Page 1

)

)

ffl Getting Started

( |Q HP-IB Interfacing

L33 Establishing Boundaries and Units

) HH RS-232-C/CCITT V.24 Interfacing

^43 Controlling the Pen and Plotting

■II HP-IL Interfacing

J[l Enhancing the Plot

) Qj An HP-IB Overview

•^3 Labeling

J

BO Instruction Syntax

INTERFACING

AND

PROGRAMMING

MANUAL

HP 7470A

Graphics Plotter

RS-232-C/CCITT V.24

..DESIGNED FOB..

'SYSTEMS'

P

Jtl Digitizing

Reference Material

Obtaining Information from the Plotter

^ Putting the Commands to Work

ID

) PART

\ MICROFICHE NO. 07470-90051 LfiM PACKARD PRINTED IN U.S.A.

NO.

07470-90001 WAo% HEWLETT OCTOBER 1984

Page 2

)

)

)

)

)

)

J

"\

)

)

3

3

1

/

)

tbutiitmt.

)

J

')

)

')

)

Page 3

•"

')

■)

-s

INTERFACING

AND

HP 7470A

Graphics Plotter

PROGRAMMING

MANUAL

s

^

RS-232-C/CCITT V.24

p

S

NO POSTAGE

NECESSARY

IF MAILED

IN

THE

UNITED STATES

BUSINESS REPLY MAIL

FIRST CLASS PERMIT

NO.

5963 SAN DIEGO. CA

U.S.A.

POSTAGE WILL BE PAID BY ADDRESSEE

HEWLETT

E£l

San Diego Division

Attn: Marketing Communications

16399 West Bernardo Drive

San Diego, CA U.S

PACKARD

A.

92127-9989

©1982,

16399 W. Bernardo Drive. San Diego, CA 921271899

1984, by Hewlett-Packard Company

-rti^sto*

''-Seim— . *- '***!&

Page 4

&

■.

Sd

,1

»j

i

Vfl

'>*S.

Page 5

)

Manual Summary

Chapter 1: Getting Started

Contains information concerning manual usage, a description of the

plotter, its interfaces, the HP-GL language, and three instructions.

Chapter 2: Establishing Boundaries and Units

Explains the concept of plotting area, plotter and user units, scaling,

and the instructions used to set and output the scaling points and

window, and to scale the plotting area.

Chapter 3: Controlling the Pen and Plotting

Describes the instructions for pen control and vector plotting.

Chapter 4: Enhancing the Plot

Describes instructions for drawing tick marks and differentiating traces.

Chapter 5: Labeling

Describes the instructions used in labeling to set direction, size, and

slant of characters, as well as instructions for character set and label

terminator selection and for designing your own characters.

Chapter 6: Digitizing

Describes the instructions used to digitize with the plotter and demonstrates how to check for the presence of a digitized point.

Chapter 7: Obtaining Information from the Plotter

Describes the instructions used to obtain information about pen position, errors, and capabilities of the plotter.

Chapter 8: Putting the Commands to Work

A step-by-step example illustrating the procedures to be followed to

draw labels and plot data using HP-GL instructions.

Chapter 9: HP-IB Interfacing

Summarizes operation of the plotter with the Hewlett-Packard Interface

Bus (HP-IB) and explains the methods for addressing and sending and

receiving data over the interface bus.

Manual Summary (Continued)

Appendix B: Instruction Syntax

Provides a summary of both HP-GL and device control instructions.

Appendix C: Reference Material

Includes a summary of default conditions, error messages, scaling

equations, NOP instructions, ASCII codes, and character sets.

Chapter 10: RS-232-C/CCITT V.24 Interfacing

Describes how to connect the plotter with a terminal and/or computer,

summarizes the methods for establishing a handshake protocol be-

tween the plotter and computer, and explains the device control instruc-

tions that are used to set up and control the handshake protocol.

Chapter 11: HP-IL Interfacing

Describes the Hewlett-Packard Interface Loop (HP-IL) and explains the

methods for sending and receiving data over the interface loop.

Appendix A: An HP-IB Overview

Provides an overview of the Hewlett-Packard Interface Bus (HP-IB).

ii MANUAL SUMMARY

MANUAL SUMMARY iii

Page 6

)

)

)

)

)

)

)

)

)

)

)

)

3

)

)

mm

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

Page 7

Table of Contents

Chapter 1: Getting Started

What You'll Learn in This Chapter

HP-GL Instructions Covered

Terms You Should Understand

How to Use HP 7470 Documentation

For First Encounters with the 7470

For First Encounters with HP-GL

For Experienced HP-GL Programmers

Understanding Manual Conventions and Syntax

A Brief Look at the 7470 Plotter

The 7470 Plotter's Instruction Set

HP-GL Syntax

How to Use the Examples in This Manual 1

The Default Instruction, DF 1

The Initialize Instruction, IN 1

The Input Mask Instruction, IM 1

Looking Ahead 1

Chapter 2: Establishing Boundaries and Units 2-1

What You'll Learn in This Chapter 2-1

HP-GL Instructions Covered 2-1

Terms You Should Understand 2-1

The Plotting Area 2-2

Unit Systems 2-3

The Plotter Unit 2-3

User Units 2-3

Setting the Scaling Points 2-3

Setting PI and P2 Manually 2-4

The Input PI and P2 Instruction, IP 2-4

The Output PI and P2 Instruction, OP 2-5

The Scale Instruction, SC 2-6

The Input Window Instruction, IW 2-9

The Output Window Instruction, OW 2-10

Advanced Programming Tips 2-11

Chapter 3: Controlling the Pen and Plotting 3-1

What You'll Learn in This Chapter 3-1

HP-GL Instructions Covered 3-1

Terms You Should Understand 3-1

; iv TABLE OF CONTENTS

P ::"! Table of Contents (Continued)

Chapter 3: Controlling the Pen and Plotting (Continued)

rrm

fgr 3^

C 3

iR.

^0~ MM Plotting with Variables 3-11

The Pen

The Select Pen Instruction, SP 3-2

The Velocity Select

-™ The Plot Absolute Instruction, PA 3-4

The Plot Relative Instruction, PR 3-8

~~ The Circle Instruction, CI 3-12

am The Arc Absolute Instruction, AA 3-17

Instructions, PU and PD 3-2

Instruction, VS 3-3

5

~U3 The Arc Relative Instruction, AR 3-19

^T 3 Chapter 4: Enhancing the Plot 4-1

" What You'll Learn in This Chapter 4-1

_ n HP-GL Instructions Covered 4-1

!■'

IB The Tick Instructions, XT and YT 4-2

The Tick Length Instruction, TL 4-2

P: 3 The Symbol Mode Instruction, SM 4-4

~ - J The Line Type Instruction, LT 4-6

jm:

:a^ Chapter 5: Labeling 5-1

What You'll Learn in This Chapter 5-1

; "J HP-GL Instructions Covered 5-1

E

:

™ Terms You Should Understand 5-1

Plotter Character Sets 5-2

E; ill The Designate Standard Character Set Instruction, CS 5-3

The Designate Alternate Character Set Instruction, CA 5-4

f *m The Select Standard Set Instruction, SS 5-4

C': ifl The Select Alternate Set Instruction, SA 5-5

i The Define Terminator Instruction, DT 5-6

C i ^3 The Label Instruction, LB 5-7

Labeling with Variables 5-9

,. The Absolute Direction Instruction, DI 5-10

E

1

i3 The Relative Direction Instruction, DR 5-11

Spacing Between Characters 5-12

C; fj The Character Plot Instruction, CP 5-13

' The Absolute Character Size Instruction, SI 5-15

_j^

The Relative Character Size Instruction, SR 5-16

Rll3 The Character Slant Instruction, SL 5-18

x

»fc^

--"3 TABLE OF CONTENTS V

Page 8

)

)

)

)

)

)

)

)

)

3

)

3

)

)

3

3

3

'iff-iftti!iiTiffiriiiiiii»iiiiiiMiii

3

)

)

)

)

)

3

)

)

)

3

)

)

3

3

m

Page 9

>

Table of Contents (Continued)

) Chapter 5: Labeling (Continued)

)

) Advanced Programming Tips 5-27

) What You'll Learn in This Chapter 6-1

\ HP-GL Instructions Covered 6-1

) The Digitize Point Instruction, DP 6-2

)

) Digitizing with the 7470 6-4

) Manual Method 6-4

) HP-GL Instructions Covered 7-1

x Terms You Should Understand 7-1

) Notes for an HP-IB User 7-2

) The Output Status Instruction, OS 7-8

\ Summary of Output Response Types 7-9

( )

The User Defined Character Instruction, UC 5-19

Parameter Interaction in Labeling Commands 5-21

Chapter 6: Digitizing 6-1

Terms You Should Understand 6-1

Preparing Your Plotter for Use as a Digitizer 6-2

The Digitize Clear Instruction, DC 6-3

The Output Digitized Point and Pen Status Instruction, OD 6-3

Monitoring the Status Byte 6-5

HP-IB Interrupts and Polling 6-7

Chapter

7:

Obtaining Information From the Plotter 7-1

What You'll Learn in This Chapter 7-1

A Brief Word about Plotter Output 7-2

Notes for an RS-232-C User 7-2

Notes for an HP-IL User 7-2

The Output Actual Position and Pen Status

Instruction, OA 7-3

The Output Commanded Position and Pen Status

Instruction, OC 7-4

The Output Error Instruction, OE 7-5

The Output Factors Instruction, OF 7-6

The Output Identification Instruction, 01 7-7

The Output Options Instruction, 00 7-7

Table of Contents (Continued)

Chapter 8: Putting the Commands to Work 8-1

What You'll Learn in This Chapter 8-1

Problem 8-2

Solution 8-2

Setup and Scaling 8-2

The Axes and Their Labels 8-3

Adding Color and Emphasis 8-5

Plotting Your Data 8-6

Listing 8-9

Advanced Programming Tips 8-10

Filling and Hatching 8-10

Filling a Bar 8-10

Hatching a Bar 8-12

Filling Segments of Pie Charts 8-13

Chapter 9: HP-IB Interfacing 9-1

What You'll Learn in This Chapter 9-1

HP-IB Implementation on the 7470 9-2

Interface Switches and Controls 9-2

Addressing the Plotter 9-2

Bus Commands ■ 9-4

Reaction to Bus Commands DCL, SDC, and IFC 9-4

Serial and Parallel Polling 9-4

Addressing the 7470 as a Talker or Listener 9-6

Computers with No High Level I/O Statements 9-6

Computer with High Level I/O Statements 9-6

Sending and Receiving Data 9-7

Computer-to-Plotter 9-7

Plotter-to-Computer 910

Chapter 10: RS-232-C/CCITT V.24 Interfacing 10-1

What You'll Learn in This Chapter 10-1

Setting Up Your RS-232-C Plotter: a Checklist 10-2

Plotter Environments 10-2

Using a Plotter Directly Connected to a

Computer Mainframe or Personal Computer 10-2

Using a Plotter in an Environment with a Terminal 10-4

Using the Plotter in a Terminal-only Environment 10-9

Connecting the RS-232-C Interface 10-10

VI TABLE OF CONTENTS

J

TABLE OF CONTENTS Vll

Page 10

)

)

)

)

)

)

3

3

)

3

3

)

)

)

)

3

3

MiiiniUiwWiiiiiiii iiiiniiir'fii -iniraBiTu utiiirwi-Tn--i-nr r r .r-.inrn iMfin.1 - .ir-.ii^.,.■ i«->i ^-n-mi.,.,!,,.

^,

MiM^m^m^MmMmWaKK^^a--^-.

3

3

)

3

)

)

)

3

)

)

)

)

)

)

3

)

ammiMmimmmm

Page 11

Table of Contents (Continued)

) Chapter 10: RS-232-C/CCITT V.24 Interfacing (Continued)

\ Output Baud Rate 10-12

Stop Bits 10-13

-' Transmission Errors 10-13

) Handshaking 10-14

N

Software Checking

Page 12

)

)

)

)

)

)

)

3

')

)

)

)

)

)

)

)

)

mm

)

)

)

:>

)

)

)

)

)

)

)

)

)

)

)

Page 13

HP-IL — Hewlett-Packard Interface Loop — an interface used on some

Hewlett-Packard personal computing products to communicate with

peripheral devices such as the 7470 plotter. The HP-IL interface is

standard on the Option 003 plotter.

)

B

)

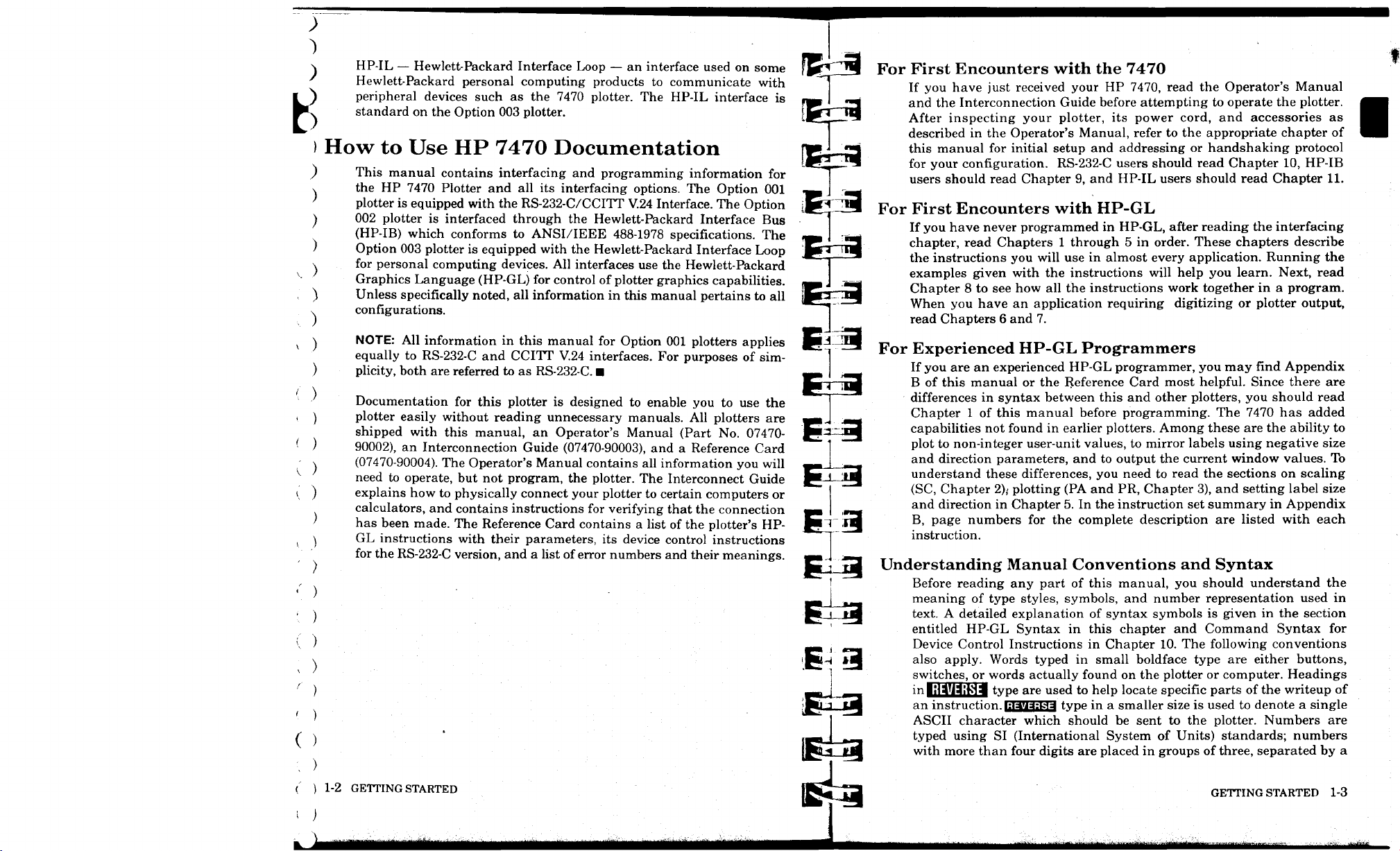

How to Use HP 7470 Documentation

) This manual contains interfacing and programming information for

the HP 7470 Plotter and all its interfacing options. The Option 001

plotter is equipped with the RS-232-C/CCITT V.24 Interface. The Option

002 plotter is interfaced through the Hewlett-Packard Interface Bus

(HP-IB) which conforms to ANSI/IEEE 488-1978 specifications. The

Option 003 plotter is equipped with the Hewlett-Packard Interface Loop

for personal computing devices. All interfaces use the Hewlett-Packard

Graphics Language (HP-GL) for control of plotter graphics capabilities.

Unless specifically noted, all information in this manual pertains to all

configurations.

NOTE: All information in this manual for Option 001 plotters applies

equally to RS-232-C and CCITT V.24 interfaces. For purposes of simplicity, both are referred to as RS-232-C. ■

Documentation for this plotter is designed to enable you to use the

plotter easily without reading unnecessary manuals. All plotters are

shipped with this manual, an Operator's Manual (Part No. 07470-

90002), an Interconnection Guide (07470-90003), and a Reference Card

(07470-90004). The Operator's Manual contains all information you will

need to operate, but not program, the plotter. The Interconnect Guide

explains how to physically connect your plotter to certain computers or

calculators, and contains instructions for verifying that the connection

has been made. The Reference Card contains a list of the plotter's HP-

GL instructions with their parameters, its device control instructions

for the RS-232-C version, and a list of error numbers and their meanings.

For First Encounters with the 7470

If you have just received your HP 7470, read the Operator's Manual

and the Interconnection Guide before attempting to operate the plotter.

After inspecting your plotter, its power cord, and accessories as

described in the Operator's Manual, refer to the appropriate chapter of

this manual for initial setup and addressing or handshaking protocol

for your configuration. RS-232-C users should read Chapter 10, HP-IB

users should read Chapter 9, and HP-IL users should read Chapter 11.

For First Encounters with HP-GL

If you have never programmed in HP-GL, after reading the interfacing

chapter, read Chapters 1 through 5 in order. These chapters describe

the instructions you will use in almost every application. Running the

examples given with the instructions will help you learn. Next, read

Chapter 8 to see how all the instructions work together in a program.

When you have an application requiring digitizing or plotter output,

read Chapters 6 and 7.

For Experienced HP-GL Programmers

If you are an experienced HP-GL programmer, you may find Appendix

B of this manual or the Reference Card most helpful. Since there are

differences in syntax between this and other plotters, you should read

Chapter 1 of this manual before programming. The 7470 has added

capabilities not found in earlier plotters. Among these are the ability to

plot to non-integer user-unit values, to mirror labels using negative size

and direction parameters, and to output the current window values. To

understand these differences, you need to read the sections on scaling

(SC,

Chapter

and direction in Chapter 5. In the instruction set summary in Appendix

B,

page numbers for the complete description are listed with each

instruction.

2),-

plotting (PA and PR, Chapter 3), and setting label size

Understanding Manual Conventions and Syntax

Before reading any part of this manual, you should understand the

meaning of type styles, symbols, and number representation used in

text. A detailed explanation of syntax symbols is given in the section

entitled HP-GL Syntax in this chapter and Command Syntax for

Device Control Instructions in Chapter 10. The following conventions

also apply. Words typed in small boldface type are either buttons,

switches, or words actually found on the plotter or computer. Headings

in liWHiMJI type are used to help locate specific parts of the writeup of

an instruction. i:i*'ia:M^ type in a smaller size is used to denote a single

ASCII character which should be sent to the plotter. Numbers are

typed using SI (International System of Units) standards; numbers

with more than four digits are placed in groups of three, separated by a

1-2 GETTING STARTED

GETTING STARTED 1-3

Page 14

)

)

.)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

MMMU

)

)

)

;

)

)

)

)

)

)

)

)

;

)

)

J

Page 15

tf

)

'

)

V

)

)

)

■■

.)

)

<:

)

;

)

'

)

<■

)

(

)

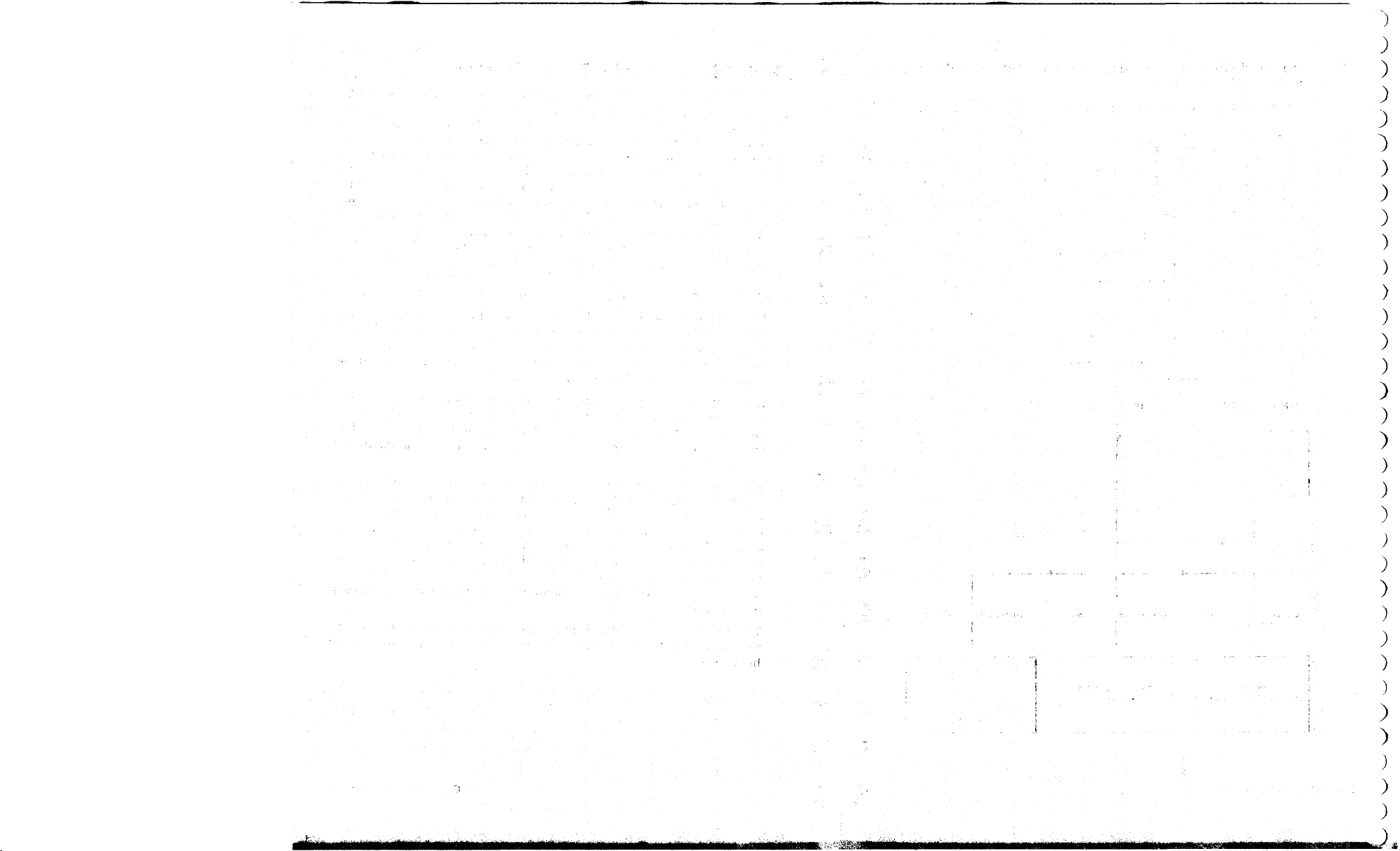

space instead of commas, counting both to the left and right of the

decimal point (54 321.123 45).

Follow the documentation road map below:

ALL USERS

OPERATOR'S

MANUAL

07470-90002

INTERCONNECTION

GUIDE

07470-90003

RS-232-C USER

INTERFACING AND

PROGRAMMING

MANUAL,

CHAPTER 10

07470-90001

HP-IB,

USERS

HP-IL

^

t

»

—4

►

•

USER OF SOFTWARE

PACKAGE

YOUR

SOFTWARE MANUAL

GRAPHICS ROM USER

GRAPHICS ROM

MANUAL

HP-GL PROGRAMMER

INTERFACING AND

PROGRAMMING

MANUAL

07470-90001

CHAPTERS 1-8, AND

CHAPTER 9, 10, OR 11

A Brief Look at the 7470 Plotter

The HP 7470 Graphics Plotter is a vector plotter which produces high

quality, multicolor graphics plots on two sizes of drawing media:

English ANSI A

programmable pen velocity and a choice of standard fiber tip or transparency pens, the 7470 can produce distinctive graphics not only on

standard paper, but also on other media such as transparency film.

The plotter offers both fast plotting speed and high line quality,

achieved using Hewlett-Packard's micro-grip drive technology. This

technology provides low-inertia grit-covered wheels to move the paper

in one axis while the pen moves along the other axis. Plotting occurs

with approximately 2 g acceleration and a maximum velocity of 38.1

cm/s (15 in./s). The result is exceptional line and character quality and

high throughput. The 7470 has addressable resolution of 0.025 mm

(0.001 in.) and repeatability of 0.10 mm (0.004 in.) for any given pen.

The multicolor graphics capability is provided by programmed or frontpanel selection of two pens. If additional colors are desired, the program can be paused to allow manual installation of additional pens.

Seven different dashed-line fonts and symbol mode plotting provide

additional trace identification capabilities.

Character plotting speed of up to six characters per second enables you

to produce fully-lettered graphs quickly. Annotation can be easily done

using any of five character sets, including three European sets. Text

can be written in any direction, with or without character slant, and in

varying sizes.

The 7470 is engineered to be especially useful in the areas of business

graphics, statistics, medicine, numerical control, surveying, and engineering design. An optional overhead transparency kit enables you to

produce high quality graphic transparencies from your plotting pro-

grams. For faster comprehension, you can present economic trends,

engineering or scientific data, marketing plans, profit data, or sales

forecasts pictorially. And with a choice of media, you can create paper

hardcopy for an individual's attention or transparencies for group

presentations.

Whether data are tabulated, measured, or computed, depend on the

reliable 7470 to prepare multicolored plots of excellent line quality and

high resolution.

(8V2 X

11 in.) or metric ISO A4 (210 X 297 mm). With

{

)

1-4 GETTING STARTED

MIMH

tJUmitmi/aH

■^^^^—

■J-^**—^-**;*

GETTING STARTED

-^.--

1-5

•,Q...i^^.

Page 16

■■•

)

)

)

0

)

)

)

)

)

)

)

)

)

)

)

)

)

m*

MMMMH

)

i

)

)

;

)

)

■'

-

)

)

;■ )

' )

\ )

)

)

.

)

)

«*_J

Page 17

)

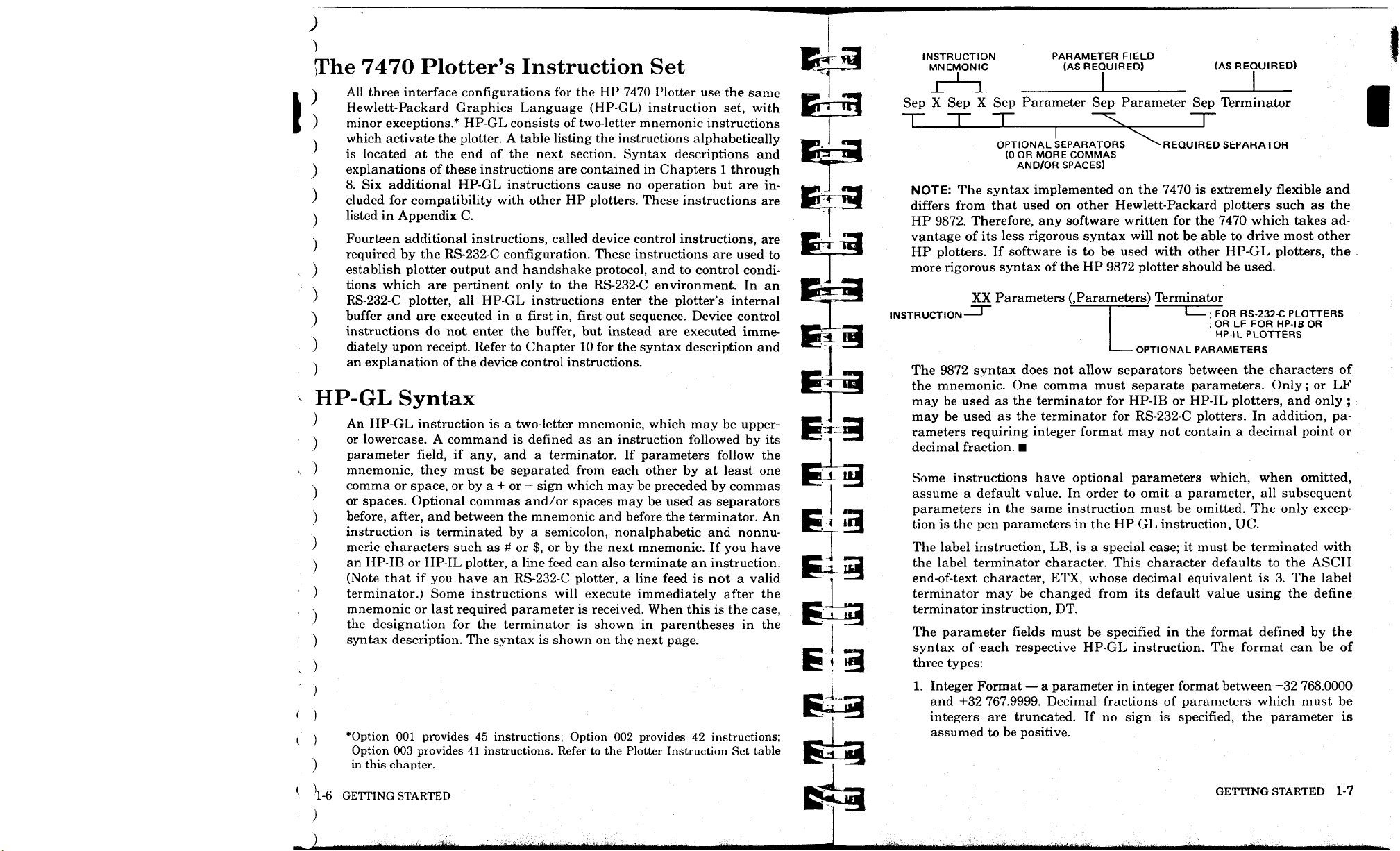

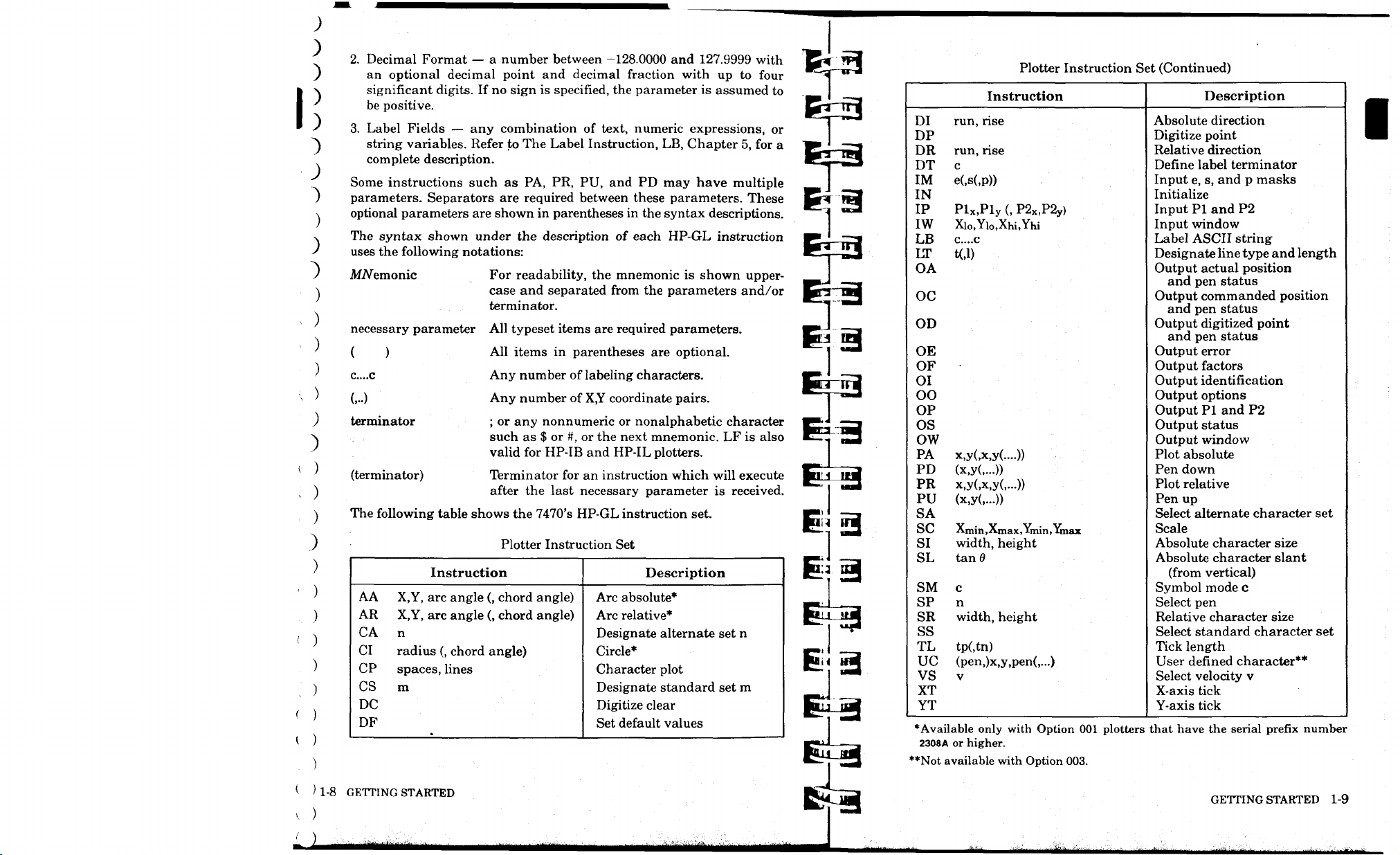

The 7470 Plotter's Instruction Set

All three interface configurations for the HP 7470 Plotter use the same

Hewlett-Packard Graphics Language (HP-GL) instruction set, with

i

minor exceptions.* HP-GL consists of two-letter mnemonic instructions

which activate the plotter. A table listing the instructions alphabetically

is located at the end of the next section. Syntax descriptions and

explanations of these instructions are contained in Chapters 1 through

8. Six additional HP-GL instructions cause no operation but are included for compatibility with other HP plotters. These instructions are

listed in Appendix C.

Fourteen additional instructions, called device control instructions, are

required by the RS-232-C configuration. These instructions are used to

establish plotter output and handshake protocol, and to control conditions which are pertinent only to the RS-232-C environment. In an

RS-232-C plotter, all HP-GL instructions enter the plotter's internal

buffer and are executed in a first-in, first-out sequence. Device control

instructions do not enter the buffer, but instead are executed immediately upon receipt. Refer to Chapter 10 for the syntax description and

an explanation of the device control instructions.

HP-GL Syntax

An HP-GL instruction is a two-letter mnemonic, which may be upperor lowercase. A command is defined as an instruction followed by its

parameter field, if any, and a terminator. If parameters follow the

mnemonic, they must be separated from each other by at least one

comma or space, or by a + or — sign which may be preceded by commas

or spaces. Optional commas and/or spaces may be used as separators

before, after, and between the mnemonic and before the terminator. An

instruction is terminated by a semicolon, nonalphabetic and nonnumeric characters such as # or $, or by the next mnemonic. If you have

an HP-IB or HP-IL plotter, a line feed can also terminate an instruction.

(Note that if you have an RS-232-C plotter, a line feed is not a valid

terminator.) Some instructions will execute immediately after the

mnemonic or last required parameter is received. When this is the case,

the designation for the terminator is shown in parentheses in the

syntax description. The syntax is shown on the next page.

*Option 001 provides 45 instructions; Option 002 provides 42 instructions;

Option 003 provides 41 instructions. Refer to the Plotter Instruction Set table

in this chapter.

INSTRUCTION PARAMETER FIELD

MNEMONIC (AS REQUIRED) (AS REQUIRED)

J-^L I _J

Sep X Sep X Sep Parameter Sep Parameter Sep Terminator

OPTIONAL SEPARATORS ^^ REQUIRED SEPARATOR

(0OR MORE COMMAS

AND/OR SPACES)

NOTE: The syntax implemented on the 7470 is extremely flexible and

differs from that used on other Hewlett-Packard plotters such as the

HP 9872. Therefore, any software written for the 7470 which takes ad-

vantage of its less rigorous syntax will not be able to drive most other

HP plotters. If software is to be used with other HP-GL plotters, the

more rigorous syntax of the HP 9872 plotter should be used.

XX Parameters (.Parameters) Terminator

INSTRUCTION '

OPTIONAL PARAMETERS

The 9872 syntax does not allow separators between the characters of

the mnemonic. One comma must separate parameters. Only; or LF

may be used as the terminator for HP-IB or HP-IL plotters, and only ;

may be used as the terminator for RS-232-C plotters. In addition, parameters requiring integer format may not contain a decimal point or

decimal fraction. ■

Some instructions have optional parameters which, when omitted,

assume a default value. In order to omit a parameter, all subsequent

parameters in the same instruction must be omitted. The only exception is the pen parameters in the HP-GL instruction, UC.

The label instruction, LB, is a special case; it must be terminated with

the label terminator character. This character defaults to the ASCII

end-of-text character, ETX, whose decimal equivalent is 3. The label

terminator may be changed from its default value using the define

terminator instruction, DT.

The parameter fields must be specified in the format defined by the

syntax of each respective HP-GL instruction. The format can be of

three types:

1.

Integer Format — a parameter in integer format between —32 768.0000

and +32 767.9999. Decimal fractions of parameters which must be

integers are truncated. If no sign is specified, the parameter is

assumed to be positive.

FOR RS-232-C PLOTTERS

;OR LF FOR HP-IB OR

HP-IL PLOTTERS

1-6 GETTING STARTED

Mann

«itei

GETTING STARTED 1-7

^^tmm^timtmit^tmimi^iiiitmm

Page 18

;

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

MlHiiiliHtfiilMiHiialli

MHWiE&i:^

mm

;

)

)

)

)

)

)

)

)

)

;

)

)

J

Page 19

)

;

)

2.

Decimal Format — a number between -128.0000 and 127.9999 with

)

)

)

:>

)

)

)

)

an optional decimal point and decimal fraction with up to four

significant digits. If no sign is specified, the parameter is assumed to

be positive.

3.

Label Fields — any combination of text, numeric expressions, or

string variables. Refer to The Label Instruction, LB, Chapter 5, for a

complete description.

Some instructions such as PA, PR, PU, and PD may have multiple

parameters. Separators are required between these parameters. These

optional parameters are shown in parentheses in the syntax descriptions.

The syntax shown under the description of each HP-GL instruction

uses the following notations:

AfA/emonic

necessary parameter

( )

C....C

(...)

terminator

(terminator)

The following table shows the 7470's HP-GL instruction set.

Instruction

AA

X,Y, arc angle (, chord angle)

AR

X,Y, arc angle (, chord angle)

n

CA

CI

radius (, chord angle)

CP

spaces, lines

CS

m

DC

DF

For readability, the mnemonic is shown uppercase and separated from the parameters and/or

terminator.

All typeset items are required parameters.

All items in parentheses are optional.

Any number of labeling characters.

Any number of X,Y coordinate pairs.

; or any nonnumeric or nonalphabetic character

such as $ or #, or the next mnemonic. LF is also

valid for HP-IB and HP-IL plotters.

Terminator for an instruction which will execute

after the last necessary parameter is received.

Plotter Instruction Set

Description

Arc absolute*

Arc relative*

Designate alternate set n

Circle*

Character plot

Designate standard set m

Digitize clear

Set default values

Plotter Instruction Set (Continued)

Description

run, rise

DI

DP

DR

run, rise

c

DT

IM

e(,s(,p))

IN

IP

Plx.Ply (, P2x,P2y)

IW

Xio,Yi0,Xhi,Yhi

C....C

LB

LT

t(,l)

OA

Instruction

Absolute direction

Digitize point

Relative direction

Define label terminator

Input e, s, and p masks

Initialize

Input PI and P2

Input window

Label ASCII string

Designate line type and length

Output actual position

and pen status

OC

Output commanded position

and pen status

OD

Output digitized point

and pen status

OE

OF

OI

OO

OP

OS

OW

PA

x,y(,x,y(....))

PD

(x,y(,...))

PR

x,y(,x,y(,...))

PU

(x,y(,...))

SA

SC

Xmin,Xmax,Ymin,Ymax

SI

width, height

SL

tan 0

Output error

Output factors

Output identification

Output options

Output PI and P2

Output status

Output window

Plot absolute

Pen down

Plot relative

Pen up

Select alternate character set

Scale

Absolute character size

Absolute character slant

(from vertical)

SM

c

SP

n

SR

width, height

ss

TL

tp(,tn)

UC

(pen,)x,y,pen(,...)

V

VS

XT

YT

*Available only with Option 001 plotters that have the serial prefix number

2308A or higher.

'*Not available with Option 003.

Symbol mode c

Select pen

Relative character size

Select standard character set

Tick length

User denned character**

Select velocity v

X-axis tick

Y-axis tick

1-8 GETTING STARTED

MMiiiHiiiitaMii

GETTING STARTED 1-9

warn

Page 20

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

;

>

>

)

Page 21

£low to Use the Examples in This Manual

The examples in this manual are designed primarily to show the use of

) the instruction with which they appear. New programmers are strongly

A encouraged to enter and run all examples. When the example consists

of only a few HP-GL commands, these commands are listed in quotes.

) No line numbers or BASIC statements are included. The literal string

A

listed should be sent to the plotter; the quotation marks only serve to

J delimit the string and are included because many computer languages

~) define literal strings by placing them inside quotation marks. Do not

send the quotation marks to the plotter.

Longer examples are given as programs or program segments in

) BASIC. The programs will run only if the plotter has been defined as

A

the system printer. Since the statement to do this is highly system-

dependent, it is not included (except in Chapter 8). Unless specific

) mention is made in the text, the BASIC used is that of the HP-83/85.

You may need to make slight changes in the BASIC statements for

)

them to run on your computer. You may also need an I/O ROM to

) obtain output from the plotter. Check with the nearest HP dealer or HP

Sales and Support Office. If you are operating in an RS-232-C environ-

) ment, you will need to establish handshaking protocol and include the

\ necessary device control statements in your program.

If you are programming in another language, substitute the output or

)

input commands of your language for the BASIC statements PRINT

) and ENTER. Change FOR...NEXT loops and replacement statements

(X = 3.14) to whatever statements are comparable in your language. All

) characters enclosed in quotes in the program listing must be sent to the

^ computer using output statements; in addition, some variables, which

are not included in quotes, may need to be sent.

Refer to Chapter 9 for some examples of complete simple programs to

) send and receive information between the plotter and specific com-

puters in an HP-IB environment. The Interconnection Guide (07470-

90003) has some examples of sending HP-GL commands from specific

) computers; there are examples using RS-232-C, HP-IB, and HP-IL

interfaces in that document.

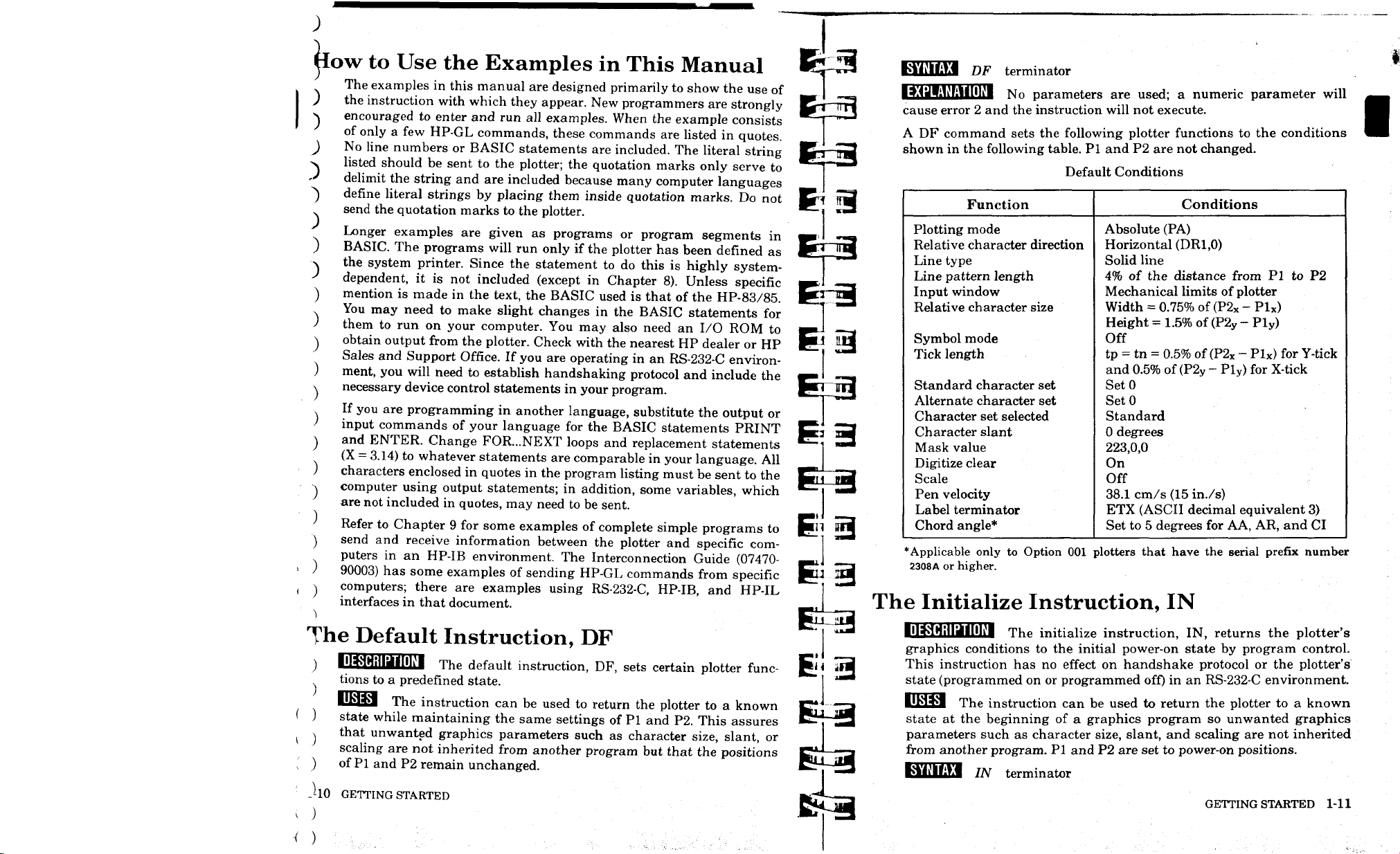

KMiUlEl DF terminator

No parameters are used; a numeric parameter will

cause error 2 and the instruction will not execute.

A DF command sets the following plotter functions to the conditions

shown in the following table. PI and P2 are not changed.

Default Conditions

Function

Plotting mode

Relative character direction

Line type

Line pattern length

Input window

Relative character size

Symbol mode

Tick length

Standard character set

Alternate character set

Character set selected

Character slant

Mask value

Digitize clear

Scale

Pen velocity

Label terminator

Chord angle*

*Applicable only to Option 001 plotters that have the serial prefix number

2308A or higher.

Absolute (PA)

Horizontal (DR1.0)

Solid line

4%

of the distance from PI to P2

Mechanical limits of plotter

Width = 0.75% of (P2X - Plx)

Height = 1.5% of (P2y - Ply)

Off

tp = tn = 0.5% of (P2X - Plx) for Y-tick

and 0.5% of (P2y - Ply) for X-tick

SetO

SetO

Standard

0 degrees

223,0,0

On

Off

38.1 cm/s (15 in./s)

ETX (ASCII decimal equivalent 3)

Set to 5 degrees for AA, AR, and CI

Conditions

The Initialize Instruction, IN

The Default Instruction, DF

tions to a predefined state.

)

f

<

lUaxl The instruction can be used to return the plotter to a known

)

state while maintaining the same settings of PI and P2. This assures

j that unwanted graphics parameters such as character size, slant, or

scaling are not inherited from another program but that the positions

) of Pi and P2 remain unchanged.

JlO GETTING STARTED

)

)

The default instruction, DF, sets certain plotter func-

The initialize instruction, IN, returns the plotter's

graphics conditions to the initial power-on state by program control.

This instruction has no effect on handshake protocol or the plotter's

state (programmed on or programmed off) in an RS-232-C environment.

The instruction can be used to return the plotter to a known

state at the beginning of a graphics program so unwanted graphics

parameters such as character size, slant, and scaling are not inherited

from another program. PI and P2 are set to power-on positions.

■tWlftyi IN terminator

GETTING STARTED 1-11

Page 22

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

;

)

)

)

)

)

)

Page 23

>. I^HUMi'MIHli'l NO parameters are used; a numeric parameter will K.-—«-3

J cause error 2 and the instruction will not execute. I

) An IN command is the equivalent of switching the plotter off and then

"\ on again (except that conditions set by escape code sequences are not

changed in an RS-232-C environment). The initialize command sets the

) plotter to the same conditions as the default command and sets these

additional conditions.

)

v • The pen is raised. 1ft! ™^3

• The scaling points Pi and P2 are set to the points PI = 250,279 and ^~ "^

) P2 = 10 250,7479.

) • All HP-GL errors are cleared. Bit position 3 of the output status byte ifW' J| j

-v is set to true(l) indicating the plotter has been initialized. (This bit is 1

) cleared by OS.) '

) • The setting of the US/A4 switch (for paper size) is read, thus

\ establishing the limits within which the pen can move (mechanical

hard clip limits).

T

El SJ

The Input Mask Instruction, IM

J HlwHHIillFlltl The input mask instruction, IM, controls the conditions

~N

under which HP-GL error status is reported, the conditions that can

' cause an HP-IB service request message, and the conditions that can

cause a positive response to an HP-IB parallel poll.

UWM With all three interface configurations (HP-IB, HP-IL, and RS- —*

232-C),

this instruction can be used to change the conditions under fT^~^~3

which HP-GL error status is reported. In an HP-IB system only, the

instruction is used to enable the plotter to send a service request «! r-—.

message when specified bits of the status byte are set, and/or enable a i^' J_3

positive response to a parallel poll under the conditions specified.

--" " " " \

"\ BJiJIiftl IM E-mask value (,S-mask value (,P-mask value))

(terminator)

or

IM (terminator)

■9<JI:Ui1llllfl

and P-masks are of no use and are ignored if present. The E-mask is H J , _

used by all three configurations. J5« ^Jj

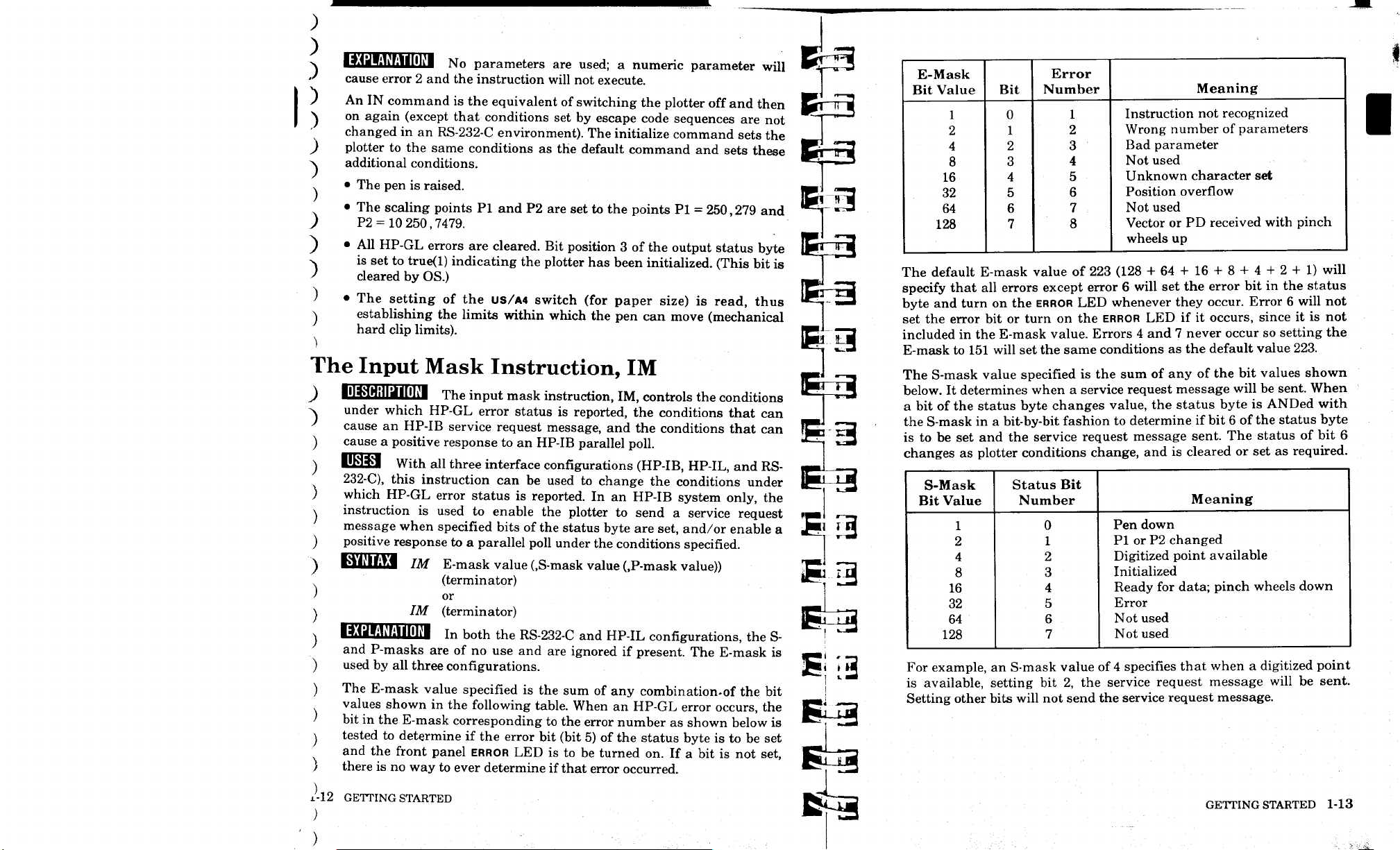

The E-mask value specified is the sum of any combination.of the bit

values shown in the following table. When an HP-GL error occurs, the

bit in the E-mask corresponding to the error number as shown below is

tested to determine if the error bit (bit 5) of the status byte is to be set

and the front panel

there is no way to ever determine if that error occurred.

In both

the RS-232-C and HP-IL configurations, the S-

ERROR

LED is to be turned on. If a bit is not set,

3

EH3

E-Mask

Bit Value

1

2

4

8

16

32

64

128

The default E-mask value of 223 (128 + 64 + 16 + 8 + 4 + 2 + 1) will

specify that all errors except error 6 will set the error bit in the status

byte and turn on the ERROR LED whenever they occur. Error 6 will not

set the error bit or turn on the ERROR LED if it occurs, since it is not

included in the E-mask value. Errors 4 and 7 never occur so setting the

E-mask to 151 will set the same conditions as the default value 223.

The S-mask value specified is the sum of any of the bit values shown

below. It determines when a service request message will be sent. When

a bit of the status byte changes value, the status byte is ANDed with

the S-mask in a bit-by-bit fashion to determine if bit 6 of the status byte

is to be set and the service request message sent. The status of bit 6

changes as plotter conditions change, and is cleared or set as required.

S-Mask

Bit Value

1

2

4

8

16

32

64

128

For example, an S-mask value of 4 specifies that when a digitized point

is available, setting bit 2, the service request message will be sent.

Setting other bits will not send the service request message.

Bit

0

1

2

3

4

5

6

7

Error

Number

1

2

3

4

5

6

7

8

Status Bit

Number

0

1

2

3

4

5

6

7

Instruction not recognized

Wrong number of parameters

Bad parameter

Not used

Unknown character set

Position overflow

Not used

Vector or PD received with pinch

wheels up

Pen down

PI or P2 changed

Digitized point available

Initialized

Ready for data; pinch wheels down

Error

Not used

Not used

Meaning

Meaning

12 GETTING STARTED

GETTING STARTED 1-13

Page 24

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

Page 25

)

)

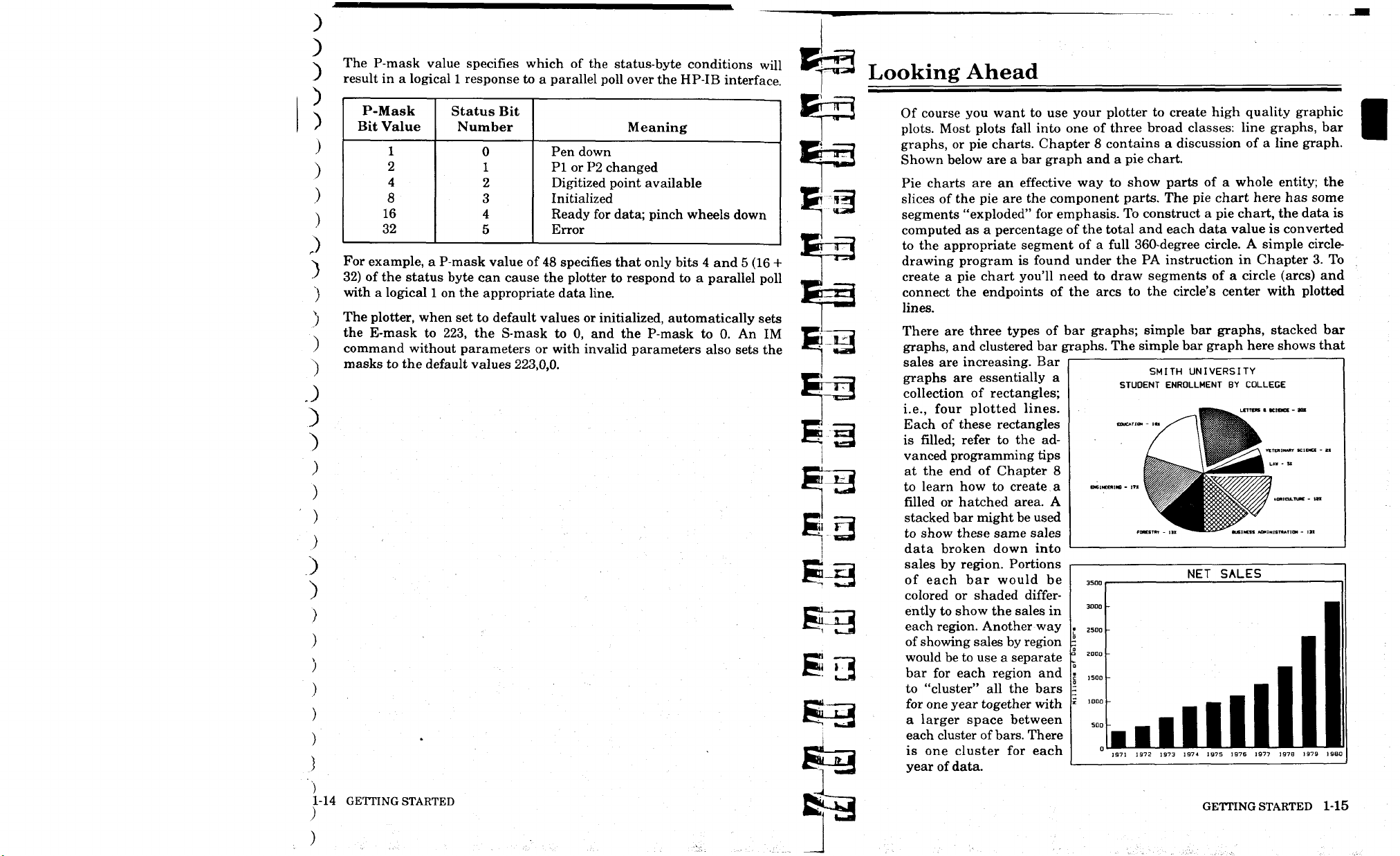

The P-mask value specifies which of the status-byte conditions will

)

result in a logical 1 response to a parallel poll over the HP-IB interface.

)

)

)

)

)

)

.)

)

)

)

)

)

P-Mask

Bit Value

1

2

4

8

16

32

For example, a P-mask value of 48 specifies that only bits 4 and 5 (16 +

32) of the status byte can cause the plotter to respond to a parallel poll

with a logical 1 on the appropriate data line.

The plotter, when set to default values or initialized, automatically sets

the E-mask to 223, the S-mask to 0, and the P-mask to 0. An IM

command without parameters or with invalid parameters also sets the

masks to the default values 223,0,0.

Status Bit

Number

0

1

2

3

4

5

Meaning

Pen down

PI or P2 changed

Digitized point available

Initialized

Ready for data; pinch wheels down

Error

J

)

;

)

)

)

)

1-14 GETTING STARTED

)

^

EE3

^3

Looking Ahead

Of course you want to use your plotter to create high quality graphic

plots.

Most plots fall into one of three broad classes: line graphs, bar

graphs, or pie charts. Chapter 8 contains a discussion of a line graph.

Shown below are a bar graph and a pie chart.

Pie charts are an effective way to show parts of a whole entity; the

slices of the pie are the component parts. The pie chart here has some

segments "exploded" for emphasis. To construct a pie chart, the data is

computed as a percentage of the total and each data value is converted

to the appropriate segment of a full 360-degree circle. A simple circledrawing program is found under the PA instruction in Chapter 3. To

create a pie chart you'll need to draw segments of a circle (arcs) and

connect the endpoints of the arcs to the circle's center with plotted

lines.

There are three types of bar graphs; simple bar graphs, stacked bar

graphs, and clustered bar graphs. The simple bar graph here shows that

sales are increasing. Bar

graphs are essentially a

collection of rectangles;

i.e., four plotted lines.

Each of these rectangles

is filled; refer to the advanced programming tips

at the end of Chapter 8

to learn how to create a

filled or hatched area. A

stacked bar might be used

to show these same sales

data broken down into

sales by region. Portions

of each bar would be

colored or shaded differ-

ently to show the sales in

each region. Another way

of showing sales by region

would be to use a separate

bar for each region and

to "cluster" all the bars

for one year together with

a larger space between

each cluster of

is one cluster for each

year of data.

bars.

There

3000

2500

I

a

2000

■5

1500

|

1000

i

SQQ

0

m.

SMITH UNIVERSITY

STUDENT ENROLLMENT BY COLLEGE

fORKTRT - I!

NET SALES

■

■

ml

JLL

1972

1971

III!

1973

1974 1975 1976 1977

GETTING STARTED 1-15

VETERINARY SCIENCE - 21

LAW - S*

AGRICULTURE - IB

1

M.

■

■

1

■ ■

■ ■

1

1979

1978

Ml

19B0

Page 26

;

)

,)

)

)

)

^

)

)

)

)

)

)

)

)

)

)

)

)

')

)

)

)

)

)

)

)

>

)

)

)

)

Page 27

Chapter

Establishing Boundaries

and Units

What You'll Learn in This Chapter

In this chapter you will learn about the plotting area, how to define a

point in this area, and the two kinds of units used to describe the plotting area. After reading this chapter, you will be able to decide which

units to use for your data. In addition, you will be able to scale the

plotting area into user units appropriate for your data, and to set or

read the current scaling points. You will be able to restrict plotting to

only a portion of the plotting area, and read the current limits of the

plotting area.

HP-GL Instructions Covered

IP The Input PI and P2 Instruction

OP The Output PI and P2 Instruction

SC The Scale Instruction

IW The Input Window Instruction

OW The Output Window Instruction

Terms You Should Understand

Scaling — dividing the plotting area into units convenient for your application. Units need not be the same physical size in both axes, nor do

there need to be an equal number of units in the X- and Y-axes.

Scaling Points — the points on the plotting surface moved to when the

front panel buttons

user-unit values specified by the parameters of the scaling instruction

SC.

Window — that part of the plotting area in which plotting of points,

lines,

and labels can occur. At power on, the window is set to the

mechanical limits of the plotter. Nothing can be drawn outside the

current window.

Clipping — restricting plotting to a portion of the plotting area by

establishing a window of a certain size.

P1

and P2 are pressed. These points are assigned the

ESTABLISHING BOUNDARIES AND UNITS 2-1

Page 28

)

3

:>

)

)

)

.)

)

)

)

>

)

)

)

)

)

)

)

)

)

)

-")

)

)

)

)

)

.)

)

)

Page 29

J

)

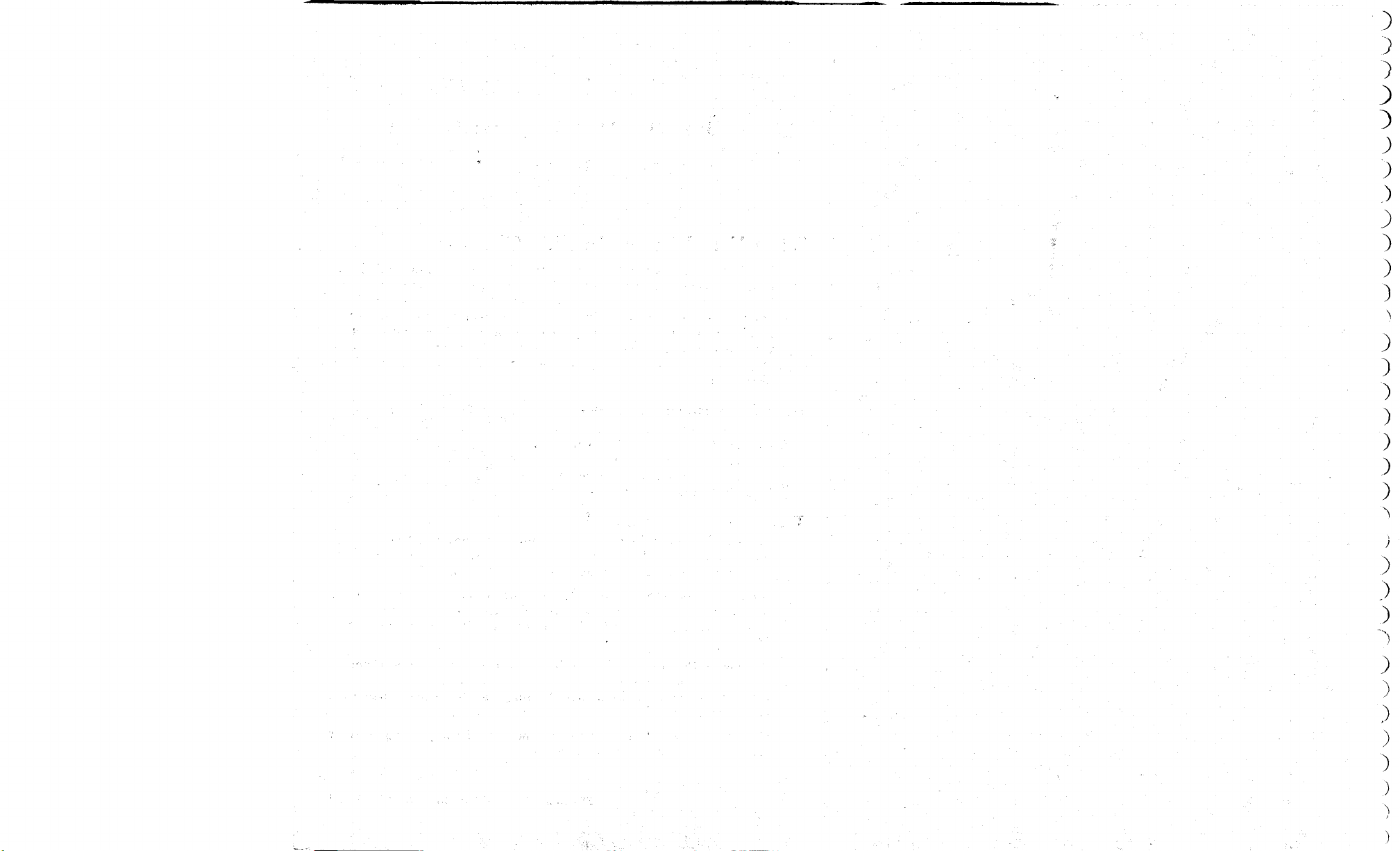

?he Plotting Area

The plotting area is that area of the paper in which the pen can draw.

)

The maximum plotting area for the HP 7470 Plotter is 191 X 272 mm

)

(7.5 X 10.7 in.) when the paper switch is set to A4, and is 191 X 257 mm

(7.5 X 10.2 in.) when the paper switch is set to us. These plotting areas

)

permit plotting on either metric A4 size paper or English

paper and allow for a margin beween the plotting area and the edges of

)

the paper.

)

The plotting area should be thought of as a two-dimensional Cartesian

coordinate system. Remember, in a two-dimensional Cartesian coordinate system, a point is defined by its X- and Y-coordinates; for example,

200,300 represents a distinct point where X = 200 and Y =

paper is loaded, the orientation of the X- and Y-axes is established as

shown in the following diagram. When looking at the plotter from the

front, the origin is located near the upper-left corner of the paper. From

now on, we will refer to that corner as lower left, since when a plot is

viewed, the minimum point is generally at the lower-left corner of the

plot.

8'/2-by-l

300.

1-inch

When

Unit Systems

There are two unit systems which can be used to define points in the

plotting area: plotter units and user units. Plotter units are always the

same size. The size of a user unit depends on the parameters of the SC

instruction and the settings of the scaling points, PI and P2.

The Plotter Unit

The plotting area is divided into plotter units; one plotter unit equals

0.025 mm. There are approximately 40 plotter units per millimetre, or

approximately 1000 plotter units per inch. One plotter unit is the

smallest move the plotter can make. When the paper switch is set to A4,

the plotting area contains 10 900 plotter units in X and 7650 plotter

units in Y. When the paper switch is set to us, the plotting area

contains 10 300 plotter units in X and 7650 in Y. While the pen can only

plot in the area mentioned above, parameters of plot commands between —32 768 and 32 767 plotter units are understood by the plotter.

When plotting in plotter units, only integer values are used; parameters

are truncated to integers. Refer to The Plot Absolute Instruction, PA, in

Chapter 3.

- )

< )

, )

' )

1 (DEFAULT)

-,i

.-wmwmmwL>mmi^w,mL

+Y

+X

HARD CLIP

LIMITS

(DEFAULT) P2

Si 3

gkj

At power on, upon front-panel reset, and whenever an IN command is

sent to the plotter, the scaling point PI is set to 250,279 plotter units

and the scaling point P2 is set to 10 250,7479 plotter units. These settings

are independent of the setting of the paper switch.

User Units

The plotting area can also be scaled into user units. This is done with

the scale instruction, SC, which assigns values to the scaling points PI

and P2. A user unit may be almost any size. The parameters of the SC

instruction are truncated to integers between -32 768 and 32 767.

Parameters of plot commands must also be in that range but may be

decimal numbers with fractional parts. Decimal fractions are not truncated; as a matter of fact, you can set the scaling points at 0,0 and 1,1

and all your data can be decimal fractions between 0 and 1. You can

also use the plot relative instruction to plot to a point which, in user

units,

is beyond the range ±32 768 as long as its location, expressed as

plotter units, is in range. Refer to the plot instructions PA and PR in

Chapter 3. You will probably use the SC instruction and user units for

most plots.

Setting the Scaling Points

Scaling points PI and P2 can be set programmatically using the input

PI and P2 instruction, IP, as described in a following section. PI and

P2 can be set manually using front panel controls ENTER, PI, and

P2.

of2

ESTABLISHING BOUNDARIES AND UNITS

)

ESTABLISHING BOUNDARIES AND UNITS 2-3

Page 30

)

;

")

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

Page 31

)

netting PI and P2 Manually

) P2 moves when Pi is moved manually. If you want P2 to be at a

specific location, set PI first and then P2. If you want to establish an

)

area of a certain size onto which the parameters of a scale instruction

)

will be mapped, you may set P2 in the desired location relative to the

current PI, and then move Pi. P2 will move to a corresponding location

)

so that both the X- and Y-distances between PI and P2 remain con-

stant. If such a move means the new location of P2 will be beyond the

;

plotting area, either or both coordinates of P2 are set to the plotting

limits.

In this case, the size of the rectangle established by PI and P2

will, of course, not remain the same. A detailed description, including

illustrations, is contained in the HP 7470 Operator's Manual.

)

To set PI or P2 manually:

)

1.

Move the pen to the desired location using the front panel arrow

buttons.

>

2.

Press ENTER simultaneously with

the pen will merely move to PI or P2 and no change in the location

) of PI or P2 will occur.

) 3. Check the new locations of the scaling points by pressing P1; then

\ press P2.

P1

or

P2.

If ENTER is not held down,

'he Input PI and P2 Instruction, IP

DESCRIPTION

means to relocate PI and P2 through program control.

lifilxi The IP instruction is often used to ensure that a plot is always

the same size, especially when the user and programmer are not the

same person. It establishes program control of plot size and label direction. This instruction can also be used to move the scaling points PI

and P2 from their default or current locations; to give mirror images of

vectors and labels; to change the size of a user unit, thus reducing or

enlarging an image; to change the size or direction of labels when

relative character size or direction is in effect; and to set PI and P2

back to their default locations.

EEEQ //•

EXPLANATION

order shown above and must be in absolute plotter units. Parameters

should be ^ 0 and within the maximum plotting area. This means

0 < X sj 10 30Q when the paper switch is set to us; 0 s$ X < 10 900 if the

paper switch is set to

The input PI and P2 instruction, IP, provides the

Plx,Ply (, P2x,P2y) (terminator)

or

IP

(terminator)

The new coordinates of Pi and P2 are specified in the

A4;

and 0

«S

Y ^ 7650 for either setting.

3

3

-a

Negative parameters greater than or equal to -32 768 will be set to zero.

Parameters outside the maximum plotting area (determined by the setting of the paper switch) but less than 32 767 will be set to the limits of

the plotting area. Parameters less than -32 768 or greater than 32 767

will cause error 3 and the coordinates of PI and P2 will not change.

An IP command without parameters will default PI and P2 to the

values 250,279,10 250,7479 regardless of the paper switch setting.

Upon receipt of a valid IP command, bit position 1 of the output status

word is set true (1).

Upon power on, front-panel reset, or execution of an IN or DF command, the character size is set relative (SR) to the locations of PI and

P2.

Unless an SI command has been entered as part of the program,

the character size will be directly affected by the IP command.

The following HP-GL command relocates the scaling points PI and P2

to the positions shown in the figure.

"IP 3000,2000,5000,5000;"

P2

#

(50005000)

• P1

(3000,2000)

The Output PI and P2 Instruction, OP

The output PI and P2 instruction, OP, provides the

means to make the current coordinates of PI and P2 available for

output.

'A

ESTABLISHING BOUNDARIES AND UNITS

( )

BS3

ESTABLISHING BOUNDARIES AND UNITS 2-5

Page 32

)

:>

)

)

)

)

)

)

)

1

)

)

)

)

)

1

)

.)

)

:>

)

)

)

)

)

)

)

)

;

Page 33

)

The Output Win

) |»|yitJHiaHllll

s means to obtain the X

right corners of the are!

) I'Hyj The instructio)

any plotting will occur

the execution of a DF

determine under progri

or A4.

EMEU OW (termi

MJWiwaii'Hi No

After an OW commam

nates of opposite corni

integers in ASCII in thi

)

)

where [TERM] is the ol

)

Should Understand in \

)

The range of the intej

switch as shown below;

)

)

)

)

If Xlower left is greater

Yupper

)

)

)

)

)

)

)

right,

The o

1

Pai

Xlower left, Yloj

US

OsSXsSK

0«S Y«S7t

no window

{

«'

)

■ )

O)

tpii

o

J

vVr)

i d

)

£0l^

trle\

pu^

)

■ )

JlA.

1 '

ist)

■■ )

)

The instruction can be used to determine the position of Pi

and P2 in plotter units. This information can be used with the input

window command, IW, to set the window to PI and P2 under program

control, to compute the number of plotter units per user unit when

scaling is on, or to determine the numeric coordinates of Pi and P2

when they have been set manually.

EffiEE] OP (terminator)

( )

EXPLANATION

put the coordinates of PI and P2 in plotter units as four integers in

ASCII in the following form:

where [TERM] is the output terminator for your system. See Terms You

Should Understand in Chapter 7.

The range of the integers is determined by the setting of the paper

switch as shown below:

<

)

o

Upon completion of output, bit position 1 of the output status byte is

cleared.

After an OP command is received, the plotter will out-

Plx,Ply,P2x,P2y [TERM]

US

0sSXsS10 300

0<Y<7650

A4

0^X^10 900

0«S YSS7650

x'he Scale Instruction, SC

DESCRIPTION

nate system by mapping values onto the scaling points PI and P2.

This instruction is used to enable you to plot in user units convenient to your application. For instance, if your X values represent

months, then Xmin = 1 and Xmax = 12. If the values for Y-coordinates

all lay between 0 and 10, you might use 0 as Ymin and 10 By

adjusting your minimum and maximum values, you can provide additional room for labeling. If your plot is a 12-month bar chart with Ycoordinates 0 to 10, you might scale the X-axis 0 to 14 so the first and

last bars are not at the edge of the graph, and scale the Y-axis 0 to 12

leaving room for a title at the top.

BEECH

The scale instruction, SC, establishes a user-unit coordi-

SC Xmin,Xmax,Yrnin,Ymax (terminator)

or

(terminator)

SC

S3

mm Executing an SC command without parameters (SC;)

turns scaling off and subsequent parameters of plot commands are interpreted as plotter units.

When parameters are used, all four parameters are required. Decimal

parameters in an SC command are truncated to integers. The parameters Xmin and Ymin define the user-unit coordinates of PI, and the

parameters Xmax and Ymax define the user-unit coordinates of P2. PI

and P2 may be any two opposite corners of a rectangle. Scaling points

PI and P2 retain the assigned user-unit coordinate values until scaling

is turned off or another SC command redefines their user-unit coordinate values. Therefore, the physical size of a user unit will change

when any change is made in the relative position and distance between

PI and P2.

Specifying Xmax= Xmin or Ymax= Ymin or parameters less than—32 768

or greater than 32 767 will turn scaling off. An SC command must have

four or no parameters. Otherwise, error 2 will be generated. An SC

command which generates an error is ignored and the scaling does not

change.

The user-unit coordinate system that is mapped onto the plotter unit

coordinate system by the SC command is not limited to the rectangle

defined by Pi and P2; it extends over the entire plotting area. When

user-unit scaling has been established by executing an SC command

with parameters, decimal parameters of plot commands are not trun-

cated; the point 3.5,7.5 is distinct from the point 3.6,7.8. This is

different from some other HP plotters and makes plotting of noninteger

data much simpler.

It is not possible to scale an area such that PI or P2 are assigned

values larger than 32 767 or less than -32 768. One way to plot data

with values beyond these limits is to reduce your data to acceptable

ranges by an arithmetic process before sending it to the plotter. Divid-

ing the data by some factor of 10 so that the integer portions fall

between ±32 767 and sending decimal plot parameters is probably the

easiest solution.

The illustrations which follow show the coordinate grids mapped onto

the plotting area as a result of executing the indicated commands when

the paper switch is set to us. In all cases, the points labeled at each

corner are just outside of the plotting area. If a PA command with these

parameters is sent to a plotter with the indicated scaling and the paper

switch set to us, the pen will move to the corner and lift, indicating the

point is outside the plotting area.

2-10 ESTABLISHING BOUNDA

.. )

i )

^•6 ESTABLISHING BOUNDARIES AND UNITS

ESTABLISHING BOUNDARIES AND UNITS 2-7

Page 34

J

)

;.)

)

)

)

)

}

)

)

)

)

>

)

)

)

)

)

")

)

..)

")

")

.)

)

)

>

>

Page 35

Chapter

Controlling the Pen

and Plotting

What You'll Learn in This Chapter

Now that you understand the unit systems in which data can be represented, you are ready to create plots. In this chapter, you will learn how

to select either of the two pens or change pens, how to set and change

pen velocity, how to raise and lower the pen, and how to plot. You will

learn how to plot to absolute X,Y coordinates or to plot relative to the

last pen position. Finally, you will learn how to send variables as

parameters of plot commands; this will enable you to write general purpose graphics programs.

HP-GL Instructions Covered

SP The Select Pen Instruction

VS The Velocity Select Instruction

PU/PD The Pen Up/Down Instructions

PA The Plot Absolute Instruction

PR The Plot Relative Instruction

CI*

The Circle Instruction

AA* The Arc Absolute

Instruction

AR* The Arc Relative

Instruction

Terms You Should Understand

Absolute Plotting — plotting to a point whose location is specified

relative to the origin (0,0). When the PA command is used to plot to a

point, the pen always moves to the same point on the plotting surface,

no matter where the pen was before the move.

Relative Plotting — plotting to a point whose location is specified

relative to the current pen position. The point moved to then becomes

the effective origin for the next parameter of a plot relative command.

When the PR command is used to plot to a point, the destination of the

pen depends on where the pen was when the command was received.

Plotter Unit Equivalent — the X,Y coordinates of a point, given in user

units,

if they were expressed in plotter units.

♦Available only with Option 001 plotters that have the serial prefix number

2308A or higher.

CONTROLLING THE PEN

AND

PLOTTING 3-1

Page 36

)

;

)

)

)

)

)

)

)

)

?

^>

)

)

)

" ■ ---IMiiiimm .atoMltfi

)

)

)

)

)

)

)

)

)

)

.)

)

)

Page 37

)

'he Pen Instructions, PU and PD

The pen up instruction, PU, and the pen down instruc-

tion, PD, raise and lower the pen.

HKiyi The instructions are used to raise and lower the pen during

plotting. They may be used with parameters to plot or move to the

points specified by the parameters.

EQMEI PU (terminator)

or

PD (terminator)

and

PU X,Y(,...)(terminator)

or

PD X,Y(,...)(terminator)

When no parameters are included, the pen up instruction, PU, raises the pen without moving it to a new location. The pen

down instruction, PD, lowers the pen without moving it to a new

location, if the pen is within the window. If parameters are included,

the pen will move, in order, to the X,Y coordinates specified. The coor-

dinates are interpreted as plotter units if scaling is off and user units if

scaling is on. Moves are either relative or absolute, depending on

whether a PA or PR was the last plot command executed.

If parameters are included, both coordinates of an X,Y coordinate pair

must be given. An odd number of parameters will set an error condi-

tion, but all X,Y pairs which precede the unmatched parameter will be

plotted. For a description of the PU and PD commands with parameters,

refer to The Plot Absolute Instruction, PA, and The Plot Relative

Instruction, PR, which follow.

NOTE: The plotter has an automatic pen lift feature which will lift the

pen after it has been in the pen-down state for 55 seconds and no pendown plot commands or label commands have been sent to the plotter

or no front-panel pen-down moves have been made for 55 seconds. ■

^he Select Pen Instruction, SP

The select pen instruction, SP, selects and/or stores one

of the two pens.

IIKlM The instruction is used to load a pen into the pen holder so

that drawing will occur. It can be used to select a pen of a different

color or width, during the plotting program. It can be used with a zero

parameter or no parameter to store the pen currently in the pen holder

into its stall at the end of a program.

mum SP pen number (terminator)

or

SP (terminator)

ED3EEEQECI The pen parameter must be in the range of -32 768 to

32 767. Decimal fractions are truncated. An odd-numbered parameter

selects the pen from the left stall; an even-numbered parameter selects

the pen from the right stall. A zero parameter or no parameter stores

the pen. When a pen parameter is less than —32 768 or greater than

32 767, an error is generated and the pen does not change.

The Velocity Select Instruction, VS

The velocity select instruction, VS, specifies the pen-

down speed for plotting and labeling operations.

BH33

The instruction is used to set velocity to a speed other than the

default velocity of 38.1 cm/s and to change the acceleration from its

default value of 2 g (980 cm/s2). This instruction should be used to slow

velocity to 10 cm/s when plotting on transparency film. A slightly

thicker line can be created by slowing down the pen speed on any

medium. A pen nearing the end of its life will write with a clearer,

sharper, more solid line if the velocity is slowed.

Bum VS pen velocity (terminator)

or

VS (terminator)

A VS command without parameters sets pen velocity

to its default velocity of 38.1 cm/s (15 in./s) and acceleration to 2 g (980

cm/s2).

zontal or vertical pen-down moves to the value specified by the first

parameter and slows the acceleration to 0.5 g. Anything after the first

parameter is ignored. Parameters must be in the range 0 to 127.9999. A

velocity of 0 is set to 0.38 cm/s. Velocity can be set in increments of 0.38

cm/s.

Negative parameters and parameters greater than or equal to 97 set an

error condition (error 3) and the velocity does not change. Parameters

between 38.1 and 96 set velocity to its default value of

When either the horizontal or vertical velocity falls in the range 0.38 to

3.8 cm/s, it is reset to a slower or faster velocity to avoid this range.

This is done to assure lines of high quality. The change is most noticeable when a line is almost vertical or almost horizontal. Pen-down

moves will be at the specified velocity except when such adjustment is

necessary.

Execution of a VS command with a parameter of 38.1 will slow the

acceleration, giving the highest line quality at that maximum speed.

A VS command with parameters sets the pen velocity for hori-

Parameters are rounded to the nearest multiple of 0.38 cm/s.

38.1

cm/s.

2 CONTROLLING THE PEN AND PLOTTING

CONTROLLING THE PEN AND PLOTTING 3-3

Page 38

)

)

)

)

)

)

)

:>

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

Page 39

)

A default instruction, DF, or an initialize instruction, IN, will also reset

) the velocity and acceleration to the values 38.1 cm/s and 2 g.

•

lie Plot Absolute Instruction, PA

The plot absolute instruction, PA, moves the pen to the

point(s) specified by the X- and Y-coordinate parameters.

IlKlM The instruction can be used together with PD to draw lines or

with PU to move the pen to a specific point on the plot. The instruction

can be executed without parameters to establish absolute plotting, as

opposed to relative plotting for PU or PD commands with parameters.

In this case, the parameters of PU and PD are interpreted as absolute

X,Y coordinates until any PR command is received.

JMifiH PA Xicoordinate.Yi coordinate (,X2 coordinate,Y2

coordinate Xn coordinate, Yn coordinp.teXterminator)

or

PA (terminator)

Recommended parameters are decimal numbers between -32 768.0000 and 32 767.9999. When scaling is off, parameters

are truncated to integers as follows:

• For positive numbers, the fractional portion is discarded and the in-

teger portion remains unchanged. For example, both 1234.4 and

1234.9 become 1234.

• For negative numbers, the fractional portion is discarded and the in-

teger portion is changed to the next more negative integer. For example, both -1234.4 and -1234.9 become -1235. Since you cannot

plot to negative values unless scaling is on, (in which case decimal

portions of parameters are used), the only time you will observe this

is when you use the output commanded position and pen status

instruction, OC, and the last

X-

and/or Y-parameter sent was negative.

will set an error condition but all X,Y pairs which precede the un-

matched parameter will be plotted.

The X-coordinate specifies, in either plotter units or user units, the

absolute X-location to which the pen will move. The Y-coordinate speci-

fies,

in either plotter units or user units, the absolute Y-location to

which the pen will move. If scaling is on, coordinates are in user units.

If scaling is off, coordinates are in plotter units.

The mnemonics PU and PD can be included ahead of, between, or after

X,Y coordinate pairs. PU lifts the pen; PD lowers the pen.

Any number of coordinate pairs, as well as PU or PD mnemonics, can

be listed after a PA instruction. (This is limited only by the ability of

the controller to output without a line feed character which is an instruction terminator.) The pen will move to each point in the order given.

Commas, spaces, or a sign are required between numeric parameters

and are optional after two-letter mnemonics. The last entry is followed

by the terminator. In the following examples, commas are used to show

optional and required separators. Optional commas or spaces which

can be used between each letter of the mnemonics are not shown. The

semicolon is used to indicate the terminator.

P A,PD,Xi)Yi,PU,X2,Y2)PD,X3,Y3>;

I ' 1 1 1 1 1 OPTIONAL

PU,Xi(Yi)PD,X2>Y2,X3)Y3,PU;

I ' ' 1 OPTIONAL

PD,Xi,Yi,X2,Y2,X3,Y3,;

• 1 OPTIONAL

NOTE: If you have an HP-IB or RS-232-C plotter that has the serial

prefix number

not observe this truncation with the OC instruction. In these plotters,

the OC instruction returns decimal parameters instead of integer

parameters when scaling is in effect. ■

(

When scaling is on, any fractional portion of a parameter is used.

A PA command without parameters sets absolute plotting mode for PU

and PD commands with parameters.

When parameters are included with a PA command, both coordinates

of an X,Y coordinate pair must be given. An odd number of parameters

CONTROLLING THE PEN AND PLOTTING

2308A,

or higher, or if you have an HP-IL plotter, you will

If no pen control parameter is given, the pen will assume the pen state

(up or down) of the previous statement. The PU or PD mnemonics can

also be substituted for the PA (or PR) mnemonic. This is equivalent to

having PU; or PD; preceding the PA or PR instruction. Therefore, PU

and PD with parameters are interpreted to be in place of PA or PR,

depending upon which mnemonic, PA or PR, was last specified.

PA is specified by any of the following:

• power-up,

• execution of an IN command,

CONTROLLING THE PEN AND PLOTTING 3-5

Page 40

;

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

■i

MmMk^m^MUimMimia^

"-^T^rf-V"

-'

'•-■ ■'^

u,:

r-L-''"-^^lilWiiMiiaMiirriifiii

i».

.- . ,^.,.^>.,<»tafc.t,t.HIy*JilLi.i^»

)

)

)

)

)

)

)

)

)

')

)

)

)

)

)

Page 41

• execution of a DF command, or

• execution of a PA instruction with or without parameters.

The pen moves and draws lines only within the currently defined

window. Refer to The Input Window Instruction, IW, in Chapter 1.

The plotter discards parameters which are out of range. Error 3 will be

set (parameter out of range). A PA command with out-of-range parameters will still establish plot absolute mode for future occurrences of PU

or PD with parameters. When scaling is off, in-range parameters are

greater than or equal to -32 768 and less than or equal to 32 767. When

scaling is on, both the parameters and their plotter unit equivalent

must also be in that same range. To find the plotter unit equivalent, use

the equations in the section Scaling Without Using the SC Instruction in

Appendix C.

There are four types of vectors that can be drawn with a PA command

from a given last point to some new point.

LAST POINT NEW POINT

1.

inside window area to inside window area

2.

inside window area to outside window area

3.

outside window area to inside window area

4.

outside window area to outside window area

In type one, the pen moves from the last point to the new point with the

pen up or down as programmed.

In type two, the pen moves from the last point toward the new point

and stops where the line between the two points intersects the current

window. The pen up/down condition is as programmed until the intersection is reached. Then, the pen is raised.

In type three, the pen moves with the pen up, to the point where the

straight line between the last and new point intersects the window limit.

When the pen reaches this point, the pen assumes its programmed (up

or down) position. The pen then moves to the new point.

In type four, no pen movement occurs unless the straight line between

the last and new point intersects the window. The X- and Y-coordinates

of the current pen position are updated. If part of the vector is in the

window area, the pen moves, pen up, to the point where the line be-

tween the last and the new point first intersects the window limit. The

pen moves under programmed pen up/down control to the intersection

of the vector and the other window limit. At this point, the pen stops

and lifts.

2.

have not executed an output error instruction; and

3.

the error light is not on at the end of your plot.

(The fact that the error light is on does not necessarily mean

out-ofrange data has been encountered; an error in any HP-GL command

will turn the light on.)

The following strings of HP-GL instructions, if sent to the plotter using

a suitable output statement such as PRINT or OUTPUT, will draw two

triangles and then move to the point 10 900,7650 with the pen up.

"IN;SP1;"

"PFI2000, 1500,PD,0,1500,2000,3500,2000, 1 500,PU,2500,1500;"

"PFIPD4500, 1500, 2500, 3500, 2500, 1500,PU, 10900,7650;"