Page 1

HP Archive

This vintage Hewlett Packard document was preserved

and distributed by

www. hparchive.com

Please visit us on the web.

For free distribution only!

Thanks to on-line curator: Bernhard Voss for supplying

and scanning this vintage document.

Page 2

OPERATING·AND

SERVICE

MANUAL

S-PARAMETER

TEST

.5-12.4

SET

GHz

87468

rh~

a:~

HEWLETT

PACKARD

Page 3

"

CERTIFICATION

of

time

the

its published specifications

Hewlett-Packard, Company certifies that this product

shipment from the factory. Hewlett-Packard further certifies that its calibration measurements are

traceable to the .United States National Bureau

calibration facility,

members.

This Hewlett-Packard instrument product

for a period

pany will,

warranty service

For

Buyer shall prepay shipping charges

Buyer. However, Buyer shall pay all shipping charges, duties, and taxes for products returned

from another country.

warrants

HP

its programming instructions when properly installed

operation

one year from date

of

its option, either repair

at

that

the instrument,

of

to the calibration facilities

and

WARRANTY

warranted against defects in material and workmanship

is

shipment. During the warranty period, Hewlett-Packard Com-

of

replace products which prove

or

repair, this product must be returned

or

its software and firmware designated by

software,

or

to

and

HP

firmware will be uninterrupted.or error free.

or

met

Standards, to the

of

of

shall pay shipping charges

HP

on

International Standards Organization

other

a service facility designated by

to

for use with an instrument will execute

HP

instrument.

that

extent

be defective.

to

HP

allowed

to

does

at

the Bure'au's

by

return the product

warrant

not

to

that

HP.

HP

the

to

WARRANTY

LIMITATION

The foregoing warranty shall

by Buyer, Buyer-supplied software

outside

tenance.

OTHER

NO

PLIED WARRANTIES

.EXCLUSIVE REMEDIES

REMEDIES PROVIDED HEREIN ARE BUYER'S SOLE AND EXCLUSIVE REMEDIES. HP

THE

SHALL NOT BE LIABLE

QUENTIAL DAMAGES, WHETHER BASED ON CONTRACT,

THEORY. .

Product maintenance agreements and

Packard products.

For any assistance, contact

provided

OF

defects resulting from improper

to

apply

not

the environmental specifications for the product,

of

WARRANTY IS EXPRESSED

the back

at

MERCHANTABILITY AND FITNESS FOR. A PARTICULAR PURPOSE.

OF

FOR

your

this manual.

of

interfacing, unauthorized modification

or

IMPLIED. HP SPECIFICALLY DISCLAIMS

OR

ANY DIRECT, IN'DIRECT, SPECIAL, INCIDENTAL,

ASSISTANCE

customer assistance agreements

other

nearest Hewlett-Packard Sales and Service Office. Addresses are

inadequate maintenance

or

improper site preparation

or

TORT,

OR

misuse, operation

or

ANY

available for Hewlett-

are

OTHER

OR

main-

or

IM-

THE

CONSE-

LEGAL

f

I

I

I

L

Page 4

S-PARAMETER TEST SET

.5-12.4

GHz

8746B

Serials Prefixed: 1114A

This manual applies directlytoHP Model 8746B

Test

Set

S-Parameter

prefixed

1114A.

Units having serial numbers

Serials Prefixed: 983-

See Section VII, Manual Changes

Other Prefixes:

See Instruments CoveredbyManual, Section I

1400

Manual Part No. 08746-90007

Microfiche" Part No."08746-90008

Copyright HEWLETT-PACKARD COMPANY 1971

FOUNTAIN

GROVE

PARKWAY,

SANTA

ROSA,

CALIFORNIA,

Flidl

~aI

U.S.A.

Printed:

AUG,

1971

HEWLETT

PACKARD

Page 5

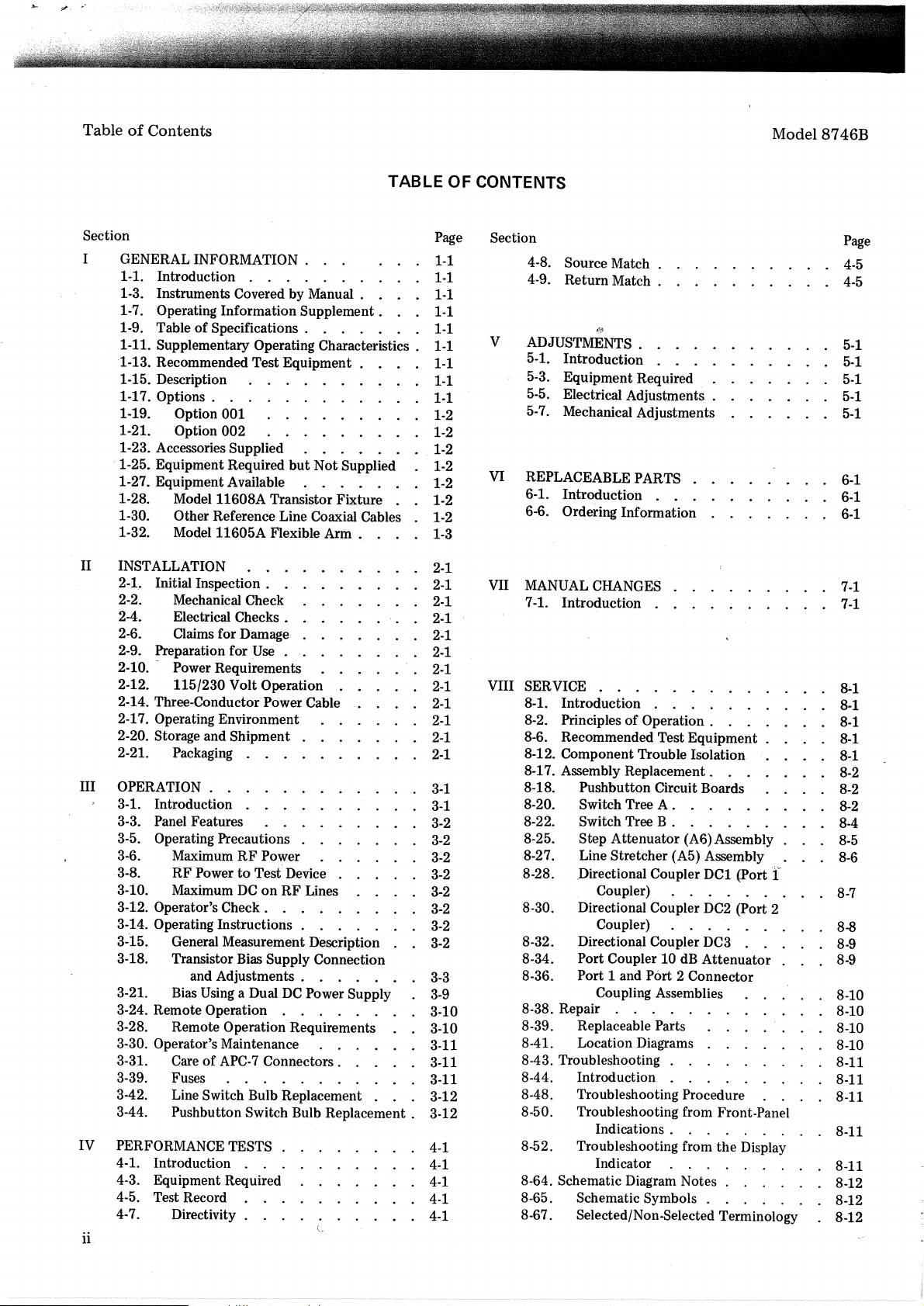

TableofContents

Model 8746B

TABLE OF CONTENTS

Section Page Section

GENERAL INFORMATION.

I

Introduction

1-1.

Instruments Covered by Manual .

1-3.

Operating Information Supplement. 1-1

1-7.

TableofSpecifications .

1-9.

1-11. Supplementary Operating Characteristics.

'1-13. Recommended Test

1-15. Description

1-17.

Options.

1-19.

1-21.

1-23. Accessories Supplied

1-25. EquipmentRequired but Not Supplied

1-27. Equipment Available

1-28.

1-30.

1-32.

II INSTALLATION

2-1.

2-2.

2-4.

2-6.

2-9.

2-10.

2-12. 115/230 Volt Operation

2-14. Three-Conductor Power Cable

2-17. Operating Environment

2-20. Storage and Shipment

2-21.

III

OPERATION.

3-1.

3-3.

3-5.

3-6.

3-8.

3-10.

3-12. Operator's

3-14. Operating Instructions .

3-t5.

3-18.

3-21.

3-24. Remote Operation

3-28.

3-30. Operator's Maintenance

3-31.

3-39.

3-42.

3-44. Pushbutton Switch Bulb Replacement . 3-12

PERFORMANCE"

IV

4-1.

4-3.

4-5.

4-7.

Option 001

"Option

Model 11608A Transistor Fixture

Other Reference Line Coaxial Cables

Model 11605A Flexible Arm .

Initial Inspection .

Mechanical Check

Electrical Checks .

Claims for Damage

Preparation for

Power Requirements

Packaging

Introduction

Panel Features

Operating Precautions

MaximumRFPower

RF

MaximumDConRFLines

General Measurement Description

Transistor Bias Supply Connection

Bias

Remote Operation Requirements

Care of

Fuses

Introduction

Equipment Required

Test Record

002

PowertoTest' Device

Check.

and Adjustments .

Using

APC-7

Line Switch Bulb Replacement

TESTS

Directivity .

Equipment.

.

.

Use

.

a DualDCPower Supply

Connectors.

c

1-1

1-1

1-1

1-1

1-1

1-1

1-1

1-1

1-2

1-2

1-2

1-2

1-2

1-2

1-2

1-3

2-1

2-1

2-1

2-1

.

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

3-1

3-1

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-3

3-9

3-10

3-10

3-11

3-11

3-11

3-12

4-1

4-1

4-1

4-1

4-1

V

VI

VII

VIII

ii

4-8.

Source Match .

4-9.

Return Match .

ADJUSTMENTS .

5-1.

5-3.

5-5.

5-7.

REPLACEABLE PARTS

6-1.

6-6.

MANUAL CHANGES

7-1. Introduction

SERVICE

8-1.

8-2.

8-6.

8-12. Component Trouble Isolation

8-17. Assembly Replacement.

8-18.

8-20.

8-22.

8-25.

8-27.

8-28.

8-30.

8-32.

8-34.

8-36.

8-38. Repair

8-39.

8-41.

8-43. Troubleshooting

8-44.

8-48.

8-50.

8-52.

8-64. Schematic Diagram Notes .

8-65.

8-67.

t.~'

Introduction

Equipment Required

Electrical Adjustments .

Mechanical Adjustments

Introduction

Ordering Information

Introduction

PrinciplesofOperation .

Recommended Test Equipment .

Pushbutton Circuit Boards

Switch Tree

Switch Tree B .

Step Attenuator (A6)Assembly .

Line Stretcher (A5) Assembly

,Directional Coupler

Coupler)

Directional Coupler

Coupler)

Directional Coupler

Port Coupler 10dBAttenuator

Port 1 and Port 2 Connector

Coupling Assemblies

Replaceable Parts

Location Diagrams

Introduction

Troubleshooting Procedure

Troubleshooting from Front-Panel

Indications .

Troubleshooting from the Display

Indicator

Schematic Symbols

Selected/Non-Selected Terminology

A.

DC1

DC2

DC3

(Port

(Port 2

Page

4-5

4-5

5-1

5-1

5-1

5-1

5-1

6-1

6-1

6-1

7-1

7-1

~1

8-1

8-1

8-1

8-1

.

8-2

8-2

8-2

8-4

8~5

8-6

'f

8-7

8-8

8-9

8-9

8-10

8-10

8-10

8-10

8-11

8-11

8-11

8-11

8-11

8-12

8-12

8-12

Page 6

Model 8746B

LIST OF ILLUSTRATIONS

List

of

lliustrations

and

Tables

Figure

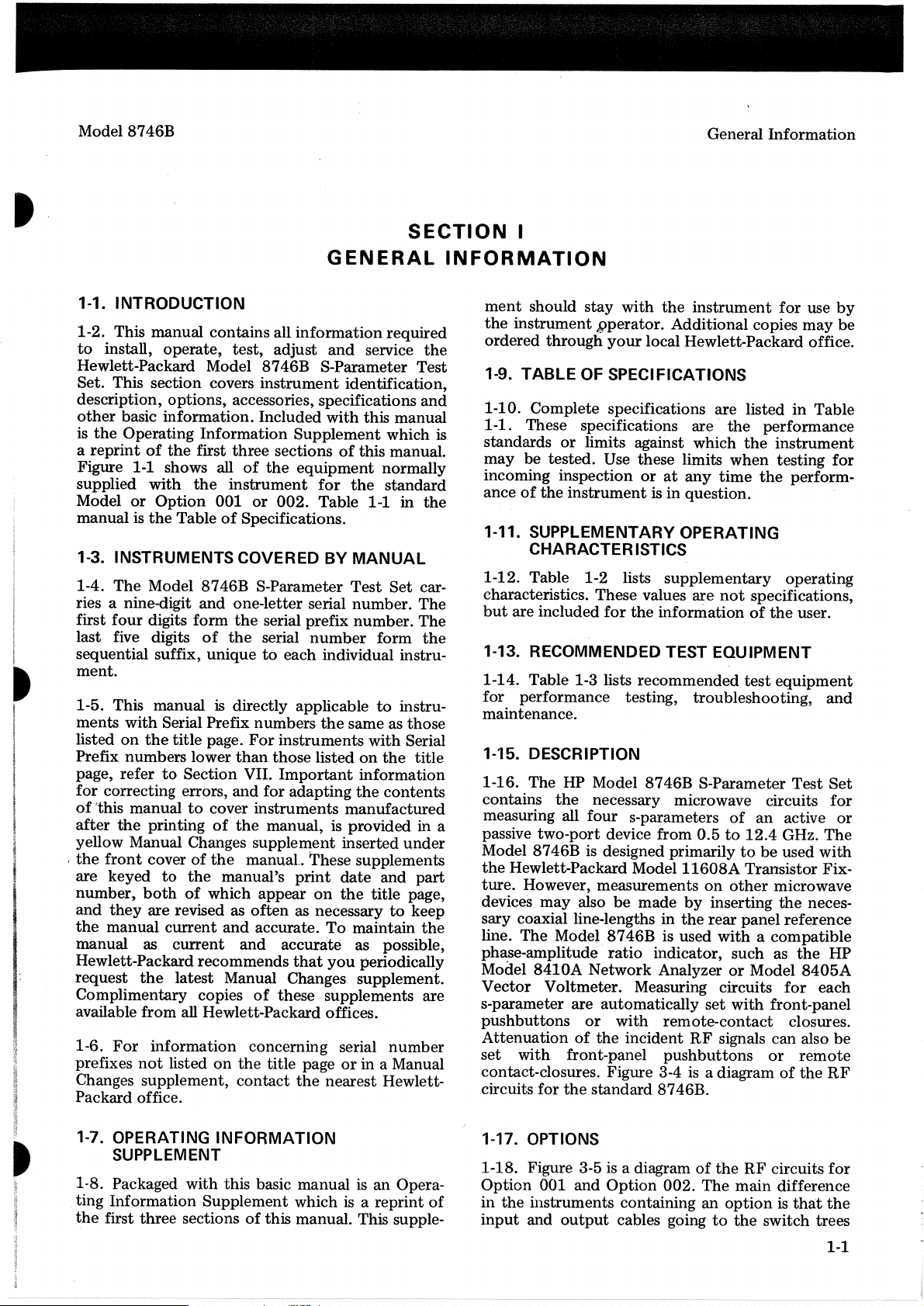

1-1. Model 8746B and Accessories . . . . .

1-2. Model 11608A Transistor Fixture Mounted

on a Model 8746B . . . . . .

3-1. Block Diagram of Equipment Setup for

S-Parameter Measurement.

3-2. Front Panel Features

,.

Circuits

. .

.'

.

3-3. Rear Panel Features .

3-4. Standard

3-5. Option 001 and 002RFCircuits . . . .

3-6. Reference Line Coaxial Patch Cables .

3-7. Line Switch Bulb Replacement

3-8. Bias Voltage Input. Connections . .

3-9. Transistor Measurement . . . .

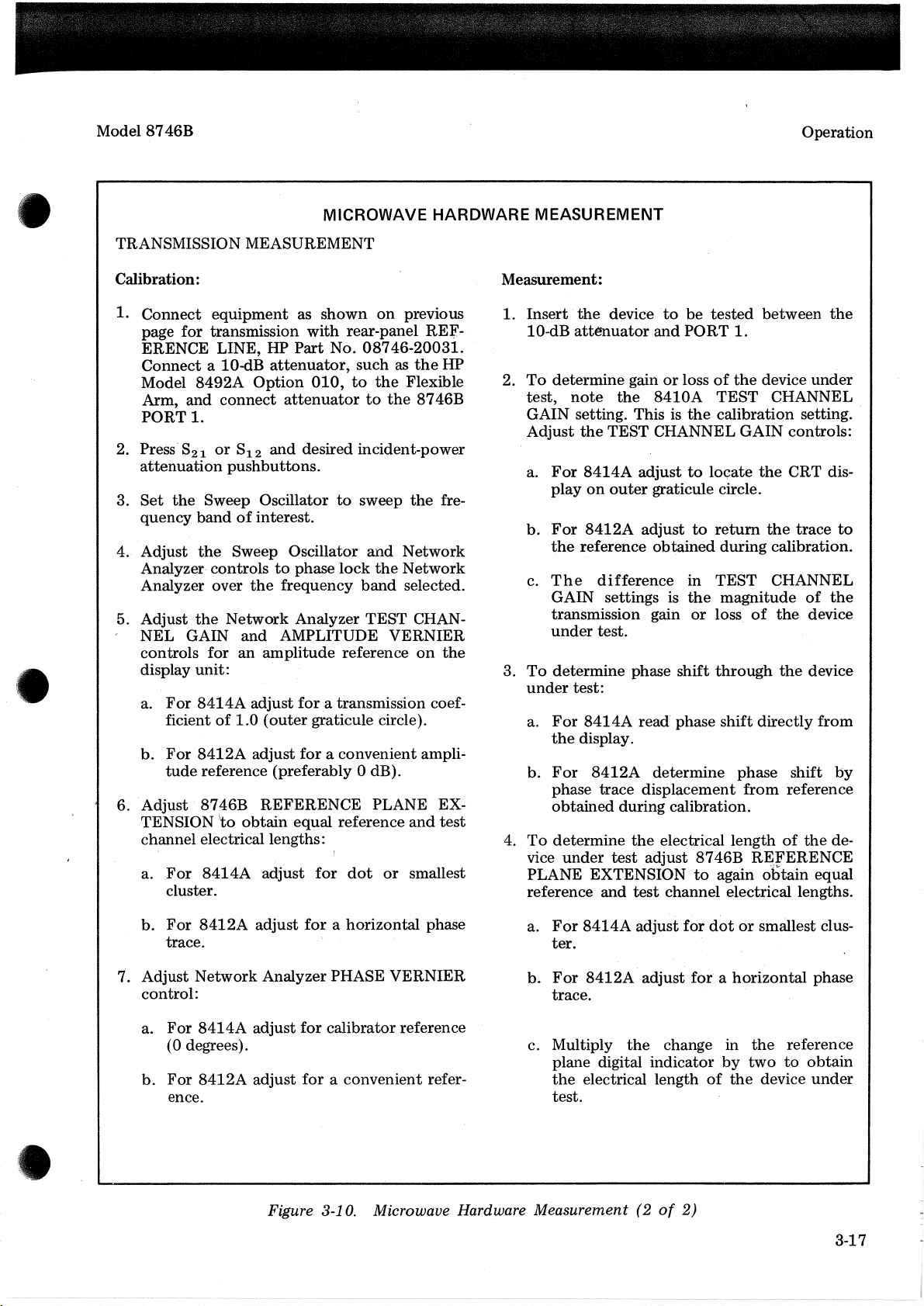

3-10. Microwave Hardware Measurement.

3-11.

APC-7

3-12. Pushbutton Selector Bulb Replacement

4-1. Directivity Test Setup . .

4-2. Source Match Test Setup .

4-3. Return Match Test Setup

Digital Counter Friction Clutch Adjustment .

5-1.

Cabinet Parts

6-1.

Front

6-2.

REFERENCE

6-3.

Outboard (W1J1) REFERENCE LINE

6-4.

REFERENCE LINE Coaxial Cable

6-5.

8-1. Troubleshooting Test Setup .

8-~.

Preliminary Troubleshooting. . .

ModelRF

Connectors . . . . . .

Panel Assembly

& TEST Channel Output and

Inboard (W3J1) REFERENCE LINE

Connectors .

Connector.

Connectors (2)

Page

· 1-0

· 1-2

·

3-1

..

3-4

·

3-5

·

3-6

·

3-7

· 3-8

· 3-12

· 3-13

· 3-14

3-16

· 3-18

· 3-19

· 4-2

· 4-4

· 4-6

5-2

6-13

6-14

6-15

6-16

6-17

. 8-13

. . 8-14

Figure

8-3. Reference Channel Troubleshooting

8-4. Test Channel Troubleshooting

8-5. Assembly,

8-6. Assembly, Bottom

8-7. Index Block Diagram

Diagram. . . . . . . . .

8-8.

RF

8-9. RF Circuitry, Top View 8-18

8-10.

RF

8-11. Port 1toPort 2 Coupler Schematic.

8-12. RF Circuit, Schematic . . .

8-13. S-Parameter Troubleshooting. . . . . . . 8-20

8-14.

A4

8-15.A3Driver Assembly, Parts Location

8-16. S-Parameter Latch and Driver Circuits,

Schematic . . . . . . . . . .

8-17. Attenuation Select Troubleshooting

8-18. A4 Switch Panel Assembly Parts Location

8-19.

A2

8-20. Attenuation Latch Circuits . . . . .

8-21. Attenuation Select Troubleshooting

8-22.

A6

8-23.A3Driver Assembly, Parts Location

8-24. Attenuator Driver Circuits. . . .

8-25. Remote Control Troubleshooting . .

8-26. Remote S-Parameter, Block Diagram

8-27. Remote Attenuator, Block Diagram

8-28.A2Buffer Assembly, Parts Location

8-29. Remote Control Circuits . .

8-30. Power Supply Troubleshooting . . . 8-28

8-31. Power Supply Adjustments . . 8-28

8-32.

AlAI

8-33.A2Buffer Assembly, Parts Location . 8-29

8-34. Power Supply,

Top

View . . . . .

View

. . . . .

&Interconnection

Troubleshooting.

CircuitrY, Bottom View . . . . . . . 8-19

Switch Panel Assembly, Parts Location . . 8-20

Buffer Assembly Parts Location

Attenuator Assembly Troubleshooting

Power Supply Assembly, Parts Location . 8-28

Schematic.

..

.....

..

..

. . . . . . . 8-29

Page

· 8-15

· · 8-16

8-.17

· 8-17

8-1

8-18

..

8-19

..

8-19

..

8-21

· . 8-21

· . 8-22

· . 8-22

· 8-23

· . 8-23

· . 8-24

· . 8-24

· 8-25

· . 8-25

· 8-26

· . 8-26

· . 8-26

..

8-27

..

8-27

7

LIST OF TABLES

..

Page

1-4

3-3

3-9

4-8

.

6-1

. 6-3

Table

1-1. Model 8746B Specifications . . . . . . . 1-3

1-2. Supplementary Operating Characteristics. . . 1-3

1-3. Recommended Test

3-1. Calibrator Display Indications .

3-2. Remote Input Connector Pin Functions . . .

3-3. Remote S-Parameter Selection Truth Table . . 3-10

3-4. Remote Attenuation Selection Truth Table . . 3-11

4-1. Performance Test Record . . . . . . .

6-1. Reference Designators and Abbreviations

Used in Parts List . . . .

6-2. Replaceable Parts . . . . . . . . .

Equipment..

Table

8-1. Servicing Aids. . . . . . . . . . .

8-2. Schematic Diagram

8-3. Paths Common to Various S-Parameter Paths

8-4. S-Parameter Truth Table . .

8-5. S-Parameter Voltage Table . . . . . .

8-6. Attenuator Truth Table . .

8-7. Attenuation Latch Voltage Table . 8-22

8-8. Attenuator Driver Truth Table . . . . . . 8-24

8-9. Attenuator Driver Voltage Table . . 8-24

8-10. Remote Control Parameter and Attenuation

Select Truth Table . . . . . 8-26

8-11. Remote Control

Notes.

Voltt;ige

. . . . . .

.. ..

Table . . . . . . 8-26

Page

·

8-1

· 8-3

· 8-18

8-20

· 8-20

8-22

iii

Page 7

General Information

Model 8746B

8746B

1-0

POWER CABLE

36-PIN CONNECTOR

Figure 1-1. Model

8746B

REFERENCE LINE

RACK

and Accessories

MOUNTING

KIT

Page 8

Model 8746B

General

Information

I

I

I

I

r

~

I

I

SECTION

GENERAL

1-1. INTRODUCTION

1-2. This manual contains all

to

install,

Hewlett-Packard Model 8746B S-Parameter Test

Set. This section covers

description, options, accessories,

other

is

the

a

reprintofthe

Figure 1-1 shows

supplied

Model

manual is

1-3. INSTRUMENTS COVERED BY

1-4.

The

ries a nine-digit

four

first

last five digits

sequential suffix, uniquetoeach individual instrument.

1-5. This manualisdirectly applicabletoinstruments

listed

Prefix numbers lower

page, refer

for

correcting errors,

of

this

after

yellow Manual Changes

I

the

front

are keyed

number,

and

they

the

manual current

manual as

Hewlett-Packard recommends

request

Complimentary copies

available from all Hewlett-Packard offices.

1-6.

For

prefixes

Changes supplement,

Packard office.

operate,

basic information. Included

Operating Information

with

or

Option

the

TableofSpecifications.

Model 8746B S-Parameter

digits

with

Serial Prefix numbers

on

the

title

to

Section VII.

manualtocover instruments

the

printingofthe

coverofthe

to

both

are revised as

current

the

latest Manual Changes supplement.

information concerning serial

not

listed

test,

first

three

all

of

the

instrument

001

and

one-letter serial

form

the

of

the

page.

than

and

manual.

the

manual's

of

which appear

and

and

on

the

contact

infonnation

adjust

instrument

sectionsofthis manual.

the

or

002.

serial prefix

serial

For

instruments

those

Import~nt

for adaptIng

manual, is provided in a

supple~ent

often

accurate.

of

these supplements are

title pageorin a Manual

and

sp~cifica~ions

WIth

Supplement

equipment

for

Table 1-1 m

number

the

listedonthe

These supplements

print

on

as necessarytokeep

To

accurate as possible,

that

you

the

nearest Hewlett-

required

service

identification,

thIS manual

which

normally

the

st~ndard

MANUAL

Test

Set

number.

number.

form

same as those

with

information

the

contents

manufactured

inserted

date

and

the

title page,

maintain

periodically

number

The

The

Serial

title

under

part

I

INFORMATION

ment

should stay

the

instrument

the

and

is

the

car-

the

the

ordered through

1-9. TABLE OF SPECIFICATIONS

1-10. Complete specifications

1-1. These specifications are

standards

may

be tested. Use these limits

incoming inspectionorat

ance

of

1-11. SUPPLEMENTARY OPERATING

CHARACTERISTleS

1-12. Table 1-2 lists supplementary operating

characteristics. These values are

but

are included

1-13. RECOMMENDED TEST EQUIPMENT

1-14. Table 1-3 lists recommended

for performance testing, troubleshooting,

maintenance.

1-15. DESCRIPTION

1-16. The HP Model 8746B S-Parameter

contains

measuring all four s-parameters

passive two-port device from

Model 8746B is designed primarilytobe

the

Hewlett-Packard Model

ture.

However, measurements

devices

sary coaxial line-lengths in

line.

The

phase-amplitude·

Model

Vector

s-parameter are automatically

pushbuttons

Attenuationofthe

set

with front-panel

contact-closures. Figure 3-4isa diagramofthe

circuits for

with

the

instrument

pperator.

your

or

limits against which.

the

instrument

for

the

necessary microwave circuits

may

also

be

Model

8410A

Voltmeter. Measuring circuits

8746B

ratio

Network AnalyzerorModel

or

with

the

standard 8746B.

Additional copies

local Hewlett-Packard offIce.

c:rre

the

when

any

time

is in question.

not

the

information.ofthe

of

0.5to12.4

11608A

on

other

made

by

inserting

the

rea:

is used WIth a compatIble

indicator, such as

set

with

remote-contact

incident

RF

signals can also

pushbuttons

for

use

by

ma~

be

listedinTable

performance

the

instrument

testing

the

specifications,

test

equipment

an

GHz.

used WIth

Transistor Fix-

microwave

the

panel

front-panel

or

for

perform-

user.

and

Test

Set

for

active

refere?ce

for

closures.

~he

neces-

the

HP

8405A

each

remote

RF

or

be

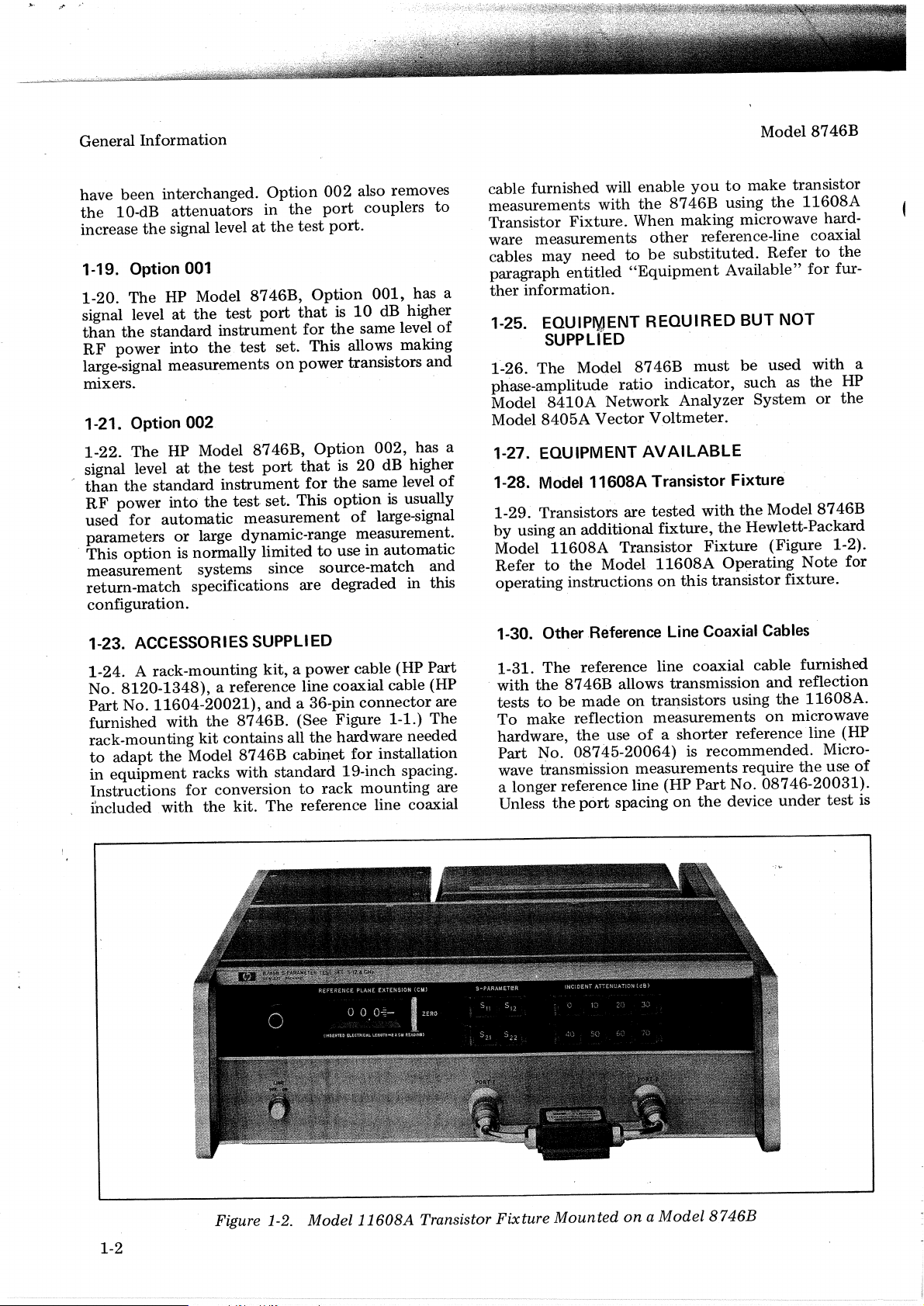

1-7. OPERATING INFORMATION

SUPPLEMENT

1-8. Packaged with this basic manualisan Opera-

is

ting Information Supplement which

the

first three sectionsofthis manual. This supple-

a reprint

of

1-17. OPTIONS

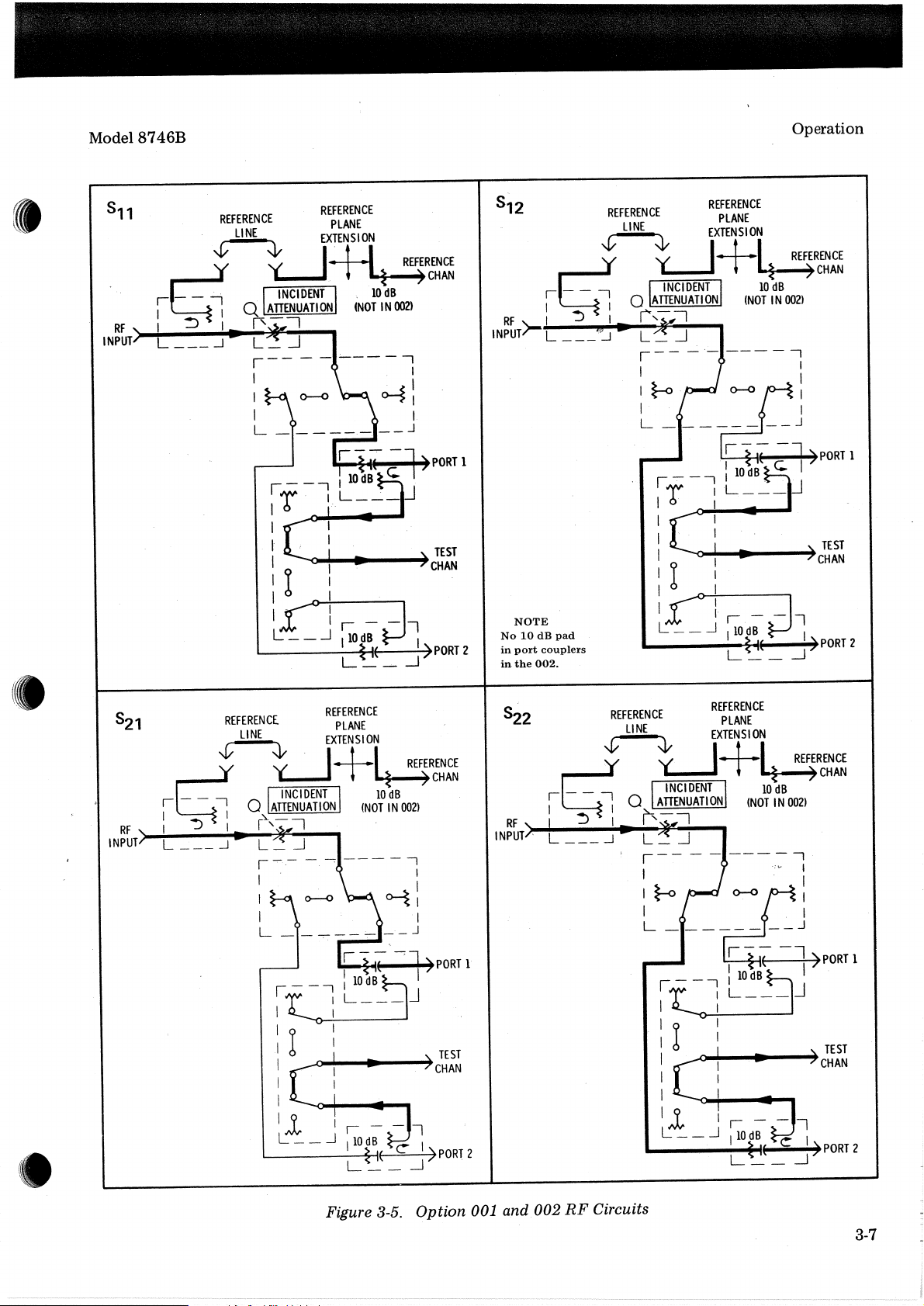

1-18. Figure 3-5isa diagramofthe

Option

in

input

001 and

the

instruments containinganoptionisthat

and

output

Option

002.

The

cables goingtothe

RF

circuits

main difference

switch trees

for

the

1-1

Page 9

General

Information

Model

8746B

have

been

the

10-dB

increase

interchanged.

attenuators

the

signal levelatthe

Option

in

the

002

port

test

1-19. Option 001

1-20.

The

signal level

than

the

standard

RF

power

HP Model

at

the

into

8746B,

test

port

instrument

the.

test

Option

thatis10

for

set..This allows making

large-signal measurementsonpower

mixers.

1-21. Option 002

1-22..The

signal level

than

RF

power

used

parameters

This

measurement

return-match

configuration.

the

standard

for

option

HP Model

at

the

into

the

automatic

or

large dynamic-range measurement.

is normally

8746B,

test

port

instrument

test,

set..This

Option

thatis20

for

measurement

limitedtouseinautomatic

systems since source-match

specifications are degraded

1-23. ACCESSORIES SUPPLIED

also removes

couplers

port.

001,

dB higher

the

same level

transistors

002,

dB higher

the

same level

option

of

large-signal

to

has a

of

and

has a

of

is usually

and

in

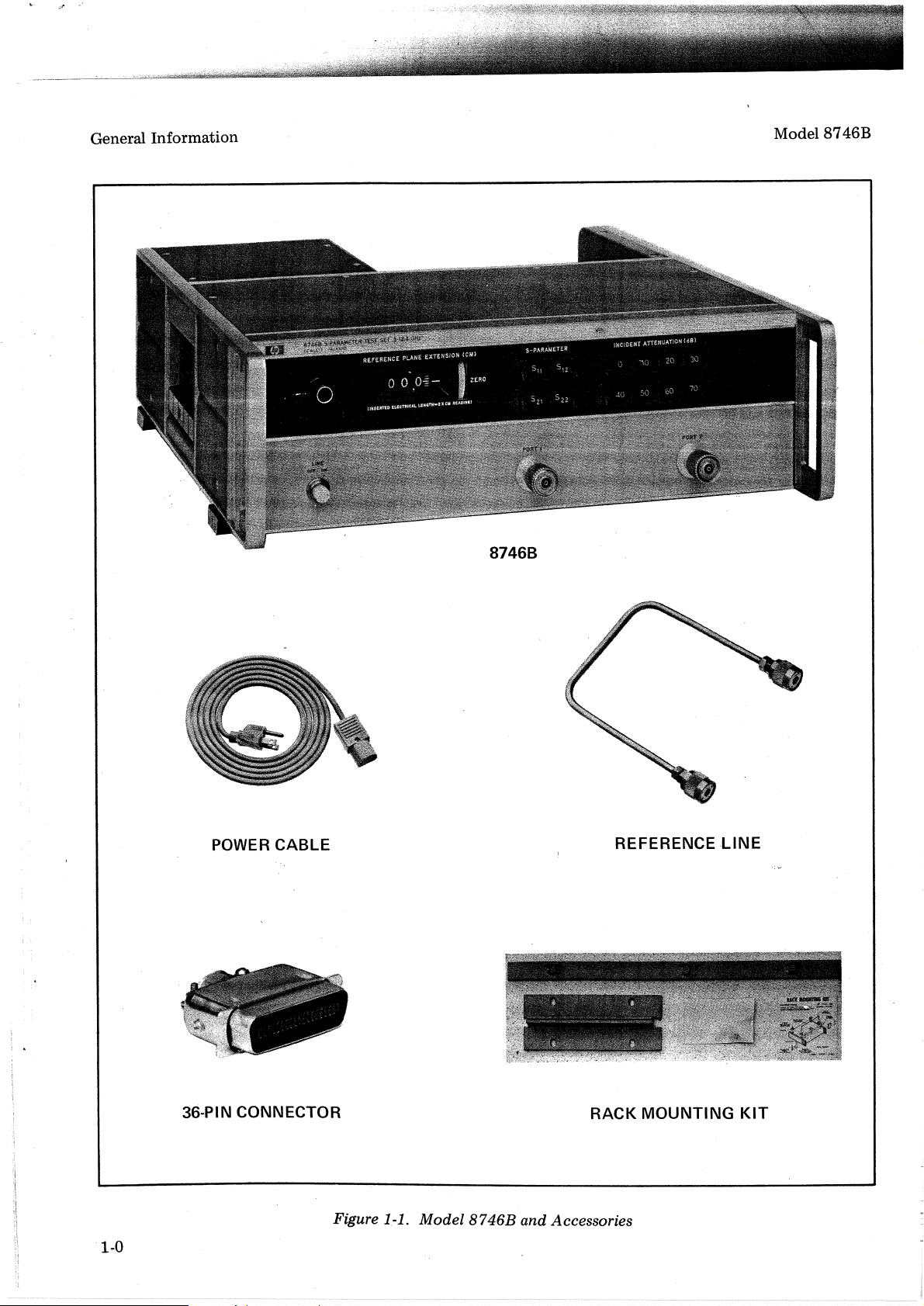

this

cable furnished will

measurements

Transistor

ware

cables

paragraph

ther

1-25.

Fixture.

measurements

may

need

entitled

information.

EQUIP~ENT

with

enable

the

youtomake

8746B

using

the

When making microwave hard-

other

to

be

"Equipment

reference-line coaxial

substituted.

Refer

Available"

REQUIRED BUT NOT

SUPPLIED '

1'~26.

The

Model

ph'ase-amplitude

Model

Model

8410ANetwork

8405A

1-27. EQUIPMENT

ratio

Vector

87

46Bmust

indicator,

Analyzer

Voltmeter.

AVAILABLE

be

such

System

used

as

1-28. Model 11608A Transistor Fixture

1-29.

Transistors are

by

usinganadditional

Model

Refer

operating

11608A

to

the

instructionsonthis

Model

tested

fixture,

Transistor

11608A

with

the

the

Hewlett-Packard

Fixture

Operating

transistor

Model

(Figure 1-2).

fixture.

1-30. Other .Reference Line Coaxial Cables

transistor

11608A

to

the

for

fur-

with

the

HP

or

the

8746B

Note

for

a

1-24. A rack-mounting

No.

8120-1348),

Part

No.

11604-20021),

furnished

with

rack-mounting

to

adapt

the

in

equipment

Instructions

included

with

a reference line coaxial cable (HP

the

8746B.

kit

contains

Model

racks

for

8746B

with

conversiontorack

the

kit.

kit,apower

and

a 36-pin

cable (HP

connector

(See Figure 1-1.)

all

the

hardware needed

cabil1et

standard

for

19-inch spacing.

mounting

The

reference line coaxial

Part

are

The

installation

are

1-31.

The

reference line coaxial cable furnished

with

the

8746B

teststobe

To

make

hardware,

Part

No.

wave transmission

allows transmission

madeontrap.sistors using

reflection

the

measurements

useofa

shorter

08745-20064)isrecommended.

measurements

a longer reference line (HP

Unless

the

port

spacingonthe

and

the

on

reference line (HP

require

Part

No.

08746-20031).

device

reflection

11608A.

microwave

Micro-

the

use

under

test

of

is

1-2

Figure

1-2. Model

11608A

Transistor

Fixture

Mountedona

Model

8746B

Page 10

Model

the

a Flexible Arm HP Model

8746B

same asonthe

8746,anadditional

11605A,

sary.

1-32. Model 11605A Flexible

1-33.Ifthe

not

the

port

same as

spacingofthe

thatofthe

Arm

device

Model

component,

willbeneces-

under

test

8746B,

a Flexi-

General

ble

Arm,

Hewlett-Packard Model

be

usedonone

the

other

11605A

three

is

almost

consistsofthree

swivel-adapters.

any

nectedtothe

port

port

connectedtothe

coaxial

8746B.

t.J!o.

·of

the

rotary-arms

'rhis

two-port

device

configuration

device to.

11605A,

under

8746B.

connected

Information

should

test

with

The

Model

by

allows

be

con-

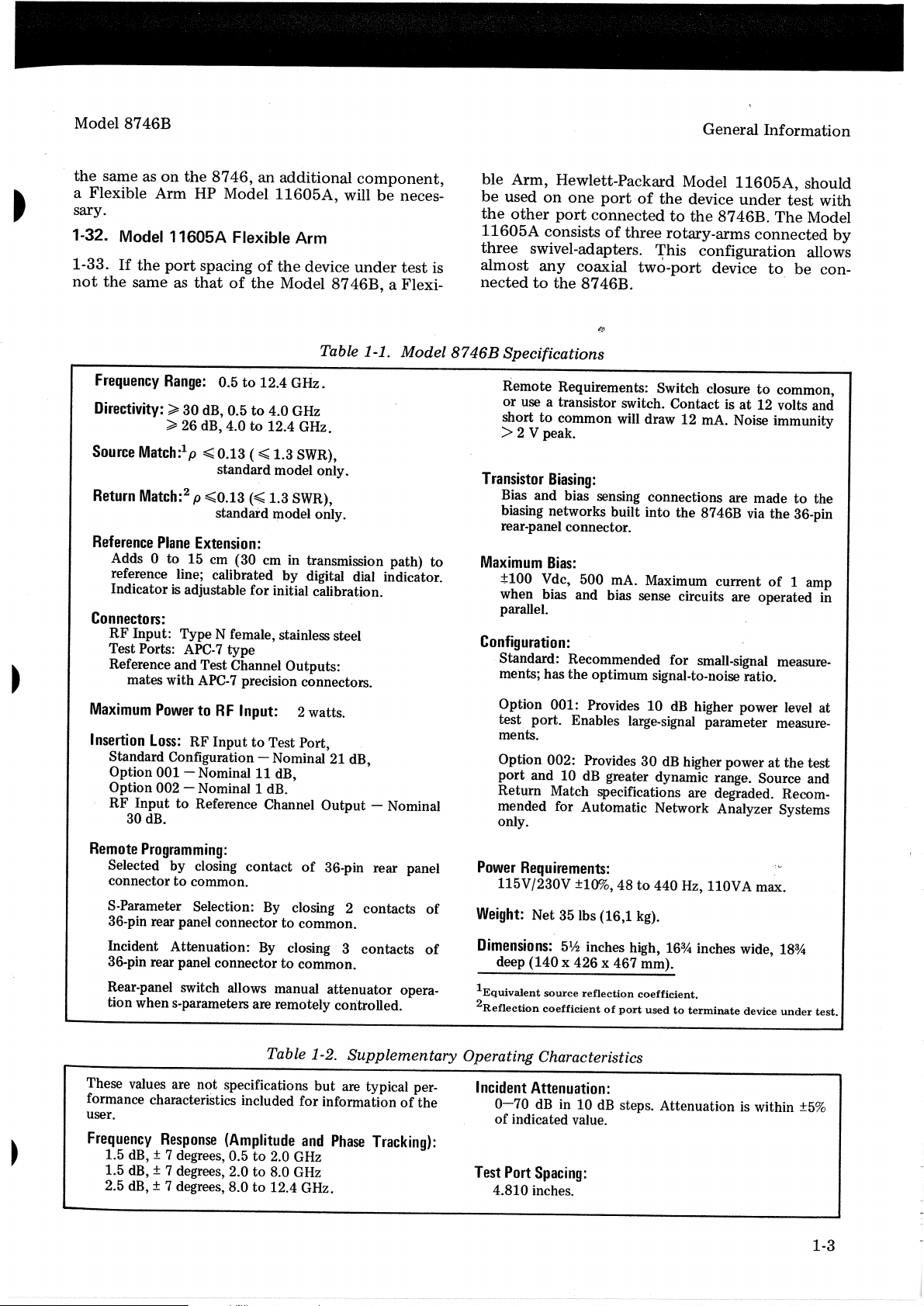

Table 1-1. Model

Frequency

Directivity:

Source

Return

Reference

Adds 0 to 15 cm (30 cm in transmission path)

reference line; calibrated by digital dial indicator.

Indicator

Range:

~

~

Match:

Match:

Plane

0.5to12.4 GHz.

30 dB, 0.5to4.0 GHz

26 dB, 4.0to12.4 GHz.

1

p

~

0.13 (~1.3 SWR),

standard model only

2

p

~0.13

standard model only.

Extension:

is

adjustable for initial calibration.

(~

1.3 SWR),

..

Connectors:

RF Input: Type N female, stainless steel

Test Ports:

Reference and Test Channel Outputs:

mates with

Maximum

Insertion

Standard Configuration - Nominal 21 dB,

Option

Option 002 - Nominal 1 dB.

RF Input

30 dB.

APC-7

type

APC-7

precision connectors.

PowertoRF

Loss:

RF InputtoTest Port,

001-

to

Input: 2 watts.

Nominal 11 dB,

Reference Channel Output - Nominal

to

8746B

Transistor

Maximum

Configuration:

Specifications

to

Remote Requirements: Switch closure

or use a transistor switch. Contactisat

shorttocommon will draw 12 rnA. Noise immunity

common,

12 volts and

>2 V peak.

Biasing:

Bias and bias sensing connections are madetothe

biasing networks built into the 8746B via the 36-pin

rear-panel connector.

Bias:

±100 Vdc, 500 rnA. Maximum currentof1 amp

when bias and bias sense circuits are operated in

parallel.

Standard: Recommended for small-signal measurements; has the optimum signal-to-noise ratio.

Option 001: Provides

test port. Enables large-signal parameter measurements.

Option 002: Provides 30dBhigher power at the test

port and 10

Return Match specifications are degraded. Recommended for Automatic Network Analyzer Systems

only.

dB

10dBhigher power level at

greater dynamic range. Source and

Remote

Programming:

Selected by closing contact

connectortocommon.

S-Parameter Selection:

36-pin rear panel connectortocommon.

Incident Attenuation:

36-pin rear panel connectortocommon.

Rear-panel switch allows manual attenuator opera-

tion when s-parameters are remotely controlled.

of

36-pin rear panel

By

closing 2 contacts

By

closing 3 contacts

of

of

Table 1-2. Supplementary Operating Characteristics

These values are not specifications but are typical performance characteristics included for informationofthe

user.

Frequency

1.5

1.5

2.5

Response

dB,

± 7 degrees, 0.5

dB,

± 7 degrees, 2.0to8.0

dB,

± 7 degrees, 8.0to12.4 GHz.

(Amplitude

to

2.0

and

GHz

GHz

Phase

Tracking):

Power

Requirements:

115V/230V ±10%,48to

Weight:

Dimensions:

lEquivalent

2Reflection

Incident

Test

Net 35 lbs (16,1 kg).

5th inches high,

deep (140 x 426 x 467 mm).

source

reflection

coefficientofport

Attenuation:

0-70

dB

of

indicated value.

Port

4.810 inches.

in 10dBsteps. Attenuationiswithin

Spacing:

440 Hz, 110VA max.

163~

inches wide,

coefficient.

usedtoterminate

device

183~

under

test.

±5%

1-3

Page 11

General

Information

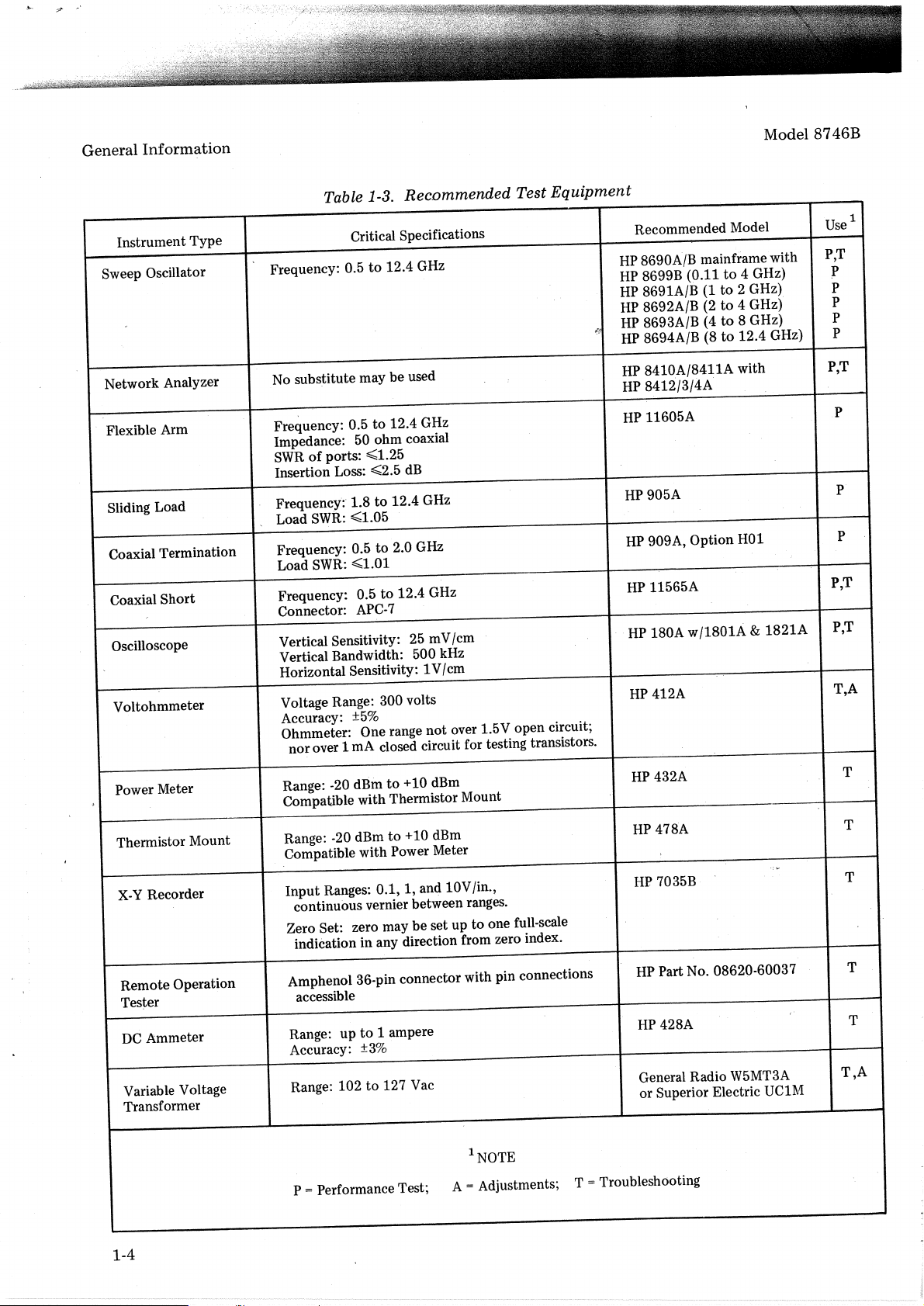

Instrument Type

Sweep Oscillator

Table

Frequency: 0.5

Rec.ommended Test Equipment

1-3.

Critical Specifications

12.4 GHz

to

Recommended Model

8690A/B mainframe with

HP

8699B (0.11

HP

8691A/B

HP

8692A/B (2

HP

8693A/B (4

HP

t"0

8694A/B (8

HP

4 GHz)

to

2 GHz)

to

(1

4 GHz) P

to

8 GHz)

to

12.4 GHz) P

to

Model

8746B

Use

P,T

;P

P

P

1

Network Analyzer

Flexible Arm

Sliding Load

Coaxial Termination

Coaxial Short

Oscilloscope

Voltohmmeter

Power Meter

No substitute may be used

12.4 GHz

Frequency: 0.5

to

Impedance: 50 ohm coaxial

SWR

Insertion Loss:

Frequency:" 1.8

~1.05

SWR:

Load

Frequency: 0.5

~1.01

SWR:

Load

Frequency: 0.5

~2.5

12.4 GHz

to

2.0 G

to

12.4 GHz

to

dB

Hz

~1.25

ports:

of

Connector: APC·7

Vertical Sensitivity: 25 mV/crn

Vertical Bandwidth: 500 kHz

Horizontal Sensitivity: 1V/cm

Voltage Range: 300 volts

Accuracy:

±5%

Ohmmeter: One range not over 1.5V open circuit;

norover 1 rnA closed circuit for testing transistors.

+10 dBm

Range: ·20 dBm

to

Compatible with Thermistor Mount

8410A/8411A with

HP

8412/3/4A

HP

11605A

HP

905A

HP

909A, Option

HP

11565A

HP

/1801A

w

l80A

HP

412A

HP

432A

HP

HOI

&

1821A

P,T

P

P

P

P,T

P,T

T,A

T

Thermistor Mount

Recorder

x·y

Remote Operation

Tester

Ammeter

DC

Variable Voltage

Transformer

1-4

+10 dBm

Range: ·20 dBm

to

Compatible with Power Meter

Input Ranges: 0.1, 1, an4 10V/in.,

continuous vernier between ranges.

Zero Set: zero may be set up to one full·scale

indication inany direction from zero index.

Amphenol 36·pin connector with pin connections

accessible

1 ampere

Range: up

Accuracy:

Range: 102

=

P

to

±3%

Vac

127

to

Performance Test; A

NOTE

1

Adjustments;

=

T

478A

HP

7035B

HP

Part No. 08620·60037

HP

428A

HP

General Radio W5MT3A

or Superior Electric

Troubleshooting

=

v

.:

UC1!\1

T

T

T

T

T,A

Page 12

Model

8746B

Installation

2-1.

INITIAL

INSPECTION

2-2. Mechanical Check

2-3.Ifdamagetothe

ask

that

the

carrier's

instrumentisinpacked.

mechanical

material

damage.

for

signsofsevere stress.

shipping

agent

Inspect

Also,

2-4. Electrical Checks

2-5.

The

should

suitable

IV,

.

performance

be

Perf.ormance

electrical

verified

for

incoming

testislistedinTable

performance

on

receipt.Aperformance

inspection

Test.

Equipment

2-6. Claims for Damage

2-7.Ifthe

in

transit,

Hewlett-Packard

shipping

rier's

replacement

waiting

2-8.

sp,ected

defects.Ifthereisany

cal

performanceisnot

your

Model

carton

inspection.

for

claims

Before

and

Hewlett-Packard

8746Bismechanically

notify

office

and

The

or

repairofyour

settlement

shipment,

found

freeofelectrical

the

carrier

immediately.

packing

HP

office

this

deficiency,orif

within

office.

2-9. PREPARATION FOR'USE

2-10. Power Requirements

cartonisevident,

be

present

the

instrument

check

against

the

cushioning

of

Model

is giveninSection

required

1-3.

and

the

Retain

material

instrument

instrument

specification,

will

the

and

for

arrange

carrier.

mechanical

the

SECTION

II

INSTALLATION

d.

e.

the

switch

tion.

when

8746B

test

for

damaged

nearest

the

car-

without

was in-

electri-

notify

the

for

the

the

for

and'the

f.

g. Slide

h.

2-14. THREE-CONDUCTOR

2-15.

Electrical

ommends

grounded.

equipped

when

grounds

3-prong

wire.

2-16.

operating

put,

the

pigtailonthe

2-17. OPERATING ENVIRONMENT

2-18.

Model

but

from0to

humidity

Remove

With

a~f.screwdriver

arm

with

The

right-hand

left-hand

Replace

clear

Replace

To

protect

Manufacturers

that

the

All

Hewlett-Packard

witha3-conductor

plugged

the

connectorofthe

To

use a

The

8746Bisroom

it

will

up

into

instrument.

preserve

the

instrument

3-prongto2-prong

normal

operate

+55

degreesC.It

to

95%.

fuse.

or

pointed

the

arrowto115or230

positionisfor

positionisfor

fuse

withafuseofcorrect

plastic

power

cable.

230

covertoright.

POWER

operating

instrument

the

adaptertoground.

operating

personnel,

Association

panel

power

an

appropriate

The

offset

power

protection

temperature

to

its

cableisthe

froma2-connector

adapter

environment

specified

will

tool,

115

volt

volt

input~

CABLE

the

National

(NEMA)

and

cabinet

instruments

cable

receptacle,

pin

on

ground

feature

and

connect

for

(25.:elegrees

performance

operate

move

posi-

input

value.

rec-

be

are

which,

the

when

out-

the

C),

in

any

2-11.

The

115or230

power.

2-12.

2-13.

combination

holder,

input

Power

115/230

This

and

voltage

a.

Remove

b.

Slide clear plastic

c. Pull

Model

8746B

Vac ±10%,48to

consumption

Volt

Operation

instrument

input-voltage

circuit

outonhandle

has a

of

power-cable

proceed

power

requiresapower

400

Hz,

is less

than

power

switch.

cable.

coverofmoduletoleft.

marked

module

receptacle,

as follows:

source

single-phase

110

To

change

"FUSE

VA.

that

is a

fuse

the

PULL".

of

2-19.

The

bench

make

when

instrument

operation.

full-width

stacked.

cabinet

The

plastic

modular

has

feet

instruments

2-20. STORAGE AND SHIPMENT

2-21. Packaging

2-22. Original-Type Packaging.

packing

factory

Packard

line,

ping

servicing

materials

are

available

office.

wrapitseparately,

container.Ifthe

and

Remove

repair,

identical

through

attachatag

to

those

your

the

rear-panel

and

includeitin

8746Bisbeing

indicating

plastic

are

Containers

nearest

feet

shaped

self-aligned

used

Hewlett-

reference

the

returned

by

type

for

to

and

the

ship-

for

of

'2-1

Page 13

Installation

Model

8746B

service

ment

required,

serial

"FRAGILE"

respondence

instrument

the

number.

serial

return

full

number.

assure careful handling.

to

regarding

its full HP

by

address,

A.lso

your

2-23. Other Packing Materials.

instructions

eral

commercially available materials:

with

Remove

a.

separately,

it

wrap

container.

plastic.

office

service

full serial

and

Wrap

(If

center,

or

required,

should

the

the

shipping

attach

return

number.)

be

rear-panel reference line,

include

and

instrument

a Hewlett-Packard service

to

tag

a

address,

and

mark

instrument,

model

following gen-

The

for

used

in

it

heavy

in

indicating

model

full instru-

box

the

cor-

any

In

refer

number

and

repackaging

shipping

the

paper

type

the

number,

to

or

of

b. Use a

carton

wall

adequate.

c. Use

4 inch layer)

to

provide

to

inside

the

cardboard.

d.

e.

assure

to

strong

made

enough

shipping

of

shock-absorbing

around

cushion

firm

container.

Protect

Seal the·shipping

shipping

the

Mark

careful

handling.

container.

lb.

350

all sides

and

the

container

container

test

the

of

prevent

control

securely.

A double-

material

material

instrument

movement

with

panel

"FRAGILE"

is

(3

2-2

Page 14

Model

8746B

Operation

3-1. INTRODUCTION

The

3-2".

S-Parameter Test

and

adapters, a signal source,

phase-amplitude

Model

Vector

tem

for

transistor

performed

.quencies, from

the

HP

ments

less.

The

below

combination

Set

ratio

8410A

Network

Voltmeter· (see Figure 3-1)

measuring s-parameters

or

device. These

at

single frequencies

0.5

to

Model

are

500

8405A

limitedtosingle frequenciesof1 GHz

Model

8746B

MHz; however, coupling

SECTION

OPERATION

of

the

Model 8746B.

with

its accessory fixtures

andacompatible

indicator,

AnalyzerorModel

12.4

Vector

canbeusedatfrequencies

SIGNAL

SOURCE

I

SW.EEP

OUTPUT

:

VOLTAGE

I

~--------

I

I

I

:

I

I INPUT:

L - - - - - - - -

such

as

m~ke

of

almost

measurements

or

at

swept

GHz.

When used

Voltmeter,

attenuation

INPUT

FOR

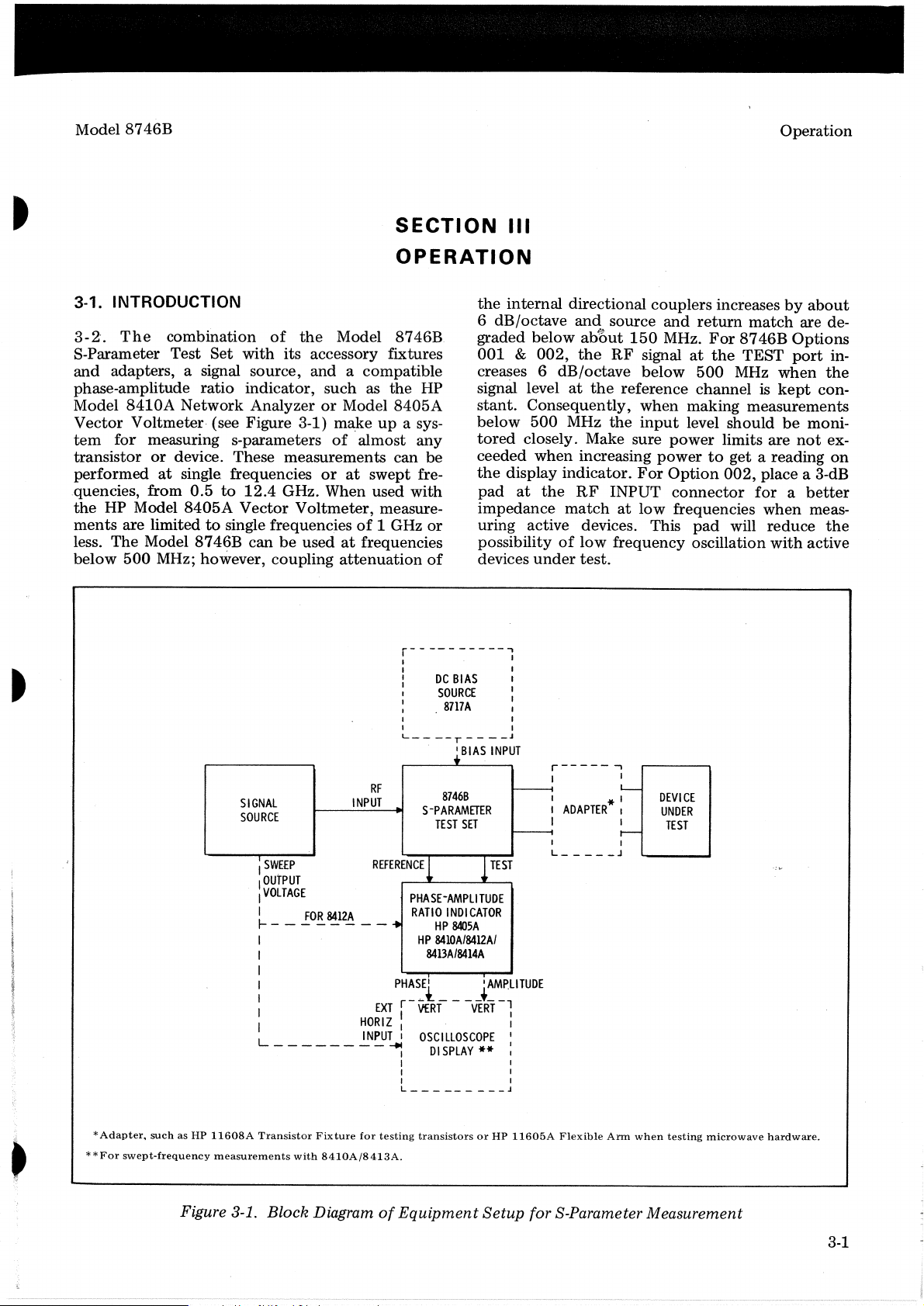

8412A

HORIZ

the

8405A

up

a sys-

can

with

measure-

r----------~

I I

I

I I

:

I

I I

I I

L----r----J

RF

...

REFERENCE

PHASE-AMPLI

RATIO

..

PrH~~~

EXT

I I

~

I I

I I

I I

L J

the

6

graded

001

creases 6

HP

sign3J.

stant.

below

any

be

fre-

tored

ceeded

the

pad

impedance

or

uring active devices. This

possibilityoflow

DC

BIAS

SOURCE

8111A

.BIAS

8146B

TEST

SET

devices

of

S-PARAMffiR

1 1

TUDE

INDICATOR

HP

8405A

HP

8410A/8412AI

8413A/8414A

~~M!l·11TUDE

VERT

OSCILLOSCOPE

01

SPLAY

VERT

** :

III

internal

dB/octave

&

display

at

I

f

I

INPUT

~

------i

TEST

I

I

directional

and

below

002,

at>6ut

the

dB/octave

level

at

Consequently,

500

MHz

closely. Make sure

when

increasing

indicator.

the

RF

matchatlow

under

test.

r-----

I I

I * I

I

ADAPTER

I I

I I

L J

source

RF

the

reference

the

INPUT

frequency

-,

L-

I

r--

couplers

and

150

MHz.

signalatthe

below

when

input

making

level

power

powertoget

For

Option

connector

frequencies

pad

oscillation

DEVICE

UNDER

TEST

increasesbyabout

return

500

For

match

8746B

TEST

MHz

Options

port

when

channeliskept

measurements

should

limits are

be

not

a reading

002,

place a 3-dB

forabetter

when

will

reduce

with

are de-

in-

the

con-

moni-

ex-

on

meas-

the

active

*

Adapter,

**For

suchasHP

swept-frequency

Figure 3-1.

11608A

Transistor

measurements

with

Block

Fixture

for

testing

transistorsorHP

8410Aj8413A.

DiagramofEquipment

Setup

11605A

Flexible

Ann

when

testing

for S-Parameter Measurement

microwave

hardware.

3-1

Page 15

Operation .

Model 8746B

3-3. PANEL FEATURES

3-4.

Front

and

indicators are described in Figures 3-2

In

these figures

keyed

to

and

rear

panel controls, connectors,

the

numbersonthe

the

description numbers.

3-5. OPERATING PRECAUTIONS

3-6.

Maximum

3-7. Powerinexcessof2

INPUT

under

the

power

3-8.

jack

test

instrument.

limitofthe

RF

PowertoTest Device

or

into

RF Power

returned

PORT'l

Also,

associated

watts,

from

or

PORT2may

do

not

network

CAUTION

Do

NOT use excessive

the

device

cause

collector

power,

under

the

transistor

current

investigate

RF

test.

Too

to

oscillate.

varies

the

possibilityofoscil-

lation.

On

3-9.

device

internal

channel

all models

under

step-attenuator

output.

test

When

of

may

the

the

8746B,

be

decreased using

without

standard

step-attenuatorissettozero,

under

level and

mately

attenuatorissettozero,

te~t

, level.

to

same levelasthe

and

,

at

s-parameter configurations are

The

test

is approximately 21

poweratthe

31

is approximately

For

zero,

powertothe

002,

with

constant,

powertothe

dB

down.

Option

the

reference channel is approxi-

For

11

002,

RF

input.

poweratthe

approximately 6 dB/octave

circuits

for

the

same circuits

standard

for

Option

powertothe

dB below

when

device

For

device

model

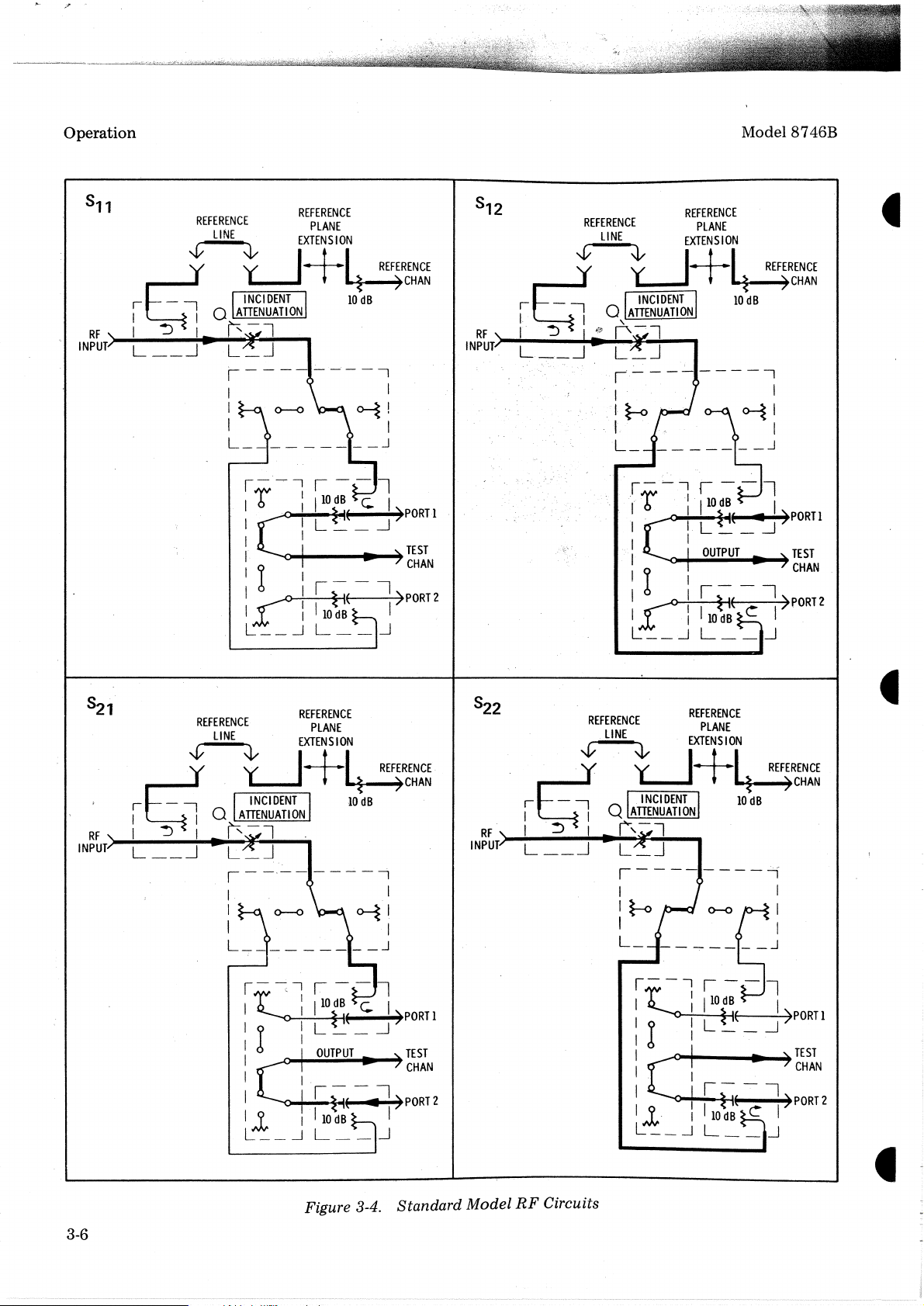

showninFigure 3-4.

Options

shown in Figure 3-5.

3-10. MaximUITI DConRF Lines

3-11. DC voltages

transmission lines in

exceed ±

100

volts as

on

the

inner

the

Model

the

insulationofthe

capacitors may break down. Do

than

0.5

amponeither BiasorBias Sense leads.

and

illustration are

either

into

the

an active device

damage

exceed

the

analyzer.

input

much

with

power

RF

RF

may

If

input

to

the

powertothe

reducing reference

8746B

powertothe

dB

below

001,

internal

device

RF

when

device

the

RF

the

attenuatorisset

under

under

below

testisat

both

Options 001

reference

test

500

8746B

001

and

port

increases

MHz.

in all

002

conductorofthe

8746B

must

internal

not

draw

3-3.

RF

input

the

input

the

under

input

the

held

RF

are

not

more

if

the

properly

tion

trace are less

pushbuttons

not

calibrate properly, refer

amplitude variations in

function normally.Ifthe8746B will

than

2.5dBl

to

the

calibra-

and

the

8746B

Section VIII, Ser-

vice.

3-14. OPERATING INSTRUCTIONS

General Measurement Description

3-15.

3-16. The Model

be

.usedtomake

binations

of

fied block diagram

Figure 3-1.

tude

ratio indicator, suchasthe

HP

8410A/8411A

external oscilloscope,

tions

for

using

Figures 3-9

modified for use

the

Operating

and adapting

operation

tested

sistor

transistor

nents also

the

at

by

connecting

Fixture

under

maybetestedinthe

physical limits

exceeded. Consult

office. Microwave hardware

the

S-Parameter Test

Model

3-17.

11605A

The

following general

steps necessary when making measurements

8746B

measurements

S-Parameter

with

Test

Set

several com-

complementary equipment. A simpli-

ofatest

The'

display indicator is a .phase-magni-

with

or

the

8410A

and

3-10. These instructions

with

the

and

Service Manual

the

instructions for single-frequency

setupisshown

HP

8405Aorthe

8412A,

8414A

8413A

plug-in. Instruc-

system are given

8405A

by

for

with

can

referring

the

8405A

lower frequencies. Transistors are

the

HP Model

to

the

8746B

testinthe

of

the

nearest Hewlett-Packard

Setbyaccessories,

11608A.

the

may

~1608A

and.

inserting

Other

11608A,

11608A

be

connected

Tran-

compo-

providing

are

suchasthe

Flexible Arm. .

outline

explains

may

in

an

in

be

to

the

not

to

the

with

any combinationofequipment. These instructions

the

same

for

both

the

are

and 002 models

a.

If

swept-frequency phase measurements

are

to

be made,

line-lengths

must

of

the

the

be

standard and

8746B.

reference and

equaL

The

reference channel is adjusted

REFERENCE PLANE EXTENSION

length

cable

can

of

the

on

the

be

removed and

REFERENCE LINE coaxial

rear paneL The REFERENCE LINE

other

length reference lines

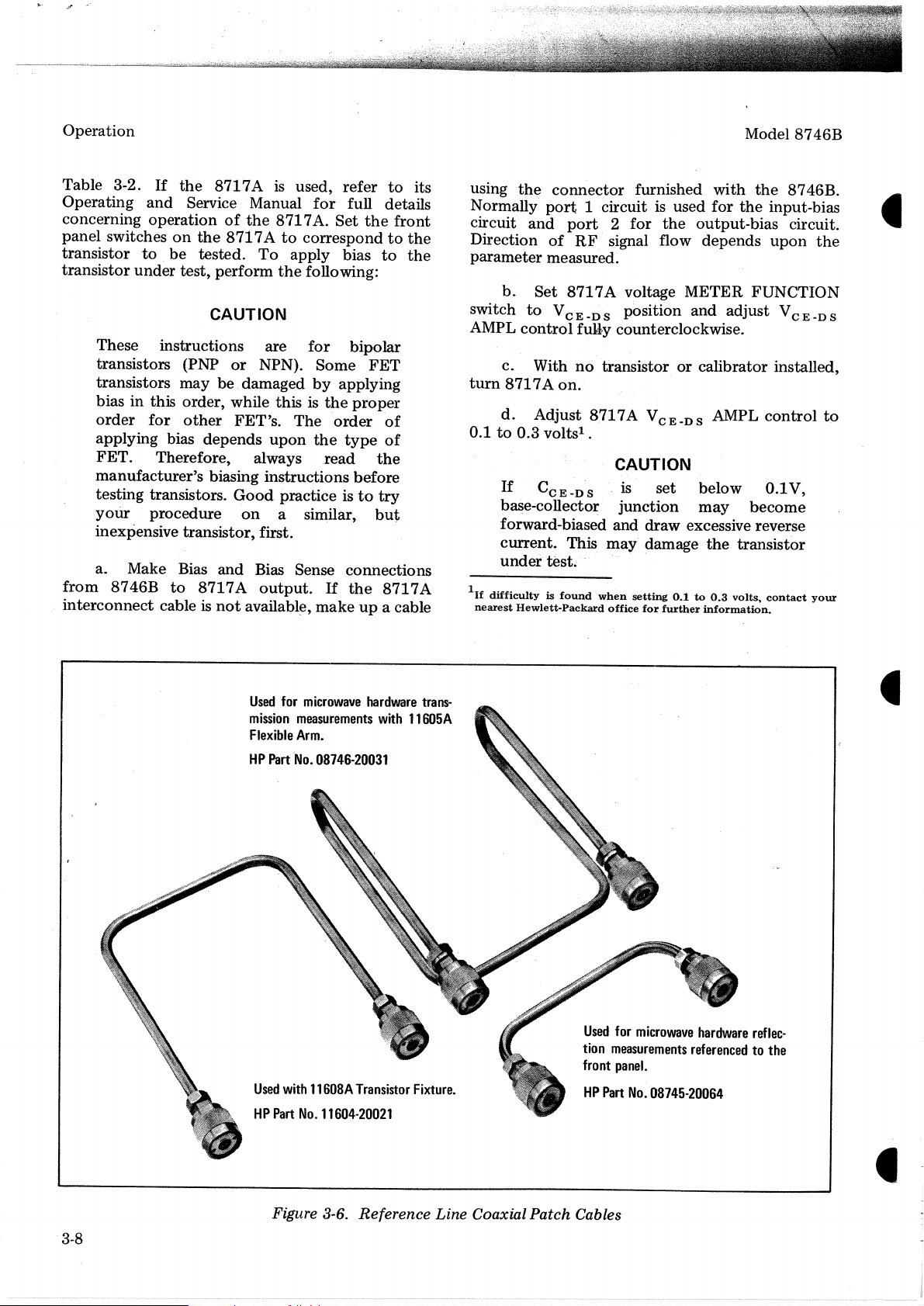

(see Figure 3-6) can be installed

equalize

To best utilize

SION range, install

ENCE LINE coaxial

the

test

and reference channel line lengths.

the

REFERENCE PLANE EXTEN-

oneofthe

patch

following

cables:

Option

I

test

channel

length

by

varying

and

to

approximately

REFER-

of

patch

001

the

the

the

TRANSISTOR FIXTURE (11608A): Use HP Part

No. 11604-20021 included with 8746B.

3-12. OPERATOR'S CHECK

3-13.

To

check

calibrate

the

the

calibration trace. The

the

system

8746B

for

a measurement. Observe

3-2

operation,

8746B

set

is

operating

up

to

INotchesof1dBat

causedbyresonancesofRF

approximately

700

chokesinthe

MHz

bias

are

input

normal.

leads.

They

are

Page 16

Model

8746B

Operation

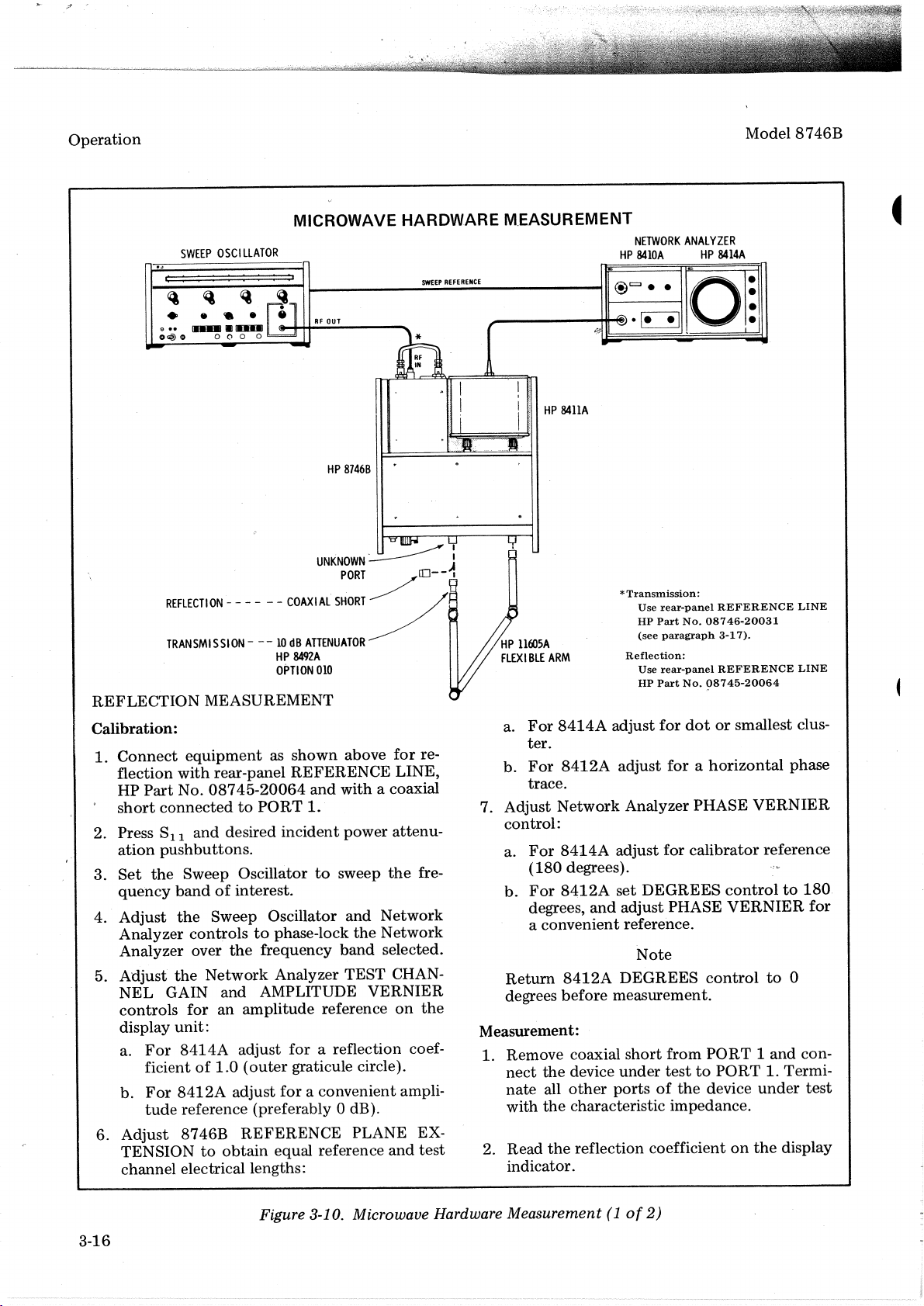

MICROWAVE HARDWARE:

Reflection:

Transmission

nated

in

Use HP

with

an

HP

Part

No.

Device

11605A:

08745-20064.

Under

Test

Use HP

08746-20031.

Note

When using

the

measurement

mismatch.

tor

(see Figure3-10)toreduce

the

Use a

11605A

the

accuracy

maybedegraded

10

dB isolating

mismatch.

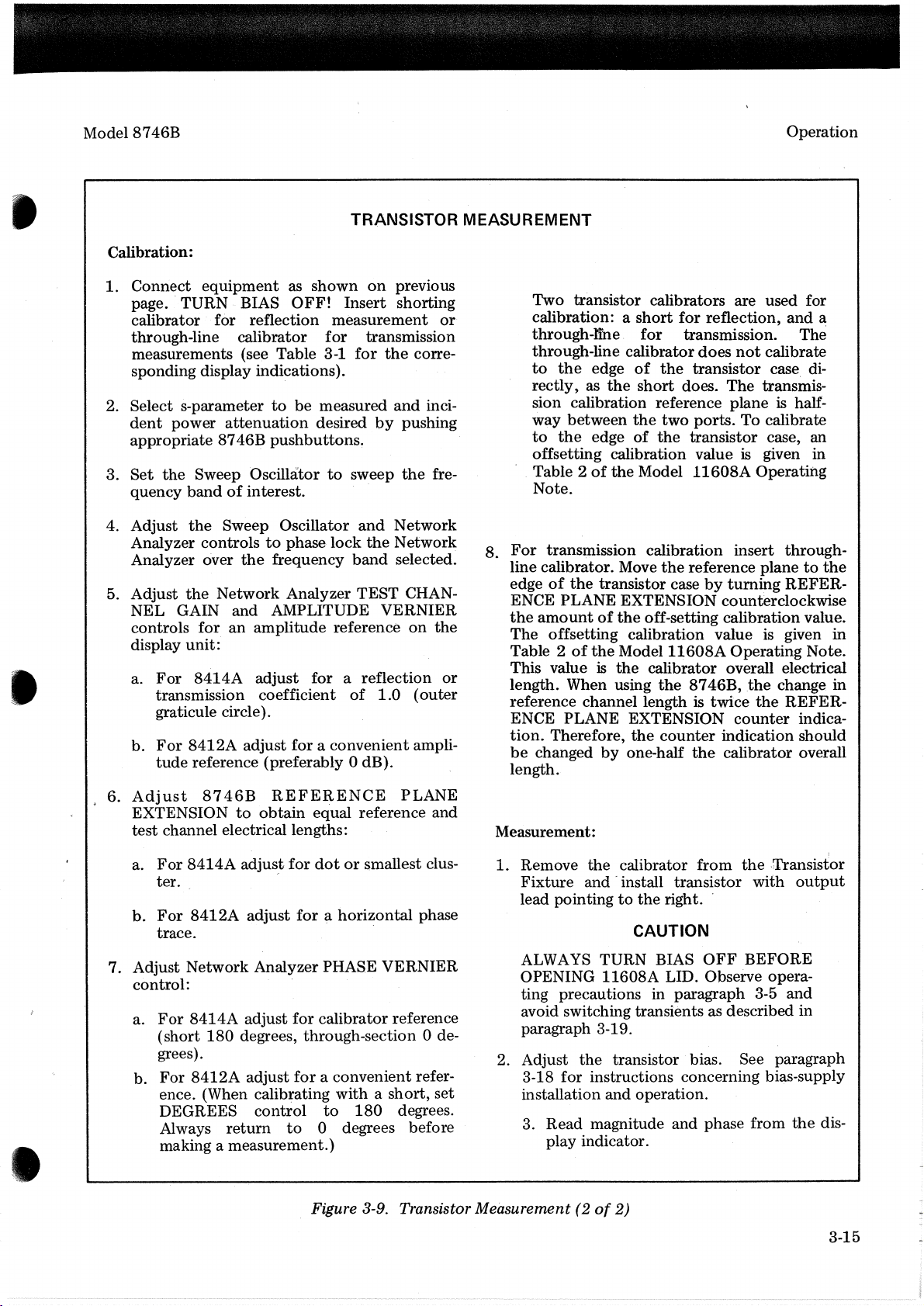

CALIBRATION

b.

Calibrate

.

urement

or

wave

short

by

through-line calibrator. When measuring micro-

hardware,

connected

measurements

ofa11605A

ing

for

transmission measurements.

1..

Balance

ence

REFERENCE

obtain

quency

.

the

system

terminat~ng

calibrate

to

the

or

a through-line

connected

the

electrical

and

test

for

the

11608A

the

8746B

test

between

channels

PLANE

the

least phase change

indication

on

s-parameter

with

port

for

calibrator

the

lengthofthe

by

adjusting

EXTENSION

the

display indica-

tor.!

2.

Adjust

tor

to

Table

for

the

3-1.

the

controls

a display

calibrator

on

the

display indica-

indication

corresponding

being used as shown

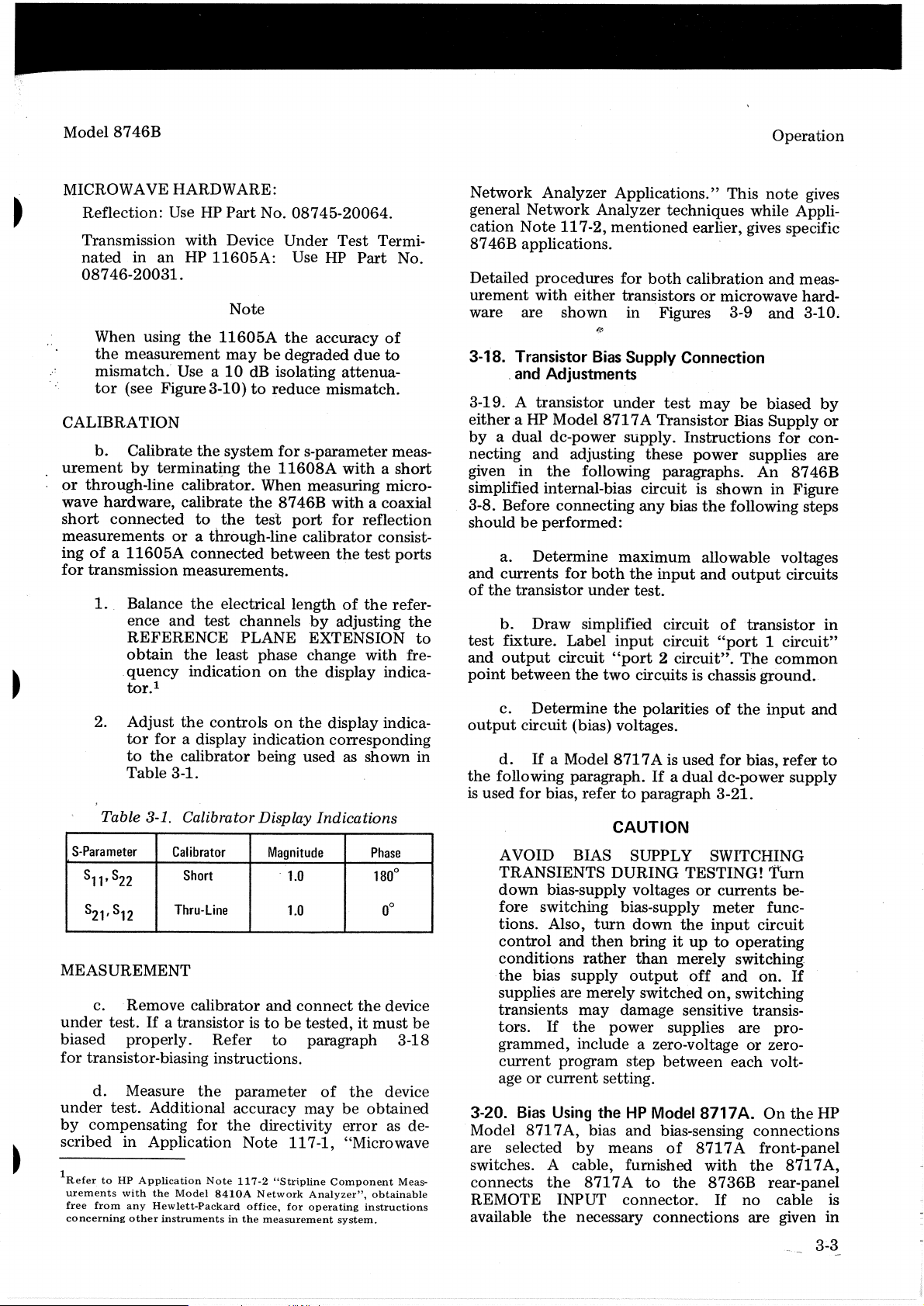

Table 3-1. Calibrator Display Indications

S-Para

meter

S11,S22

S21,S12

Calibrator

Short

Thru-line

Magnitude

.

1.0

1.0

MEASUREMENT

c.

Remove

under

biased

for

under

by

scribed

1RefertoHP

test.Ifa

properly.

transistor-biasing instructions.

d.

Measure

test.

compensating

in

from

Application

with

any

other

urements

free

concerning

calibrator

and

connect

transistoristobetested,itmust

Refer

the

Additional

for

Application

the

Hewlett-Packard

Note

Model

8410A

instrumentsinthe

to

parameter

accuracy

the

directivity

Note

117-2

"Stri.pline

Network

office,

measurement

paragraph 3-18

of

may

117-1,

Component

Analyzer",

for

operating

Termi-

Part

No.

of

due

to

attenua-

meas-

withashort

a coaxial

reflection

consist-

test

ports

refer-

the

with

fre-

Phase

0

180

0

0

the

device

the

device

be

obtained

error

as de-

"Microwave

Meas-

obtainable

instructions

system.

to

in

be

Network

general

cation

8746B

Detailed

urement

ware are

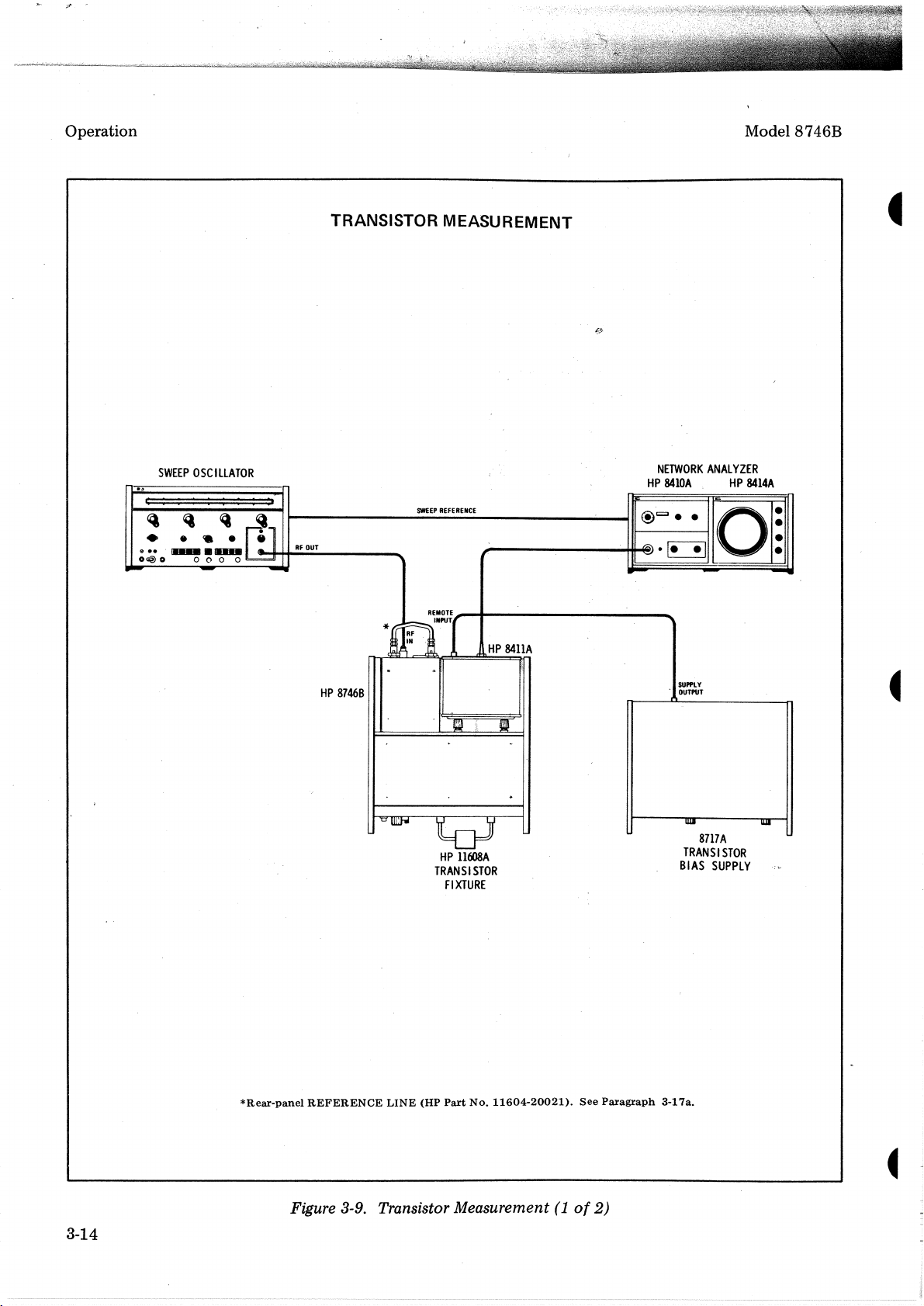

3-18. Transistor

3-19. A

either

byadual

necting

given

simplified internal-bias

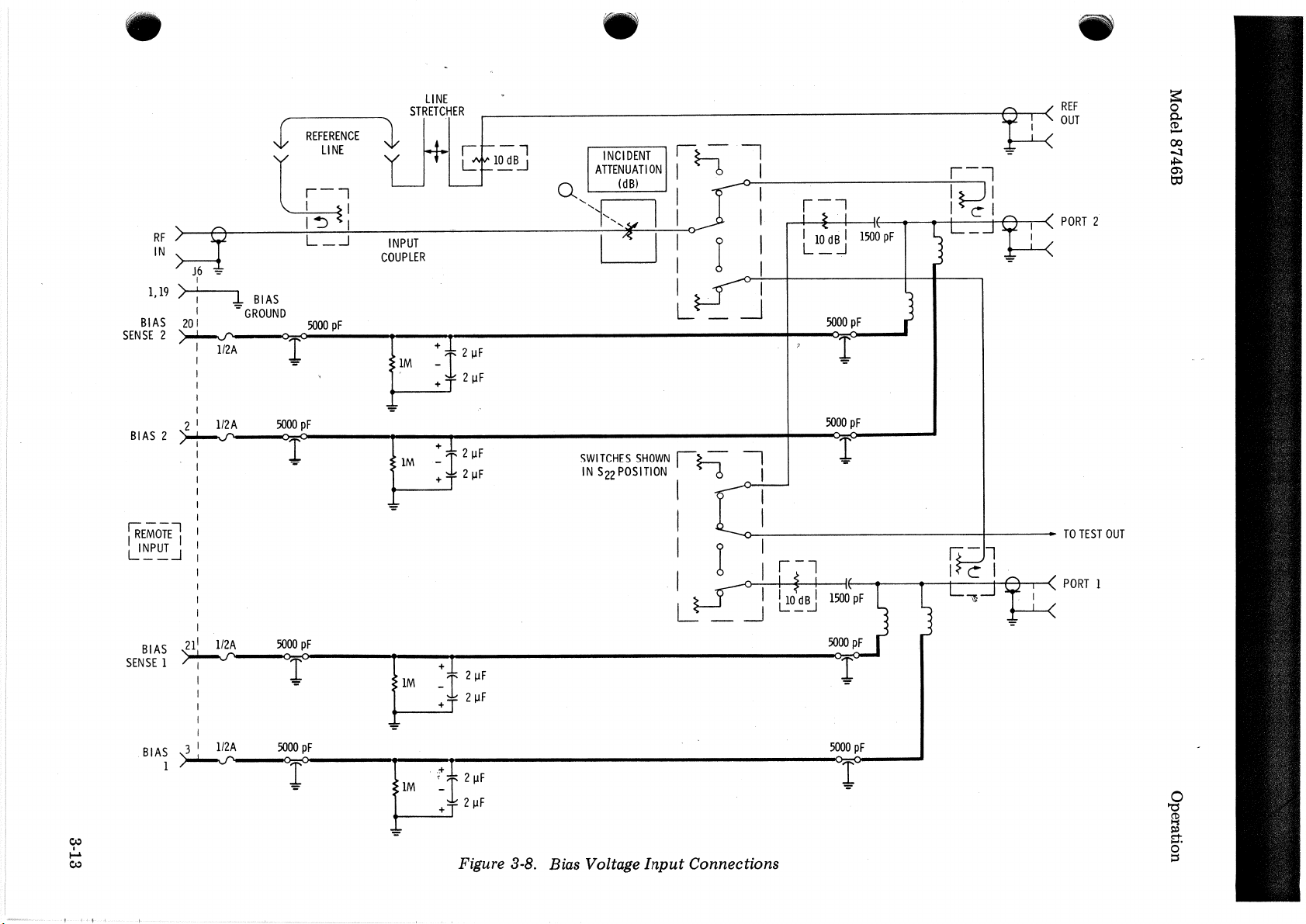

3-8. Before

should

and

of

the

test

and

point

output

the

is

used

Analyzer

Network

Note

117-2,

Applications."

Analyzer

mentioned

applications.

procedures

with

and

Adjustments

.

transistor

a HP

and

in

the

shown

Model

dc-power

adjusting

for

both

either

transistorsormicrowave

in

Figures 3-9

Bias

Supply

under

871

test

7A Transistor Bias

supply.

these

following paragraphs.

circuitisshowninFigure

be

performed:

a.

Determine

currents

transistor

b.

Draw

fixture.

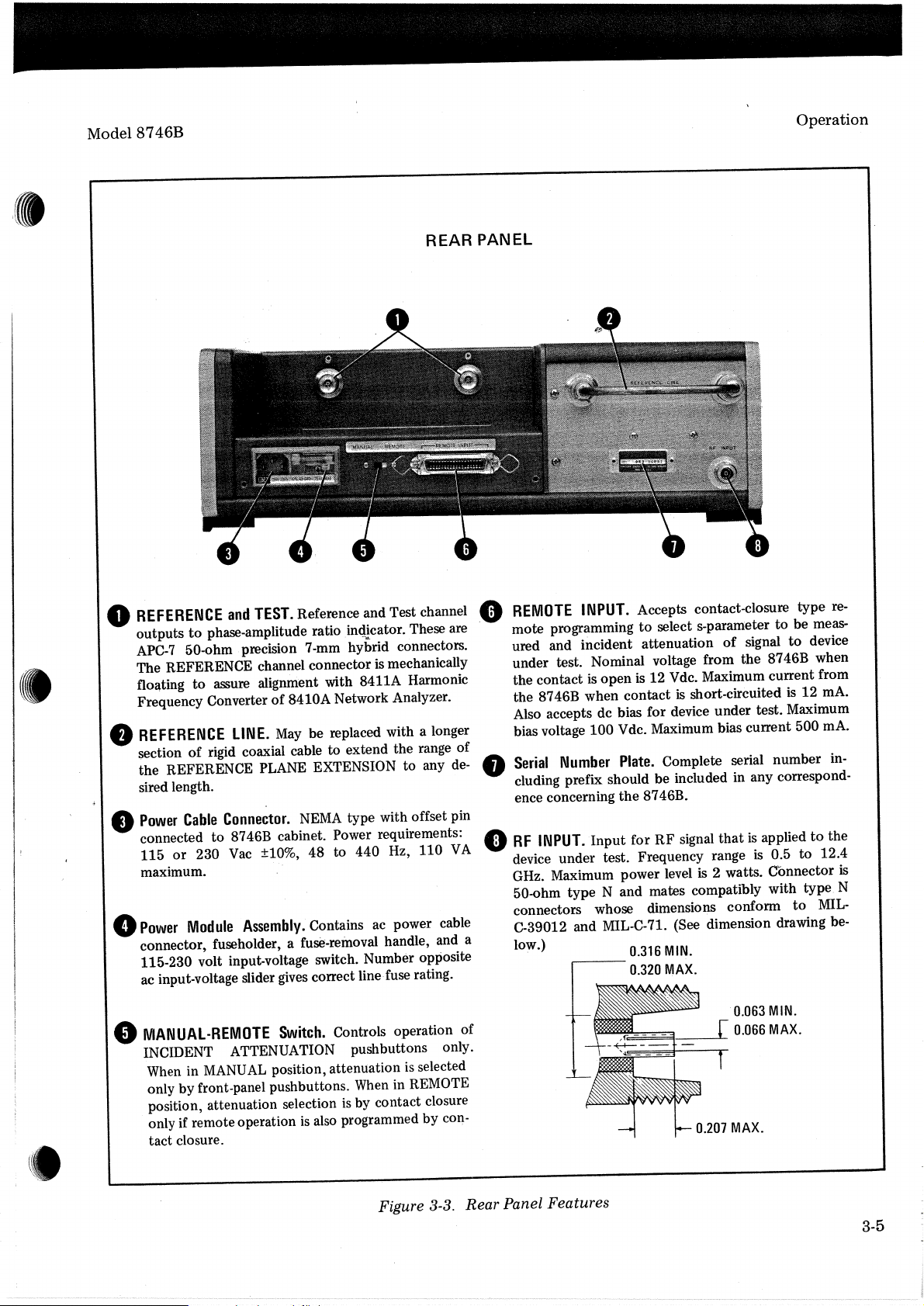

output

between

c.

Determine

circuit

d.

If

connecting

for

both

under

simplified

Label

circuit

the

(bias) voltages.

a Model

any

maximum

the

input

test.

circuit

input

circuit

"port2circuit".

two

circuits is chassis

the

polaritiesofthe

8717

A is used

following paragraph.Ifa

for

bias,

refertoparagraph

This

techniques

earlier, gives specific

calibration

Connection

may

Instructions

power

bias

the

following steps

allowable voltages

and

of

"port1circuit"

for

dual

dc-power

3-21.

CAUTION

AVOID BIAS SUPPLY SWITCHING

TRANSIENTS

down

fore

tions.

control

bias-supply voltagesorcurrents

switching bias-supply

Also,

and

conditions

the

bias

supplies are merely

transients

tors.

If

grammed,

current

age

3-20.

Model

program

or

current

Bias

Using theHPModel 8717

871

7A, bias

are selected

switches. A cable, furnished

connects

the

REMOTE INPUT

available

the

DURING

TESTING!

meter

turn

then

rather

supply

may

the

down

bringituptooperating

output

damage sensitive transis-

power

the

than

merely

switched

supplies

off

input

and

on,

include a zero-voltageorzero-

step

between

setting.

and

bias-sensing

by

means

of

8717Afront-panel

with

8717Ato

connector.

necessary

the

8736B

If

connections

note

while Appli-

and

and

be

biased

Supply

for

supplies are

An

8746B

output

circuits

transistor

The

common

ground

input

bias,

refer

supply

Turn

be-

func-

circuit

switching-

on.

switching

are

pro-

each volt-

A.

On

the

connections

the

871

rear-panel

no

cable is

are given

gives

meas-

hard-

3-10.

by

or

con-

in

.

and

to

If

HP

7A,

in

3~3

Page 17

Operation

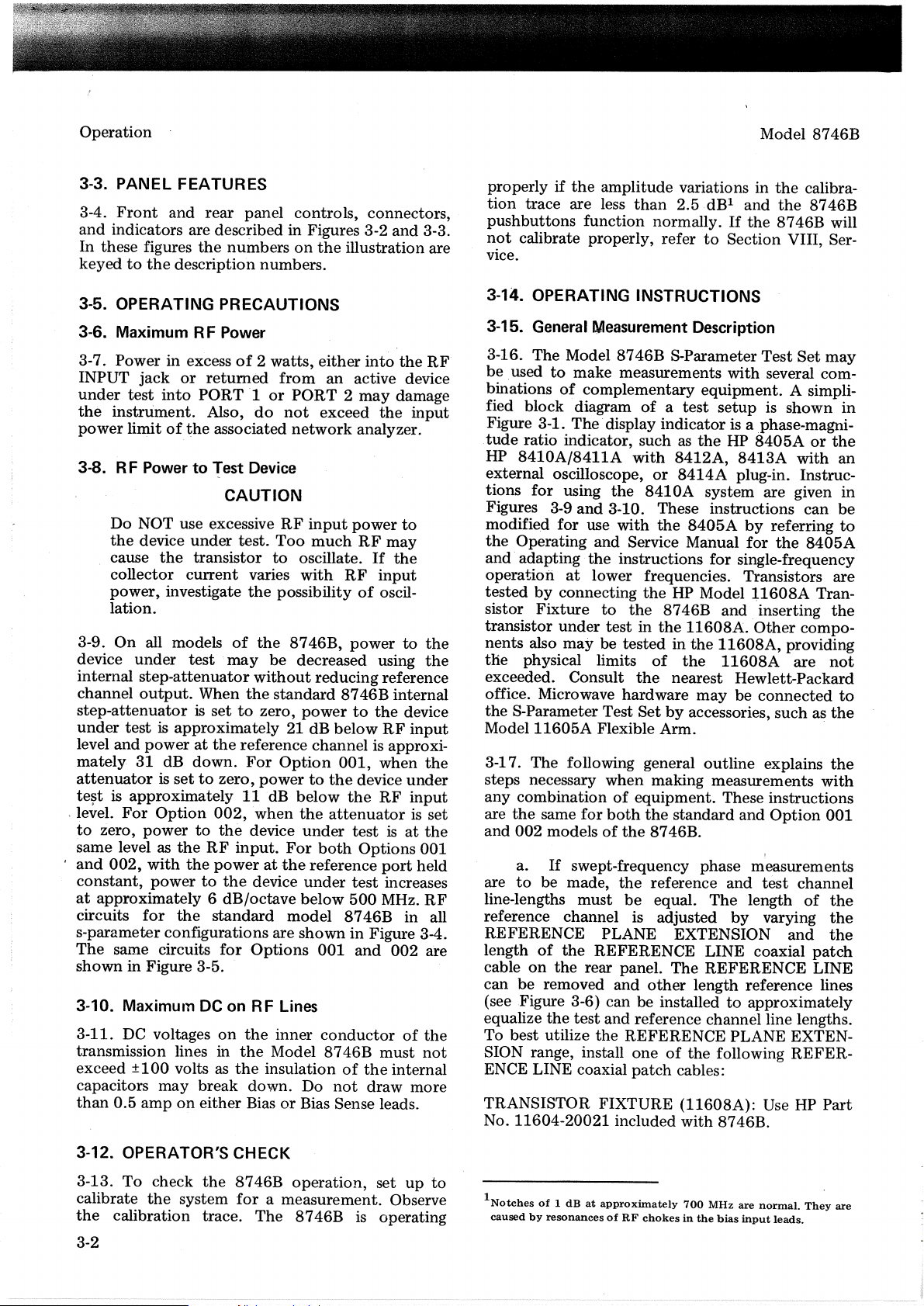

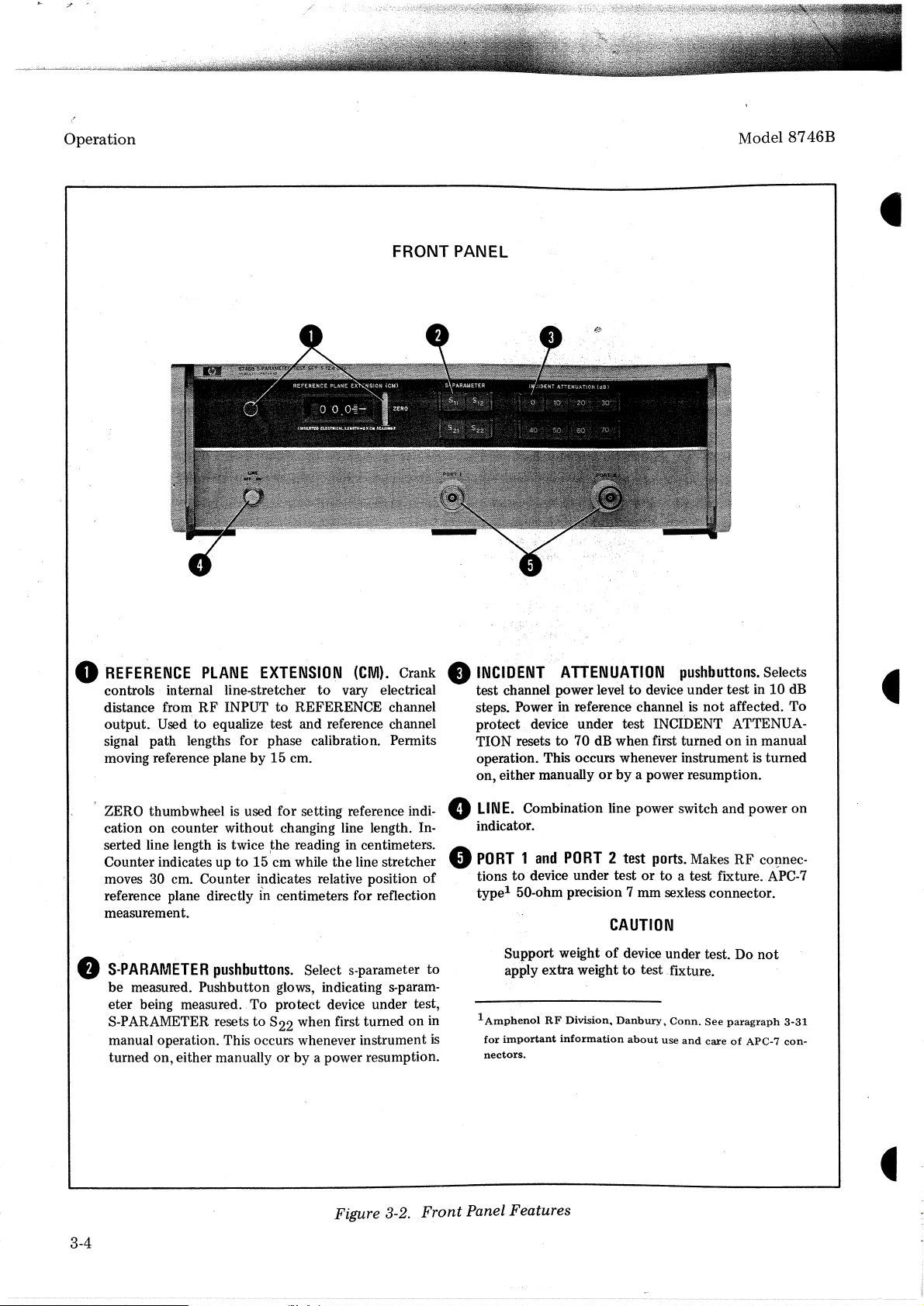

FRONT PANEL

Model

8746B

o

REFERENCE

controls internal line-stretcher

distance from

output. Used to equalize test and reference channel

signal path lengths for phase calibration. Permits

moving reference plane

ZERO thumbwheel

on

cation

serted line length

Counter indicates up

moves 30 cm. Counter

reference plane directlyincentimeters for reflection

measurement.

•

S-PARAMETER

be

measured. Pushbutton glows, indicating s-parameter being measured. To protect device under test,

S-PARAMETER resets to 822 when first turned on

manual operation. This occurs whenever instrument

turned on, either manually or by a power resumption.

PLANE

RF

counter without changing line length. In-

pushbuttons.

EXTENSION

INPUTtoREFERENCE channel

by

15 cm.

is

used for setting reference indi-

is

twice

~he

reading in centimeters.

to

15 cm while the line stretcher

i~dicates

Select s-parameter to

(CM).

to

vary electrical

relative position

Crank

of

•

INCIDENT

test channel power level

steps. Power in reference channel

protect device under test INCIDENT ATTENUATION resets

operation. This occurs whenever instrument

on, either manually

e

LINE.

indicator.

o

PORT1and

tions to· device under testorto a test fixture.

typel50-ohm precision 7 mm sexless connector.

ATTENUATION

to

to

70 dB when first turnedonin manual

orbya power resumption.

Combination line power switch and power on

PORT2test

pushbuttons.

device under test in10dB

is

not

ports.

MakesRFcQI)nec-

Selects

affected. To

is

turned

APC-7

CAUTION

Support weightofdevice under test. Do

apply extra weighttotest .fixture.

1

in

is

AmphenolRFDivision,.

for

important

nectors.

information

Danbury,.Conn.

about

use

and

See

careofAPC-7

not

paragraph

3-31

con-

3-4

Figure 3-2.

Front

Panel Features

Page 18

Model

8746B

Operation

'.

•

REFERENCE

o

outputs

APC-7

The REFERENCE channel connector

floating

Frequency Converter

REFERENCE

•

section

the REFERENCE PLANE EXTENSION to any

sired length.

Power

•

connected to 8746B cabinet. Power requirements:

or

115

maximum.

Power

e

connector, fuseholder, a fuse-removal handle, and a

115-230 volt input-voltage switch. Number opposite

ac input-voltage slider

and

phase-amplitude ratio in<llcator. These are

to

50-ohm·precision 7-mm hybrid connectors.

assure alignment with 8411A Harmonic

to

LINE.

rigid coaxial cable to extend the range of

of

Conne~tor.

Cable

Vac

230

Module

8410A Network Analyzer.

of

be replaced with a longer

May

NEMA

±10%, 48 to 440 Hz, 110

Assembly.

Contains

correct line· fuse rating.

gives

type

ac

mechanically

is

with

Reference and Test channel

TEST.

REAR

de-

pin

offset

VA

power cable

PANEL

Accepts contact-closure type

select s-parameter

open

the

to

12 Vde. Maximum current from

is

is

Maximum bias current 500

Complete serial number in-

Plate.

8746B.

RF

for

MIN.

0.316

MAX.

0.320

of

short-circuited

that

signal

2 watts. Connector

is

signal

applied

is

is

Number

INPUT.

,------

INPUT.

is

100Vdc.

Input

REMOTE

.0

mote programming

ured and incident attenuation

under test. Nominal voltage from the 8746B when

the contact

the 8746B when contact

Also accepts dc bias for device under test. Maximum

bias voltage

Serial

cluding prefix should be included in any correspond-

•

ence concerning

RF

•

device under test. Frequency range

GHz. Maximum power level

50-ohm type N and mates compatibly with type

connectors whose dimensions conform

C-39012 and MIL-C-71. (See dimension drawing below.)

to

to

is

0.5

re-

be meas-

device

rnA.

12

rnA.

the

to

12.4

to

MIL-

to

is

N

IVIANUAL-REMOTE

o

INCIDENT ATTENUATION pushbuttons only.

MANUAL

in

When

only by front-panel pushbuttons.

position, attenuation selection

only if remote operation

tact closure.

Switch.

position, attenuation

Controls operation of

in REMOTE

When

by contact closure

is

also programmed by con-

is

Figure

selected

is

3-3.

Panel Features

Rear

3-5

Page 19

Operation

8

11

Model 8746B

RF

INPUT

RF

INPUT~""'--

.....

~~r=---

.....

,--I

'.

T'

I I I

I IL

:

I 1 I

I

~(

I

J..!

L

__

---1

r

--l

10

dB

__

OUTPUT

!

10

dB

L

__

(.

I)

PORTl

-.J

TEST

CHAN

-

"I

~PORT2

C I

~

RF

INPUT~""--""'~~F-~""

3-6

I-~'

I

~(

I<j>

: 6

I I

I I

I

wl

L

__

---1

RF

INPUT------

r-

--l

<:.

I)PORTI

IL--~

OUTPUT

I

Figure 3-4. Standard Model

TEST

CHAN

RF

...........

Circuits

~=----

Page 20

•

Model

8"

RF

INPUT

8746B

Operation

RF

INPUT

r - E

r:

- -

-,

I10dB

IT

I I

,.

I

IX

I

Ii

L

IL_.-:._J

I

---<:~

.....~__

I

~l--I:....-_-

"I

__

-l

~d;-

L

~l~PORT

...

TEST

CHAN

~

~rl

( I)

--.J

PORT

1

2

INPUT~'

NOTE

No10dB

in

port

in

the

002.

RF

~-_

pad

couplers

....

-----*:--

---0""

__

--"

I.-~I

,10

dB

(

L

__

-.J

...

I)

TEST

CHAN

PORT

2

1:---'

I~:

I r I

I I

I

I

I

11

L

I

I

I

__

1--'

--!

Figure 3-5. Option 001 and

I - (

:

lOdB

L

___

\10

dB

L

__

3

(

-:

~

J )

J

-.-.J

I

I)

PORT

TEST

CHAN

PORT

1

1:---'

I~:

I r I

I I

I

I

I

11

L

__

2

.

002

RF

Circuits

I -

("

-l

)

PORT

1

IlodB

L

___

I

J

3

TEST

- I

~

CHAN

I)

PORT

-l

2

3-7

I

I

I

I

0

;-

.J

0d

(

L

__

Page 21

._d'

Operation

Table 3-2.

Operating

concerning operation

panel switchesonthe

transistor

transistor

If

and

to

under

the

8717A

Service .Manual

of

the

871 7Atocorrespondtothe

be

tested.

test, perform

is

used, refer

871 7A. Set

To

apply bias

the

following:

for

full details

CAUTION

These instructions are

or

transistors (PNP

NPN). Some

transistors may be damaged

bias in this order, while this is

order

for

other

FET's.

applying bias depends

upon

for

The

by

the

the

bipolar

applying

order

type

FET. Therefore, always .read

manufacturer's biasing instructions before

testing transistors.

your

procedure

Good

on

practice istotry

a similar,

inexpensive transistor, first.

a. Make Bias and Bias Sense connections

from

interconnect

8746B

to

8717A

cableisnot

output.

availabl~,

If

the

makeupa cable

to

the

to

FET

proper

of

of

the

but

8717A

its

front

the

using

Normally

circuit

Direction

the

and

connector

port

1 circuit is used

port

2

of

RF

signal flow depends

furnished

for

the

with

for

output-bias circuit.

parameter measured.

b.

Set

8717

A voltage METER FUNCTION

switch

AMPL

turn

0.1to0.3 volts

to

VcE

control

c. With

8717

Aon.

d.

Adjust

-D

s position and adjust VeE

full·y counterclockwise.

no

transistororcalibrator installed,

8717

AVe

E

-0

l

.

S AMPL

CAUTION

If

CCE

-0

S is set below 0.1 V,

base-collector

junction

may

forward-biased and draw excessive reverse

current. This

under

IIf

difficultyisfound

nearest

Hewlett-Packard

test.

may

when

office

damage

. .

setting

for

0.1to0.3

further

the

information.

Model

the

the

input-bias

upon

control

become

transistor

volts,

contact

8746B

8746B.

the

-0

to

your

S

Used

for

mission

Flexible

HP

Part

Used

HP

Part

microwave

measurements

Arm.

No.

08746-20031

with

11608A

No.

11604·20021

hardware

with

Transistor

trans-

11605A

Fixture.

Used

for

tion

measurements

front

panel.

HP

Part

microwave

No.

08745-20064

hardware

referencedtothe

reflec-

3-8

Figure 3-6.

Reference

Line Coaxial Patch Cables

Page 22

Model 8746B

e.

Turn

the

8717A

f.

Set

8717AIE-8AMPL/RANGE

fully counterclockwise.

Set

IE

-8

g.

to

5,

50,

transistor

or

under

LIMIT(MA) current-limit switch

500

test.

bias. off.

rnA position

to

control

protect

the

m. Turn

terclockwise.

n.

Turn

0.3 volts.

o.

Turn BIAS off.

the

IE-8AMPL

VeE

AMPL

control

control

Operation

fully coun-

downto0.1

to

h.

Place

11608A

output

leadtothe

i.

Hold

striplinebyclosing

j.

Turn

to

desired

Set

k.

to

monitor

the

with

the

right.

the

BIAS on. Adjust

output

voltage.

current

-

I

and

E

8

transistor

input

transistor in

the

11608A

under

leadtothe

contact

lid.

VeE

'METER FUNCTION switch

adjust I

-

E

8

controltodesired collector current.

1.

instructed

If

biasisnot

BIAS switch

Make

in Figure 3-9.

transistor

CAUTION

turned

to

off, transients may

measurements as

down

befor~

damage sensitive transistors.

test

in

the

left

and

the

with

the

AMPL control

AMPL/RANGE

pushing

3-21. Bias Using a Dual

sistors may also

be

supply. Additional circuitry

sistor

under

test

maybeneeded.

may

take

the

formofdiodes

emitter

the

will vary with

3-22.

with

connected

voltage

and

and/or

a series current-limiting resistor

emitterorbase lead.

the

transistor used.

Note

that

the

either

to

is

normally

the

either

input

Bias Sense terminals

voltage connected

DC

Power Supply. Tran-

biased using a

to

between

The

particular circuit used

bias supplies canbeconnected

or

output

port

terminal.

connected

to

and

to

port

2 Bias

terminals (see Figure 3-8). This

also make

flow

Transistor

or

any

be

shorted readily,

from

other

the

normal

the

Fixture

left

(forward-gain) signal (S21)

to

is used. When using

application where

the

right

bias

when

the

current-limited.

dual

dc-power

protect

Protection

the

the

circuits

base

circuit voltage

The

input

the

port

1 Bias

the

output

and

circuit

Bias Sense

convention

the

11608A

the

11608A,

bias

supply

supply should

tran-

and

in

bias

will

can

be

Table

3-2~

Remote

Input

Connector Pin Functions

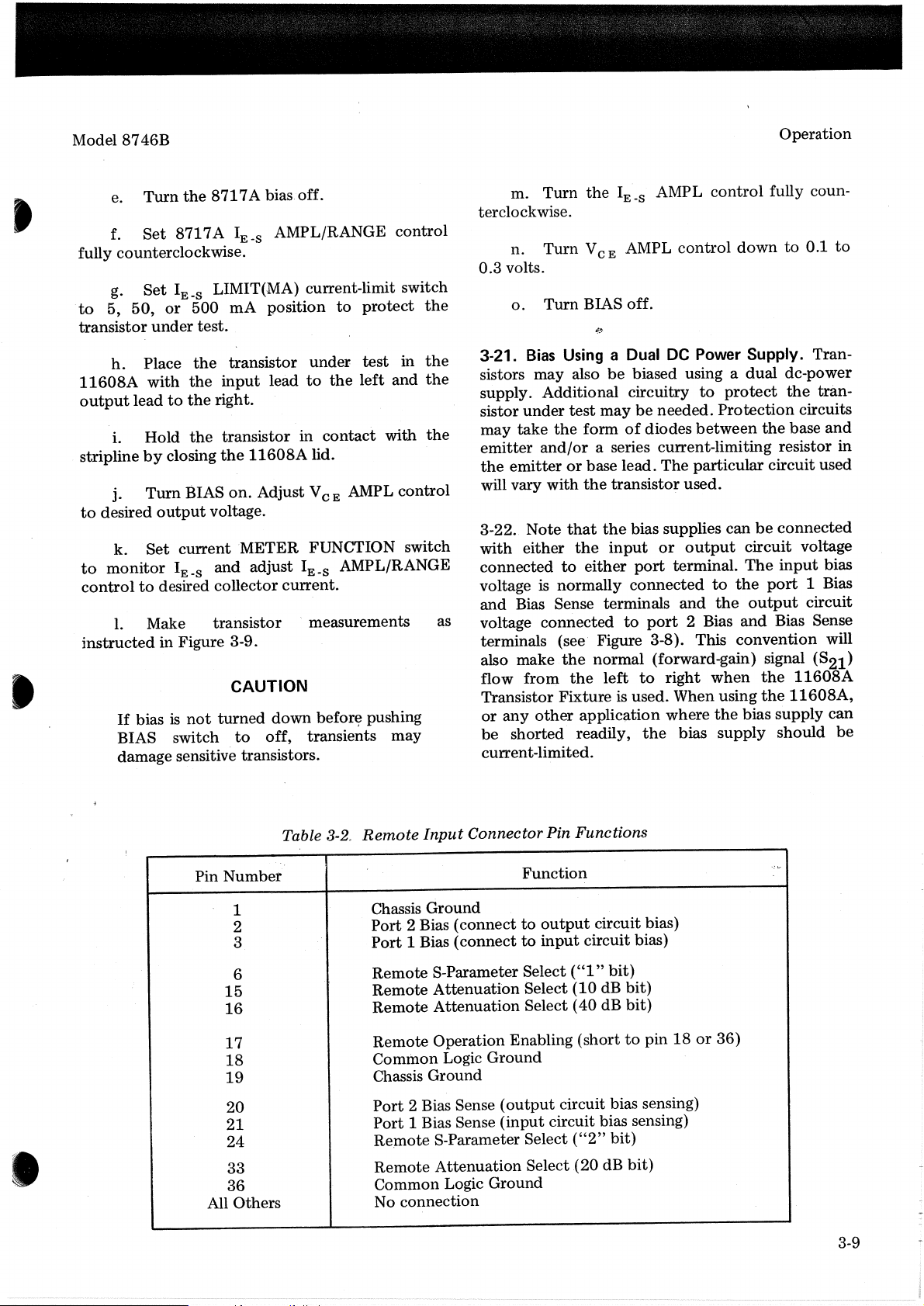

Pin Number

1

2

3

6

15

16

17

18

19

20

21

Chassis Ground

Port

2 Bias (connecttooutput

Port

1 Bias (connecttoinput

Remote

Remote

Remote

S-

Parameter Select("1"

Attenuation

Attenuation

Remote Operation Enabling (short

Common Logic

Ground

Chassis Ground

Port

2 Bias Sense

Port

1 Bias Sense

24 Re,mote S-Parameter Select

33 Remote

Attenuation

36 Common Logic Ground

All Others No connection

Function

Select

Select (40 dB

(output

(input

circuit bias sensing)

Select

circuit bias)

circuit bias)

bit)

(10

dB bit)

bit)

to

pin18or

circuit bias sensing)

("2"

bit)

(20dBbit)

·:v

36)

3-9

Page 23

Operation

If

a greater current-carrying

leadisneeded,

leads. However,

graded. See

the

parallel

remote

following

CAUTION

If

the

Bias Sense leadisusedtocarry

rent,

-

its bias-sensing

graded

rent

flow.

by

the

voltage

capacity

the

Bias

bias-sensing

caution.

function

drop

duetothe

on

and

may

will

the

Bias

Bias Sense

be

de-

cur-

be

de-

cur-

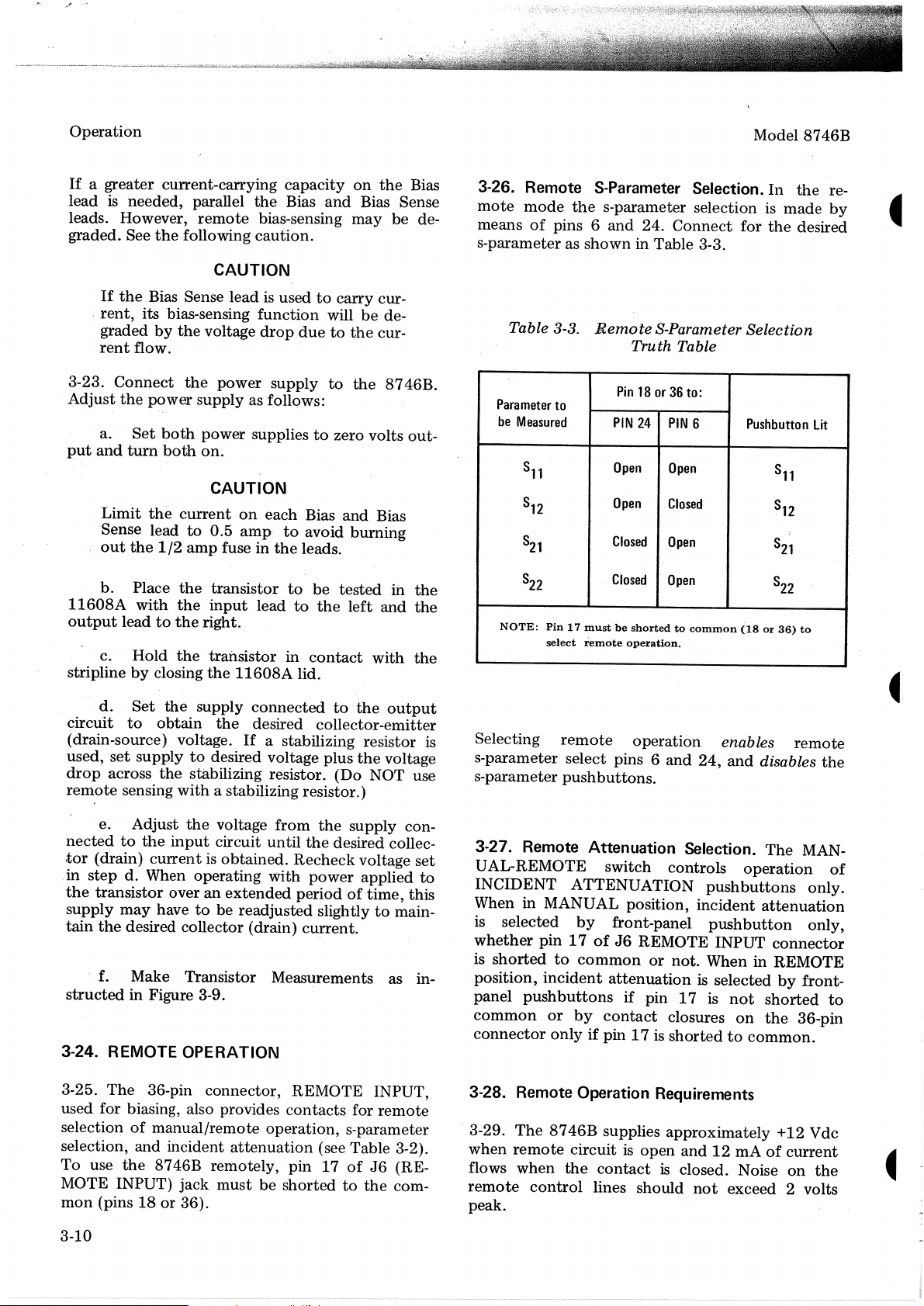

3-26. Remote S-Parameter Selection.

mote

mode

means

s-parameter as

Table 3-3.

of

the

pins 6

shown

s-parameter selection is

and

24.

Connect

for

in Table 3-3.

Remote

S-Parameter Selection

Truth Table

Model

In

made

the

8746B

the

re-

by

desired

3-23.

Adjust

a.

put

and

Connect

the

Set

turn

power

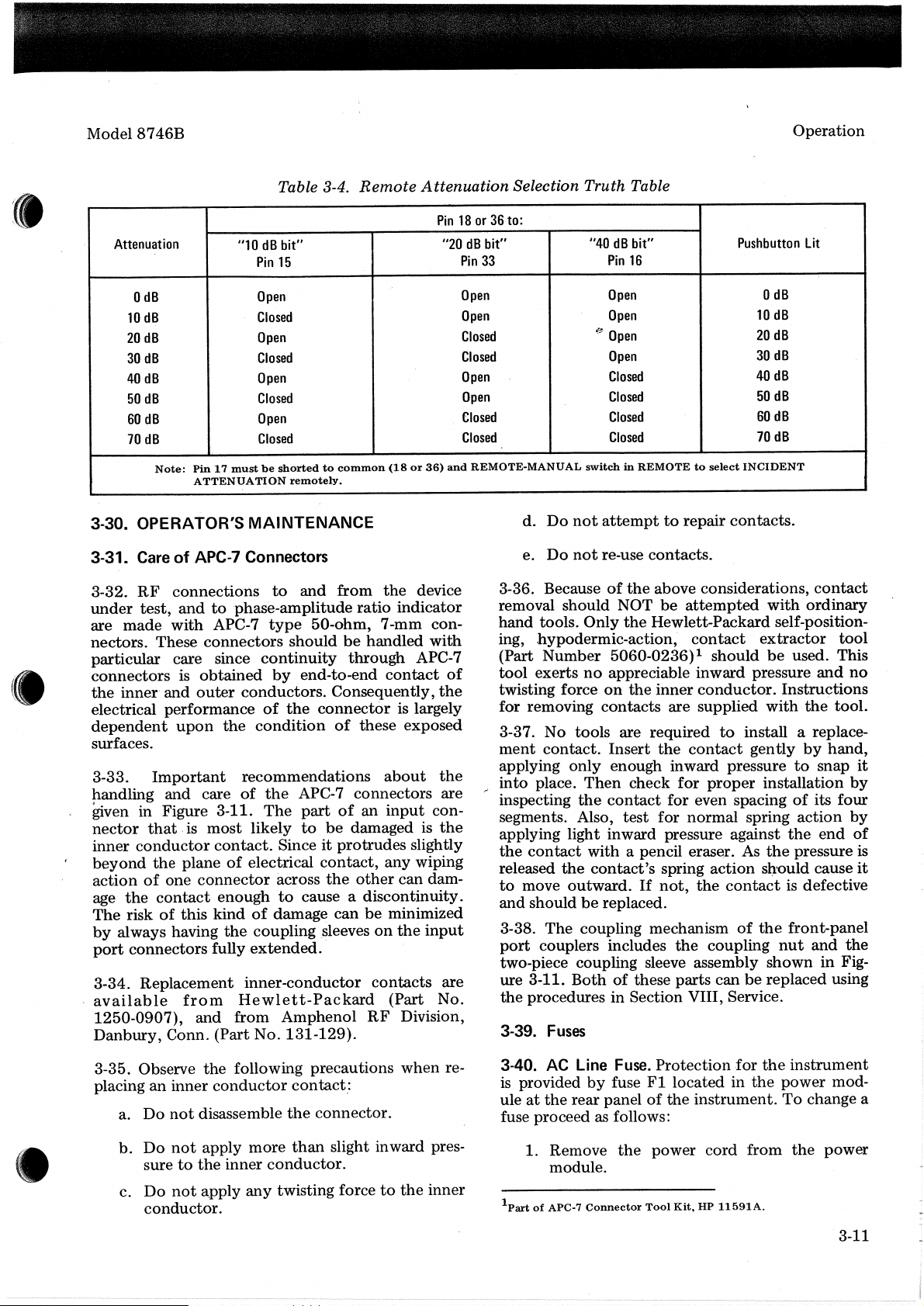

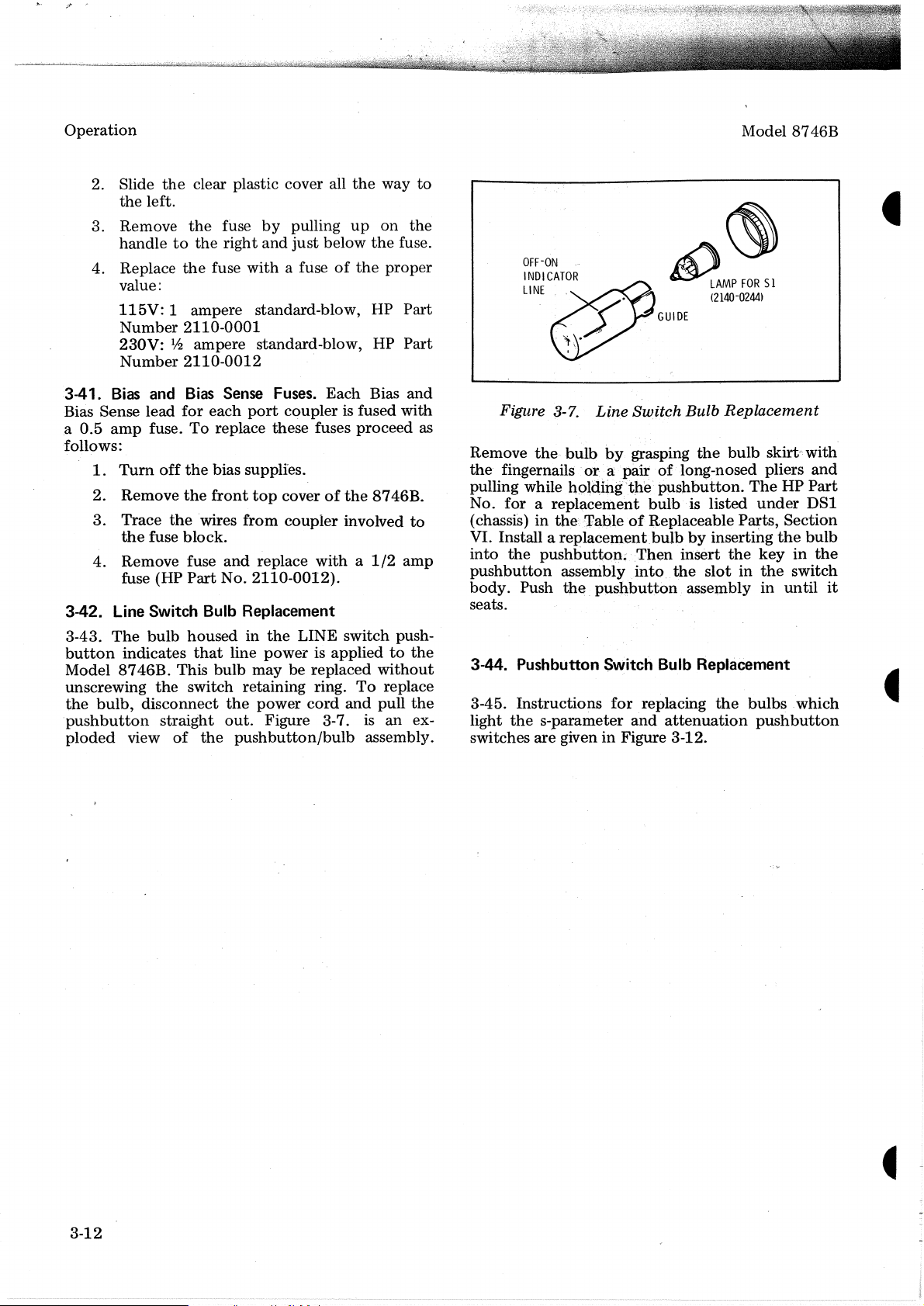

both