Page 1

HP/Agilent/Keysight 8711B Manual

Get Pricing & Availability at

ApexWaves.com

Call Today: 1-800-915-6216

Email: sales@apexwaves.com

https://www.apexwaves.com/analyzers/keysight-technologies/8712-network-analyzers/8711B

Page 2

Notice

Hewlett-Packard to Agilent Technologies Transition

This documentation supports a product that previously shipped under the HewlettPackard company brand name. The brand name has now been changed to Agilent

Technologies. The two products are functionally identical, only our name has changed. The

document still includes references to Hewlett-Packard products, some of which have been

transitioned to Agilent Technologies.

Printed in USA March 2000

Page 3

Contacting Agilent

By internet, phone, or fax, get assistance with all your test and measurement needs.

Table 1-1 Contacting Agilent

Online assistance: www.agilent.com/find/assist

United States

(tel) 1 800 452 4844

New Zealand

(tel) 0 800 738 378

(fax) (+64) 4 495 8950

Latin America

(tel) (305) 269 7500

(fax) (305) 269 7599

Japan

(tel) (+81) 426 56 7832

(fax) (+81) 426 56 7840

Canada

(tel) 1 877 894 4414

(fax) (905) 282-6495

Australia

(tel) 1 800 629 485

(fax) (+61) 3 9210 5947

Asia Call Center Numbers

Country Phone Number Fax Number

Singapore 1-800-375-8100 (65) 836-0252

Malaysia 1-800-828-848 1-800-801664

Philippines (632) 8426802

1-800-16510170 (PLDT

Subscriber Only)

Thailand (088) 226-008 (outside Bangkok)

(662) 661-3999 (within Bangkok)

Hong Kong 800-930-871 (852) 2506 9233

Taiwan 0800-047-866 (886) 2 25456723

People’s Republic

of China

800-810-0189 (preferred)

10800-650-0021

(632) 8426809

1-800-16510288 (PLDT

Subscriber Only)

(66) 1-661-3714

10800-650-0121

Europe

(tel) (+31) 20 547 2323

(fax) (+31)20 547 2390

India 1-600-11-2929 000-800-650-1101

Page 4

Service Guide

HP

8711B/12B/13B/14B

RF

Network

Analyzers

ABCDE

HP Part No. 08713-90005

Printed in USA February 1995

Page 5

Notice.

The

information contained

in

this

document

is

subject

to

change

without

notice

.

Hewlett-P

ackard makes

no

warranty

of

any

kind

with

regard

to

this

material,

including

but

not limited

to,

the

implied

warranties

of

merchantability

and

tness

for

a

particular

purpose

.

Hewlett-P

ackard

shall

not

be

liable

for

errors

contained

herein

or

for

incidental or

consequential

damages

in

connection

with

the

furnishing,

performance

,

or

use

of

this

material.

c

Copyright Hewlett-Packard Company 1995

All Rights Reserved. Reproduction, adaptation, or translation without prior written permission

is prohibited, except as allowed under the copyright laws.

1400 Fountaingrove Parkway, Santa Rosa, CA 95403-1799, USA

Page 6

Certication

Hewlett-P

ackard

Company

certies

that this

product met

its published

specications at

the

time

of

shipment

from

the

factory

. Hewlett-P

ackard further

certies that

its calibration

measurements

are

traceable

to

the

United

States National

Institute of

Standards and

T

echnology

,

to

the

extent

allowed by

the Institute's

calibration facility

,and

to the

calibration

facilities

of

other

International

Standards Organization

members.

Regulatory

Information

The

regulatory

information

is

in

the

User's

Guide

supplied

with

the

analyzer

.

How

to

Use

This

Guide

This guide

uses

the

following

conventions:

4

F

ront-P

anel Key

5

This

represents

a

key

physically

located

on

the

instrument.

NN

NN

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

NN

Softkey

This

indicates

a

\softkey

,"

a

key

whose

label

is

determined

by

the

instrument's

rmware

.

Screen

Text

This

indicates

text

displayed

on

the

instrument's

screen.

iii

Page 7

Page 8

Contents

1.

P

erformance

T

ests

System

Specications

Summary

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

1-1

Measurement P

ort

Specications

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

. 1-2

Source Specications

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

1-2

Receiver Specications

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

1-3

Performing

the

Operator's

Check

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

1-5

Make

a

Transmission

Measurement

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

1-6

Make

a

Reection

Measurement

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

1-7

If

the

Analyzer

F

ails

the

Operator's

Check

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

1-9

Instructions

for

Using

the

Network

Analyzer

P

erformance

T

est

Software

.

.

.

.

1-10

Introduction .

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

1-10

Equipment

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

1-10

File

Structure

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

1-12

Conguration

File

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

1-13

Getting

Started

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

1-13

P

erformance

T

est

Software

Installation

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

1-14

The

analyzer's

HP-IB

address

(716)

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

1-14

The

ISC

for

the

test

equipment

(7)

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

1-14

The

power

meter

model

number

(HP

437B)

and

address

(13)

.

.

.

.

..

.

1-14

The

spectrum

analyzer

(HP

8566B)

and

address

(18)

.

.

.

.

.

.

.

..

.

.

1-14

The

function

generator

model

number

(HP

8116A)

and

address

(14)

.

.

.

.

1-14

The

attenuator

switch

driver

model

number

(HP

11713A)

and

address

(28)

1-15

The

frequency

counter

model

number

(HP

5342A)

and address

(02) .

.

.

.

1-15

The

voltmeter

model

number

(HP

3456A)

and

address (22)

..

.

.

.

.

.

.

1-15

The

printer

address

(01)

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1-15

The

program

directory

and

the

mass

storage

unit specier

(the current

MSI

device)

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1-15

The

data directory

and MSUS

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

. 1-15

The

sensor's,

10 dB

step attenuator's

,

and

xed

attenuator's

(pad's)

serial

numbers

(xxxx) .

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

..

..

..

1-15

The

40

dB

step

attenuator

card

selection

(3)

.

..

.

.

.

.

.

.

.

.

.

.

..

1-15

The beeper (on)

...........

...... ....... ....

1-15

The current DUT le sux (1)

........

...... .......

1-15

Sensors .......................

...... ...

1-16

20 dB Attenuators (P

ads) . . . . . . . . . . . . . . . . . . . .

....

1-16

Step

Attenuator . . . . . . . . . . . . . . . . . . . . . . . .

....

1-16

Using

theProgram.......................

..... .

1-17

Main Menu

...... ........ ..... ......

......

1-17

Test Selection Menu

...... ..

...... ........ .....

1-18

Miscellaneous Information ... ....... ...... ...... .. 1-19

Individual Test Notes And Descriptions ................... 1-19

Frequency Accuracy........................... 1-19

Gain Compression ...... ........ ...... ..... ... 1-19

Noise Floor ............................... 1-20

Dynamic Accuracy............................ 1-20

Power Flatness ............................. 1-20

Contents-1

Page 9

Absolute

Accuracy

..

..

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

. 1-21

Broadband

Frequency Response

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

1-21

Directivity

(includes source

match

and

test

port

match)

.

.

.

.

.

.

..

..

1-22

Spurs

(including harmonics)

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

1-23

AM

Delay Modulator

(Option

1D

A/1DB

analyzers

only)

.

.

.

.

.

.

.

.

..

. 1-23

2.

A

djustments

Correction

Constants

(CCs)

A

djustments

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

2-2

Fractional-N

V

CO

A

djustment

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

2-3

Required

Equipment

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

2-3

Estimated

A

djustment

Time

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

2-3

Procedure

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-3

Fractional-N

Spur

A

djustment

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

2-6

Required

Equipment

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

2-6

Estimated

A

djustment

Time

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

2-6

Procedure

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-6

Frequency

A

ccuracy

A

djustment

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

2-10

Required

Equipment

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-10

Estimated

A

djustment

Time

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

2-10

Procedure

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-10

Set

Serial

Number

,

A

djustment

#100

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

2-12

Required

Equipment

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

2-12

Estimated

A

djustment

Time

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-12

Procedure

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

2-12

In

Case

of

Diculty

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 2-13

LO

P

ower

Correction,

A

djustment

#101

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-14

Required

Equipment

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-14

Estimated A

djustment

Time

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

2-14

Procedure

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

2-14

Switched

Gain Correction,

A

djustment

#102

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-15

Required

Equipment .

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

2-15

Estimated

Adjustment

Time .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 2-15

Procedure

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

2-15

External

Detector

Correction,

A

djustment

#103

.

.

.

.

.

.

.

.

.

.

..

..

..

2-16

Required

Equipment

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

2-16

Estimated

A

djustment

Time

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

2-17

Procedure

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

2-17

A

uxiliary

Input

Correction,

A

djustment

#111

.

.

.

.

.

.

.

.

.

.

.

..

..

..

2-18

Required

Equipment

.

.

.

.

.

.

..

..

..

..

..

..

.

.

.

.

.

.

.

.

.

.

2-18

Estimated

A

djustment

Time

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

2-18

Procedure . . . . . . . . .

...... ........ ...... ....

2-18

Source P

ower (ALC) Correction, A

djustment #104

...

............

2-19

Required Equipment . . . . . . . . . .

..................

2-19

Estimated A

djustment Time ..................

.....

2-19

Procedure . . . . . . . . . . . . . . . . . . . . .

...... ......

2-20

In Case of Diculty

...................

...... ..

2-20

B Amplitude Correction, A

djustment #105 . . . . . . . . . . . . . . . . . .

. 2-22

Required Equipment . . . . . . . . . . . . . . . . . . . . . . .

.....

2-22

Estimated Adjustment Time ....................... 2-22

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Transmission (B/R) Correction, Adjustment #106 . . . . . . . . . . . . . . . . 2-23

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Estimated Adjustment Time ....................... 2-23

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

AM Delay Correction, Adjustment #112 . . . . . . . . . . . . . . . . . . . . 2-24

Contents-2

Page 10

Required

Equipment .

..

..

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

2-24

Estimated

Adjustment

Time

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

. 2-24

Procedure

..

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

..

.

.

.

.

.

.

2-24

Reection

(One-Port)

Correction,

A

djustment

#107

.

.

.

.

.

.

.

.

.

..

..

..

2-25

Required

Equipment .

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

.

.

2-25

Estimated

Adjustment

Time

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

. 2-25

Procedure

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

2-25

R*

Amplitude

Correction,

A

djustment

#108

.

.

.

.

.

.

.

.

..

..

..

..

.

.

2-26

Required

Equipment

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

2-26

Estimated

A

djustment

Time

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

2-26

Procedure

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

2-26

R*

Frequency

Response

Correction,

A

djustment

#109

.

.

.

.

.

..

..

..

.

.

2-27

Required

Equipment

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

2-27

Estimated

A

djustment

Time

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

2-27

Procedure

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-27

B*

Amplitude

Correction,

A

djustment

#110

.

.

.

.

.

.

..

..

..

..

.

.

.

.

2-28

Running

the

B*

Amplitude

Correction

Using

the

P

erformance

T

est

Software

(08712-10011)

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-28

Required

Equipment

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

2-28

Estimated

A

djustment

Time

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-29

Procedure

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-29

Running

B*

Amplitude

Correction

A

djustment

#110

from

IB

ASIC

.

..

..

..

2-31

Required

Equipment

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-31

Estimated

A

djustment

Time

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-31

Procedure

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

2-32

3.

Assembly

Replacement

Introduction .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

3-1

Required

Tools

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

3-1

Major

Assembly Removal/Replacement

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

3-1

A1

Front P

anel Assembly

Replacement

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

3-2

How

to Remove

the Front

P

anel

Assembly

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

3-2

A2

CPU

Board

Assembly

Replacement

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

3-4

How

to

Remove

the

CPU

Board

Assembly

.

.

.

.

.

.

.

.

.

..

..

..

..

3-4

A3

Fractional-N/Reference

Assembly

Replacement

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 3-7

How

to

Remove

the

Fractional-N/Reference

Assembly

.

.

.

.

.

.

.

.

.

.

.

3-7

A4

Source

Assembly

Replacement

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

3-8

How

to

Remove

the

Source

Assembly

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

. 3-8

A5

Receiver

Assembly

Replacement

.

.

.

.

..

..

..

..

..

..

.

.

.

.

.

.

3-9

How

to

Remove

the

Receiver

Assembly

.

..

.

.

.

.

.

.

.

.

.

.

.

..

.

.

3-10

A6 P

ower Supply Assembly Replacement

....

...... ........ .

3-11

How to Remove the P

ower Supply Assembly

...

...... ......

3-11

A7 Display Assembly Replacement

........

..............

3-12

How to Remove the Display Assembly

...... ........ ..

..

3-12

A8 3.5" Internal Disk Drive Assembly Replacement

...... ........

3-13

How to Remove the 3.5" Disk Drive Assembly . . . . . . . . . . . . . . .

3-13

Attenuator Replacement . . . . . . . . . . . . . . . . . . . . . .

.....

3-13

AM Delay Modulator Replacement

.....................

. 3-13

Post Repair Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

How to Order Parts . ........ ..... ...... ...... ... 3-15

Save Money by Ordering R-E (Rebuilt-Exchange) Assemblies .... ..... 3-15

Save Time by Calling (800) 227-8164 .......... ..... ..... 3-15

Contents-3

Page 11

4.

Troubleshooting and

Block Diagrams

General

Notes .

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

..

.

.

.

.

.

4-1

Service

Kit .

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

..

.

.

.

.

.

.

4-2

How

to Use

the

Extender

Board

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

. 4-3

Initial

Observations -

Normal

P

ower-up

Sequence

.

.

.

.

.

.

.

.

.

..

..

. 4-4

Operator's

Check .

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

.

.

.

4-4

Category

1

F

ailures

-

Dead

or

No

Response

,

No

Display

,

Unreadable

Display,

or

Error

Messages

on

the

Display

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

4-5

Troubleshooting

A6

P

ower

Supply

Assembly

Problems

.

.

.

.

.

.

.

.

.

..

. 4-5

Check

the

Rear

P

anel

LEDs

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

4-5

Measure

the

P

ower

Supply

V

oltages

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

4-6

Remove

Assemblies

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

4-6

Troubleshooting

Digital

Group

Problems

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

4-7

Error

During

P

ower-up

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

4-7

T

est

Status

LEDs

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

4-9

T

est

Status

LEDs

code

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

4-9

Error

Occurs

During

DSP

Initialization

or

Calculating

Coecients

.

.

.

.

..

. 4-12

Clear

the

Nonvolatile

SRAM

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

4-12

Measure

the

5

MHz

Reference

Signal

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

4-12

Front

P

anel

Problems

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4-13

Other

P

ower-Up

Problems

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

4-13

Other

Error

messages

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

4-13

Category

2

F

ailures

-

No Error

Message,

but

Nonfunctional

Measurement

.

.

.

.

4-14

Troubleshooting

the

A3

Fractional-N/Reference

Assembly

..

..

.

.

.

.

.

.

4-14

Check

the

Output

P

ower

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4-14

Phase

Lock

Problems

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4-14

Detailed

Fractional-N/Reference

Troubleshooting

.

.

.

.

..

.

.

.

.

.

.

.

4-15

Troubleshooting the

A4

Source

Assembly

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4-16

Troubleshooting

the A5

Receiver

Assembly

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4-16

A5

Receiver Assembly

Diode

Replacement

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4-17

Trace

at

6

200 dB

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

4-20

Detailed

Receiver Troubleshooting

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4-20

Category

3F

ailures -

Inaccurate

(but

reasonably

functional)

Measurements

.

.

.

4-21

Troubleshooting

Spurious

Responses

and

Inaccurate

Data

.

.

.

.

.

.

.

.

.

.

4-21

Spurious

Signals

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

4-21

Spurs

in

the

Data

Trace

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

4-22

Inaccurate

Data

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

4-22

Receiver

P

ower

Problems

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

4-23

Category

4

F

ailures:

P

eripheral

Device

Problems

..

..

..

..

..

..

.

.

.

.

4-24

DIN

Keyboard

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

. 4-24

RS-232 Printers and Plotters

......

.................

4-24

Centronics

R

(Parallel) Printers and Plotters . . . . . .

..........

4-24

HP-IB Systems . . . . . . . . . .

....................

4-25

HP-IB Problems with Printers or Plotters

.......

...... ....

4-25

HP-IB Problems with Disk Drives . . . . . . . . . . . . . . . . .

....

4-25

General Checks for HP-IB Systems

..................

..

4-25

Contents-4

Page 12

5.

Service Related

Menus

Introduction

..

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

..

.

.

.

.

.

.

5-1

T

ests and

A

djustments

Menu

.

.

.

.

.

.

.

.

..

..

..

..

..

..

..

.

.

.

5-3

Select

Self-Test

Menu

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

.

.

.

.

5-3

Select

Adjustment

Menu

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

.

.

.

5-5

Instrument

Info .

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

.

.

.

.

.

5-7

Update

Corr

Const

Menu

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

5-7

Service

Utilities

Menu

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

5-8

Meas

Cal

Options

Menu

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

5-10

Analog

Bus

Menu

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

5-10

More

SV

C

Utilities

Menu

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

5-12

View

Array

Master

Menu/View

Array

Interpol

Menu

.

.

.

.

.

..

..

..

.

.

.

5-12

Miscellaneous

Service

Functions

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

5-13

Clearing

Nonvolatile

Memory

(SRAM)

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

5-13

HP-IB

Command

Reference

for

Service

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

5-13

Syntax

Summary

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

5-13

Softkey

SCPI

Commands

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

5-14

Alphabetical

SCPI

Command

Summary

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

5-15

6.

Theory

of

Operation

Introduction

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-1

System

Theory

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-1

Analyzer

Functional

Group

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-2

P

ower

Supply

Theory

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 6-2

Digital

Control

Theory

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-2

A1

Front

P

anel

Assembly

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-2

A2

CPU

Assembly

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-2

A7 Display

Assembly

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

6-3

A8

3.5" Internal

Disk

Drive

Assembly

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-3

Source

Theory .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

6-4

A3

Fractional-N/Reference Assembly

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6-4

A4

Source Assembly

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

6-4

Receiver

Theory

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

6-6

Dierences

Between

the

HP

8711B/12B

and

HP

8713B/14B

(1300

MHz

vs

3000

MHz)

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

6-7

HP

8713B/14B

A4

Source

Assembly

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

6-7

A5

Receiver

Assembly

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

6-8

7.

P

arts

List

Analyzer

Hardware

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

7-1

Specic Assembly and Cable Locations

.....

..............

7-1

8. Correction Constants and Firmware

Storing and Recalling Correction Constants (CC) . . . . . . . . . . . . . . . .

8-1

ToP

ermanently Store CCs in the Analyzer . . . . . . . . . . . . .

.....

8-2

To Store CCs to Disk for Archive

...... ........ .

.......

8-2

To Recall CCs from Disk

..................

...... ..

8-2

To Recall Previous CCs from a Disk after Replacing the A2 CPU Board

....

8-2

To Replace Suspected Incorrect CCs . . . . . . . . . . . . . . . . . . . . . 8-2

If

ROM Appears to be Blank

Message is Displayed at Power-up . . . . . . . 8-2

If

Warning: No Correction Constants Installed

Is Displayed at Power-up 8-2

Step 1. Storing Correction Constants to Disk .... ...... ...... 8-3

Step 2. Updating or Restoring Firmware .................. 8-4

Step 3. Installing Correction Constants from Disk .............. 8-4

Step 4. Loading Correction Constants from Disk . . . . . . . . . . . . . . . 8-4

Contents-5

Page 13

Upgrading

Firmware .

..

..

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

. 8-4

Making

a Current

Correction

Constants

Disk

(Optional)

.

.

.

.

.

.

.

..

..

. 8-5

How

to Upgrade

the

Firmware

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

..

8-5

9.

Previous Serial

Numbers

10.

Safety

,

W

arranty

,

and

Assistance

Safety

Symbols

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

10-1

General

Safety

Considerations

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

10-2

Safety

Earth

Ground

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

10-2

Servicing

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

10-2

W

arranty

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

10-3

Limitation

of

W

arranty

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

10-3

Exclusive

Remedies

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

10-3

Assistance

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

10-4

Shipment

for

Service

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

10-4

Index

Contents-6

Page 14

Figures

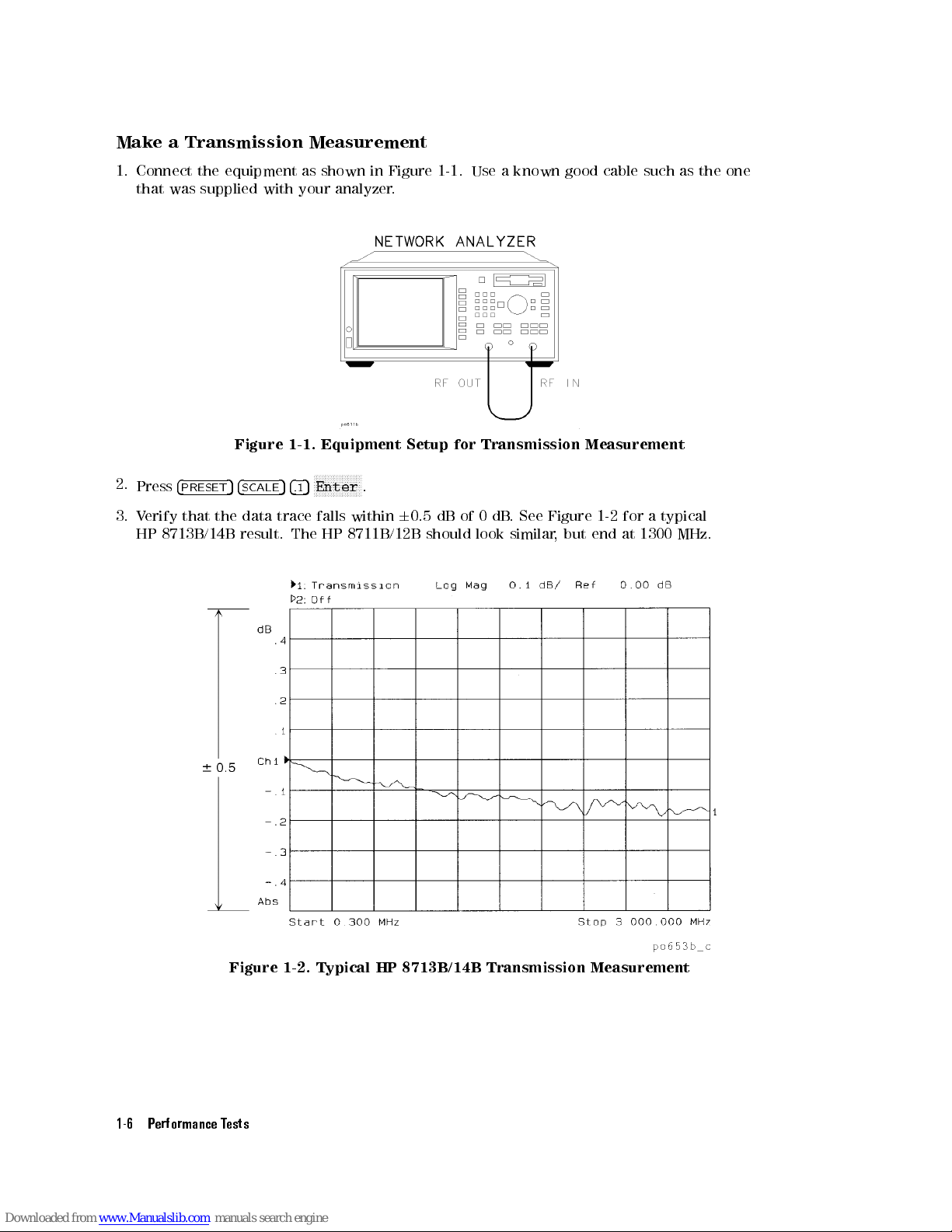

1-1. Equipment

Setup

for

Transmission

Measurement

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1-6

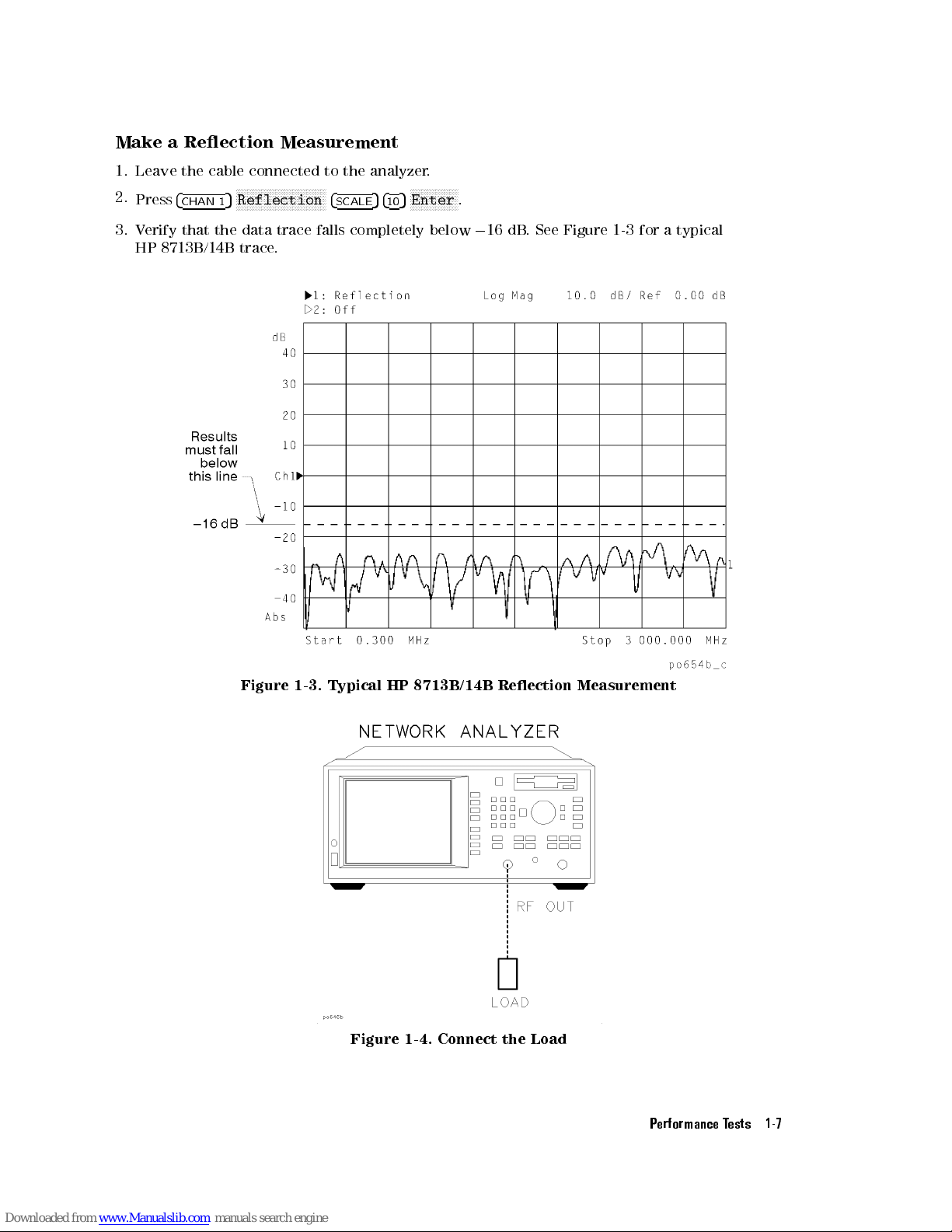

1-2. Typical

HP

8713B/14B

Transmission

Measurement

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1-6

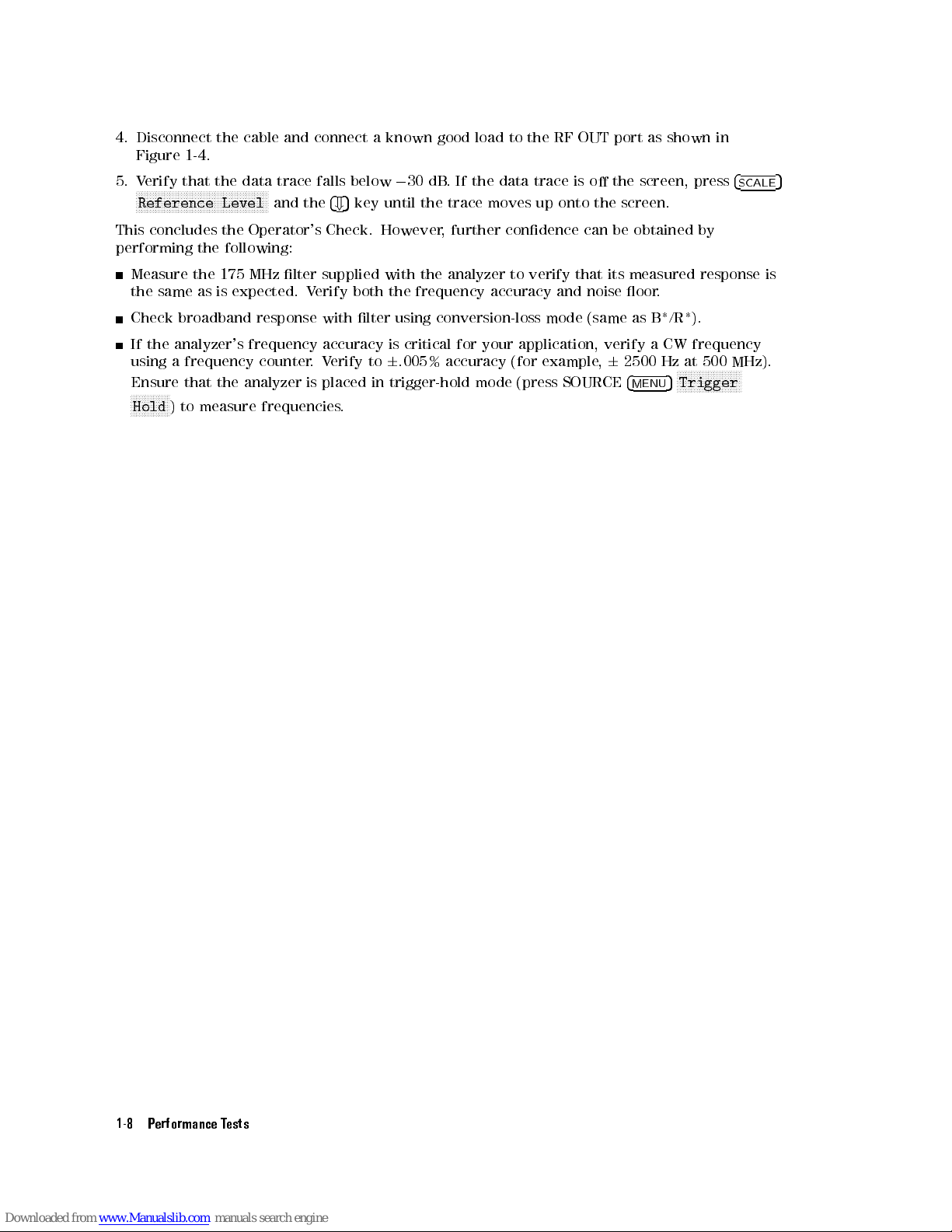

1-3. Typical

HP

8713B/14B

Reection

Measurement

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1-7

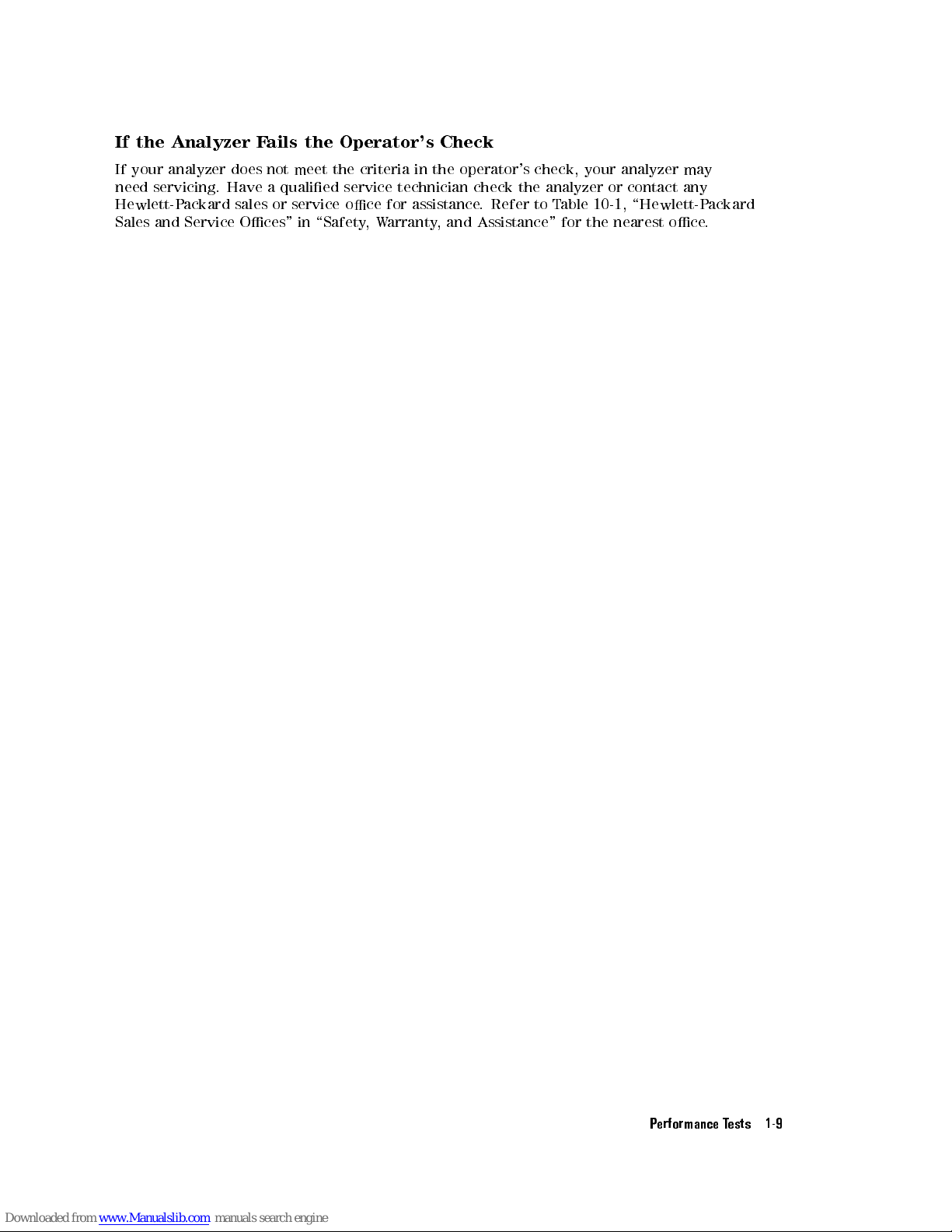

1-4. Connect

the Load

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

1-7

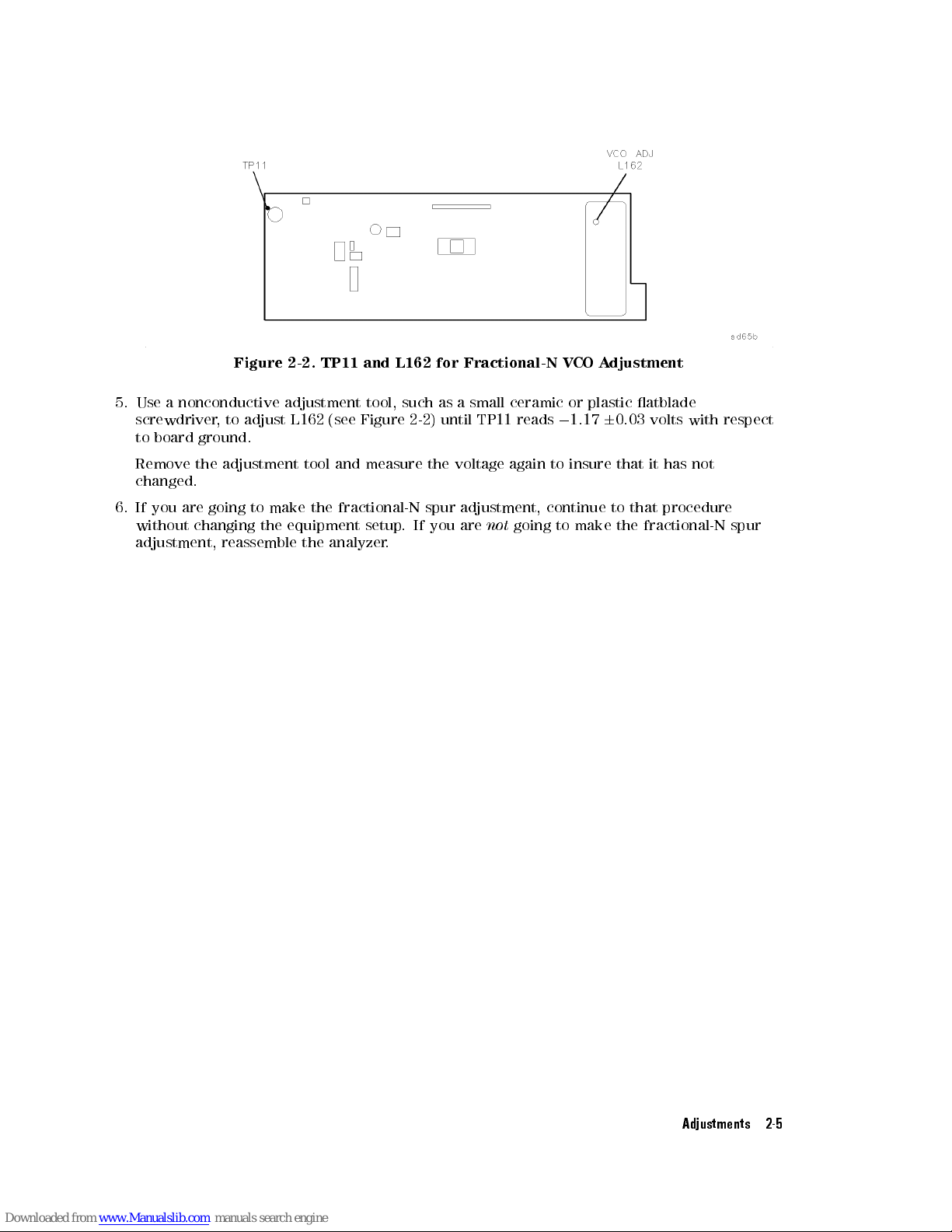

2-1. Removing

the Handles

and

Front

P

anel

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

2-4

2-2.

TP11

and

L162

for

Fractional-N

V

CO

A

djustment

.

.

.

.

.

.

.

..

..

..

. 2-5

2-3.

Removing

the

Handles

and

Front

P

anel

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

2-7

2-4.

Setup

for

Fractional-N

Spur

A

djustments

.

.

.

.

.

.

.

.

.

.

..

..

..

..

2-8

2-5.

API

and

100

kHz

A

djustments

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

2-9

2-6. Setup

for

Frequency

A

ccuracy

A

djustment

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-10

2-7.

Removing

the

Handles

and

Front

P

anel

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2-11

2-8. External

Detector

Connector

,

Front

View

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

2-16

2-9. Setup

for Source

P

ower

Correction

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

. 2-20

2-10. Setup

for

B*

Amplitude

Correction

for

50

Analyzers

.

.

.

.

.

.

.

.

.

.

.

.

2-29

2-11. Setup

for

B*

Amplitude

Correction

for

75

Analyzers

.

.

.

.

.

.

.

.

.

.

.

.

2-29

3-1. Removing

the

Handles

and

Front

P

anel

Assembly

.

.

.

.

.

.

.

.

.

.

.

.

.

.

3-2

3-2.

Removing

the

CPU

Assembly

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

3-4

3-3.

BootROM

U82,

Component

Location

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

3-5

3-4.

Removing

the

Fractional-N/Reference

Assembly

.

.

.

.

.

.

.

.

.

.

.

.

.

..

3-7

3-5.

Removing

the

A4

Source

Assembly

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

3-8

3-6.

Anchoring

Screw

Locations

for

A5

Receiver

Removal

.

.

.

.

.

.

.

.

.

.

.

. 3-10

3-7.

A8

Disk

Drive

Jumper

Conguration

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

3-13

4-1.

Example

of

an

Antistatic

W

orkstation

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

4-2

4-2.

Connecting

the

Extender

Board

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

4-3

4-3.

P

ower

Supply

Connector

,

as

Viewed

from

Rear P

anel .

..

..

.

.

.

.

.

.

.

4-6

4-4.

HP

8711B/12B

Reection

Measurement

with

Through

Cable

.

.

.

..

..

..

4-16

4-5.

HP

8713B/14B

Reection Measurement

with Through

Cable .

.

.

.

.

.

.

.

.

4-17

4-6.

HP

8711B/12B

A5CR1, CR2,

CR36, and

CR37 Component

Locations .

.

.

.

.

.

4-18

4-7.

HP

8713B/14B

A5CR45, CR46,

CR47, CR48,

CR53, and

CR54 Component

Locations

..

..

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

4-19

4-8. HP

8711B/12B

Overall

Block

Diagram

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

. 4-27

4-9. HP 8713B/14B A4 Source and A5 Receiver Assemblies Block Diagram . . . . .

4-29

5-1. The Service Key Menus

.

.........................

5-2

6-1. Simplied Analyzer System Block Diagram

.

................

6-1

6-2. Simplied HP 8711B/12B A4 Source Block Diagram

.............

6-5

6-3. Simplied Receiver Block Diagram

...

...... ........ ....

6-6

8-1. Correction Constants Flow by Keystroke and Cycling P

ower .........

8-1

Contents-7

Page 15

T

ables

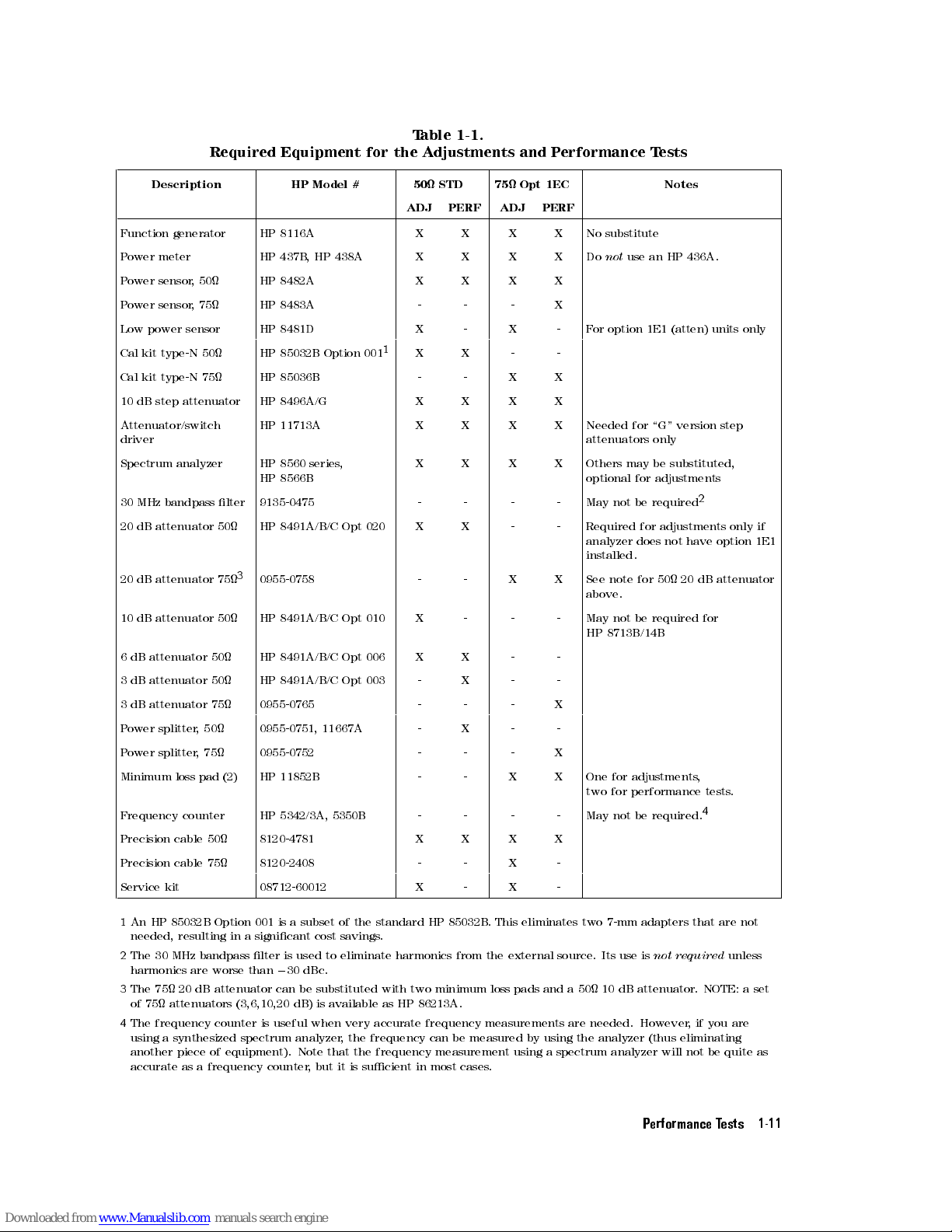

1-1. Required

Equipment for

the

A

djustments

and

P

erformance

T

ests

.

.

.

.

.

.

.

1-11

3-1.

P

ost

Repair

Procedures

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

3-14

4-1.

HP

8711B/12B/13B/14B

Self-T

ests

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

4-9

4-2. Source

Frequency

V

ersus

Fractional-N

Frequency

.

.

.

.

.

.

.

.

.

.

.

.

..

4-15

5-1. HP

8711B/HP

8712B/HP

8713B/HP

8714B

Self-T

ests

.

.

.

.

.

.

.

.

.

.

.

..

5-4

5-2. HP

8711B/12B/13B/14B

Network

Analyzer

A

djustments

.

.

.

.

.

.

.

.

.

.

.

5-6

5-3. HP

8711B/12B/13B/14B

Correction

Constant

Storage

Arrays

.

.

.

.

.

.

.

.

.

5-9

5-4.

Analog

Bus

Nodes

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

5-11

5-5.

Softkey

SCPI

Commands

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

5-14

5-6.

Alphabetical

SCPI

Command

Summary

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 5-15

7-1.

HP

8711B/12B

Major

Assembly

and

Cable

Locations

.

.

.

.

.

.

.

.

.

.

.

.

.

7-2

7-2. HP

8713B/14B Major

Assembly and

Cable

Locations

.

.

.

.

.

.

.

.

.

.

.

.

.

7-3

7-3.

A1

Front

P

anel

Assembly

and

Cable

Locations

.

.

.

.

.

.

.

.

..

..

..

..

7-4

7-4.

A2

CPU

Assembly

and

Cable

Locations

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

7-5

7-5.

A3

Fractional-N/Reference

Assembly

and

Cable

Locations

.

.

.

.

.

.

.

.

.

.

7-6

7-6.

HP

8711B/12B

A4

Source

Assembly

and

Cable

Locations

.

.

.

.

.

.

.

.

.

.

. 7-7

7-7.

HP

8713B/14B

A4

Source

Assembly

and

Cable

Locations

.

.

.

.

.

.

.

.

.

.

.

7-8

7-8.

HP

8711B/12B

A5

Receiver

Assembly

and

Cable

Locations

.

.

.

.

..

.

.

.

.

7-9

7-9.

HP

8711B/12B

A5

Receiver

Optional

Congurations

Assembly

and

Cable

Locations

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

7-10

7-10.

HP

8713B/14B

A5

Receiver

Assembly

and

Cable

Locations

.

.

.

.

.

.

..

.

.

7-11

7-11.

HP

8713B/14B

A5

Receiver

Optional

Congurations

Assembly

and

Cable

Locations

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

7-12

7-12.

A6

P

ower

Supply

Assembly

and

Cable Locations

..

.

.

.

.

.

.

.

.

.

.

.

.

.

7-13

7-13.

A7

Display

Assembly

and

Cable Locations

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

7-14

7-14.

Cabinet

and

Miscellaneous

P

arts .

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

7-15

8-1.

Storing

and

Recalling

Correction

Constants

Quick

Reference .

..

..

.

.

.

.

8-3

10-1.

Hewlett-P

ackard

Sales

and

Service

Oces

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

10-5

Contents-8

Page 16

1

P

erformance T

ests

This chapter

is divided

into

three

parts:

the

system

specications

summary

,

performing the

operator's

check,

and

instructions for

using

the

network

analyzer

performance

test

software

.

The operator's

check

can

be

used

as

a

quick

80%

condence

test.

The

only

equipment

required

for

this

check

is

a

type-N

cable

and

a

good

quality

50

type-N

load

(75

for option

1EC).

The

performance

tests

will

verify

that

the

analyzer

meets

its

published

specication

with

greater

than

a

95%

condence

level.

The

performance

tests

are

completely

automated.

The

performance test

software is

written for

an

HP

9000

Series

200

or

300

computer

(or

equivalent)

using HP

BASIC.

There are

no

manual

tests

provided,

nor

are

any

test

record

cards

provided.

Note

If

you

would

like to

order the

network

analyzer

performance

test

software

(HP

part

number

08712-10011), contact

your nearest

Hewlett-P

ackard

sales

and

service

oce

.

Results

of

the

automated

performance

tests

can

be

printed

out

at

any

time

.

They

include

all

specications

,

limits

,

and

uncertainties

.

Although

no

manual

test

is

provided,

each

test

is

described

in

enough

detail

below

to

allow

a

knowledgeable

technician

to

perform all

needed

tests

in

an

accurate

manner

.

System

Specications

Summary

The

specications and

characteristics in

this

section

describe

the

system

performance

of

the

analyzer

.

This

section is

asummary

of the

full System

Specications.

F

or

a

complete

listing

of

the

analyzer's

specications

,

see

\Specications

and

Characteristics"

in

the

User's Guide

.

Specications

(indicated by boldface type) describe the analyzer's warranted performance

over the temperature range of 25C65

C, unless otherwise stated.

Supplemental characteristics

(indicated by italics) are typical, but nonwarranted parameters

,

intended

to provide information useful in applying the analyzer

.

Performance Tests 1-1

Page 17

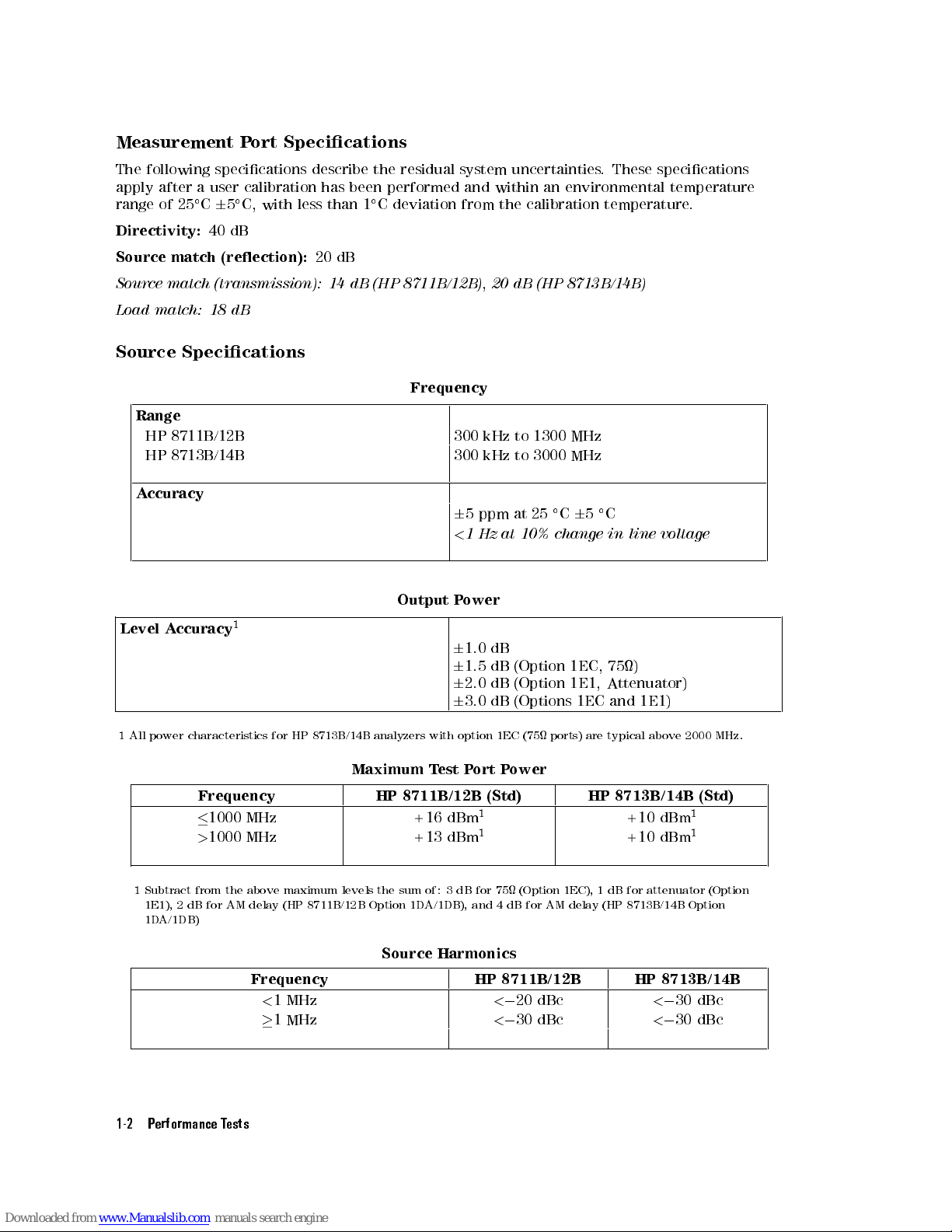

Measurement

P

ort

Specications

The

following

specications

describe

the

residual

system

uncertainties

.

These

specications

apply

after

a

user

calibration

has

been

performed

and within

an environmental

temperature

range

of

25

C

6

5

C,

with

less

than

1

C

deviation

from

the

calibration

temperature

.

Directivity:

40

dB

Source

match

(reection):

20

dB

Source

match

(transmission):

14

dB

(HP

8711B/12B)

,

20 dB

(HP 8713B/14B)

Load

match:

18

dB

Source

Specications

Frequency

Range

HP

8711B/12B

300

kHz

to

1300

MHz

HP

8713B/14B

300

kHz

to

3000

MHz

A

ccuracy

6

5

ppm

at

25

C

6

5

C

<

1Hz

at 10%

change

in

line

voltage

Output P

ower

Level

A

ccuracy

1

6

1.0

dB

6

1.5

dB

(Option

1EC,

75)

6

2.0

dB

(Option

1E1,

Attenuator)

6

3.0

dB

(Options

1EC

and

1E1)

1

All

power

characteristics

for

HP

8713B/14B

analyzers with

option 1EC

(75 ports)

are

typical

above

2000

MHz.

Maximum

Test

Port

Power

Frequency HP

8711B/12B

(Std)

HP

8713B/14B

(Std)

1000

MHz

+16

dBm

1

+10

dBm

1

>

1000 MHz +13 dBm

1

+10 dBm

1

1

Subtract from the above maximum

levels the sum of: 3 dB for 75 (Option 1EC), 1 dB for attenuator (Option

1E1), 2 dB for AM delay (HP 8711B/12B Option 1D

A/1DB), and

4 dB for AM delay (HP 8713B/14B Option

1DA/1DB)

Source Harmonics

Frequency HP 8711B/12B HP 8713B/14B

<

1 MHz

<020 dBc

<030 dBc

1 MHz

<030 dBc

<030 dBc

1-2 Performance Tests

Page 18

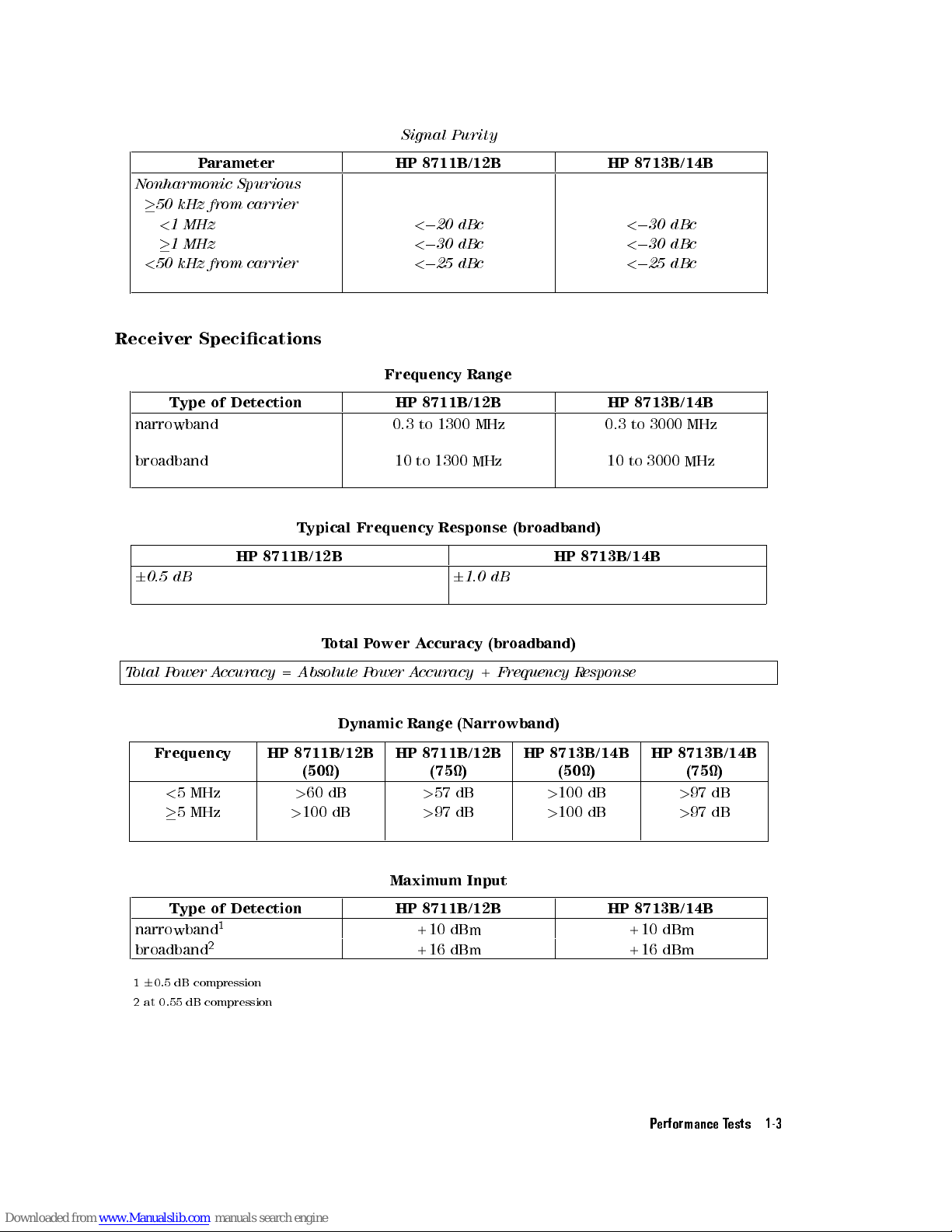

Signal

Purity

Parameter HP 8711B/12B HP 8713B/14B

Nonharmonic

Spurious

50

kHz

from

carrier

<

1

MHz

<

0

20

dBc

<

0

30

dBc

1

MHz

<

0

30

dBc

<

0

30

dBc

<

50

kHz

from

carrier

<

0

25

dBc

<

0

25

dBc

Receiver Specications

Frequency Range

Type

of

Detection

HP

8711B/12B

HP

8713B/14B

narrowband 0.3

to

1300

MHz

0.3

to

3000

MHz

broadband 10

to

1300

MHz

10

to

3000

MHz