Page 1

*TB 9-4931-700-50

CHANGE 6

DEPARTMENT OF THE ARMY TECHNICAL BULLETIN

CALIBRATION PROCEDURE FOR

AC VOLTAGE STANDARD,

HEWLETT-PACKARD MODEL 745A

AND HIGH VOLTAGE AMPLIFIER,

HEWLETT-PACKARD MODEL 746A

INCLUDING OPTIONS C90, C91, AND C93

Headquarters, Department of the Army, Washington, DC

11 September 2001

Approved for public release; distribution is unlimited.

TB 9-4931-700-50, 9 December 1977, is changed as follows:

1. Remove old pages and insert new pages as indicated below. New or changed

material is indicated by a vertical bar in the margin of the page.

Remove pages Insert pages

1 and 2 1 and 2

13 and 14 13 and 14

2. File this change sheet in front of the publication for reference purposes.

By Order of the Secretary of the Army:

0121914

Distribution:

To be distributed in accordance with Std IDS No. RLC-1500, 11 May 1992, requirements

for calibration procedure TB 9-4931-700-50.

PIN NO: 009082-006

Page 2

*TB 9-4931-700-50

Change 5

DEPARTMENT OF THE ARMY TECHNICAL BULLETIN

CALIBRATION PROCEDURE FOR

AC VOLTAGE STANDARD,

HEWLETT-PACKARD MODEL 745A

AND HIGH VOLTAGE AMPLIFIER,

HEWLETT-PACKARD MODEL 746A

INCLUDING OPTIONS C90, C91, AND C93

Headquarters, Department of the Army, Washington, DC

15 May 1989

TB 9-4931-700-50, 9 December 1977, is changed as follows:

1. Remove old pages and insert new pages as indicated below. New or changed

material is indicated by a vertical bar in the margin of the page.

Remove pages Insert pages

3 through 6 3 through 6

2. File this change sheet in front of the publication for reference purposes.

By Order of the Secretary of the Army:

CARL E. VUONO

General, United States Army

Chief of Staff

Official:

WILLIAM J. MEEHAN ii

Brigadier General, United States Army

The Adjutant General

Distribution:

To be distributed in accordance with Std IDS No. RLC-1500, 25 January 1989.

PIN NO: 009082-005

Page 3

*TB 9-4931-700-50

DEPARTMENT OF THE ARMY TECHNICAL BULLETIN

CALIBRATION PROCEDURE FOR

AC VOLTAGE STANDARD,

HEWLETT-PACKARD MODEL 745A

AND HIGH VOLTAGE AMPLIFIER,

HEWLETT-PACKARD MODEL 746A

INCLUDING OPTIONS C90, C91, AND C93

Headquarters, Department of the Army, Washington, DC

19 December 1988

TB 9-4931-700-50, 9 December 1977, is changed as follows:

Change 4

1. Remove old pages and insert new pages as indicated below. New or changed

material is indicated by a vertical bar in the margin of the page.

Remove pages Insert pages

4 and 5 4 and 5

2. File this change sheet in front of the publication for reference purposes.

By Order of the Secretary of the Army:

CARL E. VUONO

General, United States Army

Chief of Staff

Official:

WILLIAM J. MEEHAN ii

Major General, United States Army

The Adjutant General

Distributed:

To be distributed in accordance with STD IDS No. RLC-1500, 18 November 1987.

PIN NO: 009082-004

Page 4

This is a REPRINT, including changes 1 through 3.

............................

..................

.......

...........

..........

....

...............

...........

...........

.....

*TB 9-4931-700-50

DEPARTMENT OF THE ARMY TECHNICAL BULLETIN

CALIBRATION PROCEDURE FOR

AC VOLTAGE STANDARD,

HEWLETT-PACKARD MODEL 745A

AND HIGH VOLTAGE AMPLIFIER,

HEWLETT-PACKARD MODEL 746A

INCLUDING OPTIONS C90, C91, AND C93

Headquarters, Department of the Army, Washington, DC

9 December 1977

REPORTING OF ERRORS

You can help improve this publication. If you find any mistakes or if you know of a

way to improve the procedure, please let us know. Mail your letter or DA Form 2028

to: Commander, U. S. Army Aviation and Missile Command, ATTN: AMSAM-MMCMA-NP, Redstone Arsenal, AL 35898-5230. A reply will be furnished to you. You may

also send in your comments electronically to our e-mail address: ls-

lp@redstone.army.mil or FAX 256-842-6546/DSN 788-6546.

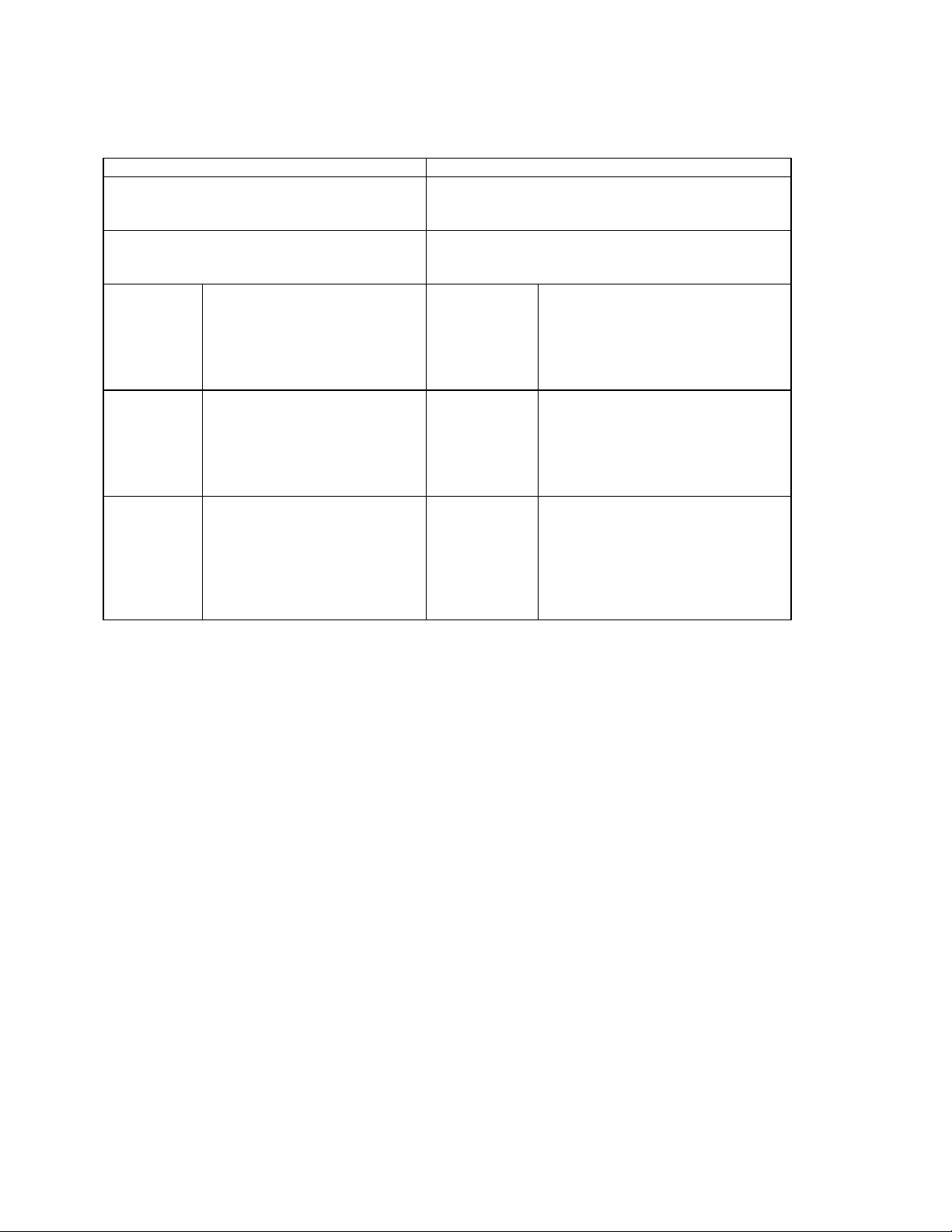

Paragraph Page

SECTION I. IDENTIFICATION AND DESCRIPTION

Test instrument identification

Calibration data card, DA Form 2416

Calibration description................................

II. EQUIPMENT REQUIREMENTS

Equipment required ................................

Accessories required................................

III. PRELIMINARY OPERATIONS

Preliminary instructions................................

Equipment Setup................................

IV. CALIBRATION PROCESS

Frequency accuracy ................................

Error measurement................................

Voltage accuracy, regulation, and frequency

response (Model 745A) ................................

__________

*This bulletin supersedes TB 9-4931-700-60, 6 October 1976. CHANGE 6

1 2

2 2

3 2

4 3

5 3

6 6

7 7

8 7

9 12

10 14

Page 5

Page 6

TB 9-4931-700-50

.....

..........................

................................

................................

..................

Paragraph Page

Voltage accuracy, regulation, and frequency

response (Model 746A) ................................

Distortion ................................

Power supply (Model 745A)

Power supply (Model 746A)

Final procedure................................

11 20

12 26

13 28

14 30

15 31

SECTION I

IDENTIFICATION AND DESCRIPTION

1. Test Instrument Identification. This bulletin provides instructions for the

calibration of Ac Voltage Standard, Hewlett-Packard Model 745A and High Voltage

Amplifier, Hewlett-Packard Model 746A including Options C90, C91, and C93. The

manufacturer's instruction manuals were used as the prime data source in compiling

these instructions. The equipment being calibrated will be referred to as the TI (test

instrument) throughout this bulletin.

a. Model Variations. There are no variations among models which affect the

calibration of the TI. The C90 option adds slides to the instrument. The C91 option

adds a blower to the instrument. The C93 option adds slides and a blower to the

instrument.

b. Time and Technique . The time required for this calibration is approximately 8

hours, using the dc (direct current) and low frequency technique.

2. Calibration Data Card, DA Form 2416

a. Forms, records, and reports required for calibration personnel at all levels arc

prescribed by TM 38-750. DA Form 2416 must be annotated in accordance with TM 38750 for ea ch calibration performed.

b. Adjustments to be reported on DA Form 2416 are designated (R) at the end of the

sentence in which they appear. When adjustments are in tables, the (R) follows the

designated adjustment. Report only those adjustments made and designated with (R).

3. Calibration Description. TI parameters and performance specifications which

pertain to this calibration are listed in table 1.

Table 1. Calibration Description

Test instrument parameters Performance specifications

Output frequency range Continuously adjustable from 10 Hz to 110 kHz in 4

decade ranges with 10% overlap

Frequency accuracy ±2% of setting

Error measurement range ±0.3% and ±0.3% with zero center dial

Error measurement accuracy ±0.51% of FS

Distortion and noise (0.05% of setting + 10 µ V)

See footnote at end of table.

CHANGE 6 2

Page 7

TB 9-4931-700-50

Table 1. Calibration Description - Continued.

Test Instrument Parameters Performance Specifications

Line regulation ±0.001% of setting change in output voltage for a 10%

change in line voltage (included in accuracy

specifications)

Voltage stability 1 mV to 100 V: short term; ±0.002% of setting for 24

hrs. 1000 V: short term; ±0.005% of setting for 24

hrs

50 Hz to 20

kHz

1 -mV 10-mV, and 100-mV

ranges

50 Hz to 20

Output

voltage

50 Hz to 20

1

Combined accuracy and load regulation.

1-V, 10-V, and 100-V ranges 20 to 50 Hz

1000-V range

20 to 50 Hz

and

20 to 110 kHz

10 to 20 Hz

kHz

and

20 to 110 kHz

10 to 20 Hz

kHz

20 to 50 Hz

and

20 to 50 kHz

10 to 20 Hz

50 to 110 kHz

±(0.04% of setting +0.002% of range

+ 10µ V)1

±(0.07% of setting +0.005% of range

+50µ V)

±(0.22% of setting +0.005% of range

+50µ V)

±(0.032% of setting +0.002% of

range +10µ V)

±(0.062% of setting +0.005% of

range +50µ V)

±(0.212% of setting +0.005% of

range +50µ V)

±0.04% of setting

±0.08% of setting

±(0.2% of setting +0.005% of range)

±0.15% of setting

SECTION II

EQUIPMENT REQUIREMENTS

4. Equipment Required. Table 2 identifies the specific equipment used in this

calibration procedure. This equipment is issued with Secondary Reference Standards

Calibration Set NSN 4931-00-621-7878 and is to be used in performing this procedure.

Alternate items may be used by the calibrating activity when the equipment listed in

table 2 is not available. The items selected must be verified to perform satisfactorily

prior to use and must bear evidence of current calibration. The equipment must meet or

exceed the minimum use specifications listed in table 2. The accuracies listed in table 2

provide a four-to-one ratio between the standa rd and TI

5. Accessories Required. The accessories listed in table 3 are issued as indicated in

paragraph 4 above and are to be used in this calibration procedure. When necessary,

these items may be substituted by equivalent items unless specifically prohibited.

3

Page 8

TB 9-4931-700-50

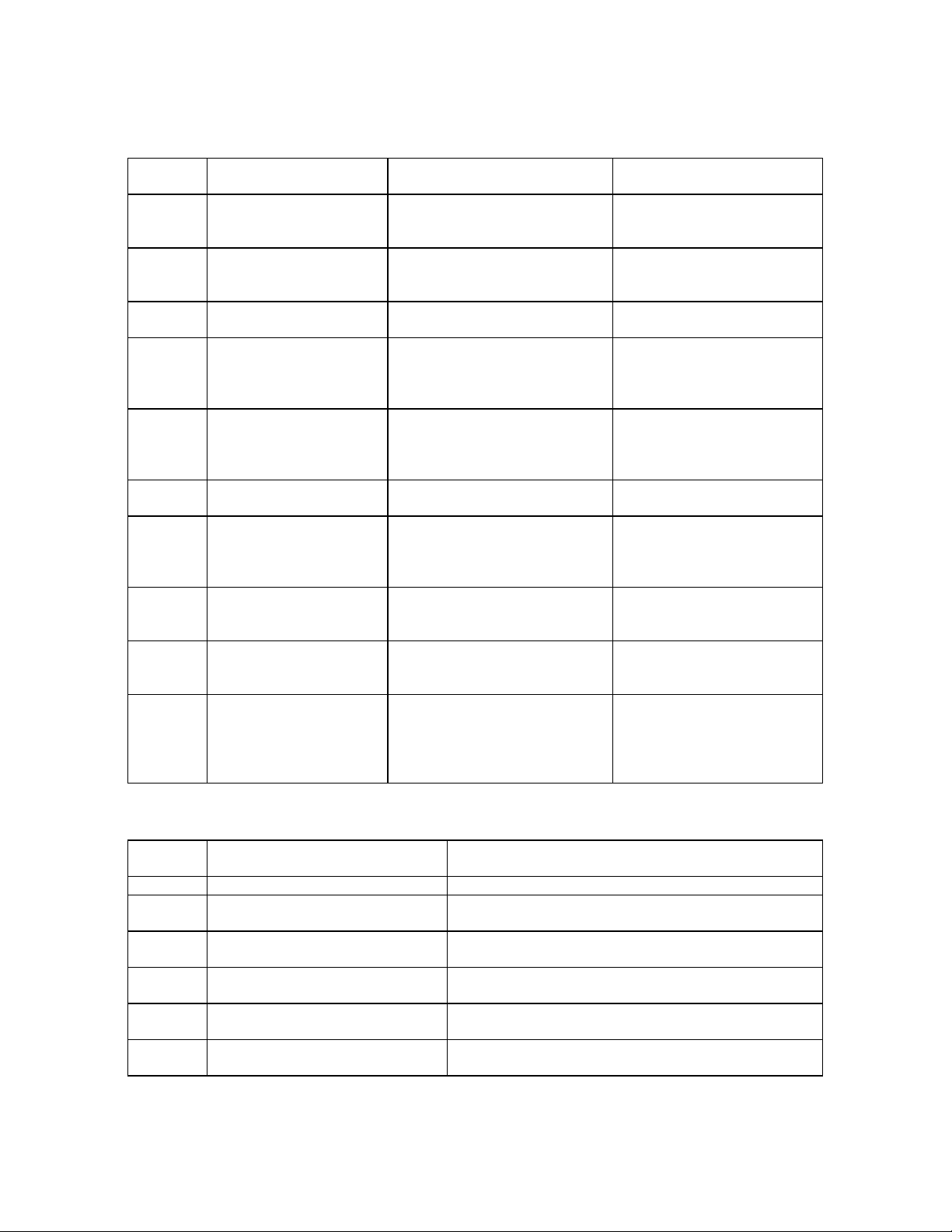

Table 2. Minimum Specifications of Equipment Required

Item

A1 AC/DC VOLTMETER

A2 AUTOTRANSFORMER

A3 DECADE RESISTOR Range: 22 to 3010 ohms Biddle Gray, Model 601147-1

A4 DISTORTION

A5 FREQUENCY

A6 LOAD (CALIBRATOR

A7 OSCILLOSCOPE Sensitivity: 0.01 to 20 V/cm

A8 RATION

A9 THERMAL TRANSFER

A10 VARIABLE

1

Combined accuracy of A1 and A9: ±0.0087%.

Common Name

(DIFFERENTIAL

VOLTMETER)

(VARIABLE POWER

TRANSFORMER)

ANALYZER

(SPECTRUM

ANALYZER)

COUNTER

(ELECTRONIC

DIGITAL COUNTER)

LOAD)

TRANSFORMER (AC

RATIO STANDARD)

STANDARD

CAPACITOR

(VARIABLE

CAPACITANCE

STANDARD)

Item

B1 ADAPTER (POWER ADAPTER) 2 to 2-wire isolation plug (7912356)

B2 ADAPTER (ELECTRICAL PLUG

CONNECTOR)

B3 ADAPTER (CONNECTOR

ADAPTER)

B4 ADAPTER (TIP JACK

ASSEMBLY)

B5 CABLE (RF CABLE ASSEMBLY) 30-in., RG -58( )/U with BNC plug terminations

B6 CABLE (RF CABLE ASSEMBLY) 36-in., RG -58( )/U with BNC plug to alligator clips

Common Name

(Official Nomenclature)

Minimum Use

Specifications

Range: 0.002 to 1850 V dc

Accuracy: 1

Capability: Use as null detector

Range: 105 to 125 V ac

Accuracy: ±1%

Range: 10 Hz to 100 kHz

Accuracy: Measure less than

.06% (Must have amplifier

capability)

Range: 9.8 Hz to 119 kHz

Accuracy: ±0.5%

Range: 2200 ohms

Accuracy: ±5%

Sweeptime: 2 ms to 10 ms/cm

Capability: Divide to 7 places

Accuracy: ±0.0085%

Range: 1 to 100 V dc 1 to 100 V

ac

Accuracy: 1

Range: 100 and 200 pF General Radio, Model 1422D

Table 3. Accessories Required

(Part Number)

Double banana plug to BNC jack terminations

(7907592)

Double banana jack to phone plug adapter (7907566)

GR plug to binding posts 874Q2 (874Q2)

(7907467)

(7909410)

Manufacturer and Model

(Part Number)

John Fluke, Models

887ABAN (887 ABAN) and

80E10 (80E10)

General Radio, Model

W10MT3AS3 (7910809)

(7910328)

Hewlett-Packard, Model

334A (7911957)

Systron-Donner, Model

1037M (7910823) w/Timer

Interval Unit, Model 1926A

(7910824)

MIRCOM, Model SKA-4850-

101

Tektronix, Model RM561A

(7910655-2) w/3A6 plug-in

(7911441-1) and 3B4

(7912040-1)

Gertsch, Model 1000

(7907060-1)

Ballantine Laboratories,

Model 1600A (MIS-10554-

2)

(8579475)

Description

4

Page 9

B7 CABLE1 (RF CABLE

ASSEMBLY)

TB 9-4931-700-50

30-in., RG -58( )/U with double banana plug

terminations (7907470)

5

Page 10

TB 9-4931-700-50

Table 3. Accessories Required - Continued.

Item

B8 CABLE (TEST LEAD) 36-in., RG -58( )/U with BNC plug and double banana

B9 HOOK-UP WIRE (ELECTRICAL

POWER CABLE)

B10 ISOLATION BOX (ADAPTER

BOX)

B11 PROBE Tektronix, Type 010-0128-00 (010-0128-00)

1

Three required.

Common Name

(Official Nomenclature)

Description (Part Number)

plug terminations (7907471)

Shielded pair No. 18 AWG, solid copper (MIS-10312)

Double banana jack terminals (SKD4850-3)

SECTION III

PRELIMINARY OPERATIO NS

6. Preliminary Instructions

a. The instructions outlined in this section are preparatory to the calibration

process. Personnel should become familiar with the entire procedure before beginning

the calibration.

b. Items of equipment used in this procedure are referenced within the text by

common name and item identification number as listed in tables 2 and 3. For the

identification of equipment referenced by item numbers prefixed with A, see table 2, and

for prefix B, see table 3.

WARNING

HIGH VOLTAGE is used during the performance of this

calibration. DEATH ON CONTACT may result if personnel

fail to observe safety precautions.

NOTE

Unless otherwise specified, verify the results of each test

and, whenever the test requirement is not met, take

corrective action before continuing with the calibration.

Adjustments required to calibrate the TI are included in this

procedure. Additional maintenance information is contained

in the manufacturer's manual, TM 9-4931-700-14/1, and TM 94931-700-14-2 for this TI.

NOTE

Unless otherwise specified, all controls and control settings

refer to the TI.

6

Page 11

TB 9-4931-700-50

7. Equipment Setup

a. Connect TI to autotransformer (A2).

b. Connect autotransformer to 115-volt ac (alternating current) and adjust its output

control to obtain a 115-volt output.

c. Set LINE switches to ON and allow 1 hour for equipment to warm-up and

stabilize.

SECTION III

CALIBRATION PROCESS

NOTE

When indications specified in paragraphs 8, 9, 10, or 12 are

not within tolerance, perform the power supply check in

paragraph 13 prior to making adjustments. After

adjustments are made, repeat paragraphs 8, 9, 10, and 12. If

indications specified in paragraph 11 are not within

tolerance, the power supply check in paragraph 14 prior to

making adjustments. Do not perform power supply checks if

all other parameters are within tolerance.

8. Frequency Accuracy

a. Performance Check

(1) Connect TI front panel output to input of frequency counter (A5), using cable

(B8).

(2) Position TI controls as listed in (a) through (d) below:

(a) Press FREQUENCY RANGE X10 pushbutton.

(b) Adjust FREQUENCY control to obtain FREQ scale indication of 1.

(c) Press VOLTAGE RANGE 1V pushbutton.

(d) Set voltage controls to obtain indication of 1.000000 V.

(3) If frequency counter does not indicate between 98.0392 and 102.041 ins

(milliseconds), perform b below.

(4) Repeat technique of (2) and (3) above , using settings and indications listed in

table 4

7

Page 12

TB 9-4931-700-50

Test Instrument Frequency Counter Indications

Frequency FREQUENCY RANGE

Settings Switch Setting Minimum Maximum

2 49.0196 ms 51.0204 ms

3 32.6797 ms 34.0136 ms

5 X10 19.6078 ms 20.4082 ms

7 14.0056 ms 14.5773 ms

10 9.8039 ms 10.2041 ms

1 9.80392 ms 10.2041 ms

2 4.90196 ms 5.10204 ms

3 X100 3.26797 ms 3.40136 ms

5 1.96078 ms 2.04082 ms

7 1.40056 ms 1.45773 ms

10 980 Hz 1020 Hz

1 980 Hz 1020 Hz

2 1960 Hz 2040 Hz

3 X1K 2940 Hz 3060 Hz

5 4900 Hz 5100 Hz

7 6860 Hz 7140 Hz

10 9.8 kHz 10.2 kHz

1 9.8 kHz 10.2 kHz

2 19.6 kHz 20.4 kHz

3 X10K 29.4 kHz 30.6 kHz

5 49.0 kHz 51.0 kHz

7 68.6 kHz 71.4 kHz

10 98.0 kHz 102.0 kHz

b. Adjustments

Table 4. Frequency Accuracy

(1) Press FREQUENCY RANGE X10K pushbutton and adjust FREQUENCY

control for FREQ scale indication of 1.0.

(2) Adjust A12C2 (fig. 1) to obtain indication of 10.000 kHz (kilohertz) on

frequency counter (R).

(3) Adjust FREQUENCY control slowly clockwise while observing frequency

counter indication. If frequency increases, proceed to b(6) below. If frequency

decreases, proceed to b(4) below.

(4) Repeat (1) above.

(5) While observing frequency counter indication, adjust A12C2 (fig. 1) to obtain a

second 10 kHz output frequency (R). If a second 10 kHz cannot be obtained by adjusting

A12C2, readjust A12C2 to obtain original 10 kHz frequency. While observing frequency

counter indication, adjust A12L1 (fig. 1) in direction that causes output to decrease and

pass through 0 (zero) Hz (hertz) and increase to 10 kHz. Adjust A12L1 to obtain

indication of 10.000 kHz on frequency counter (R).

8

Page 13

TB 9-4931-700-50

Figure 1. Model 745A bottom view - adjustment location.

9

Page 14

TB 9-4931-700-50

(6) Adjust FREQUENCY control to obtain FREQ scale indication of 10.0. Record

frequency counter indication.

(7) Refer to table 5 frequency counter indication column and locate frequency

nearest to one recorded in (6) above. Record corresponding frequency in the adjoining

column.

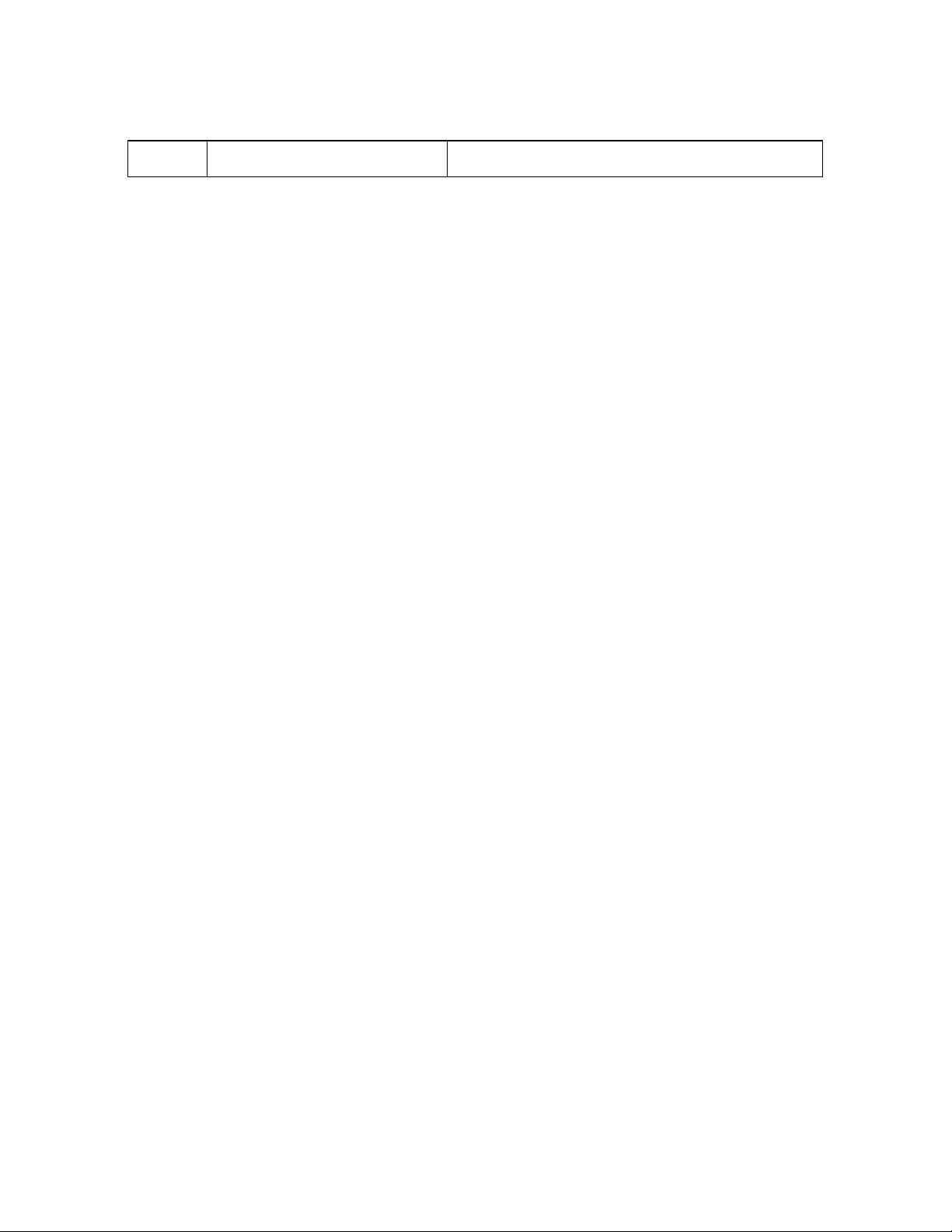

Table 5. FREQUENCY Scale Tracking

Frequency Counter Indication Set A12l1 (fig. 1) to Obtain

(kHz) (kHz)

80 150

81 147

82 144

83 142

84 139

85 137

86 134

87 131

88 129

89 126

90 124

91 121

92 119

93 117

94 114

95 112

96 109

97 107

98 104.6

99 102.3

100 100

101 97.69

102 95.41

103 93.2

104 90.9

105 88.7

106 86.4

107 84.1

108 82.1

109 79.9

110 77.8

111 75.6

112 73.5

113 71.4

114 69.3

115 67.2

116 65.1

117 63.1

118 61.0

119 59.0

10

Page 15

TB 9-4931-700-50

(8) Adjust A12L1 (fig. 1) to obtain frequency recorded in (7) above.

(9) Adjust FREQUENCY control counterclockwise to obtain FREQ scale

indication of 10 kHz while observing frequency counter to insure that indication does not

pass through 0 (zero) Hz. If output frequency passes through 0 (zero) Hz, repeat (2)

through (8) above.

(10) Adjust FREQUENCY control to obtain scale indication of 1.0. Adjust A12C2

to obtain indication of 10.00 kHz on frequency counter.

(11) Repeat (6) through (10) above until frequency counter indications are within

tolerance at frequency settings of 10 and 100 kHz.

(12) Repeat a(2) through (4) above and if lower frequency ranges (X10) through

X1K) are still out of tolerance, perform (a) through (t) below.

(a) Extend circuit board A12A2 (fig. 1), using extender board furnished with

TI.

(b) Connect oscilloscope (A7) to A12A2TP1 (fig. 1), using probe (B11).

(c) Adjust A12A2T1 (fig. 1) to obtain maximum amplitude of ac signal

displayed on oscilloscope (R).

(d) Press FREQUENCY RANGE X10K pushbutton and adjust FREQUENCY

control to obtain FREQ scale indication of 1.0.

(e) Connect oscilloscope to A12A2TP2 (fig. 1), using probe.

(f) Adjust A12A2C11 and A12A2C18 (fig. 1) to obtain maximum amplitude of

ac signal displayed on oscilloscope (R).

(g) Adjust FREQUENCY control to obtain FREQ scale indication of 11.0.

(h) Adjust A12A2C14 (fig. 1) to obtain maximum signal amplitude (R).

(i) Adjust FREQUENCY FREQ scale indication of 1.0.

(j) Adjust A12A2C11 (fig. 1) to obtain maximum signal amplitude.

(k) Adjust FREQUENCY FREQ scale indications of from 1.0 to 11.0. Signal

amplitude will be approximately same at both ends. Adjust A12A2C18 (fig. 1) to obtain

same amplitude at both ends.

(l) Signal at A12A2TP2 will be 0.7 volt p-p or greater at frequencies from 10

to 110 kHz.

(m) Replace circuit board A12A2 in the TI and extend circuit board A12A3

(fig. 1), using extender board.

(n) Connect oscilloscope to A12A3TP1 (fig. 1), using probe.

(o) Adjust A12A3T1 (fig. 1) to obtain maximum signal amplitude as indicated

on oscilloscope (R).

(p) Adjust FREQUENCY control to obtain FREQ scale indication of 5.5.

(q) Connect oscilloscope to A12A3TP2 (fig. 1), using probe.

(r) Adjust A12A3C11 A12A3C14, and AJ2A3C18 (fig. 1) to obtain maximum

signal amplitude indication on oscilloscope (R).

(s) Replace circuit board A12A3 in TI and extend circuit board A12A4 fig. 1

using extender board.

11

Page 16

TB 9-4931-700-50

(t) Repeat technique of (n) through (r) above for A12A4. Replace A12A4 in

TI.

(13) Repeat a(1) through (4) above.

9. Error Measurement

a. Performance Check

(1) Insert adapter (B1) between TI and autotransformer (A2) and connect

OUTPUT and SENSE terminals to ratio transformer (A8), using hook-up wire (B9).

Monitor output of ratio transformer, using ac/dc voltmeter (A1) and hook-up wire.

(2) Position TI controls as listed in (a) through (f) below:

(a) Press VOLTAGE RANGE 1V pushbutton.

(b) Set voltage controls to obtain indication of 1.000000 v

(c) Adjust FREQUENCY control to obtain FREQ scale indication of 1.

(d) Press FREQUENCY RANGE X1K pushbutton.

(e) Press ERROR RANGE 0 pushbutton.

(f) Press SENSE REMOTE pushbutton.

(3) Set ratio transformer dials to 1.000000 and record ac/dc voltmeter indication.

(4) Press ERROR RANGE X1 pushbutton and adjust ERROR MEASUREMENT

control to obtain an indication of 0 (zero) on % ERROR scale. If ac/dc voltmeter does not

indicate within ±0.00017 V of value recorded in (3) above, perform b below.

(5) Repeat technique of (3) and (4) above, using setting and indications listed in

table 6.

Table 6. Error Measurement

Test Instrument

ERROR RANGE % ERROR Ration Transformer Ac/dc Voltmeter

Setting Scale Setting Setting Indication (V)

X1 -3 .970874 Value of 9a(3) above ±0.00017

X1 -2 .980392 Value of 9a(3) above ±0.00017

X1 -1 .990099 Value of 9a(3) above ±0.00017

X1 01 1.000000 Value of 9a(3) above ±0.00017

X1 +3 1.030929 Value of 9a(3) above ±0.00017

X1 +2 1.020408 Value of 9a(3) above ±0.00017

X1 +1 1.010101 Value of 9a(3) above ±0.00017

X.1 01 1.000000

X.1 -3 .997009

1

Establish a new 1-volt reference as in 9a(3) above.

X.1 +3 1.003009

Value of 9a(3) above ±0.000035

Value of 9a(3) above ±0.000035

Value of 9a(3) above ±0.000035

b. Adjustments

(1) Set A1A4S1 (fig. 2) to +9.9 V position.

NOTE

Overload lamp illuminates.

12

Page 17

TB 9-4931-700-50

(2) Connect ac/dc voltmeter to A1A3TP5 (fig. 2), using cable (B6) and adapter

(B2).

(3) Press ERROR RANGE 0 pushbutton and adjust ERROR MEASUREMENT

control to obtain indication of 0 (zero) on % ERROR scale. Record ac/dc voltmeter

indication.

(4) Press ERROR RANGE X1 pushbutton. Loosen two setscrews that fasten the

drive sprocket to shaft of error potentiometer (fig. 1).

(5) Using a pair of long-nose pliers, rotate shaft of error potentiometer until ac/dc

voltmeter indicates exact value recorded in (3) above.

(6) While holding shaft of the error potentiometer in place, adjust ERROR

MEASUREMENT control to obtain exact 0 (zero) on % ERROR scale and tighten two

setscrews.

(7) Repeat adjustments as necessary to obtain optimum operation.

(8) Set A1A4S1 (fig. 2) to center position.

13

Page 18

TB 9-4931-700-50

Figure 2. Model 745A top view - adjustment location.

14

Page 19

Page 20

TB 9-4931-700-50

10. Voltage Accuracy, Regulation, and Frequency Response (Model 745A)

a. Performance Check

(1) Connect equipment as shown in figure 3. Remove isolation (B1) from between

TI and autotransformer.

Figure 3. Output voltage - equipment setup.

(2) Position TI controls as listed in (a) through (f) below:

(a) Press VOLTAGE RANGE 1V pushbutton..

(b) Set voltage controls to obtain an indication of 1.000000 V.

(c) Press FREQUENCY RANGE X1K pushbutton.

(d) Adjust FREQUENCY control to obtain FREQ scale indication of 1.0.

(e) Press ERROR RANGE 0 pushbutton.

(f) Press SENSE REMOTE pushbutton.

14 CHANGE 6

Page 21

TB 9-4931-700-50

NOTE

Each time measurement of TI output is directed, a minimum

of four readings should be taken. The first reading should be

disregarded and the other three readings averaged. The

average reading is the indication to be recorded for future

use. The ac/dc voltmeter (A1) indication should be read

between 15 and 20 seconds after thermal transfer standard

(A9) transfers to the dc output.

(3) Measure TI output, using thermal transfer standard in auto mode. Record

ac/dc Voltmeter indication.

(4) Compute and record difference between the indication recorded in (3) above

and TI voltage controls setting. If indication in (3) is large a + (plus) sign is assigned to

difference. If it is smaller, a - (minus) sign is assigned to difference. Convert difference

to percentage retaining assigned sign.

(5) Refer to test report for thermal transfer standard to obtain percentage of

ac/dc difference for 1 V at appropriate frequency.

(6) Add algebraically two percentages obtained in (4) and (5) above. The result is

percentage of TI output error. If TI output error is ±0.035 percent or more, perform b(1)

through (3) below.

(7) Repeat technique of (1) through (6) above with autotransformer (A2) set at 105

and 125 V ac. If error does not remain within ±0.035 percent and adjustments were not

performed in (6) above, perform b(1) through (3) below and repeat (2) through (6) above.

Return autotransformer setting to 115 V ac.

(8) With decade resistor (A3) set to 22 ohms, connect at input to thermal transfer

standard, using cable (B7).

(9) Repeat technique of (1) through (6) above. The TI output will remain within

specified limits.

(10) Perform technique of (1) through (6), (8), and (9) above, using settings and

indications listed in table 7.

(11) Disconnect decade resistor.

(12) Set TI frequency to 1 kHz and voltage range to 1 V.

(13) With thermal transfer standard in manual balance mode and dc output state,

adjust its manual balance controls to obtain an ac/dc voltmeter indication of 1.000000 V

dc.

15

Page 22

TB 9-4931-700-50

Table 7. Frequency Response

Test Instrument

Voltage Acceptable Decade resistor

Output Error (Percent) Setting (Ohms) Adjustments

Frequency (V) (Step a(6)) (Step a(8))

10 Hz 1 ±0.22% 22

100 Hz 1 ±0.035% 22 If an out-of-tolerance condition is

indicated for any

10 kHz 1 ±0.035% 22 frequency on the 1 V range, perform

10b(1)

20 kHz 1 ±0.035% 22 through (3) below and repeat all checks

on 1 V

50 kHz 1 ±0.072% 22 range.

100 kHz 1 ±0.072% 22

10 Hz 101 ±0.22% 221

100 Hz 10 ±0.034% 221

1 kHz 10 ±0.034% 221 If an out-of-tolerance condition is

indicated for any

10 kHz 10 ±0.034% 221 frequency on the 10 V range, perform

10b(1),

20 kHz 10 ±0.034% 221 (2), and (4) below and repeat all checks

on 10 V

50 kHz 10 ±0.068% 221 range.

100 kHz 10 ±0.068% 221

10 Hz 1001 ±0.22% 22002 If an out-of-tolerance condition is

indicated for 10

100 Hz 100 ±0.034% 2200 Hz, or 1 kHz on the 100 V range,

perform

1 kHz 100 ±0.034% 2200 10b(2), (5), and (6) below and repeat all

previous checks on 100 V range.

10 kHz 100 ±0.034% 2200

20 kHz 100 ±0.034% 2200 If an out-of-tolerance condition is

indicated for 10,

50 kHz 100 ±0.067% 2200 20, 50, or 100 kHz on the 100 V range,

perform

100 kHz 100 ±0.067% 2200 10b(2), (5), and (7) below , and repeat

1

Repeat technique of (7) above.

2

Replace decade resistor (A3) with load (A6) for remaining checks.

all checks on 100 V range.

(14) Set thermal transfer standard to ac balancing state. Adjust TI voltage

controls to obtain null indication on thermal transfer standard meter with its null X5

pushbutton pressed.. Record TI voltage control indication.

(15) Repeat (13) and (14) above twice. Average the three voltage control

indications. If average indication is 1.0 or more, subtract 1.0 from it and assign a (minus) sign. If it is less than 1.0, subtract it from 1.0 and assign a + (plus) sign. Record

value.

(16) Refer to test report for thermal transfer standard to obtain percentage of

ac/dc difference for 1 V at 1 kHz. Convert percentage to voltage error, retaining sign.

Record value.

16

Page 23

TB 9-4931-700-50

(17) Add algebraically values recorded in (15) and (16) above. Reverse sign and

add to 1.0. Record this value. This is the correct TI voltage control setting to obtain 1 V

output.

(18) Connect equipment as shown in figure 4.

Figure 4. Low voltage - equipment setup.

(19) Position TI controls as listed in (a) through (c) below:

(a) Press VOLTAGE RANGE 1 mV pushbutton.

(b) Set voltage controls to obtain indication of 1.000000 mv.

(c) Press FREQUENCY RANGE X1 K pushbutton.

(20) Set ratio transformer (A8) dials to 1.000000.

NOTE

In following checks, distortion analyzer (A4) is utilized as an

amplifier only.

(21) Set distortion analyzer to voltmeter function and 1 mV (millivolt) range.

(22) Adjust ac/dc voltmeter (A1) dials to obtain null indication. Leave voltage

readout dials set.

17

Page 24

TB 9-4931-700-50

(23) Set ratio transformer dials to .001000.

(24) Position TI controls as listed in (a) through (c) below:

(a) Press VOLTAGE RANGE 1V pushbutton.

(b) Set voltage controls to obtain same indication recorded in (17) above.

(c) Press ERROR RANGE X1 pushbutton.

(25) Adjust ERROR MEASUREMENT control to obtain a null indication on ac/dc

voltmeter. % ERROR scale will indicate within ±1.04 percent.

(26) Position TI controls as listed in (a) through (c) below:

(a) Press VOLTAGE RANGE 10 mV pushbutton.

(b) Set voltage controls to obtain indication of 10.00000 mv.

(c) Press ERROR RANGE 0 pushbutton.

(27) Set distortion analyzer range to 10 mV.

(28) Set ratio transformer dials to 1.000000.

(29) Adjust ac/dc voltmeter dials to obtain null indication. Leave voltage readout

dials set.

(30) Set ratio transformer dials to .010000.

(31) Position TI controls as listed in (a) through (c) below:

(a) Press VOLTAGE RANGE 1V pushbutton.

(b) Set voltage controls to obtain same indication recorded in (17) above.

(c) Press ERROR RANGE X.1 pushbutton.

(32) Adjust ERROR MEASUREMENT control to obtain a null indication on ac/dc

voltmeter. The % ERROR scale will indicate within ±0.142 percent.

18

Page 25

TB 9-4931-700-50

(33) Position TI controls as listed in (a) through (c) below:

(a) Press VOLTAGE RANGE 100mV pushbutton.

(b) Set voltage controls to obtain indication of 100.0000 mv.

(c) Press ERROR RANGE 0 pushbutton.

(34) Set distortion analyzer range to 100 mV.

(35) Set ratio transformer dials to 1.000000.

(36) Adjust ac/dc voltmeter dials to obtain a null indication. Leave voltage readout

dials set.

(37) Set ratio transformer dials to .100000.

(38) Position TI controls as listed in (a) through (c) below:

(a) Press VOLTAGE RANGE 1V pushbutton.

(b) Set voltage controls to obtain same indication recorded in (17) above.

(c) Press ERROR RANGE X.1 pushbutton.

(39) Adjust ERROR MEASUREMENT control to obtain null indication on ac/dc

voltmeter. The % ERROR scale will indicate within ±0.052 percent.

(40) Set decade resistor dials to 3010 ohms and connect across TI OUTPUT

terminals, using cable (B7).

(41) Repeat (33) through (39) above.

b. Adjustments

NOTE

Perform power supply check in paragraph 13 prior to making

adjustments.

(1) Press FREQUENCY RANGE X10K pushbutton and adjust FREQUENCY

control to obtain FREQ scale indication of 10.

(2) With thermal transfer standard in manual balance mode and dc output state,

adjust its manual balance controls to obtain ac/dc voltmeter indication equal to the value

of TI voltage controls setting.

(3) Set thermal transfer standard to ac balancing state. Adjust TI A3C12 (fig. 2)

to obtain null indication on thermal transfer standard meter with its null X5 pushbutton

pressed (R).

(4) Set thermal transfer standard to ac balancing state. Adjust TI A6R16 (fig. 2)

to obtain null indication on thermal transfer standard meter with its null X5 pushbutton

pressed (R).

(5) Press FREQUENCY RANGE X1K pushbutton and adjust FREQUENCY

control to obtain FREQ scale indication of 10.

(6) Set thermal transfer standard to ac balancing state. Adjust TI A14R7 (fig. 2)

to obtain null indication on thermal transfer standard meter with its null X5 pushbutton

pressed (R).

19

Page 26

TB 9-4931-700-50

(7) Set thermal transfer standard to ac balancing state. Adjust TI C9 (fig. 2) to

obtain null indication on thermal transfer standard meter with its null X5 pushbutton

pressed (R).

11. Voltage Accuracy, Regulation, and Frequency Response (Model 746A)

a. Performance Check

(1) Connect equipment as shown in figure 5.

Figure 5. High - equipment setup.

(2) Position TI controls as listed in (a) through (f) below:

(a) Press VOLTAGE RANGE 1000 V ext. pushbutton.

(b) Set voltage controls to obtain an indication of 100.000 V.

(c) Press FREQUENCY RANGE X1K pushbutton.

(d) Adjust FREQUENCY control to obtain FREQ scale indication of 1.0

(e) Press ERROR RANGE 0 pushbutton.

(f) Press OUTPUT ON pushbutton.

NOTE

Each time measurement of TI output is directed, a minimum

of four readings should be taken. The first reading should be

disregarded and the other three readings averaged. The

average reading is the indication to be recorded for future

use. The ac/dc voltmeter (A1) indication should be read

between 15 and 20 seconds after thermal transfer standard

(A9) transfers to the dc output state.

20

Page 27

TB 9-4931-700-50

(3) Measure TI output, using thermal transfer standard in auto mode. Wait

approximately 2 minutes after applying ac voltage before transferring to the dc output

state. Record ac/dc voltmeter indication. -

(4) Compute and record difference between indication recorded in (3) above and

TI voltage controls setting. If indication in (3) is larger, a + (plus) sign is to difference. If

it is smaller, a - (minus) sign is assigned to difference. Convert difference to percentage

retaining assigned sign.

(5) Refer to test report for thermal transfer standard to obtain percentage of

ac/dc difference for 100 V at appropriate frequency.

(6) Add algebraically two percentages obtained in (4) and (5) above. The result is

percentage of TI output error. If TI output error is more than ±0.04 percent, perform b

below.

(7) Repeat technique of (2) through (6) above with autotransformer set at 105 and

125 V ac. If error does not remain within ±0.04 percent and adjustments were not

performed in (6) above, perform b below and repeat (2) through (6) above. Return

autotransformer setting to 115 V ac.

(8) Repeat technique of (7) above with voltage controls set to o btain an indication

of 1000.000 V.

(9) Perform technique of (3) through (6) above, using frequencies and acceptable

errors listed in table 8.

Table 8. Accuracy and Frequency Response

Test Instrument Frequency Acceptable Error (Percent)

50 Hz ±0.04

100 Hz ±0.04

10 kHz ±0.04

20 kHz ±0.04

50 kHz ±0.08

100 kHz ±0.15

(10) Press OUTPUT OFF pushbutton.

(11) Connect variable capacitor (A10) across TI output (connect to adapter B4

using both conductors of a pair for each connection, hook-up wire B9). Set variable

capacitor dial to 125 pF (picofarad).

(12) Set voltage controls to obtain an indication of 700.000 V and press OUTPUT

ON pushbutton.

(13) Repeat (9) above.

(14) Press OUTPUT OFF pushbutton.

(15) Replace variable capacitor with decade resistor (A3). Set variable resistor

dials to 16000 ohms.

(16) Set voltage controls to obtain an indication of 100.000 V.

(17) Press FREQUENCY( RANGE )(10 pushbutton and adjust FREQUENCY

control to obtain FREQ SCALE indication of 1.0.

21

Page 28

TB 9-4931-700-50

(18) Press OUTPUT ON pushbutton.

(19) Repeat technique of (3) through (6) above. The TI output error will not be

more than ±0.25 percent.

(20) Press OUTPUT OFF pushbutton.

b. Adjustments

NOTE

Perform power supply check in paragraph 14 below prior to

making adjustments.

22

Page 29

TB 9-4931-700-50

NOTE

Perform (1) through (6) below and repeat a above. If still outof-tolerance, perform (7) through (26) below.

(1) With thermal transfer standard in manual balance mode and dc output state,

adjust its manual balance controls to obtain ac/dc voltmeter indication equal to value of

TI voltage control setting.

WARNING

Do not adjust R5 or L3 with instruments floating above earth

ground. Mounting hardware for R5 and L3 is at circuit

ground.

(2) Set thermal transfer standard to ac balancing state. Adjust R5 (fig. 6) to

obtain null indication on thermal transfer standard meter X pushbutton pressed (R).

Figure 6. Model 746A top view - Adjustment locations.

(3) Press FREQUENCY RANGE X10K pushbutton and adjust FREQUENCY

control to obtain FREQ scale indication of 10.0.

(4) Repeat (1) above.

(5) Set thermal transfer standard to ac balancing state. Adjust L3 (fig. 6) to

obtain null indication on thermal transfer standard meter with its null X5 pushbutton

pressed (R).

(6) Press OUTPUT OFF pushbutton.

23

Page 30

TB 9-4931-700-50

(7) Remove bottom cover from TI (model 746A only). Remove plastic cover from

A6 amplifier assembly (fig. 7).

Figure 7. Model 746A bottom view - adjustment location.

(8) Connect ac/dc voltmeter high voltage leads between test point B (fig. 7) and

GND (circuit ground).

(9) Press OUTPUT ON pushbutton.

NOTE

The voltages in (10) and (12) below do not have to be exact.

They may vary as much as ±50 V. The important point is that

voltage difference between them is 30 ±2 V.

(10) Adjust A6R14 (fig. 7) to obtain indication of 1850 V dc on ac/dc voltmeter (R).

(11) Move ac/dc voltmeter leads to test point A6TP6 (fig. 7) and GND (circuit

ground).

(12) Adjust A6R77 (fig. 7) to obtain indication of 1820 V dc on ac/dc voltmeter (R).

(13) Press OUTPUT OFF pushbutton.

24

Page 31

TB 9-4931-700-50

(14) Connect variable capacitor across TI output (connect at isolation box, using

cable). Set variable capacitor dial to 50 pF.

(15) Connect oscilloscope (A7) to A6TP2 (fig. 7), using probe (B11).

(16) Position TI controls as listed in (a) through (d) below:

(a) FREQUENCY RANGE X10K pushbutton pressed.

(b) FREQUENCY control to obtain FREQ scale indication of 101.

(c) Voltage controls to obtain indication of 100.000 V.

(d) OUTPUT ON pushbutton pressed.

(17) Adjust (increase) TI output in 100 V steps to 700 V or until a glitch appears on

waveform as shown in figure 8.

Figure 8. Waveform at A6TP2.

(18) If no glitch appears, adjust (increase) capacitance of variable capacitor until it

does appear. After glitch appears, adjust A6C18 (fig. 7) until waveform becomes clear

and then another glitch appears. Note range of A6C18 between points where glitches

appear.

(19) Adjust (increase) capacitance of variable capacitor and adjust A6Cl8 until

range as noted in (15) above is minimum (R).

(20) Connect ac/dc voltmeter to A6TP6 (fig. 7) (same as V3 RED) and circuit

ground, using leads supplied with ac/dc voltmeter.

(21) Adjust A6R77 (fig. 7) to obtain indication of 1800 V dc on ac/dc voltmeter (R).

(22) Adjust variable capacitor for 100 pF.

(23) Adjust TI output from 700 V to 100 V. The oscilloscope will not show signs of

oscillations.

(24) Set voltage controls to obtain indication 700.000 V and adjust frequency from

110 to 10 kHz. If oscilloscope indication is not smooth with no oscillations, repeat (7)

through (20) above.

25

Page 32

TB 9-4931-700-50

(25) Set voltage controls to obtain indications of 100.000 V. Press FREQUENCY

RANGE X1K pushbutton and adjust FREQUENCY control to obtain FREQ scale

indication of 1.0.

(26) Connect ac/dc voltmeter between A6TP5 (fig. 7) and circuit ground, using

cable and adapter (B6 and B2). If ac/dc voltmeter does not indicate 10 V ac, use ERROR

RANGE pushbuttons and ERROR MEASUREMENT control to obtain 10 V ac indication.

(27) Press FREQUENCY RANGE X10K pushbutton and adjust FREQUENCY

control to obtain FREQ scale indication of 10.0.

(28) If ac/dc voltmeter does not indicate between 10.3 and 10.7 V ac, adjust A6C12

(fig. 7) to obtain indication of between 10.3 and 10.7 V ac.

12. Distortion

a. Performance Check

(1) Connect equipment as shown in figure 9.

(2) Position TI controls as listed in (a) through (f) below:

(a) Press VOLTAGE RANGE 1V pushbutton.

(b) Set voltage set controls to obtain indication of 1.000000 V.

(c) Press FREQUENCY RANGE X10 pushbutton.

(d) Adjust FREQUENCY control to obtain FREQ scale indication of 1.0.

(e) Press ERROR RANGE 0 pushbutton.

(f) Press SENSE LOCAL pushbutton.

(3) Adjust decade resistor (A3) dials to 22 ohms.

26

Page 33

TB 9-4931-700-50

Figure 9. Distortion check - equipment setup.

(4) Measure distortion. If distortion is not .06 percent or less, perform b below.

(5) Repeat (4) above for frequencies of 50 and 100 Hz, and 1, 10, 50, and 100 kHz.

If distortion is not .06 percent or less, perform b below.

(6) Repeat technique of (2) through (5) above, using settings and indications

listed in table 9.

Table 9. Distortion

Test Instrument VOLTAGE Resistance Value Maximum Distortion

RANGE Switch Settings (V) (Ohms) Allowed (Percent)

10 221 .060

1

Replace decade resistor (A3) with load (A6).

100 22001 .060

(7) Connect output of the TI (Model 746A) to input of distortion analyzer (A1).

(8) Position TI (Model 745A) controls as listed in (a) through (d) below:

(a) Press FREQUENCY RANGE X10 pushbutton.

(b) Adjust FREQUENCY control to obtain FREQ scale indication of 1.0.

(c) Press VOLTAGE RANGE 1000V ext. pushbutton.

(d) Set voltage controls to obtain 100.000 V.

(9) Press OUTPUT ON pushbutton (Model 746A).

(10) Measure distortion. Distortion will be .06 percent or less.

27

Page 34

TB 9-4931-700-50

(11) Repeat technique of (8), (9), and (10) above for frequencies of 50 Hz, and 1, 10,

50, and 100 kHz. Distortion will be .06 percent or less.

(12) Press OUTPUT OFF pushbutton.

b. Adjustments

NOTE

Deenergize TI when removing or installing circuit boards.

(1) Remove circuit board A12A5 (fig. 1) from TI and extend -circuit board A12A7

(fig. 1) using extender board supplied with TI.

(2) Press FREQUENCY RANGE X10K pushbutton and adjust FREQUENCY

control to obtain FREQ scale indication of 5.

(3) Connect oscilloscope (A7) to A12A7TP2 (fig. 1), using probe (B11) and connect

ac/dc voltmeter (A1) to A12A8TP1 (fig. 1).

(4) Center adjustments A12A7R26 and A12A7R29 (fig. 1).

(5) Adjust 112A7C14 (fig. 1) to obtain minimum amplitude of the ac signal

displayed on oscilloscope (R).

(6) Alternately adjust A12A7R26 and A12A7R29 (fig. 1) to obtain minimum

amplitude of ac signal displayed on oscilloscope.

(7) Repeat (5) and (6) above to obtain optimum indication. The amplitude of ac

signal should be less than 0.05 V p-p.

(8) Ac/dc voltmeter will indicate 0 ±2 mV dc.

(9) Adjust A12A7R26 and A12A7R29 (slightly) to obtain an ac/dc voltmeter

indication of 0 ±2 mV dc.

(10) Repeat (5) through (9) as necessary until ac signal is less than 0.05 V P-P and

dc voltage is 0 ±2 mV dc.

(11) Replace circuit boards in TI.

(12) Press FREQUENCY RANGE X1K pushbutton and adjust FREQUENCY

control to obtain FREQ scale indication of 1.

(13) Extend circuit board A12A8 (fig. 1), using extender board furnished with TI.

(14) Connect ac/dc voltmeter to A12A8TP1 (fig. 1) and adjust A12A8R32 to obtain

indication of 0.1 V ac (R).

(15) Connect ac/dc voltmeter to A2TP4 (fig. 2) and adjust A12A6R4 (fig. 1) to obtain

indication of between -.99 and 1.1 V dc (R).

(16) Connect ac/dc voltmeter to A12A8TP2 (fig. 1) and adjust A12A8R15 (fig. 1) to

obtain indication of between 0.25 and 0.35 V dc (R).

(17) Replace circuit board in TI.

13. Power Supply (Model 745A)

NOTE

28

Page 35

TB 9-4931-700-50

Do not perform power supply check if all other parameters

are within tolerance.

NOTE

In the following procedure all voltages are measured with

respect to circuit common (1). Circuit common is available at

any point on inner chassis.

a. Performance Check

(1) Set TI for output of 1.000000 mV at 1 kHz.

(2) Connect ac/dc voltmeter (A1) between A8TP3 (fig. 2) and circuit common,

using cable and adapter (B6 and B2). If ac/dc voltmeter does not indicate between -69.5

and -70.5 V dc, perform b below.

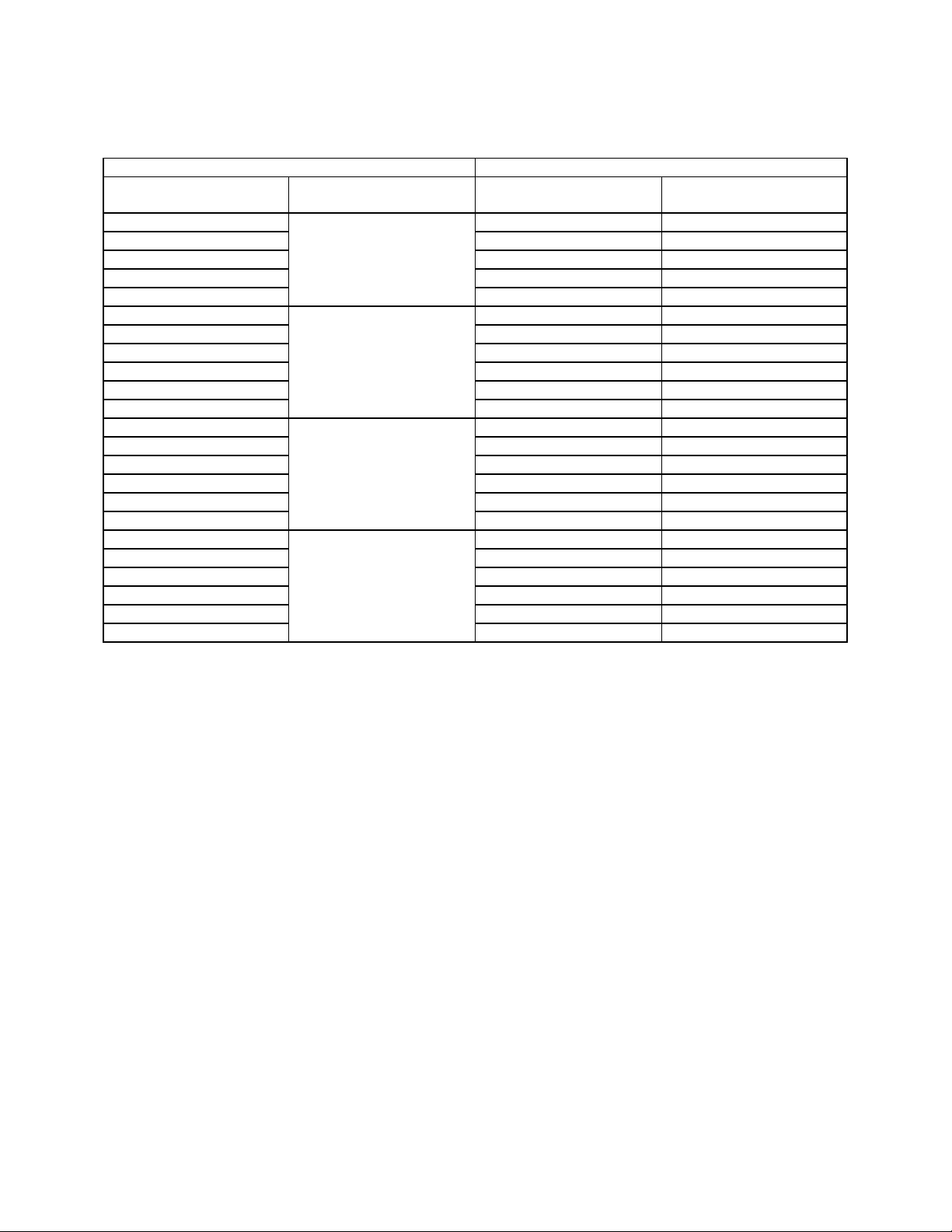

(3) Repeat technique of (1) and (2) above for settings and indications listed in

table 10. If an out-of-tolerance condition is indicated, perform specified adj ustment.

b. Adjustments. Adjust A8R30 (fig. 2) to obtain an ac/dc voltmeter indication of

-70.00 V dc (R).

29

Page 36

TB 9-4931-700-50

Table 10. Power Supply and Bias

Test Instrument Ac/dc Voltmeter, Frequency Counter, Adjustments

Connection Points or Oscilloscope (fig. 2)

(fig. 2) Indications

A8TP4 +69.50 to +70.50 V dc A8434 (R)

A8TP1 -24.80 to -25.20 V dc A8429 (R)

A8TP2 +5.10 to +5.30 V dc A8R6 (R)

A4TP1 -0.0030 to +0.0030 V dc A4R8 (R)

A3TP11 -0.0010 to +0.0010 V dc A3R34 (R)

A2 PIN 122 450 to 550 ms sample gate A3410 (R)

A25013 -0.0010 to +0.0010 V dc A2R9 (4)

A2TP24 +0.550 to +0.650 V dc A2R34 (R)

A2TP3 -0.0001 to +0.0001 V dc A2R67 (R)

A2TP45 -0.90 to -1.10 V dc - - A2TP46 Indication equal to that recorded in footnote 5

A4439 (R)

below

A1A3TP57 499 to 501 Hz A1A4R5 (R)

A1A3TP58 -9.89999 to -9.90001 V dc A1A3R32 (coarse), R34 (fine) (R)

A1A3TP59 +9.89999 to +9.90001 V dc 10 A1A3R14 (coarse), R16 (fine) (R)

1

Adjust frequency to 50 kHz and set A1A4S1 (fig. 2) to +9.9 V position. Overload lamp may illuminate, this may be

expected when A1A4S1 is switched from 19.8 V position.

2

Set A1A4S1 to 19.8 V position; connect oscilloscope (A7), using cable (B4).

3

Remove PC board A3.

4

Reinstall PC board A3 and reset frequency to 50 kHz.

5

Press FREQUENCY RANGE X1K pushbutton. Record voltage level indication.

6

Press FREQUENCY RANGE X100 pushbutton

7

Connect frequency counter (A5).

8

Set A1A4S1 to -9.9 V position.

9

Set A1A4S1 to +9.9 V position.

10

After completing check, set A1A4S1 to 19.8 V position.

14. Power Supply (Model 746A)

NOTE

Do not perform power supply check if all other . parameters

are within tolerance.

a. Performance Check

(1) Connect ac/dc voltmeter (A1) between -30 V test point (TP3) of A4 assembly

(fig. 6 and 10) and circuit ground. Ac/dc voltmeter will indicate between -29.7 and -30.3

V dc.

(2) Connect ac/dc voltmeter between +6 V test point (TP1) of A4 assembly (fig. 10)

and circuit ground. Ac/dc voltmeter will indicate between 5.94 and 6.06 V dc.

(3) Connect ac/dc voltmeter between +150 V test point (TP2) of A4 assembly (fig.

10) and circuit ground. AC/dc voltmeter will indicate between 145.5 and 154.5 V dc.

b. Adjustments. No adjustments can be made.

30

Page 37

TB 9-4931-700-50

Figure 10. A4 Assembly - test point locations.

15. Flow Procedure

a. Deenergize and disconnect all equipment and reinstall TI protective cover.

b. In accordance with TM 38-750, annotate and affix DA Label 80 (US Army

Calibrated Instrument). When the TI receives limited or special calibration, annotate

and affix DA Label 163 (US Army Limited or Sp ecial Calibration). When the TI cannot

be adjusted within tolerance, annotate and affix DA Form 2417 (US Army Calibration

System Rejected Instrument).

31

Page 38

TB 9-4931-700-50

By Order of the Secretary of the Army:

BERNARD W. ROGERS

General, United States Army

Chief Of Staff

Official:

J. C. PENNINGTON

Brigadier General, United States Army

The Adjutant General

Distribution:

To be distributed in accordance with Std. IDS No. RLC-1500, 13 March 1974.

US GOVERNMENT PRINTING OFFICE: 1984 - - 746-036/3377 REGION #4

PIN NO: 009082-000

Loading...

Loading...