Page 1

TM 11-6425-2837-14&P-6

Page 2

TM 11-6425-2837-14&P-6

i

Page 3

Section

0.

I.

1-2.

1-6.

1-8.

1-12.

1-13. 1-2

1-13.

II.

2-1

4-2.

2-5.

2-7.

2-10.

2-12.

2-14.

2-16.

2-18.

2-23.

III.

3-1.

3-4.

3-6.

3-11.

IV.

4-1.

4-3.

4-8.

4-9.

4-10.

4-11.

4-12.

4-13.

4-14.

4-15. 4-6

4-15.

Page

0-1

4-1

4-1

Model 86601A

CONTENTS

Section IV.

1-1

1-1

1-1

1-1

1-1

1-2

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1 5-4

3-1

3-1

3-1

3-1

3-1

4-1

4-1

4-1

4-2

4-2

4-3

4-4

4-5

4-7

4-17.

4-18.

4-19.

4-20.

4-21.

4-23.

4-23.

4-24.

4-25.

4-26.

V. 5-1

5-1. 5-1

5-7.

5-10.

5-13.

5-14.

5-15.

5-16.

5-17.

5-18.

VI.

6-1.

6-6.

VII.

7-1.

7-5.

VIII.

8-1.

8-3.

8-10.

8-12.

8-17.

Page

4-9

4-10

4-10

4-11

4-12

4-16

4-16

4-17

4-19

4-20

5-1

5-1

5-1

5-2

5-6

5-9

5-10

6-1

6-1

6-1

7-1

7-1

7-1

8-1

8-1

8-1

8-1

8-1

8-1

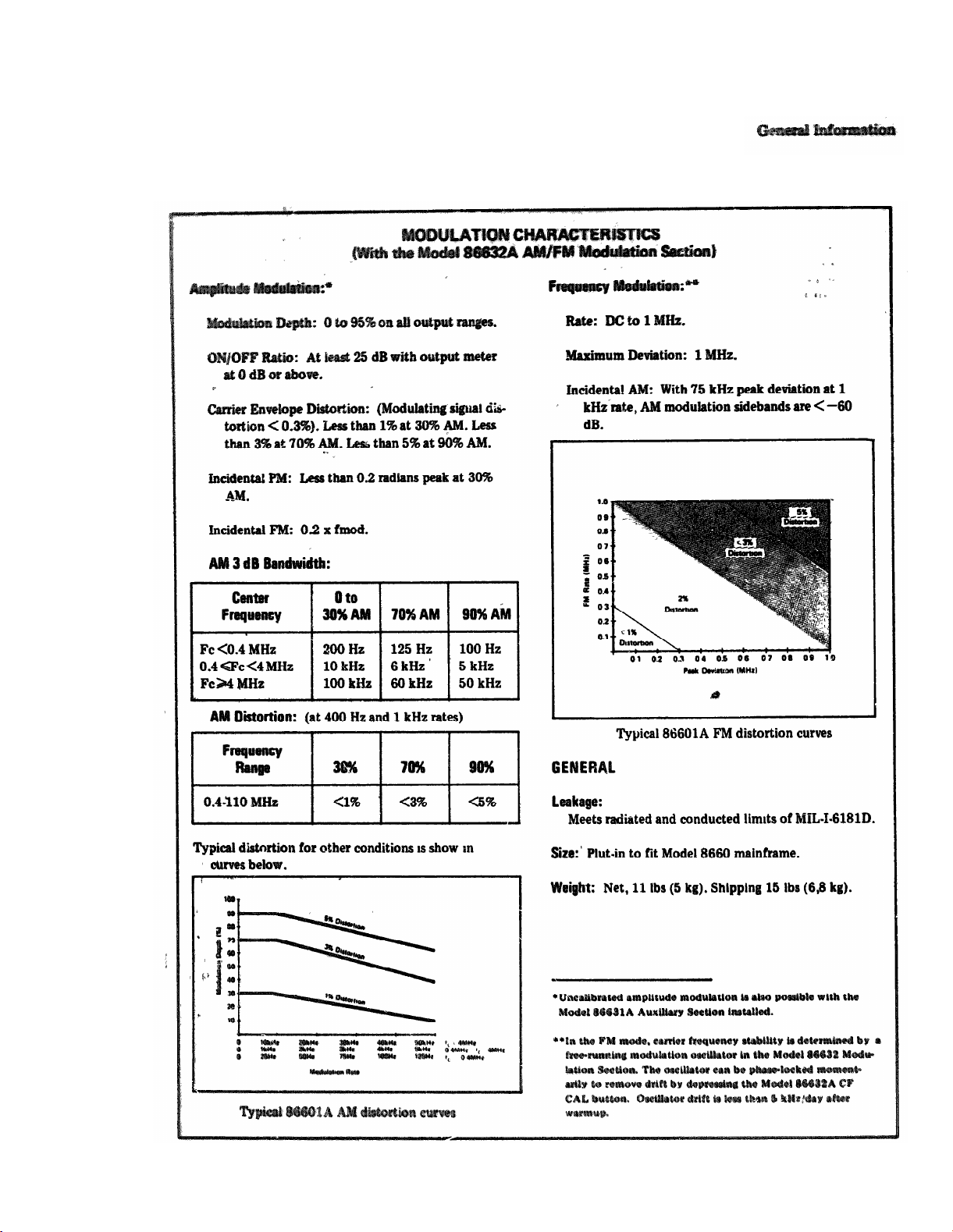

ILLUSTRATIONS

Figure

1-1.

1-2.

1-3.

1-4.

1-5.

3-1.

4-1.

ii

Page

1-0

1-1

1-6

1-6

1-6

3-0

4-1

Figure

4-2. Output Accuracy and Level Test Setup

4-3. Output Flatness Test Setup

4-4. Impedance Test Setup

4-5. Harmonic Signal Test Setup

4-6. Spurious Signal Test Setup

4-7. Signal-to-Phase Noise Test Setup.

4-8. Signal-to-AM Noise Ratio Test Setup

4-9. Amplitude Modulation Test Setup

.......

.........

.......

.......

.....

....

.....

...

Page

4-2

4-3

4-4

4-5

4-6

4-8

4-9

4-10

Page 4

Model 86601A

ILLUSTRATIONS (cont'd)

Figure

4-10. 4-12

4-11.

4-12.

4-13.

4-14.

4-15.

4-16.

5-1.

5-2.

5-3.

5-4.

5-5.

5-6.

7-1. 7-3

7-2. 7-5

7-3.

7-4.

7-5.

7-6.

7-7.

7-8.

8-1.

8-2.

8-3.

Page

4-13

4-15

4-16 8-8.

4-18 8-9.

4-19 8-10.

4-20

5-2

5-3

5-4

5-6

5-9

5-10

7-5

7-7

7-8

7-9 8-23.

7-10

7-11

8-0

8-3

8-4

Figure

8-4.

8-5.

8-6.

8-7.

8-11.

8-12.

8-13.

8-14.

8-15.

8-16.

8-17.

8-18.

8-19.

8-20.

8-21.

8-22.

8-24.

8-25.

8-26.

8-27.

8-28.

Page

8-6

8-7

8-7

8-8

8-10

8-11

8-11

8-11

8-11

8-12

8-13

8-13

8-13

8-13

8-15

8-15

8-15

8-16

8-17

8-17

8-17

8-19

8-19

8-21

8-21

TABLES

Table

1-1.

1-2. Test Equipment and

1-3. 40 dB Amplifier Specifications

4-1. Spurious checks

4-2. Carrier Envelope Distortion Test

4-3. Performance Test Record

5-1. Harmonic Distortion Level Checks

6-1. Part Numbers for

6-2. Reference Designators and

A.

B.

C.

D.

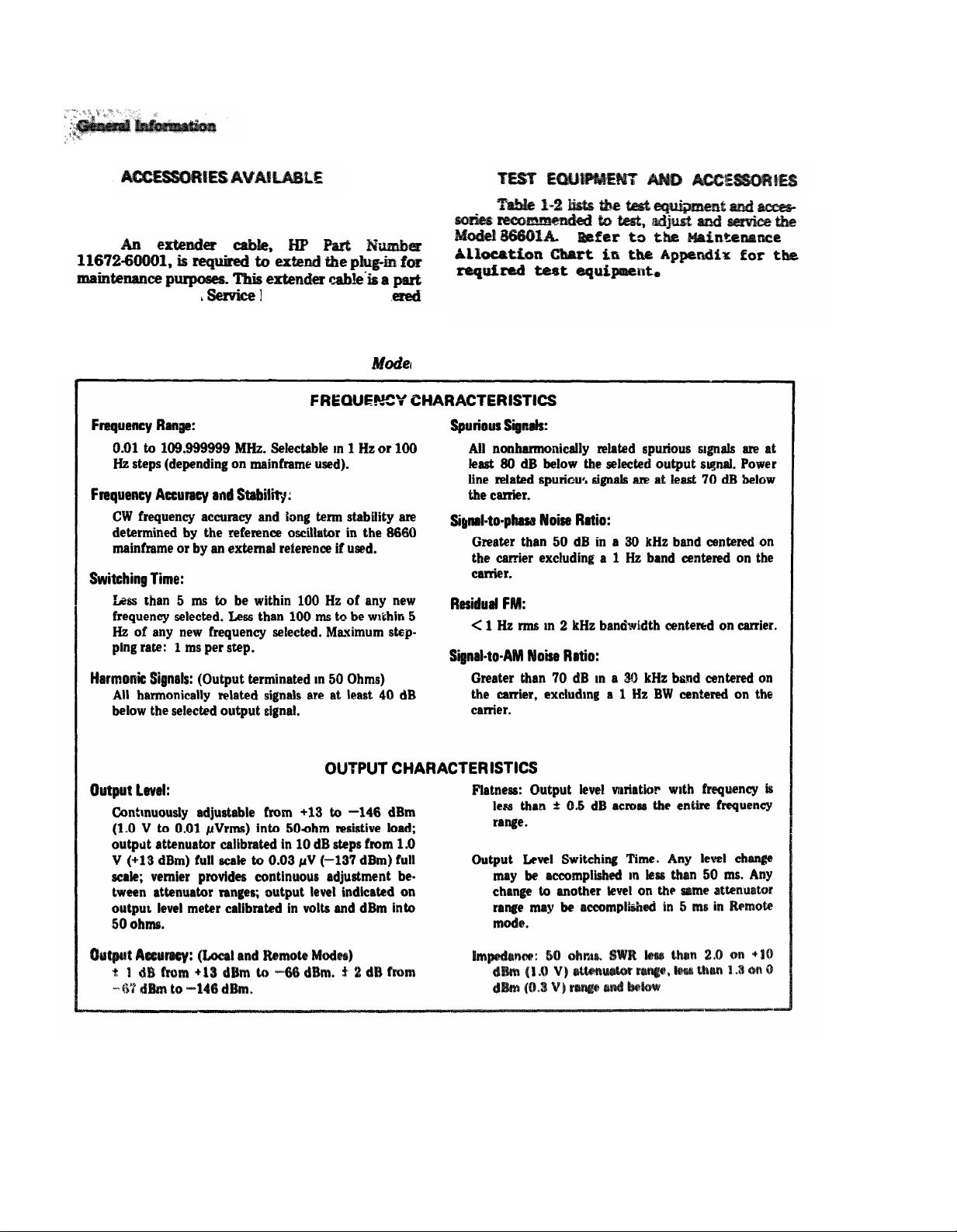

el 86601A Specifications 1-2

Accessories List 1-4

Assembly Exchange Orders

Abbreviations Used in

Parts List 6-2

REFERENCES A-1

COMPONENTS OF END ITEM LIST (NA)

ADDITIONAL AUTHORIZATION LIST (NA)

MAINTENANCE ALLOCATION

Page

1-6

4-7

4-14

4-22

5-5

6-1

APPENDIXES

D-l

Table

6-3. Replaceable Parts 6-3

6-4. Manufacture's Code List 6-15

6-5. Part Number-National Stock

Number Cross Reference Index

7-1. Manual Changes by Serial Number

7-2. Assembly-Change Cross Reference Index

8-1. Schematic Diagram Notes

8-2. Assembly Locations

8-3. 1 dB Attenuation Checks

8-4. Attenuator Driver Levels 8-20

E. REPAIR PARTS AND SPECIAL

TOOLS LISTS

EXPENDABLE SUPPLIES AND

F.

MATERIALS LIST (NA)

Page

6-16

7-1

7-4

8-5

8-7

8-16

E-1

iii

Page 5

INTRODUCTION

0-1. SCOPE

0-2. INDEXES OF PUBLICATIONS

0-3. MAINTENANCE FORMS, RECORDS,

AND REPORTS

TM 11-6425-2837-14&P-6

SECTION 0

0-4. REPORTING EQUIPMENT

IMPROVEMENT RECOMMENDATIONS

(EIR).

EIR can and must be submitted by anyone who is

aware of an unsatisfactory condition with the equip

ment design or use. It is not necessary to show a new

design or tit a better way to perform a procedure;

just simply tell why the design is unfavorable or why

a procedure is difficult. EIR may be submitted on SF

368 (Quality Deficiency Report). Mail direct to Commander, US Army Communications and Electronics

Materiel Readiness Command, ATTN: DRSEL-ME-

MQ, Fort Monmouth, NJ 07703. A reply will be fur-

nished to you.

agement System.

b. Report of Packaging ad Handling Deficiencies.

Fill out and forward DD Form 6 (Packaging Improvement Report) as prescribed in AR 700-58/NAVSUPINST 4030.29/AFR 71-13/MCO P4030.29A, and DLAR

4145.8.

c. Discrepancy in Shipment Report (DISREP) (SF

361). Fill out and forward Discrepancy in

Shipment

0-5. ADMINISTRATIVE STORAGE

Administrative storage of

used by Army activities shall be in accordance with

paragraph 2-16.

0-6. DESTRUCTION OF ARMY ELECTRONICS

MATERIEL

Destruction of Army electronics materiel to prevent

enemy use shall be in accordance with TM 750-244-2.

0-1

Page 6

Model 86601A

1-0

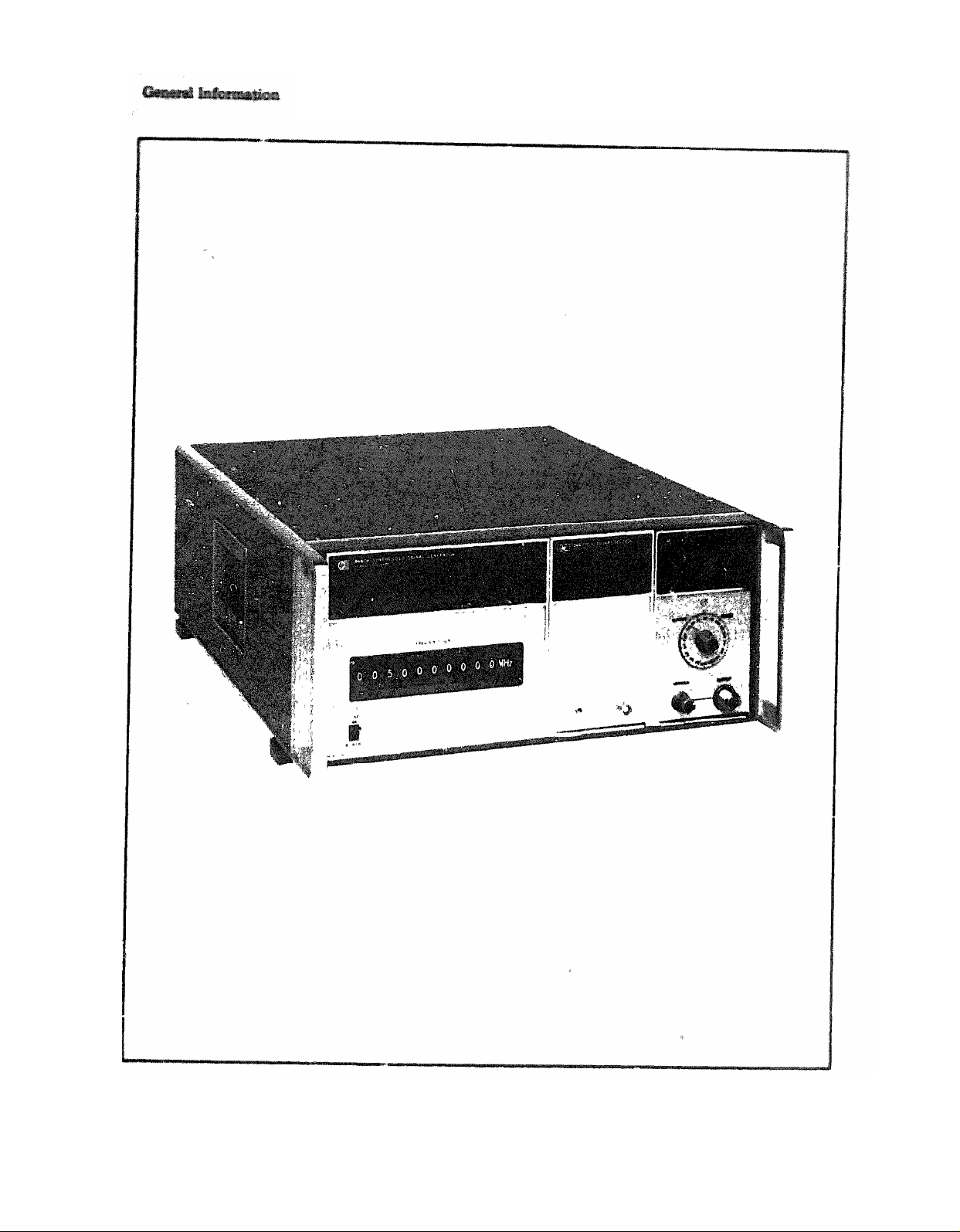

Figure 1-1. Model 88601A RF Section

Page 7

Model 86601A

SECTION I

GENERAL INFORMATION

1-1.

1-2.

1-3.

section covers instrument

ations and other basic in-

1-4. Figure 1-1 shows a front view of the HP

1A installed in the HP Model 8660A

mainframe ready for use.

1-5. The various sections of this manual provide

information as follows:

a. SECTION II, INSTALLATION, provides

information relative to incoming inspection, power

requirements, mounting, packing and shipping, etc.

b. SECTION III, OPERATION, provides in-

formation relative to operating the instrument.

c. SECTION IV, PERFORMANCE TESTS,

provides information required to asccitain that the

instrument is performin, in accordance with published specifications.

d. SECTION V, ADJUSTMENTS, provides

inform&ion required to properly adjust and align

the instrument after repairs are made.

e. SECTION VI REPLACEABLE PARTS

provides ordering information for all parts and

assemblies.

f.

SECTION VII, MANUAL CHANGES,

g.

1-6.

1-7.

Figure 1-2. Instrument Identification

1-8. DESCRIPTION

1-9. The HP Model 86601A RF Section output

plug-in provides a .01 to 109.999999 MHz output

when installed in one of the HP Model 8660

mainframes. The output frequency may be selected

in increments as low as 1 Hz or 100 Hz depending

on the mainframe used.

1-10. The only operator controls on the Model

86601A are the attenuator (OUTPUT RANGE and

VERNIER) controls. These controls provide a

the rf output at any level between

-146 dBm an +13 dBm. In remote operation

these controls are inh

1-11.

for the Model

-1.

1-12.

1-1

Page 8

Model 86601A

1-13.

1-14.

of the HP 11672A

Separately.

Kit, but may be ord

Table 1-1.

1-15.

1-16.

l 86602A Specifications

1-2

Page 9

Model 86601A

Table 1-1. Model 86601A Specifications (Cont'd)

1-3

Page 10

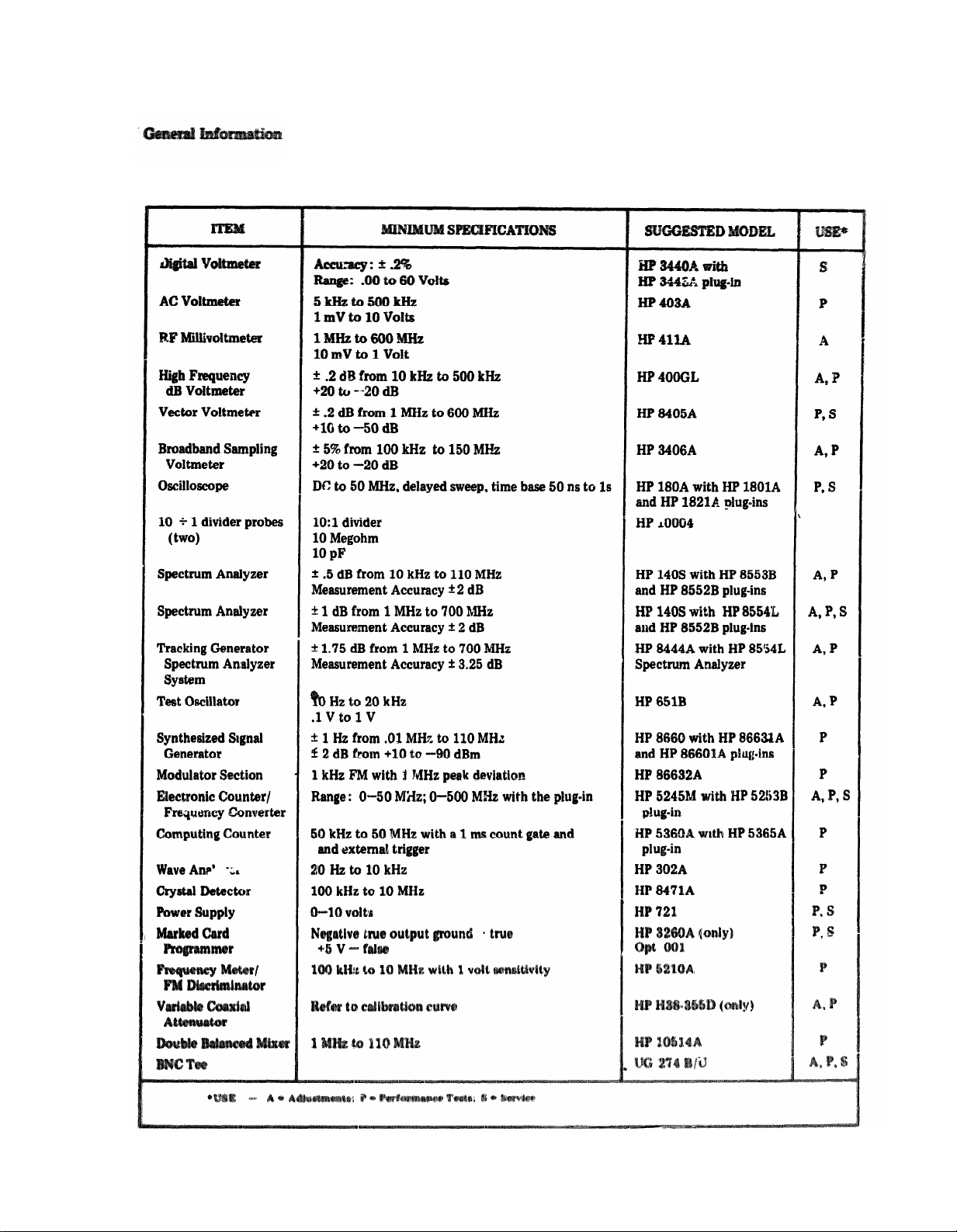

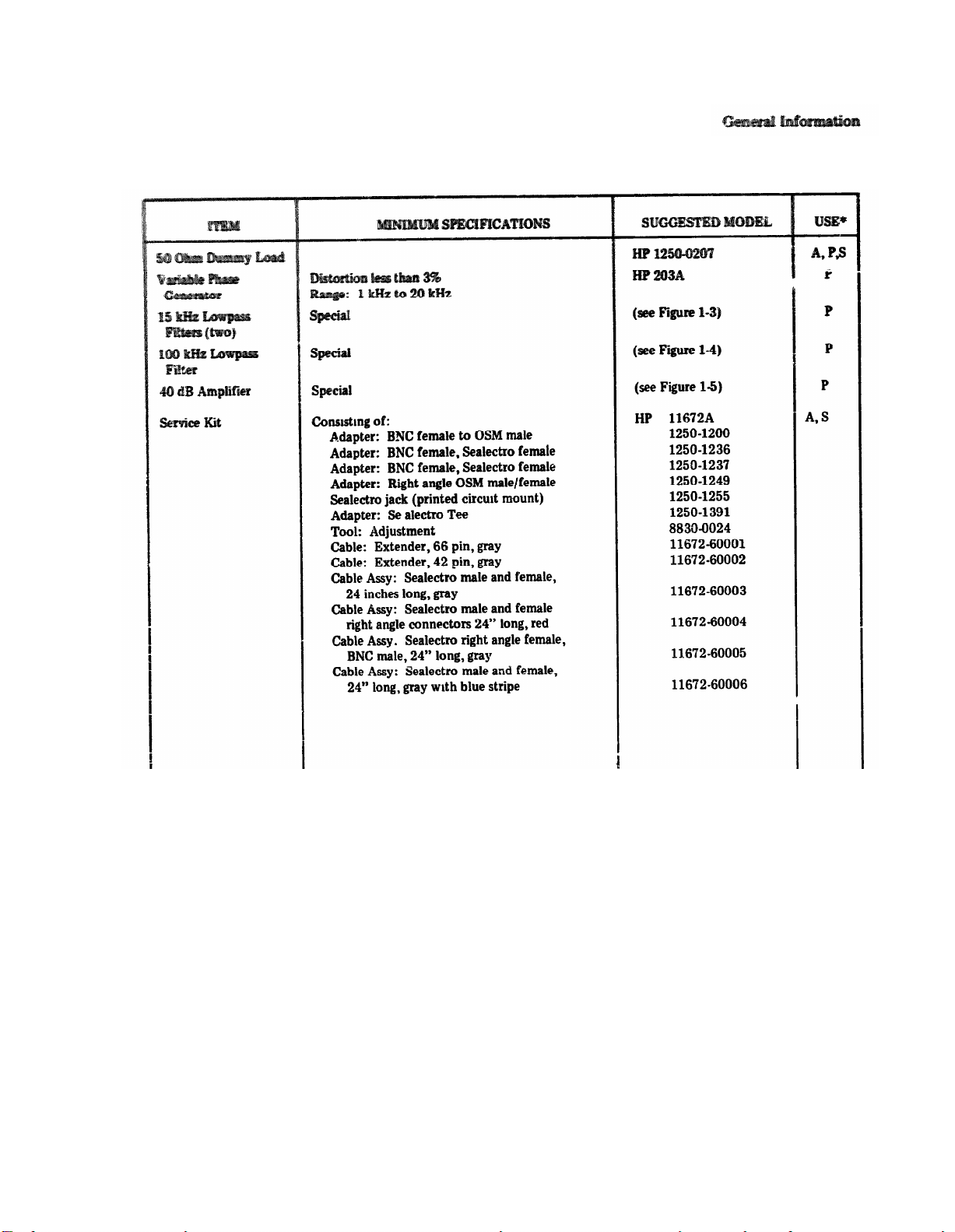

Table 1-2. Test and Equipment and Accessories List

Model 86601A

1-4

Page 11

Model 86601A

Table 1-2. Test Equipment and Accessories List (cont'd)

1-5

Page 12

Model 86601A

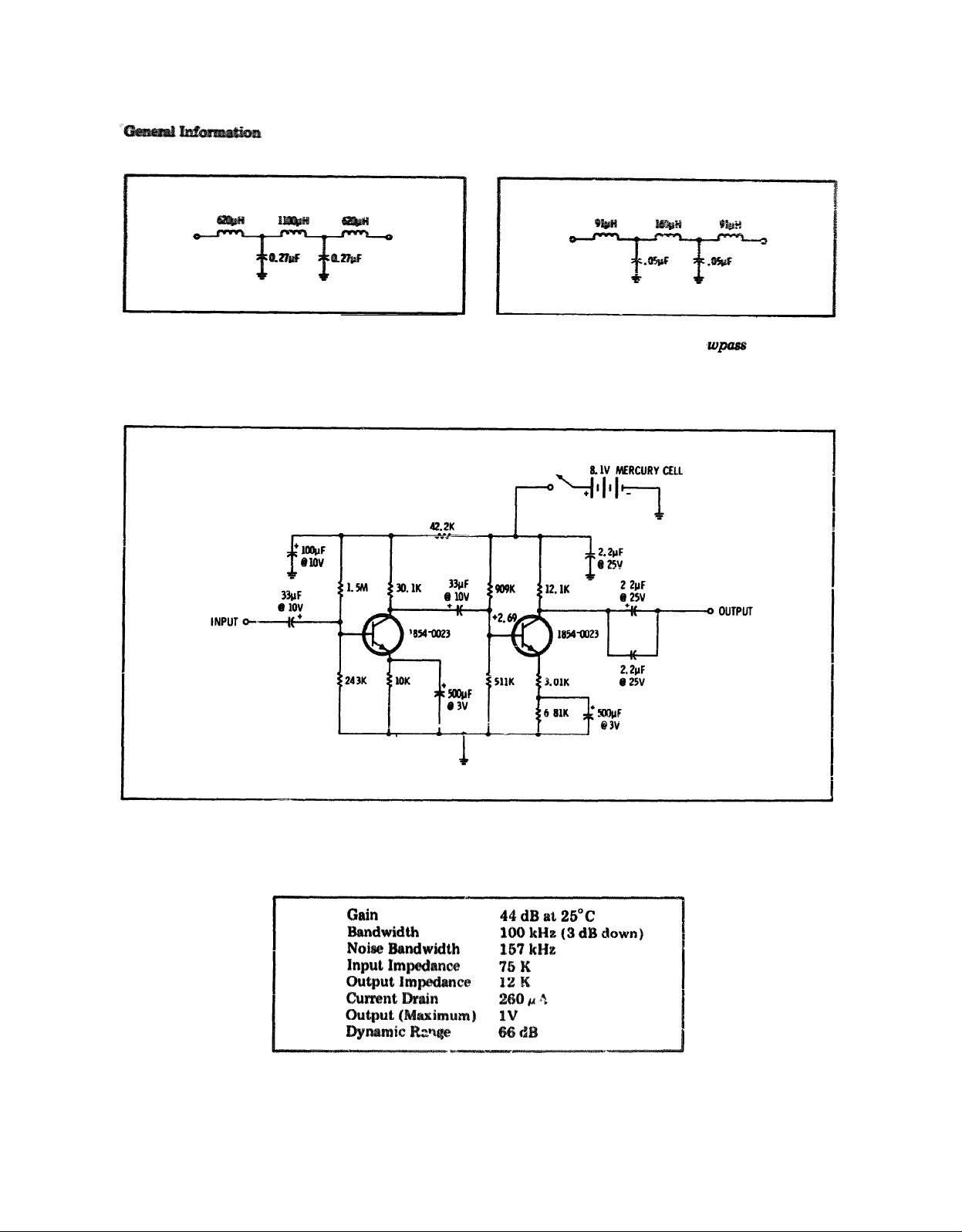

Figure 1-3.

15 kHz Lowpass Filter

Figure 1-4. 100 kHz Lo

Filter

1-6

Figure 1-5.

Table 1-3.

40 dB Amplifier

40 dB Amplifier Specifications

Page 13

Model 86601A

SECTION II

INSTALLATION

2-1.

2-2.

2-3.

2-4.

ment for physical damage

ken parts and dents or

amage is found refer to paragraph 2-7

for recommended claim procedure. If the instrument appears to be free of damage, perform the

electrical check (see paragraph 2-5). The packaging

material should be retained for possible future use.

2-5. Electrical Check

2-6. The electrical performance check consists of

performing the performance test procedures in

Section IV of this manual. These procedures enable

the operator to determine that the instrument is,

or is not, operating within the specifications listed

in Table 1-1. The initial performance and accuracy

of the instrument are certified as stated on the

inside front cover of this manual. If the instrument

does not operate as specified, refer to paragraph

2-7 for the recommended claim procedure.

2-14.

2-15.

2-16. Storage and Shipment

2-17 If the instrument is to be stored for an

extended period of time it should be enclosed in a

clean sealed enclosure.

2-18. Original Packaging

2-19. The same containers and materials used in

factory packaging can be obtained through any

Hewlett-Packard Sales/Service office l

2-20. If the instrument is being returned to

Hewlett-Packard for service attach a tag indicating

the type of service required, return address, model

number and full serial number Also mark the

container FRAGILE to assure careful handling.

2-21. In any correspondence refer to the instrument by model number and full serial number.

2-7.

2-8. If physical damage is found when the instrument is unpacked, notify the carrier and the

nearest Hewlett-Packard Sales/Service office

immediately. The HP Sales/Service office will arrange for repair or replacement without waiting for

a claim to be settled with the carrier.

2-9.

2-10.

2-11.

2-12.

2-13.

2-22. Other Packaging Material

2-23. The following general instructions should be

followed when repackaging with commercially

available materials :

a. Wrap the instrument in heavy paper or

plastic. (If shipping to a Hewlett-Packard Service

office or center, attach a tag indicating the type of

service required, return address, model number and

full serial number.)

2-1

Page 14

Model 86601A

3-0

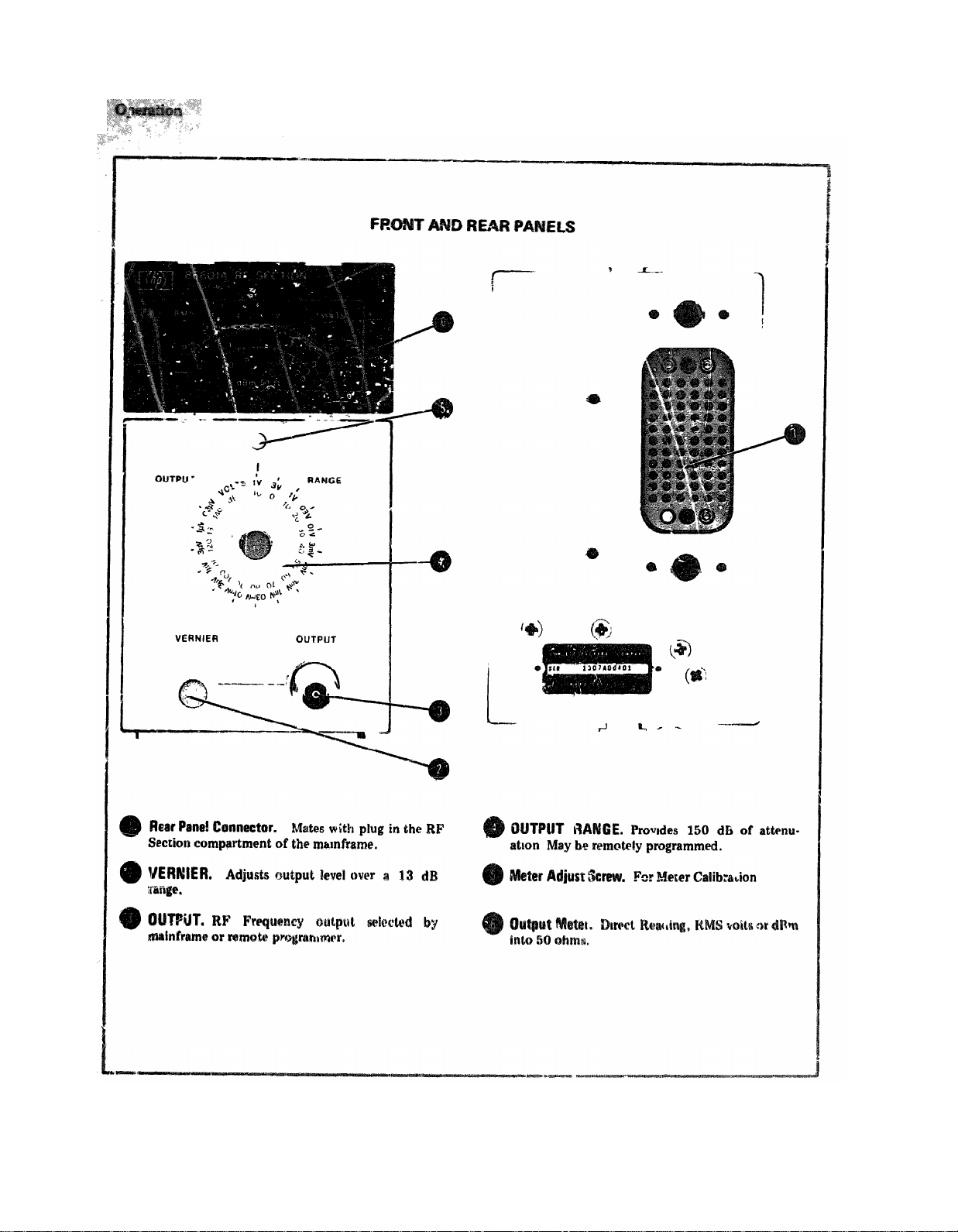

Figure 3-1. Front and Rear Panel Controls, Indicators and Connectors

Page 15

Model 86601A

SECTION III

OPERATION

3-1. INTRODUCTION

3-2.

3-3.

NOTE

If a modulation plug-in section is not used

it will be necessary to have the Model

86631A Auxiliary Section in place in the

modulation plug-in drawer.

3-4. PANEL FEATURES

3-5. Front and rear panel controls, indicators and

connectors of the Model 86601A are shown in

Figure 3-1.

3-6. OPERATING PRINCIPLES

3-7. The Model 86601A may be operated by front

panel controls in the local mode or externally

programmed in the remote mode.

NOTE

The remote mode is selected by the exter-

nal programming device which places a

ground on pin 5 of the blue ribbon con-

nector (J3) on the rear panel of the Model

3-8.

3-9. The front panel attenuator controls are inhibited when the instrument is operated in the

remote mode.

NOTE

Model 86601A Option 001 instruments

do not include the 150 dB (10 dB steps)

programmable attenuator.

3-10. In Option 001 instrumen

Model 86601A may be adjus

from +13 to 0 dBm by means

control; in the remote mode the output may be

reduced by 9 dB in 1 dB steps.

3-11. OPERATOR’S CHECKS

3-12. During checkout at the factory the Model

86601A RF Section if adjusted for proper operation. No adjustment should be required when the

instrument is received.

3-13. The Operator’s Checks specified in Section

III of the mainframe are adequate for checking the

output frequency of the Model 86601A.

3-14. If

a plug-in Modulation Section is being

used, the checks specified in Section III of the

Modulation Section Manual should also be performed.

3-1/3-2

Page 16

Model 86601A

SECTION IV

PERFORMANCE TESTS

4-1. INTRODUCTION

4-2. This section instructions for performance testing the Model

86601A RF Section

plug-in. it is assumed in all tests that the Model

86601A is interconnected with a mainframe that is

known to be functioning properly.

4-3. Purpose.

4-4. The performance test procedures are used to

check instrument performance for incoming

inspection and periodic evaluation. The tests are

designed to verify published specifications for the

instrument. Each test applies directly to a listed

specification (see Table l-l).

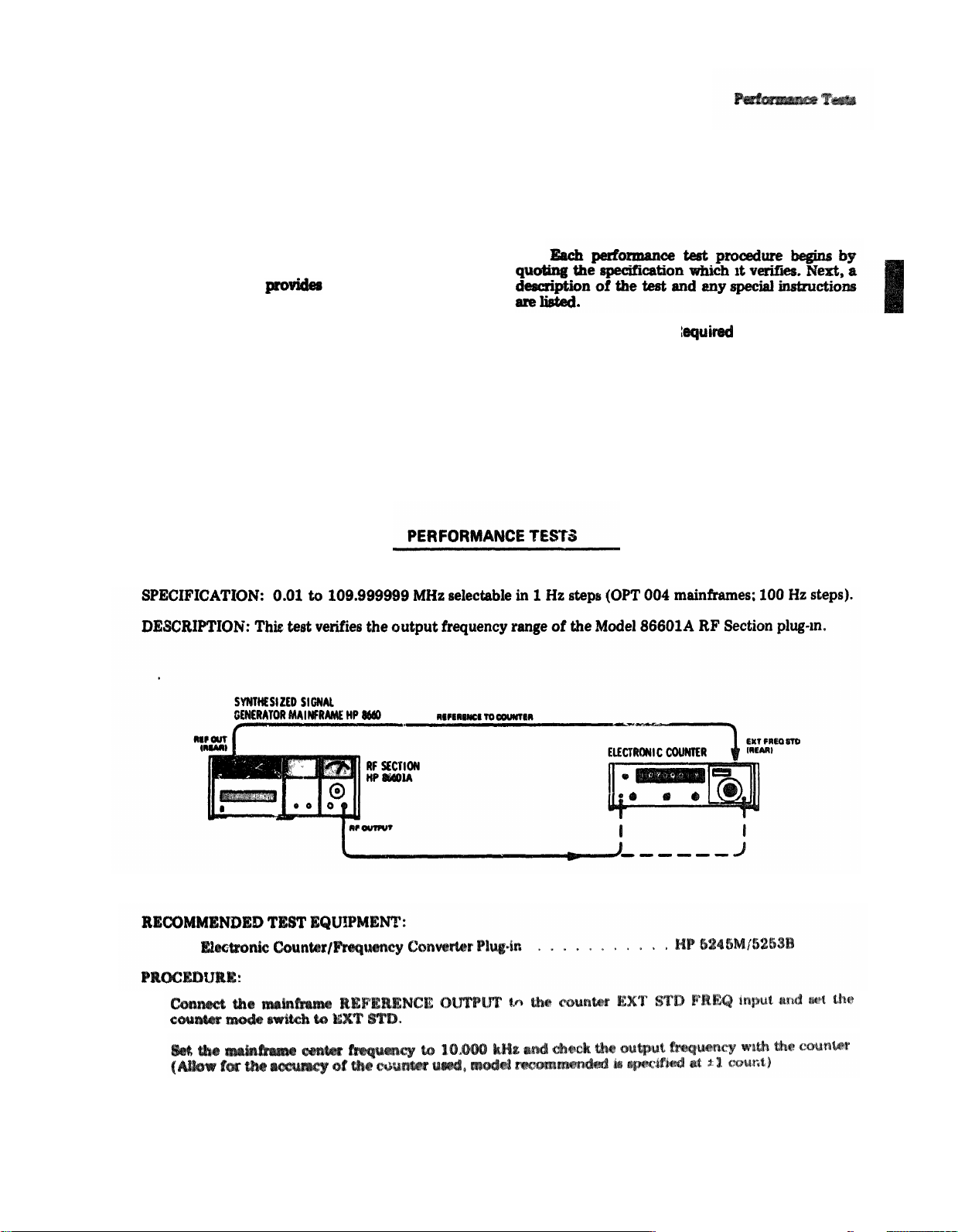

4-9. FREQUENCY RANGE

4-5.

4-6. Test Equipment

ment required for

R

The test equip-

performance testing is listed in

Table 1-2 and in the individual tests. Test instruments other than those listed may be used providing their performance equals or exceeds the specifications listed in Table 1-2.

4-7. Front Panel Checks and Adjustments. Refer

to paragraph 3-11, Operator’s Checks.

4-8. PERFORMANCE TESTS

1.

2.

Figure 4-1. Frequency Range and Accuracy Test Setup

4-1

Page 17

4-9.

3.

4-10.

4-11.

Model 86601A

PERFORMANCE TESTS

1.

2.

4-2

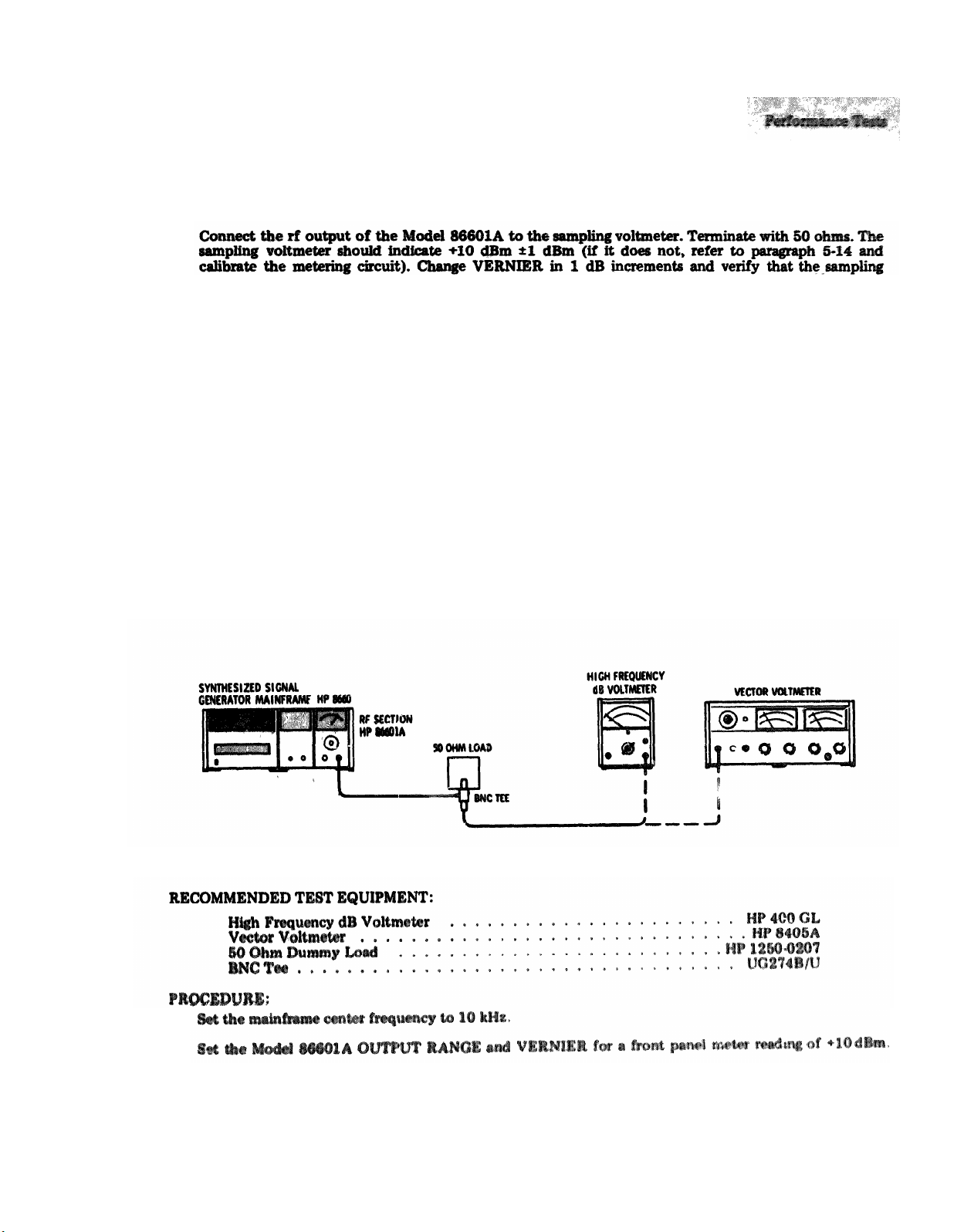

Figure 4-2. Output Accuracy and Level Test Setup

Page 18

Model 86601A

PERFORMANCE TESTS

4-11. OUTPUT ACCURACY AND LEVEL (cont'd)

3.

voltmeter indicates the correct level ±1 dB. Disconnect the sampling voltmeter.

4. Set the external attenuator to SO dB and connect it between the Model 86601A OUTPUT and the

Spectrum Analyzer RF INPUT. Set the Model 86601A output level to +10 dBm.

5. Set a convenient reference level on the Spectrum Analyzer with the vertical scale (LOG 2 dB/Div).

6. Change the external attenuator to 70 dB and the Model 86601A OUTPUT RANGE to 0 dBm. The

Spectrum Analyzer display should be within ± 1 dB of the established reference level.

7.

Continue decreasing the attenuation of the external attenuator and the Model 86601A OUTPUT

RANGE in 10 dB steps until the OUTPUT RANGE is set to

set to 0 dB. The spectrum Analyzer display should

remain within ±1 dB for levels down to --70 dBm.

-70 dBm and the external attenuator is

These tests assure the specification of ±2 dB from -67 dBm to -146 dBm.

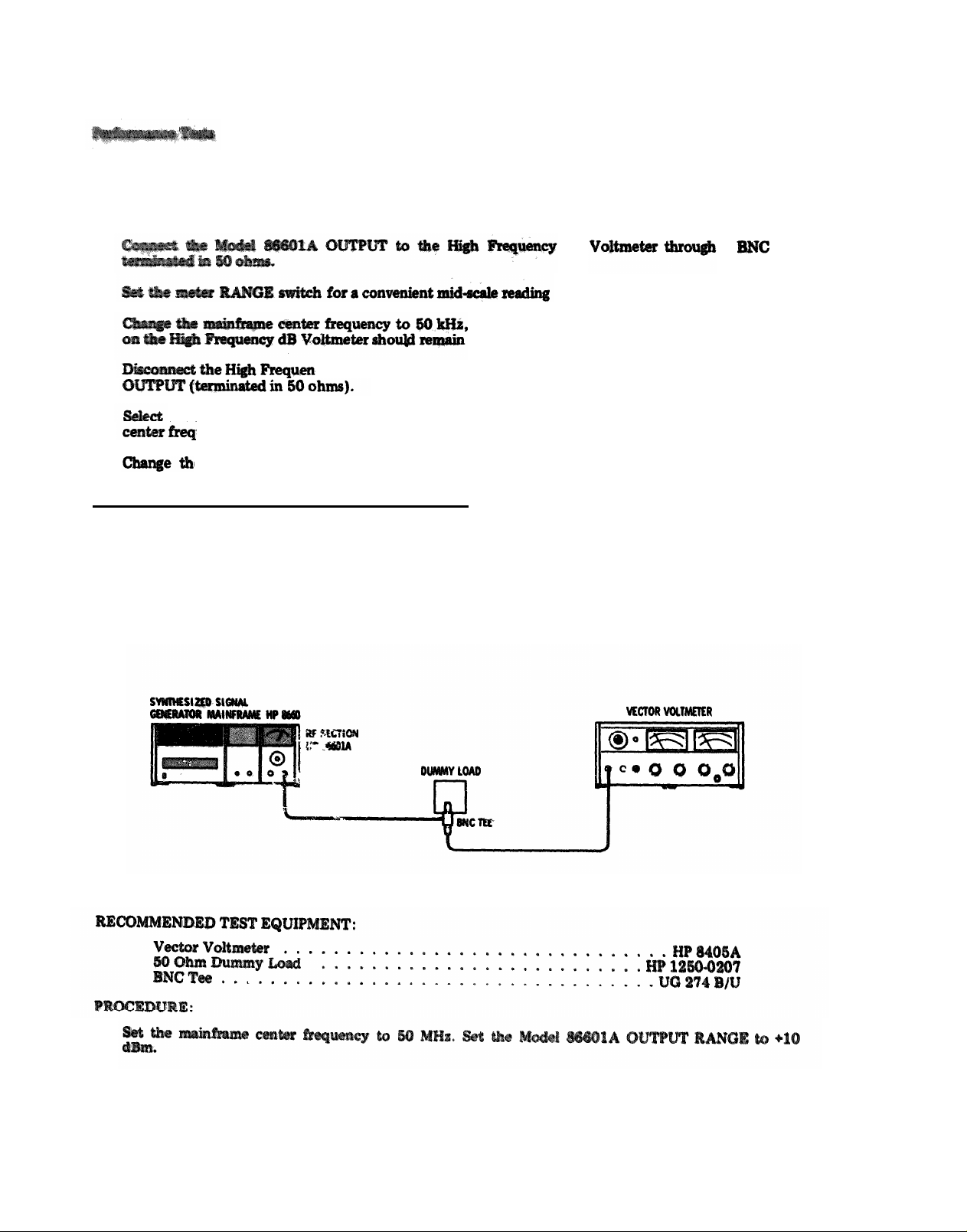

4-12. OUTPUT FLATNESS

SPECIFICATION: Output flatness: Output level variations with frequency <± 0.5 dBm across the

frequency range.

DESCRIPTION:

1.

2.

This test verifies flatness of the output signal from 10 kHz to 109.9 MHz.

Figure 4-3. Output Flatness Test Setup

4-3

Page 19

4-12. OUTPUT FLATNESS (con'd)

Model 86601A

PERFORMANCE TESTS

3.

4.

5.

then 100 kHz, and finally 500 kHz. The level read

dB

a Tee

on the High Frequency dB voltmeter.

within a ±0.5 dB window.

6.

7.

a Vector Voltmeter range that will provide a convenient mid-scale reference with the mainframe

cy dB Voltmeter and connect the Vector Voltmeter to the Model 86601A

uency set to 1 MHz.

8.

e mainframe center frequency to 10 MHz, then 50 MHz, and finally 109.9 MHz. The

reference level indicated on the Vector Voltmeter should remain within the ±0.5 dB window.

4-13. IMPEDANCE: 50 OHMS

SPECIFICATION: SWR less than 2:1 on +10 dBm output range; less than 1.3:1 on 0 dBm output range

and below.

DESCRIPTION: The Model 86601A RF OUTPUT is measured with a voltmeter, first with no external

load, then with a 50 ohm external dummy load. The source resistance RS is determined and the SWR is

calculated by dividing RO by RS (or RS by RO if RO is < RS).

1.

4-4

Figure 4-4. Impedance Test Setup

Page 20

Model 86601A

4-13. IMPEDANCE: 50 OHMS (cont'd)

2.

3. Record the RF output level.

4. Terminate the BNC Tee 50 ohms.

PERFORMANCE TESTS

V

OC

mVrms

5. Record the RF output level.

V

6. The Model 86601A source resistance is found by using the following formula:

Ro V

RS =

V

oc -R

1

O

VOC = 1st measurement (step 3)

V1 = 2nd measurement (step 5)

RO = 50 ohm termination

7. Determine SWR. SWR =

RO or RS. SWR should be < 2.0:1.

R

S

R

O

8. Record SWR

9. Reduce the Model 86601A OUTPUT RANGE to 0 dBm.

10. Repeat steps 2 through 8 at 0 dBm. SWR should be < 1.3:1.

11. Record SWR

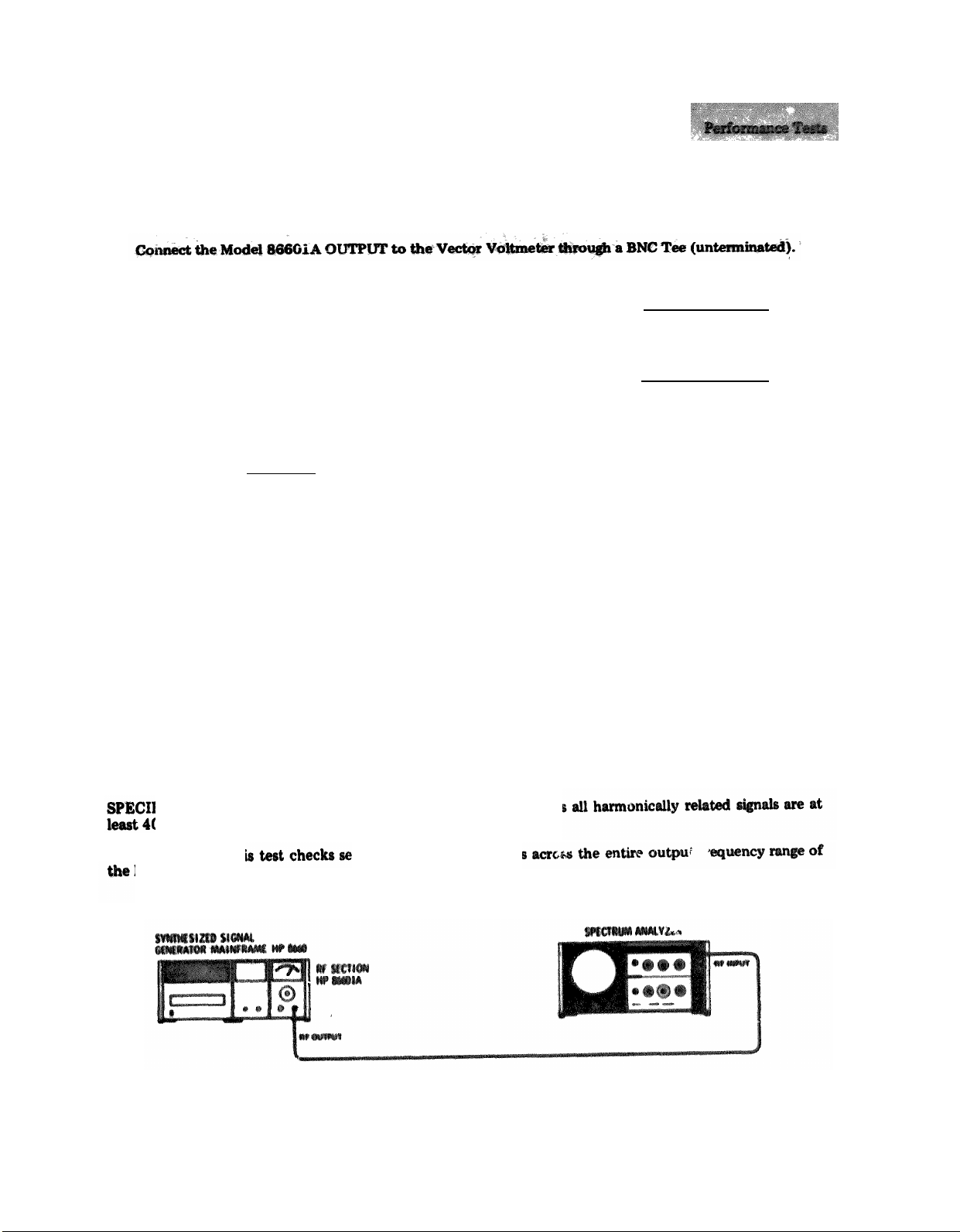

4-14. HARMONIC SIGNALS

FICATION:

With the Model 86601A terminated in 50 ohm

0 dB below the selected frequency.

1

mVrms

DESCRIPTION: Th

Model 86601A.

cond and third harmonic

Figure 4-5. Harmonic Signal Test Setup

4-5

Page 21

4-14.

Model 86601A

PERFORMANCE TESTS

HP 8554L/8552B/140S

1.

2.

1A OUTPUT RANGE to -10 dBm and set the VERNIER control to +3 dBm.

odel 8660A OUTPUT to the Spectrum Analyzer RF INPUT and set the Spectrum

INPUT ATTENUATION to 20 dB.

3.

third harmonics at the following center frequencies: 10 kHz, 400 kHz, 4 MHz, 10

MHz.All harmonic signals should be more than 40 dB below the level of the

SPURIOUS SIGNALS

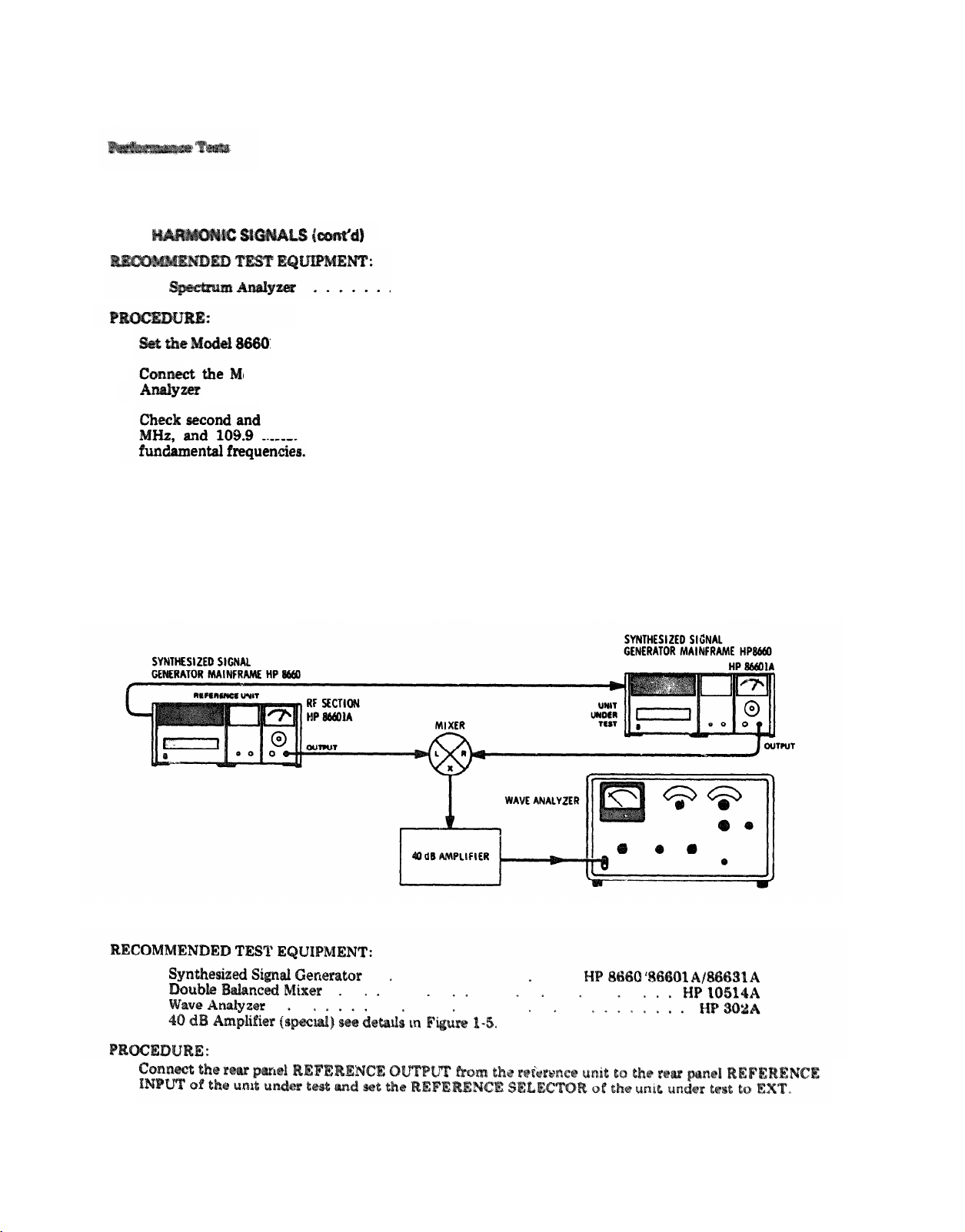

4-15.

SPECIFICATION: All nonharmonically related spurious signals are at least 80 dB below the selected

output

signal. Power line related spurious signals are at least 70 dB below the carrier.

DESCRIPTION: This test checks for common spurious signals by mixing the signal from the unit under

test with a reference signal offset by 1 kHz. The Wave Analyzer measures common spurious signals

generated in the unit under test.

1.

4-6

Figure 4-6. Spurious Signal Test Setup

Page 22

Model 86601A

PERFORMANCE TESTS

4-15. SPURIOUS SIGNALS (cont’d)

2. Connect the equipment as shown in Figure 4-6.

3. Set the reference unit center frequency to 50.001 MHz and the output level to +13 dBm.

4. Set the center frequency of the unit under test to 50 MHz and the output level to -87 dBm.

5. Set the Wave Analyze; mode switch to NORMAL and scale value to RELATIVE.

6. Set the wave Analyzer to 1 kHz and adjust levels for a 0 dB reading on the scale.

7. Set the unit under test OUTPUT RANGE and VERNIER to -7 dBm.

8. Set the reference unit and the unit under test as shown in Table 4-1 and note that spurious levels are

lower than -80 dB (0 dB on Wave Analyzer scale).

9. Corrected reading is

-80 dB minus the Wave Analyzer meter reading.

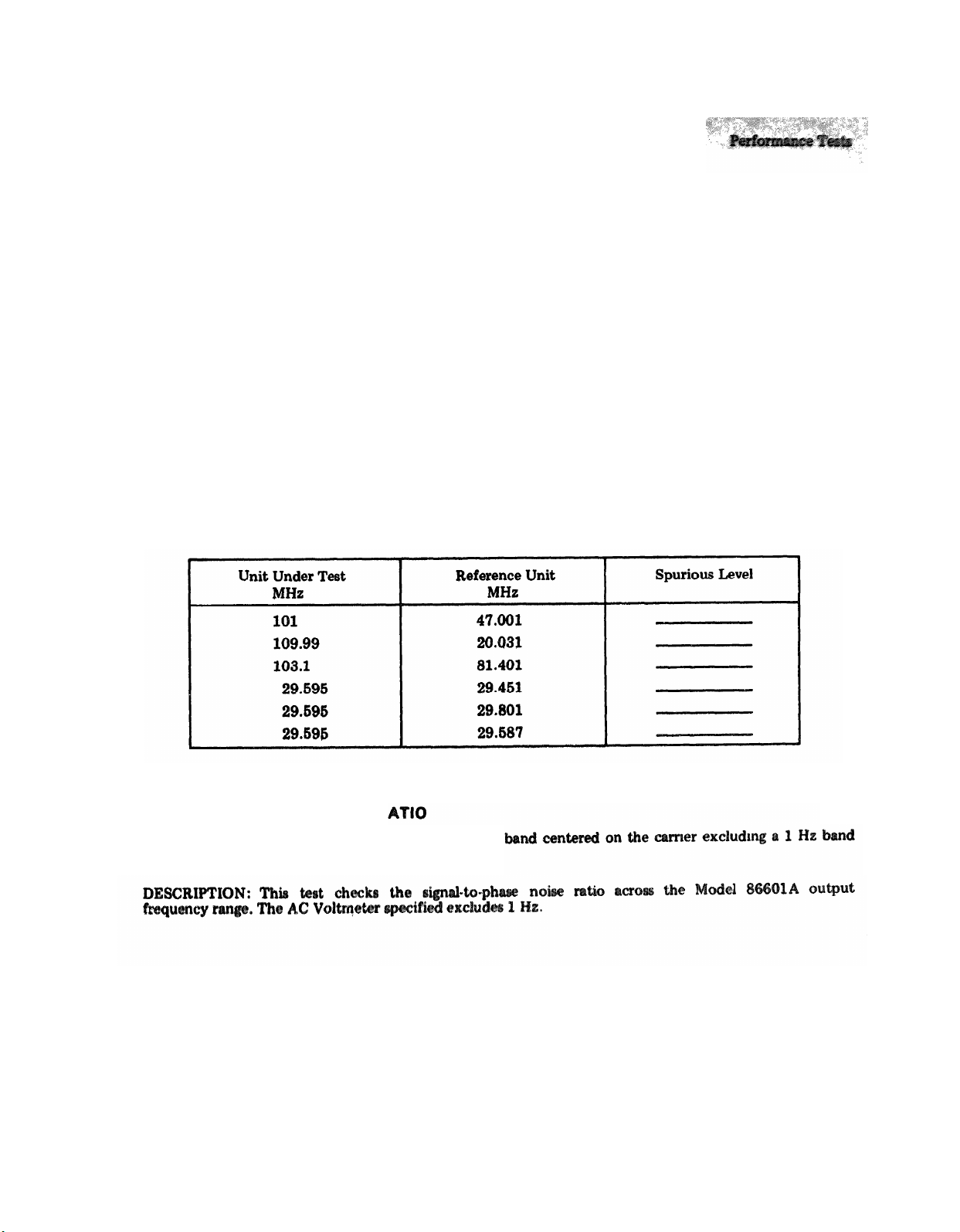

Table 4-1. Spurious Signal Checks

4-16. SIGNAL-TO-PHASE NOISE R

SPECIFICATION: Lower than -50 dB in a 30 kHz

centered on the carrier.

4-7

Page 23

4-10. SIGNAL-TO-PHASE NOISE RATIO

Model 86601A

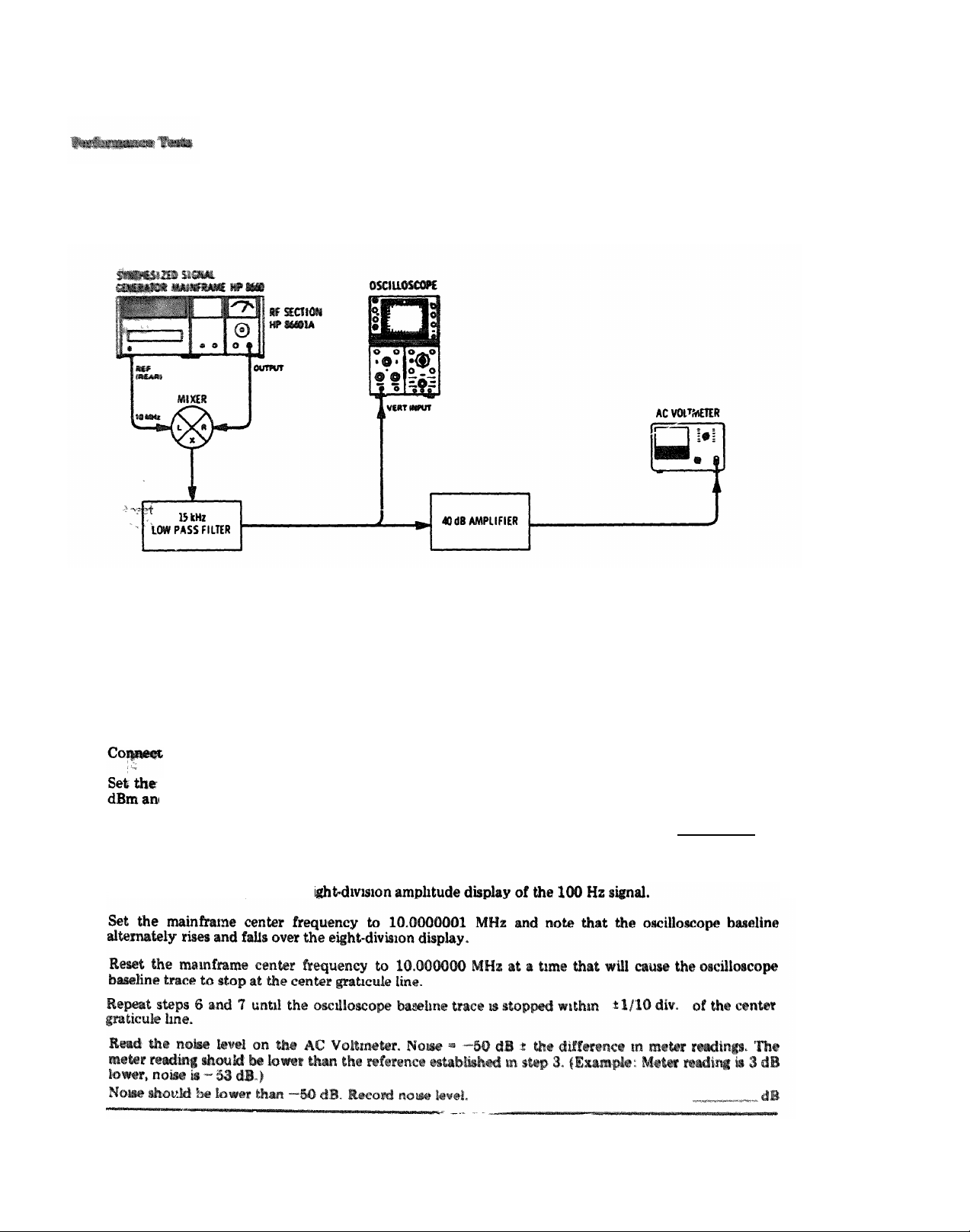

Figure 4-7. Signal-to-Phase Noise Test Setup

RECOMMENDED TEST EQUIPMENT:

Oscilloscope HP 180A/1801A/1821A

Double Balanced Mixer HP 10514A

AC Voltmeter HP 403A

40 dB Amplifier (special) see details in Figure 1-5.

Low Pass Filter (special) see details in Figure 1-3.

PROCEDURE:

1.

2.

the equipment as shown in Figure 4-7.

mainframe center frequency to 10.001 MHz. Set the Model 86601A OUTPUT RANGE to -60

d the VERNIER for a meter reading of +3 dBm.

3.

Set the RF Voltmeter Function Switch to 1 CPS-1 MC and record the reading.

4.

Set the mainframe center frequency to 10.000100 MHz and the OUTPUT RANGE to -10 dBm.

5.

Adjust the oscilloscope for an ei

6.

7.

8.

dB

9.

10.

4-8

Page 24

Model 86601A

PERFORMANCE TESTS

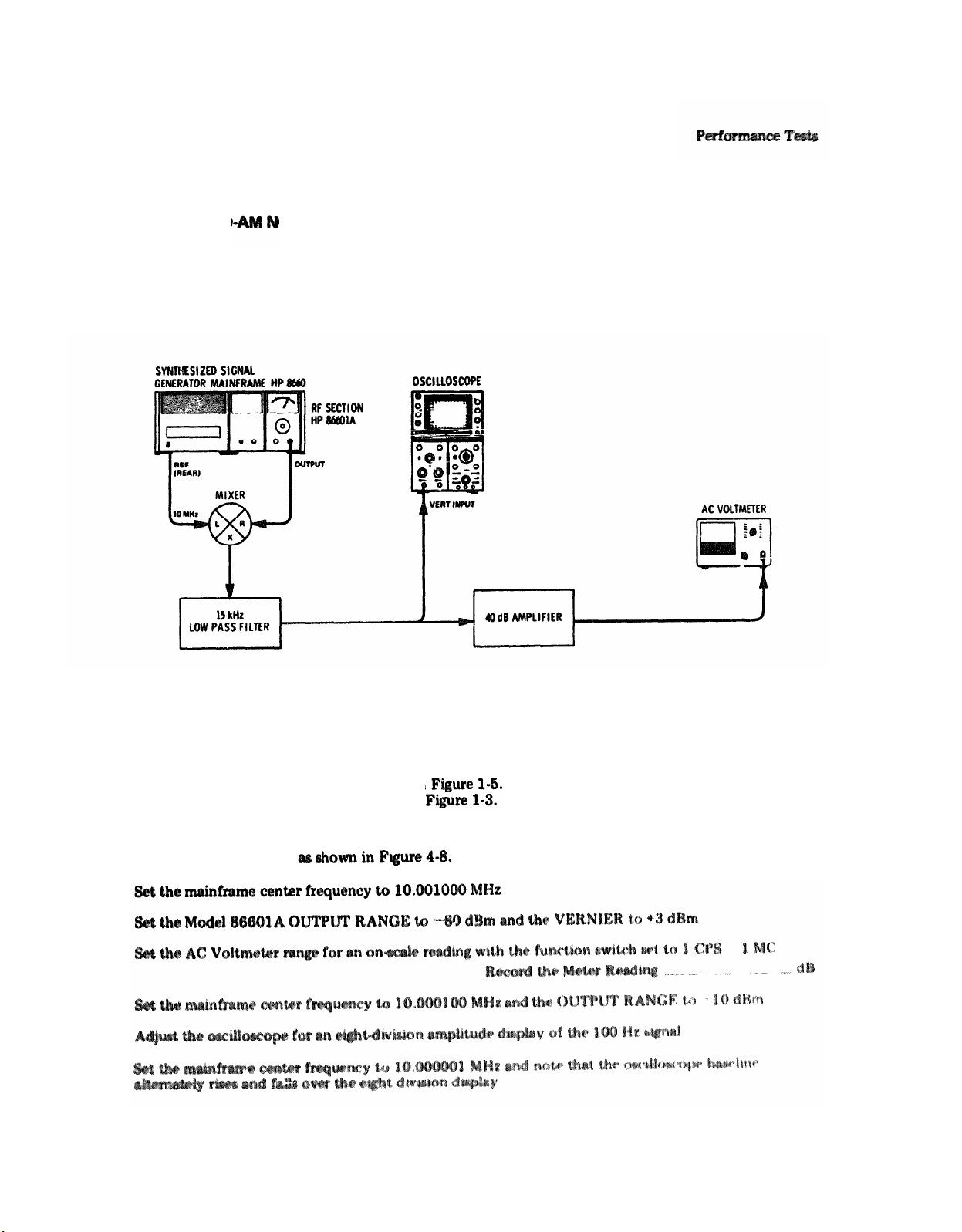

4-17. SIGNAL-TO

OISE RATIO

SPECIFICATION: Lower than -70 dB in a 30 kHz hand centered on the carrier excluding a 1 Hz

bandwidth centered on the carrier.

DESCRIPTION: This test checks AM noise across the Model 86601A frequency range. The AC voltmeter

specified excludes 1 Hz.

Figure 4-8. Signal-to-AM Noise Ratio Test Setup

RECOMMENDED TEST EQUIPMENT

Oscilloscope

Double Balanced Mixer HP10514A

AC Voltmeter

40 dB Amplifier (special); see details in

Low Pass Filter (special); see details in

PROCEDURE:

1.

Connect the equipment

2.

3.

4.

5.

6.

7.

HP 180A/1801A/1821A

HP 403A

4-9

Page 25

PERFORMANCE TESTS

4-17. SIGNAL-TO-AM NOISE RATION (cont'd)

Model 86601A

8.

MHz at a time that will cause the oscilloscope

T.

9.

10.

11.

on the AC Voltmeter. Noise =

lower than the reference established in step 4. Example: Meter reading is 3 dB

be

should be lower than -70 dB.

oscope baseline trace is stopped at the top graticule line ±1/10 div.

-70 dB ± the difference in meter readings. The

Record Noise Level

4-18. RESIDUAL FM

SPECIFICATION: <1 Hz rms in 2 kHz bandwidth centered on the carrier.

DESCRIPTION: Residual FM is checked indirectly in the checks for signal-to-phase noise across the Model

86601A frequency range.

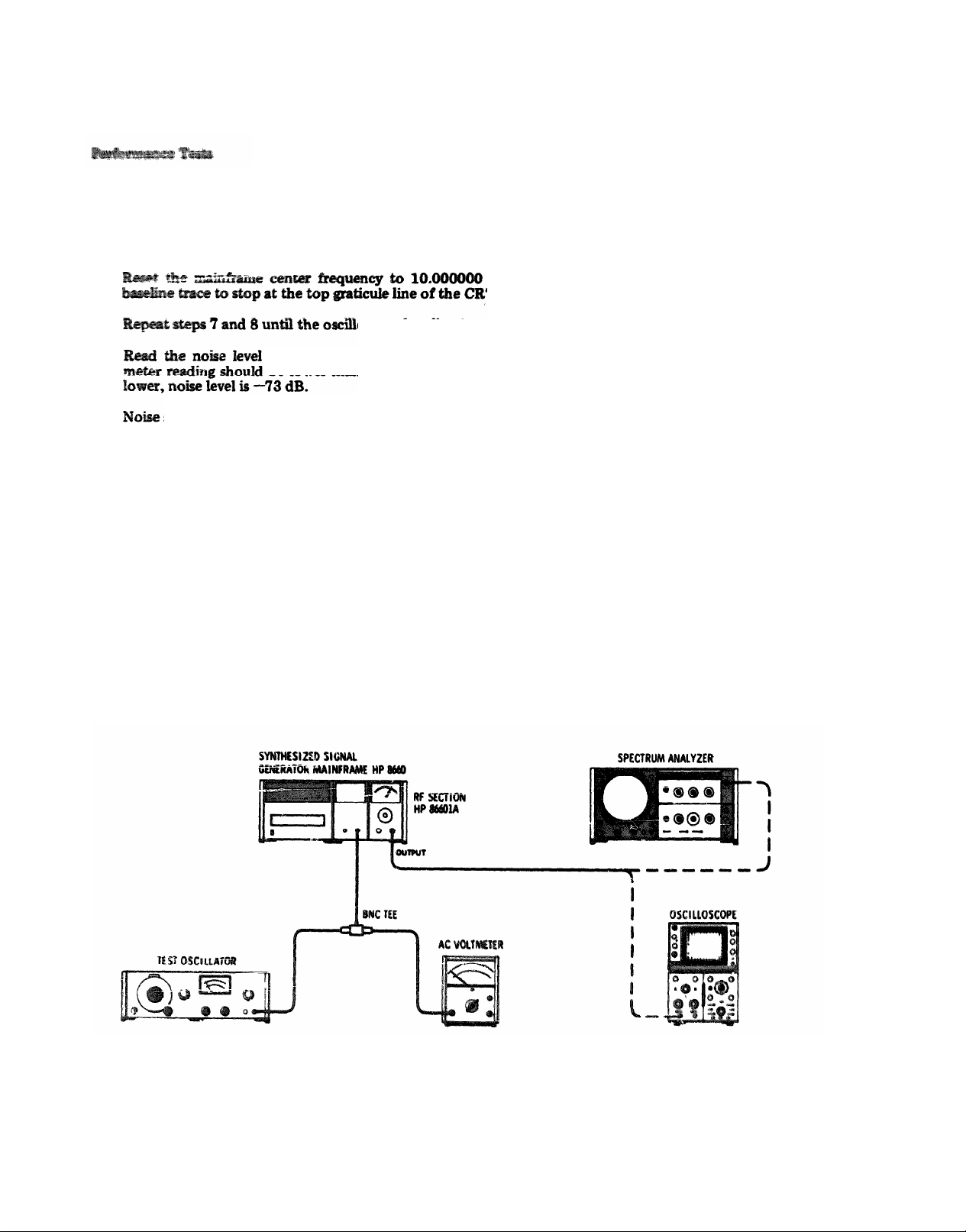

4-19. AMPLITUDE MODULATION

SPECIFICATION: 0 to 95% on all output ranges (with Model 86632A or 86631A Modulation Section in

place).

DESCRIPTION: This test checks AM frequency response with the mainframe center frequency set to 50

MHz, 3 MHz, and 300 kHz. AM rate is provided from a test oscillator and measured on a Spectrum

Analyzer and Oscilloscope.

dB

4-10

Figure 4-9. Amplitude Modulation Test Setup

Page 26

Model 86601A

PERFORMANCE TESTS

4-19. AMPLITUDE MODULATION (cont’d)

RECOMMENDED TEST EQUIPMENT:

Spectrum Analyzer

High Frequency dB Voltmeter

Oscilloscope

Test Oscillator

BNC Tee

HP 8553B/8552B/140S

HP 400 GL

HP 180A/1801A/1821A

HP 651B

UG 274 B/U

PROCEDURE:

1.

Connect the equipment as shown in Figure 4-9.

Set the Spectrum Analyzer as follows: INPUT ATTENUATION 30 dB, BANDWIDTH 1 kHz, SCAN

2.

WIDTH 10 kHZ, CENTER FREQUENCY 50 MHz, LOG-LINEAR 2 dB/Div, SCAN TIME 20 mSec/Div

and VIDEO FILTER to OFF,

3.

Set the mainframe center frequency to 50 MHz and the Model 86601A output level to +3 dBm.

4.

Set the Model 86631A AM switch to ON (if the Model 86632A is being used, set the MODE switch to

AM and the SOURCE switch to EXTERNAL AC and AM to 50%).

5.

Set the Test Oscillator output to 10 kHz at .5 Vrms as read on AC Voltmeter.

6.

Adjust the spectrum analyzer until the carrier is at the top graticule line. Amplitude Modulation should

be 50% ±5% with sidebands down -12 dB ±0.5 dB.

7.

Adjust the Test Oscillator frequency from 10 Hz to 50 kHz. The AM % should be flat ± 4 db from 10

Hz to 20 kHz and down 3 dB at about 50 kHz.

8.

Set the mainframe center frequency to 3 MHz and

Oscillator frequency from 10 Hz to 10 kHz. The side

r scan

ould b

th to 2 kHz. Adjust the

t ±.2 dB to 2 kHz; down

at about 5 kHz; down 8 dB at about 10 kHz.

Set the mainframe center

9.

frequency

to 300 kHz. Disconnect the rf OUTPUT from the Spectrum

Analyzer and connect it to the Oscilloscope.

10.

4-20.

4-11

Page 27

4-20.

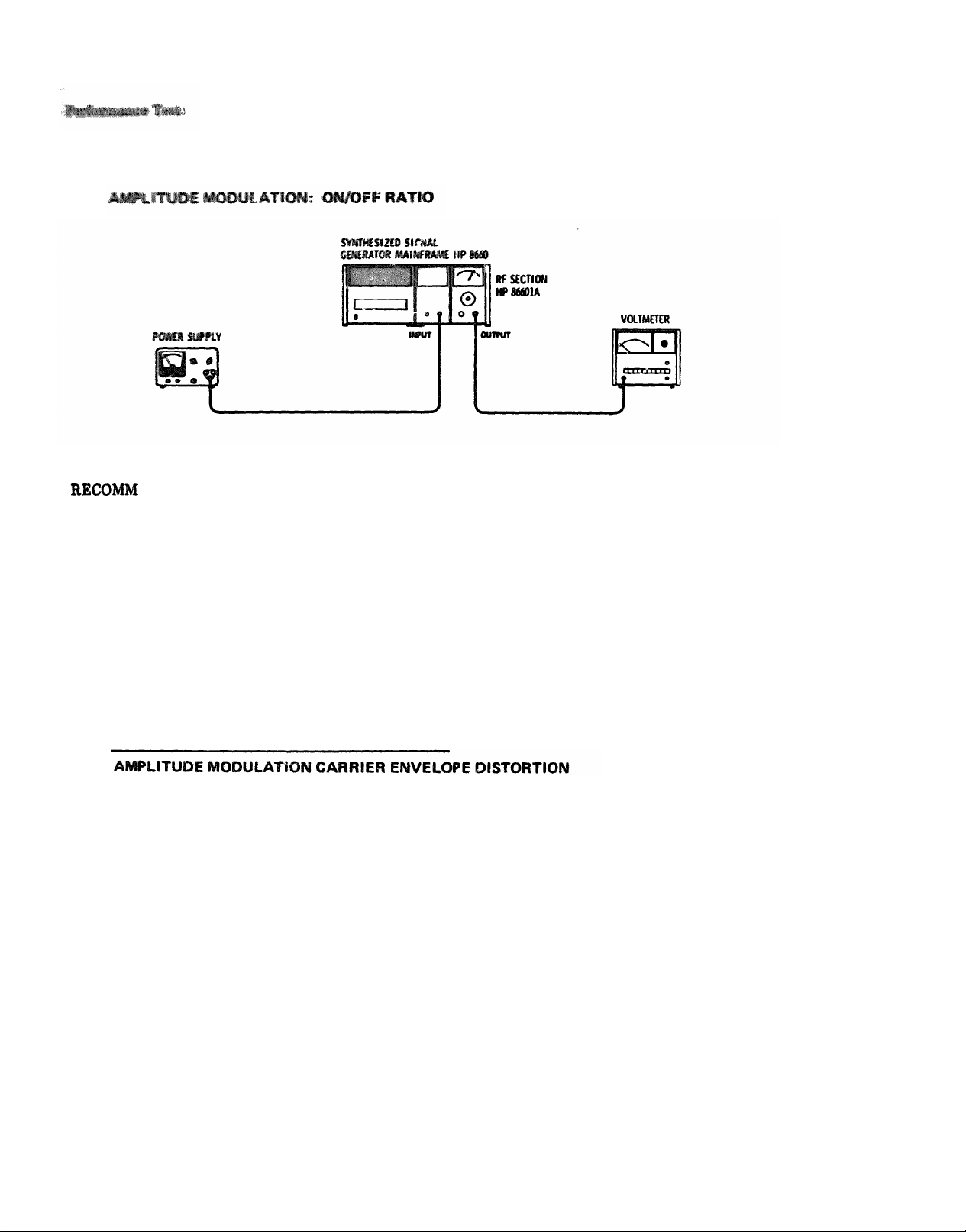

Figure 4-10. Amplitude Modulation ON/OFF Ratio Test Setup

ENDED TEST EQUIPMENT:

Broadband Sampling Voltmeter

Power Supply

Model 86601A

PERFORMANCE TESTS

HP 8406A

HP 721A

PROCEDURE:

1.

Connect the equipment as shown in Figure 4-10 (with the Model 86631A AM switch off).

2.

Set the power supply to +4 Vdc.

3.

Set the mainframe center frequency to 50 MHz and output level of the Model 86601A to +13 dBm.

Set a reference point on the Voltmeter.

4.

Switch the Model 86631A AM switch to ON.

5.

The Model 86601A output level should drop to <-12 dBm. (25 dB ON/OFF ratio).

4-21.

SPECIFICATION: Envelope distortion should be less than 1% at 30% AM. Less than 3% at 70% AM. Less

than 5% at 90% AM.

DESCRIPTION:

Amplitude Modulation distortion is checked at 30%, 70% and 90%.

4-12

Page 28

Model 86601A

PERFORMANCE TESTS

4-21. AMPLITUDE

ODULATION CARRIER ENVELOPE DISTORTION (cont’d)

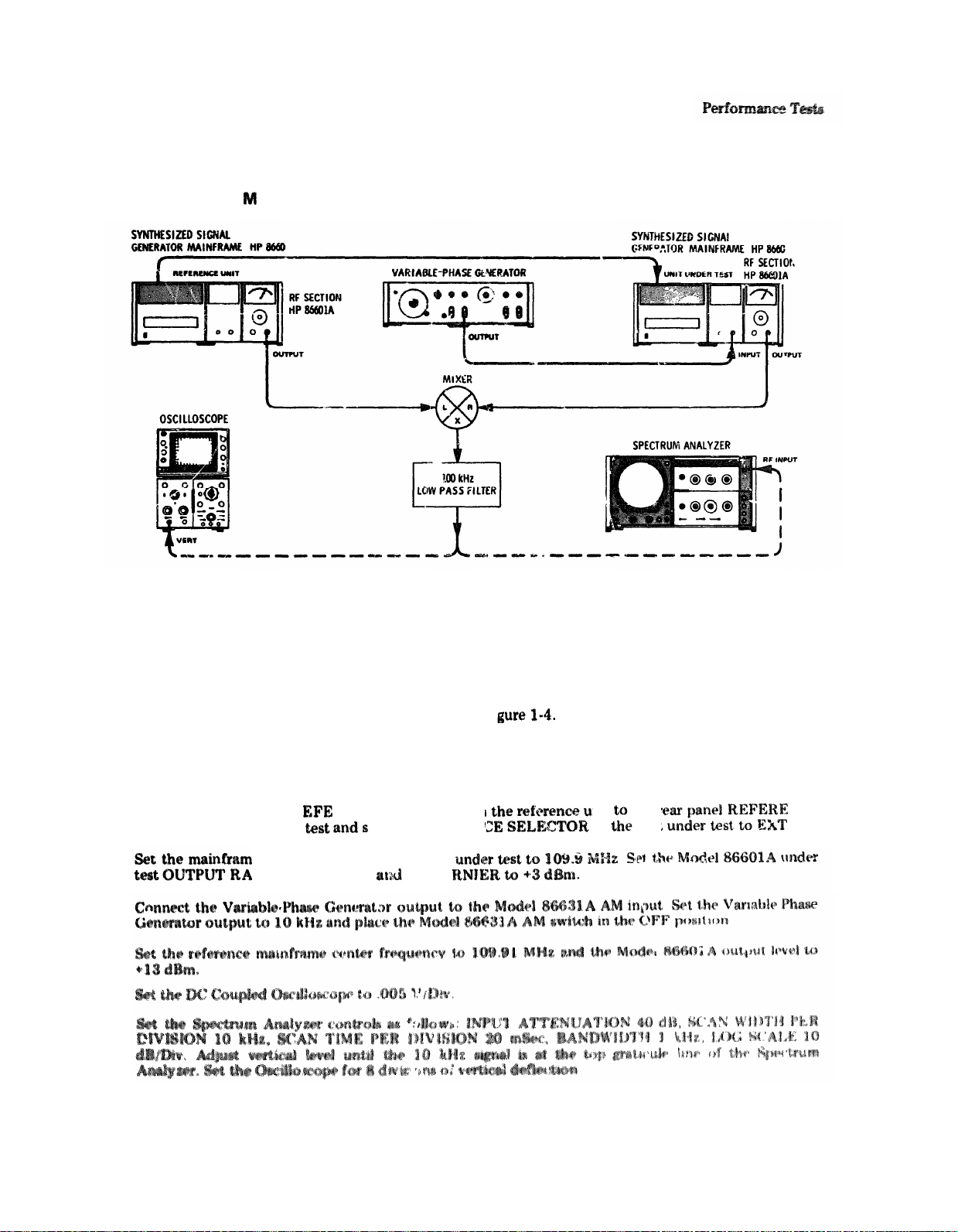

Figure 4-11. Amplitude Modulation Carrier Envelope Distortion Test Setup

RECOMMENDED TEST EQUIPMENT’:

Double Balanced Mixer

Spectrum Analyzer

Synthesized Signal Generator HP 8660A/B/866C1A/86631A

Variable Phase Generator

Oscilloscope HP 180A/1801A/1821A

Low Pass Filter 100 kHz (special); see details in Fi

HP 10514A

HP 8553B/8552B/140S

PROCEDURE:

1.

Connect the equipment as shown in Figure 4-11.

2. Connect the rear panel R

INPUT of the unit under

3.

e center

RENCE OUTPUT from

et the REFEREN

frequency

NGE to --20 dBm

4.

5.

6.

7.

of time unit

the VE

nit

of

the r

unit

NCE

.

4-13

Page 29

Model 86601A

PERFORMANCE TESTS

4-21.

8.

9.

10.

11.

12.

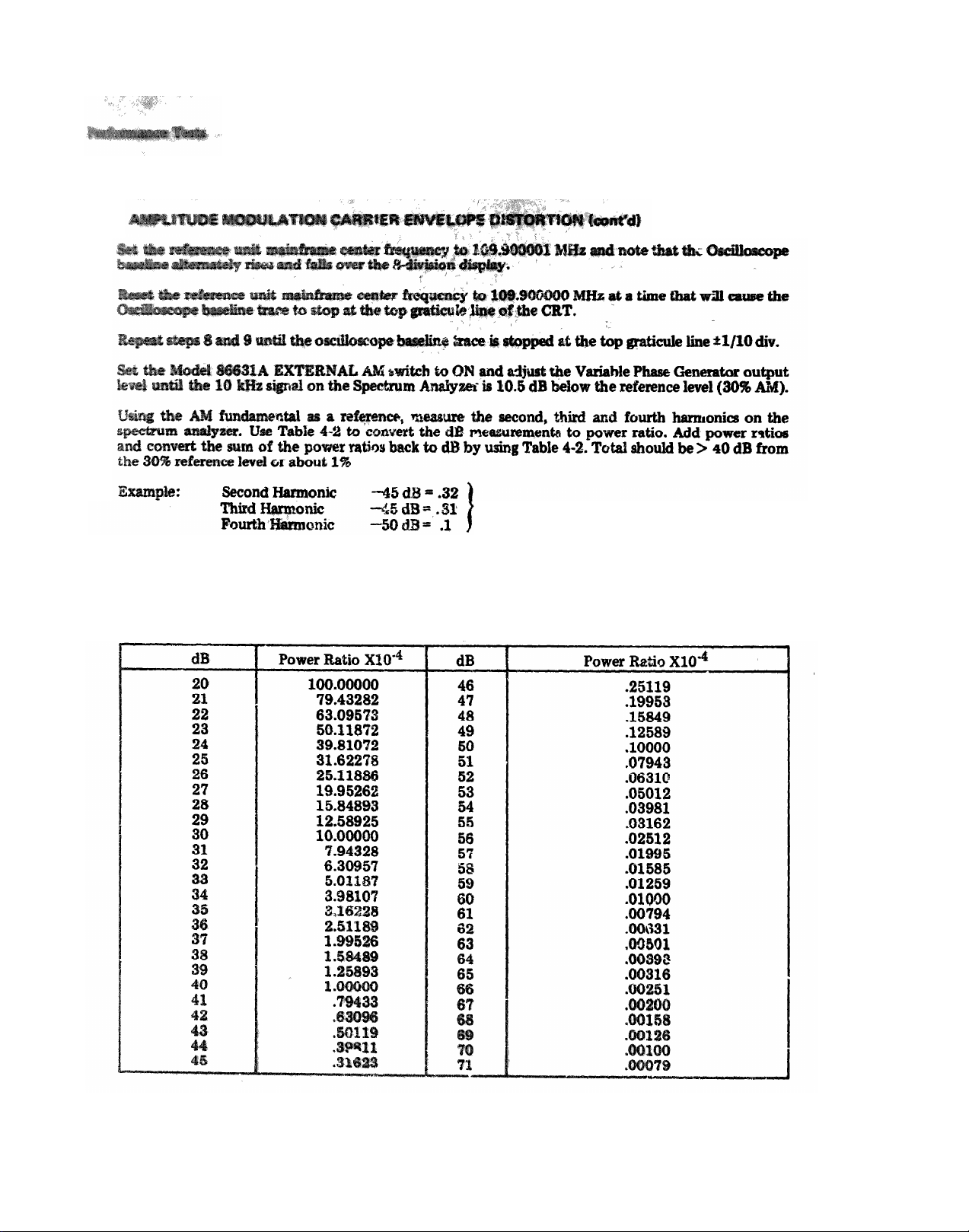

=.73 = -41.5 dB

13. Adjust the Variable Phase Generator until the 10 kHz fundamental is 3 dB below the reference (top

graticule line) (70% AM). Using the 10 kHz fundamental as a reference, measure the second,-third and

fourth harmonica and use Table 4-2 as in step 10. Total harmonics should be > 30 dB below the 70%

reference level (3%).

Table 4-2. Carrier Envelope Distortion Test

4-14

Page 30

Model 86601A

PERFORMANCE TESTS

4-21.

14.

4-22. INCIDENTAL PHASE MODULATION

SPECIFICATION: Less than 0.2 radians peak at 30% AM.

DESCRIPTION: This test checks the AM to PM ratio. AM is set to 30% Modulation with an external Test

Oscillator. The ratio is measured with a Wave Analyzer.

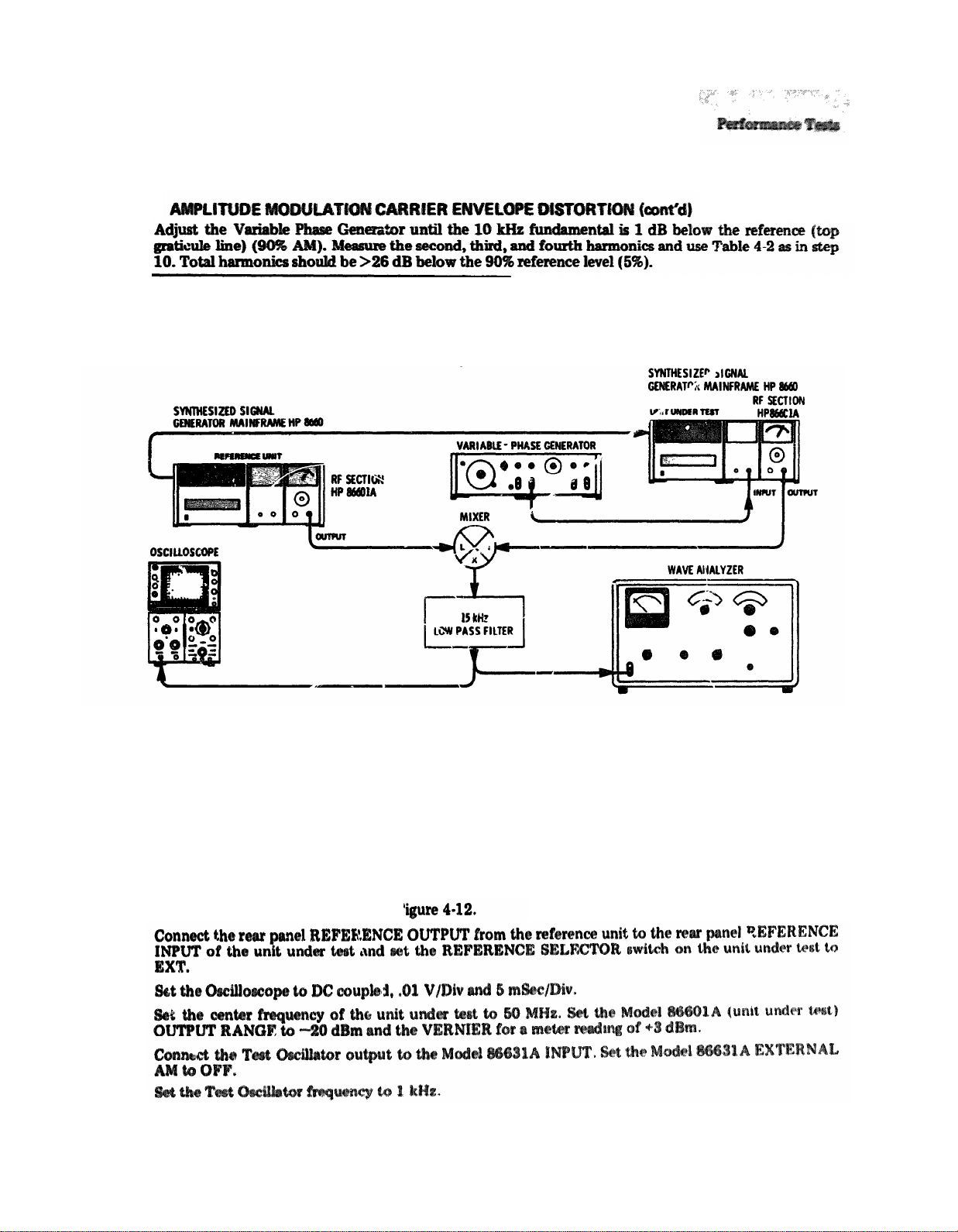

Figure 4-12. Incidental PM Test Setup

RECOMMENDED TEST EQUIPMENT:

Synthesized Signal Generator HP 8660A/B/86601A/86631A

Oscilloscope

Test Oscillator HP 651B

Wave Analyzer HP 302A

Double Balanced Mixer HP 10514A

15 kHz Low Pass Filter (special); see details in Figure 1-3.

Variable Phase Generator

PROCEDURE:

1. Connect the equipment as shown in F

2.

3.

4.

5.

6.

HP 180A/1801A/1821A

HP 203A

4-15

Page 31

4-22.

7.

8.

Model 86601A

PERFORMANCE TESTS

9.

10.

frequency to 50.000000 MHz at a time that will cause the

1 MHz and note

p graticule line of the CRT.

11.

12.

a 2.4 division deflection on the Oscilloscope (30% AM) with the Oscilloscope ac coupled. Reset

for

9 and 10 until the oscilloscope baseline trace is stopped at the top graticule line ±1/10 div.

e unit under test Model 86631A EXTERNAL AM switch to ON and adjust the Test Oscillator

pe to dc coupled.

13.

Set the Wave Analyzer near 1 kHz for a peak and set a convenient 0 dB reference in the relative mode

(this is the AM level).

14.

Switch the EXTERNAL AM switch on the Model 86631A to OFF.

15.

Repeat steps 9 and 10 until oscilloscope baseline trace is stopped at center graticule line ±1/10 div.

16.

Switch the Model 86631A EXTERNAL AM switch to ON and take a reading from the Wave Analyzer

for the PM level. The AM to PM ratio should be >5 dB.

4-23. FREQUENCY MODULATION

SPECIFICATION: Rate DC to 1 MHz. Maximum deviation 1 MHz.

DESCRIPTION: This test checks FM distortion and the 1 MHz maximum deviation FM deviation is

checked at 1 kHz rate. To check maximum deviation at the maximum rate requires special equipment.

4-16

Figure 4-13. Frequency Modulation Test Setup

Page 32

Model 86601A

PERFORMANCE TESTS

4-23. FREQUENCY MODULATION (cont'd)

PROCEDURE:

1. Connect the equipment as shown in Figure 4-13.

2. Set the Model 86632A MODE switch to FM X10 and the SOURCE switch to INTERNAL 1000. Set

the MODULATION LEVEL control for full scale meter deflection and depress the FM CF CAL.

3. Set the center frequency to 8.5 MHz and the Model 86601A output level to +13 dBm.

4. Calibrate the Frequency Meter/FM Discriminator.

5. Install a 20 kHz low pass filter in the Frequency Meter/FM Discriminator. (See the Service Manual for

the Frequency Meter/FM discriminator for details.)

6. Set the Frequency Meter/FM Discriminator for 1 V input sensitivity and 10 MHz range.

7. Set the Wave Analyzer near 1 kHz and peak the reading (absolute). The Wave Analyzer meter should

indicate 70.7 mVrms (1 MHz =

200 mV p-p or 70.7 mVrms). Set the Wave Analyzer to relative and

adjust for a 0 dB reading.

8. Set the Wave Analyzer near 2 kHz (second harmonic). Note the reading in dB on the Wave Analyzer

meter.

dB

9. Set the Wave Analyzer near 3 kHz (third harmonic). Note the reading in dB on the Wave Analyzer

meter.

dB

10. Use Table 4-2, page 4-14, to obtain power ratios for the levels recorded in steps 8 and 9, then use Table

4-2 to find the dB level corresponding to the sum of the two ratios. This should be down 34 dB from

the fundamental frequency level.

Record this level dB

4-24. FREQUENCY SWITCHING TIME

SPECIFICATION: Less than 5 milliseconds to be within 100 Hz of any new frequency selected. Less than

100 milliseconds to be within 5 Hz of any new frequency selected. Maximum stepping rate: 1 millisecond

per step.

DESCRIPTION: In this test the Synthesized Signal Generator is remotely programmed and the switching

time is detected by a computing counter. The frequencies used in this procedure were selected for

wont-case conditions.

4-17

Page 33

4-24.

Model 86601A

PERFORMANCE TESTS

Figure 4-14. Frequency Switching Time Test Setup

RECO

ENDED TEST EQUIPMENT:

DC Power Supply

Computing Counter

Marked Card Programmer

Oscilloscope

HP 721A

HP 5360A/5365A

HP 3260A/OPT 001

HP 180A/1801A/1822A

PROCEDURE:

1.

Connect the +5V from the DC Power Supply to pin 17 of the mating connector for J3 through a 1000

ohm resistor. Pin 17 (flag) of the Card Reader’s output connector is also used to trigger the main input

of the Oscilloscope.

2.

Interconnect the Marked Card Programmer with J3 on the rear panel of the Synthesized Signal

Generator.

3.

Connect the Oscilloscope DELAYED SWEEP OUTPUT (rear panel connector) through a BNC Tee

connector to the Oscilloscope vertical Channel A input and to the Ext. Time Measurement Input on

the rear panel of the Computing Counter.

4.

5.

6.

7.

8.

4-18

Page 34

Model 86601A

PERFORMANCE TESTS

4-24. FREQUENCY

9. Program the Synthesized Signal Generator to 30.000000 MHz. The frequency read on the Computing

Counter should be 30 MHz ± 100 Hz.

10. Program the Synthesized Signal Generator to 29.999999 MHz. The frequency read on the Computing

Counter should again be within ±100 Hz of the programmed frequency.

11. Set the Oscilloscope normal sweep to 10 mSec and the delay sweep to 1 uSec.

12. Set the Oscilloscope sweep mode to auto and the delay control for a delay spike at the center vertical

graticule line of the CRT.

13. Set the Oscilloscope main trigger to normal and the Computing Counter gate tune to 100 mSec.

14. Program the Synthesized Signal Generator to 30.000000 MHz. The frequency readout of the

Computing Counter should be within ±5 Hz of the programmed frequency.

15. Program the Synthesized Signal Generator to 29.999999 MHz. The frequency readout of the

Computing Counter should again be within ±5 Hz of the programmed frequency.

4-25. OUTPUT LEVEL SWITCHING TIME

SPECIFICATION: Any level change may be accomplished in less than 50 mSec. Any change to another

level on the same attenuator range may be accomplished in 5 mSec in the remote mode.

DESCRIPTION: This test checks amplitude switching speeds in the remote mode with center frequencies

of 100 kHz and 1 MHz. The Model 86601 rf output is detected and measured on an Oscilloscope.

Figure 4-15. Output Level Switching Time Test Setup

4-19

Page 35

4-25.

1.

Model 86601A

PERFORMANCE TESTS

2.

3.

ut to the channel A input of

Time/Div 5 mSec. Vertical Input DC Coupled, .5V/Div, Normal

ain

level about 11:00 o’clock.

4.

center frequency to 100 kHz. Program the Model 86601A attenuation to the

-5 dB, -9 dB. Switching time should be <5 mSec.

5.

6.

m attenuation to 0 dB, then to -20 dB. Switching time should be <50 mSec.

tests 4 and 5 with center frequency set to 1 MHz.

4-26. INCIDENTAL AM

SPECIFICATION: With 75 kHz peak deviation at a 1 kHz rate, AM modulation sidebands are down 60 dB

from the fundamental.

DESCRIPTION: This test measures AM modulation with the unit under test FM modulated at 75 kHz

peak deviation. A reference level is set on the Wave Analyzer with the two Synthesized Signal Generators

offset by 1 kHz. The unit under test is then programmed to produce a 1 kHz frequency modulated signal

with 75 kHz peak deviation.

4-20

Figure 4-16. Incidental AM Test Setup

Page 36

Model 86601A

PERFORMANCE TESTS

4-26. INCIDENTAL AM (cont'd)

1A

2A

HP180A/1801A/P821A

HP302A

i&& HP 10514A

15kHz Low Pass Filter (special): see details in Table 1-2.

PROCEDURE:

1.

Connect equipment as shown in Figure 4-16.

2.

Connect the rear panel REFERENCE OUTPUT from the reference unit to the rear panel REFERENCE

INPUT of the unit under test and set the REFERENCE SELECTOR of the unit under test to EXT.

Set the unit under test center frequency to 50 MHz and the output level to -7 dBm.

3.

4.

Set the reference unit center frequency to 50.061 MHz and the output level to +13 dBm.

5.

Set the wave Analyzer near 1 kHz and peak the meter, Set the Wave Analyzer meter level to 0 dB in

the relative mode. Set the Oscilloscope for 8-division deflection.

6.

Set the reference unit mainframe center frequency to 50.0000001 MHz and note that the Oscilloscope

baseline alternately rises and falls over the 8 division display.

7.

Reset the reference unit mainframe center frequency to 50.000000 MHz at a time that will cause the

Oscilloscope baseline trace to stop at the top graticule line of the CRT.

8.

Repeat steps 6 and 7 until the baseline stops on the top CRT graticule ±1/10 div.

9.

Set the Model 86632A Modulation Section to 1 kHz FM Xl and 75 kHz deviation (75% on the meter).

10. Note the Wave Analyzer reading. Should be >-60 dB down from the reference level.

Meter Readi

dB

4-21

Page 37

Table 4-3. Performance Test Record

Model 86601A

4-22

Page 38

Model 86601A

SECTION V

ADJUSTMENTS

5-1. INTRODUCTION

5-2. This section describes adjustments and checks

required to return the Model 86601A to peak

operating capability when repairs have been made.

Adjustment locations are identified pictorially on

Section VIII foldout service sheets referred to in

the individual tests.

5-3. If repairs to any filter have been made, it

should be necessary to adjust only the circuit in

which the component failure occurred.

5-4. If component failure occurs in any circuit

other than the logic circuits, it will be necessary to

recalibrate the RF output meter circuit (refer to

paragraph 5-14).

5-5. If component failure occurs in A3 or A9, the

AM input and AGC circuits must be readjusted

(refer to paragraph 5-15).

5-6. If component failure occurs in the A6 preamplifier or the A2 Power amplifier (other than

AGC), the harmonic levels should be readjusted

(refer to paragraph 5-16).

5-7. RECOMMENDED TEST EQUIPMENT

5-8. Each adjustment procedure in this section

contains a list of test equipment and accessories

required to perform the procedure. Each test setup

identifies test equipment and accessories by callouts.

5-10. SERVICE KIT

5-11. The HP 11678A Service Kit is an accessory

item av

le from Hewlett-Packard for use in

maintaining the Model 66601A RF Section.

5-12. Table 1-2 contains a detailed description of

the service kit. Any item in the kit may be ordered

separately.

NOTES

a. The RF Section adjustments should

be made with the Model 86601A

installed in the mainframe with the

cover removed whenever possible. It

will be necessary to remove the mainframe top cover and the top guide rail

for the Model 86601A. To make incircuit adjustments for the 480 MHz

Active bandpass filter or the dual

filter (A12), it will be necessary to

use the extender cable

(1167260001) which is part of the

service kit.

b. A modulation section or an auxiliary

t be installed in the main-

frame during these adjustments.

All tests in which a counter

c.

should be made

5-9. Minimum specifications for test equipment

used in the adjustment procedures are detailed in

Table 1-2. Because the Model 86601A is an ex-

nal reference

common source.

5-13. CHECKS AND ADJUSTMENTS

5-1

Page 39

5-14.

Model 86601A

ADJUSTMENTS

m is

Figure 5-1. RF Output Meter Calibration Setup

RECOMMENDED TEST EQUIPMENT:

Test Oscillator

Broadband Sampling voltmeter

BNC Tee Connector

50 ohm load

Extender Cable

Spectrum Analyzer HP 140/8552/8553

5-1

8-21 of Manual Ch

supplement.

ted at +3 and -7 dBm to ensure tracking across the

HP 651B

H 3406A

UG 274 B/U

HP 1250-0207

HP 11672-60001

PROCEDURE:

1.

Clean the Model 86601A meter face with anti-static

factured by Weston Instruments Inc. Newark, NJ.)

2.

Connect the equipment

3.

4.

5.

6.

5-2

(Recommended: STATNUL manu-

t the m

Page 40

Model 86601A

ADJUSTMENTS

5-14. RF OUTPUT METER CALIBRATION (Cont')

7. Connect the Test Oscillator output to the Model 86632A input (10 kHz, 1V, verify level with the AC

Voltmeter). Set the Model 86632A to AM, EXT, AC coupled and 50% modulation as indicated on the

Model 86632A meter.

8. Set the spectrum analyzer so that the 10 MHz center frequency is at the top graticule line. Verify that

the AM sidebands are -12 dB below the center frequency fundamental (50% modulation).

9. Adjust the Model 86601A VERNIER until the fundamental (10 MHz) is 10 dB below the reference

setting. Adjust A1R34 DET for 50% modulation (AM sidebands down -12 dBm from the

fundamental).

10. A9R32 and A2R34 interact. Repeat steps 5 through 9 until the modulation displayed on the spectrum

analyzer remains at 50%.

11. Disconnect the Test Oscillator and set the Model 86632A to OFF. Disconnect the spectrum analyzer

and connect the AC Voltmeter to the Model 86601A OUTPUT.

12. Set the 86601A to +13 dBm as measured by the voltmeter.

13. Adjust A9R32 as necessary for a Model 86601A meter reading of +3 dBm.

14. Turn the Model 86601A VERNIER control CCW until the AC

voltmeter reads +3 dBm (10 dB less

than step 12).

15. Adjust A9R34 for a Model 86601A meter reading of -7 dBm.

16. Repeat steps 11 through 15 until the Model 86601A meter tracks the AC voltmeter, (from +3 dBm to

-7 dBm ± 25 dBrn 86601A Meter).

5-3

Page 41

5-15.

Figure 5-2. Harmonic Distortion Adjustment Setup

RECOMMENDED TEST EQUIPMENT:

Model 86601A

ADJUSTMENTS

Spectrum Analyzer

HP 140/8554L/8552B

PROCEDURE:

1.

Connect the equipment as shown in Figure 5-3.

2.

Set the mainframe center frequency to 60 MHz and the Model 86601A output amplitude to 0 dBm.

3.

Set the Spectrum Analyzer controls as follows: CENTER FREQUENCY - 60 MHz, INPUT

ATTENUATION -

20 dB, LOG REP LEVEL - 0 dBm, BANDWIDTH - 100 kHz, SCAN WIDTH

PER DIVISION - 50 MHz, SCAN TIME PER DIVISION - 10 MILLISECONDS and LOG/LINEAR LOG.

4.

Adjust the preamplifier BIAS (A6R1) and the power amplifier BIAS (A2R6) until the second harmonic

(120 MHz) is more than 50 dB down from the fundamental frequency.

5.

Set the mainframe and the Spectrum Analyzer center frequency to 109 MHz.

6.

Adjust the power amplifier BIAS (A1R6) until the second harmonic (218 MHz) is more than 44 dB

down from the fun mental frequency.

7.

0 M to 10

monic

All

8.

5-4

Page 42

Model 86601A

ADJUSTMENTS

5-15. HARMONIC DISTORTION CHECKS AND ADJUSTMENTS (Cont’d)

Table 5-1. Harmonic Distortion Level Checks

5-16. AMPLITUDE MODULATION CALIBRATION

REFERENCE: Service Sheets 3 and 4.

DESCRIPTION: The AM input and AGC circuits

Modulation Section without recalibration.

properly

-in

5-5

Page 43

ADJUSTMENTS

Model 86601A

Figure 5-3.

Amplitude Modulation Calibration Setup

RECOMMENDED TEST EQUIPMENT:

Precision Attenuator

Test Oscillator

Spectrum Analyzer

High Frequency dB Voltmeter

BNC Tee Connector

HP 140/8553B/8552B

HP H38-355D

HP 651B

HP 400GL

UG 274B/U

PROCEDURE:

Using the 86631A Auxiliary Section. (If the Model 86632A Modulation Section is used, use step 2-a instead

of step 2.)

Connect the equipment as shown in Figure 5-2.

1.

Monitor the output amplitude of the Test Oscillator with the High Frequency dB Voltmeter. Set the

2.

Test Oscillator frequency to 1 kHz and the output amplitude to 0.5 volts rms with the Model 86631

EXTERNAL AM switch to ON.

2-a. Set the Model 86632A to AM mode; source 1 kHz, internal modulation level for 50% AM on the

86632A meter.

3.

Set the mainframe center frequency to 50 MHz, the Model 86601A output amplitude to +13 dBm and

the Precision Attenuator to 20 dB.

4.

5.

5-6

Page 44

Model 86601A

ADJUSTMENTS

5-17. A12 FILTER

REFERENCE:

DESCRIPTION: The bandpass filters in the A12 assembly are adjusted for minimum insertion loss and

maximum flatness over the specified bandwidth.

Figure 5-4. A12A1 Filter Adjustment Setup

RECOMMENDED TEST EQUIPMENT:

Tracking Generator

Spectrum Analyzer

RF Millivoltmeter

Electronic Counter

BNC Tee Connector

HP 140/8554L/8552B

HP 5245M/5253B

HP 8444A

HP 411A

UG 274B/U

PROCEDURE: 500 MHz Bandpass Filter A12A1

1. Remove the A12 Dual Filter assembly from the Model 86601A.

2. Connect the tracking Generator to the Spectrum Analyzer. (Refer to the Tracking Generator Operatin

and Service Manual for interconnections.)

3. Set the Spectrum Analyzer controls as follows: INPUT ATTENUATION - 20 dB, LOG/LINEAR - 10

dB LOG, LOG REF LEVEL - +10 dBm, SCAN WIDTH PER DIVISION -- 20 MHz, SCAN TIME PER

DIVISION - 10 MILLISECONDS and BANDWIDTH - 300 kHz.

4. Connect the Trackin Generator RF OUTPUT to the Counter with the Spectrum Analyzer in the

ZERO scan mode.

5.

ctrum Analyzer center frequency

to 500 MHz

6.

7.

8.

9.

10.

5-7

Page 45

5-17.

11.

Model 86601A

ADJUSTMENTS

Figure 5-5. Preliminary Adjustment Setup (450/460 Bandpass Filter)

Remove the A12 Dual Filter assembly from the Model 86601A.

1.

2.

Connect the Tracking Generator to the Spectrum Analyzer. (Refer to the Tracking Generator

Operating and Service Manual for interconnections.}

3.

Set the Spectrum Analyzer as follows: INPUT ATTENUATION - 20 dB, LOG/LINEAR - 10 dB

LOG, LOG REF LEVEL - 0 dBm, SCAN WIDTH PER DIVISION - 5 MHz, SCAN TIME PER

DIVISION - 5 MILLISECONDS and BANDWIDTH - 300 kHz.

4.

Connect the Tracking Generator RF OUTPUT to the Counter with the Spectrum Analyzer in the

ZERO scan mode.

5.

Set the Spectrum Analyzer center frequency to 455 MHz as displayed on the Counter and disconnect

the Counter.

6.

Set the Tracking Generator LEVEL to -14 dBm as a reference.

7.

Connect the equipment together as shown in Figure 5-5.

8.

Use a screwdriver to short the rotor of C2 to the casting. Adjust Cl for a maximum level on the

Voltmeter.

9.

Short C3 to the castin and adjust C2 for minimum readin on the Voltmeter.

10.

on the Voltmeter.

11.

12.

13.

14.

5-8

Page 46

Model 86601A

ADJUSTMENTS

5-17.

15.

16. Connect the equipment shown in Figure 5-4.

17. Change the Spectrum Analyzer scan mode from ZERO scan to SCAN WIDTH PER DIVISION.

18. Adjust Cl and C7 for minimum insertion loss and maximum flatness. (Insertion loss is approximately 5

dB.)

19. Adjust C2 through C6 for optimum flatness and minimum insertion loss.

20. Record the ripple, insertion loss and roll-off.

Ripple 2 dB maximum peak-to-peak dB

Insertion loss 6 dB maximum

Rolloff

55 dB down at 440 MHz

55 down at 470 MHz dB

5-18. 480 MHz ACTIVE FILTER CHECKS AND ADJUSTMENTS

REFERENCE: Service Sheet 2.

DESCRIPTION: The 480 MHz bandpass filter in the A4 assembly is adjusted for maximum

minimum insertion loss.

dB

- dB

flatness and

Figure 5-6. Active Filter Adjustment Setup

5-9

Page 47

5-19.

1.

Model 86601A

ADJUSTMENTS

2.

3.

4.

5.

6.

Set the Tracking Generator LEVEL to -14 dBm as a reference.

7.

Connect the equipment as shown in Figure 5-6.

8.

m Analyzer frequency to 480 MHz as indicated by the Electronic Counter.

Cl, 2, 3 and 4 for maximum output and maximum flatness across the bandwidth. At 480

tor RF OUTPUT to the Electronic Counter with the Spectrum Analyzer

INPUT ATTENUATION - 20 dB, LOG REF LEVEL

should be greater than or equal to 17 dB. The response curve should rolloff to more than 3

dB down at 477 and 483 MHz.

9.

Record the gain and rolloff.

(Refer to the Trac

.

2 MHz, SCAN TIME PER DIVISION - 10

Gain at 480 MHz

Rolloff at 477 MHz

Roiloff at 483 MHz

dB

dB

dB

5-10

Page 48

Model 86601A

SECTION VI

REPLACEABLE PARTS

6-1. INTR

ION

6-2. Table 6-1 provides correct stock numbers for

use when ordering assemblies on an exchange basis.

These factory-repaired assemblies are available-on

an exchange-for-credit basis at a considerable

savings cost.

6-3. Table 6-2 lists the meanings of the abbreviations and reference designations used in the table

of replaceable parts.

6-4. Table 6-3 lists 86601A replaceable parts in

alpha-numerical order of their reference designation.

6-5. Table 6-4 contains the names and addresses

that correspond to the manufacturers’ code num-

bers.

Table 6-1. Part Numbers for Assembly Exchange Orders

6-6. ORDERI

6-7.

6-8.

If the part

number does not have

a National Stock

through normal ordering channels using

the Hewlett-Packard part number.

6-9.

Refer to table 6-5 for part number

to NSN cross-reference.

6-1

Page 49

Table 6-2. Reference Designators and Abbreviations Used in Parts List

Model 86601A

6-2

Page 50

Model 86601A

Table 6-3. Replaceable Parts

6-3

Page 51

Table 6-3. Replaceable Parts

Model 86601A

6-4

Page 52

Model 86601A

Table 6-3. Replaceable Parts

6-5

Page 53

Table 6-3. Replaceable Parts

Model 86601A

6-6

Page 54

Model 86601A

Table 6-3. Replaceable Parts

6-7

Page 55

Table 6-3. Replaceable Parts

Model 86601A

6-8

Page 56

Model 86601A

Table 6-3. Replaceable Parts

6-9

Page 57

Table 6-3. Replaceable Parts

Model 86601A

6-10

Page 58

Model 86601A

Table 6-3. Replaceable Parts

6-11

Page 59

Table 6-3. Replaceable Parts

Model 86601A

6-12

Page 60

Model 86601A

Table 6-3. Replaceable Parts

6-13

Page 61

Table 6-3. Replaceable Parts

Model 86601A

6-14

Page 62

Model 86601A

Table 6-3. Replaceable Parts

Table 6-4.

Manufacturer’s Code List

6-15

Page 63

TM 11-6425-2837-14&P-6

PART NUMBER-NATIONAL STOCK NUMBER

TABLE 6-5

CROSS REFERENCE INDEX

NATIONAL

STOCK

NUMBER

5910-00-244-7171

5910-01-022-6482

5962-00-252-0225

5962-00-455-1814

5945-00-233-1542

5910-00-195-4107

5910-00-463-5949

5945-00-448-6876

5962-00-865-4625

5962-00-106-4287

5961-00-912-3099

5961-00-350-2205

5910-00-914-2605

5910-00-961-9591

5910-00-497-7598

5910-00-211-1611

5910-00-244-7164

5910-00-195-4107

5910-00-463-5949

5910-00-430-5685

5910-00-885-6540

5910-00-444-6724

5910-00-444-6725

5910-00-883-6281

5910-00-244-7171

5910-00-431-3956

5940-00-138-1326

5910-00-913-0802

5910-01-014-2874

5910-00-348-2617

NATIONAL

STOCK

NUMBER

5910-00-809-4701

5910-00-850-5355

5910-00-719-9907

5910-00-430-6016

5905-00-931-1066

5905-00-974-6075

5905-00-407-0052

5905-00-998-1814

5905-00-828-0388

5905-00-481-1357

5905-00-246-8634

5905-00-974-6081

5905-00-891-4215

5905-00-433-6904

5905-00-858-8927

5905-00-407-0053

5905-00-974-6082

5905-00-407-0075

5905-00-420-7136

5905-0-974-6080

5905-00-828-0377

5905-00-194-0341

5905-00-974-6083

5905-00-078-1548

5905-00-478-2244

5905-00-407-0107

5905-00-161-8921

5905-01-009-7560

5905-00-830-6677

5905-00-972-4907

6-16

5910-00-829-0245

5910-00-027-7069

5905-00-858-9105

5905-00-853-8190

Page 64

TABLE 6-5

PART NUMBER-NATIONAL STOCK NUMBER

CROSS REFERENCE INDEX

TM 11-6425-2837-14&P-6

NATIONAL

STOCK

NUMBER

5905-00-858-8826

5905-00-974-5709

5905-00-981-7475

5905-00-244-7189

5905-00-998-1906

5905-00-412-4036

5905-00-929-7774

5905-00-981-7529

5905-00-405-8091

5905-00-493-0738

5905-00-858-9417

5905-00-412-4037

5905-00-891-4219

5905-00-929-2529

5905-00-990-0303

5905-00-998-1792

NATIONAL

STOCK

NUMBER

5999-00-479-8176

5962-00-138-5248

5962-00-138-5250

5962-00-252-0225

5961-00-927-0845

5961-00-904-2540

5961-00-937-1409

5961-00-137-4608

5961-00-464-4049

5961-00-401-0507

5961-00-400-5973

5961-00-408-9807

5961-00-105-8867

5961-00-978-7468

5961-00-451-8685

5961-00-858-7372

5905-00-981-7530

5905-00-494-4628

5905-00-089-7577

5905-00-904-4412

5905-00-057-8480

5905-00-917-0580

5999-00-08-8444

5950-00-443-9518

5950-00-059-5920

5990-00-937-4420

5990-00-789-3794

5935-00-477-1147

5935-00-434-3040

5935-00-267-2973

5935-00-026-0952

5999-01-079-9981

5961-00-912-3099

5961-00-350-2205

5961-00-954-9182

5961-00-927-0845

5961-00-937-1409

5961-00-400-5973

5961-00-401-0507

5905-00-407-0077

5905-00-407-0078

5905-00-221-7472

5905-00-138-5086

5905-00-476-5797

5905-00-476-5718

5905-00-476-5796

5905-00-470-3420

5905-00-405-7709

6-17

Page 65

TM 11-6425-2837-14&P-6

TABLE 6-5

PART NUMBER-NATIONAL STOCK NUMBER

CROSS REFERENCE INDEX

NATIONAL

STOCK

NUMBER

5935-00-267-2973

5935-00-448-2236

5935-00-138-5209

5970-00-531-7134

5970-00-470-7622

5950-00-475-4996

5950-00-405-3735

5950-00-059-5920

5950-00-431-3216

5950-00-406-6419

6-18

Page 66

Model 86601A

SECTION VII

MANUAL CHANGES

7-1. INTRODUCTION changes listed opposite your instrument serial num-

ber. Perform these changes in the sequence listed.

7-2. This section contains information for adapt-

7-4. Refer to paragraph 7-8 for manual

ing this manual to instruments for which the con- changes pertaining to later aerial

tent does not apply directly. numbered instruments.

7-3. To adapt this manual to your instrument,

refer to Table 7-1 and make all of the manual

Table 7-1. Manual changes by Serial Number

7-5. MANUAL CHANGE INSTRUCT

7-6.

7-7.

Table 7-3.

CHANGE A

Page 8-19, Figure 8-26 (A10 assembly)

CHANGE B

Page 8-17, Figure 8-24 and Table 6-3 (A9 assembly)

CHANGE C

Table 6-3

7-1

Page 67

CHANGE C (Cont'd)

CHANGE D

Table 6-3

number to 1120-1561 (Option 001 1120-1563)

Page 8-17, Figure 8-24 and Table 6-3 (A3 assembly)

R4 to 0757-0442 R:FXD MET F:M 10.0 K OHM 1% 1/8 W.

Page 8-17, Figure 8-24 and Table 6-3 (A9 assembly)

A9R32 to 2100-2522 R:VARCERMET 10K OHM 10% LIN 1/2W.

CHANGE E

Page 8-13, Figure 8-17 (A5 assembly)

Move inductive bead A5A1Z1 from the Base of A5A1Q1 to the Base of A5A1Q2.

Model 86601A

CHANGE F

Page 8-13, Figure 8-17,

Table 6-1 and Table 6-3 (A5 assembly)

Change part number to 86601-60064 and exchange part number to 36601-60114.

Delete: A5J4, A5C3, A5A1C10, ASA1R10, A5A1K1.

Relabel the input to A5J1 CNTRL, change the wire color code to 80 and make the input symbol 4A.

Connect the lead from A5J1 to A1A5R9.

NOTE

strument has serial prefix 110A or 1150A do not make

s in your manual.

CHANGE G

Table 6-3

CHANGE H

Page 8-13, Figure 8-17 and Table 6-1 (A5 assembly)

7-2

Page 68

Model 86601A

CHANGE H (Cont'd)

Page 8-17, Figure 8-24 and Tab

Change part number to 8660

Refer to Figure 7-5 for schematic, Figure 7-6 for component locations and Table 7-2 for replaceable

number to 86601-60102.

Parts.

Page 8-17, Figure 8-24 and Table 6-1 (A3 assembly)

Change part number to 86601-60019 and exchange part number to 86601-60108.

Refer to Figure 7-7 for schematic, Figure 7-8 for component locations and Table 702 for replaceable

parts.

Page 8-13, Figure 8-17 and Table 6-1

Delete the A20 assembly 86601-60066.

CHANGE I

Page 8-13, Figure 8-17 and Table 6-3 (A4 assembly)

Change A4A1 and A4A2 components as follows:

C1 and C4 to 24 pF 0160-2266

C2 to .001 uF 0160-3456

R2 and R6 to 3830 ohms 0698-3153

R4 and R7 to 215 ohms 0698-3441

C5 and C7 to 1000 pF 0160-2327 Q1 and Q2 to 1854-0431

Delete the inductive bead, Z1, part number 9170-0029 from the base lead of A4A2Q2.

Page 5-2, Paragraph 5-14

Substitute the following procedure.

Figure 7-1. RF Output meter Calibration Setup

7-3

Page 69

CHANGE I (Cont'd)

Model 86601A

1.

1A

anti-static solution.

UL” manufactured by Weston Instruments Inc., Newark, NJ.)

2.

BNC Tee connector to the 86601A OUTPUT, the 50 ohm load and the

Broadband

ltmeter as shown in Figure 5-1.

3.

Set the OUTPUT RANGE switch to +10 dBm and the VERNIER full clockwise.

4.

Set the mainframe center frequency to 50 MHz.

5.

EF ADJ control (A9R2) for a +13.5 dBm reading on the Broadband Sampling Voltmeter

6. Adjust the VERNIER control counterclockwise to obtain a reading of +3 dBm on the Broadband

Sampling Voltmeter.

7.

Set the MTR ADJ Contro1 (A9R32) for a reading on the Model 86601A output meter of +13 dBm

8.

Adjust the VERNIER control counterclockwise for a reading on the Model 86601A output meter

-7 dBm.

9.

Set the DET control (A2R34) for a +3 dBm reading on the Broadband Sampling Voltmeter.

10. Repeat steps 5 through 9 until no further adjustment is necessary.

Table 7-2. Assembly-Change Cross Reference Index

7-4

Page 70

Model 86601A

Figure 7-2. Partial Logic Schematic

7-5

Page 71

Model 86601A

Figure 7-3. A5 Modulator Assembly 86601-60001

7-6

Page 72

Model 86601A

Figure 7-4. Modulator Assembly Component Locations

7-7

Page 73

Model 86601A

Figure 7-5. Reference Assembly

7-8

Page 74

Model 86601A

Figure 7-6. Reference Assembly Component Location

7-9

Page 75

Model 86601A

Figure 7-7. Feedback Amplifier

7-10

Page 76

Model 86601A

Figure 7-8. Feedback Amplifier Component Locations

7-11

Page 77

Model 86601A

7-8.

the manual to instruments containing

The manual changes given

imp

manual. Make all ERRATA corrections first and t

number related changes indicated in the table.

Page 1-2, Table 1-1:

“Change the heading “Spurious

Change the heading “Sign

Change the heading “Residual

Page 4-6, paragraph 4-15:

Change the first sentence of

t

AM modes) are at least 80

Page, paragraph 4-16:

Add the following to the SPECIFICATION

Page 4-10, paragraph 4-18:

Page 4-13, Figure 4-11:

Page 6-3, Table 6-3:

Page 6-5 and 6-6, Table 6-3:

Page 6-8, Table 6-3:

7-12

Page 78

Model 86601A

CHANGE 1

Page 6-8:

Page 8-21:

CHANGE 2

CHANGE 3

Page 6-5, Table 6-3:

28480, 0160-3875.

Add to A4A1 miscellaneous, 1200-0172, 2, INSULATOR XSTR TO-18, 28480, 1200-0172.

Add to A4A2 miscellaneous, 1200-0172, 2, INSULATOR XSTR TO-18, 28480, 1200-0172.

Page 6-6, Table 6-3:

Delete A5A1Z1

±5% 200 SVDC CER,

Page 6-8, Table 6-3:

A8R5, R6, R16, R16, R25 and R26 to 0683-0335, RESISTOR 3.3 5% .25W FC TC--400/+500, 01121,

CB33G5.

Page 8-13, Figure 8-13 (Service Sheet 2):

Page 8-21, Figure 8-28:

CHANGE 4

Page 6-1, Table 6-1:

Page 6-9, Table 6-3 and page 8-21, Figure 8-28:

A1C1, A4A1C4, A4A2C1, A4A2C4, A5A1C1, ABA1C4,

7-13

Page 79

Model 86601A

Table 6-3. Replaceable Parts (P/O Errata; Page 1 of 2)

7-14

Page 80

Model 86601A

Table 6-3. Replaceable Parts (P/O Errata; Page 2 of 2)

7-15

Page 81

Model 86601A

Table 6-3. Replaceable Parts (P/O Change 1)

7-15

Page 82

Model 86601A

Figure 8-27. Attenuator Driver Component Locations (P/O Change 1)

7-17

Page 83

Model 86601A

Figure 8-28. Attenuator Driver Assembly (P/O Change 1)

7-18

Page 84

Model 86601A

CHANGE 5

Page 6-8, Table 6-3 and page 8-21, Figure 8-28 (Service Sheet 6):

R30, R39 and R40.

CHANGE 8

Page 5-1:

components are identified on the schematics

y

an asterisk which follows the reference desig-

nator. The normal value of the components are shown. The

Page 5-1:

7-19

Page 85

Model 86601A

Add the following adjustment procedure.

5-19. MODULATOR ASSEMBLY ADJUSTMENT

REFERENCE:

Service Sheet 2.

DESCRIPTION: The fixed dynamic range of the modulator is set so the gain extremes extend beyond

specified limits. The gain extremes are set by selecting resistors with a specific control

voltage input to the modulators.

Figure 5-7. Modulator Assembly Adjustment Test Setup.

7-20

1.

2.

3.

4.

5.

6.

Page 86

Model 86601A

CHANGE 6 (Cont'd)

Set the power supply vol

7.

8.

t the equipment as shown in Figure 5-7.

9.

10.

to +5.0 WC.

t is

the

7-21

Page 87

Model 86601A

CHANGE 6 (Cont'd)

Page 6-5 and 6-6, Table 6-3:

Page 8-13, Figure 8-17 (Service Sheet 2):

Page 8-15, Figure 8-20 (Service Sheet 3):

7-22

Page 88

Model 86601A

Table 6-3. Replaceable Parts (P/O Change 6; 1 of 2)

7-23

Page 89

Model 86601A

Table 6-3. Replaceable Part (P/O Change 6; 2 of 2)

7-24

Page 90

Model 86601A

Figure 6-3.

7-25

Page 91

Model 86601A

Figure 8-1. Model 86601A Simplified Block Diagram

8-0

Page 92

Model 86601A

SECTION VIII

SERVICE

8-1. INTRODUCTION

8-2.

functioning properly.

8-3. PRINCIPLES OF OPERATION

8-4. Figure 8-1, Simplified Block Diagram, and the

following discussion illustrate the basic principles

of the Model 86601A. More detailed information

about principles of operation of the Model 86601A

may be found in the text for Service Sheet 1. In

addition, detailed information to the circuit level is

provided on the individual service sheets.

8-5. The Model 86601A RF Section has no

internal oscillators. The output frequency is

developed by mixing and filtering the precise

digitally controlled rf inputs from the mainframe.

The inputs from the mainframe are:

a.

A 500 MHz signal from the reference

section.

b. A 20 MHz signal from the reference

section which is coupled through the Modulation

Section.

II where it is mixed with the 20 to 30 MHz signal

from the mainframe SL1 Loop to provide a 450 to

460 MHz output. The output of Mixer II is filtered

and amplified, and in the AM mode, modulated

before it is coupled to Mixer III. In Mixer III the

450 to 460 MHz signal is mixed with the 350 to

450 MHz signal to produce the final output

frequency which is between. .01 and 100.999999

MHz (.01 to 109.9999 MHz when option 004

mainframe is used).

8-7. The output of Mixer III is coupled through

two 120 MHz low pass filters and a pre-amplifier to

the power amplifier.

8-8. The power amplifier assembly contains an

Automatic Gain Control circuit which controls a

feedback amplifier in the leveling loop. Code 1 and

Code 2 inputs from the mainframe DCU operate an

electronic band switch to aid in leveling the rf

output across the output range.

8-9. Three attenuators are used to control the

output level of the Model 86601A. These

attenuators function as follows:

a.

In the local mode a 150 dB programmable

attenuator, OUTPUT RANGE, controls the output

level from +10 dBm to -140 dBm in 10 dB steps.

A VERNIER control adds the capability of setting

the output level to +13 dBm and to other points

between the 10 dB steps.

NOTE

In the FM mode the 20 MHz signal is

generated in the tion tion.

b. In the remote mode the 150 dB

remotely controlled

s (OUTPUT RANGE

ive. A1 dB per step

the Model 86601A is

t the output level

e 150 dB attenuator.

8-10.0 RECOMMENDED TEST EQUIPMENT

8-11.

8-12. TROUBLESHOOTING

8-13.

8-1

Page 93

Model 86601A

Figure 8-2. Diagram of Module Exchange Program

8-3

Page 94

Model 86601A

Service

SECTION VIII

SERVICE

8-1. INTRODUCTION

8-2. This section provides instructions for testing,

troubleshooting and repairing the Hewlett-Packard

Model 86601A RF Section.

Information

throughout this section is based on the assumption

that the Model 86601A is interconnected with a

Model 8660 Synthesized Signal Generator that is

functioning properly.

8-3. PRINCIPLES OF OPERATION

8-4. Figure 8-1, Simplified Block Diagram, and the

following discussion illustrate the basic principles

of the Model 86601A. More detailed information

about principles of operation of the Model 86601A

may be found in the text for Service Sheet 1. In

addition, detailed information to the circuit level is

provided on the individual service sheets.

8-5. The Model 86601A RF Section has no

II where it is mixed with the 20 to 30 MHz signal

from the mainframe SL1 Loop to provide a 450 to

460 MHz output. The output of Mixer II is filtered

and amplified, and in the AM mode, modulated

before it is coupled to Mixer III. In Mixer III the

450 to 460 MHz signal is mixed with the 350 to

450 MHz signal to produce the final output

frequency which is between. .01 and 109.999999

MHz (01 to 109.9999 MHz when option 004

mainframe is used).

8-7. The output of Mixer III is coupled through

two 120 MHz low pass filters and a pre-amplifier to

the power amplifier.

8-8. The power amplifier assembly contains an

Automatic Gain Control circuit which controls a

feedback amplifier in the leveling loop. Code 1 and

Code 2 inputs from the mainframe DCU operate an

electronic band switch to aid in levelin

output across the output range.

8-9. Three attenuators are used to control the

output level of the Model 86601A. These

nuators function as follows:

8-6.

8-10. RECOMMENDED TEST EQUIPMENT

8-11.

8-12. TROUBLESHOOTING

8-13.

8-1

Page 95

Service

Model 86601A

8-14. The first maintenance level is designed to

utilize the Hewlett-Packard Module Exchange

Program. A troubleshooting tree enables a

relatively inexperienced technician to isolate the

cause of a malfunction to a circuit board or

assembly. A factory-repaired replacement for the

defective circuit board or assembly may be ordered

through the nearest HP Sales and Service office

using the special part numbers listed in Table 6-1.

Refer to paragraph 8-18 and to figure 8-2 for

additional information relative to the Module

Exchange Program.

8-15. The second maintenance level involves

repairing the instrument to the component level.

The troubleshooting tree, in addition to aiding in

the detection of faulty circuit boards or assemblies,

also refers the technician to the appropriate service

sheets to be used if repairs are to be accomplished

to the component level. Circuit descriptions and

test procedures for this maintenance level are

located on the page facing the schematic diagram

of the circuit to be repaired.

8-16. If the cause of a malfunction is found and

remedied in any circuit contianin

adjustable

components, the applicable adjustment procedure

in Section V of this manual should be performed.

NOTE

Do not send a defective module to the HP

office until the replacement module is

received.

8-22. Voltage Requirements. All power required to

operate the Model 86601A is provided by the main-

frame.

8-23. Servicing Aids on

Prin

Circuit Boards.

Servicing aids on printed circuit boards include

test points, transistor and integrated circuit reference designations, adjustment callouts and assembly stock numbers.

8-24. Circuit Board Extenders. Circuit board extenders are provided with the mainframe. These

extender boards enable the technician to extend

plug-in boards clear of the assembly to provide

easy access to components and test points. See

Figure 8-3 for a typical example of extender board

Use.

8-25.

otes. Table 8-1, Schematic

ovides information relative

ls

and values shown on the schematic

8-17. REPAIR

8-18. Module Exchange.

8-19.

8-20.

8-21.

8-26. Part Location Aids.

8-27.

8-28.

8-2

Page 96

Model 86601A

Figure 8-2. Diagram of Module Exchange Program

8-3

Page 97

Model 86601A

8-4

Figure 8-3.

Page 98

Model 86601A

Service

Table 8-1. Schematic Diagram Notes

Inductance is in microhenries, Resistance is in ohms and Capacitance IS in microfarads unless

otherwise noted.

part of

Screwdriver Adjustment

Encloses Front Panel

designations

Panel Control

Encloses Rear Panel

designations

Circuit assembly borderline

Other assembly borderline

Wiper moves toward CW with clockwise rotation of control as viewed from shaft or knob.

Numbers in stars on circuit assemblies show locations of test points

Encloses WIPE color

8-5

Page 99

Model 86601A

8-6

Figure 8-4.

Page 100

Model 86601A

Table 8-2. Assembly Locations

Figure 8-5.

Loading...

Loading...