Page 1

User’s Guide

HP 83487A Optical/Electrical Plug-In Module

Page 2

© Copyright Hewlett-Packard

Company 1999

All Rights Reserved. Reproduction, adaptation, or translation without prior written

permission is prohibited,

except as allowed under copyright laws.

HP Part No. 83487-90018

Printed in USA

June 1999

Hewlett-Packard Company

Lightwave Operations

1400 Fountaingrove Parkway

Santa Rosa, CA 95403-1799,

USA

(707) 577-1400

Notice.

The information contained in

this document is subject to

change without notice. Companies, names, and data used

in examples herein are fictitious unless otherwise noted.

Hewlett-Packard makes no

warranty of any kind with

regard to this material, including but not limited to, the

implied warranties of merchantability and fitness for a

particular purpose. HewlettPackard shall not be liable for

errors contained herein or for

incidental or consequential

damages in connection with

the furnishing, performance,

or use of this material.

Restricted Rights Legend.

Use, duplication, or disclosure by the U.S. Government

is subject to restrictions as set

forth in subparagraph (c) (1)

(ii) of the Rights in Technical

Data and Computer Software

clause at DFARS 252.227-7013

for DOD agencies, and subparagraphs (c) (1) and (c) (2)

of the Commercial Computer

Software Restricted Rights

clause at FAR 52.227-19 for

other agencies.

Warranty.

This Hewlett-Packard instrument product is warranted

against defects in material and

workmanship for a period of

one year from date of shipment. During the warranty

period, Hewlett-Packard Company will, at its option, either

repair or replace products

which prove to be defective.

For warranty service or repair,

this product must be returned

to a service facility designated by Hewlett-Packard.

Buyer shall prepay shipping

charges to Hewlett-Packard

and Hewlett-Packard shall pay

shipping charges to return the

product to Buyer. However,

Buyer shall pay all shipping

charges, duties, and taxes for

products returned to HewlettPackard from another country.

Hewlett-Packard warrants

that its software and firmware

designated by Hewlett-Packard for use with an instrument

will execute its programming

instructions when properly

installed on that instrument.

Hewlett-Packard does not

warrant that the operation of

the instrument, or software,

or firmware will be uninterrupted or error-free.

Limitation of Warranty.

The foregoing warranty shall

not apply to defects resulting

from improper or inadequate

maintenance by Buyer, Buyersupplied software or interfacing, unauthorized modification or misuse, operation

outside of the environmental

specifications for the product,

or improper site preparation

or maintenance.

No other warranty is

expressed or implied.

Hewlett-Packard specifically

disclaims the implied warranties of merchantability and fitness for a particular purpose.

Exclusive Remedies.

The remedies provided herein

are buyer's sole and exclusive

remedies. Hewlett-Packard

shall not be liable for any

direct, indirect, special, incidental, or consequential damages, whether based on

contract, tort, or any other

legal theory.

Safety Symbols.

CAUTION

The

hazard. It calls attention to a

procedure which, if not correctly performed or adhered

to, could result in damage to

or destruction of the product.

Do not proceed beyond a caution sign until the indicated

conditions are fully understood and met.

WAR NI NG

The

hazard. It calls attention to a

procedure which, if not correctly performed or adhered

to, could result in injury or

loss of life. Do not proceed

beyond a warning sign until

the indicated conditions are

fully understood and met.

sign denotes a

caution

warning

sign denotes a

The instruction manual symbol. The product is marked with this

warning symbol when

it is necessary for the

user to refer to the

instructions in the

manual.

The laser radiation

symbol. This warning

symbol is marked on

products which have a

laser output.

The AC symbol is used

to indicate the

required nature of the

line module input

power.

The ON symbols are

|

used to mark the positions of the instrument

power line switch.

The OFF symbols

❍

are used to mark the

positions of the instrument power line

switch.

The CE mark is a registered trademark of

the European Community.

The CSA mark is a registered trademark of

the Canadian Standards Association.

The C-Tick mark is a

registered trademark

of the Australian Spectrum Management

Agency.

This text denotes the

ISM1-A

instrument is an

Industrial Scientific

and Medical Group 1

Class A product.

ii

Page 3

The HP 83487A—At a Glance

The HP 83487A—At a Glance

The HP 83487A optical/electrical plug-in module is one of several plug-in modules available for the HP 83480A, 54750A mainframes. The main features of

the HP 83487A are:

• Integrated, calibrated optical channel.

• 2.85 GHz optical channel bandwidth and user selectable 12.4 or 20 GHz

electrical channel bandwidth.

• 750 nm to 860 nm wavelength range.

• Optical channel has 1063/1250 Mb/s datacom filters.

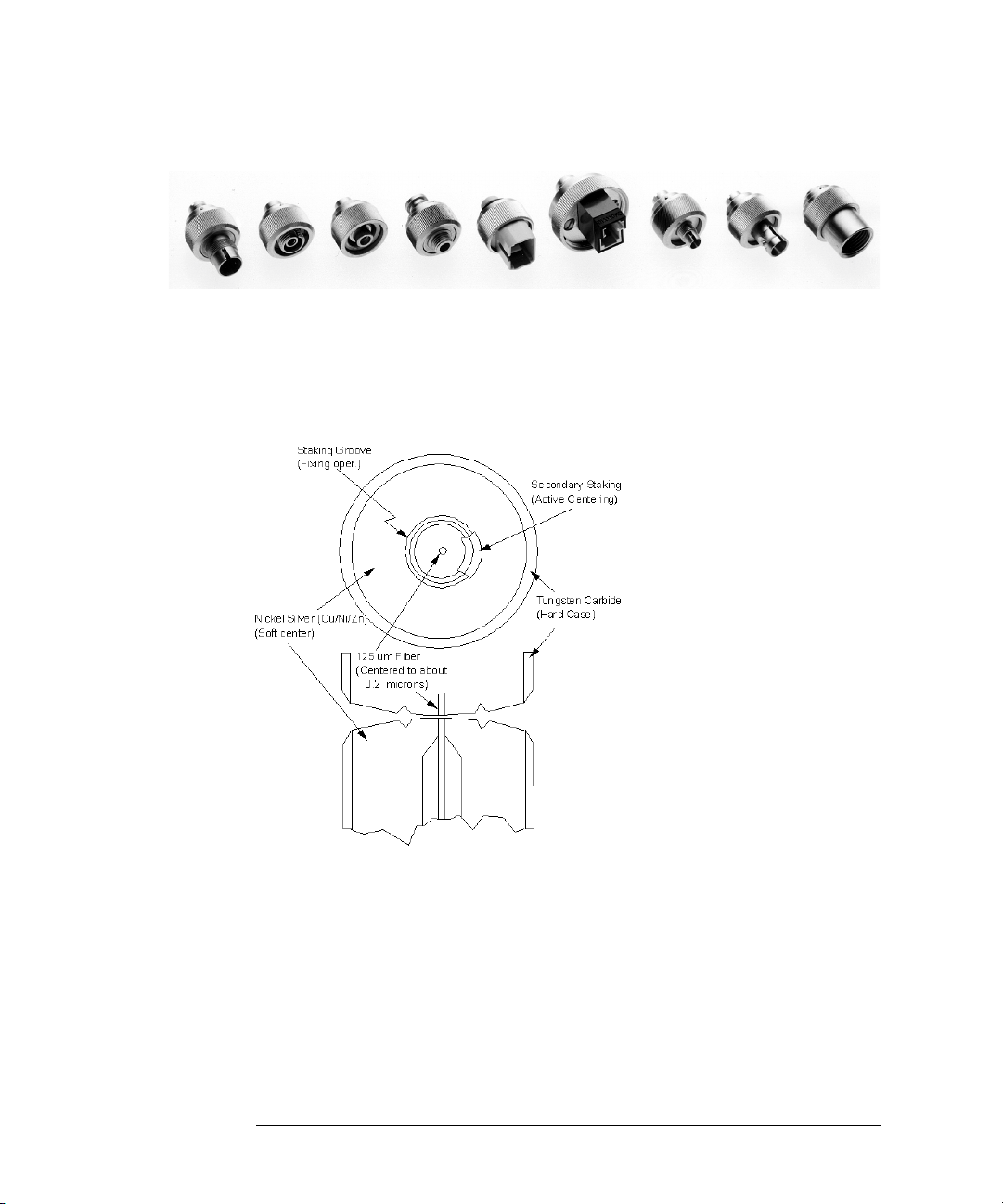

• 62.5/125 µm (maximum) multimode, user selectable optical input connector

option.

• Electrical measurement channel.

• Trigger channel input to the mainframe.

• 3.5 mm (m) connectors on the electrical measurement channel and trigger

channel.

• One probe power connector.

• One auxiliary power connector.

NOTE

If you wish to use the HP 83487A optical plug-in module in an HP 54750A digitizing

oscilloscope, a firmware upgrade must first be installed. Order the HP 83480K communications firmware kit and follow the installation instructions.

The purpose of the plug-in module is to provide measurement channels,

including sampling, for the mainframe. The plug-in module scales the input

signal, sets the bandwidth of the system, and allows the offset to be adjusted

so the signal can be viewed. The output of the plug-in module is an analog signal that is applied to the ADCs on the acquisition boards inside the mainframe.

The plug-in module also provides a trigger signal input to the time base/trigger

board inside the mainframe.

For HP-IB programming information, refer to the

grammer’s Guide

supplied with the mainframe.

HP 83480A, 54750A Pro-

iii

Page 4

Measurement Accuracy

Measurement Accuracy

To ensure that you obtain the specified accuracy, you must perform a plug-in

module vertical calibration. The calibration must also be performed when you

move a plug-in module from one slot to another, or from one mainframe to

another. Refer to Chapter 3, “Calibration Overview” for information on performing a plug-in module vertical calibration.

CAUTION

The HP 83487A optical/electrical plug-in module input circuitry can be

damaged when the

optical channel or ±2 V + peak ac (+16 dBm) on the electrical channel. To

prevent input damage, this specified level must not be exceeded.

Measurement accuracy—it’s up to you!

Fiber-optic connectors are easily damaged when connected to dirty or damaged cables

and accessories. The HP 83487A optical/electrical plug-in module’s front-panel INPUT

connector is no exception. When you use improper cleaning and handling techniques,

you risk expensive instrument repairs, damaged cables, and compromised measurements.

Before you connect any fiber-optic cable to the HP 83487A optical/electrical plug-in

module, refer to “Cleaning Connections for Accurate Measurements” on page 5-14.

total

input power levels exceed +10 dBm (10 mW) on the

iv

Page 5

General Safety Considerations

General Safety Considerations

This product has been designed and tested in accordance with IEC Publication 1010, Safety Requirements for Electronic Measuring Apparatus, and has

been supplied in a safe condition. The instruction documentation contains

information and warnings which must be followed by the user to ensure safe

operation and to maintain the product in a safe condition.

WARNING

WARNING

WARNING

WARNING

CAUTION

There are many points in the instrument which can, if contacted, cause

personal injury. Be extremely careful. Any adjustments or service

procedures that require operation of the instrument with protective

covers removed should be performed only by trained service

personnel.

If this instrument is not used as specified, the protection provided by

the equipment could be impaired. This instrument must be used in a

normal condition (in which all means for protection are intact) only.

There are many points in the system which can, if contacted, cause

personal injury. Be extremely careful. Any adjustments or service

procedures that require operation of the system with protective

covers removed should be performed only by Hewlett-Packard

personnel.

NO OPERATOR SERVICEABLE PARTS INSIDE. Refer servicing to

qualified Hewlett-Packard personnel. To prevent electrical shock, do

not remove covers.

Before this instrument is switched on,

has been adapted to the voltage of the ac power source. Failure to set the ac

power input to the correct voltage could cause damage to the instrument when

the ac power cable is plugged in.

make sure its primary power circuitry

CAUTION

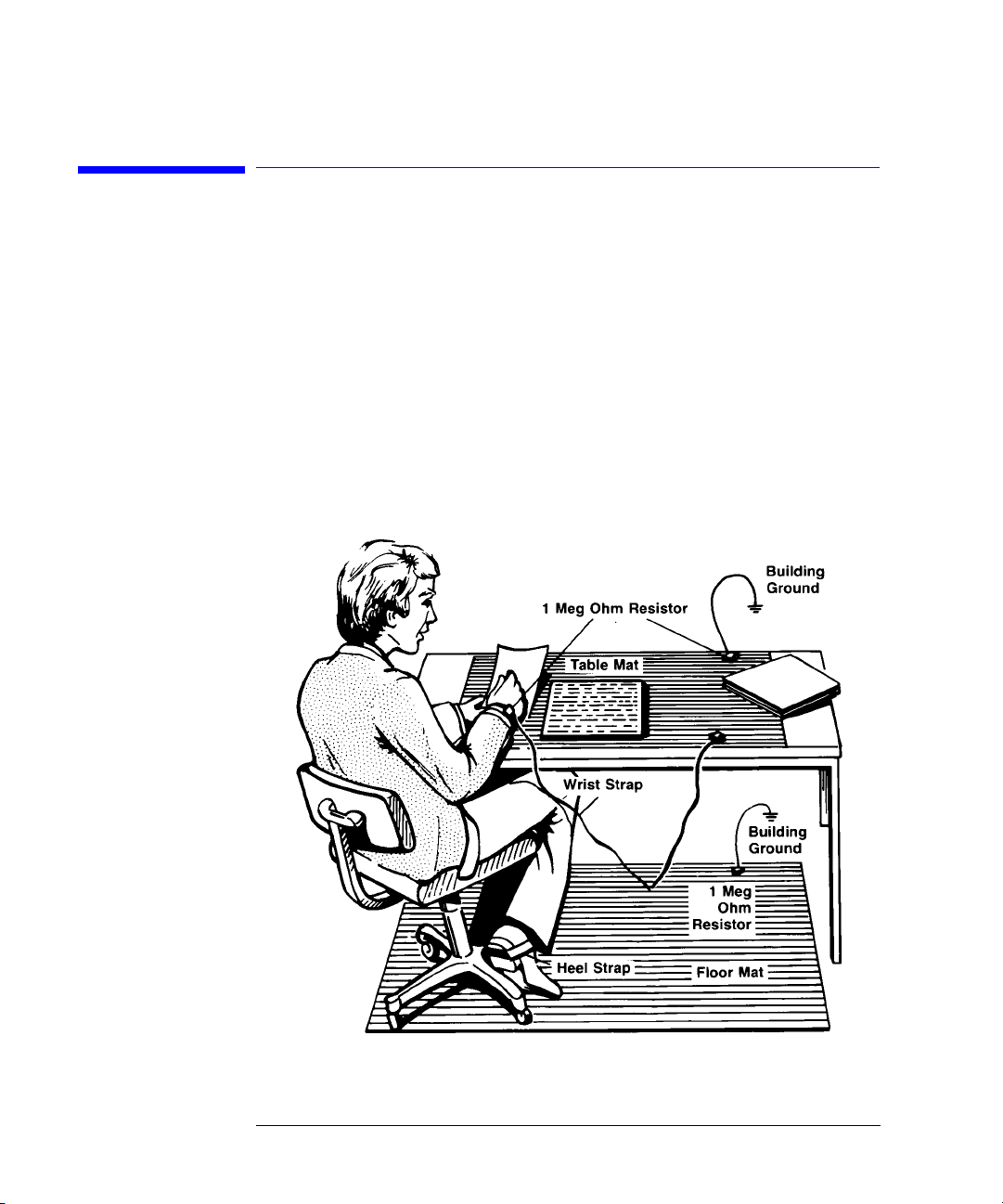

Electrostatic discharge (ESD) on or near input connectors can damage circuits

inside the instrument. Repair of damage due to misuse is

warranty. Before connecting any cable to the electrical input, momentarily

short the center and outer conductors of the cable together. Personnel should

be properly grounded, and should touch the frame of the instrument before

touching any connector.

not

covered under

v

Page 6

General Safety Considerations

vi

Page 7

Contents

The HP 83487A—At a Glance iii

1 Getting Started

The HP 83487A Optical/Electrical Plug-In Module 1-3

Options and Accessories 1-7

Menu and Key Conventions 1-9

Step 1. Inspect the Shipment 1-10

Step 2. Install the Plug-in Module 1-11

Returning the Instrument for Service 1-12

2 Channel Setup Menu

Channel Setup Menu 2-2

Displaying the Channel Setup Menus 2-5

3 Calibration Overview

Factory Calibrations 3-4

User Calibrations—Optical and Electrical 3-7

Complete Calibration Summary 3-19

4 Specifications and Regulatory Information

Specifications 4-3

Characteristics 4-8

Declaration of Conformity 4-9

5 Reference

In Case of Difficulty 5-2

Measuring High Power Waveforms 5-6

Error Messages 5-10

Electrostatic Discharge Information 5-12

Cleaning Connections for Accurate Measurements 5-14

Hewlett-Packard Sales and Service Offices 5-25

Contents-1

Page 8

Contents

Contents-2

Page 9

1

The HP 83487A Optical/Electrical Plug-In Module 1-3

Options and Accessories 1-7

Menu and Key Conventions 1-9

Step 1. Inspect the Shipment 1-10

Step 2. Install the Plug-in Module 1-11

Returning the Instrument for Service 1-12

Getting Started

Page 10

Getting Started

Getting Started

Getting Started

This chapter gives a description of the plug-in module, lists options and accessories, explains menu and key conventions used, shows how to install your

HP 83487A optical/electrical plug-in module, and gives information for returning the plug-in module for service.

Refer to Chapter 2, “Channel Setup Menu” for information on operating the

plug-in module.

Refer to Chapter 3, “Calibration Overview” for calibration information.

Refer to Chapter 4, “Specifications and Regulatory Information” for information on operating conditions, such as temperature.

CAUTION

CAUTION

This product is designed for use in INSTALLATION CATEGORY II and

POLLUTION DEGREE 2, per IEC 1010 and 664 respectively.

The input circuits can be damaged by electrostatic discharge (ESD).

Therefore, avoid applying static discharges to the front-panel input connectors.

Before connecting any coaxial cable to the connectors, momentarily short the

center and outer conductors of the cable together. Avoid touching the frontpanel input connectors without first touching the frame of the instrument. Be

sure that the instrument is properly earth-grounded to prevent buildup of

static charge. Refer to “Electrostatic Discharge Information” on page 5-12.

1-2

Page 11

Getting Started

The HP 83487A Optical/Electrical Plug-In Module

The HP 83487A Optical/Electrical Plug-In

Module

The HP 83487A optical/electrical plug-in module incorporates two measurement channels, one optical and one electrical. The electrical channel has two

selectable bandwidth settings. In the lower bandwidth mode of 12.4 GHz,

oscilloscope noise performance is excellent, while the 20 GHz mode allows

greater fidelity for high speed signals. The calibrated, integrated optical channel has over 2.85 GHz bandwidth and allows easy, precise measurements of

single-mode or multimode optical signals.

The integrated optical channel reduces electrical mismatch loss variation by

eliminating signal distorting cables and connectors associated with the use of

external receivers in order to accurately characterize optical waveforms. The

optical channel is calibrated to provide both accurate display of the received

optical waveform in optical power units and measurement of the signal’s average power. In addition, the User Cal feature provides for consistent accuracy

at any wavelength between 750 nm and 860 nm using a source and power

meter.

The HP 83487A optical/electrical plug-in module also is a calibrated reference

receiver that is measured to conform to specifications for Fibre Channel (FC)

1063 and Gigabit Ethernet for transmitter compliance testing. By pressing a

front-panel key or issuing an HP-IB command, a filter is inserted or removed

from the measurement channel by a very repeatable HP microwave switch.

The switch removes the potential variability and the time wasted by manually

inserting and removing the filter, and maximizes measurement repeatability.

The electrical measurement channel may be used to perform measurements

on tributary electrical signals, to evaluate receiver performance in transceiver

testing, for measurements with HP’s wide range of external optical receivers,

or for general purpose measurements.

1-3

Page 12

Getting Started

The HP 83487A Optical/Electrical Plug-In Module

The HP 83487A optical/electrical plug-in module provides:

• 2.85 GHz, integrated, calibrated optical channel with sensitivity to below

–17 dBm

• 12.4 GHz and 20 GHz electrical channel

• Trigger channel input to the mainframe

• Switchable reference filters for transceiver compliance testing

• Compliance testing at Fibre Channel 1063 and Gigabit Ethernet 1250 rates

• Measurement capability for single-mode or multimode optical signals

1-4

Page 13

Getting Started

The HP 83487A Optical/Electrical Plug-In Module

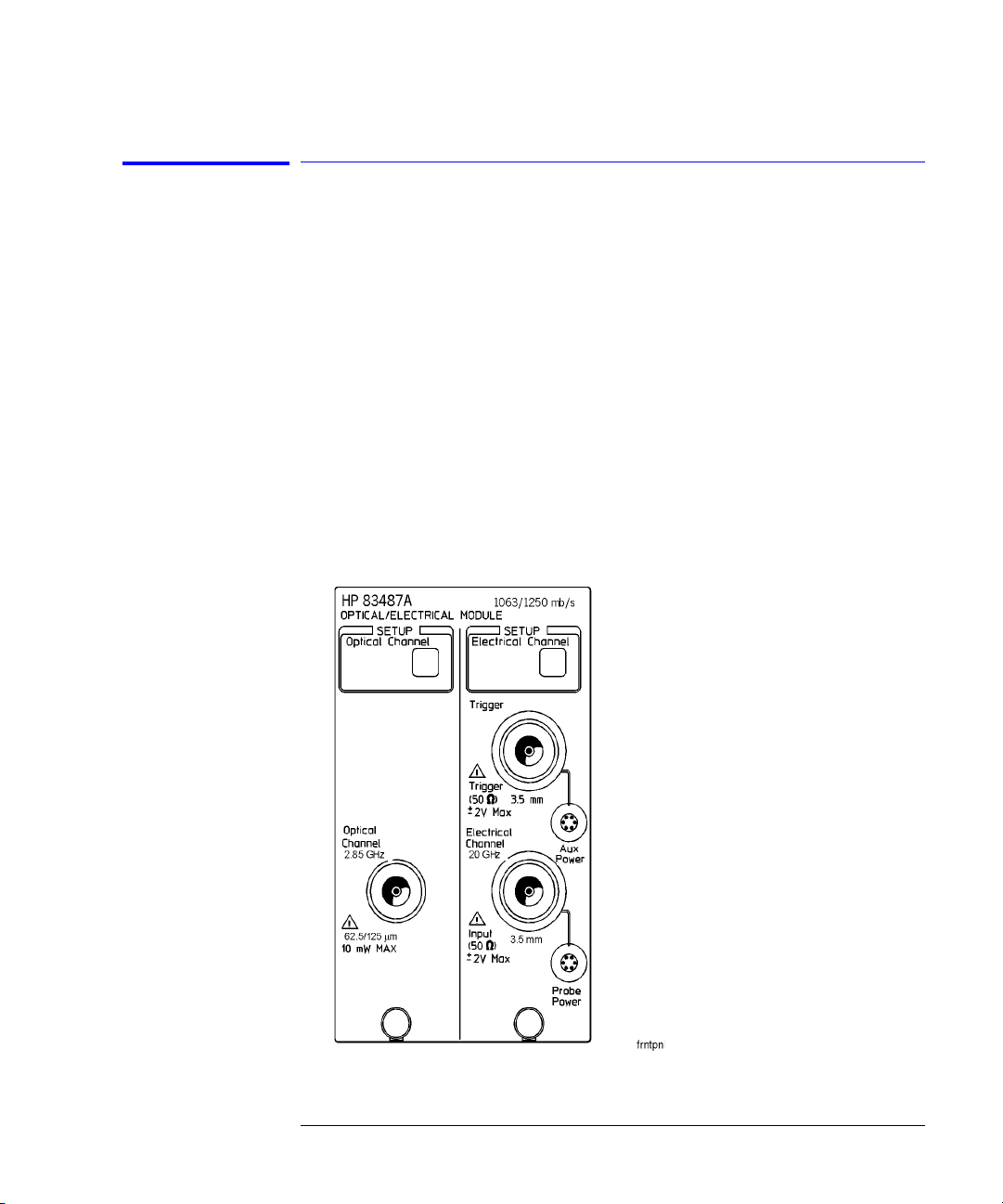

Front panel of the plug-in module

The plug-in module takes up two of the four mainframe slots. The optical

channel provides calibrated measurement of optical waveforms in power

units. The electrical channel provides calibrated measurement of electrical

signals in volts. Bandwidths are selectable on both channels to optimize sensitivity and bandwidth.

The front panel of the plug-in module has two channel inputs and an external

trigger input. The front panel also has a

series probes, an

each channel that displays the softkey menu. The softkey menu allows you to

access the channel setup features of the plug-in module.

The front-power

probe calibration with HP 54700 series probes. The front-panel

nector provides only power to HP 54700 series probes for use as a trigger

input. Probe calibration and scaling are not required for a trigger input.

Aux Power

Probe Power

connector for general purpose use, and a key for

connector allows automatic channel scaling and

Probe Power

connector for HP 54700-

Aux Power

con-

Front panel of the plug-in module.

1-5

Page 14

Getting Started

The HP 83487A Optical/Electrical Plug-In Module

Trigger

The external trigger level range for this plug-in module is ±1 V. The trigger

source selection depends on the plug-in module location. For example, if the

plug-in module is installed in slots 1 and 2, then the trigger source is listed as

trigger 2. If it is installed in slots 3 and 4, then the trigger source is listed as

trigger 4.

CAUTION

CAUTION

The maximum safe input voltage is ±2 V + peak ac (+16 dBm).

The input circuits can be damaged by electrostatic discharge (ESD).

Therefore, avoid applying static discharges to the front-panel input connectors.

Before connecting any coaxial cable to the connectors, momentarily short the

center and outer conductors of the cable together. Avoid touching the frontpanel input connectors without first touching the frame of the instrument. Be

sure that the instrument is properly earth-grounded to prevent buildup of

static charge. Refer to “Electrostatic Discharge Information” on page 5-12.

1-6

Page 15

Options and Accessories

Getting Started

Options and Accessories

Options

Optional

accessories

Option 0B1 Additional set of user documentation

Option 0B0 Deletes the user documentation

Option UK6 Measured performance data

Option 001 Latest version of operating firmware for the HP 83480A

Option 002 Latest version of operating firmware for the HP 54750A

Option 011 Diamond HMS-10/HP connector interface

Option 012 FC/PC connector adapter

Option 013 DIN connector adapter

Option 014 ST connector adapter

Option 015 Biconic connector adapter

Option 017 SC connector adapter

Option 041 1063 and 1250 Mb/s switchable internal filters

HP 10086A ECL terminator

HP 11982A high-speed lightwave receiver

HP 54006A 6 GHz divider probe

HP 54008A 22 ns delay line

HP 54118A 500 MHz to 18 GHz trigger

HP 83430A lightwave digital source

HP 83440B/C/D high-speed lightwave receiver

HP 83446A/B lightwave clock and data receiver

HP 83447A lightwave trigger receiver

83487-60006 FC/PC 5 dB (mm) 850 nm attenuator and patchcord

83487-60007 ST 5 dB (mm) 850 nm attenuator and patchcord

83487-60008 SC 5 dB (mm) 850 nm attenuator and patchcord

Connection

devices

SMA (f-f) adapter, HP part number 1250-1158

APC 3.5 (f-f) adapter, HP part number 1250-1749

HP 81000FI FC/PC/SPC/APC connector interface

HP 81000KI SC connector interface

1-7

Page 16

Getting Started

Options and Accessories

HP 81000SI DIN 47256/4108.6 connector interface

HP 81000VI ST connector interface

HP 81000WI Biconic

1-8

Page 17

Getting Started

Menu and Key Conventions

Menu and Key Conventions

The keys labeled Trigger, Disk, and Run are all examples of front-panel keys.

Some front-panel keys bring up menus on the right side of the display screen.

These menus are called softkey menus.

Softkey menus contain functions not available directly by pressing the frontpanel keys. To activate a function on the softkey menu, press the unlabeled

key immediately next to the annotation on the screen. The unlabeled keys

next to the annotations on the display are called softkeys.

Additional functions are listed in blue type above and below some of the frontpanel keys. These functions are called shifted functions. To activate a shifted

function, press the blue front-panel

the desired function.

Throughout this manual front-panel keys are indicated as, for example,

base

. Softkeys are indicated as, for example,

depend on the front-panel key pressed and which menu is selected. Shifted

functions are indicated by the front-panel

the Local function (above the

Shift, Local

A softkey with On and Off in its label can be used to turn the softkey’s function

on or off. To turn the function on, press the softkey so that On is highlighted.

To turn the function off, press the softkey so that

Off softkey function will be indicated throughout this manual as, for example,

Te s t On

A softkey such as

case, you could choose

lighted, or choose

choices softkey will be indicated throughout this manual as, for example,

Sweep Triggered Freerun Triggered

When some softkeys, such as

surement will be made and the result will be provided. Some softkeys, such as

Offset

the general purpose knob located below the front-panel

.

.

Sweep Triggered Freerun

Triggered

Freerun

by pressing the softkey until

, require the entry of a numeric value. To enter or change the value, use

Shift

key and the front-panel key next to

Mask Align

Shift

key followed by, for example,

Stop/Single

by pressing the softkey until

.

Calibrate probe

front-panel key) and will be shown as

offers you a choice of functions. In this

, are pressed the first time, a mea-

. The softkeys displayed

Off

is highlighted. An On or

Freerun

Triggered

is highlighted. A

Measure

section.

Tim e-

is high-

1-9

Page 18

Getting Started

Step 1. Inspect the Shipment

Step 1. Inspect the Shipment

1

Verify that all system components ordered have arrived by comparing the

shipping forms to the original purchase order. Inspect all shipping containers.

The shipment includes:

• HP 83487A optical/electrical plug-in module with the ordered options and

adapters.

• 5 dB optical attenuator and patch cord, 1 each

• APC 3.5 (f-f) adapter, HP part number 5061-5311, 2 each

• SMA 50Ω termination, HP part number 1810-0118, 2 each

If your shipment is damaged or incomplete, save the packing materials and

notify both the shipping carrier and the nearest Hewlett-Packard Sales and

Service office. HP will arrange for repair or replacement of damaged or incomplete shipments without waiting for a settlement from the transportation company. Notify the HP customer engineer of any problems.

2

Make sure that the serial number and options listed on the instrument’s rearpanel label match the serial number and options listed on the shipping

document.

1-10

Page 19

Step 2. Install the Plug-in Module

Step 2. Install the Plug-in Module

Getting Started

CAUTION

You do

modules.

The plug-in module can be installed in slots 1 and 2 or 3 and 4 on the

HP 83480A or HP 54750A mainframe. The plug-in module will

it is installed in slots 2 and 3.

To make sure the analyzer meets all of the published specifications, there

must be a good ground connection from the plug-in module to the mainframe.

The RF connectors on the rear of the plug-in module are spring-loaded, so finger-tighten the knurled screw on the front panel of the plug-in module to

make sure the plug-in is securely seated in the mainframe.

Do not use non-HP extender cables to operate the plug-in module outside of

the mainframe. The plug-in module can be damaged by improper grounding

when using extender cables.

not

need to turn off the mainframe to install or remove the plug-in

Note

If you wish to use the HP 83487A optical/electrical plug-in module in an HP 54750A digitizing oscilloscope, a firmware upgrade must first be installed. Order the HP 83480K

communications firmware kit and follow the installation instructions.

not

function if

Note

Use of the HP 83487A requires that firmware revision A.06.0 or later be installed in the

HP 83480A or HP 54750A mainframe.

1-11

Page 20

Getting Started

Returning the Instrument for Service

Returning the Instrument for Service

The instructions in this section show you how to properly return the instrument for repair or calibration. Always call the HP Instrument Support Center

first to initiate service

This ensures that the repair (or calibration) can be properly tracked and that

your instrument will be returned to you as quickly as possible. Call this number regardless of where you are located. Refer to “Hewlett-Packard Sales and

Service Offices” on page 5-25 for a list of service offices.

HP Instrument Support Center . . . . . . . . . . . . . . . . . . . . . . . . . .(800) 403-0801

If the instrument is still under warranty or is covered by an HP maintenance

contract, it will be repaired under the terms of the warranty or contract (the

warranty is at the front of this manual). If the instrument is no longer under

warranty or is not covered by an HP maintenance plan, Hewlett-Packard will

notify you of the cost of the repair after examining the unit.

When an instrument is returned to a Hewlett-Packard service office for servicing, it must be adequately packaged and have a complete description of the

failure symptoms attached. When describing the failure, please be as specific

as possible about the nature of the problem. Include copies of additional failure information (such as the instrument failure settings, data related to instrument failure, and error messages) along with the original cal data disks and

the instrument being returned.

before

returning your instrument to a service office.

1-12

Page 21

Getting Started

Returning the Instrument for Service

Preparing the instrument for shipping

1

Write a complete description of the failure and attach it to the instrument.

Include any specific performance details related to the problem. The following

information should be returned with the instrument.

• Type of service required.

• Date instrument was returned for repair.

• Description of the problem:

• Whether problem is constant or intermittent.

• Whether instrument is temperature-sensitive.

• Whether instrument is vibration-sensitive.

• Instrument settings required to reproduce the problem.

• Performance data.

• Company name and return address.

• Name and phone number of technical contact person.

• Model number of returned instrument.

• Full serial number of returned instrument.

• List of any accessories returned with instrument.

• The original cal data disks.

CAUTION

CAUTION

2

Cover all front or rear-panel connectors that were originally covered when you

first received the instrument.

Cover electrical connectors to protect sensitive components from electrostatic

damage. Cover optical connectors to protect them from damage due to physical

contact or dust.

Instrument damage can result from using packaging materials other than the

original materials. Never use styrene pellets as packaging material. They do not

adequately cushion the instrument or prevent it from shifting in the carton.

They may also cause instrument damage by generating static electricity.

3

Pack the instrument in the original shipping containers. Original materials are

available through any Hewlett-Packard office. Or, use the following guidelines:

• Wrap the instrument in antistatic plastic to reduce the possibility of damage

caused by electrostatic discharge.

• For instruments weighing less than 54 kg (120 lb), use a double-walled, corrugated cardboard carton of 159 kg (350 lb) test strength.

1-13

Page 22

Getting Started

Returning the Instrument for Service

• The carton must be large enough to allow approximately 7 cm (3 inches) on

all sides of the instrument for packing material, and strong enough to accommodate the weight of the instrument.

• Surround the equipment with approximately 7 cm (3 inches) of packing material, to protect the instrument and prevent it from moving in the carton. If

packing foam is not available, the best alternative is S.D-240 Air Cap™ from

Sealed Air Corporation (Commerce, California 90001). Air Cap looks like a

plastic sheet filled with air bubbles. Use the pink (antistatic) Air Cap™ to

reduce static electricity. Wrapping the instrument several times in this material will protect the instrument and prevent it from moving in the carton.

4

Seal the carton with strong nylon adhesive tape.

5

Mark the carton “FRAGILE, HANDLE WITH CARE”.

6

Retain copies of all shipping papers.

1-14

Page 23

2

Channel Setup Menu 2-2

Displaying the Channel Setup Menus 2-5

Channel Setup Menu

Page 24

Channel Setup Menu

Channel Setup Menu

Channel Setup Menu

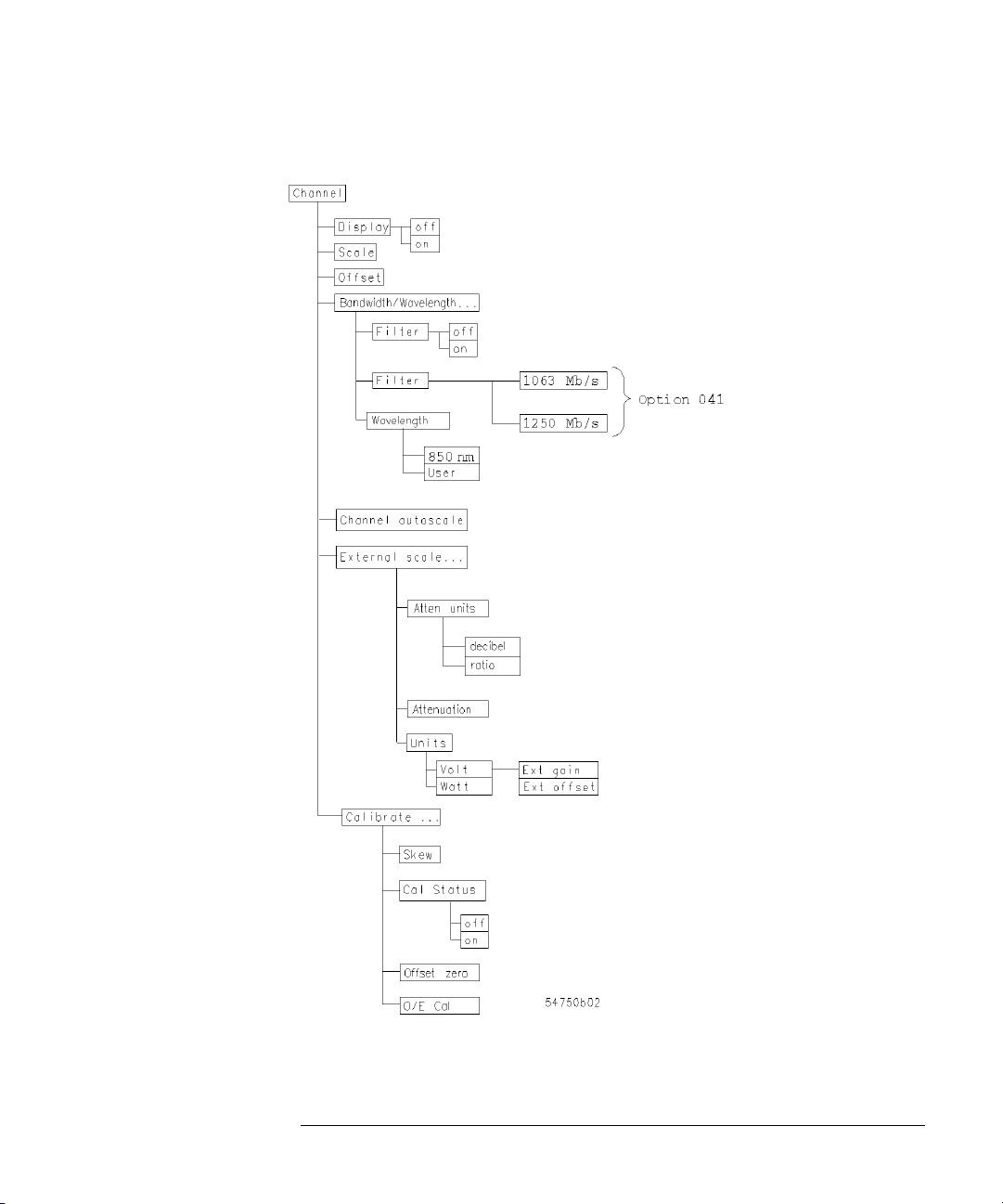

This chapter describes the Channel Setup menu. A key tree and description of

the available functions is included.

CAUTION

The input circuits can be damaged by electrostatic discharge (ESD).

Therefore, avoid applying static discharges to the front-panel input connectors.

Before connecting any coaxial cable to the connectors, momentarily short the

center and outer conductors of the cable together. Avoid touching the frontpanel input connectors without first touching the frame of the instrument. Be

sure that the instrument is properly earth-grounded to prevent buildup of

static charge. Refer to “Electrostatic Discharge Information” on page 5-12.

At the top of the plug-in module are the

access to the Channel Setup menu for each input. The Channel Setup menu is

displayed on the right side of the screen when the

There are several types of softkeys available. A description of the different

softkeys and their functions is provided in the

Quick Start Guide

NOTE

The plug-in module has both an electrical channel and an optical channel. Although

many of the softkeys are similar, some differences exist. Examples in this book using the

optical channel will note when the user would see differences if using the electrical

channel.

supplied with the mainframe.

Channel

keys. These keys give you

Channel

key is pressed.

HP 83480A, 54750A User’s

2-2

Page 25

Channel Setup Menu

Channel Setup Menu

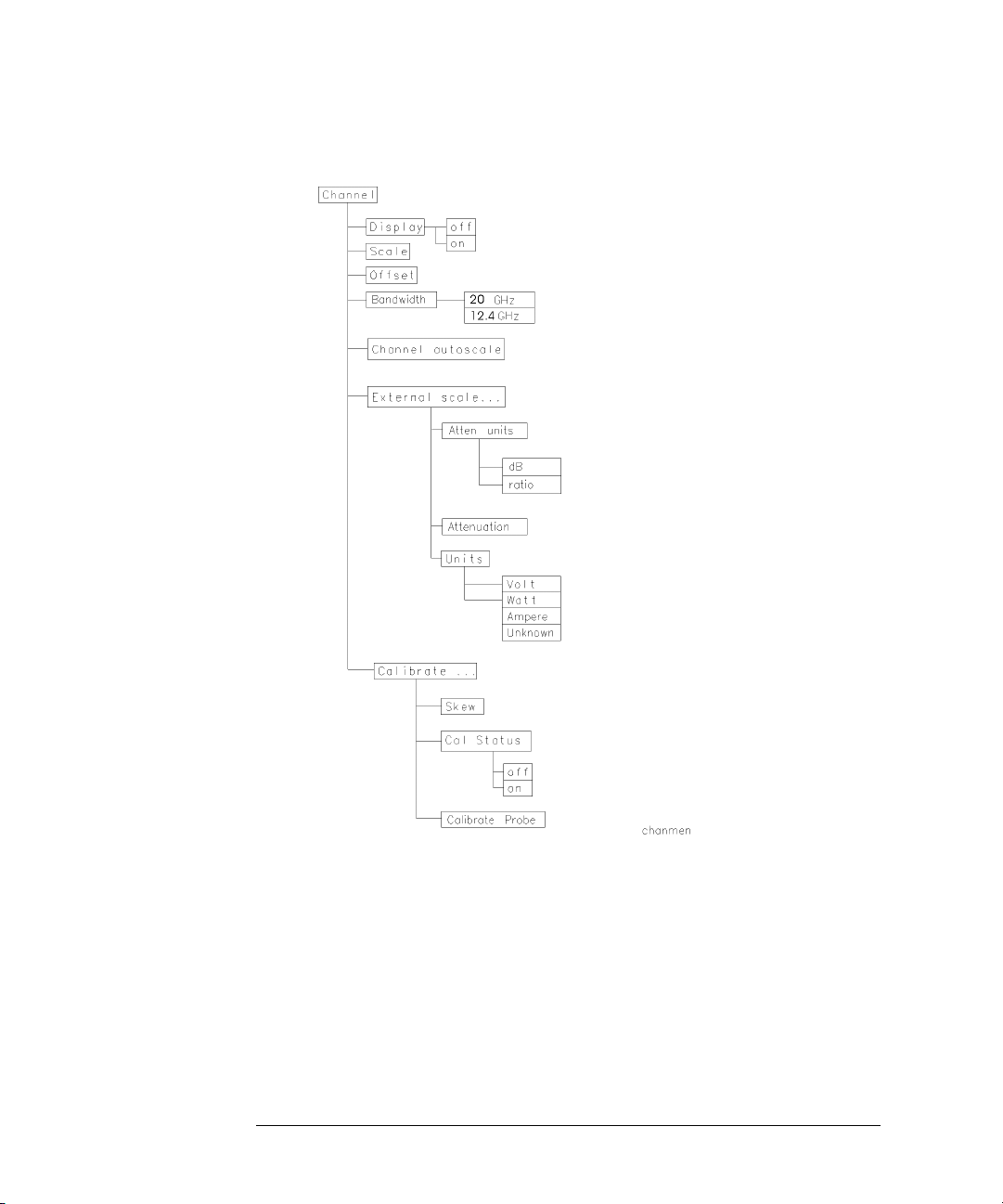

Figure 2-1. Optical Channel Setup menu.

2-3

Page 26

Channel Setup Menu

Channel Setup Menu

Figure 2-2. Electrical Channel Setup menu.

2-4

Page 27

Displaying the Channel Setup Menus

Displaying the Channel Setup Menus

Channel Setup Menu

To display the optical Channel Setup menu, press the

located above the optical input connector.

To display the electrical Channel Setup menu, press the

located above the electrical input connector.

Optical Channel

key

Electrical Channel

key

2-5

Page 28

Channel Setup Menu

Display

Display

Display

The

play is on, a waveform is displayed for that channel, unless the offset is

adjusted so the waveform is clipped off the display.

The channel number, vertical scaling, and offset are displayed at the bottom

left of the waveform area. They remain on the display until the channel is

turned off, or an automatic measurement is performed. The automatic measurement results share the same area of the display as the channel setups.

When the channel display is off, the waveform display for that channel is

turned off, pulse parameter measurements are stopped and acquisition on

that channel is stopped, unless it is needed as an operand for waveform math

functions.

Even though the channel display is off, you can still use the plug-in as a trigger

source or as a function source in the Math menu. However, the analyzer will

not trigger unless one or more of the other channel displays are turned on, or

unless a math function is using one of the channels.

softkey turns the channel display off and on. When the channel dis-

Key Path

Channel,

2-6

Display

Page 29

Channel Setup Menu

Scale

Scale

Scale

The

mode is off, then the knob and arrow keys change the vertical scaling in a

1-2-5 sequence. When fine mode is on, the knob and arrow keys change the

vertical scaling in 1 mV increments. You can also use the keypad to enter values in 1 mV increments, independent of the fine mode selection.

The scale will be displayed in volts or watts, as selected by the

(Amperes, or unknown are available on electrical channels only.)

softkey controls the vertical scaling of the waveform. If the fine

Units

softkey.

Key Path

Channel,

Scale

Offset

Offset

The

control on analog oscilloscopes. The advantage of digital offset is that it is calibrated. The offset voltage for electrical channels is the voltage at the center of

the graticule area, and the range of offset is ±12 times the full resolution channel scale. For optical channels, the offset wattage is the wattage two graticule

divisions above the bottom of the screen. This is set because, unlike voltage

displays, "negative" power levels do not exist but the zero power level can be

viewed clearly when the offset is set to zero watts. You can use the knob,

arrow keys, or keypad to change the offset setting. The fine mode also works

with offset.

When an HP 54700-series active probe is connected to the probe power connector, the offset control adjusts the external scale factor and offset of the

hybrid inside the active probe. A probe connected to the auxiliary power connector will function, but the channel scale factor will

ically.

The optical channel displays the value in watts and the electrical channel displays the value in volts.

softkey moves the waveform vertically. It is similar to the position

not

be adjusted automat-

Key Path

Channel,

Offset

2-7

Page 30

Channel Setup Menu

Bandwidth/Wavelength....

Bandwidth/Wavelength....

Key Path

Key Path

You can use the

wavelength settings.

Bandwidth

This function is available on the electrical channel only.

You can use the

bandwidth.

Channel,

Filter

The

Channel

Wavelength

This function is available on the optical channel only.

The

surements. The factory calibrated wavelength is 850 nm. A user-calibrated

wavelength is also available and can be calibrated in the range from 750 nm to

860 nm. Refer to Chapter 3, “Calibration Overview” for additional information

on performing a calibration.

Bandwidth/Wavelength

Filter

function turns the filter on and off.

Bandwidth/Wavelength...., Filter On Off

,

Wavelength

Bandwidth/Wavelength

Bandwidth

function selects the desired wavelength for calibrated mea-

function to select either the 12.4 GHz or 20 GHz

....

.... softkey to change the bandwidth and

, Bandwidth

Key Path

Key Path

Channel

Filter

This function selects the specific filter for the type of compliance testing to be

performed.

Channel

2-8

Bandwidth/Wavelength

,

Bandwidth/Wavelength

,

, Wavelength

....

Filter, 1063 Mb/s

....,

1250 Mb/s

or

Page 31

Channel Setup Menu

Channel autoscale

Channel autoscale

Channel autoscale

The

mining the standard vertical scale setting with the highest resolution that will

not clip the waveform. Timebase and trigger settings are

This function is useful in manufacturing environments where the timebase

and trigger settings remain constant and only the vertical scale needs to be

adjusted for signal level variations in multiple devices under test.

softkey provides a convenient and fast method for deter-

not

affected.

Key Path

Channel,

Channel autoscale

2-9

Page 32

Channel Setup Menu

External scale....

External scale....

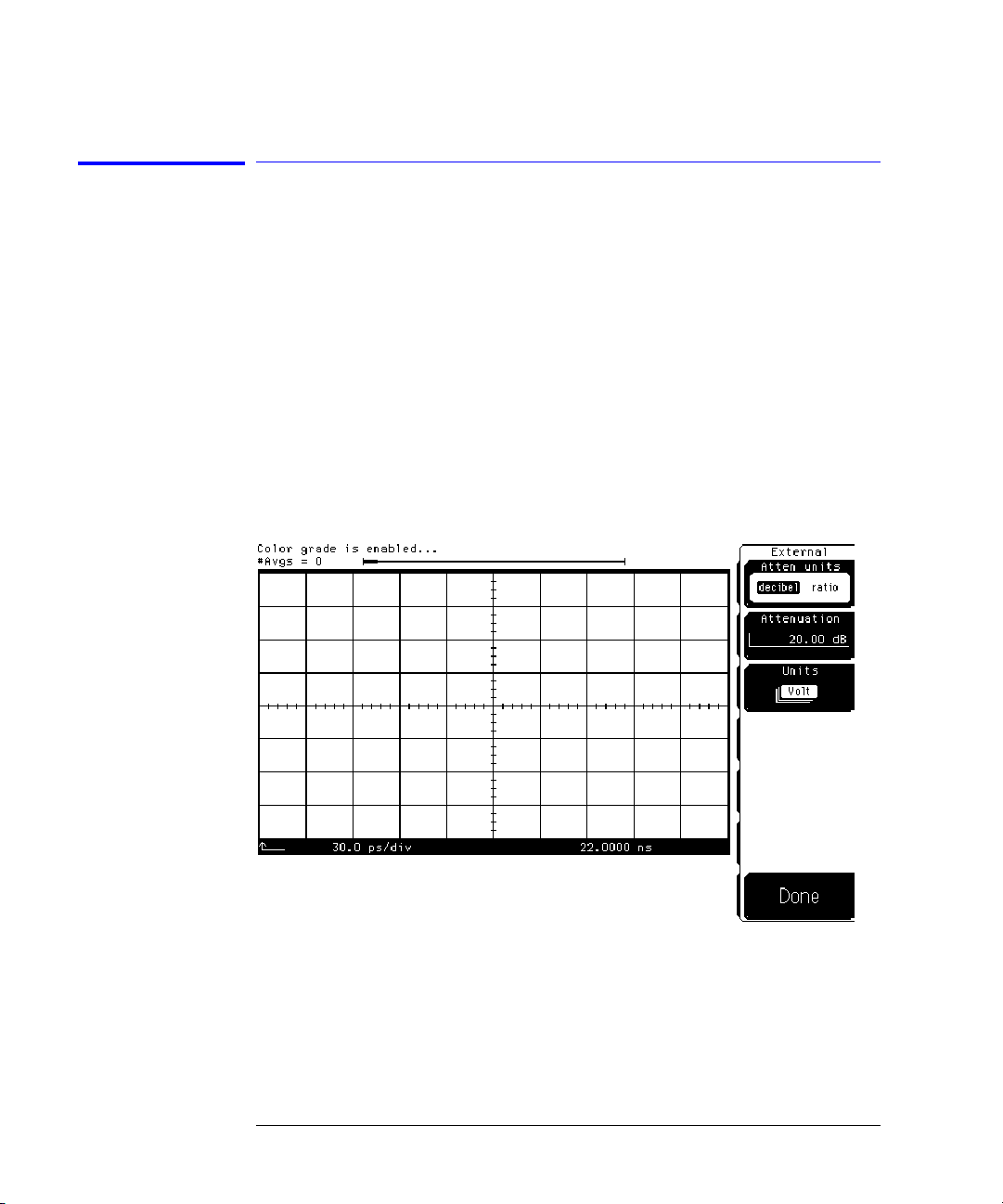

External scale

The

cal-to-electrical converters or attenuators. Scaling is automatically adjusted to

account for the external device.

softkey allows you to set up the analyzer to use external opti-

Key Path

Channel,

External scale

....

Atten units

Atten units

The

function lets you select how you want the probe attenuation

factor represented. The choices are decibel or ratio. The formula for calculating decibels is:

20

Vout

------------log or10

Vin

Pout

------------log

Pin

Attenuation

Attenuation

The

function lets you select an attenuation that matches the device

connected to the analyzer. When the attenuation is set correctly, the analyzer

maintains the current scale factors if possible. All marker values and voltage or

wattage measurements will reflect the actual signal at the input to the external device.

The attenuation range is from 0.0001:1 to 1,000,000:1. When you connect a

compatible active probe to the probe power connector, adjacent to the channel input, the instrument automatically sets the attenuation. For all other

devices, set the probe attenuation with the knob, arrow keys, or keypad.

Note

Key Path

Refer to Chapter 3, “Calibration Overview” for information on calibrating to the tip of the

probe.

Channel,

2-10

External scale

, Attenuation

....

Page 33

Channel Setup Menu

External scale....

Units

Units

The

function lets you select the unit of measure appended to the channel

scale, offset, trigger level, and vertical measurement values. For the optical

channel these units are Volts or Watts. For the electrical channel the units are

Volts, Amperes, Watts, or unknown. Use Volt for voltage probes, Ampere for

current probes, Watt for optical-to-electrical (O/E) converters, and unknown

when there is no unit of measure or when the unit of measure is not one of the

available choices.

Key Path

Key Path

Channel,

External scale

....

, Units

Ext gain and Ext offset

When you select Ampere, Watt, or unknown on an electrical channel or Voltage on an optical channel, two additional functions become available: External

Gain and External Offset. These two additional functions allow you to compensate for the actual characteristics of the probe rather than the ideal characteristics. For example, you might have an amplified lightwave converter

with ideal characteristics of 300 V/W with 0 V offset, but actual characteristics

of 324 V/W with 1 mV of output offset. In this case you would set the External

Gain to 324 V/W and the External Offset to 1 mV.

Channel,

Channel

Channel

External scale

, External scale

External scale

,

, Units, Volt, Ext gain

....

, Units, Watt, Ext gain

....

, Units, Unknown, Ext gain

....

Ext offset

or

Ext offset

or

or

Ext offset

2-11

Page 34

Channel Setup Menu

Calibrate

Calibrate

Calibrate

The

remove the effects of offsets in the internal O/E converter, recalibrate the

responsivity of the O/E converter, and check the present calibration status of

the analyzer.

softkey allows you to null any skew between probes or cables,

Key Path

Key Path

Channel,

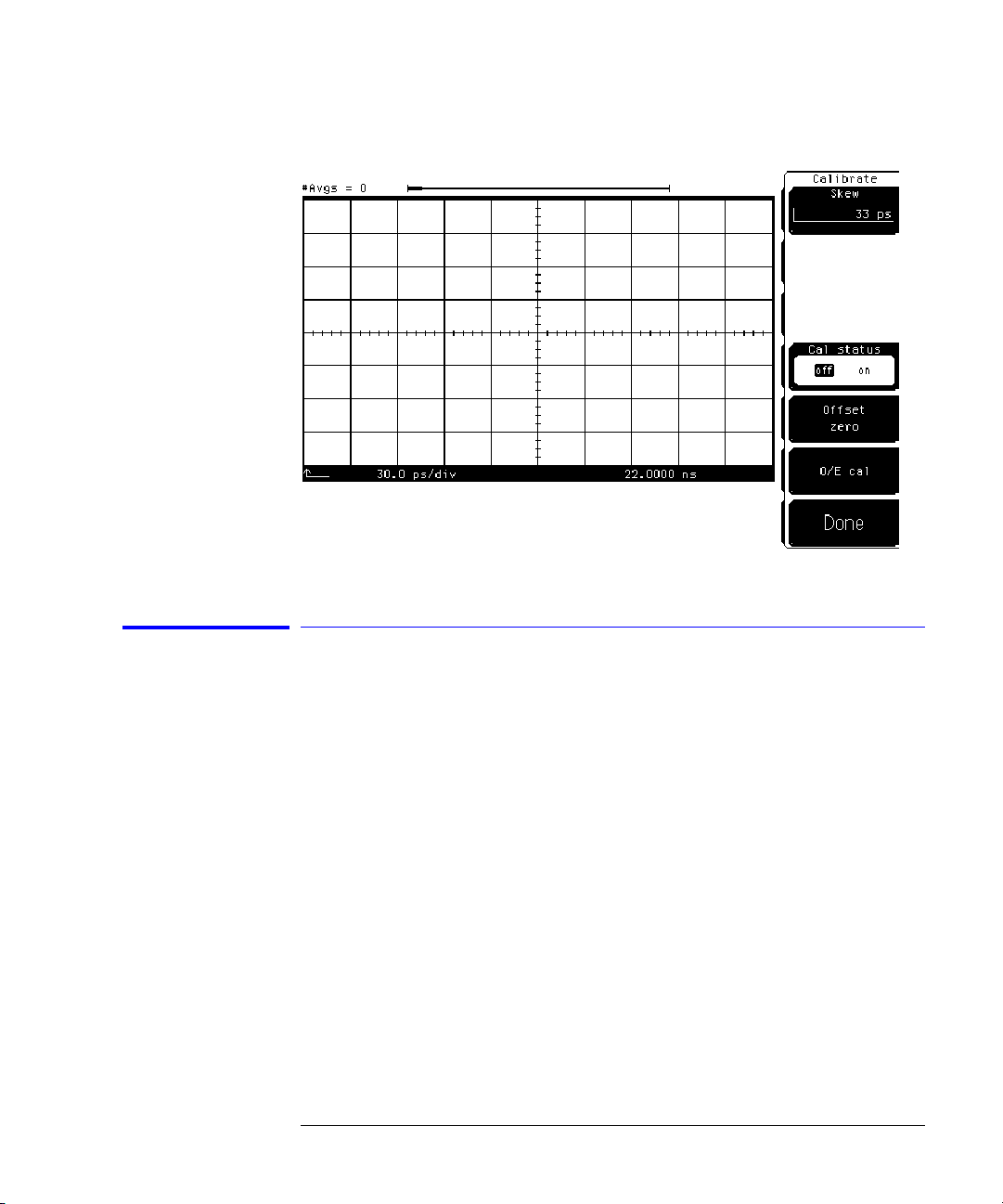

Skew

The

play. The

sate for differences in cable or probe lengths. It also allows you to place the

triggered edge at the center of the display when you are using a power splitter

connected between the channel and trigger inputs. Another use for skew is

when you are comparing two waveforms that have a timing difference. If you

are interested in comparing the shapes of two waveforms rather than the

actual timing difference, you can use

the other waveform.

Channel,

Calibrate

Skew

function changes the horizontal position of a waveform on the dis-

Skew

function has a range of ≈ +100 µs. You can use skew to compen-

Skew

to overlay one waveform on top of

To skew two channels

Turn both channels on and overlay the signals vertically.

Expand the time base so the rising edges are at about a 45 degree angle.

Adjust the skew on one of the channels so that the rising edges overlap at the 50 percent points.

Calibrate, Skew

2-12

Page 35

Cal status

Cal status

The

Channel Setup Menu

Calibrate

function displays a screen similar to Figure 2-3.

Key Path

Current Date

Current Frame

∆Temp

Channel,

Calibrate, Cal Status

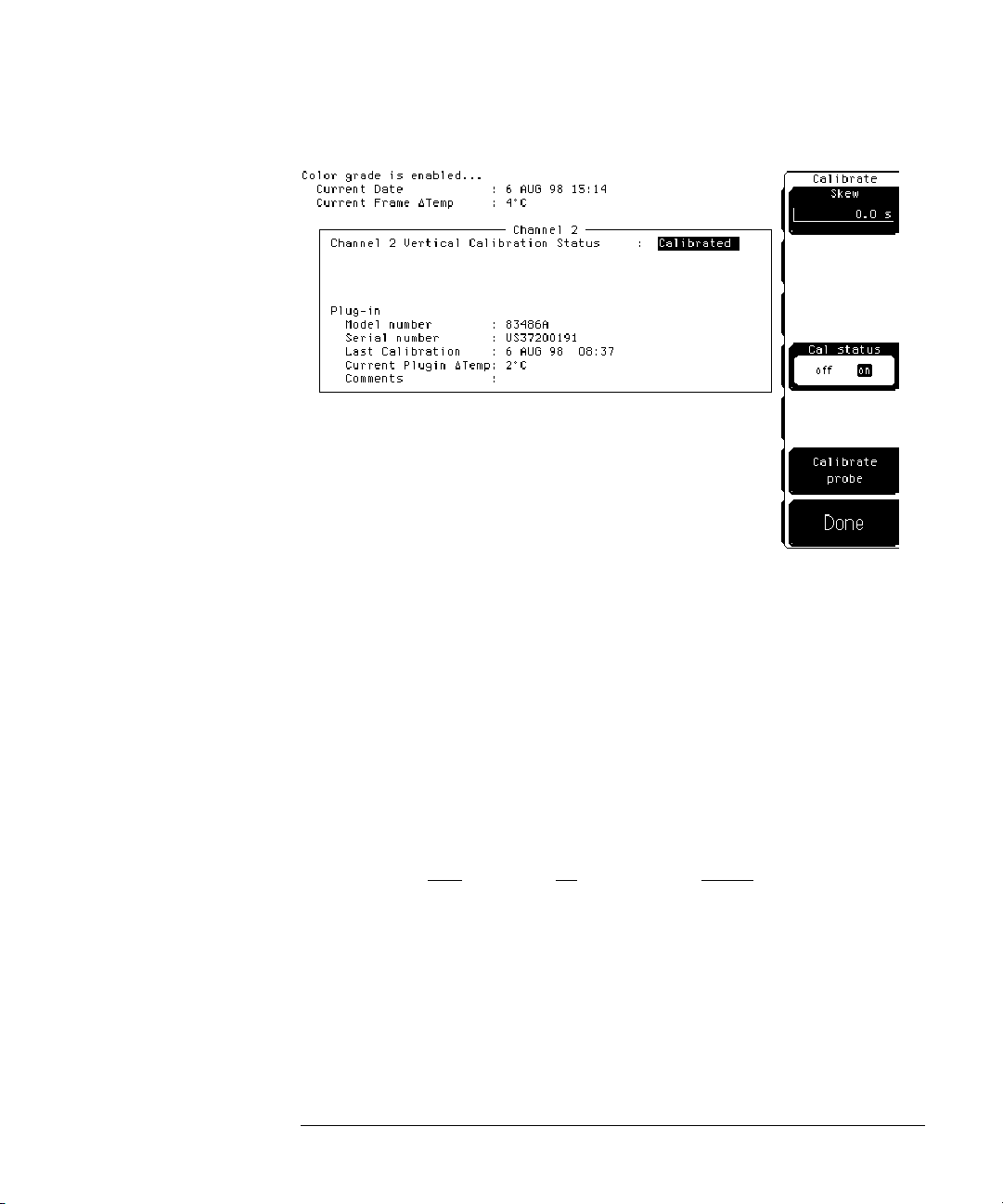

Figure 2-3. A typical Cal Status display.

This is the current date and time. You can compare this to the last plug-in

module calibration time to see how long it has been since calibration was performed.

This is the temperature change on the inside of the instrument since the last

mainframe calibration was performed. The number indicates how many

degrees warmer or cooler the mainframe is compared to the last calibration.

Channel 1

Calibration

Status

The instrument displays

Calibrated

Uncalibrated

or

, depending on

whether the last plug-in module calibration is still valid. A calibration can be

invalidated if:

• The mainframe has cycled power.

• The plug-in has been repaired, reprogrammed, or removed from the

mainframe.

• The instrument’s operating temperature has changed and remains more than

5°C from the temperature at which the Plug-in calibration was performed.

Uncalibrated

indicates the plug-in module vertical calibration is invalid.

2-13

Page 36

Channel Setup Menu

Calibrate

Plug-in

Key Path

This function lists the model number, serial number, date, time, and temperature delta. The temperature ∆ is the mainframe temperature change since the

last calibration. If this temperature ∆ is greater than ±5°C since the last mainframe calibration, then you must perform a plug-in module calibration to

achieve the specified dc accuracy.

Offset zero

Offset zero

The

function performs a quick offset calibration on the optical channel. Since the primary source of calibration error on the optical channel is offset drift, this function is useful:

• after the plug-in module vertical calibration described in Chapter 3, “Cali-

bration Overview” has been performed,

and

• if the plug-in module has not been removed and reinstalled.

Performing an Offset zero calibration is much faster than performing a complete vertical calibration.

Channel,

Calibrate, Offset zero

O/E cal

The plug-in module is provided with factory optical calibrations at 850 nm and

1550 nm. The

O/E cal

function allows you to calibrate the instrument for use at

one additional user-defined wavelength between 750 nm and 860 nm. This calibration does

not

affect the factory calibrations.

Key Path

Calibrate probe

Connect a voltage probe to the plug-in and press

Calibrate probe.

The analyzer calibrates to the tip of the probe by setting the probe attenuation

to the actual attenuation ratio of the probe. The analyzer also automatically

compensates for any offset the probe may introduce. The CAL signal is internally routed to the probe tip for HP probes.

Channel,

2-14

Calibrate, Calibrate probe

Page 37

3

Factory Calibrations 3-4

User Calibrations—Optical and Electrical 3-7

Complete Calibration Summary 3-19

Calibration Overview

Page 38

Calibration Overview

Calibration Overview

Calibration Overview

This chapter describes the calibration of the mainframe and the plug-in modules. It is intended to give you, or the calibration laboratory personnel, an

understanding of the various calibration procedures available, and how they

were intended to be used. There is a description of the calibration menu

included in the manuals provided with the plug-in modules and probes.

Proper calibration is critical to measurement accuracy and repeatability. The

HP 54750A/83480A and their associated modules and accessories require that

both factory and user calibrations be implemented at the recommended intervals in order to perform measurements at their published specifications.

This chapter is divided into three sections. The first section describes factory

calibrations. A factory calibration consists of verifying instrument performance to all specifications. If an instrument fails to meet specifications,

adjustment or repair may be necessary. For most users, this will mean shipping the instrument back to an authorized service center. Some users may

purchase the required instrumentation and perform the factory timebase calibrations themselves using the optional

The second part of the chapter addresses calibrations that are routinely performed by the end user. Subsections in each of the two main sections discuss

the individual calibrations. In addition, there are summary tables at the end of

each of these sections summarizing the main areas addressed. The third part

of the chapter consists of a complete calibration summary table. Both factory

and user calibrations must be performed regularly in order to ensure proper

measurement accuracy and repeatability.

HP 83480A, 54750A Service Guide

.

3-2

Page 39

Calibration Overview

Calibration Overview

CAUTION

The input circuits can be damaged by electrostatic discharge (ESD). Avoid

applying static discharges to the front-panel input connectors. Before

connecting a coaxial cable to the connectors, momentarily short the center and

outer connectors of the cable together. Avoid touching the front panel input

connectors without first touching the frame of the instrument. Be sure that the

instrument is properly earth-grounded to prevent buildup of static charge. It is

strongly recommended that an antistatic mat and wristband be used when

connecting to electrical channel inputs.

Calibration interval

HP recommends that the factory calibration be performed on a periodic basis.

HP designs instruments to meet specifications over the recommended calibration interval provided that the instrument is operated within the specified

operating environment. To maintain specifications, periodic recalibrations are

necessary. We recommend that the plug-in module be calibrated at an HP service facility every 12 months. Users are encouraged to adjust the calibration

cycle based on their particular operating environment or measurement accuracy needs.

Required warm-up time

The instrument requires a 1 hour warm-up period before any of the calibrations mentioned in this chapter are performed. It is not enough for the instrument to be in the standby setting. It must be turned on and running for the

entire hour.

Remote operation

Remote programming commands for calibrations are included in the

HP 83480A/HP 54750A Programming’s Guide

. Performing calibrations

remotely is slightly different than the operation of front-panel calibrations.

3-3

Page 40

Calibration Overview

Factory Calibrations

Factory Calibrations

The following calibrations are performed at the factory:

Mainframe Calibration

O/E Factory Wavelength Calibration

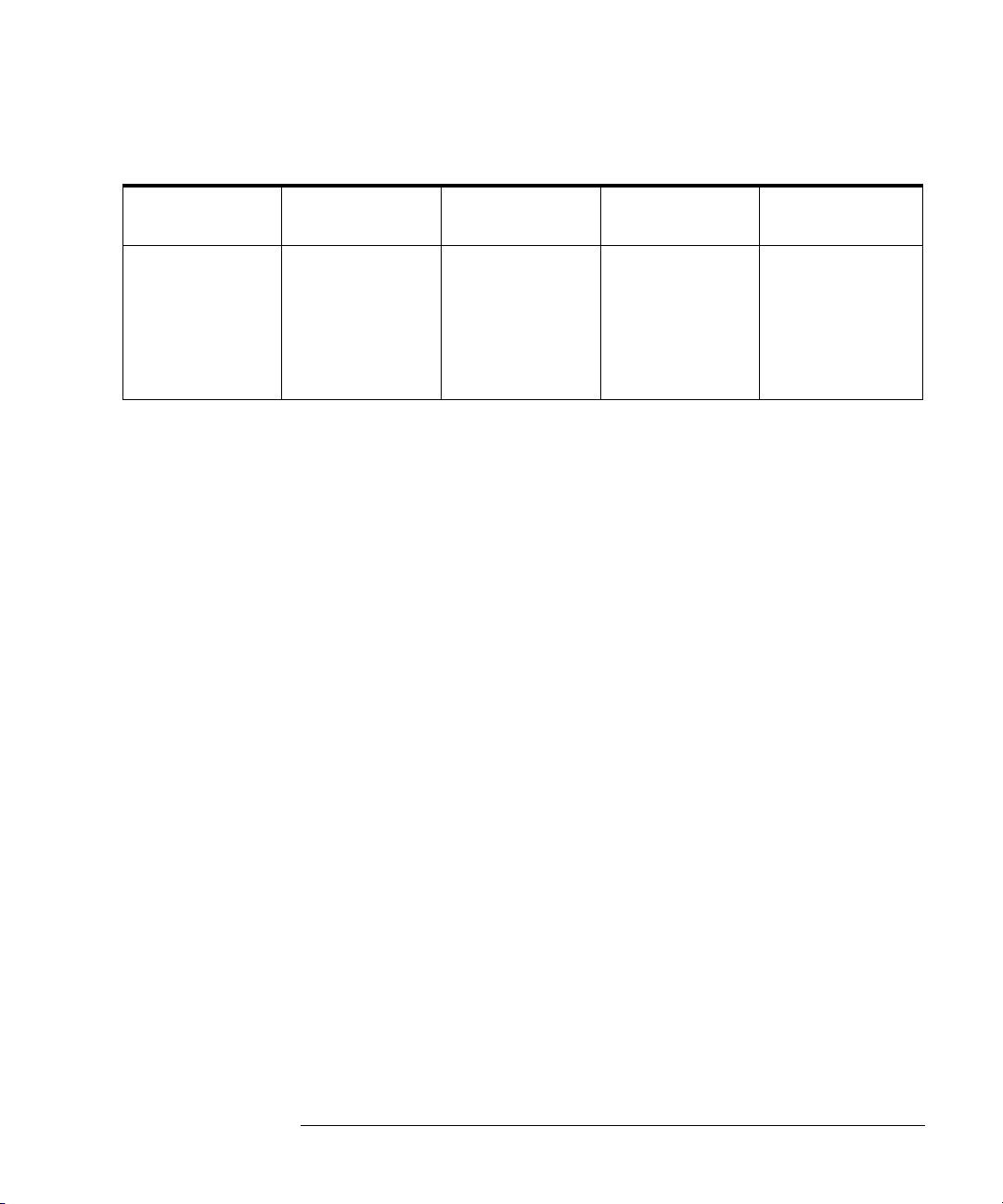

Table 3-1. Factory Calibration Summary

Calibration What is calibrated

Mainframe Calibration

O/E Factory

Wavelength

Calibration

a. Refer to “O/E User-Wavelength Calibration” on page 3-9.

Accuracy and

continuity of the

timescale

The photodetector

responsivity

Mainframe Calibration

Mainframe calibration affects both optical and electrical measurements. Mainframe calibration improves timebase accuracy. All timebase measurements

such as rise time, fall time, eye width, jitter, and so forth are affected by the

timebase accuracy.

The calibration factors are stored in the nonvolatile RAM of the instrument.

There is a switch on the back panel of the instrument that allows the mainframe calibration to be protected or unprotected. Next to the switch there is a

Measurements

Affected

Channels affected:

optical & electrical. All

time base

measurements such as

rise time, fall time, eye

width, and jitter.

Channels affected:

optical. Amplitude

accuracy of all optical

channel

measurements. Optical

power meter accuracy.

Recommended

Interval

Annually at HP service

center or if operating

temp has changed and

remains 5°C or more

from calibration

temperature. See

service manual.

Annual factory recalibration of standard

wavelengths.

Softkey Path

Utility

Calibrate

Calibrate frame

Not user accessible.

a

3-4

Page 41

Calibration Overview

Factory Calibrations

drawing that shows each switch’s function and protected position. Refer to the

optional

HP 83480A, 54750A Service Guide

for more details about the main-

frame calibration, and the position of the rear-panel memory protect switches.

CAUTION

CAUTION

To prevent access to the mainframe calibration switch, place a sticker over the

access hole to this switch.

Do not attempt a Mainframe calibration without consulting the

54750A Service Guide

.

HP 83480A,

A mainframe calibration should be performed on a periodic basis, annually, or

when the ambient operating temperature has changed by and remains 5°C different than the operating temperature at which the last mainframe calibration

was performed. To see how much the operating temperature has changed

since the last mainframe calibration and the date of the last mainframe calibration, check the Calibration status by pressing the following key sequence:

Utility

Calibrate

,

, and then

Cal status

on

.

The temperature change is displayed at the top of the display as shown in the

following figure.

Figure 3-1. Current Frame

∆∆∆∆

Temp condition

3-5

Page 42

Calibration Overview

Factory Calibrations

Current Frame ∆Temp

If the

frame should either be calibrated at the current operating temperature or be

placed in an ambient air temperature that is within 5°C of the temperature of

the current calibration.

listing is greater than ±5°C, then the main-

O/E Factory Wavelength Calibration

Optical/electrical (O/E) factory wavelength calibration, compensates for the

photodetector responsivity. The accuracy of all optical channel measurements

is dependent on proper O/E calibration. O/E calibrations should be performed

annually. Most customers return their optical plug-ins to an authorized HP service center for this calibration at the same time they are having their mainframes re-calibrated.

The HP 83480-series optical modules have one or two standard wavelengths

(850 nm or 1310/1550 nm). The O/E Calibration function allows you to calibrate the instrument for use at one additional user-defined wavelength. This

calibration does not affect the factory calibrations. See the following section

on User Calibrations for additional information on this procedure.

3-6

Page 43

Calibration Overview

User Calibrations—Optical and Electrical

User Calibrations—Optical and Electrical

The following calibrations can be performed by the user:

O/E User Wavelength Calibration

Plug-in Module Vertical Calibration

Offset Zero Calibration

Dark Calibration

Probe Calibration

Channel Skew

External Scale

Electrical channels have calibration procedures for:

• adjusting timebase skew, for matching propagation delay between channels,

probes, cables, and so forth

CAUTION

• using external probes

Optical channels have calibration procedures for:

• adjusting timebase skew

• monitoring and adjusting internal offsets

• performing a user-defined O/E responsivity adjustment

The input circuits can be damaged by electrostatic discharge (ESD). Avoid

applying static discharges to the front panel input connectors. Before

connecting a coaxial cable to the connectors, momentarily short the center and

outer connectors of the cable together. Avoid touching the front panel input

connectors without first touching the frame of the instrument. Be sure the

instrument is properly earth-grounded to prevent buildup of static charge. An

antistatic mat and wristband are strongly recommended, particularly when

working with TDR modules.

3-7

Page 44

Calibration Overview

User Calibrations—Optical and Electrical

Table 3-2. Optical and Electrical Channel User Calibration Summary

Calibration What is calibrated

O/E User Wavelength

Calibration

Plug-in Vertical

Calibration

Offset Zero

Calibration

Dark Calibration Dark calibration

The photodetector

responsivity

Vertical offset and

vertical scale accuracy

for both electrical and

optical channels.

Vertical offset is

calibrated for the

optical channel only.

This calibration

doesn’t include vertical

scale accuracy.

measures the channel

offset signal without

any light present and

this value is used in

the extinction ratio

algorithm.

Measurements

Affected

Channels affected:

optical. All optical

channel

measurements at user

wavelengths.

Channels affected:

optical & electrical.

Any optical or

electrical vertical

measurements such as

V

, eye height,

p to p

extinction ratio, and

the optical power

meter

Channels affected:

optical. Any optical

vertical measurements

including: V

height, and extinction

ratio.

Channels affected:

optical & electrical.

Extinction ratio.

p to p

, eye

Recommended

Interval

Annual re-calibration

of user defined nonfactory wavelengths

Perform after any

power cycle or once

every 10 hours during

continuous use or if

operating temperature

changes by more than

2°C.

Perform a plug-in

vertical calibration in

order to meet

published

specifications.

Because the offset

zero calibration

performs only the

offset portion of the

plug-in vertical

calibration, it should

only be used before

fast non-critical

measurements.

Before extinction ratio

measurements if the

vertical scale or offset

has changed since the

last dark calibration or

after a plug-in vertical

calibration is

performed.

Key Path

Optical Channel Setup

Calibrate

O/E Cal

Utility

Calibrate

Calibrate Plug-in

Optical Channel Setup

Calibrate

Offset 0

Shift, Meas eye

Extinction ratio

Dark Cal

3-8

Page 45

Table 3-3. Miscellaneous User Calibration Summary

Calibration Overview

User Calibrations—Optical and Electrical

Calibration What is calibrated

Probe calibration Probe Attenuation Channels affected:

Channel Skew Calibrates out the

small differences in

delay between

channels. Useful for

looking at timing

differences between

channels

External Scale Compensates for gain

or loss associated with

external devices

(calibrates vertical

scale to external

device

Measurements

Affected

electrical. Any

electrical

measurement taken

with the probe

Channels affected:

optical & electrical.

Multiple channel

measurements.

Channels affected:

optical & electrical.

Any measurement

taken through an

external device

(component or

transducer

O/E User-Wavelength Calibration

Recommended

Interval

Whenever a probe is

connected

Before multiple

channel

measurements when

measuring timing

differences between

channels.

Whenever using

external devices

(component or

transducer)

Key Path

Electrical Channel Setup

Calibrate

Calibrate probe

Channel Setup

Calibrate

Skew

Channel Setup

External Scale

This optional optical/electrical (O/E) calibration is for optical measurements

only. It compensates for the photodetector’s responsivity. The vertical accu-

racy of all optical channel user wavelength measurements is dependent on

proper O/E user wavelength calibration. O/E user-wavelength calibrations

should be performed annually or whenever a new wavelength is being measured. To perform a O/E user-wavelength calibration, a CW optical source with

a known optical output power level is required. Refer to the specifications for

the plug-in module for the acceptable power level ranges.

3-9

Page 46

Calibration Overview

User Calibrations—Optical and Electrical

NOTE

The optical channel calibration accuracy is heavily dependent on the accuracy to which

you know the optical source power. For best results, measure the optical source power

with an optical power meter such as the HP 8153A and use precision optical connectors.

In addition, proper connector cleaning procedures are essential to obtaining an accurate

calibration.

To perform an O/E user-wavelength calibration

1

Press the plug-in module’s front-panel optical channel

2

3

Press

Calibrate

, and then

O/E cal

.

Input the correct wavelength, and follow the instructions on the screen.

SETUP

key.

Figure 3-2. Plug-in calibration menu

To use an O/E user-wavelength calibration

1

Press the plug-in module’s front-panel optical channel

2

3

Bandwidth/wavelength

Press

Usr wavelength

Press

3-10

and then

and then

wavelength

Enter

.

.

SETUP

key.

Page 47

Calibration Overview

User Calibrations—Optical and Electrical

Plug-in Module Vertical Calibration

The plug-in module vertical calibration is for both optical and electrical measurements. It allows the instrument to establish the calibration factors for a

specific plug-in when the plug-in is installed in the mainframe. The plug-in calibration factors are valid only for the specific mainframe slot in which it was

calibrated. The plug-in vertical calibration establishes vertical accuracy.

A plug-in vertical calibration should be done if:

• The mainframe has cycled power.

• The plug-in has been repaired, reprogrammed, or removed from the

mainframe.

• The instrument’s operating temperature has changed and remains more than

5°C from the temperature at which the Plug-in calibration was performed.

To obtain the best measurement results, it is recommended that a user vertical calibration be performed after every 10 hours of continuous use or if the

temperature has changed by greater than 2°C from the previous vertical calibration.

To view the temperature change

This procedure displays the temperature change that the instrument has

undergone since the last Plug-in Vertical Calibration.

1

Press the front-panel channel

2

1

2

3

4

5

6

Calibrate

Press

The current plug-in ∆Temp value is listed for each installed module.

To perform a plug-in module vertical calibration

Remove any front-panel connections from electrical channels.

Cover the optical inputs for the optical channels.

Utility

Press

Select the plug-in module to be calibrated, press

Start cal

Press

Follow the on-screen instructions.

and then

Calibrate. . .

,

to start the calibration.

, and then

SETUP

Cal status on

key.

.

Calibrate plug-in. . .

.

1 and 2

or

3 and 4

.

3-11

Page 48

Calibration Overview

User Calibrations—Optical and Electrical

No additional equipment is required to perform a plug-in vertical calibration.

Reference signals are both generated and routed internally, for the optical and

electrical channels. If you are prompted to connect the calibrator output to

the electrical channel during an optical vertical calibration, then the factory

O/E calibration has been lost. The module must then be returned to HP for

calibration.

Offset Zero Calibration

The offset zero calibration performs a quick offset calibration on the optical

channel for optical measurements. Since the primary source of calibration

error on the optical channel is offset drift, this function is useful between the

plug-in module vertical calibrations if the plug-in module has not been

removed or reinstalled and the operating temperature has not changed more

than ±5°C. In order to ensure that instrument specifications are met, perform

the plug-in vertical calibration.

Performing an offset zero calibration is much faster than performing a complete vertical calibration. For critical measurements where offset measurement uncertainty is important to consider, perform an offset zero calibration

between module vertical calibrations. Perform an offset zero calibration if the

vertical scale or offset changes.

To initiate an offset calibration

1

Disconnect all inputs from the module being calibrated.

2

Cover all optical inputs.

3

Press the plug-in module’s front-panel optical channel

4

Press

3-12

Calibrate

and then

Offset zero

.

SETUP

key.

Page 49

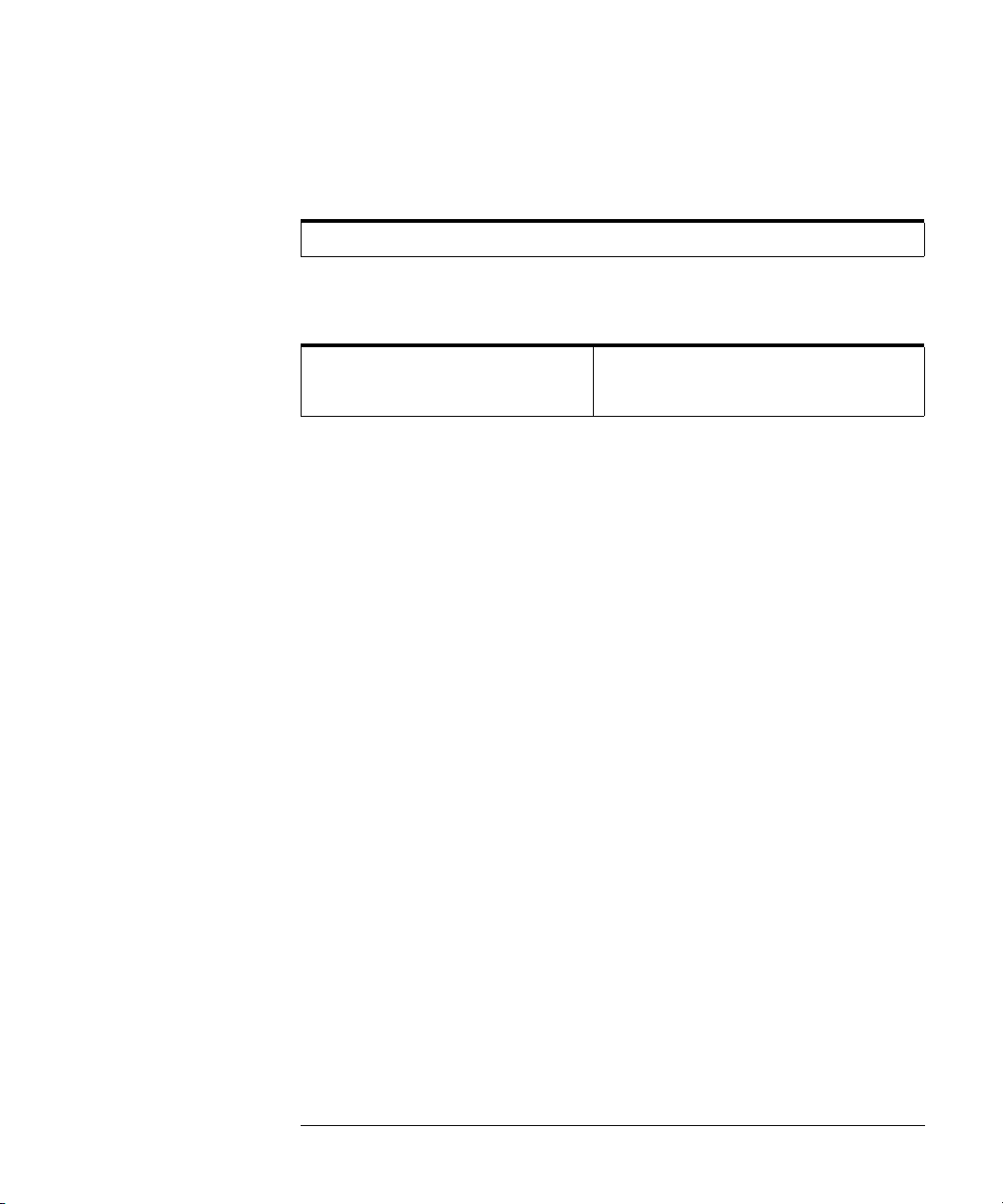

Figure 3-3. Offset Zero Calibration

Calibration Overview

User Calibrations—Optical and Electrical

Dark Calibration

The dark calibration is for optical measurements, or electrical measurements

if an external O/E is being used. This calibration measures the optical channel

offset signal when there isn’t any light present and then uses this information

in performing extinction ratio measurements. Dark calibrations should be

done for the following conditions:

• Before any critical extinction ratio measurements are made

• After a plug-in vertical calibration

• If a module has been removed

• If the mainframe power has been cycled

• If extinction ratio measurements are being made after the vertical scale or the

offset has changed.

If the line power has been cycled, the dark calibration invokes either the offset

zero calibration or plug-in vertical calibration as needed. This increases the

time required for the dark calibration to complete. The

located within the Extinction ratio menu.

Dark cal

softkey is

3-13

Page 50

Calibration Overview

User Calibrations—Optical and Electrical

To initiate a dark calibration

1

Press the

Display

key. Press the

Color grade

softkey, and set its setting to on.

Color grade must be enabled to perform an extinction ratio measurement and

a dark calibration. In addition, the dark level (amplitude when there is no signal

present) must be on the screen to perform a dark calibration.

2

Press the blue shift key, and then the

Meas eye

softkey which is located beneath

the display.

3

Extinction ratio ...

Press

and then

Dark cal

.

Disconnect all inputs from the module, including the trigger signal, and block

any ambient light to the photodetector with a connector plug. Follow the

instructions on the screen.

Figure 3-4. Dark calibration menu

3-14

Page 51

Calibration Overview

User Calibrations—Optical and Electrical

Channel Skew Calibration

This calibration affects both optical and electrical measurements. The skew

calibration changes the horizontal position of a waveform on the display. The

skew calibration has a range of approximately 100 µs. You can use skew to

compensate for the differences in cable or probe lengths. It also allows you to

place the trigger edge at the center of the display when you are using a power

splitter connected between the channel and trigger inputs. Another use for

skew is when you are comparing two waveforms that have a timing difference.

If you are interested in comparing the shapes of two waveforms rather than

the actual timing difference, you can use skew to overlay one waveform on top

of the other waveform.

To skew two channels

1

Turn both channels on and overlay the signals vertically.

2

Expand the time base so that the rising edges are at about a 45° angle.

3

Press the plug-in module’s front-panel channel

4

5

Calibrate

Press

Adjust the skew on one of the channels so that the rising edges overlap at the

50% points.

and then

Skew

.

SETUP

key.

Probe Calibration

Probe calibration applies to electrical measurements only. For active probes

such as the HP 54701A, which the instrument can identify through the probe

power connector, the instrument automatically adjusts the channel vertical

scale factors to the probe’s nominal attenuation, even if a probe calibration is

not performed.

For passive probes or non-identified probes, the instrument adjusts the vertical scale factors only if a probe calibration is performed. Probe calibration

allows the instrument to establish the gain and offset of specific probes that

are connected to a channel of the instrument, and then apply those factors to

the calibration of that channel.

The analyzer calibrates to the tip of the probe by setting the probe attenuation

to the actual attenuation ratio of the probe. The CAL signal is internally routed

to the probe tip for HP active probes.

3-15

Page 52

Calibration Overview

User Calibrations—Optical and Electrical

The mainframe’s CAL signal is a voltage source, therefore you can let the

instrument compensate for the actual characteristics of your probe by letting

the instrument calibrate to the tip of the probe. The instrument automatically

calibrates to the tip of the probe, sets the probe attenuation, and compensates

for any probe offset.

If you do not perform a probe calibration but want to use a passive probe,

enter the attenuation factor using the following steps:

1

Press the plug-in module’s front-panel channel

2

Press

External scale

and then

Attenuation

.

SETUP

key.

You can use the probe calibration to calibrate any network, including probes or

cable assemblies. The instrument calibrates the voltage at the tip of the probe

or the cable input.

To calibrate an HP identifiable probe

1

Press the plug-in module’s front-panel-channel

2

Press

Calibrate

and then

Calibrate Probe

.

SETUP

key.

To calibrate a non-identifiable probe

1

Connect the voltage probe to the plug-in.

2

Attach the probe tip to the CAL hook that is located near the floppy disk drive.

3

Press the plug-in module’s front-panel channel

4

Press

Calibrate

and then

Calibrate probe

.

SETUP

key.

If the probe being calibrated has an attenuation factor that allows the instrument to adjust the gain (in hardware) to produce even steps in the vertical

scale factors, the instrument will do so. Typically, probes have standard attenuation factors such as divide by 10, divide by 20, or divide by 100.

3-16

Page 53

Figure 3-5. Electrical Channel Calibrate Menu

Calibration Overview

User Calibrations—Optical and Electrical

To calibrate other devices

The information in this section applies to both optical and electrical measurements. Since the mainframe’s CAL signal is a voltage source, it cannot be used

to calibrate to the probe tip when the units are set to Ampere, Watt, or

Unknown. Instead, set the external gain and external offset to compensate for

the actual characteristics of the probe or device. If you do not know the actual

characteristics, you can refer to the typical specifications that came with the

probe or device.

1

Press the plug-in module’s front-panel channel

2

3

External scale

Press

Atten units Ratio

Press

.

Attenuation 1:1

,

, and then

SETUP

key.

Units Ampere

(Volt, Watt, or

Unknown).

4

5

Press

Press

Ext gain

, and enter the actual gain characteristics of the probe or device.

Ext offset

, and enter the offset introduced by the probe or device.

3-17

Page 54

Calibration Overview

User Calibrations—Optical and Electrical

External Scale

Both optical and electrical channels have an External scale setting which

allows the user to enter in an offset value to compensate for gains or losses not

associated with the device under test. This feature is useful for adjusting out

the effects of devices such as test fixtures and attenuators so that the reading

on the display gives the measurement value associated with only the actual

device under test.

To adjust the external scale

1

Press the plug-in module’s front-panel channel

2

3

Press

Press

External scale

Attenuation

, and set the

Atten units

, and enter the appropriate values.

Figure 3-6. External Scale Menu

SETUP

to "decibel".

key.

3-18

Page 55

Complete Calibration Summary

Table 3-4. Complete Calibration Summary (1 of 3)

Calibration Overview

Complete Calibration Summary

Calibration What is calibrated

Mainframe Calibration Accuracy and

continuity of the

timescale

O/E Factory

Wavelength

Calibration

O/E User Wavelength

Calibration

Plug-in Vertical

Calibration

The photodetector

responsivity

The photodetector

responsivity

Vertical offset and

vertical scale accuracy

for both electrical and

optical channels.

Measurements

Affected

Channels affected:

optical & electrical. All

time base

measurements such

as rise time, fall time,

eye width, and jitter.

Channels affected:

optical. Amplitude

accuracy of all optical

channel

measurements.

Optical power meter

accuracy.

Channels affected:

optical. All optical

channel

measurements at user

wavelengths.

Channels affected:

optical & electrical.

Any optical or

electrical vertical

measurements such

as V

extinction ratio, and

the optical power

meter

p to p

, eye height,

Recommended

Interval

Annually at HP service

center or if operating

temp has changed and

remains 5°C or more

from calibration

temperature. See

service manual.

Annual factory recalibration of standard

wavelengths.

Annual re-calibration

of user defined nonfactory wavelengths

Perform after any

power cycle or once

every 10 hours during

continuous use or if

operating temperature

changes by more than

2°C.

Key Path

Utility

Calibrate

Calibrate frame

Not user accessible.

Optical Channel Setup

Calibrate

O/E Cal

Utility

Calibrate

Calibrate Plug-in

a

3-19

Page 56

Calibration Overview

Complete Calibration Summary

Table 3-4. Complete Calibration Summary (2 of 3)

Calibration What is calibrated

Offset Zero Calibration Vertical offset is

calibrated for the

optical channel only.

This calibration

doesn’t include

vertical scale

accuracy.

Dark Calibration Dark calibration

measures the channel

offset signal without

any light present and

this value is used in

the extinction ratio

algorithm.

Probe calibration Probe Attenuation Channels affected:

Channel Skew Calibrates out the

small differences in

delay between

channels. Useful for

looking at timing

differences between

channels

Measurements

Affected

Channels affected:

optical. Any optical

vertical measurements

including: V

height, and extinction

ratio.

Channels affected:

optical & electrical.

Extinction ratio.

electrical. Any

electrical

measurement taken

with the probe

Channels affected:

optical & electrical.

Multiple channel

measurements.

p to p

Recommended

Interval

Perform a plug-in

vertical calibration in

order to meet

, eye

published

specifications.

Because the offset

zero calibration

performs only the

offset portion of the

plug-in vertical

calibration, it should

only be used before

fast non-critical

measurements.

Before extinction ratio

measurements if the

vertical scale or offset

has changed since the

last dark calibration or

after a plug-in vertical

calibration is

performed.

Whenever a probe is

connected

Before multiple

channel

measurements when

measuring timing

differences between

channels.

Key Path

Optical Channel Setup

Calibrate

Offset 0

Shift, Meas eye

Extinction ratio

Dark Cal

Electrical Channel

Setup

Calibrate

Calibrate probe

Channel Setup

Calibrate

Skew

3-20

Page 57

Table 3-4. Complete Calibration Summary (3 of 3)

Calibration Overview

Complete Calibration Summary

Calibration What is calibrated

External Scale Compensates for gain

or loss associated

with external devices

(calibrates vertical

scale to external

device

a. Refer to “O/E User-Wavelength Calibration” on page 3-9.

Measurements

Affected

Channels affected:

optical & electrical.

Any measurement

taken through an

external device

(component or