Page 1

User’s Guide

HP 8712ES and HP 8714ES

RF Network Analyzers

HP Part No. 08714-90012

Printed in USA

Print Date: October 1999

Supersedes: November 1998

© Copyright 1998, 1999 Hewlett-Packard Company

Page 2

Notice

The information contained in this document is subject to change without

notice. Hewlett-Packard makes no warranty of any kind with regard to

this material, including but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Hewlett-Packard

shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance,

or use of this material.

Key Conventions

This manual uses the following conventions:

FRONT PANEL KEY

This represents a key physically located on the instrument (a “hardkey”).

Softkey

This indicates a “softkey,” a key whose label is determined by the

instrument’s firmware, and is displayed on the right side of the

instrument’s screen next to the eight unlabeled keys.

Screen Text

This indicates text displayed on the instrument’s screen.

Safety Information

For safety and regulatory information seeChapter 10, “Safety and

Regulatory Information.” For warranty and assistance information see

Chapter 9, “Specifications.”

Firmware Revision

This manual documents analyzers with firmware revisions E.06.00 and

above.

ii ES User’s Guide

Page 3

Acknowledgments

Lotus® 1-2-3® are U.S. registered trademarks of Lotus Development

Corporation.

Windows, Word97, and Excel97 are registered trademarks of

Microsoft Corp.

Portions of the software include source code from the Info–ZIP group.

This code is freely available on the Internet by anonymous ftp

asftp.uu.net:/pub/archiving/zip/unzip51/.tar.Z, and from CompuServe

asunz51.zip in the IBMPRO forum, library 10, (data compression).

ES User’s Guide iii

Page 4

Introducing the Analyzer

The HP 8712ES and HP 8714ES are easy-to-use RF network analyzers

optimized for production measurements of S-parameters. The

instrument integrates an RF synthesized source, S-parameter test set,

multi-mode receivers, and display in one compact box.

The source features 1 Hz resolution, 40 ms (or faster) sweep time, and up

to +13 dBm output power.

S-parameter test sets provide the capability to measure reflection and

transmission characteristics of two-port devices in either the forward or

reverse direction with a single connection. RF power can come out of

either the analyzer’s port 1 or port 2, and either port can be connected to

a receiver. S-parameter test sets also allow full two-port (12 term) error

correction, which is the most accurate form available.

The three-channel, dual mode receivers provide dynamic range of

greater than 100 dB in narrowband measurement mode. For

measurements of frequency-translating devices, the network analyzer

features broadband internal detectors and external detector inputs. The

receivers incorporate digital signal processing and microprocessor

control to speed operation and measurement throughput.

Two independent measurement channels and a large display show the

measured results of one or two receiver channels in several

user-selectable formats. An external VGA monitor can be connected to

the rear panel for enhanced measurement viewing in color.

Measurement functions are selected with front panel hardkey and

softkey menus. Measurements can be printed or plotted directly with a

compatible peripheral. Instrument states can be saved to the internal

floppy disk, internal non-volatile memory, or internal volatile memory.

Built-in service diagnostics are available to simplify troubleshooting

procedures

Measurement calibrations and data averaging provide performance

improvement and flexibility. Measurement calibrations consist of

normalizing data, utilizing the internal factory calibration, or calibrating

with external standards. Measurement calibration reduces errors

iv ES User’s Guide

Page 5

associated with crosstalk, directivity, source and load match, and

frequency response. Refer to Chapter 9, “Specifications,” for error

correction specifications.

How to Use This Guide

The first 6 chapters of this guide explain how to perform measurements,

calibrate the instrument, and use the most common instrument

functions.

Chapters 7 through 11 are reference material. Use these chapters to look

up information such as front panel features, specific key functions, and

specifications.

ES User’s Guide v

Page 6

HP 8712ES and HP 8714ES

Network Analyzer

Documentation Map

The CDROM provides the contents of all of the documents

listed below.

The User’s Guide shows how to make measurements,

explains commonly-used features, and tells you how to get

the most performance from the analyzer.

The LAN Interface User’s Guide Supplement shows

how to use a local area network (LAN) for programming and

remote operation of the analyzer.

The Automating Measurements User’s Guide

Supplement provides information on how to configure and

control test systems for automation of test processes.

The Programmer’s Guide provides programming

information including HP-IB and SCPI command references,

as well as short programming examples.

The Example Programs Guide provides a tutorial

introduction using BASIC programming examples to

demonstrate the remote operation of the analyzer

.

vi ES User’s Guide

Page 7

The Service Guide provides the information needed to

adjust, troubleshoot, repair , and verify analyzer conformance

to published specifications.

The HP Instrument BASIC User’s Handbook describes

programming and interfacing techniques using

HP Instrument BASIC, and includes a language reference.

The HP Instrument BASIC User’s Handbook

Supplement shows how to use HP Instrument BASIC to

program the analyzer.

The Option 100 Fault Location and Structural Return

Loss Measurements User’s Guide Supplement provides

theory and measurement examples for making fault location

and SRL measurements. (Shipped only with Option 100

analyzers.)

The CATV Quick Start Guide provides abbreviated

instructions for testing the quality of coaxial cables.

(Shipped only with Option 100 analyzers.)

The Cellular Antenna Quick Start Guide provides

abbreviated instructions for verifying the performance of

cellular antenna systems. (Shipped only with Option 100

analyzers.)

ES User’s Guide vii

Page 8

viii ES User’s Guide

Page 9

Contents

1. Installing the Analyzer

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Step 1. Check the Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Step 2. Meet Electrical and Environmental Requirements. . . . . . . . . . . . . . . . . . . . . . 1-4

Step 3. Check the Analyzer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Step 4. Configure the Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Connecting Peripherals and Controllers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Installing the Analyzer in a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Clean the CRT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Check the RF Front Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

2. Getting Started

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Front Panel Tour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Entering Measurement Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Presetting the Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Entering Frequency Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Entering Source Power Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Scaling the Measurement Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Entering the Active Measurement Channel and Type of Measurement. . . . . . . . . . 2-7

Viewing Measurement Channels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Performing the Operator's Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Equipment List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Make S21 and S12 Transmission Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Make a Broadband Power Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Make S11 and S22 Reflection Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

If the Analyzer Fails the Operator's Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

3. Making Measurements

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Measuring Devices with Your Network Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

The Measurement Display Icon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Measuring S-Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Attenuation and Amplification in a Measurement Setup . . . . . . . . . . . . . . . . . . . . 3-11

When to Change the System Impedance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Contents-i

Page 10

Contents

The Typical Measurement Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Using the BEGIN Key to Make Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

BEGIN Key Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Using the BEGIN Key to Configure Measurements . . . . . . . . . . . . . . . . . . . . . . . . .3-16

AUTOST files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

The User BEGIN Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Measuring S-Parameters using a

Two-Port Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Enter the Measurement Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Perform a User Two-Port Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

View and Interpret the S-Parameter Measurement Results . . . . . . . . . . . . . . . . . .3-40

Measuring S21 Forward

Transmission using an Enhanced Response Calibration. . . . . . . . . . . . . . . . . . . . . . .3-41

Enter the Measurement Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-42

Perform an Enhanced Response Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-42

Connect the DUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-45

View and Interpret the S21 Measurement Results. . . . . . . . . . . . . . . . . . . . . . . . . .3-46

Measuring S11 Reflection Port 1 using a One-Port Calibration . . . . . . . . . . . . . . . . .3-48

Enter the Measurement Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-49

Perform a User One-Port Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-49

Connect the DUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-52

View and Interpret the S11 Measurement Results. . . . . . . . . . . . . . . . . . . . . . . . . .3-54

Making a Power Measurement using Broadband Detection . . . . . . . . . . . . . . . . . . . .3-56

Enter the Measurement Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-56

Perform a Normalization Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-57

Connect the DUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-58

View and Interpret the Power Measurement Results. . . . . . . . . . . . . . . . . . . . . . . .3-59

Measuring Conversion Loss. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-61

Enter the Measurement Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-62

Perform a Normalization Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-62

Connect the DUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-64

View and Interpret the Conversion Loss Results . . . . . . . . . . . . . . . . . . . . . . . . . . .3-65

Making Measurements with the Auxiliary Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-67

Auxiliary Input Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-68

Measuring Group Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-69

Enter the Measurement Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-70

Perform a User Two-Port Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-71

Contents-ii

Page 11

Contents

Connect the DUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-71

View and Interpret the Group Delay Measurement Results. . . . . . . . . . . . . . . . . . 3-71

Measuring Impedance using the Smith Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-73

Enter the Measurement Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-74

Perform a User Two-Port Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-74

Connect the DUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-75

View and Interpret the Impedance Measurement Results . . . . . . . . . . . . . . . . . . . 3-76

Measuring Impedance Magnitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-80

How the Reflection Measurement Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-80

How the Transmission Measurement Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-81

4. Using Instrument Functions

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Using Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

To Activate Markers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

To Turn Markers Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

To Use Marker Search Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

To Use Marker Math Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

To Use Delta (∆) Marker Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

To Use Other Marker Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

To Use Polar Format Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

To Use Smith Chart Markers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Using Limit Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

To Create a Flat Limit Line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

To Create a Sloping Limit Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

To Create a Single Point Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

To Use Marker Limit Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

To Use Relative Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Other Limit Line Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Additional Notes on Limit Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Using Reference Tracking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

To Track the Peak Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

To Track a Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Customizing the Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

Using the Split Display Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Enabling/Disabling Display Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Contents-iii

Page 12

Contents

Modifying Display Annotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-48

Expanding the Displayed Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-52

Saving and Recalling Measurement Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-55

Saving Instrument Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-57

To Recall from a Floppy Disk or Internal Memory . . . . . . . . . . . . . . . . . . . . . . . . . .4-60

Other File Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-63

To Use Directory Utilities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-65

Formatting a Floppy Disk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-67

Connecting and Configuring Printers and Plotters . . . . . . . . . . . . . . . . . . . . . . . . . . .4-68

Select a Compatible Plotter or Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-68

Select an Appropriate Interface Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-69

Connect the Printer or Plotter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-70

Configure the Hardcopy Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-71

Define the Printer or Plotter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-73

Printing and Plotting Measurement Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-78

To Select the Copy Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-78

To Define the Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-79

Using a Keyboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-83

To Connect the Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-83

To Use the Keyboard to Edit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-84

Front Panel Control using a Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-84

Using an External VGA Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-87

Customizing Color on an External Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-87

Synchronizing and Positioning the Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-89

5. Optimizing Measurements

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Increasing Sweep Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Select the Appropriate Calibration Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

To Increase the Start Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

To Set the Sweep Time to AUTO Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

To Widen the System Bandwidth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

To Reduce the Amount of Averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

To Reduce the Number of Measurement Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

To View a Single Measurement Channel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

To Turn Off Alternate Sweep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Contents-iv

Page 13

Contents

To Turn Off Markers and Marker Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

To Turn Off Spur Avoidance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

To Avoid Frequency Bandcrossings by

Minimizing the Span (HP 8714ES only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Increasing Network Analyzer Dynamic Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

To Increase the Receiver Input Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

To Reduce the Receiver Noise Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Reducing Trace Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

To Activate Averaging for Reducing Trace Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

To Change System Bandwidth for Reducing Trace Noise . . . . . . . . . . . . . . . . . . . . 5-12

To Eliminate Receiver Spurious Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Reducing Mismatch Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Reducing Mismatch Errors in a Reflection Measurement. . . . . . . . . . . . . . . . . . . . 5-15

Reducing Mismatch Errors in a Transmission Measurement. . . . . . . . . . . . . . . . . 5-16

Reducing Mismatch Errors when Measuring Both Reflection and Transmission . 5-17

Compensating for Phase Shift in Measurement Setups . . . . . . . . . . . . . . . . . . . . . . . 5-18

Port Extensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Electrical Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Measuring Devices with Long Electrical Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

6. Calibrating for Increased Measurement Accuracy

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Measurement Calibration Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

The Calibration Reference Plane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Default versus User-Defined Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

When to Use a Default Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

When to Perform a User-Defined Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Calibration Choices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Retrieving Previous User-Defined Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Presetting the Analyzer: How Calibration Is Affected. . . . . . . . . . . . . . . . . . . . . . . 6-13

To Perform a Normalization Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

To Perform a Transmission Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

To Perform a Reflection Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

To Perform a Conversion Loss Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Calibration Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Selecting a Calibration Kit Stored in the Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Contents-v

Page 14

Contents

Creating a User-Defined Calibration Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

Saving and Recalling the Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-33

Saving the Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-33

Recalling the Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-34

7. Front/Rear Panel

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

BNC Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Multi-pin Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

RF Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-15

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-16

Knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-18

Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-19

Display Intensity Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-20

Disk Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-21

Line Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-22

Power Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-22

The Line Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-24

The Voltage Selector Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-25

8. Hardkey/Softkey Reference

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Numeric Entries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-11

C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-14

D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-20

E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-27

F. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-30

G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-35

H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-37

I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-42

K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-45

L. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-46

M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-52

Contents-vi

Page 15

Contents

N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-60

O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-63

P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-64

R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-69

S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-75

T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-89

U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-94

V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-97

W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-99

X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-100

Y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-101

Z . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-103

9. Specifications

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

System Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Test Port Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

Test Port Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-29

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-39

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-45

Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-45

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-47

Data Hardcopy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-47

Automation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-48

Measurement Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-49

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-52

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-54

Limitation of Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-55

Exclusive Remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-55

Hewlett-Packard Sales and Service Offices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-56

10. Safety and Regulatory Information

Safety and Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Contents-vii

Page 16

Contents

Statement of Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

Shipping Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

Instrument Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-5

Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

Notice for Germany: Noise Declaration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

11. Factory Preset State and Memory Allocation

Factory Preset and Peripheral States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-2

Factory Preset State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-2

Peripheral State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-8

Volatile Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-12

Save/Recall Memory Allocation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-13

Types of Storage Disks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-13

Types of Storable Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-15

How to Determine the Size of Disk Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-16

Memory Usage Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-18

Contents-viii

Page 17

1 Installing the Analyzer

ES User’s Guide 1-1

Page 18

Installing the Analyzer

Introduction

Introduction

This chapter will guide you through the four steps needed to correctly

and safely install your network analyzer. The four steps are:

1. Check the Shipment

2. Meet Electrical and Environmental Requirements

3. Check the Analyzer Operation

4. Configure the Analyzer

1-2 ES User’s Guide

Page 19

Installing the Analyzer

Step 1. Check the Shipment

Step 1. Check the Shipment

After you have unpacked your instrument, it is recommended that you

keep the packaging materials so they may be used if your instrument

should need to be returned for maintenance or repair.

NOTE The packaging material is designed to protect the analyzer from damage

that can happen during shipping. Returning the analyzer in anything

other than the original packaging may result in non-warranted damage.

Check the items received against the Product Checklist (included in your

shipment) to make sure that you received everything.

Inspect the analyzer and all accessories for any signs of damage that

may have occurred during shipment. If your analyzer or any accessories

appear to be damaged or missing, call your nearest Hewlett-Packard

sales or service office. Refer to Table 9-10, “Hewlett-Packard Sales and

Service Offices,” in Chapter 9 for the nearest office.

ES User’s Guide 1-3

Page 20

Installing the Analyzer

Step 2. Meet Electrical and Environmental Requirements

Step 2. Meet Electrical and

Environmental Requirements

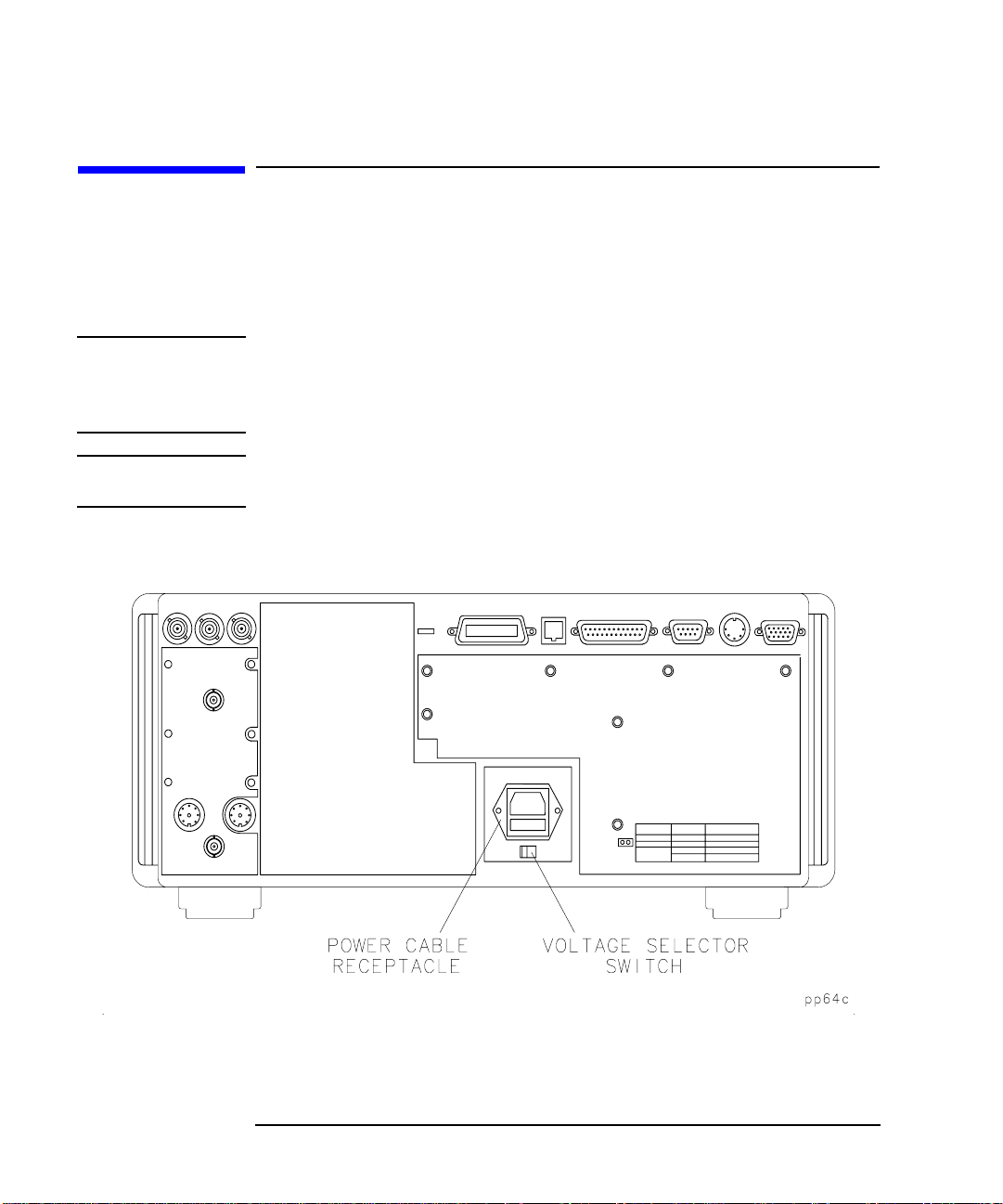

1. Set the line voltage selector to the position that corresponds to the ac

power source you will be using.

CAUTION Before switching on this instrument, make sure that the line voltage

selector switch is set to the voltage of the mains supply and the correct

fuse (T 5 A 250 V) is installed. Assure the supply voltage is in the

specified range.

NOTE The working fuse and a spare are located in the power cable receptacle.

See Figure 7-12, “Location of Line Fuses,” in Chapter 7.

Figure 1-1 Voltage Selector Switch Location

1-4 ES User’s Guide

Page 21

Installing the Analyzer

Step 2. Meet Electrical and Environmental Requirements

2. Ensure the available ac power source meets the following

requirements:

Nominal

Setting

115 V

230 V

If the ac line voltage does not fall within these ranges, an

autotransformer that provides third-wire continuity to ground should

be used.

3. Ensure the operating environment meets the following requirements

for safety:

• indoor use

• altitude up to 15,000 feet (4,572 meters)

• temperature 0 °C to 55 °C

• maximum relative humidity 5 to 95 percent relative at +40 °C

(non-condensing)

CAUTION This product is designed for use in Installation Category II and Pollution

Degree 2 per IEC 1010 and 664 respectively.

NOTE The above requirements are for safety only. Separate conditions that

must be met for specified performance are noted in Chapter 9.

AC Line Power

90 to 132 Vac (47 to 63 Hz)

198 to 264 Vac (47 to 63 Hz)

ES User’s Guide 1-5

Page 22

Installing the Analyzer

Step 2. Meet Electrical and Environmental Requirements

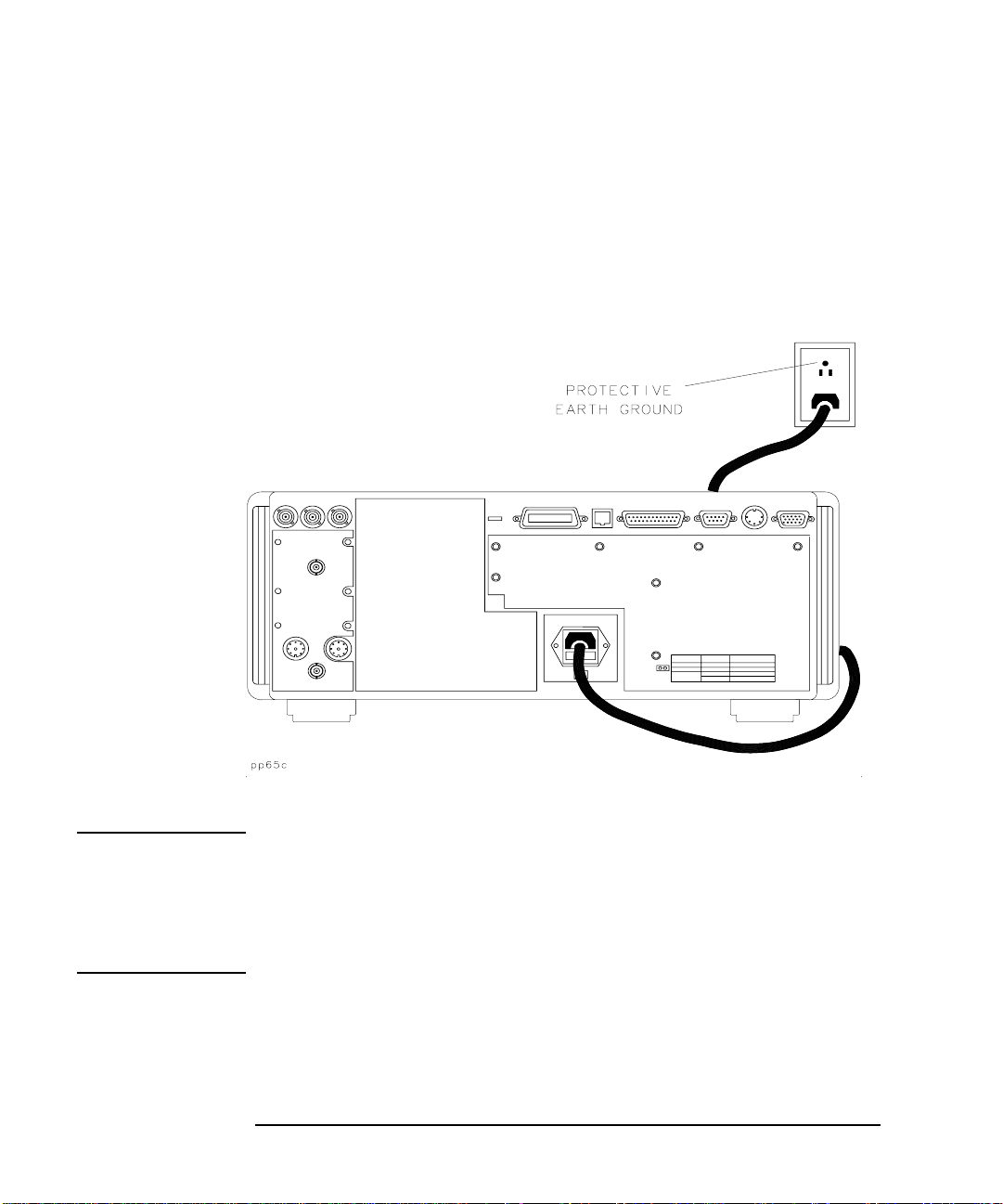

4. V erify that the power cable is not damaged, and that the power source

outlet provides a protective earth ground contact. Note that the

following illustration depicts only one type of power source outlet.

Refer to Figure 7-11 in Chapter 7 to see the different types of power

cord plugs that can be used with your analyzer.

Figure 1-2 Protective Earth Ground

WARNING This is a Safety Class I product (provided with a protective

earthing ground incorporated in the power cord). The mains

plug shall only be inserted in a socket outlet provided with a

protective earth contact. Any interruption of the protective

conductor , inside or outside the instrument, is likely to make the

product dangerous. Intentional interruption is prohibited.

1-6 ES User’s Guide

Page 23

Installing the Analyzer

Step 2. Meet Electrical and Environmental Requirements

WARNING If this instrument is to be energized via an external

autotransformer for voltage reduction, make sure that its

common terminal is connected to a neutral (earthed pole) of the

power supply.

5. Install the analyzer so that the detachable power cord is readily

identifiable and is easily reached by the operator. The detachable

power cord is the instrument disconnecting device. It disconnects the

mains circuits from the mains supply before other parts of the

instrument. The front panel switch is only a standby switch and not a

LINE switch. Alternatively, an externally installed switch or circuit

breaker (which is readily identifiable and is easily reached by the

operator) may be used as a disconnecting device.

6. Install the analyzer according to the enclosure protection provided.

This instrument does not protect against the ingress of water. It does

protect against finger access to hazardous parts within the enclosure.

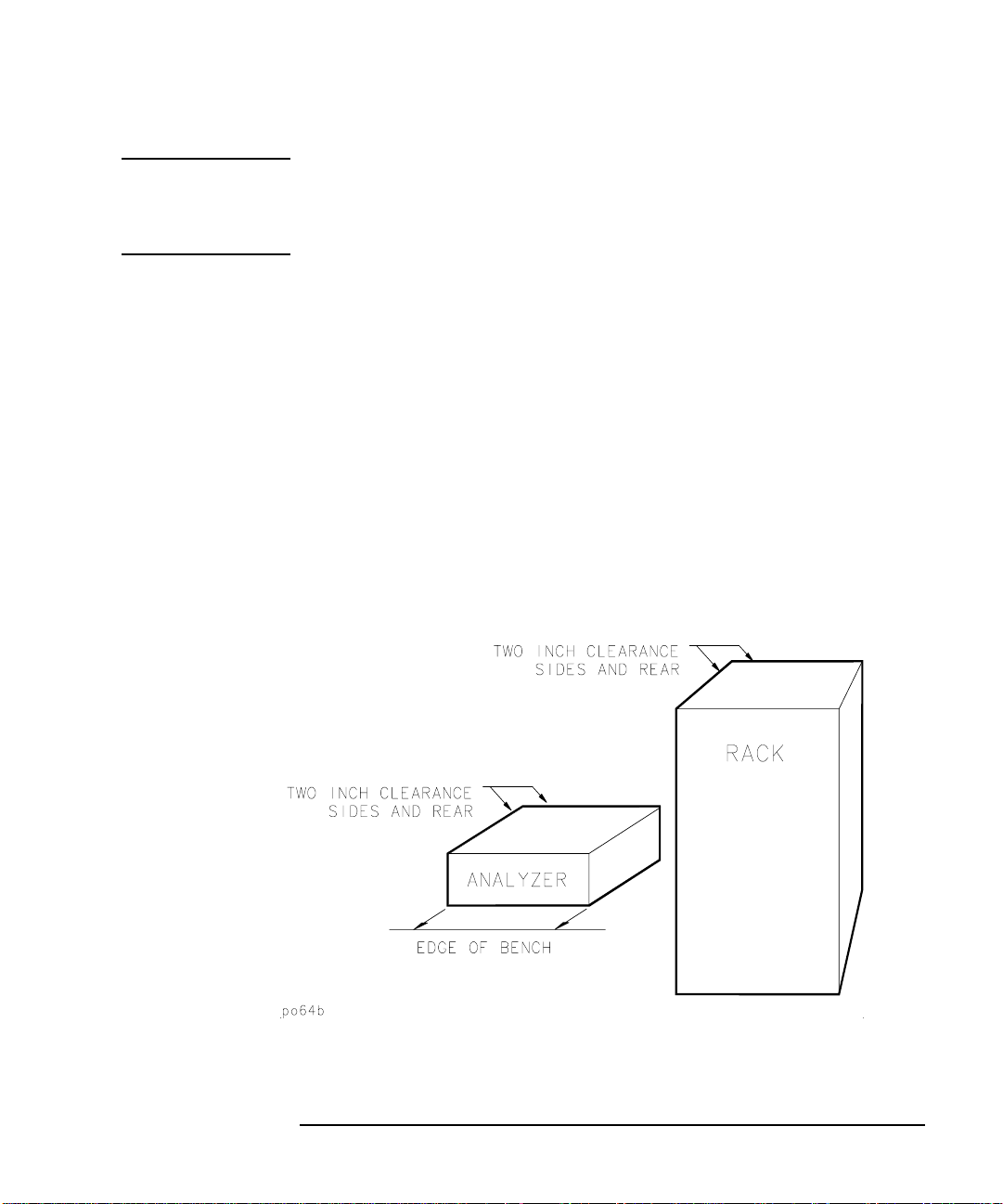

7. Ensure there are at least two inches of clearance around the sides

and back of either the stand-alone analyzer or the system cabinet.

Figure 1-3 Ventilation Clearance Requirements

ES User’s Guide 1-7

Page 24

Installing the Analyzer

Step 2. Meet Electrical and Environmental Requirements

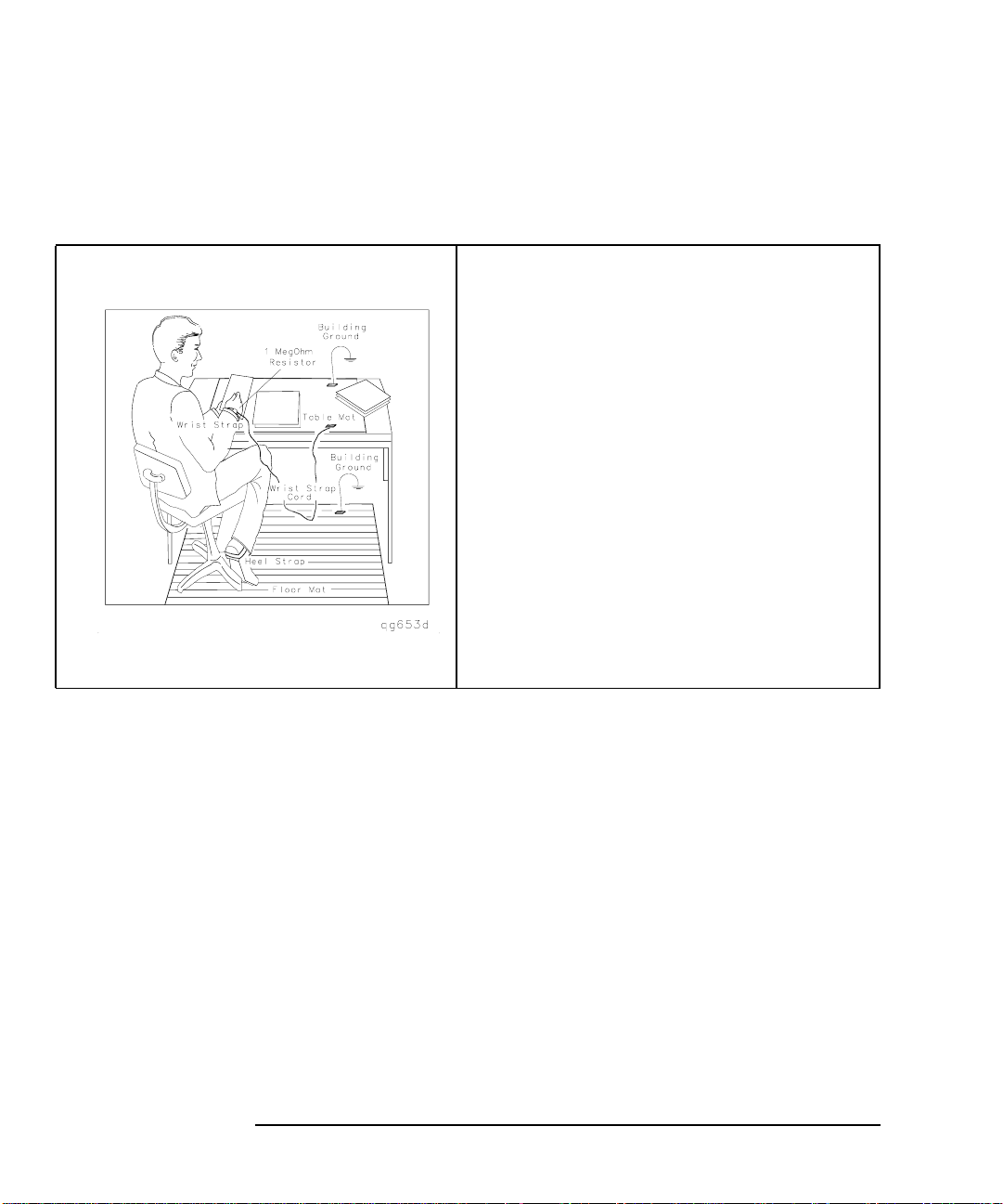

8. Set up a static-safe workstation. Electrostatic discharge (ESD) can

damage or destroy components.

• table mat with earth ground wire:

HP part number 9300-0797

• wrist-strap cord with 1 Meg Ohm resistor:

HP part number 9300-0980

• wrist-strap:

HP part number 9300-1367

• heel straps:

HP part number 9300-1308

• floor mat

1-8 ES User’s Guide

Page 25

Installing the Analyzer

Step 3. Check the Analyzer Operation

Step 3. Check the Analyzer Operation

1. Turn on the line switch of the analyzer. After approximately 30

seconds, a display box should appear on the screen with the following

information:

• the model number of your analyzer (either HP 8712ES or

HP 8714ES)

• the firmware revision

• the serial number of your analyzer

• installed options

2. Verify that the serial number and options displayed on the screen

match the information on the rear panel serial label.

3. The operator's check should be performed on the analyzer to provide a

high degree of confidence that the analyzer is working properly. Refer

to Chapter 2, “Getting Started,” for instructions on how to perform

the operator's check.

ES User’s Guide 1-9

Page 26

Installing the Analyzer

Step 4. Configure the Analyzer

Step 4. Configure the Analyzer

You can begin making measurements by simply connecting your

analyzer to an appropriate power source and turning it on. This section,

however, will explain how to connect common peripherals and

controllers, and how to install your analyzer into a rack system.

1-10 ES User’s Guide

Page 27

Installing the Analyzer

Step 4. Configure the Analyzer

Connecting Peripherals and Controllers

Figure 1-4 Analyzer Rear Panel Line Module and Selected Connectors

Refer to Figure 1-4:

• The HP-IB port is for use with computers and peripherals (printers,

plotters, etc.).

• The parallel and RS-232 (serial) ports are also for peripherals. The

parallel and serial ports can also be programmed via IBASIC for

general I/O control. See the HP Instrument BASIC User's Handbook

for information on using IBASIC.

ES User’s Guide 1-11

Page 28

Installing the Analyzer

Step 4. Configure the Analyzer

• The VIDEO OUT COLOR VGA port allows you to connect a color

VGA monitor for enhanced viewing. See “Using an External VGA

Monitor” in Chapter 4 for more information.

• The LAN ETHERTWIST connector is for connecting your analyzer to

a LAN (local area network) for control and access. See The LAN

Interface User’s Guide Supplement for information on how to use your

analyzer in a LAN.

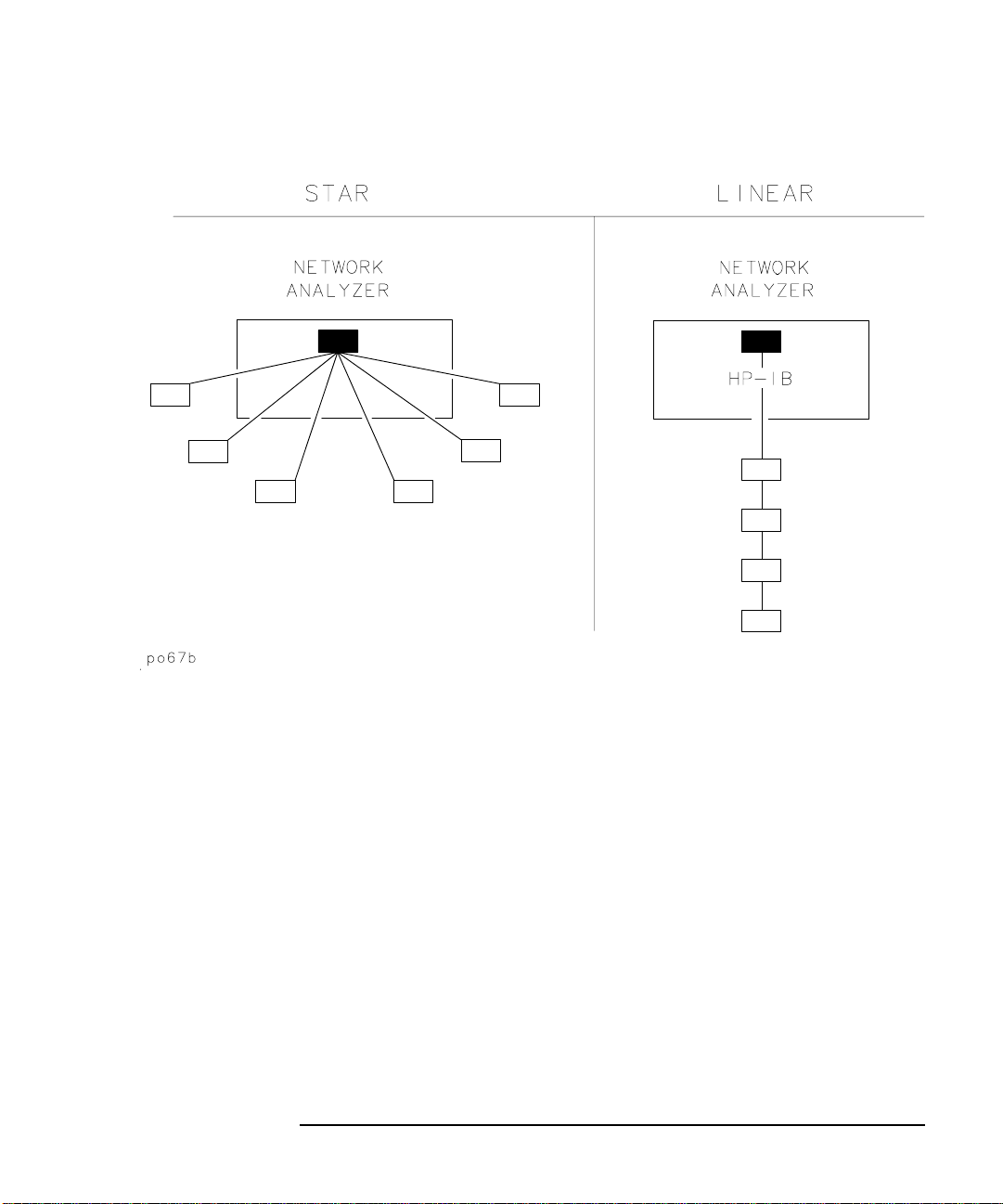

HP-IB

Connections

An HP-IB system may be connected in any configuration as long as the

following rules are observed:

• The total number of devices is less than or equal to 15.

• The total length of all the cables used is less than or equal to 2 meters

times the number of devices connected together up to an absolute

maximum of 20 meters. For example, the maximum cable length is 4

meters if only 2 devices are involved. The length between adjacent

devices is not critical as long as the overall restriction is met.

See Figure 1-5 for different connection configurations.

1-12 ES User’s Guide

Page 29

Figure 1-5 HP-IB Connection Configurations

Installing the Analyzer

Step 4. Configure the Analyzer

ES User’s Guide 1-13

Page 30

Installing the Analyzer

Select Copy Port

Select

Print/Plot HP-IB Addr

Enter

Select Copy Port

Select

Step 4. Configure the Analyzer

Table 1-1 Maximum HP-IB Cable Lengths

Instruments/Peripherals

in System

Two

Fifteen (max)

Parallel and Serial

Connections

Other Connections If you plan to use a keyboard, barcode reader, external video monitor, or

To Set HP-IB

Addresses

Parallel and serial devices often require specific cables—check their

manuals for details. Parallel cable length should not exceed 25 feet. The

analyzer may experience problems talking to a printer if this length is

exceeded. Connect the required control cables and secure them. (Tighten

the knurled screws or comparable fasteners.)

external detectors, connect them to the appropriate rear panel

connectors. See Figure 1-4, “Analyzer Rear Panel Line Module and

Selected Connectors.” Also see Chapter 7, “Front/Rear Panel,” for more

information on front and rear panel connectors.

To communicate via HP-IB, each external device must have a unique

address and the network analyzer must recognize each address. T o check

or set each external device's actual address, refer to the device's manual

(most addresses are set with switches).

The following are examples of how to check or set the device's recognized

address on the network analyzer:

Maximum HP-IB Cable

Length between Each Pair

of Devices

4 m

20 m (total)

Printer: Press . Use the

front panel knob to highlight the line that reads HP

Printer PCL HP-IB. Press . The second line

of the screen displays settings: in this case the address.

The default address is 5, however most printers are

factory set to address 1 (one). To change the recognized

address, press

Plotter: Press . Use the

front panel knob to highlight the line that reads HP

Plotter HPGL HP-IB. Press . The second

line of the screen displays settings: in this case the

address. The default address is 5 and most plotters are

factory set to address 5, so changing the address is

1-14 ES User’s Guide

HARDCOPY

number

.

HARDCOPY

Page 31

Installing the Analyzer

Print/Plot HP-IB Addr

Enter

HP-IB

HP 8712ES Address

HP 8714ES Address

Enter

Select Copy Port

Select

Select Copy Port

Select

Select Copy Port

Select

LAN Printr IP Addr

Select Copy Port

Step 4. Configure the Analyzer

probably not necessary. To change the recognized

address, press

.

NOTE Only one hardcopy HP-IB address can be set at a time. Changing the

printer address, for example, changes the plotter to the same address.

number

To Configure

Peripheral

Settings

Analyzer: Press ,

The network analyzer's address will appear (the

default is 16). To change the address, press

If your system uses serial or parallel peripherals, follow the guidelines

below to configure the system. Refer to the peripheral's manual for

correct cables and settings. The parallel and serial ports have standard

Centronics DB-25 and RS232 pinouts respectively as explained in

Chapter 7.

Serial

Devices: Press . Use the

entry controls to highlight your type of printer or

plotter, and press . If the baud rate or

handshake at the top of the screen are incorrect, use

the softkeys to change them.

Parallel

Devices: Press . Use the

entry controls to highlight your type of printer or

plotter, and press .

LAN

Printer: Press . Use the

entry controls to highlight HP LaserJet PCL5/6

PCL5 LAN, and press . If the printer IP

address at the top of the screen is incorrect, press

SYSTEM OPTIONS

, or .

number

.

HARDCOPY

HARDCOPY

HARDCOPY

to enter the correct IP address.

NOTE When is selected, the first two lines in the box at

NOTE Use a PCL5 printer for fastest hardcopies. See “Configure the Hardcopy

the top of the display screen show the current settings.

Port” on page 4-71for more information.

ES User’s Guide 1-15

Page 32

Installing the Analyzer

Step 4. Configure the Analyzer

Installing the Analyzer in a Rack

Use only the recommended rack mount kit (Option 1CM when ordered

with the analyzer or HP part number 08712-60036 when ordered

separately) with this instrument; it needs side support rails. Do not

attempt to mount it by the front panel (handles) only. This rack mount

kit allows you to mount the analyzer with or without handles.

To install the network analyzer in an HP 85043D rack, follow the

instructions in the rack manual.

CAUTION To install the network analyzer in other racks, note that they may

promote shock hazards, overheating, dust contamination, and inferior

system performance. Consult your HP customer engineer about

installation, warranty, and support details.

CAUTION VENTILATION REQUIREMENTS: When installing the product in a

cabinet, the convection into and out of the instrument must not be

restricted. The ambient temperature (outside the cabinet) must be less

than the maximum operating temperature of the instrument by 4° C for

every 100 watts dissipated in the cabinet. If the total power dissipated in

the cabinet is greater than 800 watts, then forced convection must be

used.

Place other system instruments (computer, printer, plotter) where

convenient, within the HP-IB cable length limits (see Table 1-1) or other

interface cabling limits.

1-16 ES User’s Guide

Page 33

Installing the Analyzer

Preventive Maintenance

Preventive Maintenance

Preventive maintenance consists of two tasks. It should be performed at

least every six months—more often if the instrument is used daily on a

production line or in a harsh environment.

Clean the CRT

Use a soft cloth and, if necessary, a mild cleaning solution.

Check the RF Front Panel Connectors

Figure 1-6 Maximum and Minimum Protrusion of Center Conductor from

Visually inspect the front panel connectors. The most important

connectors are those to which the DUT is connected, typically the RF

cable end or the PORT 1 and PORT 2 connectors. All connectors should

be clean and the center pins centered. The fingers of female connectors

should be unbroken and uniform in appearance. If you are unsure

whether the connectors are good, gauge the PORT 1 and PORT 2

connectors to confirm that their dimensions are correct.

Mating Plane

ES User’s Guide 1-17

Page 34

Installing the Analyzer

Preventive Maintenance

1-18 ES User’s Guide

Page 35

2 Getting Started

ES User’s Guide 2-1

Page 36

Getting Started

Introduction

Introduction

The HP 8712ES and HP 8714ES are easy-to-use, fully integrated RF

component test systems. Each instrument includes a synthesized source,

a wide dynamic range receiver, and a built-in test set. Controls are

grouped by functional block, and settings are displayed on the

instrument screen. This section familiarizes new users with the layout of

the front panel and the process of entering measurement parameters

into the analyzer.

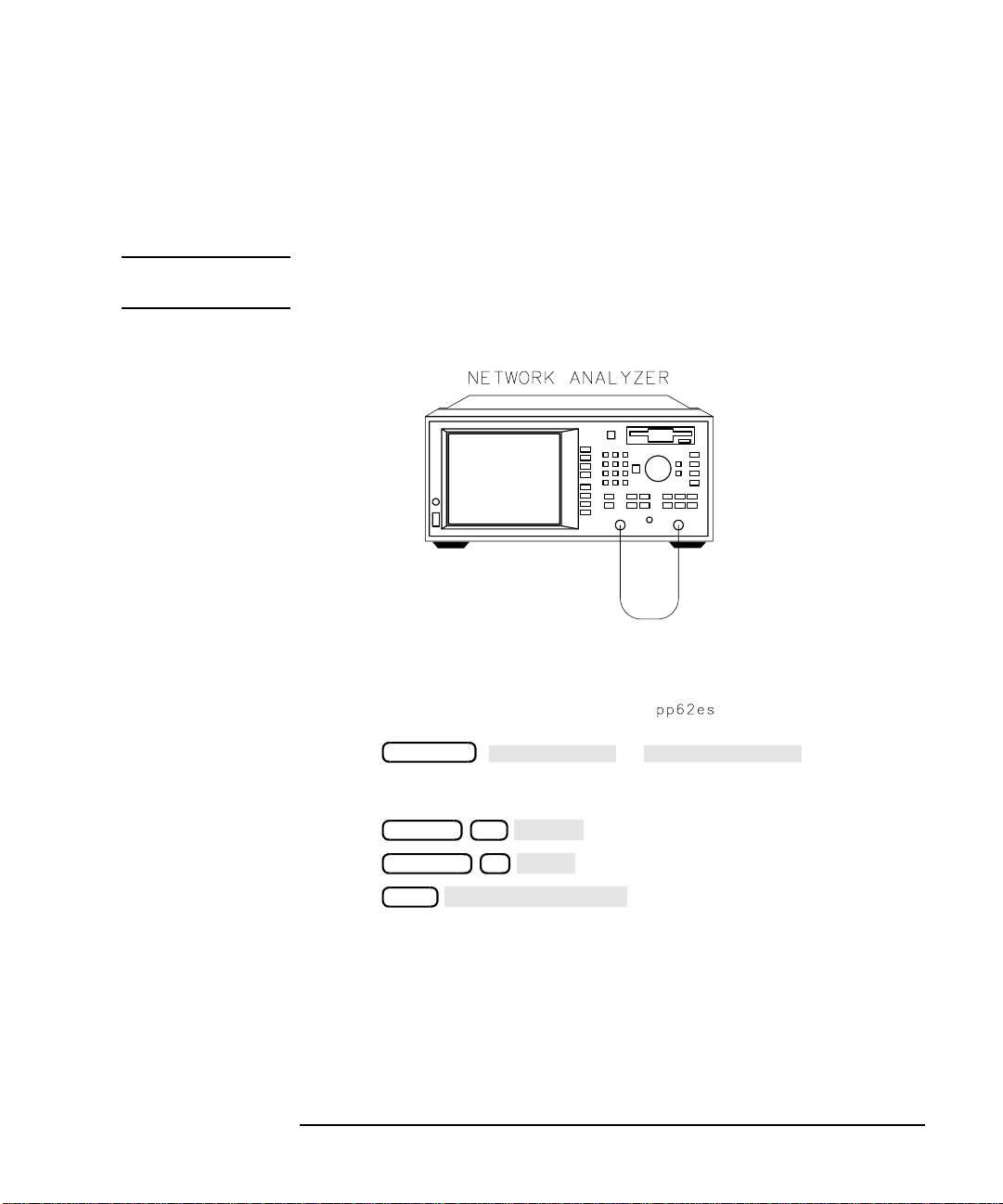

Figure 2-1 Network Analyzer Front Panel Features

2-2 ES User’ s Guide

Page 37

Getting Started

Softkeys

Sweep Time

Front Panel Tour

Front Panel Tour

1 The CRT Display The analyzer's large CRT displays data, markers, limit lines, Instrument BASIC

(IBASIC) programming code, softkey menus and measurement parameters quickly and

clearly. Refer to “Display” on page 7-16 in for more information.

2 The key simplifies measurement setups. The key allows quick

BEGIN BEGIN BEGIN

and easy selection of basic measurement parameters for a user-specified class of devices

(e.g., filters, amplifiers, or mixers). For example, when making an S

transmission measurement or an S

Filter as your device type puts the analyzer into narrowband detection mode,

maximizing measurement dynamic range. In comparison, selecting Mixer as your device

type puts the analyzer into broadband detection mode, enabling frequency translation

measurements. This capability allows new users to start making measurements with as

few as four keystrokes.

3 MEAS The measure keys select the measurements for each measurement channel. The

analyzer's measurement capabilities include S11 (reflection port 1), S21 (forward

transmission), S12 (reverse transmission), S22 (reflection port 2), power, conversion loss,

and multiport selection (for use with multiport test sets).

4 SOURCE The source keys select the desired source output signal to the device under test, for

example, selecting source frequency range or output power. The source keys also control

sweep time, number of points, and sweep triggering.

5 CONFIGURE The configure keys control receiver and display parameters. These parameters include

receiver bandwidth and averaging, display scaling and format, marker functions, and

instrument calibration.

6 SYSTEM The system keys control system level functions. These include instrument preset,

save/recall, and hardcopy output. HP-IB parameters and IBASIC are also controlled with

these system keys.

7 The Numeric Keypad Use the number keys to enter a specific numeric value for a chosen parameter. Use the

key or the softkeys to terminate the numeric entry with the appropriate

.

8

HARDKEYS

9

ENTER

units. You can also use the front panel knob for making continuous adjustments to

parameter values, while the keys allow you to change values in steps.

Hardkeys are front panel keys physically located on the instrument front panel. In text,

these keys will be represented by the key name with a box around it such as:

PRESET

Softkeys are keys whose labels are determined by the analyzer's firmware. The labels are

on the screen next to the 8 blank keys, which are located along the right edge of the

analyzer’s display. In text, these softkeys will be represented by the key name with

shading behind it such as: .

reverse transmission measurement, selecting

12

forward

21

ES User’s Guide 2-3

Page 38

Getting Started

42.5

.

Entering Measurement Parameters

Entering Measurement Parameters

This section describes how to input measurement parameter information

into the network analyzer.

NOTE When entering parameters, you can use the numeric key pad, as

described in each example, or you can use the keys or the

front panel knob to enter data.

NOTE When you are instructed to enter numeric values in this manual, it often

can get cluttered and confusing to depict each key stroke. So in this

manual, numbers (no matter how many characters) are depicted inside

one keycap. F or example, if you are instructed to enter the number−42.5,

it will be depicted inside one keycap like this: . To enter this

number , the following keys need to be pressed in succession:

.

5

You can follow along with these examples by connecting the filter and

cable that were supplied with your instrument as shown in Figure 2-2.

−

− 4 2

Figure 2-2 Connect the Filter to the Analyzer

2-4 ES User’ s Guide

Page 39

Getting Started

User Preset

Factory Preset

User Preset

Factory Preset

Entering Measurement Parameters

Presetting the Analyzer

Press the key and then press either or

PRESET

. The key returns the analyzer to

user-defined preset settings you may have saved as file UPRESET.STA.

If this file doesn’t exist, you can create it by following the instructions in

the pop-up message that appears when the key is pressed. When the

key is pressed, the following major default conditions

apply:

Frequency range (HP 8712 ES) 0.3 to 1300 MHz

Frequency range (HP 8714 ES) 0.3 to 3000 MHz

Power level

Measurement Channel 1

1

0 dBm

S21 Forward Transmission

measurement

Measurement Channel 2

Off

measurement

Format Log Magnitude

Number of points 201

Sweep time Auto

NOTE The measurement parameters that you enter will be retained in the

NOTE Refer to Chapter 11, “F actory Preset State and Memory Allocation, ” for a

Scale 10 dB/div

Reference 0 dB

System Bandwidth Medium wide

1. Preset power level can be set to other than 0 dBm if desired.

See “Entering Source Power Level” on page 2-6 for more

information.

analyzer's memory when the power is turned off, and will be restored

when the power is turned back on.

comprehensive table of factory preset conditions.

ES User’s Guide 2-5

Page 40

Getting Started

Start

MHz

Stop

MHz

Center

Span

Disp Freq Resolution

Level

dBm

Level

1.6

dBm

Pwr Level at Preset

2.5

dBm

Autoscale

Scale/Div

Enter

Reference Position

Enter

Reference Level

Enter

Entering Measurement Parameters

Entering Frequency Range

1. Press the key to access the frequency softkey menu.

FREQ

2. To change the low end of the frequency range to 10 MHz, press

10

.

3. To change the high end of the frequency range to 900 MHz, press

900

.

4. You can also set the frequency range by using the and

softkeys. For instance, if you set the center frequency to

160 MHz and the span to 300 MHz, the resulting frequency range

would be 10 to 310 MHz.

NOTE When entering frequencies, be sure to terminate your numeric entry

with the appropriate softkey to obtain the correct units. If you use the

ENTER

key to terminate a frequency entry, the units default to Hz.

The default displayed frequency resolution is kHz. You can change the

resolution by pressing , and then

FREQ

selecting a new resolution.

Entering Source Power Level

1. Press the key to access the power level softkey menu.

2. To change the power level to 3 dBm, press and or

ENTER

3. To change the power level to −1.6 dBm, press

or .

ENTER

POWER

3

.

−

Scaling the Measurement Trace

4. To change the power level that will always be restored when you

preset the analyzer, press and

or . This entry does not affect the current power level.

ENTER

1. Press the key to access the scale menu.

SCALE

2. To view the complete measurement trace on the display, press

.

3. To change the scale per division to 5 dB/division, press

5

.

4. To move the reference position (indicated by the symbol on the left

side of the display) to the first division down from the top of the

display, press . Figure 2-3 shows

9

how each reference position is identified.

5. To change the reference level to 0 dB, press

0

.

2-6 ES User’ s Guide

Page 41

Figure 2-3 Reference Positions

S21 Fwd Trans

S11 Refl Port1

Getting Started

Entering Measurement Parameters

Entering the

Active

Measurement

Channel and Type

of Measurement

The and keys allow you to choose which

MEAS 1 MEAS 2

measurement channel is active, and measurement parameters for that

channel. When a particular measurement channel is active, its display is

brighter than the inactive channel, and any changes made to

measurement parameters will affect only the active measurement

channel. (Some measurement parameters cannot be independently set

on each measurement channel. F or these parameters , both c hannels will

be affected regardless of active channel status.)

1. To measure S21on measurement channel 1 and S11 on measurement

channel 2, press the following keys:

PRESET MEAS 1

MEAS 2

2. Both channels' measurements are now visible on the analyzer's

display screen. Note that the active measurement channel's (channel

2) measurement trace is brighter than the other measurement

channel's trace. Refer to Figure 2-4.

ES User’s Guide 2-7

Page 42

Getting Started

Meas OFF

More Display

Split Disp FULL split

Entering Measurement Parameters

Figure 2-4 Both Measurement Channels Active

Viewing Measurement Channels

1. To view only the measurement channel 2 S11 measurement, press

MEAS 1

2. To view both measurement channels again, press .

3. To view both measurement channels separately on a split screen,

press . Refer to

Figure 2-5, “Split Display.”

2-8 ES User’ s Guide

DISPLAY

.

MEAS 1

Page 43

Figure 2-5 Split Display

Getting Started

Entering Measurement Parameters

You have now learned how to enter common measurement parameters

and how to manipulate the display for optimum viewing of your

measurement. You can now proceed on to performing the operator's

check, or refer to Chapter 3, “Making Measurements,” for detailed

information on making specific types of measurements.

ES User’s Guide 2-9

Page 44

Getting Started

Performing the Operator's Check

Performing the Operator's Check

The operator's check should be performed when you receive your

instrument, and any time you wish to have confidence that the analyzer

is working properly. The operator's check does not verify performance to

specifications, but should give you a high degree of confidence that the

instrument is performing properly if it passes.

The operator's check consists of making the following measurements

with the cable that was supplied with your analyzer:

•S21 and S

• broadband power

•S11 and S

•S11 and S22 (with a 50 Ω or 75 Ω load, instead of the cable)

12

22

Equipment List

To perform the operator's check you will need the following:

• A known good cable such as the one that was supplied with your

analyzer. The cable you use should have ≤0.5 dB of insertion loss up

to 1.3 GHz and ≤0.75 dB of insertion loss from 1.3 to 3.0 GHz.

• A known good load (> 40 dB return loss) that matches the test port

impedance of your analyzer such as one from calibration kit

HP 85032B/E (50 Ω) or HP 85036B/E (75 Ω).

2-10 ES User’s Guide

Page 45

Getting Started

User Preset

Factory Preset

Enter

dBm

Default Response

Performing the Operator's Check

Make S21 and S12 Transmission Measurements

1. Connect the equipment as shown in Figure 2-6. Use a known good

cable such as the one that was supplied with your analyzer.

NOTE The quality of the cable will affect these measurements; make sure you

use a cable with the characteristics described in “Equipment List.”

Figure 2-6 Equipment Setup for Performing the Operator’s Check

2. Press ( or ). The

instrument is automatically set up for an S21 measurement on

measurement channel 1.

3. Press .

4. Press .

5. Press .

6. Verify that the data trace falls within ±0.5 dB of 0 dB. See Figure 2-7

for a typical HP 8714ES result. The HP 8712ES should look similar,

but end at 1300 MHz.

ES User’s Guide 2-11

PRESET

SCALE .1

POWER 0

CAL

Page 46

Getting Started

S12 Rev Trans

Default Response

Performing the Operator's Check

Figure 2-7 Verify S21 Transmission Measurement

7. Press .

8. Press .

MEAS 1

CAL

9. Verify that the data trace falls within ±0.5 dB of 0 dB. See Figure 2-7

for a typical HP 8714ES result. (Although this figure is from an S

21

measurement, the results of your S12 measurement should look

similar.) The HP 8712ES should look similar, but will end at

1300 MHz.

2-12 ES User’s Guide

Page 47

Getting Started

More

Power

Start

MHz

Enter

dBm

Performing the Operator's Check

Make a Broadband Power Measurement

1. Leave the cable connected to the analyzer as shown in Figure 2-6.

NOTE The quality of the cable will affect these measurements; make sure you

use a cable with the characteristics described in “Equipment List” on

page 2-10.

2. Press

3. Press (unless done in the previous

measurement).

4. V erify that the data trace is within±2 dB of 0 dBm. See Figure 2-8 for

a typical HP 8714ES result. The HP 8712ES should look similar, but

end at 1300 MHz.

Figure 2-8 Verify Broadband Power Measurement

MEAS 1

SCALE 1

POWER 0

FREQ

.

10

ES User’s Guide 2-13

Page 48

Getting Started

User Preset

Factory Preset

S11 Refl Port1

Enter

dBm

Default 1-Port

Performing the Operator's Check

Make S11 and S22 Reflection Measurements

1. Leave the cable connected to the analyzer as shown in Figure 2-6.

NOTE The quality of the cable will affect these measurements; make sure you

use a cable with the characteristics described in “Equipment List”.

2. Press ( or )

3. Press

4. Press .

5. Press .

6. Verify that the data trace falls completely below −16 dB. See

Figure 2-9 for a typical HP 8714ES result. The HP 8712ES should

look similar, but end at 1300 MHz.

PRESET

.

SCALE 10

POWER 0

CAL

MEAS 1

2-14 ES User’s Guide

Page 49

Figure 2-9 Verify S11 Reflection Measurement

S22 Refl Port2

Default 1-Port

Getting Started

Performing the Operator's Check

7. Press .

8. Press .

9. Verify that the data trace falls completely below −16 dB. See

Figure 2-9 for a typical HP 8714ES result. (Although this figure is

from an S11 measurement, the results of your S22 measurement

should look similar.) The HP 8712ES should look similar, but will end

at 1300 MHz.

10.Disconnect the cable and connect a known good load to port 2 as

shown in Figure 2-10.

ES User’s Guide 2-15

MEAS 1

CAL

Page 50

Getting Started

Reference Level

S11 Refl Port1

Performing the Operator's Check

Figure 2-10 Connect the Load to Port 2

11.Verify that the data trace falls below −30 dB. If the data trace is off

the screen, press and the key

until the trace moves up onto the screen.

SCALE

12.Disconnect the load from port 2 and connect it to port 1 as shown in

Figure 2-11.

Figure 2-11 Connect the Load to Port 1

13.Press .

2-16 ES User’s Guide

MEAS 1

Page 51

Getting Started

Reference Level

Trigger

Hold

Performing the Operator's Check

14.Verify that the data trace falls below −30 dB. If the data trace is off

the screen, press and the key

until the trace moves up onto the screen.

This concludes the operator's check. However, further confidence can be

obtained by performing the following:

• Measure a known filter to verify that its measured response is the

same as is expected. (A 175 MHz filter is supplied with the analyzer.)

Verify both the frequency accuracy and noise floor.

• Check broadband response with the filter using conversion-loss mode

(same as B*/R*).

• If the analyzer's frequency accuracy is critical for your application,

verify a CW frequency using a frequency counter. Verify to ±.005%

accuracy (for example, ± 2500 Hz at 500 MHz). Ensure that the

analyzer is placed in trigger-hold mode (press

) to measure frequencies.

SCALE

MENU

If the Analyzer Fails the Operator's Check

First, repeat the operator's check using a different cable and load to

eliminate these as a possible cause of failure. If your analyzer does not

meet the criteria in the operator's check, your analyzer may need

adjustment or servicing. Contact any Hewlett-Packard sales or service

office for assistance. Refer to Table 9-10, “Hewlett-Packard Sales and

Service Offices,” inChapter 9 for the nearest office. Before shipping your

analyzer, fill out and attach the blue repair tag, located at the back of the

analyzer’s Service Guide.

ES User’s Guide 2-17

Page 52

Getting Started

Performing the Operator's Check

2-18 ES User’s Guide

Page 53

3 Making Measurements

ES User’s Guide 3-1

Page 54

Making Measurements

Introduction

Introduction

This chapter provides an overview of basic network analyzer

measurement theory, a section explaining the typical measurement

sequence, a segment describing the use of the key, and detailed

examples of the following measurements:

• “Measuring S-Parameters using a Two-P ort Calibration” on page 3-19

• “Measuring S21 Forw ard Transmission using an Enhanced Response

Calibration” on page 3-41

• “Measuring S11 Reflection Port 1 using a One-Port Calibration” on

page 3-48

• “Making a Power Measurement using Broadband Detection” on

page 3-56

• “Measuring Conversion Loss” on page 3-61

• “Making Measurements with the Auxiliary Input” on page 3-67

BEGIN

• “Measuring Group Delay” on page 3-69

• “Measuring Impedance using the Smith Chart” on page 3-73

• “Measuring Impedance Magnitude” on page 3-80

3-2 ES User’ s Guide

Page 55

Measuring Devices with Your Network Analyzer

This section provides a basic overview of how the network analyzer

measures devices. The analyzer has an RF signal source that produces

an incident signal that is used as a stimulus to the device under test.

Your device responds by reflecting a portion of the incident signal and

transmitting the remaining signal. If the device is passive, some of the

transmitted signal will be absorbed, indicating a “lossy” device. If the

device is active, the transmitted signal may be amplified, indicating that

the device has gain. Figure 3-1 shows how a device under test (DUT)

responds to an RF source stimulus.

Figure 3-1 DUT Response to an RF Signal

Making Measurements

Measuring Devices with Your Network Analyzer

ES User’s Guide 3-3

Page 56

Making Measurements

Measuring Devices with Your Network Analyzer

Refer to Figure 3-2, “Simplified Block Diagram,” for the following

discussion regarding detection schemes and modes. The forward

transmitted signal (routed to input B) and the reflected signal (input A)

are measured by comparison to the incident signal. The reverse

transmitted signal (routed to input A) and the reflected signal (input B)

are also measured by comparison to the incident signal. The analyzer

couples off a small portion of the incident signal to use as a reference

signal (routed to input R). Sweeping the source frequencies, the analyzer

measures and displays the response of your test device.

Figure 3-2 Simplified Block Diagram

3-4 ES User’ s Guide

Page 57

Making Measurements

Measuring Devices with Your Network Analyzer

Refer to Figure 3-3, “Block Diagram,” for the following discussion. The

network analyzer receiver has two signal detection modes:

• broadband detection mode

• narrowband detection mode

There are two internal broadband detectors: B* and R*. External

broadband detectors can also be used when connected to the X and Y

ports on the rear panel of the analyzer. When the network analyzer is in

the broadband detection mode, it measures the total power of all signals

present at these measurement ports, independent of signal frequency.

This enables the characterization of frequency translation devices such

as mixers, receivers, and tuners, where the RF input and output

frequencies are not the same. Figure 3-3 labels the transmitted signal for

broadband detection input as B*, and the reference signal as R*.

When the network analyzer is in the narrowband detection mode, the

receiver is tuned to the source frequency. This technique provides greater

dynamic range by decreasing the receiver's bandwidth. Figure 3-3 shows

receiver B as the narrowband detection input for the forward

transmitted signal and the reverse reflected signal. Receiver A acts as

the narrowband detection input for the reverse transmitted signal and

the forward reflected signal. Receiver R is shown as the narrowband

detection input for the reference signal.

ES User’s Guide 3-5

Page 58

Making Measurements

Measuring Devices with Your Network Analyzer

Figure 3-3 Block Diagram

3-6 ES User’ s Guide

Page 59

Making Measurements

Measuring Devices with Your Network Analyzer

The following table shows the correlation between different types of

measurements, input channels and signals.

Measurement Detection Mode

S21 Forw ard Transmission Narrowband B/R transmitted/

S12 Reverse Transmission Narrowband A/R transmitted/

S11 Reflection Port 1 Narrowband A/R reflected/

S22 Reflection Port 2 Narrowband B/R reflected/

Power Broadband B* transmitted Forward

Conversion Loss Broadband B*/R* transmitted/

Input

Detectors

Input

Signals

incident

incident

incident

incident

incident

Source

Direction

Forw ard

Reverse

Forward

Reverse

Forward

The Measurement Display Icon

The measurement display icon, located in the lower right corner of the