Page 1

TECHNICAL MANUAL

OPERATOR’S, ORGANIZATIONAL,

DIRECT SUPPORT,AND GENERAL SUPPORT

MAINTENANCE MANUAL

INCLUDING REPAIR PARTS AND

SPECIAL TOOLS LIST

(INCLUDING DEPOT MAINTENANCE REPAIR

PARTS AND SPECIAL TOOLS)

FOR

RF SECTION HP-86602B

(NSN 6625-01-031-8853)

TM 11-6625-2837-14&P-7

HEADQUARTERS, DEPARTMENT OF THE ARMY

OCTOBER 1981

Page 2

Page 3

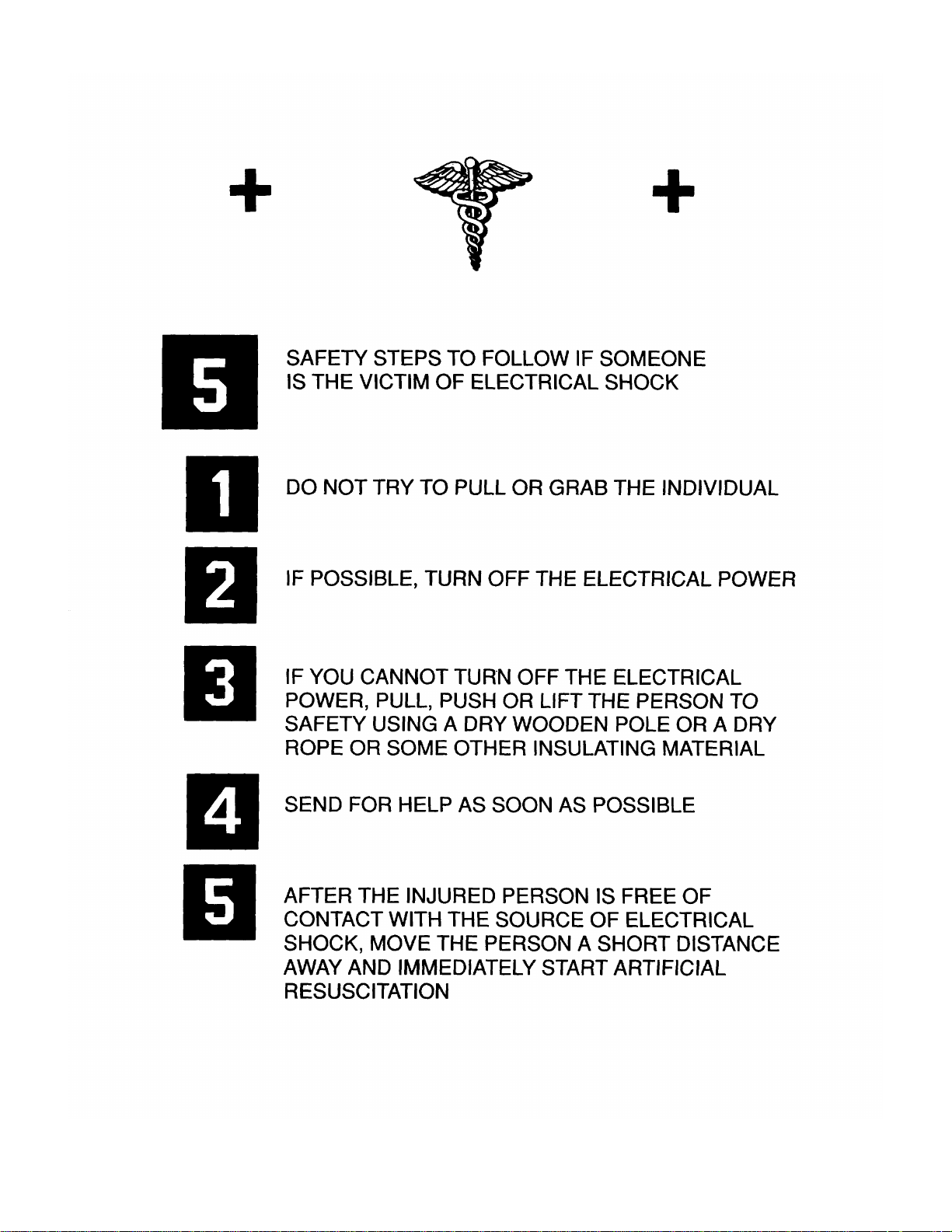

SAFETY

TM 11-6625-2837-14&P-7

WARNING

Although this instrument has been designed in

accordance with international safety standards, this

manual contains information, cautions, and warnings

which must be followed to retain the instrument in safe

condition. Be sure to read and follow the safety

information in Sections 11, III, V, an VIII.

BEFORE CONNECTING THIS SYSTEM TO LINE

(MAINS) VOLTAGE, the safety and installation

instructions found in Sections II and III of the m ainfram e

manual should be followed.

HIGH VOLTAGE

Adjustments and troubleshooting are often performed

with power supplied to the instrument while protective

covers are removed. Energy available at many points

may constitute a shock hazard

The multi-pin plug connector which provides inter

connection from mainframe to RF Section, will be

exposed with the RF Section removed from the righthand mainframe cavity. With the Line (Mains Voltage off

and power cord disconnected, power supply voltages

may still remain and may constitute a shock hazard.

COMPATIBILITY

Damage to the synthesized signal generator system m ay

result if an option 002 RF Section is used with

unmodified Model 8660A or 8660B main-frames with

serial prefixes 1349A and below.

PERFORMANCE TESTING

To avoid the possibility of damage to the instrum ent or

test equipment, read completely through each test before

starting it. Then make any preliminary control settings

necessary before continuing with the procedure.

PLUG-IN REMOVAL

Before removing the RF Section plug-in from the

mainframe, remove the line (Mains) voltage by

disconnecting the power cable from the power outlet.

SEMI-RIGID COAX

Slight but repeated bending of the semi-rigid coaxial

cable will damage them very quickly. Bend the cables as

little as possible. If necessary, loosen the assembly to

release the cable.

WARNING

Voltages are present in this instrument, when energized, which can

cause death on contact.

The multi-pin plug connector which provides interconnection from

mainfram e to RF Section, will be exposed with the RF Sect ion removed

from the righthand mainfram e cavity. With the line voltage of f and power

cord disconnected, power supply voltage may still remain and may

constitute a shock hazard.

A

Page 4

TM 11-6625-2837-14&P-7

This manual contains copyrighted material reproduced by permission of the Hewlett-Packard Company. All rights

reserved.

TM 11-6625-2825-14&p-7

TECHNICAL MANUAL ) HEADQUARTERS

) DEPARTMENT OF THE ARMY

No. 11-6625-2825-14&p-7 ) Washington, D.C., 18 October 1981

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT

AND GENERAL SUPPORT MAINTENANCE MANUAL

INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

FOR

RF SECTION PLUG-IN, HEWLETT-PACKARD MODEL 86602B

(NSN 6625-01-031-8853)

CURRENT AS OF 30 JANUARY 1981

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can help improve this manual. If you find any mistakes or if you know of a way to improve the procedures,

please let us know. Mail your letter or DA Form 2028 (R ecommended Changes to Publications and Blank Forms), direc t

to: Commander, US Army Communications and Electronics Materiel Readiness Command, ATTN: DRSEL-ME-MQ, Fort

Monmouth, New Jersey 07703. In either case, a reply will be furnished direct to you.

This manual is an authentication of the manufacturer’s commercial literature which, through usage, has been found to

cover the data required to operate and maintain this equipment. The manual was not prepared in acc or dance with military

specifications; therefore, the format has not been st ructured to consider categories of maintenance. Section IX contains

improvements made after the printing of the manufacturer’s manual.

CONTENTS

SECTION 0 INTRODUCTION PAGE

0-1. Scope 0-1

0-2. Indexes of Publications 0-1

0-3. Maintenance Forms, Records and Reports 0-1

0-4. Reporting Equipment Improvement Recommendations (EIR) 0-1

0-5. Administrative Storage 0-2

0-6. Destruction of Army Electronics Materiel 0-2

i

Page 5

CONTENTS

TM 11-6625-2837-14&P-7

Section Page

I GENERAL INFORMATION......................... 1-1

1-1. Introduction....................................... 1-1

1-7. Specifications .................................. 1-1

1-9. Instruments Covered by Manual....... 1-1

1-12. Manual Change Supplements.......... 1-1

1-15. Description........................................ 1-5

1-20. Options ............................................ 1-5

1-24. Compatibility..................................... 1-5

1-27.Equipment Required but not

Supplied........................................ 1-5

1-28.System Mainframe........................... 1-5

1-31.Frequency Extension Module........... 1-6

1-33.Auxiliary Section............................... 1-6

1-35.Modulation Section Plug-ins............. 1-6

1-37.Equipment Available......................... 1-6

1-40.Safety Considerations...................... 1-6

1-43.Recommended Test Equipment....... 1-6

II INSTALLATION........................................... 2-1

2-1. Introduction....................................... 2-1

2-3. Initial Inspection ............................... 2-1

2-5. Preparation For Use......................... 2-1

2-6. Power Requirements........................ 2-1

2-8. Interconnections............................... 2-1

2-10.Modifications..................................... 2-1

2-13.Operating Environment..................... 2-1

2-15.Installation Instructions..................... 2-1

2-17.Storage and Shipment...................... 2-2

2-18.Environment..................................... 2-2

2-20.Packaging......................................... 2-2

III OPERATION........................................... 3-1

3-1. Introduction ...................................... 3-1

3-3. Panel Features................................. 3-1

3-5. Operator’s Check.............................. 3-1

3-8. Operating Instructions ..................... 3-1

IV PERFORMANCE TESTS ....................... 4-1

4-1. Introduction....................................... 4-1

4-3. Equipment Required......................... 4-1

4-5. Test Record...................................... 4-1

4-7. Performance Tests........................... 4-1

4-9. Frequency Range............................. 4-2

4-10.Frequency Accuracy and Stability.... 4-3

4-11.Frequency Switching Time............... 4-3

4-12.Output Level Switching Time............. 4-5

4-13A. Output Accuracy.......................... 4-7

4-13B. Output Accuracy- Alternate

Procedure...................................... 4-12

4-14.Output Flatness................................ 4-15

4-15.Harmonic Signals............................. 4-16

Section Page

4-16.Pulse Modulation Risetime............... 4-17

4-17.Pulse Modulation On/Off Ratio......... 4-19

4-18.Amplitude Modulation Depth and

3 dB Bandwidth............................. 4-19

4-19.Frequency Modulation Rate and

Deviation....................................... 4-23

4-20.Output Impedance and VSWR......... 4-23

4-21.Signal-to-Phase Noise Ratio............ 4-25

4-22.Signal-to-AM Noise Ratio................. 4-27

4-23.Residual FM..................................... 4-29

4-24.Amplitude Modulation Distortion...... 4-31

4-25.Incidental Phase Modulation ........... 4-33

4-26.Frequency Modulation Distortion...... 4-35

4-27.Incidental AM................................... 4-38

4-28.Spurious Signals, Narrowband......... 4-40

4-29.Spurious Signals, Wideband............ 4-41

4-30.Phase Modulation Peak Deviation... 4-43

4-31A. Phase Modulation Distortion........... 4-43

4-31B. Phase Modulation Distortion -

Alternate Procedure...................... 4-45

V ADJUSTMENTS.......................................... 5-1

5-1. Introduction...................................... 5-1

5-4. Equipment Required........................ 5-1

5-8. Safety Considerations...................... 5-1

5-12.Factory Selected Components......... 5-1

5-14.Related Adjustments........................ 5-1

5-18.Adjustment Locations....................... 5-2

5-20.Adjustments..................................... 5-2

5-22.Post Adjustment Tests .................... 5-2

5-24.RF Output Level Adjustment............ 5-3

5-25.1 dB Step Attenuator Adjustment..... 5-4

5-26.Amplitude Modulation Input Circuit

Adjustment.................................... 5-5

5-27.Phase Modulator Driver Frequency

Response Adjustments................. 5-7

5-28A. Phase Modulation Level and

Distortion Adjustments.................. 5-8

5-28B. Phase Modulation Level and Distortion

Adjustments - Alternate Procedure5-11

VI REPLACEABLE PARTS.......................... 6-1

6-1. Introduction...................................... 6-1

6-3. Exchange Assemblies...................... 6-1

6-5. Abbreviations................................... 6-1

6-7. Replaceable Parts List..................... 6-1

ii

Page 6

CONTENTS (Cont’d)

TM 11-6625-2837-14&P-7

Section Page

VII MANUAL CHANGES ............................... 7-1

7-1. Introduction ...................................... 7-1

7-3. Manual Changes.............................. 7-1

7-6. Manual Change Instructions............. 7-2

VIII SERVICE................................................... 8-1

8-1. Introduction....................................... 8-1

8-8. Safety Considerations...................... 8-1

8-12.Principles of Operation..................... 8-1

8-16.Troubleshooting................................ 8-1

ILLUSTRATIONS

Figure Page

1-1. HP Model 86602B RF Section (Opt. 002

Shown)

1-2. 40 dB Test Amplifier................................ 1-0

1-3. 15 kHz Low Pass Filter .......................... 1-11

1-4. Low Pass Filters...................................... 1-11

2-1. RF Section Partially Inserted into

Mainframe........................................ 2-2

3-1. Front Panel Controls, Connectors, and

Indicators.......................................... 3-2

3-2. Rear Panel Connectors and Indicators... 3-3

3-3. Operator’s Check.................................... 3-4

4-1. Frequency Range Test Setup................. 4-2

4-2. Frequency Switching Time Test Setup... 4-4

4-3. Output Level Switching Time Test Setup 4-6

4-4A.Output Accuracy Test Setup.................. 4-8

4-4B.Output Accuracy Test Setup (Alternate

Procedure......................................... 4-13

4-5. Pulse Modulation Risetime Test Setup .. 4-18

4-6. Amplitude Modulation, Depth and 3 dB

Bandwidth Test Setup...................... 4-20

4-7. Output Impedance Test Setup................ 4-24

4-8. Signal-to-Phase Noise Ratio Test Setup. 4-26

4-9. Signal-to-AM Noise Ratio Test Setup..... 4-28

4-10.Residual FM Test Setup......................... 4-29

4-11.Amplitude Modulation Distortion Test

Setup................................................ 4-30

4-12.Incidental Phase Modulation Test Setup 4-32

4-13.Frequency Modulation Distortion Test

Setup................................................ 4-35

4-14.Incidental AM Test Setup ....................... 4-38

4-15.Narrowband Spurious Signal Test Setup. 4-39

4-16.Wideband Spurious Signal Test Setup... 4-41

Section Page

8-17.System Troubleshooting.................. 8-2

8-19.RF Section Troubleshooting............. 8-2

8-21.Troubleshooting Aids....................... 8-2

8-28.Recommended Test Equipment...... 8-2

8-30.Repair............................................... 8-2

8-31.General Disassembly Procedures.... 8-2

8-34.Non-Repairable Assemblies............. 8-2

8-36.Module Exchange Program.............. 8-3

8-38.Repair Procedures........................... 8-3

8-42.Post Repair Adjustments................. 8-3

IX ERRATA

Figure Page

4-17A. Phase Modulation Distortion Test Setup 4-44

4-17B.Phase Modulation Distortion Test Setup

(Alternate Procedure)....................... 4-46

5-1. RF Output Level Adjustment Test Setup 5-3

5-2. 1 dB Step Attenuator Adjustment Test

Setup................................................ 5-4

5-3. Amplitude Modulation Input Circuit

Adjustment Test Setup..................... 5-5

5-4. Phase Modulator Driver Frequency

Response Adjustment Test Setup... 5-7

5-5A.Phase Modulation Level and Distortion

Adjustment Test Setup..................... 5-9

5-5B.Phase Modulation Level and Distortion

Adjustment Test Setup (Alternate

Procedure)....................................... 5-12

7-1. Phase Modulator Driver Frequency Response

Adjustment Test Setup (Change B). 7-2

7-2. A16 Phase Modulator Driver Assembly

Component and Test Point Locations

(Change B)....................................... 7-6

7-3. Phase Modulation Section Schematic

Diagram (Option 002) (Change B)... 7-8

7-4. A17 Phase Modulator Assembly

Component Locations (Change C).. 7-9

7-5. P/O Phase Modulation Section Schematic

Diagram (Change C)........................ 7-11

7-6. P/O Attenuator Section Schematic

Diagram (Change D)........................ 7-11

7-7. P/O All Logic Assembly Schematic

Diagram (Change E)........................ 7-12

8-1. LO Signal Circuits Repair....................... 8-4

iii

Page 7

ILLUSTRATIONS (Cont’d)

TM 11-6625-2837-14&P-7

Figure Page

8-2. Rear Panel Disassembly......................... 8-8

8-3. Schematic Diagram Notes...................... 8-9

8-4. System Test Point Locations.................. 8-17

8-5. Mainframe Interconnect Jack.................. 8-17

8-6. System Troubleshooting Block

Diagram............................................ 8-17

8-7. RF Section Simplified Block Diagram..... 8-19

8-8. Main Troubleshooting Block Diagram .... 8-19

8-9. Logic Troubleshooting Block Diagram ... 8-21

8-10.A7 Mixer Assembly’s Subassembly and

Component Location........................ 8-22

8-11.Mixer Section Schematic Diagram.......... 8-23

8-12.A16 Phase Modulator Driver Assembly

Component and Test Point Locations 8-25

8-13.A17 Phase Modulator Assembly

Component Locations ..................... 8-25

8-14.Phase Modulation Section Schematic

Diagram (Option 002)....................... 8-25

8-15.A4 Detector Amplifier Assembly

Component and Test Point Locations 8-27

Figure Page

8-16..Amplifier/Detector Section

Schematic Diagram.......................... 8-27

8-17.A3 ALC Amplifier Assembly Component

and Test Point Locations.................. 8-28

8-18.A10 Reference Assembly

Component Locations ..................... 8-29

8-19.A2 ALC Mother Board Assembly

Component Locations...................... 8-29

8-20.ALC Section

Schematic Diagram.......................... 8-29

8-21.A9 Attenuator Driver Assembly

Component Locations ..................... 8-31

8-22.Attenuator Section

Schematic Diagram.......................... 8-31

8-23.All Logic Assembly

Component Locations...................... 8-33

8-24.All Logic Assembly

Schematic Diagram.......................... 8-33

8-25.Assemblies, Chassis Parts, and Adjustable

Component Locations ..................... 8-35

TABLES

Table Page

1-1. Models 86602B/11661 Specifications..... 1-2

1-2. Recommended Test Equipment............. 1-7

3-1. Operating Instructions ............................ 3-6

4-1. dB to Power Ratio Conversion................ 4-37

4-2. Narrowband Spurious Signal Checks..... 4-40

4-3. Wideband Spurious Signal Checks........ 4-41

4-4. Performance Test Record ...................... 4-47

5-1. Factory Selected Components................ 5-2

APPENDIX A. References............................................................................................. A-1

APPENDIX B. Maintenance Allocation

Section I. Introduction............................................................................................. B-1

II. Maintenance Allocation.......................................................................... B-5

III. Tool and Test Equipment Requirements............................................ B-6

Users of this manual are advised to consult SECTION IX, ERRATA. SECTION IX

contains errors and changes in text and illus trations. The user should correc t the errors

and perform the changes indicated, as needed.

Table Page

6-1. Reference Designations & Abbreviations6-3

6-2. Replaceable Parts.................................. 6-5

6-3. Code Lists of Manufacturers................... 6-15

6-4. Parts to NSN Cross Refererence........... 6-16

7-1. Manual Changes by Serial Prefix........... 7-1

7-2. Summary of Changes by Component.... 7-1

7-3. Replaceable Parts (P/O Change B)........ 7-7

8-1. Front Panel Housing Repair................... 8-7

8-2. Adjustable Components Locations.. 8-34

APPENDICES

Page

NOTE

iv

Page 8

TM 11-6625-2837-14&P-7

SECTION 0

INTRODUCTION

0-1. Scope

This manual describes RF Section Hewlett-Packard Model 86602B, hereinafter referred to as the RF Section, and

provides instructions for its operation and maintenance.

This manual applies dir ectly to instruments with serial numbers prefixed 1638A. It is also applicable to instruments with

other serial number prefixes for which manual changes are given in SECTION VII.

SECTION VI includes Table 6-4, a cross reference between the Hewlett-Packard part numbers and the equivalent

NATO/NATIONAL Stock Numbers (NSN).

Appendix A provides a reference of pertinent Department of the Army publications.

Appendix B contains the Maintenance Allocation Chart (MAC) which defines the levels and scope of maintenance

functions for the equipment in the Army system and a list of the tools and test equipment required.

0-2. Indexes of Publications

a. DA Pam 310-4

changes or additional publications pertaining to the equipment.

b. DA Pam 310-7

pertaining to the equipment.

0-3. Maintenance Forms, Records and Reports

a. Reports of Maintenance and Unsatisfac tory Equipment. Departm ent of the Arm y form s and procedures

used for equipment maintenance will be those prescribed by TM 38-750, the Army Maintenance Management System.

b. Report of Item and Packaging Discr epancies. Fill out and forward SF 364 ( Report of Discr epancy (ROD) as

prescribed in AR 735-11-2/DLAR 4140.55/NAVSUPINST 4440.127E/AFR 400.54/MCO 4430.E.

c. Discrepancy in Shipment Report (DISREP) (SF 361). Fill out and forward Disc repancy in Shipment Report

(DISREP) (SF 361) as prescribed in AR 55-38/NAVSUPINST 4610.33B/AFR 75-18/MCO P4610.19C and DLAR 4500.15.

0-4. Reporting Equipment Improvement Recommendations (EIR)

If your HP 86602B RF Section needs improvement, let us know. Send us an EIR. You, the user, are the only one

who can tell us what you don’t like about your equipment. Let us know why you don’t like the design. Tell us why a

procedure is hard to perform. Put it on an SF 368 (Quality Deficiency Report). Mail it to: Commander, US Army

Communications - Electronics Comm and, AT TN : DRSEL-ME-MQ, Fort Monm outh, New Jers ey 07703. W e’ll send you a

reply.

. Refer to the latest issue of the DA Pam 310-4 to determine whether there are new editions,

. Refer to DA Pam 310-7 to determine whether there are Modification Work Orders (MWOs)

0-1

Page 9

0-5. Administrative Storage.

Store in accordance with Paragraphs 2-17 through 2-22.

0-6. Destruction of Army Electronics Materiel

Destruction of Army electronics materiel to prevent enemy use shall be in accordance with TM 750-244-2.

TM 11-6625-2837-14&P-7

0-2

Page 10

Section 1 TM 11-6625-2837-14&P-7

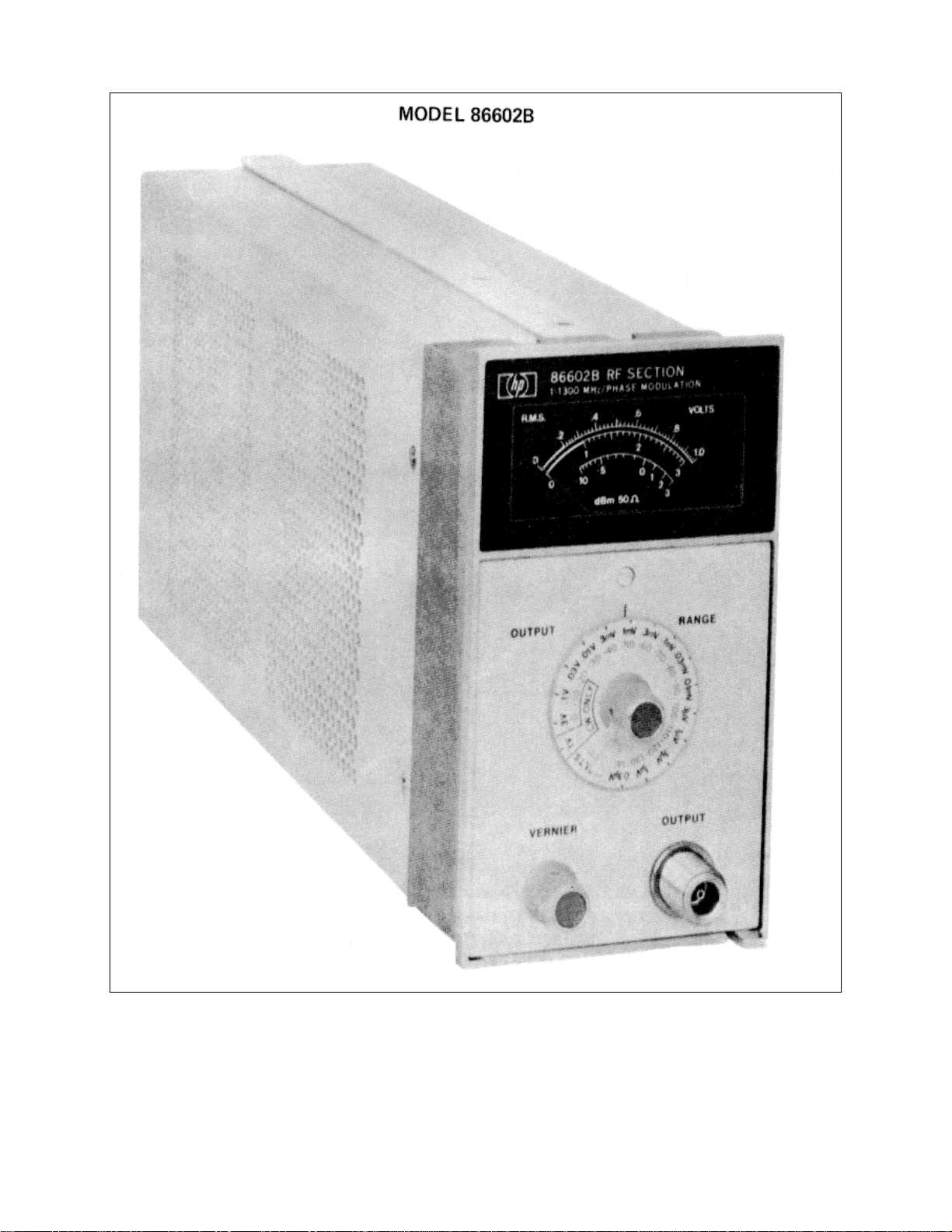

Figure 1-1. HP Model 86602B RF Section (Option 002 Shown)

1-0

Page 11

Section 1 TM 11-6625-2837-14&P-7

SECTION I

GENERAL INFORMATION

1-1. INTRODUCTION

1-4. Figure 1-1 shows the Option 002 RF Section.

1-2. This manual contains all information required to

install, operate, test, adjust and service the HewlettPackard Model 86602B RF Section plug-in, hereinafter

referred to as the RF Section. For information

concerning related equipment, such as the HewlettPackard Model 8660-series mainframes or the Model

11661 Frequency Extension Module, refer to the

appropriate manual or manuals.

1-3. This manual is divided into eight sections which

provide information as follows:

a. SECTION I, GENERAL INFORMATION,

contains the instrument desc ription and specific ations as

well as the accessory and recomm ended test equipment

list.

b. SECTION II, INSTALLATION, contains

information relative to receiving inspection, preparation

for use, mounting, packing, and shipping.

c. SECTION III, OPERATION, contains

operating instructions for the instrument.

d. SECTION IV, PERFORMANCE TESTS,

contains information required to verify that instrument

performance is in accordance with published

specifications.

e. SECTION V, ADJUSTMENTS, contains

information required to properly adjust and align the

instrument after repair.

f. SECTION VI, REPLACEABLE PARTS,

contains information required to order all replacement

parts and assemblies.

g. SECTION VII, MANUAL CHANGES, provides

information to docum ent all serial number prefixes listed

on the title page.

h. SECTION VIII, SERVICE, contains

descriptions of the circuits, schematic diagrams, parts

location diagrams, and troubleshooting pr ocedures to aid

the user in maintaining the instrument.

1-5. DELETED

1-6. On the title page of this manual, below the manual

part number, is a “Microf ic he” par t number. This number

may be used to order 4 x 6-inch microfilm transparencies

of the manual. Each m icrof iche contains up to 60 photoduplicates of the manual pages. The microfiche

package also includes the latest Manual Changes

supplement as well as all pertinent Service Notes.

1-7. SPECIFICATIONS

1-8. Instrument spec ifications are listed in T able 1-1.

These specifications are the per formance standards, or

limits against which the instrument may be tested.

1-9. INSTRUMENTS COVERED BY MANUAL 1-10.

This instrument has a two-part serial number. The f irst

four digits and the letter comprise the serial number

prefix. The last f ive digits form the sequential suff ix that

is unique to each instrument. The contents of this

manual apply directly to instruments having the same

serial number prefix(es) as listed under SERIAL

NUMBERS on the title page.

1-11. For information concerning a serial num ber prefix

not listed on the title page or in the Manual Changes

supplement, contact your nearest Hewlett-Packard

office.

1-12. MANUAL CHANGE SUPPLEMENTS

1-13. An instrument manufactured after the printing of

this manual may have a serial prefix that is not lis ted on

the title page. This unlisted serial

1-1

Page 12

Section 1 TM 11-6625-2837-14&P-7

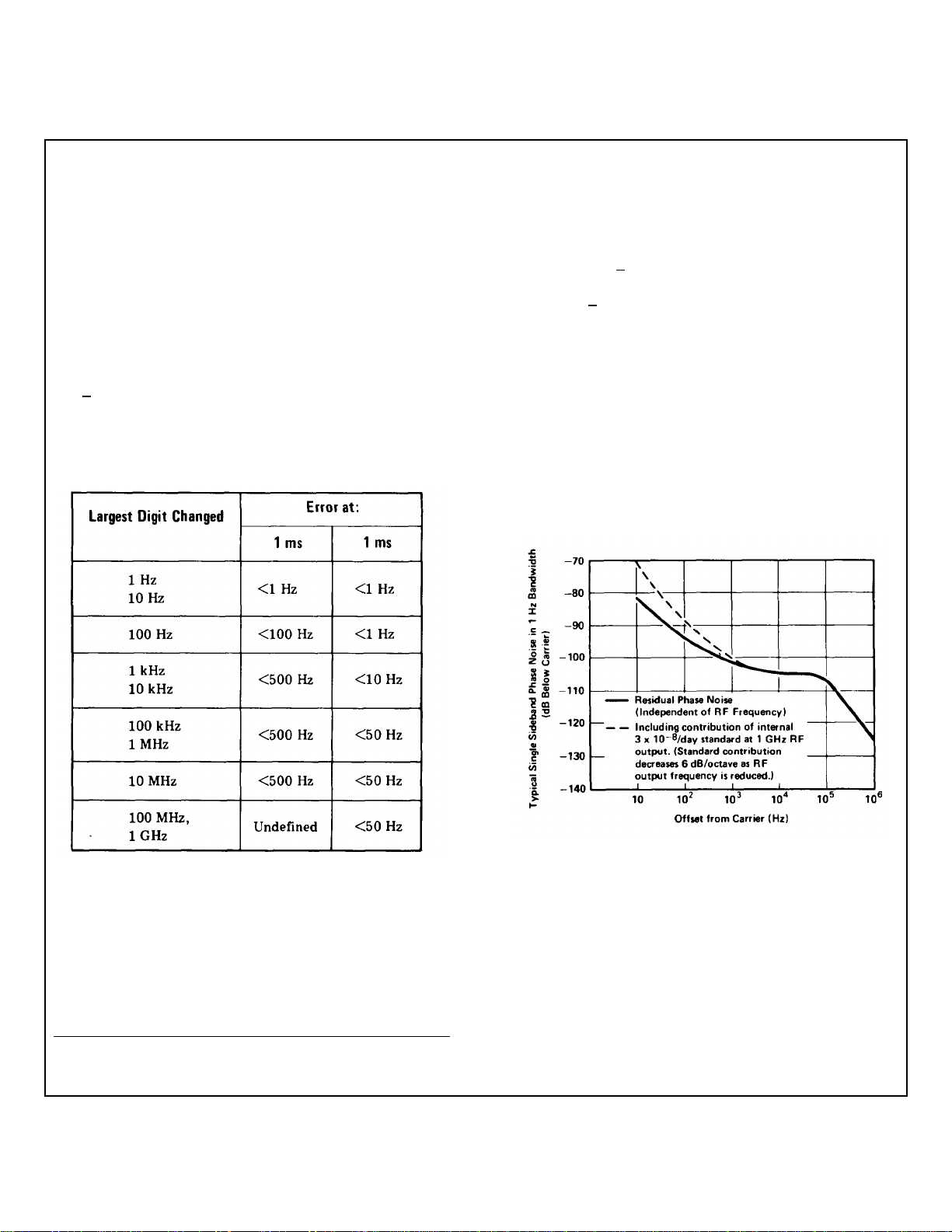

Table 1-1. Models 86602B/11661 Specifications (1 of 3)

SPECIFICATIONS

FREQUENCY CHARACTERISTICS

Spurious Signals (CW, AM, and OM only):

Range: 1.0 to 1299.999999 MHz selectable in 1 Hz

steps. Frequencies from 200 k Hz to 1 MHz may also be

selected with some degradation in specifications.

1

Accuracy and Stability

: CW f requency accuracy and

long term stability are determined by the aging rate of the

80 dB down from carrier at frequencies <700 MHz

80 dB down from carrier within 45 MHz of the carrier at

frequencies >700 MHz

70 dB down from carrier >45 MHz from carrier at

frequencies >700 MHz

50 dB down from carrier on the +10 dBm range.

time base (internal or external) and its sensitivity to

changes in temperature and line voltage. Internal

reference oscillator ac curacy = + aging rate ± 3 x 10

/°C + 3 x 10

-10

/1% change in line voltage

-10

All Power Line Related spurious signals are 70 dB down

from carrier.

Switching Time: 6 ms to be within 50 Hz of any new

frequency selected; 100 ms to be within 5 Hz of any new

frequency delected.

Typical 86602B/11661 Frequency Switching

Characteristics

Harmonic Signals:

All harmonically related signals are at least 30 dB below

the desired output signal for output levels <+3 dBm.

(25 dB down for output levels above +3 dBm.)

Signal-to-Phase Noise Ratio (CW, AM, and OM only):

Greater than 45 dB in a 30 kHz band centered

on the carrier and excluding a 1 Hz band

centered on the carrier.

Typical SSB Phase Noise Curve:

Typical 86602B Phase Noise

Signal-to-AM Noise Ratio: Greater than 65 dB down in

a 30 kHz bandwidth centered on the carrier and

excluding a 1 Hz band centered on the carrier

1

Aging rate for the time base of standard mainframes is 3 x

10-8/day: for option 001 mainframes, 3 x 10-9/day.

1-2

Page 13

Section 1 TM 11-6625-2837-14&P-7

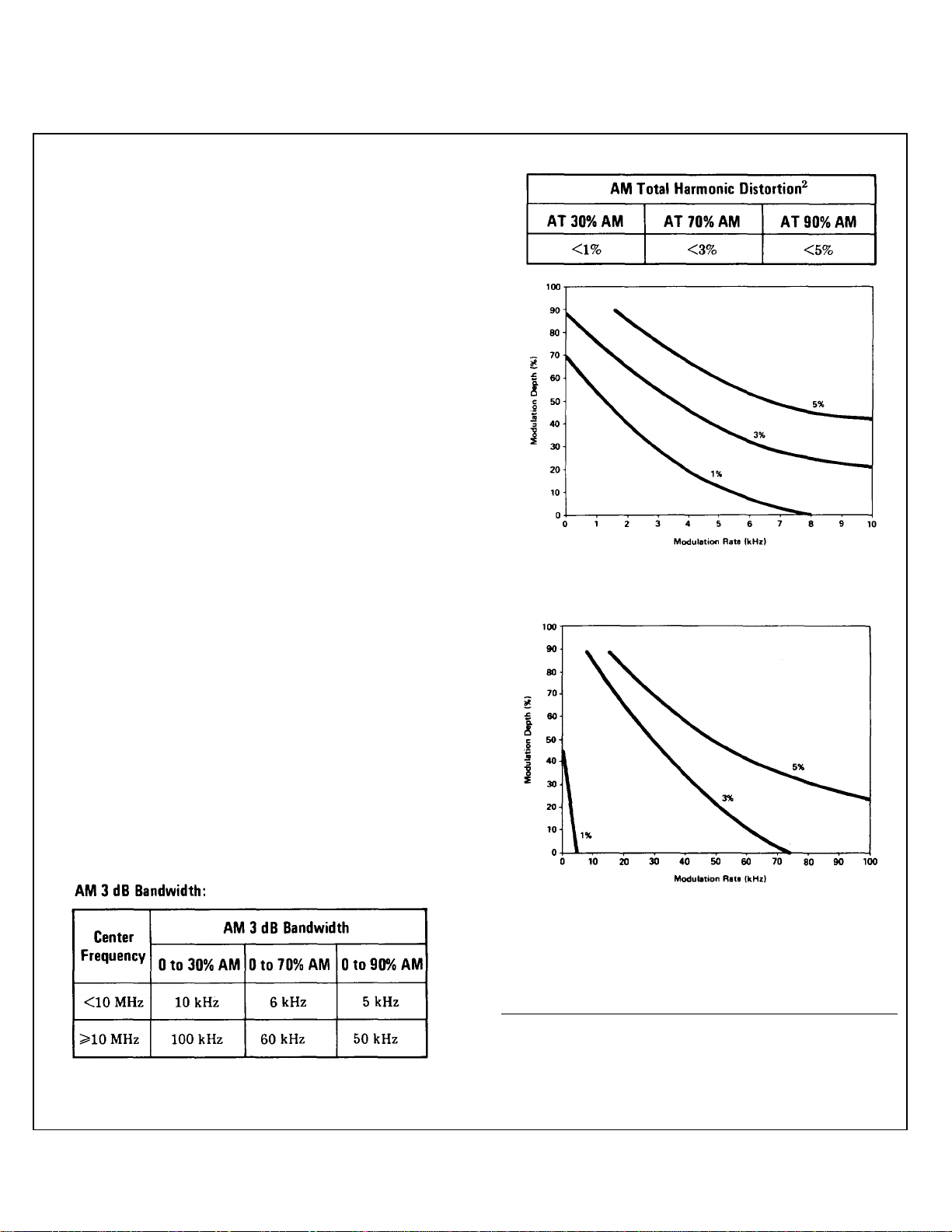

Table 1-1. Models 86602B/11661 Specifications (2 of 3)

OUTPUT CHARACTERISTICS

Level: Continuously adjustable from +10 to -146 dBm

(0.7 Vrms to 0.01 /Vrms) into a 50Q resistive

load. Output attenuator calibrated in 10 dB steps

from 1.OV full scale (+10 dBm range) to 0.03

pVrms full scale (-140 dBm range). Vernier

provides continuous adjustment between

attenuator ranges. Output level indicated on

output level meter calibrated in volts and dBm

into 50 ohms.

Accuracy: (Local and remote modes)

+ 1.5 dB to -76 dBm; + 2.0 dB to -146 dBm at

meter readings between +3 and -6 dB.

Flatness: Output level variation with frequency is less

than ±1.0 dB from 1-1300 MHz at meter

readings between +3 and --6 dB.

Level Switching Time: In the remote mode any level

change can be accomplished in les s than 50 ms.

Any change to another level on the same

attenuator range can be accomplished in less

than 5 ms.

Typical AM Distortion (Center Frequency <10 MHz)

Impedance: 50Q.

VSWR: <2.0 on +10 and O dBm range; <1.3 on -10 dBm

range and below.

MODULATION CHARACTERISTICS

(With compatible Modulation Sections)

Amplitude Modulation:

Depth: 0 - 90% for RF output level meter readings from

+3 to -6 dB and only at +3 dBm and below.

AM 3 db Bandwidth:

Typical AM Distortion (Center Frequency > 10 MHz)

Incidental PM: Less than 0.2 radians peak at 30% AM.

Incidental FM: Less than 0.2 times the frequency of

modulation (Hz) at 30% AM.

2

Applies only at 400 Hz and 1 kHz rates with the RF Section

front panel meter indicating from O to +3 dBm. At a meter

indication of 6 dB the distortion approximately doubles. The

modulating signal distortion must be <0.3% for the system

performance to meet these specifications.

1-3

Page 14

Section 1 TM 11-6625-2837-14&P-7

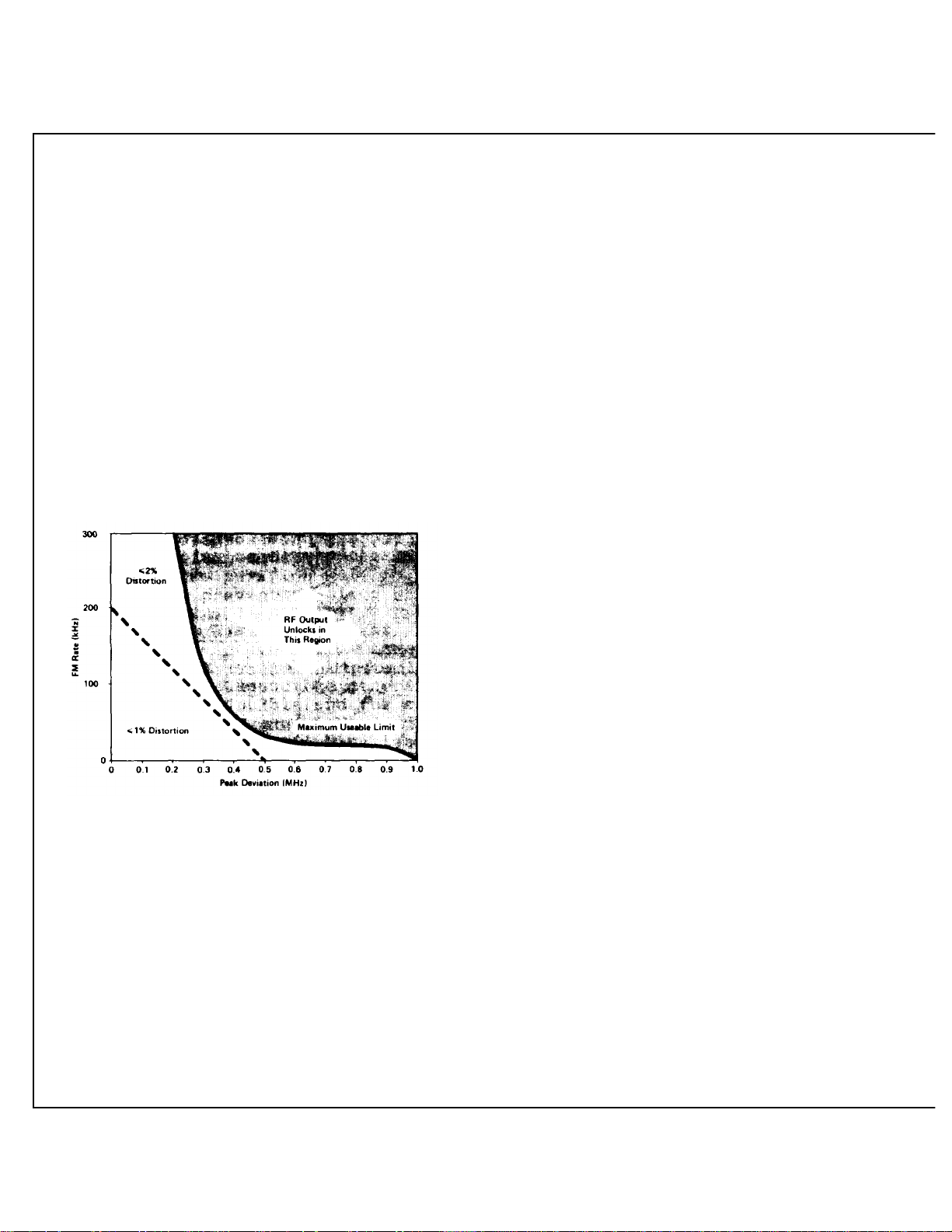

Table 1-1. Models 86602B/1 1661 Specifications (3 of 3)

FREQUENCY MODULATION

Rate: DC to 200 kHz with the 86632B and 86635A.

20 Hz to 100 kHz with the 86633B.

Maximum Deviation (peak):

200 kHz with the 86632B and 86635A

100 kHz with the 86633B

Incidental AM: AM sidebands are greater than 60 dB

down from the carrier with 75 kHz peak deviation

at a 1 kHz rate.

FM Total Harmonic Distortion (at rates up to 20 kHz);

<1% up to 200 kHz deviation. (External

modulating signal distortion must be less than

0.3%.)

Residual FM: less than 10 Hz rms average in 300 kHz,

Post-detection bandwidth, FM x 0.1 mode.

ON/OFF Ratio: At least 40 dB.

Input Level Required: -10-+ 0.5 Vdc turns RF on.

PHASE MODULATION

(Option 002 Instruments only)

Rate:

with 86635A dc to 1 MHz

with 86634A

dc to 1 MHz at center frequencies less than 100

MHz dc to 10 MHz at center frequencies greater

or equal to 100 MHz.

Maximum Peak Deviation:

0 to 100 degrees peak. May be overdriven to 2 radians

(1150) in the Modulation Section’s external dc

mode.

∅M Distortion:

<5% up to 1 MHz rates

<7% up to 5 MHz rates

<15% up to 10 MHz rates

Typical FM Distortion Curve

PULSE MODULATION

(With the 86631B Auxiliary Section only)

Source: External

Rise/Fall Time: 50 ns.

(External modulation signal distortion m ust be less than

0.3% to meet this specification.)

REMOTE PROGRAMMING

(Through the 8660-series mainframes)

Frequency: Programmable in 1 Hz steps.

Output Level: Programmable in 1 dB s teps from +10 to

-146 dBm.

Modulation: See specifications for modulation section

installed.

GENERAL

Leakage: Meets radiated and conducted limits of MIL-I-

6181D.

Size: Plug-in to fit 8660-series mainframe.

Weight: Net 9 lb (3.9 kg).

1-4

Page 15

Section 1 TM 11-6625-2837-14&P-7

prefix indicates that the instrument is different fr om those

documented in this manual. The manual for this

instrument is supplied with a yellow Manual Changes

supplement that contains “change information” that

documents the differences.

1-14. In addition to change information, the supplem ent

may contain information for correcting errors in the

manual. To keep this manual as current and accurate as

possible, Hewlett-Packard recommends that you

periodically request the latest Manual Changes

supplement. The supplem ent for this m anual is k eyed to

this manual’s print date and part number , both of which

appear on the title page. Complimentary copies of the

supplement are available from Hewlett-Packard.

1-15. DESCRIPTION

1-16. The HP Model 86602B RF Section is one of

several RF Sections available for us e in an 8660-series

Synthesized Signal Generator System. This RF Sec tion

plug-in is used with an option 100 8660-series

mainfram e (Frequenc y Extension Module installed). T he

RF Section provides precisely tuned RF output

frequencies over the 1 to 1300 MHz range with 1 Hz

frequency resolution (8660-series option 004 instr uments

have resolutions of 100 Hz.) Frequencies from 200 k Hz

to 1 MHz can also be generated with some degradation

in the amplitude leveling and other related specifications.

1-17. The output power can be set to any level between

+10 and --146 dBm by means of the front panel

VERNIER and calibrated OUTPUT RANGE controls. A

front panel-mounted meter and the OUTPUT RANGE

switch indicate the output power and voltage levels

delivered by the RF Section to any external load having a

characteristic impedance of 50 ohms. Output power

levels are maintained within + 1 dB of selected values

through internal leveling of the output signal over the full

frequency range of the instrument.

1-18. Amplitude, frequency, phase, or pulse modulation

of the RF OUTPUT signal can be accomplished within

the RF Section by using the appropriate Auxiliary or

Modulation Section plug-in.

1-19. External programm ing perm its rem ote selection of

the output signal frequency in 1 Hz steps (100 Hz for

option 004 mainframes) and the output power in 1 dB

steps over the full operating

range of the instrument. External programming is

accomplished via the mainframe computer-compatible

interface and digital control unit circuits.

1-20. OPTIONS

1-21. This RF Section has two options available. They

affect the instrument’s RF output level, and phase

modulation capabilities.

1-22. Option 001. The RF output attenuator is

removed. This lim its the RF output level range f rom +10

to -6 dBm.

1-23. Option 002. Circuits are added to provide the

phase modulation capability. A compatible modulation

section is required.

1-24. COMPATIBILITY

1-25. Except for Option 002 instruments, the Model

86602B is compatible with all 8660-series option 100

mainframes, all AM-FM Modulation Sections and the

Auxiliary Section. This RF Section is partially com patible

with the FM/OM Modulation Section.

Damage to the signal generator system

may result if an option 002 RF Section

is used with Model 8660A or 8660B

main-frames with serial prefixes 1349A

and below.

1-26. Option 002 instruments are compatible with all

instruments which are part of the Model 8660-series

Synthesized Signal Generator System except early

model 8660A and 8660B Mainframes. Refer to the

paragraph entitled Modifications in Section II of this

manual for further information.

1-27. EQUIPMENT REQUIRED BUT NOT

SUPPLIED

1-28. System Mainframe

1-29. The mainframe uses phase-locked loops to

accurately generate clock, referenc e, and tuning signals

required for operation of the Synthesized Signal

Generator System. Front panel-mounted mainframe

controls are used to digitally tune two phase-locked loops

in the Frequency Extension Module which, in turn,

produce two high-frequency output signals that are

applied to the RF Section. The RF Section mixes the

two signals

1-5

Page 16

Section 1 TM 11-6625-2837-14&P-7

and presents their frequency difference at the front panel

OUTPUT jack. The output frequency is either the value

selected by the mainframe front panel controls or

external programming.

1-30. The mainframe power supply provides all dc

operating voltages required by the RF Section,

Frequency Extension Module, and Modulation Section

plug-ins. Remote programming of the plug-ins is

accomplished via the mainframe interface and digital

control unit circuits.

1-31. Frequency Extension Module

1-32. The Frequency Extension Module plug-in extends

the output frequency range of the main-frame to meet

the input requirements of the RF Section. The

Frequency Extension Module plug-in contains two highfrequency phase-locked loops which receive digital

tuning signals, variable synthesized signals, and fixed

synthesized signals from the mainframe. The phaselocked loops use the main-frame signals, in conjunc tion

with the output frequency from a 4.43 GHz oscillator that

is common to both loops, to produce two high-frequency

output signals that are supplied to the RF Section. O ne

output signal is generated by a phase-locked loop using

a Voltage Controlled Oscillator (VCO) that is tuneable in

1 Hz steps (100 Hz steps for option 004 mainframe) over

the 3.95 to 4.05 GHz range. The other output signal is

generated by a phase-locked loop using a Yittrium-IronGarnet (YIG) oscillator that is tunable in 100 MHz steps

over the 3.95 to 2.75 GHz range. The two outputs from

the Frequency Extension Module plug-in are applied to

the RF Section for mixing, amplification of the converted

signal, and final output power level control.

1-33. Auxiliary Section

1-34. The Auxiliary Section plug-in provides a means of

applying externally generated amplitude or pulse

modulation drive signals to modulate the RF Section’s

output carrier.

1-35. Modulation Section Plug-ins

1-36. The Model 86630-series Modulation Section plugins can accept external modulation drive signals or

generate internal drive signals to amplitude, frequency,

phase or pulse modulate the RF Sections output signal.

1-37. EQUIPMENT AVAILABLE

1-38. Extender cables, coaxial adapters, and an

adjustment tool are available for use in performance

testing, adjusting, and maintaining the RF Section. Each

piece may be ordered separately or as part of the

11672A Service Kit.

1-39. Extender cards for use in ser vicing the RF Section

and a type N to BNC adapter for use on the front panel

RF OUTPUT connector are contained in the HP Rack

Mount Kit, Part Number 08660-60070, that is supplied

with the mainframe.

1-40. SAFETY CONSIDERATIONS

1-41. This instrument has been designed in accord-ance

with international safety standards and has been

supplied in safe condition.

1-42. Although this instrument has been designed in

accordance with international safety standards, this

manual contains information, cautions, and warnings

which must be followed to retain the instrument in sa fe

condition. Be sure to read and follow the safety

information in Sections II, III, V, and VIII.

1-43. RECOMMENDED TEST EQUIPMENT 1-44.

Table 1-2 lists the test equipment and accessories

recommended for use in testing, adjusting, and s ervicing

the RF Section. If any of the recommended test

equipment is unavailable, instruments with equivalent

specifications may be used. See Appendix B, Section III.

1-6

Page 17

Section 1 TM 11-6625-2837-14&P-7

See Appendix B, Section III

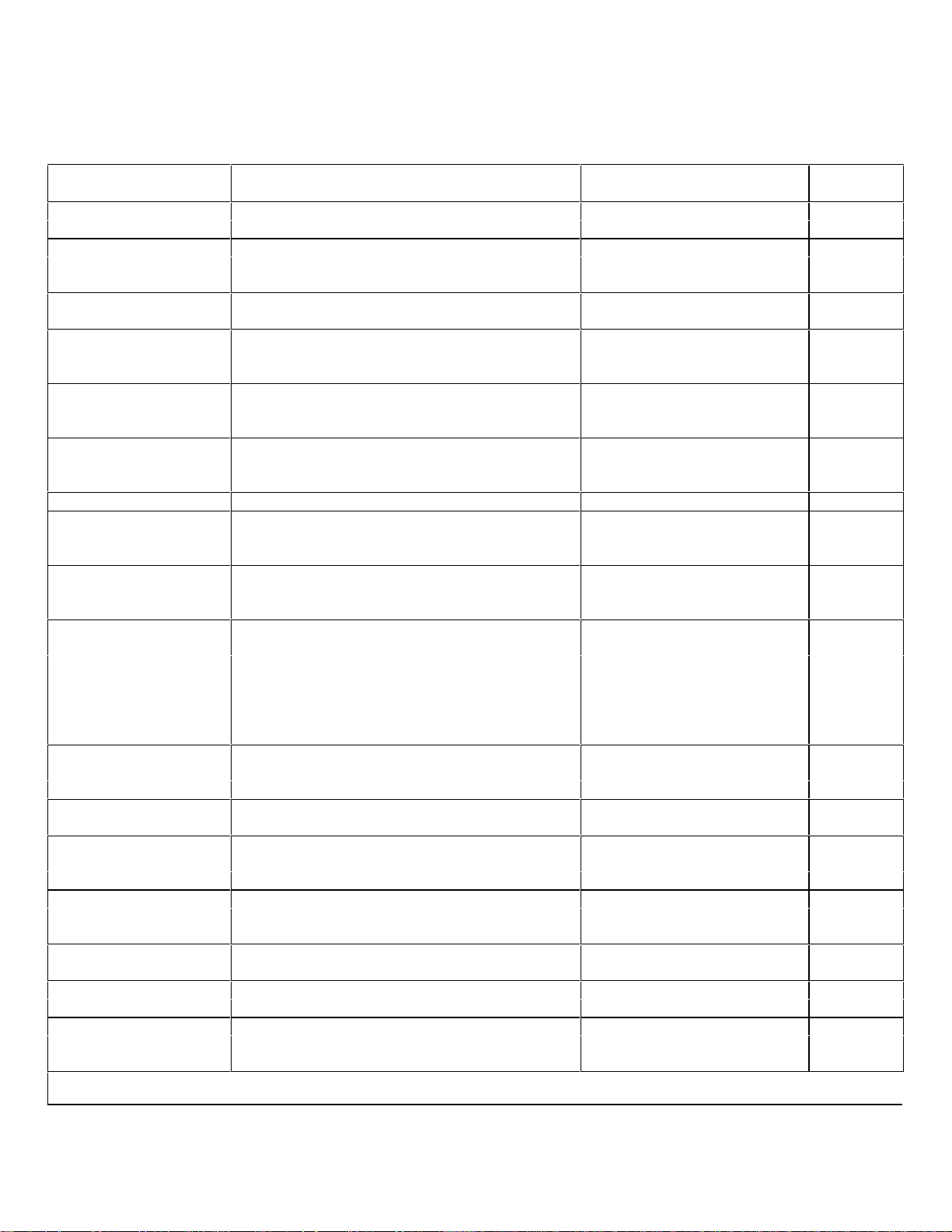

Table 1-2. Recommended Test Equipment (1 of 4)

Item Critical Specifications Suggested Model Use*

Adapter (Male Type N Frequency range 100 MHz to 1.3 GHz HP 1250-0847 P

to GR874 )

Adapter, SMA-to-BNC 2 required OSM 21190 P

Adapter, SMA-to-OSM OSM 219 P

Right Angle

Adapter, Type N-to- OSM 21040 P

SMA

Amplifier, 20 dB -20 dB gain at 30 MHz HP 8447A P

Input SWR <1.7

Amplifier, 40 dB Special (see Figure 1-2) P

Analyzer, Distortion 20 Hz to 20 kHz; must measure <0.1% distortion HP 333A P

Analyzer, Spectrum Measurement Accuracy +2.0 dB from 1 kHz HP 8553B with HP 8552B P.,A

to 110 MHz and HP 1-10T

Analyzer, Spectrum Measurement Accuracy +2.0 dB from 10 MHz HP 8555A with HP 8552B P. A, T

to 8 GHz and HP 140T

Analyzer, Wave Center frequencies 20 to 40 kHz HP 3581A P

Resolution bandwidth <3 Hz

Bandpass shape factor 10:1

Analog output 0 to 5V

Noise level (at 11 kHz center frequency with a

3 Hz bandwidth) <-150 dBV

Attenuator, 3 dB 3 dB HP 8491A Option 003 P

Fixed

Attenuator, 10 dB Step Calibrated at 30 MHz; refer to calibration curve HP 355D-H38 (only) P, A

Attenuator, 40 dB 40 dB HP 8491A Option 040 P

Fixed

Cables, Double Minimum input <300 mVrms (5 required) HP 08708-6033 P

Shielded

Capacitor, 1500 pF HP 0160-2222 P

Capacitor, 100 pF HP 0180-2207 P

Connector, BNC HP 1250-0118 T

Panel Mount

*Use: P = Performance Tests, A = Adjustments, T = Troubleshooting

1-7

Page 18

Section 1 TM 11-6625-2837-14&P-7

Table 1-2. Recommended Test Equipment (2 of 4)

Item Critical Specifications Suggested Model Use*

Counter, Computing 50 kHz to 50 MHz with a 1 ms gate time and HP 5360A with HP 5365A P

external trigger; 1 Hz resolution plug-in

Counter, Frequency Range: 0.2-1300 MHz HP 5340A P

Resolution: 1 Hz

10 MHz external reference output

7.2 Vrms output into 170 ohms

Coupler, Directional Frequency range 100 MHz to 1.3 GHz HP 778D Option 12 P

Detector, Crystal 1 to 1200 MHz HP 8471A P

Detector, Crystal 10 MHz to 1.3 GHz HP 423A P, A

FM Discriminator Input frequency 100 kHz to 10 MHz HP 5210A P, A

Linear Analog Output 1V full scale

Filter Kit Accessory for HP 5210A HP 10513A P, A

Filter, Low Pass, Special (see Figure 1-3) P

15 kHz

Filter, Low Pass, Cutoff frequency: 4 MHz CIR-Q-TEL P

4 MHz FLT/21B-4-3/50-3A/3B

Filter, Low Pass, Cutoff frequency: 2200 MHz HP 360C P

2200 MHz

Filters, Low Pass, 100 kHz at 50 and 600 ohms Specials (See Figure 1-4) A

100 kHz

Filters, Low Pass, 1 MHz - 50 and 600 ohms Specials (See Figure 1-4) P, A

1 MHz

Filters, Low Pass, 5 and 10 MHz - 50 ohms Specials (See Figure 1-4) P

5 and 10 MHz

Filter, Band Pass Pass band 1-2 GHz HP 8430A P

Generator, Distortion less than 0.3% HP 203A P

Function Range: 0.5 Hz to 20 kHz

Output level: 0.1 to 2.0 Vrms into 600 ohms

Generator, Pulse Output -10 Vpk with <10 ns risetime in 600 HP 8013B P

ohms

Generator, Sweep Sweep Width 0.1 to 100 MHz HP 8601A A

Output Level +20 to -80 dBm

Flatness +0.25 dB

Generator, Synthe- +1 Hz from 1 MHz to 1300 MHz, +7 dBm output HP 8660 with HP 86631B P, A

sized Signal 10 MHz Reference output

>0.5V into 170 ohms

*Use: P = Performance Tests, A = Adjustments, T = Troubleshooting

1-8

Page 19

Section 1 TM 11-6625-2837-14&P-7

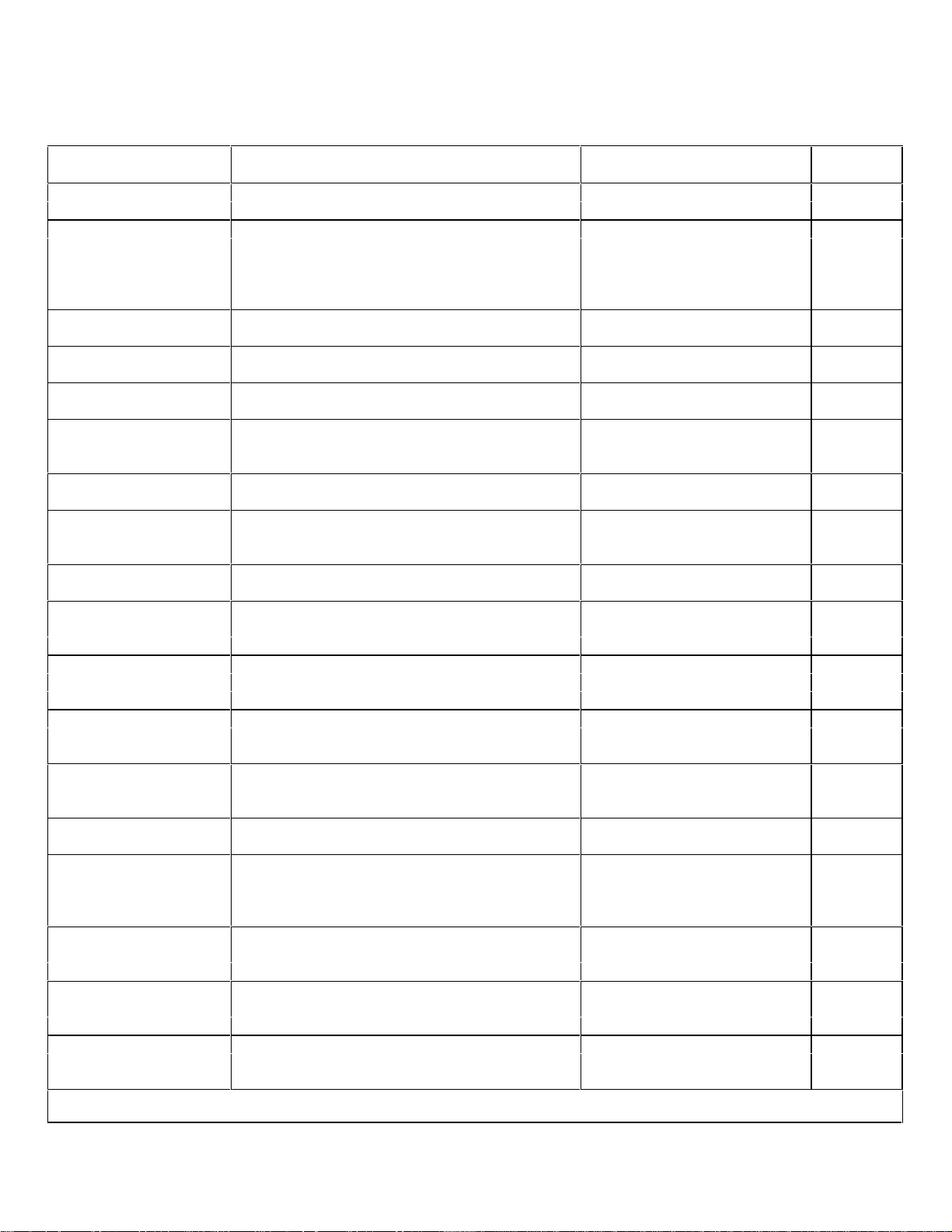

Table 1-2. Recommended Test Equipment (3 of 4)

Item Critical Specifications Suggested Model Use*

Mixer, Double 1 MHz to 110 MHz HP 10514A A

Balanced

Mixer, Double 300 to 1300 MHz Watkins-Johnson M1J P

Balanced

Oscillator, Test 1 kHz to 10 MHz HP 651B P, A

1.0 to 2.0 Vrms into 600

or 50 ohms

Oscilloscope Vertical: HP 180C with HP 1801A P, A, T

Bandwidth 50 MHz with sensitivity of and HP 1821A plug-ins

5mV/ division minimum

Horizontal:

Sweep time 10 ns to 1 s

Delayed sweep

External triggering to 100 MHz

Oscilloscope, Input impedance HP 10004 P, A, T

10:1 divider probes 10 megohm shunted by 10 pF

Power MeterISensor Range: -10 to +10 dBm from 10 MHz to 1.3 HP 435A/8481A P, A, T

GHz

Power Supply, DC 0-10 volts HP 721A P

Programmer, Marked Capable of programming BCD or HP-IB data HP 3260A Option 001 P, A

Card

Probe, Logic TTL Compatible HP 10525T T

Resistor, 1000 ohm +2% HP 0757-0280 P, A

Resistor, 10K ohm +2% HP 0757-0442 P

Resistor, 100K ohm f2% HP 0698-7284 P

Service Kit Interconnect cables, adaptors, and coaxial HP 11672A (See A, T

cables compatible to 8660-series plus and Operating Note or

jacks mainframe manual for

parts list)

Stub, Adjustable Frequency range 100 MHz to 1.3 GHz General Radio 874-D50L P

Tee, Coaxial 2 required HP 1250-0781 (BNC) P, A

Termination, 50 50 ohm HP 11048C P

ohm Feed Thru

*Use: P = Performance, A = Adjustments, T = Troubleshooting

1-9

Page 20

Section 1 TM 11-6625-2837-14&P-7

Table 1-2. Recommended Test Equipment (4 of 4)

Item Critical Specifications Suggested Model Use*

Termination, 50 ohm 50 ohm, (2 required) HP 11593A P

Test Set, Phase Input Frequency Range 250 to 950 MHz HP 8660C-K10 (only) P, A

Modulation Distortion

<2% up to 2 MHz rates

<3.5% up to 5 MHz

<5.0% up to 10 MHz

Voltmeter, AC Accuracy +2% of full scale from HP 403B P, A, T

1 Hz to 1 MHz

1 mVrms to 10 Vrms full scale

Voltmeter, Digital Range 0.00 to 60.00 volts HP 34740A/34702A P, A, T

DC Accuracy +(0.3%, of reading +0.01% of

range)

AC Accuracy +(0.25% of reading +0.05% of

range)

45 Hz to 20 kHz

Voltmeter, Vector Frequency range 5 to 15 MHz HP 8405A P

Input level 100 mVrms to 1 Vrms

Analog output: +0.5 Vdc for +180°

*Use: P = Performance Tests. A = Adjustments, T = Troubleshooting

1-10

Page 21

Section 1 TM 11-6625-2837-14&P-7

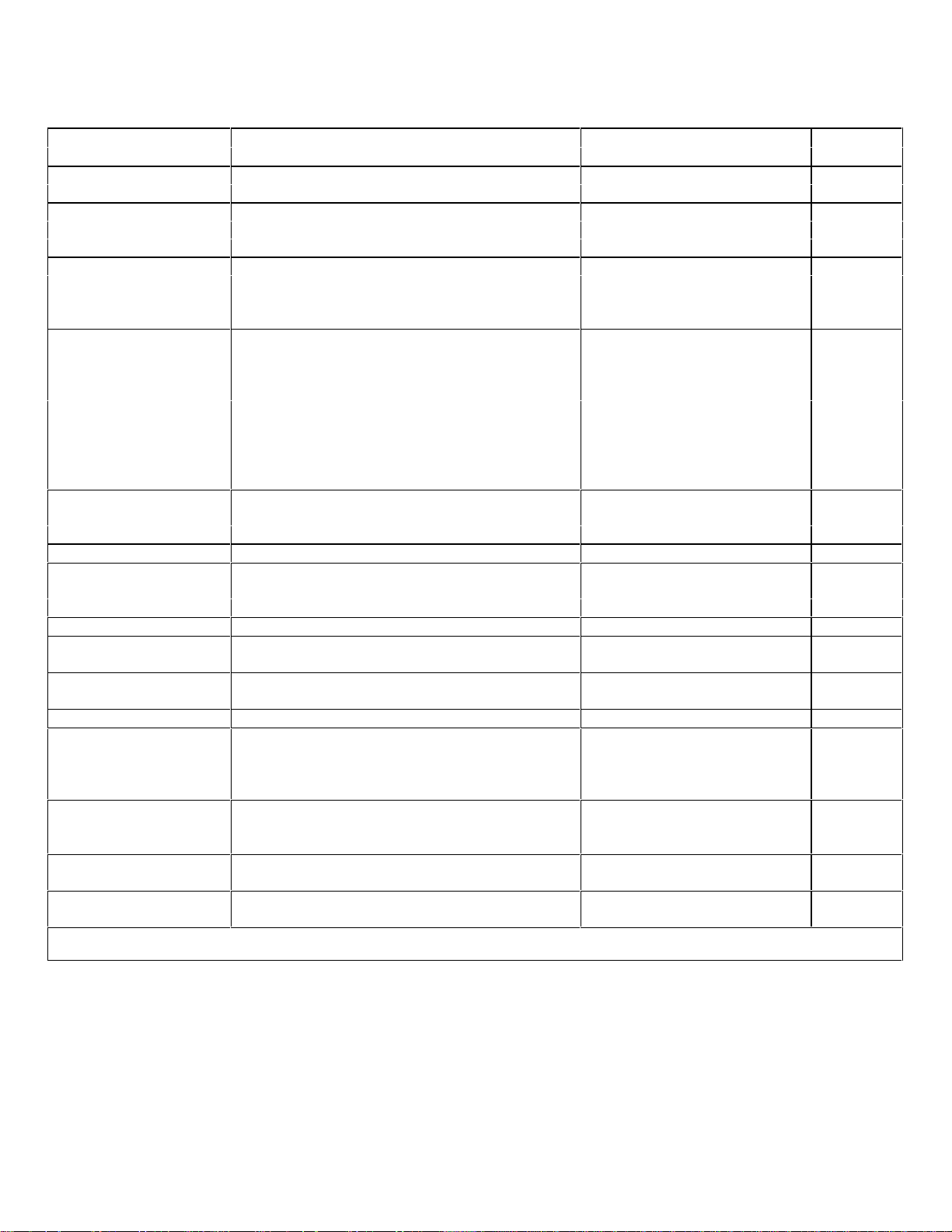

40 dB TEST AMPLIFIER

Amplifier Specifications

Gain 44 dB at 25°C

Bandwidth 100 kHz (3 dB down)

Noise Bandwidth 157 kHz

Input Impedance 75K Ohms

Output Impedance 12K Ohms

Current Drain 260 Microamperes

Output (Maximum) 1 Volt

Dynamic Range 66 dB

Figure 1-2. 40 dB Test Amlifier

Figure 1-3. 15 kHz Low Pass Filter

1-11

Page 22

Section 1 TM 11-6625-2837-14&P-7

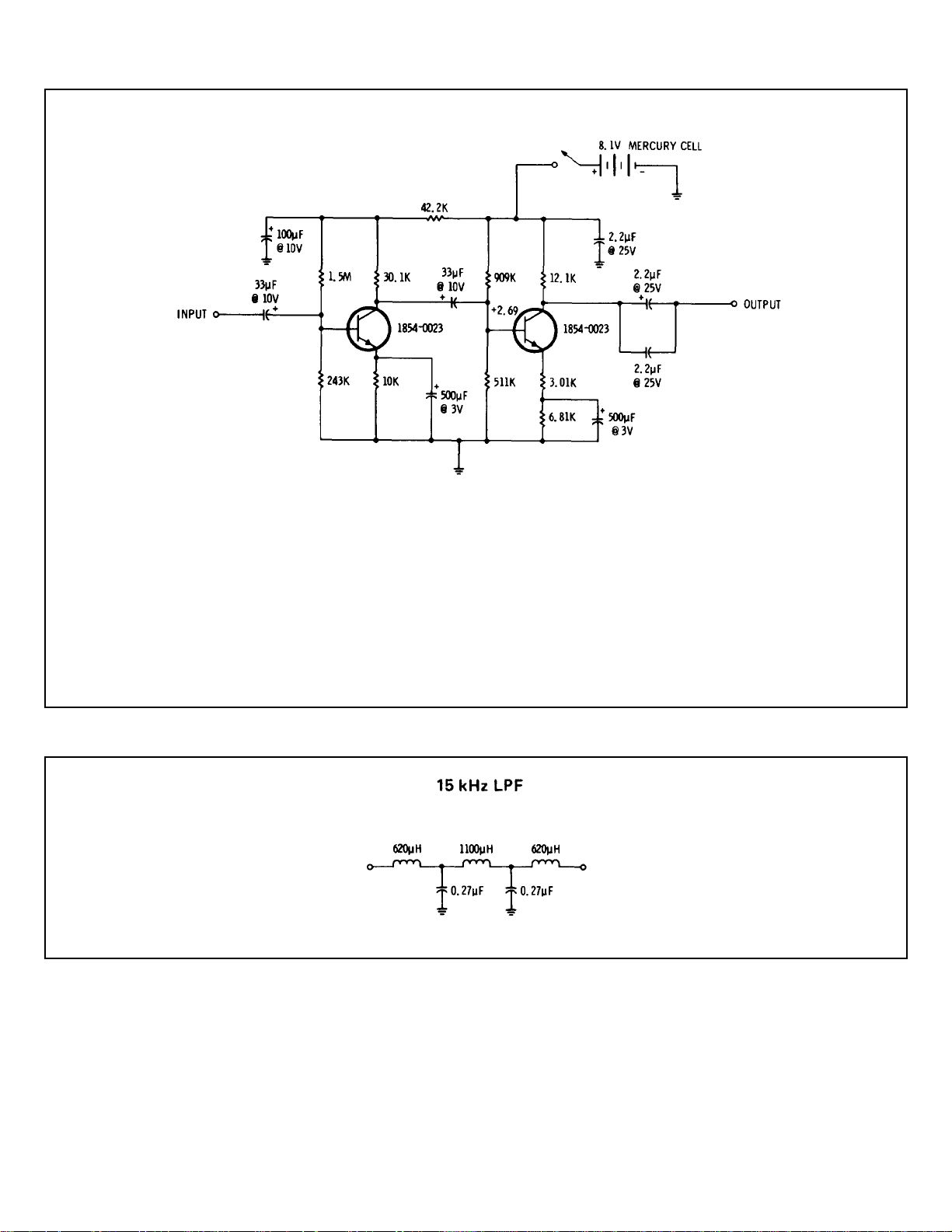

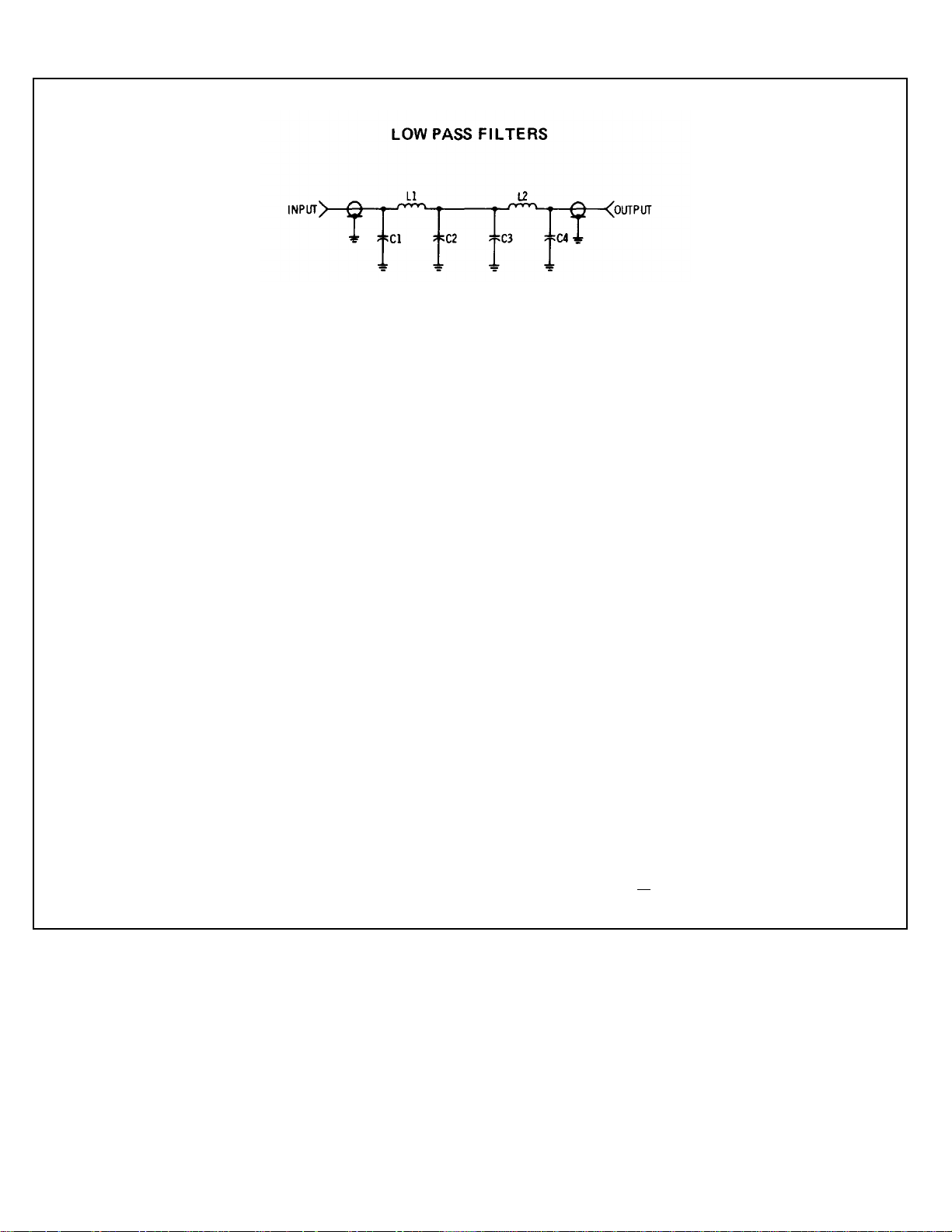

100 kHz - 50 ohms 100 kHz - 600 ohms

C1, C4 0.015 µF Mylar 0160-0194 C1, C4 1300 pF 0160-2221

C2 0.027 µF Mylar 0170-0066 C2 3000 pF 0160-2229

C3 0.022 µF Mylar 0160-0162 C3 1100 pF 0160-2219

L1, L2 100 µH 9140-0210 L1, L2 1200 µH 9100-1655

1 MHz -50 ohms 1 MHz - 600 ohms

C1, C4 1500 pF 0160-2222 C1, C4 130 pF 0140-0195

C2 3300 pF 0160-2230 C2 300 pF 0160-2207

C3 1600 pF 0160-2223 C3 120, µH 0140-0194

L1, L2 10H ±10% 9140-0114 L1, L2 120

5 MHz - 50 ohms 10 MHz - 50 ohms

C1, C2, C4 300 pF 0160-2207 C1, C4 150 pF 0140-0196

C3 680 pF 0160-3537 C2 330 pF 0160-2208

L1, L2 2 µH 9100-3345 C3 160 pH 0160-2206

L1, L2 1 µH±10% 9140-0096

NOTE

µ

9100-1637

Unless otherwise noted, tolerance of components is + 5%

and capacitors are mica. Part numbers are Hewlett-Packard

Figure 1-4. Low Pass Filters

1-12

Page 23

Section 2 TM 11-6625-2837-14&P-7

SECTION II

INSTALLATION

2-1. INTRODUCTION

2-2. This section provides information relative to initial

inspection, preparation for use, and storage and

shipment of the Model 86602B RF Section plug-in. Initial

Inspection provides instructions to be followed when an

instrument is received in a damaged condition.

Preparation For Use gives all necessary interconnection

and installation instructions. Storage and Shipment

provides instructions and environmental limitations

pertaining to instrument storage. Also provided are

packing and packaging instructions which should be

followed in preparing the instrument for shipment.

2-3. INITIAL INSPECTION

2-4. Inspect the shipping container for dam age. If the

shipping container or cushioning material is dam aged, it

should be kept until the contents of the shipment have

been checked for com pleteness and the instrument has

been checked mechanically and electrically. The

contents of the shipment s hould be as shown in Figure

1-1, and procedures for chec king electrical perform ance

are given in Section IV. If the contents are inc om plete, if

there is mechanical damage or defect, or if the instrument does not pass the electrical performance test,

notify the nearest Hewlett-Packard office. If the s hipping

container is damaged, or the c ushioning material shows

signs of stress, notify the carrier as well as the Hewlett-

Packard office. Keep the shipping m aterials for car rier’s

inspection. The HP office will arrange for repair or

replacement without waiting for claim settlement.

2-10. Modifications

2-11. A power supply modification to older versions of

Model 8660A and 8660B mainfram es are requir ed if they

are to be used with the option 002 RF Section.

Damage to the synthesized signal generator

system may result if an option 002 RF

Section is used with an older 8660A or 8660B

mainframe.

2-12. Due to the increased power consumption of the

option 002 instrument, mainframes with serial prefixes

1349A and below must be modif ied by installing a Field

Update Kit. For mainframe configurations other than

option 003 (60 Hz line operation), order kit number

08660-60273. For option 003 mainframes ( 50 - 400 Hz

line operation) order kit number 08660-60274.

NOTE

Verify that a new higher current fuse, HP Part

Number 2110-0365, 4A Slow Blow, is used in

mainframes with the power supply modification.

2-13. Operating Environment

2-14. The RF Section is designed to operate within the

following environmental conditions:

2-5. PREPARATION FOR USE

2-6. Power Requirements

2-7. All power required for operation of the RF Section

is furnished by the mainfram e. T his RF Section requir es

approximately 40 volt-amperes.

2-8. Interconnections

2-9. Prior to installing the RF Section plug-in into the

mainfram e, verify that the Frequency Extension Module

plug-in and interconnecting cable assem blies have been

installed in accordance with the instru ctions contained in

the Frequency Extension Module manual.

Temperature ........................................ 0° to +55°C

Humidity..................................... less than 95% relative

Altitude....................................... less than 15,000 feet

2-15. Installation Instructions

WARNING

The multi-pin plug connector which provides

interconnection from mainframe to RF

Section, will be exposed with the RF Section

removed from the right-hand mainframe

cavity. With the Line (Mains) Volt age off and

power cord disconnected, power supply

voltages may still remain which, if contacted,

may constitute a shock hazard.

2-1

Page 24

Section 1 TM 11-6625-2837-14&P-7

2-16. Insert the plug-in approximately half-way into the

right cavity of the mainframe. Rotate the latch (lower

right corner) to the left until it protrudes perpendicular to

the front panel. Refer to Figure 2-1, which shows the

plug-in partially inserted into the mainfram e and the latc h

rotated to a position that is perpendicular to the plug-in

front panel. Push the plug-in all the way into the

mainframe cavity and then rotate the latch to the right

until it snaps into position.

2-17. STORAGE AND SHIPMENT

2-18. Environment

2-19. The storage and shipping environm ent of the RF

Section should not exceed the following limits:

Temperature................................ 40° to +75°C

Humidity....................................... less than 95% relative

Altitude......................................... less than 25,000 feet

2-20. Packaging

2-21. Original Type Packaging. Containers and

materials identical to those used in f ac tor y pack aging are

available through Hewlett-Packard offices. If the

instrument is being returned to Hewlett-Packard for

servicing, attach a tag indicating the type of service

required, return address, model number, and full serial

Figure 2-1. RF Section Partially Inserted into Mainframe

number. Also mark the container FRAGILE to assure

careful handling. In any correspondence, refer to the

instrument by model number and full serial number.

2-22. Other Packaging. The following general

instructions should be used for re-packaging with

commercially available materials:

a. Wrap the instrument in heavy paper or

plastic. (If shipping to a Hewlett-Packard office or

service center, attach a tag indicating the type of ser vice

required, return address, model number, and full serial

number.)

b. Use a strong shipping container. A doublewall carton made of 350-pound test material is adequate.

c. Use enough shock-absorbing material (3 to 4inch layer) around all the sides of the instrument to

provide firm cushion and prevent movement inside the

container. Protect the control panel with cardboard.

d. Seal the shipping container securely.

e. Mark the shipping container FRAGILE to

assure careful handling.

Figure 2-1. RF Section Partially Inserted into Mainframe

2-2

Page 25

Section 3 TM 11-6625-2837-14&P-7

SECTION III

OPERATION

3-1. INTRODUCTION

3-2. This section contains information which will enable

the operator to learn to operate and quickly check for

proper operation of the RF Section plug-in as part of the

Synthesized Signal Generator System.

3-3. PANEL FEATURES

3-4. The front and rear panel controls, connectors , and

indicators of the RF Section and its options are

described by Figure 3-1 and 3-2.

3-5. OPERATOR’S CHECKS

3-6. The RF Section, as part of the Synthesized Signal

Generator System, accepts inputs from the rest of the

system but controls only the RF output level. Even

though the controlled circuits for most other functions are

within the RF Section, the actual checks are f ound in the

manual of the instrument which controls that function.

3-7. The Operator’s Check s in this m anual are intended

to verify proper operation of the circuits which control and

are controlled by the RF output level controls. This

includes the meter, the VERNIER control, the OUT PUT

RANGE switch, and the Output Range Attenuator when

operating in the local mode. W hen the system is being

remotely controlled, the 1 dB and 10 dB remote step

attentator switches are checked in place of the VERNIER

control and OUTPUT RANGE switch. Refer to Figure 3-

3.

3-8. OPERATING INSTRUCTIONS

3-9. In this system, the mainframe and plug-ins contain

the controls for frequency, modulation, and RF level

selection. The mainframe controls frequency, the

Modulation Section plug-in controls m odulation type and

level, and the RF Section plug-in controls RF output

level. The Operating Instructions for the RF Section

plug-in are included in Table 3-1.

3-1

Page 26

Section 3 TM 11-6625-2837-14&P-7

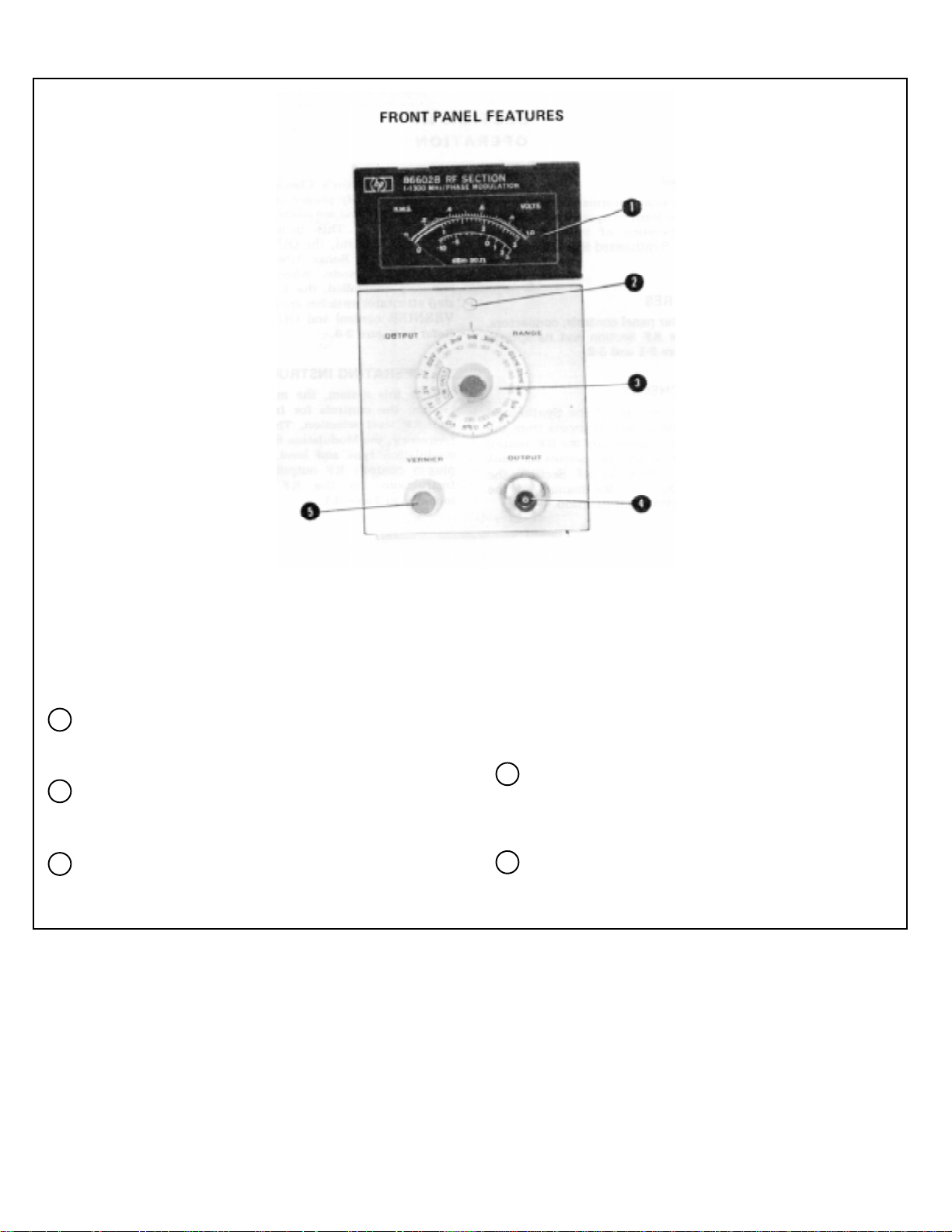

The front panel of the option 002 instrument is shown.

The standard instrument does not have the term PHASE

MODULATION after 1-1300 MHz. The option 001

instrument has an OUTPUT RANGE switc h whic h s hows

only the +10 and 0 dBm ranges.

1 Meter. Indicates the RF Output level in Vrms and

dBm (50w) with the scale reference indicated by the

OUTPUT RANGE switch.

2 Mechanical Meter Zero Control. Sets the Panel

Meter indicator to zero when the mainfram e LINE Switch

is set to STBY.

3 OUTPUT RANGE Switch. Sets the output level

range of all except option 001 instruments from

Figure 3-1. Front Panel Controls, Connectors, and Indicators

NOTE

+10 to -140 dBm (502) in 10 dB steps. For option 001

instruments, +10 and 0 dBm ranges only.

4 OUTPUT Jack. Type-N female coaxial connector.

RF Output level +10 to -146 dBm (0.7 Vrms to 0.01

/IVrms) into a 50Q load. Frequency range is 1 to

1299.999 999 MHz in 1 Hz steps.

5 VERNIER Control. RF Output continuously var-iable

within the useable range (+3 to --6 dB) as indicated by

the meter.

3-2

Page 27

Section 3 TM 11-6625-2837-14&P-7

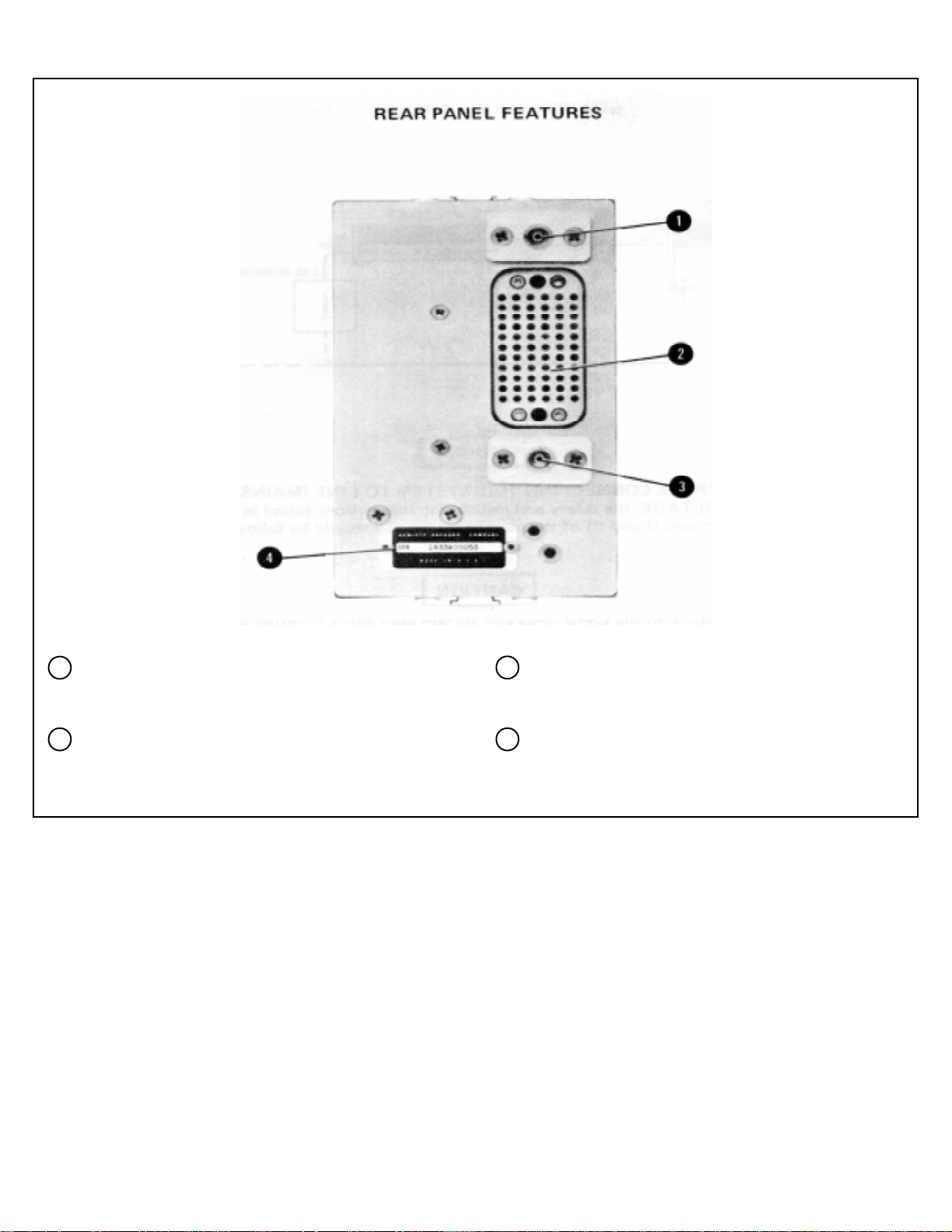

1 Coaxial Plug. Connects the 3.95 to 2.75 GHz RF

Input signal to the RF Section from the Frequency

Extension Module.

2 Interconnect Plug. Provides interconnection of

power supply voltages; RF and control signals between

the RF Section plug-in and the Main-frame, Frequency

Extension Module, and Modulation Section plug-in.

Figure 3-2. Rear Panel Connectors and Indicators

3 Coaxial Plug. Connects the 3.95 to 4.05 GHz LO

Input signal to the RF Section plug-in from the Frequency

Extension Module.

4 Serial Number Plate. Metal plate with stamped

serial number. Four-digit and letter f or prefix. Suffix is

unique to an instrument.

3-3

Page 28

Section 3 TM 11-6625-2837-14&P-7

WARNING

BEFORE CONNECTING TH IS SYSTEM TO LINE (MAINS) VOLTAGE,

the safety and installation instructions found in Sections II and III of the

mainframe manual should be followed.

Damage to the signal generator system may occur if option 002 RF

Sections are used with unmodified 8660A and 8660B main f rames with

serial prefixes 1349A and below. See the paragraph entitled

Modifications in Section II.

Refer to Section HI for RF Section Installation instructions.

1. Set the System controls as follows:

Mainframe

LINE Switch.................................................................................... ON

REFERENCESELECTOR.............................................................. EXT

CENTER FREQUENCY................................................................. 500 MHz

Modulation Section plug-in

MODE Switch................................................................................. OFF

RF Section plug-in

OUTPUT RANGE Switch ............................................................... 0 dBm

VERNIER Control........................................................................... +3 dB meter reading

NOTE

Figure 3-3. Operator’s Checks (1 of 2)

3-4

Page 29

Section 3 TM 11-6625-2837-14&P-7

OPERATOR’S CHECKS

2. Connect the RF Section OUTPUT to the power sensor input. Ver if y that the amplitude of the 500 MHz s ignal

is approximately +3 dBm.

3. Set the OUTPUT RANGE Switch to +10 dBm and adjust the VERNIER control for a -3 dB meter reading.

Verify that the output level is approximately +7 dBm.

4. Connect the RF Section OUTPUT to the frequenc y counter input through the 3 dB attenuator. Verify that the

signal is accurate within +1 Hz.

5. To check the remote control capabilities of the RF Section, connect a control unit to the m ainfram e. Repeat

steps 1 through 4 while the system is remotely programmed fr om an external source. Application Note 164-1

"Programming the 8660A/B Synthesized Signal Generator" provides the inform ation needed for r emote BCD

operation of this system. Application Note 164-2 "Calculator Control of the 8660A/B/C Synthesized Signal

Generator" provides the inform ation needed for calculator control of the s ystem us ing the HP- IB ( option 005).

Section III of the mainframe manual contains the same information in abridged form.

Figure 3-3. Operator’s Checks (2 of 2)

3-5

Page 30

Section 3 TM 11-6625-2837-14&P-7

Table 3-1. Operating Instructions (1 of 2)

OPERATING INSTRUCTIONS

TURN ON

BEFORE CONNECTING THIS SYSTEM TO THE LINE (MAINS)

VOLTAGE, the safety and installation instructions found in Sections

II and III of the mainframe manual should be followed.

Damage to the signal generator system may occur if option 002 RF

Sections are used with unmodified 8660A and 8660B main- frames

with serial prefixes 1349A and below. See the paragraph entitled

Modifications in Section II.

NOTE

Refer to Section II for RF Section Installation Instructions.

1. Set the mainf ram e’s LINE Switch to ON and the rear panel REFERENCE SELECTOR Switch to INT . Wait for the

mainframe "oven" indication to go out.

FREQUENCY SELECTION

2. Refer to Section III of the mainframe operating and service manual for information on system frequency selection.

RF OUTPUT LEVEL

3. dBm . Set the OUTPUT RANG E switch to within +3 and --6 dB of the desired output level. Adjust the VERNIER

control for a meter r eading which when added to the O UT PUT RANGE switch indication equals the desired output

level.

4. VOLTS. To set the RF output level in rms volts, the OUTPUT RANGE switch selec ted the f ull s c ale meter reading

and the VERNIER control is adjusted for the cor rect voltage reading on the meter. The voltage level f or meter

scale 1.0 should not be set below 0.32 of full scale. T he voltage level should not be set below 1 when using the

meter scale of 3.

NOTE

In order to achieve the output level accuracy specified, the level

selected must be S<+10 dBm and the RF Section front panel meter

reading must be as stated above.

5. Connect the RF Output to the Devic e Under Test. The front panel m eter r eading of RF Output level will be c or rec t

only if the input impedance of the Device Under Test is 50w2.

3-6

Page 31

Section 3 TM 11-6625-2837-14&P-7

Table 3-1. Operating Instructions (2 of 2)

MODULATION SELECTION

6. Refer to Section III of the Modulation Section plug-in operating and service manual for information relating to

selection of modulation type and level.

REMOTE OPERATION

7. Application Note 164-1 "Programming the 8660A/B Synthesized Signal Generator" provides most of the

information needed for remote BCD operation of this system. AN 164-2 "Calculator Control of the 8660A/B/C

Synthesized Signal Generator" provides information for r emote HP-IB operation of this system. In abridged f orm,

Section III of the mainframe manuals contain the same information.

3-7

Page 32

Section 4 TM 11-6625-2837-14&P-7

SECTION IV

PERFORMANCE TESTS

4-1. INTRODUCTION

4-2. The procedures in this section test the

instrument’s electrical performance using the

specifications of Table 1-1 as the per formance standard

All tests can be perform ed without access to l interior of

the instrument. A simpler operation test is included in

Section III under Operator’s Checks.

4-3. EQUIPMENT REQUIRED

4-4. Equipment required for the per formance tests is

listed in the Recommended Test Equipment table in

Section I. Any equipment that satisfies critical

specifications given in the table m ay substituted for the

recommended model(s).

4-5. TEST RECORD

4-6. Results of the perform ance tests may tabulated

on the Test Record at the end of the procedures. T he

Test Record lists all of the test specifications and their

acceptable limits. Test results recorded at incoming

inspection can be used for comparison in periodic

maintenance and trouble-shooting, and after repairs or

adjustments.

4-7. PERFORMANCE TESTS

4-8. For each test, the specifications are written

exactly as they appear in the specification table in

Section I. Next, a description of the test and any special

instructions or problem areas are included. Most tests

that require test equipment have a setup drawing; each

has a list of required equipment. The initial steps of each

procedure give control settings required for that

particular list.

To avoid the possibility of damage to the

instrument or test equipment, read

completely through each test before starting

it. Then make any preliminary control

settings before continuing with the

procedure.

4-1

Page 33

Section 4 TM 11-6625-2837-14&P-7

PERFORMANCE TESTS

4-9. FREQUENCY RANGE

SPECIFICATION:

1 to 1299.999999 MHz selectable in 1 Hz steps. Frequencies from 200 to kH z to 1 MHz m ay also be selec ted with som e

degradation in specifications.

DESCRIPTION:

The Synthesized Signal Generator System RF OUTPUT is monitored by a frequency counter which supplies a common

time base reference signal. The frequencies are checked at the extremes. Any specified frequency may be checked.

Figure 4-1. Frequency Range Test Setup

EQUIPMENT:

Frequency Counter....................................HP 5340A

10 dB Fixed Attenuator..............................HP 8491A Opt 003

NOTE

In the following procedure, allow for accuracy of counter used. -Model

recommended is specified at +1 count.

1. Connect frequency counter 10 MHz output reference signal to mainframe EXT REF input as shown in Figure 4-1

and set mainframe rear panel REF switch to EXT.

2. Set the RF Section OUTPUT RANGE switch to 0 dBm; set the VERNIER control full CW.

3. Set mainframe center frequency to 1.000 000 MHz and check RF section output frequency with counter. Record

the frequency.

0.999999_______________________1.000001 MHz

4. Set m ainf ram e center f requenc y to 1299.999 999 MHz (Option 004 mainf ram e set to 1299.,s pace 9999 MHz) and

check RF Section output frequency with counter. Record the frequency.

1299.999 998________________1300.000 000 MHz

4-2

Page 34

Section 4 TM 11-6625-2837-14&P-7

PERFORMANCE TESTS

4-10. FREQUENCY ACCURACY AND STABILITY

SPECIFICATION:

CW f requenc y accuracy and long term stability are determ ined by the aging rate of the time base (internal or external) and

its sensitivity to changes in temperature and line voltage. Internal ref er enc e osc illator acc ur ac y = + aging rate +3 x 10-10/°

C + 3 x 10-10/1% change in line voltage. (Aging rate for the tim e base in the standard mainfram e is 3 x 10- 8/day; for

option 001 mainframes, 3 x 10-9/day.)

NOTE

If there is any reason to doubt the mainframe crystal oscillator

accuracy or stability, r efer to the per formanc e tes t in Sec tion IV of

the mainframe manual.

_______________________________________

4-11. FREQUENCY SWITCHING TIME

SPECIFICATION:

6 ms to be within 50 Hz of any new frequency selected; 100 ms to be within 0.5 Hz of any new frequency selected.

DESCRIPTION:

A change in the Synthesized Signal Generator System's frequency is remotely programmed; af ter a preset time interval

the frequency is measured. A trigger pulse from the program m ing device is f irst c oupled to the oscillos cope. T he pulse is

delayed a preset interval by the oscilloscope and then coupled to the computing counter at which tim e the frequency is

measured.

NOTE

The frequencies in this test were selected for worst-case

conditions (longest switching time).

4-3

Page 35

Section 4 TM 11-6625-2837-14&P-7

PERFORMANCE TESTS

4-11. FREQUENCY SWITCHING TIME (Cont’d)

Figure 4-2. Frequency Switching Time Test Setup

EQUIPMENT:

DC Power Supply.......................................HP 721A

Computing Counter....................................HP 5360A/5365A

Marked Card Programmer.........................HP 3260A Opt 001

Oscilloscope...............................................HP 180C/1801A/1821A

Coaxial Tee................................................HP 1250-0781

PROCEDURE:

1. Connect the dc power supply +5 volt output through a 1000 ohm resistor to pin 17 of the m ating connector f or J3.

Pin 17 (flag) of the Marked Card Programmer output connector is also connected to the oscilloscope ext trigger

input.

2. Connect the marked card programmer to mainframe rear panel connector J3.

3. Connect oscillos cope delayed sweep output through a BNC TEE to oscilloscope channel A vertical input and to

computing counter rear panel external time measurement input.

4. Set counter controls as f ollows: rear panel switch to trigger ; "B" channel to X1 sensitivity; m odule switch pres sed;

digits displayed for necessary resolution; measurement time to 1; counter gate time to 1 ms.

5 Program the System for 29.999 999 MHz. Set the mainframe rear panel reference switch to external.

6. Set oscilloscope controls as follows: trigger to ac slow; ext, negative slope, trigger level at about 9:00 o’clock;

sweep mode auto; delay trigger auto; main sweep 1 ms; delay sweep 0.1 ps; main sweep mode.

7. Set oscilloscope trace to start at left vertical graticule line. Use oscilloscope delay control to delay spike 5.5

divisions from CRT left graticule line.

8. Switch oscilloscope sweep mode from auto to normal.

4-4

Page 36

Section 4 TM 11-6625-2837-14&P-7

PERFORMANCE TESTS

4-11. FREQUENCY SWITCHING TIME (Cont’d)

9 Program the system for 30.000 000 MHz. Frequency displayed on computing counter should be 30 MHz + 50 Hz.

Record the frequency.

29.999950__________________30.000050 MHz

10. Program the system for 29.999 999 MHz. Frequency displayed on counter should be within + 50 Hz of 29.999 999

MHz.

29.999949__________________30.000049 MHz

11. Set Oscilloscope normal sweep for 10 ms and delay sweep to 1 us.

12. Set Oscilloscope sweep mode to auto and delay control for delay spike 9.5 divisions from the CRT left graticule

line.

13. Set Oscilloscope main trigger to normal and computing counter gate time to 10 ms.

14. Program the System for 30.000 000 MHz. Frequency displayed on computing counter should be within + 5 Hz or

programmed frequency.

29.999995__________________30.000005 MHz

15. Program the System for 29.999 999 MHz. Frequency Displayed on computing counter should be within + 5 Hz of

programmed frequency.

29.999994___________________30.000004 MHz

NOTE

To reduce the effect of random errors, steps 5 thr ough 10 and 13 through

15 may be repeated several times (5 minimum). Record the average

frequency.

______________________________________________

4-12. OUTPUT LEVEL SWITCHING TIME

SPECIFICATION:

In remote mode, any level change can be accom plished in less than 50 ms. Any change to another level on the same

attenuator range can be accomplished in 5 ms.

DESCRIPTION:

The Synthesized Signal Generator System RF OUTPUT level (attenuation) is remotely programmed while the RF

OUTPUT is detected and monitored by an oscilloscope. Because the oscilloscope is triggered by the programming

device, the time needed to effect the level change may be measured directly on the oscilloscope CRT.

4-5

Page 37

Section 4 TM 11-6625-2837-14&P-7

PERFORMANCE TESTS

4-12 OUTPUT LEVEL SWITCHING TIME (Cont’d)

Figure 4-3. Output Level Switching Time Test Setup

EQUIPMENT:

Marked Card Programmer...................................... HP 3260A Opt 001

Oscilloscope............................................................ HP 180C/1801A/1821A

Crystal Detector ..................................................... HP 8471A

Power Supply.......................................................... HP 721A

PROCEDURE:

1. Connect equipm ent as illustrated in Figure 4-3. Note that + 5 volt output from DC Power Supply is connected

through a 1000 ohm resistor to pin 17 of mating connector to J3 and to Oscilloscope external trigger input.

2. Connect RF Section OUTPUT through crystal detector to oscilloscope Channel A input.

3. Set Oscillos cope controls as follows: Main Tim e/Div, 5 ms; Vertical input, dc coupled, 0.2 V/Div; Norm al Sweep;

Ext Trigger, negative slope, AC slow Trigger level about 9:00 o’clock.

4. Program the System’s center f requency for 500 MHz and 10 dB attenuation of the RF output signal. Reprogram

for 19 dB attenuation. Switching time should be less than 5 ms. Record switching time.

10 to 19 dB_______________________5 ms

5. Program RF Section attenuation for 10 dB, then for 30 dB. Switching time should be less than 50 ms.

10 to 30 dB_______________________50 ms

4-6

Page 38

Section 4 TM 11-6625-2837-14&P-7

PERFORMANCE TESTS

4-12. OUTPUT LEVEL SWITCHING TIME (Cont’d)

6. Repeat steps 4 and 5 with center frequency set to 1 MHz.

10 to 19 dB__________________________5 ms

_______________________________________________

4-13A. OUTPUT ACCURACY

SPECIFICATION: (for local and remote modes)

+1.5 dB to -76 dBm; +

DESCRIPTION:

The RF level accuracy for the +10 and 0 dBm ranges is measured with a power meter. For the lower ranges, an IF

substitution measurement technique is used.

2.0 dB to -146 dBm at meter readings between +3 and -6 dB.

RF level (attenuation) measurements using IF substitution is accomplished by 1) converting the RF output to a low

frequency IF signal, 2) offsetting the decrease in RF level ( increas e in attenuation) by an equal decrease in IF attenuation.

This maintains a fairly constant output level at the IF load. The intermediate frequency is selected on the basis of

availability of a precision attenuator. Therefore, any variation in output level from an established r eferenc e is pr im arily due

to the RF attenuator.

4-7

Page 39

Section 4 TM 11-6625-2837-14&P-7

PERFORMANCE TESTS

4-13A. OUTPUT ACCURACY (Cont’d)

EQUIPMENT:

Figure 4-4A. Output Accuracy Test Setup

Power Meter/Sensor............................................... HP 435A/8481A

Synthesized Signal Generator ............................... HP 8660C/86602B/86631B

40 dB Attenuator..................................................... HP 8491A Option 040

Mixer....................................................................... Watkins-Johnson M1J

4 MHz Low Pass Filter............................................ CIRC-Q-TEL FLT/21B-

4-3/50-3A/3B

Coaxial Tee............................................................. 1250-0781 (BNC)

50 Ohm Termination............................................... HP 11593A

40 dB Amplifier........................................................ (See Figure 1-2)

Double Shielded Cables (5 required)...................... HP 08708-6033

Capacitor, 100 #F ................................................... .HP 0180-2207

Resistor, 100 k........................................................ HP 0698-7284

Type N-to SMA Adaptor.......................................... OSM 21040

SMA-to-OSM Right Angle Adapter ......................... OSM 219

SMA-to-BNC Adapter (2)........................................ OSM 21190

10 dB Step Attenuator............................................. HP 355D Option H38

Wave Analyzer........................................................ HP 3581A

4-8

Page 40

Section 4 TM 11-6625-2837-14&P-7

PERFORMANCE TESTS

4-13A. OUTPUT ACCURACY (Cont’d)

PROCEDURE:

1. Set the System Under Test Controls for a center frequency of 1000.000000 MHz and an output level of +10 dBm.

2. Set the power meter controls for the +15 dBm range.

3. Connect the power sensor to the RF Section OUTPUT jack of the System Under Test.

4. Set the RF Section c ontrols as shown in the table below and verify that the RF output level is within the specif ied

tolerance.

Synthesized Signal Generator System

OUTPUT RANGE

Switch

(dBm)

+10 0 +8.5________+11.5

+10 -3 +5.5________+ 8.5

+10 -6 +2.5________+ 5.5

0 -6 -7.5_________- 4.5

0 -3 -4.5_________- 1.5

0 0 -1.5_________+ 1.5

0 +3 +1.5_________+ 4.5

Panel Meter

Reading

(dB)

Power Reading

Reading

(dBm)

NOTE

Be careful not to vary the RF Section ‘s VERNIER control setting

throughout the rest of this procedure.

5. Connect the 40 dB attenuator directly to the OUTPUT jack of the RF Section in place of the power sensor.

6. Connect the “R” port of the mixer directly to the 40 dB attenuator using the Type N-to SMA adapter and the SMA-

to-OSM right angle adapter.

7. Connect the 4 MHz Low Pass Filter to the “I” port of the mixer with a SMA-to-BNC adapter.

8. Connect the cable from the Reference System output to the “L” port of the mixer with a SMA-to-BNC adapter.

NOTE

Be sure all connections are tight to prevent RF leakage.

9. Set the reference system c ontrols for a center frequency of 1000.011000 and an output level of +7 dBm . Set the

rear panel reference selector to external.

10. Set the 10 dB Step Attenuator to 50 dB.

4-9

Page 41

Section 4 TM 11-6625-2837-14&P-7

PERFORMANCE TESTS

4-13A. OUTPUT ACCURACY (Cont’d)

11. Set the wave analyzer controls as follows: frequency 11 kHz, resolution bandwidth 3 Hz, sweep mode of f, dBv/LIN

- dBm 600:1 switch to dBv/LIN, amplitude reference level -40 dB, AFC switch unlock and scale 10 dB.

12. Connect the other equipment which follows the 4 MHz Low Pass Filter as shown in Figure 4-4A.

13. Tune the wave analyzer frequency control for the maxim um m eter reading. Adj ust the input s ensitivity and vernier

controls for a midscale meter reading. Press the AFC control for frequency lock.

14. Wait 30 seconds for the DVM reading to stabilize. Record the DVM reading. This is the reference level equivalent

to the last power meter reading ( +3 dBm).

15. Use the following formula to calculate the obsolute RF output level from the System Under Test:

dBm = dBm1 -A dB +2(V-Vre

ff

dBm is the RF output level

dBm1 is the actual RF level measured at the +3 dBm (O dBm OUTPUT RANGE setting) in Step 4.