Page 1

Automating Measurements

HP 8712ET/ES and HP 8714ET/ES

RF Network Analyzers

User’s Guide Supplement

HP Part No. 08714-90014

Printed in USA

Print Date: October 1999

Supersedes: October 1998

© Copyright 1998, 1999 Hewlett-Packard Company

Page 2

Notice

Softkey

The information contained in this document is subject to change without

notice. Hewlett-Packard makes no warranty of any kind with regard to

this material, including but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Hewlett-Packard

shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance,

or use of this material.

Key Conventions

This manual uses the following conventions:

FRONT PANEL KEY

analyzer (a “hardkey”).

: This indicates a “softkey”—a key whose label is determined

by the instrument’s firmware, and is displayed on the right side of the

instrument’s screen next to the eight unlabeled keys.

: This represents a key physically located on the

ii

Page 3

Acknowledgments

Excel™ is a product of Microsoft Corp.

Lotus® 1-2-3®, and Lotus WordPro are U.S. registered trademarks of

Lotus Development Corporation.

Microsoft is a U.S. registered trademark of Microsoft Corporation.

QuickBasic™ is a product of Microsoft Corp.

Portions of the software include source code from the Info–ZIP group.

This code is freely available on the Internet by anonymous ftp

asftp.uu.net:/pub/archiving/zip/unzip51/.tar.Z, and from CompuServe

asunz51.zip in the IBMPRO forum, library 10, (data compression).

iii

Page 4

Hewlett-Packard Sales & Service Offices

UNITED STATES

Instrument Support Center

Hewlett-Packard Company

(800) 403-0801

EUROPEAN FIELD OPERATIONS

Headquarters

Hewlett-Packard S.A.

150, Route du Nant-d’Avril

1217 Meyrin 2/ Geneva

Switzerland

(41 22) 780.8111

Great Britain

Hewlett-Packard Ltd.

Eskdale Road, Winnersh Triangle

Wokingham, Berkshire RG41 5DZ

England

(44 734) 696622

INTERCON FIELD OPERATIONS

Headquarters

Hewlett-Packard Company

3495 Deer Creek Rd.

Palo Alto, CA 94304-1316

USA

(415) 857-5027

France

Hewlett-Packard France

1 Avenue Du Canada

Zone D’Activite De Courtaboeuf

F-91947 Les Ulis Cedex

France

(33 1) 69 82 60 60

Australia

Hewlett-Packard Australia Ltd.

31-41 Joseph Street

Blackburn, Victoria 3130

(61 3) 895-2895

Germany

Hewlett-Packard GmbH

Hewlett-Packard Strasse

61352 Bad Homburg v.d.H

Germany

(49 6172) 16-0

Canada

Hewlett-Packard (Canada) Ltd.

17500 South Service Road

Trans-Canada Highway

Kirkland, Quebec H9J 2X8

Canada

(514) 697-4232

Japan

Hewlett-Packard Japan, Ltd.

Measurement Assistance Center

9-1, Takakura-Cho, Hachioji-Shi

Tokyo 192-8510, Japan

TEL (81) -426-56-7832

FAX (81) -426-56-7840

China

China Hewlett-Packard Co.

38 Bei San Huan X1 Road

Shuang Yu Shu

Hai Dian District

Beijing, China

(86 1) 256-6888

iv

Singapore

Hewlett-Packard Singapore (Pte.) Ltd.

150 Beach Road

#29-00 Gateway West

Singapore 0718

(65) 291-9088

Taiwan

Hewlett-Packard Taiwan

8th Floor, H-P Building

337 Fu Hsing North Road

Taipei, Taiwan

(886 2) 712-0404

Page 5

HP 8712ET/ES and HP 8714ET/ES

Network Analyzer

Documentation Map

The CDROM provides the contents of all of the documents

listed below.

The User’s Guide shows how to make measurements,

explains commonly-used features, and tells you how to get

the most performance from the analyzer.

The LAN Interface User’s Guide Supplement shows

how to use a local area network (LAN) for programming and

remote operation of the analyzer.

The Automating Measurements User’s Guide

Supplement provides information on how to configure and

control test systems for automation of test processes.

The Programmer’s Guide provides programming

information including HP-IB and SCPI command

references, as well as short programming examples.

v

Page 6

The Example Programs Guide provides a tutorial

introduction using BASIC programming examples to

demonstrate the remote operation of the analyzer

.

The Service Guide provides the information needed to

adjust, troubleshoot, repair, and verify analyzer

conformance to published specifications.

The HP Instrument BASIC User’s Handbook describes

programming and interfacing techniques using

HP Instrument BASIC, and includes a language reference.

The HP Instrument BASIC User’s Handbook

Supplement shows how to use HP Instrument BASIC to

program the analyzer.

The Option 100 Fault Location and Structural Return

Loss Measurements User’s Guide Supplement provides

theory and measurement examples for making fault location

and SRL measurements. (Shipped only with Option 100

analyzers.)

vi

The CATV Quick Start Guide provides abbreviated

instructions for testing the quality of coaxial cables.

(Shipped only with Option 100 analyzers.)

The Cellular Antenna Quick Start Guide provides

abbreviated instructions for verifying the performance of

cellular antenna systems. (Shipped only with Option 100

analyzers.)

Page 7

Contents

1. Introduction

Automating Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2. Configuring Your Test System

Measurement System Configurations and Considerations. . . . . . . . . . . . . . . . . . . . . . 2-2

Stand-Alone Network Analyzers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

External Computer Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Expandability and Large Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Throughput Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Selecting a Measurement Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Stand-Alone Operation using IBASIC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Computer-Controlled HP-IB Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Computer-Controlled LAN Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Using IBASIC and External Control Together. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Selecting a Programming Language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

HP BASIC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

IBASIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

HP VEE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Microsoft® QuickBasic™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

C and C++ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

VXI plug&play Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Example Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

3. Operator Interaction

Prompting the Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Using Graphics to Create On-Screen Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

User-Defined BEGIN Key Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Loading a User BEGIN Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Modifying a User BEGIN Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Using a Switch with User BEGIN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Using a Barcode Reader for Data Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Using an External Keyboard for Data Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Using the Analyzer's Title Feature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Hot Keys on External Keyboard for Common Functions . . . . . . . . . . . . . . . . . . . . . . 3-16

User-Defined TTL Input/Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Using a Foot or Hand Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

vii

Page 8

Contents

Limit-Test Pass/Fail TTL Input/Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Analyzer Port Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Output for External VGA-Compatible Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

4. Measurement Setup and Control with Fast Recall

Using Fast Recall with the Front Panel or a Keyboard . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Using Fast Recall with a Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

5. Automated Measurement Setup and Control

Setting the Instrument State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Recalling Instrument States from Disk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Using Learn Strings to Save and Recall Instrument States . . . . . . . . . . . . . . . . . . .5-6

SCPI Commands that Modify a Single Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Fast Iterative Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Responsive Communication using SRQs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Using Both of the Analyzer's Measurement Channels . . . . . . . . . . . . . . . . . . . . . . . .5-11

Using Single Sweep to Measure and View All Four S-Parameters. . . . . . . . . . . . . . .5-12

AUTOST files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

6. Controlling Peripherals

Using the Parallel Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Writing to the Parallel Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Reading from the Parallel Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Hardcopy Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

Using the Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

7. Displaying Measurement Results

Graticule On/Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Limit Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

To turn limit lines on or off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

To turn the fail icon on or off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

To turn the pass/fail text on or off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

To move the position of the pass/fail indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Customized X-axis Annotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

To turn on user-defined X-axis annotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

To specify your start and stop values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

viii

Page 9

Contents

To specify a custom suffix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

To turn the X-axis annotation on or off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Customized Measurement-Channel Annotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

To turn on user-defined measurement-channel annotation. . . . . . . . . . . . . . . . . . . . 7-8

To specify the string to be displayed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

To restore default measurement-channel annotation . . . . . . . . . . . . . . . . . . . . . . . . 7-8

To turn measurement-channel annotation on or off. . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Title and Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

8. Saving Measurement Results

Querying Measurement Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Saving the Measurement to Disk — Save ASCII. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Saving the Measurement to Disk — Save Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Querying Marker Searches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Saving Measurement Results to Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Using Hardcopy Features to Print or Plot Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Faster Hardcopies using a PCL5 Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Customizing Page Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Custom Data Sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Statistical Process Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Transferring Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

ix

Page 10

Contents

x

Page 11

1 Introduction

1-1

Page 12

Introduction

Automating Measurements

Automating Measurements

An automated measurement system is one where a computer performs

some of the tasks that you would normally have to do manually.

The information in this book will help you learn how to automate your

measurement system. Several features of the instrument that are useful

for automation are explained.

NOTE The information in this book assumes that you are familiar with the

information provided in the Programmer's Guide, the HP Instrument

BASIC User's Handbook, and the HP Instrument BASIC User’s

Handbook Supplement that were supplied with your analyzer.

This book explains how to control your analyzer using internal IBASIC

or with an external computer connected via HP-IB. The analyzer’s

internal CPU running IBASIC programs acts as a complete system

controller residing inside your analyzer. You have the additional

capability of controlling the analyzer over a LAN. Refer to the LAN

Interface User’s Guide Supplement (supplied with the analyzer) for

information.

Some of the analyzer features that support automation are built-in and

operate solely on the analyzer; limit testing is one example of a built-in

automation feature. Other features can be executed by programs

running internally under IBASIC or on an external computer.

NOTE Example programs can be found in the following four locations:

• Web site http://www.hp.com or http://www.agilent.com. Use the

search function to find Web pages related to 8712 example programs.

• Example Programs Disk, HP 8712ET/ES and HP 8714ET/ES (DOS

format): HP part number 08714-10003

• Example Programs Disk, HP 8712ET/ES and HP 8714ET/ES (LIF

format): HP part number 08714-10004

• Example Programs Guide, HP 8712ET/ES and HP 8714ET/ES: HP

part number 08714-90016

1-2 Automating Measurements

Page 13

Introduction

Automating Measurements

Use of automation improves the productivity of a measurement system

by increasing the system's throughput. Throughput is typically

measured as the amount of units or components produced over a

particular period of time. Throughput can be increased by minimizing

the time for the following factors:

• device handling time

• operator interaction time

• measurement speed

• data transfer speed

• computation speed (when applicable)

Be sure to consider all of these factors when choosing and setting up an

automated system.

Automating your measurements can help ensure consistent quality on a

production line. An automated system can perform repetitive tasks

quickly and consistently. Automation can be used to direct you through a

sequence of tests, to set instrument parameters, and to send prompts

with helpful directions or diagrams. Automation is also used to collect

data, to monitor production line performance, and to archive and analyze

data.

Using a consistent, documented production process, while monitoring

product quality, are important attributes of modern production and

quality standards such as ISO-9000. These attributes are best achieved

with an automated system.

NOTE Hewlett-Packard offers professional consulting services to help increase

your manufacturing productivity. A complete test process analysis can be

performed by HP system engineers, who will work with your factory

management, engineering, and production groups to evaluate various

automation solutions. F or more information contact the nearest HP sales

office. Refer to the front of this book for a table of sales and service

offices.

Automating Measurements 1-3

Page 14

Introduction

Automating Measurements

1-4 Automating Measurements

Page 15

2 Configuring Your Test System

2-1

Page 16

Configuring Your Test System

Measurement System Configurations and Considerations

Measurement System Configurations

and Considerations

When configuring your test system, there are many things to consider,

such as:

• how many test stations do you need now?

• how many test stations will be needed in the future?

• how much space is available at each test station?

• what type of testing will be done?

• how will the measurements be controlled?

• how will the data be analyzed and archived?

• what level of throughput is required?

After answering these questions, you should decide which of the

following configurations best meets your needs.

2-2 Automating Measurements

Page 17

Configuring Your Test System

Measurement System Configurations and Considerations

Stand-Alone Network Analyzers

In the stand-alone configuration, you can either take advantage of the

operator-initiated automation features, or you can use the internal CPU

and IBASIC programs to further automate your measurements.

Stand-Alone Analyzer under Operator Control

In this configuration, the measurement is controlled directly by the

operator, with very little automation. No computer or IBASIC control is

used, however the fast-recall feature may be used to quickly change

between different instrument states. This configuration is well suited for

simple pass/fail testing using the built-in limit-testing features.

Configure your system as a stand-alone analyzer if you would like to

• simplify test-system configuration

• maintain full control by operators

• minimize test-development time

Stand-Alone Analyzer under IBASIC Control

In this configuration, the measurement is controlled by an IBASIC

program running inside the analyzer. With IBASIC, the measurement

setup and control can be highly automated, reducing the burden on the

operator. Since the measurement is under programmatic control, data

can be collected and analyzed in order to monitor your process and

quality. IBASIC's keystroke recording lets you construct programs

quickly, without needing to refer to the programming documentation.

Using AUTOST files, the analyzer will load and run your program when

power is turned on.

Since no external computer is required, there are fewer system

components to purchase, maintain, connect, and synchronize.

Automating Measurements 2-3

Page 18

Configuring Your Test System

Measurement System Configurations and Considerations

Configure your system as a stand-alone instrument with IBASIC if you

would like to

• simplify test-system configuration

• minimize the space required for a system

• simplify programming with keystroke recording

• use key macros

• automate measurement setup and control

• simplify measurements

• collect data

• run application programs on the analyzer

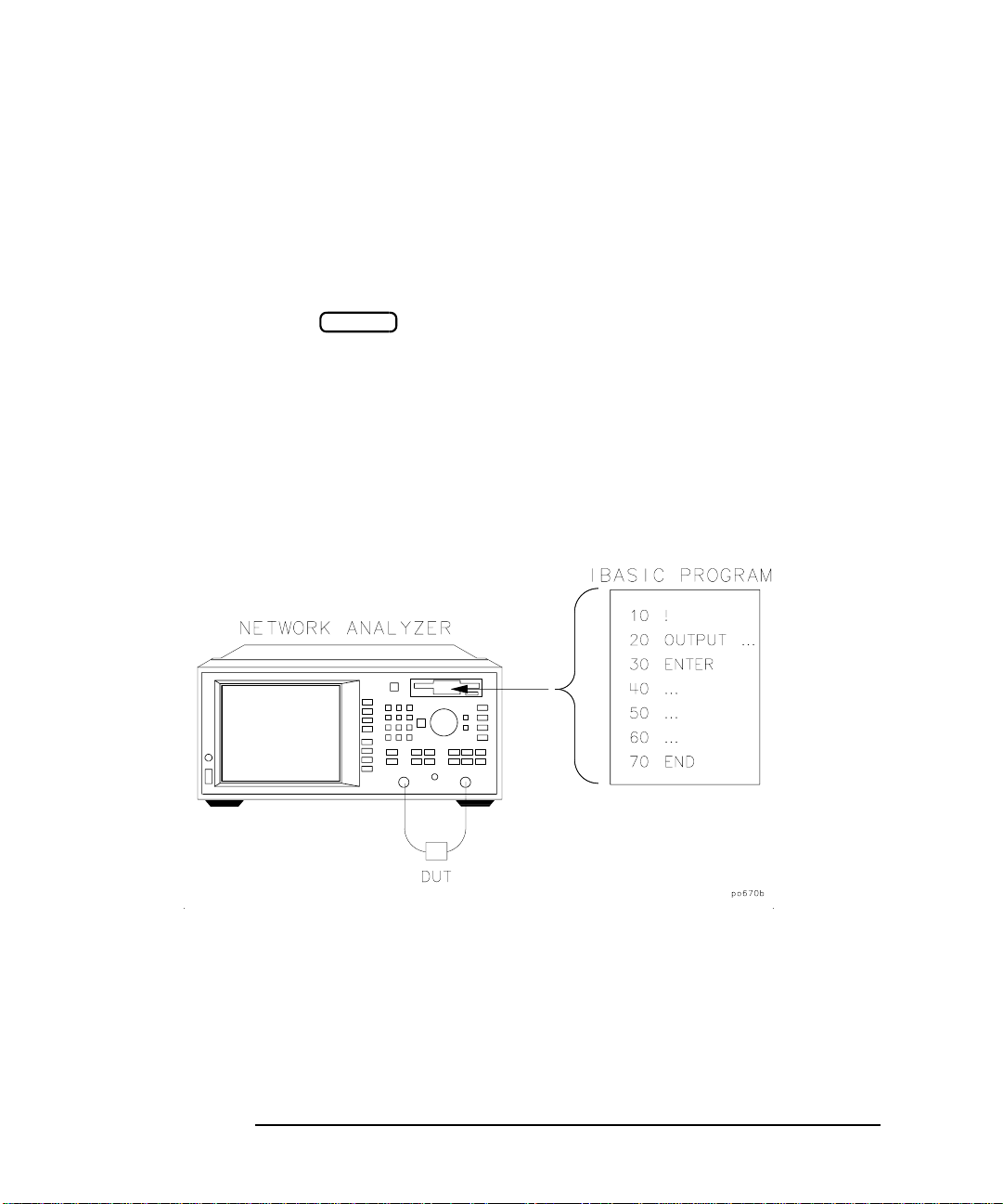

Figure 2-1 depicts a stand-alone network analyzer running IBASIC.

Figure 2-1 Stand-Alone Network Analyzer Running IBASIC

BEGIN

2-4 Automating Measurements

Page 19

Configuring Your Test System

Measurement System Configurations and Considerations

External Computer Control

You can use an external computer to control your analyzer or test system

by using the LAN or HP-IB interface on your analyzer. Additionally, you

can use an external computer in conjunction with the analyzer’s internal

CPU running IBASIC for optimum throughput. (F or more information on

using the LAN interface, refer to The LAN Interface User’s Guide

Supplement.)

External Computer Alone

In this configuration, the measurement is controlled by a computer

external to the analyzer, using the LAN or the HP-IB interface. The

measurement setup and control can be highly automated and designed

for optimum throughput. Data can be automatically collected and

analyzed in order to monitor quality and processes. You can connect one

or more analyzers to each computer. Since the computer can be

connected to other computers via a Local Area Network (LAN),

measurement statistics can be easily tracked and archived using

computer applications.

Configure your system as an analyzer controlled by an external

computer if you would like to

• centralize automation and application programs

• develop a more sophisticated data collection system

• add networking capability

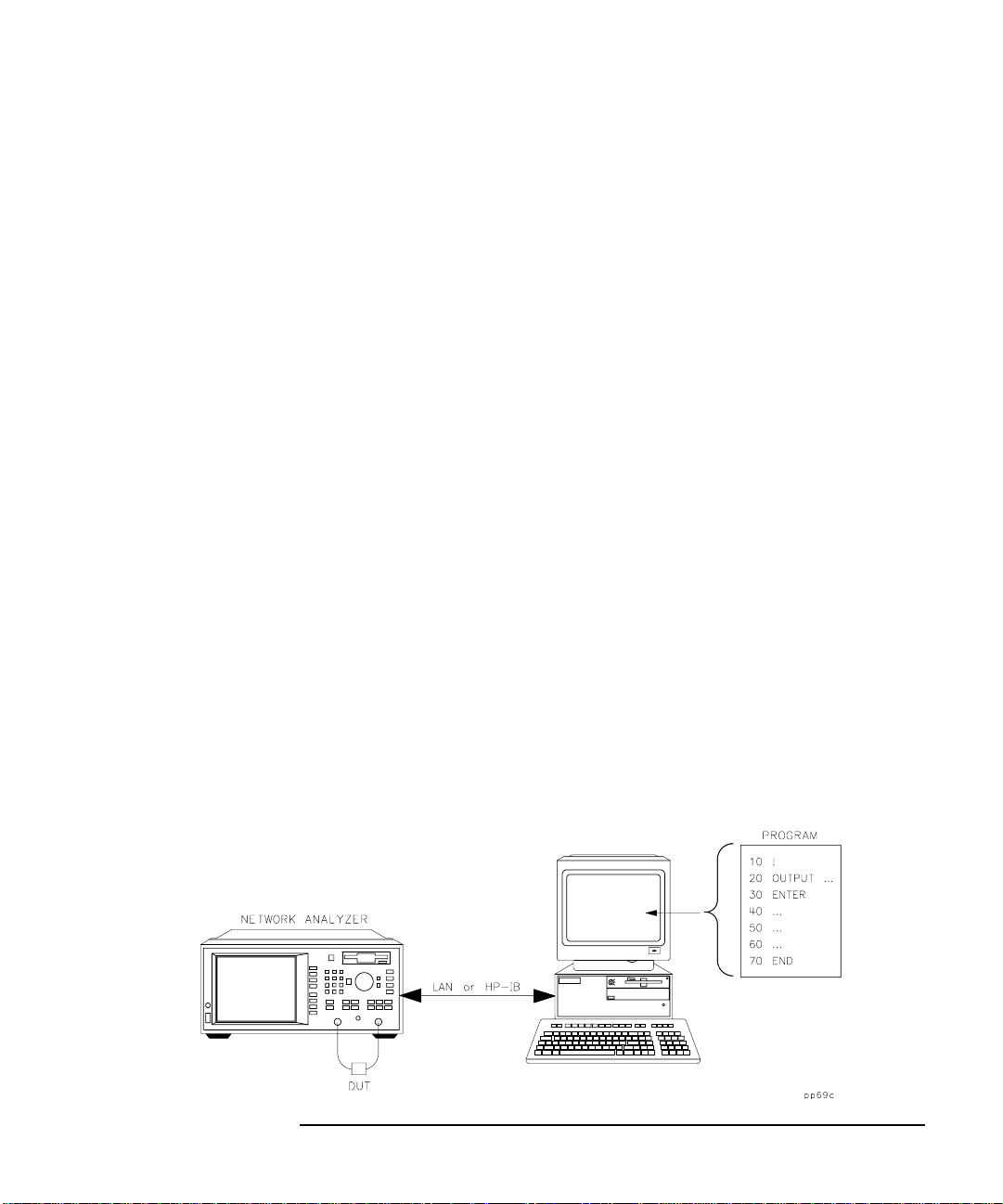

Figure 2-2 Network Analyzer Controlled by a Computer

Automating Measurements 2-5

Page 20

Configuring Your Test System

Measurement System Configurations and Considerations

External Computer in Conjunction with IBASIC

In this configuration, the measurement is controlled by an IBASIC

program running inside the analyzer. IBASIC can provide high-speed

measurement control and data collection, and save the results in

program memory or on a disk. The external computer then

communicates with IBASIC, and collects the measurement results at

some defined interval. This configuration can result in higher

throughput, especially if the measurement setup and control is complex.

Configure your system as an analyzer with IBASIC and an external

computer if you would like to

• centralize automation and application programs

• develop a more sophisticated data collection system

• add networking capability

• add local-automation capability

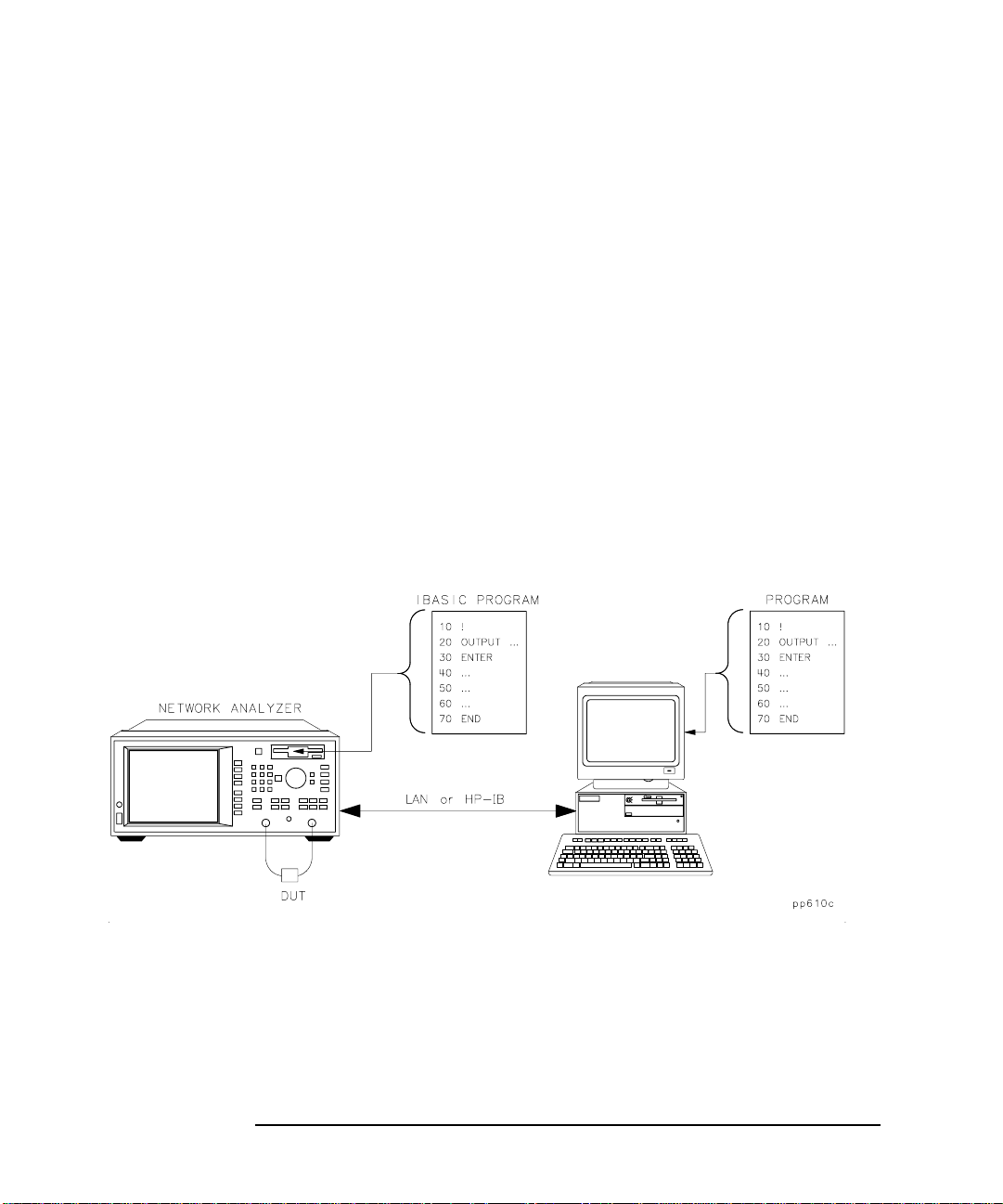

Figure 2-3 Network Analyzer Running IBASIC, Controlled by a Computer

2-6 Automating Measurements

Page 21

Configuring Your Test System

HP-IB

Expandability and Large Systems

Expandability and Large Systems

You can connect up to 10 analyzers to a single computer without

compromising maximum HP-IB bus speed. The IEEE-488 standard

states that the bus can achieve a data rate of 500 KBytes per second for

buses up to 20 meters in length, with up to 10 devices (one device per

2 meters of cable).

IEEE-488 provides for 31 unique addresses (0 through 30), however it

restricts the number of devices on the bus to 15. Due to this restriction,

you may need to add more computers as you add more analyzers. Set

each analyzer's address via the menu.

With your analyzer’s LAN feature, you can overcome the physical

limitations of HP-IB cabling and create large systems with hundreds of

analyzers. 10-BaseT LAN provides a theoretical bandwidth of close to

1 MByte/second, although in practice, throughput will be slower. See The

LAN Interface User’s Guide Supplement for more information.

SYSTEM OPTIONS

Automating Measurements 2-7

Page 22

Configuring Your Test System

Throughput Considerations

Throughput Considerations

When considering the throughput of the system configuration,

contributing factors are

• device handling time

• operator interaction time

• measurement speed

• data transfer speed

• computation speed (when applicable)

For more information, refer to Improving Throughput in Network

Analyzer Applications, HP application note number AN 1287-5

(or literature number 5966-3317E).

2-8 Automating Measurements

Page 23

Configuring Your Test System

Selecting a Measurement Controller

Selecting a Measurement Controller

There are three standard configurations that you can use to control the

analyzer:

• stand-alone operation using IBASIC

• computer-controlled HP-IB operation

• computer-controlled LAN operation

Stand-Alone Operation using IBASIC

IBASIC, in effect, puts a controller inside your analyzer and eliminates

the need for an external computer. IBASIC controls the analyzer by

sending SCPI commands to address 800 (OUTPUT 800;”Command”), or

by using high-speed built-in subprograms. Since IBASIC shares CPU

time with the analyzer, it may cause some degradation in measurement

throughput if your program performs intensive computations. However,

for most applications, it provides excellent performance and convenience.

Refer to the HP Instrument BASIC User's Handbook and HP Instrument

BASIC User’s Handbook Supplement for more information.

Computer-Controlled HP-IB Operation

An external computer can be used to control the analyzer. It can be a

personal computer (PC) or a dedicated HP BASIC controller. The

external computer sends standard SCPI commands to address

716 (default) (OUTPUT 716;”Command”) to control the analyzer . Refer to

the Programmer's Guide for more information.

You can use one computer to control several analyzers (see

“Expandability and Large Systems” earlier in this chapter). However , if a

large number of SCPI commands are required per measurement,

throughput may be degraded. Typical limits are 3 to 10 analyzers per

computer.

Automating Measurements 2-9

Page 24

Configuring Your Test System

Selecting a Measurement Controller

Computer-Controlled LAN Operation

An external computer can send SCPI commands via the LAN using a

telnet connection. Refer to The LAN Interface User’s Guide Supplement

for more information.

You can use one computer to control several analyzers. Performance will

typically be limited by the computer's speed, which in turn will limit the

number of analyzers per computer.

Using IBASIC and External Control Together

The analyzer can be controlled by commands from an external computer,

internal IBASIC, or from both at the same time, as long as certain

precautions are observed. Things to consider:

1. If both the analyzer and the computer send SCPI commands at the

same time, the analyzer may not finish the IBASIC command before

executing the computer's command, or vice-versa. The programmer

must ensure that SCPI commands executed by IBASIC do not overlap

with SCPI commands sent from an external computer, otherwise the

system may lock up. Synchronization between the analyzer and the

external computer must be ensured. See “Synchronizing IBASIC with

an External Controller” in HP Instrument BASIC User’s Handbook

Supplement for additional information.

2. Both IBASIC (SelectCode 8) and the external computer (LAN or

SelectCode 7) share the same HP-IB status model (the same analyzer

status bits go to each). Be careful sending commands which affect

status reporting, such as *CLS, STAT:PRES, *RST, etc.

2-10 Automating Measurements

Page 25

Configuring Your Test System

Selecting a Programming Language

Selecting a Programming Language

HP BASIC

HP BASIC has long been a favorite programming language for

instrument control. It features an extensive list of keywords, and

powerful OUTPUT and ENTER formatting, making it easy to perform

common tasks. This generally results in very high programming

productivity. HP BASIC runs on HP series 700 workstations and series

300 instrument controllers.

IBASIC

IBASIC is a version of BASIC that runs inside of the network analyzer.

IBASIC is a sub-set of HP's BASIC . It has roughly the same keywords as

HP BASIC 4.0. With very little effort, you can design your program so

that it will run either inside the analyzer or on a computer with no

modification.

The IBASIC program runs concurrently with normal instrument

measurement processing. Since IBASIC has direct access to the

analyzer's measurement arrays, it can read them and write to them very

quickly, eliminating the need to use SCPI commands. Using IBASIC's

keystroke recording, you can write a large portion of your instrument

control program by pressing the keys on the analyzer's front panel.

IBASIC can be used in a stand-alone instrument, or in conjunction with

an external computer.

For more information on IBASIC, refer to the HP Instrument BASIC

User's Handbook and HP Instrument BASIC User’s Handbook

Supplement that were shipped with your analyzer.

Automating Measurements 2-11

Page 26

Configuring Your Test System

Selecting a Programming Language

HP VEE

HP VEE is a powerful application which lets you graphically create

programs to control your instrument. VEE automatically handles the

programming details so you can focus on higher level tasks. It also

contains statistical functions which you can use to monitor your

production process.

VEE runs on PCs as well as HP-UX and Sun Workstations.

VEE can be used in conjunction with a VEE instrument driver. The VEE

instrument driver presents a picture of the instrument's front panel on

the computer display. Using the mouse, you can click on the front panel

keys to control the instrument, similar to IBASIC keystroke recording.

For information on VEE, including literature and preview disks, please

call the nearest HP instrument support center, or sales or service office.

Refer to the front of this book for a table of sales and service offices.

Microsoft® QuickBasic™

QuickBasic has been a popular programming language since it runs on

PCs. It does not offer a rich keyword set as does HP BASIC, and is not

optimized for instrument control. To control the analyzer via HP-IB, an

HP-IB card and driver library must be installed in the computer. The

driver library will provide subroutines such as IOOUTPUT and IOENTER

which let you control your analyzer.

C and C++

If you are using C or C++, you will need a driver library to use your

HP-IB card. HP offers a library called Standard Instrument Control

Library (SICL). SICL is available for PCs running Microsoft Windows®

and using HP's HP-IB card. SICL is also available on HP series 700

UNIX workstations.

For LAN communication with your analyzer, C or C++ is often used.

Multi-threaded programs can be created to allow easy and precise

control of many analyzers operating asynchronously. This approach

maximizes speed and throughput.

2-12 Automating Measurements

Page 27

Configuring Your Test System

Selecting a Programming Language

VXI plug&play Driver

Your analyzer is VXI plug&play compliant. VXI plug&play drivers

provide a high level control interface for the analyzer, thereby reducing

the level of instrument-specific knowledge required to program the

analyzer. The driver for the HP 8712ET/ES and HP 8714 ET/ES

functions in Win95, Win98, and WinNT (3.51 or higher) and was

designed for the following programming platforms:

• Microsoft Visual C++ version 4.0 or higher

• Microsoft Visual BASIC version 5.0 or higher

• Borland C++ version 4.5 or higher

• HP VEE version 3.2 or higher

• National Instruments Lab Window/CVI version 4.0.1 or higher

• National Instrument LabVIEW version 5.00 or higher

The free VXI plug&play driver for your analyzer should be available

soon on the Web at:

http://www.tmo.hp.com/tmo/software/English/comptest_VXI_drivers.html

OR

http://www.hp.com/go/ena

Example Programs

The Programmer's Guide contains detailed information on controlling

the analyzer via HP-IB. The Example Programs Guide includes several

example programs written in HP BASIC and in IBASIC.

The HP Instrument BASIC User's Handbook and HP Instrument BASIC

User’s Handbook Supplement contain detailed information on how to

control the analyzer using IBASIC.

The LAN Interface User’s Guide Supplement contains detailed

information on controlling the analyzer via LAN, including example

programs.

Automating Measurements 2-13

Page 28

Configuring Your Test System

Selecting a Programming Language

2-14 Automating Measurements

Page 29

3 Operator Interaction

3-1

Page 30

Operator Interaction

Many tests are performed by technicians, operators, or testers who

interact with the measurement system. When designing the automation

system, it is important that the system allow operators to perform the

measurement tasks quickly and consistently. The system must also be

easy to learn and easy to use, providing the user with instructions and

feedback.

The analyzer provides many features to satisfy these requirements. The

features include

• user-defined pop-up messages to prompt the operator

• on-screen graphics to create custom diagrams

• user-defined measurement channel and frequency annotation

• ability to define the key menu with frequently-used custom

softkeys

• IBASIC display window; configurable as full or split

• IBASIC DISP line and INPUT line

• data entry using a barcode reader

• data entry using an external keyboard

• hot keys on external keyboard for common functions

• operator control of measurements using a foot or hand switch

• beeper with adjustable volume and pitch

• limit test pass/fail TTL output

• user-defined TTL input/output

• output for external VGA-compatible color monitor

The following sections explain how to use these features, and show

several examples.

BEGIN

3-2 Automating Measurements

Page 31

Figure 3-1 shows an example test system setup which utilizes the

extensive connectivity capabilities of the analyzer. All of the interface

ports shown are standard equipment on your analyzer.

Figure 3-1 Example Test System Setup

Operator Interaction

Automating Measurements 3-3

Page 32

Operator Interaction

Prompting the Operator

Prompting the Operator

You can display a customized message in the center of the analyzer's

display by using the following SCPI command:

DISPlay:ANNotation:MESSage

For example,

OUTPUT @Rfna;"DISP:ANN:MESS 'Connect device, then press button'"

You can specify how long you want the message to remain on the screen

by using one of the following timeout words: SHORt, MEDium, LONG,

NONE. For example,

OUTPUT @Rfna;"DISP:ANN:MESS 'Test passed.'",MEDIUM

To clear the message immediately, use the following command:

DISPlay:ANNotation:MESSage:CLEar

The message string can contain a maximum of 25 lines with up to

47 characters per line. However , it cannot be more than 254 characters in

length, including carriage returns and line feeds.

If you are using IBASIC, you can use the B ASIC keywordDISP to display

a small one-line message near the bottom of the screen. For example,

DISP "Connect device to REFLECTION port"

3-4 Automating Measurements

Page 33

Operator Interaction

Using Graphics to Create On-Screen Diagrams

Using Graphics to Create On-Screen

Diagrams

Diagrams showing how to connect devices or perform measurements can

be a powerful tool. You can draw customized diagrams on the analyzer's

display using the following SCPI commands:

DISPlay:WINDow[1|2|10]:GRAPhics:

These commands let you draw lines, rectangles, circ les , and text onto the

screen. The number specified in the WINDow part of the command selects

where the graphics are to be drawn:

WINDow1 draws the graphics to the measurement channel 1

window.

WINDow2 draws the graphics to the measurement channel 2

window.

WINDow10 draws the graphics to the IBASIC display window.

Using split display, you can display the measurement in one half of the

screen while displaying a connection diagram in the other half.

command

For more details on SCPI graphics commands, refer to “Using Graphics”

in the Programmer's Guide.

If you are using IBASIC, you can use the B ASIC graphics keywords such

as MOVE and DRAW to draw diagrams in the IBASIC window.

MOVE X1,Y1

DRAW X2,Y2

Since IBASIC keywords always draw to the IBASIC window, you cannot

use them to draw in the same window as your measurement. To draw in

the measurement window, your IBASIC program must use the standard

SCPI commands.

DISP:WIND1:GRAPHICS:

and

DISP:WIND2:GRAPHICS:

For more details on IBASIC graphics, refer to “Graphics and Display

Techniques” in the HP Instrument BASIC User’s Handbook Supplement.

Automating Measurements 3-5

command

command

Page 34

Operator Interaction

User BEGIN

User BEGIN

User BEGIN

User-Defined BEGIN Key Menu

User-Defined BEGIN Key Menu

The feature adds the following capabilities:

• Create softkeys to allow one-key-press operation of functions that

usually take several key presses.

• Reassign softkeys to implement your most-used functions/features.

• Create softkeys to implement new features created with IBASIC—for

example, a gain-compression measurement.

• Create softkeys to implement application support.

This feature is designed to provide the fastest possible sweep speeds

while taking advantage of the flexibility provided by IBASIC. This is the

simplest way for recalling instrument states or configuring most-used

softkey functions under a single softkey menu. The eighth softkey in the

BEGIN

softkey to enable/disable or . You cannot

redefine the eighth softkey.

menu provides access to the menus below. Toggle the eighth

BEGIN

BEGIN

Amplifier

Filter

Broadband Passive

Mixer

Cable (Option 100 only)

User BEGIN on OFF −−−−>

Once you have selected a menu, the same menu will be displayed for

subsequent key presses of the hardkey.

3-6 Automating Measurements

BEGIN

User label 1

User label 2

User label 3

User label 4

User label 5

User label 6

User label 7

User BEGIN ON off

Page 35

Operator Interaction

System Config

User TTL Config

Softkey Auto-Step

User BEGIN

User BEGIN

User-Defined BEGIN Key Menu

By selecting

SYSTEM OPTIONS

, you can automatically step

through the user-defined menu keys by use of a switch

BEGIN

connected to the USER TTL IN/OUT rear panel connector. See “Using a

Switch with User BEGIN” on page 3-11 for more information.

Selecting the softkey will run a macro function defined

by a sequence of IBASIC commands defined within an IBASIC program.

IBASIC programs to be used for must have the following

structure:

10 !The following label must be present. DO NOT REMOVE

20 User_begin: !

30 ...

40 ! Define softkey labels

50 OUTPUT @871X;"DISP:MENU2:KEY1 'Test Setup 1';*WAI"

60 OUTPUT @871X;"DISP:MENU2:KEY2 'Test Setup 2';*WAI"

70 OUTPUT @871X;"DISP:MENU2:KEY3 'Save Results';*WAI"

80 OUTPUT @871X;"DISP:MENU2:KEY4 'Print Results 4';*WAI"

100 User_pause: PAUSE

110 GOTO User_pause

120 !The following key labels must be present. DO NOT REMOVE

140 User_key1: !Insert code for softkey 1 here

150 GOTO User_pause

160 User_key2: !Insert code for softkey 2 here

170 GOTO User_pause

200 User_key7: !Insert code for softkey 7 here

210 GOTO User_pause

...

Automating Measurements 3-7

Page 36

Operator Interaction

User BEGIN

User BEGIN

Mkr --> Max

User-Defined BEGIN Key Menu

The labels required are:

User_begin

User_pause

User_key1

User_key2

User_key3

User_key4

User_key5

User_key6

User_key7

NOTE Y our program must contain all of these labels, even if you

are not using all of the softkeys.

A default program is created automatically when there

is no IBASIC program installed. In the default program, the third

softkey is defined to be the function, the fourth softkey

prompts the user for a title, and also enables the clock. The default

program is listed next. You may edit this program to change the

functions you need. Once you have edited the program, be sure to save

the program to memory for later recall.

1 ! The following line is required. DO NOT REMOVE!

2 User_begin: ASSIGN @Hp8714 TO 800 ![User Begin] Program

3!

4 ! To Modify:

5 ! Use [IBASIC][EDIT] or [IBASIC][Key Record]

6!

7!

8 ! Declare storage for variables.

9 DIM Name$[60],Str1$[60],Str2$[60],Str3$[60]

10 !

11 ! Clear the softkey labels

12 OUTPUT @Hp8714;"DISP:MENU2:KEY8 '';*WAI"

13 !

14 ! Re-define softkey labels here.

15 OUTPUT @Hp8714;"DISP:MENU2:KEY1 '*';*WAI"

16 OUTPUT @Hp8714;"DISP:MENU2:KEY2 '*';*WAI"

17 OUTPUT @Hp8714;"DISP:MENU2:KEY3 'Mkr -> Max';*WAI"

18 OUTPUT @Hp8714;"DISP:MENU2:KEY4 'Title and Clock';*WAI"

19 OUTPUT @Hp8714;"DISP:MENU2:KEY5 '*';*WAI"

20 OUTPUT @Hp8714;"DISP:MENU2:KEY6 '*';*WAI"

21 OUTPUT @Hp8714;"DISP:MENU2:KEY7 '*';*WAI"

22 !

23 !The following 2 lines are required. DO NOT REMOVE!

3-8 Automating Measurements

Page 37

Operator Interaction

User BEGIN

User-Defined BEGIN Key Menu

24 User_pause: PAUSE

25 GOTO User_pause

26 !

27 User_key1: ! Define softkey 1 here.

28 GOSUB Message ! Remove this line.

29 GOTO User_pause

30 !

31 User_key2: ! Define softkey 2 here.

32 GOSUB Message ! Remove this line

33 GOTO User_pause

34 !

35 User_key3: ! Example Marker Function

36 OUTPUT @Hp8714;"CALC1:MARK1 ON"

37 OUTPUT @Hp8714;"CALC1:MARK:FUNC MAX"

38 GOTO User_pause

39 !

40 User_key4: ! Example Title Entry

41 INPUT "Enter Title Line 1. Press [Enter] when done.",Name$

42 OUTPUT @Hp8714;"DISP:ANN:TITL1:DATA '""'"

43 OUTPUT @Hp8714;"DISP:ANN:TITL ON"

44 GOTO User_pause

45 !

46 User_key5: ! Define softkey 5 here.

47 GOSUB Message ! Remove this line.

48 GOTO User_pause

49 !

50 User_key6: ! Define softkey 6 here.

51 GOSUB Message ! Remove this line.

52 GOTO User_pause

53 !

54 User_key7: ! Define softkey 7 here.

55 GOSUB Message ! Remove this line.

56 GOTO User_pause

57 !

58 Message: !

59 Str1$="This key is programmable."

60 Str2$="To modify, select"

61 Str3$="[System Options], [IBASIC], [Edit]."

62 OUTPUT @Hp8714;"DISP:ANN:MESS '""', MEDIUM"

63 RETURN

64 !

65 END

NOTE For more programs, see the Example Programs Disk and

the Example Programs Guide.

Automating Measurements 3-9

Page 38

Operator Interaction

User BEGIN

Autost

User BEGIN

User BEGIN

User BEGIN

IBASIC

Edit

Prior Menu

Key Record ON

IBASIC

Key Record OFF

User-Defined BEGIN Key Menu

Loading a User BEGIN Program

A program can be automatically loaded at power up if

the program is named “AUTOST”. An “AUTOST” program is loaded at

power up from the internal non-volatile memory or from a 3.5 inch floppy

disk inserted into the analyzer's disk drive. (To manually load and run

an “AUTOST” file, press .) A program

does not have to be an “AUTOST” program; it can also be loaded as any

other IBASIC program. (See the HP Instrument BASIC User’s Handbook

Supplement for more information.)

When the key is pressed, the program will remain idle

until it is needed. The program remains idle until a softkey is pressed

and code related to that softkey is executed. After the code is executed,

the program returns to idle. Use of does not restrict

access to any normally available front panel feature, nor does this key

affect sweep update rates.

BEGIN

Modifying a User BEGIN Program

You can modify the User BEGIN program with the built-in editor, an

ASCII file editor on a computer, or with keystroke recording. For

example, to modify the default program to recall a setup:

1. Select . Move the edit cursor

to line:

15 OUTPUT @Hp8712;"DISP:MENU2:KEY1 '*';*WAI"

2. Use an external keyboard to replace ‘*’ with ‘Setup 1’.

3. Move the edit cursor to line 28. Delete the line.

4. Use keystroke recording to create a setup function if you like, or you

can now insert code you have written.

To use keystroke recording to modify the program:

5. Exit the editor by selecting .

6. Enable keystroke recording with .

7. Now perform the keystrokes required for Setup 1.

8. When the setup is completed, select

3-10 Automating Measurements

SYSTEM OPTIONS

SYSTEM OPTIONS

.

Page 39

Operator Interaction

User BEGIN ON

User-Defined BEGIN Key Menu

9. To verify your change, select

.

10.Select the first softkey which should be labeled “Setup 1”. This should

return you to your correct setup.

11.You may save this program as an AUTOST file or other file for later

recall.

Refer to the HP Instrument BASIC User’s Handbook Supplement.

PRESET BEGIN

Using a Switch with User BEGIN

When user-defined is used in conjunction with a switch

connected to the USER TTL IN/OUT rear-panel connector, you can cycle

through up to seven softkeys in sequence by activating the switch.

1. Connect a switch to the USER TTL IN/OUT rear panel connector as

shown in Figure 3-2.

Figure 3-2 Connecting a Switch to the USER TTL IN/OUT Connector

BEGIN

Automating Measurements 3-11

Page 40

Operator Interaction

System Config

User TTL Config

Softkey Auto-Step

User-Defined BEGIN Key Menu

2. Make sure the analyzer is configured to use the USER TTL IN/OUT

connector for softkey sequencing: press

3. Press the switch several times while observing the analyzer.

4. Notice that with each press of the switch, the softkey labels are

highlighted (boxed) in succession, and that after the last available

key has been used, the sequence starts again at the top of the softkey

menu.

SYSTEM OPTIONS

.

3-12 Automating Measurements

Page 41

Operator Interaction

Using a Barcode Reader for Data Entry

Using a Barcode Reader for Data Entry

Devices under test (DUTs) are often labeled with a serial number and

part number. If the DUT is labeled with this information in barcode

format, a barcode reader can be used to enter the DUT information into

the analyzer or into the computer controlling the analyzer. Doing so

provides a simple and safe link between the DUT and the measurement

data. Information such as the operator's name or test station number can

also be entered, to allow correlation of the devices tested with the test

station.

Connect a barcode reader, such as the HP KeyWand HBKW-1220, to the

analyzer's DIN KEYBOARD connector (on the rear panel). Once

connected, the barcode reader will send scanned barcode characters to

the analyzer just as if they were typed on a keyboard. The barcode

characters will be followed by a carriage return. The barcode wand and

the external keyboard can be connected simultaneously.

See “Using the Analyzer's Title Feature” on page 3-15 for more

information on using the title feature with a barcode reader.

In addition to Hewlett-Packard's barcode wand, other vendors offer

products such as cordless barcode readers, laser scanner readers,

barcode label printers, barcode fonts for Windows®, and barcode labeling

software. For more information about Hewlett-Packard barcode

products—including listings for distributors worldwide—please visit our

Web page at http://www.hp.com/HP-COMP/barcode.

Automating Measurements 3-13

Page 42

Operator Interaction

Using an External Keyboard for Data Entry

Using an External Keyboard for Data

Entry

An IBM PC-AT compatible keyboard can be connected to your analyzer's

DIN KEYBOARD connector and used to quickly and conveniently enter

file names for instrument state save/recall, or text for title lines.

NOTE If your keyboard has a standard (large) DIN connector, you will need to

use a DIN to mini-DIN adapter to connect the keyboard to the analyzer.

These adapters are available as HP part number 1252-4141. Contact the

nearest HP sales or service office for more information.

See “Using the Analyzer's Title Feature” on page 3-15 for more

information.

3-14 Automating Measurements

Page 43

Operator Interaction

More Display

Title and Clock

Title Line 1

Using the Analyzer's Title Feature

Using the Analyzer's Title Feature

The analyzer has two 30-character title lines which can be entered using

the barcode reader. From the front panel, press

keyboard, press F9. Then use the barcode reader to scan in the

information from the DUT or use a keyboard to type in the information.

Once stored in the title line, the information will be included on hardcopy

dumps. The title lines can also be set or queried using the following SCPI

command:

DISPlay:ANNotation:TITLe[1|2]:DATA

For example:

OUTPUT @Rfna;"DISP:ANN:TITL1:DATA 'BPF-177, SN US95170001'"

and

OUTPUT @Rfna;"DISPlay:ANNotation:TITLe1:DATA?"

ENTER @Rfna;Title1$

Use the command

"DISPlay:ANNotation:TITLe[1|2] ON|OFF"

to display or hide the title. If you are using IBASIC, you can use the

INPUT statement to read in barcode or keyboard characters. For

example:

30 INPUT "Scan in the Barcode now",Dut$

40 OUTPUT 800;"DISP:ANN:TITL1:DATA '";Dut$;"'"

50 OUTPUT 800;"DISP:ANN:TITL1 ON"

60 END

DISPLAY

, or on an external

Automating Measurements 3-15

Page 44

Operator Interaction

Hot Keys on External Keyboard for Common Functions

Hot Keys on External Keyboard for

Common Functions

You can use a keyboard's keys instead of the analyzer's keys to control

the analyzer. provides the same information that can be found on a

template that is supplied with each analyzer (HP part number

08712-80028). Function keys F9, F10, and F11 are “hot keys” which

perform common operations such as entering measurement titles and

saving measurement results to disk.

3-16 Automating Measurements

Page 45

Hot Keys on External Keyboard for Common Functions

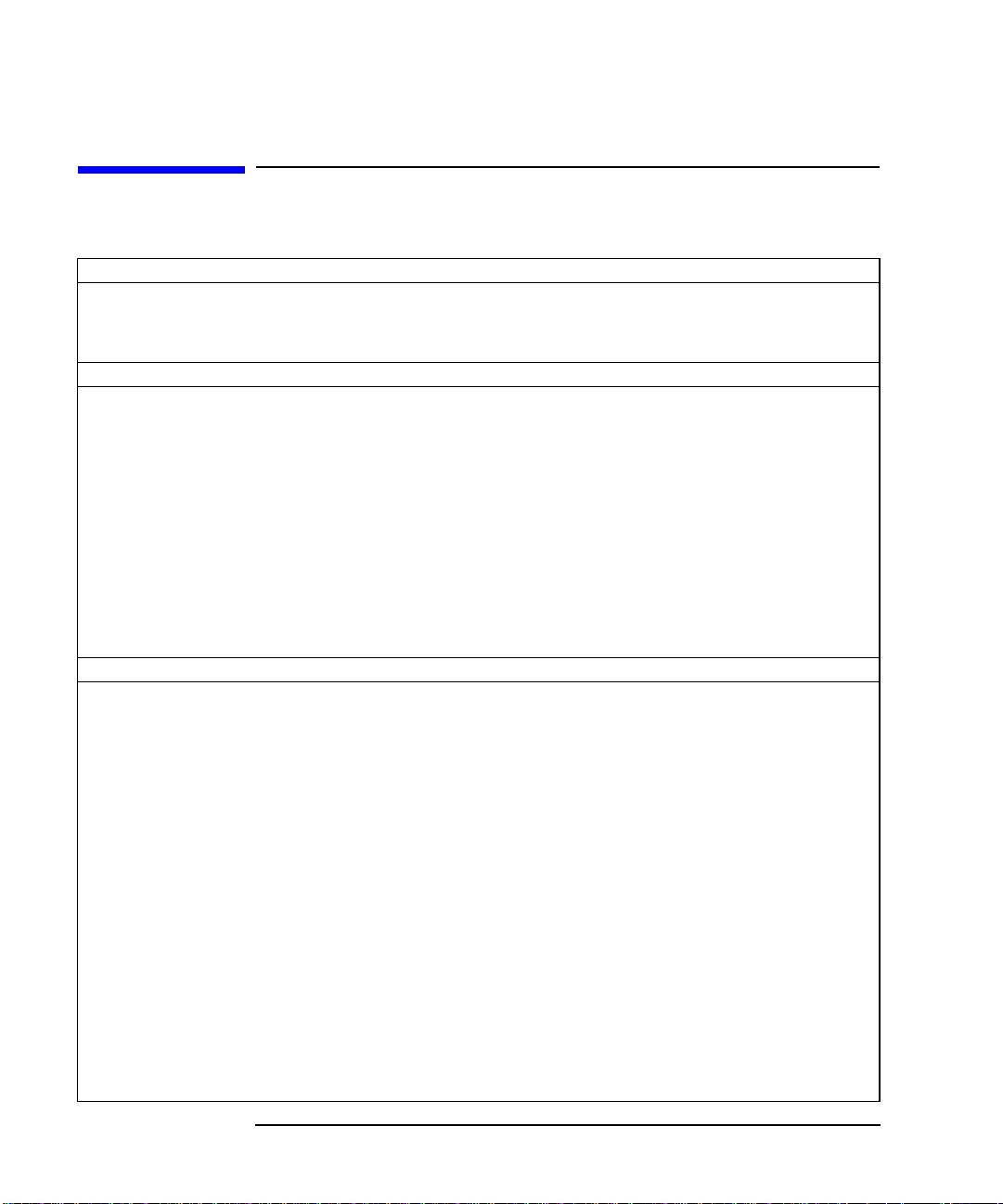

Table 3-1 Keyboard Template Definition

Operator Interaction

Keyboard

Key Name

F1 Softkey 1 Shift-F1

F2 Softkey 2 Shift-F2

F3 Softkey 3 Shift-F3

F4 Softkey 4 Shift-F4

F5 Softkey 5 Shift-F5

F6 Softkey 6 Shift-F6

F7 Softkey 7 Shift-F7

F8 Softkey 8 Shift-F8

F9 Title Keys Line 1 or RCL

F10

F11

F12

Analyzer Function

1

Title Keys Line 2 or Edit

Title Keys Clock or Window

Re-save File or Run

1

1

1

Keyboard

Key Name

Shift-F9

Shift-F10

Shift-F11

Shift-F12

Analyzer Function

MEAS 1

MEAS 2

FREQ

POWER

SWEEP

MENU

SCALE

MARKER

DISPLAY

FORMAT

CAL

AVG

Esc IBASIC Command Line On/Off Ctrl-F2

Print Screen Help Ctrl-F3

Ctrl-Print Screen Hardcopy Keyboard Template Ctrl-F4

Shift-Print Screen Hard Copy Graph and Softkeys Ctrl-F5

Ctrl-F1

1. When the IBASIC command line is enabled

SAVE RECALL

Automating Measurements 3-17

HARDCOPY

SYSTEM OPTIONS

PRESET

BEGIN

Page 46

Operator Interaction

System Config

User TTL Config

Default

User-Defined TTL Input/Output

User-Defined TTL Input/Output

The USER TTL port can be used as a general-purpose input or output.

Like the LIMIT TEST IN/OUT line, the USER TTL IN/OUT line is an

open-collector drive. When used as an input, the state of the USER TTL

IN/OUT line can be read with either the SCPI command

"DIAG:PORT:READ? 15,1"

or with the IBASIC command

I = READIO(15,1)

When used as an output, the state of the USER TTL IN/OUT line can be

set with either the SCPI command

"DIAG:PORT:WRITE 15,1,value"

or with the IBASIC command

WRITEIO 15,1;value

The USER TTL IN/OUT port can also be used in conjunction with an

external switch for softkey auto-stepping, or as a “sweep out” port. Be

sure that USER TTL IN/OUT port is configured properly for

general-purpose I/O by pressing

SYST:COMM:TTL:USER:FEED DEFAULT

SYSTEM OPTIONS

. Or use the following SCPI command:

CAUTION Be sure to observe static precautions when using this port.

3-18 Automating Measurements

Page 47

Operator Interaction

Using a Foot or Hand Switch

Using a Foot or Hand Switch

You can connect a foot switch, button box, or custom keyboard which has

a few function keys that are custom-labeled, and use this in conjunction

with IBASIC to allow consistent, error-free step-by-step measurement

control. The operator presses one key, then the next, in order.

NOTE A switch can also be used with the analyzer’s fast-recall feature. See

“Using Fast Recall with a Switch” on page 4-5.

The foot-switch simply connects two wires together, grounding the center

pin of the analyzer's USER TTL IN/OUT rear panel connector. (See

Figure 3-2.) The status of the USER TTL IN/OUT can be read using the

SCPI commands:

30 OUTPUT 716;"DIAG:PORT:READ? 15,1"

40 ENTER 716;X

or the IBASIC command:

30 X=READIO(15,1)

When the foot-switch is open, the variable “X” will be set to 1. When it is

closed, the variable “X” will be set to 0. Switch debounce is generally not

a problem, due to the relatively slow polling rate of the program.

Refer to “Analyzer Port Numbers” on page 3-22 for tables describing the

various analyzer ports that you can access using SCPI or IBASIC

commands.

Following is an example program which shows how to displa y a message

and read the foot switch to control your measurements. This program is

named “TTL_IO” on your Example Programs Disk.

For an example which uses the IBASIC READIO command, refer to the

program “USER_BIT” on your Example Programs Disk.

100 ! Filename: TTL_IO

110 !

120 ! This program reads the USER TTL IO

130 ! port, and counts how many times a

140 ! switch connected to the port is pressed.

150 !

160 DIM Msg$[200]

170 INTEGER X

180 !

190 IF POS(SYSTEM$("SYSTEM ID"),"HP 871") THEN

200 ASSIGN @Hp8711 TO 800

Automating Measurements 3-19

Page 48

Operator Interaction

Using a Foot or Hand Switch

210 ELSE

220 ASSIGN @Hp8711 TO 716

230 ABORT 7

240 CLEAR 716

250 END IF

260 !

270 Pass_count=0

280 Start: !

290 LOOP

300 ! Display message

310 Msg$="'DUTs passed: "&VAL$(Pass_count)&CHR$(10)

320 Msg$=Msg$&"Press button to measure next DUT.'"

330 OUTPUT @Hp8711;"DISP:ANN:MESS ";Msg$

340 !

350 ! Wait for button to be pressed

360 REPEAT

370 OUTPUT @Hp8711;"DIAG:PORT:READ? 15,1"

380 ENTER @Hp8711;X

390 UNTILX=0

400 DISP "Button is now pressed."

410 OUTPUT @Hp8711;"DISP:ANN:MESS:CLEAR"

420 !

430 ! Wait for button to be released

440 REPEAT

450 OUTPUT @Hp8711;"DIAG:PORT:READ? 15,1"

460 ENTER @Hp8711;X

470 UNTILX=1

480 DISP "Button is now released."

490 !

500 OUTPUT @Hp8711;"DISP:ANN:MESS 'Measuring...'"

510 ! Add code here to take sweep

520 ! and measure DUT.

530 WAIT 1

540 Pass_count=Pass_count+1

550 END LOOP

560 END

3-20 Automating Measurements

Page 49

Operator Interaction

Limit-Test Pass/Fail TTL Input/Output

Limit-Test Pass/Fail TTL Input/Output

When limit testing is turned on, the LIMIT TEST IN/OUT rear-panel

BNC connector indicates the status of the limit test. If the limit test

passes, this TTL output goes high. If the limit test fails, this TTL output

goes low. This signal can be used, for example, as an input to a materials

handler.

CAUTION Since the TTL output has limited current drive capability, it should be

buffered when controlling high current devices such as mechanical

relays. Otherwise, damage to the instrument may result.

The limit-test TTL can also be used as a general-purpose input, since the

analyzer drive to this line is open collector. When used as an input, limit

testing should be turned off so the instrument will allow the limit test

line to float high. The line can then be connected to an external switch

which should only pull the signal to ground or let it float (an external

circuit should not drive this line). A push button or foot switch can be

attached to the line to pull the signal to ground.

The state of the signal can be monitored by the automated system to

determine when the operator is ready for some action. The state of the

limit TTL line can be read with either the SCPI commands

20 INTEGER X

30 OUTPUT 716;"DIAG:PORT:READ? 15,2"

40 ENTER 716;X

or using the IBASIC command

30 X=READIO(15,2)

Finally, the LIMIT TEST TTL IN/OUT line can be used as a

general-purpose output line. With limit testing turned off, the state of

the line can be set to logic high or low with either the SCPI command

"DIAG:PORT:WRITE "

or with the IBASIC command

"WRITEIO ,value".

The following is an example of reading the LIMIT TEST TTL IN/OUT

line when used as an input:

30 Limit = READIO(15,2)

40 ! The "Limit" variable will be set to 0 if the signal is low

50 ! and 1 if the signal is high.

Automating Measurements 3-21

Page 50

Operator Interaction

Analyzer Port Numbers

Analyzer Port Numbers

Table 3-2 Writeable Ports

Port

Number

15 0 Outputs 8-bit data to the Cent_D0 thru D7 lines of the Centronics port.

15 1 Sets/clears the user bit according to the least significant bit of A. A least

15 2 Sets/clears the limit pass/fail bit according to the least significant bit of A.

15 3 Outputs 8-bit data to the Cent_D0 thru D7 lines of the Centronics port.

9 0 Outputs a byte to the serial port. The byte is output serially according to

Register Description

Cent_D0 is the least significant bit, Cent_D7 is the most significant bit.

Checks Centronics status lines for:

Out of Paper

Printer Not on Line

BUSY

ACKNOWLEDGE

significant bit equal to 1 sets the user bit high. A least significant bit of 0

clears the user bit.

A least significant bit equal to 1 sets the pass/fail bit high. A least

significant bit of 0 clears the pass/fail bit.

Cent_D0 is the least significant bit, Cent_D7 is the most significant bit.

Sets the Printer_select signal high (de-select). Does not check Centronics

status lines.

the configuration for the serial port.

NOTE When using the WRITEIO(15,0) or WRITEIO(15,3) command, the

Printer_Select Line is set high. However, when the instrument is doing

hardcopy, the Printer_Select Line is set low. The Printer_Select line may

or may not be used by individual printers. Check with your printer

manual.

3-22 Automating Measurements

Page 51

Table 3-3 Readable Ports

Operator Interaction

Analyzer Port Numbers

Port

Number

9 0 Reads the serial port.

15 0 Reads the 8-bit data port Cent_D0 thru D7.

15 1 Reads the user bit.

15 2 Reads the limit test pass/fail bit.

15 10 Reads the 8-bit status port.

Register Description

D0 — Cent_acknowledge

D1 — Cent_busy

D2 — Cent_out_of_paper

D3 — Cent_on_line

D4 — Cent_printer_err

Automating Measurements 3-23

Page 52

Operator Interaction

Output for External VGA-Compatible Monitor

Output for External VGA-Compatible

Monitor

You can connect a VGA-compatible external monitor to the VIDEO OUT

COLOR VGA connector for a large-screen color view of your

measurement if you wish. See “Using an External VGA Monitor” in

Chapter 4 of your analyzer’s User’s Guide for information on using an

external monitor with your system.

3-24 Automating Measurements

Page 53

4 Measurement Setup and

Control with Fast Recall

4-1

Page 54

Measurement Setup and Control with Fast Recall

The production and testing of RF components often involves several

steps, with each step requiring a unique set of instrument settings.

Likewise, the different test configurations at each step may require

associated calibrations. Manually entering these sets of parameters (or

“states”) or calibrating at each step in the manufacturing process is slow,

prone to operator error, and costly. The fast-recall feature allows you to

recall one of seven instrument states with just a single key press, or to

cycle through up to seven different instrument states with a switch.

4-2 Automating Measurements

Page 55

Measurement Setup and Control with Fast Recall

Fast Recall on OFF

Select Disk

Non-Vol RAM Disk

Prior Menu

Fast Recall on OFF

Rename File

Using Fast Recall with the Front Panel or a Keyboard

Using Fast Recall with the Front Panel

or a Keyboard

NOTE The following explanation assumes that you are familiar with the

information presented in “Saving and Recalling Measurement Results”

in Chapter 4 of your analyzer’s User’s Guide.

1. Press .

2. If the measurement display area changes to a listing of files on the

currently selected disk, fast recall is off.

If the measurement display area remains unchanged, fast recall is on.

To follow along with this explanation, turn fast recall off by pressing

3. If necessary, select the internal non-volatile RAM disk by pressing

4. If you have previously saved any files to this disk, they will now be

listed on the display.

5. The fast recall feature utilizes only the first seven files listed that

contain instrument state, calibration, or measurement data.

6. If you have not previously saved any files to this disk, you may want

to save a few instrument states now, to follow along.

7. Press so that “ON” is

capitalized. Note that the measurement display now reappears on the

screen and that there are file names next to the first seven softkeys.

(If any of the softkeys are blank, it's because you had less than seven

files saved on the disk.)

The files are placed on the softkeys in the order in which they appear

in the disk's directory table.

SAVE RECALL

so that “OFF” is capitalized.

.

NOTE You may want to use the feature to give your files more

meaningful names. See “Other File Utilities” in Chapter 4 of your

analyzer’s User’s Guide for information on renaming files.

8. To “fast recall” an instrument state, press the softkey next to the file

name that contains the instrument state.

Automating Measurements 4-3

Page 56

Measurement Setup and Control with Fast Recall

Using Fast Recall with the Front Panel or a Keyboard

9. The fast-recall mode will remain on (even when the analyzer is

PRESET

10.With the fast-recall feature turned on, you will always be only one or

two key presses away from recalling an instrument state.

11.With an external keyboard connected to the rear panel DIN

connector, keys F1 through F7 are equivalent to pressing softkeys 1

through 7 on the analyzer. See “Using a Keyboard” in Chapter 4 of

your analyzer’s User’s Guide for information on connecting and using

an external keyboard.

NOTE For test systems that include a multiport test set:

See the example program titled “MPSVRCL.” This IBASIC/RMB

program requires an HP 8712ET/ES or HP 8714ET/ES analyzer

connected to a multiport test set. The program saves three instrument

states, each measuring various ports in ALT sweep mode. Fast recall is

enabled so that subsequent recalls require a single keypress.

Example programs can be found in the following four locations:

• Web site http://www.hp.com or http://www.agilent.com. Use the

search function to find Web pages related to 8712 example programs.

• Example Programs Disk, HP 8712ET/ES and HP 8714ET/ES (DOS

format): HP part number 08714-10003

• Example Programs Disk, HP 8712ET/ES and HP 8714ET/ES (LIF

format): HP part number 08714-10004

• Example Programs Guide, HP 8712ET/ES and HP 8714ET/ES: HP

part number 08714-90016

) until manually turned off.

4-4 Automating Measurements

Page 57

Measurement Setup and Control with Fast Recall

System Config

User TTL Config

Softkey Auto Step

Fast Recall

Using Fast Recall with a Switch

Using Fast Recall with a Switch

When fast recall is used in conjunction with a switch connected to the

USER TTL IN/OUT rear panel connector, you can cycle through up to

seven instrument states in sequence by activating the switch.

1. Connect a switch to the USER TTL IN/OUT rear panel connector as

shown in Figure 4-1.

Figure 4-1 Connect a Switch to the USER TTL IN/OUT Connector

2. Make sure the analyzer is configured to use the USER TTL IN/OUT

connector for softkey sequencing: press

3. With toggled to ON, press the switch several times

while observing the analyzer.

4. Notice that with each press of the switch, the files are highlighted

(boxed) in succession, and that after the last available file has been

used, the sequence starts again at the top of the softkey menu.

Automating Measurements 4-5

SYSTEM OPTIONS

.

Page 58

Measurement Setup and Control with Fast Recall

Using Fast Recall with a Switch

4-6 Automating Measurements

Page 59

5 Automated Measurement Setup

and Control

5-1

Page 60

Automated Measurement Setup and Control

The production of RF components often involves several steps, with each

step requiring a unique set of instrument settings. Likewise, the

different test configurations at each step may require associated

calibrations. Requiring the operator to manually enter these sets of

parameters (or “states”) or to calibrate at each step in the manufacturing

process is slow, prone to operator error, and costly.

An automated measurement system can be used to achieve fast and

consistent transitions between measurement setups. In an automated

system, the instrument parameters are set under program control. The

control program can be an IBASIC program running inside the analyzer,

or a program in another language running on an external computer. The

control program sends SCPI and IEEE-488 commands to the analyzer's

HP-IB or LAN interface. The HP-IB commands rapidly change the

instrument settings or calibration.

Figure 5-1 Measurement Control

5-2 Automating Measurements

Page 61

Automated Measurement Setup and Control

The HP-IB or LAN interfaces can also be used to trigger sweeps, read

measurement values, or signal events within the analyzer. Most

operations that can be done from the front panel can also be done over

the HP-IB or LAN interface. See the Programmer's Guide and the LAN

Interface User’s Guide Supplement for details.

This chapter describes methods for changing instrument settings rapidly

under program control. It then briefly discusses how to synchronize the

modification of instrument settings with the collection of data and how to

use service requests (SRQs) to signal instrument states. Finally, it

describes how to utilize both measurement channels and a feature to

automatically start an IBASIC control program.

For information on techniques that can improve your sweep speed, refer

to “Optimizing Measurements” in your analyzer’s User’s Guide.

Automating Measurements 5-3

Page 62

Automated Measurement Setup and Control

Setting the Instrument State

Setting the Instrument State

A DUT will often undergo several different tests while at a single test

station. The analyzer's parameters (such as sweep frequencies, output

power, markers, and limits) must be set to the desired values before each

test is performed. In an automated test system, the controlling computer

modifies the instrument settings for the operator. The analyzer offers

several techniques for quickly changing the instrument's measurement

parameters:

• Recall of instrument states from disk

• The learn string HP-IB command (*LRN)

• SCPI commands that change specific parameters

Recalling Instrument States from Disk

The analyzer has two internal memory (RAM) disks: “Non-Vol RAM

Disk” and “Volatile RAM Disk.” A “RAM Disk” is a block of memory

inside the analyzer which you can access in the same way that you access

files on a floppy disk. In addition, the analyzer has a built-in 3.5 inch

floppy-disk drive accessible on the front panel.

The “Non-Vol RAM Disk” is non-volatile, meaning that its contents are

preserved while the analyzer is turned off. The contents of the “Volatile

RAM Disk” are erased when the analyzer is turned off. The volatile RAM

disk can be configured to be much larger than the non-volatile RAM disk,

allowing it to hold many more instrument states.

The instrument settings and calibrations associated with several tests

can be saved to instrument state files on any of the analyzer’s three disks

described above. The instrument states can later be recalled during a

test sequence. The advantage of using RAM disks rather than the

3.5 inch floppy disk is that recalling a state from RAM disks takes

several seconds less than recalling a state from the floppy disk.

5-4 Automating Measurements

Page 63

Automated Measurement Setup and Control

Setting the Instrument State

For example, suppose the instrument settings are entered for the third

test of a sequence of tests. The instrument settings can be saved in a file

with the name “TEST3.STA” on the non-volatile RAM disk. When the

third test must be performed, the control program can recall the

instrument state from the non-volatile RAM disk with the following

SCPI command:

MMEM:LOAD:STATe 1,'MEM:TEST3.STA'

Recalling a state from RAM disk typically takes about 4 seconds, but the

time is dependent on settings such as number of points.

One strategy for managing a large set of recall states is to initially store

them on a floppy disk. The files can then be copied from the floppy disk to

the volatile RAM disk at the start of each day. Since recall time from the

RAM disk is faster than recall from the floppy disk drive, throughput can

be increased. For example , to copy the file 'TEST3.ST A' from the 3.5 inch

disk to the non-volatile RAM disk, use the following SCPI command:

MMEM:COPY 'INT:TEST3.STA', 'MEM:'

For more details, see the Programmer's Guide.

When controlling the analyzer with a computer, you may want to copy an

instrument state file from your computer to one of the analyzer's built-in

RAM disks or the 3.5 inch disk. Later, the instrument can be instructed

to recall the state from its internal disk. The file can be sent from the

computer to the analyzer's disk using the SCPI MMEMory:TRANsfer

commands. For more details, see the Programmer's Guide.

For manually controlled test systems, the instrument state files for each

measurement can be stored onto disk by the test-system designer.

During the test sequence, the operator can press the

SAVE RECALL

key and recall the instrument state for a particular measurement.

Automating Measurements 5-5

Page 64

Automated Measurement Setup and Control

Define Save

Setting the Instrument State

Using Learn Strings to Save and Recall

Instrument States

The IEEE 488 *LRN (“learn”) command can also be used to set or query a

complete set of instrument parameters. This can be used as a

programming convenience, eliminating the need for using disk files when

saving and recalling instrument states.

To obtain the learn string containing the instrument state, use the

command *LRN? as follows:

10 DIM State1$[4000]

20 OUTPUT @Rfna;"*LRN?"

30 ENTER @Rfna USING "-K";State1$

...

160 ! Put the learn string back

170 OUTPUT @Rfna;State1$

Since *LRN?, by IEEE definition, only contains the actual instrument

state, exclusive of data traces and calibration arrays, the network

analyzer provides the command

SYST:SET:LRNLong?

This command saves the data traces and calibration arrays if they are

enabled using or by using the