Page 1

TM11-6625-2752-14&P

(NSN6621-00-621-6568)

Page 2

WARNING

Page 3

TM11-6625-2752-14&P

TM11-6625-2752-14&P

(NSN6625-00-621-6568)

o-i

Page 4

TABLE OF CONTENTS

TM11-6625-2752-14&P

Paragraph

SECTION 0. INTRODUCTION .......0-1

SECTION I. GENERAL INFORMATION .......1-1

1-1. Introduction..............1-1

1-3. Eight-Channel Recorder..........1-1

1-9. Application and Specifications.......1-1

1-13. Accounts and Optics 1-2.

1-15. Preamplifier 1-2

SECTION II. INSTALLATION..........2-1

2-1. Initial Inspection.........2-1

2-3. Mechanical Check..........2-1

2-5. Performance Tests.............2-1

2-7. Damage Claims..............2-1

2-9. Storage.......2-1

2-11. Installation ............2-1

2-13. Premaplifier Installation.........2-1

2-15. Power Connections.............2-1

2-18. Signal Connections............2-1

2-22. Remote Control and Marker Connections .,.2-4

SECTION III. OPERATION..........3-1

3-1. Introduction..........3-1

3-3. Control Locations.........3-2

3-5. System Operation.........3-3

SECTION IV. PRINCIPLES OF OPERATION

4-1. Introduction.........5-2

4-4. Preamplifier Power Supply 8848A.....4-0

4-7 Guarded Input Circuits..........4-1

4-9. Unregulated 18 Volt Supplies.......4-1

4-11. Preamplifier Supplies...........4-1

4-13. Oscillator Supply..........4-1

4-14. Regulated 12 Volt Supplies.........4-1

4-16 regulator Assembly..........4-1

4-18. 440 Hz Oscillator...........4-2

4-21. 2400 Hz Oscillator............4-2

4-24. Recorder Signal Circuits..........4-4

4-28. Galvanometer Dumping..........4-4

4-30. Damping.........4-4

4-31. Stylus Linkage.........4-4

4-33. Galvanometer Position Feedback.......4-7

4-37. Host Control Circuit........4-8

4-39. Power Control Circuits..........4-8

4-43. Chart Drive...............4-8

4-45. Chart Motor..............4-8

4-47. Speed Control............4-8

4-50. Speed Selection Solenoids.......4-11

4-51. Power Flow...............4-11

4-52. Paper Feed...........4-11

Page

Paragraph

4-54.

4-56.

4-58.

4-60.

4-61.

4-62.

4-63.

4-64.

4-66.

4-69.

4-70.

SECTION V. MAINTENANCE............5-1

5-1.

5-3.

5-5.

5-8.

5-10.

5-12.

5-16.

5-18.

5-20. Electrical Checks............5-4

5-22.

5-24.

5-26.

5-27.

5-28.

5-29.

5-31. Stylus Pressure Adjustment

5-32. Stylus Center Adjustment

5-33. Stylus Parallax Adjustment

5-34.

5-35. Stylus Removal and Replacement

5-37.

5-38.

5-40.

5-43.

5-46. Paper Table Disassembly

5-48.

5-49. Pressure Roller Replacement

5-50. Drive Roller Replacement

5-51.

5-53.

5-54. Gearbox Removal

5-55.

5-56.

Page

Recorder Power Supply and Regulator

Circuits.........4-13

Recorder DC Power Supplies.......4-13

Regulator/Oscillator..........4-13

+5 Volt Regulator...........4-13

+12 Volt Regulator......4-13

_12 Volt Regulator...........4-13

200kHz.................4-13

Oscillator Regualtion Circuit.......4-13

Marker Circut...........4-13

Marker Switches.......4-14

Marker Heat Driver...........4-14

Introduction.............5-1

Test Equipment and Lubricants........5-1

Performance Checks....................5-1

Variable Line Voltage...........5-2

Proventive Maintenance.........5-2

Operational Checks and Inspection.....5-2

Cleaning...............5-4

Lubrication.............5-4

Adjustments and Minor Repairs........5-4

Paper Drive Adjustments.........5-4

Paper Tracking Adjustment

Paper Timing Check

Paper Tension Adjustment

Stylus Adjustments

Channel Time Synchronization

Stylus Lapping

Corrective Maintenance

Galvanometer Removal and Replacement . 5-20

Drive Unit Removal and Replacement

Platen Replacement

Gerbox Removal and Overhaul

Gearbox Inspection

Gearbox Disassembly and Lubrication

(Overhaul)

Gearbox Lubrication

...........5-17

............

...............

.......

..........5-17

.......

.......

........

......

.....

...........

...........

.........

...........

......

........

.....

...........

..........

....

. . 5-22

5-17

5-17

5-17

5-18

5-19

5-19

5-19

5-20

5-20

5-24

5-24

5-24

5-24

5-27

5-27

5-27

5-28

5-28

i

Page 5

TM11-6625-2752-14&P

TABLE OF CONTENTS

Paragraph

5-57.

5-58.

5-59.

5-61.

5-62.

Gearbox Reinstallation. . . .5-31

Gearbox Run-In. . . . . . . . . . . . . . .5-34

Marker Assembly Maintenance. . . . . . . . . .5-34

APPENDIX

Figure

1-1

Model 7758A and 7418A Recording

Systems. . . . . . . . . . . . .1-0

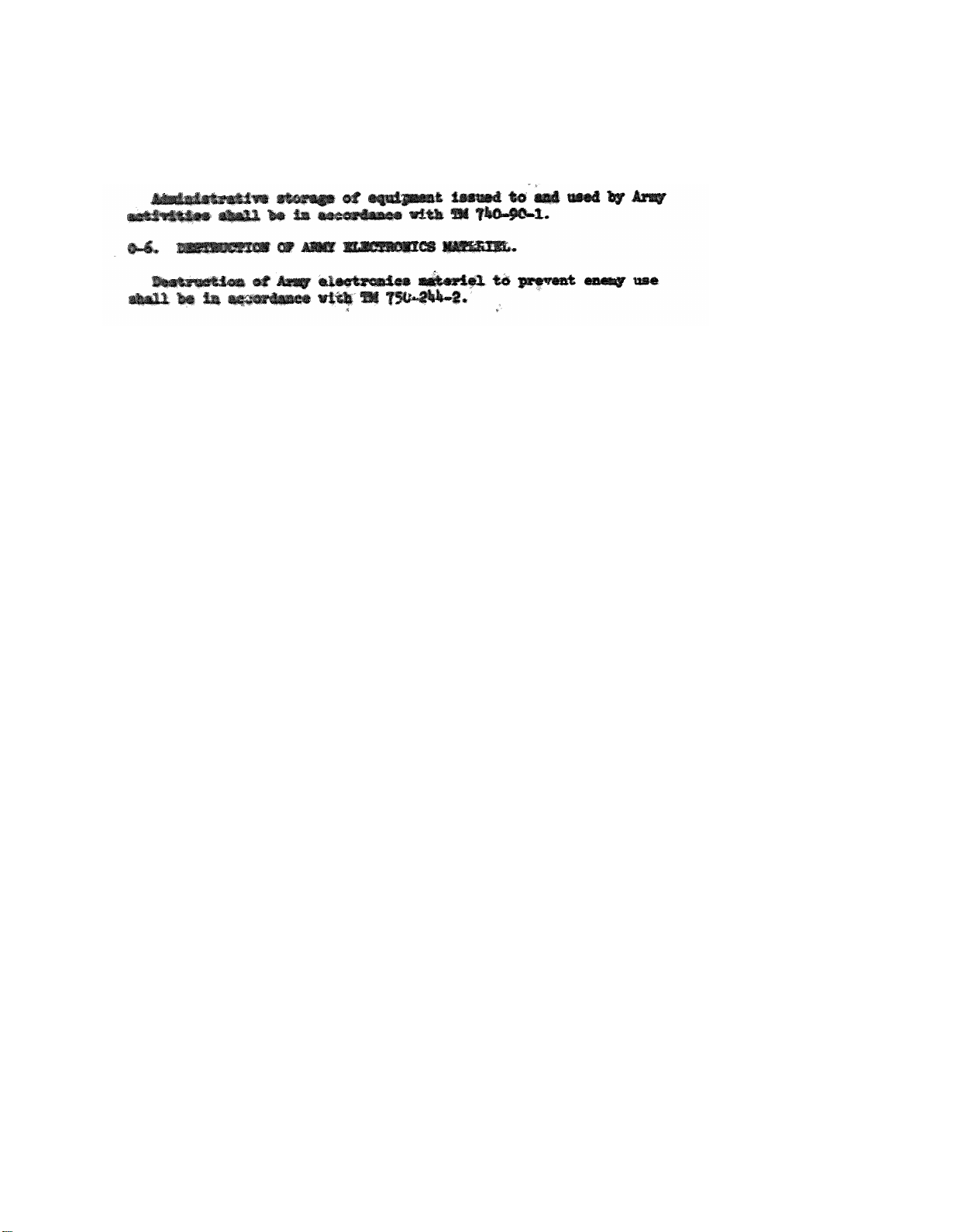

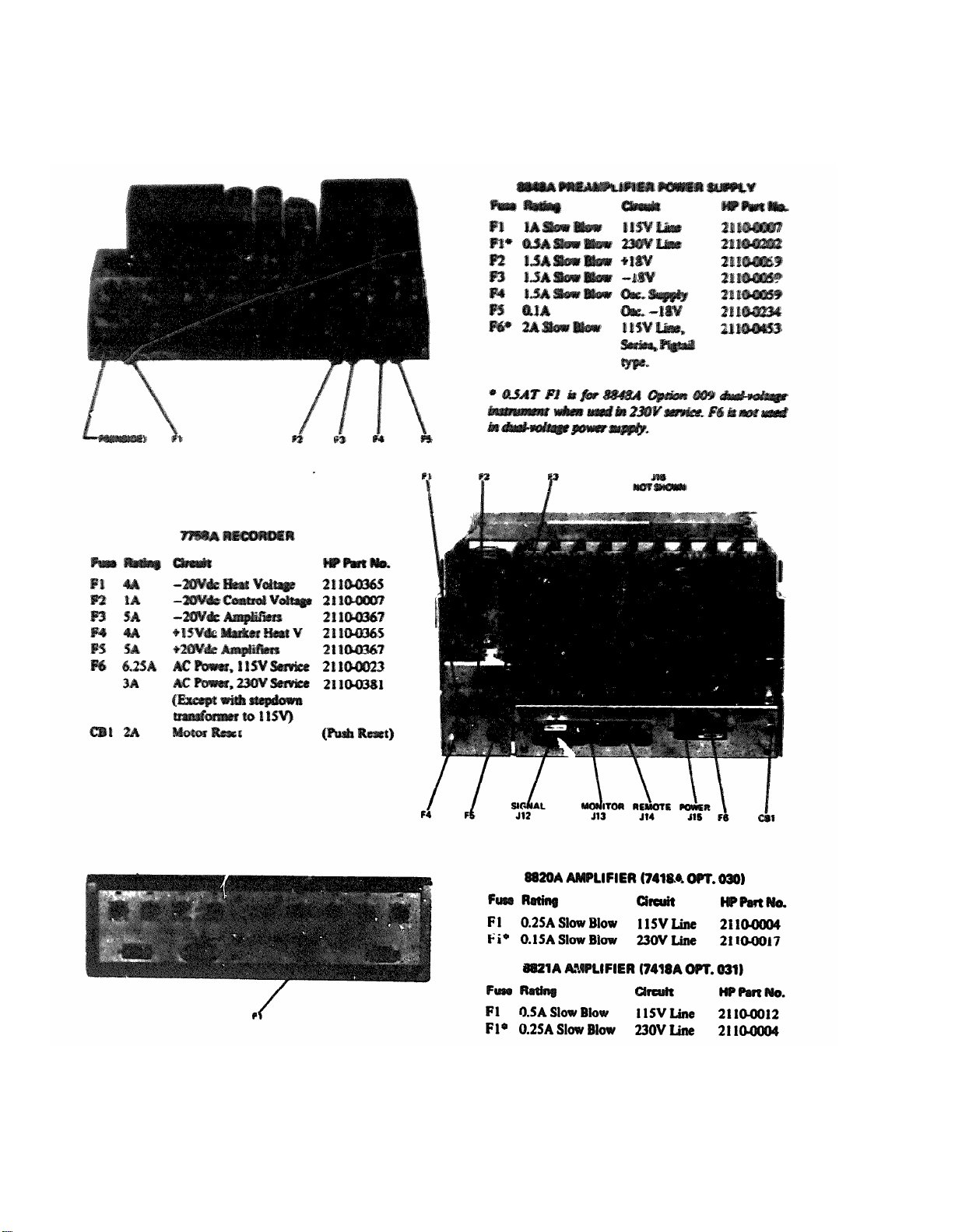

8848A Preamplifier Power Supply. . . . . . .1-1

1-2

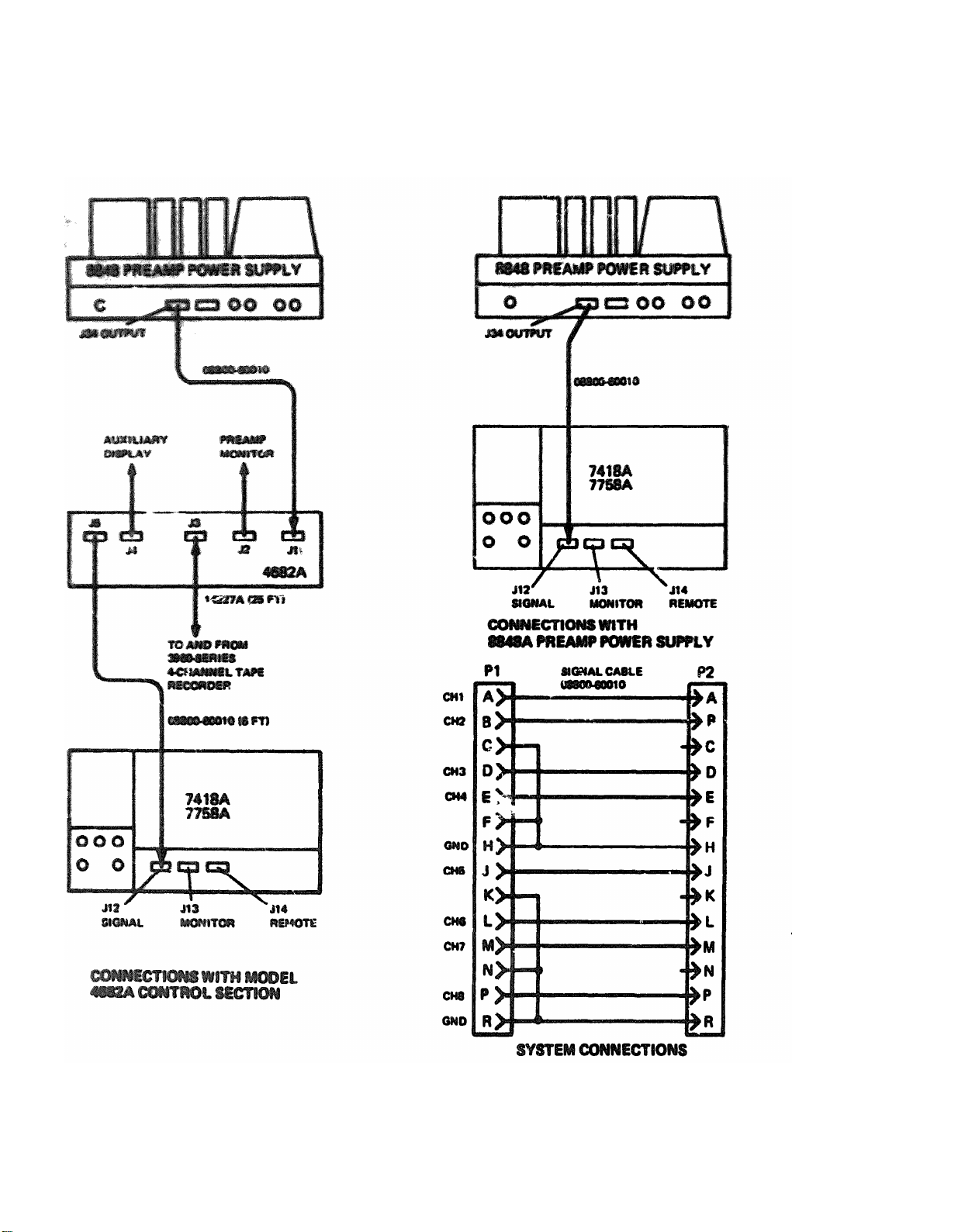

2-1.

2-2

2-3.

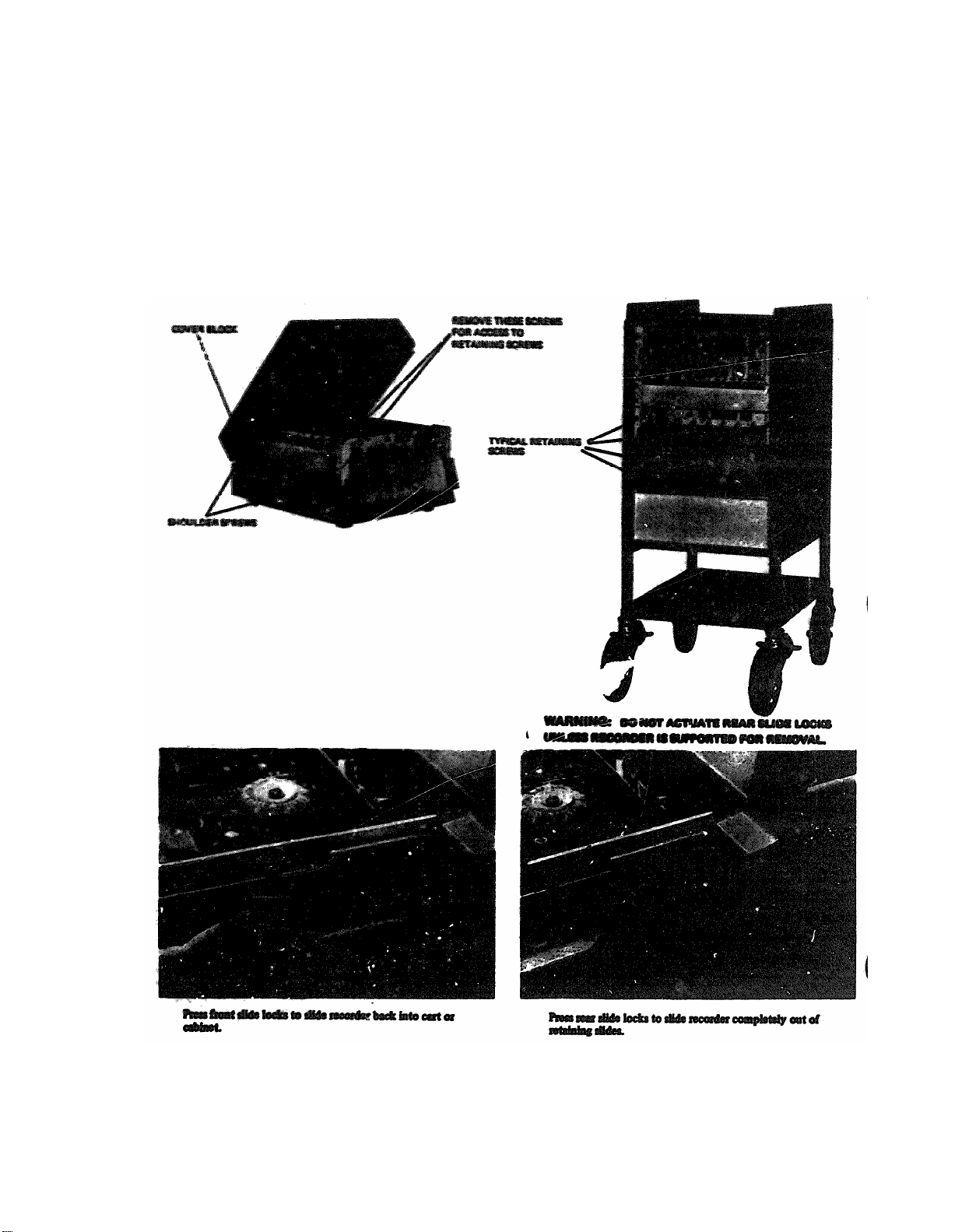

Recorder Access for Receiving Inspection . . . .2-2

Rear Panel Connectors and Fuses. . . . . . . . .2-3

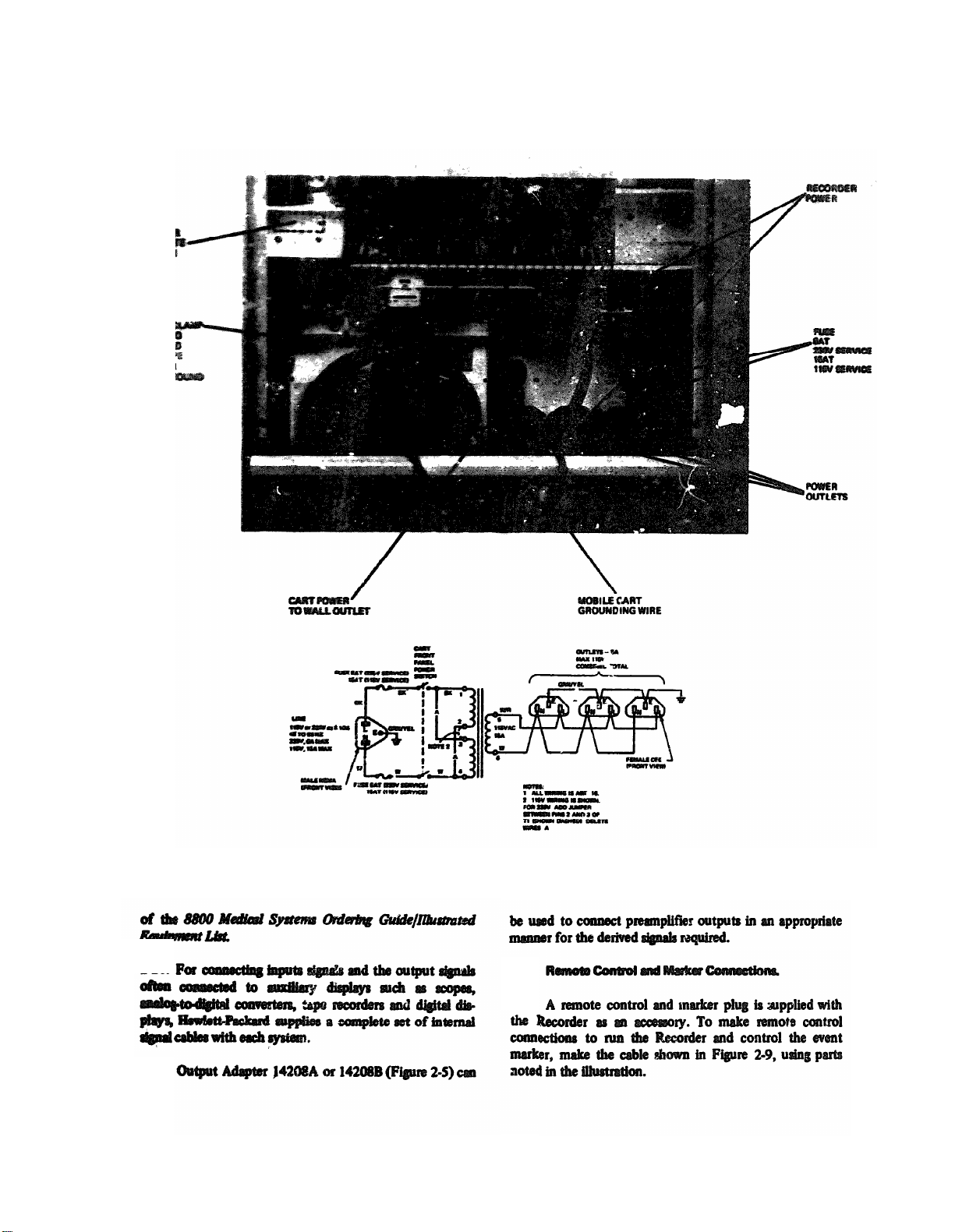

Recorder and Mobile Cart Power

Connections. . . . . . . . . . . .2-4

2-4.

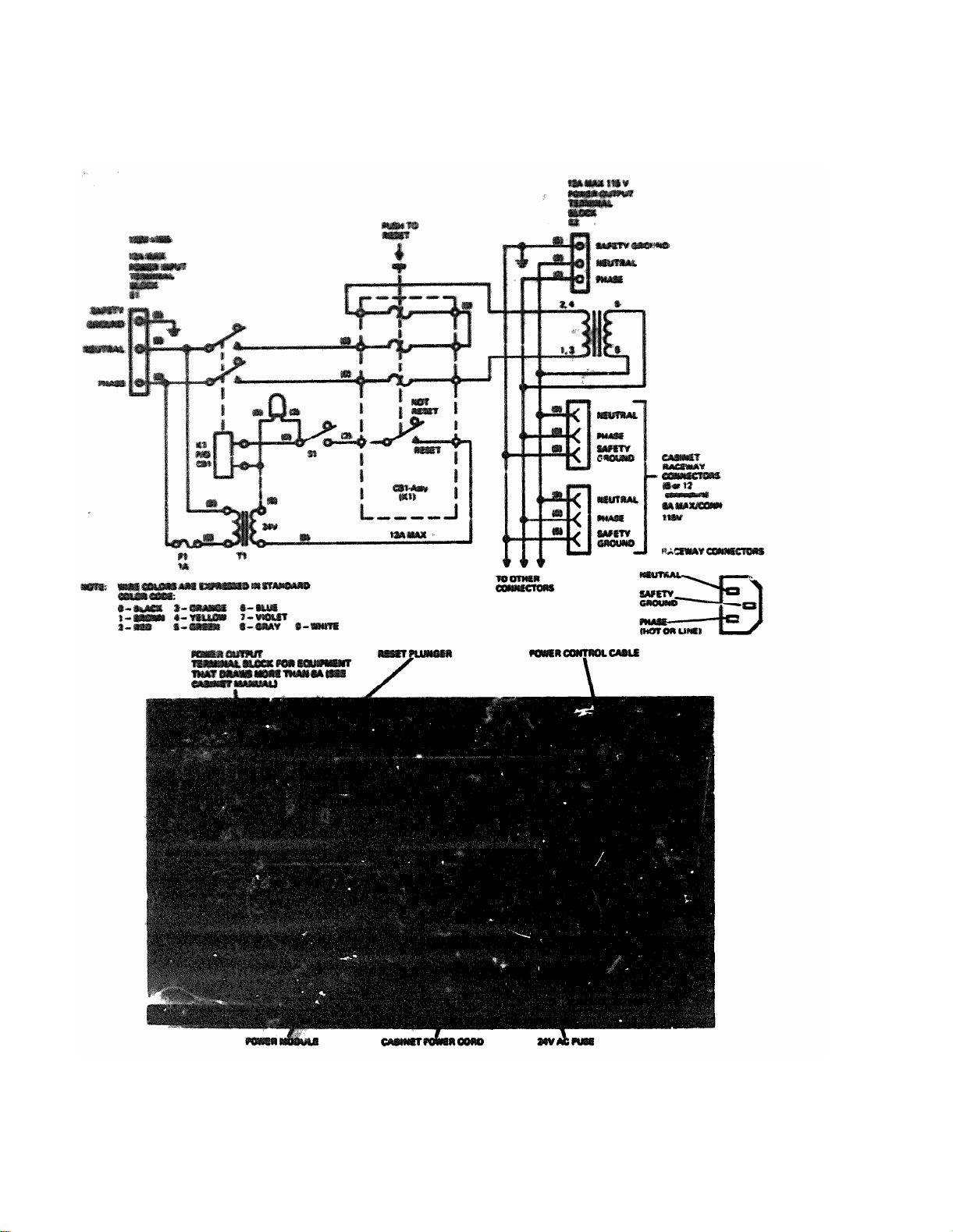

1065-Series Cabinet Power Module and

Schematic Diagram (typical). . . . . . . . . . 2-5

2-5.

2-6.

Output Adapter 14208A, 142088. . . . . . . .2-6

System Connection (with Control Section

4682A). . . . . . . . . . . . . 2-7

2-7.

Preamplifier Power Supply 884A. Input and

Output Connection. . . . . . . . . . . 2-8

2-8.

7418A System Input Cable Preparation (Multi- Text

channel Amplifier Options 030, 031). . . . . . 2-9

Cabel and Connector Assembly Diagrams for

2-9.

SIGNAL, MONITOR, and REMOTE Rear

Panel Connectors, Models 7758A, 7418A. 2-10

Option 001, 010 Mounting Kit 07758-60400 2-11

2-10.

3-1

4-1.

Control Locations. . . . . . . . . . .3-1

3-2.

Paper Loading Procedure. . . . . . . 3-2

Preamplifier Power Supply., Simplified

Diagram. . . . . . . . . 4-0

4-2.

12-Volt Regulator Circuit Power

Supply 8848). . . . . . . . . . . 4-2

4-3.

440 Hz Oscillaotr Circuit (Preamplifier Power

Supply 8848A). . . . . . . . . . . 4-3

4-4.

2400 Hz Oscillator Circuit (Preamplifier Power

Supply 8848A). . . . . . . . . . . 4-3

4-5.

4-6.

Galvanometer Damping. . . . . . . . . .4-4

Recorder Signal Circuits, Simplified Diagram. . .4-5

ii

Page

Gearbox Shift Play Adjustment. . . . 5-31

Paragraph

SECTION VI. REPLACEABLE PARTS. . . . . . . . 6-1

Page

Solanoid Adjustment. . . . . . . . . . . . . .5-31

Introduction. . . . . . . . . . . . . . .6-1

6-1.

6-4.

Reference Designations. . . . . . . . . . . . . . . . 6-1

6-10.

Ordering Information. . . . . . . . . . . . . . . .6-2

A .DIFFERENCE DATA SHEETS. . . . . . . . . . . . . . . . . . . .A-1

B. DIFFERENCE. . . . . . . . . . . . . . . . . . . . . B-1

C. MAINTENANCE ALLOCATION. . . . . . . . . . . . . . . . . . . . .C-1

D. REPAIR PARTS AND SPECIAL TOOLS LIST. . . . . . . . . . . . . .D-1

LIST OF ILLUSTRATIONS

Page

Figure Page

4-7.

4-8.

4-9.

Model 7758A, 7418A Recorder, Block Digagram 4-6

Galvanometer Position Feedback Circuit. . . 4-7

Recorder Power Control Circuit, Simplified

Diagram. . . . . . . . . . . . . .4-9

4-13.

Chart Drive Gears. v. . . . . . . . . . . . .4-9

Gearbox Power Flow. . . . . . . . . . . . 4-10

Paper Feed Path. . . . . . . . . . . .4-11

Recorder Power Supply and Regulator Ciruits,

4-10.

4-11.

4-12.

Simplified Diagram. . . . . . . . . .4-12

4-14.

Marker Heat Driver Output Current

Waveforms. . . . . . . . . . .4-14

Recorder Test and Adjustment Points. . . . .5-3

5-1

Recorder Lubrication Points (Typical). . . . . . . .5-5

5-2

5-3

Preamplifier Power Supply 8848A, Power

Test Points, Test Cable. . . . . . . . . .5-7

5-4.

5-5.

5-6.

5-7.

5-8.

5-9.

5-10.

5-12.

5-13.

Test Cable and Fixture. . . . . . . . . . . .5-8

Driver or Regulator Board Test Setup. . . . . .5-9

Regulator/Oscillator Board Test Points. . .5-11

Driver Amplifier Board Test Points. . . . . . .5-14

Paper Tension Adjustment. . . . . . . . . .5-18

Stylust Adjustments. . . . . . . .5-19

Channel Time Synchroniztic Adjustment 5-20

Stylus Removal and Replacement. . . . .5-21

5-11.

Stylus Lapping Procedure. . . . . . . . .5-22

Drive Unit and Galvanometer Mounting

Screws. . . . . . . . . . . . . . . . . .5-23

Drive Unit Removal and Replacement. . .5-24

5-14.

5-15.

Paper Removal, Table Link and Drive

Roller Disassembly. . . . . . . . . . 5-25

Gearbox Removal. . . . . . . . . . .5-26

5-16.

5-17.

5-18.

5-19.

5-20.

5-21.

Gearbox Disassembly. . . . . . . . .5-29

Clutch Lubrication. . . . . . . .5-30

Gearbox Shaft End Play Adjustment. . . . . . . 5-31

Gearbox Solenoid Adjustmentl. . . . . . . . . .5-33

Marker Assembly Adjustment and Removal 5-34

Page 6

LIST OF FIGURES

TM11-6625-2752-14&P

Figure

6-1.

6-2.

6-3.

6-4

6-5.

Page

6-3

6-22

6-22

6-23

Figure

6-18

6-19

6-20.

6-21.

6-23

6-6.

6-7.

6-8.

6-9.

6-10.

6-24

6-25

6-26

6-27

6-28

6-22.

6-23.

6-24.

6-11.

6-29

6-25.

6-12.

6-30 6-26.

6-13.

6-14

6-15.

6-16.

6-31

6-31

6-32

6-33

6-27.

6-28.

6-17.

6-33

6-29.

Page

6-34

6-35

6-35

6-36

6-41

6-41

6-42

6-42

6-43

6-43

6-44

6-45

Table

Page

1-1.

1-2.

1-3.

5-1.

5-2.

5-3.

1-2

1-3

1-4

5-1

5-2

5-6

Table

5-4.

5-5.

6-1.

6-2.

6-3.

Page

5-9

5-32

6-4

6-21

6-36

6-4.

6-40.1

iii

Page 7

TM11-6625-2752-14&P

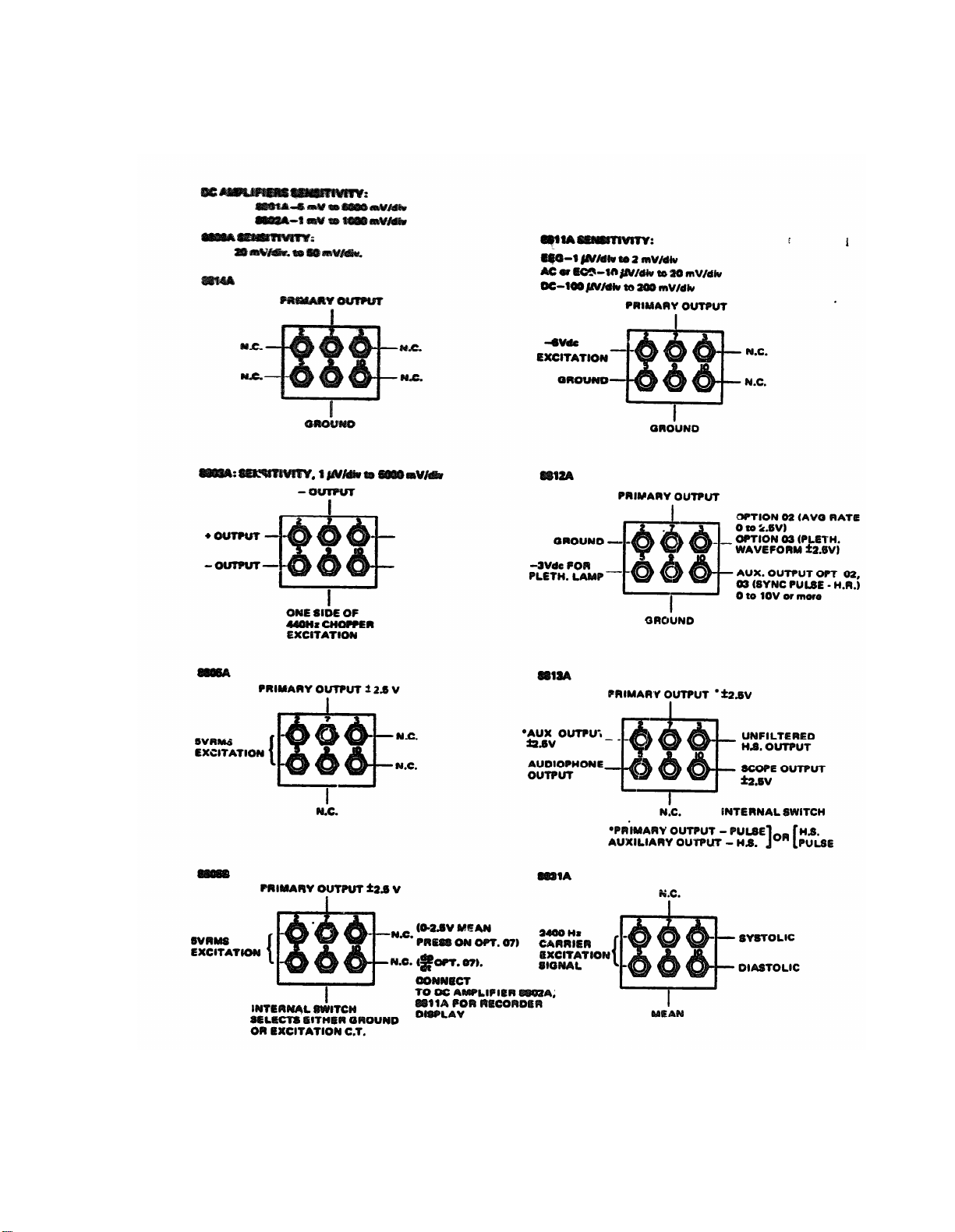

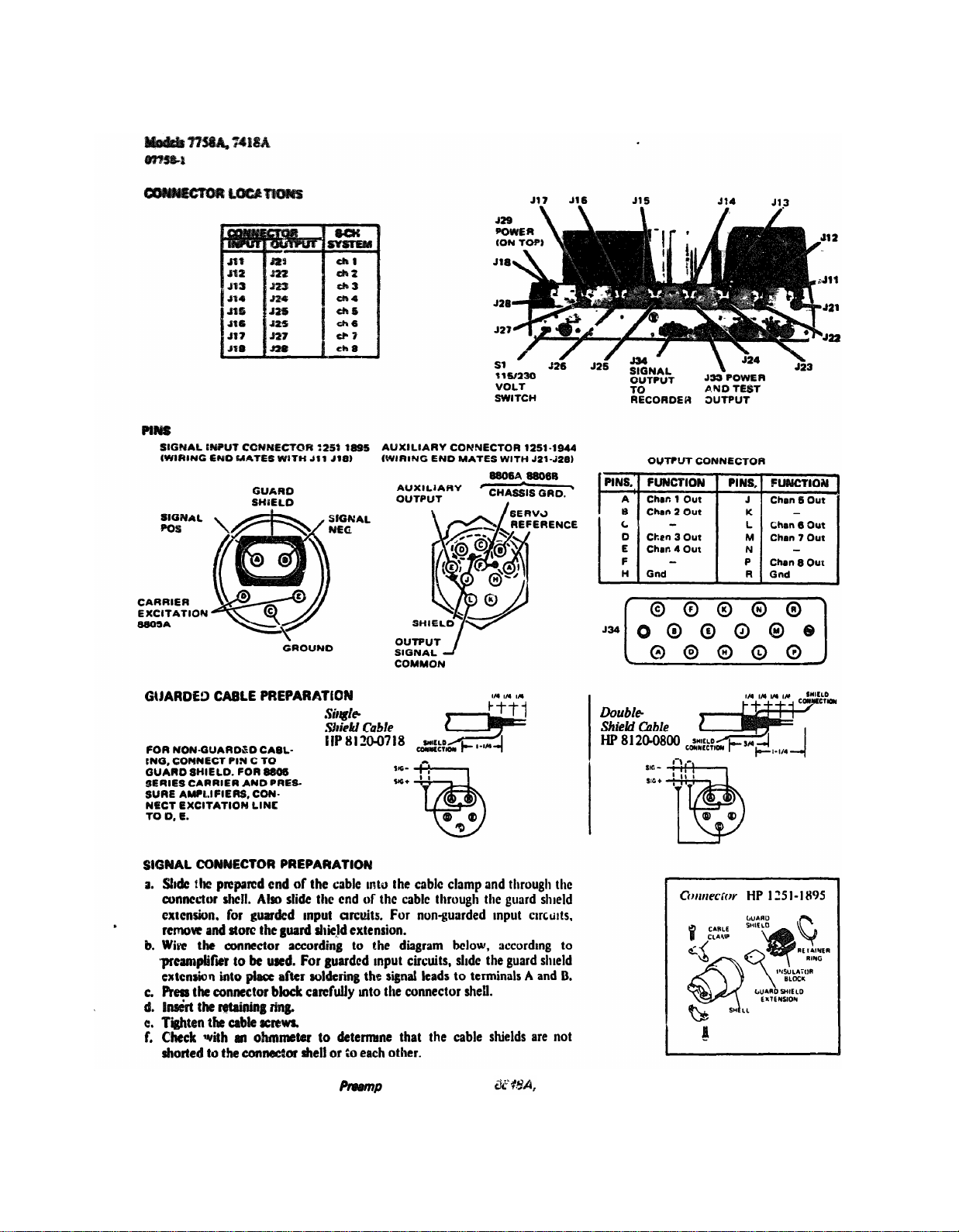

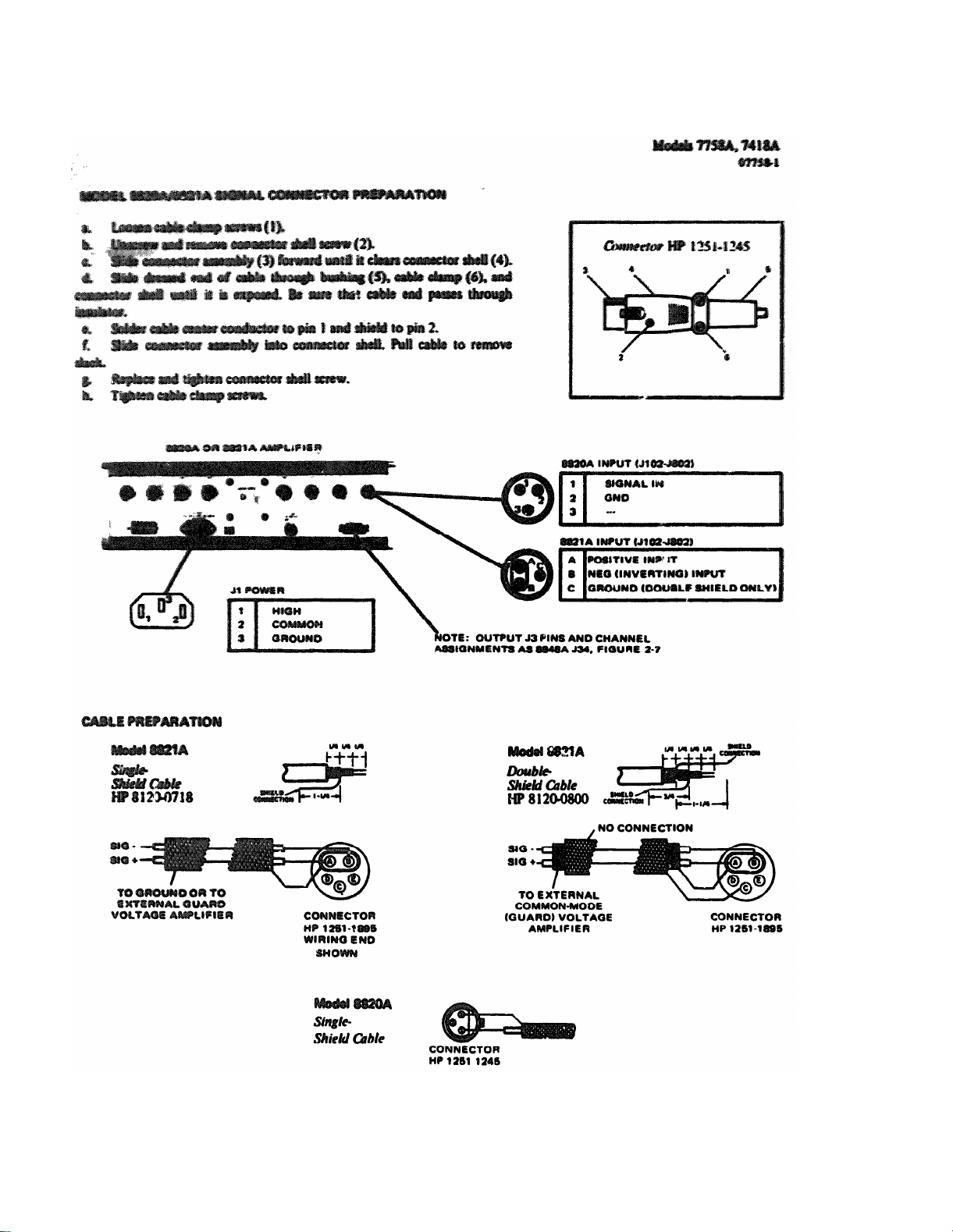

Section I - Channel Information

Models 7758A, 7418A

07758-1

1-0

Figure 1-1. Model 7758A and 7418A Recording Systems

Page 8

SECTION O

0-1. SCOPE.

0-2. INDEXES OF PUBLICATIONS.

0-3. FORMS AND RECORDS.

TM11-6625-2752-14&P

0-4. REPORTING EQUIPMENT IMPROVEMENT (EIR).

0-1

Page 9

TM11-6625-2572-14&P

0-5. ADMINISTRATIVE STORAGE.

0-2

Page 10

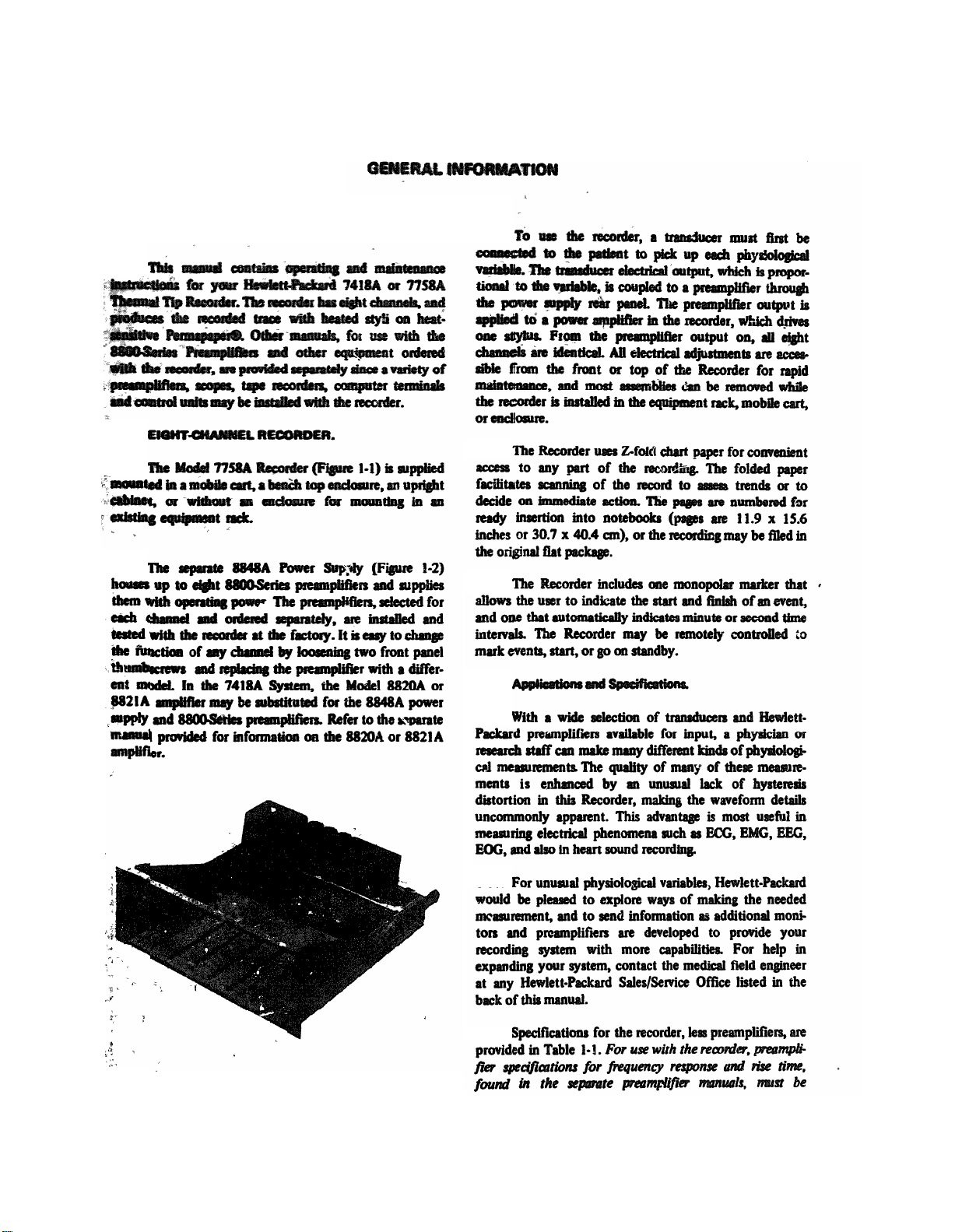

INTRODUCTION.

1-1.

1-2.

1-3.

1-4.

SECTION I

1-6.

1-7.

TM11-6625-2752-14&P

Section I - General Information

Models 7758A, 7418

07758-1

1-5.

1-8.

1-9.

1-11.

Figure 1-2. Preamplifier Power Supply

1-12.

1-1

Page 11

TM11-6625-2752-14&P

SECTION I. General Information

Models 7758A, 7418A

07758-1

1-13.

1-14.

1-15.

1-16.

1-17.

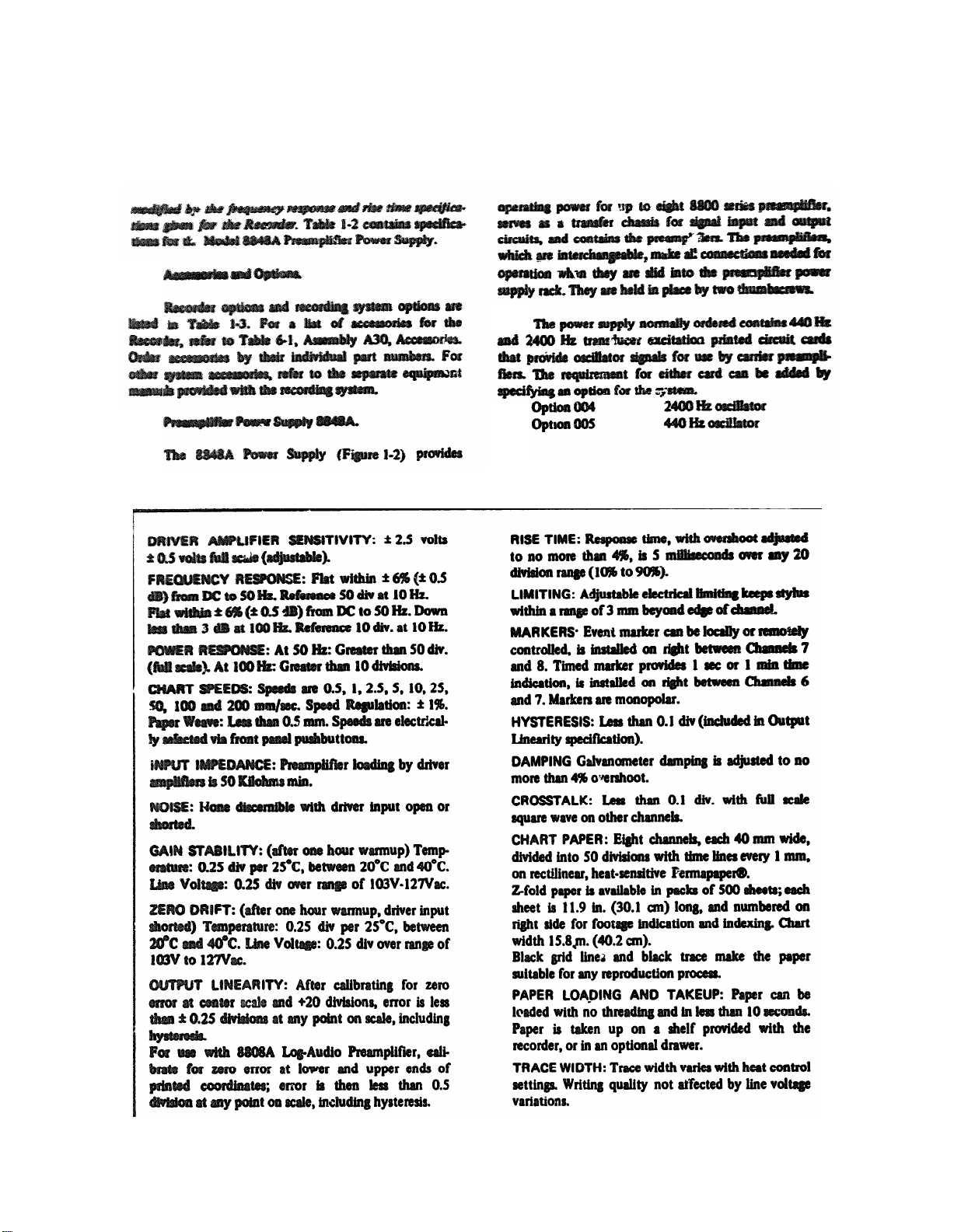

Table 1-1. Specifications

1-2

Page 12

Table 1-1. Specifications (continued)

TM11-6625-2752-14&P

SECTION I -

General Information

Models 7758A, 7418A

07758-1

Bench Enclosure (Accessory

(30.2 cm). Width, 20.25 in. (51 cm). Depth, 24 in.

(60.5 cm). Paper Takeup Tray projects 11.5 in. (29.2

cm) from front enclosure and hangs down 5.5 in.

(13.8 cm).

Mobile Cart: Height, 50.5 in. (128 cm). Width, 21.5

In. (55 cm). Depth, 26 in. (67 cm). Paper Takeup

Tray projects 11.5 in. (29.2 cm). Add 6 in. (15 cm)

to

WEIGHT: Recorder alone: 110 lb (49.9 kg including

driver amplifiers. With bench top enclosure: 128 lb

(58 kg). In mobile cart with power supply, but less

preamplifier: 354 lb (160 kg).

Each Channel: Position (10 div trim), Gain,

Damping, High Limit, Low Limit.

POWER REQUIREMENTS: 60 Hz or 5O Hz (option-

al), 115/230 Vac), 10% Power consumption is less

-than 5A in 115 Vac operation. Warmup Time:

Approximately

DIMENSIONS:

ENVIRONMENT: Maximum ambient temperature

(free air circulation) 40 C (104 F); if blocked from

free air flow, 25 C (77 F). Location should be

reasonably free from dust, explosive or corrosive

vapors, and extreme cold.

C0NNECTIONS: Signal Input J12 for preamp signals

from power supply. Through Signal Monitor J13,

preamplifier outputs for monitor scope, tape, and

Recorder Alone: Height, 10.5 in. 26.6 (cm) Width,

19.0 in (483 cm), for standard RETMA equivalent

rack. Depth, 22.75 in. (57.3 an). Projects 2.5 in. (6.3

an) from front of rack.

inputs, low voltage dc power and remote control

functions.

Width

or Depth for caster projections

devices are available at the rear

to preamplifier inputs and auxiliary

): Height, 11.875 in.

Table 1-2. 8848A Preamplifier Power Supply

Regulated Outputs:

+12Vdc at 800 mA maximum.

- 12Vdc at 800 mA maximum.

Ripple not more than 4 mV under full load.

Unregulated outputs:

+18Vdc at 600 mA maximum.

-18Vdc at 600 mA maximum.

(Current capacity is 1.4 amperes minus current

supplied by regulated output circuits.)

Power Requirements:

115 or 230 volts (switch provided), 50 to 400

Hz, 120 watts full load.

Specifications

Oscillator Outputs:

440 Hz + 2% floating, 14Vac peak-to-peak, 4

watts maximum. Amplitude stability + 5%.

2400 Hz 2% floating, 10Vac rms, 50 mW

maximum. Amplitude stability + 5%.

Weight:

About 26 lbs. (11,8 Kg) less preamplifiers.

Dimensions:

7 in. high x 19 in. wide x 2O in. front-to-back

(178x483x521 mm).

1-3

Page 13

TM11-6625-2752-14&P

SECTION I- General Information

Models 7758A, 7418A

00758-1

Table 1-3. Recorder Options and System Options

045 System installed in 1065B tall cabinet, with

051 With writing shelf on right side facing system

cabinet or cart.

052 With writing shelf on left side facing system

cabinet or cart.

053 With l top-mounted tilt stand for display on

1064C cart or 1065C short cabinet.

054

With 14217A Transducer Holder for two 1280Series Physiological Pressure Transducers,

mounts on IV Pole.

055 System installed in 1065C short cabinet, with

paper tray.

057

With 14217-6O010 mount for IV pole on right

side, facing cart or cabinet. Accepts 0.25 to

0.75 inch (0.63 to 1.9 cm) diameter IV pole.

Includes pole for mounting Option 054 Trans-

ducer Holder.

058 Same as Option 057 except mounted on left

side.

078 Lass 8848A Power Supply and enclosure,

7758A System.

Less 8848A Power Supply, 7758B, C, or D

System.

079 Add Power Supply Enclosure for 77588

system.

080 Replace paper takeup tray with 7-inch high

paper takeup drawer on rack mount slides.

081 Add 3 inch supply drawer.

082

Add 7-inch supply drawer.

1-4

Page 14

TM11-6625-2752-14&P

SECTION I-General Information

Table 1-3 Recorder Options and System Option (continued)

Models 7758A, 7418A

07758-1

1-5

Page 15

2-1.

2-3.

2-4.

2-5.

2-6.

TM11-6625-2752-14&P

Section II -Installation

Module 773A, 7412A

SECTION II

2-13.

2-14.

23758-1

2-7.

2-8.

2-9.

2-10.

2-11.

2-15.

2-16.

2-17.

2-3)

2-18.

2-12.

2-19.

2-1

Page 16

TM11-6625-2752-14&P

Section II.-Installation

Module 7758A, 7418A

87738-1

2-2

Figure 2-1. Recorder Access for Receiving Inspection

Page 17

TM11-6625-2752-14&P

Section II.-Installation

Module 7758A, 7418A

07728-1

Figure 2-2. Reer Panel Connectors and Fuses

2-3

Page 18

TM11-6625-2752-14&P

Section II-Installation

Module 7758A, 7418A

07158-1

2-20.

2-21.

2-4

Figure 2-3. Recorder and Mobile Cart Power Connections

2-22.

2-23.

Page 19

TM11-6625-2752-14&P

Section II-Installation

Module 7758A, 7418A

07758-1

Figure 2-4. 1085-Series Cabinet Module and Schematic Diagram (typical)

2-5

Page 20

TM11-6625-2752-14&P

Section II-Installation

Module 7758A, 7418A

07758-1

2-6

Figure 2-5. Output Adapter 14208A, 14208B

Page 21

TM11-6625-2752-14&P

Section II-Installation

Module 7758A, 7418A

07758-1

Figure 2-6. System Connections (with Control Section 4682A)

2-7

Page 22

TM 11-6625-2752-14&P

Section II - Installation

2-8

Figure 2-7.

lifier Power Supply Input and Output Connections

Page 23

TM 11-6625-2752-14&P

Section II - Installation

Figure 2-8. 7418A System Input Cable Preparation (Multichannel Amplifier Options 030, 031)

2-9

Page 24

TM11-6625-2752-14&P

Section II-Installation

Models 7758A,7418A

07758-1

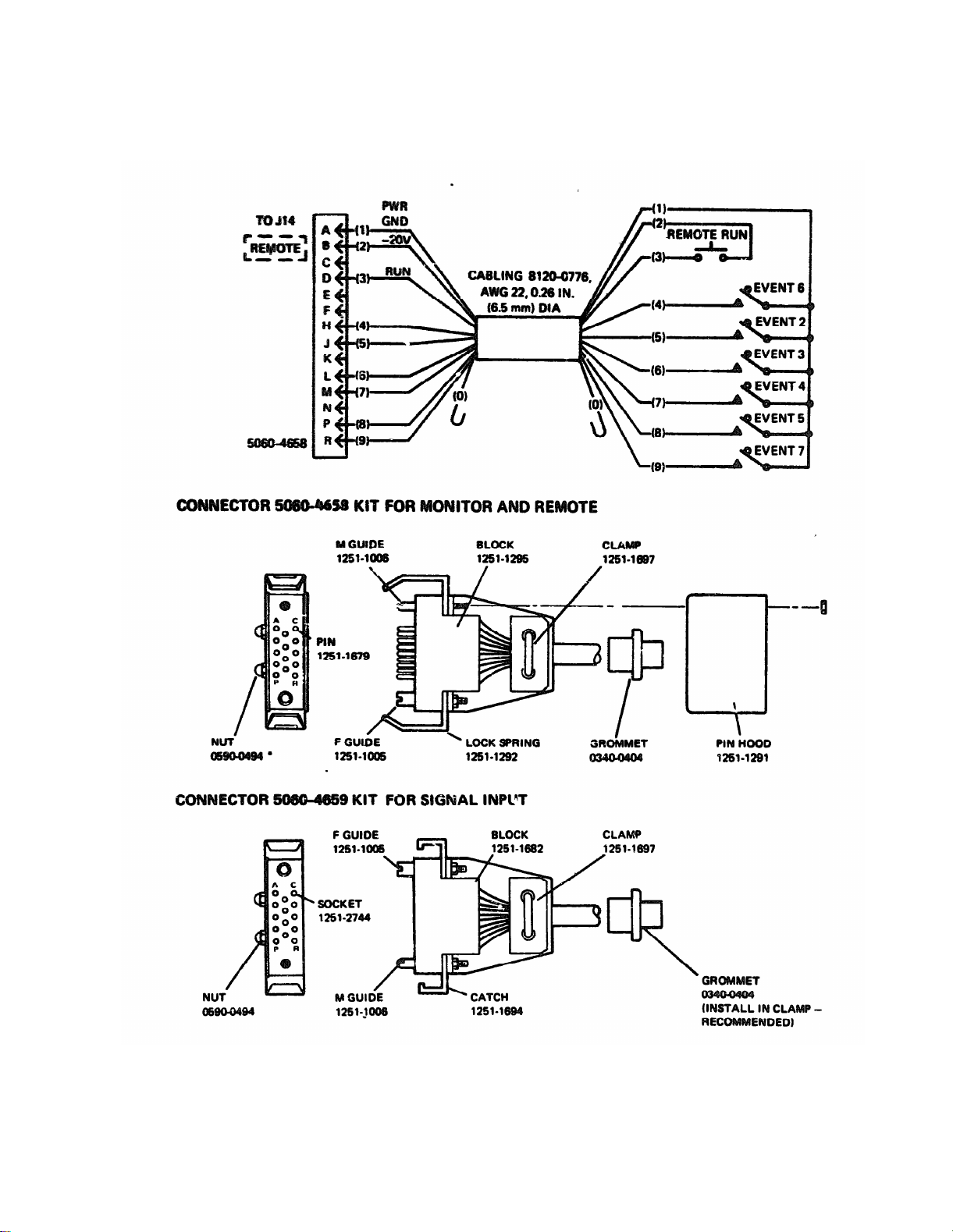

Figure 2-9. Cable and Connector Assembly Diagrams for SIGNAL, MONITOR and REMOTE Rear Panel Connector

Models 7758A, 7418A

2-10

Page 25

TM11-6625-2752-14&P

Section II-Installation

Models 7758A, 7418A

07758-1

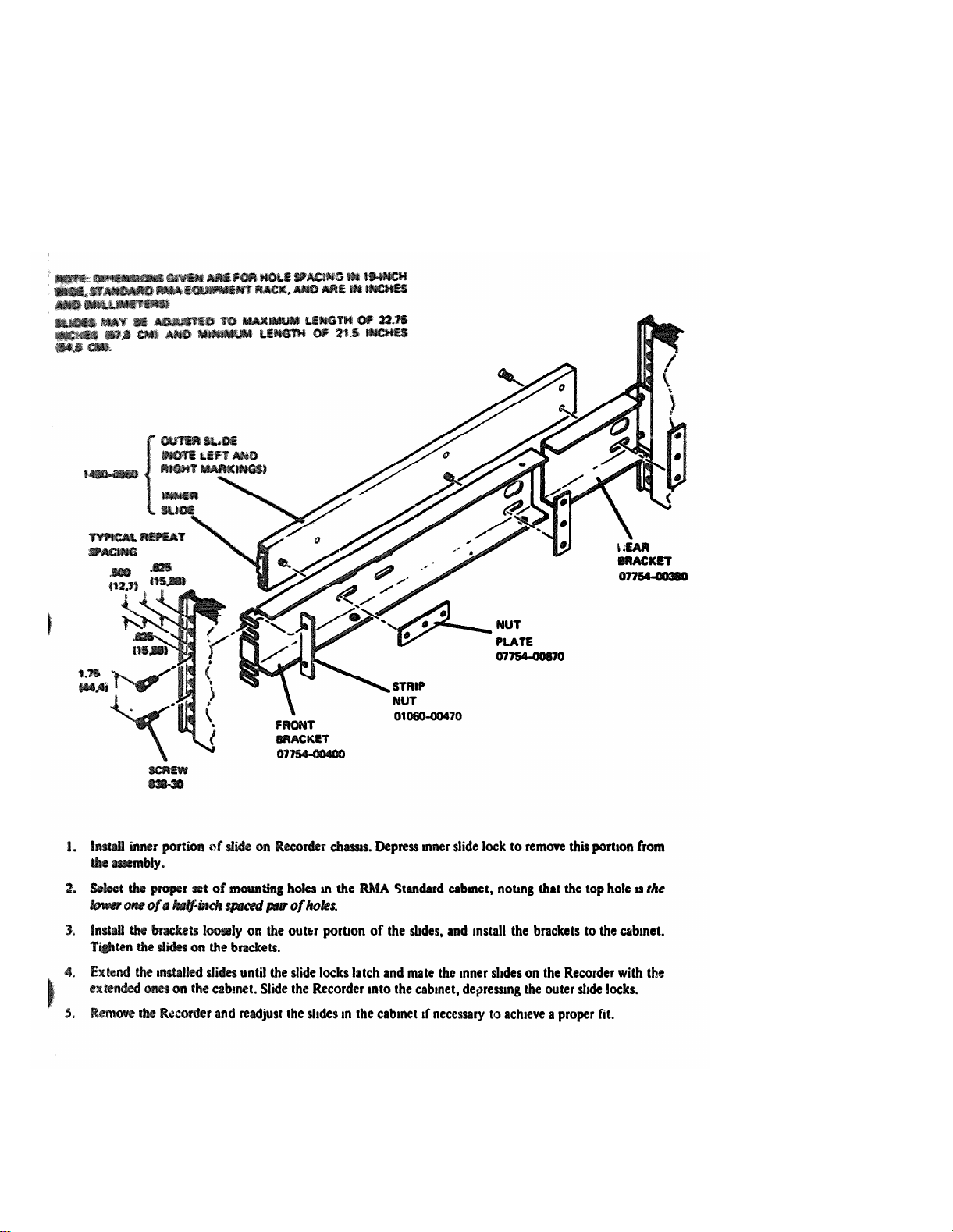

Figure 2-10 Option 001,010, Mounting Kit 07758-60400

2-11

Page 26

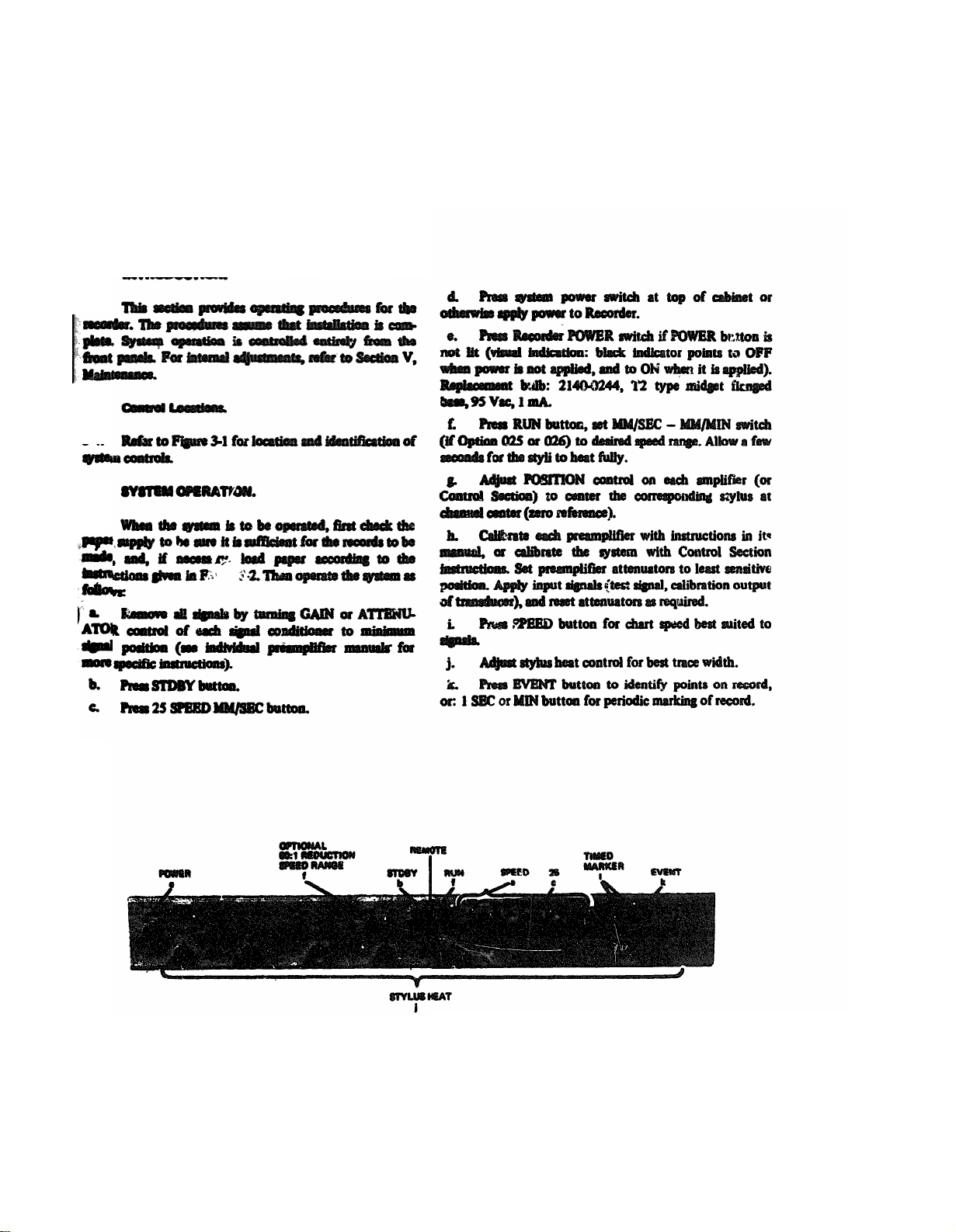

3-1. INTRODUCTION..

3-2.

3-3.

3-4.

3-5.

3-6.

SECTION III

OPERATION

TM11-6625-2752-14&P

Section III-Operation

Models 7758A, 7418A

07758-1

Figure 3-1. Control Locations

3-1

Page 27

TM11-6625-2752-14&P

Section III-Operation

Models 7758A, 7418A

07758-1

3-2

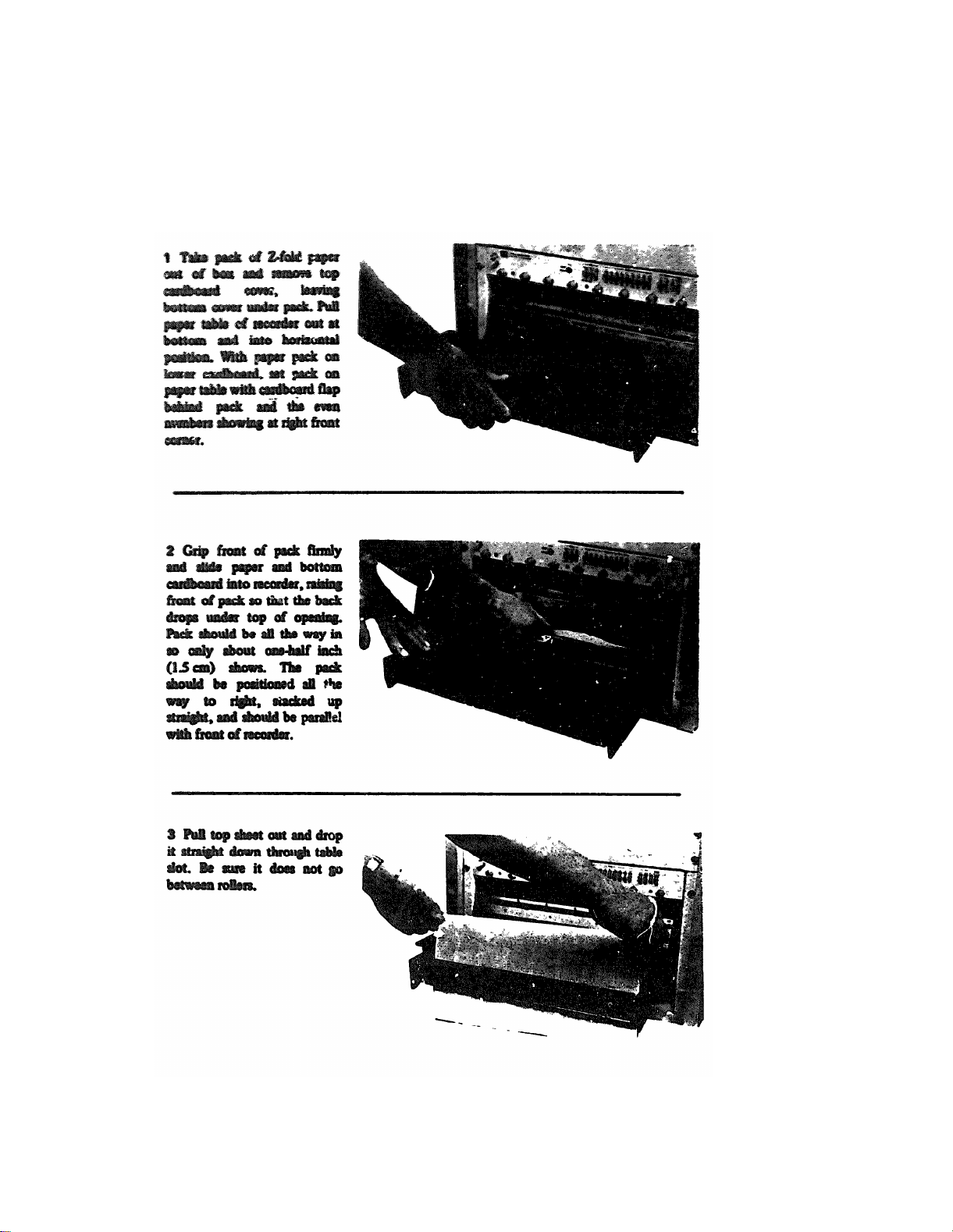

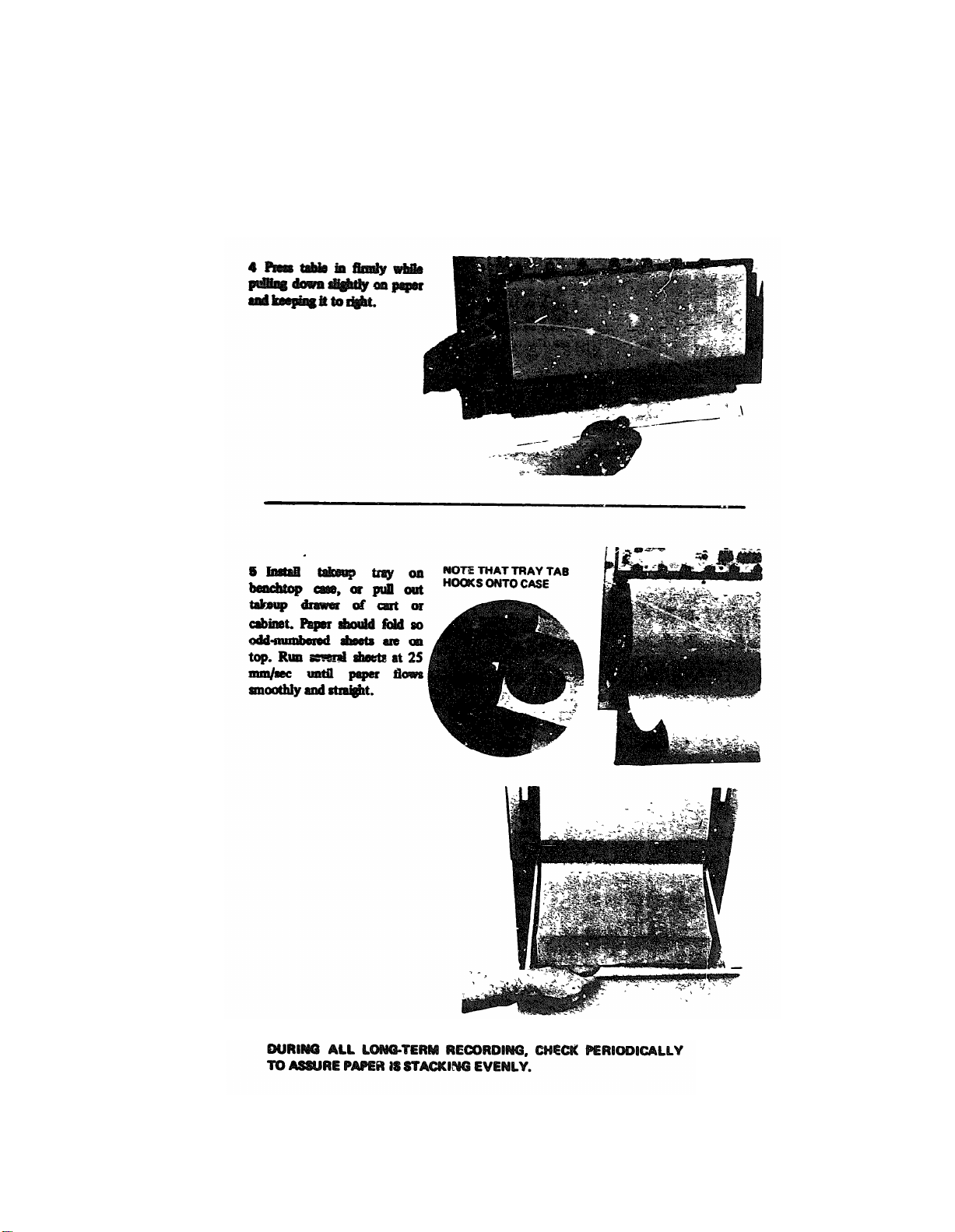

Figure 3-2. Power Loading Procedure, Models 7758A. 7418A

Page 28

TM11-6625-2752-14&P

Section III-Operation

Models, 7758A, 7418A

07758-1

CAUTION

Figure 3-2. Paper Loading Procedure, Models 775BA, 7418A (continued)

3-3

Page 29

TM11-6625-2752-14&P

Section IV- Principles of Operations

Models 7758A, 7418A

00758-1

4-0

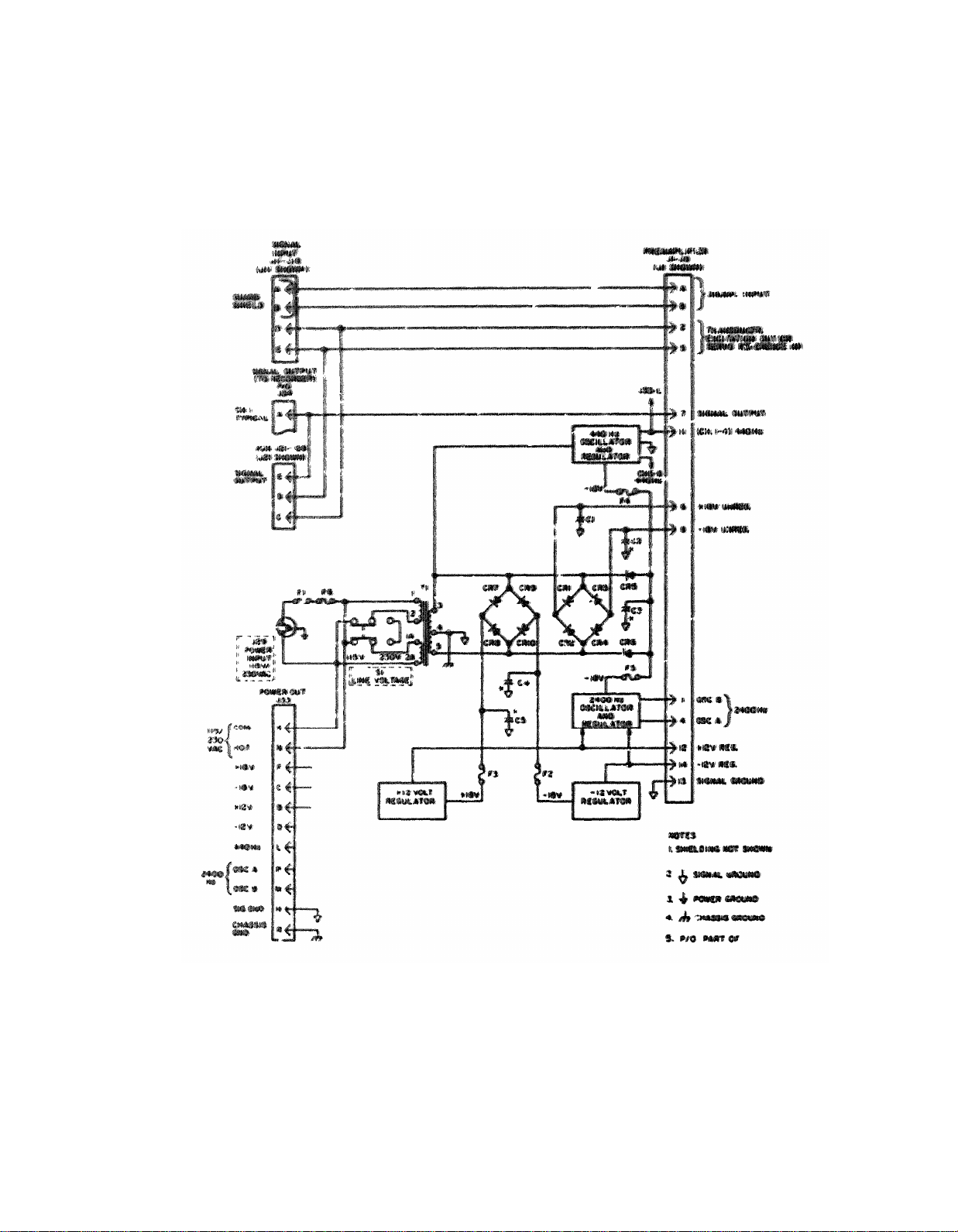

Figure 4-1. Preamplifier, Power Supply, Simplified Diagram

Page 30

SECTION IV

PRINCIPLES OF OPERATION

TM11-6625-2752-14&P

Section IV-Principles of Operation

Models 7758A, 7418A

07758-1

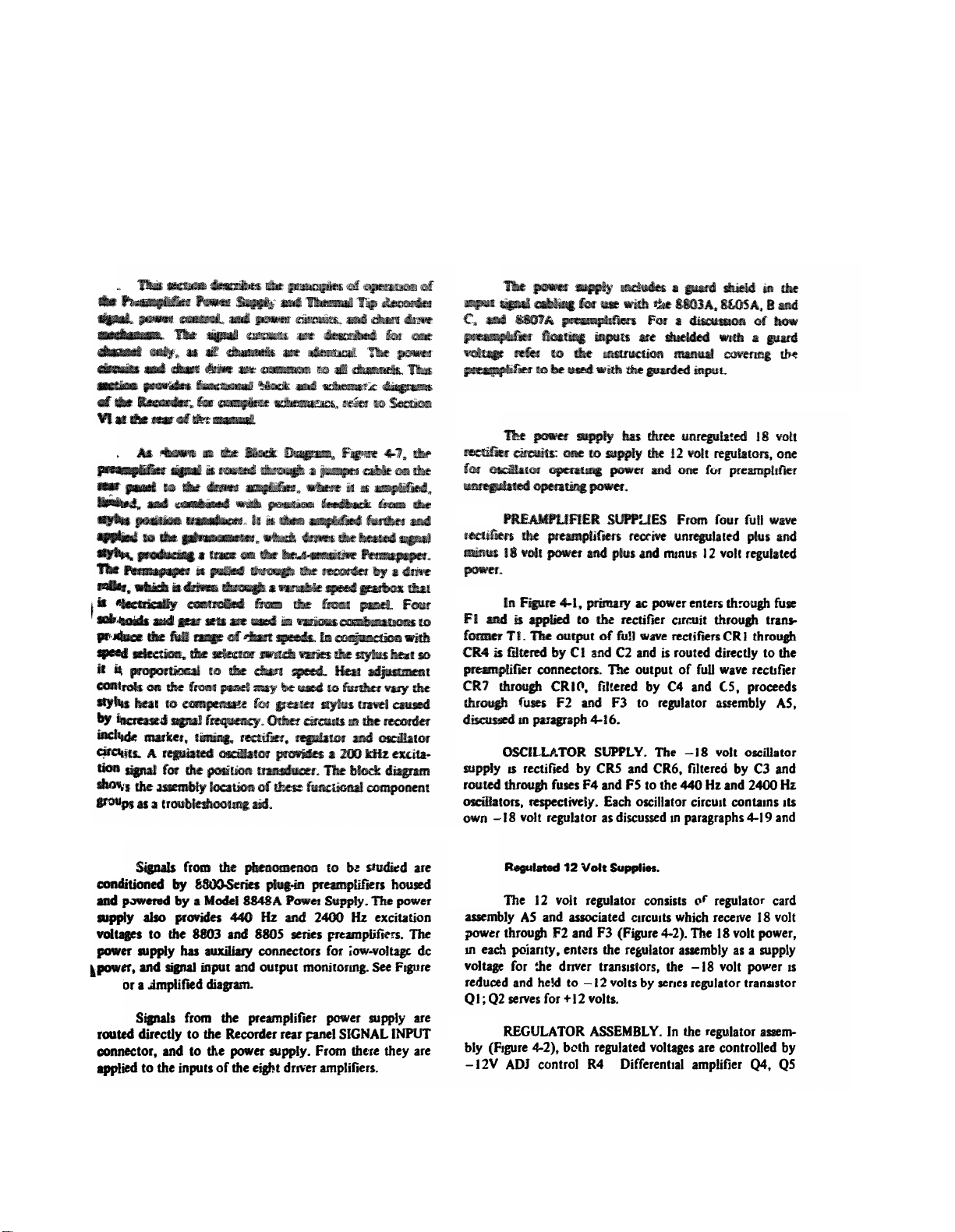

4-1. INTRODUCTION.

4-2.

4-3.

4-7.

Guarded Input Circuits.

4-8.

4-9. Unregulated 18 Volt Supplies.

4-10.

4-11.

4-4. PREAMPLIFIER POWER SUPPLY 8848A.

4-5.

4-1

4-6.

4-13.

4-14.

4-15.

4-16.

4-1

Page 31

TM11-6625-2752-14&P

Section IV-Principles of Operation

Models 7758A, 7418A

00758-1

4-17.

4-20.

4-21.

4-18.

4-19.

4-22.

4-2

Figure 4-2. 12-Volt Regulator Circuit (Preamplifier Power Supply 8848A)

Page 32

TM11-6625-2752-14&P

Section IV-Principles of Operation

Models 7758A, 7418A

Figure 4-3. 440 Hz Oscillator Circuit (Preamplifier Power Supply 8848)

07758-1

4-23.

Figure 4-4. 2400 Hz Oscillator Circuit Preamplifier Power Supply 8848A)

4-3

Page 33

TM11-6625-2752-14&P

Section IV-Principles of Operation

Models 7758A, 7418A

07752-1

4-24.

4-25.

4-26.

4-27.

4-28.

4-29.

4-30.

4-31.

4-32.

4-4

UNDERDAMPED

Figure 4-5. Galvanometer Damping

Page 34

TM11-6625-2752-14&P

Section IV-Principles of Operation

Models 7758A, 7418A

07758-1

Figure 4-7. Model 7758A/7418A Recorder, Block Diagram

4-6

Page 35

TM11-6625-2752-14&P

Section IV-Principles of Operation

Models 7758A, 7418A

07758-1

Figure 4-6. Recorder Signal, Circuits, Simplified Diagram

4-5

Page 36

TM11-6625-2752-14&P

Section IV-Principles of Operation

Models7758A, 7418A

07758-1

4-33.

4-.34.

4-35.

Figure 4-8. Galvanometer Position Feedback Circuit

4-7

Page 37

TM11-6625-2752-14&P

Section IV-Principles of Operation

Models 7758A, 7418A

07758-1

4-36. An example of unbalance is shown in Figure 4-8. As

the positive signal causes the galvanometer to move the

stylus as shown, the rotor moves so that more of the

oscillator output is felt on the split capacitor

plates/. These plates are connected to the CR1-Q1 half of

the demodulator, so that more positive voltage is impressed

upon C1. The unshaded plates receive proportionately less

of the oscillator output, and so CR2-Q2. the negative side

of the demodulator, produces less positive output for C1.

C1, then, sends a positive feedback voltage to the driver

amplifier, which tends to return the stylus toward the

center of the chart. The feedback voltage is sided by a

torsion spring that facilitates setting of the sylus mechani-

cal center. For maintenance purposes, note that one volt of

position voltage corresponds to 10 division s of stylus

movement

4-37.

4-38.

Stylus heat is controlled from the Heat Pot Board,

A2A2, on the front panel. The heat control voltage is

applied to a simple feedback amplifer located on the driver

amplifier assembly. Q11, Q12, and Q13, which has a

current limiting circuit similar to that used for the

galvanometer. The amplifer output drives the resistive

stylus heat element. A good stylus should have about 34

ohms resistance.

4-39. Power Control Circuits

works, the -20V supply voltage, applied to

to the switch via

the main feeder line at the top of Figure 4-9 energizes the

center contacts of the switch segment. /when the push-

button marked "5" is depressed, -20V is applied to

solenoids. L3 and L4 through diodes CR5 and CR6,

respectively, aelecting the

speeds of 5 mm/sec

ted

by fixed voltages applied to the heat control

proper gear combination

and higher, the

heat control voltage is

In

potentiometers by the control switch. The heat control

potentiometer setting permits front panel adjustment of the

trace density through the heat control circuit each driver

amplifier.

4-43. CHART DRIVE.

4-44. The recorder chart drive consists of a 115 volt ac

motor, a gearbox with four pairs of clutches and speed

selection solenoids, a paper drive roller, and a paper brake.

4-45. Chart Motor.

4-46. The chart motor is a continuous duty, synchronous

motor with a speed of 1800 rpm for 60 Hz operation. A

pulley on the motor shaft engages a drive belt

that

transmits power to the gearbox. To provide additional

electrical safety, the motor IS Insulated from the recorder

chassis by non-conducting spacers.

4-40. Power IS controlled from the recorder front panel.

Figure 4-9 shows recorder power switching together with

chart motor control circuits and speed control solenoid

circuit.

4-41

Line common reaches the chart drive motor through

Sl, the power switch and the Ul voltage selector, whenever

Sl IS on. The high side of line power IS applied to the chart

drive motor through motor relay Kl, which is actuated

by

the control switch RUN button on the front panel, or

a remote run signal (Figure 2-9). The motor is described

further in Paragraph 4-46. Kl also turns on

stylus

heat

through the control switch.

4-42. The motor drives the gearbox, the speeds of which

are controlled by speed selection solenoids Ll, L2, L3, and

L4. The speed control action of these solenolds is described

in Paragraph

4-51. The segments of the control switch are

so arranged that the solenoids are energized in the correct

combinaiton for each speed desired. The switch IS

shown in

the 5 mn/sec position. As an example of how the switch

4-8

4-47.

4-48.

Control.

Chart paper speed IS varied by a gear train consisting

of sets of four gears, on two shafts (Figure 4-10) These

shafts are fixed in place and do not rotate. Each set of four

gears (A, B, C, and D) either provides a speed reduction

with all four gears transmitting power, or no speed

reduction, with power bypassing the reduction gears

through a spring clutch that links gears A and D on the

primary shaft. Gear D IS mechanically part of Gear, A on the

next set, so power IS directly transmitted to the next set of

gears

When direct drive is desired, the associated solenoid

4-49

is energized, withdrawing the plunger from the clutch

pawls. The clutch then engages, coupling gears A and D

The spring clutch between gears B and C automatically

disengages since gear C, being smaller than gear B, rotates

faster when gears A and D are in direct drive

Page 38

Figure 4-9. Recorder Power Control Circuits, Simplified Diagram

Figure 4-9.

Page 39

TM11-6625-2752-14&P

Section IV- Principles of Operations

Models 7758A, 7418A

07158-1

Recorder Power Control Circuits, Simplified Diagram

Figure 4-9.

Figure 4-10. Chart Drive Gears

4-9

Page 40

TM11-6625-2752-14&P

Section IV-Principles of Operation

Models 7758A, 7418A

07758-1

4-10

Page 41

TM11-6625-2752-14&P

Section IV-Principles of Operation

Models 7758A, 7418A

07758-1

Figure 4-11. Gearbox Power Flow

4-10

Page 42

4-50.

4-51.

TM11-6625-2752-14&P

Section IV-Principles of Operation

Models 7758A, 7418A

07758-1

4-52.

4-53.

Figure 4-12. Paper Feed Path

4-11

Page 43

TM11-6625-2752-14&P

Section IV-Principles of Operation

Models 7758A, 7418A

07758-1

4-12

Figure 4-13. Recorder Power Supply and Regulator Circuits, Simplified Diagram

Page 44

TM11-6625-2752-14&P

Section IV-Principles of Operation

Models 7758A, 7418A

07758-1

4-54.

4-55.

4-56.

4-57.

4-58.

4-59.

4-62.

4-63.

4-64.

4-60.

4-61.

4-65.

4-66.

4-67.

4-13

Page 45

TM11-6625-2752-14&P

Section IV-Principles of Operation

Models 7758A, 7418A

07758-1

4-68.

4-69.

4-70.

4-91. To switch the current, differential input circuit

is controlled by two things, to turn the current

on at the appropriate time. The height of the

output voltage pulse, and thus the quantity of current, is

determined by the heat control voltage level. It is limited

by the point at which the main +l5V supply starts (or

stops) drawing current. The differential circuit switches

series regulator Q18, Q12 to pulse the marker heat current

as drown by the shaded areas in Figure 4-14. This provides

a pulse on the steep leading and trailing edges of the main

waveform, when the capacitive supply is not drawing

current. Board exchange instead of troubleshooting is

recommended if this circuit IS found to be inoperative.

4-14

Figure 4-14. Marker Heat Driver Output Current Waveforms

Page 46

5-1.

5-2.

5-3.

5-4.

MAINTENANCE

Paragraph 5-5

Paragraph 5-10

Paragraph 5-20

Paragraph 5-22

Paragraph 5-38.

SECTION V

5-5.

5-6.

TM11-6625-2752-14&P

Section V-Maintenance

Models 7758A, 7418A

07758-1

Table 5-1. Recommended Test Equipment

To be made, see Figures 5-3, 5-4.

5-1

Page 47

TM11-6625-2752-14&P

Section V-Maintenance

Models 7758A, 7418A

07758-1

Table 5-2. Lubricants and Solvents Required

5-14. Operate the Recorder in all speed

perform the operating procedure, using all controls listed in

Figure 3-l.

5-15. The following steps check operation of the

Recorder:

a.

Recorder slides..

smoothly and that they lock in the full open position

(Figure 2-1).

5-7. To facilitate by checking the Driver Amplifiers and the

Regulator/Oscillator Assembly, extender boards (Table 5-1)

are available as accessories.

Paper tension: Run the Recorder at the highest

speed and inspect paper travel over the platen at the paper

table (see Figure 4-12). The paper should travel snugly over

the paper table. Adjust the paper brake if necessary, or

5-8.

Variable Line Voltage.

5-9.

During the performance

checks, the Recorder should

be connected to the power source through an adjustable

autotransformer so the line voltage can be changed 10%

from the nominal 115 or 230 Vac.

CAUTION

TO AVOID DAMAGE, REMOVE POWER FROM THE

RECORDER BEFORE DISCONNECTING ASSEMBLIES

OR COMPONENTS. NEVER TlP RECORDER ONTO

REAR PANEL AREA, TO AVOID DAMAGING THE

TRANSFER PC ASSEMBLY AND DRIVER

AMPLIFIERS.

5-10. PREVENTIVE MAINTENANCE.

5-11. Preventive maintenance is recommended every six

months or 1000 hours of operation, and new procedures

may be used as an aid for minor repairs, adjustments and

troubleshootmg.

5-12.

Operational Checks and Inspection.

5-13. Switch Recorder power OFF Inspect the Recorder

for evidence of mechanical or electrical overload, dents,

rust, and corrosion. Check that all components are securely

mounted, including the cable connectors Also check ex-

ternal connecting cables for strain, breaks, and frayed

insulation. If the Recorder is installed in a cart or cabinet,

the cables should be free when the Recorder is moved in

and out.

replace the brake felt (Paragraph 5-28).

C.

Paper tracking Run the Recorder at 25 mm/sec for

5 sheets. Paper should follow the right table guide without

weaving or damaging the edge of the paper. A static trace

position should not vary-more than 0.5 mm from any

reference grid line, after 6 to 12 sheets have passed and

tracking has settled down. Check several more sheets at 200

mm/second. For tracking adjustments, see paragraph 5-26.

d.

Galvanometer to Paper Parallax

will have the same time reference with respect to the paper,

all stylus tips must fall on the same time reference line of

the paper, 0.25 division. To check parallax, apply power

to the Recorder, and set to STANDBY mode. With finger

pressure, gently move the stylus off center full scale, in the

positive and negative directions The trace over the width of

each channel should be within 0. 25 mm of the reference

grid line. If not, see Paragraph 5-33 to adjust stylus

parallax. All 8 channels should be referenced to the same

grid line, that is, all traces should end at the same point

when the Recorder stops If not, see Paragraph 5-34

channel time synchronization procedure, which is used to

adjust galvanometer parallax, that is, to line up the

galvanometers in a straight line so the style will fall on the

same time line.

Signal Stylus.

e

and condition. If a stylus is bent or twisted, replace it

(Paragraph 5-35).

Stylus

f.

the trace lacks definition, but when pressure is too heavy,

friction causes noticeable non-linearity and hystereais

Refer to Paragraph 5-31 for stylus pressure adjustments.

WARNING

Check that the slides roll in and out

each signal stylus for cleanliness

Pressure

When stylus pressure is too light,

So that all channels

5-2

Page 48

TM11-6625-2752-14&P

Section V-Maintenance

Models 7758A, 7418A

07758-1

SIGNAL STYLUS

ADJUSTMENTS.

MARKER STYLUS

ADJUSTMENTS, SEE

SEE FIGURE 5-9 FlGURE 5-21

Figure 5-1.

Recorder Test and Adjustment Points

5-3

Page 49

TM11-6625-2752-14&P

Section V-Principles of Operation

Models 7758A, 7418A

07758-1

d.

Carefully clean the writing and marker stylus with

Chlorothene. Do not use steel wool or abrasive cleaning

compounds. Be careful not to bend the styli vertically , they

are easily distorted in the vertical direction.

5-18. Lubrication.

5-19. Minor lubrication should be performed during preventive maintenance Major lubncation (minor lubrication

plus gearbox) is done at overhaul and at regular intervals of

12 months or 2000 hours operation, if used mostly in the

upper half of the speed range. If the Recorder is used

mostly for low speed operation, more clutches are engaged

and

more reduction gears are used. Thus, a more

frequent

lubrication may be required, typically every 6 months or

1000 hours. To help assure uninterrupted service if an

extended period of recording is anticipated, overhaul and

lubricate the Recorder before placing it in service

Lubricants are listed in Table 5-2, lubrication points are shown in

Figure 5-2.

5-20. ELECTRICAL

5-21.

5-16. Cleaning

To check out the Model 8848A Power Supply, make

the cable shown in Figure 5-3, and follow the steps in Table

5-17. Depending on environmental conditions, cleaning

may be required at much shorter intervals than the regular

maintenance intervals:

Unplug Recorder power cord. Remove chart paper.

a.

Expose top

and rear of

Recorder, and remove dust with a

vacuum hose.

b.

Clean Recorder

and

Preamplifier front panels and

controls with a soft, lint-free cloth or a wax-impregnated

polishing cloth.

CAUTION

IF A SOLVENT IS

NECESSARY TO CLEAN THE

PANEL, USE ONLY CHLOROTHENE OR ETHYL ALCOHOL. OTHER SOLVENTS, SUCH AS ACETONE OR

ISO-PROPYL ALCOHOL, MAY REMOVE PANEL PAINT

5-3 To check out the 7758A or 7418A Recorder, follow

the procedure in Table 5-4 To facilitate checking, make the

cable shown in Figure 5-4 To support the Driver Amplifier

or Regulator, Oscillator for testing, fasten the PC board test

support shown in Figure 54 onto the rear of the heat sink

with a No 10 nut (Figure 5-5)

5-22. ADJUSTMENTS

5-23. Mechanical adjustments are confined to the

drive and galvanometer assemblies. Paper drive minor repair

and troubleshooting information is presented in Table 5-5

If necessary, galvanometer superficial parts may be replaced

only to the extent indicated in the Replaceable Parts List

Do not attempt to disassemble the Galvanometer, but

return it to Hewlett-Packard for service.

OR MARKINGS. IF THE PANEL MUST BE MARKED,

FOR INSTANCE WITH CHANNEL IDENTITY, USE

5-24. Paper Drive Adjustment

ONLY CHINA MARKING WAX CRAYON, OR COLORCODED EMBOSSING TAPE. DO NOT USE FELT.

NYLON, OR BAMBOO-TIPPED MARKERS ON THE

INSTRUMENT PANEL OR THE MARKING MAY DISCOLOR THE PANEL PAINT PERMANENTLY.

5-25. The rubber drive roller pulls paper over the

table, where it is aligned by the paper guide The pa

kept snug on the table by the paper brake felt, which

presses the paper against the back of the platen The paper

is kept from shipping on the drive roller by two spring-

Pull the paper table out at the bottom (Figure 3-2,

C.

Step I). Clean the surface of the paper table with

Chlorothene solvent.

metal pressure rollers with Chlorothene.

front

of

the

Under

bottom of the table, clean the

At

the bottom

Drive

Unit, clean the rubber drive roller with

Chlorothene (Figures 5-13, 5-15).

loaded pressure rollers To set up the Recorder so that

run on the channel centerlines, the paper is first adjusted to

run at the right edge of the paper guide, which is fixed in

location. Then the stylus position for each channel is

adjusted (see Table 5-4), the mechanical limit stops

adjusted, and the electrical limiters are adjusted

CHECKS.

AND

MINOR

REPAIRS.

5-4

Page 50

TM11-6625-2752-14&P

Section V-Maintenance

Models 7758A, 7418A

07758-1

Figure 5-2. Recorder Lubrication Points (Typical)

5-5

Page 51

TM11-6625-2752-14&P

Section V-Maintenance

Models 7758A, 7418A

07758-1

Table 5-3. Performance Checks Model 8548A Power Supply

5-6

Page 52

TM11-6625-2752-14&P

Section V-Maintenance

Models 7758A, 7418A

07758-1

Figure 5-3. Preamplifier Power Supply 8948A, Power Test Points, Test Cable

5-7

Page 53

TM11-6625-2752-14&P

Section V-Maintenance

Models 7758A, 7418A

07758-1

CONNECTOR 5080-4650 KIT

(SAME AS REMOTE, FIGURE 2-7)

5-8

PC BOARD TEST FIXTURE 07754-00800

Figure 5-4. Test Cable and Fixture

Page 54

Figure 5-5. Driver or Regulator Board Test Setup

TM11-6625-2752-14&P

Section V-Maintenance

Models 7758A, 7418A

07758-1

Table 5-4. Electrical Performance Checks and Adjustments for 7758A/7418A Recorder

5-9

Page 55

TM11-6625-2752-14&P

Section V-Maintenace

Models 7758A, 7418A

07758-1

Table 5-4. Electrical Performance Checks and Adjustments for 7758A/7418A Recorder (Continued)

5-10

Page 56

TM11-6625-2752-14&P

Section V - Maintenance

Models 7758A, 7418A

07758-1

Figure 5-5A. Removal and Disassembly

5-10.1

Page 57

TM11-6625-2752-14&P

Section V-Maintenance

Models 7758A, 7418A

07758-1

Figure 5-6. Regulator/Oscillator Board Test Points

5-11

Page 58

TM11-6625-2752-14&P

Section V-Maintenance

Models 7758A, 7418A

07758-1

Table 5-4. Electrical Performance Checks and Adjustments (cont.)

5-12

Page 59

TM11-6625-2752-14&P

Section V-Principles of Operation

Models 7758A, 7418A

07758-1

Table 5-4. Electrical Performance Checks and Adjustment (cont.)

beyond left

line

of chart.

b.

Adjust Channel LIMIT R control (R9 Figure

to limit stylus travel to 1.5 divisions beyond

line of chart.

C.

Repeat Steps a and b for remaining channels

d.

Turn amplitude control of Function Generator

cow so stylus travel stops at last grid line of chart top

and bottom. Triangular waveform must not limit at

either top or bottom of chart.

e.

Set MODE switch to STDBY.

2. D

SEC speed.

square wave.

to produce a 20 division deflection on Recorder.

Figure 5-7 inset) so overshoot on chart IS between 0.5

a.

Set Function Generator frequency to 1 Hz, and

and 0.8 division.

output to triangular waveform. set amplitude control

to 10.0 volts p-p.

b. Set Recorder MODE switch to RUN.

(c. Adust LIMIT controls and (R() R13, Figure

3.

5-7 inset) on each Driver Amplifier board fully

clockwise. to cause all styli to travel at least 1.5

diviations beyond chart channel edge, for channels

next to markers, and 3 divisions on all other channels.

d.

Adjust Channel 1 right and left bumpers to

limit travel of stylus to 2.5 divisions beyond top and

for a 10 division stylus deflection.

bottom line of chart channel.

e.

Repeat Step d for remaining chart

NOTE: Stylus travel beyond the edge of the

grid must not interfere with any adjacent channel

stylus or marker stylus when syli are at maximum

to 100 Hz and back to 10 Hz three times before

reading deflection on chart.

on chart.

excursion toward each other.

Push Recorder SPEED button for 100 MM/

b. Adjust Function Generator output to 1 Hz

C.

Set Recorder MODE switch RUN.

d.

Adjust Function Generator amplitude control

e.

Adjust Channel I DAMPING control (R30,

f. Set MODE switch to STDBY.

Repeat steps b to f for remaining channels.

g.

a.

Set Function Generator to 10 Hz sine wave.

b.

Push Recorder SPEED button for 5 MM/SEC.

Set MODE switch to RUN.

C.

d. Adjust Function Generator amplitude control

e.

Switch Function Generator output from 10 Hz

f.

Stylus must deflect 7.07 divisions (3 dB down)

Set MODE switch to STDBY.

g.

5-13

Page 60

TM11-6625-2752-14&P

Section V- Maintenance

Models 7758A, 7418A

07758-1

5-14

Figure 5-7. Amplifier Board Test Points

Page 61

TM11-6625-2752-14&P

Section V-Maintenance

Models 7758A, 7418A

Table 5-4. Electrical Performance Checks and Adjustments (cont.)

07758-1

5-15

Page 62

TM11-6625-2752-14&P

Section V- Maintenance

Models 7758A, 7418A

07758-1

Table 5-4. Electrical Performance Checks and Adjustment (cont.)

5-16

Page 63

Table 5-4. Electrical Performance Checks and 'Adjustments

(cont.)

5-26.

TM11-6625-2752-14&P

Section V-Maintenance

Models 7758A, 7418A

07758-1

5-28.

5-27.

5-29.

5-30.

5-31.

5-17

Page 64

TM11-6625-2752-14&P

Section V - Maintenance

Models 7758A, 7418A

07758-1

WARNING

CAUTION

5-32.

CAUTION

5-18

Figure 5-8. Paper Tension Adjustment

Page 65

TM11-6625-2752-14&P

5-19

Section V - Maintenance

Models 7758A, 7418A

07758-1

5-33.

5-34.

Figure 5-9. Stylus Adjustments

5-35.

CAUTION

Page 66

TM11-6625-2752-14&P

Section V - Maintenance

Models 7758A, 7418A

07758-1

5-36.

5-37.

Figure 5-10. Channel Time Synchronization Adjustment

5-38.

5-39.

5-40.

5-41.

5-20

Page 67

Section V

Maintenance

TM11-6625-2752-14&P

Section V - Maintenance

Models 7758A, 7418A

07758-1

Figure 5-11. Stylus Removal and Replacement

5-21

Page 68

TM11-6625-2752-14&P

Section V - -Maintenance

Models 7758A, 7418A

07758-1

5-42.

5-22

Figure 5-12. Stylus Lapping Procedure

5-43.

5-44.

WARNING

Page 69

CAUTION

TM11-6625-2752-14&P

Section V - Maintenance

Models 7758A, 7418A

07758-1

Figure 5-13. Drive Unit and Galvanometer Mounting Screws

WARNING

WARNING

5-45

5-23

Page 70

TM11-6625-2752-14&P

Section V - Maintenance

Models 7758A, 7418A

07758-1

5-46.

5-47.

5-48.

5-49.

Figure 5-14. Drive Unit Removal and Replacement

5-50.

Remove the screw and standoff standoff holding the chain

guard at the drive roller sprocket, and pivot the guard down

and to the left.

(Loosen the drive roller sprocket setscrew (No. 8

d.

spline wrench). Remove sprocket and 0510-1051 shaft key

being careful not to lose the key . Count the number of

shim washers, if any are required for chain alignment.

5-24

Page 71

Page 72

TM11-6625-2752-14&P

Section V - Maintenance

Models 7758A, 7418A

07758-1

Figure 5-15. Paper Table Removal, Table Link and Drive Roller Disassembly

5-25

Page 73

TM11-6625-2752-14&P

Section V - Maintenance

Models 7758A, 7418A

07758-1

Page 74

TM11-6625-2752-14&P

Section V - Maintenance

Models 7758A, 7418A

07758-1

5-26

Figure 5- 16. Gearbox Removal

Page 75

TM11-6625-2752-14&P

Section V - Maintenance

Models 7758A, 7418A

07758-1

end

While listening as closely as is safely practical

gearbox in all chart speeds (selected from the Recorder

front panel), and listen for chattering of clutch springs,

which indicates a need for lubrication or for replacement of

a clutch spring or of a gear, if the gear hub

obviously faulty parts, such as a clutch spring jamming the

gearbox, during overhaul.

5-54. GEARBOX REMOVAL.

Loosen drive unit side plate screws noted in Figure

e.

5-51. Spring the right side plate outward u

pressure only, and pull the right end of the drive roller and

table link forward to remove them. Then work the

left

of the drive roller and its shaft out of the bearing in the left

side plate. The bearing may come out with the roller &aft.

Press the other bearing out of the right side plate.

NOTE

For greater clearance while springing the side plates

yet still maintaining support of the bank of galvanometers,

the two screws holding up galvanometer mount A22MP59

(Figure 6.15) may be temporarily replaced with longer 6-32

x 1 inch screws. Reinstall the original screws

Before reinstalling the bearings, clean them as

f.

of soft wire (Figure 5-16) It will be used in Step e to

suspend the gearbox chain from the top of the side plate

follows.

(1) Wash, but do not soak, the bearings in

Chlorothene solvent.

(2)

0il them with penetrating oil (Table 5-2),

side plate. Remove rear clamp attachment screw from side

plate.

letting it soak into the porous metal, then with No. 10

lubricating oil.

5-52. The gearbox may be removed without taking the

Drive Unit out of the Recorder. A small motor and belt

drive may be provided on the bench for gearbox run-m, or

the gearbox , may be run in after reinstallation, since it is

and slip the MM/SEC drive belt off its pulley. The MM/SEC

motor IS the larger motor.

easily accessible from the top of the recorder.

NOTE.

Gearbox Lubrication Intervals The gearbox should

be lubricated whenever the recorder IS overhauled, in

addition to the normal lubrication at 12 months or 2000

output sprocket with screwdriver as shown. Be sure chain

held up by bent wire over side plate.

hours of operation at varying speeds. Under continued

low-speed operation, the gearbox should be lubricated

every 6 months or 1000 hours. Whenever an extended

period of recording is anticipated, that is. for 30, 60, or 90

recorder, lift gearbox input pulley over belt drive output

pulley, and slip belt off gearbox pulley Be careful not to

bend pulley flanges while twisting gearbox

days continuous duty, a lubrication and inspection before

the recording period will help to assure uninterrupted

service For a list of recommended lubricants, see Table 5-2.

and gearbox together and place on bench Separate belt

drive and gearbox by twisting apart, then lift gearbox input

pulley over belt drive output pulley and slip belt off

5-53. GEARBOX INSPECTION. Before removing the

gearbox pulley

gearbox, take off the top cover and inspect inside for brass

particles from the gears If any are found, move the gears

by hand and look for excessive wear or damage to the gear

teeth.

unfasten two screws D on one side, and slip one bearing

mount (MP6 or MP7) off the shaft

WARNING

from either bearing mount, install a new bearing, and

retighten the setscrew, set with either Glyptal or Loctite.

IS

worn. Replace

a.

Make a wire chain hanger out of a paper clip or piece

b.

Remove cables from clamps on left Unit Housing

C.

Refer to Figure 5-16 and remove

4 screws A from gearbox base plate.

2 screws B from drive belt and pulley assembly

In MM/MIN units, 3 screws C from 60.1 motor

chassis assembly. Catch nuts and insulators from

below.

Note that motor chassis is electrically insulated.

d.

Slightly twist belt drive pulley assembly, as shown,

e.

Release chain by twisting gearbox and lifting it off

f.

(MM/MIN UNITS) Leave belt drive assembly in

(UNITS WITHOUT MM/MIN) Remove belt drive

To remove belts from the belt drive assembly,

g.

h

To replace the belt drive bearings, remove setscrew E

is

1

Re-installation

Generally the reverse of removal,

reinstallation of MM/MIN gearboxes requires that the

MM/MIN motor chassis front screw be tightened before the

two rear screws, to keep the MM/MIN drive belt tight

Reposition cable connector as shown in Figure 5-20 Pull

drive belts hand tight only.

5-27

Page 76

TM11-6625-2752-14&P

Section V - Maintenance

Models 7758A, 7418A

07758-l

WARNING

TO AVOID SERIOUS SHOCK HAZARD, REINSTALL

MOTOR ELECTRICAL INSULATING PADS AND WASHERS REMOVED IN PARAGRAPH 5-544, STEP C.

SHOULDERS SHOULD BE UPWARDS.

5-55. GEARBOX DISASSEMBLY AND LUBRICATION

OVERHAUL). Use the following procedure to disassemble

the gearbox, and to

inspect for clutch wear. The procedure

is Illustrated in Figure 5-17. Note that each gear has, in

addition to one or two toothed discs, one or two hub

sections that fit

inside the

clutch springs. The hub sections

of adjacent gears meet inside the spring, and must fit very

closely or else the spring will wind

down between the hubs,

disabling the gearbox. The shaft end play adjustment,

which follows

this overhaul procedure, is essential. End

play must be adjusted before running the gearbox, to

prevent damage.

NOTE Obtain a

cm), and with a diameter of 5/16 inch (0.8 cm)

in order after cleaning but before lubrication, at

parts

wooden dowel rod about a foot long (30

to keep

which time they will be put back on the gearbox shaft.

a.

Remove the gearbox top cover, and the flat mount-

ing plate (four screws each).

Remove four screws holding the curved bottom

b

cover (solenoid plate). This should leave only the gears,

shafts, and gearbox sideplates.

c.

Remove the two round-head, slotted Nylock

screws holding the output sprocket and input pulley. Keep

the same number of shun washers on each

screw. Detach

the side plates from each other, leaving one shaft on each

side plate Do not remove the

orientation and position of each component on

shaft end hex nuts. Note the

each of the

shafts.

NOTE If gears are to be replaced or components

lubricated, remove only one shaft at a time

order of the gears on the shaft for best

d

While holding one end plate in

to preserve the

wear characteristics.

each hand, pull

out

the primary shaft from the gears (Figure 5-17). Lift the

entire primary gear tram out as one unit. Note the

orientation and position of each component.

Remove the parts from the gear tram one at a time,

e.

and clean each part by brushing it with Chlorothene

solvent Wipe plastic clutch sleeves with Chlorothenedampened cloth.

CAUTION

f. Inspect each part for damage and wear before

lubrication, To check for hub

hub surface and check for grooves.

g.

Arrange each part in order on dowel for proper

position during reassembly on the shaft during lubrication.

5-56. GEARBOX LUBRICATION. After all gears are

arranged on the dowel, lubricate as follows:

a

Gil each gear bearing with Mystery Oil (Table 5-2) to

soften gum residues.

b. Primary Shaft Lubrication.

Grease

shown in Figure 5-18 using the following steps to grease

each assembly:

(1) Work grease into coils of each spring, and

install on one half of clutch hub. Note

be in proper position (Figure 5-18).

(2) Slip plastic clutch sleeve (with ratchet teeth)

over spring; mate sleeve cutout to spring tab.

(3)

hub into assembled clutch and spring. As a test

wear, clutch hub should “grab” spring when twisted in one

direction, and

together

slips

to be sure the hub faces are in contact. If clutch

in both

worn spring.

NOTE:

Do not over-grease clutches, which may cause them

to slip.

C.

When all gears are reassembled onto shaft, slip shaft

out as shown in Figure 5-17, leaving gear tram as

Gil shaft lightly

excess oil Note that shaft does not rotate. Steel washer on

shaft end must be properly positioned.

d.

Remove secondary shaft in same way as primary

shaft (Paragraph 5-55), clean gears and spring clutches

without submerging them in solvent, and arrange them in

order (Figure 5-18). 0il with Mystery 0il (Table 5-2).

e.

Secondary Shaft Lubrication

Grease each secondary clutch and gear assembly as

shown in Figure 5-18. Inspect each part for damage or wear

before greasing, as noted in illustration Drag a fingernail

across hub surface to inspect for wear grooves Use

following steps to grease springs and hubs

(1) Work grease into the coils of each clutch spring

(2) Grease each clutch hub

(3) Twist spring and hub together Remove excess

grease. Test clutch hub by twisting in both directions Press

the hubs together to be sure the hub faces are in contact

Hub should “‘grab” when twisted one way and slip when

twisted the other way

wear;

drag a fingermail across

each

primary clutch and gear assembly as

that spring tab must

Coat mating gear hub with grease and twist

of

clutch

slip when

twisted in other. Press the hubs

directions, replace hub and attached gear, or

one

unit.

with No

10 oil (Table 5-2), and remove

5-28

Page 77

Page 78

TM11-6625-2752-14&P

Section V - Maintenance

Models 7758A, 7418A

0758-1

Figure 5-17. Gearbox Disassembly

5-29

Page 79

TM11-6625-2752-14&P

Section V - Maintenance

Models 7758A, 7418A

07758-1

5-30

Page 80

TM11-6625-2752-14&P

Section V - Maintenance

Models 7758A, 7418A

07758-1

5-30

Figure 5-18. Clutch Lubrication

Page 81

TM11-6625-2752-14&P

5-59.

Section V - Maintenance

Models 7758A,

7418A

07758-1

Figure 5-19. Gearbox Shaft End Play Adjustment

f.

When all gears are reassembled onto shaft, slip shaft

out, leaving gear tram as one unit (Figure 5-17). 0il shaft

lightly (do not use grease).

Reassemble both shafts with the side plates and

g.

tighten Nylock shaft-end Screws so gears will just rotate

by hand.

Grease gearbox gear teeth with HP 6040-0222 gear

h.

grease

Replace rounded bottom cover (four screws, Figure

1.

5-17); leave screws loose and install mounting plate. Then

tighten them.

CAUTION

5-57. GE

The end

the gearbox top cover removed, as shown in Figure 5-19.

Tighten the shaft end screw snug, then back off

while using a feeler gage at the side plate to obtain 0.007

inch (0.178 mm) end play.

OX

SHAFT END PLAY ADJUSTMENT.

play

of both gearbox shafts must be adjusted with

CAUTlON

SHAFT, NOT JUST TO THE SPACER WASHER. TOO

TIGHT ADJUSTMENT WILL CAUSE BURNOUT. END

PLAY MUST BE NO MORE THAN 0.007 INCH (0.178

MM), OTHERWISE CLUTCH SPRINGS WILL WIND

DOWN BETWEEN THE HUBS AND DISABLE THE

GEARBOX.

5-58. SOLENOID ADJUSTMENT. Position the gearbox

on top of the Recorder top cover, which has been slid back

onto the driver amplifiers, as shown in Figure 5-20. Plug the

speed control cable into the rear of the front panel Control

Switch PC Board, with the blank pm to the MM/SEC motor

side of the recorder, as shown (left as you face the rear

panel). Then select the highest MM/SEC chart speed, apply

power to the Recorder, and select STANDBY mode. With

all the solenoids thus energized, adjust the clearance

between the solenoid pawls and the clutch sleeves with the

typical adjustment screw shown. Place an 0.01 inch (.254

mm) feeler gauge between the paw1 and sleeve for each

adjustment.

5-60.

Position the input pulley over the belt drive output

pulley, and slip the belt on. Placing the gearbox into

position on the motor chassis, twist the output chain onto

the output sprocket. Adjust the input and output drive

tension by holding (twisting) the gearbox hand-tight against

the resistance of its input belt and output chain, while

5-31

Page 82

TM11-6623-2752-14&P

Section V - Maintenance

Models

7758A,

7418A

07758-1

Table 5-5. Paper Drive Troubleshooting

TROUBLE

BAD PAPER TRACKING (paper

moves to one side or climbs paper

guide flange)

PAPER WEAVES FROM SIDE

TO SIDE

PAPER TEARS AT FOLD

PAPER JAMS IN PRESSURE

ROLLERS

IRREGULAR PAPER SPEED

INCORRECT BUT STEADY

PAPER SPEED

PROBABLE CAUSE

Uneven tension on pressure rollers

Brake pressure springs came off

Worn brake felt or bent paper guide

Paper table unevenly adjusted

Slick or duty paper brake felt or

drive roller

Excessive brake pressure (should

cause 2-3 lb pull)

One pressure roller spring is weaker

or misadjusted

Slick or duty drive roller, loose

pressure roller adjustment, or

excessive brake tension

Gearbox clutch shipping or

grabbing

Speed control solenoid malfunction,

coi1 or lead open, felt paper brake

misadjusted, or incorrect paper

loading

SOLUTION

Provide even tension on paper.

Reseat springs.

Replace felt or guide.

Adjust table comers.

Clean drive roller and pressure

rollers, or replace brake felt.

Adjust both screws evenly cow for

less tension.

Balance tension (NOTE.

goes to side with tighter

ment) or replace both springs.

Clean drive roller, or adjust pressure roller or felt brake.

Adjust clutch solenoid. D

dean clutch, re-lube with

twist to check for wear.

Make sure paper is not be

pressure rollers Adjust brake. Check

solenoid circuits, also gearbox for

Jammed clutch actuators, pawls,

clutches

NO PAPER DRIVE

NO SIGNAL ON PAPER

5-32

Defective drive motor, broken

timing belt or drive roller chain,

drive roller sprocket key or setscrew

missing Motor power open circuit

or blown fuse

Drive amplifier. oscillator, heat, or

galvanometer problem

CAUTION GALVANOMETER IS

Visually check for belt, chain,

roller motion, Check motor fuse, and

motor cable from bottom of power

supply Test connections to motor

chassis terminal blocks.

Refer to Table 5-4 for driver

troubleshooting. See text for stylus

and galvanometer adjustments

NOT FIELD REPAIRABLE REPLACE ONLY EXTERNAL PARTS

SHOWN IN FIGURE 6-14

Page 83

TM11-6625-2752-14&P

Section V - Maintenance

Models 7758A, 7418A

07758-1

Figure 5-20. Gearbox Solenoid Adjustment

5-33

Page 84

TM11-6625-2752-14&P

Section V - Maintenance

Models 7758A, 7418A

07758-1

Figure 5-21. Marker Assembly Adjustment and Removal

tightening the mounting plate screws. Re-attach the sole-

noid control cable. If the input belt tends to “walk” off the

that all solenoids are operating properly, retracting the

pawls fully, and not hanging up on the clutch sleeves.

pulley, the Gear Drive Assembly probably needs repositioning in its four elongated holes in the Drive Unit side plates.

The Gear Drive Assembly is the main motor chassis(see

Section VI). Then reposition the gearbox to bring the input

pulley back in line with the belt.

5-63. The marker assemblies are attached between the

galvanometers. To adjust the stylus position, first set the

writing stylus bumpers (Table 5-4) and then loosen the

attachment screw (Figure 5-21). Position the marker stylus

5-61. GEARBOX RUN-IN.. To disperse excess lubricant

and test the gearbox, give it a test run after reinstallation.

First, run the gearbox at lowest speed (selected at the

recorder control panel).Excess Mystery oil, applied in the

procedure in Paragraph 5-56, will run from

gears, carrying with it dissolved gum and grease residue.

Stop the drive motor and wipe away this residue frequent-

of

ly. After 15 minutes

running run through a complete set

of gear changes at the front panel of the recorder while

inspecting the action of the gearbox (top cover removed).

All clutches should operate properly and the gears should

rotate smoothly. Stop the drive motor and place three

No. for drops of No. 10 oil (Table 5-2) between the

gears to lubricate the gear bearing (a typical point is

indicated in Figure 5-20). Run the gearbox at its lowest

speed for several minutes to ensure that the oil will seep

down into the gear bearings and be stored for future

so that it does not hit either bumper during its excursion,

and tighten the attachment screw. Unfasten this screw to

remove the stylus, and also remove the heat lead and its

attachment screw. To increase stylus pressure, move stylus

toward paper by loosening the screw in the slotted hole just

above mounting screw for stylus. To remove the marker

coil, unfasten the marker leads (Figure 5-l) by unplugging a

small cable, and unfasten the two marker mounting screws

shown in Figure 5-21. Two stylus heat leads also must be

disconnected in the marker frame area.

5-62.

heat leads from standoffs on galvanometer and remove

Pozidriv screw from maker mounting bracket (Figure

5-21). Install the new stylus on the mounting bracket with

the screw, and reinstall the heat leads. Reset stylus pressure

with each new installation, and readjust the marker

amplitude stop, if necessary.

If the stylus only, less coil, must be replaced, remove

5-34

Page 85

SECTION VI

6-1.

6-2. This section contains schematics, figures and

information for identifying, locating and ordering replace-

and 6-3 list parts in Order of the ref-

designations (circuit references) and provide the

information for each item.

a. Description 0f the part (see list of abbreviations on the

following page).

b. Typical manufacturer of the part using a five-digit

See the code list of manufacturers in Table 6-2.

c. Manufacturer's part number.

d. Total quantity used in the instrument (TQ column).

NOTE: Identification of the attaching parts (screws, nuts,

washers, rivets, etc.) used to secure a component in place is

entered immediately after the listing of the respective

component in Table 6-1 or 6-3.

TM11-6625-2752-14&P

Section VI - Replaceable Parts

Models 7758A, 7418A

07758-l

6-4. REFERENCE DESIGNATIONS

6-5. Tables 6-1 and 6-3 are baaed On an alpha-numerical

method of listing the end item, assemblies, subassemblies

and circuit components. These items are defined as

follows:

a. AN END ITEM instrument with all the supplied

accessories. The END ITEM is made up of assemblies to aid

in the location of parts.

The complete reference designation is read as the first

resistor (Rl) of the second subassembly (A2) of the first

assembly (Al).

6-7. Partial reference designation are normally used on

equipment and illustrations. The partial reference

designation consists of the component alpha designation

and numeric designation. The complete reference

designations are obtained by placing the proper assembly

the partial reference designations.

that can be purchased have part numbers in the part

number columns; that cannot be purchased have the

word “Reference” in the column.

6-8. In this section, these assembly prefix numbers are

usually shown with each reference designation, in the title

of the figure or at the bottom of the illustration block

following the notation “REF DESIG PREFIX”. The complete reference designation should be used to easily locate

a part and the description in the Parts List.

capacitor, R1 resistor etc). These parts are prefaced by the

assembly number (A1CI, A1C2, A1R1, A2R2,

etc.) to

indicate thee assembly On which the part is located.

6-9. For example, to determine the value and the part

number of resistor R6 in the A2 assembly (A2R6), locate

the A2 group listing (the second group) in the parts list.

6-6. Examples of the alpha-numeric

used to identify assemblies , sub

components follow:

numbering method

assemblies and circuit

Then refer to the R (resistor) designations in the group and

find R6. The value and the part number are in the columns

adjacent to the description.

6-1

Page 86

TM11-6625-2752-l4&P

6-10.

Section VI - Replaceable Parts

Models 7758A, 7418A

07758-l

6-11. To order a replacement part, address order or inquiry

to the local Hewlett-Packard Sales/Service Office (see list of’

addresses at the rear of the manual) and supply HP part

number of the item from Table 6-1 or 6-3.

6-12. To order a part not listed in the table, provide the

following information:

6-13.

6-2

Page 87

Table 6-1. Replaceable Parts

Page 88

TM11-6625-2752-14&P

Section VI - Replaceable Parts

Models 7758A, 7418A

07758-1

Figure 6-1. Model 7758A, or 7418A Thermal Tip Recorder Assemblies

6-3

Page 89

TM11-6625-2752-14&P

Section VI - Replaceable Parts

Models 7758A, 7418A

07758-1

07750-60010

07750-60011

07750-00062

07758-00064

07758-00061

07756-00063

07758-200010

2510-0123

07758-20010

2510-0123

07754-008070

2516-0123

2560-0086

07754-00070

2510-0123

2580-0086

07758-00320

1490-0960

2510-0123

Table 6-1. Replaceable Parts (continued)

6-4

07758-60020

07758-60021

2530-0084

2580-0006

07758-00181

07758-00182

0370-1005

0370-1005

0370-1005

0370-1005

0370-1005

0370-1005

0370-1005

0370-1005

0370-1005

0370-1005

07758-00190

0590-0199

2200-0166

07758-10360

See introduction to this section for ordering Information

Page 90

2200-0166

07758-20360

2200-0166

07758-20360

2200-0166

07758-20360

2200-0166

07750-20360

2200-0166

07758-20360

2200-0166

07758-20360

2200-0166

07758-20360

2200-0166

0370-2051

0370-2051

0370-2051

0370-2051

0370-2051

0370-2051

0370-2051

0370-2051

0370-2051

0370-2051

0370-2051

0370-2051

0370-2051

0370-2051

0370-2051

0370-2051

6960-0006

7120-1254

07758-60150

07758-60170

Table 6-1. Replaceable Parts (continued)

TM11-6625-2752-14&P

Section VI - Replaceable Parts

Models 7758A, 7418A

07758-1

07758-60270

2200-0183

0360-1730

0150-0052

0150-0052

0150-0052

0150-0052

0150-0052

1901-0033

1901-0033

1901-0033

1901-0033

1901-0033

1901-0033

1901-0033

1901-0033

1901-0033

1901-0033

1901-0033

1901-0033

1200-0151

1200-0151

1200-0151

1200-0151

1200-0151

1200-0151

1200-0151

1010-0032

0683-2705

0686-1865

0683-1525

0683-4715

0683-2715

0683-1015

0683-2705

See introduction to this section for ordering information

6-5

Page 91

TM11-6625-2752-14&P

Section VI - Replaceable Parts

Models 7758A, 7418A

07758-1

0683-2705

0683-2705

0683-2705

0683-2705

0683-3315

0683-1815

2100-2031

2100-2031

2100-2031

2100-2031

2100-2031

2100-2031

2100-2031

2100-2031

2100-2031

2100-2031

2100-2031

2100-2031

2100-2031

2100-2031

2100-2031

2100-2031

3101-1289

07758-00270

07758-68260

2200-0103

2190-0027

2950-0071

1251-1968

2100-2853

2100-2853

2100-2853

2100-2853

2100-2853

2100-2853

2100-2853

2100-2853

07758-00260

Table 6-1. Replaceable Parts (continued)

6-6

07758-60150

08821-40011

03821-40012

2200-0147

2340-0001

1251-1190

1251-1190

07758-60170

08821-40011

08821-40012

2200-0147

2340-0001

07758-08280

1251-1190

07758-60030

2530-0004

2580-0006

0180-1873

0180-1873

See introduction to this section for ordering information

Page 92

0180-2529

0180-0052

3185-0032

1901-0525

2510-0145

2580-0084

1901-0525

2530-0145

2580-0806

2110-0014

2110-0087

2110-0030

2110-0014

2110-0030

3110-0023

2110-0381

2110-0303

8120-0951

1251-2995

0490-0424

07750-59620

2650-0051

2680-0110

07758-00560

07750-00010

07750-00480

2200-0185

07758-00550

07750-08030

2200-0105

0180-0078

2510-0045

2580-0006

0180-0075

2510-0045

2500-0084

0160-2149

2350-0197

2420-0886

7120-0684

7124-1928

07758-06050

2368-8115

7124-1605

1251-0333

1251-1005

1251-1086

1251-1292

1251-1694

0683-2735

0686-1515

0686-2225

3101-1395

9100-2373

0590-0304

5060-1188

077750-60190

07750-60200

1400-0085

1400-0035

1400-0085

1400-0085

1400-0085

1200-0727

0361-0346

07750-60250

TM11-6625-2752-14&P

Section VI - Replaceable Parts

Models 7758A, 7418A

07758-1

Table 6-1. Replaceable Parts (continued)

0590-0199

2200-0111

8168-0153

6-7

Page 93

TM11-6625-2752-14&P

Section VI - Replaceable Parts

Models 7758A, 7418A

07758-1

0160-0153

0160-0153

0160-0153

0160-0153

0160-0161

1251-0962

2200-0113

2340-0001

1251-2205

1251-1962

2200-0113

2340-0001

1291-2205

1251-1962

2200-0113

2340-0001

1251-2295

1251-1962

2200-0113

2340-0001

1251-2205

1251-1962

2200-0113

2340-0001

1251-2205

1251-1962

2200-0113

2340-0001

1251-2205

1251-1962

2200-0113

2340-0001

1251-2205

1251-1962

2200-0113

2340-0001

1251-2205

1251-1962

2200-0113

2340-0081

1251-2205

1251-1626

07758-08250

0403-0062

0360-1730

07758-60190

1251-1295

1251-1292

1251-1679

1251-1291

1251-1682

1251-2745

1251-1696

1251-0190

07758-60200

1251-1682

1251-2744

1400-0249

1251-1694

1251-0198

Table 6-1. Replaceable Parts (continued)

6-8

07754-60170

2680-0157

2190-0759

2190-0780

0180-0186

0180-0196

Page 94

0160-0154

0160-0165

0160-0165

0160-0165

0160-0207

1901-0033

1901-0033

1902-3182

1902-3182

1901-0033

2500-0001

2680-0157

07754-20340

2190-0759

2190-0780

2360-0119

1853-0066

1854-0071

1853-0066

1854-0039

1200-0181

1853-0066

0853-0223

0340-0464

2190-0007

2360-0201

2500-0001

1853-0045

1200-0181

1854-0071

1854-0063

0340-0464

2190-0007

2360-0201

2500-0001

1854-0409

1853-0066

1854-0071

1854-0063

0046-0464

2150-0007

2360-0201

2500-0001

0683-1035

0698-6909

0757-0452

0683-6835

0098-6909

0683-1055

0698-5143

0683-1035

2100-2464

0698-3134

0683-1035

0690-3136

2100-2464

0683-1035

0698-7382

0083-5635

0683-1515

0686-5605

0683-1015

0811-2619

0761-0026

0686-2715

0686-1525

0686-1825

0686-5685

0683-1515

0683-1015

0811-1732

0683-2235

2100-2464

0757-0123

TM11-6625-2752-14&P

Section VI - Replaceable Parts

Models 7758A, 7418A

07758-1

Table 6-1. Replaceable Parts (continued)

6-9

Page 95

TM11-6625-2752-14&P

Section VI - Replaceable Parts

Models 7758A, 7418A

07758-1

0683-2735

0683-1035

0683-1025

0698-6909

0683-1065

0757-0869

0683-2235

0683-1015

0683-1515

0686-3915

0683-1015

0811-1732

1820-0283

1820-0203

07754-00170

07754-60170

07754-60170

07754-60170

07754-60170

Table 6-1. Replaceable Parts (continued)

07754-60170

07754-60170

07754-60170

07758-60240

2680-0157

2190-0758

2190-0780

0148-0208

0150-0052

0160-2222

0160-0174

0180-1930

0100-0291

0150-0052

0180-0291

0150-0052

0160-2891

0150-0052

0160-0174

0160-0161

0160-0174

0140-0280

0160-2222

0160-0174

0160-0174

0160-0174

0150-0032

0150-0052

0160-0174

0160-0174

0180-2060

0160-8161

6-10

Page 96

0180-2060

0160-0174

0180-0097

1901-0033

9140-0210

07754-29340

2853-0300

2853-0300

1854-0071

1854-0071

1854-0063

0340-0464

2190-0088

2360-0201

2500-0081

1854-0063

0340-0464

2190-0008

2360-0201

2500-0001

1854-0071

1853-0300

1854-0022

1200-0181

1854-0071

1854-0071

1854-0063

0340-0464

2190-0008

2360-0201

2500-0001

1854-0071

1854-0071

1853-0300

1853-0300

1853-0045

1200-0181

1853-0045

1853-0300

0698-4002

2100-1703

0698-5353

0683-3325

0698-4002

0683-1515

0683-2725

0811-1732

0686-1515

0757-0442

0757-0442

0698-4002

0698-4002

0683-4725

0811-1732

0683-1025

0698-6273

0698-6866

0698-5323

0683-4725

0683-1245

0683-5625

0683-1505

0761-0025

0683-1825

0811-1202

0683-3335

0683-3335

0683-3335

0683-1035

0683-3335

0683-4715

0683-1245

0683-1825

0683-1825

0683-1245

TM11-6625-2752-14&P

Section VI - Replaceable Parts

Models 7758A, 7418A

07758-1