(Updated

March

1999)

1

Page 4

Regulatory

Safety Considerations

Information

(Updated

March

1999)

GENEFtAL

This product and related documentation must be reviewed for familiarization with safety

markings and instructions before operation.

This product has been designed and tested in accordance with

IEC

Publication

"Safety Requirements for Electronic Measuring Apparatus," and has been supplied in

safe condition. This instruction documentation contains information and warnings which

must be followed by the user

to

ensure safe operation and

to

maintain the product in a safe

condition.

SAFETY EARTH GROUND

A

uninterruptible safety earth ground must be provided from the main power source

or

product input wiring terminals, power cord,

SAFETY

A

Indicates instrument damage can occur

A

Indicates hazardous voltages.

&

-

Indicates earth (ground) terminal

WARNING

SYMBOLS

A

WARNING

~~~~ ~

note denotes a hazard. It calls attention to a procedure,

practice, or the like, which,

could result in personal injury.

if

supplied power cord set.

indicated operating limits are exceeded.

~ ~

if

not correctly performed or adhered to,

Do

not proceed beyond a

WARNING

sign until the indicated conditions are fully understood and met.

~

A

CAUTION

CAUTION note denotes a hazard. It calls attention

procedure, practice,

to,

could result in damage

or

the like, which, if not correctly performed

to

or

destruction

of

part

to

an operation

or

all of the product.

not proceed beyond an CAUTION note until the indicated conditions are hlly

understood and met.

1010,

or

adhered

to

Do

a

the

2

Chapter

1

Page 5

Safety Considerations for this Instrument

Regulatory

Information

(Updated

March

1999)

WARNING

This product is a Safety Class I instrument (provided with

a

protective earthing ground incorporated in the power cord). The

mains plug shall only be inserted in

a

socket outlet provided with a

protective earth contact. Any interruption of the protective

conductor inside or outside of the product is likely

product dangerous. Intentional interruption

Whenever it

is

likely that the protection has been impaired, the

is

to

make the

prohibited.

instrument must be made inoperative and be secured against any

unintended operation.

If

this instrument

voltage reduction), make sure the common terminal

is

to be energized

via

an auto transformer (for

is

connected

the earth terminal of the power source.

If

this product

is

not used as specified, the protection provided by

the equipment could be impaired. This product must be used in

normal condition (in which

No

operator serviceable parts in this product. Refer servicing to

all

means for protection are intact) only.

qualified personnel. To prevent electrical shock, do not remove

covers.

Servicing instructions are for use by qualified personnel only. To

avoid electrical

qualified to do

shock,

so.

do not perform any servicing unless you are

to

a

The opening

dangerous voltages. Disconnect the product from

while it

The power cord

live for

5

of

covers

is

being opened.

is

or

removal of parts

connected to internal capacitors that

seconds after disconnecting the plug

is

likely to expose

all

voltage sources

from

its

my

remain

power supply.

For Continued protection against fire hazard, replace the line fuse(s)

only with

example, normal blow

250

V

fuse(s) or the same current rating and type (for

or

time delay). Do not use repaired fuses or

short circuited fuseholders.

Always use the three-prong ac power cord supplied with this

product. Failure

to

ensure adequate earth grounding by not using

this cord may cause product damage.

This product

Pollution Degree

INDOOR

is

USE

designed for use in Installation Category

2

per

IEC

1010

and

IEC

664

respectively. FOR

ONLY.

I1

and

This product has autoranging line voltage input, be sure the supply

voltage is within the specified range.

~~~~

Chapter

1

3

Page 6

Regulatory Information (Updated

To

prevent electrical shock, disconnect instrument from mains (line)

before cleaning. Use a dry cloth or one slightly dampened with water

to clean the external case parts.

Ventilation Requirements: When installing the product in a cabinet,

the convection into and out of the product must not be restricted.

The ambient temperature (outside the cabinet) must be less than the

maximum operating temperature of the product by

watts dissipated in the cabinet.

cabinet

is

used.

March

1999)

greater than

Do

not attempt to clean internally.

4"

C

for every

If

the total power dissipated in the

800

watts, then forced convection must be

100

Product

Markings

CE - the CE mark

accompanied by

CSA

-

the

CSA

a

mark

is

a registered trademark

of

the European Community. A CE mark

year indicated the year the design was proven.

is

a registered trademark

of

the Canadian Standards Association.

4

Chapter

1

Page 7

CERTIFICATION

Hewlett-Packard Company certifies

from

the factom. Hewlett-Packard further certifies that its calibration measurements are traceable to the

United States National Bureau of Standards, to the extent allowed

that

this

product met

its

published specifications at

by

the

Bureau's calibration facility, and

the

time of shipment

to the calibration facilities of other International Standards Organization members.

WARRANTY

This Hewlett-Packard instrument product is warranted against defects

date

period of one year from

option, either repair

For

warranty senrice

shall prepay shipping charges to

However, Buyer shall pay all shipping charges, duties, and taxes for products returned

country.

HP warrants that its software and firmware designated by HP for use with an instrument will execute

its programming instructions when properly installed on that instrument. HP does not warrant that the

operation of the instrument,

The foregoing warranty shall not apply to defects resulting from improper

Buyer, Buyer-supplied software

environmental specifications

NO OTHER WARRANTY

IMPLIED WARRANTIES

or

or

of shipment. During the warranty period, Hewlett-Packard Company will at

replace products which prove

repair, this product must be returned

HP

and HP shall pay shipping charges to return the product

or

sohare,

or

firmware will be uninterrupted

LIMITATION

or

interfacing, unauthorized modification

for

the product,

IS

EXPRESSED OR IMPLIED. HP SPECIFICALLY DISCLAIMS THE

OF

MERCHANTABILITY AND FITNESS FOR A PAWICULAR PURPOSE.

or

to

be defective.

to

a service facility designated by HP. Buyer

OF

WARRANTY

improper site preparation

in

material and workmanship for a

to

the Buyer.

to

HP from another

or

error free.

or

inadequate maintenance by

or

misuse, operation outside of the

or

maintenance.

its

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYERS SOLE AND EXCLUSIVE REMEDIES.

HP

SHALL NOT BE LIABLE FOR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TOFU', OR

LEGAL THEORY.

ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

ANY

OTHER

ASSISTANCE

Product maintenance agreements and other customer assistance agreements are available for HewlettPackard products.

For

any assistance, contact your nearest Hewlett-Packard Sales and Service Office. Addresses are provided

at the back

of

this manual.

Page 8

Safety Considerations

Model

8903B

SAFETY

GENERAL

This product and related documentation must be reviewed for familiarization with safety markings and

instructions before operation.

This product

with a protective earth terminal).

BEFORE

Verify that the product is set to match the available

line voltage and the correct fuse

SAFETY EARTH GROUND

An uninterruptible safety earth ground must be provided from the main power source to the product input

wiring terminals, power cord,

set.

SAFETY SYMBOLS

/I\

is

necessary for the user to refer to the instruction

manual (refer to Table of Contents).

is

a Safety Class I instrument (provided

APPLYING

Instruction manual symbol: the product will

be marked with this symbol when

Indicates hazardous voltages.

POWER

or

is

installed.

supplied power cord

CONSIDERATIONS

it

(WARNING

Any interruption of the protective (grounding) conductor (inside

ment)

terminal will cause a potential shock hazard

that could result

ing one conductor of a two conductor outlet

is not sufficient protection).

been impaired, the instrument

inoperative and be secured against any unintended operation.

If this instrument is to be energized via an

autotransformer (for voltage reduction) make

sure the common terminal

earth terminal

Servicing instructions are

trained personnel only.

electric shock, do not perform any servicing

unless qualified to do

or

disconnecting the protective earth

Whenever it

is

likely that the protection has

of

or

in

personal injury. (Ground-

the power source.

so.

I

outside

is

for

To

the

must

be made

connected to the

use by service-

avoid dangerous

instru-

Indicates earth (ground) terminal.

The WARNING sign denotes a

hazard. It calls attention to a

procedure, practice,

performed

jury.

the indicated conditions are fully understood and met.

operating procedure, practice,

correctly performed

age to

not proceed beyond a CAUTION sign until the indicated conditions are fully understood and met.

or

Do

not proceed beyond a WARNING sign until

or

destruction of part

or

the like, which,

adhered to, could result in personal in-

The

CAUTION

ard. It calls attention to an

or

or

adhered to, could result in dam-

or

all of the product.

if

not correctly

sign denotes a haz-

the like, which, if not

Do

Adjustments described

formed with power supplied to the instrument

while protective covers are removed. Energy

available at manypoints may,

sult in personal injury.

Capacitors inside the instrument may still be

charged even

connected from its source of supply.

For

continued protection against fire hazard,

replace the line fuse(s) only with

of the same current rating and type (for exam-

ple, normal blow, time delay, etc.).

rep a ired fuses

fuseholders.

if

the instrument

in

the manual are per-

if

contacted, re-

has

250V

Do

o

r

s

ho r t

c irc

been dis-

fuse(s)

not use

u

i

t ed

Page 9

Model

8903B

Safety Considerations

ATTENTION

Static Sensitive

Devices

This instrument was constructed in an ESD (electro-static discharge) protected environment. This is because most of the semiconductor devices used

by static discharge.

Depending on the magnitude of the charge, device substrates can

be punctured

charge. The results can cause degradation of device performance,

early failure,

These charges are generated

tact, separation of materials, and normal motions of persons

working with static sensitive devices.

When handling

devices, adequate precautions must be taken to prevent device damage

or

Only those who are thoroughly familiar with industry accepted

techniques for handling static sensitive devices should attempt to

service circuitry with these devices.

In all instances, measures must be taken to prevent static charge

build-up on work surfaces and persons handling the devices.

For

further information on ESD precautions, refer to “SPECIAL

HANDLING CONSIDERATIONS

DEVICES,’

or

or

destruction.

in

Section VIII Service Section.

in

this

instrument are susceptible to damage

destroyed by contact

immediate destruction.

in

or

servicing equipment containing static sensitive

or

mere proximity of a static

numerous ways such

FOR

STATIC SENSITIVE

as

simple con-

Page 10

HP 8903B

Table

of

Contents

TABLE

Section +General Information

Introduction

Specifications

Safety Considerations

Instruments Covered By Manual

Manualchanges

Description

General

Audio Testing

Transceiver Testing

Systems

Options

Electrical Options

Mechanical Options

Hewlett-Packard Interface Bus

Compatibility

Selecting the HP-IB Address

Accessories Supplied

Electrical Equipment Available

HP-IB Controllers

Front-to-Rear-Panel Connectors Retrofit Kit

Rear-to-Front-Panel Connectors Retrofit Kit

Mechanical Equipment Available

Chassis Slide Mount Kit

Chassis Tilt Slide Mount Kit

Recommended Test Equipment

Principles

Voltmeter and Notch Filter

Counter

Source

Controller

Basics

of

ACLevel

Frequency

DCLevel

Signal Impurities

Distortion

SINAD

Signal-to-Noise Ratio

Internal Source

Plotting

.....................................................

.....................................................

................................................

..........................................

...................................................

......................................................

......................................................

..................................................

...............................................

......................................................

........................................................

................................................

...............................................

...........................................

...................................................

..........................................

.................................................

...........................................

................................................

..........................................

............................................

..........................................

...........................................

of

Operation

for

Simplified Block Diagram

..........................................

.....................................................

.....................................................

....................................................

Audio Measurements

..........................................

....................................................

....................................................

....................................................

................................................

...................................................

.....................................................

.............................................

.................................................

.....................................................

OF

CONTENTS

.................................

.................................

..............................

1.1

1-1

1.2

1.2

1-2

1-3

1-3

1-3

1-4

1-5

1-6

1-6

1-6

1-8

1-8

1-8

1-8

1-8

1-8

1-8

1-8

1-9

1-9

1-9

1-9

1-9

1-10

1-11

1-11

1-12

1-12

1-12

1-13

1-13

1-13

1-13

1-15

1-15

1-16

1-16

Page 11

Table

of

Contents

Section 2-Installation

HP

8903B

Introduction

Initial Inspection

Preparation

Power Requirements

Line Voltage and Fuse Selection

Power Cables

HP-IB Address Selection

Interconnections

Mating Connectors

Operating Environment

Bench Operation

Rack Mounting

Storage and Shipment

Environment

Packaging

.....................................................

...................................................

for

Use

.................................................

...............................................

........................................

...................................................

............................................

.................................................

...............................................

...............................................

.................................................

..................................................

................................................

...................................................

.....................................................

Section %Operation

Introduction

General

Operating Characteristics

"urn-On Procedure

Local Operation

Remote Operation

Operator's Checks

Operator's Maintenance

Front-Panel Features

Basic Functional Checks

Simplified Operation

Rear-Panel Features

Description

Equipment

Procedure

Preliminary Check

AC Level and Output Level Check

Filter Check

Distortion Check

SINAD Check

Signal-to-Noise Ratio Check

Sweep, X Axis, Y Axis, Pen Lift, and DC Level Check

HP-IB Functional Checks

Description

Initial Setup

Equipment

Address Recognition

Remote and Local Messages and the LCL Key

Sending the Data Message

Receiving the Data Message

Local Lockout and Clear Lockout/Set Local Messages

....................................................

......................................................

............................................

...............................................

..................................................

................................................

..................................................

.............................................

.................................................

..............................................

.................................................

................................................

...................................................

...................................................

....................................................

...............................................

......................................

..................................................

................................................

.................................................

.........................................

.............................................

...................................................

..................................................

...................................................

..............................................

..........................................

.........................................

...........................

...............................

...........................

2.1

2.1

2.1

2.1

2-2

2.2

2.3

2.5

2.5

2.6

2.6

2.6

2.8

2.8

2.8

-3-1

3-1

3-1

3-1

3-2

3-3

3-3

3-4

3-6

3-12

3-8

3-11

3-12

3-12

3-12

3-12

3-12

3-13

3-15

3-15

3-15

3-15

3-16

3-16

3-16

3-16

3-16

3-17

3-17

3-18

3-18

Page 12

HP 8903B

Table

of

Contents

ClearMessage

AbortMessage

Status Byte Message

Require Service Message

Trigger Message and Clear Key Triggering

Remote Operation. Hewlett-Packard Interface Bus

HP-IB Compatibility

Remote Mode

LocalMode

Addressing

Data Messages

Receiving the Data Message

Sending the Data Message

Receiving the Clear Message

Receiving the Trigger Message

Receiving the

Receiving the Local Message

Receiving the Local Lockout Message

Receiving the Clear Lockout/Set Local Message

Receiving the Pass Control Message

Sending the Require Service Message

Selecting the Service Request Condition

Sending the Status Byte Message

Sending the Status Bit Message

Receiving the Abort Message

HP-IB

ACLevel

Amplitude

Automatic Operation

CommonMode

DCLevel

Default Conditions and Power-up Sequence

Detector Selection

Display Level in Watts

Display Source Settings

Distortion

Distortion Level

Error Disable

Error Message Summary

Filters

Float

Frequency

Hold Decimal Point

Hold Settings

HP-IB Address 3-79

Increment

Input Level Range (DC Level)

Input Level Range (Except DC Level)

Monitor

Notch~ne

Output Impedance

Plot Limit 3-96

Post-Notch Detector Filtering (Except SINAD)

Syntax

......................................................

.......................................................

......................................................

......................................................

........................................................

.........................................................

......................................................

......................................................

.......................................................

.....................................................

......................................................

.................................................

.................................................

..............................................

...........................................

..................................

...............................

.............................................

.................................................

...................................................

...................................................

.................................................

.........................................

..........................................

.........................................

........................................

Remote

Message

........................................

.........................................

....................................

..............................

.....................................

....................................

...................................

......................................

.......................................

.........................................

and Characteristics Summary

..................................

................................................

...................................................

...................................

.................................................

...............................................

..............................................

..................................................

....................................................

..............................................

................................................

....................................................

...................................................

..........................................

......................................

.................................................

.................................

3-18

3-19

3-20

3-21

3-22

3-22

3-23

3-23

3-23

3-23

3-26

3-26

3-30

3-31

3-32

3-32

3-33

3-33

3-33

3-33

3-33

3-34

3-34

3-35

3-35

3-35

3-42

3-44

3-46

3-47

3-50

3-52

3-53

3-55

3-57

3-58

3-60

3-62

3-64

3-68

3-72

3-74

3-76

3-78

3-82

3-84

3-86

3-88

3-91

3-93

3-98

Page 13

Table of Contents HP 8903B

Post-Notch Gain

Rapid Frequency Count

Rapidsource

RATIO and LOG/LIN

Read Display

Service Request Condition

Signal-to-Noise

Special Functions

Sweep

Sweep Resolution

Time Between Measurements

X-YRecording

.......................................................

.................................................

.............................................

...................................................

..............................................

to

HP-IB

.............................................

............................................

..................................................

.................................................

.................................................

..........................................

..................................................

Section 4-Performance

Introduction

Equipment Required

TestRecord

Calibration Cycle

Abbreviated Performance Testing

Performance Test

Performance Test

Performance Test 3 Distortion and Noise

Performance Test 4 Distortion, SINAD, and Signal-to-Noise Accuracy

Performance Test 5 Frequency Accuracy and Sensitivity

Performance Test 6 Audio Filters

Performance Test

Performance Test

.....................................................

.................................................

......................................................

...................................................

..........................................

1

AC

Level Accuracy and Output Level Accuracy and Flatness

2

DC Level Accuracy

.....................................

....................................

............................

.........................................

7

Input and Output Impedance

8

Common-Mode Rejection Ratio

................................

..............................

...............

....................

3-100

3-102

3-105

3-109

3-112

3-114

3-116

3-121

3-128

3-131

3-134

3-135

4.1

4.1

4-1

4.1

4.1

4-2

4-12

4-14

4-16

4-19

4-21

4-28

4-29

Section 5-Adjustments

Introduction

Safety Considerations

Equipment Required

Factory-Selected Components

Post-Repair Tests, Adjustments, and Checks

Related Adjustments

Adjustment

Adjustment

Adjustment 3 Common Mode Rejection

Adjustment 4 Input DC

Adjustment 5 400 Hz High-Pass and Weighting Bandpass Filters

Adjustment 6 Notch Filter Tune and Balance

Adjustment

Adjustment

Adjustment 9 Oscillator and Output Attenuator

.....................................................

................................................

.................................................

............................................

....................................

.................................................

1

Internal Reference Frequency

2

Input Flatness

............................................

....................................

......................................

Offset

...........................................

..................................

7

Voltmeter

8

SINAD Meter

..............................................

............................................

.................................

.......................

5.1

5.1

5.1

5.1

5.2

5.2

5.4

5.5

5.8

5.9

5-10

5-12

5-13

5-15

5-16

Page 14

Model

8903B

General Information

1-1.

INTRODUCTION

This manual contains information required to install, operate, test, adjust, and service the HewlettPackard Model 8903B Audio Analyzer. This manual documents options installed in the Audio Analyzer

such

This section of the manual describes the instruments documented by the manual and covers

instrument description, options, accessories, specifications, and other basic information. This section

also contains principles of operation on a simplified block diagram level and basic information on audio

measurements. The other sections contain the following information:

Section

address selection for remote operation), and storage and shipment.

Section

operating instructions for both local and remote operation, and maintenance information.

Section

instrument against the critical specifications in Table

Section

1

GENERAL INFORMATION

as

rear-panel connections and internal plug-in filters.

2,

Installation:

3,

Operation:

4,

Performance Tests:

provides information about initial inspection, preparation for use (including

provides information about panel features, and includes operating checks,

provides the information required

1-1.

to

check performance of the

Section

Section

Section

Section

Sections 1 through 5 are bound in this volume, the Operation and Calibration Manual. One copy of the

Operation and Calibration Manual is supplied with the instrument. Sections 6 through

in

two

instrument unless specifically requested (as Option 915) at time of instrument order. Copies of all

volumes can be ordered separately through your nearest Hewlett-Packard office. The part numbers are

listed on the title page of this manual.

Also listed on the title page of this manual, below the manual part number, is a microfiche part number.

This number may be used to order 100

Each microfiche contains up to 96 photo-duplicates of the manual’s pages. The microfiche package also

includes the latest MANUAL UPDATES packet, as well as all pertinent Service Notes.

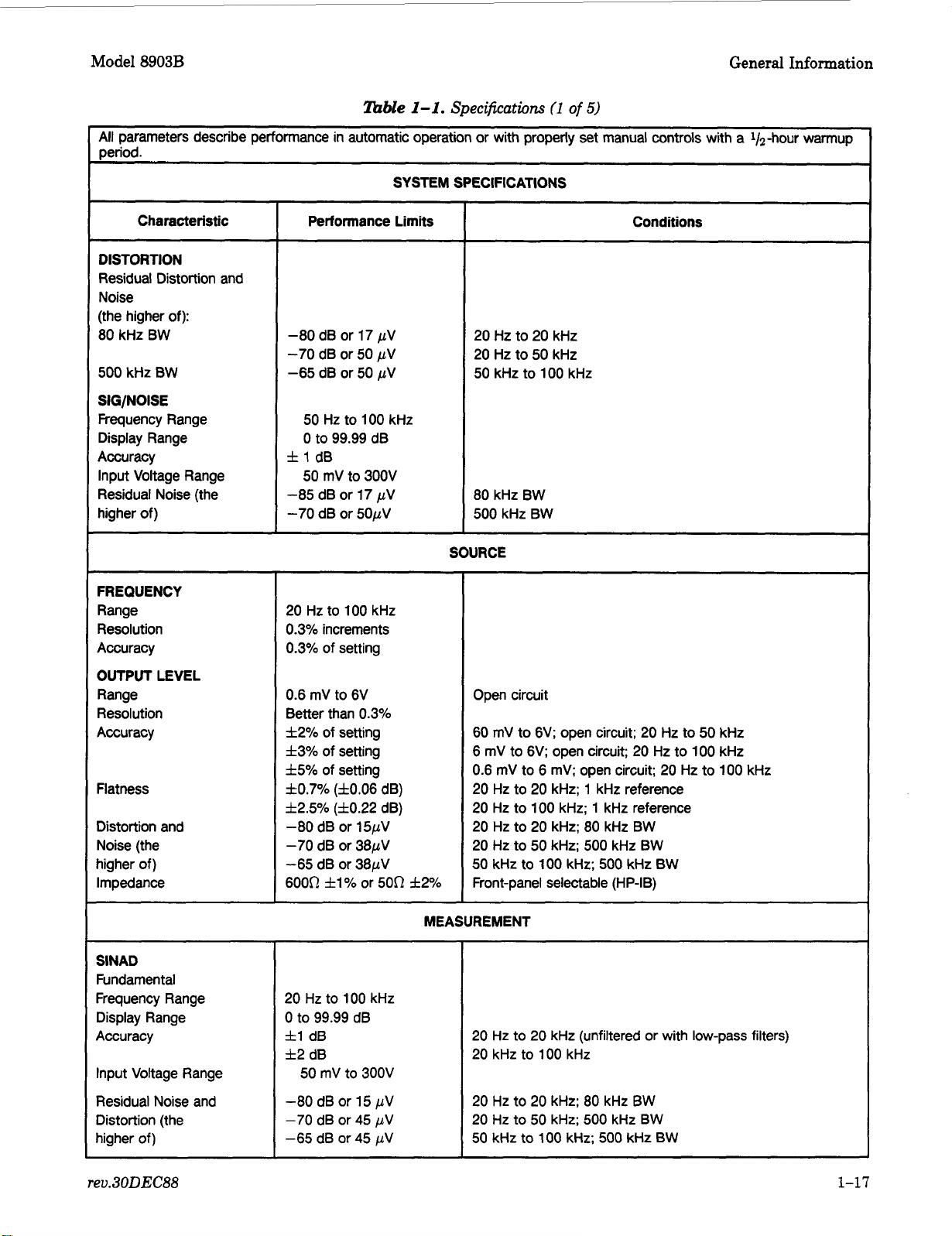

1-2.

SPECIFICATIONS

Instrument specifications are listed in Table

which the instrument may be tested. Characteristics listed under Supplemental Information, Table

are not warranted specifications but are typical characteristics included as additional information for

the user.

5,

Adjustments:

6,

Replaceable Parts:

7,

Instrument Changes:

8,

Service:

separate volumes, the Service Manual. Copies of the Service Manual are not supplied with the

provides the information required to properly adjust the instrument.

provides ordering information for all replaceable parts and assemblies.

provides instrument modification recommendations and procedures.

provides the information required

x

150

mm

1-1.

These are the performance standards, or limits against

to

repair the instrument.

(4

x

6 inch) microfilm transparencies of this manual.

8

are bound

1-2,

1-1

Page 15

General Information Model

1-3.

SAFETY CONSIDERATIONS

8903B

This product is a Safety

Audio Analyzer and all related documentation must be reviewed for familiarization with safety markings

and instructions before operation. Refer to the Safety Considerations page found at the beginning of

this manual

(installation, performance testing, adjustment,

1-4.

INSTRUMENTS COVERED

Serial

stamped on the serial number plate attached to the rear

letter constitute the serial number prefix, and the last five digits form the suffix. The prefix is the same

for all identical instruments.

however,

apply directly to instruments having the same serial prefix(es) as listed under SERIAL NUMBERS

on the title page.

Options.

documented in this manual. The differences are noted under the appropriate paragraph such

in Section

1-5.

MANUAL UPDATES

An instrument manufactured after the printing of this manual

listed on the title page. Having a serial number prefix that

indicates that the instrument is slightly different from those documented in the manual. In this case,

your manual

information includes any hardware

manual.

Class

I instrument (that is, provided with a protective earth terminal). The

for

a summary of the safety information. Safety information pertinent to the task at hand

or

service) is found throughout the manual.

BY

MANUAL

Numbers.

is

assigned sequentially and is different for each instrument. The contents of this manual

Electrical Option

1,

This instrument has a two-part serial number in the form

of

the instrument. The first four digits and the

It

changes only when a change

001,

internal plug-in filter options, and various mechanical options are

the Replaceable Parts List, and the schematic diagrams.

is

provided with updating information to make it as current

or

software changes that have occurred as well as corrections to the

is

made to the instrument. The suffix,

may

is

greater than that shown on the title page

OOOOAOOOOO

have a serial prefix that

as

possible. This updating

which is

as

Options

is

not

A Description

A

“MANUAL UPDATES” packet is shipped with the Operation and Calibration Manual when

necessary to provide you with the most current information available at the time

packets consist of replacement and addition pages which should be incorporated into the manual to

bring it up to date.

Signing Up

Hewlett-Packard offers a Documentation Update Service that will provide you with further updates

and changes as they become available. If you have not received update information that matches the

serial number of your instrument, you can receive this information through the Update Service.

If

you

join this service immediately to ensure that your manual is kept current. For more information, refer

to the Documentation Update Service reply card included in this manual

Hewlett-Packard Company

Technical Writing Department

24001

Spokane, WA. 99220

(509) 922-4001

of

the Manual Update Packet

for

the Documentation Update Service

operate

E.

or

service instruments with different serial prefixes, we strongly recommend that you

Mission-TAF C-34

or

contact:

of

shipment. These

1-2

Page 16

Model 8903B

1-6.

DESCRIPTION

General

The HP Model 8903B Audio Analyzer is a complete audio measurement system covering the frequency

range of

source has a maximum open-circuit output of 6 Vrms and a selectable output impedance of either

6000. The analyzer can perform distortion analysis, frequency count, and ac level, dc level, SINAD, and

signal-to-noise ratio measurements. The Audio Analyzer reduces the number of instruments required

in many applications involving audio signal characterization.

20

Hz

to

100 kHz.

General Information

It

combines a low-distortion signal source with a signal analyzer. The

50

or

The Audio Analyzer is easy

distortion measurements, the Audio Analyzer automatically tunes to and levels the input signal.

Measurement and output ranges are automatically selected for maximum resolution and accuracy.

firthermore, tuning is independent of the source. Thus, the source can be set to one frequency while

is

the analyzer

tune the analyzer

The combined capabilities of the instrument are enhanced by microprocessor control, resulting

capability than would be available from separate instruments. For example, when making signal-to-noise

ratio measurements, the Audio Analyzer monitors the ac level while turning the source on and

microprocessor then computes and displays the ratio of the on and

in either

In addition, the source can be swept. This makes measurements such as frequency response

distortion characterization simple

parameters and versatile display formats. For example, ac level can be displayed in V, mV, dBm into

6000, watts,

Virtually all functions are remotely programmable through the Hewlett-Packard Interface Bus

(HP-IB'). Programming is easy

input. This eliminates the need to switch between multiple inputs under remote control and reduces

software development time and hardware costs. The Audio Analyzer measures the true rms level

on all ac measurements. True rms measurements assure greater accuracy when measuring complex

waveforms and noise. For those applications where average detection

be switched to average-responding

distortion measurements typically can be made to less than

20

kHz

at

(Serial Prefix 2730A and above) can be switched

This detector is designed

measuring the distortion on a signal

to

the source).

5%

or

dB.

or

as a ratio (in

a 1.5V level. For those applications where quasi-peak detection

to

use. All measurements are selected by one

at

another frequency (that is, there

off

levels. The ratio can be displayed

to

perform. Microprocessor control allows flexible entry of source

%

or

dB)

referenced to an entered

and

straightforward; all measurements are made through a single

(rms

calibrated) detection through special functions. Accurate

to

this type of detection through special functions.

to

meet the requirements specified by CCIR 468-3.

or

measured value.

0.003%

or

two keystrokes. For

is

no need to

or

complete

is

required, the analyzer can

(-90

dB)

between

is

required, the analyzer

20

in

more

off.

The

Hz and

Audio Testing

The Audio Analyzer has numerous features which make audio testing simple and convenient.

These features include flexible data entry and display formats, convenient source control, and swept

For

measurements capability.

measurements can be displayed in volts, dBm into 600R,

%

or

dB

in

is simplified by using the source frequency increment and decrement keys together with the relative

display feature.

When sweeping, the Audio Analyzer tuning steps

an x-y recorder, hard copy measurement results can be obtained. X-axis scaling

entered start and stop frequencies. Y-axis scaling

the plot limits entered through the keyboard. Any valid display units (except mV) are allowed when

plotting. To change the scaling from frequency response to swept distortion plots, simply key in new

HP-IB: Not just IEEE-488, but the hardware, documentation and support that delivers the shortest path to a

measurement system.

relative to a measured

A

major contribution of the Audio Analyzer is its ability to make swept measurements.

example, distortion results can be displayed in

or

watts. Measurement results can be displayed

or

entered value. Finding the

its

source frequency in logarithmic increments. With

is

determined by the measurement units selected and

3

dB

points of filters and amplifiers

%

or

dB.

AC level

is

determined by the

1-3

Page 17

General Information Model

8903B

values for the plot limits.

No

adjustment of the x-y recorder

is

necessary. The Audio Analyzer also

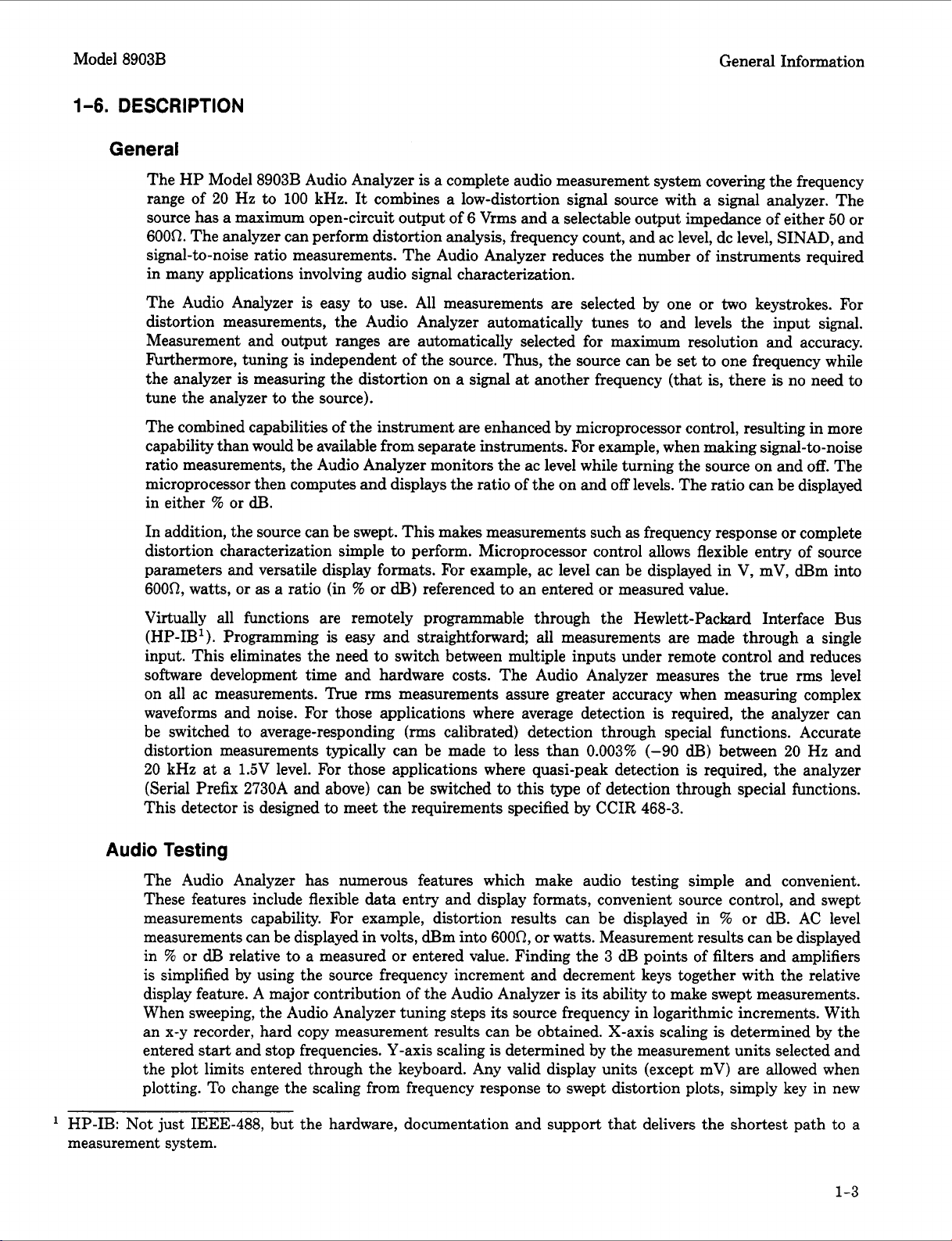

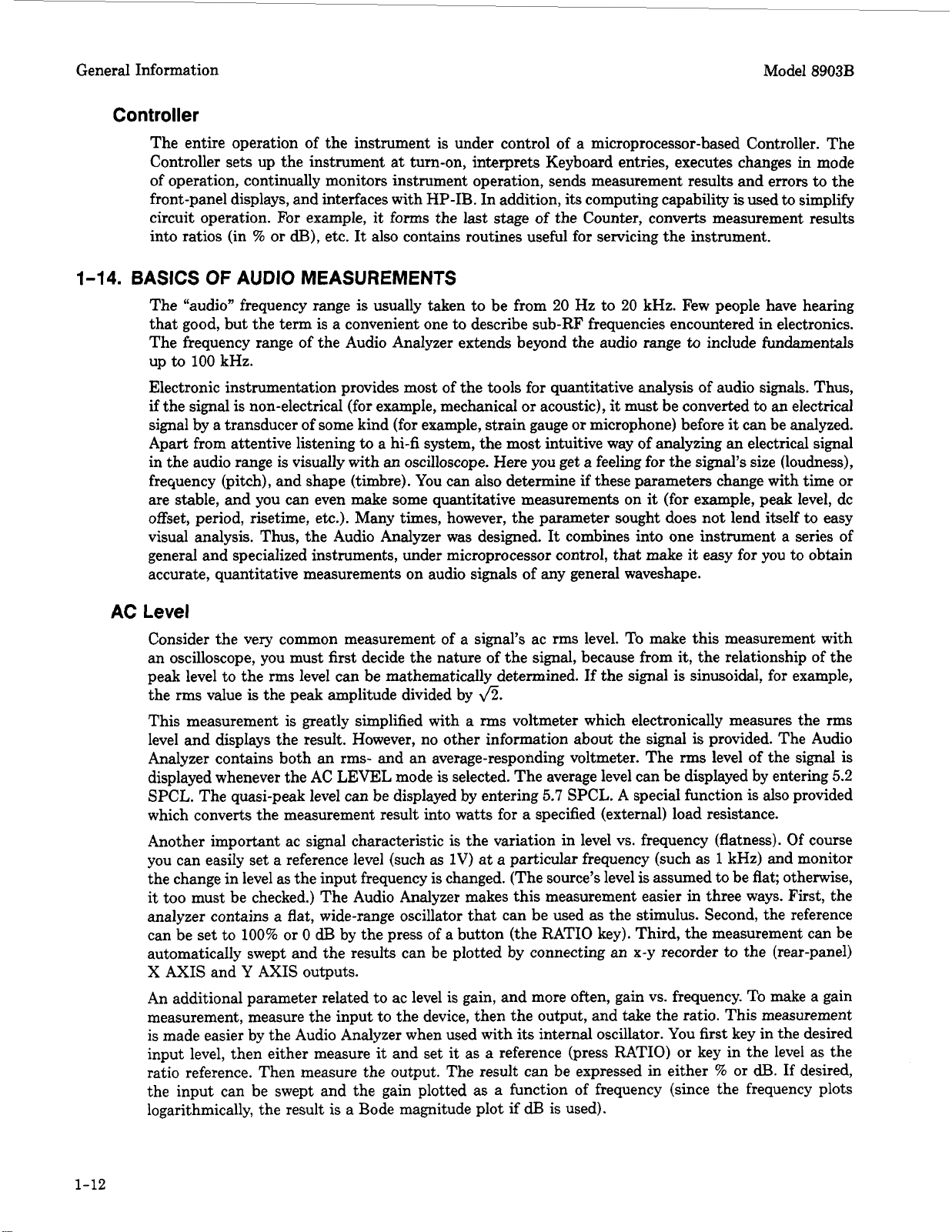

features high accuracy. The instrument can typically measure flatness

of

20

Hz to

20

and

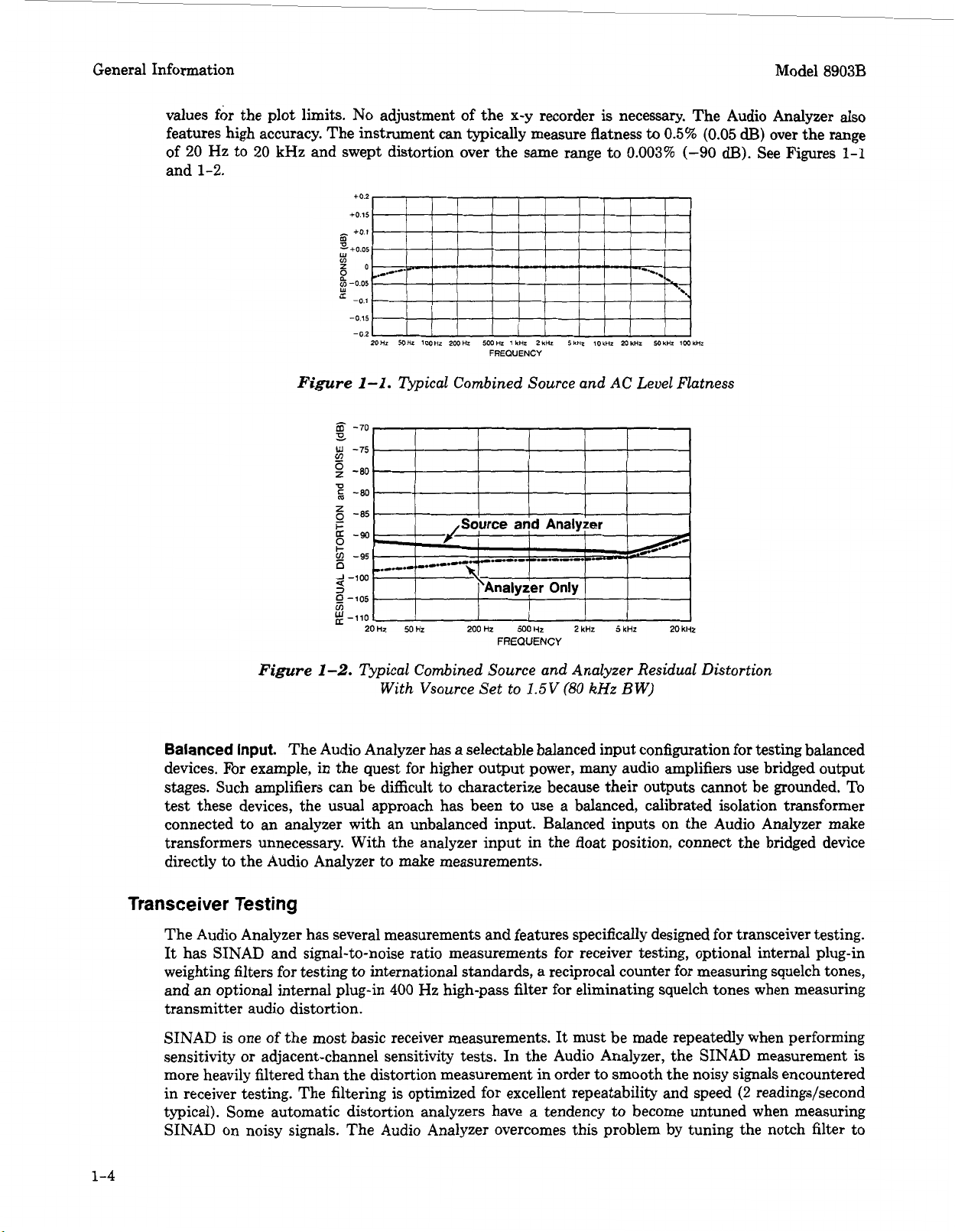

1-2.

kHz and swept distortion over the same range to

Figure

9

w

v,

p

'0

g

'?o

-

I-

+0.2,

1-1.

npical Combined Source and

-70

-75

-80

-80

-85

I,,

0.003%

AC

!

9

-95

D

2

-100

3

0

-105

v)

-110

20Hz

5OHz

2OOHz

500Hz

FREQUENCY

PkHr

5kHz

to

0.5%

(0.05

(-90

dB).

I1

Level Flatness

20kHz

dE3)

over the range

See Figures

1-1

Balanced

Figure

Input.

1-2.

Typical Combined Source and Analyzer Residual Distortion

(80

kHz

With Vsource Set to 1.5V

BW)

The Audio Analyzer has a selectable balanced input configuration for testing balanced

devices. For example, in the quest for higher output power, many audio amplifiers use bridged output

stages. Such amplifiers can be difficult to characterize because their outputs cannot be grounded. To

to

test these devices, the usual approach has been

use a balanced, calibrated isolation transformer

connected to an analyzer with an unbalanced input. Balanced inputs on the Audio Analyzer make

transformers unnecessary. With the analyzer input in the float position, connect the bridged device

directly to the Audio Analyzer to make measurements.

Transceiver Testing

The Audio Analyzer has several measurements and features specifically designed for transceiver testing.

It

has SINAD and signal-to-noise ratio measurements for receiver testing, optional internal plug-in

weighting filters for testing to international standards, a reciprocal counter for measuring squelch tones,

400

and an optional internal plug-in

Hz high-pass

transmitter audio distortion.

SINAD is one

sensitivity

of

the most basic receiver measurements. It must be made repeatedly when performing

or

adjacent-channel sensitivity tests. In the Audio Analyzer, the SIN AD measurement is

more heavily filtered than the distortion measurement in order to smooth the noisy signals encountered

in receiver testing. The filtering is optimized for excellent repeatability and speed

typical). Some automatic distortion analyzers have

SINAD on noisy signals. The Audio Analyzer overcomes this problem by tuning the notch filter to

filter

for eliminating squelch tones when measuring

(2

readings/second

a

tendency to become untuned when measuring

1-4

Page 18

Model

8903B

the source frequency when measuring SINAD. SINAD measurement results are indicated both by the

digital display and a front-panel analog meter. The meter is specifically marked for

25

dB,

sensitivity and selectivity. For SINAD ratios less than

0.5

dB

rounded to the nearest

Signal-to-noise ratio measurements are also filtered for improved repeatability and speed

ing/second typical), and automatic display rounding

Audio Analyzer uses true

instruments employ average detection which reads low for noise. The discrepancy can be

greater and varies with the ratio being measured. For correlating results with past test data, the Audio

Analyzer’s detector can be switched via special functions

For those applications where quasi-peak detection is required, the analyzer (Serial Prefix

above) can be switched

to

meet the requirements specified by CCIR

For transceivers, the Audio Analyzer has an optional, internal plug-in seven-pole 400 Hz high-pass filter

for rejecting squelch tones. Rejection of squelch tones up to

audio distortion measurements

squelch tones.

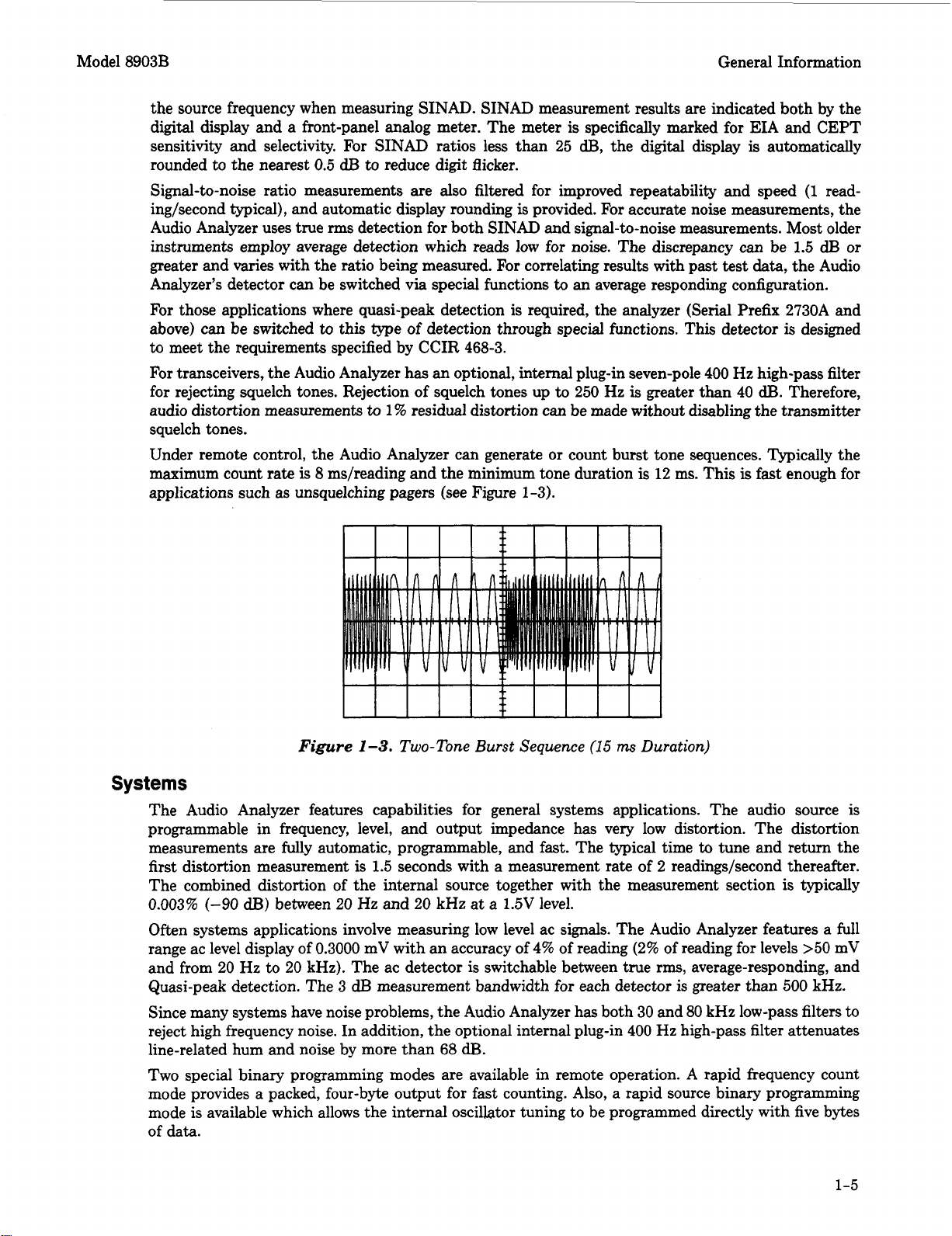

Under remote control, the Audio Analyzer can generate

is

maximum count rate

applications such as unsquelching pagers (see Figure

8

to reduce digit flicker.

is

provided. For accurate noise measurements, the

rms

detection for both SINAD and signal-to-noise measurements. Most older

to

to

this type of detection through special functions. This detector is designed

468-3.

to

1%

residual distortion can be made without disabling the transmitter

or

ms/reading and the minimum tone duration

1-3).

the digital display

an average responding configuration.

250

Hz

is

greater than

count burst tone sequences. Typically the

is

12

General Information

EIA

is

40

dB.

ms. This

is

fast

and CEPT

automatically

1.5

2730A

Therefore,

enough for

(1

read-

dB

and

or

Figure

1-3.

Two-Tone

Burst

Sequence

(15

ms

Duration)

Systems

The Audio Analyzer features capabilities for general systems applications. The audio source

programmable in frequency, level, and output impedance has very low distortion. The distortion

measurements are fully automatic, programmable, and

is

1.5

first distortion measurement

The combined distortion of the internal source together with the measurement section is typically

0.003%

Often systems applications involve measuring low level ac signals. The Audio Analyzer features a full

range ac level display of

and from

Quasi-peak detection. The

Since many systems have noise problems, the Audio Analyzer has both

reject high frequency noise. In addition, the optional internal plug-in

line-related hum and noise by more than

Two special binary programming modes are available in remote operation. A rapid frequency count

mode provides a packed, four-byte output for fast counting. Also, a rapid source binary programming

mode

of data.

(-90

dB)

between

20

Hz

to

20

is

available which allows the internal oscillator tuning to be programmed directly with five bytes

20

0.3000

kHz). The ac detector is switchable between true rms, average-responding, and

3

seconds with a measurement rate of 2 readings/second thereafter.

Hz

and

20

kHz at a

mV with an accuracy of

dB

measurement bandwidth for each detector is greater than

68

dB.

1.5V

fast.

The typical time

level.

4%

of reading

to

(2%

of reading for levels

30

and

80

kHz low-pass filters

400

Hz

high-pass filter attenuates

tune and return the

500

>50

kHz.

is

mV

to

1-5

Page 19

General Information

1-7.

OPTIONS

Electrical Options

Model 8903B

Electrical Option

001.

This option provides rear-panel (instead of front-panel) connections for both

the INPUT and OUTPUT HIGH and LOW BNC connectors.

Internal Plug-in Filter Options.

The Audio Analyzer has

two

plug-in filter positions; each position

can be loaded with any one of six optional filters. Each filter is referenced to its corresponding filter

position by one

as Option 010 which corresponds to the left-most filter position,

of

two

option numbers. For example, the 400 Hz high-pass filter option can be ordered

or

as

Option

050

which corresponds

to the right-most filter position. These optional plug-in filters can be configured in any combination

desired.

there is no filter ordered for a position, a jumper

is

loaded and a label marked

(If

is placed above the filter key on the front panel.) The following list includes the name and option

numbers for each available filter.

0

400 Hz High-Pass Filter (Option 010,050)

0

CCITT Weighting Filter (Option 011, 051)

0

CCIR Weighting Filter (Option 012, 052)

0

C-MESSAGE Weighting Filter (Option 013, 053)

0

CCIR/ARM Weighting Filter (Option 014,

0

“A”

Weighting Filter (Option 015,

055)

054)

Specific information on each plug-in filter option can be found in the Detailed Operating Instructions

in Section 3 under “Filters”.

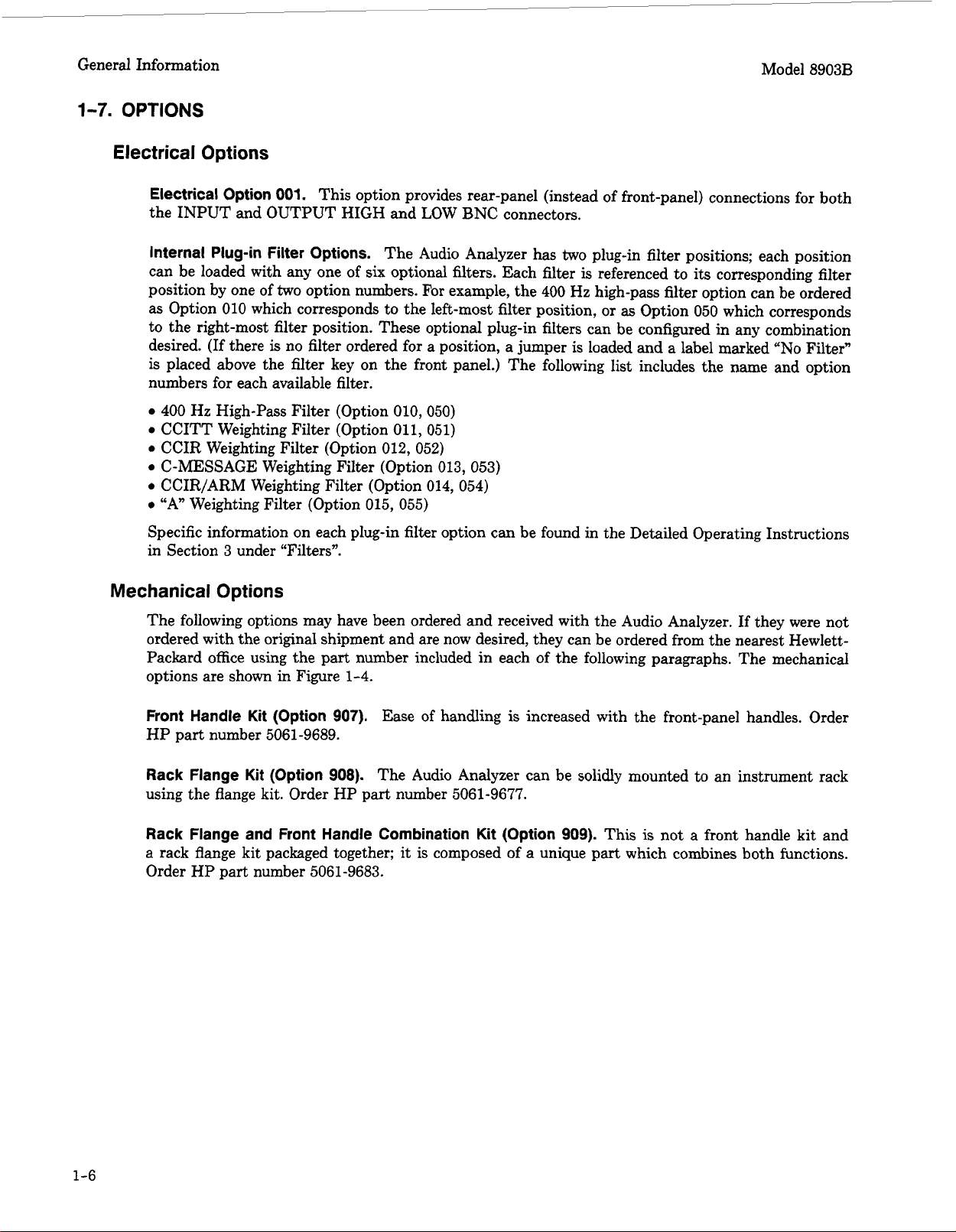

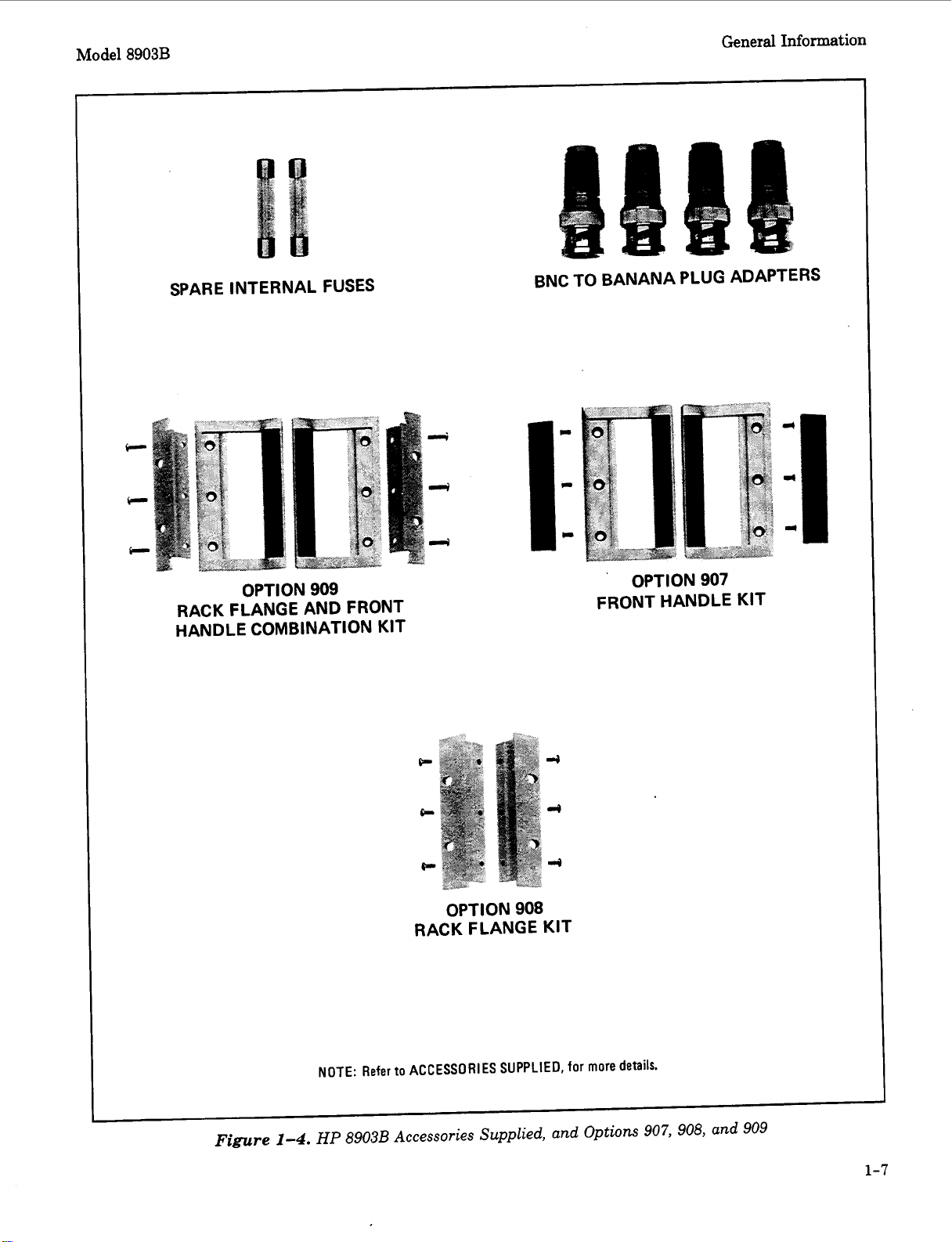

Mechanical Options

The following options may have been ordered and received with the Audio Analyzer.

ordered with the original shipment and are now desired, they can be ordered from the nearest HewlettPackard office using the part number included in each of the following paragraphs. The mechanical

options are shown in Figure 1-4.

If

they were not

“No

Filter”

Front Handle Kit (Option

HP

part number 5061-9689.

Rack Flange

Kit

(Option

907).

908).

Ease of handling

is

increased with the front-panel handles. Order

The Audio Analyzer can be solidly mounted to an instrument rack

using the flange kit. Order HP part number 5061-9677.

Rack Flange and Front Handle Combination Kit (Option 909).

a

a rack flange kit packaged together; it is composed of

HP

Order

part number 5061-9683.

unique part which combines both functions.

This

is

not a front handle kit and

1-6

Page 20

Model

8903B

General Information

SPARE INTERNAL FUSES

OPTION

909

RACK FLANGE AND FRONT

HANDLE COMBINATION KIT

BNC TO BANANA PLUG ADAPTERS

’

OPTION907

FRONT HANDLE KIT

Figure

1-4.

OPTION

908

RACK FLANGE KIT

NOTE:

Refer

to

ACCESSORIES

HP

8903B Accessories Supplied, and Options

SUPPLIED,

for

more

details.

907,

908, and 909

1-7

Page 21

General Information Model 8903B

1-8.

HEWLETT-PACKARD INTERFACE BUS

Compatibility

The Audio Analyzer is compatible with HP-IB to the extent indicated by the following code: SH1,

T5,

AH1,

bus via open collector TTL circuitry. An explanation of the compatibility code can be found in IEEE

Standard 488,

ANSI Standard MC1.l.

Analyzer, refer to

TEO, L3, LEO,

IEEE Standard Digital Interface for Programmable Instrumentation

Remote Operation, Hewlett-Packard Interface

SR1,

RL1, PPO, DC1, DT1,

For

more detailed information relating to programmable control of the Audio

CO,

El.

The Audio Analyzer interfaces with the

or the identical

Bw

in Section 3 of this manual.

Selecting the HP-IB Address

The HP-IB address switches are located within the Audio Analyzer. The switches represent a fivebit binary number. This number represents the talk and listen address characters which an HP-IB

two

controller is capable of generating. In addition,

to talk only

HP-IB

1-9.

ACCESSORIES SUPPLIED

or

Address Selection

listen only. A table in Section 2 shows all HP-IB talk and listen addresses. Refer to

in Section 2

of

this manual.

more switches allow the Audio Analyzer to be set

The accessories supplied with the Audio Analyzer are shown in Figure

Fast

blow fuses with a 1.5A rating for 100/120 Vac operation (HP 2110-0043) and a

220/240 Vac operation (HP 2110-0001) are supplied. One fuse is installed in the instrument at the

time of shipment. The rating of the installed fuse is selected according to the line voltage specified by

1-1

the customer.

to the country of destination.

Four type BNC-to-banana-plug adapters (HP 1250-2164) are also supplied for use when double-ended

inputs

conductor of the BNC connector adapted to. These adapters are used when the front-panel INPUT

or

0.

ELECTRICAL EQUIPMENT AVAILABLE

(Also refer to Service Accessories, Table

HP-I6

The Audio Analyzer has

controller

or

OUTPUT FLOAT switches are set to FLOAT.

Controllers

If

the voltage

outputs are desired. The conductor of the banana connector is connected to the center

or

computer for automatic systems applications.

is

not specified, the rating of the installed fuse will be selected according

an

HP-IB interface and can be used with any HP-IB compatible computing

Front-to-Rear-Panel Connectors Retrofit Kit

This kit contains all the necessary components and full instructions for converting instruments with

front-panel connections for INPUT and OUTPUT HIGH and LOW to rear-panel connections.

serial prefixes 2730A and below, order

above, order HP part number 08903-60199. After installation and calibration, performance will be

identical to the

HP

8903B Option 001.

1-4.

1.OA

1-4.)

HP

part number 08903-60171. For serial prefix 2742A and

rating for

For

Rear-to-Front-Panel Connectors Retrofit Kit

This kit contains all the necessary components and full instructions for converting instruments with

rear-panel connections for INPUT and OUTPUT HIGH and

serial prefix 2730A and below order HP part number 08903-60172.

order HP part number 08903-60200. After installation and calibration, performance will be identical

to the standard HP 8903B.

1-8

LOW

to front-panel connections. For

For

serial prefix 2742A and above,

rev.26JU.9

Page 22

Model

1-1

1.

8903B

MECHANICAL EQUIPMENT AVAILABLE

General Information

Chassis

This kit

components

part number

adapters for non-HP rack enclosures.

Chassis Tilt

This kit

instrument up

part

AC/OC

HIGH

IN^

c>-

I" I

%?

ACfOC

Slide

number

ATTFTOR

Mount Kit

is

extremely useful when the Audio Analyzer

or

the rear-panel

1494-0060

Slide

is

INPUT

-

Mount Kit

the same as the Chassis Slide Mount Kit above except

or

down

90".

1494-0061

OVER- TO-SINGLE- PROGRAMMABLE

VOLTAGE ENOEO- GAIN

PROTECTION

-

OVFII-

VOLTAGE

PROTECTION

for

OIFFERENTIAL-

AMPLICIER AMPLIFIER

VOLTAGETO-TIME

CONVERTER

is

possible without removing the instrument from the rack. Order HP

for

431.8

mm

(17

Order HP part number

the correct adapters for non-HP rack enclosures.

I

is

rack mounted. Access

in.) fixed slides and part number

it

also allows the tilting of the

INTERNAL

PLUG-IN

HP/BP

I

1494-0062

1I

FILTER

for

431.8

mm

PROGRAMMABLE PROGRAMMABLE

to

internal circuits and

1494-0061

(17

for the correct

in.) tilting slides and

!t

MONITOR

1-12.

1-13.

SINAO METER

-0

RB8giE;o

2

rn

KEYBOARO AN0 OISPLAY

a8

ooDD

..--

D

w..

0

-P

Figure

1-5.

Simplified

HP

8903B

Audio Analyzer

Block

Diagram

RECOMMENDED TEST EQUIPMENT

Table

1-3

lists the test equipment recommended for use in testing, adjusting, and servicing the Audio

If

Analyzer.

any of the recommended equipment

specifications may be substituted. Table

1-3

is

unavailable, instruments with equivalent minimum

also includes some alternate equipment listings.

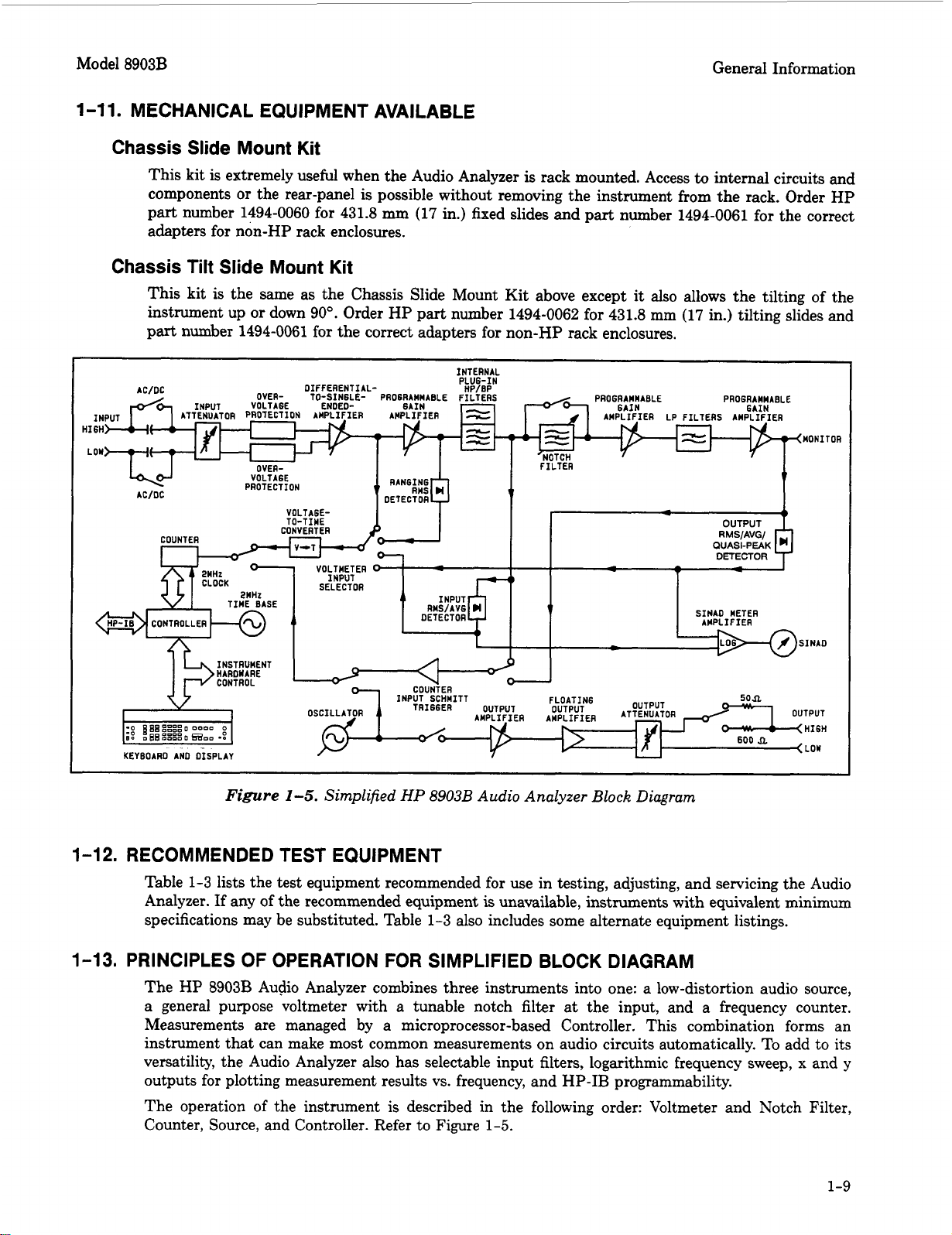

PRINCIPLES OF OPERATION FOR SIMPLIFIED BLOCK DIAGRAM

The HP

a general purpose voltmeter with

Measurements are managed by a microprocessor-based Controller. This combination forms an

instrument that can make most common measurements on audio circuits automatically. To add to its

versatility, the Audio Analyzer also has selectable input filters, logarithmic frequency sweep,

outputs

The operation

Counter, Source, and Controller. Refer to Figure

8903B

for

Audio Analyzer combines three instruments into one: a low-distortion audio source,

a

tunable notch filter at the input, and a frequency counter.

plotting measurement results vs. frequency, and HP-IB programmability.

of

the instrument

is

described in the following order: Voltmeter and Notch Filter,

1-5.

x

and

y

1-9

Page 23

General Information Model

8903B

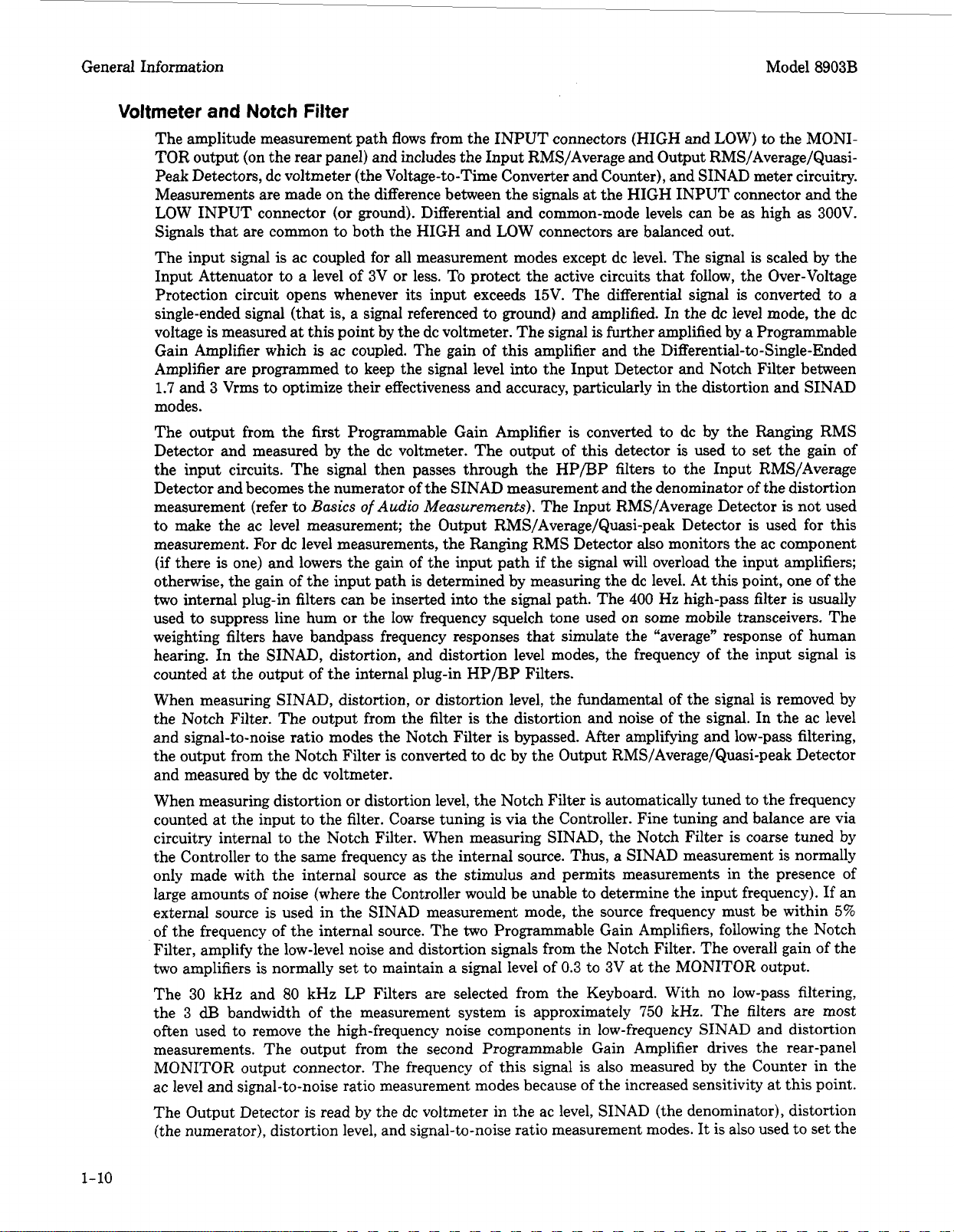

Voltmeter

The amplitude measurement path flows from the INPUT connectors (HIGH and LOW) to the MONITOR output (on the rear panel) and includes the Input RM$/Average and Output RMS/Average/QuasiPeak Detectors, dc voltmeter (the Voltage-to-Time Converter and Counter), and SINAD meter circuitry.

Measurements are made on the difference between the signals at the HIGH INPUT connector and the

LOW INPUT connector

Signals that are common to both the HIGH and LOW connectors are balanced out.

The input signal

Input Attenuator to

Protection circuit opens whenever its input exceeds 15V. The differential signal

single-ended signal (that is, a signal referenced to ground) and amplified. In the dc level mode, the dc

voltage

Gain Amplifier which

Amplifier are programmed to keep the signal level into the Input Detector and Notch Filter between

1.7

modes.

The output from the first Programmable Gain Amplifier is converted to dc by the Ranging RMS

Detector and measured by the dc voltmeter. The output of this detector is used to set the gain of

the input circuits. The signal then passes through the

Detector and becomes the numerator of the SINAD measurement and the denominator of the distortion

measurement (refer to

to make the ac level measurement; the Output RMS/Average/Quasi-peak Detector is used for this

measurement. For dc level measurements, the Ranging RMS Detector also monitors the ac component

(if there

otherwise, the gain of the input path is determined by measuring the dc level.

two internal plug-in filters can be inserted into the signal path. The

used to suppress line hum

weighting filters have bandpass frequency responses that simulate the “average” response of human

hearing. In the SINAD, distortion, and distortion level modes, the frequency of the input signal is

counted at the output of the internal plug-in HP/BP Filters.

When measuring SINAD, distortion,

the Notch Filter. The output from the filter

and signal-to-noise ratio modes the Notch Filter

the output from the Notch Filter is converted to dc by the Output RMS/Average/Quasi-peak Detector

and measured by the dc voltmeter.

When measuring distortion

counted at the input to the filter. Coarse tuning

circuitry internal to the Notch Filter. When measuring SINAD, the Notch Filter

the Controller to the same frequency as the internal source. Thus, a SINAD measurement

only made with the internal source as the stimulus and permits measurements in the presence

large amounts of noise (where the Controller would be unable to determine the input frequency).

external source

of

Filter, amplify the low-level noise and distortion signals from the Notch Filter. The overall gain of the

two amplifiers is normally set to maintain a signal level of

The 30 kHz and

the

often used to remove the high-frequency noise components in low-frequency SINAD and distortion

measurements. The output from the second Programmable Gain Amplifier drives the rear-panel

MONITOR output connector. The frequency of this signal

ac

The Output Detector is read by the dc voltmeter in the ac level, SINAD (the denominator), distortion

(the numerator), distortion level, and signal-to-noise ratio measurement modes.

and

Notch

is

measured at this point by the dc voltmeter. The signal

and 3 Vrms

is

one) and lowers the gain of the input path

the frequency of the internal source. The

3

dB

bandwidth of the measurement system is approximately

level

and signal-to-noise ratio measurement modes because of the increased sensitivity at this point.

Filter

(or

ground). Differential and common-mode levels can be as high as 300V.

is

ac coupled for all measurement modes except dc level. The signal

a

level of 3V

is

ac coupled. The gain

to

optimize their effectiveness and accuracy, particularly in the distortion and SINAD

Basics

or

less. To protect the active circuits that follow, the Over-Voltage

of

this amplifier and the Differential-to-Single-Ended

of

Audio Measurements).

is

further amplified by a Programmable

HP/BP

The Input RMS/Average Detector

if

the signal will overload the input amplifiers;

filters to the Input RMS/Average

At

400

Hz high-pass filter

or

the low frequency squelch tone used on some mobile transceivers. The

or

distortion level, the fundamental of the signal is removed by

is

the distortion and noise of the signal. In the ac level

is

bypassed. After amplifying and low-pass filtering,

or

distortion level, the Notch Filter

is

via the Controller. Fine tuning and balance are via

is

used in the SINAD measurement mode, the source frequency must be within

two

Programmable Gain Amplifiers, following the Notch

80

kHz LP Filters are selected from the Keyboard. With no low-pass filtering,

is

automatically tuned to the frequency

0.3

to 3V at the MONITOR output.

750

kHz. The filters are most

is

also measured by the Counter in the

It

is

scaled by the

is

converted

this point, one of the

is

coarse tuned by

is

is also used to set the

is

not used

is

usually

normally

If

to

5%

a

of

an

1-10

Page 24

Model

8903B

gain

of

the

two

Programmable Gain Amplifiers. Both the input and output detectors can be configured

via special functions to respond to the absolute average of the signal instead

In the SIN AD mode the outputs from the Input RMS/Average and Output RMS/Average/Quasi-peak

of

Detectors are converted to a current representing the log of the ratio

to

Meter Amplifier

very noisy conditions, the panel meter makes

The Voltage-to-Time Converter converts the dc inputs into a time interval which

Counter. The Output Detector can also be configured via special functions to respond

of the signal. This type of detector

types. The Quasi-peak Detector has a fast rise time coupled with a slow decay time constant which

“captures” impulses

drive the SINAD panel meter. Since SINAD measurements are often made under

it

or

other

signals

easier

is

designed

with a high crest factor (noise

to

to

average the reading and to discern trends.

respond to impulse type signals better than other

the

or

repetitive signal bursts).

General Information

of

the true

two

signals by the SINAD

is

measured by the

to

the quasi-peak

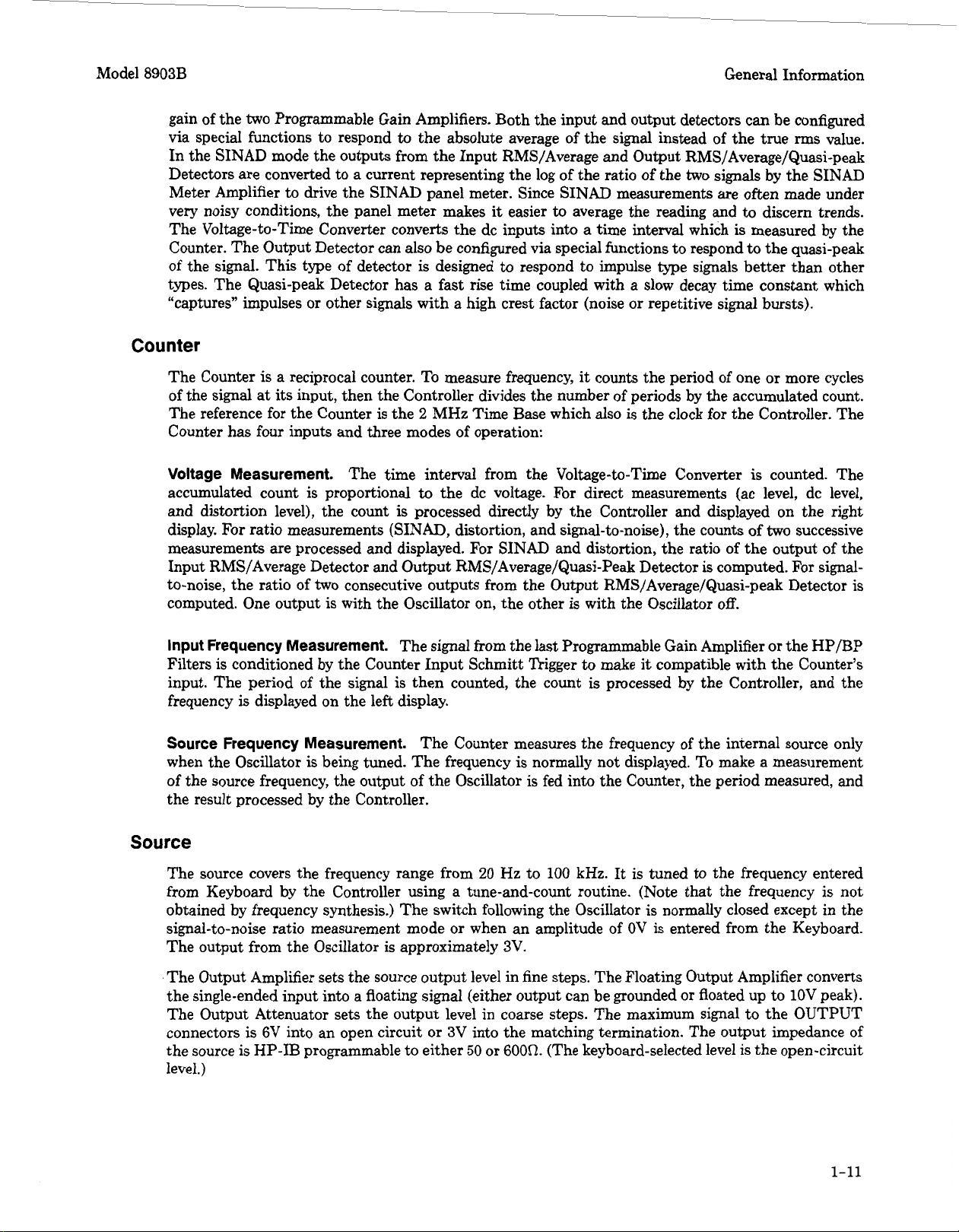

Counter

rms

value.

The Counter

of the signal at

The reference

Counter has four inputs and three modes of operation:

Voltage Measurement.

accumulated count is proportional

and distortion level), the count

display. For ratio measurements (SIN

measurements are processed and displayed. For SINAD and distortion, the ratio of the output of the

Input RMS/Average Detector and Output RMSIAveragejQuasi-Peak Detector

to-noise, the ratio of

computed. One output is with the Oscillator on, the other is with the Oscillator

Input Frequency Measurement.

Filters is conditioned by the Counter Input Schmitt Trigger to make it compatible with the Counter’s

input. The period of the signal is then counted, the count

frequency is displayed on the left display.

Source Frequency Measurement.

when the Oscillator

of the source frequency, the output

the result processed by the Controller.

is

a reciprocal counter. To measure frequency, it counts the period of one

its

input, then the Controller divides the number of periods by the accumulated count.

for

the Counter is the 2 MHz Time Base which also is the clock for the Controller. The

The time interval from the Voltage-to-Time Converter

to

the dc voltage.

is

processed directly by the Controller and displayed on the right

AD,

distortion, and signal-to-noise), the counts

two

consecutive outputs from the Output RMS/Average/Quasi-peak Detector is

The signal from the last Programmable Gain Amplifier or the HP/BP

The Counter measures the frequency

is

being tuned. The frequency is normally not displayed. To make a measurement

of

the Oscillator is fed

For

direct measurements (ac level, dc level,

is

computed. For signal-

off.

is

processed by the Controller, and the

of

the internal source only

into

the Counter, the period measured,

or

more cycles

is

counted. The

of

two

successive

and

Source

The source covers the frequency range from

from Keyboard by the Controller using a tune-and-count routine. (Note that the frequency is not

obtained by frequency synthesis.) The switch following the Oscillator is normally closed except in the

signal-to-noise ratio measurement mode

is

The output from the Oscillator

The Output Amplifier sets the source output level in fine steps. The Floating Output Amplifier converts

the single-ended input into a floating signal (either output can be grounded

The Output Attenuator sets the output level in coarse steps. The maximum signal to the OUTPUT

connectors is 6V into an open circuit

the source is

level.)

HP-IB

programmable to either

approximately

or

20

Hz

to

100

kHz.

It is tuned to the frequency entered

or

when an amplitude of OV

3V.

3V into the matching termination. The output impedance of

50

or

600R. (The keyboard-selected level

is

entered from the Keyboard.

or

floated up to

is

the open-circuit

1OV

peak).

1-11

Page 25

General Information Model

Controller

The entire operation of the instrument is under control of a microprocessor-based Controller. The

Controller sets up the instrument at turn-on, interprets Keyboard entries, executes changes

of operation, continually monitors instrument operation, sends measurement results and errors to the

is

used

front-panel displays, and interfaces with HP-IB. In addition, its computing capability

For

circuit operation.

into ratios (in

’3%

example, it forms the last stage of the Counter, converts measurement results

or

dB),

etc. It also contains routines useful for servicing the instrument.

to

8903B

in

mode

simplify

1-14.

AC

BASICS

The “audion frequency range is usually taken to be from

that good, but the term is a convenient one to describe sub-RF frequencies encountered in electronics.

The frequency range of the Audio Analyzer extends beyond the audio range

up

Electronic instrumentation provides most of the tools for quantitative analysis of audio signals. Thus,

if

signal by a transducer of some kind (for example, strain gauge or microphone) before

Apart

in the audio range

frequency (pitch), and shape (timbre). You can also determine

are stable, and you can even make some quantitative measurements on it (for example, peak level, dc

offset, period, risetime, etc.). Many times, however, the parameter sought does not lend itself

visual analysis. Thus, the Audio Analyzer was designed.

general and specialized instruments, under microprocessor control, that make it easy for you to obtain

accurate, quantitative measurements on audio signals of any general waveshape.

OF

AUDIO MEASUREMENTS

to

100

kHz.

the signal is non-electrical (for example, mechanical

from attentive listening

is

visually with an oscilloscope. Here you get a feeling for the signal’s size (loudness),

to

a hi-fi system, the most intuitive way of analyzing an electrical signal

20

Hz to

or

acoustic),

It

combines into one instrument a series of

20

kHz. Few people have hearing

to

include fundamentals

it

must be converted

it

can be analyzed.

if

these parameters change with time

to

an electrical

to

Level

Consider the very common measurement of a signal’s ac rms level. To make this measurement with

an oscilloscope, you must first decide the nature of the signal, because from it, the relationship of the

rms

peak level to the

the rms value

This measurement is greatly simplified with a rms voltmeter which electronically measures the rms

level and displays the result. However, no other information about the signal is provided. The Audio

Analyzer contains both an rms- and an average-responding voltmeter. The

displayed whenever the AC

SPCL. The quasi-peak level can be displayed by entering

which converts the measurement result into watts for

is

level can be mathematically determined. If the signal is sinusoidal, for example,

the peak amplitude divided by

LEVEL

mode is selected. The average level can be displayed by entering

a.

rms

level of the signal

5.7

SPCL. A special function

a

specified (external) load resistance.

is

also provided

or

easy

is

5.2

1-12